Patents

Literature

742 results about "Walnut oil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

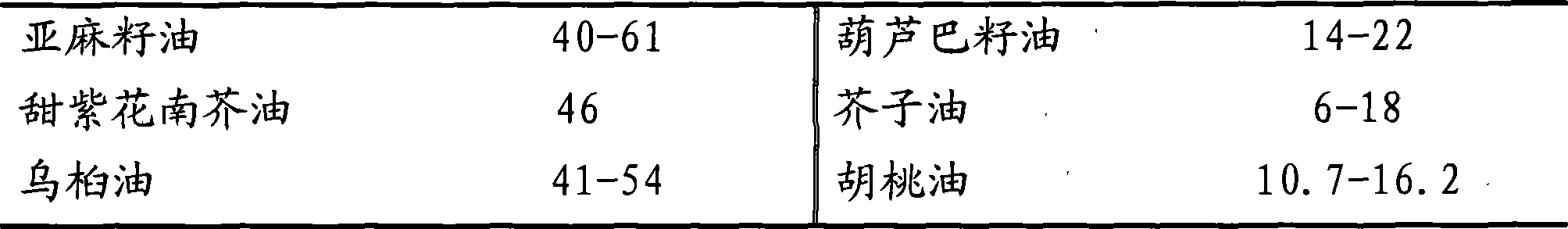

Walnut oil is oil extracted from walnuts, Juglans regia. The oil contains polyunsaturated fatty acids, monounsaturated fatty acids, and saturated fats.

Food spreads

The present invention is of a food spread containing a mixture of at least one edible oil of natural or synthetic origin and a monoglyceride. The oil is preferably one or more of the oils from the group of olive oil, avocado oil, canola oil, soybean oil, sunflower oil, nut oils, walnut oil, peanut oil, safflower oil, cottonseed oil, coconut oil, rice bran oil, mustardseed oil, camelina oil, chia oil, flaxseed oil, perilla oil, fish oil, palm oil, sesame oil, wheatgerm oil, jojoba oil or corn oil. More preferably an oil such as avocado oil, fish oil, palm oil or olive oil is used and most preferably the oil is olive oil and fish oil. The monoglycerides used are preferably derivatives of oleic, or palmitic acid. The oil is present preferably in an amount of from about 85 to about 98 percent and most preferably in an amount of from about 93 to about 96 percent. The more monoglyceride used, the greater the degree of solidity of the food spread at room temperature. It is therefore possible to produce a desired degree of solidity, by changing the proportion of monoglyceride.

Owner:DR EGER OLIVE OIL PROD IND

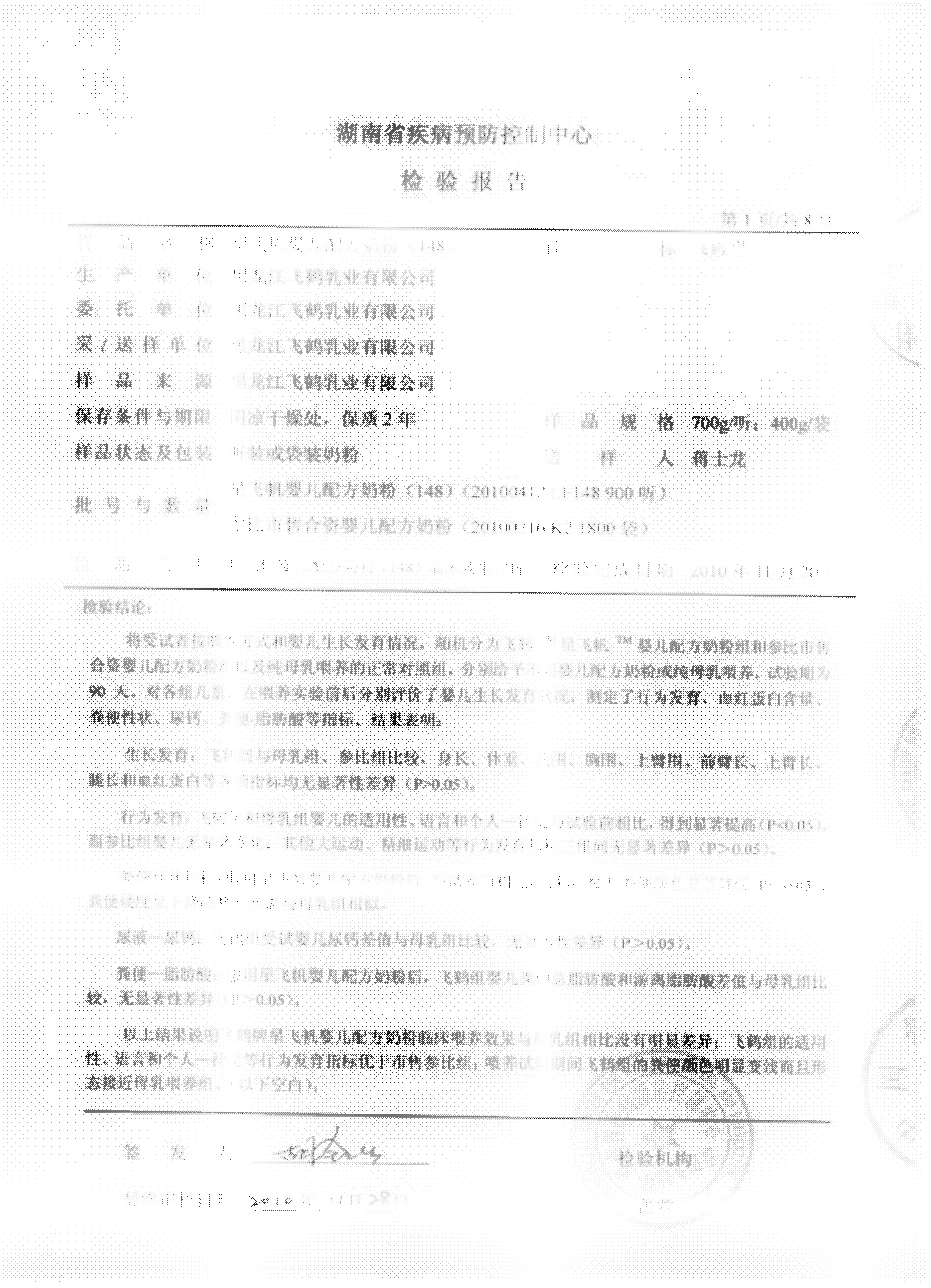

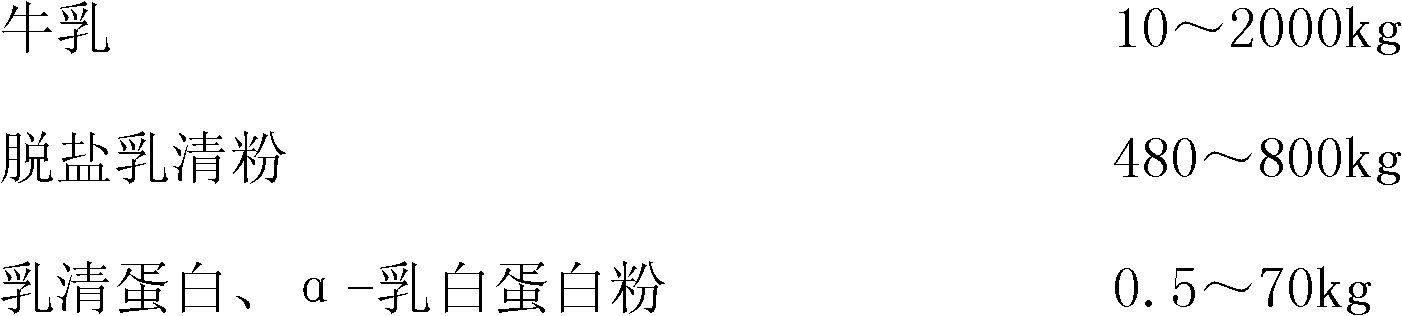

Formula milk powder for promoting absorption of fatty acid and calcium and preparation method thereof

The invention discloses a formula milk powder for promoting the absorption of fatty acid and calcium and a preparation method thereof. Raw cow milk, lactose, 1,3-Dioleoyl 2-palmitoyl triglyceride and demineralized whey powder as main materials are added with concentrated whey albumen powder, Alpha-lactalbumin powder, oligosaccharide, walnut oil, casein phosphopeptide, docosahexaenoic acid, arachidonic acid, nucleotide, lutein, inositol, carnitine and the like as well as vitamins, mineral substances and other nutrients needed for strengthening infants, and fat humanization, protein humanization and carbohydrate humanization are realized. The powdery product is produced by the processes of blending, homogenization, concentration, spray-drying, packaging and the like. According to the physiological characteristics and nutritional demand of the infants, the invention reinforces the calcium, the 1,3-Dioleoyl 2-palmitoyl triglyceride, other nutrient ingredients and the like, and aiming at the oversea clinical test conclusion of the 1,3-Dioleoyl 2-palmitoyl triglyceride, the final test conclusion of comparison with breast milk and infant formula milk powder sold on the market in the process of a clinical feeding test is that the feeding result of the designed formula approximates the feeding result of the breast milk and is better than the feeding result of an infant formula milk powder group sold on the market.

Owner:HEILONGJIANG FEIHE DAIRY

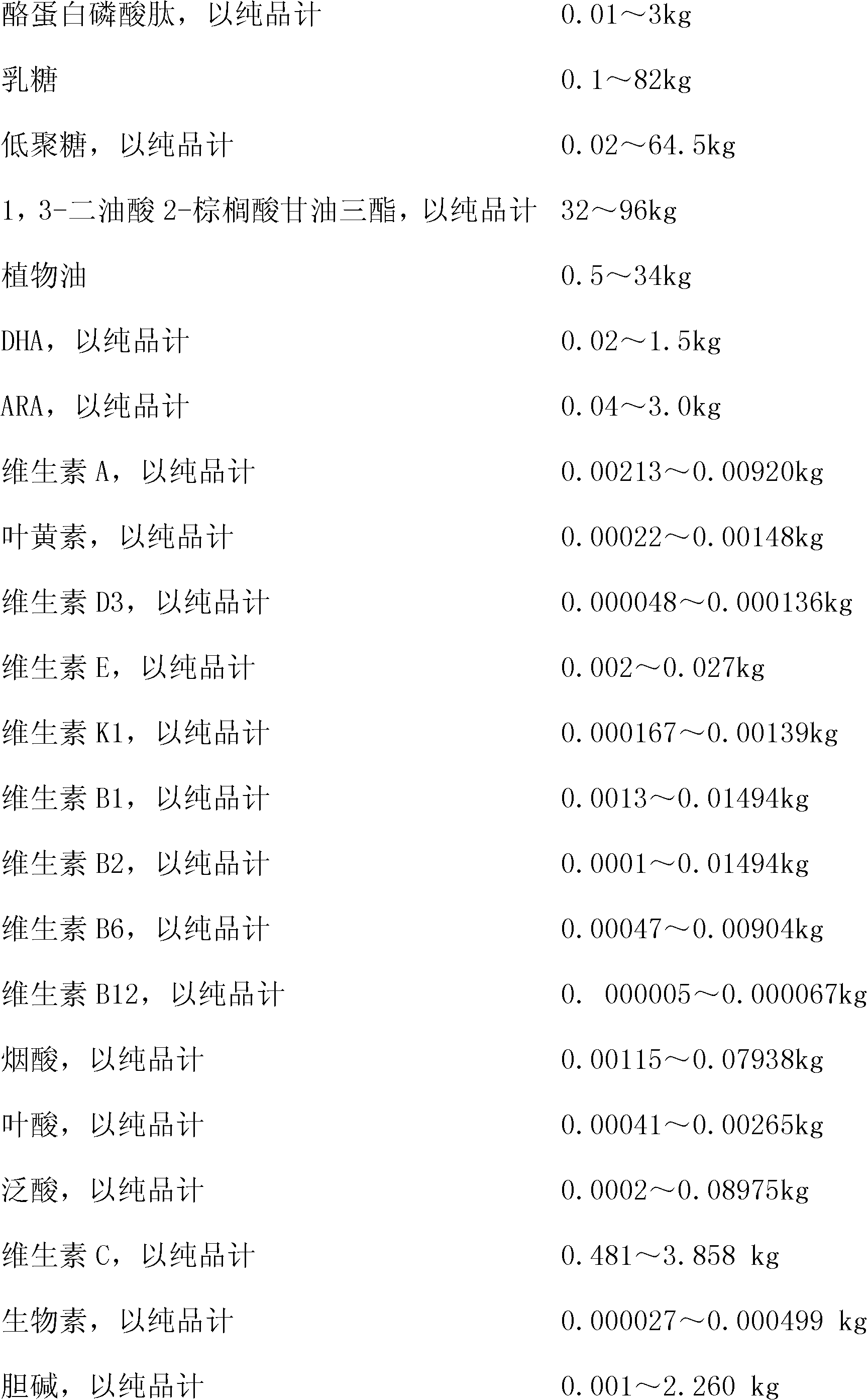

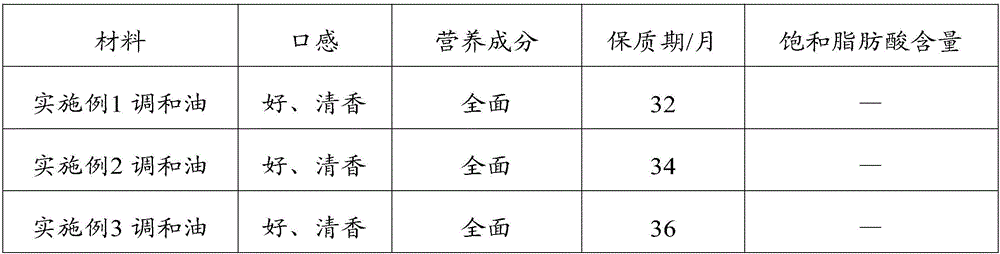

Blend oil with proportional fatty acid prepared by walnut oil and other plant oils

InactiveCN101690526AReduce contentReduce concentrationEdible oils/fatsFood preparationVegetable oilCholesterol

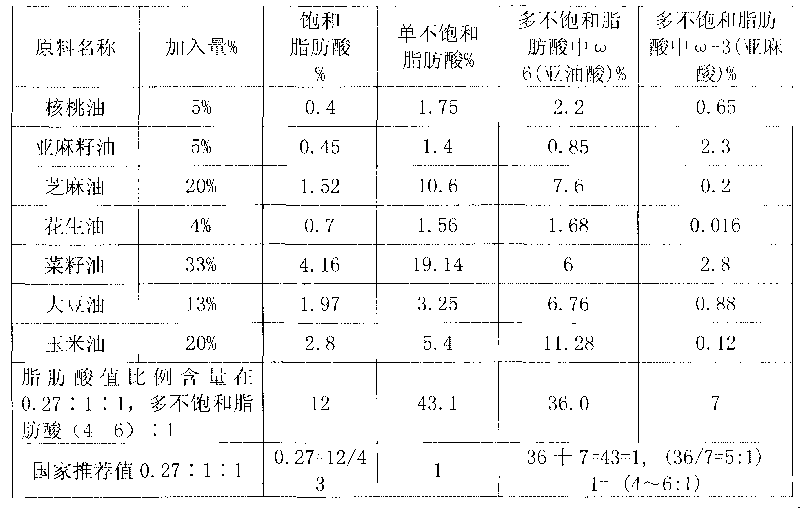

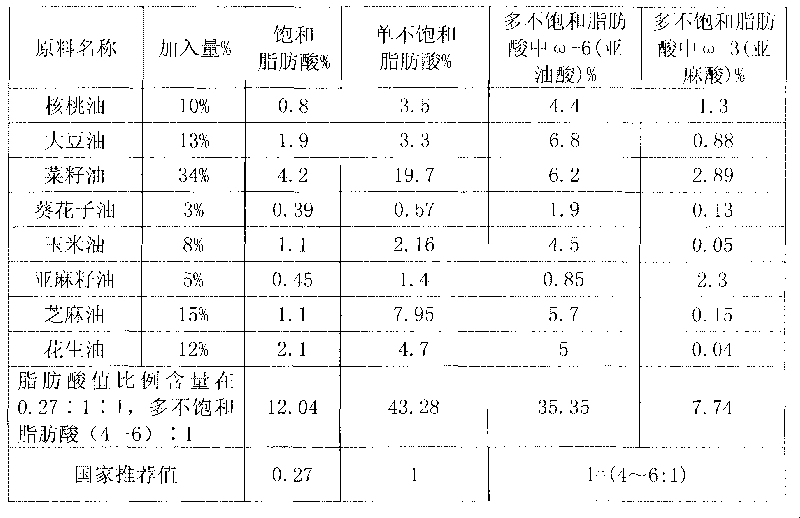

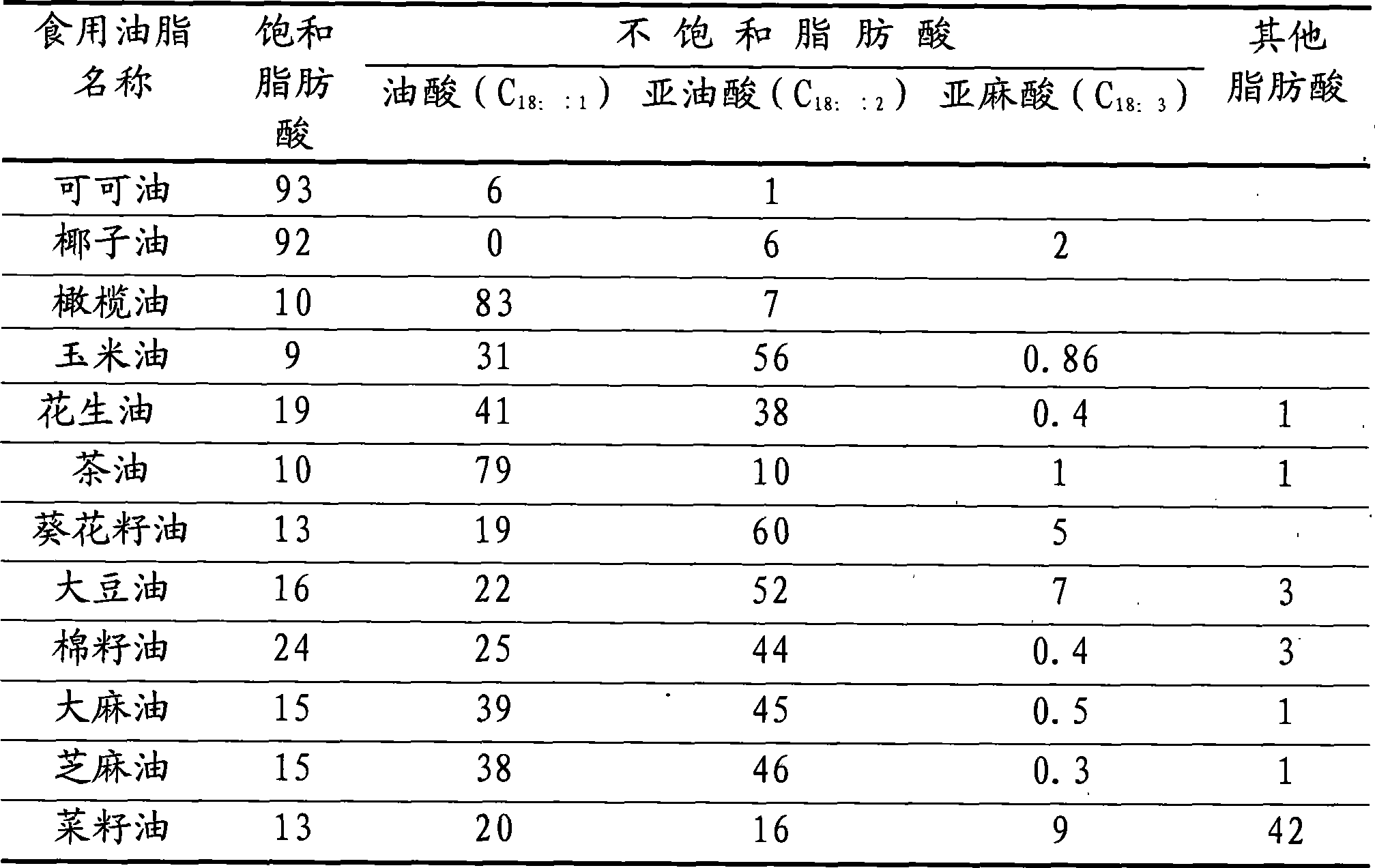

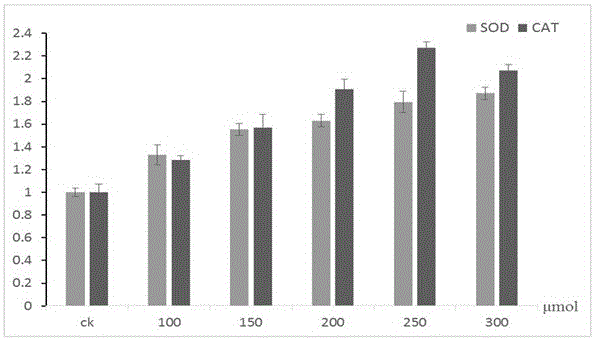

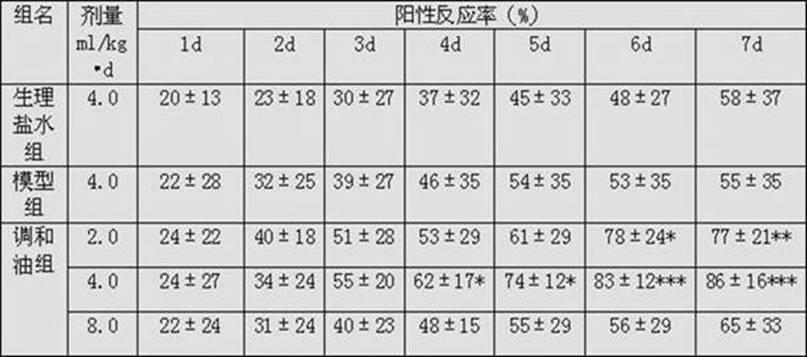

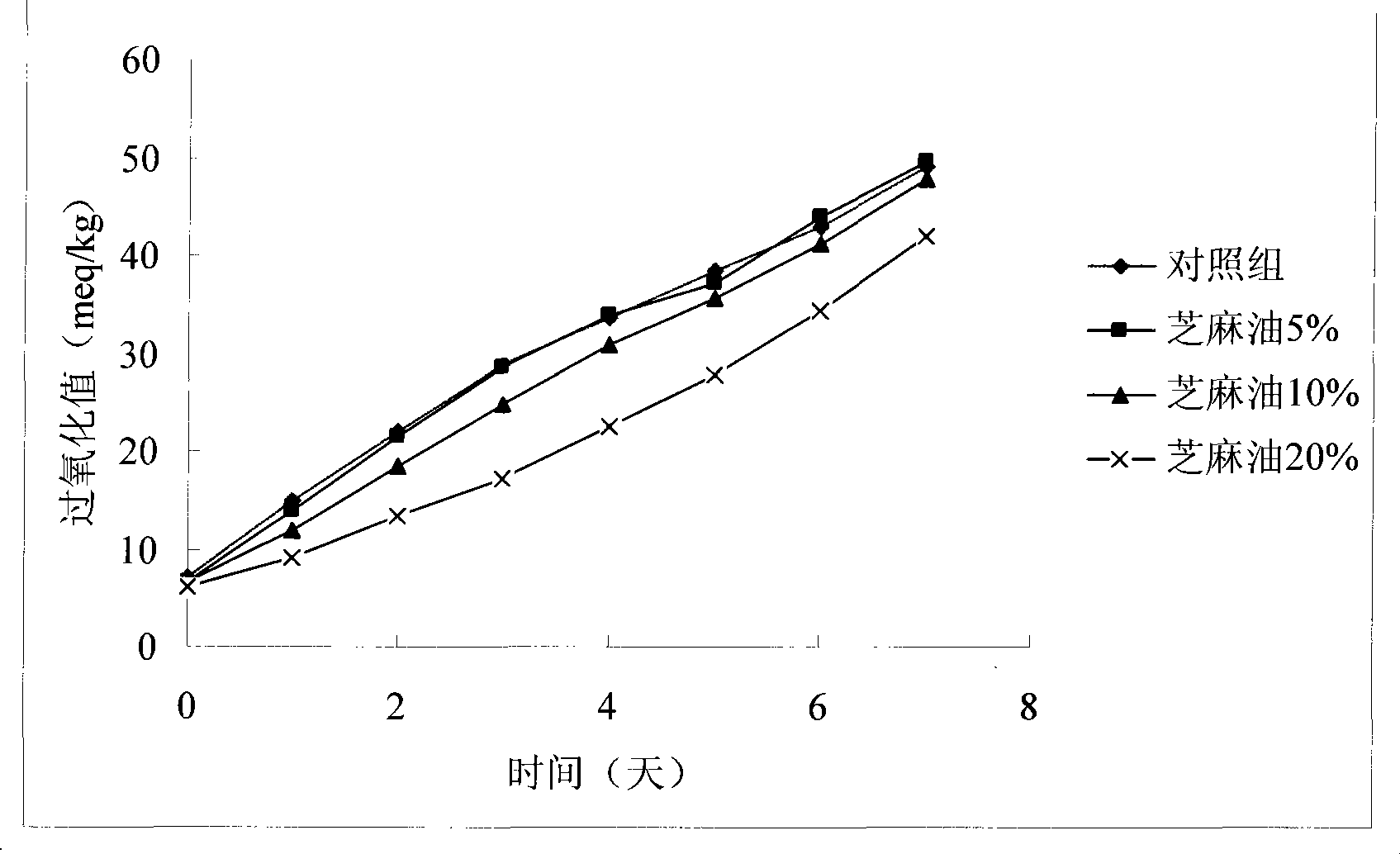

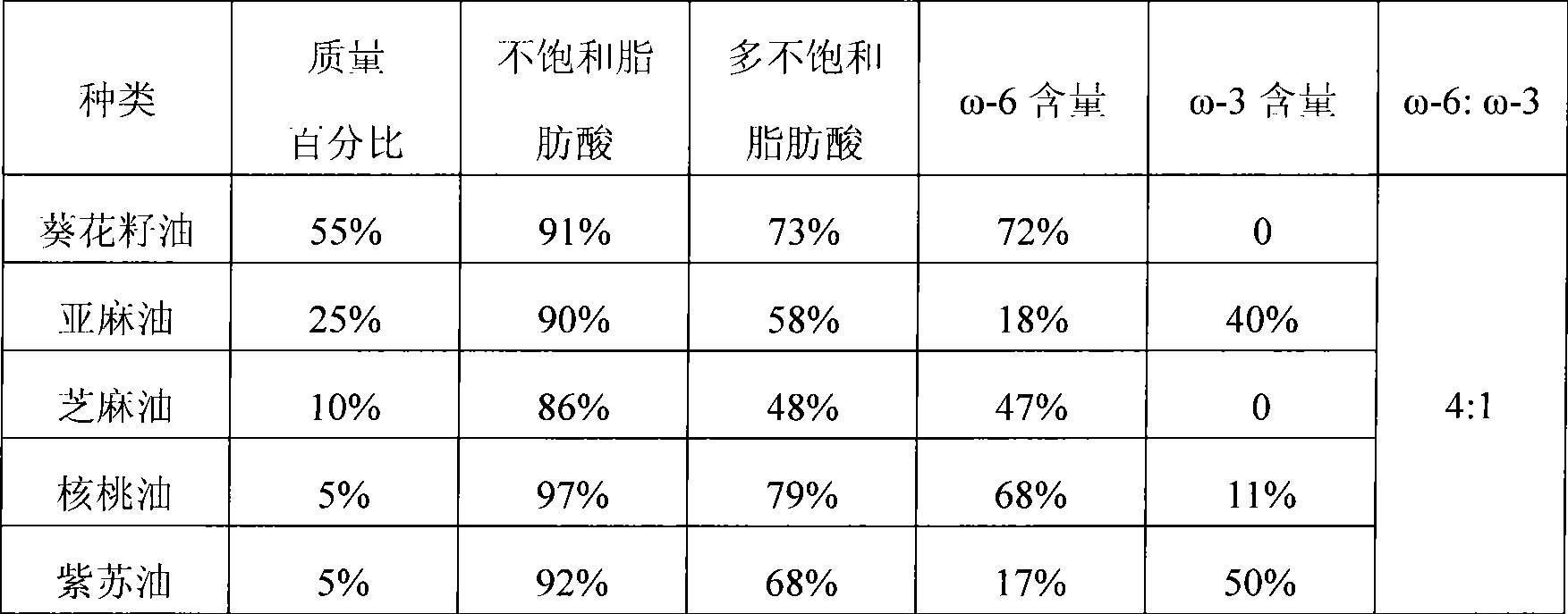

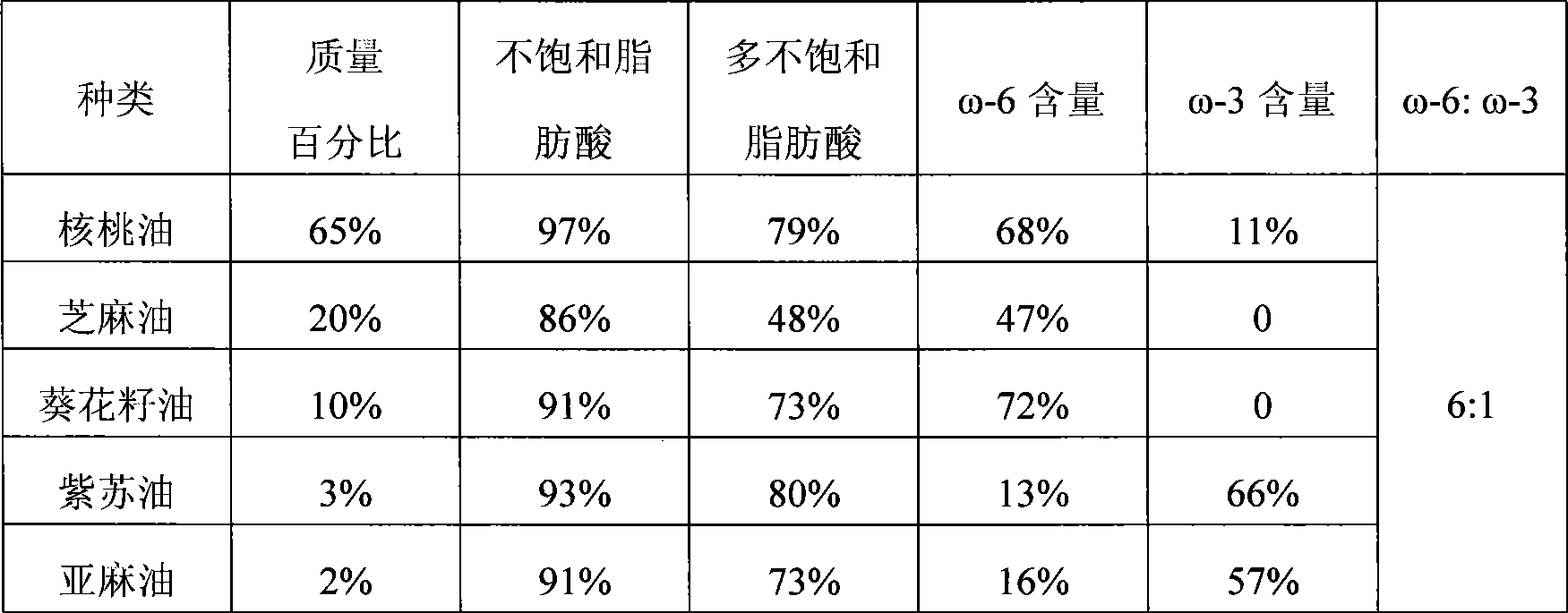

The invention relates to blend oil with proportional fatty acid prepared by walnut oil and other plant oils, which is composed of 5-20% of walnut oil by weight and 80-95% of common plant oils by weight, wherein the common plant oils are selected from any 6 to 11 from peanut oil, soybean oil, sunflower seed oil, teal oil, cotton seed oil, corn oil, almond oil, olive oil, tea oil, linseed oil and colza oil. The ratio of three fatty acids in the blend oil provided by the invention can reach 0.27:1:1, wherein the ratio of omega-6 (linoleic acid) to omega-3 (linolenic acid) in polyunsaturated fatty acids is (4-6):1, and the blend oil in the invention also can overcome the disadvantages that walnut oil is expensive in price and little in market acceptance space while common plant oil has single nutrition and is difficult to supplement fatty acids essential to human body, therefore, by long term administration of the walnut blend oil, cholesterol can be effectively reduced, hyperlipaemia can be reduced, heart cerebrovascular disease can be prevented, and the holistic health level of people can be improved.

Owner:祁景泉

Process for producing corn germ oil and table oil made by products produced thereby

InactiveCN1523094AReduce lossesReduce production consumptionFatty-oils/fats refiningEdible oils/fatsOil and greaseVegetable oil

The present invention provides a production process of maize germ oil, at the same time discloses a table oil made up by its product. It is characterized by that it makes the maize germ raw material oil undergo the processes of degumming, deacidification, water-washing, decolouring, dewaxing and deodorization so as to obtain the refined edible finished oil. According to the physicochemical properties and nutrient components of other plant oil said maize germ oil and other plant oil can be made into the table oil using maize germ oil as main component. The described plant oil can be one of rice oil, carthamus oil, walnut oil, scabish oil, pine seed oil, sesame oil, peanut oil, wheat-germ oil, sunflower oil and soybean oil or their mixture.

Owner:高元财 +1

Plant blend oil and method for preparing same

The invention belongs to the field of edible oil products and in particular relates to plant blend oil with balanced nutrition and a method for preparing the same. The technical proposal comprises: the plant blend oil comprises the following compositions in portion by weight: 7.5 to 23 weight portions of maize oil, 8.6 to 20.7 weight portions of soybean oil, 7.7 to 21.8 weight portions of peanut oil, 7.5 to 19.7 weight portions of sunflower seed oil, 6.5 to 18.8 weight portions of rice bran oil, 2.1 to 15.6 weight portions of perilla oil, 2 to 13.5 weight portions of safflower seed oil, 4.9 to 12 weight portions of flaxseed oil, 5.2 to 12 weight portions of walnut oil , 2 to 11.5 weight portions of wheat germ oil, 6.5 to 15 weight portions of tea seed oil and 0.2 to 8 weight portions of evening primrose oil. The invention also provides the method for preparing the plant blend oil; and the blend oil highlights reasonableness of the proportional composition of various unsaturated fatty acids, namely the ratio of oleic acid to linoleic acid to linolenic acid is 5:4:1 and also highlights the trophic function of a product.

Owner:邹平三星油脂工业有限公司

Synchronous aqueous enzymatic ultrasonic extraction for walnut oil and walnut protein peptide

InactiveCN101280327AQuality improvementMild treatment conditionsCheese manufactureVegetable proteins working-upOil phaseDietary fibre

The invention relates to an enzyme method ultrasonic extraction method of walnut oil and walnut protein, which belongs to the food and the functional food field. Water is added into walnut kernel or walnut powder to be grinded into paste, protease or compound protease are added into to be performed hydrolization, and simultaneously ultrasonic processing is performed, then the walnut kernel or walnut powder is agitated to perform enzymatic extraction, and then centrifugal separation oil phase, protein peptide oil water phase and residual solid phase are performed; walnut oil is acquired by refining the obtained oil phase, which meets the requirements of green foods; the protein peptide aqueous solution can be directly used to produce degreased walnut protein nutrient milk, or to prepare walnut antioxidation peptide after performed nanofiltration, which is used in health products, food additives, cosmetics or daily chemical articles, or to produce nutrient condensed milk after being performed low temperature concentrating, or to produce walnut protein nutrition powder after performed spray drying; the solid phase residue is prepared into diet fiber food after being dried and grinded into powder; walnut nutrient protein peptide products can be obtained through performing vacuum concentration and spray drying to walnut protein peptide extracting solution containing nutrient content.

Owner:KUNMING UNIV OF SCI & TECH

Nutritional blend oil with balanced fatty acid component and active component for middle and old aged

The invention relates to a nutritional blend oil with balanced fatty acid components and active components for the middle and old aged, which is prepared by a plurality of plant oils selected from flaxseed oil, walnut oil, double-low rapeseed oil, soybean oil, wheat germ oil, corn oil, teal oil, peanut oil, grape seed oil, rice bran oil, camellia oil, evening primrose seed oil, sunflower seed oil and the like, wherein, Omega 6 serial polyunsaturated fatty acids (PUFA) and Omega 3 serial PUFA are contained to enable the ratio of saturated fatty acid (SFA) to monounsaturated fatty acid (MUFA) to PUFA to be 0.6-0.8:1:1, the ratio of Omega 6 to Omega 3 to be 4:1 in the comprehensive evaluation of the blend oil absorbed by the middle and old aged and the fat from other sources, thereby meeting the recommended value of Chinese Nutrition Society; the nutritional blend oil contains 2% of gama-linolenic acid, thereby beneficial to improving the contents of DH-gama-linolenic acid and arachidonic acid; the total content of lauric acid, myristic acid and palmitic acid contained in the nutritional blend oil is below 8.5% in order to avoid over rising the level of Low density lipoprotein (LDL) in the plasm of the middle and old aged; in addition, the nutritional blend oil also comprises a plurality of active components with oxidation resistant property, so other antioxidants do not need to be added in the blend oil.The blend oil provided by the invention is characterized by low cost, balanced fatty acid nutrition, a plurality of abundant active components and higher security, thereby better improving the health and intelligence of eaters, preventing cardiovascular and cerebrovascular diseases, and avoiding fatness, hyperlipidemia, thrombotic diseases and the like caused by unbalanced fatty nutrition.

Owner:ZHEJIANG OIL MASTER

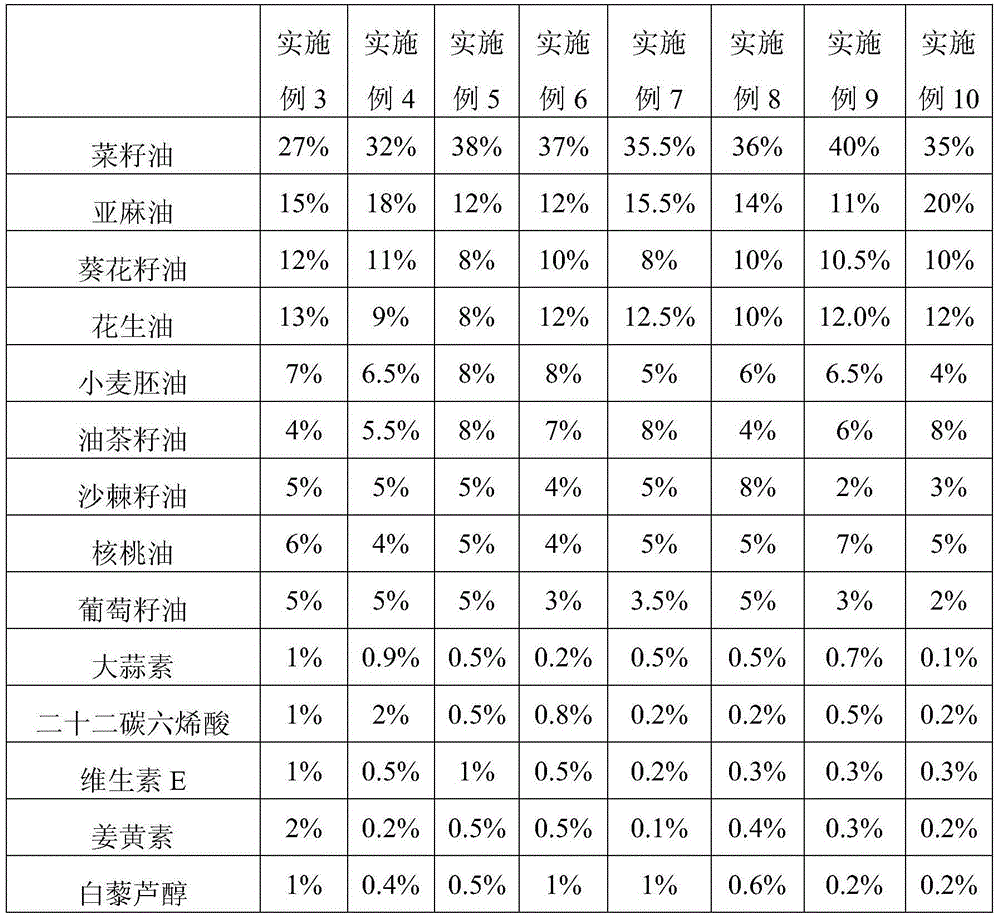

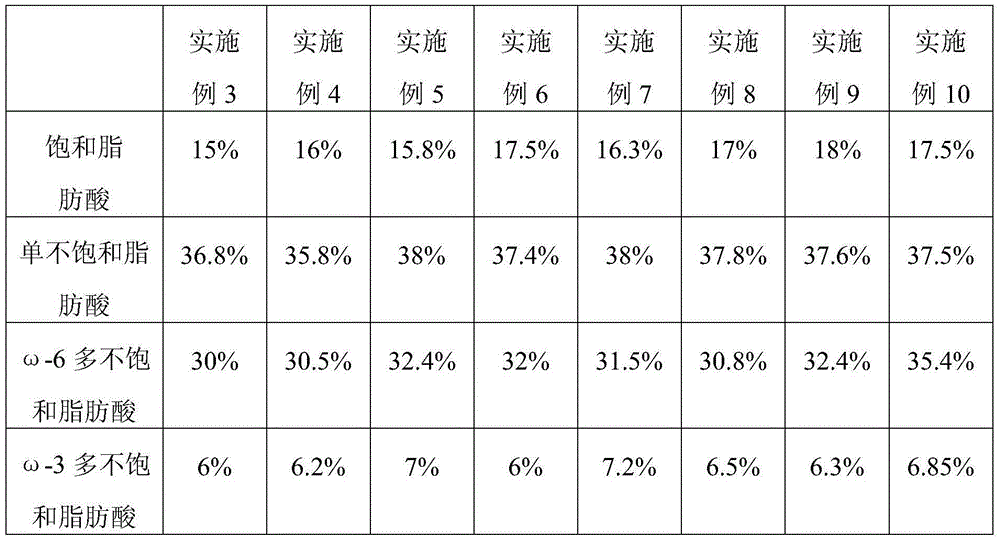

Nutrient plant blending oil and production method thereof

The invention provides nutrient plant blending oil. The nutrient plant blending oil comprises components in percentage by weight as follows: 20%-40% of rapeseed oil, 10%-20% of linseed oil, 6%-12% of sunflower seed oil, 5%-15% of peanut oil, 4%-8% of wheat germ oil, 2%-10% of camellia seed oil, 1%-5% of seabuckthorn seed oil, 3%-8% of walnut oil, 2%-5% of grape seed oil, 0.1%-2% of allicin, 0.1%-2% of docosahexaenoic acid, 0.1%-2% of vitamin E, 0.1%-2% of curcumin and 0.1%-1% of resvaritrol. The production method of the blending oil comprises steps as follows: the raw materials are weighed in the proportion and then added to a mixing vessel, nitrogen is injected at the temperature of 40-60 DEG C, so that pressure in the mixing vessel can keep 0.1-0.5 Mpa, vibration and blending are performed through ultrasonic waves for 60-120min and then are left to stand for 3-5 hours, and primary blending oil is obtained; then bentonite and activated carbon in the weight ratio of 1:(2-4) are added to the primary blending oil, the mixture is stirred for 30-60min at a rotation speed of 80-100 r / min, then solid impurities are filtered out, and the nutrient plant blending oil is obtained. The blending oil integrates edible and health-care functions of various kinds of plant oil, and the nutrient plant blending oil has more nutrition and health-care functions due to addition of functional additives.

Owner:SICHUAN CHAOFENG GRAIN & OIL

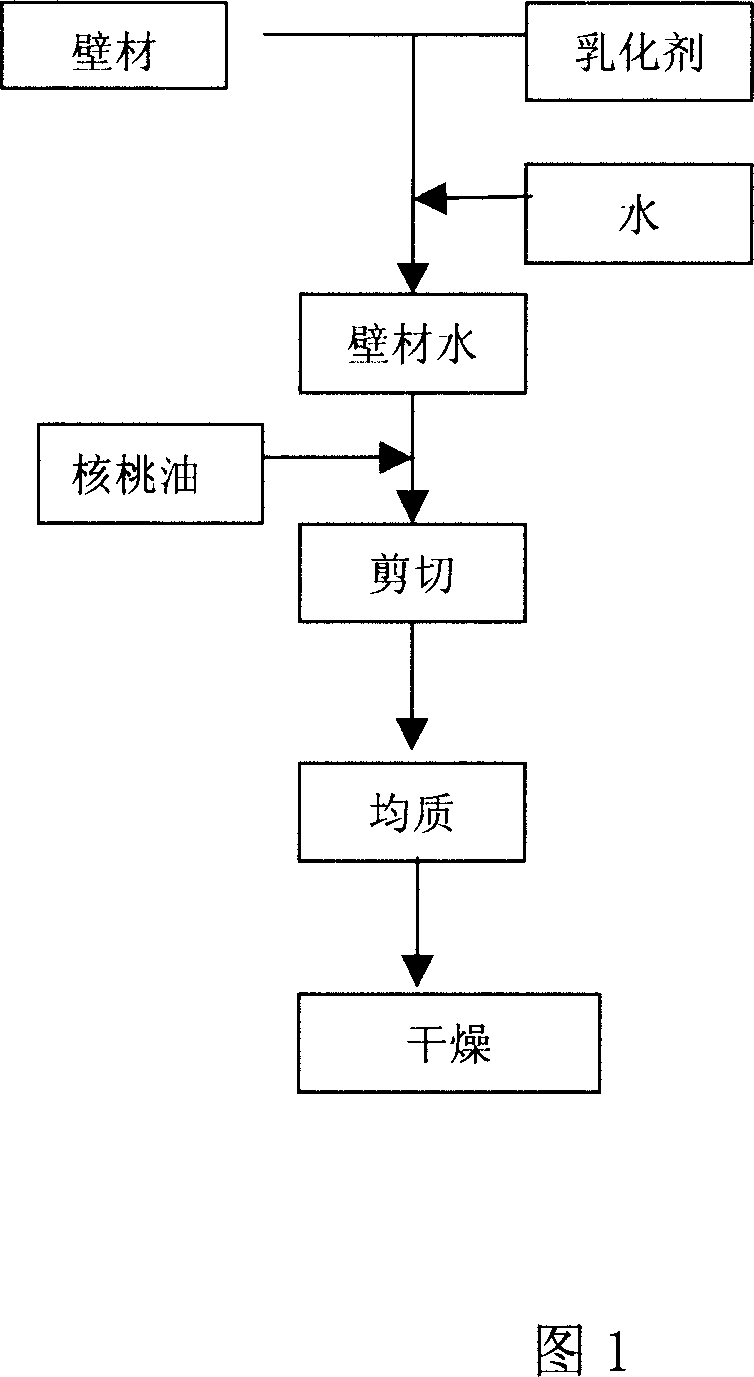

Microcapsule powder and preparation method thereof

InactiveCN105996040AEffectively Regulate CholesterolImprove immunityFood homogenisationInorganic compound food ingredientsOil phaseLinseed oil

The invention provides microcapsule powder containing linseed oil and walnut oil. The microcapsule powder is prepared from, by weight, 1-1000 parts of wall material, 5000-50000 parts of core material, 10-1000 parts of emulsifier and 1-200 parts of stabilizer, the wall material comprises one or multiple of dextrin, starch and protein, and the core material comprises the linseed oil and the walnut oil according to a weight ratio of 1-2:1. The invention further provides a preparation method of the microcapsule powder. The preparation method includes: sequentially preparing a water phase and an oil phase; emulsifying, homogenizing, and spraying and drying to obtain the microcapsule powder. The microcapsule powder has the advantages that the linseed oil and the walnut oil are mixed and emulsified according to a certain proportion to prepare oil-in-water microcapsule powder, and the microcapsule powder is easy to store, long in shelf life, balanced in nutrition, needless of antioxidant adding and highly good for human health.

Owner:FUJIAN NORMAL UNIV

Plants blend oil

ActiveCN101194653AReasonable contentAppropriate compositionEdible oils/fatsFood preparationAdditive ingredientSunflower oil

The invention discloses a plant blend oil, which comprises peanut oil, corn germ oil, sunflower seed oil, tea seed oil, walnut oil, safflower oil and sesame oil, wherein the weight percentage of the peanut oil is 20-40 percent, the weight percentage of the corn germ oil is 20-40 percent, the weight percentage of the sunflower seed oil is 10-20 percent, the weight percentage of the tea seed oil is 3-10 percent, the weight percentage of the walnut oil is 3-10 percent, the weight percentage of the safflower oil is 3-10 percent, and the weight percentage of the sesame oil is 2-6 percent. The invention has the characteristics of high nutritional contents, balanced nutrition and no transgenic ingredients, and meets nutritional requirements of people.

Owner:莱阳齐花特香纯正花生油有限公司

Family balance formula oil and preparation method thereof

ActiveCN102239933AMeet the nutritional needs of oilPromote growth and developmentEdible oils/fatsLinseed oilEdible oil

The invention belongs to the field of edible oil, particularly relates to nutritive formula oil which is suitable for families in China, and has good stability and functions of promoting growth and development and assisting the blood fat reduction, and a preparation method thereof. The family balance formula oil provided by the invention is characterized by comprising the following raw materials in percentage by mass: 34.96-50% of oil tea camellia seed oil rich in monounsaturated fatty acid, 20-40% of corn oil rich in n-6 fatty acid, 5-10% of grape seed oil rich in n-6 fatty acid, 15-30% of linseed oil rich in n-6 fatty acid, 5-10% of walnut oil rich in n-6 fatty acid and 0.04-0.2% of mixed tocopheryl. The family balance formula oil has good cooking stability, and has the functions of promoting growth and development and assisting the blood fat reduction.

Owner:HUNAN DASANXIANG TEA OIL CO LTD

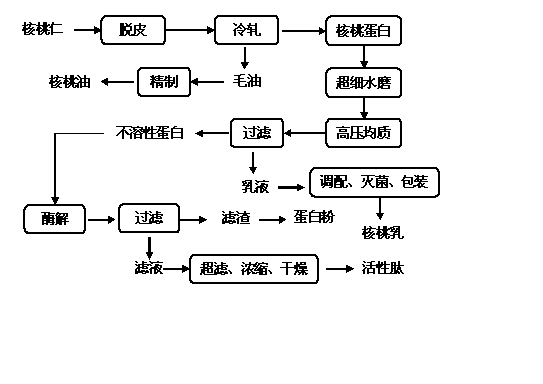

Deep processing method for preparing low-fat walnut milk, active peptide and protein powder by comprehensively utilizing walnut kernels

The invention aims at the high-value processing of walnut protein. A deep processing method comprises the following steps: firstly, separating out walnut oil by a low-temperature cold-rolling method to obtain walnut kernel protein; secondly, dissolving the soluble protein to prepare walnut milk drink through micro-grinding and homogenizing processes; thirdly, performing enzymatic hydrolysis on the insoluble walnut protein to obtain the active peptide through enzymatic degradation; and finally, developing the rest of protein residues into walnut powder so as to realize full-value utilization of the walnut protein.

Owner:JIANGNAN UNIV +1

Blending oil containing corn oil and preparation method of blending oil

ActiveCN103891924AWide variety of sourcesImprove securityEdible oils/fatsPOMEGRANATE SEED OILRapeseed

The invention belongs to the technical field of edible oil, particularly relates to blending oil containing corn oil, and further relates to a preparation method of the blending oil. The blending oil comprises maize germ oil, sesame oil, walnut oil, olive oil, peony seed oil, sunflower seed oil, rapeseed oil, lard oil, apple seed oil, grape seed oil, pomegranate seed oil, camellia oil, peanut oil, wheat germ oil, kiwi fruit seed oil, linseed oil and pine nut oil. The blending oil containing the corn oil has the beneficial effects that the source of nutrients is wide and the safety is high; a processing process is simple and the production cost is low; the blending oil is convenient to eat and the stability of the blending oil is higher than that of single oil; various types of edible oil beneficial to human health are blended to change the composition of fatty acids, so that the blending oil does not generate bad influences on the body and has the active effects of inhibiting and preventing cardiovascular and cerebrovascular diseases including hypertension, hyperlipidemia, atherosclerosis and the like, reducing serum cholesterol and triglyceride, eliminating in-vivo lipid hyperoxide and moistening skins.

Owner:SHANDONG SANXING CORN IND SCI CO LTD

Method for synchronously preparing walnut oil and walnut peptide

InactiveCN101962596AOperational securityEasy to operateCosmetic preparationsToilet preparationsFood additiveOil phase

The invention relates to a technology for synchronously preparing walnut oil and walnut peptide by means of microwave-assisted enzymolysis, belonging to the technical field of the food or the health food. The technology comprises the following steps of: removing the coat and the core of the walnut, grinding the walnut into walnut slurry, adding the water to prepare the slurry, hydrolyzing by adding the protease or the composite protease, treating by microwave, and centrifugally separating the oil phase, the peptide water phase and the residual solid phase, wherein the obtained oil phase is the cleaning and bright walnut oil which can meet the requirement of the green food; and further physically refining the oil phase at low temperature to be taken as the raw material oil of the high-class edible oil, the health food oil, the blend oil and the like. The obtained walnut peptide water solution can be directly used for preparing the degreased walnut peptide beverage by means of the enzyme inactivating, or can be used for preparing the active polypeptide product such as the walnut antioxidant peptide by means of the ultra-filtrating for the health food, the food additive, the nutrition reinforcing agent, the cosmetic, the daily chemicals and the like, or can be used for preparing the walnut peptide powder by means of the mist spray drying at low temperature. The technology improves the extraction efficiency of the walnut oil and the walnut peptide, and is simple in equipment, short in period, safe, low in energy consumption, high in use ratio and free of three-waste pollution.

Owner:KUNMING UNIV OF SCI & TECH

Blend oil and preparation method thereof

The invention discloses blend oil and a preparation method thereof. The blend oil is prepared by blending taking walnut oil as base oil, the blending is scientific, the nutrients are complete, and the nutritional values are high; the ingredients in the blend oil are as follows in percentage by weight: 3.12%-4.18% of saturated fatty acid, 53.6%-60.8% of monounsaturated fatty acid, 15.4%-25.6% of omega-6 linoleic acid, and 9.0%16.0% of alpha-linolenic acid; the ingredients of the blend oil includes walnut oil, linseed oil, grape seed oil, perilla oil, almond oil, sea buckthorn oil, evening primrose oil, rice bran oil, soybean oil, corn oil, peanut oil, rapeseed oil, sesame oil, sunflower seed oil, cotton seed oil, olive oil, cannabis oil, linseed oil, tea oil and additives. The blend oil is reasonable in price, complete in nutrients, long in shelf life, and has special flavor, and the preparation method is simple, and suitable for promotion.

Owner:SHAANXI RIRIXIN BIOTECH CO LTD

Extraction of hickory nut oil from water enzyme

The invention relates to the pecan oil which is a kind of natural health product, it is essentially an aqueous enzymatic extraction method of the pecan oil, the following is the process: (1) the peeled pecan kernel is milled according to the ratio of the weight of the material and the volume of the liquid is 1:3-5, the pecan kernel is milled approximately to 60-150 sieve number, and the juice is put out. (2) The pH of the juice will be adjusted: the pH of the juice from the milling process will be adjusted to 4.0-5.5 with chlorhydric acid and citric acid. (3) The process of thermolysis catalyzing: put the juice in the water bath, the temperature of which is 50-60DEG C,to thermolysis catalyze it for 1-5h,after the pH of it has been adjusted (4) Centrifuging to isolate it: the juice or above will be centrifuged at 4000-6000r / min for 15-3o minutes, the boiled oil which is at the super layer of the juice after the isolation will be exsucted out, and the boiled oil is just the the pecan oil that we need. The excellence of the method is: the oil yield and the oil quality are high, the technology is simple and secure, tand the cost is very lower.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

Nutritious health-caring vegetable blend oil

InactiveCN1806642AReasonable structureFull of nutritionEdible oils/fatsFood preparationVegetable oilPerilla oil

The invention relates to a nutriment health mixed plant oil which comprises (by weight percent): purple perilla oil 20-40%, flaxseed oil 10-30%, rapeseed oil 10-50%, soybean oil 1-20%, walnut oil 1-10%, and sunflower oil 1-10%. The vegetable oil also comprises tea polyphenol as fat antioxidative stabilizer, VE, omega-6 unsaturated fatty acid and omega-3 unsaturated fatty acid.

Owner:INST OF MEDICINAL PLANTS YUNNAN ACAD OF AGRI SCI

Nourishing and health care capsule with intelligence development and memory improvement function and method for making same

InactiveCN1919233AHigh nutritional valueEnhance memoryOrganic active ingredientsNervous disorderMemory improvementMarine fish

The invention discloses an intelligence developmental brain tonic hygienic soft capsule and preparing method, which comprises the following parts: calico salmon carrier extract oil (1-5)%, condensed deep-marine fish oil (50-65)%, walnut oil (15-25) %, perilla oil (5-20)%, phosphatidyl serine (1-5)% and vitamin E (0.1-0.2)%. The manufacturing method comprises the following steps: (1) preparing calico salmon carrier extract oil, (2) allocating, (3) metering filled soft capsule.

Owner:李富民

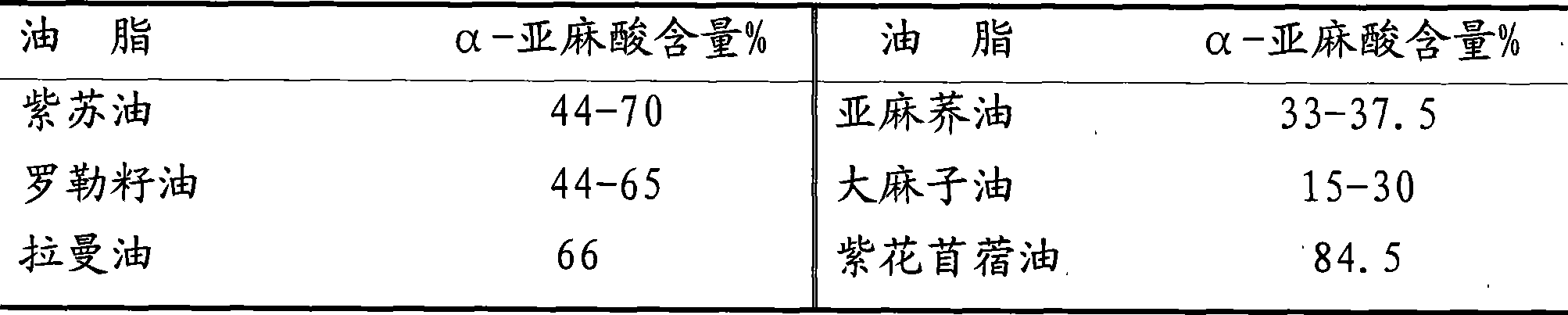

Blend oil rich in alpha-linolenic acid and capable of protecting cardiovascular system

The invention discloses blend oil rich in alpha-linolenic acid and capable of protecting the cardiovascular system. The blend oil is blended by at least five of linseed oil, eucommia seed oil, peony seed oil, purple perilla seed oil, walnut oil, tomato seed oil, safflower seed oil, acer truncatum seed oil and black sesame oil. The blend oil has the advantages that the content of the alpha-linolenic acid reaches 20-48%, the alpha-linolenic acid can convert into EPA and DHA needed by human bodies, the total content of saturated fatty acid is lower than 10%, and various fatty acids are coordinated in proportion and conform to the recommended amount of dietary nutrition guidelines; the raw material oil is obtained through cold pressing and physical refining, no chemically-synthesized antioxidant is added, and accordingly the blend oil is rich in active components capable of protecting the cardiovascular system and has an evident cardiovascular system protecting function.

Owner:厦门农特康生物科技有限公司

Brain tonifying and intelligence developing blend oil

ActiveCN102422907APromote intellectual developmentPromote growth and developmentEdible oils/fatsNervous systemSunflower oil

The present invention relates to a brain tonifying and intelligence developing blend oil. The oil is characterized in that: the blend oil comprises, by weight, 60-74% of a walnut oil, 6-9% of a peanut oil, 3-5% of a camellia-seed oil, 3-5% of a soybean oil, 2-5% of an olive oil, 4-6% of a polly seed oil, and 8-10% of a sesame oil. According to the blend oil of the present invention, the walnut oil is adopted as the main formula component, such that the intelligence developments of children and infants are promoted, good effects are provided for maintenance of the normal function operation of the nervous system, the growth and the development of the children are promoted, the bone density is maintained, and the immunity is strengthened; the walnut oil further provides effects of balance ofmetabolism and improvement of digestive system for infants and young children; the walnut oil is combined with the peanut oil, the camellia-seed oil, the soybean oil, the olive oil, the polly seed oil and the sesame oil to blend into the blend oil, such that other materials benefit for the infants are supplemented, the nutrition is balanced, the taste of the oil product is blended so as to increase the appetite.

Owner:金利油脂(苏州)有限公司

Walnut oil microcapsule and preparation method thereof

ActiveCN103238680AEliminate the peculiar fishy smellFlat surfaceFinished edible oils/fats preservationPolymer scienceMonoglyceride

In order to solve the problems that the granules are non-uniform, the surface is provided with cracks and recesses and the compactness of the microcapsule wall is low in the conventional microcapsule product and the product is low in thermal solubility, low in emulsifying property and high in sugar content and has the soybean smell, the invention provides a walnut oil microcapsule and a preparation method thereof belonging to the technical field of oil microencapsulation. The walnut oil microcapsule is prepared by taking 15-25 parts of walnut oil, 0.6-3.4 part of sucrose ester and 1.5-3.2 parts of monoglyceride as the core material and taking 3-10 parts of cane sugar, 18.3-27.6 parts of maltodextrin, 17.6-28.3 parts of peanut protein isolate and 1.3-3.5 parts of dipotassium phosphate as the wall material. Therefore, the prepared walnut oil microcapsule has the advantages of smooth surface, uniform particle size and high compactness of microcapsule wall.

Owner:INST OF AGRO FOOD SCI & TECH SHANDONG ACAD OF AGRI SCI

Edible mixed oil containing highland barley bran oil

InactiveCN101455243AReasonable structureFull of nutritionEdible oils/fatsFood preparationBARLEY BRANBlack Pepper Oil

The present invention relates to an edible mixed oil containing highland barley bran oil. The mixed oil contains 30-60 weight parts of edible base oil, 35-65 weight parts of highland barley bran refined oil, and 1-5 weight parts of seasoning oil, wherein, the edible base oil is one of the coconut oil, palm oil, rapeseed oil, tea seed oil, olive oil, linseed oil or perilla seed oil: the seasoning oil is one ore more of the ginger oil, garlic oil, scallion oil, onion oil, red onion oil, sesame oil, pepper oil, bathypelagic fish oil, vitamin E, sunflower oil, walnut oil, almond oil, coriander oil, star aniseed oil, anise oil, chili oil, black pepper oil, cinnamon oil, mushroom oil, litsea cubeba oil, celery oil or leek oil. The mixed oil is rich in linolic acid, and has equalizing content of saturated fatty acids, mono-unsaturated fatty acids, polyunsaturated fatty acids, and a significant reduction in product prices, to satisfy the consumer demand.

Owner:智芯睿控(深圳)科技有限公司

Technique for producing walnut oil by cold pressing and cold refining method

The main contents of the invention are as follows: 1. the walnut kernel picked up in the same year is selected, and impurities of the walnut kernel are removed; 2. the walnut kernel is soaked in warm water at the temperature of between 55 and 60 DEG C for 10 minutes. 3. walnut kernel is peeled off by the washing of high-pressure water at the pressure of between 0.4 and 0.5MPa; 4. the walnut kernel is dried by hot air at a temperature of between 80 and 90 DEG C; 5. the walnut kernel is put in a cold pressing machine to extract walnut oil; 6. the crude walnut oil is stood for sedimentation for 10 to 12 hours; 7. the crude walnut oil is filtered by a plate-and-frame filter and a microfroc filter; and 8. filling. The invention is characterized in that all processes are performed at the normal temperature, and are not affected by the high temperature, and no any solvent is left, thereby keeping the natural quality of the walnut oil.

Owner:王丰俊 +1

Nutrient blend oil with balanced fatty acid proportion

InactiveCN101502290AMeet the recommended valueReduce usageEdible oils/fatsFood preparationBiotechnologyOMEGA-3 POLYUNSATURATED FATTY ACIDS

The present invention provides nutritional blend oil with balanced fatty acid proportion, wherein the perilla herb oil and flaxseed oil respectively accounts for 5-30% according to the weight percentage in the oil. The perilla herb oil and flaxseed oil are mixed with a random ratio, and the balance is sunflower seed oil, sesame oil and walnut oil. The sunflower seed oil, sesame oil and walnut oil are deployed according to the confirmed content of omega-6 and omega-3 polyunsaturated fatty acids (PUFA) in the perilla herb oil and flaxseed oil to cause that the weight ratio between the final omega-6 and omega-3 polyunsaturated fatty acids in the nutritional blend oil obtains 4-6: 1. The sesame oil is preferably the unrefined sesame oil. The weight percentage content of sesame oil is preferably larger than 10 The nutritional blend oil of the invention has an appropriate omega-6 / omega-3 ratio, namely the omega-6 / omega-3 = 4-6: 1. The ratio accords with the commend value of ''concept of reference intake dose of nutrients from diets''. The nutritional blend oil of the invention can effectively prolong the shelf life or reduce the using dosage of added antioxidant.

Owner:大连圣基投资咨询有限公司

Method for making high-embedding-ratio powder walnut oil

InactiveCN101023763AIncrease contentHigh nutritional valueEdible oils/fatsMonoglycerideSuccinic acid

The present invention discloses a method for preparing powder walnut oil with high embedding rate. Said method includes the following steps: (1), after the monoglyceride, lecithine and Tween-60 as emulsifying agent are dissolved in water, successively adding octylene succinic acid esterified starch HI-CAP100 and maltodextrin as wall material to obtain wall material aqueous solution for stand-by; (2), adding walnut oil into the above-mentioned wall material aqueous solution, shearing and homogenizing to make the walnut oil be uniformly dispersed in the wall material aqueous solution; under the action of emulsifying agent forming O / W (oil-in-water) type emulsion with good emulsification stability; and (3), utilizing drying process to remove water content from emulsion, making wall material be formed into film, then the walnut oil can be uniformly embedded by all material film so as to obtain the invented powder walnut oil with high embedding rate.

Owner:BEIJING ACADEMY OF AGRICULTURE & FORESTRY SCIENCES

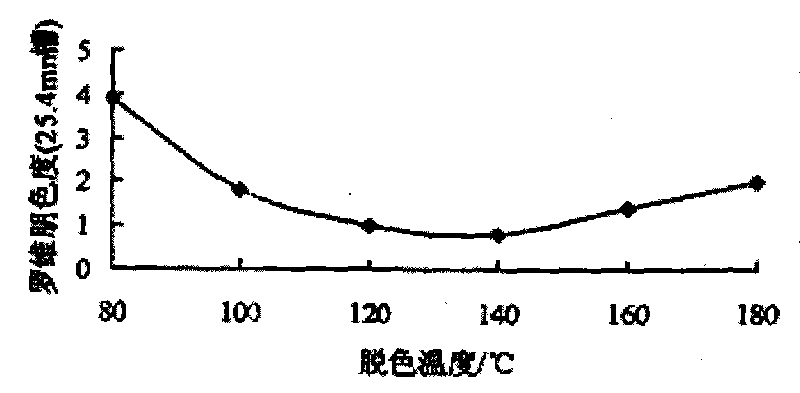

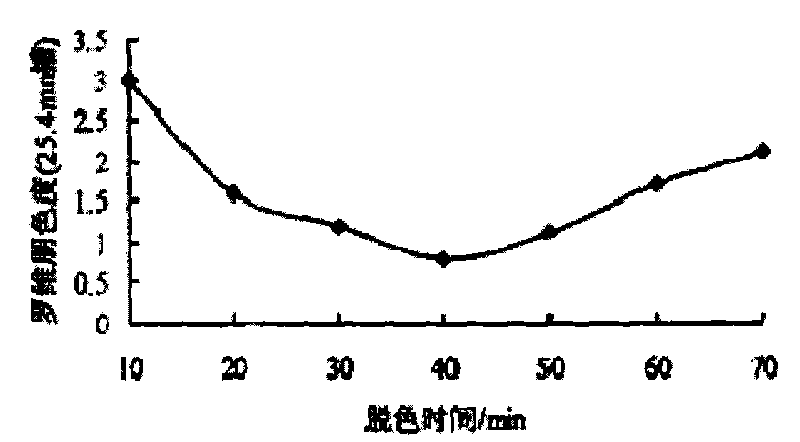

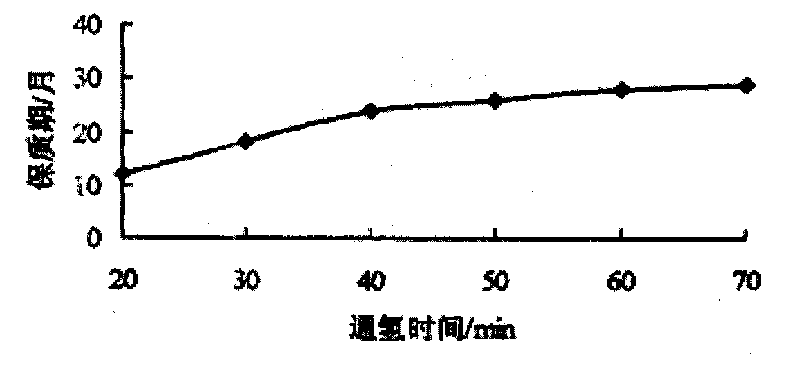

Walnut oil refining method

InactiveCN101691520ALow peroxide valueSolve the technical difficulties of easy oxidationFatty acid hydrogenationFatty-oils/fats refiningSocial benefitsWalnut oil

The invention provides a walnut oil refining method; walnut crude oil is prepared into the refined walnut oil by alkali refining, hydration, decoloring, hydrogenation, deodorization and drying; by utilizing multiple technologies comprehensively, the peroxide value of the walnut oil is reduced, the technical difficult point that the walnut oil is easy to oxidize is solved well, and the quality of the walnut oil is improved, the quality of the product is stable and the quality guarantee period of the walnut oil can reach more than 24 mouths. The method has the advantages of rational technology, advanced technology, strong innovativeness and good economic and social benefits.

Owner:石家庄市丸京干果有限公司

Extraction of aqueous solvent from hickory nut oil

The invention relates to a method to deoxidize the end coarse oil product and abstract gasoline and diesel oil with the coarse oil waste, and the facility and device used. The process is as following: (1)The material waste will be catalytic cracked at the temperature 50-480DEG C after some quartz sand,and grains of sand have been put in, the material waste is just the coarse oil waste. (2) Te gas from the cracking will be catalytic cracked further in the fixed bed and the oil steam can be gained. (3) The oil steam will be fractionated and the gasoline and diesel oil fraction will be collected respectively. (4) The gasoline and diesel oil fraction will be refined respectively. A lot of processes are set to remove the impurity in the whole technology, so the quality of product can be assured, and the facility is simple and the volume of it can be reduced, the technology has been predigested, and the production period has been reduced. The quality of the oil gained with the method is high, the transparence of the oil is also high, just like the pure water, the carbon content of the oil is low, and the oil belongs to gasoline without lead, the oil can reach the gasoline standard of the Chinese Standard of 93# gasoline, the yield of the oil is high, the quantity of the whole oil gained from the method is as much as the weight of 8-83% of the diesel oil waste.

Owner:SHENYANG INST OF APPLIED ECOLOGY - CHINESE ACAD OF SCI

Edible oil for infants

InactiveCN101731370AImprove developmentImprove thinkingEdible oils/fatsFood preparationPerilla oilRecommended Intake

The invention discloses edible oil for infants, comprising the following components in percentage by weight: 49-50% of sunflower seed oil, 9-11% of flaxseed oil, 9-11% of perilla oil, 9-11% of sesame oil and 19-21% of walnut oil. In the finished product of the edible oil for infants, total fatty acid comprises the following fatty acids forming fat by weight percent: 7-15% of saturated fatty acid, 15-25% of monounsaturated fatty acid, 53-63% of n-6 polyunsaturated fatty acid and 10-18% of n-3 polyunsaturated fatty acid, wherein, the total polyunsaturated fatty acid accounts for 68-80% of the total fatty acid. The invention is designed on the basis of intake and ratio of fat and fatty acid recommended by Chinese Nutrition Society to Chinese residents, fatty acid proportion is reasonable, so the oil is very suitable for infants to eat. The ratio of linolenic acid to linoleic acid is approximate to 1:4; and the content of linolenic acid can promote the growth of infant brains, thereby enhancing brain power and memory.

Owner:中欧天然食品股份有限公司

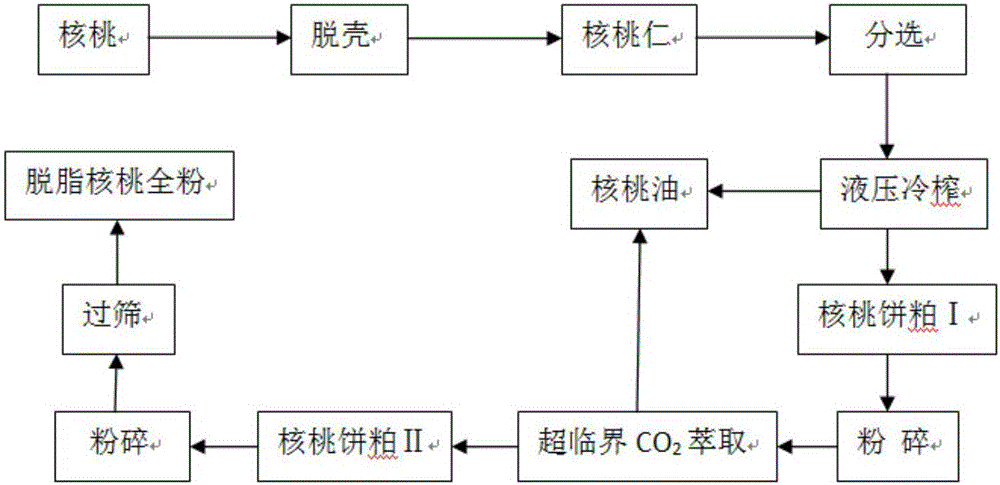

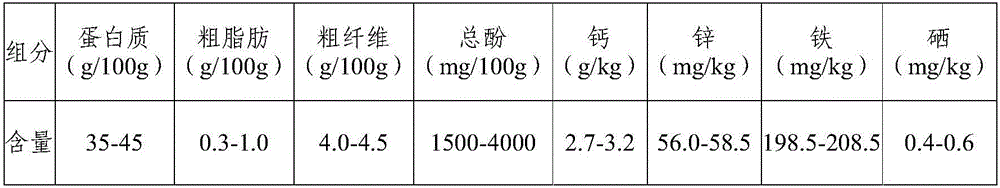

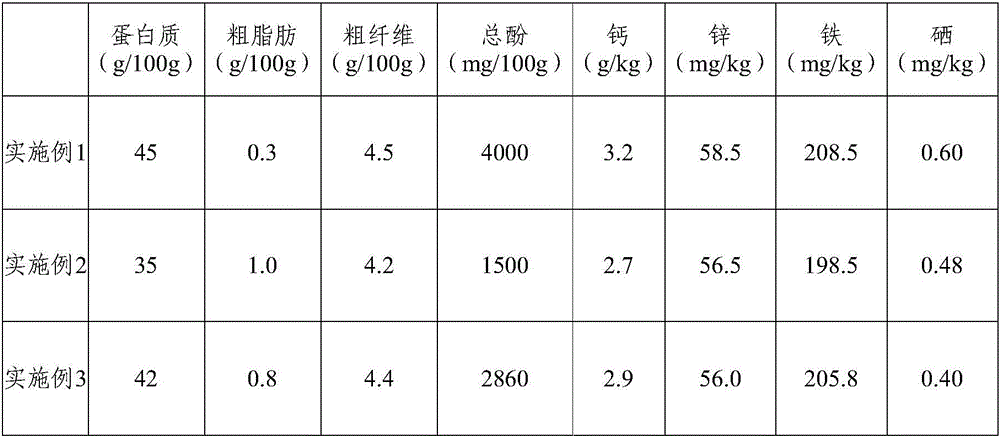

Pure walnut skim powder and manufacturing method and application thereof

The invention provides pure walnut skim powder and a manufacturing method thereof. The pure walnut skim powder contains walnut protein, polyphenols, crude fibers, trace elements and mineral substances. The content of walnut fat is no more than 3%, and the adverse effect on the quality of the walnut powder due to oxidation and rancidity of walnut fat is prevented. The pure walnut skim powder is made through associative de-fatting by hydraulic cold-pressing and supercritical CO2 extraction. The two methods don't cause denaturation of walnut protein, and in a pre-treatment process, peel of walnut seeds is not removed, thereby furthest preserving polyphenols in the peel and establishing foundation for well development of a curative effect. The pure walnut skim powder can be applied to a cooked wheaten food or a baked food which is low in color and taste requirements and has a walnut curative effect. The curative effect of walnut nutritional ingredients is furthest developed; reuse of by-products produced from oil expression of walnuts is promoted; and the development of walnut industry is accelerated.

Owner:BEIJING ACADEMY OF AGRICULTURE & FORESTRY SCIENCES

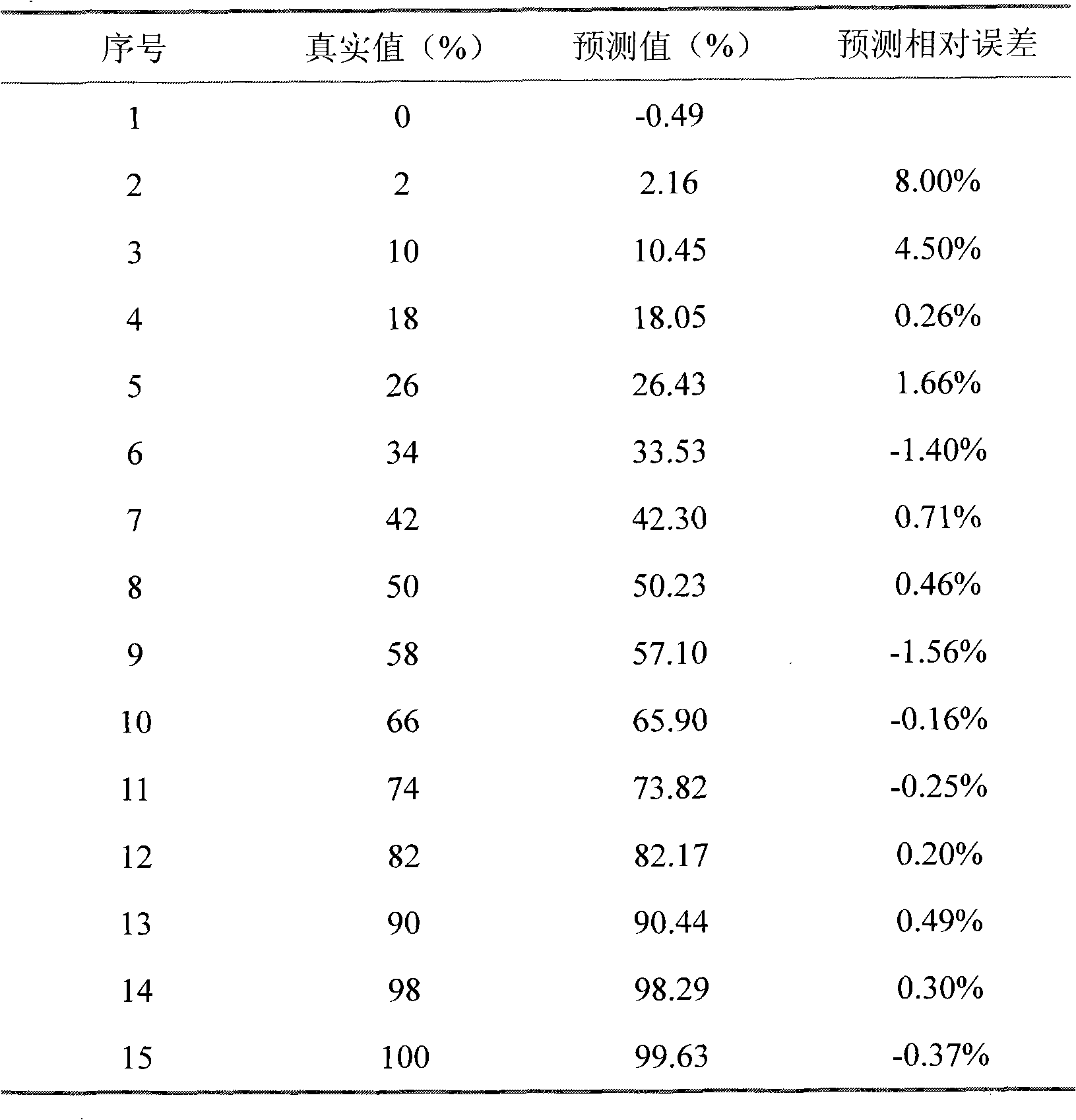

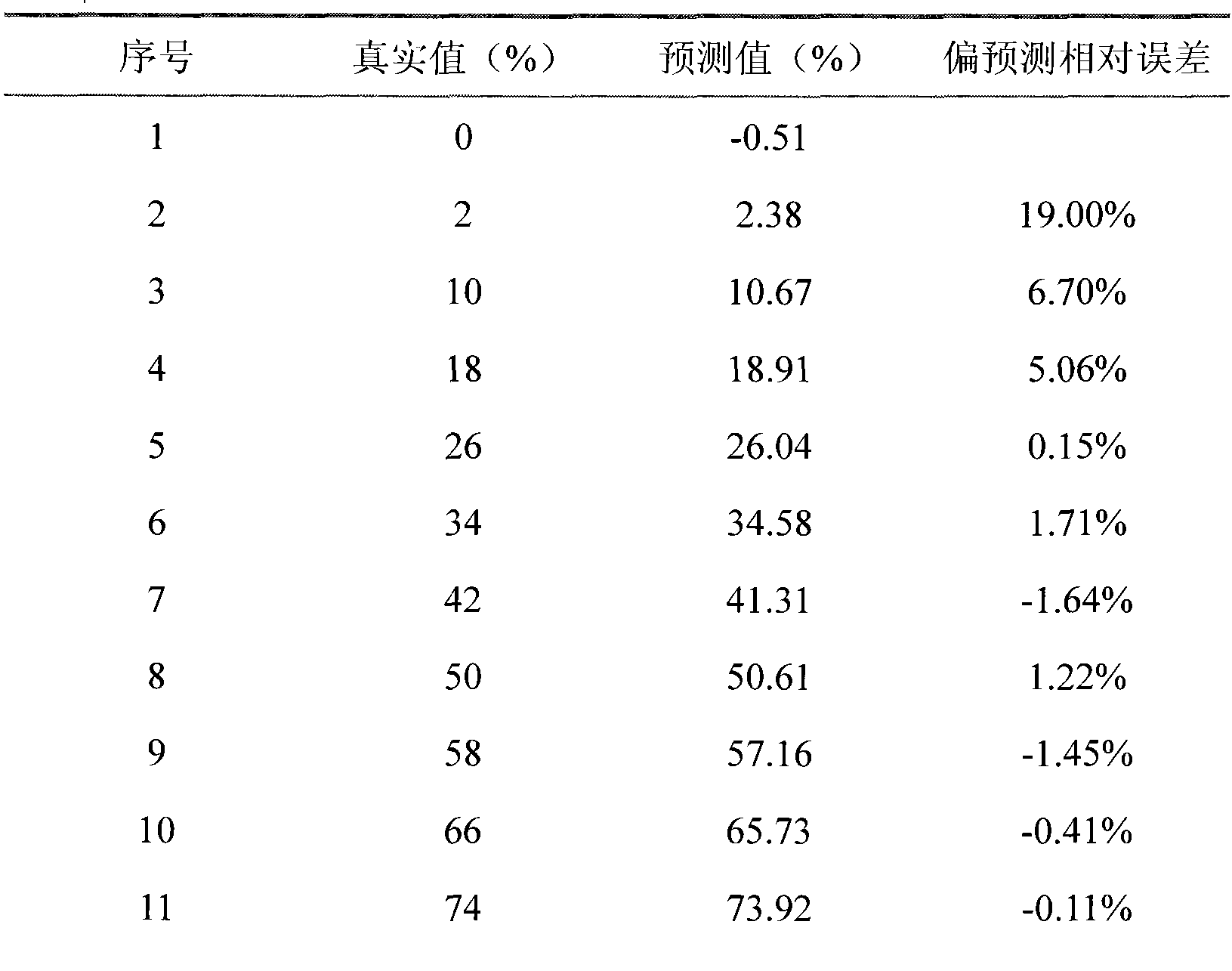

Method for identification and content determination of walnut oil

InactiveCN101936902AQuick analysisMeet testing needsPreparing sample for investigationFluorescence/phosphorescenceFluorescence spectrometryContent determination

The invention relates to a method for identification and content determination of walnut oil, which mainly comprises the following operating steps of: (1) manufacturing a sample of mixed oil; (2) manufacturing a detection sample; (3) rapidly measuring the fluorescence spectra of pure walnut oil, pure soybean oil and the detection sample of the mixed oil by using a synchronous fluorescence method; and (4) analyzing and processing spectrum data. The method has easy and simple operation and good effect, the rapid detection of walnut oil content in the mixed sample of the walnut oil and the soybean oil can be realized, and the method is applicable to the quality control field of pure walnut oil and walnut blend oil.

Owner:KUNMING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com