Load plug-in of superfine fiber membrane electrostatic adsorption catalyst and use method of load plug-in

An electrostatic adsorption and ultra-fine fiber technology, applied in chemical instruments and methods, chemical/physical processes, etc., can solve problems such as insufficient contact between gas and catalyst, loss of mercuric chloride catalyst, complexity of mercury removal process, etc., to avoid Sublimation of mercuric chloride, prevention of sublimation of mercuric chloride, and effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

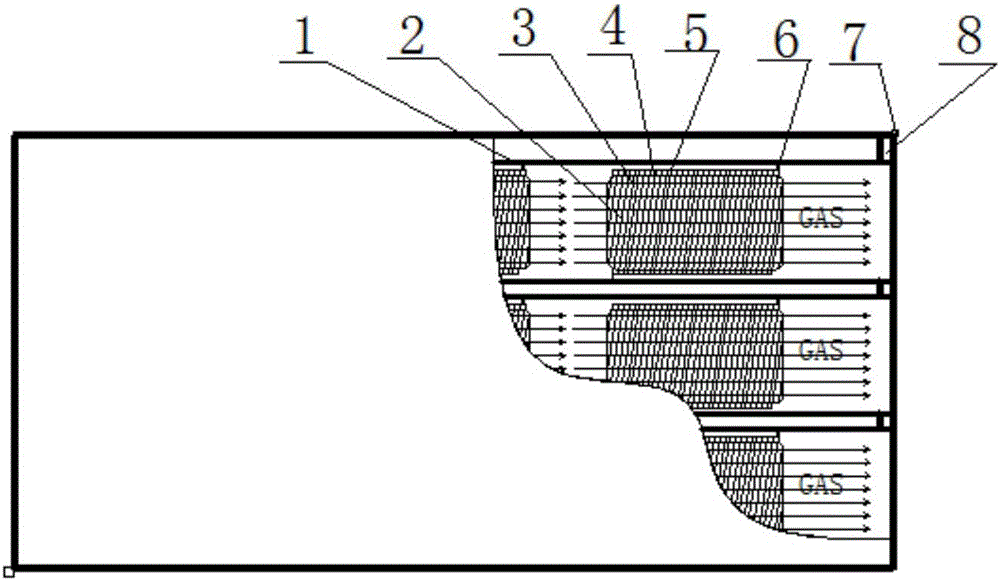

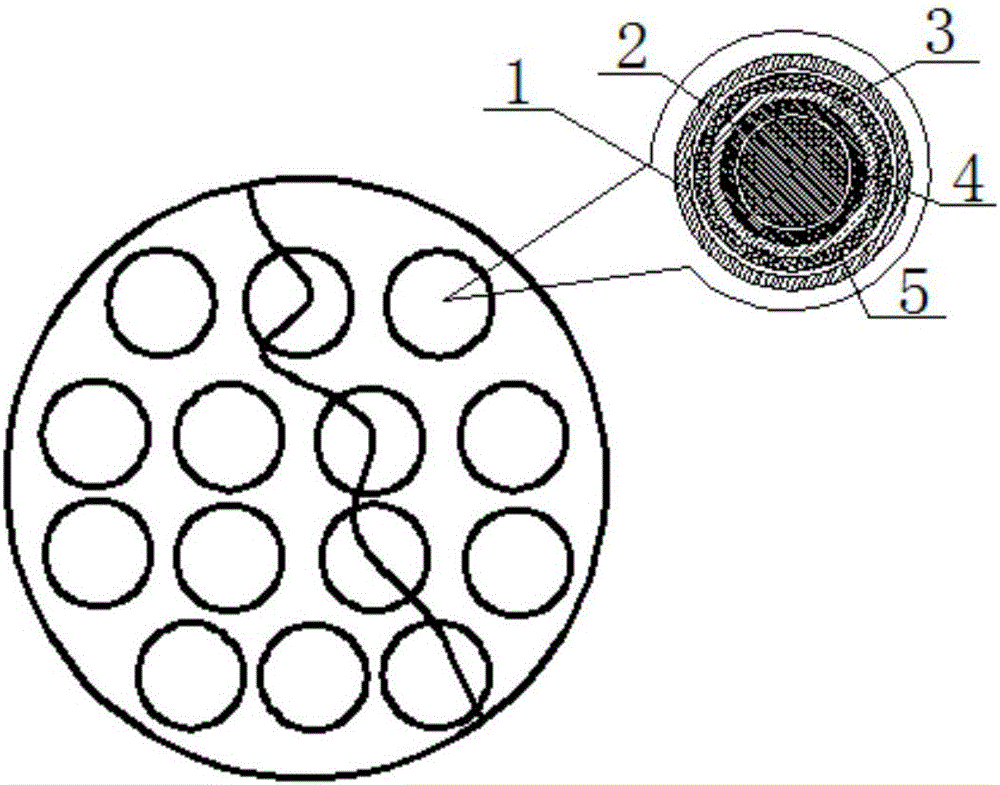

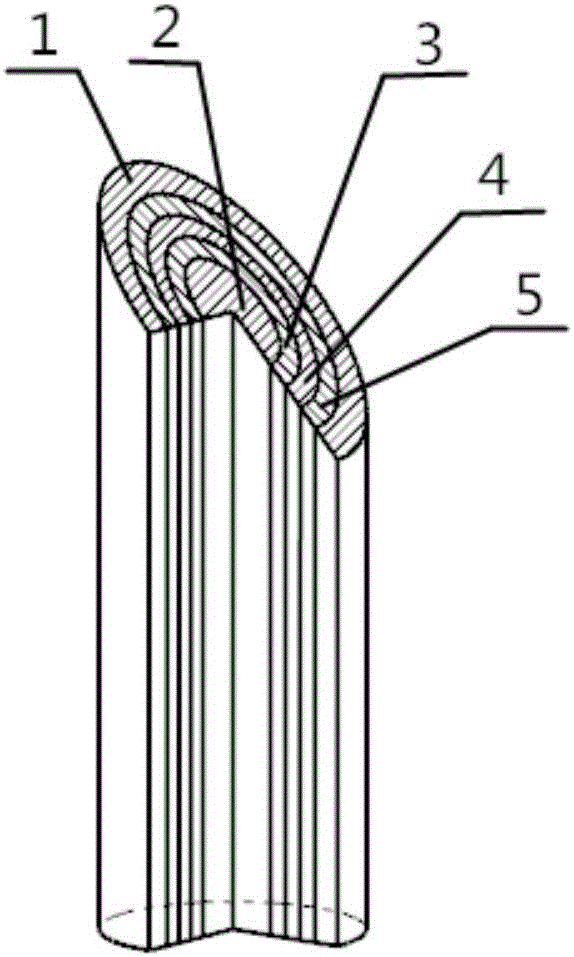

[0025] like figure 1 , the mercuric chloride catalyst is placed in the middle of the double-layer polytetrafluoroethylene (PTFE) microfiber support membrane 3, and one deck electrostatic isolation layer 4 is encapsulated in the outer layer of the load membrane (the isolation layer comprises an insulating layer and a shielding layer), and the electrostatic The outer side of the isolation layer 4 is encapsulated by the electro-adsorption microfiber film layer 5, and the whole is made into a cylindrical shape, which forms a clearance fit with the inner diameter of the heat exchange tube 1, and 20 catalyst inserts (such as figure 1 ), the length of the heat exchange tube is 3 meters, and the tube sheet flange 8 is connected to 24V direct current. In the PVC production process, the catalyst insert is placed in the reaction device where the mixed gas of hydrogen chloride and ethylene passes through, and the conductive microfiber membrane is energized. After a month of testing, the f...

Embodiment 2

[0027] like figure 1, the mercuric chloride catalyst particle that will be placed in activated carbon is wrapped with polytetrafluoroethylene (PTFFE) superfine fiber support film 3, and one deck static isolation layer 4 is encapsulated in the outer layer of support film (separation layer comprises insulating layer and shielding layer ), the outer side of the electrostatic isolation layer 4 is encapsulated by the electro-adsorption microfiber film layer 5, and the whole is made into a cylindrical shape, which forms a clearance fit with the inner diameter of the heat exchange tube 1, and 20 catalyst inserts are placed in each heat exchange tube, and the heat exchange The length of the tube is 3 meters, and the tube plate flange 8 is connected to 24V direct current. In the PVC production process, the catalyst insert is placed in the reaction device where the mixed gas of hydrogen chloride and ethylene passes, and the conductive microfiber membrane is energized. After a month of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com