Patents

Literature

464 results about "Shellac" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Shellac is a resin secreted by the female lac bug, on trees in the forests of India and Thailand. It is processed and sold as dry flakes (pictured) and dissolved in alcohol to make liquid shellac, which is used as a brush-on colorant, food glaze and wood finish. Shellac functions as a tough natural primer, sanding sealant, tannin-blocker, odour-blocker, stain, and high-gloss varnish. Shellac was once used in electrical applications as it possesses good insulation qualities and it seals out moisture. Phonograph and 78 rpm gramophone records were made of it until they were replaced by vinyl long-playing records from the 1950s onwards.

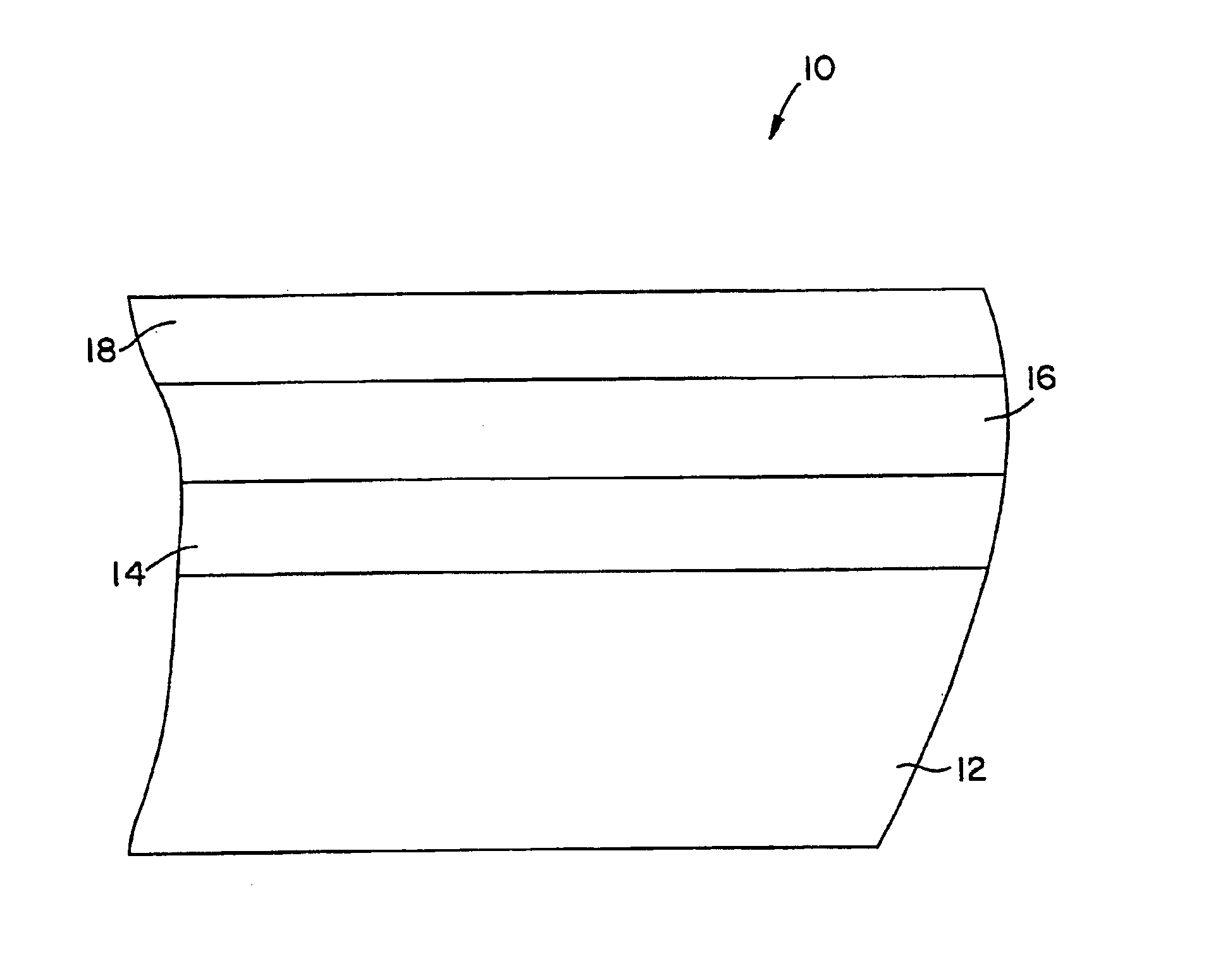

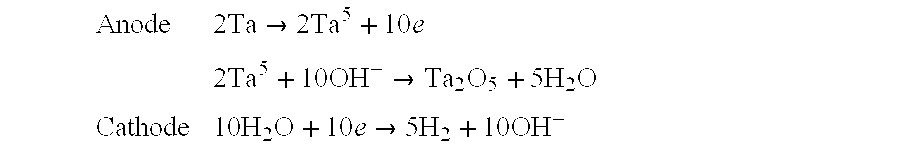

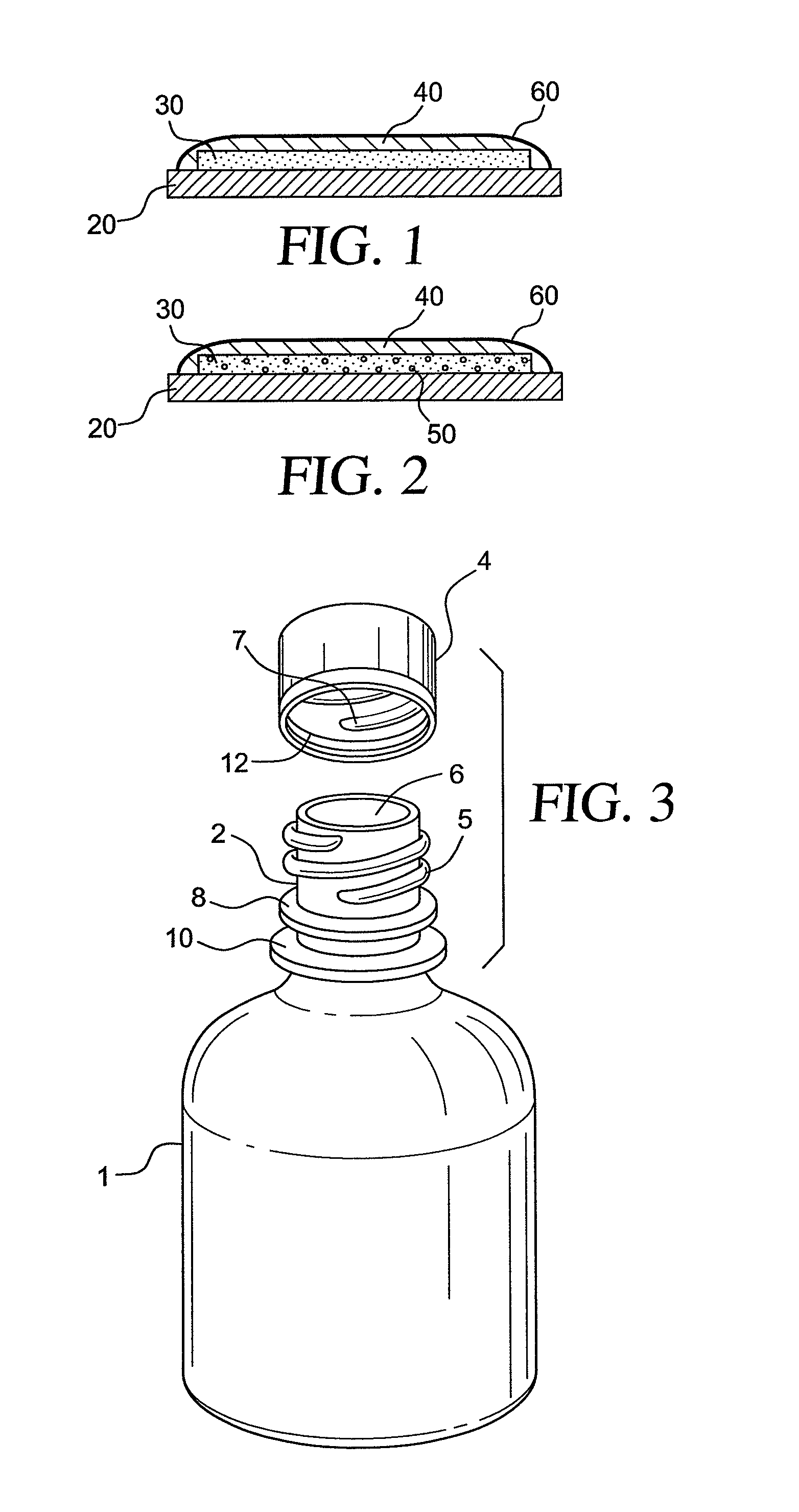

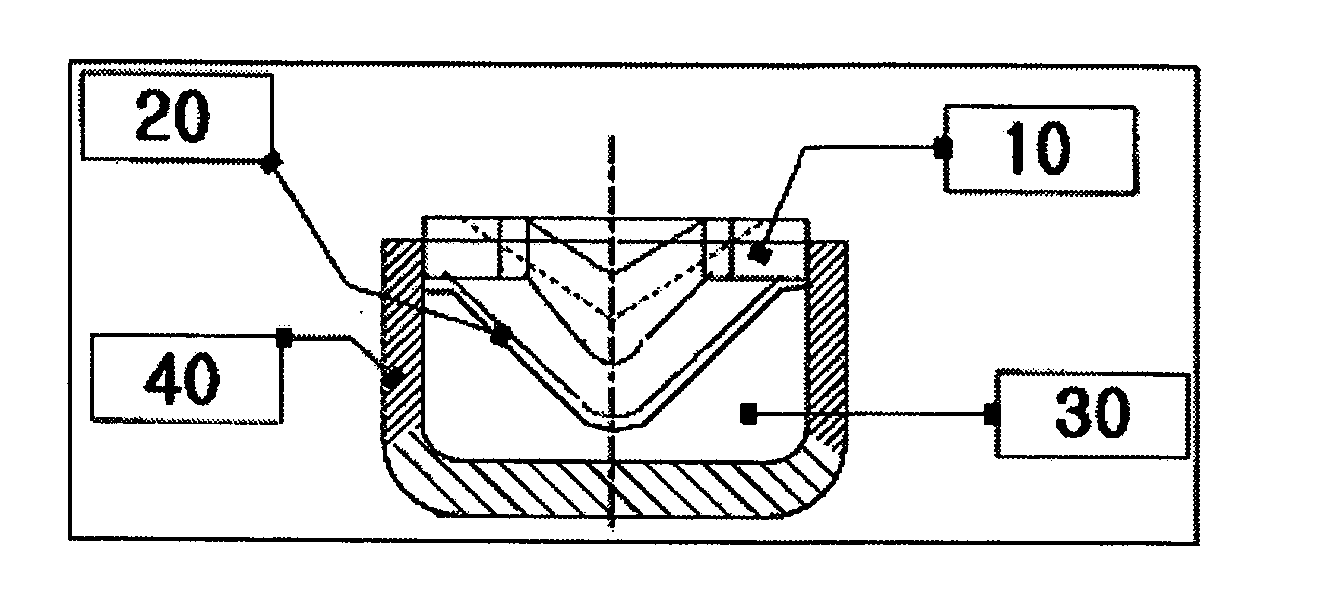

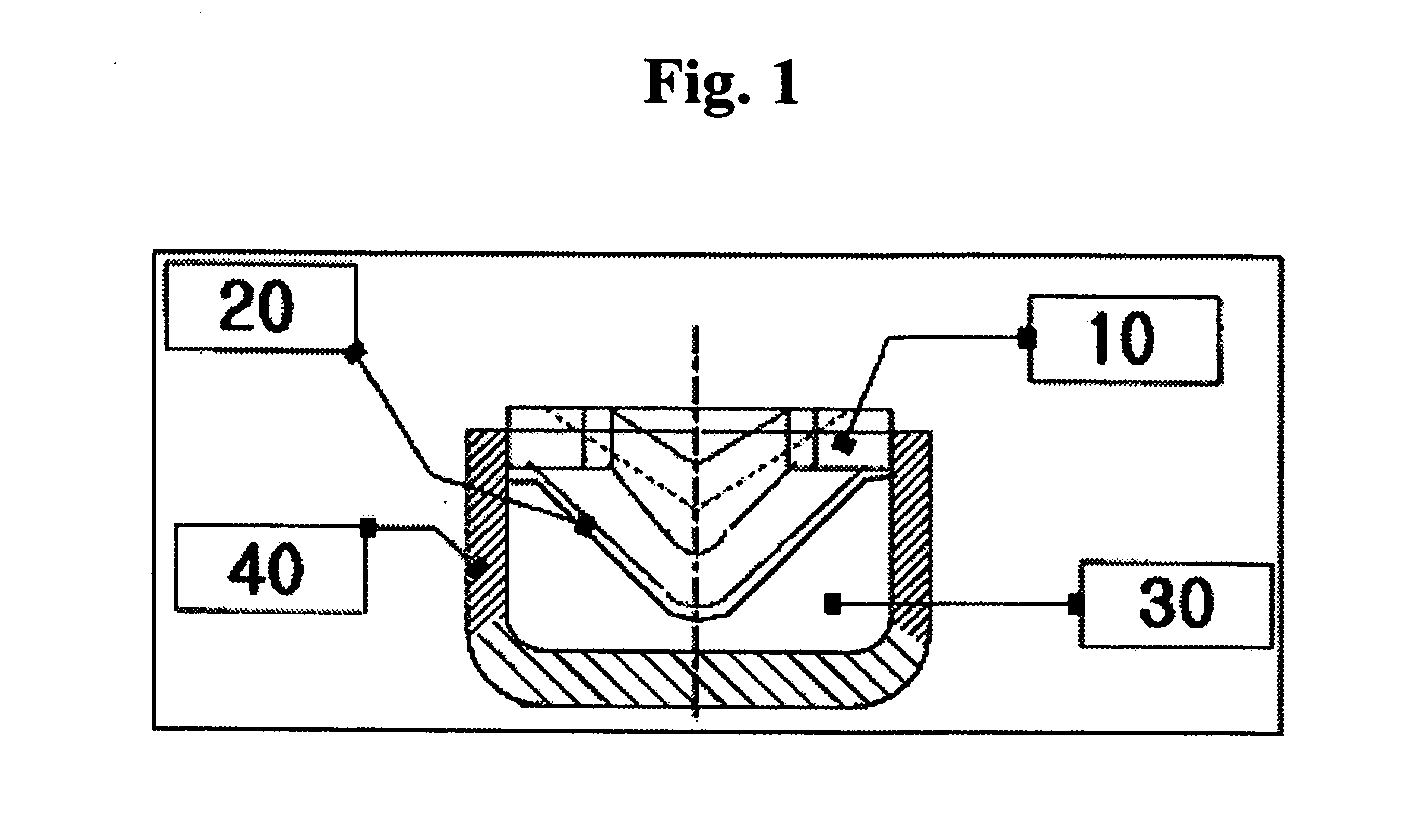

Protective coating for electrolytic capacitors

InactiveUS6864147B1Low dissipation factorLow leakage currentSolid electrolytic capacitorsSemiconductor/solid-state device manufacturingShellacElectrolysis

A solid electrolytic capacitor that comprises an anode that contains a valve-action metal (e.g., tantalum, niobium, and the like) and a dielectric film overlying the anode is provided. The capacitor also comprises a protective coating overlying the dielectric film, wherein the protective coating contains a relatively insulative, resinous material. For example, in one embodiment, the resinous material can be a drying oil, such as olive oil, linseed oil, tung oil, castor oil, soybean oil, shellac, and derivatives thereof. The capacitor also comprises a conductive polymer coating overlying the protective coating. As a result of the present invention, it has been discovered that a capacitor can be formed that can have a relatively low leakage current, dissipation factor, and equivalents series resistance.

Owner:KYOCERA AVX COMPONENTS CORP

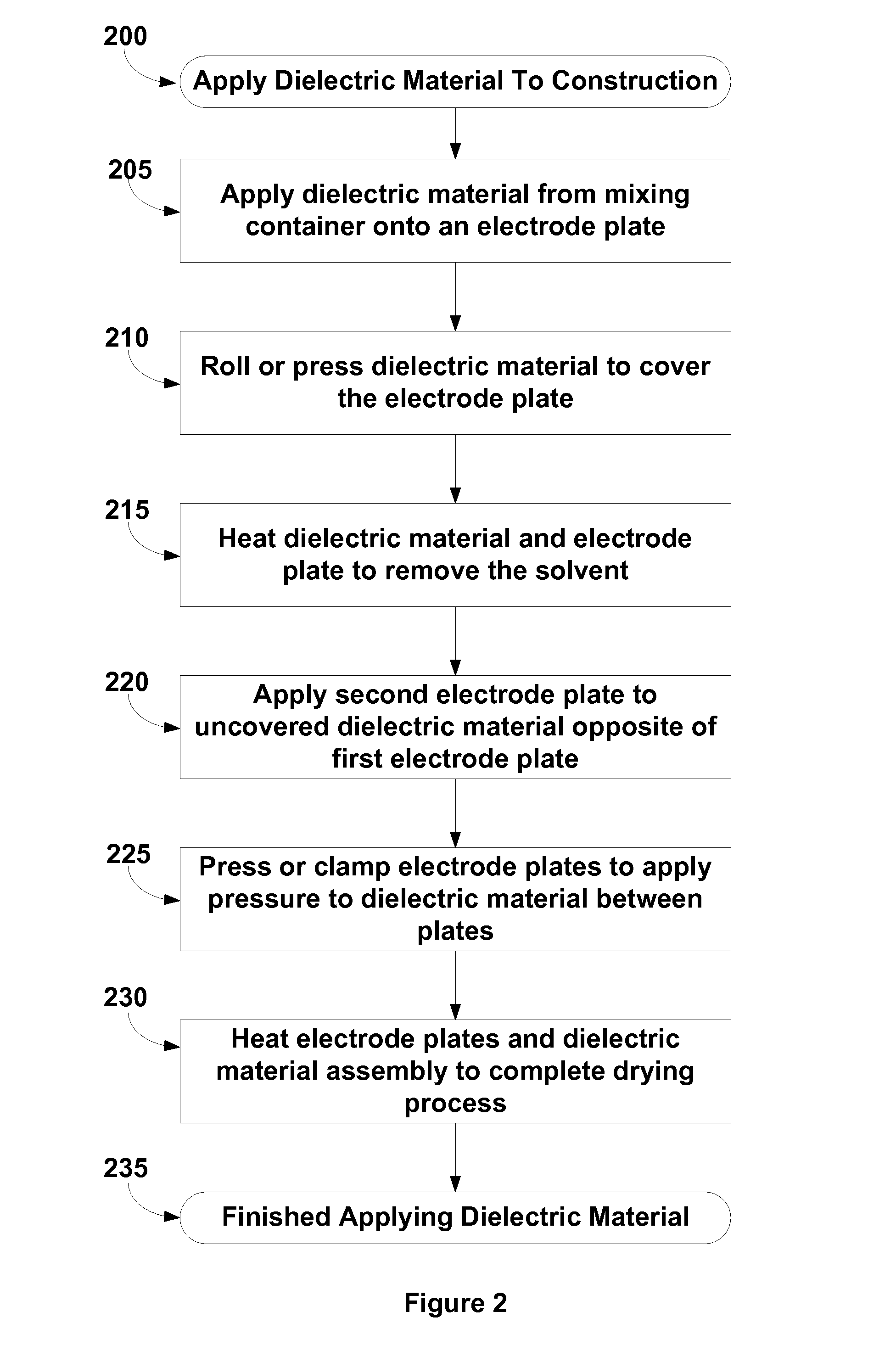

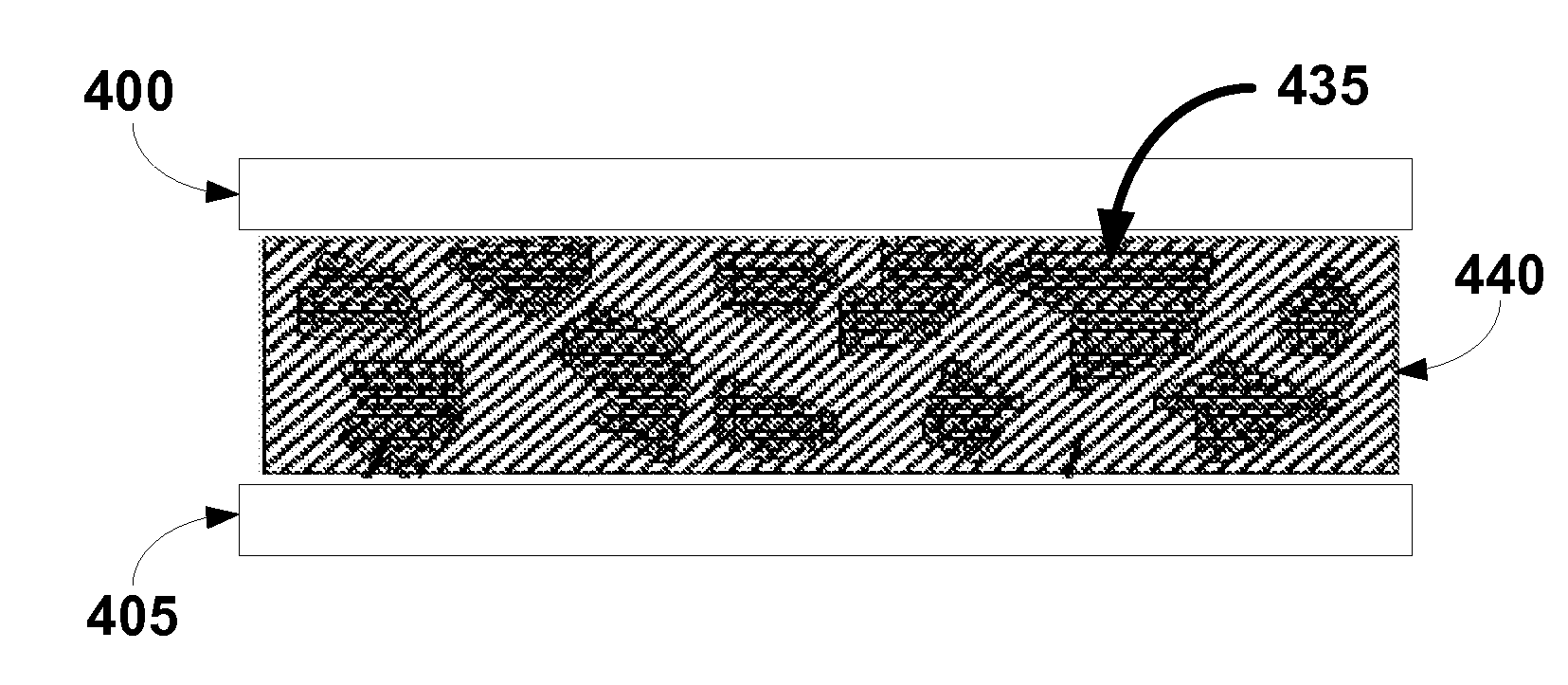

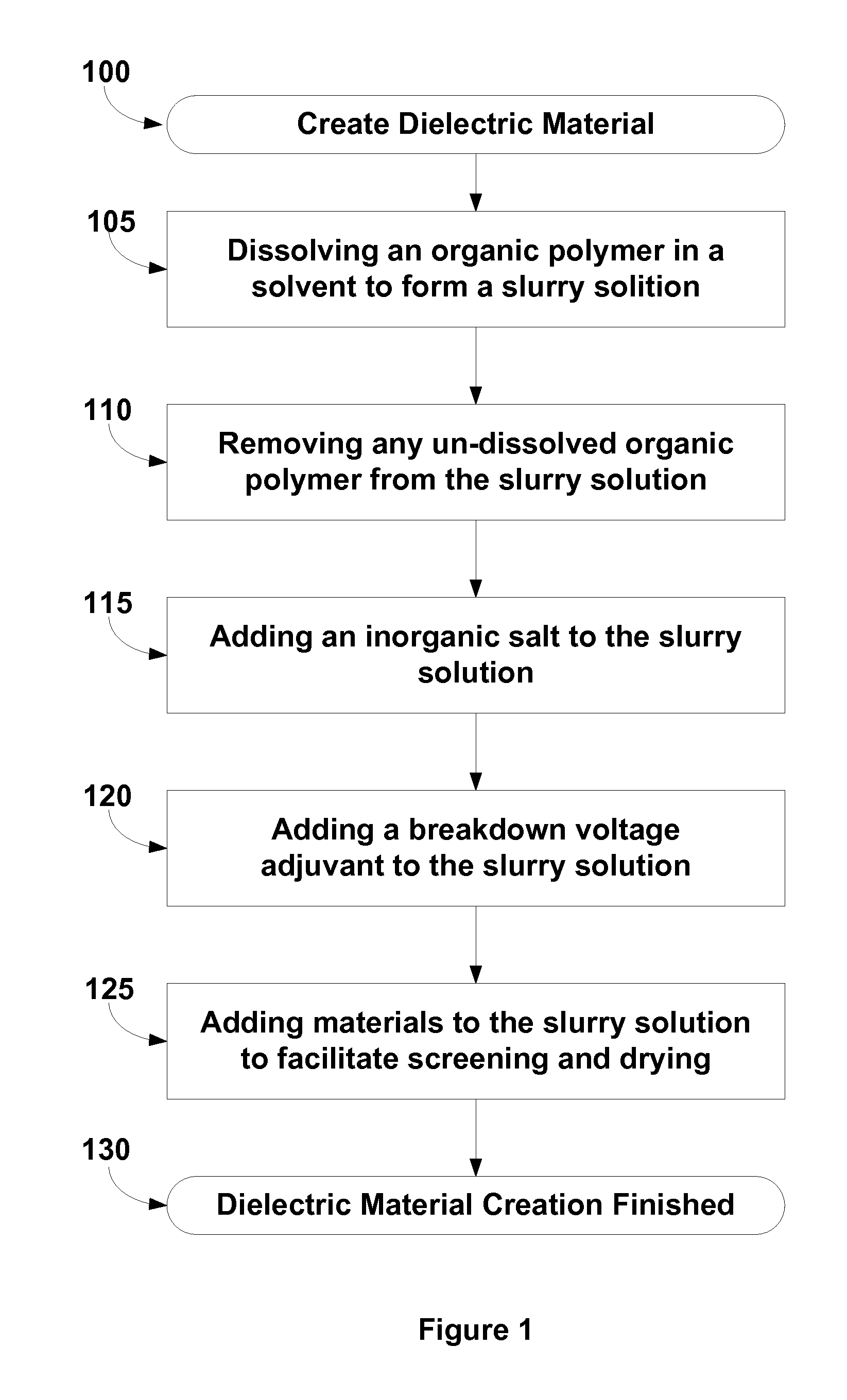

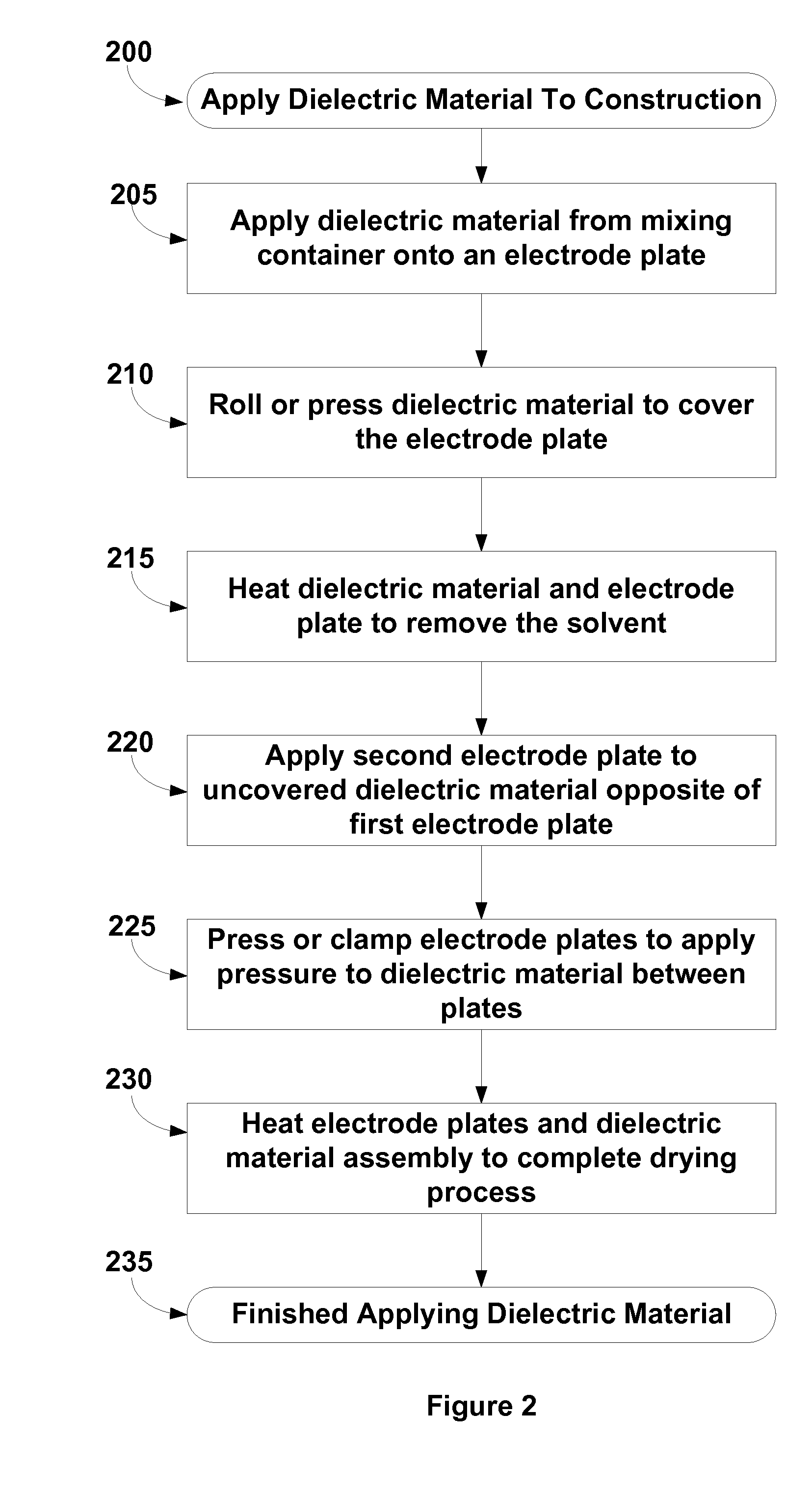

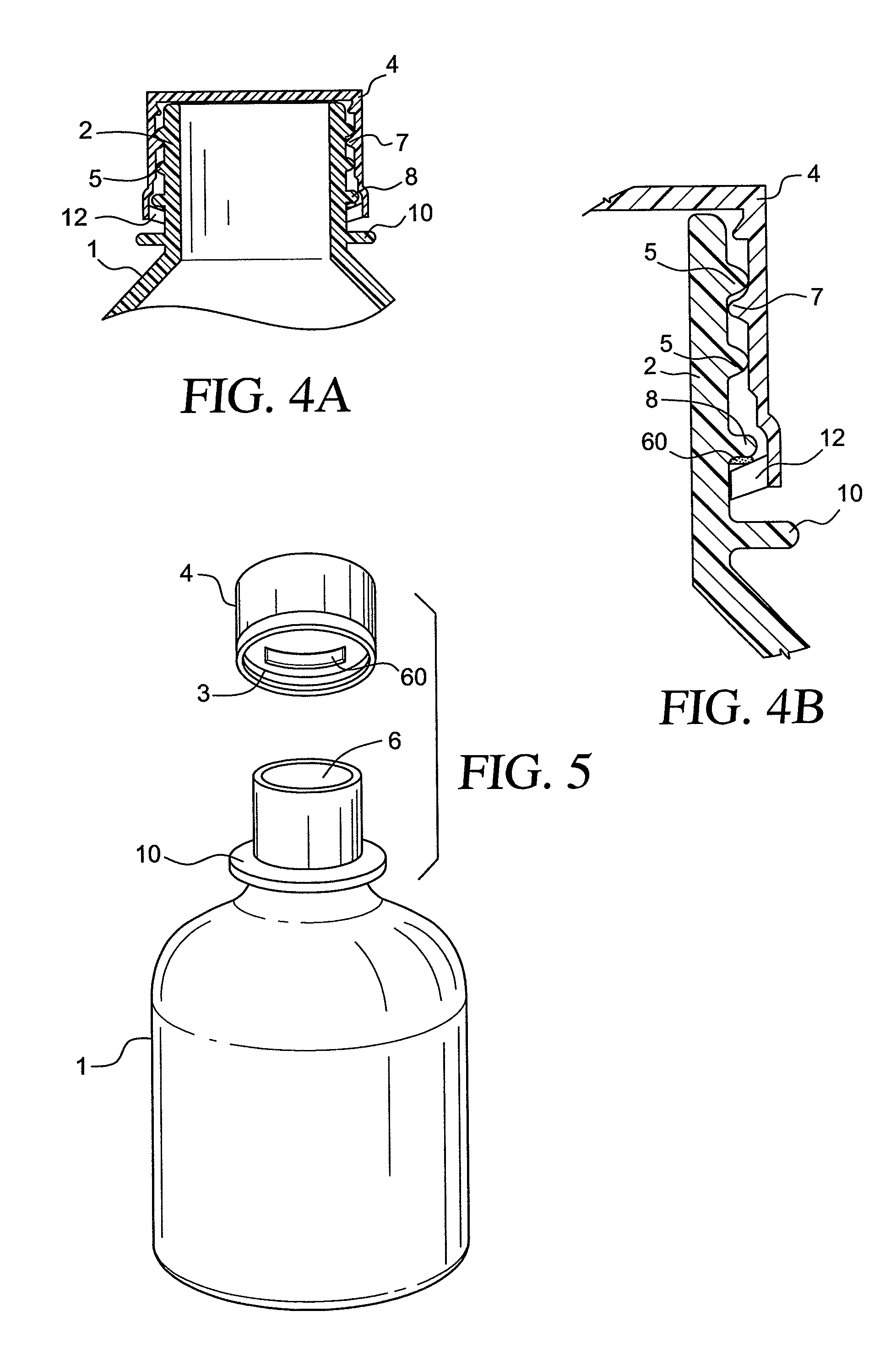

Very thin dielectrics for high permittivity and very low leakage capacitors and energy storing devices

ActiveUS20150000090A1High dielectric constantAvoiding electrical breakdownLamination ancillary operationsFixed capacitor dielectricShellacPermittivity

Methods are disclosed for creating extremely high permittivity dielectric materials for use in capacitors and energy storage devices. High permittivity materials suspended in an organic non-conductive media matrix with enhanced properties and methods for making the same are disclosed. Organic polymers, shellac, silicone oil, and / or zein formulations are utilized to produce thin film low conductivity dielectric coatings. Transition metal salts as salt or oxide matrices are formed at low temperatures utilizing mild reducing agents.

Owner:CARVER SCI INC

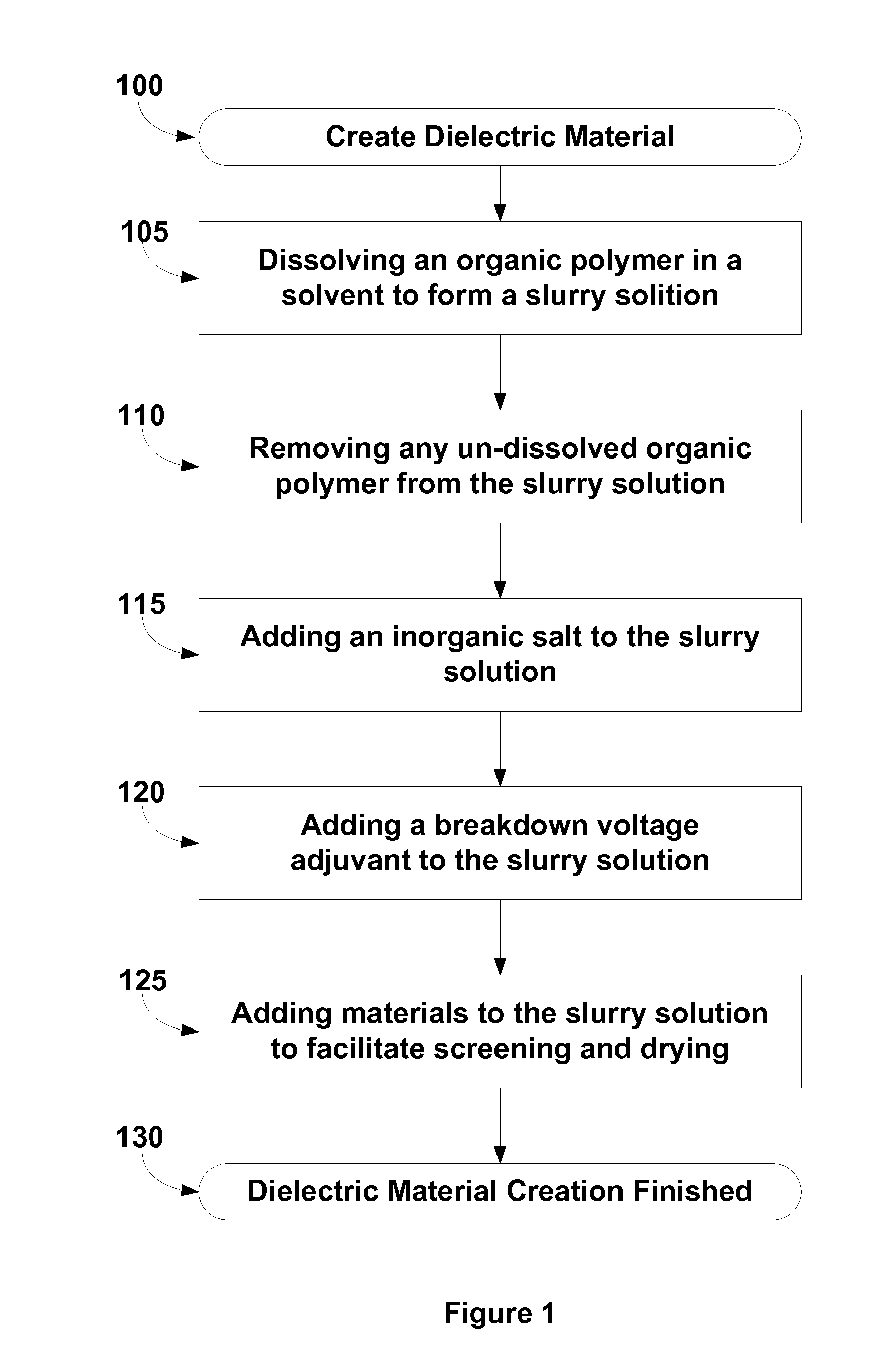

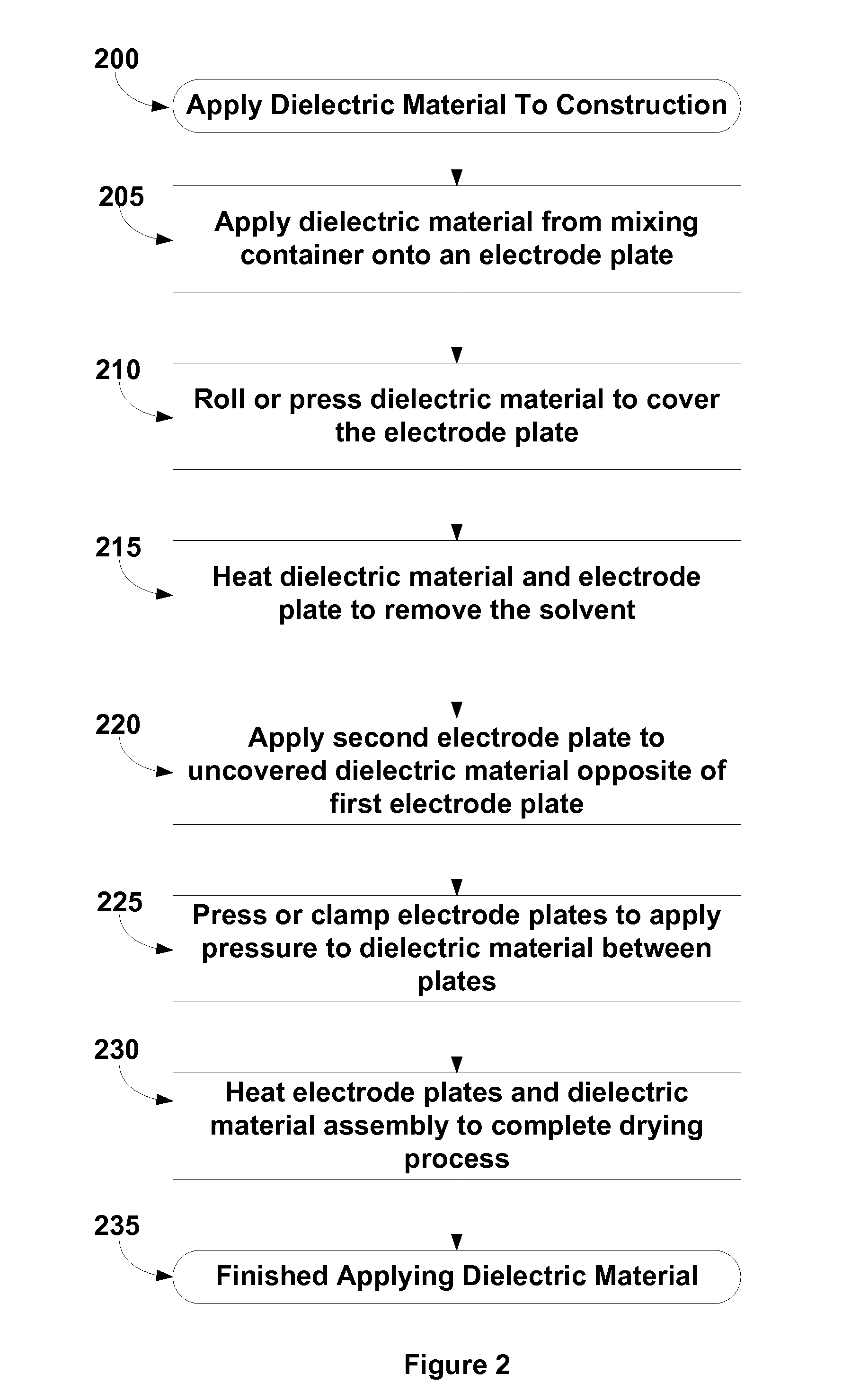

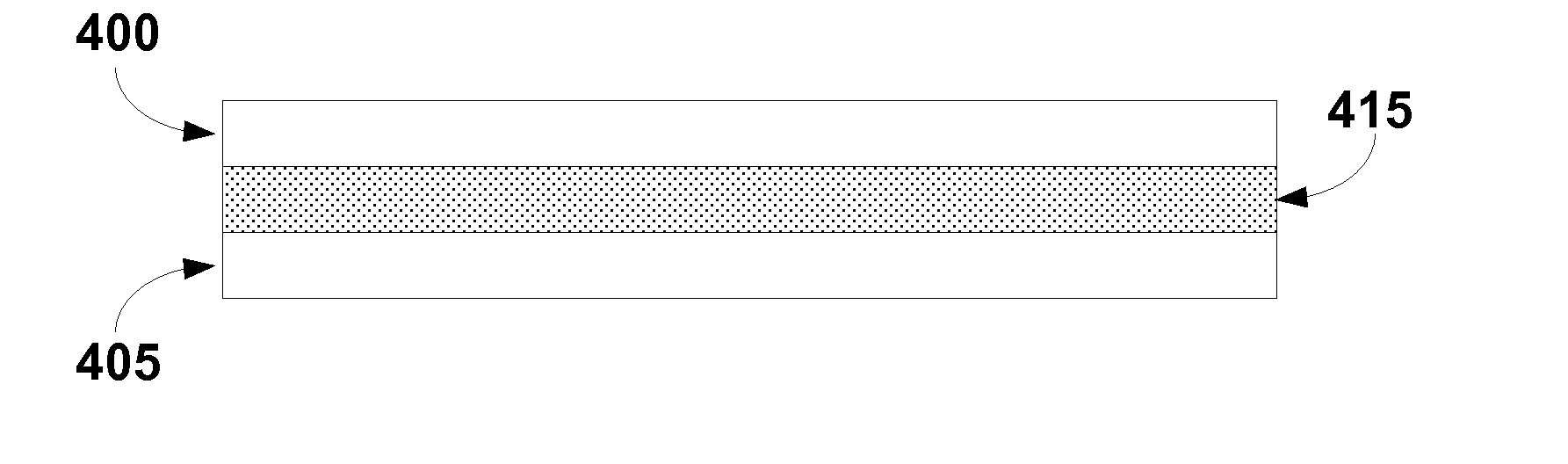

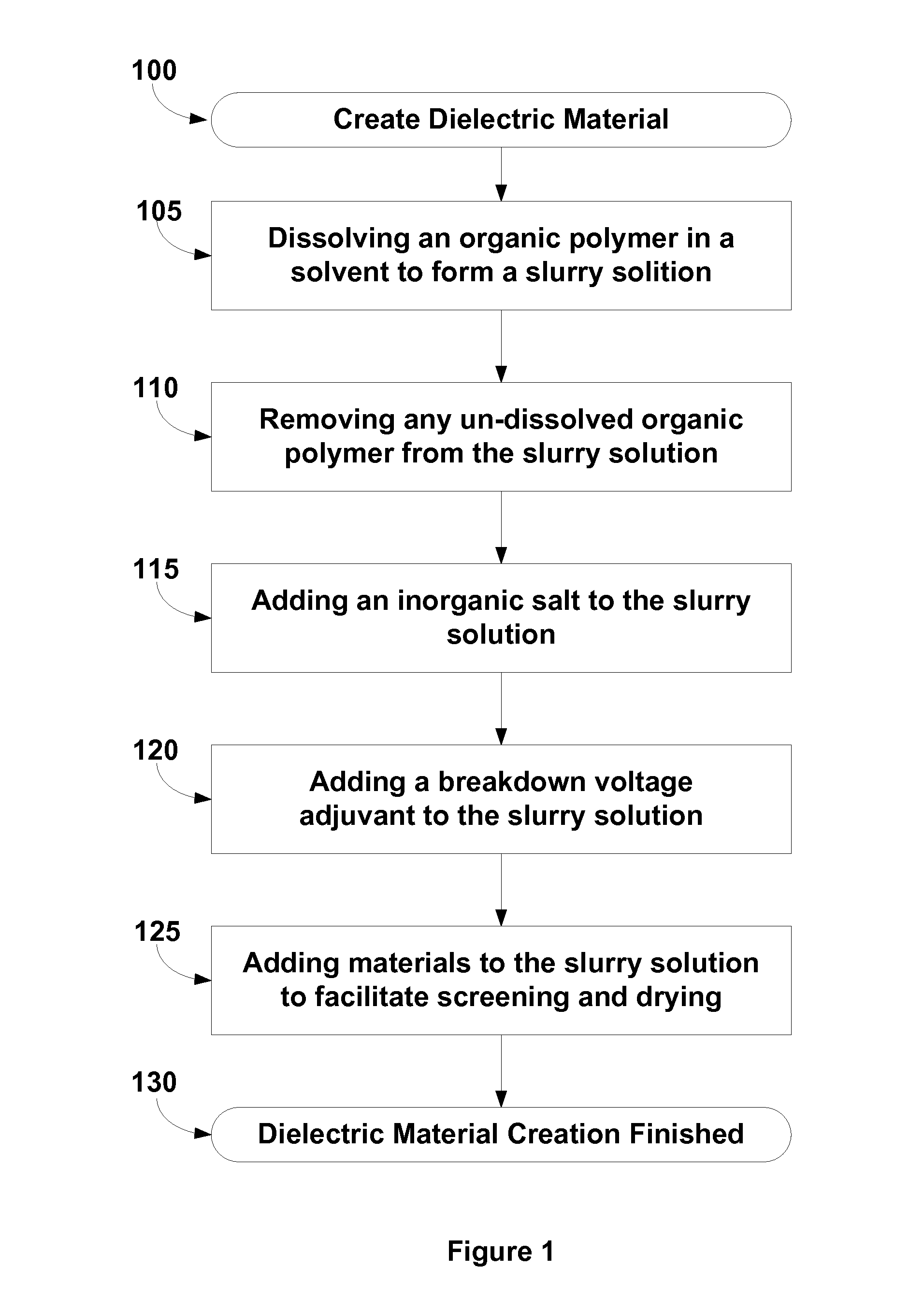

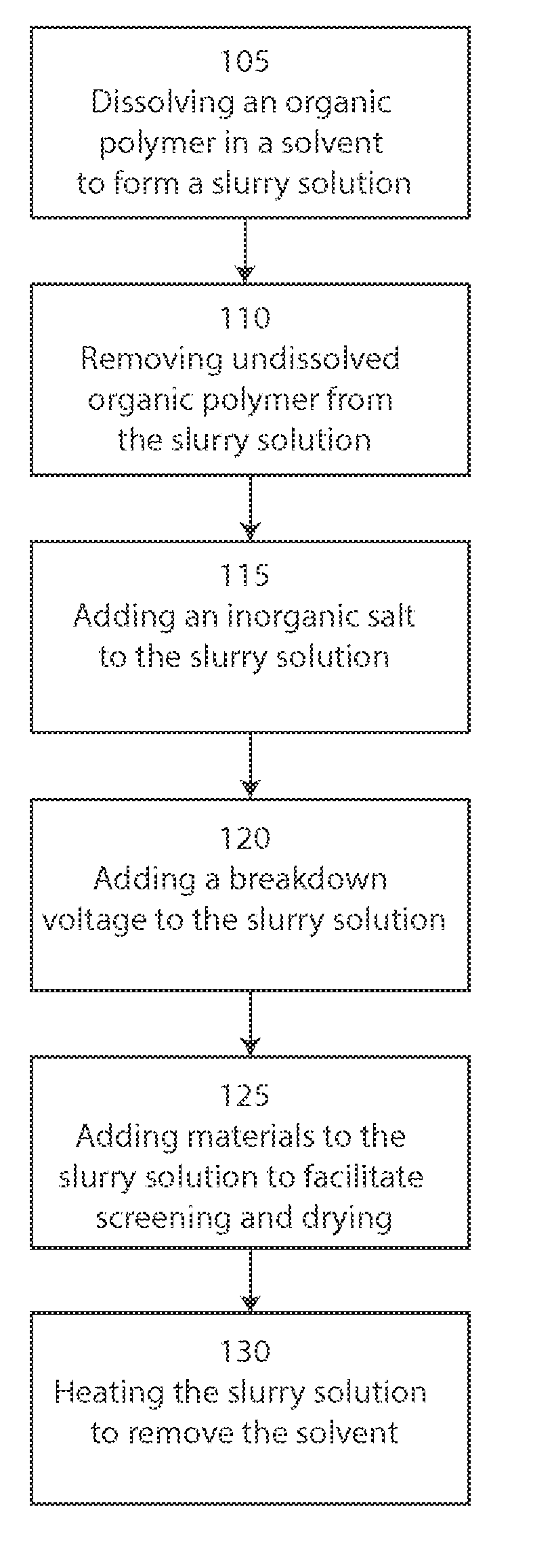

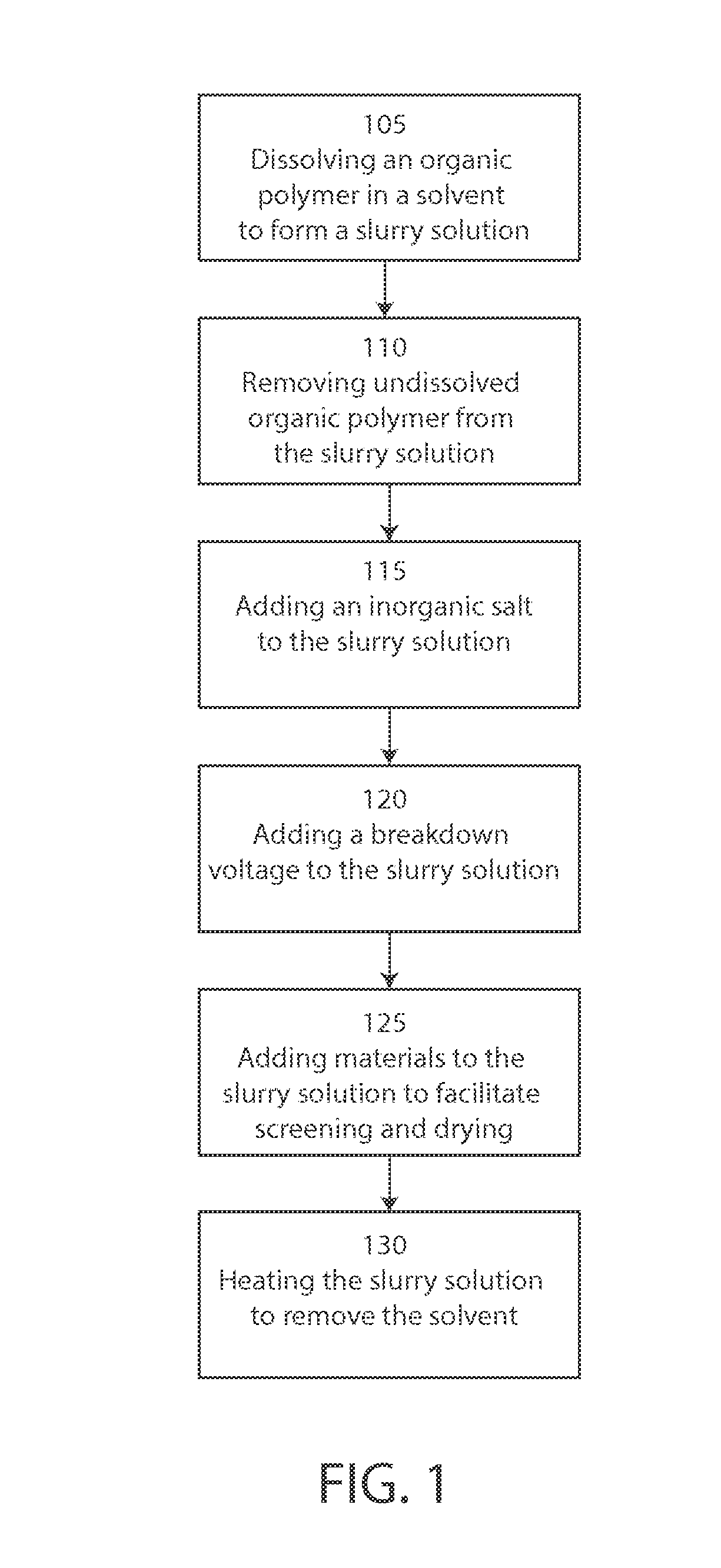

Creation of very thin dielectrics for high permittivity and very low leakage capacitors and energy storing devices and methods for forming the same

InactiveUS20120241085A1High dielectric constantHigh energyLamination ancillary operationsFibre treatmentShellacLow leakage

Methods are disclosed for creating extremely high permittivity dielectric materials for use in capacitors and energy storage devices. High permittivity materials suspended in an organic non-conductive media matrix with enhanced properties and methods for making the same are disclosed. A general method for the formation of thin films of some particular dielectric material is disclosed, wherein the use of organic polymers, shellac, silicone oil, and / or zein formulations are utilized to produce thin film low conductivity dielectric coatings. Additionally, methods whereby the formation of certain transition metal salts as salt or oxide matrices at low temperatures utilizing mild reducing agents are disclosed. Further, a method for the enhancement of dielectric permittivity formation in the dielectric material of the capacitor is taught.

Owner:CARVER SCI INC

Very thin dielectrics for high permittivity and very low leakage capacitors and energy storing devices

ActiveUS20150000833A1Avoiding electrical breakdownReduce conductivityLamination ancillary operationsFixed capacitor dielectricShellacOxide matrix

Methods are disclosed for creating extremely high permittivity dielectric materials for use in capacitors and energy storage devices. High permittivity materials suspended in an organic non-conductive media matrix with enhanced properties and methods for making the same are disclosed. Organic polymers, shellac, silicone oil, and / or zein formulations are utilized to produce thin film low conductivity dielectric coatings. Transition metal salts as salt or oxide matrices are formed at low temperatures utilizing mild reducing agents.

Owner:CARVER SCI INC

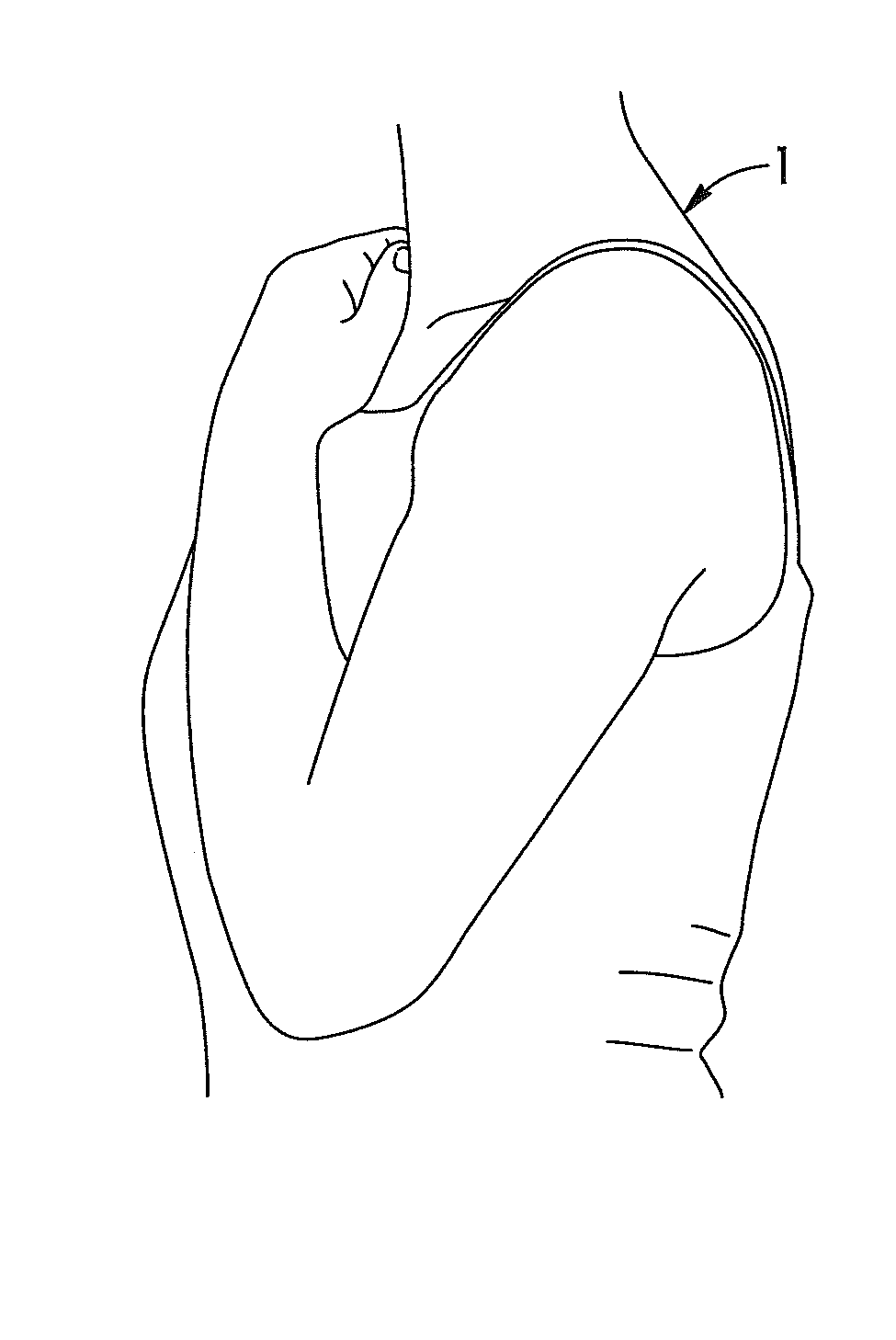

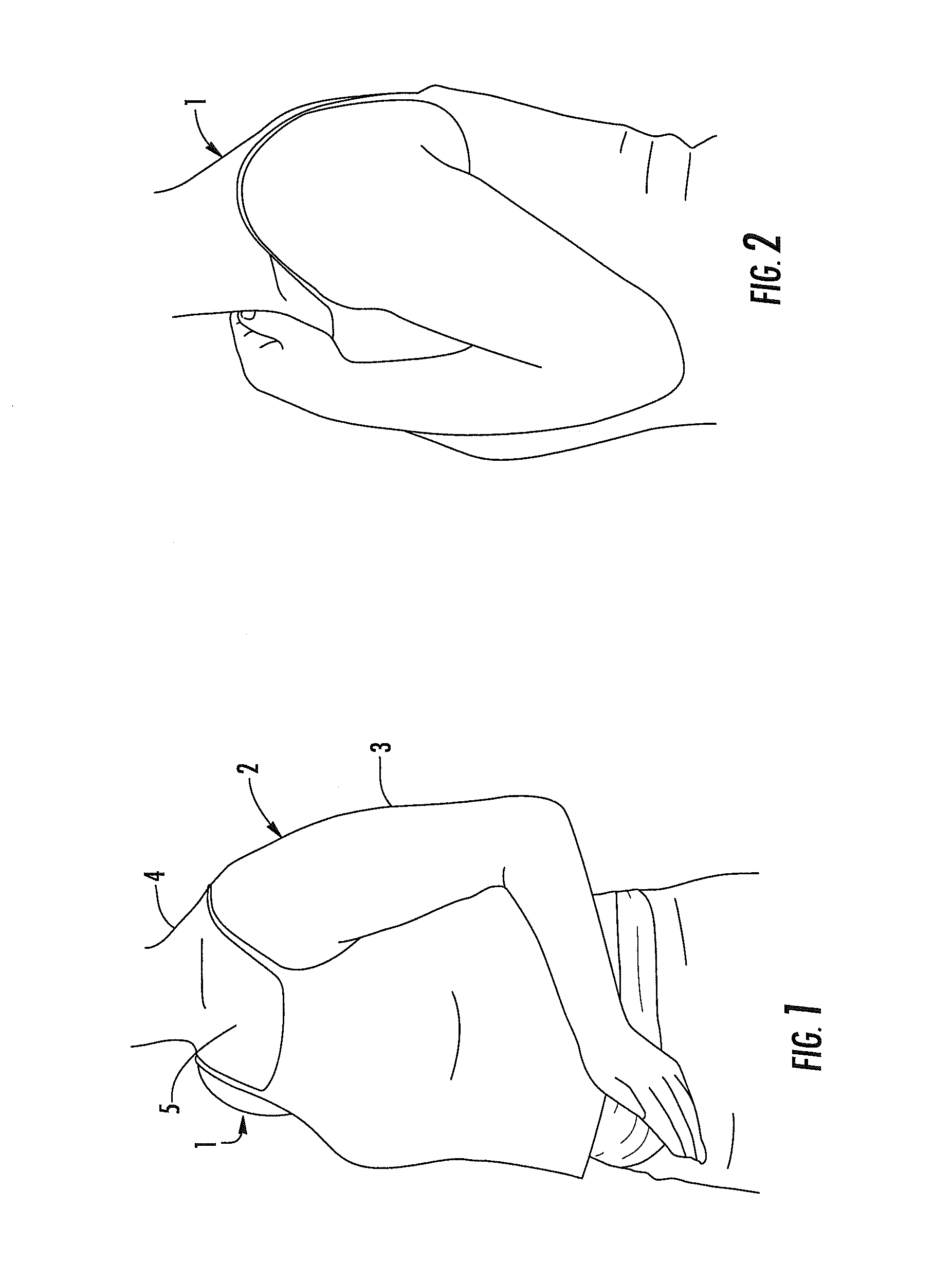

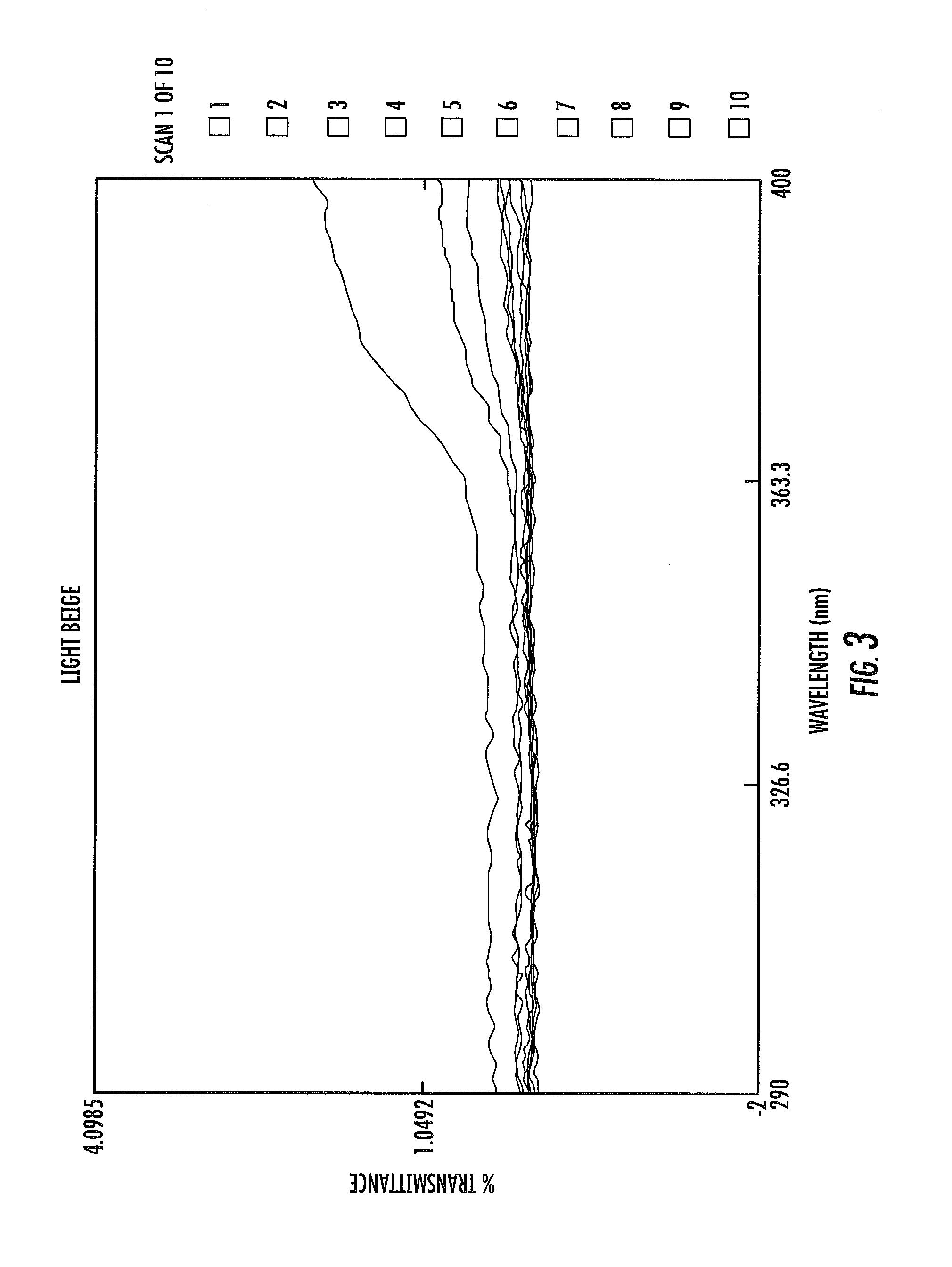

Skin coating composition and uses thereof

ActiveUS20100297043A1Providing with sun protectionCosmetic preparationsOrganic active ingredientsSunscreen agentsShellac

A composition for coating skin comprising shellac, ethanol, castor oil, ethyl cellulose and fumed silica or nano zinc oxide, wherein the composition forms a long lasting waterproof flexible film on skin. The composition may include different ingredients for different applications. In one embodiment, the composition includes pigment and / or dye and may be used to coat a skin blemish such that the skin blemish blends in with the surrounding skin. In another embodiment, the composition includes a sunscreen agent and may be used as a sunscreen. In yet another embodiment, the composition includes a therapeutic agent for treating a disorder of the skin.

Owner:BLONDE HLDG PTY LTD

Water- and heat-resistant scratch-and-sniff coating

ActiveUS8440265B2Improve manufacturingRecord carriersCellulosic plastic layered productsShellacHeat resistant

A scratch-and-sniff coating is provided comprised of a first coating on a substrate having a water- and heat-resistant second coating thereon, the first coating being comprised of a non-encapsulated flavor / fragrance component and a polysaccharide component, and the second coating comprised of a shellac component. The scratch-and-sniff coating is made by forming a first coating comprised of a non-encapsulated flavor / fragrance component and a polysaccharide component and drying the first coating, and forming a water- and heat-resistant shellac-containing second coating on the first coating, and drying the second coating. An encapsulated flavor / fragrance component may optionally be present in the first coating. The scratch-and-sniff coating can be applied to a package for a consumer article.

Owner:ENCAPSYS LLC

Oil-resistant aging-resistant chlorhydrin rubber and polyacrylate rubber mixed rubber sealing ring

InactiveCN102731987AHigh tensile strengthExcellent high and low temperature resistanceVulcanizationPolymer science

The invention discloses an oil-resistant aging-resistant chlorhydrin rubber and polyacrylate rubber mixed rubber sealing ring which is prepared by carrying out banburying, open refining and secondary vulcanization on the raw materials of chlorhydrin rubber, polyacrylate rubber, shellac, and the like. The sealing ring provided in the invention has the advantages of oil resistance, aging resistance, excellent high temperature resistance and low temperature resistance, high tensile strength and a simple preparation method.

Owner:CGP WUHU SEALING

High gloss film coating and stable solution therefor

A coating composition for use in coating foods, confections, nutraceuticals and pharmaceuticals is comprised of shellac in aqueous solution, a hydrolyzed starch product having a dextrose equivalent of 10 or greater and an effective amount of a plasticizer. The coating composition provides a surprisingly high gloss coating. The edible film coating composition solution may be stabilized by adding an effective amount of ethylene diamine tetraacetic acid salt wherein the solution may remain stable for at least three months. The ethylene diamine tetraacetic acid salt may include disodium, trisodium and tetrasodium salts of ethylene diamine tetraacetic acid. Preferably, the concentration of ethylene diamine tetraacetic acid is about 0.5% to 2% of the solution.

Owner:EMERSON RESOURCES

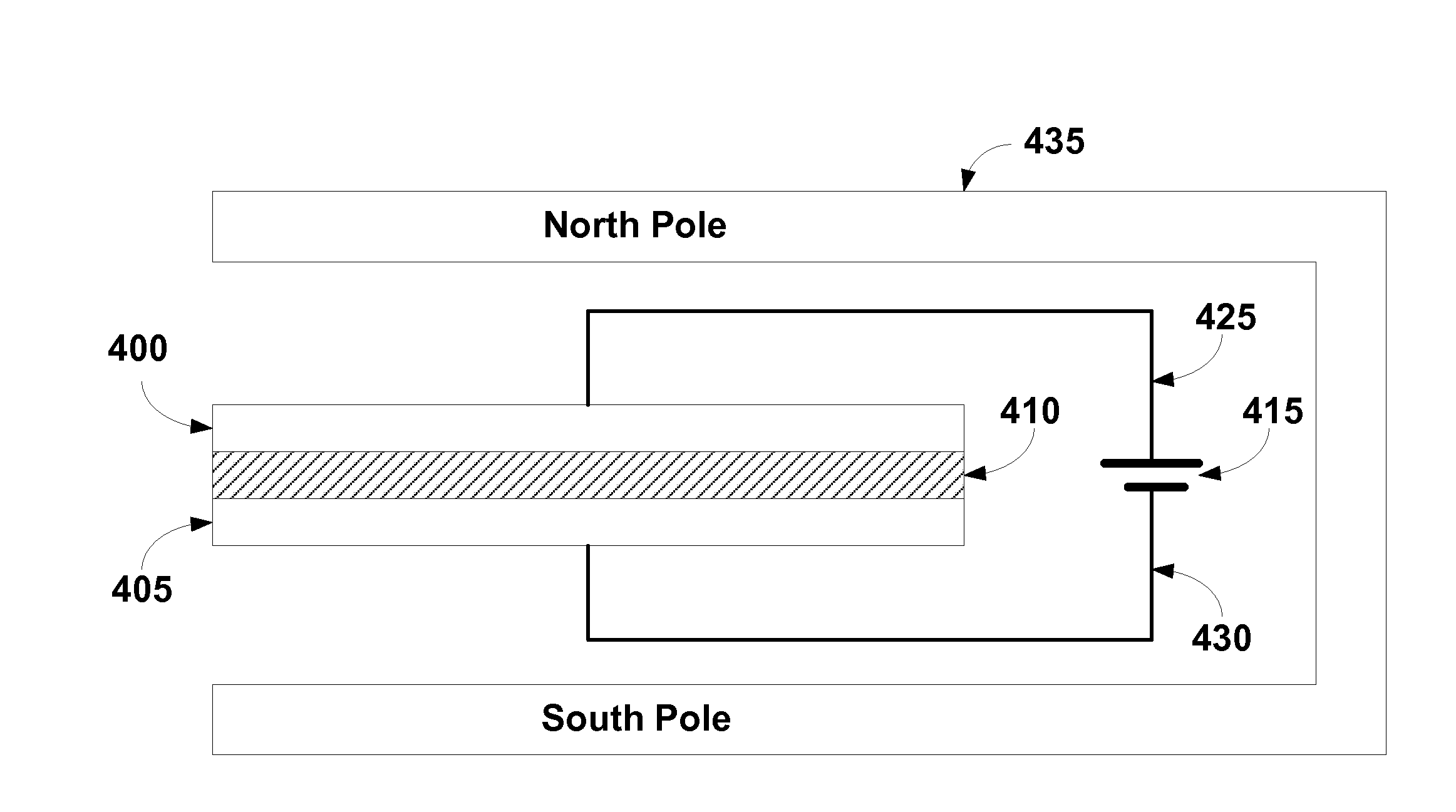

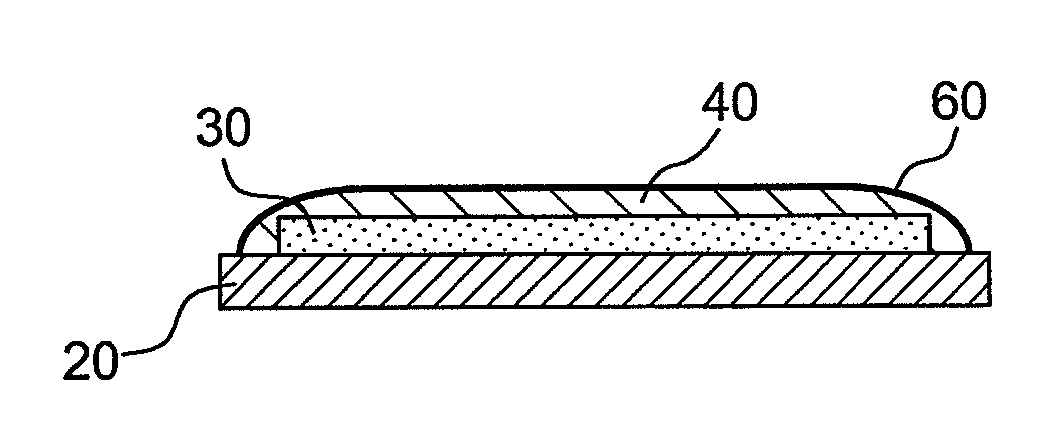

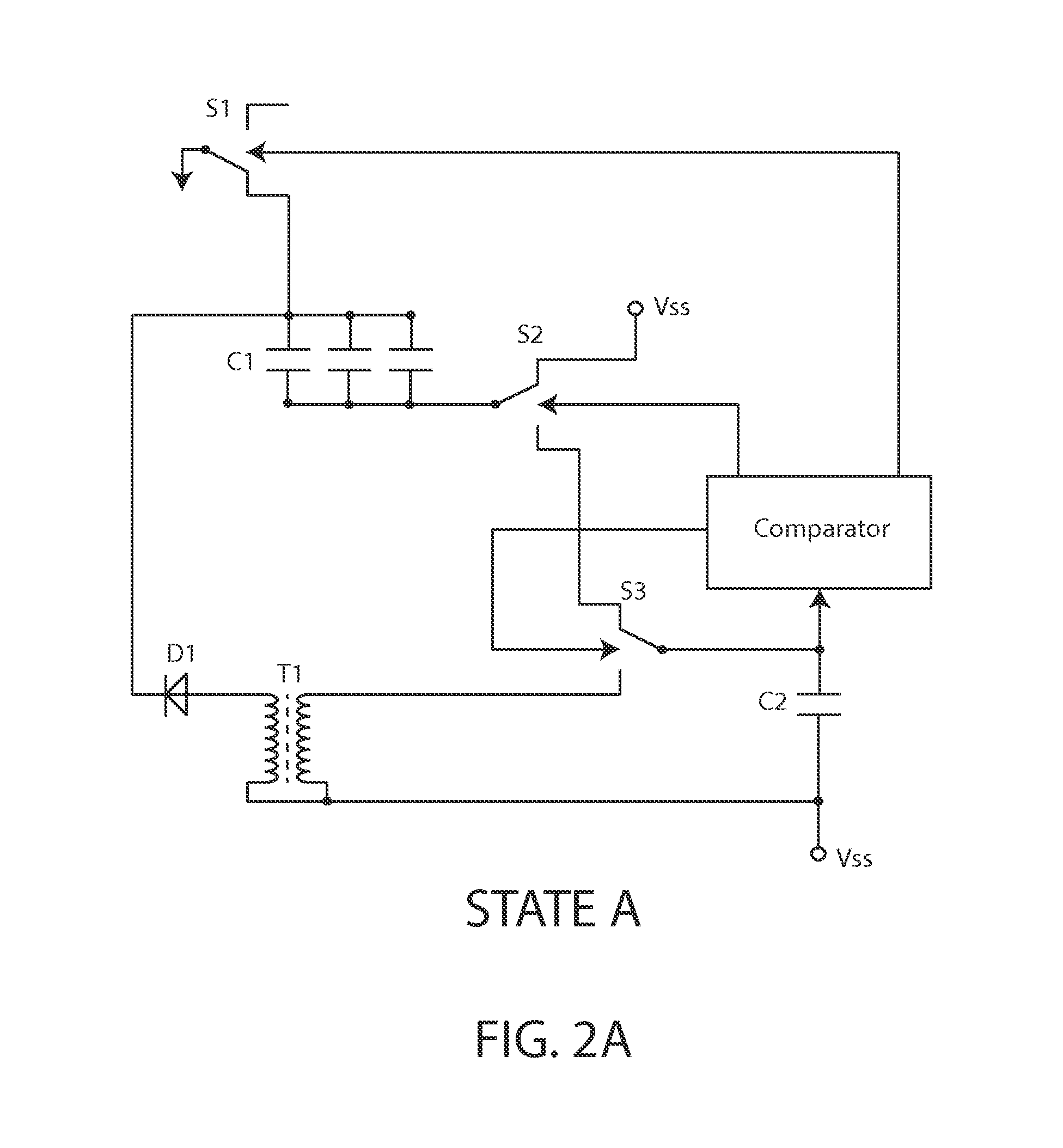

High permittivity low leakage capacitor and energy storing device

ActiveUS20130229157A1Improve performance utilizationGood yield performanceMultiple fixed capacitorsBatteries circuit arrangementsShellacOxide matrix

A method is provided for making a high permittivity dielectric material for use in capacitors. Several high permittivity materials in an organic nonconductive media with enhanced properties and methods for making the same are disclosed. A general method for the formation of thin films of some particular dielectric material is disclosed, wherein the use of organic polymers, shellac, silicone oil, and / or zein formulations are utilized to produce low conductivity dielectric coatings. Additionally, a method whereby the formation of certain transition metal salts as salt or oxide matrices is demonstrated at low temperatures utilizing mild reducing agents. Further, a circuit structure and associated method of operation for the recovery and regeneration of the leakage current from the long-term storage capacitors is provided in order to enhance the manufacturing yield and utility performance of such devices.

Owner:CARVER SCI INC

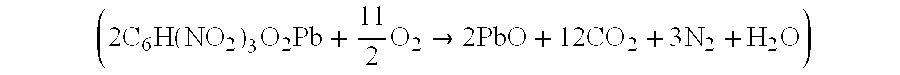

Non-toxic primer powder composition for small caliber ammunition

The present invention relates to a non-toxic primer powder composition for small caliber ammunition characterized by comprising potassium nitrate coated with shellac as an oxidizer, and particularly characterized by comprising 25-40 wt % of an initiating explosive, 10-30 wt % of nitrate ester as a fuel, 32-40 wt % of a shellac-coated potassium nitrate (KNO3) as an oxidizer, 5-10 wt % of tetracene as a first sensitizer, 3-9 wt % of a borosilicate powder as a second sensitizer and 0.1-0.2 wt % of a chemical binder.

Owner:POONGSAN CO LTD

Special composite emulsifier for wax emulsion, and preparation method thereof

The present invention provides a special composite emulsifier for a wax emulsion. The special composite emulsifier is characterized by comprising, by weight, 45-50 parts of peregal, 20-25 parts of stearic acid, and 25-30 parts of fatty alcohol polyoxyethylene ether. The process comprises: sequentially adding peregal, stearic acid and fatty alcohol polyoxyethylene ether to a reaction kettle, heating to achieve a temperature of 60-70 DEG C until completely melting the material, and stirring to achieve a uniform state so as to discharge the material. According to the present invention, during preparation of various wax emulsions, the emulsifier having the amount of 8-10% of the mass of wax and the wax are co-melted and then uniformly stirred, and hot water with a temperature of 90-95 DEG C is added until the solid content is 50% so as to obtain the corresponding wax emulsion, or deionized water can be added according to requirements so as to adjust the wax emulsion content to 5-50% and the like. The special composite emulsifier can be provided for emulsifying paraffin wax, polyethylene wax, palm wax, montan wax, beeswax, rice bran wax, candelilla wax, shellac wax, and other types of waxes, such that material preparation of wax emulsion manufacturers is simply, and the prepared emulsion is translucent, has blue light , and has characteristics of good stability and small particle size; and the emulsifying system is consistent, such that various wax emulsions can be compounded according to any ratios without generation of phenomena such as precipitation, flocculation, layering and the like, and the special composite emulsifier can be conveniently used in various fields.

Owner:山东力厚轻工新材料有限公司

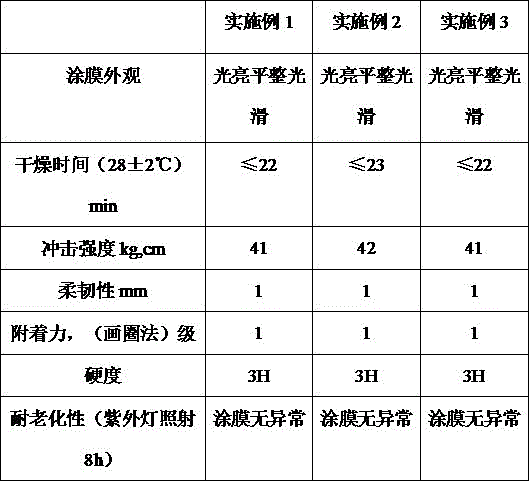

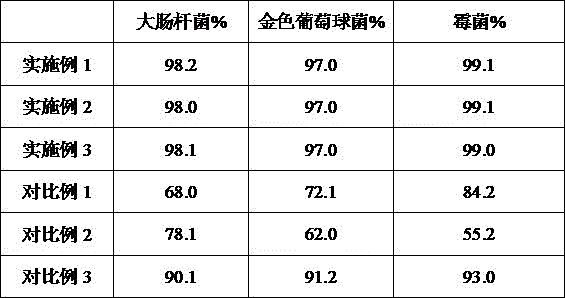

High-performance wickerwork coating

InactiveCN106349908AAvoid breedingImprove antibacterial propertiesFireproof paintsAntifouling/underwater paintsShellacPolyvinyl alcohol

The invention discloses a high-performance wickerwork coating which is prepared from the following components: waterborne polyurethane, silicon-acrylate emulsion, dioctyl phthalate, shellac resin, mung bean starch, polyvinyl alcohol, a filler, an antibacterial additive and water. Compared with the existing wickerwork coating, the wickerwork coating disclosed by the invention is high in storage stability and long in coating film service life; compared with the coating film service life of the common wickerwork coating, the coating film service life of the high-performance wickerwork coating is prolonged by twice or triple; a paint layer formed by the coating is touch, high in brightness, high in adhesive force, anti-acid, anti-sulfur, high in salt resistance, stable in performance, and not liable to corrode and discolor; the coating disclosed by the invention is extremely high in high-temperature resistance, high in adhesive force, and not liable to fall off; furthermore, during use, the coating can be quickly dried and is high in leveling property; moreover, the coating is harmless to the environment and a human body, and is environment-friendly.

Owner:安徽阜南县万家和工艺品有限公司

Pretreatment method of surface of decorative wood

The invention discloses a pretreatment method of a surface of decorative wood. The method comprises steps as follows: drying the wood until the moisture content ranges from 8%-10%, and then grinding and shaving the wood; cleaning the wood with a sodium carbonate solution with the concentration ranging from 5% to 6%, then scrubbing the wood clean, and brushing cleaned parts with shellac varnish for 12 times after the surface is clean; applying a bleaching agent to the surface of the wood for bleaching treatment, then wiping the surface of the wood clean with wet gauze, smearing a layer of acetic acid with the concentration of 1.2%, and then scrubbing the wood clean; preparing a dyeing agent for dyeing, wherein the dyeing agent comprises components in parts by weight as follows: 6 parts of alcohol solution dye, 70 parts of alcohol and 24 parts of the shellac varnish, and the components are evenly mixed and sprayed. The method is simple, and the treated surface of the wood is smooth and uniform in color.

Owner:QINGDAO SHOUSHENG IND

Powder coating, method for production thereof, method for using said powder coating and coated article

InactiveUS20060014031A1BondImprove bindingShellac coatingsLiquid surface applicatorsProduction rateShellac

The present invention provides a powder paint excellent in productivity and cost, because the powder paints that are not adhered to the substrate can recovered and reused. And in case of using the powder paint of the present invention, coating efficiency is high and fine textured coated films excellent in attractiveness of appearance and water resistance can be obtained, because the base paint powder and the pigment particle thereof hardly separate. The powder paints of the present invention are characterized in that the pigment particles are bound to the base paint powders via shellac. The powder paints of the present invention not only allows uniform and firm binding of pigment particles to base paint powders by the action of shellac, but also provides the resulting coated films with excellent attractiveness of appearance.

Owner:KUBOKO PAINT CO LTD +1

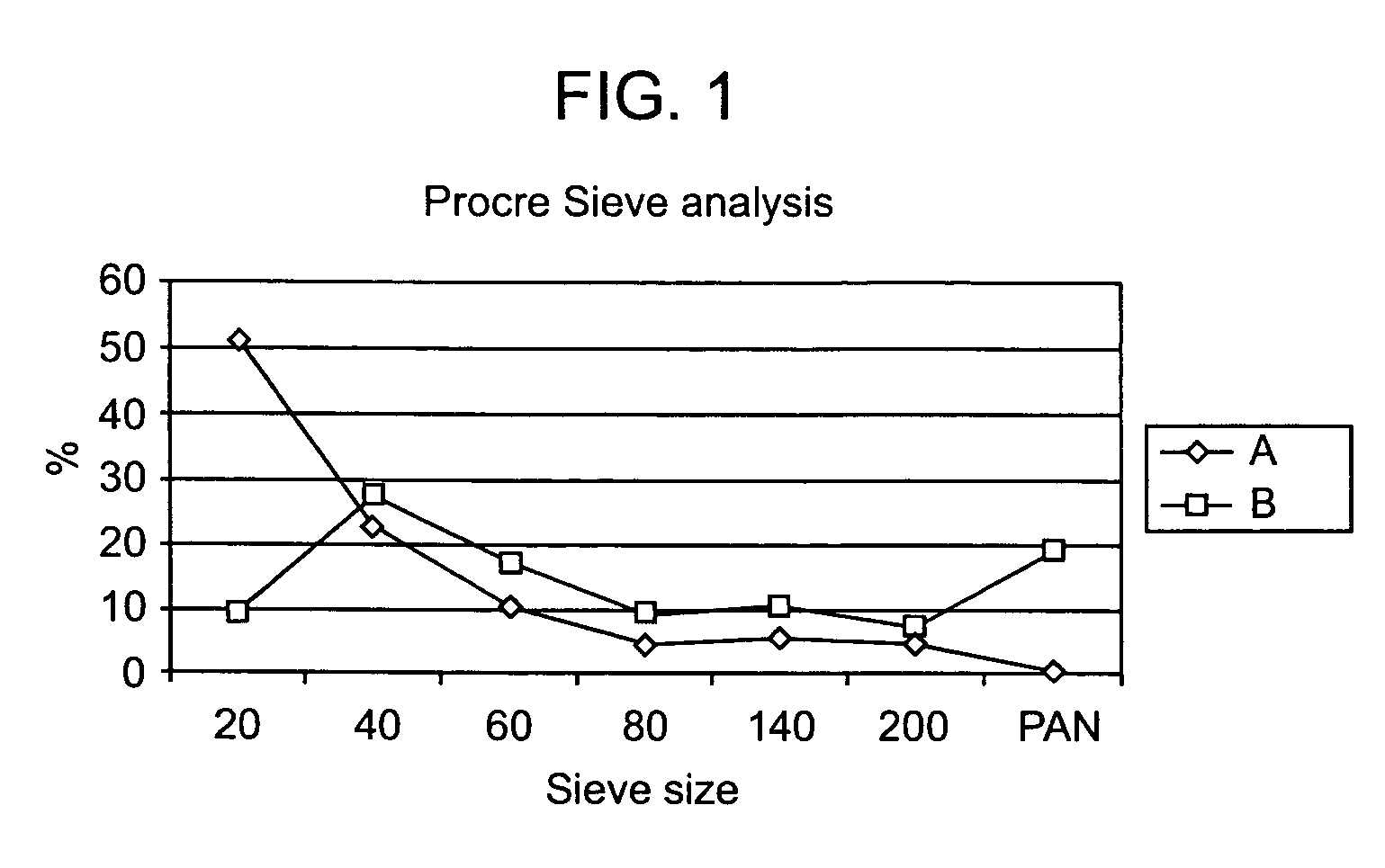

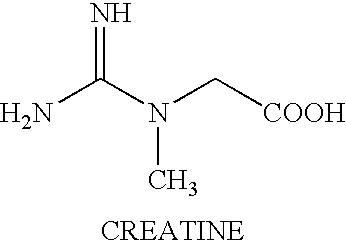

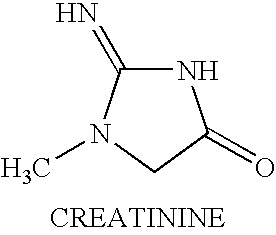

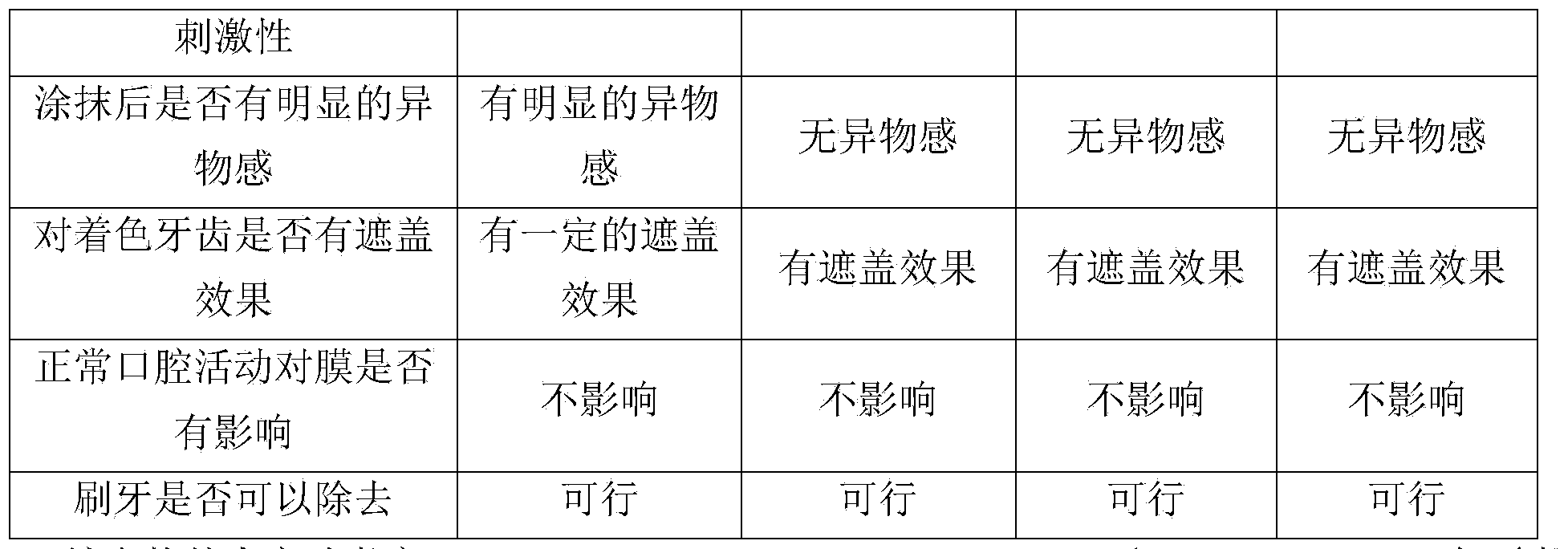

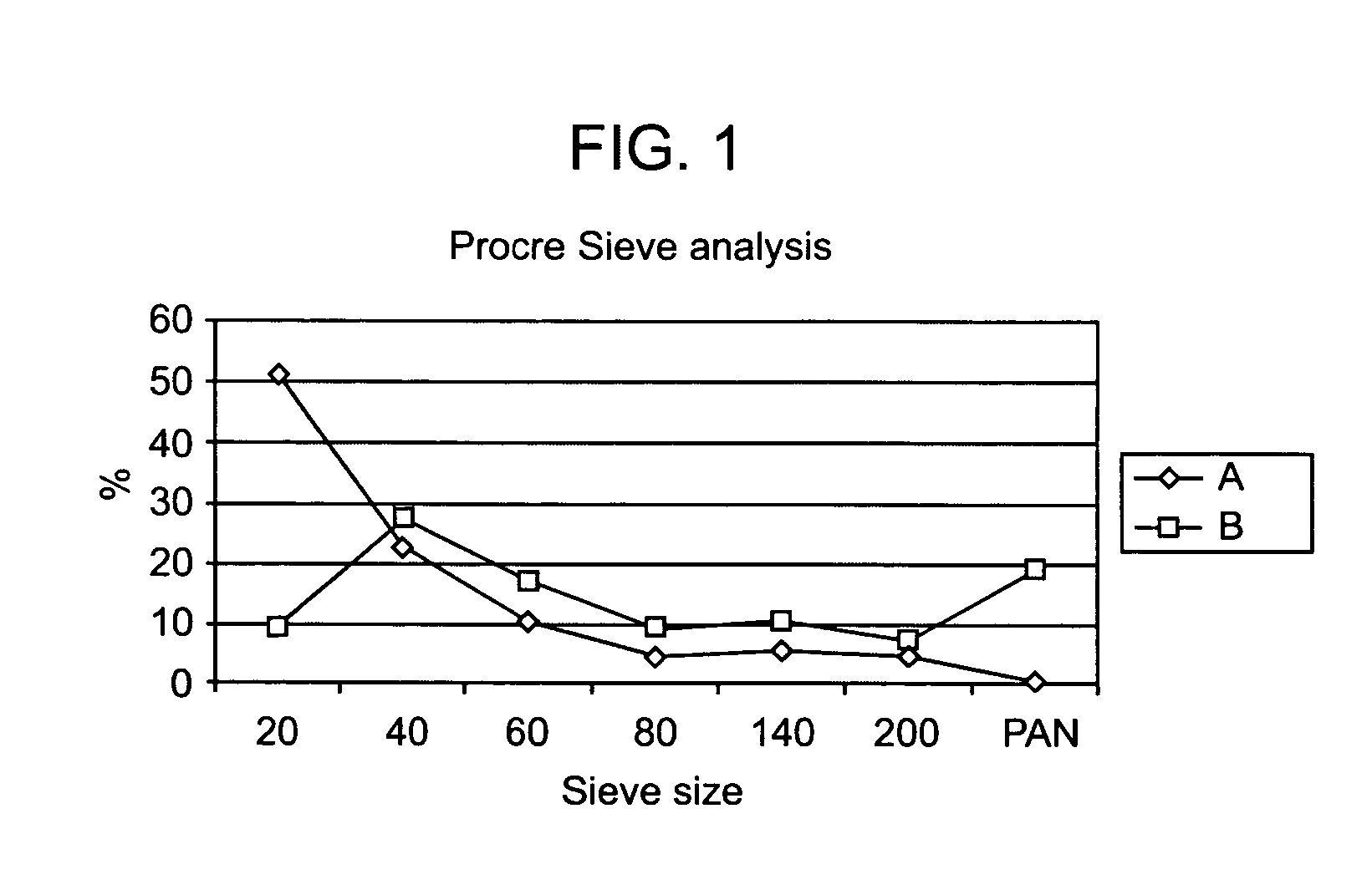

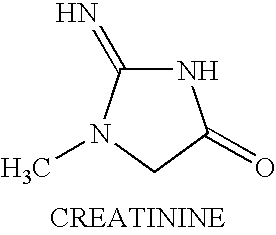

Treating neuromuscular disorders with an oral formulation of creatine derivatives

InactiveUS20060062853A1Extended shelf lifeEliminate water absorptionPowder deliveryOrganic active ingredientsDiseaseShellac

Treating human muscle tissue by the oral administration of a formulation of creatine derivative and in particular creatine esters and more particularly ethyl esters of creatine are described. The formulations comprise a phosphate such as dicalcium phosphate, a biodegradable polymer such as a polyvinyl pyrrolidine and a starch. The formulation may further comprise other excipients such as metal salt of a stearate, e.g. magnesium stearates. The formulation is produced as flowable particles with a sieve size of about 20 to 60 which particles are coated with a shellac to mask taste, avoid moisture uptake, and extend shelf life.

Owner:MEDICAL RES INT

Method for prolonging storage period of walnut kernels

ActiveCN103250783APrevent oxidative rancidityConducive to sales and transportationEdible seed preservationShellacPolyphenol

The invention relates to a method for prolonging the storage period of walnut kernels and belongs to the technical field of food freshness preservation storage. The method comprises the following steps of: uniformly spraying prepared bleached shellac and tea polyphenol composite solution on the cleaned and dried walnut kernels, and naturally drying the walnut kernels in the air; packaging the dried walnut kernels into package bags, and carrying out vacuumizing and thermal sealing to package the walnut kernels; and storing the packaged walnut kernels at normal temperature or in the cold. By the method, the walnut kernels are smeared with the natural prepared bleached shellac and tea polyphenol composite solution, so that the limitation of a synthesized antioxidant is eliminated; furthermore, by vacuum package, oxidative rancidity of the walnut kernels is effectively suppressed; the storage period of the walnut kernels is prolonged; selling and transportation of the walnut kernels are facilitated; and the edible quality of the walnut kernels is kept for a longer time.

Owner:SOUTHWEST FORESTRY UNIVERSITY

Method for performing antique treatment on leather surface

InactiveCN101892331AAchieve antique effectLeather surface mechanical treatmentLeather surface finishingColor effectWax

The invention relates to a method for performing antique treatment on a leather surface. Mixed polish is utilized to treat the leather surface and comprises shellac, rosin and alcohol in a weight ratio of 5-25:5-15:100, preferably 20:5:100. The method comprises the following steps of: a, polishing the surface of animal skin blank into a plush shape; b, expanding the animal skin blank, spraying the mixed polish on the animal skin blank, and then performing air drying; c, moving the air-dried animal skin blank to a drying room and roasting for 2 to 3h at the temperature of between 42 and 47 DEG C; d, coloring effect under colors on the animal skin blank at normal temperature; e, moving the colored animal skin blank to the drying room for drying; f, treating cracks of the animal skin blank; g, coloring effect colors on the animal skin blank by using a mixed pigment, and then spraying a layer of the mixed polish on the animal skin blank uniformly; h, moving the animal skin blank to the drying room for drying; i, pulling the cracks of the animal skin blank out, and polishing and burnishing; k, moving the burnished animal skin blank to the drying room and roasting for 5 to 7h at the temperature of between 30 and 40 DEG C; and j, cooling the product, coating leather protective wax on the product to obtain the finished product.

Owner:廖顺南

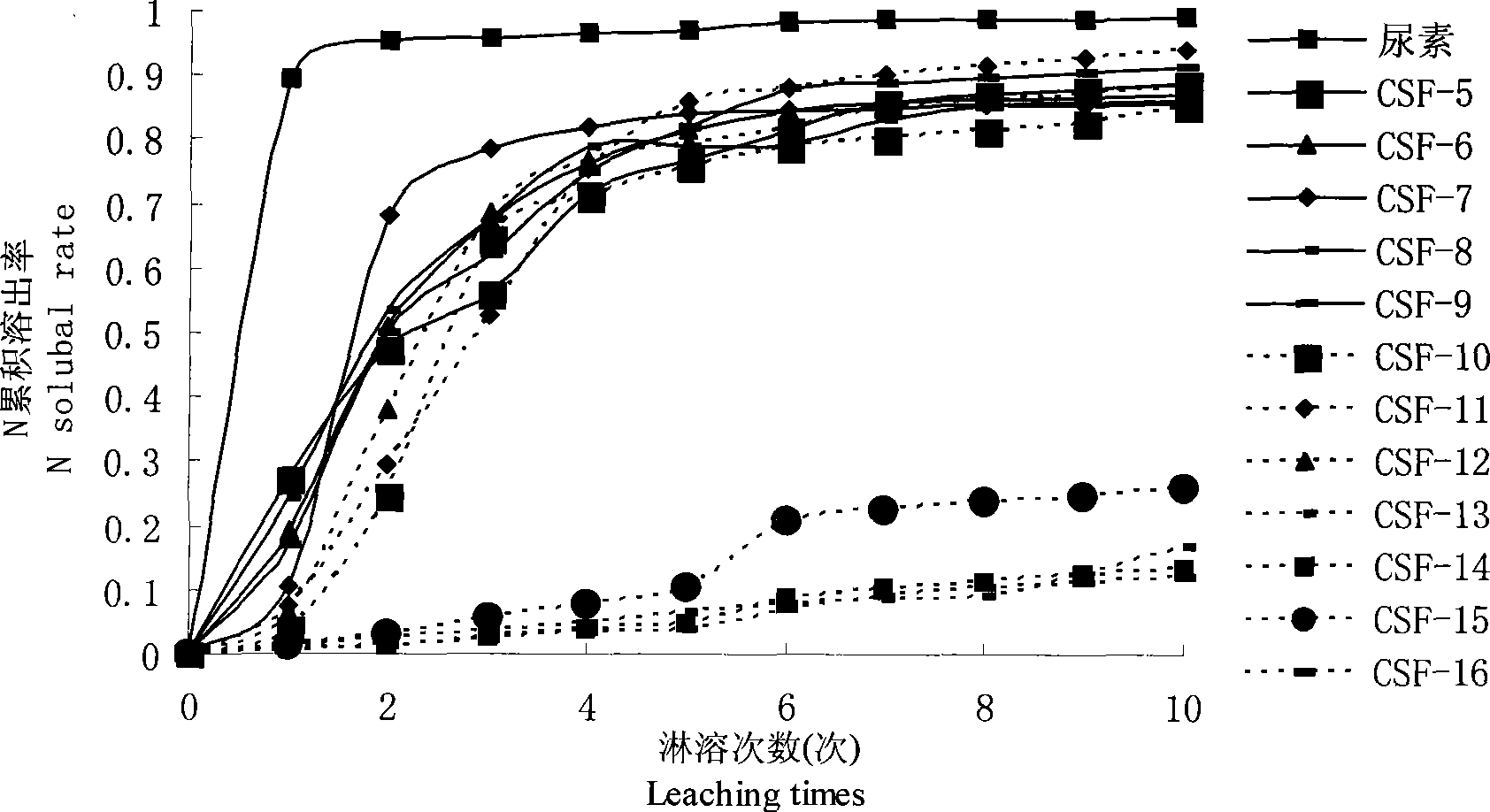

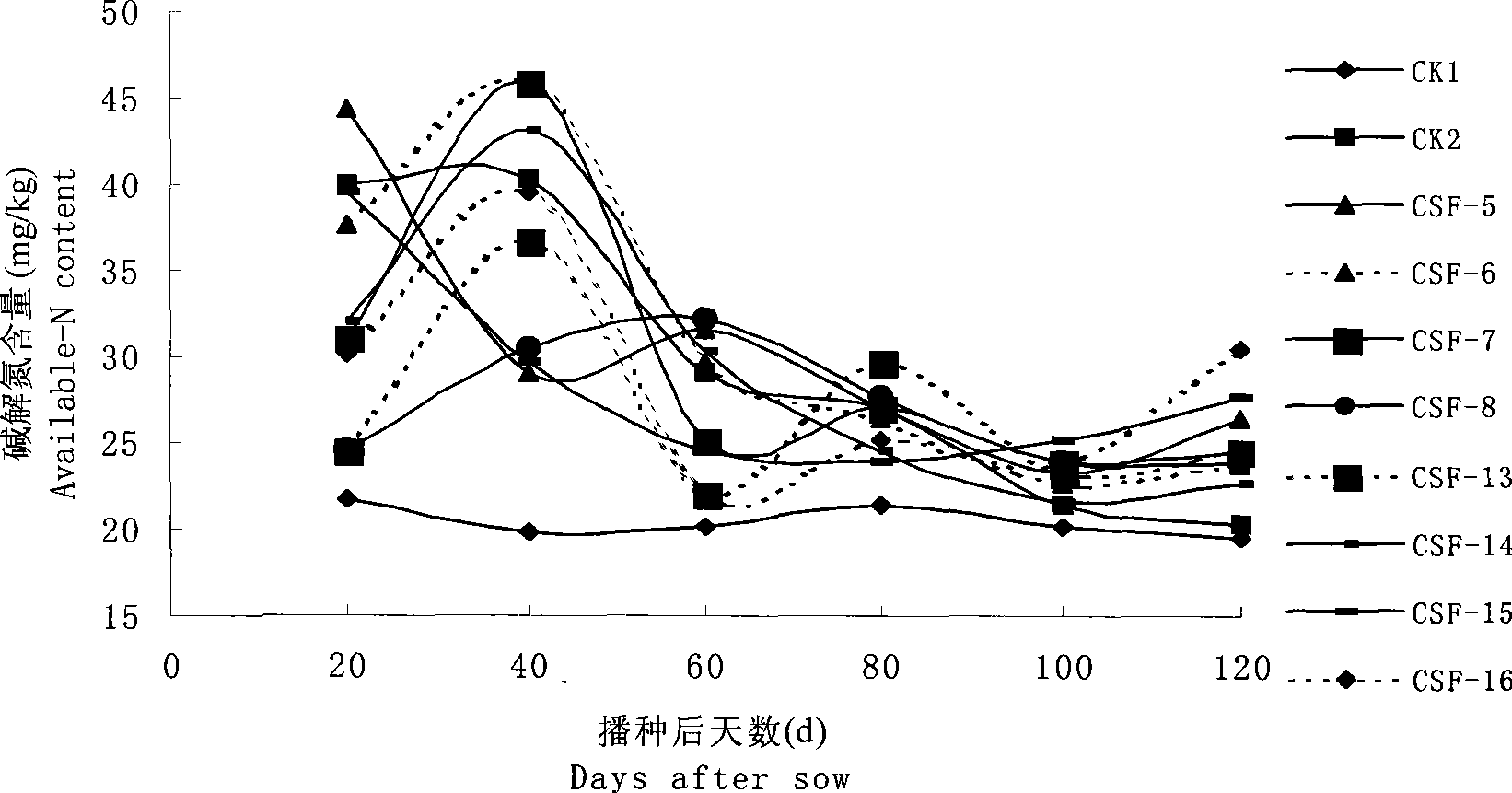

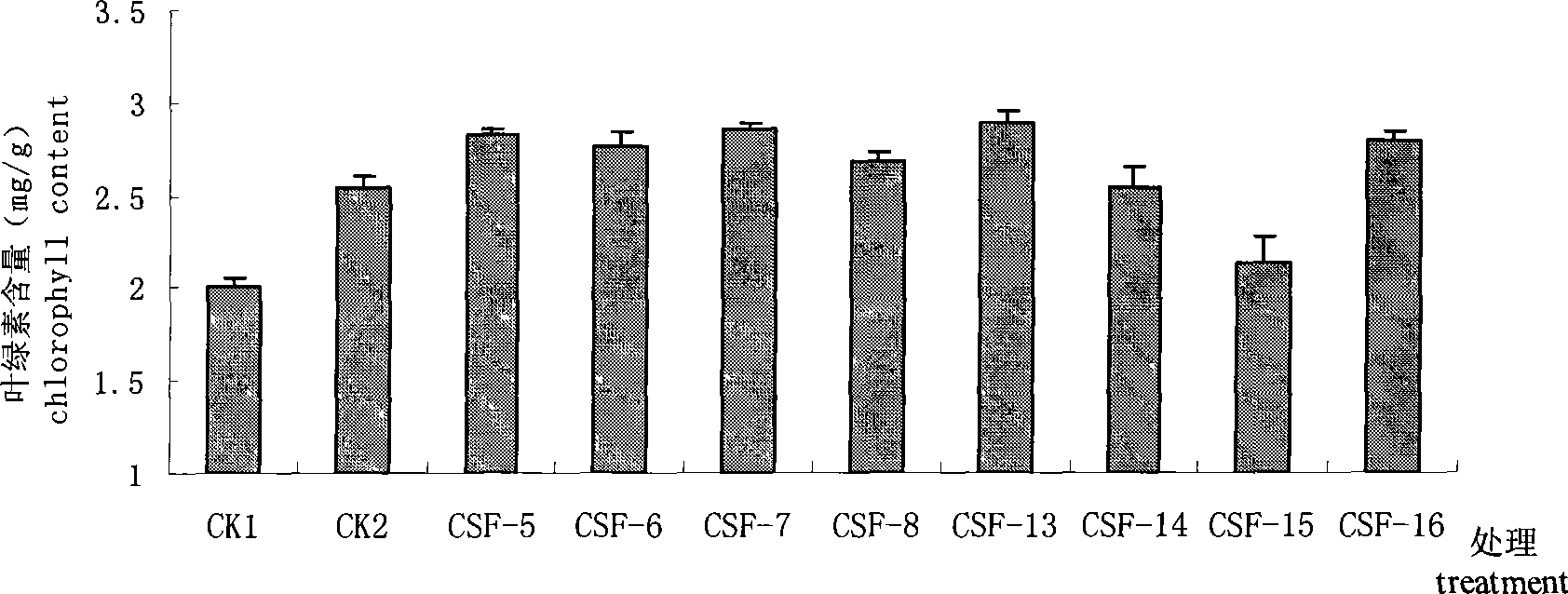

Organic-mineral material coated slow release fertilizer

The invention relates to a coated slow release fertilizer, in particular to a production method of an organic-mineral material coated fertilizer. The invention solves the problems of selecting coating materials and determining process parameters of the coated fertilizer in the prior art. The coated slow release fertilizer consists of a fertilizer core and a coating material, and is characterized in that: the coating material uses mineral material, shellac and perchlorethylene, and the mineral material is any one or two or all of vermiculite, mica and zeolite. Generally speaking, the product obtained by the technical proposal has good slow-release property and can improve the utilization rate of fertilizer elements, reduce the environmental pollution and promote the growth of crops.

Owner:SHANXI UNIV OF FINANCE & ECONOMICS

Surface-sizing agent

InactiveCN1402805AImprove mechanical stabilityGood storage stabilityWater-repelling agents additionPaper/cardboardHydrophilic monomerShellac

A surface-sizing agent for papermaking which itself is excellent in mechanical stability and storage stability, and which is highly suitable for the sizing of acidic to neutral papers. When applied to papers for information, especially ink-jet printing papers, the sizing agent imparts excellent suitability for ink-jet printing. When the sizing agent is used to prepare a coating fluid, the coating fluid is significantly reduced in foaming. The sizing agent has excellent compatibility with other chemicals to be used in combination therewith. The surface-sizing agent is characterized by being obtained by polymerizing a nonionic hydrophilic monomer (b) with a hydrophobic monomer (d) in the presence of an alkali salt of shellac (a) and then mixing a polymeric dispersant (e) therewith.

Owner:SEIKO PMC CORP

Automotive glass-washing fluid

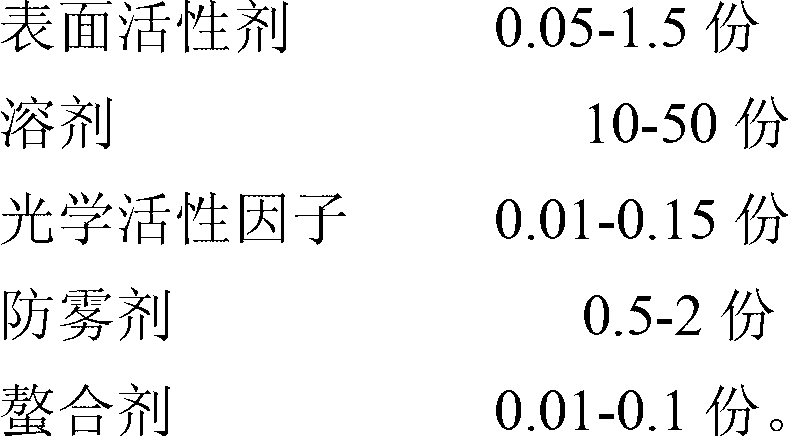

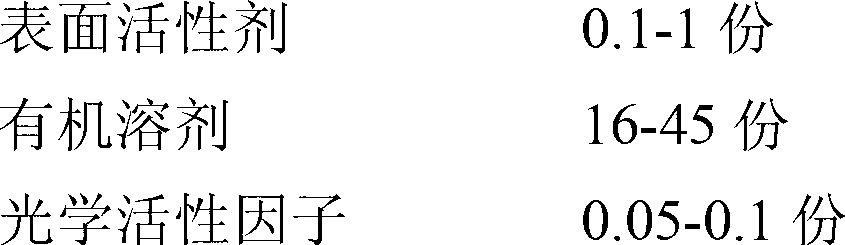

The invention relates to an antifreeze automotive glass-washing fluid comprising an optically active factor. The fluid comprises main active components of, by mass, 0.05-1.5 parts of a surfactant, 10-50 parts of an organic solvent, 0.01-0.15 parts of the optically active factor, 0.5-2 parts of an anti-fog agent, and 0.01-0.1 parts of a chelating agent. According to the invention, the antifreeze automotive glass-washing fluid comprising the optically active factor can be used for thoroughly removing waterlines, shellac, and dirt on automotive glass. With the fluid, glass can be maintained bright and transparent. Also, a glass refraction phenomenon can be prevented, and frost-removing and fog-removing functions are provided. Therefore, a good sight is provided for drivers.

Owner:BEIJING REWARD HOME CARE CHEM

Aqueous shellac coating agent and production process therefor, and coated food and production process therefor, coated drug and production process therefor, glazing composition for oil-based confectionary, glazing process, and glazed oil-based confectionary using same

InactiveUS20060233917A1Maintain good propertiesQuality improvementConfectionerySweetmeatsShellacPhosphate

There are provided an aqueous shellac coating agent comprising shellac, a basic amino acid and / or a basic phosphate as well as a production process therefor; a coated food and a coated drug that have been coated with such a coating agent; a glazing composition for oil-based confectionary which is in a liquid form and comprises an aqueous shellac solution (A) containing shellac, a basic amino acid and / or a basic based confectionary in which this glazing composition is applied, to oil-based confectionary to be glazed, thereby generating a glaze; and glazed oil-based confectionary produced using this process for glazing oil-based confectionary.

Owner:FREUNT IND

Metal oxide ultraviolet detector and production method thereof

InactiveCN104752546AWide variety of sourcesPromote low temperature conversionFinal product manufactureSemiconductor devicesHigh concentrationShellac

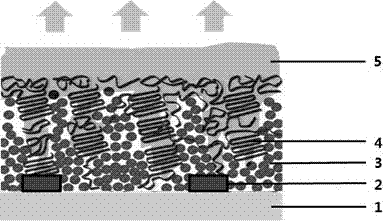

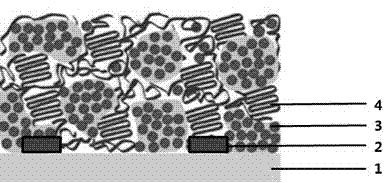

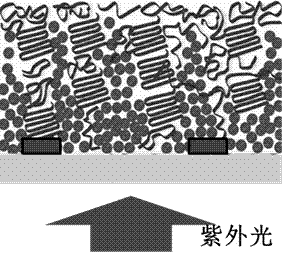

The invention discloses a metal oxide ultraviolet detector and a production method thereof, belongs to the field of optical detectors and solves the problems that due to structure and material reasons of a detection layer, the prior metal oxide ultraviolet detector has high requirement on the production environment, is low in sensitivity and is high in production cost. The metal oxide ultraviolet detector comprises a quartz glass substrate, interdigital electrodes, metal oxide nano-particles and a shellac mixed layer. The production method includes: mixing metal oxide precursor and shellac into mixed solution, coating the quartz glass substrate which the interdigital electrodes are sputtered to, through the mixed solution, after heating and pretreatment, subjecting thin film to solvent annealing with high-concentration ethanol vapor, allowing the shellac in the mixed thin film to rise to the top of the film, subjecting metal elements in the mixed thin film and hydroxyl in the shellac to coordination to convert the metal oxide precursor into metal oxide nano-particles at low temperature, and forming a pointed cone structure by natural stacking; finally, according to the unique thermal polymerization characteristic of the shellac, continuously heating the shellac to solidification, thereby packaging the detection layer of the detector in situ.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

Use of a matrix for orally administering sustained release magnesium, and composition containing said matrix

A tablet for oral administration comprises a matrix of progressive and continuous released magnesium. For the administration of 90 to 110 parts by weight of magnesium, the matrix comprises 180 to 190 parts by weight of hydroxypropylmethylcellulose, 19.8 to 22.2 parts by weight of glyceryl behenate, 10 to 12 parts by weight of lactose and 10 to 12 parts by weight of colloidal silica. A non-enteric protective coating that slows down the gastric dissolution of the magnesium may comprise 15 to 75 parts by weight of shellac, cellulose ether or a mixture thereof. The tablet may be administered to patients in need thereof.

Owner:JOANNY FABIENNE

Shellac based sprayable sunscreen

ActiveUS20140348757A1Excellent film forming polymerReadily solubleBiocideCosmetic preparationsShellacNuclear chemistry

Owner:MANTROSE HAEUSER

Fruit-vegetable antistaling agent

InactiveCN1891058AImprove performanceGood water solubilityFruits/vegetable preservation by coatingAlcoholShellac

The present invention relates to a fresh-keeping agent for fruits and vegetables. It is made up by using (by wt%) 2.5-5% of borax1 57-70% of water, 10-25% of refined bleached shellac, 1% of plasticizer, 0-5% of brightening agent and 0-10% of edible alcohol through a certain preparation process. Said invention also provides its application method.

Owner:李彬

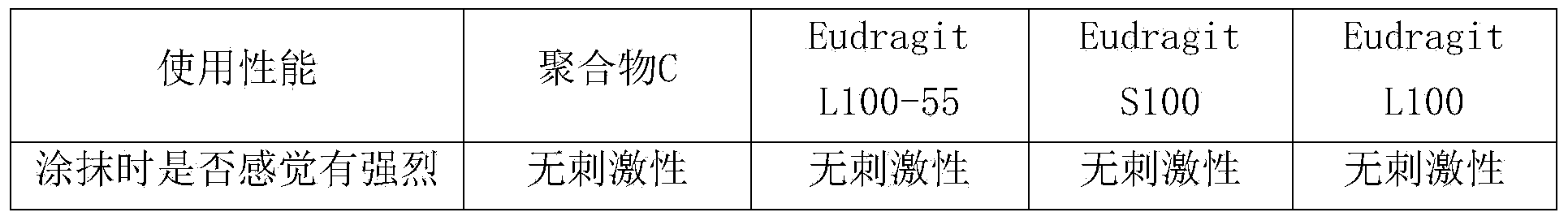

Film-forming product used for beautifying teeth

ActiveCN104013536AGloss whiteningIsolationCosmetic preparationsToilet preparationsBrush toothShellac

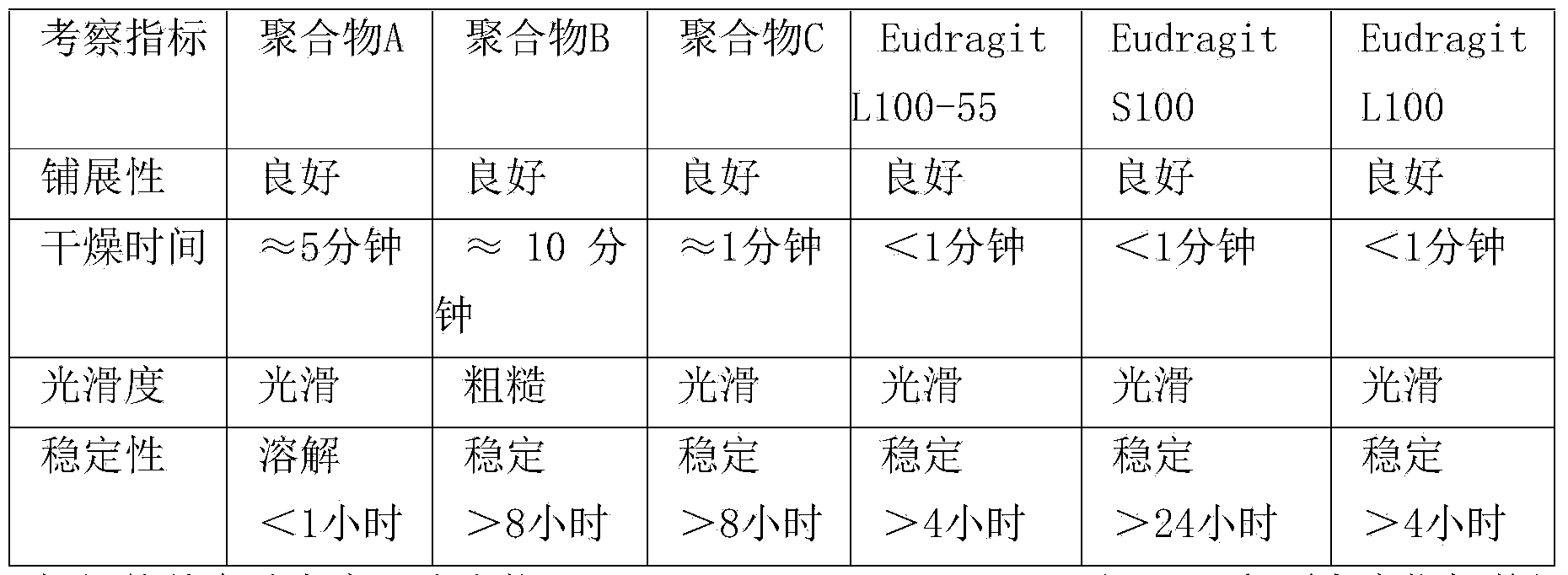

The invention provides a film-forming product used for beautifying teeth. The film-forming product comprises the following components in percentage by weight: 60%-85% of a solvent, 0%-5% of water, 10%-30% of a film-forming agent, 2%-5% of a humectant and 0.1%-2.0% of a covering, whitening and brightening substance, wherein the film-forming agent is a mixture of polymer and shell-lac, and the polymer is one or more of Eudragit L100-55, Eudragit S100, Eudragit L100 or Eudragit L100-55, Eudragit S100, Eudragit L100. The product disclosed by the invention can quickly form a film on a dried tooth surface, and the film is tightly adhered with the tooth surface, so that the tooth can be dried without being adhered after the film coats the tooth for 30 seconds. Even under a masticatory movement condition, the film is also can be kept un-dropped and un-dissolved, and the uniform covering, whitening and brightening substance in the film can enable the tooth to be bright and white, so that effects of instantly beautifying teeth are achieved. Meanwhile, the coated film can isolate eaten substances from invading the tooth, can protect the tooth and can relieve tooth exogenous coloring. The coated film is stable in an oral cavity, can be removed by brushing teeth, is simple and convenient to use; the content is an oral cavity material or a medical-grade component material, and safe to use.

Owner:广州舒客实业有限公司

Oral formulation of creatine derivatives and method of manufacturing same

InactiveUS20060062849A1Extended shelf lifeEliminate water absorptionBiocideGranular deliveryShellacPhosphate

Oral formulation of creatine derivative and in particular creatine esters and more particularly ethyl esters of creatine are described. The formulations comprise a phosphate such as dicalcium phosphate, a biodegradable polymer such as a polyvinyl pyrrolidine and a starch. The formulation may further comprise other excipients such as metal salt of a stearate, e.g. magnesium stearates. The formulation is produced as flowable particles with a sieve size of about 20 to 60 which particles are coated with a shellac to mask taste, avoid moisture uptake, and extend shelf life.

Owner:MEDICAL RES INT

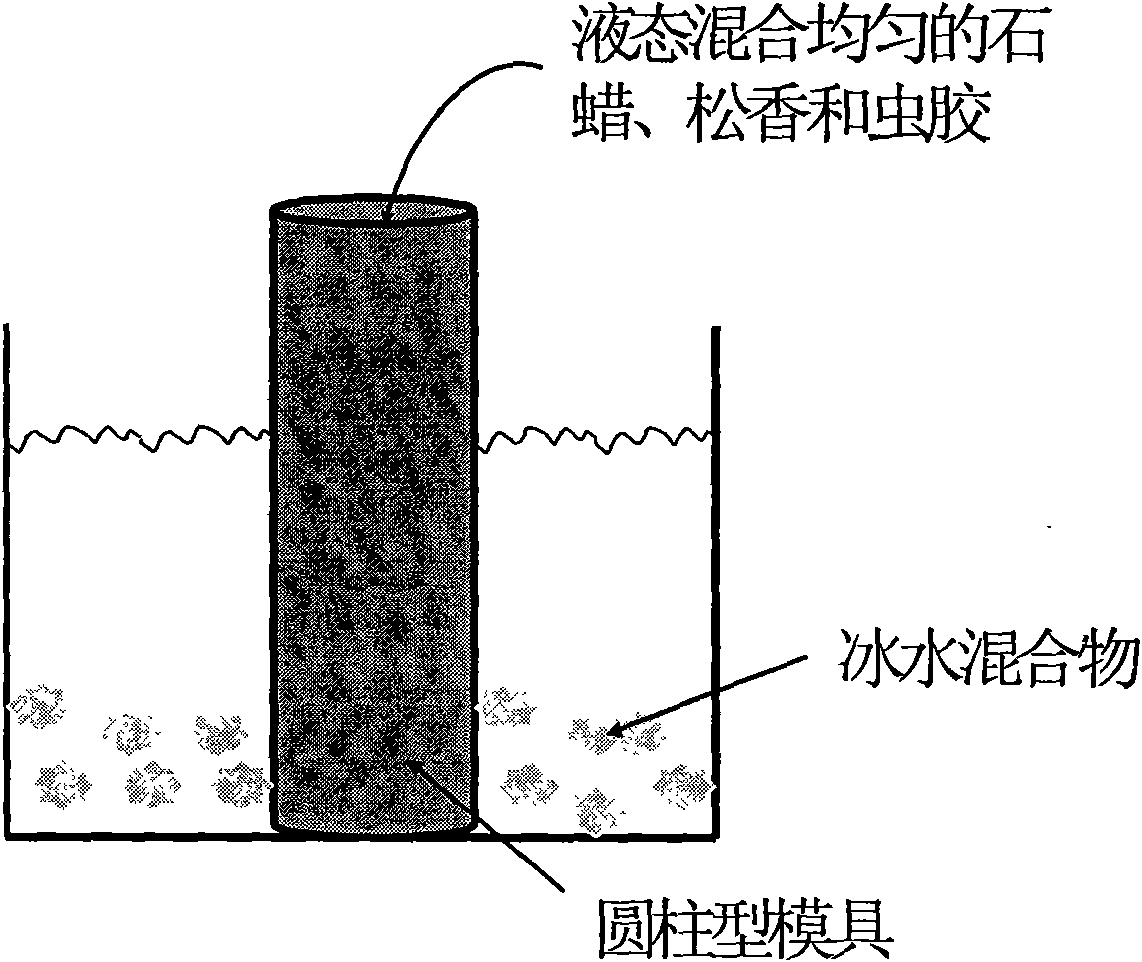

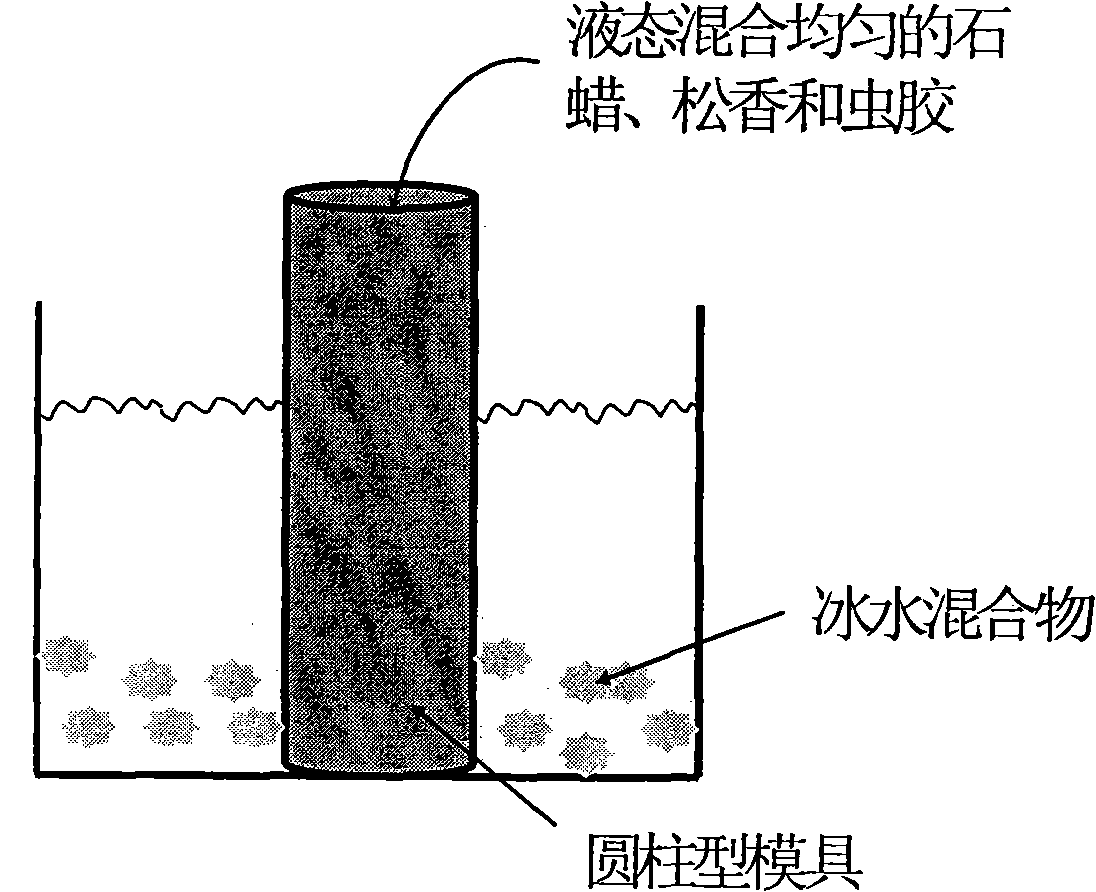

Bonding agent for wax processing of wafer and preparation method thereof

InactiveCN101984012AAdjust the melting pointHigh melting pointWax adhesivesSemiconductor/solid-state device manufacturingParaffin waxShellac

The invention discloses a bonding agent for wax processing of a wafer and a preparation method thereof. The bonding agent mainly comprises paraffin wax, rosin and shellac, wherein the paraffin wax, the rosin and the shellac are proportioned according to the weight ratio of 20-50: 40-75: 5-20. The bonding agent can regulate the melting point by changing the adding proportion of raw materials, and the melting point can be generally controlled within the range of 70 DEG C-130 DEG C, in particular to 80 DEG C-120 DEG C. The preparation method of the bonding agent for was processing of the wafer comprises the step of utilizing a die to prepare the melted bonding agent which is uniformly stirred into a finished product bonding agent with a certain shape. The bonding agent utilizes the die for processing and molding and can meet various application needs in the actual production by changing the size and the shape of a model when being applied in the wafer processing process, and be easy to store.

Owner:苏州天科合达蓝光半导体有限公司 +2

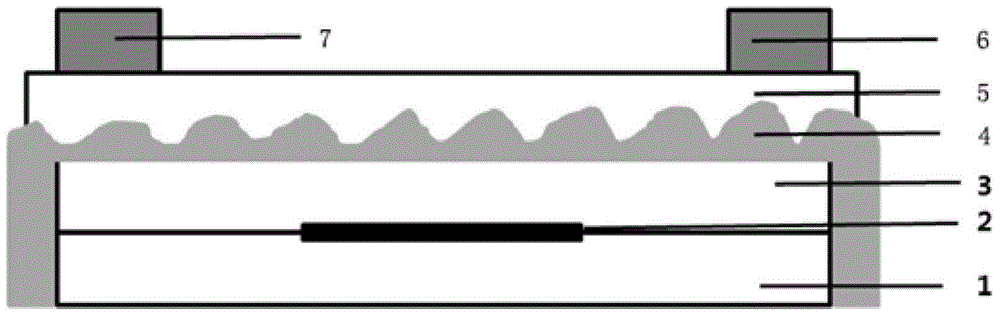

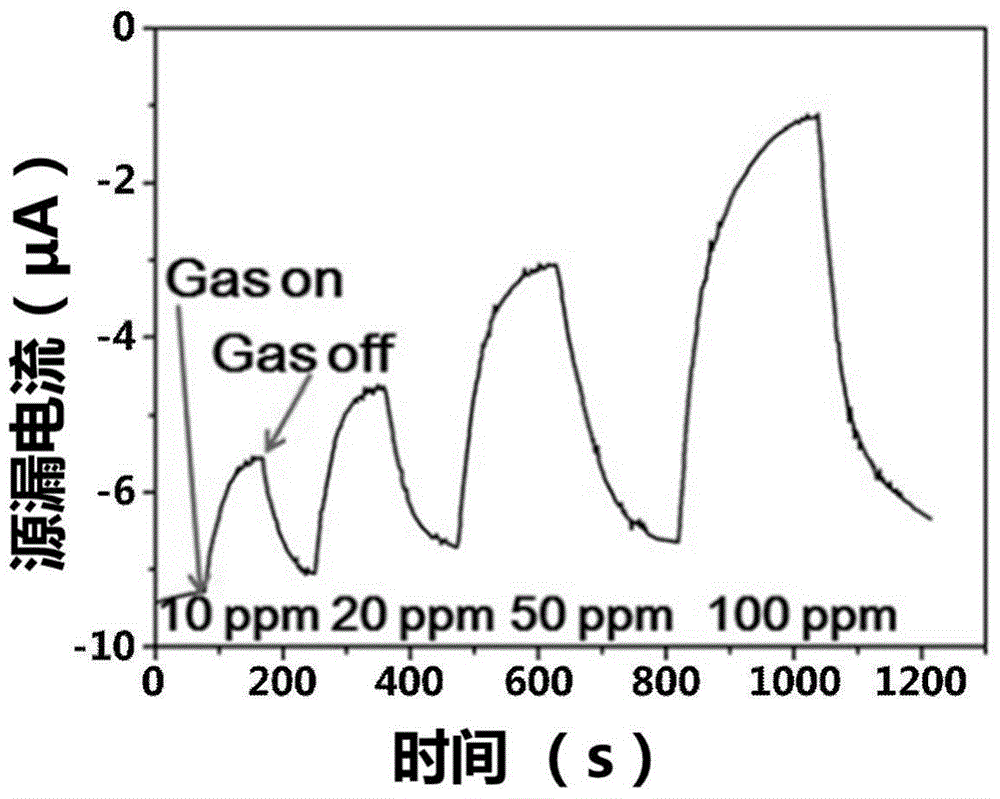

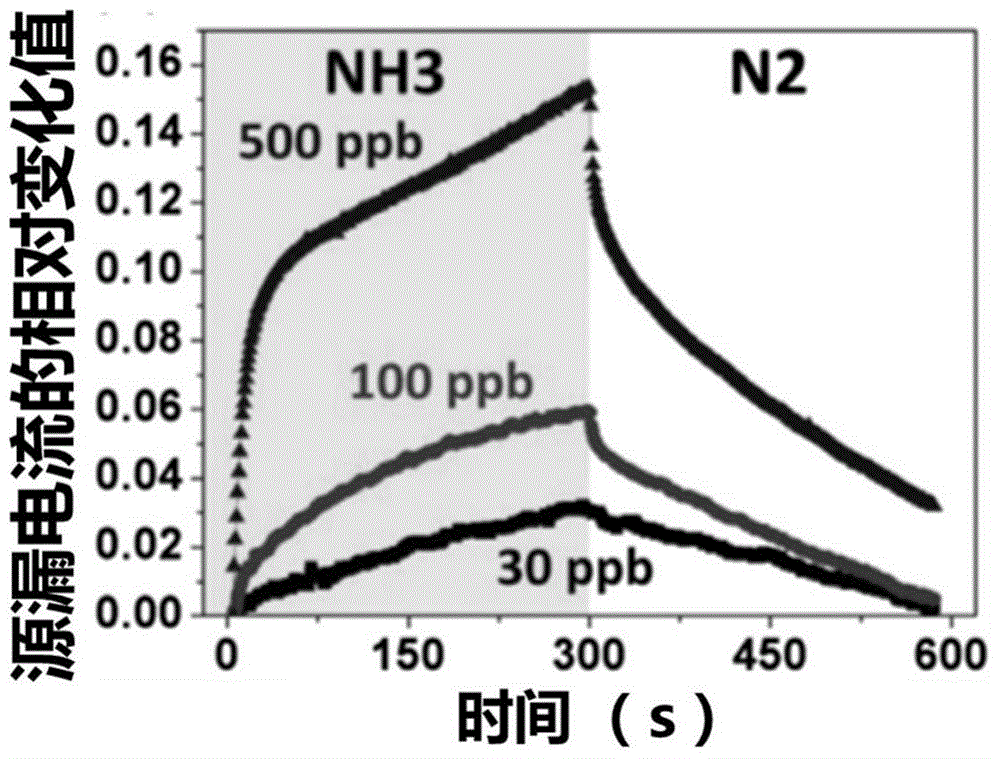

Field effect tube gas sensor based on shellac encapsulation/regulation and preparation method thereof

InactiveCN104792849AAchieve green packagingExcellent electrical propertiesMaterial analysis by electric/magnetic meansSemiconductor/solid-state device manufacturingShellacInsulation layer

The invention discloses a field effect tube gas sensor based on shellac encapsulation / regulation and a preparation method thereof. The field effect tube gas sensor comprises a degradable substrate, a grid electrode, an insulation layer, a semiconductor layer, a source electrode and a drain electrode in sequence from top to bottom, wherein a shellac layer is arranged between the insulation layer and the semiconductor layer. The insulation layer is coated with shellac, and the shellac is good in bonding property and compactness and high in dielectric intensity, so that the erosion of water and oxygen on the degradable substrate and the insulation layer is prevented and the stability of the degradable substrate and the insulation layer is improved; at the same time, based on unique thermal plasticity and polymerization properties of the shellac, the shellac layer is directly treated, so that various morphologies of the semiconductor layer on the shellac can be obtained, the area of reaction with target gas is enlarged, and the gas response property is improved; the shellac belongs to natural materials and is wide in source and lower in cost; the field effect tube gas sensor adopts a material for realizing encapsulation and patterning and is easier to prepare, lower in cost, more environment-friendly and suitable for large-scale mass production, and the degradable substrate is practical.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Environment-friendly stable leather finishing wax

ActiveCN104513616AImprove stabilityGood application effectWax coatingsPolyurea/polyurethane coatingsParaffin waxShellac

The invention discloses an environment-friendly stable leather finishing wax, which is characterized by comprising the following components: by weight, 10-12 parts of cera alba, 8-10 parts of oxidated paraffin, 10-13 parts of vaseline, 5-8 parts of oily lanolin, 0.5-1 part of an antiseptic, 8-12 parts of a paraffin emulsion prepared by oleyl alcohol-terminiated polyurethane, 1-2 parts of stearic acid, 0.5-0.8 part of rosin, 5-8 parts of a shellac alcohol solution having a concentration of one part of shellac to eight parts of alcohol, 1-2 parts of silicone oil, 5-7 parts of alcohol, 0.3-0.5 part of essence, 0.4-0.6 part of dibutyl phthalate, 0.3-0.5 part of polyoxyethylene alkyl phosphate ester, 0.6-0.8 part of polyoxyethylene octylphenol ether, 0.2-0.5 part of alkyl sodium sulfonate, and 200-300 parts of deionized water. The finishing wax in the invention is quite environment-friendly; the paraffin emulsion prepared by the polyurethane is quite stable; and the obtained finishing wax has characteristics of toughness, water-proofness, thermodynamic stability, low cost, various functions, bright application prospect, and good economic value.

Owner:江西福兴皮革皮件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com