Patents

Literature

685results about How to "Improve dyeing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environment-friendly type terylene low temperature dyeing assistant with alkyl phthalic imide as vector and preparation thereof

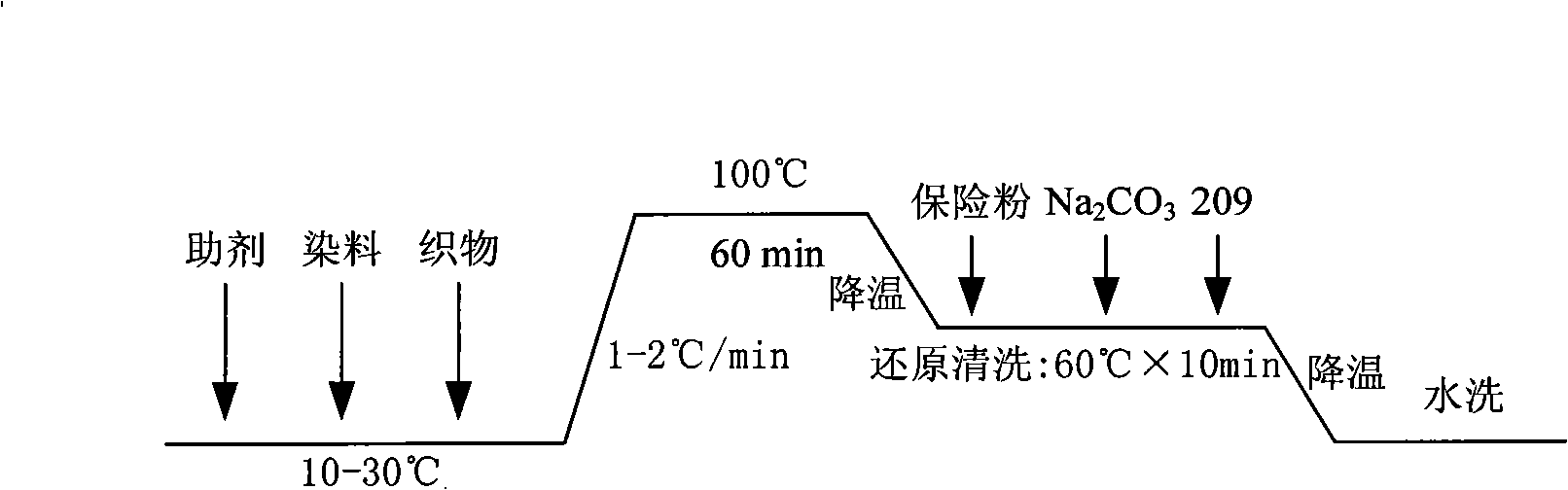

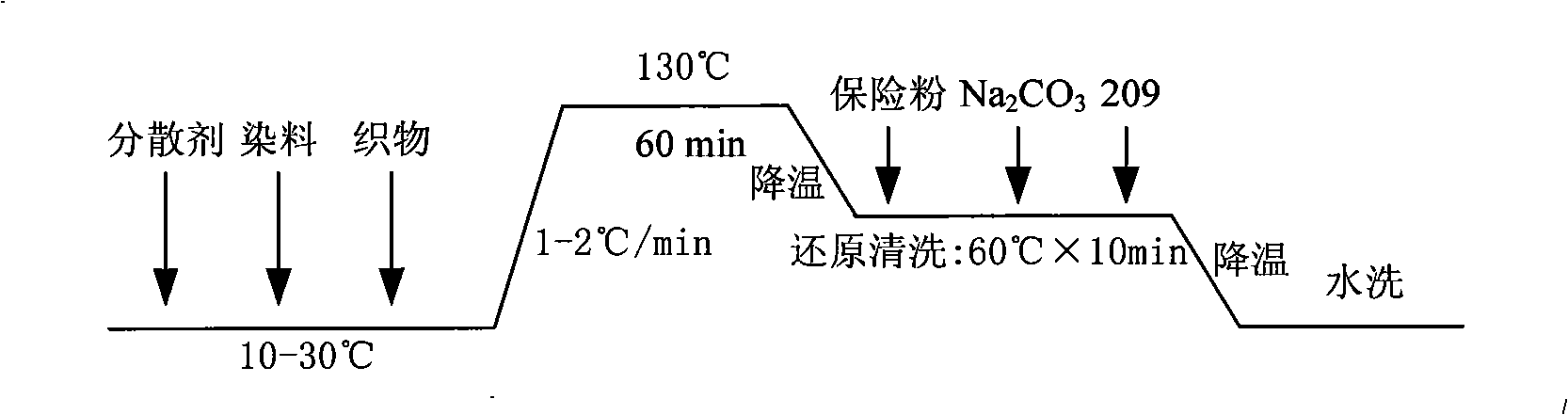

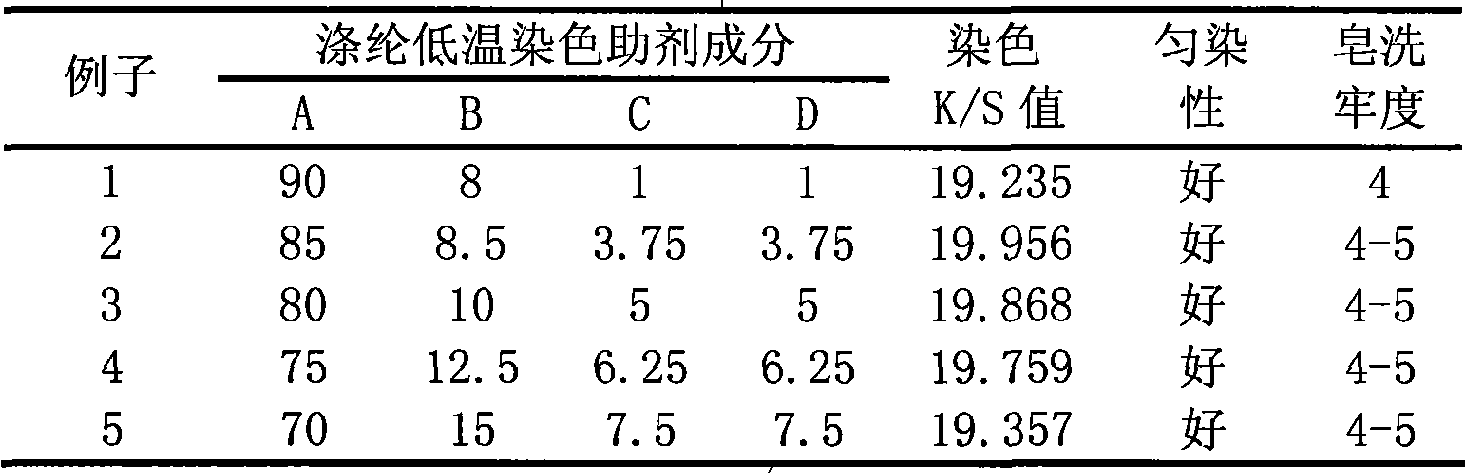

The invention discloses an environment-friendly terylen low-temperature dyeing auxiliary agent taking alkyl phthalimide as a carrier and a preparation method thereof. The compositions in percentage by weight of the dyeing auxiliary agent are: 70 to 90 percent of alkyl phthalimide compound, 8 to 15 percent of concentrated emulsion 8206, 1 to 7.5 percent of castor oil polyoxyethylene ether sulphonated matter and 1 to 7.5 percent of alkyl phenol polyoxyethylene ether, wherein the alkyl phthalimide is takes as the carrier; and the concentrated emulsion 8206, the castor oil polyoxyethylene ether sulphonated matter and the alkyl phenol polyoxyethylene ether are takes as an emulsifying agent. The environment-friendly terylen low-temperature dyeing auxiliary agent is used in low-temperature dyeing of terylen and terylen-containing textile fabrics; moreover, the dyeing auxiliary agent not only has the characteristics of nontoxicity, tastelessness, environmental protection and low cost, etc., but also has the advantages of high dye uptake, excellent level dyeing property, high dyeing fastness and wide application range, etc., thereby meeting the requirements of low-temperature dyeing production of terylen-containing textile fabrics.

Owner:ZHEJIANG SCI-TECH UNIV +1

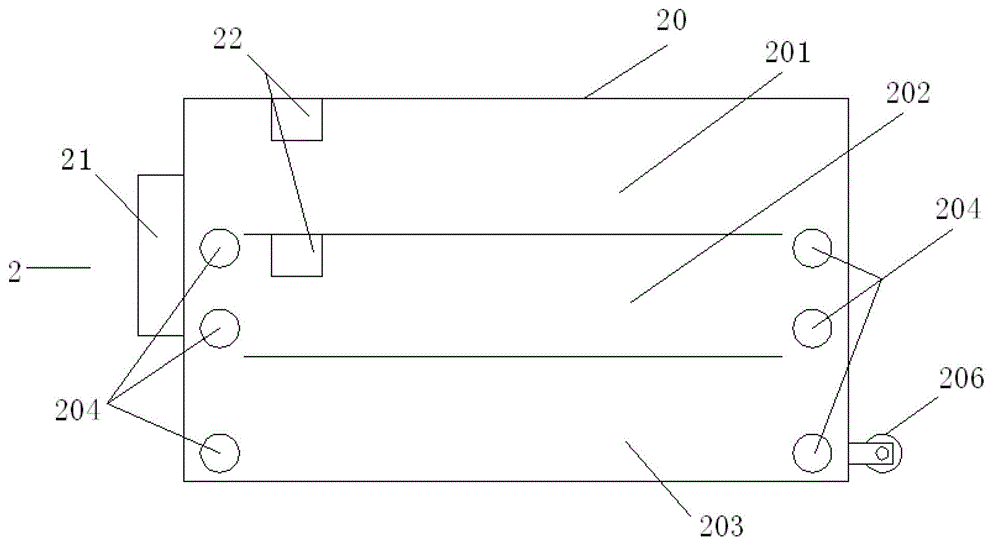

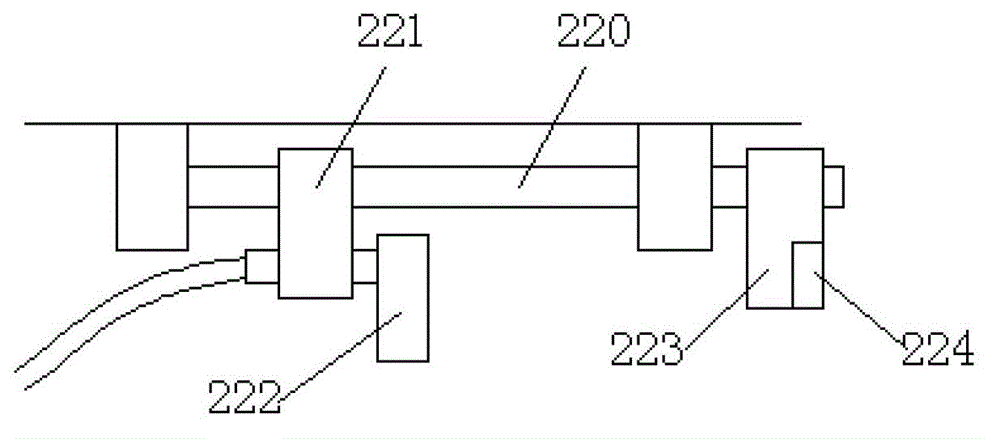

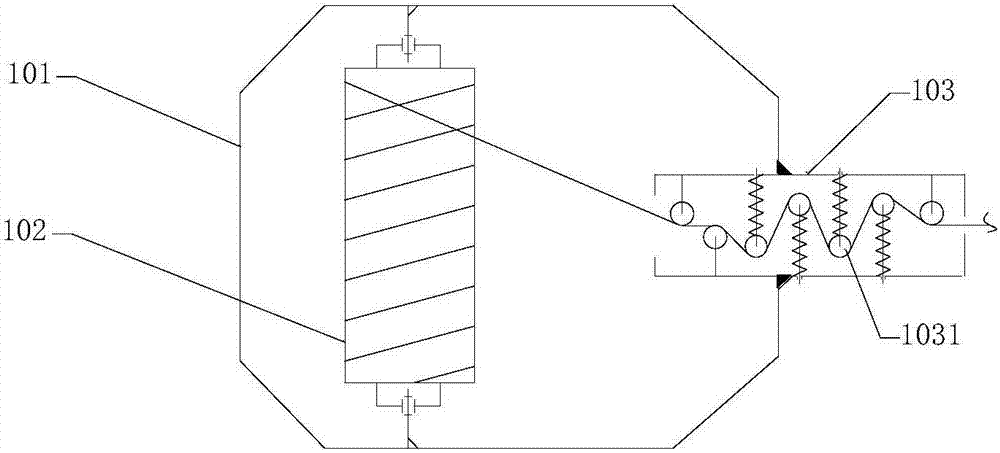

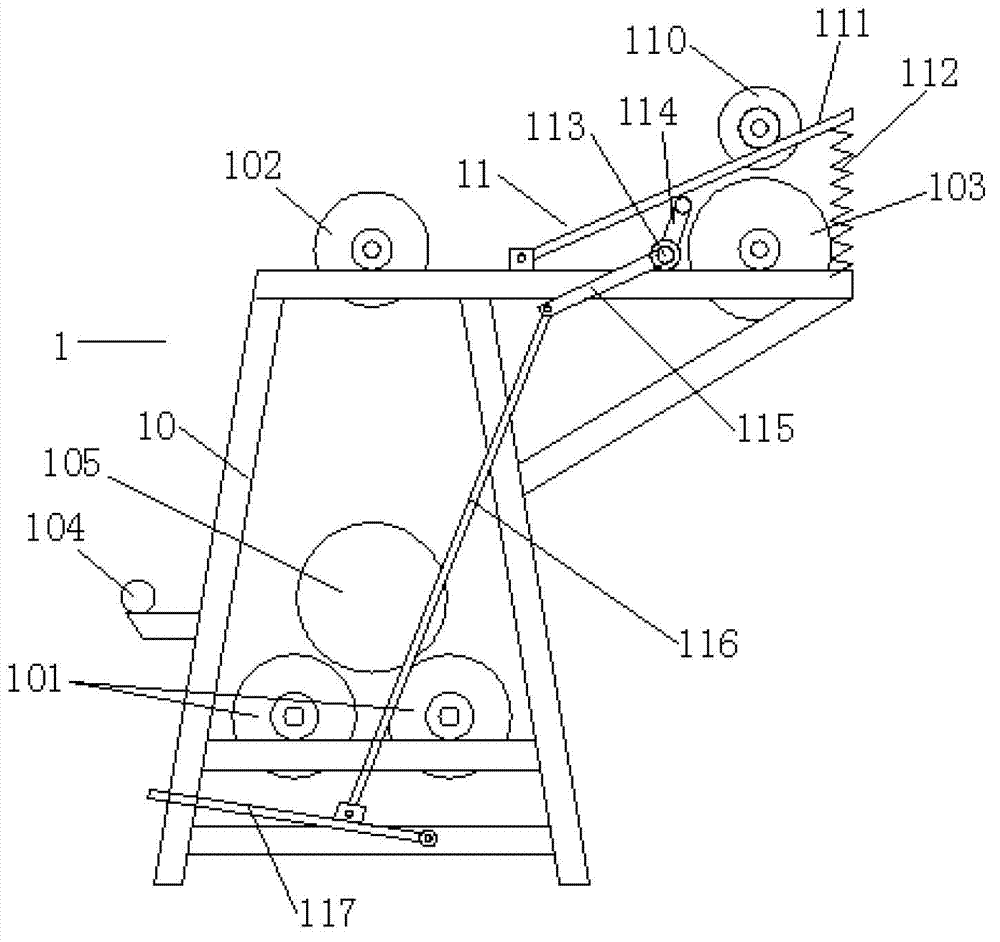

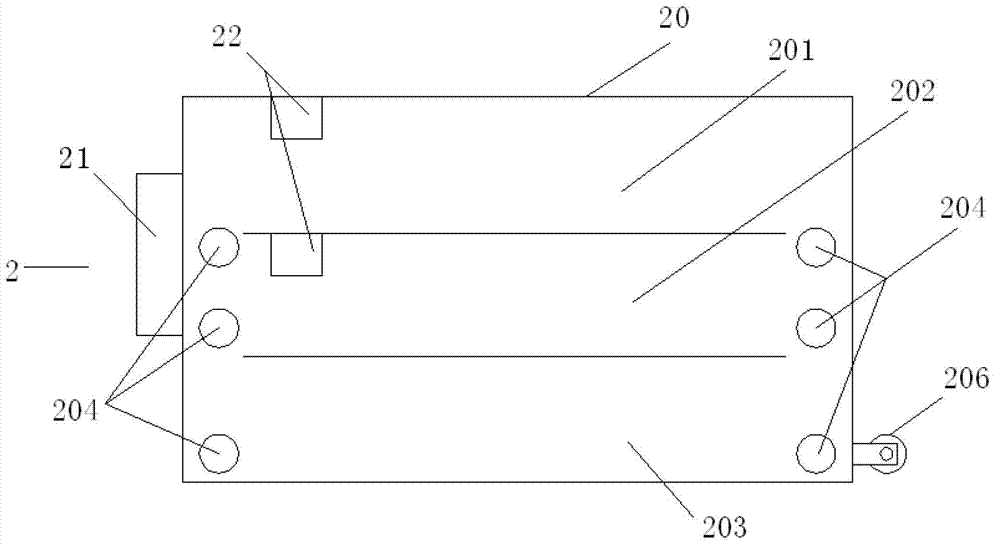

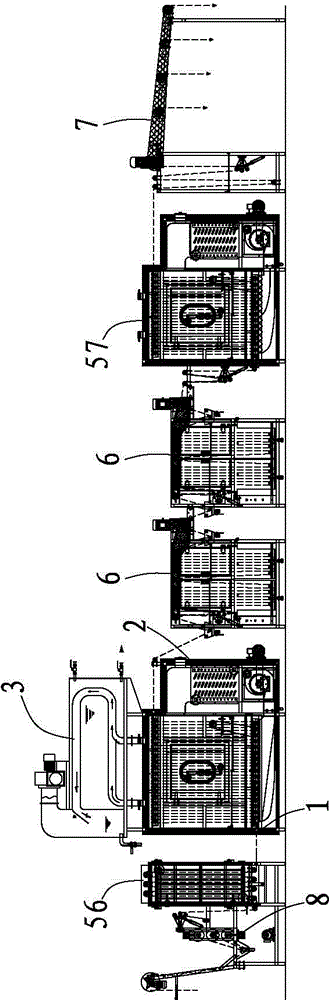

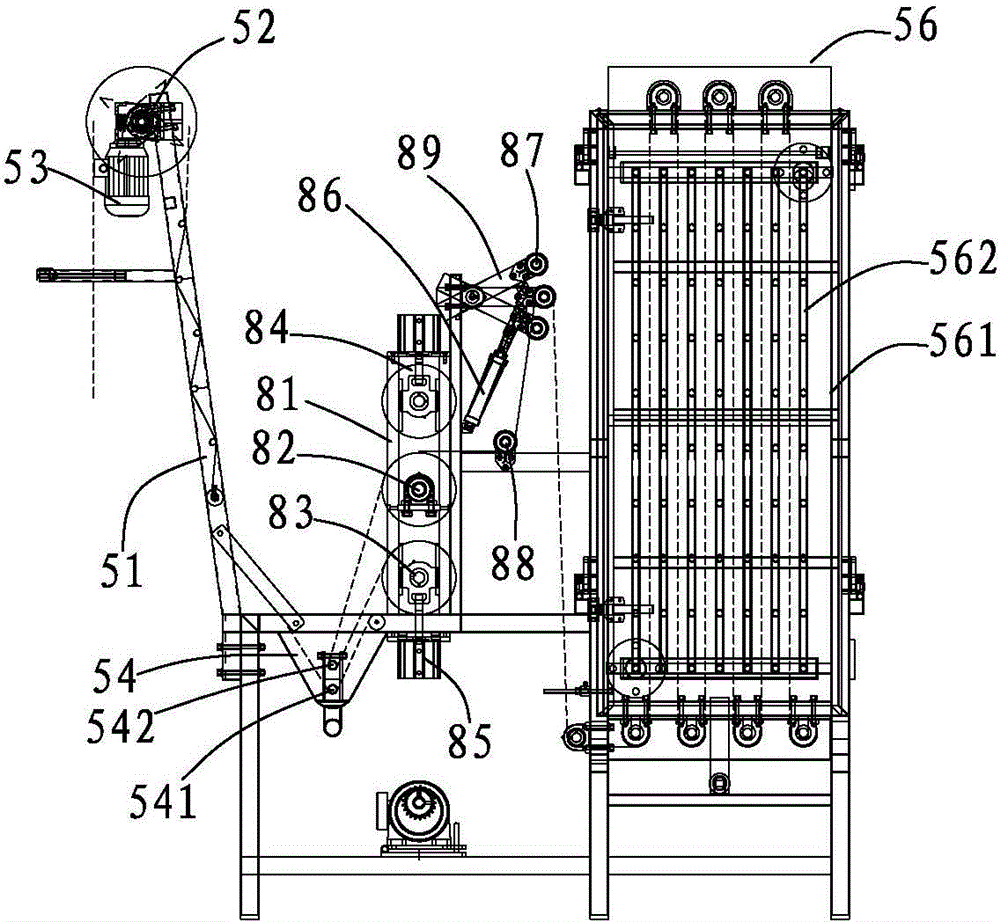

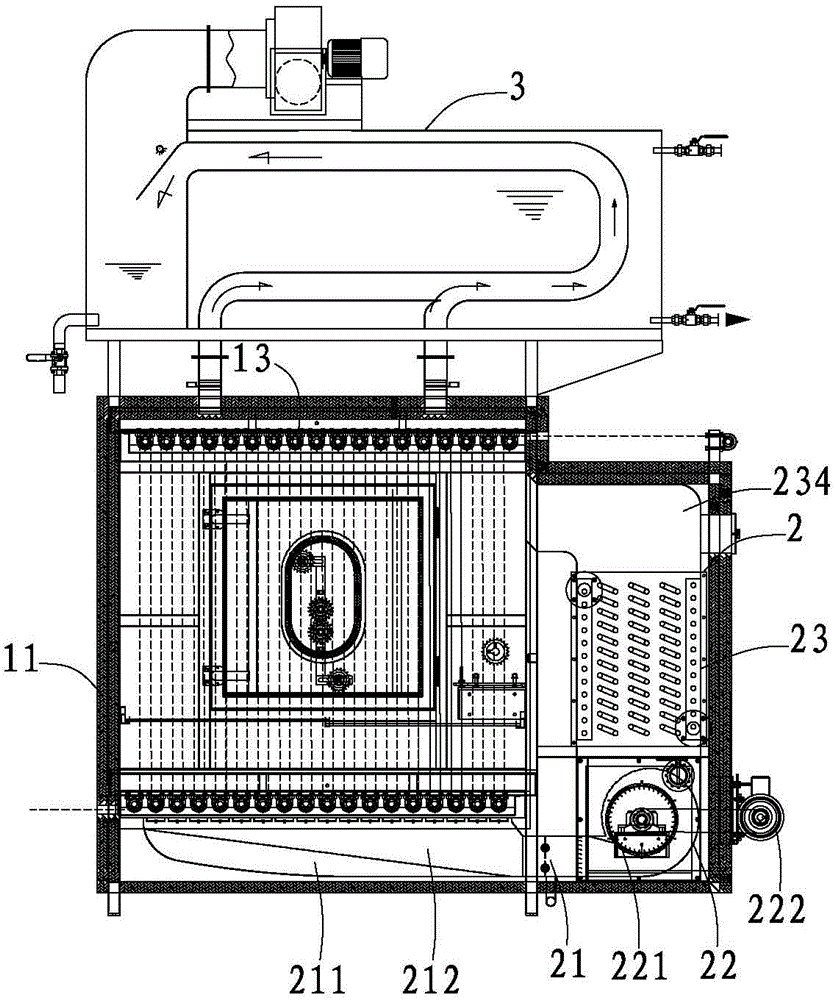

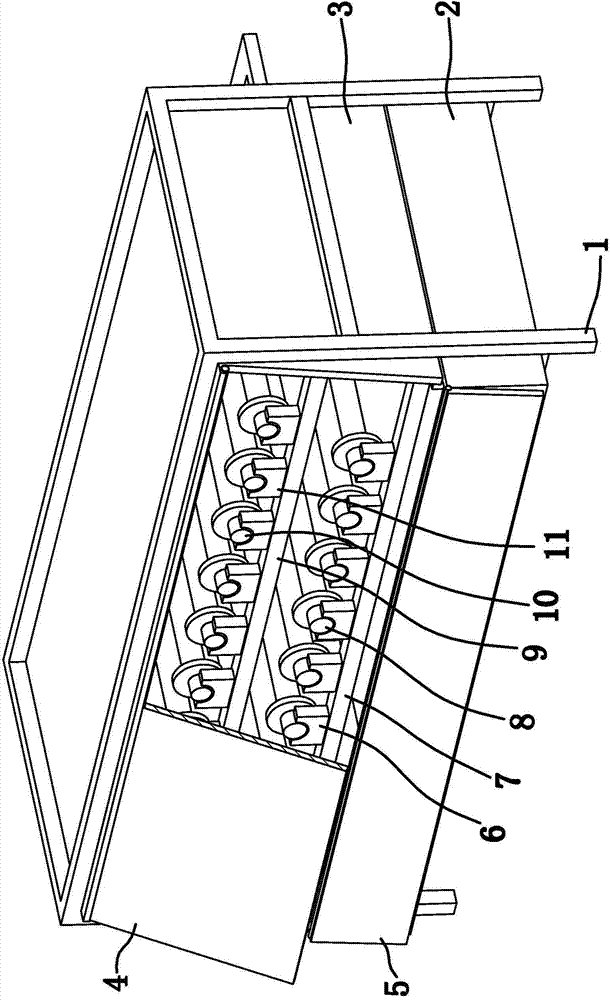

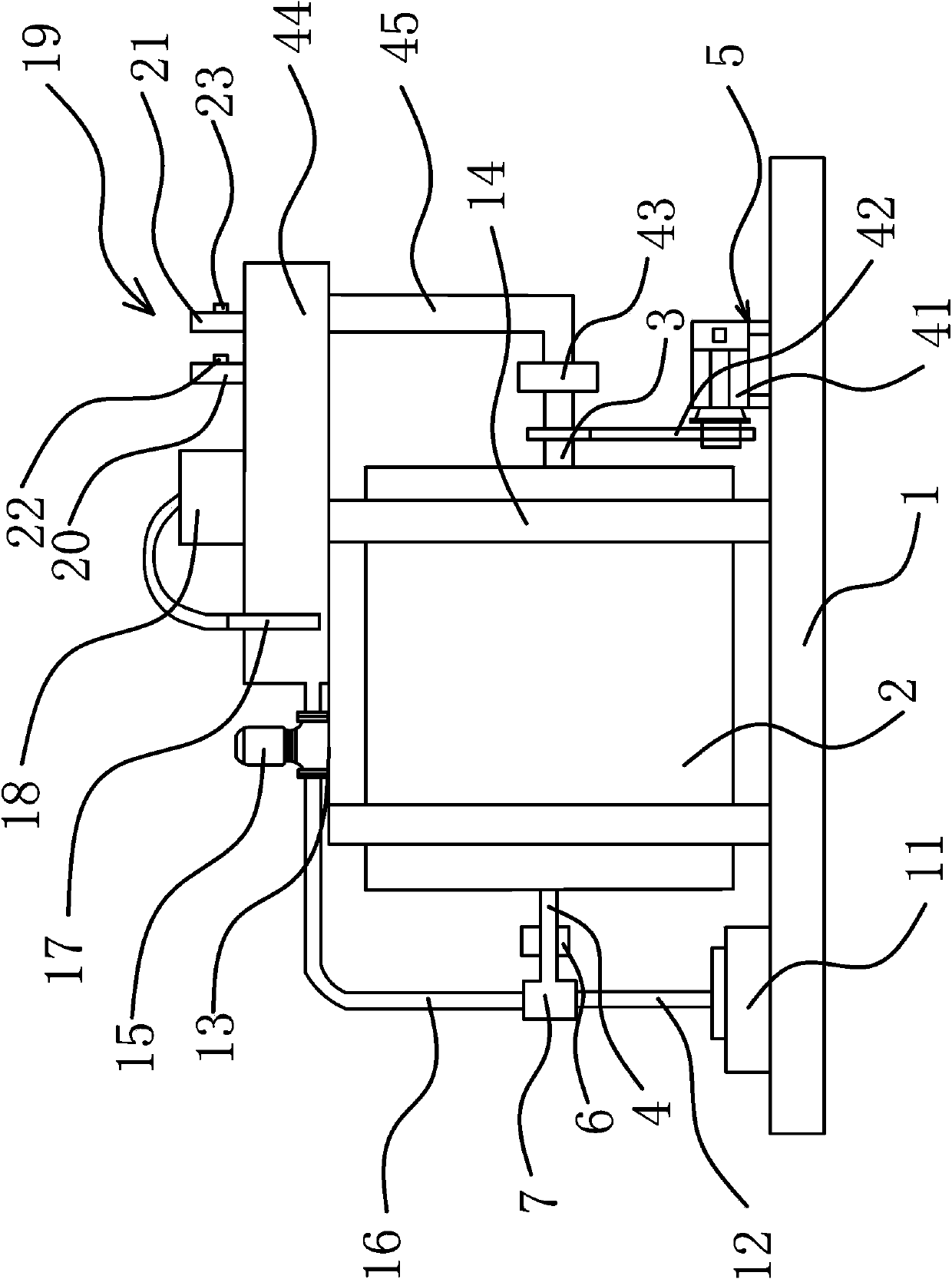

Chinese iris mat spreading, dyeing and drying integrated equipment

ActiveCN103144162AImprove dyeing efficiencyImprove drying efficiencySpraying apparatusWood treatment detailsWork in processMechanical engineering

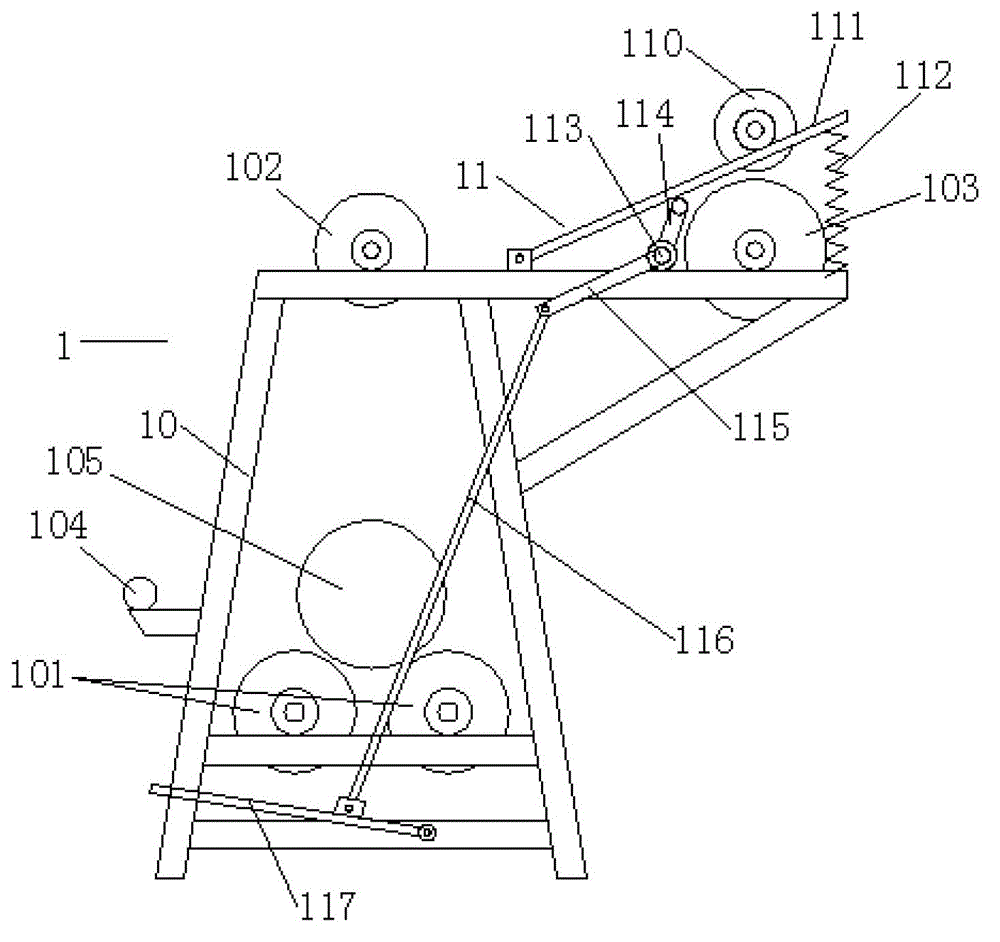

The invention discloses Chinese iris mat spreading, dyeing and drying integrated equipment comprising a mat spreading device, a dyeing box and a drying box, which are arranged in a straight line, wherein three layers of spaces are arranged up and down in the dyeing box; transfer rollers are arranged on both front and rear sides of each layer of space; dye jetting mechanisms are arranged on the rear sides of the upper-layer space and the middle-layer space of the dyeing box; an inner chamber of the drying box is divided into upper and lower layers by a meshed plate, the lower layer of chamber is a heating chamber and the upper layer of chamber is a drying chamber; and a mat rolling device is arranged on the front side of the drying box for folding and rolling the mat. During operation of the equipment disclosed by the invention, the mat spreading device spreads a semi-finished mat product first, the mat passes through the dye box so that both the front and back surfaces are dyed; the dyed mat is delivered to the drying chamber of the drying box by a mat delivering device, so that the mat is dried, thereby improving the spreading, dyeing and drying efficiency effects.

Owner:苏州盛泽科技创业园发展有限公司

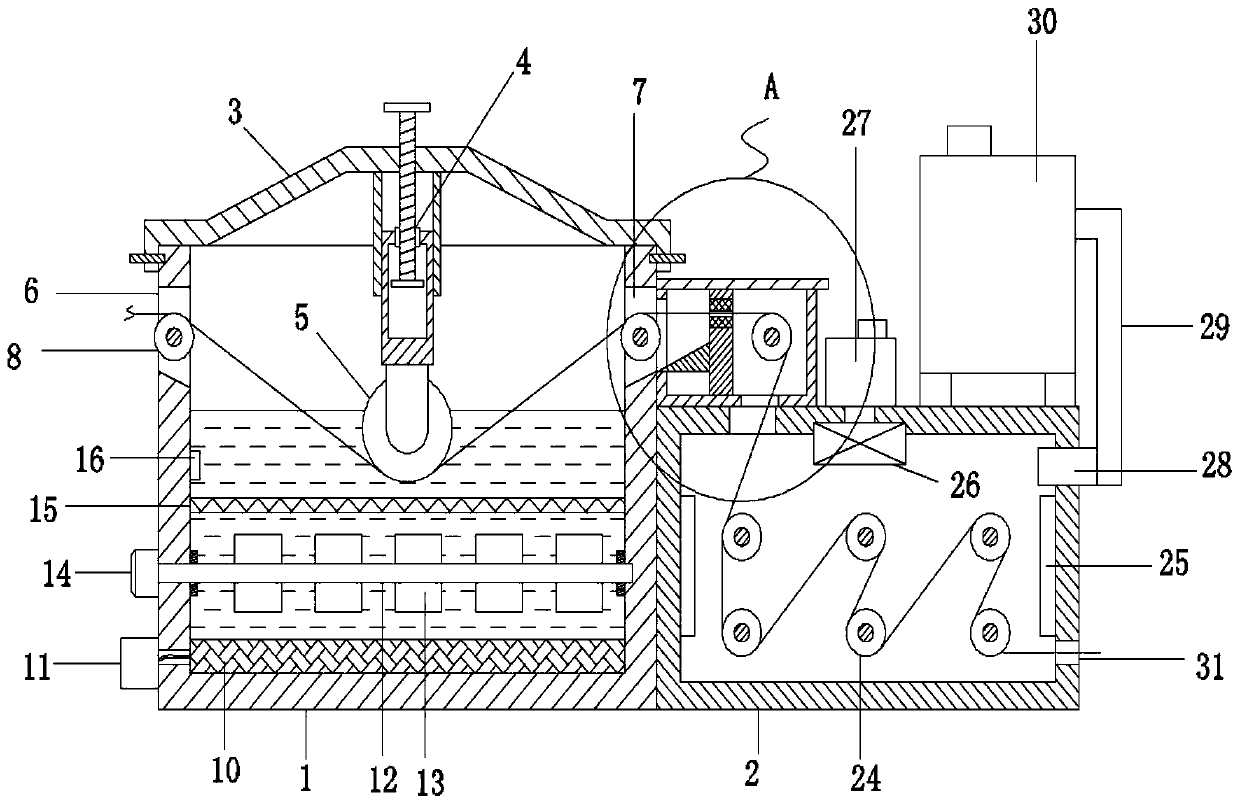

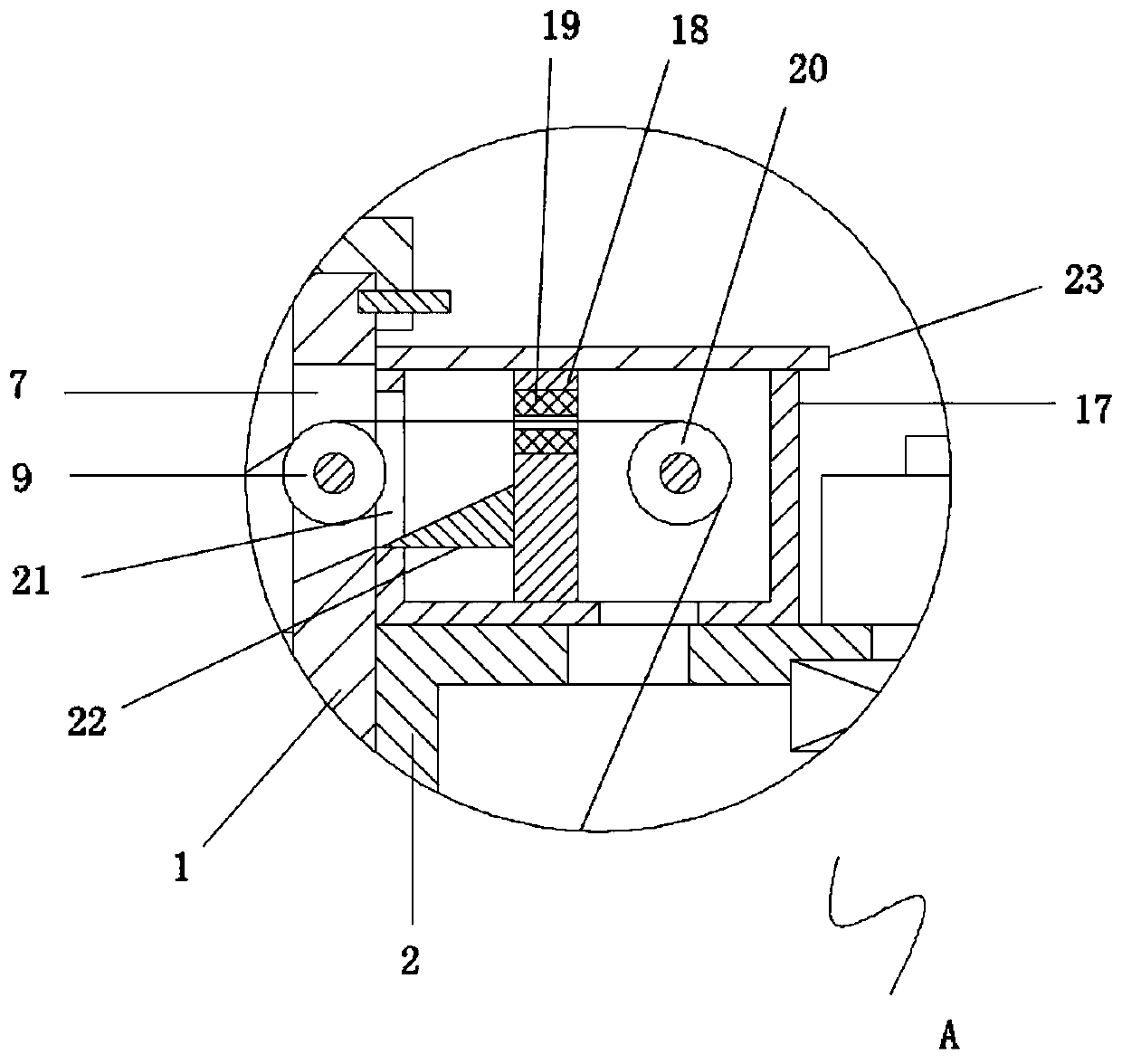

Nonwoven fabric dyeing device for clothing production

InactiveCN110004622AAvoid layered settlementImprove dyeing effectTextile treatment containersSucessive textile treatmentsLiquid temperatureDyeing

The invention discloses a nonwoven fabric dyeing device for clothing production in the technical field of nonwoven fabric production. The nonwoven fabric dyeing device comprises a dyeing tank and a drying tank, and the drying tank is fixedly connected to the right side wall of the dyeing tank. Dyeing liquid can be stirred by a stirring mechanism to avoid layered settlement; by arrangement of a heating plate and a component thereof, dyeing liquid temperature can be changed; by arrangement of an end cover and a telescopic mechanism, convenience in mounting of a nonwoven fabric in the dyeing tankis achieved; by arrangement of a protective screen, the problem of fabric loss caused by contact of the nonwoven fabric and the stirring mechanism can be avoided; by the drying tank and dyeing tank integrated structure, fabric dyeing and drying processes are integrated, a fabric dyeing process is simplified, and processing cost is reduced; by arrangement of array cloth rollers, two surfaces of the nonwoven fabric can be dried completely, and drying effects are improved; by arrangement of a filter tank, waste gas generated in dyeing and drying can be purified.

Owner:安徽职业技术学院

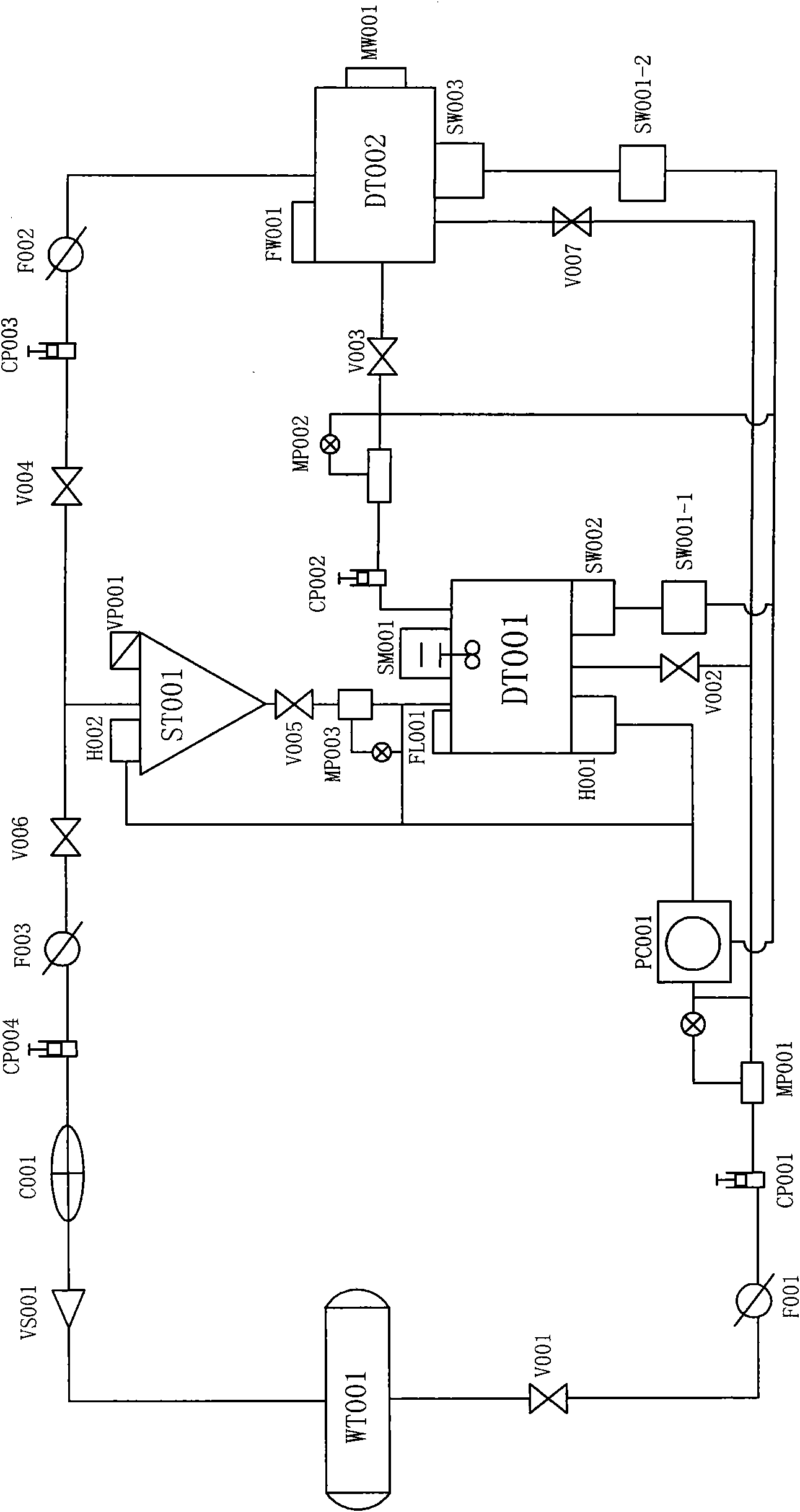

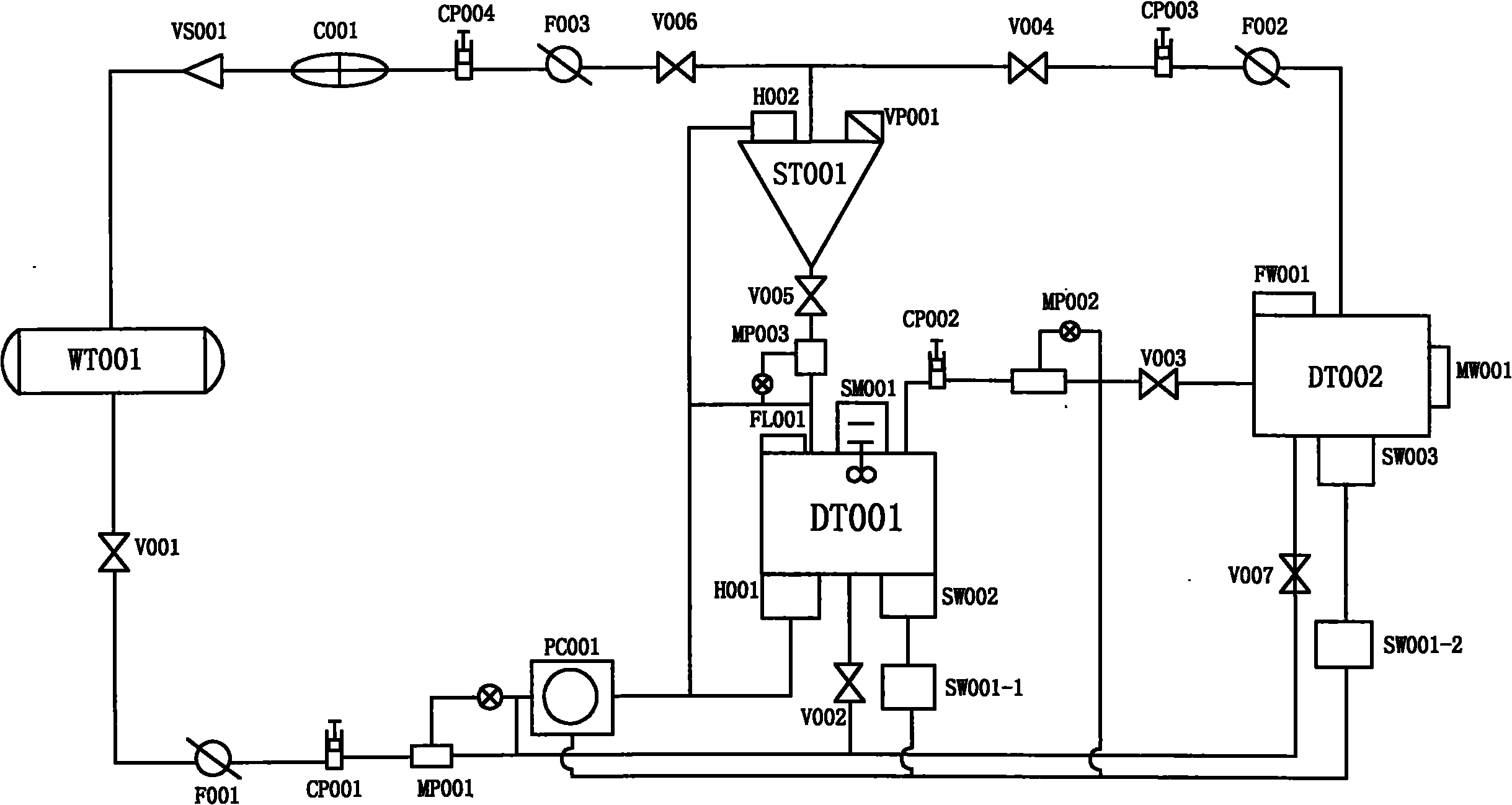

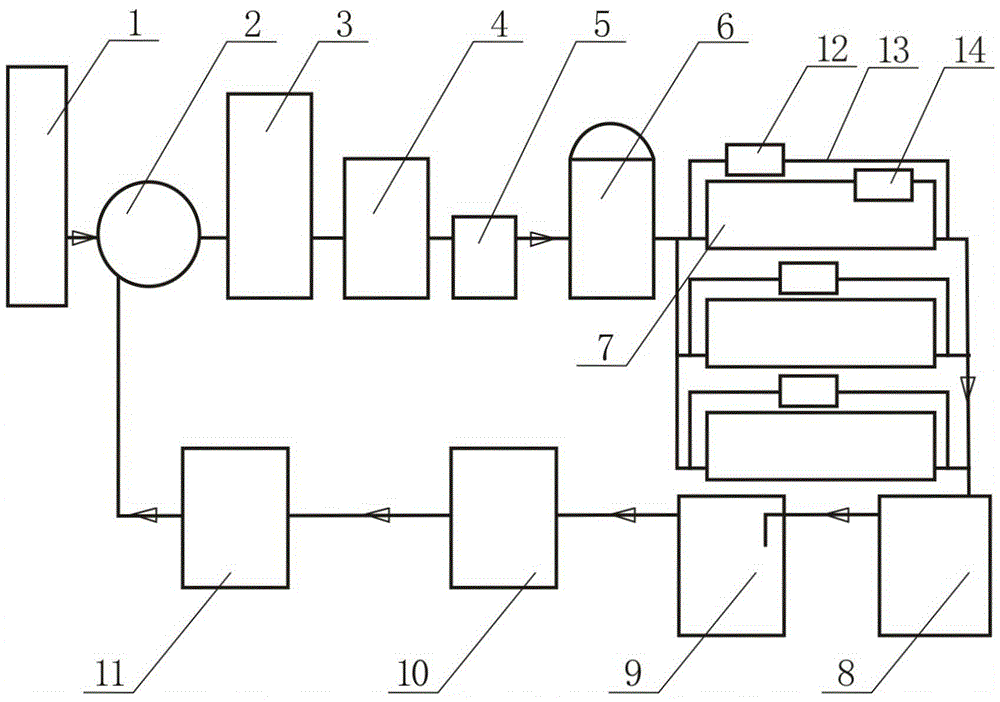

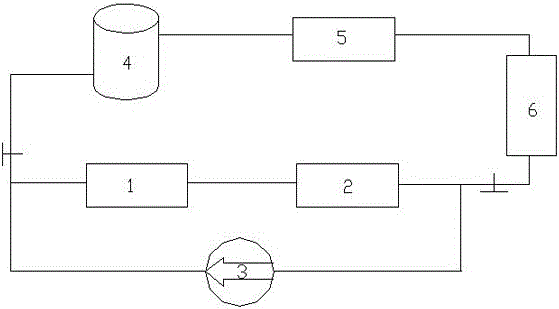

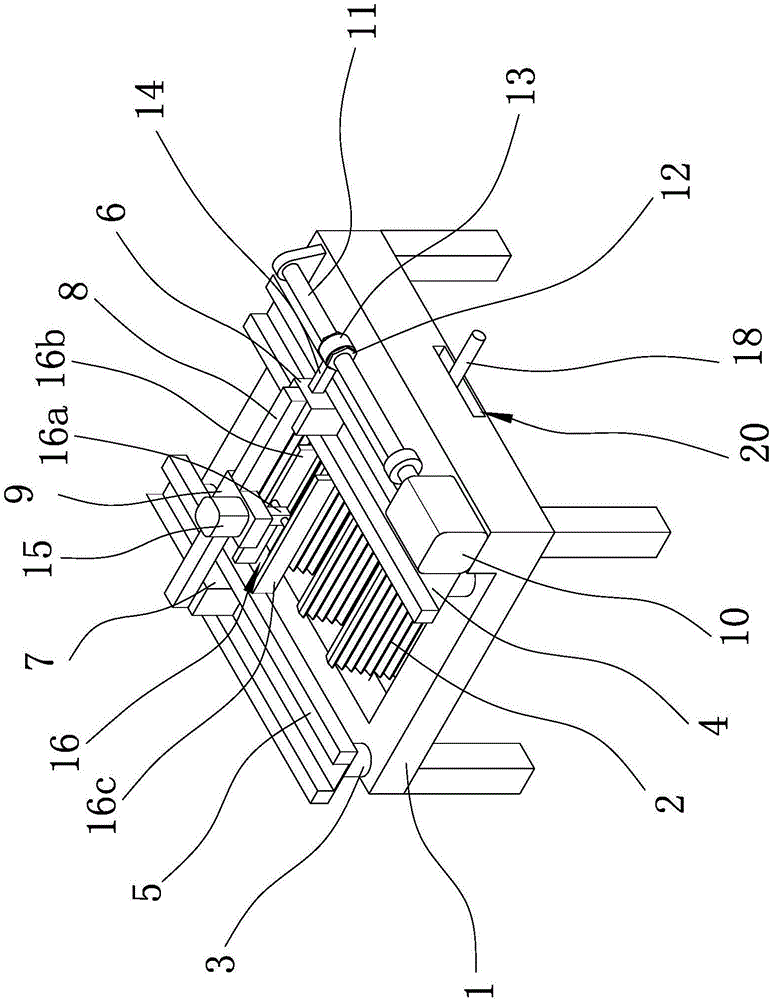

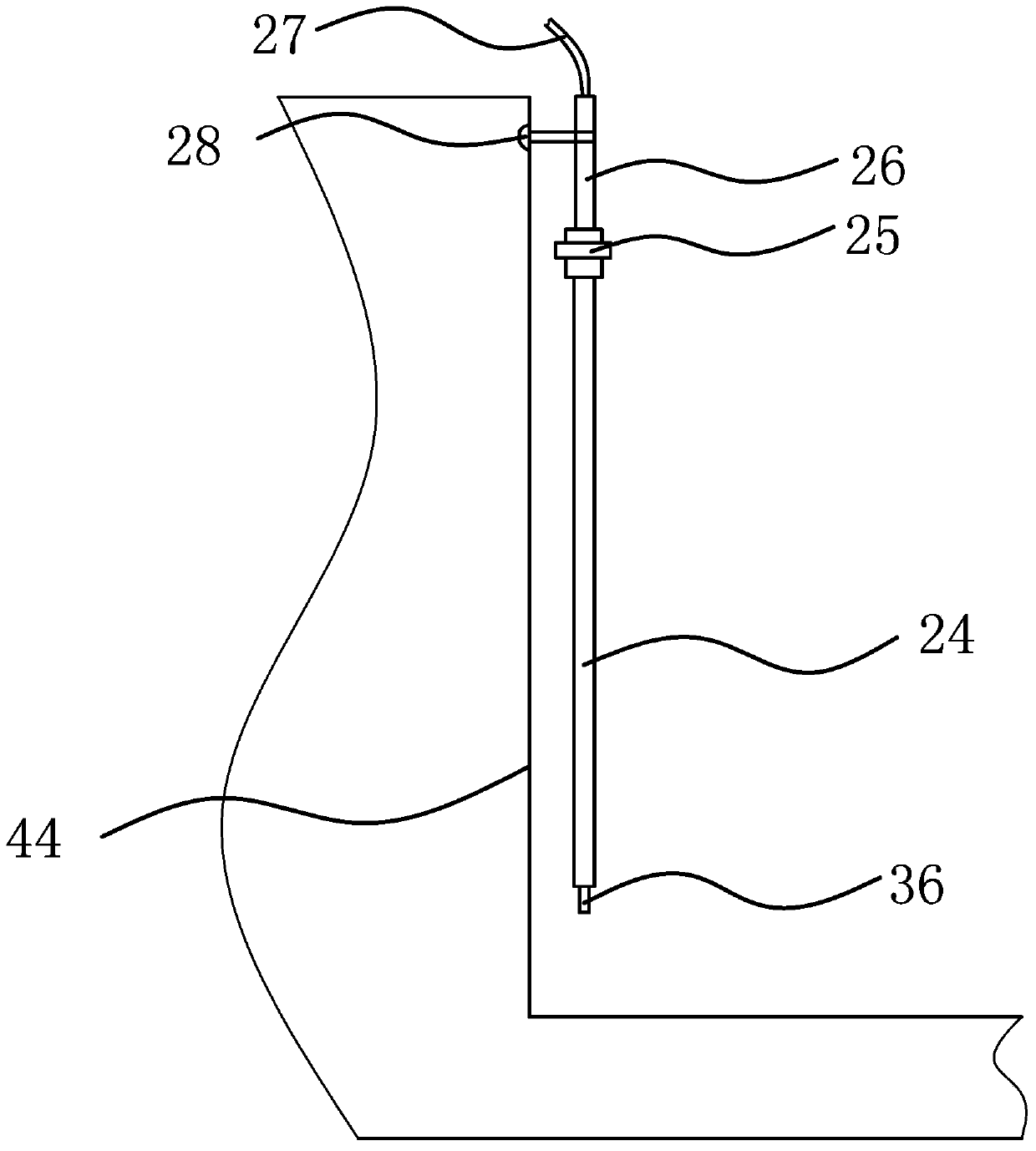

Method and device for dyeing by utilizing ultrasonic wave and microwave

InactiveCN102080315ASimple structureEasy to controlTextile treatment machine arrangementsVibration treatmentUltrasound - actionMicrowave

The invention provides a method and device for dyeing by utilizing ultrasonic waves and microwaves. The dyeing device comprises a water storage tank WT001, a dye kettle DT001, a dyeing kettle DT002, a separator ST001, an ultrasonic generator SW001-1, an ultrasonic generator SW001-2, an ultrasonic transducer SW001, an ultrasonic transducer SW002 and a microwave generator MW001. The dyeing method comprises the steps of: preparing dye liquor under the action of ultrasonic waves, dyeing fabric under the action of ultrasonic waves and microwaves, treating the dye liquor after dyeing, and recycling the recovered water and dye. The method and device for dyeing has the following benefits: the dyeing efficiency and the dyeing effect are effectively improved without using assistants, and the dye can be recycled; and simultaneously, the dyeing device has simple structure, is convenient to control, reduces energy consumption and saves water resources.

Owner:YANCHENG INST OF IND TECH

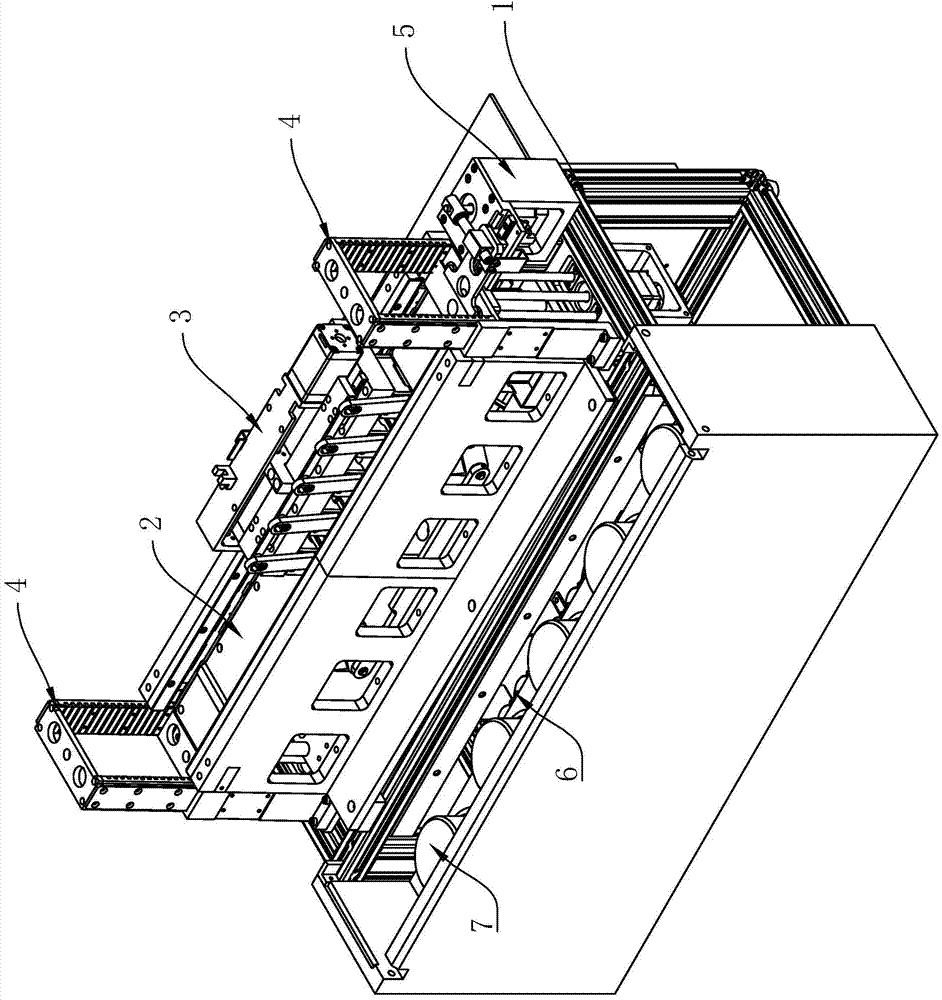

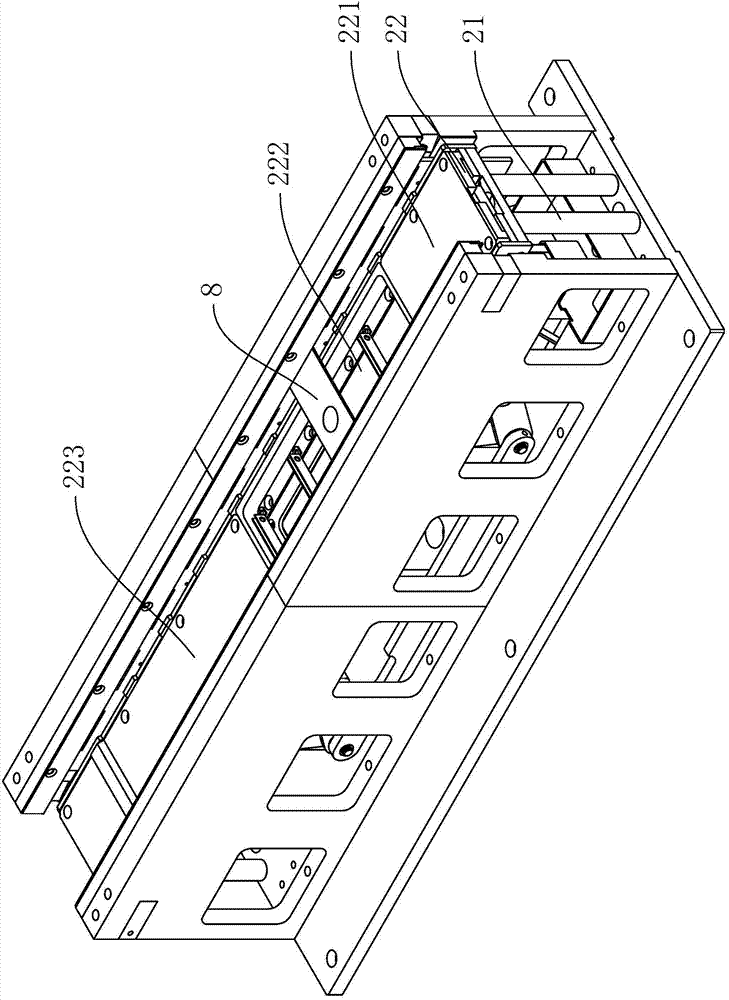

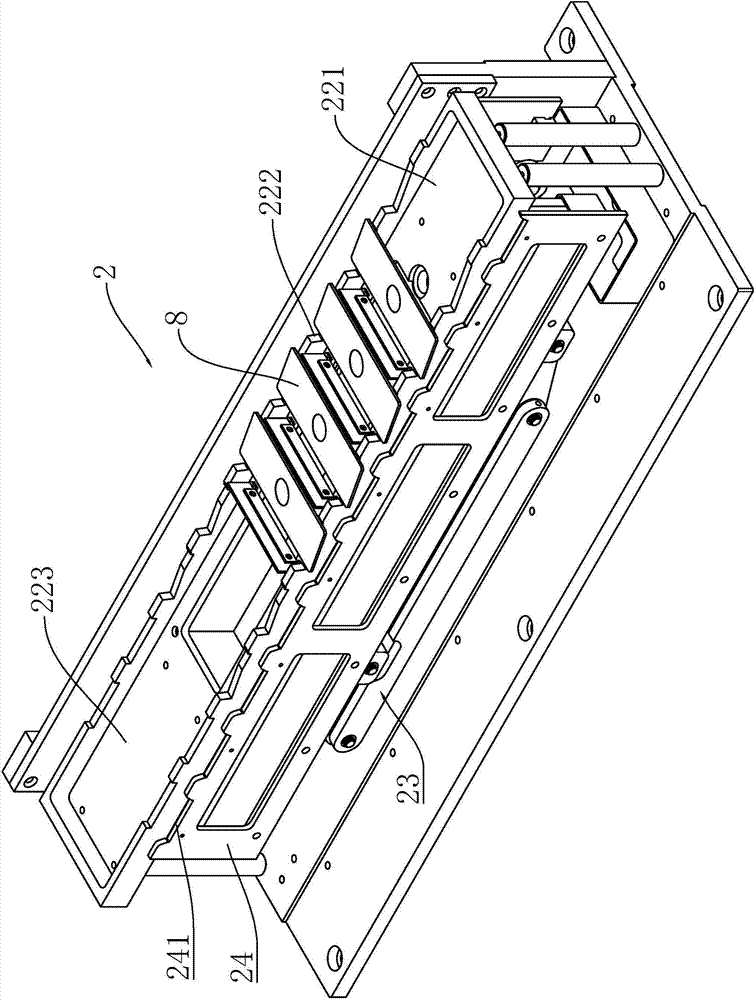

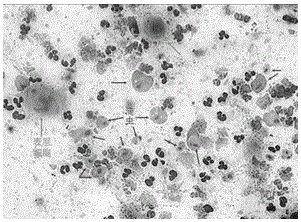

Multifunctional fully-automatic Gram staining instrument

ActiveCN104777027AImprove dyeing efficiencyAvoid false positivesPreparing sample for investigationStainingResource saving

The invention relates to a multifunctional fully-automatic Gram staining instrument. The instrument comprises a glass slide lateral movement device, a microbe automatic staining device, a glass slide entering and departing device, a push rod device and a liquid path control device, the push rod device pushes a coated glass slide positioned on the glass slide entering and departing device into the glass slide lateral movement device, the glass slide moves with a first glass slide rack on a reciprocating movement mechanism to the automatic staining device, is stained, cleaned and blow-dried, the liquid path control device cooperates a computer program in order to control a staining solution in a Gram staining solution bottle to carry out staining, water spraying, gas spraying, drying and other fully-automatic activities on the coated glass slide according to preset steps and time, and the push rod device moves the processed glass slide into the glass slide entering and departing device in order to carry out subsequent operation. The instrument has the advantages of fully-automatic realization of the whole Gram staining process, accurate delivery, cross infection avoiding, staining solution waste avoiding and manpower resource saving.

Owner:JIANGSU BIOPERFECTUS TECH CO LTD

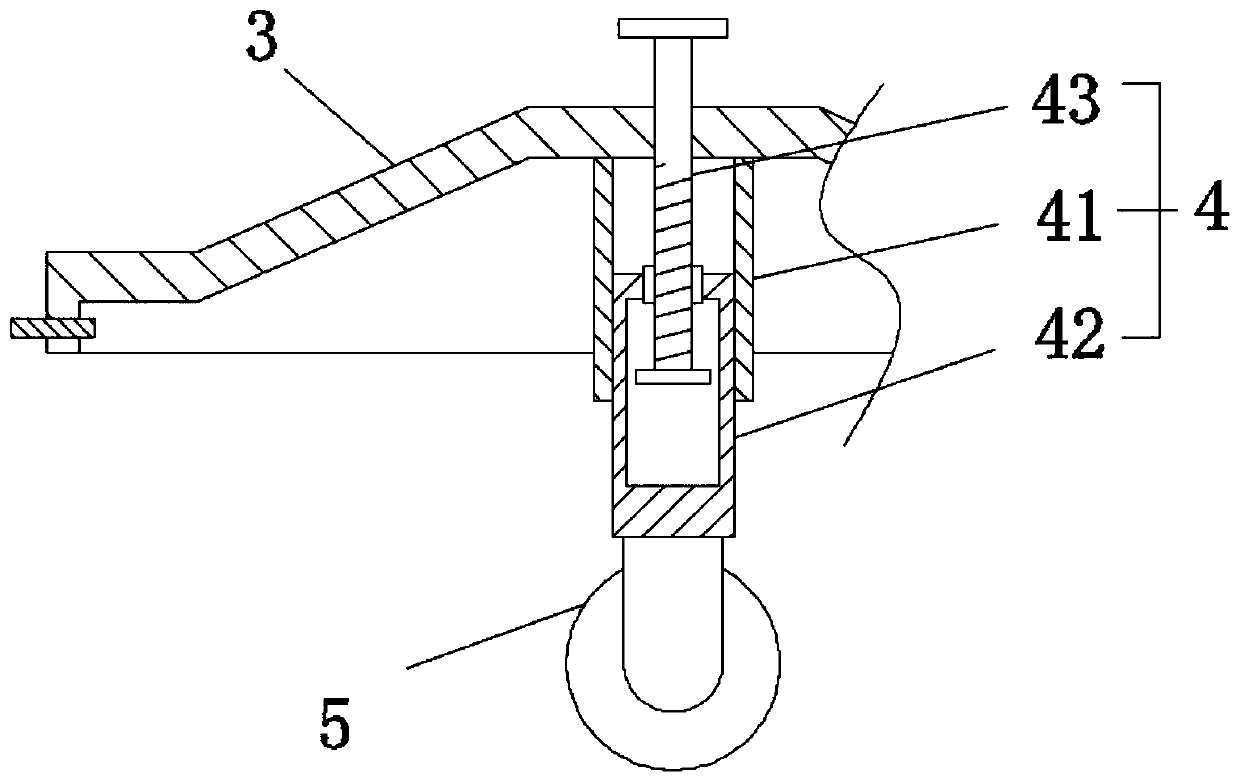

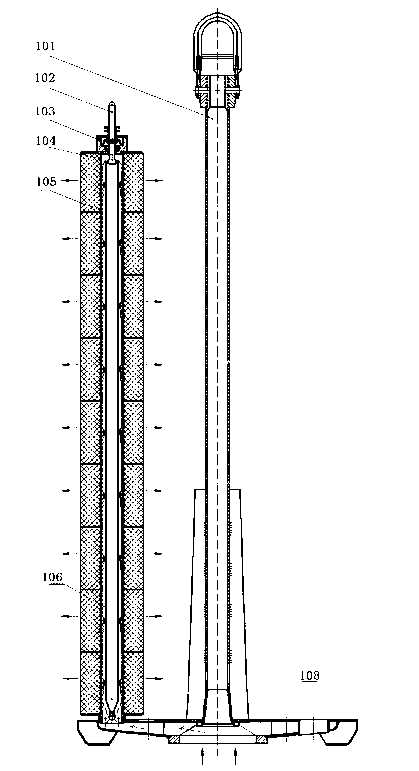

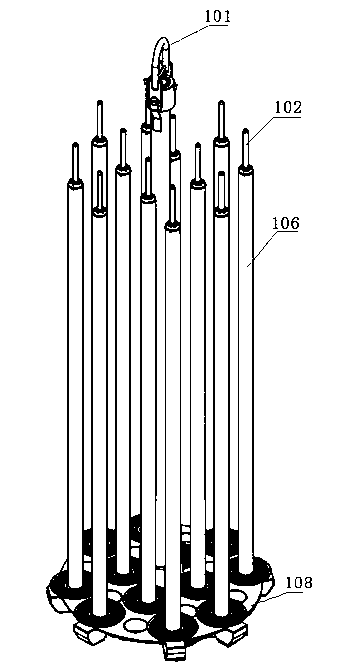

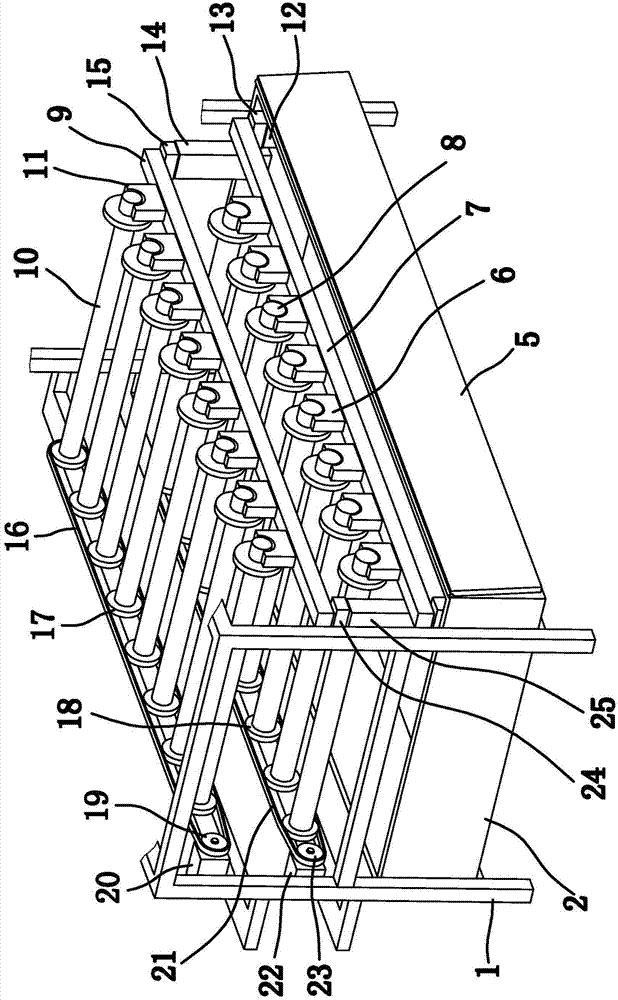

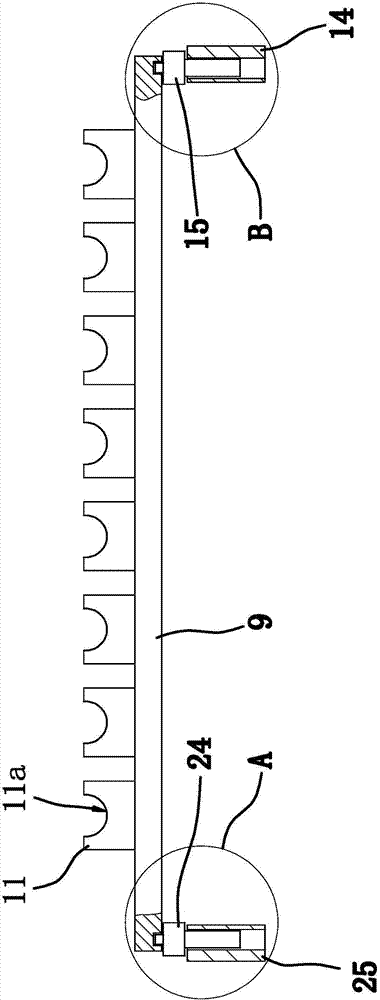

Dyeing rack for tatting yarn, zippers, ropes, ribbons and loose fibers of loading needles of dyeing machine

InactiveCN103132264AReduce processing timeReduce consumptionLiquid/gas/vapor treatment of definite length materialsTextile treatment carriersYarnFiber

The invention discloses a dyeing rack for tatting yarn, zippers, ropes, ribbons and loose fibers of loading needles of a dyeing machine. The dyeing rack for tatting the yarn, the zippers, the ropes, the ribbons and the loose fibers of the loading needles of the dyeing machine comprises a yarn plate, a suspender and a yarn rod. The upper surface of the yarn plate is in a disc shape. The lower end of the yarn plate is in a cavity structure. A center seat of the dyeing machine is connected with the bottom of the lower end of the yarn plate. A yarn plate water outlet, a yarn plate water return hole and a suspender hole seat are formed in the upper surface of the yarn plate. The suspender hole seat is arranged at the center of the yarn plate. A suspender is fixedly installed in the suspender hole seat. The bottom of the yarn rod is fixed on the yarn plate water outlet of the upper surface of the yarn plate. The yarn rod is in a solid structure or a hollow structure. A gap is reserved between a to-be-dyed object and the yarn rod. Dye liquor flows out of the yarn plate water outlet hole of the bottom of the yarn rod and fills the gap to form a hollow water column. The dye liquor permeates the to-be-dyed object through flowing of the hollow water column. The dye liquor permeated from the to-be-dyed object flows into the yarn plate water return hole. A bolt at the upper end of the yarn rod is provided with a gravity tapered end. The dyeing rack for tatting the yarn, the zippers, the ropes, the ribbons and the loose fibers of the loading needles of the dyeing machine is simple in structure, capable of reducing consumption of dye, auxiliaries, energy sources and water resources, and capable of improving dyeing efficiency.

Owner:GUANGZHOU GAOSHENG DYEING & FINISHING EQUIPCO

Dyeing finishing process of elastic jean fabric

InactiveCN104032595AShort dyeing timeImprove dyeing efficiencyDry-cleaning apparatus for textilesDyeing processAfter treatmentEngineering

The invention relates to the textile field and in particular relates to a dyeing finishing process of an elastic jean fabric. The dyeing finishing process comprises the steps of material selection, pretreatment, water washing, slacking treatment, dyeing, water washing, color fixation, heat setting and after-treatment. The dyeing finishing process is characterized in that the water washing and slacking treatment steps are added after the pretreatment step so that the jean fabric is more stable and subsequent dye homogeneity can be achieved more easily; in addition, as the color fixation step is added after the second time of water washing to further fix the dyeing of the fabric, the dyeing effect of the fabric can be improved; the dyeing finishing process has obvious beneficial effects and is suitable for popularization and utilization.

Owner:TAICANG QISHENG CHEM FIBER FACTORY

Aggregation-induced emission nanoparticle and preparation method and application thereof

ActiveCN106085416AGood tracer effectHigh cell staining efficiencyFluorescence/phosphorescenceIn-vivo testing preparationsBone cellWater soluble

The invention discloses an aggregation-induced emission nanoparticle and preparation method and application thereof. The preparation method comprises the following steps: dissolving an aggregation-induced emission compound shown in a formula I and an amphiphilic polymer in a water-soluble organic solvent, then adding the mixture to water, and conducting ultrasonic reaction; removing organic solvents by volatilization to form nanoparticles loaded with the aggregation-induced emission compound; adding cell penetrating peptides in aqueous solution of the nanoparticle, reacting to form aggregation-induced emission nanoparticles capable of efficiently staining cells. The fluorescent particles can be used for tracing long-term differentiation of stem cells, especially the tracing of mouse bone marrow mesenchymal stem cells in the process of osteogenic differentiation. Compared with the commercial tracer reagent in the prior art, which can only trace 6 generations of cell proliferation, the nanoparticle has a better tracing effect, which can trace to more than 12 generations of cell proliferation. The aggregation-induced emission nanoparticle has the advantages of high cell staining efficiency, long-term tracing ability, high light stability and low cell toxicity.

Owner:SOUTH CHINA UNIV OF TECH

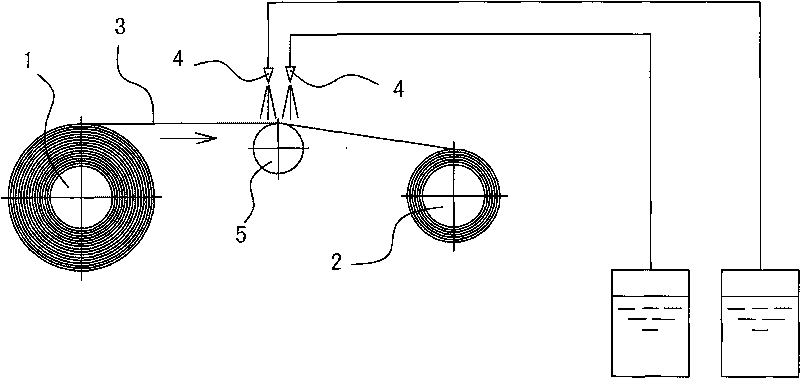

Spray coloring stack dying process for cotton woven fabrics

InactiveCN101736615AIncrease concentrationImprove dyeing efficiencyDyeing processTextile treatment by spraying/projectingCotton fibreReactive dye

The invention relates to a spray coloring stack dying process for cotton woven fabrics, Gray fabrics are dyed by adopting a reactive dye, an accelerating agent and an alkaline agent. The spray coloring stack dying process for cotton woven fabrics is characterized in that pre-processed gray fabrics are wound to two parallel fabric guide rollers, wherein one end of the gray fabrics is wound on the first fabric guide roller, and the other end of the gray fabrics is wound on the second fabric guide roller so that the gray fabrics between the two fabric guide rollers are in a flat condition; and spray heads are arranged on the front or / and the back of the flat gray fabrics opposite to the gray fabrics, and are used for applying a reactive dye water solution, an accelerating agent water solution and an alkaline agent water solution to the gray fabrics. In the process, the cotton woven fabrics and the dyeing solutions are in the ultralow proportion in weight of 1:1 to 1:1.5, the dye, and the accelerating agent and the alkaline agent are applied in a continuous and circular spray mode, and are stacked in a container in a temperature controlled condition so that more than 90% of the dye can be in linking reaction with the cotton fibers sufficiently. The spray coloring stack dying process for cotton woven fabrics has the advantages of high dyeing efficiency, low exhaust, no color differences among the front, middle and back parts as well as the left, middle and right parts, and flat dyed fabrics without color embossing.

Owner:常熟市精晟达诚金属制品有限公司

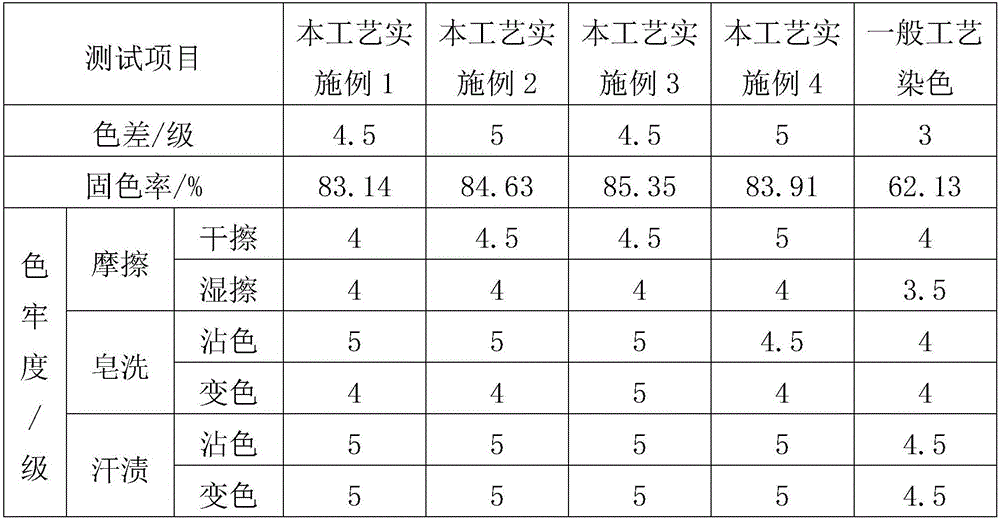

Disperse reactive dye one-bath two-step dip dyeing method for polyester cotton fabric

ActiveCN106223076APreserve surface hydrophilic propertiesGood dyeing rateDyeing processDisperse dyePre treatment

The invention discloses a disperse reactive dye one-bath two-step dip dyeing method for polyester cotton fabric. The method comprises the following steps: S1, pretreatment: padding a polyester cotton fabric to be dyed in a finishing liquid, conducting two dipping and two rolling, pre-drying at 60-80 DEG C, baking at 120-140 DEG C, washing with cold water and drying; S2, polyester dyeing: immersing the polyester in a disperse dye, insulating at 65-75 C, and insulating at 110-130 DEG C; S3, cotton dyeing: adding a quaternary ammonium salt cationic etherifying agent, stirring for reaction, adding a reactive dye, insulating at 70-80 DEG C, adding a dyeing auxiliary, insulating, adding soda ash, and insulating at 60-100 DEG C; and S4, posttreatment: conducting an initial washing, soaping and post washing. The disperse reactive dye one-bath two-step dip dyeing method for polyester cotton fabric has the advantages of simple process, easy industrial implementation, wide dye application, uniform coloration, high fixation rate and good levelness.

Owner:ANHUI YAYUAN PRINTING & DYEING CO LTD

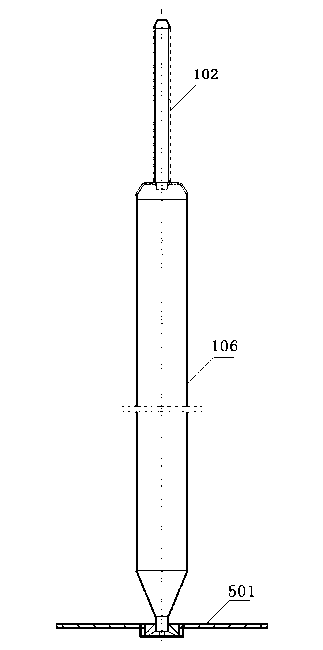

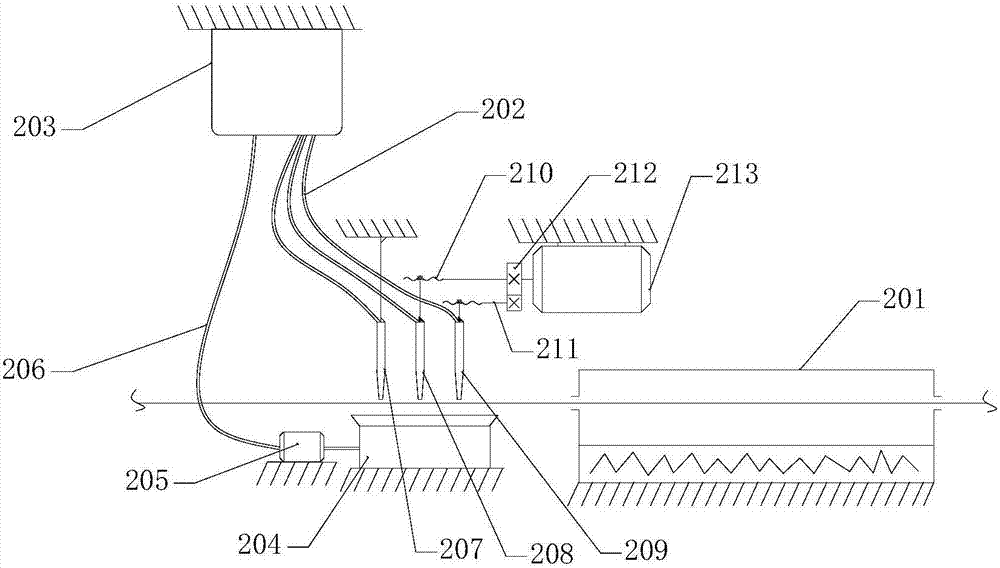

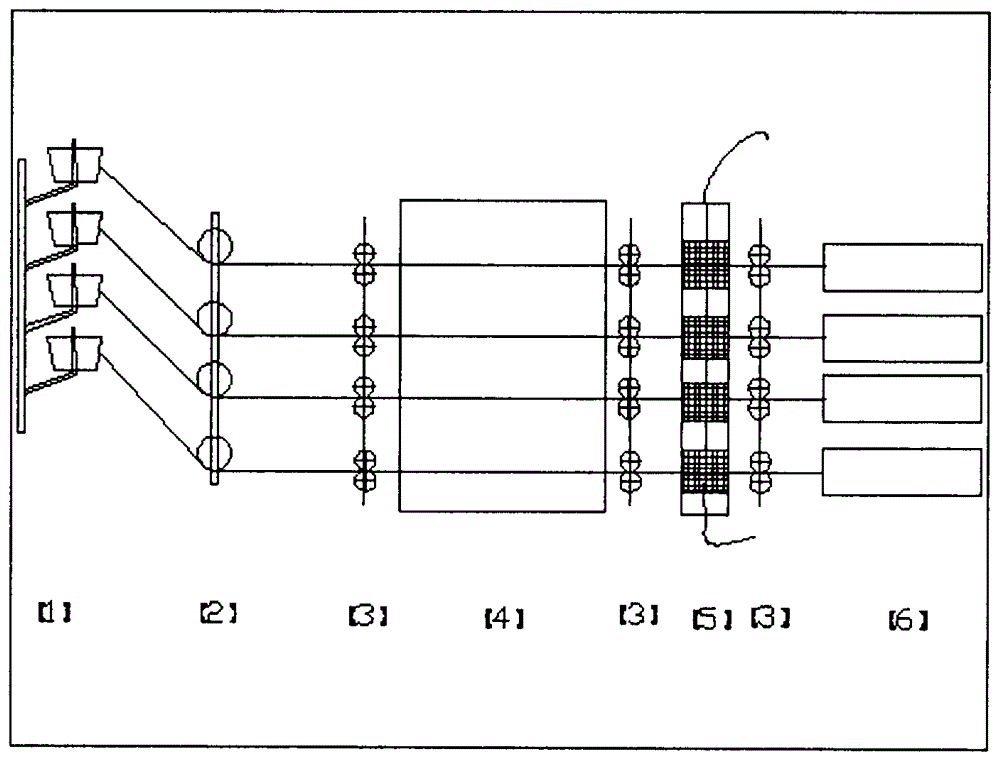

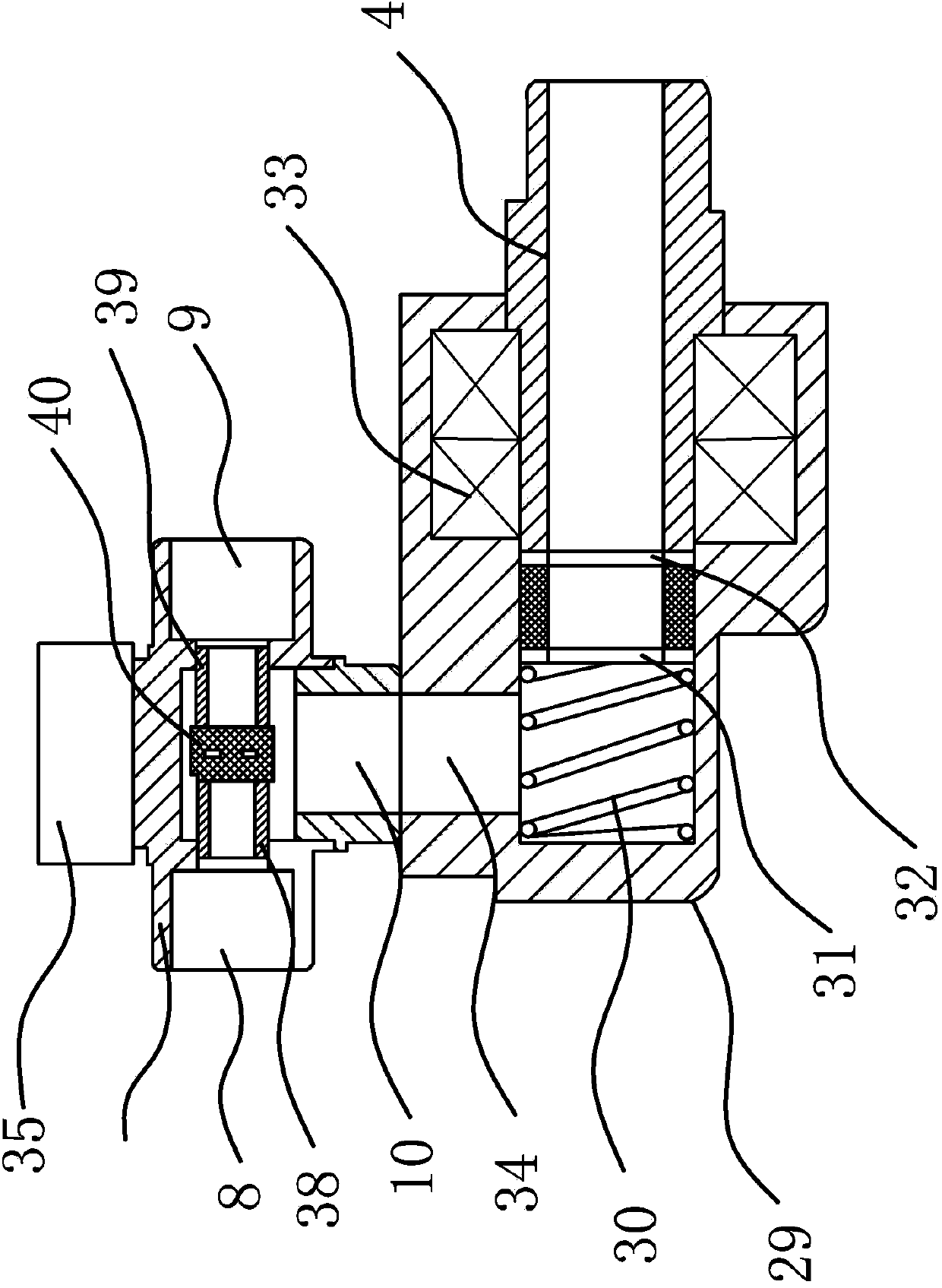

Spiral single-yarn piezoelectric spray dyeing device

InactiveCN106906584ASpray evenlySaving dye solutionTextile treatment machine arrangementsTextile treatment by spraying/projectingYarnDyeing

The invention relates to the technical field of yarn dyeing, in particular to a spiral single-yarn piezoelectric spray dyeing device. The device comprises a rotary yarn pay-off module, a piezoelectric spray dyeing module and a rotary yarn take-up module which are connected in sequence. The rotary yarn pay-off module and the rotary yarn take-up module synchronously rotate in the same direction, yarn between the rotary yarn pay-off module and the rotary yarn take-up module rotates around the center axis of yarn in the piezoelectric spray dyeing module, the rotating yarn is subjected to spray dyeing of a plurality of piezoelectric spray heads in the piezoelectric spray dyeing module, the rotary yarn pay-off module is used for supplying yarn to be spray-dyed to the piezoelectric spray dyeing module, and the rotary yarn take-up module is used for the yarn which is spray-dyed by the piezoelectric spray dyeing module and dried is spooled into rolls. The device has the advantages that the rotationally advancing yarn is coated through the piezoelectric spray heads arranged above the yarn, the yarn can be evenly spray-dyed after the spray dyeing tracks of the spray heads are overlapped, the device is more even than single-side spray dyeing of traditional spray dyeing, more dyeing liquid is saved compared with traditional dip dyeing, and different sections of one piece of yarn can be dyed with different colors.

Owner:WUHAN TEXTILE UNIV

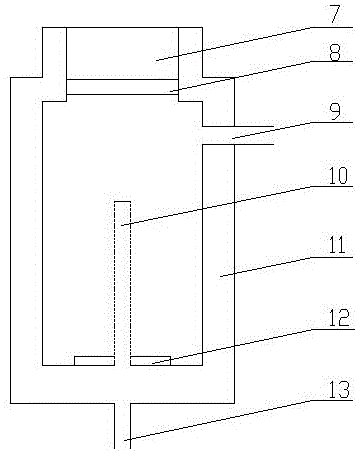

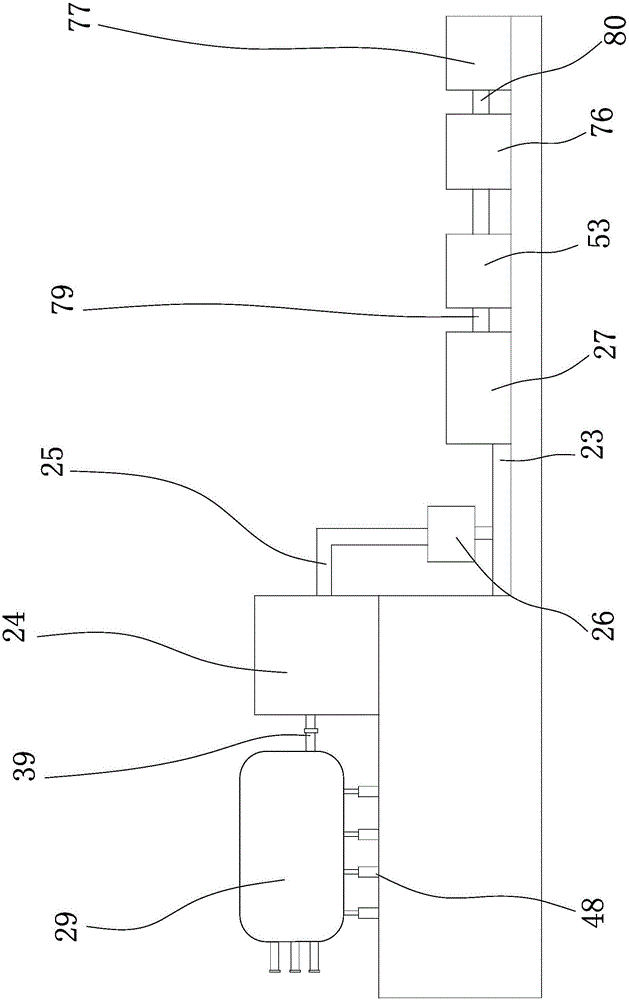

Supercritical CO2 waterless dyeing system and cloth dyeing method thereof

InactiveCN105297320AImprove permeabilityImprove solubilityTextile treatment containersSolvent treatment with solvent recoveryCirculating pumpCotton material

The invention discloses a supercritical CO2 waterless dyeing system and a cloth dyeing method thereof. The method comprises the following steps of A, preparing and storing of CO2; B, cooling; C, pressurizing; D, heating, wherein a heating device is utilized for enabling CO2 to form supercritical fluid, and the supercritical fluid is heated to 120-150 DEG C; E, dyeing, wherein a circulating pump pushes a mixture of the supercritical fluid and dye to circularly flow inside a circulation channel, cloths inside a pressure kettle are dyed, the pressure inside the pressure kettle is 28-30 MPA, the temperature is 120-150 DEG C, the circulation flowing time is 20-40 min, and the circulation flow is not smaller than 10 M<3> per hour; F, pressure relieving, wherein a nanoscale color masterbatch is dissolved through the supercritical CO2 fluid, the cloths are dyed, and dyeing technological conditions such as pressure, temperature and time are optimized at the same time so as to improve the dyeing efficiency and dyeing quality.

Owner:梁鼎天 +1

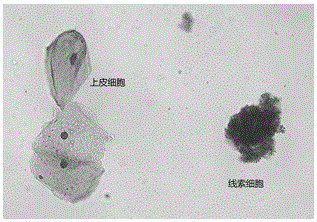

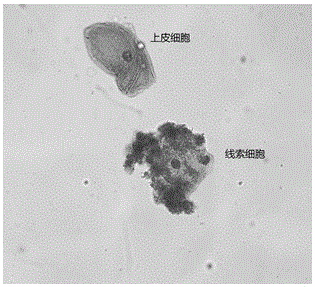

Vaginal secretion staining fluid, and preparation method and staining method thereof

ActiveCN105067412ASpeed up screeningShorten dyeing timePreparing sample for investigationStainingSurface layer

The invention discloses a vaginal secretion staining fluid, and a preparation method and a staining method thereof. According to the preparation method, a blue basic dyestuff and a red basic dyestuff are mixed so as to obtain the vaginal secretion staining fluid, so that the vaginal secretion staining fluid possesses staining effects of universal staining fluid, staining time can be shortened greatly, staining time is shortened from general 5-30min to 20s, staining efficiency is increased greatly, and screening speed of clinical samples is accelerated. And in addition, imagines obtained via staining with the vaginal secretion staining fluid are clear, and are convenient for identification; surface layer squamous epithelial cells, middle layer epithelial cells, bottom layer epithelial cells, clue cells, leukocytes, erythrocytes, monilia albicans, and trichomonad can be identified clearly; and the vaginal secretion staining fluid is suitable for large-scale sample clinical screening.

Owner:DIRUI MEDICAL TECH CO LTD

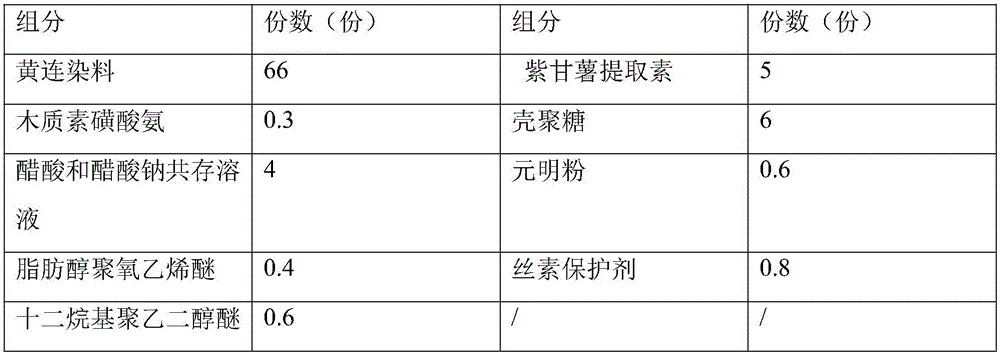

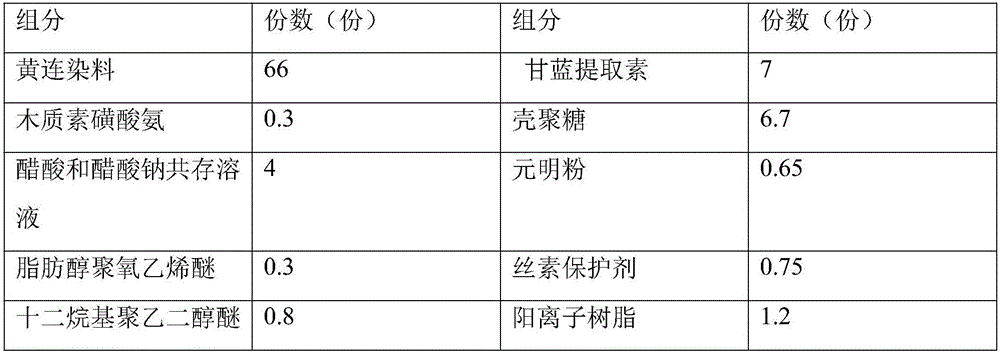

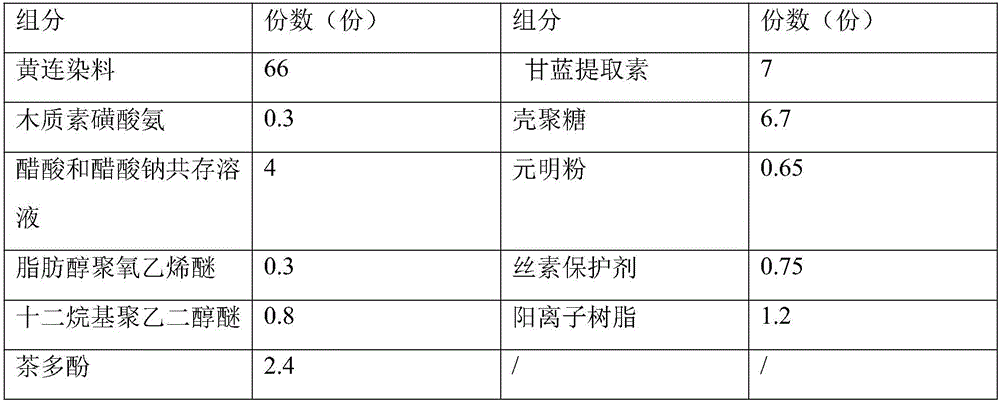

Dyeing agent and process for dyeing real silk by aid of dyeing agent

InactiveCN105970682AIncrease the amount of cationsFirmly attachedLight resistant fibresDyeing processFiberMordant

The invention discloses a dyeing agent and a process for dyeing real silk by the aid of the dyeing agent. According to the technical scheme, the dyeing agent and the process have the advantages that the problem that existing fiber fabrics contain heavy metal ions after being dyed can be solved; purple sweet potato extract elements, cabbage extract elements and purple perilla extract elements in the dyeing agent do not contain heavy metal ions, effects which are identical to effects of a mordant can be realized by the purple sweet potato extract elements, the cabbage extract elements and the purple perilla extract elements, accordingly, post-dye-uptake fiber fabrics are colorful and attractive on the premise that the dyeing agent and the process are favorable for improving the dye-uptake efficiency of the fiber fabrics, and environmental pollution can be prevented.

Owner:杭州余杭兴隆绸厂

Process of wet steaming salt-free dyeing for cellulose fiber fabric

InactiveCN102635000AOvercoming the disadvantages of contaminationShorten dyeing timeDyeing processProcess engineeringCellulose fiber

The invention belongs to the fiber fabric dyeing process, especially relating to a process of wet steaming salt-free dyeing for a cellulose fiber fabric, which has the effects of energy conservation and emission reduction. A method of dyeing fabric with an active dye by means of a proportional pump comprises the following three process steps: (1) a step of mixing a padding dye with a fixing agent; (2) a step of steaming fixation; and (3) a step of water washing. The technical proposal of the process, compared with the traditional pad drying and pad steaming processes, only employs a reducing soaper without a padding machine, so that the dyeing time is shortened and the dyeing efficiency is improved; the wet steaming salt-free process, compared with the batch-type cold pad dyeing process, has the advantages that the time of dyeing padding is shortened and the tinctorial yield is consistent; as the improvement of the fixing alkaline agent overcomes the shortcoming of water glass contamination, the continuity of pad dyeing is realized and the production efficiency is improved.

Owner:HUAFANG

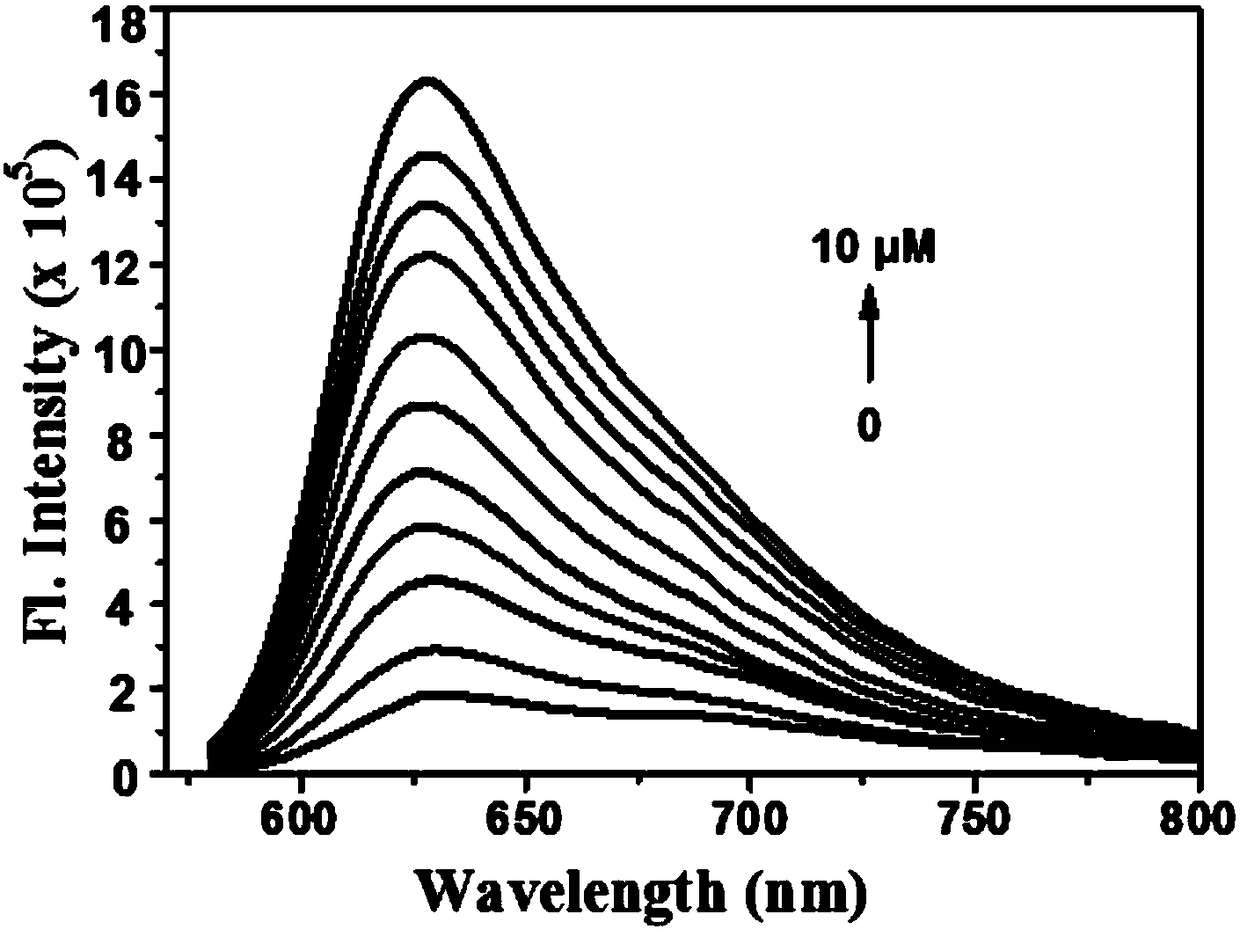

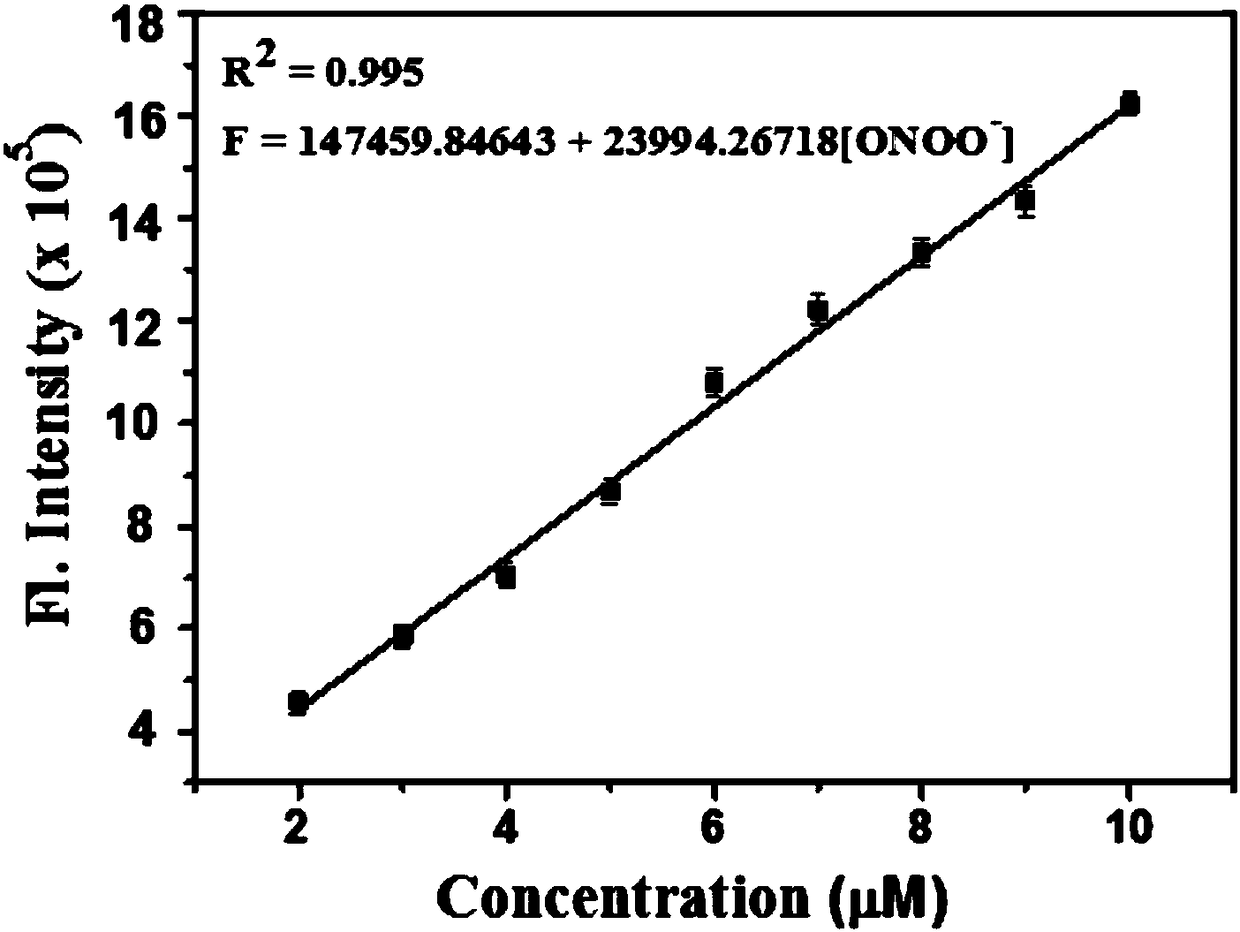

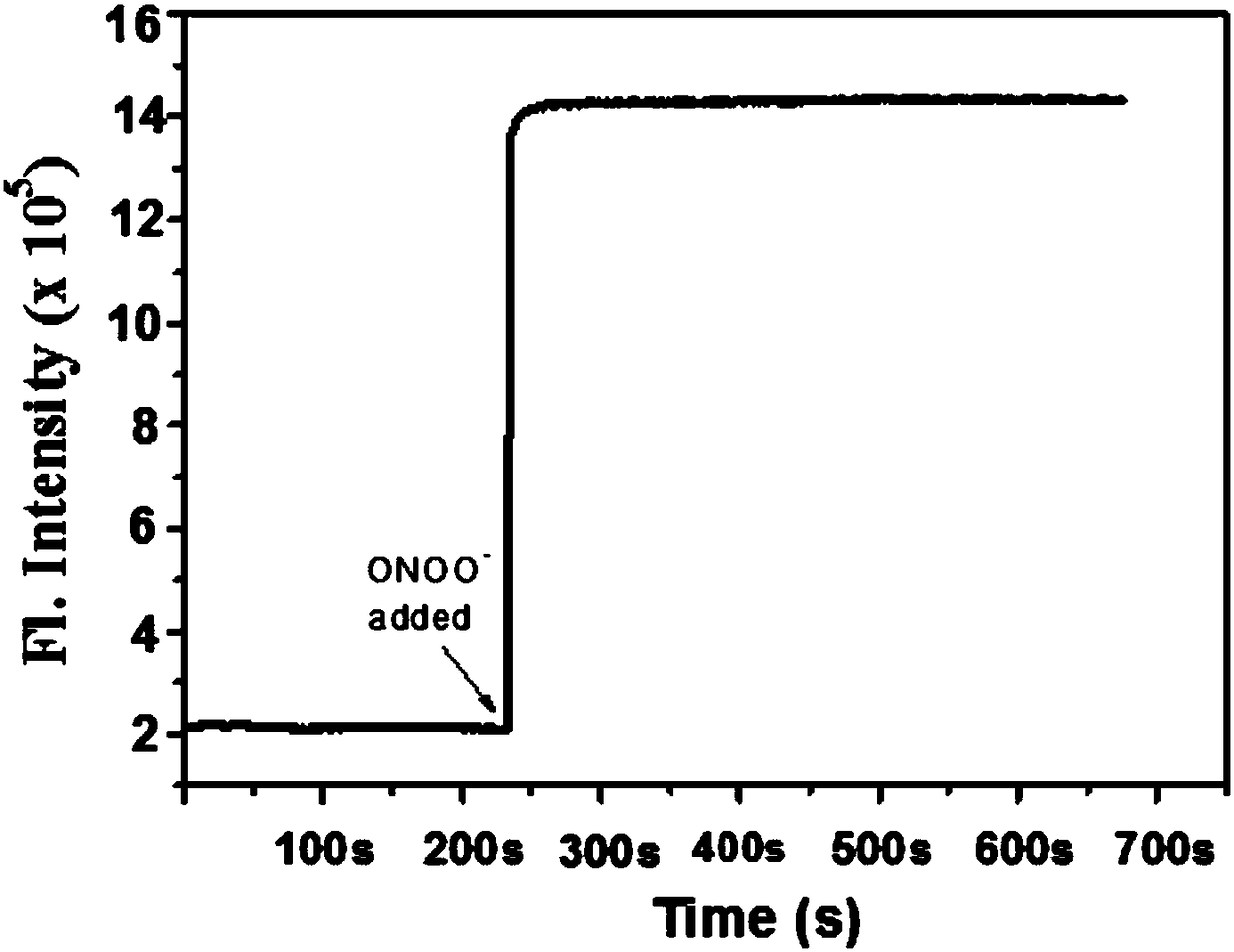

Two-photon fluorescence probe for detecting peroxynitrite as well as preparation method and application of two-photon fluorescence probe

ActiveCN108164494AIncrease penetration depthReduce self-absorptionOrganic chemistryFluorescence/phosphorescencePeroxynitriteStructural formula

The invention discloses a two-photon fluorescence probe for detecting peroxynitrite as well as a preparation method and application of the two-photon fluorescence probe. The two-photon fluorescence probe has the structural formula as shown in the description. The two-photon fluorescence probe is named as TPNIR-FP. The two-photon fluorescence probe adopts a Nile red derivative as a fluorescent group and an alpha-keto-amide functional group as an ONOO-reaction group, can rapidly respond to ONOO- (within 10 seconds), and in addition is high in sensitivity and good in selectivity. The two-photon fluorescence probe can be applied to imaging research on ONOO- in antharcycline antibiotic induced cardiac muscle cell and cardiac muscle tissue damage.

Owner:SHANDONG NORMAL UNIV

Cone yarn anhydrous dyeing equipment and method and product

ActiveCN106757915AGood colorImprove permeabilityTextile treatment containersSolvent treatment with solvent recoveryYarnEngineering

The invention provides cone yarn anhydrous dyeing equipment and method and a product. The cone yarn anhydrous dyeing equipment comprises a dye kettle, a dyeing kettle, a recycling kettle and a dyeing circulating system communicated with the dye kettle, the dyeing kettle and the recycling kettle. The cone yarn anhydrous dyeing equipment is characterized in that a cone yarn inlet is formed in the top of the dyeing kettle, a sealing cover is arranged on the cone yarn inlet, a yarn center shaft is vertically arranged in the middle in the dyeing kettle, and the yarn center shaft is an air outlet pipe with fluid release holes formed in the pipe wall; an air inlet pipe is arranged at the bottom of the dyeing kettle and communicated with the air outlet pipe, and a dyeing kettle outlet is formed in the dyeing kettle; the dyeing circulating system comprises a CO2 gas storage cylinder, a booster pump, a circulating pump and a pipeline. Various dyes are placed in the dye kettle, cone yarn is placed in the dyeing kettle, CO2 is introduced into the dye kettle, the dyes are gradually dissolved and reach the dyeing kettle along with CO2 fluid, and the coloring and dispersing processes are started. The advantages of being high in production efficiency, good in level dyeing effect, high in safety and suitable for anhydrous dyeing of the dacron cone yarn are achieved.

Owner:QINGDAO JIFA GROUP

Schoenoplectus trigueter (L.) Palla mat dyeing and drying technology

InactiveCN103158182AHigh hardnessReduce water consumptionSpraying apparatusWood treatment detailsEngineeringHumidity

The invention discloses a Schoenoplectus trigueter (L.) Palla mat dyeing and drying technology. The Schoenoplectus trigueter (L.) Palla mat dyeing and drying technology comprises the following steps of shaking out a Schoenoplectus trigueter (L.) Palla mat semi-finished product bundle by a mat shaking device, putting the spread Schoenoplectus trigueter (L.) Palla mat on a base plate, feeding the Schoenoplectus trigueter (L.) Palla mat into a dyeing tank, carrying out dyeing by a dye composed of white glue, dry jelly belly, pure green pulp, alkaline bright yellow powder and water, feeding the dyed Schoenoplectus trigueter (L.) Palla mat into a drying tank, and carrying out drying, wherein a Schoenoplectus trigueter (L.) Palla mat transmission rate in the drying tank is in a range of 1000-1500m / h; a temperature in the dyeing tank is controlled in a range of 90-120 DEG C; and the humidity is controlled in a range of 55-80%. The Schoenoplectus trigueter (L.) Palla mat dyeing and drying technology improves drying efficiency, and reduces a labor cost. The Schoenoplectus trigueter (L.) Palla mat dyed by the Schoenoplectus trigueter (L.) Palla mat dyeing and drying technology has a light yellow Schoenoplectus trigueter (L.) Palla natural color and an elegant appearance.

Owner:郑文君

Natural dye for spinning and preparation method thereof

InactiveCN105542509AImprove dyeing efficiencyHigh color fastnessNatural dyesChitin formationALLYL SUCROSE

The invention discloses natural dye for spinning. The dye is prepared from, by weight, 50-70 parts of green alga extraction solution, 30-45 parts of polyacrylic acid compound, 10-15 parts of chitosan, 5-9 parts of chitin, 12-18 parts of styrene-butadiene rubber latex and 16-25 parts of iron oxide red. The invention further discloses a preparation method of the natural dye for spinning. Raw materials of the dye are low in price and easy to obtain, and the dye is natural and healthy and free of toxicity and harms to human bodies; the whole dye is beneficial to coloring, firm in dyeing, not prone to fading, easy and convenient to use, green, environmentally friendly and quite suitable for large-scale industrial production.

Owner:SUZHOU INSILK CO LTD

High-temperature continuous type dyeing machine for woven tapes

InactiveCN104894785AReduce lossImprove dyeing efficiencySucessive textile treatmentsTextile treatment machine arrangementsDistributed structureProcess engineering

The invention relates to the technical field of dyeing and discloses a high-temperature continuous type dyeing machine for woven tapes. The dyeing machine has the advantages that in a whole process from tape unwinding to tape winding, multiple woven tapes are conveyed by means of rollers and can be dyed simultaneously, and accordingly, dyeing efficiency is high; the dyeing machine is provided with a heat energy recovery device for recovering used hot air, and recovered heat energy is used for heating water for other use; since the heat energy is recovered, energy resource loss can be reduced greatly, and energy conservation and production cost reduction are achieved; the dyeing machine is of a distributive structure, thereby being higher in operational reliability and simpler to repair and maintain.

Owner:东莞市坚华机械有限公司

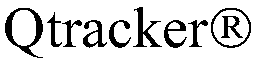

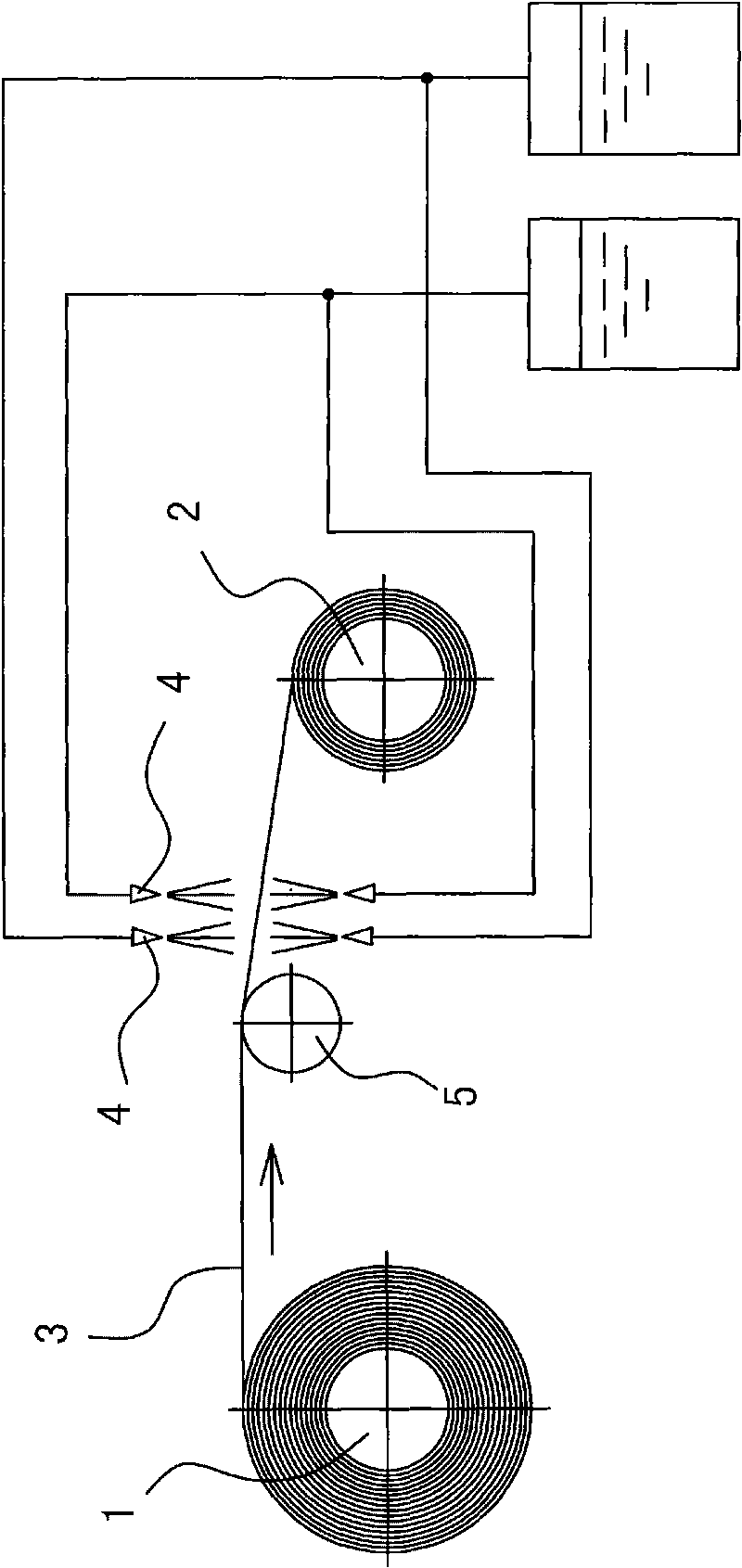

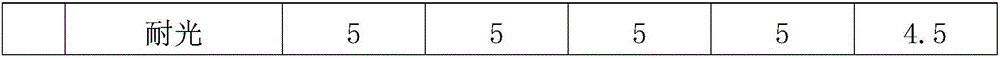

Temperature control atomization yarn dyeing process and system thereof

ActiveCN105088582AEmission reductionEasy to dyeSucessive textile treatmentsTextile treatment by spraying/projectingYarnEngineering

The invention discloses a single yarn dyeing process and system. The system comprises an unwinding mechanism, a guide roller mechanism, a wetting mechanism, a spray dyeing mechanism, a drying mechanism and a winding and rewinding mechanism. Dyeing steps comprise procedures of yarn rewinding and unwinding, yarn humidity adjusting, yarn dyeing, drying, yarn rewinding and forming, and the like, wherein in a dyeing process, a temperature control high-frequency atomization dyeing process is adopted, dyeing effects of more efficiency and more stable chromaticity can be achieved by adjusting atomization chamber temperature and atomization chamber humidity during dyeing, and a dyeing effect of more evenness can be achieved by adjusting yarn humidity before dyeing. By adopting the dyeing process and system, the dyeing course is simple, dyeing permeation is even, the course is continuous, the operation is simple, the yield is high, water consumption and sewage drainage are less, energy consumption is low, loss is less, and economic benefit can be greatly improved.

Owner:上海帆绣机电科技有限公司

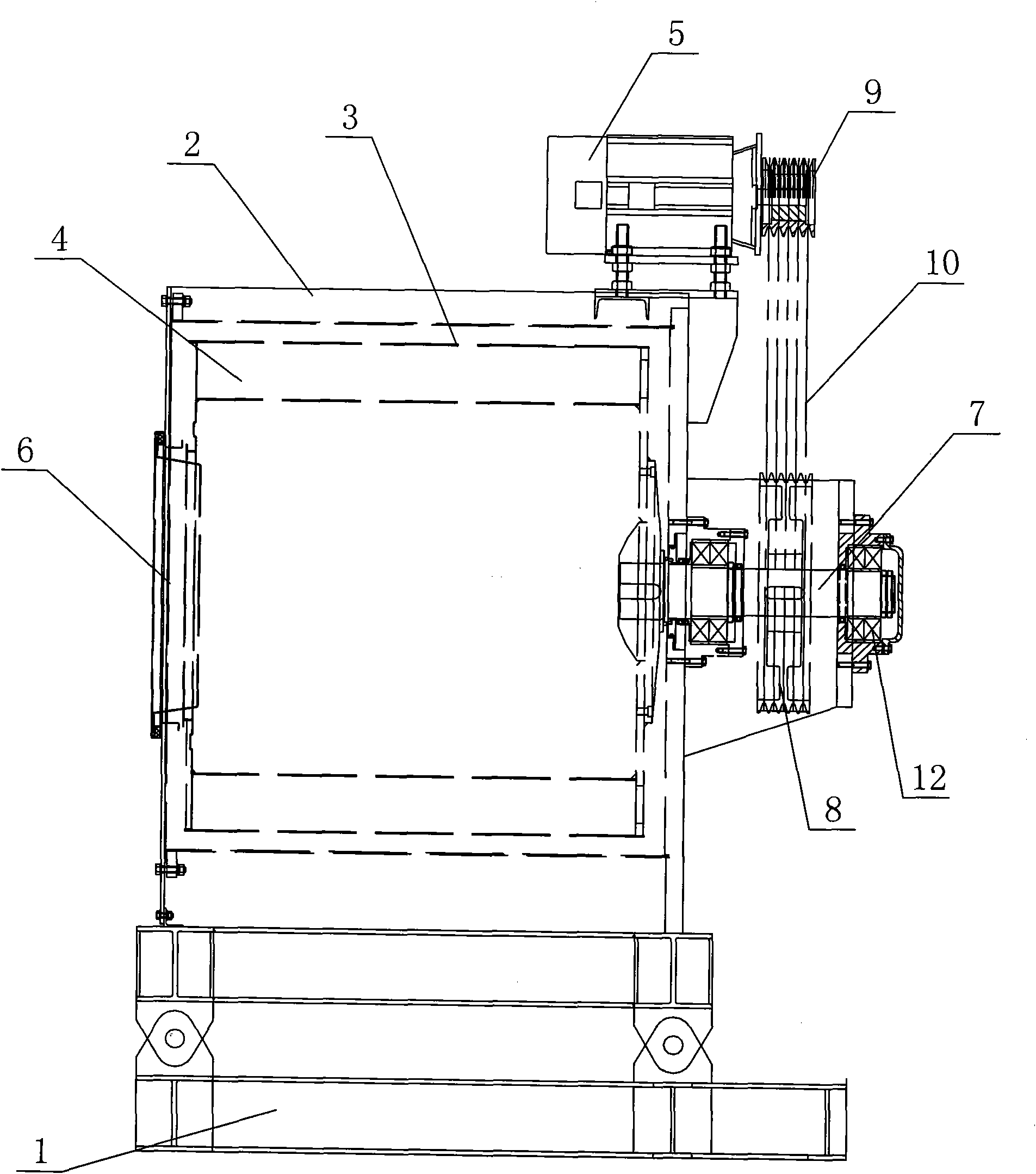

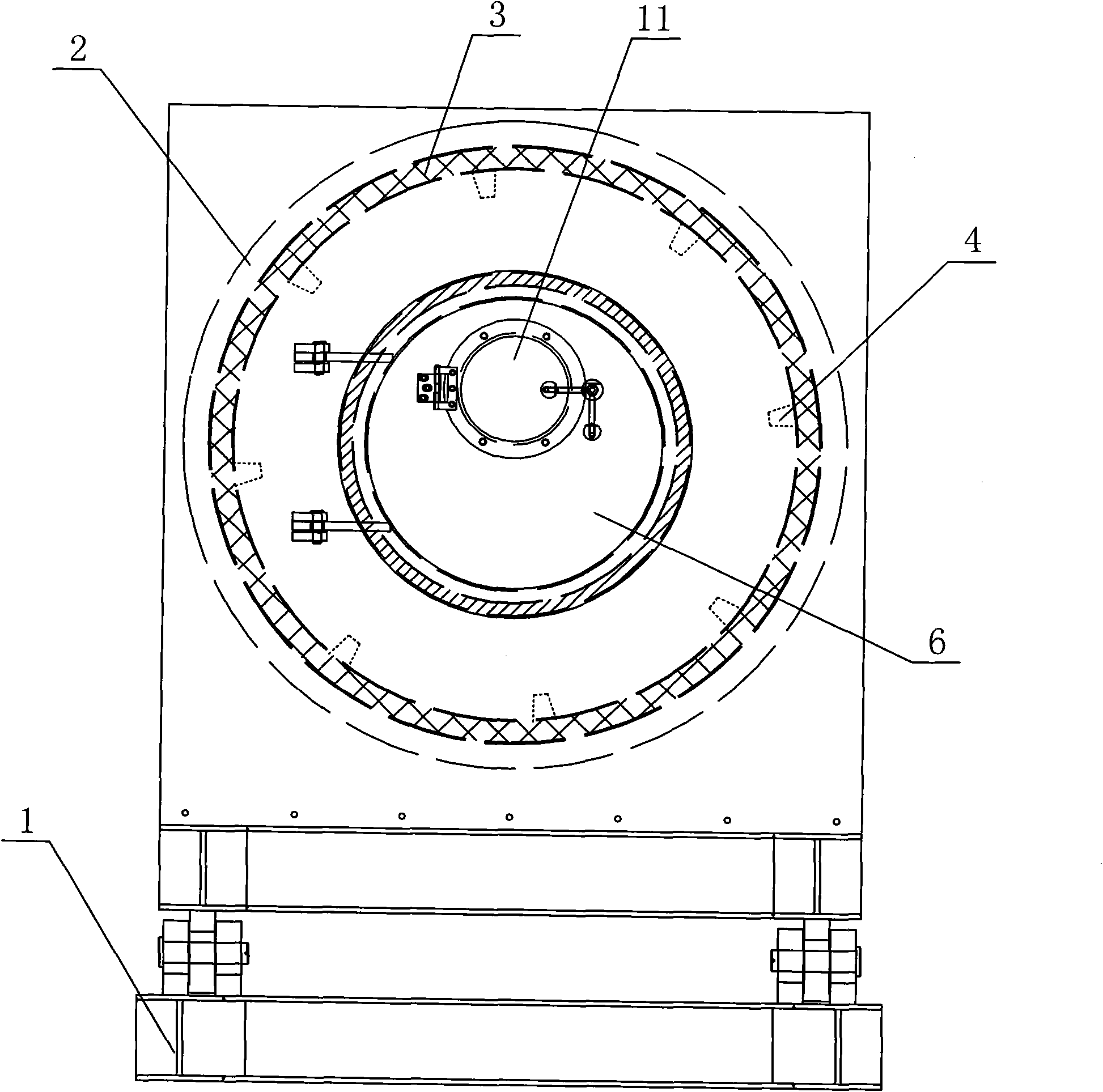

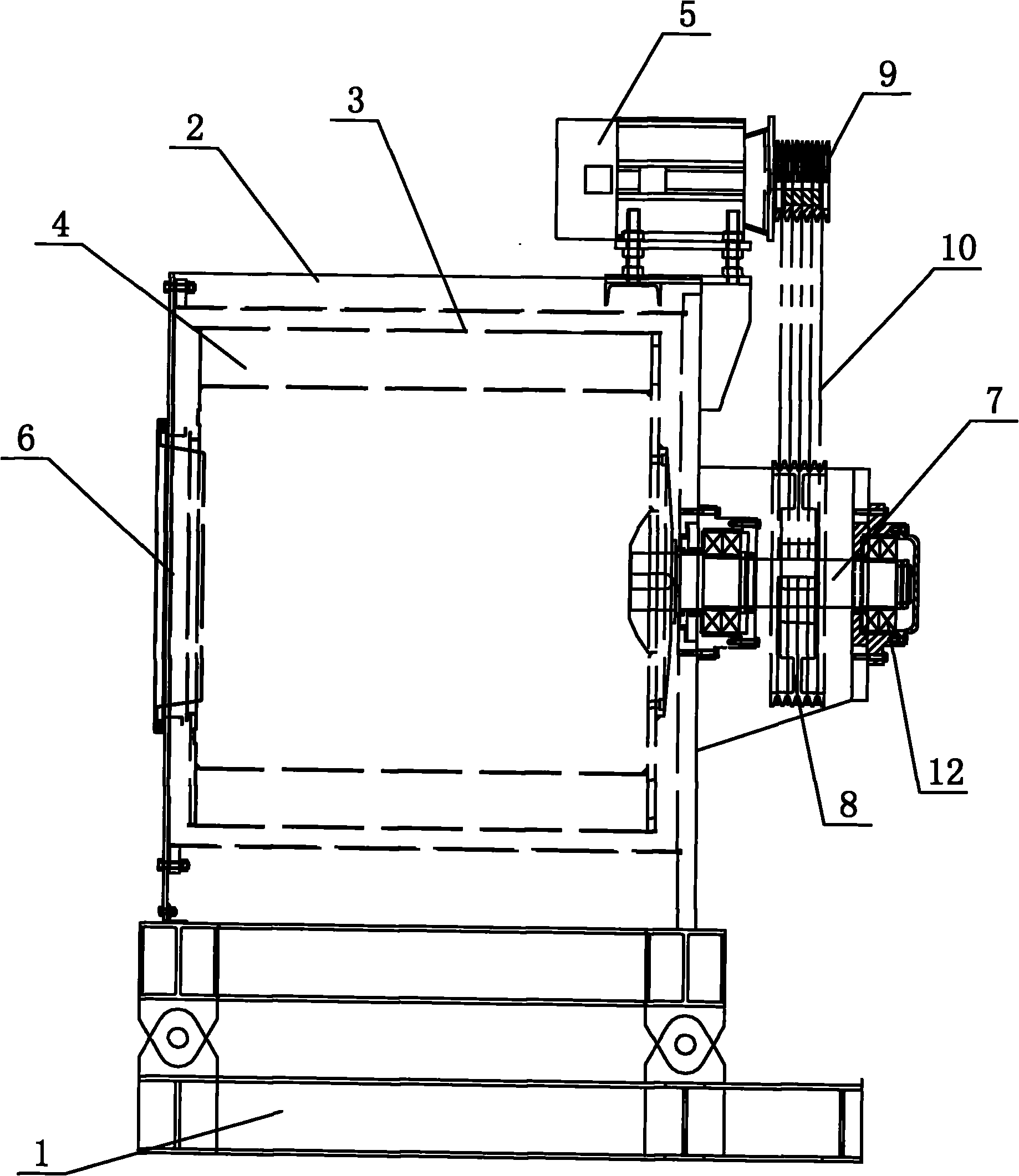

360-degree rotating drum type dyeing machine with low bath ratio

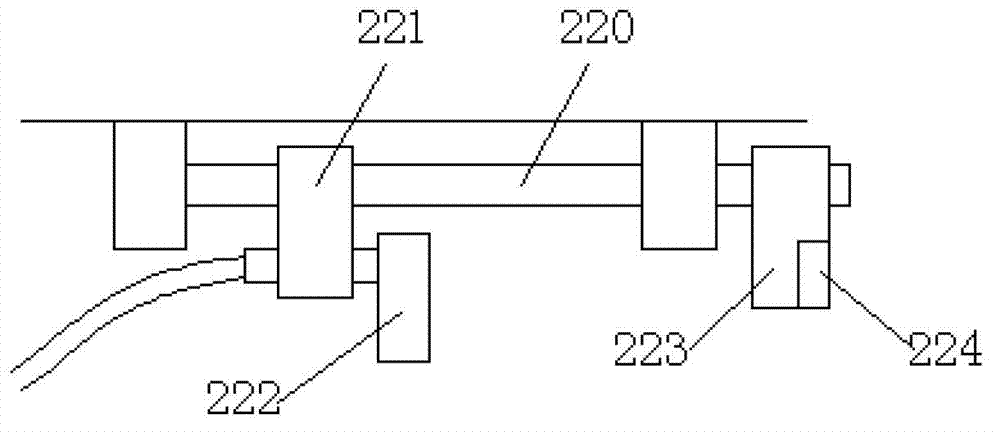

InactiveCN102182027ASimple structureImprove dyeing efficiencyLiquid/gas/vapor treatment machines driving mechanismsTextile treatment rollersMotor driveTransmission belt

The invention discloses a 360-degree rotating drum type dyeing machine with low bath ratio. The dyeing machine comprises a box body arranged on a dyeing machine base; one end of the box body is provided with a door, an open rotating drum is arranged in the box body, the open end of the rotating drum is arranged corresponding to the door, and a transmission shaft is fixed at the other end of the box body; the transmission shaft is connected with a power output shaft of a power device through a transmission belt, and the power device drives the rotating drum to rotate through the transmission belt; and a plurality of through holes are uniformly distributed on the side wall of the rotating drum, and a plurality of reinforcing plates are fixed on the inner side of the side wall of the rotating drum. According to the 360-degree rotating drum type dyeing machine with low bath ratio, the open rotating drum is arranged in the box body, a motor drives the rotating drum to rotate in the box body, and dyeing solution flows into the rotating drum from the through holes on the side wall of the rotating drum to dye the textiles in the rotating drum; and the dyeing machine has simple structure, integrates multiple functions of dyeing, washing and dehydrating, and has low bath ratio and high dyeing efficiency.

Owner:无锡赛腾机电科技有限公司

Fluorescent probe for detecting peroxynitrite and preparation method and application thereof

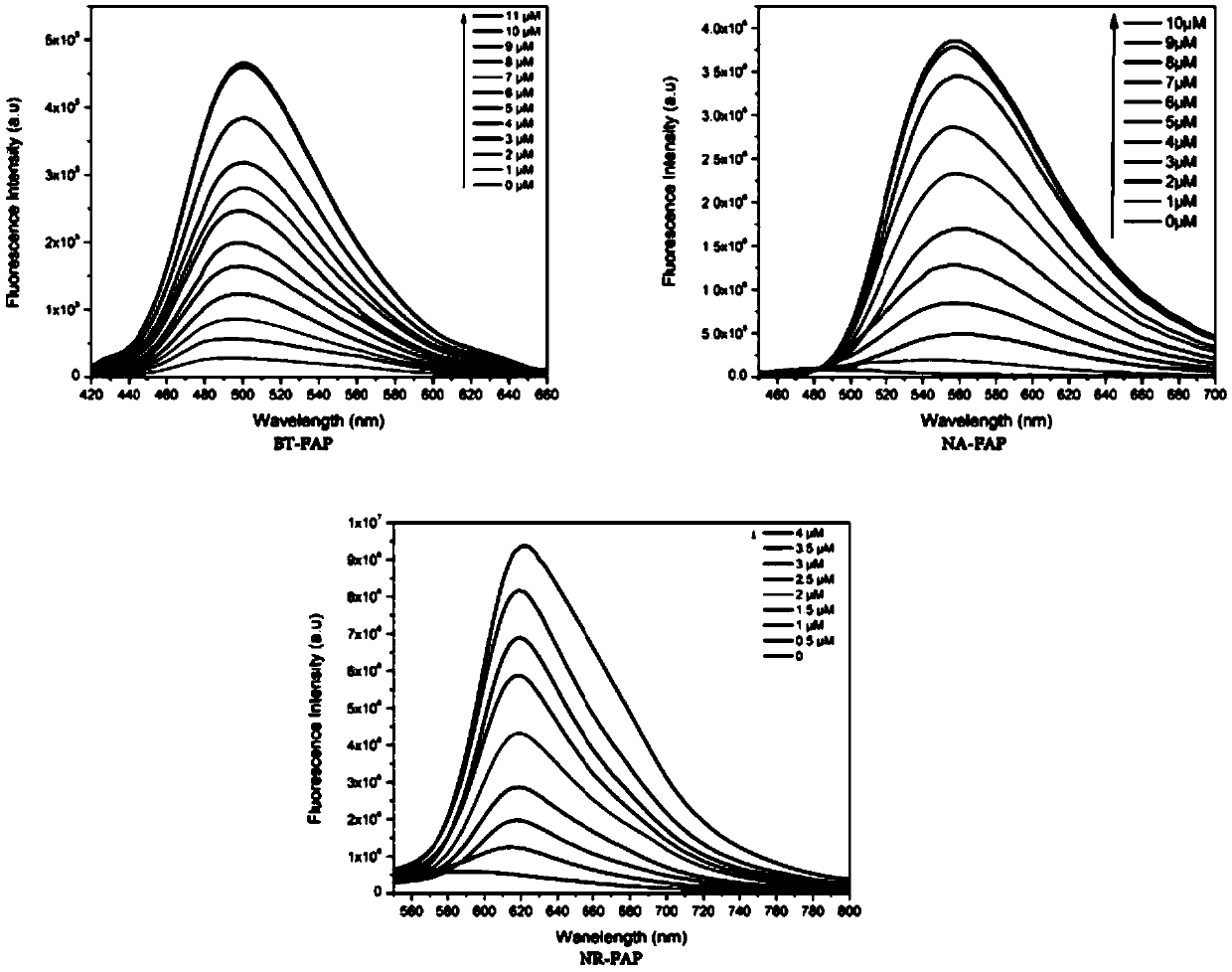

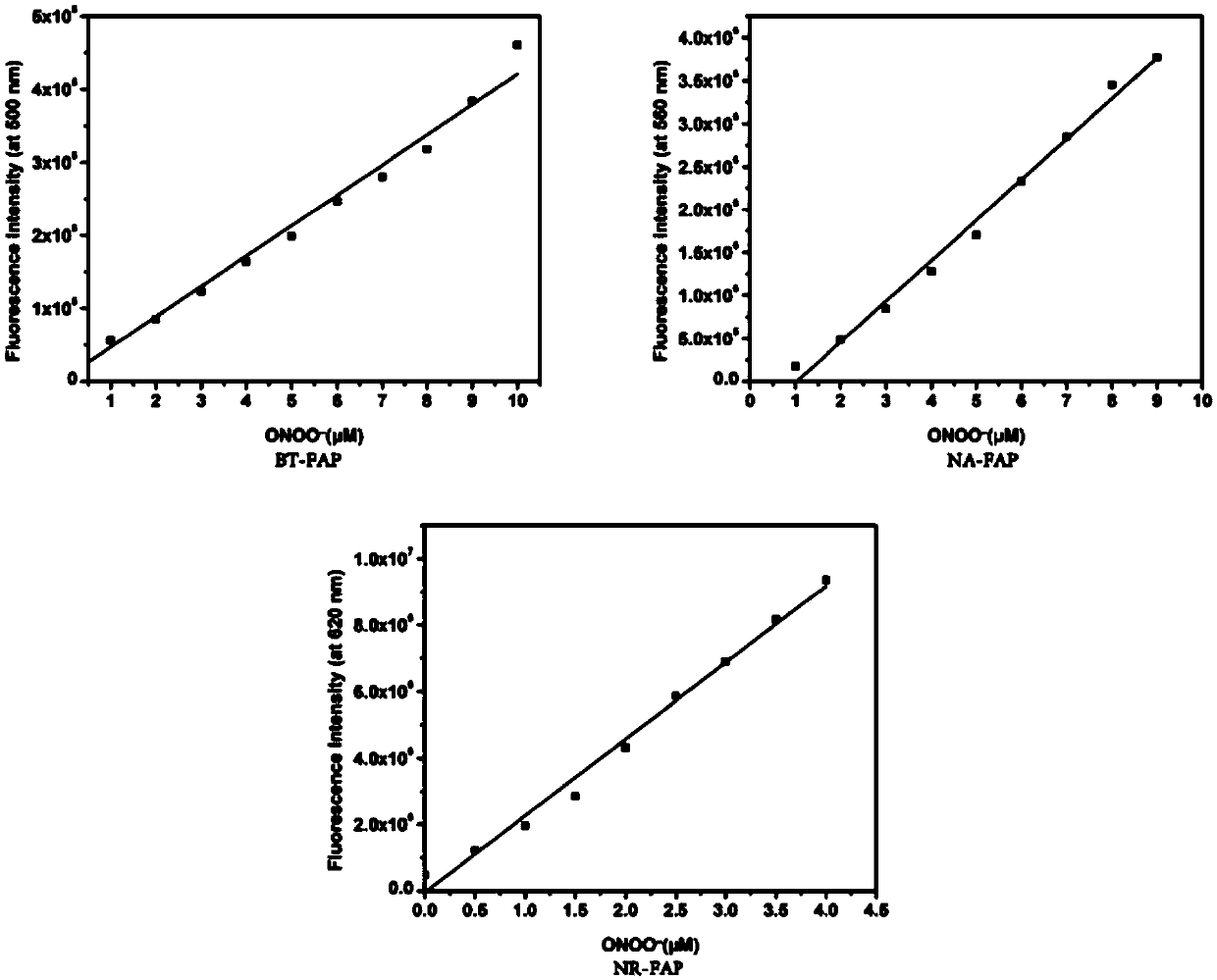

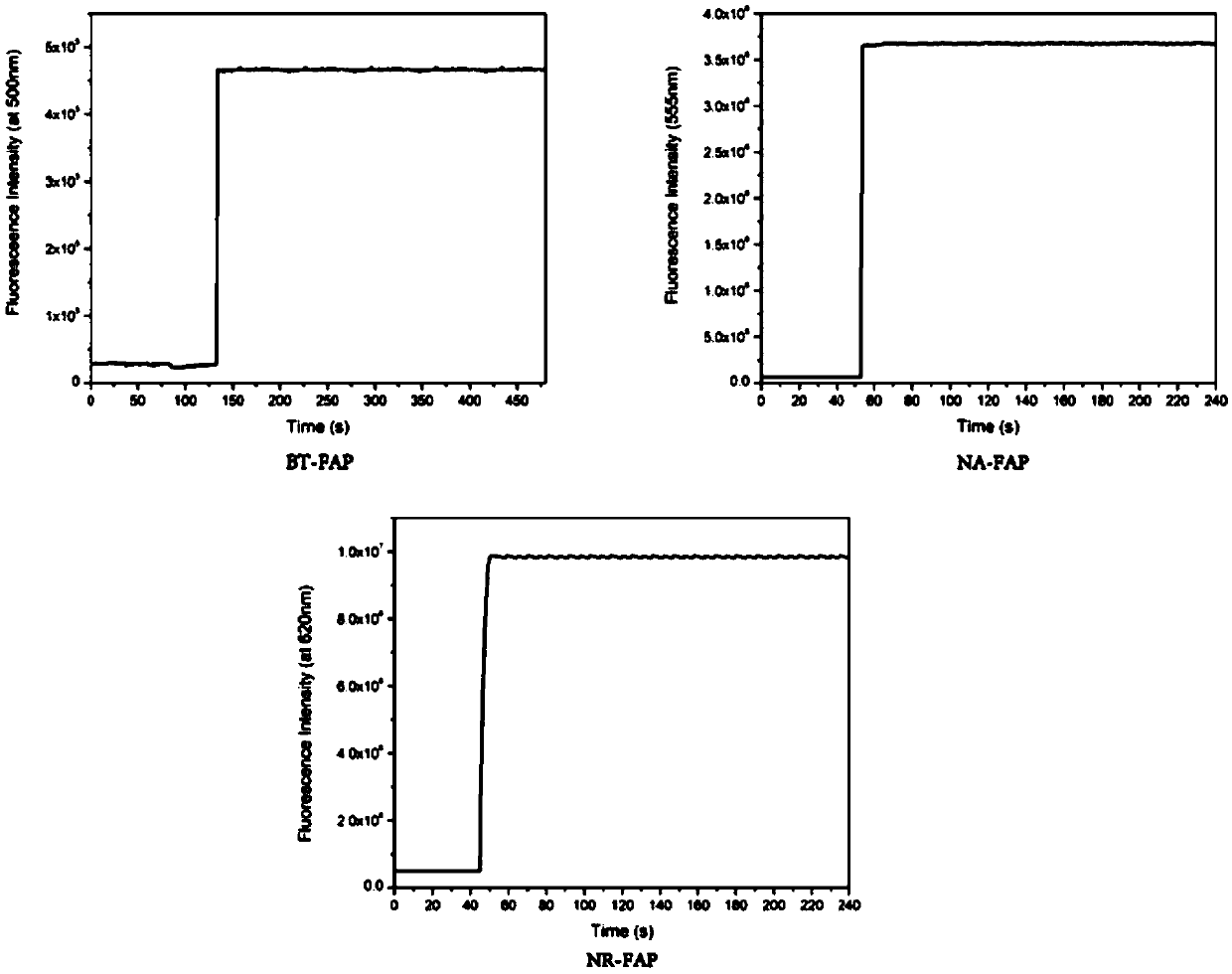

ActiveCN109608414AImprove accuracyReduce self-absorptionOrganic chemistryFluorescence/phosphorescenceNitriteImaging study

The invention belongs to the technical field of synthesis and detection, and particularly relates to a fluorescent probe for detecting peroxynitrite and a preparation method and application thereof. The invention provides a universal identification group for detecting peroxy nitrite, and three new fluorescent probes which are respectively named as BT-FAP, NA-FAP and NR-FAP are formed by connectingthe universal identification group with common fluorophores, wherein aminonaphthalene (BT), naphthalimide (NA) and benzophenoxazine (NR) are the fluorophores, and formamide (FAP) is the identification group to achieve the instant reaction with ONOO (all 4s), the fluorescent probe has high sensitivity and good selectivity, and is very suitable for ONOO fluorescence imaging studies in cells.

Owner:SHANDONG NORMAL UNIV

Cotton yarn dyeing process

ActiveCN106283448AStir wellWell mixedTextile treatment machine arrangementsTextile treatment cleaning apparatusYarnPulp and paper industry

The invention provides a cotton yarn dyeing process, and belongs to the technical field of dyeing treatment. A method for dyeing cotton yarns used for weaving a jean fabric comprises the following steps: a, preparing the cotton yarns; b, performing surface treatment on the cotton yarns; c, rinsing the cotton yarns for the first time; d, rinsing the cotton yarns for the second time; e, dyeing the cotton yarns; f, drying the cotton yarns; and g, rolling up the cotton yarns. The cotton yarn dyeing process disclosed by the invention has the advantage of capability of dyeing the cotton yarns used for weaving the jean fabric more effectively.

Owner:HAINING DENIM WEAVING CO LTD

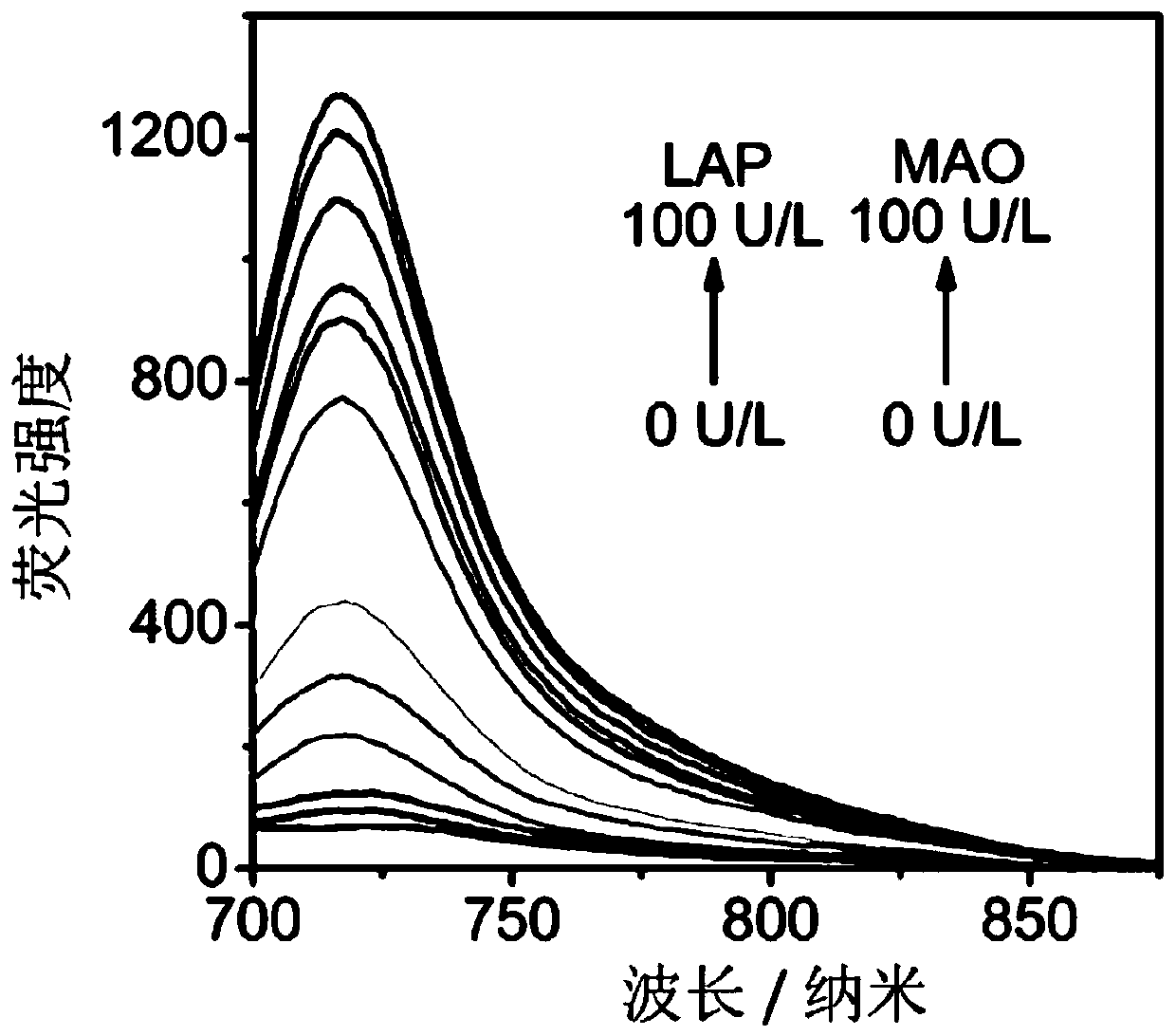

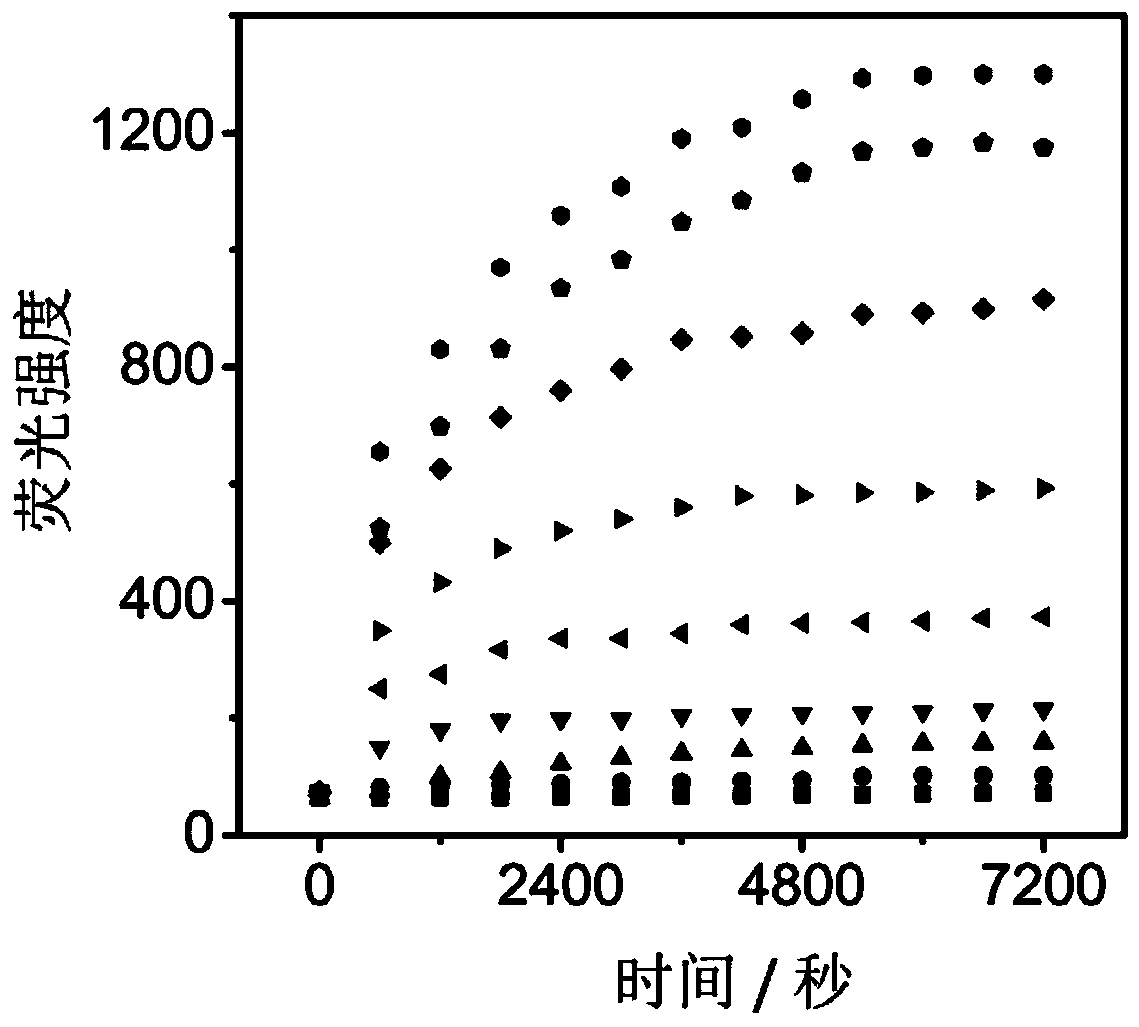

Leucine aminopeptidase and monoamine oxidase-activated near-infrared fluorescent probe as well as synthetic method and biological application thereof

ActiveCN110746410AHas near-infrared luminescent propertiesHigh sensitivityOrganic chemistryFluorescence/phosphorescenceFluoProbesStaining

The invention discloses a leucine aminopeptidase and monoamine oxidase-activated near-infrared fluorescent probe as well as a synthetic method and biological application thereof. The adopted syntheticmethod includes the following step: (1) synthesizing the novel leucine aminopeptidase and monoamine oxidase-activated near-infrared fluorescent probe (NML); and the biological application comprises the following step: (1) applying the probe to biological imaging and serum detection. The leucine aminopeptidase and monoamine oxidase-responsive fluorescent probe is synthesized for the first time, and the problem of low specificity of a traditional single-enzyme fluorescent probe is overcome; the fluorescent probe has near-infrared fluorescence properties, the background fluorescence signal can be effectively reduced, and the sensitivity of the probe can be improved; and the fluorescent probe has a good staining effect on living cells and high staining efficiency, and can detect cell endogenous leucine aminopeptidase and monoamine oxidase.

Owner:HUNAN UNIV

One-step dyeing method of porous cellulose microspheres-modified dyed cotton blended fabric

The invention provides a one-step dyeing method of a porous cellulose microspheres-modified dyed cotton blended fabric. The one-step dyeing method comprises the steps of soaking a polyester-cotton blended fabric in an alkaline pretreating solution containing hexadecyl trimethyl ammonium chloride, and padding to obtain a pretreated polyester-cotton blended fabric; adding cellulose fibers into a formate mixed liquid, heating, stirring for dissolving, adjusting pH to neutrality, dispersing in an aqueous solution to obtain a methylated cellulose microcrystalline solution, dropwise adding into acidic regenerating solution, curing, taking out cellulose nano hydrogel spheres, lyophilizing to obtain porous cellulose microspheres, dispersing in a solution containing dimethylol dihydroxy ethylene urea resin, mixing, soaking the pretreated polyester-cotton blended fabric under vibrating, and washing repeatedly to obtain a cellulose microspheres-modified polyester-cotton blended fabric; soaking the cellulose microspheres-modified polyester-cotton blended fabric in a dye, heating for dyeing, taking out, drying, and baking to obtain the dyed polyester-cotton blended fabric.

Owner:HUAIAN JIADE TEXTILE CO LTD

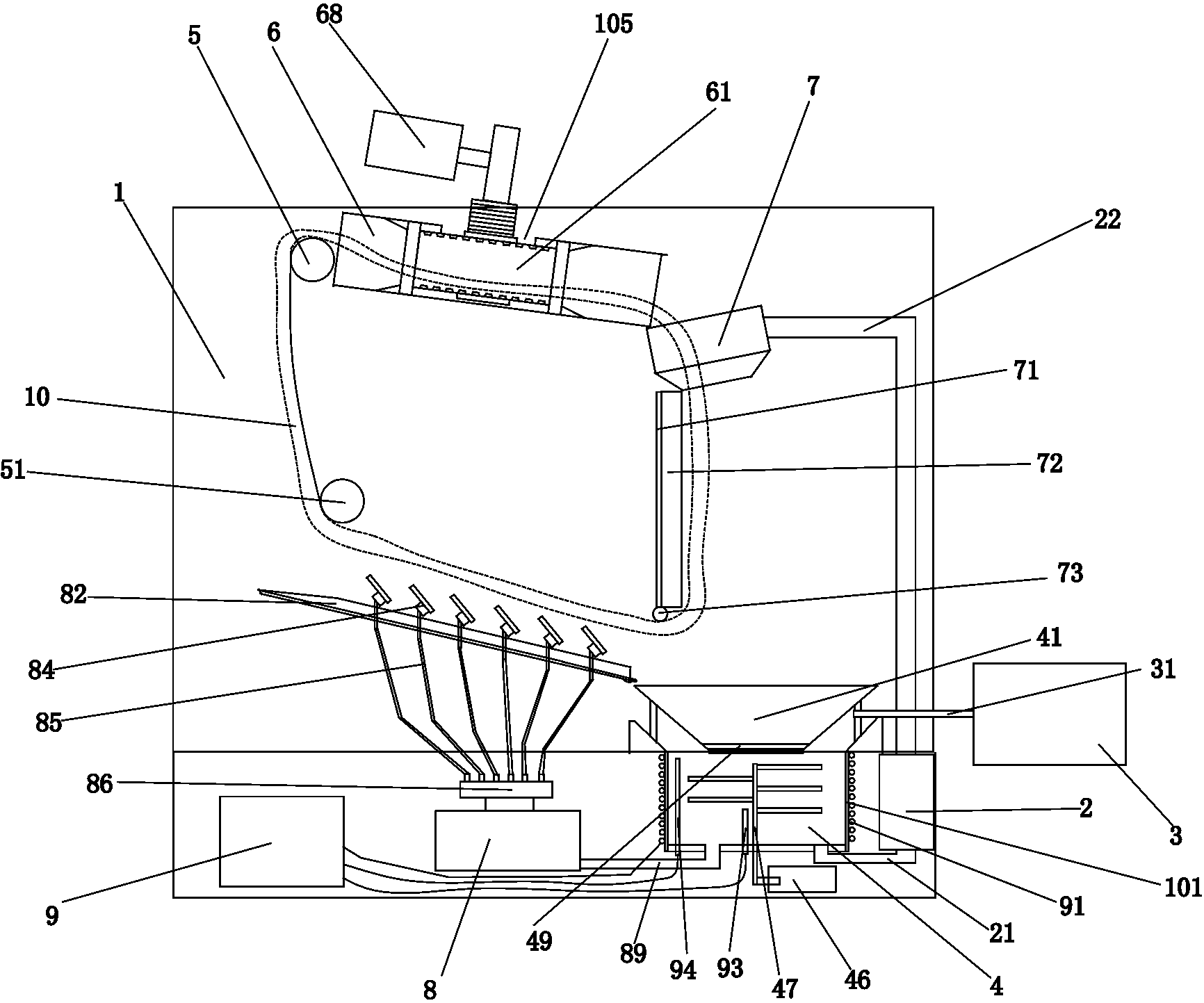

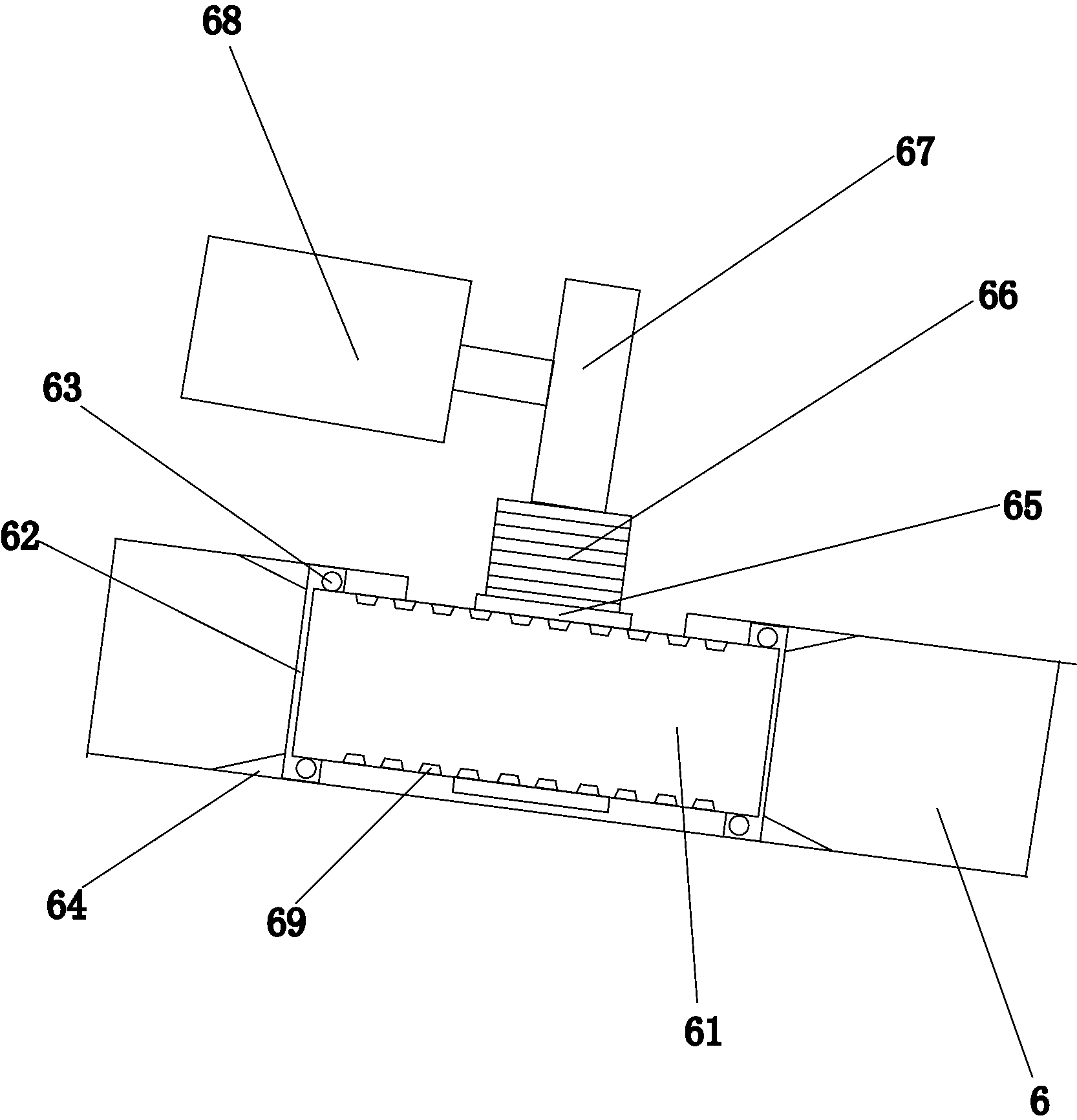

Cashmere-like yarn dyeing method and cashmere-like yarn dye vat

ActiveCN104499224APrevent splashEasy to assemble and disassembleSucessive textile treatmentsTextile treatment containersTextile technologyYarn

The invention provides a cashmere-like yarn dyeing method and a cashmere-like yarn dye vat, belongs to the technical field of textile and solves the technical problems that one end of a yarn hanger of an existing double-cylinder dyeing machine is a suspended end, bearing capacity is poor, the existing double-cylinder dyeing machine is not provided with a pedal device, an operator cannot conveniently take down upper yarns, operation is strenuous, a preparation method omits dye liquor and the like. The cashmere-like yarn dyeing method includes the steps: a, blank inspection; b, threading; c, dye liquor manufacture; d, feeding; e, dewatering; f, drying; g, warehousing. The dye vat is used for dyeing cashmere-like yarns and comprises a frame, a plurality of upper dyeing sticks and a plurality of lower dyeing sticks, and an upper vat body and a lower vat body are fixed on the frame. The dye vat has the advantages of high dyeing efficiency, fine supporting effect and fine working stability.

Owner:ZHEJIANG YINGSHANHONG TEXTILE TECH CO LTD

Dyeing machine

InactiveCN103898684AFully infiltratedIncrease contact areaTextile treatment by spraying/projectingTextile treatment carriersElectric machineryPulp and paper industry

The invention provides a dyeing machine, and relates to a textile fabric dyeing machine. The dyeing machine comprises a tank, a circulating pump and a dye liquor box. A large nozzle, a cloth guide pipe and a cloth lifting wheel are arranged in the tank. The dyeing machine is characterized in that a roller is rotationally arranged in the cloth guide pipe, an annular rack is arranged on the roller, an opening matched with the annular rack is formed in the cloth guide pipe, a motor is arranged outside the tank, a gear matched with the annular rack is arranged in the tank, the motor is in transmission connection with the gear, and a plurality of tidily-arranged protrusions are arranged in the roller. Compared with the prior art, textile fabric in the dyeing machine can be automatically turned over, the contact area of the textile fabric and dye liquor is increased, the textile fabric is fully soaked in the dye liquor, dyeing efficiency is improved, meanwhile, the bath ratio is reduced, and drainage of waste water is reduced.

Owner:NINGBO EASTSUN TEXTILES

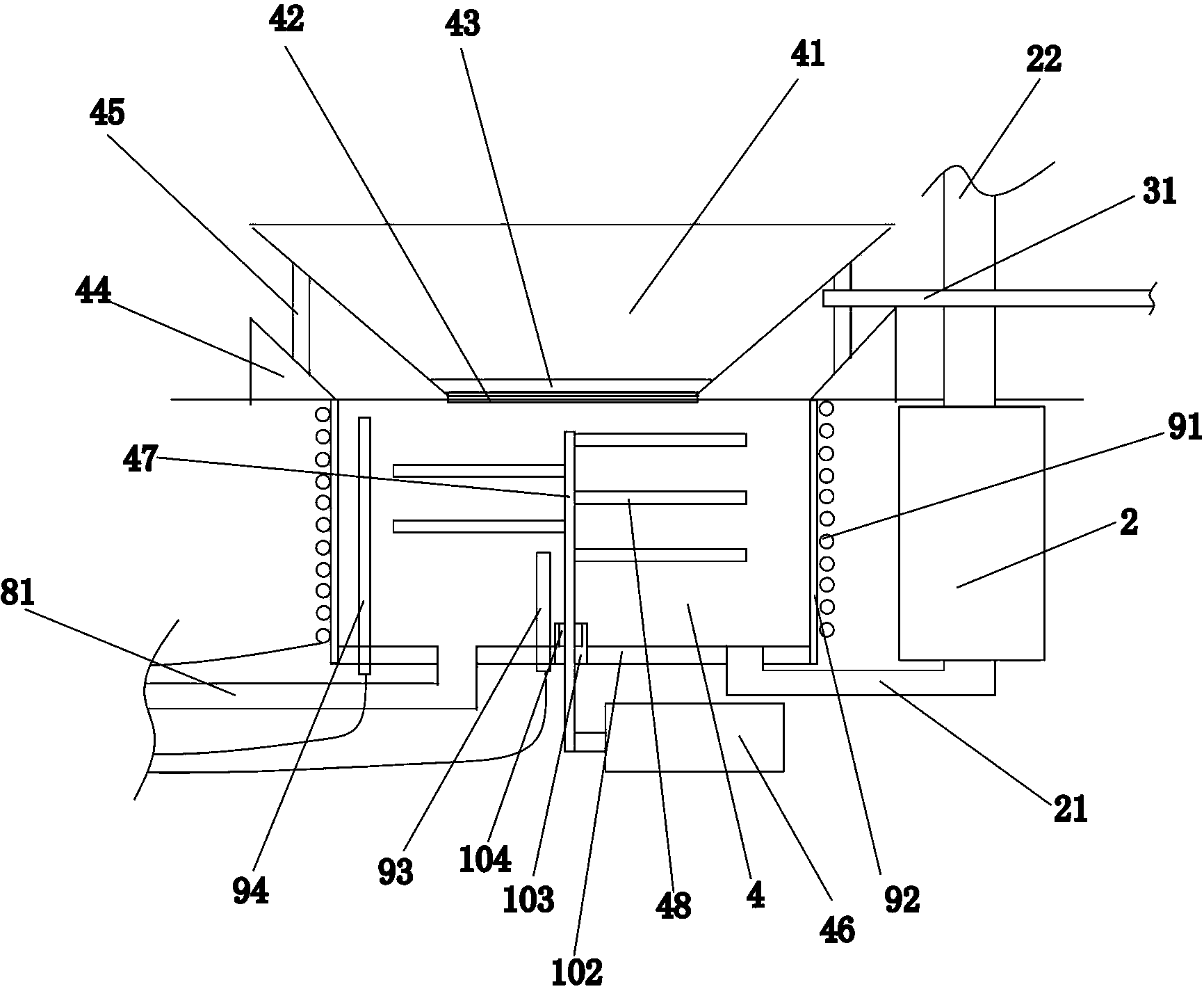

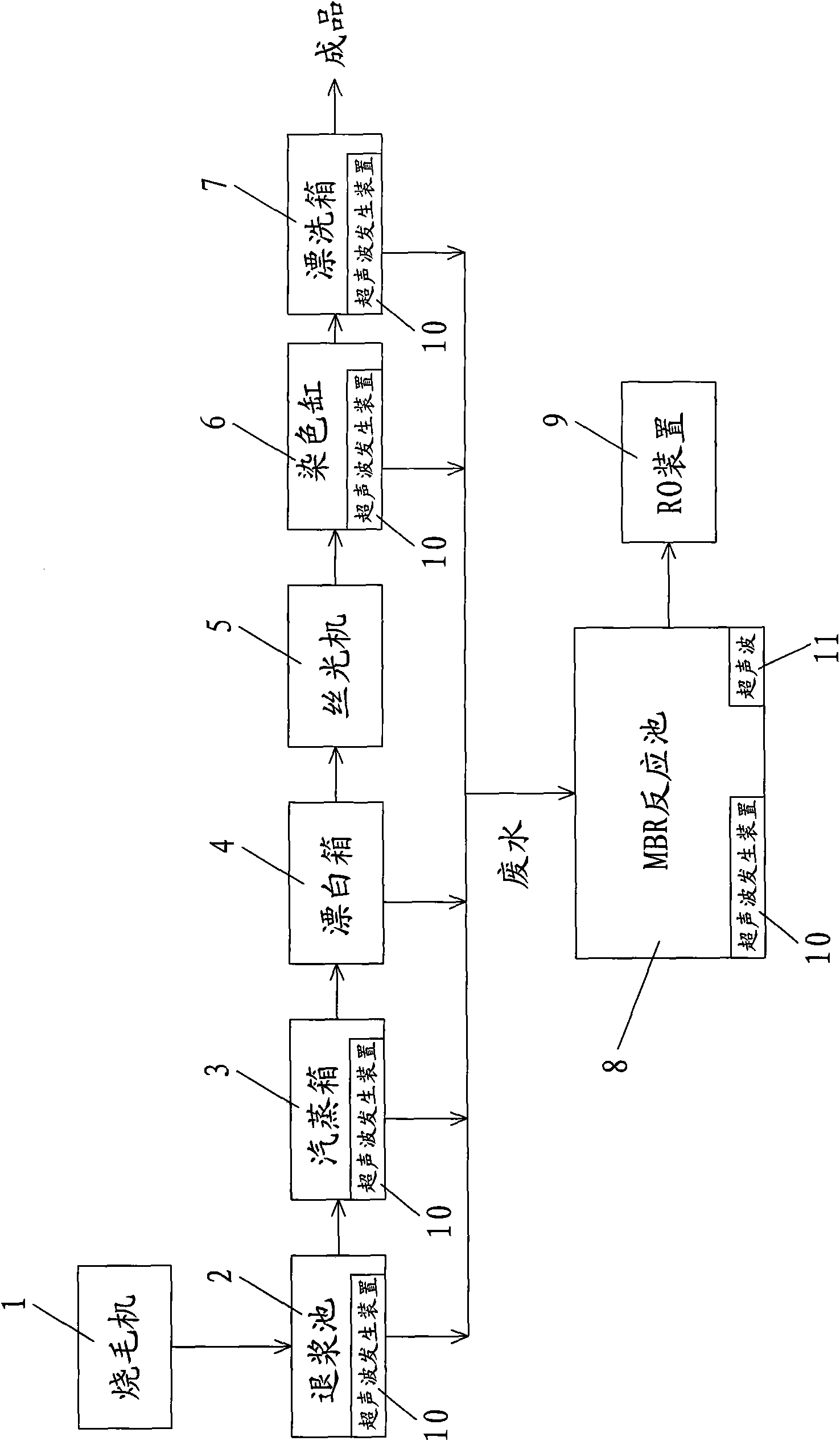

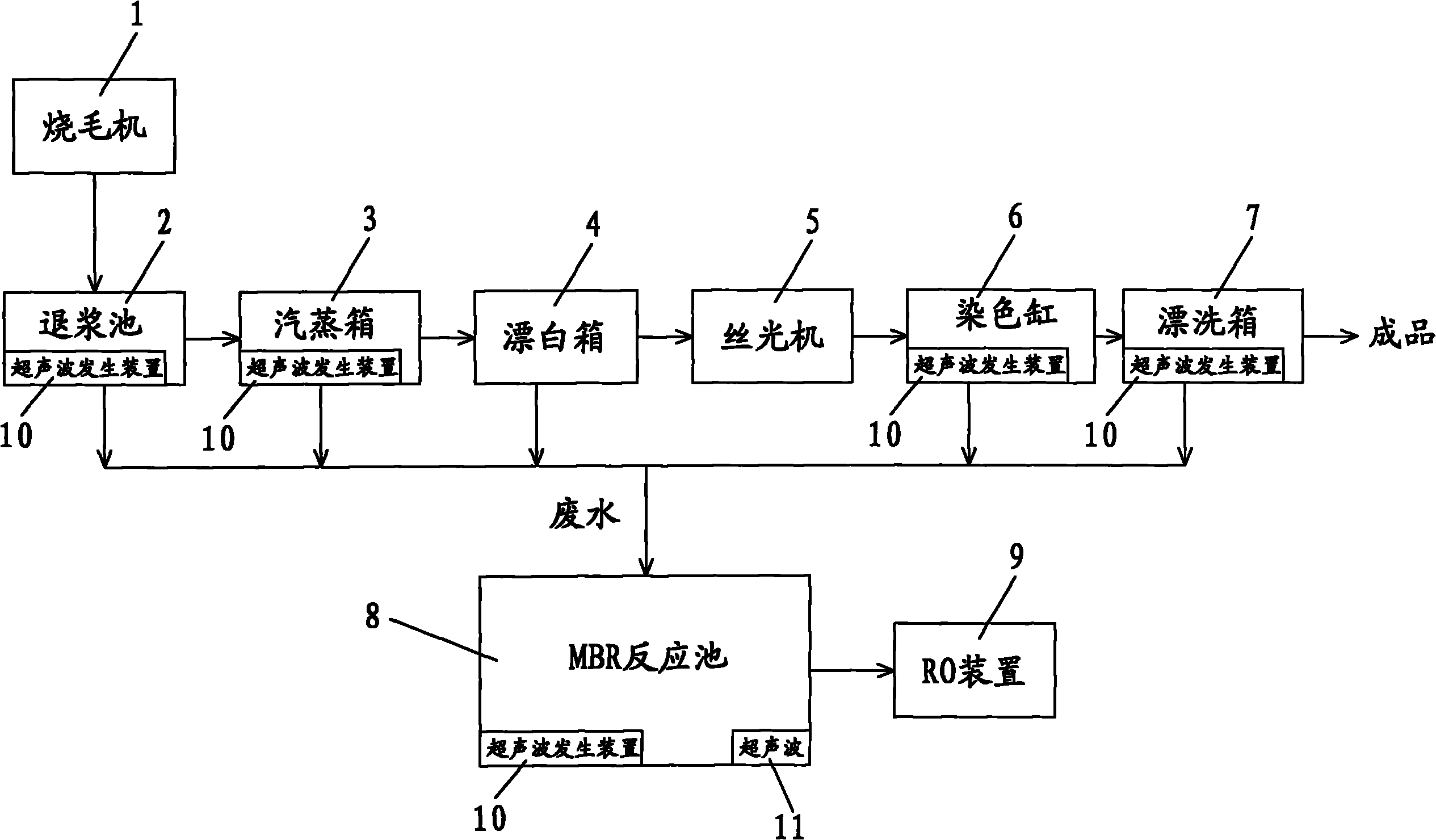

Cleaning production process in dyeing and printing industry

InactiveCN101781842AIncrease profitImprove dyeing efficiencyWater/sewage treatment with mechanical oscillationsUltrasonic/sonic fibre treatmentBiochemical engineeringWastewater

The invention relates to a production process in textile dyeing and printing industry, which provides a cleaning production process and equipment in the dyeing and printing industry. The process comprises the processes of singeing, desizing, boiling, bleaching, mercerizing, dyeing / pattern printing, tidying (rinsing) and finished product obtaining, wherein in the work procedures of desizing, boiling, dyeing / pattern printing and tidying (rinsing), 20 to 50 KHz ultrasonic waves are adopted for irradiation. Correspondingly, ultrasonic wave generators are arranged in production equipment such as a desizing tank, a vapor steaming box, a dyeing cylinder, a rinsing box and the like. The cleaning production process and the equipment thereof in the dyeing and printing industry provided by the invention adopt the ultrasonic wave technology, improve the dye utilization rate and the dyeing efficiency, reduce the dye consumption, enhance the dye coloring and color fixation effect, accelerate the permeation and the moistening of the dye on the textile, short the dyeing time, reduce the waste water discharge quantity of the dyeing and printing industry, improve the biodegradability of the dyeing and printing waste water, reduce the pollution of an MBR system, improve the cleaning effect, and reduce the pollution.

Owner:XIAMEN LEEBAM MEMBRANE TECH

Leather dyeing machine

ActiveCN103388038AIncreased dyeing rateEliminate surface resistanceLeather/skins/hides/pelt chemical treatment apparatusDyeing processEngineeringPre treatment

The invention provides a leather dyeing machine, and belongs to the technical field of leather dyeing equipment and the leather dyeing machine can be used for solving the technical problem in the prior art that the leather dyeing machine has low dyeing efficiency. The leather dyeing machine comprises a base, wherein the base is provided with a drum body, the drum body is internally provided with an inner cavity, a rotary shaft I and a rotary shaft II are respectively fixed at two ends of the drum body, a drive device is arranged between the base and the outer end of the rotary shaft I, the rotary shaft II is pivoted on the base, a rotary joint II is arranged outside the rotary shaft II, a power-driven three-way valve is connected outside the rotary joint II, the power-driven three-way valve comprises an outlet I, an outlet II and an inlet, the inlet is communicated with the outer side of the rotary joint II, a vacuum pump is also fixed on the base, and the vacuum pump is communicated with the outlet I through a gas guide tube. Through vacuum pretreatment on the leather in the inner cavity of the drum body, the dyeing efficiency of the leather dyeing machine is improved.

Owner:浙江富邦汽车内饰科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com