Method for extracting and separating rare earth elements in hydrochloric acid system

A separation method and technology of rare earth elements, applied in the field of extraction, can solve problems such as changes in the composition of the extractant, affecting the extraction effect of the system, and differences in solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Dissolve 5.6g, 0.10mol of potassium hydroxide in 56ml of ethanol to obtain an alcoholic solution of the alkali, add 40g of 0.1mol quaternary ammonium chloride 336 dropwise into the alcoholic solution of the above alkali, stir at room temperature for 1 hour, and filter out the chlorinated Potassium precipitates to obtain a clear ionic liquid [A336][OH]; add 0.08mol P507 to the obtained 0.1mol [A336][OH], stir at room temperature for 2 hours, take the upper organic phase of the ionic liquid, and wash it 3 times with deionized water , and then the solvent ethanol was recovered by distillation under reduced pressure, and the product was dried in vacuum to obtain [A336][P507].

Embodiment 2

[0050] Dissolve 5.6g, 0.10mol of potassium hydroxide in 56ml of ethanol to obtain an alcoholic solution of the alkali, add 40g of 0.1mol quaternary ammonium chloride 336 dropwise into the alcoholic solution of the above alkali, stir at room temperature for 1 hour, and filter out the chlorinated Potassium precipitates to obtain a clear ionic liquid [A336][OH]; add 0.08mol P204 to the obtained 0.1mol [A336][OH], stir at room temperature for 1 hour, take the upper organic phase of the ionic liquid, and wash it 3 times with deionized water , and then the solvent ethanol was recovered by distillation under reduced pressure, and the product was dried in vacuum to obtain [A336][P204].

Embodiment 3

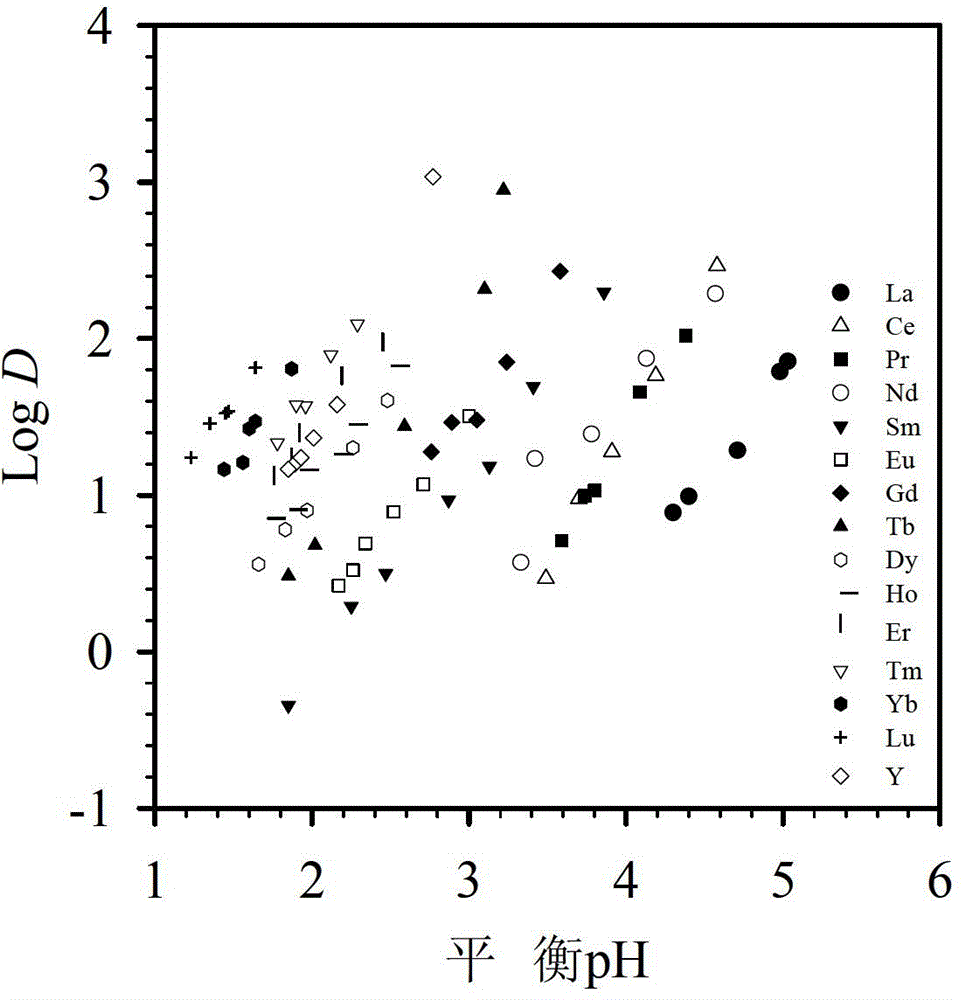

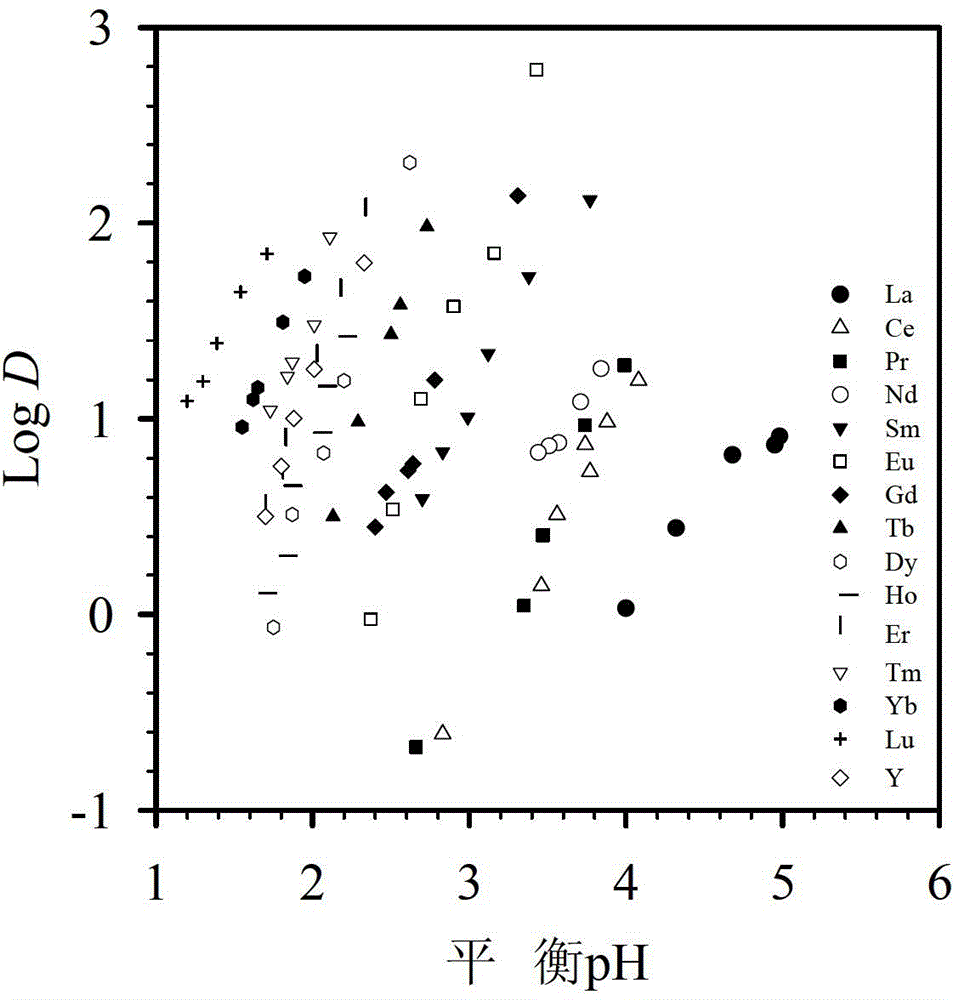

[0052] [A336][P507] Extraction and separation of single rare earth ions.

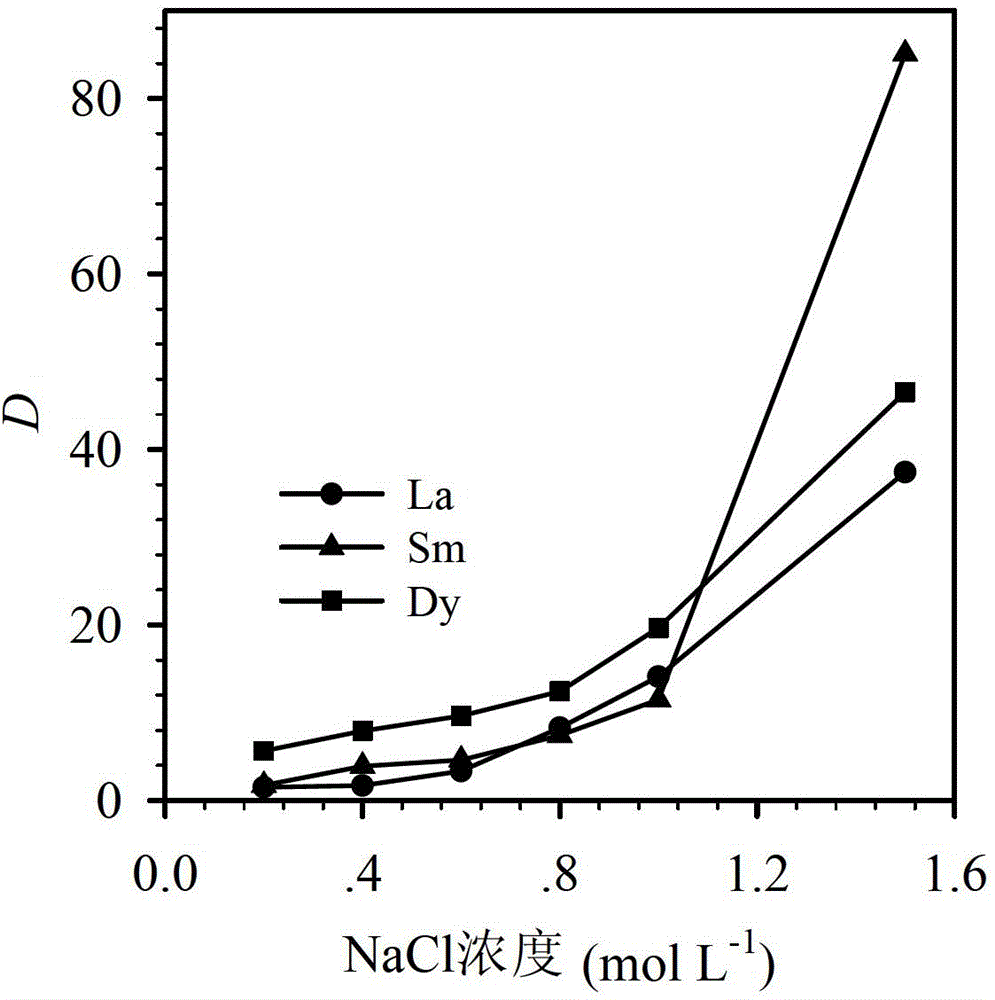

[0053] Mix 1.0 mL of 0.05 mol / L [A336][P507] n-heptane solution with 5.0 mL of an aqueous solution containing NaCl and La(III), wherein the concentration of NaCl in the aqueous solution is 1.0 mol / L, and the concentration of La(III) is 7.5 ×10 -4 mol / L, after shaking at a constant temperature of 25°C for 1 h, measure the concentration of La(III) in the aqueous phase, and then calculate the extraction rate and distribution ratio of La(III).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com