Patents

Literature

118results about How to "Avoid sublimation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

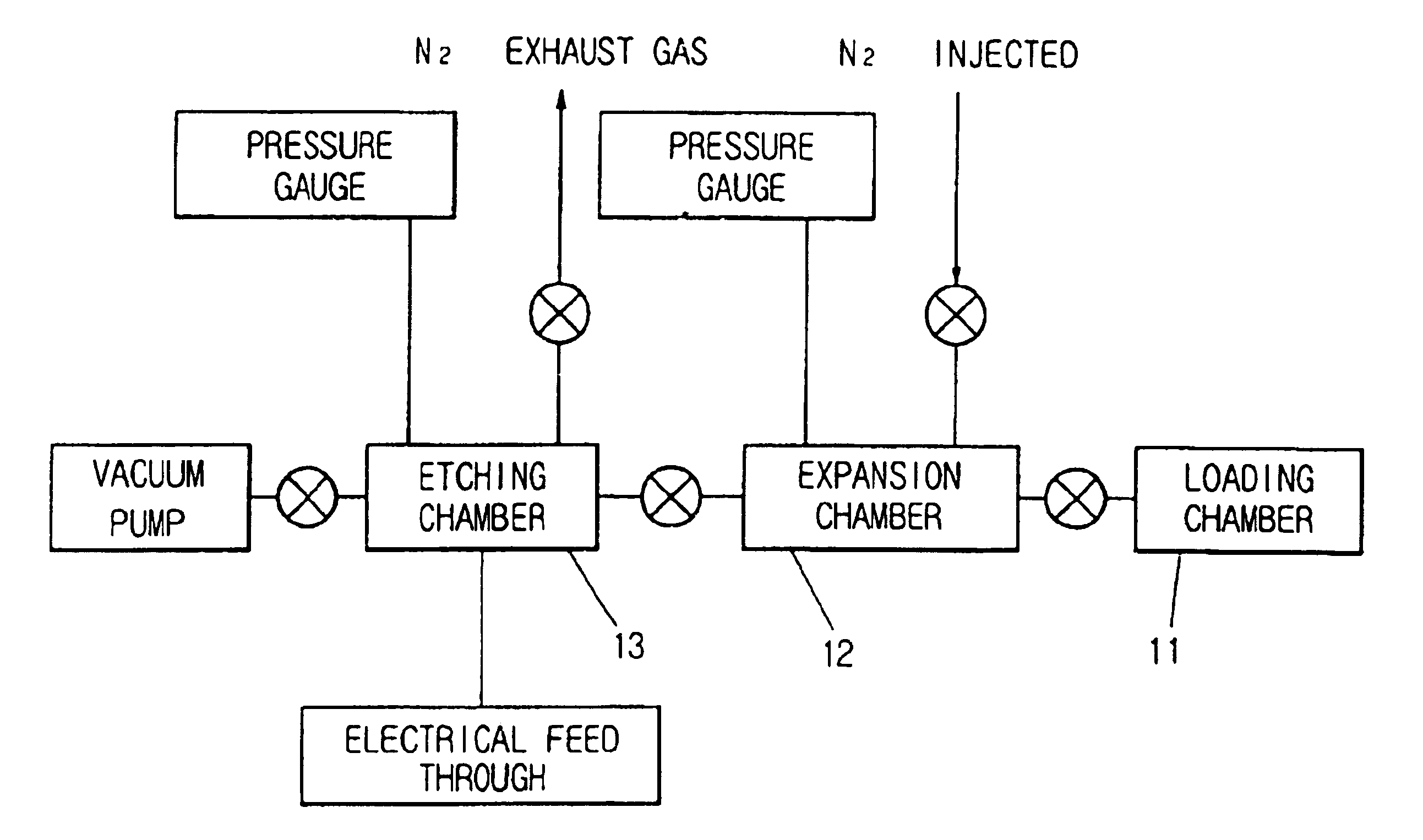

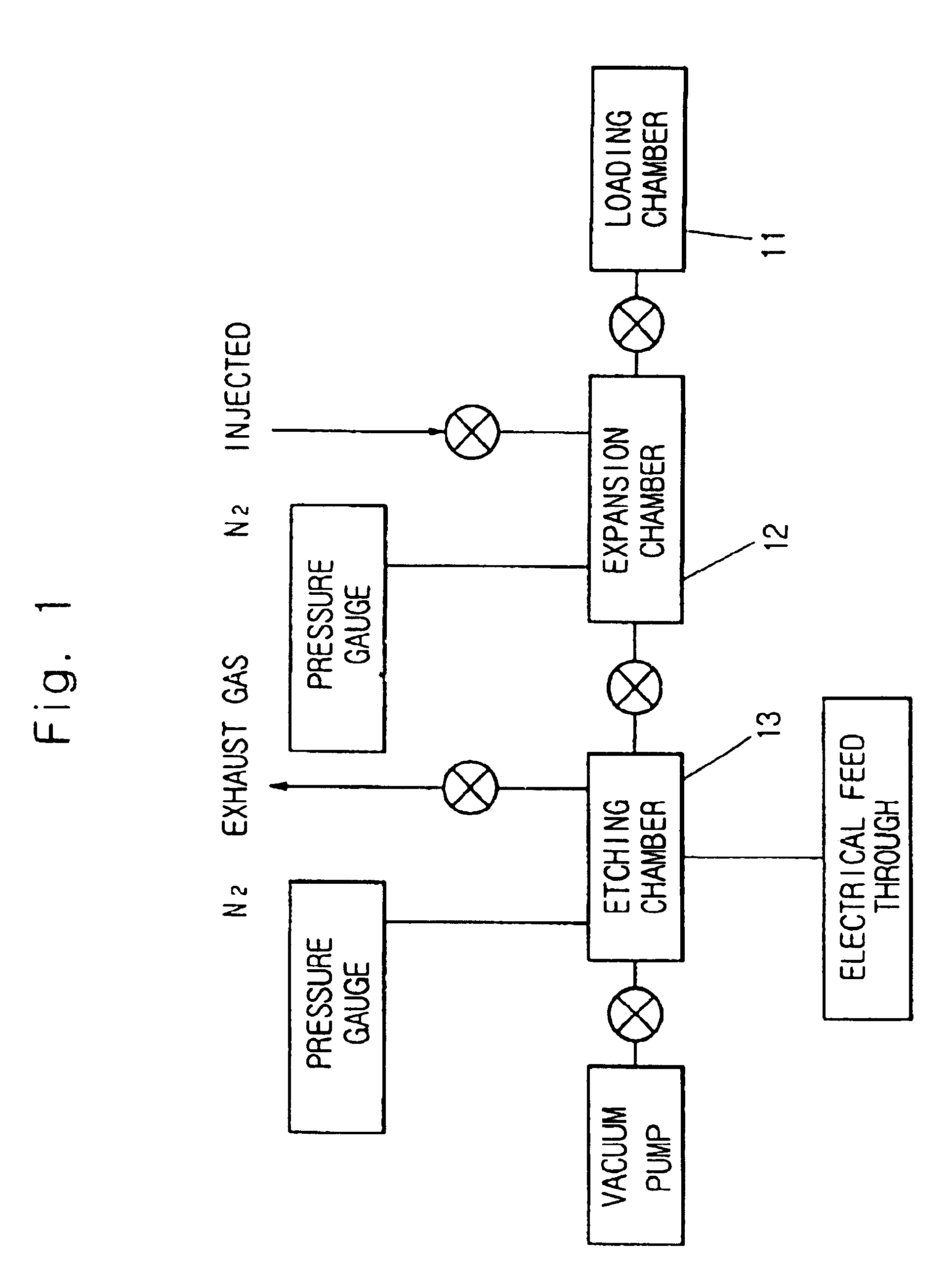

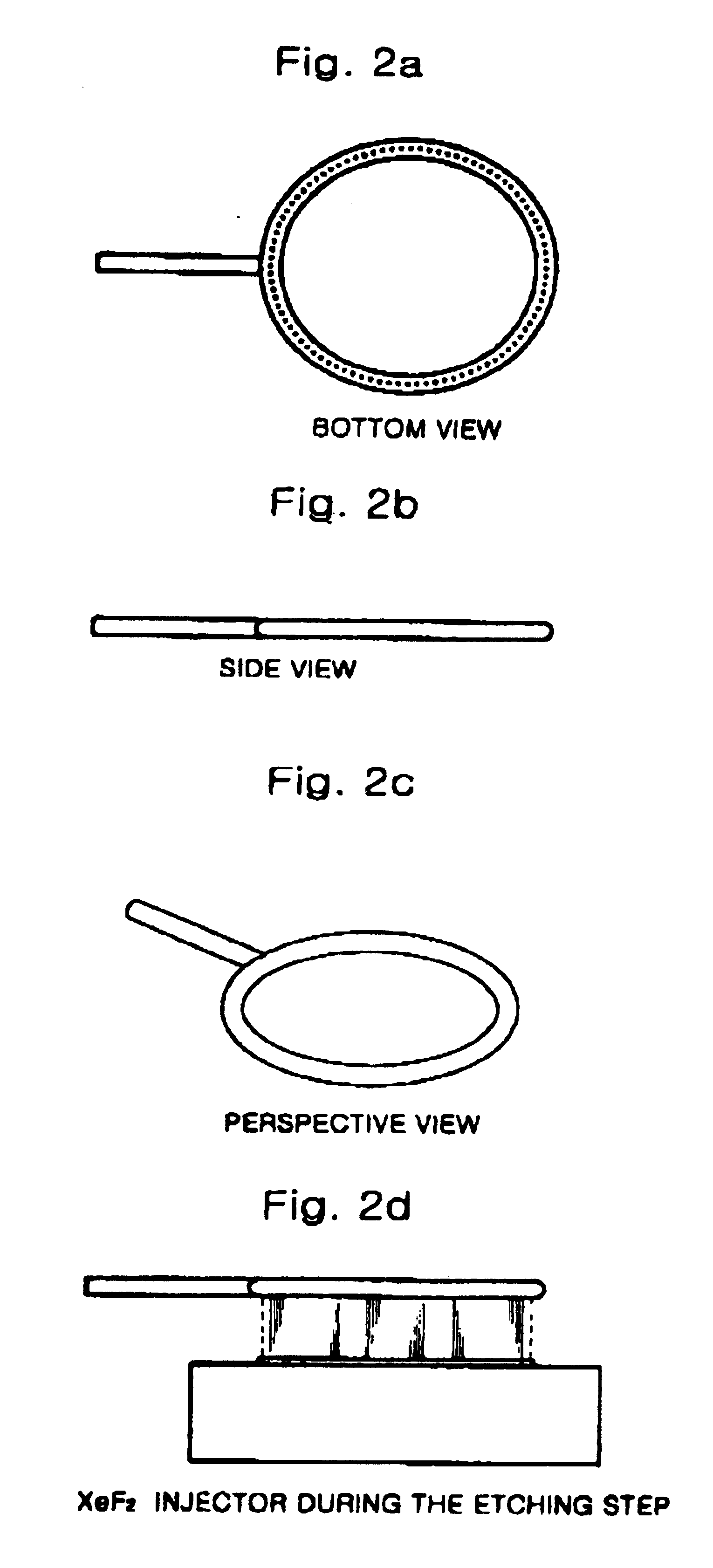

Silicon etching apparatus using XeF2

InactiveUS6736987B1Minimize damageUniform etchingVacuum gauge using ionisation effectsDecorative surface effectsInternal pressureFeedback controller

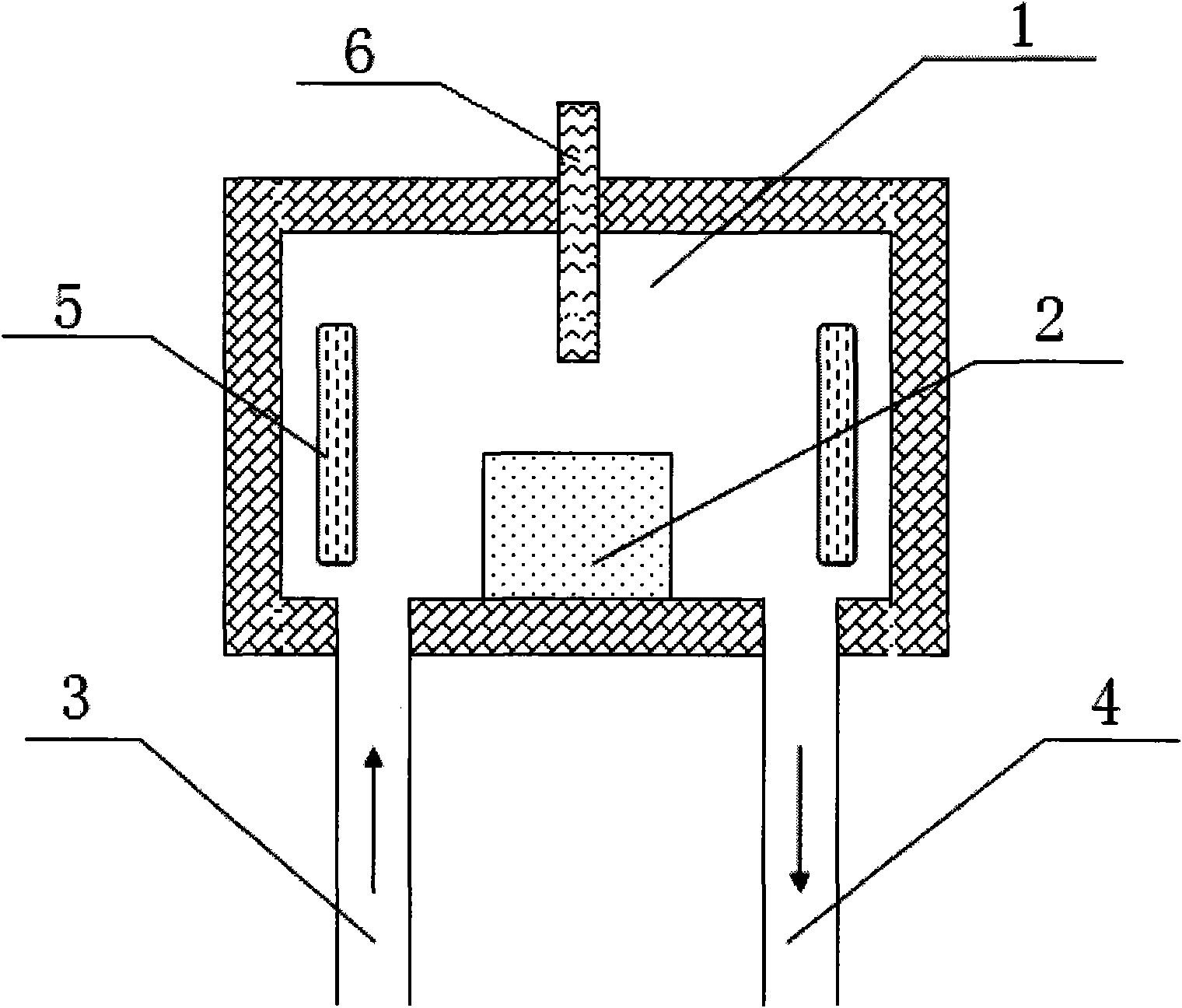

The silicon etching apparatus using XeF2 includes: a basic structure composed of a loading chamber tot loading XeF2, an expansion chamber for collecting sublimated XeF2 gas, and an etching chamber for performing an etching process; and a means for injecting nitrogen prior to the etching process to eliminate air moisture in the apparatus and thus preventing the formation of HF. The silicon etching apparatus using XeF2 further includes: an injector having a predefined shape provided in the etching chamber for uniformly injecting the XeF2 gas downward on to surface of a wafer; a feedback controller for feedback controlling the internal pressure of the loading chamber in order to prevent sublimation of the residual XeF2 in the loading chamber; and a weight scale for measuring the weight of XeF2 in the loading chamber.

Owner:TECHBANK

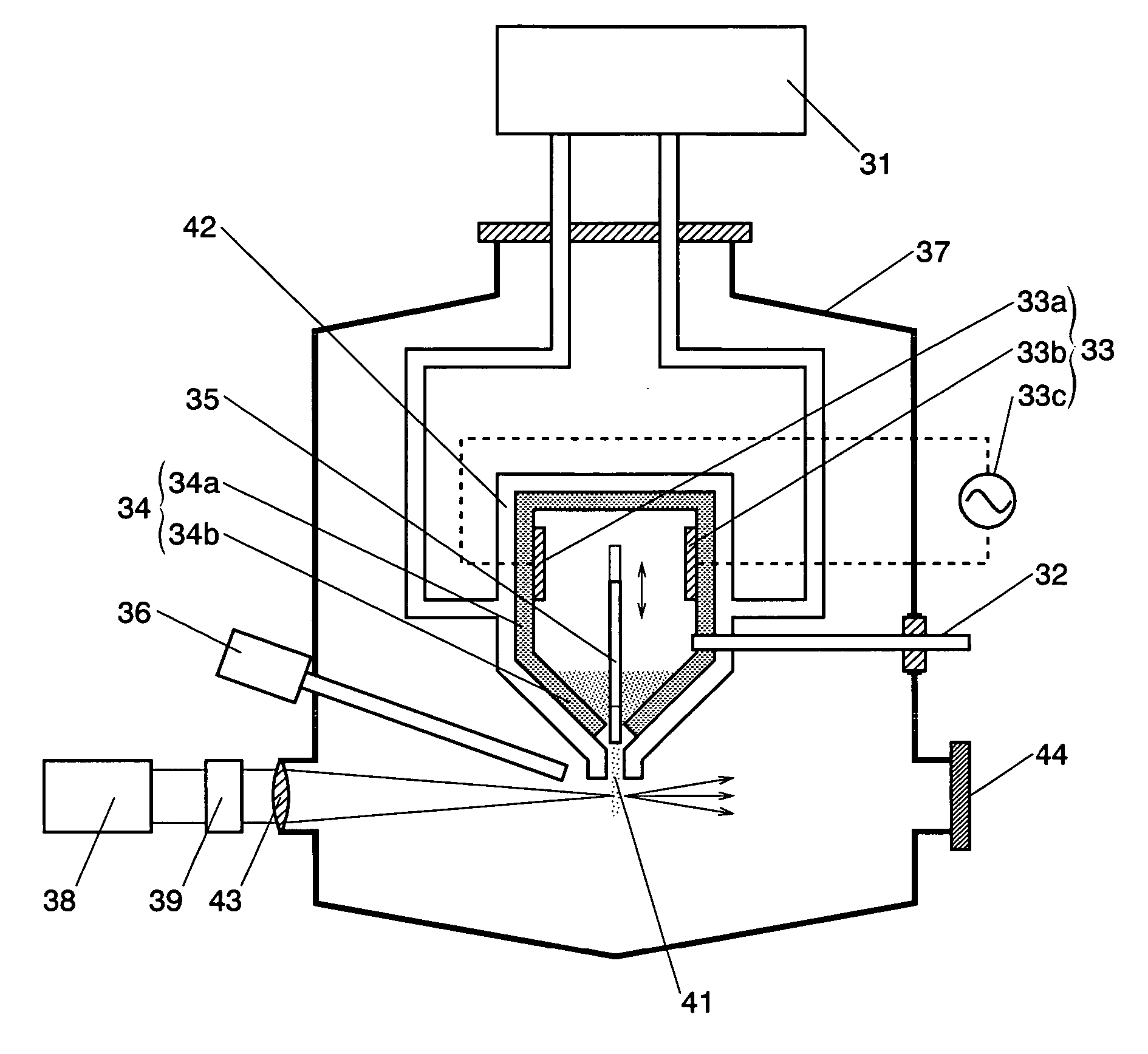

Extreme ultraviolet light source and extreme ultraviolet light source target

ActiveUS20060133574A1Avoid sublimationImprove efficiencyNanoinformaticsPhotomechanical exposure apparatusAbsorbed energyVolumetric Mass Density

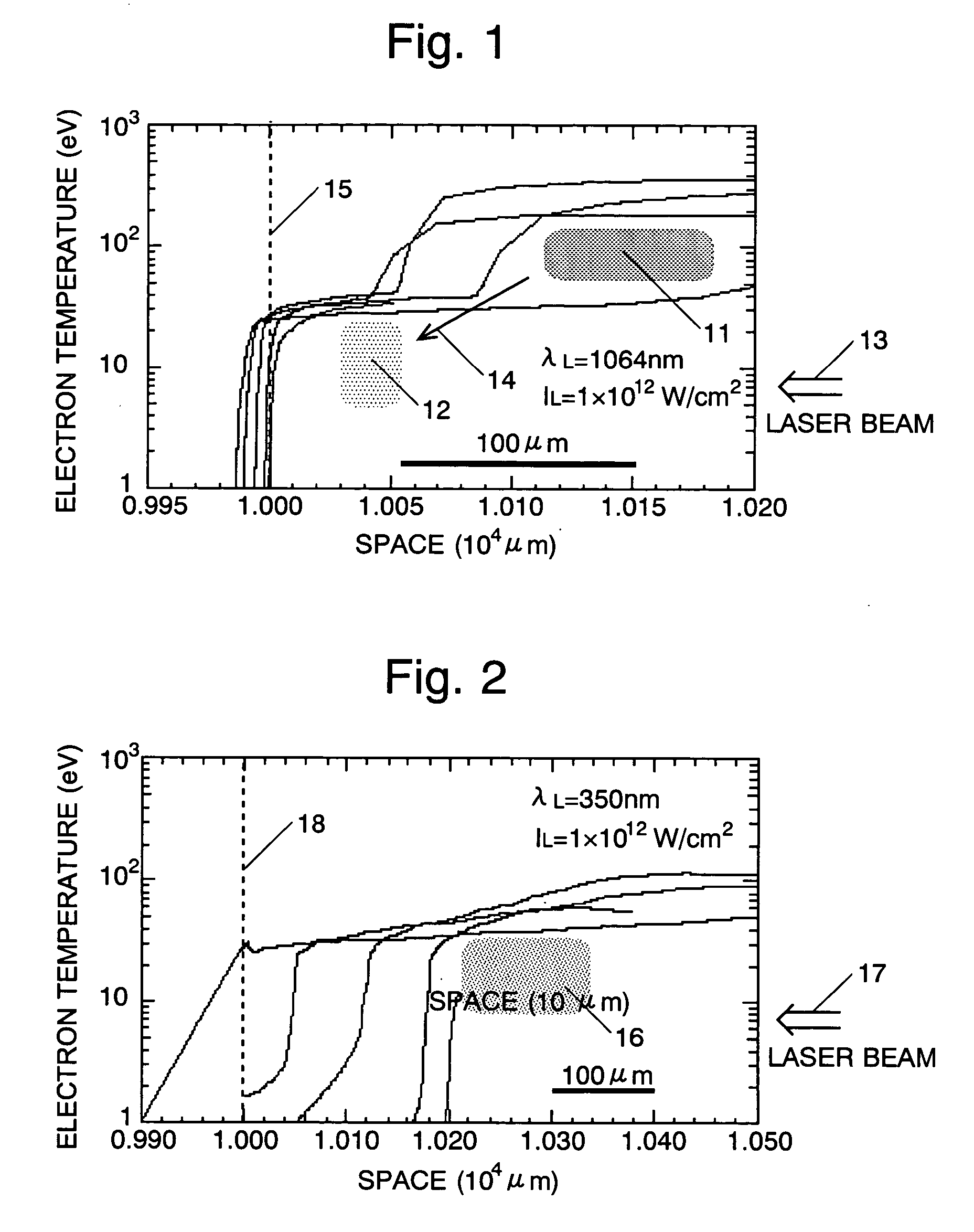

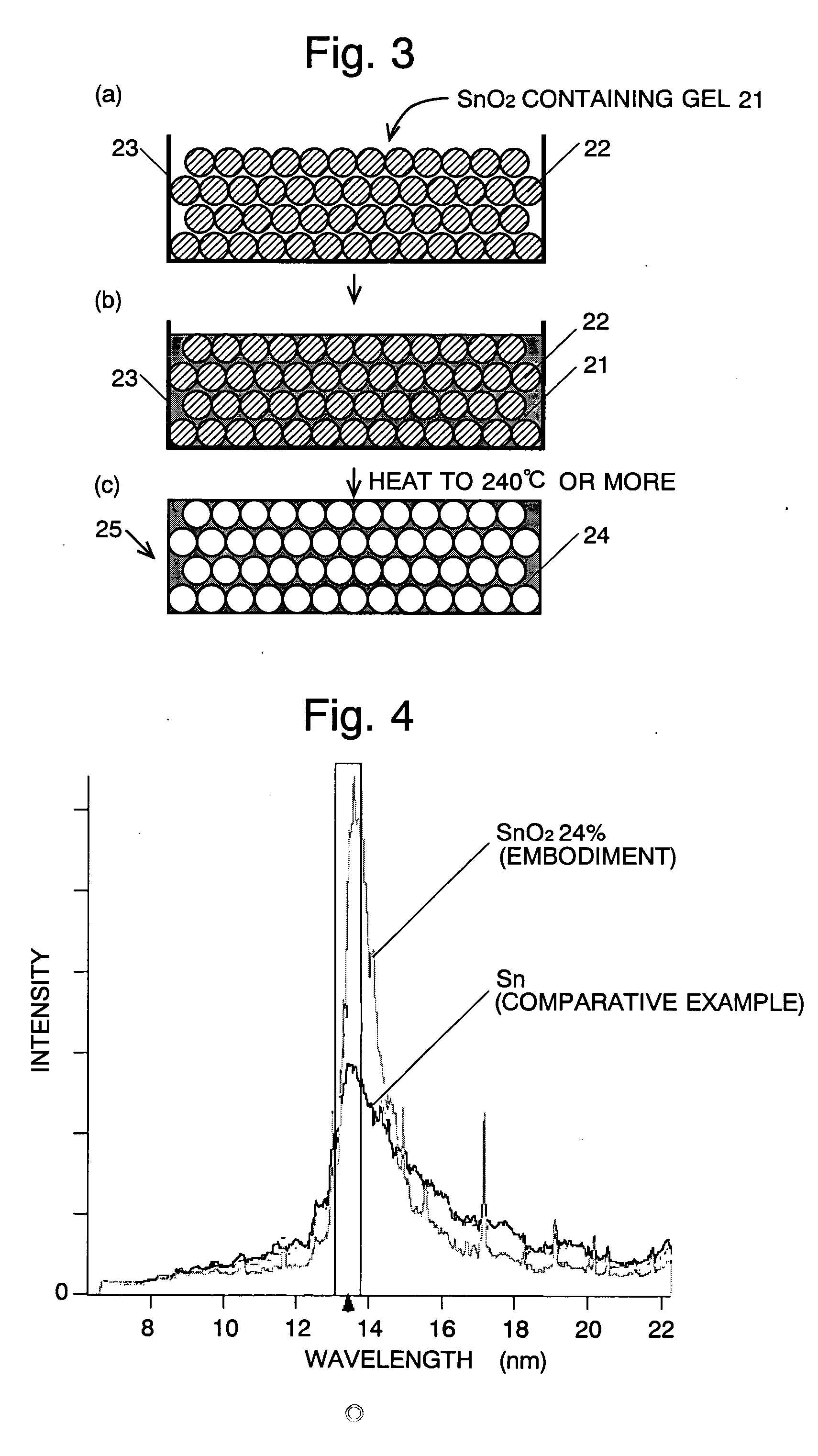

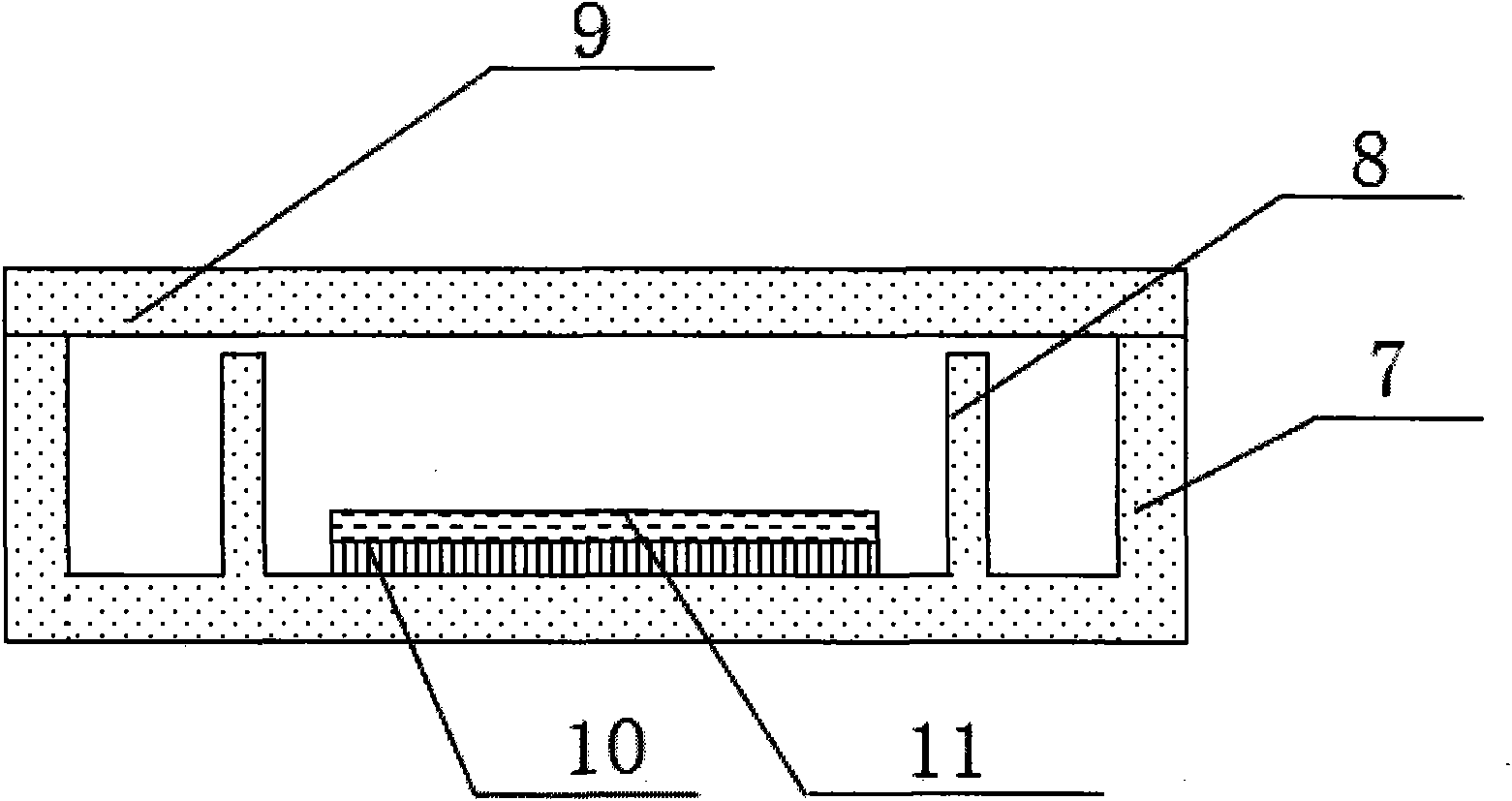

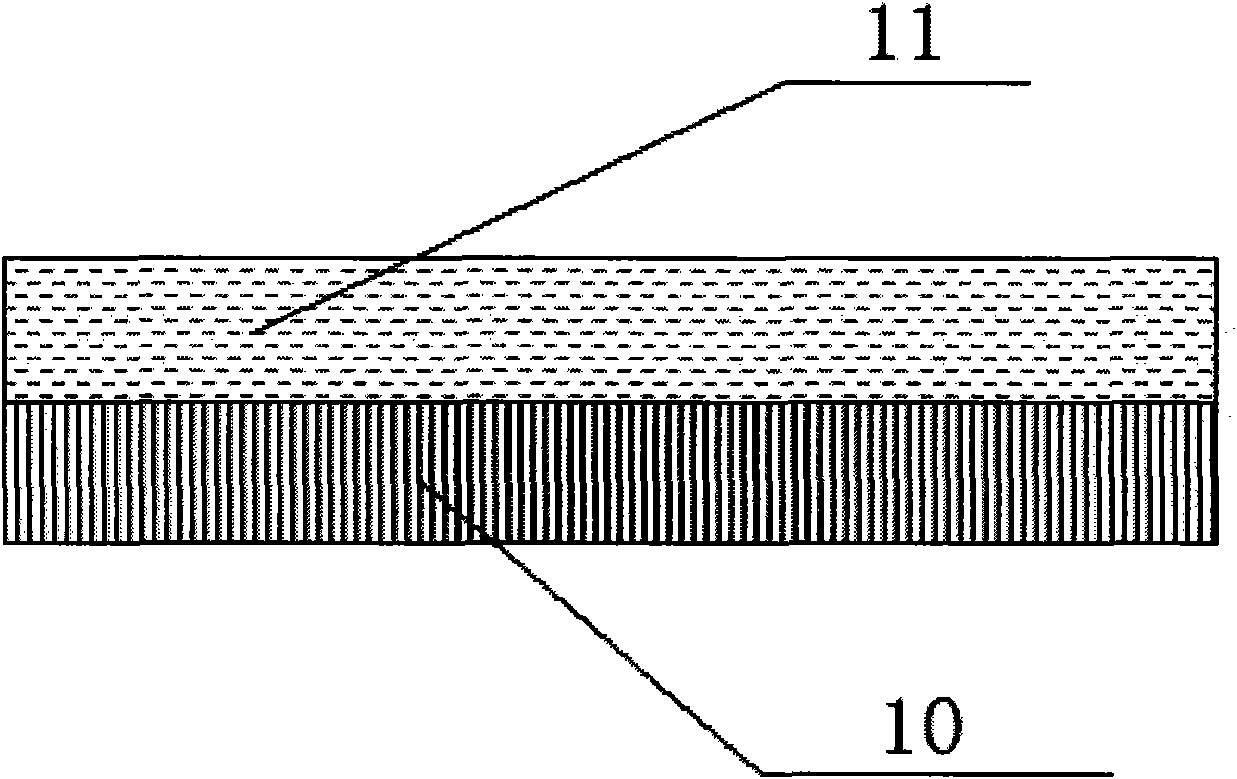

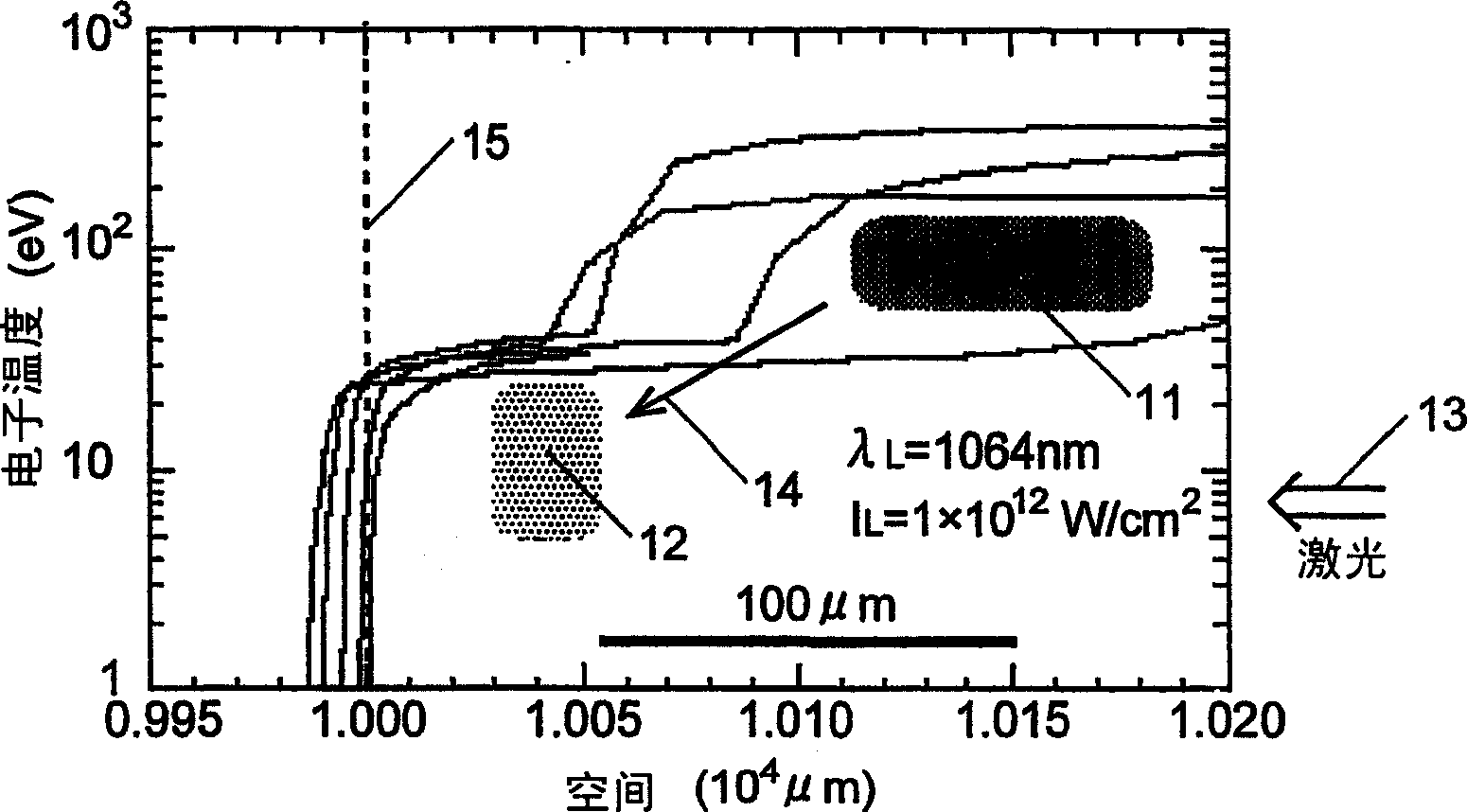

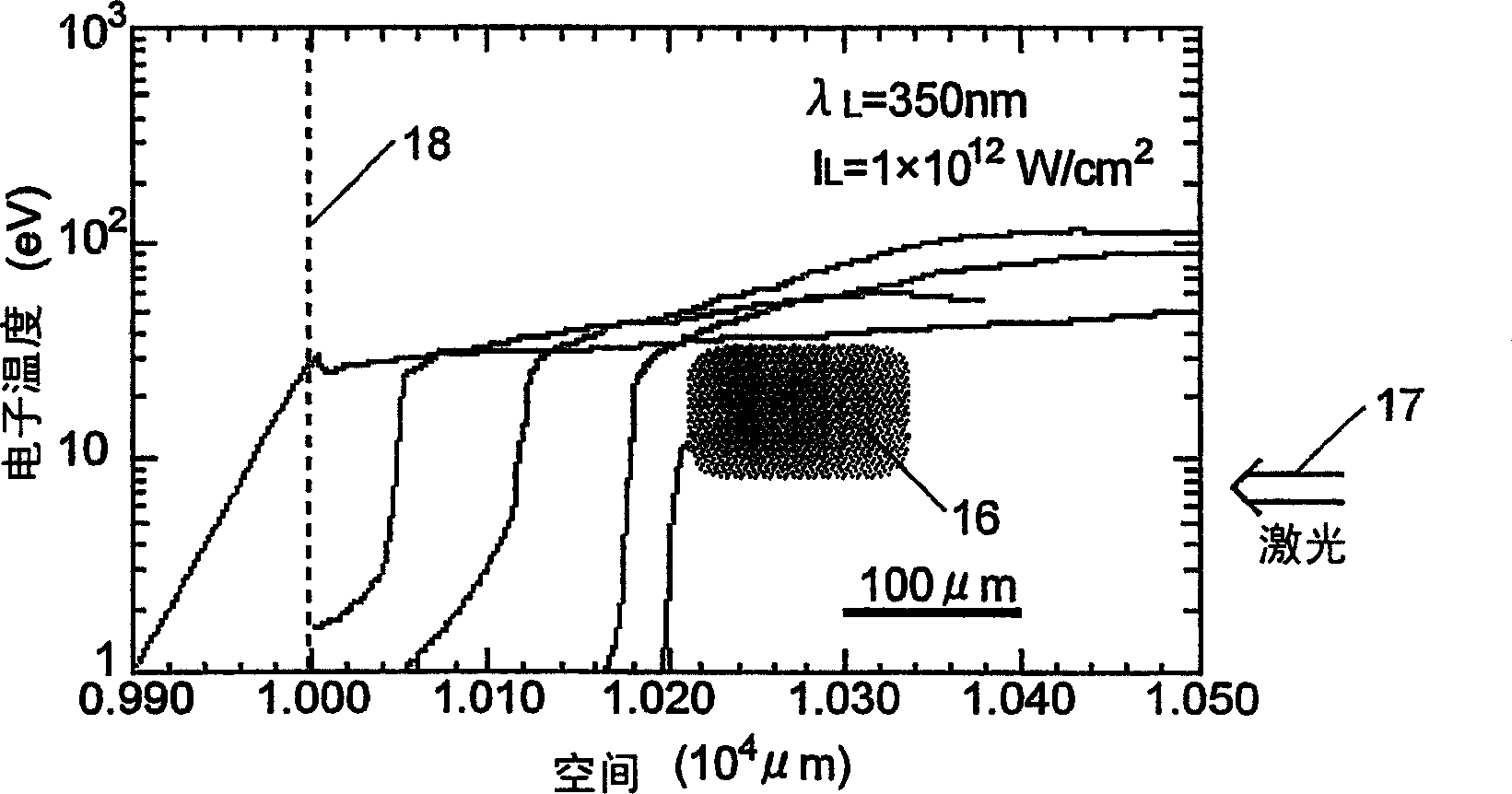

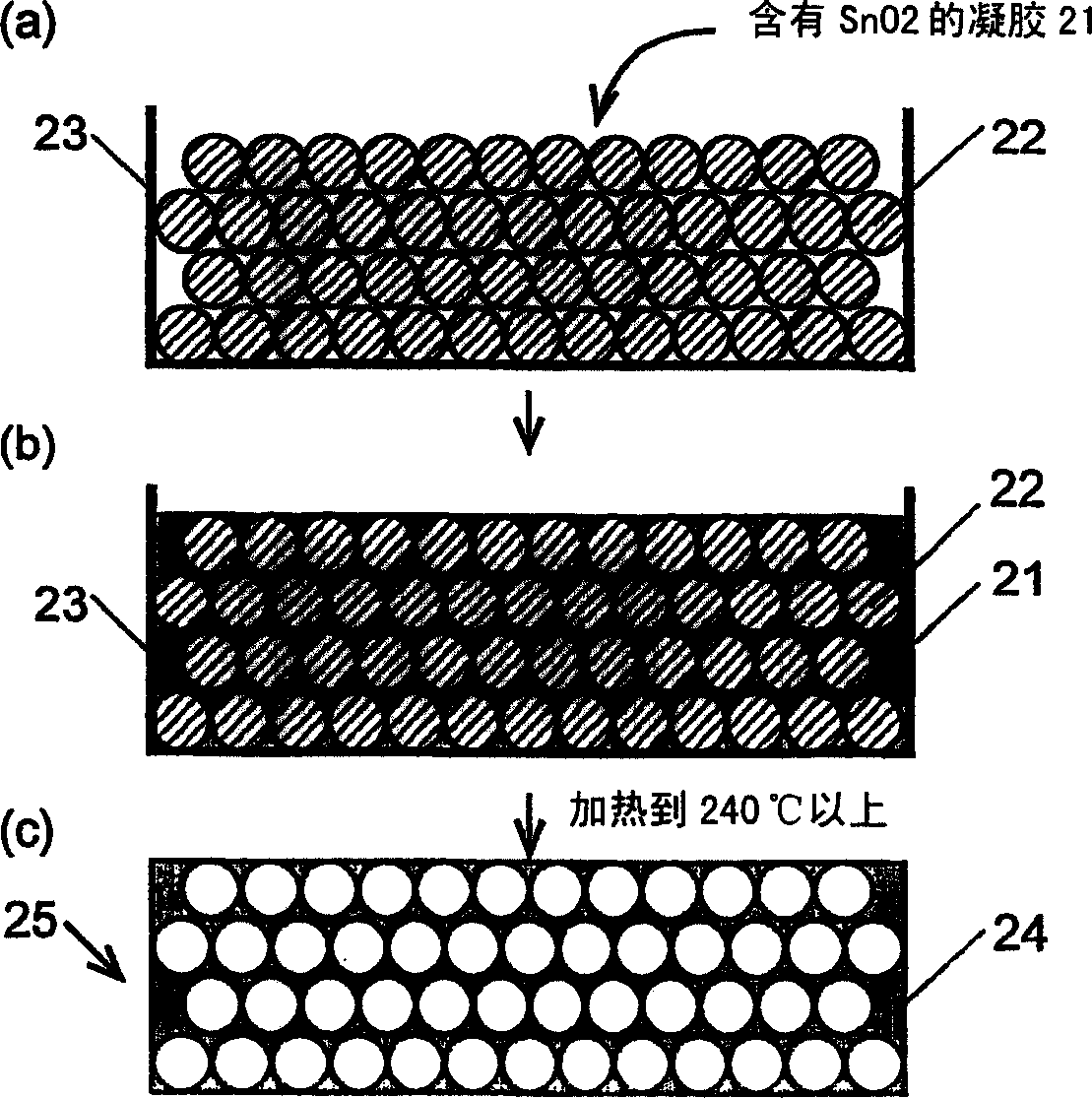

An object of the present invention is to provide an extreme ultraviolet light source target which can emits extreme ultraviolet light with high emission efficiency. A solid target made of heavy metal or heavy-metal compound and having a density 0.5 to 80% that of the crystal density is used. When the target is irradiated with a laser beam, plasma of the heavy metal contained in the target is generated, and extreme ultraviolet light having a predetermined wavelength which corresponds to the kind of the heavy metal is emitted from the plasma. When the density of the target is made to be smaller than the crystal density as described above, space distribution of the density of the generated plasma can be controlled, and the region in which plasma absorbs energy of the laser beam overlaps the region in which the plasma emits the extreme ultraviolet light. Thus, emission efficiency can be improved, preventing energy loss. For example, in a case where the SnO2 target having a density 24% of the crystal density is used, the emission efficiency at around 13.5 nm wavelength is higher than in the case where a Sn crystal target is used.

Owner:OSAKA UNIV

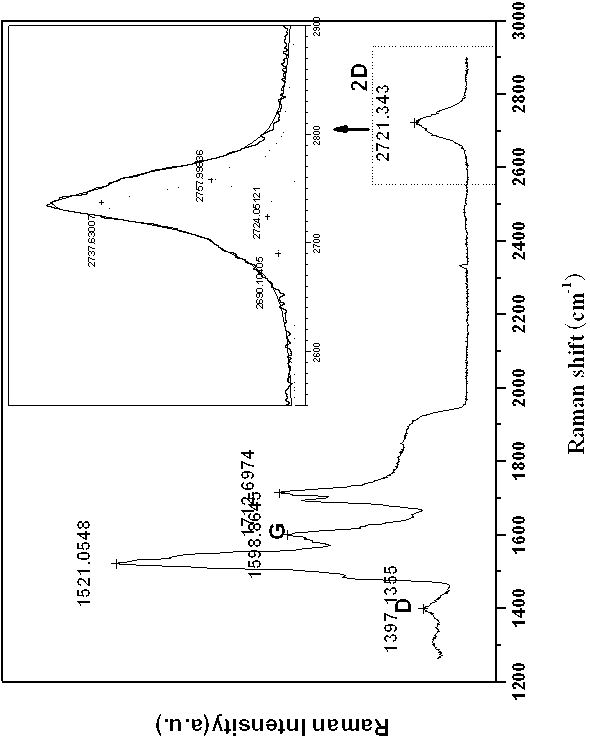

Method for manufacturing low layer number graphene film on silicon carbide substrate

ActiveCN102936009AReduce the amount of residual hydrogenAvoid sublimationGrapheneCarbonizationGraphite

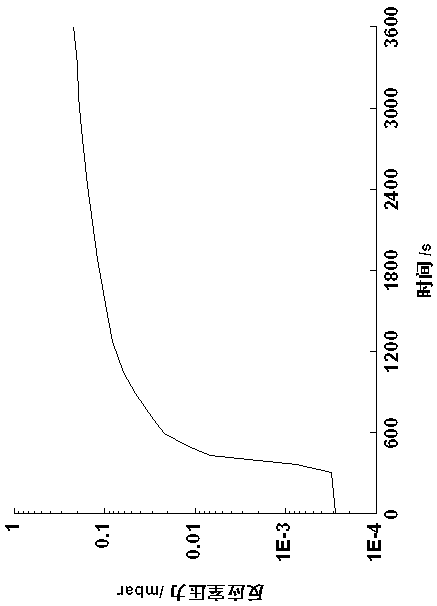

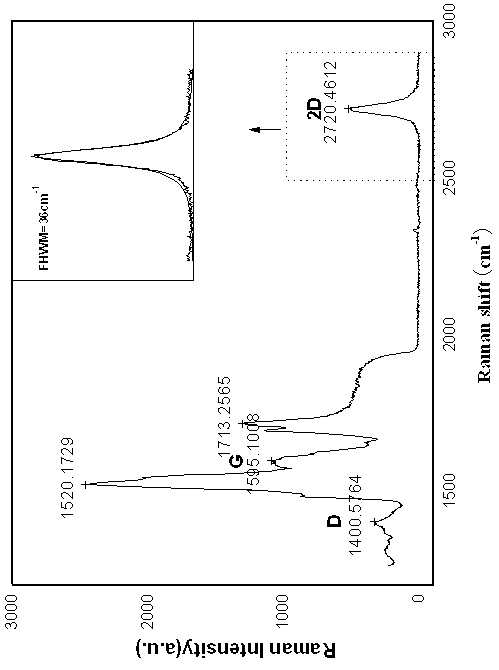

The present invention relates to a method for manufacturing a low layer number graphene film on a silicon carbide substrate. The method comprises the following process steps: 1) selecting a silicon surface silicon carbide substrate, and placing on a graphite base having a tantalum carbide coating; 2) carrying out system heating; 3) reducing a reaction chamber temperature to less than 1200 DEG C; 4) increasing argon flow; 5) carrying out system heating; 6) reducing argon flow, and reducing reaction chamber pressure to 0-1 mbar; 7) continuously adopting a mechanical pump to control a reaction chamber vacuum degree; 8) adopting a molecular pump to control the reaction chamber vacuum degree, and starting a carbonization process; 9) closing heating, and introducing argon; 10) reducing the reaction chamber temperature to 1000 DEG C, and closing argon; and 11) reducing the reaction chamber temperature, introducing argon to the reaction chamber to achieve atmospheric pressure, opening the chamber, and taking the sheet. The method has the following advantages that: graphene film formation can be promoted, sublimation of silicon atoms in the SiC substrate during heating and cooling processes can be effectively inhibited, and the carbonization process is easily controlled so as to achieve low layer number graphene film preparation.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

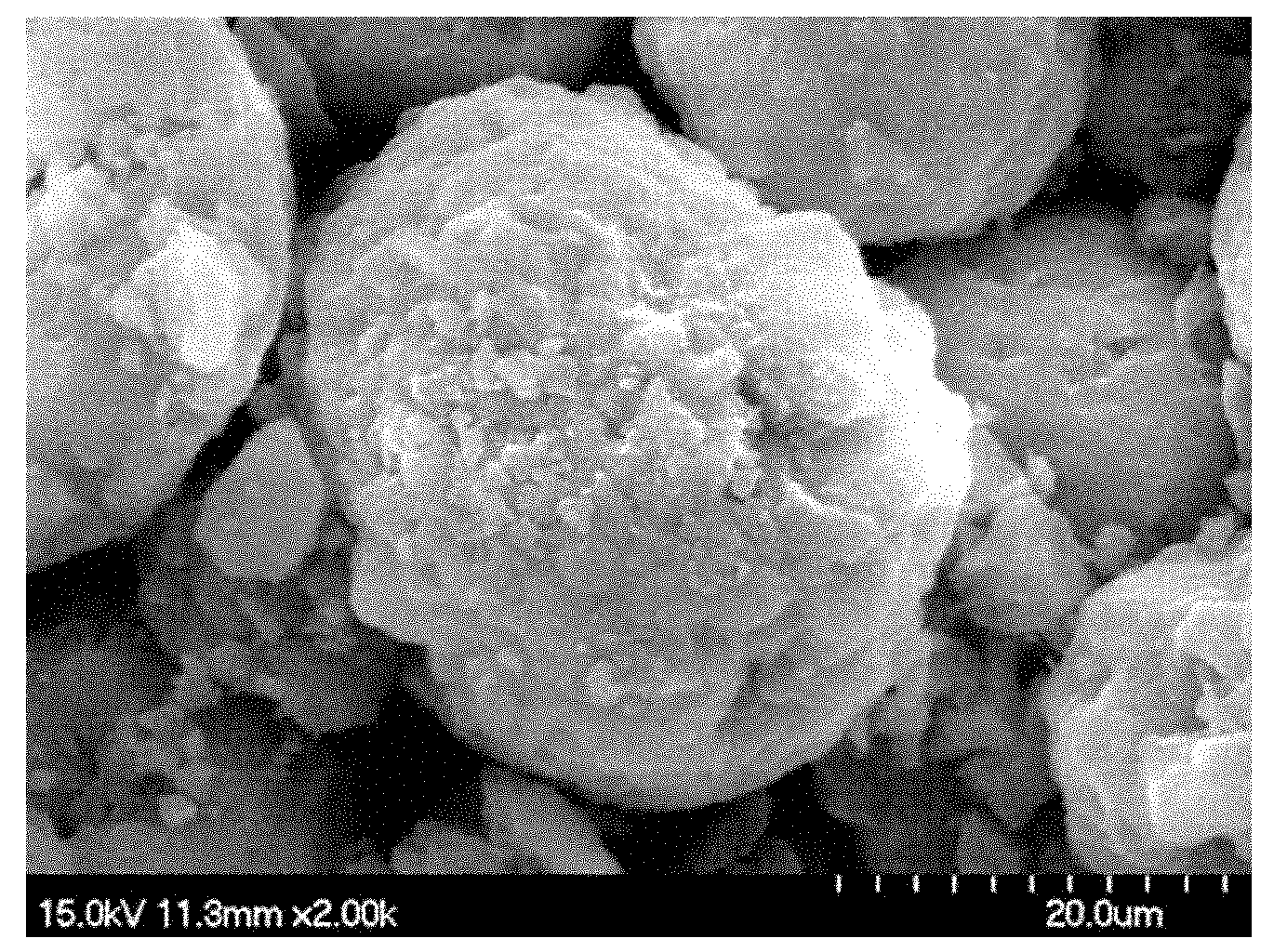

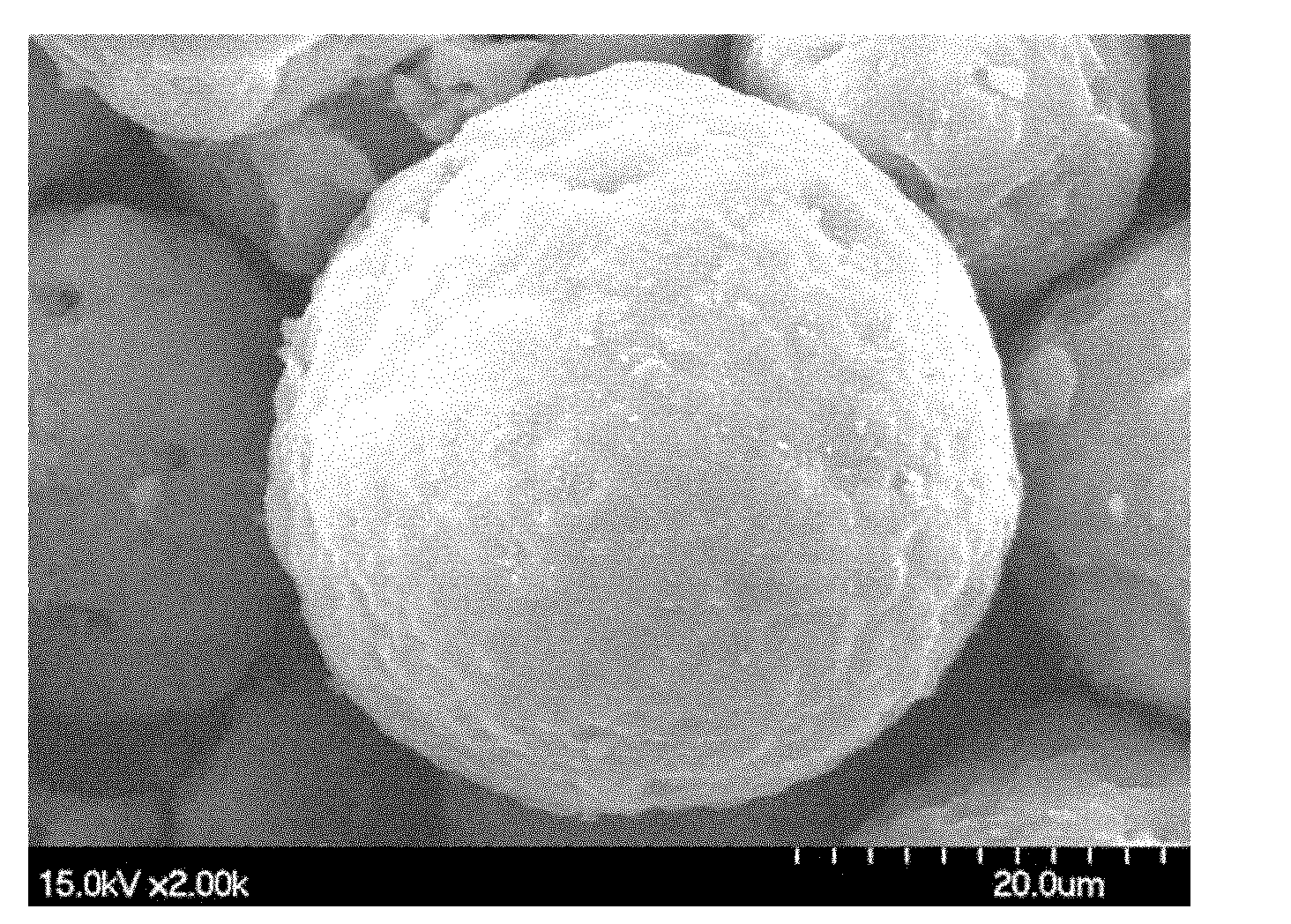

Seed crystal processing method for silicon carbide single crystal growth

InactiveCN106757321AQuality improvementAvoid sublimationPolycrystalline material growthFrom condensed vaporsGraphiteSingle crystal growth

In order to solve the problems in the prior art, the invention provides a seed crystal processing method for silicon carbide single crystal growth. The back of a seed crystal is enabled to obtain two compact graphite layers by means of a one-step method, and the graphite layers can be maintained to be stable at high temperature, so that the sublimation of the back of the seed crystal is inhibited; therefore, a plane hexagonal hole defect caused by the sublimation of the back of the seed crystal in a crystal growth process can be eliminated, and the quality of a silicon carbide crystal is greatly improved. The method is easy to implement, the cost is controllable, and the method has prominent large-scale application prospect.

Owner:HEBEI SYNLIGHT CRYSTAL CO LTD

Environmental-friendly mercuric chloride metal catalyst and preparation method thereof

InactiveCN102145303ALow toxicityIncreased toxicityPreparation by halogen halide additionOrganic-compounds/hydrides/coordination-complexes catalystsMetal catalystChloride

The invention discloses an environmental-friendly mercuric chloride metal catalyst, which consists of an inhomogeneous mercuric chloride metal catalyst and a polymer coated on the surface of the inhomogeneous mercuric chloride metal catalyst in a film mode. In a reaction of producing vinyl chloride by acetylene hydrochlorination, due to the adoption of the catalyst, on the premise of ensuring the activity of the catalyst and the selectivity of vinyl chloride, the environment and health problems caused by Hg sublimation are reduced. The catalyst has the characteristics of high catalyzing efficiency, low toxicity, mild catalyst release and the like. The invention also discloses a preparation method of the environmental-friendly mercuric chloride metal catalyst. In the preparing process, few parameters need to be controlled. The preparation method has high repeatability and strong controllability and is easy for industrial production.

Owner:ZHEJIANG UNIV

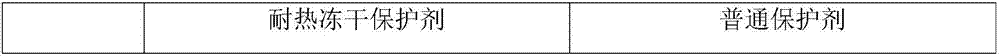

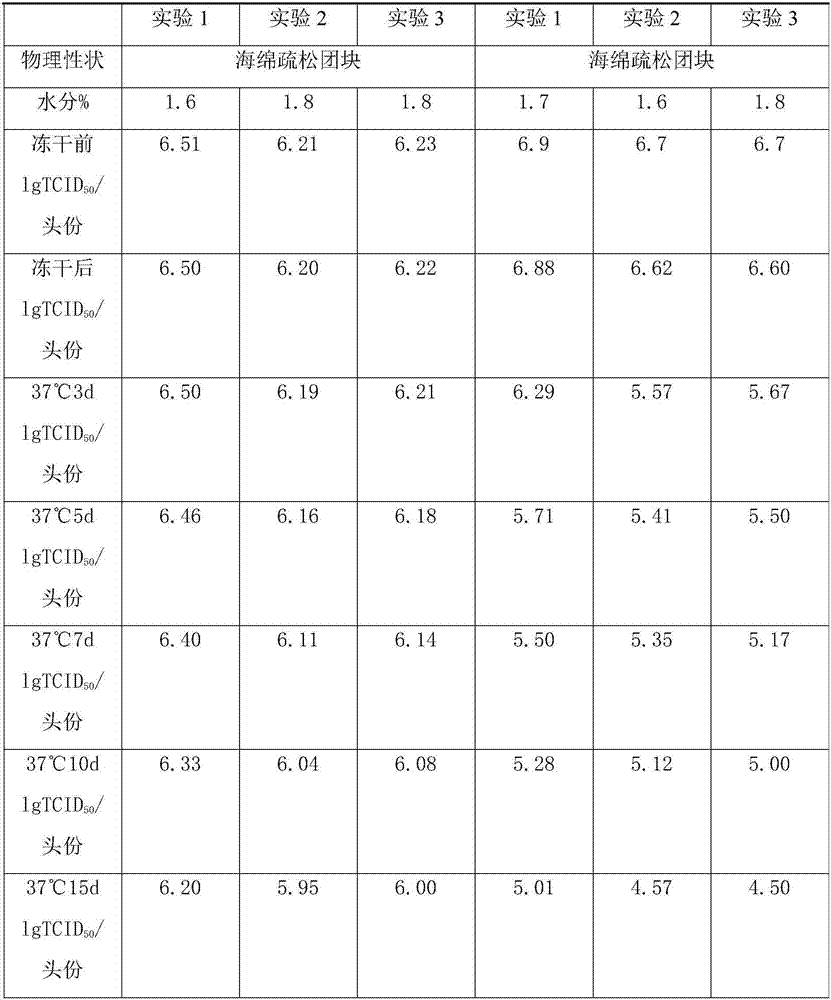

Heatproof lyoprotectant for live vaccine against pseudorabies and preparation method thereof, and lyophilized vaccine and preparation method thereof

ActiveCN107281481AFunction increaseImprove protectionViral antigen ingredientsAntiviralsMonosodium glutamateSucrose

The invention provides a heatproof lyoprotectant for a live vaccine against pseudorabies. The heatproof lyoprotectant comprises, by weight, 3 to 10 parts of gelatin, 1 to 5 parts of trehalose, 5 to 15 parts of sucrose, 0.1 to 2 parts bovine serum albumin, 1 to 8 parts of tryptone, 2 to 10 parts of enzyme-hydrolyzed casein, 1 to 5 parts of thiourea, 0.8 to 2 parts of L-monosodium glutamate, 0.1 to 3 parts of arginine, 0.5 to 5 parts of polyvinylpyrrolidone (PVP-K30) and 0.1 to 2 parts of mannitol. The invention also discloses a preparation method of the heatproof lyoprotectant and a lyophilized vaccine prepared from the heatproof lyoprotectant. When the heatproof lyoprotectant is used for protecting the vaccine and a specific lyophilization process is employed, lyophilization loss of viruses can be effectively reduced, the temperature tolerance of the viruses can be improved, and the vaccine can still maintain good physical properties and titer after long-term storage; i.e., the vaccine has stable characters and has the characteristics of heat resistance and long storage time.

Owner:SICHUAN HUAPAI BIO PHARMA

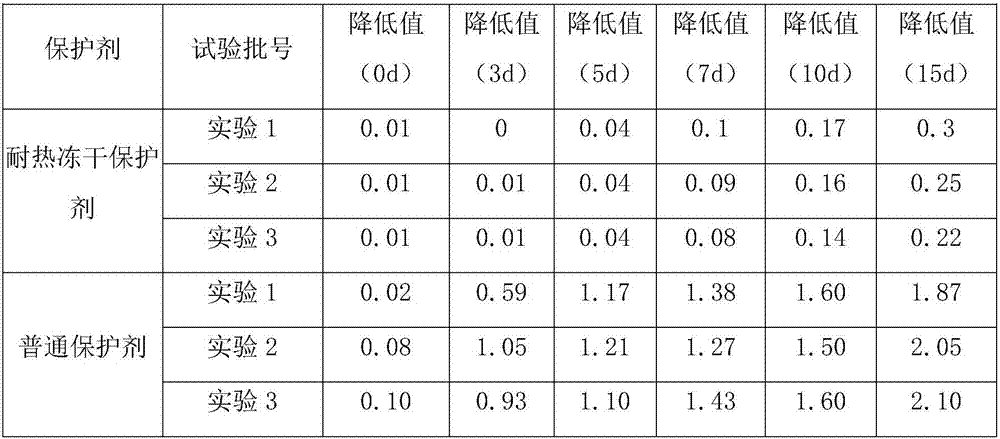

Method of treating hexane diacid preparation waste liquid

InactiveCN1907941AHighlight substantiveSignificantly progressiveNature of treatment waterWater/sewage treatment by extractionLiquid wasteAcetic acid

This invention provides a treatment method for waste liquid from adipic acid production with simple process, good effect and low cost. Said method comprises: (1) adding waste liquid from adipic acid production and the extraction agent of ethyl acetate with the same volume as the waste liquid in an extraction equipment, vibrating and extracting, and standing to stratify the water and organic item, and flowing out the water and the remained extract containing three acids (adipic acid, glutaric acid and succinic acid), (2) repeating above steps to extract, (3) distilling the three acids-bearing extract no longer to be treated, evaporating the extraction agent of ethyl acetate, recycling, cooling the remainder and molding to obtain the three acids, and (3) adding alkaline substance to the water no longer to be treated, adjusting its pH within a range of 7-8, and discharging or taking it as liquid fertilizer. The approach is an advanced and mature technology with low energy consumption and no pollution. The three acid obtained have good quality and high efficiency.

Owner:李强国

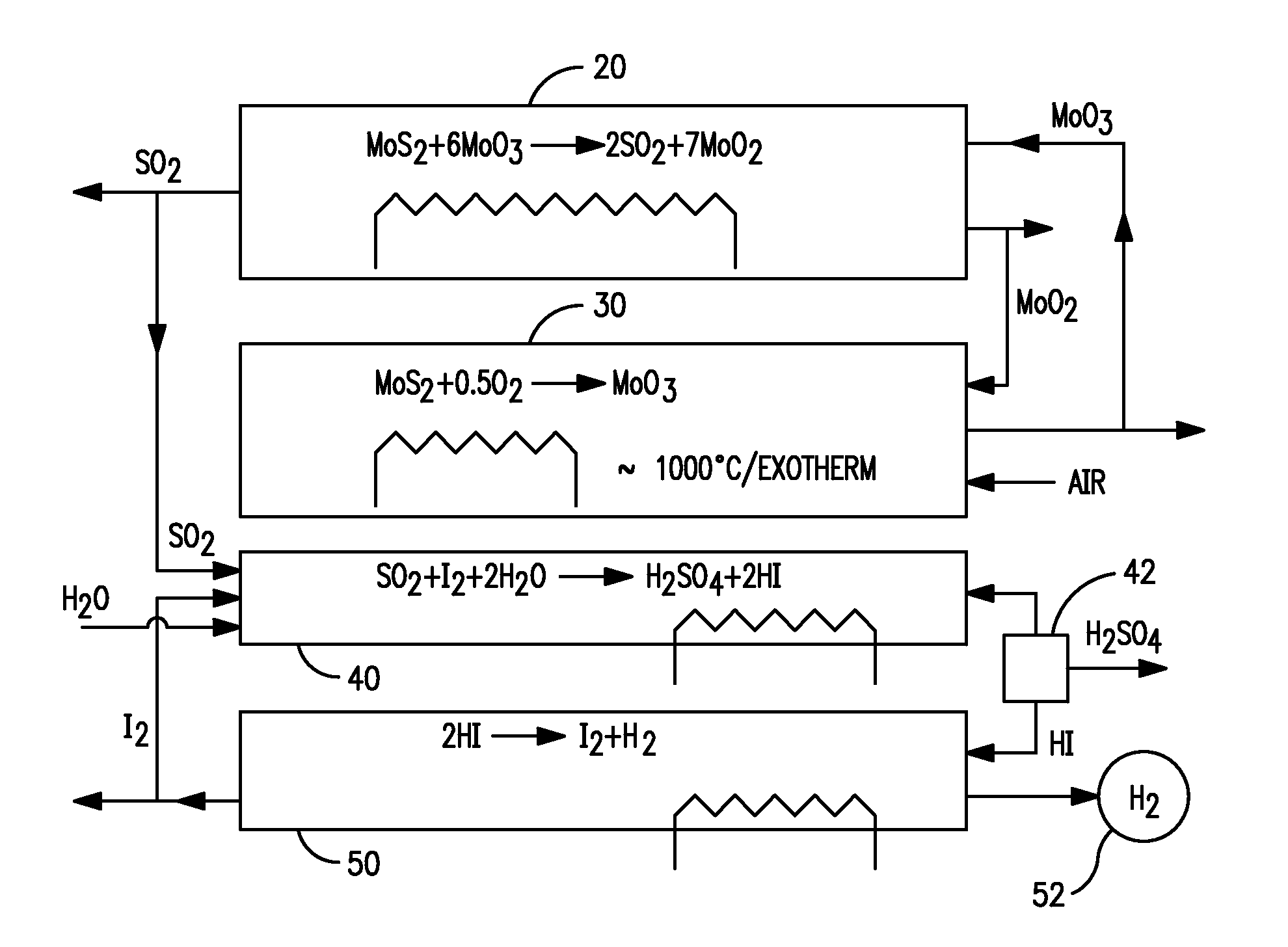

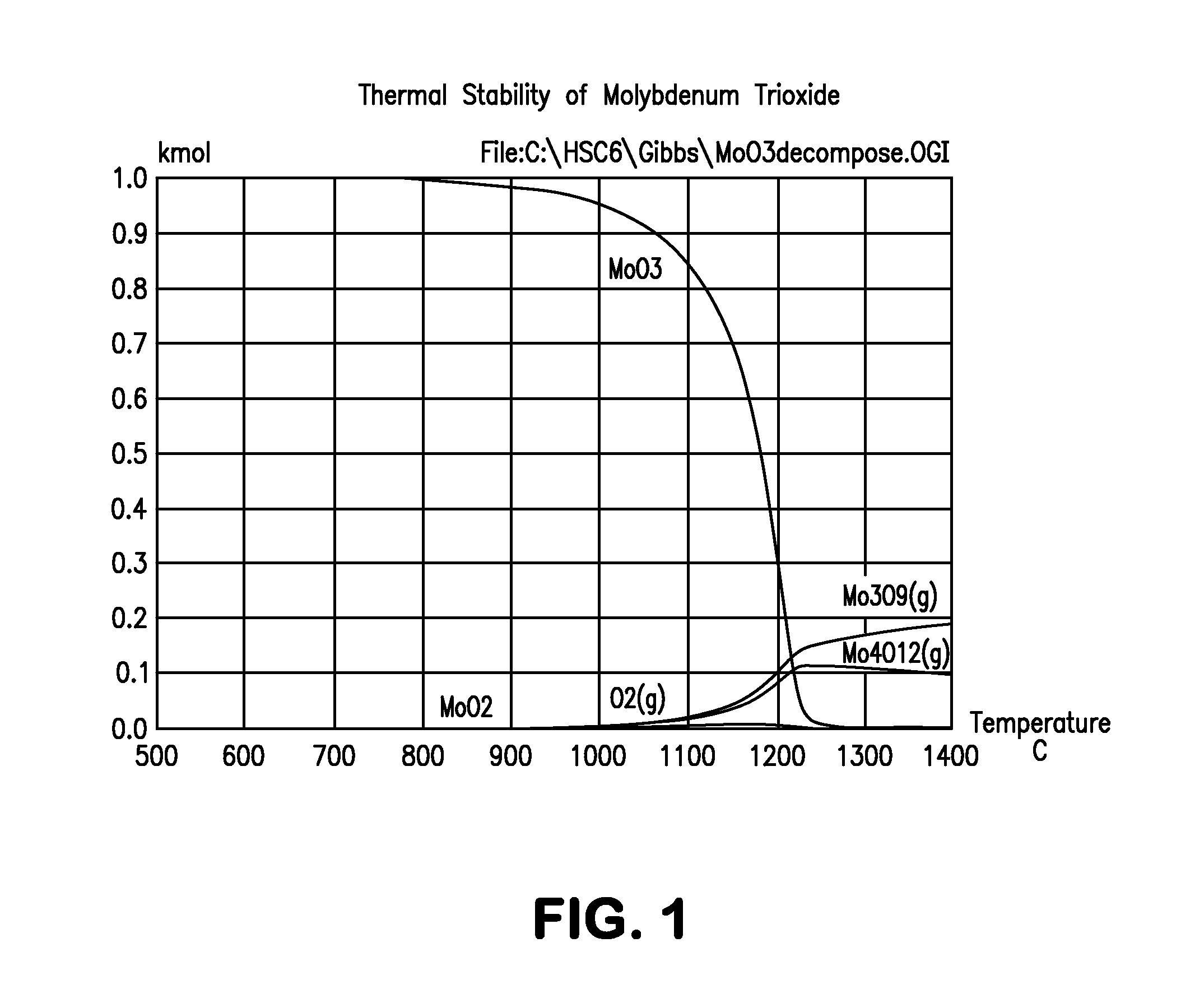

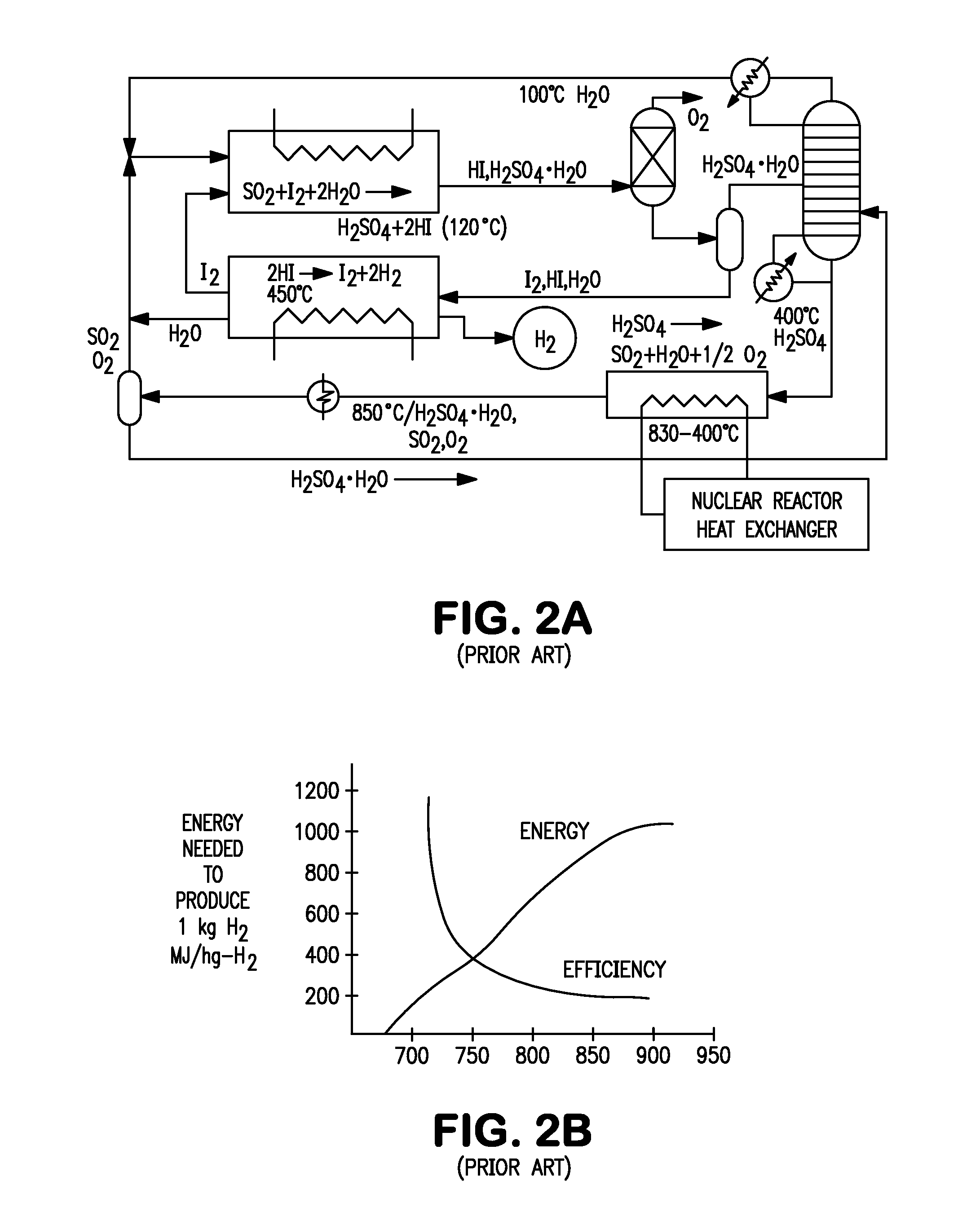

Production of hydrogen through oxidation of metal sulfides

InactiveUS20120034154A1Good benefitEfficiency benefitSulfur-dioxide/sulfurous-acidHydrogen productionMetallic sulfideTwo step

Utilization of process and equipment for oxidation of metal sulfides, preferably two step metal sulfide oxidation reactions, and more preferably with looping back of second step oxide to the first step as an oxidizing agent, to generate sulfur dioxide and a useful metal or metal oxide, and react the sulfur dioxide with halogen (iodine or bromine) and water to produce sulfuric and halogen acid under moderate process conditions and equipment requirements and then dissociating the halogen acids (HI or HBr) to halogen and hydrogen as an overall environmentally and cost efficient and otherwise acceptable safe process for producing hydrogen and other useful products.

Owner:ORCHARD MATERIAL TECH

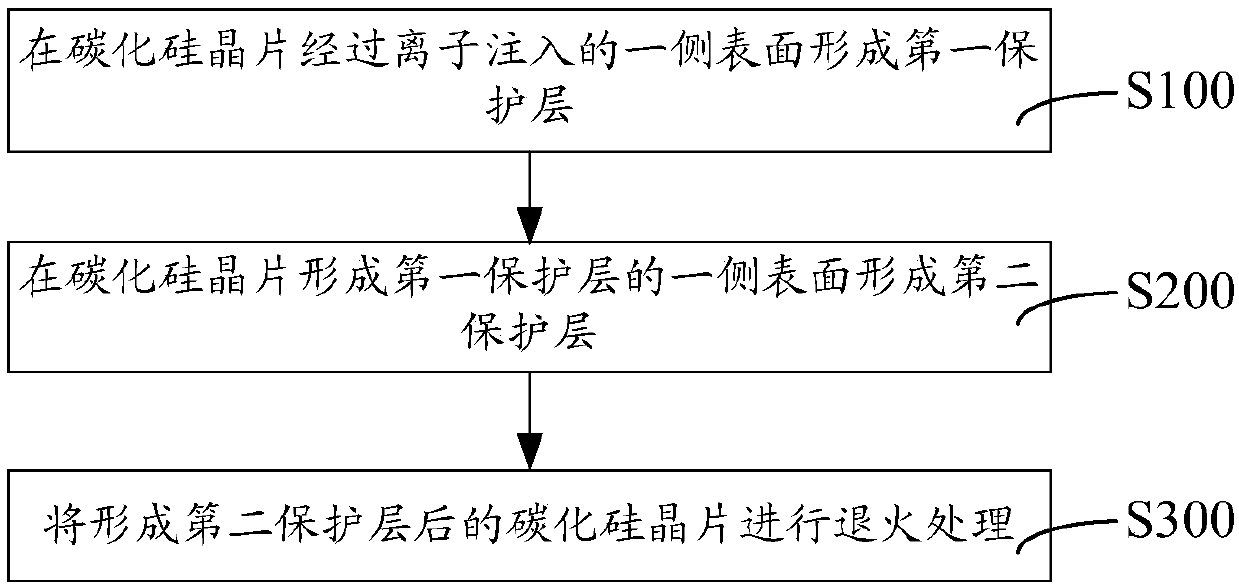

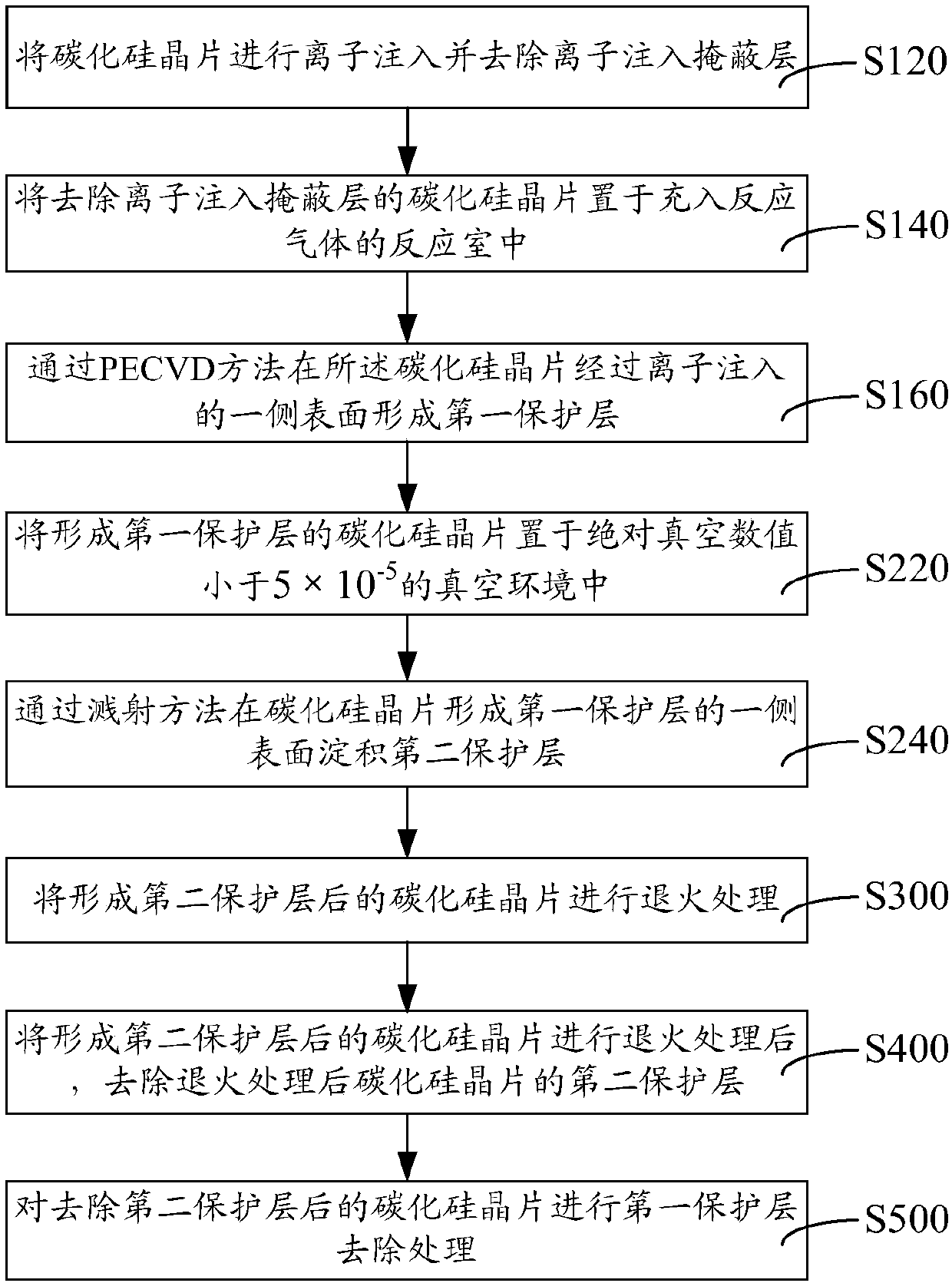

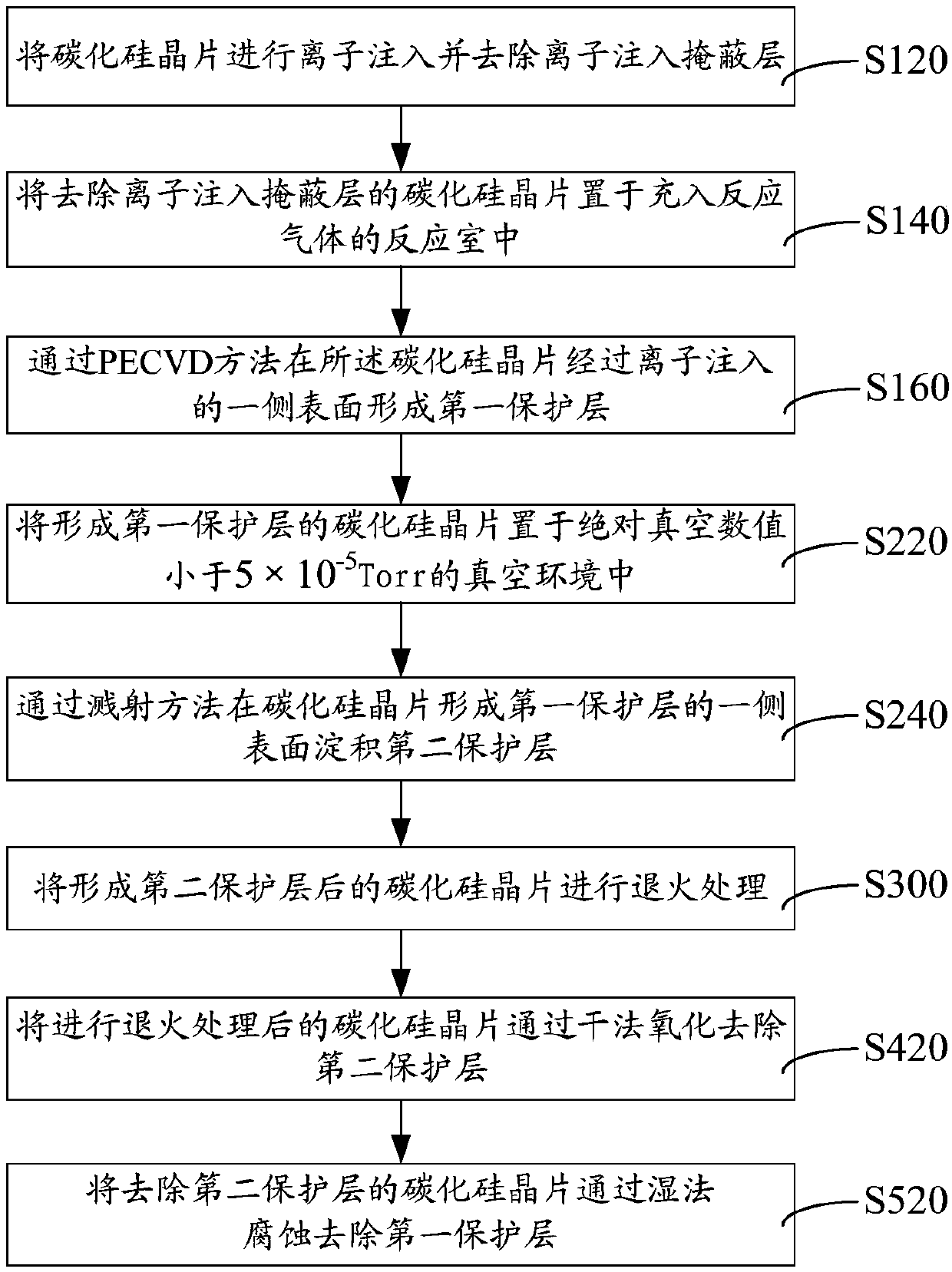

Silicon carbide activation annealing method

InactiveCN109979829AImprove protection reliabilityImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesThermal stabilityBiological activation

The invention discloses a silicon carbide activation annealing method. The method comprises the following steps: forming a first protection layer on the surface, subjected to ion implantation, of oneside of a silicon carbide wafer; forming a second protective layer on the surface of one side, at which the first protective layer is formed, of the silicon carbide wafer; carrying out annealing treatment of the silicon carbide wafer with the second protection layer, wherein the thermal stability of the second protection layer is superior to that of the first protection layer during annealing treatment. A first protection layer and a second protection layer are formed on the surface of silicon carbide. During the annealing treatment of the silicon carbide wafer, the second protection layer canprevent the first protection layer from melting at a high temperature and prevents the sublimation of silicon atoms, and the first protection layer can effectively prevent silicon atoms on the surface of the silicon carbide wafer from sublimating and depositing again, so the problems of sublimation and deposition of silicon atoms on the surface of silicon carbide in the annealing process can be solved through the two protection layers, and the reliability of activating annealing protection of silicon carbide is improved.

Owner:WUXI CHINA RESOURCES MICROELECTRONICS

Processing method for high-quality aeronautic convenient hold Luo powder

InactiveCN104026452ASmooth appearanceGlossyFood ingredient as taste affecting agentFood preparationFood safetySteaming

The invention relates to a processing method for high-quality convenient hold Luo powder. The method disclosed by the invention comprises the following steps; mixing and mashing raw materials; performing steaming slices, extruding, short cutting, gelation, steaming, cooling, and shaping for sub-packaging on the raw materials; preparing seasoning sauce, spraying, quick-freezing, inspecting and packaging to obtain finished products. The method is simple in technology, little in equipment investment and short in processing cycles, and obtained products are convenient to eat and has storage resistant. On the basis of keeping the fresh mouth feel of rice flour, in the technology link, a spraying seasoning sauce and quick-freezing technology is adopted, the rice flour is directly heated, and the hold Luo power with rich cooking liquor is made in a fresh manner. The rice flour can keep soft and flexible mouth feel in aeronautic heating; for aeronautic food, the problem that cooking liquor products overflow in the transportation process is solved, the food safety is ensured, and in the aspect of quality, the quality guarantee period is prolonged. The method disclosed by the invention overcomes the defects of short quality guarantee period and the like caused by a traditional handmade technology, and the products are convenient to eat, so that the hold Luo power, as a traditional local dainty, gradually moves towards industrialized mass production.

Owner:SANYA YANGYUMING BIOTECH CO LTD

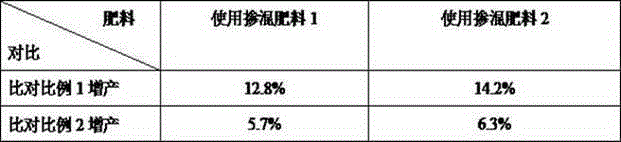

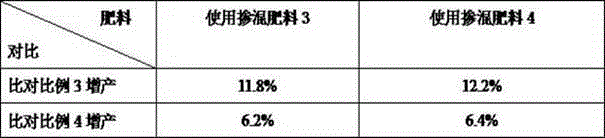

Slow-release synergist granule for blended fertilizer, and preparation method and application method of slow-release synergist granule

InactiveCN104447025AEffective regulation of activityRegulatory activityLayered/coated fertilisersFertilizer mixturesPotashAmmonium

The invention discloses a slow-release synergist granule for a blended fertilizer, and a preparation method and an application method of the slow-release synergist granule. The slow-release synergist granule is prepared from NBPT powder, 4-amidogen-1,2,4 triazole powder, ammonium humate powder, ammonium citrate powder, attapulgite powder and a binder in a pelleting manner. The slow-release synergist granule is added to a nitrogenous fertilizer granule, a phosphatic fertilizer granule and a potash fertilizer granule according to a certain ratio, thus the blended fertilizer with long effective period and good fertilization effect can be prepared.

Owner:张彬

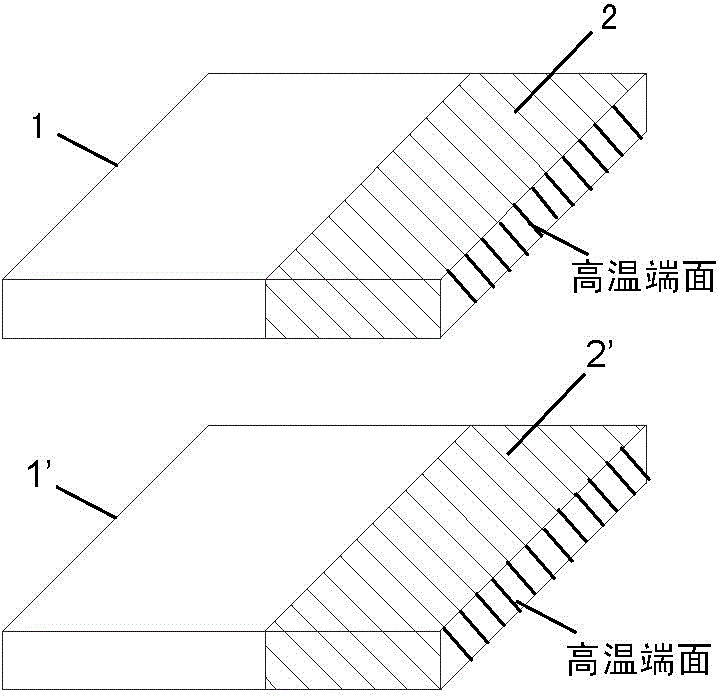

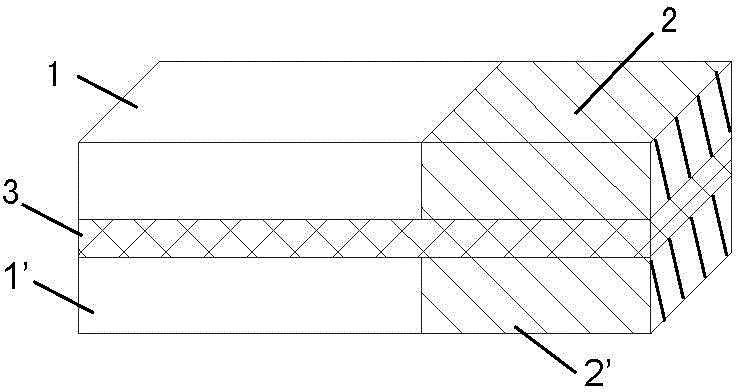

Middle-high temperature thermoelectric module

ActiveCN104934523ABlock sublimationPrevent oxidationThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentThermal insulationOxidation resistant

The invention relates to a middle-high temperature thermoelectric module. The middle-high temperature thermoelectric module comprises at least one group of thermoelectric pair, wherein the thermoelectric pair comprises two thermoelectric blocks connected through an insulating supporting plate; an electrode formed on a high temperature end surface of the thermoelectric pair; a diffusion blocking protection layer formed at least on the surface of the thermoelectric pair and / or the surfaces of the two thermoelectric blocks; an anti-oxidation layer formed at least on the surface of the thermoelectric pair and / or the surfaces of the two thermoelectric blocks; and an aerogel thermal insulation layer filling a gap of the at least one group of thermoelectric pair. The thermoelectric module provided by the invention simultaneously has the performance of sublimation prevention, anti-oxidation, heat insulation and the like, and the thermoelectric performance and the efficiency of the thermoelectric module are improved; in addition, the thermoelectric module has a self-protection function when working under conditions relating to corrosive gas, moist, chemical medium corrosion, temperature cold-hot alternation and the like.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

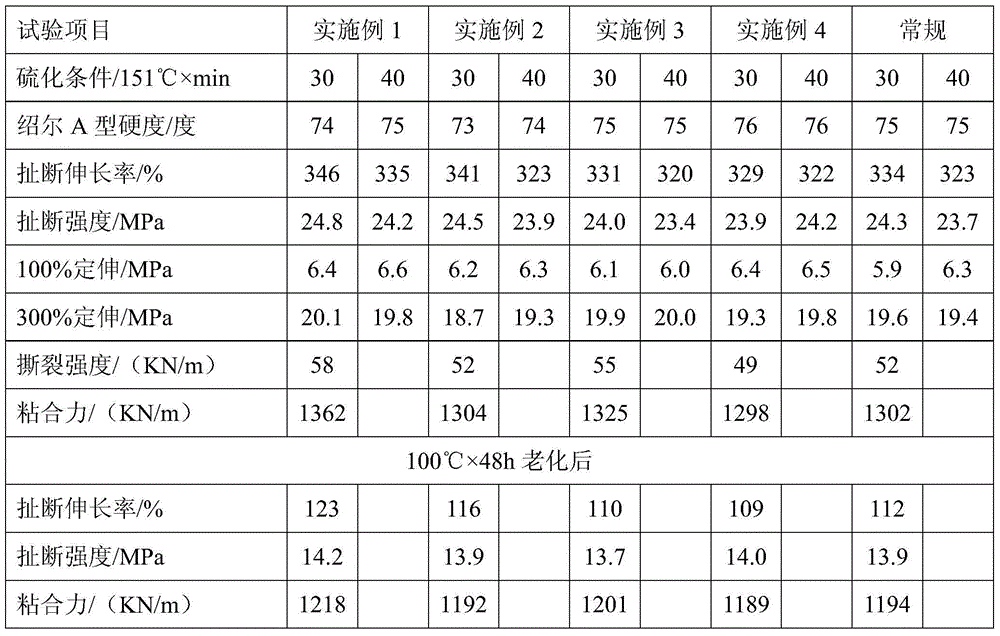

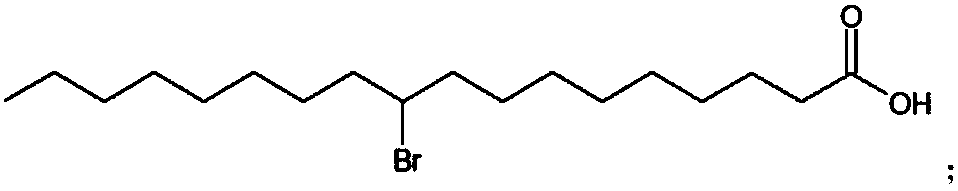

Steel wire adhesive material for tire and preparation method of adhesive material

InactiveCN104017515AAvoid sublimationImprove adhesionNatural rubber adhesivesNon-macromolecular adhesive additivesAntioxidantAccelerant

The invention belongs to the field of tires, and particularly relates to a steel wire adhesive material for a tire and a preparation method of the adhesive material. The steel wire adhesive material comprises the following raw materials in parts by weight: a first adhesive system comprising 1.0-2.5 parts of adhesion promoter, 4.0-6.0 parts of adhesive, 10 parts of white carbon black and 2.0-4.0 parts of adhesive antioxidant; a second adhesive system comprising 0.6-1.5 parts of cobalt salt, 100 parts of natural rubber, 35-55 parts of carbon black, 6-10 parts of zinc oxide, 1.0-2.5 parts of anti-aging agent, 4.0-6.0 parts of sulphur, 0.8-1.5 accelerant and 0-0.3 part of scorch retarder. Resorcinol is replaced with the adhesion promoter, and meanwhile, the adhesive antioxidant is added, so that the smoking phenomenon in production is removed, the adhesive effect of a sizing material and the steel wire is improved, and meanwhile, the environmental pollution and the damage to physical health of a worker are relieved.

Owner:SHANDONG WANSHINE TIRE

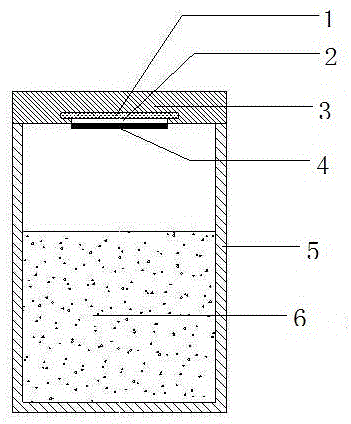

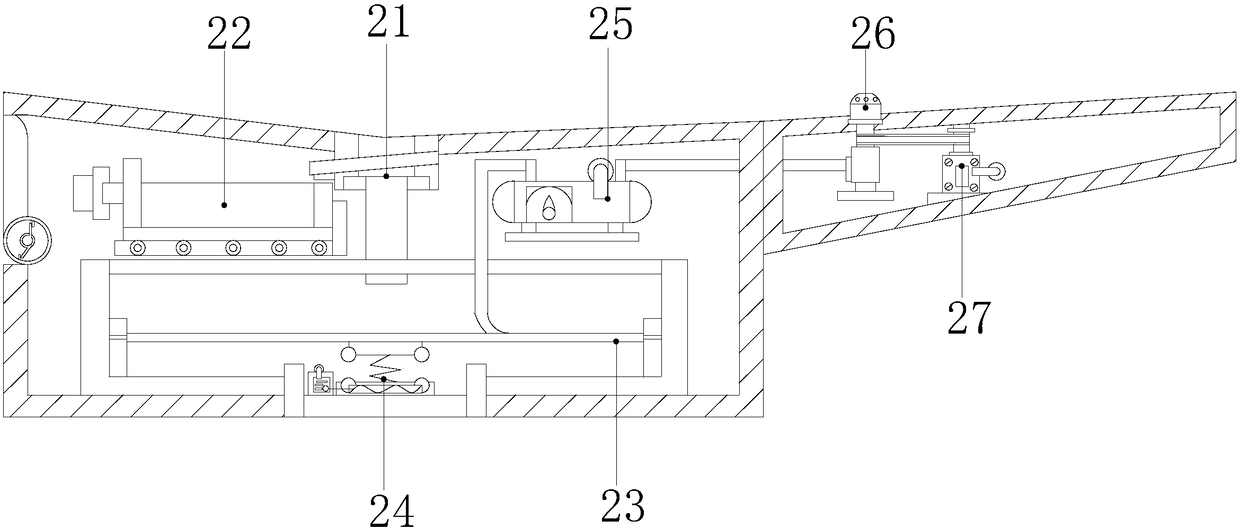

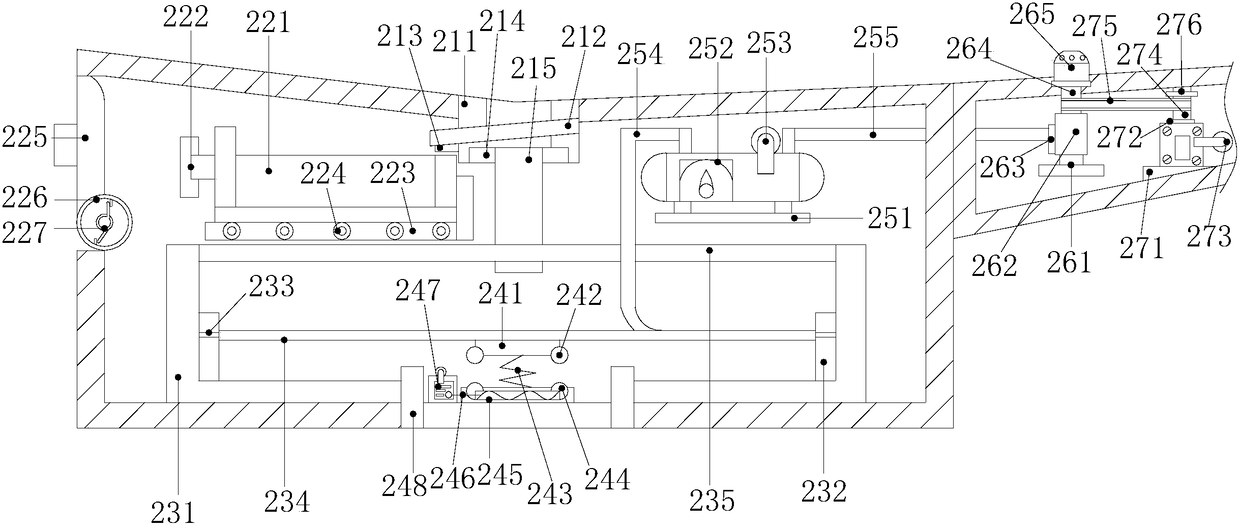

Silicon carbide ion activation annealing device and silicon carbide ion activation annealing method

InactiveCN101651101AEasy to manufactureLow costAfter-treatment detailsSemiconductor/solid-state device manufacturingSiliconMaterials science

The invention discloses a silicon carbide ion activation annealing device and a silicon carbide ion activation annealing method; the silicon carbide ion activation annealing device comprises a high-temperature furnace and a graphite crucible; the wall of the high-temperature furnace is provided with an air inlet and an air outlet; the graphite crucible is arranged in a hearth of the high-temperature furnace; the graphite crucible is provided with an outer shell, an inner shell and a crucible cover; the inner part of the inner shell forms an inner hearth; and an outer hearth is formed between the outer shell and the inner shell; after the crucible cover is covered, the outer shell and the crucible cover are closed in a sealing way, and a gap exists between the top end of the inner shell andthe crucible cover; the silicon carbide ion activation annealing method comprises the following steps: a protective layer is coated on the silicon carbide to be annealed, and then the silicon carbideis placed in the inner hearth of the graphite crucible; high-purity silicon carbide powder is arranged in the outer hearth of the graphite crucible, inert gas is led in the inner hearth of the high-temperature furnace, and then the high-temperature furnace is used for heating to the temperature of 1200 DEG C to 1800 DEG C for 0.52 hours; meanwhile, the silicon carbide surface is smooth and the finished product ratio is improved.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

Extreme ultraviolet light source and target for extreme ultraviolet light source

InactiveCN1759467AAvoid sublimationRadiation/particle handlingX-ray tube electrodesPlasma densityExtreme ultraviolet

A target for extreme ultraviolet light sources for emitting an extreme ultraviolet light with high luminous efficiency. The target is solid and made of a heavy metal or the heavy metal compound with a density of 0.5 to 80% of the crystal density. If the target is irradiated with a laser beam, a plasma of the heavy metal contained in the target is produced and an extreme ultraviolet light with a predetermined wavelength corresponding to the heavy metal is emitted from the plasma. Since the density of the target is smaller than the crystal density as stated above, the spatial distribution of the plasma density can be controlled, and the region in which the plasma absorbs the energy of the laser beam can be made to agree with the region in which the plasma emits extreme ultraviolet light. Therefore, the energy loss is reduced and the luminous efficiency is improved. For example, the luminous efficiency of light with a wavelength at or near 13.5 nm generated when an SnO2 target the density of which is 24% of the crystal density is used is higher than that when an Sn crystal target is used.

Owner:KANSAI TLO KK

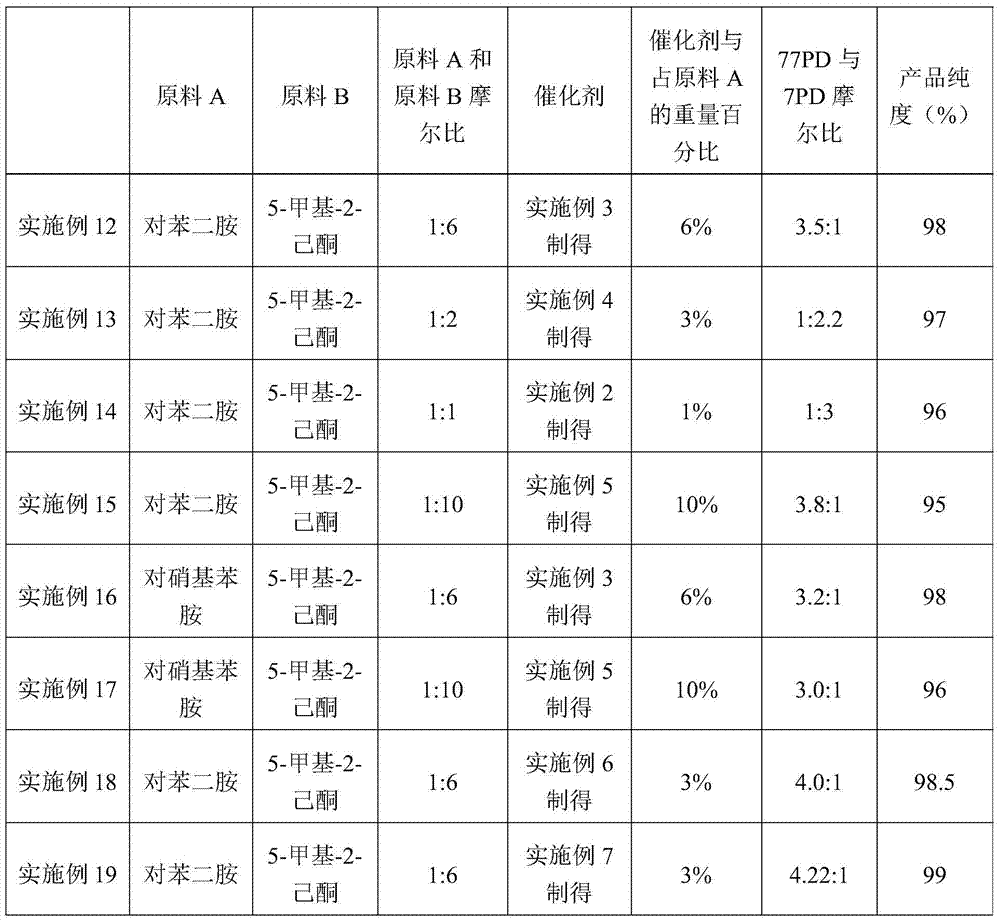

Method for preparing N,N'-bi(alkyl)-p-phenylenediamine

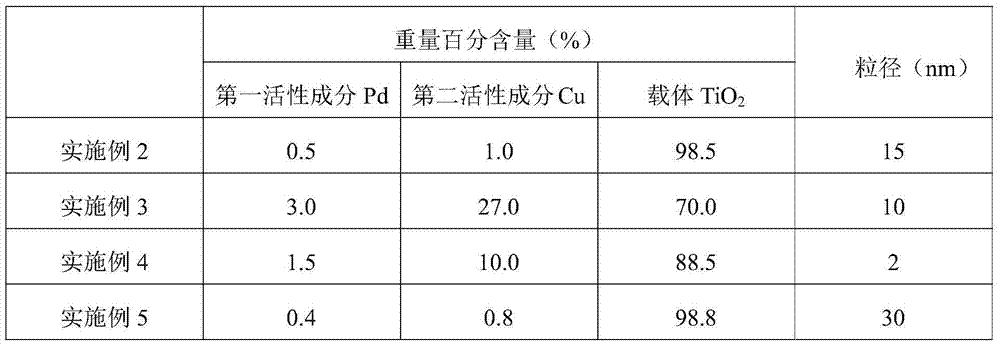

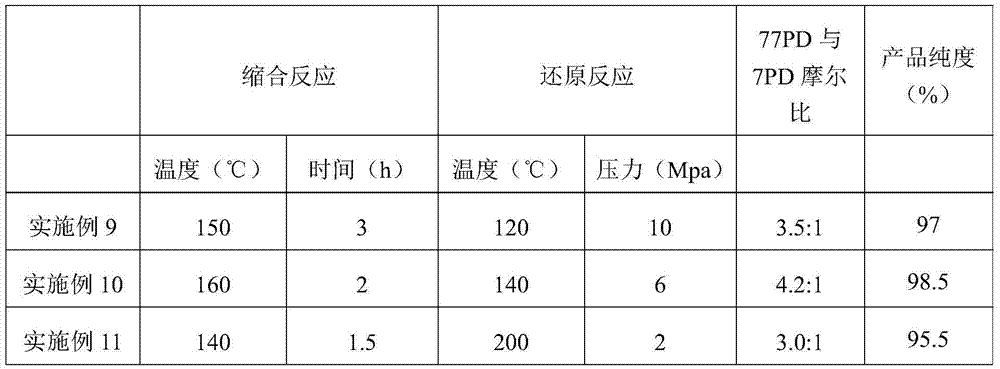

ActiveCN106957231AHigh catalytic activityHigh selectivityPreparation by reductive alkylationImino compound preparationChemistryKetone

The invention discloses a method for preparing N,N'-bi(alkyl)-p-phenylenediamine. The method comprises the following steps: mixing a raw material A and a raw material B to react to obtain a reaction liquid, and performing dehydration treatment on the reaction liquid so as to obtain a Schiff base intermediate; and introducing hydrogen into the Schiff base intermediate, and performing reduction reaction under the catalysis action of a loaded nano composite metal catalyst, thus obtaining the N,N'-bi(alkyl)-p-phenylenediamine, wherein the raw material is p-phenylenediamine and / or paranitroaniline; and the raw material B is alkyl ketone. The method disclosed by the invention has the advantages of being gentle in reaction condition, high in selectivity, easy in reaction control, easy in product separation and high in yield, and industrial production is easily achieved.

Owner:JIANGSU SINORGCHEM TECH CO LTD

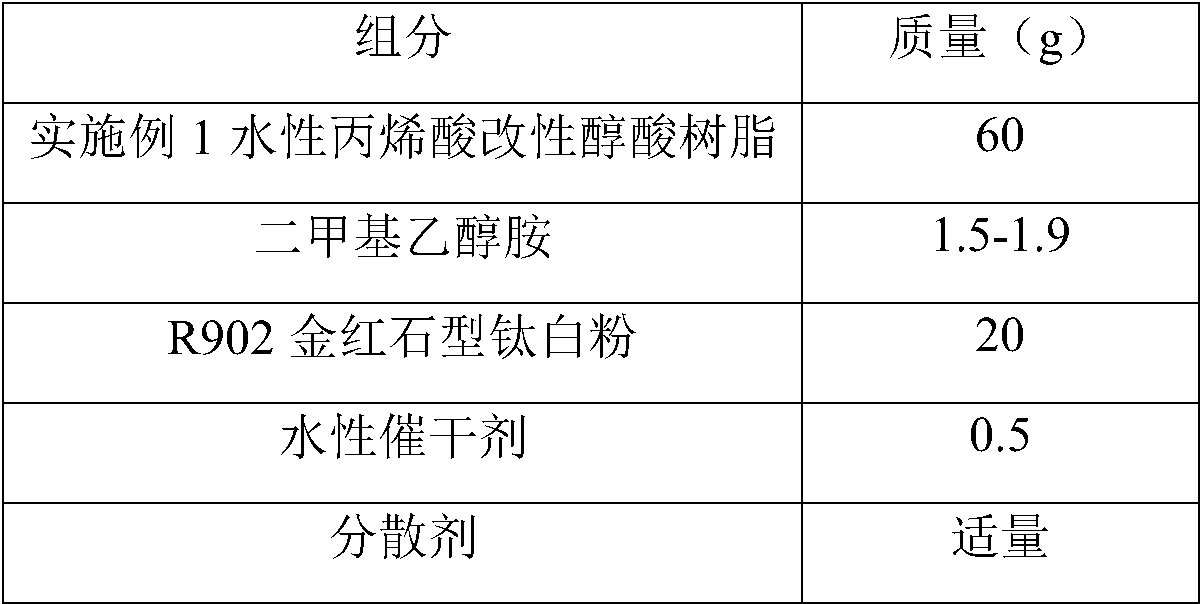

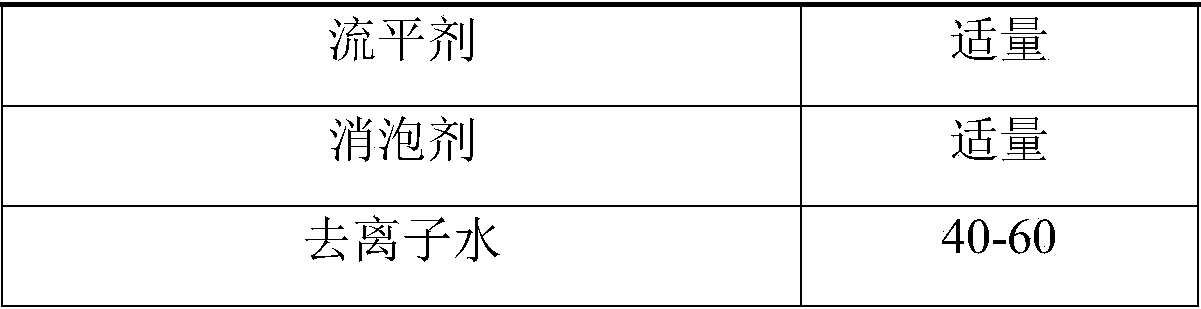

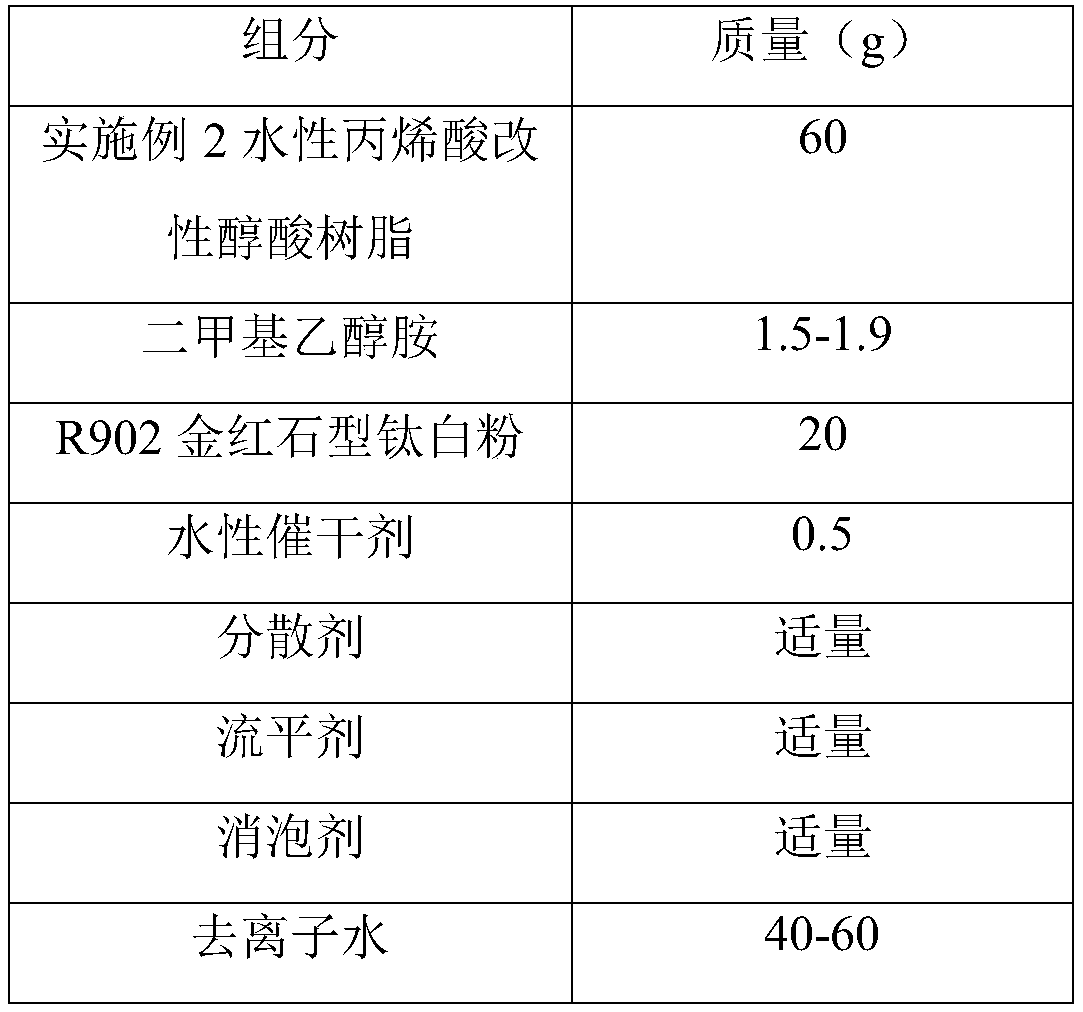

Waterborne acrylic acid modified alkyd resin and preparation method

ActiveCN109306037AUniform molecular weightDry no differencePolyester coatingsSide chainOleic Acid Triglyceride

The invention discloses waterborne acrylic acid modified alkyd resin and a preparation method. The waterborne acrylic acid modified alkyd resin is prepared from the following raw materials: 22 to 24 percent of dry or semi-dry plant oleic acid, 14 to 15 percent of tribasic alcohol with a side chain, 13 to 14 percent of phthalic anhydride, 0.05 to 0.15 percent of a color reduction agent, 1 to 3 percent of refluxing xylol, 0.7 to 1 percent of cis-butenedioic anhydride, 2.5 to 2.7 percent of trimellitic anhydride, 4 to 5 percent of methyl methacrylate, 6 to 8 percent of styrene, 1 to 2 percent ofbutyl acrylate, 0.5 to 1 percent of an initiator and 28 to 29 percent of propylene glycol methyl ether. The waterborne acrylic acid modified alkyd resin is obtained by combining the above preferable raw materials; the waterborne acrylic acid modified alkyd resin has good environment protection performance and low toxicity, also keeps excellent comprehensive performance including glossiness, adhesion and, rigidity and the like and has very good technical effects.

Owner:江苏三木化工股份有限公司 +1

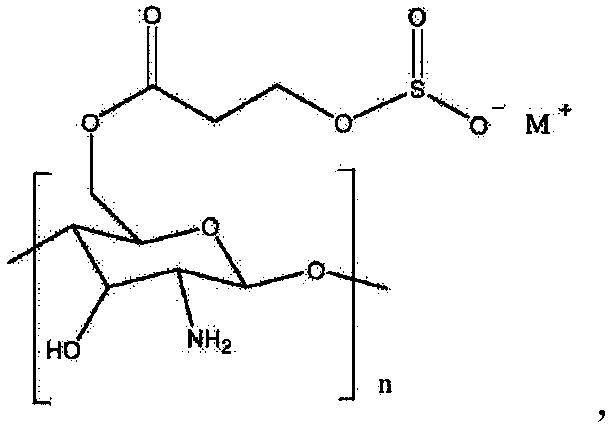

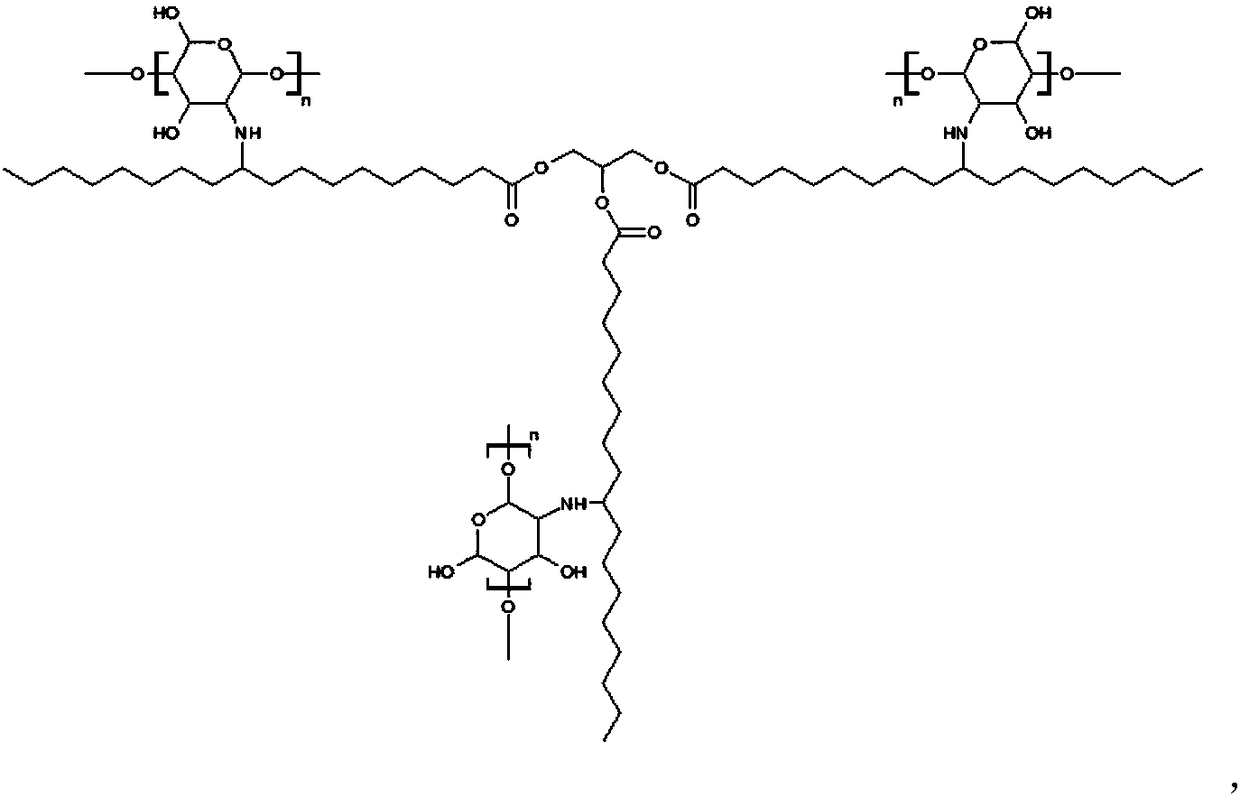

Levelling agent and preparation method and application thereof

The invention relates to a levelling agent and a preparation method and an application thereof. A structural formula of the levelling agent is as shown in the following specification, wherein n is a number between 5 and 10. The levelling agent has the good film-forming property, and contains abundant ester groups, and is capable of combining with dye through a hydrogen bond, thereby uniformly carrying the dye to the surface of fabric and forming a film in uniform thickness, enabling the dye to be uniformly adhered to the fabric, and preventing the non-uniform dispersion because of the short contact time of the dye and the fabric. In addition, the film can also prevent migration and sublimation of the dye in a drying and color development process, and the chromatic aberration of a warp direction, a weft direction and positive and negative faces of the fabric is prevented. The levelling agent is suitable for continuous padding-type dyeing and coating-type dyeing. Compared with vat dyeingin high-temperature and high-pressure, the energy consumption can be reduced, the dyeing efficiency is improved, and the product quality is improved, the color fastness of the fabric and the color uniformity reach a A-grade level stated by a national standard, so the vat dyeing in high-temperature and high-pressure can be possibly replaced by the continuous dyeing in normal pressure and temperature.

Owner:SUZHOU TANGHUA NANO TECH

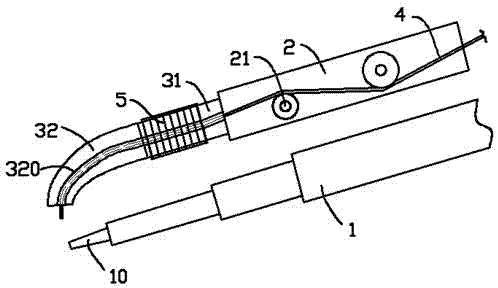

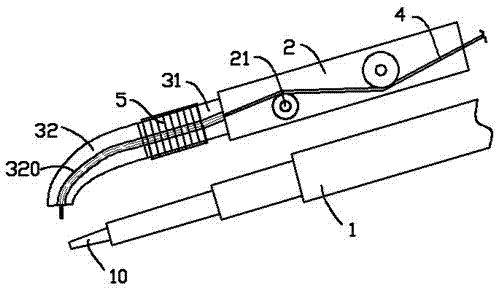

Preheating tin soldering machine

InactiveCN102416513AGood flexibilityImprove surface smoothnessHeating appliancesMetal working apparatusEngineeringHeating temperature

The invention provides a preheating tin soldering machine. The machine comprises a base, wherein a welding gun and a tin wire spinning gun parallelly extend in front of the base; the tin wire spinning gun comprises a transfer arm; a transfer roller is arranged in the transfer arm and draws a tin wire to extend to a spinning pipe in front of the transfer arm; the spinning pipe consists of a metal body; a spinning curved channel is formed in the spinning pipe; an electric heating structure is arranged outside the spinning pipe; and the heating temperature of the electric heating structure is between 80 and 120 DEG C. The tin soldering machine can conveniently perform tin soldering operation, can slowly heat the tin wire to prevent the tin wires from being sublimated, and is favorable for improving a spinning smooth degree.

Owner:吴江市合成电子机械厂

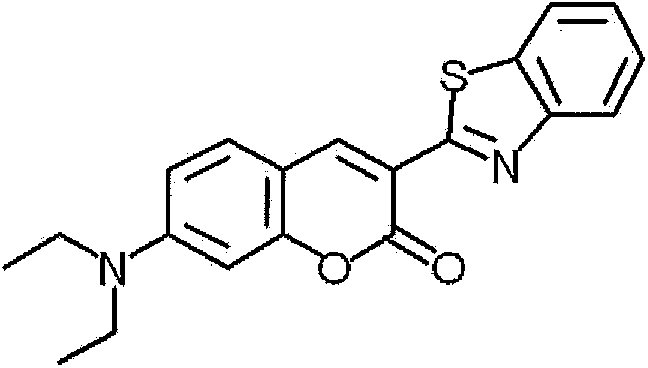

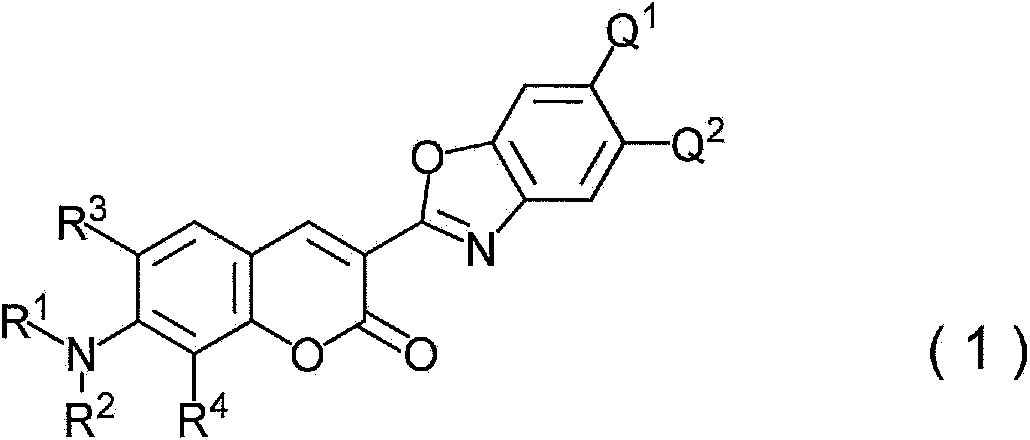

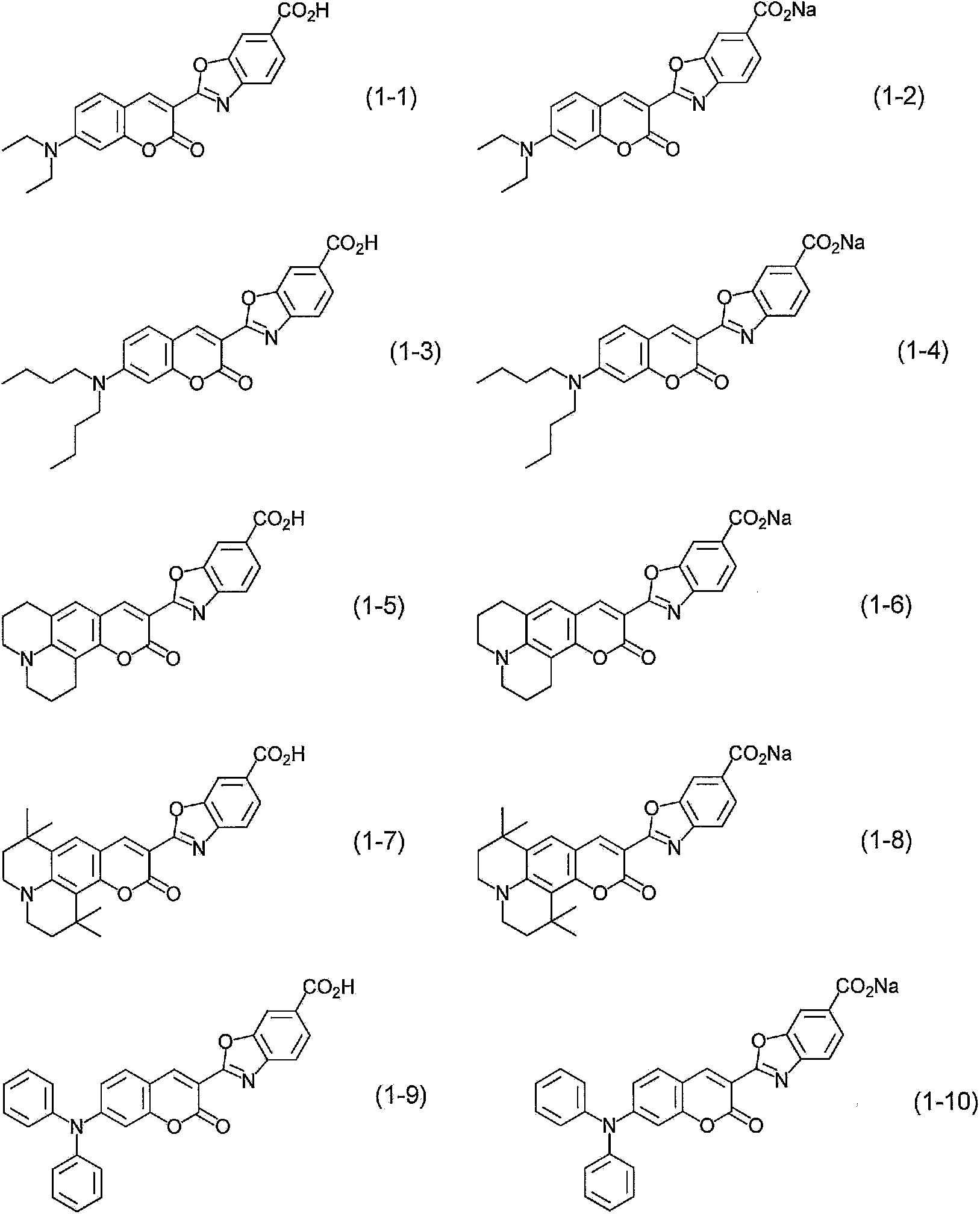

Colored curable resin composition

ActiveCN103365088AAvoid sublimationOptical filtersPhotomechanical exposure apparatusBenzeneHydrogen atom

Provided is a colored curable resin composition which contains a composition, a resin, a polymeric compound and a polymerization initiator which are represented in formula (I). In formula (1), Q1 and Q2 independently and respectively represent a hydrogen atom or -CO2M, while any one of the Q1 and Q2 represents -CO2M. R1 to R4 independently and respectively represent a monovalent hydrocarbyl having a hydrogen atom number or a carbon atom number being 1 to 20; or, R1 and R3 are bonded to together form a ring with carbon atoms on adjacent benzene rings and adjacent nitrogen atoms; R2 and R4 are bonded to together from a ring with carbon atoms on adjacent benzene rings and adjacent nitrogen atoms; R1 and R2 are bonded to together from a ring with adjacent nitrogen atoms. R5 represents a monovalent hydrocarbyl having a hydrogen atom number or a carbon atom number being 1 to 20. When multiple R5s exist, the R5s are mutually identical or different. M presents a hydrogen atom or an alkali-metal atom.

Owner:SUMITOMO CHEM CO LTD +1

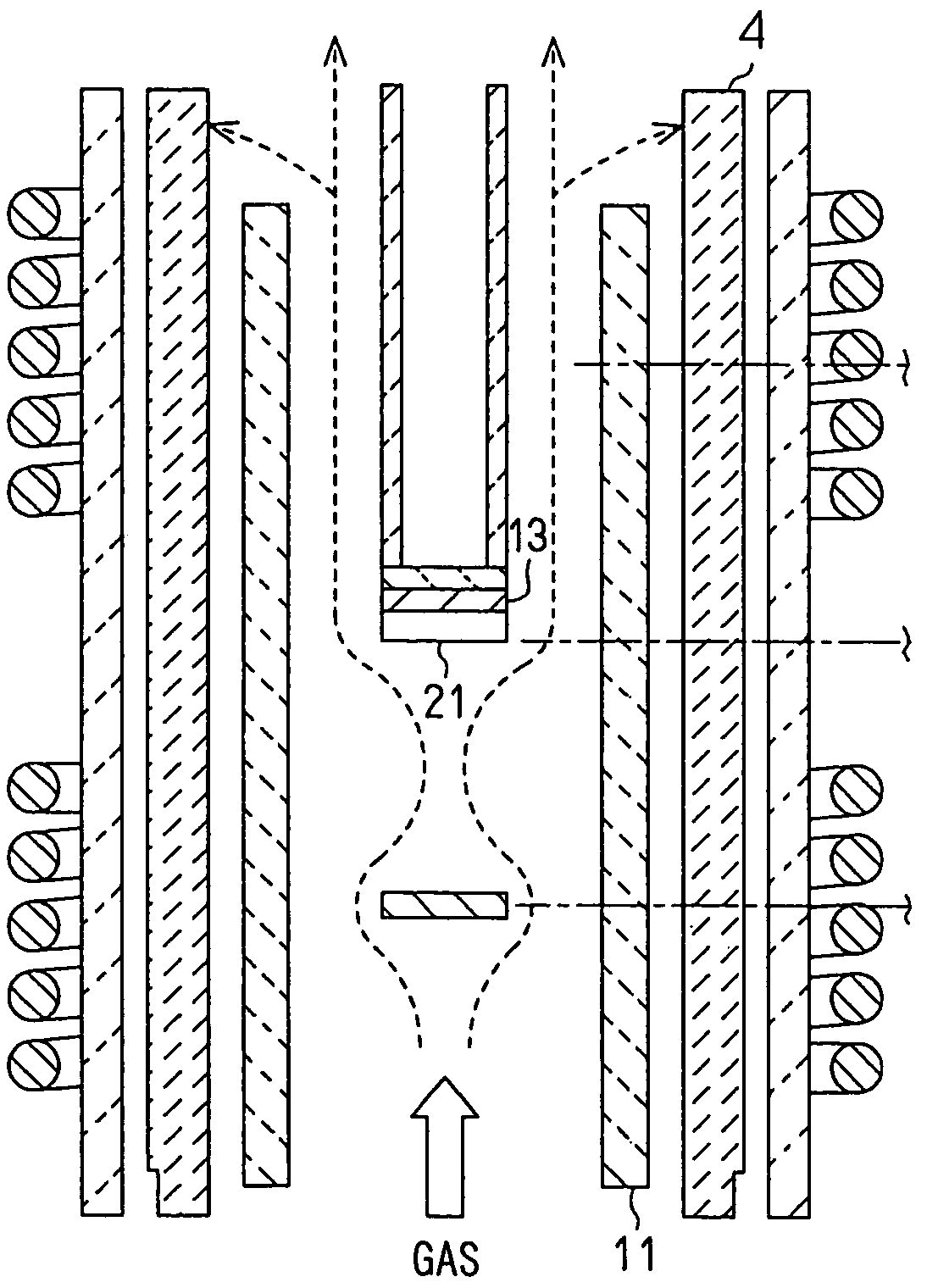

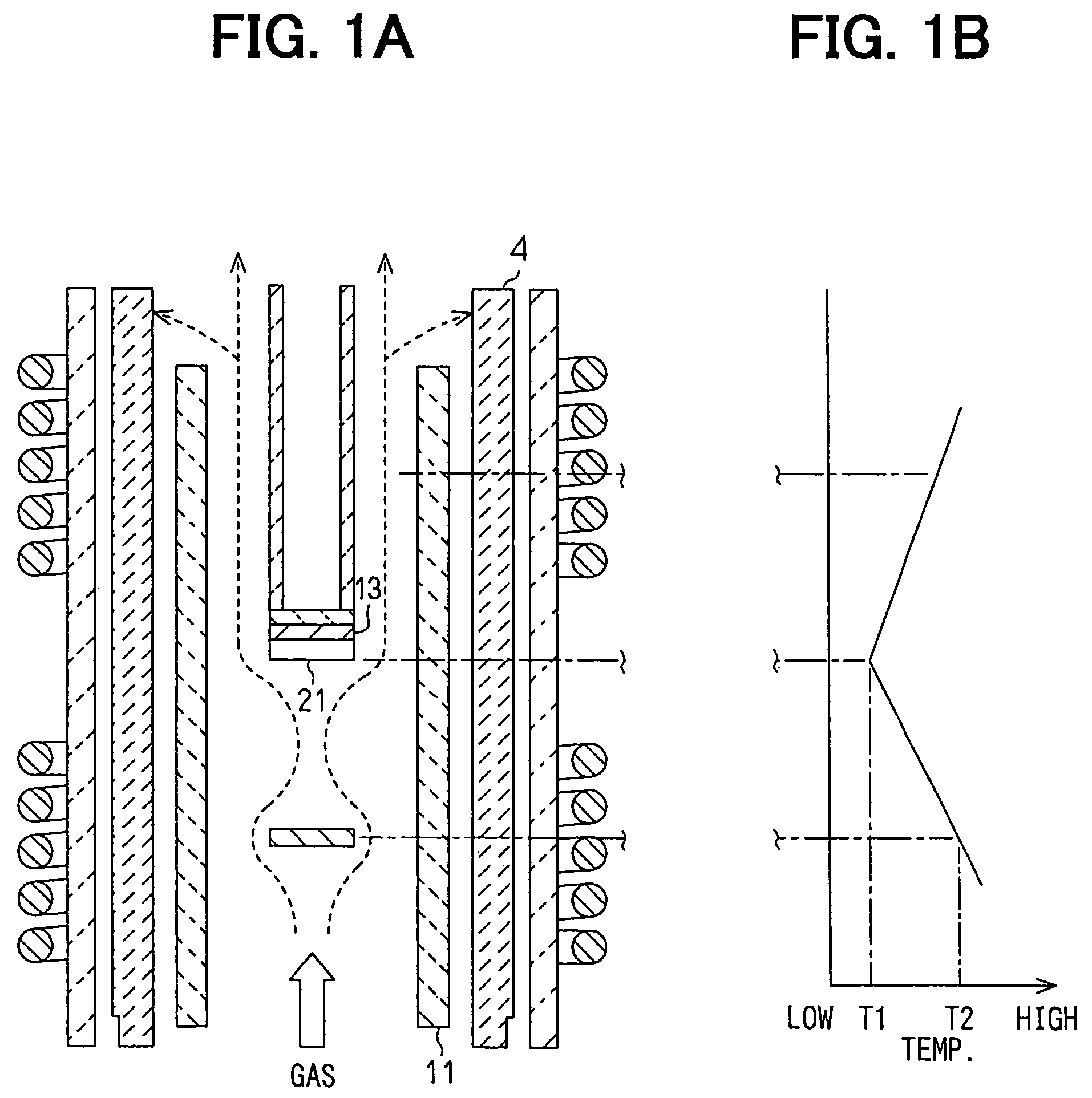

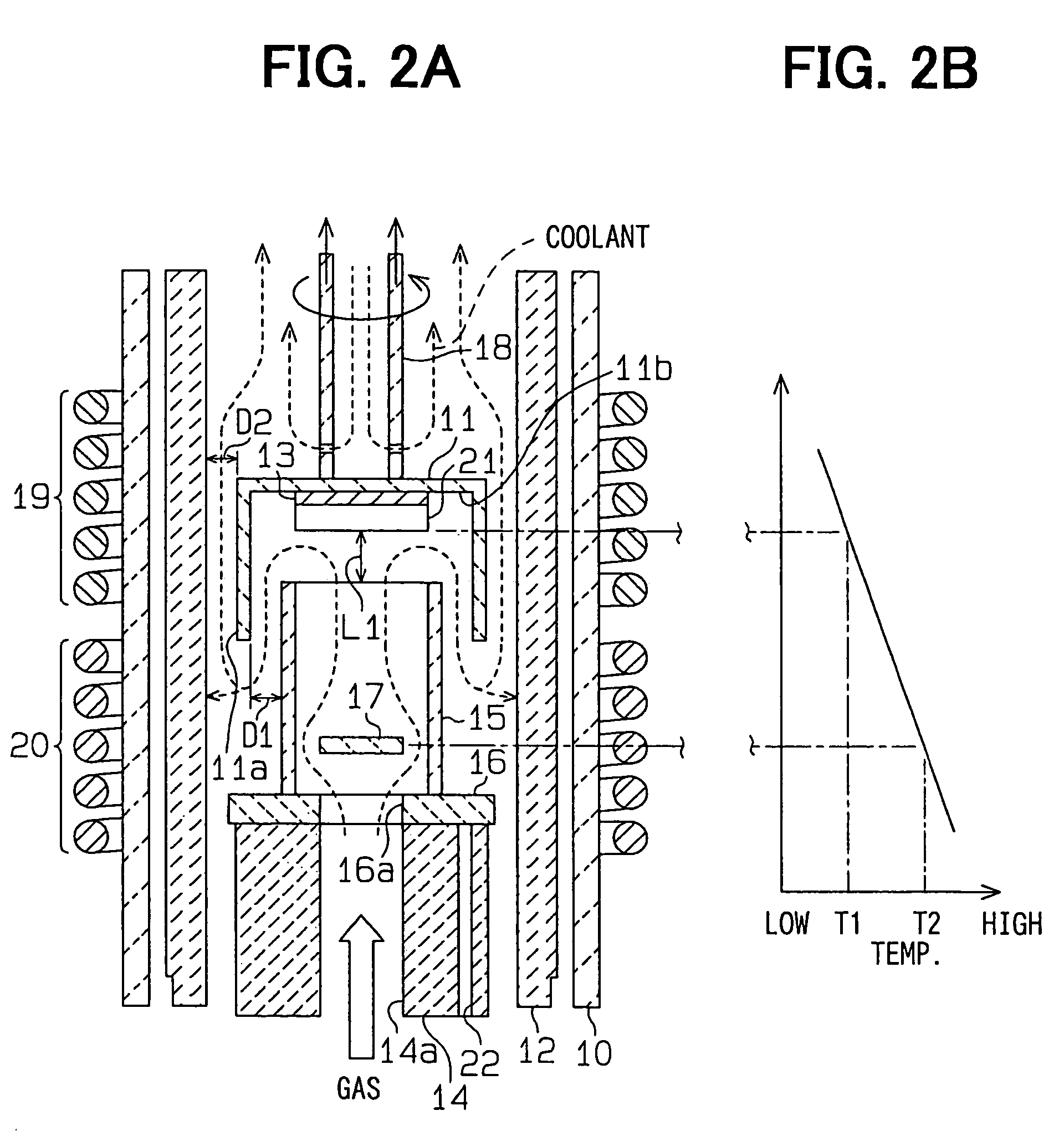

Equipment and method for manufacturing silicon carbide single crystal

ActiveUS7217323B2Growth of crystal growth highLarge temperature differenceAfter-treatment apparatusPolycrystalline material growthProduct gasCrystal growth

Owner:DENSO CORP

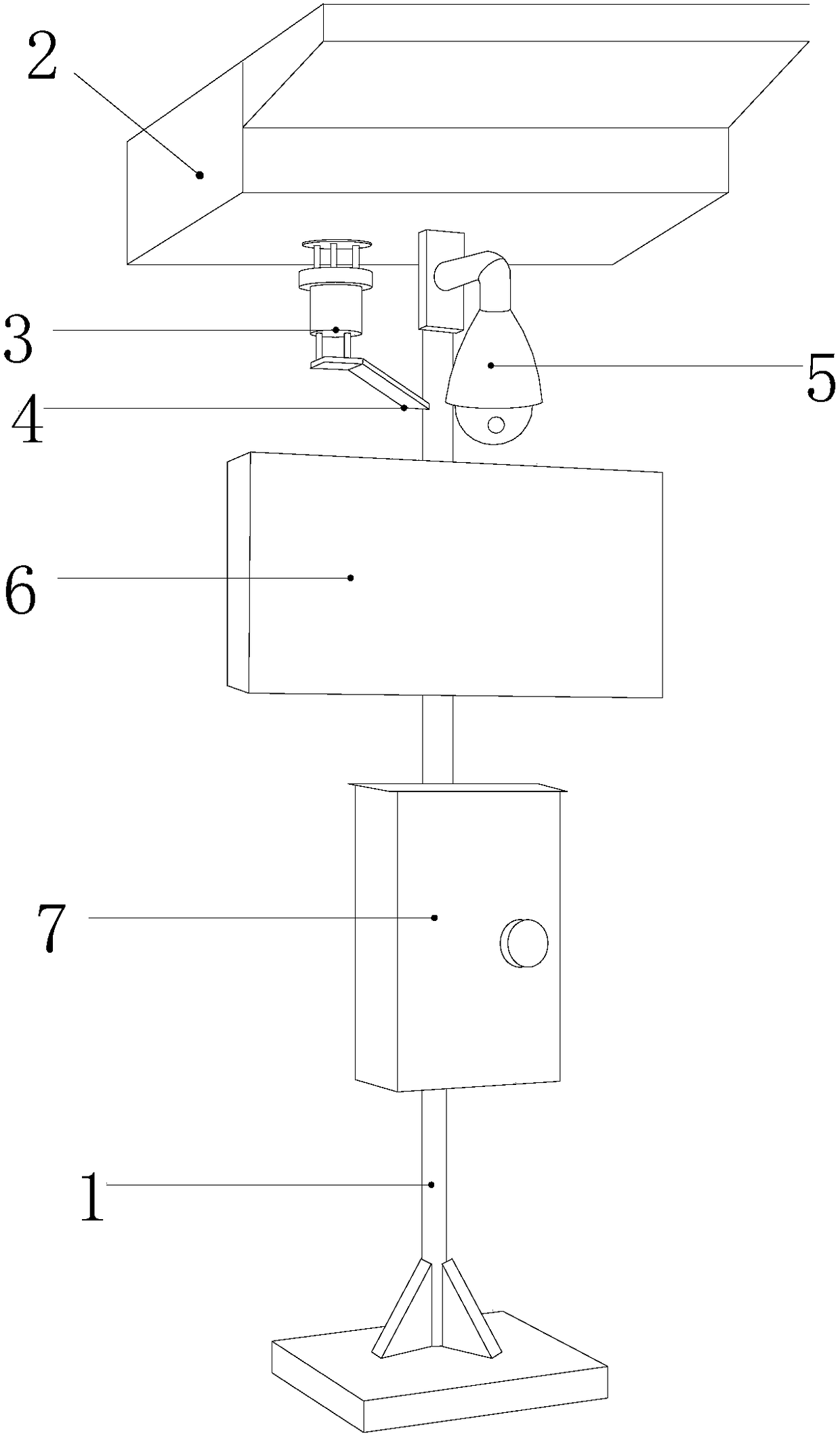

Dust-raising monitoring device for building monitoring

ActiveCN109224724AAvoid sublimationGeneral water supply conservationUsing liquid separation agentStormwaterEngineering

The invention discloses a dust-raising monitoring device for building monitoring. The dust-raising monitoring device structurally comprises a device support seat, a rainwater-accumulation and dust-fall protection device, a dust-raising monitor, a device support plate, a camera, a digital display and a monitoring tank, wherein the top of the device support seat is vertical to the bottom of the rainwater-accumulation and dust-fall protection device and is welded to the bottom of the rainwater-accumulation and dust-fall protection device, the bottom of the rainwater-accumulation and dust-fall protection device is mounted below the dust-raising monitor, and the dust-raising monitor is connected with the device support seat through the support plate. According to the dust-raising monitoring device, rainwater can be guided and collected, a touch point is in a normally open state by virtue of the gravity, and a watering function can be started so as to realize dust fall when much dust is raised around, so that much raised dust can be avoided; and equipment can be mounted above the dust-raising monitor so as to shield rain, so that the situation that rainwater enters the dust-raising monitoring device to sublimate is avoided.

Owner:山东网云信息技术股份有限公司

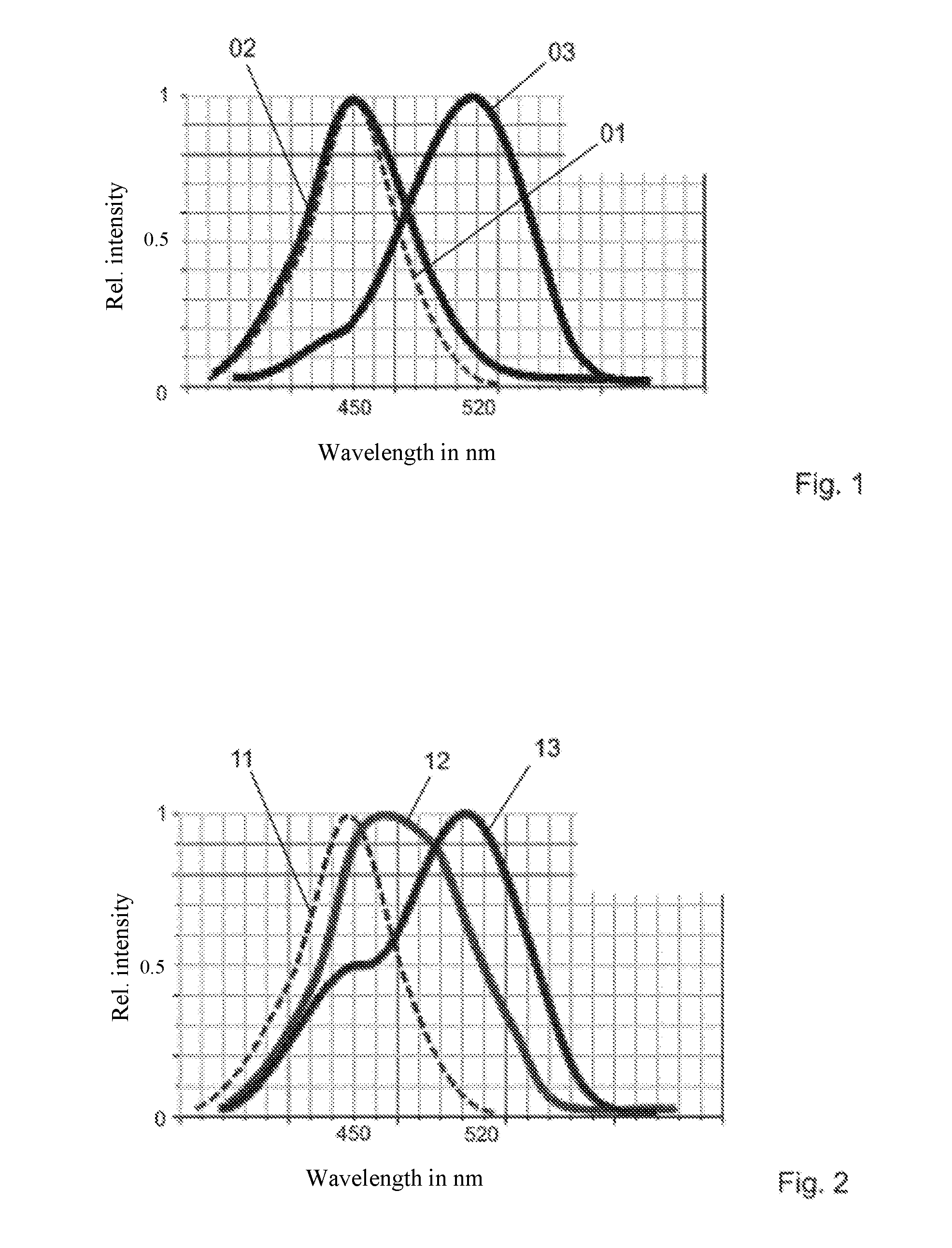

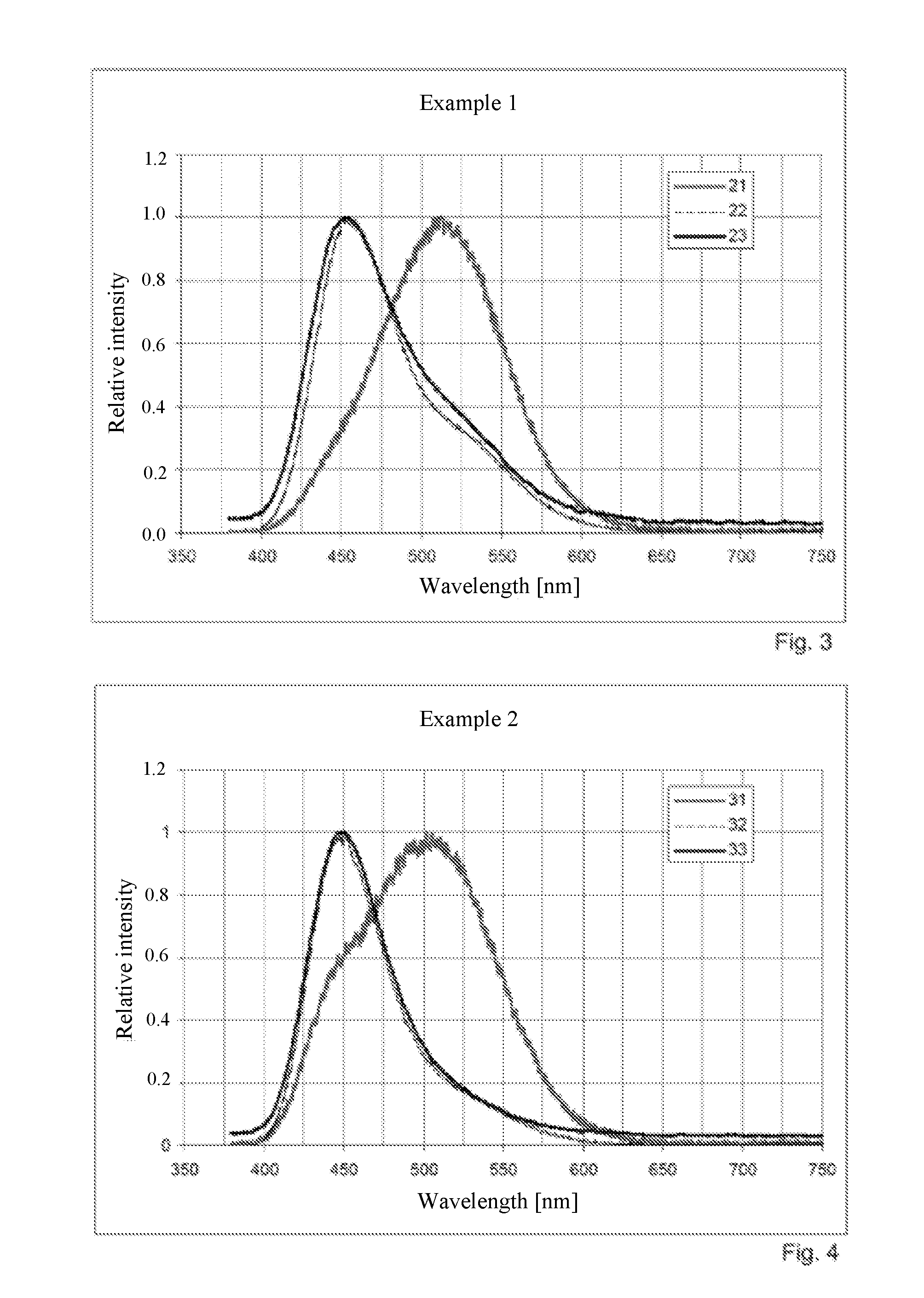

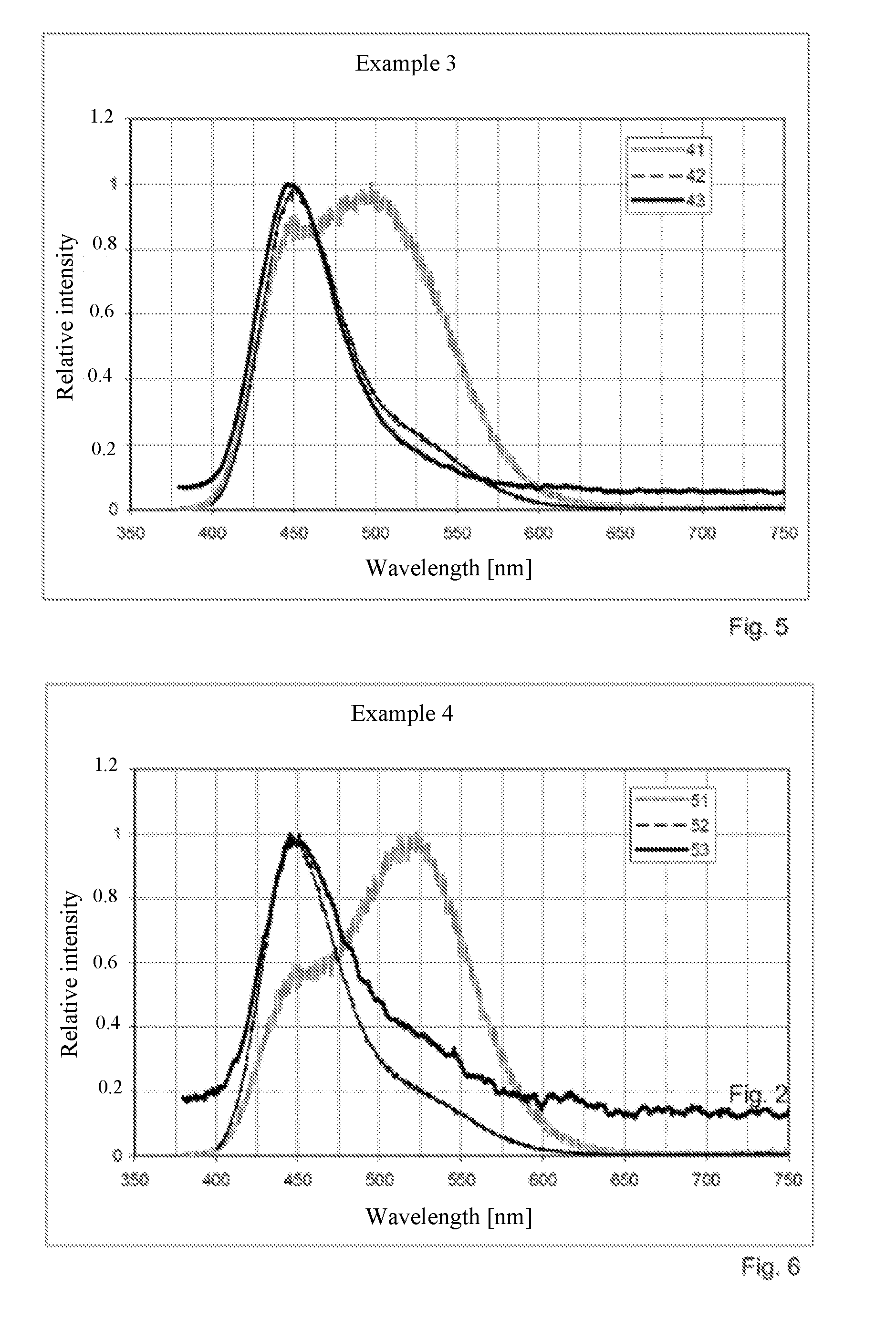

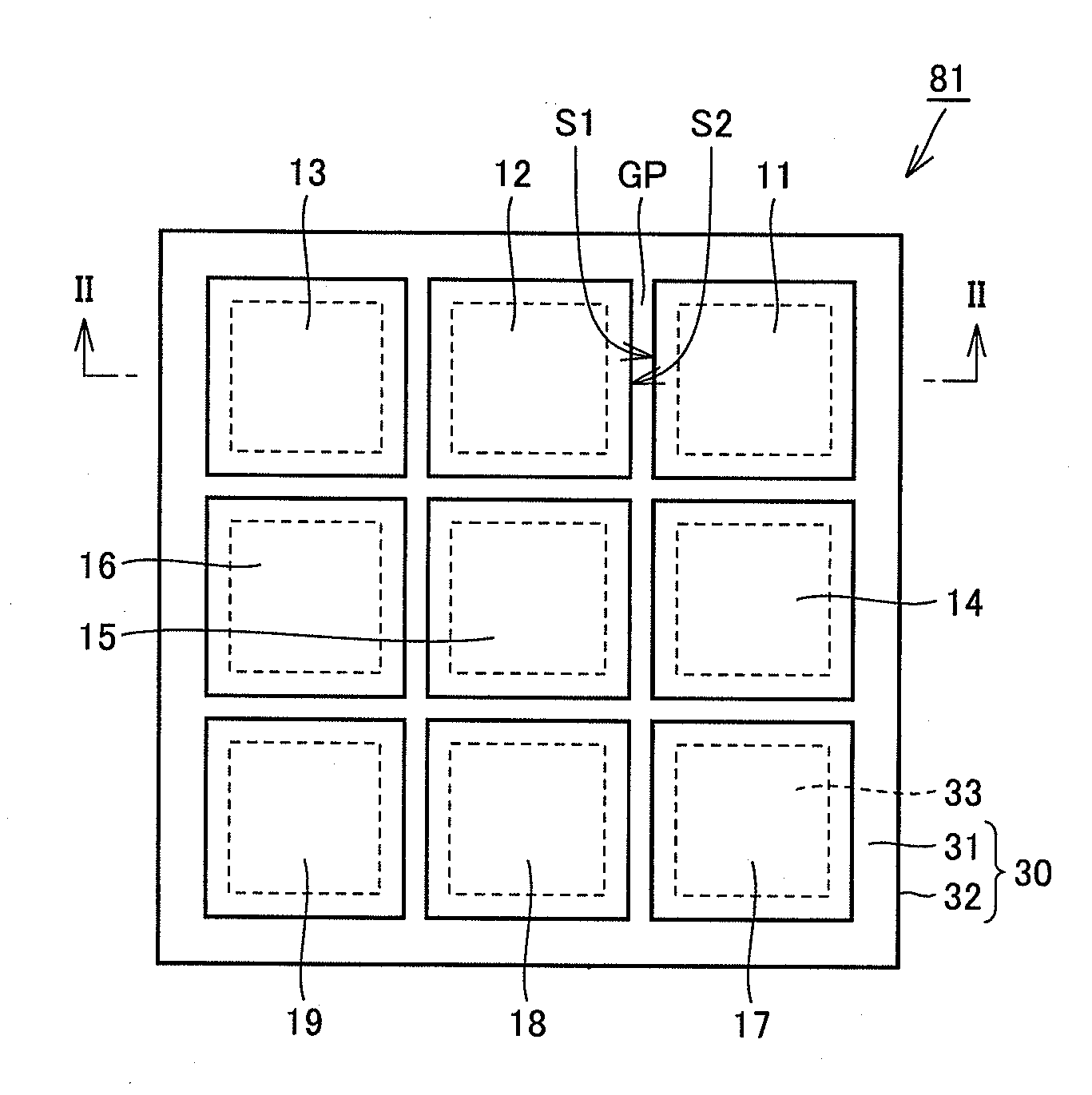

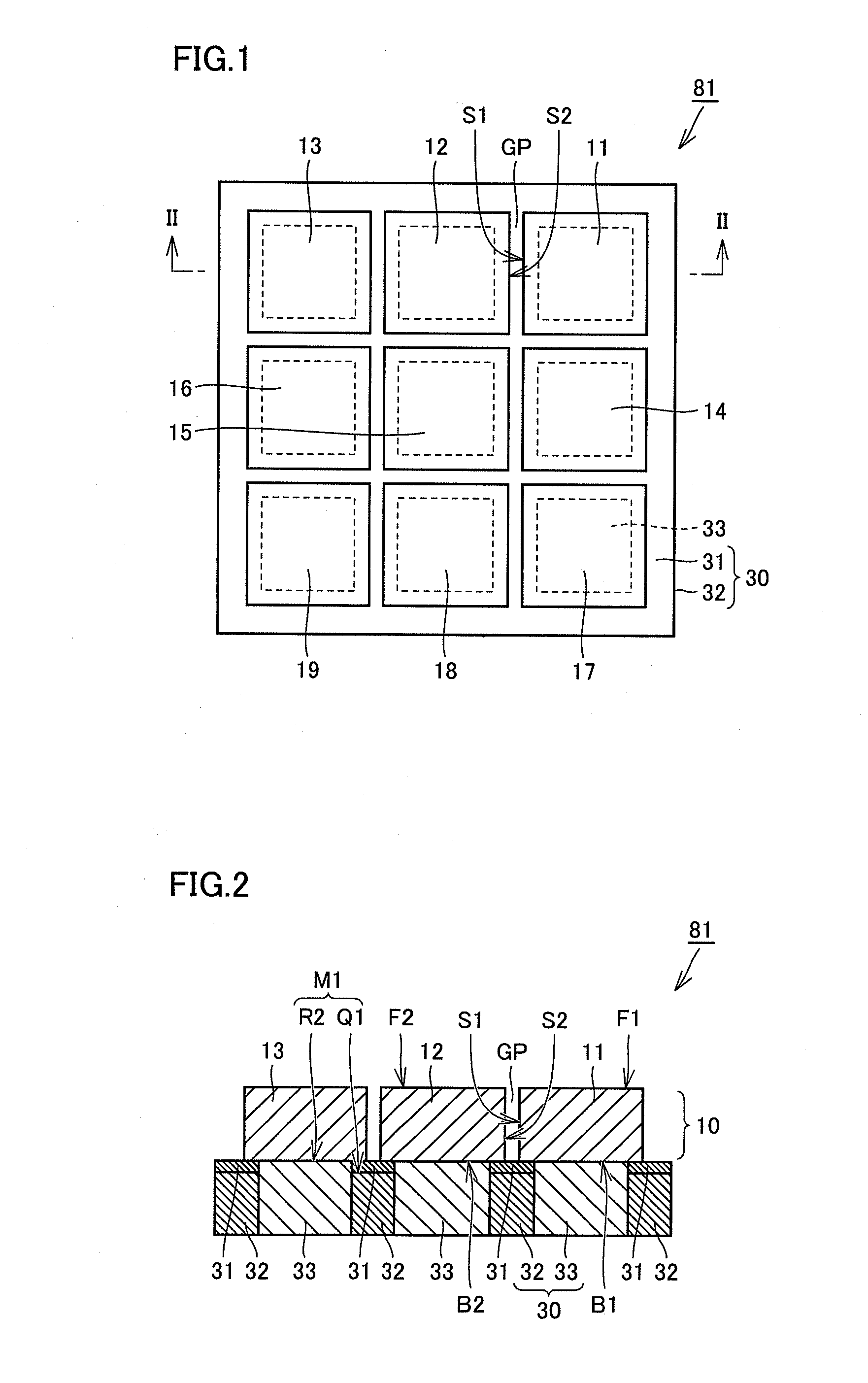

Zinc sulphide phosphor having photo-and electroluminescent properties, process for producing same, and security document, security feature and method for detecting same

ActiveUS20160312115A1Reliable stationaryHigh speed detectionNon-fibrous pulp additionPaper-money testing devicesElectricityPhotoluminescence

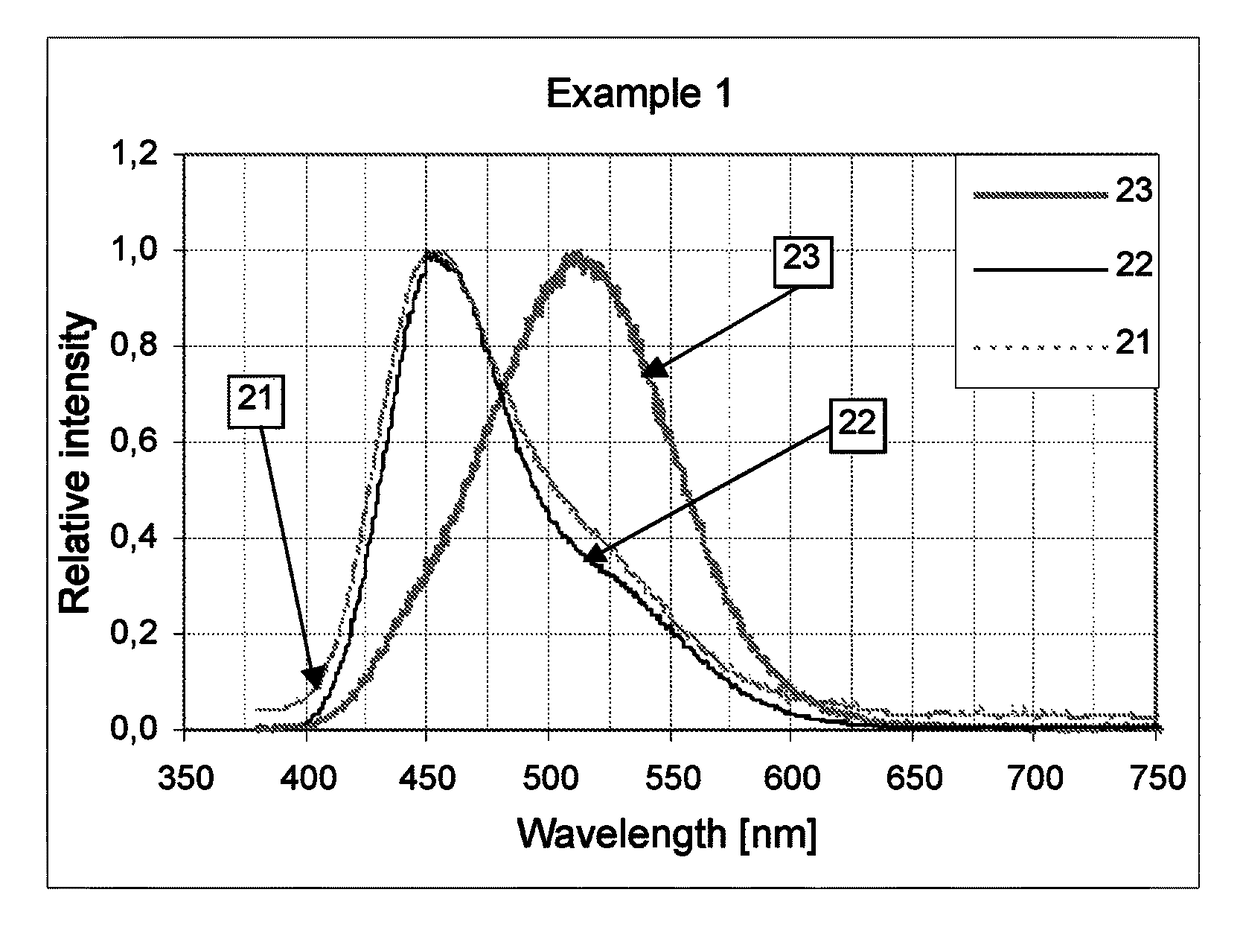

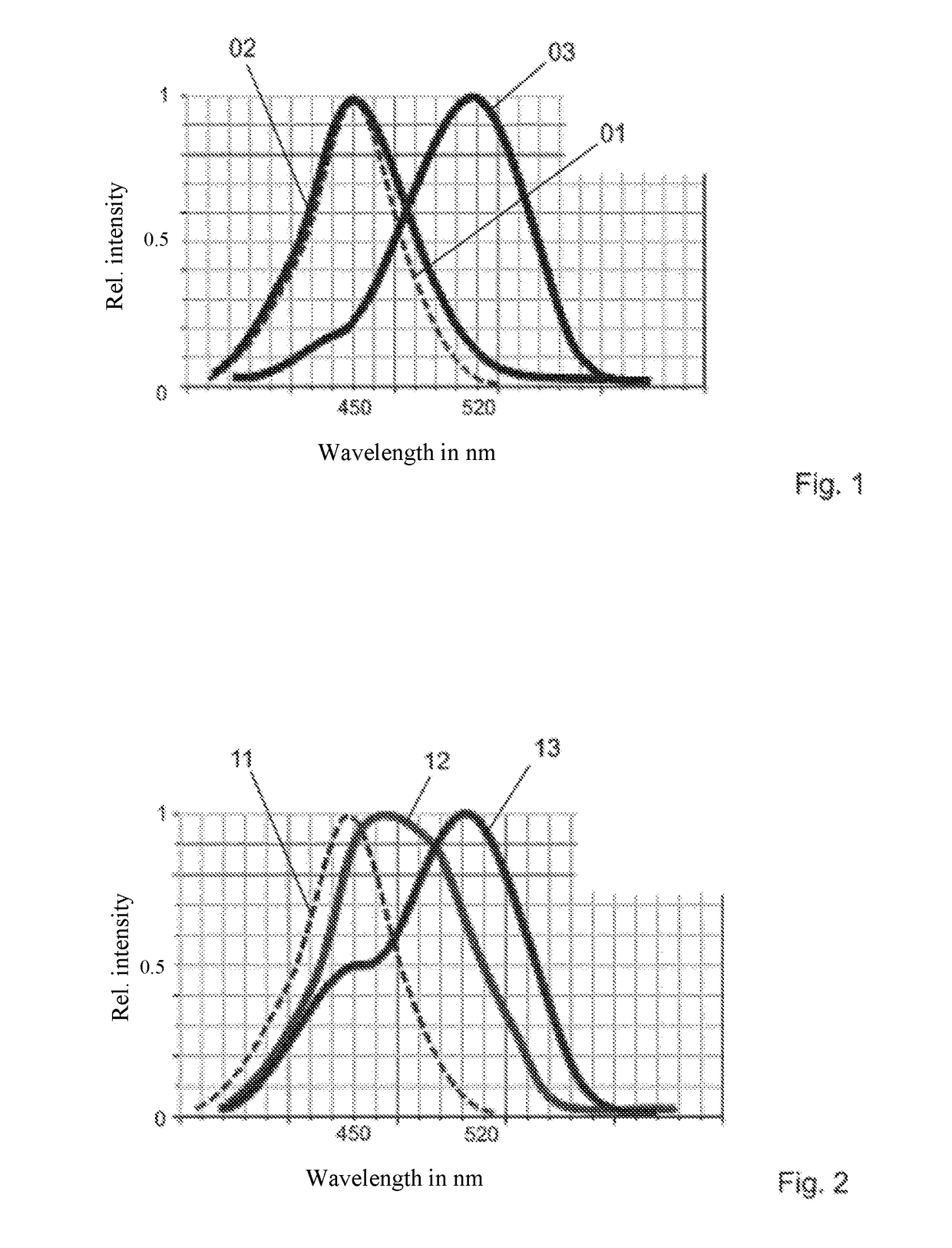

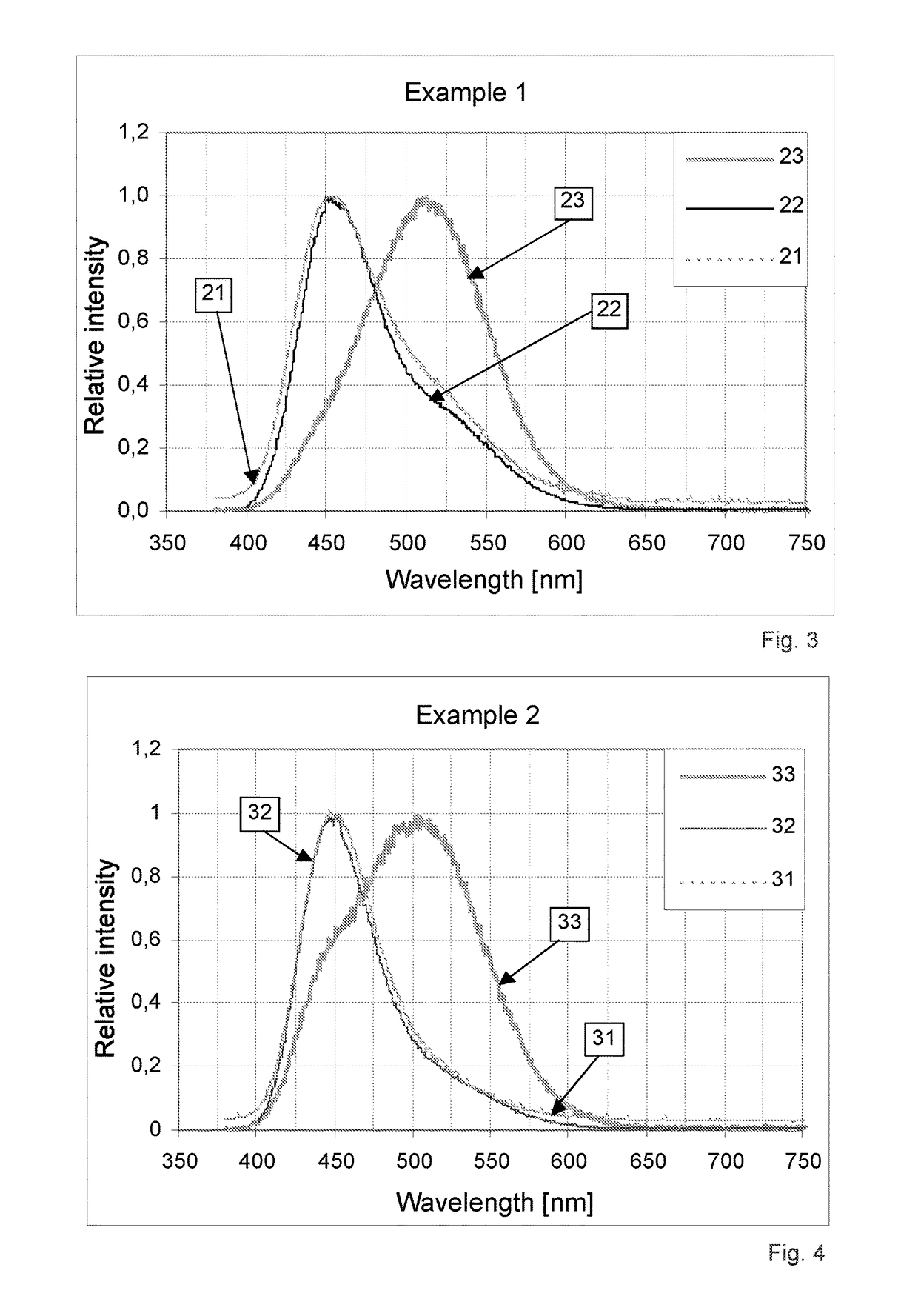

The present invention relates to a zinc sulphide phosphor and to a process for producing same. The invention further relates to a security document or document of value, to a security feature and to a method for detecting same. The phosphor according to the invention can act as electroluminescent phosphor and thus be excited by an electrical field, and this can result in emission of electroluminescent light in the blue and / or green colour region of the visible spectrum. The phosphor can moreover be excited by UV radiation in the wavelength range from 345 nm to 370 nm, and can thus emit photoluminescent light in the blue colour region of the visible spectrum. The phosphor can moreover be excited by UV radiation in the wavelength range from 310 nm to 335 nm, and can thus emit photoluminescent light in the green colour region of the visible spectrum.

Owner:LEUCHTSTOFFWERK BREITUNGEN +1

Silicon carbide substrate and method for manufacturing silicon carbide substrate

InactiveUS20110262681A1Inhibition formationAvoid sublimationPolycrystalline material growthAfter-treatment detailsCarbon layerOptoelectronics

A carbon layer is formed on a first region of a main surface of a material substrate. On the material substrate, first and second single-crystal layers are arranged such that each of a first backside surface of the first single-crystal layer and a second backside surface of the second single-crystal layer has a portion facing a second region of the main surface of the material substrate and such that a gap between a first side surface of the first single-crystal layer and a second side surface of the second single-crystal layer is located over the carbon layer. By heating the material substrate and the first and second single-crystal layers, a base substrate connected to each of the first and second backside surfaces is formed. In this way, voids can be prevented from being formed in the silicon carbide substrate having such a plurality of single-crystal layers.

Owner:SUMITOMO ELECTRIC IND LTD

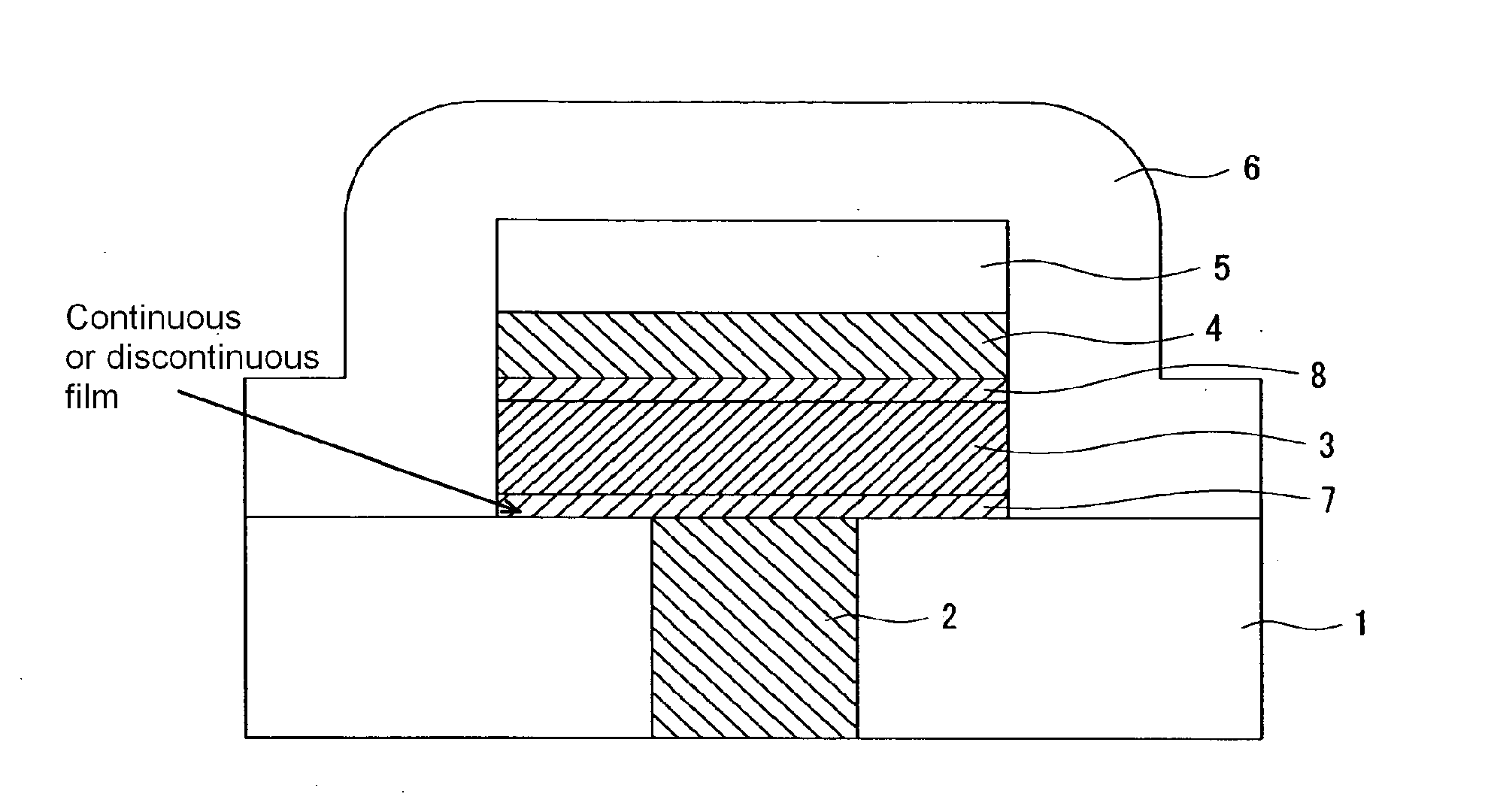

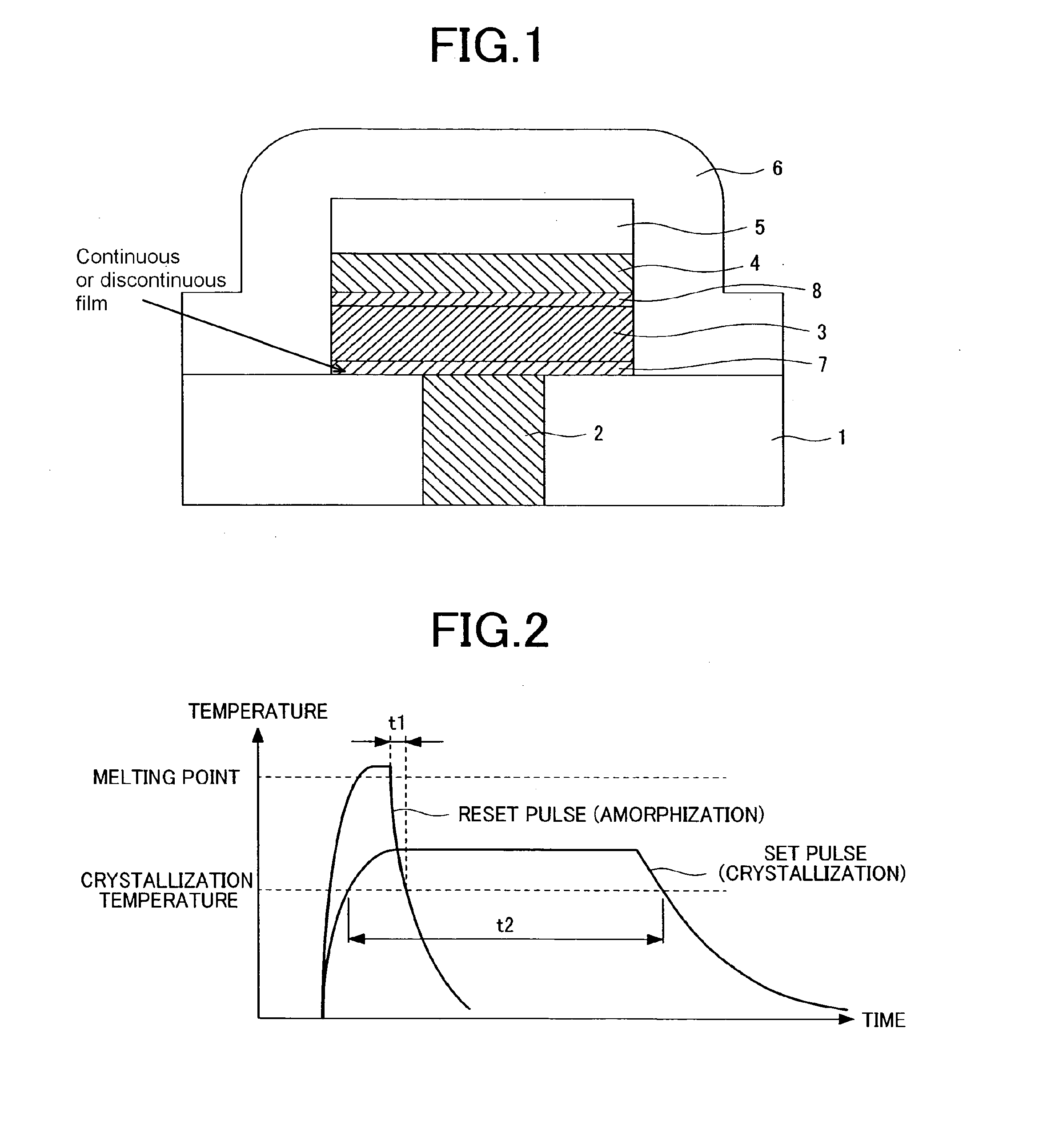

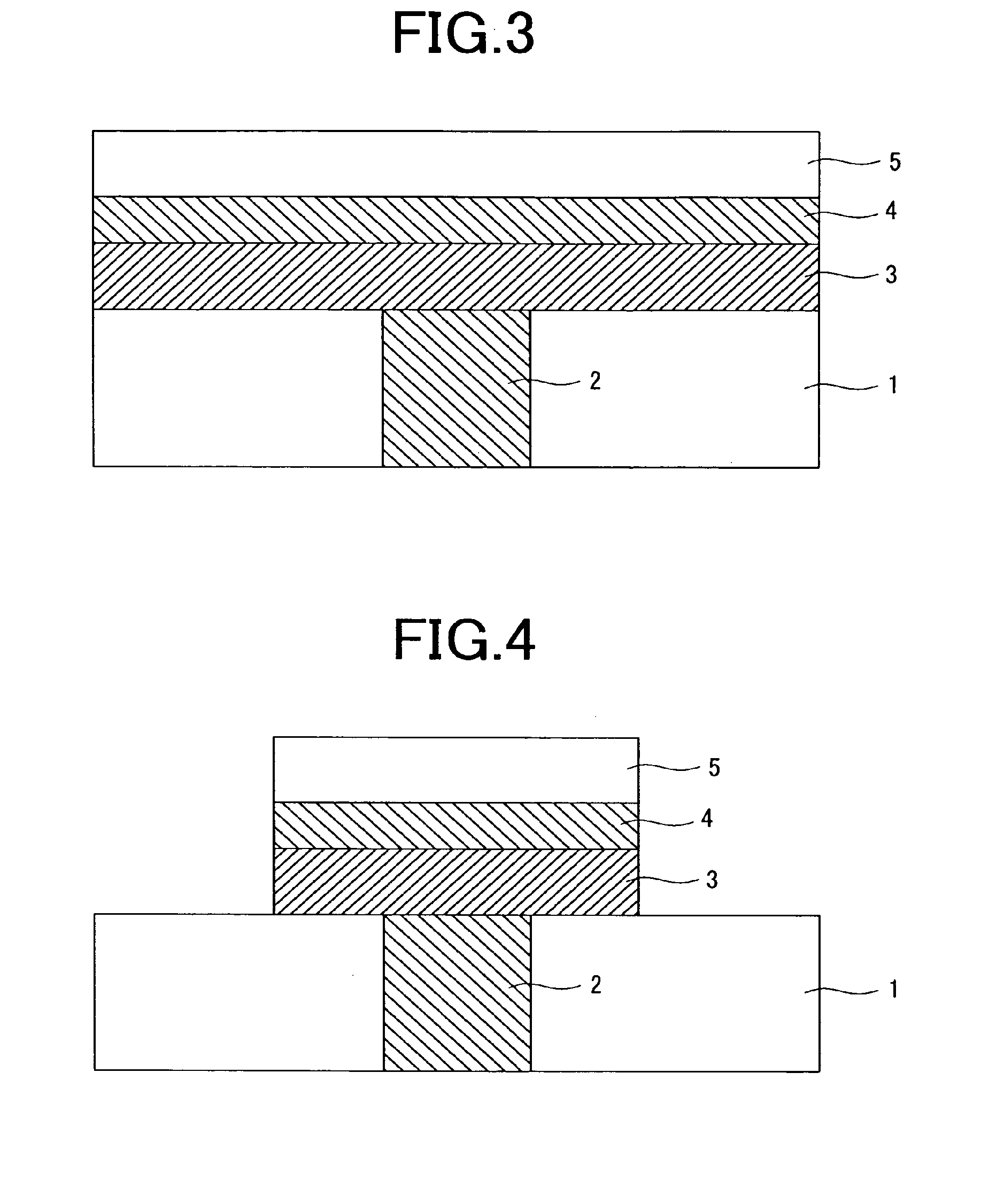

Semiconductor memory

ActiveUS20100044672A1Avoid layeringAvoid sublimationSolid-state devicesBulk negative resistance effect devicesPhase-change memoryManufacturing technology

Manufacturing processes for phase change memory have suffered from the problem of chalcogenide material being susceptible to delamination, since this material exhibits low adhesion to high melting point metals and silicon oxide films. Furthermore, chalcogenide material has low thermal stability and hence tends to sublime during the manufacturing process of phase change memory. According to the present invention, conductive or insulative adhesive layers are formed over and under the chalcogenide material layer to enhance its delamination strength. Further, a protective film made up of a nitride film is formed on the sidewalls of the chalcogenide material layer to prevent sublimation of the chalcogenide material layer.

Owner:RENESAS ELECTRONICS CORP

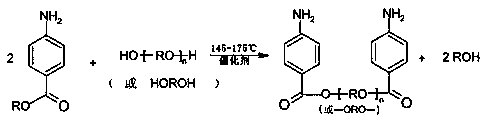

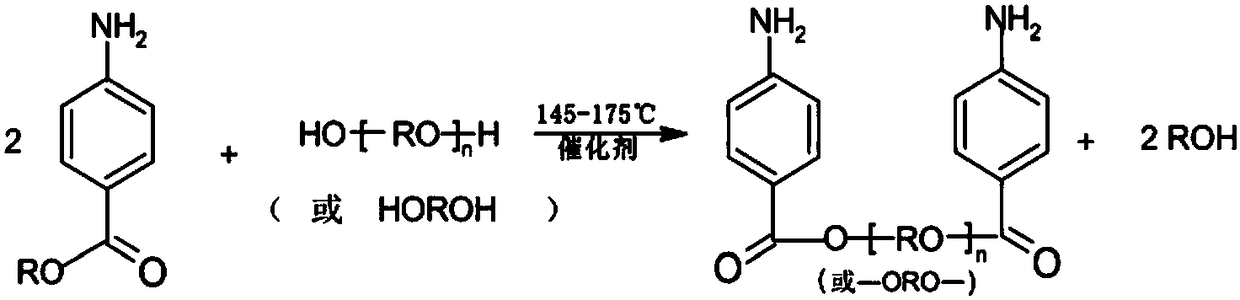

Method for preparing ether, alkyl diol-bis (p-aminobenzoate)

InactiveCN108329222AGuaranteed contentShorten the timeOrganic compound preparationAmino-carboxyl compound preparationBenzoic acidEther

The invention provides a method for preparing ether, alkyl diol-bis (p-aminobenzoate). The technology for preparing the compound comprises the following steps: ether diol or alkyl diol is used as a raw material of bridge formation, an ester interchange reaction is carried out for the material and an ester of para amino benzoic acid short chain under the effects of a high efficient catalyst, the reaction is carried out at low temperature and high temperature two reaction segments, a solvent employs mixed xylenes which are mixed according to a certain proportion, and a one pot process is used for finally obtaining a light color product with high purity. The content of the target product is analyzed by high performance liquid chromatography and reaches 99% or above, monoester is less than 1%,a volatile matter (100 DEG C / 10 torr) is less than 0.2%, heat loss at 220 DEG C / 5 torr is 0.1% or below, and consumption of short chain ester of para amino benzoic acid approaches to a theoretical amount.

Owner:江苏湘园化工有限公司

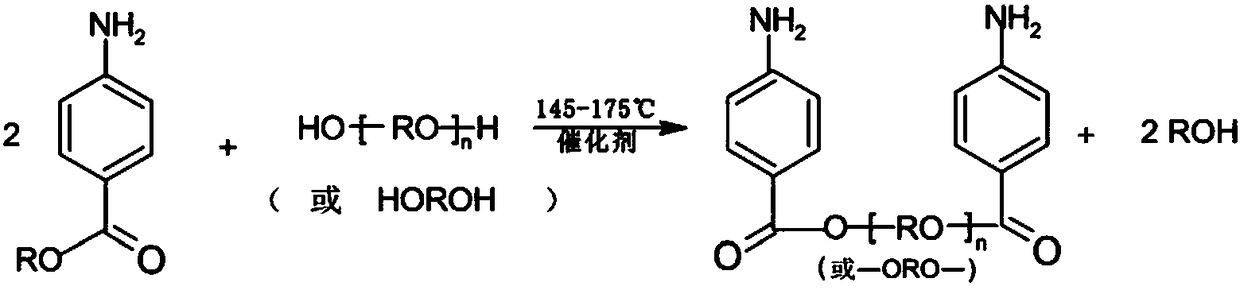

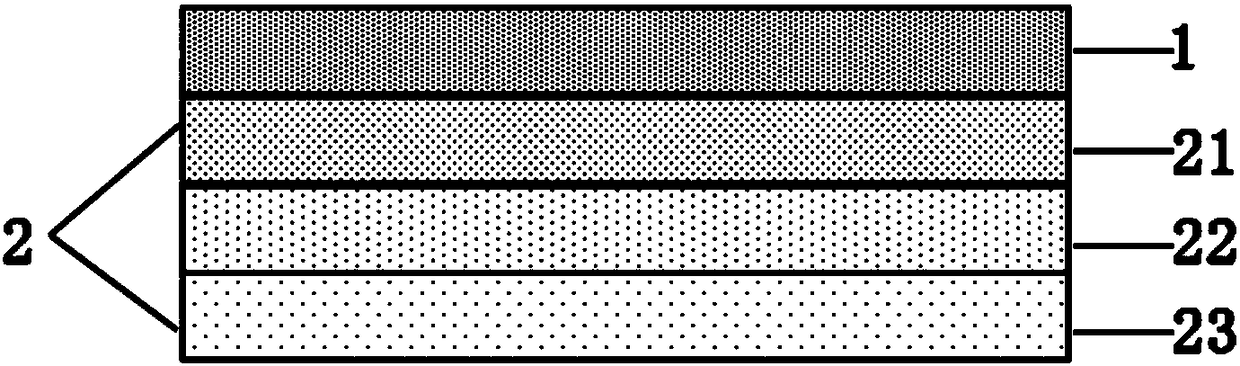

Anti-sublimation and water washing-resistant decorative film for textiles and preparation method thereof

ActiveCN108264859ASoft touchGood washing resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesTextilePolymer

The invention belongs to the technical field of polymer decoration and clothing and particularly relates to an anti-sublimation and water washing-resistant decorative film for textiles and a preparation method thereof. The anti-sublimation and water washing-resistant decorative film for textiles is composed of a matte PET release film and a coating layer on the matte surface of the matte PET release film. The coating layer comprises an anti-sublimation layer, an intermediate treated layer and a glue layer from inside to outside. The anti-sublimation and water washing-resistant decorative filmis soft, has good water washing resistance and dry washing resistance, effectively prevents the sublimation and migration of the textile fabric color, can adapt to various styles of textile and garment designs, and can adapt to textiles with color fastness of 1 to 5 level. The anti-sublimation and water washing-resistant decorative film is easy to operate in use and has a good application prospect.

Owner:GUANGDONG YETOM NEW MATERIALS CO LTD

Zinc sulphide phosphor having photo- and electroluminescent properties, process for producing same, and security document, security feature and method for detecting same

ActiveUS9670406B2Avoid sublimationReduce spendingNon-fibrous pulp additionPaper-money testing devicesPhotoluminescencePhosphor

The present invention relates to a zinc sulphide phosphor and to a process for producing same. The invention further relates to a security document or document of value, to a security feature and to a method for detecting same. The phosphor according to the invention can act as electroluminescent phosphor and thus be excited by an electrical field, and this can result in emission of electroluminescent light in the blue and / or green color region of the visible spectrum. The phosphor can moreover be excited by UV radiation in the wavelength range than 345 nm to 370 nm, and can thus emit photoluminescent light in the blue color region of the visible spectrum. The phosphor can moreover be excited by UV radiation in the wavelength range from 310 nm in 335 nm, and can thus emit photoluminescent light in the green color region of the visible spectrum.

Owner:LEUCHTSTOFFWERK BREITUNGEN +1

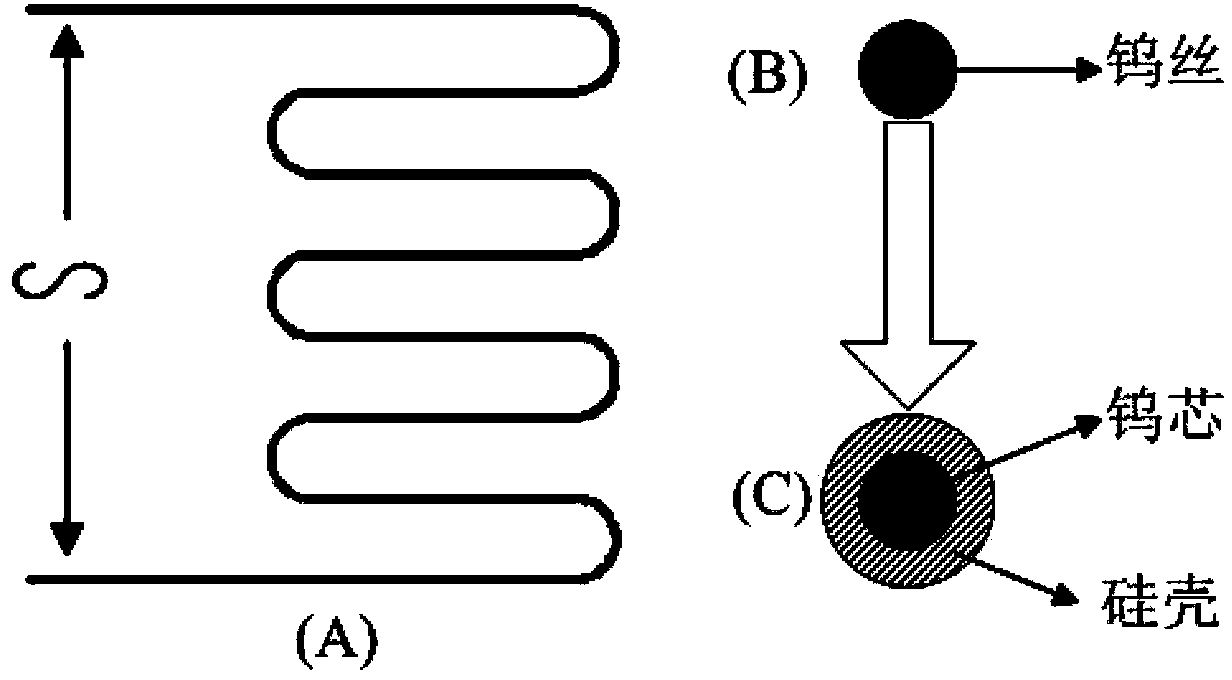

Silicon shell tungsten core heater strip and preparation method

InactiveCN103428908AAvoid sublimationExtended service lifeHeating element materialsChemical vapor deposition coatingMaterials preparationGas phase

The invention discloses a silicon shell tungsten core heater strip and a preparation method thereof, and belongs to the technical field of heating material preparation. High-purity silicon wraps the outer surface of a tungsten wire to form the heater strip. The preparation method includes the steps: winding the tungsten wire into a needed shape and placing the tungsten wire into a chemical vapor deposition reaction furnace; depositing the high-purity silicon on the surface of the tungsten wire through chemical vapor deposition reaction. The heater strip can be widely applied to various vacuum devices needing to be heated, and can stably and effectively provide heat sources for a system for along time.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

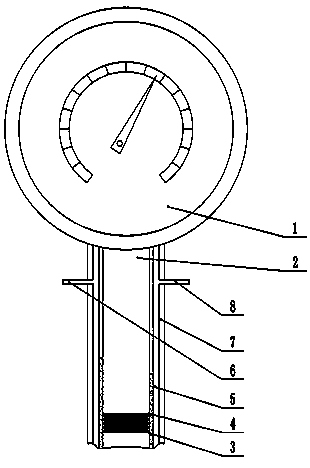

Anti-freezing water pressure gauge for corrugated pipe

InactiveCN104280181ADoes not affect pressure transfer performanceAvoid boilingFluid pressure measurement using elastically-deformable gaugesAnti freezingEngineering

The invention discloses an anti-freezing water pressure gauge for a corrugated pipe and belongs to the field of instruments. The anti-freezing water pressure gauge for the corrugated pipe comprises a gauge head and a connector, wherein the connector is sequentially wrapped in an overheating resisting layer, a heating layer and a heat insulating layer. The overheating resisting layer is filled with an anti-freezing solution. The heating layer is a cavity formed between the overheating resisting layer and the heat insulating layer. Two symmetrical through holes are formed in the heating layer and the heat insulating layer. A water inlet pipeline and a water outlet pipeline penetrate through the through holes respectively to enter the heating layer. By the adoption of the anti-freezing water pressure gauge, the problem that measurement is not accurate when a water pressure gauge is used outdoor in cold weather is solved.

Owner:成都卓微科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com