Photo-cured and heat-cured resin composition and pcondensate thereof

A resin composition, thermosetting technology, applied in the fields of adhesion, chemical resistance, moisture resistance and heat resistance of various substrates, can solve the problems of solder resist peeling, coating film residue, negative film traces, etc. The effect of excellent electrical insulation and excellent resistance to electroless tin plating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

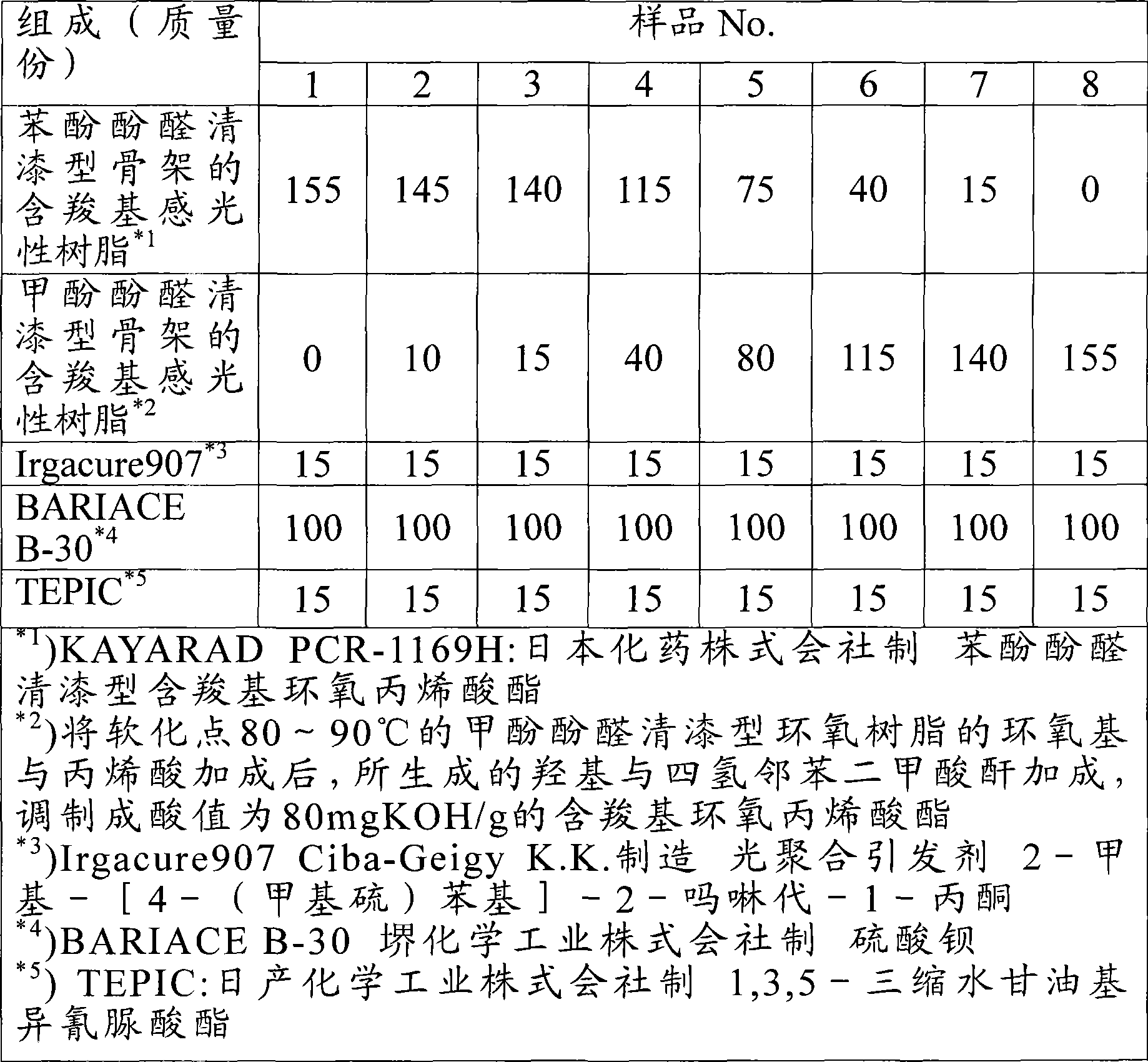

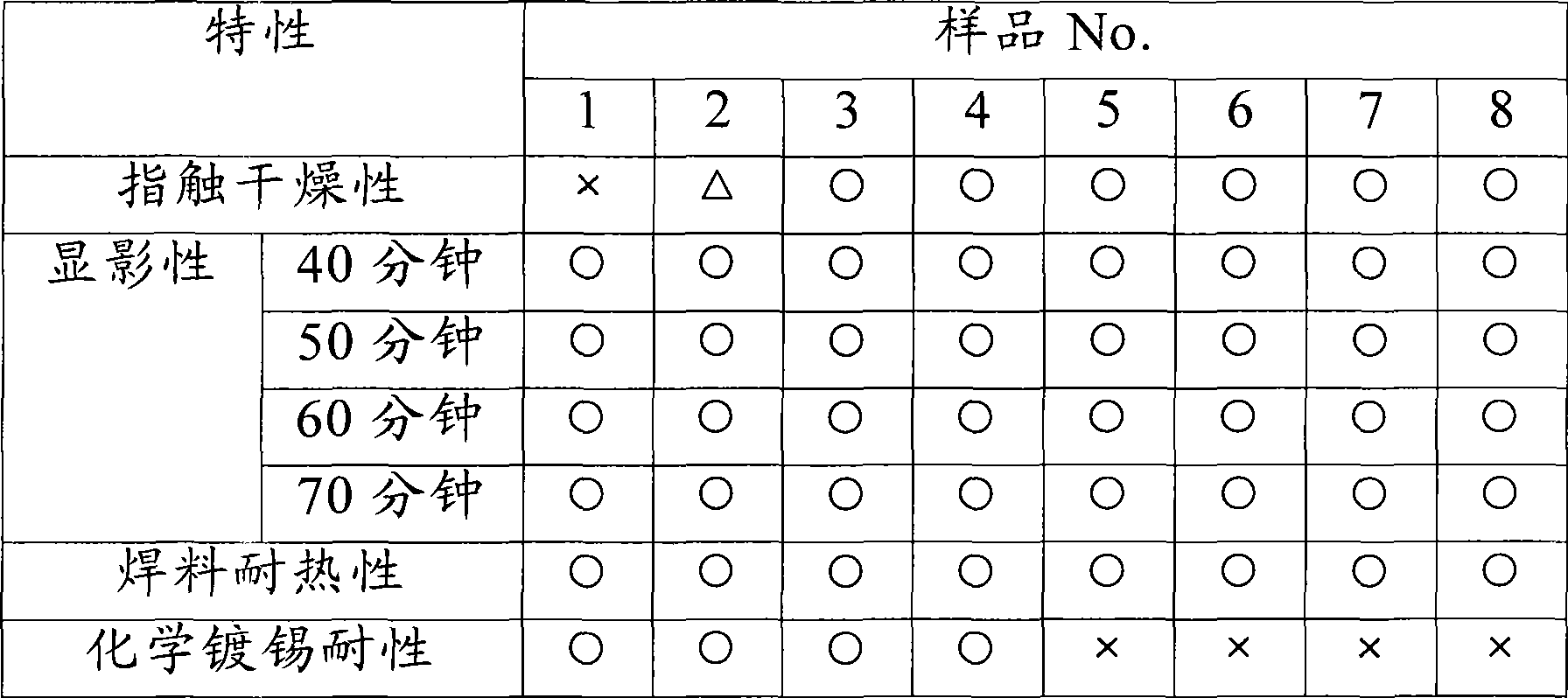

[0054] In the combinations shown in Table 1, the respective components were mixed in a dissolver and uniformly dispersed to obtain a photocurable / thermosetting resin composition. The composition was coated on the entire surface of a patterned copper through hole printed circuit board using a 100-mesh polyester screen with a thickness of 20 to 30 μm by a screen printing method. Next, the coating film was dried for 30 minutes using a hot air circulation drying oven at 80° C., and tests for dryness to touch and developability were performed by the test method and evaluation method described later.

[0055] Next, a negative film having a resist pattern was adhered to the coating film, and ultraviolet light was irradiated (exposure amount: 300 mJ / cm 2 ), followed by development in 1 wt% sodium carbonate aqueous solution with a spray pressure of 0.2 MPa for 60 seconds. Thereafter, heat and solidify in a hot air circulation drying oven at 150°C for 60 minutes, and cool to room tempe...

Embodiment 2~7 and comparative example 1、2

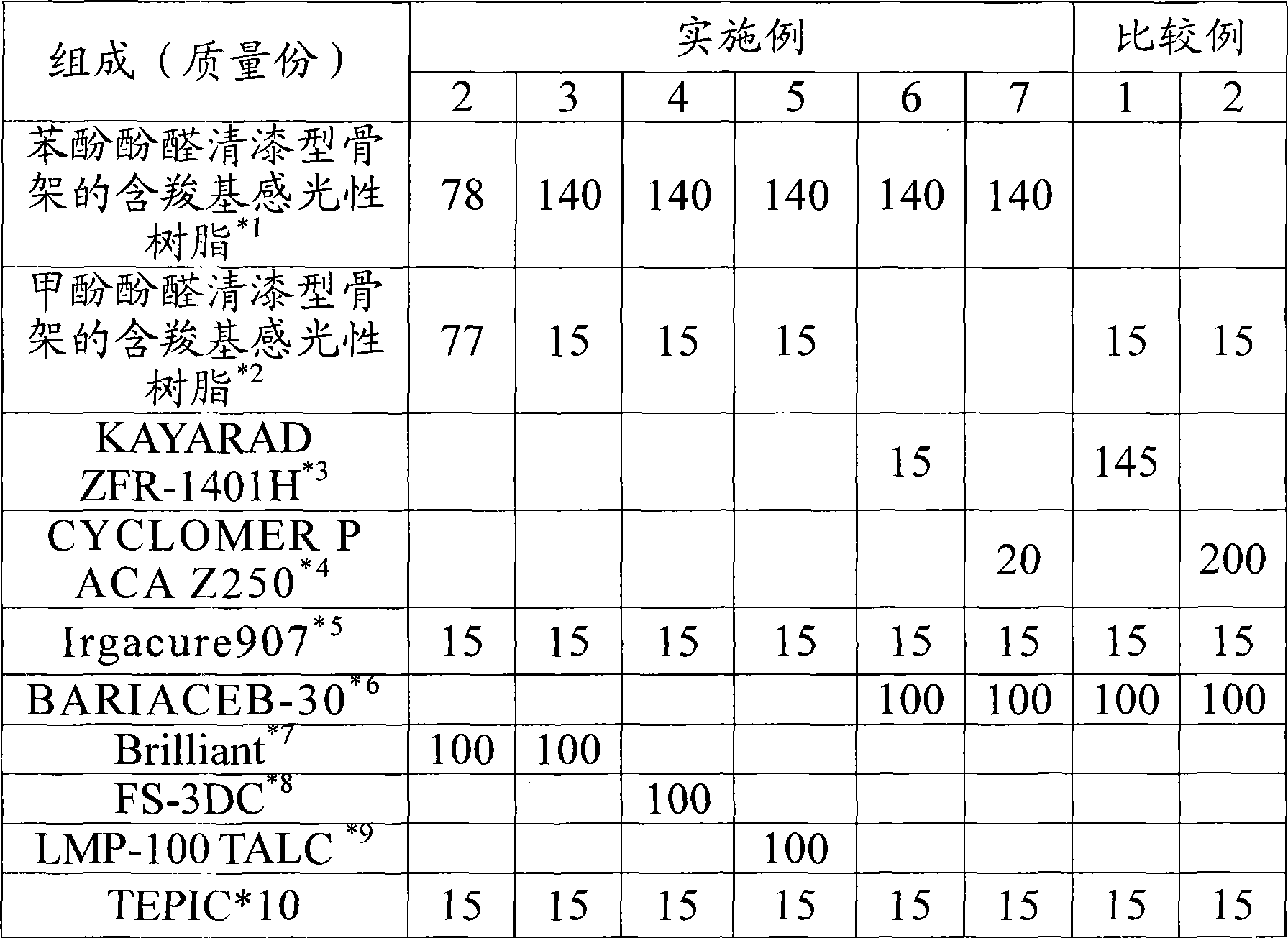

[0092] Except for making the formula combination shown in Table 3, the same operation was carried out as in the aforementioned Example 1 to prepare a photocurable and thermosetting resin composition, and the dryness to touch, developability, solder heat resistance and Test for resistance to electroless tin plating. The results are shown in Table 4.

[0093] table 3

[0094]

[0095]

[0096] Table 4

[0097]

[0098] As can be seen from the results shown in Table 4 above, the cured film formed from the photocurable / thermosetting resin composition of the present invention is excellent in dry-to-touch properties, developability, solder heat resistance, and electroless tin plating resistance. On the other hand, in the case of Comparative Examples 1, 2, and 4, which do not contain a carboxyl group-containing photosensitive resin having a phenol novolak-type skeleton as the carboxyl group-containing photosensitive resin, the developability and electroless tin plating res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com