Manufactured sand high-impermeability dry-mixed decorative mortar

A technology for decorative mortar and machine-made sand, applied in the field of building materials, can solve the problems of poor impermeability and waterproof ability of mortar, contrary to expected functions of mortar, and increase in cost of mortar, so as to meet the needs of aesthetics, sufficient operating time, and impermeability. The effect of improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A machine-made sand high-impermeability dry-mixed decorative mortar. The raw materials for preparing the mortar include the following materials in parts by weight: 15 parts of ordinary Portland cement, 2.8 parts of fly ash, 81 parts of aggregate machine-made sand, and 0.4 parts of binder part, 0.8 part of anti-cracking and seepage reducing agent, and 0.09 part of water reducing agent; the specific preparation method is as follows:

[0032] Weigh each component material (cementing material, aggregate, admixture) for preparing the mortar according to the ratio, and dry-mix fully; according to the set water-binder ratio of 0.48, weigh the water consumption, and then mix each group after dry-mixing Pour it into the mixing container. The mixing procedure is: after stirring slowly at a low speed (130-150r / min) for 60s, scrape the powder adhered to the wall into the slurry, and then stir quickly (250-300r / min). After 180s, the machine-made sand high impermeability decorative m...

Embodiment 2

[0036] A machine-made sand high-impermeability dry-mixed decorative mortar. The raw materials for preparing the mortar include the following materials in parts by weight: 17 parts of ordinary Portland cement, 0.5 parts of calcined sludge, 3.5 parts of fly ash, and inorganic iron oxide red pigment 0.5 parts, 77 parts of aggregate machine-made sand, 0.5 parts of binder, 1 part of anti-cracking and seepage reducing agent, 0.086 parts of water reducing agent;

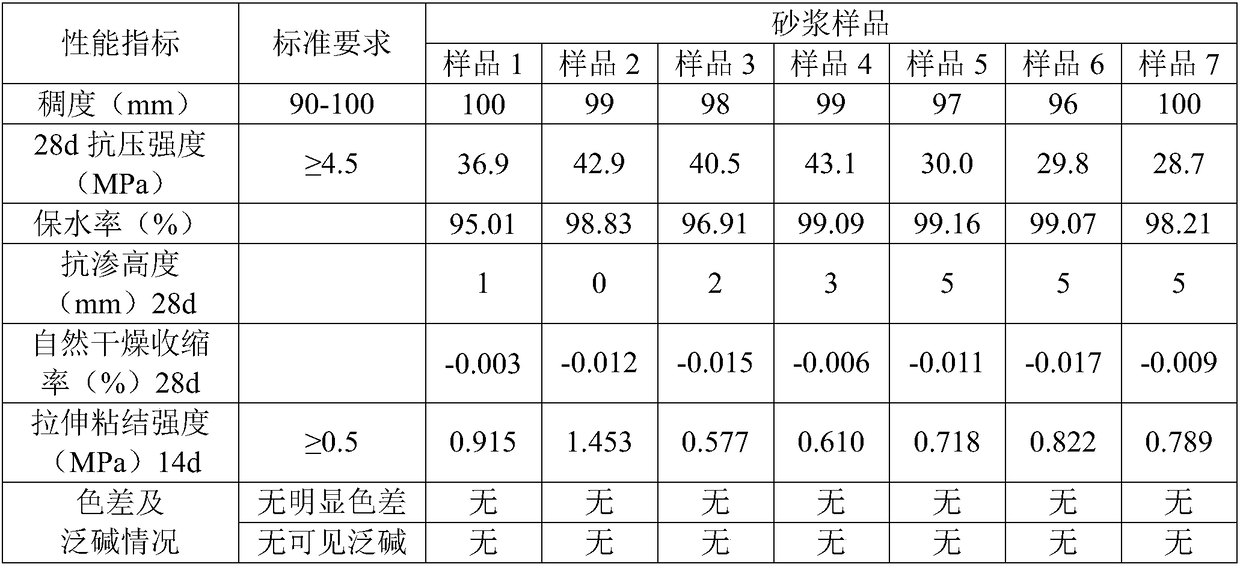

[0037] Mortar was prepared by the same method as in Example 1 with a water-binder ratio of 0.39, and the performance parameters of the mortar were tested by the same test method as in Example 1. See sample 2 in Attached Table 1 for specific results.

[0038] From the data of sample 2 in attached table 1, it can be seen that the compressive strength of the prepared mortar reaches 42.9MPa, and the anti-water osmotic pressure reaches 1.5MPa (Note: the maximum water pressure value set by the mortar impermeability instrument, the...

Embodiment 3

[0040] A machine-made sand high-impermeability dry-mixed decorative mortar. The raw materials for preparing the mortar include the following materials in parts by weight: 16 parts of ordinary Portland cement, 3 parts of fly ash, 0.6 parts of inorganic iron oxide red pigment, aggregate mechanism 79 parts of sand, 0.5 parts of binder, 0.9 parts of anti-cracking and seepage reducing agent, and 0.078 parts of water reducing agent;

[0041]The water-binder ratio is 0.42 and the same method as in Example 1 is used to prepare mortar, and the same test method as in Example 1 is used to test the performance parameters of the mortar. For specific results, see Sample 3 in Attached Table 1.

[0042] From the data of sample 3 in attached table 1, it can be seen that the compressive strength of the prepared mortar reaches 40.5MPa, and the anti-water osmotic pressure reaches 1.5MPa (Note: the maximum water pressure value set by the mortar impermeability instrument, the same below) There is n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com