Patents

Literature

245results about "Liquid/gas/vapor treatment of definite length materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-grade flax fabric weaving method based on crystallized and modified flax yarns

InactiveCN102839508ASoft textureImprove evennessLiquid/gas/vapor treatment of definite length materialsWoven fabricsAir-jet loomPulp and paper industry

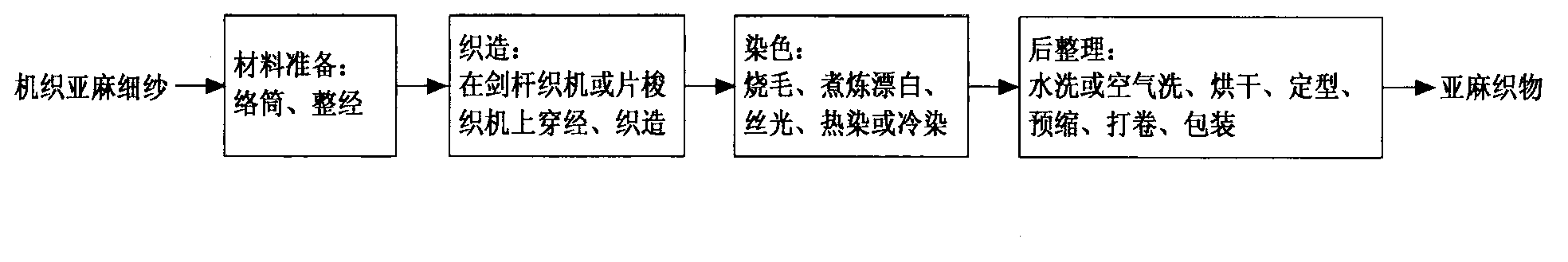

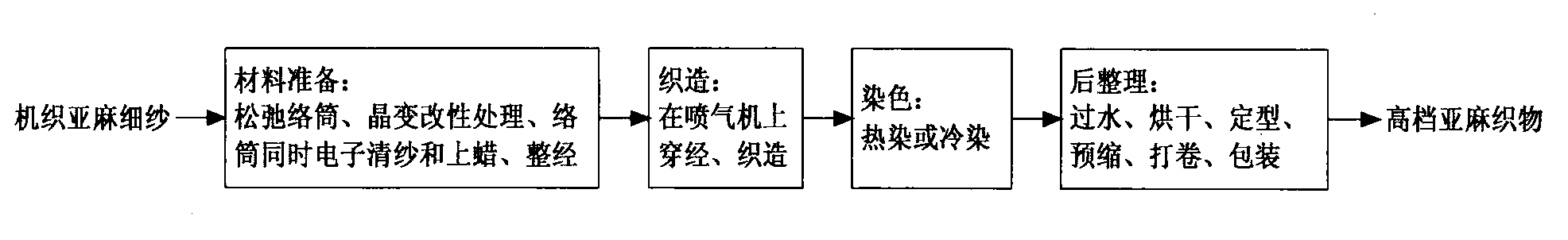

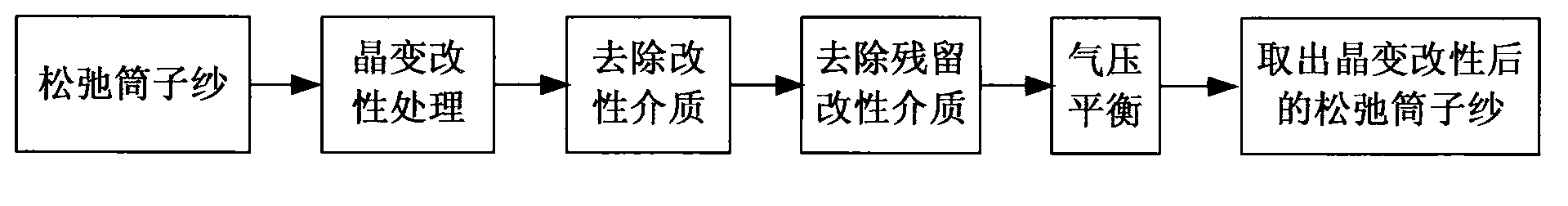

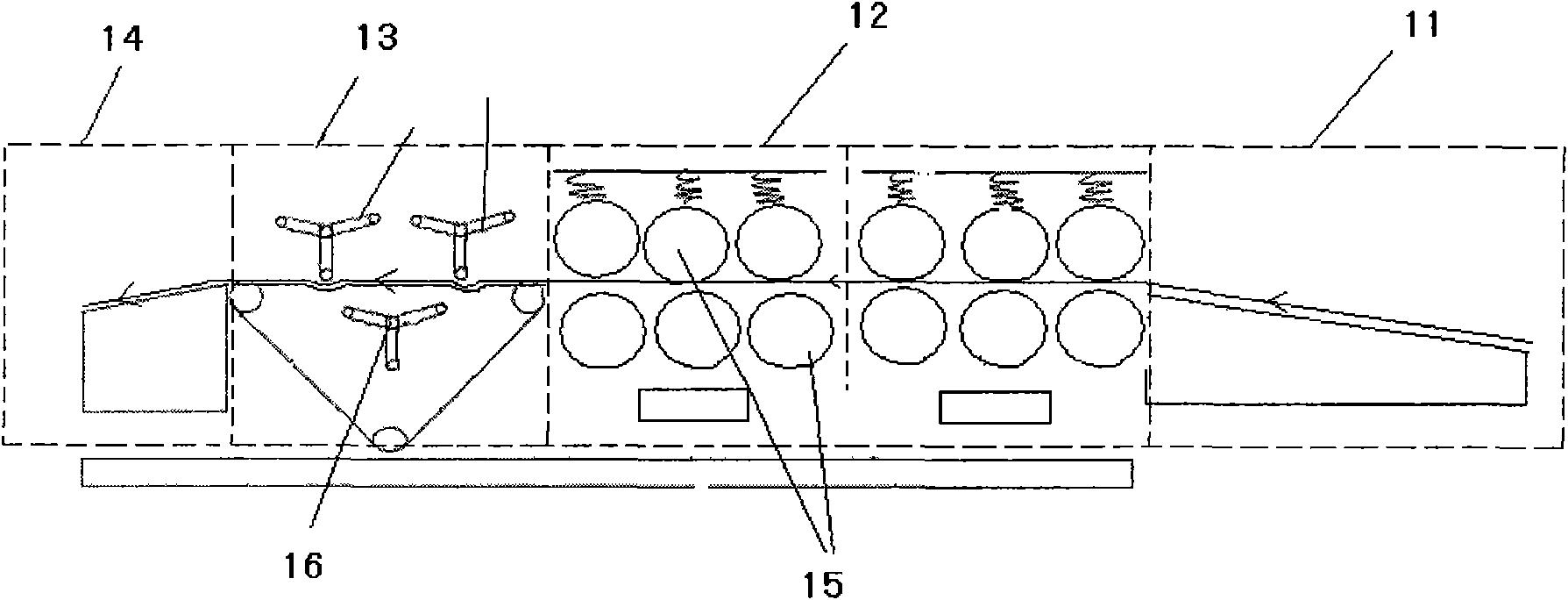

The invention provides a high-grade flax fabric weaving method based on crystallized and modified flax yarns. The method comprises the following steps: in the material preparing stage, woven flax spun yarns are subjected to relaxation and winding, so as to form relaxed yarns on cones; the relaxed yarns on cones are subjected to crystallization and modification treatment; the crystallized and modified relaxed yarns on cones are simultaneously subjected to winding, electronic yarn clearing and waxing, so that weaving yarns on cones are obtained; the weaving yarns on cones are subjected to warping according to the quantity of warp yarns; in the weaving stage, flax grey cloth is woven by taking the weaving yarns on cones as weft yarns, the warp yarns after warping as warp yarns, and drawing weft and warp yarns in an air jet loom; in the dyeing stage, the woven flax grey cloth is subjected to hot dyeing or cold dyeing; in the after finishing stage, the dyed flax grey cloth is rinsed, dried, finalized, preshrunk, wound and packaged to form the high-grade flax fabric. According to the high-grade flax fabric weaving method, the bottleneck of wearability of traditional flax fabric is solved, the flax fabric is enabled to obtain the sense of cotton, the production efficiency is improved, the production cost is reduced, and the energy conservation and emission reduction in the production process are realized.

Owner:DONGHUA UNIV +1

Technological process of ramie bast fiber

ActiveCN101824658AImprove processing uniformityImprove qualityCombing machinesDrafting machinesBiochemical engineeringCombing

The invention relates to a technological process of a ramie bast fiber, which comprises a basic degummed ramie production route: raw ramie skin-sorting and derooting-mechanical ungluing-cage loading-biological ungluing-high-temperature rinsing-cage unloading-sub-fiber washing-soft rinsing-radio frequency drying- degummed ramie. Long ramie can be growth through the mechanical hemp oiling- infiltration and health care-stretch breaking and carding-pre-gilling-combing and sorting-final gilling of the degummed ramie. Short ramie can be produced through the combing and the sorting of combed noil. Oakum can be produced through biological ungluing-high-temperature stewing and ungluing-high-temperature rinsing-cage unloading-sub-fiber washing-soft rinsing-dehydration and drying-radio frequency drying-mechanical hemp oiling- infiltration and health care-opening and edulcoration- combing and sorting. Improving methods are adopted for the mechanical ungluing, biological ungluing, high-temperature rinsing, sub-fiber washing, stretch breaking and carding, combing and sorting and the like. The preparation process has the advantages of short process, high production efficiency, high mechanical automation degree, stable product quality, excellent fiber quality and strong operability of fiber length and fineness, and can be used in the production processes of various bast fiber raw material, gramineae fiber raw material, leaf fiber raw material and other fibers.

Owner:THE QUARTERMASTER RES INST OF THE GENERAL LOGISTICS DEPT OF THE CPLA +2

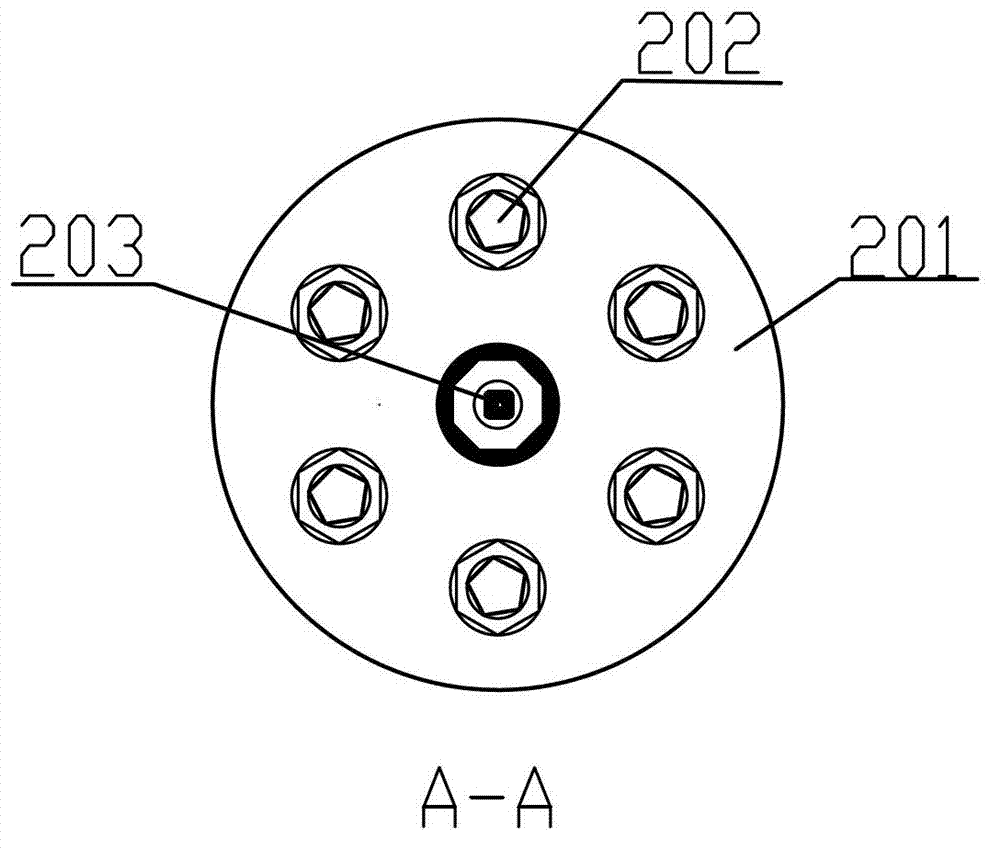

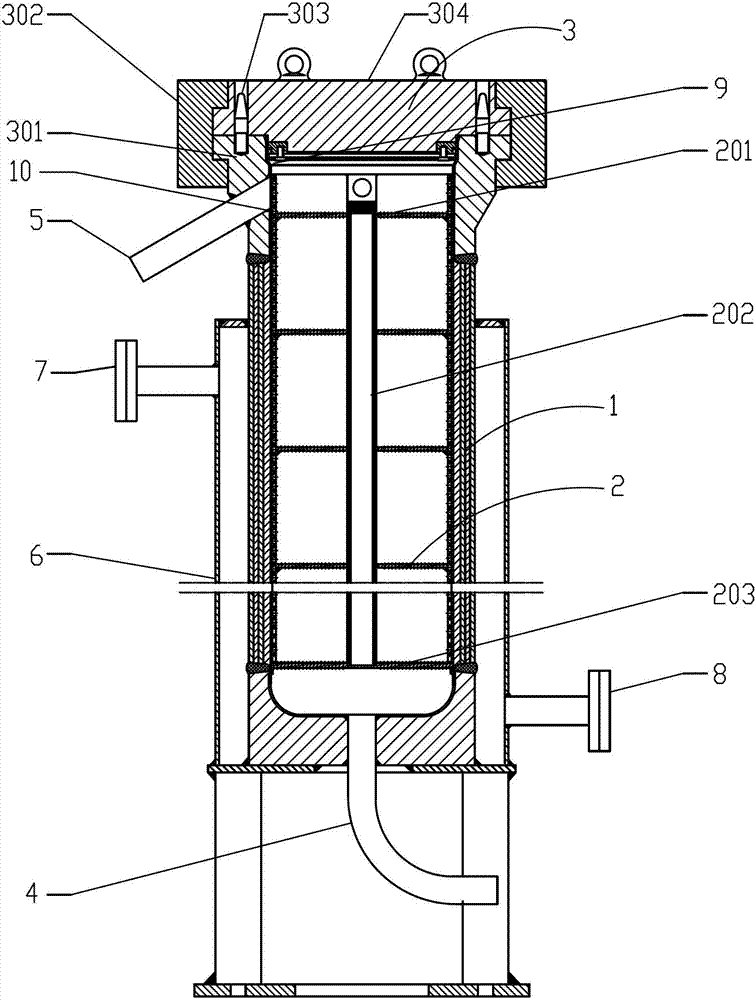

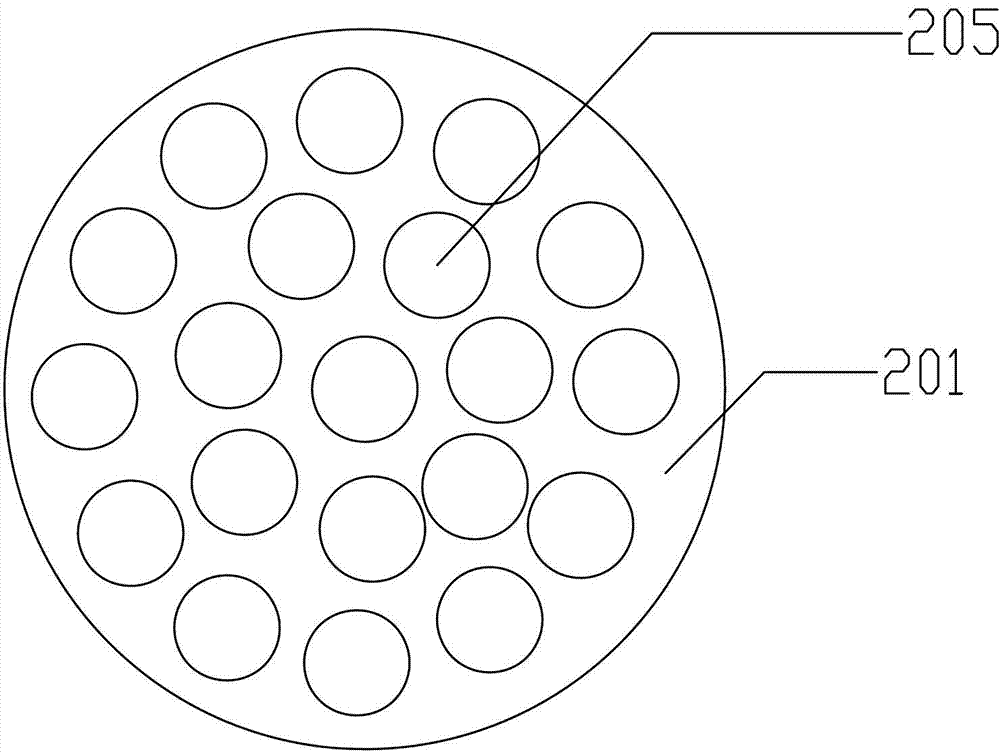

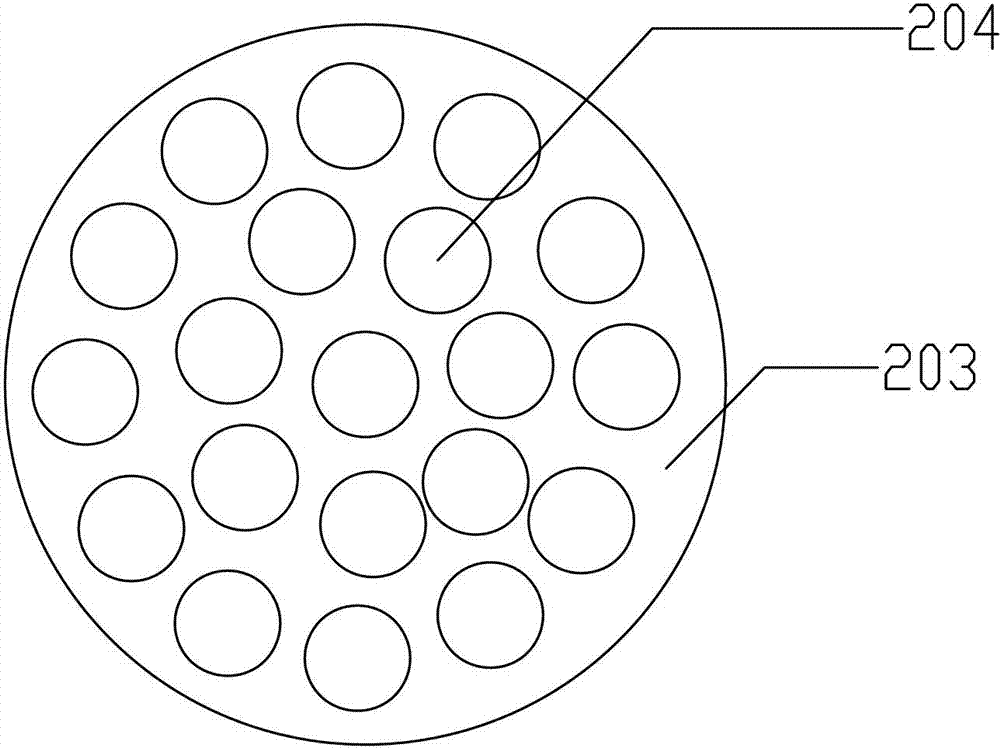

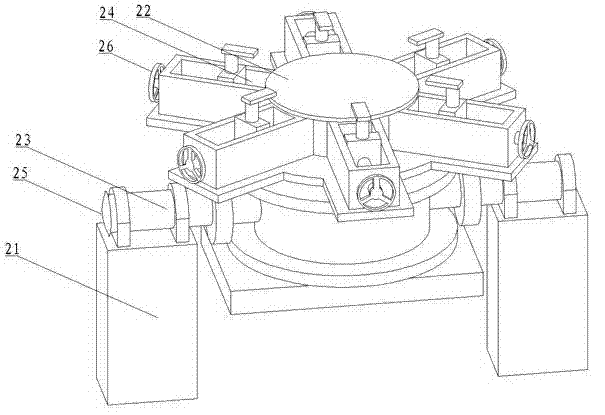

Supercritical carbon dioxide cheese dyeing kettle and waterless supercritical carbon dioxide cheese dyeing method

ActiveCN102787459ATextile treatment containersSolvent treatment with solvent recoveryEngineeringDrill

The invention relates to a supercritical carbon dioxide cheese dyeing kettle and a waterless supercritical carbon dioxide cheese dyeing method. In the dyeing kettle, when carbon dioxide fluid enters a distribution tray from an inlet, blades start rotating clockwise under the effect of pressure; inserted drill rods are driven to rotate by a rotation part; and the rotating speed of the inserted drill rods is increased along with the increase of pressure in a cylinder body. When a cheese is dyed, the cheese on the inserted drill rods is dyed at a speed of 0.2-0.5 r / s. When the rotating cheese is dyed, the cheese is subjected to the pressure of the fluid flowing out from a central shaft; the rotation and bicirculation of the cheese dyeing are realized; the uniform dyeing effect of the dyed cheese can be improved; and the migration ability and the diffusibility can be improved.

Owner:晋江国盛新材料科技有限公司

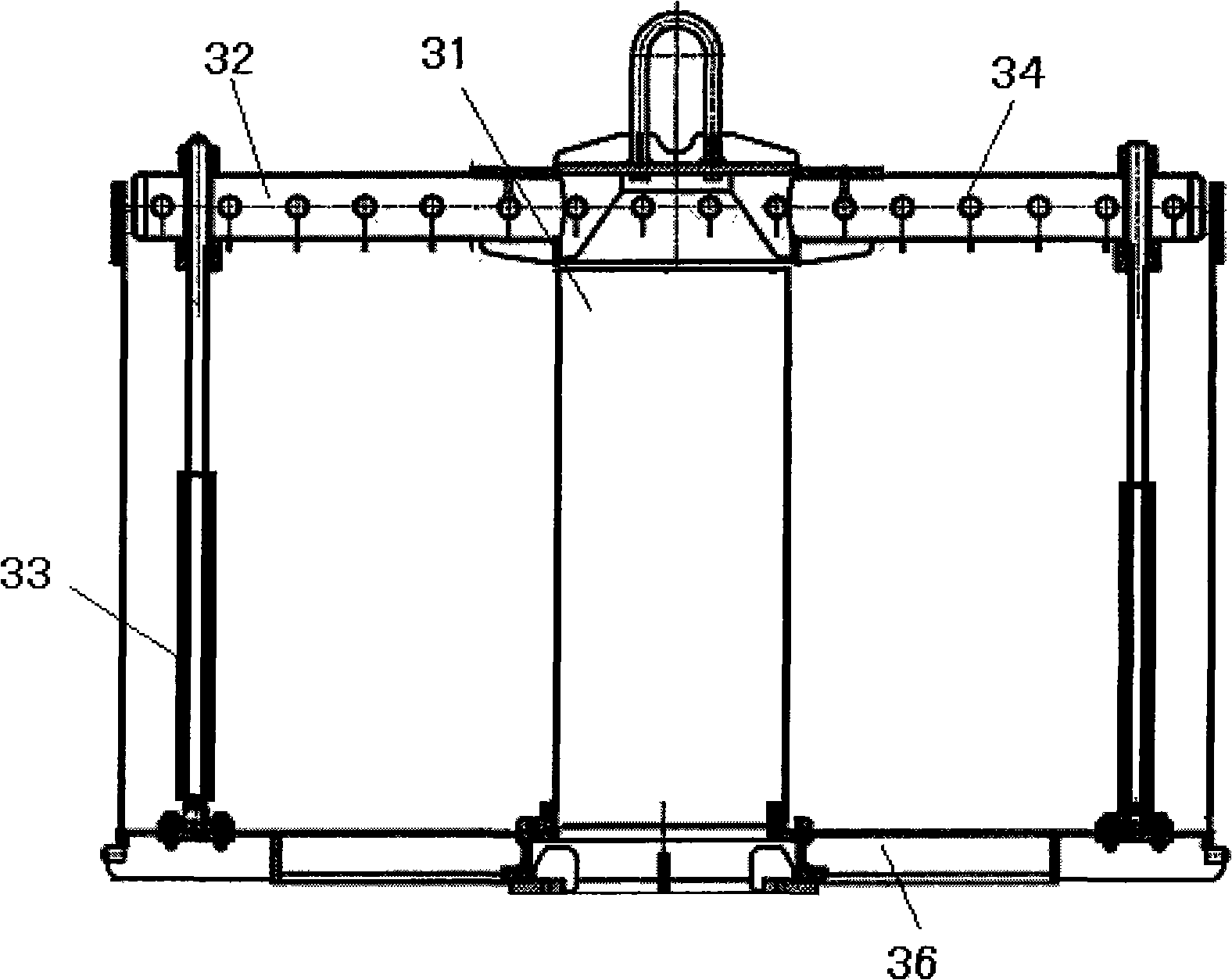

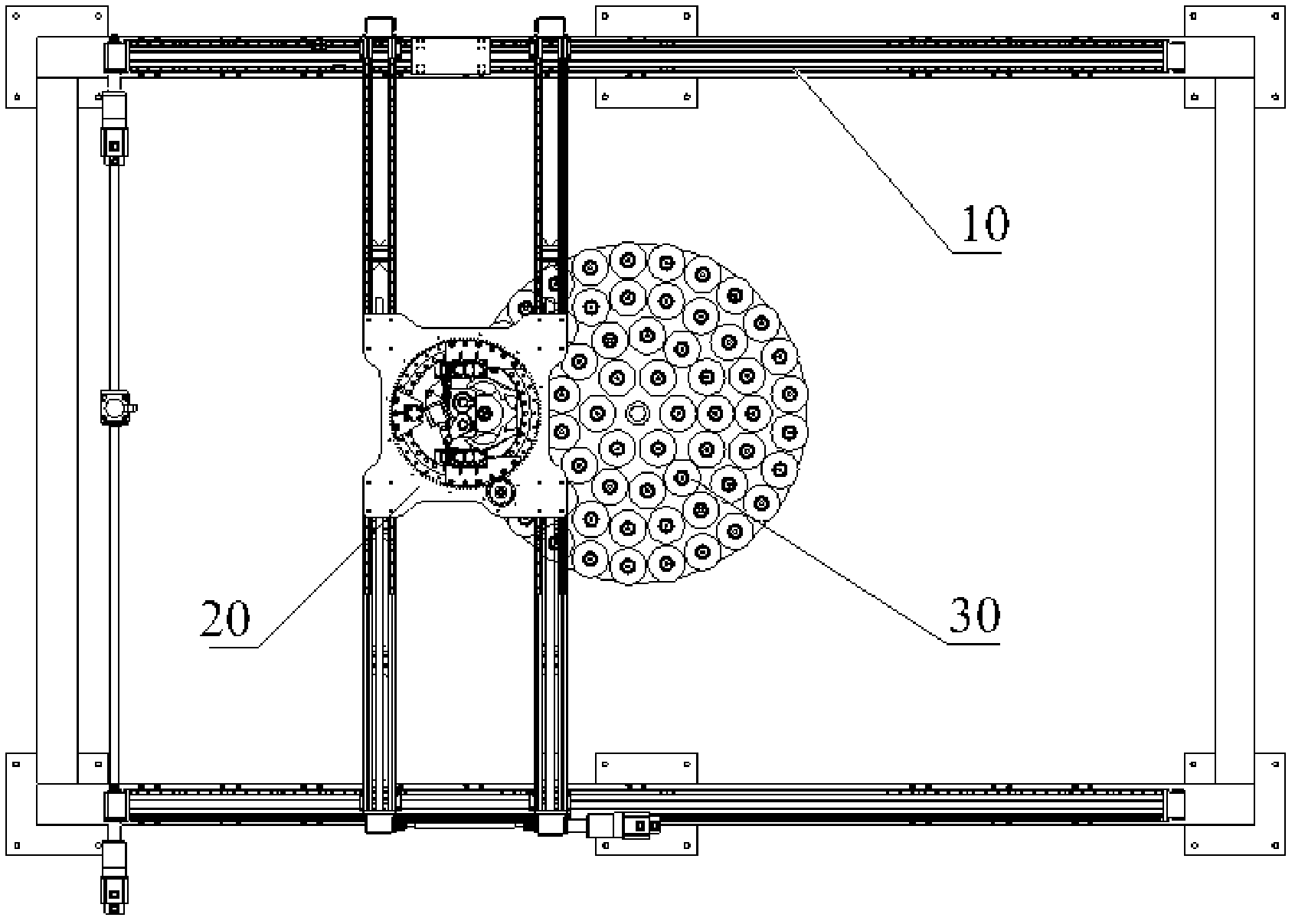

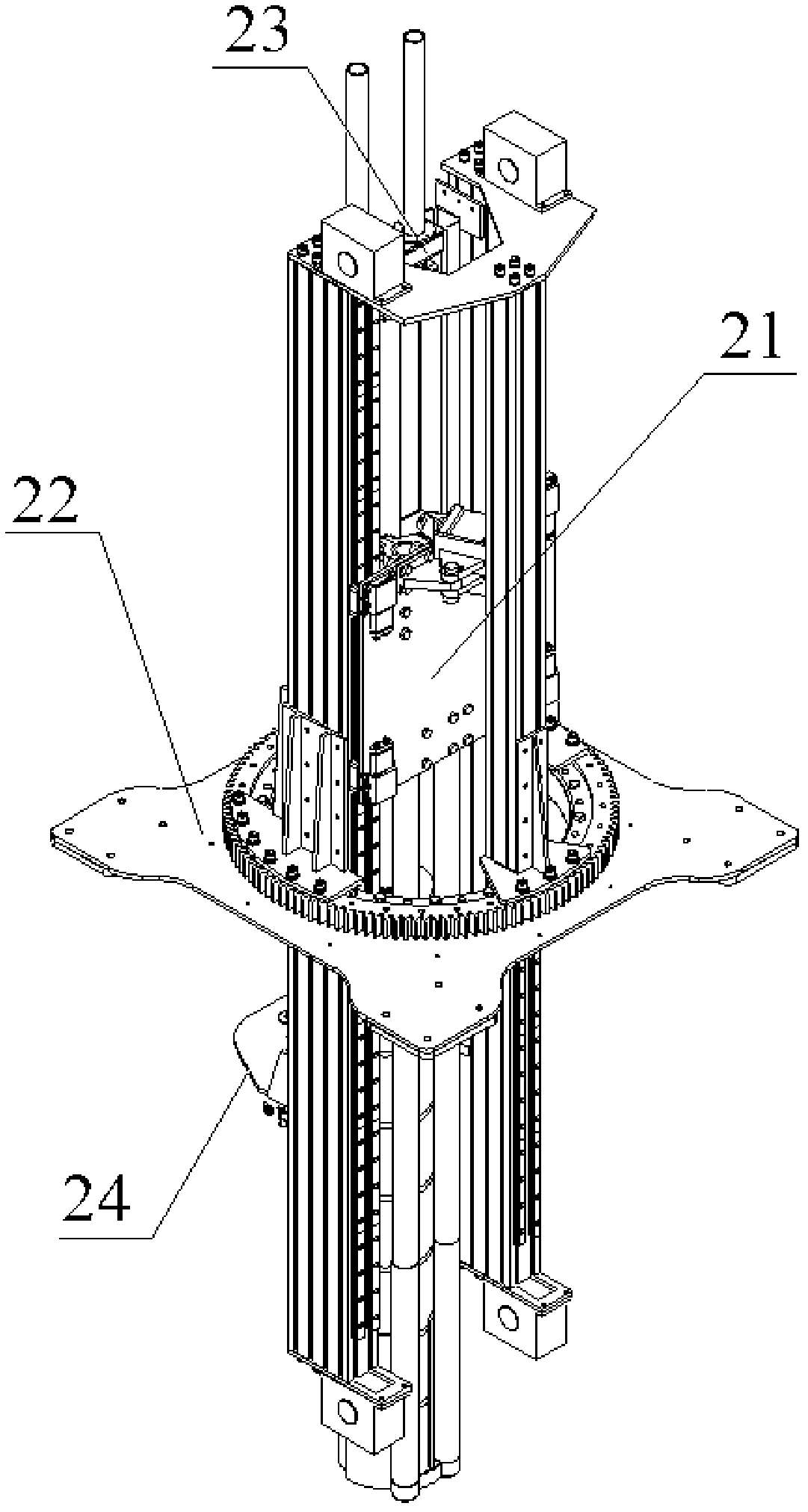

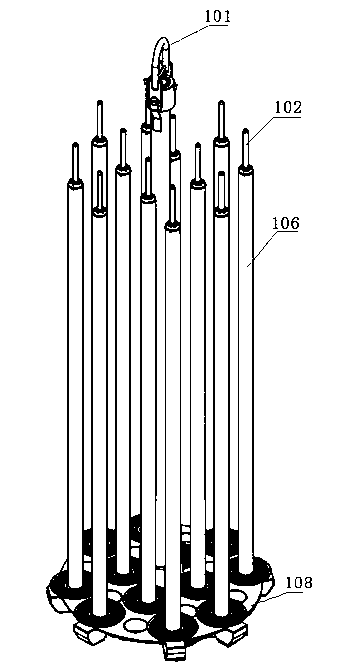

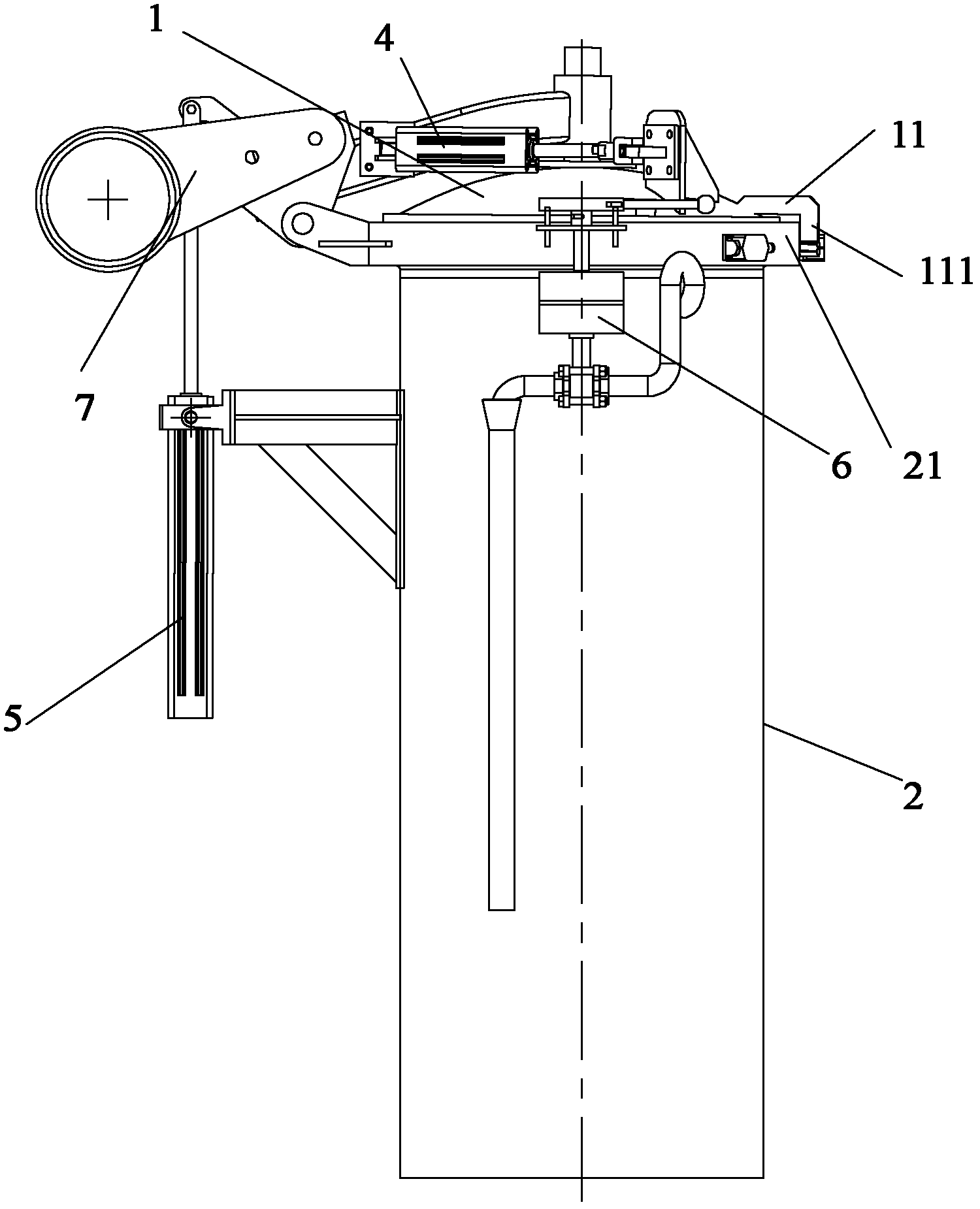

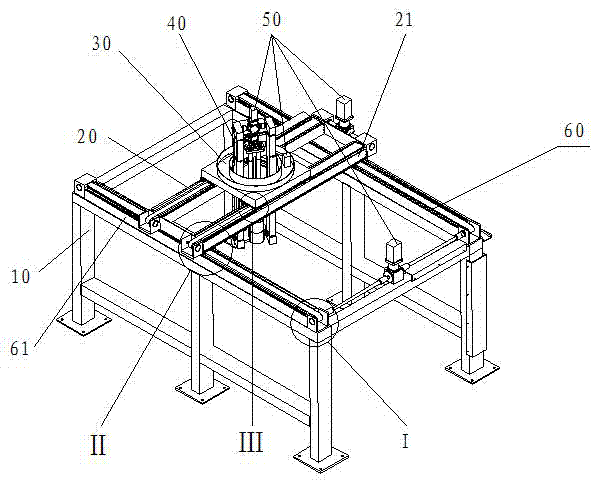

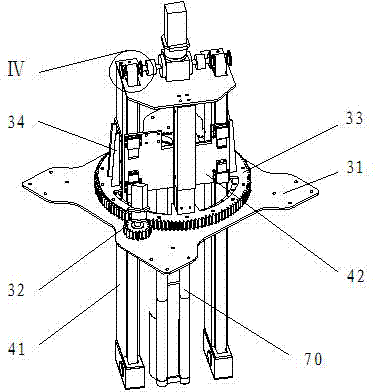

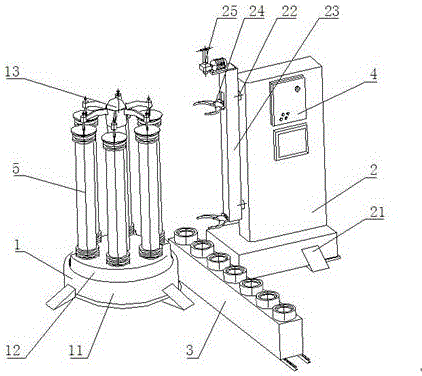

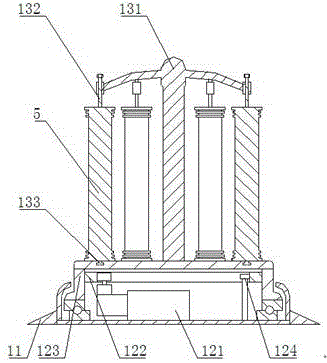

Automatic yarn grabbing machine and automatic yarn grabbing method

ActiveCN102583046AImprove efficiencyReduce labor costsProgramme-controlled manipulatorGripping headsYarnBobbin

The invention provides an automatic yarn grabbing machine and an automatic yarn grabbing method. The automatic yarn grabbing machine of the invention comprises a yarn grabbing unit comprising a clamping mechanism used for grabbing cheese and a rotary lifting mechanism used for driving the clamping mechanism to rotate and lift; and a planar moving mechanism used for driving the yarn grabbing unit to move on a horizontal plane. The automatic yarn grabbing machine of the invention mainly has the following advantages: yarns are grabbed in an automatic manner, so as to fill the blank in a bobbin dyeing procedure, improve efficiency and greatly save labor cost.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH +1

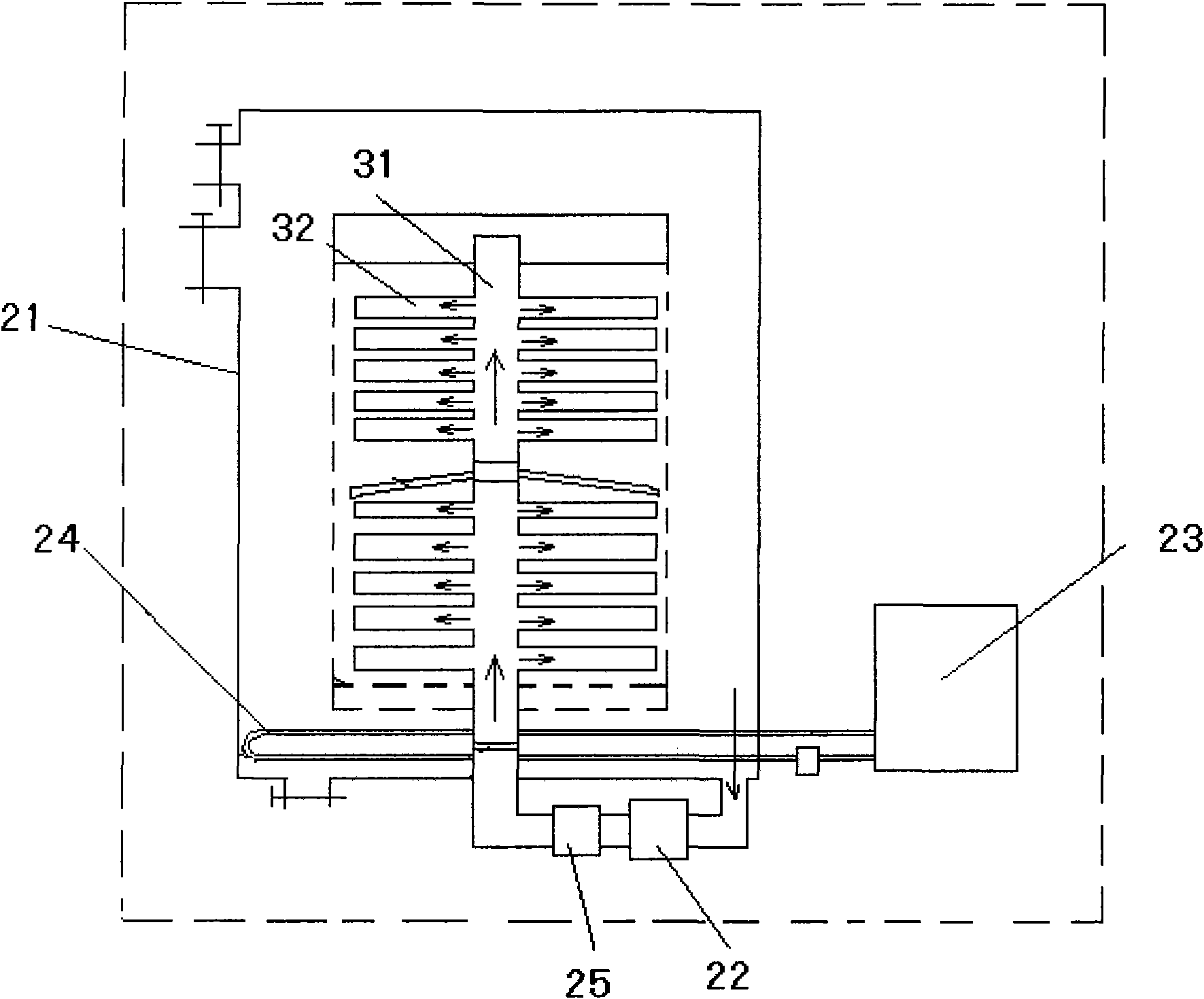

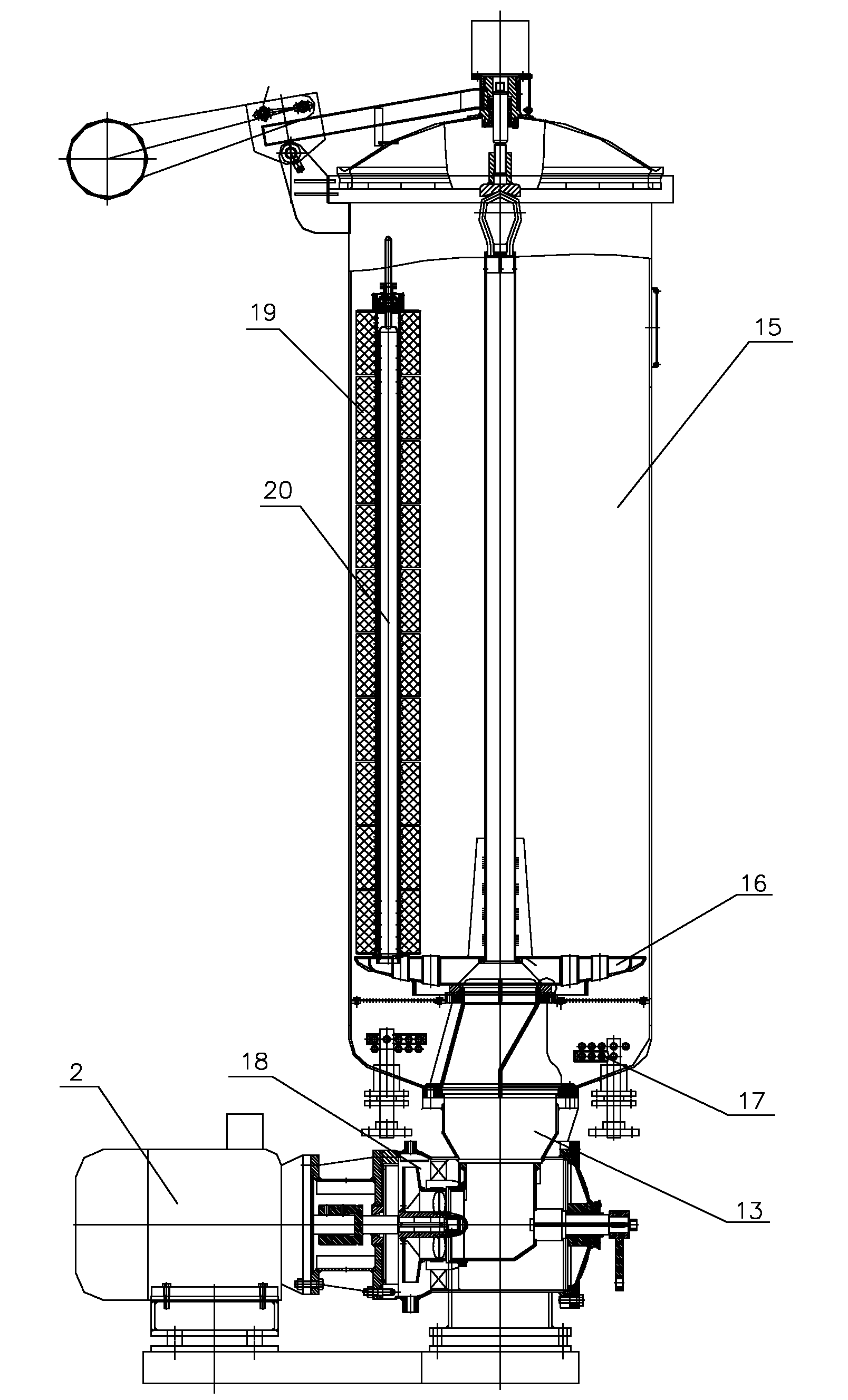

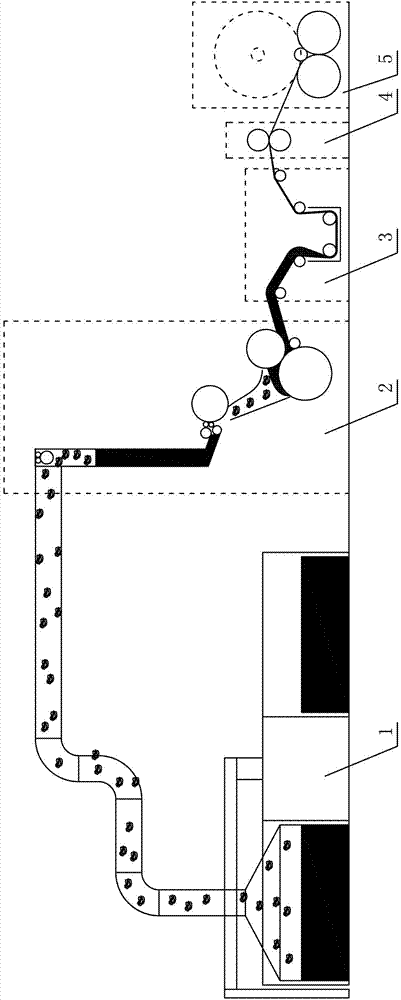

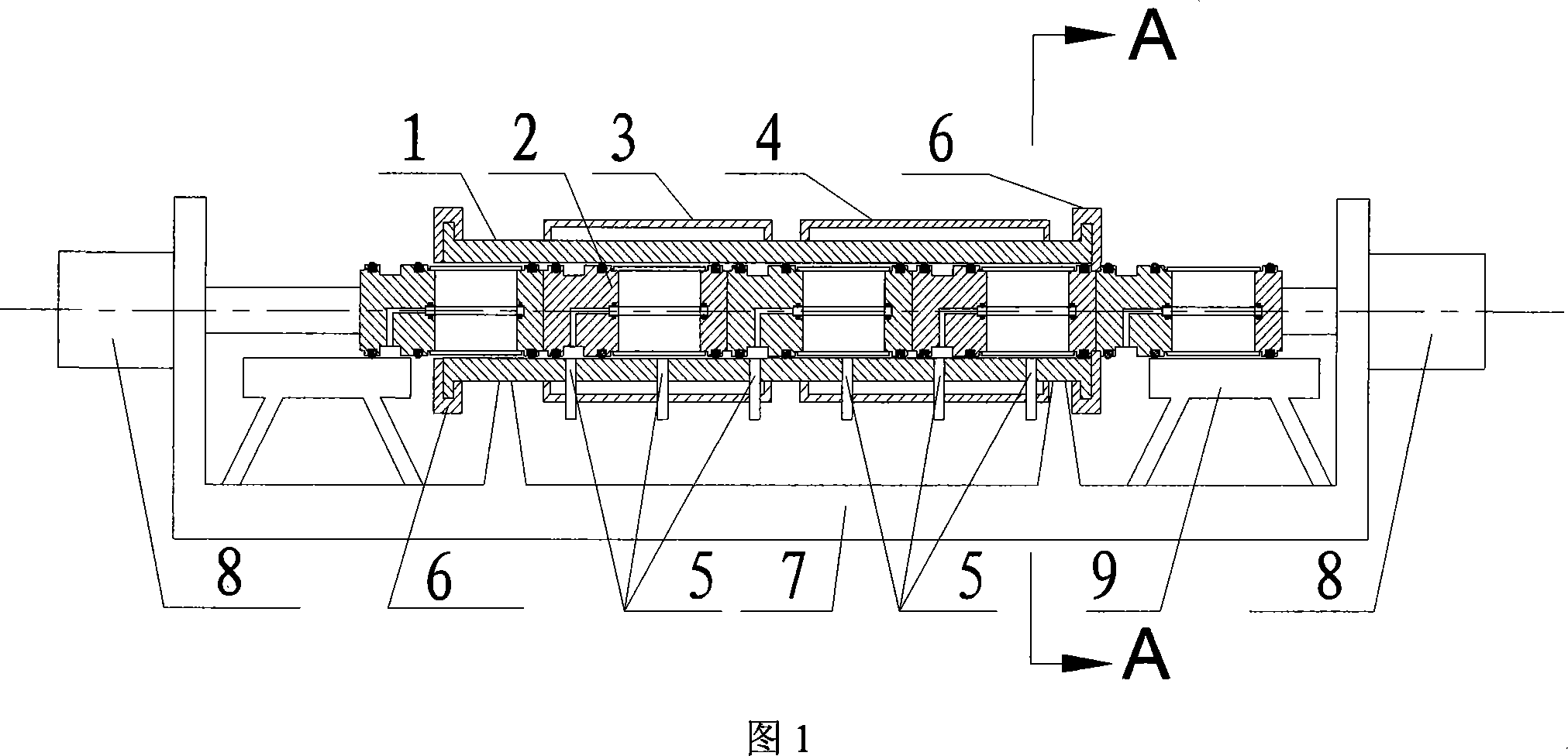

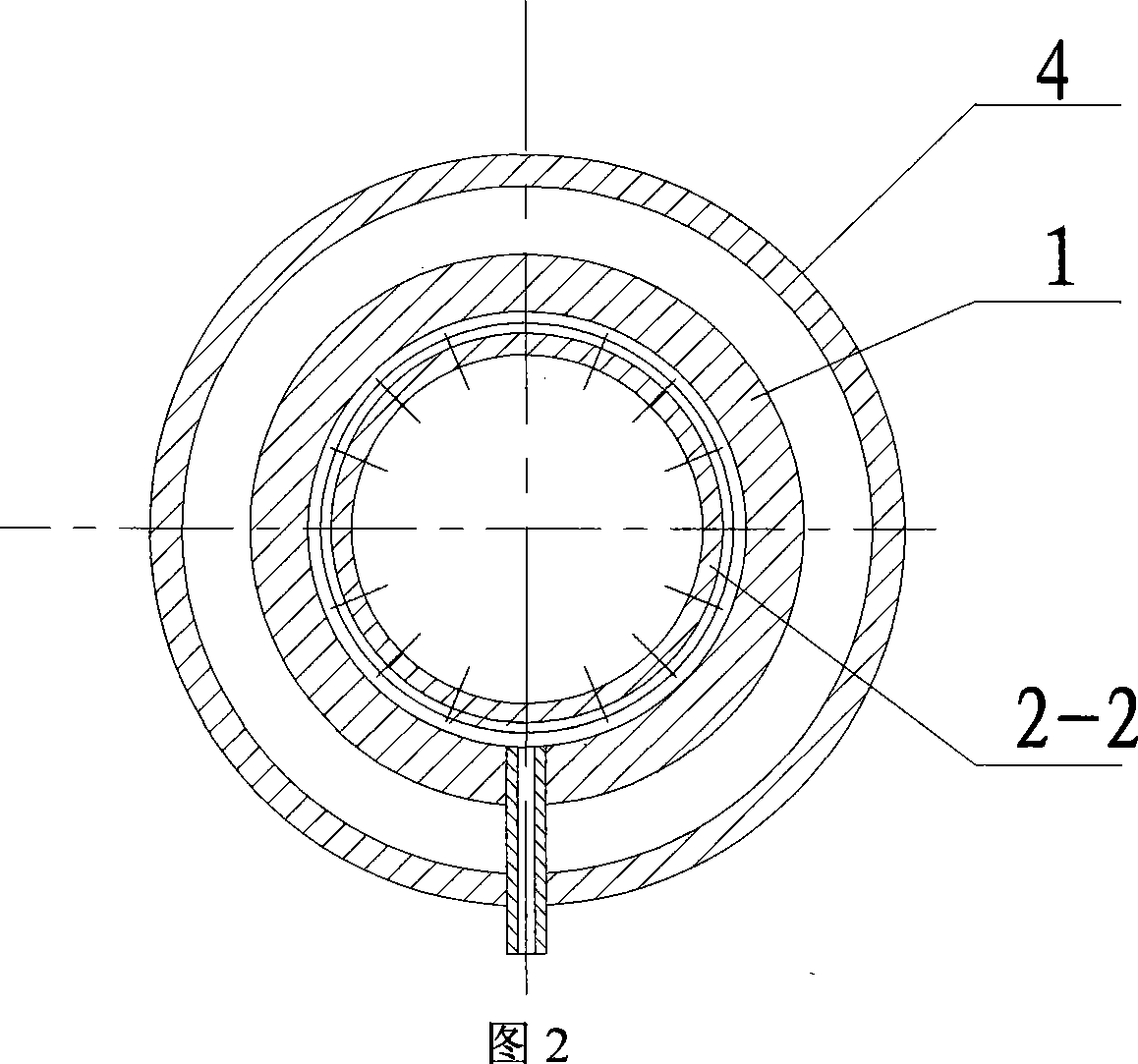

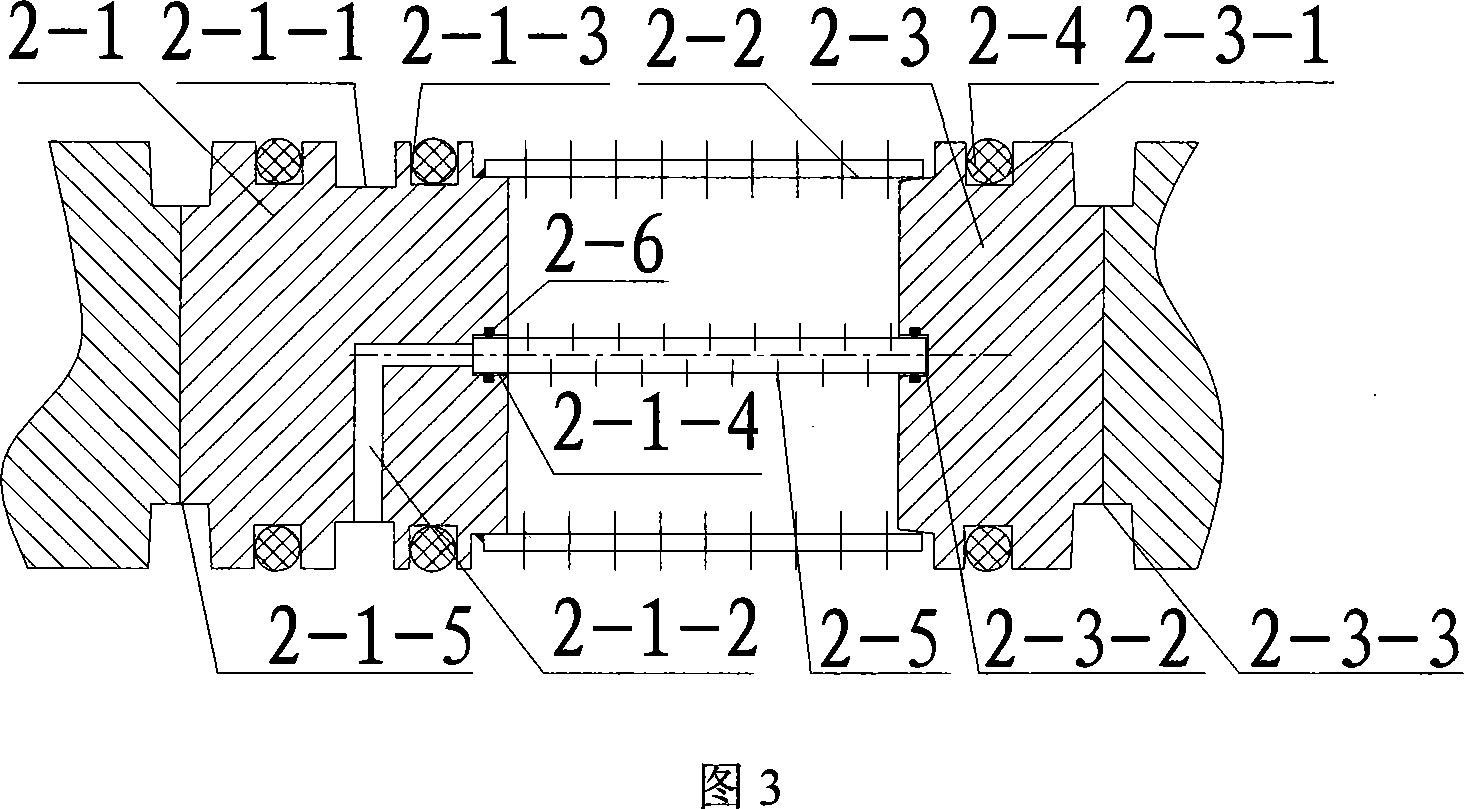

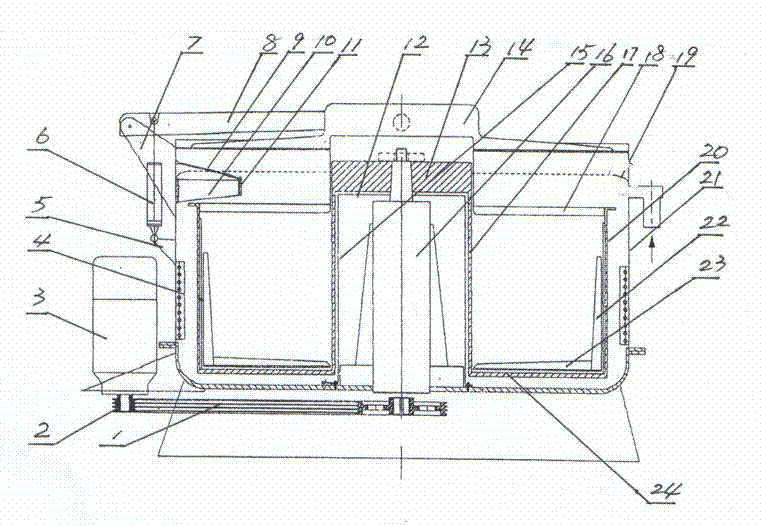

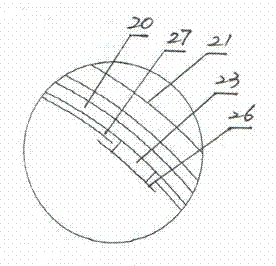

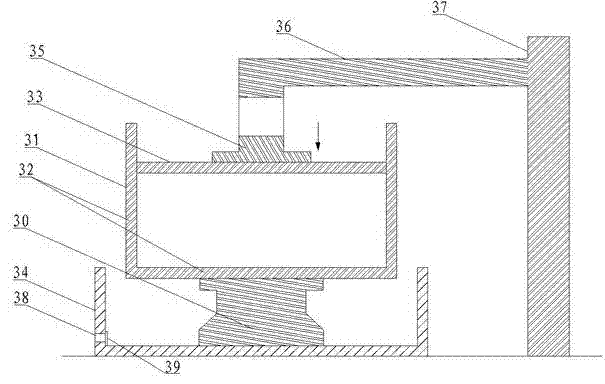

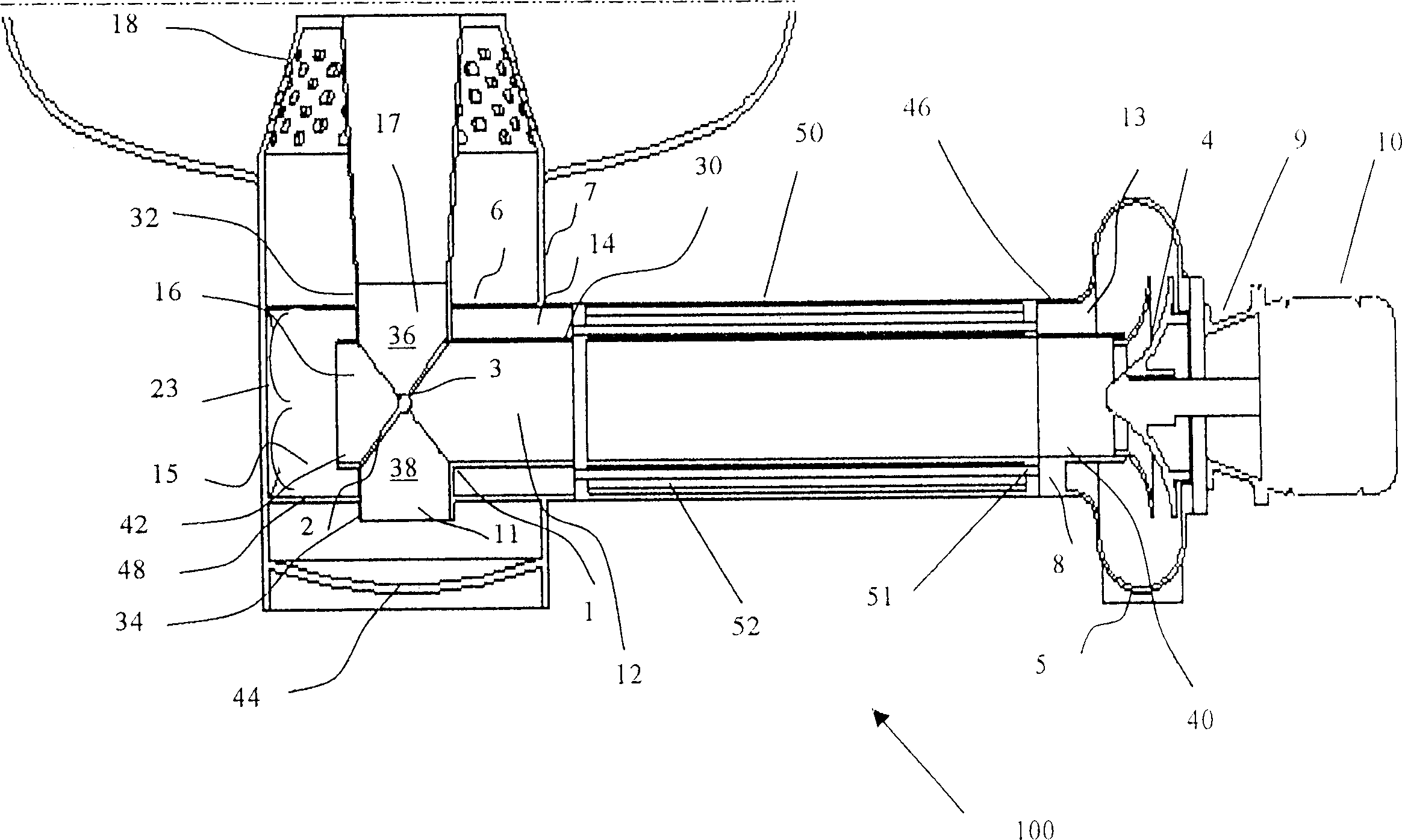

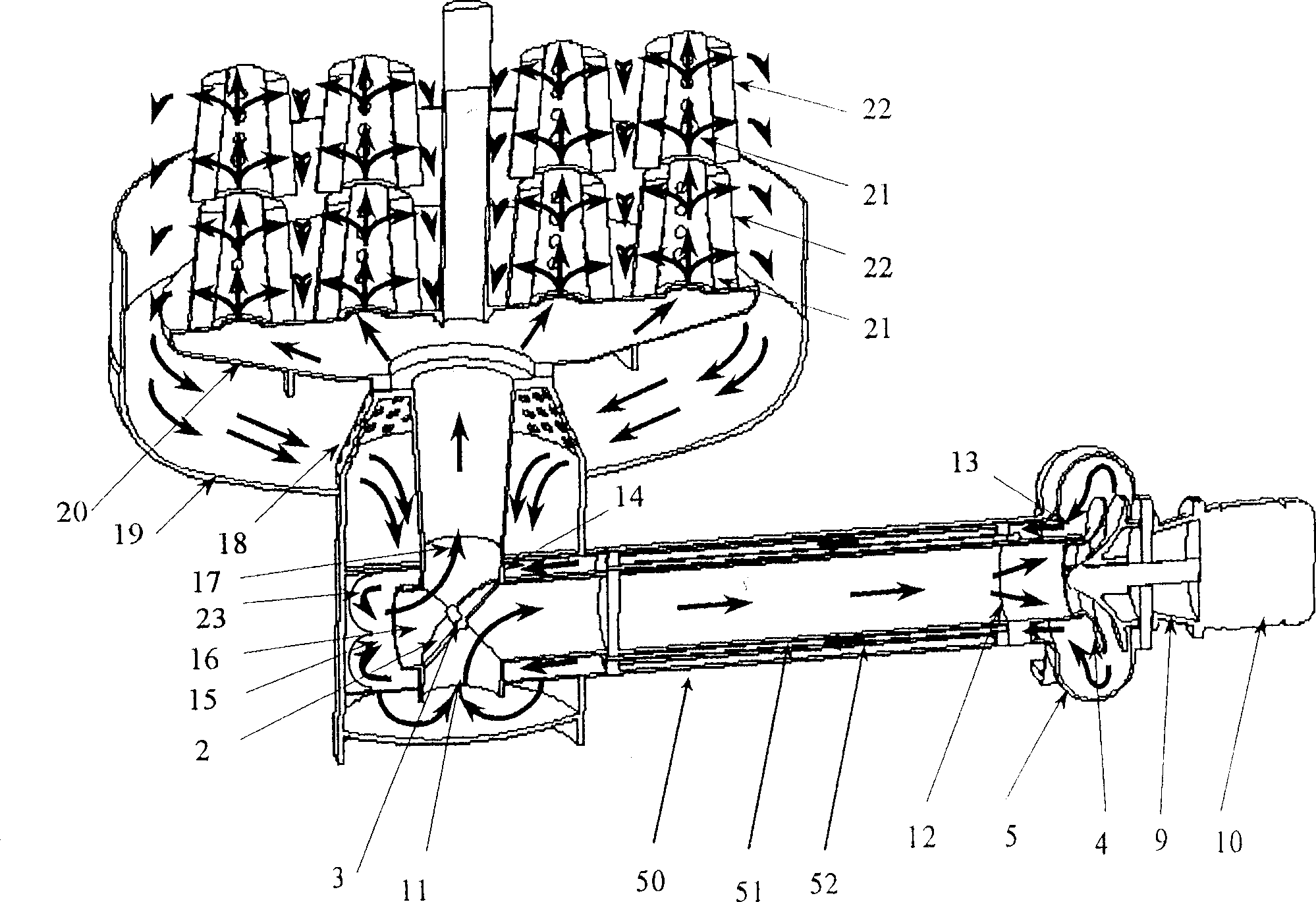

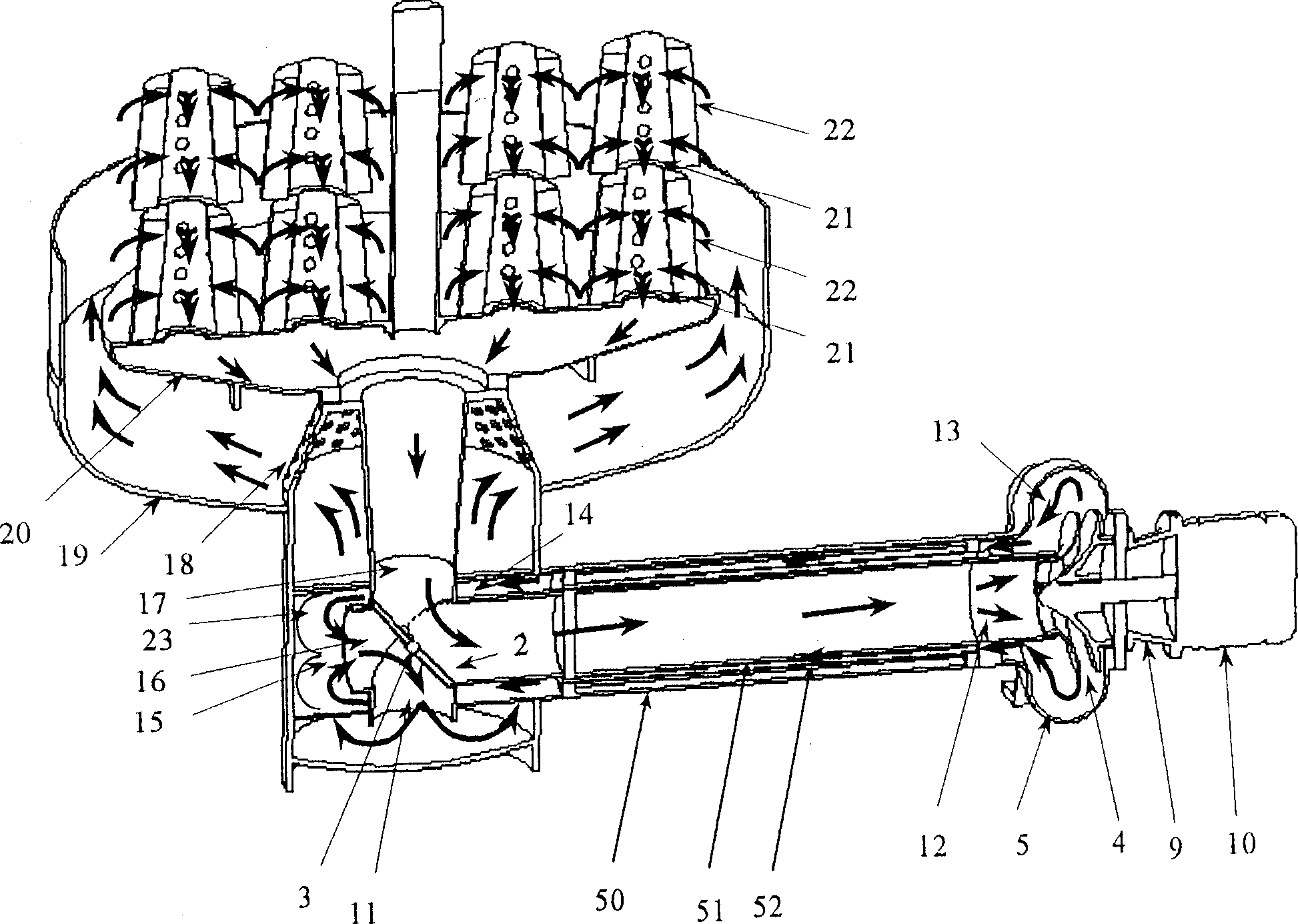

Ultralow bath-ratio yarn dyeing machine with three-level vane pump

InactiveCN102134793ACycle fastAvoid layer chromatic aberrationTextile treatment using short bath ratio liquorTextile treatment machine arrangementsYarnThree level

The invention discloses an ultralow bath-ratio yarn dyeing machine with a three-level vane pump, comprising a dye vat, a yarn stand and a vane pump, wherein the bottom of the yarn stand is a yarn stand disk; the yarn stand disk is provided with a hole communicated with a dye liquor input channel in the dye vat; the vane pump is arranged below the whole dye vat and is a three-level vane pump; a shaft of the three-level vane pump is connected with an internal motor shaft coaxially; the dye vat is connected with the inlet of the three-level vane pump; the three-level vane pump comprises an axial flow level, a centrifugal level and a fixed guide vane level; the axial flow level and the centrifugal level are connected with the motor in sequence through the same transmission shaft; dye liquor flows into the axial flow level through an in-flow channel; the dye liquor flowing out of the axial flow level directly enters the inlet of the centrifugal level; and the dye liquor flowing out of the centrifugal level enters an out-flow channel after passing through the fixed guide vane level. During work, the dye liquor in the dye vat does not exceed the yarn stand disk all the time and the bath ratio is lower than 1:3. The ultralow bath-ratio yarn dyeing machine can achieve required lift when the dye liquor in the yarn dyeing machine is lower than a spindle, so as to realize the low bath ratio of the yarn dyeing machine as well as the purpose of saving energy and reducing emission.

Owner:高勋绿色智能装备(广州)有限公司

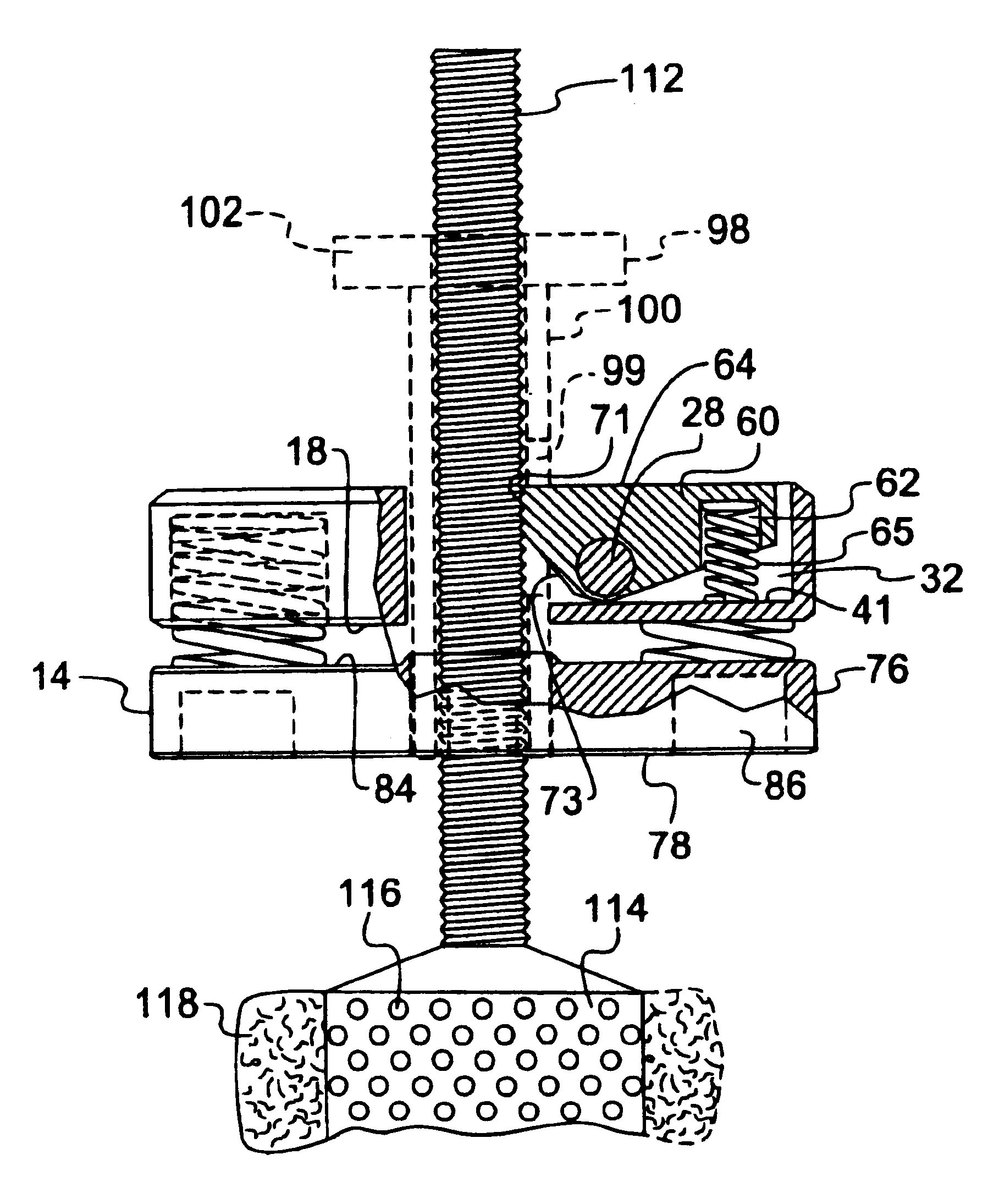

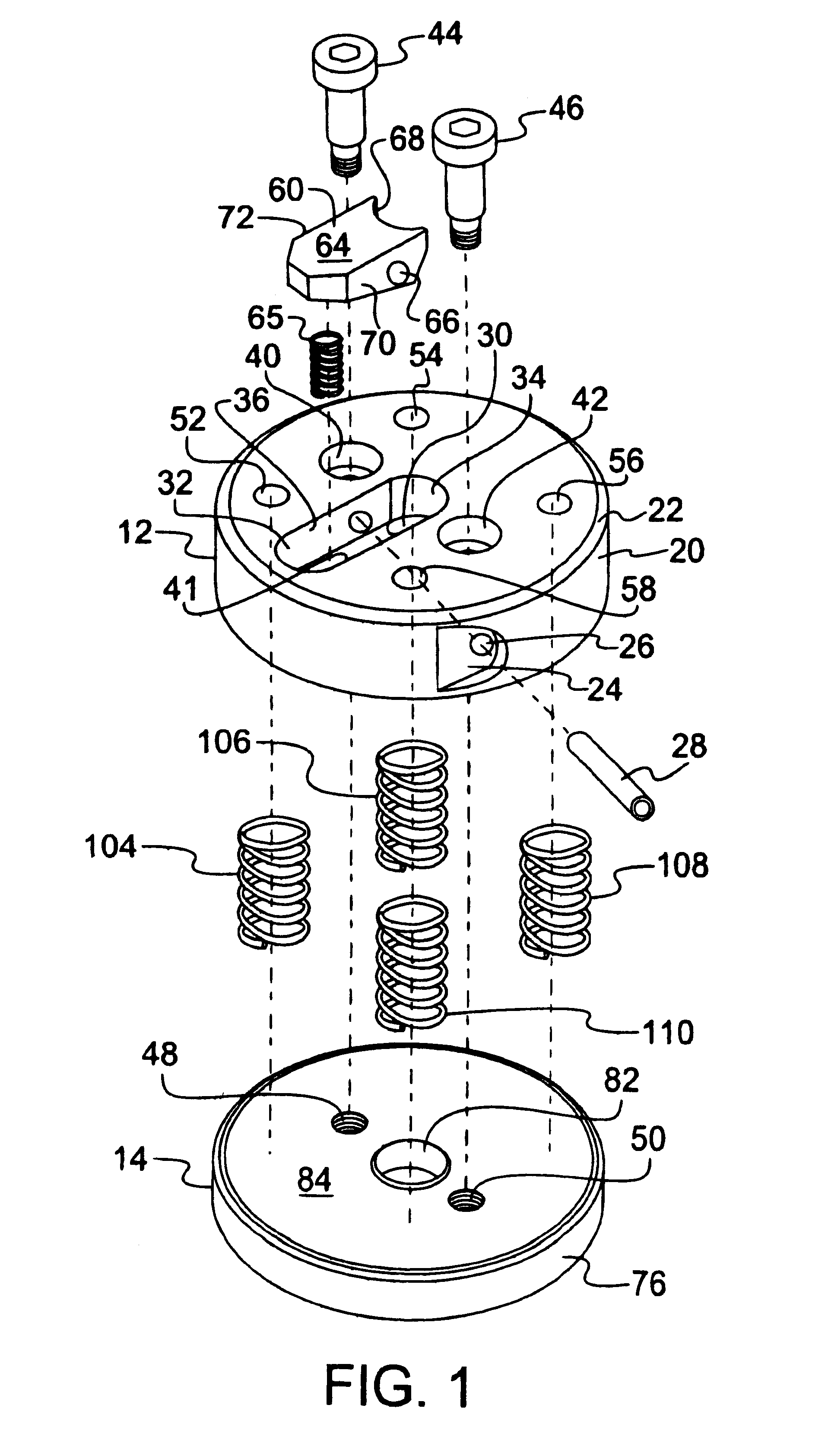

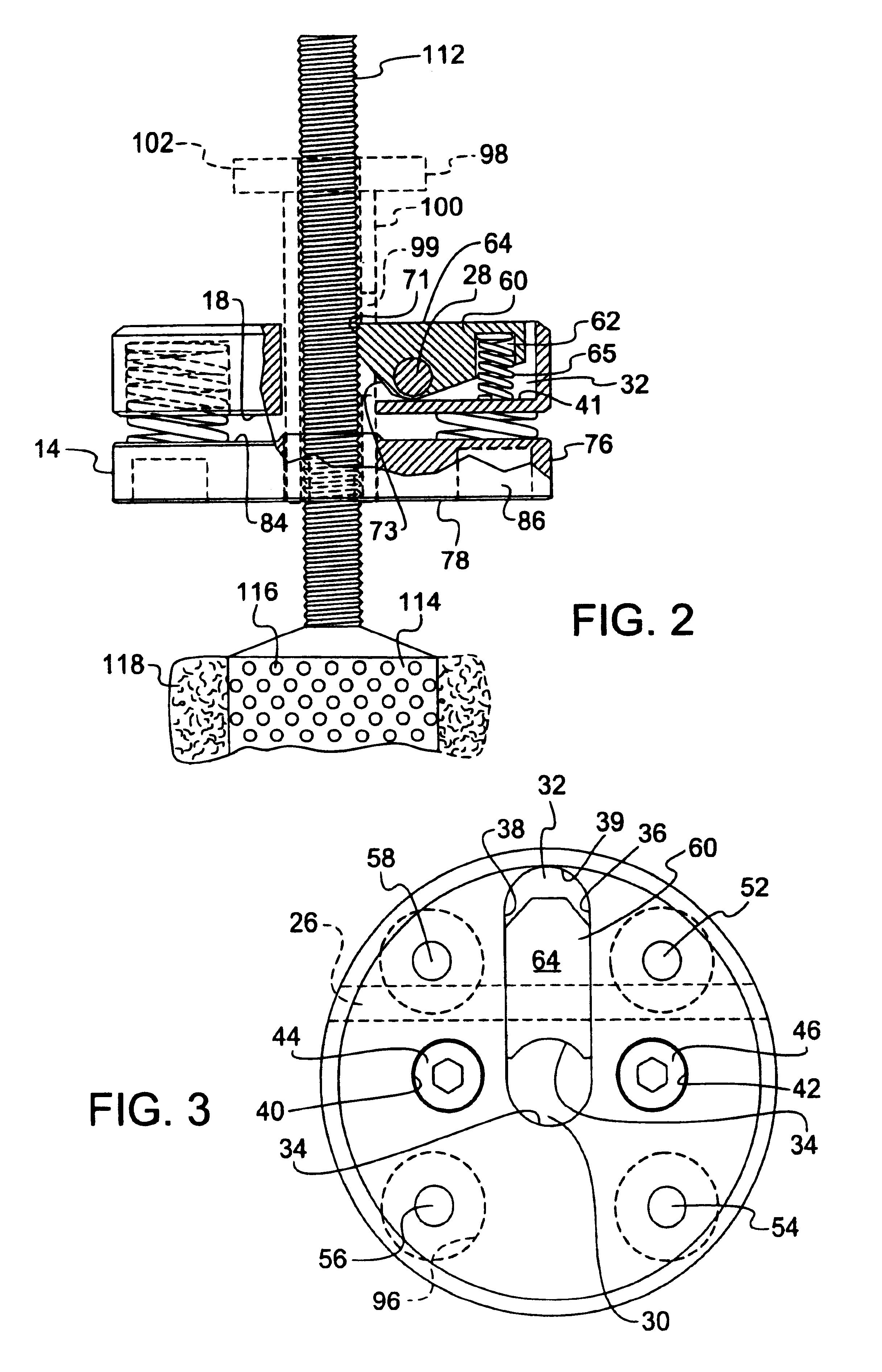

Quick-release lock assembly with compression/expansion capability

A yarn roll spindle locking assembly including a pivotally translating engagement / release mechanism. The locking assembly may be dropped onto a spindle to self-actuatingly lock in position and is readily removable from the spindle by manual depression of a release element. The locking assembly includes upper and lower body members coupled to one another so that the upper main body member and lower main body member are resiliantly biased apart from one another to provide the locking assembly with compression / expansion capability.

Owner:R TEX

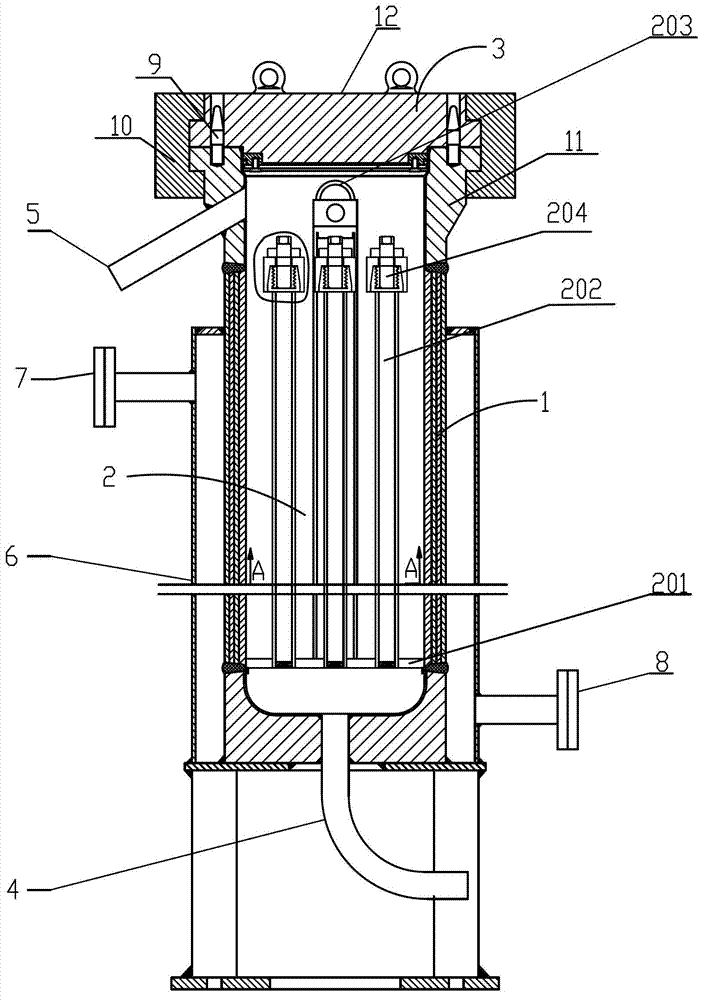

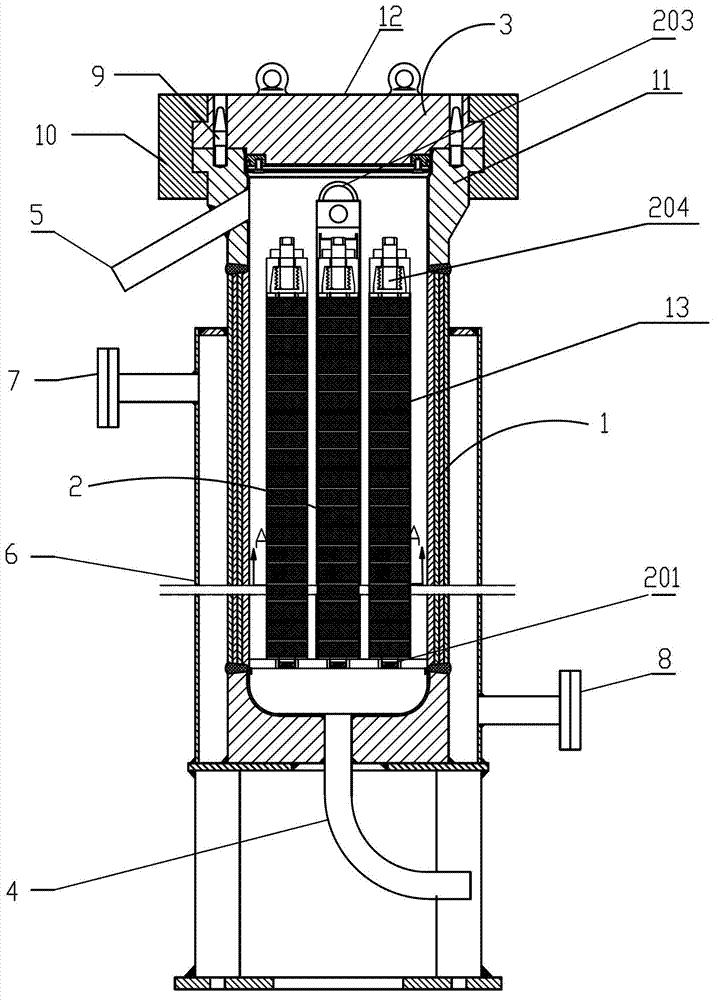

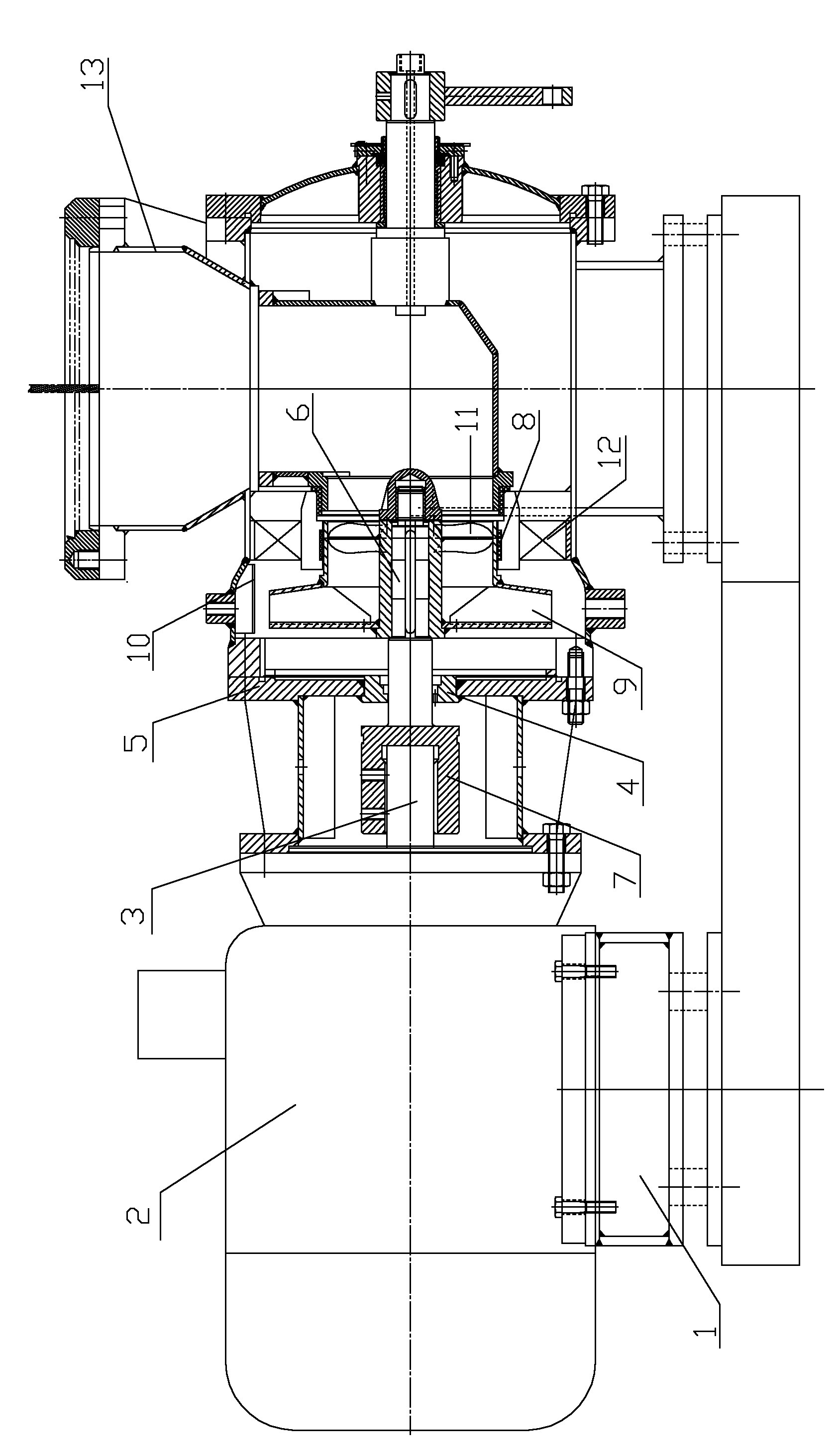

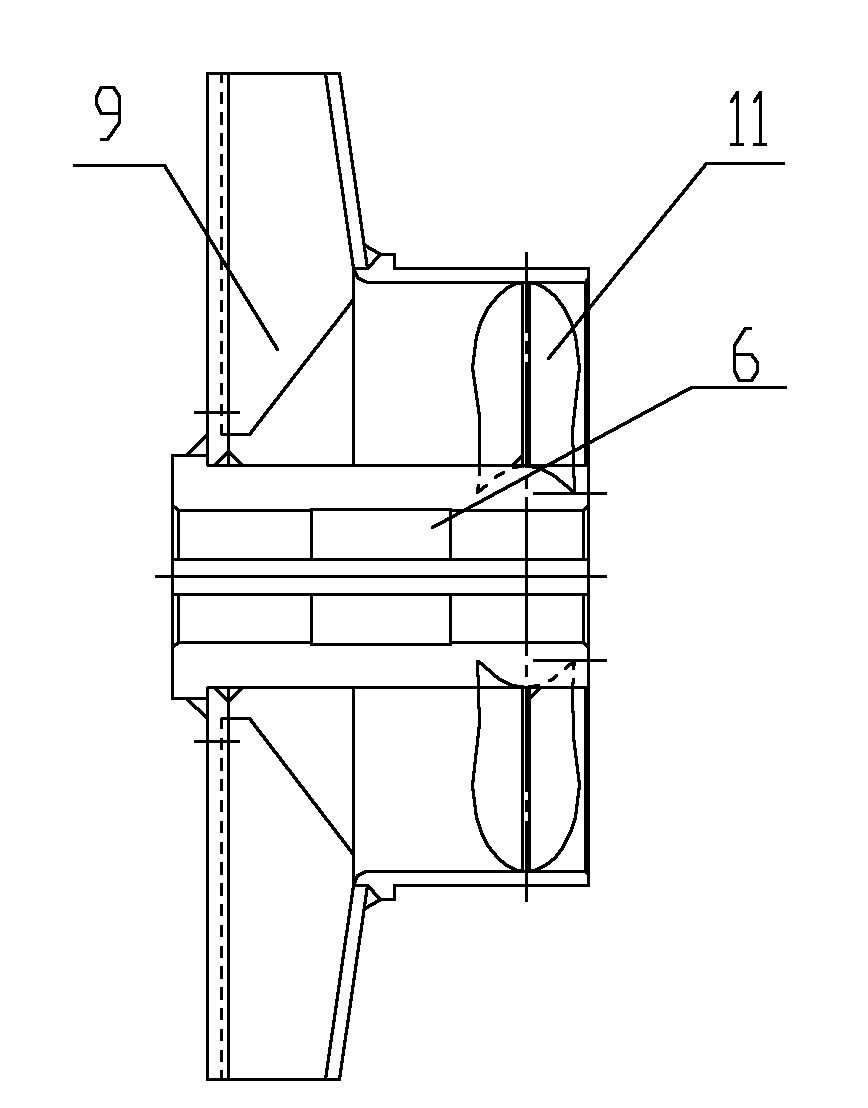

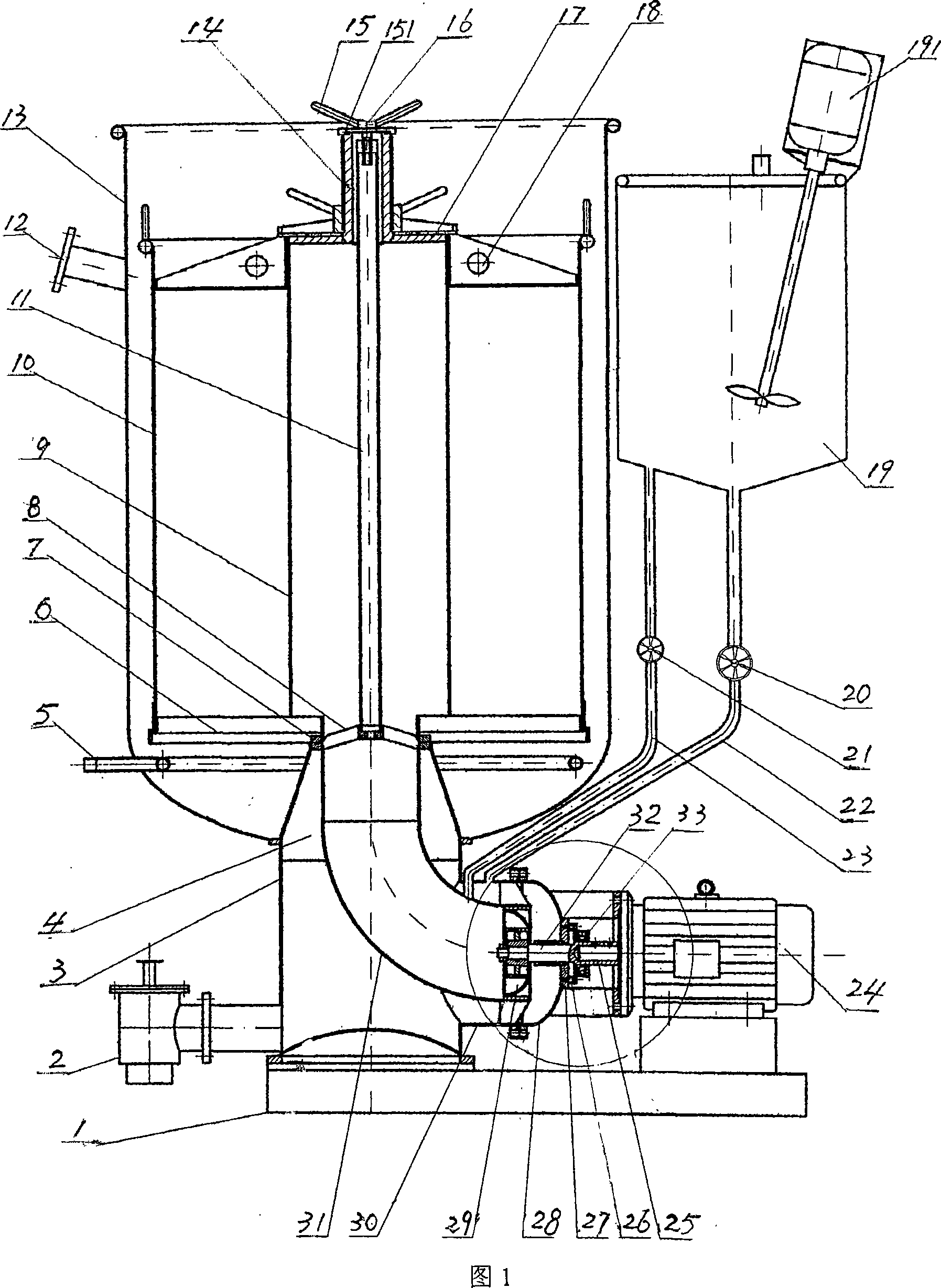

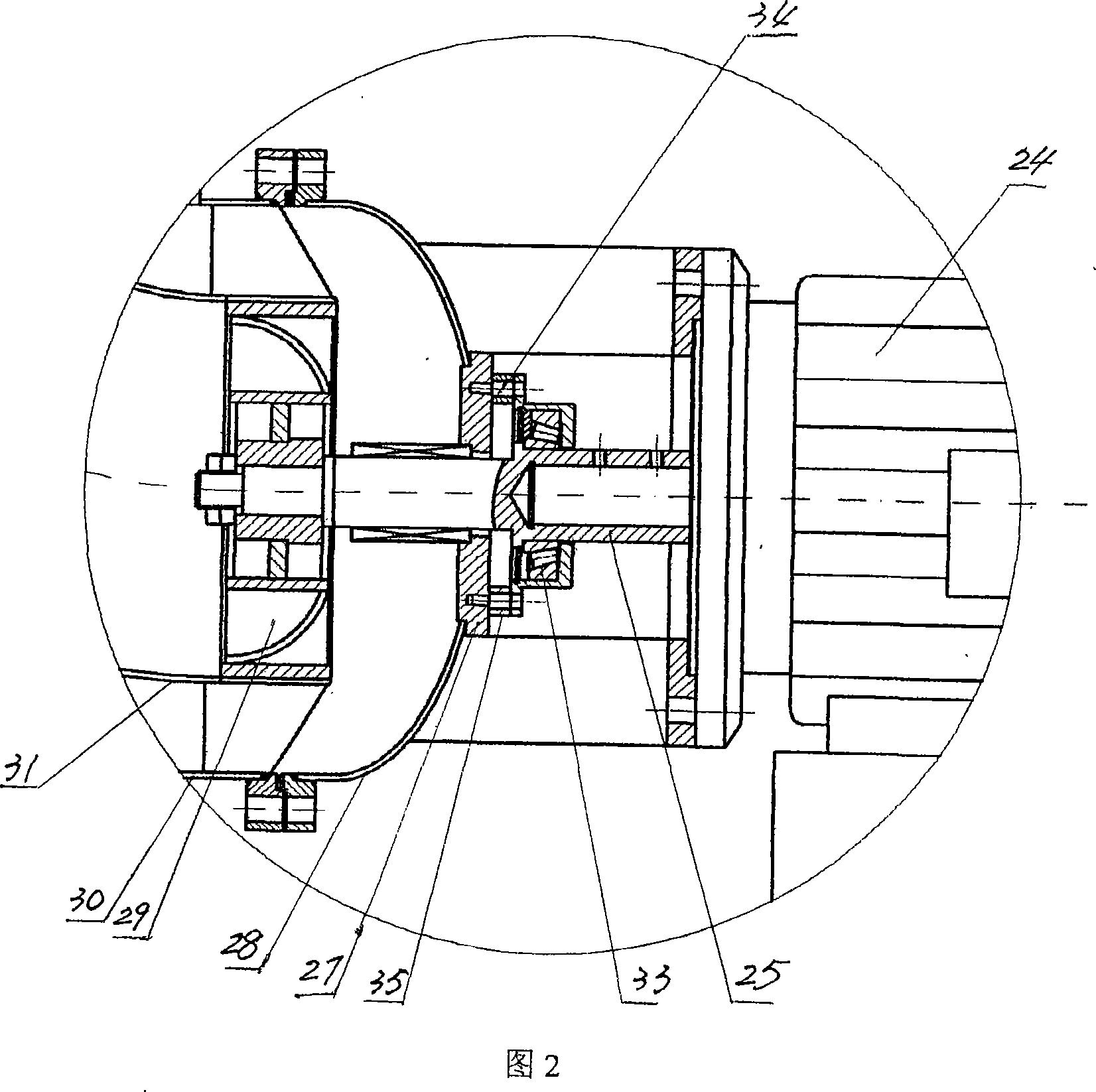

Loose fibre dyeing machine

InactiveCN101122078AReduce consumptionReduce manufacturing costTextile treatment machine partsLiquid/gas/vapor treatment of definite length materialsImpellerDyeing

The invention discloses a loose fiber dyeing machine, which contains a cylinder. The cylinder is provided with a fiber cage and a central spray pipe from in to out. A heating coil is arranged below the cage bottom. The bottom of the cylinder is provided with a motor and an impeller and one side of the cylinder is provided with a preplasticator cylinder; the preplasticator cylinder is communicated with the inner cavity of the cylinder. The invention is characterized that the cylinder bottom is provided with a central hole, and a guide cylinder is arranged below the central hole. The upper end of the guide cylinder is communicated with the inner cavity of the cylinder; a guide flow cylinder is arranged in the guide cylinder; the side wall is provided with a through hole, and a transverse short cylinder is connected to the outside of the through hole. The opening of the transverse short cylinder is provided with a seal cover. The guide flow cylinder is a bend cylinder, with the upper end subsequently inserted into the cylinder and the central spray pipe, and the lower end arranged in the transverse short cylinder and some distance away from the seal cover, so as to communicate the guide cylinder and the guide flow cylinder. The impeller is positioned in a transverse section of the guide flow cylinder, with a wheel shaft extending out of the seal cover and connected with an output shaft of the motor. The loose fiber dyeing machine can reduce the manufacturing cost, extend the service life of the motor, and is applicable in dyeing of all loose fiber.

Owner:郑国洪

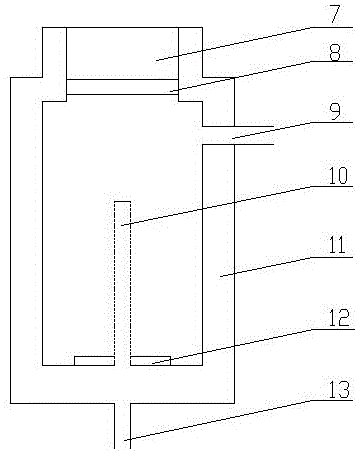

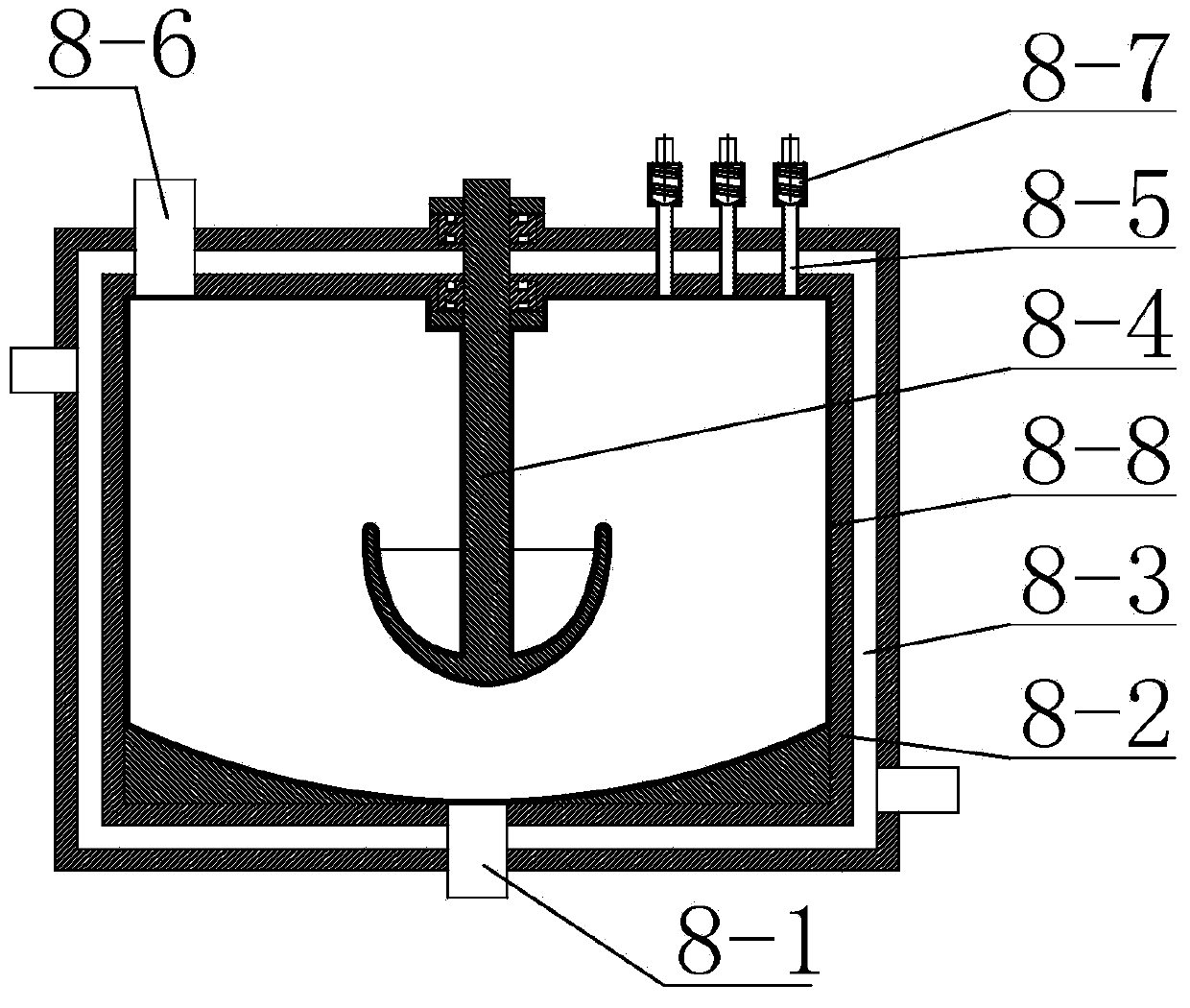

Supercritical carbon dioxide hairball dyeing kettle and waterless dyeing method thereof

ActiveCN102776738AMeet the development requirementsSimple and convenient production and processingTextile treatment containersSolvent treatment with solvent recoveryHairballSupercritical carbon dioxide

The invention relates to a supercritical carbon dioxide hairball dyeing kettle which comprises a cylinder body and a hairball dyeing barrel body fixed in the cylinder body, wherein a movable sealing cover is fixed at the upper end of the cylinder body, and the lower end of the cylinder body is provided with a carbon dioxide liquid outlet; a carbon dioxide liquid inlet is arranged at the upper part of the cylinder body; a heating clamping sleeve is fixed outside the cylinder body; a heating medium outlet is arranged at the upper end of one side of the heating clamping sleeve, and a heating medium inlet is arranged at the lower end of the other side of the heating clamping sleeve; the supercritical carbon dioxide hairball dyeing kettle is characterized in that a hole III is formed in the wall of the hairball dyeing barrel body; a central pipe is fixed to the centre of the hairball dyeing barrel body, and at least one upper limiting cover is fixed to the central pipe; the central pipe has a multi-pore shaft structure; a hole I is formed in a supporting plate at the bottom of the barrel body; a central hole Ia is corresponding to an internal chamber of the central pipe; and a hole II is formed in the upper limiting cover. According to the supercritical carbon dioxide hairball dyeing kettle increased, the direct contacting surface area of the a hairball and the dyeing liquid can be increased, and improves the influence due to the gravity in hairball dyeing can be improved, and the dyeing speed and the dye pickup can be improved, as well as the dyeing uniformity is improved.

Owner:晋江国盛新材料科技有限公司

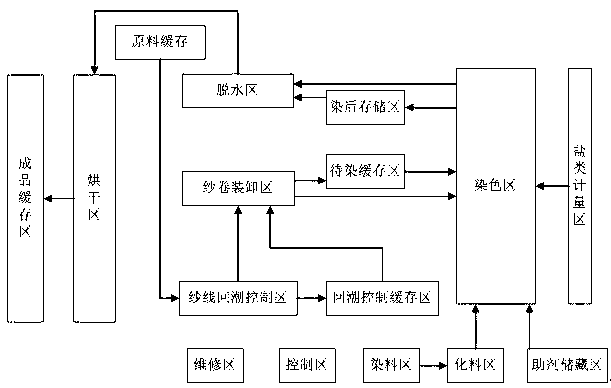

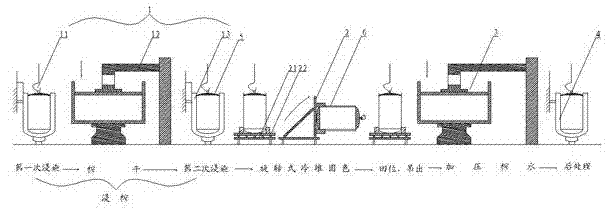

Cheese dyeing method and cheese dyeing production device

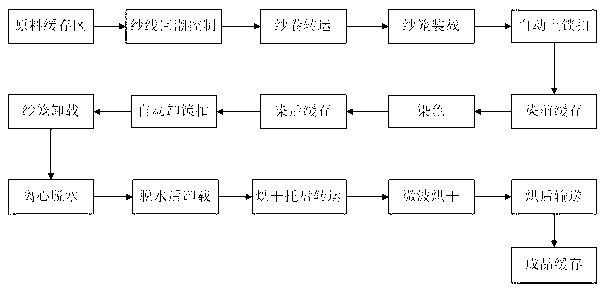

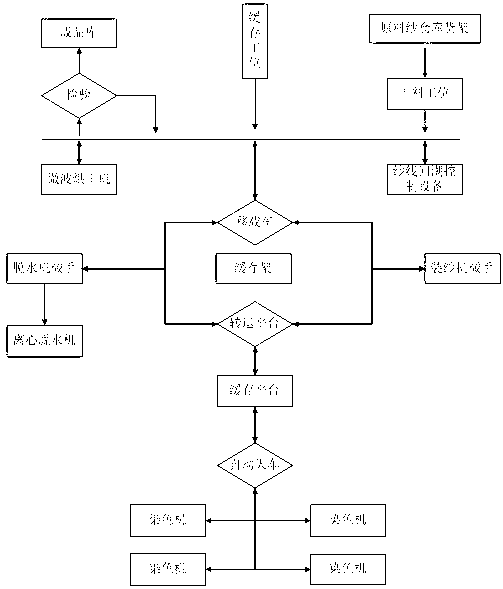

ActiveCN103225189AIncrease the level of automationIncrease productivitySucessive textile treatmentsLiquid/gas/vapor treatment of definite length materialsYarnMicrowave

The invention provides a cheese dyeing method and a cheese dyeing production device. The cheese dyeing method comprises the following steps of yarn return control: yarn return control equipment is adopted to carry out return control on a cheese; yarn cage loading: a yarn loading robot is adopted to load the cheese subjected to return control in a yarn cage; yarn cage transferring: an automatic crown block is adopted to transfer the yarn cage to a pre-dyeing cache region, and then is transferred into a vertical dyeing machine from the pre-dyeing cache region; dyeing: the vertical dyeing machine is adopted to dye the cheese subjected to return control; automatic dye weighing; dissolving and dispatching; liquid additive accurate metering and conveying; automatic powder salt additive weighing and conveying; dewatering: the dyed cheese is dewatered; and drying: a microwave drying machine is adopted to dry the dewatered cheese. In the technical scheme, various automatic devices are adopted to improve the automatic dyeing level of the cheese.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH +1

Cold-pad batch dyeing process for bulk fiber

InactiveCN102817192AReduce fluid volumeReduce laborLiquid/gas/vapor removalTextile treatment machine arrangementsBleachMaterials science

The invention relates to the field of bulk fiber dyeing, in particular to a cold-pad batch dyeing process for bulk fibers, which comprises the steps of: (1) bulk fiber web formation: forming a uniform fiber layer with bulk fibers by an automatic bale plucker and a web forming machine; (2) padding: controlling a bleaching mangle expression to be 100-120 percent and a dyeing mangle expression to be 120-140 percent, only adding a refining agent and a bleaching agent for pretreatment into an immersion solution tank during bleaching, and adding dyes, a penetrant and an alkaline agent into the immersion solution tank during dyeing; (3) stacking after uniform padding and rolling: performing stacking on a cold-pad batch unit after the fiber layer is rolled so as to complete bleaching or dyeing; and (4): washing and drying: making the fibers treated by a washing machine and a soaping tank after dying and then treated by a drying machine. The cold-pad batch dyeing process has the advantages of little pollution and low energy consumption.

Owner:ZHEJIANG CHUNLANFANG TRADE

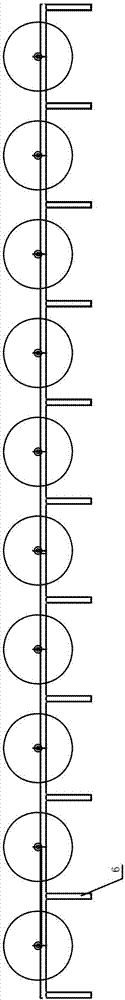

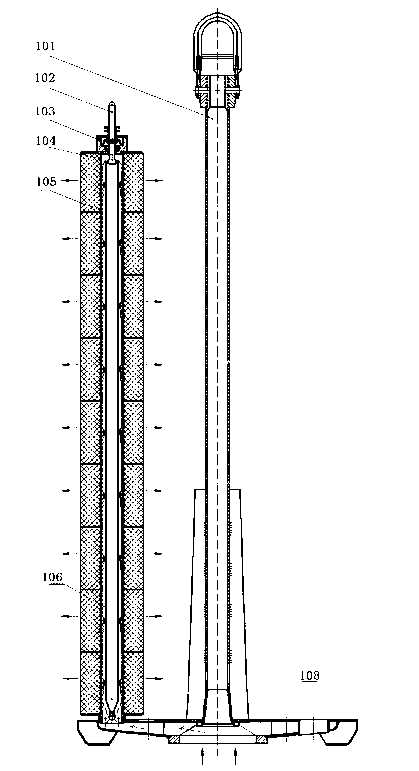

Dyeing rack for tatting yarn, zippers, ropes, ribbons and loose fibers of loading needles of dyeing machine

InactiveCN103132264AReduce processing timeReduce consumptionLiquid/gas/vapor treatment of definite length materialsTextile treatment carriersYarnFiber

The invention discloses a dyeing rack for tatting yarn, zippers, ropes, ribbons and loose fibers of loading needles of a dyeing machine. The dyeing rack for tatting the yarn, the zippers, the ropes, the ribbons and the loose fibers of the loading needles of the dyeing machine comprises a yarn plate, a suspender and a yarn rod. The upper surface of the yarn plate is in a disc shape. The lower end of the yarn plate is in a cavity structure. A center seat of the dyeing machine is connected with the bottom of the lower end of the yarn plate. A yarn plate water outlet, a yarn plate water return hole and a suspender hole seat are formed in the upper surface of the yarn plate. The suspender hole seat is arranged at the center of the yarn plate. A suspender is fixedly installed in the suspender hole seat. The bottom of the yarn rod is fixed on the yarn plate water outlet of the upper surface of the yarn plate. The yarn rod is in a solid structure or a hollow structure. A gap is reserved between a to-be-dyed object and the yarn rod. Dye liquor flows out of the yarn plate water outlet hole of the bottom of the yarn rod and fills the gap to form a hollow water column. The dye liquor permeates the to-be-dyed object through flowing of the hollow water column. The dye liquor permeated from the to-be-dyed object flows into the yarn plate water return hole. A bolt at the upper end of the yarn rod is provided with a gravity tapered end. The dyeing rack for tatting the yarn, the zippers, the ropes, the ribbons and the loose fibers of the loading needles of the dyeing machine is simple in structure, capable of reducing consumption of dye, auxiliaries, energy sources and water resources, and capable of improving dyeing efficiency.

Owner:GUANGZHOU GAOSHENG DYEING & FINISHING EQUIPCO

Loose fiber cold pad-batch dyeing machine

ActiveCN102660846AContinuous productionReduce fluid volumeTextile treatment machine arrangementsLiquid/gas/vapor treatment of definite length materialsElectricityFiber

The invention relates to a loose fiber cold pad-batch dyeing machine which sequentially comprises an automatic bale plucker, a lapper, an immersion liquid tank with an automatic dosing system, an evenness calender, a coiling machine I, a cold pad-batch unit, an uncoiling machine I, a washing machine, a water calender, a coiling machine II, an uncoiling machine II, a drying machine and a packaging machine; in a bale storage box of the lapper, a centrifugal fan is arranged below a foot nail roller and communicated with the foot nail roller through a circulating air flue; a high-speed circulating spray pipe is mounted at the bottom of the immersion liquid tank; and a spray head on the high-speed circulating spray pipe is directly opposite to a fiber layer above the spray head. The machine provided by the invention has the advantages of high production efficiency, uniform dyeing, low water, electricity and energy consumption and low production cost.

Owner:浙江华晨印染有限公司

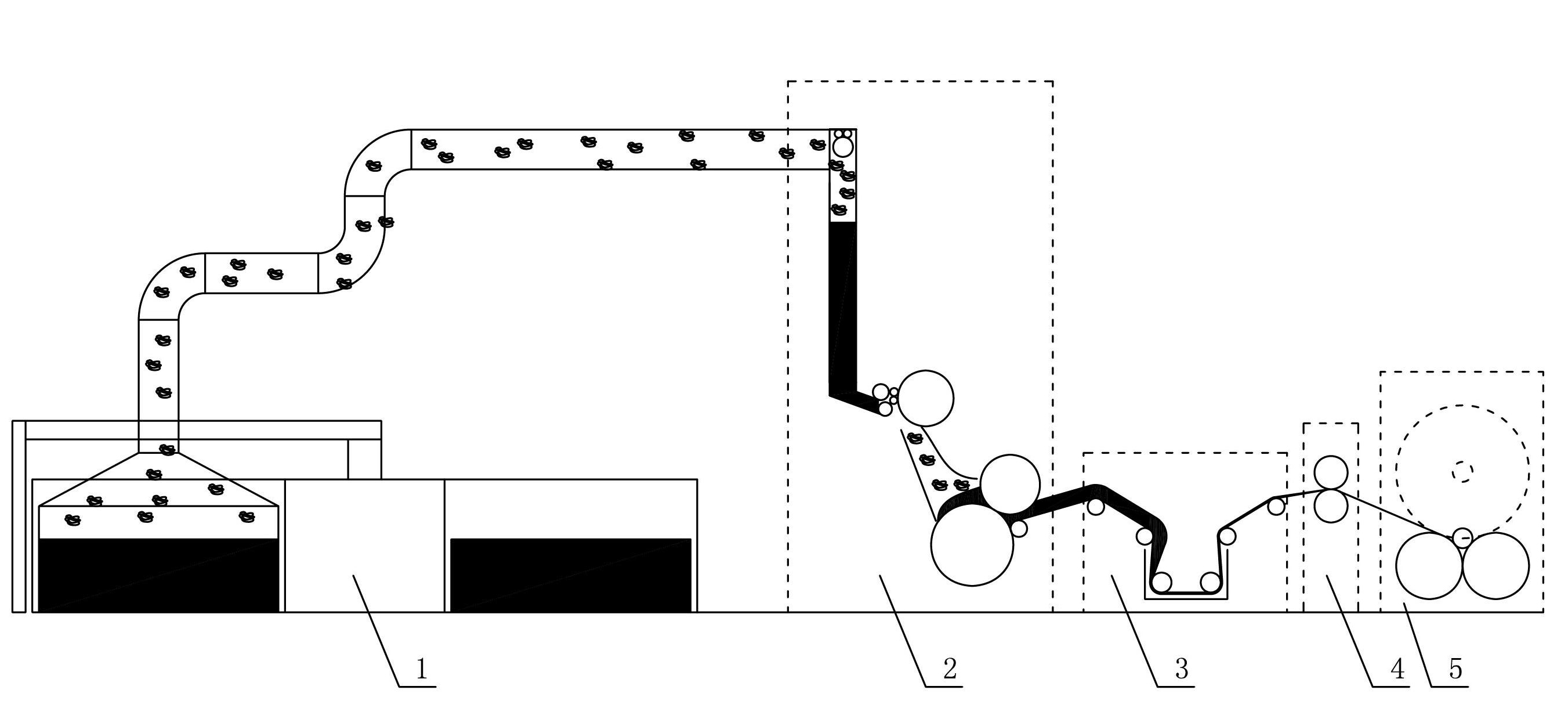

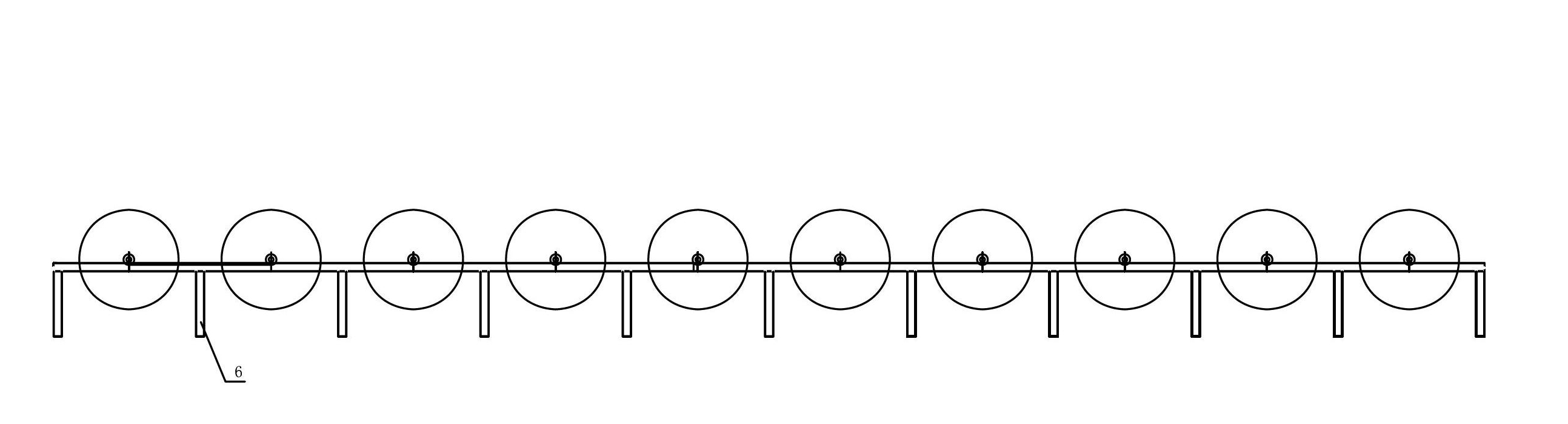

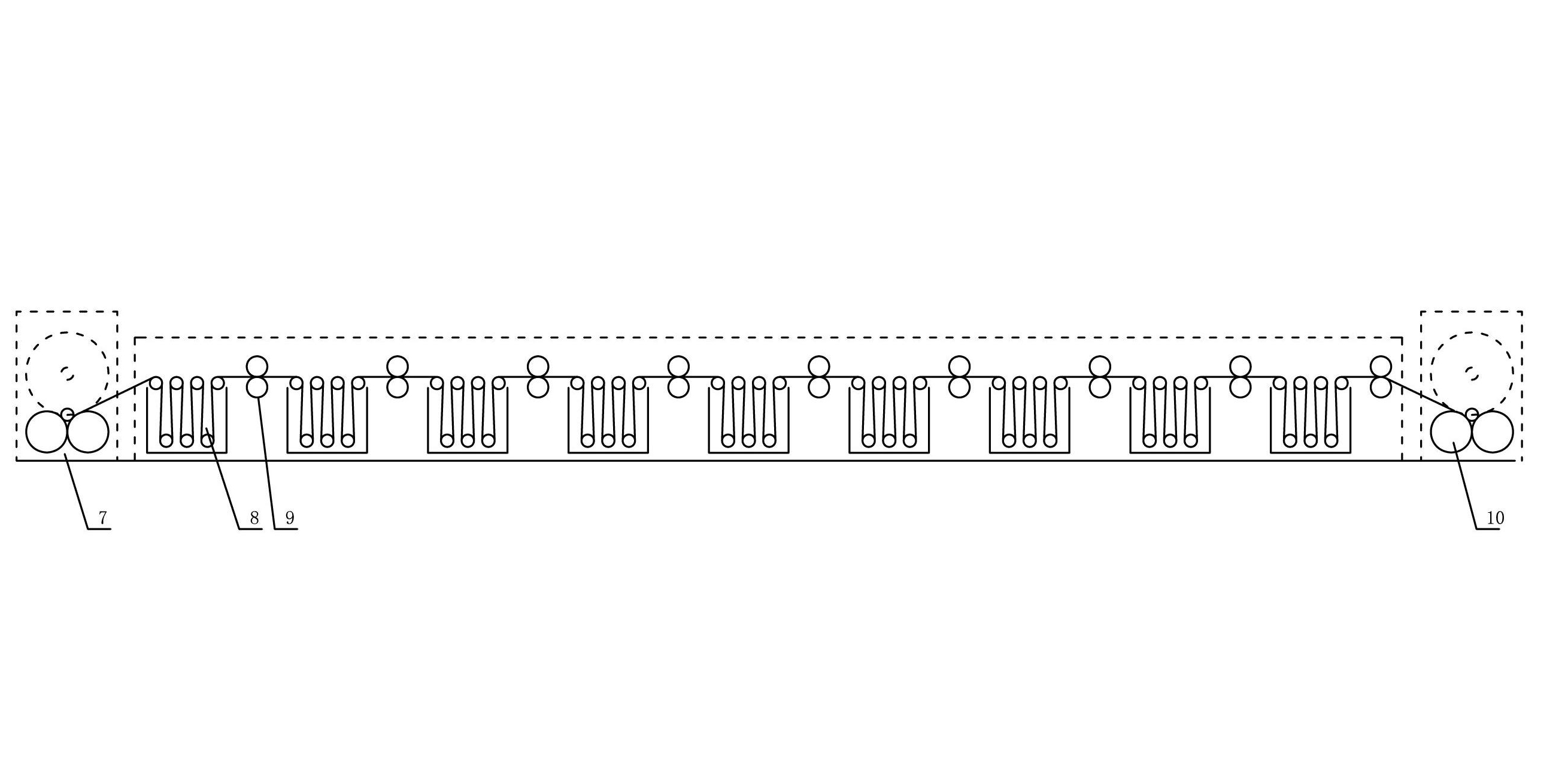

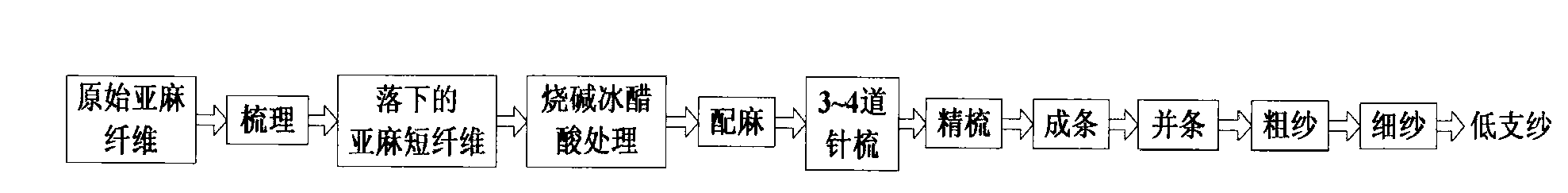

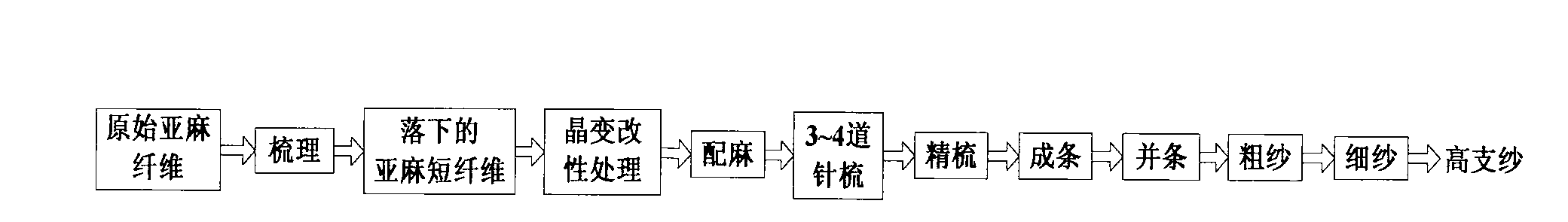

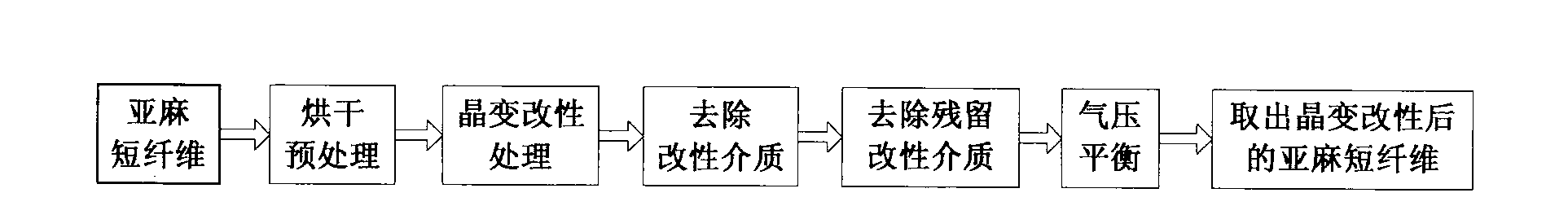

Dry spinning method for spinning flax short fiber into high count yarn

InactiveCN102839456AAvoid pollutionQuality improvementLiquid/gas/vapor treatment of definite length materialsYarnYarnPulp and paper industry

The invention provides a dry spinning method for spinning flax short fiber into high count yarn, comprising the following steps: step 1, original flax fiber is combed to enable flax short fiber to fall down, and then the flax short fiber is used as the raw material for dry spinning; step 3, crystallized and modified flax short fiber obtained in the step 1 is subjected to flax assorting, and the crystallized and modified flax short fiber is spun into flax rough yarn through 3-4 times of gilling, combing, slivering, drawing and roving procedures; step 4, the flax rough yarn is dry-spun into high quality and high count flax fine yarn by a dry spinning frame; the drying spinning method is characterized in that a step 2 is carried out between the first step and the third step; and step 2, the flax short fiber is subjected to crystallization and modification treatment. The dry spinning method has the advantages that the dry spinning method can be used for spinning flax short fiber into 50 metric count according to the fiber proportion which is adopted by the traditional dry spinning method used for spinning flax short fiber into 36 metric count flax yarn, and the technological and process innovation that low-quality flax short fiber can be spun into high quality and high count flax yarn is realized; and the caustic soda and glacial acetic acid treatment adopted in the traditional dry spinning method is replaced by the crystallization and modification treatment, so that no exhaust gas and liquid waste are generated in the whole technological process.

Owner:DONGHUA UNIV +1

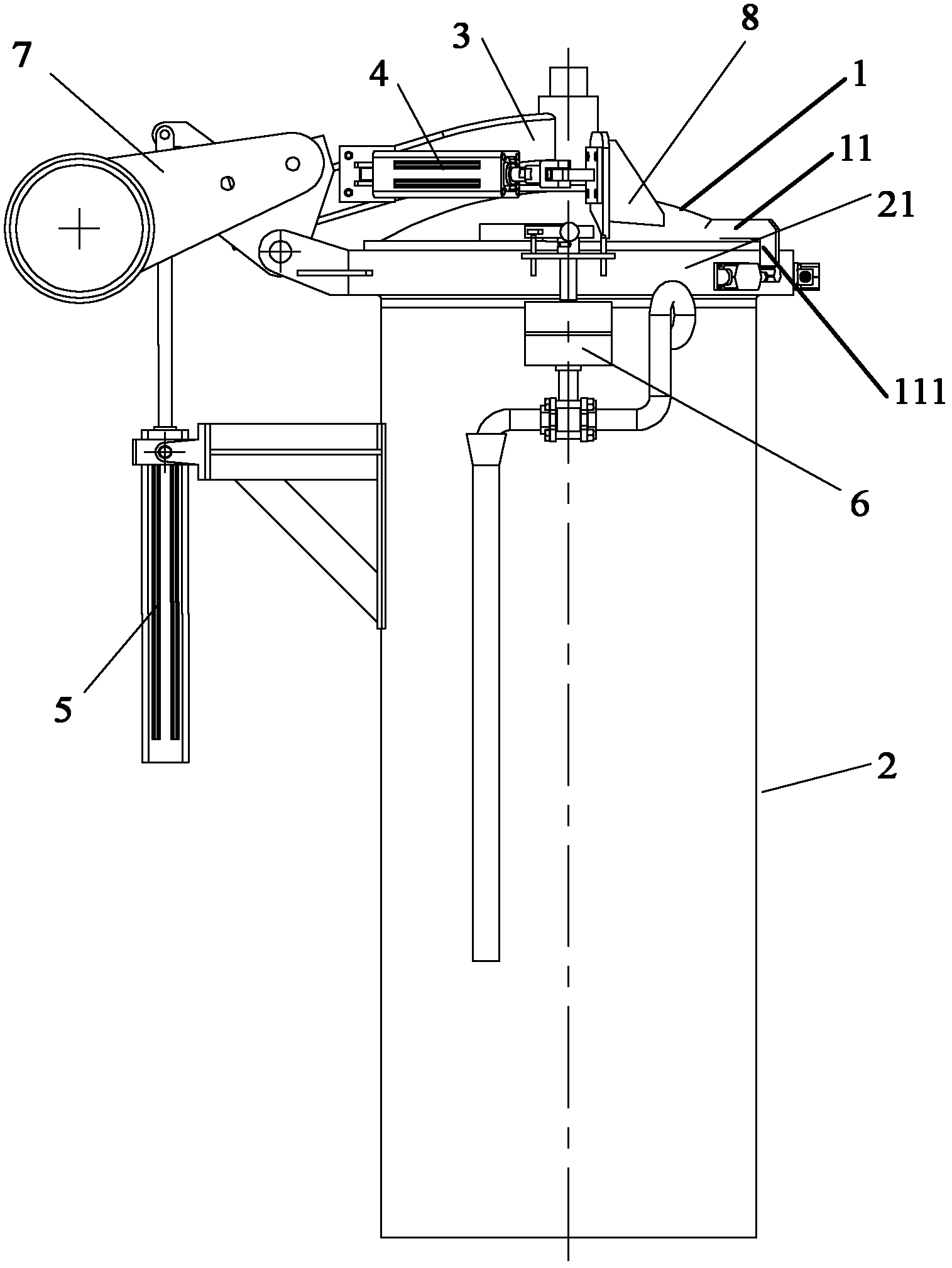

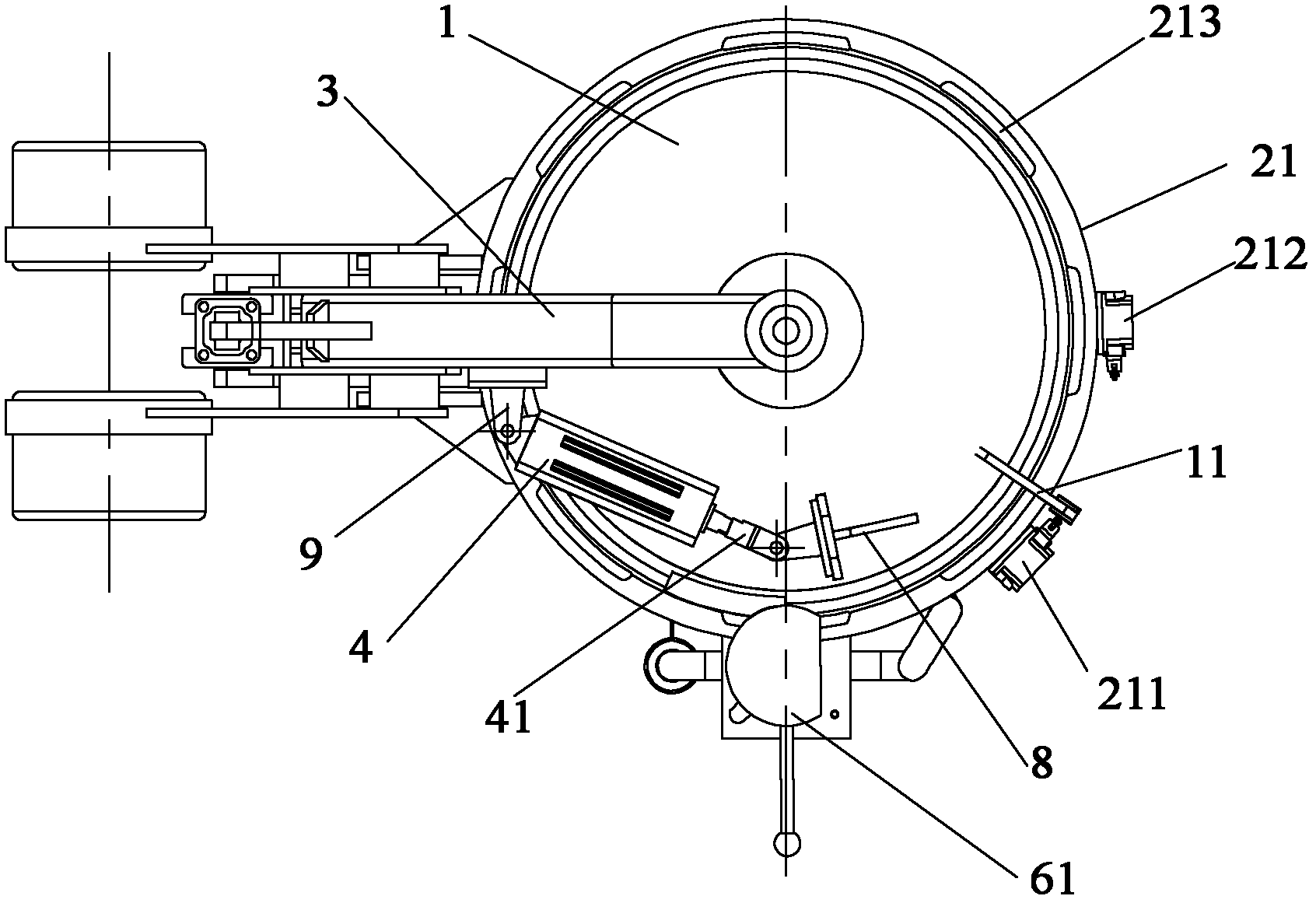

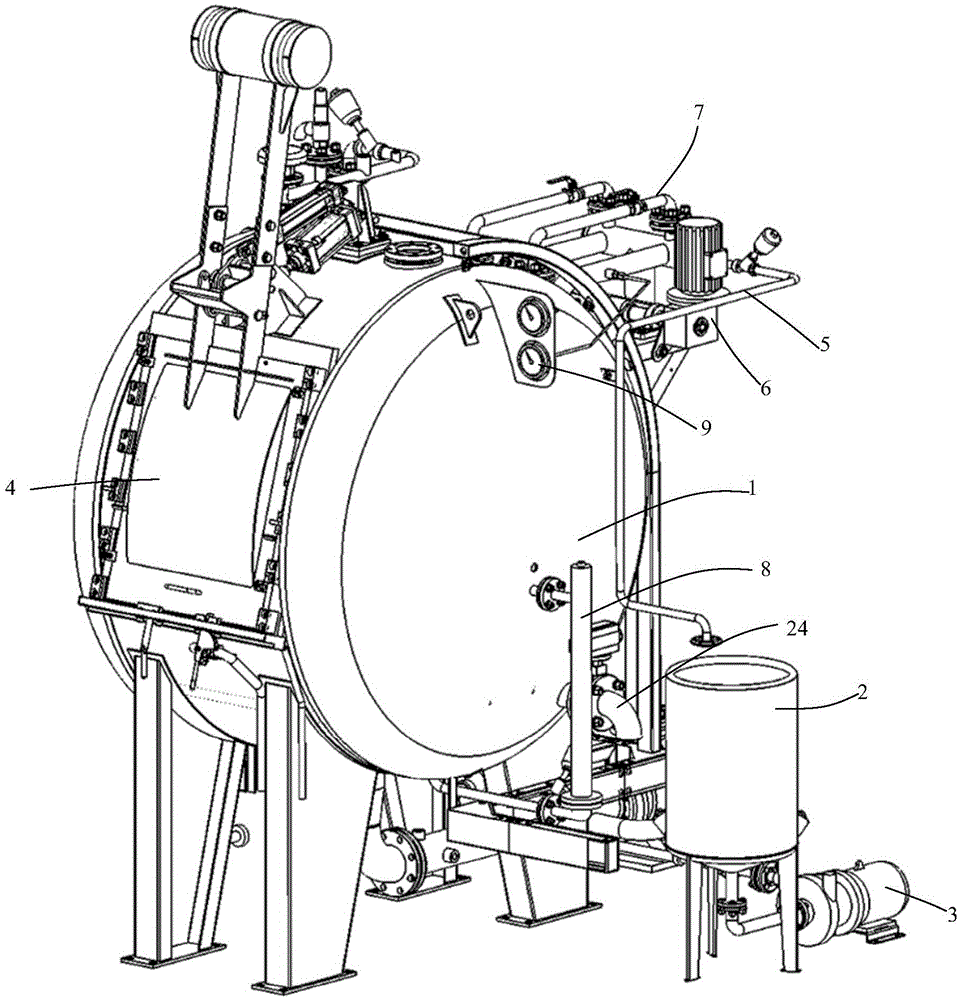

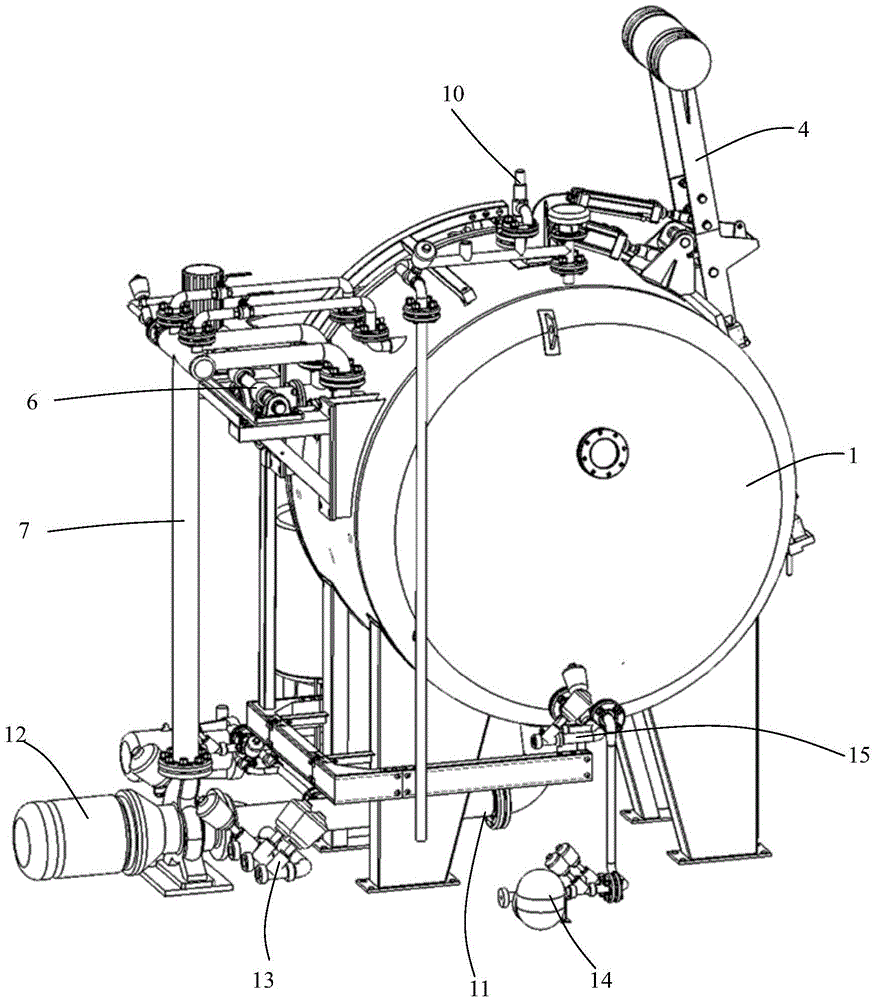

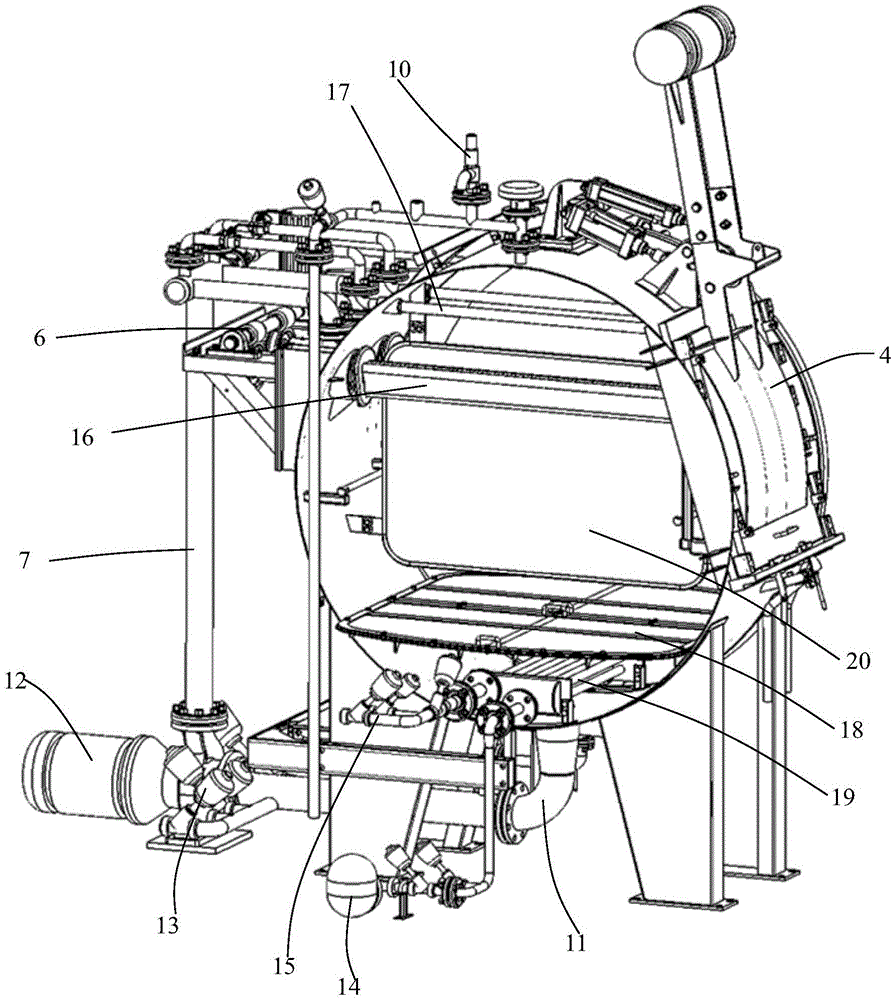

Automatic cylinder cover locking device and cheese dyeing machine comprising same

ActiveCN102587054ALarge operating forceLabor savingTextile treatment containersLiquid/gas/vapor treatment of definite length materialsEngineeringMechanization

The invention provides an automatic cylinder cover locking device and a cheese dyeing machine with the automatic cylinder cover locking device. The automatic cylinder cover locking device is arranged between a cylinder cover and a cylinder body, the cylinder cover is provided with teeth uniformly distributed along the circumference, the upper end of the cylinder body is provided with a clamping hoop supporting the cylinder cover, the clamping hoop is provided with an annular groove for holding the teeth and an annular flange positioned above the annular groove, and the annular flange is provided with slots matched with the teeth. The automatic cylinder cover locking device also comprises a suspension arm and a driving device, wherein the suspension arm is arranged above the cylinder cover, a first end of the suspension arm is pivoted with the cylinder cover, and a second end of the suspension arm is pivoted with the clamping hoop; the driving device is provided with a driving end which is connected to a position on the cylinder cover, deviating from the central axis of the cylinder cover, to drive the cylinder cover to rotate around the central axis of the cylinder cover, so as to lock or unlock the cylinder cover. With the automatic cylinder cover locking device and the cheese dyeing machine with the automatic cylinder cover locking device, labor force is saved, the production efficiency is high, the labor cost is lowered, the mechanization level and automation level of equipment are improved, and realization of automatic production is facilitated.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH +1

Tech. for bobbin dyeing of stretch yarn

InactiveCN1793475ASlow contractionShrink evenlyLiquid/gas/vapor treatment of definite length materialsYarnBobbin

The invention relates to resiliency yarn cone dyeing technique. It includes the following working procedures: loose type coning; pre-processing; dyeing; post processing; dehydrating; drying. Its feature is that it practices once or two times preshrinking forming before loose type coning procedure. This can prevent out layer yarn from covering the inner layer. Compared with the current technique, the invention is simple, economic, and stable; and it can make dye fully permeate into inner, middle, and outer layers yarn to ensure no color difference.

Owner:金国周

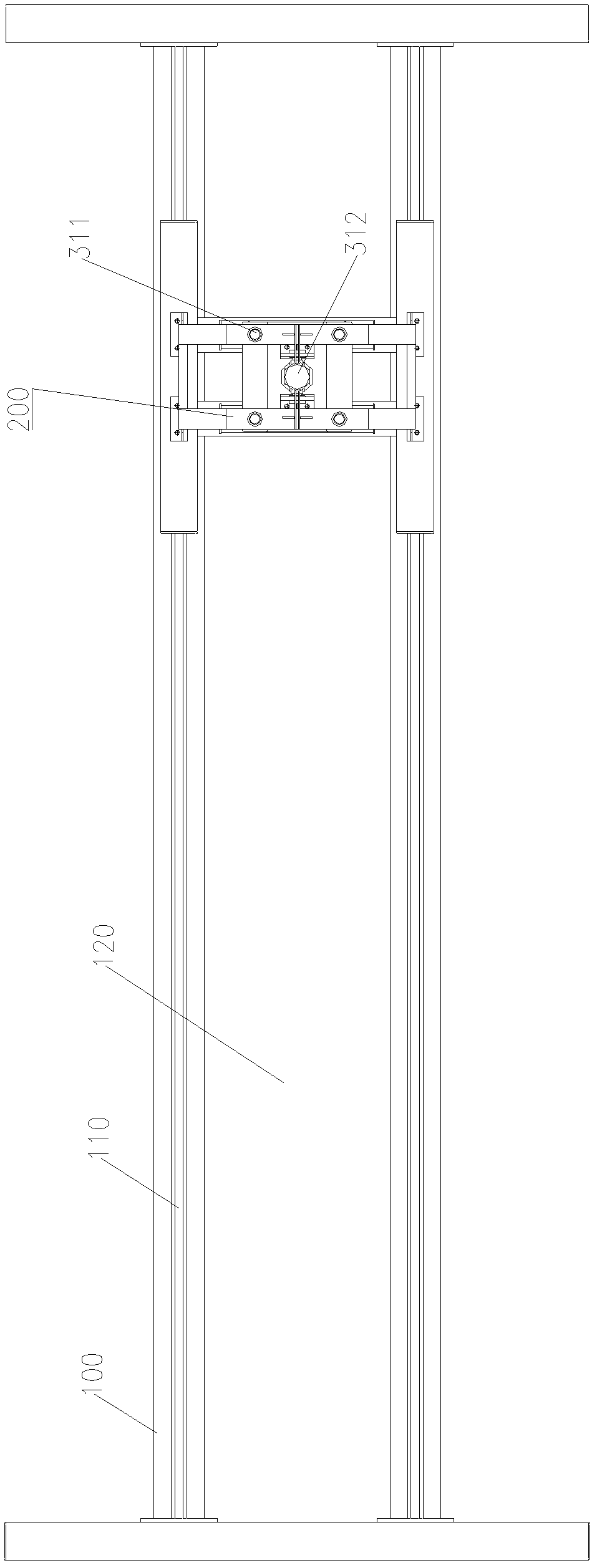

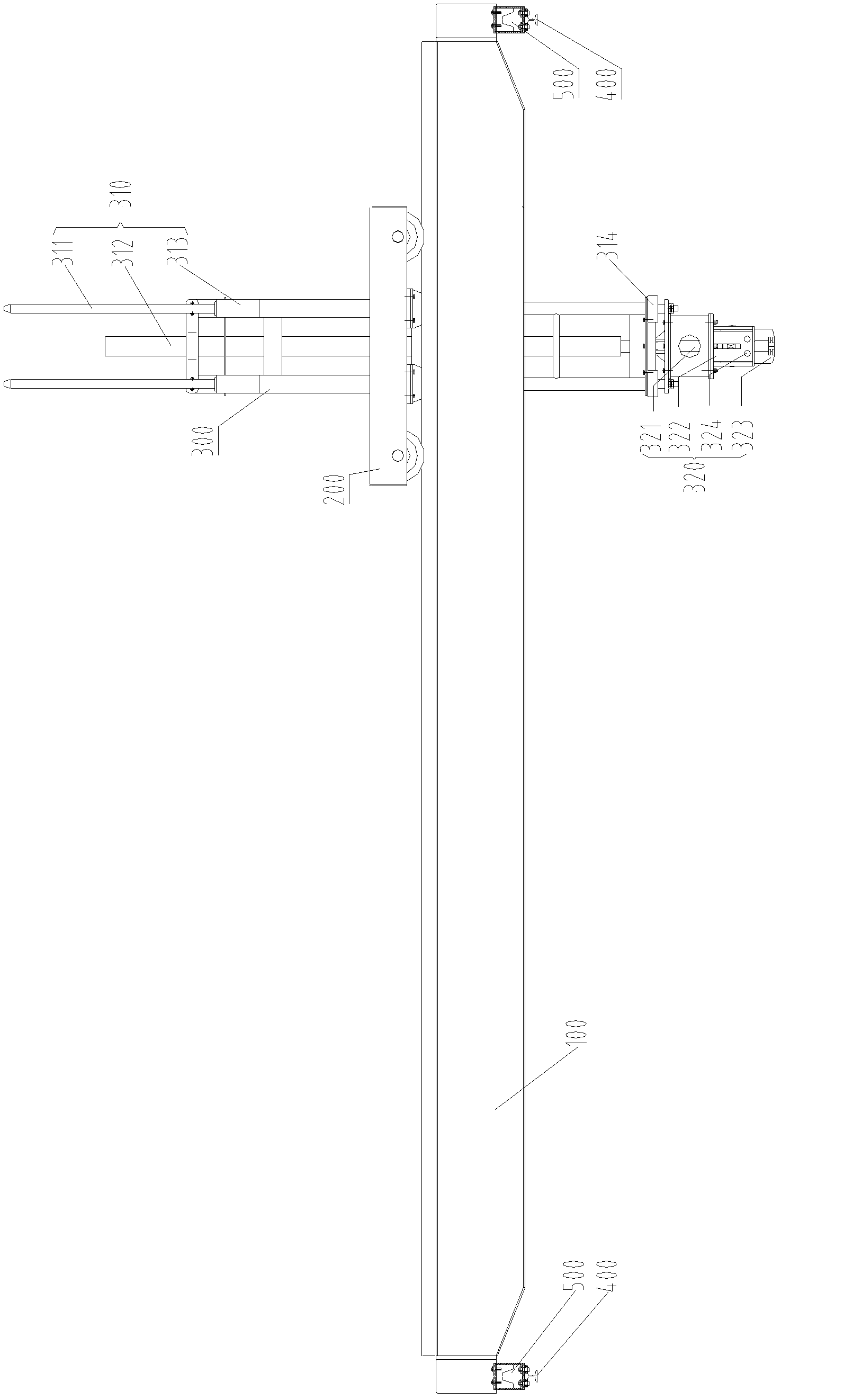

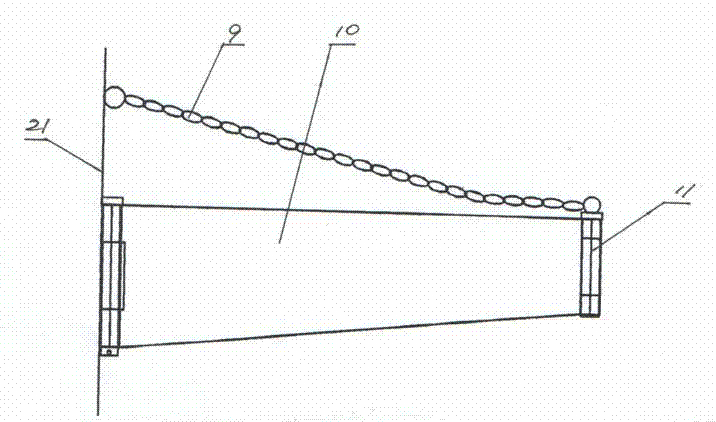

Sarong transportation equipment

InactiveCN102583045AIncrease productivityImprove production safetyLiquid/gas/vapor treatment of definite length materialsTravelling cranesElectrical and Electronics engineering

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH +1

Supercritical fluid continuous yarn dyeing instrument

InactiveCN101078154AReasonable structureEasy to controlTextile treatment machine partsLiquid/gas/vapor treatment of definite length materialsYarnFiber

This invention belongs to the dyeing device for the fibre, yarn and textile, it especially relates to the super critical fluid continuously yarn dyeing machine of the device. It consists of the cavity body, yarn storehouse, heater, cut-off device for the yarn storehouse, basement, driving configure and bracket of the yarn storehouse. The cavity body installs on the basement, the outside of the body is heater, and there is pipe interface for the fluid on the cavity body. The yarn storehouse sets up in the cavity, the cut-off device installs on the both sides of the cavity. The driving configure installs two sides of the basement, and the momentum output device is corresponding to the yarn storehouse inside the cavity, and the bracket of the yarn storehouse fixes on the inlet of the cavity. The structure of this invention is rational, the controlling is simple, and it realize the continuously operation of dyeing and cleaning the float color at the sealing high pressure condition.

Owner:SHANDONG UNIV

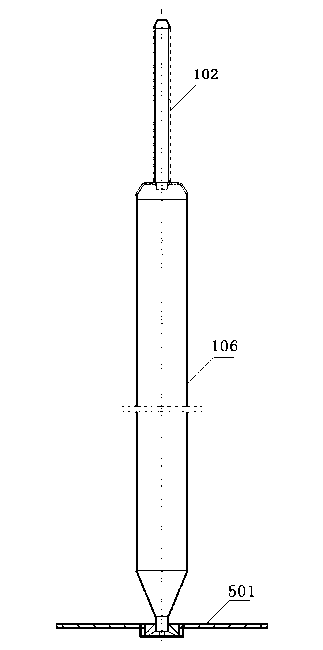

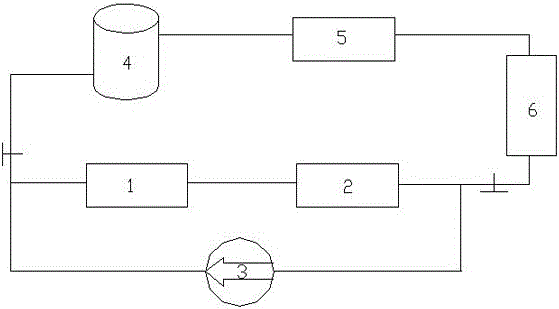

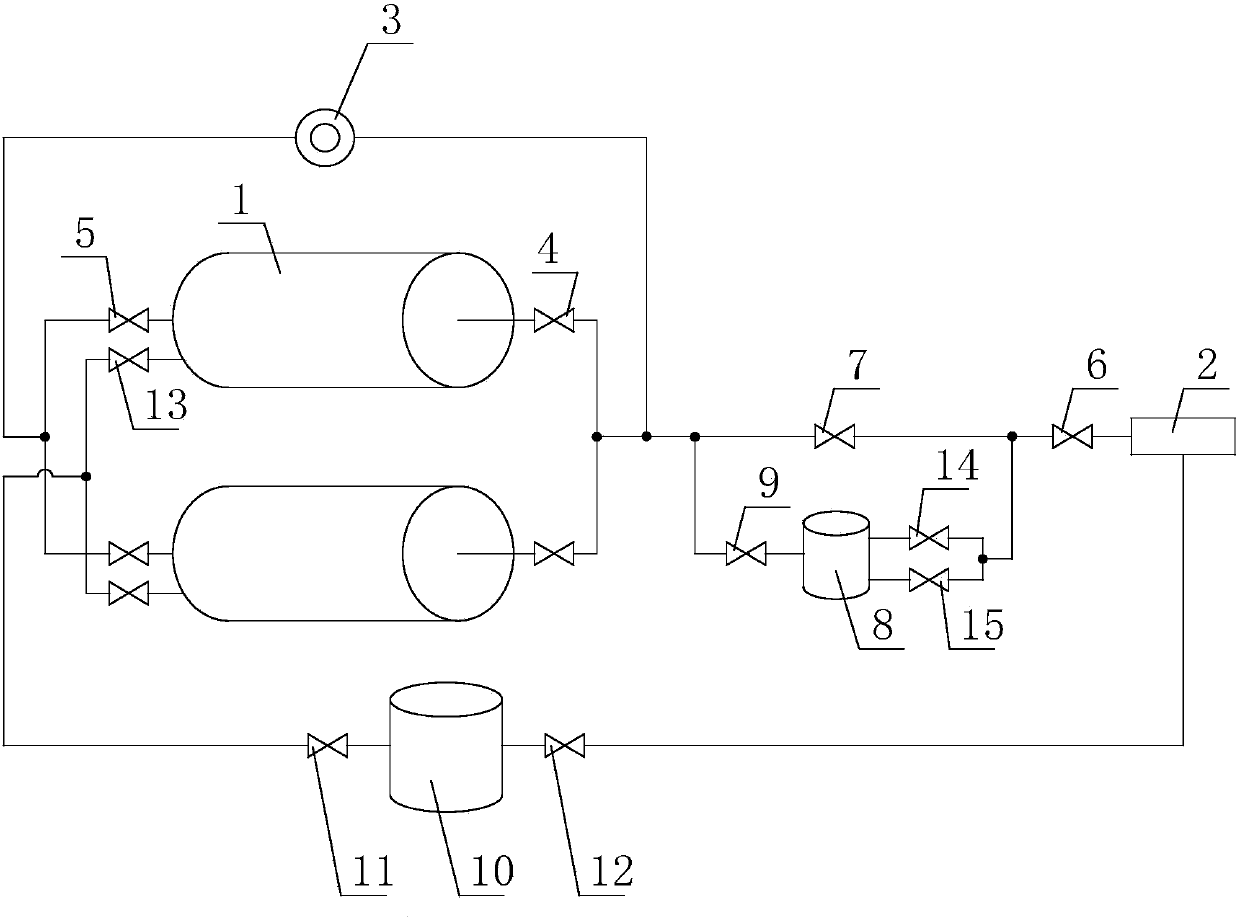

Cone yarn anhydrous dyeing equipment and method and product

ActiveCN106757915AGood colorImprove permeabilityTextile treatment containersSolvent treatment with solvent recoveryYarnEngineering

The invention provides cone yarn anhydrous dyeing equipment and method and a product. The cone yarn anhydrous dyeing equipment comprises a dye kettle, a dyeing kettle, a recycling kettle and a dyeing circulating system communicated with the dye kettle, the dyeing kettle and the recycling kettle. The cone yarn anhydrous dyeing equipment is characterized in that a cone yarn inlet is formed in the top of the dyeing kettle, a sealing cover is arranged on the cone yarn inlet, a yarn center shaft is vertically arranged in the middle in the dyeing kettle, and the yarn center shaft is an air outlet pipe with fluid release holes formed in the pipe wall; an air inlet pipe is arranged at the bottom of the dyeing kettle and communicated with the air outlet pipe, and a dyeing kettle outlet is formed in the dyeing kettle; the dyeing circulating system comprises a CO2 gas storage cylinder, a booster pump, a circulating pump and a pipeline. Various dyes are placed in the dye kettle, cone yarn is placed in the dyeing kettle, CO2 is introduced into the dye kettle, the dyes are gradually dissolved and reach the dyeing kettle along with CO2 fluid, and the coloring and dispersing processes are started. The advantages of being high in production efficiency, good in level dyeing effect, high in safety and suitable for anhydrous dyeing of the dacron cone yarn are achieved.

Owner:QINGDAO JIFA GROUP

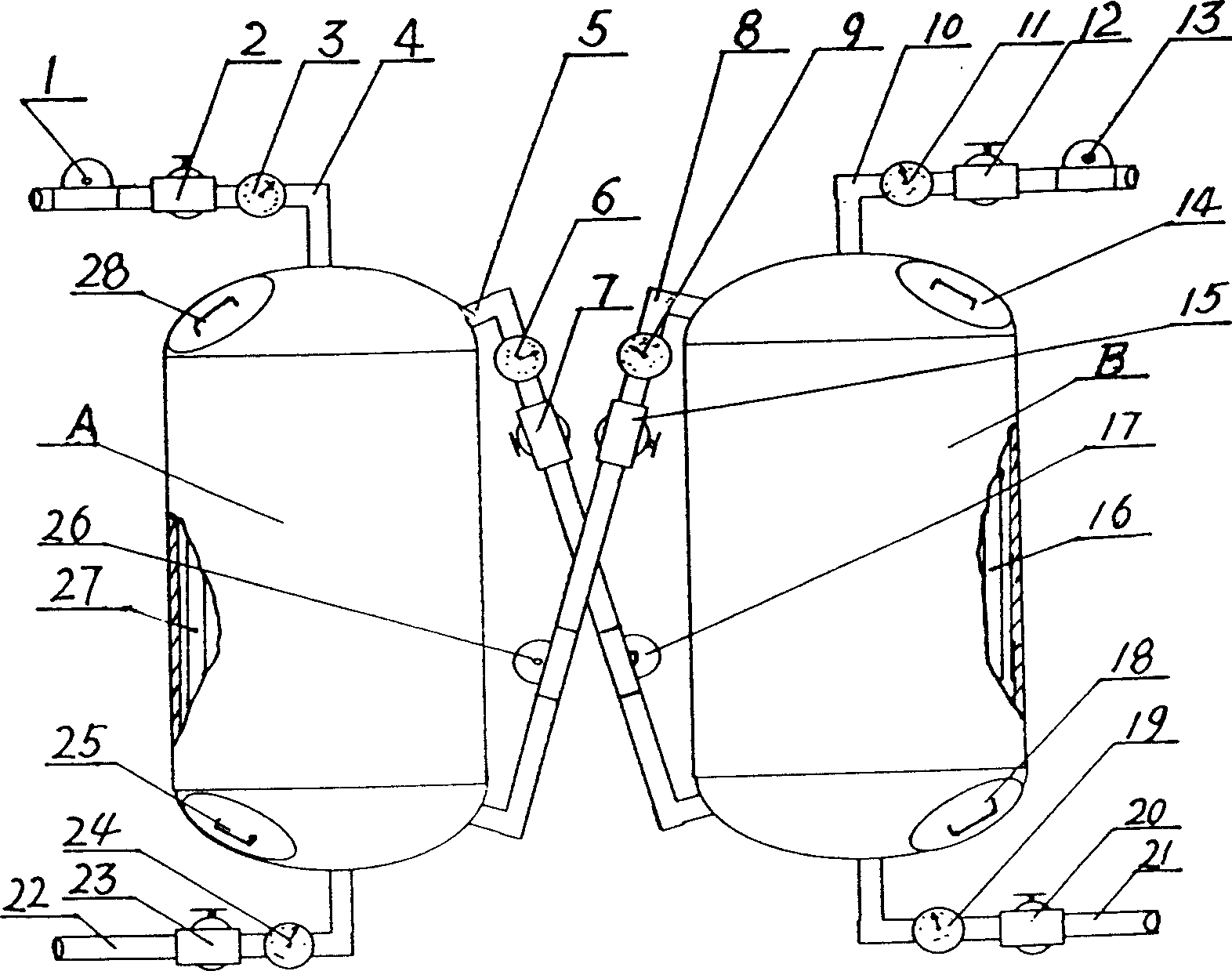

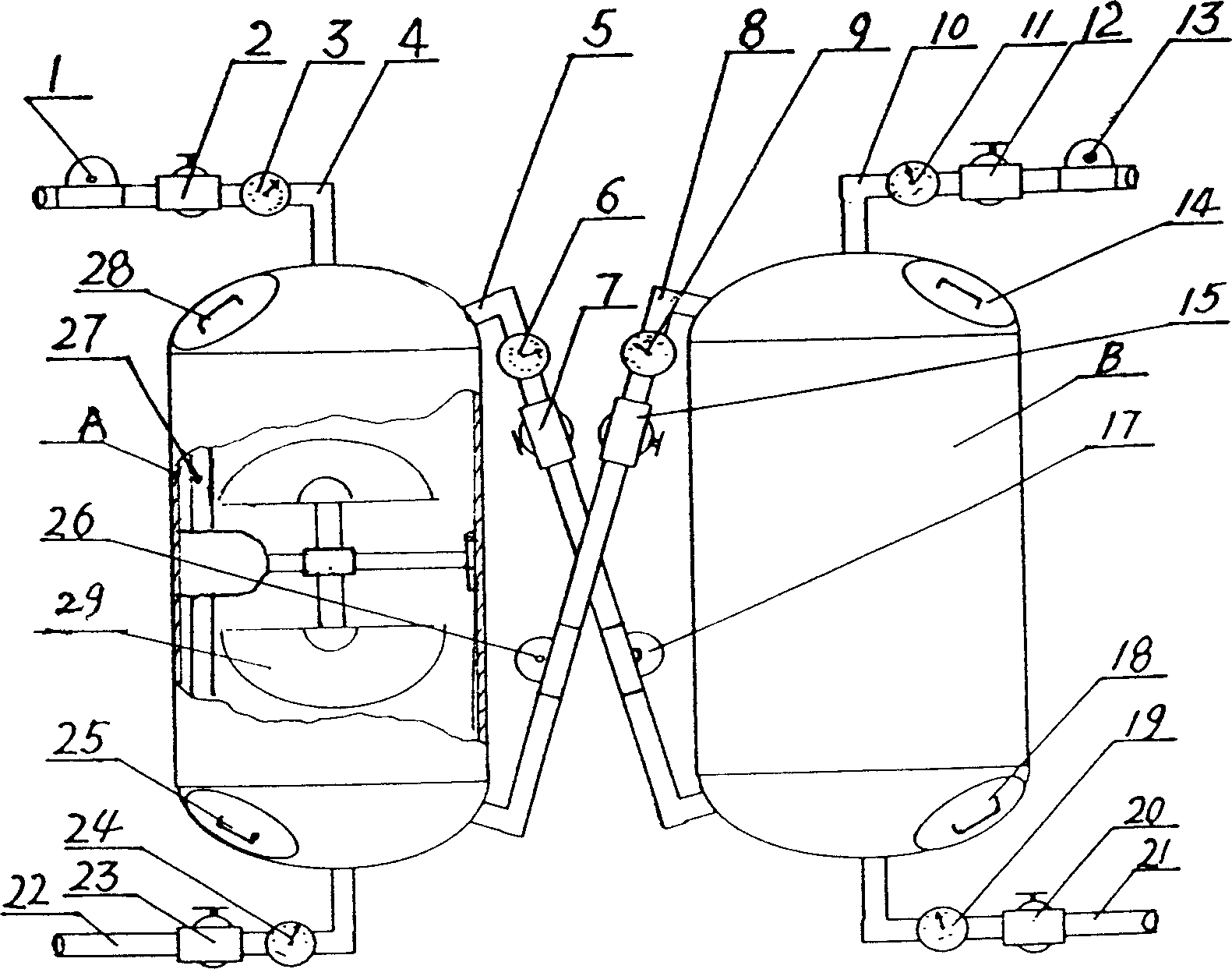

Production device of reclaimed white cotton from coloured cotton fabric an dits technology

InactiveCN1693568AUniform and thorough decolorizationGuaranteed concentrationBleaching apparatusLiquid/gas/vapor treatment of definite length materialsWater resourcesEngineering

The invention discloses a device for producing regenerated white cotton of colored cotton textile and its process, where there are two parallel reaction cylinders, there are top and bottom crosswise communicating tail gas pipes on the two reaction cylinders, and each tail gas pipe is installed with a valve, a flow meter and a vacuum pump; there is a UV lamp arranged in each reaction cylinder; another flow meter is installed on each air inlet pipe, and a pressure meter and another vacuum pump are installed on each air outlet pipe; the production process is: firstly humidifying the colored cotton textile to be processed, by steam, to make the water content of the colored cotton textile at 10-25%; making prophase decoloring treatment on the humidified cotton textile by ozone at a concentration of 5-25%; synchronously performing late UV decoloring treatment on the treated cotton textile in an ozone-containing environment to make the cotton textile turn white; and finally making cotton opening treatment on the white cotton textile to make the regenerated white cotton. The invention has the characters of simple process, high production efficiency, no pollution, no damage to cotton spinning material, saving water resources, and safety and reliability in production.

Owner:黄继理

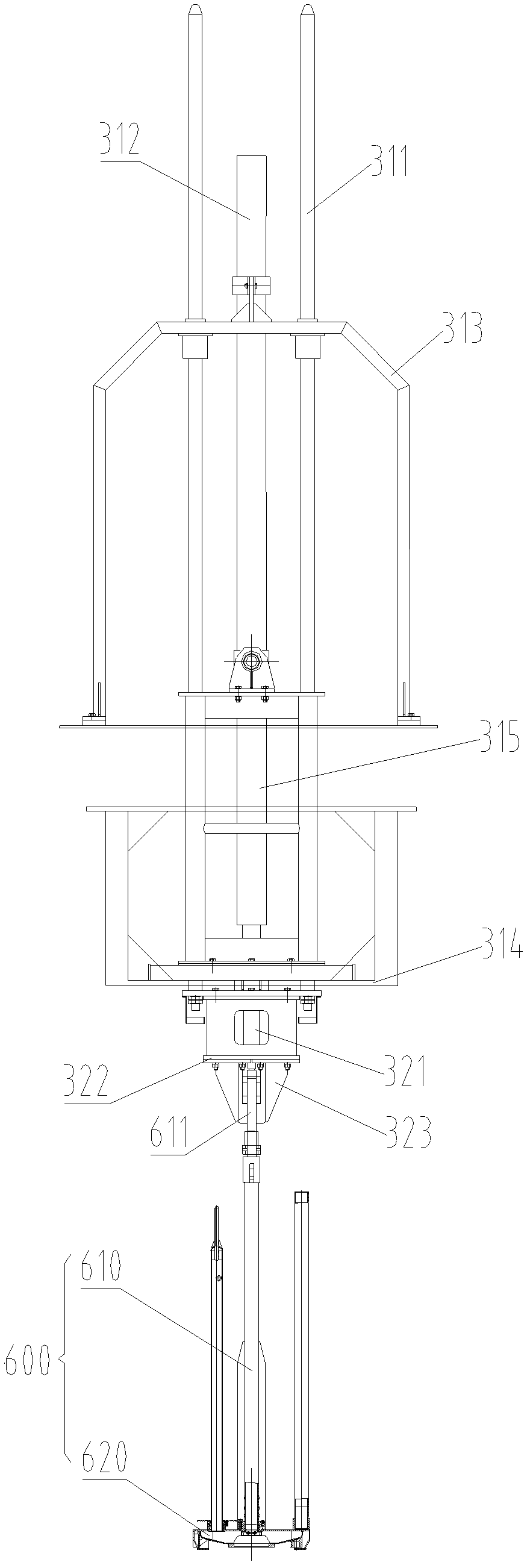

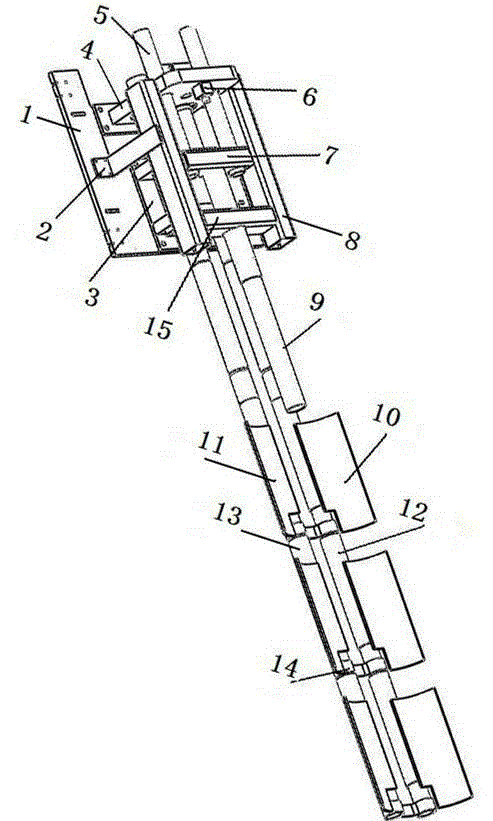

Yarn-grabbing robot

InactiveCN102729248AImprove general performanceEasy to install and maintainProgramme-controlled manipulatorLiquid/gas/vapor treatment of definite length materialsProduction lineYarn

The invention provides a yarn-grabbing robot. The yarn-grabbing robot comprises a bracket, an X-axle motion system arranged on the bracket, a Y-axle motion system connected with the X-axle motion system, an A-axle rotary motion system connected with the Y-axle motion system, a Z-axle motion system connected with the A-axle motion system, and a drive system for driving the X-axle motion system, the Y-axle motion system, the Z-axle motion system and the A-axle rotary motion system to move. According to the yarn-grabbing robot, a two-claw manipulator can reciprocate along the X-axle, Y-axle and Z-axle directions and rotate around the Z-axle direction, and yarn grabbing fingers can be controlled flexibly so that the fingers can be in any required postures. The robot has stronger generality on dyeing and finishing production lines, and the yarn plate racks on stations in the dyeing and finishing process do not need to be designed and manufactured by being matched with the yarn grabbing fingers, so that the robot is convenient in maintenance and installation, and requirements of low cost and efficient automatic production in the dyeing and finishing production line are met.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

Direct fluorination method for producing surface fluorine-containing fiber

ActiveCN102587058AImprove uniformityImprove efficiencyTextile treatment machine arrangementsLiquid/gas/vapor treatment of definite length materialsVacuum assistedEngineering

The invention discloses a direct fluorination method for producing surface fluorine-containing fiber, which is characterized by comprising the steps of: firstly winding raw material fiber on a winding drum with through holes uniformly distributed on the wall, putting in two fluorination reactors and heating and enabling fluorine gas mixture to carry out pulse circulation between the two fluorination reactors by utilizing a vacuum accessory system to ensure that the fluorine gas mixture repeatedly penetrates through fiber layers on the winding drum and is forcedly diffused to uniformly fluoridate the fiber wound on the drum. The method disclosed by the invention has the advantages that the batch surface treatment of whole-drum fiber can be realized; the inner / outer layer surface effect uniformity of the treated fiber is good; the fluorination rate is high; the treatment period is short; the consumed fluorine gas amount is little; the production cost is lower; the safety is high; the process is simple and controllable; and wider application prospect is provided.

Owner:SICHUAN UNIV

Multifunctional dehydrator

InactiveCN102517823AQuality improvementEasy to separateTextile treatment machine arrangementsLiquid/gas/vapor treatment of definite length materialsFiberEngineering

The invention relates to a multifunctional dehydrator, which comprises a cylinder. A cylinder cover is arranged at an upper opening of the cylinder. The bottom of the cylinder is provided with a center hole, and a spindle is arranged in the center hole. The lower end of the spindle extends out of the bottom of the cylinder, a power mechanism is arranged outside the cylinder, and the lower end of the spindle is connected with an output shaft of the power mechanism through a pulley and a transmission belt. A rotary cage is arranged in the cylinder, and a space is reserved between an inner cylinder of the rotary cage and the spindle while another space is reserved between an outer cylinder and the cylinder. A support board is connected to the upper end of the inner cylinder, and the upper end of the spindle is connected with the support board. An annular cage cover is arranged at the upper end of the rotary cage and is a meshed cage cover. The multifunctional dehydrator is characterized in that a sleeve for water proofing and heat insulation is arranged in the inner cylinder, and the lower end of the sleeve is hermetically connected with the bottom of the cylinder. A heater is arranged between the cylinder wall of the cylinder and the outer cylinder of the rotary cage. The dehydrator is multifunctional and used for treating linen fibers, quality of linen fiber products can be improved, and high loss of short staples is avoided. The multifunctional dehydrator is applicable to boiling, bleaching, washing and dehydrating of the linen fibers.

Owner:WUXI QIANZHOU YAODA MACHINERY FACTORY

Cold-pad batch dyeing process for loose fibers

ActiveCN103774363AEvenly distributedPromote absorptionTextile treatment machine arrangementsLiquid/gas/vapor treatment of definite length materialsFiberPolymer science

The invention belongs to the technical field of loose fiber dyeing and relates to cold-pad batch dyeing process for loose fibers. The cold-pad batch dyeing process for loose fibers comprises the steps of soaking and squeezing, rotating type cold-patch treatment, pressing and water squeezing and post-treatment. The loose fibers are soaked and squeezed in a twice soaking and once squeezing mode, the rotating type cold-patch treatment is then conducted, the loose fibers are pressed and water is squeezed out after the rotating type cold-patch treatment is conducted, and after the water and dye in a loose fiber cake or loose fibers are squeezed out, the loose fiber cake or loose fibers are sent for post-treatments of drying and the like. The cold-pad batch dyeing process for loose fibers is applied to cold-pad batch dyeing of the loose fibers and has the advantages of being uniform in dyeing, small in water consumption and the like. In addition, procedures are simple.

Owner:绍兴国周针织科技有限公司

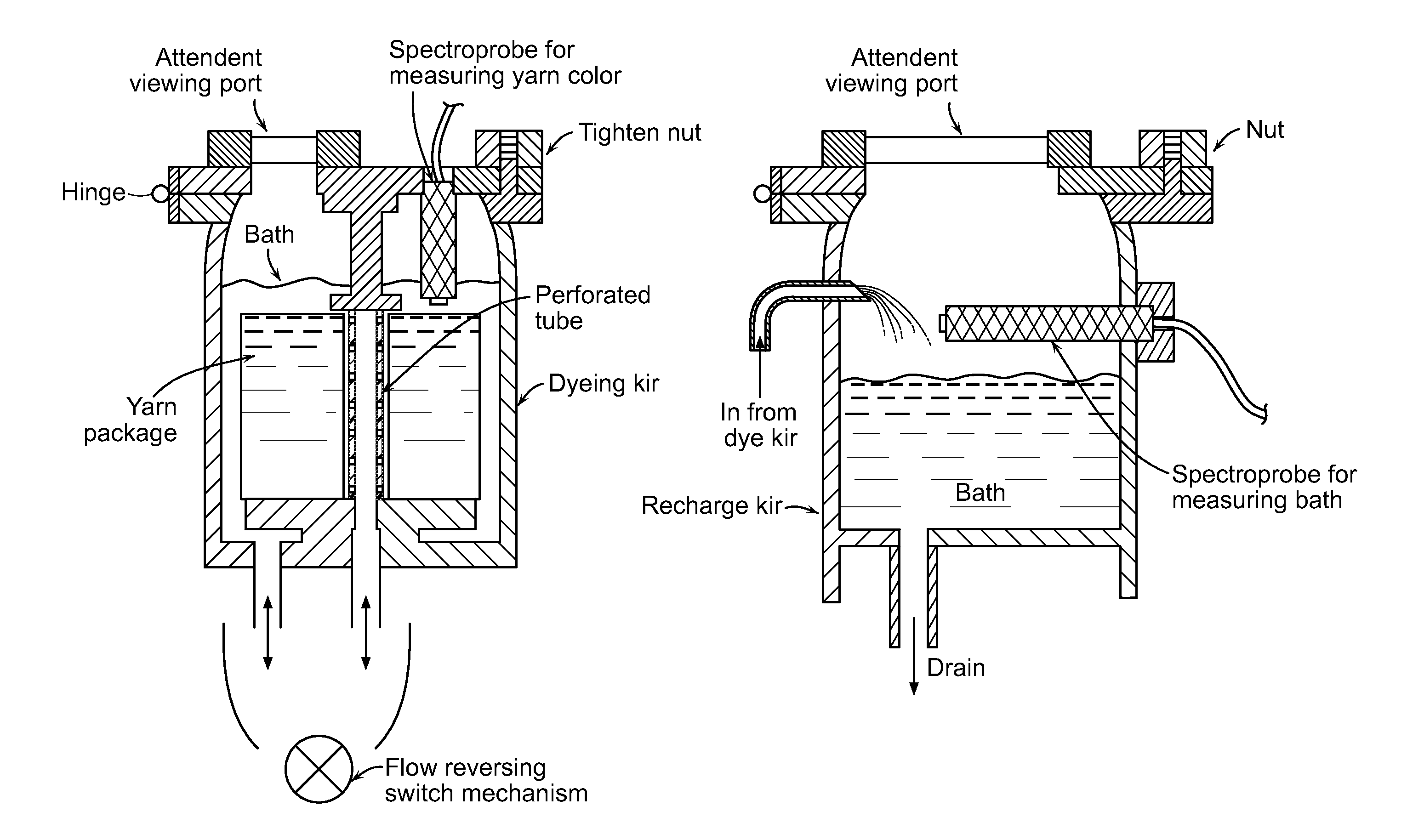

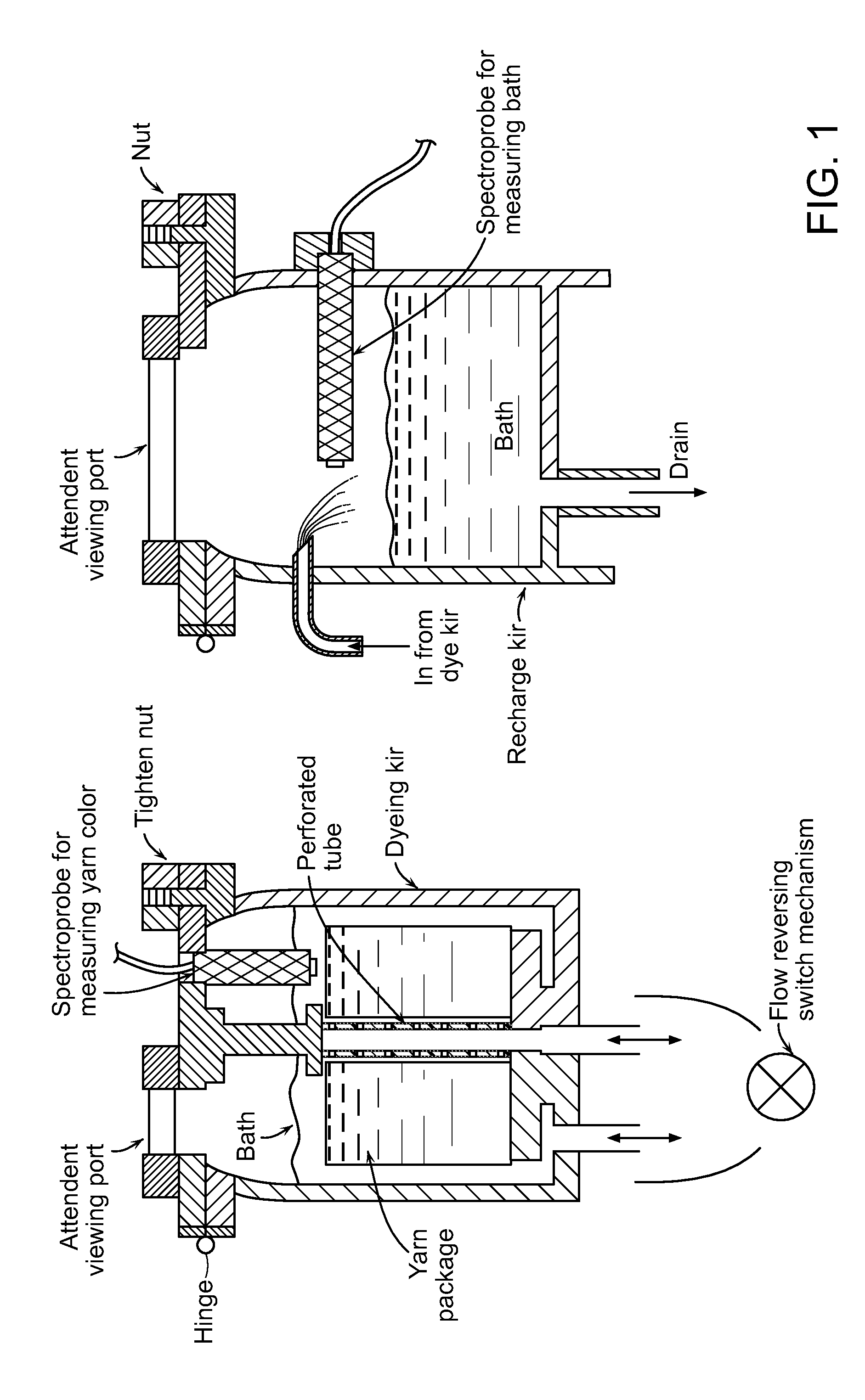

Compositions and methods for dying natural fibers with natural dyes to ensure color (hue and shade)-match consistency

InactiveUS20150218748A1Improve dye penetrationAccurate hueTextile treatment dyeing devicesLiquid/gas/vapor treatment of definite length materialsNatural fiberNatural dye

This invention discloses novel and nonobvious compositions and methods suitable for the dyeing of natural fibers with natural dyes that ensure shade-match consistency.

Owner:RAMBLERS WAY FARM

Low-bath-ratio high-temperature pulse type jet dyeing machine

ActiveCN105603654AControl flowControl pressureTextile treatment containersTextile treatment machine arrangementsSocial benefitsJet flow

The invention provides a low-bath-ratio high-temperature pulse type jet dyeing machine. The jet dyeing machine mainly comprises a main cylinder, an auxiliary cylinder, a liquid adding pump, a cylinder cover assembly, an auxiliary cylinder liquid return pipe, a movement system, a dye flow dividing pipe, a liquid level meter, a pressure meter, a decompression valve, a main cylinder liquid return pipe, a main pump, an adding valve set, a steam trap assembly, a coiled pipe steam inlet, a star-shaped spraying pipe, a sprinkler spraying pipe, a filter screen, a heat exchanger, a partition board, a spraying pipe support, a center pipe, a transmission shaft and other parts. According to the pulse type high-temperature jet dyeing machine, spray dyeing is conducted on fabric from the upper direction and the lower direction by means of the star-shaped spraying pipe and the sprinkler spraying pipe, and dyeing uniformity can be effectively improved. A central control system controls the jet flow and pressure of dye liquid according to properties of the fabric and fabric winding thickness, and accordingly dyeing quality can be effectively controlled. The jet dyeing machine can obviously save auxiliaries and dye, reduces waste liquid discharge, and has extremely remarkable economic and social benefits.

Owner:高勋绿色智能装备(广州)有限公司

Improvement relative to pump

InactiveCN1427111AReduce manufacturing costReduce the amount of treatment liquidTextile treatment containersMultiple way valvesBiomedical engineering

Owner:FALMER INVESTMENTS LTD

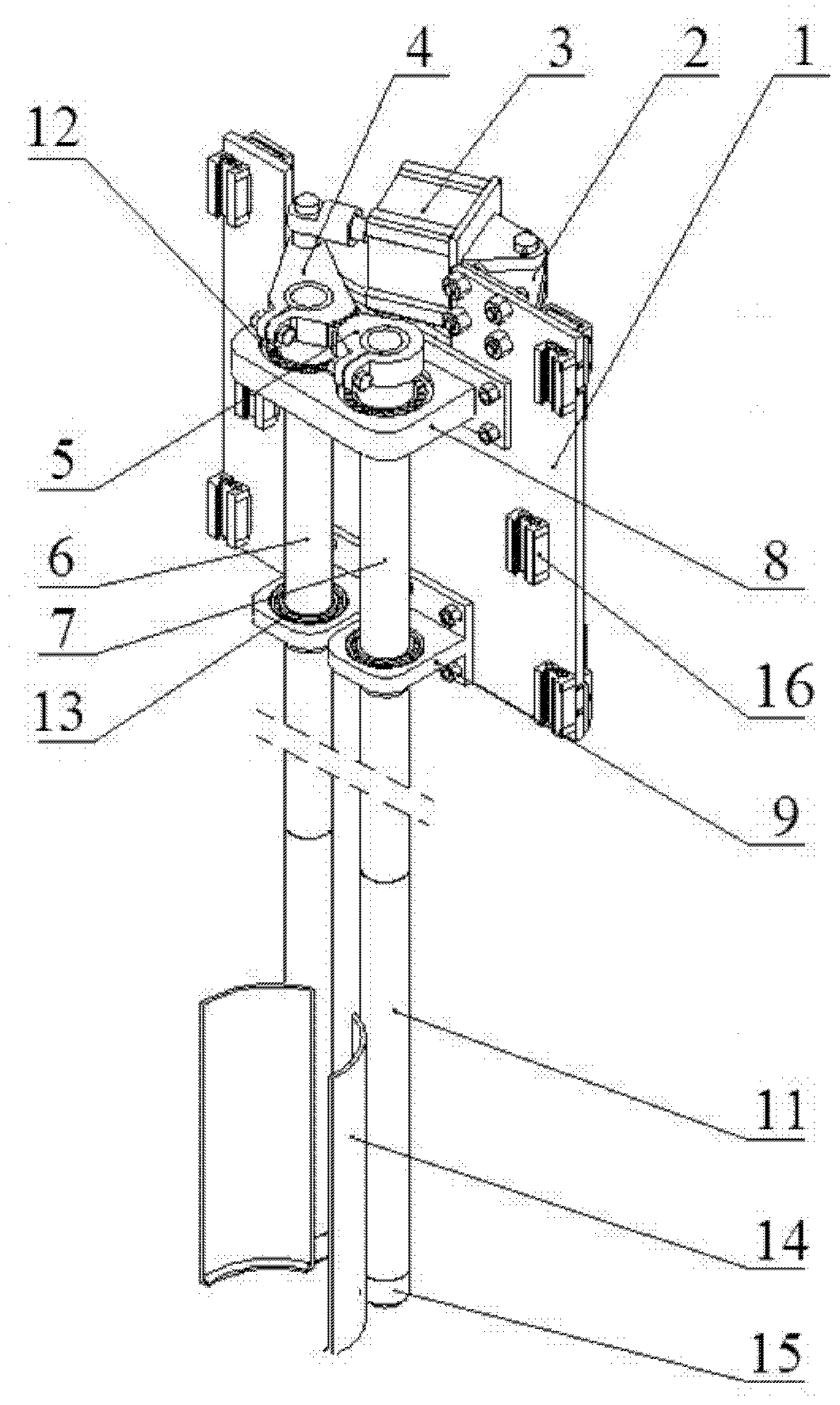

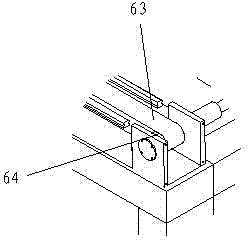

Gripping device and method for high-level sarong to load and unload yarn rolls

InactiveCN104609175AAvoid damageGuarantee the accuracy of yarn grabbingLiquid/gas/vapor treatment of definite length materialsTextile treatment carriersYarnEngineering

The invention relates to a gripping device and method for a high-level sarong to load and unload gauze rolls. The gripping device comprises a base, fixing plates, a lower supporting seat, an upper supporting seat, guide rods, an industrial camera, a centralizing mobile base, fixing rods, a centralizing rod, left yarn gripping grippers, right yarn gripping grippers, left yarn gripping rods, right yarn gripping rods, yarn gripping rod connecting sleeves and a centralizing base. According to the technical scheme, because the height of the guide rods of the high-level sarong is high, the guide rods are inclined after being used for a period of time, the yarn rolls on the guide rods are inclined too, and therefore the yarn rolls are prone to falling down to be damaged when a robot grips the yarn rolls; in addition, because the height of the high-level sarong is high, the yarn rolls also can be damaged caused by overlarge force or falling when a common gripping mechanism grips the yarn rolls. According to the method, the industrial camera is used for positioning yarn gripping and improving the gripping device, therefore, the yarn rolls are avoided from being damaged in the process of yarn gripping of the high-level sarong, and work efficiency and quality are improved.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

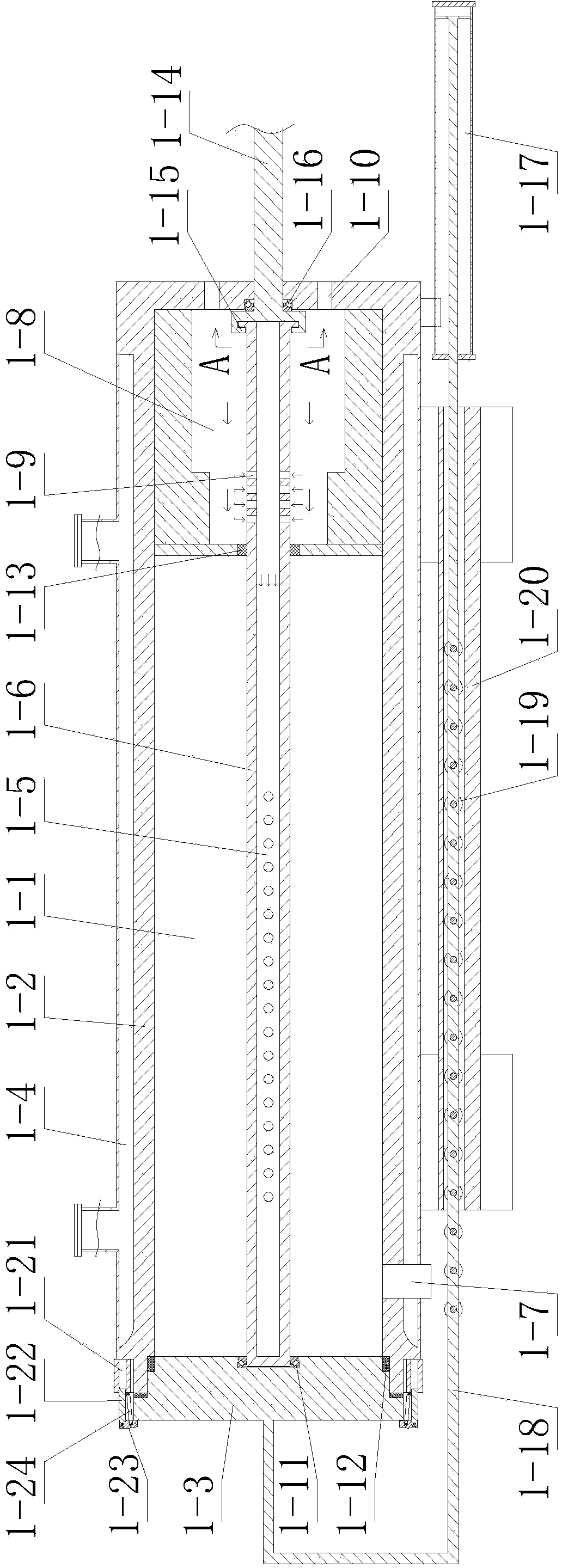

Supercritical CO2 anhydrous rotating warp beam horizontal type dyeing kettle and dyeing system thereof

ActiveCN103806234AIncrease contact timeReduce the effects of uneven dyeingTextile treatment containersTextile treatment machine arrangementsState of artDyeing

The invention relates to a supercritical CO2 anhydrous rotating warp beam horizontal type dyeing kettle and a dyeing system thereof. The supercritical CO2 anhydrous rotating warp beam horizontal type dyeing kettle comprises a dyeing kettle body, a kettle cover, a dyeing fabric frame and a dyeing kettle heating and cooling device, wherein a dyeing cavity is formed inside the dyeing kettle body, the dyeing fabric frame comprises a hollow dyeing warp beam, air exhaust micropores are distributed in the wall of the dyeing warp beam, and the dyeing kettle body is provided with a dyeing kettle air outlet enabling the dyeing cavity to be communicated with the outside for air exhausting; the dyeing kettle body is arranged in a horizontal mode, and the dyeing warp beam is rotationally supported and connected inside the dyeing kettle body in a horizontal mode; an air suction cavity which is parallel to the dyeing cavity in an isolated mode is formed inside the dyeing kettle body, one end of the dyeing warp beam stretches in the air suction cavity and is provided with a warp beam air suction hole, the dyeing kettle body is provided with a dyeing kettle air inlet and a rotation driving device, the dyeing kettle air inlet enables the air suction cavity to be communicated with the outside for air suction, and the rotation driving device drives the dyeing warp beam to rotate. According to the supercritical CO2 anhydrous rotating warp beam horizontal type dyeing kettle and the dyeing system thereof, a vertical dyeing mode is changed into a horizontal dyeing mode, influence of gravity factors on the dyeing effect is overcome, the problem that cloth is dyed unevenly in the prior art is solved, the uniform dyeing effect is achieved, and production efficiency is improved.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

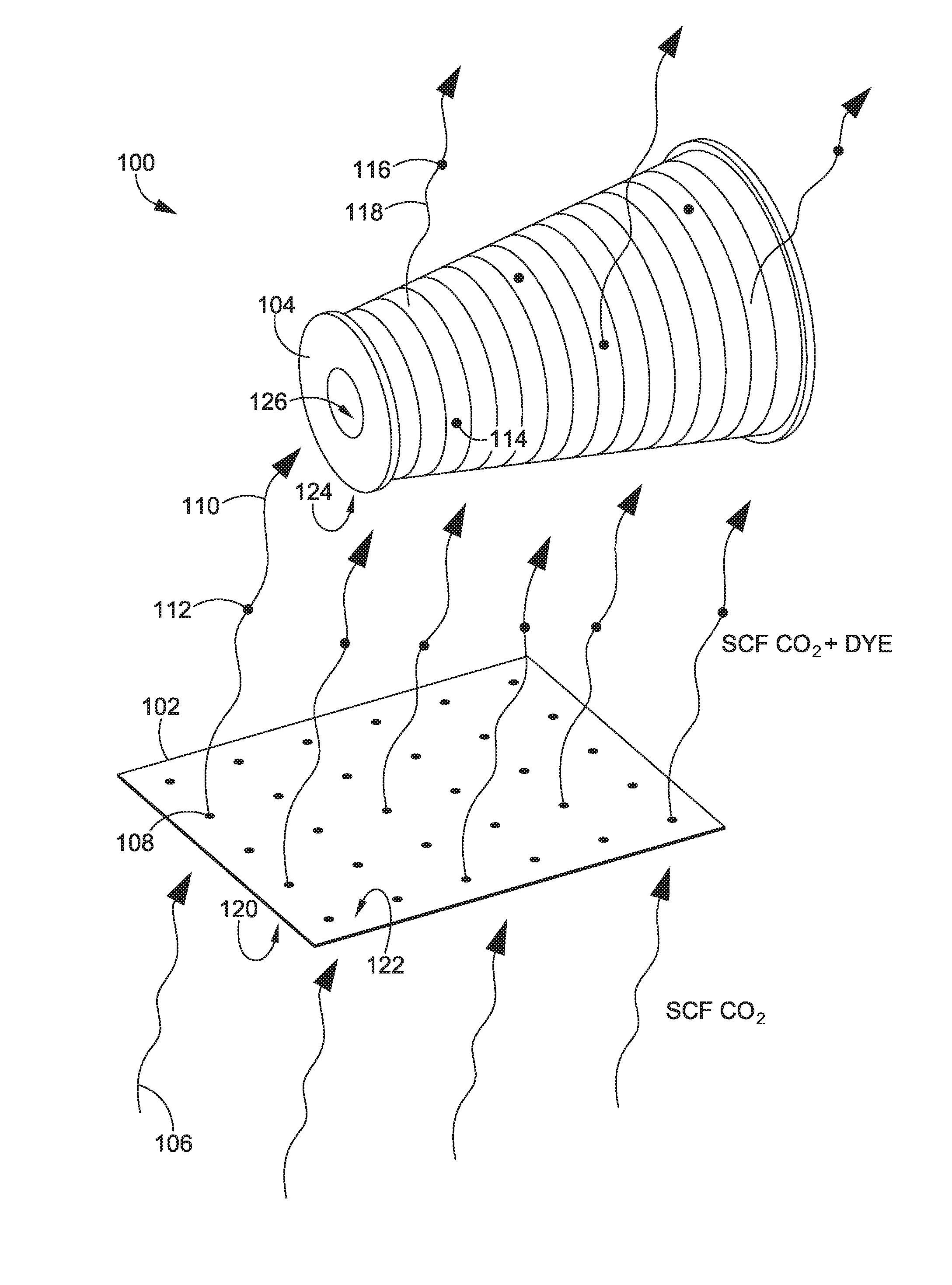

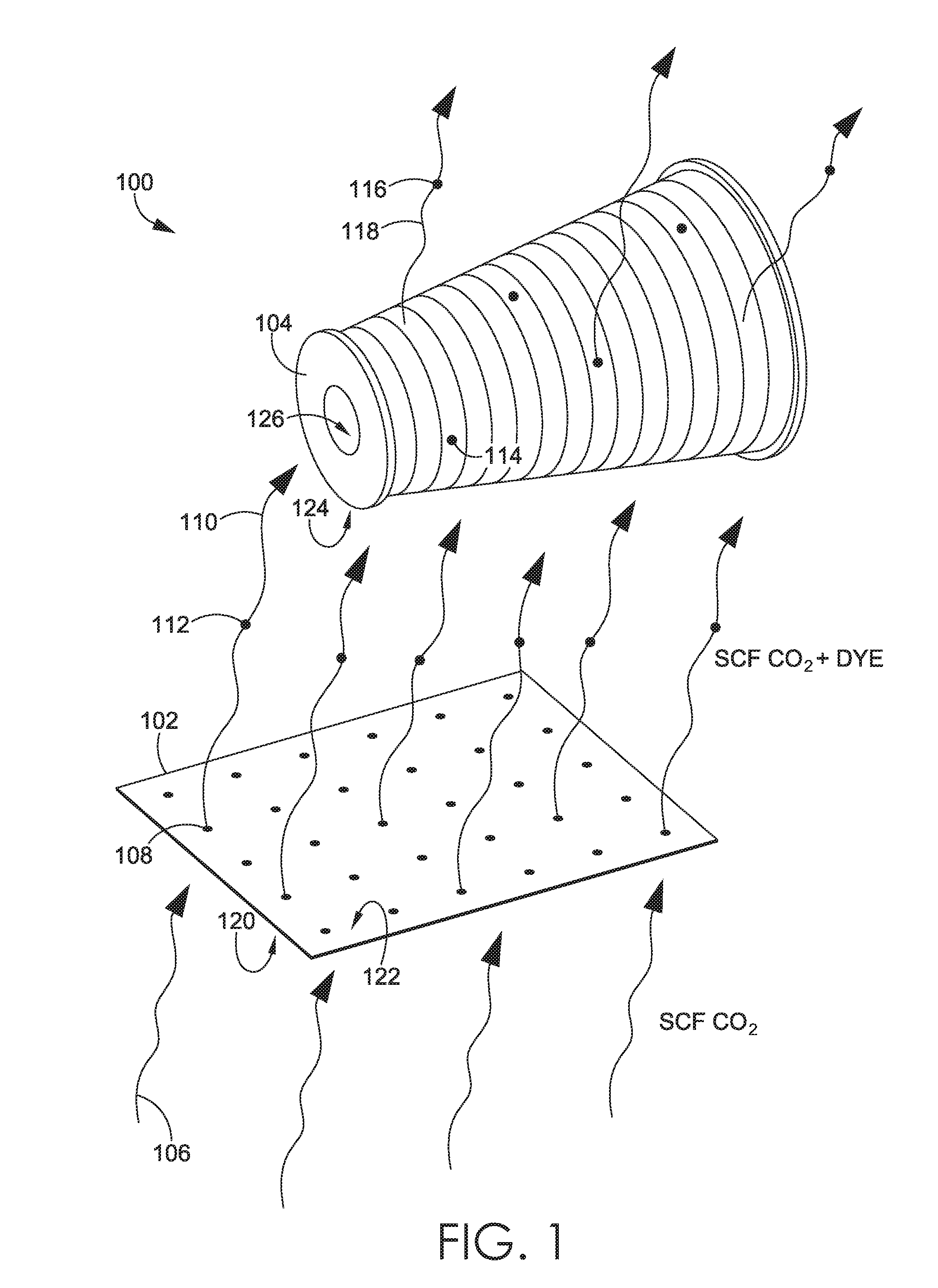

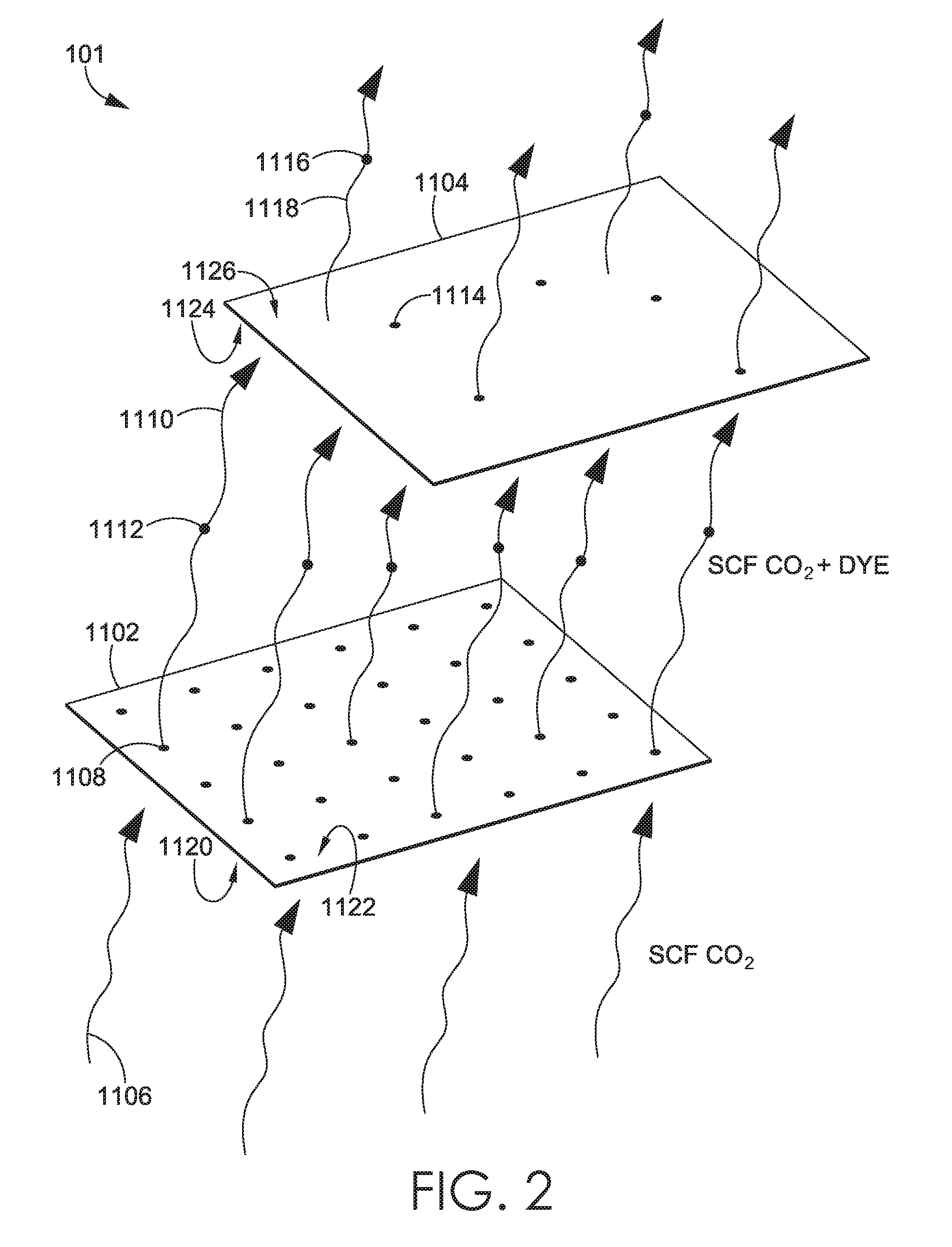

Supercritical fluid material finishing

ActiveUS20160244911A1Efficient transferPromote absorptionFibre treatmentTextile treatment machine partsProcess engineeringMachining process

Owner:NIKE INC

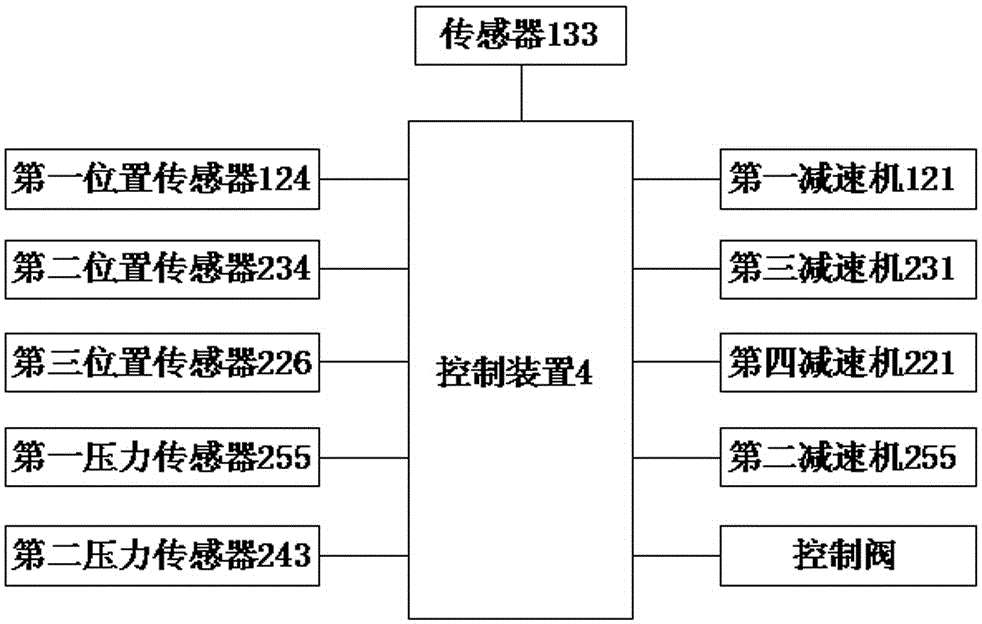

Warp beam loading and unloading machine

ActiveCN104999245ARun orderlyGuaranteed uptimeLiquid/gas/vapor treatment of definite length materialsTextile treatment carriersYarnLocking mechanism

The invention discloses a warp beam loading and unloading machine which comprises a rotating base, a mechanical hand component and a warp beam transport vehicle. The rotating base comprises a rotating mechanism. The rotating mechanism is provided with a dyeing yarn cage capable of clamping a plurality of warp beams. An existing yarn cage or dyeing cage can be adopted as the dyeing yarn cage. The mechanical hand component comprises a telescoping mechanism and a lifting mechanism which are connected with each other. The lifting mechanism is connected with a mechanical hand used for clamping the warp beams and a locking mechanism used for locking the warp beams. The mechanical hand corresponds to the dyeing yarn cage in position. The warp beam loading and unloading machine further comprises a control device used for controlling the warp beam loading and unloading machine to act. The warp beams are clamped by the dyeing yarn cage in the rotating base; the rotating mechanism can rotate the warp beams to the position where the mechanical hand can grab the warp beams; the mechanical hand is controlled by the telescoping mechanism and the lifting mechanism to move and grab the warp beams; the transmission mechanisms are controlled by the control device to run in order.

Owner:TAIAN COMPANION MACHINERY

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com