Cone yarn anhydrous dyeing equipment and method and product

An anhydrous dyeing and bobbin yarn technology, applied in the field of dyeing, can solve the problems of undiscovered polyester bobbin yarn dyeing technology disclosure, increased design requirements and difficulty of circulating pump, immature process technology, etc. The effect of improving solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

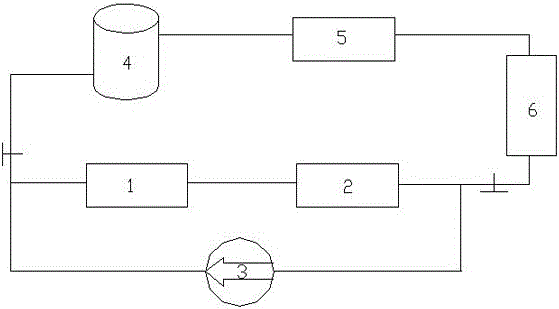

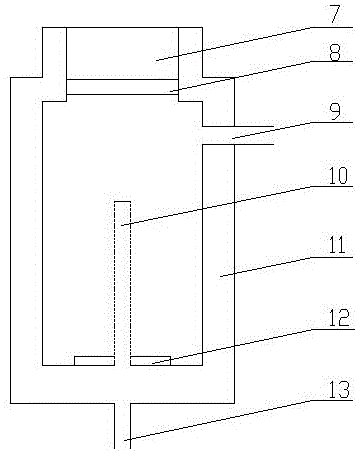

[0034] see figure 1 , figure 2 , an embodiment of an anhydrous dyeing equipment for bobbins in the present invention, comprising a dye kettle 1, a dyeing kettle 2, a recovery kettle 6 and a dyeing circulation system connecting the dye kettle 1, the dyeing kettle 2 and the recovery kettle 6. A bobbin inlet is arranged on the top of the dyeing kettle 1, and a sealing cover 7 is arranged at the bobbin inlet, and a yarn central axis 10 is vertically arranged in the middle of the dyeing kettle. trachea. An air inlet pipe 13 is arranged at the bottom of the dyeing kettle 2, and the air inlet pipe 13 is communicated with the yarn axis 10 (outlet pipe), and the dyeing kettle outlet 9 is set on the dyeing kettle 2; the dyeing circulation system includes CO 2 Gas cylinder, booster pump, circulation pump 3 and pipelines.

[0035] Specifically: the above-mentioned dye kettle 2 includes 3 parallel sub-dye tanks, and the air inlets at the lower parts of the 3 sub-dye tanks are provided ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com