Improvement relative to pump

A catheter and shell technology, applied in the field of reversible pumps, can solve the problem of high material cost and achieve the effect of reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] specific implementation plan

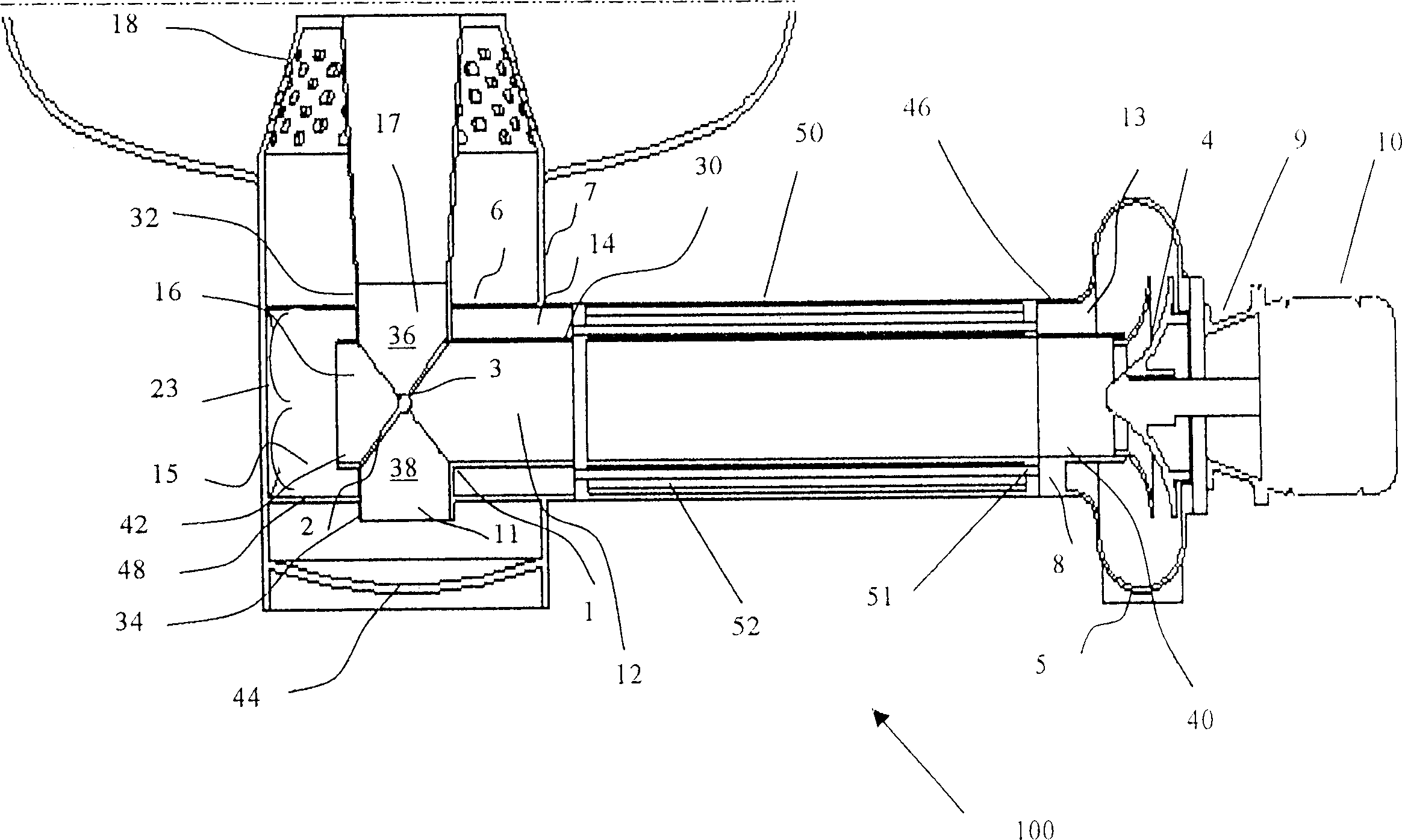

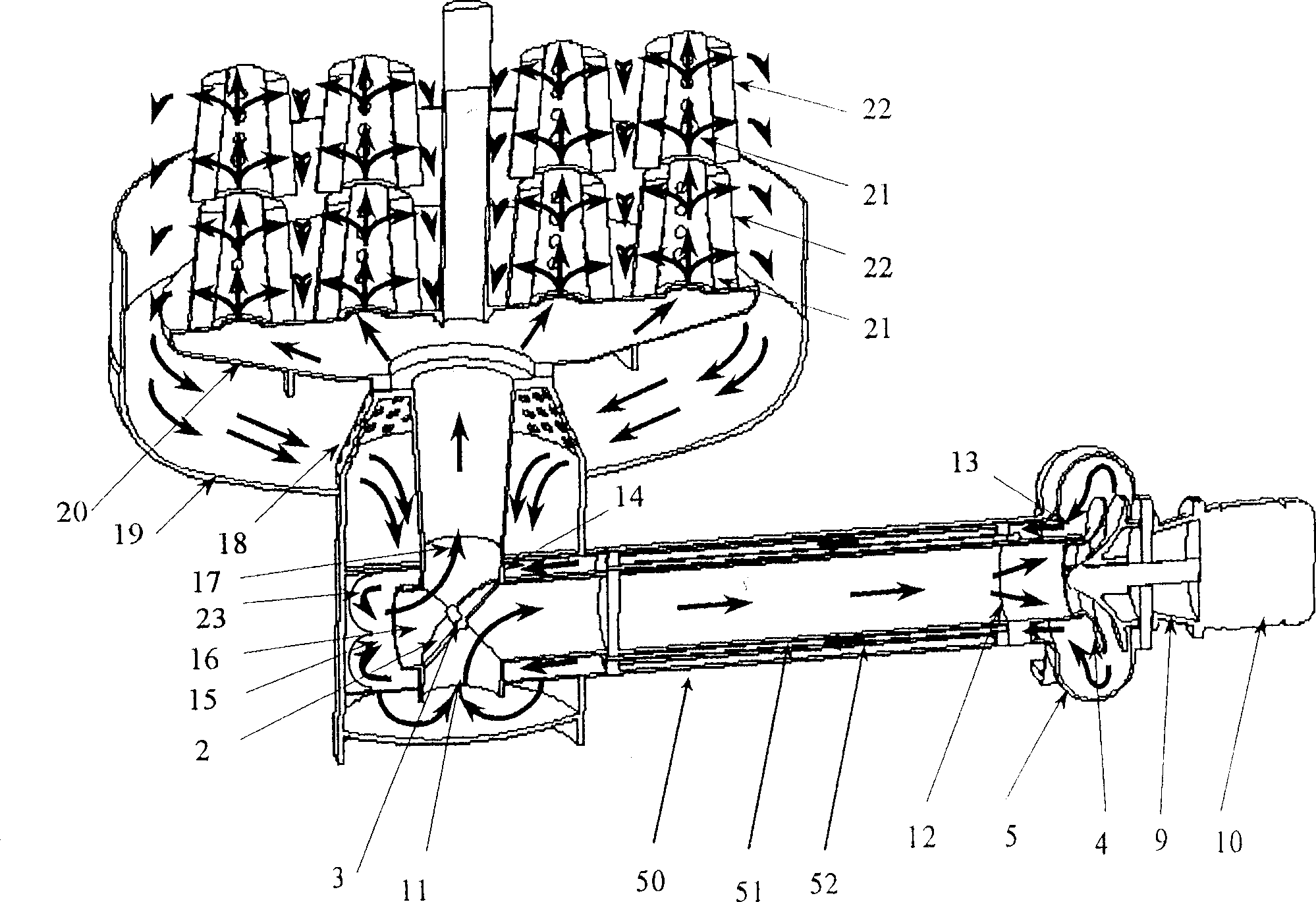

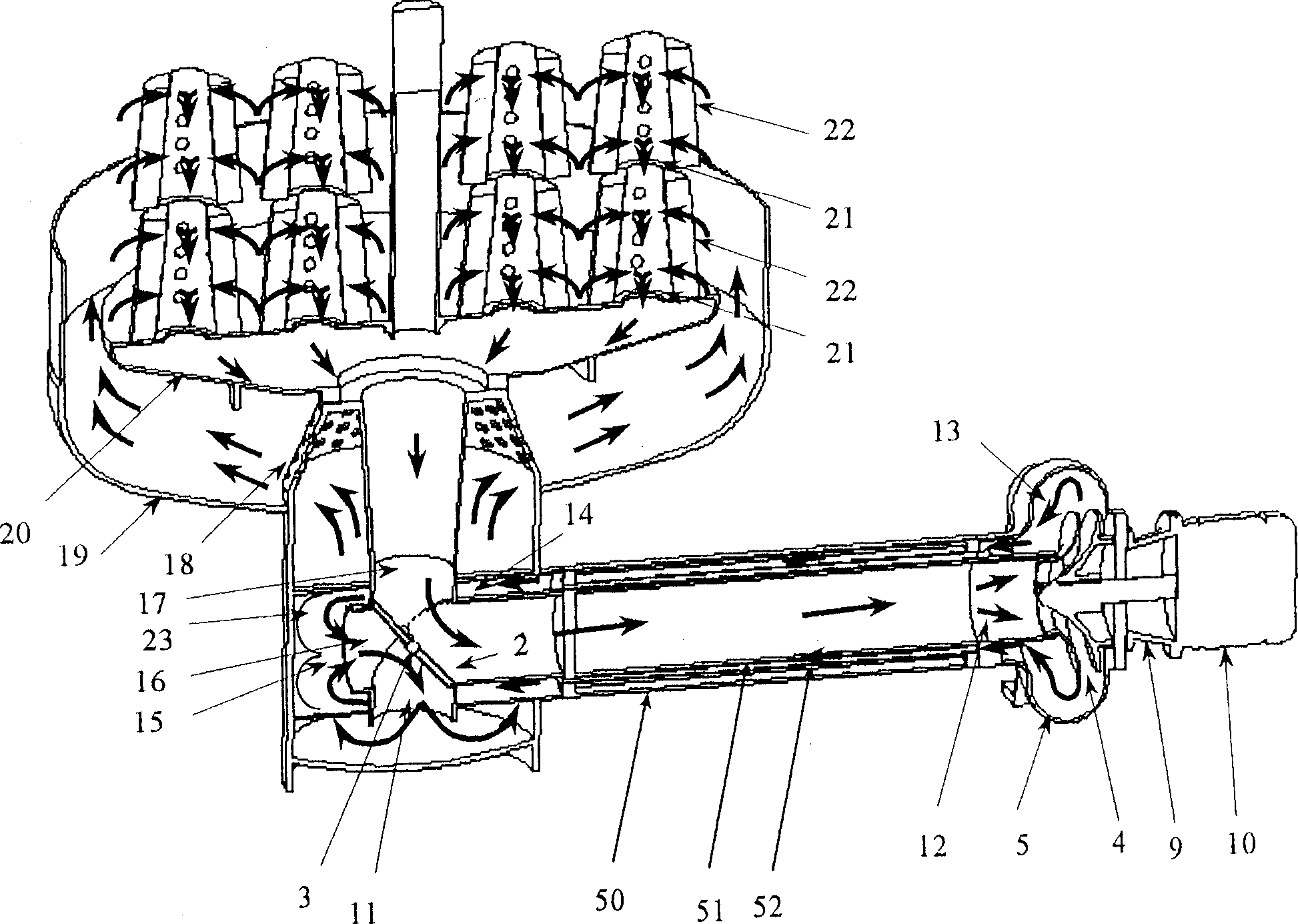

[0054] figure 1 , 2a and 2b show a liquid flow reversing device 100 comprising a cross tube 1 , a rotatable closure member 2 mounted on a shaft 3 , an outer tube 6 and a housing 7 .

[0055] The cross tube 1 comprises a first tube 30 , and first and second tube sections 32 , 34 extending approximately perpendicular to the first tube 30 . The first and second tube sections 32 , 34 extend from opposite sides of the first tube 30 . The first opening 36 and the second opening 38 in the side wall of the first tube 30 ensure that the first tube section 32 and the second tube section 34 respectively communicate with the first tube 30 . The cross pipe 1 has four ports 11 , 12 , 16 and 17 .

[0056] The port 16 of the first tube 30 extends into the interior of the outer tube 6 , so that the cross tube 1 communicates with the outer tube 6 through the port 16 .

[0057] The port 12 of the cross tube 1 is the liquid inlet connected to the centrif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com