Patents

Literature

91 results about "Mercury contamination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sorbents for the oxidation and removal of mercury

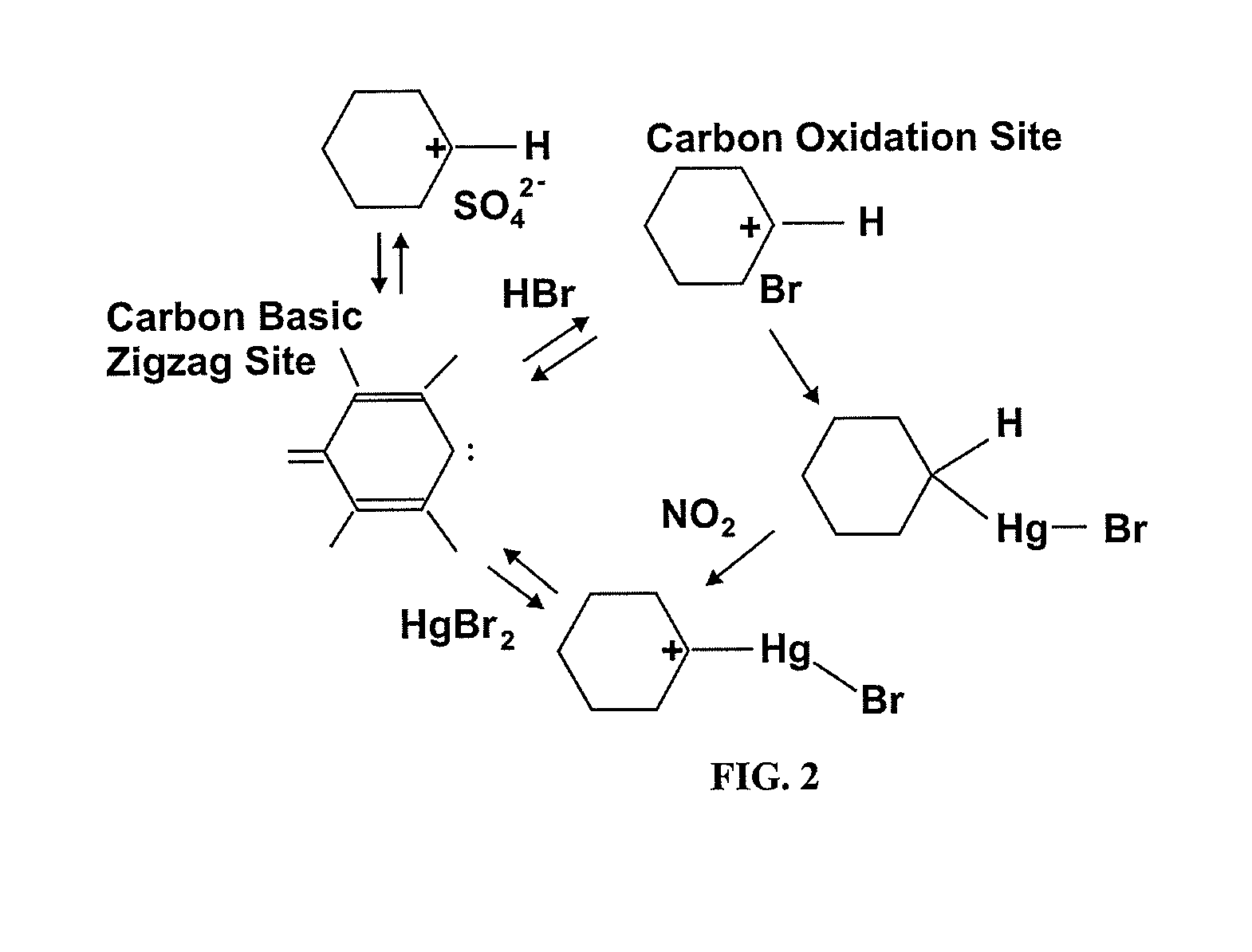

ActiveUS8652235B2Efficient use ofEasy to controlGas treatmentDispersed particle filtrationHalogenSorbent

Owner:MIDWEST ENERGY EMISSIONS CORP

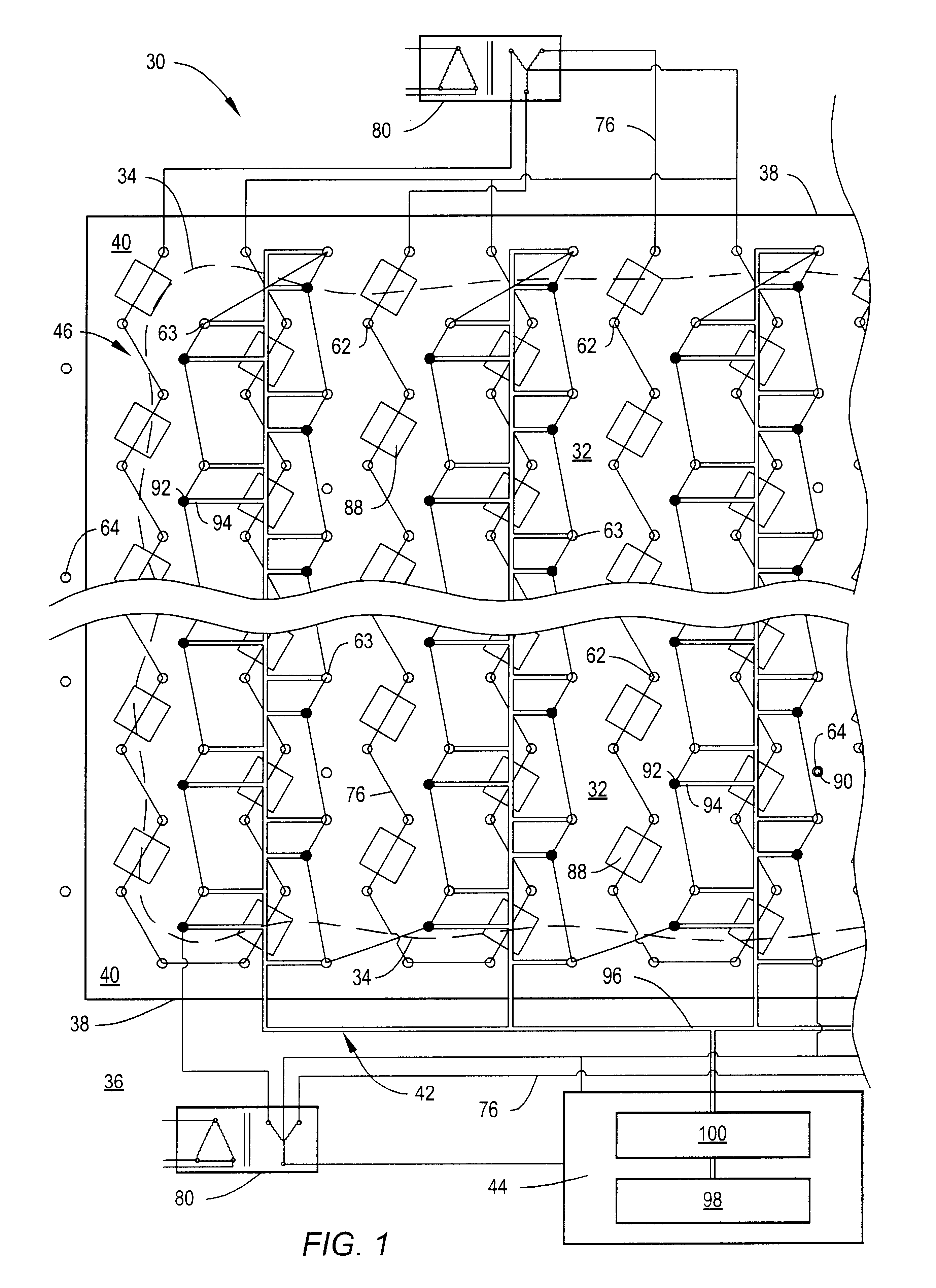

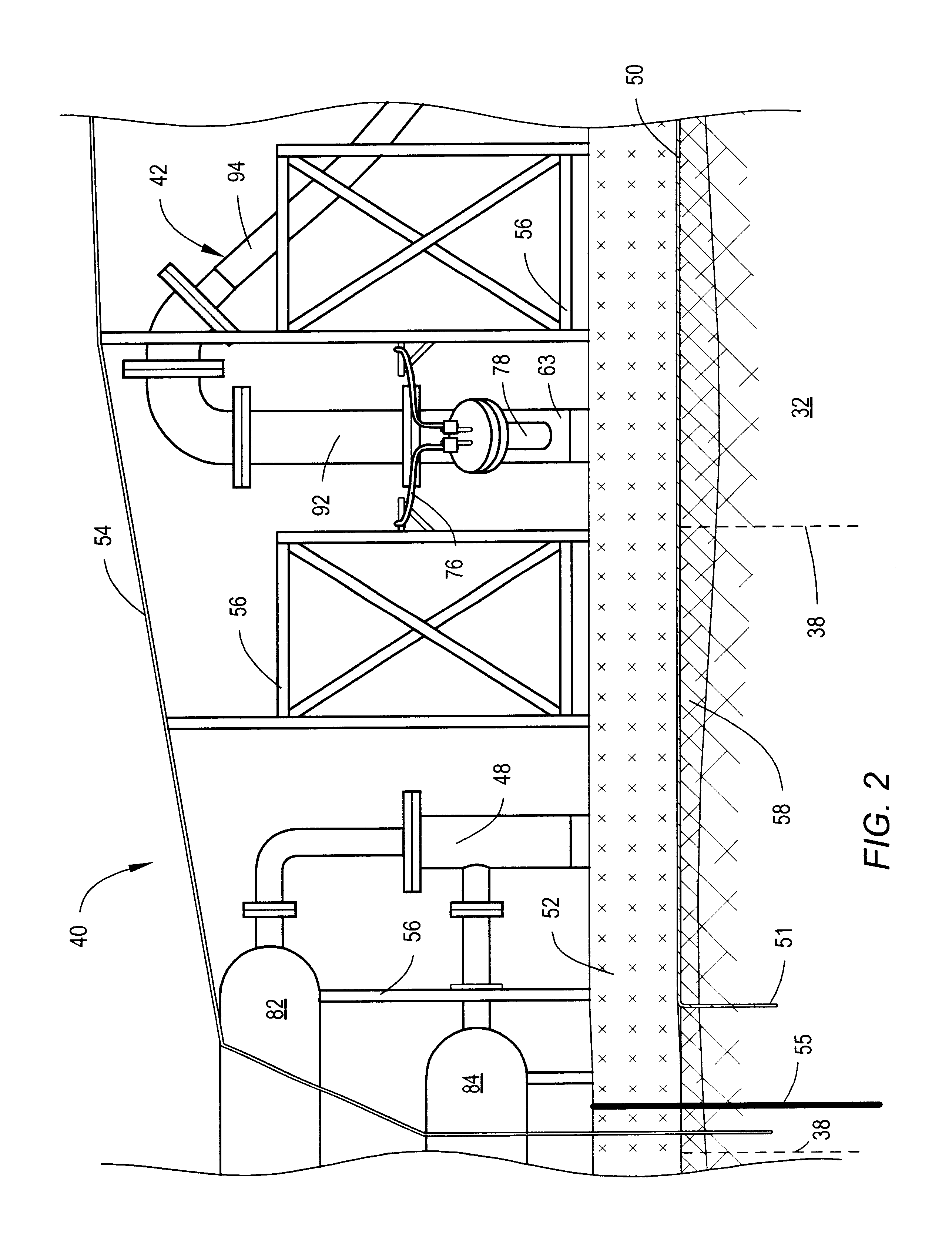

Soil remediation of mercury contamination

InactiveUS6962466B2Limited effectivenessHigh densityGas treatmentDry-docksSoil remediationMercury contamination

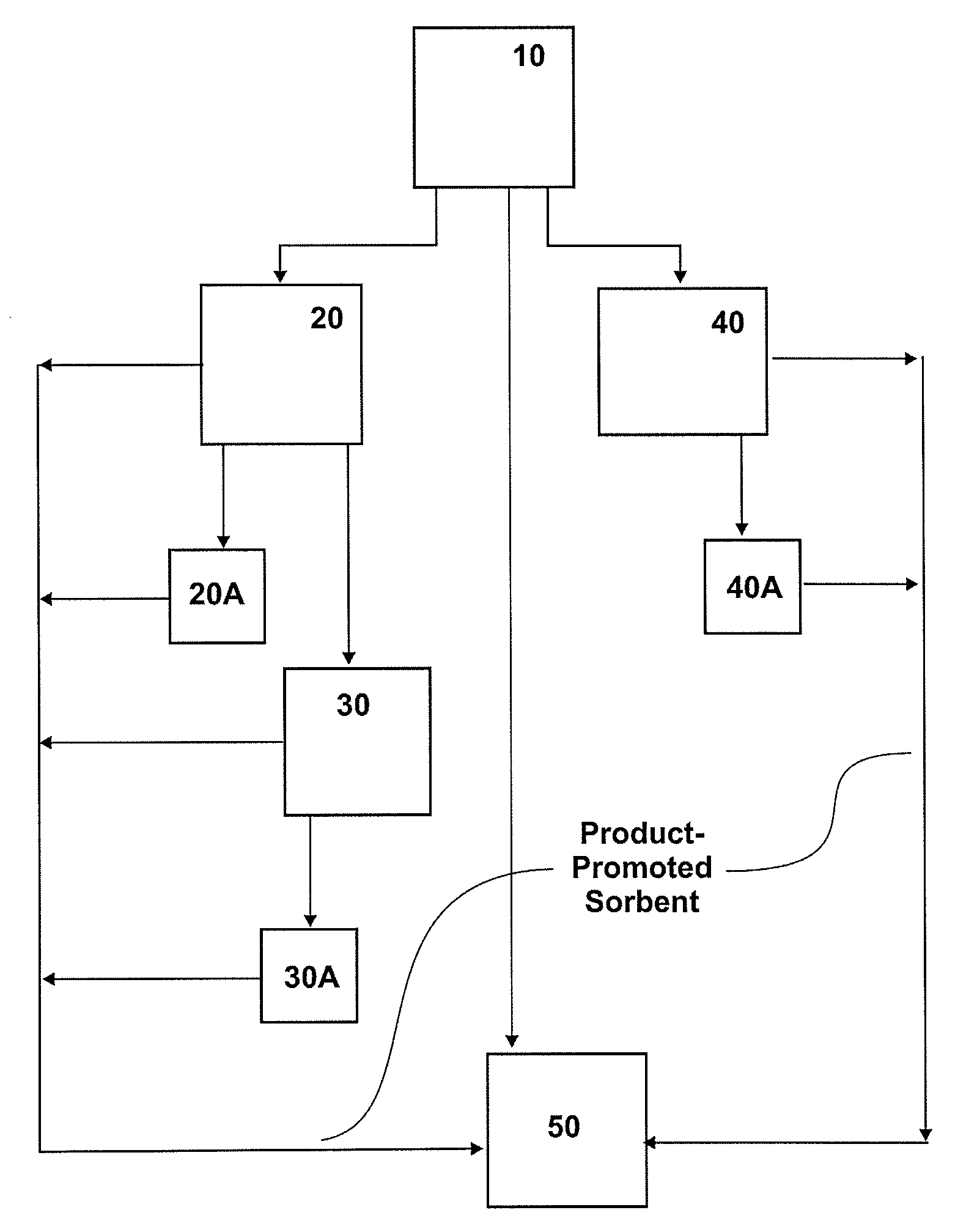

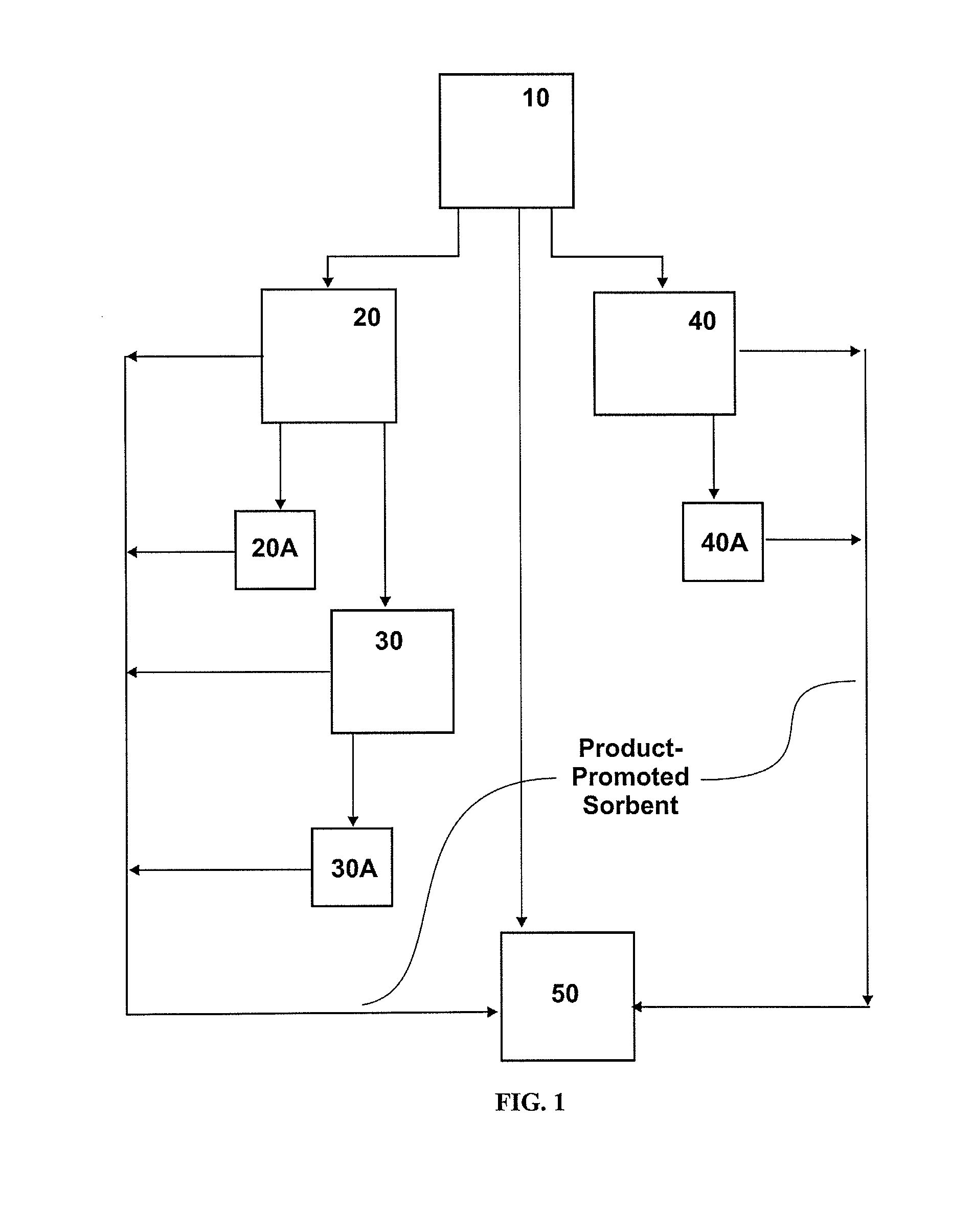

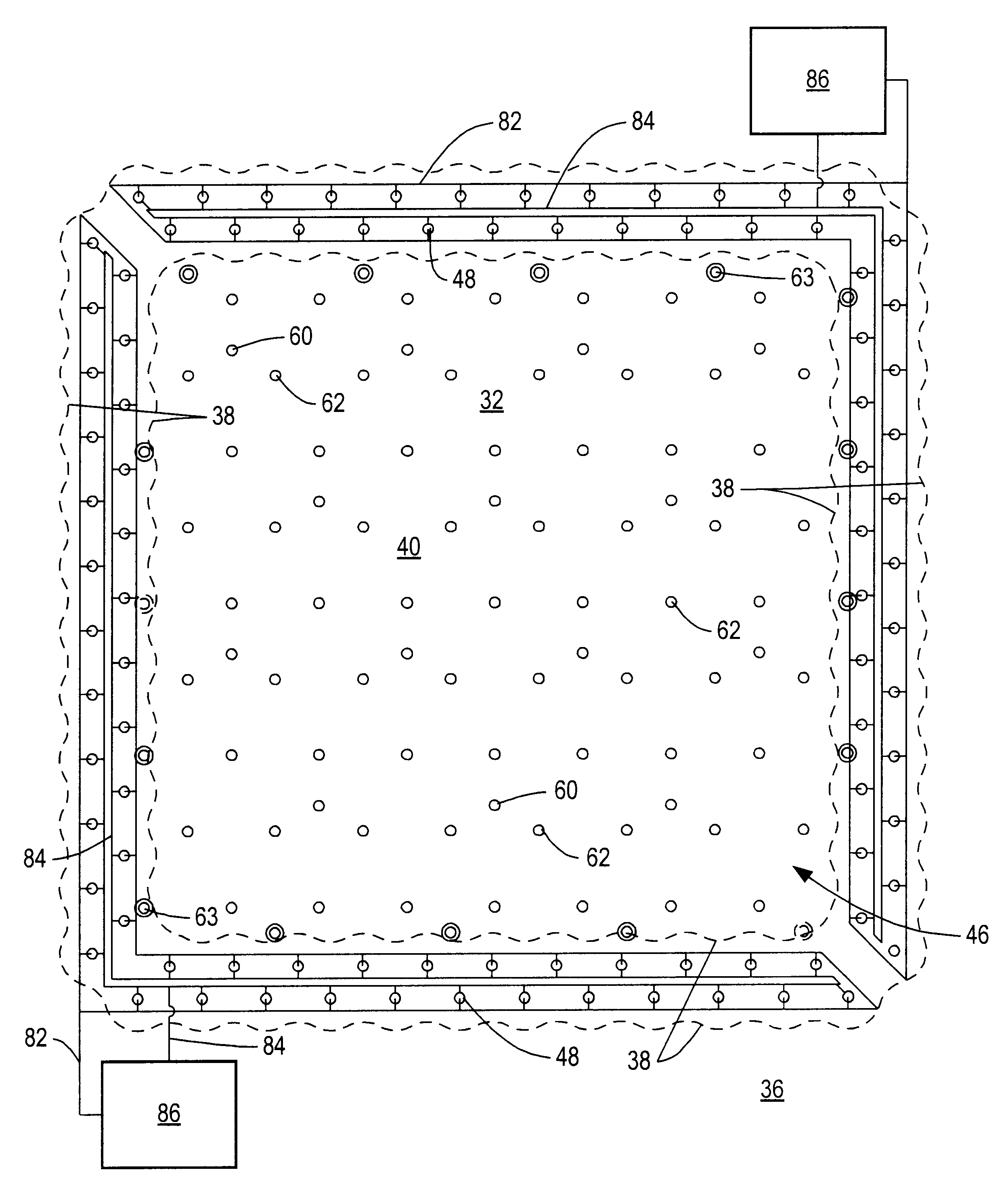

An in situ soil remediation system may be used to remove or reduce levels of mercury contamination within soil. The soil remediation system may also remove or reduce levels of other contaminants within the soil. Mercury may be vaporized within the soil by a heating system. The vaporized mercury may be removed from the soil by a vacuum system. The vaporized mercury may pass through heated risers that elevate the vaporized mercury. After the vaporized mercury passes from the heated risers, the vaporized mercury may be allowed to cool, condense, and flow downward to a treatment facility. Removing mercury from the soil as a vapor may provide an economical, safe, and efficient way to remediate mercury contaminated soil.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

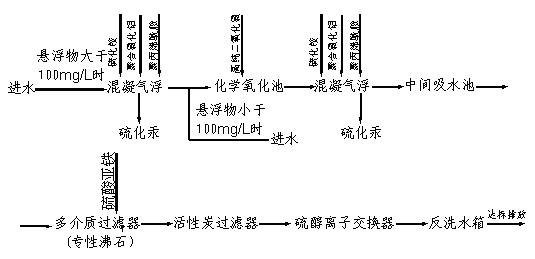

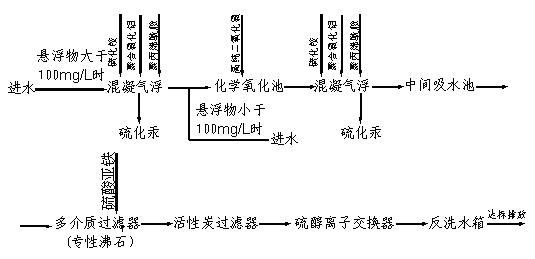

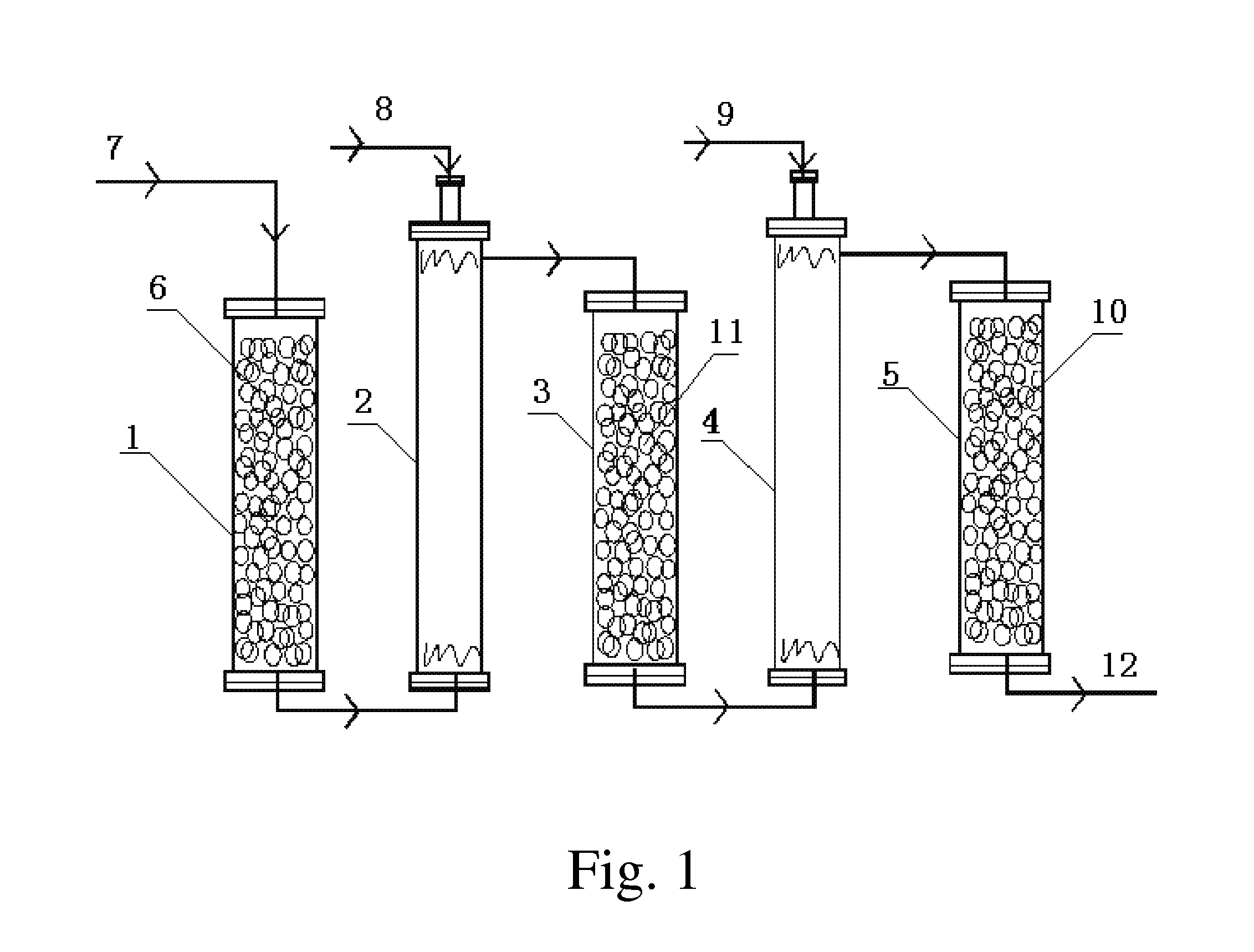

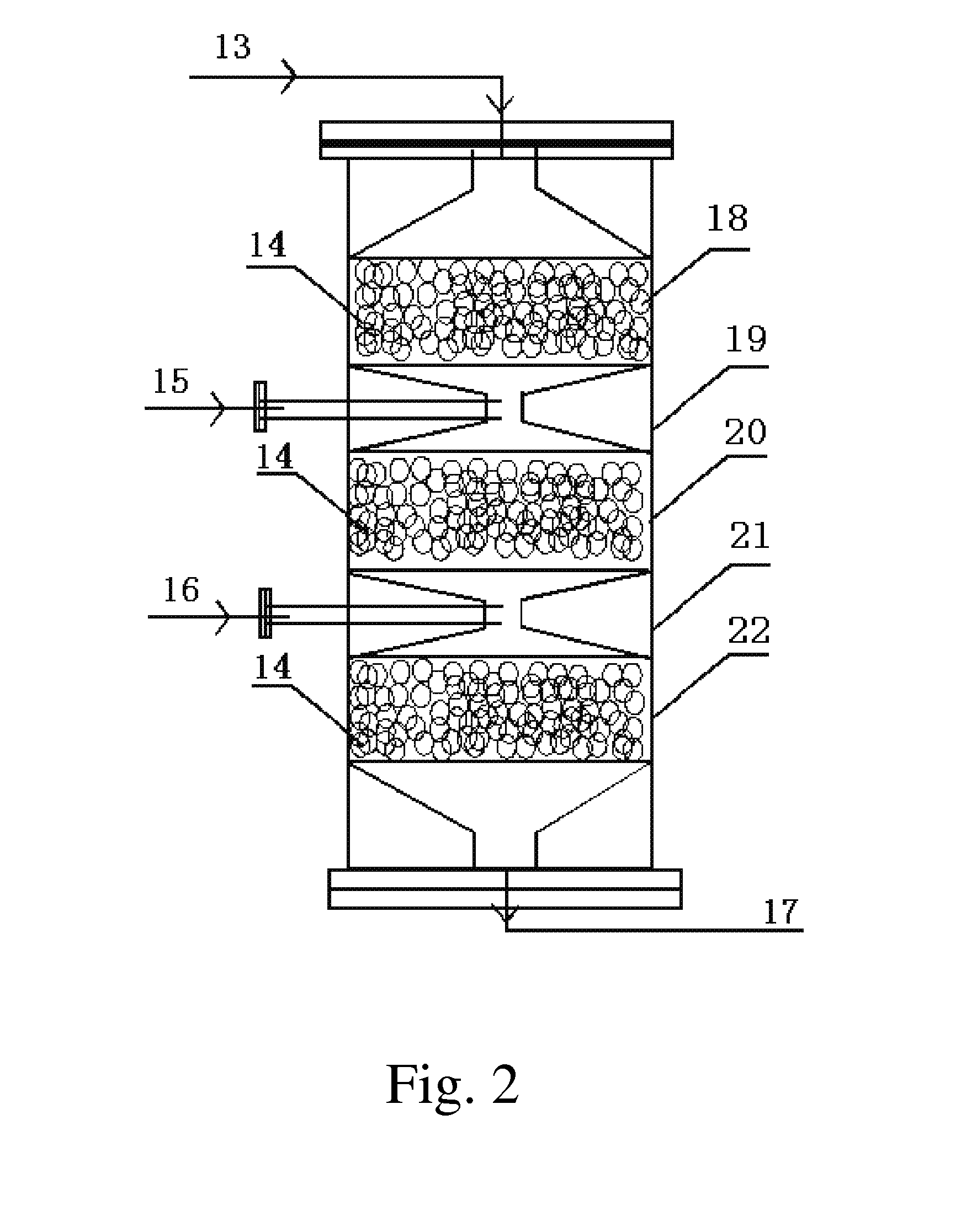

Mercury-polluted water treatment process

InactiveCN102030440AEffectively and completely removesSimple processWater contaminantsWater/sewage treatment by ion-exchangeMercuric ionIon exchange

The invention relates to the field of sewage treatment, in particular to a treatment method of mercury-polluted water. The mercury-polluted water treatment process mainly comprises pretreatment and mercury removal, wherein the pretreatment is as follows: pretreatment is carried out on the collected polluted water, the suspended matter concentration in the water body is less than or equal to 100mg / L; mercury removal is as follows: (1) inorganic mercury is removed; (2) mercury and mercuric salt are removed by adsorption; secondary adsorption is carried out by an obligate zeolite and hydroxide radical activated carbon, wherein the hydroxide radical activated carbon further adsorbs inorganic mercuric salts in the polluted water; (3) mercury and mercuric salts are removed by ion exchange, and final treatment is carried out on mercury in the polluted water, so as to enable mercury ions in the treated polluted water to reach mercury discharge limit value 0.5mug / l. In the invention, the process is simple, organic mercury and inorganic mercury in the polluted water can be thoroughly removed effectively, so as to enable the mercury-containing concentration to reach emission standards.

Owner:周光毅

Method for treating pesticide residue and heavy metal mercy in sewage

InactiveCN104876370AImprove removal efficiencyEasy to handleSpecific water treatment objectivesWater contaminantsPesticide residueNutrition

The invention relates to the field of sewage treatment unitization, in particular to a method for reducing pollution of mercury and pesticide residue in sewage. The method can effectively eliminate the pollution of the mercury in the sewage, the method has the advantages of being high in efficiency, low in nutritional requirement, simple in operation and high in safety, compared with existing other technologies, the cost of pollution treatment on the mercury and the pesticide residue in the sewage is obviously reduced, the efficiency of pollution treatment on the mercury and the pesticide residue in the sewage is improved, and the very important practical application value is achieved.

Owner:顾博钧

Solidification and stabilization method for mercury in mercury contaminants

InactiveCN106391694AReduce dosageReduce the risk of double releaseContaminated soil reclamationUltimate tensile strengthStabilization methods

The invention provides a solidification and stabilization method for mercury in mercury contaminants. The method includes the following steps that (1) mercury contaminant particles with the grain diameter not larger than 5 mm are mixed with soluble sulfide and water, and a first mixture is obtained; (2) the first mixture, cement and water are stirred and mixed, the stirring speed ranges from 20 r / min to 40 r / min, and a second mixture is obtained; and (3), after the second mixture is placed, the treated mercury contaminants are obtained. According to the method, the solidification effect of mercury in the contaminants is enhanced, the cement use amount is reduced on a large scale, the solidification capacity-increase ratio is small, and ready-made construction is rapid; and the leaching concentration of mercury after solidified bodies are stabilized for a long time is low, the mechanical strength of the solidified bodies can meet the requirements of ordinary road paving, and the solidification and stabilization method is suitable for mercury contamination repair projects with the large area, the tight schedule, the simple construction conditions and the low one-time invested cost requirement.

Owner:北京南科大蓝色科技有限公司 +1

Normal-temperature and normal-pressure preparation method and application of metal selenide mercury adsorbent

PendingCN113231004AImprove adsorption capacityIncrease speedGas treatmentOther chemical processesSorbentCobalt

The invention discloses a normal-temperature and normal-pressure preparation method and application of a metal selenide mercury adsorbent. The metal selenide mercury adsorbent is prepared at normal temperature and normal pressure by adopting a precipitation method. The metal selenide mercury adsorbent comprises a compound formed by selenium and one or more of chromium, manganese, iron, copper, cobalt, nickel, zinc, molybdenum, silver and cadmium and a composite of the compound, unstable mercury is converted into stable mercury selenide, mercury in industrial tail gas or by-products of fire coal, metallurgy, waste incineration, cement production and the like is removed, mercury enriched in mercury-containing articles for daily use is absorbed, the recovery and reutilization of mercury resources are realized, and mercury to be treated can exist in the forms of a simple substance state, a free state and / or a compound state and the like. As the metal selenide has extremely high mercury adsorption capacity and adsorption rate, realization of large-scale preparation of the metal selenide under normal temperature and pressure conditions has great significance on mercury pollution prevention and control, and the corresponding technology has wide market application prospects.

Owner:CENT SOUTH UNIV

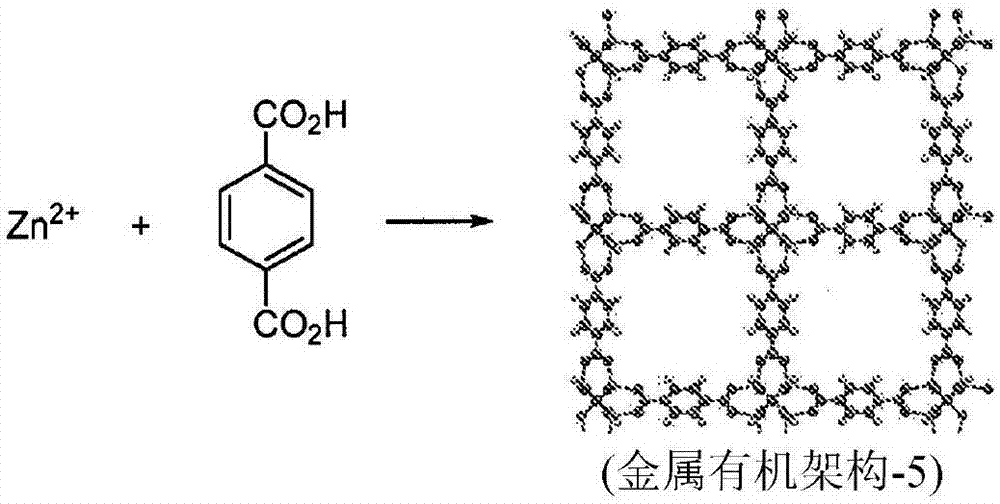

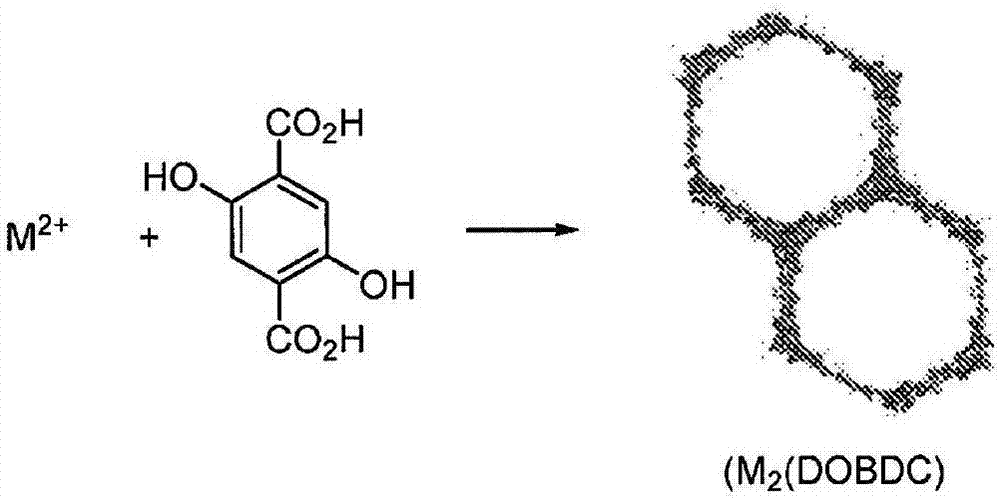

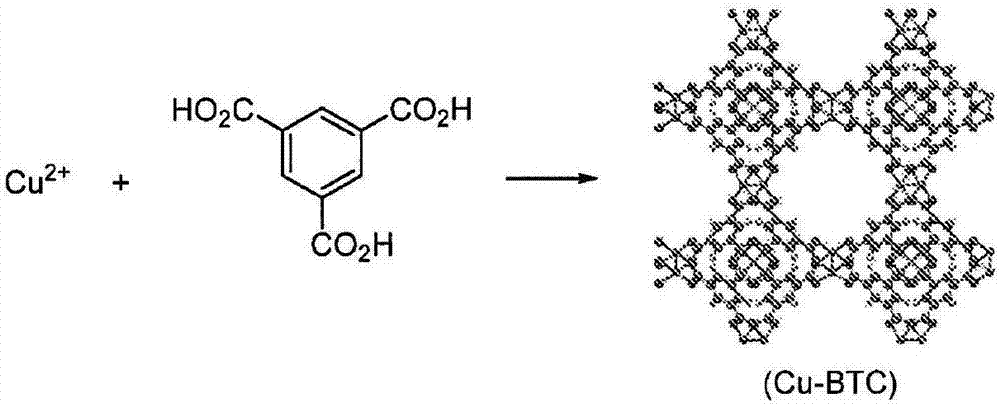

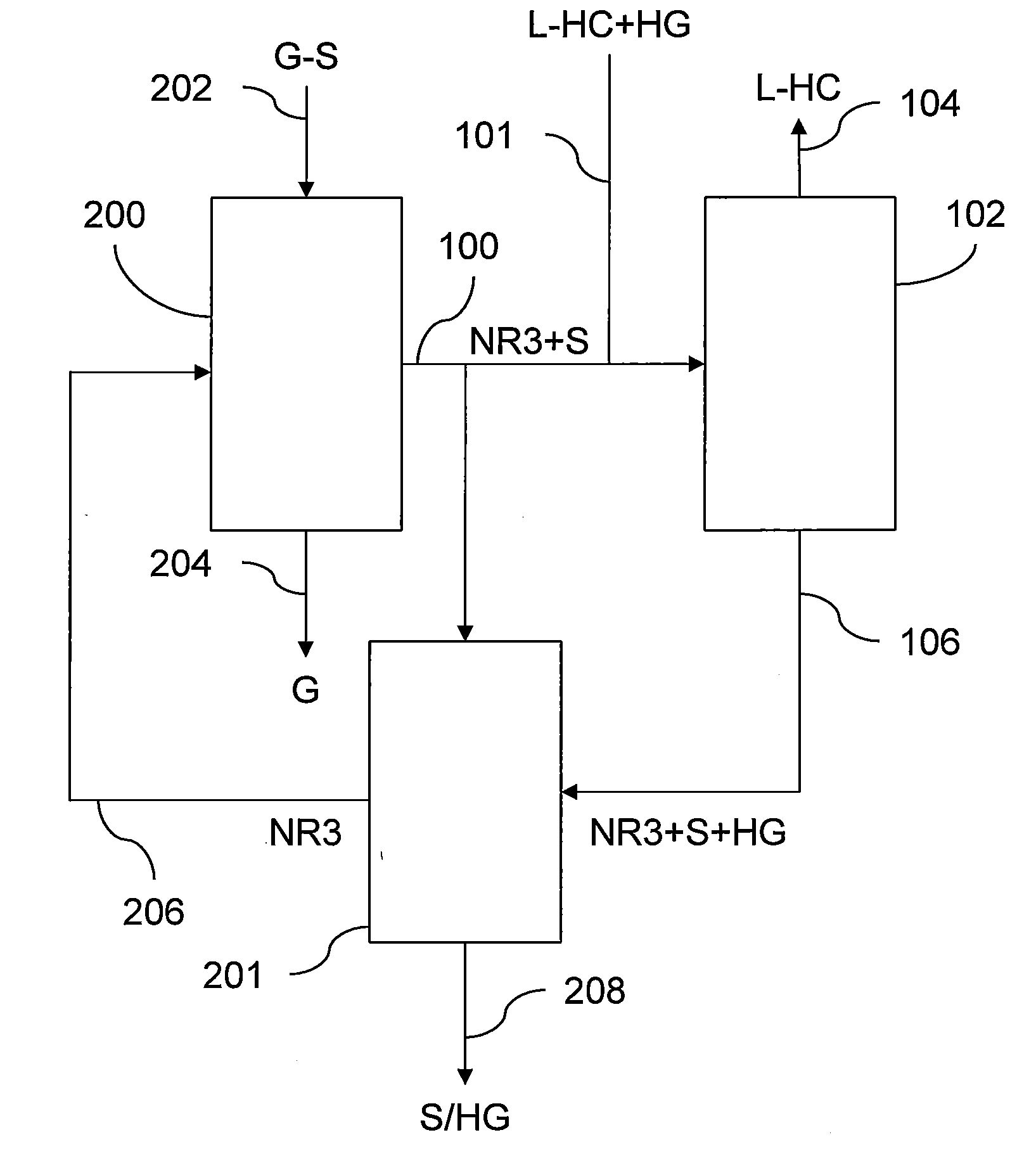

Porous polymers for the abatement and purification of electronic gas and the removal of mercury from hydrocarbon streams

ActiveCN107107028AHigh purityOther chemical processesGroup 4/14 organic compounds without C-metal linkagesMetal-organic frameworkOrganic polymer

A porous material, including metal organic frameworks (MOFs) and porous organic polymer (POP), with reactivity with or sorptive affinity towards (a) electronic gas to substantially remove or abate electronic gas in an electronic gas-containing effluent, or (b) contaminants in a stream of electronic gas to substantially remove the contaminants from a stream of electronic gas and increase the purity of said electronic gas, or (c) trace mercury contaminant in a hydrocarbon stream to substantially remove said mercury contaminant and increase the purity of said hydrocarbon stream. MOFs are the coordination product of metal ions and multidentate organic ligands, whereas POPs are the product of polymerization between organic monomers.

Owner:NUMAT TECH INC

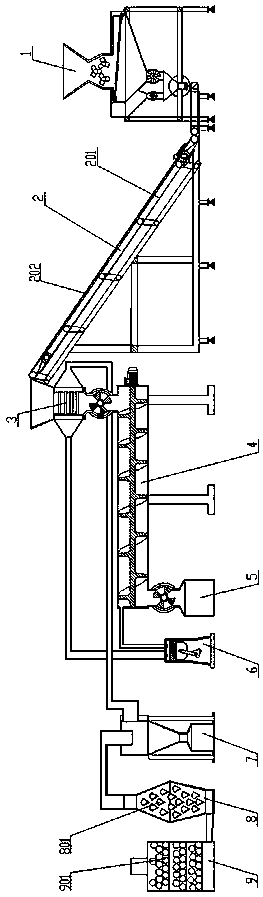

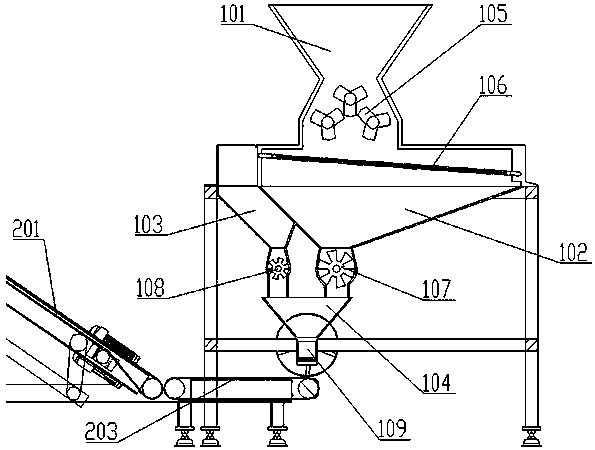

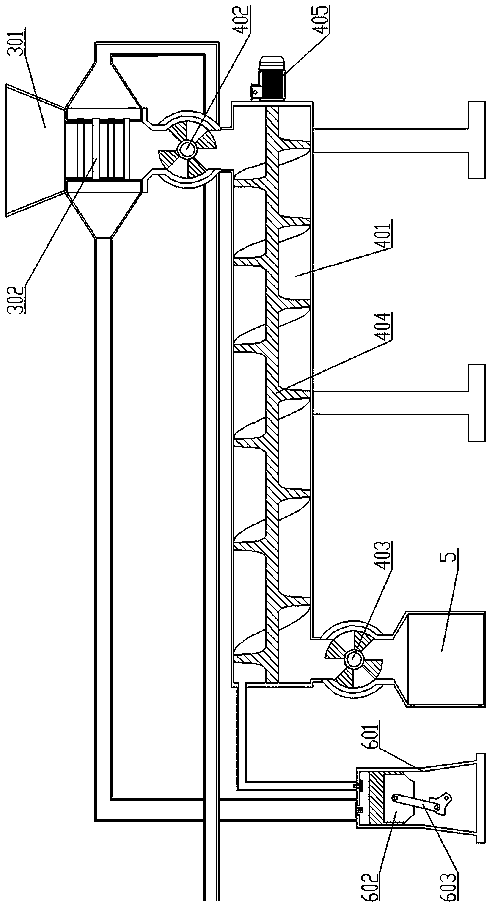

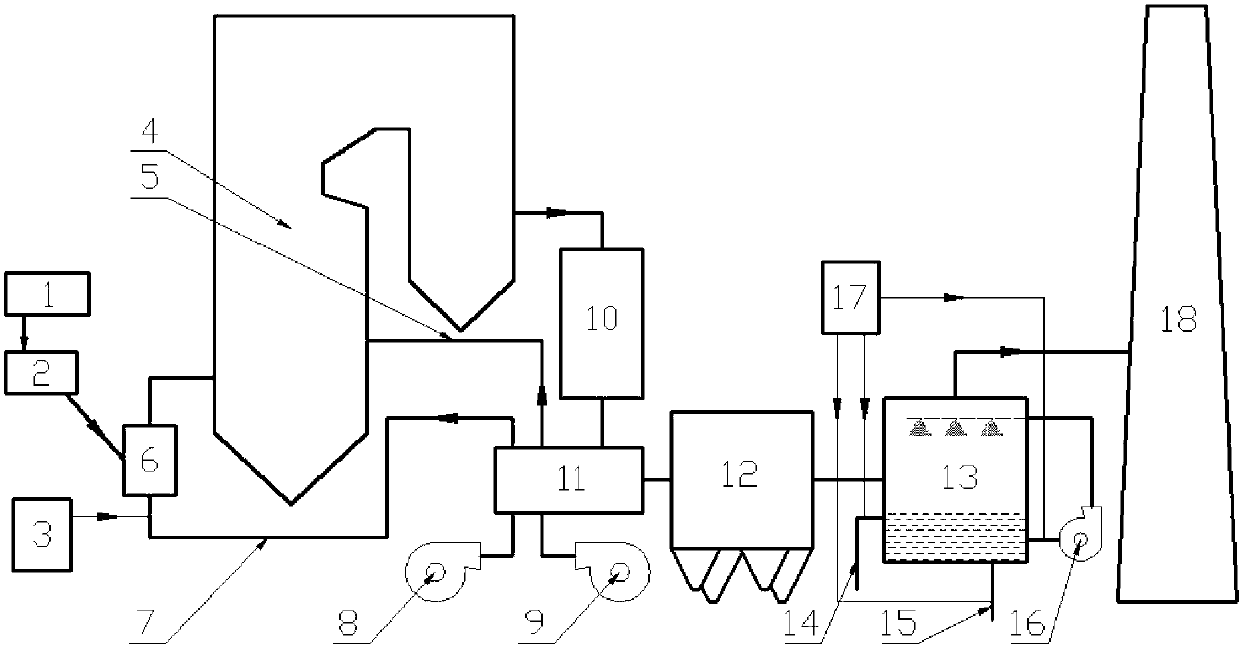

Negative-pressure thermal desorption treatment system for mercury contaminated soil

ActiveCN111558611ATo achieve the effect of desorptionGuaranteed desorption effectContaminated soil reclamationGrain treatmentsCyclonic spray scrubberThermal desorption

A negative pressure thermal desorption treatment system for mercury contaminated soil comprises a pretreatment device, a feeding device, a waste heat utilization heat exchanger, a negative pressure heating device, a soil collecting box and an air extractor. The pretreatment device is used for crushing soil and mixing the soil with a catalyst; the feeding device conveys the soil from the pretreatment device to the waste heat utilization heat exchanger; the waste heat utilization heat exchanger is used for preheating the soil and enabling the soil to fall into the negative pressure heating device; the negative pressure heating device is used for carrying out thermal desorption treatment on the soil and enabling the soil to fall into the soil collecting box; the air extractor extracts hot airin the negative pressure heating device to form negative pressure in the negative pressure heating device; the air extractor is connected with an air inlet of the waste heat utilization heat exchanger, hot air flows into the waste heat utilization heat exchanger to exchange heat with the soil; and an air outlet of the waste heat utilization heat exchanger is sequentially connected with a cyclonedust collector, a condensing device and a tail gas treatment device. Safe and efficient negative pressure thermal desorption treatment can be conducted on mercury-containing soil.

Owner:HENAN UNIV OF SCI & TECH

Mercury removal with amine sorbents

ActiveUS20110068048A1Treatment with plural serial refining stagesHydrocarbon oil dewatering/demulsificationSorbentSulphur compound

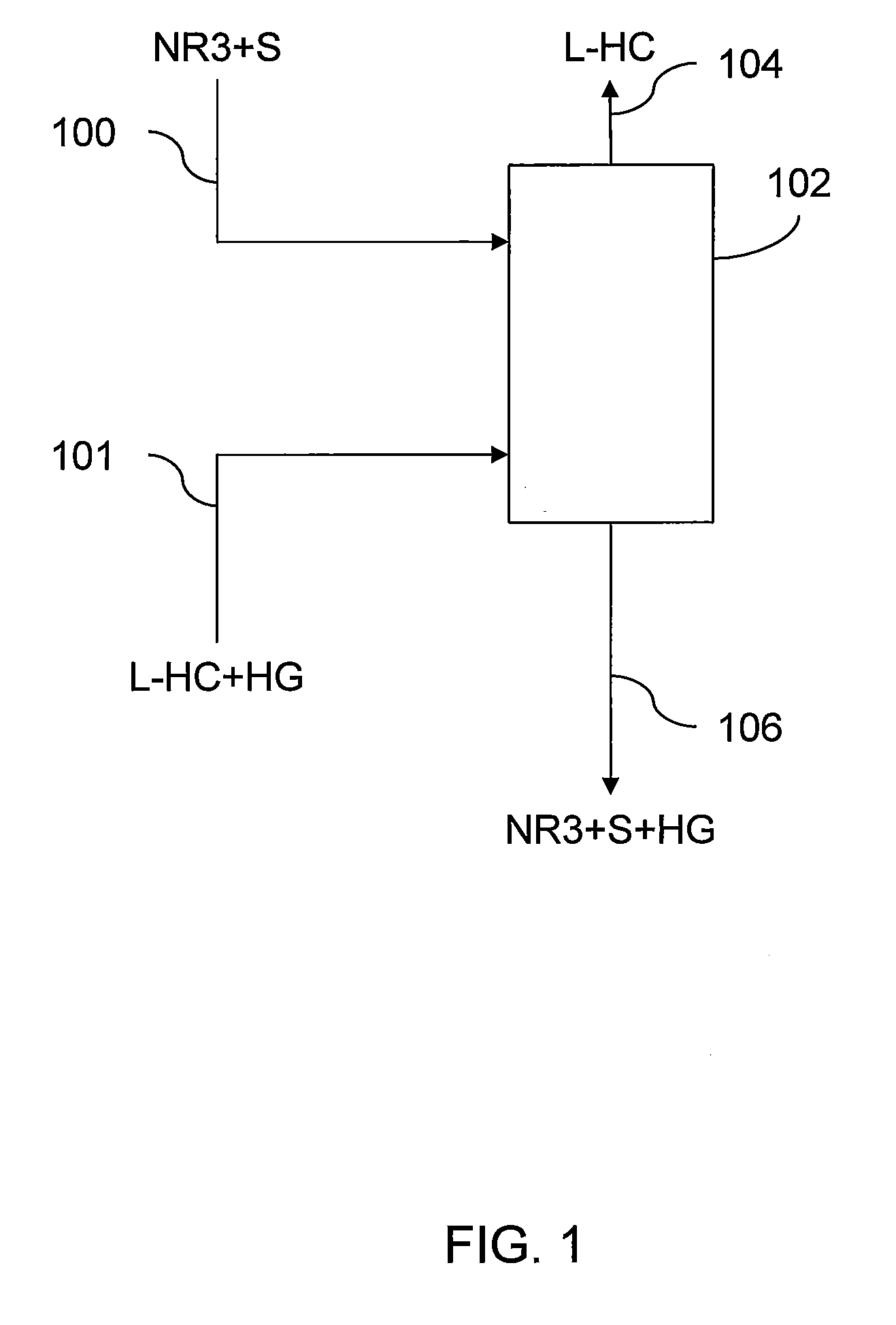

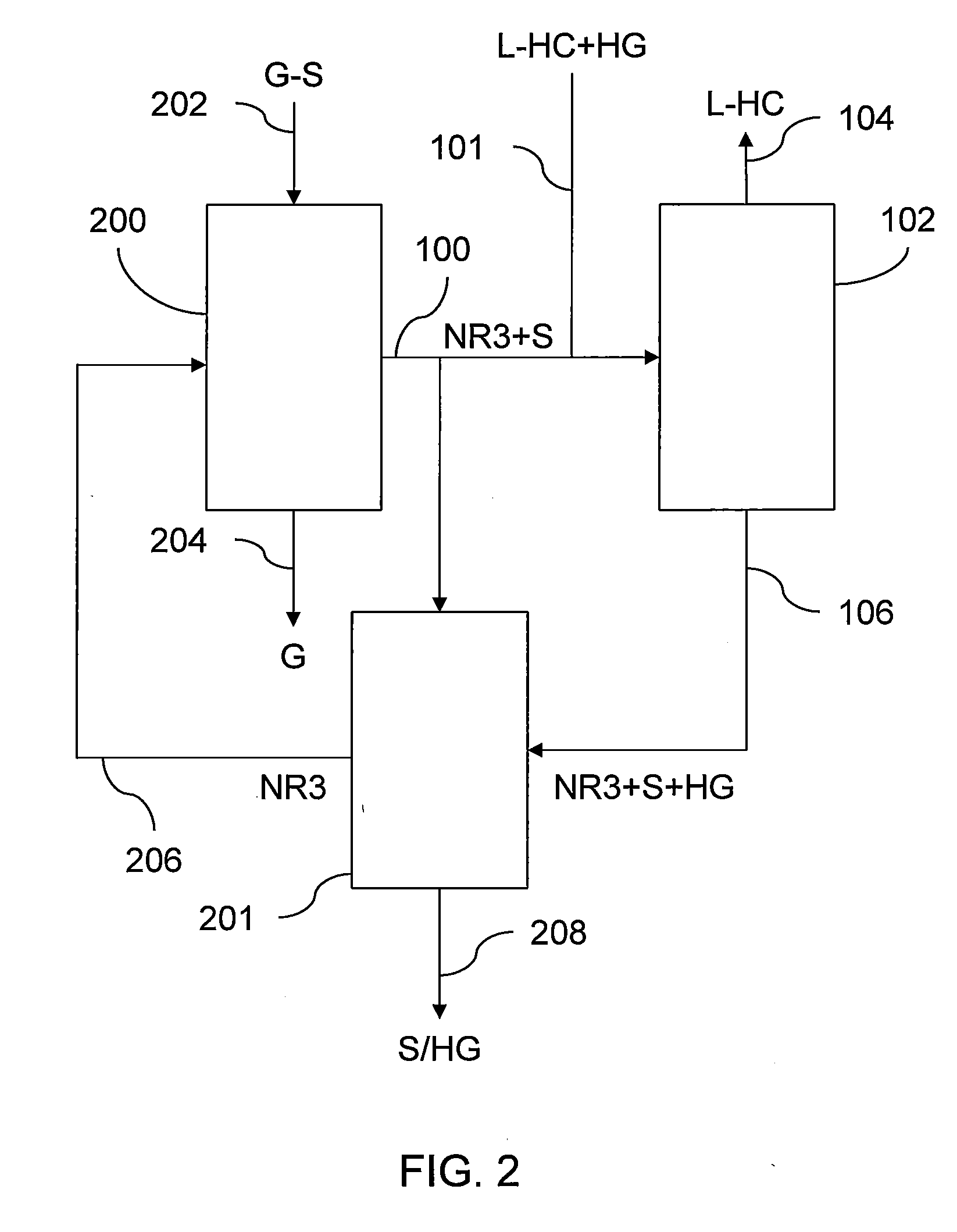

Methods and apparatus relate to treatment of fluids to remove mercury contaminants in the fluid. Contact of the fluid with an amine that has absorbed a sulfur compound causes the mercury contaminants to be absorbed by the amine. Phase separation then removes from the fluid the amine loaded with the mercury contaminants such that a treated product remains.

Owner:PHILLIPS 66 CO

Method suitable for controlling mercury contamination in coal-fired power plants adopting wet-process flue gas desulfurization

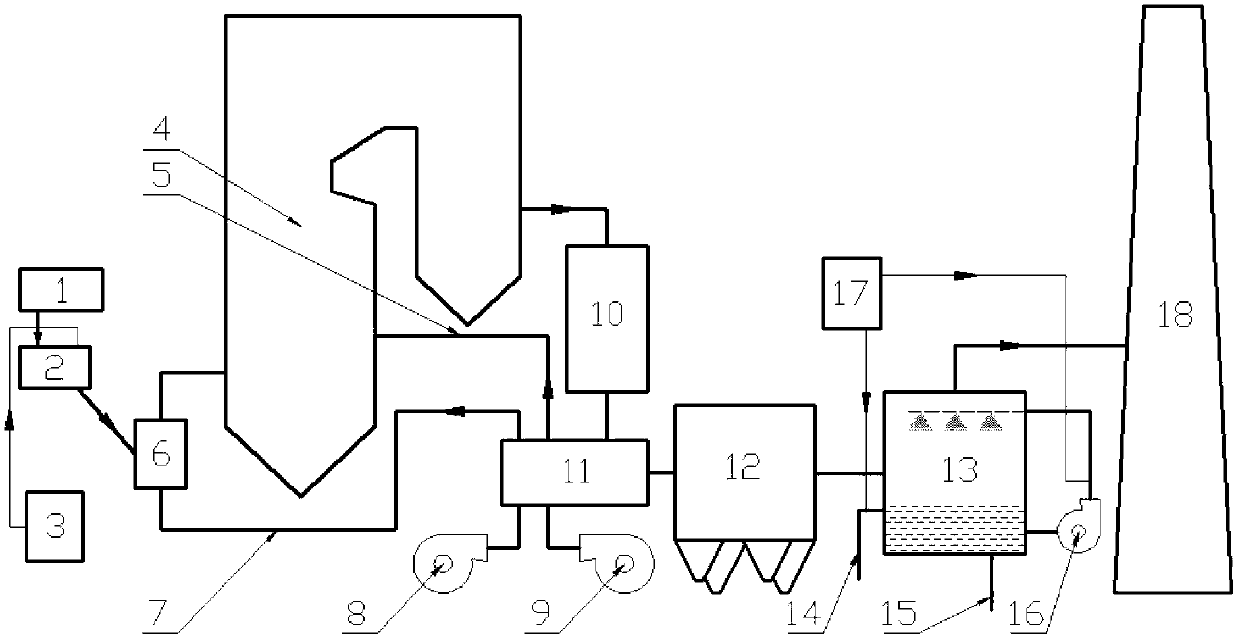

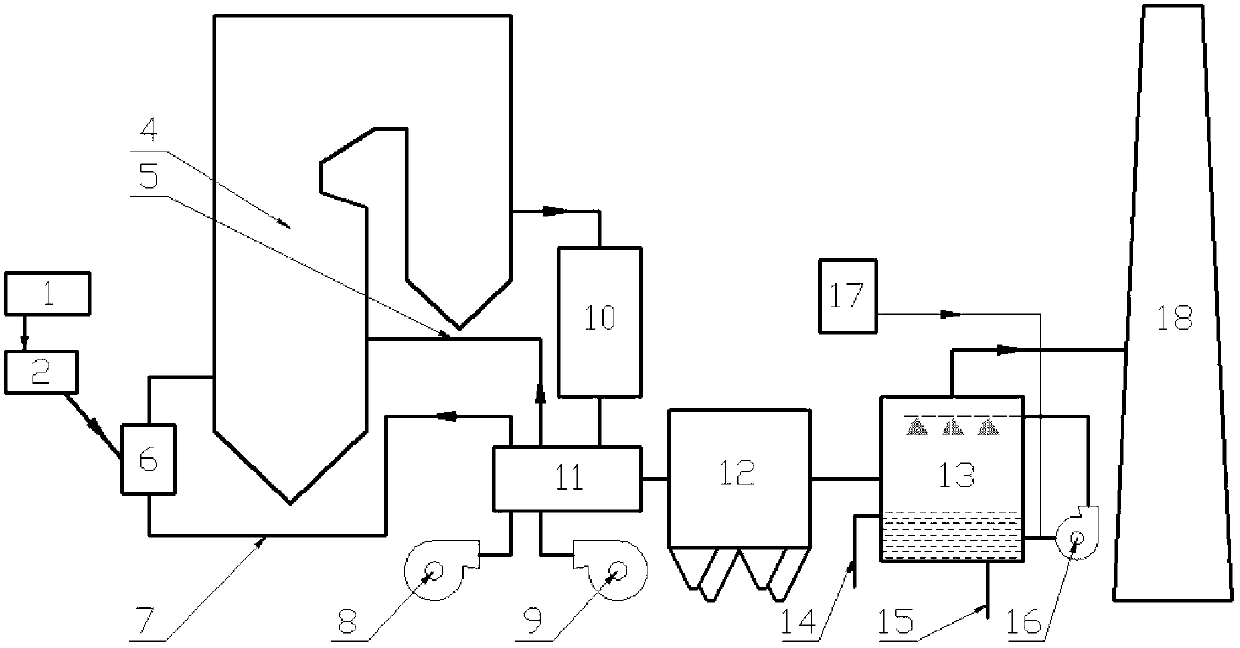

InactiveCN102989305ARaise the ratioImprove mercury removal efficiencyDispersed particle separationSlurrySulfur containing

The invention discloses a method suitable for controlling mercury contamination in coal-fired power plants adopting wet-process flue gas desulfurization. The method is characterized in that halide additive solution is added into a boiler body to participate in combustion reaction so as to promote oxidization of mercury in flue gas and improve the proportion of mercury oxide in the flue gas; and sulfur-contained additive solution enters a desulfurizing tower and reacts with the flue gas or mercury oxide in size to produce mercuric sulfide precipitation or flocculent complex, and finally mercury in the flue gas of the coal-fired power plants can be effectively removed, wherein a sulfur-contained additive solution storage tank is arranged on the side of a wet-process flue gas desulfurization system and communicated with at least one of a fresh size pipeline of a desulfurizing tower and an inlet and an outlet of a circulating pump of the desulfurizing tower. The method has the advantages of low investment and running cost of a mercury contamination control system while ensuring that the emission level of mercury contaminations in the coal-fired power plants meets stricter environmental protection standard requirements; and as the wet-process flue gas desulfurization system is widely adopted in the coal-fired power plants in China, the method is wide in applicability.

Owner:HUANENG CLEAN ENERGY RES INST

Fly ash modification method used for mercury contamination in situ soil remediation, and applications

InactiveCN109652079AWide variety of sourcesRealize resourcesAgriculture tools and machinesContaminated soil reclamationPhosphateSlurry

The invention discloses a fly ash modification method used for mercury contamination in situ soil remediation, and applications. The method includes the following steps: (1) the step of acid modification, namely the step of preparing fly ash into slurry with a certain mass concentration under normal temperature, and adding sulfuric acid and hydrochloric acid with a certain concentration to performmodification; (2) the step of washing, namely the step of filtering the fly ash slurry obtained by the step (1), performing washing with clear water until a pH value is 7, and performing filtering for later use; (3) the step of combined modification, namely the step of preparing the washed fly ash into the slurry with a certain mass concentration, and adding phosphate, hydrogen peroxide and manganese dioxide to perform full stirring; and (4) the step of drying, namely the step of filtering the fly ash obtained by the step (3), and obtaining modified fly ash through drying. Mercury can be passivated by adding the modified fly ash into mercury-contaminated soil, so that the purpose of soil remediation can be achieved. As the fly ash can be adopted as a main material of mercury-contaminatedsoil remediation, the method can have advantages of being wide in raw material source and low in cost, and other heavy metal can be passivated as well.

Owner:长沙湘朴科技有限公司

Method for curing soil mercury with bacteria under anaerobic condition

InactiveCN104889153ANo secondary pollutionSimple processContaminated soil reclamationMetaboliteElemental mercury

The invention discloses a method for curing soil mercury with bacteria under the anaerobic condition. The method includes that Thauear selenatis, ATCC 55363 which can be used for dissimilatory reduction of sodium selenite is selected and is from ATCC (American type culture collection), the Thauear selenatis is transferred to a culture medium containing sodium selenite for culture so as to obtain a bacterial dissimilatory reduction metabolite, then mixed liquor containing the metabolite is added with sodium dodecyl sulfate, and finally the treated metabolite is added into elemental mercury contaminated soil for culture in an anaerobic workstation for several days prior to ending experiment. Under the condition of presence of sodium selenite, the anaerobic dissimilatory reduction metabolite is a good curing agent of mercury, the elemental mercury in soil can be cured into residual-form mercury so as to fix the soil mercury and repair soil mercury contamination, and the method is particularly applicable to repair of deep contaminated soil. The method is simple in process, convenient to operate, low in treatment cost, large in treatment range and free of secondary contamination.

Owner:XINJIANG INST OF ECOLOGY & GEOGRAPHY CHINESE ACAD OF SCI

Treatment method of water polluted by mercury

ActiveCN104150634AReduce mercury levelsProcessing speedWater contaminantsMultistage water/sewage treatmentHydrogen SulfateP-tert-Butylphenol

The invention relates to the field of water treatment, and in particular relates to a treatment method of water polluted by mercury. The method comprises the following steps: (1) regulating the pH value of mercury-containing sewage to be 6-6.5, and adding sodium alcohol ether sulfate and sodium hypochlorite into the mercury-containing sewage, wherein the additive amount of sodium alcohol ether sulfate accounts for 1-2 times of the mass concentration of mercury in the sewage, and the additive amount of sodium hypochlorite accounts for 3-5 times of the mass concentration of mercury in the sewage; (2) regulating the pH value of the sewage to be 8-9, and then adding poly p-tert-butylphenol disulfide, ferrous sulfide and sodium hydrogen sulfate into the sewage under the conditions that the mass ratio of p-tert-butylphenol disulfide to ferrous sulfide to sodium hydrogen sulfate is (1-2) to (2-4) to 5, and the mass concentration of poly p-tert-butylphenol disulfide in the sewage is 1-5%; (3) then adding a flocculating agent, calcium oxide and alkylphenol polyoxyethylene into the sewage under the conditions that the mass ratio of the flocculating agent to calcium oxide to alkylphenol polyoxyethylene is 1 to 3 to 2, and the additive quantity of the flocculating agent is 0.1-0.3% of the quantity of the sewage; (4) standing the sewage for 3-5 days in a separation tank, and then performing solid-liquid separation; (5) adsorbing the separated sewage by adopting an activated carbon absorber, and then discharging the sewage.

Owner:ZHEJIANG OCEAN UNIV

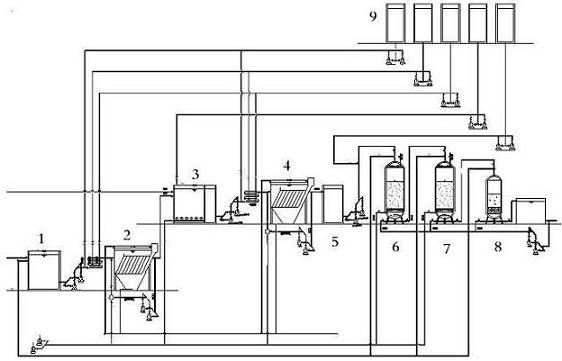

Efficient thermal desorption treatment system and method for restoring mercury contamination

InactiveCN106216380AReduce the amount of fine dustReduce the amount of mercury-containing dustContaminated soil reclamationPre conditioningThermal efficiency

The invention relates to an efficient thermal desorption treatment system and method for restoring mercury contamination. The efficient thermal desorption treatment system comprises a pelletizing pretreatment unit, a feeding unit, a thermal desorption unit, a dust collecting unit, a cooling condensing unit, an exhaust gas washing unit, a gas-liquid separation unit, a water treatment unit, an exhaust gas absorption treatment and emission unit and a cooling discharging unit, wherein the pelletizing pretreatment unit is connected with the feeding unit, the feeding unit, the cooling discharging unit and the dust collecting unit are all connected with the thermal desorption unit, the dust collecting unit is separately connected with the cooling condensing unit and the pelletizing pretreatment unit, the cooling condensing unit is connected with the exhaust gas washing unit, the exhaust gas washing unit is connected with the gas-liquid separation unit, the gas-liquid separation unit is connected with the exhaust gas absorption treatment and emission unit, the cooling condensing unit, the exhaust gas washing unit and the gas-liquid separation unit are separately connected with the water treatment unit, and at the same time, the water treatment unit is connected with the cooling discharging unit. The efficient thermal desorption treatment system has the characteristics of high thermal efficiency, high contaminant removing rate, low exhaust gas dust content and low energy consumption.

Owner:中钢集团天澄环保科技股份有限公司

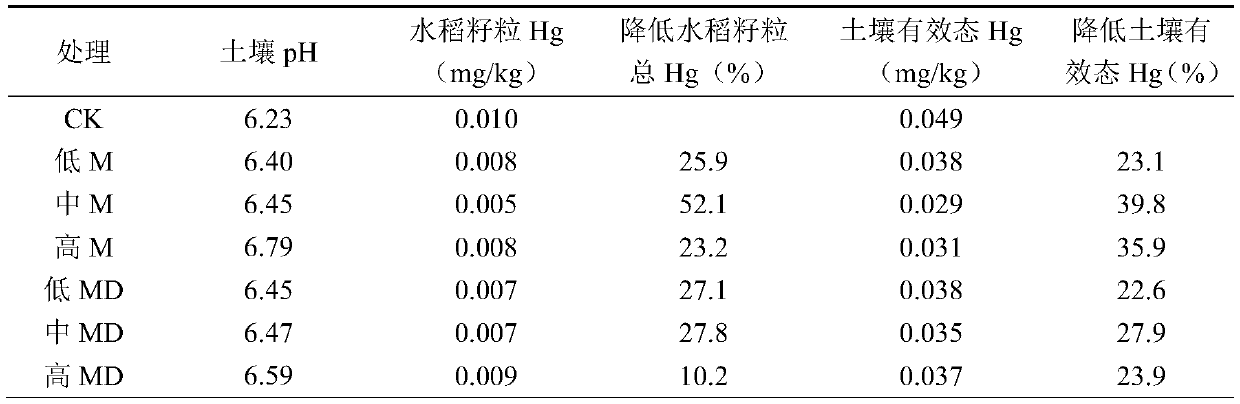

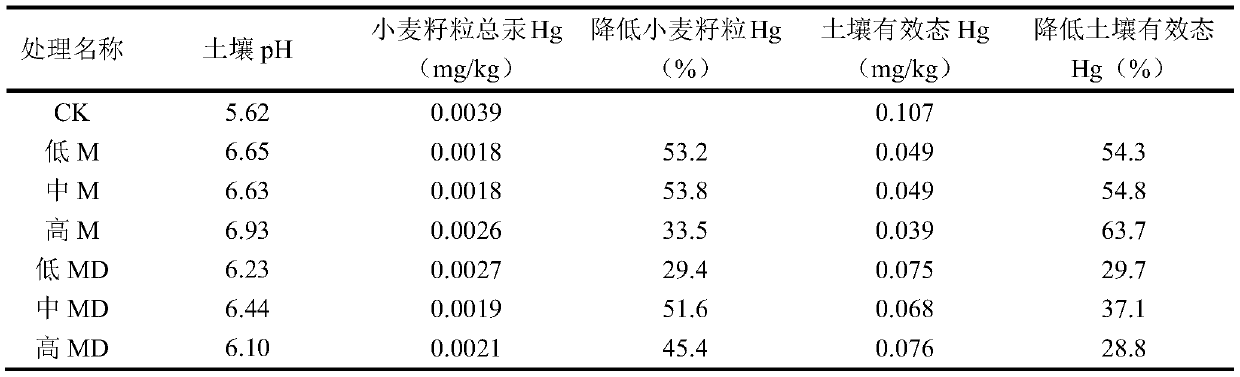

Passivating agent and application thereof in repairing medium-light mercury polluted farmland soil

PendingCN111205870AInhibit methylationEffectively fixedOther chemical processesContaminated soil reclamationSoil scienceEnvironmental engineering

The invention discloses a passivating agent and application thereof in repairing medium-light mercury polluted farmland soil. The passivating agent comprises sodium selenite which is used for reducingthe microbial activity of the mercury polluted farmland soil and is cooperatively applied to an alkaline material with adsorption performance on heavy metals. The passivating agent is prepared from the following components in parts by mass: 90-100 parts of zeolite and 0-10 parts of sodium selenite, and the adding amount of the passivator is 0.33-0.67% of the mass of the surface soil. According tothe passivating and repairing method for farmland soil polluted by medium-light mercury, the pH value of acid soil can be increased, heavy metal mercury in polluted soil can be effectively fixed, thebiological availability of the heavy metal mercury is reduced, absorption and accumulation of heavy metal mercury by crop grains are reduced, the safety of agricultural products is guaranteed, and the passivating agent and application thereof have the advantages of being easy to operate, low in cost and obvious in remediation effect.

Owner:JIANGSU GEOLOGICAL SURVEY INST +1

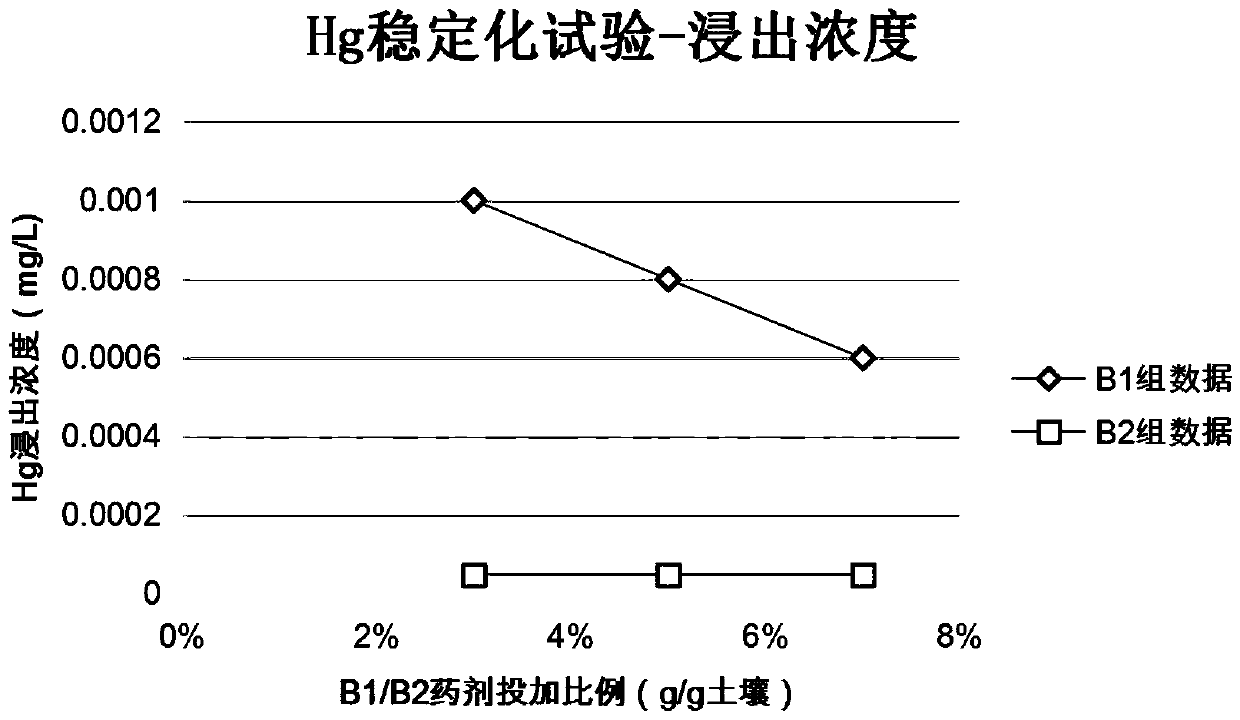

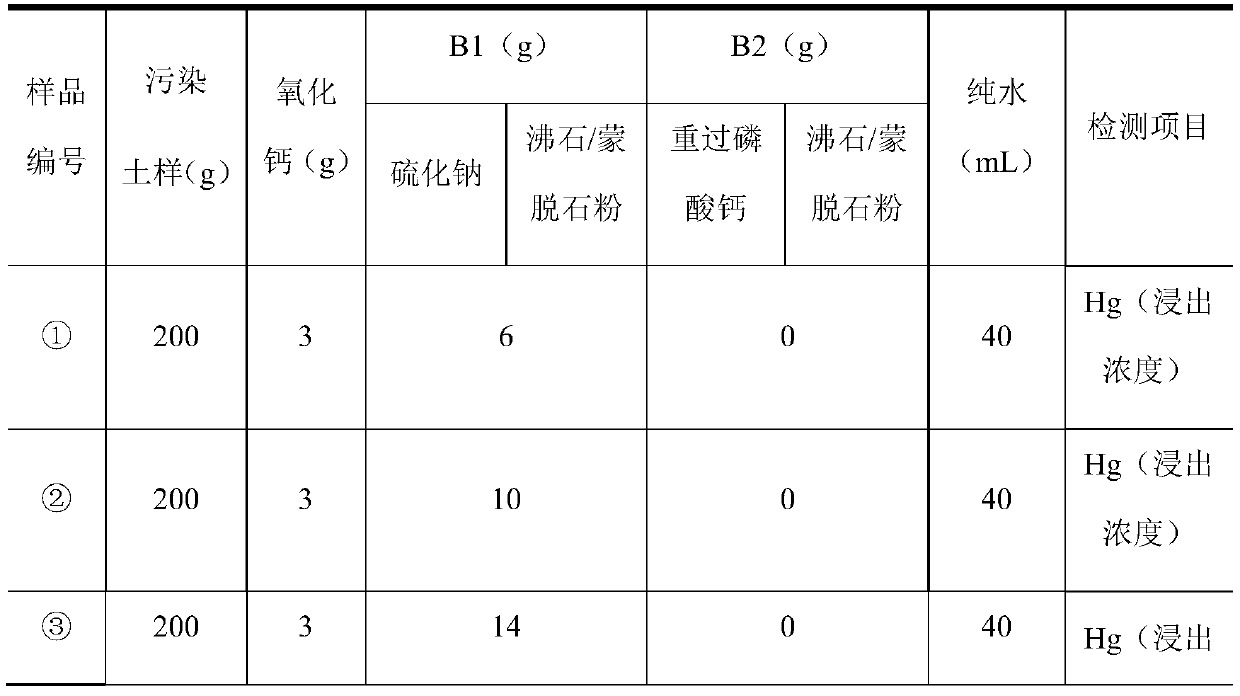

Preparation method and use method of agentia for stabilization repairing of mercury-contaminated soil

InactiveCN110369488ACo-precipitationWith adsorptionContaminated soil reclamationOrganic fertilisersZerovalent ironMercury contamination

The invention discloses a preparation method and a use method of agentia for stabilization repairing of mercury-contaminated soil. The preparation method includes the steps that 1, contaminated soil is excavated, screened and crushed; 2, the water content, pH value, redox potential value and initial concentration of mercury in the soil are measured by sampling analysis; and 3, the ratio of components in the agentia is determined, and materials in the components are crushed and mixed evenly. The agentia includes a component A and a component B, the component A includes calcium oxide and zero-valent iron powder, and the component B includes sodium sulfide, triple superphosphate, montmorillonite powder, zeolite powder and ferrous sulfate. The invention further provides the use method of the agentia for stabilization repairing of the mercury-contaminated soil. According to the preparation method and the use method, the mechanisms of 'coarse stabilization' and 'fine stabilization' are combined, he preparation method and the use method are suitable for a variety of soil environments, the agentia is flexibly used, the configuration method is simple, field service is convenient, and the cost can be further saved.

Owner:SHANGHAI GREENMENT ENVIRONMENTAL TECH CO L

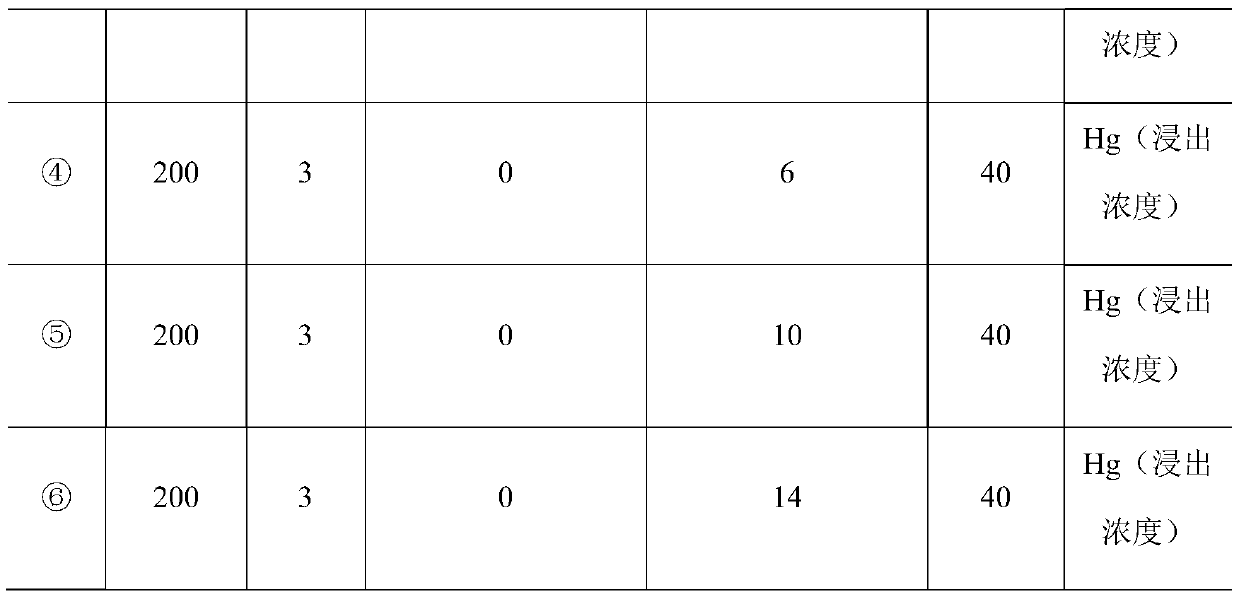

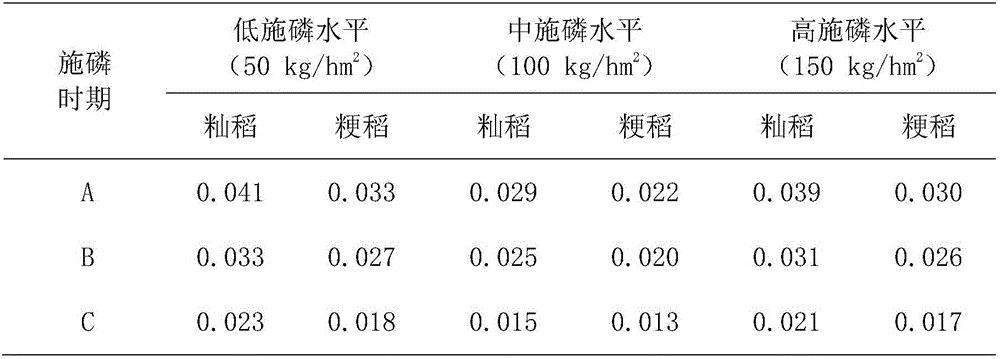

Method for applying phosphate fertilizer to reduce content of mercury in rice grains of heavy mercury polluted rice field

InactiveCN106358553AReduce mercury levelsEliminate health threatsFertilising methodsHectareJaponica rice

The invention relates to a method for applying a phosphate fertilizer to reduce the content of mercury in rice grains of a heavy mercury polluted rice field, belonging to the technical field of agricultural product heavy metal pollution prevention and treatment. The method is characterized by comprising the following steps: in the heavy mercury polluted rice field (the soil Hg concentration is 2mg / kg, which is 4 times the national limit standard), applying 100kg / hm<2> (at a middle phosphorus application level by an effective component P2O5) of the phosphate fertilizer for three times, namely, applying 1 / 2 of the total phosphatic fertilizer 3 days before rice transplanting, and applying 1 / 4 of the total phosphatic fertilizer 5 days before earing and 10 days after head sprouting respectively; throwing the phosphate fertilizer 3 days before rice transplanting, namely, uniformly throwing the phosphate fertilizer into the rice field; applying the phosphate fertilizer in a leaf surface spraying mode 5 days before earing and 10 days after head sprouting, dissolving a water-soluble phosphate fertilizer into water, and spraying 300L of water with the phosphate fertilizer to each hectare of the rice field. Compared with a common high-level one-time phosphate fertilizer application method used in practical rice production, the method has an application effect that the content of mercury in the rice grains can be greatly reduced (the content of the mercury in indica type rice is reduced by 61.54%, and the content of mercury in japonica rice is reduced by 56.67%), and the yield of rice is not greatly reduced.

Owner:CHANGZHOU UNIV

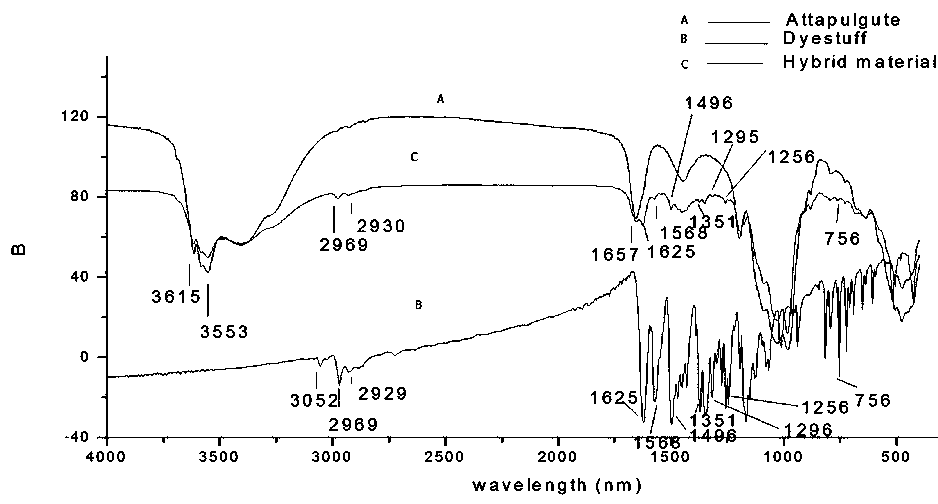

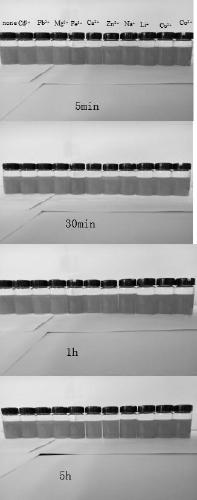

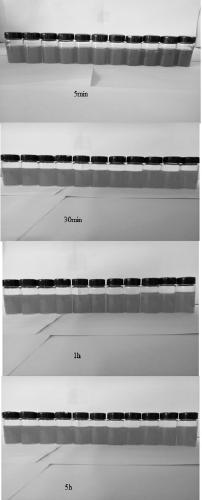

Attapulgite clay-thiocoumarin functional hybrid material and preparation method and application

ActiveCN110389117AImprove stabilityHigh sensitivityFluorescence/phosphorescenceCoumarine dyesHybrid materialColor reaction

The invention discloses an attapulgite clay-thiocoumarin functional hybrid material, which is characterized in that it is prepared by hybridizing a thiocoumarin fluorescent dye having a molecular sizematching the size of an attapulgite clay pore, and the attapulgite clay under a certain condition; the material can be subjected to a specific selective fluorescence reaction with mercury ions, so that the fluorescence intensity at a certain wavelength is significantly improved; further, the material can produce an eye-recognizable color reaction so as to be used in the detection of mercury ionsto detect mercury contamination in water. The invention also discloses a method for preparing the attapulgite clay-thiocoumarin functional hybrid material, comprising an attapulgite clay preprocessingstep and a wet hybridization step. The processed attapulgite clay has a greatly increased specific area. The isopropyl alcohol wet hybridization can effectively promote the dissociation of the attapulgite clay and further promote the combination with the dye. The high-temperature baking promotes the dehydration of the attapulgite clay and promotes the hybridization of the thiocoumarin and the attapulgite clay.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

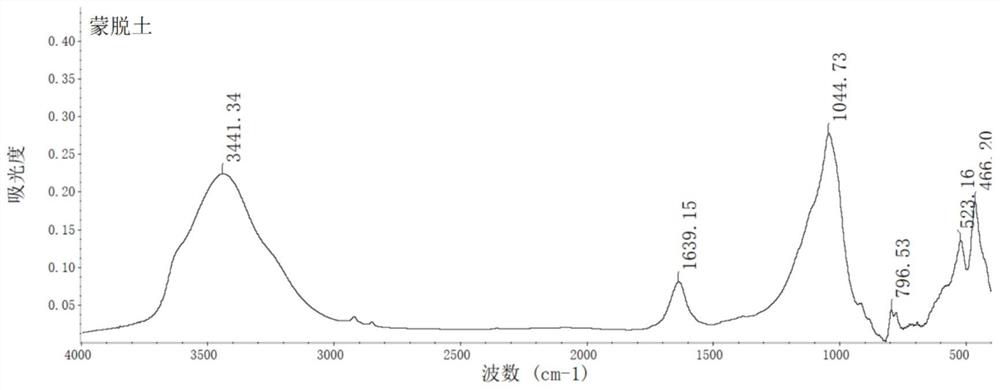

Mercury-polluted soil remediation agent and preparation method thereof

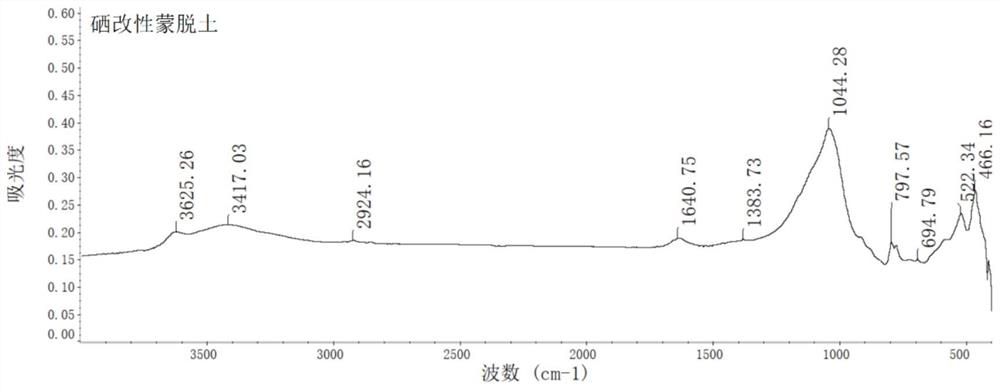

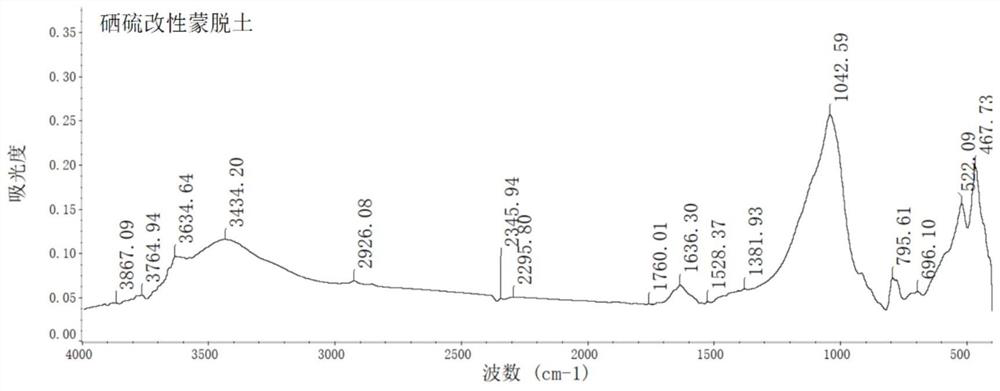

ActiveCN114045173AReducing effect of high plant mercury contentReduced mercury levels in plantsAgriculture tools and machinesContaminated soil reclamationSelenateClay minerals

The invention provides a mercury-polluted soil remediation agent and a preparation method thereof. The mercury-polluted soil remediation agent comprises clay mineral, and selenite and a sulfur-containing compound which are bonded on the clay mineral; wherein the clay mineral is montmorillonite and / or medical stone, and the sulfur-containing compound is a soluble sulfide and / or a sulfydryl-containing compound. The mercury-polluted soil remediation agent is prepared by a method of mixing and reacting various clay minerals, selenite and a sulfur-containing compound in a solvent. The selenium-containing remediation agent for mercury-polluted soil provided by the invention not only can improve the reduction effect of each component on the mercury content of crops, but also can reduce the enrichment capacity of the crops on selenium, and reduces the risk that the selenium of the crops is greatly increased due to the addition of selenium.

Owner:GUIZHOU UNIV

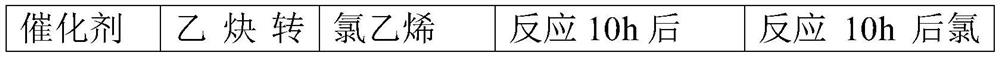

Method for preparing vinyl chloride with acetylene and dichlorethane

ActiveUS20150141713A1Outstanding advantageAvoid mass productionPreparation by hydrogen halide split-offPreparation by halogen halide additionEthane DichlorideHydrogen chloride

Provided is a method for preparing vinyl chloride with acetylene and dichlorethane for large-scale industrial production. Acetylene, dichlorethane vapor and hydrogen chloride gas at a molar ratio of 1:(0.3-1.0):(0-0.20) are mixed; the raw mixed gas is preheated; the preheated raw mixed gas passes through a reactor containing a catalyst and reacts; the resultant mixed gas is cooled to 30-50° C. and pressurized to 0.4-1.0 MPa, and then cooled to ambient temperature, and further frozen to −25-15° C. for liquefaction isolation, and unliquefied gas is recycled and reused; liquefied liquid is sent to a rectifying tower for rectification, and vinyl chloride monomers meeting polymerization requirements are obtained. The present invention has the advantages of eliminating mercury contamination completely, simplifying the reactor structure, recycling hydrogen chloride and acetylene, reducing waterwash process, avoiding mass production of waste acid and improving utilization of chlorine.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI +1

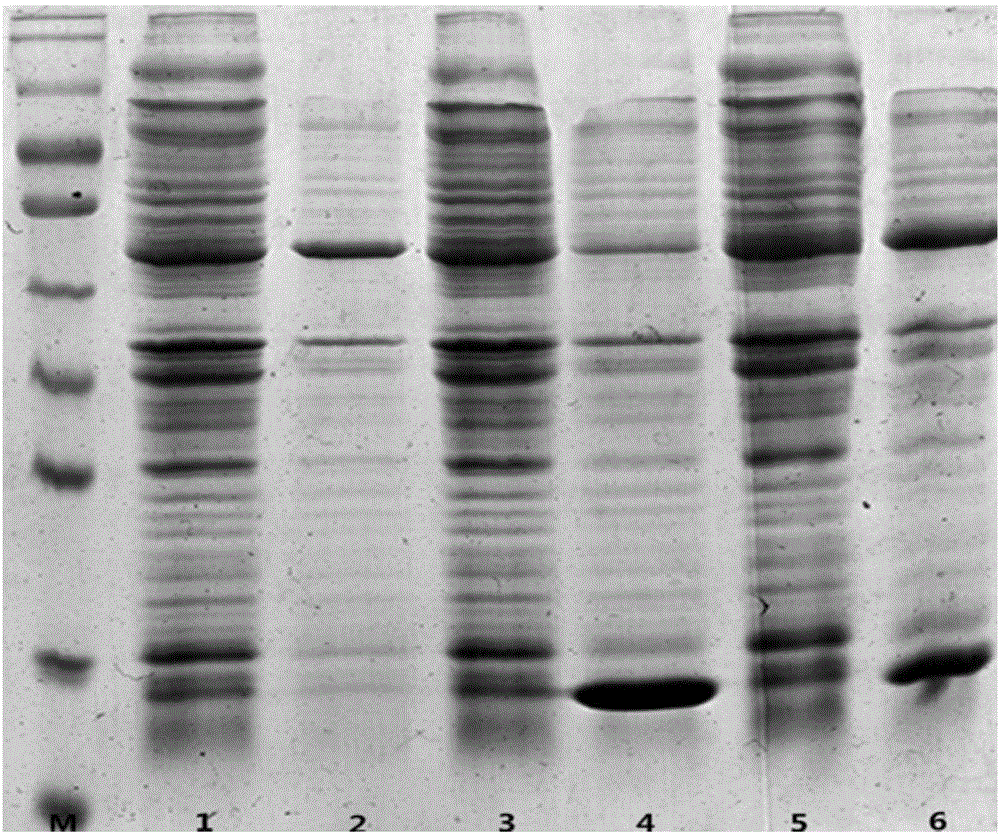

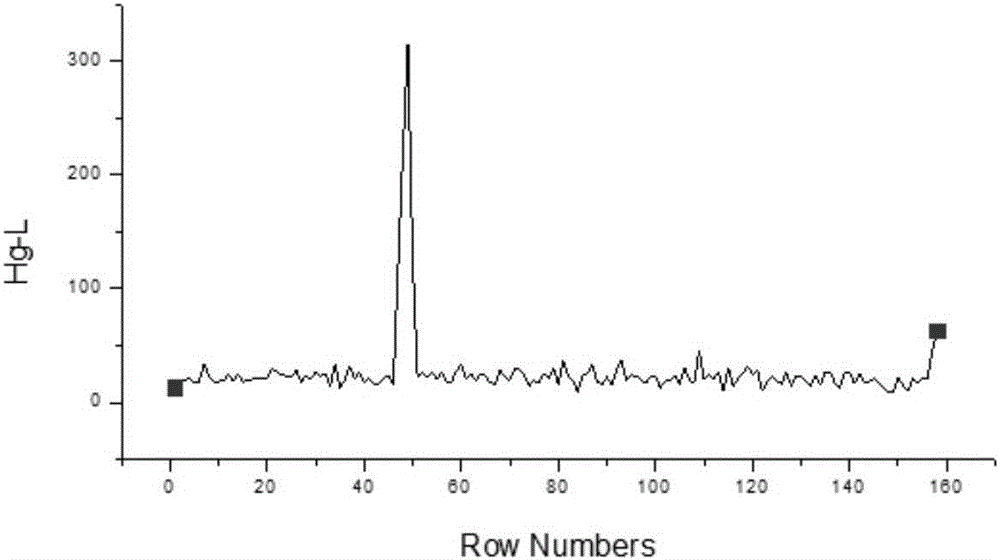

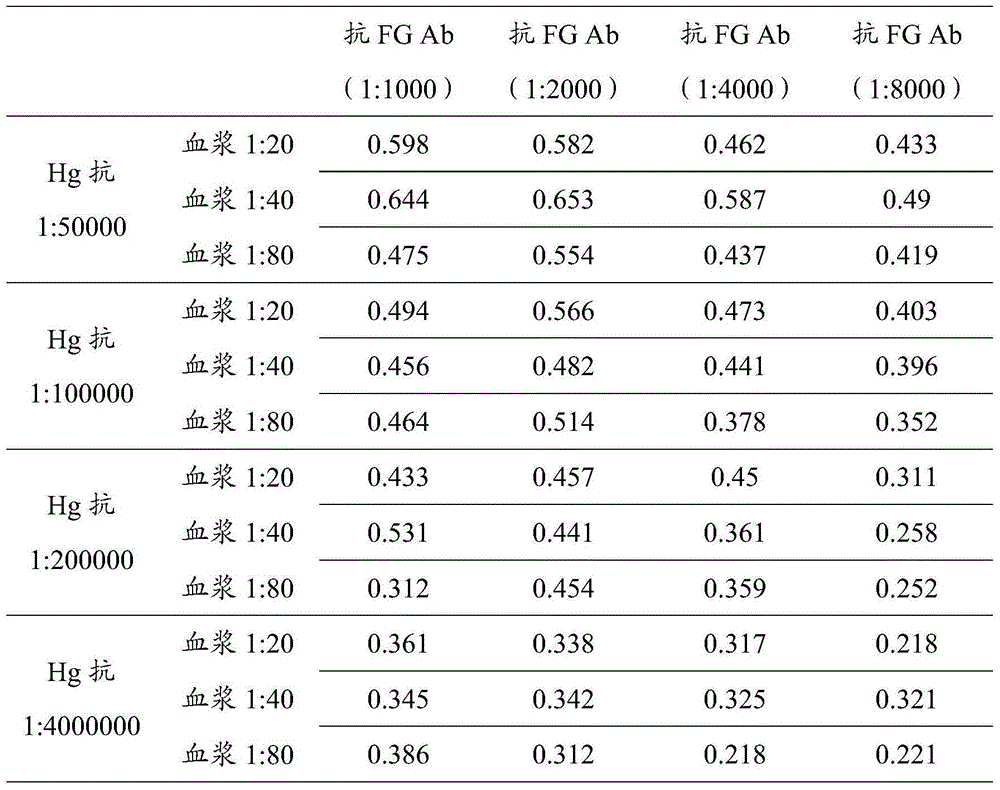

Mercury-fibrinogen chelate and preparation method therefor and application thereof

InactiveCN105001321AImprove accuracyGood repeatabilityFibrinogenPeptide preparation methodsFibrinogenMercury contamination

The present invention discloses a mercury-fibrinogen chelate, a preparation method therefor and an application thereof. The mercury-fibrinogen chelate is obtained by chelating mercury ions with a fibrinogen by a mercapto and / or cysteine residues. The present invention establishes a qualitative and quantitative detection method for the mercury-fibrinogen chelate, so as to quantitatively detect the mercury-fibrinogen chelate in the application of evaluating the mercury contamination degree of a specific region. By quantitatively detecting the mercury-fibrinogen chelate in human serum in the specific region, the mercury contamination influence on human bodies can be reflected indirectly, and the mercury contamination degree of the specific region can be reflected indirectly thereby. The quantitative detection method for the mercury-fibrinogen chelate established in the present invention has much higher accuracy and greatly improved detection repeatability.

Owner:上海拜豪生物科技有限公司

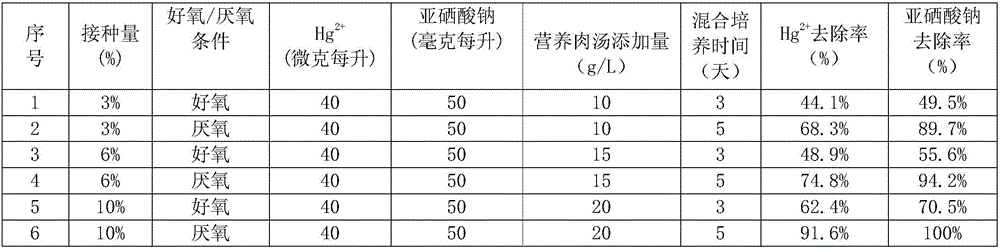

Method for purifying mercury and selenium in sewage through escherichia coli under aerobiotic and anaerobic conditions

InactiveCN105923785AHarm reductionAvoid secondary pollutionWater contaminantsTreatment with aerobic and anaerobic processesBacteroidesEscherichia coli

The invention relates to a method for purifying mercury and selenium in sewage through escherichia coli under the aerobiotic and anaerobic conditions. The method comprises the steps that enrichment culture is conducted on the escherichia coli in a nutrient broth culture medium under the aerobiotic and anaerobic conditions until the escherichia coli is in a stable growth period, then water containing divalent mercury and selenite radicals is inoculated with the escherichia coli, bacterium growth is maintained by taking nutrient broth as nutrition, after the escherichia coli is cultured for several days at room temperature under the aerobiotic and anaerobic conditions, the escherichia coli reduces selenite ions contained in the water into negative bivalent selenium ions, the negative bivalent selenium ions are combined with bivalent mercury ions to generate mercury selenide precipitates, the mercury selenide precipitates can stably exist in a water body without being absorbed and utilized by organisms, therefore, divalent mercury contamination and selenite radical contamination in the water body are simultaneously removed, harm to a human body is reduced, and secondary contamination is avoided. The method has the advantages of being low in cost, wide in application range and the like.

Owner:XINJIANG INST OF ECOLOGY & GEOGRAPHY CHINESE ACAD OF SCI

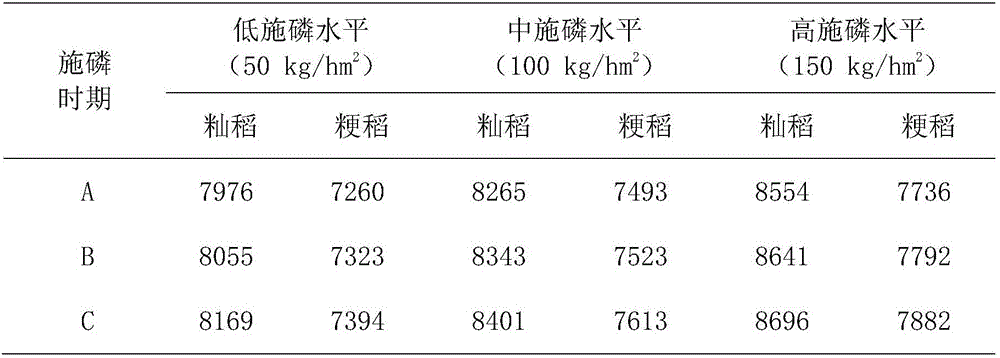

Selenium application method for reducing mercury content of rice grains in rice field with severe mercury contamination

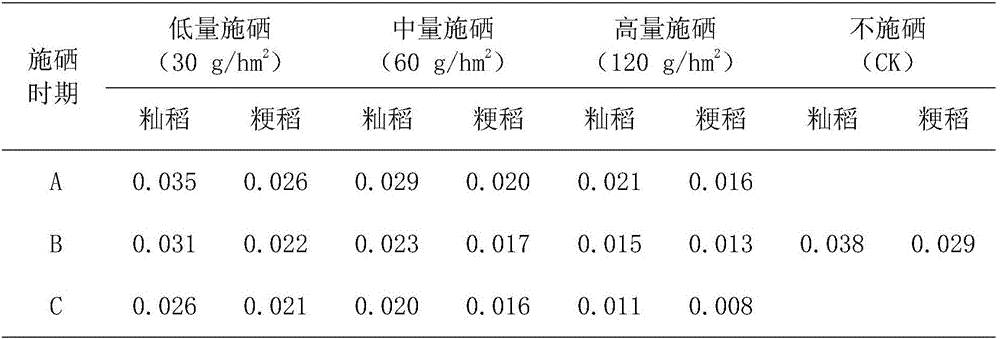

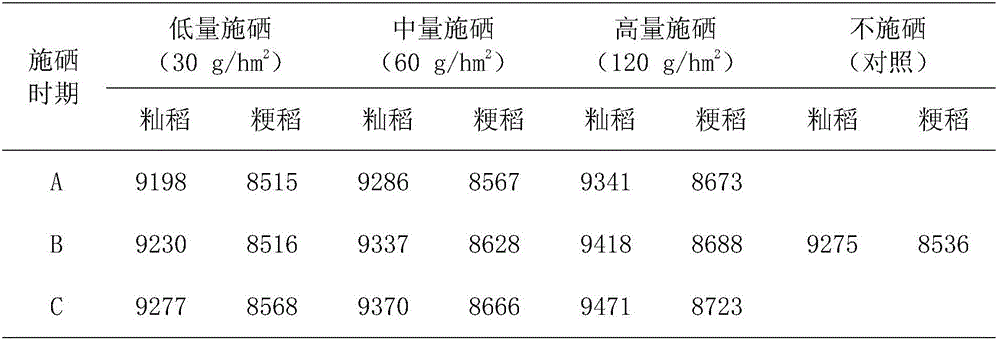

InactiveCN106612833AReduce mercury levelsYield was not significantly affectedFertilising methodsWater solubleJaponica rice

The invention relates to a selenium application method for reducing mercury content of rice grains in a rice field with severe mercury contamination and belongs to the technical field of controlling heavy metal contamination in agricultural products. The method is characterized by applying selenium three times under total application amount of 120 g / hm<2> (high application amount) to a rice field with severe mercury contamination (having soil Hg concentration of 2 mg / kg, four times the national limit standard), to be specific, applying 1 / 2 of total selenium 20 days after rice transplanting, applying 1 / 4 of the total selenium 5 days before heading, and applying 1 / 4 of the total selenium 10 days after heading. Compared with common selenium-free application in actual rice production, the method provides a great decrease in the mercury content of rice grains (71.05% for Indica rice, and 72.41% for Japonica rice).

Owner:CHANGZHOU UNIV

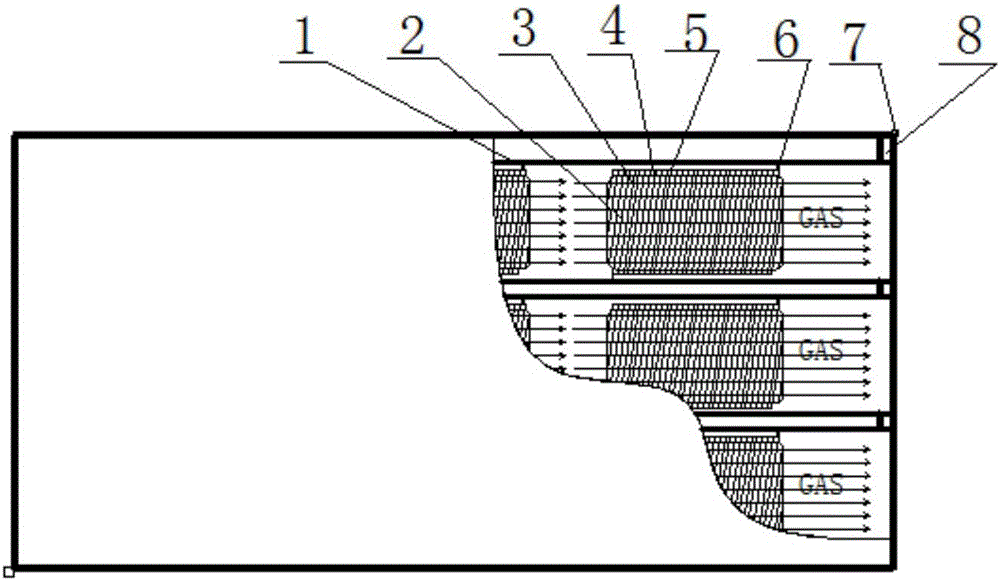

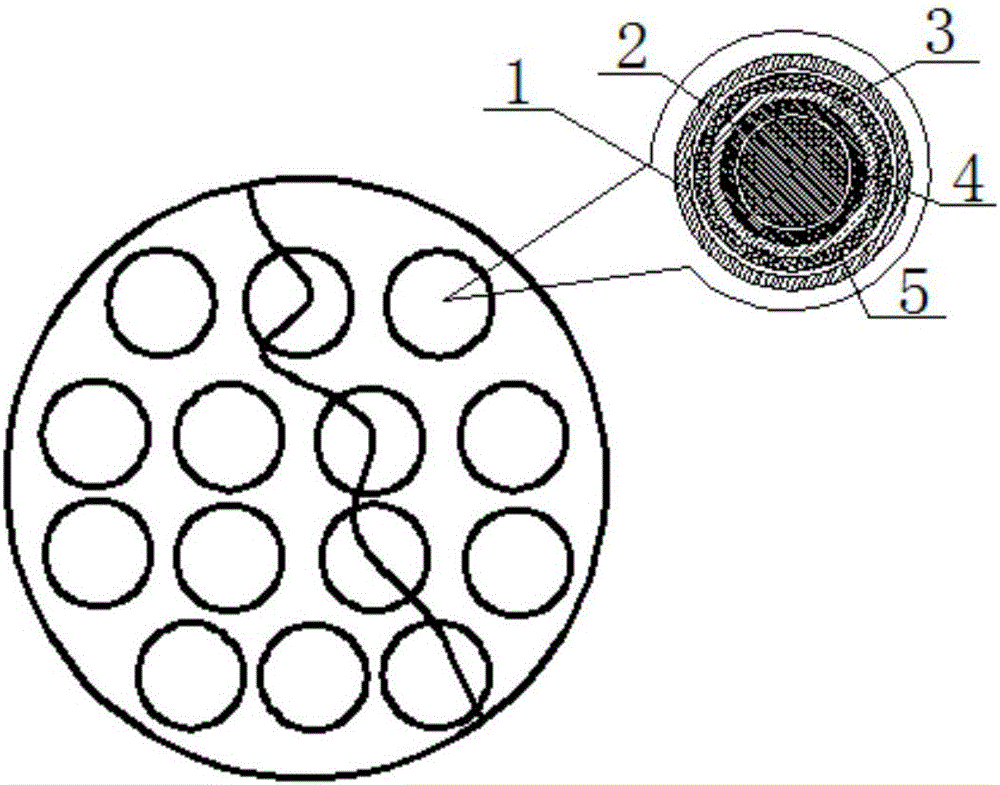

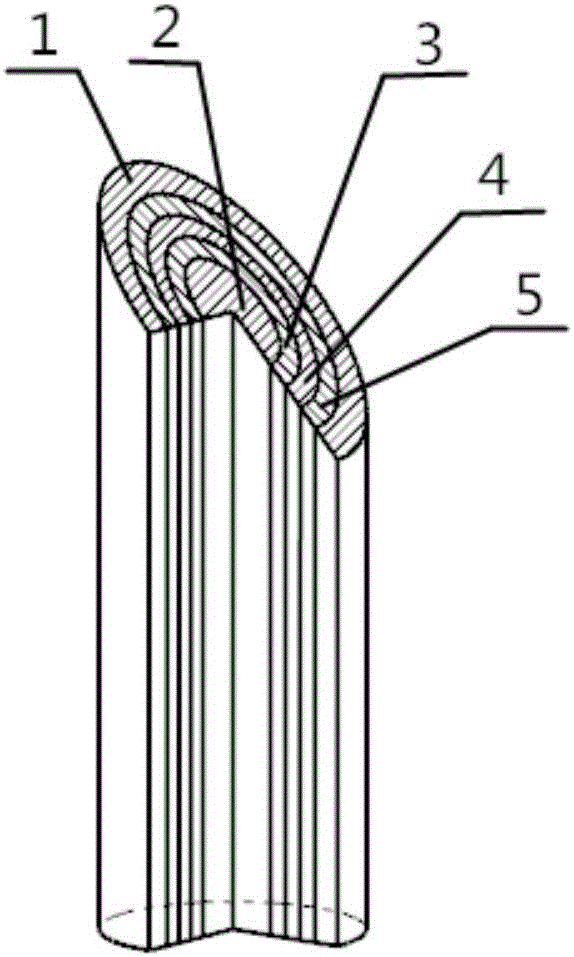

Load plug-in of superfine fiber membrane electrostatic adsorption catalyst and use method of load plug-in

ActiveCN106622038AUniform charge distributionReduce lossChemical/physical processesFiberRates reactions

The invention discloses a load plug-in of a superfine fiber electrostatic adsorption catalyst and a use method of the load plug-in. The load plug-in mainly comprises a mercuric chloride catalyzing particle, an electro-adsorption superfine fiber membrane layer, a catalyst load layer and a static isolating layer, the catalyst load layer covers the surface of the mercuric chloride catalyzing particle, the static isolating layer covers the surface of the catalyst load layer, the electro-adsorption superfine fiber membrane layer is wrapped on the outermost layer, and electro-adsorption superfine fiber membrane electric terminals are arranged at the two ends of a tube plate flange. In the use process, the plug-ins are sequentially arranged in a heat exchanger, the two ends of the tube plate flange are powered on with a direct current power supply, the electro-adsorption superfine fiber membrane electric terminals are arranged at the two ends of the tube plate flange, so that an electric conduction fiber membrane contains even electric charges, finally the mixed gases are introduced into the heat exchanger filled with the mercuric chloride catalyst plug-in, and the gases react with the catalyst when passing through catalyst plug-in. According to the load plug-in of the superfine fiber electrostatic adsorption catalyst and the use method of the load plug-in, the use efficiency of the catalyst is improved, the reaction speed is increased, and the mercury contamination and treatment are also reduced.

Owner:BEIJING UNIV OF CHEM TECH

Treatment method for methyl mercury polluted water

InactiveCN104108815AAchieve regenerationDecomposition of molecular structureWater contaminantsWater/sewage treatment by ion-exchangeMethylmercuryEnvironmental engineering

The invention discloses a treatment method for methyl mercury polluted water. The treatment method comprises the following steps: introducing water containing methyl mercury into a cationic resin exchanger, and stopping exchanging when the concentration of methyl mercury in a water solution flowing from the cationic resin exchanger is greater than 0.00005mg / L; taking out cationic resin, utilizing a saturated sodium chloride mixed liquor of 8-12% stannous chloride as regenerated liquid, and performing regeneration under a mixing condition, wherein the ratio of the regenerated liquid to the resin is (1-2) to 5, the mixing time is 40-60 minutes, and the temperature is 40-45 DEG C; separating the resin from mercury-containing liquid after regeneration is ended, returning the regenerated resin to the resin exchanger to recycle, and feeding the mercury-containing liquid into a sedimentation basin; adjusting the pH of the obtained mercury-containing liquid to be greater than 10 by using sodium hydroxide, and filtering the mercury-containing liquid to obtain mercury-containing sediments; smelting the mercury-containing sediments by using a smelting furnace at high temperature of 560 DEG C, recovering mercury vapor, and condensing the vapor, so as to obtain a metal mercury product. By adopting the treatment method, methyl mercury pollution in water can be removed, and the methyl mercury can be converted into metal mercury to recycle.

Owner:何华

A method for efficiently repairing mercury-contaminated soil by leaching and a leaching agent

ActiveCN107457258BEfficient elutionImprove removal abilityContaminated soil reclamationOrganic acidSoil science

The invention discloses a method for efficient remediation of mercury-contaminated soil by leaching and a leaching agent. The leaching agent is composed of an oxidizing agent, a leaching solution I and a leaching solution II, wherein the oxidizing agent is a persulfate solution, a solute of the leaching solution I is composed of organic acid, iodized salt and chloride salt, and a solute of the leaching solution II is composed of sodium sulfide and sodium hydroxide. The method for leaching the mercury-contaminated soil by adopting the leaching agent comprises the steps that oxidation treatment is carried out on the mercury-contaminated soil, and then the mercury-contaminated soil is sequentially subjected to leaching by adopting the leaching solution I and the leaching solution II. The method has the advantages that efficient elution of mercury with various valence state in the mercury-contaminated soil can be realized, mercury residues are little, in addition, secondary pollution to the environment can be avoided, and the cost is low.

Owner:AEROSPACE KAITIAN ENVIRONMENTAL TECH CO LTD

Environment-friendly mercury-free catalyst for synthesizing vinyl chloride and preparation method thereof

ActiveCN113385202AReduce pollutionHarm reductionPreparation by halogen halide additionCatalyst activation/preparationActivated carbonPtru catalyst

The invention discloses a mercury-free catalyst for synthesizing vinyl chloride and a preparation method thereof. The mercury-free catalyst comprises an active component, a first auxiliary agent, a second auxiliary agent and a carrier, the active component is a copper salt, the first auxiliary agent is a tin salt, and the second auxiliary agent is a platinum salt; the carrier is coal-based activated carbon; and according to the mass percentage, the active component accounts for 10%-30% of the mass of the catalyst, the first auxiliary agent accounts for 1%-10% of the mass of the catalyst, and the second auxiliary agent accounts for 0.01%-0.1% of the mass of the catalyst. According to the catalyst, metal copper is used as a main active component, tin and platinum are used as the auxiliary agents, the three components interact with each other, the activity of the catalyst can be effectively improved, the stability of the catalyst is improved, mercury pollution is reduced, the preparation mode is simple, and industrialization is easy to achieve.

Owner:内蒙古瑞翔拓创新材料有限公司

A kind of treatment method of mercury polluted water

ActiveCN104150634BReduce mercury levelsProcessing speedWater contaminantsMultistage water/sewage treatmentHydrogen SulfateP-tert-Butylphenol

The invention relates to the field of water treatment, and in particular relates to a treatment method of water polluted by mercury. The method comprises the following steps: (1) regulating the pH value of mercury-containing sewage to be 6-6.5, and adding sodium alcohol ether sulfate and sodium hypochlorite into the mercury-containing sewage, wherein the additive amount of sodium alcohol ether sulfate accounts for 1-2 times of the mass concentration of mercury in the sewage, and the additive amount of sodium hypochlorite accounts for 3-5 times of the mass concentration of mercury in the sewage; (2) regulating the pH value of the sewage to be 8-9, and then adding poly p-tert-butylphenol disulfide, ferrous sulfide and sodium hydrogen sulfate into the sewage under the conditions that the mass ratio of p-tert-butylphenol disulfide to ferrous sulfide to sodium hydrogen sulfate is (1-2) to (2-4) to 5, and the mass concentration of poly p-tert-butylphenol disulfide in the sewage is 1-5%; (3) then adding a flocculating agent, calcium oxide and alkylphenol polyoxyethylene into the sewage under the conditions that the mass ratio of the flocculating agent to calcium oxide to alkylphenol polyoxyethylene is 1 to 3 to 2, and the additive quantity of the flocculating agent is 0.1-0.3% of the quantity of the sewage; (4) standing the sewage for 3-5 days in a separation tank, and then performing solid-liquid separation; (5) adsorbing the separated sewage by adopting an activated carbon absorber, and then discharging the sewage.

Owner:ZHEJIANG OCEAN UNIV

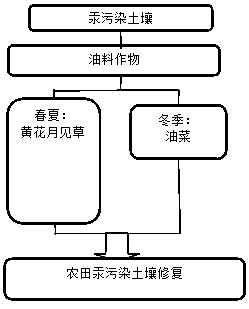

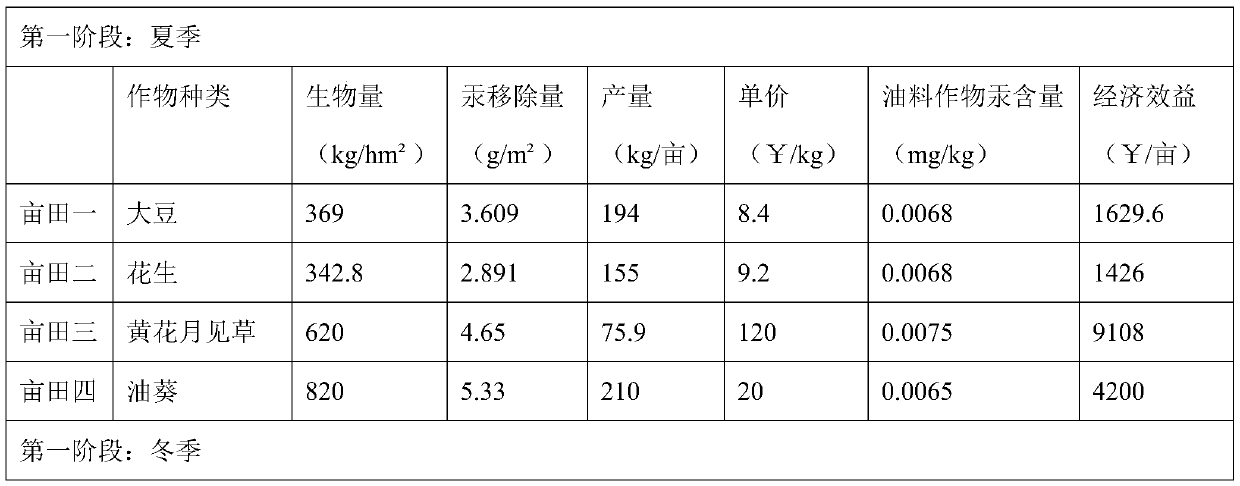

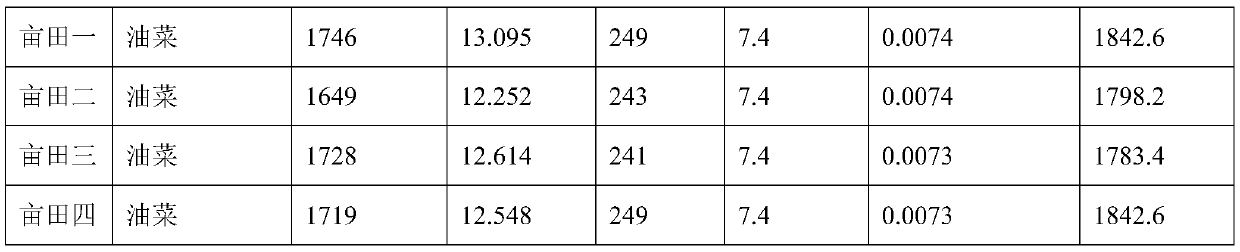

Method for safely utilizing mercury-contaminated soil

InactiveCN111438181AIncrease profitReduce risk of migrationContaminated soil reclamationBiologyOenothera glazioviana

The invention discloses a method for safely utilizing mercury-contaminated soil. According to the method, the mercury-contaminated soil is reasonably and safely utilized and the remediation effect ofthe mercury-contaminated soil can be realized. The method specifically comprises the following steps: in mercury-contaminated farmlands in the Yangtze River basin, a crop rotation mode of planting oilseed rape in winter and planting oenothera biennis, or oil sunflower, or soybean, or peanut and other oil crops in summer is adopted, the mercury content of edible parts of crops is ensured to be in asafe range by utilizing the mercury element enrichment difference of different crops and the accumulation difference of mercury in the edible parts; meanwhile, the accumulation effect of non-edible parts (high biomass) of the selected crops on mercury is utilized, and the effect of removing and repairing mercury in soil is achieved. The method aims to ensure the edible safety of agricultural products while repairing the mercury-contaminated soil, improve the utilization and repair efficiency of the mercury-contaminated soil, relieve the conditions of shortage of cultivated land resources andsevere safety situation of grains and foods in China, and create good economic, social and ecological benefits.

Owner:JIANGSU GEOLOGICAL SURVEY INST +1

Closed in-situ leaching, extracting and stabilizing remediation method for mercury-contaminated soil

InactiveCN111659721ASolve the problem of mercury secondary pollution diffusionSolve the problem of secondary pollution diffusionContaminated soil reclamationSoil scienceFiltration

The invention relates to a closed in-situ leaching, extracting, stabilizing, solidifying and repairing process method for mercury-contaminated soil. Based on a place with serious soil mercury pollution, a curtain grouting method is firstly adopted to form a continuous closed impermeable shell at the bottom and the periphery of a mercury-polluted soil area, then a vertical suction filtration pipe system is arranged in the closed mercury-polluted soil, and a leaching liquid A and a leaching liquid B are respectively sprinkled, permeated and leached from the surface of the soil and are extractedfrom the bottom of the impermeable shell through a suction filtration system; and after the soil is leached, a mercury passivator C and a curing agent D are fully and uniformly mixed with the soil byadopting large jet grouting pile stirring equipment to form a stable mercury compound, and the mercury compound and the soil are cured together to form a stable soil body structure which is safe and reliable for a long time. The method is especially suitable for in-situ treatment and soil remediation engineering of soil mercury heavy pollution caused by industrial production and mercury leakage, and is also suitable for remediation of soil heavily polluted by other heavy metals.

Owner:北京万之悦科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com