Patents

Literature

130 results about "Nitric acid ester" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A nitrate ester is the organic functional group with the formula RONO2, where R stands for any organic residue. They are the esters of nitric acid and alcohols. A well-known example is nitroglycerin, which is not a nitro compound, despite its name.

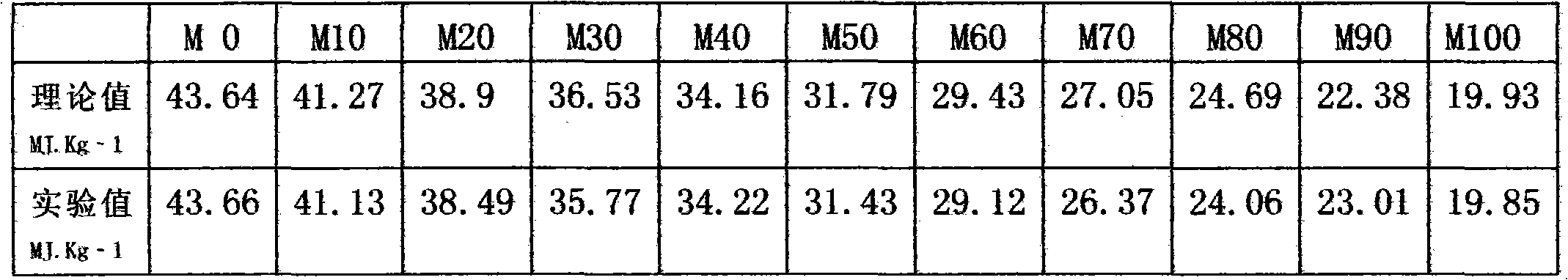

Methanol diesel oil manufacturing mode

The invention relates to a manufacturing mode of environment-friendly and energy-saving M15_M85 methanol diesel oil. The methanol diesel oil is composed of diesel oil, methanol, and additives. The methanol diesel oil is prepared with operations under normal temperatures and normal pressures. The invention discloses a plurality of common additives used for preparing methanol diesel oil in modern times. If explosives and aviation fuels are appropriately utilized, methanol defalcated heat value can be well compensated. The theory is tentatively considered as a gaseous detonation theory. The additives can be selected from nitric acid esters, nitrates, nitro compounds, non-aromatic compounds, peroxides, and the like.

Owner:陈若歆

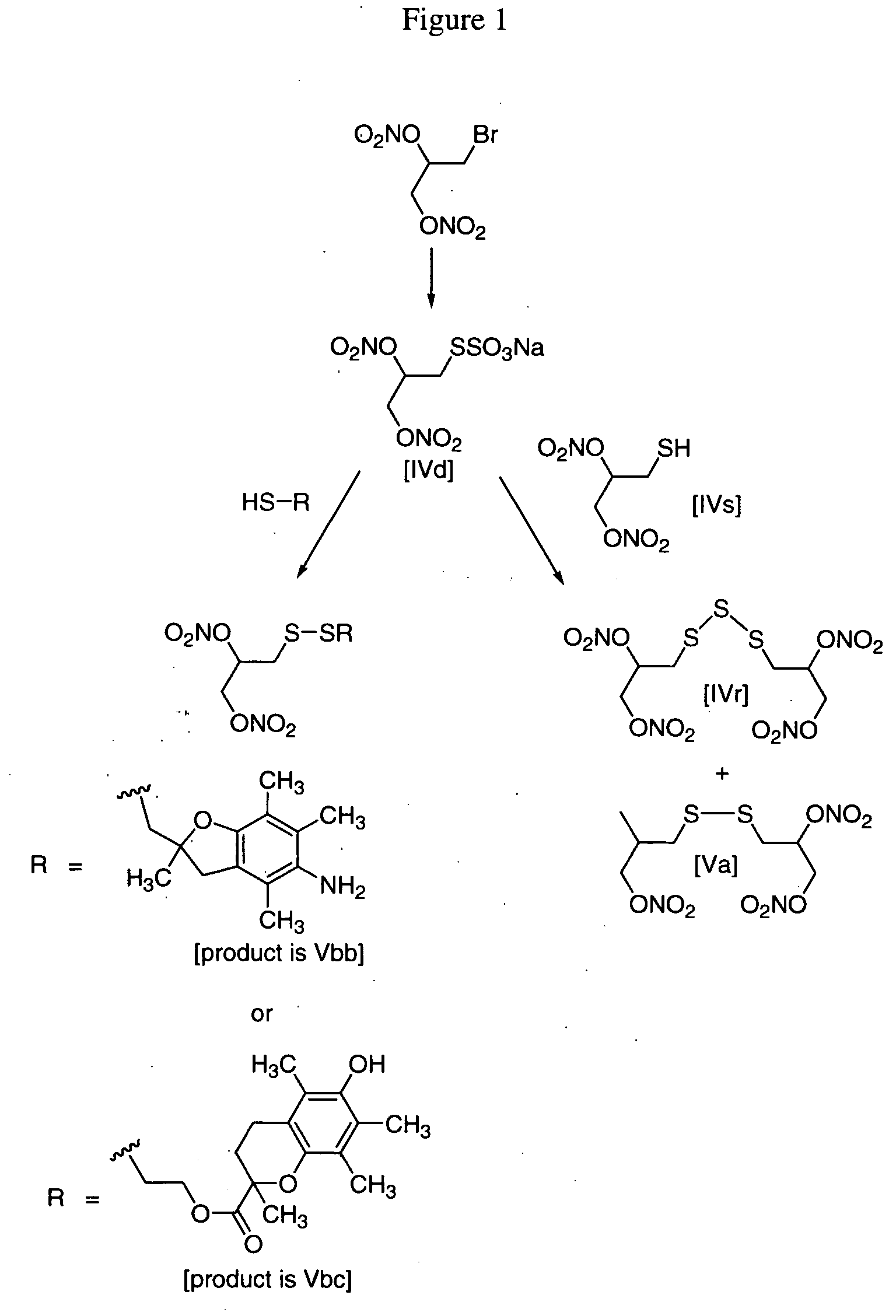

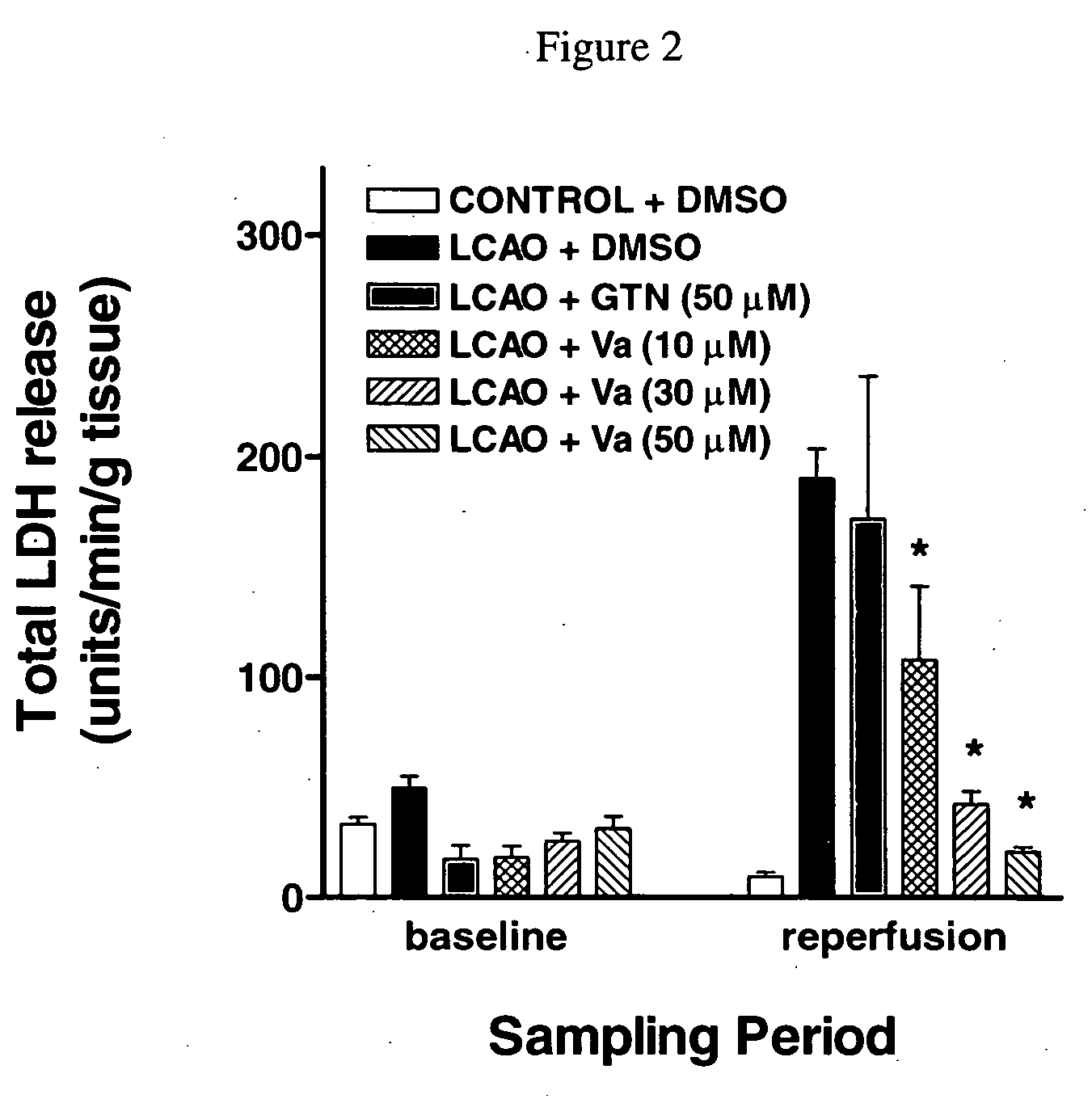

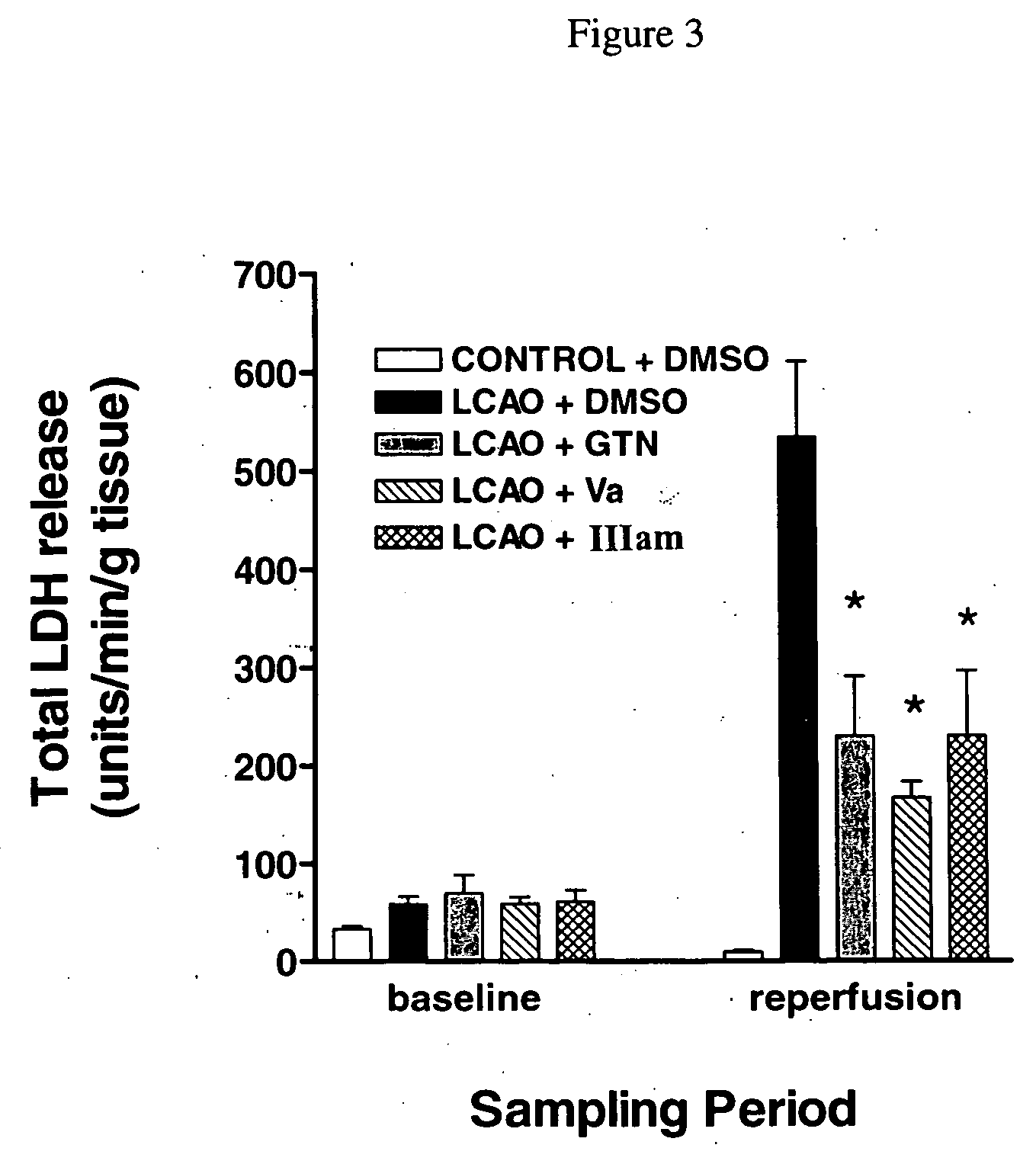

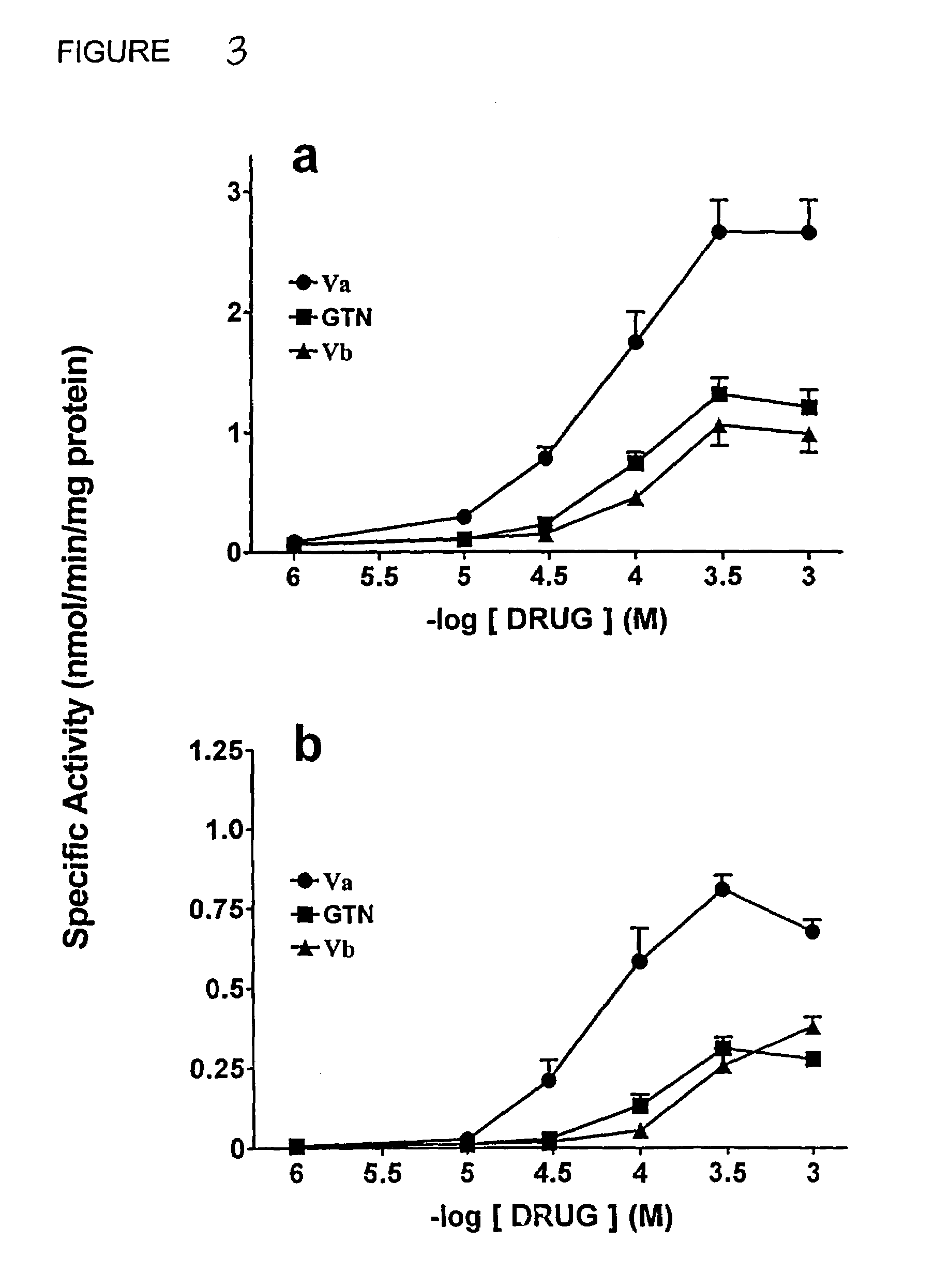

Nitrate esters and their use for mitigating cellular damage

InactiveUS20050137191A1Realize regulationBiocideNitro compound active ingredientsCognitionNitric acid ester

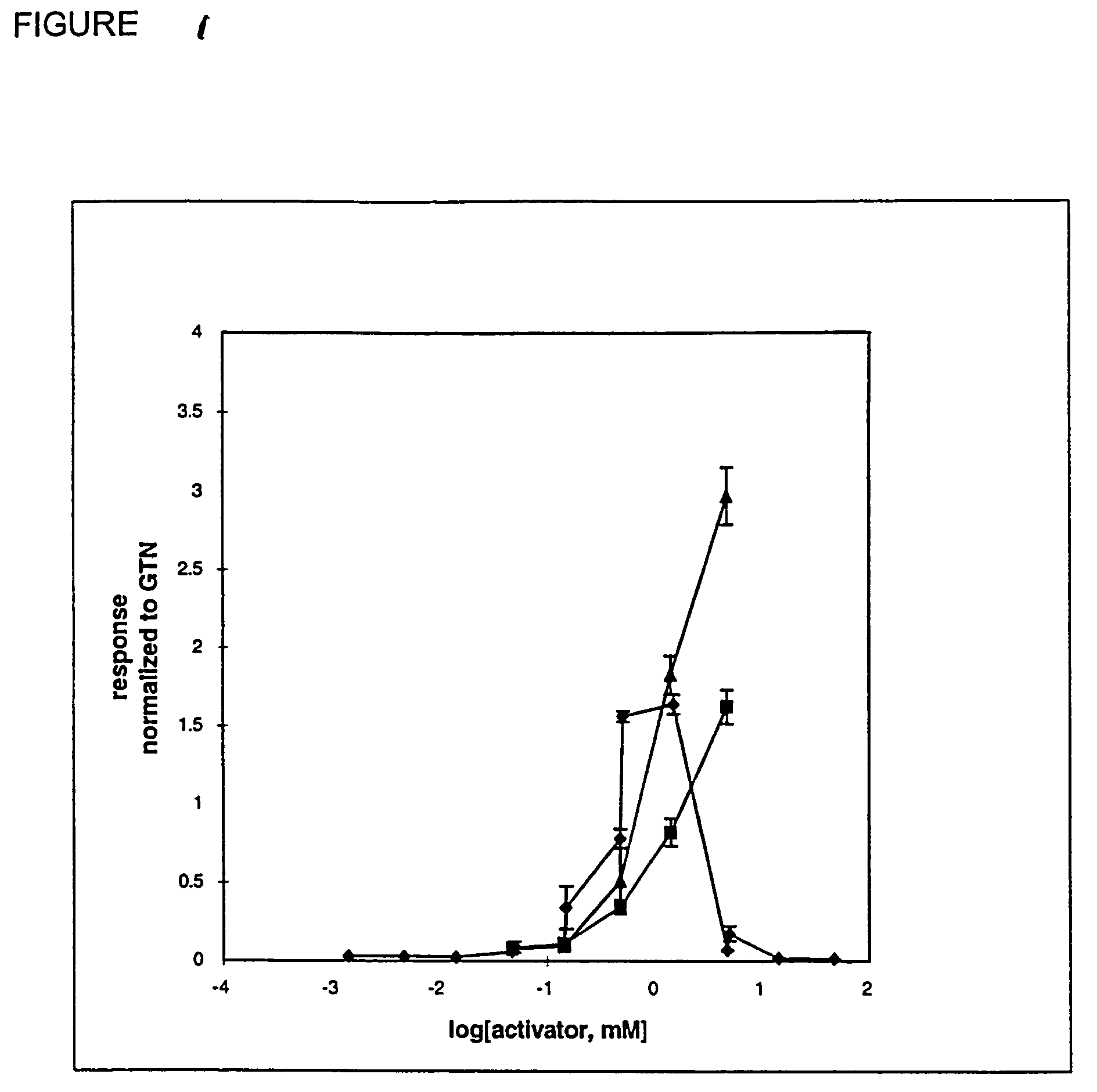

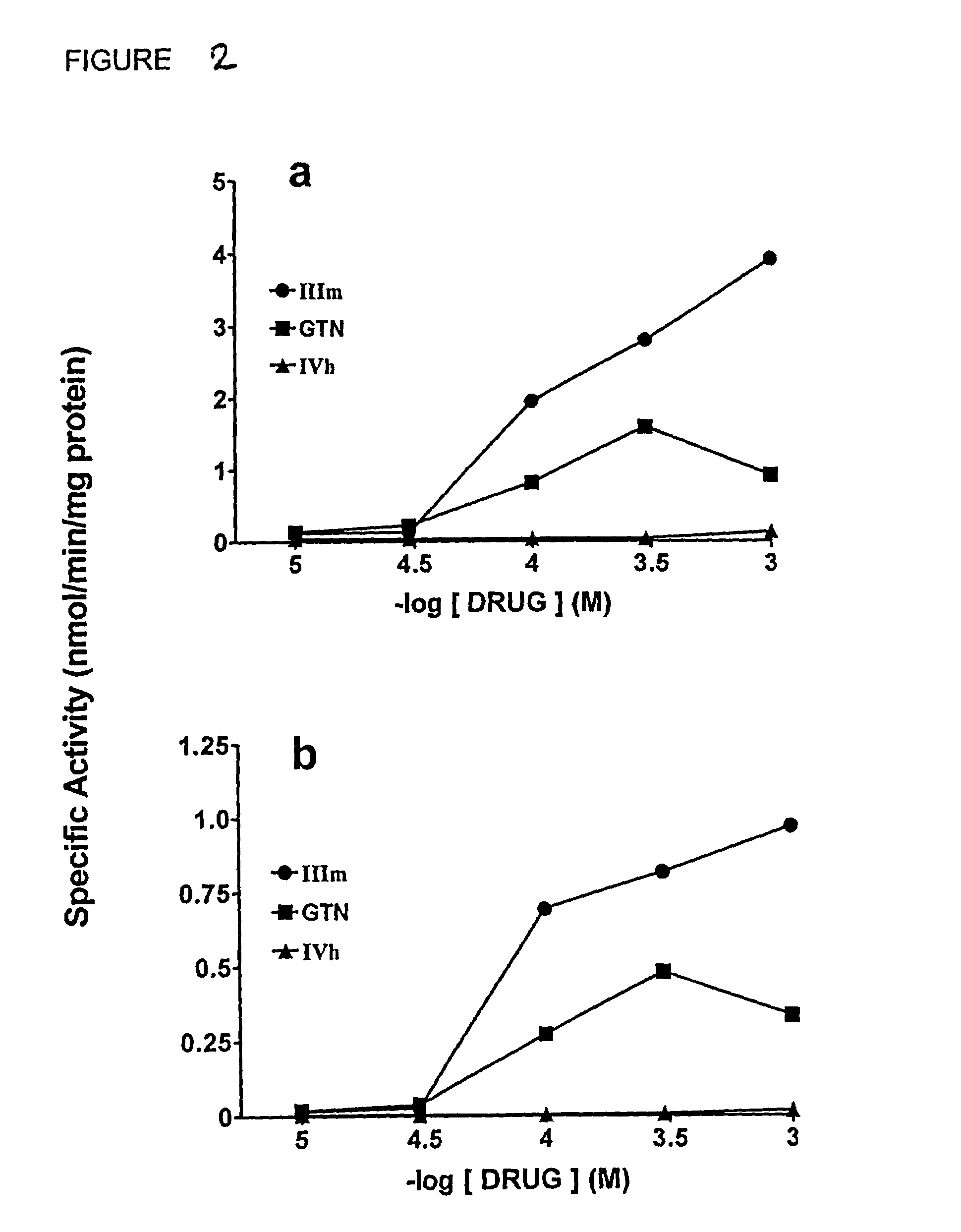

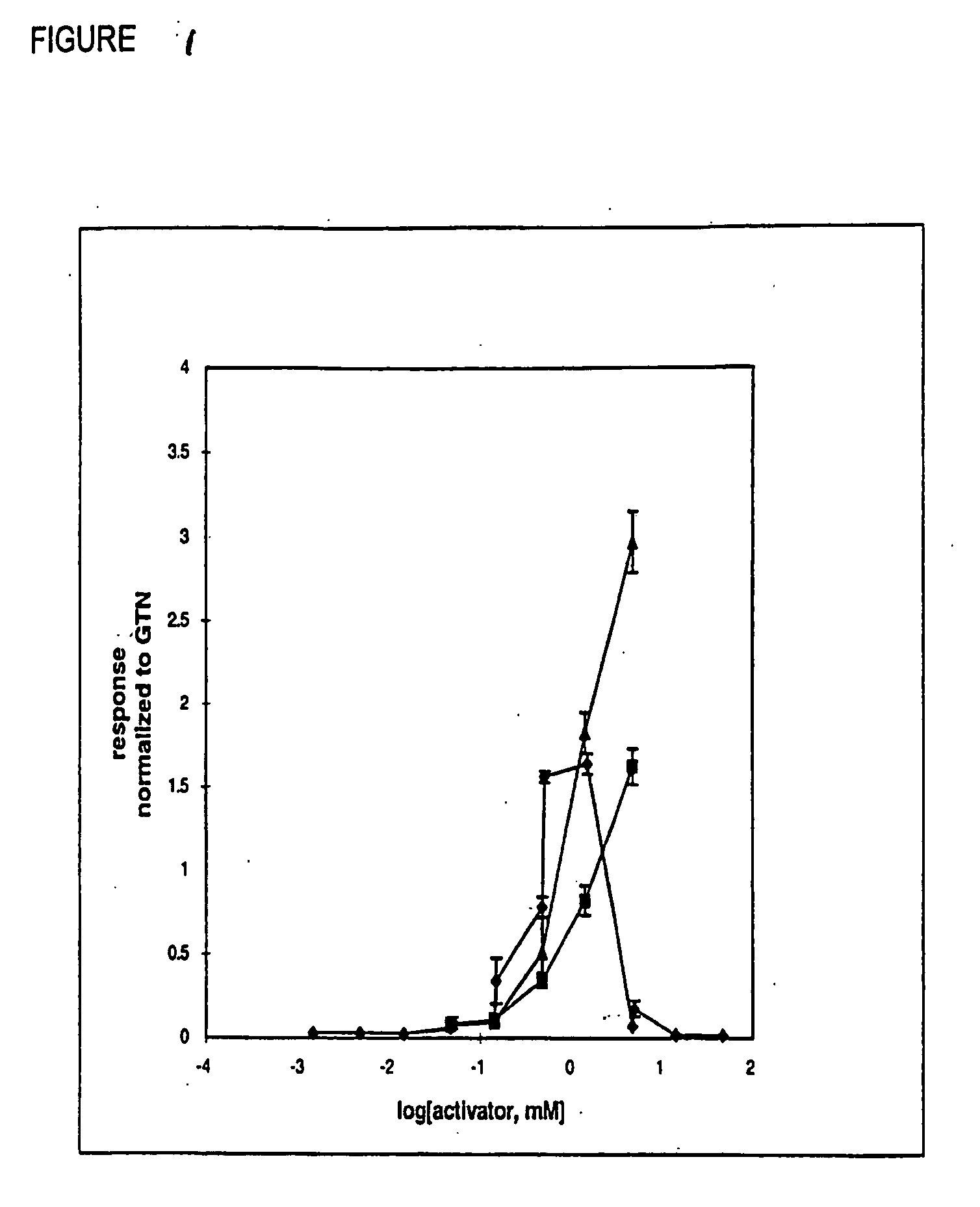

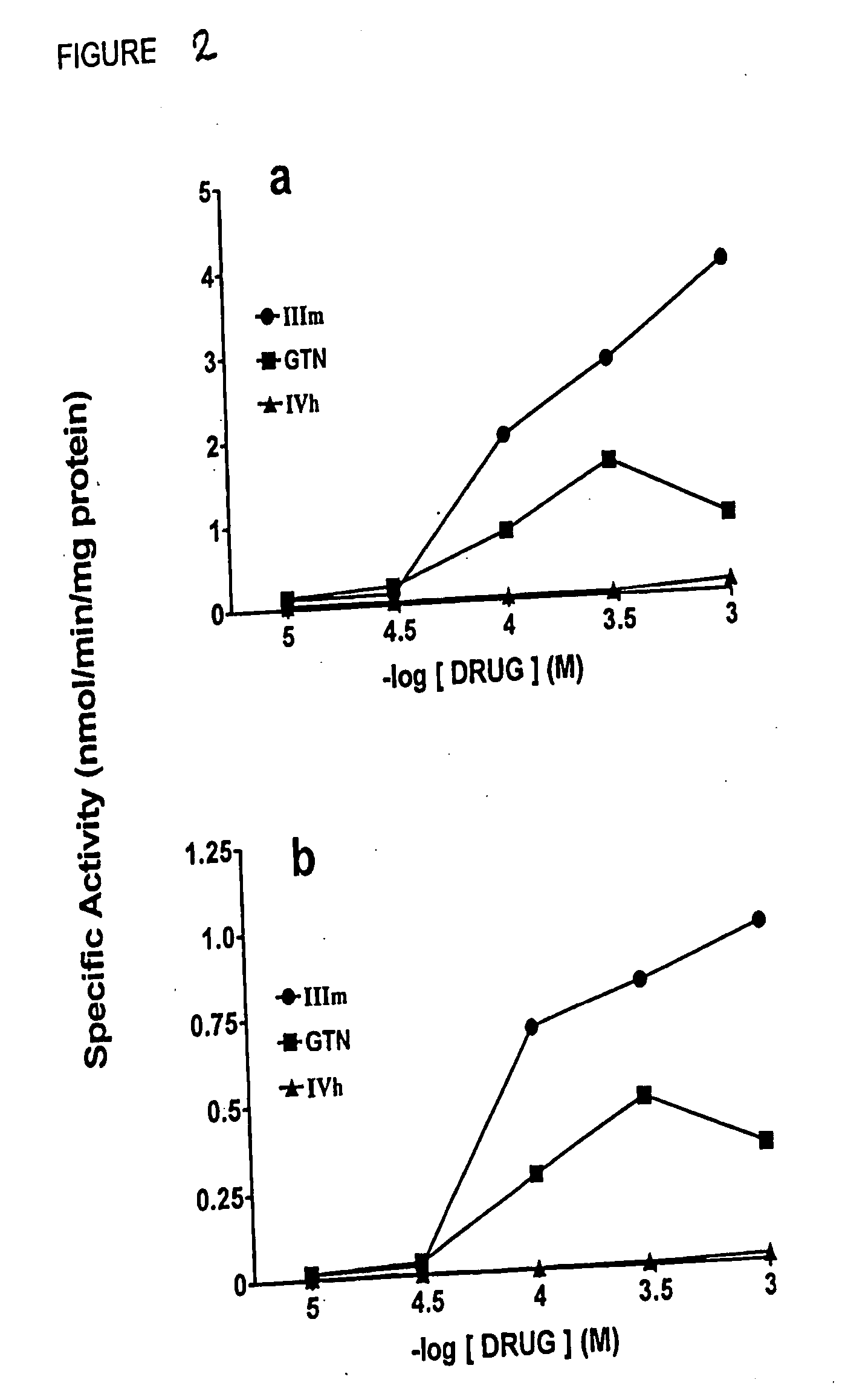

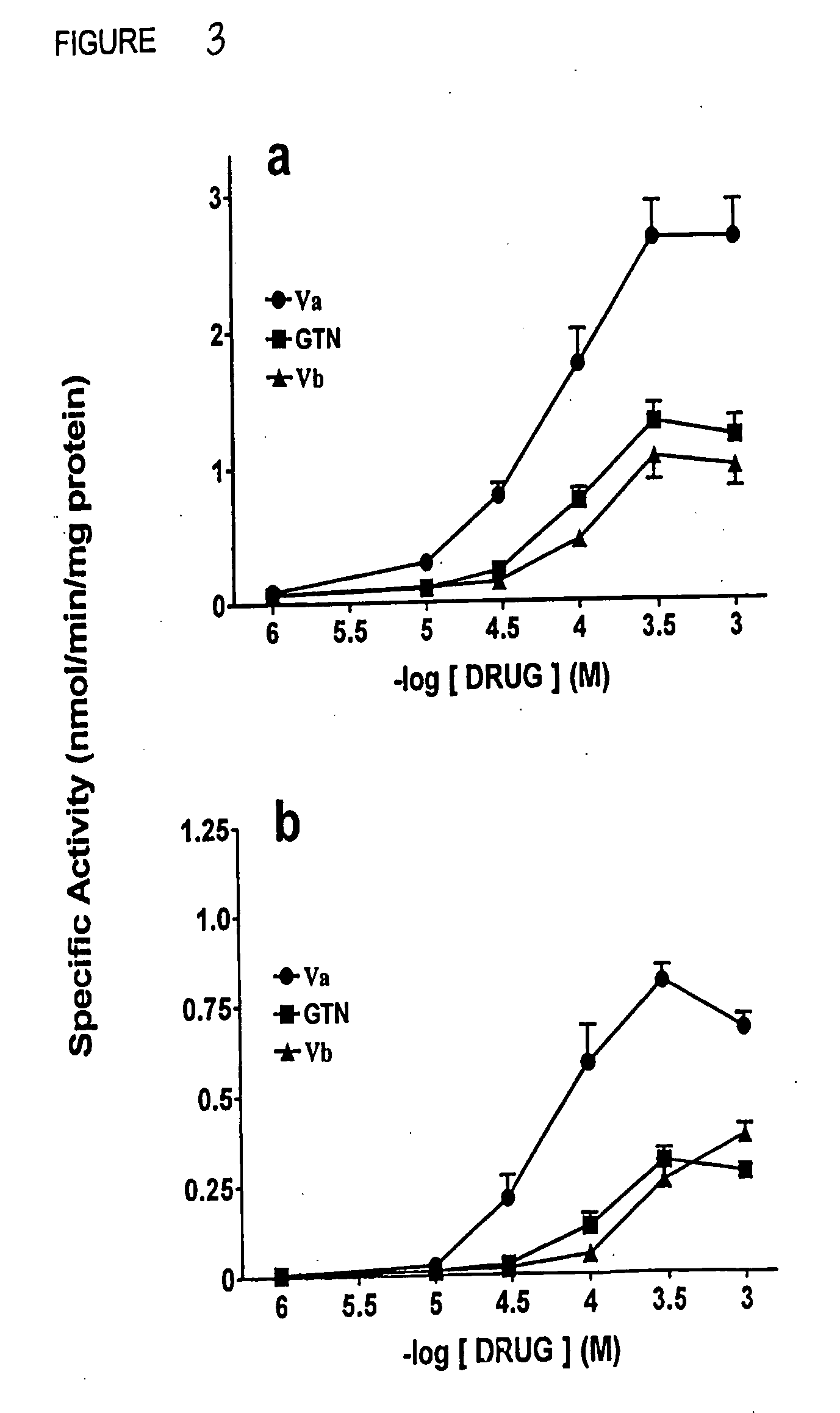

Nitrate esters and methods for mitigating neurodegeneration, affecting neuroprotection, affecting cognition enhancement, and / or preventing or mitigating tissue and / or cellular damage in a subject are described. Neurological or cognitive conditions, or damage mediated by free radicals are treated by administering to a subject an effective amount of a therapeutic compound comprising a nitrate ester, or a pharmaceutically acceptable salt thereof.

Owner:PARTEQ INNOVATIONS +1

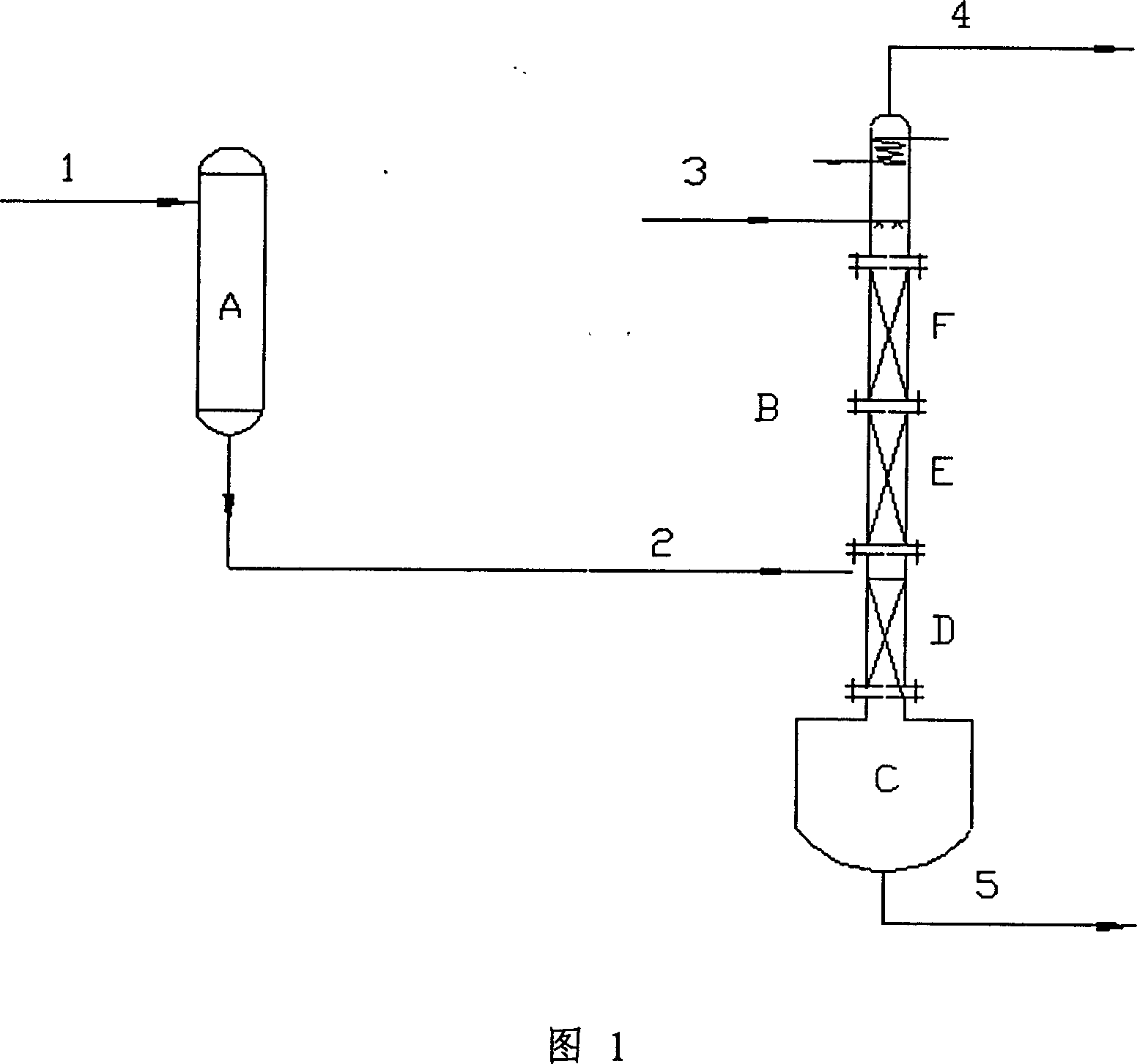

Process for the preparation of C1-C4-alkyl nitrites

ActiveCN101096340AAvoid it happening againReasonable useNitrous acid preparation ester preparationNitrogen oxidesPhysical chemistry

The invention discloses a making method of C1-C4 alkyl ester of nitrous acid, which comprises the following steps: doing the oxidizing reaction and esterifying reaction in two reactors separately; doing the oxidizing reaction in the oxidizing reactor; doing the esterifying reaction in the esterifying tower reactor; inputting nitrogen oxide, oxygen and one or more of inert gas into oxidizing reactor; selecting the nitrogen oxide from one or more composite gas of NO, N2O3, NO2 and N2O4 with NO constantly; making the mole of NO more than the mole of NO2; using 0.15-0.3 m oxygen for each NO m; making the bulk of inert gas at 0-90% corresponding to total gas; inputting the oxidizing reacting product into the esterifying tower reactor to react with C1-C4 alkanol; using 0.8-3.0 m alkanol for each gram atom nitrogen. The invention can transfer heat effectively to reduce by-product, which is smaller than traditional equipment.

Owner:SHANGHAI HUAYI ENERGY CHEM

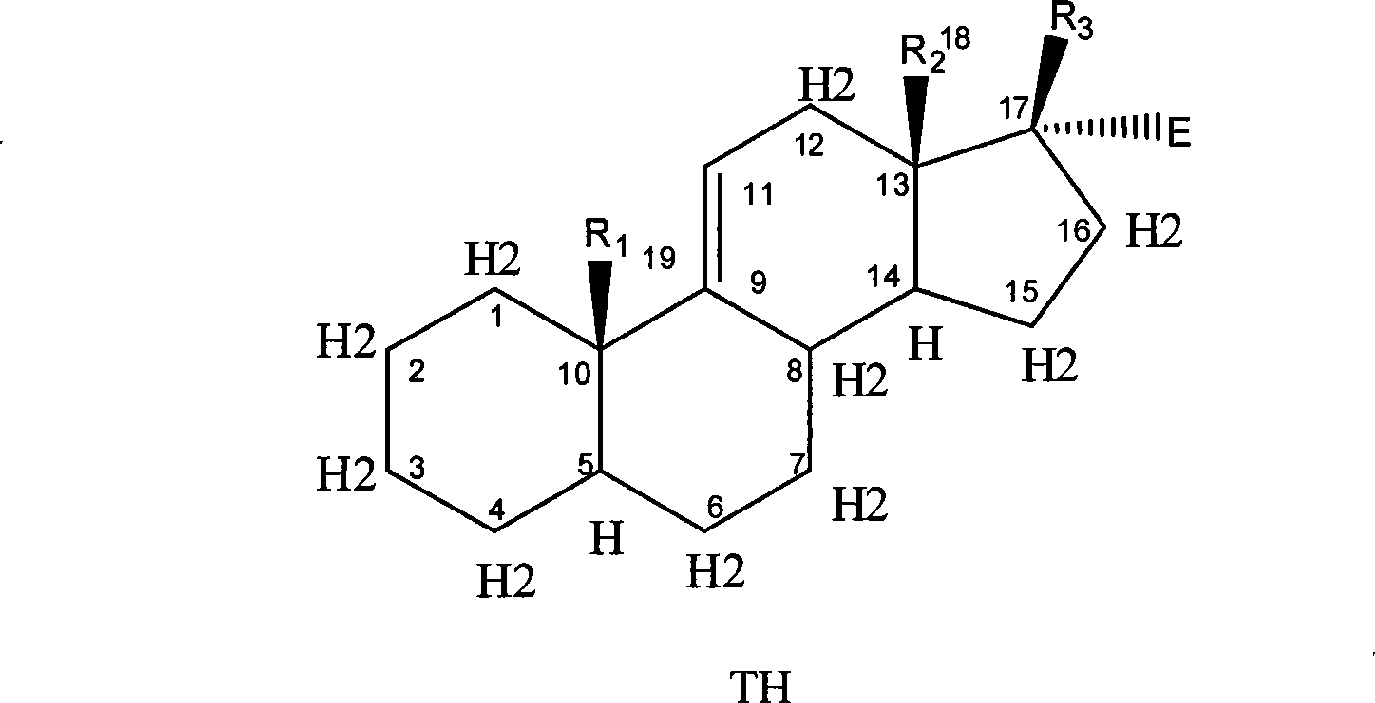

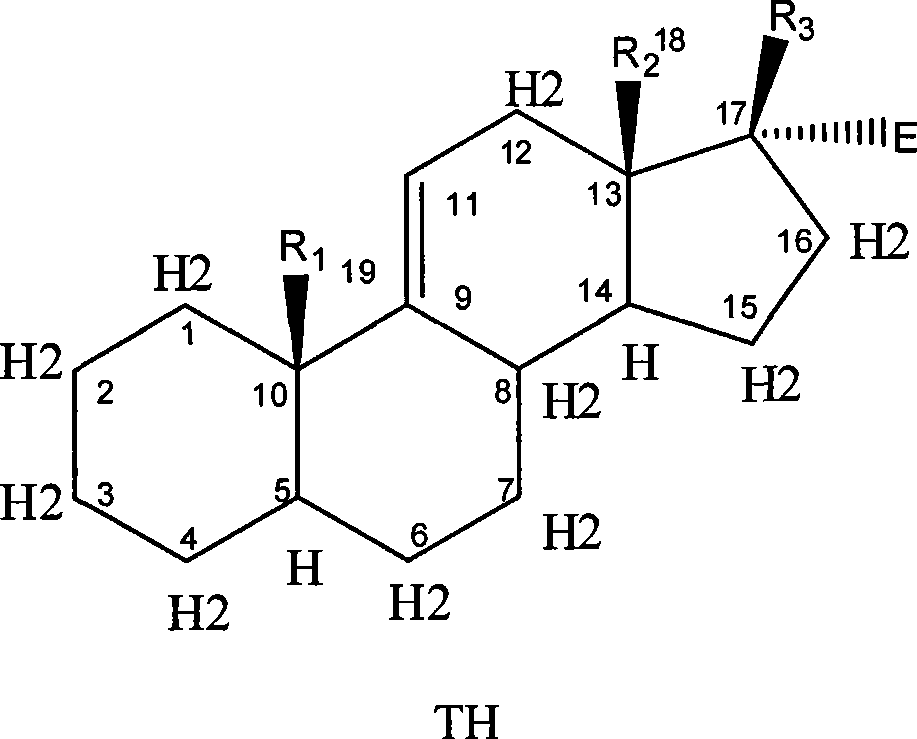

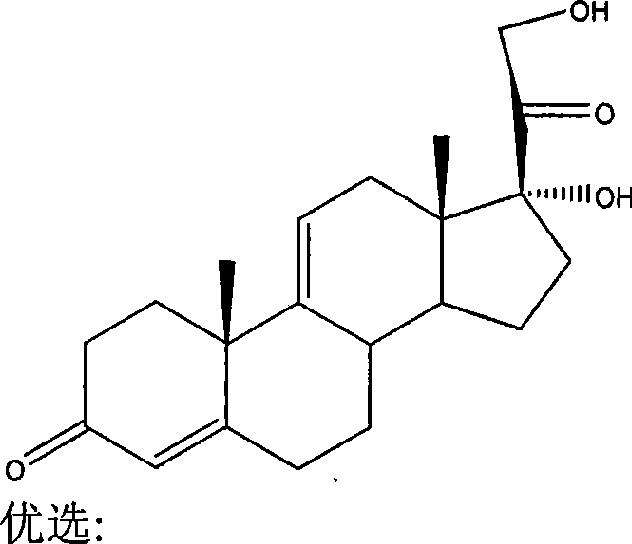

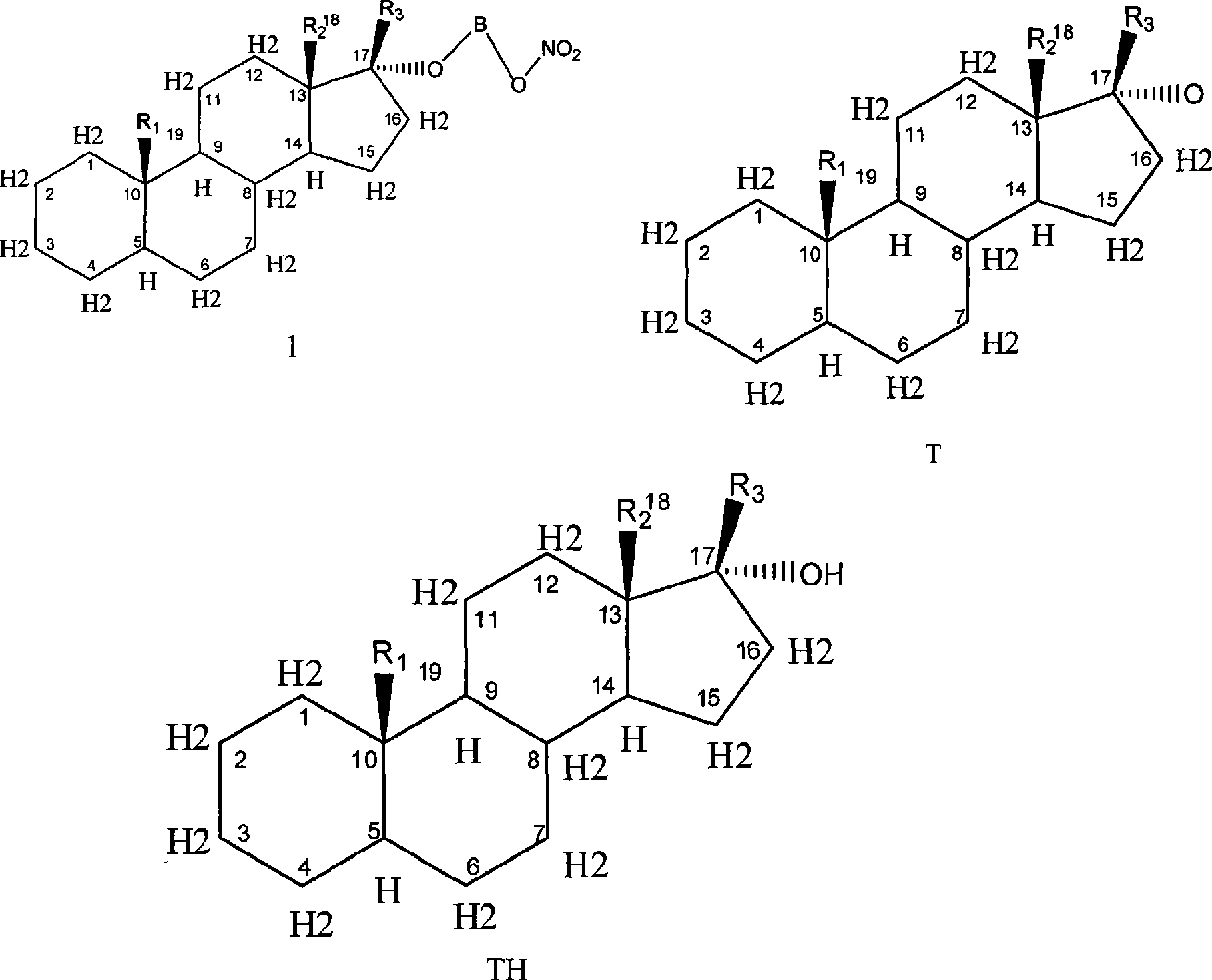

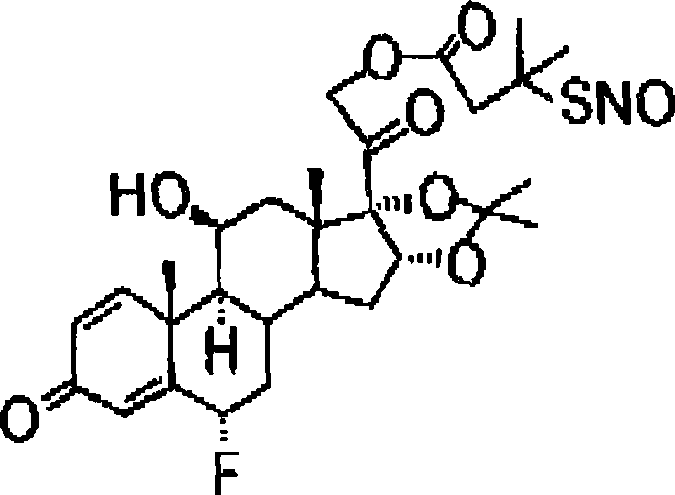

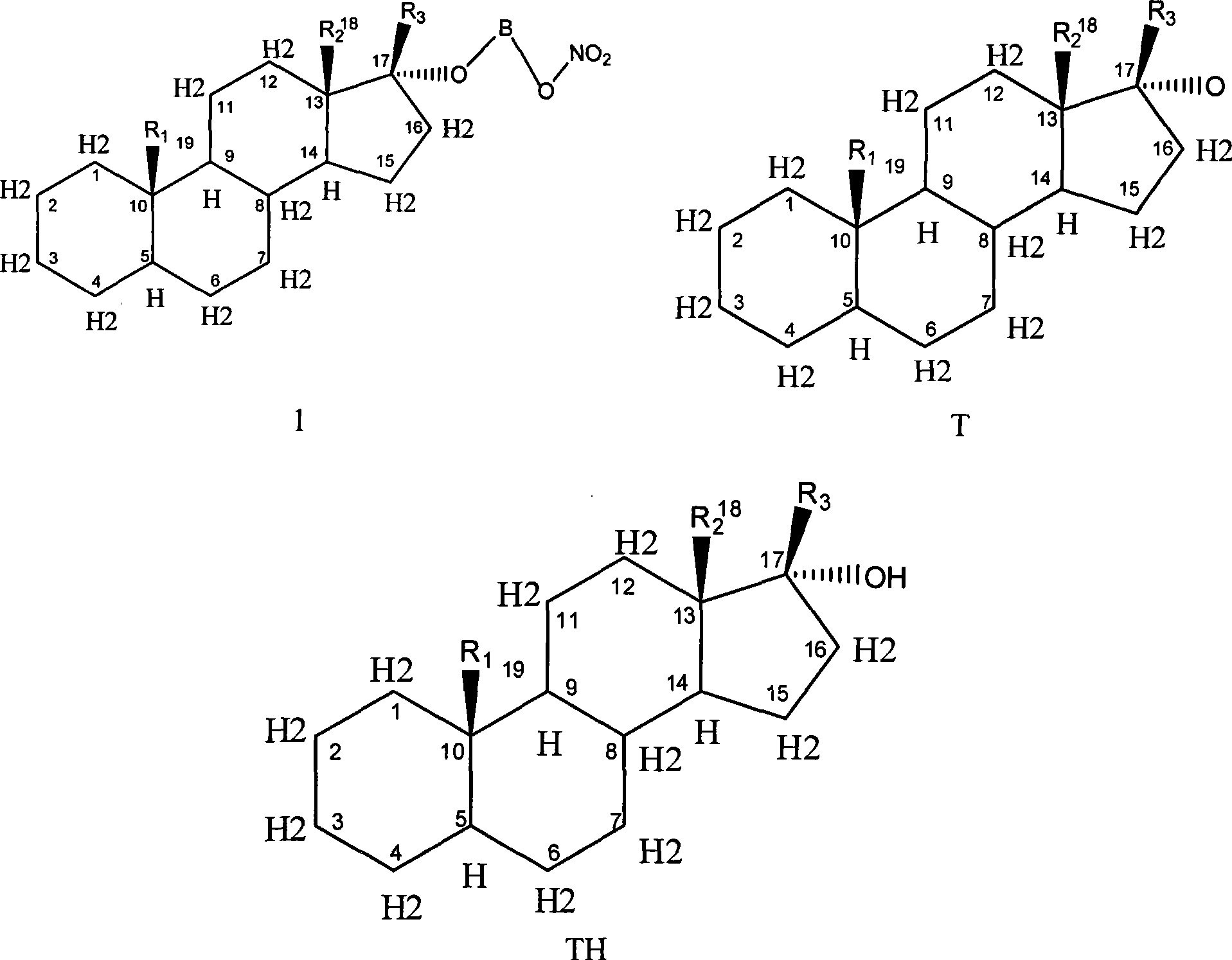

Nitric acid ester medicament for inhibiting angiogenesis

ActiveCN101412742AOrganic active ingredientsPharmaceutical non-active ingredientsDiseaseAbnormal tissue growth

The invention relates to a nitric acid ester drug for inhibiting the regeneration of blood vessels. The drug is the compound 1, ester or salt of the compound with the following general formula: T-(B-O-NO2)t1, wherein t1 is 1 or 2; T-H is a steroids compound; T is a residual steroids radial of the compound 1 after removing H, and T and H are connected in the form of O-H, namely connecting an oxygen atom on T and H, to form a hydroxide radical The compound is used for preparing the drug for treating tumor and ocular neovascularization disease.

Owner:TIANJIN JINYAO GRP

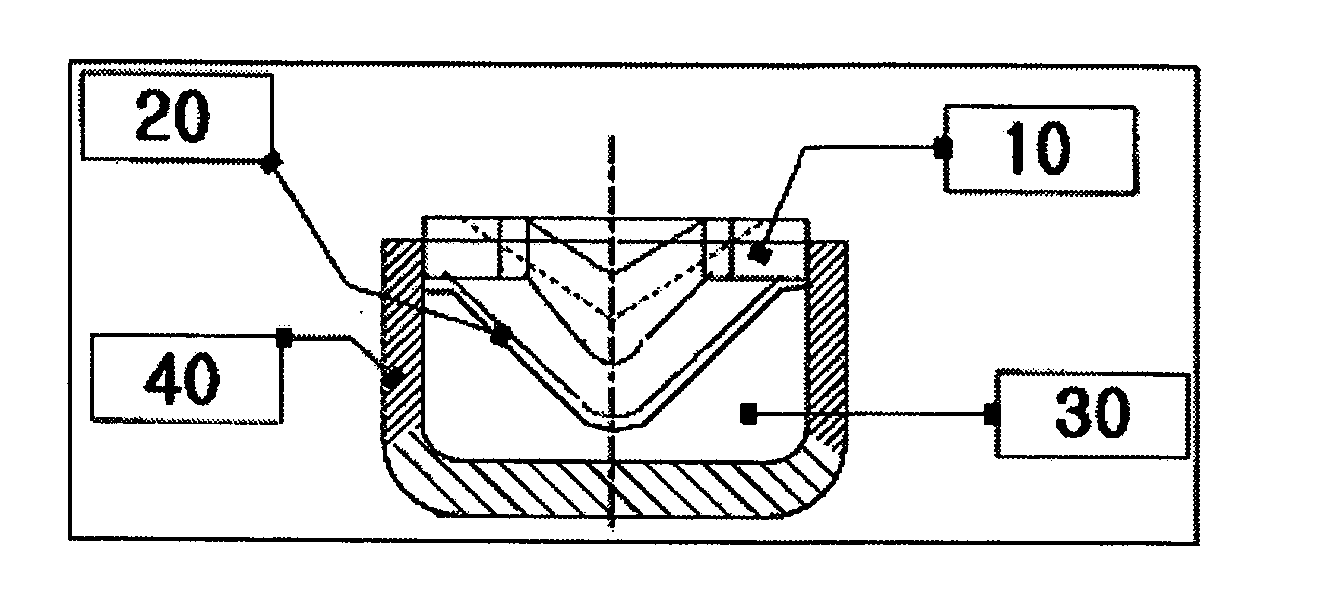

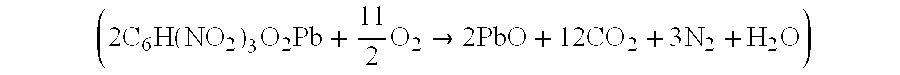

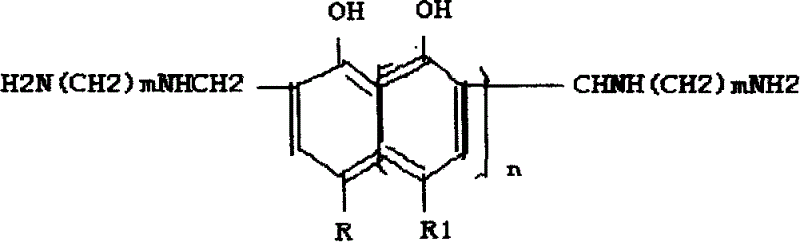

Non-toxic primer powder composition for small caliber ammunition

The present invention relates to a non-toxic primer powder composition for small caliber ammunition characterized by comprising potassium nitrate coated with shellac as an oxidizer, and particularly characterized by comprising 25-40 wt % of an initiating explosive, 10-30 wt % of nitrate ester as a fuel, 32-40 wt % of a shellac-coated potassium nitrate (KNO3) as an oxidizer, 5-10 wt % of tetracene as a first sensitizer, 3-9 wt % of a borosilicate powder as a second sensitizer and 0.1-0.2 wt % of a chemical binder.

Owner:POONGSAN CO LTD

Self-lubricating antiseiznig materials and preparing method thereof

InactiveCN1583904AImprove coating application performanceOvercoming the disadvantages of electrostatic sprayingCoatingsFritAtmospheric temperature

This invention adopts the ceramic material and Fluorine resin with moist slippery characteristic to mix altogether, it is wear-resisting to make one, it is warm to be able to bear, corrosion-resistant, do not glue the wear-resisting sizing of pottery of the function. It is become membrane material, ceramic packing, a piece of coating of one pair of groups made up of the solvent and solidification pharmaceutical, succeed the membrane material and include the cellulosic nitric acid ester, gather the acrylic acid. the mixture of three kinds of resin of the polytetrafluoroethylene (PTFE), low-temperature glass dust, the ceramic pcking makes up. Will become membrane material and solvent first while preparing, the solidification pharmaceutical will be mixed evenly, and then put into the ceramic packing, then adopts the disperse the equipment, after mixing evenly, processes in grinding the equipment, sieve, pack. It becomes membrane under normal atmospheric temperature, improve coating coating construction performance, adopt and brush and roll scribbling and spraying, overcome coating must adopt static shortcoming of spraying at present, become low temperature products after the membrane, the high temperature frits again, any little member does not remain materials, has guaranteed this application in the tableware and wear-resisting trade of coating.

Owner:华东船舶工业学院

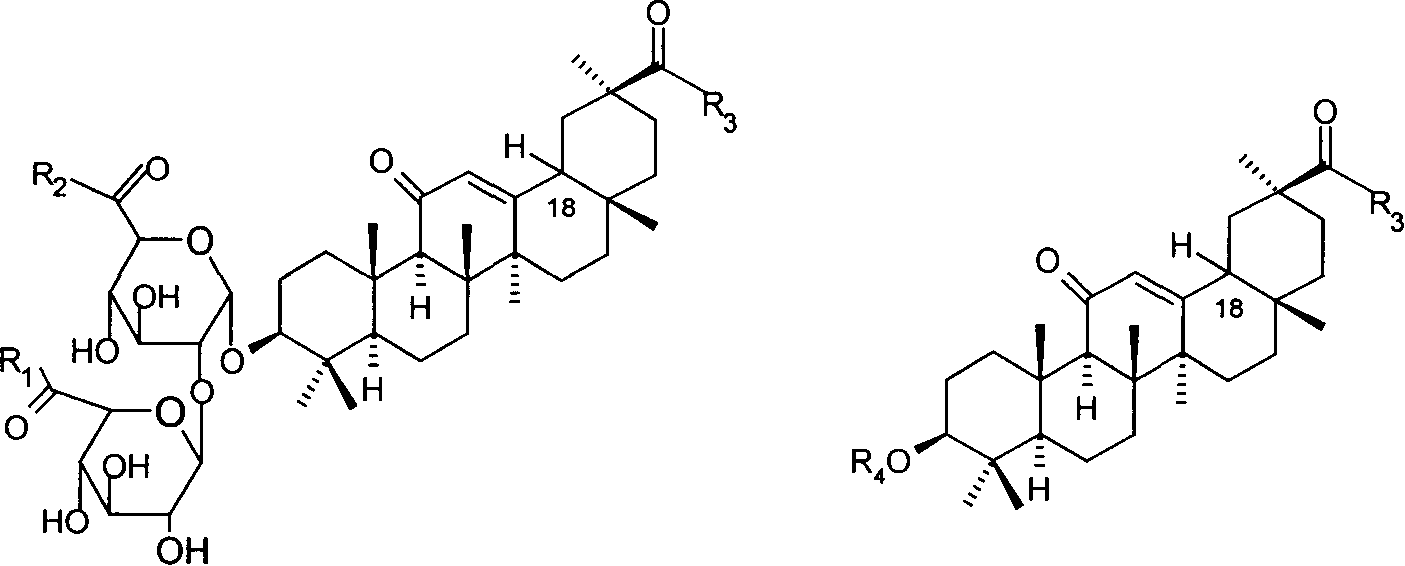

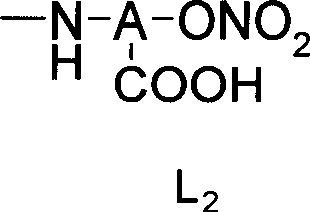

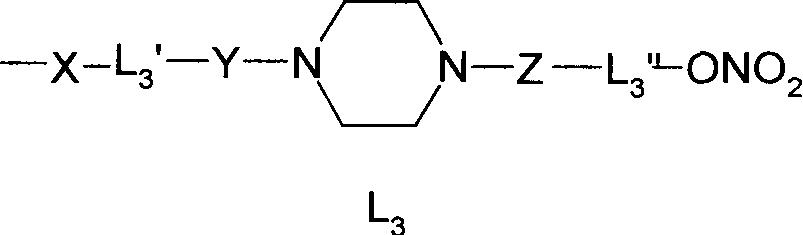

Nitrate derivatives of glycyrrhetic acid and glycyrrhetinic acid and pharmaceutical use thereof

Disclosed are nitrate derivant of glycyrrhizic acid or glycor represented by formula Ia and Ib and its nontoxic salt which can be accepted in the sphere of pharmacy, their precoss for preparing, and components and usage of the drugs which contain these compounds.Thereinto, R1, R2 and R3 stand for hydroxyl or -X-L-oxo-oxonitryl (X stands for oxygen,imino; L stands for alkyl with 2-6 of canbon atoms, substituted alkyl or cycloalkyl, hydroxyl amino acid residue or N,Ní»-disubstituted piperazine); R3 stands for hydrogen, oxonitryl or carbonyl -Lí»oxo-oxonitryl (Lí»stands for alkyl with 1-6 of canbon atoms, substituted alkyl or cycloalkyl, aralkyl, N,Ní»-disubstituted piperazine); in formula Ib, R1, R2 and R3 may be the same or different, but in which at least one of them contains -X-L-oxo-oxonitryl; in formula Ib, at least one of R3 or R4 must contain oxonitryl. In formula Ia and Ib, hydrogen of 18-carbon can be alpha-isomer or beta-isomer.

Owner:BEIJING MEIBEITA DRUG RES

A method for preparing nitro compounds using nitrogen suboxides

ActiveCN102276471AIncrease profitAtom economy is highNitro compound preparationNitro compoundHydrogen Nitrate

The invention discloses a method for preparing a nitro compound from a low-valent nitric oxide. The method comprises that a low-valent nitric oxide such as nitric oxide, nitrogen dioxide, nitrous oxide, nitrogen trioxide, dinitrogen tetroxide and the like react with an alicyclic compound, an aromatic compound or a heterocyclic compound through promoting effects of molecular oxygen and effects of catalysts comprising a transition metal oxide, a triphenylphosphine metal organic complex, transition metal ion clay and heteropoly acid salts such as aluminosilicate, silicoaluminophosphate, sodium phosphomolybdate and the like. The method can replace the traditional industrial method for preparing a nitro compound from a high-valent (V-valent) nitrogen compound such as nitrogen pentoxide, hydrogen nitrate, nitric acid salts, nitric acid esters and the like. The method improves an atom utilization rate of a reaction in industrial nitration preparation of a nitro compound, and has atom economic characteristics of industrial preparation of a nitro compound.

Owner:彭新华

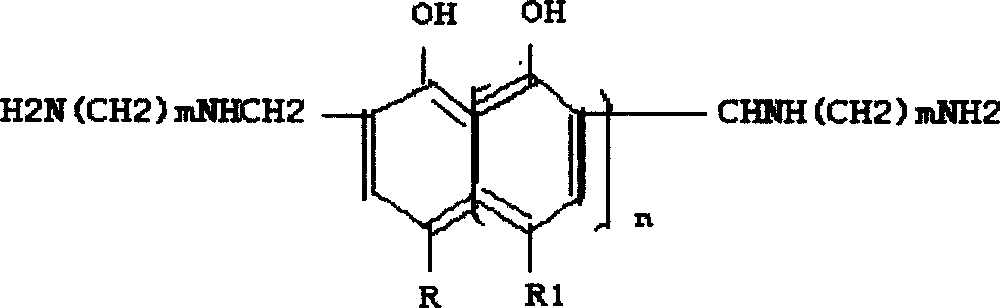

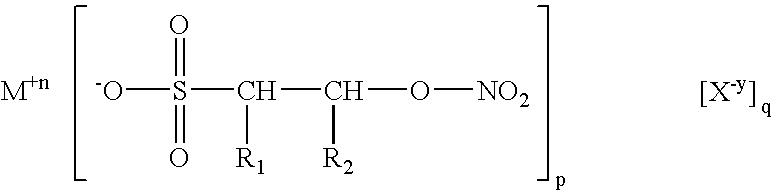

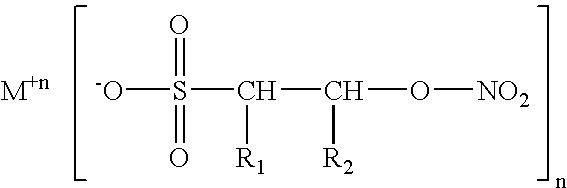

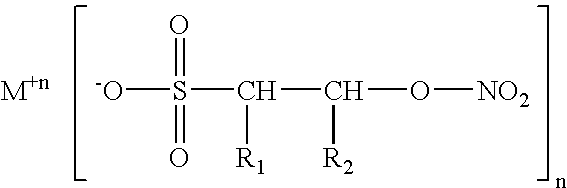

Isethionyl nitrates and compounds thereof

The present invention provides nitric ester compound corresponding to the formula: in which the cation M is selected from the group consisting of: hydrogen, alkali metal cations, alkaline earth metal cations, Group III metal cations, transition metal cations, ammonium ions (including organic-substituted ammonium cations), including mixtures of any two or more of the foregoing; R1 and R2 are each independently selected from the group consisting of: hydrogen and a C1 to C6 hydrocarbyl group; n represents the valence of the cation, including the integers 1, 2, and 3; X is an anion selected from the group consisting of: fluoride, chloride, bromide, iodide, nitrate, nitrite, phosphate, phosphate, monohydrogen phosphate, taurate, dihydrogen phosphate, monohydrogen sulfate, sulfate, carbonate, bicarbonate, hydroxide, carboxylate, dicarboxylate and polycarboxylate anions; y is the valence of the anionic species X and may be 1, 2, or 3; p may be any integer including 1, 2, and 3, subject to the proviso that p is not greater than n; q may be any integer selected from the group consisting of: 0, 1, 2, 3 subject to the proviso that q is not greater than n−p, and further subject to the provisos that the sum of p plus the product of (y times q) equals the valence n of the cation M and that p is not equal to zero. The compounds of the invention are useful as coronary vasodilators.

Owner:WHEWELL CHRISTOPHER J

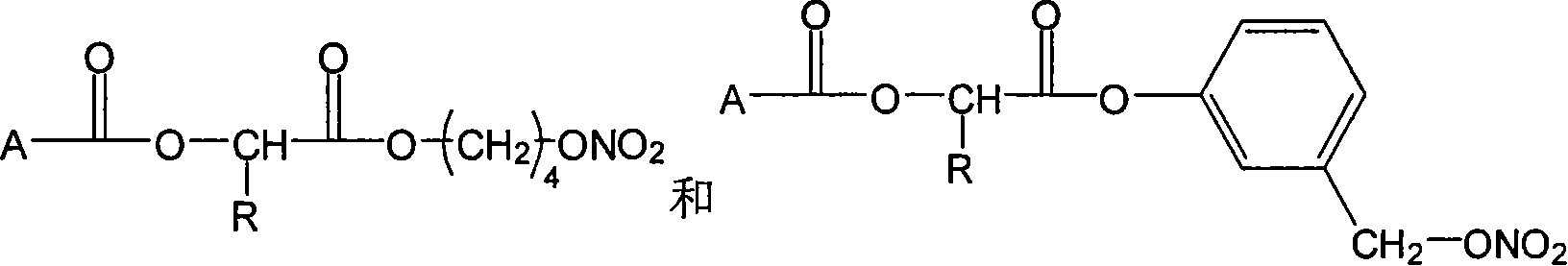

Nonsteroidal antiinflammatories with nitric oxide donors and its preparation method

InactiveCN101053662ALittle side effectsMild reaction conditionsAntipyreticAnalgesicsIndometacinSide effect

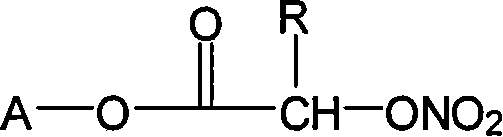

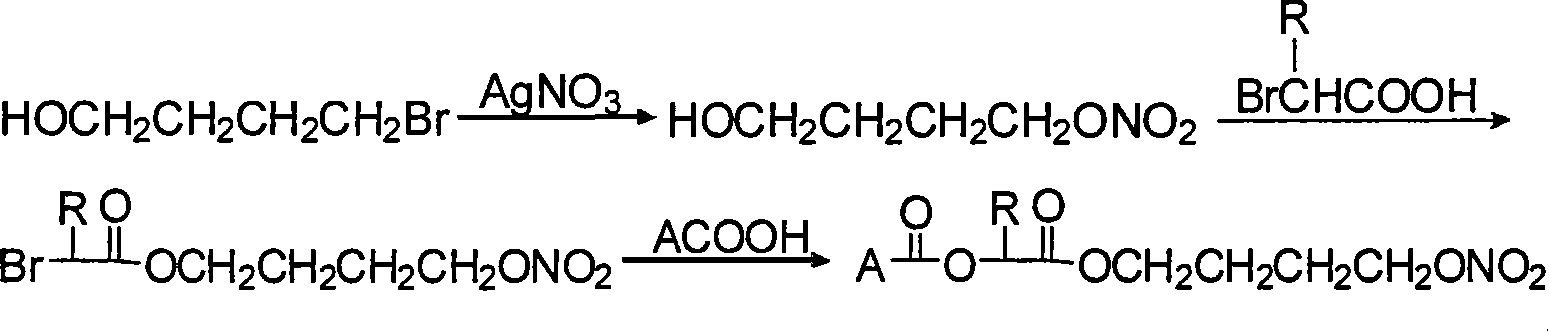

The invention relates to a non-steroidal anti-inflammatory drug with nitrogen oxide donor and a method for preparing same, which can be used to eliminate inflammation, relieve fever and stop pain, and can decrease the frequently seen side effect thereof on the gastrointestinal tract. The structure of which is A-O(X)-CO-O(y)-B-ONO2,wherein, A is the non-steroidal anti-inflammatory group; B is the connection group, when x=0, y=1; when x=1 then y=0. The the non-steroidal anti-inflammatory groups includes aspirin, diclofenac, indometacin, lumiracoxib, brufen, ketoprofen, naproxen, piroxicam, and meloxicam. The preparation process are that the bromhydrin (or hydroxybenzene) reacts with silver nitrate into hydroxy nitrate, then reacts with bromo acid into the connection group of nitrogen oxide donor, then connects with the non-steroidal anti-inflammatory drug; or the non-steroidal anti-inflammatory drug condensates with bromo acid into a bromide intermediate, then reacts with silver nitrate into the non-steroidal anti-inflammatory drug with nitrogen oxide donor.

Owner:江苏吴中苏药医药开发有限责任公司

Methods and compositions for mitigating pain

Methods and therapeutic compounds for treating pain, mitigating inflammation, effecting analgesia and / or effecting sedation in a subject are described. A subject is administered an effective amount of a therapeutic compound which is a nitrate ester. Novel pharmaceutical compositions are also described.

Owner:QUEENS UNIV OF KINGSTON

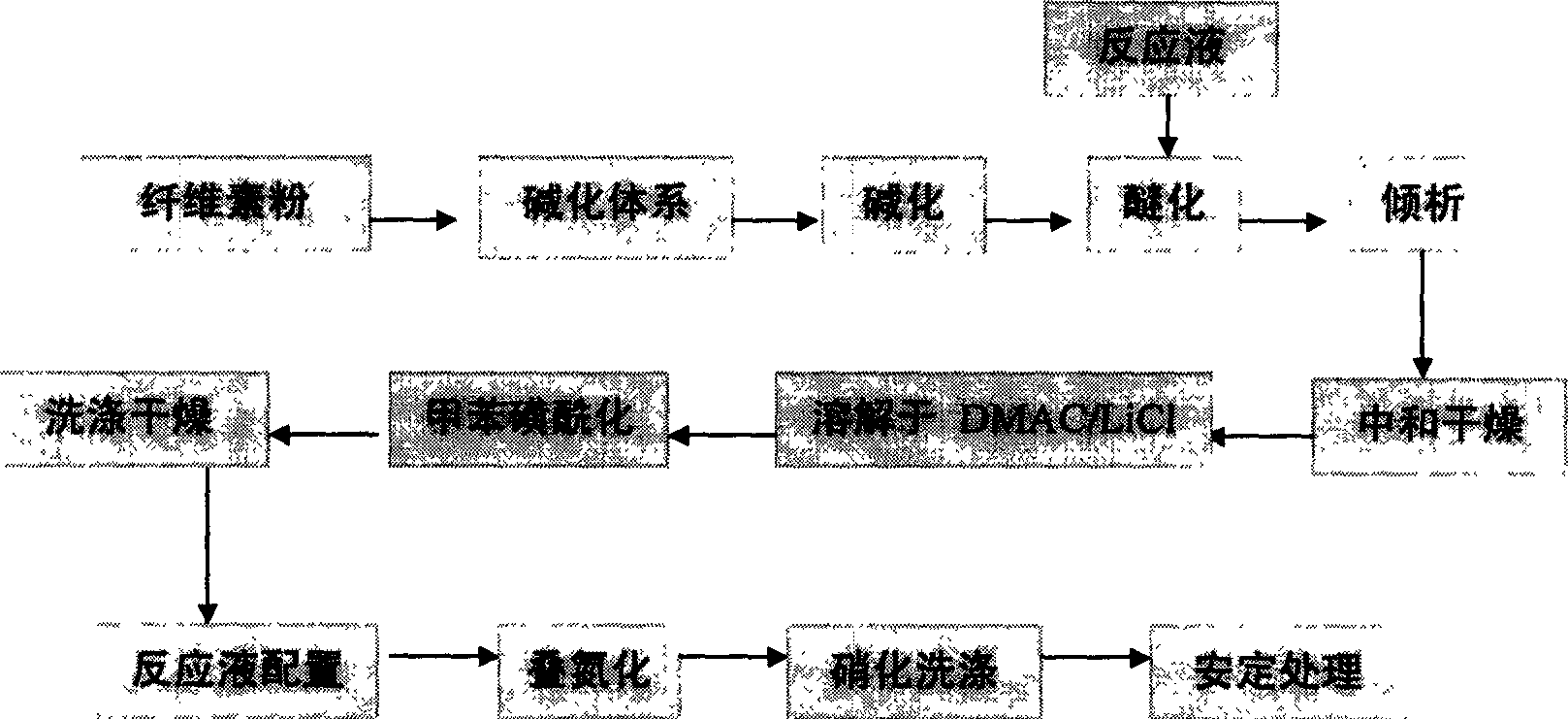

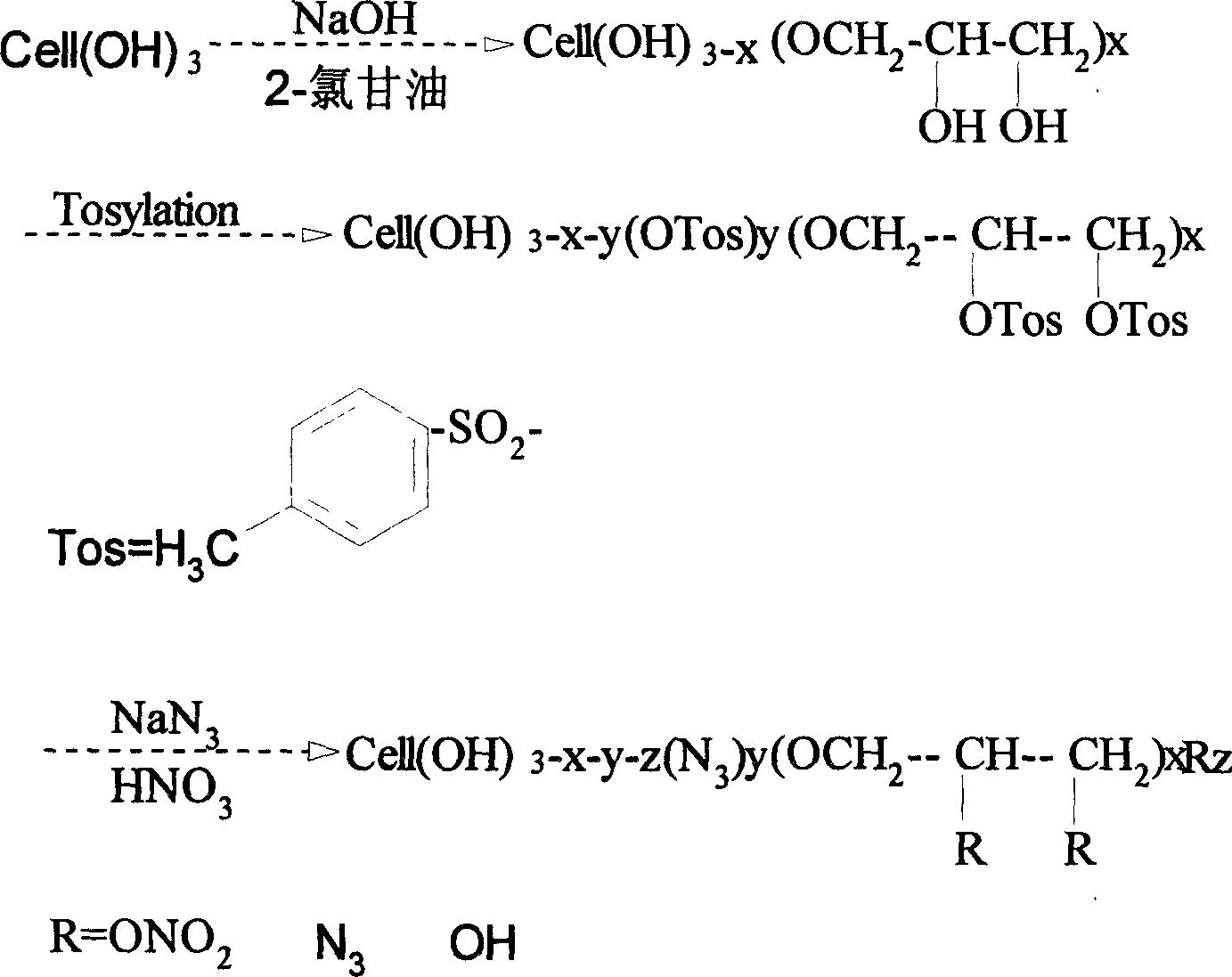

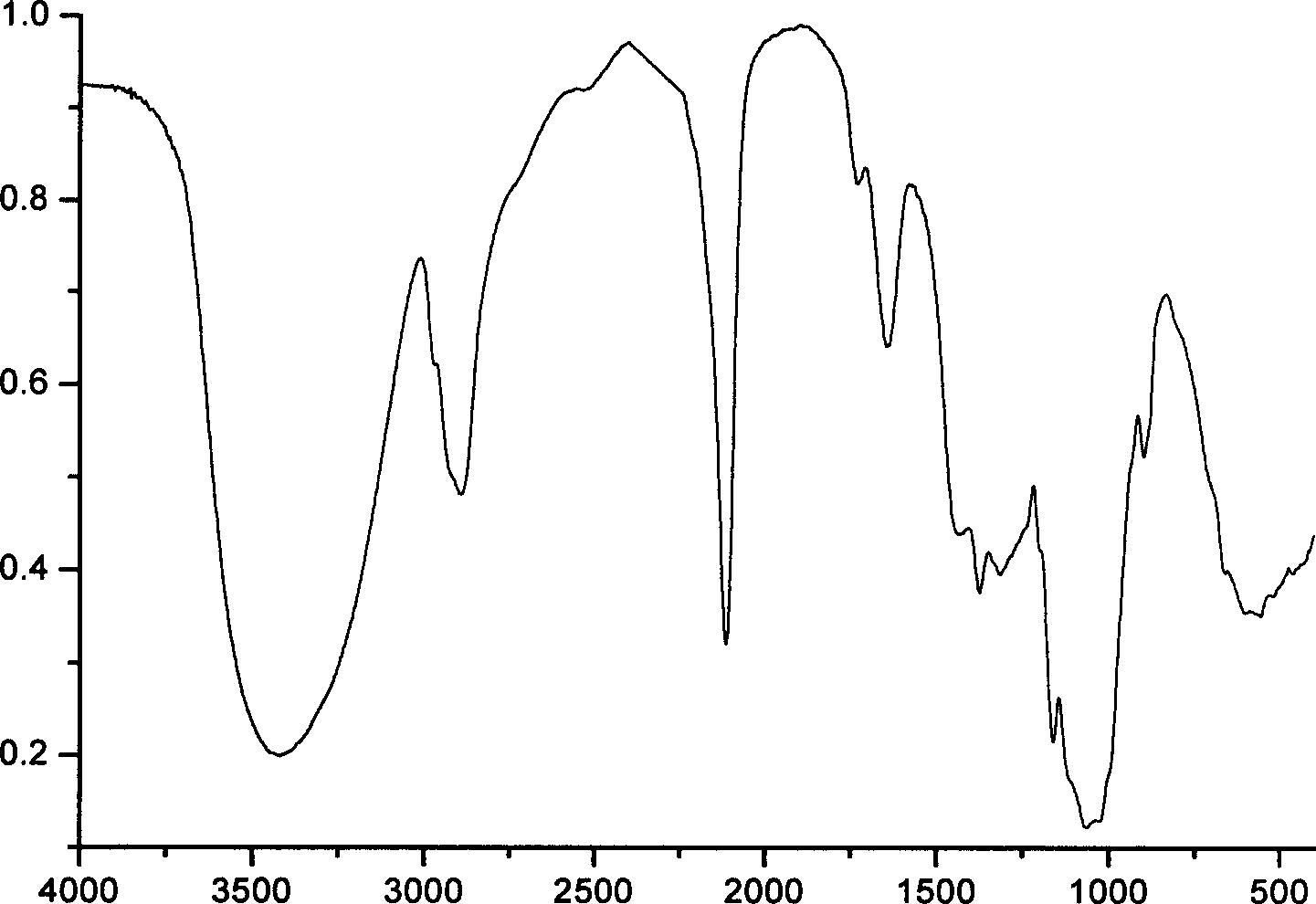

Azido dihydroxypropyl cellulose nitrate preparation method and synthesis

The invention discloses the azido dihydroxypropyl cellulose nitrate preparation method and synthesis which comprises, subjecting natural cotton and cellulose to alkalization under semi-homogeneous phase reaction condition, charging epoxy propyl alcohol for sectionwise etherification to the alkali cellulose, obtaining dihydroxy cellulose ether whose substitution degree is between 0.5-1.2, completely dissolving in dimethyl polyamide / 9% LiCl system, scouring, purifying, drying and dissolving in dimethyl sulfoxide, carrying out homogeneous phase nitrine at high temperature.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

Novel nitric acid esters steroidal compounds

InactiveCN101397317AImprove stabilityOrganic active ingredientsAntipyreticDiseaseMedicinal chemistry

The invention relates to novel nitrate-steroidal compounds and the preparation method of the compounds. The invention also relates to the medical preparation containing the compounds and the therapeutic application of the compounds, especially the treatment to inflammatory, allergic and anaphylactic diseases.

Owner:TIANJIN PHARMA GROUP CORP

Detection of nitro- and nitrate-containing compounds

InactiveUS20100291698A1Material analysis by observing effect on chemical indicatorBiological testingCompound aNitrite

A method of the invention is a method of detecting nitramines and nitrate esters believed to be present on a sampling substrate. In the method, a sampling substrate is exposed to a first reagent that is formulated to react with nitramine- and nitrate ester-type explosives to release nitrite. The sampling substrate is then exposed to a second reagent that contains an acid to react with the nitrite and a diaminoaromatic present in either the first or second reagent, to form a triazole that will luminesce. Another method of the invention combines this process for nitramine- and nitrate ester-based explosives detection with a technique to detect nitroaromatic-based explosives using luminescent polymers, for a three-step process for the detection of explosives in these three classes.

Owner:RGT UNIV OF CALIFORNIA

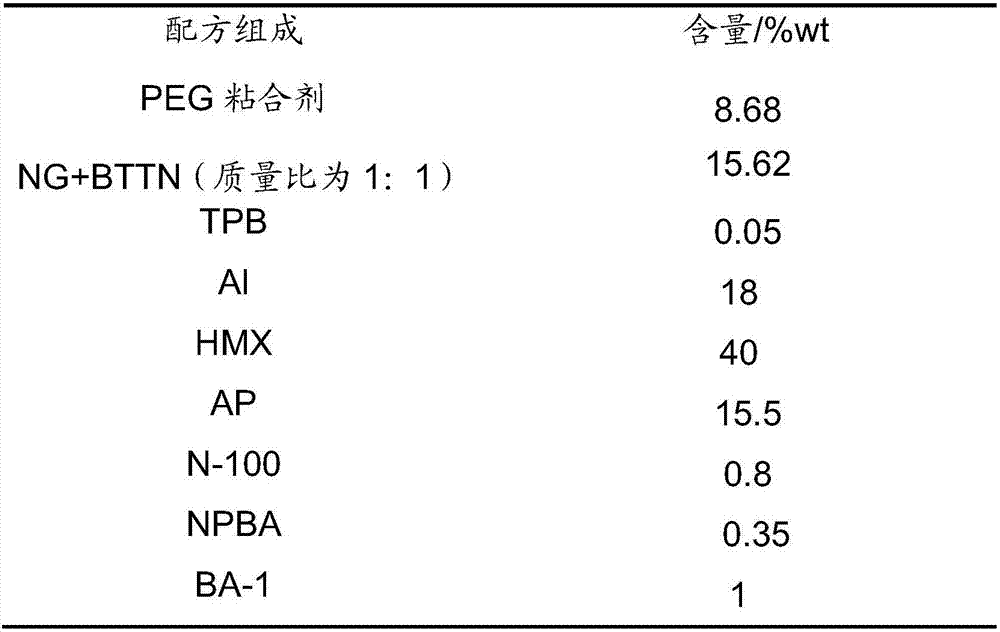

Composition function agent for improving mechanical property of solid propellant, and solid propellant comprising composition function agent

ActiveCN107311826AGood chemical compatibilityHigh strengthNitrated aromatic explosive compositionsNon-explosive/non-thermic compositionsMedicineHigh energy

The invention relates to a composition function agent for improving the mechanical property of a solid propellant, and the solid propellant comprising the composition function agent. The composition function agent is prepared from phenylamine and a stabilizer, wherein the percentage contents of the phenylamine and the stabilizer accounting for the total mass of the solid propellant are respectively 0.03 percent to 0.35 percent and 0.3 percent to 2 percent. By adopting the composition function agent prepared from the phenylamine and the stabilizer, an interface effect is improved, hydroxyl in the phenylamine can enter to a propellant network structure to adjust the network density of an adhesive, and meanwhile, a benzene ring in the phenylamine is of a rigid structure and can be beneficial to remarkably improving the strength and the modulus of the propellant when being used as a hard segment, so that the mechanical property of the high-energy solid propellant is improved; meanwhile, the high-efficient stabilizer is adopted, so that the suppression of the chemical compatibility of phenylamine composition function agent and nitric acid ester is improved, the decomposition of the nitric acid ester under a weak alkali condition is suppressed, and the function of further improving the mechanical property of the propellant is realized.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

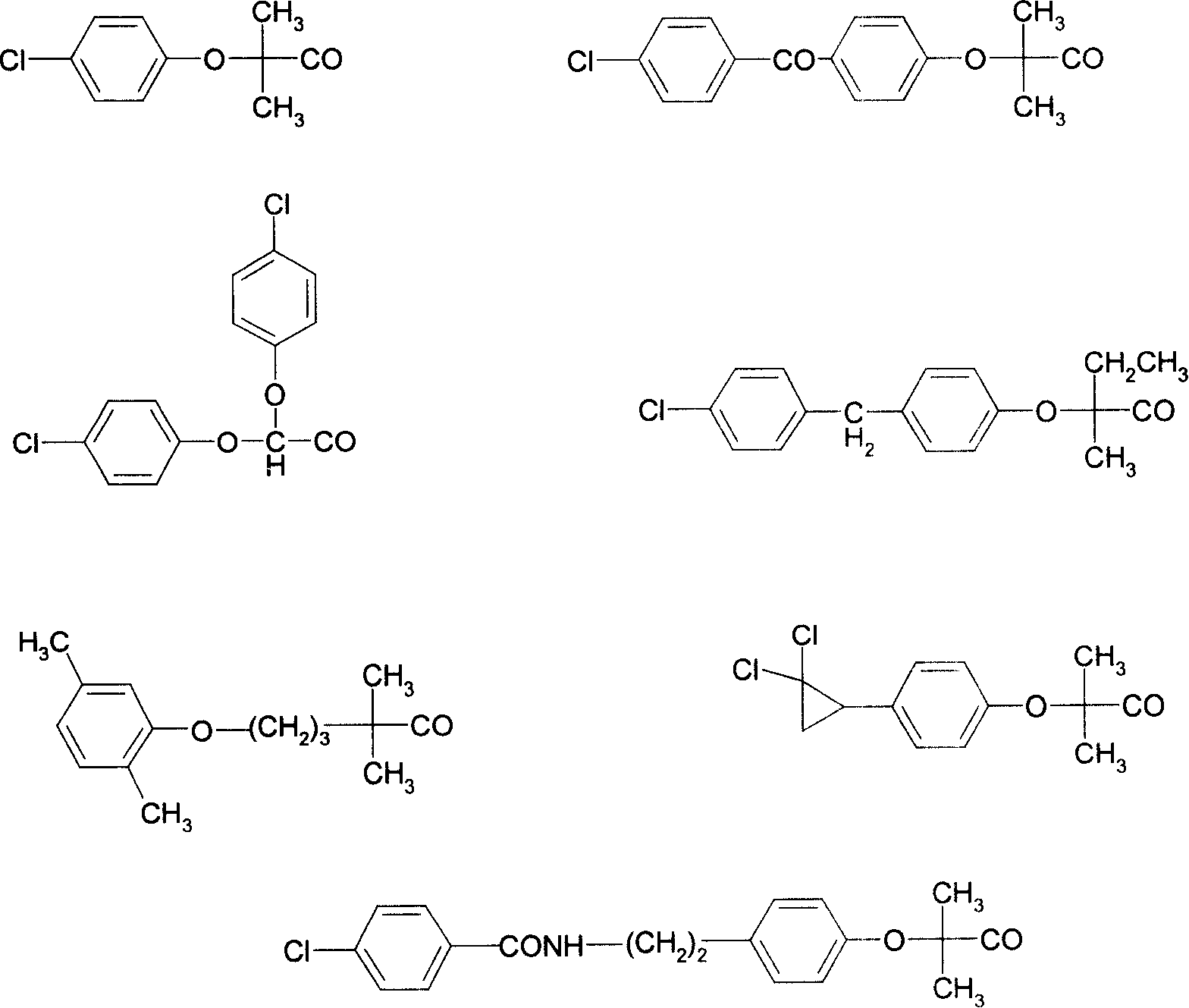

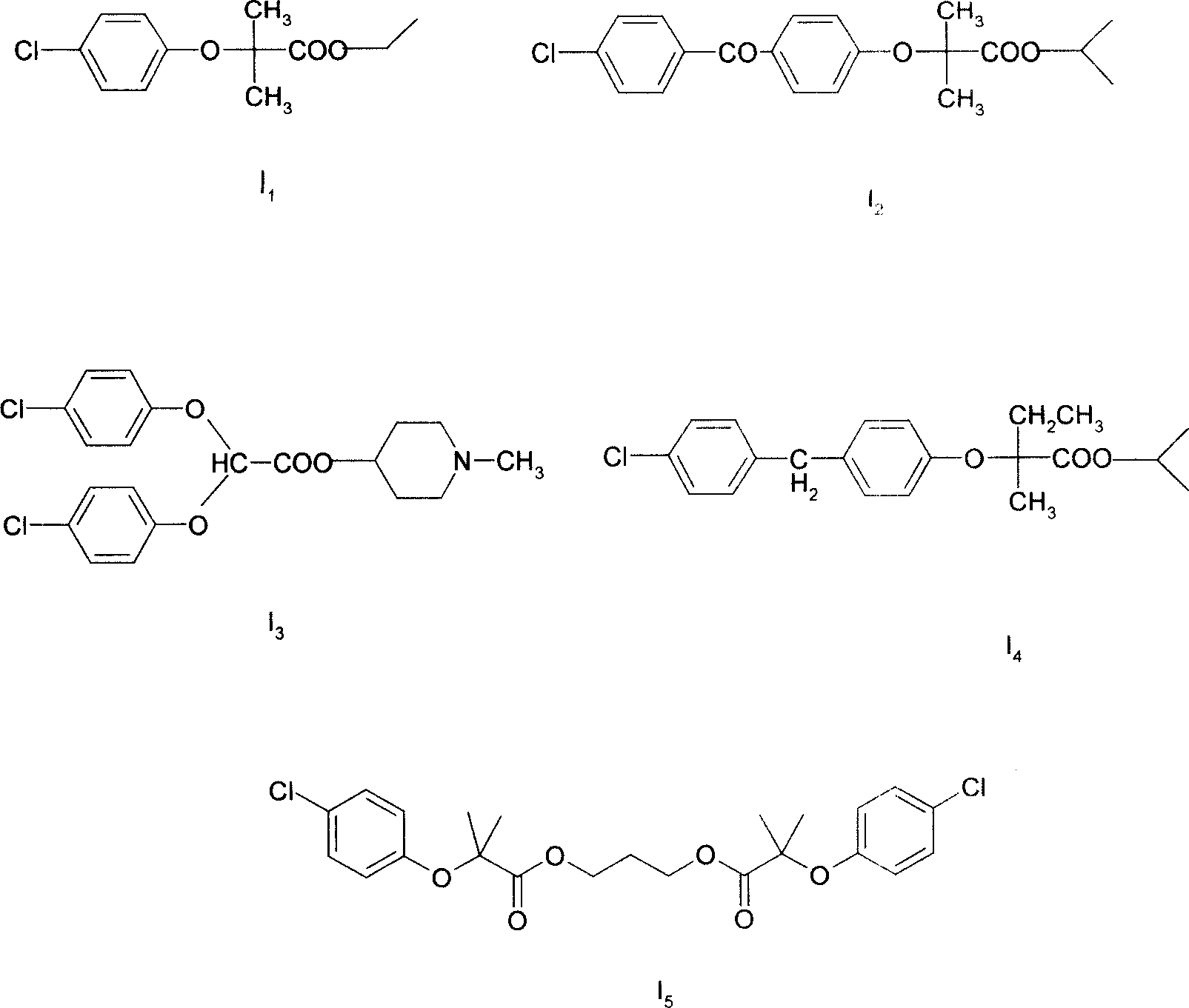

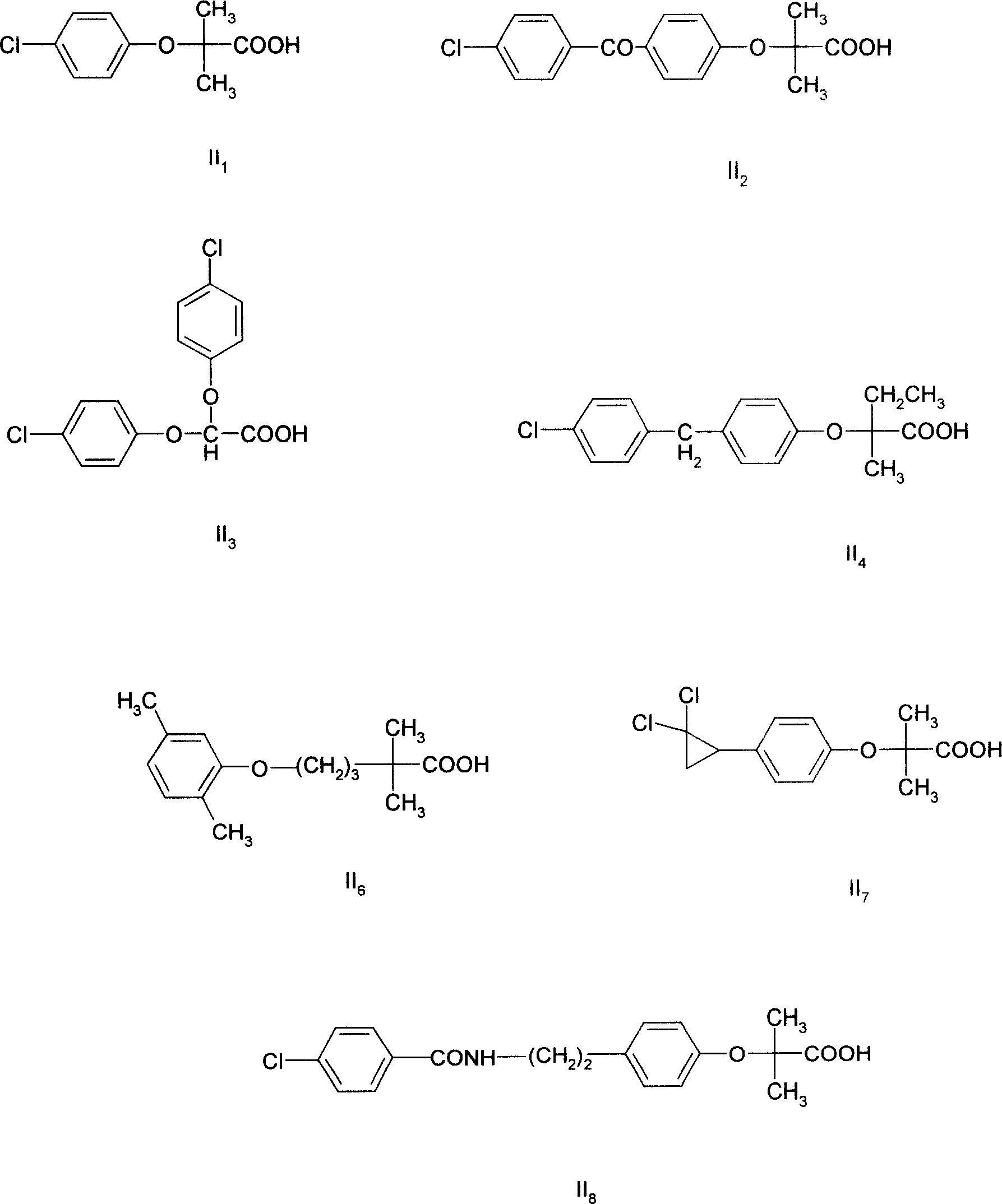

New phenoxy eicosanoic acid derivative and its medical use

InactiveCN1966484AGood liver protectionLower triglyceridesOrganic chemistryMetabolism disorderCarboxyl radicalThreonine

The invention provides new phenoxy carboxylic acid derivatives represented by the formula A-COX-L-ONO2. The structure is characterized by linking nitrate and carboxyl in phenoxy carboxylic acid molecule through coupling bridge structure. In the formula, A is the role for the phenoxy residues of phenoxy acetic acid compounds with lipid-lowering effect, X represents O or NH, and L is for C2-C6 alkyl and substituted alkyl, C3-C6 naphthene, hydroxyl-containing amino acid residues such as serine and threonine residues, or dialkyl substituted piperazine. The invention also provides the drug combinations using the new phenoxy carboxylic acid derivatives as active components and their applications in liver treatment and lipid-lowering.

Owner:BEIJING MEIBEITA DRUG RES

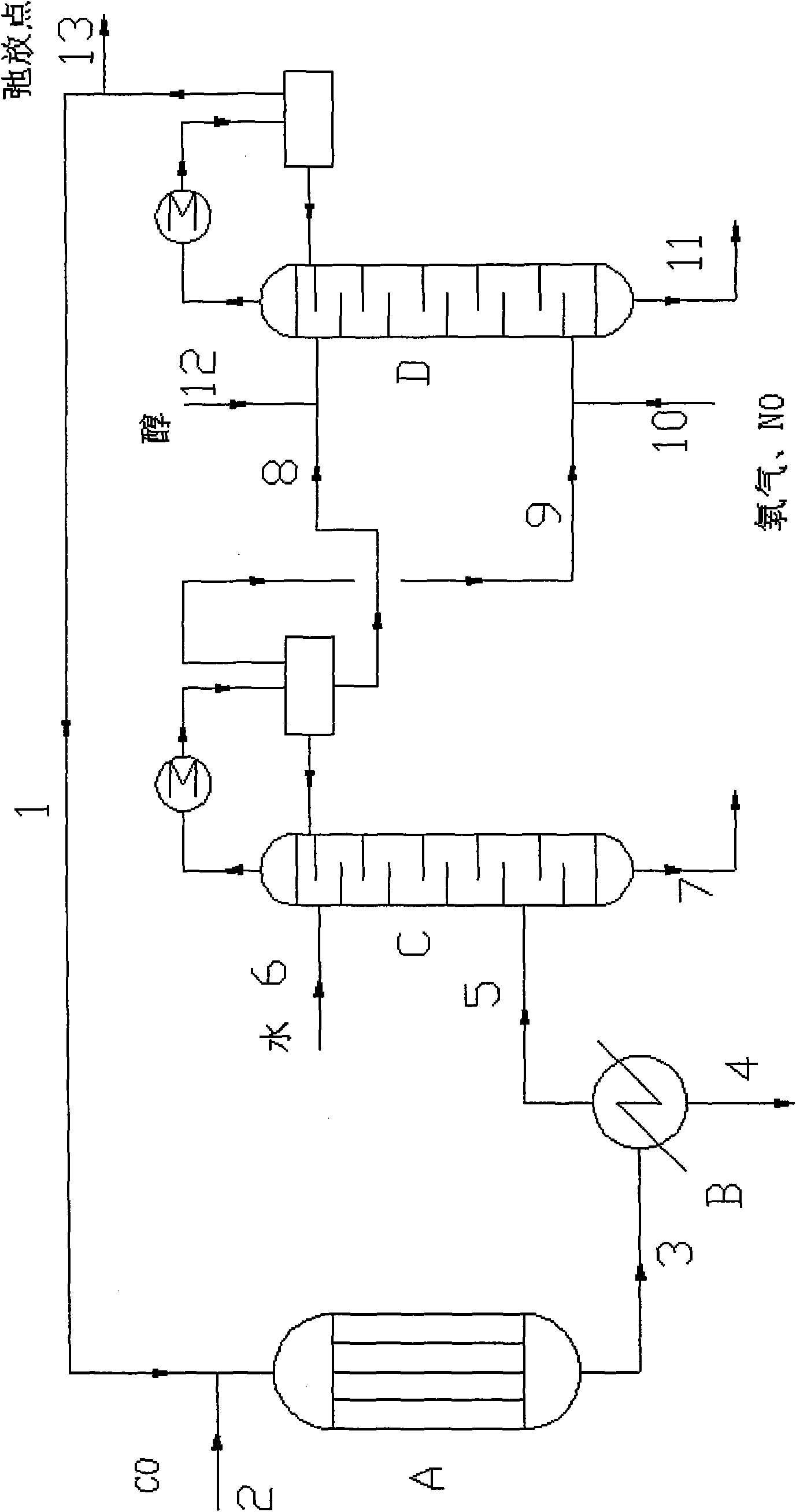

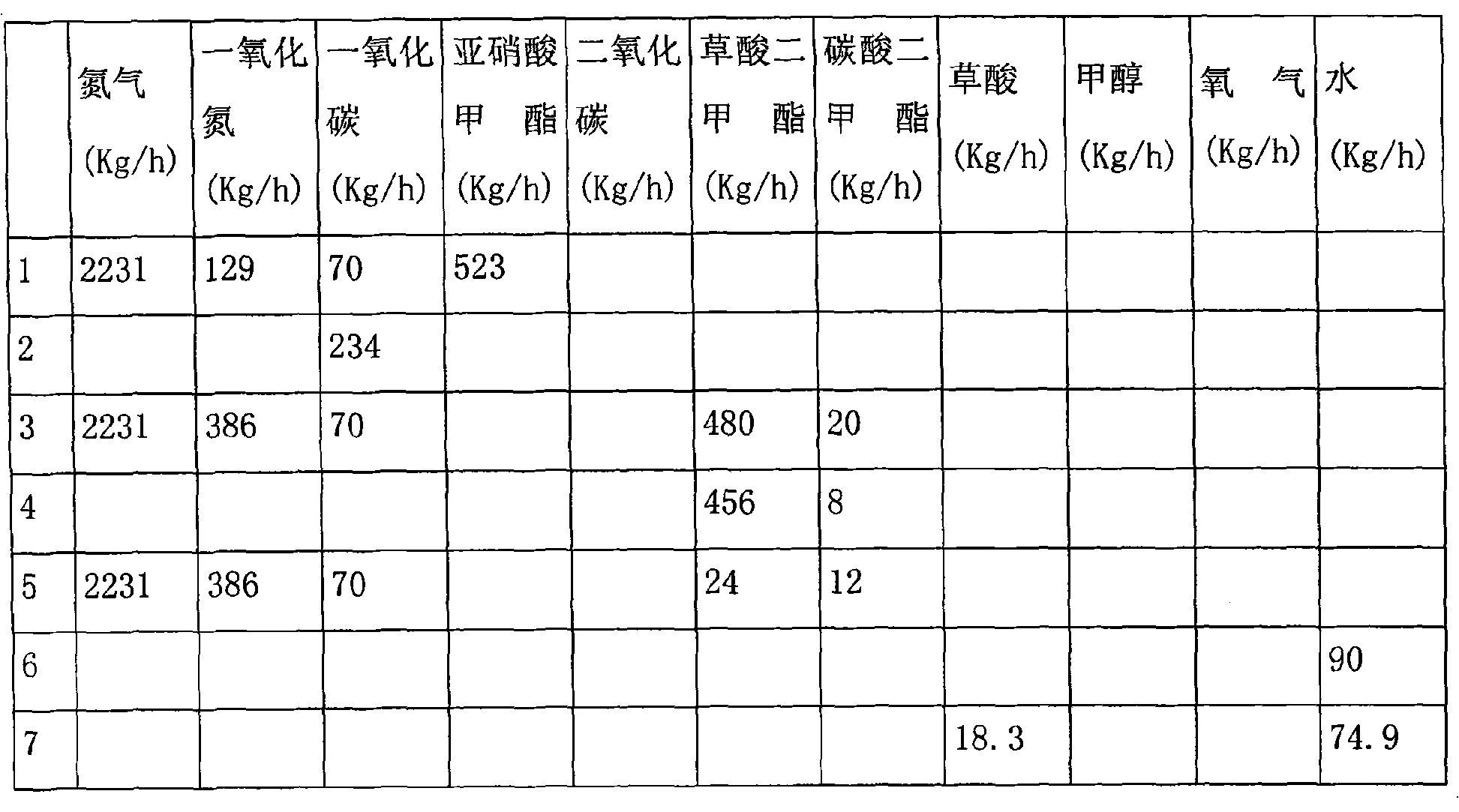

Process and production system for synthesizing dimethyl oxalate or diethyl oxalate and coproducing oxalic acid

ActiveCN102001938ASmall scaleHigh speedPreparation from carboxylic acid esters/lactonesPreparation by carbon monoxide or formate reactionGas phaseDiethyl oxalate

The invention discloses a process and a production system for synthesizing dimethyl oxalate or diethyl oxalate and coproducing oxalic acid. The method comprises the following steps of: reacting nitrogen oxide with alcohol in an esterification reactor to form nitrite, adding the nitrite into a gas phase coupling carbonylation reactor, and connecting the gas phase coupling carbonylation reactor with a condenser and an oxalate hydrolysis reactor. After being condensed by the condenser, outlet gas of the gas phase coupling carbonylation reactor is condensed into liquid-phase or solid-phase oxalate; the oxalate in the gas phase enters the oxalate hydrolysis reactor to generate the oxalic acid and the alcohol of corresponding ester; the ester solution of the corresponding ester can enter the subsequent esterification reactor for reaction; and the amount of the oxalate which enters the gas phase can be adjusted by adjusting the temperature of the condenser so as to adjust the distribution of the synthetic amount of the oxalate and the oxalic acid. Nitrogen oxide-containing noncondensable gas which passes through the oxalate hydrolysis reactor is recycled to enter the esterification reactor so as to realize the recycling of the nitrogen oxide. The process and the production system for synthesizing the dimethyl oxalate or the diethyl oxalate and coproducing the oxalic acid have low energy consumption and high productivity and meet the industrial requirement.

Owner:SHANGHAI HUAYI ENERGY CHEM

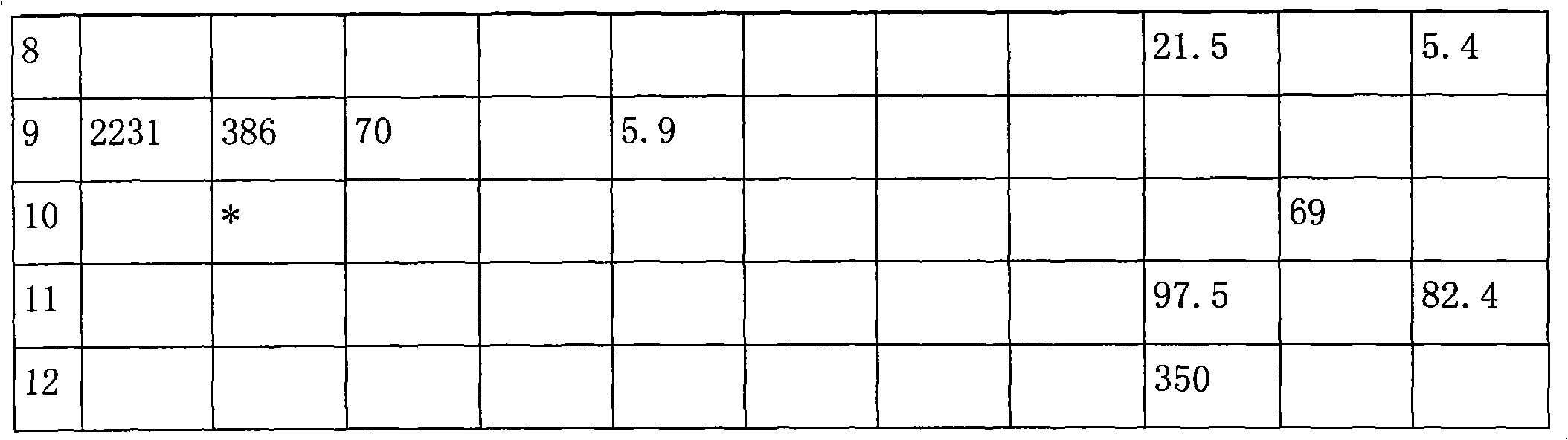

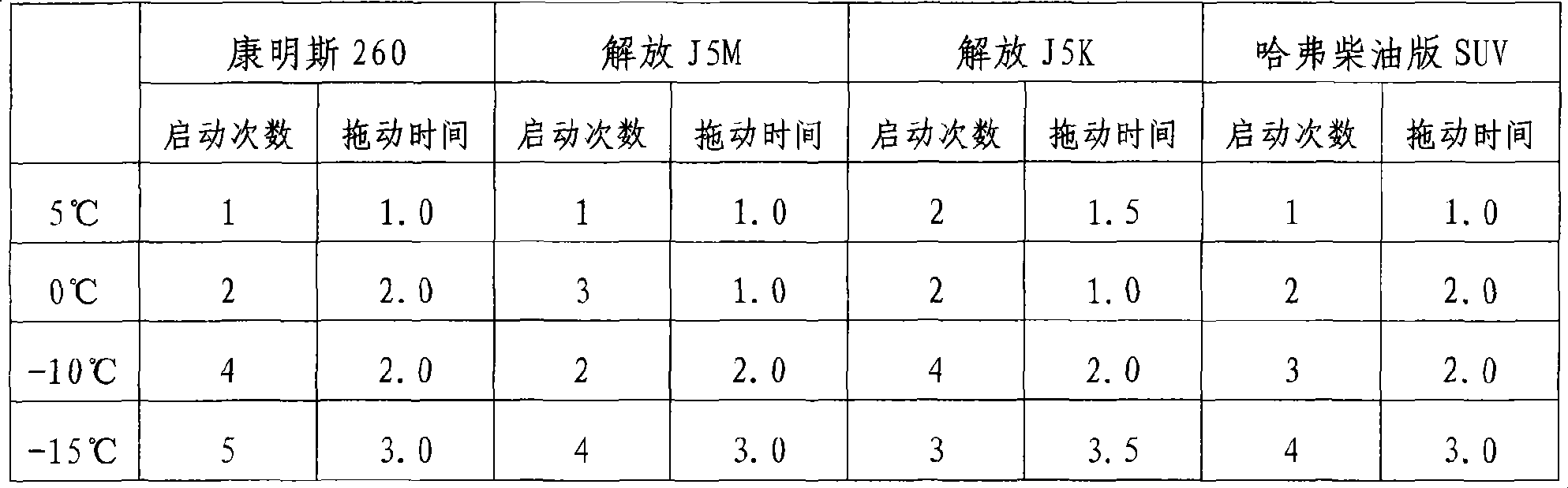

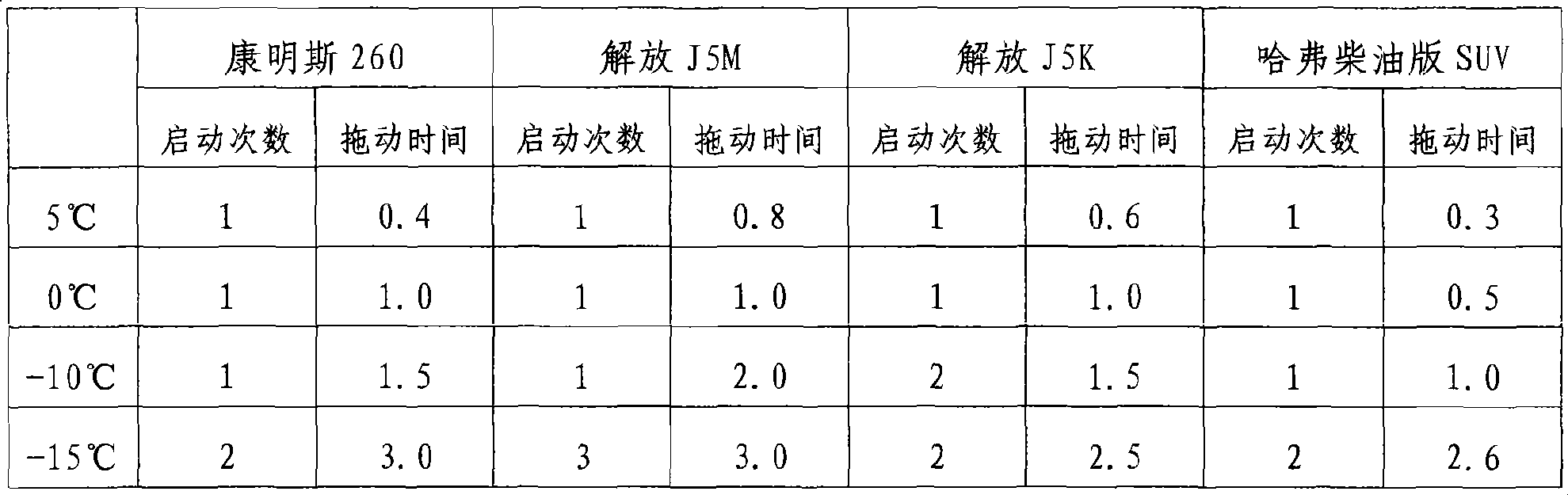

Additive for improving low-temperature startup of methanol diesel oil

InactiveCN101445754AImprove performanceLong storage periodLiquid carbonaceous fuelsChemistryBENZYL ALCOHOL/WATER

The invention discloses an additive for improving low-temperature startup of methanol diesel oil. The additive consists of 10-30 parts of ethyl acetate, 15-45 parts of dibutyl oxalate, 20-40 parts of diisopentyl oxalate, 0.3-5 parts of vinyl ester of versatic acid 10, 0.2-3 parts of N-(beta-aminoethyl)-gamma-aminopropyl methyl dimethoxysilane, 7-20 part of 2,5-dimethoxytetrahydrofuran, 2-15 parts of zirconium iso-octoate, 8-25 parts of 2-nitro-2-methyl-propyl nitrate, 10-40 parts of 2-methoxyl-ethyl nitrate, 15-30 parts of 3-tetrahydrofuran nitrate, 12-30 parts of methyl-benzyl-alcohol nitrate, 0.2-10 parts of 3-methyl-2-nitro-2-hexene, 0.2-10 parts of 3-ethyl-2-nitro-2-hexene, 0.1-10 parts of barium nitrate, 0-10 parts of manganese dioxide and 0-20 parts of potassium pentachloride. The low-temperature startup of the methanol diesel oil can be improved, the combustion performance of the methanol diesel oil becomes better, and the tail gas emission is obviously reduced by mixing the additive with the methanol diesel oil.

Owner:山西华顿实业有限公司

Palladium catalyst for synthesizing oxalate using liquid phase coupling method and use thereof

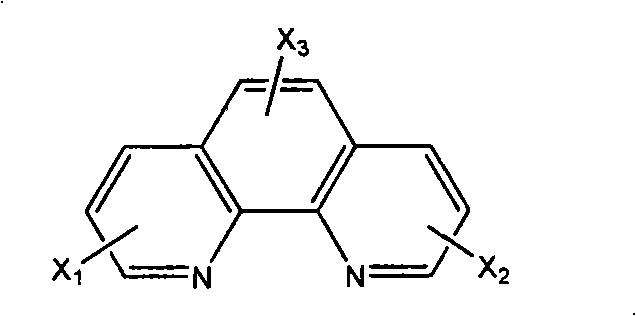

InactiveCN101306386AHigh selectivityHigh reaction yieldOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by carbon monoxide or formate reactionOxalateCoupling

The invention relates to a catalyst of palladium complex containing N-N bidentate ligand used for synthesizing oxalate through the liquid phase coupling method as well as the preparation and the application methods thereof. Aiming at the disadvantages of the prior catalyst for synthesizing oxalate that the synthetic ratio is low, the catalyst is not easy to separate from the product and the service life is short, a catalyst of palladium complex containing N-N bidentate ligand with high activity and high selectivity is invented, and the catalyst is applied to the liquid phase coupling reaction synthesis of nitric acid ester and CO. The catalyst has the advantages that the preparation is easy, the selectivity is high, the catalyst is easy to separate from the product, and the service life of the catalyst is long.

Owner:HUAZHONG UNIV OF SCI & TECH +1

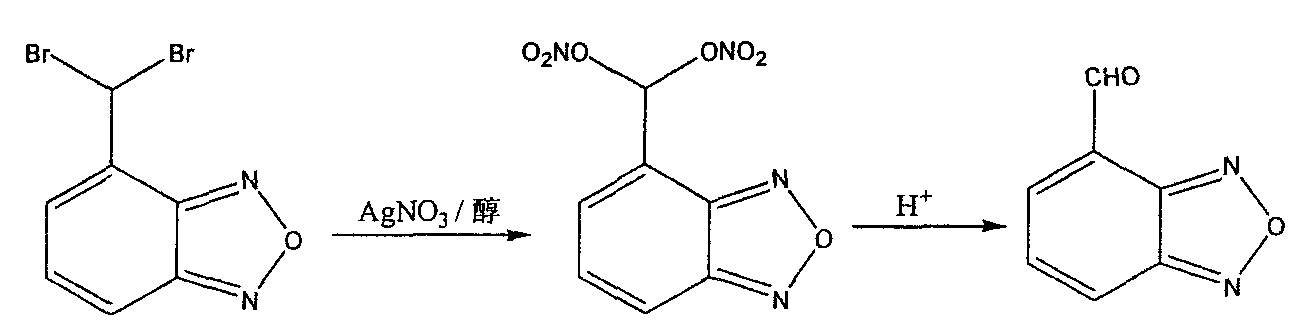

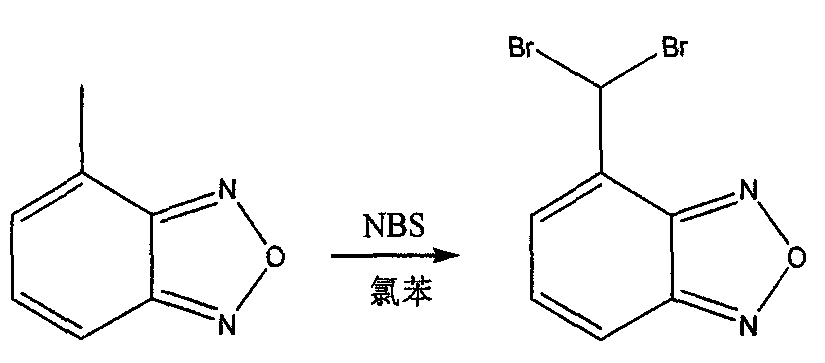

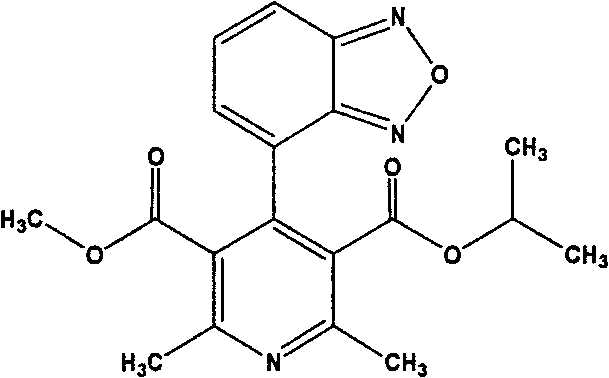

A method for preparing isradipine key intermediate 4-formylbenzofura

InactiveCN102276547ASimple processSuitable for industrializationOrganic chemistryAcyl groupHydrolysis

The invention discloses a novel preparation method of an isradipine key intermediate 4-formoxylbenzofuran. According to the invention, 4-(bisbromomethyl) benzofuran reacts in a mixed system of silver nitrate aqueous solution and organic alcoholic solution to generate a nitric acid ester intermediate; the intermediate product, without being separated, can directly and mildly hydrolyze under an acidic condition to obtain the 4-formoxylbenzofuran.

Owner:SHANDONG INST OF PHARMA IND

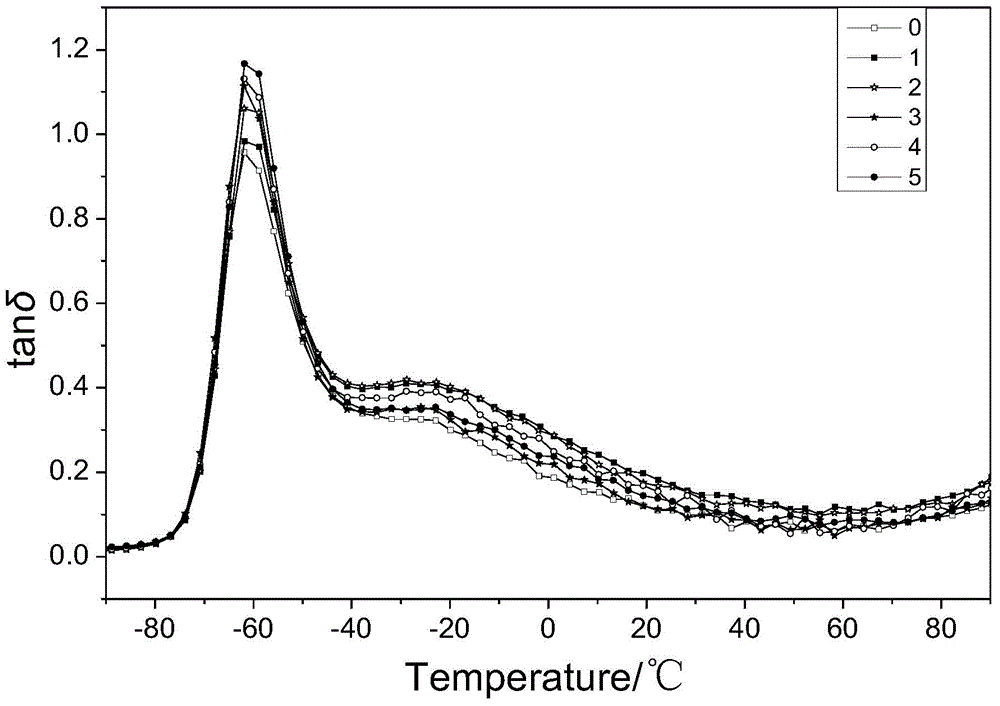

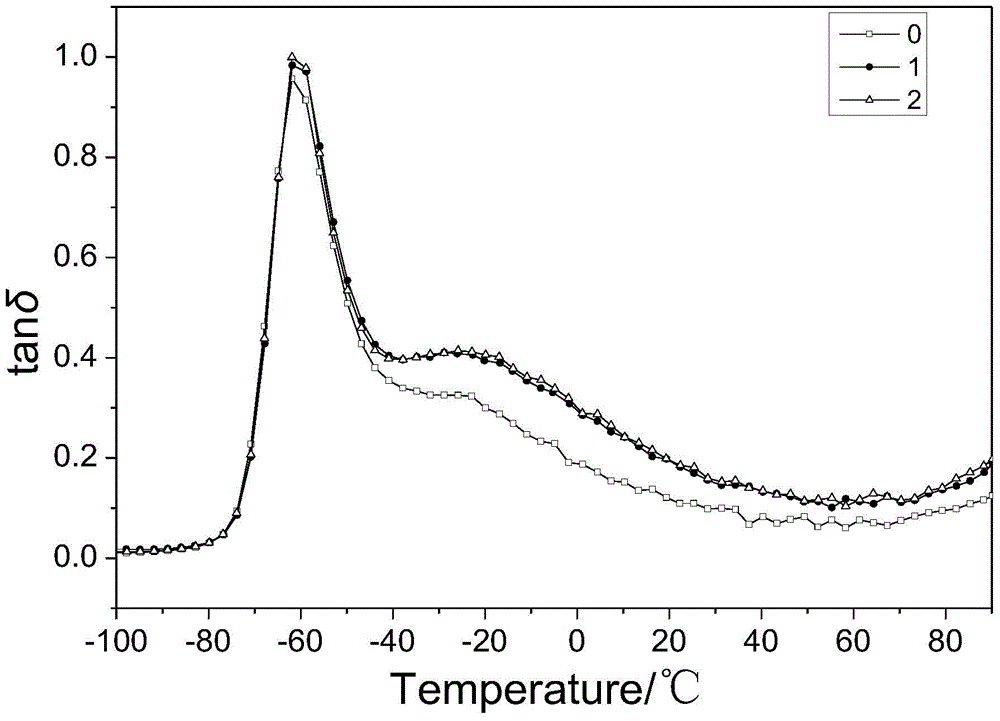

Method of determining sampling time in accelerated storage test of NEPE (nitrate ester plasticized polyether) propellant

ActiveCN104897478AReduce wasteThe test dose is smallWeather/light/corrosion resistanceMaterial strength using tensile/compressive forcesTest sampleDynamic mechanical analysis

The invention discloses a method of determining sampling time in accelerated storage test of NEPE (nitrate ester plasticized polyether) propellant and aims to solve the problems that sampling is only made by experience for the prior accelerated storage test of the NEPE propellant, the consumption of chemicals is high and test samples are unable to be accurately sampled. The method includes: acquiring dynamic chemical characteristics by means of dynamic mechanical analysis, indirectly recognizing the information about changes in chemical properties of an accelerated storage sample for the NEPE propellant, and determining the sampling time of a tensile strength change sample for the accelerated storage test of the NEPE propellant. The method has the advantages that adding more drugs is never required in the accelerated storage test of the NEPE propellant, the defect that sampling cannot be accurately made in the accelerated storage test is overcome, and the method is suitable for the determination of the sampling time in the accelerated storage test of the NEPE propellant.

Owner:XIAN MODERN CHEM RES INST

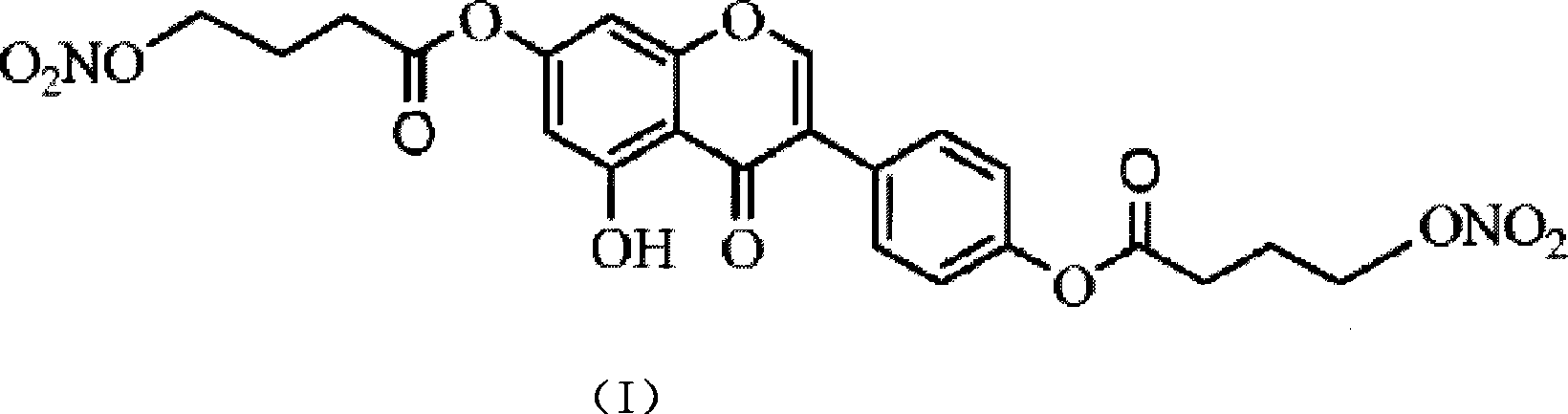

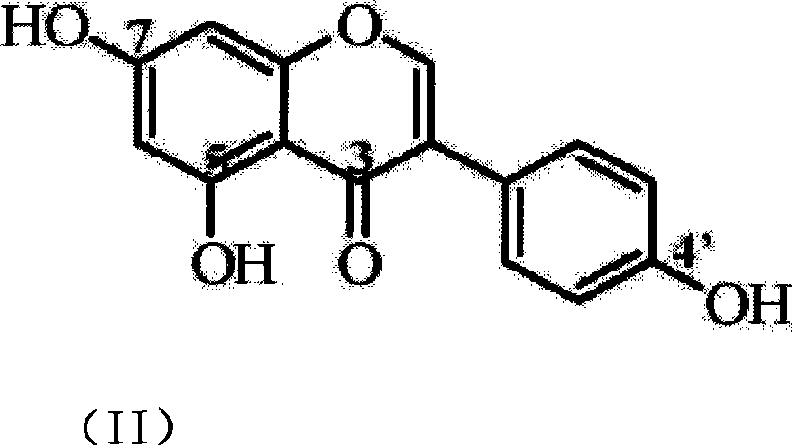

Preparation method of genistein nitric oxide donor type derivant and uses thereof

The present invention provides a dye lignin derivative containing nitrogen monoxide donor, and in particular relates to a compound which is produced by ester bond connection of dye lignin (Genistein, Gen) and nitric acid ester NO (nitrogen monoxide) donor. The precursor derivative of nitrogen monoxide donor dye lignin (NO-G) with connected ester bonds is produced through chemical reaction between dye lignin (genistein) and a corresponding nitric acid ester NO donor. The ester bonds are broken in the structure through biological changes and drift out of the original drug Gen and the NO donor; NO can be slowly released to coordinate with the Gen, and the dual coordinated anti-tumor mechanism demonstrates excellent effects on apoptosis inhibition for ovary cancer and apoptosis induction of the ovary cancer.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

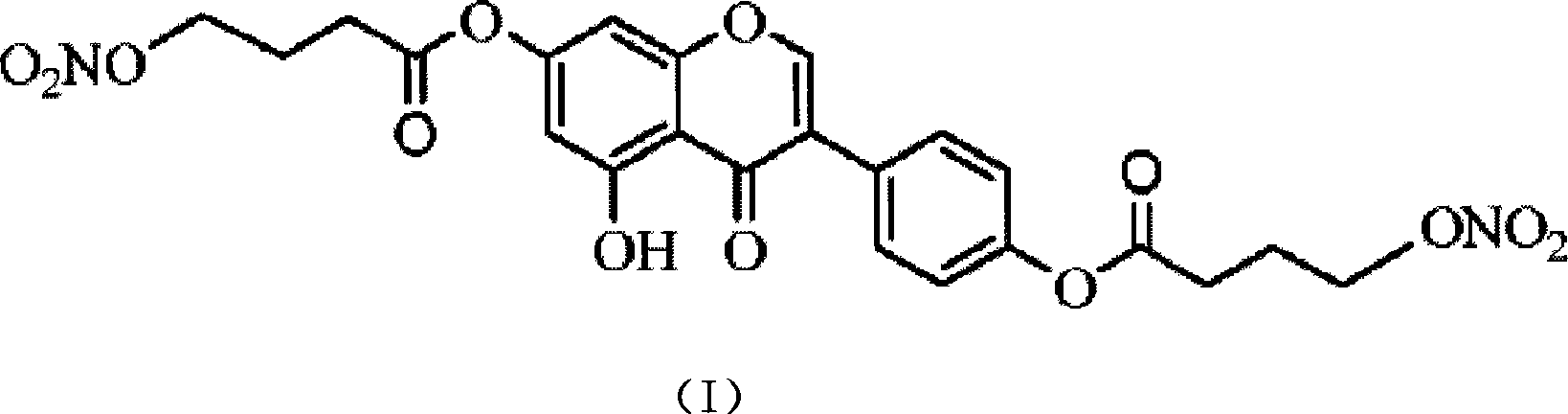

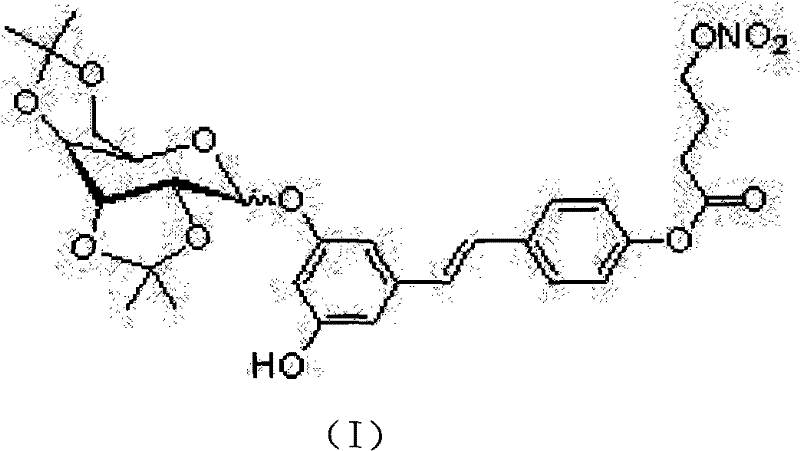

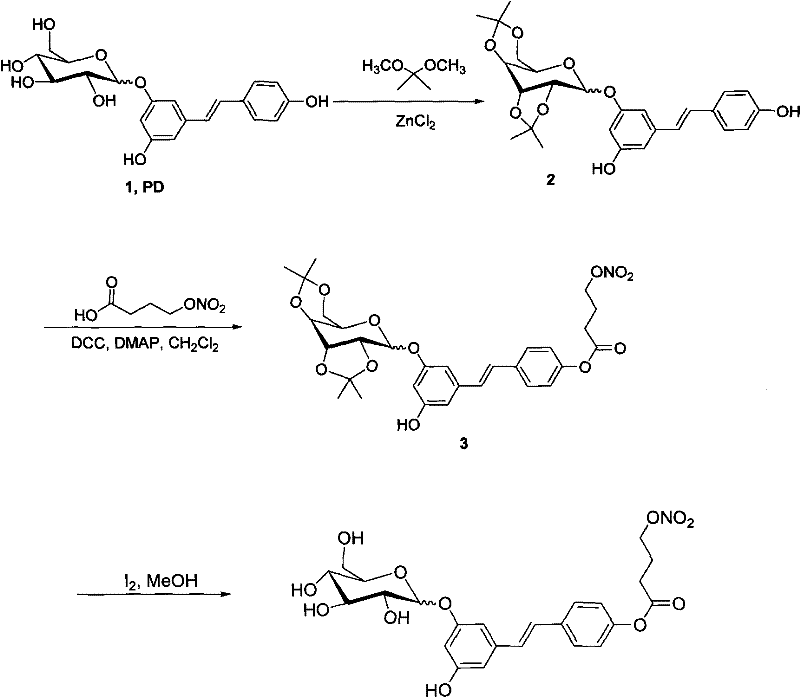

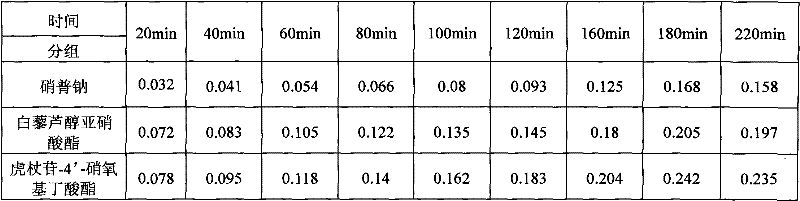

NO (nitric oxide) donor type polydatin (PD) derivative as well as preparation method and medical application thereof

InactiveCN102336790AIncrease contentReduce contentOrganic active ingredientsSugar derivativesDiseaseChemical reaction

The invention relates to the field of pharmaceutical chemistry and particularly provides a polydatin (PD) derivative containing a NO (nitric oxide) donor. A PD (3,4',5-trihydroxystilbene-3-beta-D-glucoside)4' hydroxyl group and a corresponding nitrate ester are subjected to chemical reaction so as to generate the NO donor type PD derivative which is in ester bond connection. After being absorbed into a lung tissue, the compound is subjected to biological transformation and ester bond breakage so that a bulk pharmaceutical chemical PD and the NO donor are dissociated, the NO donor can release NO slowly, and NO and PD can play roles of reducing pulmonary hypertension, relieving right ventricular hypertrophy, improving the pulmonary vascular endothelium function and resisting lipid peroxide cooperatively. The NO donor type PD derivative has an application in the aspect of preparing medicaments for preventing or treating pulmonary hypertension and high altitude pulmonary edema diseases caused by oxygen deficiency.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

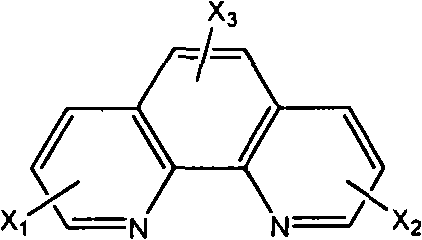

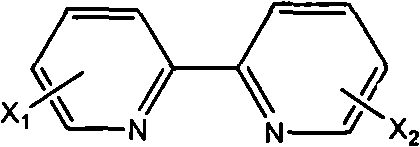

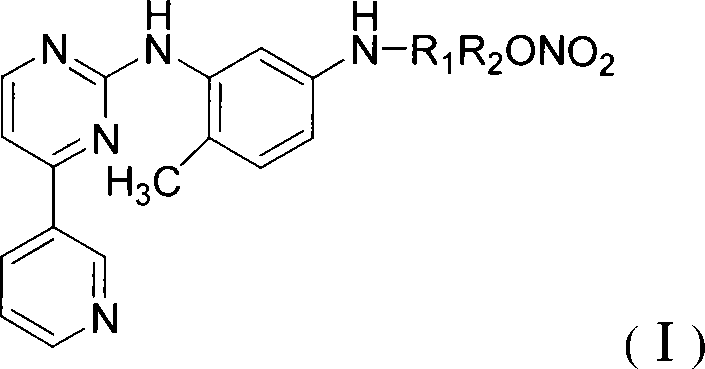

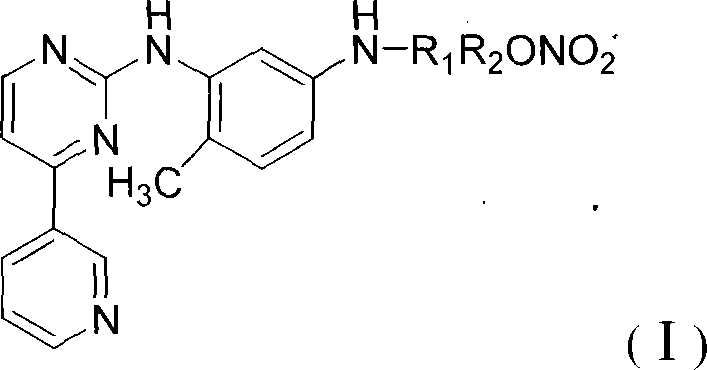

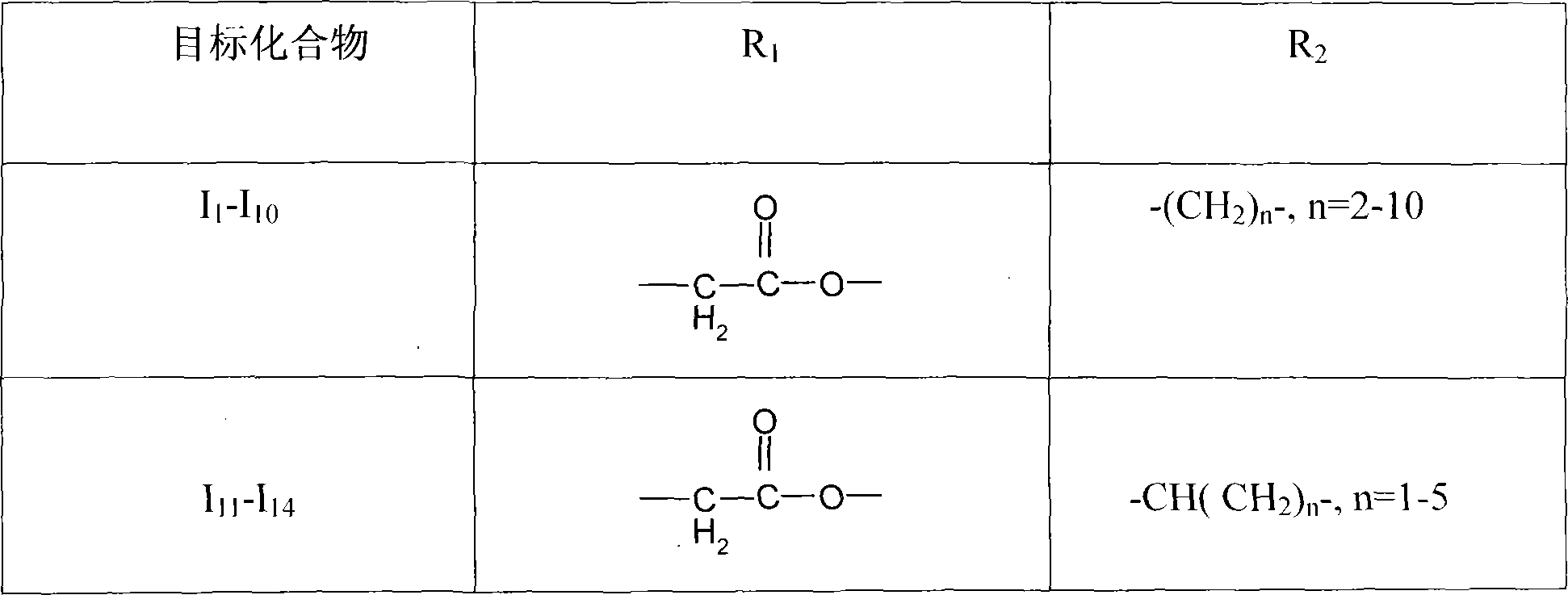

N-(5-amido-2-methyl phenyl)-4-(3-pyridinyl)-2-aminopyrimidine nitric oxide donating derivant, production method and uses thereof

The invention provides an N-(5-amino-2-methylphenyl)-4-(3-pyridyl)-2-pyrimidinamine derivative, in particular to a compound which is obtained by connecting the N-(5-amino-2-methylphenyl)-4-(3-pyridyl)-2-pyrimidinamine with an NO(nitric oxide) supply body for nitrate esters by ester bonds or amide bonds. The compound is obtained by coupling the N-(5-amino-2-methylphenyl)-4-(3-pyridyl)-2-pyrimidinamine and the corresponding NO supply body for nitrate esters by different connecting groups for carrying out substitution reaction. The dual-coordination anti-tumor mechanism demonstrates good functions on inhibiting the cell apoptosis or inducing the apoptosis of tumor cells.

Owner:JIANGSU TASLY DIYI PHARMA CO LTD

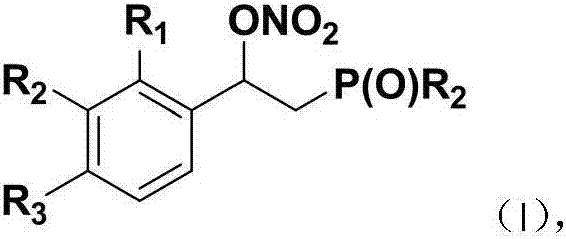

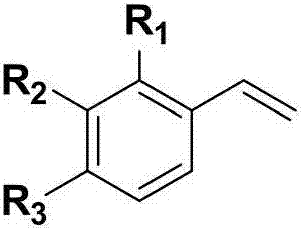

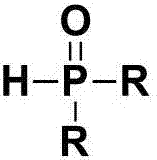

Beta-phosphoryl nitrate ester compounds and preparation method thereof

ActiveCN107973819AEconomy of stepsRich varietyGroup 5/15 element organic compoundsNitrogen atmosphereSolvent

The invention relates to beta-phosphoryl nitrate ester compounds and a preparation method thereof. Novel compounds, namely the beta-phosphoryl nitrate ester compounds as shown in a general formula (I)are synthesized, and the prepared beta-phosphoryl nitrate ester compounds will have a dual property both of nitrate esters and organic phosphines. The invention also discloses the preparation methodof the beta-phosphoryl nitrate ester compounds, and the preparation method is that olefin compounds, phosphorus reagents and an oxidant are dissolved in a solvent, and are allowed to react at 30-60DEGC under a nitrogen atmosphere, so as to prepare and obtain the beta-phosphoryl nitrate ester compounds in one-step with a one-pot method. According to the beta-phosphoryl nitrate ester compounds andthe preparation method thereof, the starting raw material is olefins which are cheap, readily available, low in cost, and have many types for selection; step economy and atom economy are high; the obtained products have various types and generally have high yields; and meanwhile, the preparation method has mild reaction conditions, is safe for operation, is easy to control, has simple post-treatment, and is suitable for large-scale production.

Owner:YANTAI UNIV

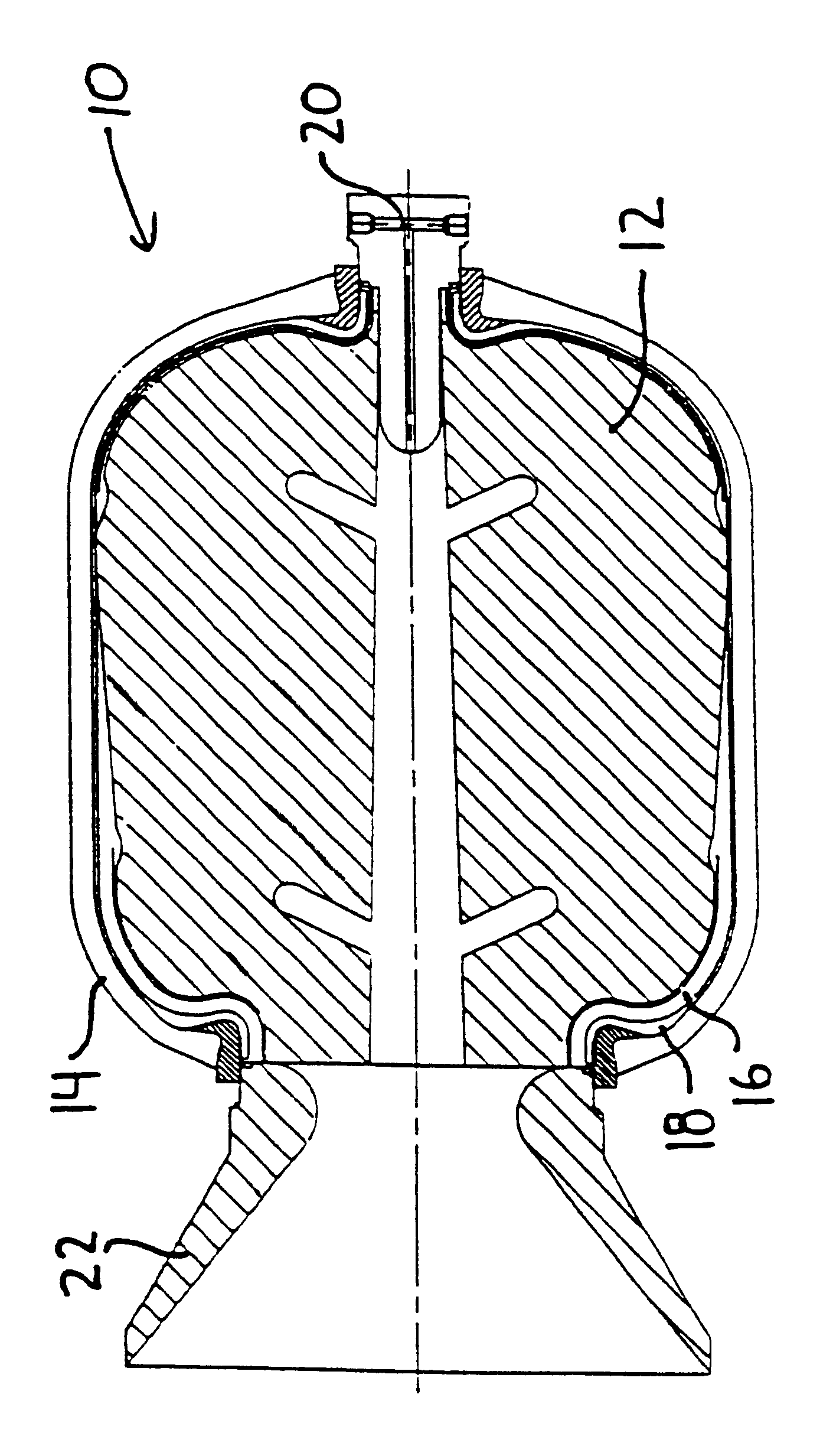

Double-base rocket propellants, and rocket assemblies comprising the same

InactiveUS6607617B1Reduce frictionLow impact sensitivityNon-explosive fillers/gelling/thickening agentsRocket engine plantsPolyesterNitrocellulose

Owner:NORTHROP GRUMMAN INNOVATION SYST INC

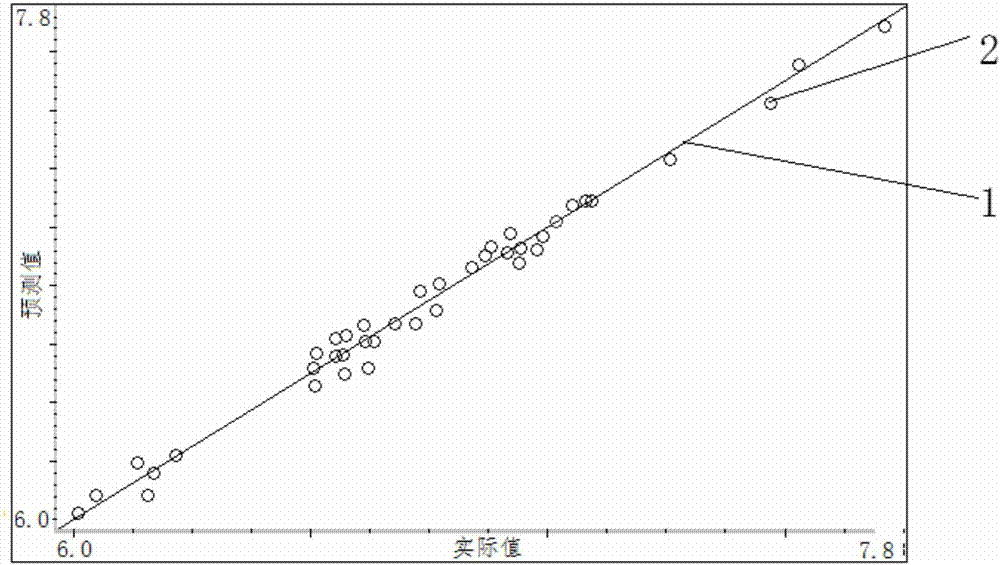

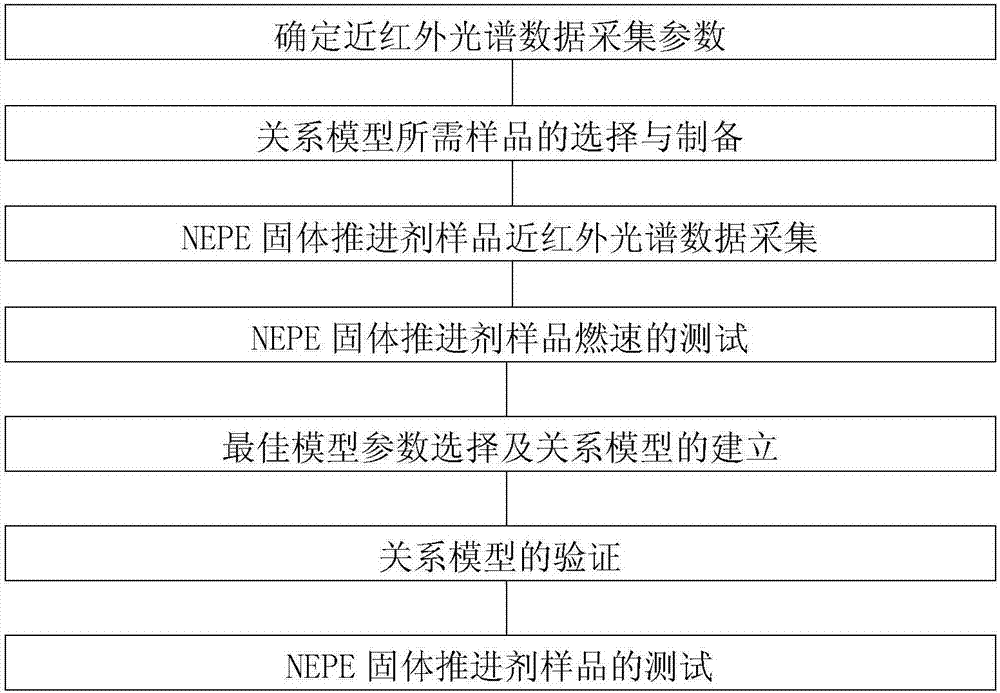

Method for testing combustion speed of NEPE (nitrate ester plasticized polyether) solid propellant

InactiveCN107121409AReduce curingShorten test timeMaterial analysis by optical meansNon destructiveCombustion

The invention relates to a method for testing combustion speed of an NEPE (nitrate ester plasticized polyether) solid propellant. The method comprises the following steps of testing the data of a near-infrared spectrum map of a standard product; after processing by a spectrum pre-processing method, determining the relationship between the data of the near-infrared spectrum of the standard product and the combustion speed of the NEPE solid propellant. The method has the advantages that the sample curing process is reduced in the testing process, and the sample testing time is effectively shortened; when the combustion speed of the NEPE solid propellant is detected, the high-efficiency and non-destructive analyzing purpose is realized, the defect of long curing and forming time in the traditional testing process is thoroughly overcome, and a convenient and rapid detection method is provided for the production quality and safety manufacturing of the NEPE solid propellant.

Owner:XIAN AEROSPACE CHEM PROPULTION PLANT

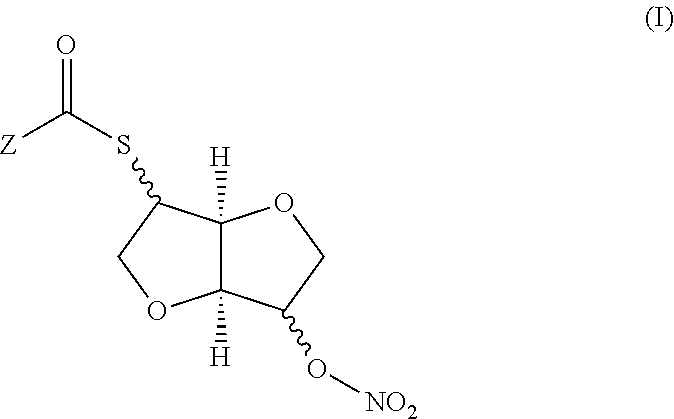

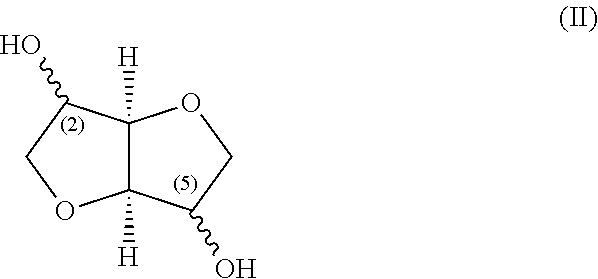

Stereospecific method for the preparation of dioxa-bicyclooctane nitrate compounds

This invention relates to a new method for the stereospecific thiocarboxylation and nitration of organic compounds for the preparation of compounds according to formula (I):comprising the following steps:(a) reacting a compound of formula (II):with a sulfonic derivative of formula (III)wherein the R is selected from the groups C1-3-alkyl, C1-3-alkyl substituted with 1 to 3 halogen atoms, phenyl, C1-3-alkyl-phenyl and C1-3-alkyl-phenyl wherein the alkyl is substituted with 1 to 3 halogen atoms and G is a halogen atom or a group —O—SO2—R wherein R is as hereinabove definedto yield a compound of formula (IV)(b) treating compound (IV) with a thiocarboxylic acid of formula (V) or a salt thereof:wherein Z is as defined above, to yield compound (VI)and(c) treating compound (VI) with tetrabutylammonium nitrate to yield a compound of formula (I).

Owner:LACER SA

Methods and compositions for mitigating pain

Methods and therapeutic compounds for treating pain, mitigating inflammation, effecting analgesia and / or effecting sedation in a subject are described. A subject is administered an effective amount of a therapeutic compound which is a nitrate ester. Novel pharmaceutical compositions are also described.

Owner:QUEENS UNIV OF KINGSTON

Preparation method for methylnitrate

The invention relates to a preparation method for methylnitrate and belongs to the technical field of energetic materials. The preparation method comprises the following steps: dissolving a protective agent into distilled water, adding into a three-necked bottle and then adding nitric acid; adding methanol and nitric acid dropwise and performing nitration reaction; after the reaction is finished, separating the liquid, wherein the lower layer is nitric acid ester; washing and drying the nitric acid ester to obtain a coarse product; rectifying to obtain a coarse product nitric acid ester; and rectifying and collecting a product with the boiling point of 64.5 to 66 DEG C to obtain the methylnitrate with the purity of 99.80 percent. By the method, the preparation safety is improved; the nitration yield of the product is high and can reach 97 percent; side reaction is not generated; waste water is little; and environmental pollution can not be caused.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com