Hollow blow-molded micro-foamed automobile air duct material and preparation method thereof

A micro-foaming and automotive technology, applied in the field of materials, can solve the problems of excessive toxic volatile organic compound VOC, unstable outer EVA foam size, high failure rate of assembly assembly, etc., achieve good long-term thermal aging performance, reduce VOC release amount and the effect of meeting the requirements of VOC standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

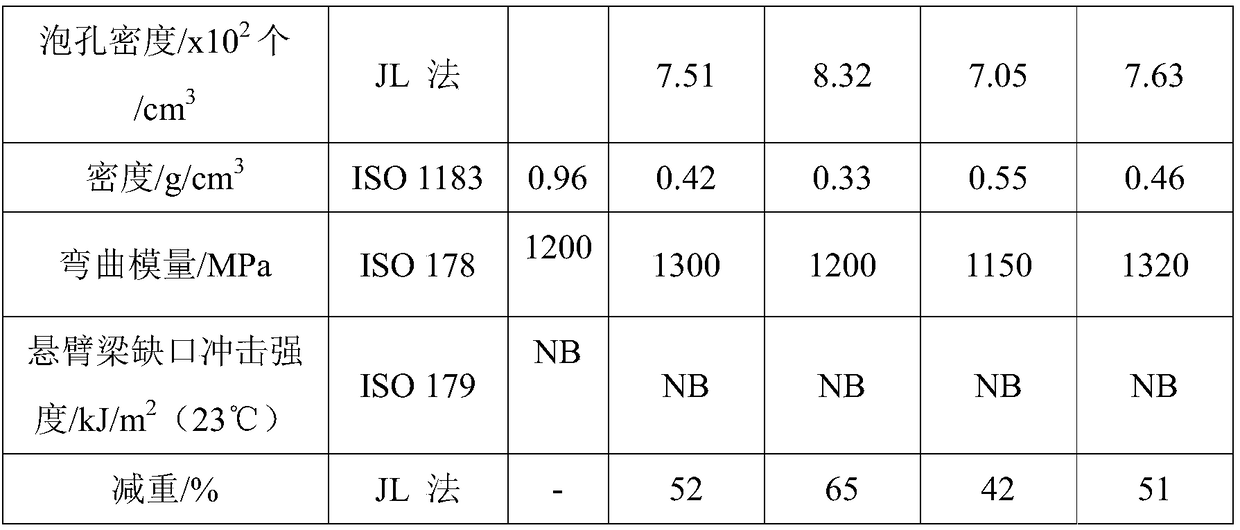

Embodiment 1

[0037] A preparation method for hollow blow molding micro-foamed automobile air duct material, comprising the following steps:

[0038] Step 1: Mix 50 parts of high-density polyethylene, 1 part of tert-butyl peroxybenzoate, 10 parts of talcum powder, and 10100.2 parts of antioxidant in a mixer for 1-3 minutes according to certain parts by weight, and add them to the double In a screw extruder, granulate at a temperature of 160-200°C and a screw speed of 200-400r / min to obtain a polyethylene composite material;

[0039] Step 2: Fully mix 1.6 parts of OBSH and 6.4 parts of DPT in a high-mixer in advance, and then add them to the single-screw blow molding machine from the side feeding port; at the same time, the polyethylene composite material, PET Add 30 parts, 1 part of organically modified montmorillonite, 1 part of organic silicone oil, 1 part of EBS, and 2 parts of maleic anhydride graft-modified POE into the single-screw blow molding machine barrel; at a temperature of 150-...

Embodiment 2

[0041] A preparation method for hollow blow molding micro-foamed automobile air duct material, comprising the following steps:

[0042] Step 1: Mix 60 parts of high-density polyethylene, 20 parts of linear low-density polyethylene, 0.5 parts of lauroyl peroxide, 15 parts of calcium carbonate, and 0.5 parts of antioxidant 168 in a mixer for 1-3 minutes according to certain parts by weight , fed into a twin-screw extruder through a hopper, granulated at a temperature of 160-200°C, and a screw speed of 200-400r / min, to obtain a polyethylene composite material;

[0043] Step 2: Fully mix 1 part of OBSH and 9 parts of NTA in a high-mixer in advance, and then feed it into the single-screw blow molding machine from the side feeding port; at the same time, mix 1 part of polyethylene composite material and PET obtained in step 1 , 3 parts of nano-silica, 4 parts of silicone oil, 3 parts of EBS, and 5 parts of maleic anhydride graft-modified POE are added to the barrel of a single-screw...

Embodiment 3

[0045] A preparation method for hollow blow molding micro-foamed automobile air duct material, comprising the following steps:

[0046]Step 1: Mix 60 parts of high-density polyethylene, 0.2 parts of tert-butyl peroxy tert-butyl valerate, and 10100.3 parts of antioxidant in a mixer for 1-3 minutes, and add them to a twin-screw extruder through a hopper. Pelletizing at -200°C, with a screw speed of 200-400r / min, to obtain polyethylene composites;

[0047] Step 2: Fully mix 0.2 parts of p-toluenesulfonylhydrazide and 0.3 parts of NTA in a high-mixer in advance, and then add them to the single-screw blow molding machine from the side feed port; at the same time, the polyethylene composite material obtained in Step 1 , 10 parts of PBT, 2 parts of organically modified montmorillonite, 2 parts of polyethylene glycol ether, 1 part of stearic acid, and 4 parts of maleic anhydride grafted SEBS are added to the single-screw blow molding machine barrel; at 150-200 Blow molding at ℃ tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com