Process for separating zirconium and hafnium by solvent extracting method

An extraction method and process technology, which is applied in the field of separation of zirconium and hafnium by solvent extraction, can solve the problems that the extraction operation is difficult to perform normally, the extraction capacity is small, and the separation factor is high, so as to avoid the accumulation of a large amount of chloride ions, the extraction process is stable, and the separation factor high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

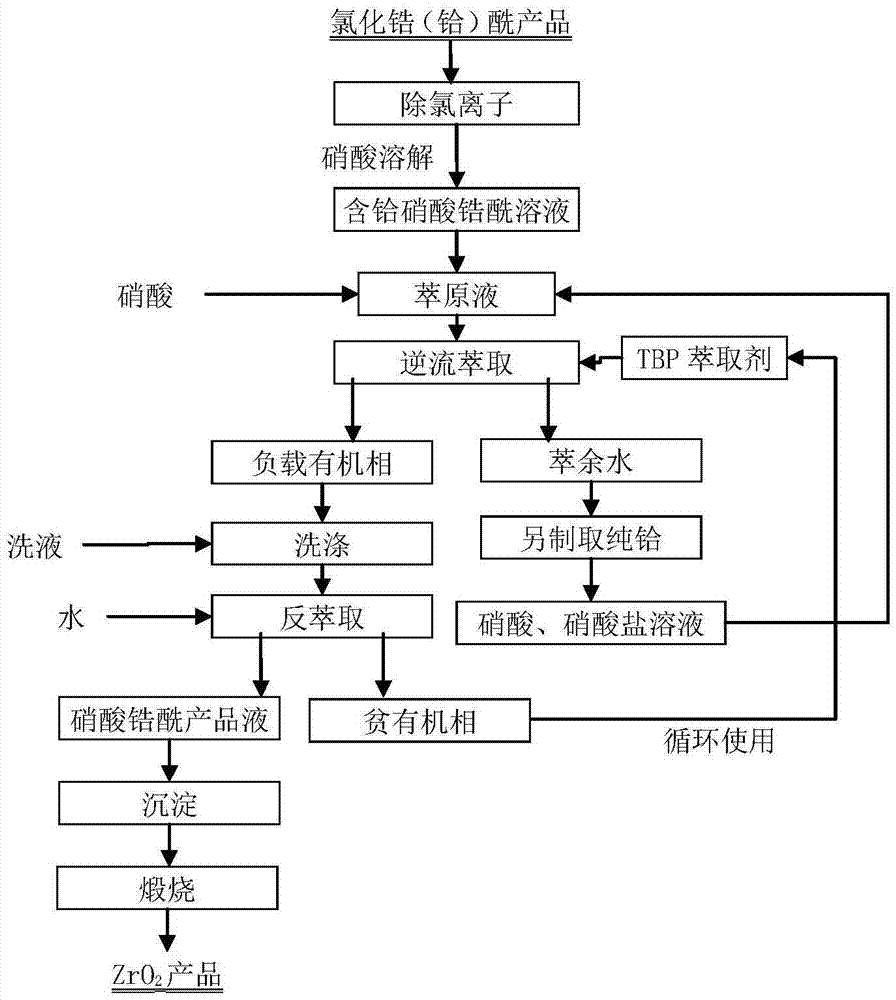

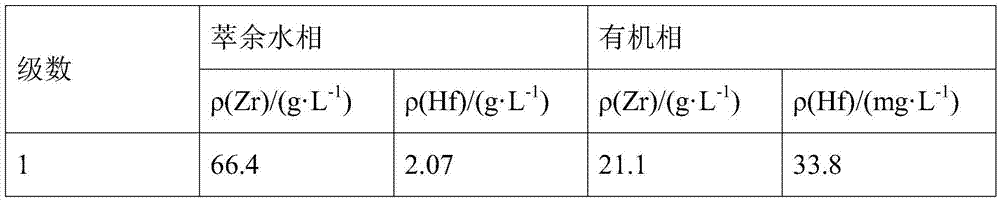

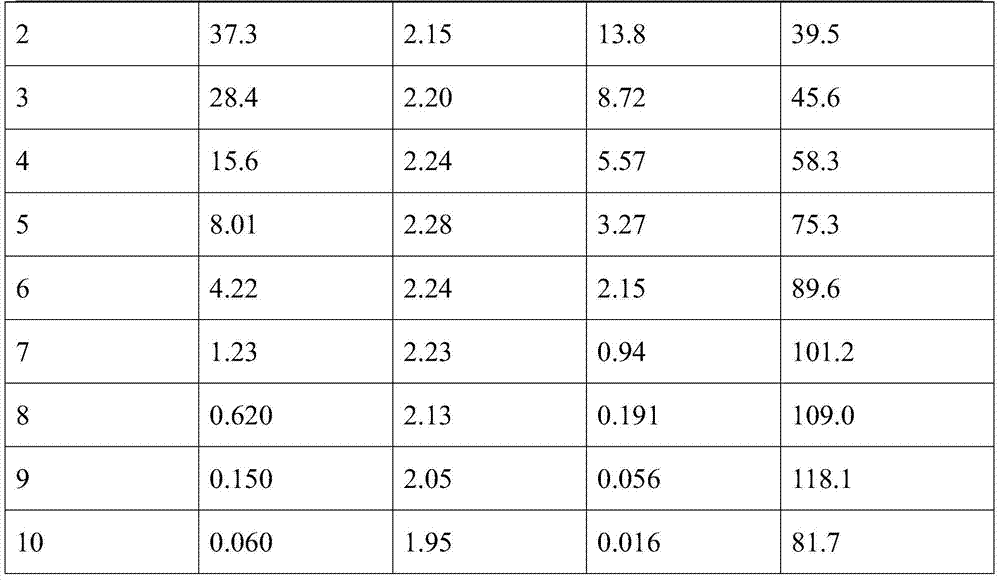

[0053] Such as figure 1 Shown, a kind of solvent extraction method of the present invention separates zirconium and hafnium technology to be raw material with the hafnium-containing zirconyl chloride industrial product, prepare zirconium nitrate (hafnium) acid solution through operations such as water-soluble, alkali precipitation, washing, nitric acid dissolution; Then Using the TBP kerosene solution added with n-octanol as the extraction agent, taking advantage of the characteristics of TBP to preferentially extract zirconium, through multi-stage countercurrent extraction, most of the zirconium and a very small amount of hafnium are extracted into the organic phase; the organic phase is loaded with a certain Washing with a concentrated nitric acid solution can further remove most of the hafnium in the organic phase; back-extract the loaded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com