Preparation method for amino modified adsorption material

An adsorption material and amino modification technology, which is applied in chemical instruments and methods, and other chemical processes, can solve the problems of poor stability and volatility of materials in adsorption and desorption cycle, and achieve the purpose of improving selectivity and adsorption capacity, inhibiting adsorption, The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

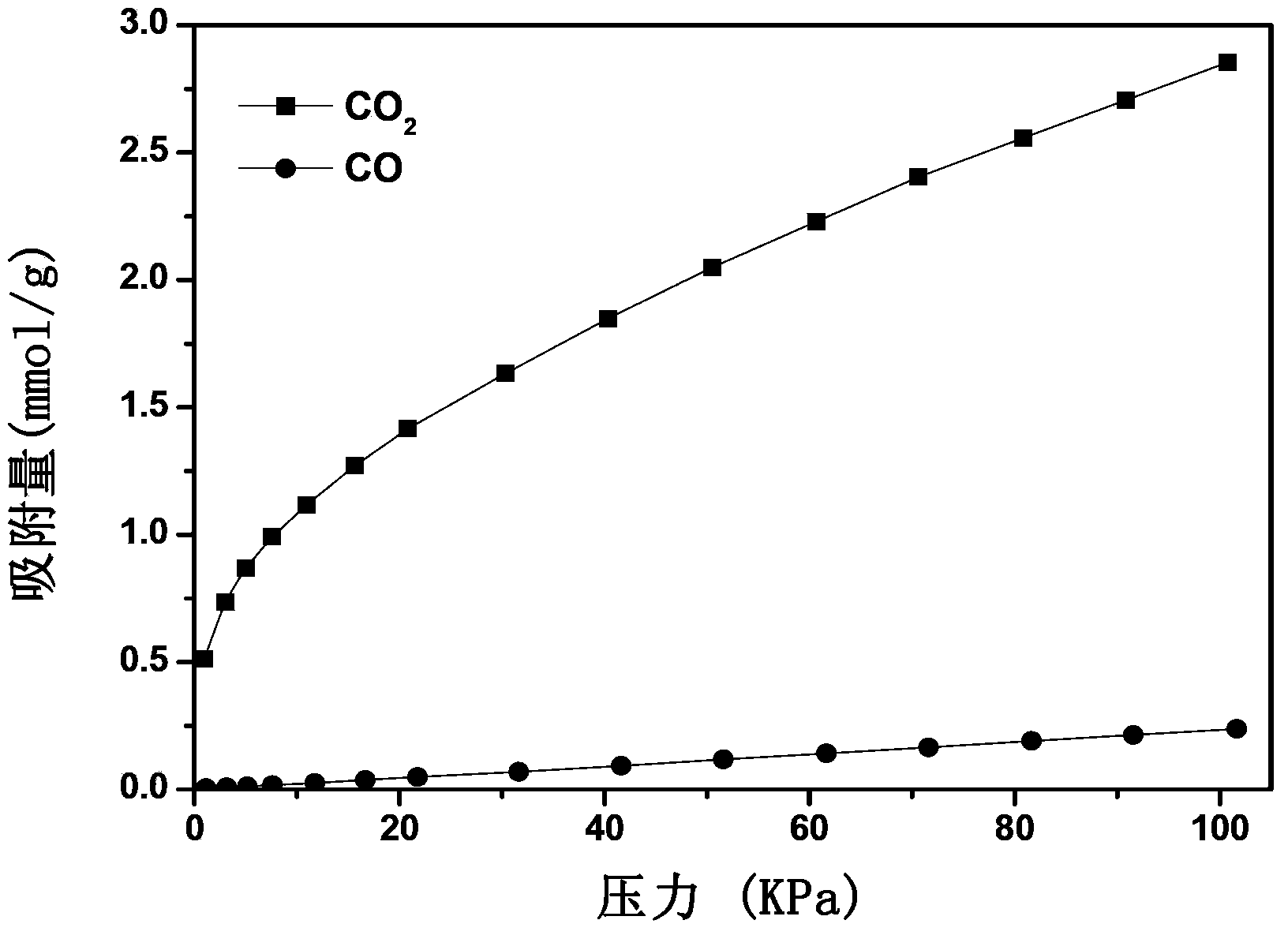

Embodiment 1

[0020] Take 1g of 40-120 mesh MIL-101 at 100°C, vacuum degree of about 1Pa and keep it warm for 1h for degassing treatment; then add the degassed MIL-101 to the toluene solution of ethylenediamine, the solution concentration is 50mmol ethylenediamine / L toluene, the composition ratio of MIL-101 and ethylenediamine is 12mmol ethylenediamine / g MIL-101; stir at room temperature for 1h, then react for 3h at 80°C and nitrogen flow rate of 50ml / min; after the reaction product is filtered, Wash twice with ethanol, and dry at 60°C for 8 hours to obtain an amino-modified adsorbent. After testing, this material is maintained at 25°C and 100KPa for a period of time, CO 2 The equilibrium adsorption capacity reaches 2.2mmol / g, CO 2 The selectivity to CO reaches 20.1.

Embodiment 2

[0022] Take 2g of 40-120 mesh MIL-101 at 120°C and keep it under a vacuum of about 10Pa for 2 hours for degassing treatment, then add the degassed MIL-101 to the xylene solution of diethylenetriamine, the solution concentration is 100mmol Diethylenetriamine / L xylene, the composition ratio of MIL-101 and diethylenetriamine is 24mmol diethylenetriamine / g MIL-101; stir at room temperature for 2h, then react at 100°C and nitrogen flow rate of 100ml / min 5h; the reaction product was filtered, washed with ethanol three times, and dried at 80°C for 6h to obtain an amino-modified adsorbent. After testing, this material is maintained at 25°C and 100KPa for a period of time, CO 2 The equilibrium adsorption capacity reaches 2.5mmol / g, CO 2 The selectivity to CO reaches 22.3.

Embodiment 3

[0024] Take 1.5g of 40-120 mesh MIL-101 at 120°C and keep it under a vacuum of about 30Pa for 6 hours for degassing treatment, then add the degassed MIL-101 into the chlorobenzene solution of triethylenetetramine, the solution concentration is 200mmol triethylenetetramine / L chlorobenzene, the composition ratio of MIL-101 and triethylenetetramine is 48mmol triethylenetetramine / g MIL-101; stir at room temperature for 4h, then at 130°C, nitrogen flow rate 200ml / min React for 6 hours; filter the reaction product, wash with ethanol 4 times, and dry at 100° C. for 4 hours to obtain an amino-modified adsorbent. This material is maintained at 25°C, 100KPa for a period of time, CO 2 The equilibrium adsorption capacity reaches 2.7mmol / g, CO 2 The selectivity to CO reaches 25.2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com