Method for separating octadecadienoic acid from mixed long-chain fatty acid

An octadecadienoic acid and long-chain fatty acid technology, which is applied in the field of chemical engineering, can solve the problems of unsuitable large-scale industrial production, low functional group density, small adsorption capacity, etc., and achieves easy recycling and processing, good product quality, Simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

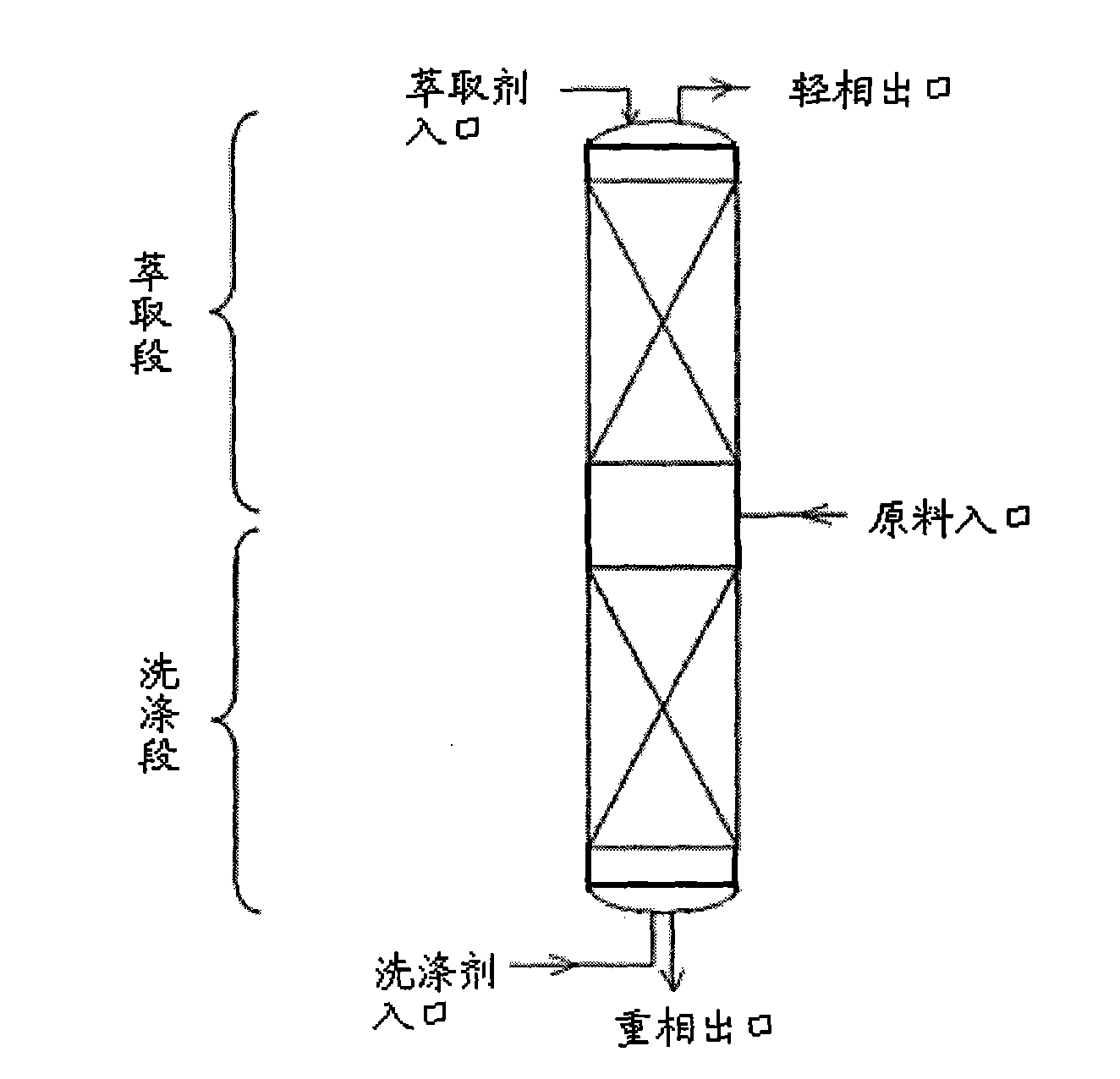

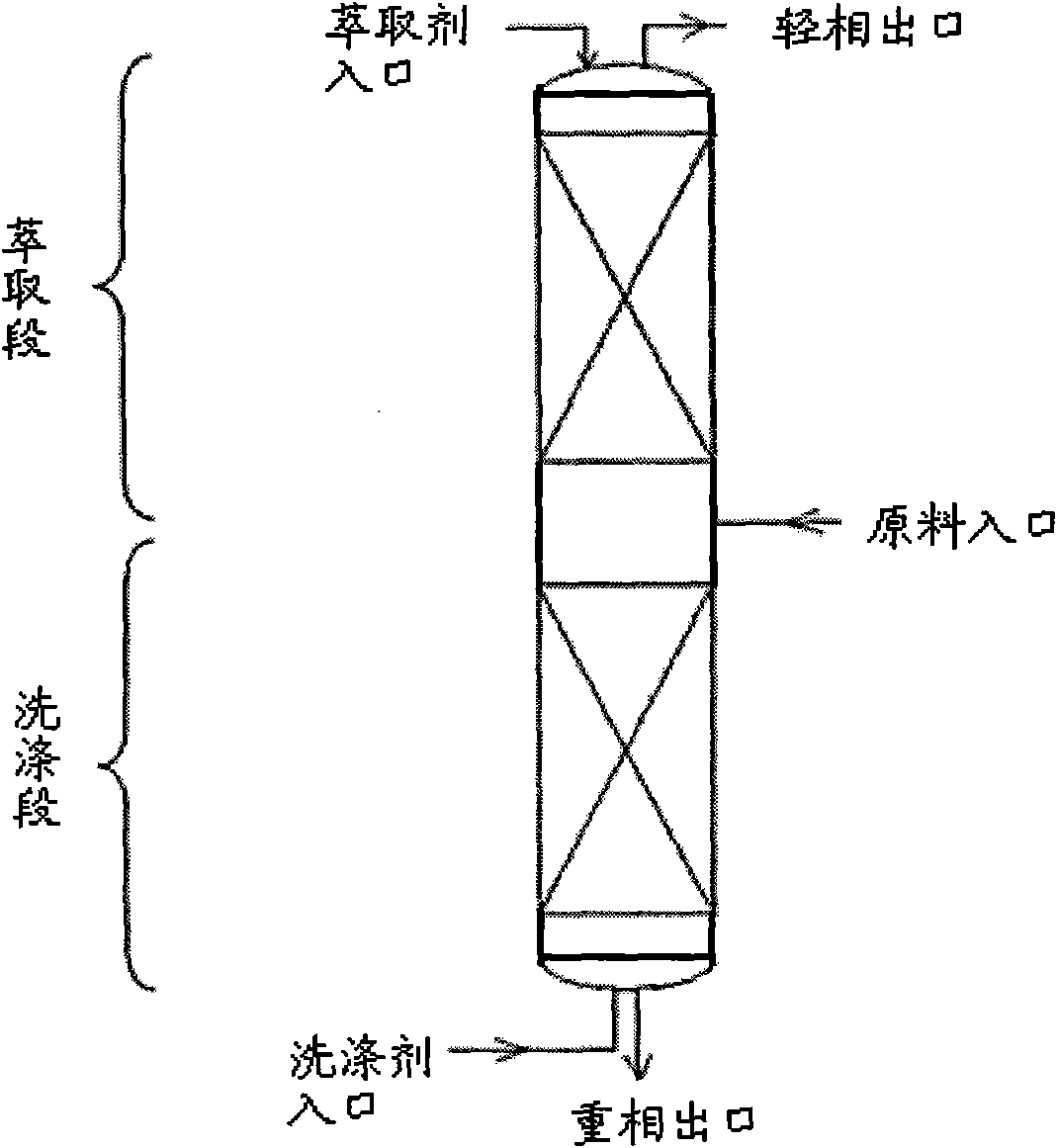

Embodiment 1

[0028] Sunflower oil is subjected to saponification and isomerization reactions to obtain mixed long-chain fatty acids mainly containing conjugated linoleic acid, oleic acid, stearic acid and palmitic acid (the total content of fatty acids is 99%, wherein the content of conjugated linoleic acid is 70%). The prepared mixed long-chain fatty acids were dissolved in hexane to prepare a raw material solution with a total concentration of 40 g / L. Furfural is used as extractant, hexane is used as detergent, the volume flow ratio of raw material liquid, extractant, and detergent is 1:4:5, the extraction packing is 2mm stainless steel θ ring packing, fractional extraction is carried out at 40°C . The extract solution is vacuum evaporated to remove the solvent to obtain a conjugated linoleic acid product with a product purity of 99% and a product yield of 96.5%.

Embodiment 2

[0030]Safflower seed oil undergoes saponification and isomerization reactions to obtain mixed long-chain fatty acids mainly containing linoleic acid, oleic acid, stearic acid and palmitic acid (the total content of fatty acids is 99%, and the content of linoleic acid is 76%) , the prepared mixed long-chain fatty acids are dissolved in heptane, and the total concentration is 60g / L for preparation. Using dimethyl sulfoxide as the extractant and heptane as the detergent, the volume flow ratio of the raw material solution, the extractant and the detergent is 1:8:4, the extraction packing is 4mm stainless steel θ ring packing, at 40°C Extraction by fractional distillation. The extract was collected, and the solvent was evaporated in a vacuum to obtain a linoleic acid product with a product purity of 97% and a product yield of 95.3%.

Embodiment 3

[0032] Cottonseed oil undergoes saponification and isomerization reactions to obtain mixed long-chain fatty acids mainly containing conjugated linoleic acid, oleic acid, stearic acid, palmitic acid, and myristic acid (the total content of fatty acids is 99%, of which conjugated linoleic acid Acid content is 56%), and the prepared mixed long-chain fatty acid is dissolved in hexane, and is mixed with the raw material liquid that total concentration is 80g / L. Using dimethylformamide as extractant and hexane as detergent, the volume flow ratio of raw material liquid, extractant and detergent is 2:20:6, the extraction packing is 2mm stainless steel θ ring packing, at 30°C Extraction by fractional distillation. The extract was collected, and the conjugated linoleic acid product was obtained after vacuum evaporation to remove the solvent, the product purity was 95%, and the product yield was 90.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com