Patents

Literature

93 results about "Uniform coloring" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In geometry, a uniform coloring is a property of a uniform figure (uniform tiling or uniform polyhedron) that is colored to be vertex-transitive. Different symmetries can be expressed on the same geometric figure with the faces following different uniform color patterns.

Color master batch for plastic cement and preparation method thereof

The invention discloses black master batch for plastic cement and a preparation method thereof. The color master batch for plastic cement is prepared from the following components by mass percentage: 60-80% of pigment, 10-30% of carrier, 5-15% of compatibilizer, 0.1-2% of dispersant, and 0.1-1% of anti-oxidant. The beneficial effects reside in that: when used for coloring a plastic cement product, the color master batch provided by the invention has characteristics of good dispersibility, uniform coloring, high concentration, small usage amount and no influence on mechanical properties of the plastic cement product; and in secondary usage, the color master batch provided by the invention simplifies a production technology process co-mixed with the plastic cement raw material, avoids environment pollution, and has advantages of convenient usage, easy coloring, and time and raw material saving.

Owner:QINGDAO XINZHAN PLASTIC

Large-area complex-terrain-region unmanned plane sequence image rapid seamless splicing method

InactiveCN104156968AAvoid blind matchingNarrow searchImage analysisLevenberg–Marquardt algorithmTerrain

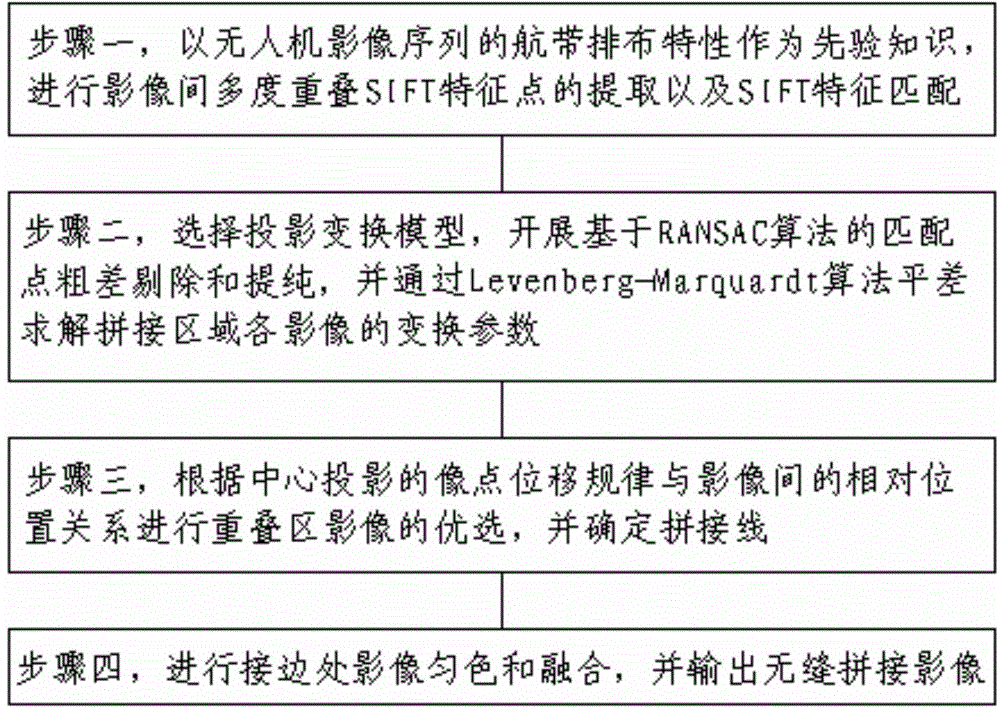

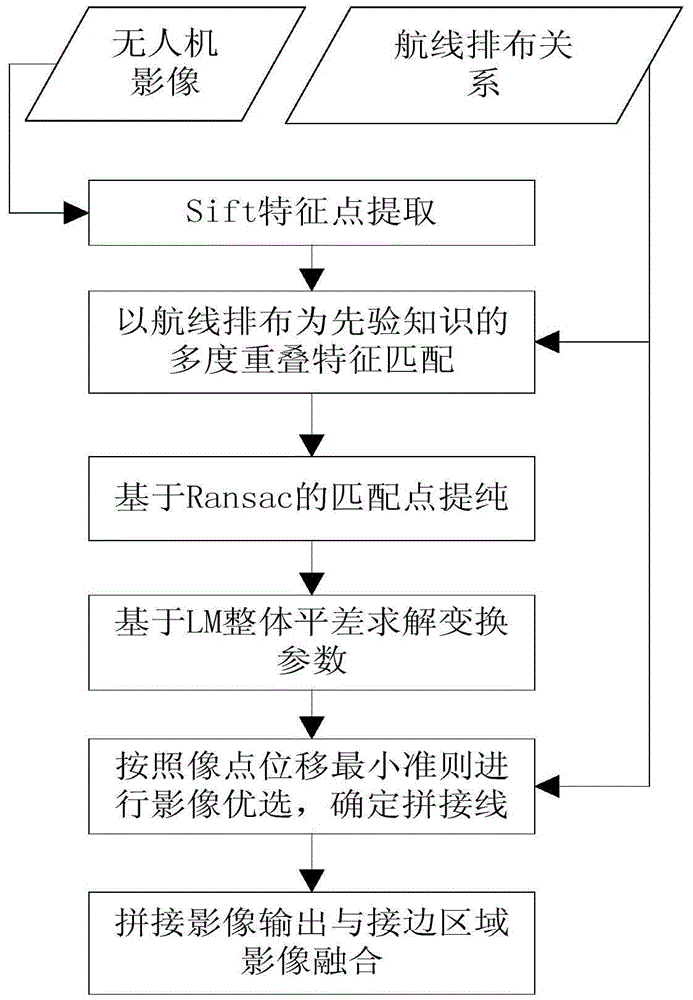

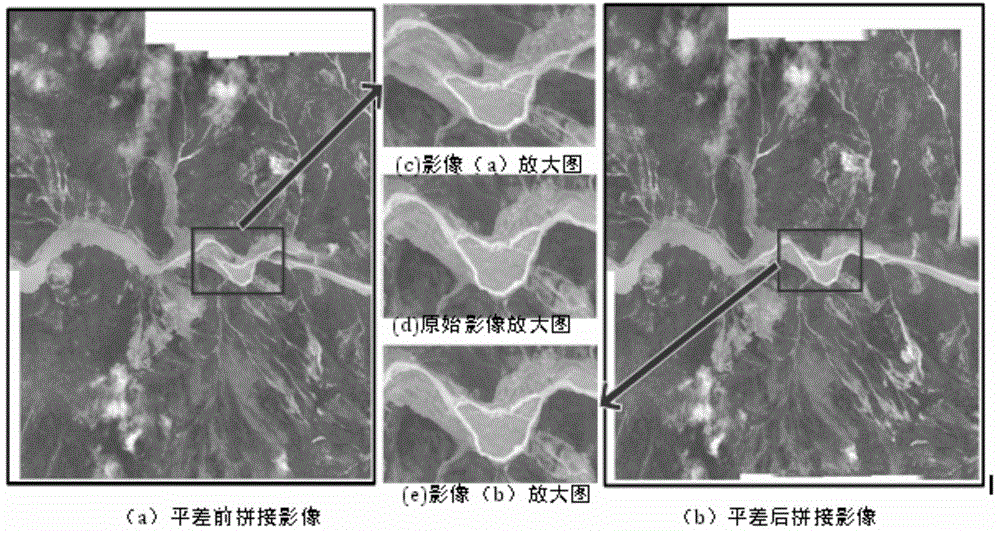

Provided is a large-area complex-terrain-region unmanned plane sequence image rapid seamless splicing method which comprises the following steps: to begin with, with air strip arrangement features of unmanned plane image sequence being prior knowledge, carrying out inter-image multiple-overlap SIFT feature point extraction and matching; then, carrying out matching point gross error removing and purifying based on random sample consensus algorithm, and solving transformation parameters of each image in spliced regions in an adjustment manner through an Levenberg-Marquardt algorithm; next, carrying out overlapped region image optimized selection according to the relative position relationship between central projection image point displacement rules and the images, and determining splicing lines; and finally, carrying out image uniform-coloring and fusion at the edge-connection places, and outputting spliced images, thereby realizing mass unmanned plane image seamless splicing. The seamless splicing method helps to improve the extraction efficiency of the SIFT feature points, guarantee the geometric accuracy of the spliced images, and eliminate the tiny color difference at the two sides of the image splicing line, and thus the spliced images with natural color transition and good natural object and landform continuity are obtained.

Owner:SHANDONG LINYI TOBACCO

Glaze coloring agent for waterborne woodenware coating and preparation method thereof

A glaze coloring agent for waterborne woodenware coating and a preparation method thereof belong to the coating field. The coloring agent comprises a color-spreading component and a color-fixing component. The color-spreading component comprises amphiphilic polymer resin which has the effect of pigment loading and bonding, and can allow the pigment to spread and penetrate on a wood surface; the color-fixing component comprises acrylate polymer which has excellent color retention and weatherability. The coloring agent of the invention can provide proper open time for construction, can be rewiped, is easy for color modification, has good color retention for recoating, does not cause floating color or loose color, has good compatibility and interlayer binding force with various waterborne priming paint and top finish, and can well improve the wood-grain contrast of a wood surface; with the matching application of various waterborne woodenware coating processes, the coloring agent has thecharacteristics of safety and environmental protection, no irritant smell, uniform coloring, plump filling, and excellent color fixing; by adjusting the ratio of the color-spreading component and thecolor-fixing component, the coloring agent is applicable to waterborne coloring and American antique coating processes of various wood furniture products.

Owner:BEIJING UNIV OF CHEM TECH

Spiced egg manufacturing method

InactiveCN104000225AGuaranteed to tasteGuaranteed authentic tasteFood ingredient as colourFood processingSugarZoology

The invention provides a spiced egg manufacturing method. The spiced egg manufacturing method comprises the following steps of 1, carrying out egg cleaning, illumination, drying, sorting and sterilization, 2, steaming the egg, 3, removing the shell of the egg, 4, flushing the egg without shell by clear drinking water and drying the water on the surface of the egg without shell at a temperature of 50-60 DEG C for 20-40min, 5, carrying out pickling by adding a proper amount of clear water into anise, cassia bark, common fennel fruit, myrcia and table salt to obtain a pickling material, boiling the pickling material, cooling the pickling material to a temperature of 4-10DEG C, putting the egg without shell into the pickling material, and carrying out pickling for 8-12h so that the egg has a pickling material taste, 6, carrying out boiling coloring: preparing a coloring material from water, dry capsicum, Chinese prickly ash, myrcia, white sugar and soy sauce and putting the pickled egg into the coloring material for uniform coloring, 7, carrying out vacuum sealing packaging, and 8, carrying out high-temperature disinfection. Through drying and low-temperature pickling, the egg has a complete pickling material taste and energy is saved. The pickling process and the boiling coloring process are carried out respectively so that a pure taste of the spiced egg is guaranteed. The spiced egg has a quality guarantee period prolonged by at least 1-2 months.

Owner:房县天森食品有限公司

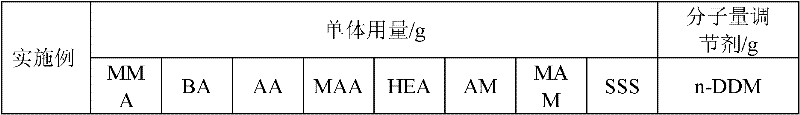

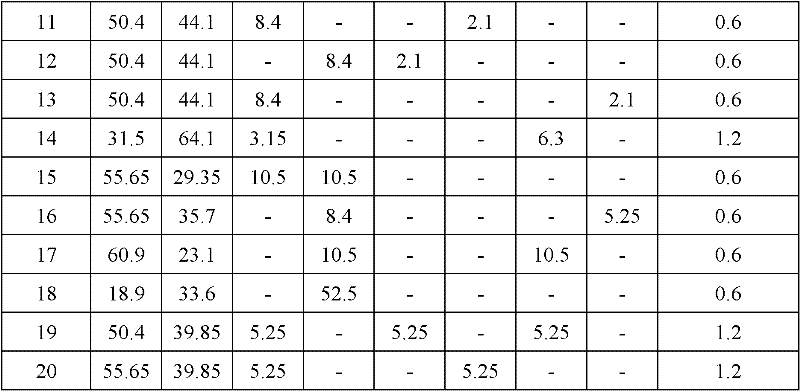

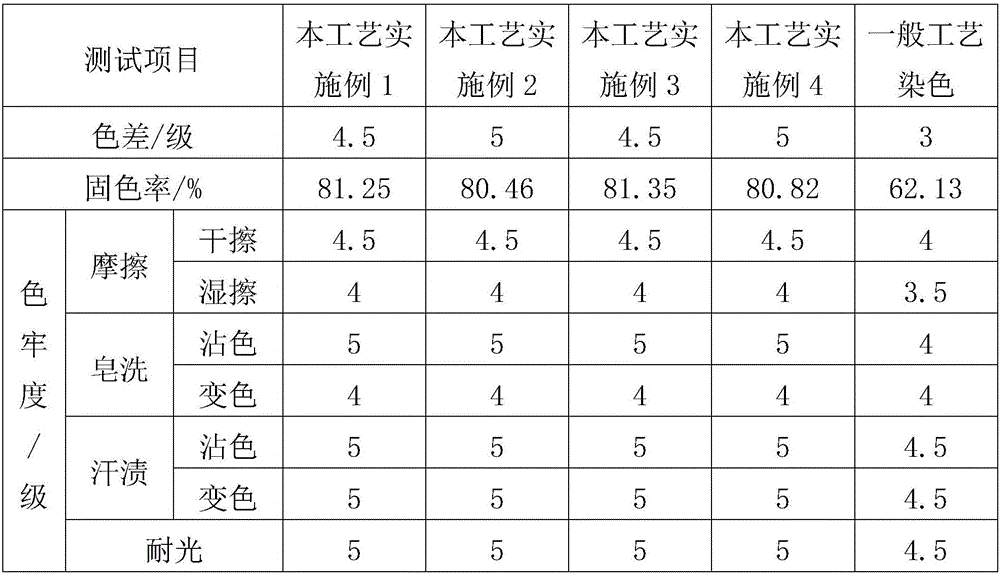

Polyester-cotton microcapsule disperse reactive dye one-bath dyeing technology

ActiveCN106245352AImprove adsorption capacityImprove dyeing uniformityDyeing processMicroballoon preparationDisperse dyeOrganic solvent

The invention discloses a polyester-cotton microcapsule disperse reactive dye one-bath dyeing technology. The technology comprises the steps of: S1, polyester dyeing: dipping a to-be-dyed polyester-cotton fabric in a dye solution containing microcapsule disperse dye, conducting heat preservation at 65-75DEG C, then performing heat preservation at 110-130DEG C, and carrying out cooling to 30-40DEG C, using chitosan to serve as the carrier of the disperse dye, and then conducting crosslinking curing; S2. cotton dyeing: adding a quaternary ammonium salt cationic etherifying agent, carrying out stirring reaction, then adding a reactive dye, performing heat preservation at 55-65DEG C, adding an organic solvent, conducting heat preservation at 70-90DEG C, then adding organic amine and sodium carbonate, and performing heat preservation at 60-100DEG C; and S3, aftertreatment: performing cooling to room temperature, and then carrying out primary washing, soaping and after-washing. The polyester-cotton microcapsule disperse reactive dye one-bath dyeing technology provided by the invention has the advantages of simple process, little pollution, wide dye applicability, uniform coloring, high color fixation rate and good level-dyeing properties.

Owner:ANHUI YAYUAN PRINTING & DYEING CO LTD

Coloring master batches for polyethylene and preparation method thereof

The invention discloses coloring master batches for polyethylene and a preparation method thereof. The coloring master batches for polyethylene disclosed by the invention comprise the following components in percentage by mass: 70%-90% of pigment, 10%-20% of polyethylene resin, 3%-5% of dispersant, 0.1%-1% of antioxidant and 0.1%-1% of antistatic agent. Compared with the prior art, the coloring master batches for polyethylene have the beneficial effects that the prepared coloring master batches for polyethylene are applied to coloring of polyethylene products, have the characteristics of good dispersibility, uniform coloring, high concentration, little dosage and no influence on the mechanical property of the polyethylene products, and are low in cost, easy to color, convenient to use and capable of saving production time and raw materials and the like.

Owner:QINGDAO SANLI ZHONGDEMEI WATER EQUIP

Meta-aromatic polyamide pure-white grey cloth industrialized dyeing method

InactiveCN101086142ARealize industrial dyeingUniform colorHeating/cooling textile fabricsDyeing processPolyamideEngineering

A meta-position aramid fiber white grey fabric industrial dyeing method belongs to dyeing technology, it is characterized by: the meta-position aramid fiber white grey fabric is pretreated before it is dyed, the pretreatment includes high-temperature pre-shaping procedure. The dyeing method of the invention achieves 100% pure industrialization dye of aramid fiber grey fabric, the products dyed through the invention has smooth cloth surface, uniform coloring and no folded trace; the dyeing fastness of cloth is high, and, the dyeing process in the invention is more suitable for industrial production.

Owner:SHANDONG WOYUAN NEWFASHIONED FABRIC

Terylene air-jet textured yarn fabric with high color fastness

ActiveCN102628194AGuaranteed color brightnessHigh color fastnessMonocomponent polyesters artificial filamentYarnTitanium nitride

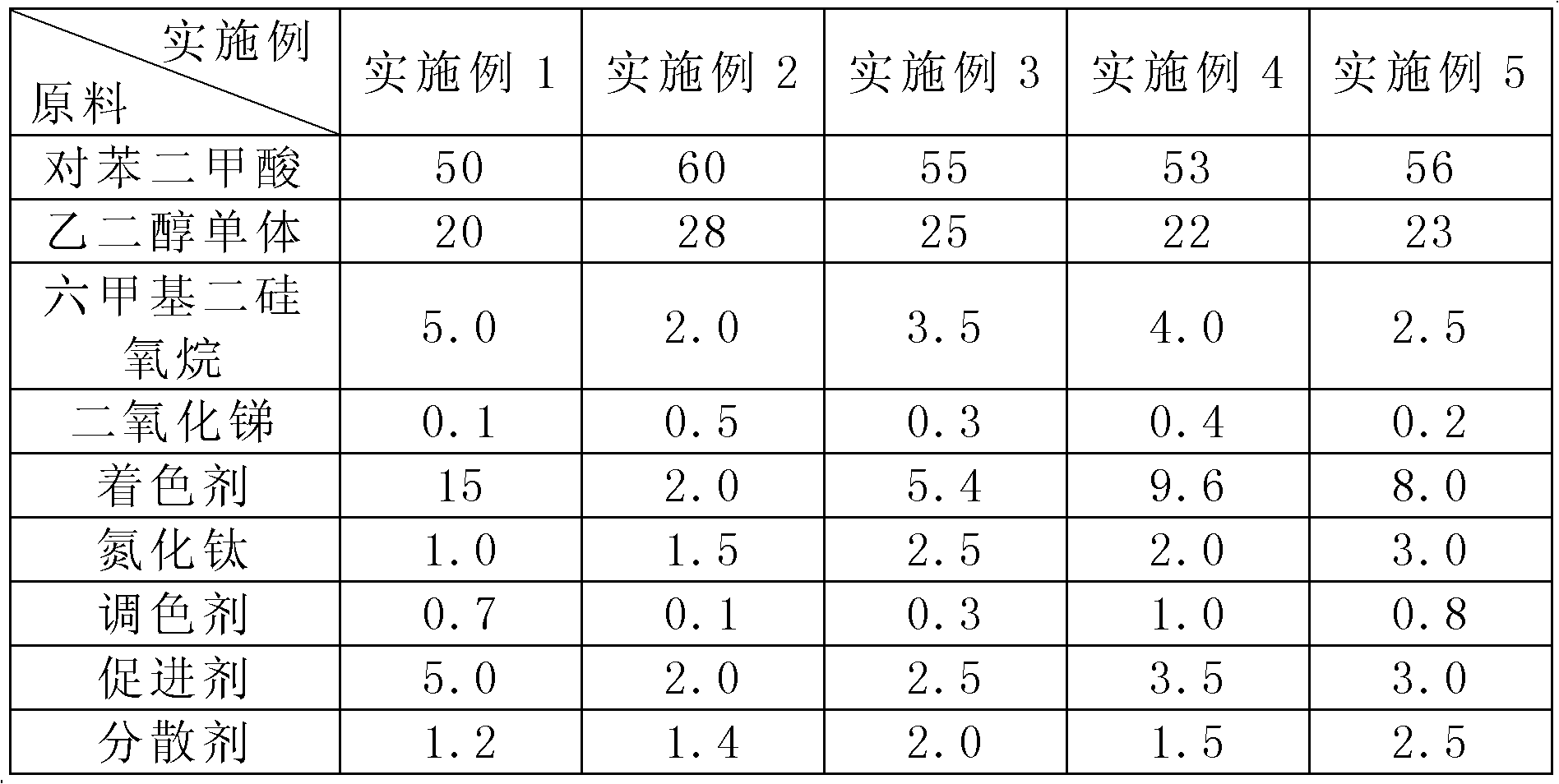

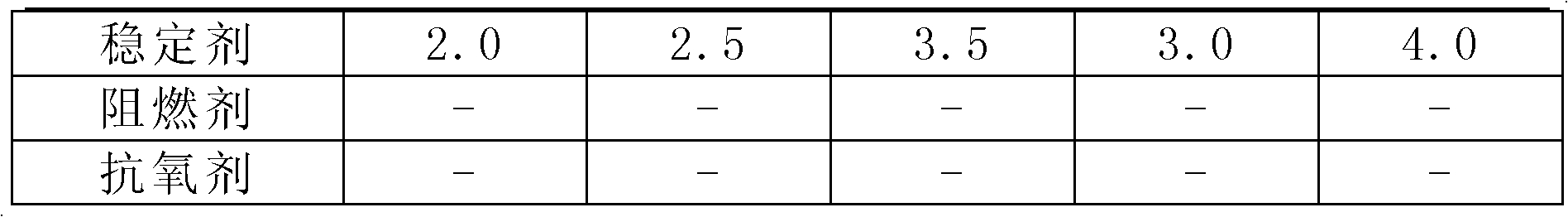

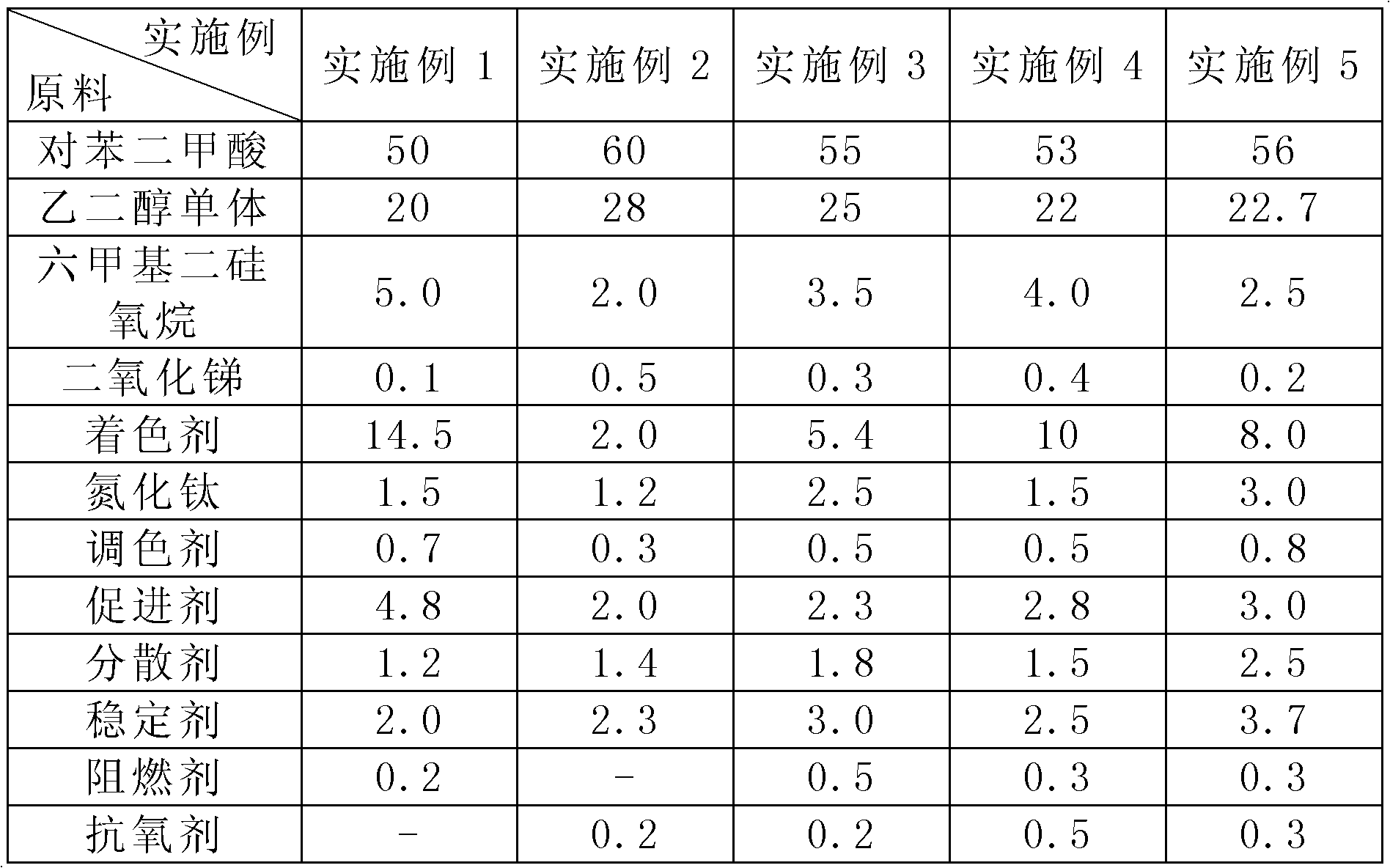

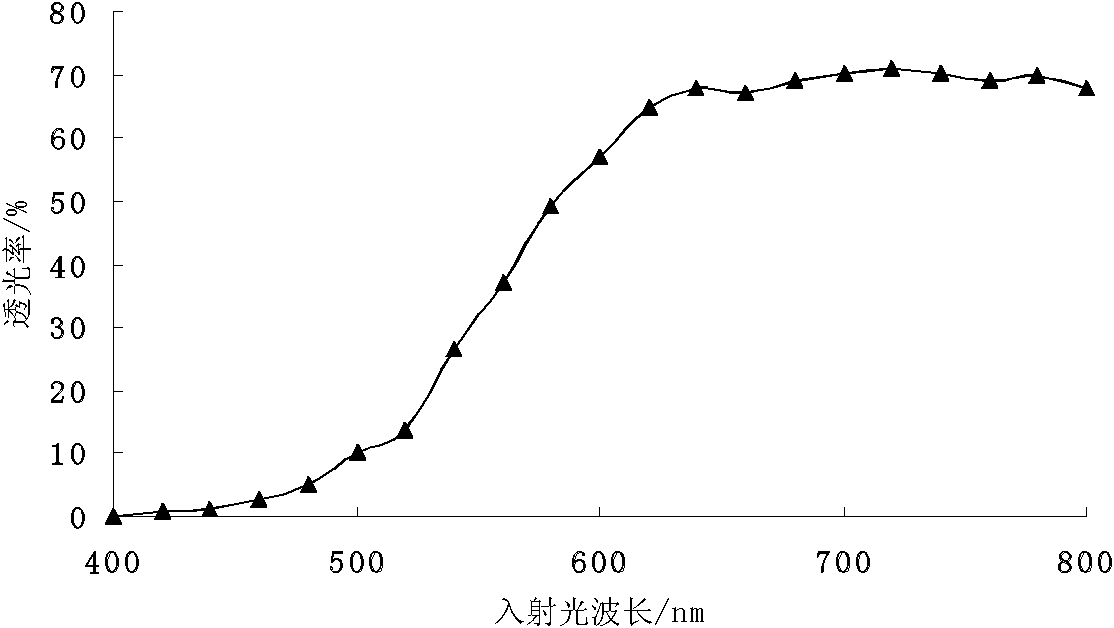

The present invention relates to a terylene air-jet textured yarn fabric with high color fastness and belongs to the technical field of textile. In order to solve a problem of poor color fastness of a fabric in the existing technology, the invention provides terylene air-jet textured yarn fabric with high color fastness. The fabric is mainly weaved from terylene air-jet textured yarn, wherein the terylene air-jet textured yarn is mainly prepared from raw materials of terephthalic acid, glycol monomer, hexamethyldisiloxane, tellurium dioxide, colouring agent, titanium nitride, toner, promoter, dispersant and stabilizer, and the raw materials can also be added with fire retardant or antioxidant. The invention has advantages of high color fastness, uniform coloring and good brightness, and reaches washing resisting color fastness of grade 4-5 , sweat resisting color fastness of grade 4-5 and light resisting color fastness of higher than grade 7; and the raw materials of the invention do not need dyeing after spinning to realize the reduction of environmental pollution, reduction of high temperature dyeing process, and improvement of the strength property of the yarn.

Owner:台州东海翔织造有限公司

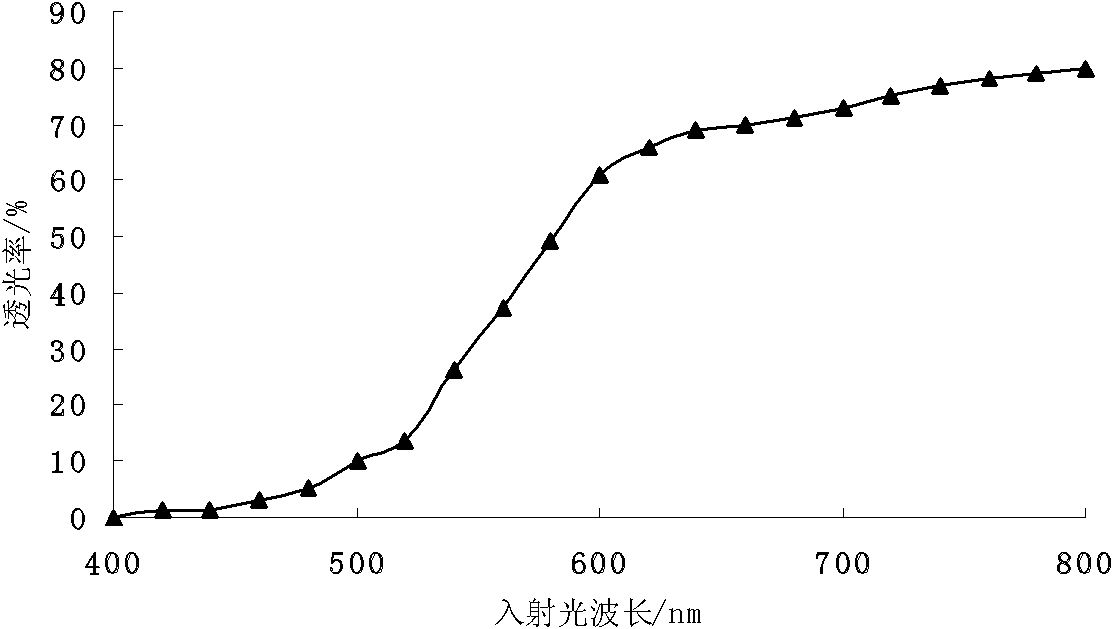

Method for preparing erbium-containing red glass

The invention relates to a method for preparing erbium-containing red glass, which comprises the following steps of: firstly, mixing P2O5, BaO, Al2O3, Er2O3, CeO2 and Fe2O3 uniformly, and then melting the mixture to obtain glass liquid; secondly, performing water quenching on the glass liquid, and then drying and performing ball milling to be 50 meshes to obtain coloring agent glass; thirdly, after mixing P2O5, BaO, Al2O3, Fe2O3 and the coloring agent glass uniformly, melting the mixture; pouring the bubble-free molten glass liquid into a metal mould for molding; fourthly, placing the molded glass sample into a muffle furnace at the temperature of 450 DEG C for 3 hours, raising the temperature to be 600 DEG C at the speed of 20 DEG C per minute and preserving the heat for 1 hour; and finally, cooling the glass sample to room temperature at the speed of between 0.5 and 1 DEG C per minute to obtain the erbium-containing red glass. The erbium-containing red glass is prepared by a high temperature melting method; the method has the advantages of simple operation procedure, low melting temperature, low cost, energy conservation, environmental protection and suitability for industrial production; and the erbium-containing red glass prepared by the method has the advantages of high chemical stability, uniform coloring, high light transmittance and stable product quality.

Owner:SHAANXI UNIV OF SCI & TECH

ABS color master batch and preparation process thereof

The present invention discloses an ABS color master batch and a preparation process thereof. The ABS color master batch is prepared by adopting a carrier, a dispersing agent, toner, a polymer compatibilizing agent, an impact modifier, a heat stabilizer, a plastic additive and a filler as raw materials, wherein an air drying treatment is performed on the carrier, premixing is performed on the carrier resin, the toner and the dispersing agent, extrusion granulation is performed, sample plate and sample strip injection molding is performed, and finally a color performance, a tension performance and an impact performance are tested. According to the ABS master batch, characteristics of convenient use, no pollution on molded environment, high impact resistance, and uniform and stable coloring are provided; the resin carrier is subjected to the reasonable drying treatment so as to solve problems of easy flow mark production and non-uniform coloring of the traditional ABS master batch coloring; the pigment is added with the inorganic nanometer filler so as to improve dispersity of the pigment in the plastic product, coloring power of the pigment and covering power of the film product; and the production cost can be reduced, and the preparation method is simple, and is suitable for promotional use.

Owner:胡君

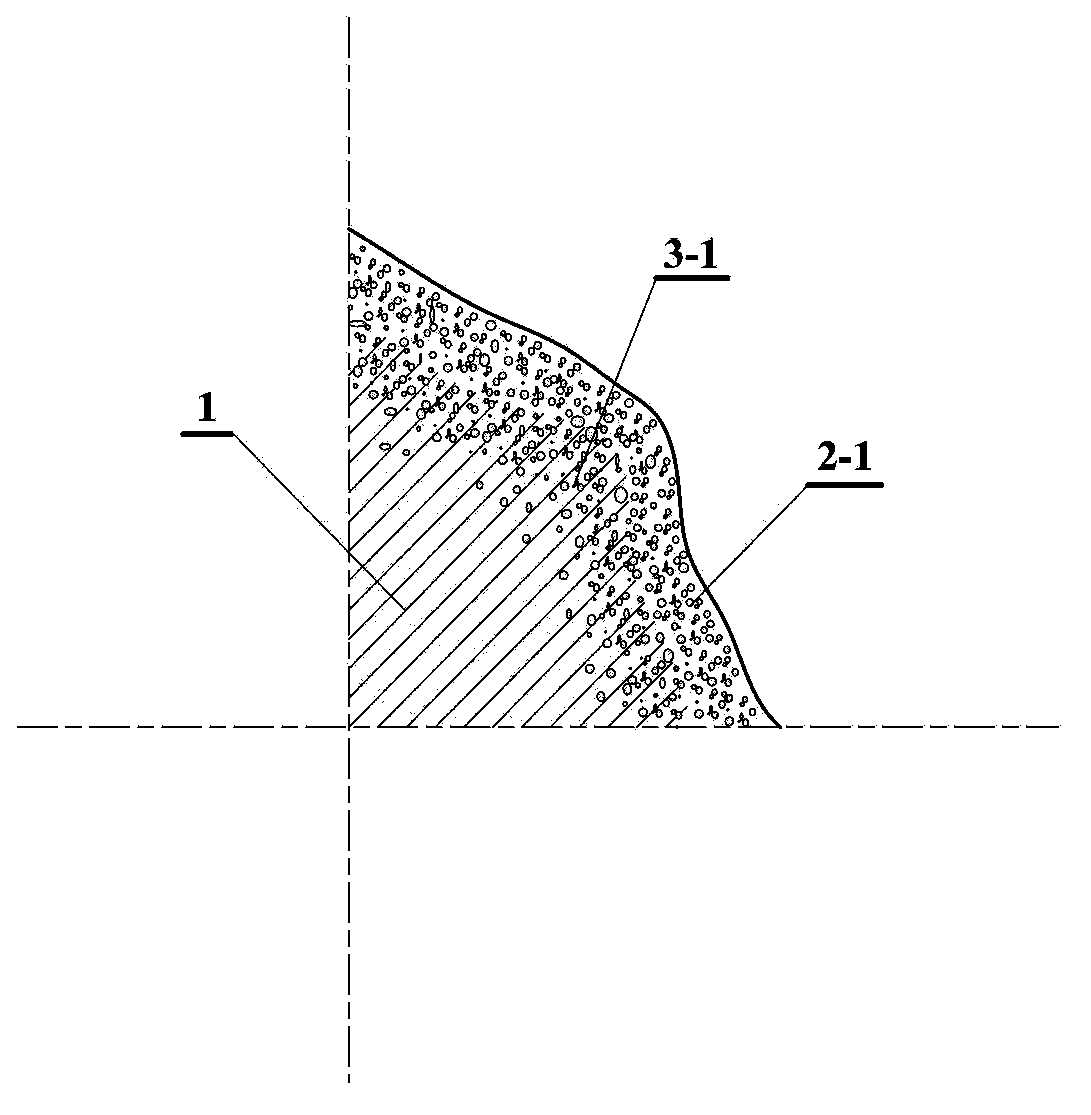

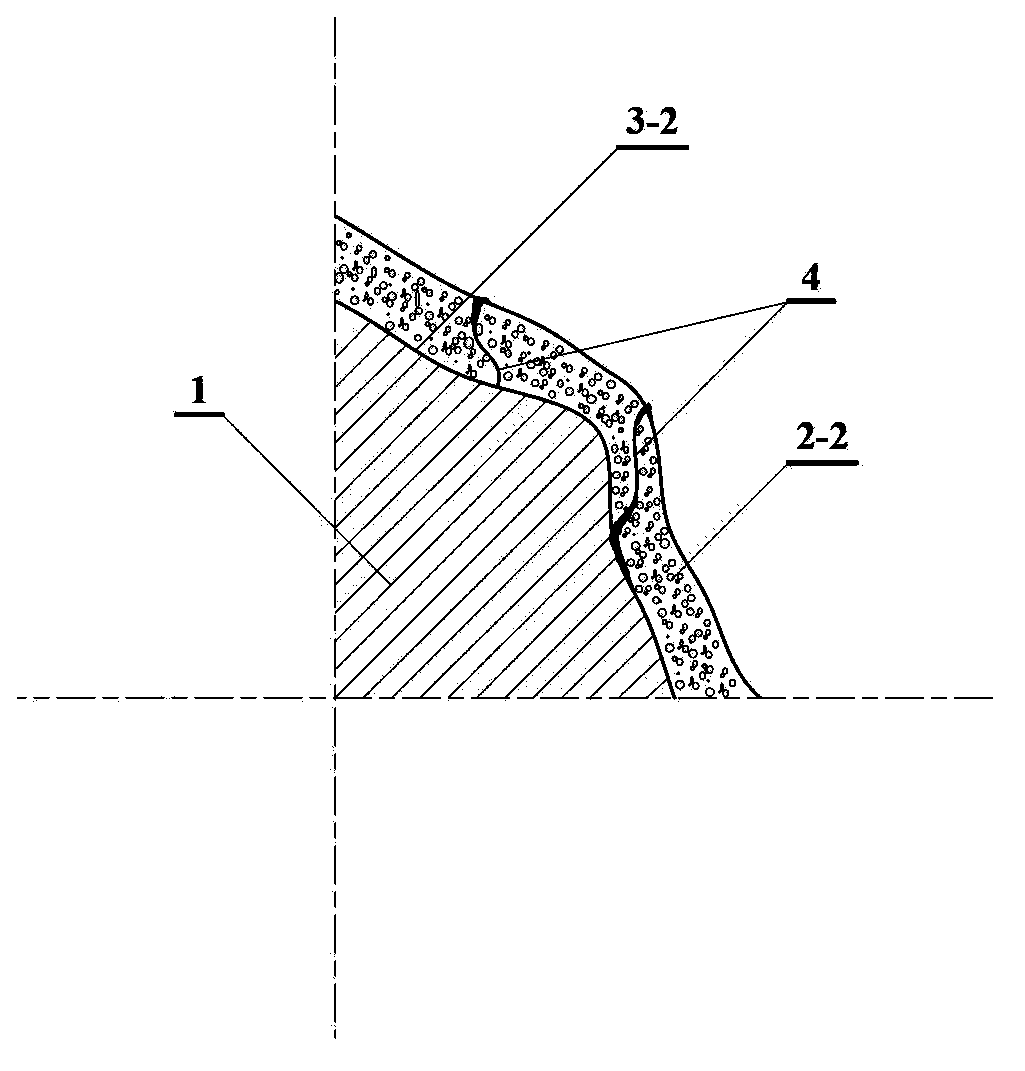

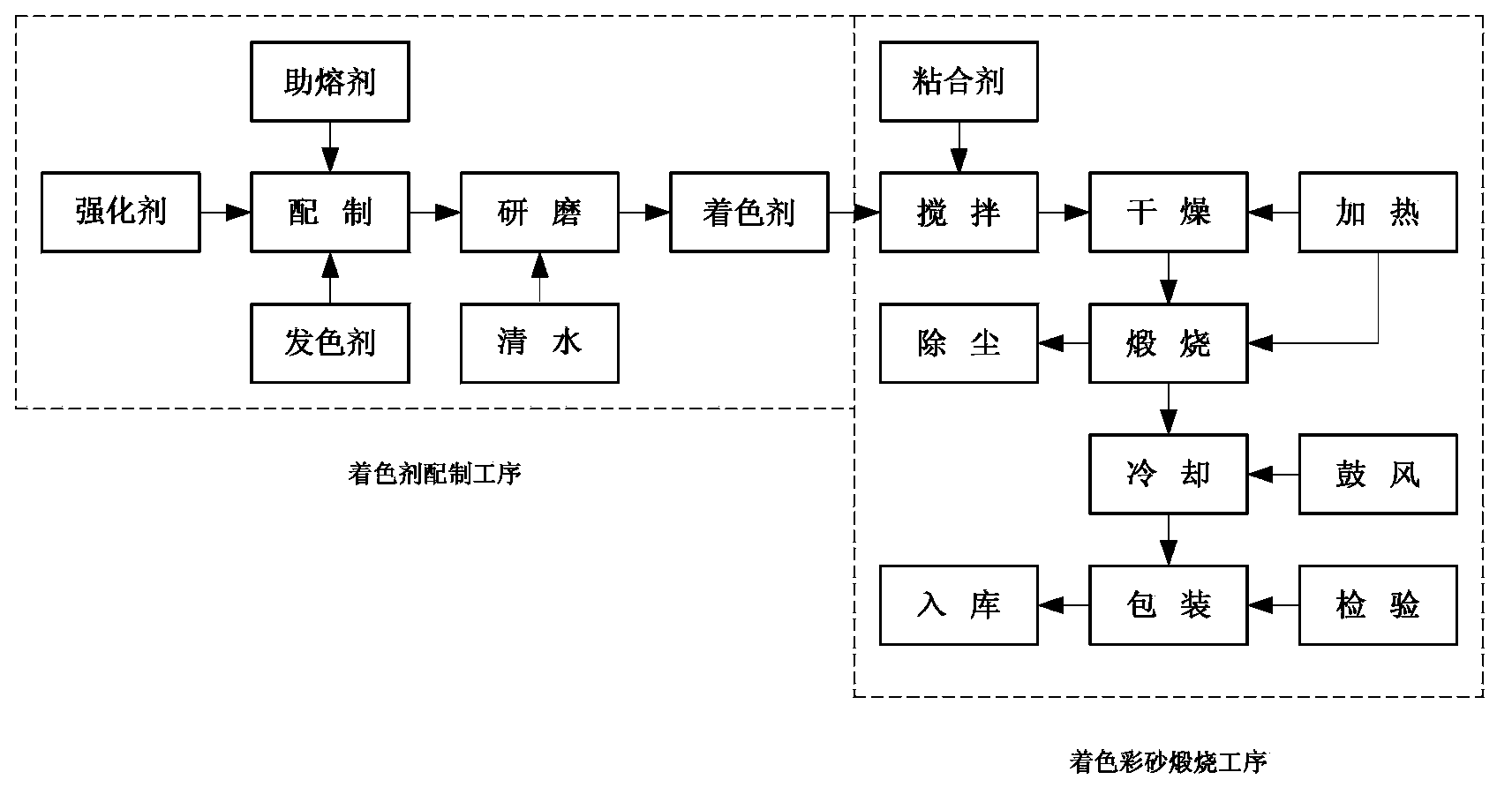

Colored sand capable of coloring by reaction and its preparation method

The invention relates to colored sand capable of coloring by reaction and its preparation method, the colored sand is prepared by the following components: 100wt parts of aggregate, 1.0-5.0wt parts of adhesive and 0.2-3.5wt parts of colouring agent; wherein the aggregate is other sandstone such as basalt sand, quartz sand, yellow sand or sea sand; and the colouring agent is composed 30.0-45.0wt parts of intensifying agent, 50.0-65.0wt parts of fluxing agent, 2.5-7.0wt parts of colour former and 50.0-80.0 wt parts of clear water according to a mechanism of ceramic colored glaze. The preparation method is characterized in that the colouring agent and the adhesive through grinding are coated on the surface of the aggregate together, then dried and calcined under the temperature of 700-950 DEG C to obtain the reaction-type colored sand. The colored sand has the advantages of uniform coloring, bright color and various types; a color layer is combined with the aggregate through reaction, and has the advantages of fastness and stabilization, no fading, strong corrosivity resistance, good weatherability and long usage life.

Owner:WEIFANG LONGCHENG BUILDING MATERIAL

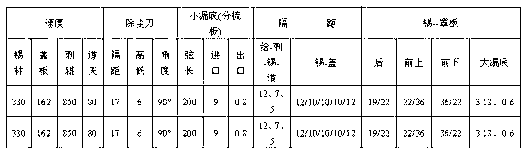

Air vortex spinning method of multi-component full-colored spun yarns

ActiveCN102995176AExpand the color spinning spaceAvoid craft difficultyContinuous wound-up machinesOpen-end spinning machinesYarnCarding

The invention discloses an air vortex spinning method of multi-component full-colored spun yarns, belonging to the technical field of novel spinning. The air vortex spinning method comprises the steps of: blending preprocessed dyed loose yarns according to a certain proportion, obtaining card slivers by cotton blending, blowing and cotton carding, obtaining drawn slivers by drawing and blending the card slivers for three times, and obtaining finished products by vortex spinning of the drawn slivers. The loose yarns comprise viscose, tencels, wools and spun silks at the mass percent ratio of 50:20:10:10; and 14 yarns for sweaters are spun. The air vortex spinning method of the multi-component full-colored spun yarns can meet multi-component full-colored spinning technical requirements and has the advantages of low cost, uniform coloring, no color difference and the like; and vortex spinning is applied to the color spinning field.

Owner:SHAOXING GUOZHOU TEXTILE NEW MATERIAL

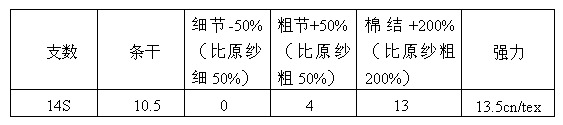

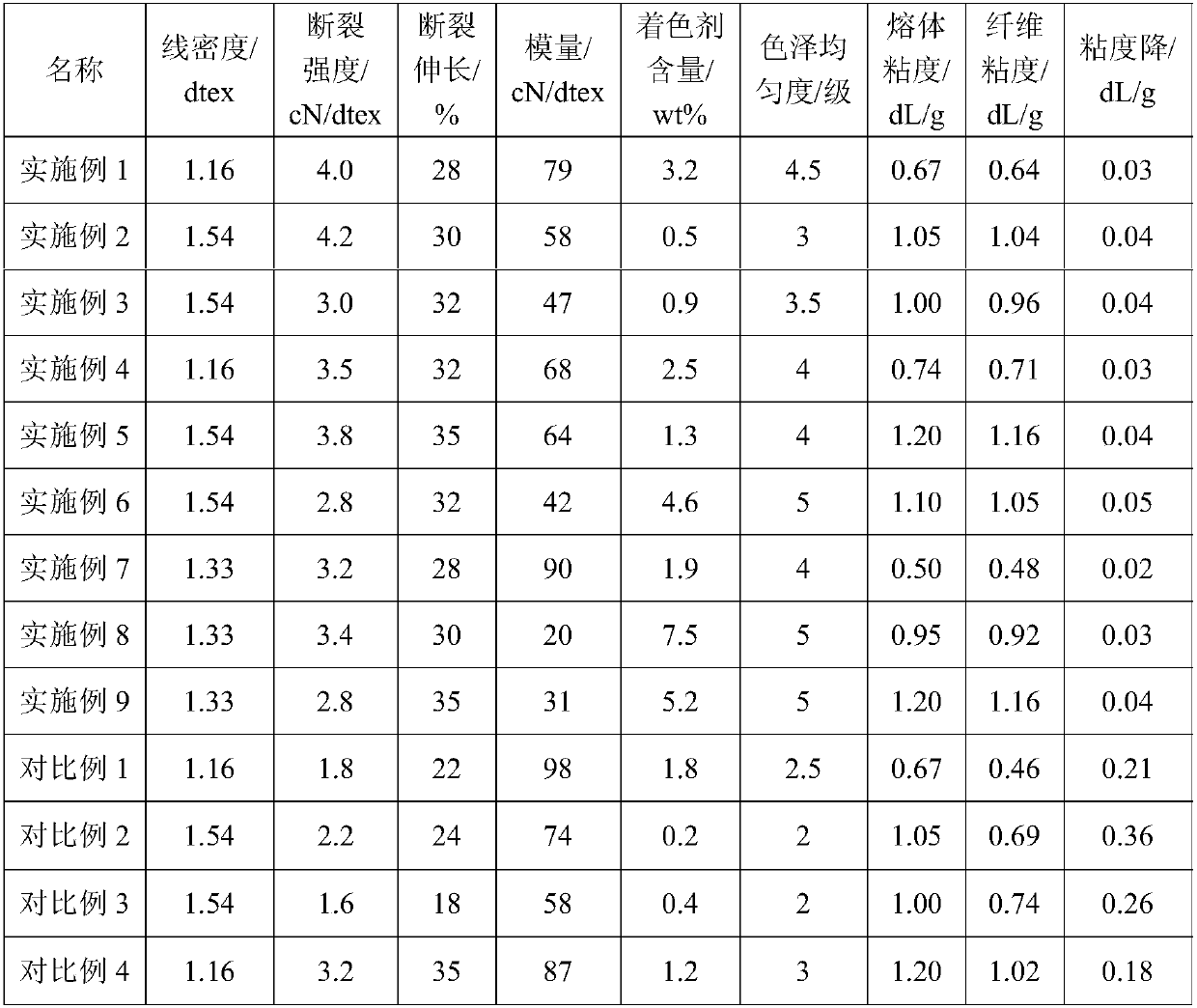

Stock solution coloring polyester fiber and preparation method thereof

ActiveCN107723831AImprove solubilityEvenly dispersedPigment addition to spinning solutionMonocomponent polyesters artificial filamentFiberPolyester

The invention belongs to the technical field of textiles, and particularly relates to a stock solution coloring polyester fiber and a preparation method thereof. The preparation method comprises the following steps: (1) adding a coloring agent into carrier polyester polyhydric alcohols, and preparing into uniform coloring mother solution; (2) adding the coloring mother solution into a polyester oligomer, uniformly mixing, and successively carrying out pre-condensation reaction and final condensation reaction in a condensation system to obtain coloring polyester melt; and (3) spinning and stretching the obtained coloring polyester melt, and obtaining the stock solution coloring polymeter fiber. The coloring agent is uniformly scattered in a polyester component, so that the compatibility problem of the polyester component and the coloring agent carrier can be effectively solved, the influence of the coloring agent and a carrier thereof on the spinning performance of the coloring polyester melt can be eliminated, and the prepared stock solution coloring polyester fiber is high in content of coloring agent, stable in quality, free from color difference, soft in hand touching, and goodin mechanical performance.

Owner:CHINESE TEXTILE ACAD

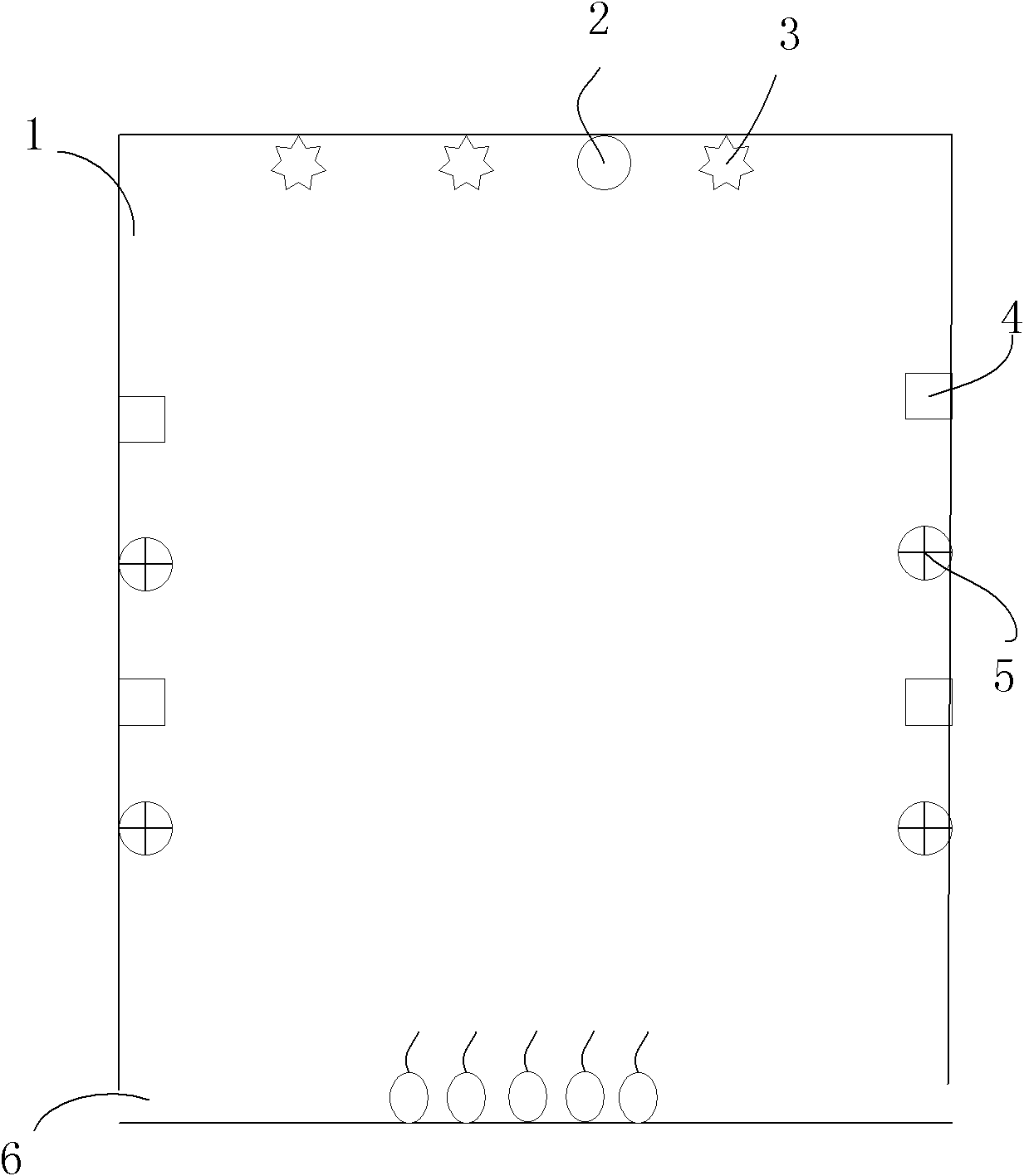

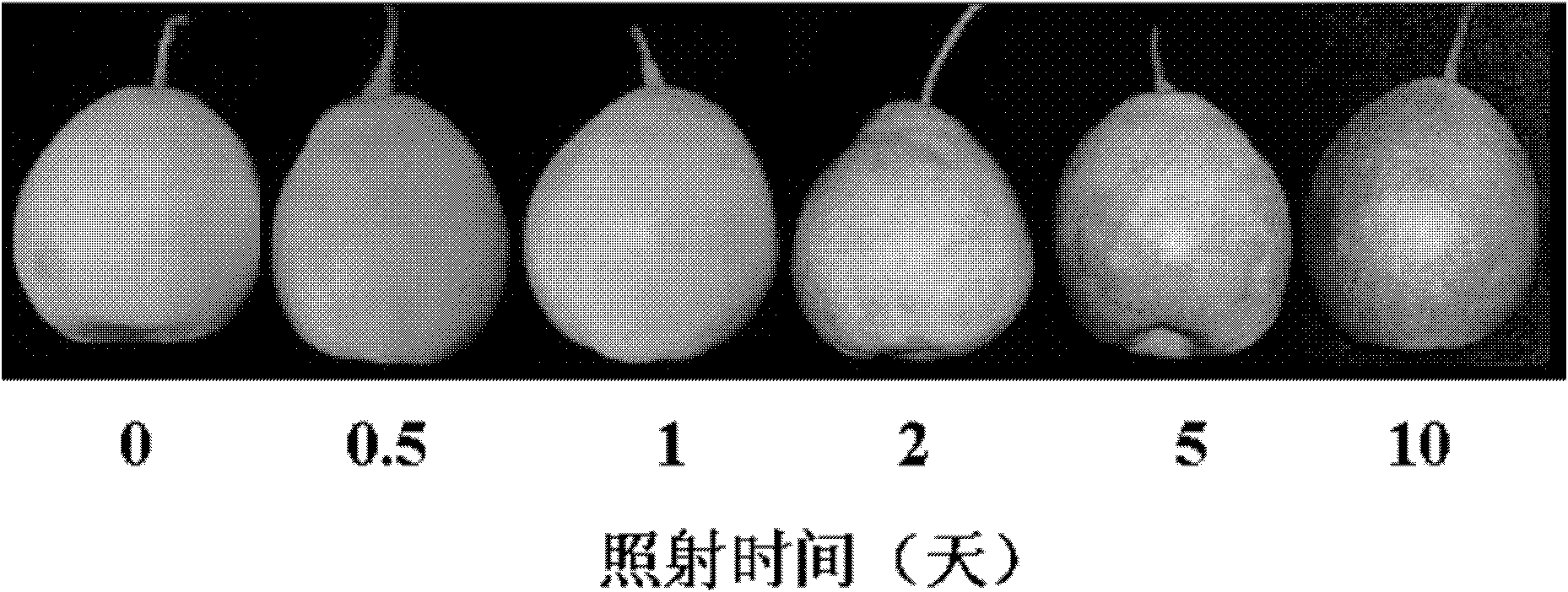

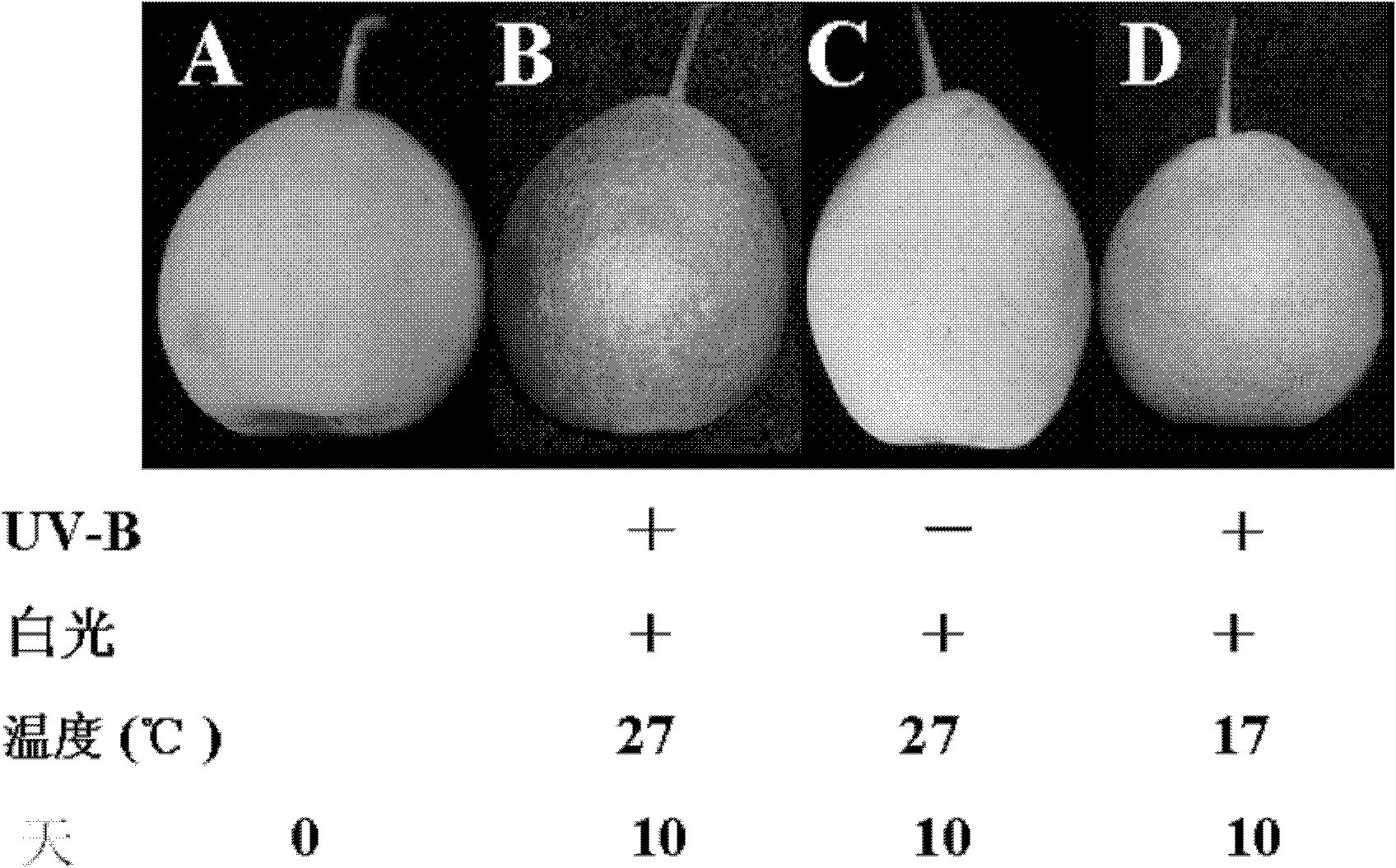

Device and method for coloring red Chinese sand pears after harvesting

The invention relates to a device and a method for coloring red Chinese sand pears after harvesting, and the method comprises the following steps: standing the Chinese sand pears which achieve the physiological maturity stage and are not colored under an environment with UV-B (ultraviolet-B) luminous intensity of 1-2 mu mol.m-2.s-1, luminous intensity of white light of 3-4 mu mol.m-2.s-1, average temperature of 25-29 DEG C, and average relative humidity of 55-75% for 5-10 days. The device comprises a closed storage room for placing the Chinese sand pears, wherein an UV-B light source and a white light source are mounted at the top of the storage room, a temperature control device and a humidification device are mounted on the side wall, and a ventilation opening is arranged at the bottom. After the Chinese sand pears are harvested, the Chinese sand pears are placed in the environment with the controllable temperature and the humidity, the fruits with relatively sufficient, stable and uniform coloring can be obtained by performing continuous irradiation under the artificial light source for a period of time, and the device and the method are specially used for promoting the coloring of the red Chinese sand pears, and can promote the synthesis of anthocyanin in the red Chinese sand pears in a quicker manner and improve the appearance quality.

Owner:ZHEJIANG UNIV

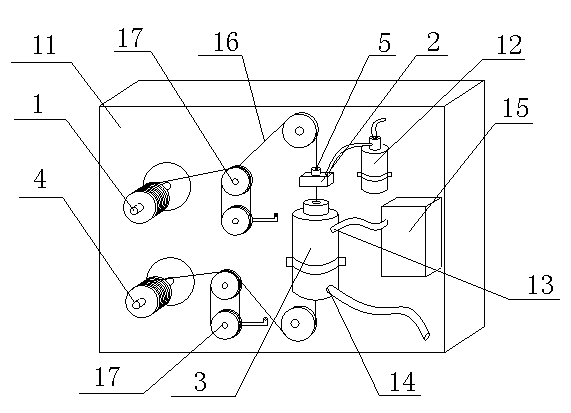

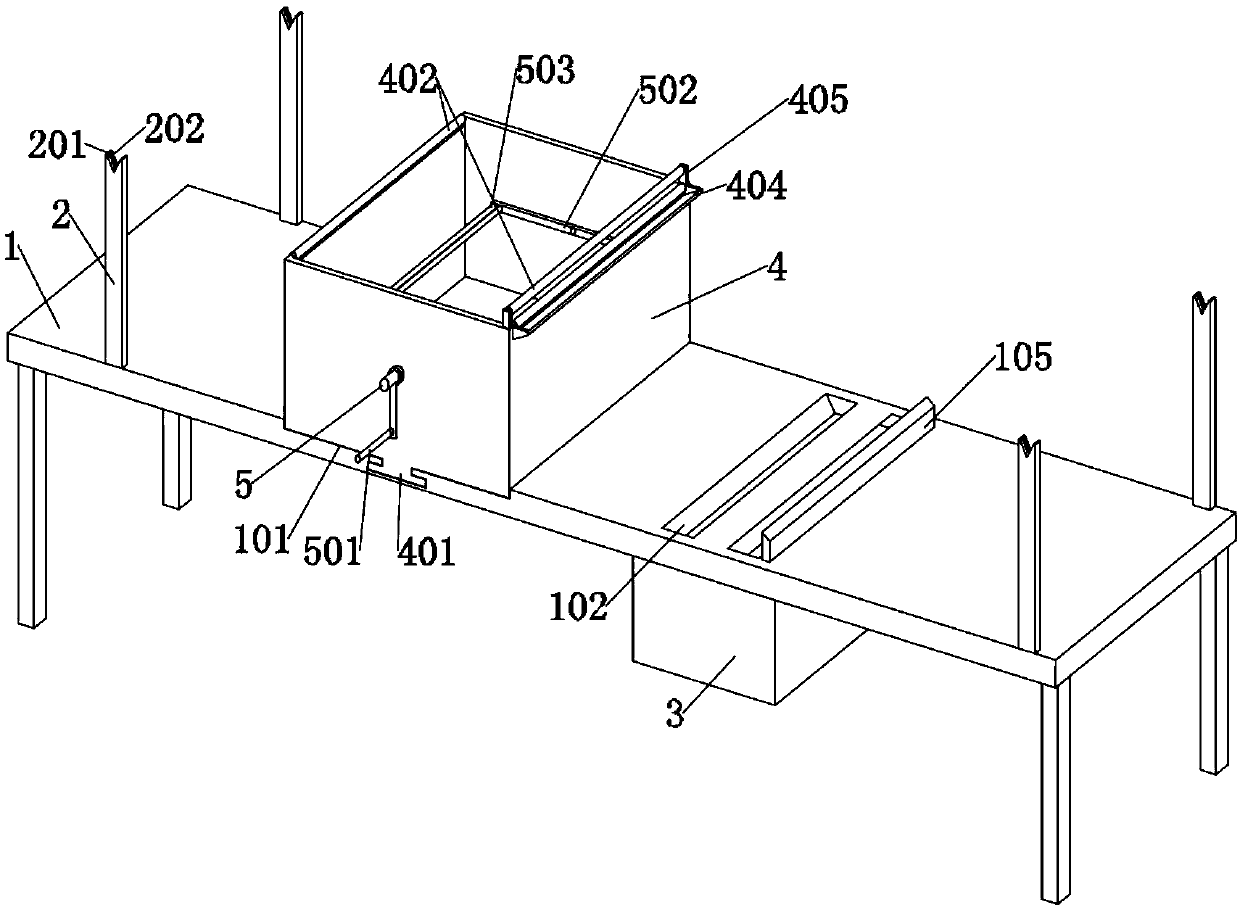

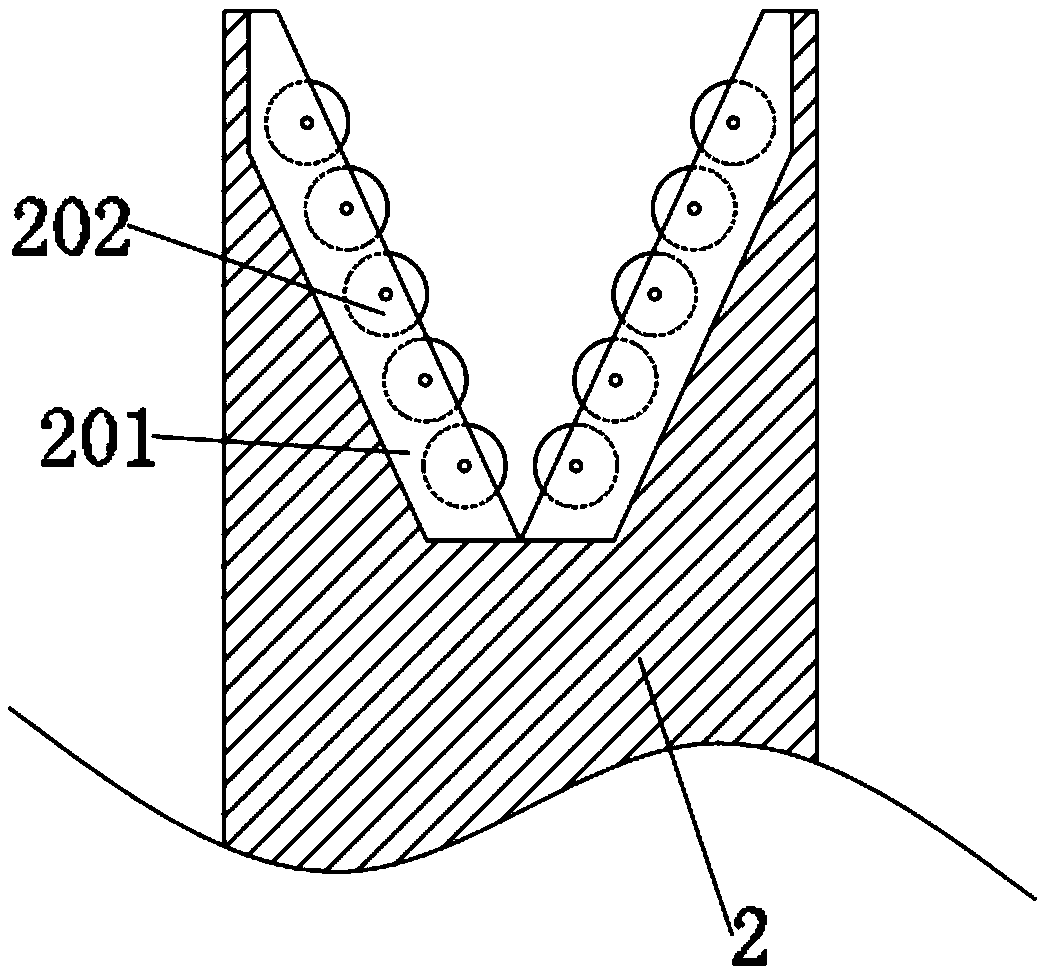

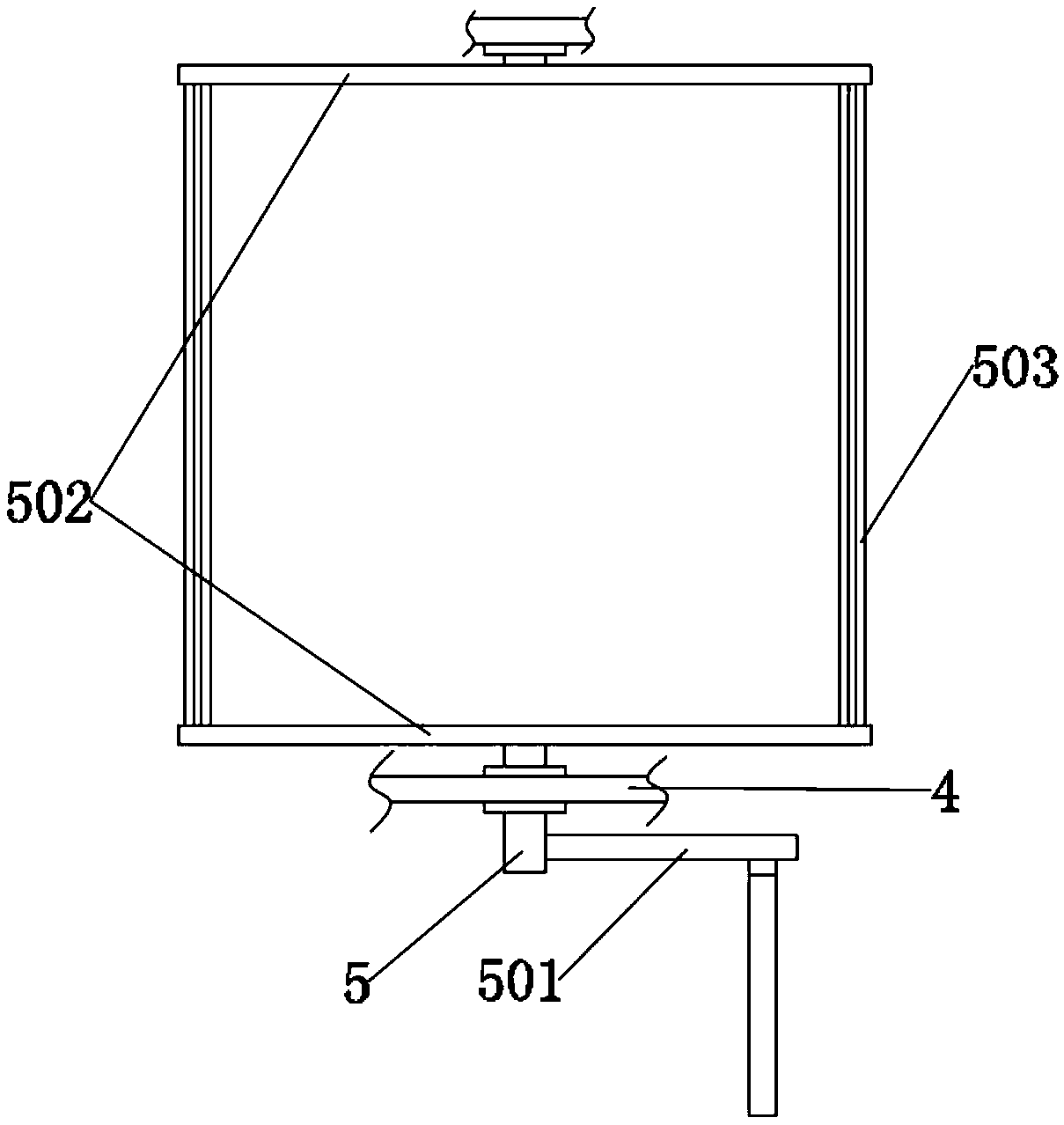

Uniform coloring machine of fibers

The invention discloses a uniform coloring machine of fibers. The machine comprises a base (11), and a pay-off reel (1), a coloring device (2), a curing furnace (3), a take-up reel (4) and a pigment pot (12) which are installed on the base (11), the pay-off reel (1), the coloring device (2), the curing furnace (3) and the take-up reel (4) are annularly assigned, a tension regulator (17) is arranged between the pay-off reel (1) and the coloring device (2), a tension regulator (17) is also arranged between the curing furnace (3) and the take-up reel (4), and the pay-off reel (1) and the take-up reel (4) are respectively installed on the base (11) through a motor. The machine which allows the tension regulator to be arranged in each of a pay-off position and a take-up position has the advantages of guarantee of the tension in fiber transmission, no fiber relax phenomenon, avoiding of the non-uniform dyeing phenomenon, and improvement of the fiber dying quality.

Owner:成都亨通光通信有限公司

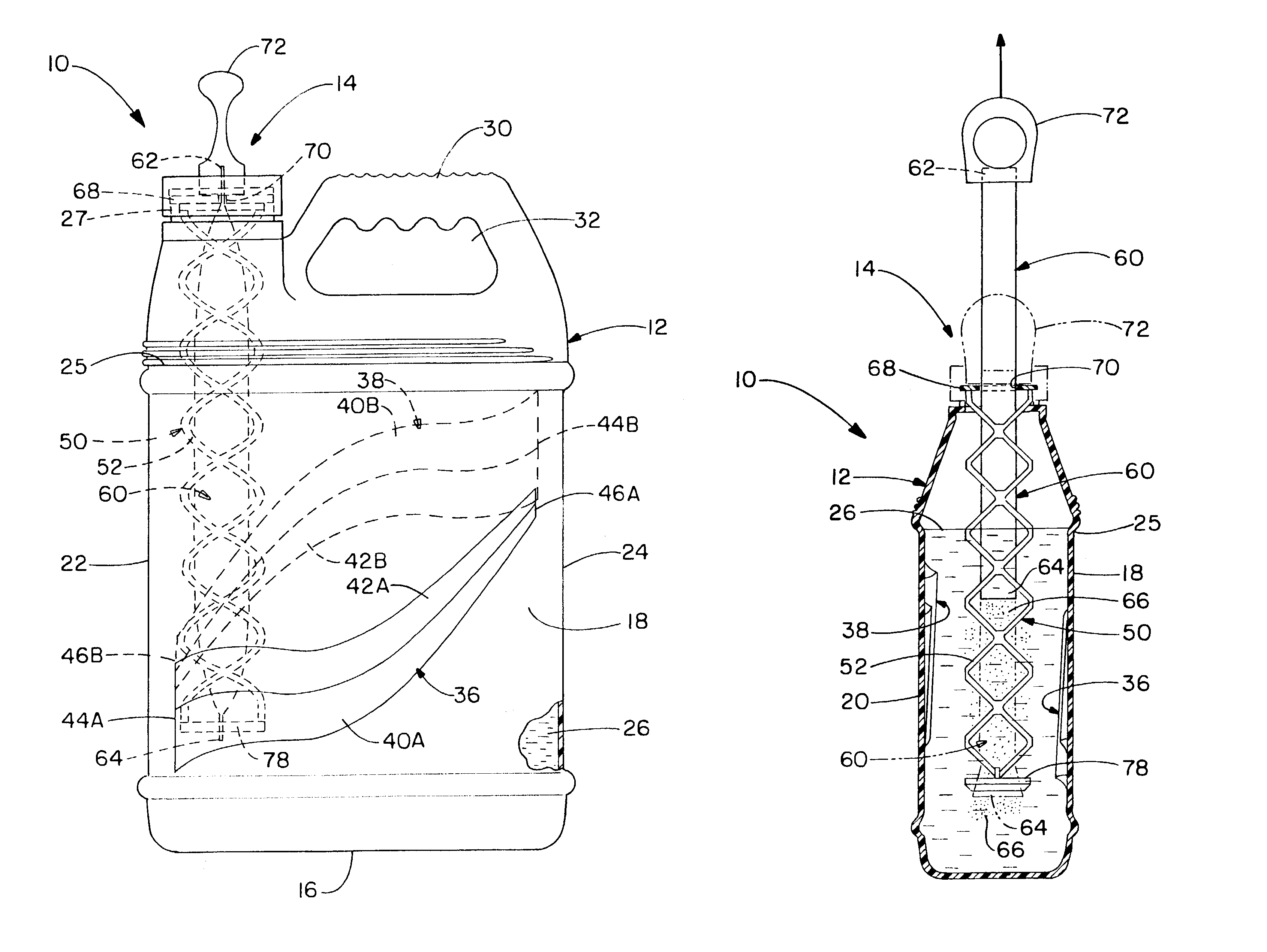

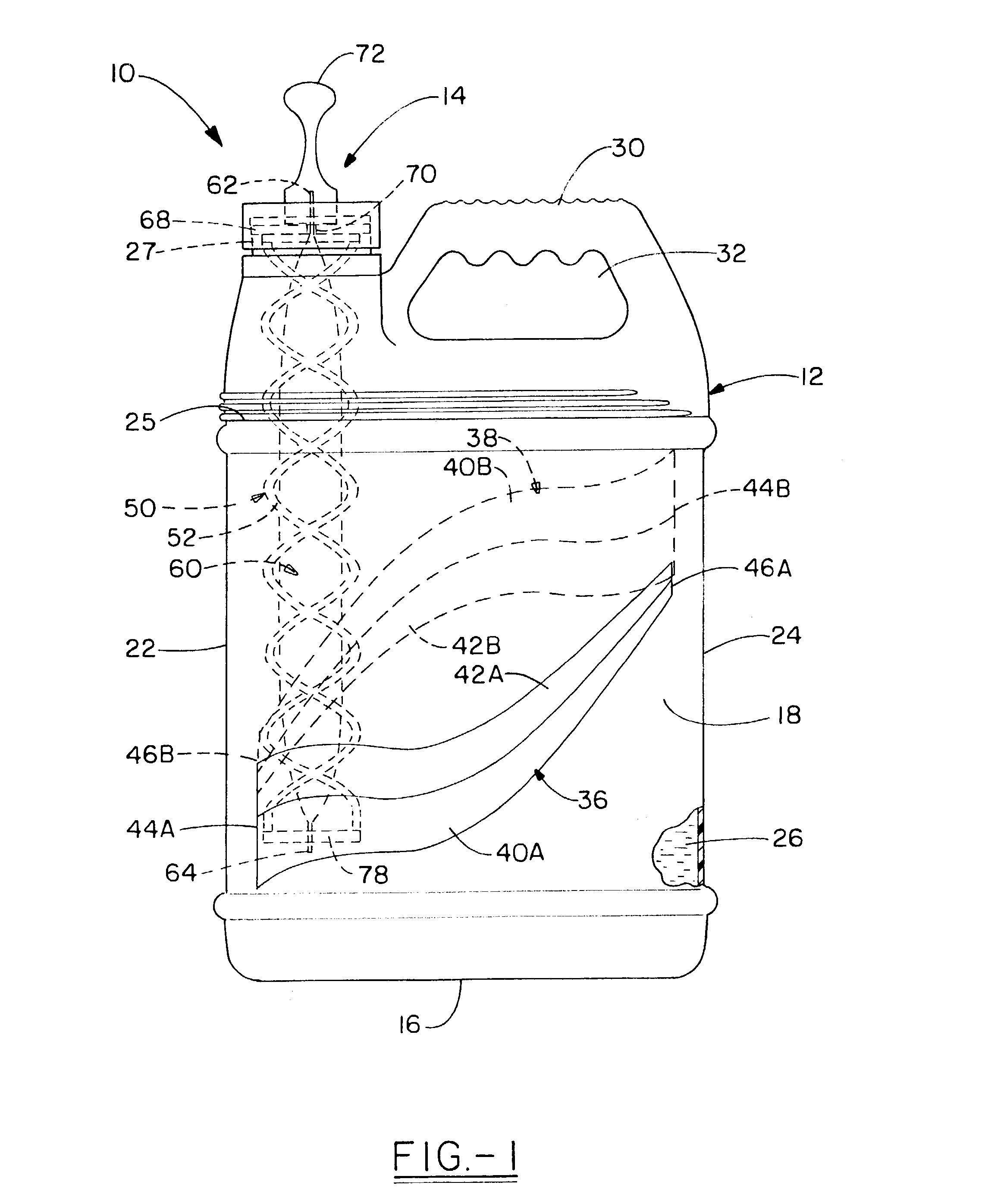

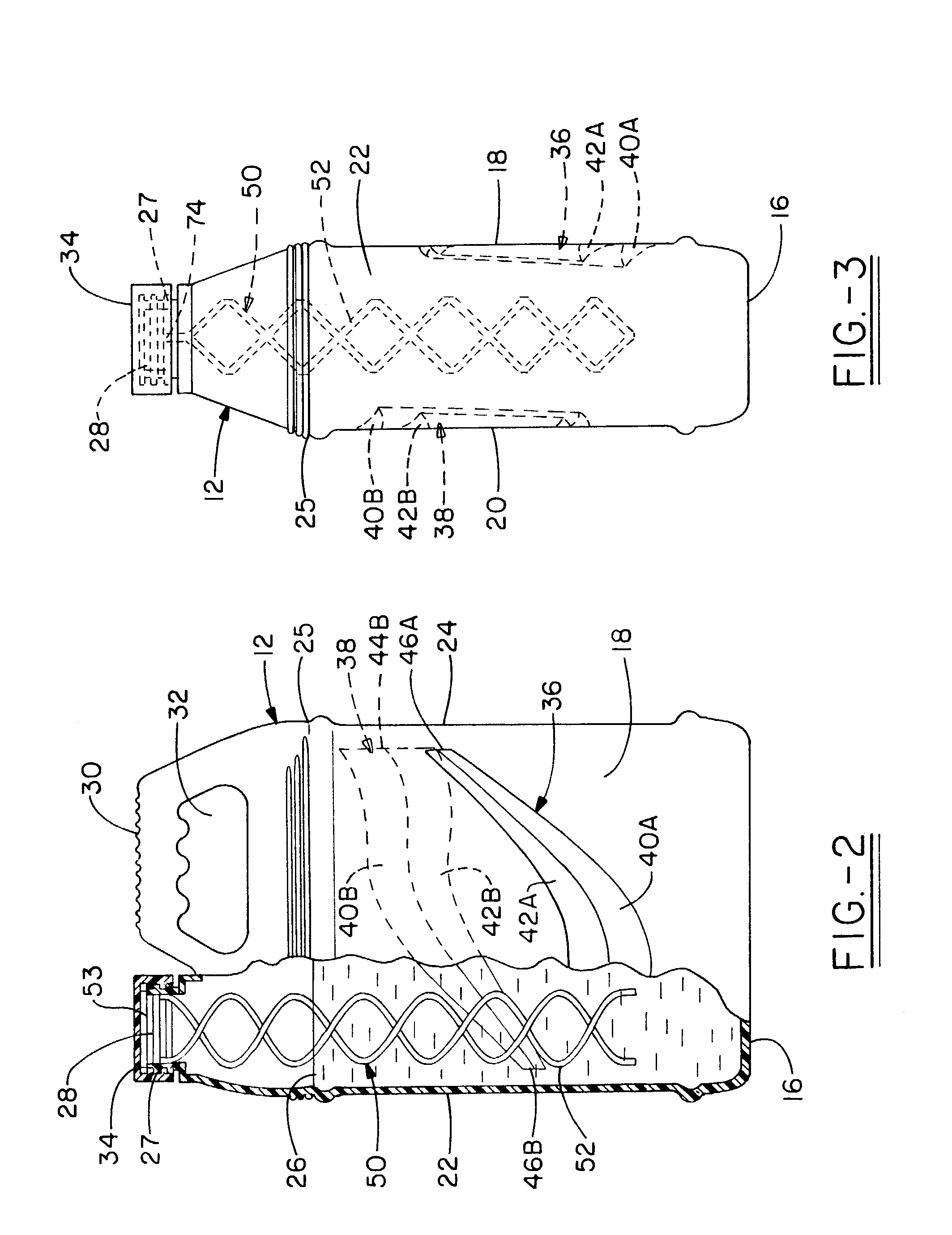

Paint container and colorant injector apparatus and method

InactiveUS7086776B2Shaking/oscillating/vibrating mixersOther chemical processesUniform coloringColoring agents

The present invention provides a paint container and colorant injector apparatus that includes a paint container that retains a base paint therein and provides an opening allowing access to the base paint. An injector assembly couples with the paint container and is operable to locally disperse colorant into the base paint. Such an apparatus is employed in a method for dispersing a colorant throughout a base paint. The method includes providing a base paint in a container, locally dispersing colorant in the base paint, thereafter sealing the container and shaking the container to further disperse the colorant in the base paint throughout the remainder thereof to effect uniform coloring of the base paint.

Owner:ADAMS ROGER W

High weatherability PVC (Polyvinyl Chloride) masterbatch and preparation method thereof

The invention discloses a high weatherability PVC (Polyvinyl Chloride) color masterbatch. The high weatherability PVC color masterbatch is prepared from the following raw materials: 40 to 60 parts ofpolyvinyl chloride resin, 20 to 30 parts of inorganic pigment, 10 to 15 parts of fibers, 2 to 3 parts of a compound dispersant, 2 to 3 parts of an ultraviolet light absorber, 2 to 3 parts of an antioxidant and 1 to 2 parts of a fortifier. The PVC color masterbatch provided by the invention has the advantages of reasonable formula, high weatherability, excellent wear resistance, easiness in dispersion, low cost and simple preparation process. When being applied to the coloring of PVC products, the PVC color masterbatch has the advantages of lower dosage, higher colorant concentration, high utilization rate, high antibacterial property, good weatherability, uniform coloring, no discoloration and no effect on mechanical properties of the PVC products; the service life of the PVC products is effectively prolonged.

Owner:合肥卡洛塑业科技有限公司

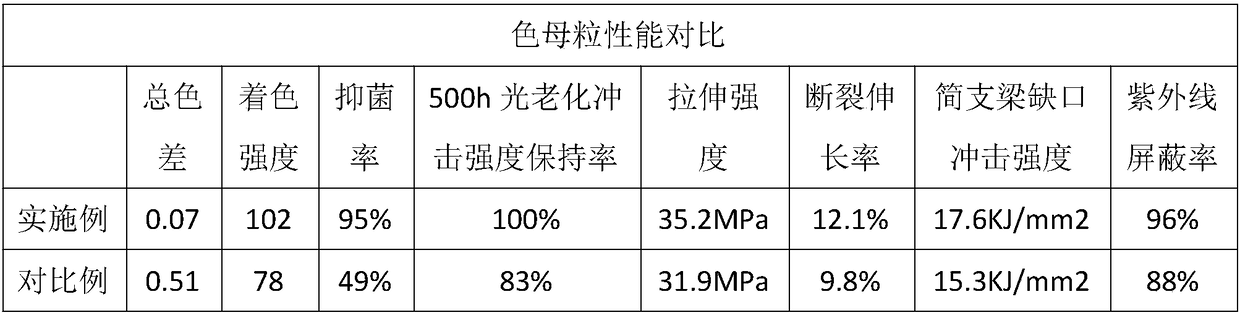

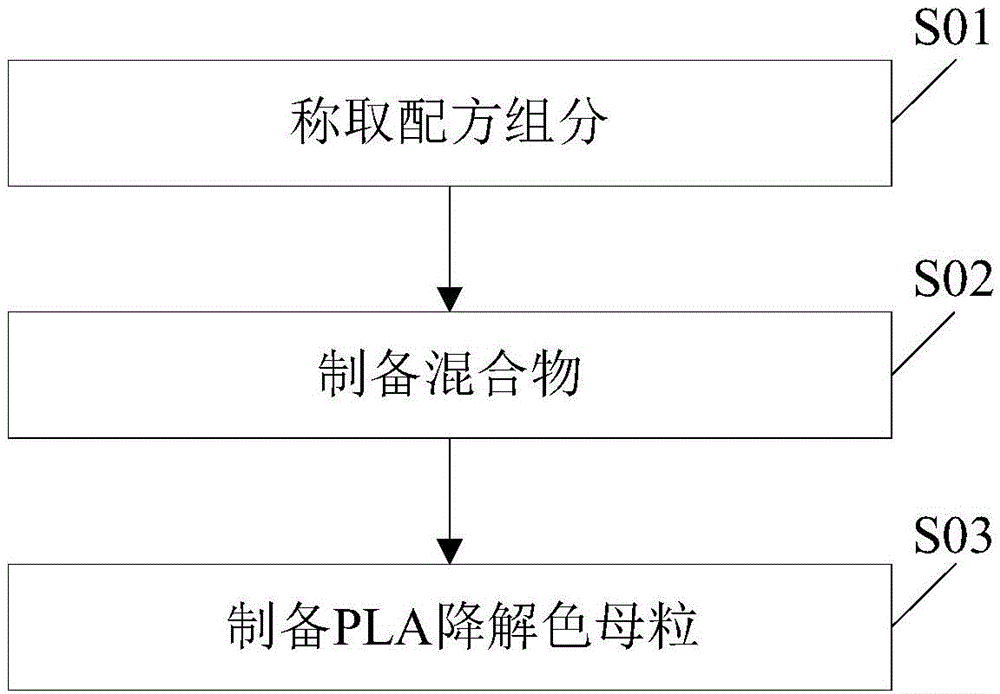

PLA (polylactic acid) degradable color master batch and preparation method thereof

The invention belongs to the field of plastic coloring, and provides a PLA (polylactic acid) degradable color master batch and a preparation method thereof. The PLA degradable color master batch is prepared from the following raw materials in percentage by weight: 66-74% of PLA plastic, 19-25% of refined pigment and 7-9% of assistant. The preparation method comprises the following steps: weighing the components according to percentage by weight, uniformly mixing the components to obtain a mixture, adding the obtained mixture into a double screw extruder, and carrying out melt extrusion to obtain the PLA degradable color master batch. The PLA degradable color master batch has the advantages of uniform coloring, low cost, controllable processing technique and the like on the premise of not changing the advantages of environment friendliness and degradability of the PLA plastic, and is widely used in the traditional plastic processing techniques, such as injection molding, blow molding, film blowing, sheet making and the like.

Owner:LIFENG NEW MATERIAL TECH SHENZHEN

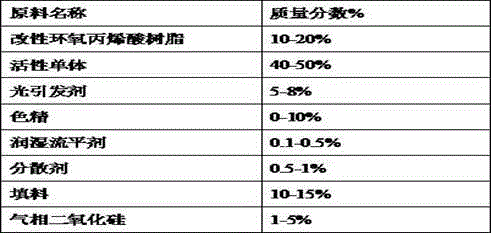

Rib crack or bogging resistant environmentally-friendly photocurable high-filling GLAZE coloring agent

ActiveCN104830208AImprove wood grain contrastImprove dispersion stabilityEpoxy resin coatingsDispersion stabilityAcrylic resin

Owner:上海君子兰新材料股份有限公司

PBT high density color master batch and preparation method thereof

The invention discloses PBT high density color master batch and a preparation method thereof. The PBT high density color master batch is prepared from the following components by mass percent: 70-90% of pigment, 10-20% of PBT resin, 3-5% of dispersant, 0.1-1% of anti-oxidant, and 0.1-1% of antistatic agent. Compared with the prior art, the beneficial effects reside in that: when used for coloring a PBT product, the color master batch provided by the invention has characteristics of good dispersibility, uniform coloring, high concentration, small usage amount and no influence on mechanical properties of the PBT product, and also has advantages of low cost, simple process, easy coloring, convenient usage and time and raw material saving.

Owner:QINGDAO XINZHAN PLASTIC

Dyeing composition applicable to weft-knitted fabric

InactiveCN104893358AImprove washing fastnessColorfulOrganic dyesDyeing processDisperse dyeCycloparaffins

The invention discloses a dyeing composition applicable to weft-knitted fabric. The dyeing composition comprises the following raw materials in parts by mass: 5-50 parts of natural plant dye extract, 10-100 parts of disperse dye, 10-60 parts of compound with a cycloparaffin group, 5-15 parts of kieselguhr, 4-10 parts of polyethylene sodium propionate, 6-25 parts of fatty alcohol compound, 5-100 parts of hydrophobic compound, 1-8 parts of dispersing agent, 2-8 parts of water reducing agent and 40-400 parts of water. The dyeing composition is developed according to the structure of the weft-knitted fabric, realizes fast dyeing and high color fastness and avoids frequent color change as well as the phenomena of color dislocation in coloring and non-uniform coloring; and the weft-knitted fabric dyed by the dyeing composition has excellent washing fastness as well as bright and rich colors and is beautiful and elegant after heat setting treatment or softening treatment.

Owner:JURONG SHENTU TECH KNITTING FACTORY

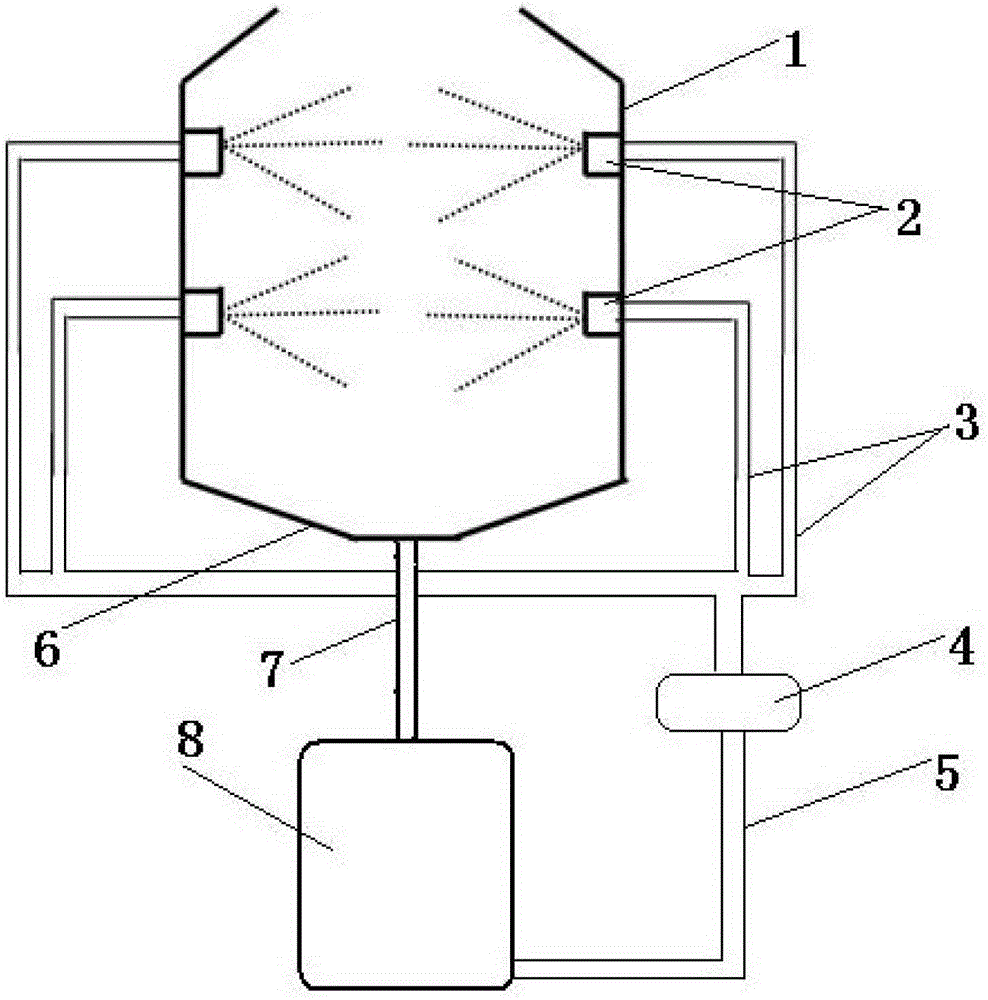

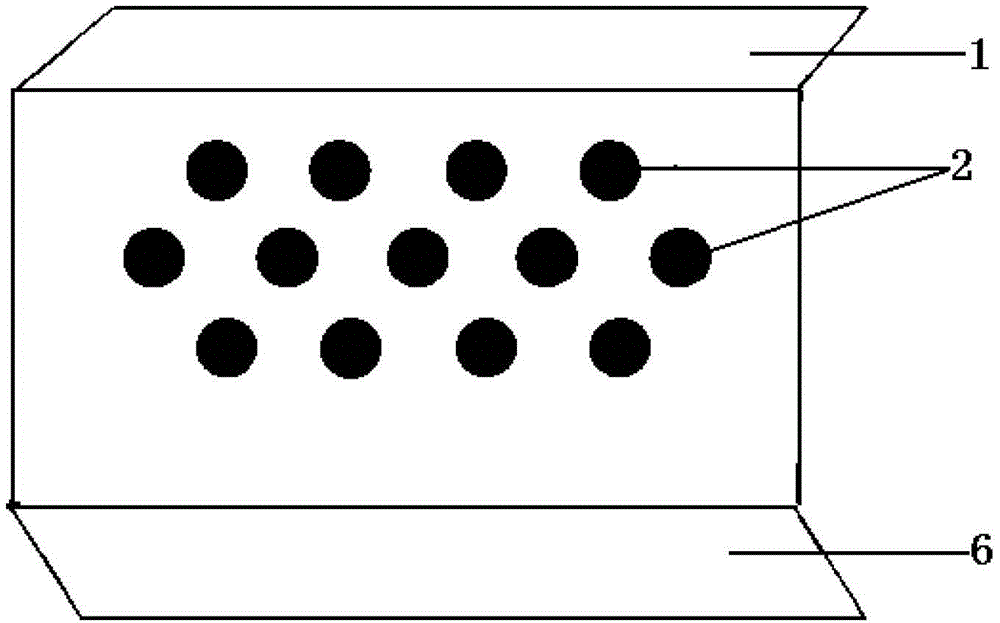

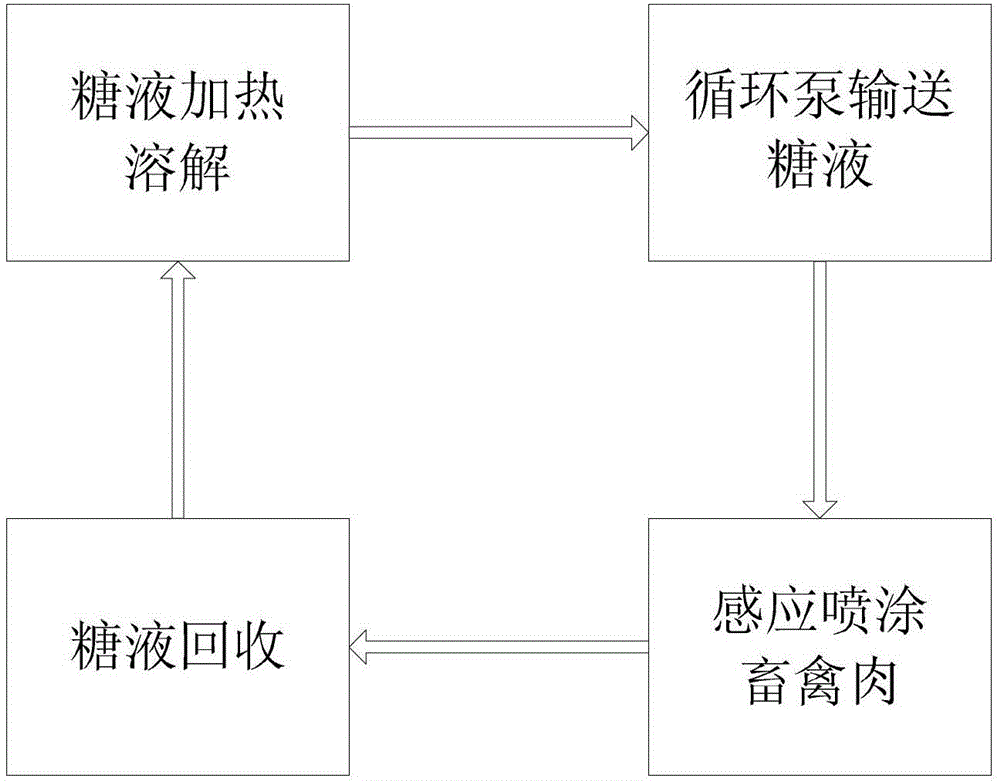

Automatic sugar spraying system

ActiveCN103330271ASpray evenlyGuaranteed sugar effectFood coatingFood shapingProduction lineAutomatic control

The invention discloses an automatic sugar spraying system which comprises a circulating pump, a spraying device, a sugar solution collection guide plate and a sugar solution storage tank, wherein the spraying device comprises two baffles and a plurality of nozzles; the nozzles are communicated with the circulating pump by sugar solution output pipelines; the sugar solution collection guide plate is horizontally and fixedly arranged at the lower end between the two baffles; a groove is formed in the middle of the sugar solution collection guide plate; a through hole is formed in the middle of the groove; a sugar solution recovery pipeline is arranged below the through hole and communicated with the sugar solution storage tank; and the sugar solution storage tank is a tank body, and is communicated with the circulating pump by a sugar solution pumping pipeline and communicated with the sugar solution collection guide plate by the sugar solution recovery pipeline. The automatic sugar spraying system can be applied to an industrial serial production line of livestock meat products, has the characteristics of automatic control, manpower saving, uniformity in sugar solution spraying and high drying rate, is simple in structure and easy to maintain, and lays a foundation for stable and uniform coloring effects of the livestock meat products in a production process.

Owner:北京中农探味科技有限公司

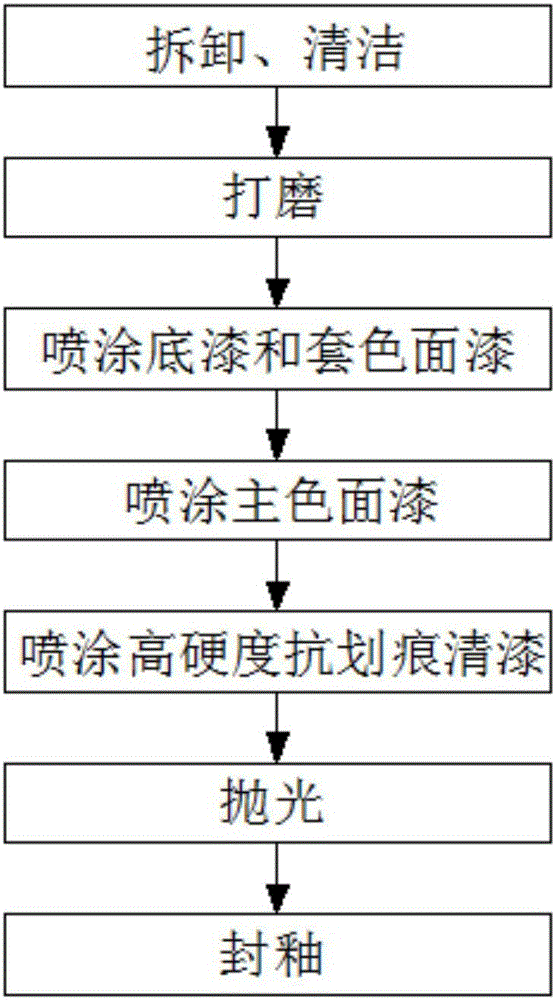

Method for coloring mobile phone shell

InactiveCN106694340AUniform colorAvoid chromatic aberrationPretreated surfacesSpecial surfacesTemperature resistanceWear resistance

The invention discloses a method for coloring a mobile phone shell in the technical field of coloring methods. The method for coloring a mobile phone shell comprises the following steps: S1: detaching and cleaning; S2: polishing; S3: primer spraying and finish paint color registering; S4: spraying of main color finish paint; S5: spraying of high hardness anti-scratch varnish; S6: burnishing; and S7: glaze sealing. The primer spraying, the finish paint color registering, the spraying of main color finish paint and the spraying of high hardness anti-scratch varnish are performed by steps, drying and burnishing are performed after each paint spraying step is finished, uniform coloring of the mobile phone is ensured, aberration of the mobile phone shell is avoided, the high hardness anti-scratch varnish is sprayed to improve wear resistance of the mobile phone shell, and the glaze sealing is performed on the mobile phone shell after burnishing and waxing to further improve the surface flatness and brightness of the mobile phone shell, such that the mobile phone shell has the advantages of high temperature resistance, sealing, oxidation resistance, brightness increasing, water washing resistance, corrosion resistance and the like, and the service life of the mobile phone shell is prolonged.

Owner:郑州微森电子科技有限公司

Uniform-coloring dyeing device for garment fabric production

InactiveCN109097936AQuick installationUniform dyeingLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsDrive shaftEngineering

The invention provides a uniform-coloring dyeing device for garment fabric production. The uniform-coloring dyeing device comprises tension springs, a transmission shaft, a hand-cranking part, mounting plates and clamping rods. Bottom ends of supporting rods are mounted on two upper sides of a body by welding; the hand-cranking part is mounted on the outer lateral side of the transmission shaft bywelding, and the middle of the transmission shaft is mounted in the middle of the front end of a dyeing chamber through a connector; the outer middle of the mounting plate in the rear side of the dyeing chamber is connected with the inner middle of the dyeing chamber through a rotating shaft, and clamping parts drive guide parts to move, so that clamping of the two guide parts is realized, a dyedfabric is extruded to remove excessive dyes from the fabric, and the dyes infiltrate the fabric to improve uniformity in fabric dyeing. The tension springs at the bottoms of the clamping parts pull the clamping parts to enable the guide parts above to move downwards.

Owner:杨智超

High-performance reactive printing paste

The invention relates to the technical field of preparation of vapor deposition materials, in particular to high-performance reactive printing paste. The high-performance reactive printing paste comprises the following components in percentages by weight: 2-5% of composite paste, 2-5% of an aqueous thickener, 3-7% of an alkaline agent, 0.1-1% of a leveling agent, 0.5-3% of a dye inhibitor, 10-15%of urea and the balance of water. The composite paste and the aqueous thickener are used in combination, so that the color yield is higher than that of traditional sodium alginate, and the color is bright; and in addition, the printing paste prepared by the method disclosed by the invention not only can improve the screen permeability of printing, but also can improve the stability of reactive dyes, uniform coloring is ensured, the reproducibility is good, and a printed fabric is tidy, soft and comfortable in surface, and meets demands of the public.

Owner:杭州桑瑞斯新材料有限公司

Dyeing process of color knitted denim coating

ActiveCN105484073ASolve the problem that the knitted fabric cannot be dyed by the rope dyeing machineSolve the problem of dyeing one sideDyeing processThermal energyStaining

The present invention relates to a dyeing process of a color knitted denim coating. The process includes coloring and fixation. The coloring is as below: beating a coloring agent into coloring foam by a foam generator, applying the coloring foam onto a staining surface of a full width traveling fabric, controlling the amount of foam and fabric speed to reach liquid amount of the fabric at 8-15%, and progressively drying by seven groups of cloth drying cylinders at different temperatures at a drying temperature with constant temperature increment of 70 DEG C-120 DEG C. The fixation is as below: beating a coloring agent into coloring foam by a foam generator, applying the coloring foam onto a staining surface of a full width traveling fabric in the step B, controlling the amount of foam and fabric speed to reach liquid amount of the fabric at 8-15%, and progressively drying by seven groups of cloth drying cylinders at different temperatures at a drying temperature with constant temperature increment of 70 DEG C-120 DEG C. The coloring and fixation both use a foam coating manner, and the liquid amount of the fabric is controlled at a low range of 8%-15%, so as to realize the dyeing process of knitted denim. The process has the advantages of uniform coloring, firm staining, and reduction of heat and water consumption.

Owner:JIANGYIN FUBO TEXTILE CO LTD

Method for preparing colored toner used for laser printing and electrostatic copying

InactiveCN101526765ANarrow particle size distributionSimple processDevelopersXerographyPolymer chemistry

The invention discloses a method for preparing colored toner used for laser printing and electrostatic copying. The invention combines with bulk polymerization, phase inversion polymerization, suspension polymerization technology and emulsion polymerization technology, and comprises the following steps: firstly, colorant and other additives are mixed with trace macromolecule, monomer and initiator completely for bulk polymerization for several hours, and aqueous phase solution which is dissolved with surfactant and dispersant is added to carry out the phase inversion and then polymerization is continuously carried out to obtain the product. The method obtains red, yellow and blue tricolor toner by polyreaction directly; the method has simple technology, less investment on equipment, energy saving and the uniform coloring of the product; and resin molecular weight shows bimodal distribution, thereby being good for fixation performance. The method overcomes the problem that unimodal distribution of the resin molecular weight causes poor fixation effect, uneasy even distribution of the colorant in the colored toner and over-wide particle size distribution during preparing the colored toner by the polymerization process.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

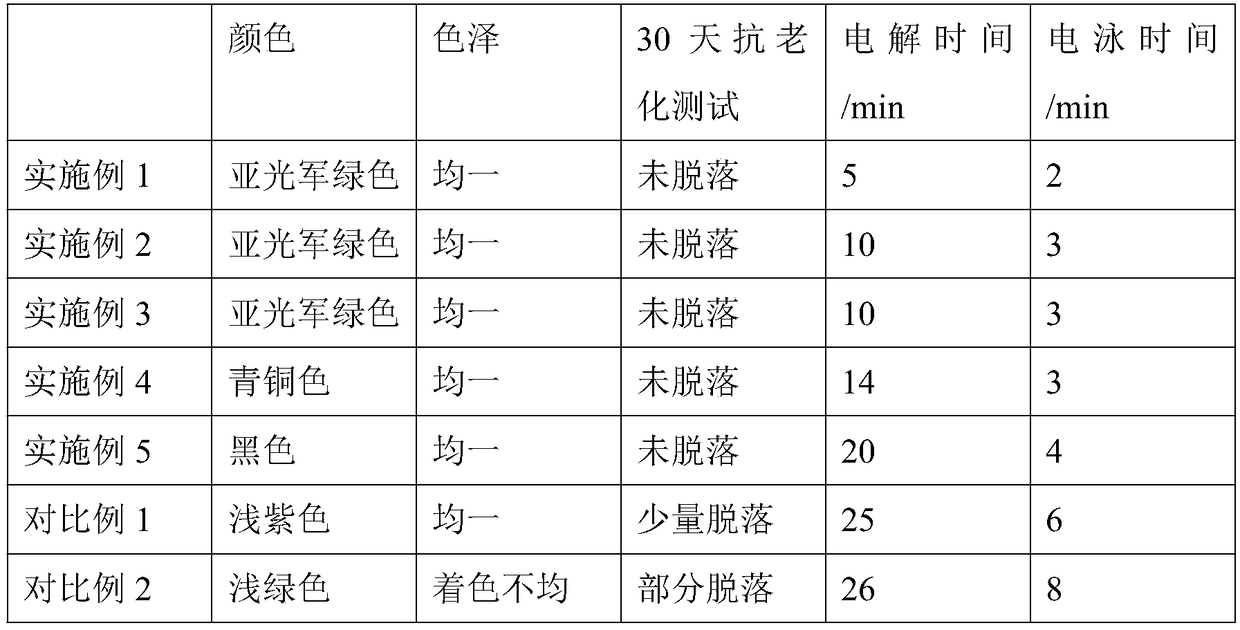

Coloring technological method for aluminum alloy shell cases

InactiveCN109208053AFast dark coloringUniform coloring process qualityAnodisationElectrophoretic coatingsElectrochemical responseHigh concentration

The invention discloses a coloring technological method for aluminum alloy shell cases. Through anodic oxidation, coloring, hole sealing and elecrophoretic coating, the colored shell cases are finallyobtained. According to the coloring technological method, by reasonably setting the ranges of all technological parameters, the shell cases can be colored with different colors according to the production needs, the technological parameters are suitable for coloring of different colors, and a coloring technology is uniform and stable in quality; the optimum ratio of high-concentration metal saltand an acid solution is utilized in coloring liquid, and thus quick and uniform coloring is achieved; a pH value of a coloring agent is stabilized through a buffering agent, thus the high-concentration metal salt can be in a stable environment and does not generate metal precipitation when an electrochemical reaction occurs on a metal interface, thus metal ions are reduced in micropores of an anodic oxide film, and quick and dark coloring is further promoted.

Owner:HUNAN UNIV OF TECH

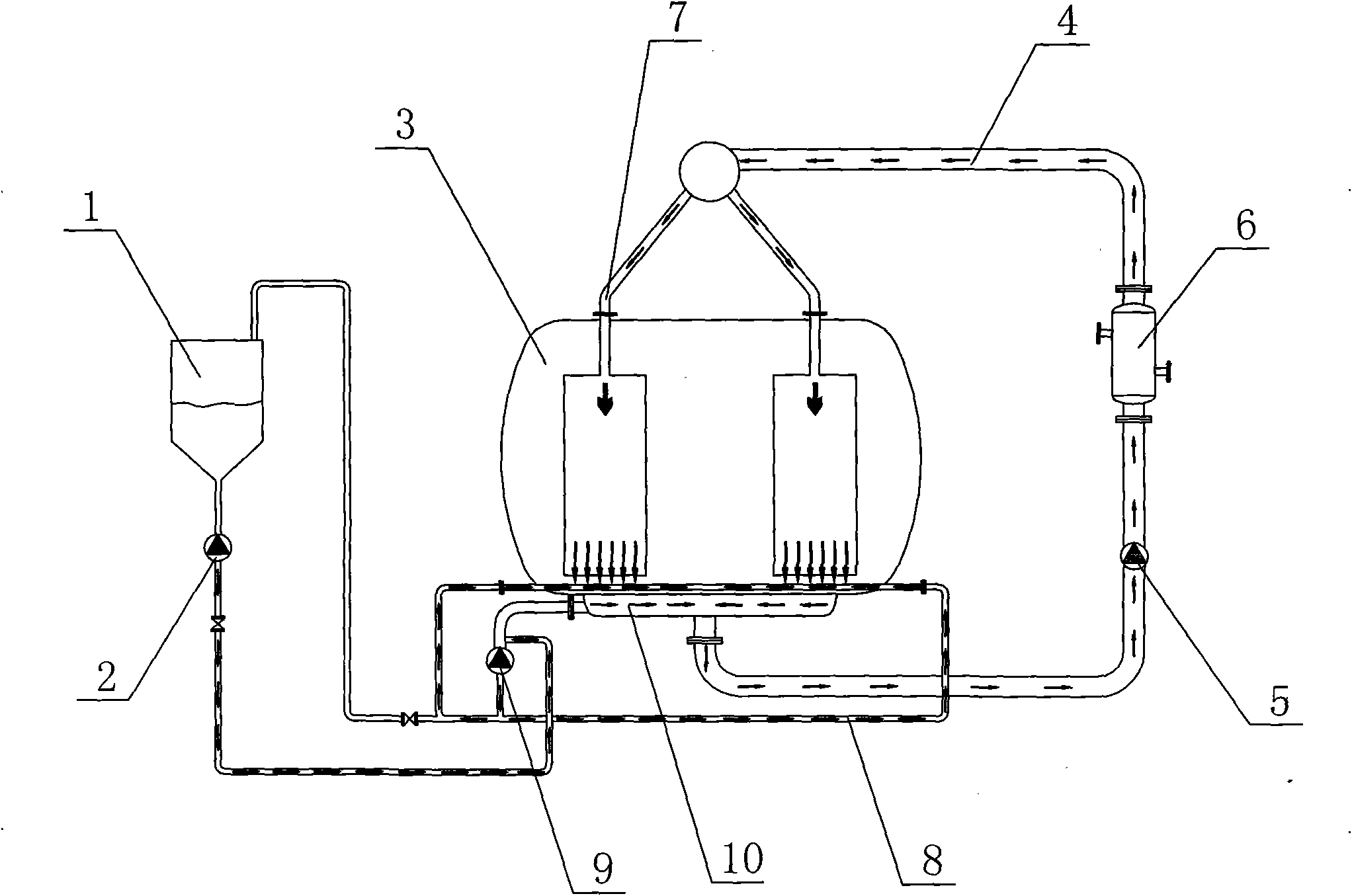

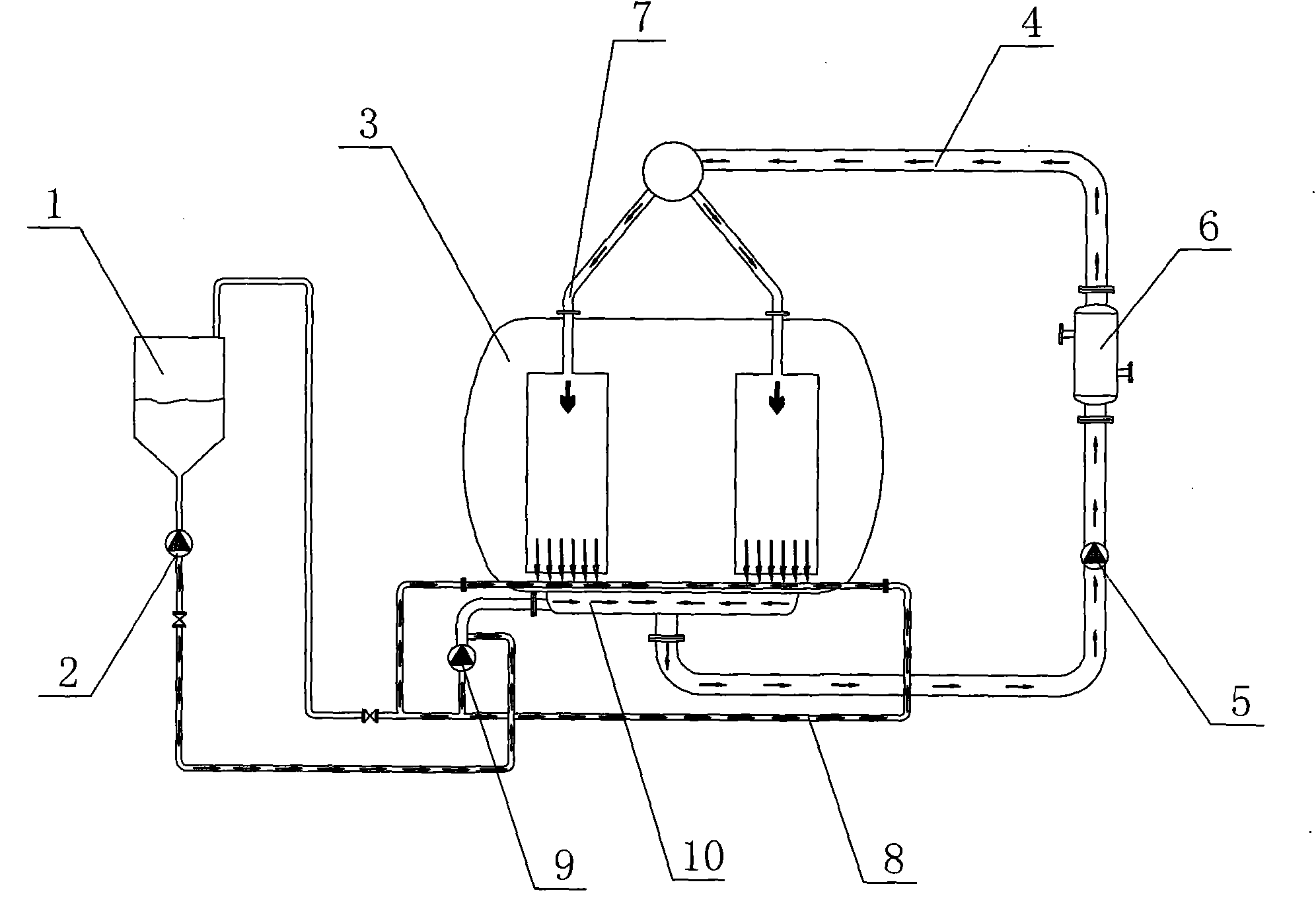

Dye liquor traverse circulating system of dyeing machine

InactiveCN101974836AAchieve thorough horizontal mixingReduce generationTextile treatment machine arrangementsCost effectivenessSewage

The invention discloses a dye liquor traverse circulating system of a dyeing machine, which comprises a dye liquor tank and a main circulating pipeline for communicating the top and the bottom of the barrel body of the dyeing machine, wherein the dye liquor tank is communicated with the main circulating pipeline through a dye liquor pump; a main pump and a heater are arranged on the main circulating pipeline; the dye liquor pump is communicated with the main circulating pipeline through a traverse circulating pipeline; a circulating pump is arranged on the traverse circulating pipeline; the bottom of the barrel body of the dyeing machine is provided with a dye liquor traverse blending cavity communicated with the bottom of the barrel body of the dyeing machine; and the dye liquor traverse blending cavity is communicated with the main circulating pipeline. The dye liquor traverse circulating system of the dyeing machine has the advantages that the water consumption can be obviously reduced; the generation of sewage is reduced; the usage of chemical auxiliaries is reduced; the energy consumption is reduced; the dyeing processing cycle is shortened; the cleaning production capacity and the cost efficiency of dyeing enterprises can be enhanced simultaneously; and the product produced by the dyeing machine has the advantages of good dyeing quality, uniform coloring, bright color, strong color fastness, special softness and overhanging feeling, and high additional value of the product.

Owner:WUXI XINDA DYEING MACHINE FACTORY

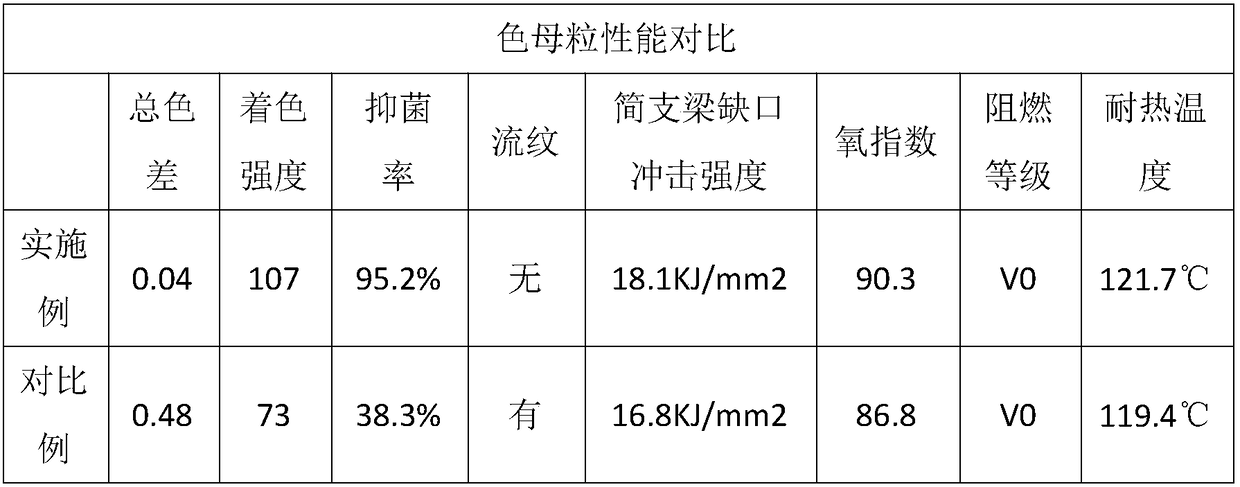

High-dispersion flame-retardant ABS color masterbatch and preparation method thereof

The invention discloses high-dispersion flame-retardant ABS color masterbatch. The color masterbatch is prepared from the following raw materials in parts by weight: 40-60 parts of polystyrene, 20-30parts of an inorganic pigment, 4-6 parts of a composite dispersant, 10-15 parts of fibers, 6-9 parts of a magnesium hydroxide flame retardant, and 0.1-1 part of a filler. The ABS color masterbatch provided by the invention has good dispersibility and flame retardance, low processing costs and a simple preparation process; the bamboo charcoal fibers are added, so that the antibacterial rate is up to 90% or more, the ultraviolet transmittance is low, and the anti-aging performance is strong; and when the color masterbatch is applied to coloring of an ABS product, the color masterbatch has the advantages of uniform coloring, good flame retardance, good antibacterial performance, high color stability, small color difference and no influence on mechanical properties of the plastic product.

Owner:合肥卡洛塑业科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com