Non-toxic primer powder composition for small caliber ammunition

a primer powder and composition technology, applied in the direction of explosives, instruments, sport apparatus, etc., can solve the problems of environmental hazards, dust-containing, harming the shooter,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0036] On a dry basis, 30 wt % of DDNP and 7.5 wt % of tetracene was mixed together, to the resulted mixture, 37.5 wt % of a shellac-coated potassium nitrate and 17 wt % of nitrate ester were added and mixed, and then thereto 7.8 wt % of a borosilicate powder and 0.2 wt % of a chemical binder which is a mixture of arabian gum, tragacanth and gelatin with a mixing ratio of 9:5:1 were added and mixed thoroughly, in a mixer.

[0037] The shellac-coated potassium nitrate was prepared by adding 2 liter of ethyl alcohol to 1 kg of dried potassium nitrate to wet, adding 80 ml of a shellac resin solution, stirring the mixture sufficiently for one hour or more, allowing to stand it for 12 hours or more, removing the excessive ethyl alcohol, drying and sieving the resulted product.

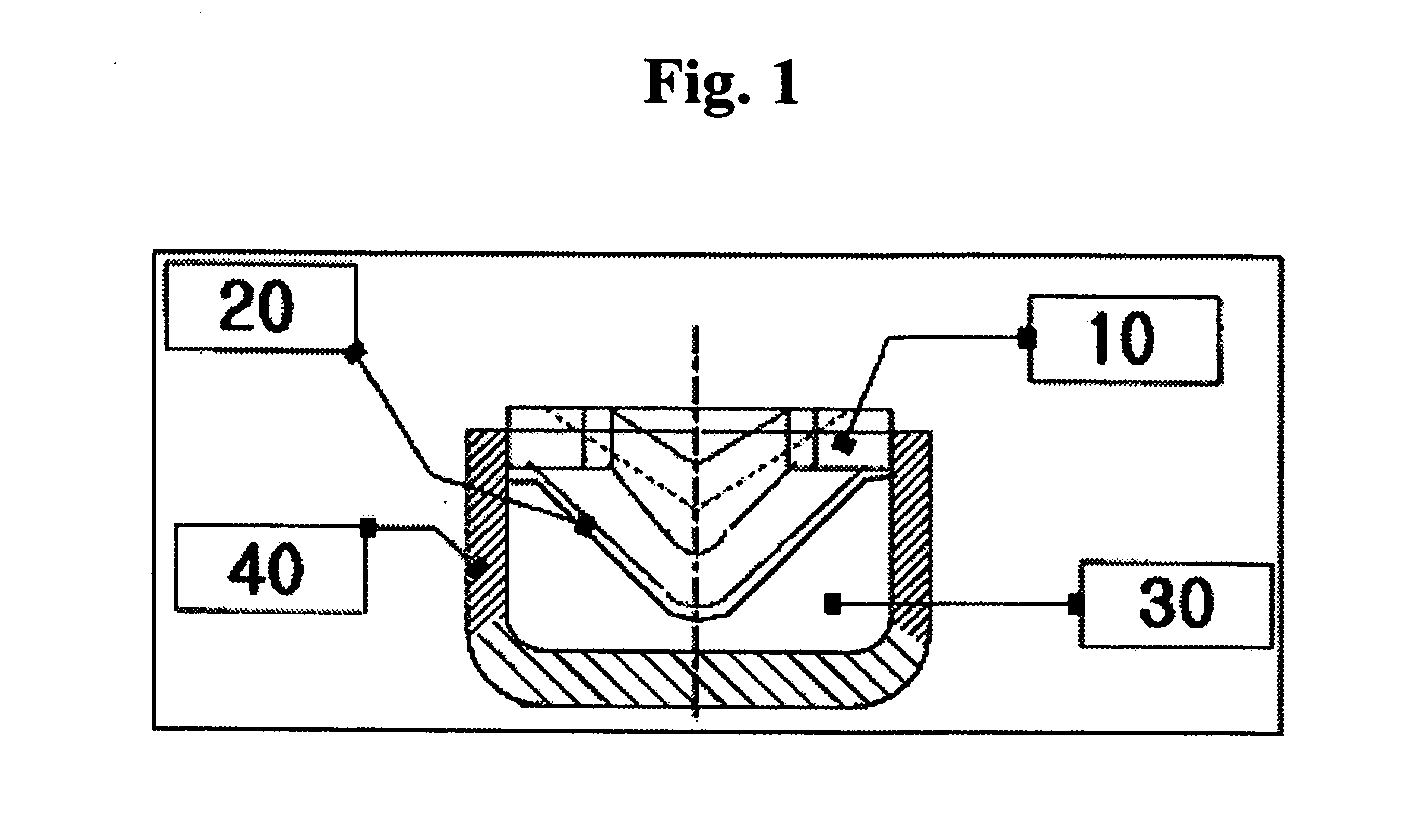

[0038] The resulted mixture, as a primer powder, was charged into a cup (40) represented in FIG. 1, sealed with a foiling paper (20) and compressed. The cup (40) charged with the primer powder (30) was coupled with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| weight ratio | aaaaa | aaaaa |

| explosive power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com