Patents

Literature

157results about How to "No emulsification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

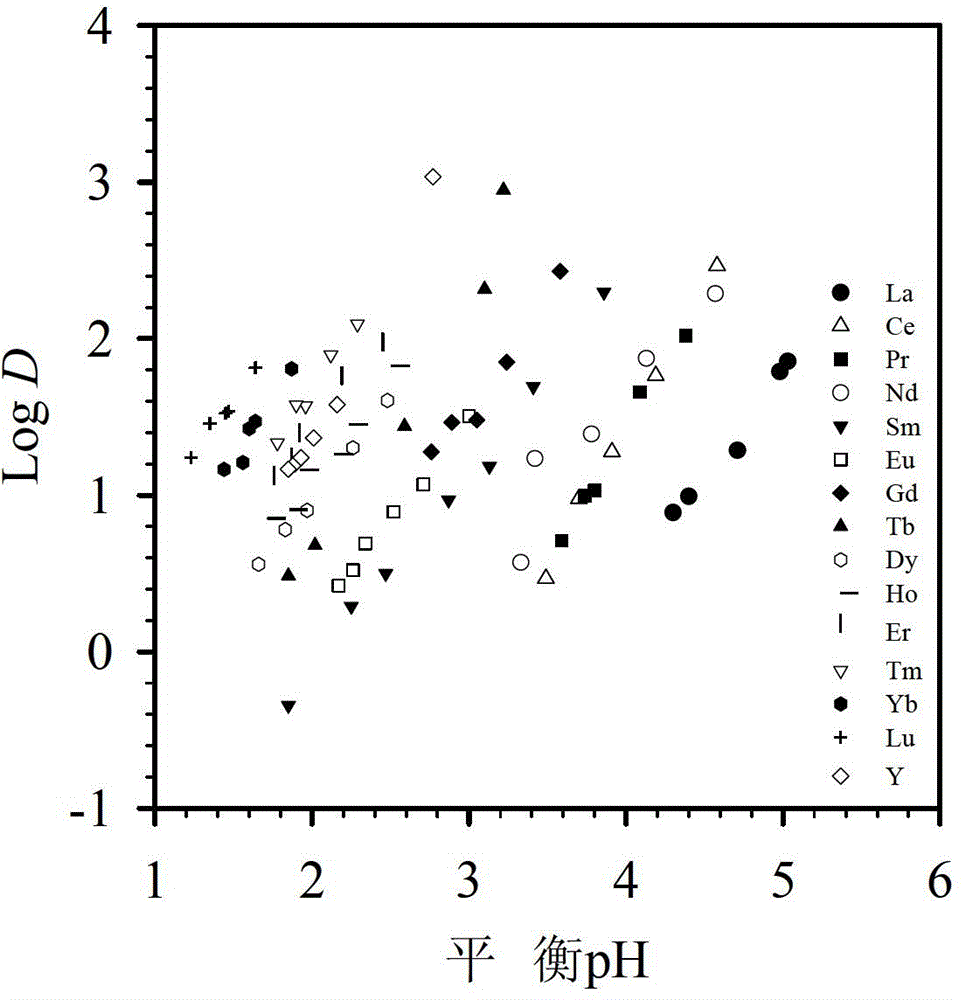

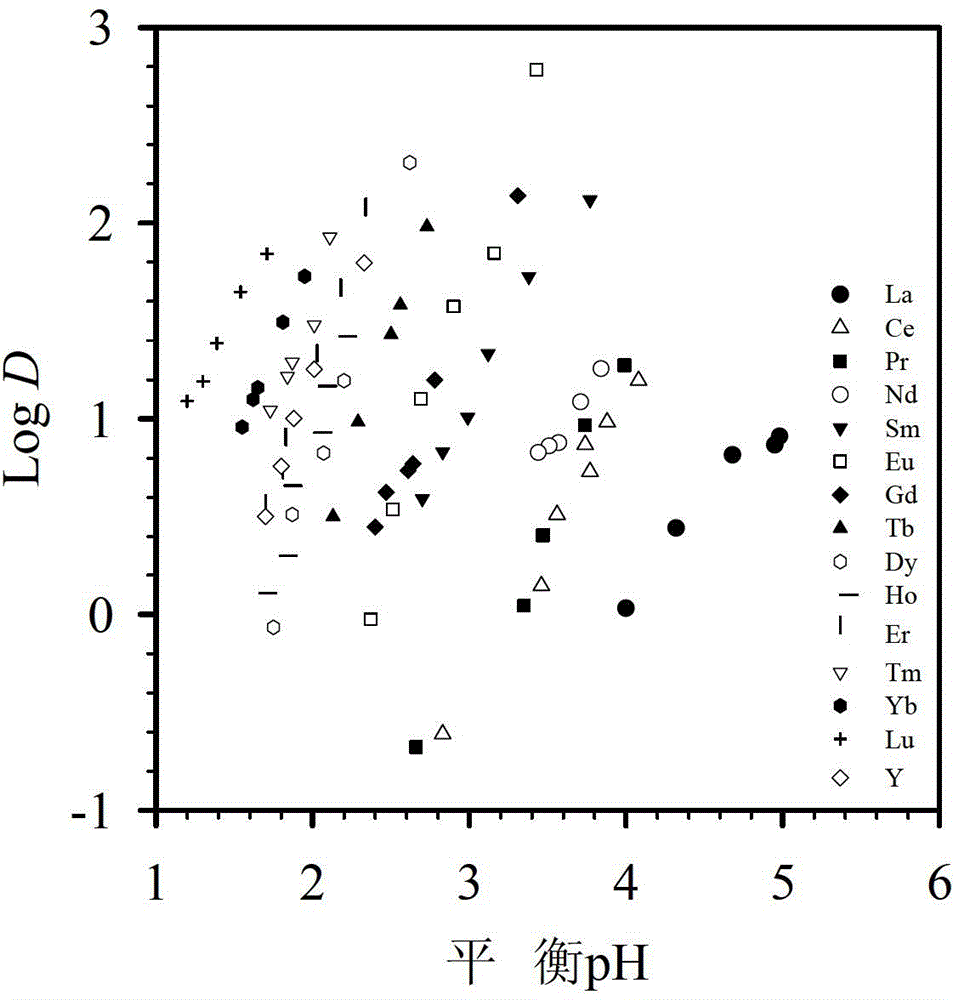

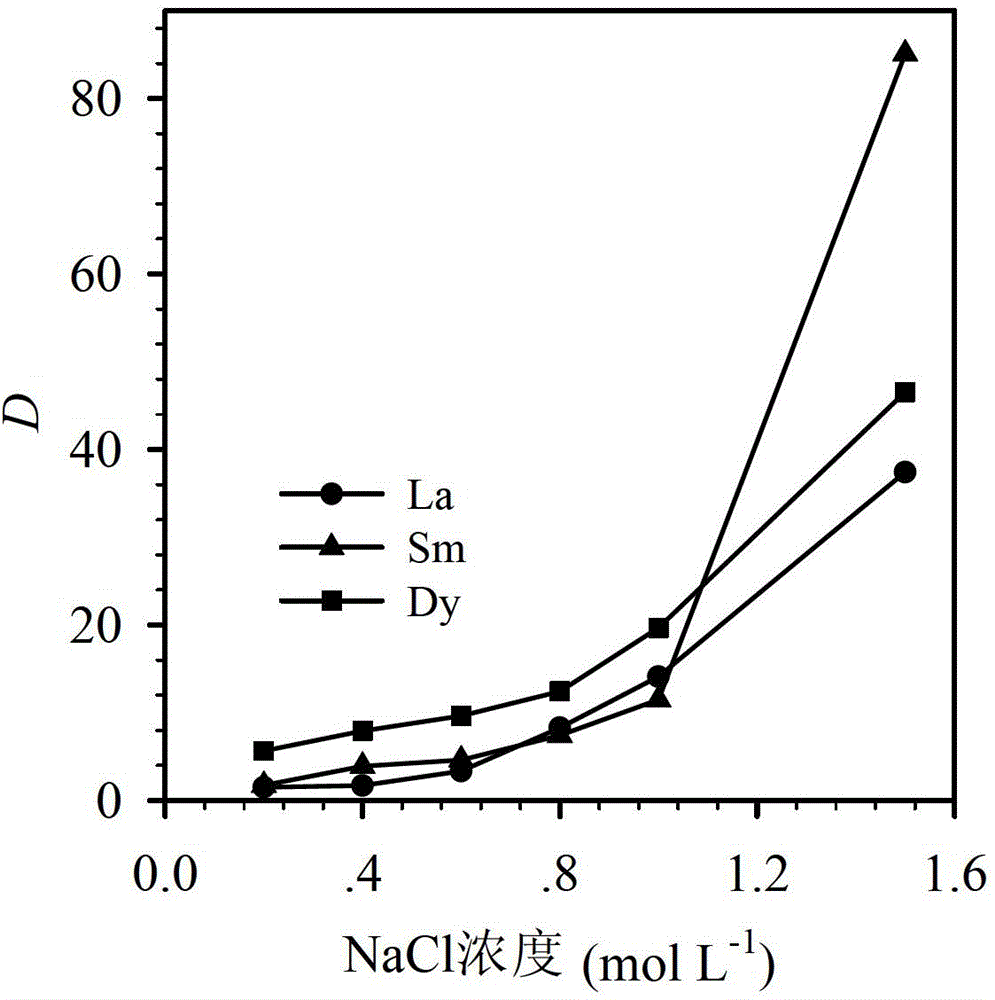

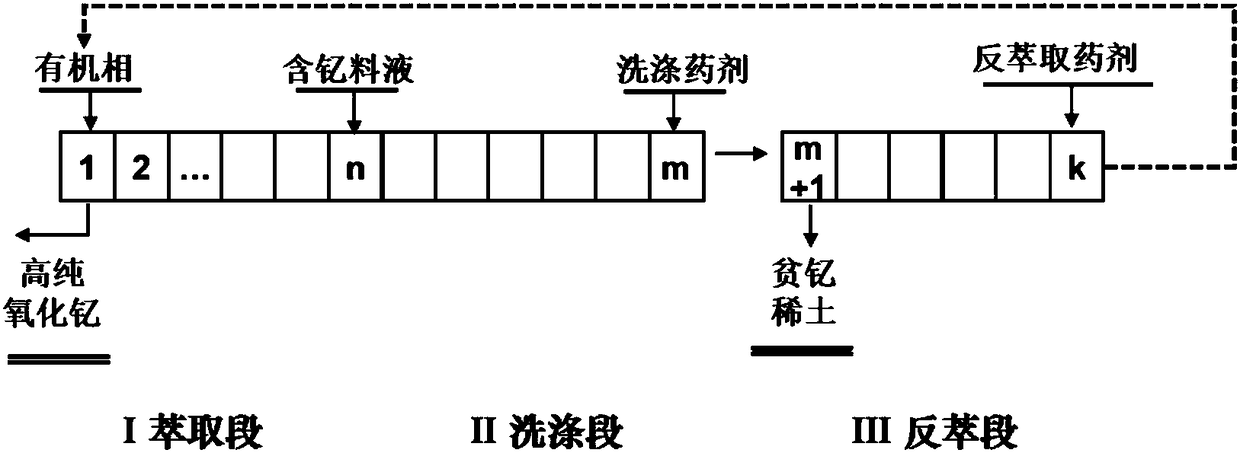

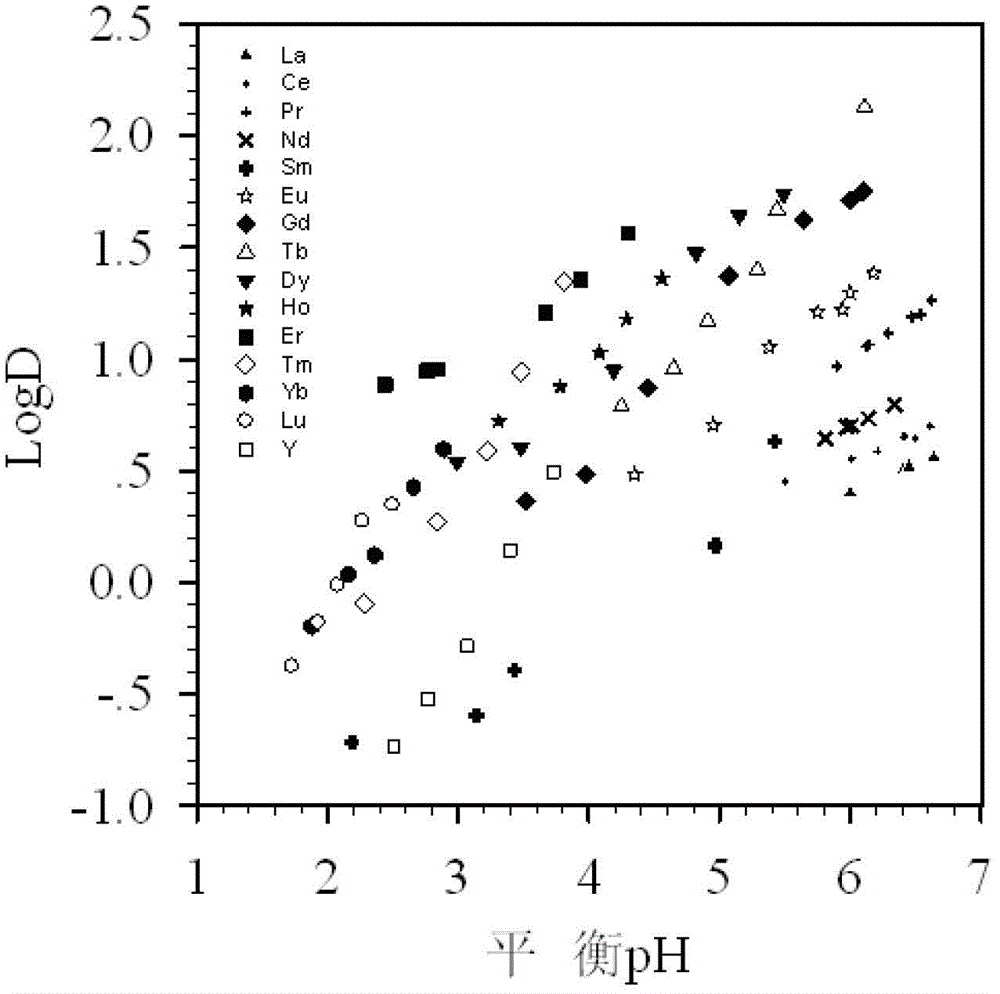

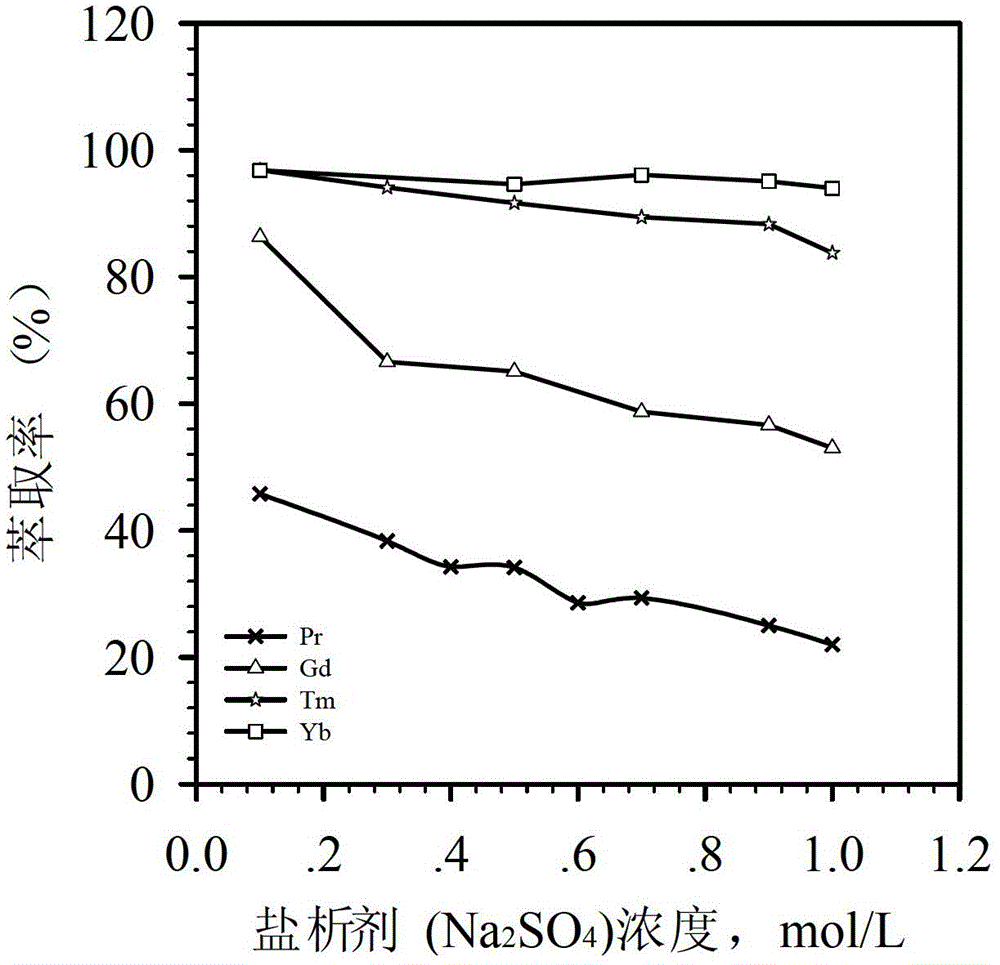

Extraction seperation method of rare-earth element

ActiveCN102618736AHigh separation factorLow extraction acidityProcess efficiency improvementRare-earth elementRare earth ions

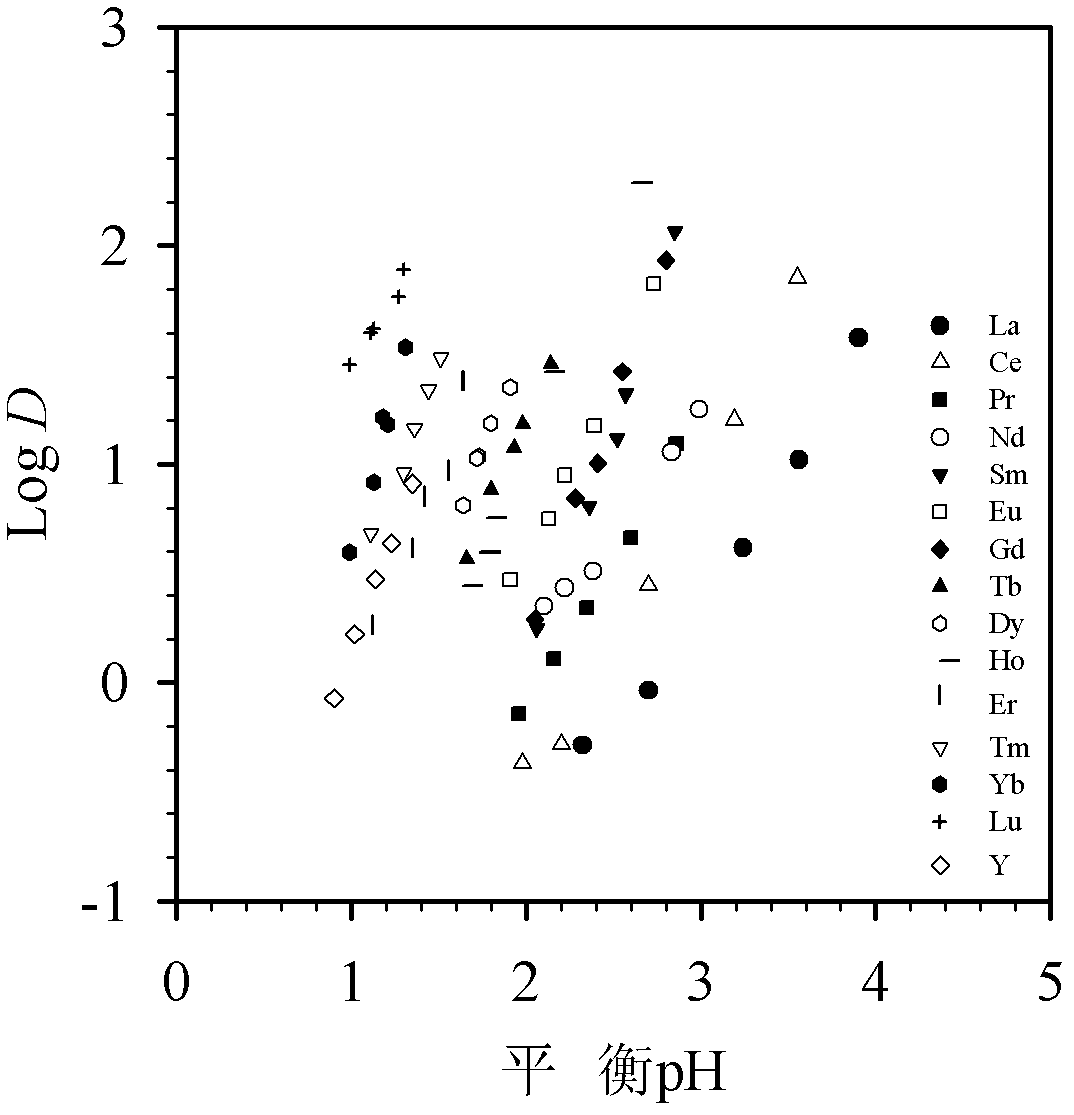

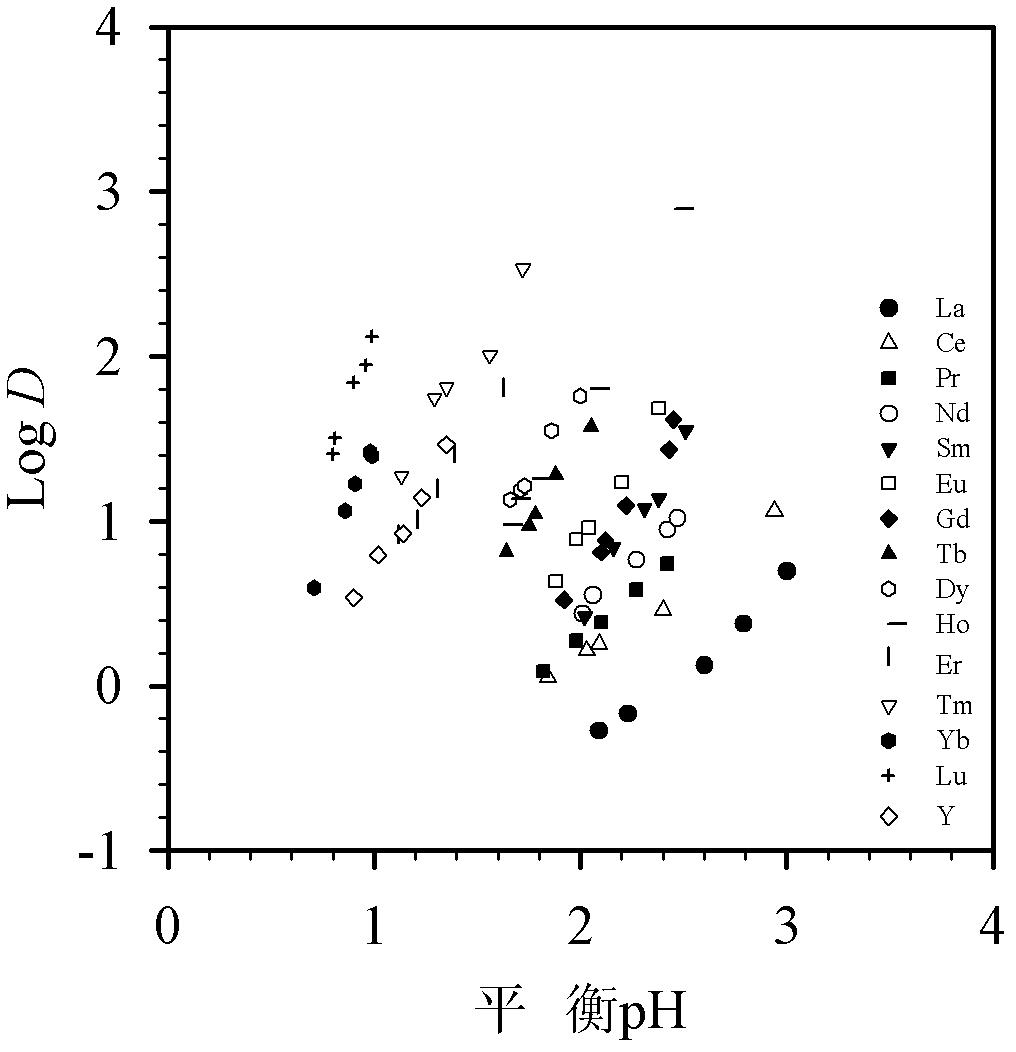

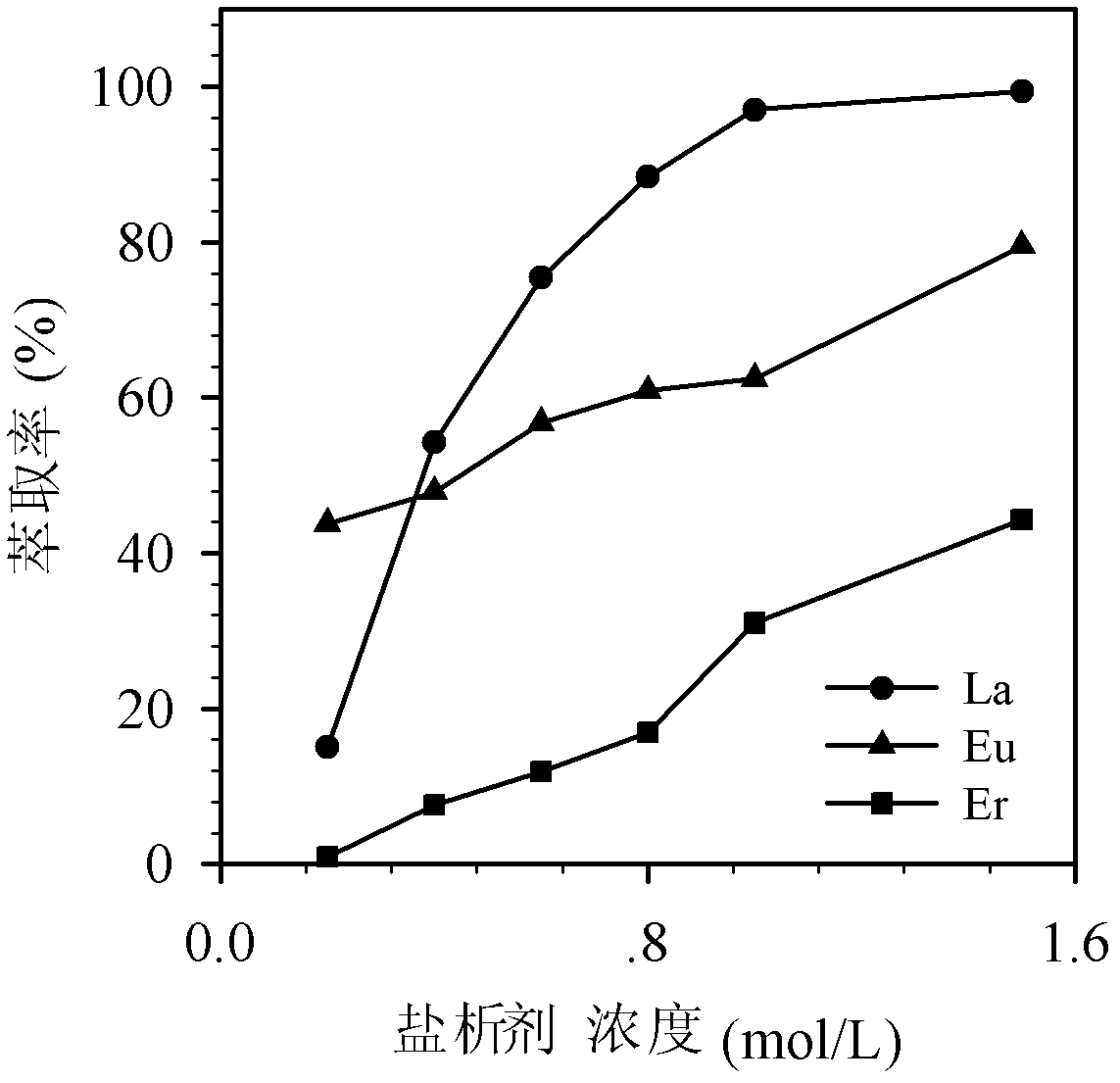

The invention discloses an extraction seperation method of a rare-earth element. According to extraction seperation method, positive ions and negative ions in a quaternary ammonium salt ionic liquid extracting agent, i.e. 2-ethylhexyl phosphonic acid mono 2-ethylhexyl ester trialkyl methyl ammonium and phosphonic acid binary (2-ethylhexyl) ester trialkyl methyl ammonium react with rare earth ions to form neutral complex molecules, and the positive ions and negative ions in the quaternary ammonium salt ionic liquid extracting agent have inner synergistic effect and competitive effect in the process of extracting the rare-earth element, thereby the seperation factor of the rare-earth element is increased. Therefore, the extraction seperation method provided by the invention has the advantages that an interfacial phenomenon is good in the extraction process, no emulsification is generated, and an extracting solvent does not need to be saponified, the extraction seperation method has higher seperation factor of the rare-earth element and particularly high extraction seperation effect on heavy rare earth. In addition, the extraction seperation method of the rare-earth element, which is provided by the invention, has low extraction acidity and back extraction acidity and consumes little acid.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

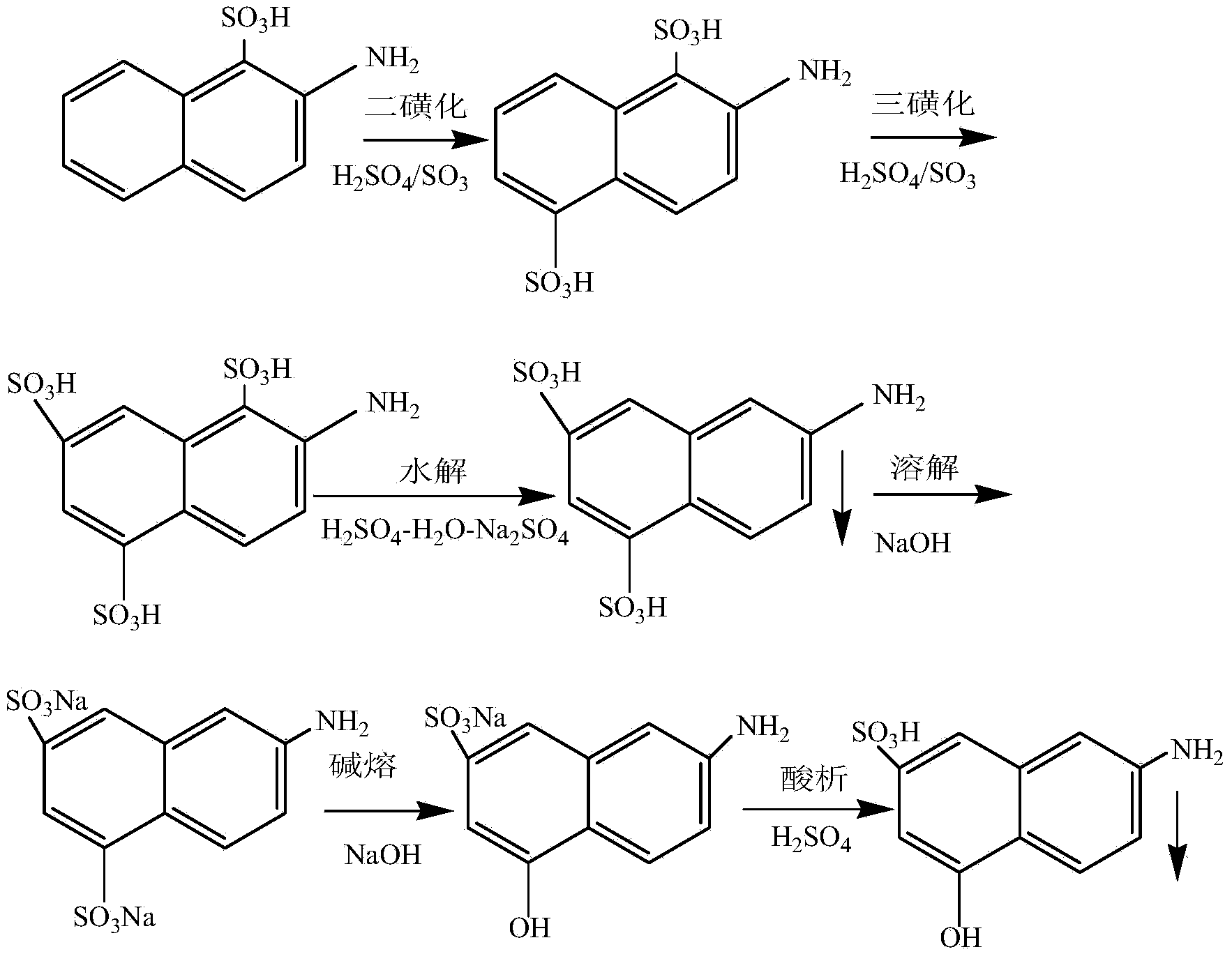

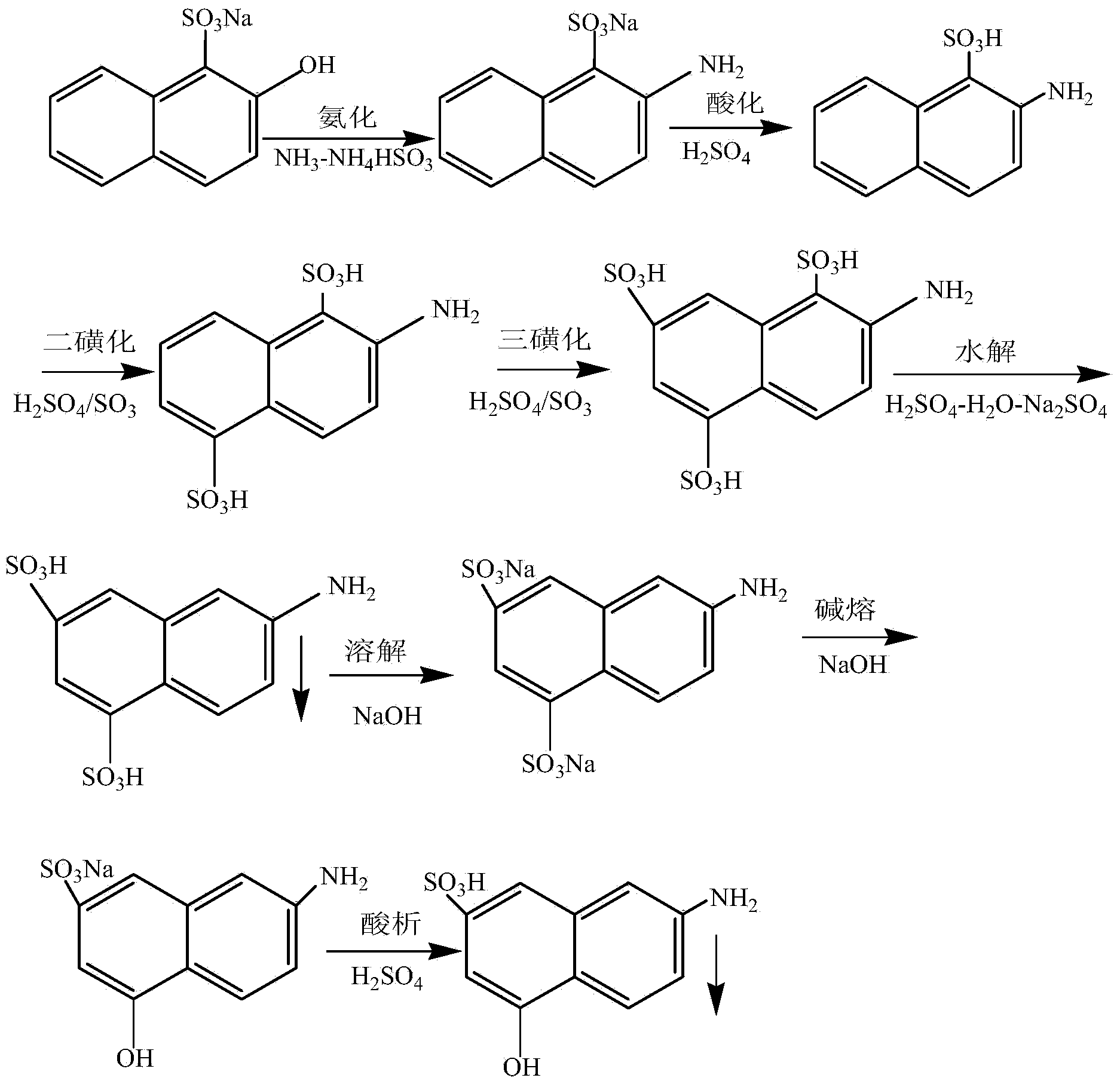

Preparation method of J acid and J acid waste water comprehensive treatment and recycling method

ActiveCN103896438ALow costDoes not affect productivityMultistage water/sewage treatmentSulfonic acid preparationWastewaterHydrolysis

The invention relates to a preparation method of J acid and a J acid waste water comprehensive treatment and recycling method. The J acid waste water comprehensive treatment and recycling method is as follows: the following treatment is carried out on hydrolysis waste water: (1) 30-40% of the total quantity of the hydrolysis waste water is used in an acidification reaction for preparing 2-naphthylamine-1-sulphonic acid by utilizing sodium 2-naphthylamine-1-sulphonate; (2) extraction and reextraction are carried out on the residual hydrolysis waste water, so that Na2SO4 and extraction waste liquor are obtained, the extraction waste liquor is used in a hydrolysis working procedure in a J acid production process, an extraction agent adopted during extraction is composed of 10-30wt% of complex agent, 30-70wt% of diluent and 5-20wt% of tributyl phosphate, and the complex agent is trioctylamine, or trialkyl tertiary amine or combination of trioctylamine and trialkyl tertiary amine. By adopting the preparation method of the J acid, the cost of water for the J acid and waste water treatment cost can be greatly reduced, and environmental pollution can be reduced.

Owner:XIANGSHUI HENRYDA TECH CHEM

Static mixed rotational flow separation and extraction process of regenerative base oil N-methyl pyrrolidone

The invention relates to a static mixed rotational flow separation and extraction process of regenerative base oil N-methyl pyrrolidone, comprising the following steps in sequence: (a) carrying out sedimentation of used oil and removing moisture and solid impurities; (b) filtering by a filter, and removing tiny solid particles and colloids; (c) adding sodium hydroxide solution and flocculating; (d) removing floccules and residual sodium hydroxide solution; (e) carrying out reduced pressure distillation by a distiller, and collecting distillate oil; (f) mixing the distillate oil with organic solvent by a static mixer on line; (g) separating out raffinate oil and raffinate oil containing organic solvent from mixed liquor by a swirler; (h) carrying out the reduced pressure distillation on the raffinate oil by a climbing film evaporator, and removing the organic solvent in the raffinate oil; and (i) carrying out the reduced pressure distillation by a molecule (short range) distiller, removing residual organic solvent and peculiar smell gas, and obtaining the regenerative base oil. The separation and extraction process provided by the invention has the advantages of conciseness in procedure, safety in operation, less equipment investment, high product yield, energy conservation, environmental friendliness and the like.

Owner:ANHUI GUOFU LUBRICANT IND

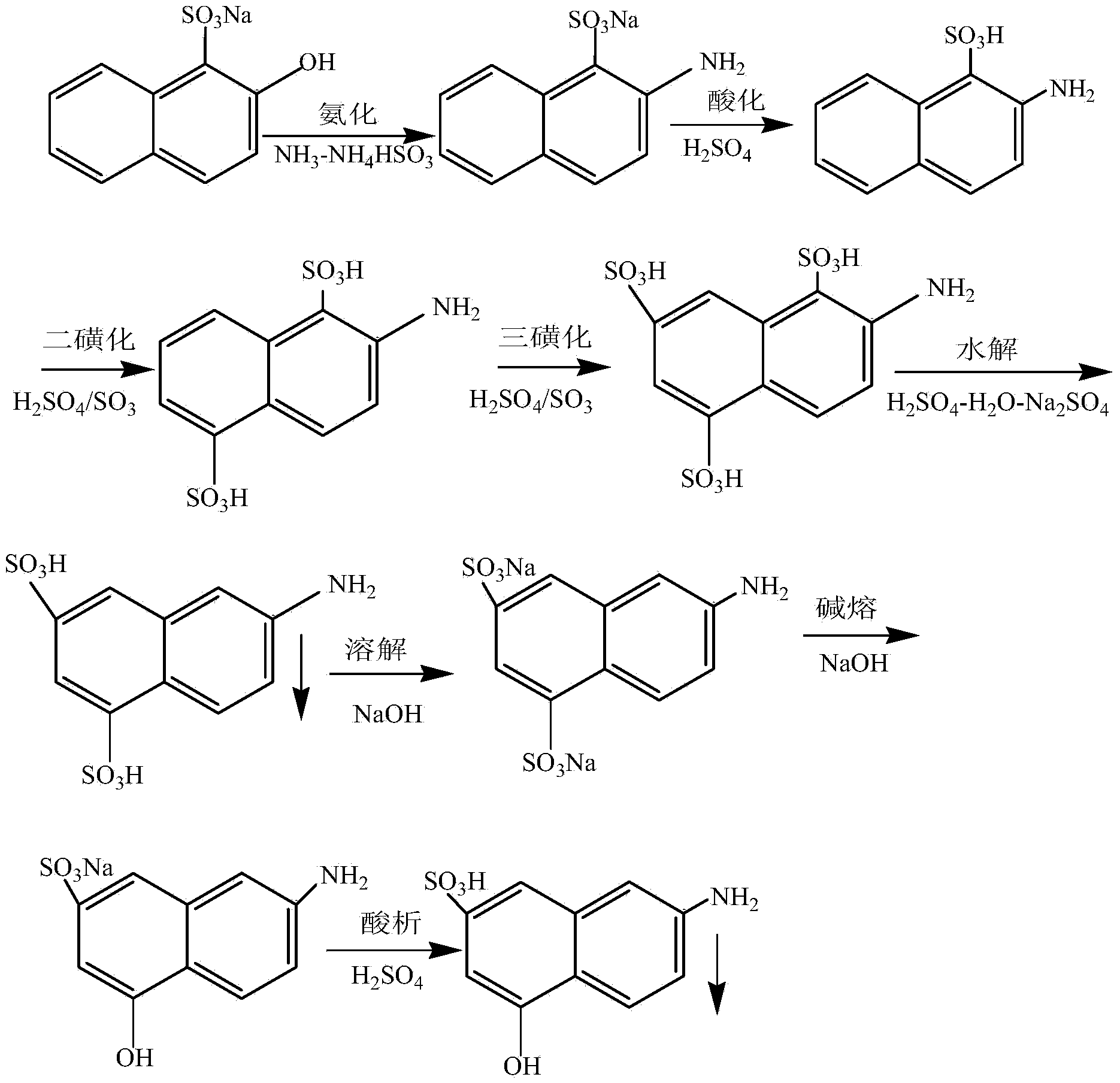

Method for removing metal ion purity of rare earth aqueous solution extraction

ActiveCN103468950AImprove separation efficiencySimple separation processProcess efficiency improvementHydroxylamine HydrochlorideInorganic electrolyte

The invention relates to a method for removing metal ion purity of rare earth solution aqueous solution aqueous solution extraction, and belongs to the metallurgy filed of rare earth extraction. The method comprises the following steps: hydroxylamine hydrochloride or ascorbic acid taken as a deoxidizer and a hydrosoluble chemical complexing agent are added to an aqueous solution containing various kinds of rare earth ions and purity metal ions of aluminum, iron and / or silicon; the pH value of the aqueous solution is regulated; a hydrosoluble high polymer and an inorganic electrolyte salt are sequentially added into the aqueous solution, and are vibrated and mixed at the room temperature, so that a polymer dual-phase aqueous system is obtained; an organic solution not dissolving in water is added, and a liquid-liquid-liquid three-layer liquid phase coexistence system is obtained. Purity metal ions of aluminum, iron and silicon can gather in a three-phase system polymer while rare earth ion selectively gather in the organic upper phase and / or brine lower phase of a three-phase system. The method can extract and separate rare earth ions, and extract and remove purity metal ions of the aluminum, silicon, iron and the like, and is simple in process flow and high in separation efficiency.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

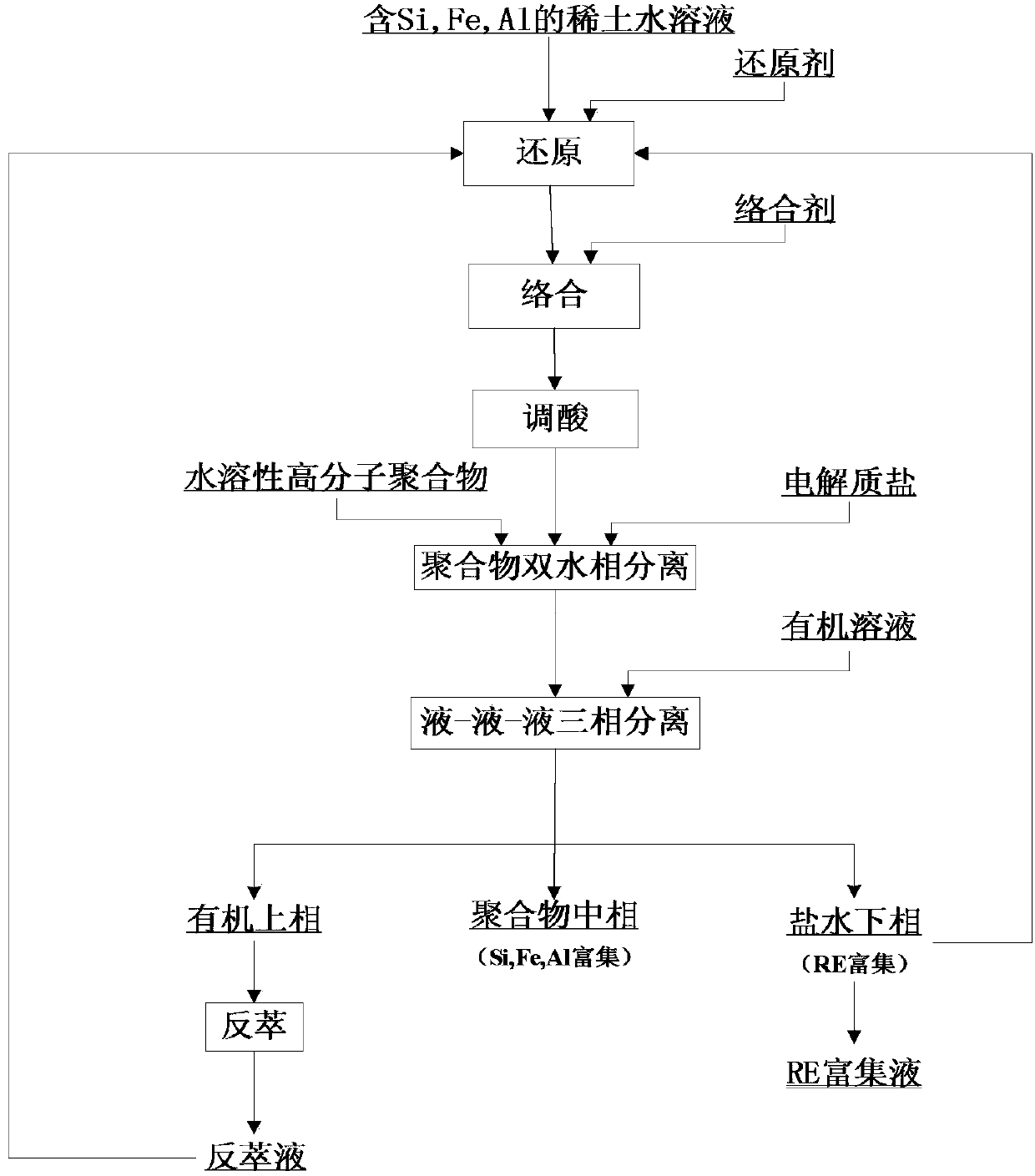

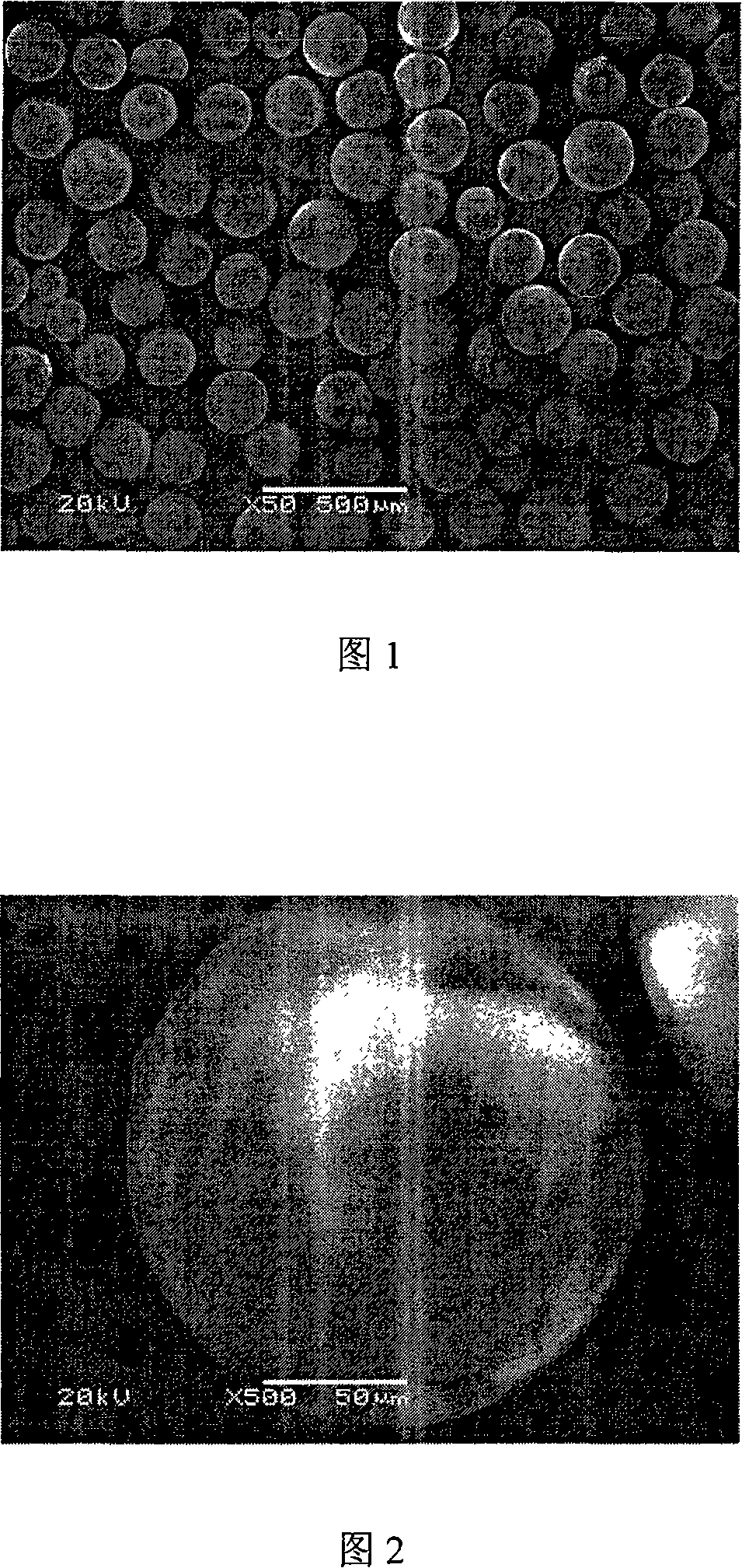

Elution-extracting resin using amide compound as extracting agent and preparation method thereof

InactiveCN101139418AHigh selectivityImprove extraction abilitySolid sorbent liquid separationLiquid wasteGram

The present invention discloses the solvent impregnated resin which uses amide compound as the extraction agent. The extraction agent is embedded in the polymer. The prevent invention is characterized in that the polymer is the styrene - divinylbenzene copolymer resin, and the extraction agent is the amide compound with the content of 20 percent to 60 percent. The solvent impregnated resin is ivory ball particle in appearance, with a particle diameter of 60 to 200 items a heap density of 0.53 to 0.94 gram per milliliter, and a specific surface area of 128 to 260 millimeters 2 / gram. The present invention also discloses the preparation method for the solvent impregnated resin. The solvent impregnated resin provided by the present invention has the advantages of low cost, less wastage of extraction agent, high column load, good mass transfer performance, easiness to be regenerated, long service life, ease use, good repeatability, and high reproducibility and so on. The solvent impregnated resin is of the characteristics of both particle and liquid in terms of extraction and cleaning. The present invention can be widely used in the separation and analysis of 90Sr in the plant and the animal samples, in the removal and callback of 90Sr during the treatment of nuclear fuel high-level radioactive liquid waste, as well as in the separation, purifying and callback of radioactive medical isotopes 90Sr.

Owner:SICHUAN UNIV

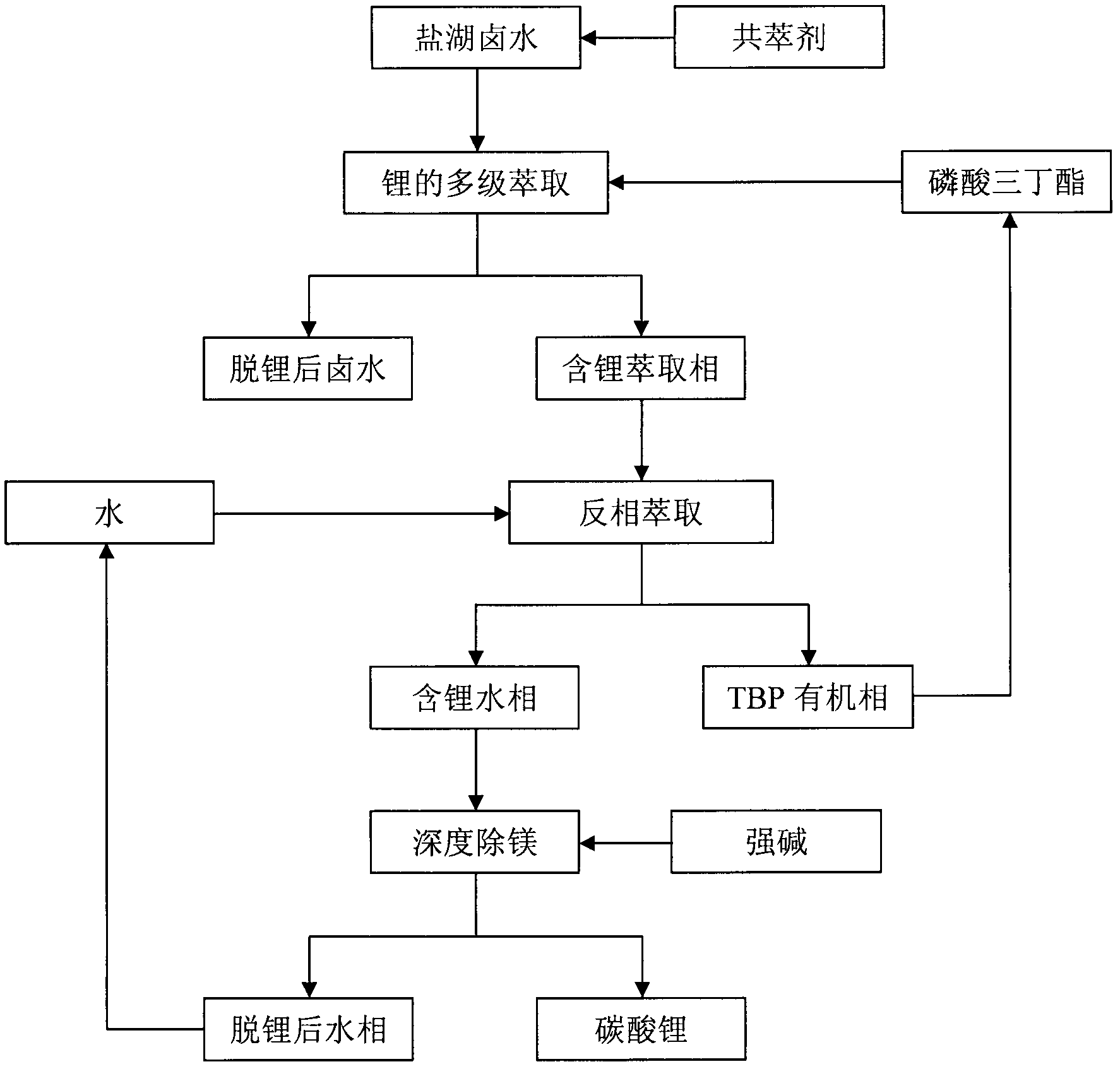

Method for separating magnesium and extracting lithium from salt lake brine with high magnesium-lithium ratio

InactiveCN102633284AStable in natureEasy to separateMagnesium carbonatesLithium carbonates/bicarbonatesHigh magnesiumKerosene

The invention discloses a method for separating magnesium and extracting lithium from salt lake brine with a high magnesium-lithium ratio. With adoption of the method, tributyl phosphate is taken as an extractant, number 200 solvent oil or kerosene is taken as a diluent, perchlorate is taken as a co-extraction agent, and water is taken as a stripping agent to form an extraction system; and lithium carbonate is prepared through extraction, reversed-phase extraction and deep magnesium removal by the salt lake brine. The method has the following beneficial effects: 1. the property of the co-extraction agent is stable, lithium magnesium separation can be carried out in neutral brine and the pH value of an aqueous phase needs not to be controlled; 2. the emulsification phenomenon doesn't exist and a third phase doesn't appear in the extraction process, two phases are easy to separate, the reversed-phase extraction is carried out by water and the device has little corrosion; and 3. the whole technique is simple in process, high in lithium extraction rate, good in separation effect and low in economic cost, is suitable for industrial production of the salt lake brine and is low in environmental damage degree because the co-extraction agent in water can be recycled.

Owner:XIANGTAN UNIV

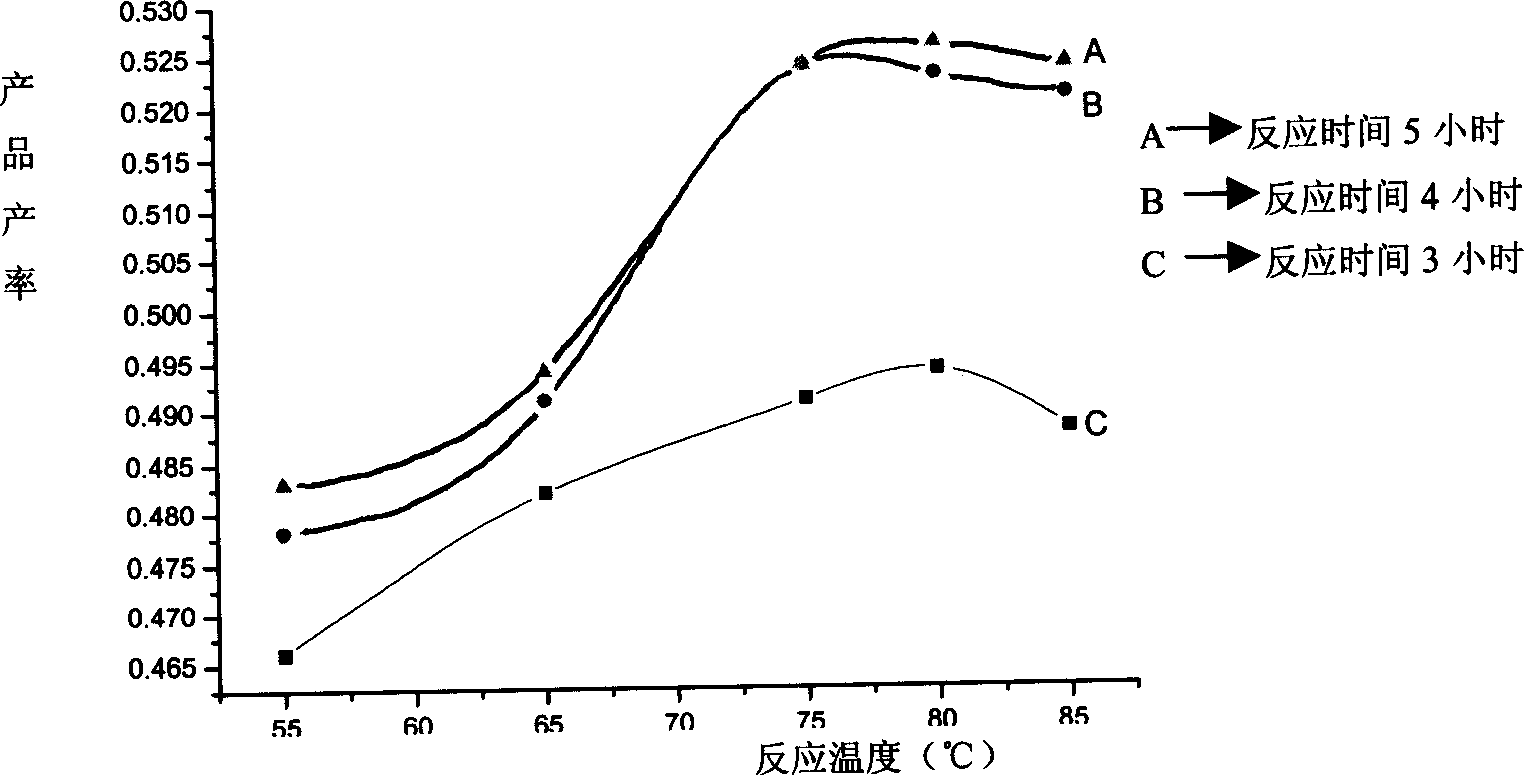

C9 solid petroleum resin preparation method

The invention relates to a process for preparing C9 petroleum coal resin suitable for pasting in paper-making industry by utilizing C9 fraction of petroleum, which comprises subjecting C9 petroleum fraction to vacuum distillation under the pressure of 0.08-0.09MPa, collecting 90-120 deg C C9 fraction as raw material of the reaction, charging 2-10% of maleio anhydride, 89-97% of C9 fraction and 0.2-1% of BF3-ether complex compound, reacting 3-5 hours at 50-80 deg. C, washing the polymerization liquid with NaOH and water to neutral, finally subjecting the polymerization liquid to vacuum distillation under the vacuum degree of 0.08-0.095MPa.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Method for extracting and separating rare earth elements in hydrochloric acid system

InactiveCN102876894AHigh separation factorLow extraction acidityProcess efficiency improvementRare-earth elementSeparation coefficient

The invention provides a method for extracting and separating rare earth elements in a hydrochloric acid system. The method includes the steps: taking mono (2-ethylhexyl) phosphonate 2-ethylhexyl methoxy cinnamate trialkyl methyl ammonium or phosphonate (2-ethylhexyl) diester trialkyl methyl ammonium as an extracting agent; taking normal heptane as diluent; and extracting the rare earth elements in rare earth chloride water solution into the normal heptane. The extracting agent used in the method does not need to be saponified, extraction and reverse extraction acidity is low, and separation coefficient for the rare earth elements is high.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

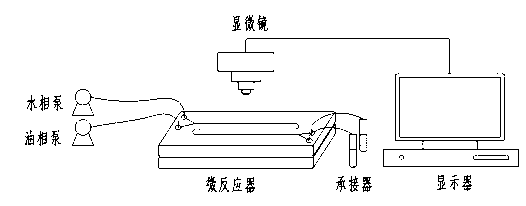

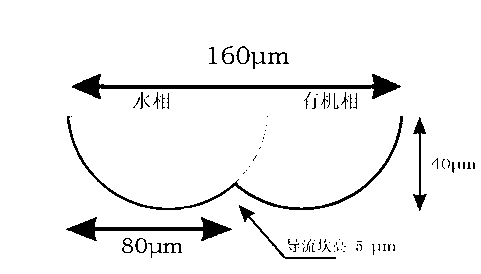

Microfluid extraction method for extracting and separating In, Fe and Zn

InactiveCN103060559ANo emulsificationImprove recycling efficiencyProcess efficiency improvementIndiumSolvent

The invention provides a microfluid extraction method for extracting and separating In, Fe and Zn. The microfluid extraction method comprises the steps of: using a sulfuric acid system solution containing indium, ferrum and zinc as a water phase and a P204 extracting agent diluted through solvent oil as an organic phase, which are respectively fed into two flow pumps, wherein the outlet end of the flow pump is connected with an inlet of a microreactor; simultaneously, observing a two-phase laminar flow phase interface formed inside a microchannel through an optical microscope, so that two phases flow in parallel and then begins to be separated when reaching a Y-type fork at the outlet of the microchannel, and the two phases flow out of the microreactor from outlets of the two phases; respectively collecting the two phases; and extracting indium to enter the organic phase and leaving ferrum and zinc in the water phase, so that the separation of indium, ferrum and zinc is realized. The extraction rate of In can be up to more than 90%, but ions of Fe and Zn are not extracted completely; moreover, no emulsion appears; and reaction time is greatly shortened, the using amount and consumption of the extracting agent can be reduced, the condition controllability is high, the safety is high, and extracted organic solvent is prevented from being exposed in the air.

Owner:KUNMING UNIV OF SCI & TECH

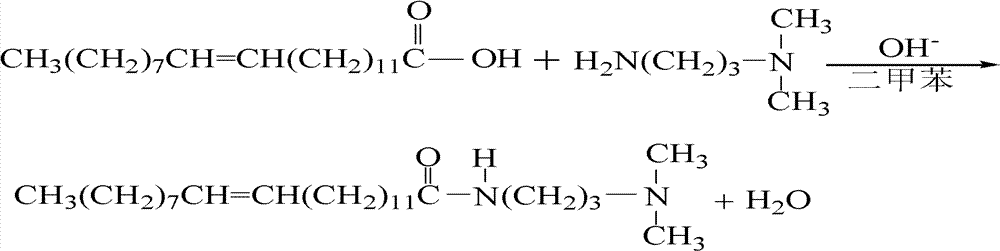

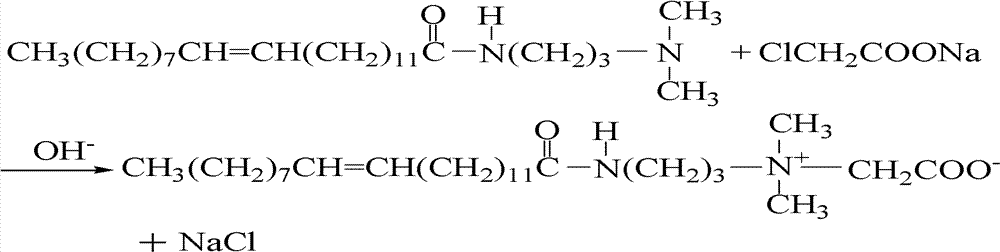

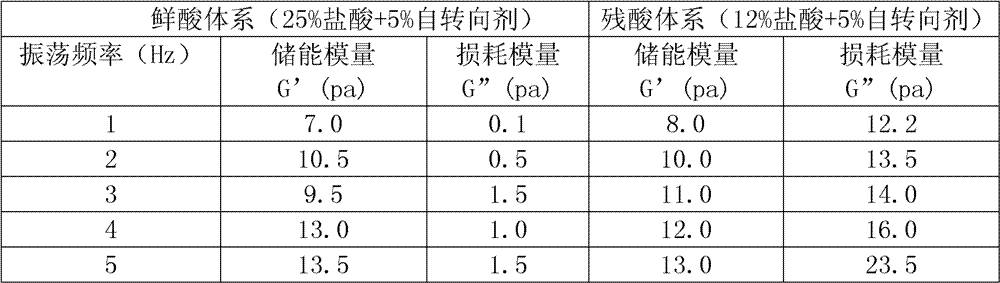

Self-diverting agent for heterogeneous carbonate rock acidizing system

InactiveCN103086909AGood heat resistanceThe synthesis process is simpleOrganic compound preparationCarboxylic acid amides preparationSolution systemChemistry

The invention relates to a self-diverting agent for a heterogeneous carbonate rock acidizing system. The self-diverting agent is characterized by: taking erucic acid as an initiator, adding 3-dimethylaminopropylamine to make them undergo a reaction under oil bath conditions and under the action of a water carrying agent dimethylbenzene and a catalyst KOH; subjecting the reacted mixed solution to pressure reduced vacuum pumping and cooling, thus obtaining erucamide tertiary amine; mixing the erucamide tertiary amine with a sodium chloroacetate solution and leaving them to react under water bath conditions; dissolving the reacted mixed solution in an acetone solution, conducting cooling to room temperature, and carrying out standing and pumping filtration so as to obtain erucamidopropyl betaine, i.e. the self-diverting agent for the heterogeneous carbonate rock acidizing system involved in the invention. Along with the progression of an acid-rock reaction, the acid solution system prepared in the invention can realize automatic viscosity change to generate high flow resistance, thus realizing effective distribution of the acid solution in a reservoir. The self-diverting agent has the characteristics of reducing acid solution filter loss, increasing the acid solution penetration distance, and ensuring effective self-diverting of the acid solution system.

Owner:YANGTZE UNIVERSITY

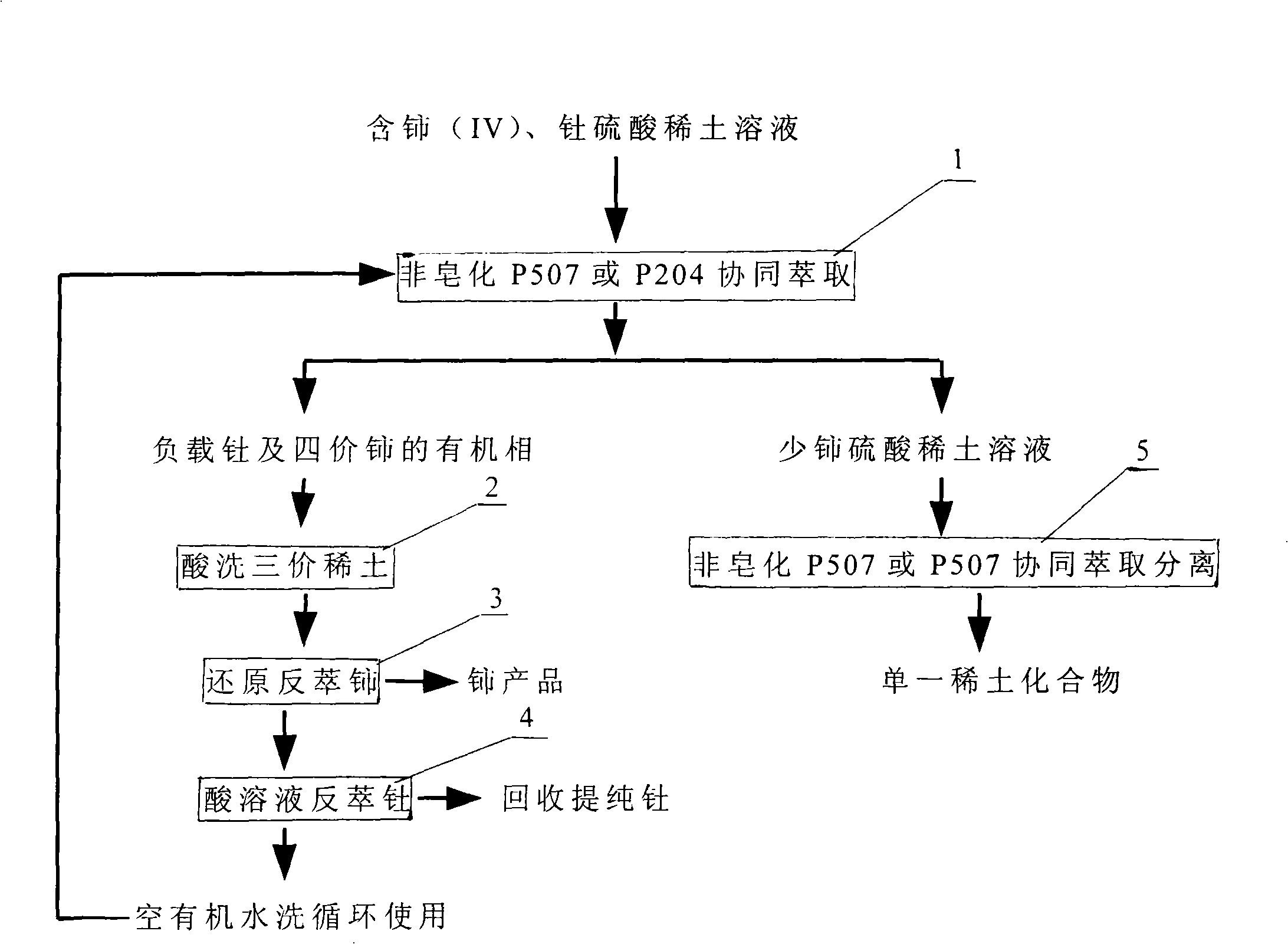

Technique for extraction separation of quadravalence cerium, thorium and cerium less tervalence rare earth from sulphuric acid rare earth solution

InactiveCN101294245ANo pollution in the processReduce consumptionProcess efficiency improvementRare-earth elementSulfate

The invention relates to a technological method for extracting and separating quadrivalent cerium, thorium, and less-cerium trivalent rare-earth from rare earth sulfate solution. The rare earth sulfate solution, which is obtained through processing the rare-earth ores and contains the thorium and high-valence cerium, is used as raw material; synergistic extraction agent basing on P507 and P204 is adopted for extracting and separating; the cerium (4) and the thorium are extracted into an organic phase, then selective washing and back extraction are performed step by step to obtain the products including pure cerium and pure thorium, the trivalent rare-earth is left in a water phase, and then unsaponifiable P507 or the synergistic extraction agent basing on P507 is adopted to perform multistage fractional extraction to separate single rare earth elements after impurity removal. The technological methodn has the characteristics that the synergistic extraction agent basing on P507 and P204 is adopted, the thorium is easy to perform the back extraction, and extraction capacity is large, and the emulsification is not generated during the extraction process; the cerium (4), the thorium and trivalent rare-earth are extracted and separated in the same extraction system; both extraction and the separation adopt unsaponifiable extraction agent, and ammonia-nitrogen wastewater is not generated; in addition, the thorium is recovered as products, and the pollutions caused by thorium-containing waste residue and the ammonia-nitrogen containing wastewater are eliminated from headstream. Therefore, the technological method has the advantages of simple procedures, green environmental protection, and low manufacturing cost.

Owner:GRIREM ADVANCED MATERIALS CO LTD

Industrial cleaning agent and its production method

InactiveCN1730640ANo rust treatment requiredNo solubilityOrganic detergent compounding agentsSurface-active detergent compositionsSodium bicarbonateAlkylphenol

The invention discloses a cleaning agent for industrial use and its preparing process, wherein the product comprises sodium carbonate, sodium bicarbonate, sodium tripolyphosphate, sodium silicate, sodium metasillcate, sodium polyacrylate, sodium acrylate, alkylphenol polyether, triethanolamine, and sodium alkyl benzene sulphonate.

Owner:XIAN JIANNENG TECH

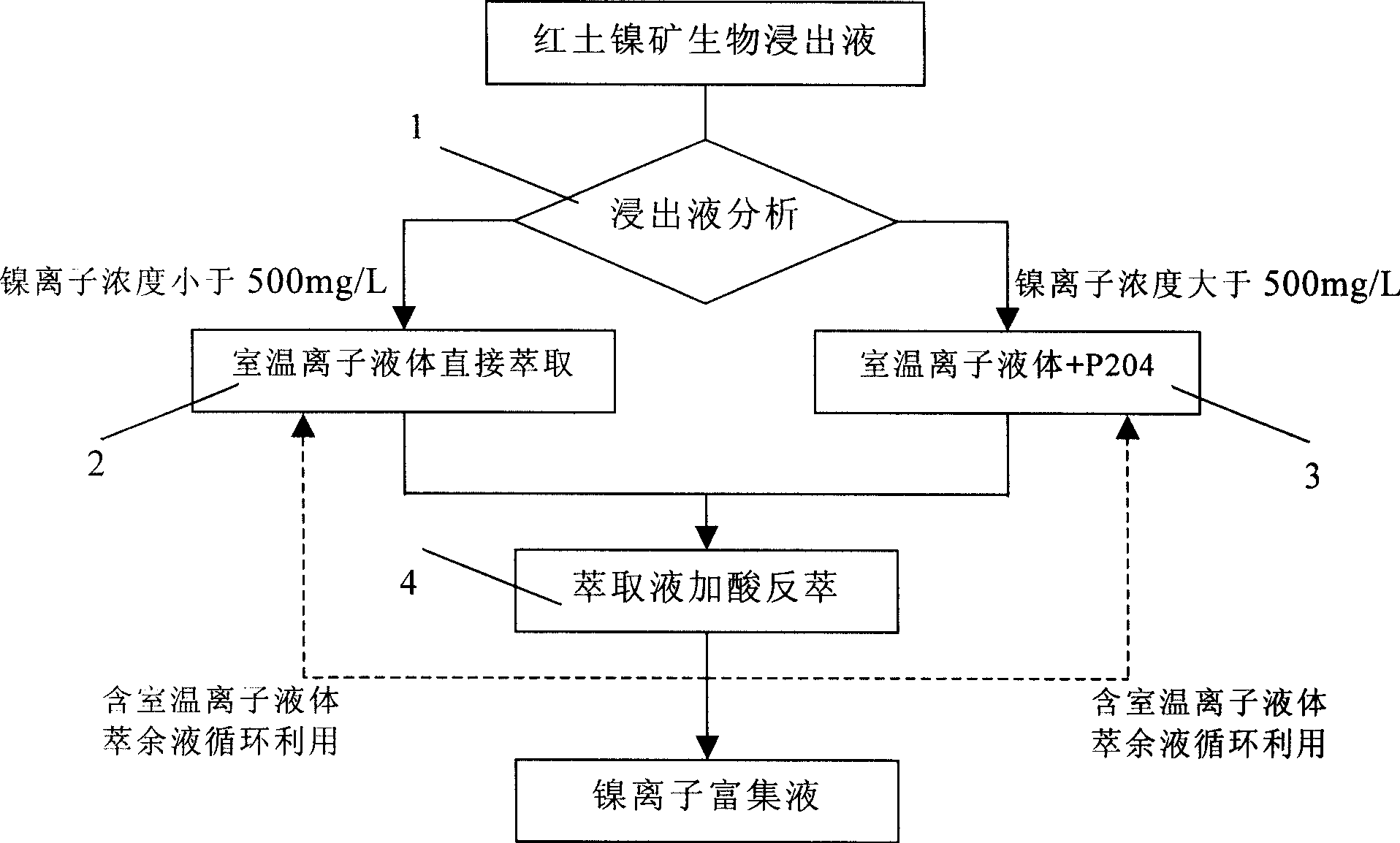

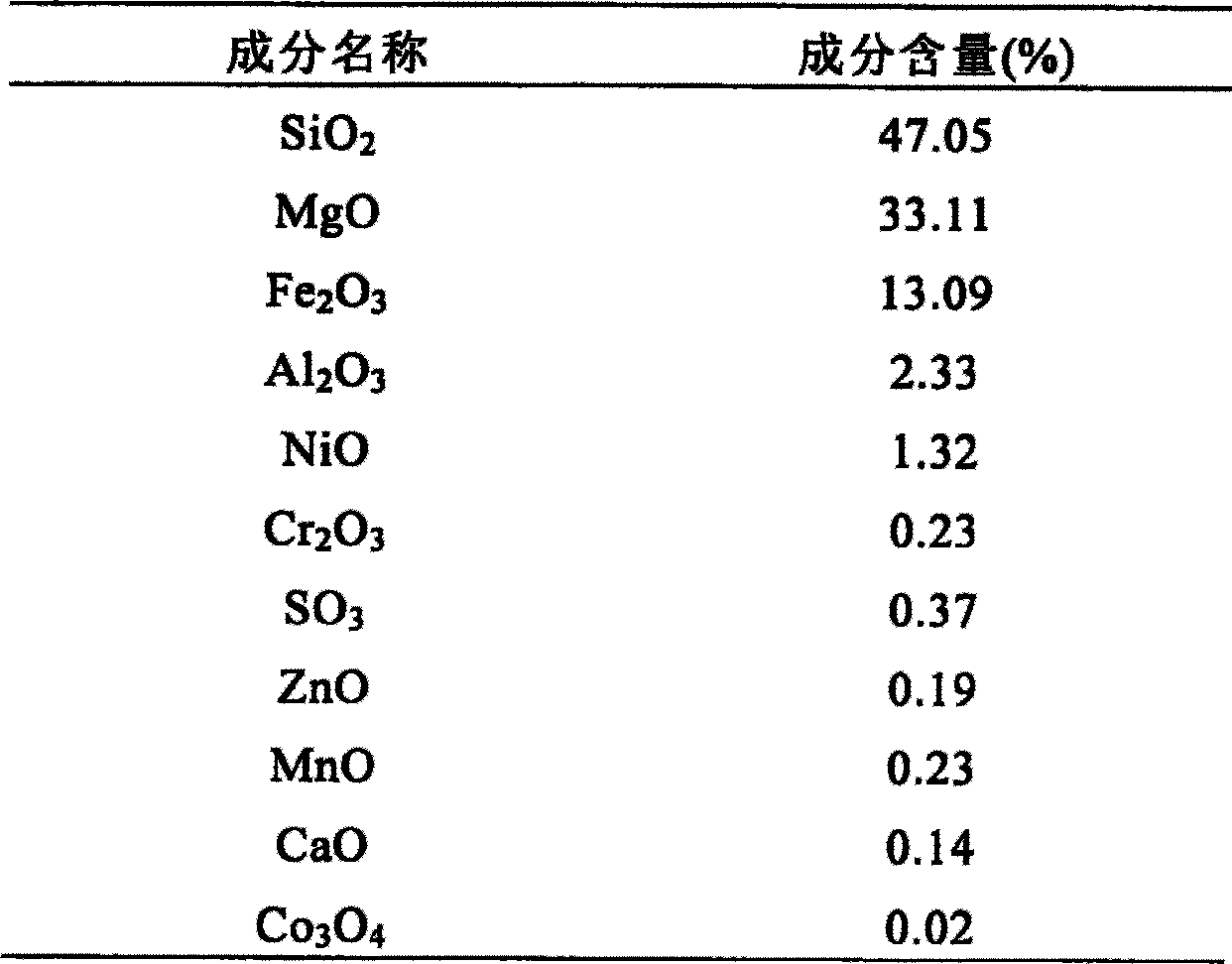

Process for recovering nickel ion from biochemical lixivium of laterite nickel mine by using room temperature ion liquid

InactiveCN101457292AReduce pollutionImprove the level of comprehensive utilizationProcess efficiency improvementLateriteCobalt

The invention discloses a process for recovering nickel ions from a bio-leaching solution of a laterite nickel ore by a room temperature ionic liquid. The process comprises the following steps: (1) mixing the room temperature ionic liquid and the bio-leaching solution of the laterite nickel ore at volume ratio of 1:50-100, fully stirring followed by standing for stratification during which an organic solvent of chelated metallic ion in the leaching solution can be partially enriched in a room temperature ionic liquid phase, and the metallic ions such as nickel, iron, cobalt and the like are transferred into the room temperature ionic liquid phase; (2) separating the room temperature ionic liquid phase, then serially adding dilute hydrochloric acid the concentration of which is 2-3mol / L and the volume of which is 1-1.5 times of the volume of the room temperature ionic liquid phase to perform a progressive re-extraction to realize the aim of recovering various metallic ions. The process has the advantages of simple operation, no emulsification, high extraction efficiency, short operation time, being easy in realizing multistage combination, high efficiency and being economic and environment-friendly. The invention establishes a new high-efficiency extraction process of the bio-leaching solution of the laterite nickel ore, fully utilizes low grade original nickel oxide ore resources, improves the comprehensive utilization level of mineral resources, reduces environmental pollution and improves economic benefit, thereby the process is applicable to exploitation and utilization of the laterite nickel ore mines in China.

Owner:有研资源环境技术研究院(北京)有限公司

Polyether crude oil demulsifier using straight chain alkyl phenolic resin as initiator and preparation method and application thereof

ActiveCN103396828ASimple preparation processImprove surface activityDewatering/demulsification with chemical meansCarbon numberDemulsifier

The invention discloses a polyether crude oil demulsifier using straight chain alkyl phenolic resin as an initiator and a preparation method and an application thereof. The general formula of the polyether crude oil demulsifier using straight chain alkyl phenolic resin as an initiator is A-(PO)a-(PO)b-(EO)c-(PO) m, wherein PO is -(CH2-O-CH2CH2)-, EO is -(O-CH2CH2)-, A and R are straight chain alkyls with carbon number of 6, n is an integer of 5-13, a+b is equal to m, and in the general formula, the mass of EO accounts for 15-25% of the mass sum of EO and PO. The polyether crude oil demulsifier prepared by the invention is simple in preparation process, good in surface activity, strong in demulsification capability and diffusion capability, good in dehydration effect, excellent in capability of perfecting oil-water interface emulsification performance and strong in universality, and the demulsification and dehydration rate of the crude oil reaches to 80-92%.

Owner:金浦新材料股份有限公司

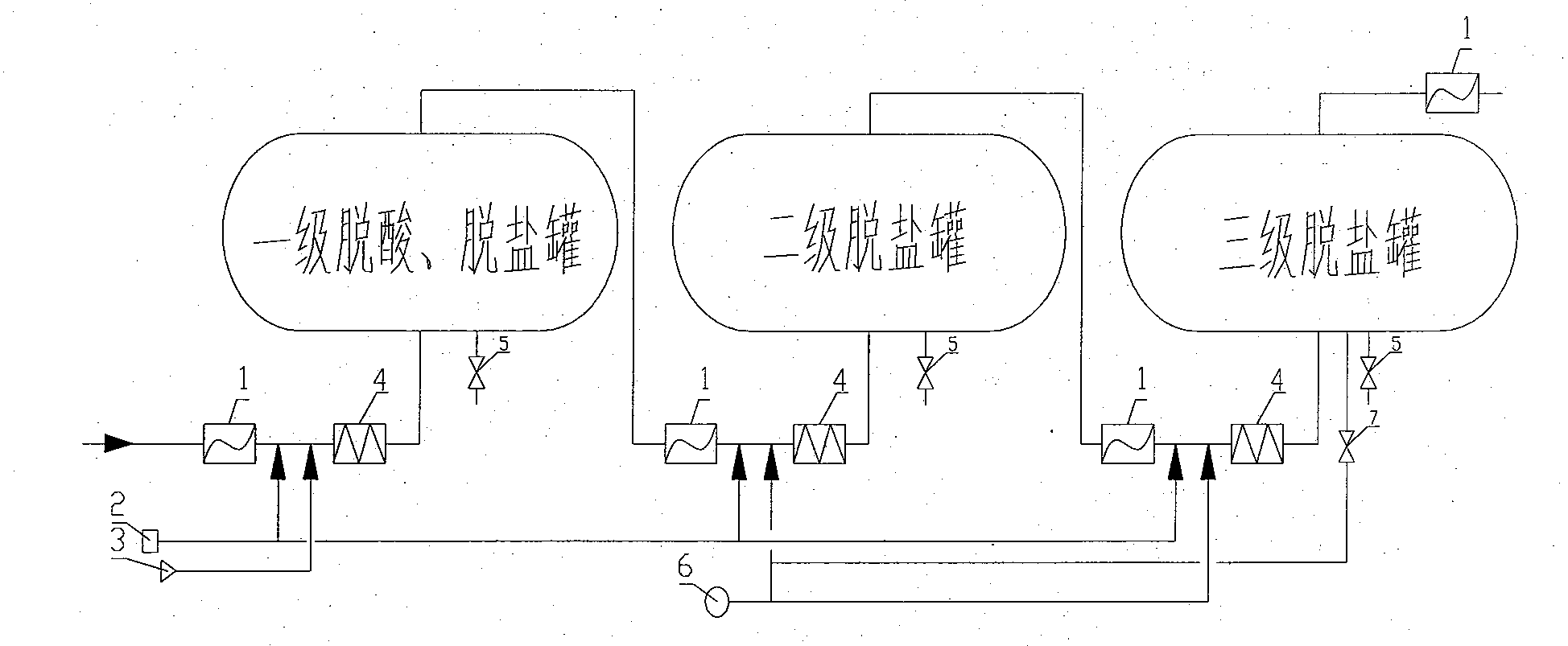

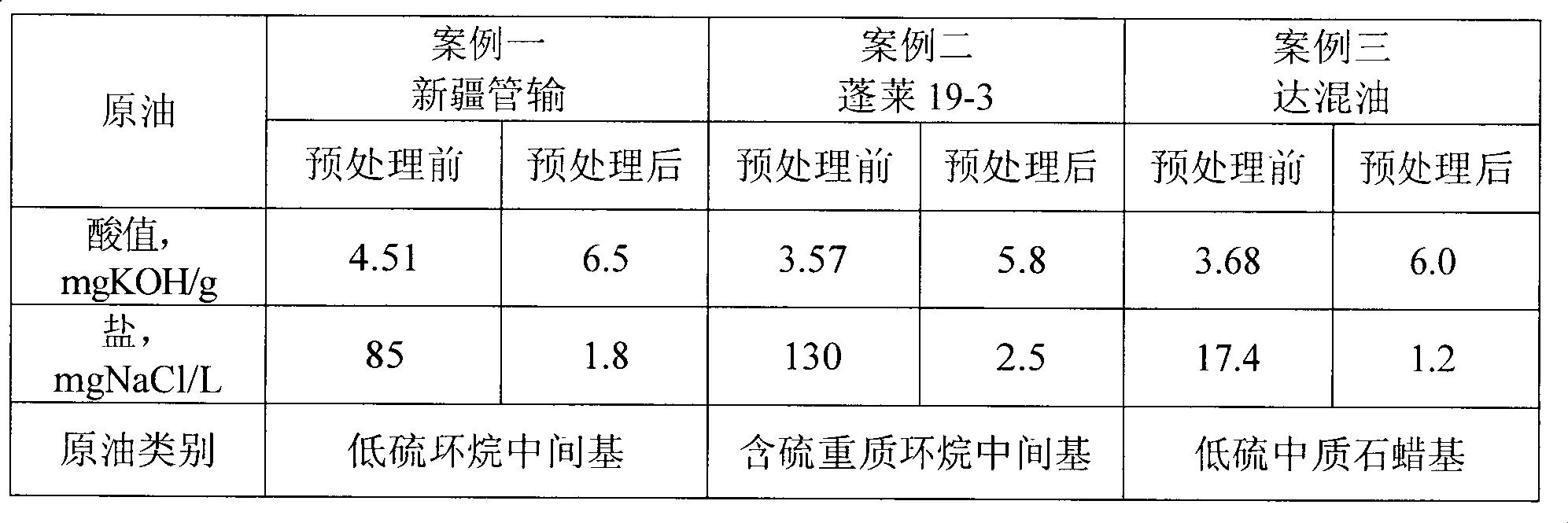

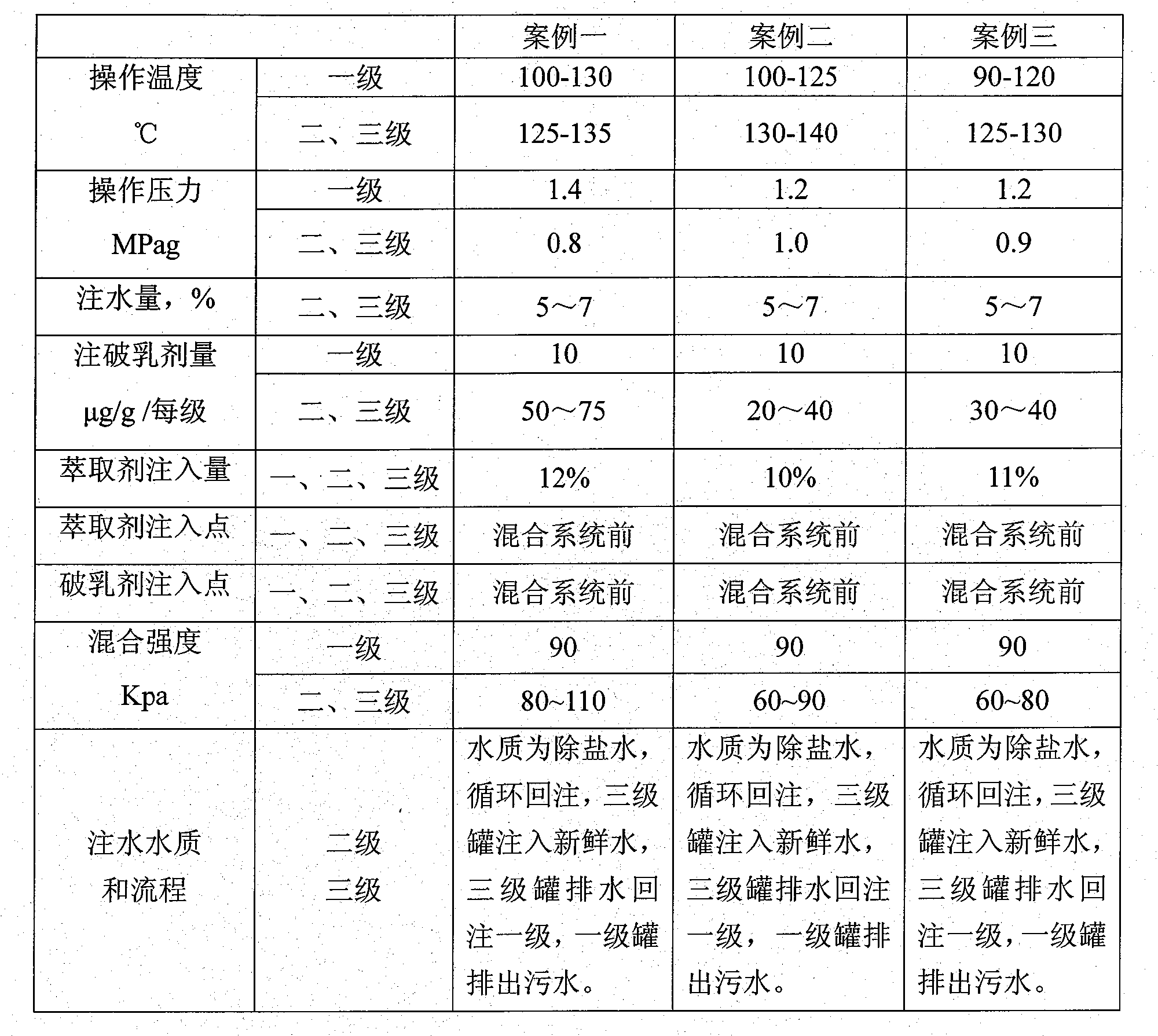

Pre-treatment process method of high acid crude oil

ActiveCN103805227AAvoid corrosionSimple processDewatering/demulsification with electric/magnetic meansRefining with two or more solventsDemulsifierDesalination

The invention relates to a pre-treatment process method of high acid crude oil. The method comprises the following steps that high acid crude oil is treated by coupling deacidification and electro-desalting processes by combining chemical extraction and electro-desalting; a first level tank is taken as a deacidification and electro-desalting tank; a demulsifier and an extractant are injected before a crude oil electro-desalting static mixer; after being fully mixing with crude oil, the mixture enters into the first level desalting tank; generated naphthenate and salt-containing sewage in the crude oil are dissolved in the extractant; treated deacidified oil enters into second and third level desalting tanks after being mixed with the demulsifier and water through the static mixer for desalination and dehydration; treated crude oil enters into a subsequent heat exchange unit; after a period time of operation of an electro-desalting system, impurities such as mud in raw material oil are flushed by a non-stop back purge device to discharge mud-containing sewage out of the tank; an extract phase is acidified to separate out naphthenic acid which is further extracted and purified by light dydrocarbon, and the extractant is purified and recovered and recycled.

Owner:长江三星能源科技股份有限公司

Method for performing extraction separation on cobalt and nickel by using microfluid technology

The invention provides a method for performing extraction separation on cobalt and nickel by using a microfluid technology. The method comprises the following steps of: uniformly mixing an extraction agent and diluent which are subjected to homogeneous phase saponification by using a mixed material liquid of Co<2+> and Ni<2+>, using 2-ethyl cthylhexyl phosphonate mono 2-ethyl cthylhexyl ester as the extraction agent and using No.260 solvent oil and using the extraction agent and the diluent as an oil phase; introducing the water phase and the oil phase into a micro-reactor by virtue of two flow pumps; mixing the two phases in the micro-reactor and performing extraction reaction at 25-50 DEG C; and collecting a product at an outlet of the micro-reactor and standing for separating the phases to ensure that Co<2+> enters the oil phase and Ni<2+> stays in the water phase so as to realize extraction separation of cobalt and nickel. According to the method, continuous flow micro-reactor with an enhanced hybrid channel structure is adopted, the extraction separation of cobalt and nickel is carried out, and the reaction time is shortened to be within a micro-second level range, so that single-level cobalt extraction efficiency is obviously improved, and the extraction levels are reduced; and moreover, standing layering on the water phase and the oil phase can be quickly carried out without any emulsion phenomenon.

Owner:KUNMING UNIV OF SCI & TECH

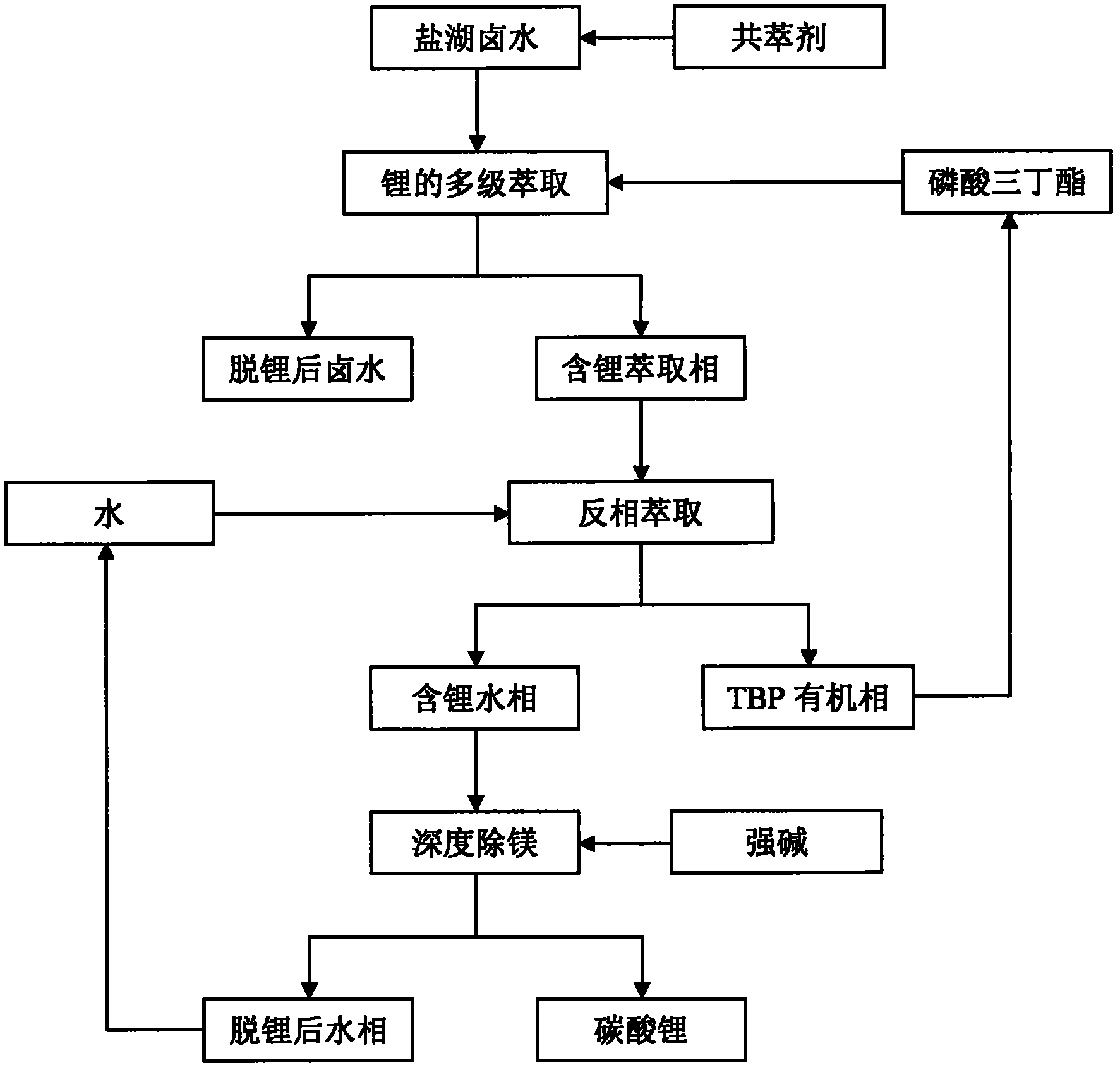

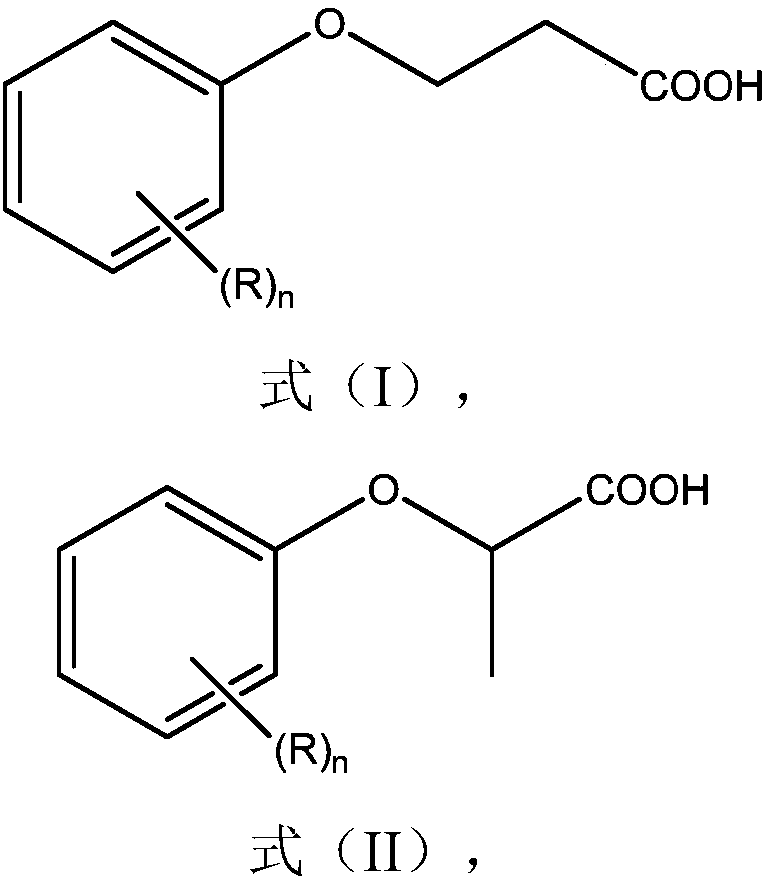

Extracting agent for rare earth extraction separation, preparing method thereof and extraction separation method using same

ActiveCN108456792AEfficient synthesisEasy to synthesizeProcess efficiency improvementSeparation coefficientDiluent

The invention discloses an extracting agent for rare earth extraction separation, a preparing method thereof and an extraction separation method using the extracting agent. The extraction separation method comprises the following steps of (1), mixing one or a plurality of diluents in an extracting agent which is represented by a formula (I) and / or a formula (II), and obtaining an organic phase; (2), mixing the organic phase obtained in the step (1) with yttrium-containing rare earth material solution, performing selective extraction for keeping the yttrium in a water phase and making poor-yttrium rare earth enter an organic phase, namely realizing extraction of rare earth yttrium. The extracting agent and the extraction separation method are advantageous in that 1, high selectivity of theextracting agent in rare earth extraction separation is realized, not only is a separation coefficient between light rare earth and yttrium kept, but also a separation range between heavy rare earth and the yttrium is improved; 2, the organic phase of the process can be cycled by more than one year without remarkable concentration reduction; 3, high extraction phenomenon and no emulsification arerealized; and 4, simple synthesis and low cost of the extracting agent are realized.

Owner:XIAMEN INST OF RARE EARTH MATERIALS

Method for extracting and separating cerium, fluorine and phosphorus from sulfuric acid leaching solution of Baotou rare earth mine

ActiveCN105132682AAchieve recyclingSimple processRare earth metal compoundsProcess efficiency improvementDecompositionCerium

The invention relates to a method for extracting and separating cerium, fluorine and phosphorus from a sulfuric acid leaching solution of a Baotou rare earth mine. According to the method, recycling of the fluorine (F) and recycling of the phosphorus (P) in the Baotou rare earth mine are achieved at the same time through a solvent extraction method. A sulfuric acid rare earth solution serves as a raw material solution, and the sulfuric acid rare earth solution is obtained by conducting oxidizing roasting and sulfuric acid leaching on the Baotou rare earth mine, and the sulfuric acid rare earth solution can also be obtained by conducting liquid alkali decomposition, wet air oxidation and sulfuric acid leaching on the Baotou rare earth mine; the cerium, the fluorine and the phosphorus are separated through the solvent extraction method under proper process conditions, and recycling of F and recycling of P in the Baotou rare earth mine are achieved at the same time; the method is simple in process procedure and high in yield, the concomitant F resources and P resources are recycled, and the process method is clean. The recovery rate of cerium (IV) in the process reaches over 95%, the extraction recovery rate of F reaches over 93%, and the extraction recovery rate of P is over 95%; the content of CeO2 / REO in obtained CeO2 products and mixed micro powder of CeF3 and CePO4 reaches 99-99.9999%, and the content of ThO2 / TCeO is less than 0.01%.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

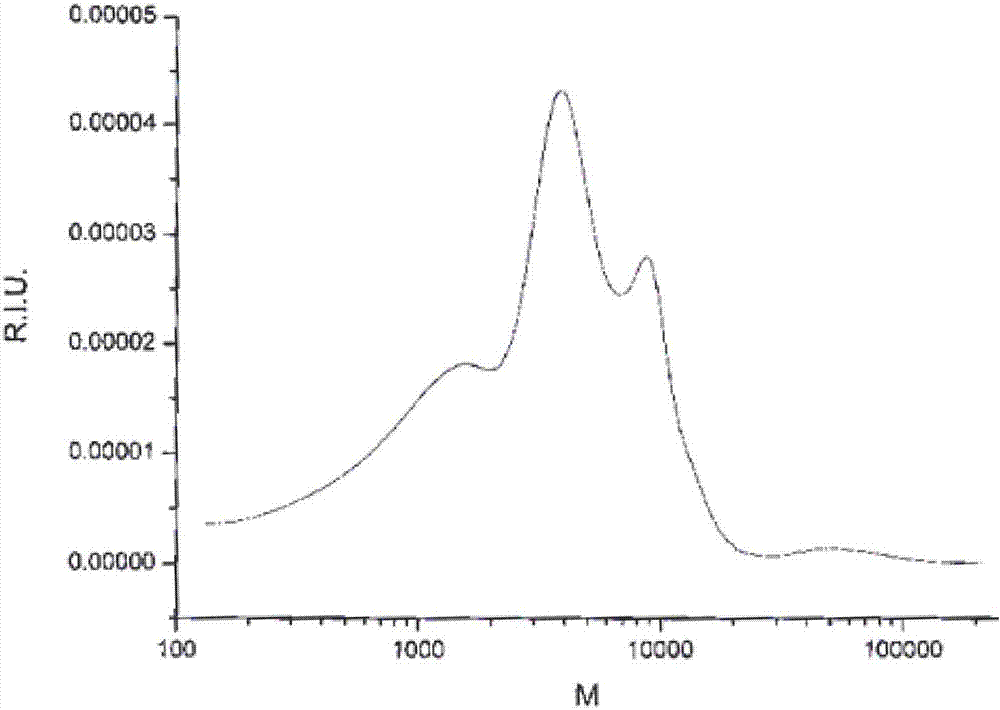

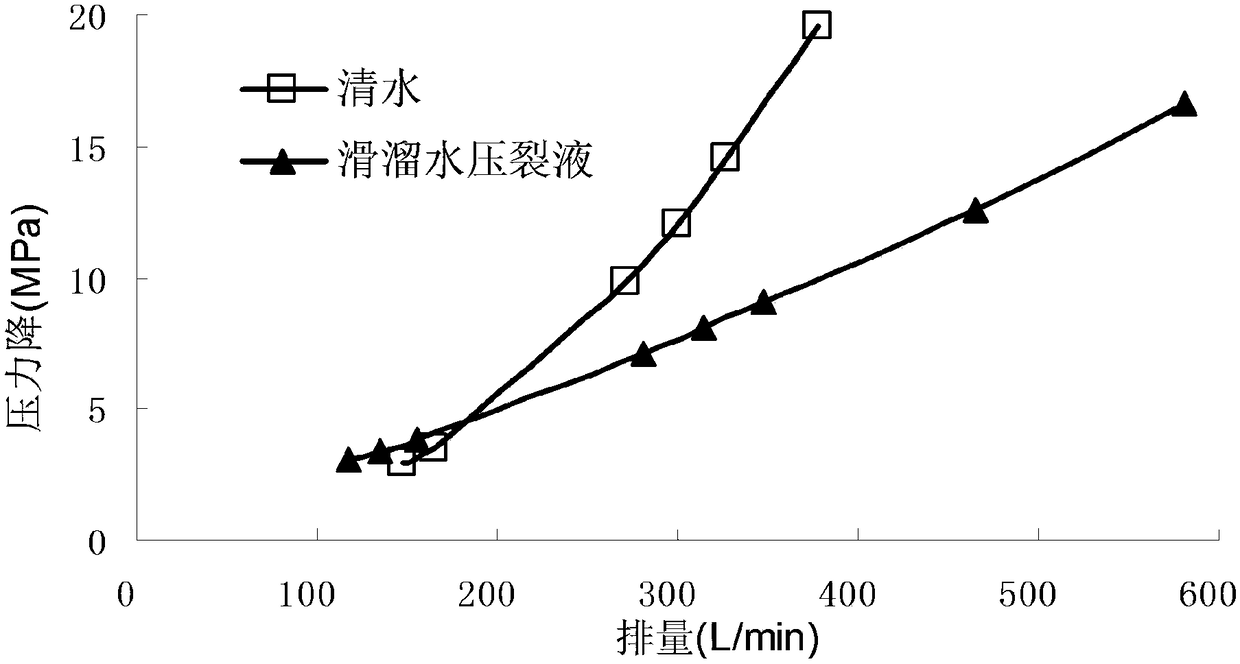

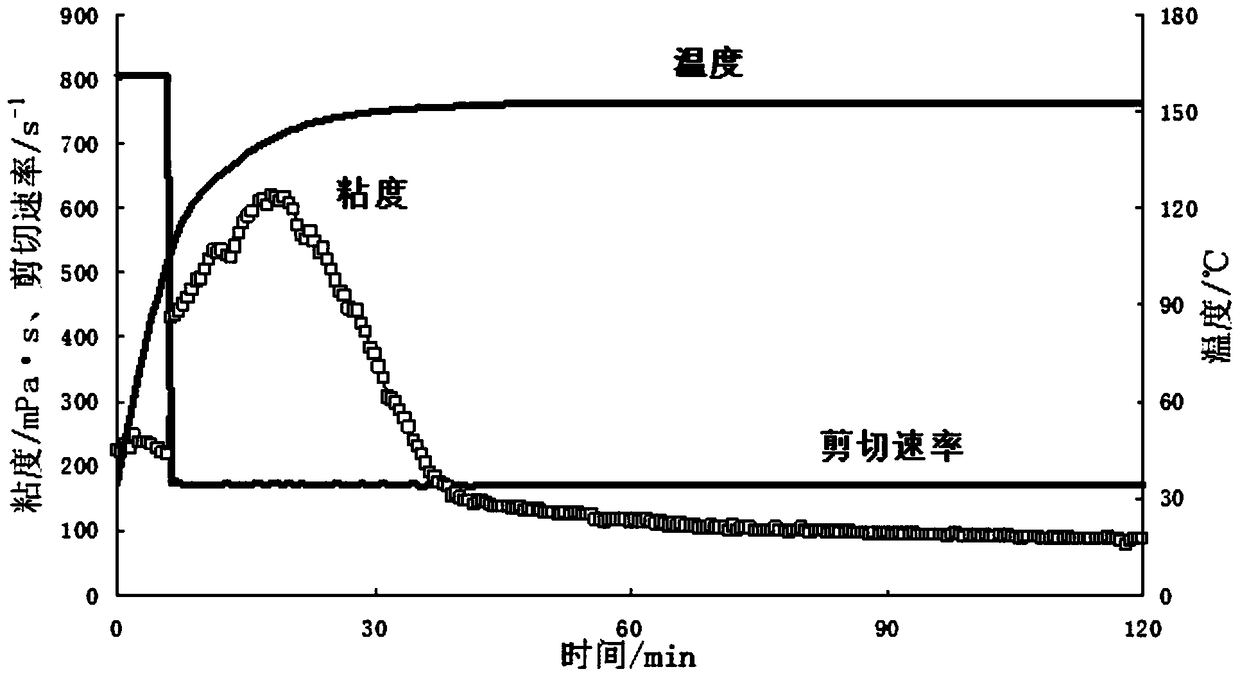

Inverse-phase micro-emulsion polymer fracturing fluid system with online construction function

ActiveCN108559479AGood resistance reduction effectEasy to reuseDrilling compositionMethacrylatePolymer science

The invention discloses an inverse-phase micro-emulsion polymer fracturing fluid system with an online construction function. The inverse-phase micro-emulsion polymer fracturing fluid system comprisesinstant dissolving emulsion thickening agents, functional auxiliaries, a clay stabilizer and fluid preparation water. The instant dissolving emulsion thickening agents are inverse-phase micro-emulsion polymers, and inverse-phase micro-emulsion polymerization is carried out on raw materials including acrylamide, acrylic acid, strong-hydrophilicity monomers, a functional monomer A, a functional monomer B, pH (potential of hydrogen) regulators, solubilizers, composite emulsifiers, oil solvents, initiators and deionized water to obtain the instant dissolving emulsion thickening agents; the functional monomer A is methyl methacrylate or ethyl methacrylate or a mixture of the methyl methacrylate and the ethyl methacrylate; the functional monomer B is vinylphosphonic acid or vinyl sulfonic acid;the functional auxiliaries are non-ionic surfactants; the clay stabilizer is potassium chloride, and the fluid preparation water is clear water or high-mineralization water or treated stratum flow-back fluid. The inverse-phase micro-emulsion polymer fracturing fluid system has the advantages that the inverse-phase micro-emulsion polymer fracturing fluid system is high in dispersing and swelling speed and can be prepared in a batch manner or can be continuously mixed, 'online construction' requirements even can be completely met by the inverse-phase micro-emulsion polymer fracturing fluid system, processes for constructing the inverse-phase micro-emulsion polymer fracturing fluid system are simple, and the fracturing cost can be reduced.

Owner:SOUTHWEST PETROLEUM UNIV +1

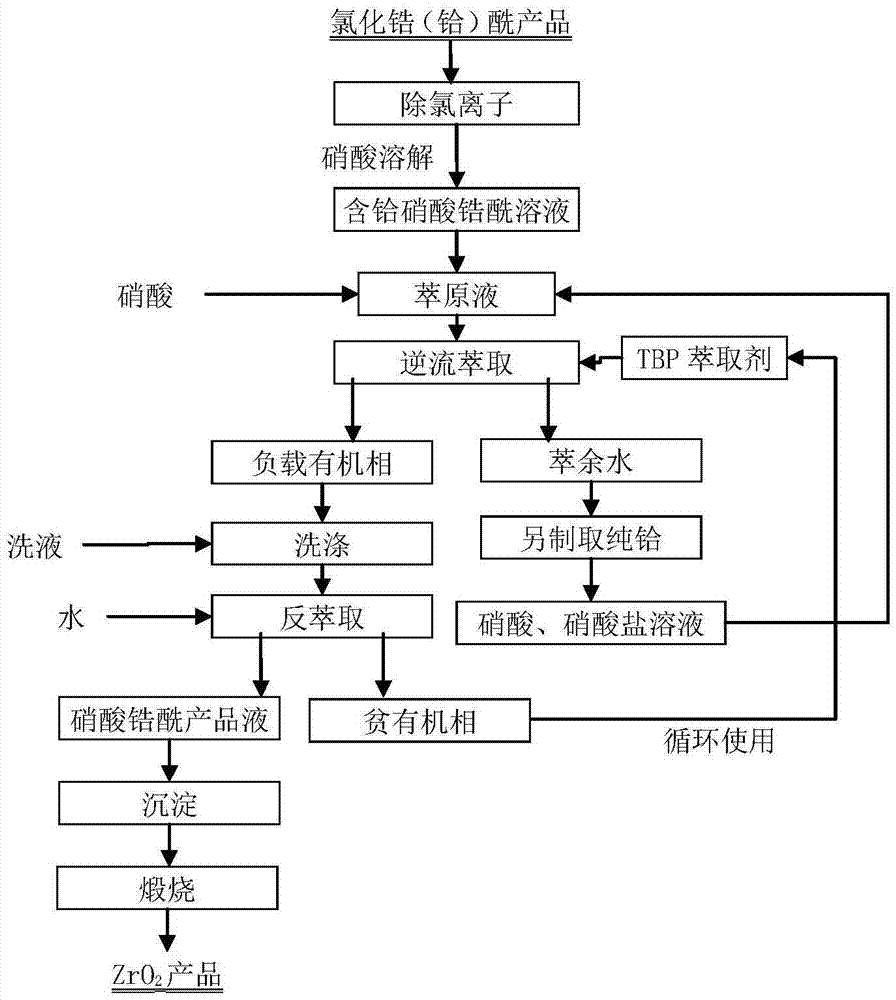

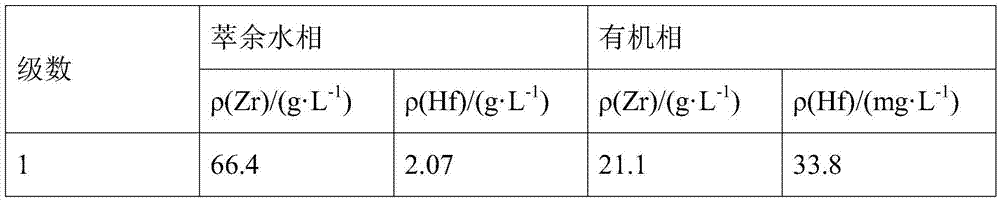

Process for separating zirconium and hafnium by solvent extracting method

ActiveCN106929695AFulfil requirementsImprove product qualityProcess efficiency improvementZirconium oxidesKeroseneHydrometallurgy

The invention belongs to the field of wet metallurgy and the technical field of zirconium and hafnium separation, and in particular, relates to a process for separating zirconium and hafnium by a solvent extracting method. Industrial products containing hafnium zirconium chloride acetyl are used as raw materials for such procedures as water solution, alkali sinking, washing and nitric acid dissolving to prepare zirconium (hafnium) nitrate acetyl solution; TBP kerosene solution of adding phase modifying agent octanol is used as an extracting agent; most zirconium and less hafnium are extracted into an organic phase through multistage counter-current extraction by using the characteristic of TBP priority extraction of zirconium; the loaded organic phase is washed by nitric acid solution with a certain concentration to further remove most hafnium in the organic phase; the acid-washed loaded organic phase is reversely extracted by water to obtain zirconium nitrate acetyl solution; the solution is precipitated in ammonia, dried and calcined to obtain zirconium dioxide powder, and the mass of the zirconium dioxide powder accords with the atomic energy-level zirconium dioxide standard; less zirconium and most hafnium only remained in residual water phase of zirconium after reverse extraction are extracted; the content of zirconium in hafnium meets the requirements on impurity zirconium by atomic energy-level hafnium; and atomic energy-level hafnium can be directly prepared by enrichment.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

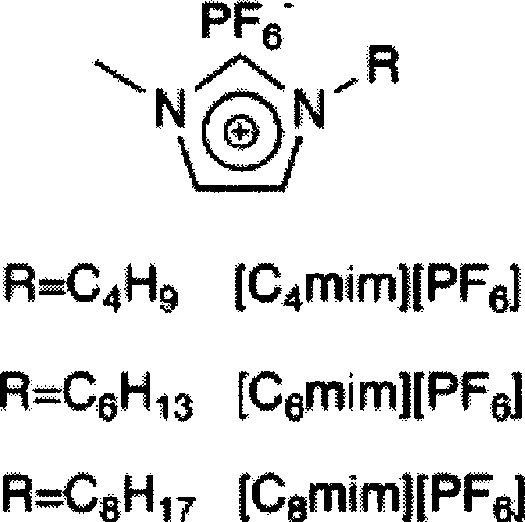

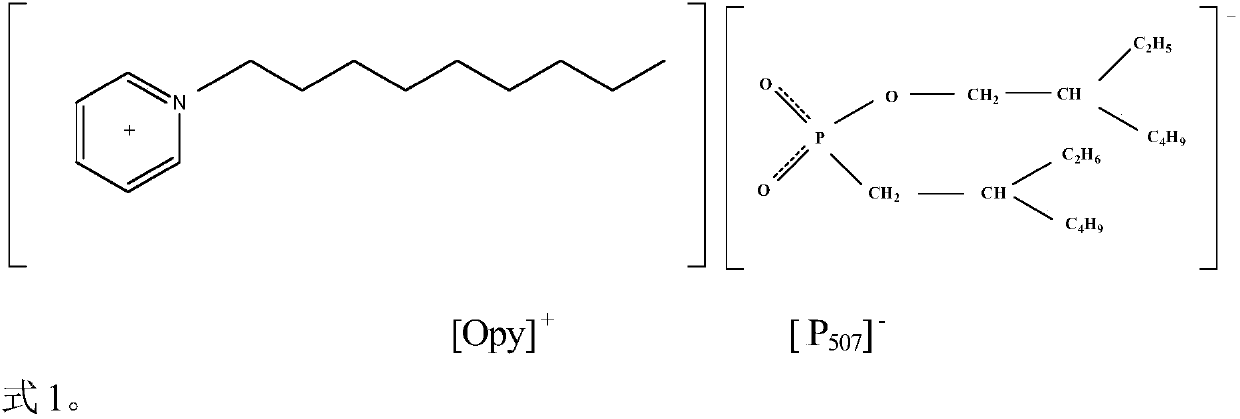

Method for extracting and separating light rare earth elements by using dual-functional ionic liquid

ActiveCN109517985AHigh extractabilityImprove extraction efficiencyProcess efficiency improvementRare-earth elementIon

The invention belongs to the technical field of rare earth separation and ionic liquid extraction and particularly relates to a method for extracting and separating light rare earth elements by usingdual-functional ionic liquid. The method comprises the following steps: taking an aqueous solution containing light rare earth elements as a raw material solution, combining 2-ethylhexyl phosphonic acid mono-2-ethylhexyl ester with N-octyl pyridine chloride salt, adding sodium hydroxide and adjusting, retaining negative ions of 2-ethylhexyl phosphonic acid mono-2-ethylhexyl ester and positive ionsof N-octyl pyridine chloride salt, combining the negative ions of 2-ethylhexyl phosphonic acid mono-2-ethylhexyl ester with the positive ions of N-octyl pyridine chloride salt to synthesize dual-functional ionic liquid, mixing the dual-functional ionic liquid with acidic raw material liquid, mixing and extracting, centrifuging to obtain an organic phase loaded with rare earth and extraction raffinate, carrying out back extraction of the rare earth by using a back extractant, and centrifuging to obtain a pure rare earth solution and recyclable ionic liquid. The method is high in extraction efficiency, short in equilibration time, simple to operate and free of emulsification phenomena.

Owner:NORTHEASTERN UNIV

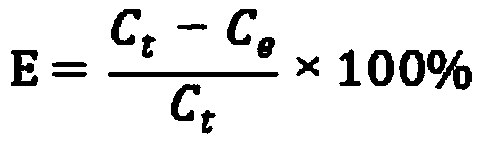

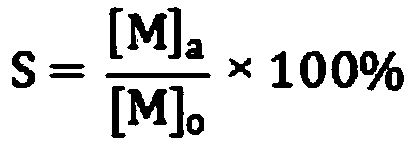

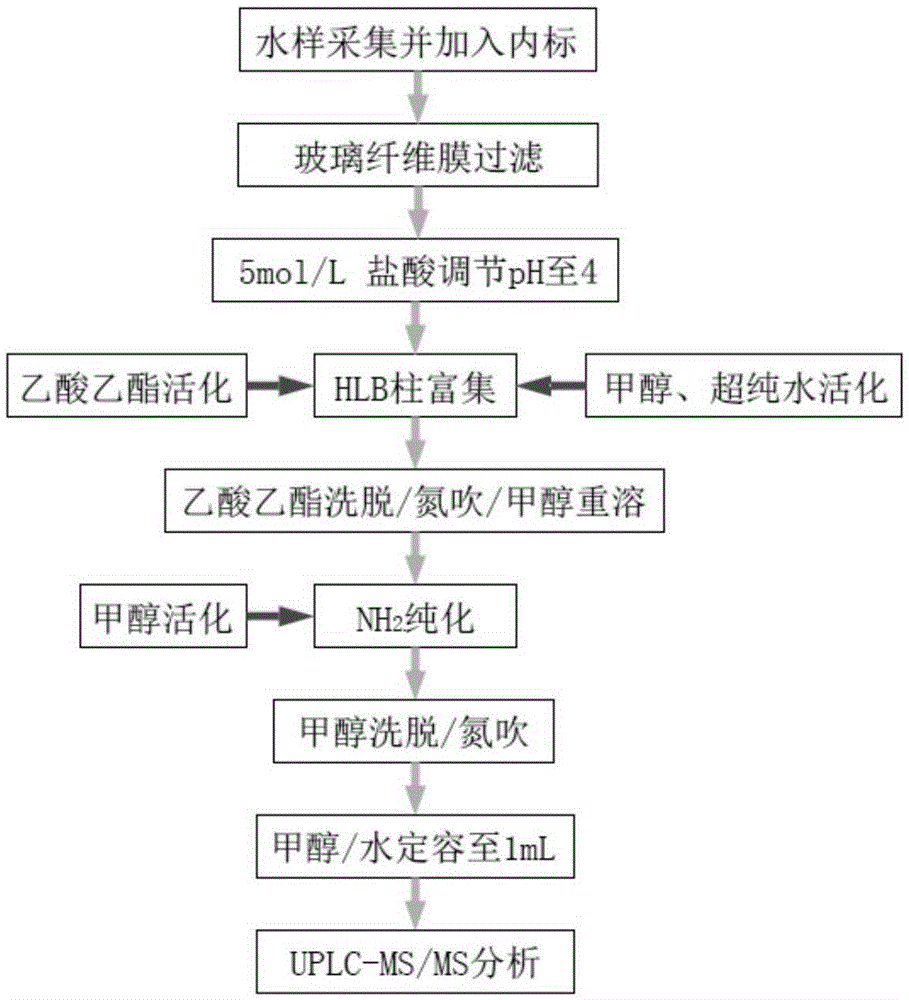

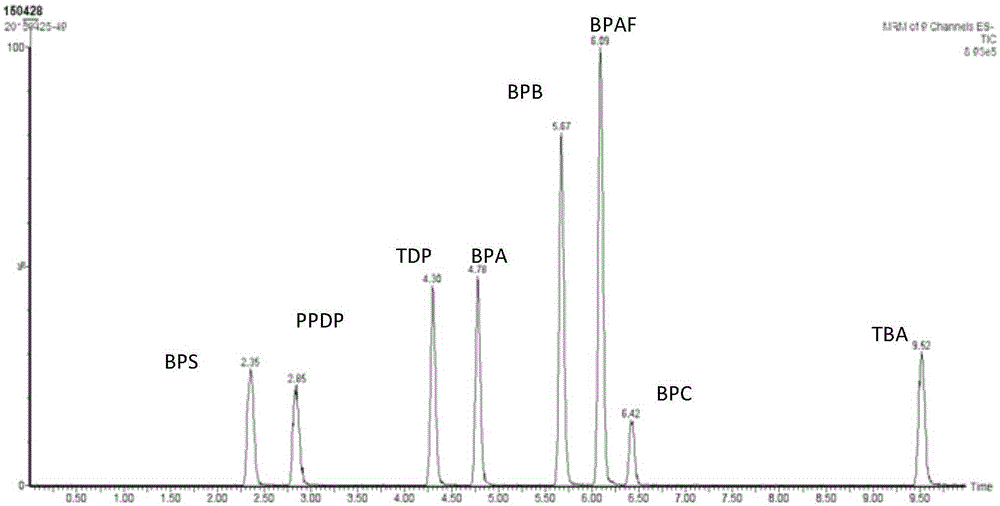

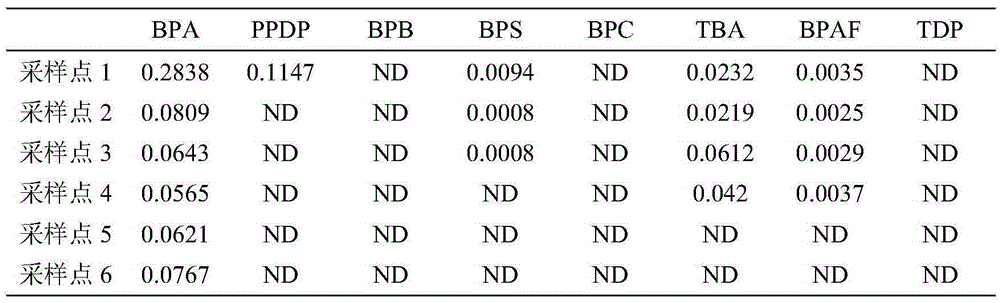

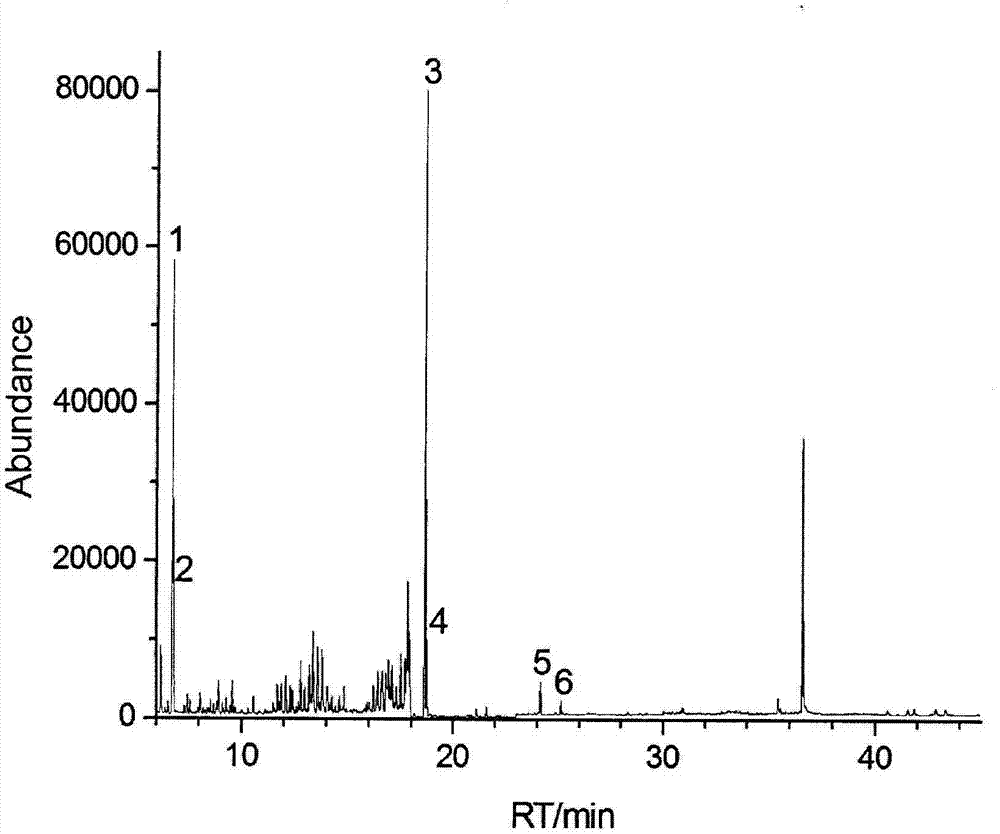

Second-order mass spectrometric detection method for bisphenol substances in water environment

InactiveCN105259287AUniform extractionReduce dosageComponent separationSolid phase extractionMass spectrometric

The invention relates to a second-order mass spectrometric detection method for bisphenol substances in a water environment, and belongs to the field of bisphenol substance detection. The problems that an existing analysis method for bisphenol pollutants is low in accuracy and precision due to interference of a natural water body matrix are solved. According to the second-order mass spectrometric detection method for the bisphenol substances in the water environment, an HLB column is adopted for solid-phase extraction, an amino column is purified, a full scanning mode is selected and used for qualitative and quantitative detection, all target objects used in a sample can be detected out at the same time by means of the mode, the mode is used for analyzing trace substances in a complex matrix, and for each substance, only one or two specific pairs of parent ions and daughter ions are selected to be detected. Matrix interference can be effectively removed, and sensitivity of detection and accuracy of qualitation and quantitation are improved.

Owner:HARBIN INST OF TECH

Method for extracting and separating rare earth elements in sulfuric acid system

InactiveCN102876893AHigh separation factorLow extraction acidityProcess efficiency improvementRare-earth elementSeparation coefficient

The invention provides a method for extracting and separating rare earth elements in a sulfuric acid system. The method includes the steps: taking mono (2-ethylhexyl) phosphonate 2-ethylhexyl methoxy cinnamate trialkyl methyl ammonium as an extracting agent; taking normal heptane as diluent; and extracting the rare earth elements in rare earth sulfate water solution into the normal heptane. The extracting agent used in the method does not need to be saponified, extraction and reverse extraction acidity is low, and separation coefficient for the rare earth elements is high.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

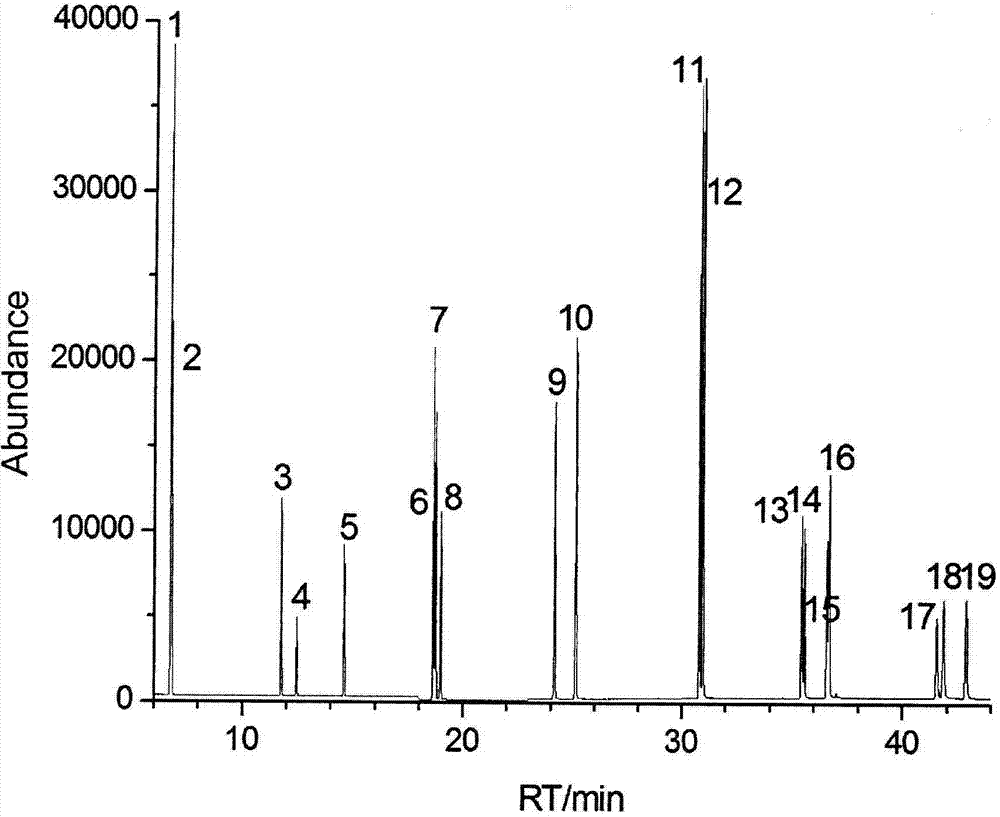

Method for measuring sixteen polycyclic aromatic hydrocarbons in cigarette liquid of electronic cigarette

ActiveCN104764851AEasy to handleReduce usageComponent separationPolycyclic aromatic hydrocarbonOrganic solvent

The invention provides a method for measuring sixteen polycyclic aromatic hydrocarbons in cigarette liquid of an electronic cigarette. The method is characterized in that a small amount of water is added to a cigarette liquid sample of the electronic cigarette, a mixture vibrates evenly, so that the mixture is fully dispersed in a kieselguhr solid phase supporting liquid-liquid extraction column, cyclohexane is used for extraction, and after extraction liquid is concentrated, the sixteen polycyclic aromatic hydrocarbons in the cigarette liquid of the electronic cigarette are measured through a GC-MS. Compared with a commonly-used polycyclic aromatic hydrocarbon analysis method, the method for measuring the sixteen polycyclic aromatic hydrocarbons has the advantages that sample pretreatment is greatly simplified, the use amount of organic solvents is saved, experiment repeatability is good, the experiment recovery rate is high, and the method is suitable for treating samples automatically on a large scale.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC +1

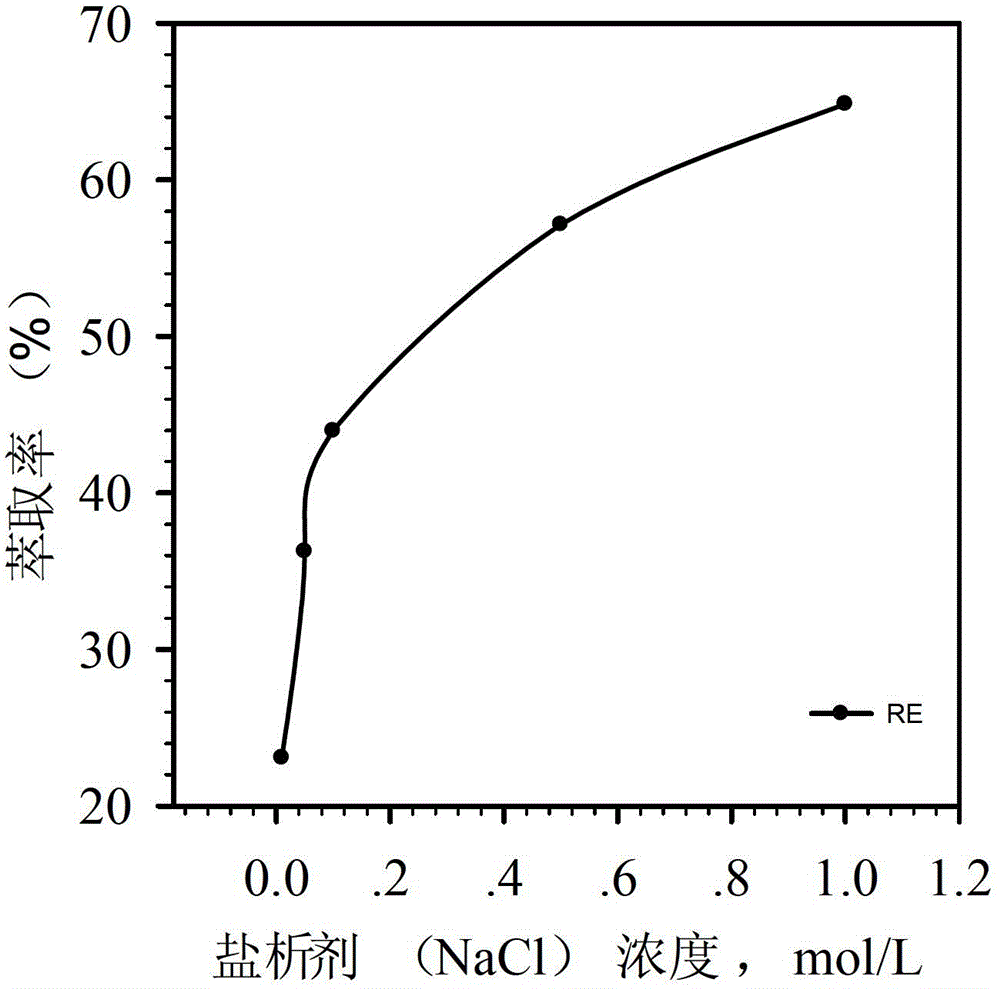

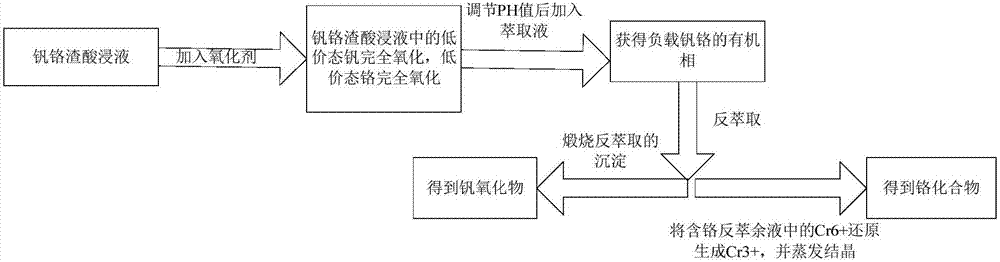

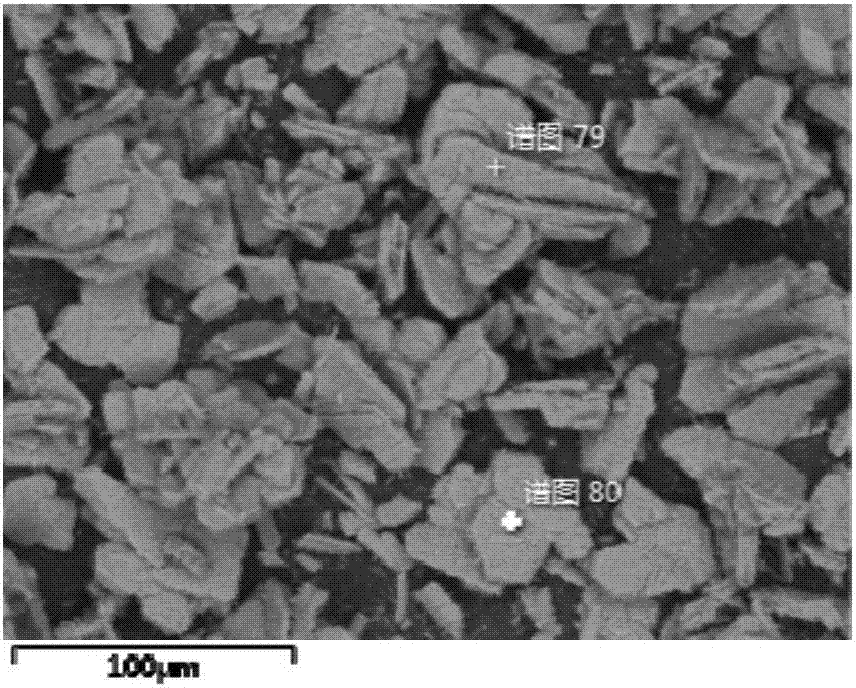

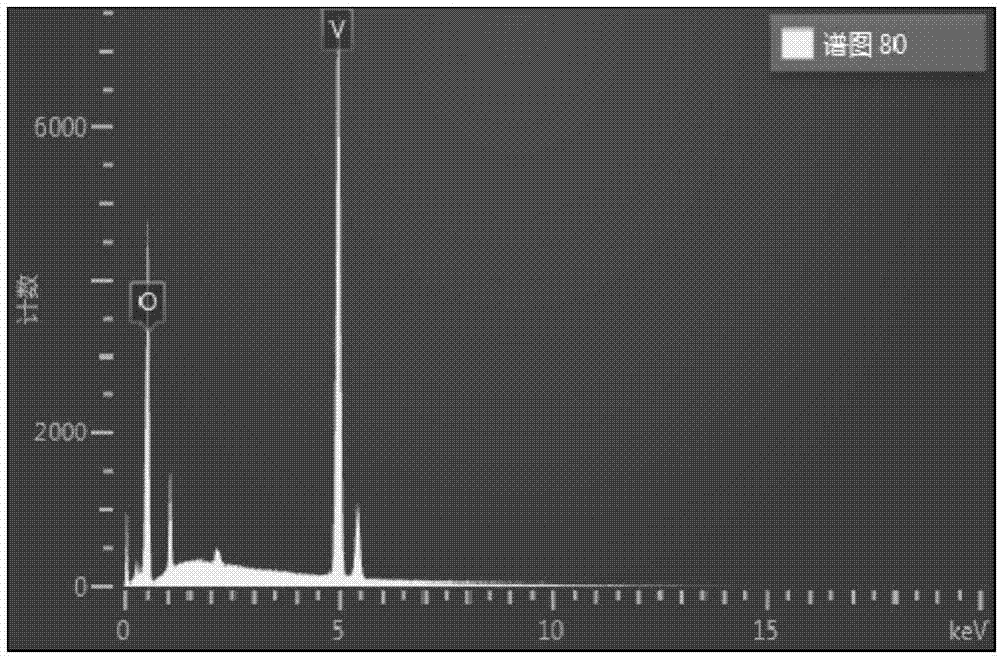

Method for extraction separation of vanadium and chromium from vanadium-chromium slag pickle liquor

InactiveCN107312942AImprove extraction abilityGood lipophilic and hydrophobicProcess efficiency improvementSolubilitySlag

The invention provides a method for extraction separation of vanadium and chromium from vanadium-chromium slag pickle liquor. The method comprises the steps that S1, pentavalent vanadium and hexavalent chromium in the vanadium-chromium slag pickle liquor are extracted into organic phases through extract liquor and then separated from aqueous phases, and vanadium-chromium-loaded organic phases are obtained; S2, the vanadium-chromium-loaded organic phases obtained in the S1 are subjected to reverse extraction through a stripping agent, and after reverse extraction is completed, chromium-containing raffinate, ammonium metavanadate or ammonium polyvanadate precipitation and regenerative ionic liquid are obtained; S3, the ammonium metavanadate or ammonium polyvanadate precipitation obtained in the S2 is roasted at 550-600 DEG C, and vanadium oxides are obtained; and S4, Cr6+ in the reverse raffinate obtained in the S2 is reduced into Cr3+, after the pH of chromium is adjusted, chromium is precipitated in a precipitation form, and Cr2O3 is obtained through roasting. The method is high in extraction efficiency, layering is rapid after extraction, emulsion is avoided, ionic liquid has good lipophilic-hydrophobic property, has good solubleness in long-chain alcohol and is not mutually soluble with water, and thus organic phase losses caused by aqueous phase inclusion or dissolution can be reduced.

Owner:NORTHEASTERN UNIV

Mixed solvent and method for extracting montan wax

The invention provides mixed solvent extracting lignite wax and an extraction method, wherein the mixed solvent comprises the following raw materials: 10-70 mass percent of octanol, 10-70 mass percent of methylbenzene and 10-70 mass percent of alcohols. Lignite is pelletized and then is extracted by the mixed solvent, and the lignite wax is obtained by dehydration, concentration, evaporation and dryness. The lignite wax is extracted in the innoxious environment, and the extracted solvent can be recovered, thereby the mixed solvent is safe and reliable, the extraction cost is low, the process condition during the whole extraction process is more common, the process is simple, the operation is convenient, the comprehensive processing cost is low, the processing ability is strong, and the product yield is higher; in addition, the extraction method can not produce emulsion phenomenon during the whole extraction process, and is an effective, low-cost, massive and innoxious extraction process.

Owner:刘润民 +4

Removal and recovery of naphthenic acid in oil based on ion switch principle

ActiveCN101058745AHigh yieldEfficient separationOrganic chemistryRefining with aqueous alkaline solutionsTetramethylammonium hydroxideAcid value

The invention discloses a removing and recycling method of naphthenic acid in the oil based on ion-switch elementary, which comprising the following steps: choosing a mixture or a plurality of mixtures in ammonium hydroxide tetramethyl , ammonium hydroxide tetraethyl, ammonium hydroxide tetrapropyl quaternary ammonium hydroxide; regarding the homogeneous solution of the mixtures and a reacting agent as a deacidificator; reacting with the naphthenic acid in the oil according to 1:1-1:20 ratio of flux and oil at the temperature of 20-70Deg. C; getting an ion liquid phase; separating the ion liquid phase and the oil product reducing acid value efficiently owing to the great polarity difference; adding the volatile acid to the ion liquid phase; separating and recovering the naphthenic acid from the iron liquid phase; recovering separately the volatile acid and deacidificator with the vacuum distillation. The invention provides an efficient deacidifying technique, which saves the time, has a high recovering ratio.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Process for separating and recovering minim organic solvent from waste water using ion liquid

InactiveCN1594116AAdjust solubilityAdjust polarityWater/sewage treatment by extractionWater useOrganic solvent

The invention discloses a process for separating and recovering minim organic solvent from waste water using ion liquid consisting of, mixing hydrophobic ionic liquid with aqueous solution of organic solvent whose concentration is lower than 0.1-10 wt% by the volume ration of 1 : 1-10, fully stirring and depositing for stratification, gathering the organic solvent in the aqueous phase into ionic liquid phase, separating the ionic liquid phase, evaporating the organic solvent in the ionic liquid through decompression, thus achieving the goal of reclaiming organic solvent.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

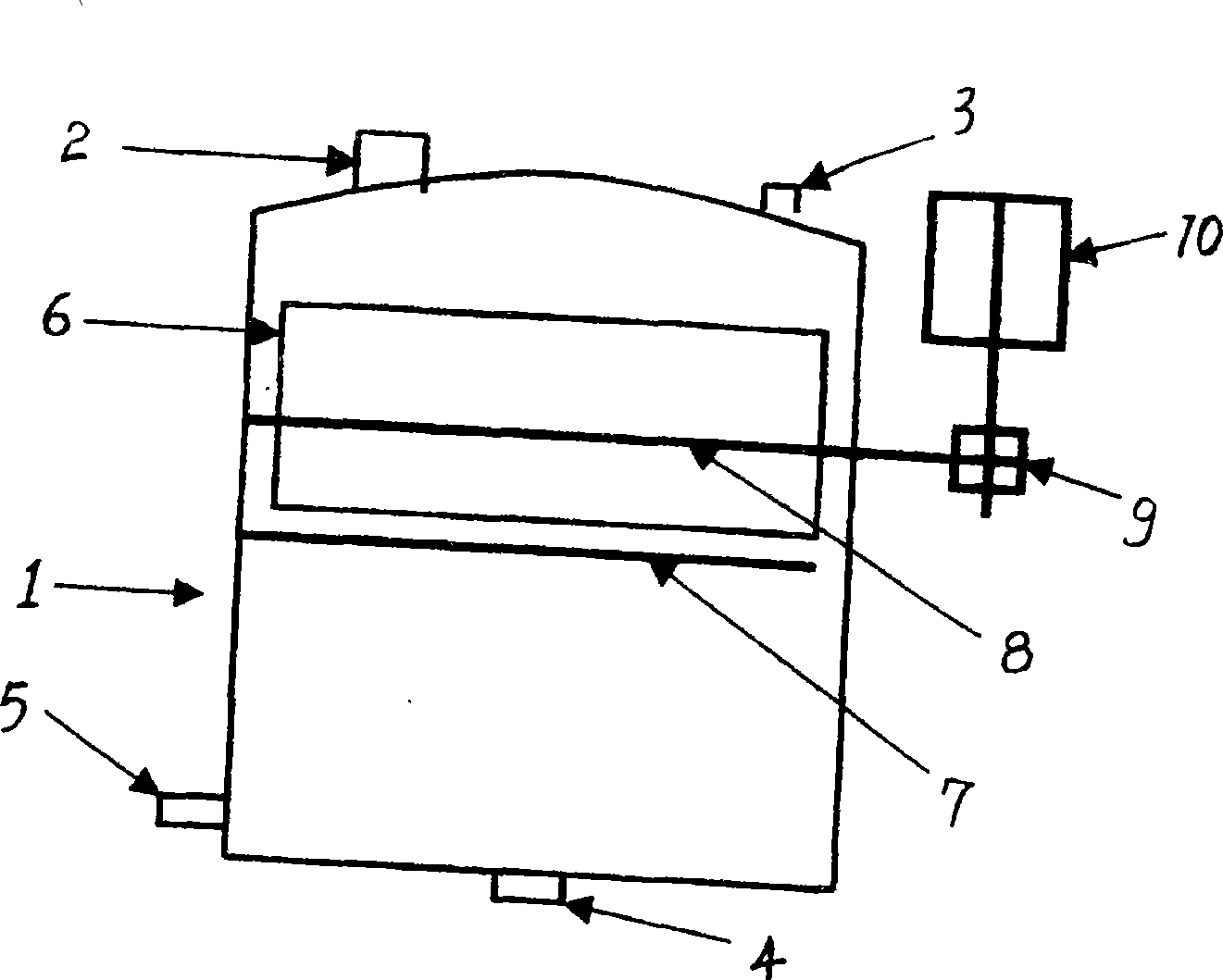

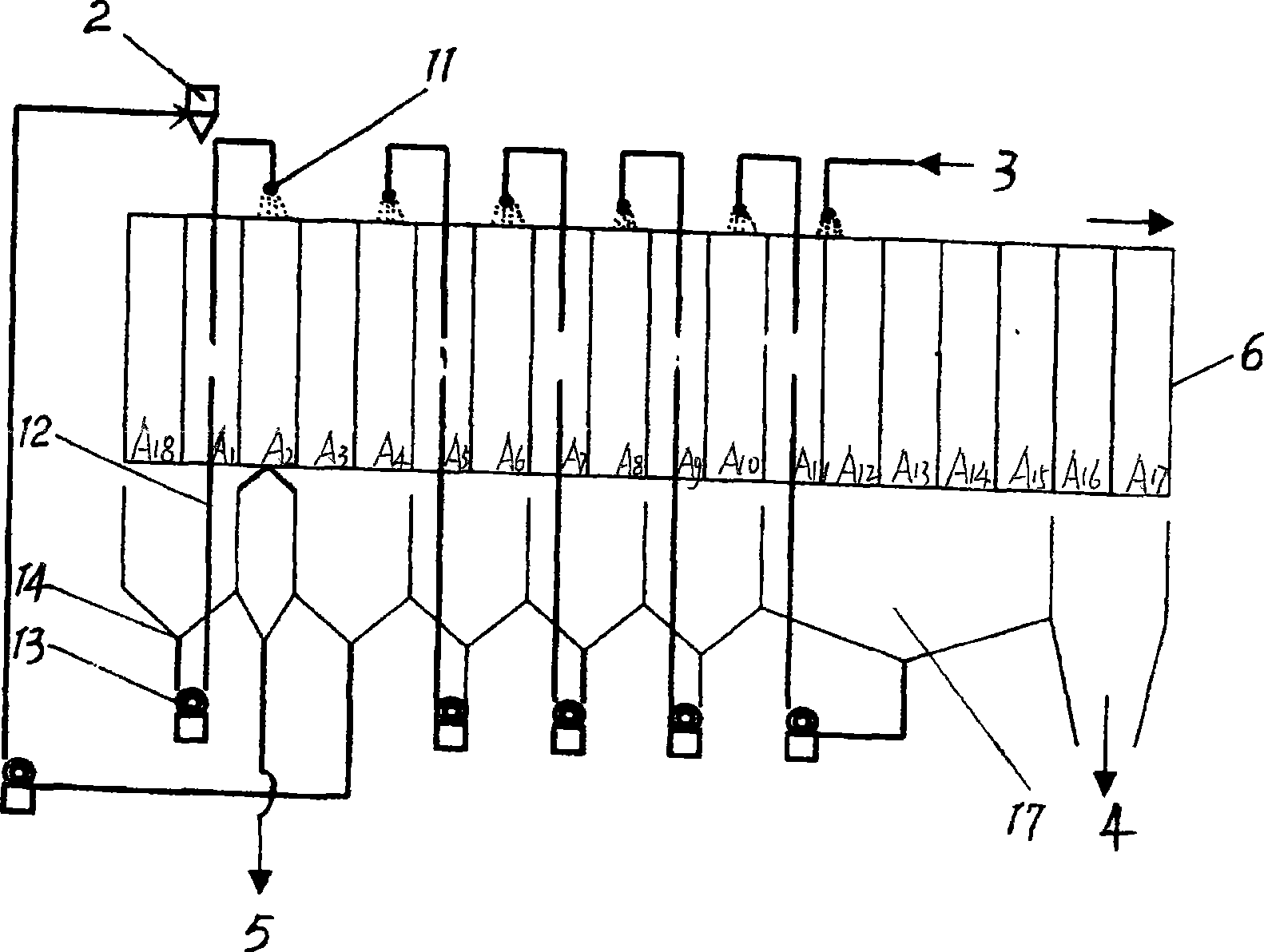

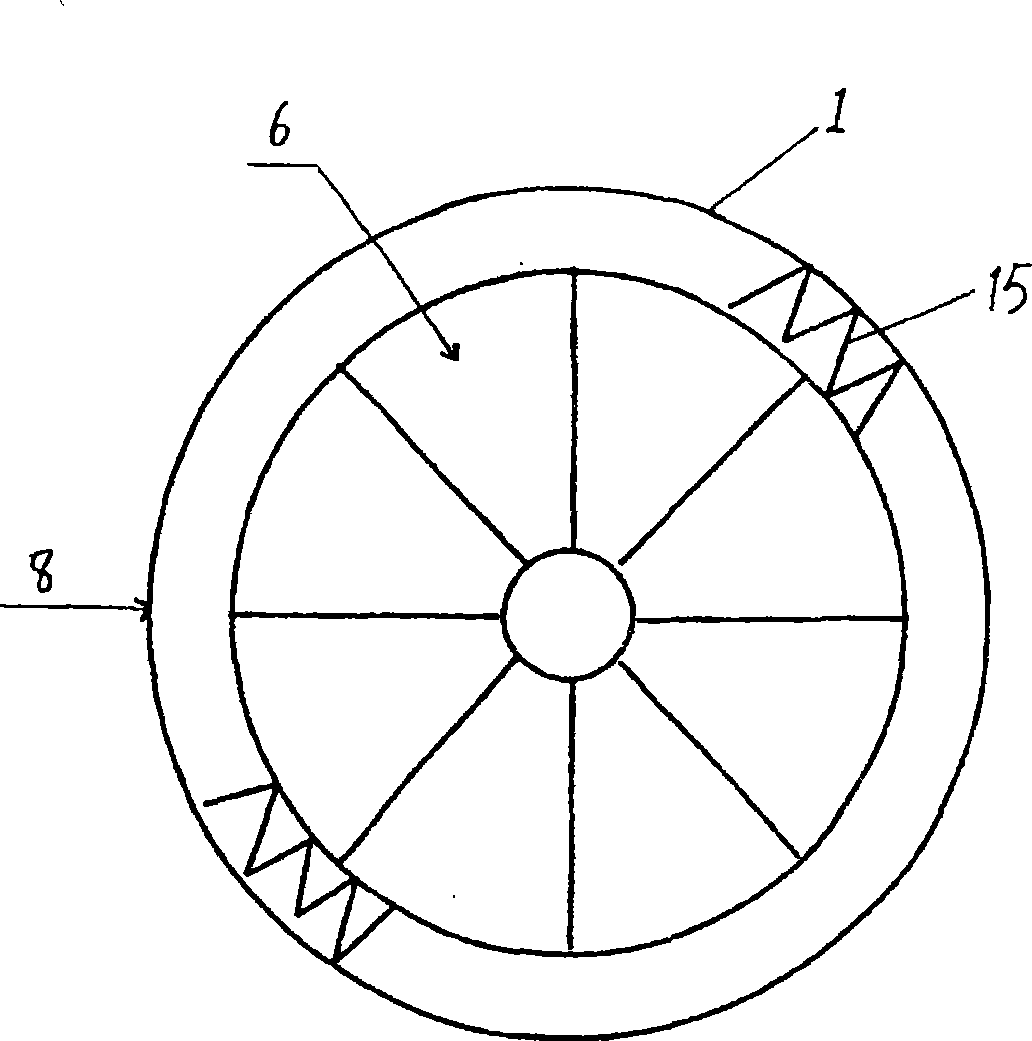

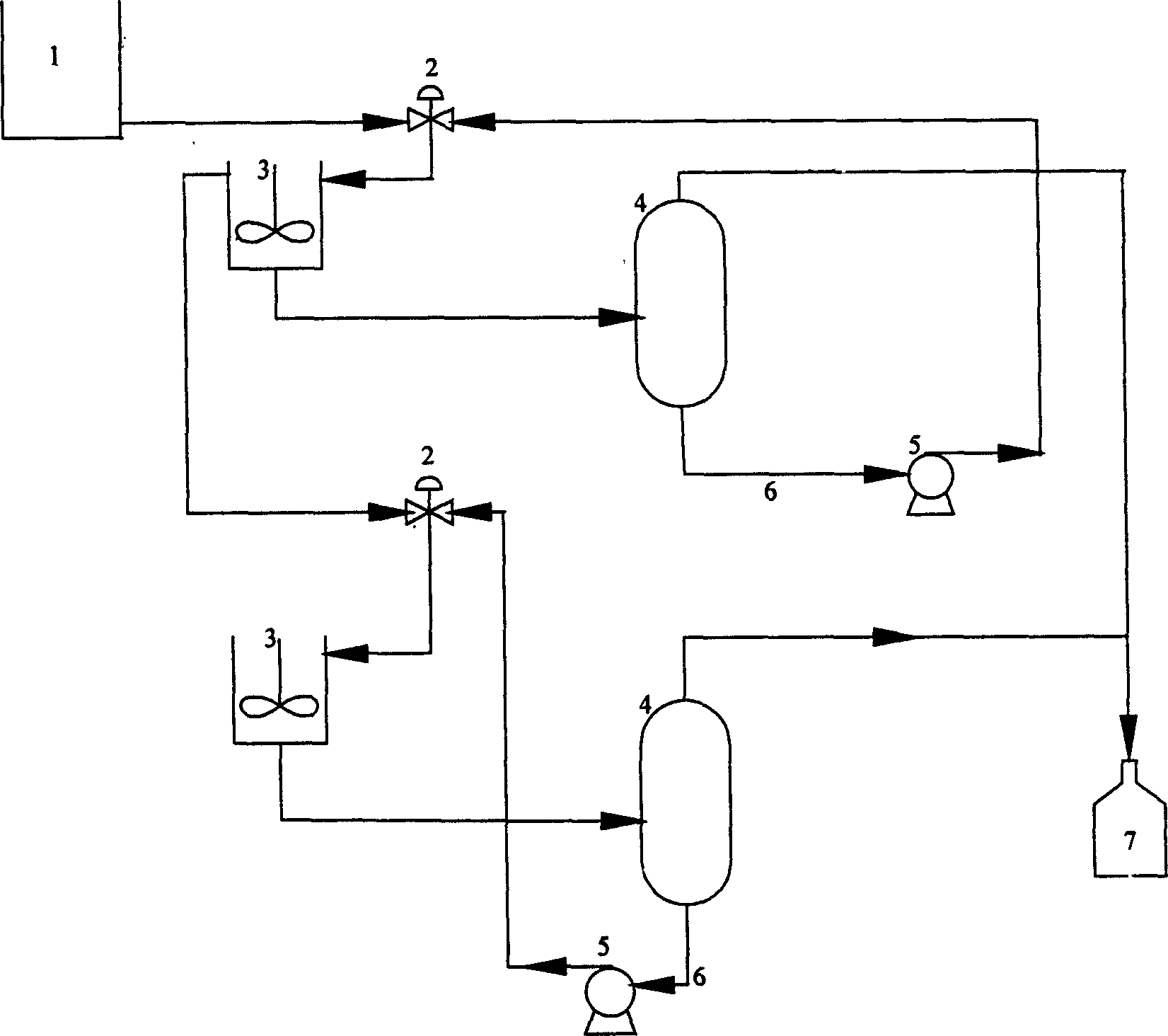

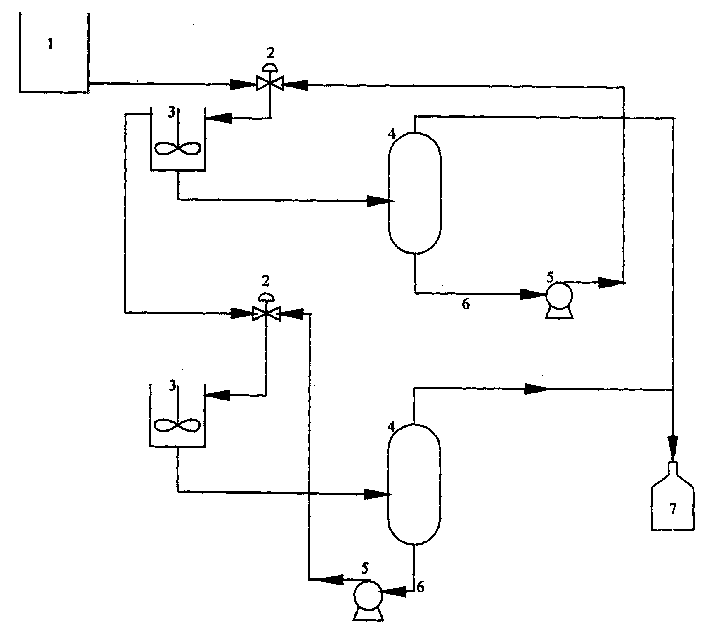

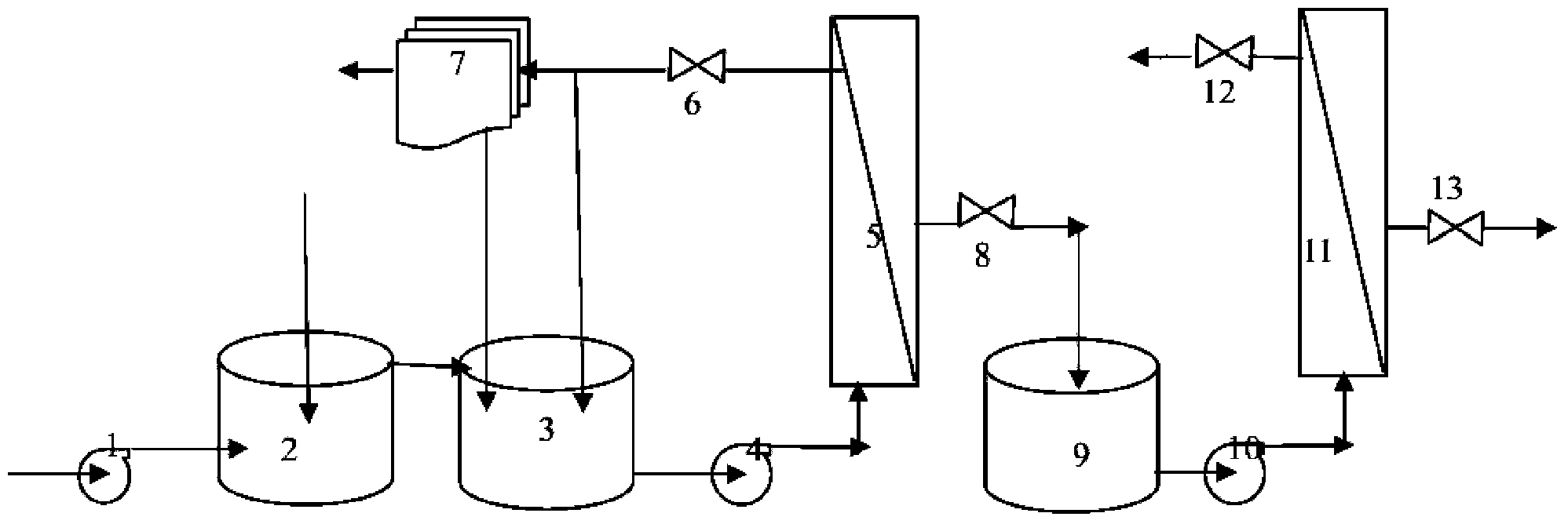

Membrane technology-based ionic rare earth ore extraction technology and device therefor

The invention relates to a membrane technology-based ionic rare earth ore extraction technology and a device therefor. The membrane technology-based ionic rare earth ore extraction technology comprises the following steps of removing impurities in a rare earth ore percolation liquid, carrying out solid-liquid separation by a ceramic membrane to remove suspended solids in the rare earth ore percolation liquid, carrying out nanofiltration on the ceramic membrane clear liquid for further enrichment concentration, treating the ceramic membrane concentrated solution by a plate-and-frame filter press, removing dreg, when the rare earth ore percolate has the content of 60-70g / L after nanofiltration concentration, feeding the rare earth ore percolate into an extraction unit, carrying out extraction separation of a single rare earth element, and directly feeding the nanofiltration clear liquid rich in an extraction agent back to a percolation unit. Through the membrane separation and integration technology, the rare earth ore percolate is subjected to purification, separation, and concentration enrichment so that rare earth ions in the percolate are purified and concentrated and the next extraction process is convenient, and the rare earth ore percolation liquid subjected to separation from rare earth has a low rare earth ion concentration and a high extraction agent concentration and can be directly used for the percolation process. The membrane technology-based ionic rare earth ore extraction technology greatly improves a rare earth ion recovery rate, reduces a percolation waste water discharge amount and has obvious environmental and economic benefits.

Owner:JIANGSU JIUWU HITECH

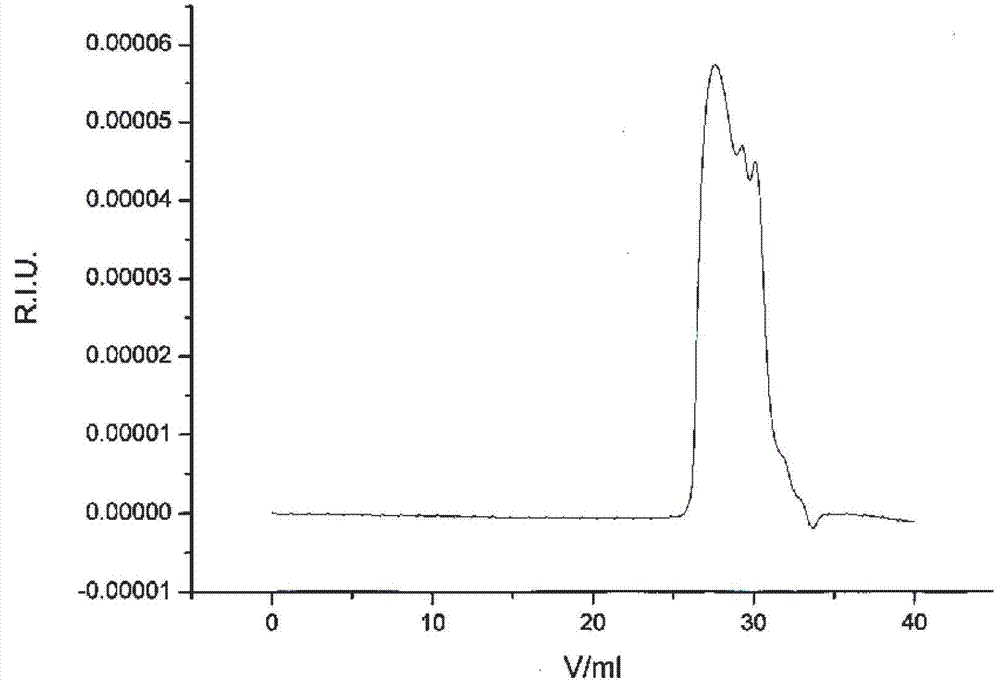

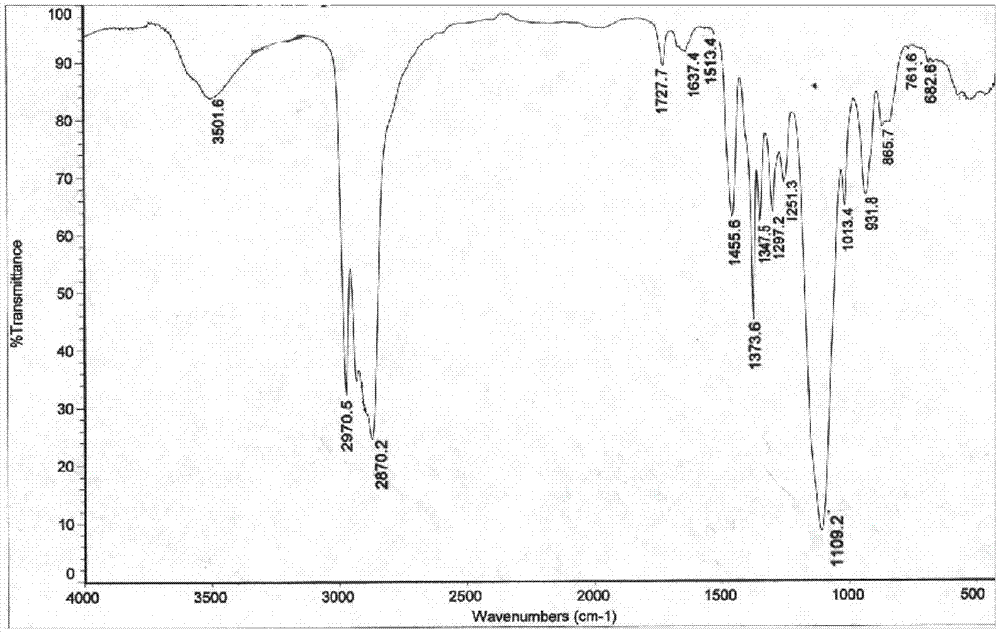

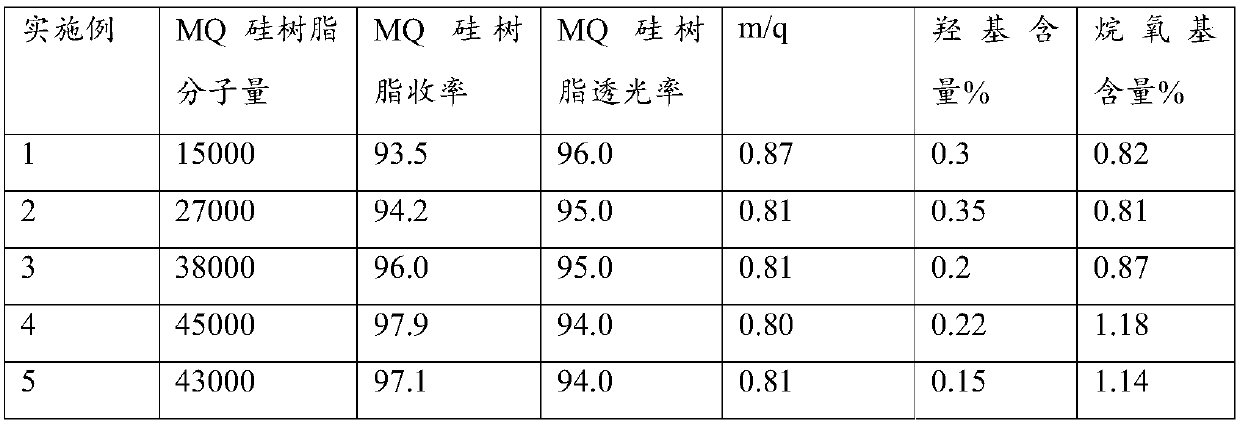

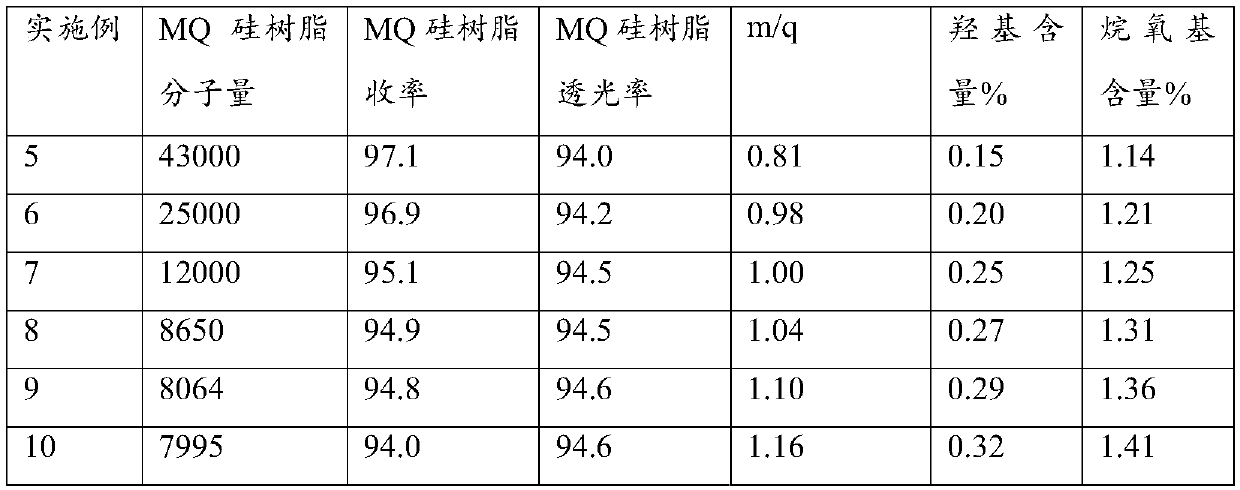

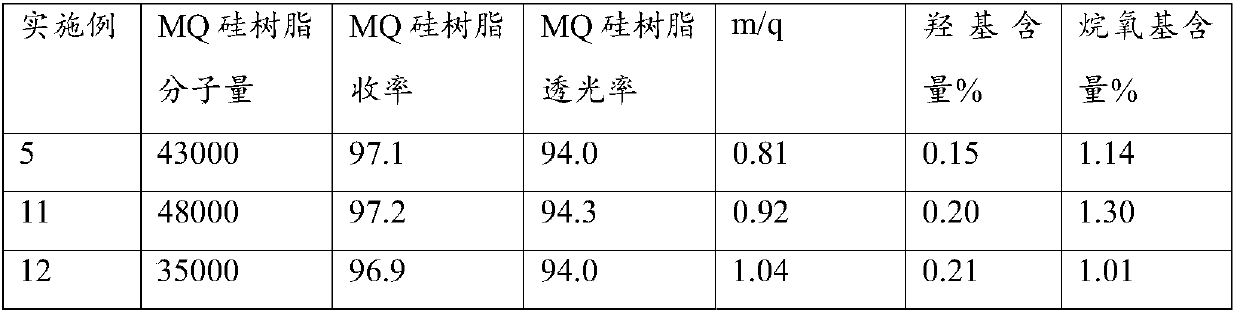

High-molecular-weight MQ silicon resin and synthesis method and application thereof

The invention provides high-molecular-weight MQ silicon resin and a synthesis method and application thereof. The synthesis method of the MQ silicon resin comprises the steps that silicate ester and partial M unit silane monomers carry out a pre-reaction in a mixed solution composed of water, catalysts and cosolvents for a pre-reaction; then remaining M unit silane monomers and partial extractionagents are added in the mixed solution for a reaction under a heating condition, afterwards, remaining extraction agents are added, and an organic phase is obtained through extraction; the organic phase is adjusted to be neutral, and afterwards, the high-molecular-weight MQ silicon resin is obtained through distillation, wherein the mass ratio of the M unit silane monomers which are added twice is10:1-1:10. The synthesis method is simple in procedure, a large amount of washing is not needed, the product yield is high, and an extra curing agent is not needed to remove silicon hydroxyl and silicon alkoxy in the MQ silicon resin; meanwhile, the molecular weight of a target product can be controlled according to the ratio for adding the M monomers in batches and the ratio for adding the extraction agents in batches.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com