Heavy metal pollution bottle sediment curing agent and curing method thereof

A technology of polluting sediment and solidifying method, applied in chemical instruments and methods, water pollutants, sludge treatment, etc., can solve the problems of high pH value of sediment solidified body leachate, unsatisfactory solidification effect, and harm to water quality, etc. Low cost of curing treatment, ideal curing effect and reduced toxicity risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

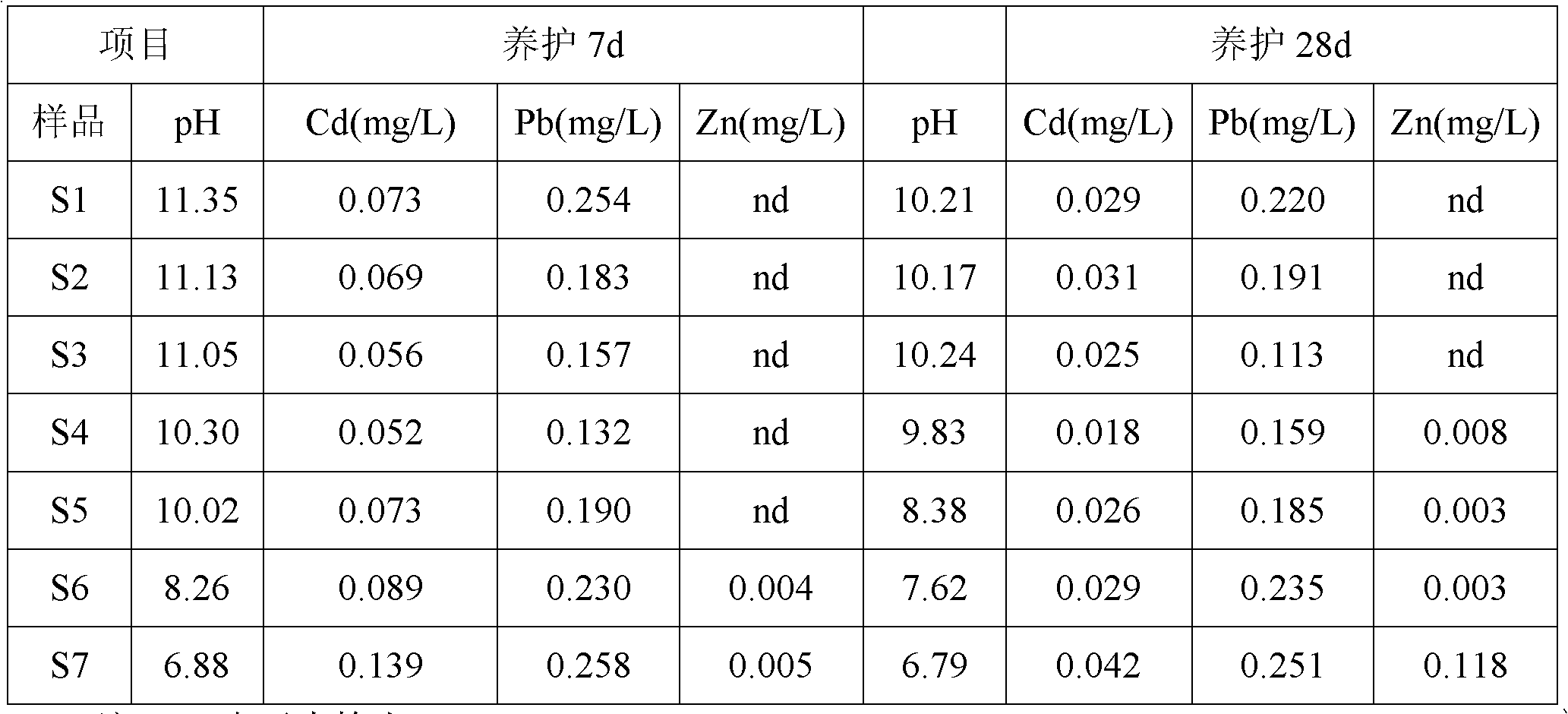

[0016] A kind of heavy metal pollution sediment solidifying agent of the present invention, this solidifying agent comprises cement (the 425# ordinary Portland cement that Changsha Shifeng Cement Factory produces) and fly ash, the mass ratio of fly ash and cement is by 1: 11. 1:5, 1:2, 1:1 and 2:1 were prepared to obtain five curing agents of the present invention respectively S2, S3, S4, S5 and S6 (see Table 1 below). At the same time, two kinds of curing agents S7 and S1 were prepared according to the mass ratio of fly ash and cement as 5:1 and no fly ash was added, as a comparative example of the curing agent of the present invention (see table 1 below).

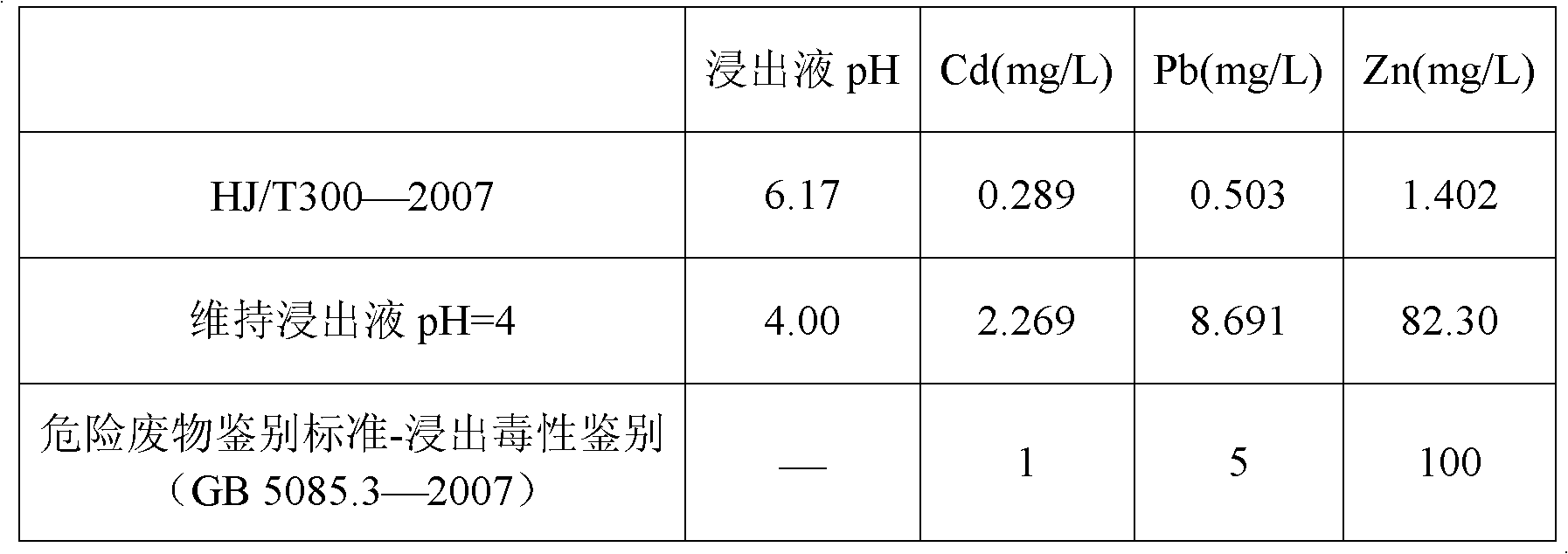

[0017] A solidification method of the heavy metal-contaminated bottom sludge solidifying agent of the present invention, the heavy metal leaching situation of the heavy metal-contaminated bottom sludge used in the present embodiment is shown in Table 2 below, and the above-mentioned solidifying agent is directly added to s...

Embodiment 2

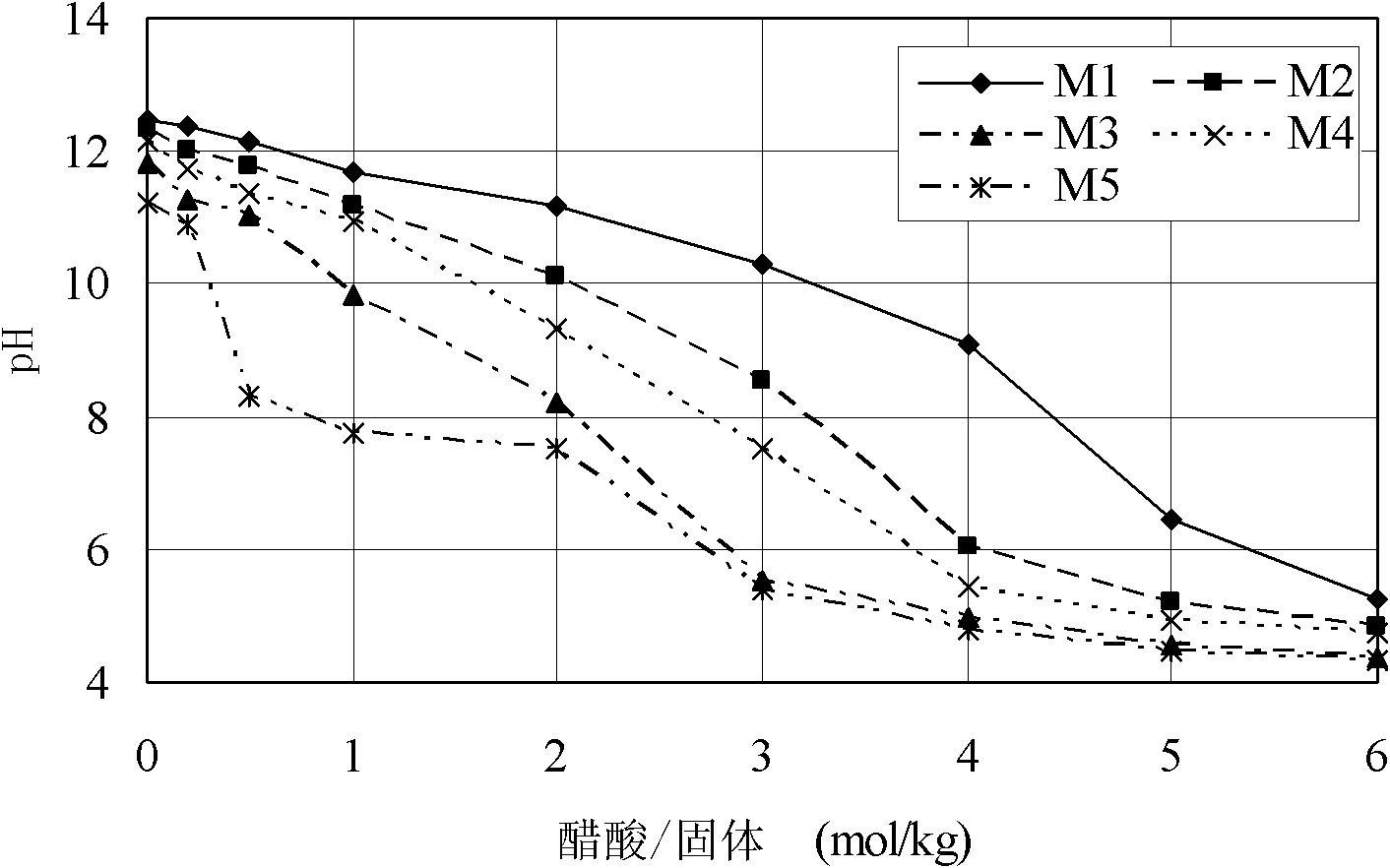

[0031] A heavy metal contaminated bottom mud solidifying agent of the present invention, the solidifying agent comprises cement and fly ash, and the mass ratio of fly ash and cement is configured according to 3: 7, 3: 2, 1: 4 and 1: 1 respectively, Obtain M2, M3, M4, M5 four kinds of curing agents of the present invention respectively (see table 5 below). Meanwhile, prepare a kind of pure cement solidifying agent M1 according to not adding fly ash, as the comparative example of solidifying agent of the present invention (see table 5 below).

[0032] Table 5: curing agent formulation and consumption in embodiment 2

[0033] sample

Sediment (g)

cement (g)

Fly ash (g)

M1

50

50

0

M2

50

35

15

M3

50

20

30

M4

50

20

5

M5

50

10

10

[0034]A solidification method of the heavy metal-contaminated bottom sludge solidifying agent of the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com