Patents

Literature

452results about How to "Inhibition of adsorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plasma display unit, phosphor and process for producing phosphor

InactiveUS7208102B2Inhibition of adsorptionDecrease in luminanceAddress electrodesSustain/scan electrodesPhosphorFluorescence

A plasma display device exhibits suppressed luminance degradation of a phosphor, a suppressed change in chromaticity and improved discharge characteristics as a result of suppression of adsorption of water or hydrocarbon-containing gas on a surface of a blue phosphor. A blue phosphor layer used in the plasma display device is formed of a compound expressed by Ba1−XMgAl10O17:EuX or Ba1−x−ySryMgAl10O17:EuX and includes at least one element that is selected from Nb, Ta, Pr, P, As, Sb, Bi and Tm which substitutes for a part of its Al or Mg element.

Owner:PANASONIC CORP

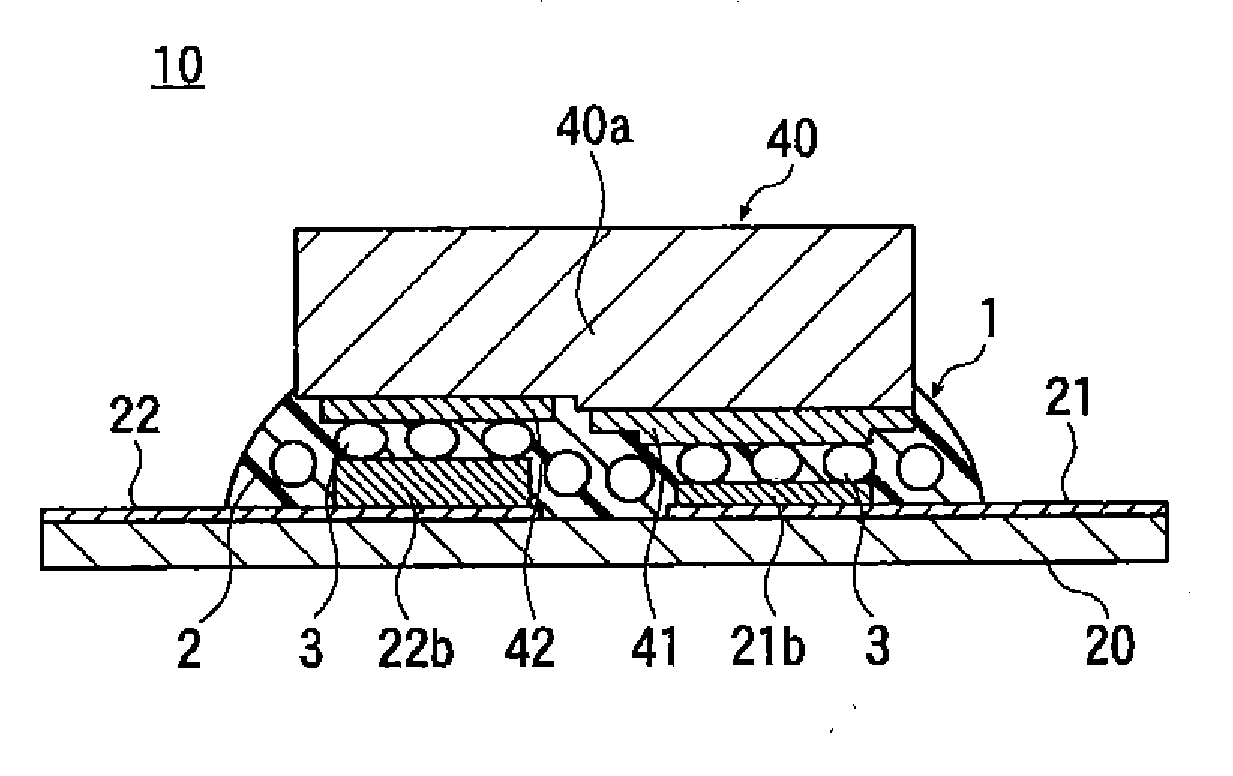

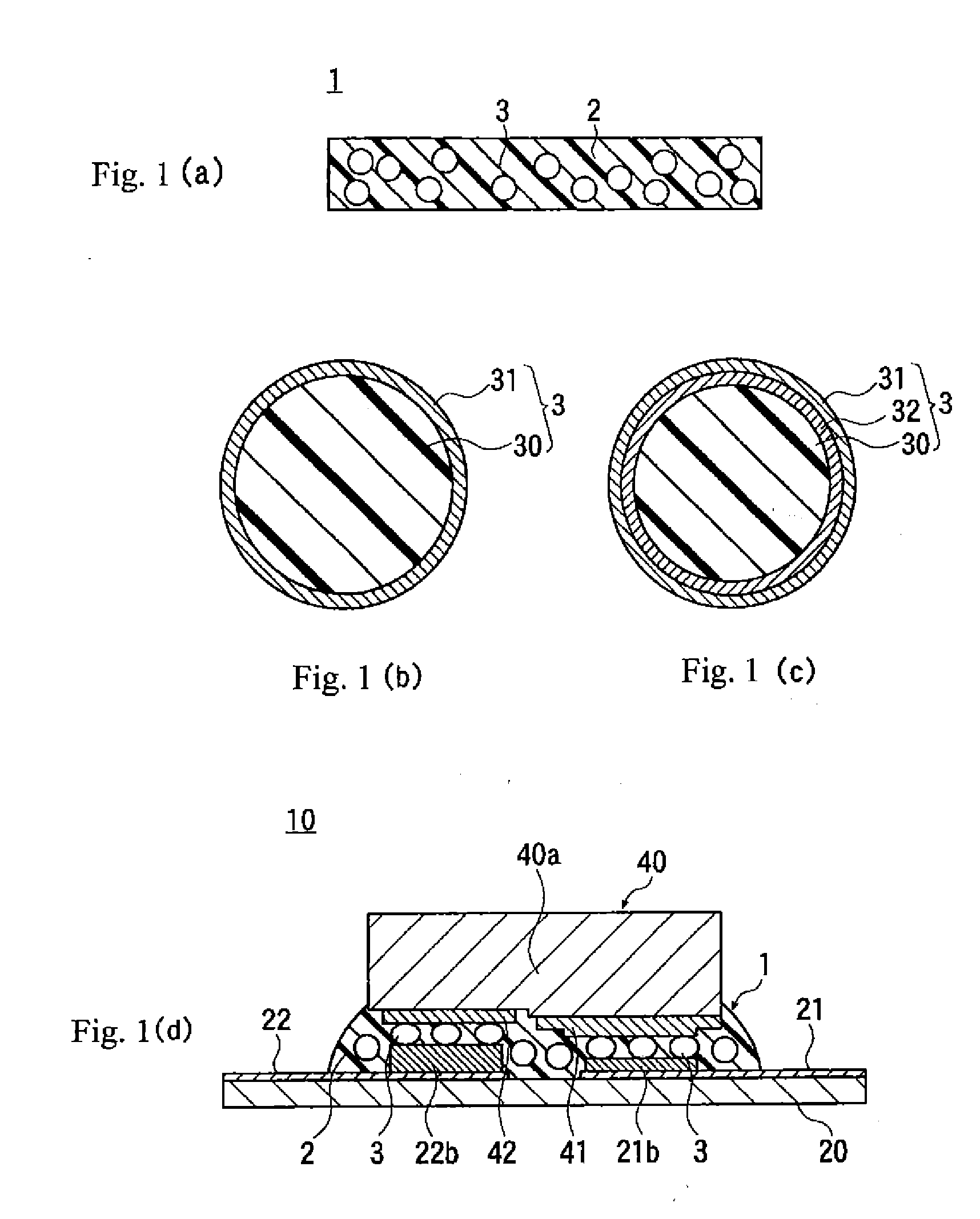

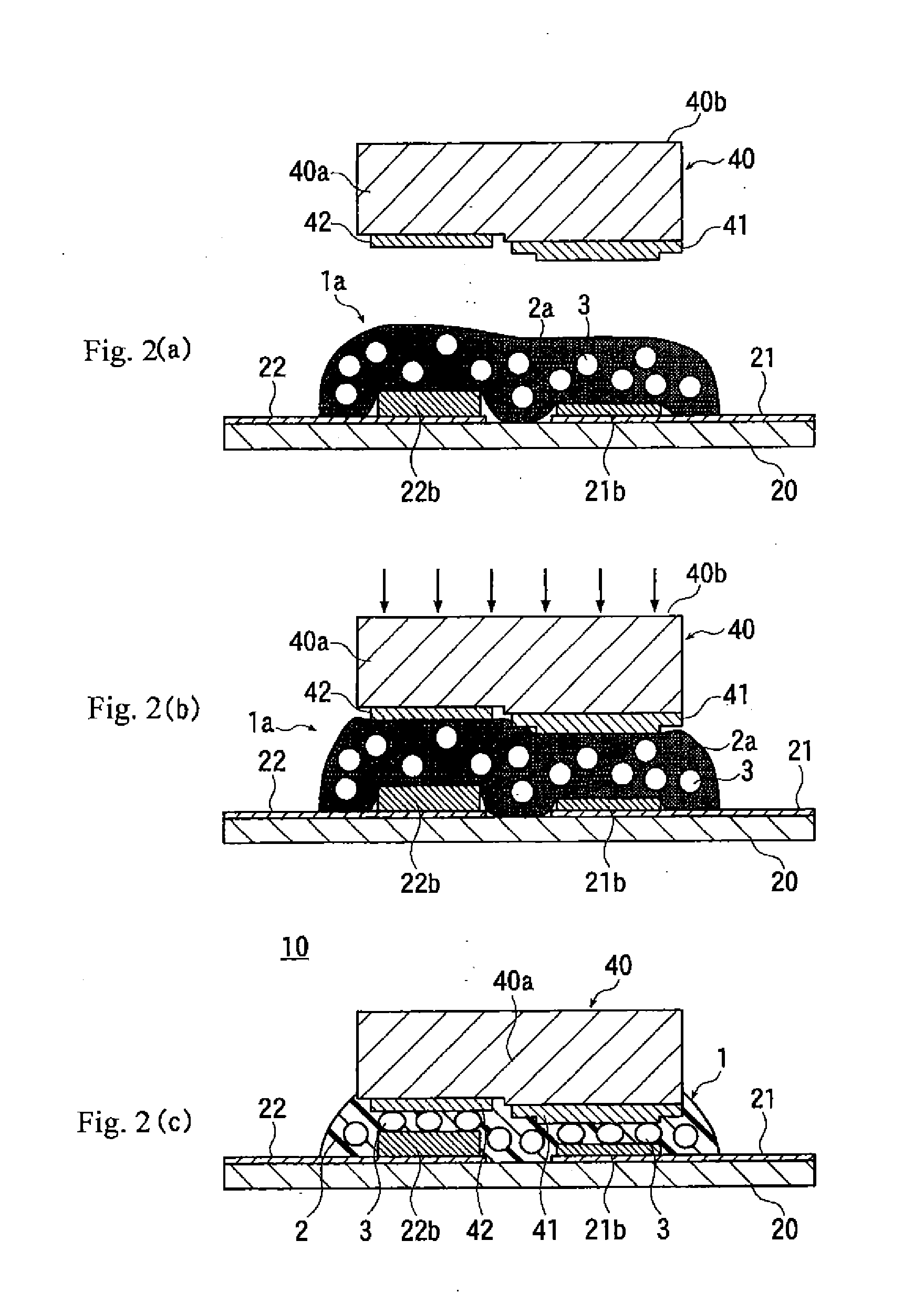

Anisotropic conductive adhesive and method for manufacturing same, light-emitting device and method for manufacturing same

InactiveUS20150034989A1Inhibition of adsorptionEfficiently take out lightConductive materialVacuum evaporation coatingAnisotropic conductive adhesiveMetal alloy

an anisotropic conductive adhesive which uses conductive particles where a silver-based metal is used as a conductive layer, having high light reflectance and excellent migration resistance is provided. The anisotropic conductive adhesive includes light reflective conductive particles in an insulating adhesive resin. The light reflective conductive particle includes a light reflective metal layer made of a metal alloy including silver, gold and hafnium formed on the surface of a resin particle as a core by sputtering method. The light reflective metal layer is preferably formed having a composition ratio of a silver of at least 50% by weight to at most 80% by weight: a gold of at least 10% by weight to at most 45%: a hafnium of at least 10% by weight to at most 40% by weight, and a total ratio does not exceed 100% by weight.

Owner:DEXERIALS CORP

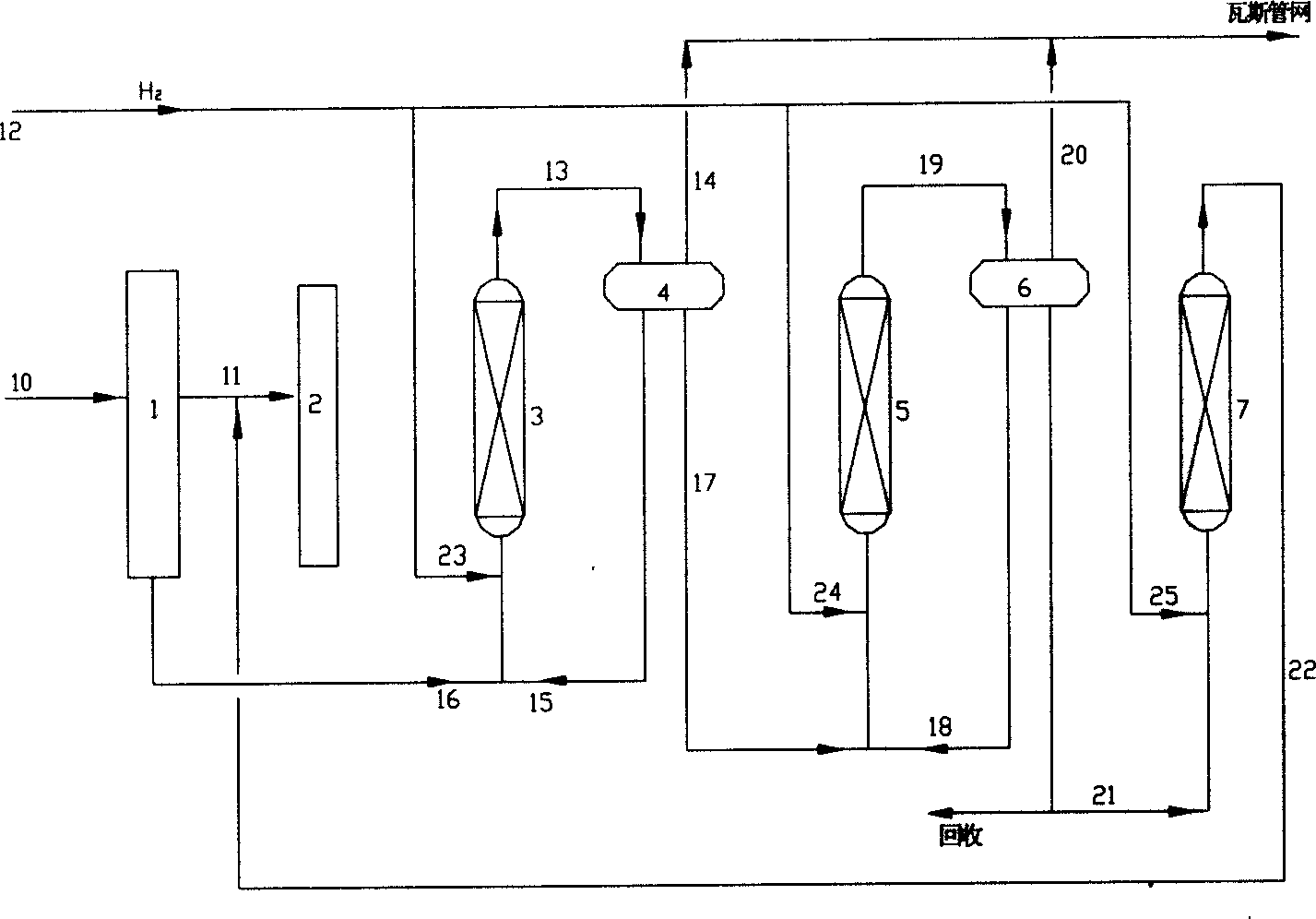

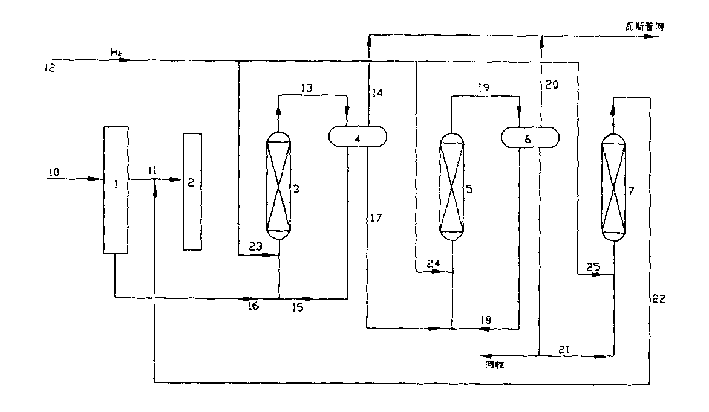

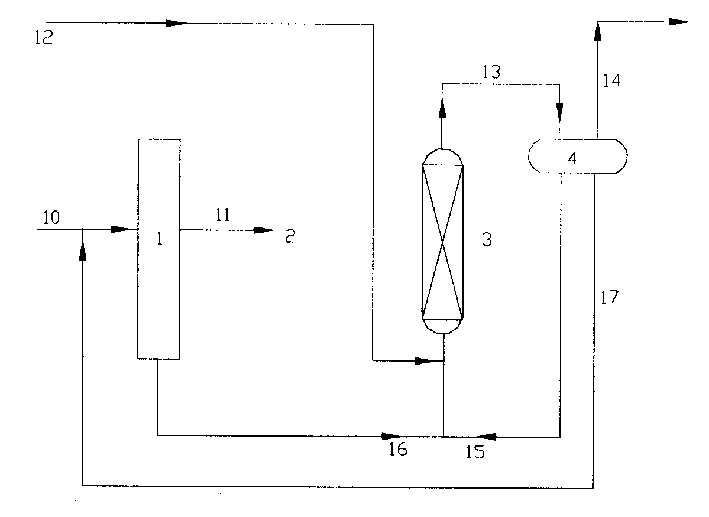

Utilization method of butadiene extraction device residue

InactiveCN1590353AImprove performanceExtend your lifeHydrocarbon by hydrogenationButadiene DioxideFixed bed

A process for reclaiming the residue of butadiene extractor features that said residue rich in acetylene hydrocarbon is selectively hydrogenated under the action of catalyst in the fixed-bed hydrogenating reactor with circulating device to generate fuel, and recover 1-butene and monoolefin.

Owner:CHINA PETROLEUM & CHEM CORP

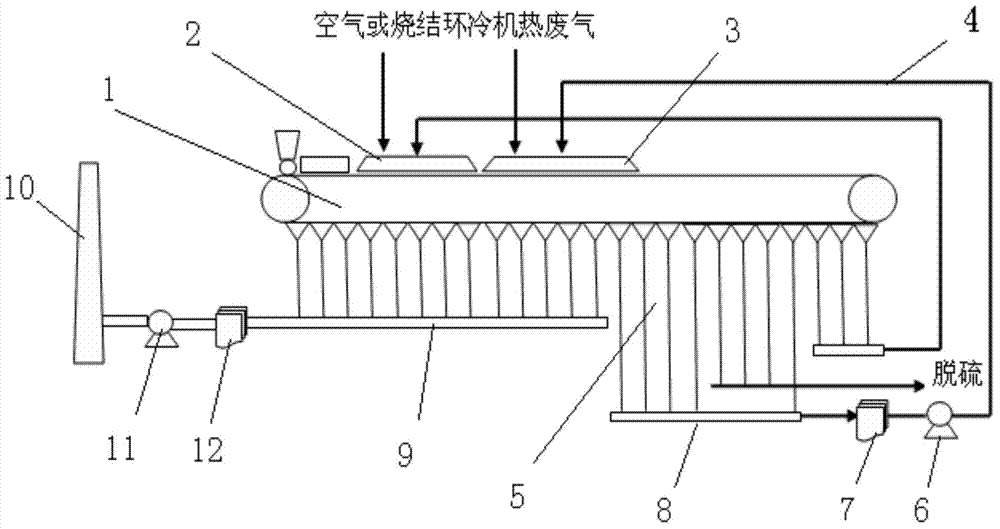

Iron mine sintering flue gas segmented circulation method

ActiveCN103499216AGuaranteed emission reductionAvoid enrichmentIncreasing energy efficiencyWaste heat treatmentFlue gasDust emission

The invention discloses an iron mine sintering flue gas segmented circulation method. Sintering flue gas high in O2 content on the tail portion of a sintering machine is circulated to the interior of a head flue cover of a sintering feed surface of the head portion of the sintering machine, flue gas of two to three bellows highest in SO2 content in a bellow on the tail portion of the sintering machine is conveyed to a desulfurization system to be desulfurized, and flue gas in other bellows is circulated to a middle flue cover of a sintering feed surface of the middle portion of the sintering machine. After segmented flue gas circulation is adopted, SO2 will not be accumulated in sintering ore, dust emission is reduced by 20-40%, NOx emission is reduced by 20-40%, dioxin emission is reduced by 50-80%, and CO2 emission is reduced by 20-45%.

Owner:CENT SOUTH UNIV

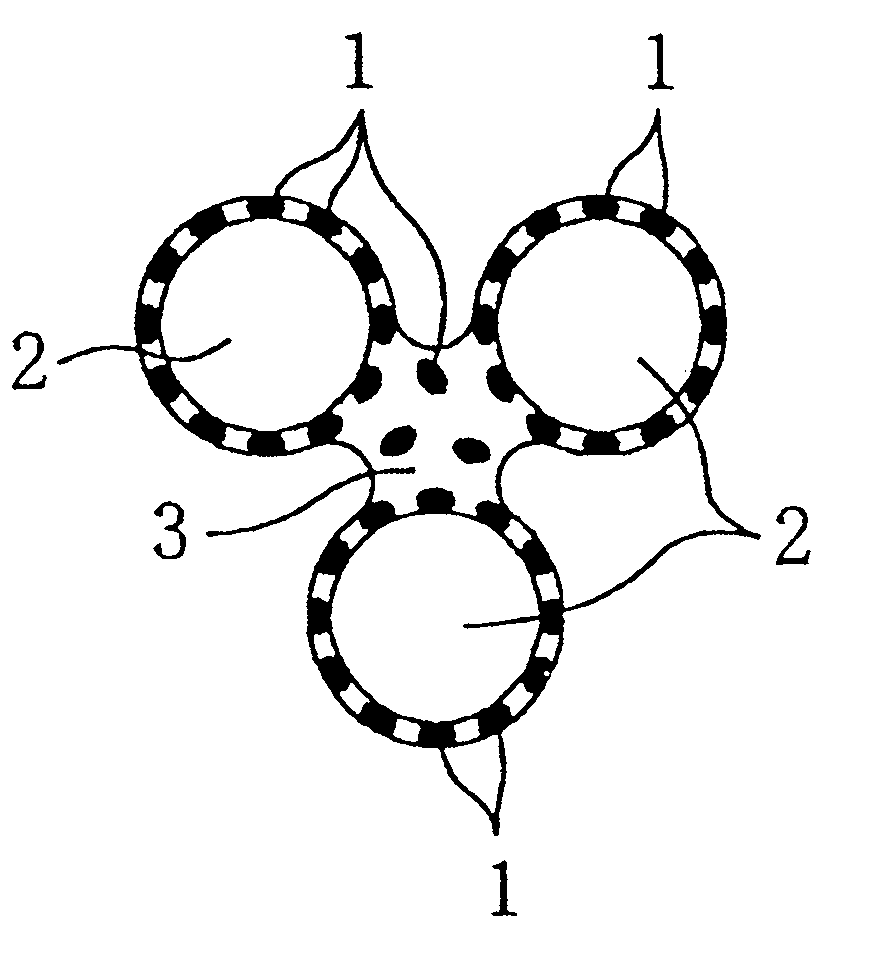

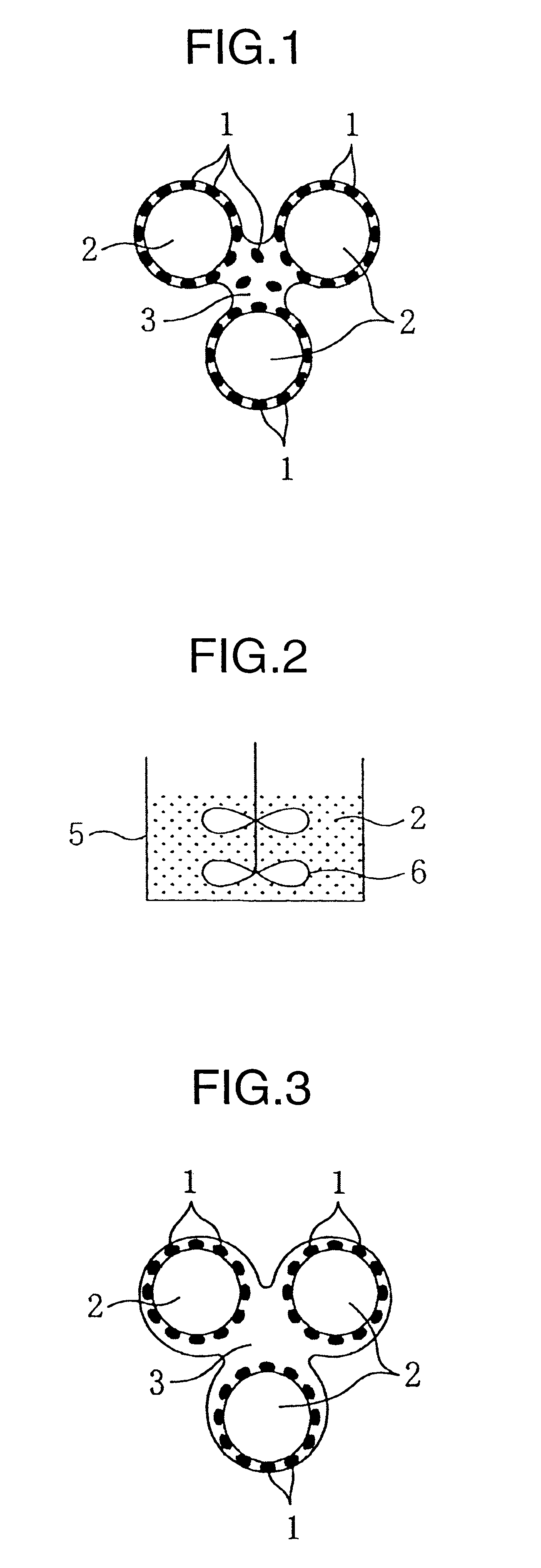

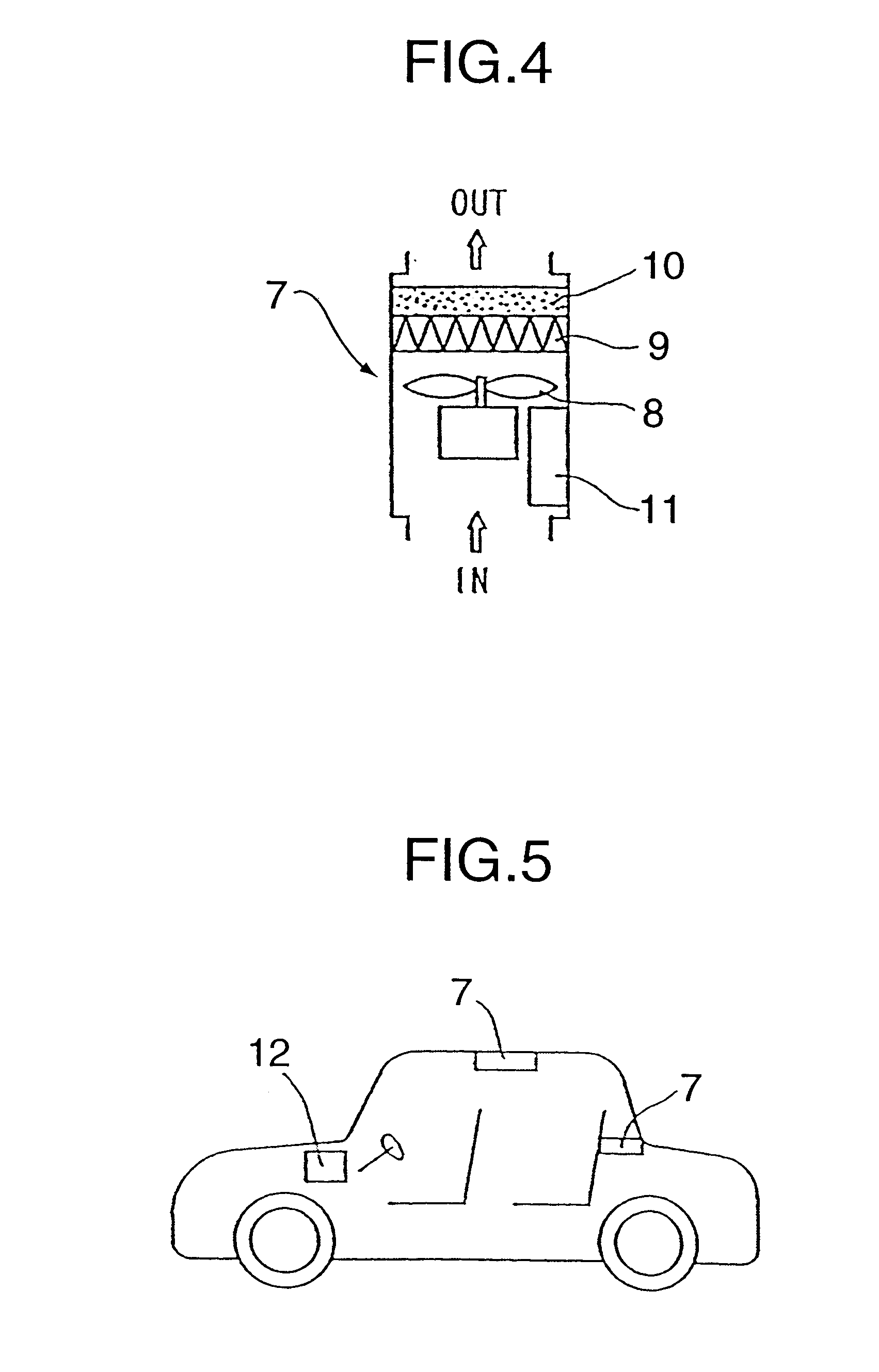

Composition for use in adsorption treatment, products formed with the same, and a method for producing adsorbent using the same

InactiveUS6432872B1Easy to handleInhibition of adsorptionGas treatmentOther chemical processesSorbentAir cleaning

An object of the present invention is to provide a composition for use in adsorption treatment which is easy to handle; a method for easily preparing the composition in the form of grains without inhibiting its adsorption ability; products such as an adsorption treatment device and a filter for air-cleaning formed with the composition; and a method of adsorption treatment. The composition for use in adsorption treatment of the present invention includes an adsorbing substance which is reactive with components to be adsorbed in the presence of moisture, a water-absorbing substance, and a binder, wherein the binder is 1.3 to 8 weight percent with respect to the water-absorbing substance.

Owner:MAZDA MOTOR CORP

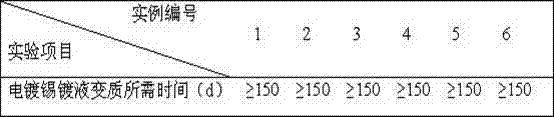

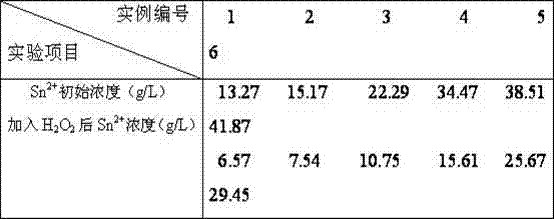

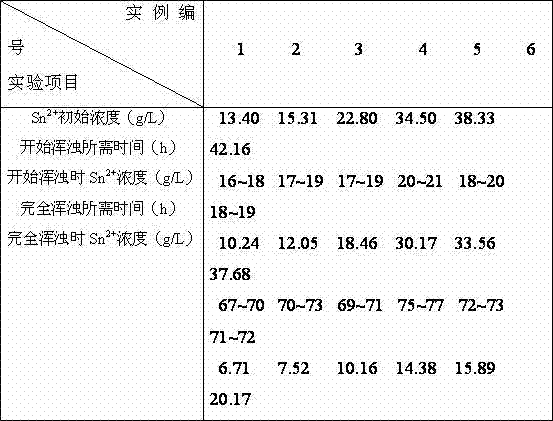

Methyl sulfonate tinning electrolyte and tinning method of steel strip or steel plate

The invention discloses methyl sulfonate tinning electrolyte using cerium salt as an additive. The electrolyte comprises the following components: 30 to 120 g / L of stannous methyl sulfonate, 60 to 180 g / L of methylsulfonic acid, 1 to 10 g / L of cerium sulfate, 0.1 to 2 g / L of antioxidant, 5 to 10 g / L of brightening agent and 5 to 10 g / L of surfactant. The invention also discloses a method for tinning a steel strip or a steel plate by adopting the electrolyte. During plating, the cerium salt in the electrolyte lightens the harm degree of 'hydrogen brittleness', and plays roles of the antioxidant and the brightening agent. On the basis of adaptability to the environment, the electrolyte meets the requirements that the process is simple, the solution is stable, the maintenance is easy and the quality of a coating is high.

Owner:张家港市凤凰科技开发有限公司

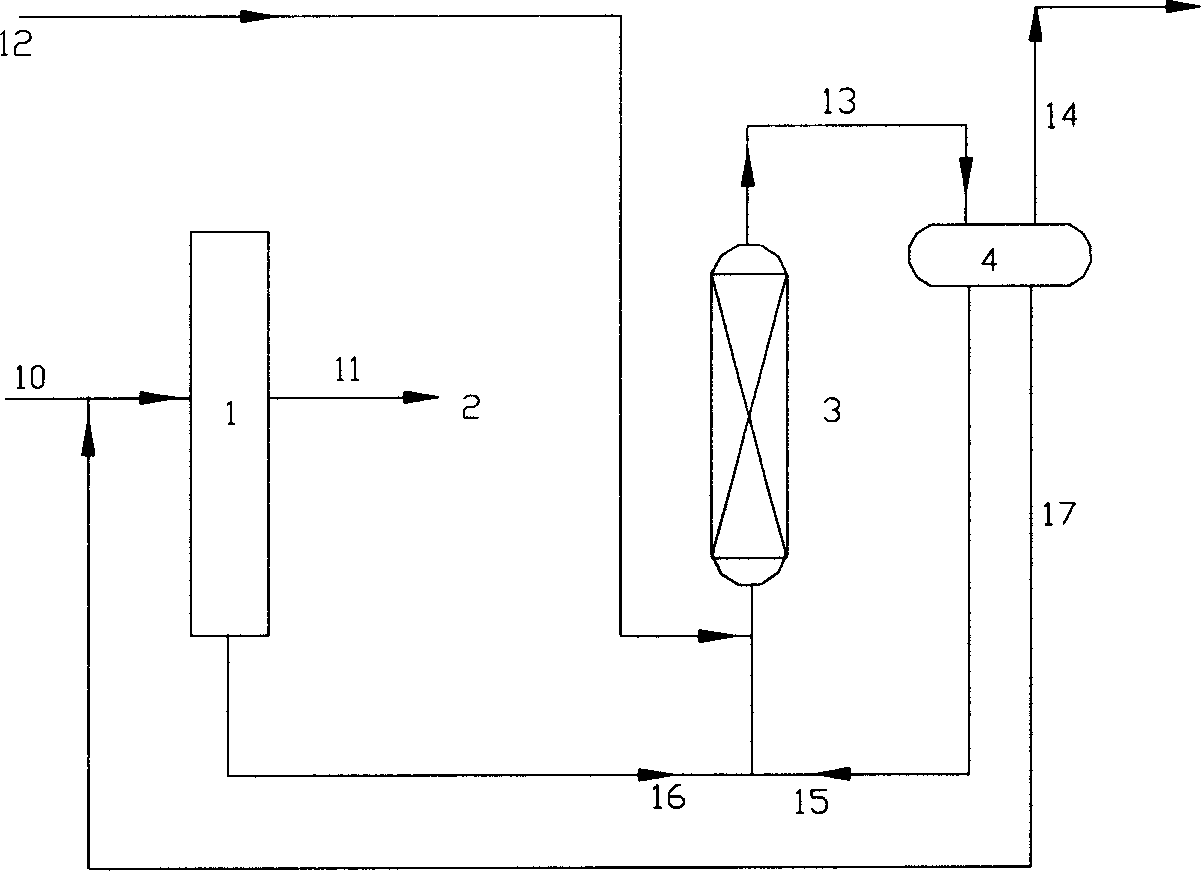

Selective hydrogenation technology of hydrocarbon material flow rich acetylene in hydrocarbon

InactiveCN1590513AReduce lossesImprove performanceRefining by selective hydrogenationFixed bedAlkyne

A process for selectively hydrogenating the hydrocarbon material rich in acetylene hydrocarbon, which is the residue in butadiene extractor, features that said hydrocarbon material flows through a fixed-bed hydrogenating reactor with circulator, where acetylene hydrocarbon reacts on H2 to remove the acetylene hydrocarbon, and then back to said butadiene extractor.

Owner:CHINA PETROLEUM & CHEM CORP

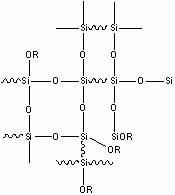

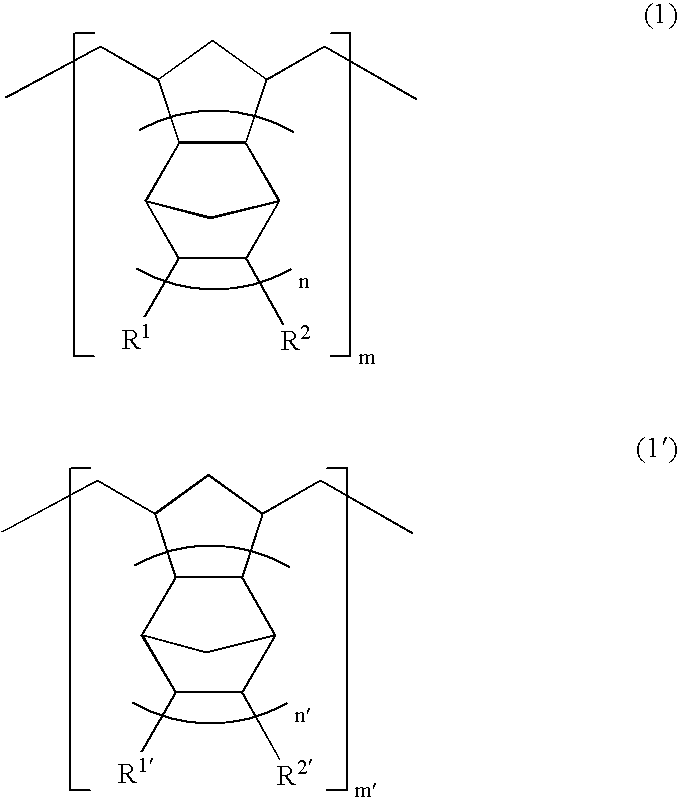

Organosilicon type marine antifouling paint binder and preparation method and application thereof

ActiveCN102212306AInhibition of adsorptionReduce usageAntifouling/underwater paintsPaints with biocidesQuaternary ammonium cationSide chain

The invention discloses organosilicon type marine antifouling paint binder. The structure of the paint binder is shown in the formula (1), wherein the paint binder is an organosilicon-polyurethane compound with bactericide side chain and R represents CH2CH3. The preparation method comprises the following preparation steps: 1) using chloropropylmethyldimethoxysilane and dimethyldimethoxysilicane to react and obtain chloropropyl-containing polysiloxane; 2) using chloropropyl-containing polysiloxane, tertiary amine and hydroxyl-containing tertiary amine to perform reflux reaction and generate polysiloxane with quaternary ammonium salt and hydroxyl; and 3) mixing isocyanate, butyltin dilaurate and polysiloxane with quaternary ammonium salt and hydroxyl with solvent, adding gamma-aminopropyltriethoxysilane to extend the chain and obtain prepolymer with the crosslinked group -Si(OCH2CH3), and using the prepolymer to perform crosslinking and condensation in the air and obtain the finished product. The organosilicon type binder has low surface energy performance and very good hydrophobicity; and the molecular chain has environmentally-friendly bactericide, thus the binder has very good bactericidal effect and marine antifouling effect.

Owner:ZHEJIANG UNIV

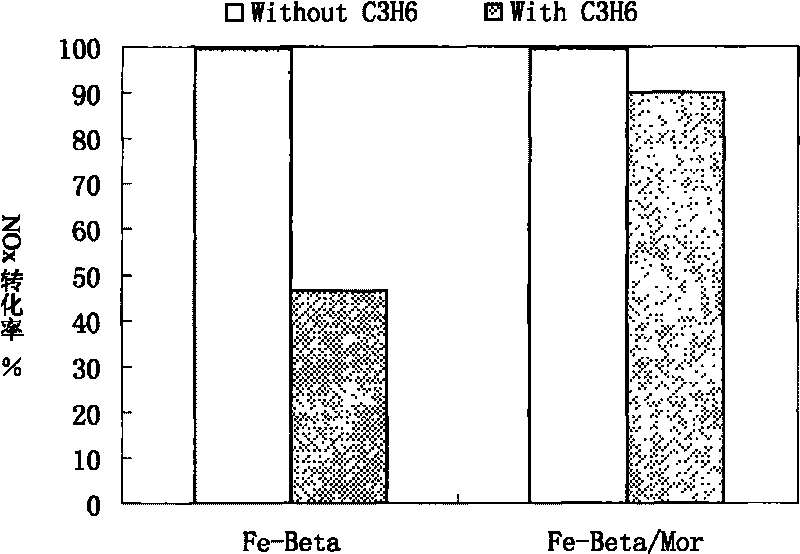

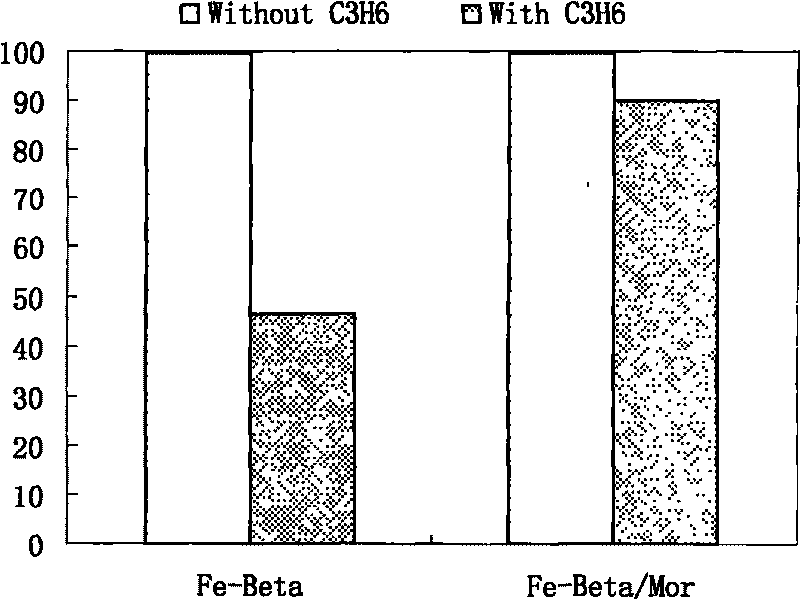

Fe molecular sieve composite catalyst and preparation method thereof

ActiveCN101711991AHigh catalytic activityInhibition of adsorptionMolecular sieve catalystsDispersed particle separationIon exchangeMordenite

The invention relates to a Fe molecular sieve composite catalyst, which comprises an active component Fe, a catalyst carrier Beta and a mordenite. A preparation method comprises the following steps of: 1, performing ion exchange on a Si / Al H-Beta molecular sieve and FeCl2; 2, removing Cl ions in the solution, and drying the obtained filter cake and roasting the filter cake in a muffle furnace to obtain the Fe / Beta molecular sieve catalyst; 3, placing the Fe / Beta molecular sieve catalyst in the water, adding the mordenite, and roasting the mixture to obtain the Fe / Beta / Mor molecular sieve composite catalyst; 4, dissolving the Fe / Beta / Mor molecular sieve into the de-ionized water, and adding concentrated nitric acid to obtain coating serum; and 5, dipping a Cordierite honeycomb ceramic carrier in the serum, blowing a residual liquid, and after drying the mixture in the shade, drying and roasting the mixture. The catalyst can efficiently purify NOx in the tail gas of a diesel vehicle, a lean-burning gasoline car and a lean-burning natural gas vehicle, and has the characteristics of environment protection and highly efficient catalytic activity.

Owner:TSINGHUA UNIV

Method for forming simulated cell outer layer membrane structure on surface of cross-linked chitosan

The invention discloses a method for forming a simulated cell outer layer membrane structure on the surface of cross-linked chitosan. The method comprises the following steps that: firstly, the chitosan is cross-linked by glutaraldehyde; and secondly, the surface of the cross-linked chitosan is grafted with phosphinylideyne choline groups to construct the simulated cell membrane structure, the reaction of the grafted phosphinylideyne choline groups is carried out in an anhydrous non-protonic solvent, the reaction temperature is between 40 and 80 DEG C, and the concentration of phosphorylcholine dichloride is between 0.1 and 20mg / ml. The test results show that for the surface modified by the simulated cell outer layer membrane structure, the capabilities of adsorbing protein and blood platelet are obviously reduced, and the blood compatibility is obviously improved. The modified material with the simulated cell outer layer membrane structure has wide application prospect in fields such as blood purification, body implantation materials, tissue engineering, slow release of medicines, biological sensors, and the like.

Owner:NORTHWEST UNIV(CN)

Microorganism feed additive capable of promoting goose liver development and preparation method thereof

InactiveCN101084780AGrowth inhibitionInhibition of reproductionAnimal feeding stuffAccessory food factorsCelluloseBiotechnology

The invention relates to a method for preparing microbial feed additive used for promoting growth of goose liver. All of the microbial strain is screened out from the animal intestinal tract. The method comprises culturing all the strains on the same culture medium through combined culture, constituting powerful compound microbial community by using mixed sync solid fermentation process, and forming effective enzyme producing ability to make the product has amount of physiologic metabolite such as organized enzyme for analysing cellulose and fructose, peptide, antioxidants, free amino acid, and vitamin. The invention can promote feed digestion and absorption of animal, promote synthesize and utilization of protein, enhance immunologic competence of livestock, fowl and aquatic livestock, and improve feed conversion ratio and production capacity of breed animal. The inventive product has good practicability and pertinency.

Owner:SHANGHAI CHUANGBO ECOLOGICAL ENG

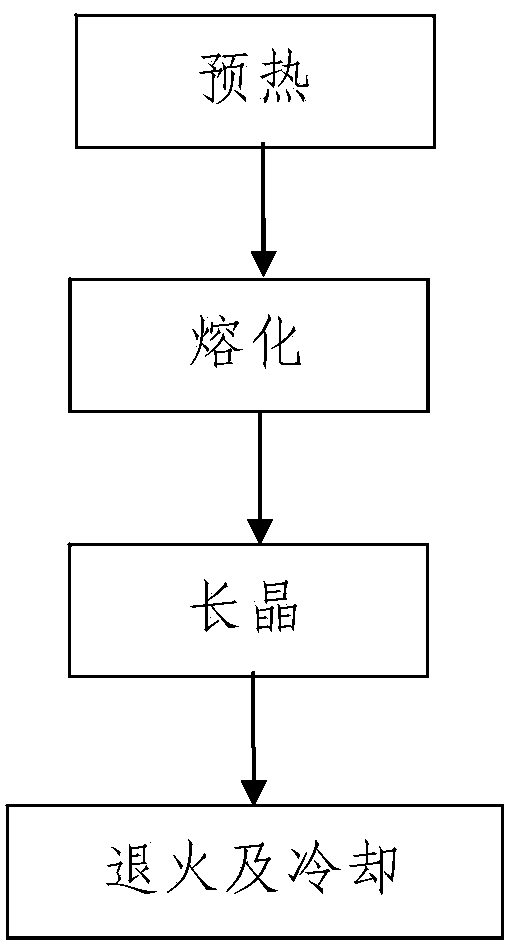

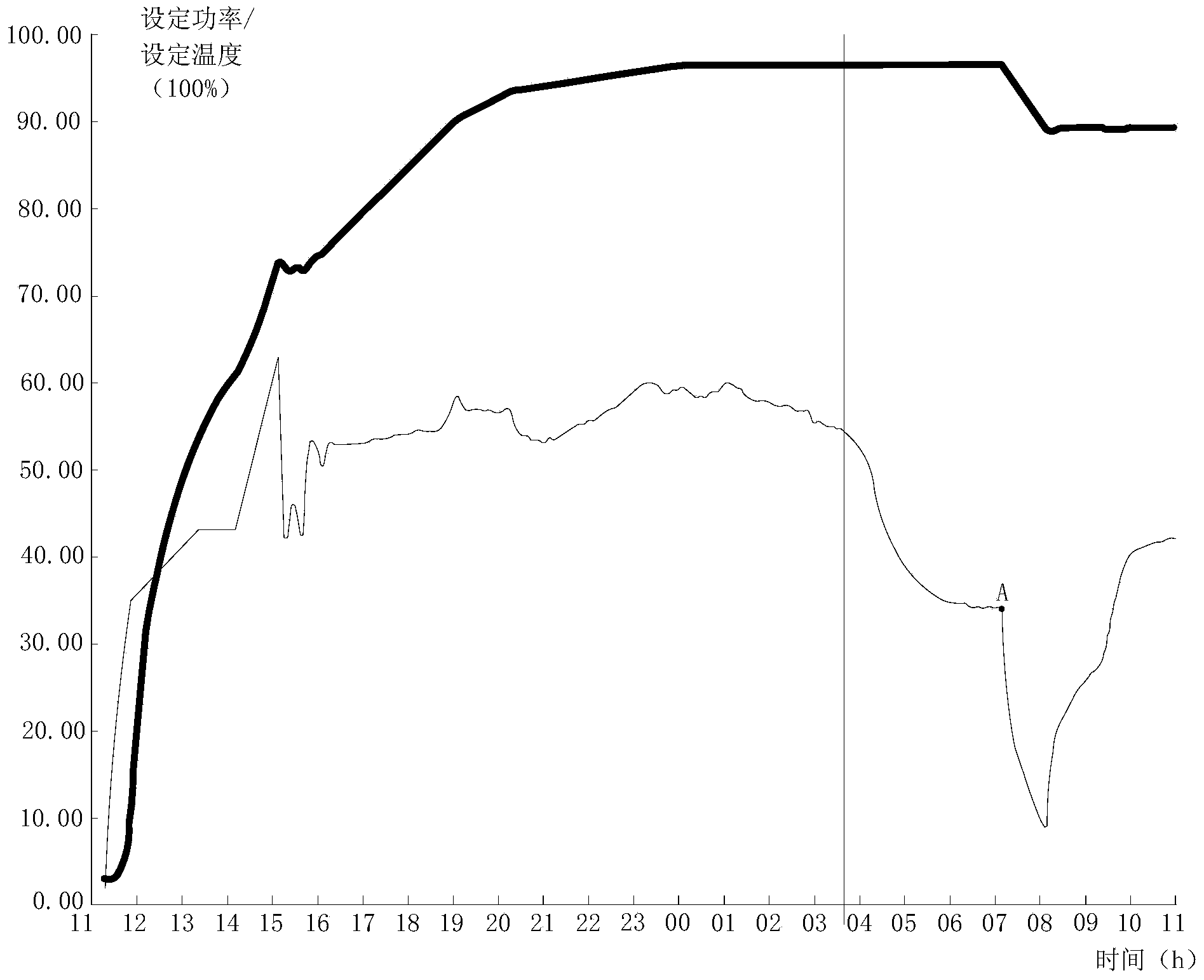

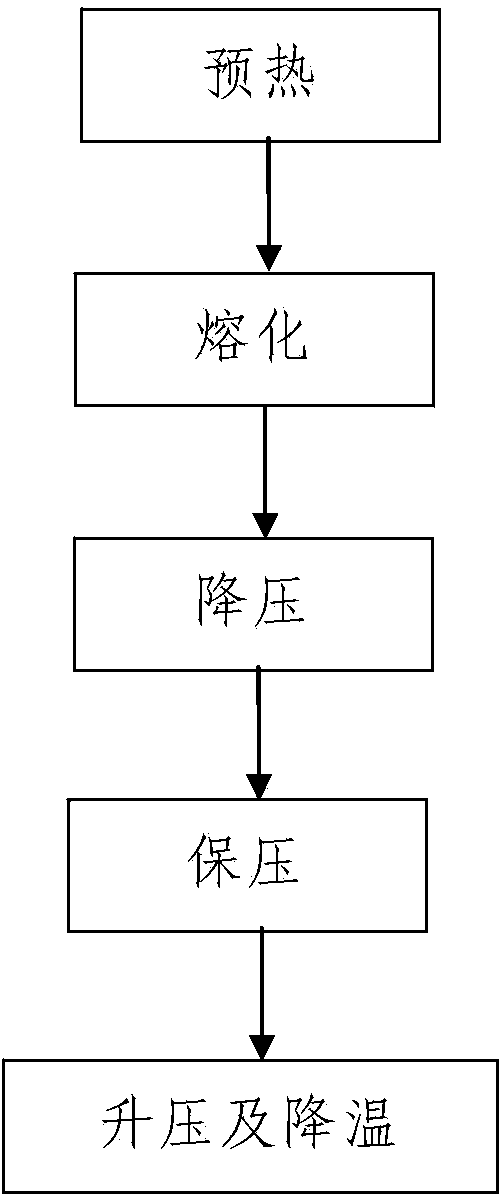

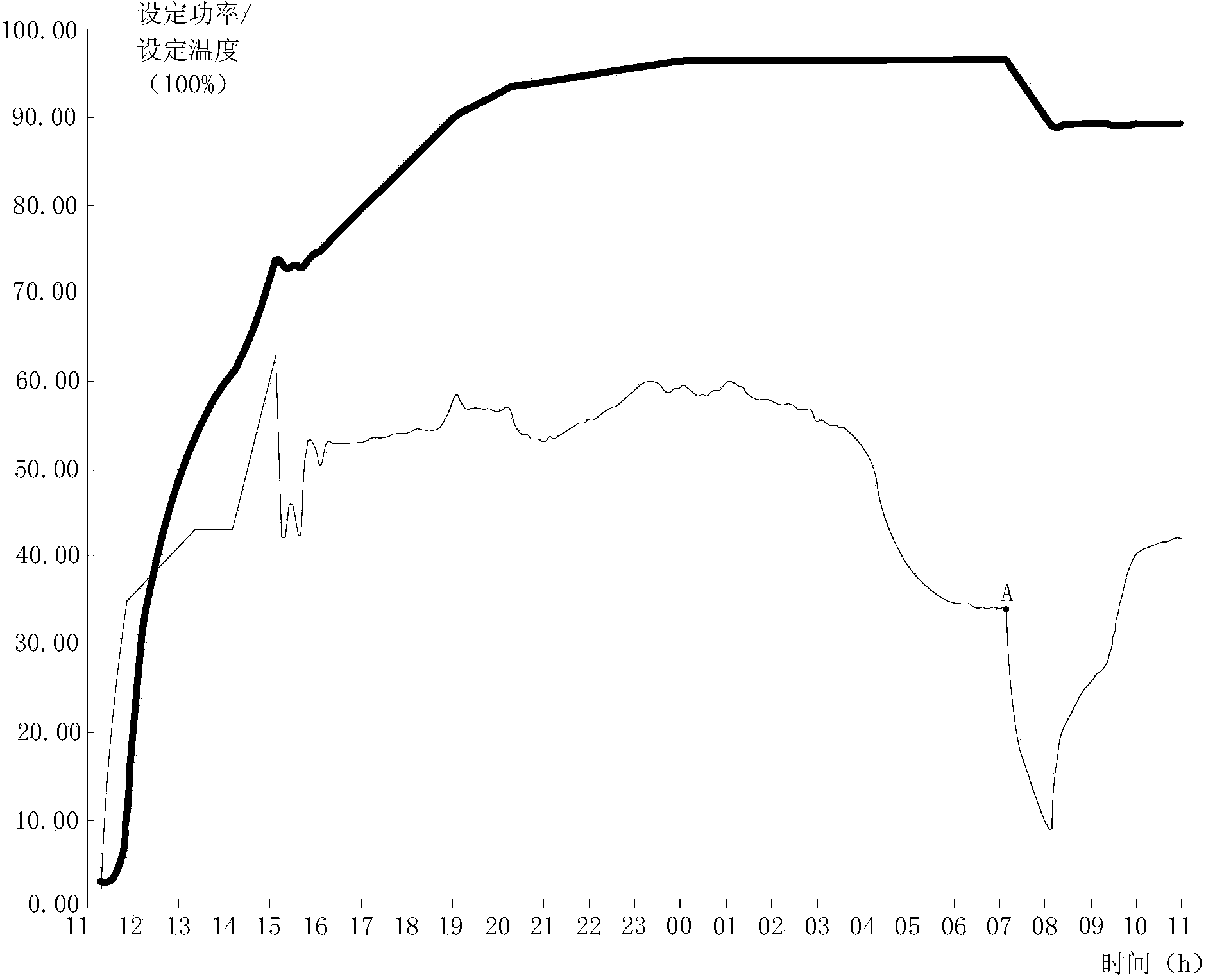

Polycrystalline silicon ingot casting process

InactiveCN103741214AReasonable designSimple processing stepsPolycrystalline material growthSingle crystal growth detailsPolycrystalline siliconMetallurgy

The invention discloses a polycrystalline silicon ingot casting process. The process comprises the following steps: 1, preheating; 2, melting; 3, growing crystal: the temperature is controlled to T6 and is preserved for 1h, and T6=1420 DEG C; the hoisting height of a heat insulation cage is 90mm; the temperature is controlled to T6 and is preserved for 2h, and the hoisting height of the heat insulation cage is not changed; the temperature is controlled to T6 and is preserved for 3h, and the hoisting height of the heat insulation cage is 110mm; the temperature is gradually lowered from T6 to T7, the temperature lowering time is 7-9h, and the hoisting height of the heat insulation cage is 210mm; T7=1405 DEG C; the temperature is controlled to T7 and is preserved for 7-9h, and the hoisting height of the heat insulation cage is not changed; the temperature is controlled to T7 and is preserved for 7-9h, and the hoisting height of the heat insulation cage is not changed; the temperature is gradually lowered from T7 to T8, and the hoisting height of the heat insulation cage is not changed; T8=1395 DEG C; 4, annealing and cooling. The polycrystalline silicon ingot casting process has the advantages of simple steps, reasonable design, convenience in realization, easiness in grasp and good using effect and can reasonably control the ingot casting crystal growth process.

Owner:XIAN HUAJING ELECTRONICS TECH

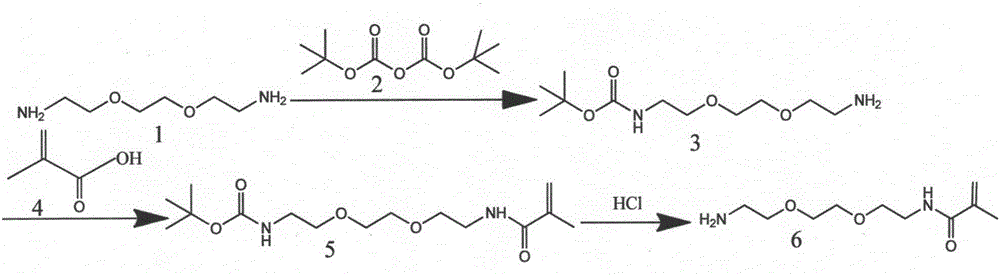

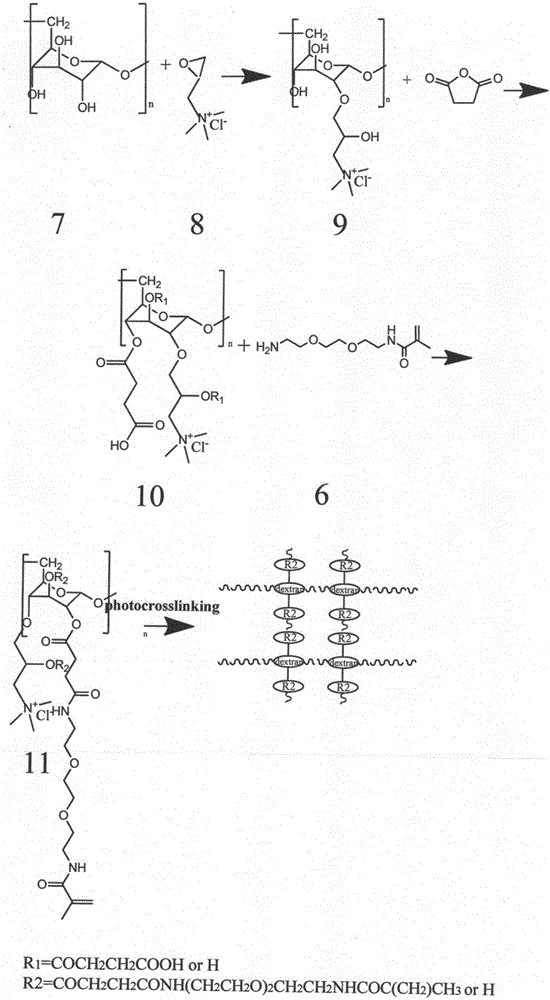

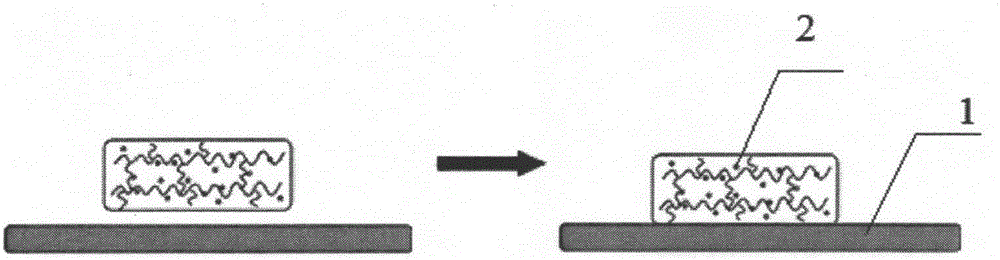

Glucan-based transparent hydrogel dressing and preparation method thereof

InactiveCN106039382AGood biocompatibilityBoosts Collagen ProductionOrganic compound preparationCarboxylic acid amides preparationGlucanDouble bond

The invention provides a glucan-based transparent hydrogel dressing and a preparation method thereof. The preparation method of the glucan-based transparent hydrogel dressing comprises the following steps: conducting a reaction between a glucan quaternary ammonium salt derivative and succinic anhydride; then promoting an obtained product to react with small molecules of amination, so that a macromonomer which contains illuminated cross-linking double bonds is obtained; mixing the macromonomer which contains illuminated cross-linking double bonds with an antibacterial agent and an initiating agent; conducting photo initiation so as to prepare a glucan-based transparent hydrogel; and combining the glucan-based transparent hydrogel with a polyurethane film by virtue of a bonding agent, so that the glucan-based transparent hydrogel dressing is prepared. The finished product (the glucan-based transparent hydrogel dressing) prepared by the invention not only can absorb a great amount of wound exudates so as to keep a wound surface wet, but also can avoid wound adhesion, so that the probability of wound infection is reduced and wound surface healing is promoted.

Owner:深圳市菩安科技有限公司

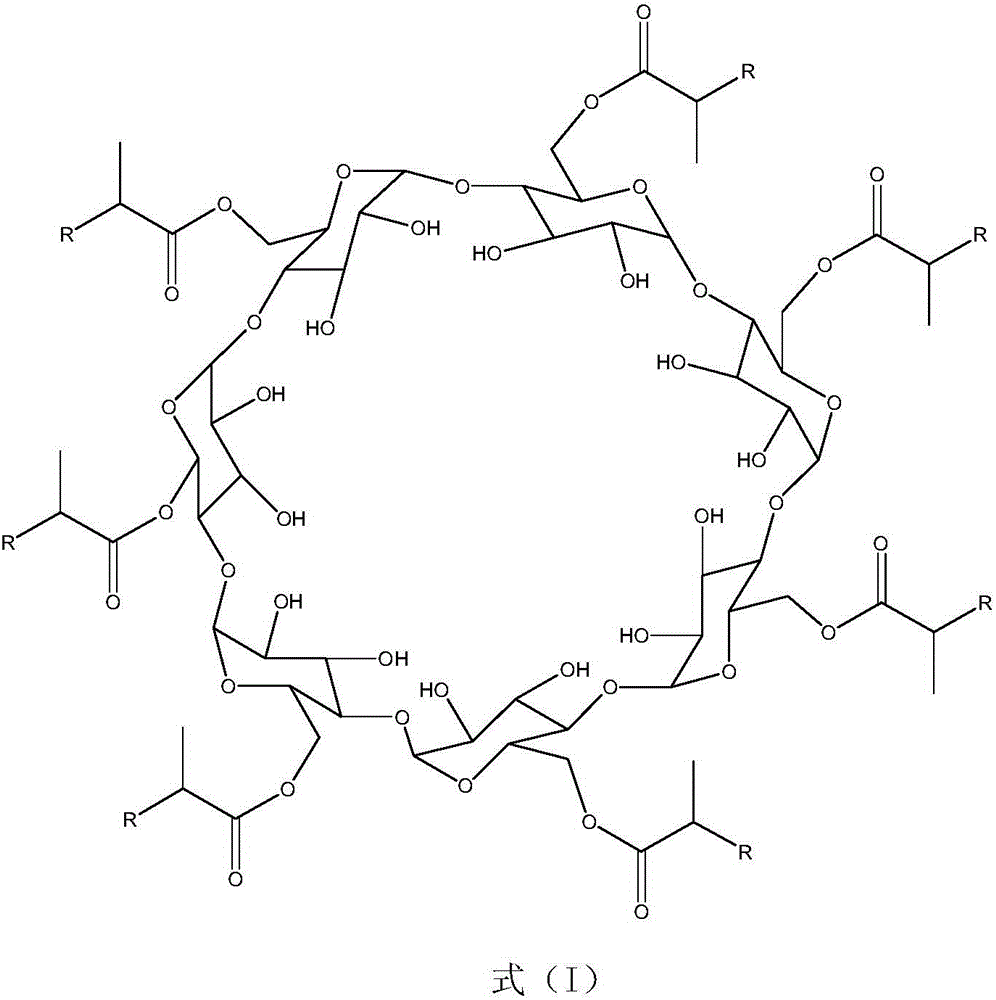

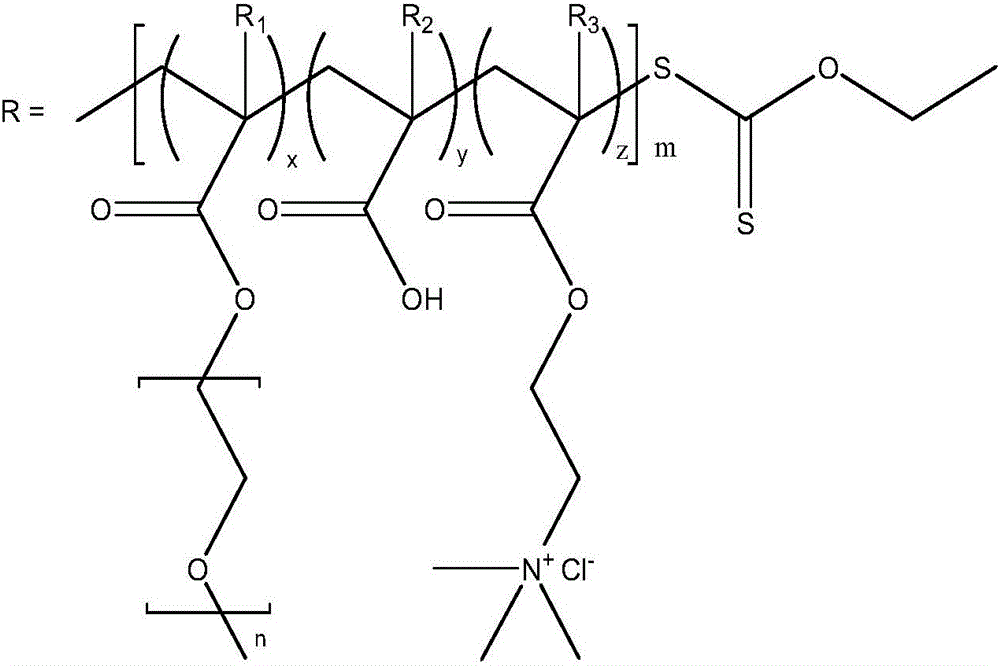

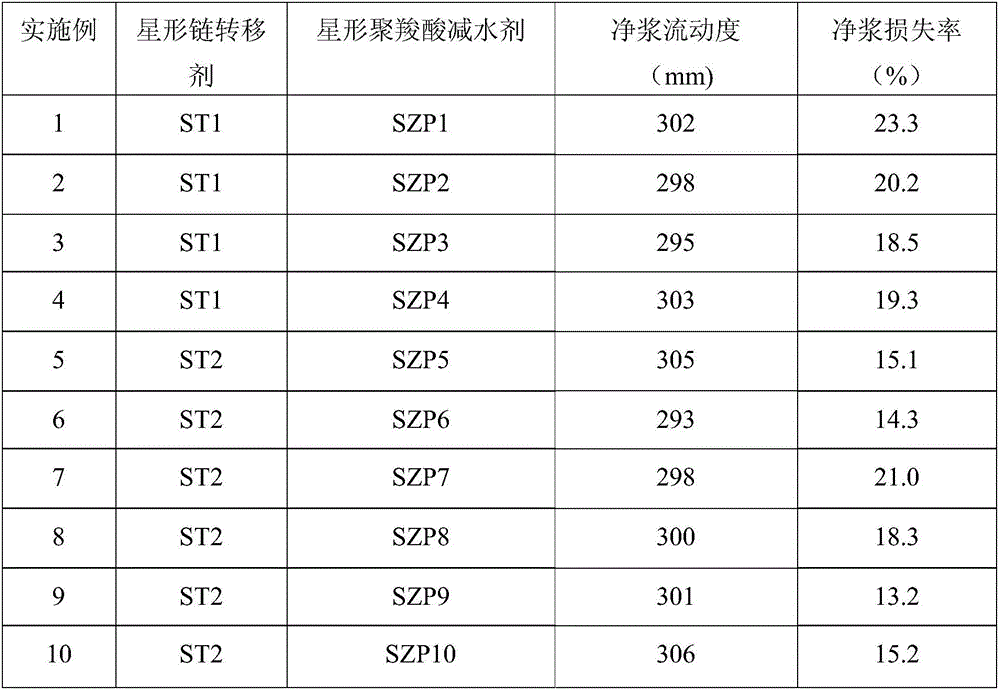

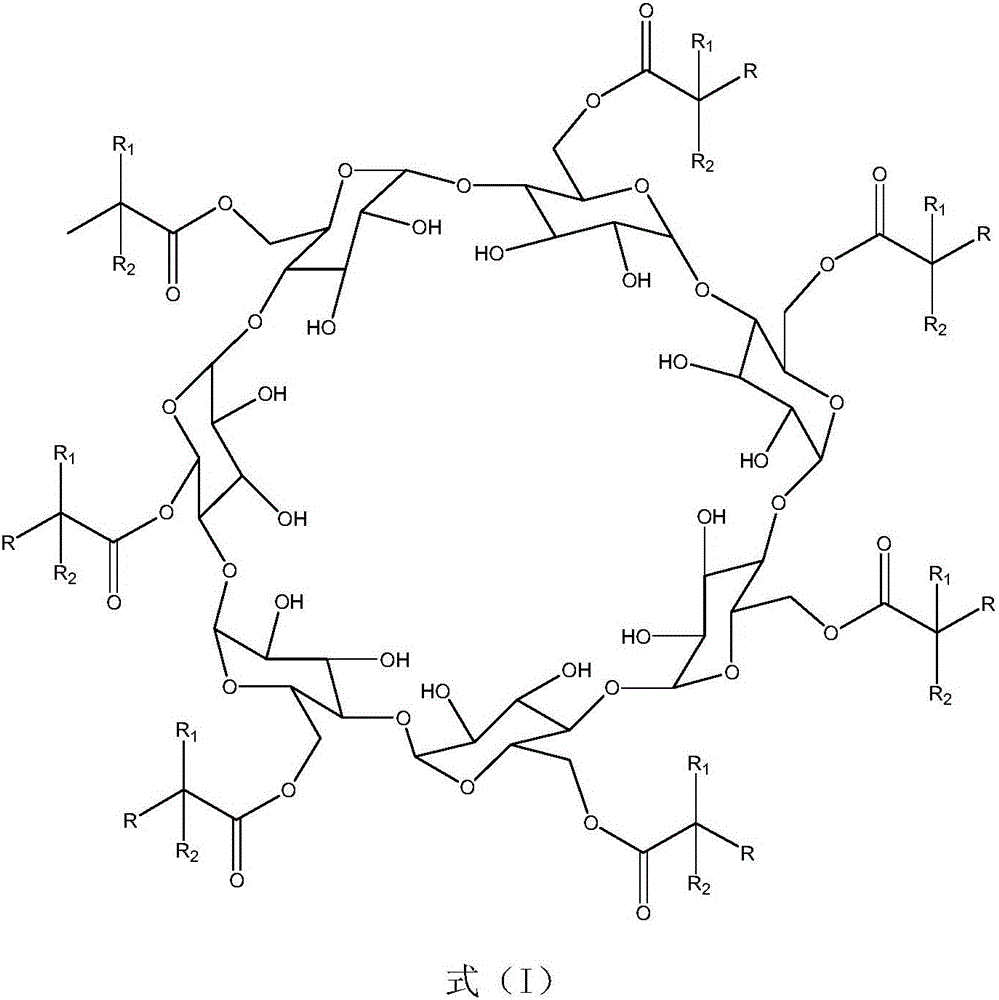

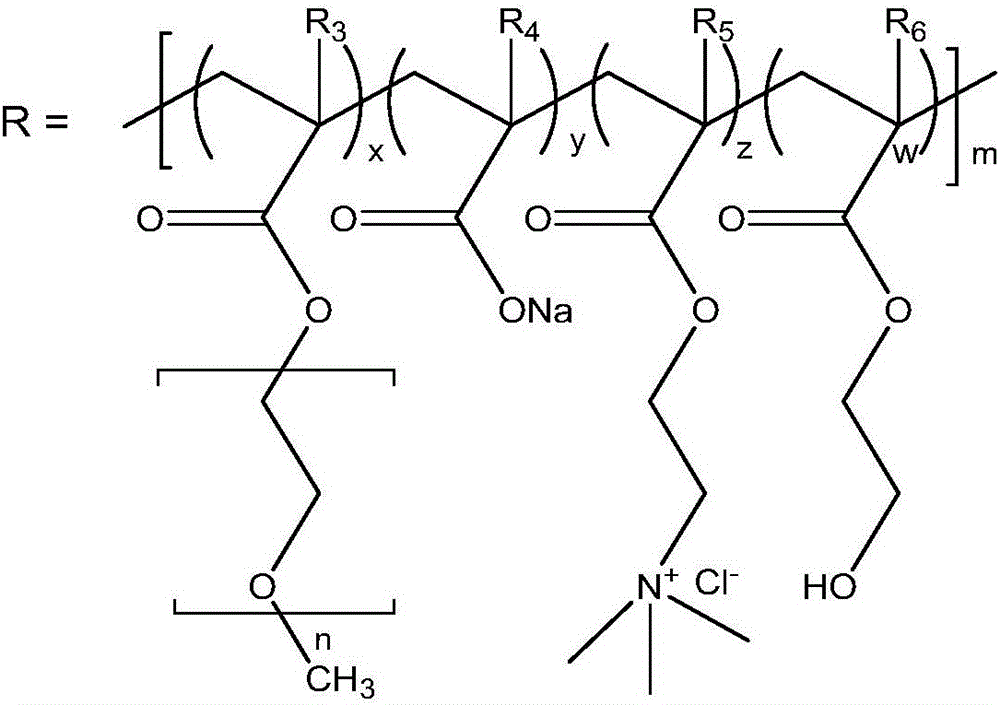

Star-like amphoteric polycarboxylate superplasticizer with efficient anti-mudding function and preparation method thereof

The invention discloses a star-like amphoteric polycarboxylate superplasticizer with efficient anti-mudding function and a preparation method thereof; the preparation method comprises: esterifying Beta-cyclodextrin and a dithioester compound with acyl halide groups to obtain star-structure reversible addition-fragmentation chain transfer agent (RAFT agent), initiating RAFT polymerization of (methyl)polyethylene glycol diacrylate, (methyl)acrylic acid and (methyl)acryloyloxyethyl trimethyl ammonium chloride under the action of the chain transfer agent and an initiator to obtain star-like amphoteric copolymer, and carrying out further processing to obtain the star-like amphoteric polycarboxylate superplasticizer having a solid content of 20% and efficient anti-mudding function. The polycarboxylate superplasticizer prepared herein has high water-reducing rate and efficient ant-mudding function and may meet high construction requirements.

Owner:SHANDONG JIAOTONG UNIV

Rare earth element-doped perovskite-type Ru-loading ammonia-synthesis catalyst

InactiveCN103357406ALow activation temperatureReduce dosageCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementPtru catalyst

The invention discloses a rare earth element-doped BaZrO3-delta-based perovskite-type Ru-loading ammonia-synthesis catalyst and a preparation method thereof. The rare earth element-doped BaZrO3-delta-based perovskite-type Ru-loading ammonia-synthesis catalyst utilizes a rare earth element-doped BaZrO3-delta-based perovskite-type composite oxide as a carrier having a molecular formula of Ba1-xLnx+yZr1-yO3-delta and comprises Ru as an active component. A rare earth element doping amount is 1-20wt% of the total amount of the carrier. K2RuO4 is utilized as a precursor of the active component and is directly dipped into the carrier, wherein the Ru loading amount is 0.5-10wt% of the carrier amount. The preparation method has simple processes, adopts simple equipment, does not need an auxiliary agent, and has a low precious metal use amount. The rare earth element-doped BaZrO3-delta-based perovskite-type Ru-loading ammonia-synthesis catalyst has good low-temperature low-pressure activity and high stability.

Owner:FUZHOU UNIV

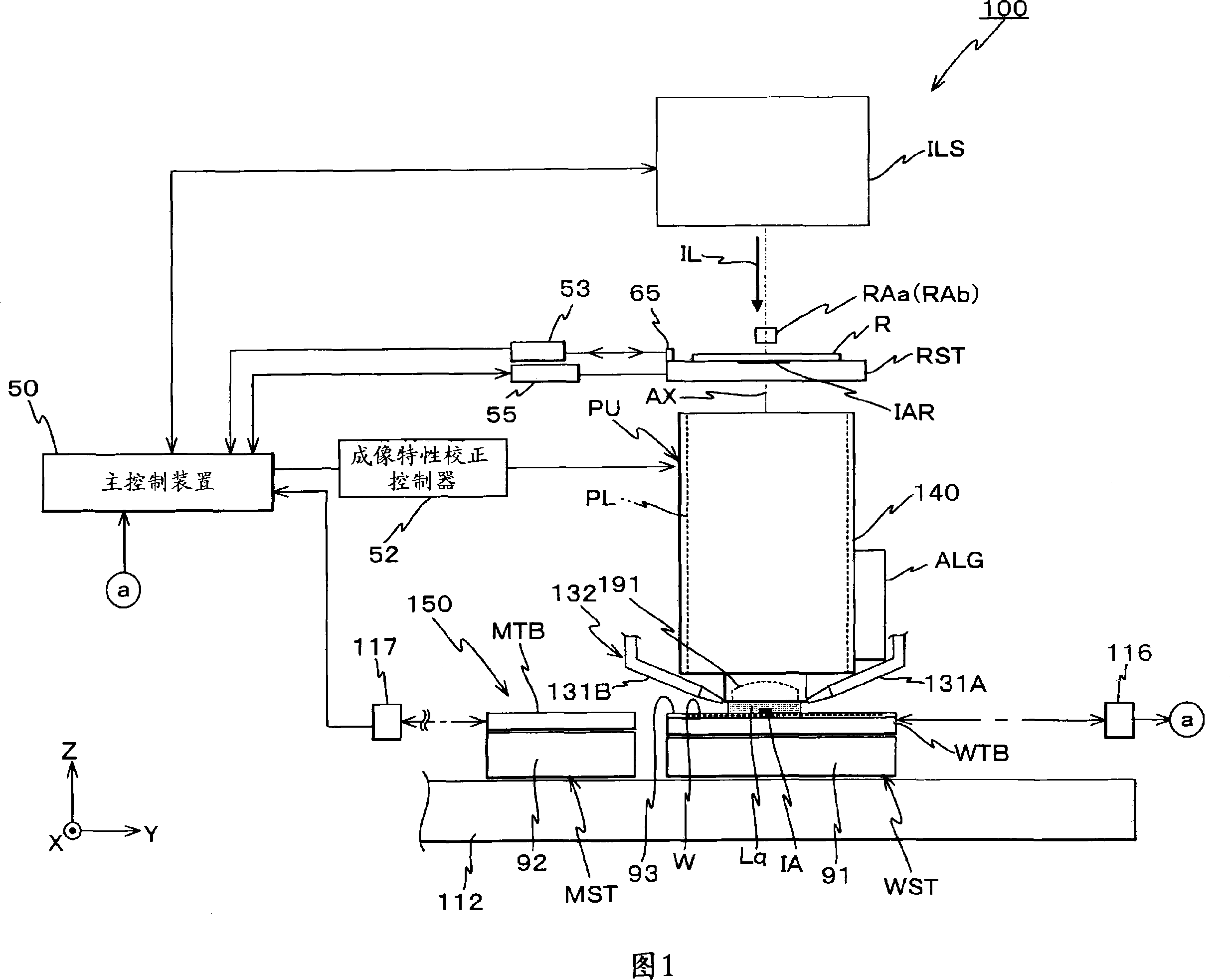

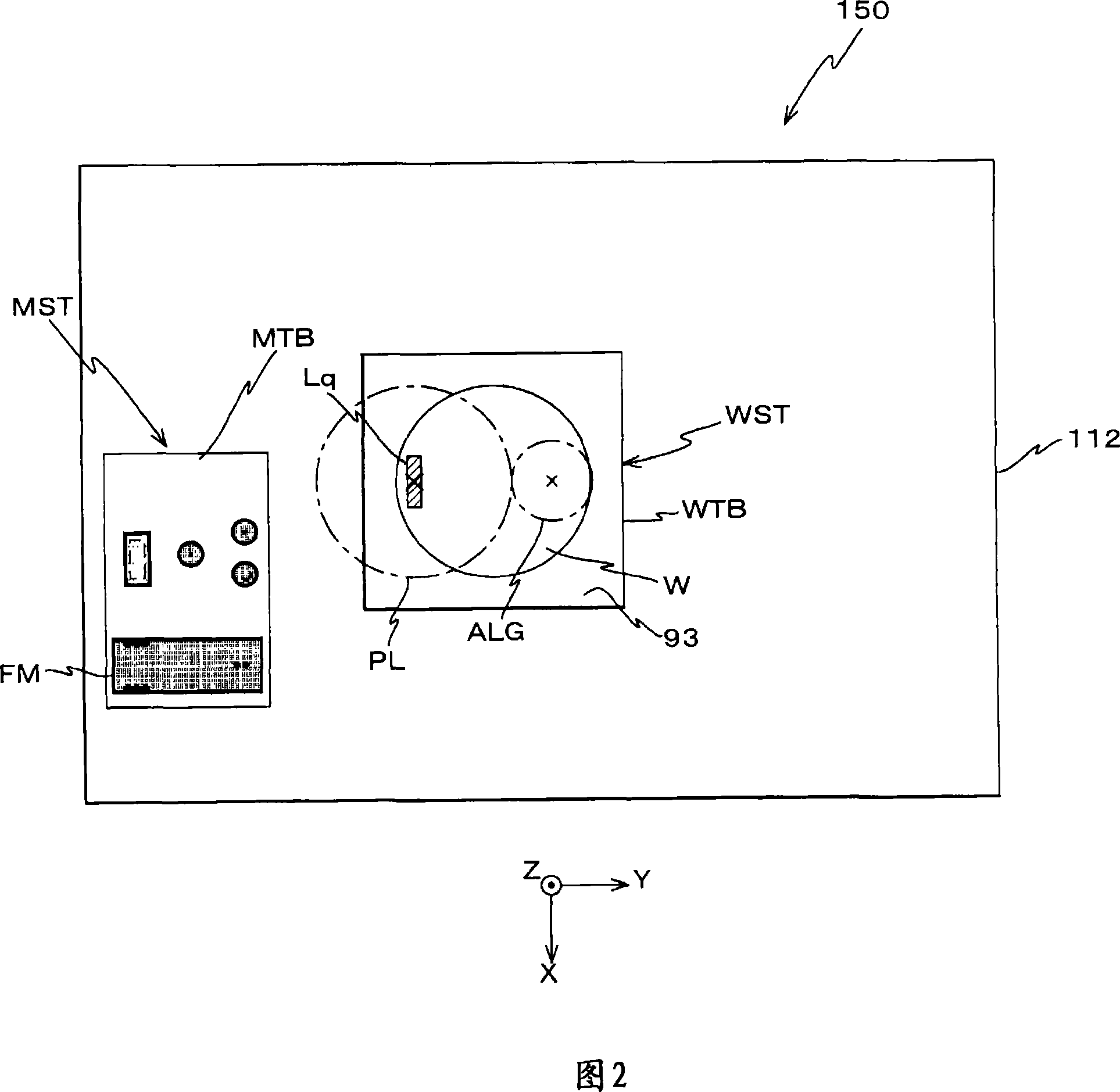

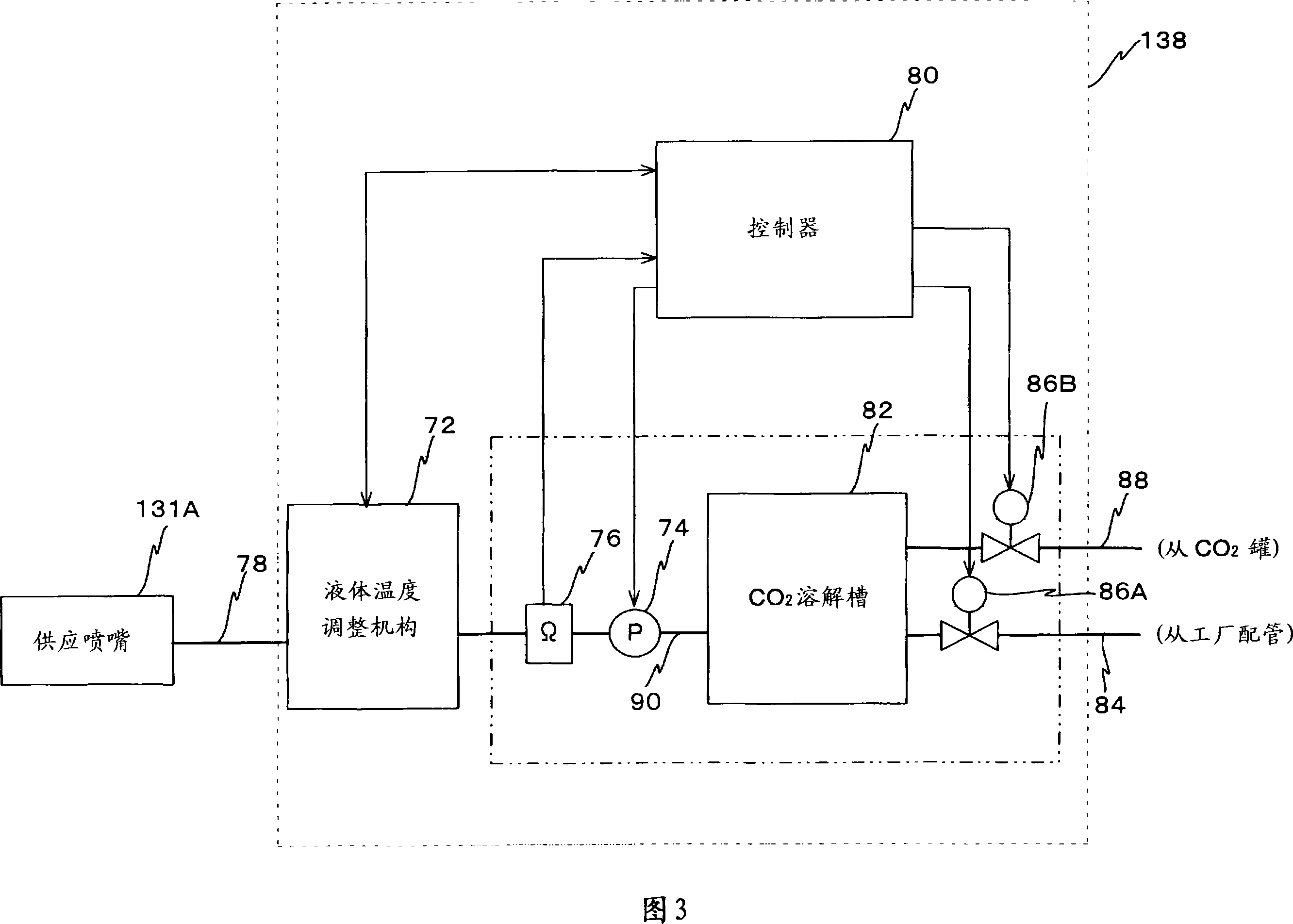

Exposure method, exposure apparatus, and device manufacturing method

InactiveCN101099224AIncrease exposureInhibition of adsorptionSemiconductor/solid-state device manufacturingOptics

An immersion apparatus (132) is provided with a mixing mechanism for mixing a prescribed substance with a liquid supplied on a liquid-repellent film on the surface of an object (member) arranged on a light outgoing side of a projection optical system (PL) and dissolving the substance. The prescribed substance adjusts the specific resistivity of the liquid. A liquid (Lq) wherein the prescribed substance is dissolved is supplied on the liquid-repellent film and an immersion region is formed.

Owner:NIKON CORP

Amnion eye drops for curing cornea alkali burn

ActiveCN101658491AImprove stabilitySolubility temperature increasesSenses disorderPharmaceutical delivery mechanismSide effectIrritation

The invention provides amnion eye drops for curing cornea alkali burn and a preparation method thereof. The preparation method comprises the steps of: taking amnion homogenate supernate as main activeconstituent; and adding with trehalose, hyaluronic acid or salt thereof, heparin or salt thereof, sodium chloride, benzalkonium bromide, vitamin, etc. The eye drops belongs to an ophthalmology drug delivery system, has a good lubrication function, and can provide a conglutination-resistant surface; and the drug delivery system is added with the other pharmacological active constituents, thereby being capable of increasing the viscocity of medical liquid, prolonging the residence time of the drug in eye surface, improving the bioavailability of the drug, reducing the side effect of the drug, reducing the drug irritation, and having a slow release effect. The amnion eye drops is an effective ophthalmology new drug, and has good clinic application foreground.

Owner:HARBIN MEDICAL UNIVERSITY

Conditioning agent of high-nutrient saline soil and preparation method and application thereof

ActiveCN106748540AHigh porosityLight weightOrganic fertilisersSoil-working methodsSoil porosityPolyacrylamide

The invention discloses a conditioning agent of high-nutrient saline soil and a preparation method and application thereof. The conditioning agent is prepared from charcoal, non-ionic polyacrylamide, anionic polyacrylamide, cationic polyacrylamide, lignite and kieselguhr according to the mass ratio of (5 to 10):(2 to 4):(2 to 4):(1 to 3):(3 to 5):1. The conditioning agent provided by the invention solves a series of problems of poor soil physical property, high ion content, low soil quality and the like caused by the saline phenomenon on the soil; the soil volume weight is reduced; the soil porosity degree is increased; the exchange of water, gas, heat and the like in the soil can be facilitated; the soil fertility is improved; meanwhile, the salt ion content and the whole salt content are reduced; the harm to the soil and the crops is reduced, so that the crop yield is increased.

Owner:BEIJING ACADEMY OF AGRICULTURE & FORESTRY SCIENCES

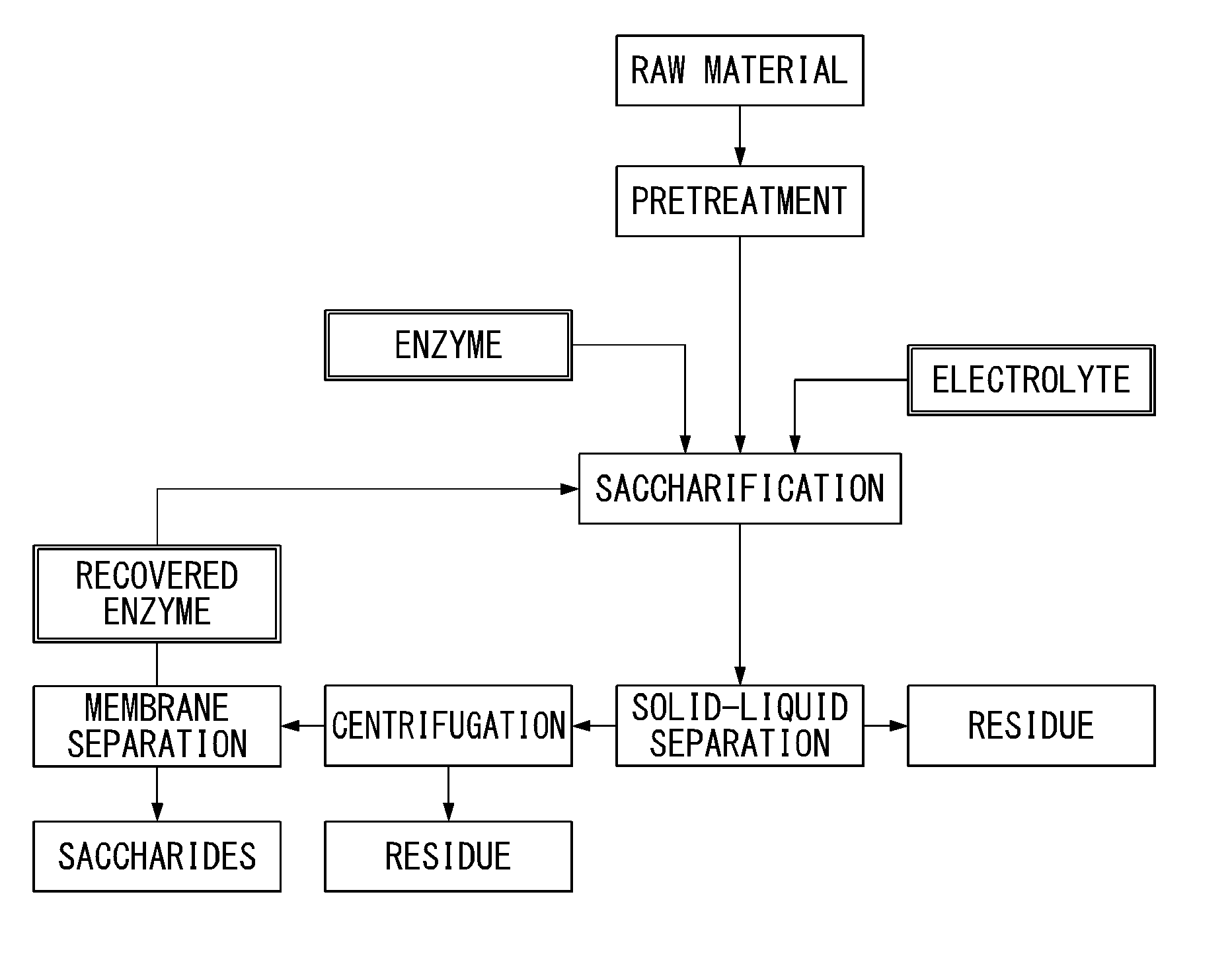

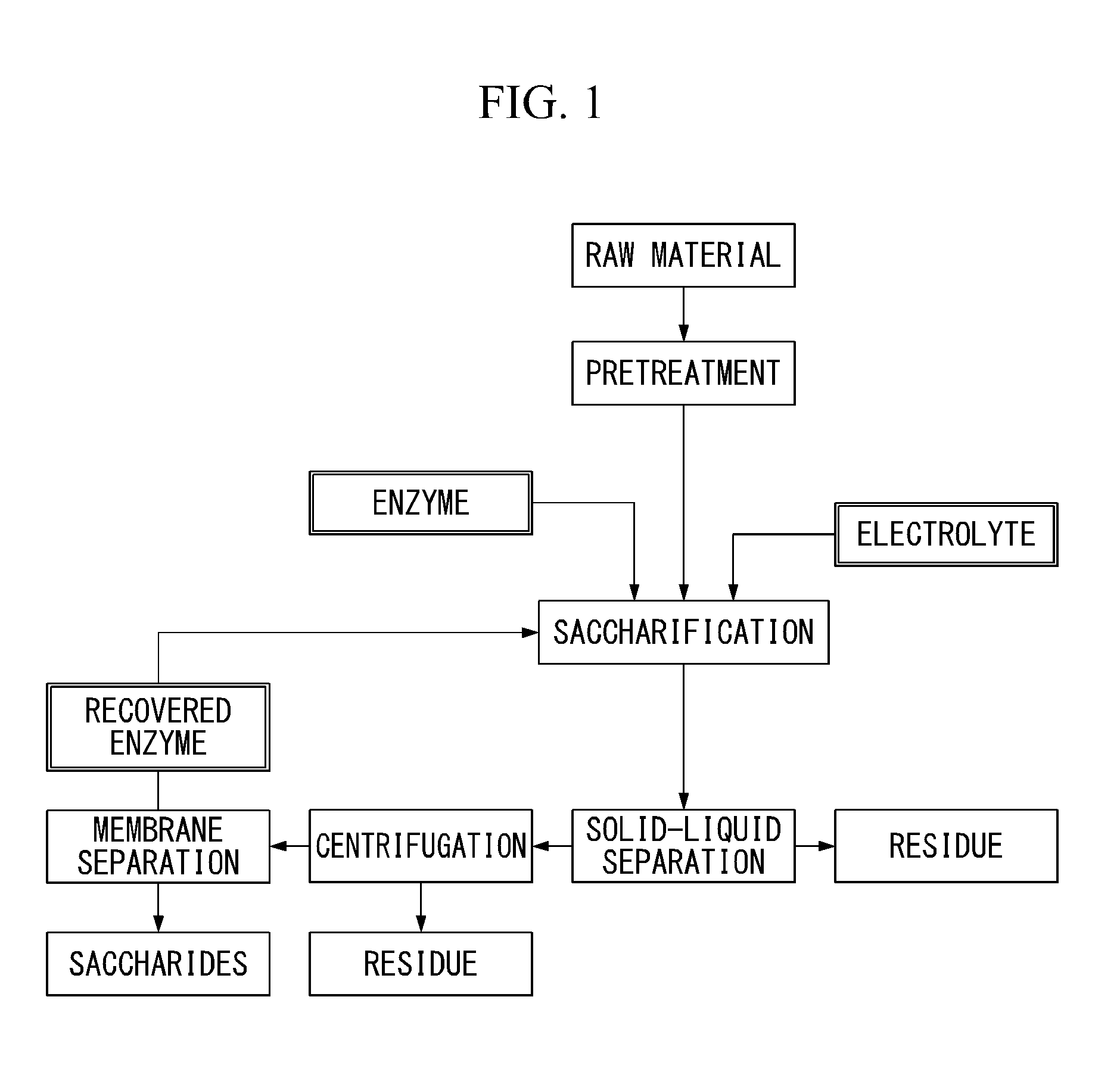

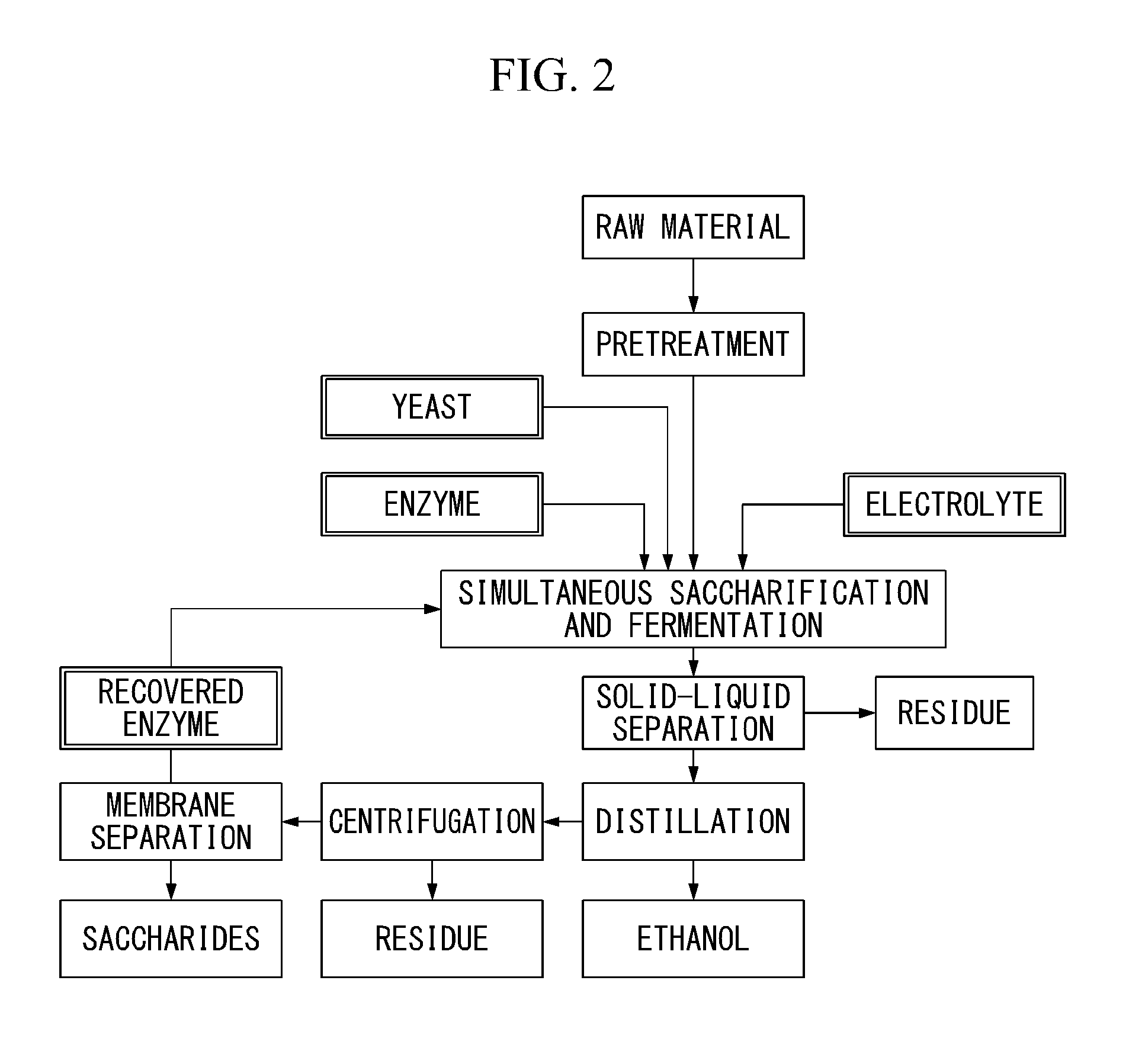

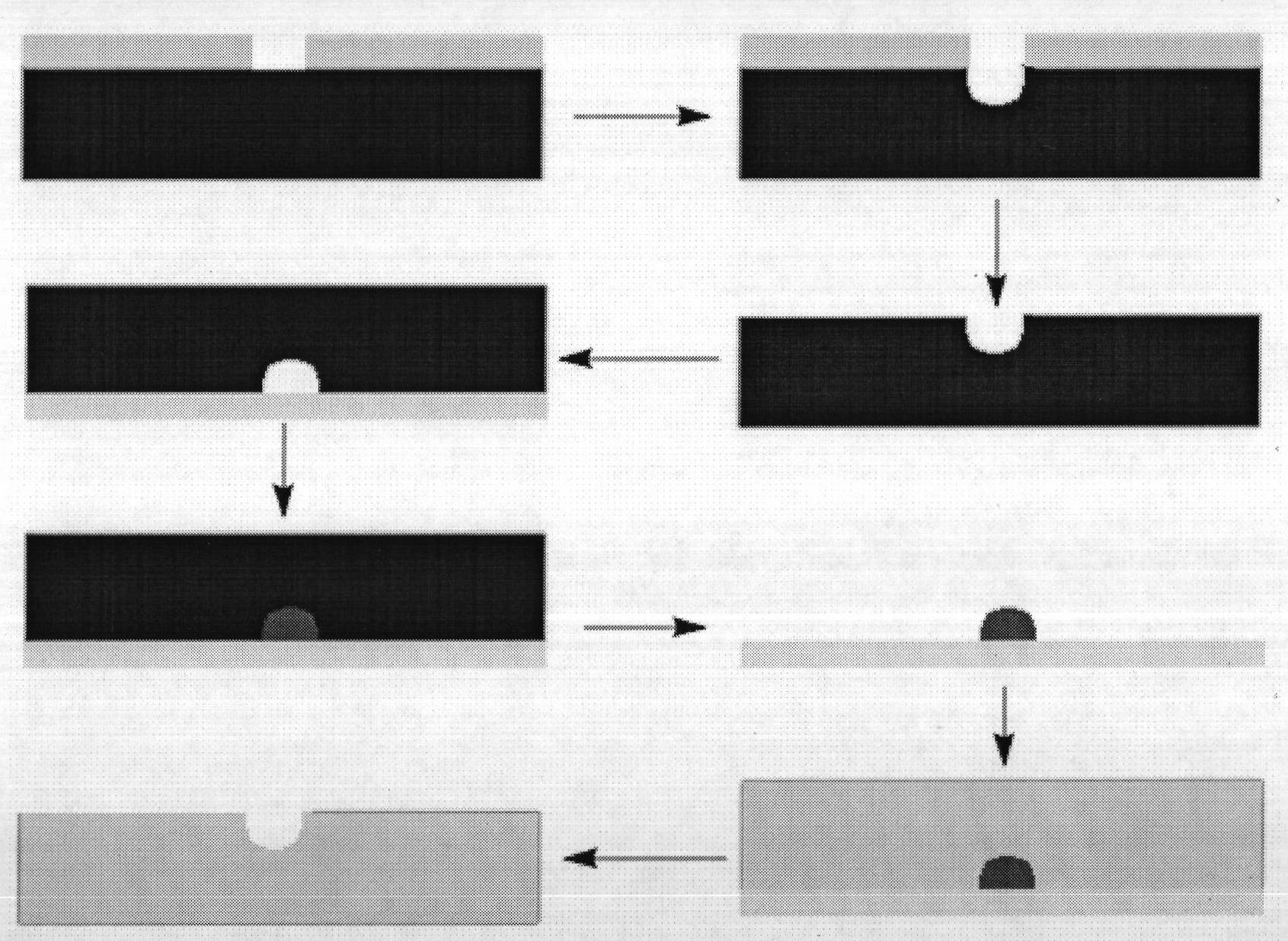

Method for enzymatic saccharification treatment of lignocellulose-containing biomass, and method for producing ethanol from lignocellulose-containing biomass

ActiveUS8728770B2Inhibition of adsorptionFacilitated separation and recoverySolid waste disposalBiofuelsCelluloseWater soluble

A method for the enzymatic saccharification of a lignocellulosic raw material, including adding a pretreated lignocellulosic raw material as a material suitable for an enzymatic saccharification reaction, together with an electrolyte containing a water-soluble salt, to water that contains a celluolose saccharification enzyme; saccharifying the raw material by an enzymatic saccharification reaction, as a suspension of the raw material having an electrical conductivity adjusted to 5-25 mS / cm; separating and recovering a reaction product and an enzyme-containing solution from the enzymatically saccharified treatment suspension; and recycling the recovered enzyme-containing solution as the enzyme for the enzymatic saccharification step.

Owner:OJI HLDG CORP

Long-acting antibacterial multifunctional coating based on bionic dopamine as well as preparation method and application thereof

PendingCN112717207AImprove stabilityImprove the bactericidal effectSurgeryPharmaceutical containersAnti bacteriaDopamine

The invention provides a long-acting antibacterial multifunctional coating based on bionic dopamine as well as a preparation method and an application thereof. The preparation method comprises the following steps: carrying out ultrasonic cleaning on a base material by using acetone, absolute ethyl alcohol and ultrapure water in sequence; immersing the obtained base material into dopamine rapid deposition liquid for reaction to obtain a base material coated with a polydopamine coating; washing the obtained base material with deionized water, and drying; soaking the obtained base material in a multifunctional coating aqueous solution for reaction, and obtaining a functional coating on the surface of the base material; washing the obtained base material with ultrapure water and then drying; wherein Cu<2+> and H2O2 are dissolved in the dopamine rapid deposition liquid, and the multifunctional coating aqueous solution contains a hydrophilic polymer or a zwitterionic polymer. The preparation process is simple, conditions are mild, deposition preparation time is greatly shortened, and the method is suitable for large-scale industrial production.

Owner:SHANDONG UNIV

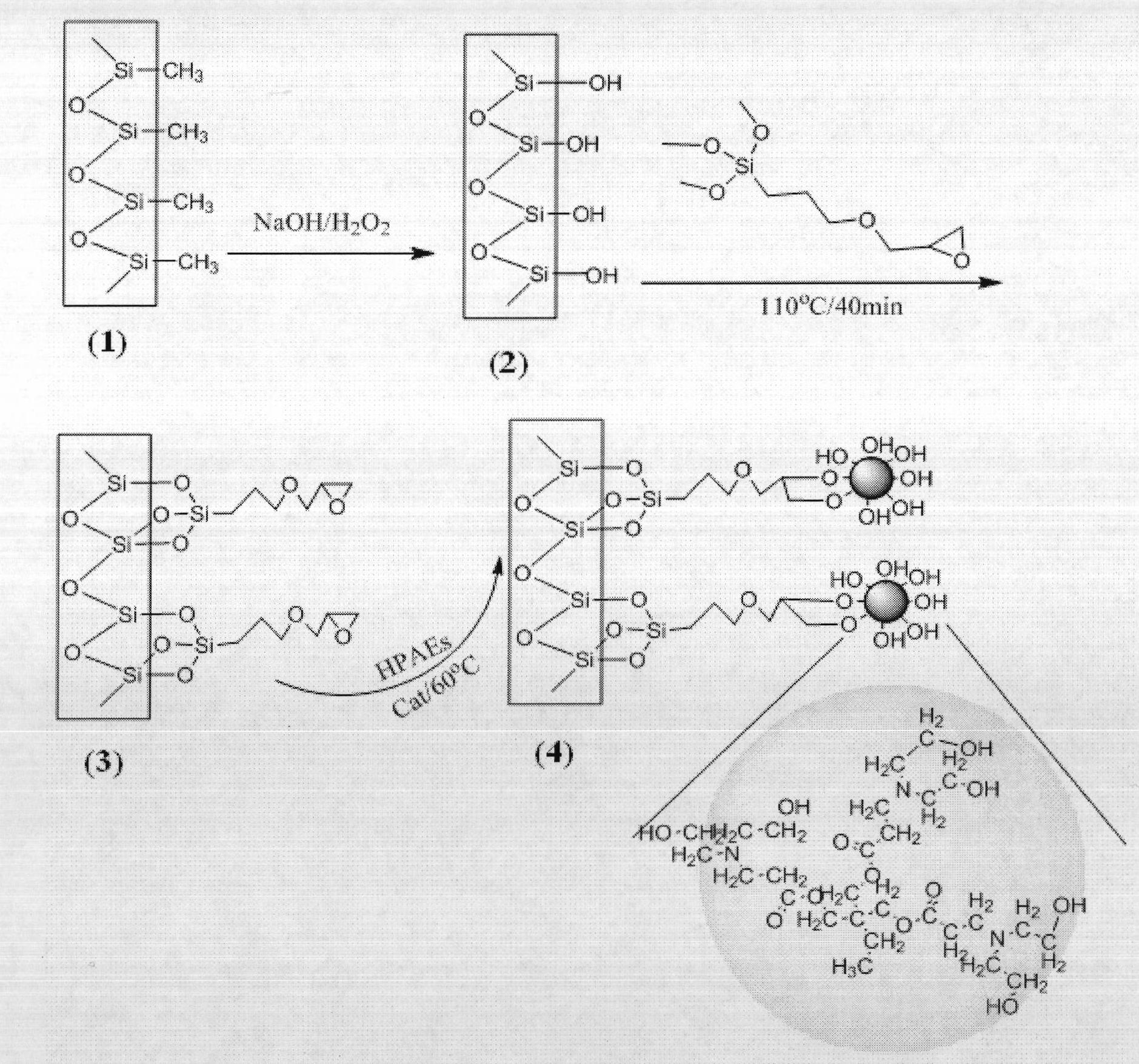

Hydroxy-terminated hyperbranched polyamine-ester polymer and application thereof in microfluidic chip

InactiveCN102060988AImprove hydrophilicityInhibition of adsorptionMaterial analysisPolymer scienceTrimethylolpropane

The invention relates to hydroxy-terminated hyperbranched polyamine-ester polymer and an application thereof in a microfluidic chip. The preparation method of the hydroxy-terminated hyperbranched polyamine-ester polymer comprises the following steps: using equimolar diethanol amine and methyl acrylate to react and obtain N,N-dihydroxyethyl-3-aminomethyl propionate; and using trimethylolpropane and N,N-dihydroxyethyl-3-aminomethyl propionate to react, wherein G2 hydroxy-terminated hyperbranched polyamine-ester polymer, G3 hydroxy-terminated hyperbranched polyamine-ester polymer and G4 hydroxy-terminated hyperbranched polyamine-ester polymer are obtained respectively when the molar ratio of trimethylolpropane to N,N-dihydroxyethyl-3-aminomethyl propionate is 1:9, 1:21 or 1:45. The hydroxy-terminated hyperbranched polyamine-ester polymer is used to prepare the hydrophilic microfluidic chip. The preparation method of the chip comprises the following steps: oxidizing a polydimethylsiloxane (PDMS) microfluidic chip substrate in oxygen atmosphere; and connecting silane coupling agent with the inside of the substrate, and connecting the polymer with silane coupling agent. By strictly controlling the reaction conditions and the molar ratio of reactants, relatively regular polymer can be prepared. The polymer in the invention is used to modify PDMS, thus the hydrophilicity can be maintained permanent, any expensive instrument is not used and the preparation is convenient and fast.

Owner:UNIV OF JINAN

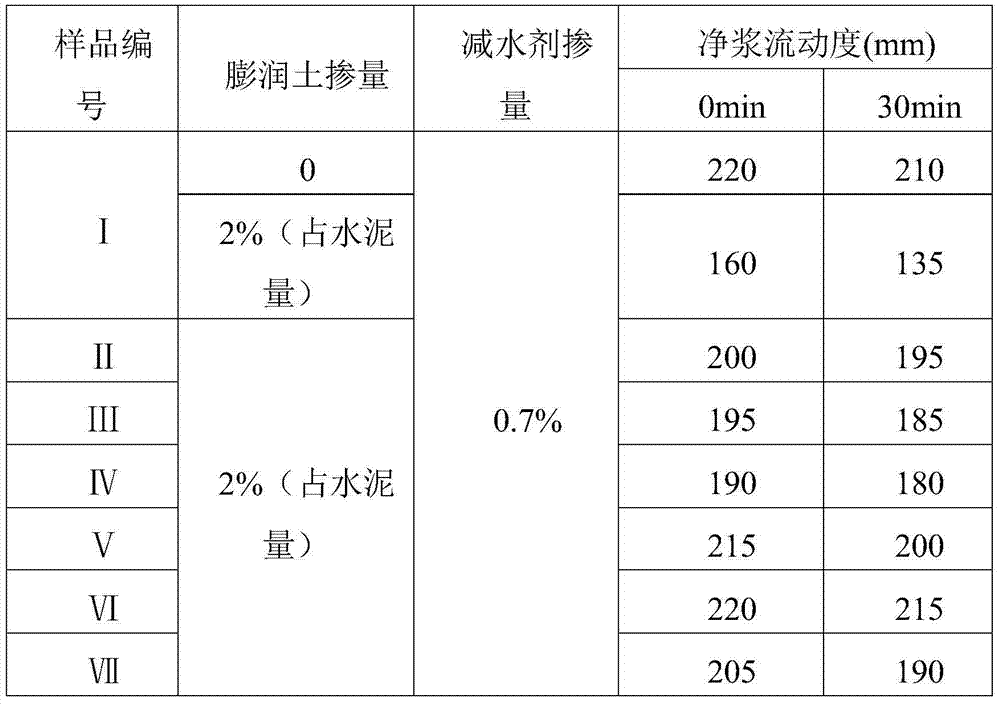

Treating agent for inhibition of harm of montmorillonite clay to concrete and using method thereof

The invention discloses a treating agent for inhibition of harm of montmorillonite clay to concrete and a using method thereof, and the treating agent belongs to the technical field of concrete additives, is used for inhibition of harm of the montmorillonite clay to concrete with a poly carboxylic acid doped water reducing agent, and solves the problem of complex technology, high cost, and bad effect of technological means in the prior art. The treating agent for inhibition of harm of montmorillonite clay to concrete comprises the following components by mass: 25%-35% of an intercalation adsorbent, 45%-55% of a dispersing agent and 10%-25% of a stabilizer. When in use, the dosage of the treating agent for inhibition of harm of montmorillonite clay to concrete is 0.01% to 0.03% of the dosage of a cementitious material in the concrete. The treating agent can effectively reduce the poly carboxylic acid doped water reducing agent adsorption of the montmorillonite clay, improves concrete performance, and has the advantages of simple preparation process, small dosage, and low cost of production and use.

Owner:SHANGHAI CONSTRUCTION GROUP

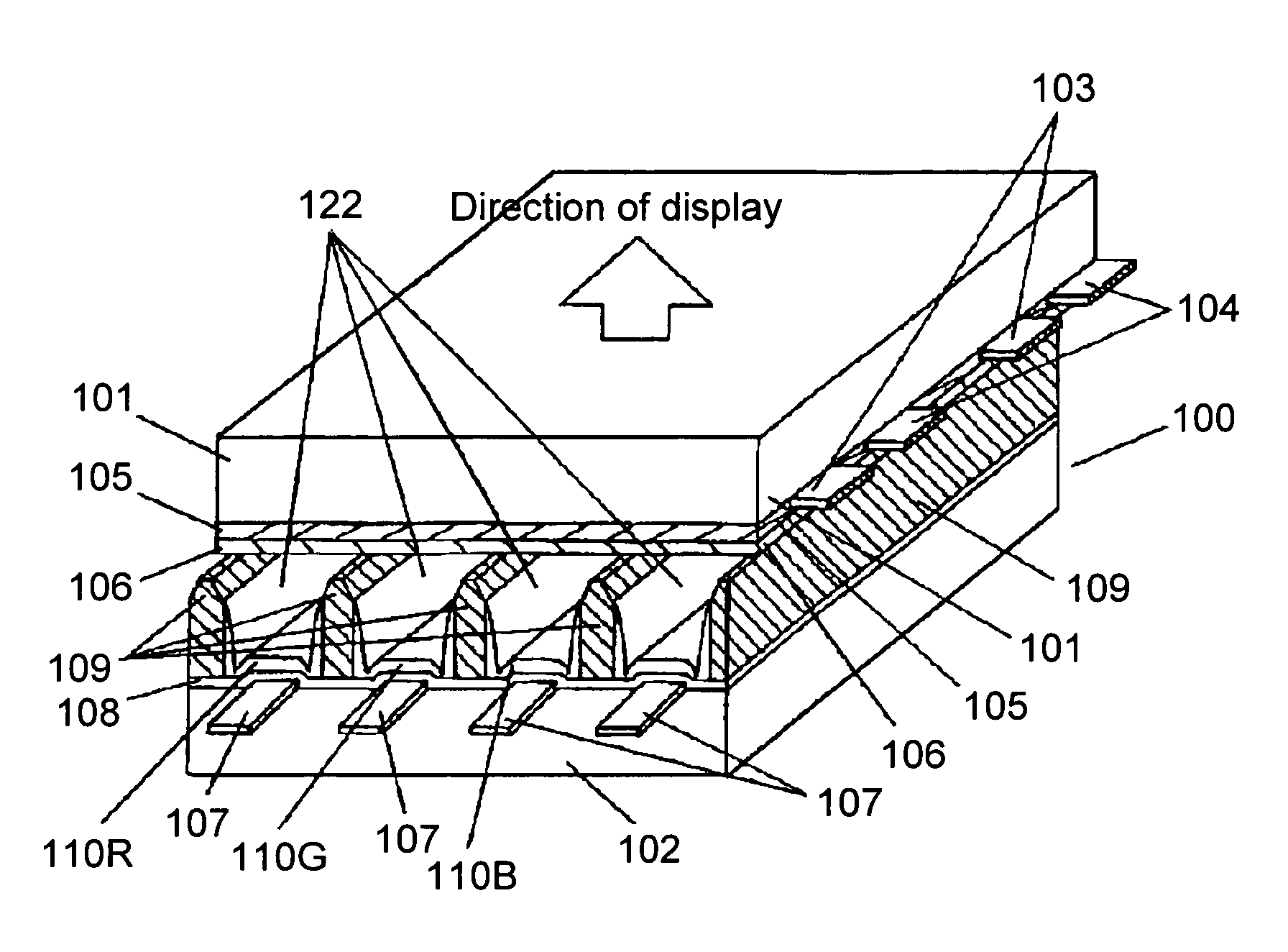

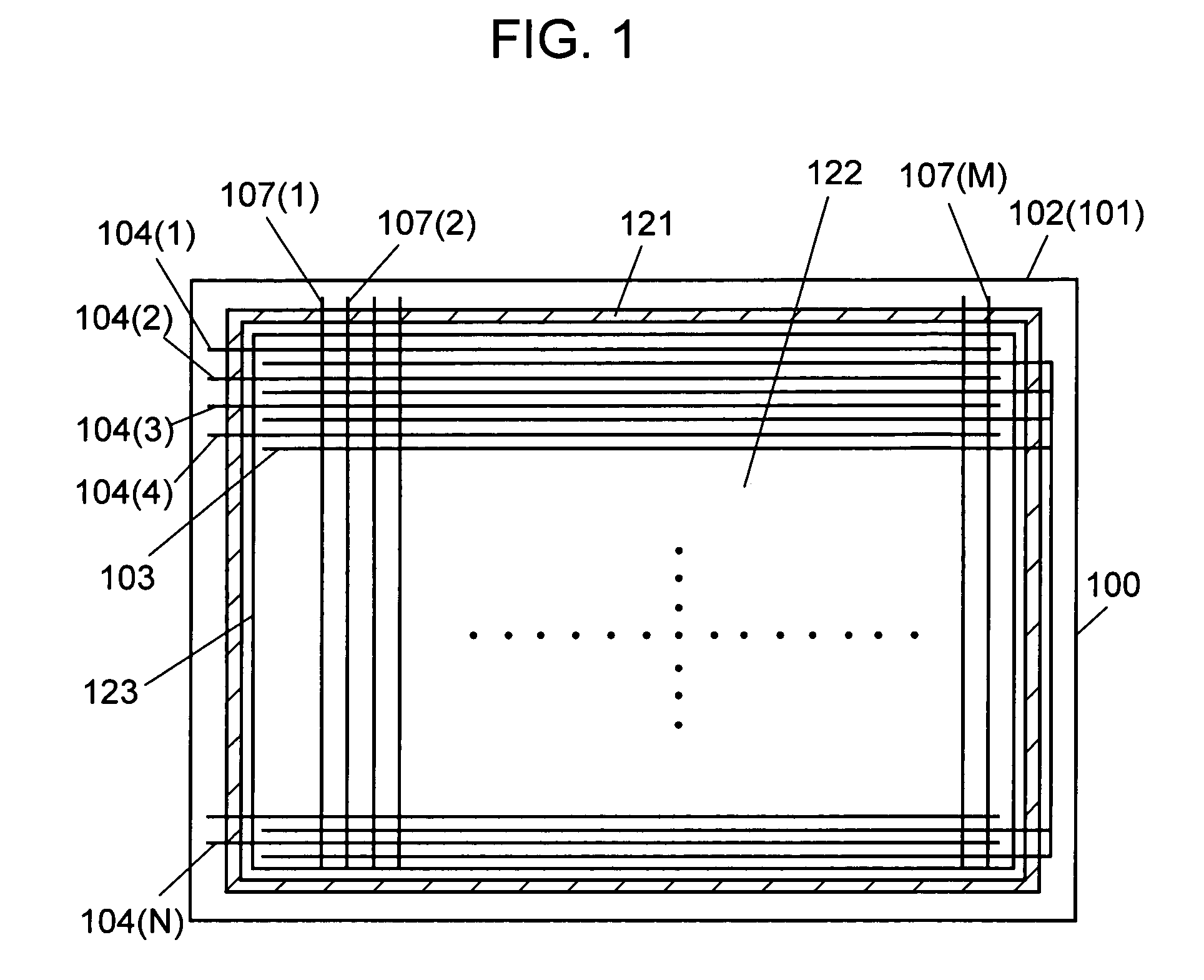

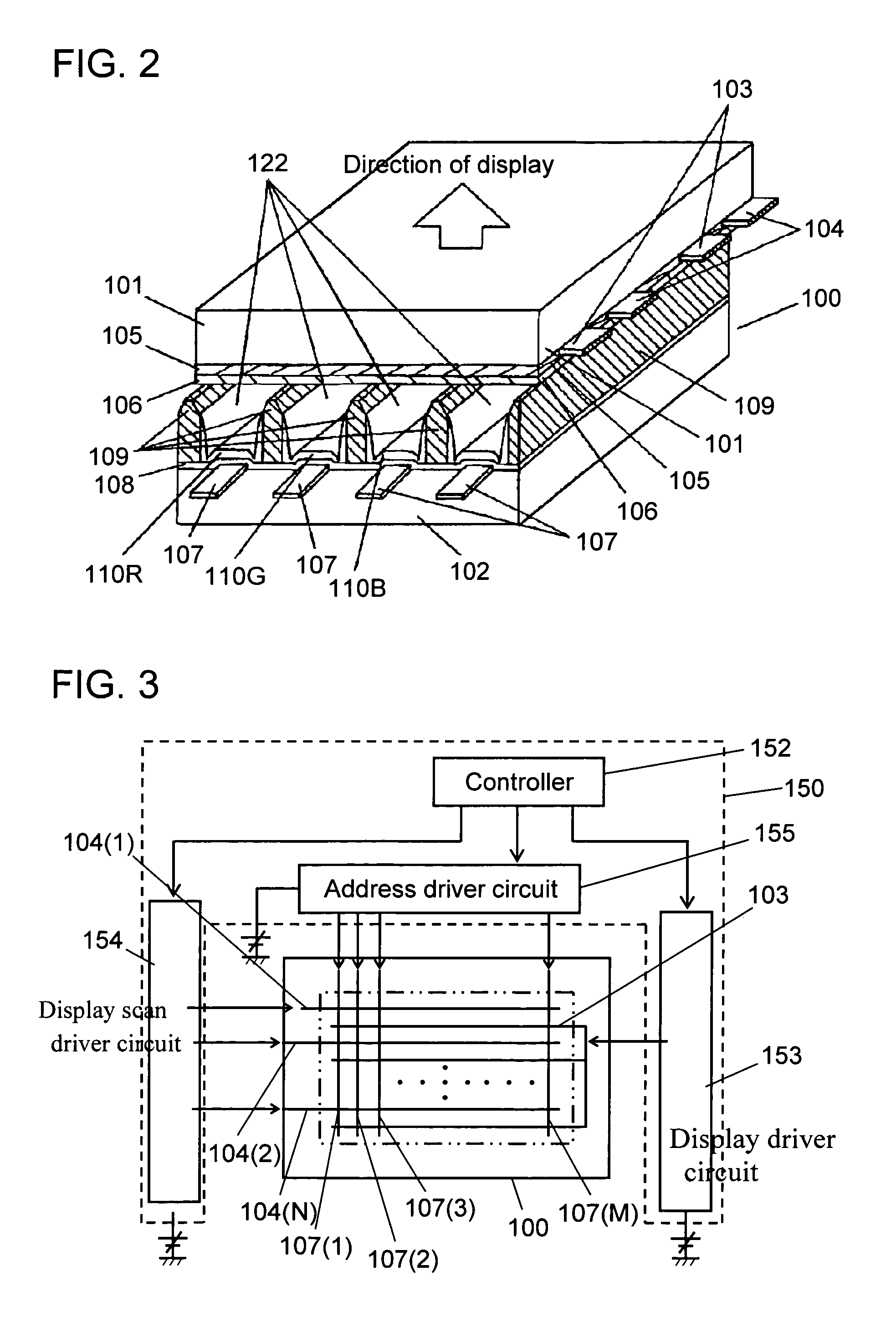

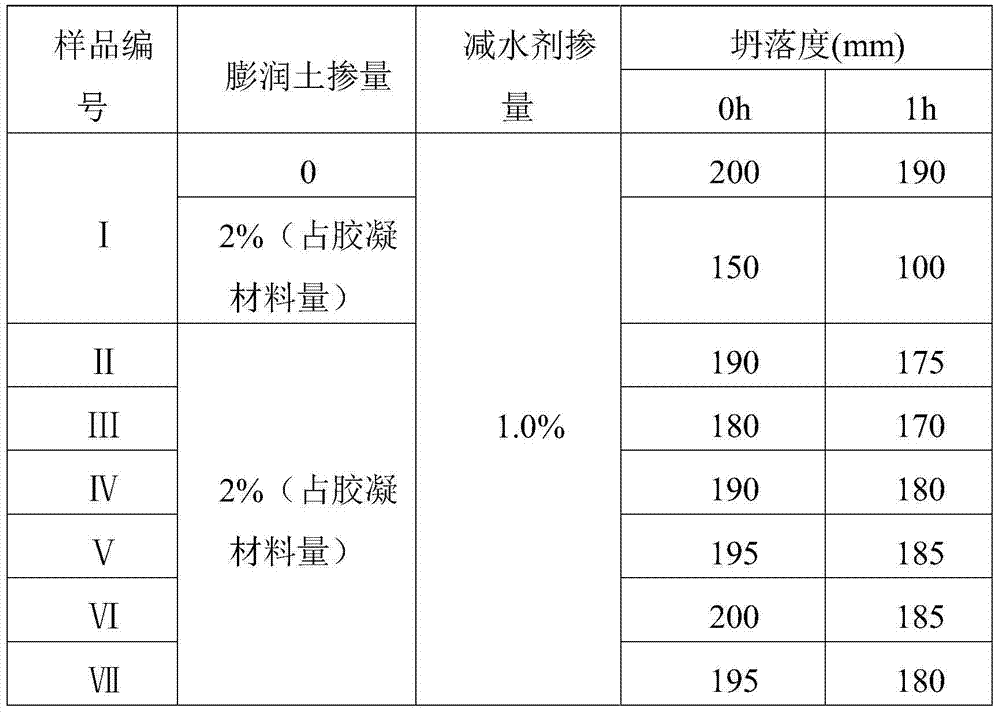

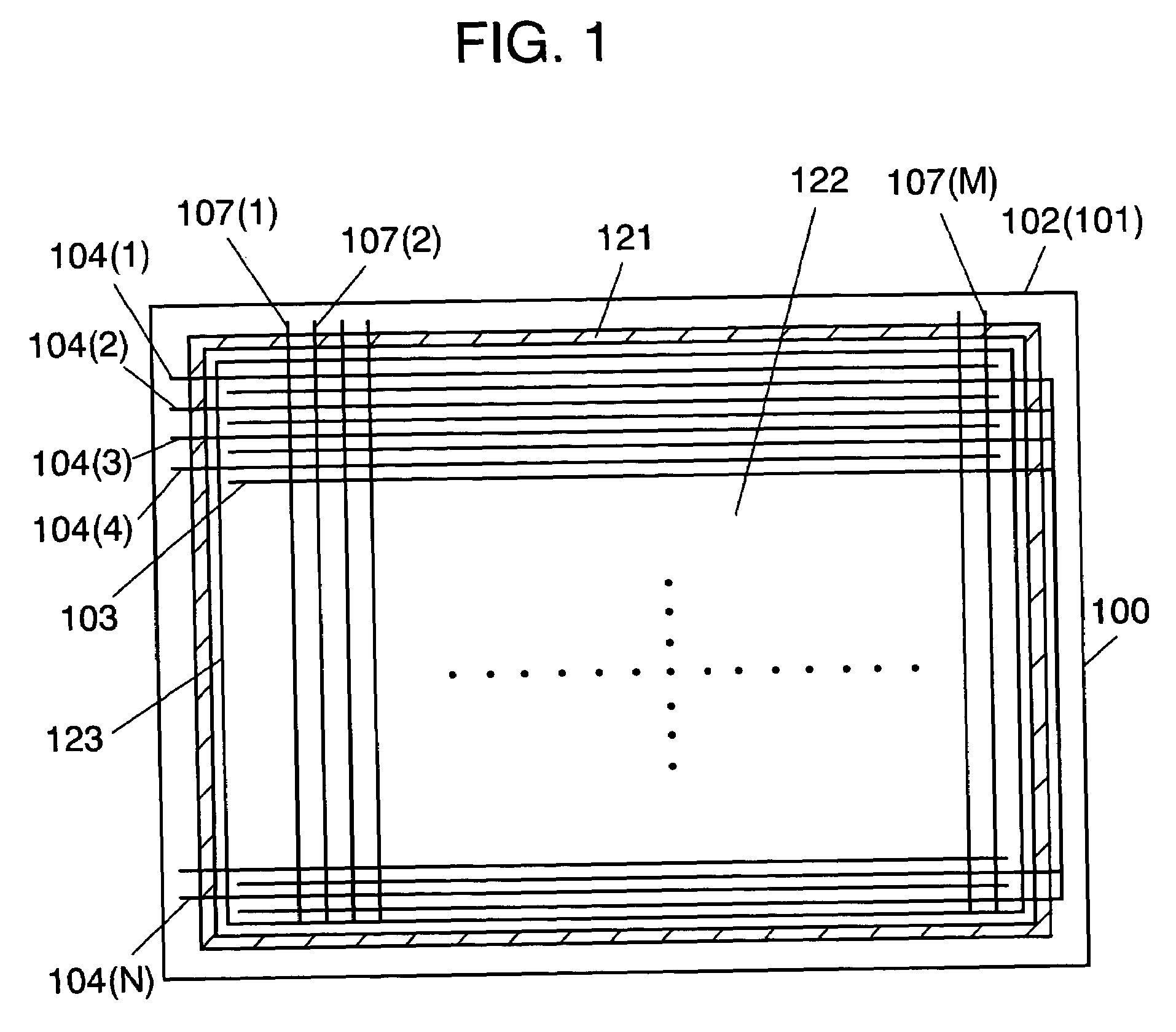

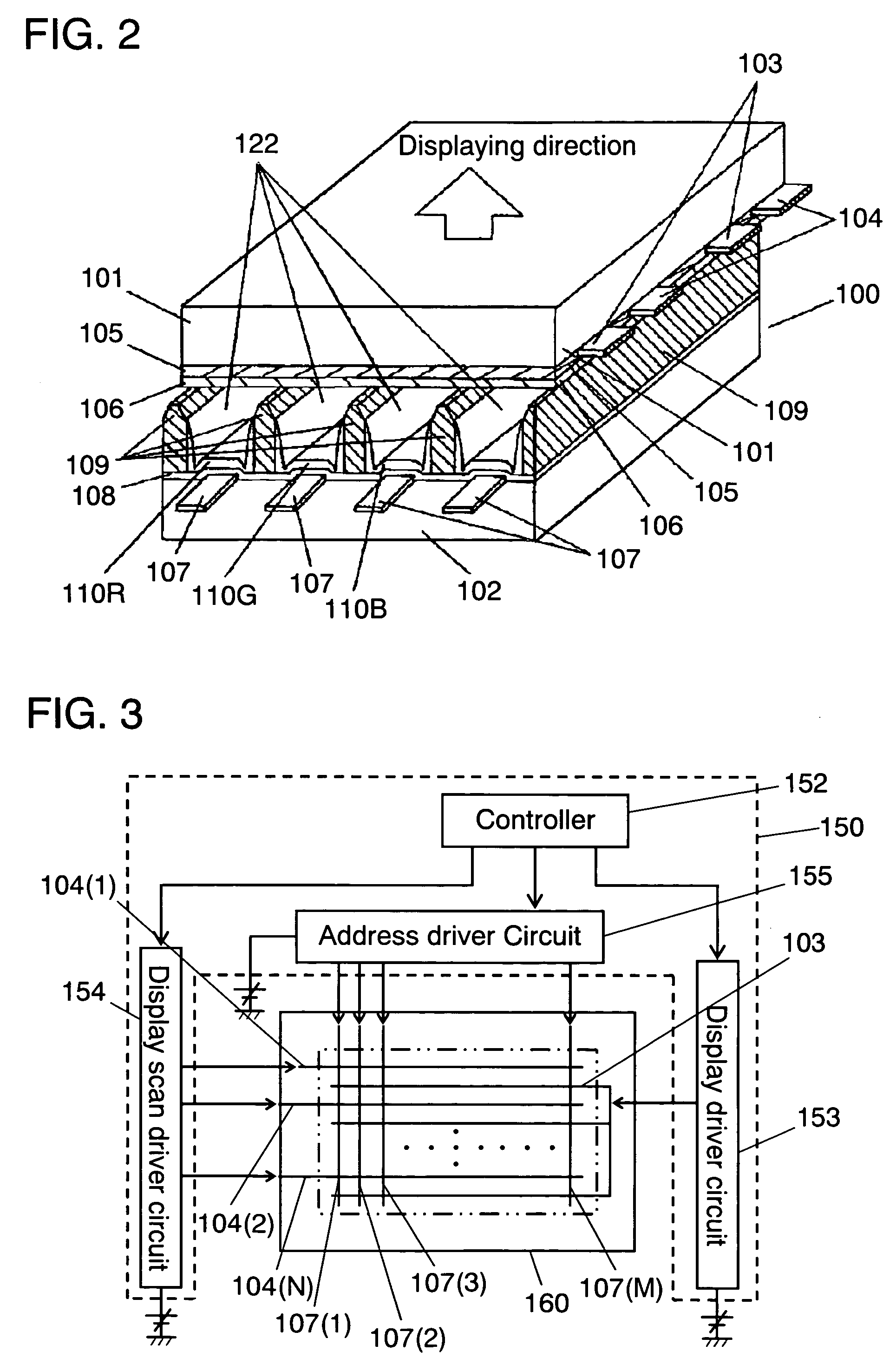

Plasma display unit

InactiveUS7161298B2Inhibition of adsorptionReduce changesAddress electrodesSustain/scan electrodesFluorescenceDisplay device

A plasma display device includes a blue phosphor composed of a compound represented by Me3MgSi2O8:Eu (where, Me is at least calcium (Ca), strontium (Sr), or barium (Ba)). Concentration of bivalent Eu ions is 45 to 95% and concentration of trivalent Eu ions is 5 to 55%, of the europium (Eu) atoms contained in the blue phosphor layer. The plasma display device has less luminance degradation in a panel manufacturing process, high luminance, and long lifetime.

Owner:PANASONIC CORP

Polycrystalline silicon ingot casting molten material and impurity removing process

InactiveCN103741206AReasonable designThe process steps are simplePolycrystalline material growthFrom frozen solutionsCrucibleIngot casting

The invention discloses a polycrystalline silicon ingot casting molten material and an impurity removing process. The process comprises the following steps: 1, preheating: adopting an ingot furnace to preheat a silicon material filled in a crucible, and gradually raising the heating temperature of the ingot furnace to T1; the preheating time is 6-10h, and T1=1165-1185 DEG C; 2, melting: the melting temperature is T1-T5; T5=1540-1560 DEG C; in the melting process, filling insert gases into the ingot furnace, and keeping air pressure in the furnace in Q1, and Q1=550-650mbar; 3, removing impurities: the process is as follows: the 11th step, reducing pressure: the air pressure of the ingot furnace is reduced from Q1 to Q2, and the pressure reducing time is 8-12min, and Q2=350-450mbar; the 12th step, maintaining pressure; the 13th step, boosting pressure and lowering temperature. The process has the advantages of simple steps, reasonable design, convenience in realization, easiness in grasp and good using effect, can discharge gas containing carbon in the furnace in time, and increases the polycrystalline silicon ingot casting quality.

Owner:XIAN HUAJING ELECTRONICS TECH

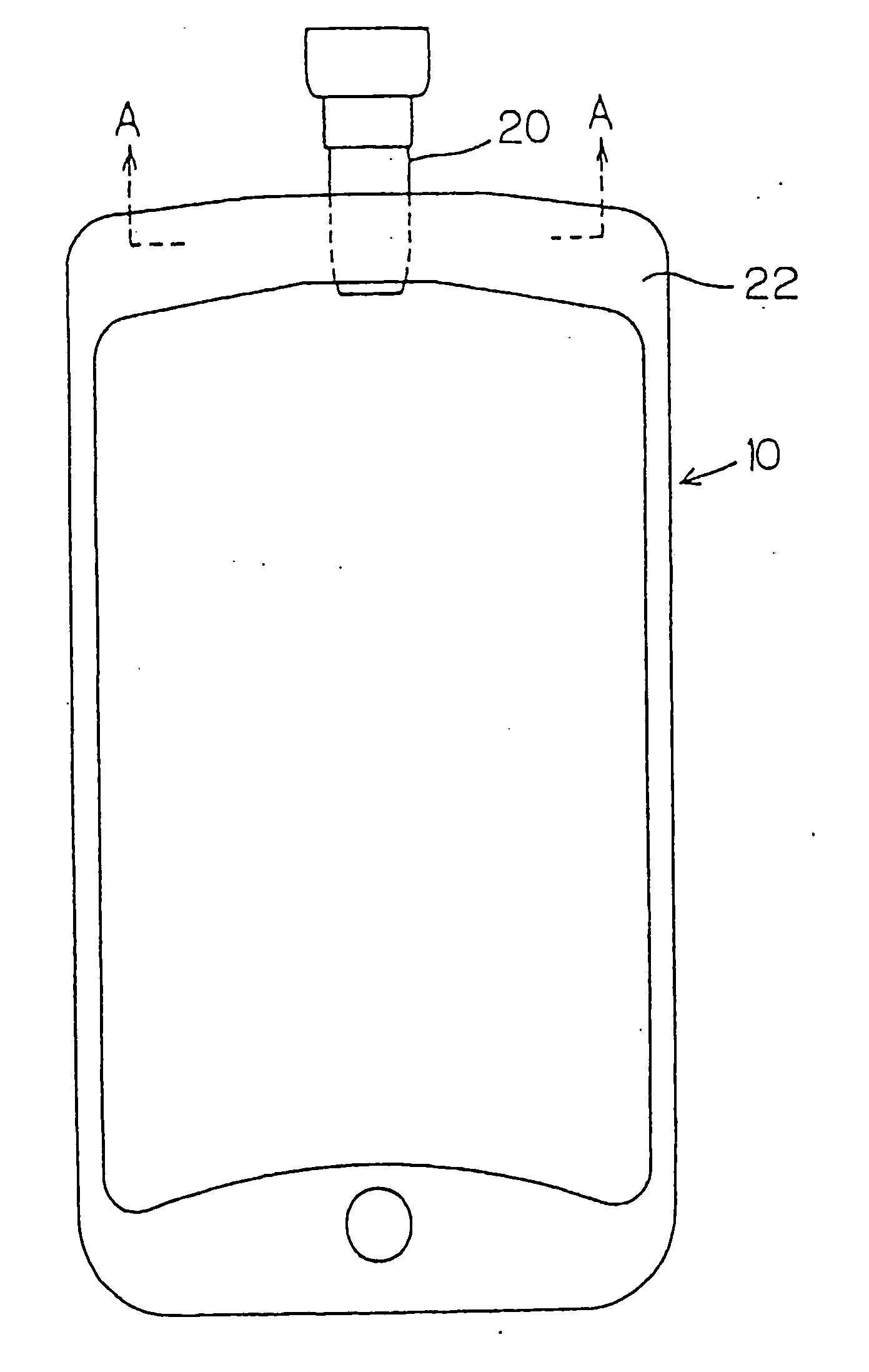

Multi-layer film and medicine container using the same

InactiveUS20050208240A1Improve heat resistanceIncrease flexibilitySynthetic resin layered productsDomestic containersSurface layerMedicine

Disclosed is a multi-layer film comprising: a surface layer having a thickness of 10 to 50 ƒÊm made of an ethylene-ƒ-olefin copolymer halving a density of 0.935 to 0.950 g / cm3, a flexible layer having a thickness of 100 to 200 ƒÊm made of an ethylene-ƒ-olefin copolymer having a density of 0.860 to 0.930 g / cm3, a barrier layer having a thickness of 10 to 80 ƒÊm made of a mixed resin containing 60 to 95% by weight of a cyclic olefin polymer and 5 to 40% by weight of an ethylene-ƒ-olefin copolymer having a density of 0.900 to 0.965 g / cm3, and a seal layer having a thickness of 5 to 80 ƒÊm made of an ethylene-ƒ-olefin copolymer having a density or 0.910 to 0.950 g / cm3. This multi-layer film is suited for use as a material for production of a medicine container 10 because it suppresses adsorption of a medicine by the barrier layer and is also superior in strength and flexibility.

Owner:OTSUKA PHARM FAB INC

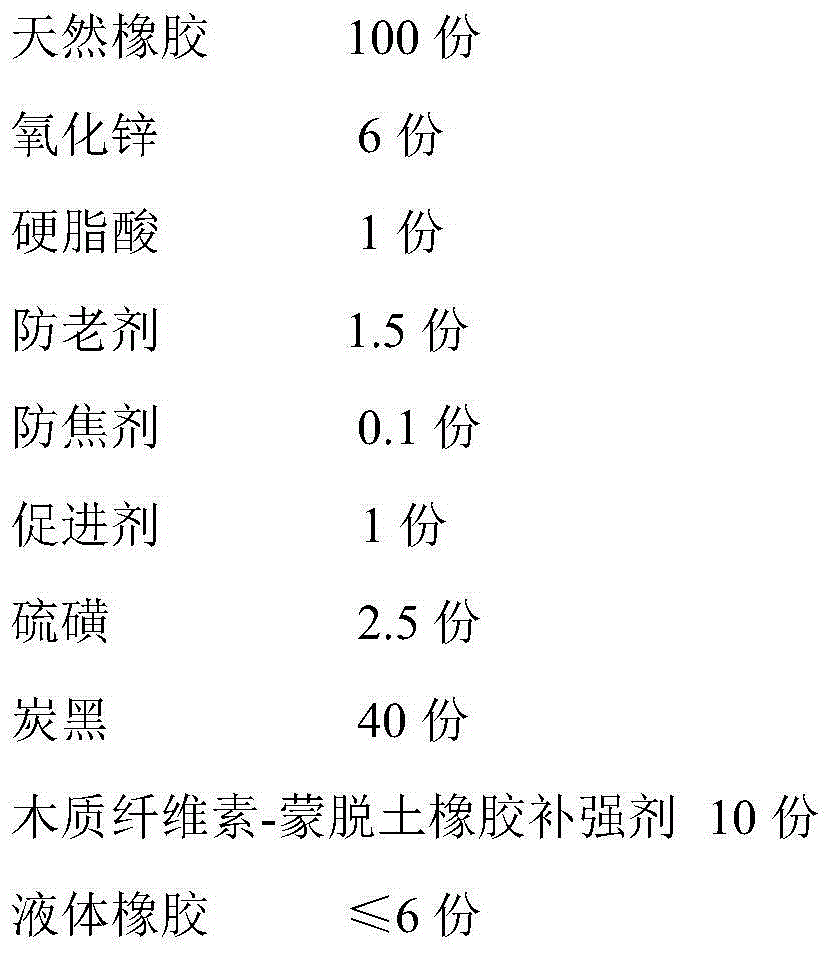

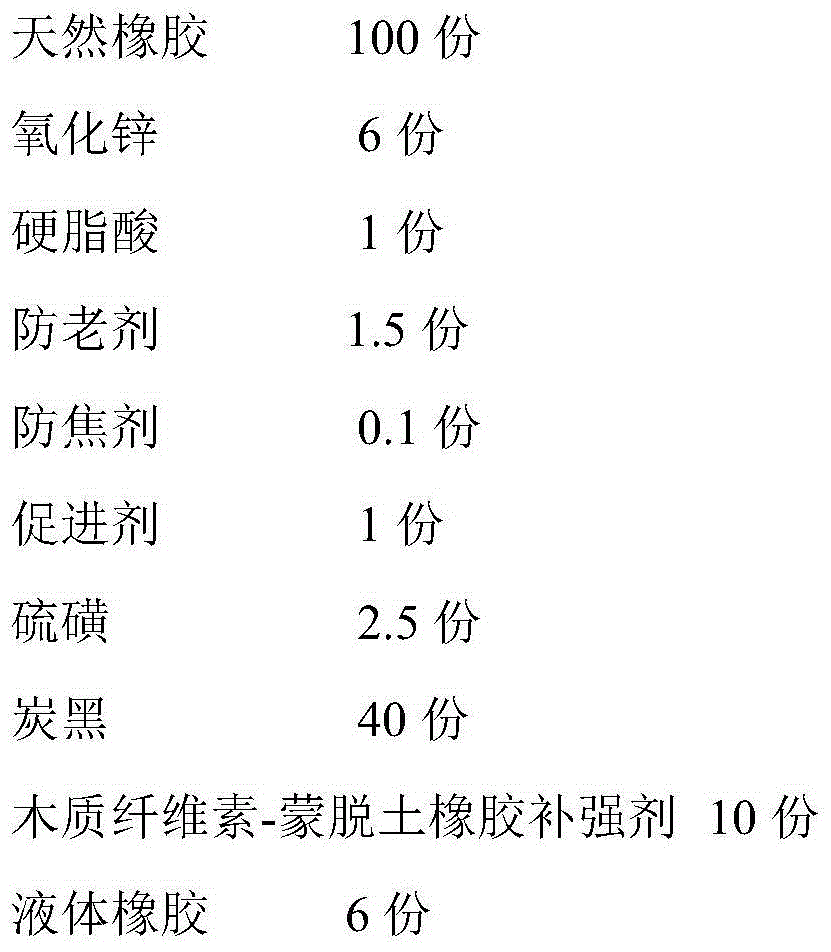

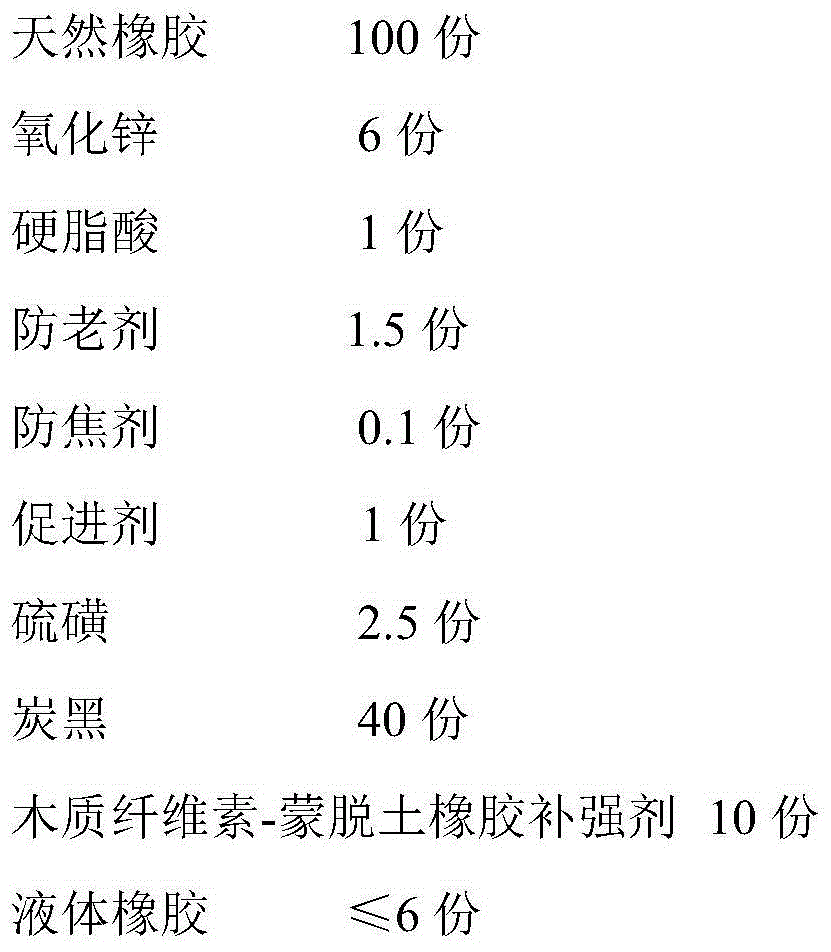

Rubber composite material and preparation method thereof

The invention provides a rubber composite material, which comprises the following components in parts by weight: 100 parts of natural rubber, 6 parts of zinc oxide, 1 part of stearic acid, 1.5 parts an antioxidant, 0.1 part of a scorch retarder, 0.7 part of an accelerator CZ, 0.3 part of an accelerator TMTD, 2.5 parts of sulfur, 40 parts of carbon black, 10 parts of a wood cellulose-montmorillonite rubber reinforcing agent, and less than or equal to 6 parts of liquid rubber. According to the composite material provided by the invention, the liquid rubber is added to a formula of rubber, so that the tensile strength and the elongation at break of rubber can be improved, the dispersion of the lignocellulose-montmorillonite reinforcing agent in a natural rubber matrix is improved, the interfacial interaction of the rubber and the wood cellulose-montmorillonite reinforcing agent is effectively enhanced, and the environment is protected. The invention also provides a preparation method of the rubber composite material. The preparation method has the advantages of simple process, low cost and easiness in industrial production.

Owner:合肥市和裕达塑业有限公司

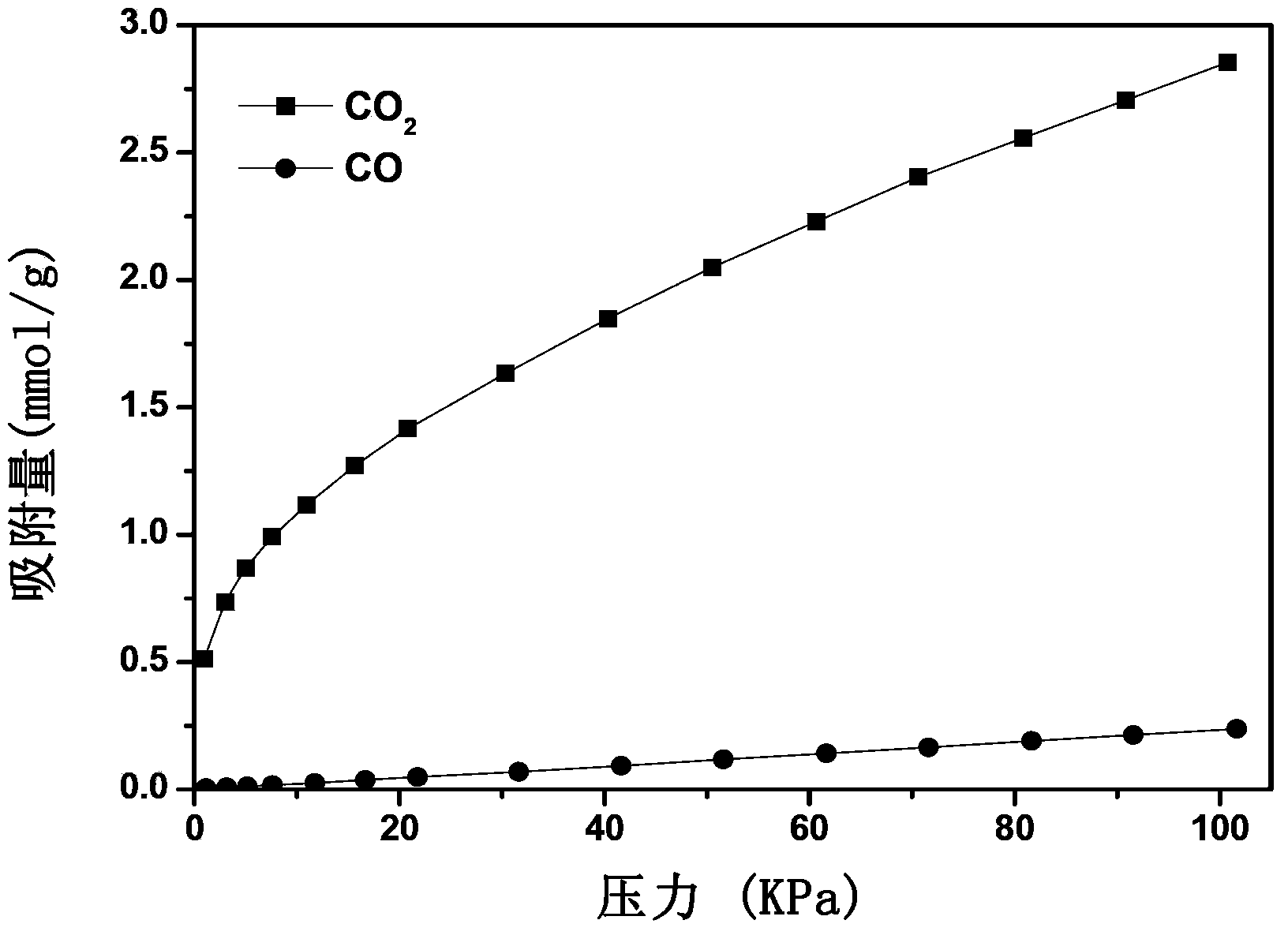

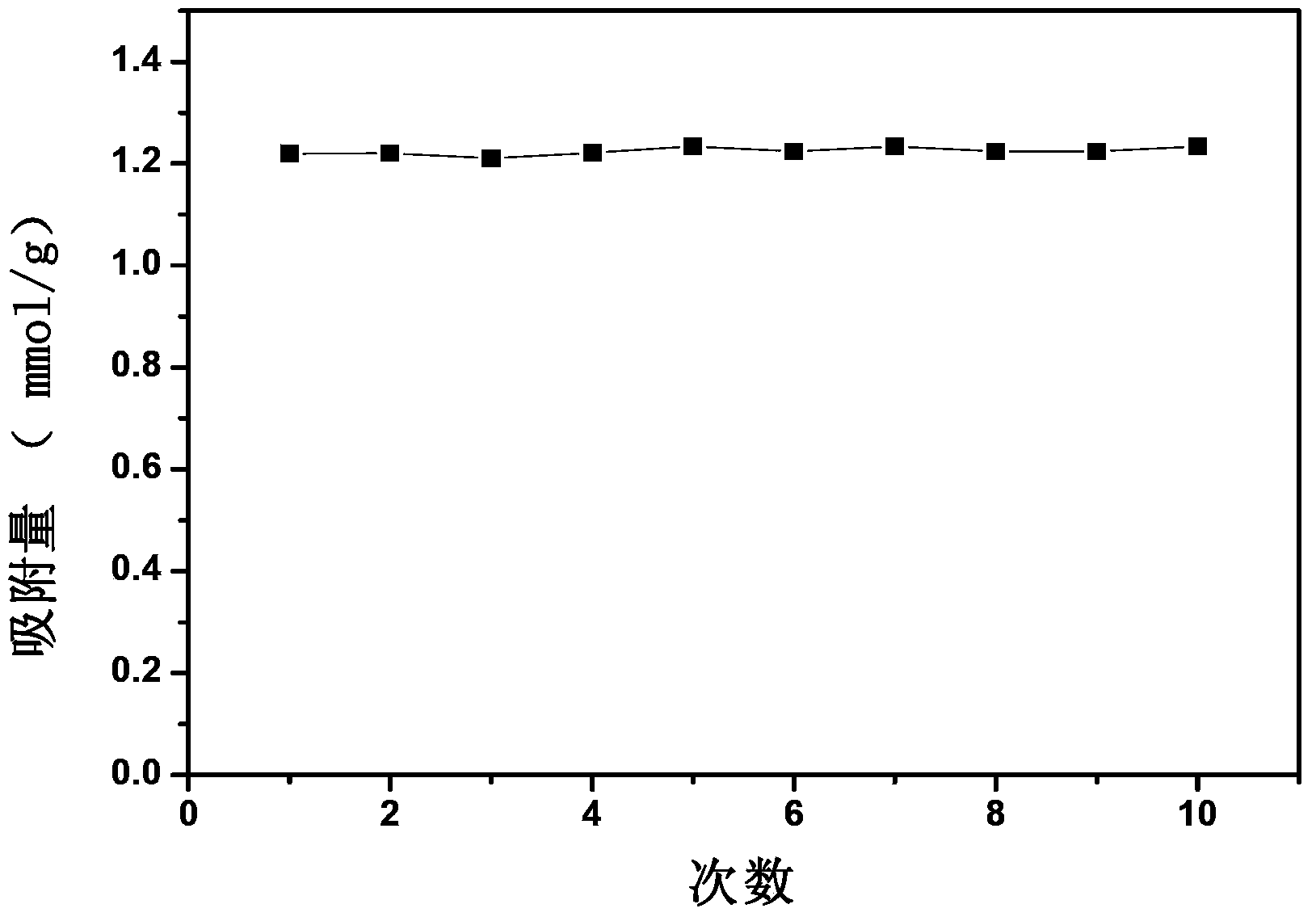

Preparation method for amino modified adsorption material

InactiveCN103721679AHigh selectivityImprove adsorption capacityOther chemical processesGraft reactionOrganic chemistry

A preparation method for an amino modified adsorption material is used to improve the selective separation of CO2 in blast furnace gas, and belongs to the technical field of CO2 adsorption and separation. The preparation method comprises: taking porous material MIL-101 and an amino modifier as raw materials, and performing vacuum degassing, grafting reaction, filtering, drying and the like to prepare the amino modified adsorption material. Compared with conventional materials, the prepared amino modified adsorption material has the advantages of being high in adsorption quantity, strong in CO2 selectivity, recyclable and the like, and the preparation technology is simple and is easy for industrialized production.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

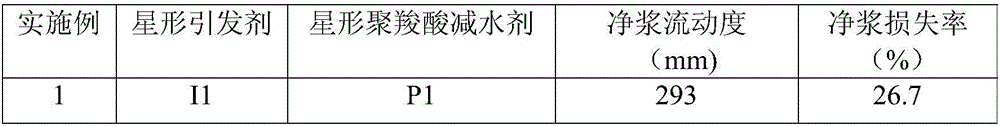

Star-shaped amphoteric polycarboxylate superplasticizer and preparation method thereof

The invention discloses a star-shaped amphoteric polycarboxylate superplasticizer and a preparation method thereof. The method includes: esterfying cyclodextrin to obtain a star-shaped initiator, initiating atom transfer radical polymerization of (methyl) polyethylene glycol acrylate, (methyl) sodium acrylate, (methyl) acryloyloxyethyl trimethyl ammonium chloride and (methyl) hydroxylethyl acrylate to obtain a star-shaped copolymer of the four monomers, and conducting further treatment to obtain a star-shaped amphoteric polycarboxylate superplasticizer with a solid content of 20%. The polycarboxylate superplasticizer prepared by the method provided by the invention has high water reducing rate and good mud resistance, meets high construction requirements, and has good application prospect.

Owner:SHANDONG JIAOTONG UNIV

Super hydrophilic oil-water separation filter paper and preparation method thereof

ActiveCN105771322AInhibition of adsorptionEfficient separationMembrane filtersNon-miscible liquid separationAlcoholOil water

The invention discloses a preparation method of super hydrophilic oil-water separation filter paper. The method comprises the following steps: by a dip coating method, immersing filter paper into a solution which is formed by evenly mixing nano silicon dioxide particles, a silane coupling agent, a catalyst, absolute ethyl alcohol and deionized water; and carrying out ultrasonic dispersion, taking out and naturally drying the filter paper to obtain the super hydrophilic oil-water separation filter paper. The filter paper disclosed by the invention is simple in preparation method; the raw materials are universal and available; the stability is good; the prepared super hydrophilic oil-water separation filter paper is high in pore permeability, and can be applied to the fields of oil-water mixture separation, oily sewage treatment and the like; the separation efficiency can reach 99.5% and higher; and the industrial production and application prospect is wide.

Owner:SHANDONG JIAOTONG UNIV

Composition for soft contact lens and adsorption suppressing method

Disclosed is a composition for soft contact lenses which enables to suppress adsorption of a basic chemical substance onto a soft contact lens. This composition for soft contact lenses comprises (A) a basic chemical substance selected from amines having a secondary amino group and / or a tertiary amino group and salts thereof, and (B) one or more substances selected from amino acids and salts thereof, acid mucopolysaccharides and salts thereof and cyclodextrin, while having a pH of 3.5 to 4.8. Also disclosed is a method for suppressing adsorption of the basic chemical substance onto a soft contact lens.

Owner:LION CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com