High-solid phenolic aldehyde epoxy glass scale anti-corrosion paint and preparation method thereof

A technology of phenolic epoxy glass and high solid content, which is applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of environmental and construction personnel health hazards, short maintenance period, VOC emissions, etc., and achieve excellent chemical resistance Corrosion resistance, maintenance cost saving, and the effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

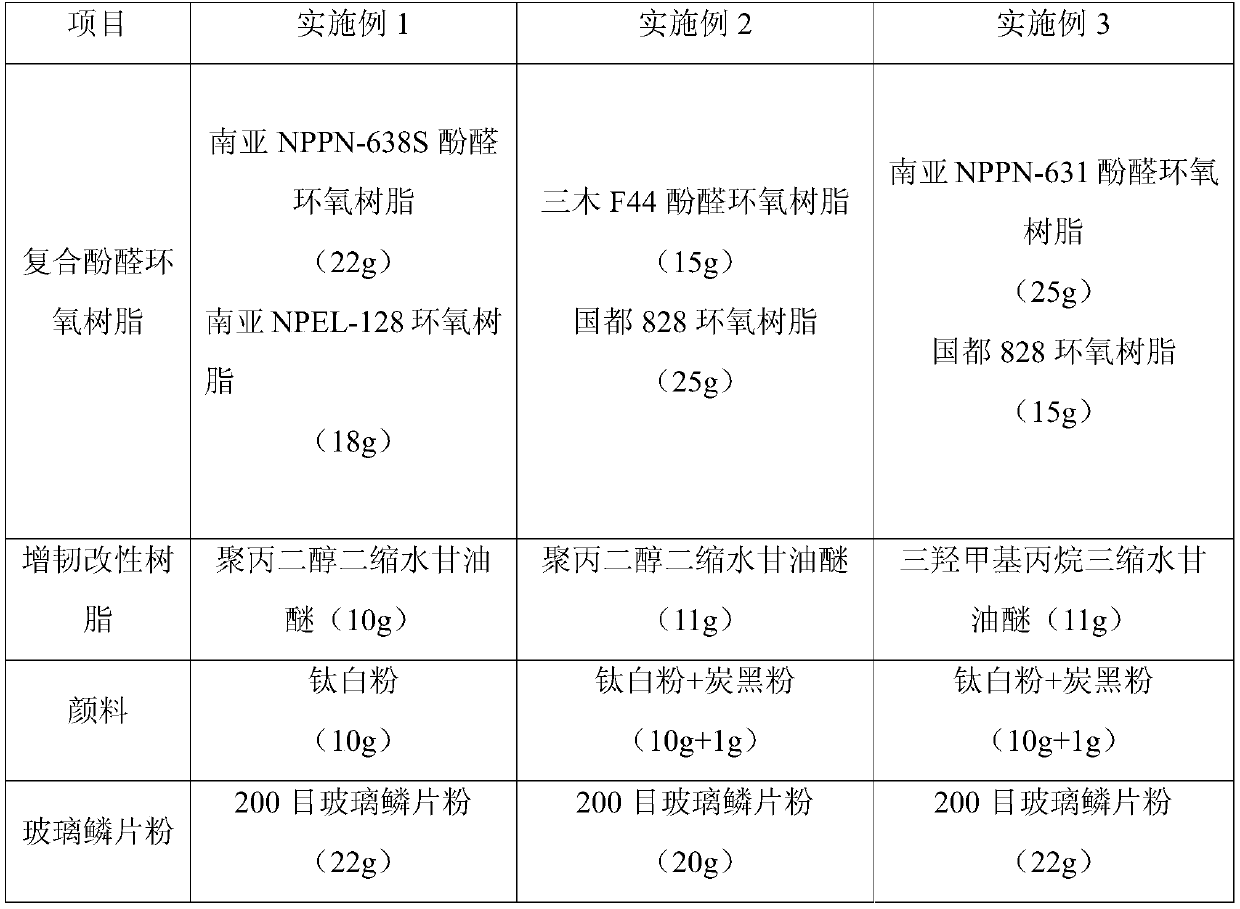

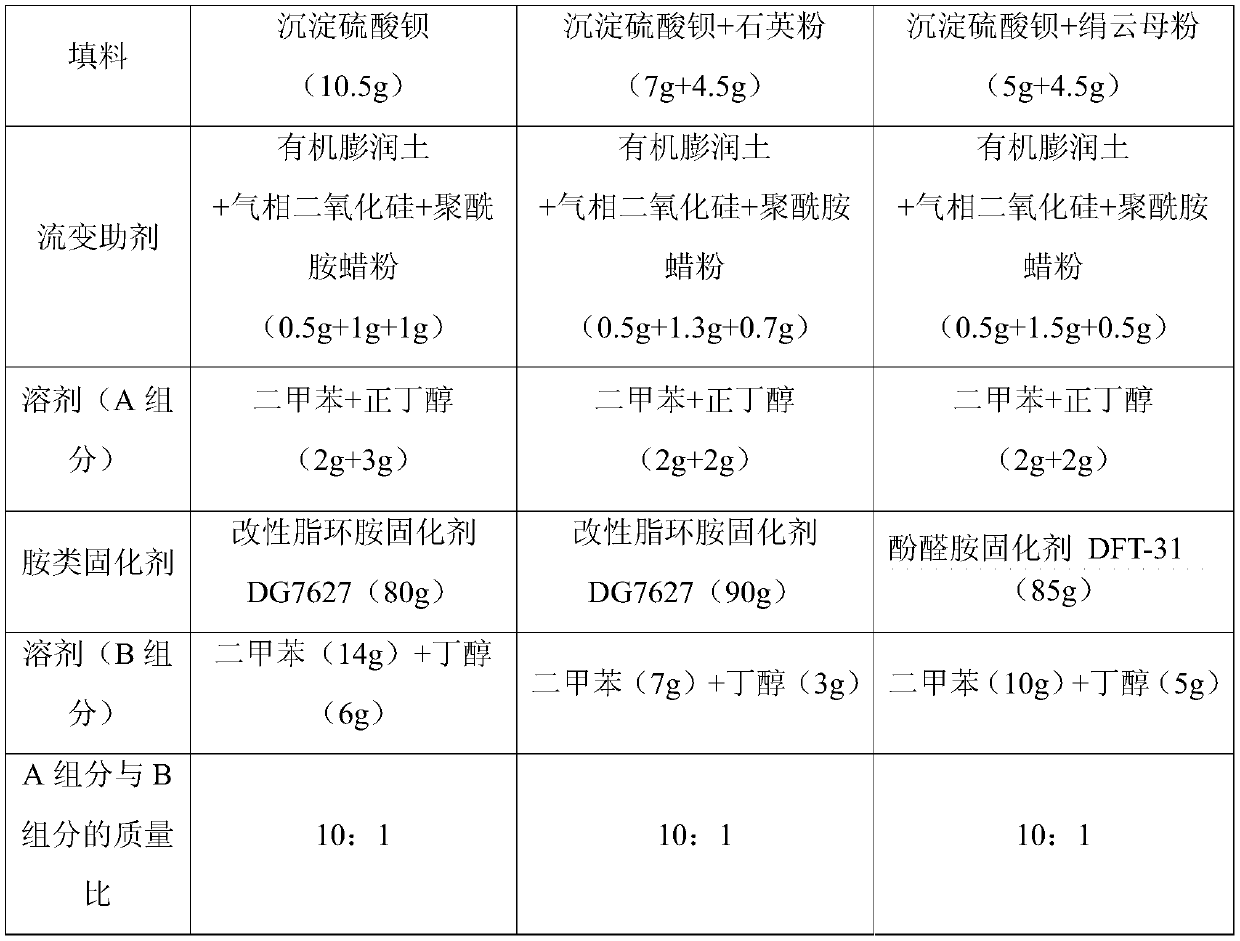

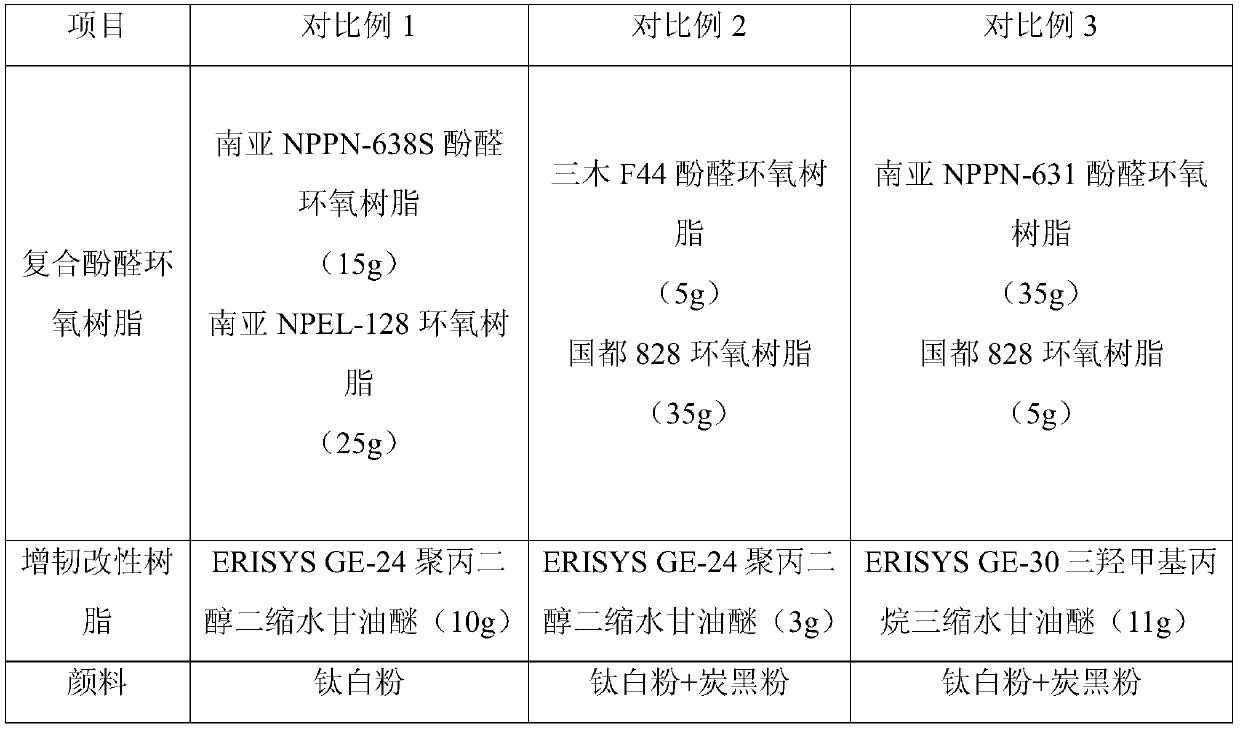

Embodiment 1~3 and comparative example 1~3

[0040] The preparation method of embodiment 1~3 and comparative example 1~3:

[0041] The preparation method of A component comprises the steps:

[0042] First, the composite novolac epoxy resin, toughened modified resin and solvent are stirred and dispersed at high speed to obtain a mixture; secondly, rheological additives are added to the mixture and dispersed evenly at high speed, and finally pigments and fillers are added to the mixture, stirred at high speed and dispersed evenly, and then put into grinding Machine dispersion to a fineness of ≤40μm; after grinding, add glass flake powder to disperse evenly at high speed, add xylene and mix evenly, and set aside;

[0043] The preparation method of B component comprises the steps:

[0044] Add the formula amount of amine curing agent and solvent into the stirring tank, disperse evenly at high speed, and set aside;

[0045] The mass ratio of A component and B component is 10:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com