Methanol diesel oil manufacturing mode

A methanol and diesel technology, applied in the petroleum industry, liquid carbon-containing fuels, fuel additives, etc., can solve problems such as vapor resistance, delamination, and corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

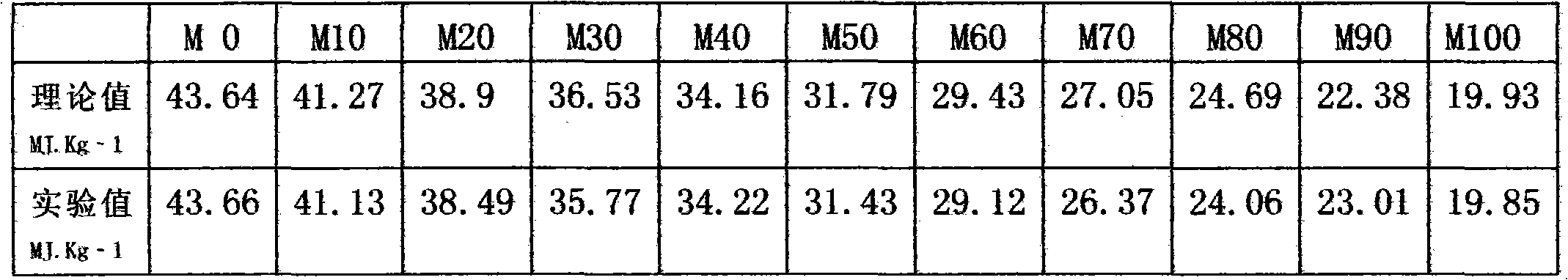

[0059] Invention example

[0060] To sum up, a successful methanol diesel must successfully solve the seven major problems caused by the mixing of methanol, such as insolubility of alcohols and hydrocarbons, power drop, difficulty in cold starting, delamination when encountering water, corrosion of metals, swelling of rubber, and generation of air resistance. The problem is the additives that must be added, namely: detergent and dispersant, anti-oxidant and anti-corrosion agent, corrosion inhibitor, metal passivator, anti-wear agent, waterproof agent, antifreeze agent, antiknock agent, anti-swelling agent, stabilizer, destroyer Additives, combustion aids, co-solvents, antistatic agents, cold start additives, etc., are the must-follow modes for methanol diesel formulations.

[0061] The principle of mode application is:

[0062] 1. It must meet the general requirements of various engines for the quality of liquid fuels, that is, proper evaporation, good combustion, high stabil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com