Terylene air-jet textured yarn fabric with high color fastness

A technology of high color fastness and air-varying yarn, applied in the field of fabrics, can solve the problems of uneven penetration of dye liquor, small motion binding force, low service life, etc., to improve the difficulty of coloring, improve compatibility and improve service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Adopt the following method to prepare air variable yarn fabric with high color fastness:

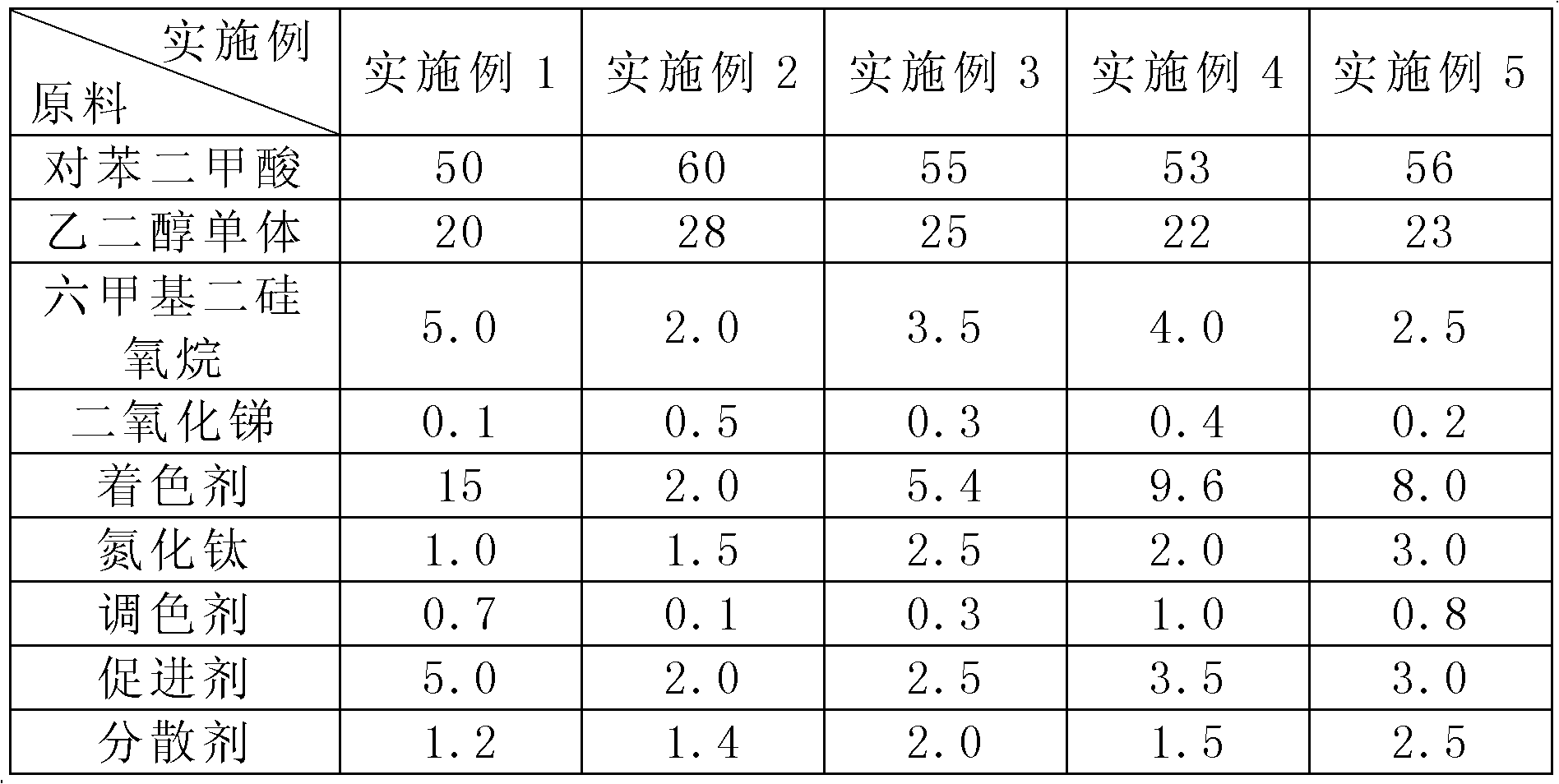

[0059] A. Preparation of polyester chips: Add terephthalic acid, ethylene glycol, antimony dioxide and hexamethyldisiloxane into continuous polyester equipment according to the percentage by weight of each raw material in Example 1 of the above table 1 Ester reaction, the polyester reaction temperature is 240 ° C ~ 250 ° C, so that the polymerization rate is 96%, the reaction is completed, and the modified polyester melt is obtained, and the above-mentioned modified polyester melt is passed through the casting belt, pelletizing, Dried to obtain polyester chips;

[0060] B. Preparation of color masterbatch: Add the above-mentioned polyester chip, colorant, titanium nitride, toner, accelerator, dispersant, flame retardant, antioxidant and stabilizer into a plastic extruder for extrusion The color masterbatch is obtained by granulation; the extrusion temperature of each section of t...

Embodiment 2-5

[0064] A polyester air-converted yarn fabric with high color fastness, the specific preparation method is consistent with the method described in Example 1, the difference is that the weight ratio of the raw materials used to prepare the polyester air-converted yarn is according to Examples 2-5 in Table 1 The specific weight proportion of corresponding embodiment is chosen.

Embodiment 6

[0066] Adopt the following method to prepare air variable yarn fabric with high color fastness:

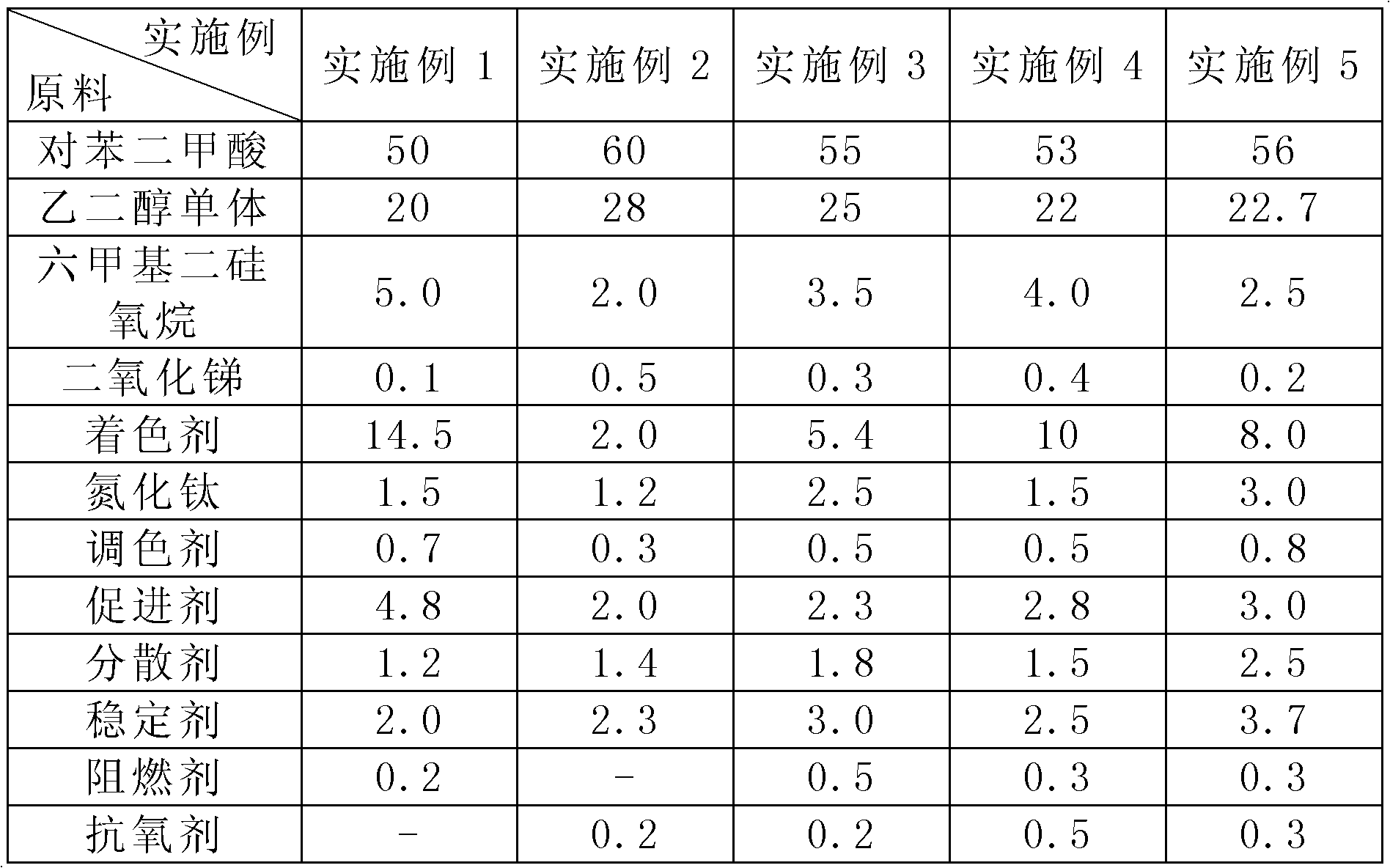

[0067] A. Preparation of polyester chips: according to the weight percentage of each raw material in the above-mentioned Table 2 Example 6, terephthalic acid, ethylene glycol, antimony dioxide and hexamethyldisiloxane are added to the continuous polyester equipment for polymerization Ester reaction, the polyester reaction temperature is 240 ° C ~ 245 ° C, so that the polymerization rate is 98%, the reaction is completed, and the modified polyester melt is obtained, and the above-mentioned modified polyester melt is passed through the casting belt, pelletizing, Dried to obtain polyester chips;

[0068] B. Preparation of color masterbatch: Add the above-mentioned polyester chip, colorant, titanium nitride, toner, accelerator, dispersant, flame retardant, antioxidant and stabilizer into a plastic extruder for extrusion The color masterbatch is obtained by granulation; the extrusion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com