Levelling agent and preparation method and application thereof

A technology of leveling agent and solvent, which is applied in the field of textile printing and dyeing, and can solve problems such as the inability to achieve dyeing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

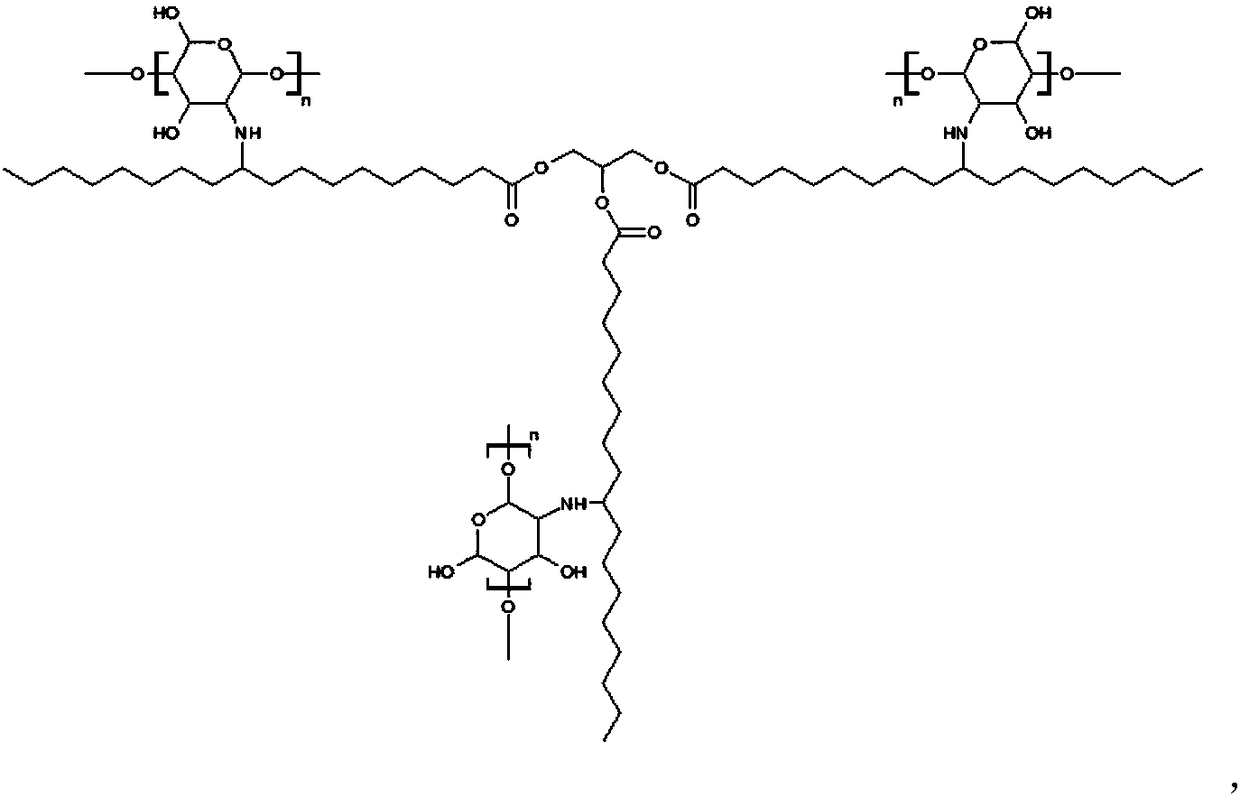

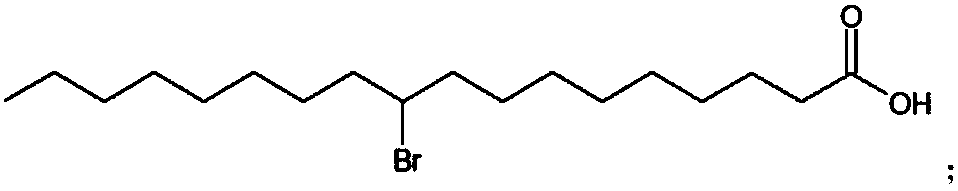

[0071] Step 1: Preparation of halogenated crosslinking agent

[0072] Under the condition of ice-water bath, add oleic acid, hydrogen bromide, and chloroform respectively in a certain mass ratio to the three-necked flask, reflux with a straight condenser tube, stir, and react for 30-50 minutes, wash the product with water until it is neutral, add distilled bottle, and placed in a constant temperature water bath at 70-75°C to distill off the solvent chloroform and unreacted hydrogen bromide to obtain the yellow product A.

[0073] The mass ratio of oleic acid, hydrogen bromide and chloroform is: 1:0.28-0.35:1.78-2.14.

[0074] The equation for the reaction is:

[0075]

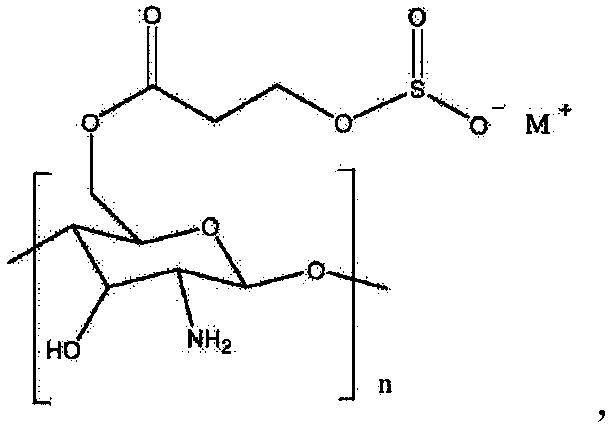

[0076] Step 2: Chitosan Modification

[0077] Add chitosan, sodium hydroxide, and product A to carbon tetrachloride in a certain proportion, stir at 80-100°C, react for 3-4 hours, and distill under reduced pressure at 40°C to obtain product B. Wherein chitosan selects the relative molecular mass produced ...

Embodiment 2

[0094] The overall idea of embodiment 2 is carried out according to embodiment 1, and specific parameters are as follows:

[0095] The mass ratio of oleic acid, hydrogen bromide, and chloroform in step one is set as: 1:0.28:1.78, and product A is obtained by distillation at 70 ° C, and then chitosan, sodium hydroxide, product A, tetrachloromethane The mass ratio of carbonization is set as: 1:0.50:2.30:5.00, react at 80°C for 3 hours to obtain product B, and then set the mass ratio of glycerin, product B, catalyst, and toluene in step 3 as: 1:16.50 : 0.07: 4.00, product C was obtained by reacting at 140°C for 4 hours.

[0096] In step four, disperse red 3B, sodium lauryl sulfate, glycerin, and dispersant are ground with mass fractions of 2wt%, 3wt%, 2wt%, and 1wt% to prepare nano dyes, and then use 1.0g / L Add product C, add acetic acid to adjust the pH value of the dyeing slurry to 5.5, choose 190T, 58g / m 2 For polyester taffeta, according to step 4 dyeing method 1, set the...

Embodiment 3

[0097] The overall idea of embodiment 3 is carried out according to embodiment 1, and specific parameters are as follows:

[0098] The mass ratio of oleic acid, hydrogen bromide, and chloroform in step one is set as: 1:0.31:2.00, and product A is obtained by distillation at 73°C, and then chitosan, sodium hydroxide, product A, tetrachloromethane The mass ratio of carbonization is set as: 1:0.55:2.35:5.50, react at 90°C for 3.5 hours to obtain product B, and then set the mass ratio of glycerin, product B, catalyst, and toluene in step 3 as: 1:17.00 : 0.08: 4.10, reacted at 145°C for 4.5 hours to obtain product C.

[0099] In step 4, disperse yellow G, sodium lauryl sulfate, glycerin, dispersant are ground with the mass fraction of 3.5wt%, 4wt%, 2.5wt%, 1.5wt%, prepare nano-dye, then with 1.5g / Add the amount of L to solid C, add acetic acid to adjust the pH value of the dyeing slurry to 6.0, choose 300T, 63g / m 2 Pongee, according to step 4 dyeing method 1, set the fabric ru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com