Patents

Literature

1655 results about "Tinning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tinning is the process of thinly coating sheets of wrought iron or steel with tin, and the resulting product is known as tinplate. The term is also widely used for the different process of coating a metal with solder before soldering.

Corrosion protective cleaning agent for tin-plated steel

InactiveUS6060122ASignificant positive effectGood effectOther chemical processesPretreated surfacesTitaniumNonionic surfactant

PCT No. PCT / EP96 / 01137 Sec. 371 Date Sep. 24, 1997 Sec. 102(e) Date Sep. 24, 1997 PCT Filed Mar. 15, 1996 PCT Pub. No. WO96 / 30558 PCT Pub. Date Oct. 3, 1996The invention concerns an aqueous corrosion-protective cleaning solution for tin-plated steel, in particular for tin-plated steel cans, the solution containing complex fluorides of the elements boron, titanium, zirconium, and hafnium; non-ionic surfactants; and corrosion inhibitors and having a pH within the range from 3 to 6. The invention also concerns an aqueous concentrate for preparing the solution by dilution with water and a method of cleaning tin-plated cans using the solution.

Owner:HENKEL KGAA

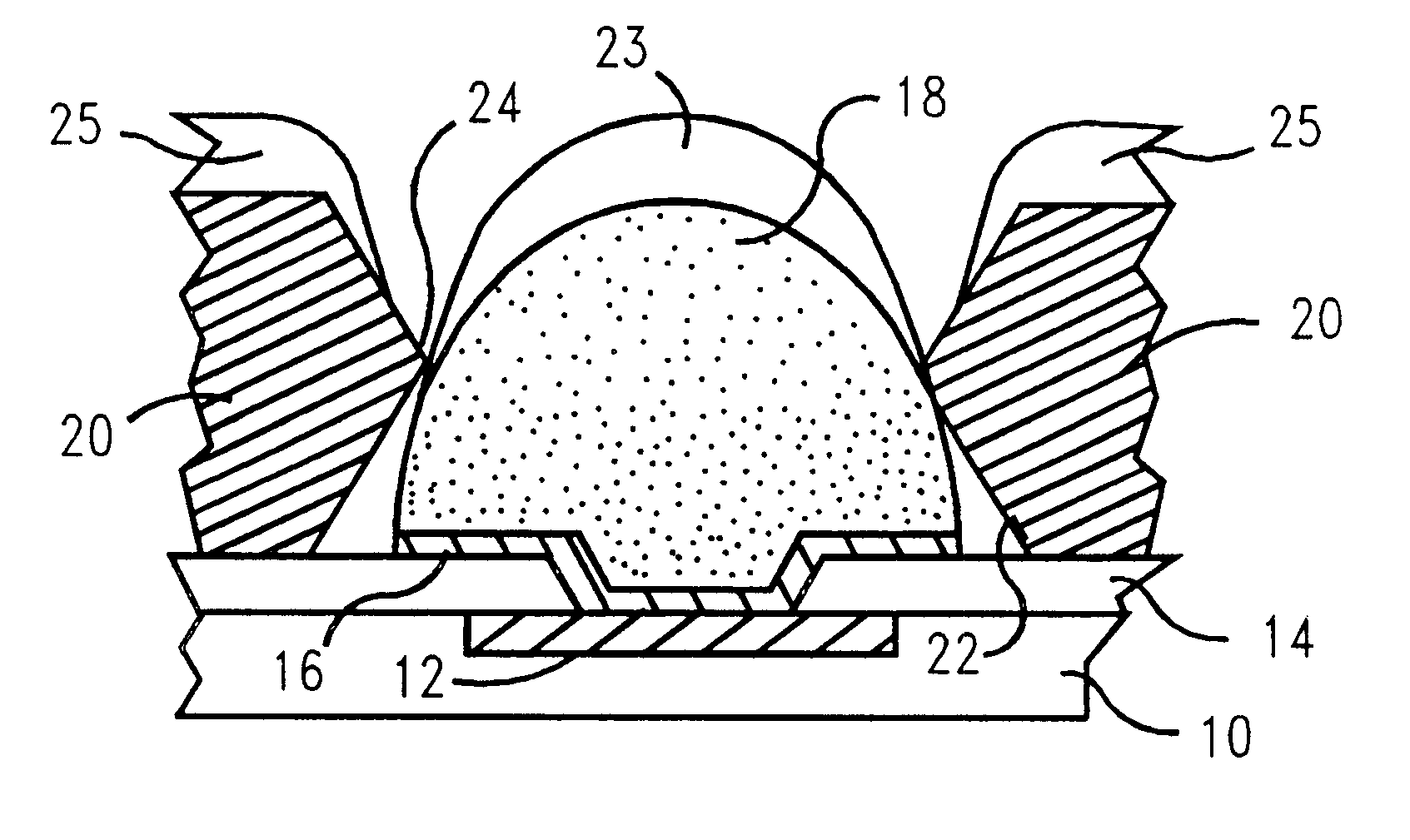

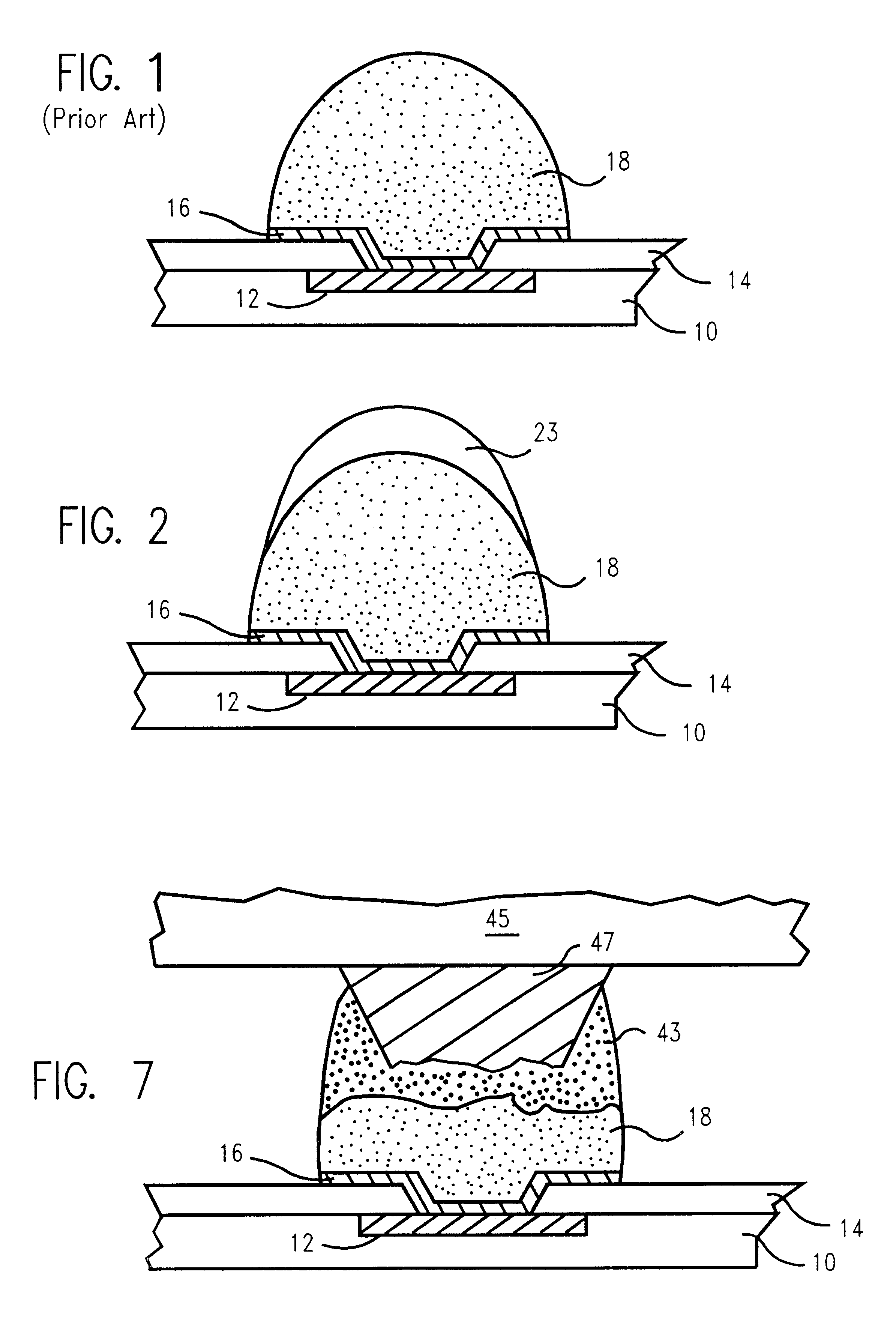

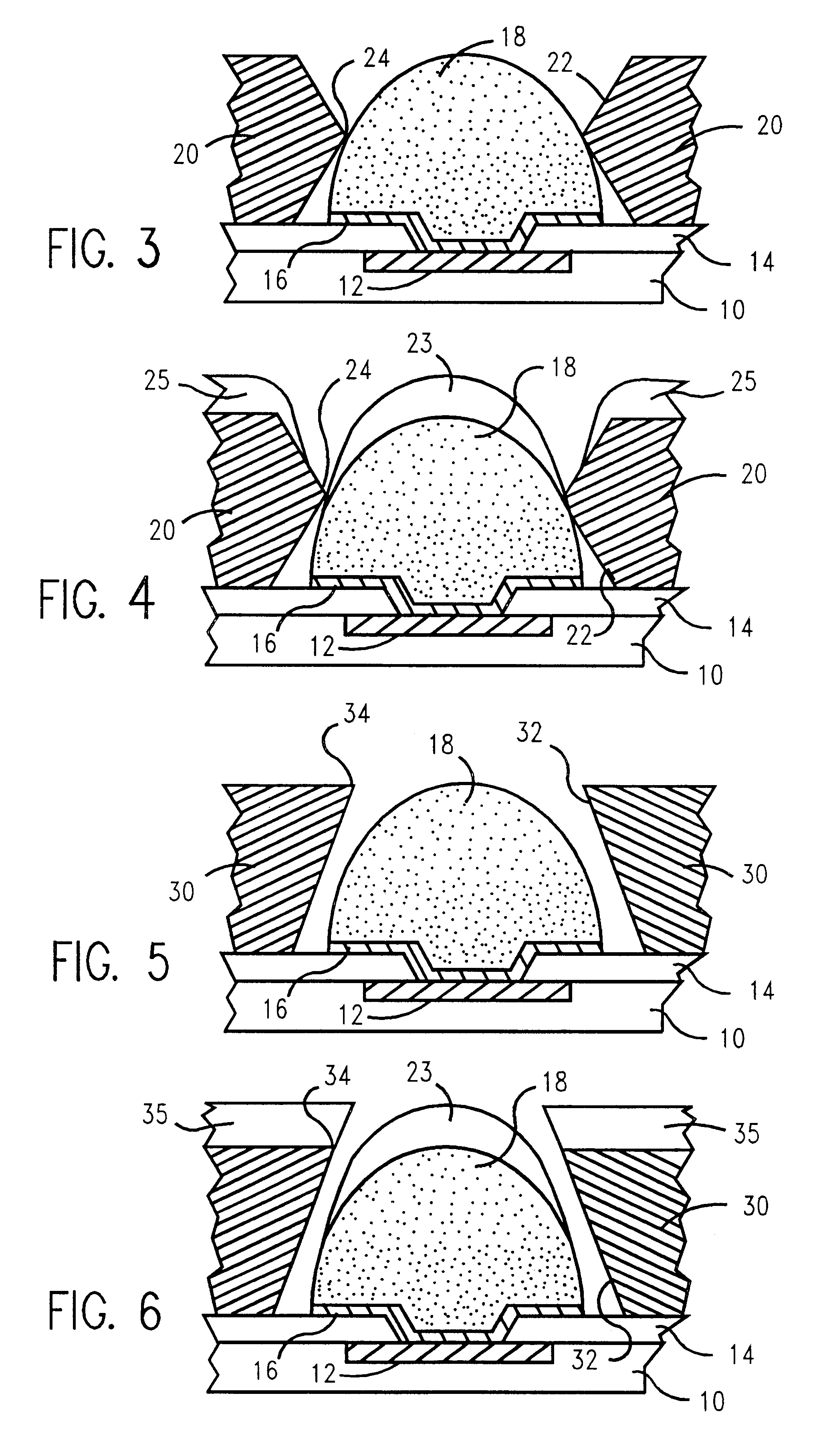

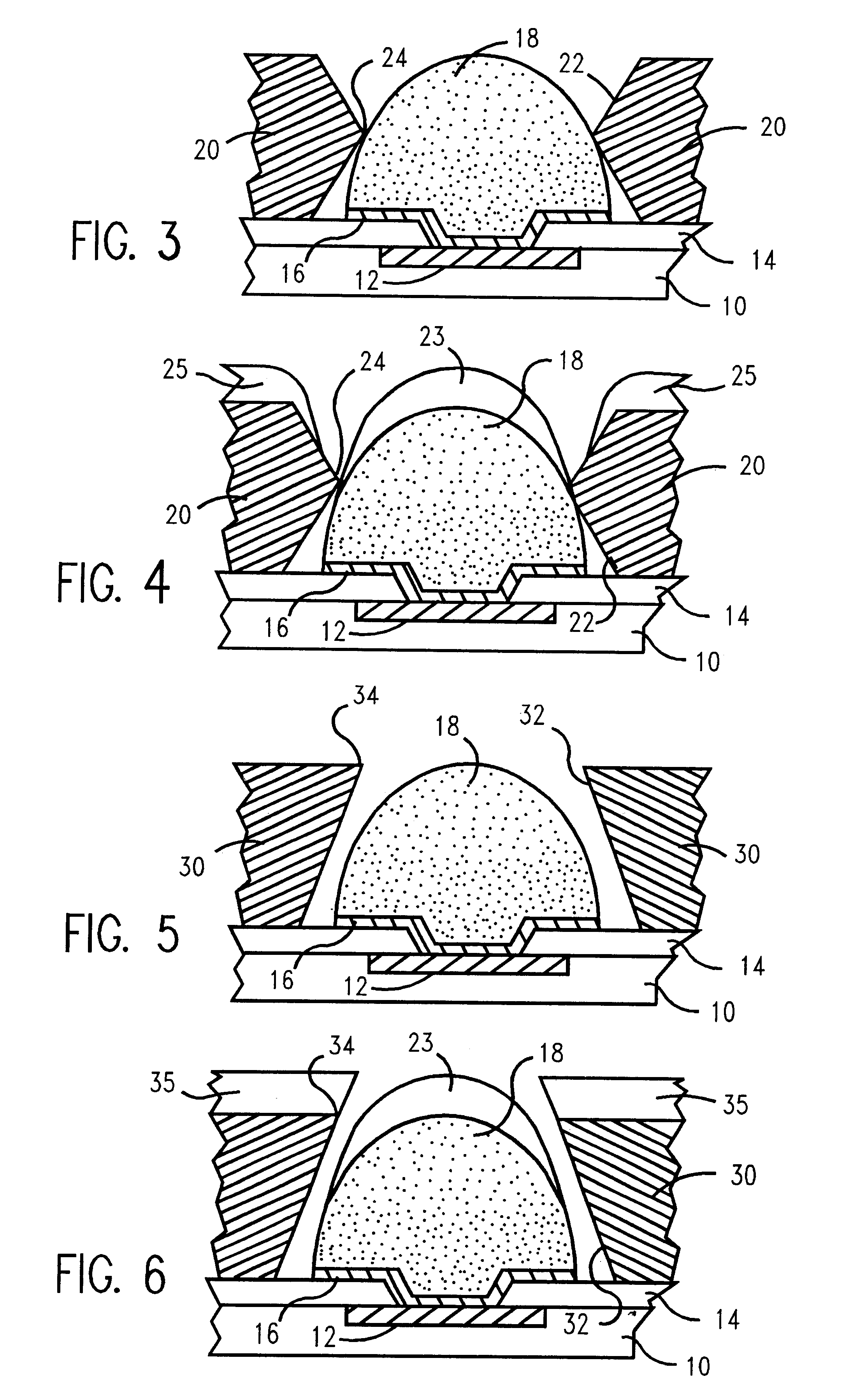

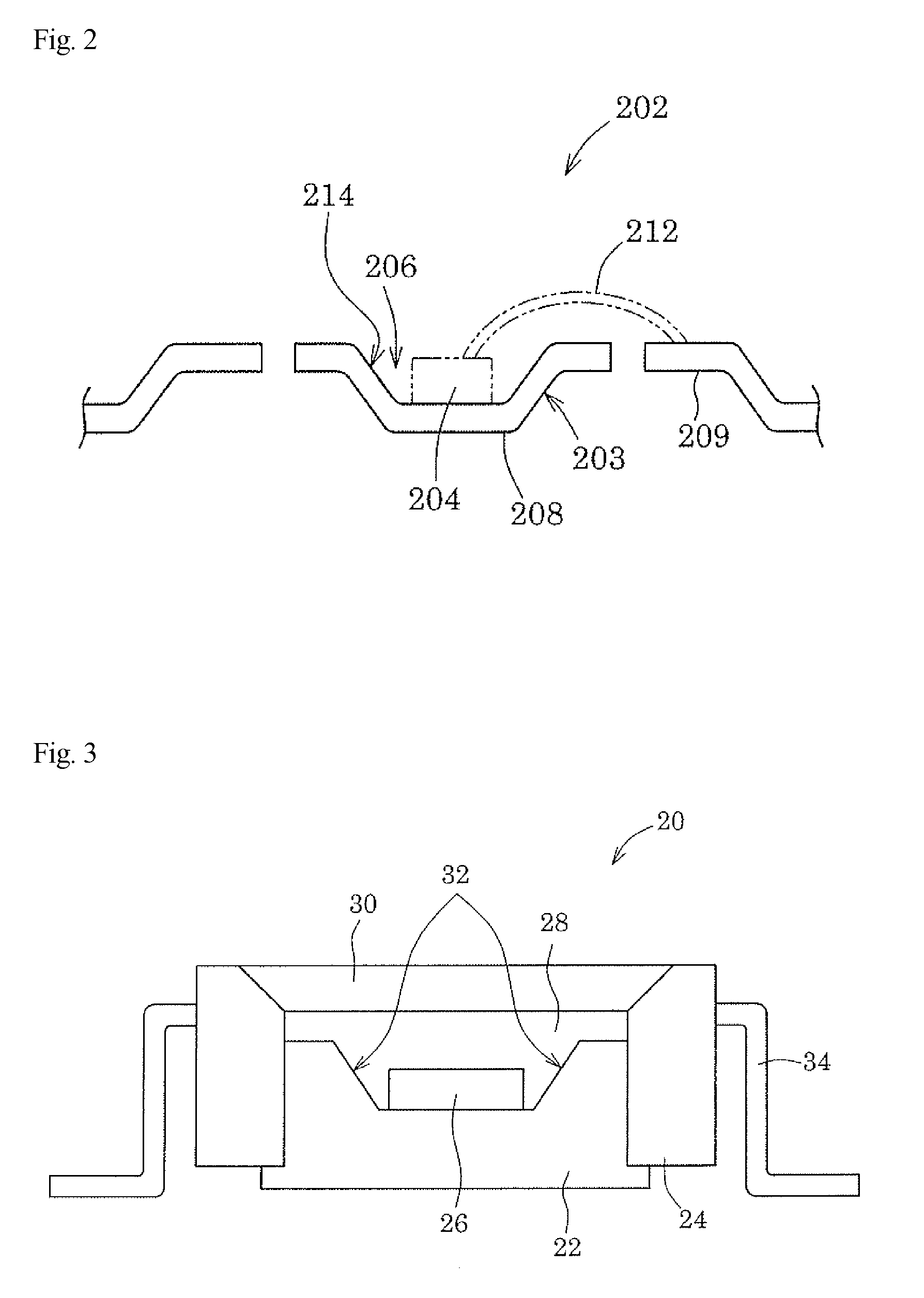

Method for forming reflowed solder ball with low melting point metal cap

InactiveUS6344234B1Reduce the hole diameterMinimal diameterFinal product manufactureSemiconductor/solid-state device detailsTinningIndium

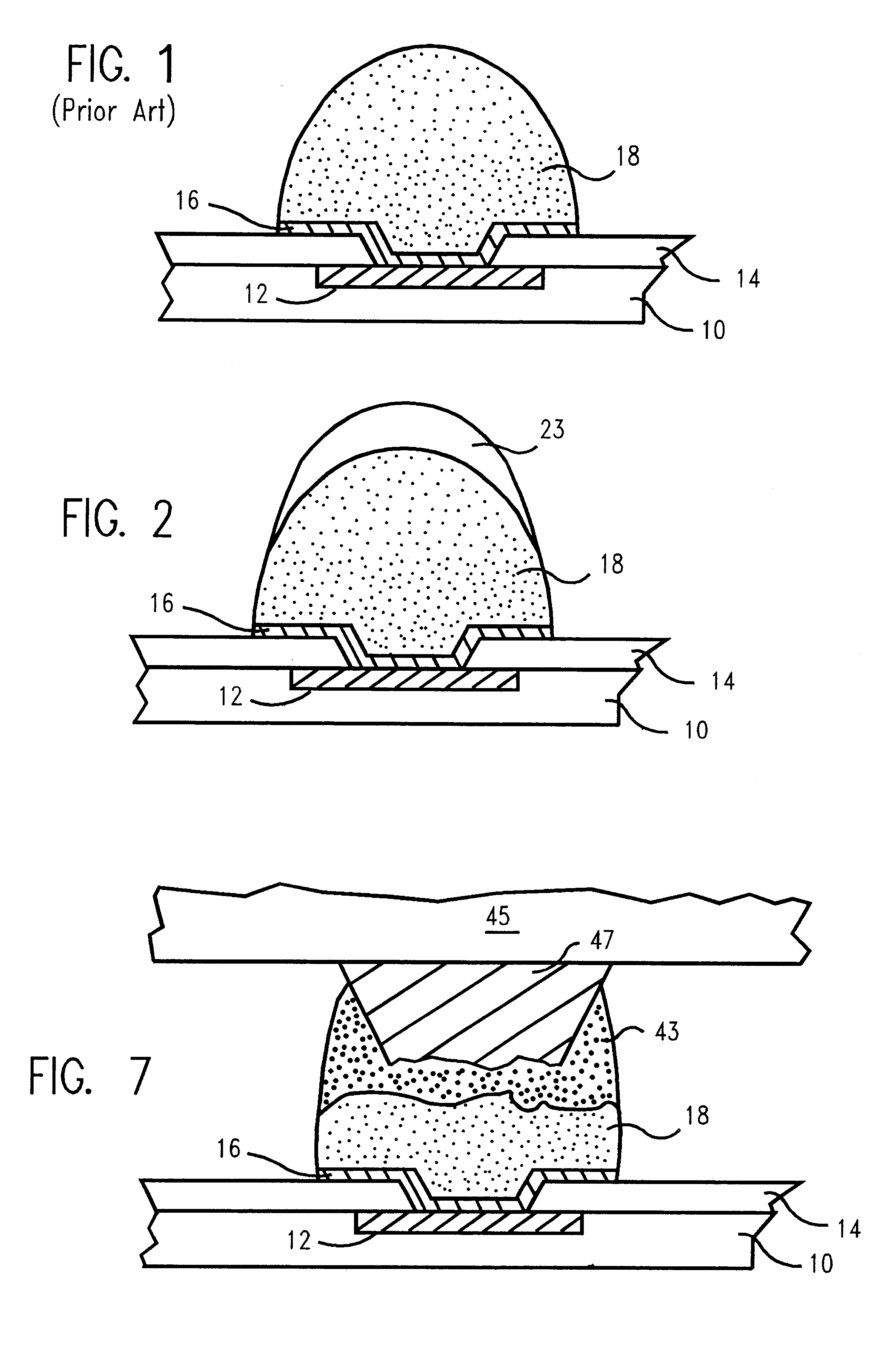

A method and structure for a solder interconnection, using solder balls for making a low temperature chip attachment directly to any of the higher levels of packaging substrate is disclosed. After a solder ball has been formed using standard methods it is reflowed to give the solder ball a smooth surface. A layer of low melting point metal, such as, bismuth, indium or tin, preferably, pure tin, is deposited on the top of the solder balls. This structure results in localizing of the eutectic alloy, formed upon subsequent low temperature joining cycle, to the top of the high melting solder ball even after multiple low temperature reflow cycles. This method does not need tinning of the substrate to which the chip is to be joined, which makes this method economical. It has also been noticed that whenever temperature is raised slightly above the eutectic temperature, the structure always forms a liquid fillet around the joint with copper wires. This liquid fillet formation results in substantial thermal fatigue life improvement for reduced stress at interface; and secondly, provides an easy means to remove chip for the purpose of chip burn-in, replacement or field repairs.

Owner:ULTRATECH INT INC

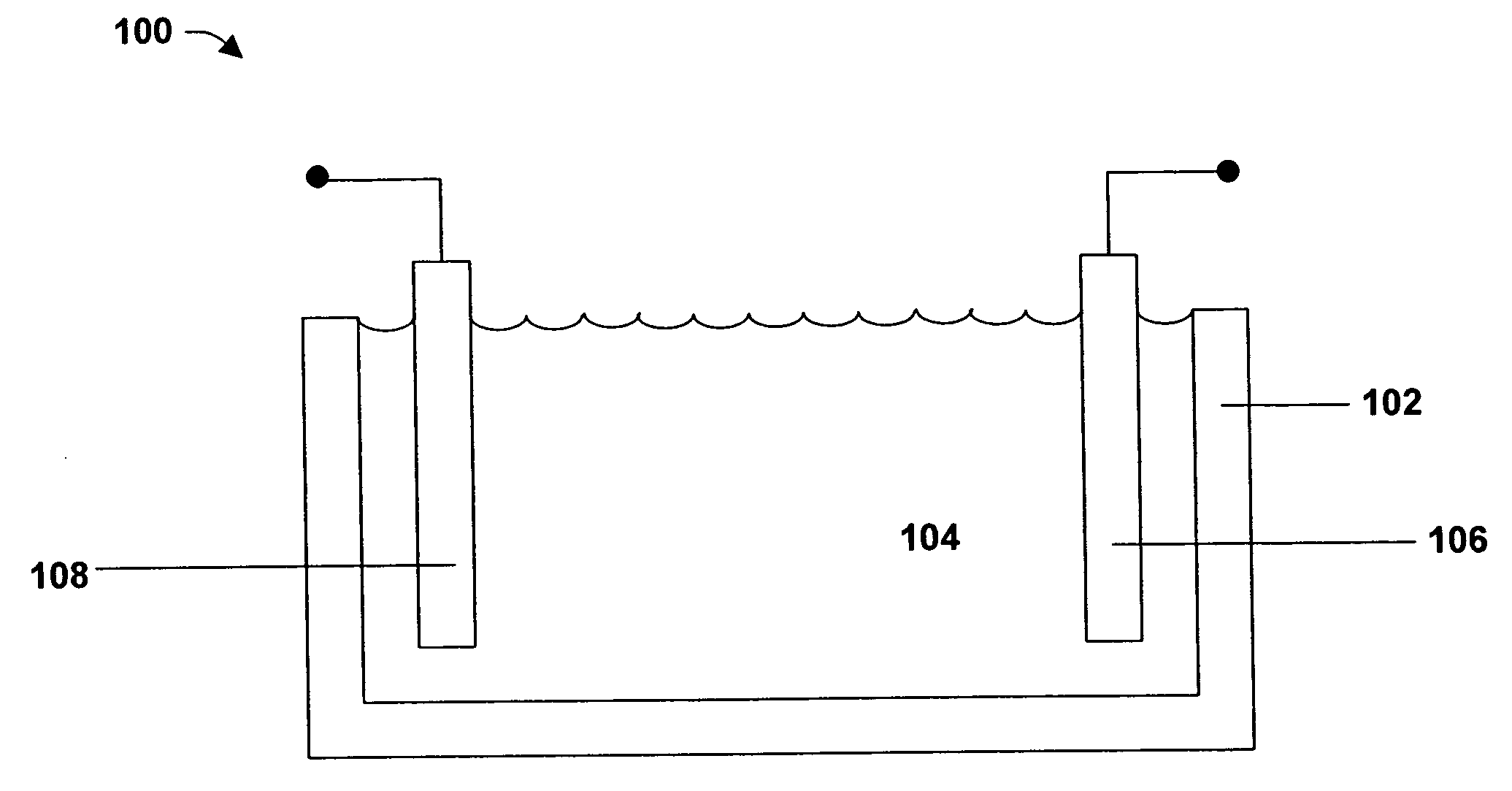

Tin alloy electroplating system

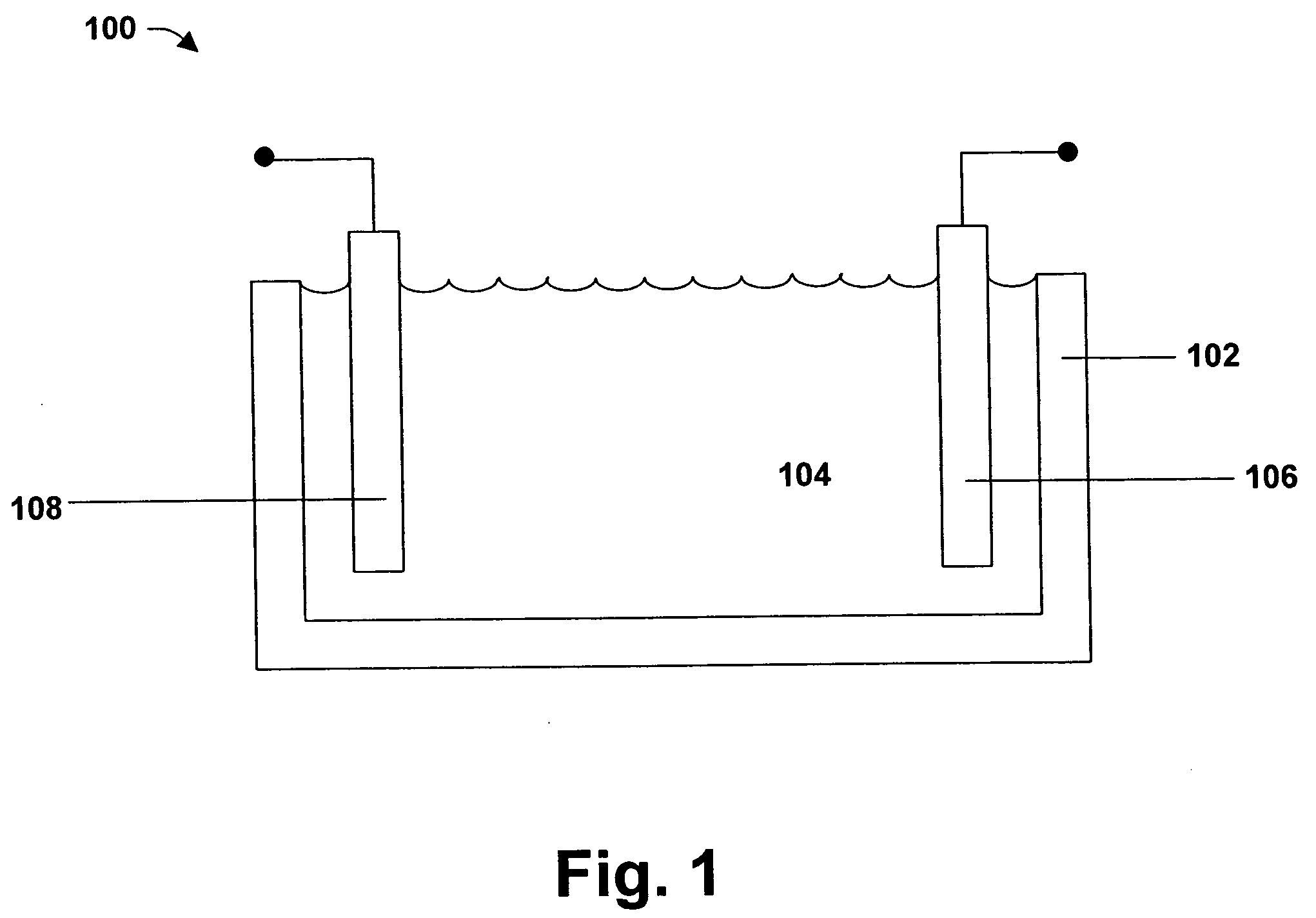

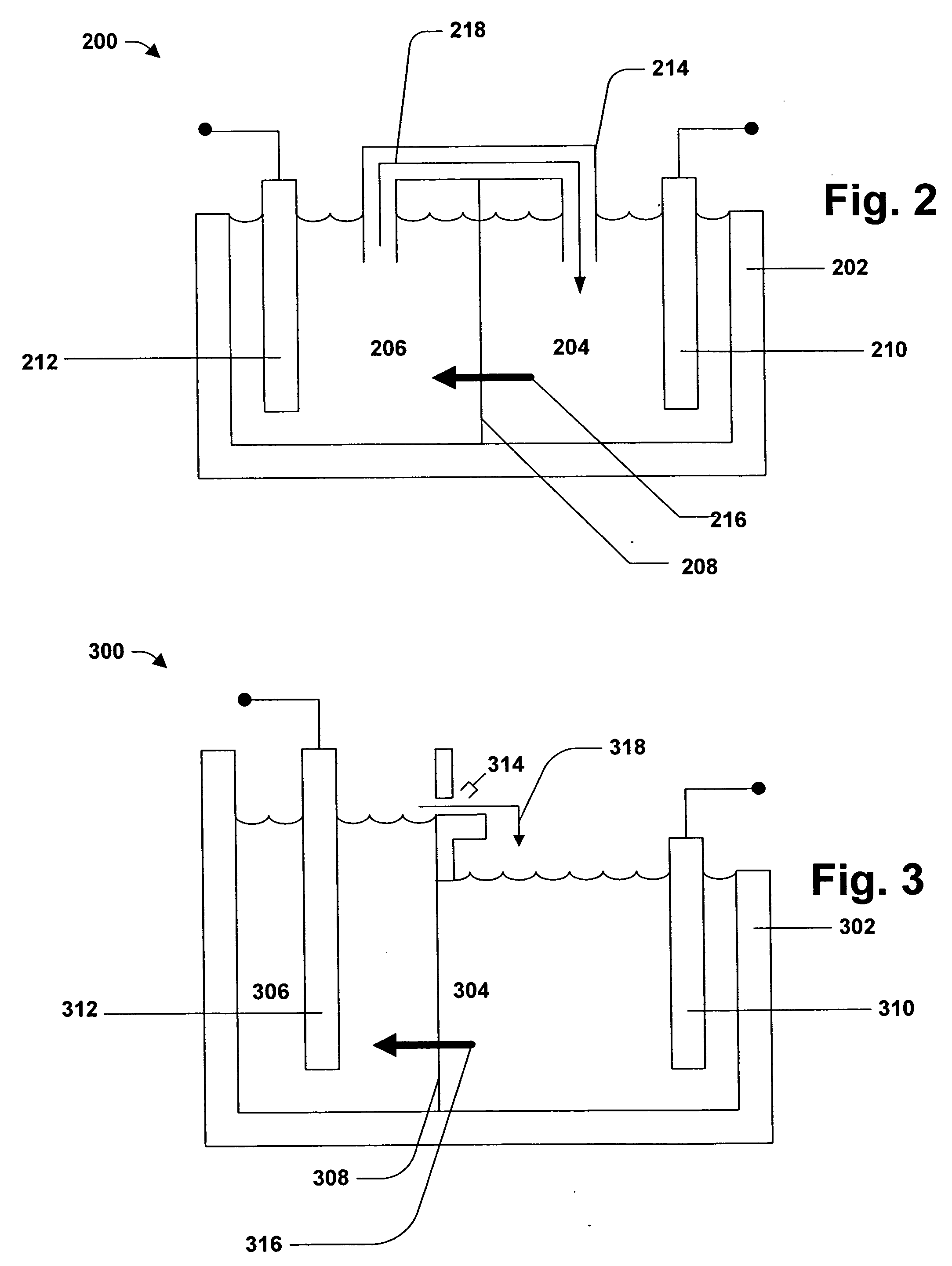

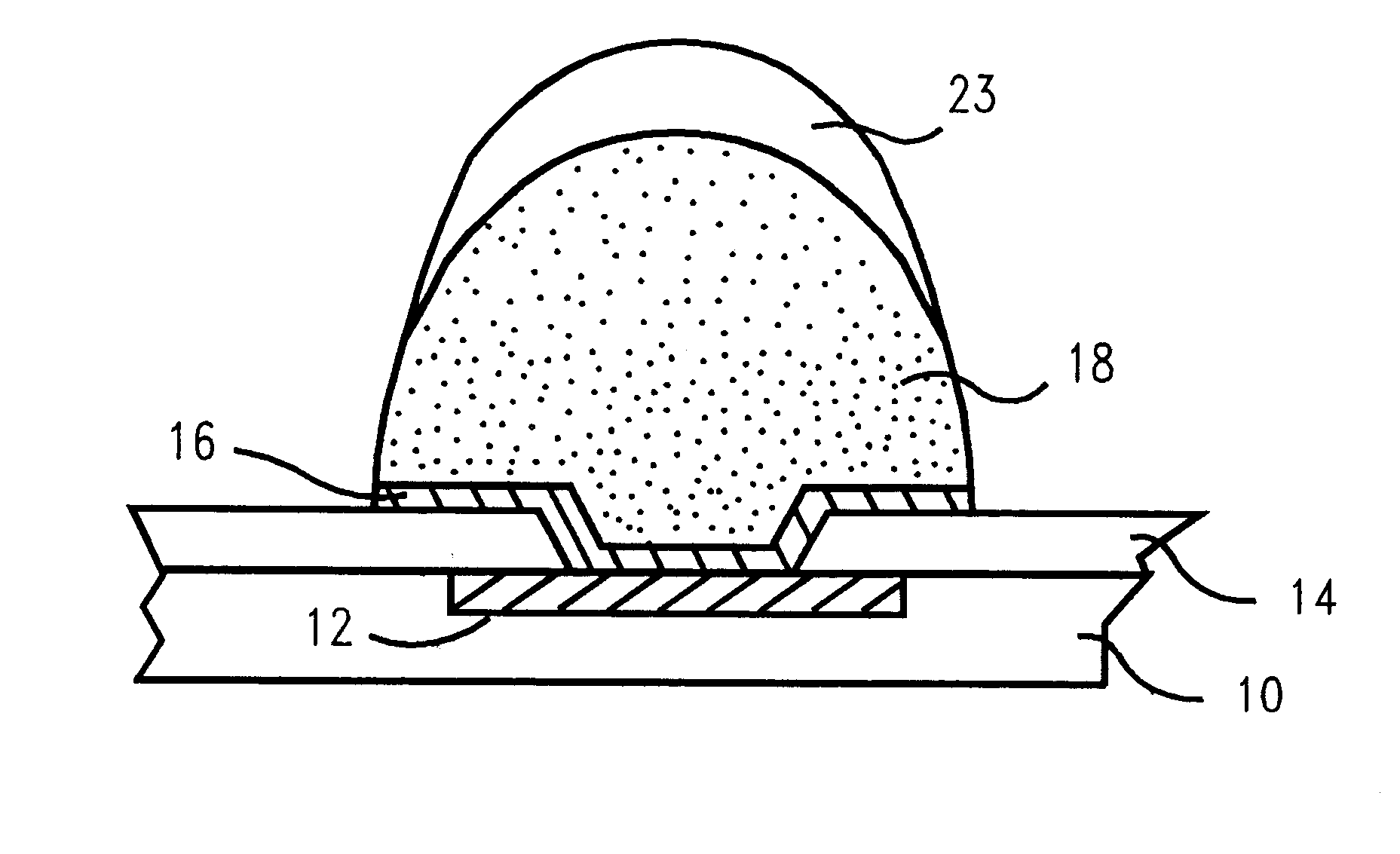

Disclosed are systems and methods of plating a tin alloy in an efficient, economical, and environmentally friendly manner. The system for plating a tin alloy contains an electrochemical cell containing an anode, the cathode, and an electroplating bath. The electroplating bath contains water, an acid, at least one nitrogen-containing heterocyclic complexing agent, an ionic alloy metal, and ionic tin. The methods involve applying a current to the electroplating bath whereby a tin alloy forms on the cathode.

Owner:TASKEM

Reflowed solder ball with low melting point metal cap

InactiveUS6259159B1Low costEasy to buildPrinted circuit assemblingFinal product manufactureTinningIndium

A method and structure for a solder interconnection, using solder balls for making a low temperature chip attachment directly to any of the higher levels of packaging substrate is disclosed. After a solder ball has been formed using standard methods it is reflowed to give the solder ball a smooth surface. A layer of low melting point metal, such as, bismuth, indium or tin, preferably, pure tin, is deposited on the top of the solder balls. This structure results in localizing of the eutectic alloy, formed upon subsequent low temperature joining cycle, to the top of the high melting solder ball even after multiple low temperature reflow cycles. This method does not need tinning of the substrate to which the chip is to be joined, which makes this method economical. It has also been noticed that whenever temperature is raised slightly above the eutectic temperature, the structure always forms a liquid fillet around the joint with copper wires. This liquid fillet formation results in substantial thermal fatigue life improvement for reduced stress at interface; and secondly, provides an easy means to remove chip for the purpose of chip burn-in, replacement or field repairs.

Owner:IBM CORP

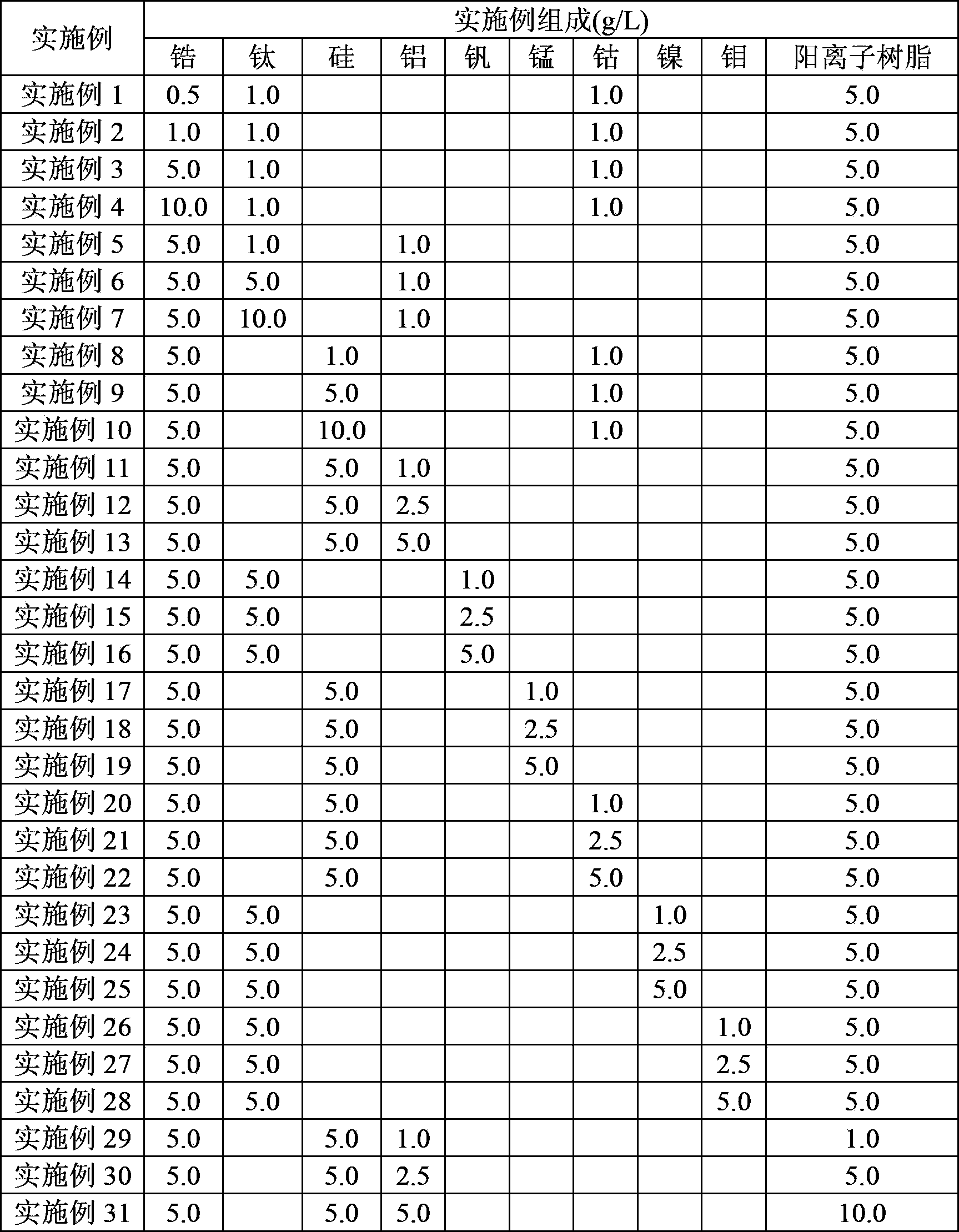

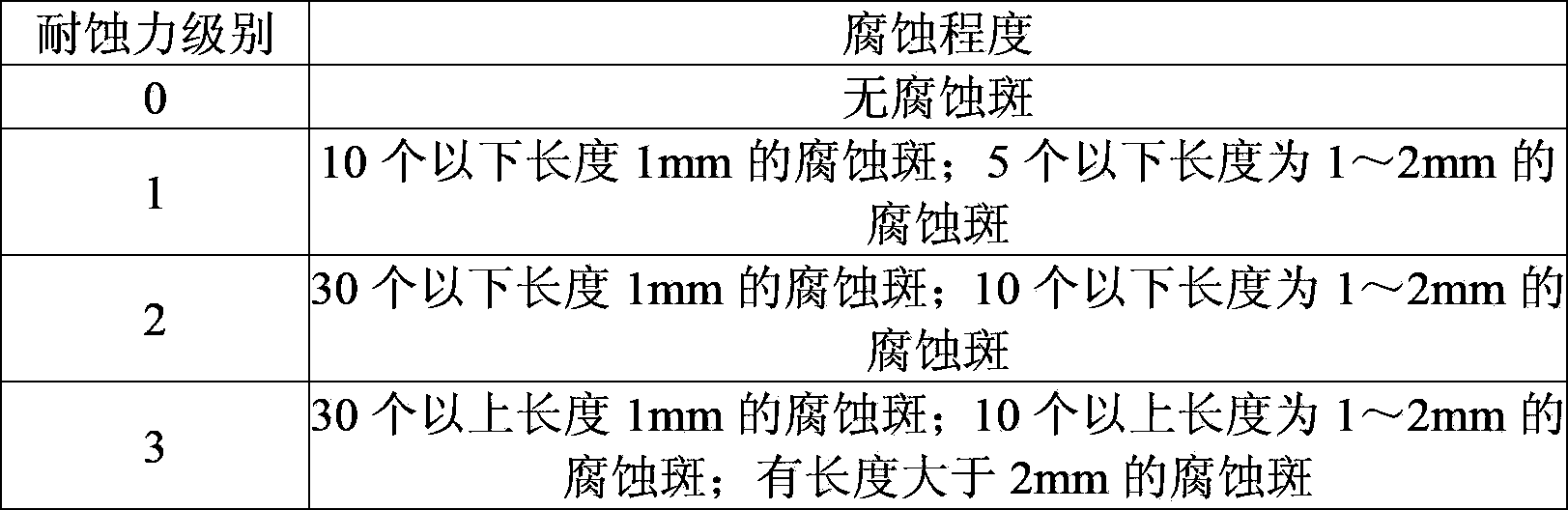

Chromium-free passivation liquid for treating tin-plated steel plate

InactiveCN103805977AImprove corrosion resistanceExcellent anti-vulcanization performanceAnodisationMetallic material coating processesTinningChromium free

The present invention discloses a chromium-free passivation liquid for treating a tin-plated steel plate, wherein the pH value of the chromium-free passivation liquid is 3-4. The chromium-free passivation liquid comprises an inorganic compound containing at least one selected from silicon, titanium and zirconium, a metal compound containing at least one selected from aluminum, vanadium, manganese, cobalt, nickel and molybdenum, a soluble resin, an acid for adjusting the pH value of the passivation liquid to 3-4, and the balance of water and other unavoidable impurities, wherein the contents of silicon, titanium and zirconium are 0.1-20 g / L, the contents of aluminum, vanadium, manganese, cobalt, nickel and molybdenum are 0.1-20 g / L, and the soluble resin content is 0.1-20 g / L. The tin-plated steel plate treated by the chromium-free passivation liquid obtained with the technical scheme has characteristics of excellent corrosion resistance, excellent sulfurization resistance, excellent coating material adhesion and excellent processability.

Owner:上海丰野表面处理剂有限公司

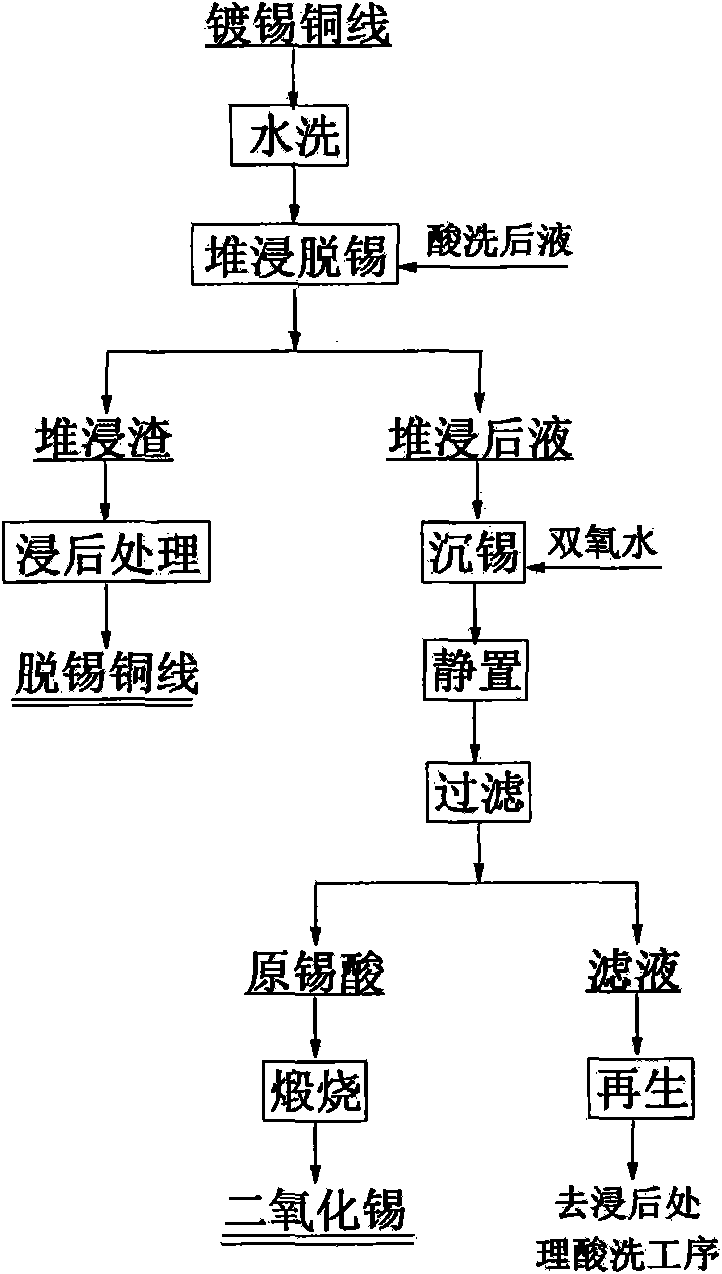

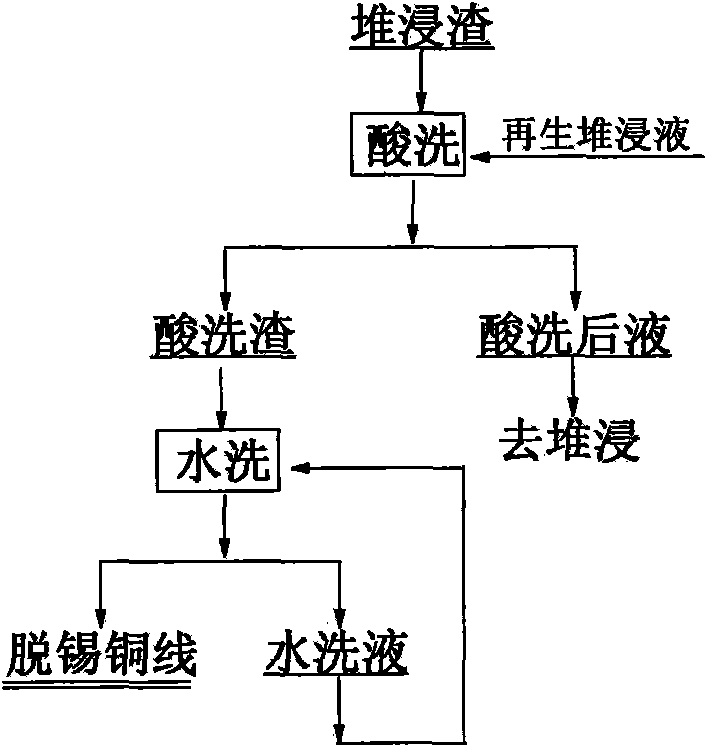

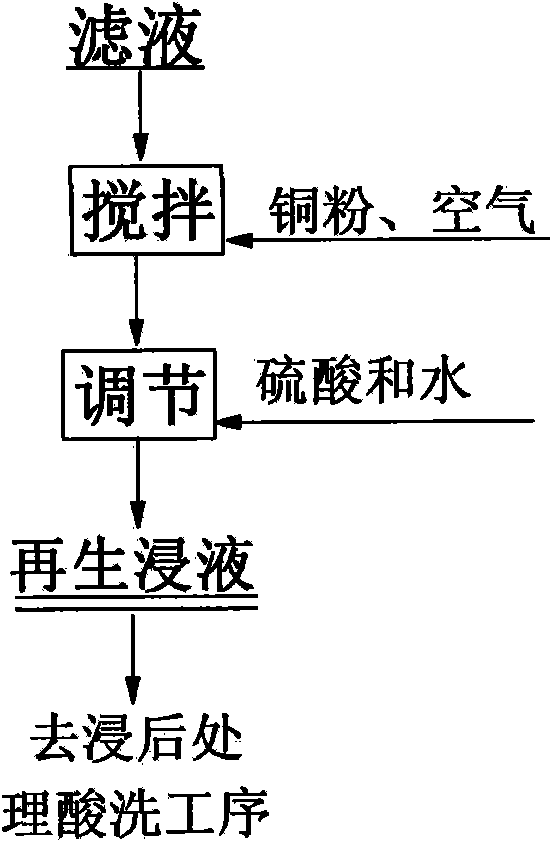

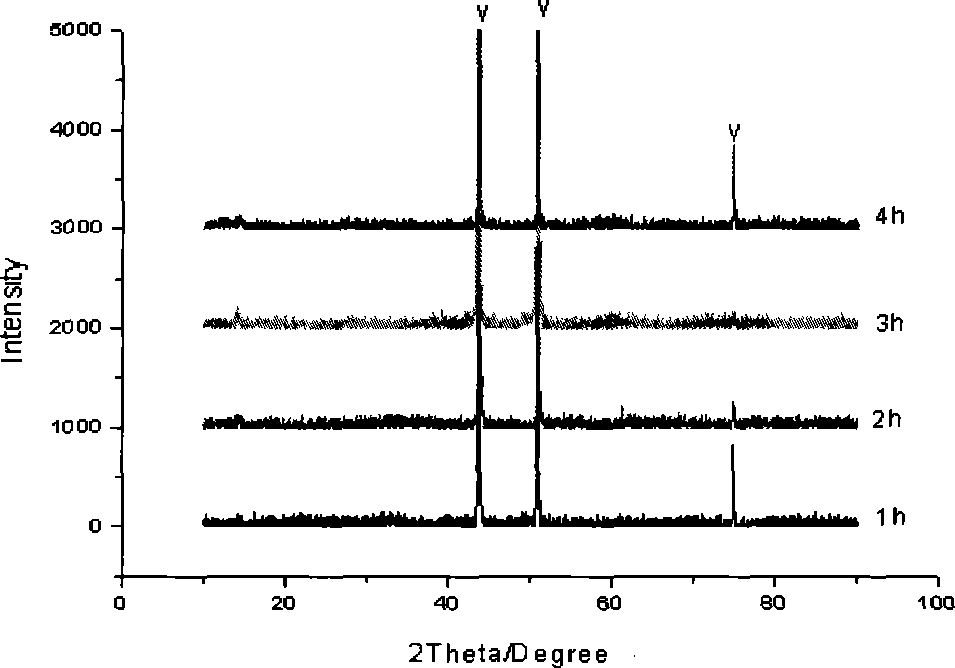

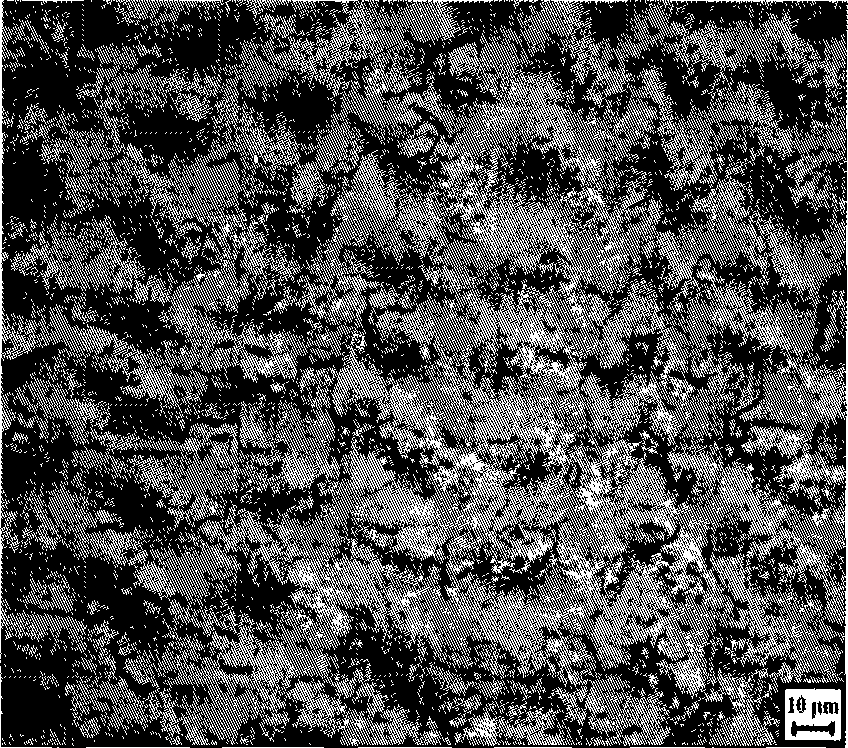

Heap-leaching method for separating copper and tin from tin-plated copper wires

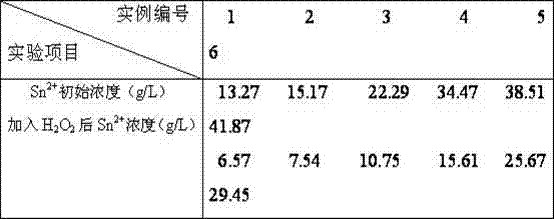

ActiveCN101643852ASolve the problem of difficult mixingSimple processProcess efficiency improvementTinningHydrogen

The invention provides a heap-leaching method for separating copper and tin from tin-plated copper wires, belonging to the recovery processing of waste tin-plated copper wires. The method adopting thecopper sulfate replacement / heap-leaching method comprises the following steps: washing and stacking peeled waste tin-plated copper wires on an acid-proof and alkali-proof heap-leaching platform for heap-leaching; pickling the heap-leaching residue with recycling heap-leaching solution, and further washing the pickled heap-leaching residue to obtain detinned copper wires; adding hydrogen peroxideto the heap-leaching solution until no white precipitation is generated, heating the reaction solution until the reaction solution is boiling, standing, filtering, and drying to obtain original stannic acid, and further calcining the original stannic acid to obtain stannic oxide; adding a proper amount of copper powder and blowing air to the filtrate, wherein the addition amount of the copper power is the copper amount required by copper sulfate in the recycling heap-leaching solution; and controlling the temperature and time of the reaction and adjusting the concentrations of copper sulfate and sulfuric acid of the solution by sulfuric acid and water. The method has the advantages that the process is simple and easy-to-operate, the materials and devices are common and cheap, the tin-plated copper wires dispense with stirring in the heap-leaching process, the heap-leaching solution is recyclable and pollution-free, the removal rate of tin is higher than 95%, and the recovery rate of hydrogen peroxide immersion tin is higher than 98%.

Owner:UNIV OF SCI & TECH BEIJING +1

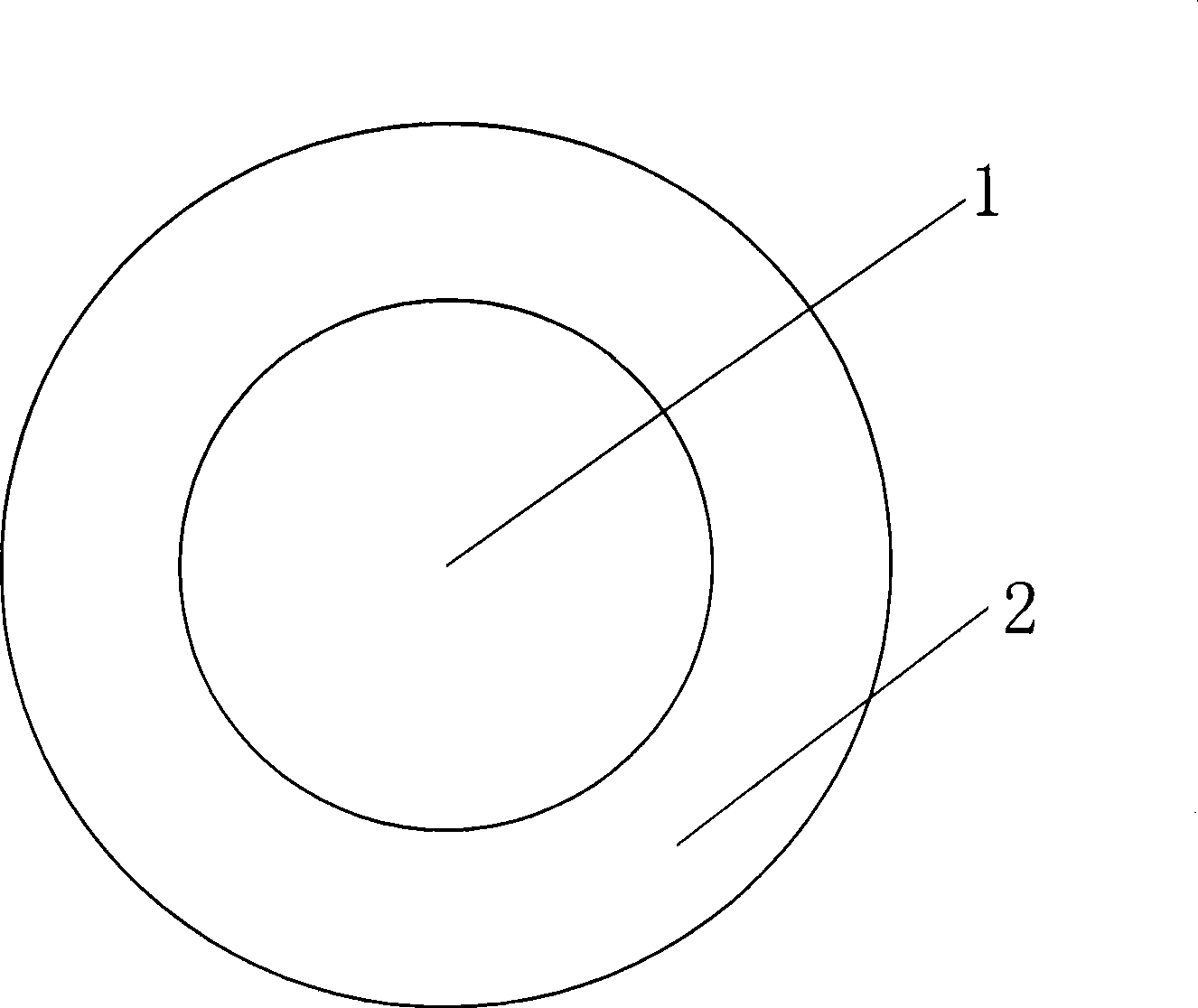

Method for producing nickel coating on metal surface

A method for preparing nickel coating on metal surface relates to metal plating and provides a method for preparing nickel coating on the metal surface. The metal surface goes through oil removal and is placed in a solution tank and plated with tin coating and then placed in the solution tank; after being plated with tin, the metal surface is plated with the nickel coating; the metal plated with the nickel coating is placed in the solution tank for passivation treatment, heat preservation, hydrogen removal from the nickel coating, diffusion annealing treatment and stress relief heat treatment. High interfacial strength single-phase solid solution is obtained by rapid cooling after adopting thick nickel and tin coating, adding thin tin coating and diffusion annealing treatment. Plating bath is not added with a brightening agent while the plating coat is bright and smooth and forms a single-phase solid solution structure, thus enhancing interface combining power of the plating coat and a base plate. The method makes use of the principle predicted by a binary phase diagram that tin and nickel are mutually exclusive within a large composition range, so as to lead iron uncoated rate and copper uncoated rate to tend to be zero under the effect of a tin diffusion blocking layer, thus the plating coat can keep relatively high antiseptic property. Other machinery properties are also good; therefore, the nickel coating prepared by the method of the invention can serve as multifunctional antirust coating.

Owner:XIAMEN UNIV

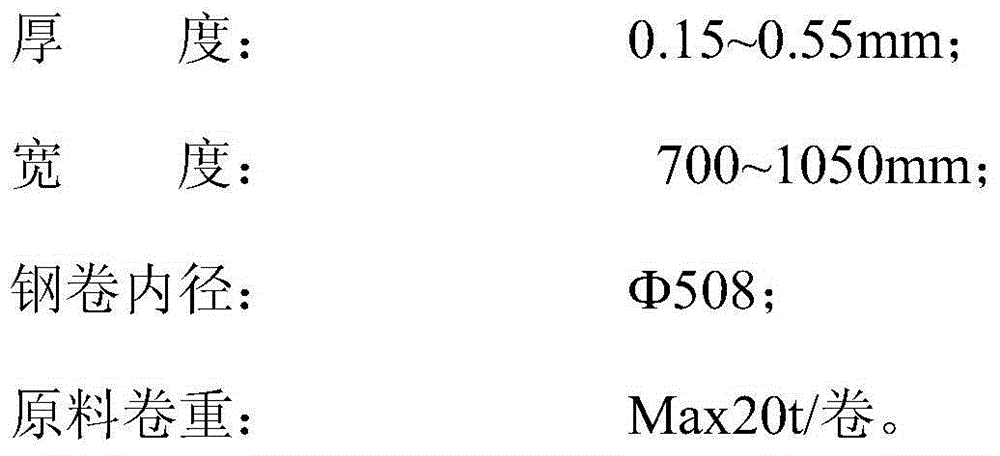

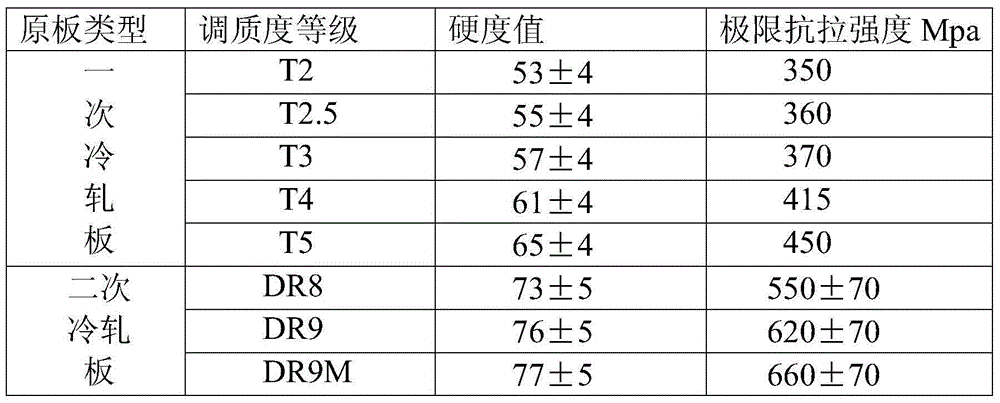

Hard tinned sheet steel and its production method

The invention relates to a hard tinned sheet steel produced from low carbon aluminium killed steel so as to solve the technical problems of easy appearance of local edge waves during current pickling rolling production of tinned sheet steel, high incidence of surface iron oxide scale during continuous annealing production, high yield ratio of tin plates, undesirable stamping processing and the like. The hard tinned sheet steel and its raw sheet comprise the following chemical components (by weight): 0.05-0.07% of C, less than or equal to 0.1% of Si, 0.20-0.30% of Mn, less than or equal to 0.020% of P, less than or equal to 0.020% of S, 0.010-0.060% of Alt, less than or equal to 0.0060% of N, and the balance Fe and some inevitable impurity elements. The production method of the hard tinned sheet steel includes: steelmaking, continuous casting, hot rolling, combined pickling rolling, continuous annealing, double-stand tempering, and electrotinning. The hard tinned sheet steel produced in the invention has the advantages of small production control difficulty, excellent appearance quality, thin specification, stable hardness, and good stamping processing performance, etc., can meet the use requirements of high-speed canning, and can be widely used as a food cans, beverage cans, aerosol cans and other packaging materials.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

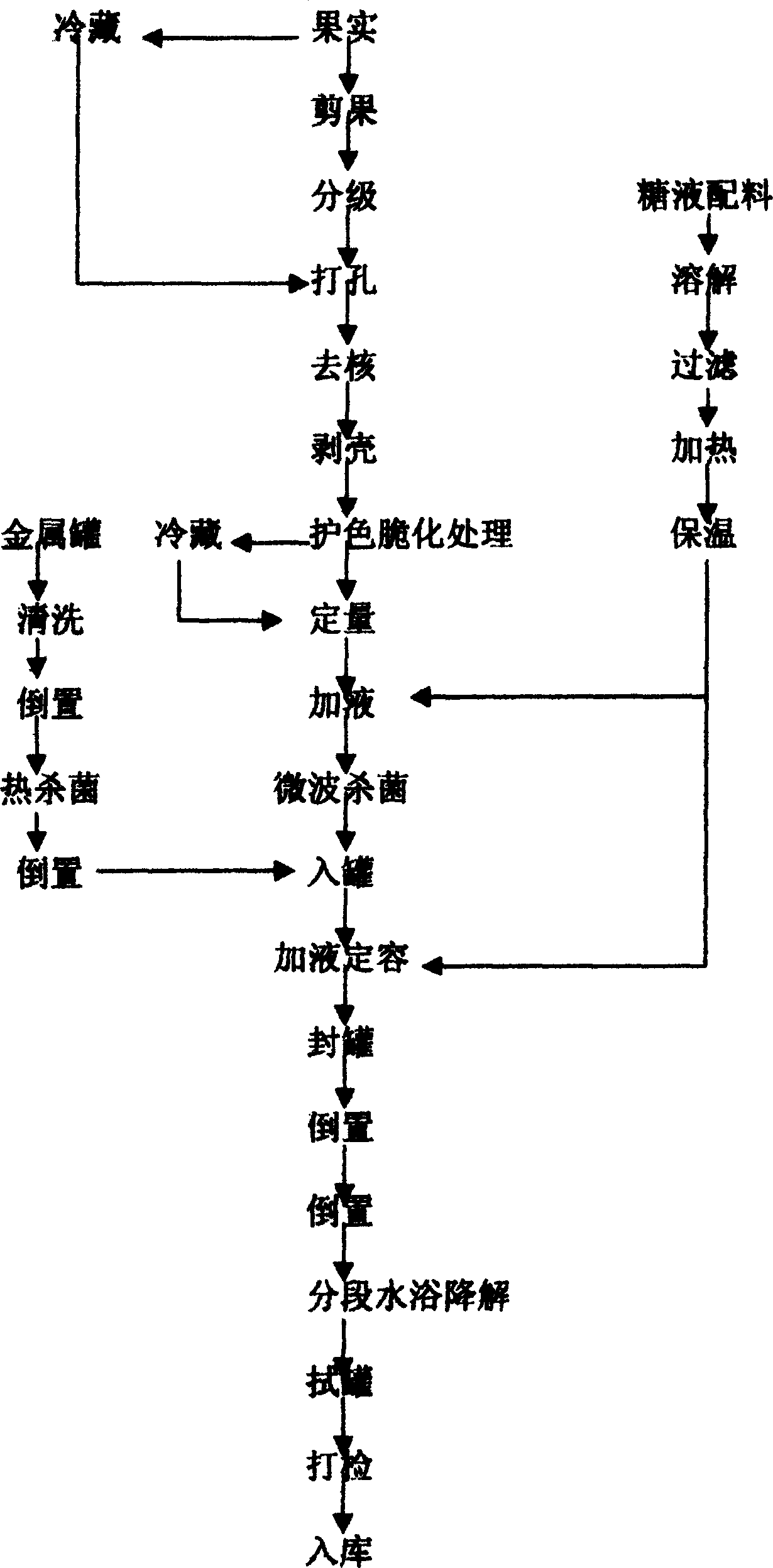

Tinned fruit production process

InactiveCN1478401AImprove completenessLess investmentFruits/vegetable preservation by heatingWater bathsTinning

Owner:POMOLOGY RES INST GUANGDONG ACADEMY OF AGRI SCI

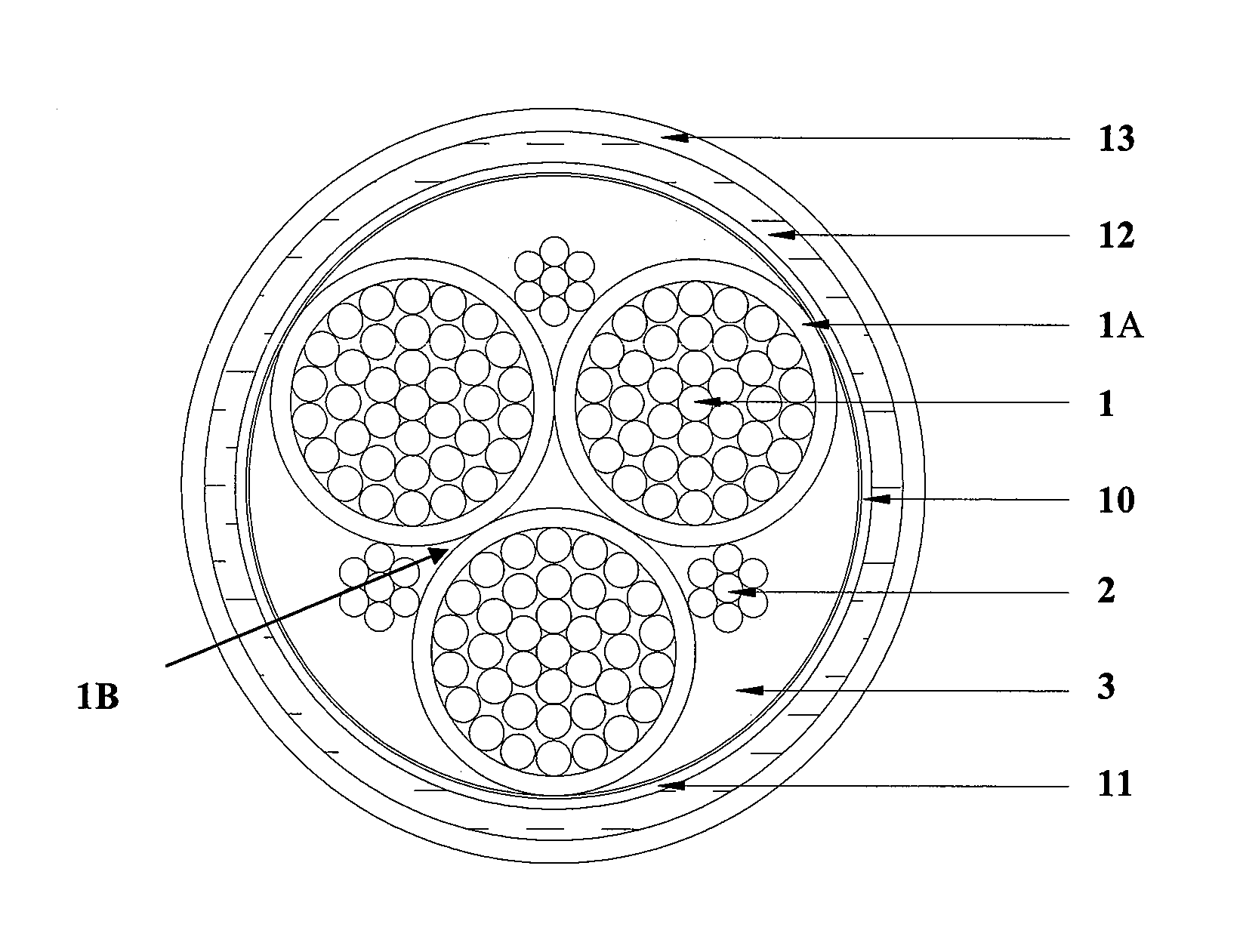

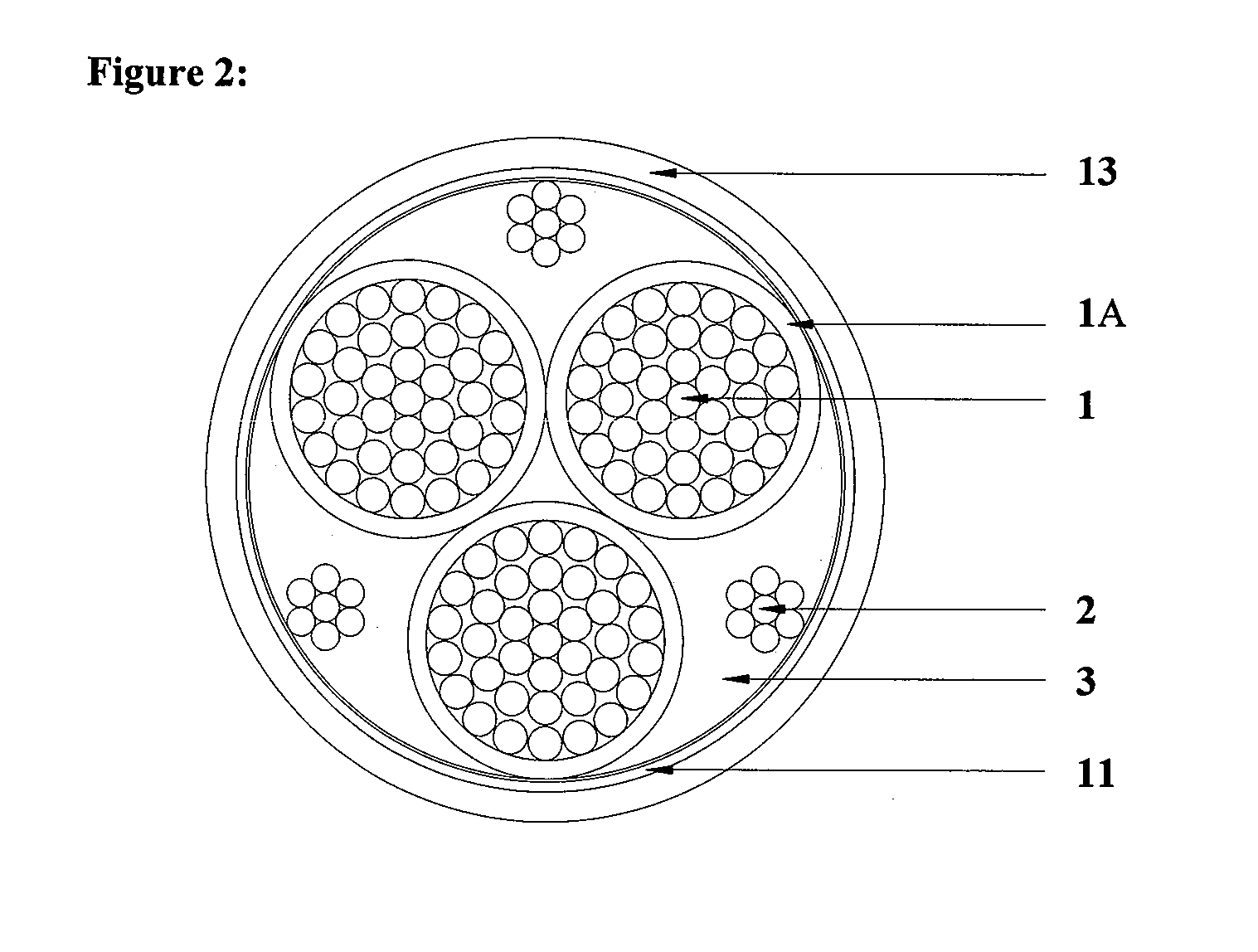

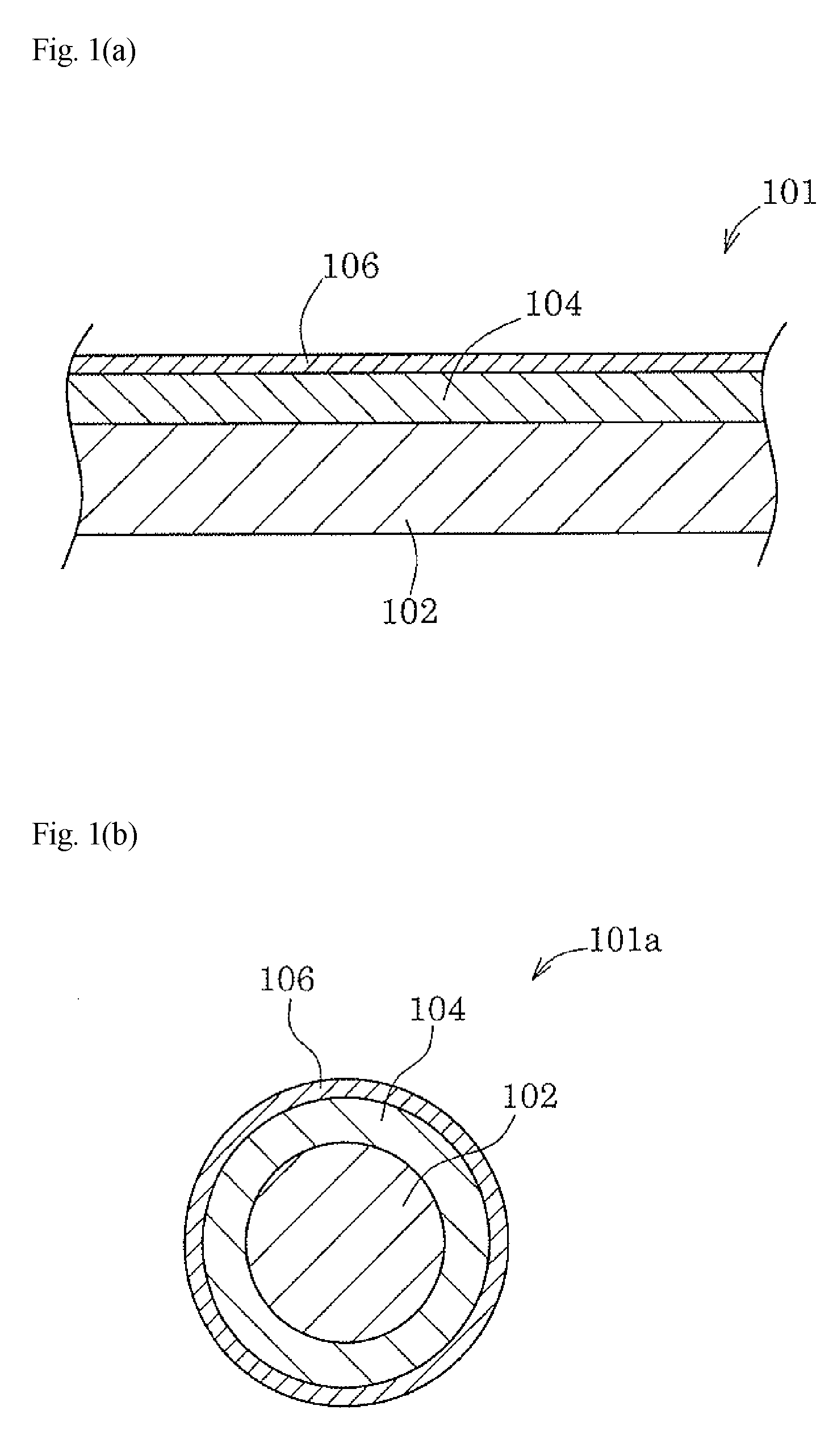

Adjustable Speed Drive Cable and Shield Termination

ActiveUS20070107921A1Power cables with screens/conductive layersInsulated cablesThree-phaseAdjustable-speed drive

The product of the present invention comprises flexible tray cables and metal-clad cables designed for use with adjustable speed drives, and terminations coupled therewith. The cables comprise, generally, three phase conductors, three ground conductors and fillers, and are wrapped with copper tape and other elements. The terminations comprise a plurality of connectors and a plurality of flexible, tinned-copper braids acting as the shield termination for the copper tape. More detailed and other embodiments of the present invention are disclosed in the specification hereof.

Owner:SERVICE WIRE

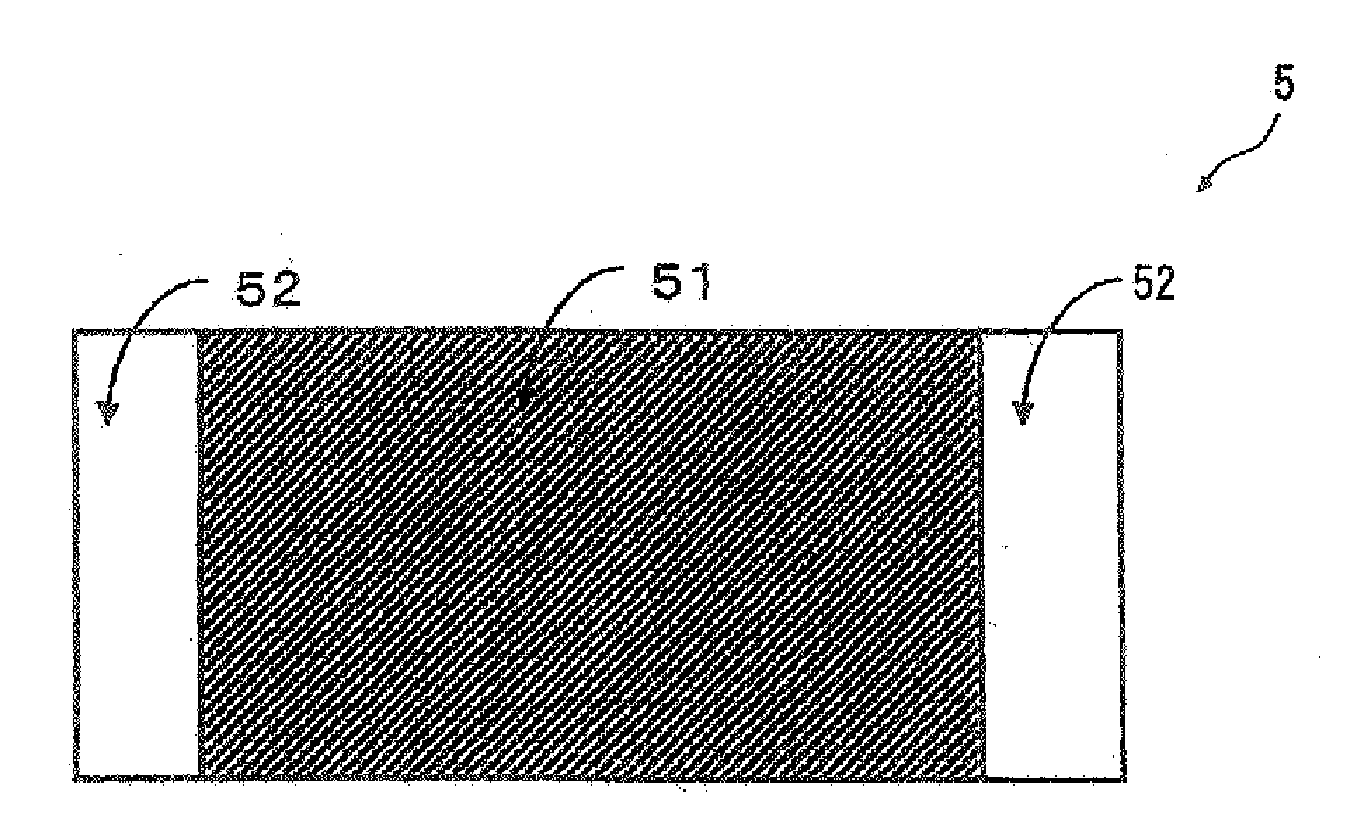

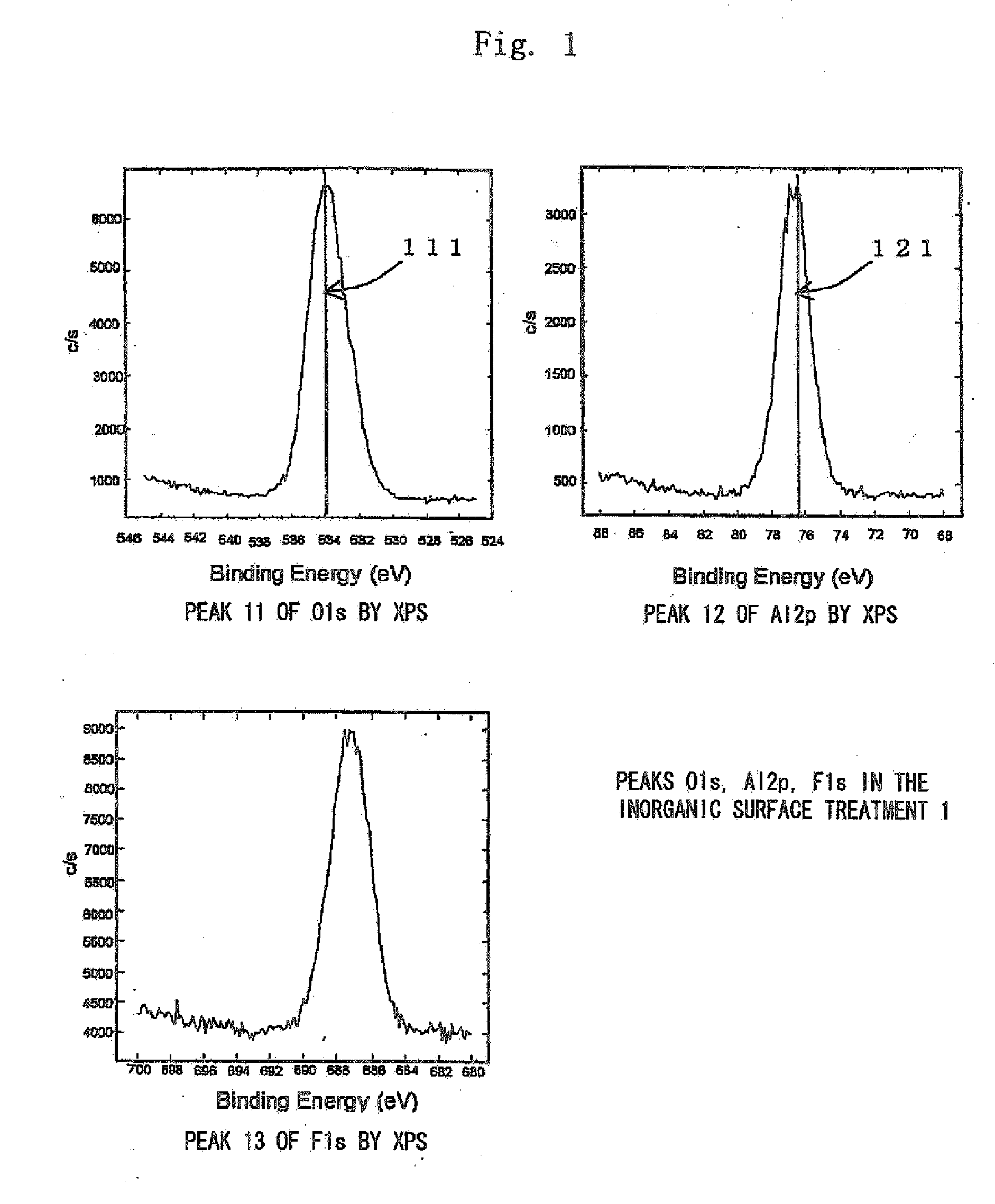

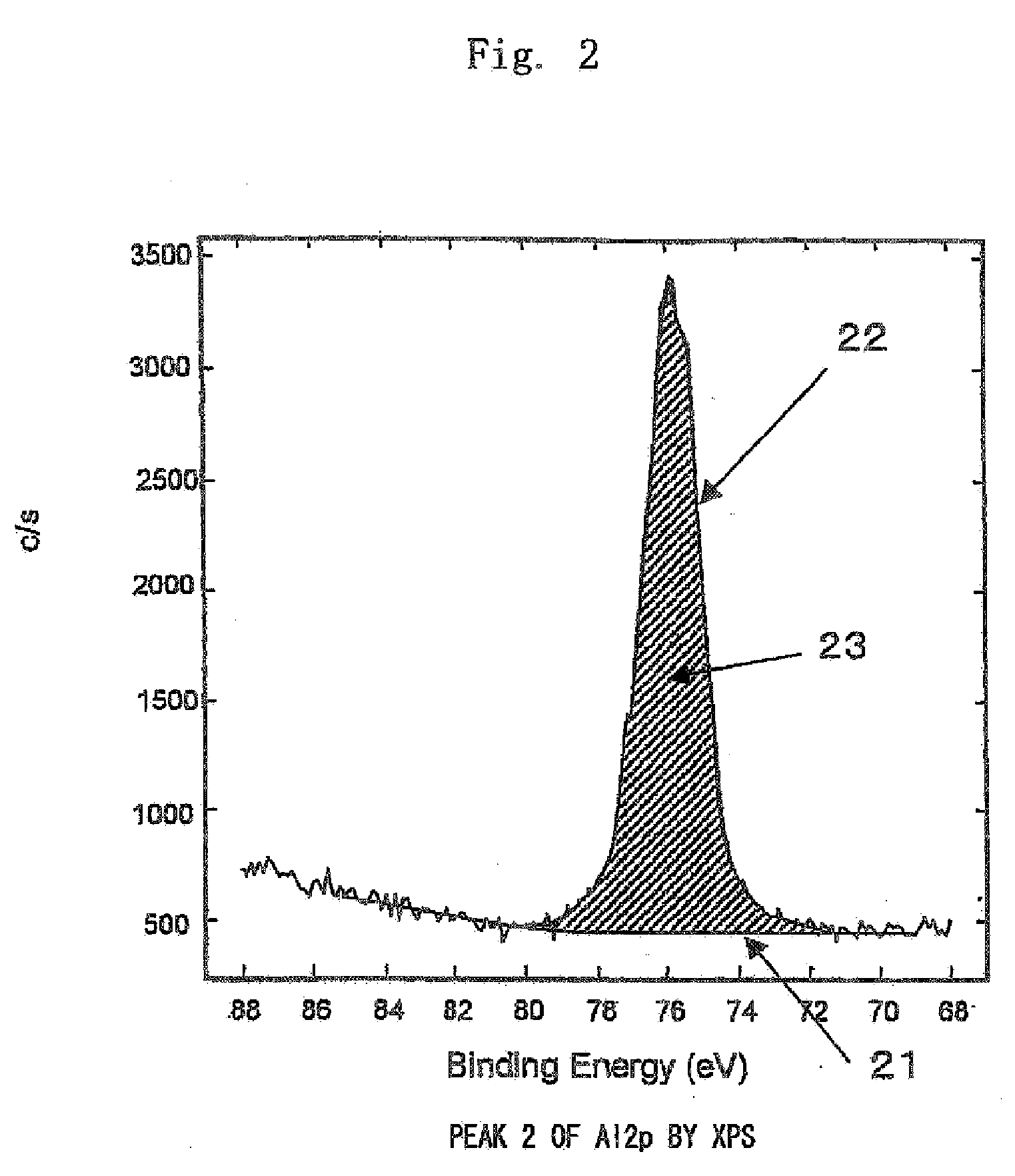

Surface-Treated Metal Materials, Method of Treating the Surfaces Thereof, Resin-Coated Metal Materials, Cans and Can Lids

InactiveUS20080057336A1Corrosion resistance is not sufficientSurface reaction electrolytic coatingThin material handlingMetallic materialsResin coating

A surface-treated metal material having, formed on the surface of a metal base member, an inorganic surface-treating layer that contains inorganic components or, further, having an organic surface-treating layer formed on the inorganic surface-treating layer, the inorganic surface-treating layer containing at least M (M is at least one of Ti, Zr or Al), O and F. The organic surface-treating layer comprises a silane coupling agent containing Si in an amount of 0.8 to 30 mg / m2 or a phenol-type water-soluble organic compound. The surface treatment without using chromium can be applied to various metal base members featuring excellent environmental friendliness, excellent resistance against discoloration even when applied to tin-plated steel plates, and offering excellent characteristics such as the close adhesion to the organic resin coating, adhesive property, corrosion resistance and dent resistance. Owing to the cathodic treatment in an aqueous solution, further, the surface-treated metal material can be produced at a high speed, easily and at a low cost.

Owner:TOYO SEIKAN KAISHA LTD +1

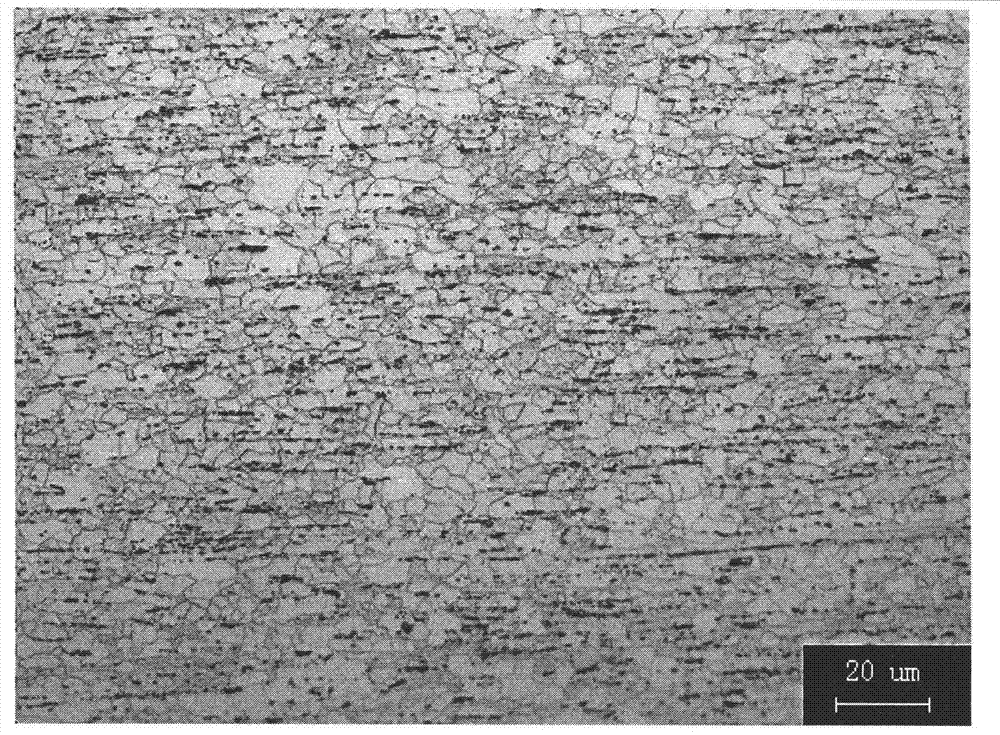

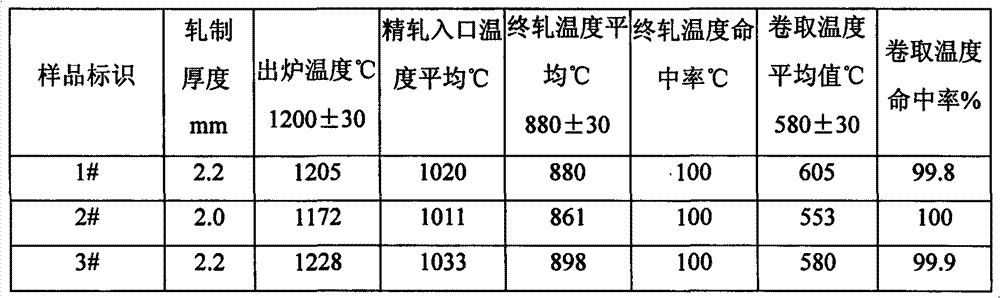

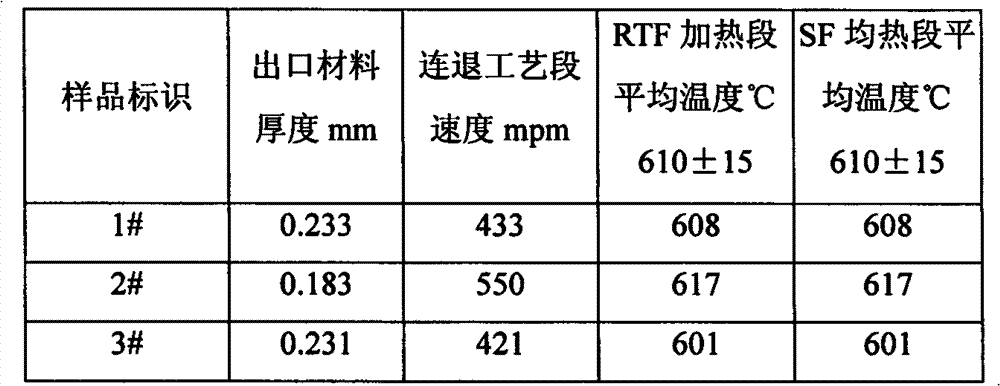

Steel for hard tinplate bottle caps and production method thereof

InactiveCN102766800AImprove surface qualityGood performance uniformityTemperature control deviceTinningChemical composition

The invention relates to steel for bottle caps and a preparation method thereof, especially to steel for hard tinplate bottle caps and a production method thereof. The invention mainly solves the technical problems of unstable rolling, high hole ratio for pickling-rolling and poor surface quality of each process during pickling-rolling production of present steel for bottle caps. The technical scheme provided by the invention is as follows: the steel for hard tinplate bottle caps comprises the following chemical components of: by weight, 0.045-0.088% of C, Si being less than or equal to 0.1%, 0.30-0.50% of Mn, P being less than or equal to 0.020%, S being less than or equal to 0.020%, 0.010-0.060% of Alt, N being less than or equal to 0.0060%, and the balance Fe and some unavoidable impurity elements. The production method comprises four steps of steeling-making, hot rolling, pickling-rolling and continuous annealing, and is characterized in that hot rolling is controlled in the way: tapping temperature is 1200+ / -30 DEG C, finishing temperature is 880+ / -30 DEG C and coiling temperature is 580+ / -30 DEG C; cooling mode is forepart cooling; pickling-rolling and continuous annealing are controlled in the way: RTF section temperature is 610+ / -15 DEG C and SF section temperature is 610+ / -15 DEG C. Hardness of the obtained tinplate finished product is HR30T63+ / -3. The production method provided by the invention is mainly used for production of steel for bottle caps.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

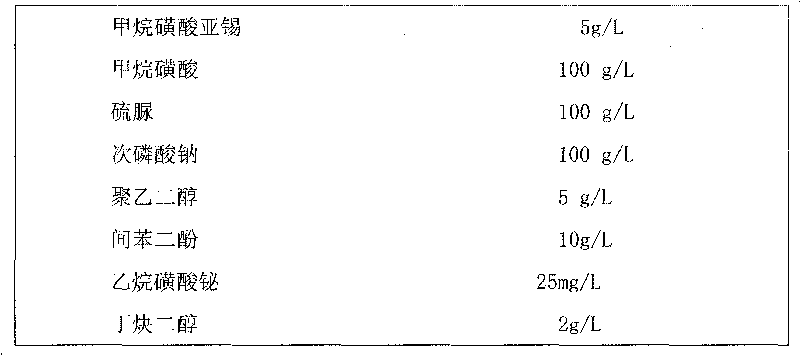

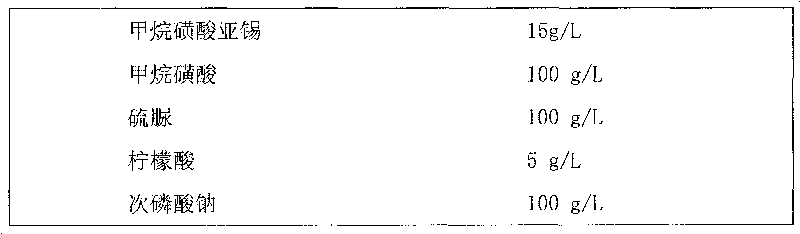

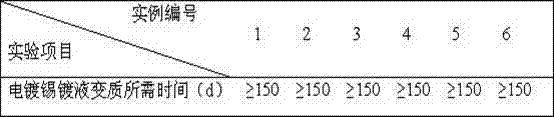

Alkyl sulfonic acid chemical tinning solution and chemical tinning solution based tinning process

InactiveCN101705482ANon-aggressiveImprove solderabilityLiquid/solution decomposition chemical coatingTinningAntioxidant

The invention discloses alkyl sulfonic acid chemical tinning solution, which comprises the following components in terms of contents: 1 to 40 g / L of organic sulfonic acid tin salt, 5 to 250 g / L of organic acid, 5 to 300 g / L of complexing agent, 20 to 150 g / L of reducing agent, 0.5 to 50 g / L of surfactant, 0.1 to 25 g / L of antioxidant, 1 to 500 mg / L of noble metal salt and 0.5 to 3 g / L of brightening agent. The invention also discloses an alkyl sulfonic acid chemical tinning solution based tinning process, which comprises the following steps: 1) pre-treating a copper or copper alloy workpiece to be tinned; 2) putting the pre-treated copper or copper alloy workpiece into the alkyl sulfonic acid chemical tinning solution to be tinned; and 3) after tinning, performing neutralization and color change preventing treatment. The process adopts a two-step method of presoaking and chemical tinning to deposit a tin layer with the thickness of 2.0 mu m on the copper or copper alloy matrix; and the tin layer is applied to chemical tinning processes for PCBs and integrated circuits and the like, has the advantages of good weldability, strong whisker growth resistance, low cost, stable process and the like.

Owner:广州电器科学研究院

High tensile and bend resistant movables cable conductor

InactiveCN101447244AHigh strength and high temperature resistanceHigh strength bending resistanceNon-insulated conductorsInsulated cablesTinningElectrical conductor

The invention discloses a high tensile and bend resistant movable cable conductor. The cable conductor comprises a tensile wire layer positioned in an inner layer and formed by adopting a plurality of strands of aramid silk fiber strands and multiple strands and a conductor layer formed by respectively enwinding a plurality of homocentric tinning annealed copper wires or annealed bare copper wires on the tensile wire layer. The enwinding directions of each layer of tinning annealed copper wires or annealed base copper wires are opposite from inside to outside. The invention can be taken as the conductor of various movable cables; the cables can freely move, have smaller bending radius, and can freely move along with a movable device, and the conductor service life thereof can be improved to tens of times.

Owner:ANHUI HUALING CABLE GRP

Methyl sulfonate tinning electrolyte and tinning method of steel strip or steel plate

The invention discloses methyl sulfonate tinning electrolyte using cerium salt as an additive. The electrolyte comprises the following components: 30 to 120 g / L of stannous methyl sulfonate, 60 to 180 g / L of methylsulfonic acid, 1 to 10 g / L of cerium sulfate, 0.1 to 2 g / L of antioxidant, 5 to 10 g / L of brightening agent and 5 to 10 g / L of surfactant. The invention also discloses a method for tinning a steel strip or a steel plate by adopting the electrolyte. During plating, the cerium salt in the electrolyte lightens the harm degree of 'hydrogen brittleness', and plays roles of the antioxidant and the brightening agent. On the basis of adaptability to the environment, the electrolyte meets the requirements that the process is simple, the solution is stable, the maintenance is easy and the quality of a coating is high.

Owner:张家港市凤凰科技开发有限公司

Natural plant mosquito-repellent liquid

The invention discloses natural plant mosquito-repellent liquid, which comprises the following raw materials in parts by weight: 40-60 of eatable ethanol, 1-10 of dementholized peppermint oil, 1-6 of citionella oil, 3-12 of wintergreen oil, 3-12 of citriodora oil, 3-12 of blumea oil, 3-12 of lavender oil, 1-5 of menthol, and 3-12 of rosemary oil. The natural plant mosquito-repellent liquid disclosed by the invention is prepared by adding enough eatable ethanol into a stainless steel container at first, adding other enough raw materials into the eatable ethanol to stir uniformly, filtering and tinning after standing for one day, emptying, storing, inspecting a semi-finished product, sterilizing a wrappage, filling, inspecting a finished product, and warehousing. The natural plant mosquito-repellent liquid disclosed by the invention is formed by scientifically refining a plurality of plant extract substances; the effective time for repelling mosquito bite outdoors is up to six hours; and the natural plant mosquito-repellent liquid is very obvious in effect and free from toxic and side effects and stimulation on human body.

Owner:蚌埠天泽家用化学品有限公司

Hard tinned plate suitable for stamping processing and production process thereof

InactiveCN101603147AProduction control is less difficultLow costRoll force/gap control deviceTinningSteelmaking

The invention relates to a hard tinned plate which is suitable for stamping processing and is produced from low carbon Al-killed steel. The original plate comprises the chemical components by weight percentage: 0.08 to 0.13 percent of C, less than or equal to 0.025 percent of Si, less than or equal to 0.65 percent of Mn, less than or equal to 0.020 percent of P, less than or equal to 0.020 percent of S, 0.02 to 0.06 percent of solAl, less than or equal to 0.03 percent of Ti, less than or equal to 0.005 percent of N, and Fe and unavoidable impurities accounting for the margin. The production process adopts the steps of steelmaking with molten iron->continuous casting-hot rolling->push-pull mode pickling->HC rolling mill cold rolling->electrolytic degreasing->hydrogen bell furnace annealing(BA)->double-machine leveling->electrolytic tinning, and finally the hard tinned plate can be obtained. The hard tinned plate of the invention has the advantages of low cost, high hardness, favorable stamping processability, and the like, and can be widely used as packing materials for food, drinks, etc.

Owner:武钢集团有限公司

Method and device for separating and recovering metallic copper and tin in tinplating copper rice

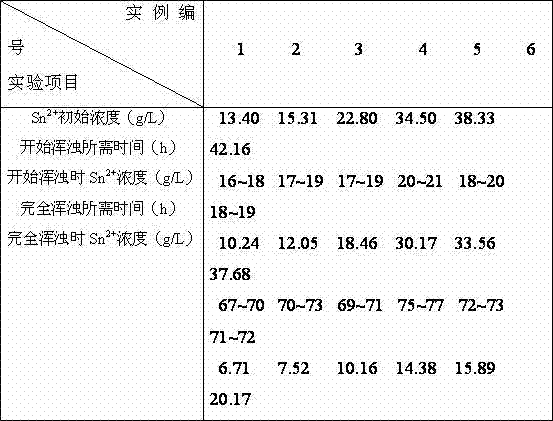

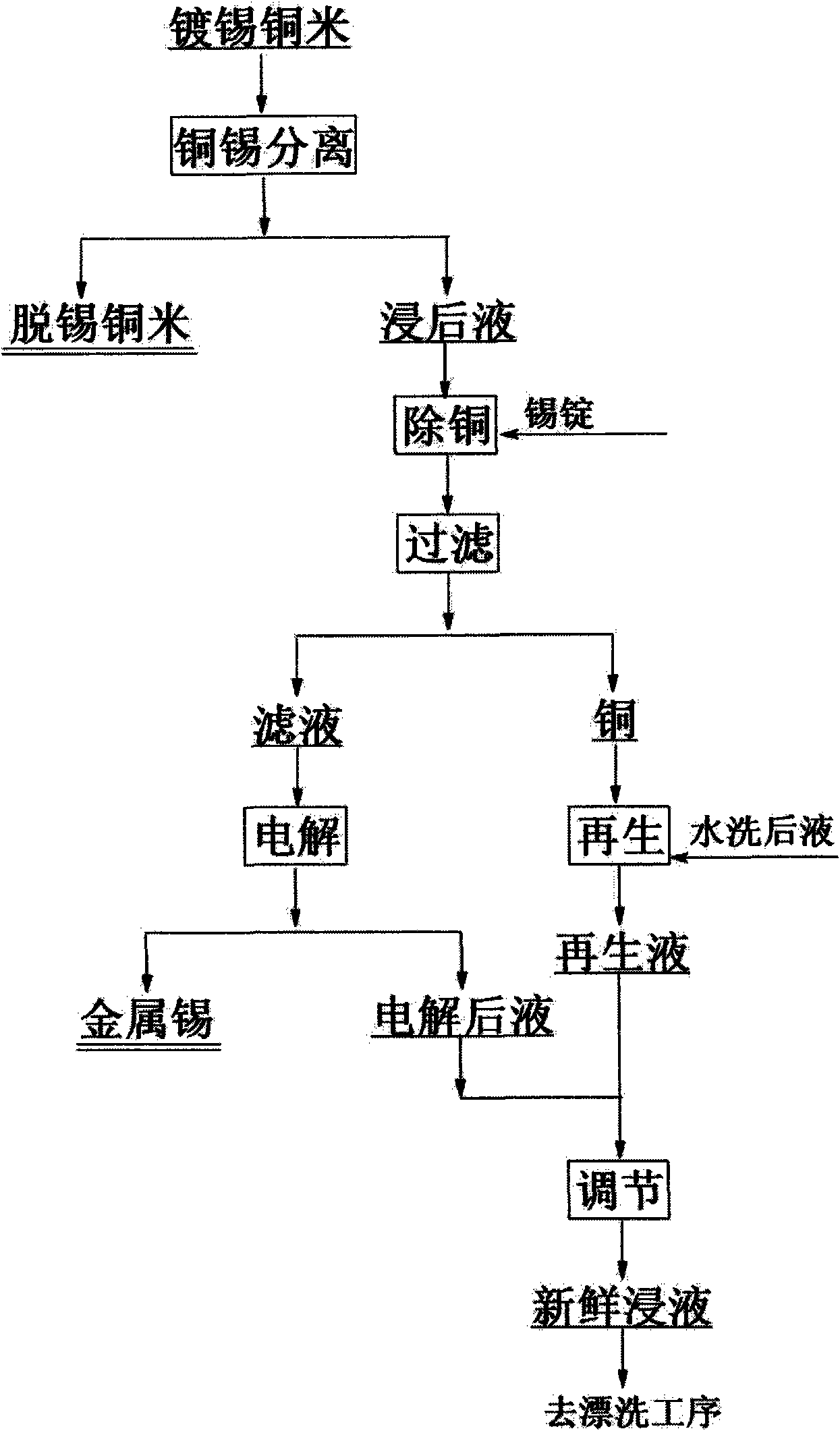

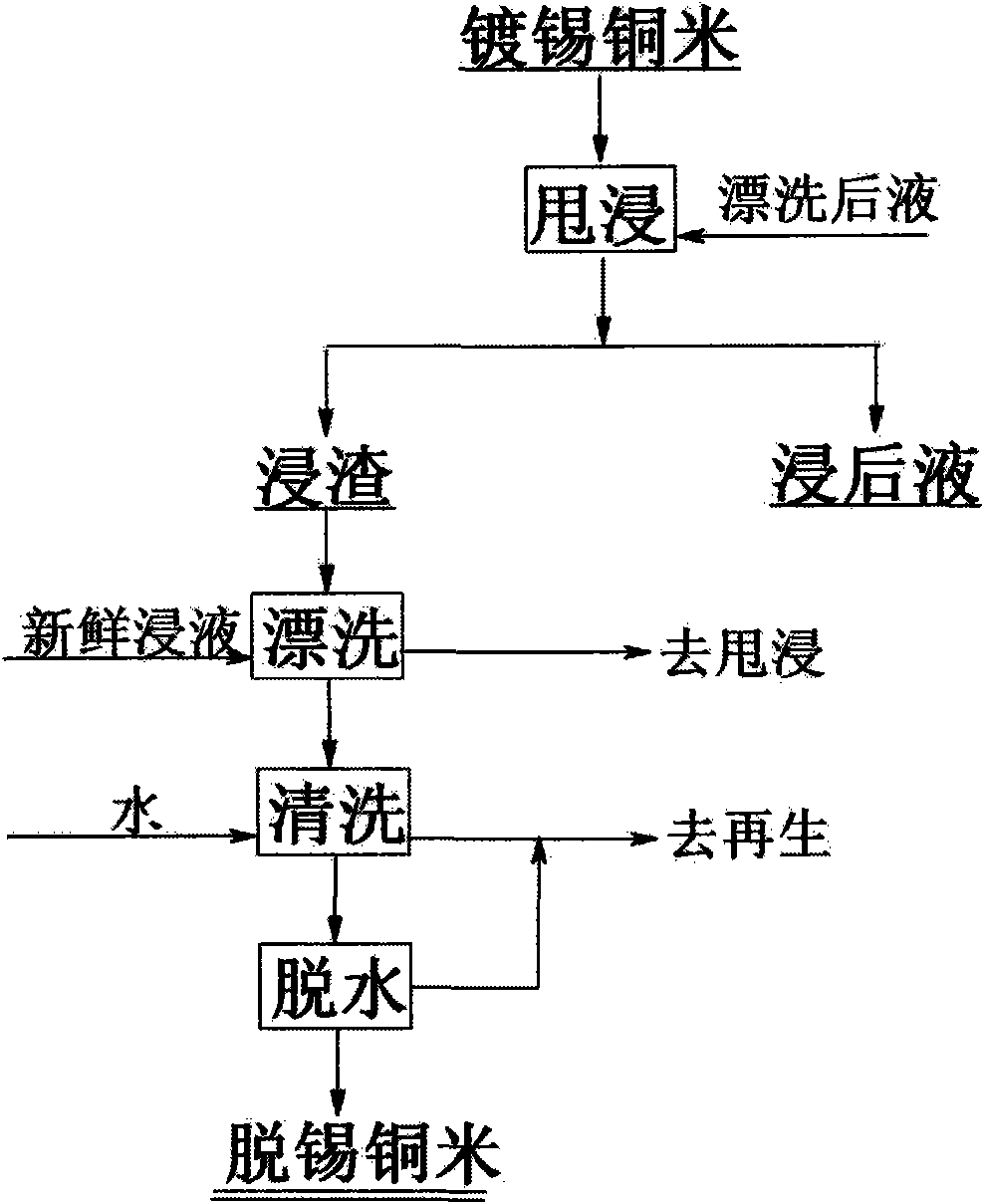

InactiveCN101937742AHigh removal rateHigh recovery rateBasic electric elementsElectronic waste recyclingTinningIngot

The invention relates to a method and a device for separating and recovering metallic copper and tin in the tinplating copper rice by a wet method. The method comprises the following steps: placing the tinplating copper rice into a dedicated leaching plant for copper and tin separation according to the design requirement; adding excessive tin ingot to the immersion liquid to remove the copper until the blue of the immersion liquid is completely eliminated; filtering to obtain filter liquor and copper powder; electrolyzing the filter liquor in an electrolytic cell to obtain the metallic tin and liquid after electrolyte; adding a proper amount of copper powder and blowing air into the liquid for regeneration after being washed with water; mixing the regenerated liquid and the liquid after the electrolyte; regulating the concentration of copper sulfate and sulfuric acid in the solution by utilizing water, copper sulfate and 98% of sulfuric acid to obtain fresh immersion liquid to be used in the next tinplating copper process. The copper and tin separation processing device is composed of the dedicated leaching plant, an immersion liquid trough, a fresh immersion liquid trough and a rinsing bath. The method and the device have simple and feasible process; and all the raw materials and equipment are more common and have low price.

Owner:UNIV OF SCI & TECH BEIJING

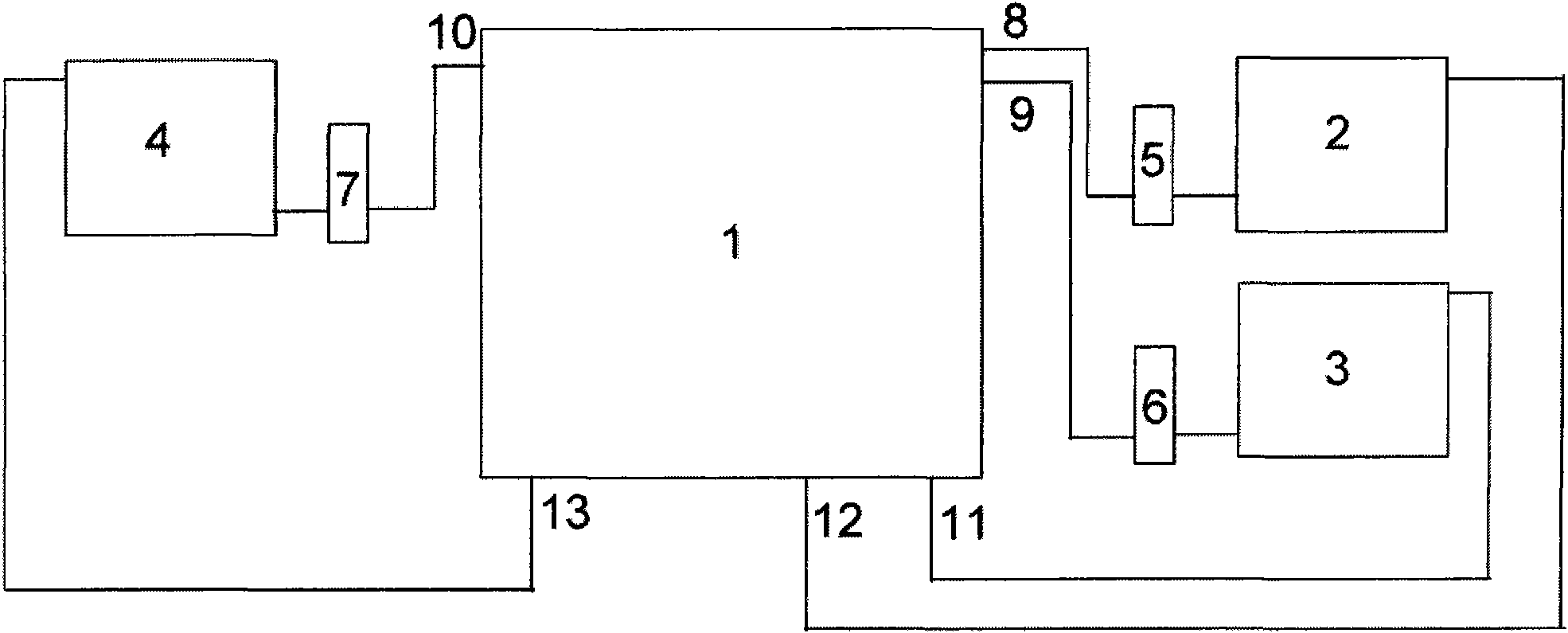

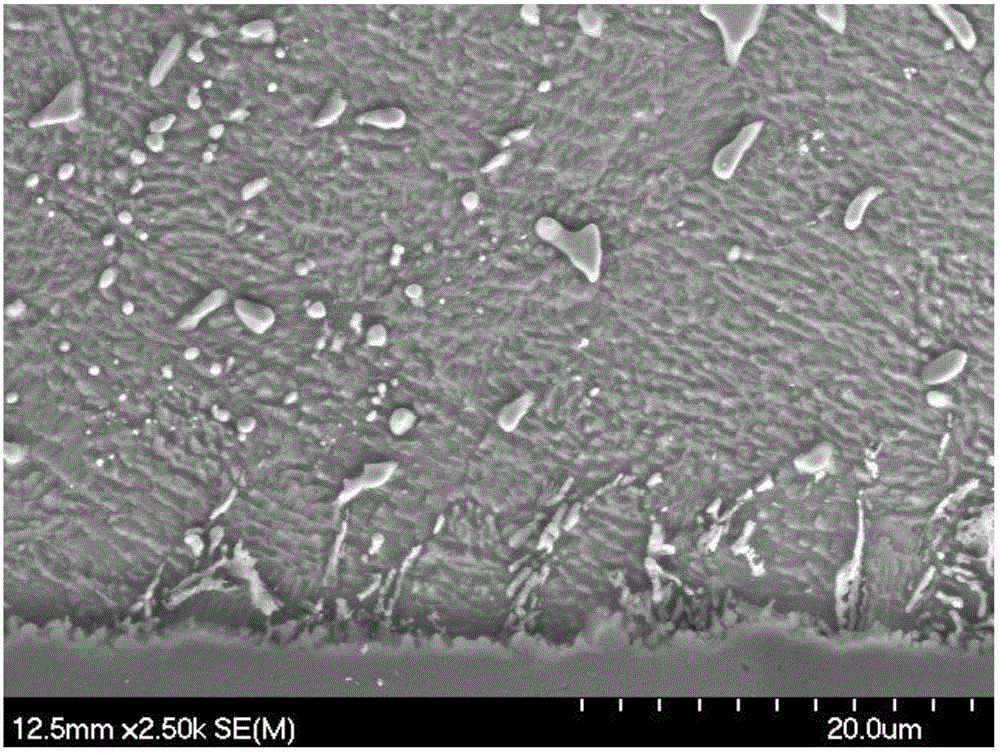

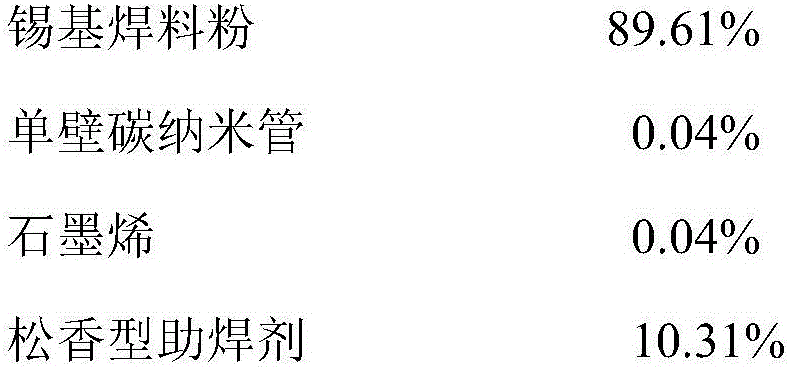

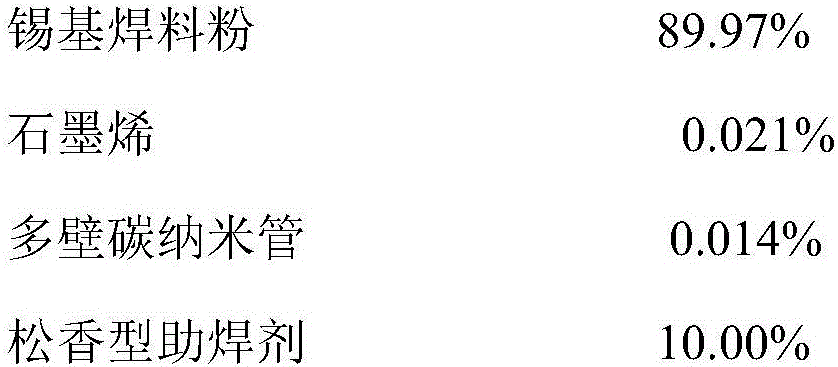

Tinned carbon nanomaterial reinforced compound solder alloy and solder paste thereof

ActiveCN106363315AImprove creep resistanceImproved electromigration performanceWelding/cutting media/materialsSoldering mediaTinningAging resistance

The invention provides tinned carbon nanomaterial reinforced compound solder alloy and solder paste thereof. The tinned carbon nanomaterial reinforced compound solder alloy comprises, by weight, 84-95 parts of tin-based solder, 0.01-0.2 part of carbon nanomaterials and 5-15 parts of soldering flux. By the adoption of the technical scheme, the creep resistance, electrical conductivity and thermal aging resistance of soldered dots generated by the tinned carbon nanomaterial reinforced compound solder alloy and the solder paste thereof are improved. The carbon nanomaterials in the prepared solder paste are uniform in distribution, the process is simple and reliable, adaptability is high, and cost is low.

Owner:YIK SHING TAT SOLDER MFR KUNSHAN +2

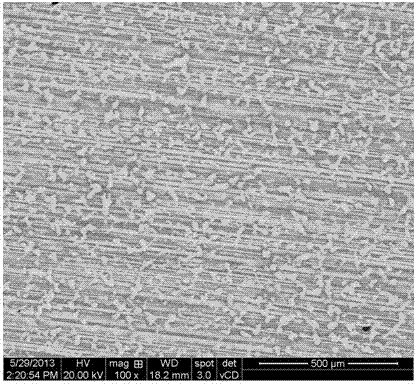

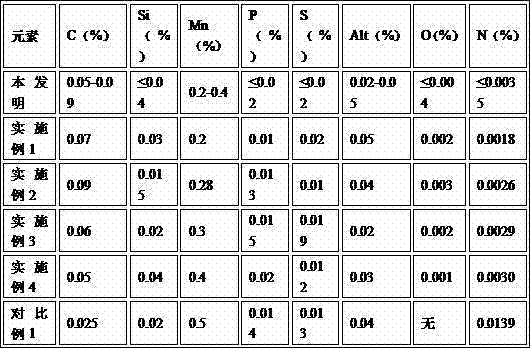

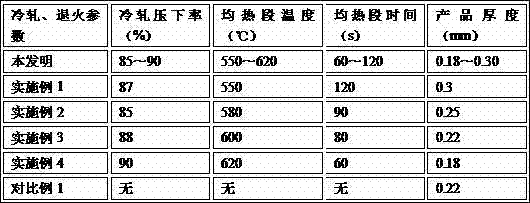

Cold rolled tin-plated steel plate for multiple printing and painting and manufacturing method thereof

The invention relates to a cold rolled tin-plated steel plate for multiple printing and painting and a manufacturing method thereof, and aims to solve the technical problems that in the prior art, the coating on the conventional cold rolled tin-plated steel plates for multiple printing and painting can be easily peeled off, the adhesive force between the coating and the steel plate is weak, and the color developing effect is bad after printing. The manufacturing method comprises the following steps: washing a hot-rolled hard tin-plated steel plate with a thickness of 1.8 to 2.3 mm by acid, performing continuous cold rolling, carrying out continuous annealing, flattening, electroplating tin on the steel plate, passivating the steel plate, and finally rolling the steel plate to obtain a finished product; wherein the cold rolling reduction ratio is 85 to 90%, the annealing temperature is 550 to 620 DEG C, the temperature is maintained for 60 to 120 seconds, the steel plate is flattened by two machines, the work roller of the first machine is an electro-discharge texturing roller with a Ra of 1.2 to 1.6 um, the rolling force is 500 to 700 t; the work roller of the second machine is a grinding roller with a Ra of 0.3 to 0.5 um, the rolling force is 250 to 350 t; the flattening elongation rate is 1 to 2%, and the passivation is carried out through an electrochemical method and a chemical method. The provided steel plate is mainly used to produce food / beverage cans, which have requirements on multi-color printing.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

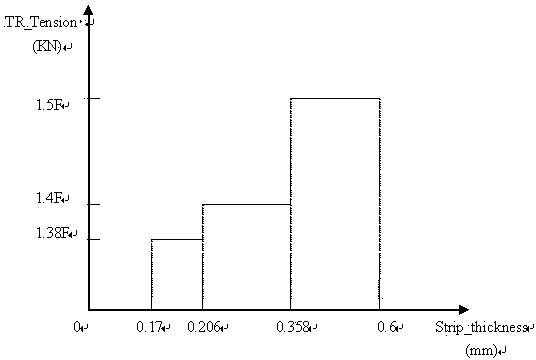

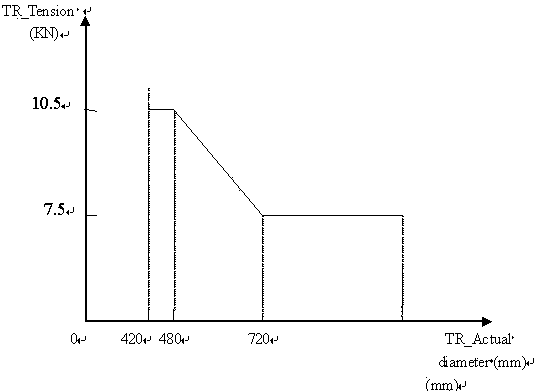

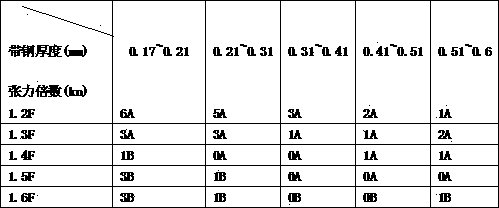

Anti-buckling coiling machine strip steel threading tension control method

ActiveCN103832897AReduce hoop stressAvoiding Collapse DefectsHot-dipping/immersion processesTinningEngineering

The invention relates to an anti-buckling coiling machine strip steel threading tension control method. Currently, in the aspect of coiling tension control of a coiling machine of an electrolytic tinning machine set, a single and fixed strip steel threading tension control mode is adopted, obvious thickness grades of tinned products are not considered, buckling and displacement are prone to happen in the coiling process, and the appearance and quality of a finished coil are affected. In the method, strip steel threading tension of a coiling machine is controlled in a graded mode according to the thickness grades of the strip steel, strip steel threading tension 1.38 times larger than set tension is adopted when the thicknesses are smaller than 0.206 mm, strip steel threading tension 1.4 times larger than the set tension is adopted when the thicknesses range from 0.206 mm to 0.358 mm, and strip steel threading tension 1.5 times larger than the set tension is adopted when the thicknesses are larger than 0.3580 mm. By means of the method, buckling caused by incorrect strip steel threading tension can be effectively avoided, and stable and effective operation of a machine set are guaranteed.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

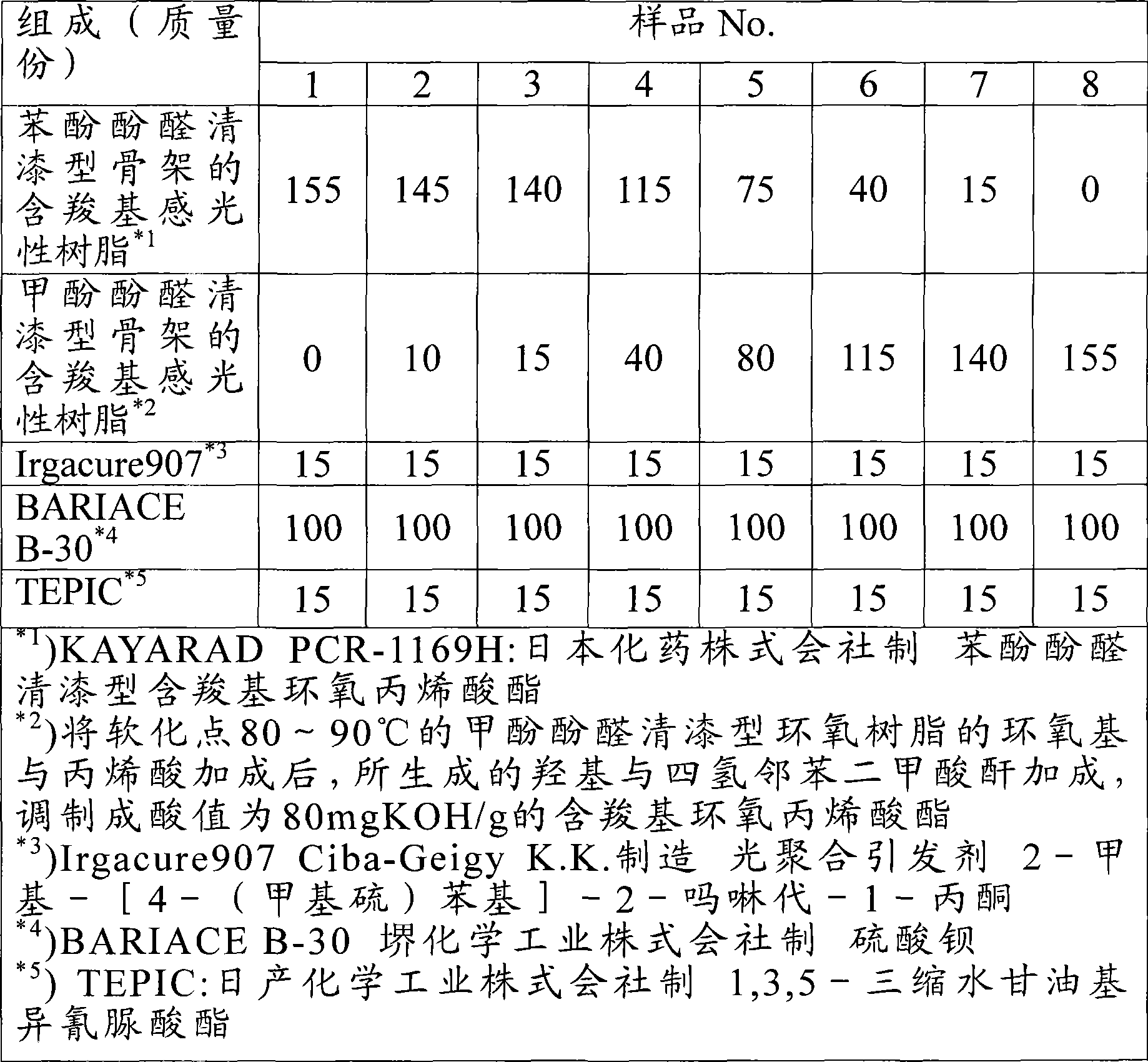

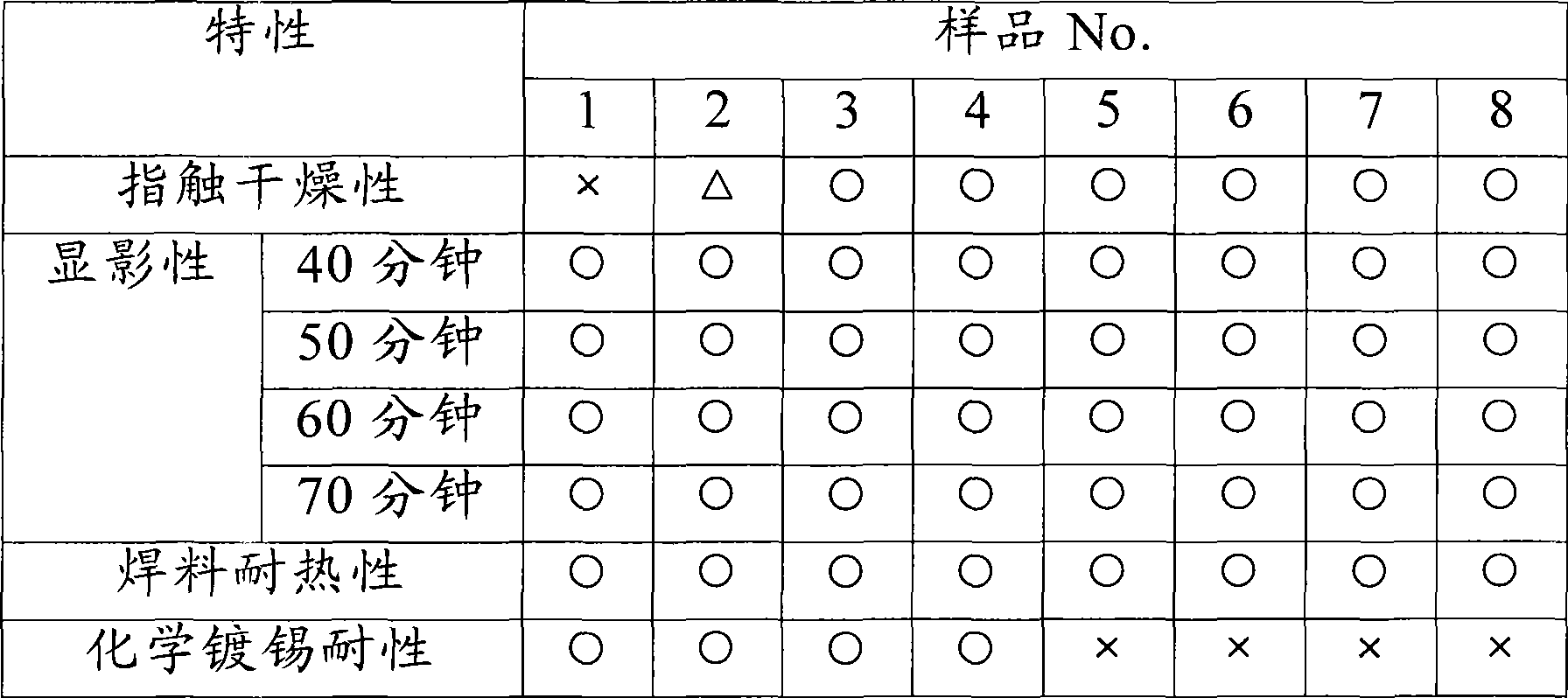

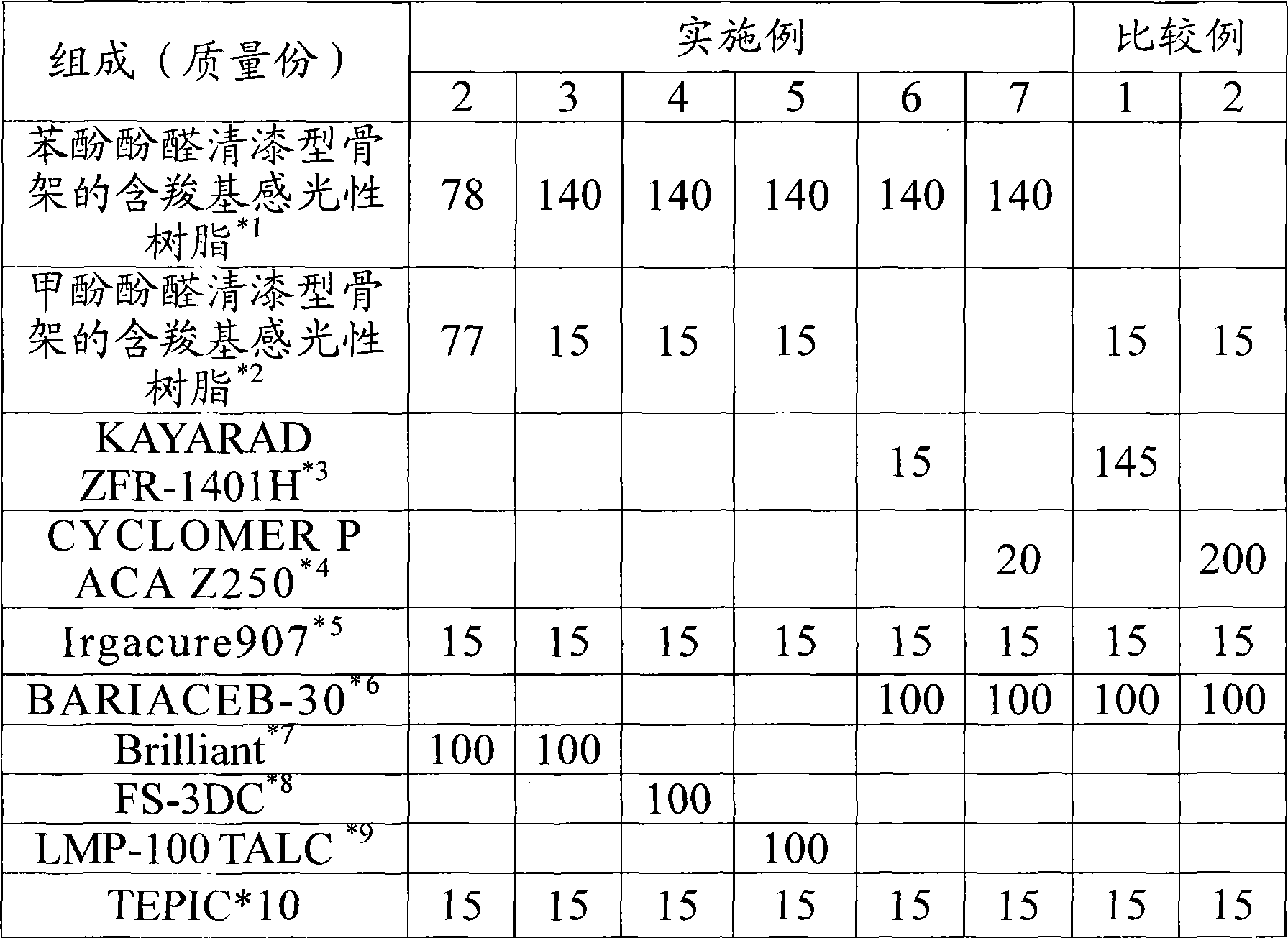

Photo-cured and heat-cured resin composition and pcondensate thereof

ActiveCN101393394AImprove curing effectExcellent soldering heat resistancePhotomechanical apparatusPrinted circuit manufactureTinningEpoxy

The invention provides a light curing and thermal curing resin composition which can not produce the problem of touch drying deterioration, and form curing coating pattern with good chemical tinning resistance, curing material, and printed circuit board formed of solder mask made of the curing material. The light curing and thermal curing resin composition comprises (A) carboxyl containing photosensitive resin obtained from the reaction between the reaction product of phenol phenolic varnish type epoxy resin and unsaturated monocarboxylate and saturated or unsaturated multi-anhydride, (B) other carboxyl containing photosensitive resin except for (A), (C) photopolymerization initiator, (D) diluent, and (E) thermal curing composition, the ratio of (A) and (B) is 50 to 95:50 to 5 (mass ratio). Moreover, (F) curing accelerant is comprised, or barium sulfate and / or silicon dioxide is used as inorganic filler.

Owner:TAIYO INK MFG

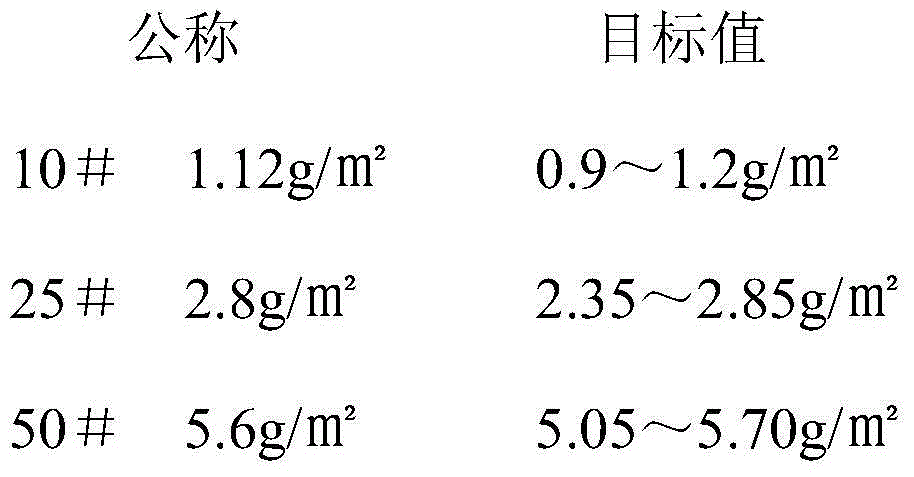

Steel strip tinning method

The invention discloses a steel strip tinning method which comprises the following steps: 1) pretreatment; 2) electrotinning; 3) 1# baking; 4) soft melting; 5) passivating treatment; 6) 2# baking; and 7) oil application. The tinned plate obtained by the continuous tinning method has uniform thickness; the tin coating is uniform and smooth on the whole surface and does not have flaws, dents, wrinkles, rusty stains and other defects unsuitable for use; and under normal storage and use conditions, the whole surface is suitable for paints and printing.

Owner:张家港市新港星科技有限公司

Heavy-copper step circuit board and preparation method thereof

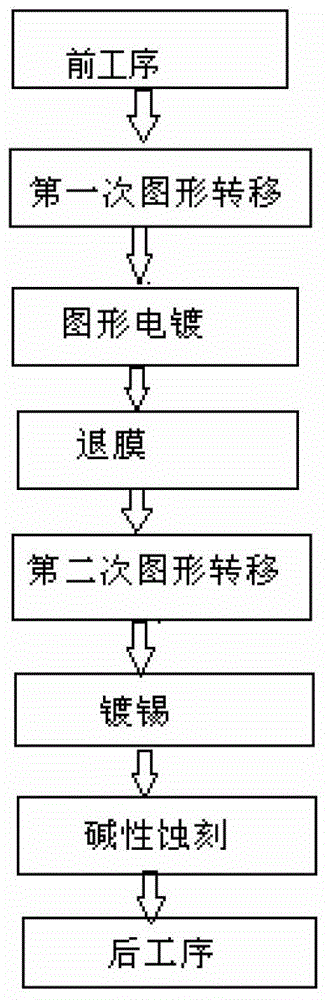

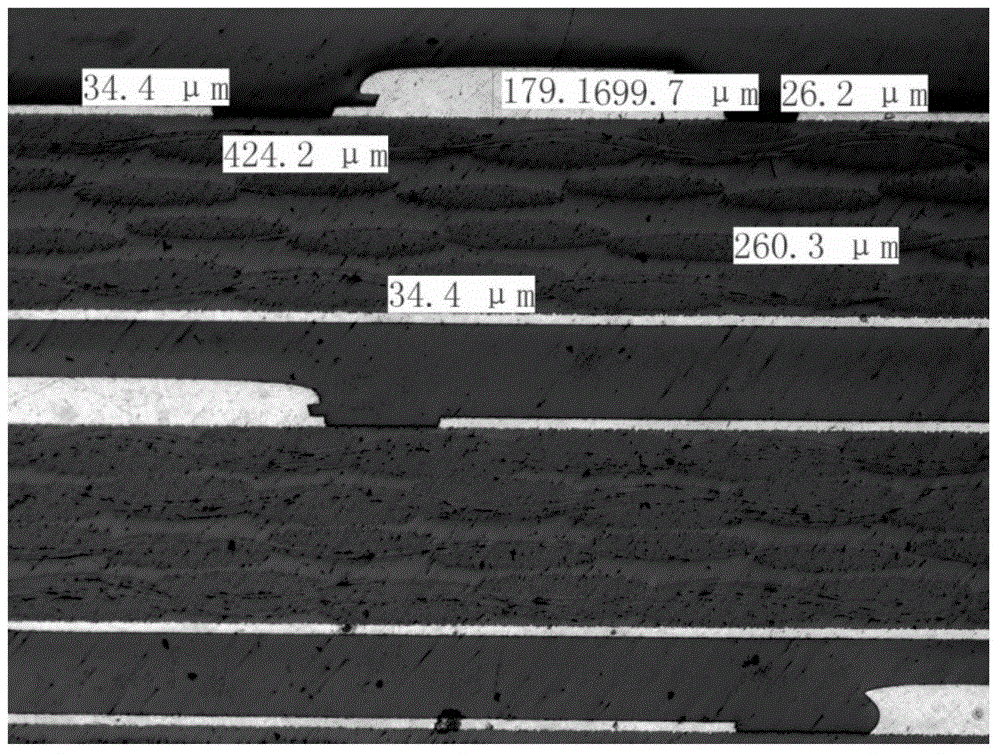

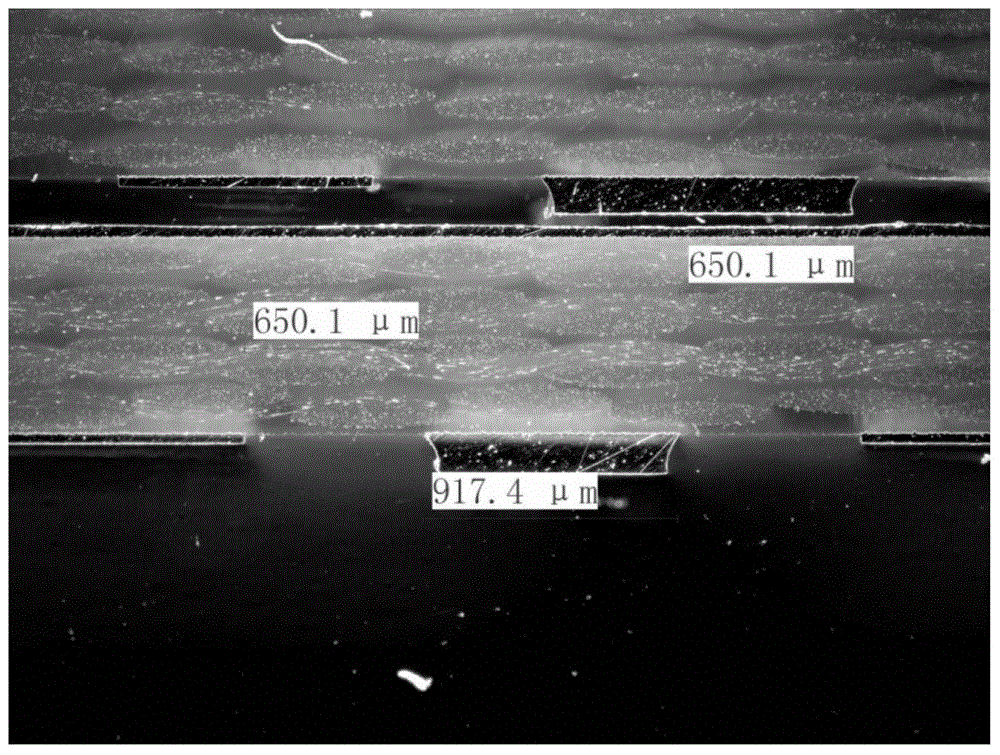

ActiveCN103338595AOptimize grinding plateOptimizing the etch processConductive material chemical/electrolytical removalTinningAlkaline etching

The invention discloses a heavy-copper step circuit board and a preparation method thereof. The preparation method comprises the working procedures of primary pattern transfer, pattern electroplating, film removal, secondary pattern transfer, tinning and alkaline etching. The preparation method solves the quality problem of a clamping film and the quality problems such as circuit nicks and unclean etching due to the fact that an anti-corrosion layer cannot be closely bonded with a circuit by a dry film technology by utilizing the production capacity of the available equipment and optimizing roll film, board grinding and etching processes; the whole preparation process is compatible with the traditional circuit board technology; and the quality and the cost can be compatible effectively.

Owner:KALEX MULTI LAYER CIRCUIT BOARD (ZHONGSHAN) CO LTD

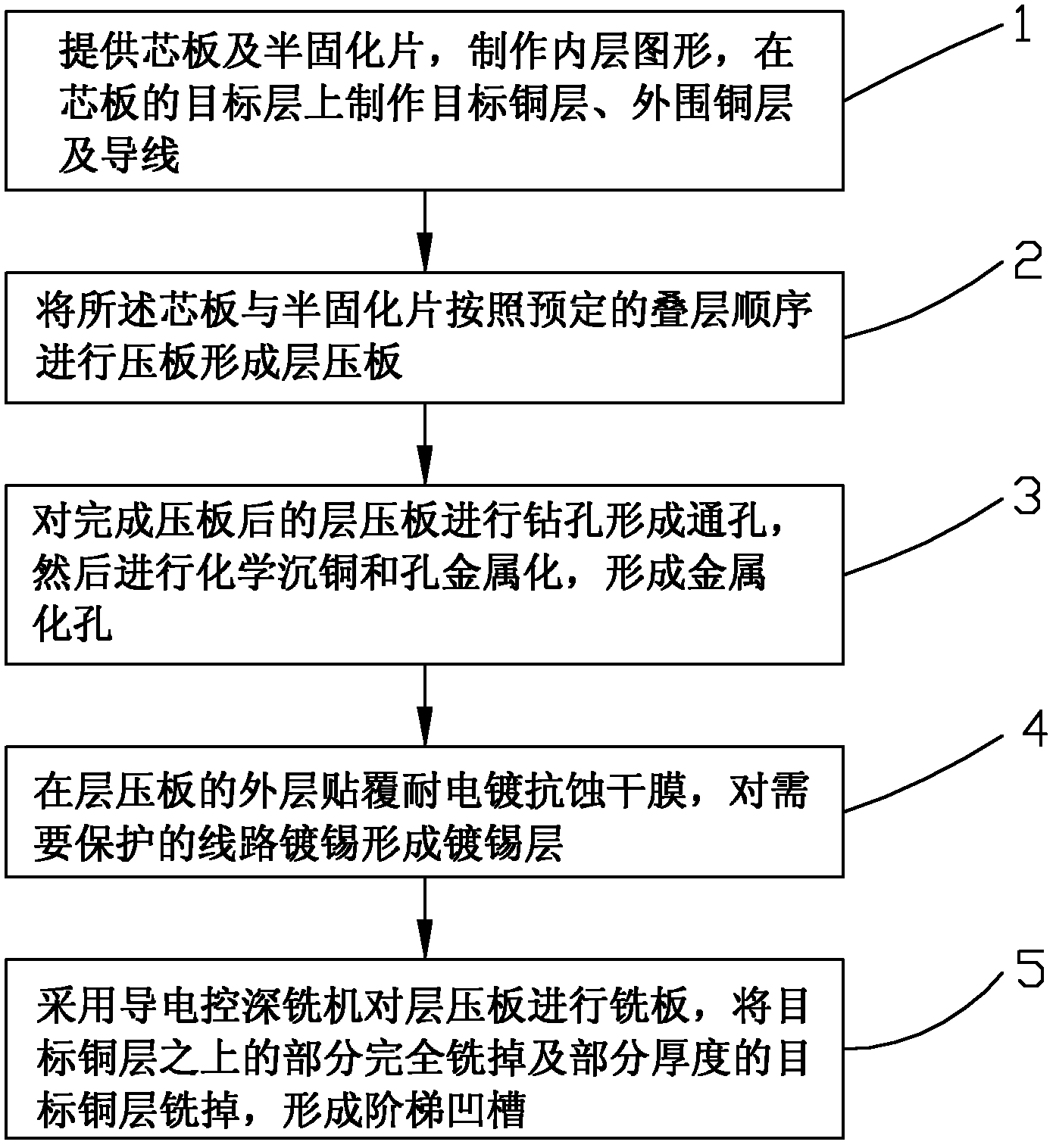

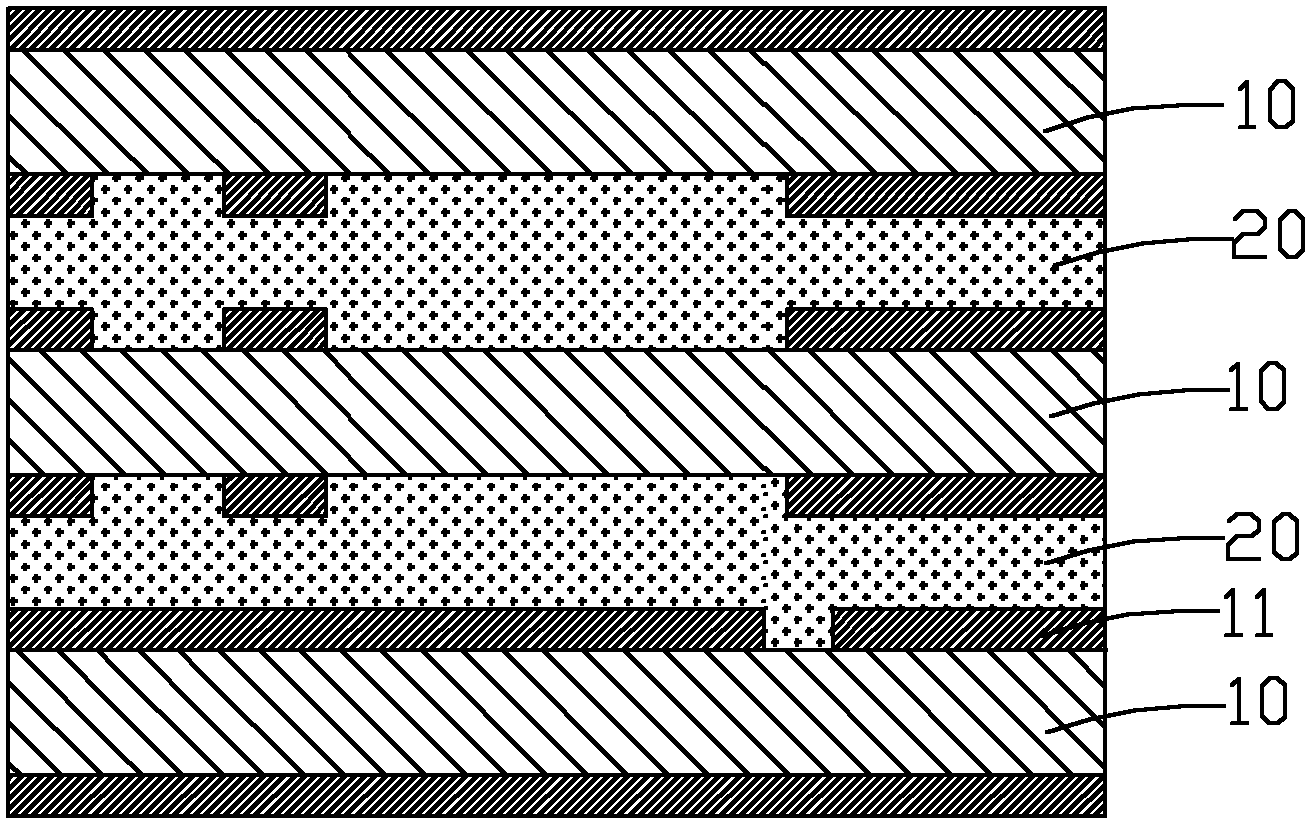

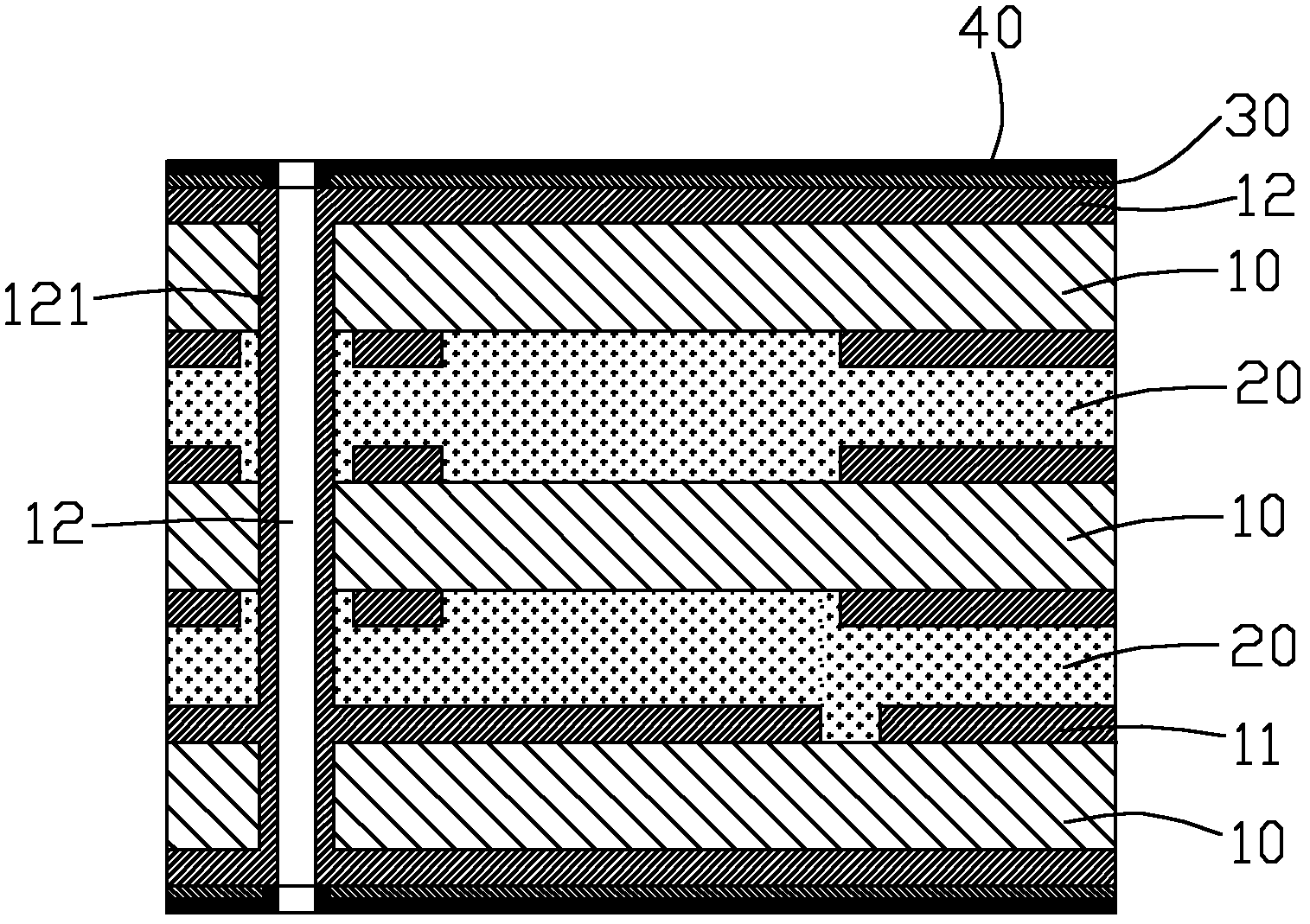

Method for manufacturing printed circuit board (PCB) with step-shaped grooves

ActiveCN102497737AControl depthThe production process is simplePrinted circuit manufactureTinningEngineering

The invention relates to a method for manufacturing a printed circuit board (PCB) with step-shaped grooves. The method comprises the following steps of: 1, providing core plates and prepregs, preparing an inner-layer image and preparing a target copper layer, a peripheral copper layer and wires on a target layer of one of the core plates; 2, pressing the plates to form a laminated plate; 3, drilling to form a through hole and then performing chemical copper deposition and hole plating so as to form a plated hole which is connected with the peripheral copper layer of the target layer; 4, gluing an electroplating-and-corrosion-resisting dry film and tinning to form a tin coating; and 5, milling the laminated plate by an electricity-conducting depth-controllable milling machine to ensure that all parts on the target copper layer and part of the target copper layer are milled off and the step-shaped grooves are formed. Through the method for manufacturing the PCB with the step-shaped grooves, the target copper layer is prepared on the target layer and is connected with the superficial tin coating, and the plates are milled by the electricity-conducting depth-controllable milling machine to ensure that the milling depth can be effectively controlled, the manufacturing process is simple and is high in efficiency, and the method is suitable for batch production.

Owner:DONGGUAN SHENGYI ELECTRONICS

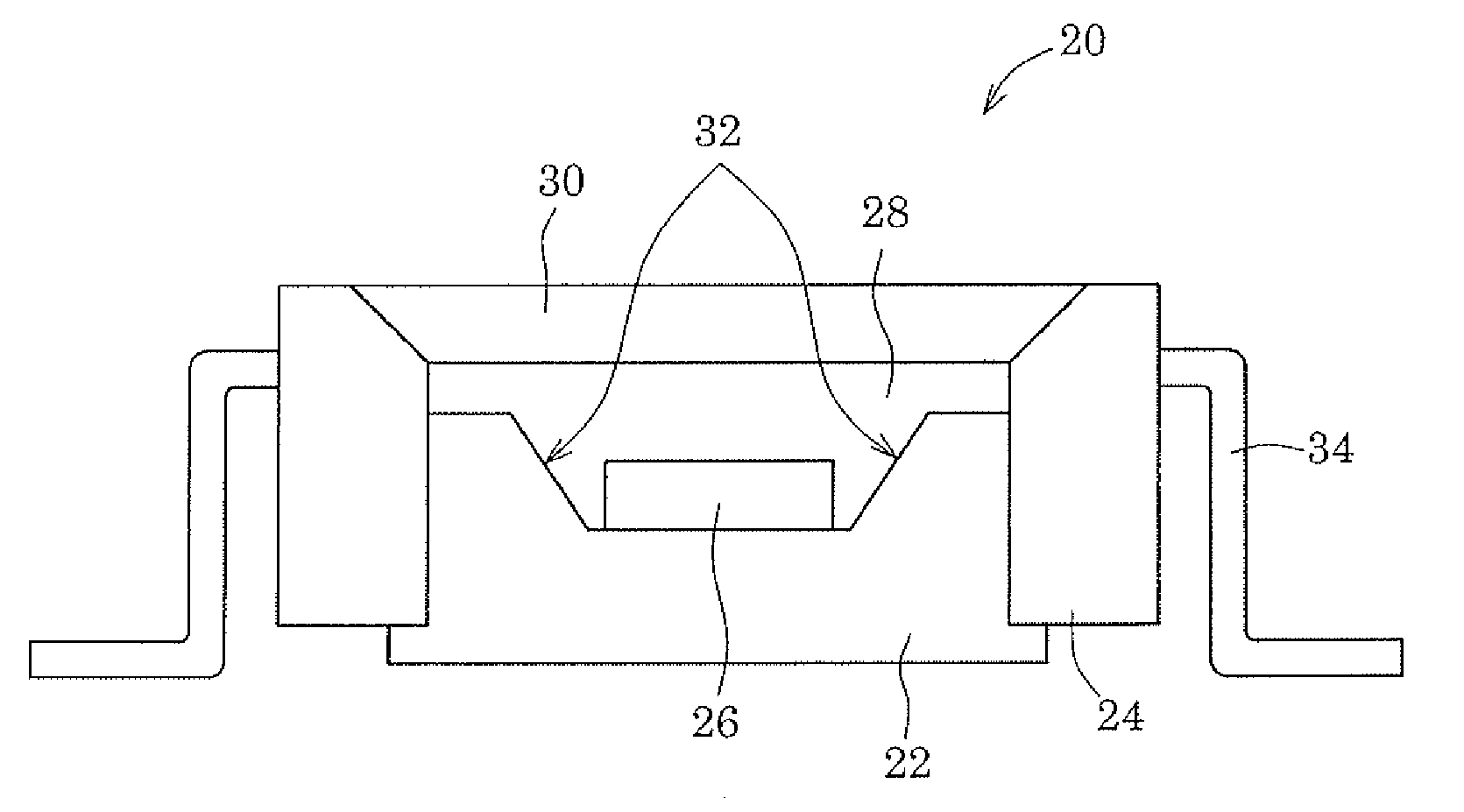

Plating structure and method for manufacturing electric material

InactiveUS20110012497A1Increase resistanceReduce contact resistanceIncadescent screens/filtersElectric discharge tubesTinningSilver plate

There is provided a plating structure obtained by heat-treating a silver-plated structure obtained by forming a tin-plated layer, an indium-plated layer, or a zinc-plated layer, having a thickness of 0.001 to 0.1 μm, on a surface of the silver-plated layer formed on a surface of a plating base. There is also provided a coating method for obtaining the plating structure which comprises the step of melting a particle deposit spottedly deposited at 2×10−6 to 8×10−6 g / cm2 such that the spot-deposited particles have gaps therebetween as viewed above and the particles each having an average diameter of 20 to 80 nm do not pile up in a direction perpendicular to the surface of the silver layer to obtain a film.

Owner:KYOWA ELECTRIC WIRE

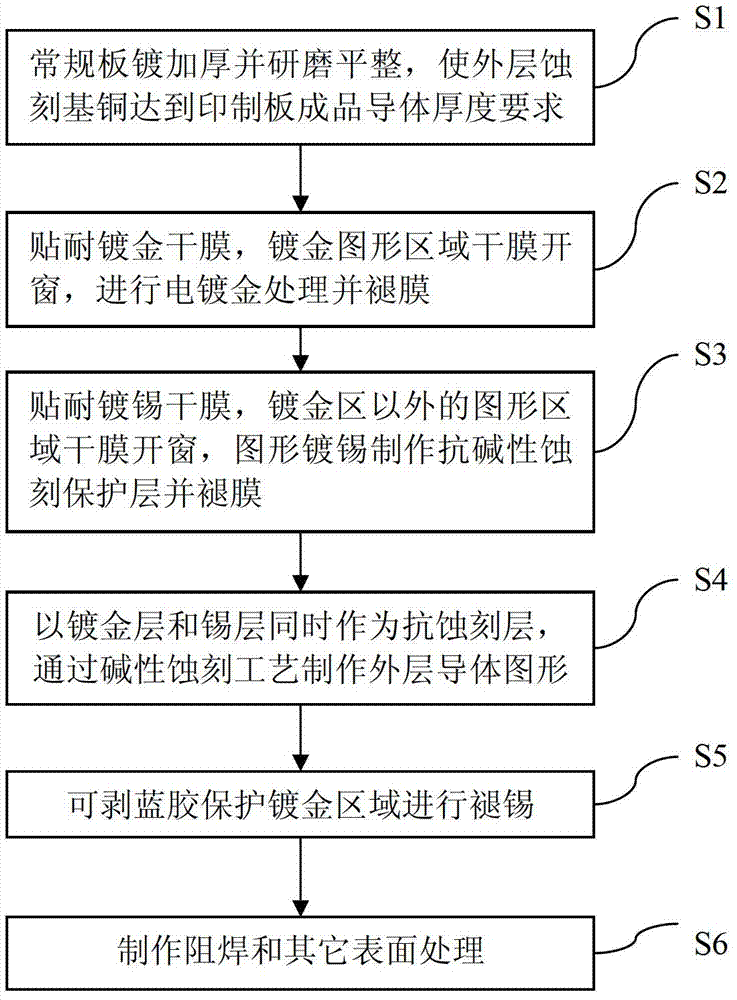

Making method of outer layer patterns of local gold-plating printed plate

ActiveCN103179795AMeet the process requirementsMeet the requirements of partial gold-plated surface treatmentConductive pattern reinforcementTinningResist

The invention provides a making method of outer layer patterns of a local gold-plating printed plate. A printed plate is conducted to conventional plate planting and thickening and is ground to be smooth, so that outer layer etched base copper is in accordance with the requirements on the thickness of a printed plate finished conductor. A gold-plating resistant dry film is bonded on the printed plate, dry film window cutting is performed in a gold-plating pattern area, and then electrogilding treatment and stripping are performed. Tin-plating resistant dry film is bonded on the printed plate, dry film window cutting is performed in an area corresponding to pattern design other than the gold-plating area, patterns exposed after window cutting are conducted to tin plating, so as to be served as a tin plate of an alkaline etching resistant protective layer, and stripping is performed after tin plating. The gold-plating layer and the tin layer are both served as etching resistant layers, and outer layer conductor patterns are prepared through an alkaline etching technology. Peelable blue gel is screen-printed on the outer layer gold-plating conductor patterns and is cured, so that the gold-plating area is protected, and then the tin layer is conducted to tin stripping treatment. Solder resist is prepared and other surface treatment is performed.

Owner:JIANGNAN INST OF COMPUTING TECH

Antistatic, conductive and electromagnetic shielding textile and preparation method thereof

InactiveCN101580998AImprove bonding fastnessFeel goodWeft knittingFibre treatmentTinningTextile fiber

The invention relates to an antistatic, conductive and electromagnetic shielding textile and a preparation method thereof, being characterized in that fiber filament is firstly processed by electroless plating copper in a way of continuous proceeding and then processed by electrolytic tinning to prepare conductive filament; then, the conductive filament is cut into conductive short fiber which is processed by pure spinning or blend spinning with other common textile fibers to be made into yarn, and the antistatic, conductive and electromagnetic shielding textile can be prepared by fabric manufacture as well as dyeing and finishing; or the conductive short fiber is blended with other common textile fibers and then processed into non-weaving cloth by pinprick or spunlace. The textile prepared by the invention has beautiful appearance and soft feel, and is safe to the skin.

Owner:ZHEJIANG SCI-TECH UNIV

Double-surface pressing connecting through hole structure of printed-circuit board and machining method thereof

ActiveCN103458627AEliminate parasitic capacitanceImprove integrityElectrical connection printed elementsPrinted element electric connection formationTinningCopper plating

The invention discloses a double-surface pressing connecting through hole structure of a printed-circuit board and a machining method of the double-surface pressing connecting through hole structure of the printed-circuit board. The machining method comprises the following steps that a small hole A is drilled in the upper surface of a substrate in a depth-control mode; a pressing connecting hole B is drilled in the same position of the small hole A; the substrate is overturned; a small hole C is drilled in the surface opposite to the small hole A in a depth-control mode and is communicated with the small hole A; a pressing connecting hole D is drilled in the position of the small hole C; electroless copper plating, copper electroplating and tinning are carried out; a hole E is drilled in the position of the small hole A in a depth-control mode; the substrate is overturned; a hole F is drilled in the position of the small hole C in a depth-control mode; alkaline etching and tin stripping are carried out; part of a copper layer at each pressing connecting hole is thickened in a plating mode until the design requirement of a finished product is met, and finally the double-surface pressing connecting through hole structure is obtained. The double-surface pressing connecting through hole structure of the printed-circuit board and the machining method of the double-surface pressing connecting through hole structure of the printed-circuit board completely eliminate the stray capacitance among pressing connecting elements, facilitates the integrality of signal transmission and improves wire distribution density; the process is reasonable, the difficulty that plating layers of the middle small holes are eliminated in a drilling mode is largely lowered, and the diameter of the pressing connecting holes is made to be the smallest; the completeness of the plating layers on the walls of the pressing connecting holes is guaranteed, and the non-metallic middle small holes are achieved; copper wire defects in the holes are avoided.

Owner:SHANTOU ULTRASONIC PRINTED BOARD NO 2 FACTORY +1

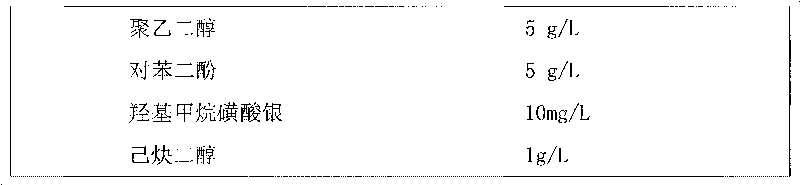

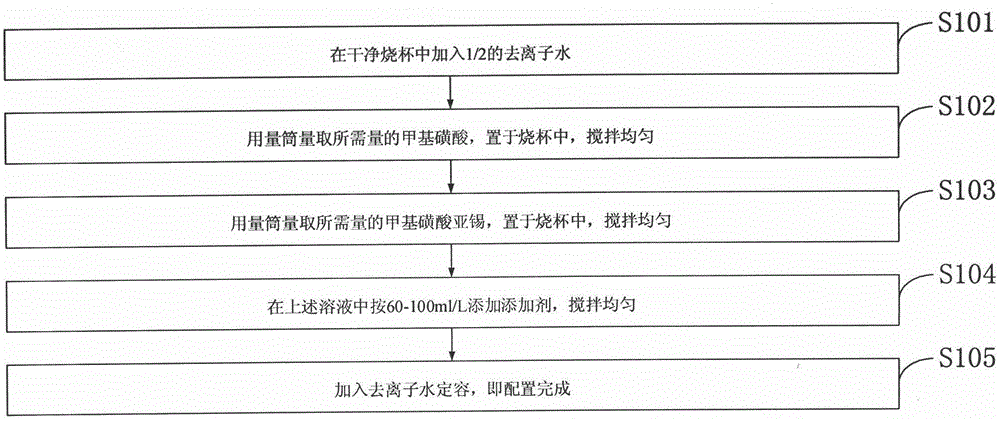

High-speed tinning solution and preparation method thereof

The invention discloses a high-speed tinning solution and a preparation method thereof. Deionized water is added to a clean beaker until the volume of the water accounts for 1 / 2 that of the beaker; a required amount of methanesulfonic acid is measured through a measuring cylinder and put in the beaker, and the mixture is stirred uniformly; a required amount of tin methanesulfonate is measured through the measuring cylinder and put in the beaker, and the mixture is stirred uniformly; additives with the concentration being 60-100 ml / L are added to a tin methanesulfonate solution and stirred uniformly; the deionized water is added until the mixture is in a predetermined volume, and the high-speed tinning solution is prepared. Plating with uniform color and consistent crystal grains is obtained in a wider current density range, formation of tin whisker is effectively controlled, the anti-tarnishing capability and the excellent weldable performance of the plating are guaranteed, the current density can be increased to the greatest extent, the anti-tarnishing capability and the weldable performance are guaranteed, meanwhile, a defoaming agent is not used, and fewer organic impurities are mixed in the plating.

Owner:济南德锡科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com