Patents

Literature

1564 results about "Palmitic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Palmitic acid, or hexadecanoic acid in IUPAC nomenclature, is the most common saturated fatty acid found in animals, plants and microorganisms. Its chemical formula is CH₃(CH₂)₁₄COOH, and its C:D is 16:0. As its name indicates, it is a major component of the oil from the fruit of oil palms (palm oil). Palmitic acid can also be found in meats, cheeses, butter, and other dairy products. Palmitates are the salts and esters of palmitic acid. The palmitate anion is the observed form of palmitic acid at physiologic pH (7.4).

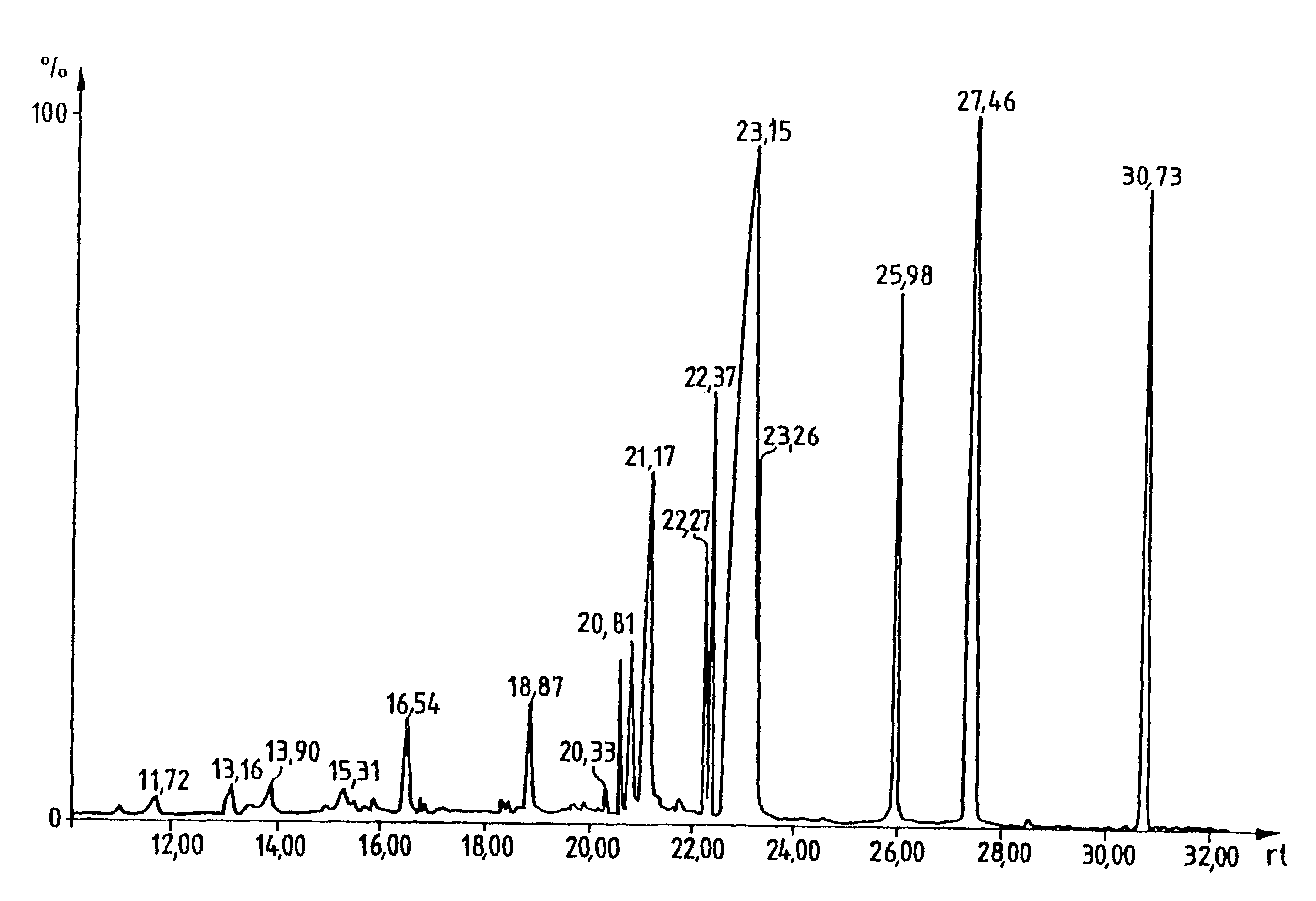

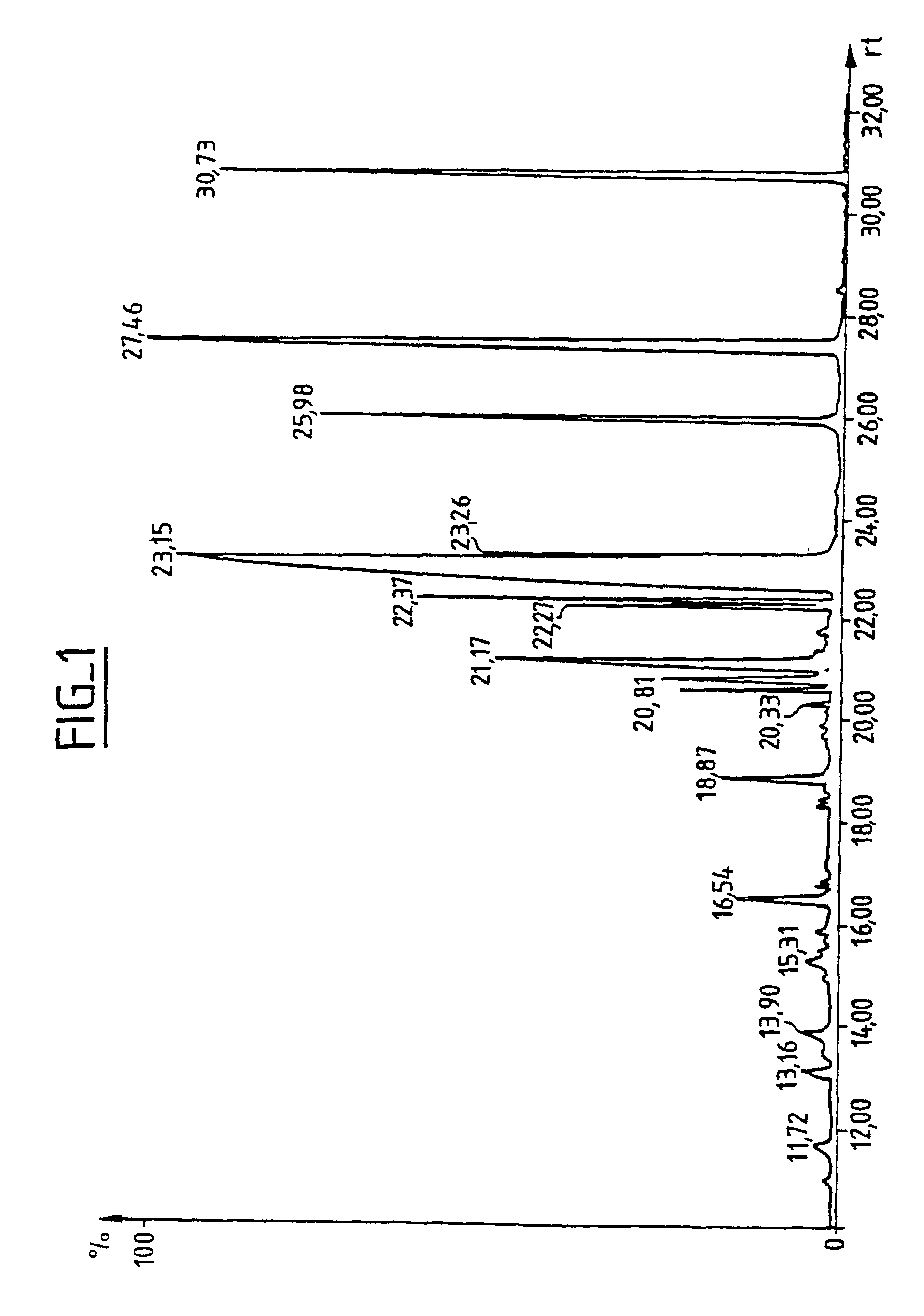

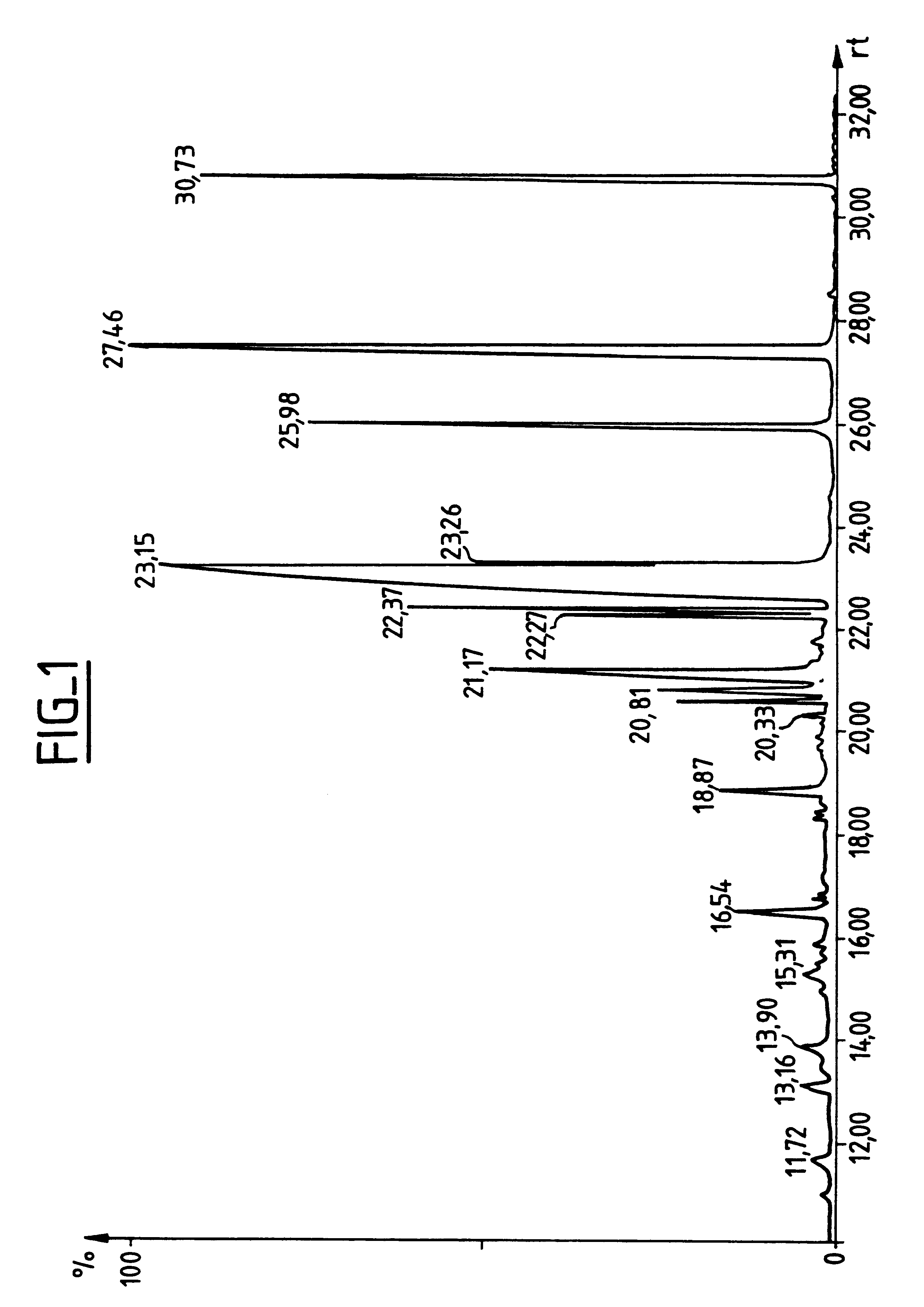

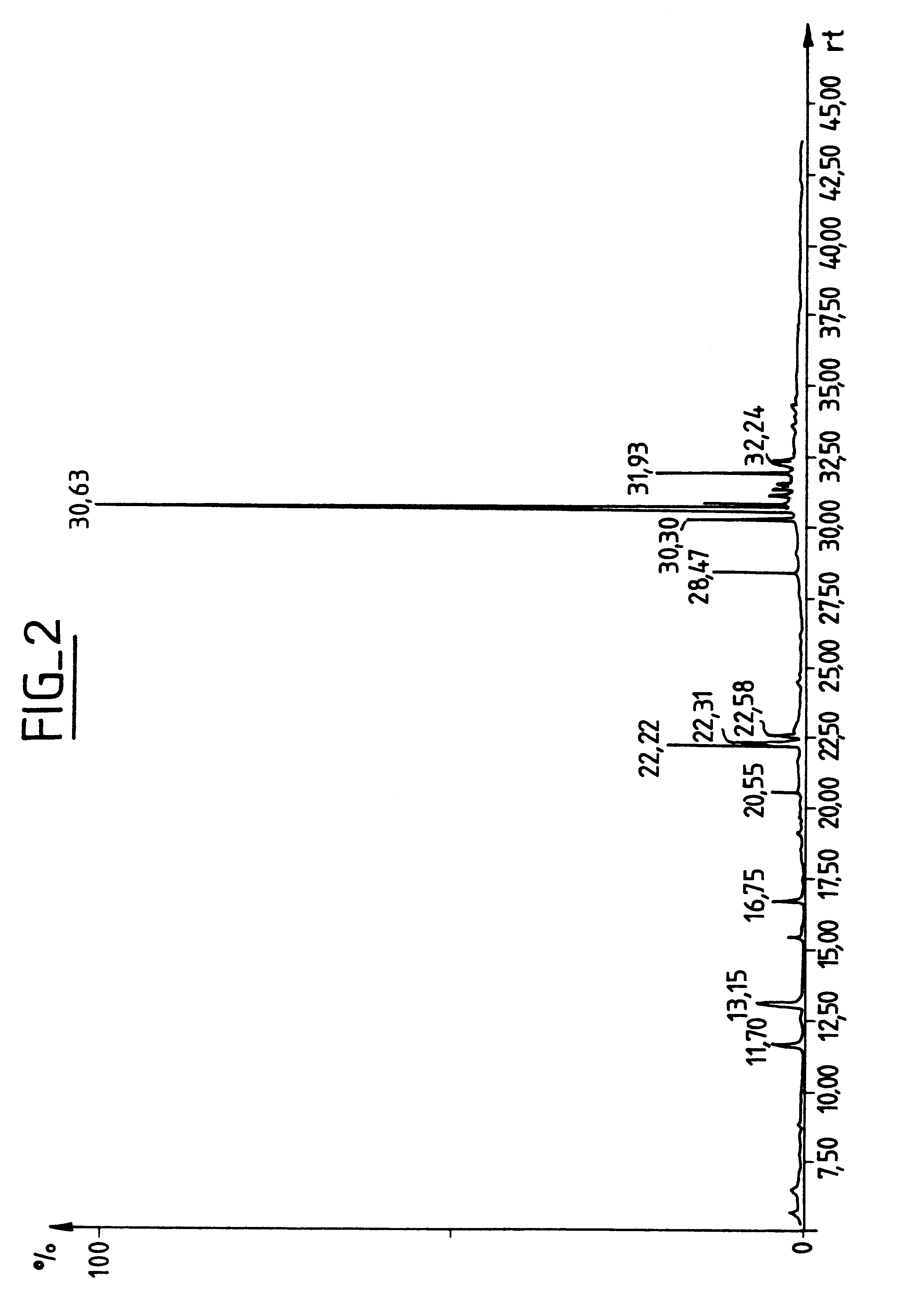

Lipid composition for infant formula and method of preparation

InactiveUS6034130AImprove stabilityBiocideFatty acid esterificationDocosahexaenoic acidLipid composition

Synthetic lipid composition in which the content and the distribution of the fatty acids are similar to those of human milk fat, containing less than 2% by weight of free fatty acids, in which palmitic acid is predominantly at the 2-position of the triacylglycerols and the arachidonic and docosahexaenoic acids are distributed between the 1-, 2- and 3-positions and in particular predominantly at the 2-position of the triacylglycerols.

Owner:NESTEC SA

Food spreads

The present invention is of a food spread containing a mixture of at least one edible oil of natural or synthetic origin and a monoglyceride. The oil is preferably one or more of the oils from the group of olive oil, avocado oil, canola oil, soybean oil, sunflower oil, nut oils, walnut oil, peanut oil, safflower oil, cottonseed oil, coconut oil, rice bran oil, mustardseed oil, camelina oil, chia oil, flaxseed oil, perilla oil, fish oil, palm oil, sesame oil, wheatgerm oil, jojoba oil or corn oil. More preferably an oil such as avocado oil, fish oil, palm oil or olive oil is used and most preferably the oil is olive oil and fish oil. The monoglycerides used are preferably derivatives of oleic, or palmitic acid. The oil is present preferably in an amount of from about 85 to about 98 percent and most preferably in an amount of from about 93 to about 96 percent. The more monoglyceride used, the greater the degree of solidity of the food spread at room temperature. It is therefore possible to produce a desired degree of solidity, by changing the proportion of monoglyceride.

Owner:DR EGER OLIVE OIL PROD IND

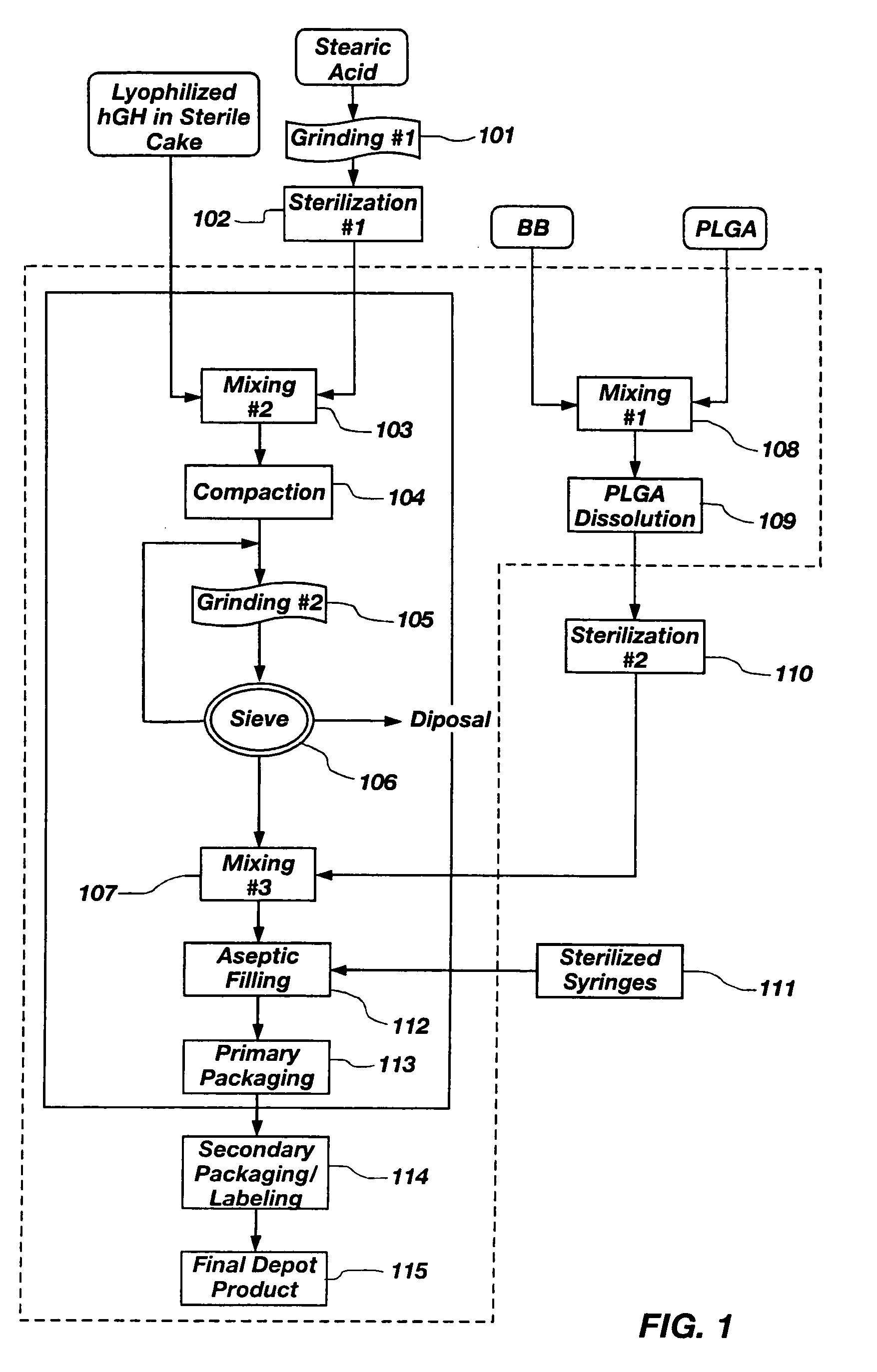

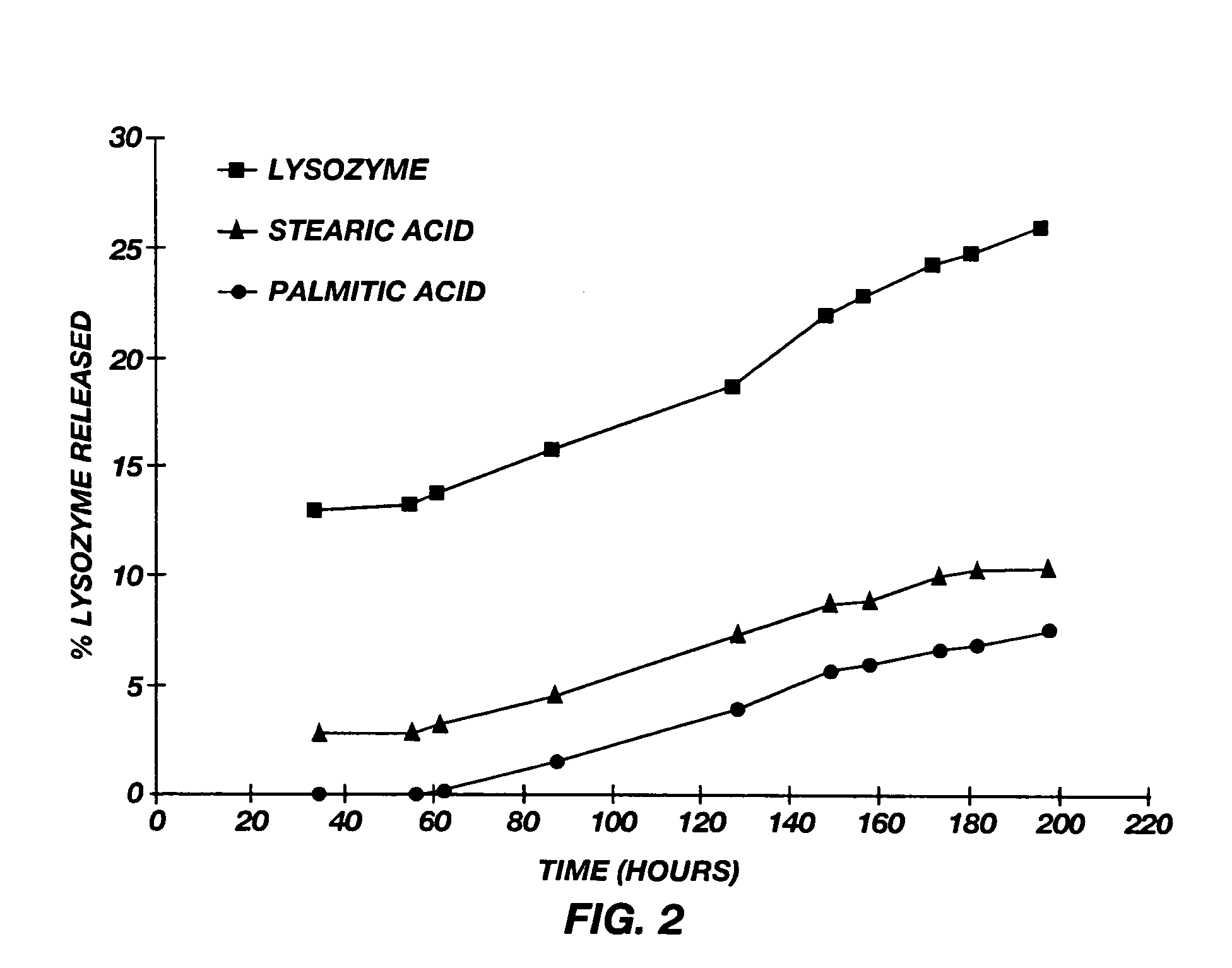

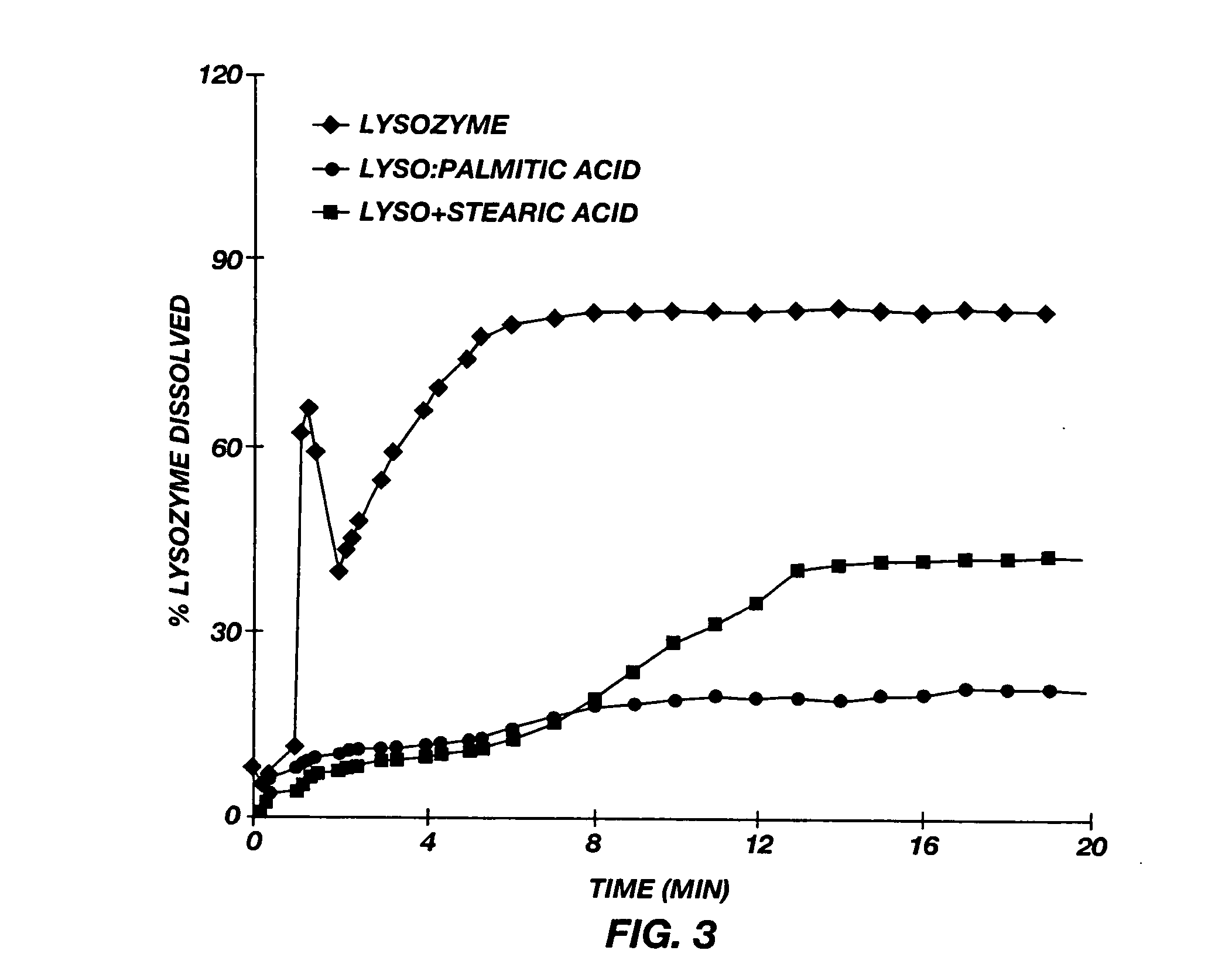

Implantable gel compositions and method of manufacture

Methods and compositions for reducing the burst of beneficial agent from implantable systems is described. Such systems utilize compressed particulates of a beneficial agent, optionally mixed with a dissolution rate modulator or an agent exhibiting a characteristic of low solubility in water, such as a mixture of stearic acid and palmitic acid, dispersed throughout a bioerodible and biocompatible carrier.

Owner:DURECT CORP

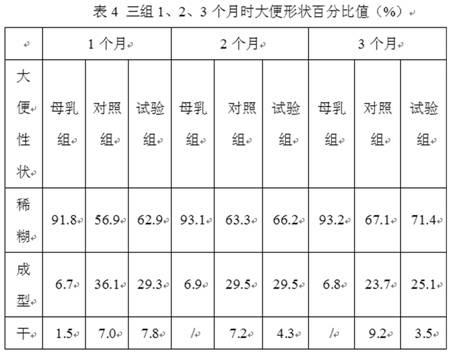

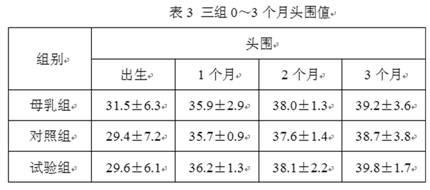

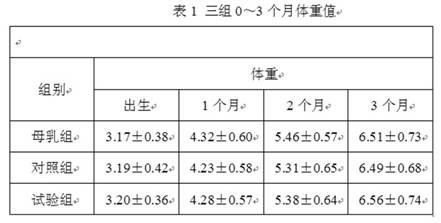

A kind of infant formula milk powder that does not get angry and its preparation process

ActiveCN102283289ANot ediblePromote digestion and absorptionMilk preparationVegetable oilFructooligosaccharide

The invention relates to an anti-inflaming infant formula milk powder and a preparation process thereof. The anti-inflaming infant formula milk powder comprises the following components in percentage by weight: 22%-50% of lactose, 10%-20% of goat milk whey protein concentrate, 9.8%-20% of structural grease 1,3-dioleoyl 2-palmitoyl triglyceride, 10%-13.5% of non-fat goat milk powder, 8%-10% of vegetable oil, 2%-8% of beta-casein, 0.8%-1.6% of fructooligosaccharides, 0.5%-1.5% of mineral premix, 0.3%-1% of galactooligosaccharide, 0.2%-1% of immunoglobulin G, 0.2%-0.5% of lactulose, 0.10%-0.45% of arachidonic acid, 0.1%-0.6% of docosahexaenoic acid, 0.06%-0.12% of vitamin premix, 0.04%-0.06% of lactoferrin, and 0.01%-0.06% of nucleotide. The invention also includes the preparation process ofthe infant formula milk powder. The nutrition constituents and the functions of the infant formula milk powder are close to those of breast milk, the infant formula milk powder is easy to assimilate,and infants do not get inflamed after eating the milk powder.

Owner:AUSNUTRIA DAIRY CHINA

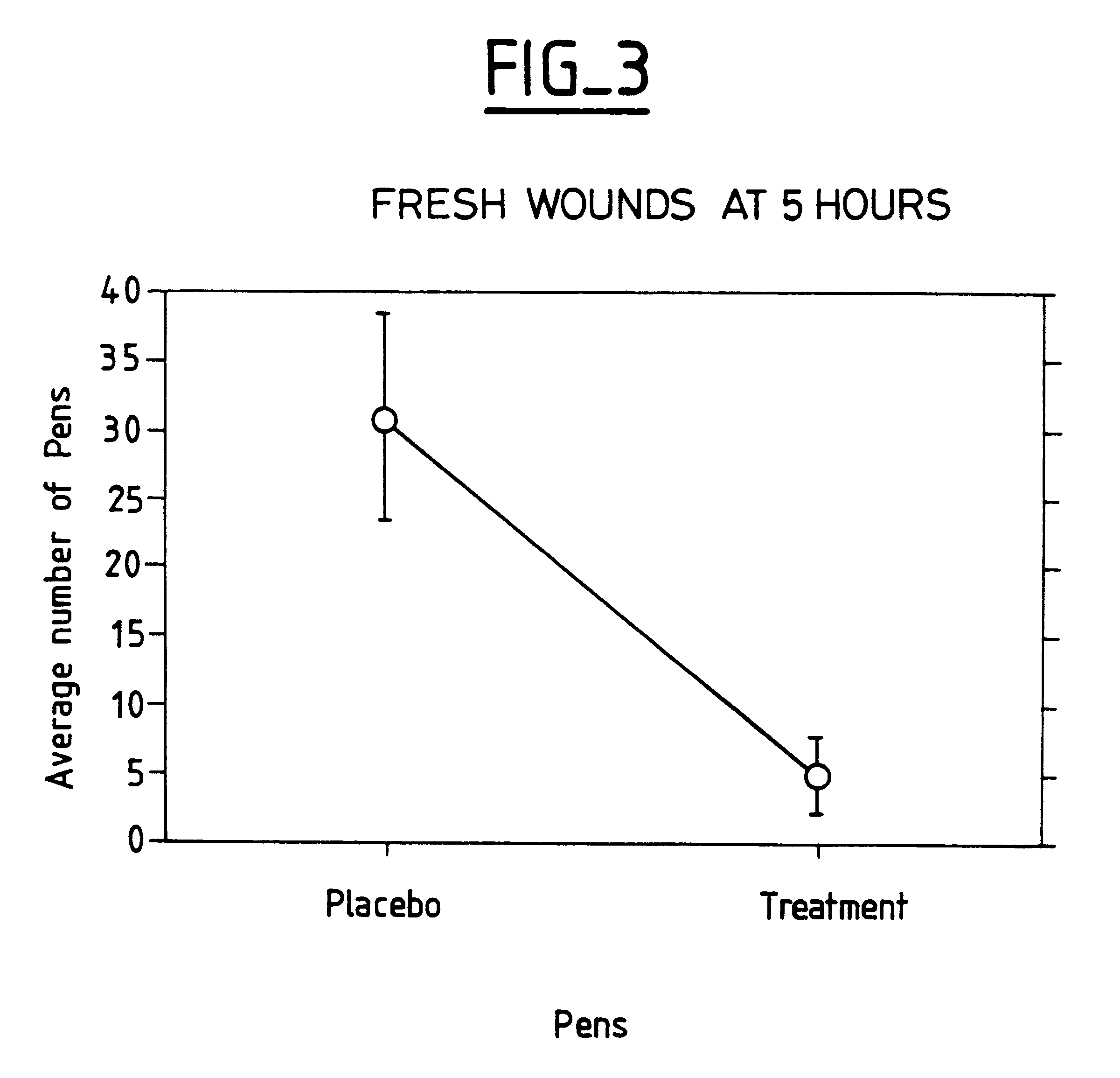

Animal appeasing pheromones

A composition comprising a mixture of fatty acids such as, linoleic, oleic and palmitic acids or deriviatives thereof dervived from secretions o mammalian mammary glands. The compositions can be utilized to decrease stress, anxiety and aggressiveness in mammals.

Owner:FIDELINE

Healthy food spreads

InactiveUS6117476AGreat degree of solidityUnlimited shelf lifeEdible oils/fats with aqeous phaseFood borneMonoglyceride

The present invention is of a food spread containing a mixture of an edible oil of natural origin and a monoglyceride. The oil is preferably one or more of the oils from the group of olive oil, avocado oil, canola oil, soybean oil, sunflower oil, peanut oil, safflower oil, cottonseed oil, coconut oil, rice bran oil, mustardseed oil, camelina oil, chia oil, flaxseed oil, perilla oil, fish oil or corn oil. More preferably an oil such as avocado oil or olive oil is used and most preferably the oil is olive oil. The monoglycerides used are preferably derivatives of oleic, or palmitic acid. The ratio of oil to monoglyceride is preferably from about 9 to about 1 to from about 49 to about 1 and most preferably from about 15 to about 1 to from about 24 to about 1. The more monoglyceride used, the greater the degree of solidity of the food spread at room temperature. It is therefore possible to produce a desired degree of solidity, by changing the proportion of monoglyceride.

Owner:DR EGER OLIVE OIL PROD IND

Fat compositions for infant formula and methods therefor

InactiveUS20040013787A1Improve the level ofLower levelVitamin food ingredientsFood preparationPhysiologyLinoleic acid

Fat compositions and infant formulas containing oleic acid in an amount of at least about 50% by weight of total fatty acids, lauric acid in an amount of at least about 10% by weight, palmitic acid in an amount of not more than about 10% by weight and, in certain embodiments, linoleic acid in an amount of not more than about 16% by weight. The fat compositions can be prepared to contain one or more oleic acid oils in a total amount of at least about 50% by weight, one or more linoleic acid oils in a total amount of not more than about 18% by weight and, in certain embodiments, one or more lauric acid oils in an amount of at least about 20% by weight. Also disclosed are methods of making the fat compositions and infant formulas and methods for providing a fat component to infant diets.

Owner:THEUER RICHARD C

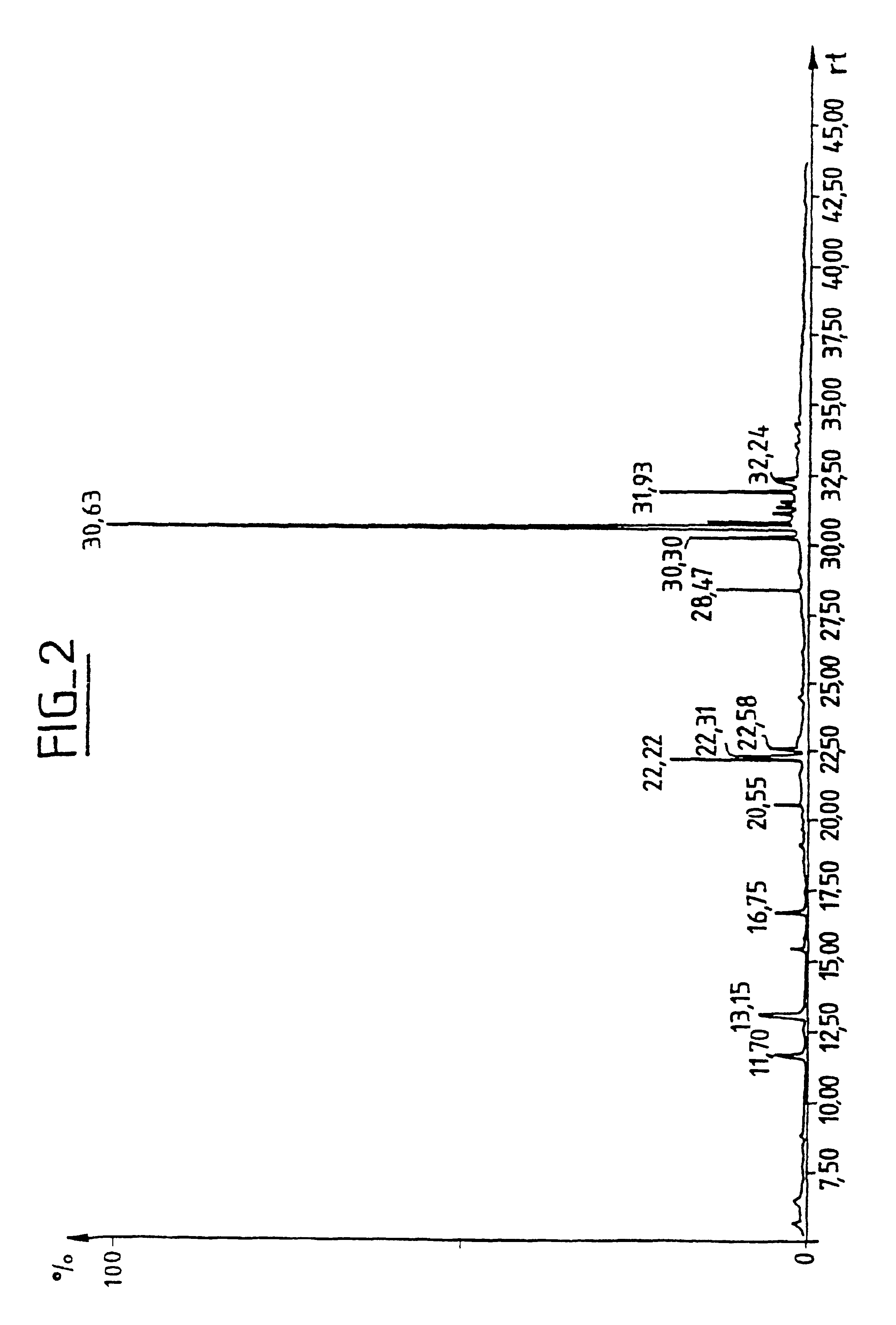

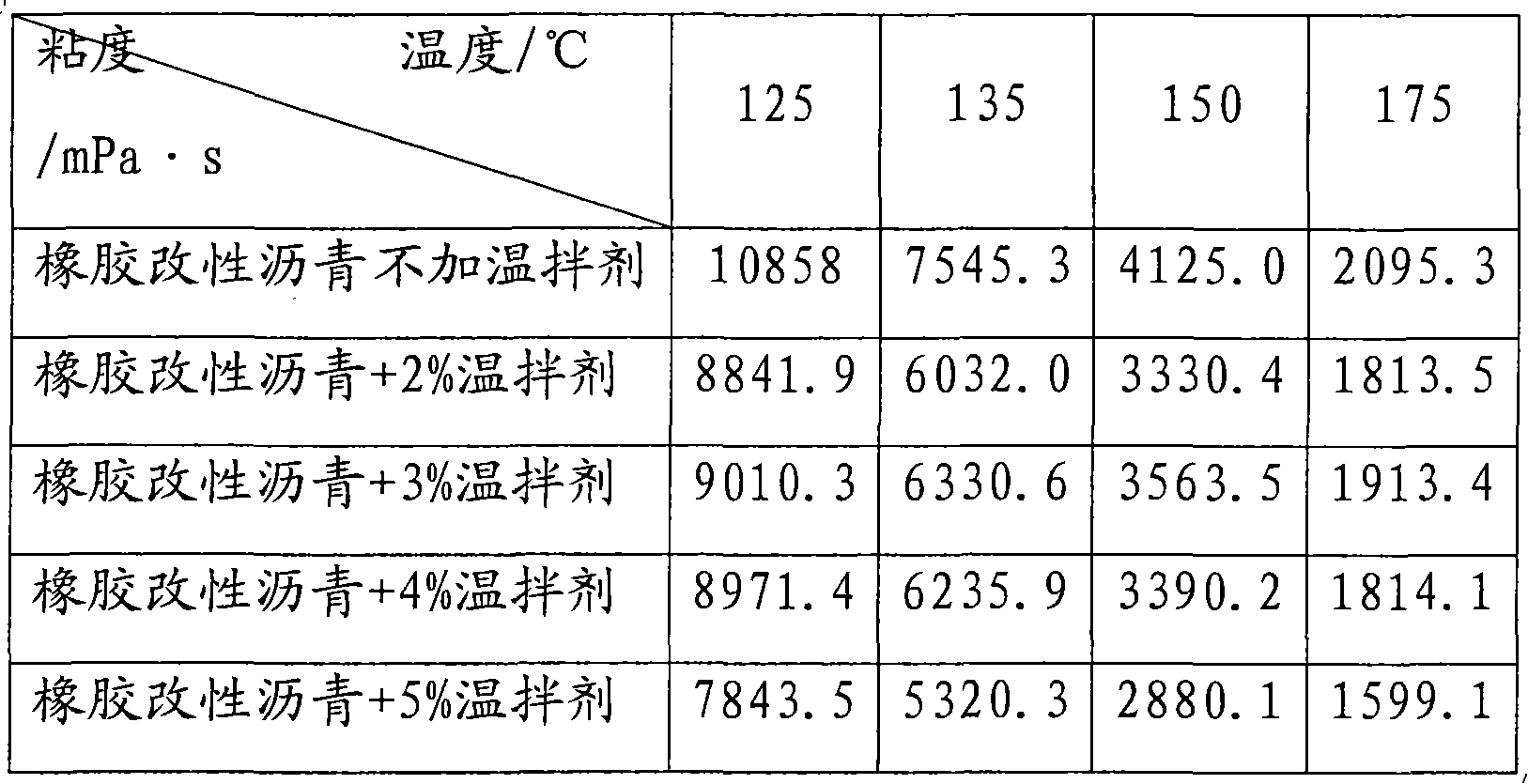

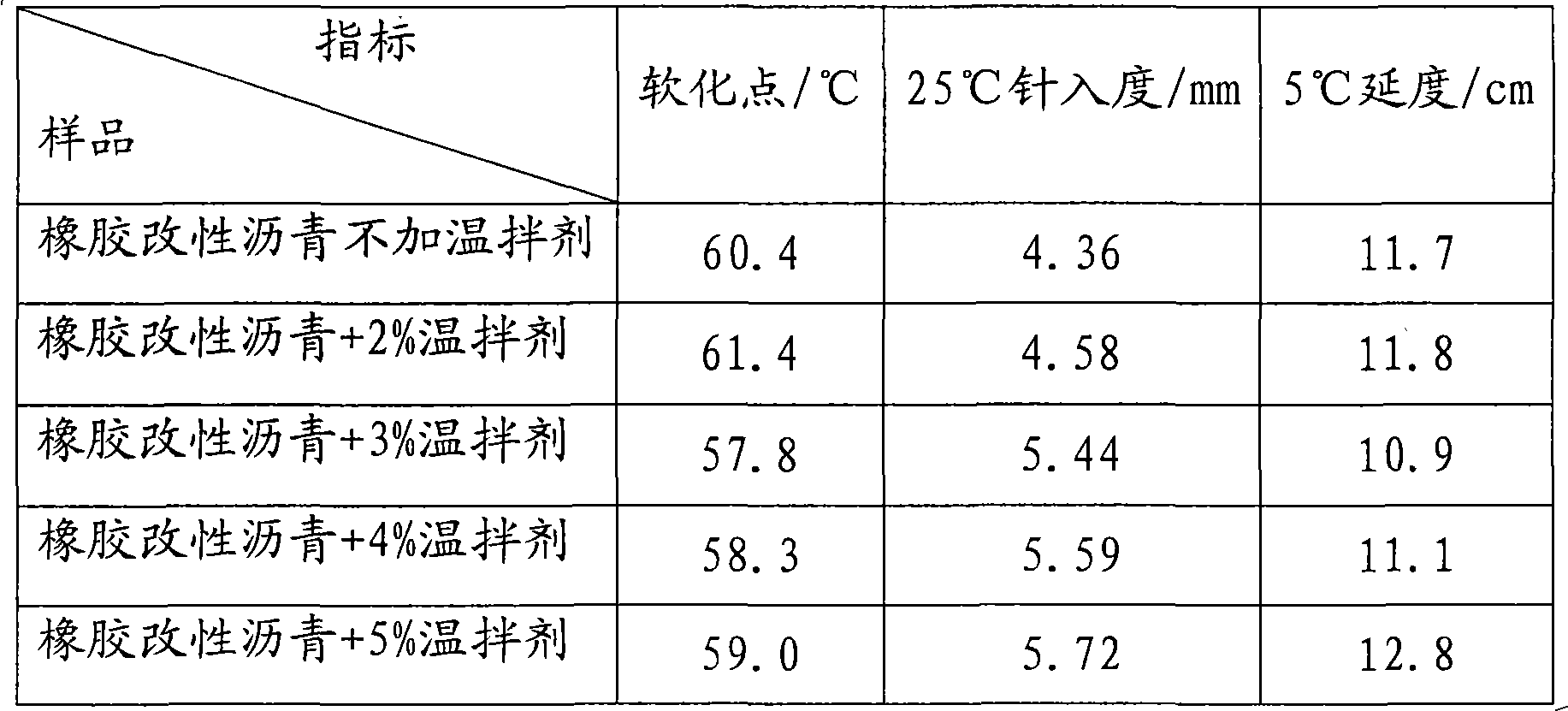

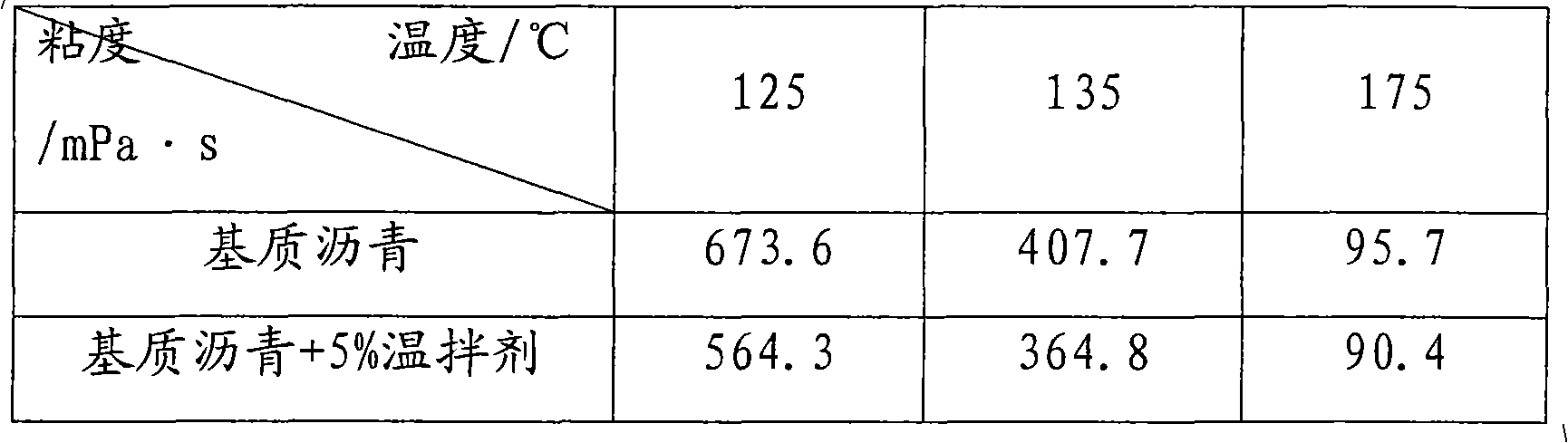

Rubber modified asphalt warm-mixing agent, preparation method and application

InactiveCN101831187ALow viscosityLow softening pointClimate change adaptationBuilding insulationsSurface-active agentsFatty alcohol

The invention discloses a rubber modified asphalt warm-mixing agent, a preparation method and application thereof. The warm-mixing agent comprises the following components in parts by weight: 100 parts of water, 5-30 parts of fatty alcohol sodium sulfate, 15-30 parts of palmitic acid, 5-30 parts of oleic acid, 1-20 parts of sodium dodecyl benzene sulfonate, 1-15 parts of cetyltrimethylammonium chloride and 10-30 parts of imidazoline-type cationic surface active agent ODD. The preparation method comprises the following steps of: adding the water in a container at the temperature of 65 DEG C, and then adding the following substances under the condition of stirring: the fatty alcohol sodium sulfate, the palmitic acid, the oleic acid, the sodium dodecyl benzene sulfonate, the cetyltrimethylammonium chloride and the imidazoline-type cationic surface active agent ODD, and stirring for 15 min to obtain the warm-mixing agent. The warm-mixing agent is directly applied to rubber asphalt or matrix asphalt to reduce the viscosity of the asphalt. The kinematic viscosity of the rubber powder asphalt added with the warm-mixing agent at the temperature of 150 DEG C can reach less than 3.0Pa.s of the kinematic viscosity at the temperature of 180 DEG C, and the production temperature can be reduced by about 30 DEG C, thereby not only preventing the rubber asphalt from being aged but also saving energy and reducing equipment loss.

Owner:BEIJING UNIV OF CHEM TECH

Plastic fat composition

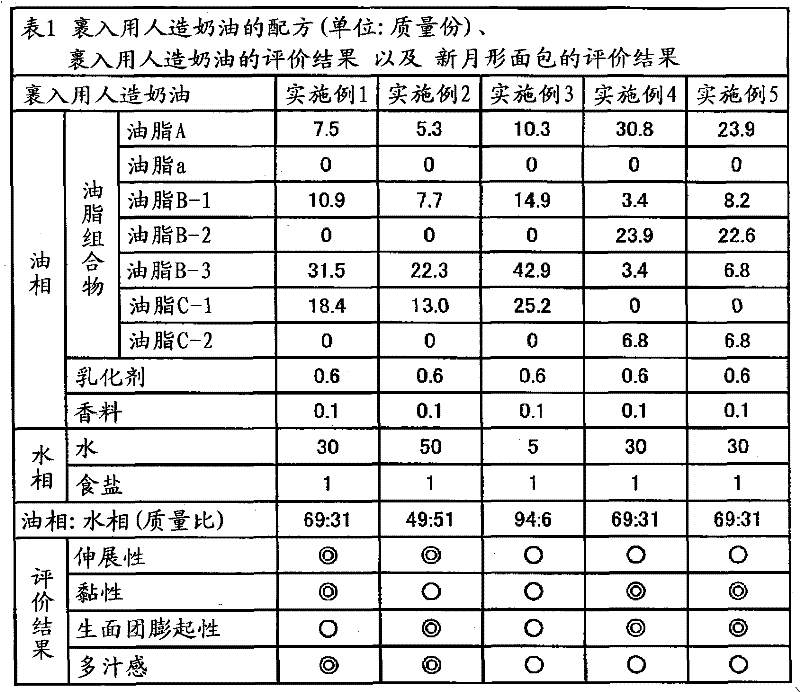

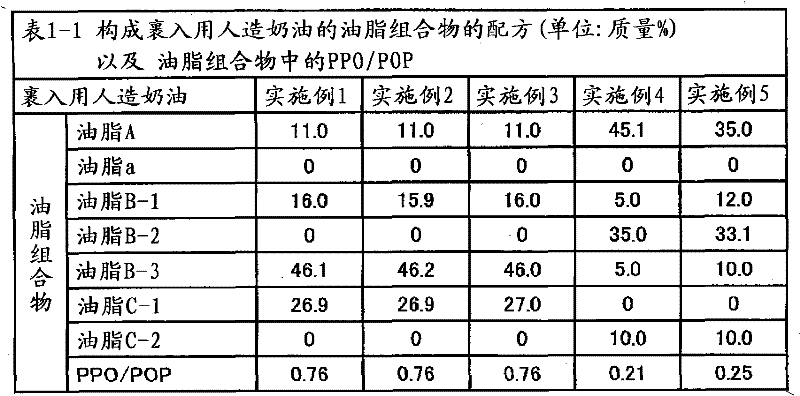

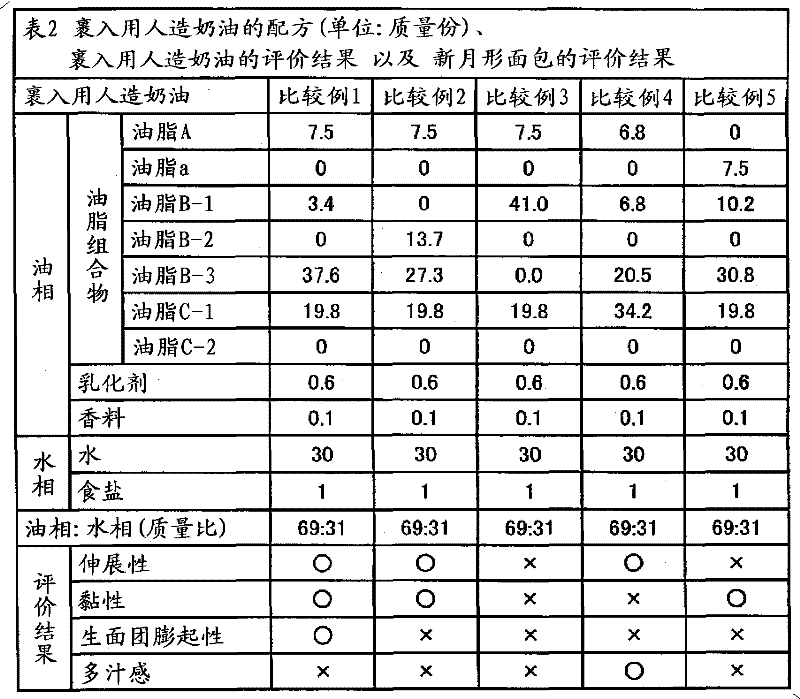

ActiveCN102056493AEasy to stretchEasy to operateSpread compositionsFatty acid esterificationStearic acidOleic Acid Triglyceride

Provided are a plastic fat composition having a small trans fatty acid content, which is suitable for roll-in, spreading, kneed-in and similar purposes, and a fat composition to be used in the preceding plastic fat composition. A fat composition which contains the following fats A, B and C and satisfies the following requirements (a) to (c): fat A: a fat which contains 20 to 60% by mass of a saturated fatty acid having 12 to 14 carbon atoms and 40 to 80% by mass of a saturated fatty acid having 16 to 18 carbon atoms in the total constituting fatty acids thereof, and in which the fats have been obtained by ester exchange; fat B: a fat which contains 20 to 60% by mass of palmitic acid, 0.5 to 6% by mass of stearic acid and 30 to 60% by mass of oleic acid in the total constituting fatty acids thereof; and fat C: a liquid oil; (a) the content of fat A in the fat composition being 0.1 to 50% by mass; (b) the content of fat B in the fat composition being 0.1% by mass or more but less than 40% by mass; and (c) the PPO / POP of the fat composition being 0.15 to 1.00.

Owner:THE NISSHIN OILLIO GRP LTD

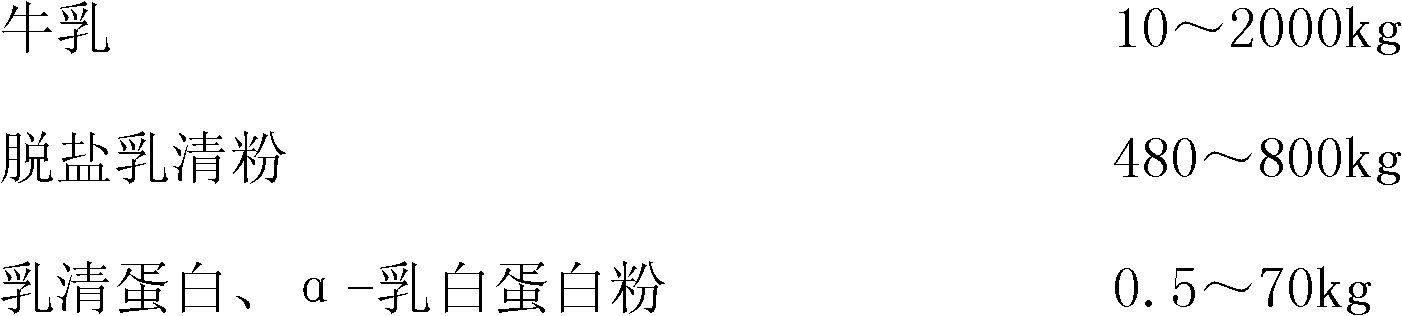

Formula milk powder for promoting absorption of fatty acid and calcium and preparation method thereof

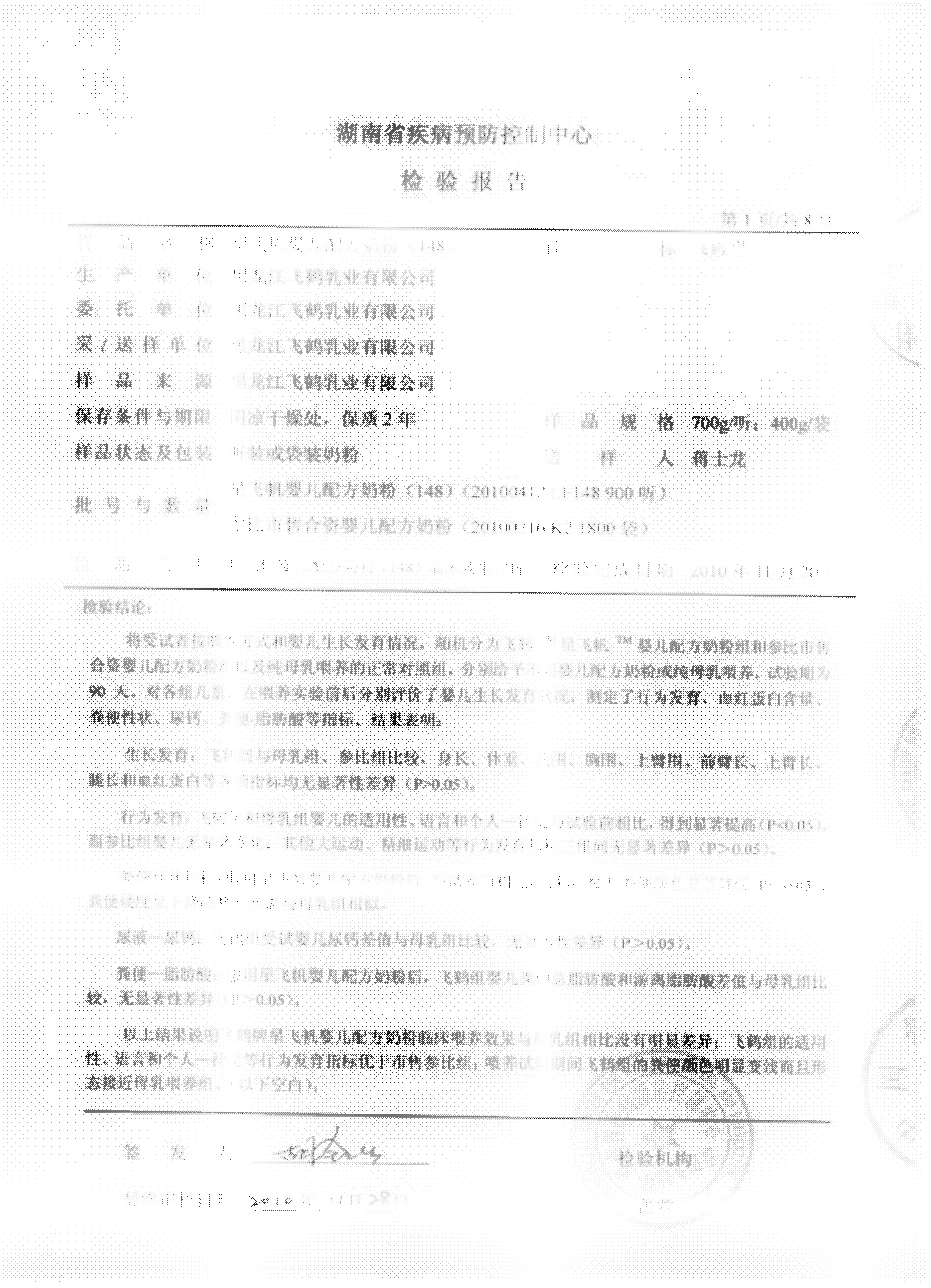

The invention discloses a formula milk powder for promoting the absorption of fatty acid and calcium and a preparation method thereof. Raw cow milk, lactose, 1,3-Dioleoyl 2-palmitoyl triglyceride and demineralized whey powder as main materials are added with concentrated whey albumen powder, Alpha-lactalbumin powder, oligosaccharide, walnut oil, casein phosphopeptide, docosahexaenoic acid, arachidonic acid, nucleotide, lutein, inositol, carnitine and the like as well as vitamins, mineral substances and other nutrients needed for strengthening infants, and fat humanization, protein humanization and carbohydrate humanization are realized. The powdery product is produced by the processes of blending, homogenization, concentration, spray-drying, packaging and the like. According to the physiological characteristics and nutritional demand of the infants, the invention reinforces the calcium, the 1,3-Dioleoyl 2-palmitoyl triglyceride, other nutrient ingredients and the like, and aiming at the oversea clinical test conclusion of the 1,3-Dioleoyl 2-palmitoyl triglyceride, the final test conclusion of comparison with breast milk and infant formula milk powder sold on the market in the process of a clinical feeding test is that the feeding result of the designed formula approximates the feeding result of the breast milk and is better than the feeding result of an infant formula milk powder group sold on the market.

Owner:HEILONGJIANG FEIHE DAIRY

Pig appeasing pheromones to decrease stress, anxiety and aggressiveness

Owner:PAGEAT PATRICK

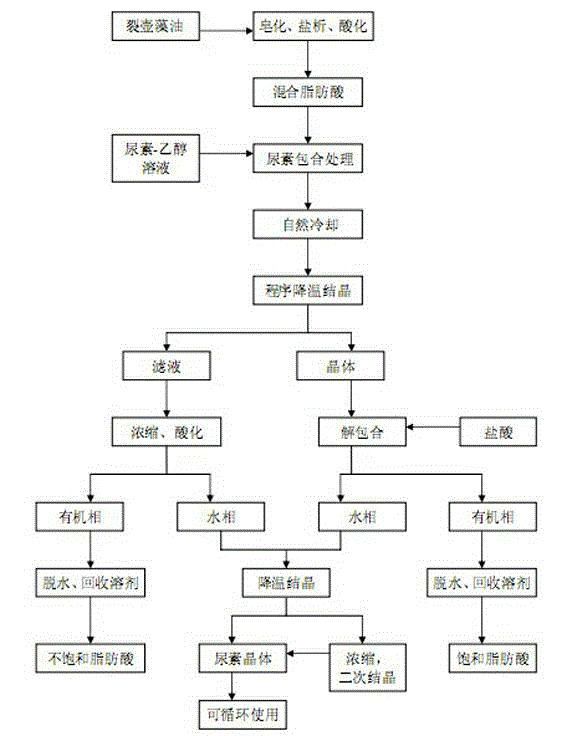

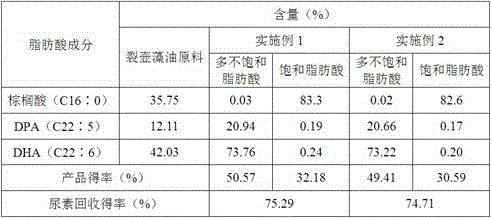

Method for separating and purifying DHA (docosahexaenoic acid) and saturated fatty acid from schizochytrium limacinum oil

ActiveCN102746947AIncrease contentPrevent oxidationPreparation from carboxylic acid saltsFatty acids production/refiningMixed fatty acidSalting out

The invention discloses a method for separating and purifying DHA (docosahexaenoic acid) and saturated fatty acid from schizochytrium limacinum oil. The method includes: firstly, saponifying, salting out and acidizing the schizochytrium limacinum oil under protection of nitrogen so as to obtain free mixed fatty acid, and separating the fatty acid different in degree of saturation by urea adduction fractionation so as to obtain filtrate and solids after filtration; concentrating and extracting the filtrate so as to obtain polyunsaturated fatty acid rich in DHA and DPA (docosapentenoic acid); and allowing the solids to leach by means of acidolysis, extracting the saturated fatty acid (mainly comprising palmic acid) and recovering urea, wherein the urea is recyclable. The method is performedat a low temperature, oxidization of the unsaturated fatty acid is avoided, biological activity and nutrition of the unsaturated fatty acid are kept intact, and the problem of residual solvent is avoided. Products are high in purity, and the obtained polyunsaturated fatty acid mainly comprises the DHA and the DPA and hardly comprises EPA (eicosapentaenoic acid), the content of the DHA and the DPAis higher than 93%, and the content of the palmic acid of the saturated fatty acid is higher than 82%.

Owner:福建华尔康生物科技有限公司

Human Milk Fat Substitutes

ActiveUS20080193624A1Produced cost-effectivelyReduce lossesFatty acid esterificationFood preparationVegetable oilTriglyceride

Disclosed are human milk fat (HMF) substitutes, processes for their preparation, uses thereof and fat blends and infants formulae containing them. A fat base composition of the invention comprises a mixture of vegetable-derived triglycerides, with less than 50% of the fatty acid residues bonded at the sn-2 position being saturated; and / or with the amount of saturated fatty acid residues bonded at the sn-2 position of the glycerol backbone less than about 43.5% of the total amount of saturated fatty acid residues. Typically, substantially all of the saturated fatty acids bonded at the sn-2 position of the glycerol backbone are palmitic acid residues. Also disclosed are substitute HMF compositions comprising a blend of at least 25% or at least 30% of the said fat base composition of the invention with up to 75%, or respectively up to 70%, of at least one vegetable oil. Processes for preparing the fat base compositions and blend are also disclosed. Further disclosed are infant formulas comprising the fat base composition or substitute human milk fat composition.

Owner:ENZYMOTEC

Infant formula goat milk powder added with structural oil and preparation method thereof

ActiveCN102283288APromote growth and developmentPromote fitnessMilk preparationDocosahexaenoic acidVegetable oil

The invention discloses infant formula goat milk powder added with structural grease and a preparation method thereof. The infant formula goat milk powder is prepared from the following components: 20 to 40 percent of lactose, 16 to 22 percent of edible vegetable oil, 3.2 to 9.6 percent of structural grease (1,3-dioleic acid and 2-palmitic acid triglyceride), 16 to 22 percent of concentrated goatwhey protein, 11 to 15 percent of degreased goat milk powder, 2 to 6 percent of glucose syrup solid, 1.0 to 1.5 percent of fructooligosaccharide, 0.5 to 1.0 percent of galactooligosaccharide, 0.15 to0.50 percent of arachidonic acid, 0.12 to 0.48 percent of docosahexaenoic acid, 0.6 to 1.2 percent of mineral premix, 0.08 to 0.12 percent of vitamin premix, and 0.01 to 0.05 percent of nucleotide. The invention also discloses the preparation method of the infant formula goat milk powder. According to the infant formula goat milk powder, the goat smell is effectively eliminated, growth and development of infants are promoted, absorption and utilization rate of calcium are improved, and bone toughness of the infants is promoted.

Owner:HYPROCA NUTRITION CO LTD

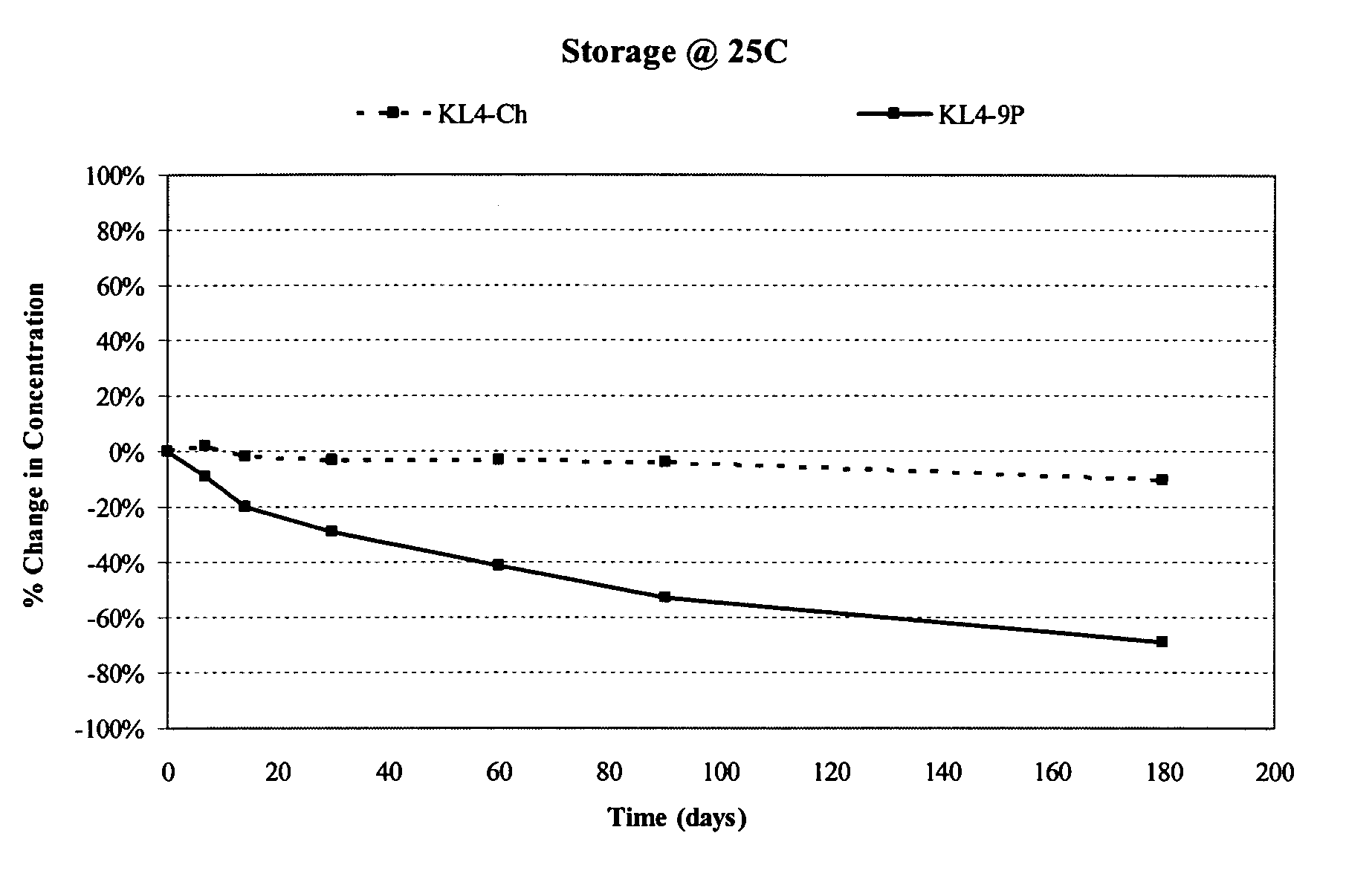

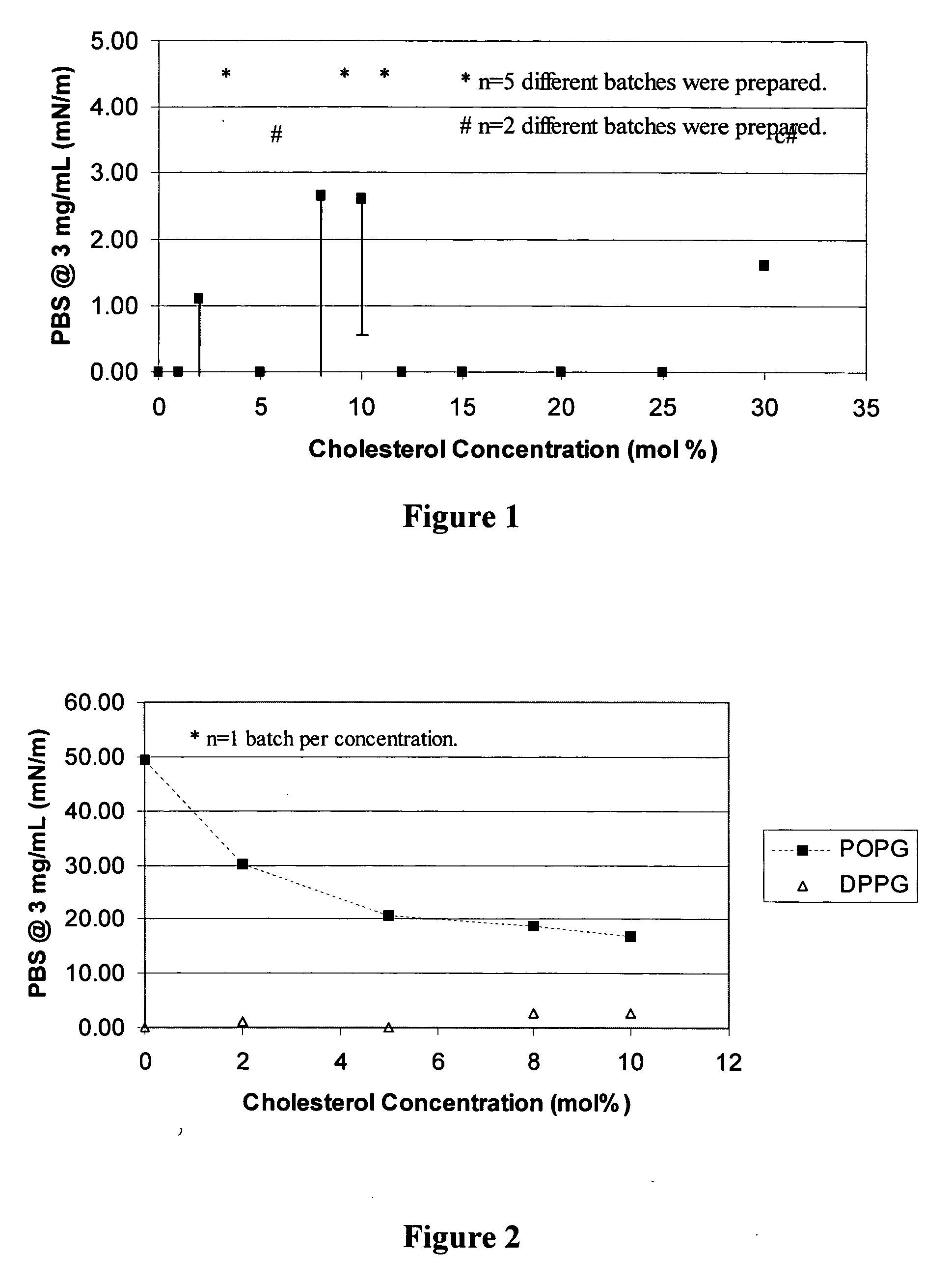

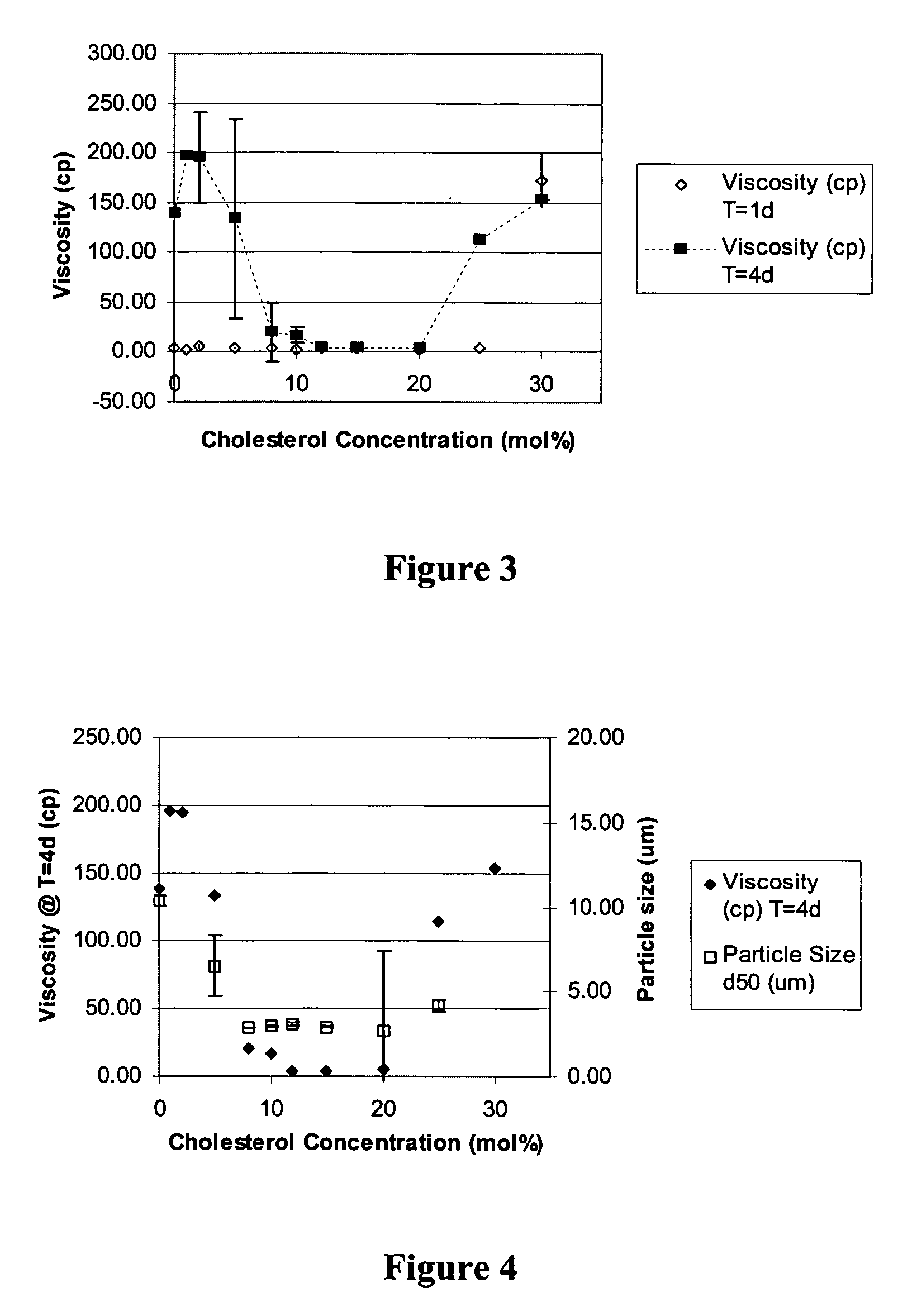

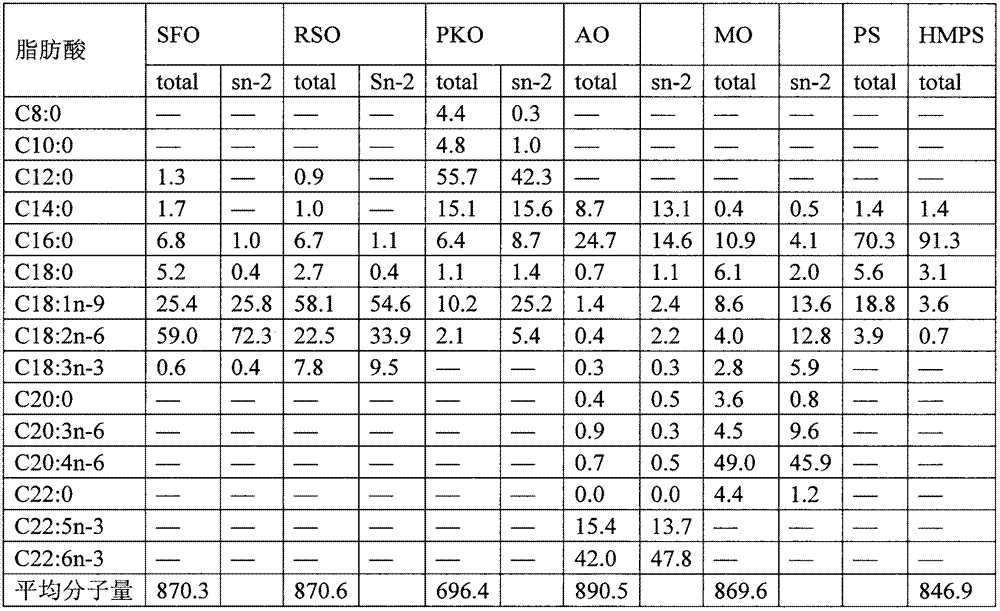

Pulmonary surfactant formulations

InactiveUS20060286038A1Increase ratingsImprove drug stabilityBiocideOrganic active ingredientsDiseaseDipalmitoyl Phosphatidylcholine

Synthetic pulmonary surfactant compositions comprising dipalmitoyl phosphatidylcholine, phosphatidylglycerol, and essentially neutral lipid, and having essentially no 1-palmitoyl 2-oleoyl phosphatidylglycerol and essentially no palmitic acid are provided. Methods for treating respiratory disease are also provided comprising administering a therapeutically effective amount of a synthetic pulmonary surfactant comprising dipalmitoyl phosphatidylcholine, phosphatidylglycerol, and essentially neutral lipid, and having essentially no 1-palmitoyl 2-oleoyl phosphatidylglycerol and essentially no palmitic acid.

Owner:DISCOVERY LABORATORIES INC

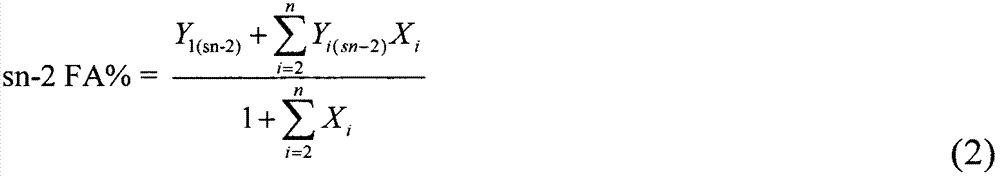

Preparation method of human milk fat substitute

ActiveCN102845537AIncrease contentReduced total palmitic acid contentEdible oils/fatsFood preparationMicrobial oilButterfat

The invention relates to a preparation method of a human milk fat substitute. The method comprises the steps of: step 1) conducting an acid hydrolysis reaction on a raw material of high melting palm stearin subjected to chemical interesterification and alcohol leaching, and an acyl donor of rapeseed oil fatty acid by using Lipozyme RM IM as a catalyst, so as to reduce the total palmitic acid content and increase the relative content of site-two palmitic acid of the raw material; and step 2) deacidifying an intermediate product; and at the same time, calculating the amount of sunflower seed oil, rapeseed oil, palm kernel oil, algae oil and microbial oil added to the intermediate product according to the composition and distribution of fatty acids in human milk fat, by a grease adding model, so as to ensure composition and distribution of fatty acids in a final product meeting requirements of a human milk fat substitute, as well as realize a maximum addition amount. The invention adopts two steps to produce the human milk fat substitute, in order to reduce usage amount of free fatty acids in the acid hydrolysis reaction; meanwhile, two times of oil additions increase yield. Therefore, the invention greatly reduces the cost, and achieves a more than doubled yield compared with a similar products with a similar cost.

Owner:JIANGNAN UNIV

Infant formula milk powder with the fatty acid structure adjusted

InactiveCN101061819AAvoid exposureDelayed Post OxidationMilk preparationWhey manufactureDocosahexaenoic acidVegetable oil

The invention provides an infant milk powder with adjusted structure of aliphatic acid, which comprises the following raw materials (by weight portion in tons): dry matter of fresh milk 276, desalinized whey powder 450, structured fatty oil 105, lactose 50, fructooligosaccharide 20, alpha-lactalbumin 10, docosahexaenoic acid 5, arachidonic acid 6, nucleic acid 0. 42, taurine 0. 45, choline 0. 42, L-carnitine 0. 06, beta-carotene 0. 012, composite vitamin 2. 5, composite microelement 3. 5 and balancing refined vegetable oil.

Owner:SANLU GROUP

Pangasianodon gigas lipid, application and method for preparing breast milk lipid substitutes thereof

ActiveCN101940241AHigh in palmitic acidFatty acid esterificationFatty-oils/fats productionFractionationPalmitic acid

The invention provides pangasianodon gigas lipid, application and a method for preparing breast milk lipid substitutes thereof. The lipid from the pangasianodon gigas is catfish fat or a fractionation liquid component thereof extracted from whole fish of the pangasianodon gigas or other positions after fillets are removed. The pangasianodon gigas lipid is used for preparing the breast milk lipid substitutes. The palmitic acid content on the Sn-2 position in the breast milk lipid substitutes prepared by the pangasianodon gigas lipid is relatively high, which is accordant to that on the Sn-2 position in the breast milk lipid, namely reaches over 60 percent. Meanwhile, AA and DHA exist in the pangasianodon gigas fat or the fractionation liquid component thereof, so the breast milk lipid substitutes does not need the extra AA and DHA or only needs to add a small quantity of the AA or DHA .

Owner:SHENZHEN EXCELSIOR LIPIDS TECH

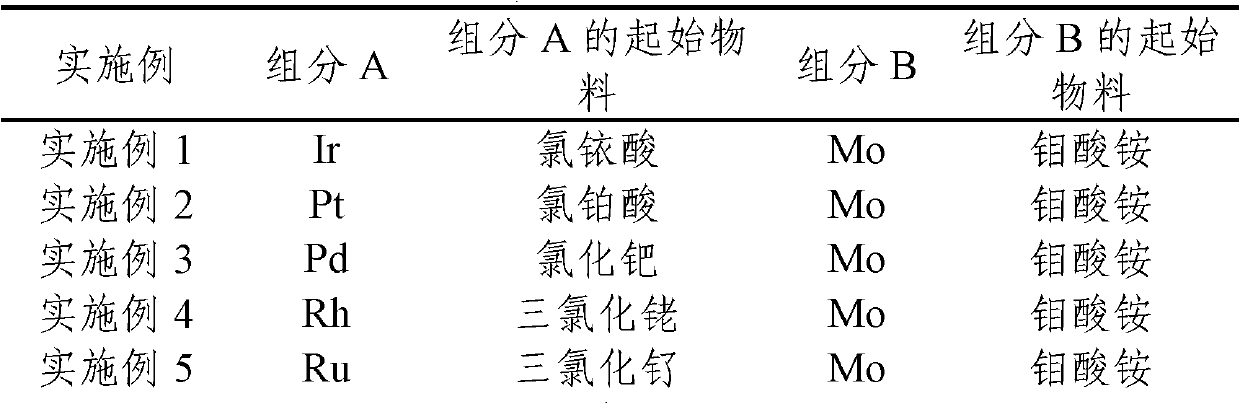

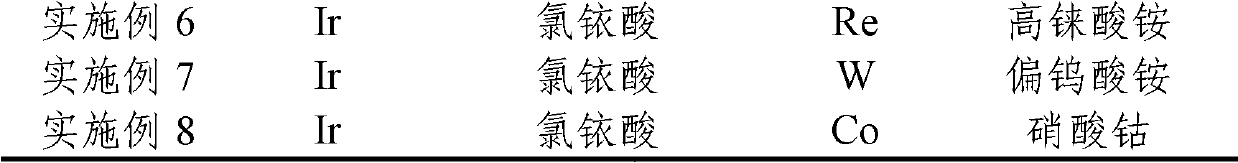

Method for preparing monohydric alcohol or dihydric alcohol through organic acid hydrogenation

ActiveCN103288596AOrganic compound preparationHydroxy compound preparation3-Hydroxypropionic acidPropanoic acid

The invention relates to a method for preparing monohydric alcohol or dihydric alcohol through organic acid hydrogenation. According to the method, any one of acetic acid, propionic acid, valeric acid, stearic acid, oleic acid, palmitic acid, levulinic acid, lactic acid, succinic acid, 3-hydracrylic acid and other organic acids is taken as a reactant, and an A-B / X supported catalyst is adopted, wherein the component A is any one or more than two from Ir, Pt, Pd, Rh and Ru, the assistant B is any one or more than two from Mo, Re and W, the carrier X is any one in SiO2, activated carbon, titanium oxide, zirconium oxide, SiO2-Al2O3 (the mass content of Al2O3 accounts for 17 percent) and molecular sieves, the mass load amount of A in the catalyst is 0.5-10 percent, the molar ratio of the assistant B to A is 0.01-1.0, the reaction pressure is 2-20 MPa, and the reaction temperature is 40-180 DEG C. The catalyst has the characteristics of mild reaction conditions, high reaction activity and good selectivity, and a novel effective way for preparing monohydric alcohol or dihydric alcohol from biomass is provided.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Goat milk powder for infant and preparation method thereof

InactiveCN104996576ANutritional balanceImprove immunityMilk preparationVegetable oilCORN SYRUP SOLIDS

The invention provides goat milk powder for an infant. The goat milk powder is prepared from the following raw materials in parts by weight: 18 to 30 parts of skim goat milk powder, 5 to 10 parts of corn syrup solid, 5 to 12 parts of whole goat milk powder, 4 to 8 parts of special grease, 1.0 to 1.6 parts of fructo-oligosaccharide, 1.0 to 1.6 parts of galactooligosaccharide, 10 to 25 parts of vegetable oil, 25 to 40 parts of milk sugar, 14 to 24 parts of concentrated goat whey protein powder, 0.5 to 1.2 parts of alpha-whey protein, 0.2 to 0.4 part of DHA, 0.2 to 0.5 part of arachidonic acid, 0.12 to 0.16 part of vitamin premix, 0.4 to 0.9 part of mineral substance premix, 0.0004 to 0.01 part of L-carnitine, 0.01 to 0.03 part of taurine and 0.02 to 0.04 part of nucleotide, wherein the special grease is triglyceride with the ratio of 50 to 70 percent, on the Sn-2 position, of palmitic acid. According to the goat milk powder provided by the invention, effort is further made for enabling the formula goat milk powder to be more like breast milk, so that the absorption of the infant to nutrients in the milk powder is more comprehensive, and the probability of dyspepsia and easiness in getting inflamed and diarrhea of the infant is further reduced.

Owner:HYPROCA NUTRITION CO LTD

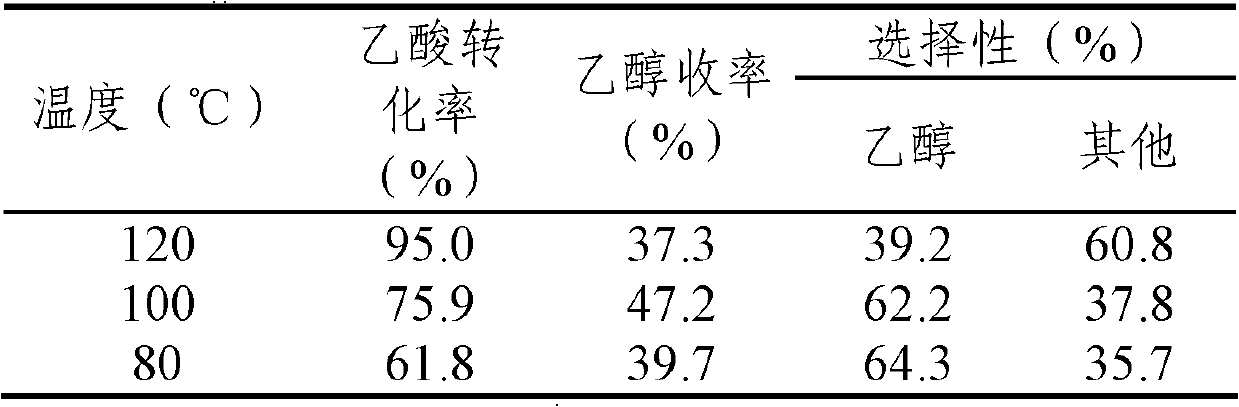

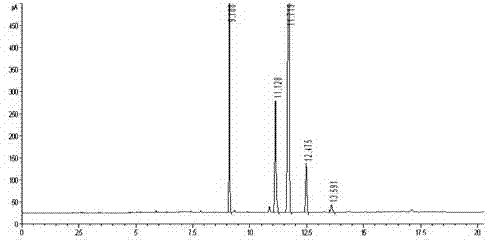

Solid-phase synthesis method of liraglutide

InactiveCN103087181ALess usableSmall quantityPeptide preparation methodsBulk chemical productionSide chainWang resin

The invention discloses a method for synthesizing liraglutide. The method comprises the following steps of: 1, selecting Fmoc-Gly-Wang resin and N terminal Fmoc protected and side chain protected amino acid as raw materials, wherein lysine on a 26th site adopts Fmoc-Lys(Mtt)-OH or Fmoc-Lys(Mmt)-OH, histidine on an N terminal adopts Boc-His(Trt)-OH or Boc-His(Boc)-OH; 2, selectively removing a Mtt or Mmt protecting group on the lysine by adopting 1 percent TFA (Trifluoroacetic Acid); 3, sequentially coupling one g-glutamic acid and palmitic acid on a side chain; and 4, cutting resin by the TFA to obtain a crude product of the liraglutide, and carrying out preparative liquid chromatography purification and lyophilization to obtain a pure product of the liraglutide. The method for synthesizing the liraglutide is simple in steps, saves time and labor, is less in difficult sequences in a coupling process, simple and easy to operate during side chain de-protection, less in byproducts and high in yield, and is suitable for industrialized production.

Owner:刘卫 +1

Trans-free fat base for application in filling creams

InactiveUS20110177227A1Great tasteAvoid layeringFatty acid esterificationFatty-oils/fats separationStearic acidOleic Acid Triglyceride

A fat base is described comprising a mixture containing from 4 to 20% C12:0 lauric acid, preferentially from 5 to 17%, from 30 to 50% C16:0 palmitic acid, preferentially from 34 to 45%, and 4 to 10% C18:0 stearic acid, preferentially from 4.5 to 7.5%, and from 20 to 40% C18:1 oleic acid, preferentially from 25 to 35%, the balance being a mixture of other C4:0 to C22:0 fatty acids, having application, for example, as filling for wafer biscuits.

Owner:TEAM FOODS COLOMBIA

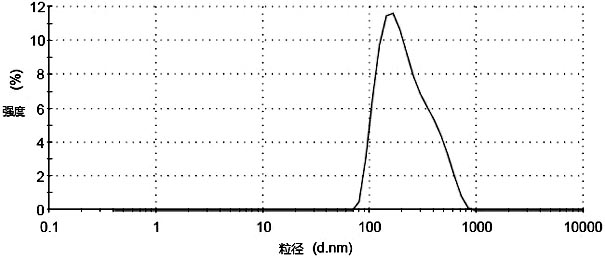

Preparation method of compound bacteria coated microcapsule

ActiveCN103976975AHigh yieldImprove efficiencyMetabolism disorderBacteria material medical ingredientsBiotechnologyPolyethylene glycol

Disclosed is a preparation method of a compound bacteria coated microcapsule. Sodium alginate, CaCl2, polyethylene glycol and palmitate are used as a coating wall material mixed solution, which is stirred uniformly with compound bacteria at the temperature of 50-60 DEG C by a constant temperature magnetic stirrer; and the mixture is cooled and subjected to centrifugation to prepare the microcapsule. The compound bacteria is bacillus bacteria, lactic acid bacteria and yeast. The invention provides a simple preparation method, the prepared compound bacteria microcapsule has good encapsulation yield and encapsulation efficiency, and can pass through the stomach and dissolve in intestinal tracts, so as to avoid bacteria number loss of living bacteria in the stomach and produce the biggest effect in the intestinal tracts.

Owner:NANHAI CHANTAI ANIMAL PHARMACY FOSHAN

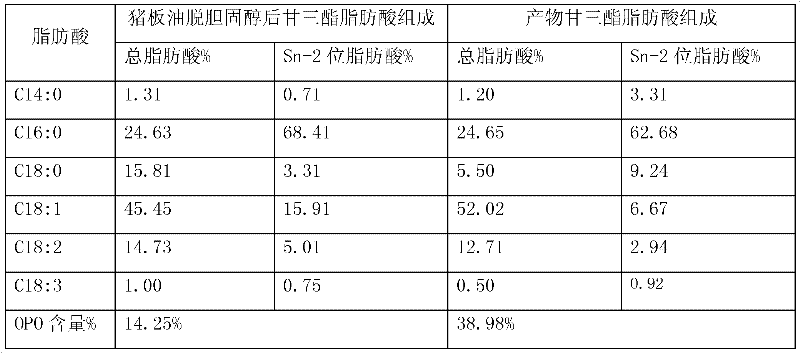

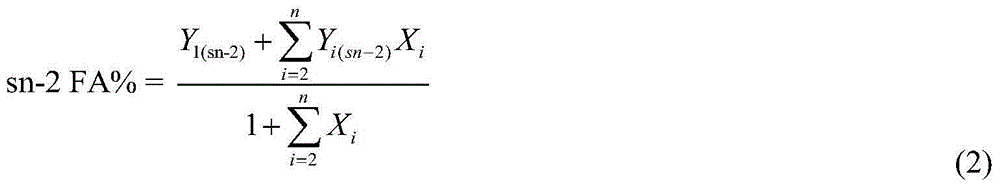

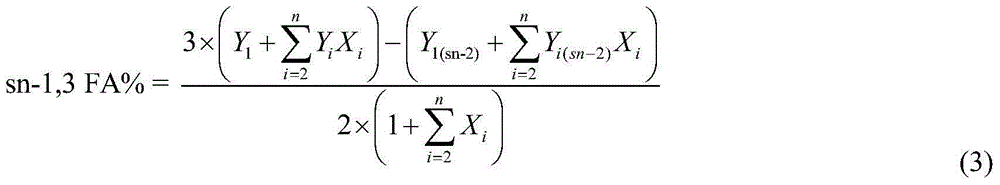

Method for producing 1,3-dioleoyl-2-palmitoyl triglyceride

InactiveCN102229866AIncrease OPO contentImprove catalytic performanceFatty acid esterificationFatty-oils/fats refiningTriglyceridePalmitic acid

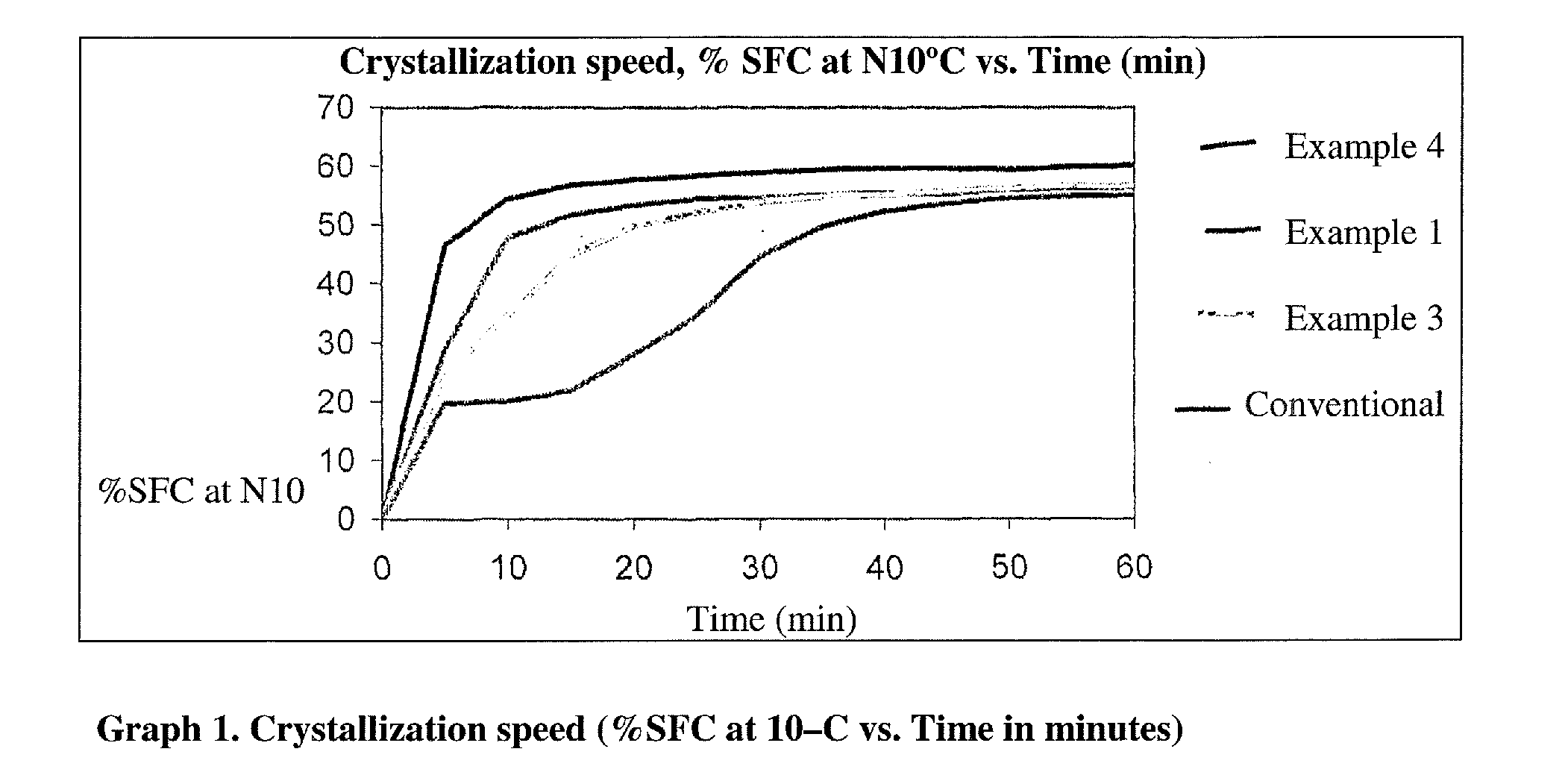

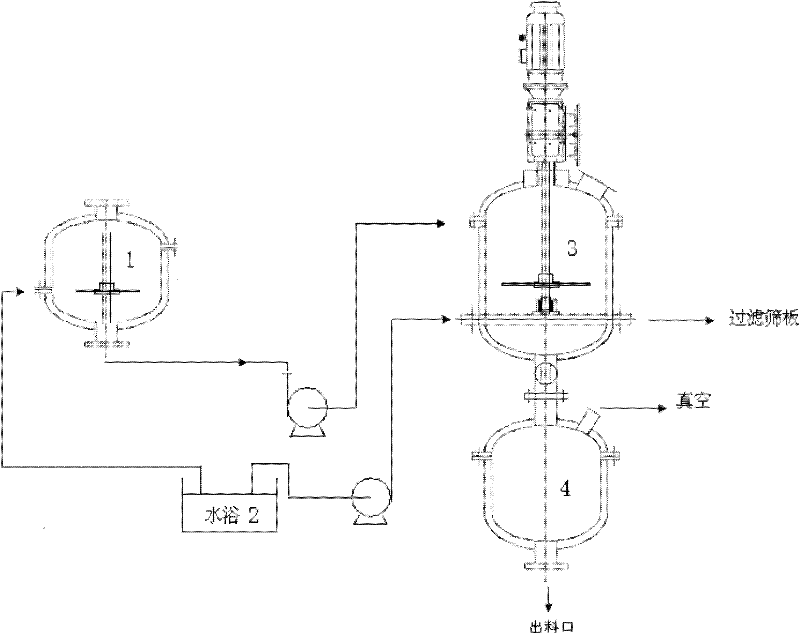

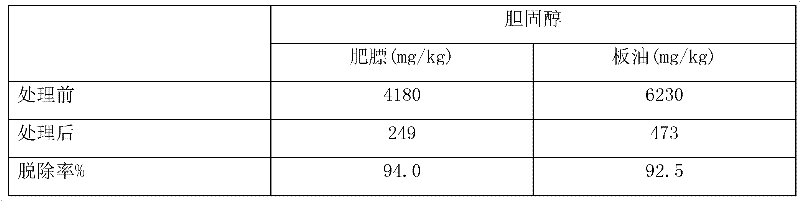

The invention discloses a method for producing 1,3-dioleoyl-2-palmitoyl triglyceride. The invention belongs to the field of human milk substitutes and particularly relates to a method for producing triglyceride, which comprises: 1, removing cholesterol from lard by an ethanol extraction process till the cholesterol content reduces to below 500mg / kg; 2, reacting the lard from which cholesterol is removed with refined fatty acid in the presence of 1-position and 3-position selective lipase serving as a catalyst; 3, filtering to remove lipase from the mixed reactants; 4, removing the fatty acid from the product, and obtaining triglyceride; and 5, crystallizing to refine triglyceride with high OPO content. In the invention, a cholesterol removal process is introduced for the lard raw materialused in preparation, the cholesterol removal rate reaches over 92 percent, and the cholesterol content in the lard raw material from which cholesterol is removed is lowered to less than 500mg / kg. Theaddition of the refining process improves the OPO content in the triglyceride reaches over 53 percent. The difference between the palmitic acid content before reaction in sn-2 fatty acid and the palmitic acid content after the reaction in the sn-2 fatty acid is less than 10 percent.

Owner:BEIJING UNIV OF CHEM TECH

Preparation method of human milk alternative fat combining enzymatic acidolysis and physical mixing

The invention discloses a preparation method of human milk alternative fat combining enzymatic acidolysis and physical mixing. The preparation method mainly comprises the following two steps: S1, adjusting the composition (greater than 1%) of a plenty of fatty acids of catfish oil or a fractionation product of the catfish oil by virtue of acidolysis; and S2, adjusting the composition of trace fatty acids (less than 1%) of an enzymatic product by virtue of physical mixing. The raw materials catfish oil or the fractionation product of the catfish oil used by the method are wide in source and low in price, and contain a relatively high content of sn-2 palmitic acid and a relatively low content of total palmitic acid. In the acidolysis reaction, the free fatty acids used is small in proportion, and in the process, the composition and distribution of the plenty of fatty acids are emphasized at the same time as well as the composition of trace fatty acids containing polyunsaturated fatty acids with medium carbon chains and long carbon chains. The obtained product is highly similar to human milk fat and has a relatively huge market application prospect.

Owner:JIANGNAN UNIV

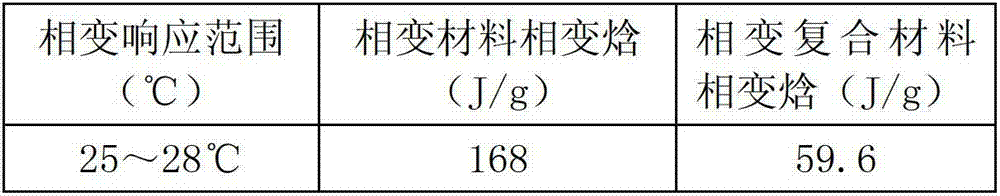

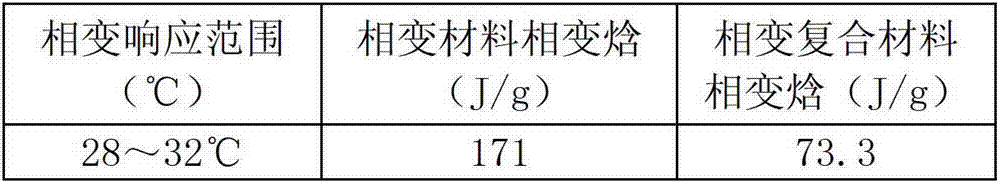

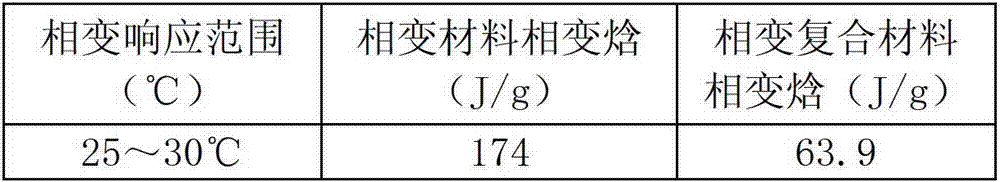

Phase change composite material and preparation method thereof

InactiveCN102827583AHigh phase change enthalpyCrystal stableHeat-exchange elementsThermal insulationStearic acid

The invention relates to a phase change composite material and a preparation method thereof. The phase change composite material is composed of a phase change material, expanded perlite particles and polymer emulsion in a weight ratio of (0.55-0.75): 1: (0.5-2.0), wherein the polymer emulsion is coated over the surface of the expanded perlite particles which have adsorbed the phase change material, and the phase change material is a blend of three or four selected from the group consisting of decanoic acid, lauric acid, tetradecanoic acid, palmitic acid and stearic acid. The preparation method comprises a step of combining the phase change material and the expanded perlite particles together by using a vacuum adsorption process and a step of coating a compound of the phase change material and the expanded perlite particles with the polymer emulsion. The phase change composite material provided by the invention has the advantages of great phase change energy storage capacity, good sealing capacity, wide material sources and low cost, can be used to substitute or partially substitute thermal insulation aggregate in conventional inorganic thermal insulation mortar for indoor and outdoor insulation of a building and can be mixed with inorganic cementing materials like cement and gypsum to prepare a sheet material product.

Owner:上海英硕聚合材料股份有限公司

Method for demulsification for extracting wheatgerm oil by using aqueous enzymatic method

InactiveCN103113978AImprove qualityWith fragranceFatty-oils/fats productionEnzymatic hydrolysisWheat germ

Owner:INST OF AGRO FOOD SCI & TECH SHANDONG ACAD OF AGRI SCI

Beta-carotene micro-capsule powder and preparation method thereof

InactiveCN101999577AImprove stabilityUniform particle sizeNatural dyesFood shapingBiotechnologyVitamin C

The invention discloses beta-carotene micro-capsule powder and a preparation method thereof. The beta-carotene micro-capsule powder comprises the following components in weight percentage: 3%-6% of beta-carotene, 3%-5% of vitamin C palmitic acid esters, 30%-45% of food-grade gelatin, 15%-30% of starch, 3%-5% of vitamin C sodium, 2%-5% of soybean lecithin and 20%-30% of cane sugar. The preparationmethod comprises the following steps of: extracting the beta-carotene, preparing and mixing an organic-phase solution and a water-phase solution, then carrying out ultrasonic high-speed shearing, high-pressure homogenized emulsification and spraying drying, and the like to finally obtain the beta-carotene micro-capsule powder reaching the nano grade in particle size. The obtained beta-carotene micro-capsule powder has short dissolving time and stability without delamination; in addition, because the food-grade material is fully used as a production reagent and an auxiliary material in a preparation process, the beta-carotene micro-capsule powder accords with the safety standard of food, has the characteristic of simplicity in preparation method and low product cost, and is easy for continuous and automatic production.

Owner:SHANGHAI INST OF TECH

Method for preparing composition containing 2-palmitin

InactiveCN104087626ASimple preparation processHigh content of 2-bit palmitic acidFatty acid esterificationFermentationGLYCERYL PALMITATEPalmitates

The invention relates to a method for preparing a composition containing 2-palmitin. The method comprises the steps of providing a glyceride containing a palmitate residue; mixing the glyceride containing the palmitate residue with palmitic acid, palmitate or palmitic acid non-glyceride, and performing ester exchange to obtain grease A; performing enzymatic directional ester exchange on the grease A and unsaturated fatty acid or non-glyceride of the unsaturated fatty acid to obtain mixed oil B; refining the mixed oil B to obtain the composition containing 2-palmitin. The preparation process is simple. Compared with the existing method, the method disclosed by the invention has the advantages that the content of palmitic acid at the second site in the product prepared by using the method is higher, and fewer byproducts are produced after preparation, so that the method is favorable for environment friendliness.

Owner:CABIO BIOTECH WUHAN CO LTD

Oil-and-fat composition, process for production of the composition, chocolate, and process for production of the chocolate

InactiveUS20100278985A1Low in fatCoating suitableFood ingredient as viscosity modification agentMilk preservationAdditive ingredientTriglyceride

Disclosed is an oil-and-fat composition suitable for the coating with a tempered chocolate, particularly suitable for the enrobing with the chocolate. Also disclosed is a low-fat tempered chocolate suitable for coating, particularly enrobing. Specifically disclosed is an oil-and-fat composition which has a content of an oleoyldipalmitin (P2O) component of 70 to 85% by mass, which contains a symmetric triglyceride 1,3-dipalmitoyl-2-oleoylglycerin (POP) in the oleoyldipalmitin (P2O) component at a ratio of the amount of 1,3-dipalmitoyl-2-oleoylglycerin (POP) to the amount of the oleoyldipalmitin (P2O) component [(POP) / (P2O)] of 0.95 or more by mass, and which has a content of tripalmitin (PPP) of 2 to 6% by mass. The oil-and-fat composition is added to a tempered chocolate.

Owner:THE NISSHIN OILLIO GRP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com