Patents

Literature

203results about How to "Reduce leaching concentration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Treatment method of chromium-polluted soil

InactiveCN102228901AReduce leaching concentrationEasy to operateContaminated soil reclamationHigh concentrationIron salts

The invention discloses a treatment method of chromium-polluted soil, which comprises the following steps of: 1, adding a ferrous iron salt solution in the chromium-polluted soil, uniformly stirring to ensure that a ferrous iron salt reacts with hexavalent chromium in the soil, and reducing the hexavalent chromium in the soil into trivalent chromium; and 2, adding a lime solution in the soil obtained from the step 1, and uniformly stirring to ensure that the trivalent chromium in the soil is converted into chromium hydroxide. The high-concentration chromium-polluted soil is treated by using an in situ curing / stabilizing method, thus the treatment method is rapid and efficient, is simple in operation, and is especially suitable for in situ emergence treatment of chromium pollution accidents caused by paroxysmal heavy environmental contamination events. The curing / stabilizing rate reaches above 99 percent.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

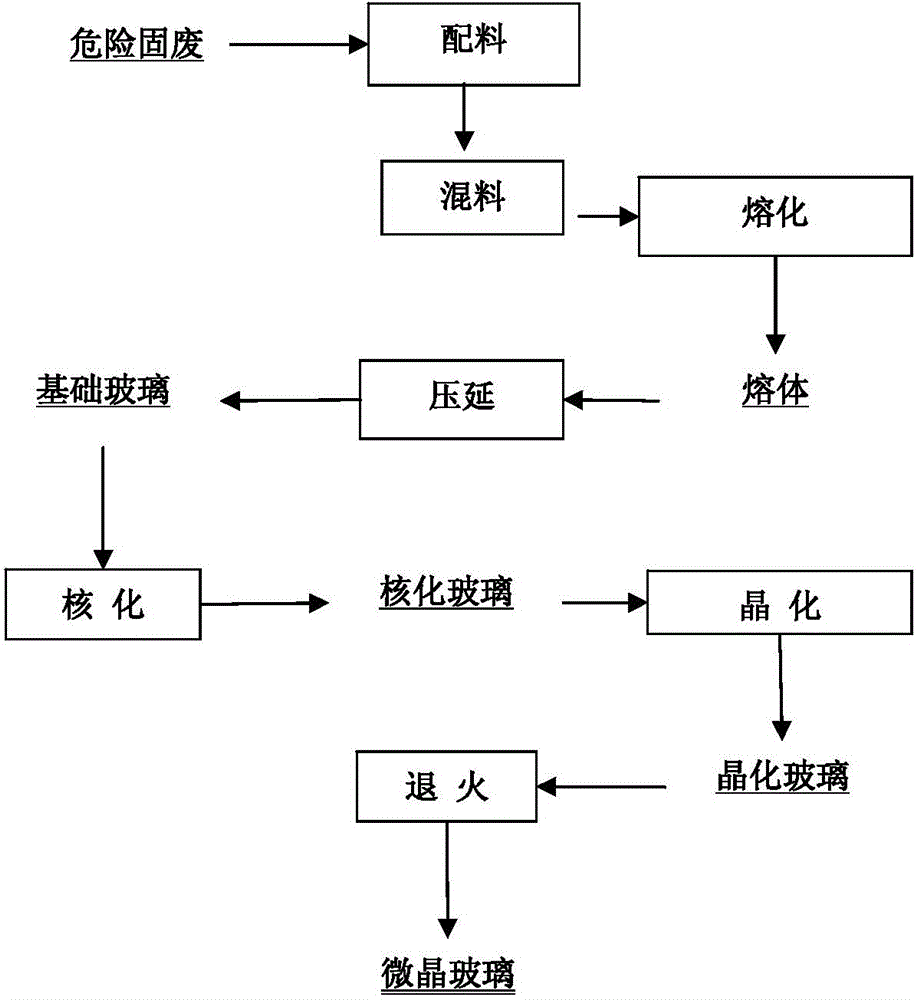

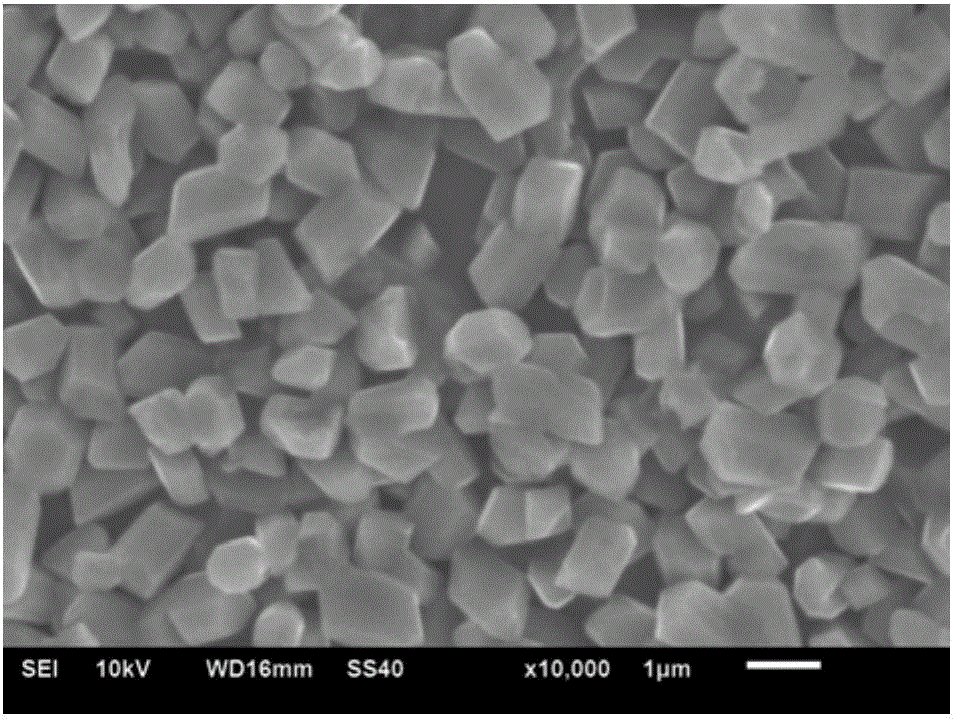

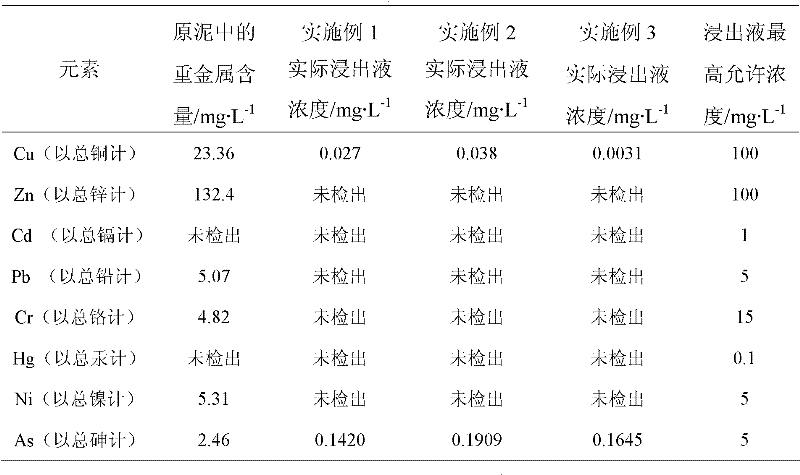

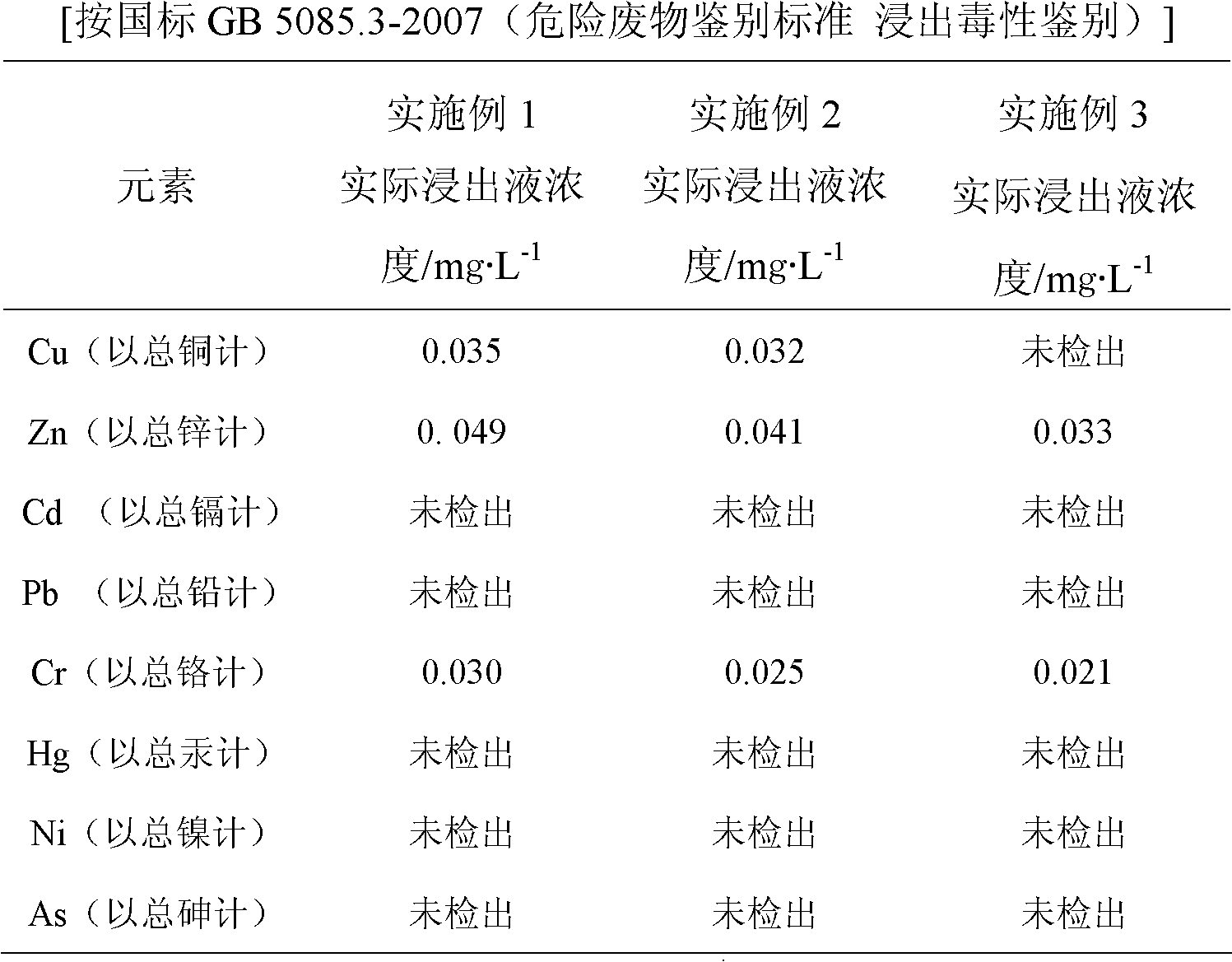

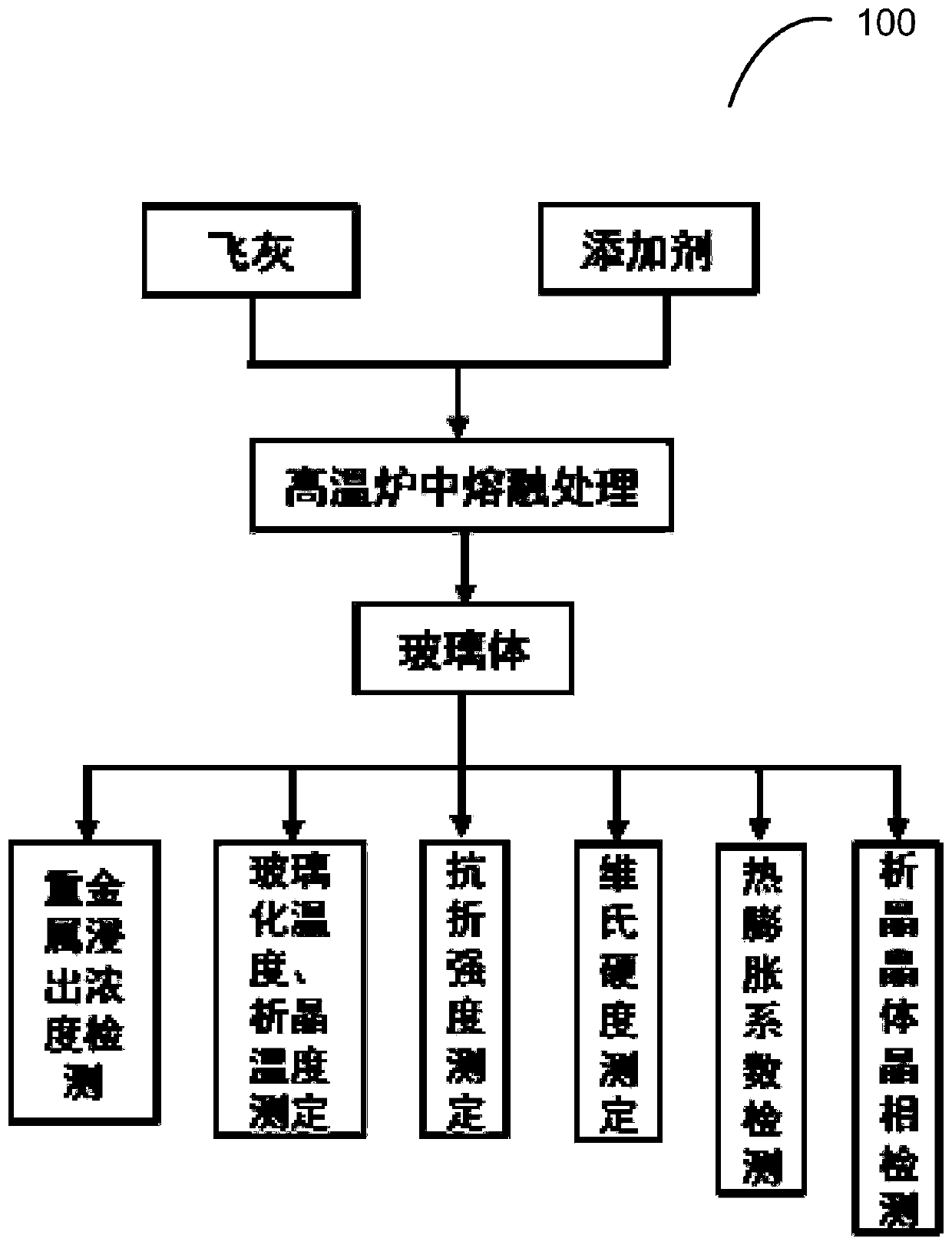

Method for preparing microcrystalline glass from hazardous solid wastes

The invention discloses a method for preparing microcrystalline glass by taking hazardous solid wastes which are hazardous solids for short. The method is characterized by taking heavy metals in the hazardous solids as nucleating agents, mixing, fusing, rolling, nucleating, crystallizing and annealing to obtain the microcrystalline glass. The method has the advantages that the heavy metal elements in waste incineration ash, stainless steel slag, stainless steel acid pickling sludge, electroplating sludge, chromium slag, lead-zinc smelting slag and coal ash can be stably solidified; the pollution is avoided; meanwhile, high-additional-value microcrystalline glass is prepared; the harmless high-value application of the hazardous solids is realized; and the method has remarkable environmental and economic benefits and wide market prospects.

Owner:UNIV OF SCI & TECH BEIJING

Method for preparing ceramsite by utilizing dried sludge and burnt fly ash

InactiveCN102060426AAchieving simultaneous reductionAchieving processing powerSludge treatment by de-watering/drying/thickeningSodium BentoniteExpanded clay aggregate

The invention discloses a method for preparing ceramsite by utilizing dried sludge and burnt fly ash, belonging to the technology of reduction, harmless treatment and disposal and recycling of dangerous solid waste. The method comprises the following steps of: drying dewatered sludge with moisture content of 75-85% to obtain dry sludge; crushing the dry sludge, and then screening; mixing the screened dry sludge, burnt fly ash and bentonite uniformly according to a certain proportion to obtain a mixture; injecting the mixture into a powder pressing machine for extruding and forming to obtain a blank; preheating the blank at certain time; roasting the blank at high temperature at certain time; and naturally cooling to room temperature to obtain a ceramsite product. Simultaneous reduction, harmless treatment and disposal and recycling of two dangerous wastes of the burnt fly ash and municipal sludge are realized with the method, and the produced ceramsite product conforms to the standard of toxic leaching and meets the requirement of lightweight aggregate of buildings. The method has the advantages of simplicity in process, less investment, low operating cost, large required quantity of the produced ceramsite products and the like.

Owner:TIANJIN TEDA ENVIRONMENTAL PROTECTION +1

Method for preparing haydite from sludge incineration ash in chemical industry

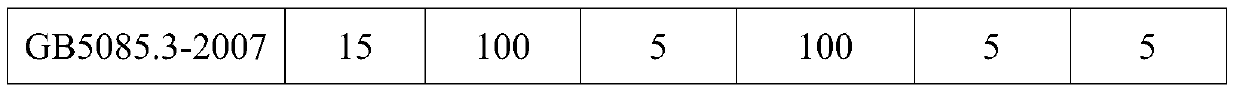

ActiveCN102249730AAchieve reductionRealize resourcesSludge treatmentCeramicwareChemical industryDry mixing

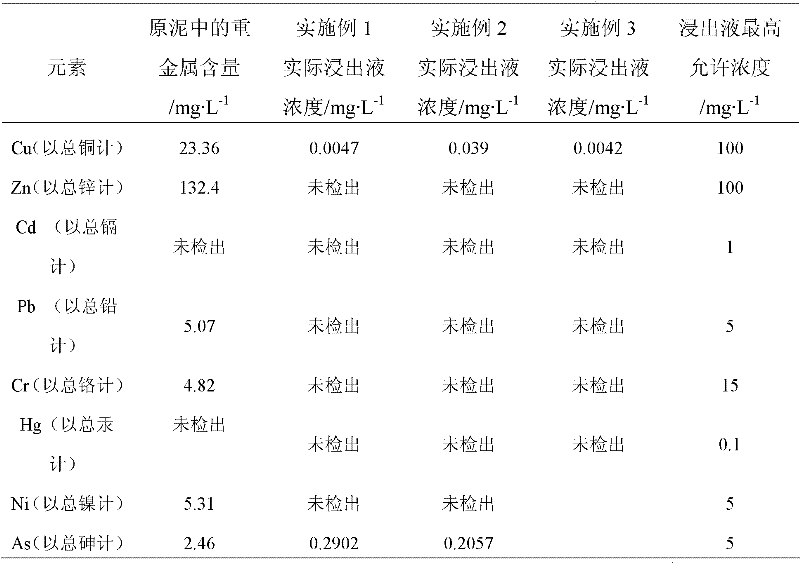

The invention relates to recycling of industrial solid waste, and discloses a method for preparing haydite from sludge incineration ash in chemical industry. The method comprises the following steps: drying sludge subjected to mechanical dewatering, incinerating at high temperature, proportioning, carrying out dry mixing, adding water, evenly mixing, granulating to obtain fresh pellets, drying the fresh pellets, and roasting at 1050-1150 DEG C to form sludge haydite. The leaching concentration of heavy metals is far below GB 5085.3-2007 (Identification Standards for Hazardous Wastes-Identification for Extraction Toxicity). The method has the advantages of low energy consumption and low production cost, develops a new way for recycling sludge in the fields of waste treatment with waste andcyclic utilization of waste, and has obvious environmental benefit and economic benefit.

Owner:江苏江淮环保科技有限公司

Method for preparing haydite from wet sludge and incineration fly ash

The invention discloses a method for preparing haydite from wet sludge and incineration fly ash, belonging to solid hazardous waste treatment and recycling technology. The method comprises the following steps: proportionally and uniformly mixing municipal sludge of which the water content is 75-85%, incineration fly ash and bentonite; carrying out extrusion forming on the mixture to obtain a haydite blank; drying the blank for a period of time; preheating the blank for a period of time; roasting the blank at high temperature for a period of time; and naturally cooling to room temperature to obtain the haydite product. In the invention, the wet sludge (municipal sludge of which the water content is 75-85%) and other raw materials are directly mixed, formed and granulated; and thus, the invention avoids the problem of sludge drying, and facilitates forming and granulation based on the viscosity of the wet sludge. The invention has the advantages of simple process, low investment, low operating cost, high demand for the haydite product and the like, thereby having wide development prospects and high popularization value.

Owner:TIANJIN TEDA ENVIRONMENTAL PROTECTION +1

Process for preparing active carbon by adding husks into chemical sludge

InactiveCN102107872AAlleviate shortagesWide variety of sourcesSludge treatmentChemical industrySludge

The invention relates to a process for preparing active carbon by adding husks into chemical sludge. The process comprises the following steps of: drying residual sludge which is generated from sewage treatment in chemical industry and serves as a raw material; adding the husks; grinding; adding an activating agent; drying; performing carbonizing activation under the protection of inert gases; and cooling, washing and drying to prepare sludge-based active carbon. The active carbon is prepared from a great deal of the residual sludge which is generated from sewage treatment in chemical industry and serves as the raw material, so the discharge value of the residual sludge in the chemical industry is reduced, preparation cost of an active carbon adsorbent is reduced, and obvious environmental and economic benefits are achieved. The heavy metal concentration of the prepared active carbon is lower than the highest allowable leachate concentration stated in national standard GB 5085.3-2007 (hazardous waste identification standard leaching toxicity identification); and under a high-temperature pyrolysis condition, organic matters in the sludge can be completely mineralized. The active carbon prepared by the process can be applied in the fields of wastewater treatment, waste gas absorption and the like and has a wide market prospect.

Owner:NANJING UNIV OF TECH

Method for reducing and stabilizing chromium-contaminated soil by chemical-biological coupling

InactiveCN104492802AImprove stabilityReduce leaching concentrationContaminated soil reclamationCouplingSulfate

The invention relates to a method for reducing and stabilizing chromium-contaminated soil by chemical-biological coupling. The method comprises the following steps: mixing chromium-contaminated soil and ferrous sulfate, uniformly stirring, adding water to control the water content, and maintaining until the concentration of hexavalent chromium in the chromium-contaminated oil is reduced to be lower than 500mg / kg to obtain chemically reduced soil; adding a microbial nutrient prepared from honey and soybean cake powder according to a certain proportion into the chemically reduced soil, uniformly stirring, regulating the water content, and isolating air to maintain for over 30 days to obtain the repaired soil. The method provides a new thought for repairing chromium-contaminated soil, has the advantages of low cost, good effect, small chemical reagent dosage, short repairing time, environmental friendliness, simple operation and the like, and has remarkable economic and environmental benefits.

Owner:SHANDONG ACAD OF ENVIRONMENTAL SCI

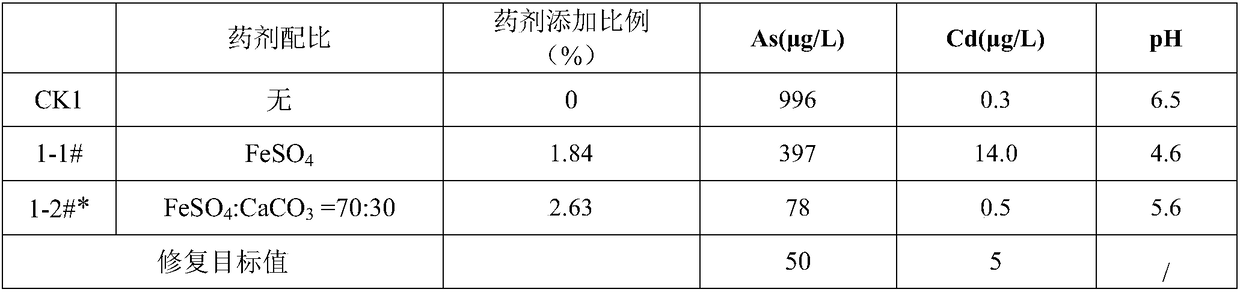

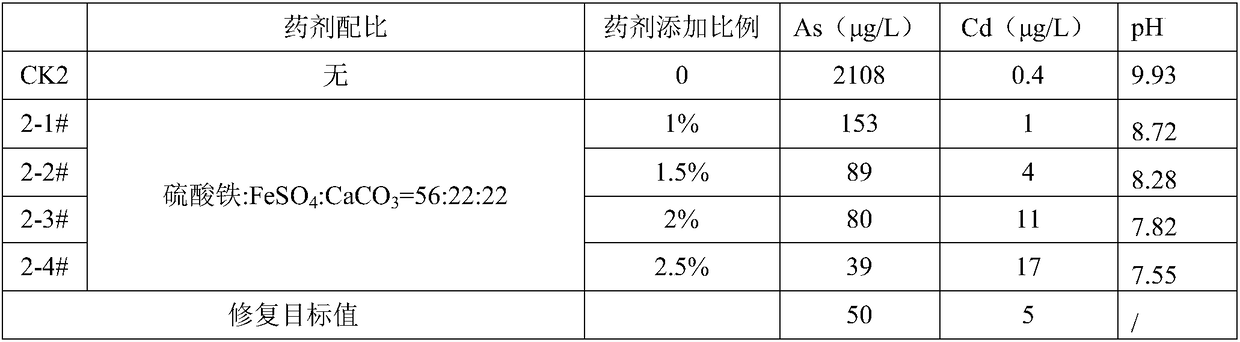

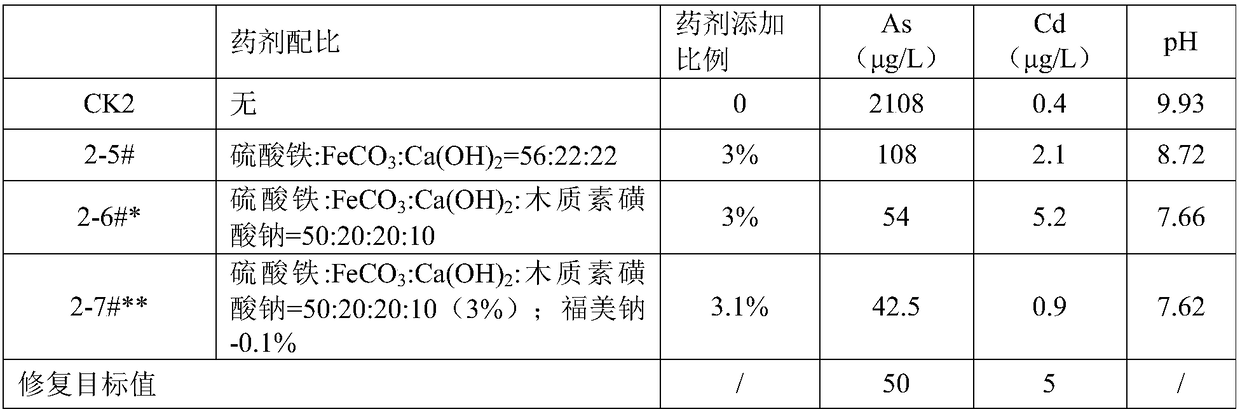

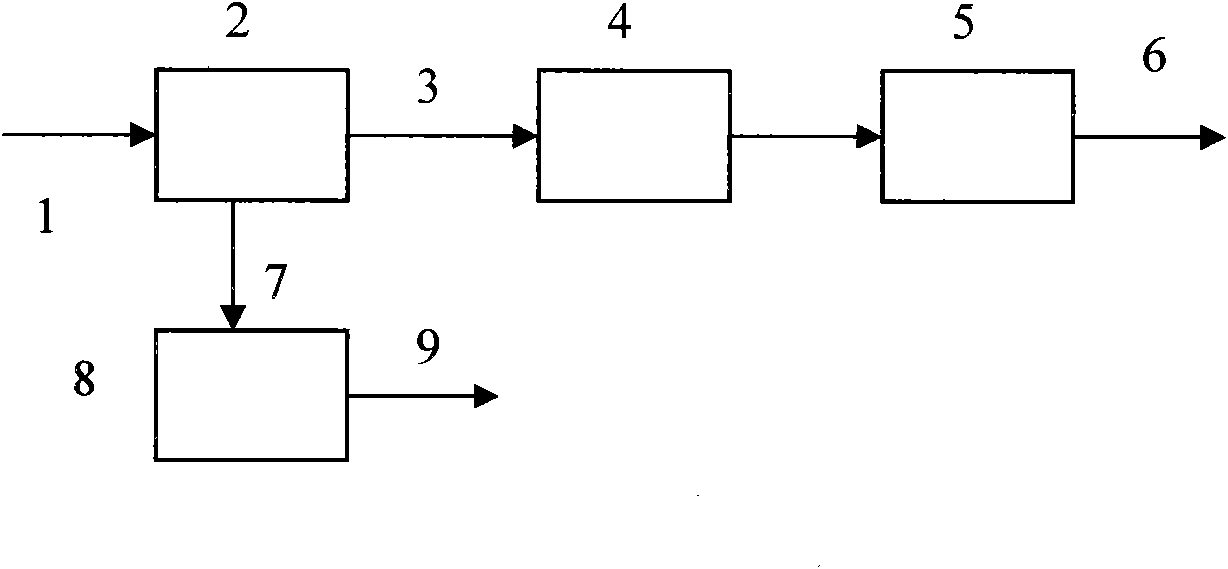

Compound agent for repairing heavy metal contaminated soil and application thereof

ActiveCN108641726AMitigation of cadmium leachingImprove stability efficiencyOther chemical processesContaminated soil reclamationContaminated soilsSodium lignosulfonate

The present invention discloses a compound agent for repairing heavy metal contaminated soil and an application thereof. The compound agent comprises the following components in parts by mass: 30-75 parts of soluble ferric salts and / or ferrous salts, 10-60 parts of calcium-based compounds, 5-20 parts of sodium lignosulfonate and 2-10 parts of an organic sulfur chelating agent. The soluble ferric salts and / or ferrous salts, calcium-based compounds, sodium lignosulfonate, and organic sulfur chelating agent of sodium dimethyl dithiocarbamate, etc. can effectively repair the compound contaminatedsoil by heavy metals of arsenic, cadmium, etc.

Owner:YONKER ENVIRONMENTAL PROTECTION

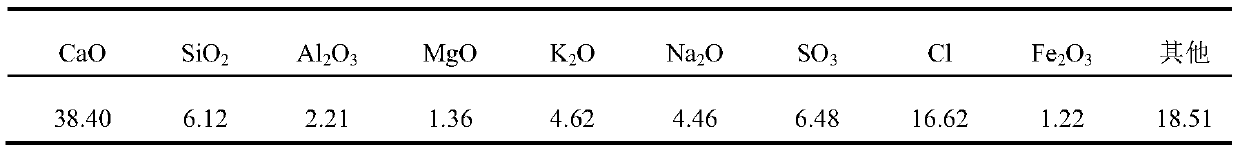

Method for treating waste incineration fly ash by electric melting

The invention discloses a method for treating waste incineration fly ash by electric melting. The method comprises the following steps of: uniformly mixing the fly ash, quartz sand and an alkaline agent according to a weight ratio of fly ash: quartz sand: alkaline agent of (90-99):(1-10):(1-10), wherein the quartz sand and the alkaline agent are used as a melt preparation; then adding a mixture into a glass electric melting furnace; fully melting the mixture to form a glass metal at a high temperature of between 1,250 and 1,500 DEG C; and after performing water quenching by using cold water, cooling the glass metal at the room temperature to form glass dregs. In the method, the quartz sane and the alkaline agent (such as lime or sodium carbonate) are added to vitrify the flay ash, dioxin and other organic pollutants in the fly ash are decomposed at a high temperature, heavy metals such as copper, zinc, lead and the like are cured and stabilized after entering a glass crystal lattice, and the extraction concentration of the heavy metals is far lower than a standard limit value of 'Identification Standard for Hazardous Wastes-Identification for Extraction Toxicity (GB 5085.3-2007). The fly ash is transformed into inert solid waste in a glassy state.

Owner:刘阳生 +1

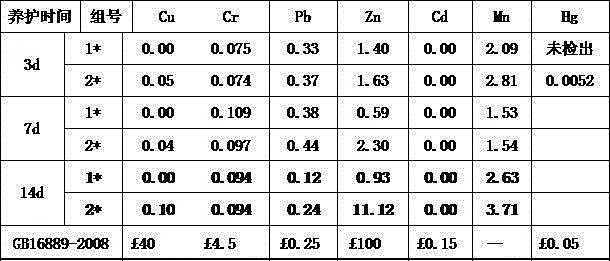

Municipal solid waste incineration fly ash curing method

InactiveCN104607434AReduce dosageRealize comprehensive utilizationSolid waste disposalStrontium carbonateEnvironmental engineering

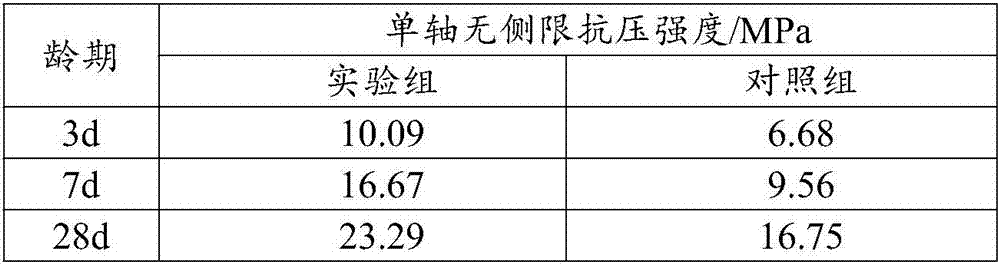

The invention discloses a municipal solid waste incineration fly ash curing method. The method comprises the steps of mixing waste incineration fly ash, cesium carbonate waste residue, potassium carbonate and cement according to the ratio of (40-50): (25-38): (3-6): (15-25); then, feeding right amount of purified water into the mixture, evenly mixing, enabling a molding model to be filled with the mixture, extruding and compacting; after that, standing the model in the air for 24 hours, and then demoulding to obtain a cured green body; maintaining the cured green body to obtain a cured body which can be directly buried, wherein the maintaining time is not shorter than 14 days. According to the method, the cesium carbonate waste residue is taken as an important raw material for curing the fly ash, so that the consumption of the cement is greatly reduced, waste recycling is realized, and the waste incineration fly ash curing cost is lowered. After the method is used, the compressive strength of the cured body and the heavy metal leaching completely meet the landfill requirements.

Owner:CHONGQING UNIV

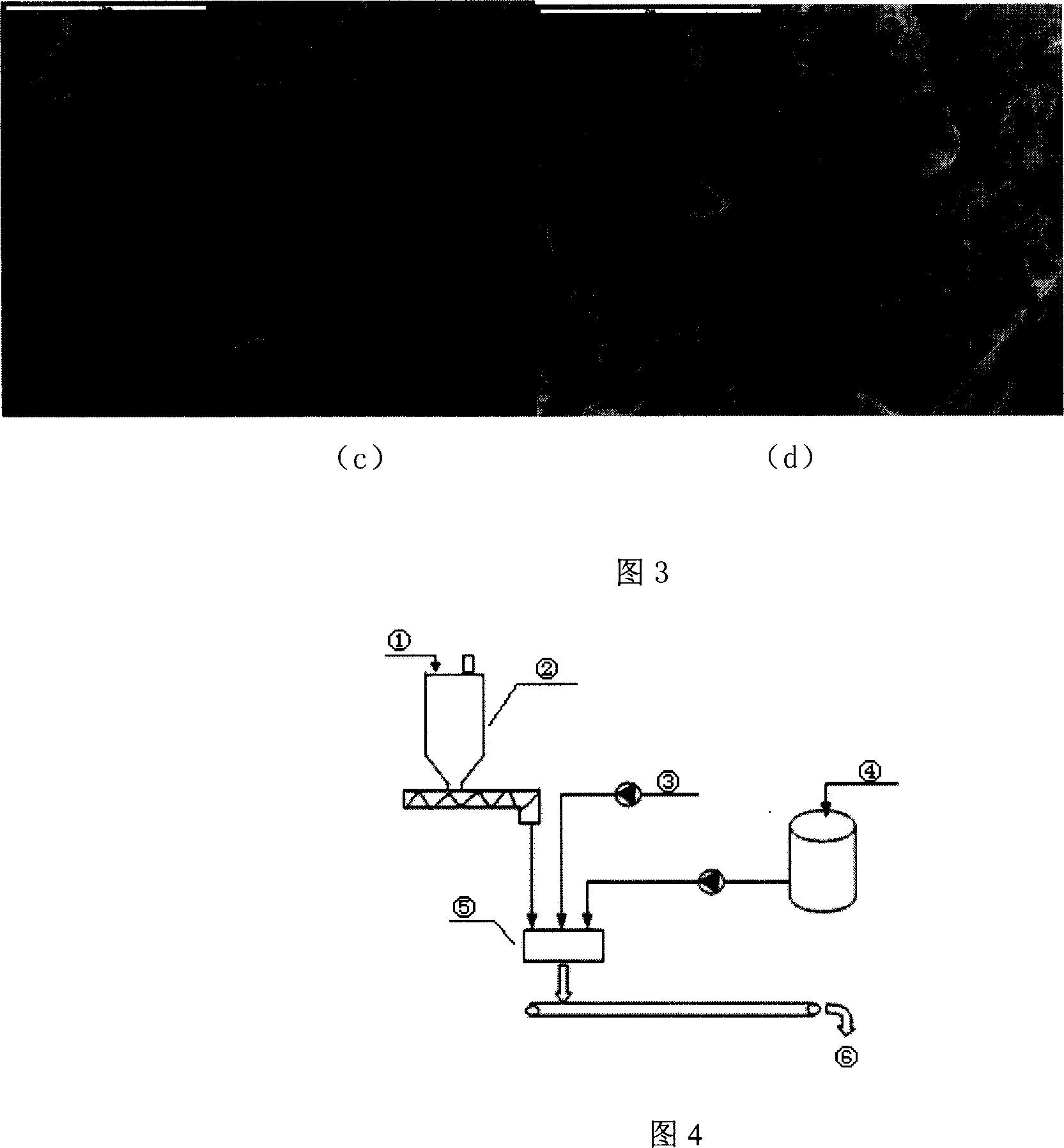

Method for stabilizing treatment of refuse burning fly ash by using accelerated carbonation process

InactiveCN1963304ATo achieve the goal of emission reductionAchieve stabilizationLighting and heating apparatusSolid waste disposalCarbonizationWaste treatment

The carbonization speeding up technique for stabilizing the heavy metals in the burnt fly ash belongs to the field of hazardous solid wastes treatment. Filling 10-50% of water into the fly ash of the burnt residue and making it into the fly ash with certain ratio of water, putting it into a shakable or a turnover container, then let the burnt fly ash have carbonization reaction with CO2 intermittently or continuously input. Small portion of heavy metal and large portion of limestone in the burnt fly ash carbonize with CO2 and turn into carbonate material that can last stably in the natural world. The carbonization process promotes the stabilization of the burnt fly ash, with water against limestone equaling to 20%, reducing Pb intensity to 0.081mg / 1. Besides, the burnt fly ash absorbs CO2 well, with dried burnt fly ash can absorb CO2 3% of its own weight. The invention is low in cost and feasible for mechanical operation.

Owner:TSINGHUA UNIV

Magnesium oxychloride fiber light wallboard

InactiveCN103979921AAvoid the phenomenon of moisture absorption and return to halogenHigh strengthSolid waste managementCompressive resistanceSlag

The invention provides a magnesium oxychloride fiber light wallboard, and relates to the wallboard field in the construction materials. The wallboard is composed of the following components in parts by weight: 40 to 60 parts of magnesium chloride water solution, 20 to 30 parts of magnesium oxide, 0.1 part of fly ash, 0.2 part of slag, 0.5 part of construction waste, 0.1 part of waste ceramic, 2 parts of short glass fiber, 2 parts of straw, 2 parts of saw dust, 3 parts of perlite, and 0 to 2 parts of modifier. The formula of the wallboard comprises industrial and agricultural wastes such as fly ash, slag, mineral slag, construction wastes, broken ceramics, straws, and saw dust, thus the wastes are fully recycled and reutilized, and moreover the using amount of sands and stones is reduced, so the destroy on mountain and river bed is avoided, resources are saved, and environment is protected. The prepared magnesium oxychloride fiber light wallboard has the advantages of good water resisting property, high compressive strength, good freeze resisting performance, good acid / alkali resistant property, no halogen appearance, no scumming, and no deformation.

Owner:四川省元程中博能源开发有限公司

Chemical stabilization compound medicament for reducing heavy metal leaching concentration of soil

InactiveCN102357518AImprove the stabilization effectReduce leaching concentrationContaminated soil reclamationCoalMetal leaching

The invention provides a chemical stabilization compound medicament for reducing a heavy metal leaching concentration of soil, and aims to solve the technical problem that: most solidification and stabilization medicaments are only directed at one heavy metal, and research on stabilization medicaments able to simultaneously reduce leaching concentrations of a plurality of heavy metals is uncommon. The main points of the invention lie in that: the medicament comprises 5-10 parts of Ca(OH)2, 2-5 parts of coal ash, and 0.1-2 parts of Na2CO3 that are mixed uniformly. The compound medicament provided in the invention can reduce leaching concentrations of a plurality of heavy metals in soil.

Owner:SHENYANG ACAD OF ENVIRONMENTAL SCI

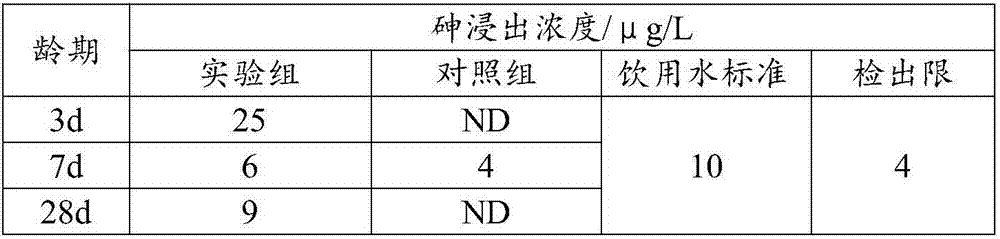

Method for repairing soil polluted by arsenic

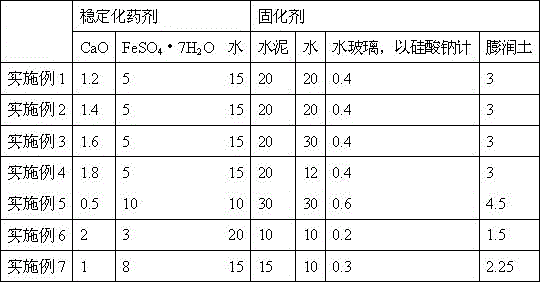

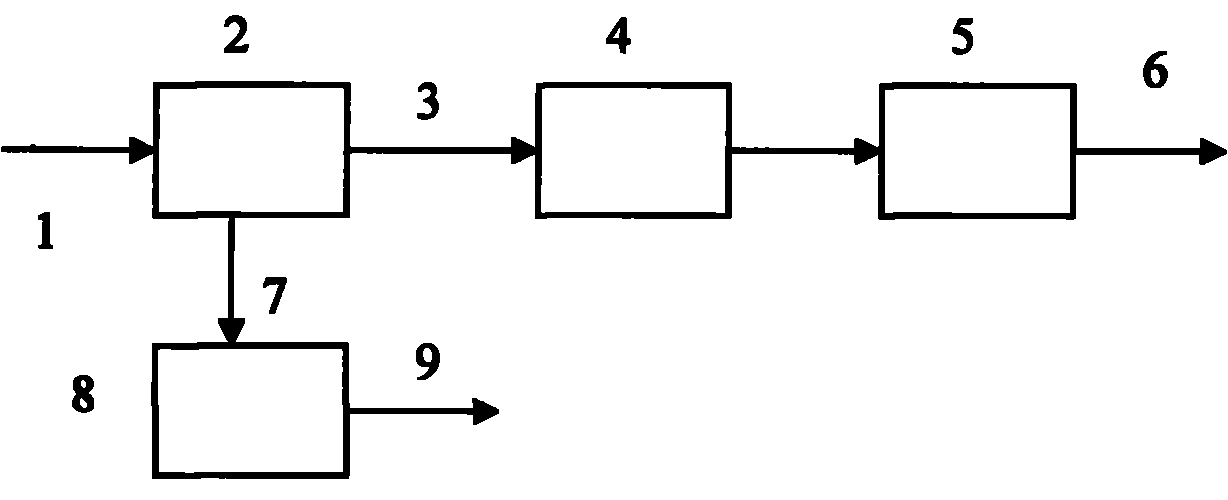

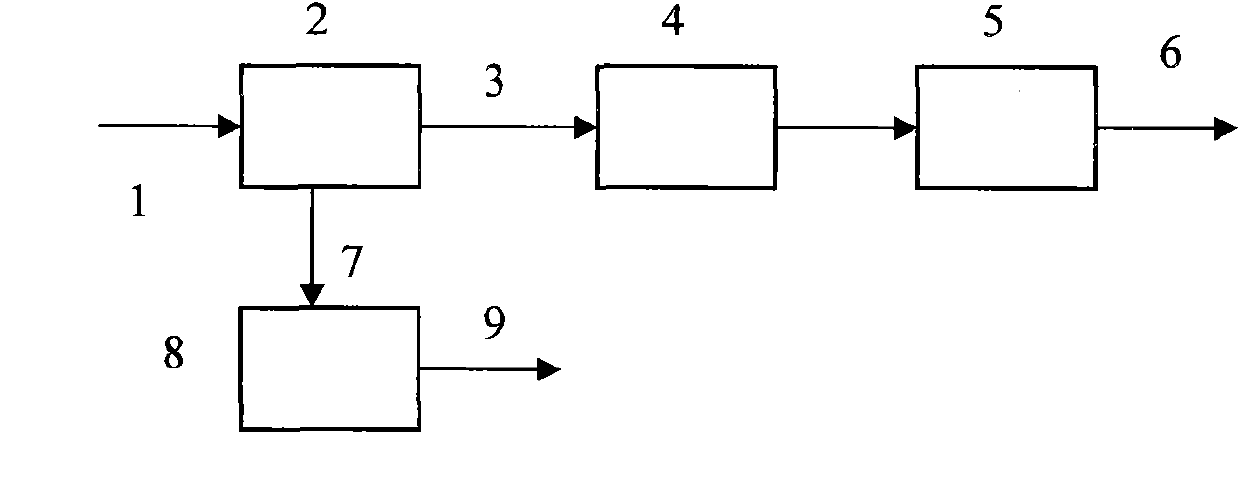

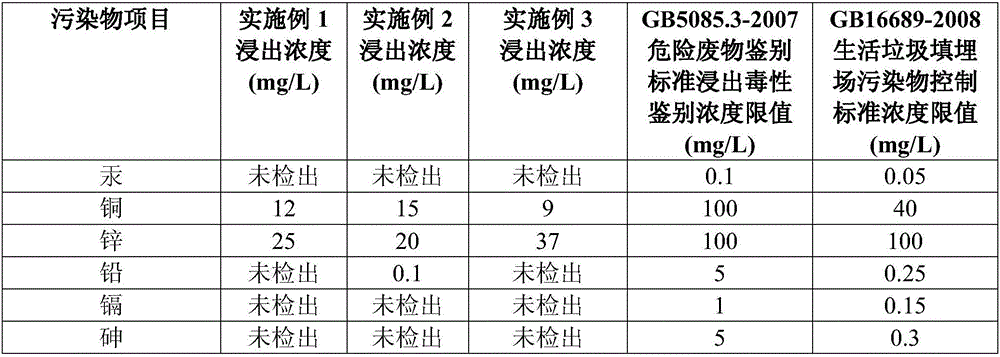

ActiveCN105598154ALow environmental impactImprove efficiencyContaminated soil reclamationSodium silicateArsenic

The invention discloses a method for repairing soil polluted by arsenic. The method is characterized by comprising the following steps: (1) taking a stabilized medicament and mixing with the soil polluted by arsenic, and conserving, wherein the stabilized medicament is prepared from the following components: FeSO4.7H2O, CaO and water; (2) taking a curing agent and mixing into the soil treated by the step (1), and conserving, wherein the curing agent is prepared from the following components: cement, water, sodium silicate and bentonite. By adopting a manner of combining the stabilized medicament with the curing agent and injecting in situ, the site soil polluted by heavy metal is subjected to curing and stabilization treatment, and the leaching concentration of heavy metal arsenic in the treated soil is lower than IV type water standards in the Underground Water Quality Standards (GB / T14848-93).

Owner:BEIJING GEOENVIRON ENG & TECH

Novel chromium slag innocent treatment method

The invention discloses a novel chromium slag innocent treatment method. In the method, quartz sand and an alkaline medicament are taken as melting agents, and chromium slag, the quartz sand and the alkaline medicament are uniformly mixed in a weight ratio of 25-45:35-75:5-22; the mixture is added into an electric glass melting furnace and is fully melted at a high temperature of between 1,350 and 1,500 DEG C to form molten glass; and the molten glass is subjected to water quenching by cold water, and cooled at room temperature to form glass slag. Through high-temperature electric melting treatment, hexavalent chromium in the chromium slag is reduced into trivalent chromium and is cured and stabilized after entering glass lattices, and the chromium slag is converted into glass state inert waste, and the leaching concentration of heavy metals is far lower than a standard limit value in Identification Standard for Hazardous Wastes-Identification for Extraction Procedure Toxicity (GB5085.3-2007) of the nation.

Owner:刘阳生 +1

Method for preparing ceramsite from industrial sludge, waste incineration fly ash and straw as raw materials

ActiveCN106830892ALight weightHigh strengthCeramic materials productionCeramicwareSodium BentoniteAdhesive

The invention relates to a method for preparing ceramsite from industrial sludge, waste incineration fly ash and straw as raw materials. The method comprises process steps as follows: the industrial sludge, the waste incineration fly ash, sodium bentonite, straw powder and clay are mixed uniformly, and a primary mixed material is obtained; water is added to the mixed material, granulation forming is performed after sufficient stirring is performed, and 5-10 mm spherical ceramsite raw materials are formed; sodium bentonite, straw powder and a sodium silicate and calcium lignosulphonate mixed adhesive with the total content being 1% are continuously added to the ceramsite raw materials and sufficiently stirred for secondary granulation, and 8-15 mm spherical ceramsite raw materials are formed; the ceramsite raw materials are calcined at a high temperature in a rotary kiln, and the lightweight ceramsite is obtained after natural cooling. Multiple industrial solid wastes (including the industrial sludge, the waste incineration fly ash and the straw) are taken as the raw materials of the ceramsite to be recycled, secondary pollution is realized through harmless and resourceful treatment of the solid wastes, and environmental and economic benefits are realized synchronously.

Owner:SHAOXING ENVIRONREM ENVIRONMENTAL TECH CO LTD

Neutral modifying agent for fluorgypsum and method for utilizing neutral modifying agent to modify fluorgypsum

The invention relates to a neutral modifying agent for fluorgypsum. A modifying method comprises the following steps of: uniformly mixing calcined lime, steel slags and coal ash according to a certain mass percent to prepare the neutral modifying agent, and doping a proportion of neutral modifying agent into the fluorgypsum so as to reach alkalescence. The neutral modifying agent has the advantages that the self-prepared neutral modifying agent takes full advantages of wastes, and the modifying cost is reduced. The modified fluorgypsum obtained by the method can be used as chemical gypsum with excellent performance, which is used for preparation of cement retarders or inorganic bond materials.

Owner:WUHAN UNIV

Stabilizer for heavy metal compound contaminated soil and preparation method of stabilizer for heavy metal compound contaminated soil

InactiveCN104449745AReduce leaching concentrationReduced ability to migrateContaminated soil reclamationOrganic fertilisersHeavy metal compoundRed mud

The invention relates to a stabilizer for heavy metal compound contaminated soil and a preparation method of the stabilizer for heavy metal compound contaminated soil. The stabilizer comprises sulfide, shell powder and red mud, wherein the molar ratio of the sulfide to effective-state gross of heavy metals lead, zinc and cadmium is 1.5 to 6; the molar ratio of the shell powder to the effective-state gross of heavy metals lead, zinc and cadmium is 1-4; and the red mud is added in a molar ratio of the content of iron in the red mud to the effective-state content of arsenic in soil of 2-8. The preparation method of the stabilizer comprises the following steps: drying the red mud by airing, grinding and sieving the dried red mud; then, cleaning the shell powder, grinding and sieving after drying by air; and preparing the sulfide into an aqueous solution, thereby obtaining the stabilizer. Based on the effective-state content of the heavy metals in the soil, the content of each component is reasonably prepared, so that the stabilizer can be applicable to compound contaminated soil with high leaching concentration, can be used for effectively reducing the leaching concentration of heavy metals in the soil and overcoming the defect of poor stabilization effects of the existing medicament, and has a certain application value.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

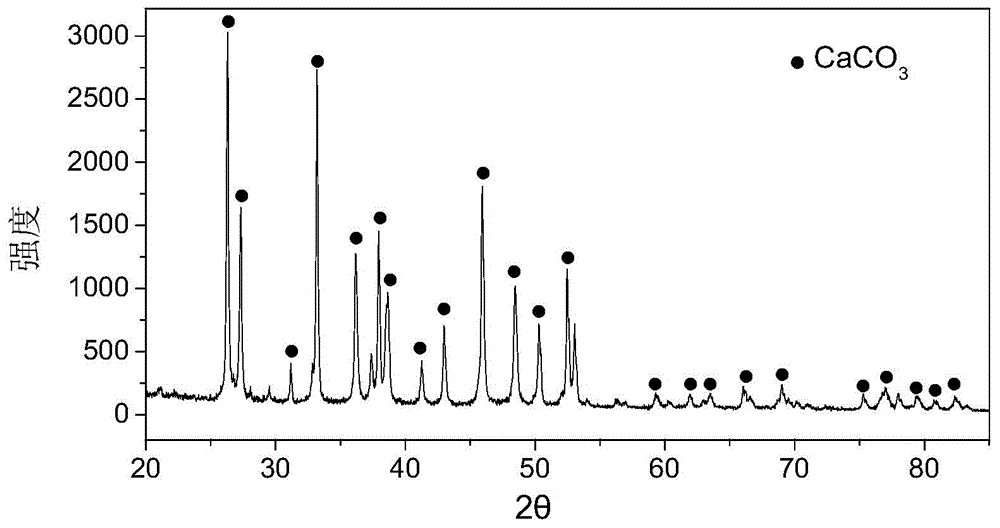

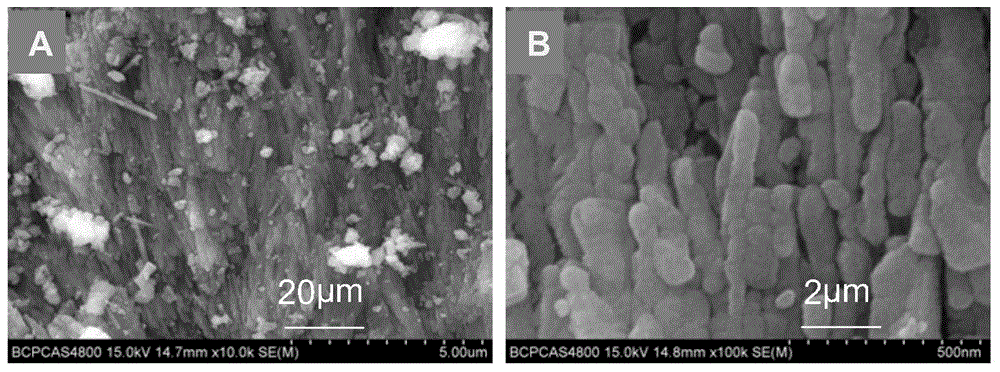

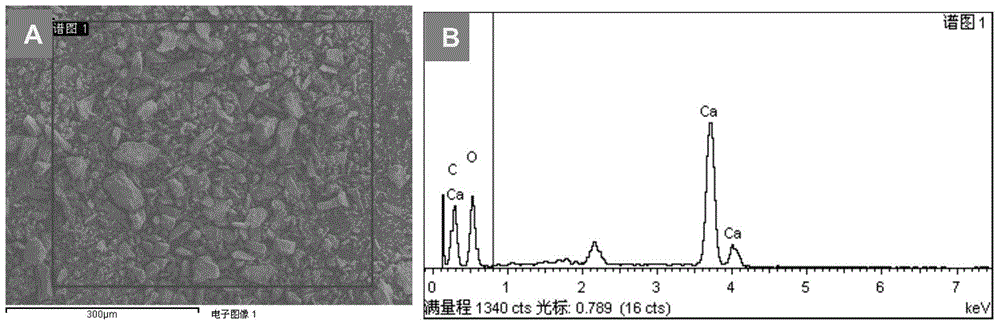

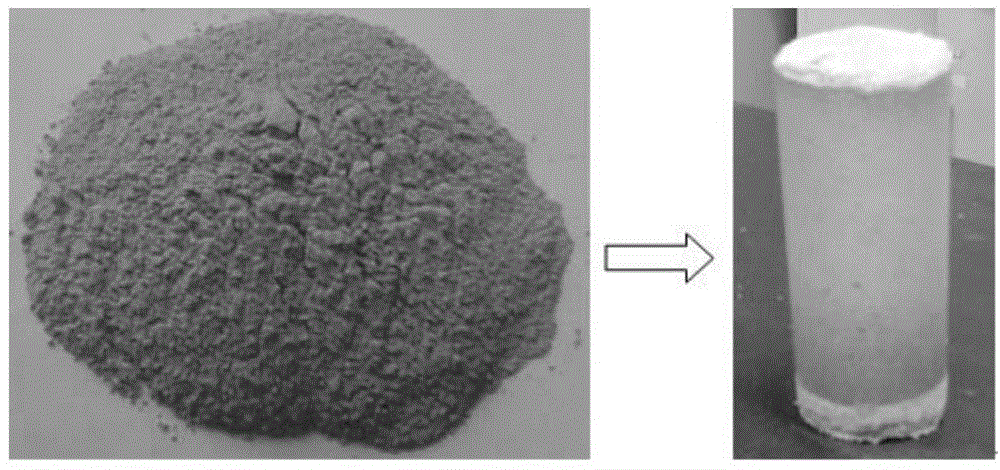

Method for consolidating waste incineration fly ash heavy metal through microorganism cement mineralization

InactiveCN104926167APollution will not occurReduce leaching concentrationSolid waste disposalCalciteBuilding material

The invention discloses a method for consolidating waste incineration fly ash heavy metal through microorganism cement mineralization. Through the method disclosed by the invention, microorganism cement is obtained and a microorganism cement bonded product, namely calcite, is obtained, and the calcite is used for consolidating waste incineration fly ash according to the method. A consolidated product formed by consolidating the waste incineration fly ash with the method is low in heavy metal leaching and high in stability of induration, and can be used as a building material.

Owner:TIANJIN CHENGJIAN UNIV

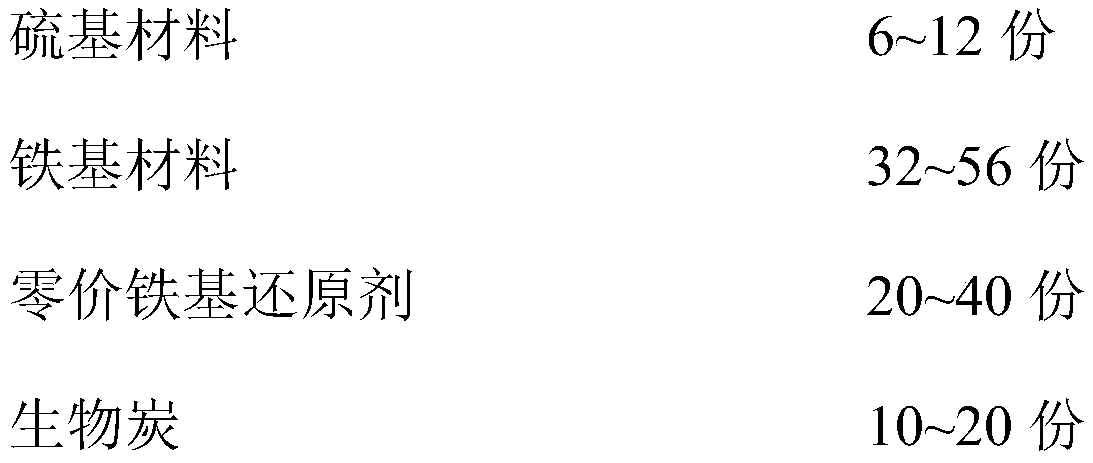

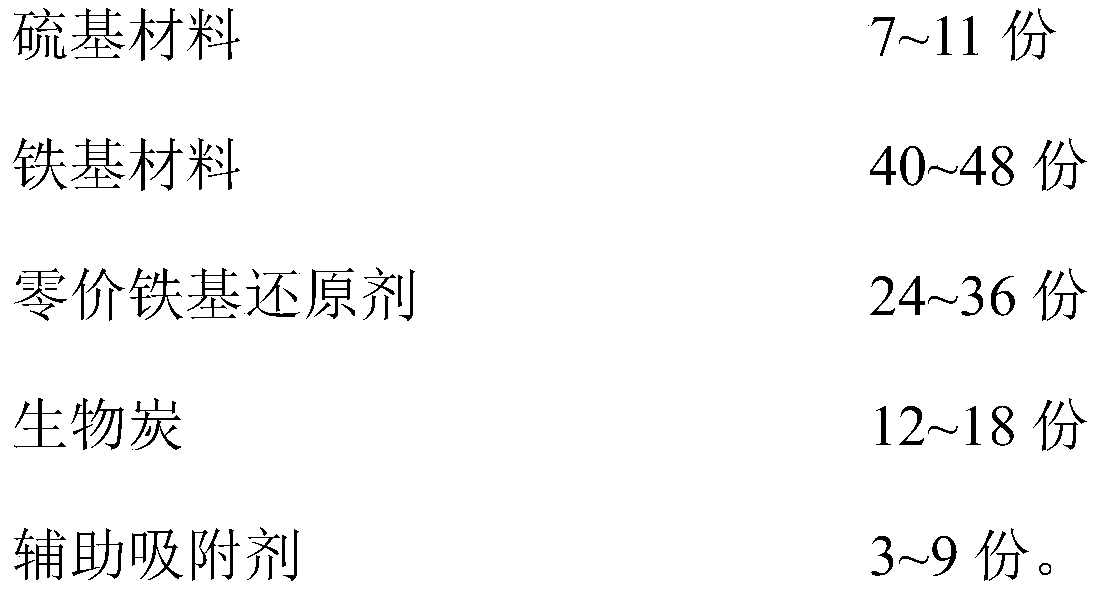

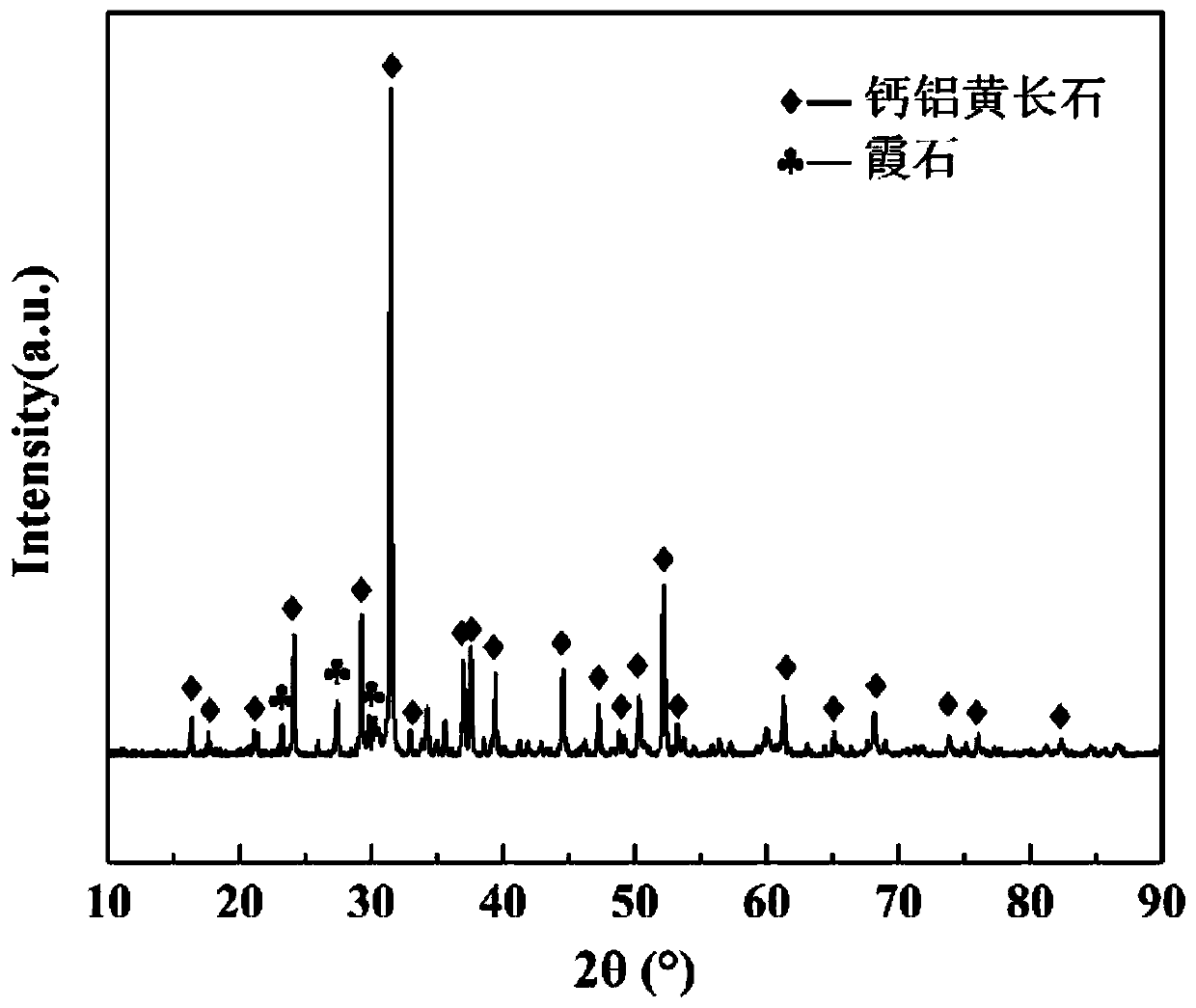

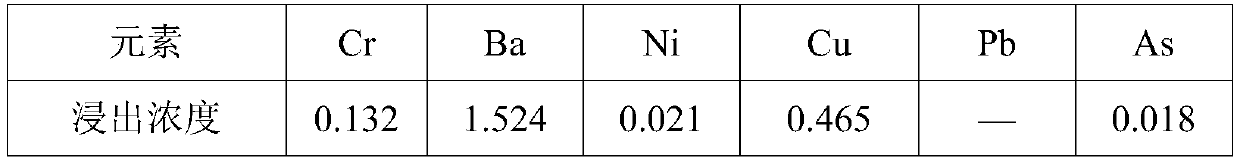

Low-sulfur chromium contaminated soil remediation agent, preparation method and use method thereof

ActiveCN110423622AImprove reducibilityEfficient reductive stabilizationContaminated soil reclamationOrganic fertilisersSorbentSoil remediation

The invention relates to a low-sulfur chromium contaminated soil remediation agent, a preparation method and a use method thereof. The low-sulfur chromium contaminated soil remediation agent includesa sulfur-based material with a sulfur element content of less than or equal to 10wt%, an iron-based material, zero-valent iron-based reductant, biochar and an assistant adsorbent. By utilizing the synergistic effect of the sulfur-based material, the iron-based material, several assistants and other components, the obtained soil remediation agent can achieve chemical stabilization on hexavalent chromium pollutants in the soil, and can reduce the toxic leaching concentration of hexavalent chromium and the total alkali digestion amount. The low-sulfur chromium contaminated soil remediation agentobtained by the invention can be applicable to environmental restoration of various hexavalent chromium contaminated soil, has a moderate dosage and good remediation effect on common hexavalent chromium contaminated soil, and also has the advantages of adjustable shape, low comprehensive cost, and no secondary pollution.

Owner:北京润鸣环境科技有限公司

Cassava dreg composite heavy metal curing agent and preparation method thereof

InactiveCN104773932AGood curing effectReduce leaching concentrationSludge treatment by thermal conditioningSpecific water treatment objectivesManufacturing technologyPhosphogypsum

The invention discloses a cassava dreg composite heavy metal curing agent, which is composed of the following raw materials in parts by weight: 20 to 30 parts of cassava dreg, 20 to 30 parts of phosphogypsum, 10 to 15 parts of fly ash, 5 to 10 parts of attapulgite, 3 to 5 parts of glutinous rice flour, 0.3 to 0.5 part of chitosan, 4 to 8 parts of gelatin, 0.5 to 1 part of borax, and 1 to 2 parts of calcium lignin sulfonate. The provided curing agent is mainly composed of industrial and agricultural wastes, has a good curing effect on a plurality of heavy metals, is capable of reducing the leaching concentration of heavy metals to prevent separation-out, and has the advantages of low price, energy saving, waste utilization, simple manufacturing technology, and high social and economical benefits.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

Use of fly ash from burning city domestic garbage

InactiveCN1810894AImprove securityReduce leaching concentrationPigment treatment with non-polymer organic compoundsActive agentEnvironmental engineering

The present invention relates to new use of fly ash from burning city domestic garbage, and the fly ash is used as stuffing for polymer material after being activated with surfactant in a dry process. Fly ash is first crushed to 500-1200 mesh and stoved, and then mixed with surfactant in the ratio of 100 to 1-5 inside a ball mill through grinding for 5-30 min, with the modified fly ash being preserved hermetically. The modified fly ash in 10-15 wt% is added into polypropylene base material to produce product reaching relevant standard. The present invention has wide material source, low cost, no secondary pollution caused by the activation treatment and excellent market foreground.

Owner:TONGJI UNIV

Harmless and resourceful treatment method for smelting slag generated during iron capture of waste catalysts

The invention relates to the technical field of harmless and resourceful treatment of solid waste and provides a harmless and resourceful treatment method for smelting slag generated during iron capture of waste catalysts. The method comprises the following steps: directly carrying out casting and calendering to obtain base glass by using glassy-state smelting slag generated by capturing a waste catalyst with iron as a raw material and heavy metals such as Fe2O3, Cr2O3, TiO2, NiO and PbO in the smelting slag as nucleating agents without adding any other reagent; subjecting the base glass to synchronous nucleation and crystallization at a certain temperature; and performing annealing to eliminate stress so as to obtain a microcrystalline glass product. The method has the advantages that heavy metal in the smelting slag generated smelting slag generated during iron capture of waste catalysts is solidified, so pollution is avoided; nucleation and crystallization heat treatment are synchronously carried out, so the method has the advantages of short flow, low energy consumption and easiness in industrial production; the harmless and resourceful utilization of the smelting slag is realized; the added value of the obtained microcrystalline glass is high; obvious environmental protection and economic benefits are obtained; and the method has good market prospects.

Owner:UNIV OF SCI & TECH BEIJING

A method for preparing ceramsite from chemical sludge

InactiveCN102285787AAchieve reductionRealize resourcesCeramic materials productionClaywaresSocial benefitsSludge

The invention relates to a recycling process of industrial solid wastes and provides a method for preparing hadite from chemical sludge. The method comprises the steps of firstly drying sludge treated by mechanical press-filtering and dewatering in chemical enterprises, proportioning, carrying out dry mixing, adding water, uniformly stirring and mixing, granulating to obtain raw material pellets,drying the raw material pellets, baking at a high temperature according to a preset sintering system and cooling to prepare sludge-based hadite. The extraction concentration of heavy metals in the hadite is far lower than GB 5085.3-2007 (Identification standards for hazardous wastes-Identification for extraction toxicity). The method develops a new way for sludge recycling, has significant environmental benefits, economical benefits and social benefits, and meets the industrial policy guidance of developing circular economy in China.

Owner:NANJING UNIV OF TECH

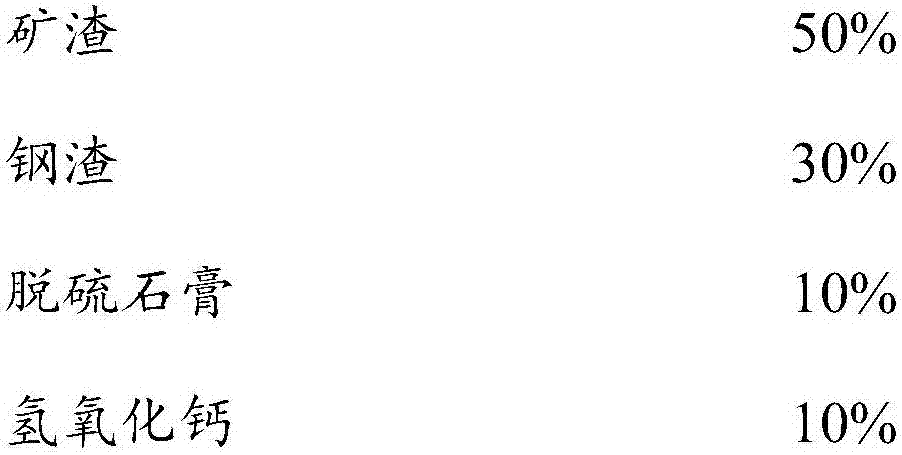

Cement filling material for co-solidifying arsenic and preparation method thereof

The invention discloses a mine cement filling material for co-solidifying arsenious hazardous wastes and a preparation method thereof, and belongs to the environment protection fields, such as the mine cement filling, solid waste resource utilization and the co-processing of the arsenious hazardous wastes. The preparation method comprises the following steps: milling the needed raw materials, such as mine slag, steel slag and desulfurization gypsum, with 0.01%-1% of the water content according to the dry basis weight percentage of 45%-50% of the mine slag, 10%-30% of the steel slag and 10-15% of the desulfurization gypsum, milling independently or milling by mixed powder until the specific surface area is 200-600 m<2> / Kg, adding 10%-35% of calcium hydroxide, uniformly mixing to obtain a cementing agent, and drying the arsenious hazardous wastes until the water content is 0.01%-1%, according to the weight proportion of the cementing agent / aggregate material of 1 / 4-1 / 8, the weight proportion of the arsenious hazardous wastes / (cementing agent + aggregate material) of 1 / 1000-1 / 100, adding 0%-1% of a water reducer, until the mass fraction of slurry is 65%-86%, and uniformly stirring to obtain the qualified mine cement filling material. The preparation method has the characteristics of simple and easy operation, low energy consumption, low cost, no new solid waste generation, small environmental pollution, and environmental protection.

Owner:BEIJING BEIKE FANGXING ENVIRONMENTAL PROTECTION TECH CO LTD

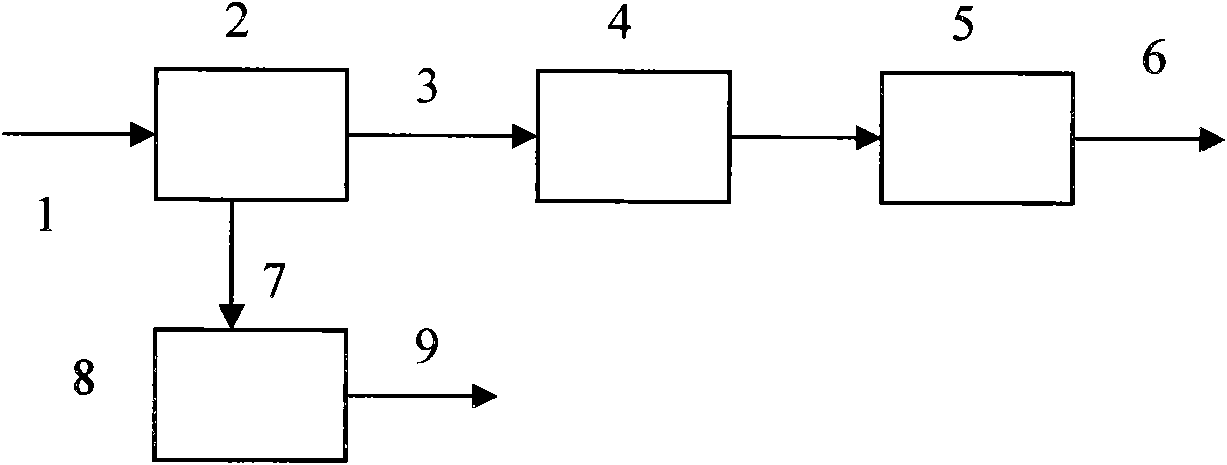

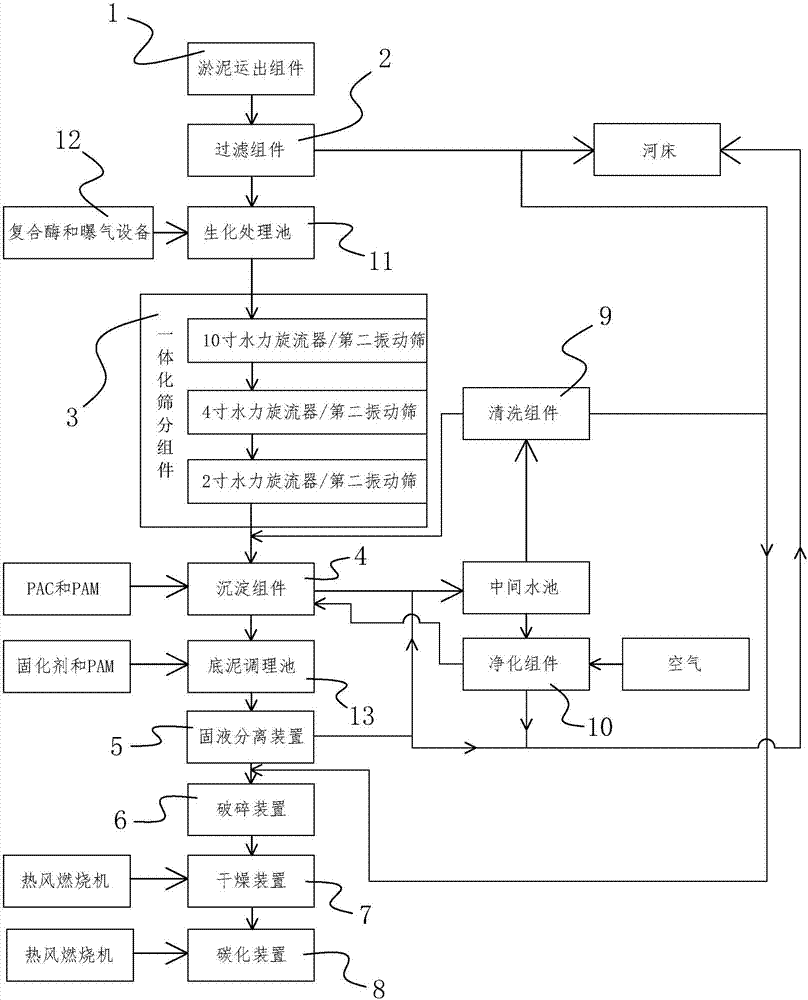

River and lake sludge harmless treatment system and method

InactiveCN107265800APrevent leakagePrevent over miningSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesSludgeSmall footprint

The invention discloses a river and lake sludge harmless treatment system. The system comprises a sludge carting component, a filtering component for separating impurities from sludge, an integrated screening component for separating powder particles from sludge, a sedimentation component for precipitating bottom mud from sludge, a solid-liquid separator for bottom mud dehydration, a crushing device for crushing clinker after dehydration, a drying device for drying the crushed clinker and a carbonation device for converting the dried clinker into carbonized sludge. The river and lake sludge harmless treatment system is easy to operate, needs short sludge treatment time and has a small occupied land area.

Owner:江门市三清环境技术工程有限公司

Solidification and stabilization method for mercury in mercury contaminants

InactiveCN106391694AReduce dosageReduce the risk of double releaseContaminated soil reclamationUltimate tensile strengthStabilization methods

The invention provides a solidification and stabilization method for mercury in mercury contaminants. The method includes the following steps that (1) mercury contaminant particles with the grain diameter not larger than 5 mm are mixed with soluble sulfide and water, and a first mixture is obtained; (2) the first mixture, cement and water are stirred and mixed, the stirring speed ranges from 20 r / min to 40 r / min, and a second mixture is obtained; and (3), after the second mixture is placed, the treated mercury contaminants are obtained. According to the method, the solidification effect of mercury in the contaminants is enhanced, the cement use amount is reduced on a large scale, the solidification capacity-increase ratio is small, and ready-made construction is rapid; and the leaching concentration of mercury after solidified bodies are stabilized for a long time is low, the mechanical strength of the solidified bodies can meet the requirements of ordinary road paving, and the solidification and stabilization method is suitable for mercury contamination repair projects with the large area, the tight schedule, the simple construction conditions and the low one-time invested cost requirement.

Owner:北京南科大蓝色科技有限公司 +1

Curing agent and method for heavy metal in polluted soil

ActiveCN104479684AEnhanced inhibitory effectStrong metal adsorption capacityAgriculture tools and machinesOther chemical processesSoil heavy metalsPeat

The invention discloses a curing agent and method for heavy metal in polluted soil. The curing agent for heavy metal in polluted soil is characterized by comprising the three components in percentage by weight: 33-40% of pulverized fuel ash, 34-51% of lime and 16-33% of peat. When the curing agent is used for treating the polluted soil, the curing method comprises the steps of sufficiently mixing the curing agent and heavy metal polluted soil according to the ratio of 1:(10-20) (weight ratio); then, adding water accounting for 40% (weight ratio) of the mixture; and then, sufficiently stirring and mixing. The curing agent for heavy metal in polluted soil, disclosed by the invention, is prepared by taking natural minerals as raw materials, so that no secondary pollution is caused, the soil fertilizer efficiency can be effectively improved while the heavy metal is cured, and the technical problems that the pH value of the soil is remarkably changed and the soil is hardened in the existing chemical remediation method are solved.

Owner:JIANGXI LYVJUREN MUNICIPAL GARDEN CO LTD

Soil stabilizer and preparation method thereof

InactiveCN106883855AImprove propertiesPassivation stableOrganic fertilisersSoil conditioning compositionsSodium BentoniteSoil properties

The invention discloses a soil stabilizer and a preparation method thereof, and relates to the technical field of attapulgite. The soil stabilizer comprises the following raw materials in parts by weight: 220 parts of attapulgite, 40 parts of bentonite, 40 parts of rice straw, 40 parts of acetylene sludge, 30 parts of kieselguhr, 30 parts of mushroom dregs, 15 parts of a phosphorus compound mixture, 15 parts of sepiolite, 15 parts of iron powder, 15 parts of a sulfenyl compound mixture and 8 parts of shell powder. The soil stabilizer is capable of passivating and stabilizing multiple heavy metals in soil and achieving the purposes of fertilizing soil and improving soil properties, and is low in cost, simple and convenient to operate, wide in source, and easy to popularize.

Owner:ANHUI BOSHUO TECH

Waste incineration fly ash plasma fusing method

PendingCN110142278ALower melting temperatureReduce leaching concentrationSolid waste disposalTransportation and packagingPhase splittingBoric acid

The invention provides a waste incineration fly ash plasma fusing method. The method at least comprises the following steps that step 1), a fusing additive is added into to-be-fused fly ash so as to obtain a fusing mixture; and step 2), fusion treatment is carried out on the fusing mixture so as to obtain a fusing glass body. The fusing additive comprises quartz sand, Al2O3, ZrO2 and boric acid. SiO2 and Al2O3 in quartz sand serve as a forming body of a network structure of a fusing glass body, ZrO2 serves as a nucleating agent, so that the surface crystallization is converted into the overallcrystallization under the action of an induced phase splitting mechanism of the glass body, and the boric acid is used as a fluxing agent to form a low eutectic point with the to-be-fused fly ash, sothat the fusing temperature of the to-be-fused fly ash is reduced.

Owner:EVERBRIGHT ENVIRONMENTAL TECH EQUIP CHANGZHOU +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com