Catalyst as well as preparation method and application of catalyst

A catalyst and metal technology, applied in the field of catalyst and its preparation and application, can solve the problems of less than ideal, large difference in properties, catalytic reaction, adverse effects of product quality and production equipment, etc. Dechlorination inhibitory effect is remarkable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

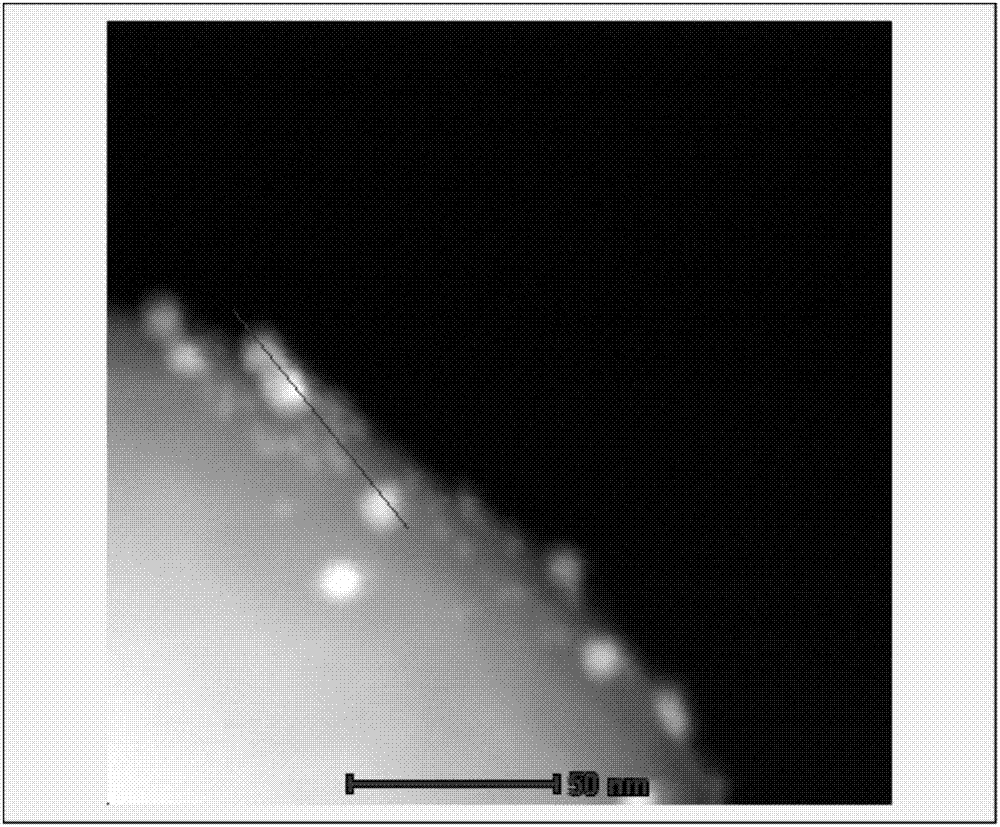

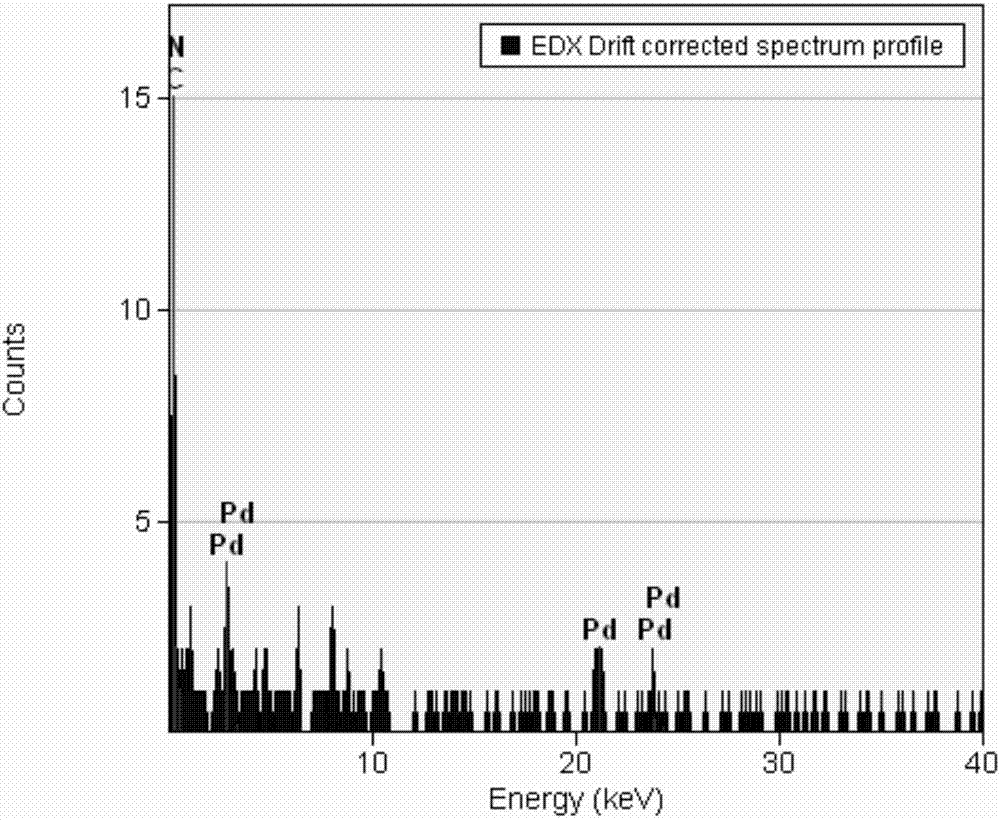

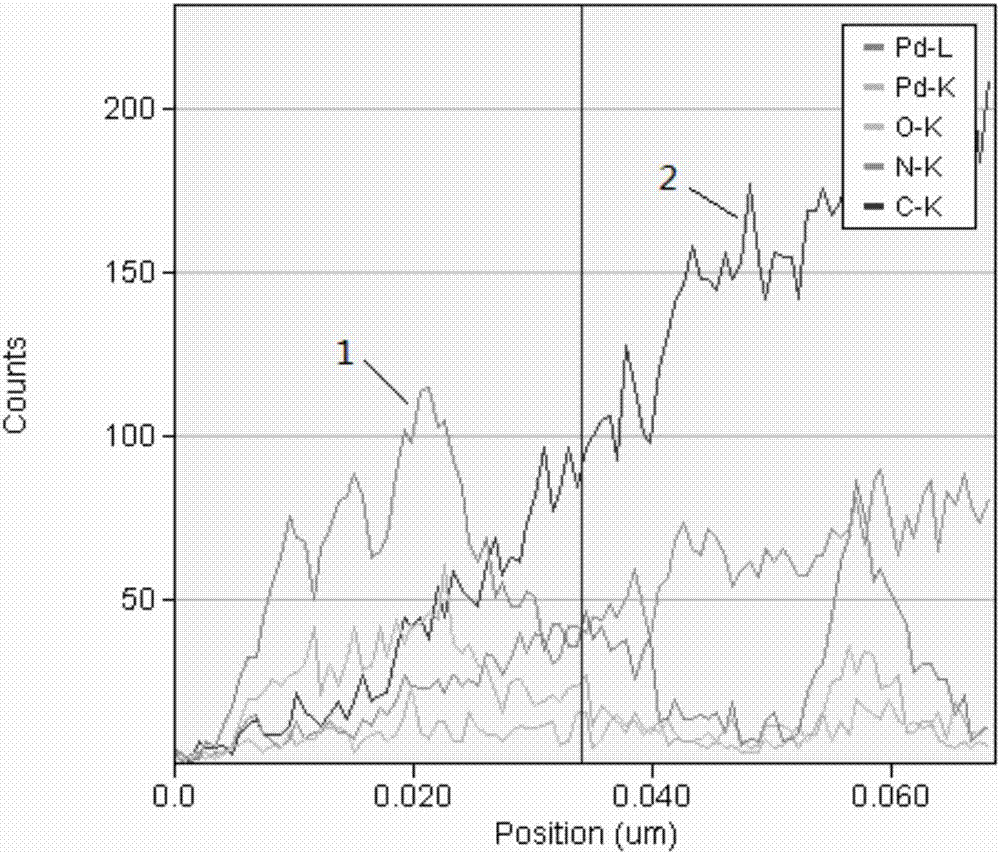

Image

Examples

Embodiment 1

[0043] Measure 0.8mL of ammonia water with a mass concentration of 25% to 28%, 64mL of ethanol, and 160mL of deionized water, stir the three thoroughly, then add 1.6g of resorcinol, stir until completely dissolved, and slowly add 2.24ml Formaldehyde aqueous solution with a mass concentration of 37-40% was stirred at 20°C for 12 hours, then transferred to a hydrothermal reaction kettle at 80°C for 12 hours, and then centrifuged and washed to obtain a reddish-brown polymer solid powder.

[0044] Dissolve 2g of citric acid in 30ml of deionized water, then add 0.2942g of sodium chloropalladate and 6.67ml of ethylenediamine, mix and stir evenly, then transfer the mixture to a reaction kettle at 100°C for 5 hours, then freeze Drying, the relative vacuum degree is -0.05MPa, the temperature is -10°C, and freeze-drying is carried out for 10 hours to obtain a solid powder of composite noble metal carbon quantum dots. The result of ICP analysis in the composite carbon-metal quantum dots ...

Embodiment 2

[0048] Measure 0.8mL of ammonia water with a mass concentration of 25% to 28%, 48mL of ethanol, and 180mL of deionized water, stir the three thoroughly, then add 1.6g of resorcinol, stir until completely dissolved, and slowly add 1.6ml dropwise Formaldehyde aqueous solution with a mass concentration of 37-40% was stirred at 25°C for 20 hours, then transferred to a hydrothermal reaction kettle at 100°C for 15 hours, and then centrifuged and washed to obtain a reddish-brown polymer solid powder.

[0049] Dissolve 1.19g of citric acid in 165ml of deionized water, then add 0.5618g of sodium chloroplatinate and 6.67ml of ethylenediamine, mix and stir evenly, then transfer the mixture to a reaction kettle at 100°C for 24 hours, then carry out Freeze-drying, the relative vacuum degree is -0.05MPa, the temperature is -10°C, and the freeze-drying is carried out for 10 hours to obtain the quantum dot solid powder. Wherein the mass percentage of metal in the composite carbon-metal quantu...

Embodiment 3

[0053] Measure 0.8mL of ammonia water with a mass concentration of 25% to 28%, 96mL of ethanol, and 240mL of deionized water, stir the three thoroughly, then add 1.65g of resorcinol, stir until completely dissolved, then slowly add 4.48ml dropwise Formaldehyde aqueous solution with a mass concentration of 37-40% was stirred at 10°C for 30 hours, then transferred to a hydrothermal reaction kettle at 120°C for 12 hours, and then centrifuged and washed to obtain a reddish-brown polymer solid powder.

[0054] Dissolve 3g of citric acid in 60ml of deionized water, then add 0.2842g of ammonium tetrachloropalladate and 10ml of ethylenediamine, mix well, then transfer the mixture to a reaction kettle at 100°C for 20 hours, then freeze Drying, the relative vacuum degree is -0.099MPa, the temperature is -10°C, and the freeze-drying is carried out for 10 hours to obtain the quantum dot solid powder. Wherein the mass percentage of metal in the composite carbon-metal quantum dot is 90%.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com