Patents

Literature

2501 results about "Linseed oil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Linseed oil, also known as flaxseed oil or flax oil, is a colourless to yellowish oil obtained from the dried, ripened seeds of the flax plant (Linum usitatissimum). The oil is obtained by pressing, sometimes followed by solvent extraction. Linseed oil is a drying oil, meaning it can polymerize into a solid form. Owing to its polymer-forming properties, linseed oil can be used on its own or blended with combinations of other oils, resins or solvents as an impregnator, drying oil finish or varnish in wood finishing, as a pigment binder in oil paints, as a plasticizer and hardener in putty, and in the manufacture of linoleum. Linseed oil use has declined over the past several decades with increased availability of synthetic alkyd resins—which function similarly but resist yellowing.

Method for supplementing the diet

InactiveUS6579544B1Increased susceptibilityPrevent diseaseHeavy metal active ingredientsBiocideDietary supplementAlpha-Lipoic Acid

A dietary supplement blend composition is disclosed, the basic formulation of the composition containing vitamins, minerals, and carotenoids. The composition can also contain bioflavonoids, cartilage protectors such as glucosamine or chondroitin, alpha-lipoic acid, coenzyme Q10, and a source of omega-3 fatty acids such as flax seed oil. The composition is beneficial for improving health and preventing disease, particularly for degenerative conditions. A method for supplementing the diet is also disclosed, wherein the quantity of daily rations of the dietary supplement blend composition is determined based on the person's age, body weight, and quality of diet.

Owner:NUTRIEX

Food spreads

The present invention is of a food spread containing a mixture of at least one edible oil of natural or synthetic origin and a monoglyceride. The oil is preferably one or more of the oils from the group of olive oil, avocado oil, canola oil, soybean oil, sunflower oil, nut oils, walnut oil, peanut oil, safflower oil, cottonseed oil, coconut oil, rice bran oil, mustardseed oil, camelina oil, chia oil, flaxseed oil, perilla oil, fish oil, palm oil, sesame oil, wheatgerm oil, jojoba oil or corn oil. More preferably an oil such as avocado oil, fish oil, palm oil or olive oil is used and most preferably the oil is olive oil and fish oil. The monoglycerides used are preferably derivatives of oleic, or palmitic acid. The oil is present preferably in an amount of from about 85 to about 98 percent and most preferably in an amount of from about 93 to about 96 percent. The more monoglyceride used, the greater the degree of solidity of the food spread at room temperature. It is therefore possible to produce a desired degree of solidity, by changing the proportion of monoglyceride.

Owner:DR EGER OLIVE OIL PROD IND

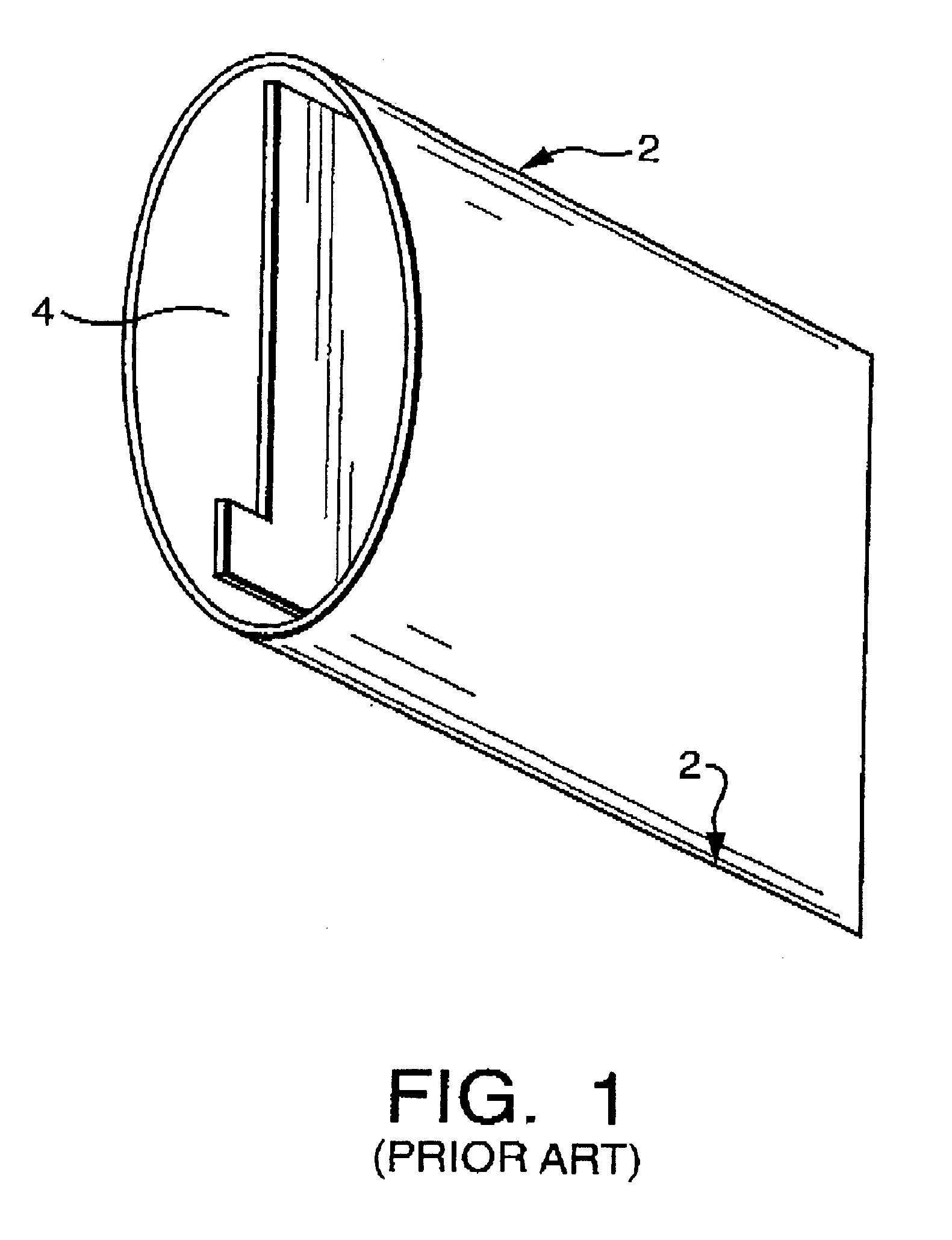

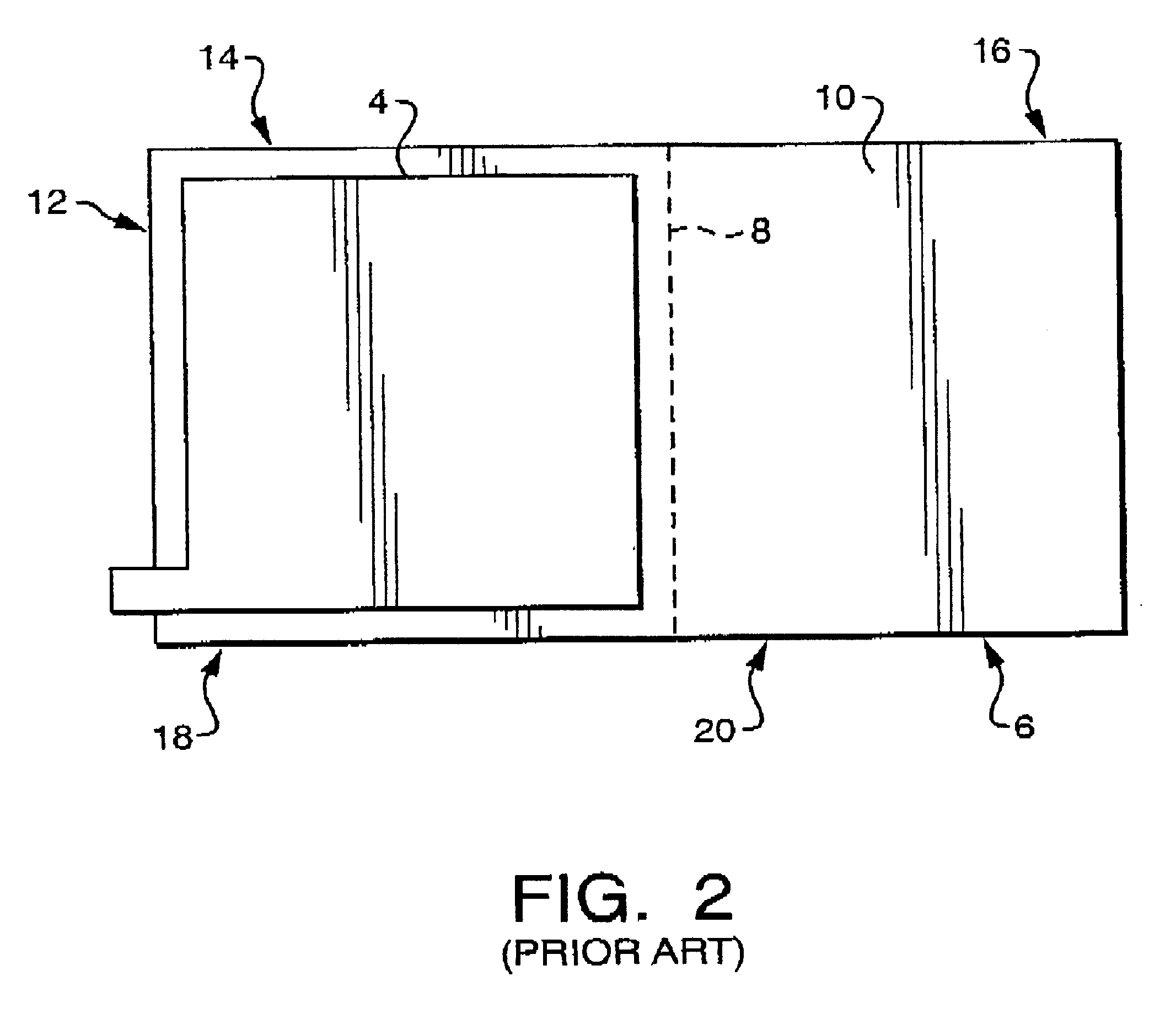

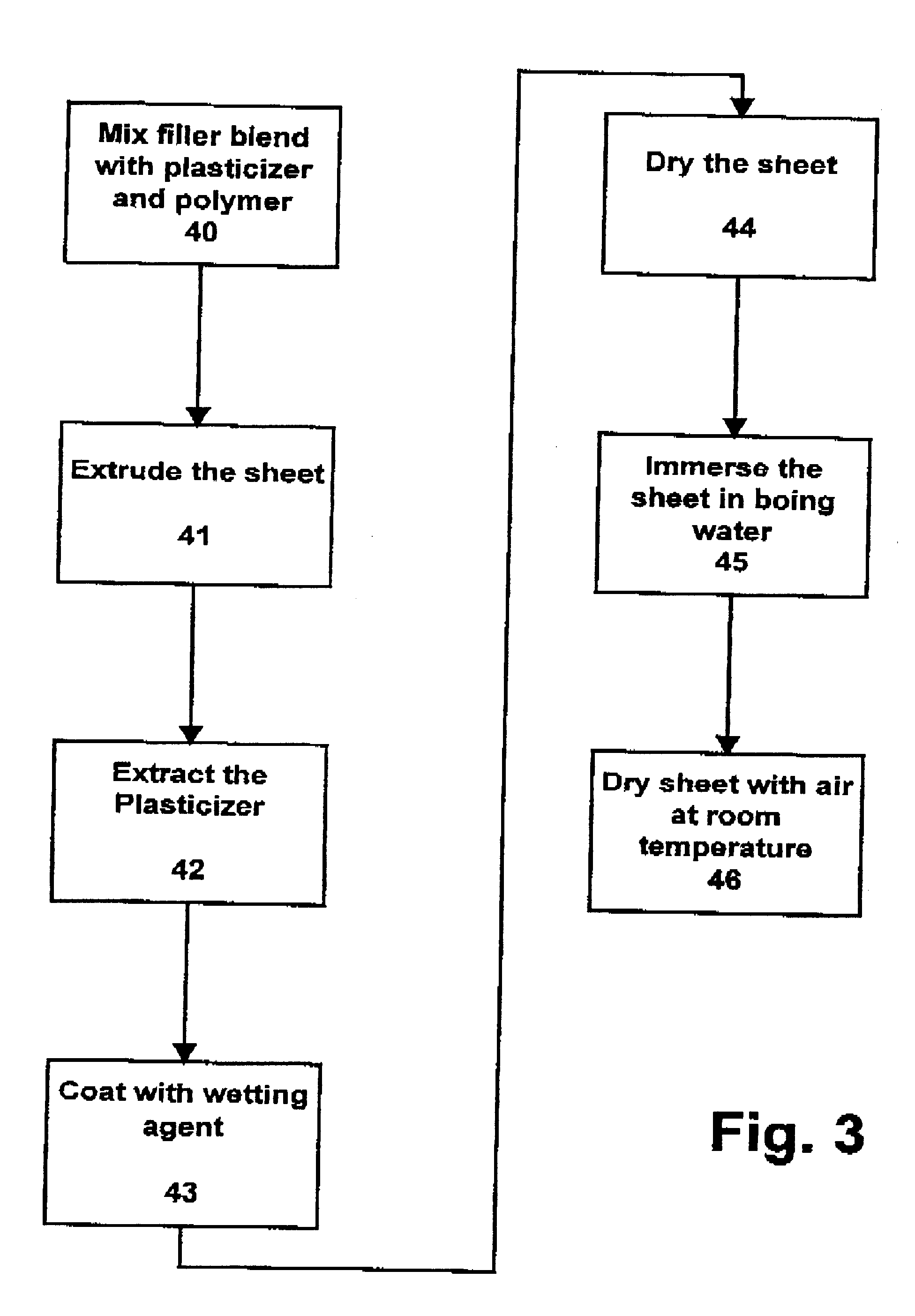

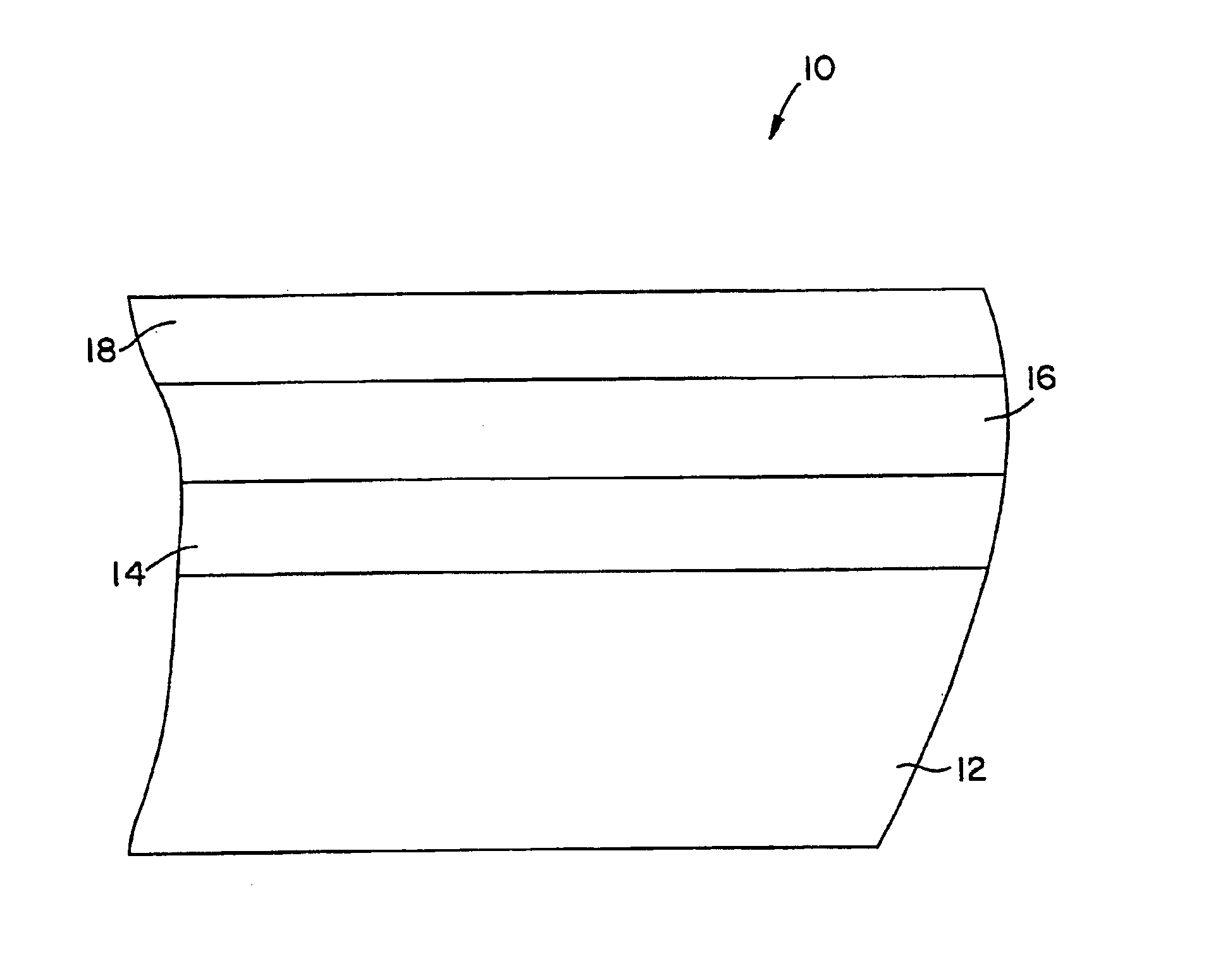

Microporous membrane battery separator for silver zinc batteries

InactiveUS6372379B1Improve cycle lifeExtended calendar lifeSilver accumulatorsCell component detailsPolyolefinFuel oil

A separator membrane for use in silver-zinc batteries is produced by extruding a blend of two fillers with the same chemical formula but different particle size. A polyolefine polymer and a plasticizer are blended and extruded to form a thin sheet of 1 to 10 mil thickness. The plasticizer is then extracted to leave submicron voids in the membrane. Plasticizers are added as processing aids, and can be either soluble or insoluble in water, and include petroleum oils, lubricating oils, fuel oils, and natural oils such as tall oils and linseed oils. The oil are then extracted from the membrane by conventional procedures such as single stage extraction using a suitable solvent. Commercially available wetting agents known to the art such as dodecylphenoxy polyethoxy ethanol and isooctyl phenyl polyethoxy ethanol are coated onto the sheet to improve wettability. The sheet is then dried, and boiled in distilled water for one minute or more, before being finally dried.

Owner:ZPOWER LLC

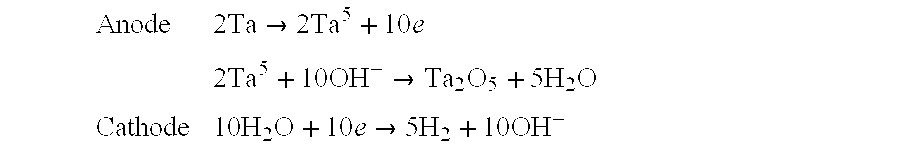

Protective coating for electrolytic capacitors

InactiveUS6864147B1Low dissipation factorLow leakage currentSolid electrolytic capacitorsSemiconductor/solid-state device manufacturingShellacElectrolysis

A solid electrolytic capacitor that comprises an anode that contains a valve-action metal (e.g., tantalum, niobium, and the like) and a dielectric film overlying the anode is provided. The capacitor also comprises a protective coating overlying the dielectric film, wherein the protective coating contains a relatively insulative, resinous material. For example, in one embodiment, the resinous material can be a drying oil, such as olive oil, linseed oil, tung oil, castor oil, soybean oil, shellac, and derivatives thereof. The capacitor also comprises a conductive polymer coating overlying the protective coating. As a result of the present invention, it has been discovered that a capacitor can be formed that can have a relatively low leakage current, dissipation factor, and equivalents series resistance.

Owner:KYOCERA AVX COMPONENTS CORP

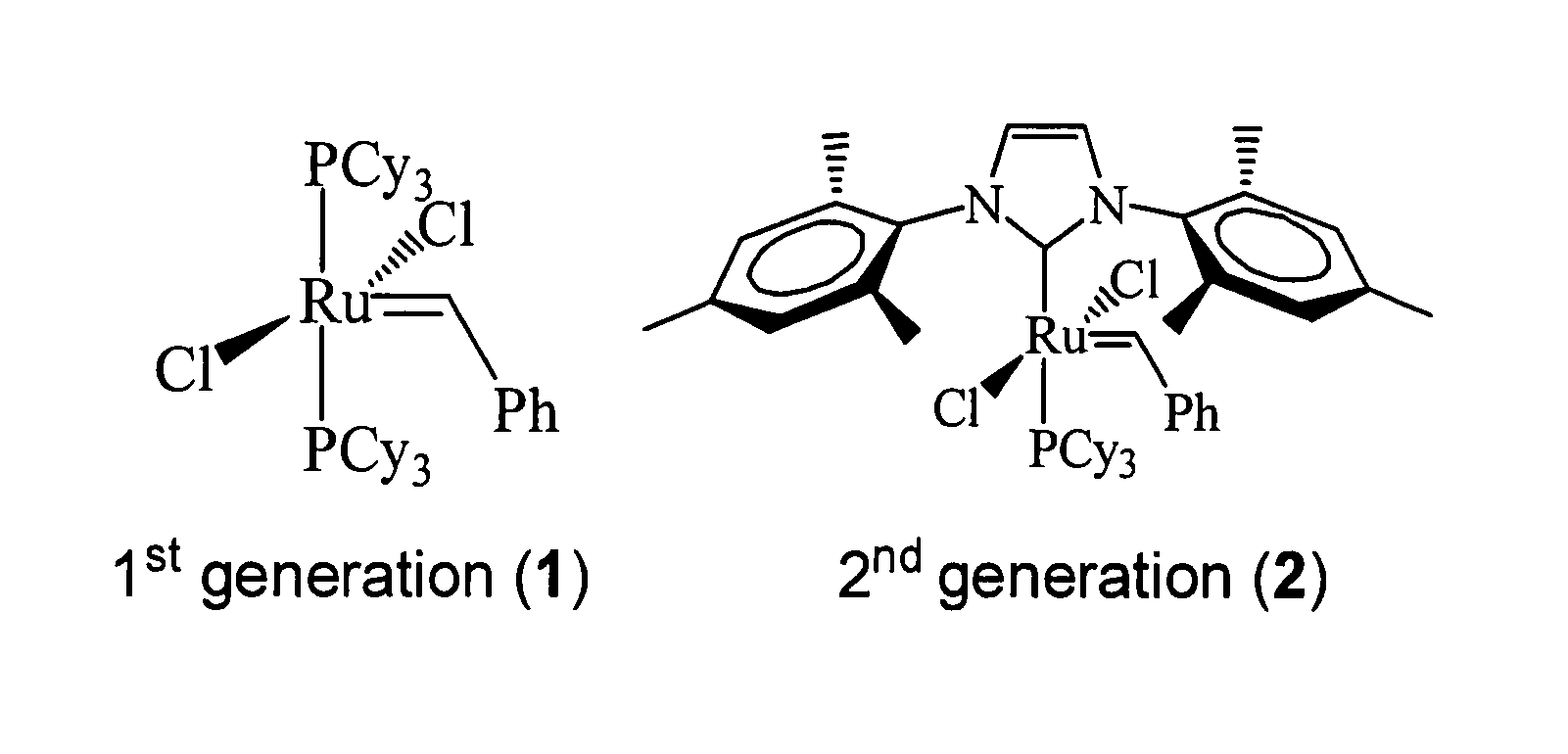

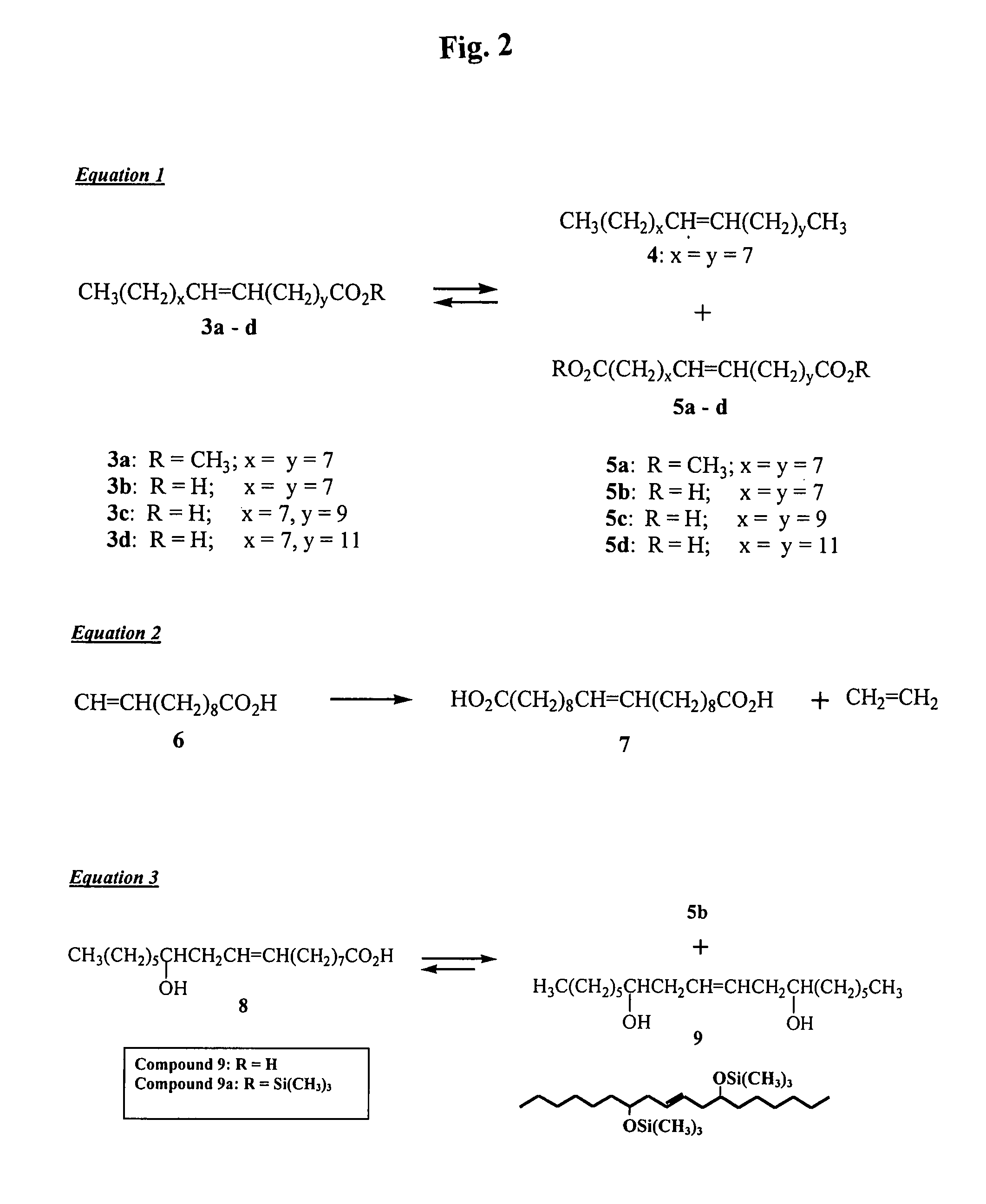

Method of producing dicarboxylic acids

InactiveUS7534917B1Organic compound preparationCarboxylic acid esters preparationCarboxylic acidDouble bond

A method of producing dicarboxylic acids (e.g., α,ω dicarboxylic acids) by reacting a compound having a terminal COOH (e.g., unsaturated fatty acid such as oleic acid) and containing at least one carbon-carbon double bond with a second generation Grubbs catalyst in the absence of solvent to produce dicarboxylic acids. The method is conducted in an inert atmosphere (e.g., argon, nitrogen). The process also works well with mixed unsaturated fatty acids obtained from soybean, rapeseed, tall, and linseed oils.

Owner:US SEC AGRI

Healthy food spreads

InactiveUS6117476AGreat degree of solidityUnlimited shelf lifeEdible oils/fats with aqeous phaseFood borneMonoglyceride

The present invention is of a food spread containing a mixture of an edible oil of natural origin and a monoglyceride. The oil is preferably one or more of the oils from the group of olive oil, avocado oil, canola oil, soybean oil, sunflower oil, peanut oil, safflower oil, cottonseed oil, coconut oil, rice bran oil, mustardseed oil, camelina oil, chia oil, flaxseed oil, perilla oil, fish oil or corn oil. More preferably an oil such as avocado oil or olive oil is used and most preferably the oil is olive oil. The monoglycerides used are preferably derivatives of oleic, or palmitic acid. The ratio of oil to monoglyceride is preferably from about 9 to about 1 to from about 49 to about 1 and most preferably from about 15 to about 1 to from about 24 to about 1. The more monoglyceride used, the greater the degree of solidity of the food spread at room temperature. It is therefore possible to produce a desired degree of solidity, by changing the proportion of monoglyceride.

Owner:DR EGER OLIVE OIL PROD IND

Edible mixed oil

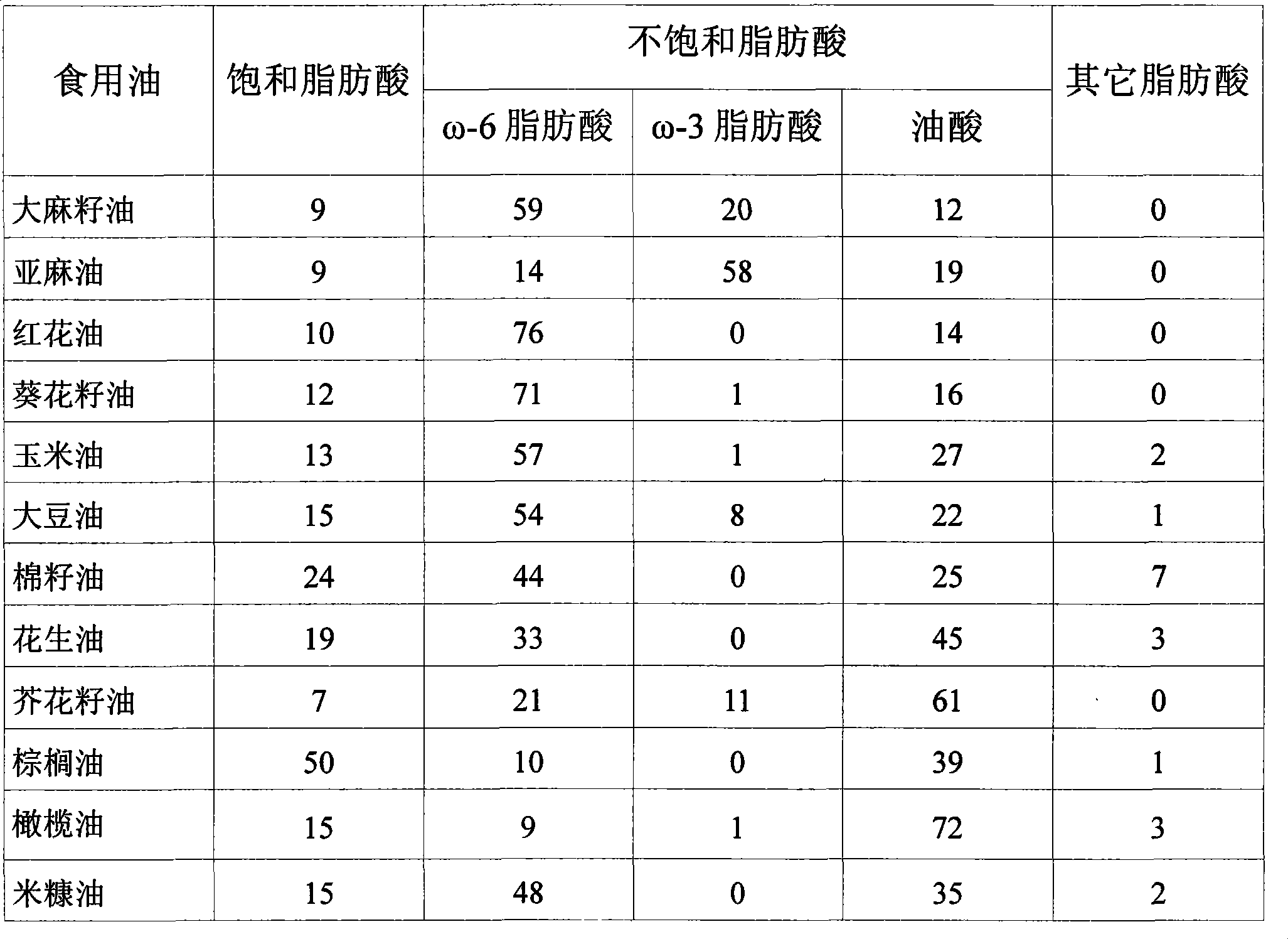

ActiveCN101422200AReduce chronic diseaseEdible oils/fatsFood preparationVegetable oilOMEGA-3 POLYUNSATURATED FATTY ACIDS

The invention relates to an edible blend oil, which aims at solving the problem of the improper ratio between Omega-6 polyunsaturated fatty acid and Omega-3 polyunsaturated fatty acid in the current single plant edible oil and provides an edible plant blend oil with the ratio between Omega-6 polyunsaturated fatty acid and Omega-3 polyunsaturated fatty acid being the best, meeting the health need of Chinese residents and simultaneously being capable of controlling the amount and stability of saturated fatty acids. The technical keys are as follows: the edible blend oil is prepared with a hemp seed oil and another edible plant oil or other edible plant oils according to weight percentage; wherein, the hemp seed oil is 8 to 85 and the edible plant oil is 15 to 92; and the other edible plant oil can be as follows: grape seed oil, olive oil, camellia oil, rice bran oil, safflower oil, canola oil, sunflower oil, corn oil, linseed oil, sesame oil, rapeseed oil, soybean oil, peanut oil and other edible plant oils. The content of the saturated fatty acids does not exceed 15 percent and the ratio between Omega-6 and Omega-3 is 4-6:1.

Owner:淮安市淮安区综合检验检测中心

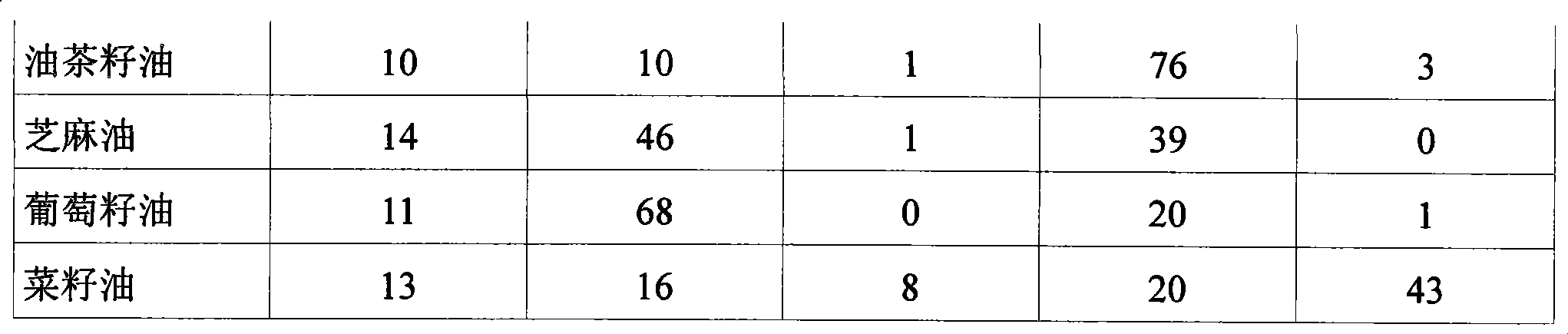

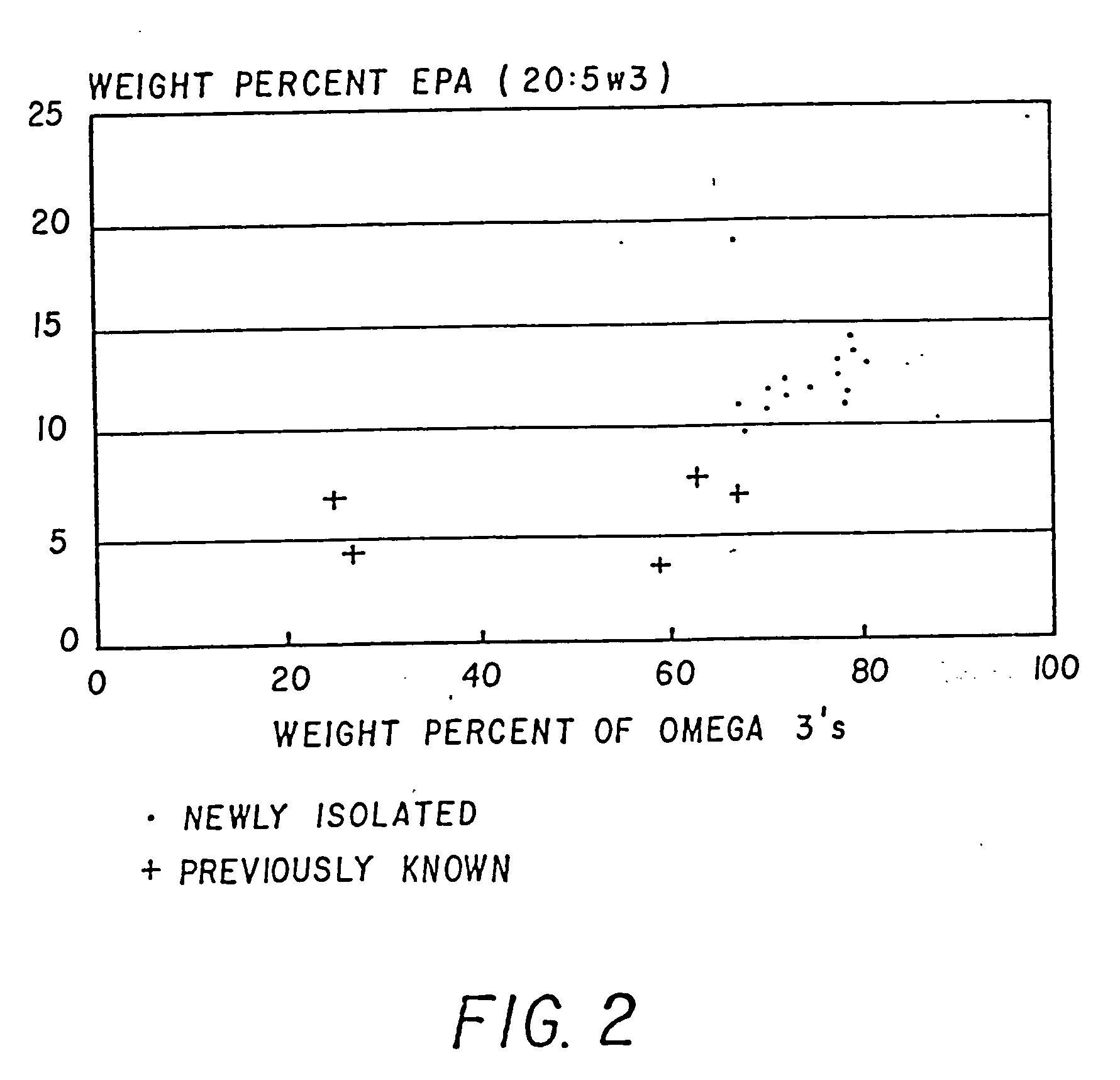

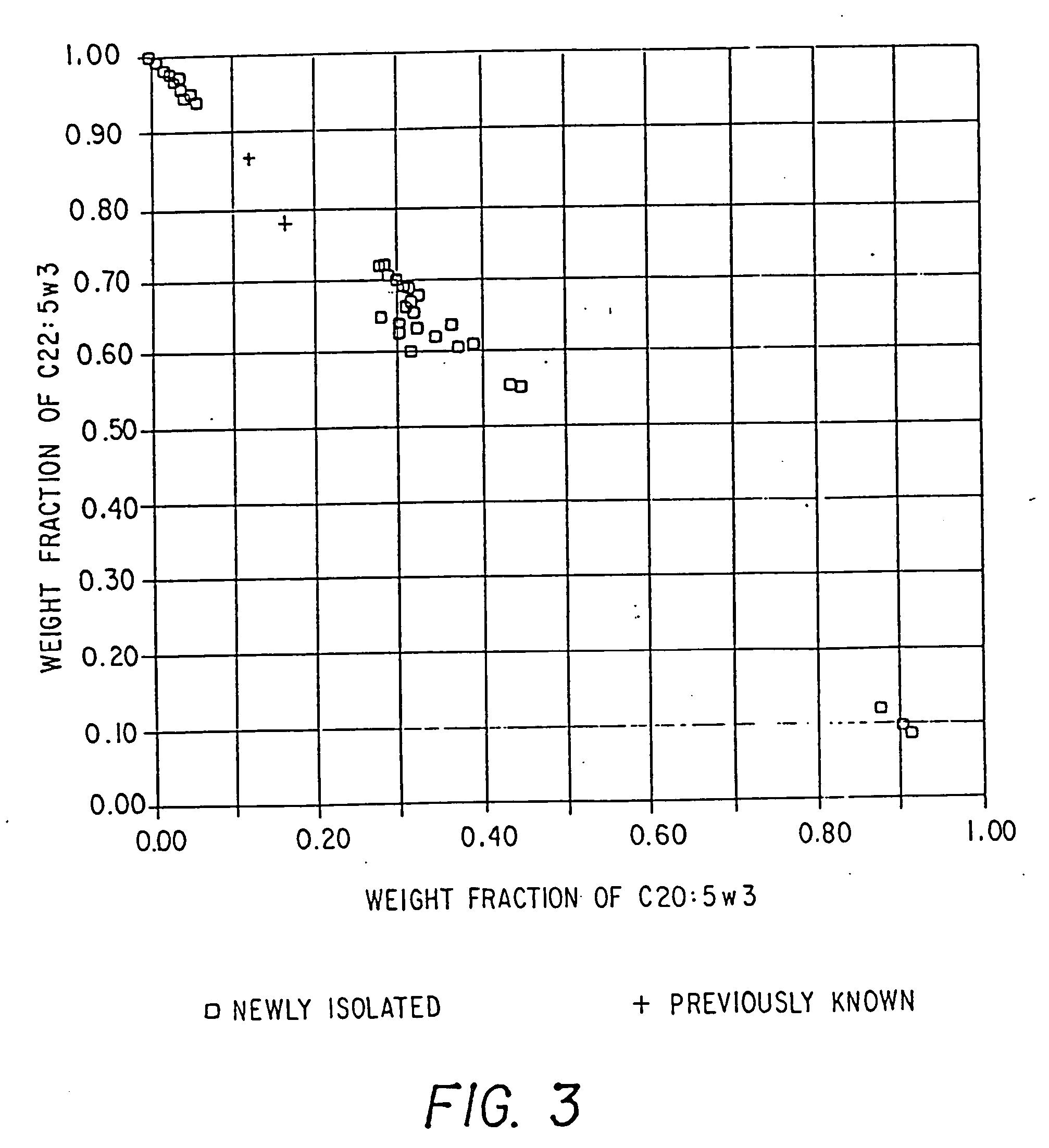

Process for the heterotrophic production of microbial products with high concentrations of omega-3 highly unsaturated fatty acids

InactiveUS20060160203A1Improve filtering effectLipid content can be increasedFungiBacteriaHigh concentrationRapeseed

Disclosed is a process for growing the microflora Thraustochytrium, Schizochytrium, and mixtures thereof, which includes the growing of the microflora in fermentation medium containing non-chloride containing sodium salts, in particular sodium sulfate. In a preferred embodiment of the present invention, the process produces microflora having a cell aggregate size useful for the production of food products for use in aquaculture. Further disclosed is a food product which includes Thraustochytrium, Schizochytrium, and mixtures thereof, and a component selected from flaxseed, rapeseed, soybean and avocado meal. Such a food product includes a balance of long chain and short chain omega-3 highly unsaturated fatty acids.

Owner:DSM IP ASSETS BV

Blend oil, preparation method and application thereof

InactiveCN101766235AImprove stabilityFix stability issuesEdible oils/fatsFood preparationBeef TallowRice bran oil

The invention provides a blend oil, a preparation method and application thereof. The blend oil, counted in 100 parts by weight, comprises 0.1-5 parts of phytosterol ester, 0.01-5 parts of microalgae DHA and 90-99.8 parts of other oil components; the other oil components are sorted from three or more than three of soybean oil, colza oil, maize oil, sunflower oil, peanut oil, sesame oil, tea seed soil, palm oil, cottonseed oil, rice bran oil, olive oil, safflower oil, linseed oil, cannabis oil, pig tallow, beef tallow, or microalgae oil.

Owner:嘉里特种油脂(上海)有限公司

Linseed oil microcapsule powder and its prepn

InactiveCN101019838AImprove stabilityKeep aliveOrganic active ingredientsPharmaceutical non-active ingredientsFreeze-dryingHigh pressure

The present invention is linseed oil microcapsule powder and its preparation, and features that modified polysaccharide, sodium octyl alkenyl succinate starch, is used as capsule wall material for forming microcapsule in preparing linseed oil microcapsule powder. The preparation process includes adding linseed oil into the solution of sodium octyl alkenyl succinate starch, stirring to form homogeneous emulsion, high pressure homogenizing to obtain linseed oil emulsion of granularity smaller than 1000 nm, and final spray drying or freeze drying to obtain white linseed oil microcapsule powder with high stability and high flowability. The linseed oil microcapsule powder has high linseed oil activity, high stability and high bioavailability, and may be applied in food and health product.

Owner:TSINGHUA UNIV +1

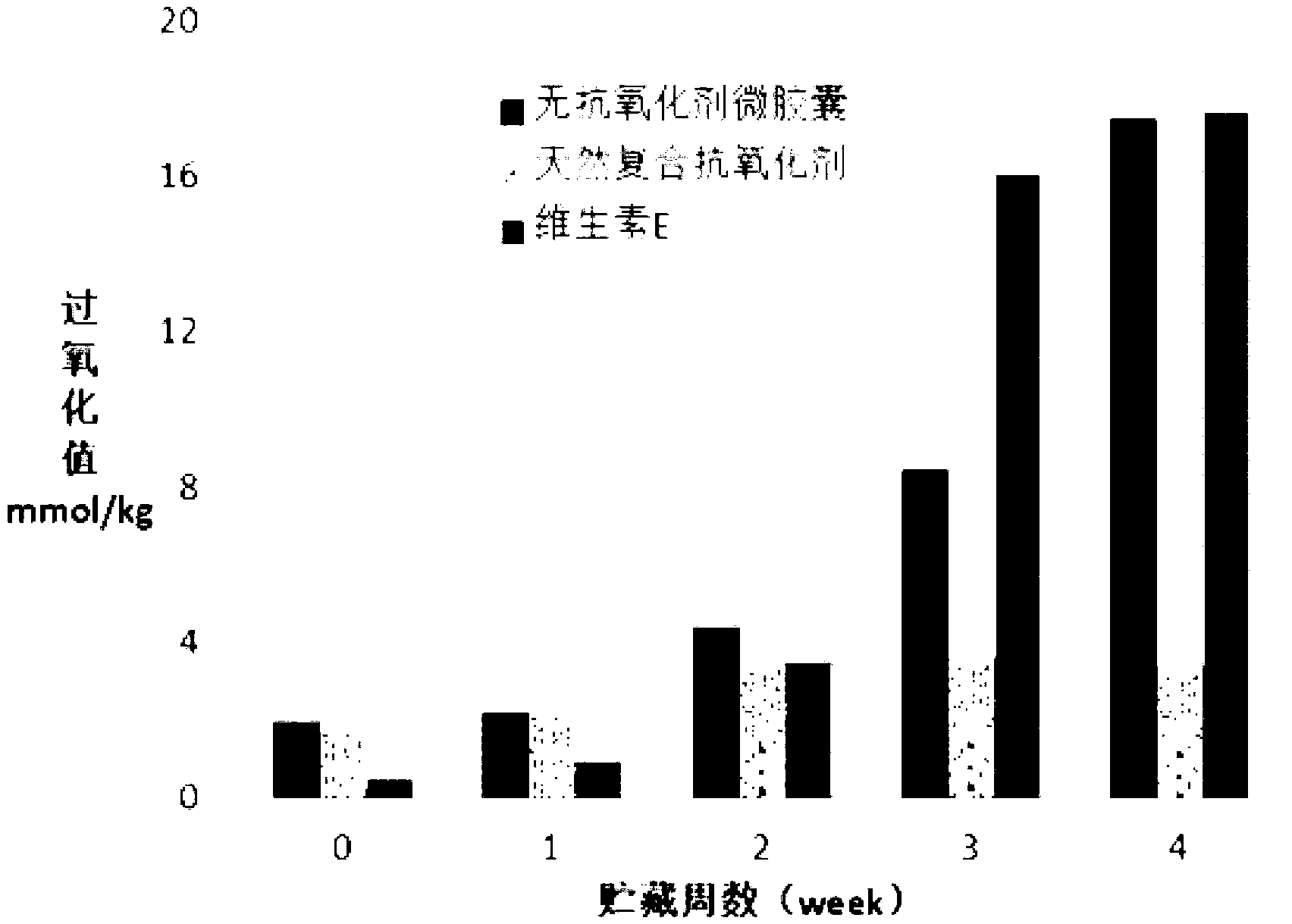

Flaxseed oil microcapsule and production method thereof

ActiveCN102934703AFit for consumptionImprove stabilityFood shapingEdible oils/fatsSodium CaseinateOil phase

The invention discloses a flaxseed oil microcapsule and a production method thereof. The core material of the flaxseed oil microcapsule is flaxseed oil, and the wall material is made of modified starch, maltodextrin and sodium caseinate. The production method comprises steps of adding the modified starch, the maltodextrin and the sodium caseinate to hot water with high-speed stirring until the the modified starch, the maltodextrin and the sodium caseinate are dissolved completely and forming a water phase; weighing and taking the flaxseed oil, adding vitamin E, rosemary and tea polyphenol step by step, stirring the mixture until the mixture is dissolved completely and forming an oil phase; conducting high-speed cutting for the obtained water phase by using a cutting machine, adding the obtained oil phase slowly and obtaining an emulsion; homogenizing the emulsion by using a high-pressure homogenizer; sterilizing the emulsion which is homogenized by using an ultra high-temperature sterilizing machine; and spraying and drying the sterilized and obtaining the flaxseed oil microcapsule. The embedding rate of the flaxseed oil microcapsule is more than 90%, the capacity of the flaxseed oil can reach 45%, the process is simple, the taste is special, the scent is obvious and the shelf life is long.

Owner:CHINA NAT RES INST OF FOOD & FERMENTATION IND CO LTD +3

Hydrosilation in high boiling natural vegetable oils

An improved process is provided for the preparation of siloxane-oxyalkylene and siloxane-alkyl copolymer compositions via a hydrosilation reaction in the presence of high boiling point natural vegetable oils as the reaction solvent. The reaction solvent need not be removed from the block copolymer product, and indeed is beneficial to remain with the copolymer particularly when the copolymer is used as a surfactant for polyurethane foam formulations. Soybean oil and linseed oil are the preferred high boiling natural oil solvents when the copolymer product is to be used in the preparation of the surfactants for polyurethane foams. High resiliency polyurethane foam prepared with these natural oils present in the surfactant preparation afforded improved compression sets, wet compression sets and humid aged compression sets. Additionally, the use of the surfactants made with natural oils as a reaction solvent or consequently surfactants post diluted with natural oils when employed in the preparation of polyurethane foam afforded foams with greatly reduced amounts of "glass fogging".

Owner:GENERAL ELECTRIC CO

Chinese medicine health type pet cat and dog food

InactiveCN101473903AImprove smoothness and supplenessNot easy to depilateAnimal feeding stuffAccessory food factorsDiseaseAntioxidant

The invention relates to a traditional Chinese medicine health care type pet food for cats and dogs, comprising the following components: animal protein, vegetable protein, carbohydrate, flaxseed oil, antioxidant, multi-vitamin, mineral substance, seaweed and natural fermentation seafood seasoner. The invention is characterized in that the pet food contains milk veteh, rhizoma atractylodis alba, medicated leaven, dyer woad leaf and lotus leaf. The pet food of the invention has the following beneficial effects: the pet food has total nutrition and health care function; the added milk veteh contributes to replenishing qi and improving immunity and disease-resistance capability of pets, the rhizoma atractylodis alba and medicated leaven can help improve the appetite of pets and promote the digestion thereof, the dyer woad leaf can help resist virus and eliminate minor inflammation, while the lotus leaf can help the pets lose weight with ease without food amount restriction. In the invention, comparative trials are carried out on pet cats and pet dogs, results show that the capability of resisting disease of the pet cats and pet dogs eating the pet food of the invention are twice as that of the pet cats and pet dogs eating ordinary pet food; in addition, skin and hair thereof are obviously smooth and soft, body thereof is sturdy and mobility and playfulness thereof are also improved; moreover, no pets put on weight while not resisting food amount.

Owner:威海同仁食品有限公司

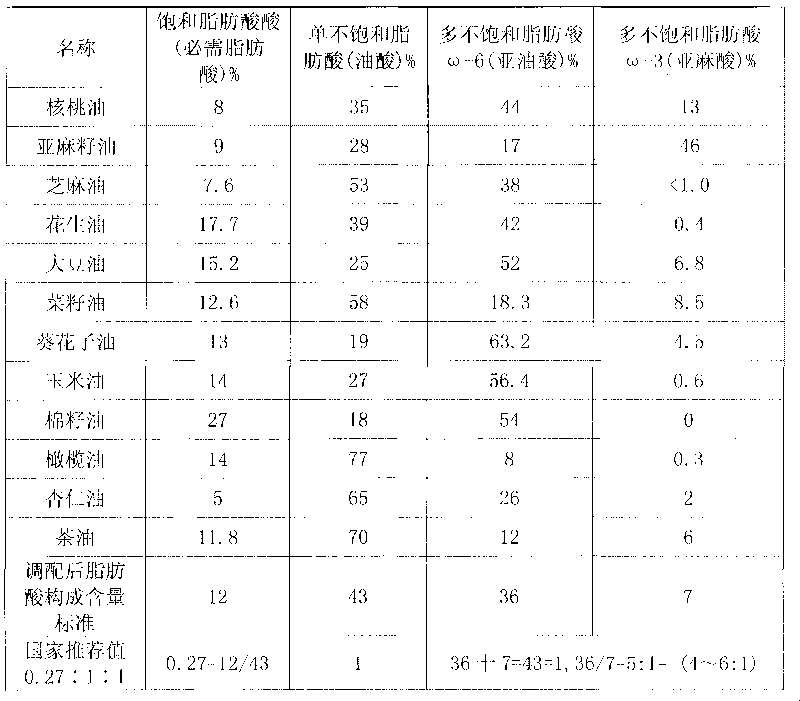

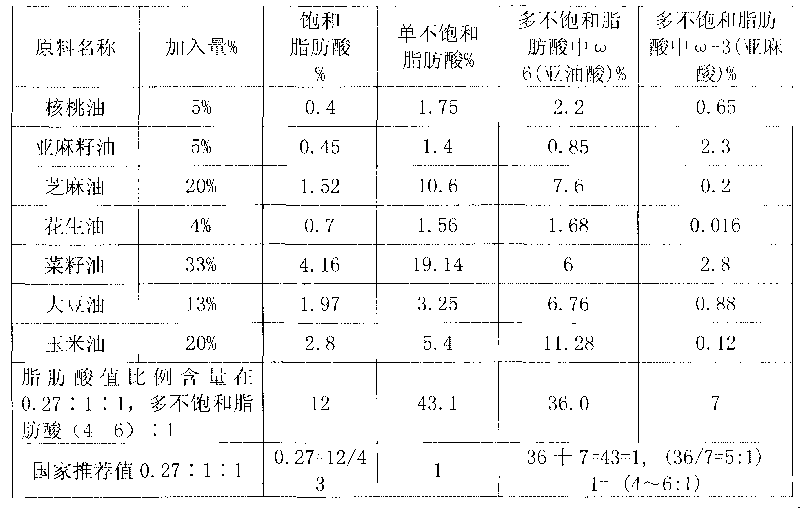

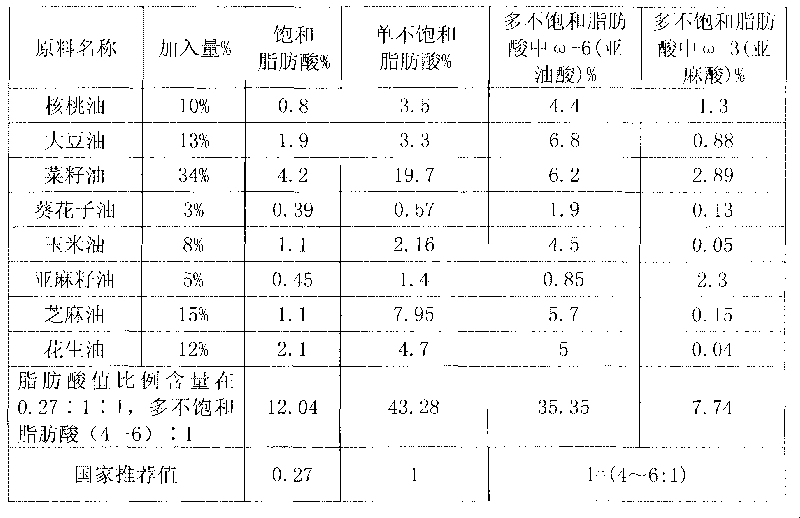

Blend oil with proportional fatty acid prepared by walnut oil and other plant oils

InactiveCN101690526AReduce contentReduce concentrationEdible oils/fatsFood preparationVegetable oilCholesterol

The invention relates to blend oil with proportional fatty acid prepared by walnut oil and other plant oils, which is composed of 5-20% of walnut oil by weight and 80-95% of common plant oils by weight, wherein the common plant oils are selected from any 6 to 11 from peanut oil, soybean oil, sunflower seed oil, teal oil, cotton seed oil, corn oil, almond oil, olive oil, tea oil, linseed oil and colza oil. The ratio of three fatty acids in the blend oil provided by the invention can reach 0.27:1:1, wherein the ratio of omega-6 (linoleic acid) to omega-3 (linolenic acid) in polyunsaturated fatty acids is (4-6):1, and the blend oil in the invention also can overcome the disadvantages that walnut oil is expensive in price and little in market acceptance space while common plant oil has single nutrition and is difficult to supplement fatty acids essential to human body, therefore, by long term administration of the walnut blend oil, cholesterol can be effectively reduced, hyperlipaemia can be reduced, heart cerebrovascular disease can be prevented, and the holistic health level of people can be improved.

Owner:祁景泉

Nutritive defatting food

InactiveCN107960664AAvoid damageReduce cholesterolVitamin food ingredientsNatural extract food ingredientsRice proteinMedium-chain triglyceride

The invention relates to a nutritive defatting food. The nutritive defatting food comprises the following components of whey protein concentrate, hydrolyzed fish collagen protein, soy protein isolate,rice protein, inulin, psyllium husk, resistant dextrin, resistant starch, chenopodium quinoa willd, konjaku flour, chia seeds, fructo-oligosaccharide, xylooligosaccharide, isomaltulose, erythrite, steviosides, linseeds, linseed oil, CMC, medium chain triglyceride, conjugated linoleic acid glycerides, L-carnitine, ferment, complex vitamins, and composite mineral substances. The nutritive defattingfood is good in satiety, balanced in nutrients, and good in defatting effect.

Owner:春雨壹品(北京)国际信息科技有限公司

Production of pigments

InactiveUS6235104B1Low viscosityHigh flash pointFatty acid chemical modificationConductive materialVegetable oilLinseed oil

Metal pigment, especially aluminum pigment is produced in a non toxic environment by milling and / or blending in an inert medium comprising transesterified alkyl, especially methyl esters of vegetable oils selected from soybean oil, cotton seed oil and linseed oil. The metallic pigments produced are of improved quality and appearance. They have improved brightness and the non-leafing pigments produced have highly leafing characteristics.

Owner:DAHLIA IRELAND

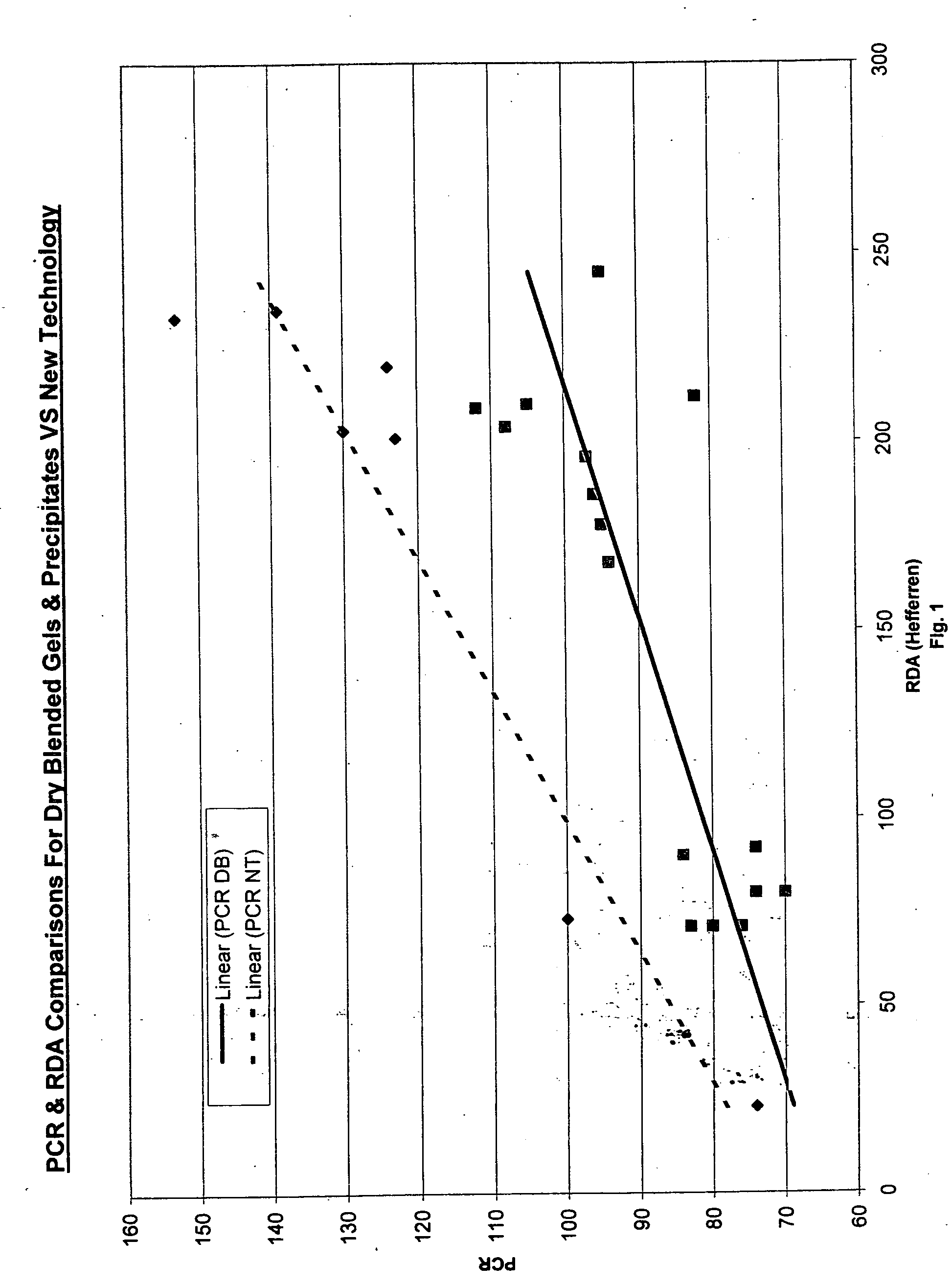

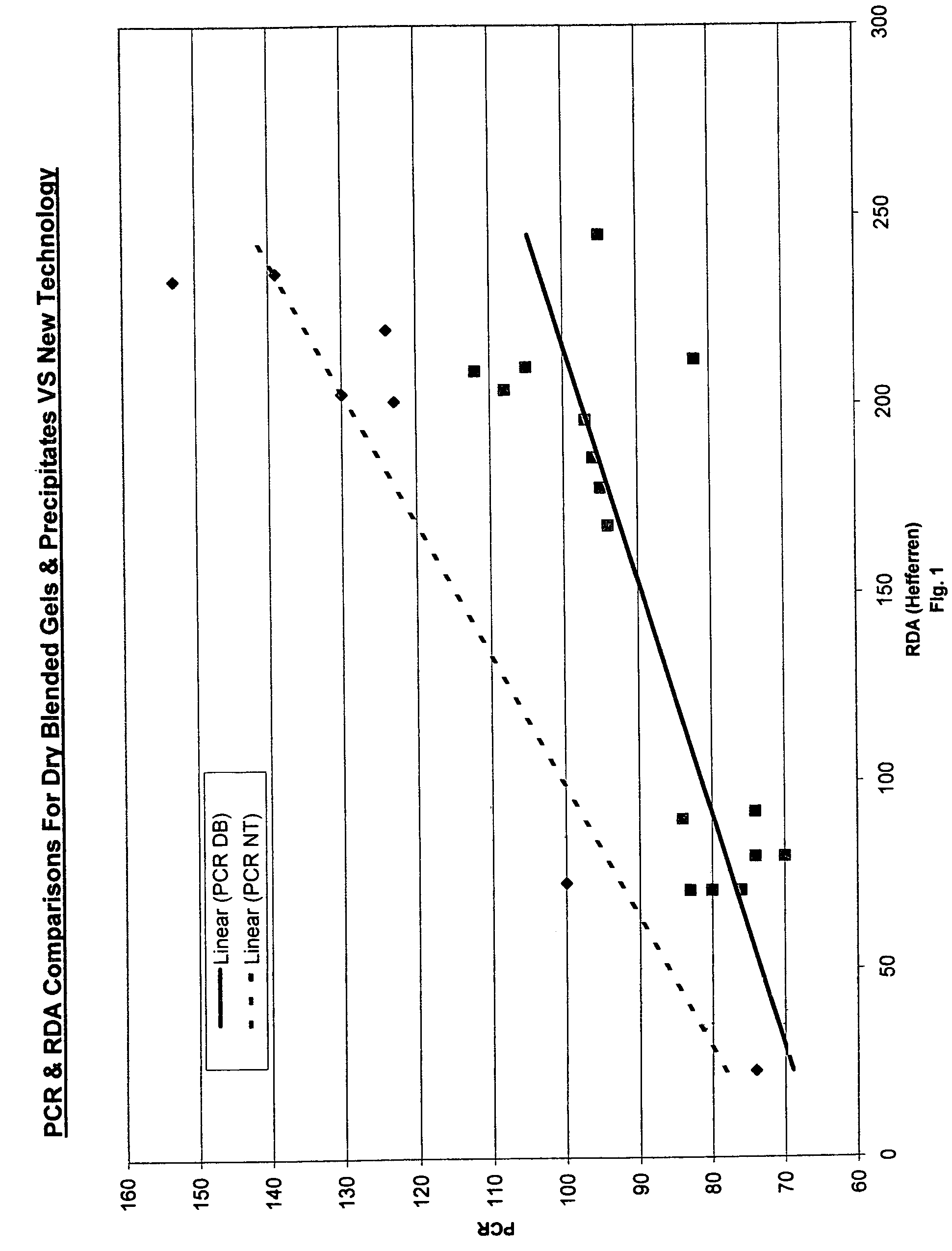

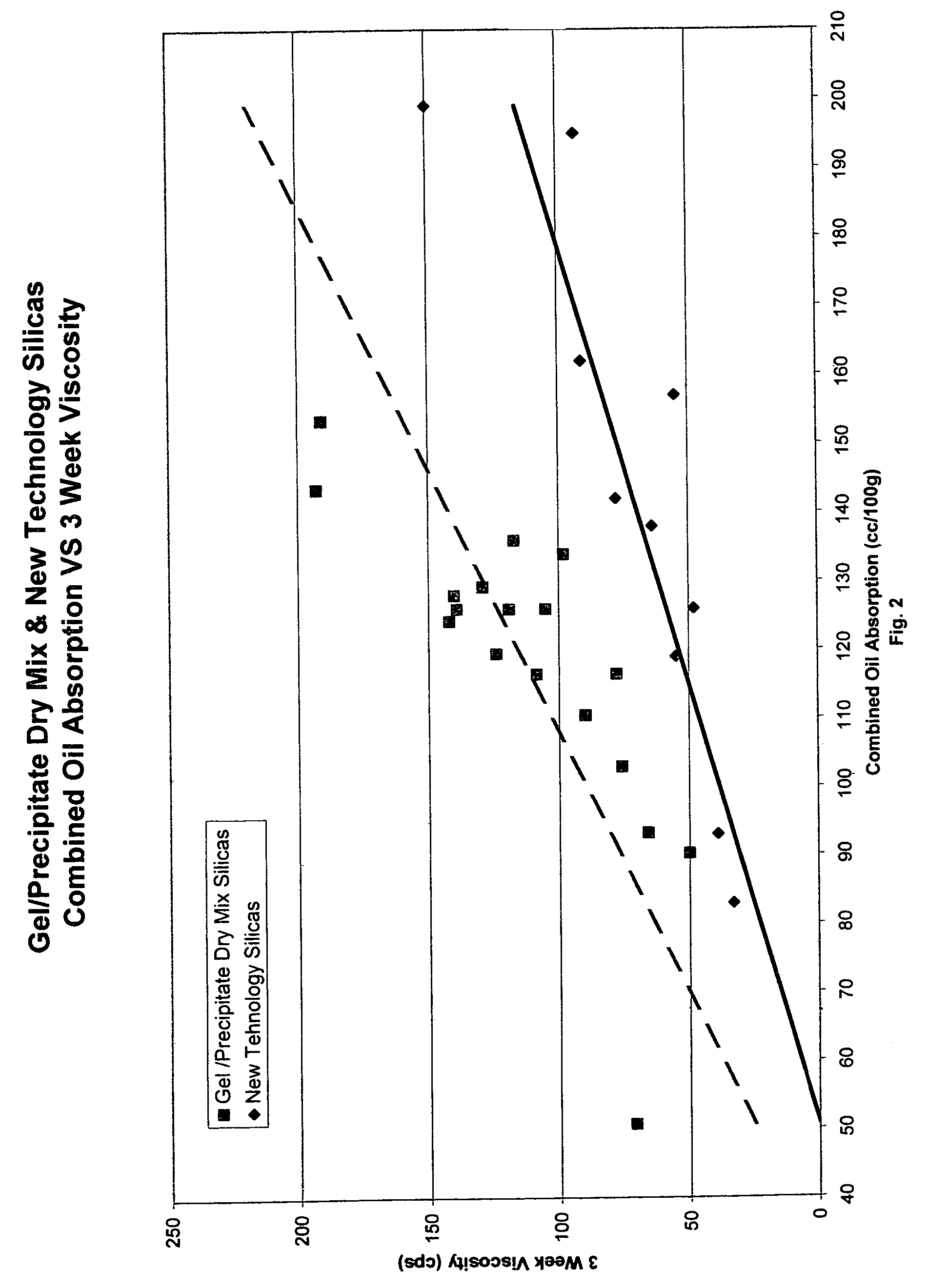

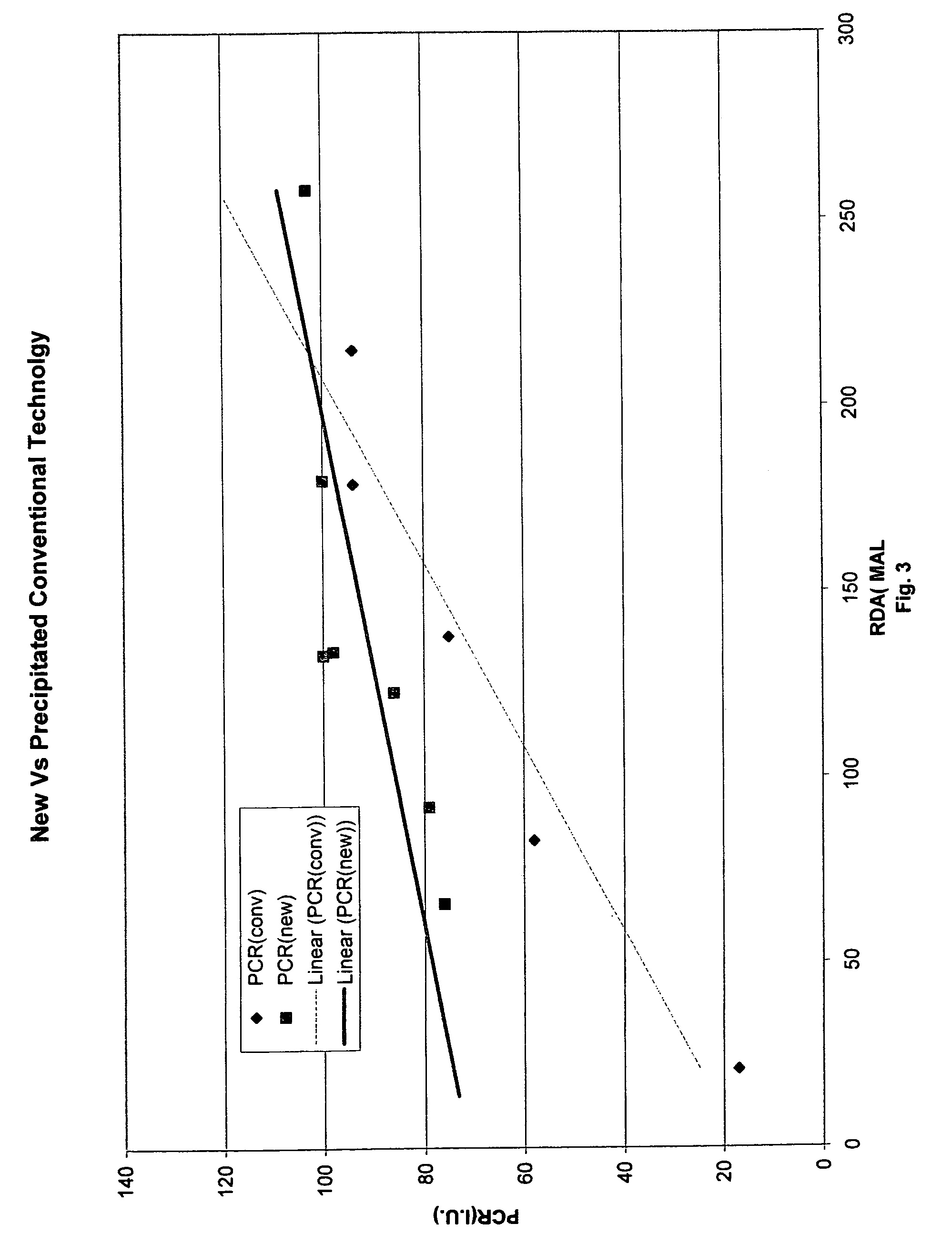

High-cleaning/low abrasive silica and materials and dentifrice containing such materials

InactiveUS20060110338A1Desirable abrasiveGood thickening effectPigmenting treatmentCosmetic preparationsSilica gelSilicon dioxide

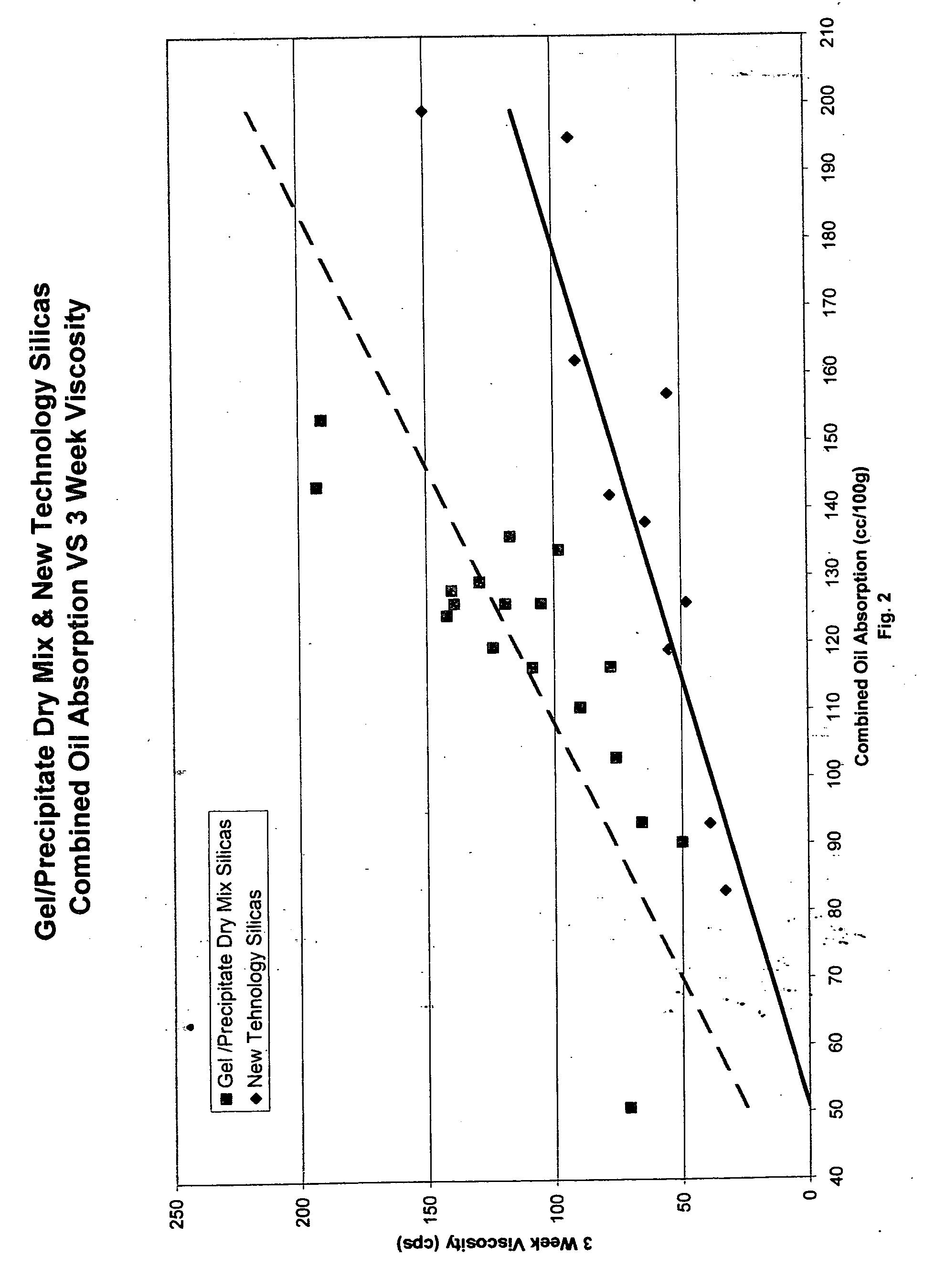

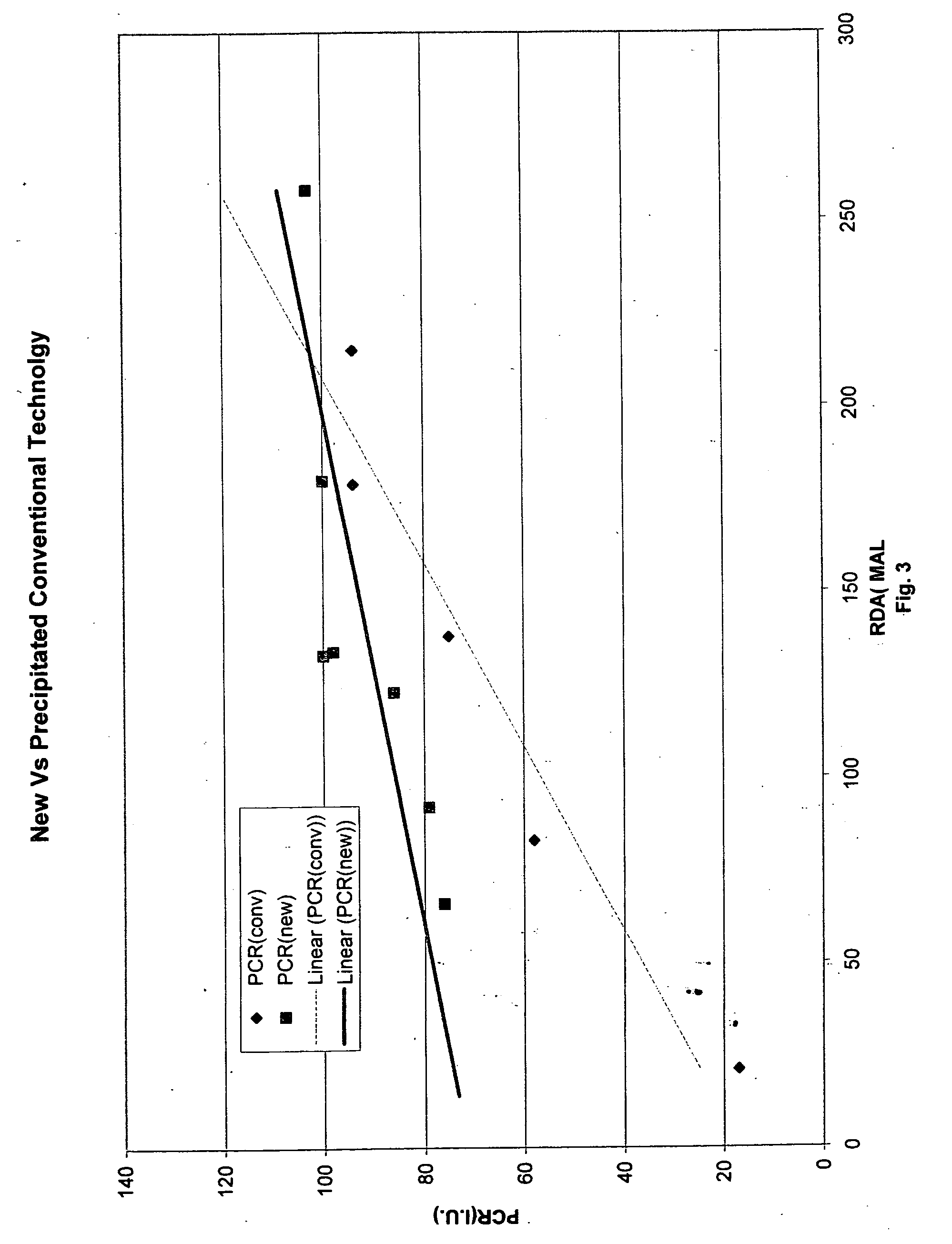

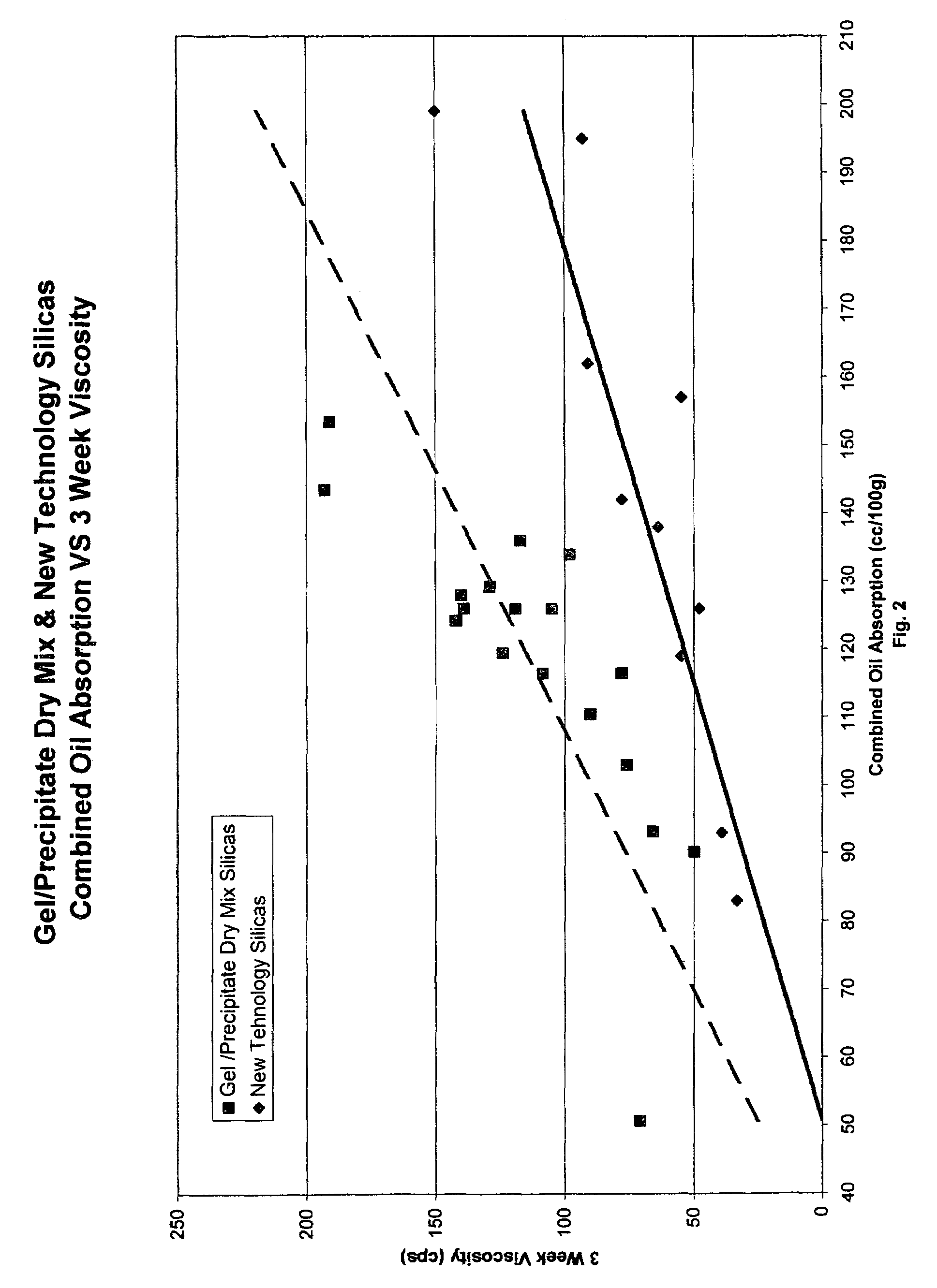

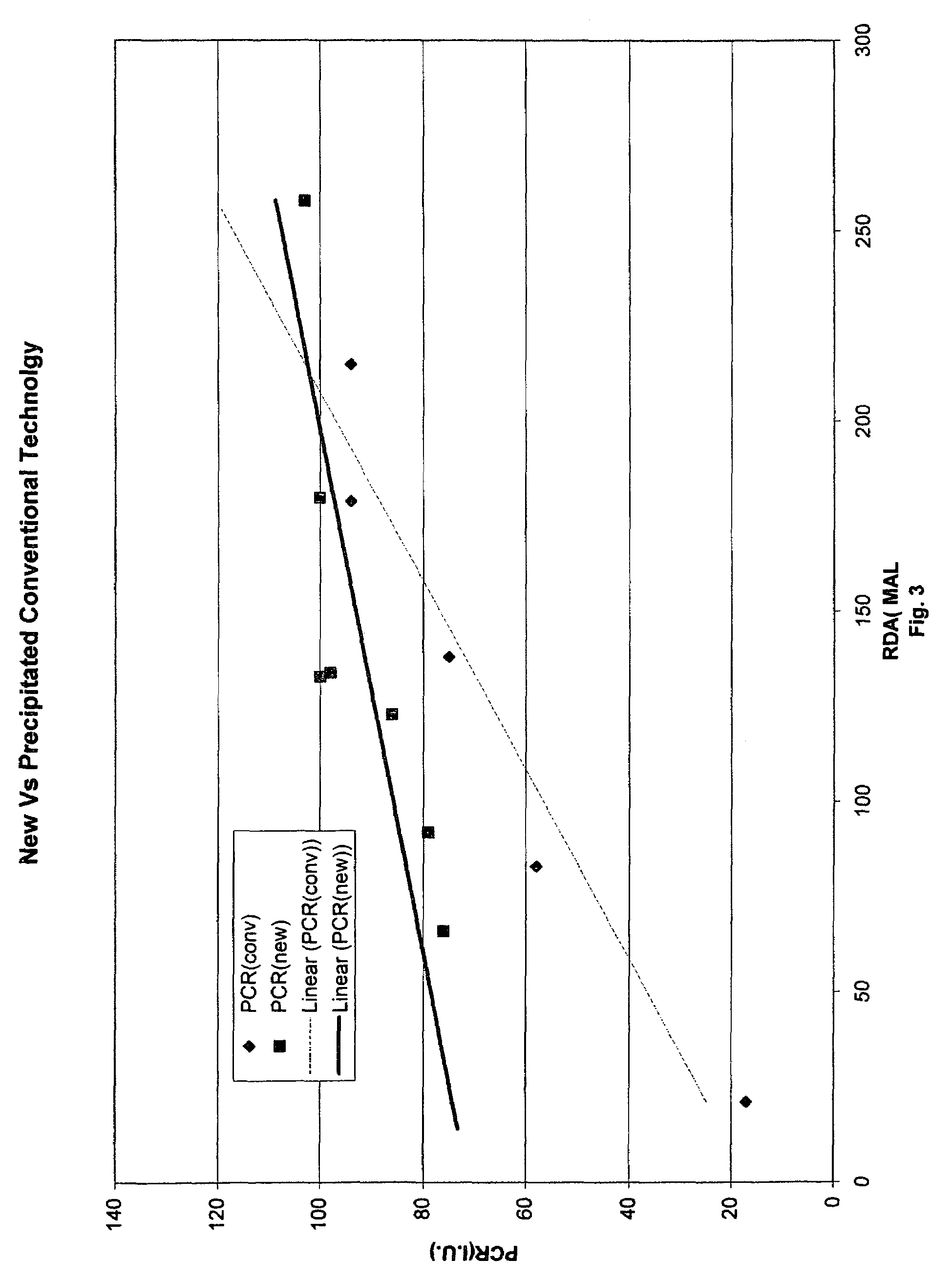

Unique abrasive and / or thickening materials that are in situ generated compositions of precipitated silicas and silica gels are provided. Such compositions exhibit different beneficial characteristics depending on the structure of the composite in situ generated material. With low structured composites (as measured via linseed oil absorption levels from 40 to 100 ml oil absorbed / 100 g composite), simultaneously high pellicle film cleaning properties and moderate dentin abrasion levels are possible in order to accord the user a dentifrice that effectively cleans tooth surfaces without detrimentally abrading such surfaces. Increased amounts of high structure composite materials tend to accord greater viscosity build and thickening benefits together with such desirable abrasion and cleaning properties, albeit to a lesser extent than for the low structure types. Thus, mid-range cleaning materials will exhibit oil absorption levels from an excess of 100 to 150, and high thickening / low abrasion composite exhibit oil absorption properties in excess of 150. Such an in situ, simultaneously produced precipitated silica / silica gel combination provides such unexpectedly effective low abrasion and high cleaning capability and different thickening characteristics as compared to physical mixtures of such components. Encompassed within this invention is a unique method for making such gel / precipitated silica composite materials for such a purpose, as well as the different materials within the structure ranges described above and dentifrices comprising such.

Owner:J M HUBER CORP

Capacitor thin film containing modified nano-titanium dioxide and preparation method thereof

InactiveCN103102582AImprove barrier propertiesImprove air tightnessFixed capacitor dielectricLow-density polyethyleneCross-link

The invention discloses a capacitor thin film containing modified nano-titanium dioxide and a preparation method thereof. The capacitor thin film comprises the following raw materials in parts by weight: 57-65 of metallocene polypropylene resin, 25-30 of LLDPE (Linear low density polyethylene) resin, 10-15 of low-density polyethylene, 10-15 of homo-polypropylene, 3-5 of epoxy linseed oil, 2-3 of polyvinyl alcohol, 1-2 of aluminum hydroxide, 1-2 of polyisobutylene, 8-12 of diatomite, 1-2 of ferrocene, 0.5-1.5 of poly-4-methyl-1-amylene, 7-9 of modified nano-titanium dioxide, 1.5-2.5 of cross-linking agent TAC, 0.2-0.4 of expoxy butyl oleate, 0.8-1.2 of epoxidation triglyceride, 3-5 of calcium stearate and 0.5-0.7 of modified trees ash. The preparation method disclosed by the invention is simple; and simultaneously, the diatomite, the modified nano-titanium dioxide and the modified trees ash are added to the raw materials so that the barrier property and air tightness of the thin film are improved, and the thin film has good resistance to pressure and impact resistance and simultaneously has the characteristics of high heat-seal strength and good heat sealing property.

Owner:TONGLING YIHENGDA ELECTRONICS

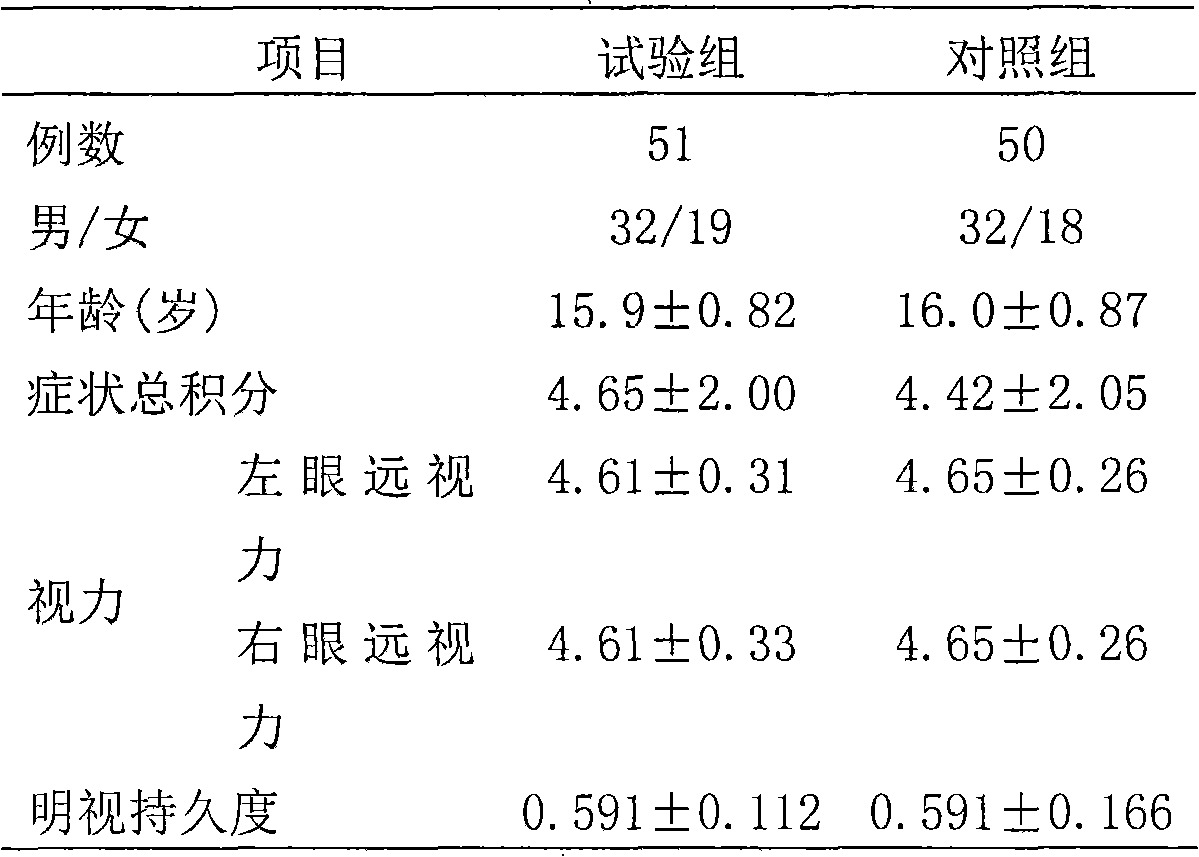

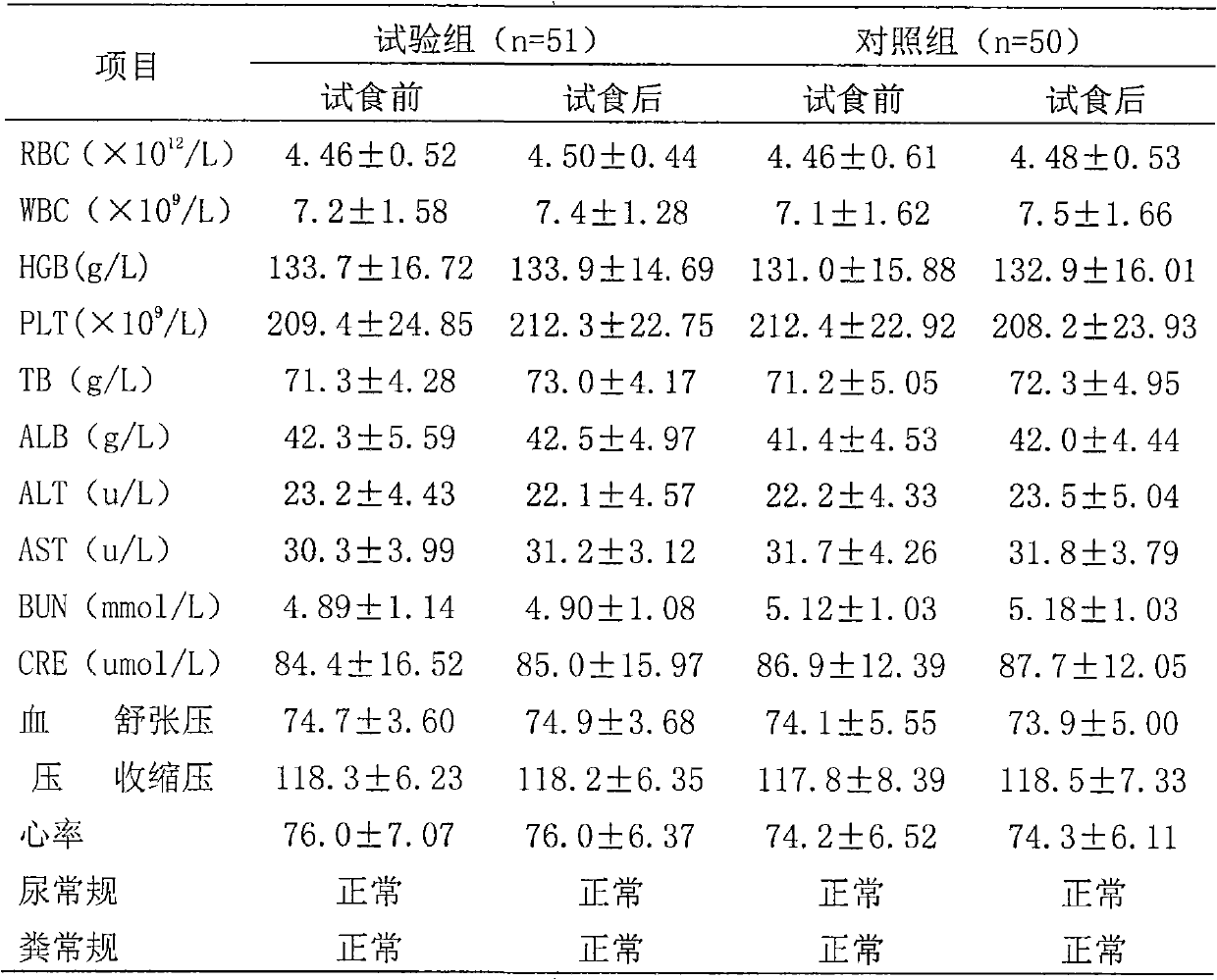

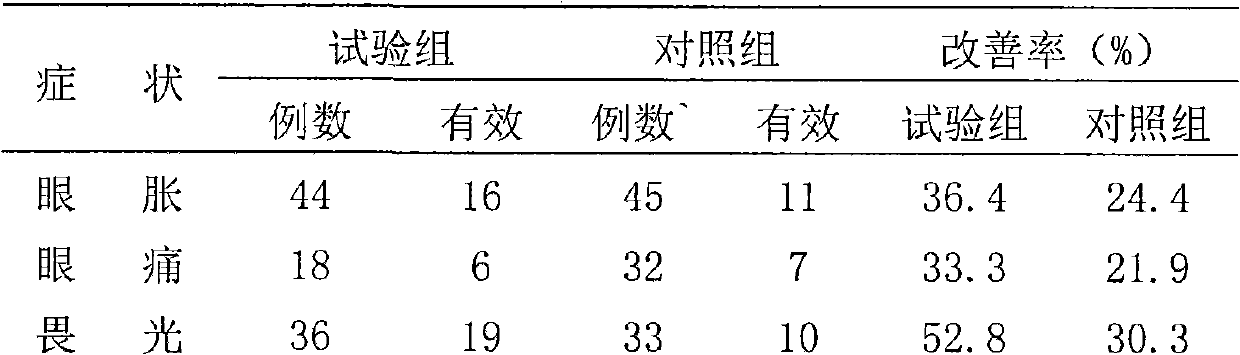

Health food with function of relieving visual fatigue and preparation method thereof

The invention relates to a health food with a function of relieving visual fatigue and a preparation method thereof, belonging to the technical field of health foods. The health food with the function of relieving visual fatigue is characterized in that active ingredients and additives are used for preparing the health food into soft capsules, hard capsules, oral liquid or tablets, wherein the active ingredients comprise the following raw materials: flaxseed oil or perilla oil, beta-carotene or vitamin A, lutein, zeaxanthin, vitamin E, ginkgo leaf extract and grape pip extract or cowberry extract; when the health food is prepared into the soft capsules, an emulsifying agent is used as the additive; when the health food is prepared into the hard capsules, a diluting agent is used as the additive; when the health food is prepared into oral liquid, a preservative, a flavoring agent, an emulsifying agent and water are used as the additives; and when the health food is prepared into the tablets, a diluting agent and a disintegrating agent are used as the additives. The health food prepared by the invention has the function of relieving visual fatigue.

Owner:INST OF OIL CROPS RES CHINESE ACAD OF AGRI SCI

High-cleaning/low abrasive silica and materials and dentifrice containing such materials

InactiveUS7267814B2Excellent abrasionImprove rendering capabilitiesCosmetic preparationsPigmenting treatmentCleaned teethLinseed oil

Unique abrasive and / or thickening materials that are in situ generated compositions of precipitated silicas and silica gels are provided. Such compositions exhibit different beneficial characteristics depending on the structure of the composite in situ generated material. With low structured composites (as measured via linseed oil absorption levels from 40 to 100 ml oil absorbed / 100 g composite), simultaneously high pellicle film cleaning properties and moderate dentin abrasion levels are possible in order to accord the user a dentifrice that effectively cleans tooth surfaces without detrimentally abrading such surfaces. Increased amounts of high structure composite materials tend to accord greater viscosity build and thickening benefits together with such desirable abrasion and cleaning properties, albeit to a lesser extent than for the low structure types. Thus, mid-range cleaning materials will exhibit oil absorption levels from an excess of 100 to 150, and high thickening / low abrasion composite exhibit oil absorption properties in excess of 150. Such an in situ, simultaneously produced precipitated silica / silica gel combination provides such unexpectedly effective low abrasion and high cleaning capability and different thickening characteristics as compared to physical mixtures of such components. Encompassed within this invention is a unique method for making such gel / precipitated silica composite materials for such a purpose, as well as the different materials within the structure ranges described above and dentifrices comprising such.

Owner:J M HUBER CORP

Coating combination for pure natural woodenware

The invention relates to a coating combination for pure natural woodenware, which is characterized in that the coating combination is made of natural animal and plant products which are non-toxic, natural and environment-friendly, and capable of sinking into the surface layer of wood and avoiding coating film formation on the surface of the wood when in use, thus enabling the wood to breathe naturally, maintaining the elasticity of the natural wood and preventing the coating combination from cracking, tilting and dropping. The coating combination comprises the following components by weight percent: 30wt% to 70wt% of solvent; 70wt% to 30wt% of natural plant oil derivative; 1wt% to 10wt% of natural wax; 0wt% to 10wt% of pigment; 0wt% to 3wt% of dye and 0wt% to 3wt% of additives, wherein the natural plant oil derivative is particularly one of linseed oil, castor oil, tung oil and soya-bean oil or the product chemically processed from the mixture thereof; and the natural wax is particularly one of carnauba wax, candelilla wax, insect-white wax (Chinese wax) and natural bee wax or the mixture thereof.

Owner:深圳嘉汉林业科技有限公司

Nutritional blend oil with balanced fatty acid component and active component for middle and old aged

The invention relates to a nutritional blend oil with balanced fatty acid components and active components for the middle and old aged, which is prepared by a plurality of plant oils selected from flaxseed oil, walnut oil, double-low rapeseed oil, soybean oil, wheat germ oil, corn oil, teal oil, peanut oil, grape seed oil, rice bran oil, camellia oil, evening primrose seed oil, sunflower seed oil and the like, wherein, Omega 6 serial polyunsaturated fatty acids (PUFA) and Omega 3 serial PUFA are contained to enable the ratio of saturated fatty acid (SFA) to monounsaturated fatty acid (MUFA) to PUFA to be 0.6-0.8:1:1, the ratio of Omega 6 to Omega 3 to be 4:1 in the comprehensive evaluation of the blend oil absorbed by the middle and old aged and the fat from other sources, thereby meeting the recommended value of Chinese Nutrition Society; the nutritional blend oil contains 2% of gama-linolenic acid, thereby beneficial to improving the contents of DH-gama-linolenic acid and arachidonic acid; the total content of lauric acid, myristic acid and palmitic acid contained in the nutritional blend oil is below 8.5% in order to avoid over rising the level of Low density lipoprotein (LDL) in the plasm of the middle and old aged; in addition, the nutritional blend oil also comprises a plurality of active components with oxidation resistant property, so other antioxidants do not need to be added in the blend oil.The blend oil provided by the invention is characterized by low cost, balanced fatty acid nutrition, a plurality of abundant active components and higher security, thereby better improving the health and intelligence of eaters, preventing cardiovascular and cerebrovascular diseases, and avoiding fatness, hyperlipidemia, thrombotic diseases and the like caused by unbalanced fatty nutrition.

Owner:ZHEJIANG OIL MASTER

Non aqueous gel technology

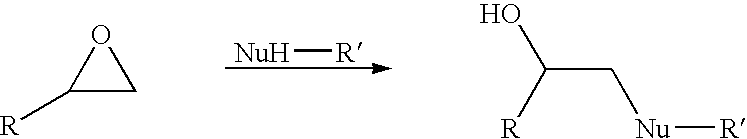

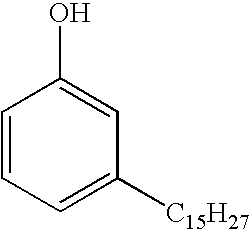

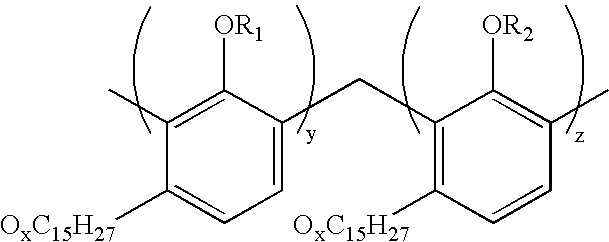

A method of treating an earth formation that includes injecting at least one lipophilic monomer into the earthen formation; wherein the at least one lipophilic monomer is selected from epoxide-functionalized derivative of soybean oil linseed oil, rapeseed oil, cashew nut shell oil; perilla oil, tung oil, oiticia oil, safflower oil, poppy oil, hemp oil, cottonseed oil, sunflower oil, high-oleic triglycerides, triglycerides of euphorbia plants, peanut oil, olive oil, olive kernel oil, almond oil, kapok oil, hazelnut oil, apricot kernel oil, beechnut oil, lupine oil, maize oil, sesame oil, grapeseed oil, lallemantia oil, castor oil, herring oil, sardine oil, menhaden oil, whale oil, and tall oil, injecting at least one crosslinking agent into the earthen formation; wherein the at least one crosslinking agent comprises at least one primary amine; and allowing the lipophilic monomer and the crosslinking agent to react in the earth formation is disclosed.

Owner:MI

High-cleaning/moderate abrasive silica materials and dentifrice containing such materials

InactiveUS7306788B2Excellent abrasionImprove rendering capabilitiesCosmetic preparationsSilicaLinseed oilSilica gel

Unique abrasive and / or thickening materials that are in situ generated compositions of precipitated silicas and silica gels are provided. Such compositions exhibit different beneficial characteristics depending on the structure of the composite in situ generated material. With low structured composites (as measured via linseed oil absorption levels from 40 to 100 ml oil absorbed / 100 g composite), simultaneously high pellicle film cleaning properties and moderate dentin abrasion levels are possible in order to accord the user a dentifrice that effectively cleans tooth surfaces without detrimentally abrading such surfaces. Increased amounts of high structure composite materials tend to accord greater viscosity build and thickening benefits together with such desirable abrasion and cleaning properties, albeit to a lesser extent than for the low structure types. Thus, mid-range cleaning materials will exhibit oil absorption levels from an excess of 100 to 150, and high thickening / low abrasion composite exhibit oil absorption properties in excess of 150. Such an in situ, simultaneously produced precipitated silica / silica gel combination provides such unexpectedly effective low abrasion and high cleaning capability and different thickening characteristics as compared to physical mixtures of such components. Encompassed within this invention is a unique method for making such gel / precipitated silica composite materials for such a purpose, as well as the different materials within the structure ranges described above and dentifrices comprising such.

Owner:J M HUBER CORP

Nutrient plant blending oil and production method thereof

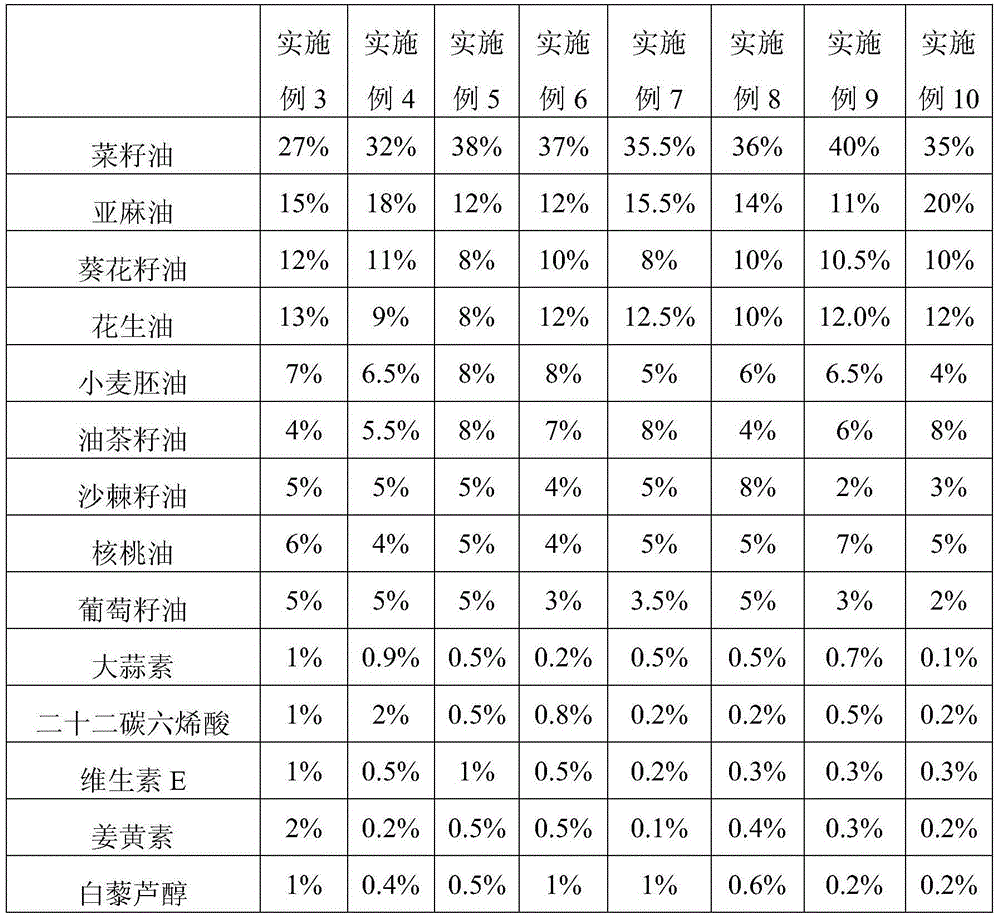

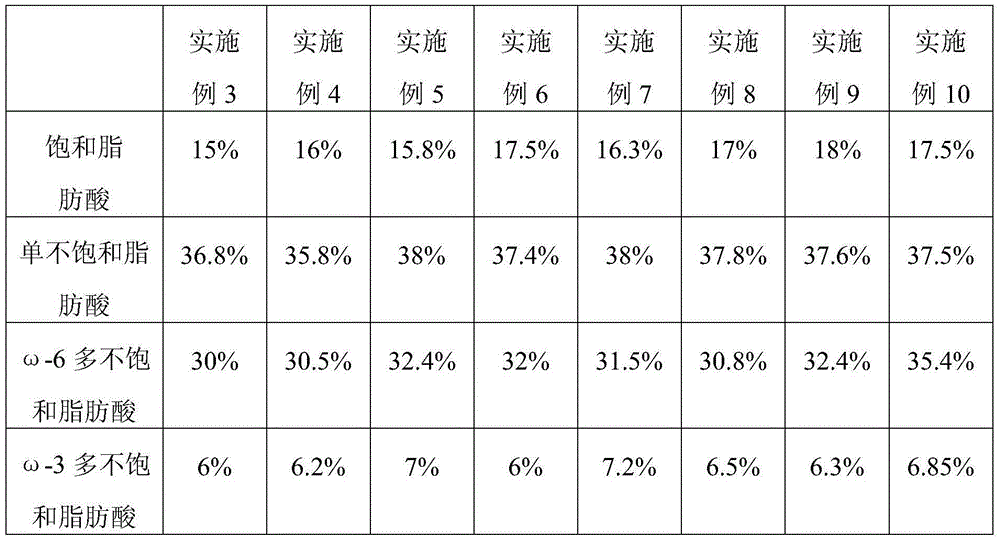

The invention provides nutrient plant blending oil. The nutrient plant blending oil comprises components in percentage by weight as follows: 20%-40% of rapeseed oil, 10%-20% of linseed oil, 6%-12% of sunflower seed oil, 5%-15% of peanut oil, 4%-8% of wheat germ oil, 2%-10% of camellia seed oil, 1%-5% of seabuckthorn seed oil, 3%-8% of walnut oil, 2%-5% of grape seed oil, 0.1%-2% of allicin, 0.1%-2% of docosahexaenoic acid, 0.1%-2% of vitamin E, 0.1%-2% of curcumin and 0.1%-1% of resvaritrol. The production method of the blending oil comprises steps as follows: the raw materials are weighed in the proportion and then added to a mixing vessel, nitrogen is injected at the temperature of 40-60 DEG C, so that pressure in the mixing vessel can keep 0.1-0.5 Mpa, vibration and blending are performed through ultrasonic waves for 60-120min and then are left to stand for 3-5 hours, and primary blending oil is obtained; then bentonite and activated carbon in the weight ratio of 1:(2-4) are added to the primary blending oil, the mixture is stirred for 30-60min at a rotation speed of 80-100 r / min, then solid impurities are filtered out, and the nutrient plant blending oil is obtained. The blending oil integrates edible and health-care functions of various kinds of plant oil, and the nutrient plant blending oil has more nutrition and health-care functions due to addition of functional additives.

Owner:SICHUAN CHAOFENG GRAIN & OIL

Microcapsule powder and preparation method thereof

InactiveCN105996040AEffectively Regulate CholesterolImprove immunityFood homogenisationInorganic compound food ingredientsOil phaseLinseed oil

The invention provides microcapsule powder containing linseed oil and walnut oil. The microcapsule powder is prepared from, by weight, 1-1000 parts of wall material, 5000-50000 parts of core material, 10-1000 parts of emulsifier and 1-200 parts of stabilizer, the wall material comprises one or multiple of dextrin, starch and protein, and the core material comprises the linseed oil and the walnut oil according to a weight ratio of 1-2:1. The invention further provides a preparation method of the microcapsule powder. The preparation method includes: sequentially preparing a water phase and an oil phase; emulsifying, homogenizing, and spraying and drying to obtain the microcapsule powder. The microcapsule powder has the advantages that the linseed oil and the walnut oil are mixed and emulsified according to a certain proportion to prepare oil-in-water microcapsule powder, and the microcapsule powder is easy to store, long in shelf life, balanced in nutrition, needless of antioxidant adding and highly good for human health.

Owner:FUJIAN NORMAL UNIV

Capacitor film with low density polyethylene as substrate and preparation method thereof

ActiveCN102964658AImprove barrier propertiesImprove air tightnessFixed capacitor dielectricEpoxyPolyvinyl alcohol

The invention discloses a capacitor film with low density polyethylene as substrate and a preparation method thereof. The capacitor film comprises the following raw materials by weight: 50-55 parts of LDPE (low density polyethylene), 20-25 parts of LLDPE (linear low density polyethylene), 10-15 parts of homo-polymer, 3-5 parts of epoxy linseed oil, 2-3 parts of polyvinyl alcohol, 1-2 parts of aluminum hydroxide, 1-2 parts of polyisobutylene, 8-12 parts of diatomite, 1-2 parts of ferrocene, 0.8-1.2 parts of poly-4-methyl-1-pentene, 5-10 parts of calcium carbonate, 2-4 parts of hydrotalcite, 1.3-1.8 parts of zinc dialkyl dithiophosphate, 0.4-0.6 part of phthalic acid ester, 0.4-0.7 part of smoke sheet rubber, 1-3 parts of zinc stearate and 0.9-1.3 parts of modified wood ash. The invention mainly adopts low density polyethylene assisted with linear low density polyethylene; and various accessories and additives are subjected to mixing and extrusion, blown film sizing and cutting to prepare the capacitor film. The preparation method is simple; and diatomite, hydrotalcite and modified wood ash are added into the raw materials at the same time to enhance barrier property and air tightness of the film; besides, the capacitor film has characteristics of good pressure resistance, impact resistance, high heat sealing strength, and good heat sealing performance.

Owner:安徽芯智达电子科技有限公司

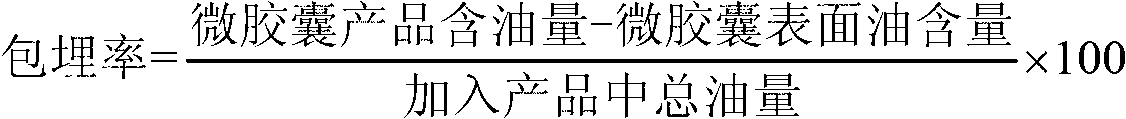

Linseed oil microcapsule powder and preparation process thereof

InactiveCN104544092AImprove liquidityGood rehydration stabilityFood shapingEdible oils/fatsEmbedding rateAlpha-Linolenic acid

The invention relates to linseed oil microcapsule powder and a preparation process thereof. The microcapsule powder is prepared from the following components in parts by weight: 38-45 parts of linseed oil, 0.002-0.02 part of an antioxidant, 48-54 parts of a filling agent, 6-8 parts of an emulsifier, 0-0.1 part of a stabilizer and 65-80 parts of water. The preparation process comprises the following steps: preparing an aqueous phase, preparing an oil phase, performing pre-emulsification, homogenizing and granulating. According to the final product obtained in the technical scheme of the invention, the surface is spherical under an environment scanning electron microscope, the particle size ranges from 35 microns to 100 microns, and the obtained product is a quick-dissolving product and is high in liquidity, high in re-watering stability, high in microcapsule oil embedding rate, good in embedding performance, good in taste and high in absorption rate; and moreover, the preparation process is simple, large-scale production is conveniently realized, contact between the linseed oil and air is effectively isolated by virtue of the microcapsule embedding technology, the biological activity of alpha-linolenic acid in the linseed oil is protected, waste residues and wastewater are not produced in the production process, and the product is green and environment-friendly.

Owner:王维义

Grass carp feed and preparation method thereof

InactiveCN103518993AMeet nutritional contentFast growthFood processingAnimal feeding stuffBiotechnologyAnimal science

The invention discloses a grass carp feed and a preparation method thereof. The grass carp feed is prepared by the following raw materials in parts by weight: 15-20 parts of bean pulp, 10-15 parts of rapeseed dregs, 5-10 parts of fish meal, 4-8 parts of rice bran, 15-20 parts of wheat middling, 8-12 parts of bran, 1-2 parts of an additive, 3-6 parts of beer yeast, 5-10 parts of corn proteins, 2-4 parts of locust tree leaves, 1-3 parts of sesbania powder, 1-2 parts of citrus peel powder, 1-2 parts of monocalcium phosphate, 0.1-0.2 part of edible salt, 2-3 parts of linseed oil and 1-2 parts of dai-dai flower oil. The grass carp feed is complete and balanced in nutrition, high in food calling property, high in palatability, high in digestion rate and complete in nutrition indexes and has various nutritious components required by the growth of grass carps. After being fed with the feed, the grass carps grow fast, the disease resistance rate is obviously increased, and the survival rate can be increased to be over 95 percent; therefore, the breeding cost is greatly reduced, and high-quality intensive breeding is realized.

Owner:ANHUI CHENNUO FEED GREASE PROCESSING

Method for production of preserved flower, and processing solution for use in the method

InactiveCN101861092AKeep natural colorReduce processDead plant preservationNatural resinVegetable oil

Disclosed is a method for producing a preserved flower, which enables to keep the original color of a real flower, particularly the subtle gradation in color of the real flower. Also disclosed is a processing solution for use in the method. Specifically disclosed is a method for producing a preserved flower, which comprises immersing a real flower in a processing solution and drying the flower, wherein the processing solution comprises a solution or dispersion containing at least one component selected from a natural oil material oil, a natural resin material, a siloxane, a synthetic resin, a water-addition-reaction-type urethane, a fatty acid ester and a surfactant, wherein the natural oil material is terpin oil, stand oil, whale oil, boiled oil, linseed oil, camellia oil, olive oil, rapeseed oil, a salad oil (a purified plant oil), sesame oil, camphor oil or the like, wherein the natural resin material is rosin, glue, wax, bees wax, rubber, rhus lacquer or the like, and wherein the fatty acid ester is an ester of a saturated or unsaturated fatty acid such as lauric acid, palmitic acid, stearic acid and myristic acid and a lower or polyhydric alcohol.

Owner:坂本好央

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com