Patents

Literature

63results about How to "Large extraction capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

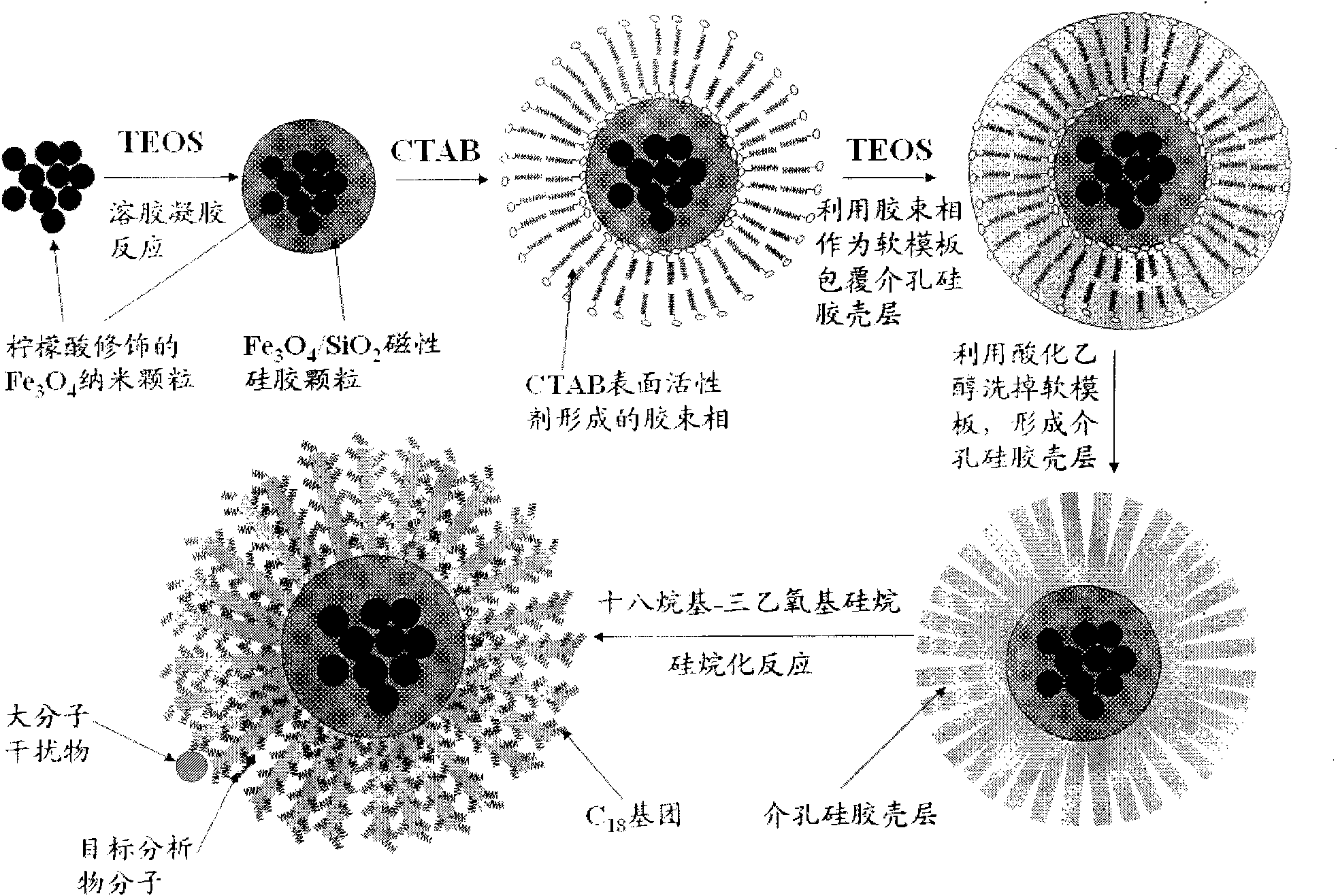

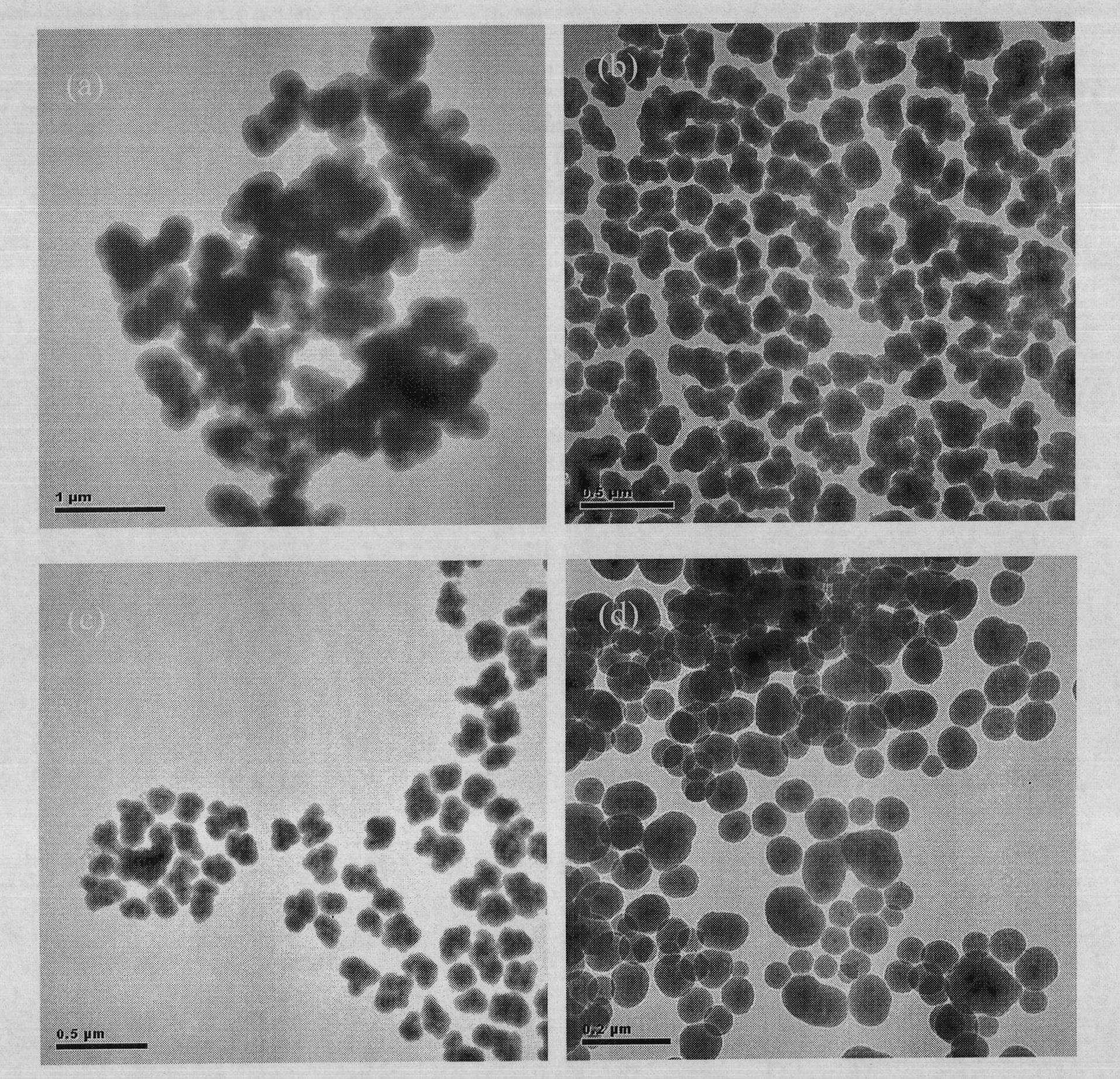

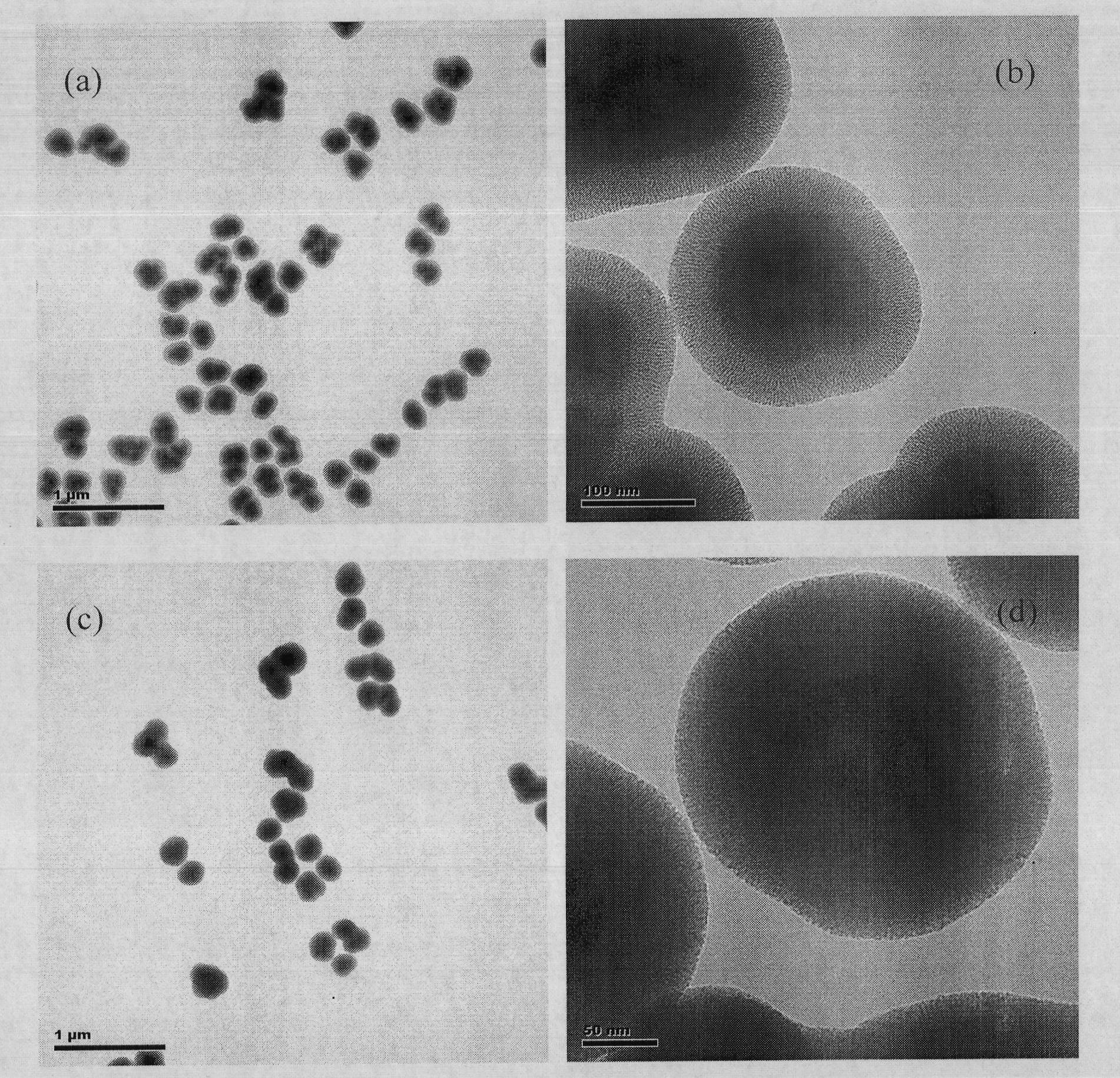

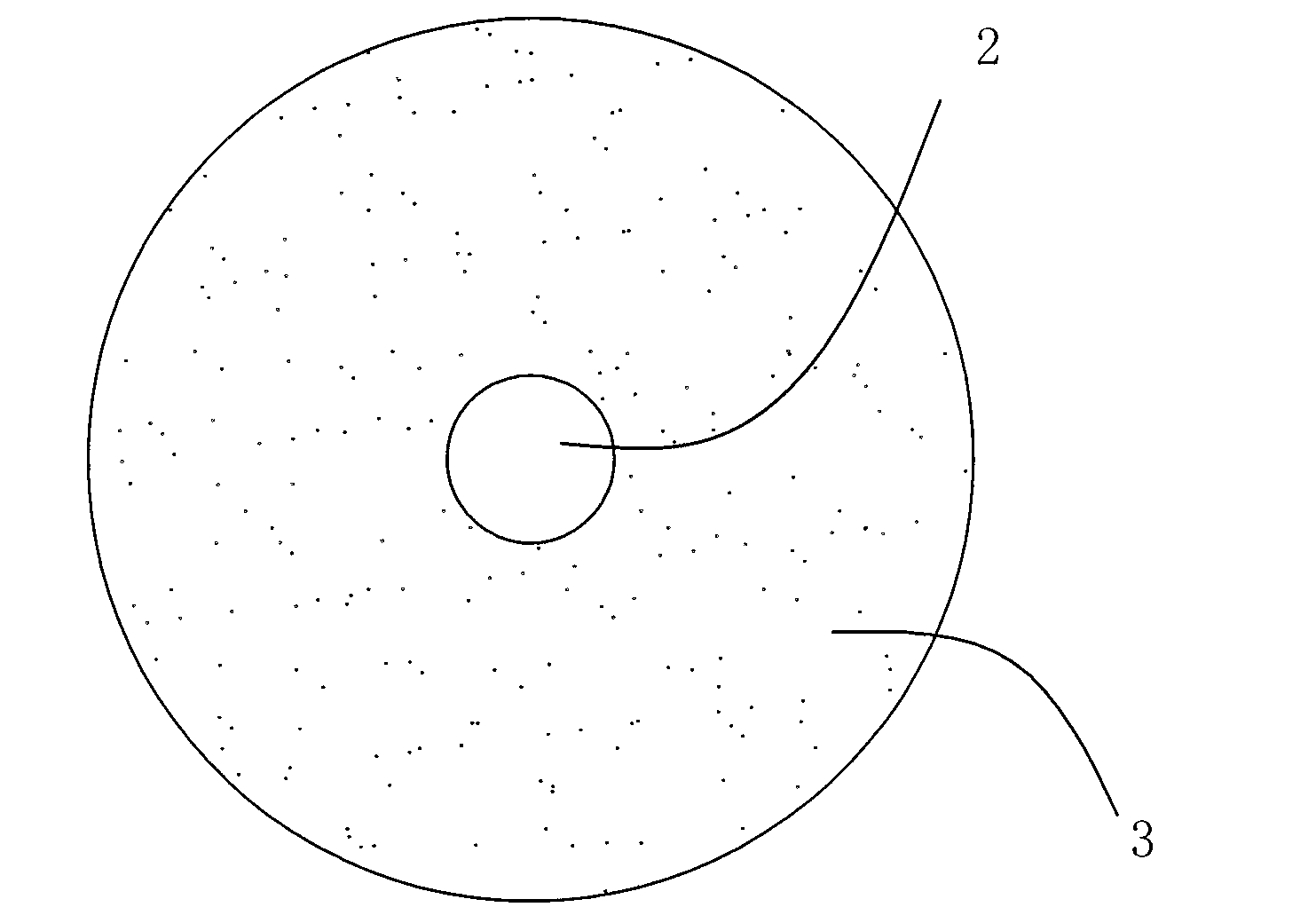

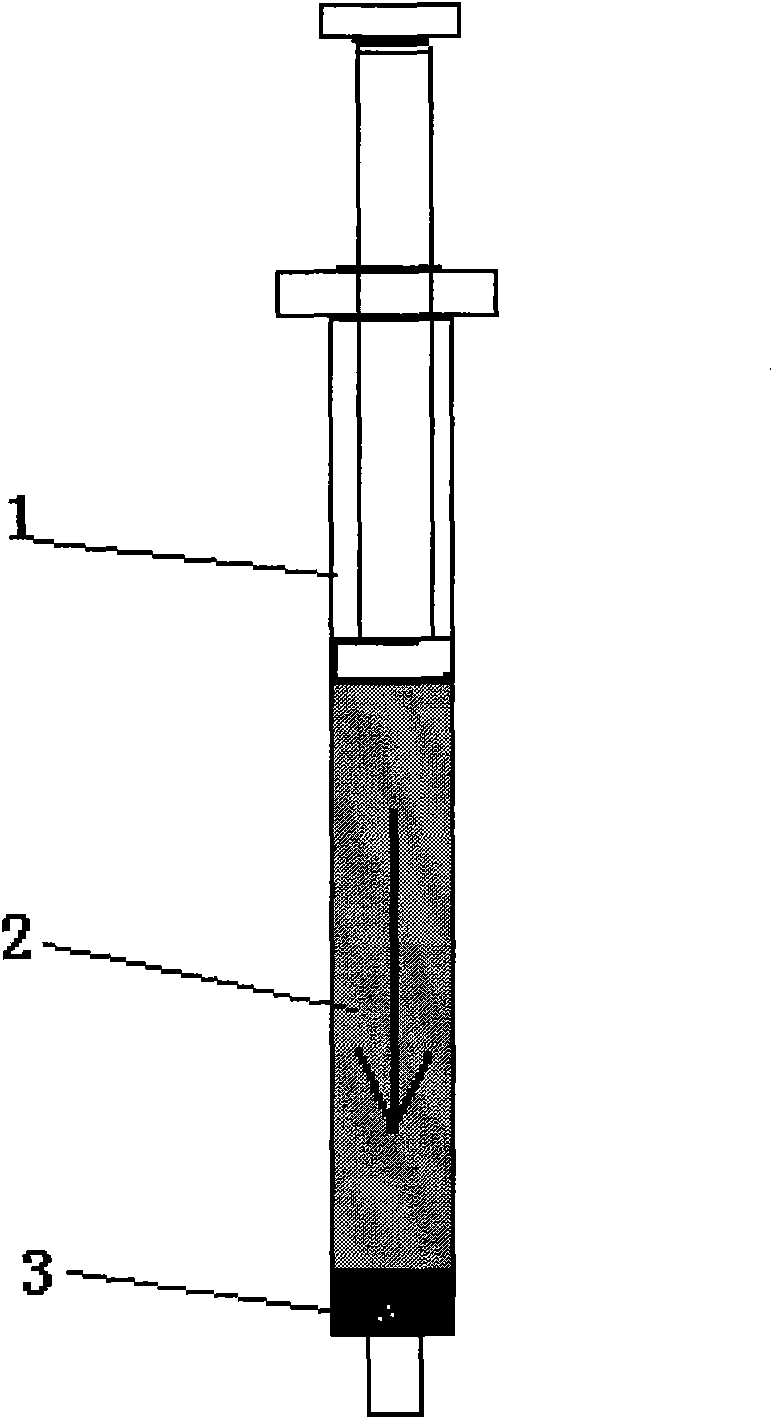

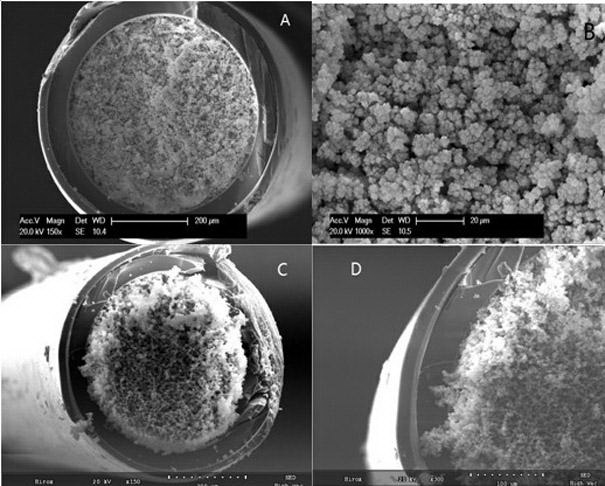

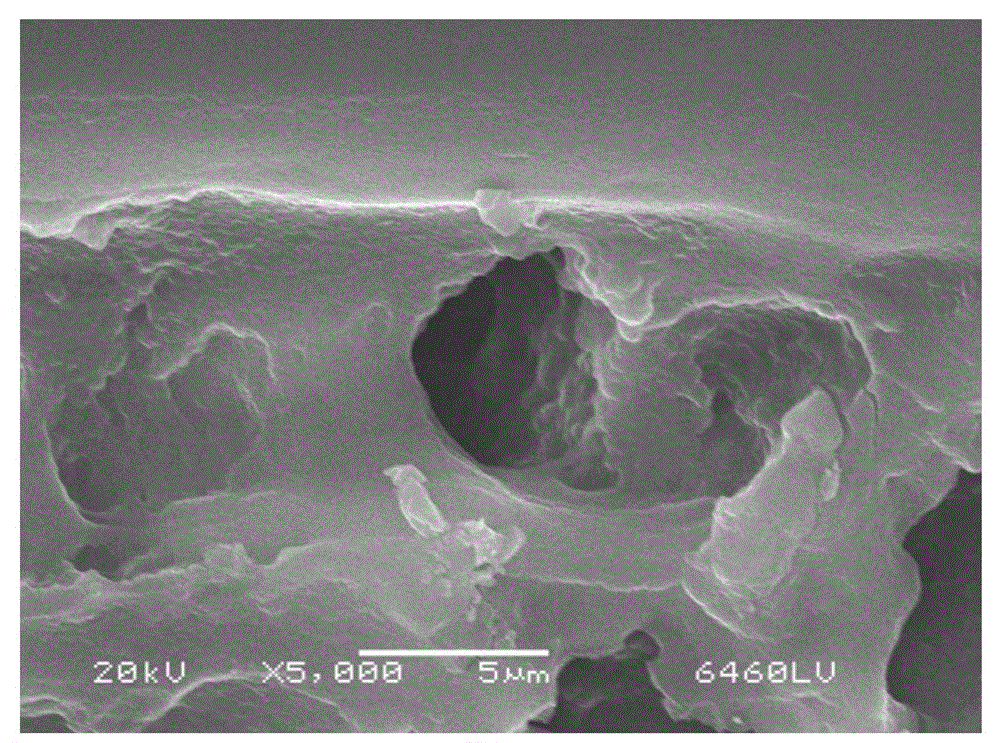

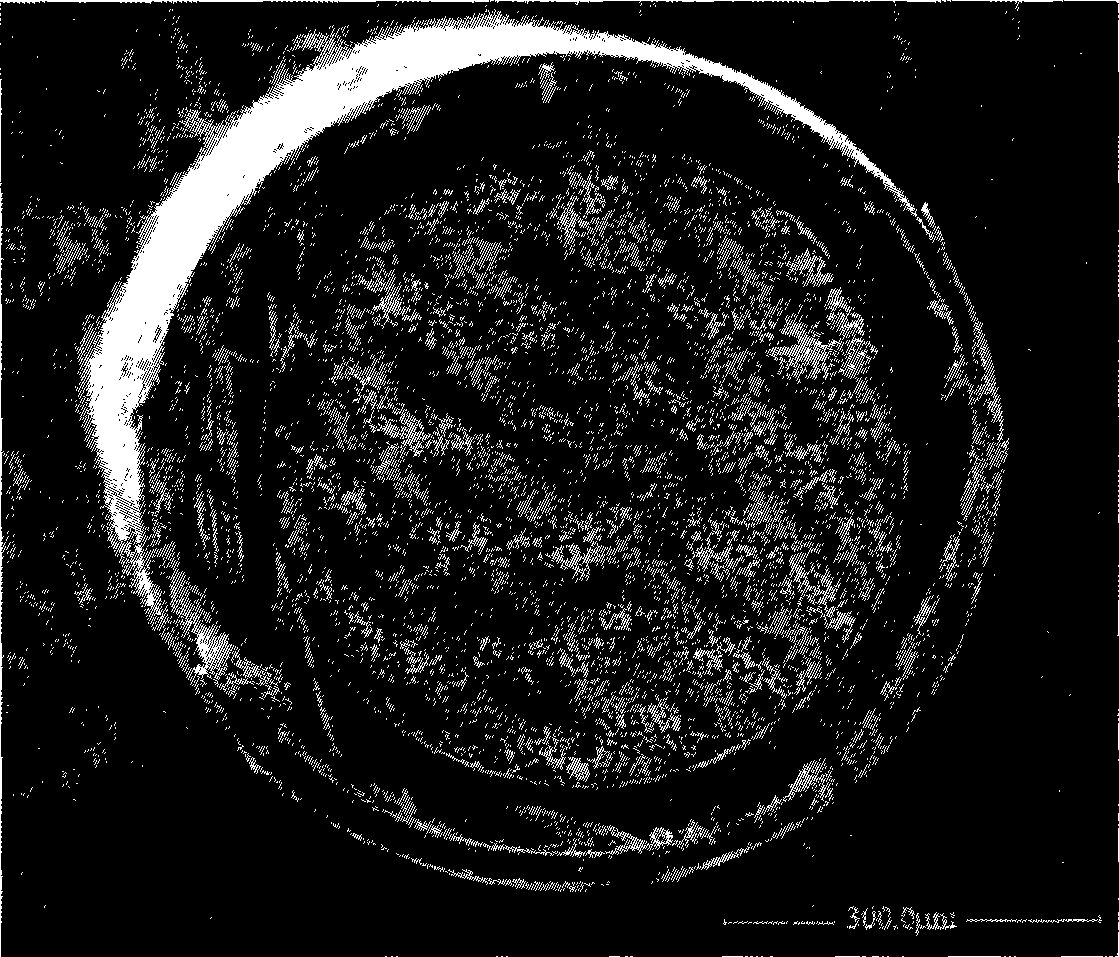

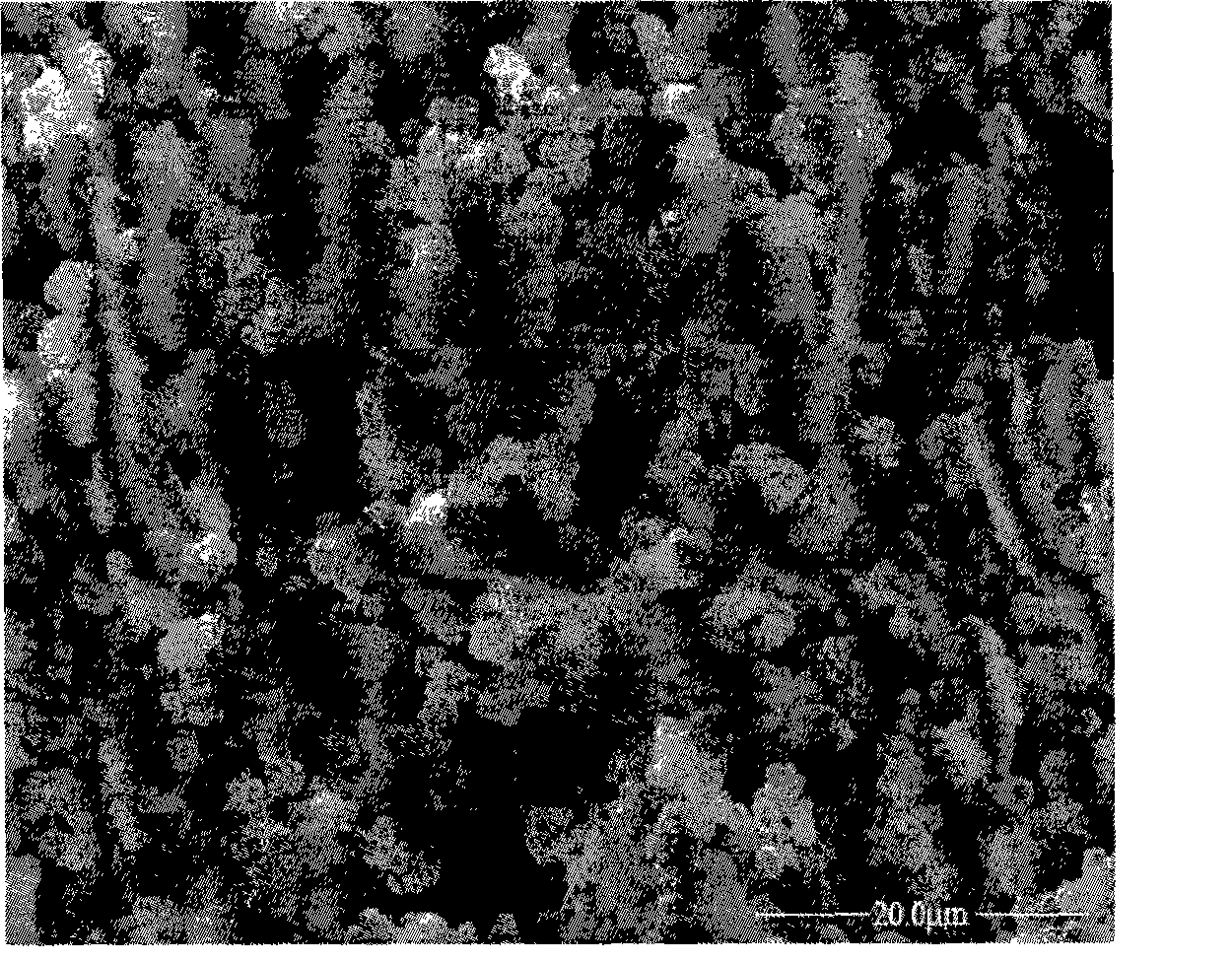

Preparation and application of high-capacity magnetic mesoporous silica gel solid phase extracting agent

InactiveCN102091605AIncrease surface areaStrong superparamagnetismIon-exchange process apparatusOther chemical processesMicrosphereMesoporous silica

The invention provides a magnetic mesoporous silica gel material extracting agent used for enriching and / or separating trace organic pollutants in an environment water sample, and a preparation method thereof. A core of the extracting agent provided by the invention is a silicon gel microsphere (i.e. magnetic silicon gel microsphere) wrapped with a plurality of Fe3O4 magnetic nano particles, and a shell of the extracting agent is a mesoporous silicon gel shell layer with inner and outer surfaces modified by C18 silanization. The extracting agent integrates huge special surface area, excellent extracting capacity and ultrahigh extracting volume of a mesoporous material, magnetic separating capacity of a magnetic material, strong extracting capacity of C18 groups and special volume exclusion function of a vertical channel of the mesoporous material. In addition, the extracting agent provided by the invention has the advantages of high extracting efficiency, low preparation cost and simple preparation method, and is very suitable for preprocessing samples of the trace organic pollutants in a bulk-mass water sample.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

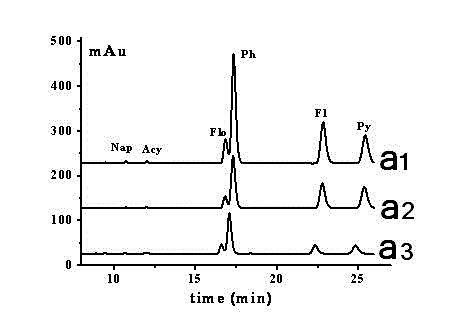

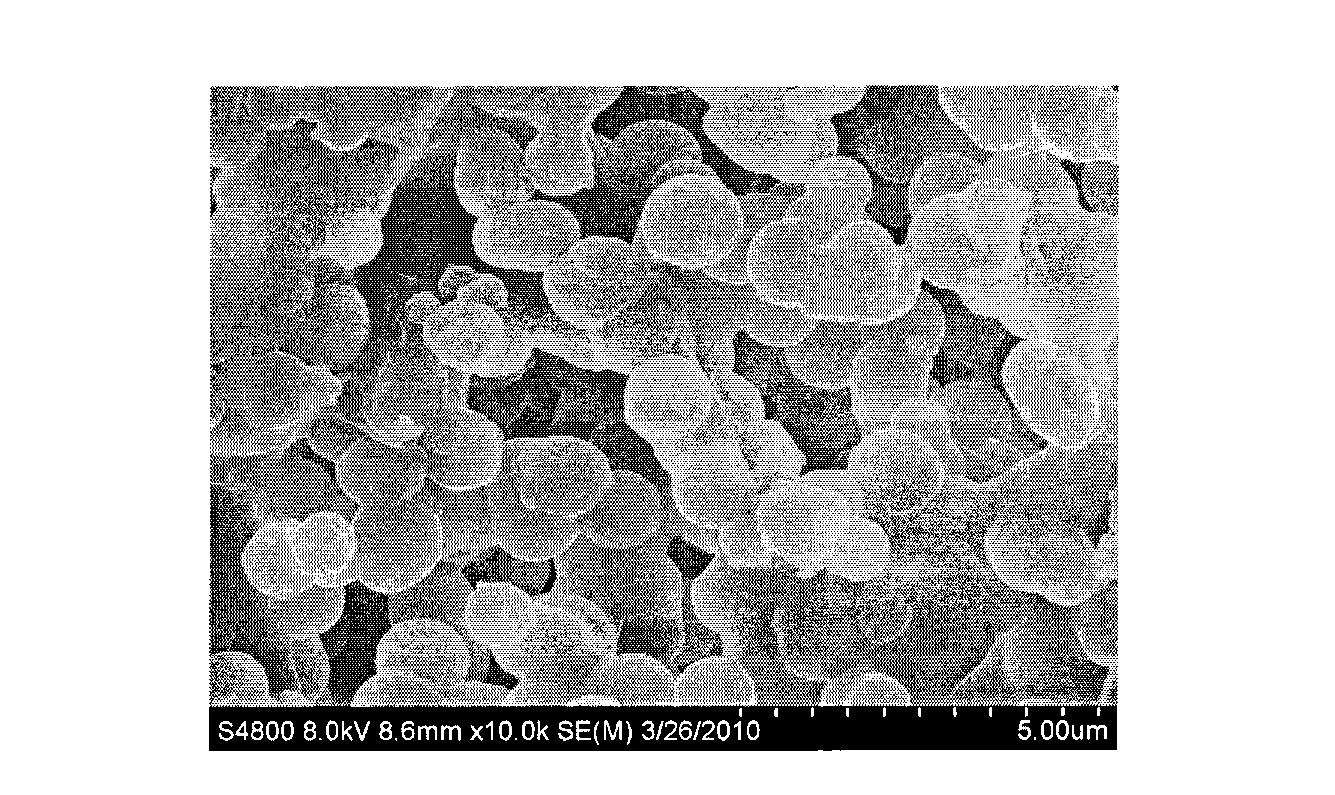

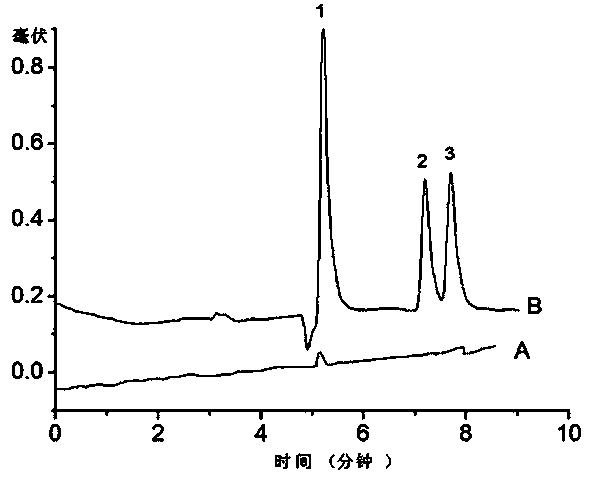

Solid phase extraction column based on graphene bonded silica gel, and preparation method and application thereof

InactiveCN102872843AImprove adsorption capacityReduce adsorptionComponent separationOther chemical processesAcenaphthyleneFluoranthene

The invention relates to a solid phase extraction column based on graphene bonded silica gel, which is used in concentration and separation of organic pollutants in an environmental water sample. A graphene bonded silica gel padding is prepared by taking 3-aminopropyl triethoxy silane (APTES) as the cross-linking agent; then graphene is bonded on the surface of silica gel; after product graphene bonded silica gel granules are evenly filled in a solid phase extraction column, the graphene bonded silica gel based solid phase extraction column is obtained. The performance indicators of the solid phase extraction column are tested through polycyclic aromatic hydrocarbons, including naphthalene, acenaphthylene, fluorene, phenanthrene, fluoranthene and pyrene, and the test result shows that the solid phase extraction column has good extraction efficiency, reproducibility and stability. The graphene bonded silica gel has the characteristics of big specific surface area, strong Pi electron adsorption ability and high extraction capacity of the graphene, and the stable mechanical property and good adsorption ability of the silica gel. Moreover, the solid phase extraction column based on the graphene bonded silica gel is low in preparation cost and simple to operate and is suitable to be used for pretreatment of low-concentration organic pollutants in a big-volume water sample. The solid phase extraction column has a good application prospect in the concentration and separation of environmental organic pollutants.

Owner:XINYANG NORMAL UNIVERSITY

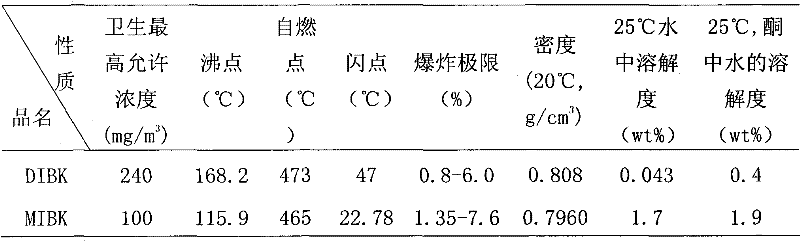

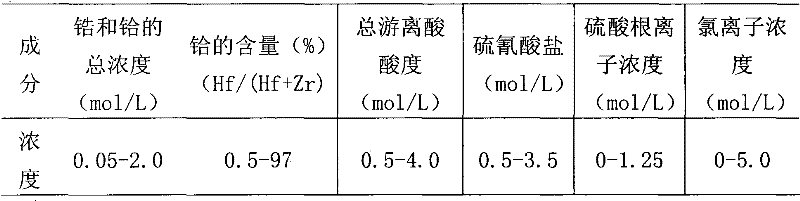

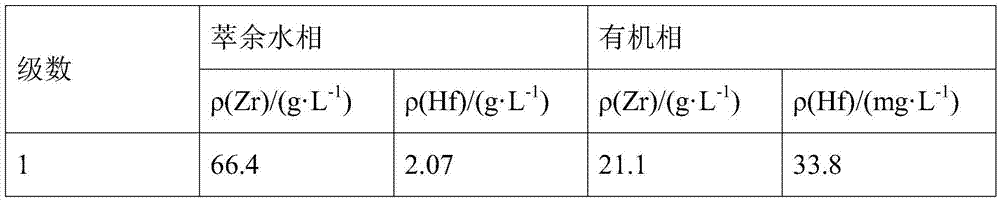

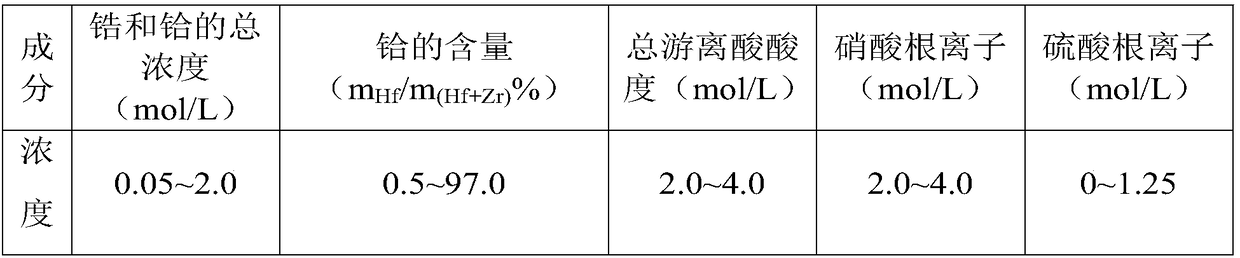

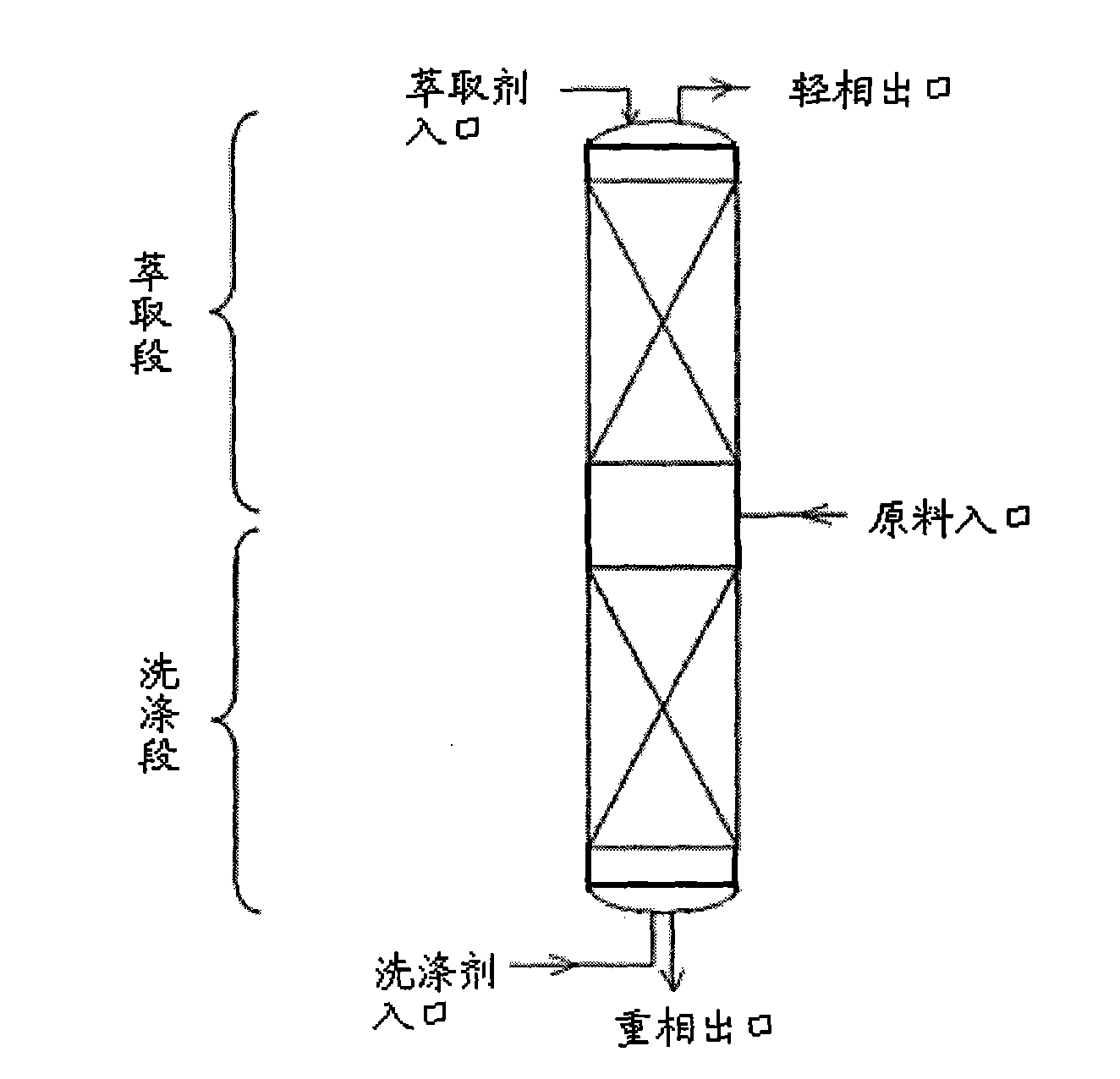

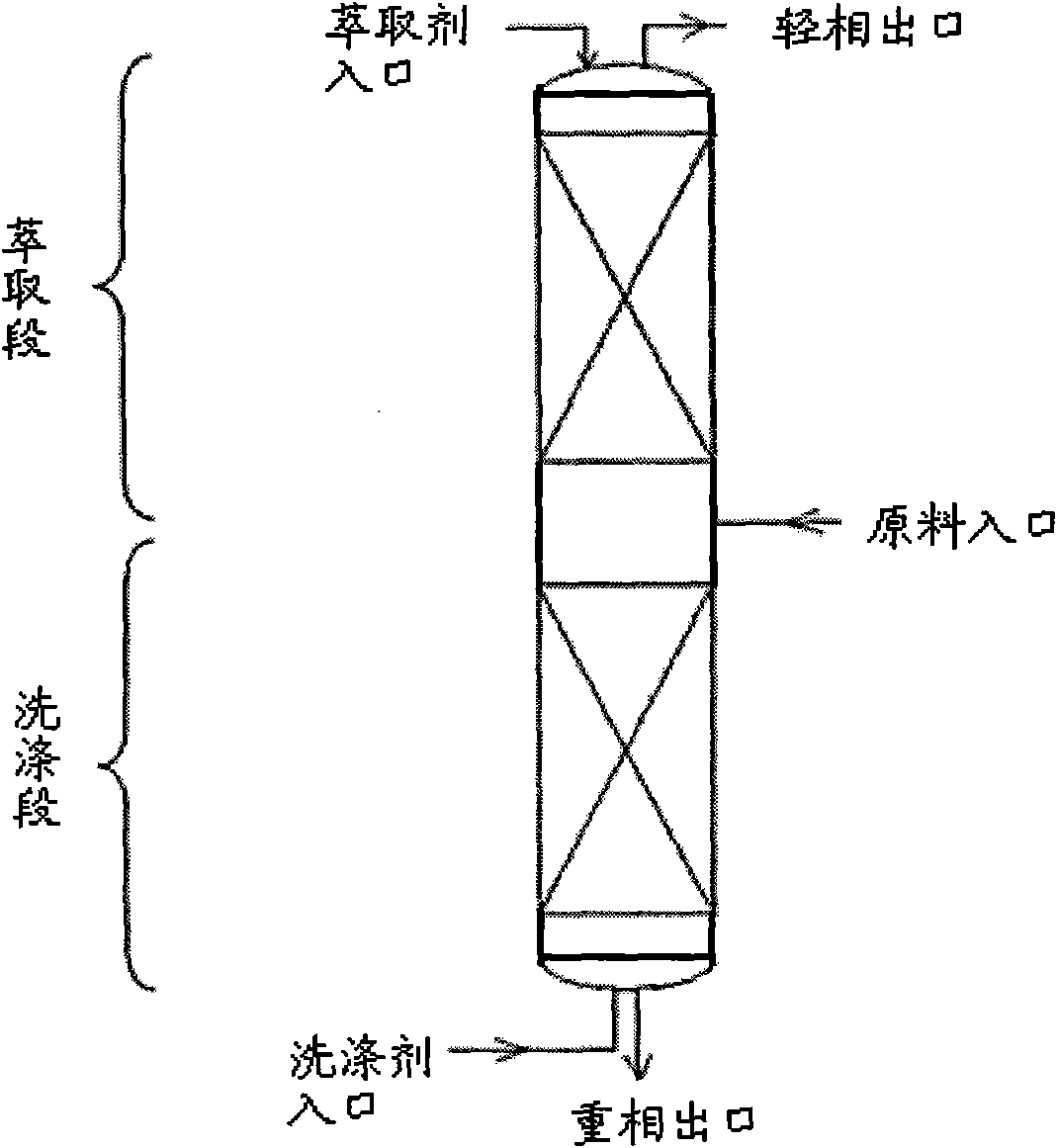

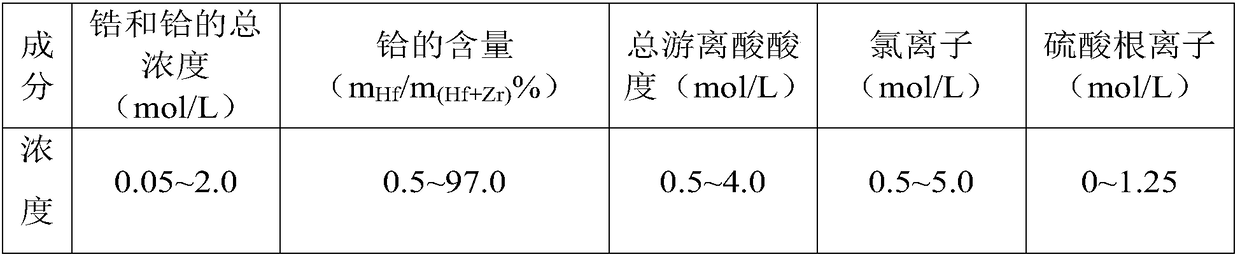

Method for separating zirconium and hafnium

ActiveCN102453801ALess mass transferLarge extraction capacityProcess efficiency improvementSolubilityHafnium

The invention relates to a method for separating zirconium and hafnium, which specifically comprises the following steps of: using the acidic water solution of a zirconium compound as a raw material, extracting hafnium in the material liquid into an organic phase by using diisobutyl ketone (DIBK) or the synergism of DIBK with a neutral phosphorous extracting agent or the synergism of DIBK with anacidic phosphorus-containing extracting agent, and washing and stripping the oganic phase to produce a hafnium-rich liquid such that the separation of zirconium and hafnium is realized; respectively precipitating the hafnium-rich liquid and the remaining organic phase by using ammonia water, and washing and roasting the precipitates to obtain atomic energy level zirconium oxide and hafnium oxide.In the technical method provided by the invention, low content of hafnium in zirconium hafnium is preferably extracted, and the method has simple process and high extraction efficiency. The extraction system used in the method reaches the same zirconium and hafnium separation performance to MIBK (Methyl Isobutyl Ketone) but has smaller water solubility, high boiling point and flashing point and smaller toxicity compared with MIBK, and the problems of great solvent loss, easy outbreak of fire, environmental pollution and the like in the MIBK extraction separation method are solved.

Owner:有研资源环境技术研究院(北京)有限公司

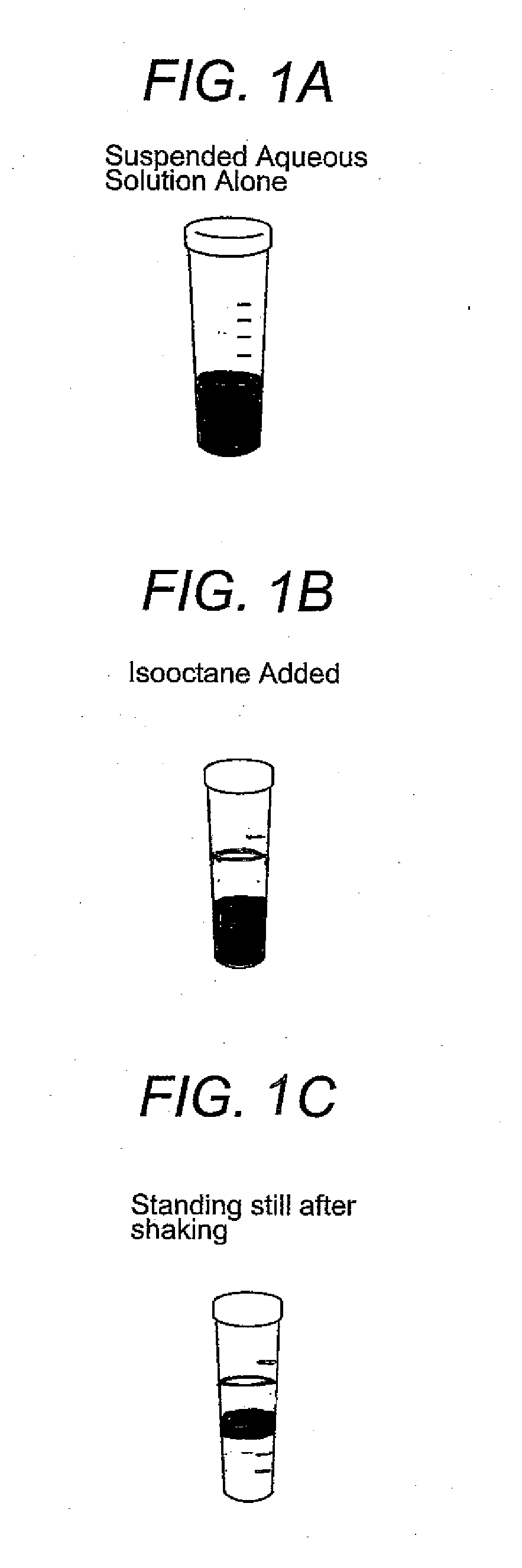

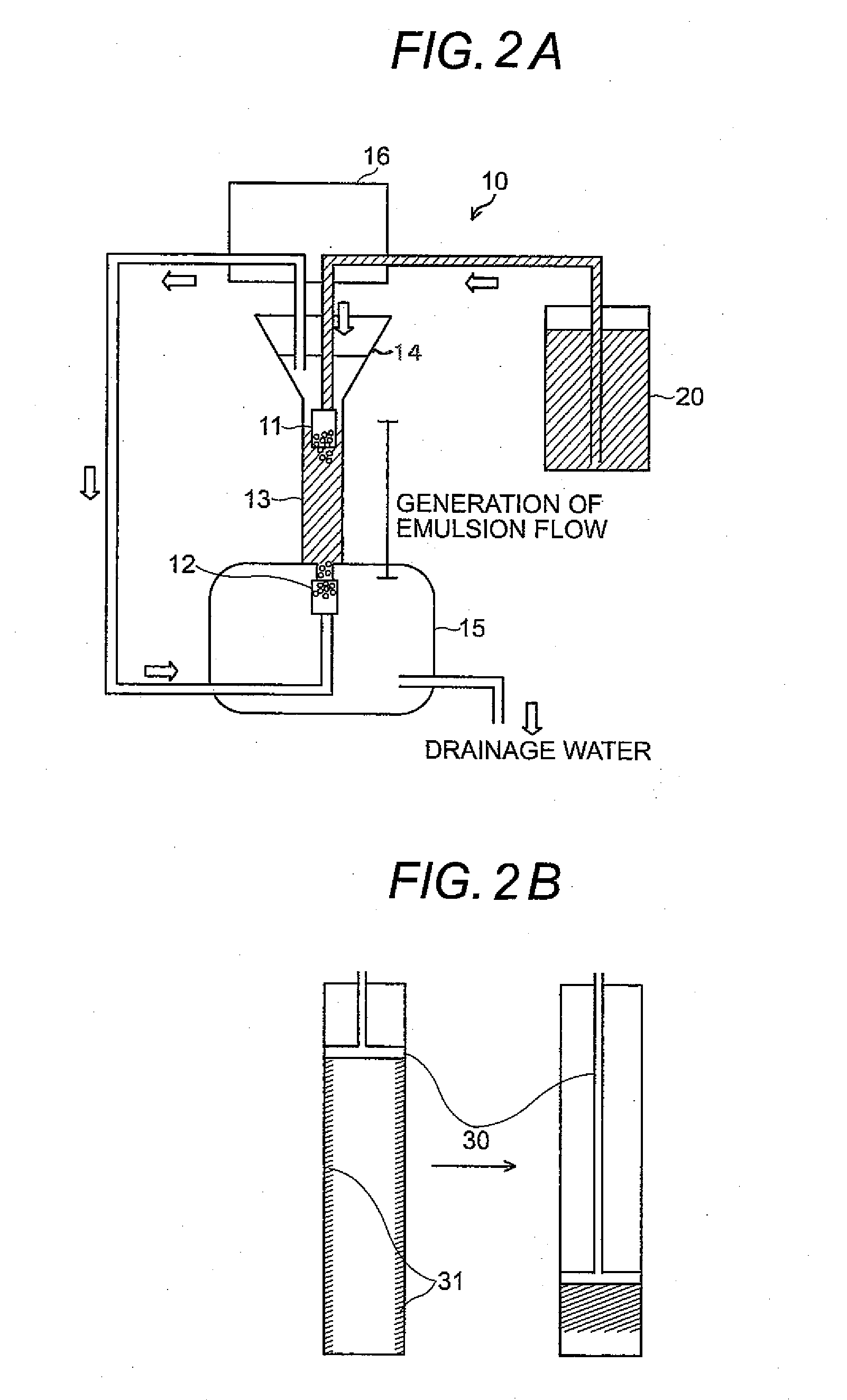

Continuous collection method of particle component in aqueous solution and apparatus therefor

InactiveUS20100078382A1More stabilityMore fine-grainedIon-exchange process apparatusSolvent extractionEmulsionSolvent

The particle components may be collected by using a phenomenon that the particle components in the aqueous phase aggregate at the liquid-to-liquid interface. Both of the particle components and the dissolved components in the aqueous phase may be simultaneously collected if combined with liquid-liquid extraction phenomenon that the dissolved components in the aqueous phase are collected into the solvent phase through the liquid-to-liquid interface. The aggregation phenomenon of the particle components at the liquid-to-liquid interface may be promoted by using an emulsion flow method, a method of applying mechanical external forces (such as stirring and vibrating) or another method combining both the above-mentioned methods.

Owner:JAPAN ATOMIC ENERGY AGENCY INDEPENDANT ADMINISTRATIVE CORP

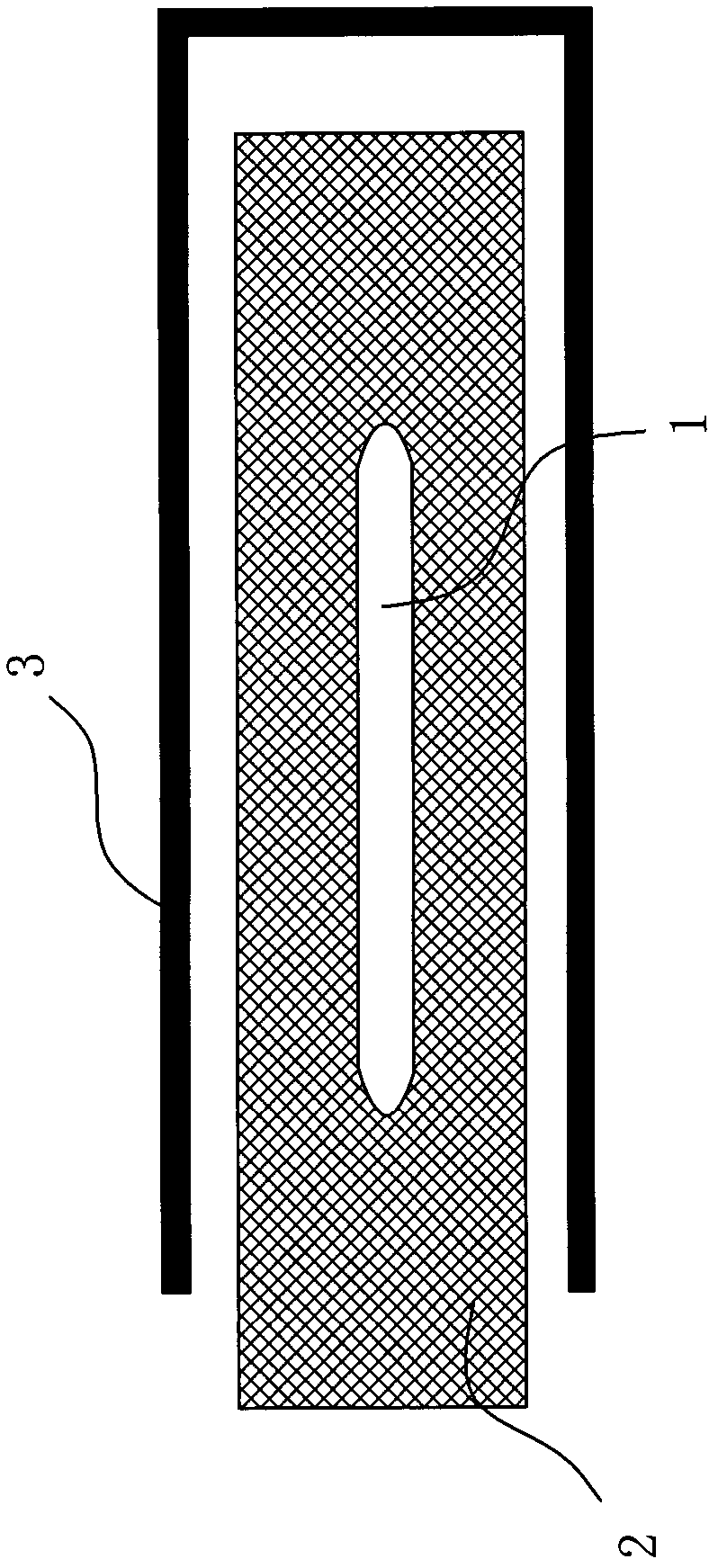

Electrically-driven solid phase micro-extraction method and device thereof

InactiveCN102879255AReduces the disadvantage of being prone to wear and tearOvercomes the disadvantage of being difficult to use with magnetic stirringPreparing sample for investigationMagnetic tension forceEpoxy

The invention relates to an electrically-driven solid phase micro-extraction method and a device thereof. An integrated porous material prepared through treating an epoxy resin as a base material, diethylenetriamine as a curing agent and polyethylene glycol as a pore forming agent and utilizing an in-situ gradual polymerization process is adopted as a solid phase micro-extraction material, the form of the solid phase micro-extraction material to prepare a solid micro-extraction column is combined with a rotation-speed-adjustable motor, a stirring effect is realized through rotation, and simultaneously the solid phase micro-extraction material which is adopted as an electrical adsorption work electrode and a platinum wire electrode which is adopted as a counter electrode are combined with a high-voltage direct current power supply to realize an electric adsorption effect in order to complete the electrically-driven solid phase micro-extraction. The electrically-driven solid phase micro-extraction method combining the electric adsorption technology with the stirring technology effectively overcomes a disadvantage that magnetic stirring cannot be used in a small-volume solution and simultaneously reduces a disadvantage that the abrasion of a solid phase micro-extraction stirring bar is easy, so the service life can be prolonged; the integrated epoxy resin based porous polymer is treated as the adsorption material, so the extraction amount and the detection sensitivity are improved. The method has the advantages of simplicity, easy operation and high flexibility.

Owner:NINGBO UNIV

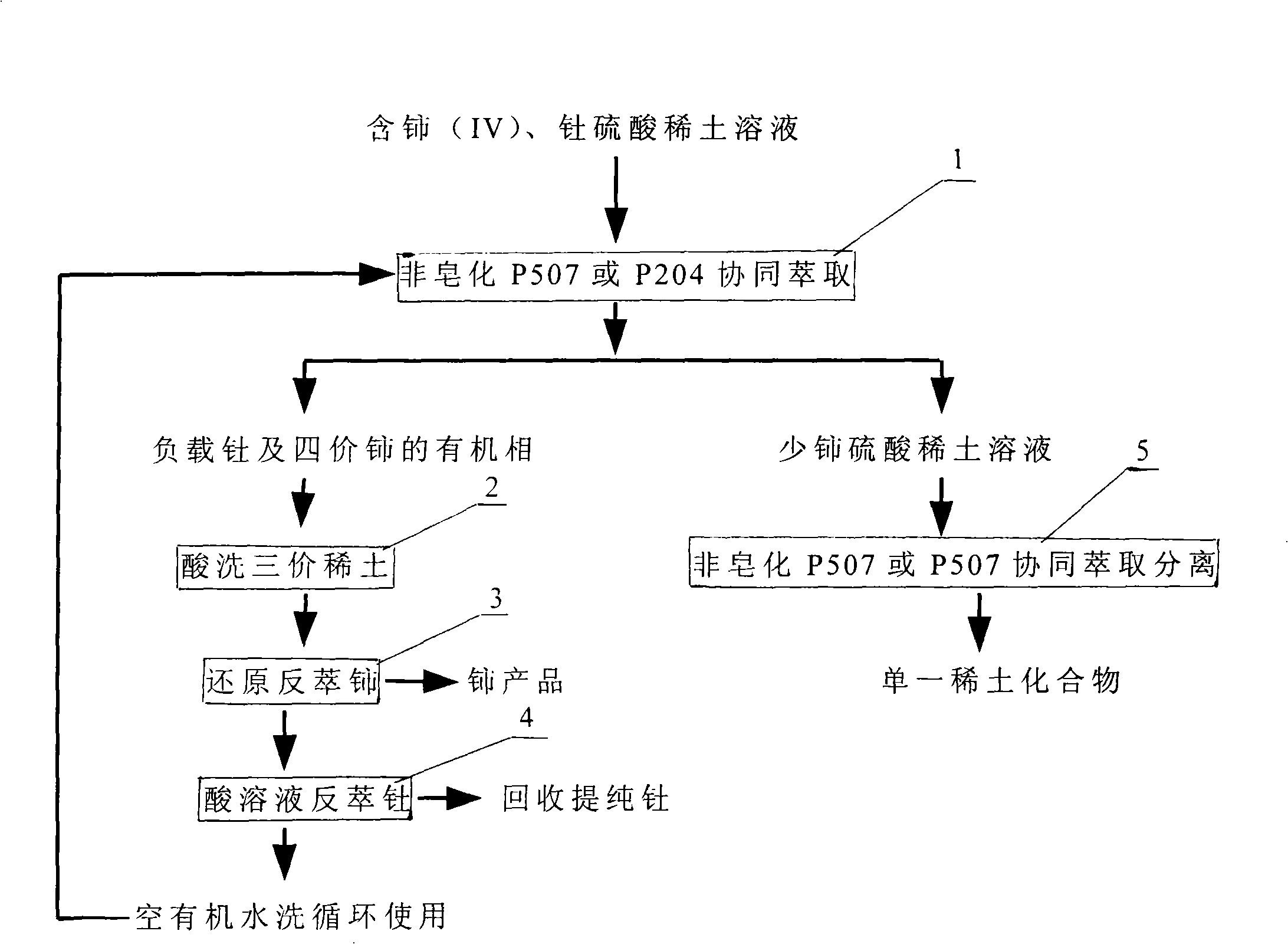

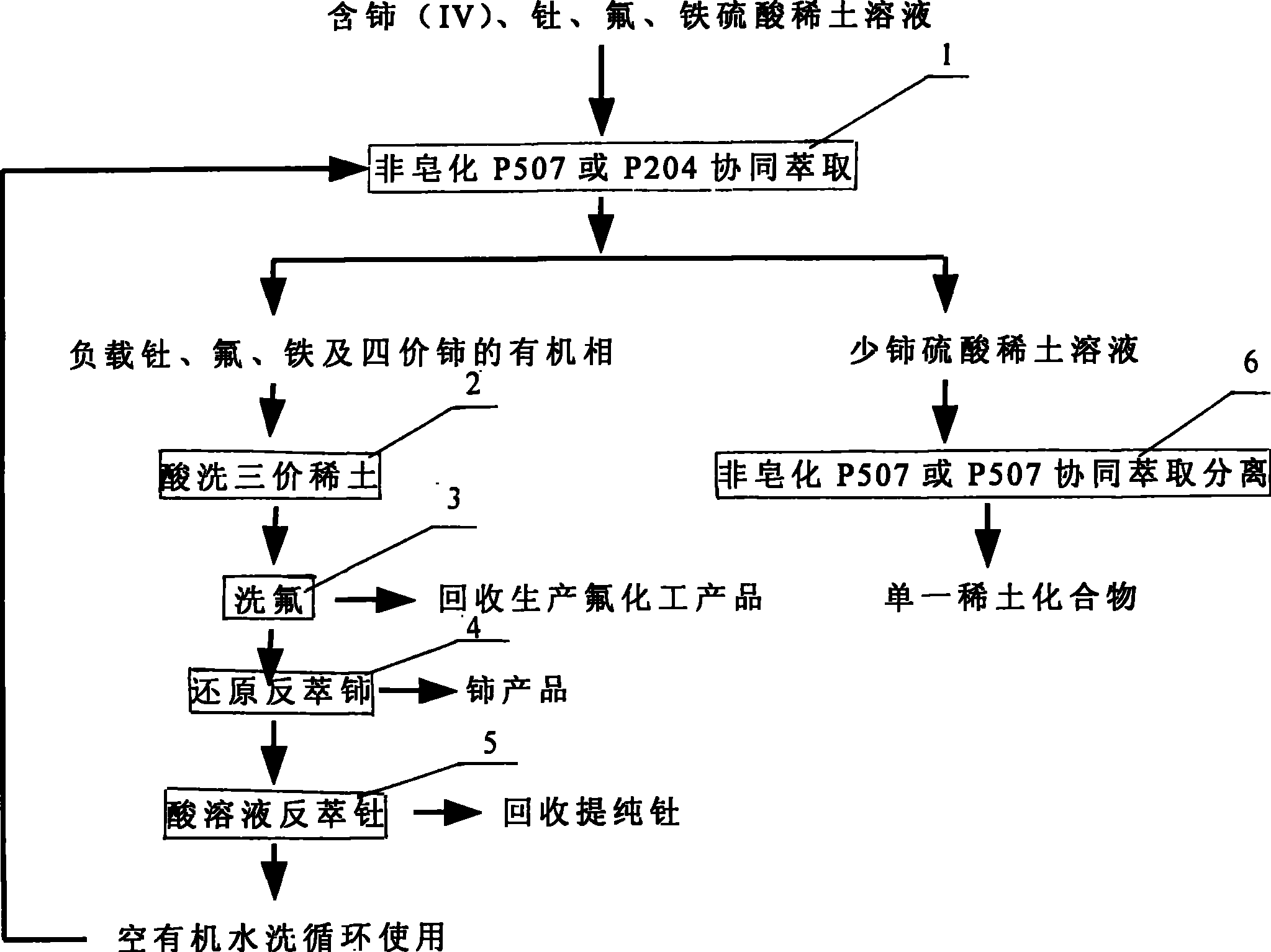

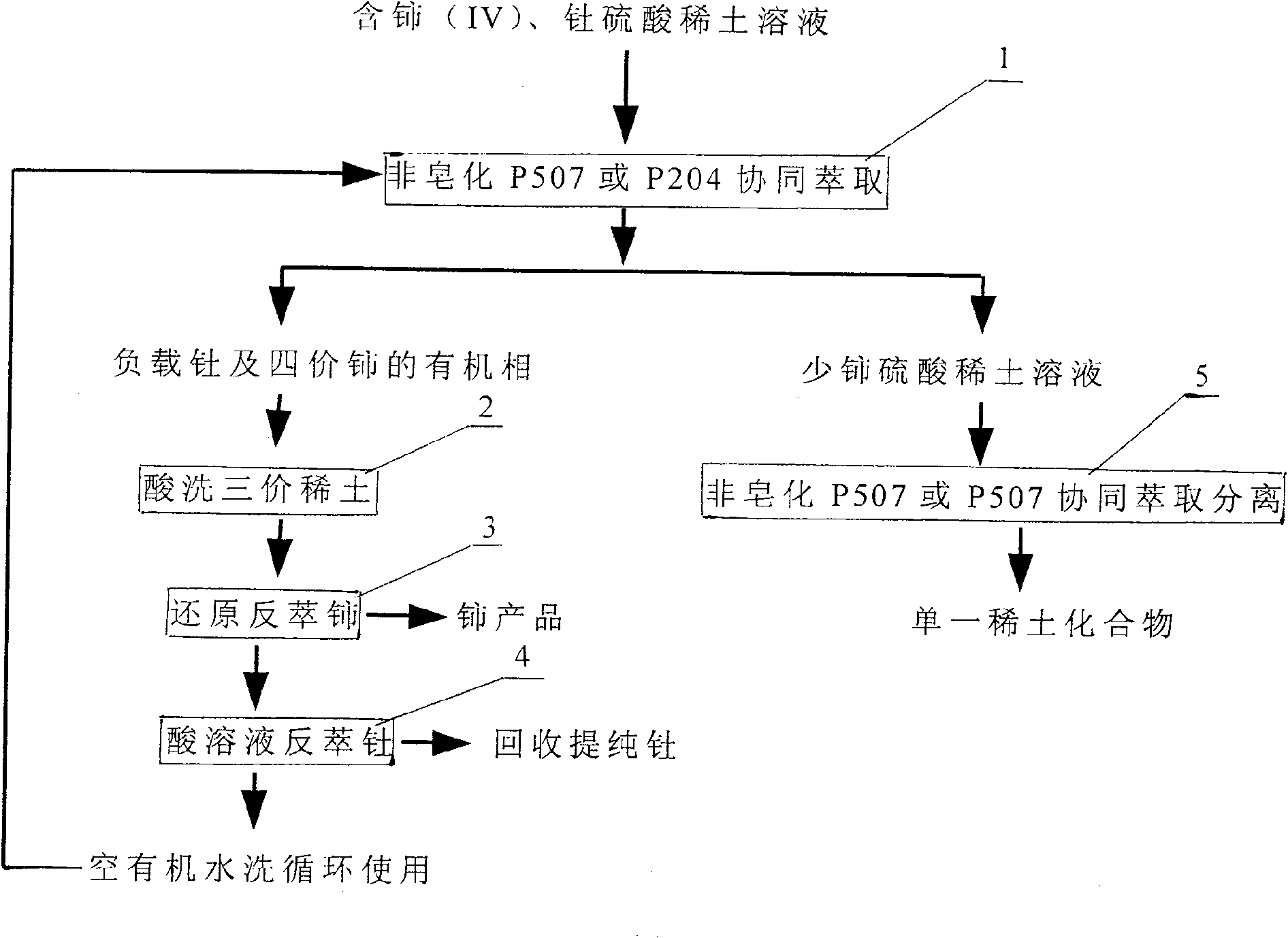

Technique for extraction separation of quadravalence cerium, thorium and cerium less tervalence rare earth from sulphuric acid rare earth solution

InactiveCN101294245ANo pollution in the processReduce consumptionProcess efficiency improvementRare-earth elementSulfate

The invention relates to a technological method for extracting and separating quadrivalent cerium, thorium, and less-cerium trivalent rare-earth from rare earth sulfate solution. The rare earth sulfate solution, which is obtained through processing the rare-earth ores and contains the thorium and high-valence cerium, is used as raw material; synergistic extraction agent basing on P507 and P204 is adopted for extracting and separating; the cerium (4) and the thorium are extracted into an organic phase, then selective washing and back extraction are performed step by step to obtain the products including pure cerium and pure thorium, the trivalent rare-earth is left in a water phase, and then unsaponifiable P507 or the synergistic extraction agent basing on P507 is adopted to perform multistage fractional extraction to separate single rare earth elements after impurity removal. The technological methodn has the characteristics that the synergistic extraction agent basing on P507 and P204 is adopted, the thorium is easy to perform the back extraction, and extraction capacity is large, and the emulsification is not generated during the extraction process; the cerium (4), the thorium and trivalent rare-earth are extracted and separated in the same extraction system; both extraction and the separation adopt unsaponifiable extraction agent, and ammonia-nitrogen wastewater is not generated; in addition, the thorium is recovered as products, and the pollutions caused by thorium-containing waste residue and the ammonia-nitrogen containing wastewater are eliminated from headstream. Therefore, the technological method has the advantages of simple procedures, green environmental protection, and low manufacturing cost.

Owner:GRIREM ADVANCED MATERIALS CO LTD

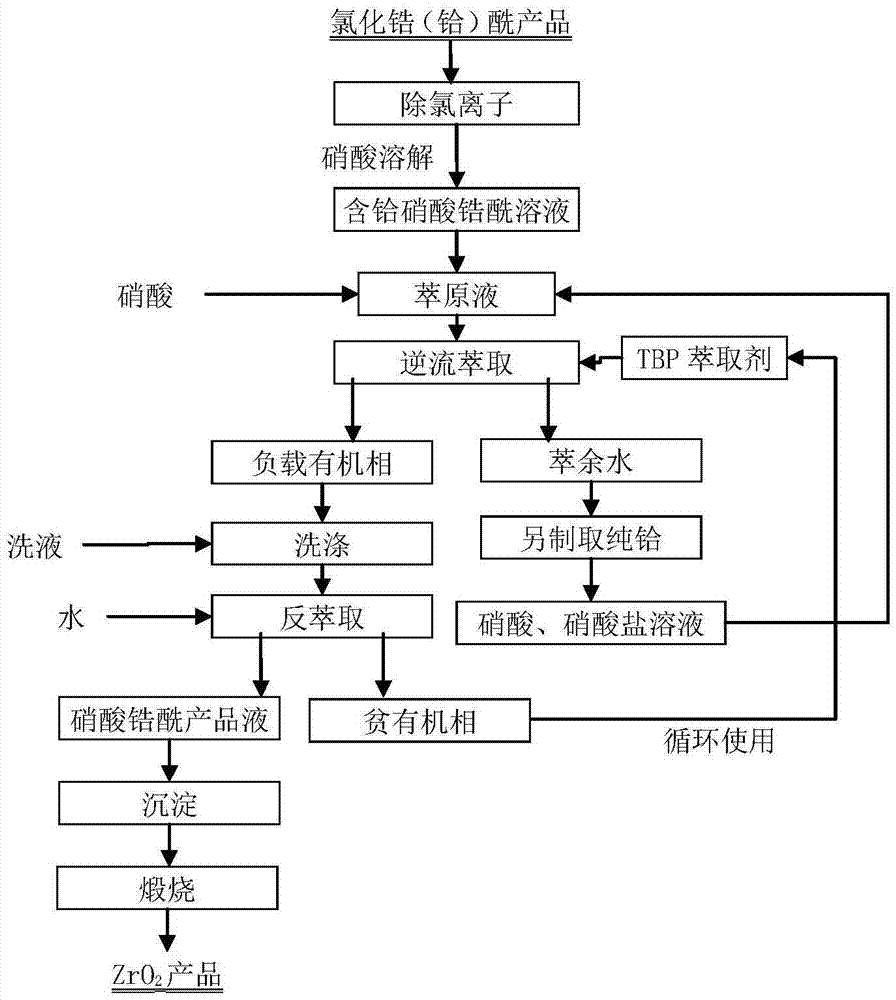

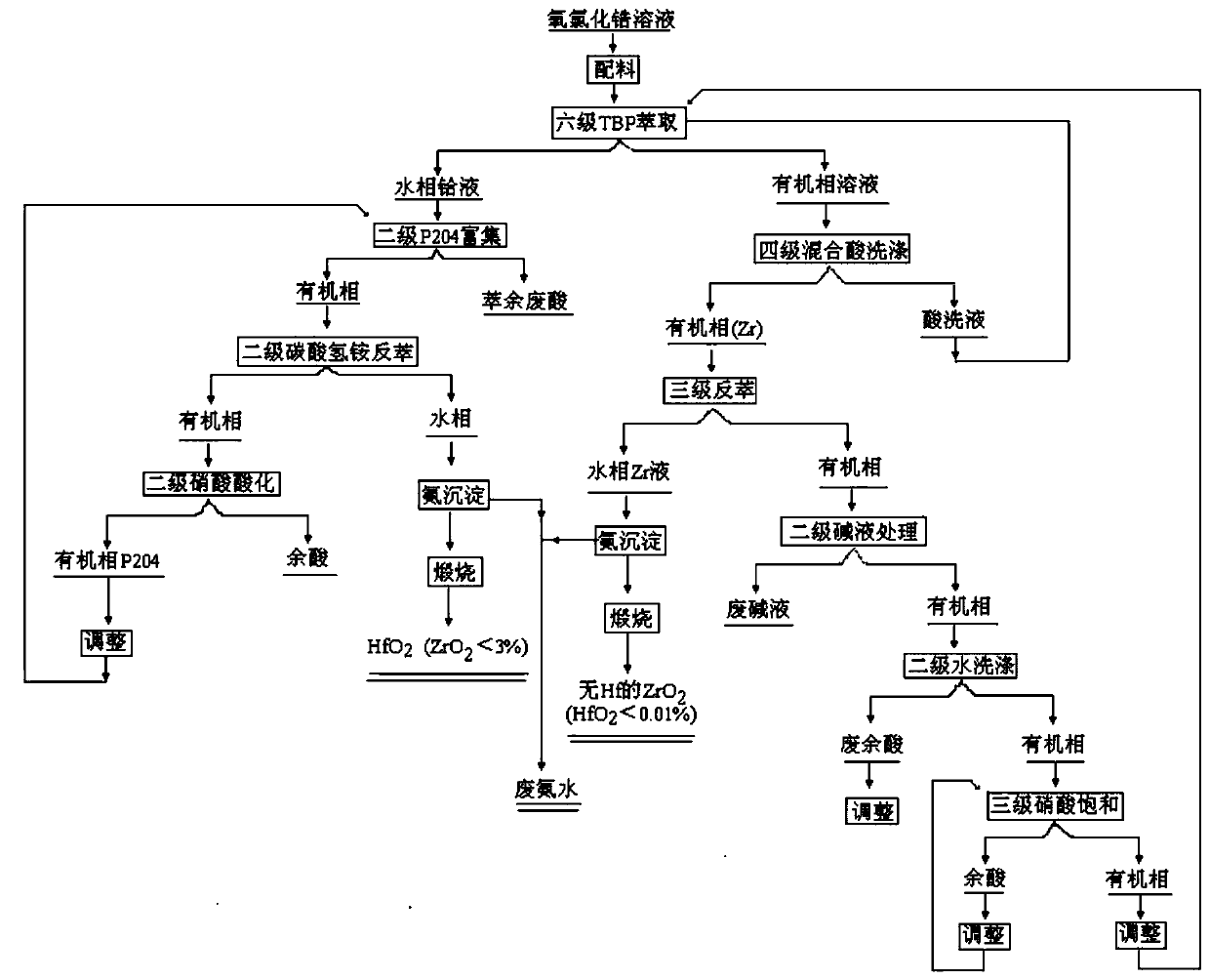

Process for separating zirconium and hafnium by solvent extracting method

ActiveCN106929695AFulfil requirementsImprove product qualityProcess efficiency improvementZirconium oxidesKeroseneHydrometallurgy

The invention belongs to the field of wet metallurgy and the technical field of zirconium and hafnium separation, and in particular, relates to a process for separating zirconium and hafnium by a solvent extracting method. Industrial products containing hafnium zirconium chloride acetyl are used as raw materials for such procedures as water solution, alkali sinking, washing and nitric acid dissolving to prepare zirconium (hafnium) nitrate acetyl solution; TBP kerosene solution of adding phase modifying agent octanol is used as an extracting agent; most zirconium and less hafnium are extracted into an organic phase through multistage counter-current extraction by using the characteristic of TBP priority extraction of zirconium; the loaded organic phase is washed by nitric acid solution with a certain concentration to further remove most hafnium in the organic phase; the acid-washed loaded organic phase is reversely extracted by water to obtain zirconium nitrate acetyl solution; the solution is precipitated in ammonia, dried and calcined to obtain zirconium dioxide powder, and the mass of the zirconium dioxide powder accords with the atomic energy-level zirconium dioxide standard; less zirconium and most hafnium only remained in residual water phase of zirconium after reverse extraction are extracted; the content of zirconium in hafnium meets the requirements on impurity zirconium by atomic energy-level hafnium; and atomic energy-level hafnium can be directly prepared by enrichment.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

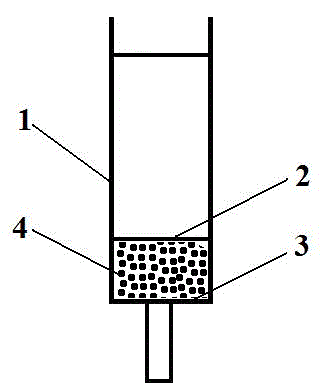

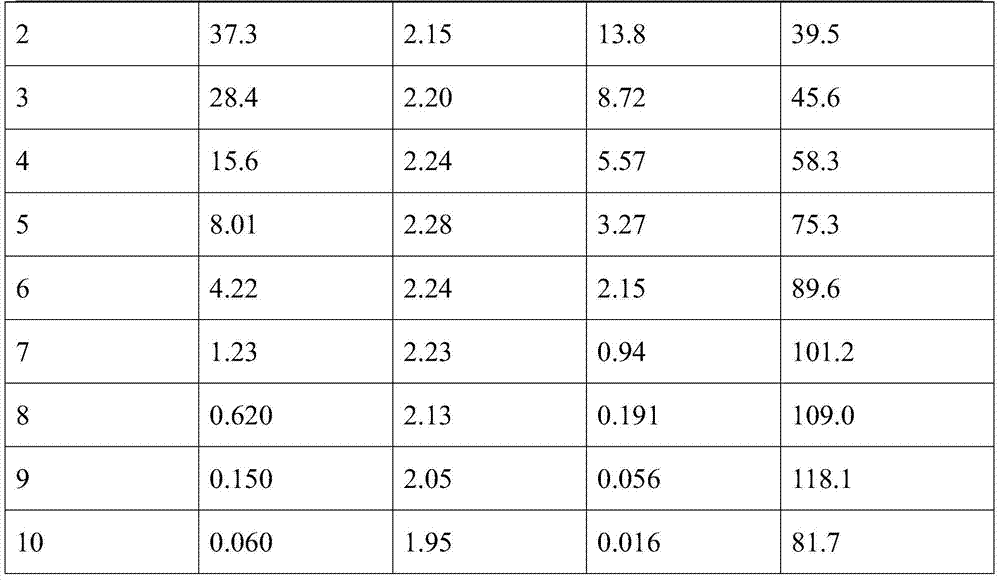

Monolithic column solid phase extraction sample pretreatment method

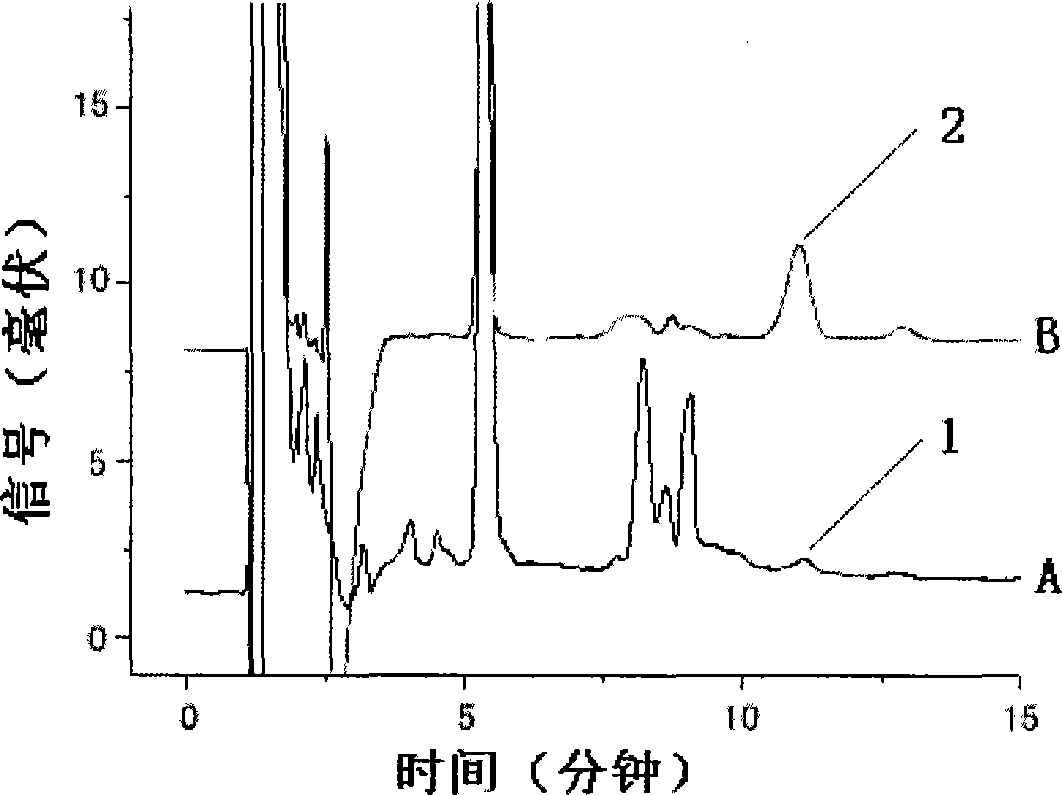

InactiveCN101858898AThe synthesis method is simpleLarge extraction capacityComponent separationChromatographic separationPretreatment method

The invention discloses a monolithic column solid phase extraction sample pretreatment method, which comprises the following steps of: 1) taking a 1-milliliter syringe and a sieve plate, wherein the sieve plate has the diameter of 4.8 millimeters, the thickness of 1.6 millimeters and micron-sized pores; 2) synthesizing the material of a monolithic column on the sieve plate, stuffing the sieve plate serving as a fixed phase into the 1-milliliter syringe, injecting sample solution serving as a liquid phase from the tail end of the syringe, pushing the solution, and enriching target analytes in the sample solution by using the material of the monolithic column on the sieve plate; and 3) analyzing the target analytes enriched on the sieve plate of the monolithic column by using analytic liquid, and performing high resolution liquid chromatographic separation detection. The monolithic column solid phase extraction method has the advantages of high extraction capacity, low extraction backpressure, effectively shortening of extraction time, high extraction efficiency, high detection sensibility, simple operation, good repeatability, and suitability for extracting and enriching trace components in complicated sample matrixes.

Owner:HUAZHONG NORMAL UNIV

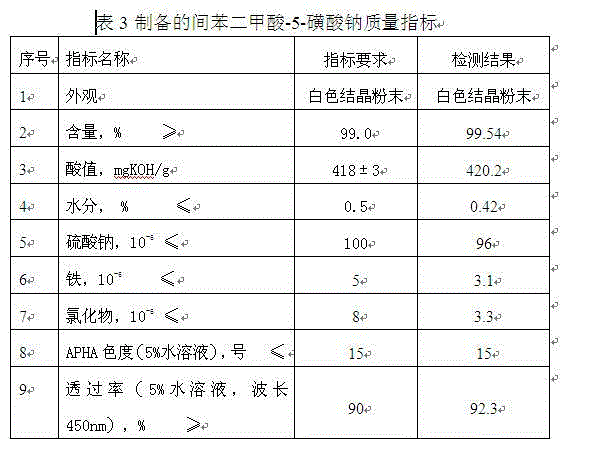

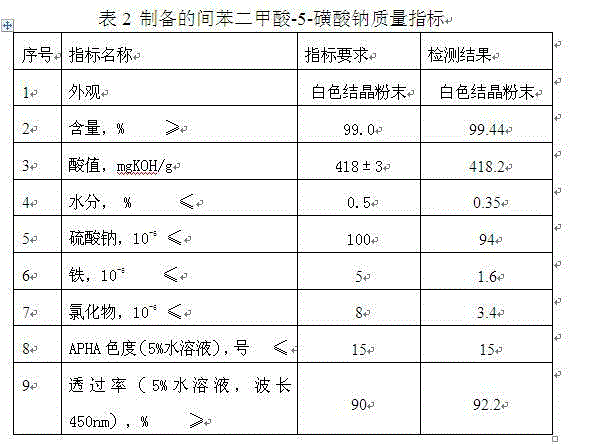

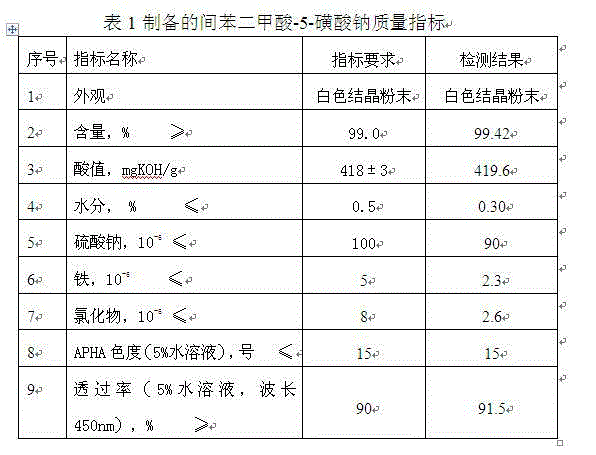

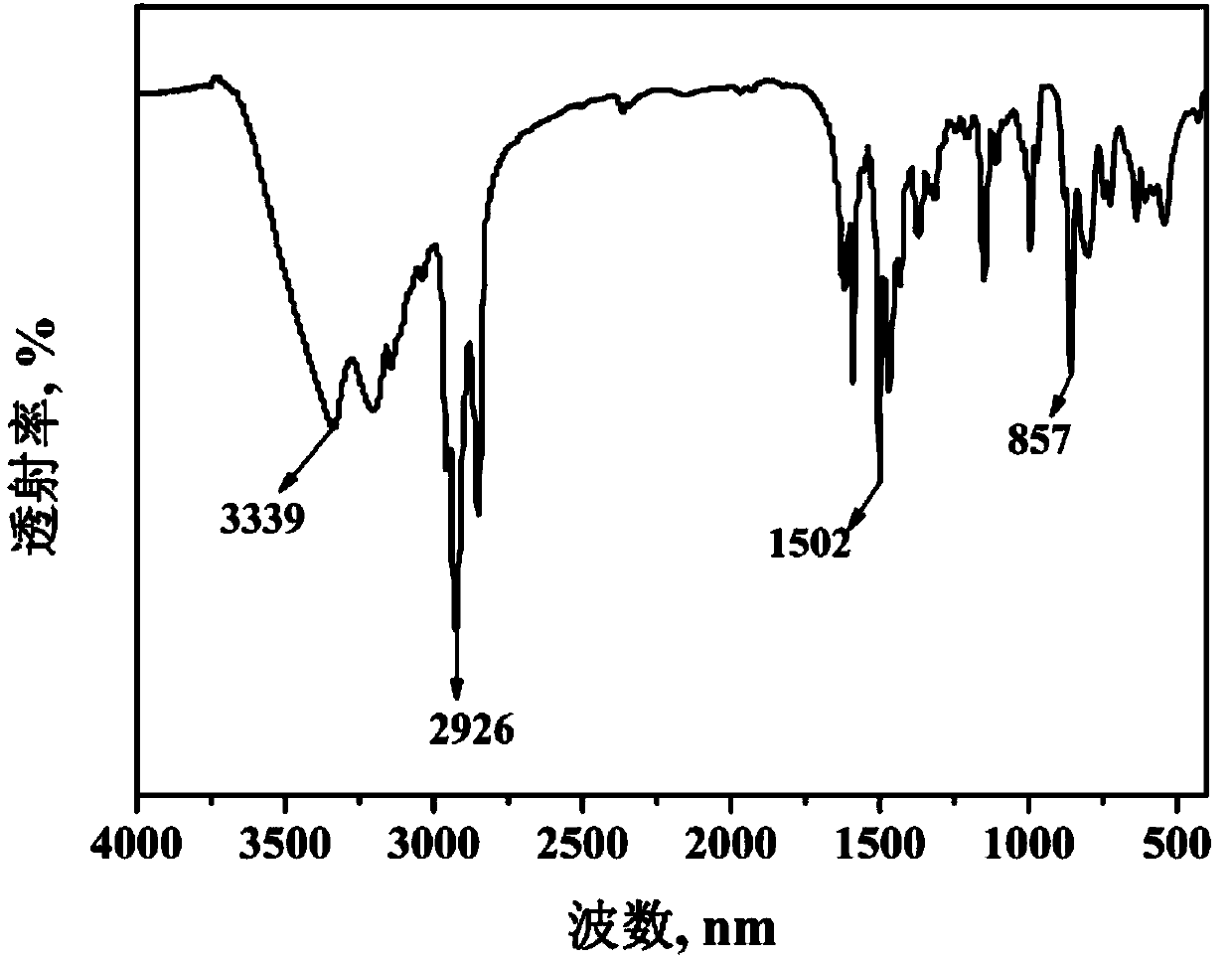

Method for extracting m-phthalic acid-5-sodium sulfonate from trimonomer production wastewater

ActiveCN104086462AHigh extraction rateLarge extraction capacityOrganic chemistryOrganic compound preparationPhthalic acidAlkylbenzenes

The invention discloses a method of extracting m-phthalic acid-5-sodium sulfonate from trimonomer production wastewater. The method sequentially comprises the following steps: preparing an extraction agent; adjusting the pH value; extracting; re-extracting; concentrating re-extracting liquid; acidifying; concentrating and crystallizing; and drying. In the extraction agent, double components (trioctylamine and ditertiary amine 2, 4-di(N, N-dihexyl) amino dodecylbenzene) are used as complexing agents, 2-heptyl undecyl alcohol is used as a cosolvent and double components (sulfonated kerosene and n-octyl alcohol) are used as diluents. According to the method provided by the invention, a complexing and extracting process is adopted for extracting m-phthalic acid-5-sodium sulfonate from liquid waste at the bottom of a tower after methanol is recovered from trimonomer and the best extraction system and reasonable extraction conditions are selected, so that the extraction rate of m-phthalic acid-5-sodium sulfonate is over 99%, the economic benefit of the trimonomer product is greatly improved, and comprehensive utilization of resources is realized.

Owner:WEIFANG WORLD CHEM

Double-pyrazole extracting agent derived from o-phenanthroline, and preparation method and application of double-pyrazole extracting agent

ActiveCN108017632AUnique rigid structureImprove extraction kineticsOrganic chemistryRadioactive decontaminationSolubilityLanthanide

The invention discloses a double-pyrazole extracting agent derived from o-phenanthroline with the following structural general formula, and a preparation method and application of the double-pyrazoleextracting agent. In the formula, R is any one selected from n-octyl, n-butyl, isobutyl, ethyl, pyridyl and phenyl. The double-pyrazole extracting agent derived from the o-phenanthroline provided by the invention has a unique rigid structure and an alkyl chain for improving the solubility, and simultaneously only four elements of C, H, O and N are contained, so that the extraction kinetics of a separation extraction system can be greatly increased, the extraction capacity of an organic phase can be increased, secondary pollutants cannot be produced, and thus the environmental protection is facilitated. The extraction agent can be used to separate Ans (actinide elements) / Lns (lanthanide elements), and can not only form a separation extraction system of the Ans / Lns, but also can be used to form a separation reverse extraction system of the Ans / Lns.

Owner:SICHUAN UNIV

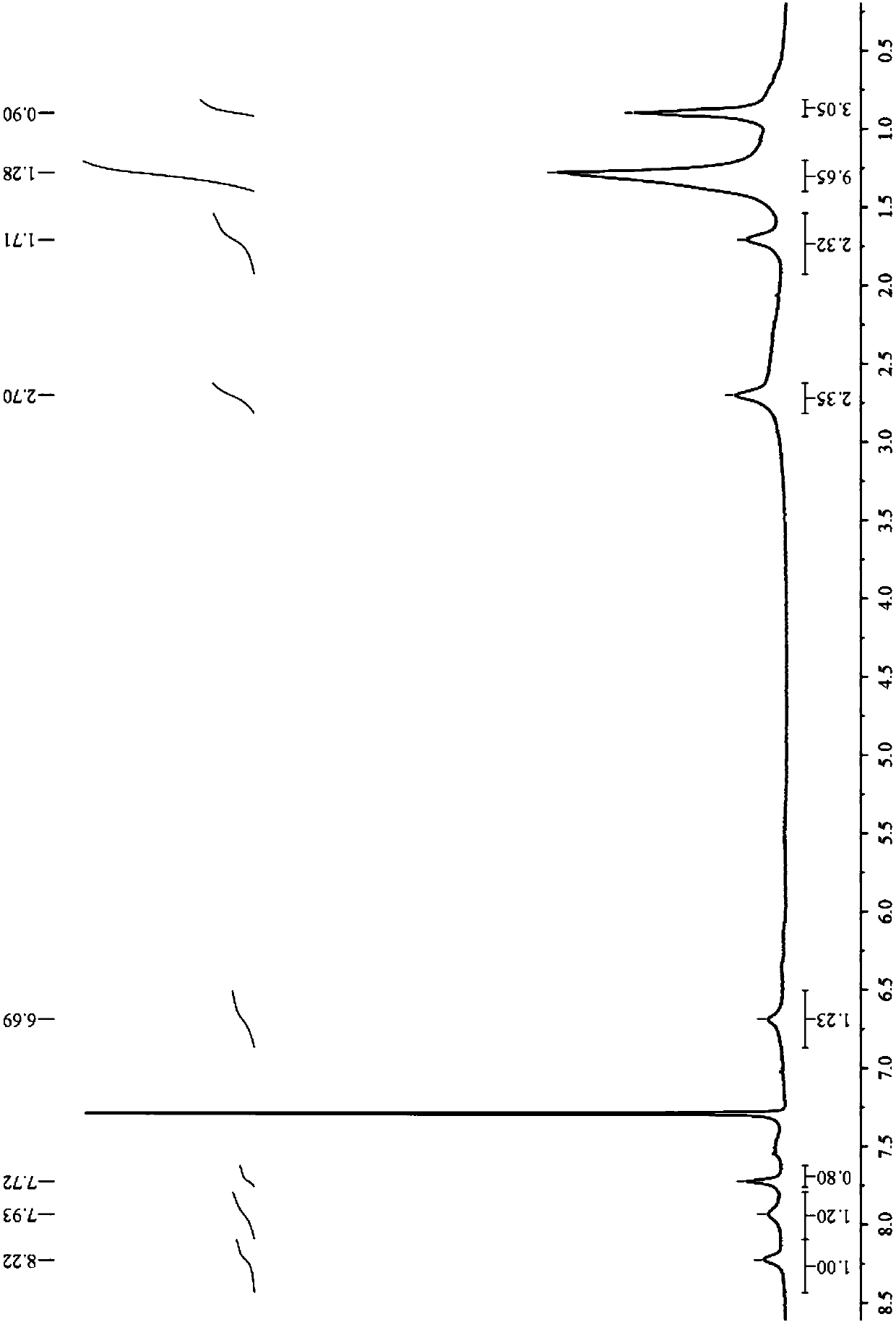

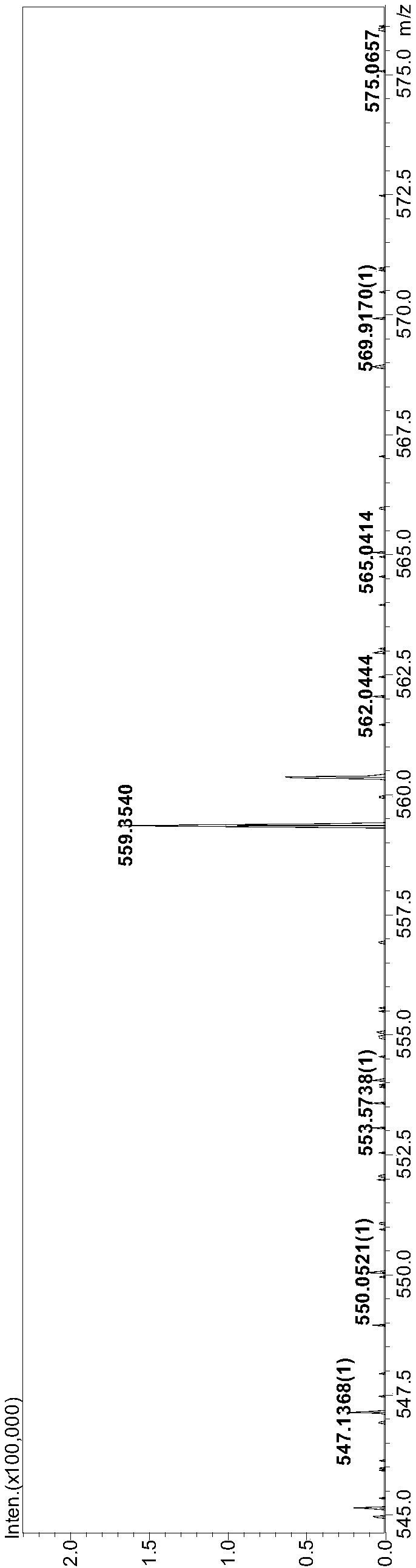

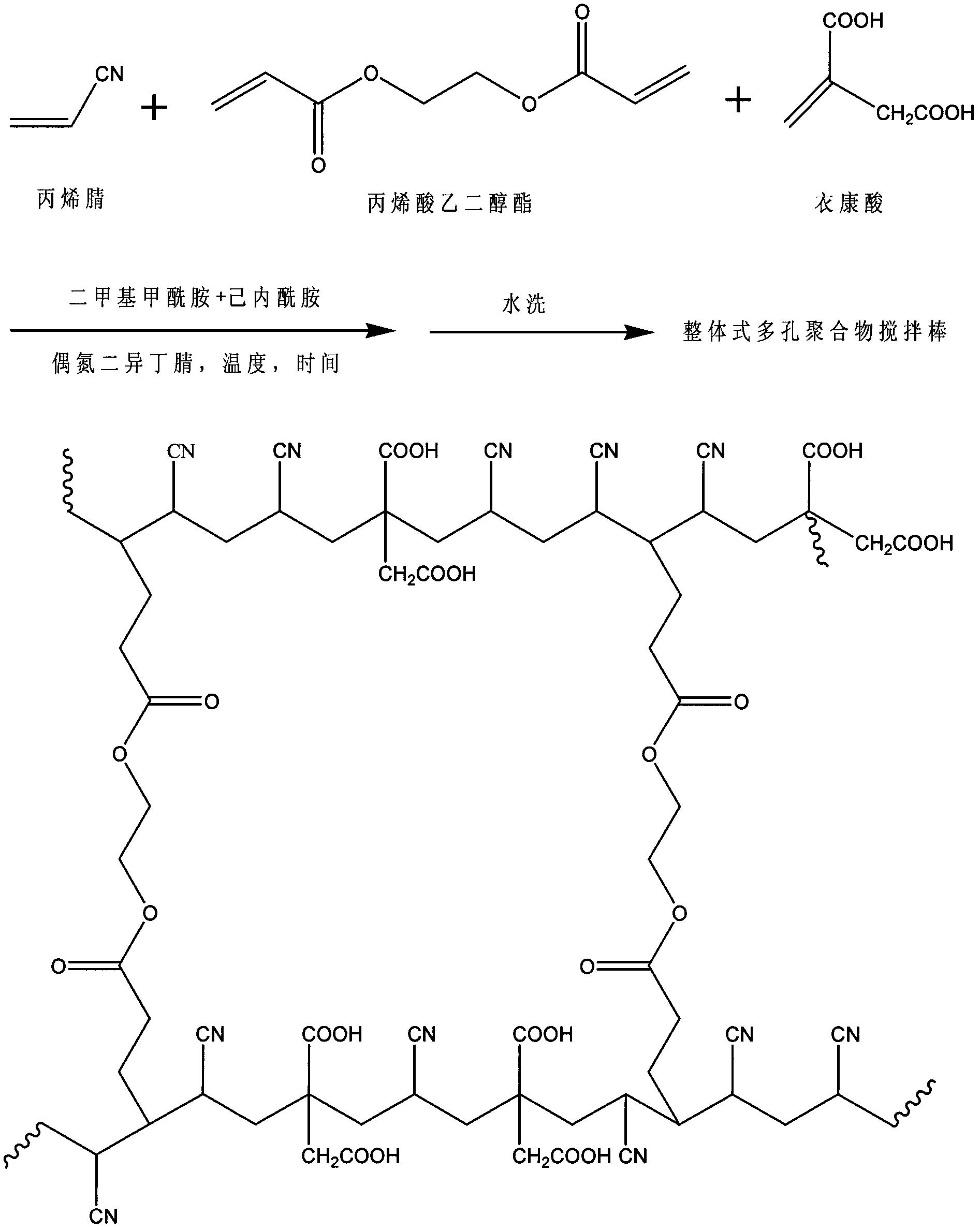

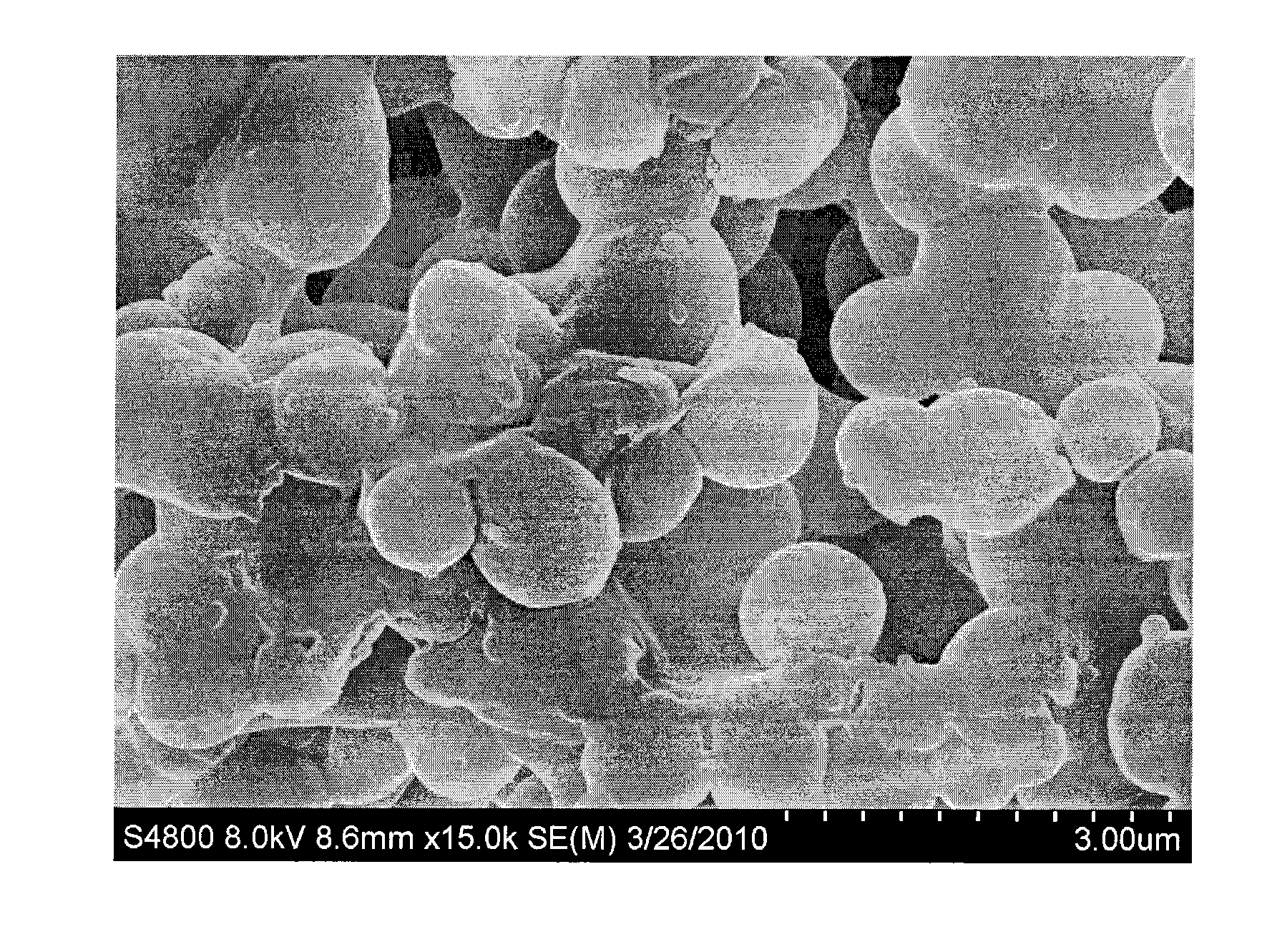

Integrated porous polymer adsorption extraction stirring bar and its manufacturing method

InactiveCN102872834AExtended service lifeImprove adsorption capacityIon-exchange process apparatusOther chemical processesPolymer scienceDesorption

The invention relates to an integrated porous polymer adsorption extraction stirring bar and its manufacturing method. The stirring bar comprises a stirring magneton and a coat coated outside the stirring magneton, wherein the coat is an acrylonitrile-ethylene glycol acrylate-itaconic acid copolymer. A mixed solvent of dimethyl formamide and caprolactam is added to a reaction system as a pore forming agent, azodiisobutyronitrile is used to carry out thermal initiation of an in-situ free radical polymerization reaction, and a prepared integrated porous material is adopted as the coat of the adsorption extraction stirring bar, so the adsorption extraction stirring bar has the advantages of rapid adsorption and desorption rates, large extraction capacity, and realization of the adoption of an equilibrium extraction mode of solid phase micro-extraction or a depleted extraction mode of solid phase extraction. The ethylene glycol acrylate which is a crosslinking agent improves the mechanical performances of the coat of the stirring bar and prolong the service life. The itaconic acid which is a modifier makes the extraction coat contain a plurality of carboxyl groups, and can directly adsorb and extract parts of heavy metal cations and polar organic compounds. The preparation method is simple and can be easily operated.

Owner:NINGBO UNIV

Micro-extraction monolithic column of ionic liquid polymer capillary tube and preparation method thereof

ActiveCN103833885AEnhanced mass transferHigh enrichment efficiencyOther chemical processesSolid sorbent liquid separationFunctional monomerEthyleneglycol dimethacrylate

The invention discloses a micro-extraction monolithic column of an ionic liquid polymer capillary tube and a preparation method thereof. The method comprises the following steps: by adopting imidazolium ionic liquids and dodecyl methacrylate as functional monomers, taking ethylene glycol dimethyl acrylic ester as a cross-linking agent, taking normal propyl alcohol and butanediol as pore-foaming agents and taking azodiisobutyronitrile as an initiator, evenly mixing the raw materials at room temperature in an oscillating manner, and injecting into a vinyl-modified quartz capillary tube; sealing, and carrying out thermal initiation one-step polymerization, so as to obtain the micro-extraction monolithic column of the ionic liquid polymer capillary tube in manners of cleaning and drying. The micro-extraction monolithic column is simple and convenient in synthetic process, controllable in reaction, and low in cost. The prepared micro-extraction column for the capillary tube has good permeability, porosity, and chemical and mechanical stability; a plurality of interaction sites such as an imidazole ring with positive electricity and different lengths of carbon chains and the like are formed on the surface; the micro-extraction monolithic column has good extraction ability on the substances such as phenolic environmental hormone and the like, and is quick to extract, and easy to build an analysis method with high sensitivity by combining with capillary electrochromatography.

Owner:FUZHOU UNIV

Solid phase extraction filler and preparation method thereof

InactiveCN101530779AIncreased durabilityLarge extraction capacityOther chemical processesWater bathsCyanide

The invention discloses a solid phase extraction filler and a preparation method thereof. In the method of the invention, acetone is used for dissolving surface active agent, thus obtaining active agent acetone solution with a concentration of 10% (m / v) for standby use; porous graphitized carbon black is placed in a dry container, the porous graphitized carbon black is stirred while the standby active agent acetone solution is added to the container to be mixed evenly; stirring is continued and the mixture is evaporated to dryness by water bath at the temperature of 50-70 DEG C, the obtained graphitized carbon black attached with the surface active agent is exactly the needed solid phase extraction filler. The filler is used for concentrating gold from alkaline cyanide solution, the first extraction yield of gold exceeds 96.5%, concentration multiple exceeds 250 times, extraction capacity of the materials on the gold is more than 29mg / g; the attached surface active agent is not washed away when being eluted by aqueous medium and can be used repeatedly, durability thereof is much better than the durability of C18; in addition, material cost is only 1 / 5 of octadecyl silane (C18), thereby enjoying a good prospect for promotion and application.

Owner:YUXI NORMAL UNIV

Technology for recovery of uranium in ceramic UO2 pellet by supercritical CO2 extraction

InactiveCN102936655AHigh degree of automationImprove extraction efficiencyRetention timeRadioactive waste

The invention belongs to a technology for recovery of uranium in a ceramic UO2 pellet by supercritical CO2 extraction. The technology includes the steps of: (1) preparing Sc-CO2 / TBP-HNO3; (2) preparing a UO2 extraction sample; (3) extracting the extraction raw material in step (2) by an extraction system of Sc-CO2 / TBP-HNO3; and (4) separating an extracted product. The technology provided in the invention has the advantages of minimum secondary radioactive waste, high automation degree, high extraction efficiency and selectivity, high extraction capacity, fast extraction speed, maximum reduction of nuclear material retention time, critical safety risk reduction, and minimum damage to the environment and operators.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Method for extracting and separating zirconium and hafnium in nitric acid medium

InactiveCN108220597ALess mass transferLarge extraction capacityProcess efficiency improvementToxic materialHafnium

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES

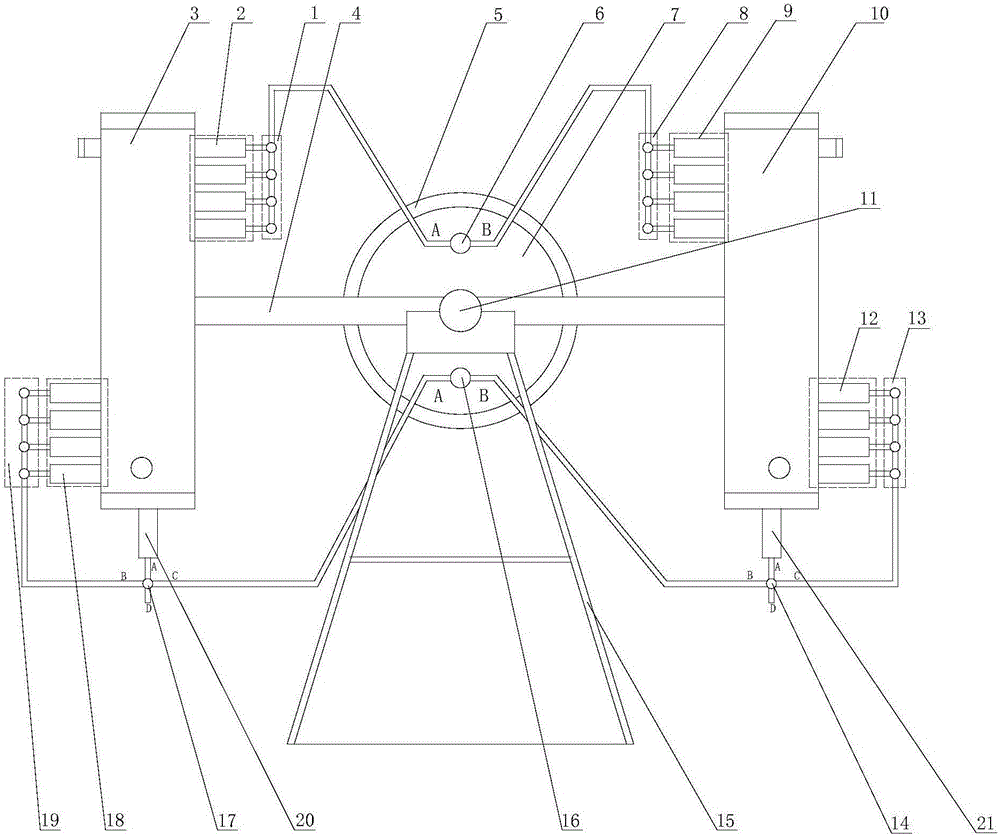

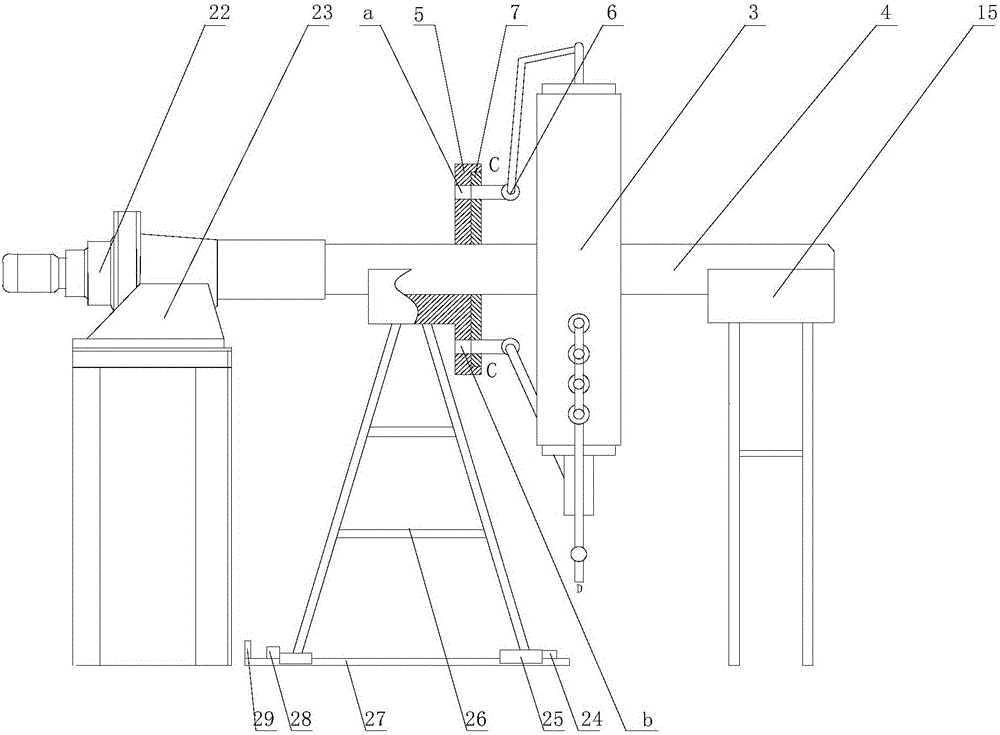

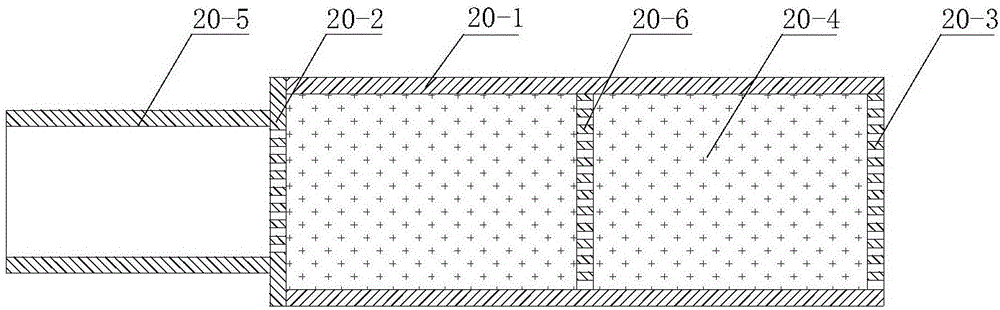

Double-kettle turning type supercritical fluid extraction device

ActiveCN106833883AFully contactedAvoid it happening againFatty-oils/fats productionSolid solvent extractionDrive shaftEngineering

The invention relates to a double-kettle turning type supercritical fluid extraction device. A motor is arranged on a first support seat; a transmission shaft is arranged on a power output shaft of the motor; a second support seat and a third support seat are arranged on the transmission shaft; a fixing disc is fixed on the upper part of the second support seat; a walking mechanism is arranged at the bottom of the second support seat; the transmission shaft passes through the fixing disc; a rotating disk and an extraction kettle support rod are sequentially and fixedly arranged on the transmission shaft; the two ends of the extraction kettle support rod are respectively and fixedly provided with a left extraction kettle and a right extraction kettle; one end opening of a fifth three-way valve arranged on the rotating disc communicates with a liquid inlet hole formed in the fixing disc through a pipeline, and the other two end openings respectively communicate with the left extraction kettle and the right extraction kettle through pipelines; one end opening of a sixth three-way valve arranged on the rotating disc communicates with a liquid outlet hole formed in the fixing disc, and the other two end openings respectively communicate with the left extraction kettle and the right extraction kettle through pipelines.

Owner:SHAANXI NORMAL UNIV

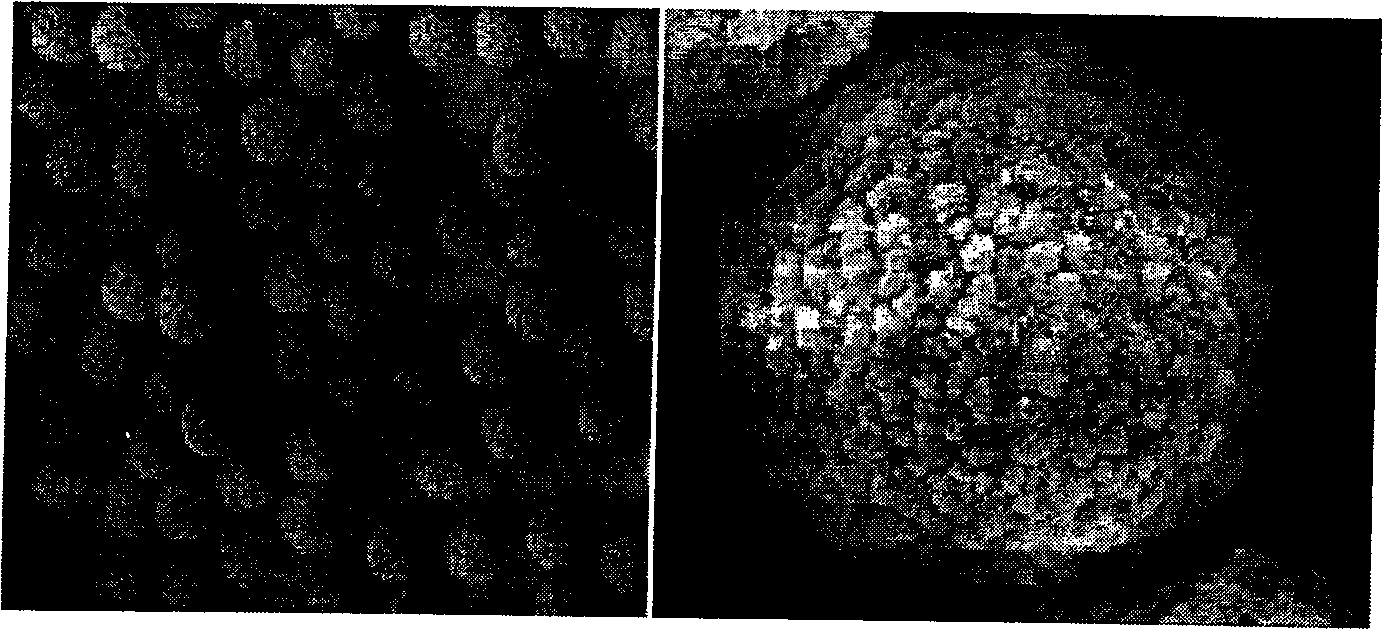

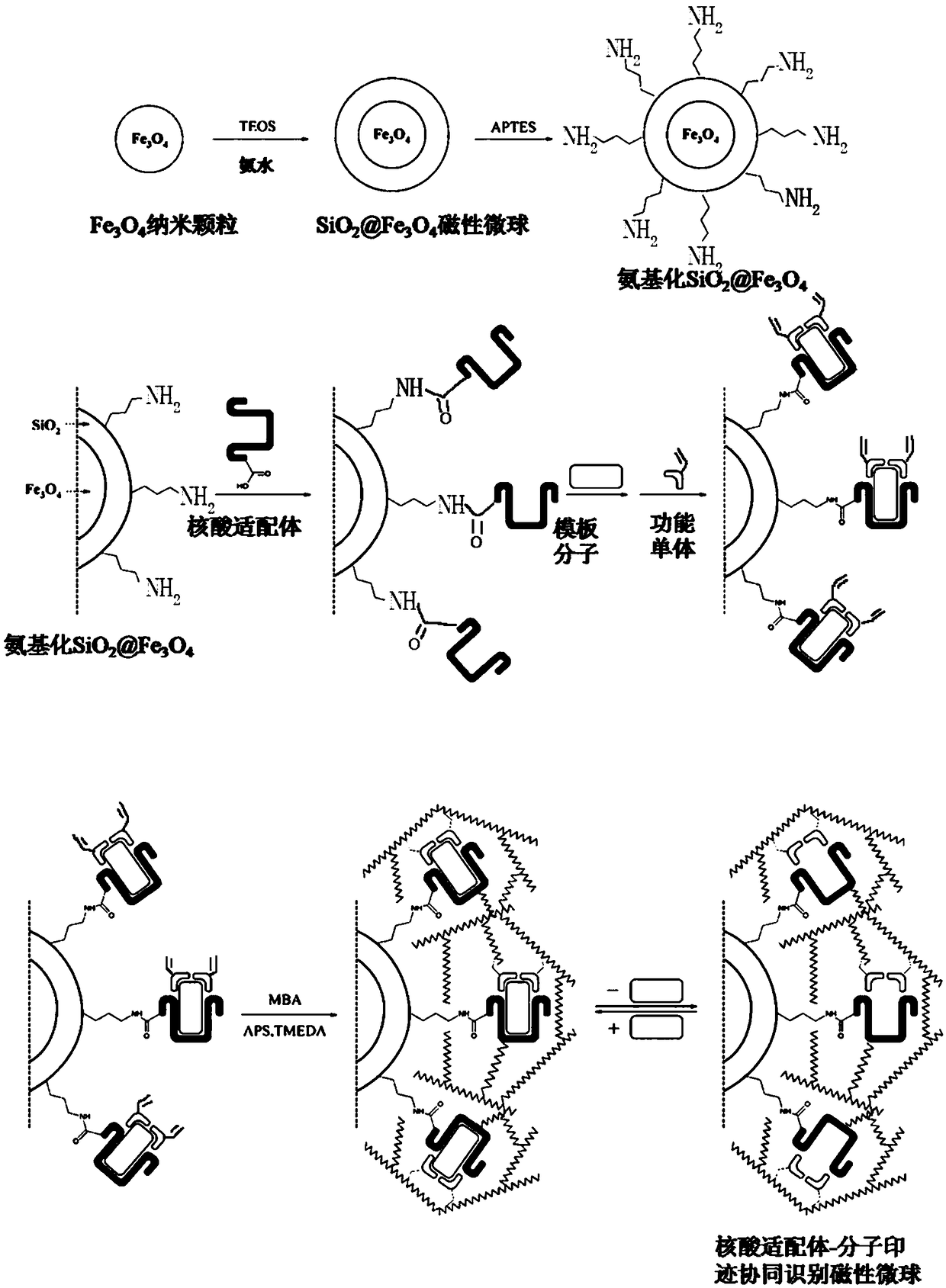

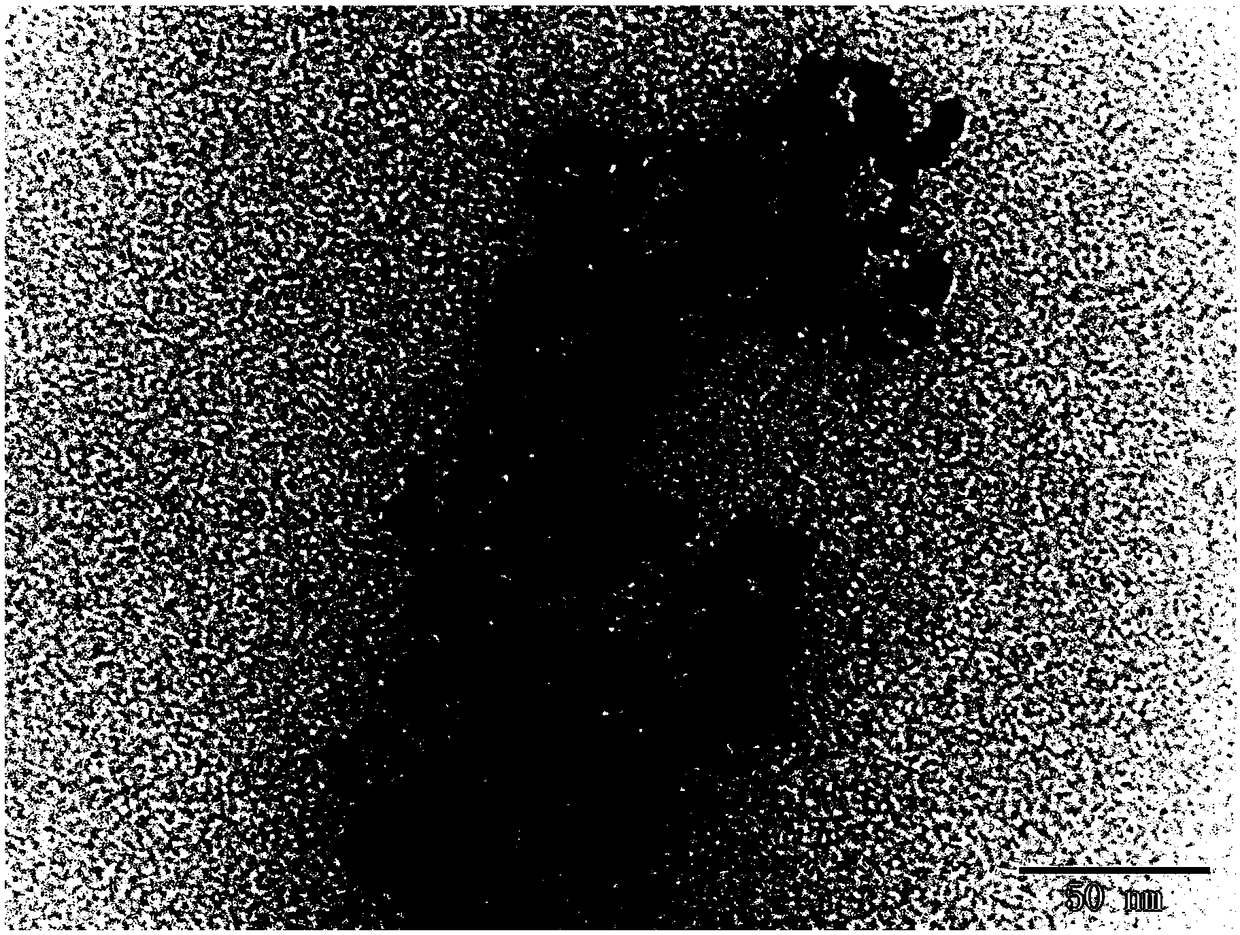

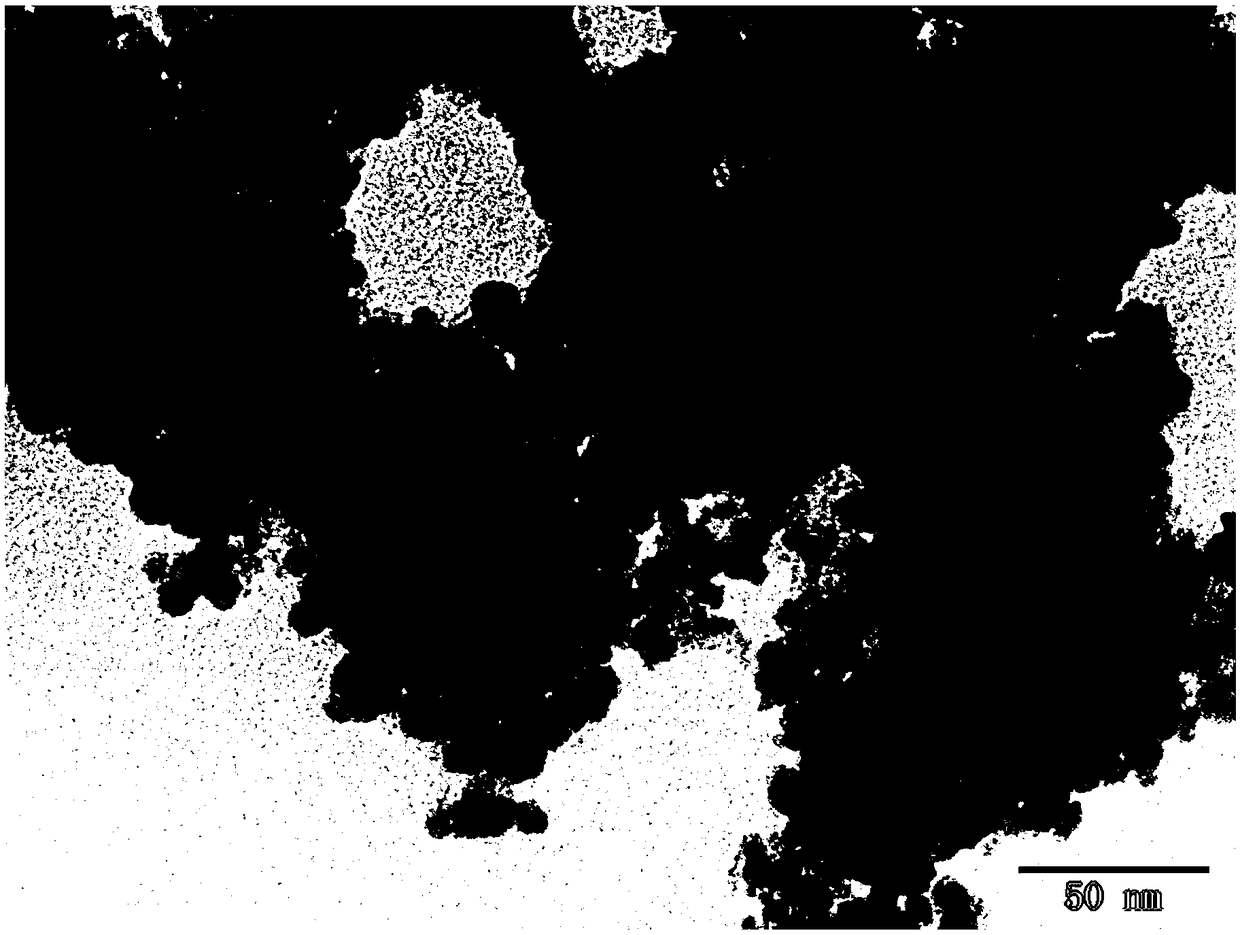

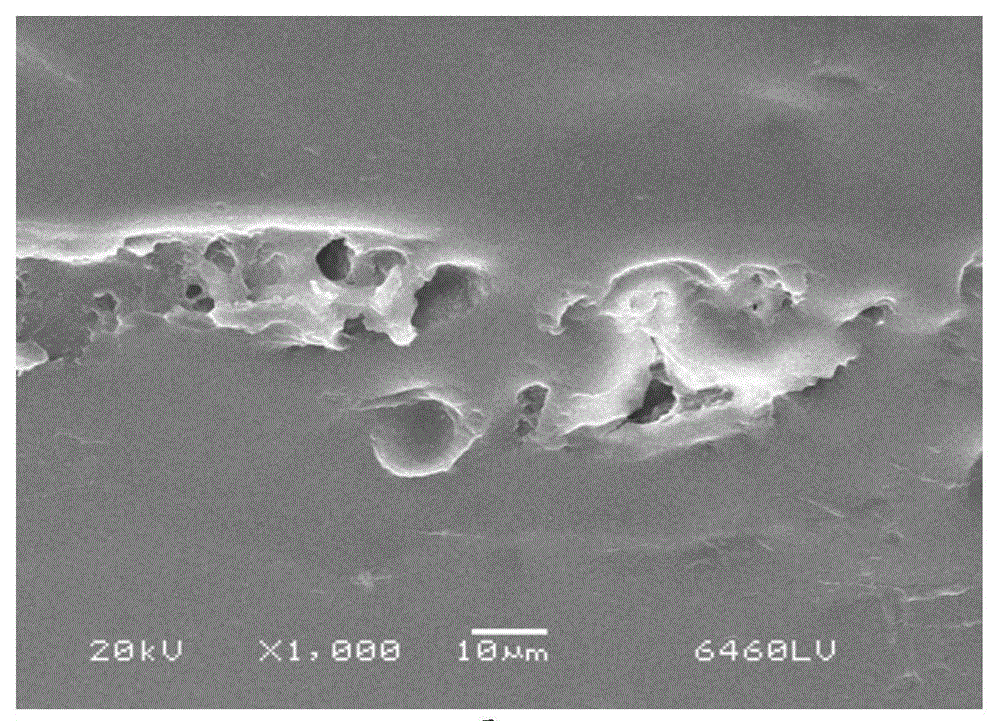

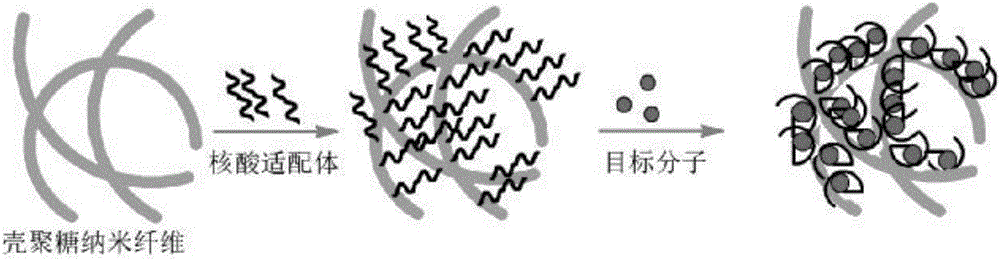

Nucleic acid aptamer-molecular imprinting synergistic recognition magnetic microspheres and preparation method and application thereof

ActiveCN108659255AHigh specific surface areaHigh bonding capacityIon-exchange process apparatusComponent separationAptamerMicrosphere

The invention discloses nucleic acid aptamer-molecular imprinting synergistic recognition magnetic microspheres and a preparation method and application thereof. The nucleic acid aptamer-molecular imprinting synergistic recognition magnetic microspheres disclosed by the invention comprise magnetic microsphere inner cores and nucleic acid aptamer-molecular imprinting synergistic recognition shells;the nucleic acid aptamer-molecular imprinting synergistic recognition shells have molecular imprinting polymer rigid recognition cavities; the molecular imprinting polymer rigid recognition cavitieshave structural stability, difficult deformation and strong specific adsorptivity; and nucleic acid aptamers are not easy to digest.

Owner:SOUTH CHINA NORMAL UNIVERSITY

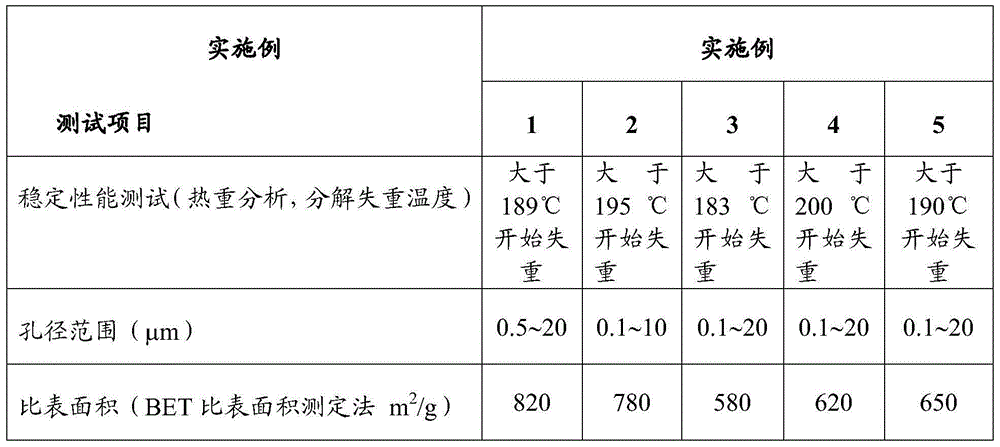

Solid-phase micro-extraction fiber and preparation method thereof

InactiveCN104162417AThe polymerization reaction is stableLow requirements for polymerization reaction conditionsOther chemical processesFiberFoaming agent

The invention discloses a solid-phase micro-extraction fiber and a preparation method thereof. The preparation method comprises the steps of mixing alpha-methacrylic acid, styrene, an organic crosslinking agent, an organic pore-foaming agent and an azo initiator to obtain a mixed organic liquid; putting the mixed organic liquid in an oxygen-free environment, putting a capillary tube into the mixed organic liquid, and enabling the interior of a cavity of the capillary tube to be filled with the mixed organic liquid; in the oxygen-free environment, heating the mixed organic liquid put into the capillary tube up to 50-70 DEG C, and carrying out polymerization reaction; and after the polymerization reaction is finished, washing the capillary tube, and removing the capillary tube to obtain the solid-phase micro-extraction fiber. The preparation method of the solid-phase micro-extraction fiber is stable in polymerization reaction, free from a by-product of the reaction and easy in reaction control; the solid-phase micro-extraction fiber prepared by adopting the method is good in performance stability and has the universality.

Owner:FOOD INSPECTION CENT OF CIQ SHENZHEN +1

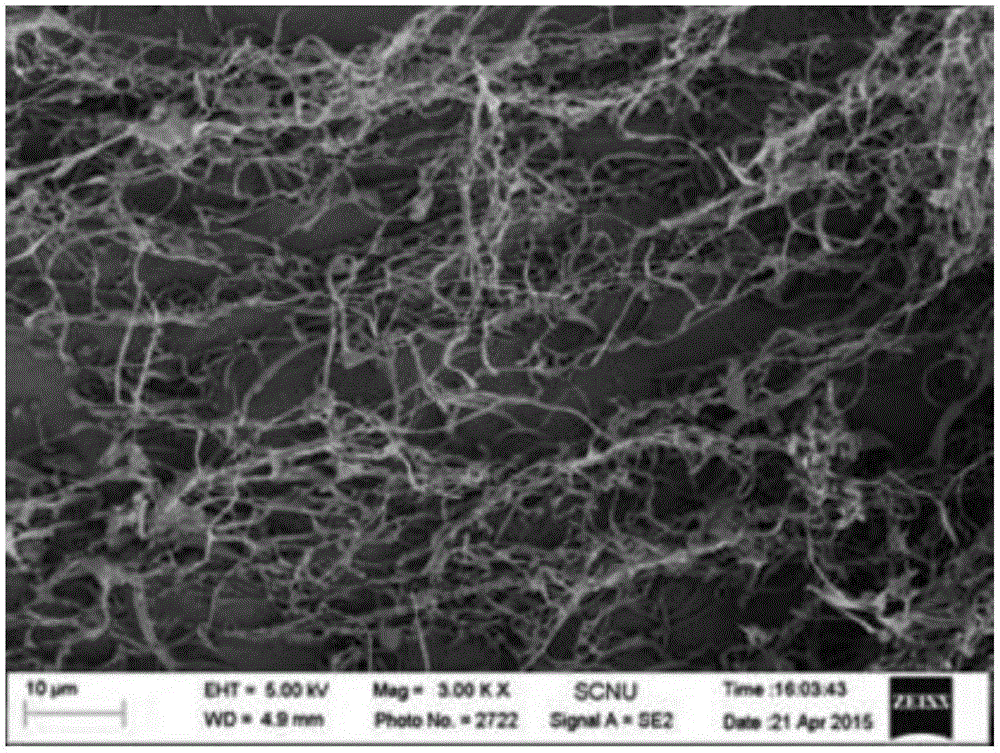

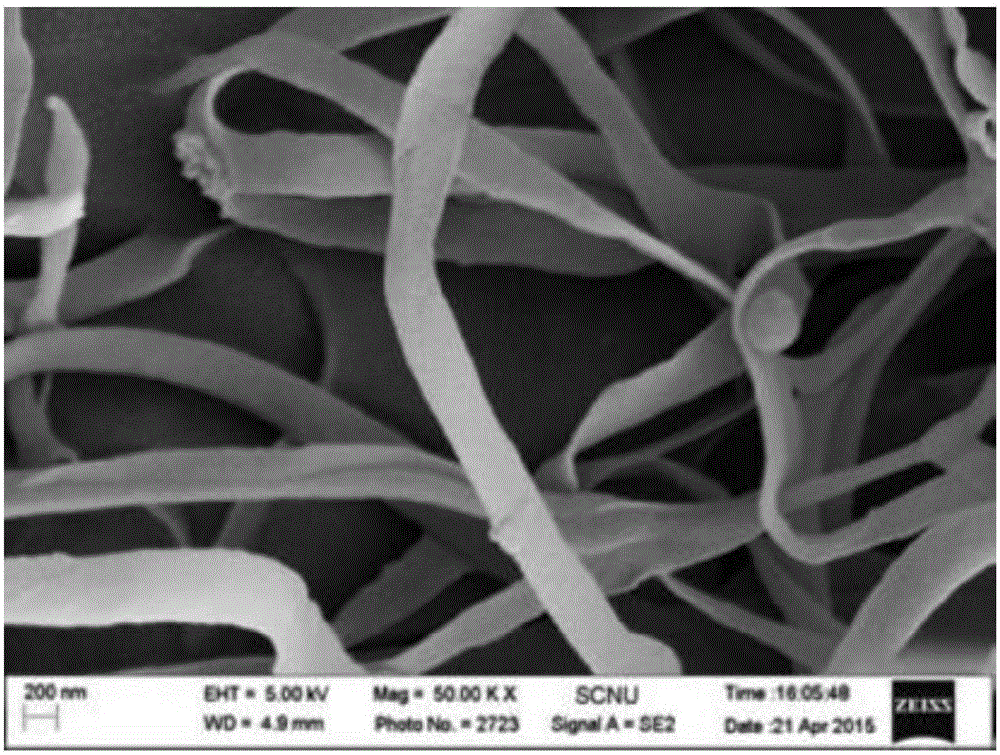

Preparation method and application of aptamer-modified chitosan nano fibers

ActiveCN106512958AHigh extraction selectivityImprove stabilityIon-exchange process apparatusOther chemical processesFiberAfter treatment

The invention discloses a preparation method and application of aptamer-modified chitosan nano fibers. The preparation method comprises the following steps: (1) preparing a chitosan solution; (2) preparing chitosan nano fibers; (3) chemical immobilization: taking the aptamer solution, adding an EDC / NHS (1-ethyl-3-(3-dimethylaminopropyl)carbodiimide / N-hydroxysuccinimide) solution for activation, adding the chitosan nano fibers obtained in the step (2), and oscillating to react at normal temperature; and (4) after-treatment: carrying out solid-liquid separation on the reaction mixed solution obtained in the step (3) to obtain the aptamer-modified chitosan nano fibers. The aptamer-modified chitosan nano fibers are suitable for high-selectivity separation and enrichment of trace or ultra-trace mycotoxin substances and other substances in the food and environment, and have the advantages of high selectivity, high extraction capacity, high stability and simple preparation process.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Method for separating octadecadienoic acid from mixed long-chain fatty acid

ActiveCN101851155ALarge extraction capacityIncrease production capacityCarboxylic compound separation/purificationSulfolaneMethyl group

The invention relates to a method for separating octadecadienoic acid from mixed long-chain fatty acid, which adopts a fractional extraction method to separate the octadecadienoic acid from the mixed long-chain fatty acid by taking one of acetonitrile, furfural, dimethyl sulfoxide, dimethylformamide, N-methyl-2-pyrrolidone and sulfolane or a mixture thereof as an extracting agent and one of petroleum ether the boiling range of which is 60-90 DEG C or 90-120 DEG C, hexane, heptane and octane or a mixture thereof as a detergent. The process adopts organic solvents commonly used in industry, andthe method has the advantages of simple process, high product quality, high yield, low production cost, high safety, environmental production, easy industrial production and the like.

Owner:ZHEJIANG UNIV

Method for extracting zirconium and hafnium from hydrochloric acid medium

ActiveCN108118150ALess mass transferLarge extraction capacityZirconium compounds preparationZirconium oxidesToxic materialHafnium

The invention provides a method for extracting zirconium and hafnium from a hydrochloric acid medium and belongs to the technical field of fine separation of substances. The method is mainly characterized in that acid material liquid of a zirconium compound is extracted by a synergic extraction system consisting of DIBK and a phosphonic acid extracting agent, zirconium is enabled to enter an aqueous phase, and hafnium is enabled to enter an organic phase for realizing separation; toxic substances are not needed in the whole process and the aim of clean production is achieved.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES

Method for extracting and separating zirconium and hafnium in nitric acid medium

InactiveUS20200024687A1Less mass transferLarge extraction capacityProcess efficiency improvementZirconium compoundsPhysical chemistry

A method for extracting and separating zirconium and hafnium in nitric acid medium mainly includes extraction of acidic raw liquid containing zirconium compounds with a synergistic extraction system consisting of DIBK and a phosphonic acids extraction agent, so that the zirconium goes to the aqueous phase and the hafnium goes to the organic phase, thus achieving separation. There is no need of use of toxic substance throughout the process.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES

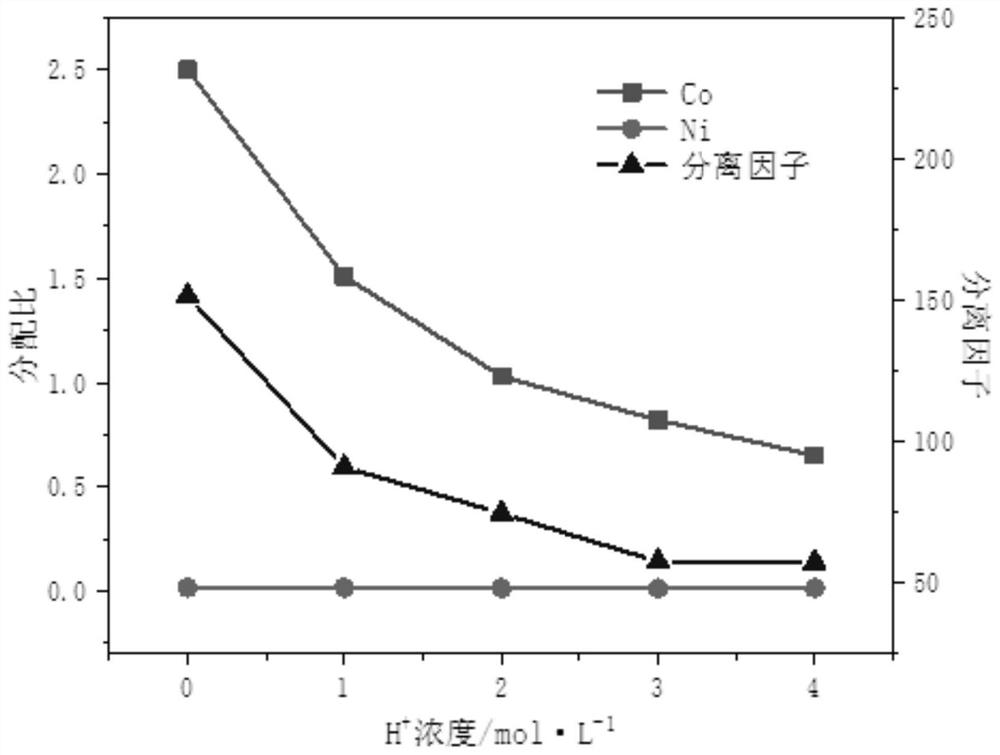

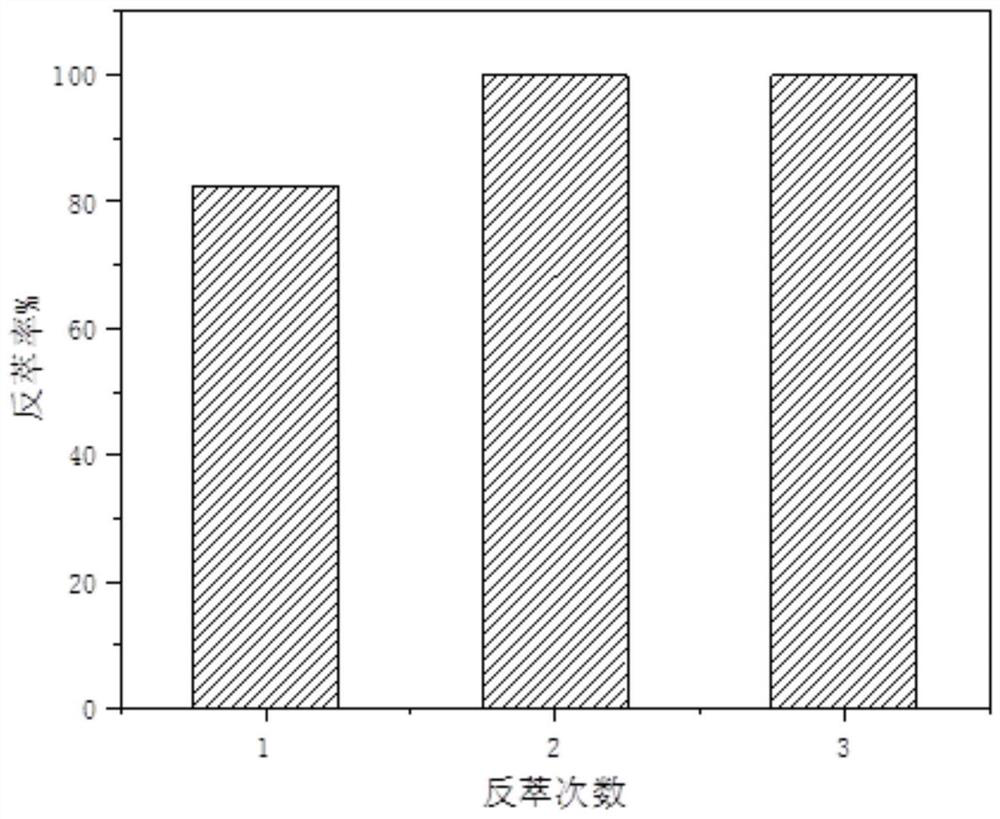

Hydrophobic deep-eutectic solvent used for separating nickel and cobalt ions, preparation method of hydrophobic deep-eutectic solvent and method for separating nickel and cobalt ions

ActiveCN112981139ALarge extraction capacityReduce usageProcess efficiency improvementSolventAmmonium bromide

The invention discloses a hydrophobic deep-eutectic solvent used for separating nickel and cobalt ions, a preparation method of the hydrophobic deep-eutectic solvent and a method for separating the nickel and cobalt ions. In the hydrophobic deep-eutectic solvent, the molar ratio of a hydrogen bond donor to a hydrogen bond acceptor is (1: 1)-(1: 1.5); the hydrogen bond acceptor adopts trioctyl methyl ammonium chloride, and the hydrogen bond donor adopts menthol; or the hydrogen bond acceptor adopts trioctyl methyl ammonium bromide, and the hydrogen bond donor adopts menthol; or the hydrogen bond acceptor adopts trioctyl methyl ammonium bromide, and the hydrogen bond donor adopts thymol. The method for separating the nickel and cobalt ions comprises the following steps that a nickel-cobalt mixed solution is mixed with the hydrophobic deep-eutectic solvent, centrifugal phase separation is carried out after extraction equilibrium to obtain a cobalt-containing organic phase, cobalt in the organic phase is reversely extracted into a water phase by adopting a sodium sulfate water solution, and meanwhile, the hydrophobic deep-eutectic solvent is reused. The method is not easily influenced by acidity during nickel and cobalt ion separation, meanwhile, the extraction capacity is high, and reverse extraction is easy.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Strong cation exchange polymer integral column capillary tube and its production method and use

InactiveCN101464440ABiocompatibleEasy extractionComponent separationN dimethylformamideFunctional monomer

The invention discloses a monolithic column capillary of a strong cation interchange polymer as well as a preparation method and the application thereof. The monolithic column capillary comprises a quartz capillary modified by ethylene and a monolithic column generated through in-situ polymerization in the capillary; and the monolithic column is 2-acrylamide-2-methyl-1-propane sulfonic acid-glycol dimethyl methacrylate polymer. A 2-acrylamide-2-methyl-1-propane sulfonic acid is taken as a functional monomer, glycol dimethyl methacrylate is taken as a crosslinking agent, N, N-dimethylformamide and polyethyleneglycol are taken as a mixed perforating agent, and azodiisobutyronitrile is taken as an evocating agent; the materials are evenly stirred at room temperature, injected into the quartz capillary modified by ethylene, and then sealed off; polyreaction is performed through heating; and the monolithic column capillary is finally prepared through being washed by acetonitrile or methanol. The monolithic column capillary has strong cation interchange sites on a skeleton surface, has good biocompatibility, does not perform nonspecific adsorption with proteins, etc., is used as an extraction medium for measuring melamine in milk-containing products, and has large extraction capacity and high enrichment factor.

Owner:WUHAN UNIV

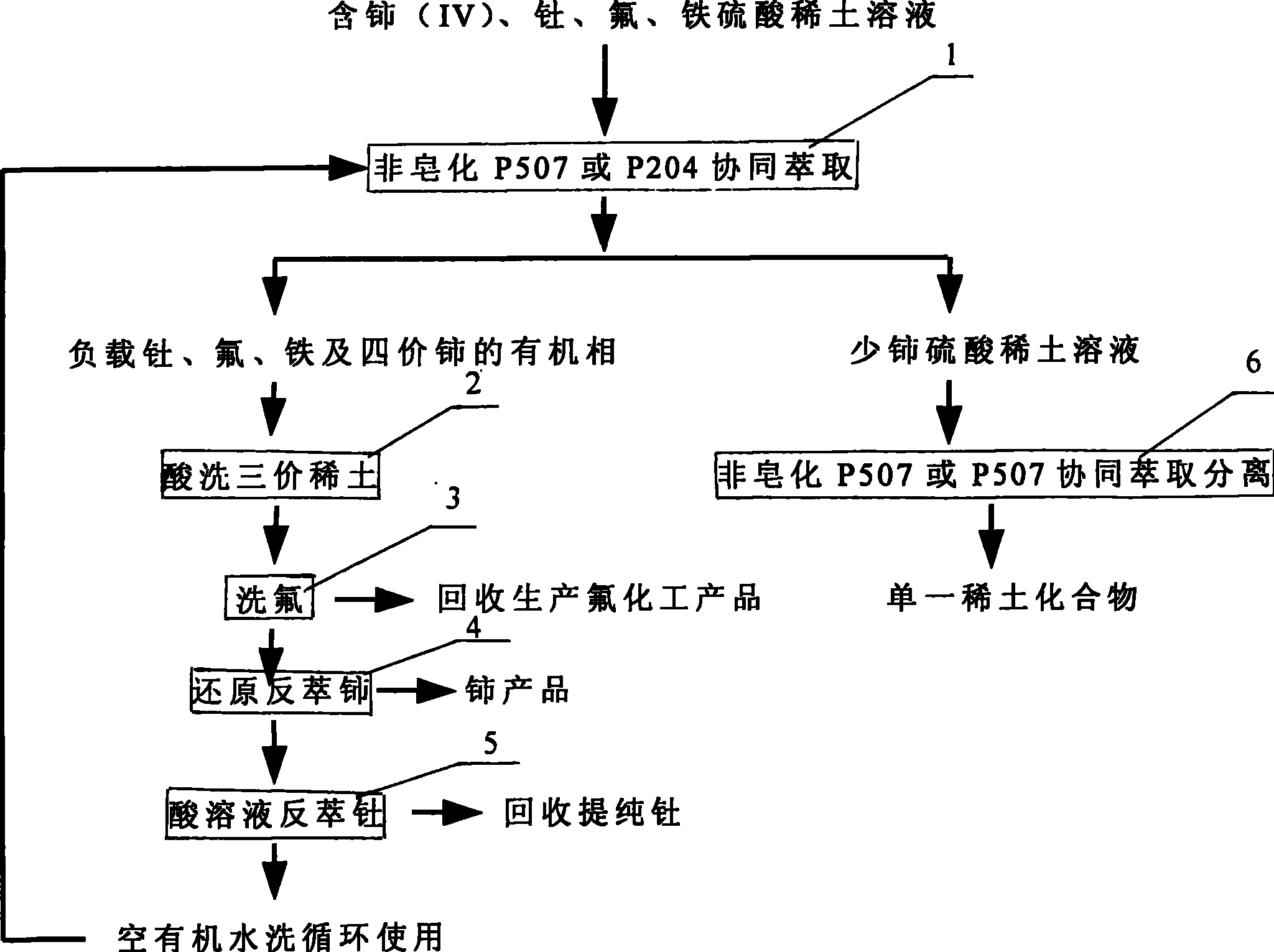

Technique for extraction separation of quadravalence cerium, thorium, fluorine and cerium less tervalence rare earth from sulphuric acid rare earth solution

ActiveCN101294244BNo pollution in the processReduce consumptionProcess efficiency improvementRare-earth elementAmmoniacal nitrogen

The invention relates to a technological method for extracting and separating quadrivalent cerium, thorium, fluorine and less-cerium trivalent rare-earth from rare earth sulfate solution. The rare earth sulfate solution, which is obtained through processing the rare-earth ores and contains high-valence cerium, the fluorine, the thorium and ferrum, is used as raw material; synergistic extraction agent basing on P507 and P204 is adopted for extracting and separating; the cerium (1V), the thorium, the fluorine, and the ferrum are extracted into an organic phase, then selective washing and back extraction are performed step by step to obtain three products that are the cerium, the fluorine, and the thorium, the trivalent rare-earth is left in a water phase, and then unsaponifiable P507 or thesynergistic extraction agent basing on P507 is adopted to perform multistage fractional extraction to separate single rare earth elements. The technological method has the characteristics that the synergistic extraction agent basing on P507 and P204 is adopted, the thorium is easy to perform the back extraction, and extraction capacity is large, and the emulsification is not generated during the extraction process; the cerium (1V), the thorium, the fluorine, the ferrum and the trivalent rare-earth are extracted and separated in the same extraction system; both extraction and the separation adopt unsaponifiable extraction agent, and ammonia-nitrogen wastewater is not generated; in addition, the thorium and the fluorine are recovered as products, and the pollutions caused by thorium-containing waste residue, fluoride-containing wastewater and the ammonia-nitrogen wastewater are eliminated from headstream. Therefore, the technological method has the advantages of simple procedures, greenenvironmental protection, and low manufacturing cost.

Owner:GRIREM ADVANCED MATERIALS CO LTD

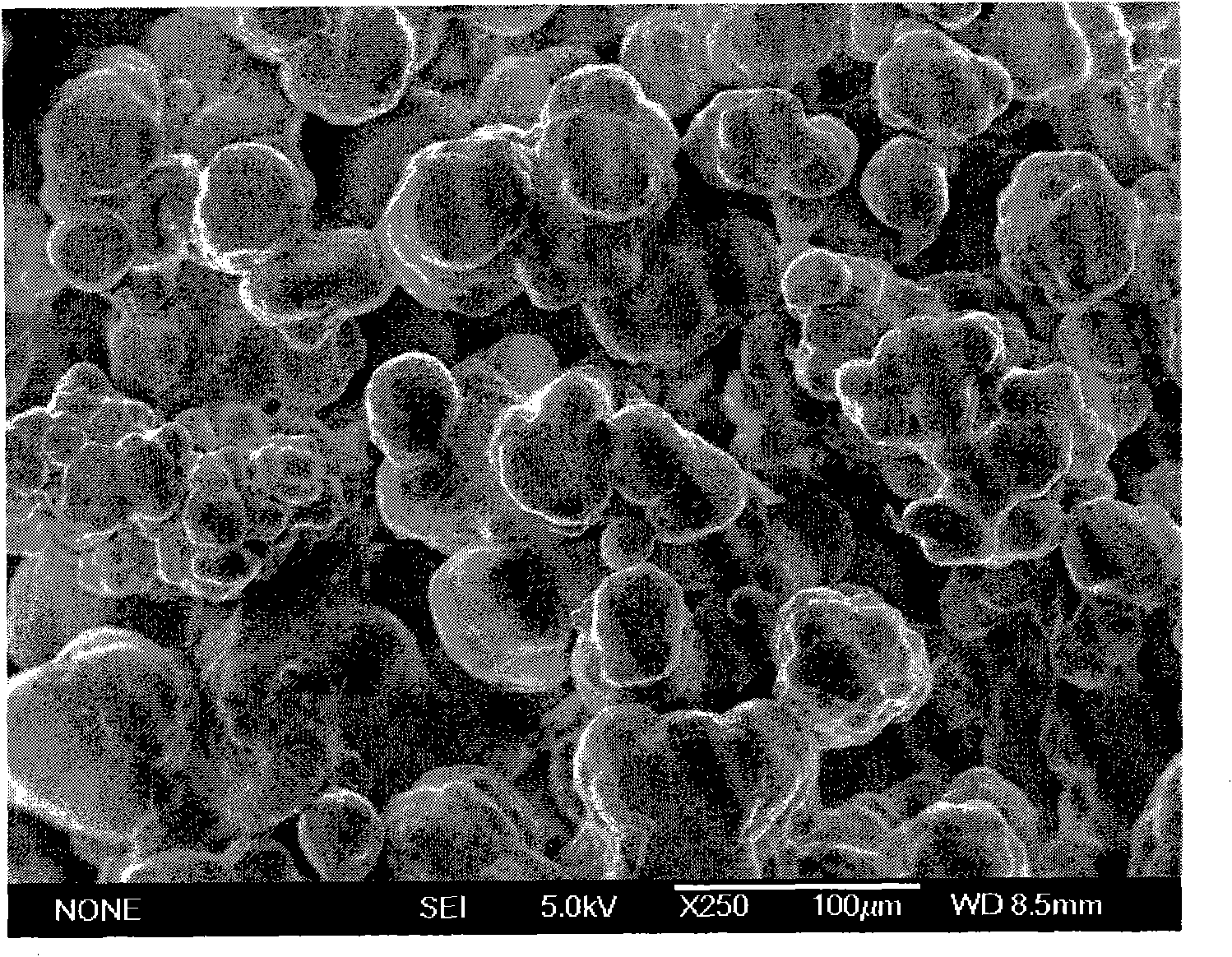

Functional nano-fiber based method for extracting and enriching pollutants in water

InactiveCN1928527BStrong interactionThe efficiency of adsorption and extraction is improvedPreparing sample for investigationFiberSample water

The pollutant-in-water enrichment and extraction method based on functional nano fiber comprises: with electronic-spinning technology, adding or not the functional material, or using post-process fiber surface, manufacturing fiber; preparing members with different diameter and thickness to match with proper fitting. This invention can improve interactive force between fiber and target, reduces balance time, and fit to instrumental analysis.

Owner:NANJING DONGJIAN BIOLOGICAL TECH

Methylene rhodanine reagent and application thereof in solid phase extraction of platinum

InactiveCN102659711AGood choiceReduce complexationOrganic chemistryProcess efficiency improvementPlatinumAcetic acid

The invention discloses a methylene rhodanine reagent and application thereof in solid phase extraction of platinum, belongs to the field of hydrometallurgy, and in particular relates to a new methylene rhodanine reagent and application thereof in solid phase extraction of platinum. The extracting reagent has a structural formula shown as the specifications, and is named 2,4-dimethyl benzol-methylene rhodanine. The reagent is prepared by condensing 2,4-dimethylbenzylidene and rhodanine in a glacial acetic acid medium. A solid phase extraction column prepared from the reagent can be used for the solid phase extraction of platinum, has high selectivity and high enrichment factor, and has high extraction capacity for the platinum, and the material can be repeatedly used. The primary extraction rate for the platinum is over 95.3 percent, and the enrichment factor is more than 500; and the material has the extraction capacity of 28.5mg / g for the platinum.

Owner:YUNNAN MINZU UNIV

Technique for extraction separation of quadravalence cerium, thorium and cerium less tervalence rare earth from sulphuric acid rare earth solution

InactiveCN100584969CNo pollution in the processReduce consumptionProcess efficiency improvementRare-earth elementSulfate

Owner:GRIREM ADVANCED MATERIALS CO LTD

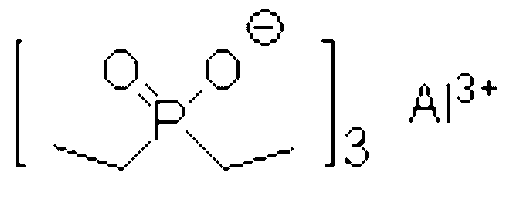

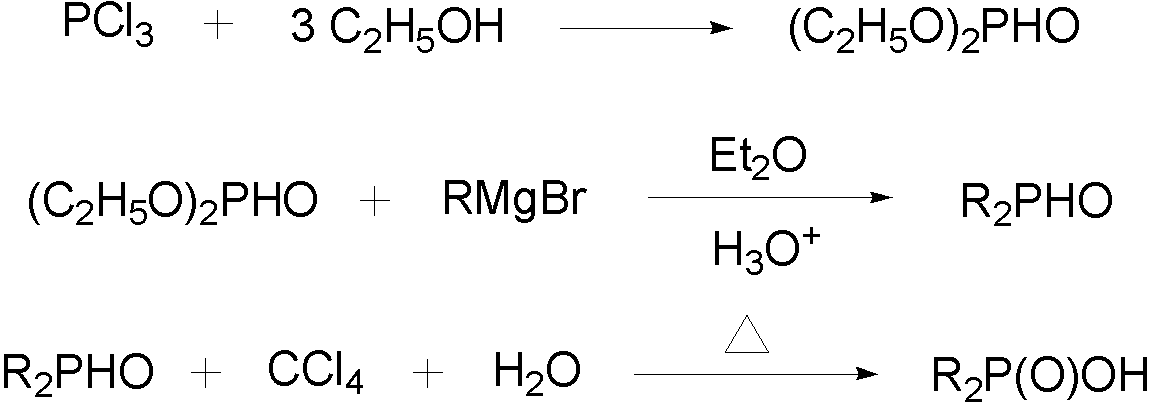

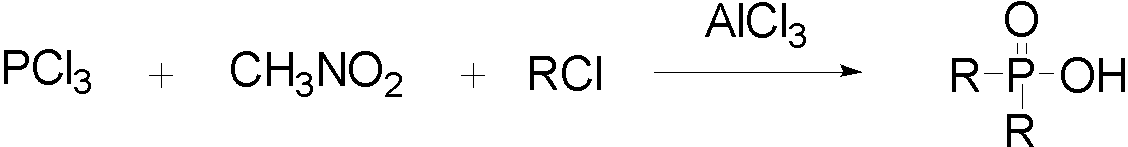

Dibenzyl phosphinic acid synthetic method

InactiveCN103073578AEasy extractionLarge extraction capacityGroup 5/15 element organic compoundsGrignard reagentPhosphinic Acids

The invention relates to a preparation method of dibenzyl phosphinic acid. The method comprises the following steps: after performing reaction on diethyl phosphite and a Grignard reagent in anhydrous ether, carrying out acidified hydrolysis to obtain dibenzyl phosphine oxide; after purifying the dibenzyl phosphine oxide, placing the dibenzyl phosphine oxide in mixed solution of carbon tetrachloride and water to perform reflux reaction so as to obtain the dibenzyl phosphinic acid. According to the invention, the optimal reaction conditions are obtained by changing conditions of a charging manner, a charge rate, quantity of a solvent and the like, the side reaction is reduced as far as possible and the reaction yield is improved.

Owner:TSINGHUA UNIV

Method for preparing zirconium by TBP extraction method

InactiveCN111378837ALarge Si/Zr ratioHigh Si/Zr ratioProcess efficiency improvementZirconium oxychlorideOxychlorination

The invention discloses a preparation method of zirconium oxide. The preparation method comprises the following steps: 1, after ingredients is added into a zirconium oxychloride solution, TBP extraction is performed to obtain an aqueous phase hafnium solution and an organic phase solution; 2, the obtained organic phase solution carried out mixed acid washing to obtain a zirconium-containing organic phase and an acid washing solution; 3, the obtained zirconium-containing organic phase carried out reverse extraction to obtain water phase zirconium liquid and an organic phase; 4, the obtained aqueous phase zirconium liquid carried out ammonia precipitation, and the precipitate is calcined to obtain zirconium oxide; and 5, the obtained organic phase carried out alkali liquor treatment, water washing and nitric acid saturation treatment to obtain residual acid and an organic phase. The method has the advantages that the extraction capacity is large, the extraction equipment is small, the separation coefficient is high, the separation effect is good, the efficiency is high, the process is stable, the process is easy to control, the yield is high, and the recovery rate is high; and a closed system is adopted for extraction, so that environmental pollution is avoided. The Si / Zr ratio in the zirconium oxychloride solution is small, the production process does not produce emulsification,and meanwhile zirconia conforming to the atomic energy level is obtained.

Owner:林钢 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com