Multi-color spraying process

A multi-color and process technology, applied in the direction of coating, liquid coating device on the surface, surface pretreatment, etc., can solve the problems of reducing the appearance aesthetics, rough surface of the coating layer, paint leakage, etc., to avoid mutual penetration or fusion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

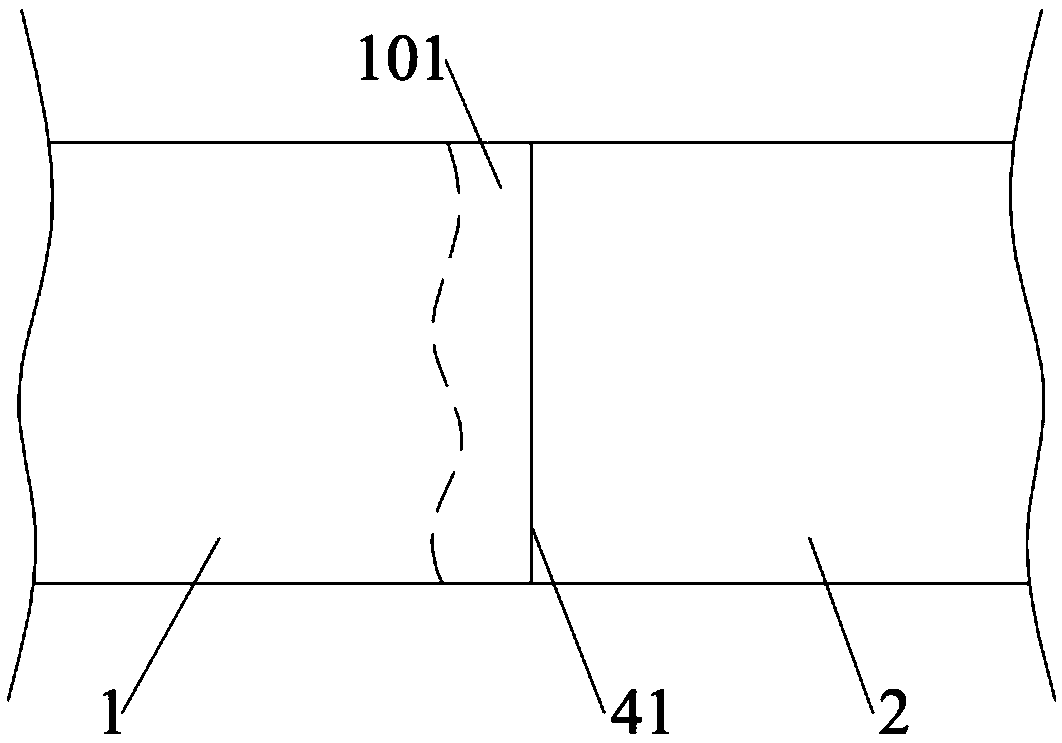

[0038] Such as Figures 1 to 2 As shown, this embodiment provides a multi-color spraying process for forming colors on a surface. The surface is the shell surface of an electronic device, may be the shell surface of a mobile phone, or may be the shell surface of a computer, and the material of the shell of the electronic device may be metal or plastic. A surface consists of at least two regions such as figure 1 As shown, the two adjacent areas are the first area 1 and the second area 2 respectively, there is a first dividing line 41 between the first area 1 and the second area 2, and the first area 1 is close to the second area 2 Part of the area is the first sub-area 101 .

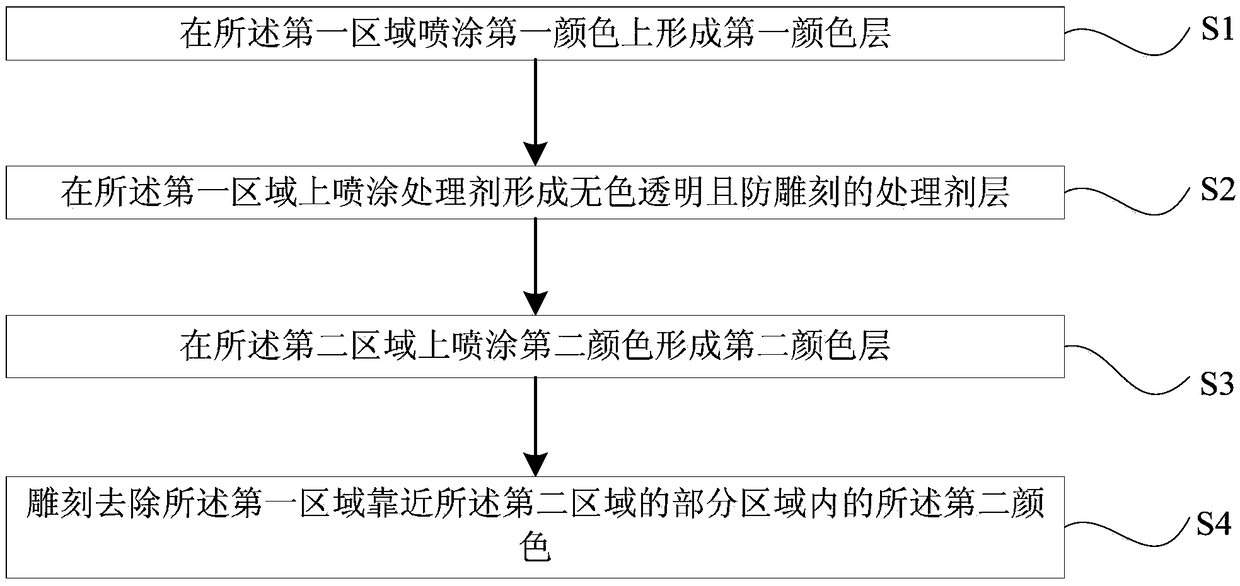

[0039] figure 2 It is the flow chart of multi-color spraying process in the present embodiment, with reference to figure 2 The multi-color spraying process is described in detail as follows:

[0040] S1: Spraying a first color on the first area 1 to form a first color layer.

[0041] S2: Spraying ...

Embodiment 2

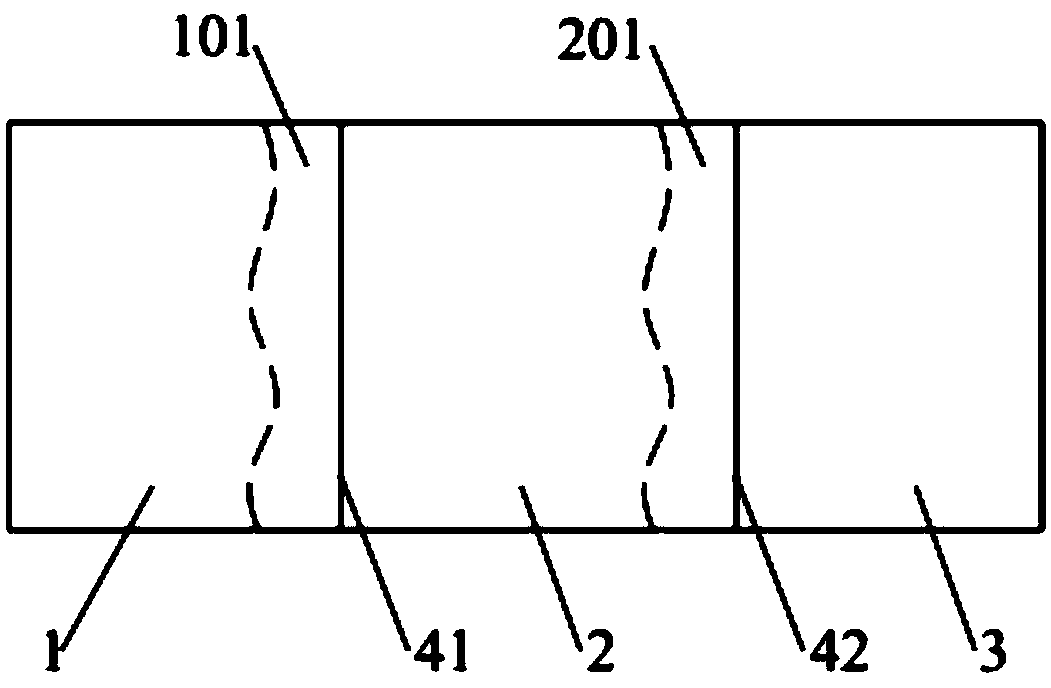

[0050] Such as image 3 As shown, when the surface includes three areas, respectively the first area 1, the second area 2 and the third area 3, the second area 2 is located between the first area 1 and the third area 3, the first area 1 and the third area There is a first boundary line 41 between the two regions 2, a second boundary line 42 between the second region 2 and the third region 3, and a part of the first region 1 close to the first boundary line 41 is the first sub-region 101, Part of the second area 2 close to the second boundary line 42 is the second sub-area 201 .

[0051] Figure 4 It is the flow chart of multi-color spraying process in the present embodiment, with reference to Figure 4 The multi-color spraying process is described in detail as follows:

[0052] S11: Spraying a first color on the first area 1 to form a first color layer.

[0053] S12: Spraying a treatment agent on the first area 1 to form a colorless, transparent and anti-engraving treatmen...

Embodiment 3

[0066] This embodiment provides a multi-color spraying process. The difference from Embodiment 2 is that the part of the third area 3 close to the second dividing line 42 is the third sub-area 301, such as Figure 5 shown.

[0067] Figure 6 It is the flow chart of color spraying process in the present embodiment, with reference to Figure 6 The color spraying process is described in detail as follows:

[0068] S101: Spraying a first color on the first area 1 to form a first color layer, and spraying a third color on the third area 3 to form a third color layer.

[0069] S102: Spraying a treatment agent on the first region 1 and the third region 3 to form a colorless, transparent and anti-engraving treatment agent layer.

[0070] S103: Spraying a second color on the second region 2 to form a second color layer.

[0071] When spraying the second color in the second area 2, the range of the second color actually sprayed generally also includes the first sub-area 101 where th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com