Patents

Literature

137results about How to "Good rigidity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of tensile compressive high temperature resistant modified polypropylene power pipe

The invention discloses a preparation method of a tensile compressive high temperature resistant modified polypropylene power pipe. The pipe comprises 100 weight parts of modified polypropylene, 0.5-15 weight parts of tackifier, 0.1-15 weight parts of nano material, 0.1-15 weight parts of liquid crystal material, 0.5-15 weight parts of shock resistant modifier, 0.1-15 weight parts of nucleating agent, 0-30 weight parts of filling masterbatch, 0.1-5 weight parts of color masterbatch, 0.5-30 weight parts of engineering plastic, 0.5-15 weight parts of compatibilizer, 0.05-5 weight parts of antioxidant, and 0.05-5 weight parts of light stablilizer, and is prepared by carrying out mixing granulation on the raw materials and then conducting extrusion molding through a mold. According to the invention, compared with existing MPP pipe, the bending strength of the produced MPP pipe disclosed herein is raised by 30-50%, the bending elastic modulus is raised by 25-60%, the welding tensile strength reaches 26-33 MPa, 70 DEG C ring hot compression force is raised by 30-50%, the photooxidation aging resistant time is prolonged by 5-15 years, the vicat softening point is raised by 5-20 DEG C, the shock strength and corrosion resistance are good, thus the produced MPP pipe disclosed herein can meet the requirements for high standard quality electric power engineering, and the engineering cost is reduced.

Owner:HONGYUE PLASTIC GROUP

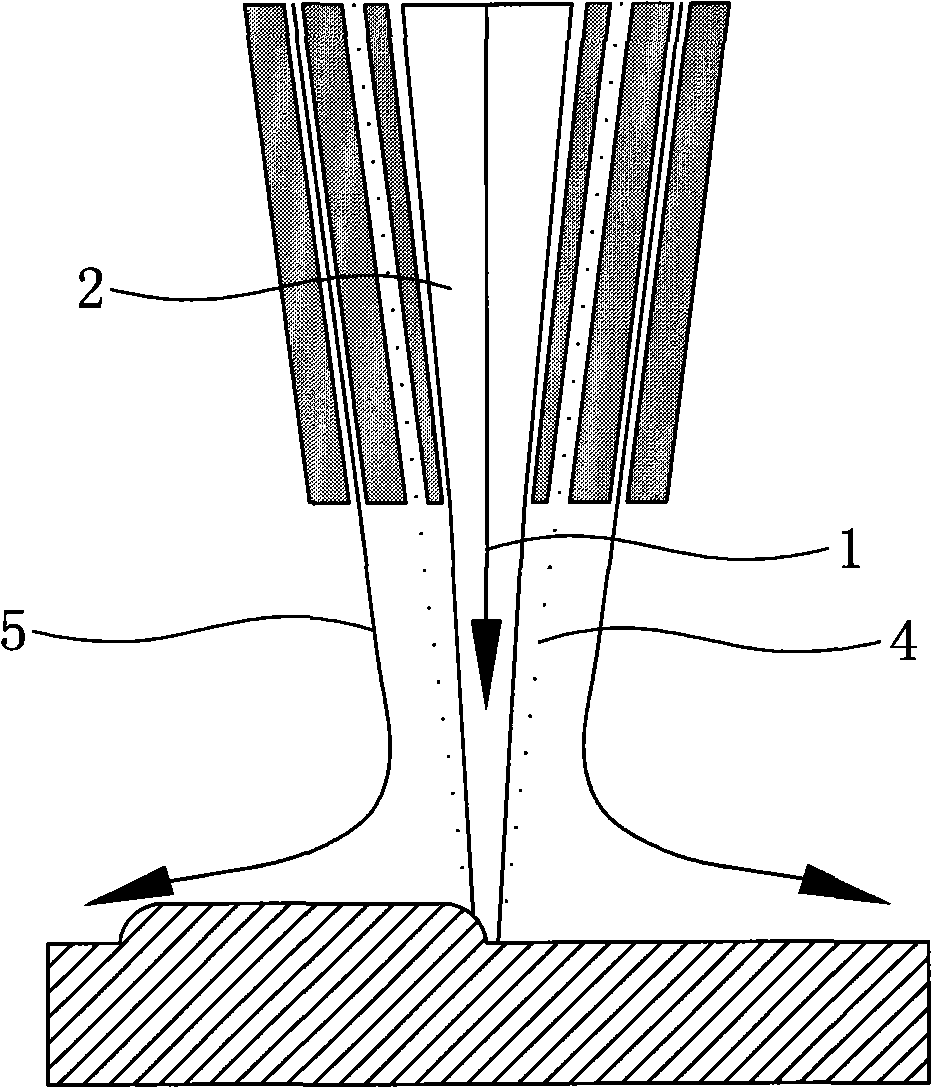

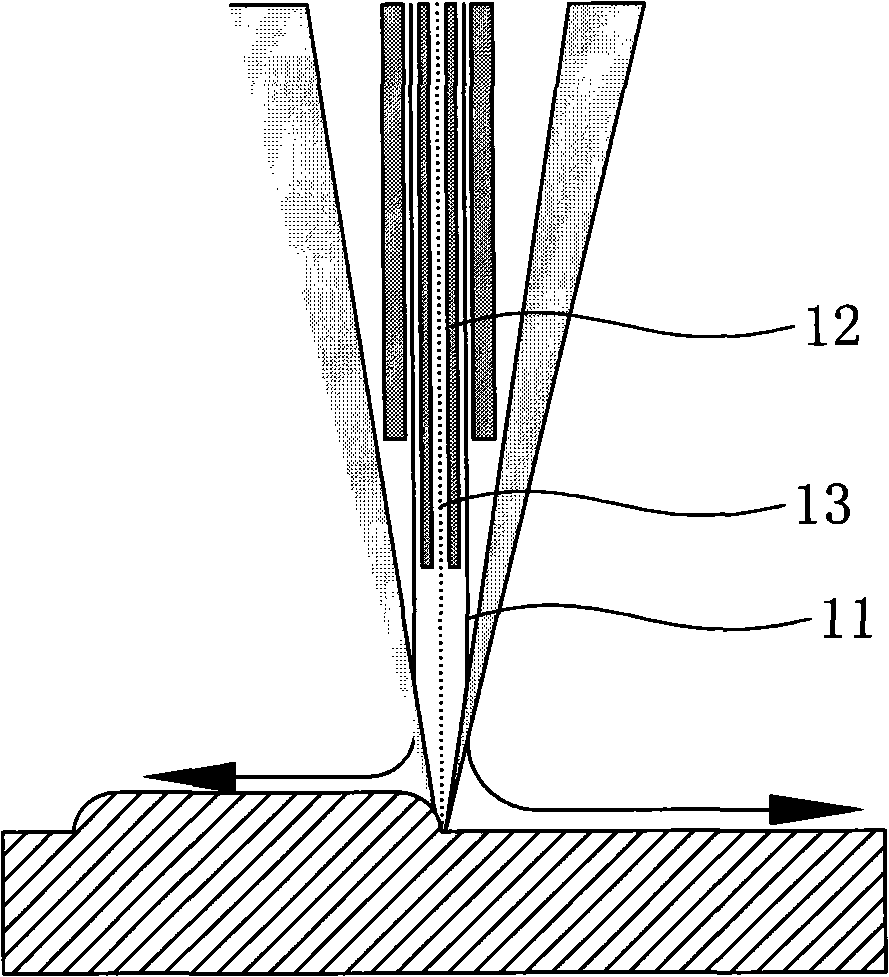

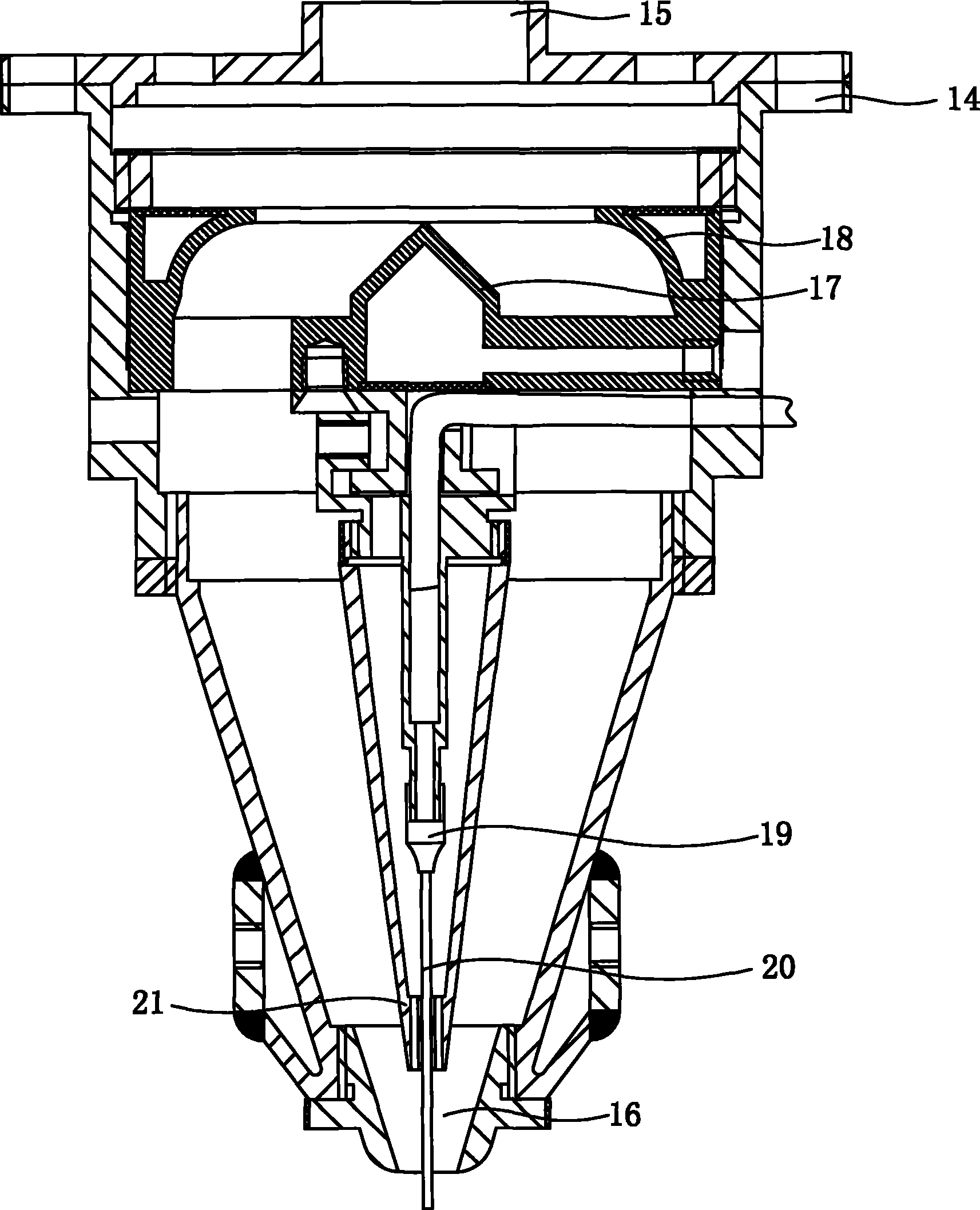

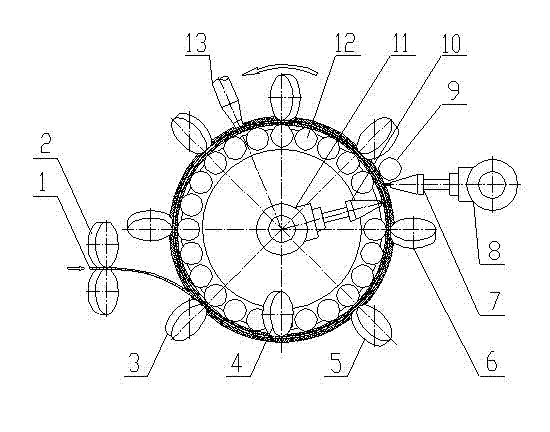

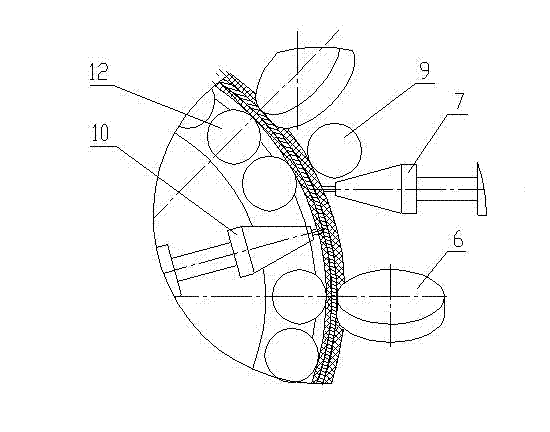

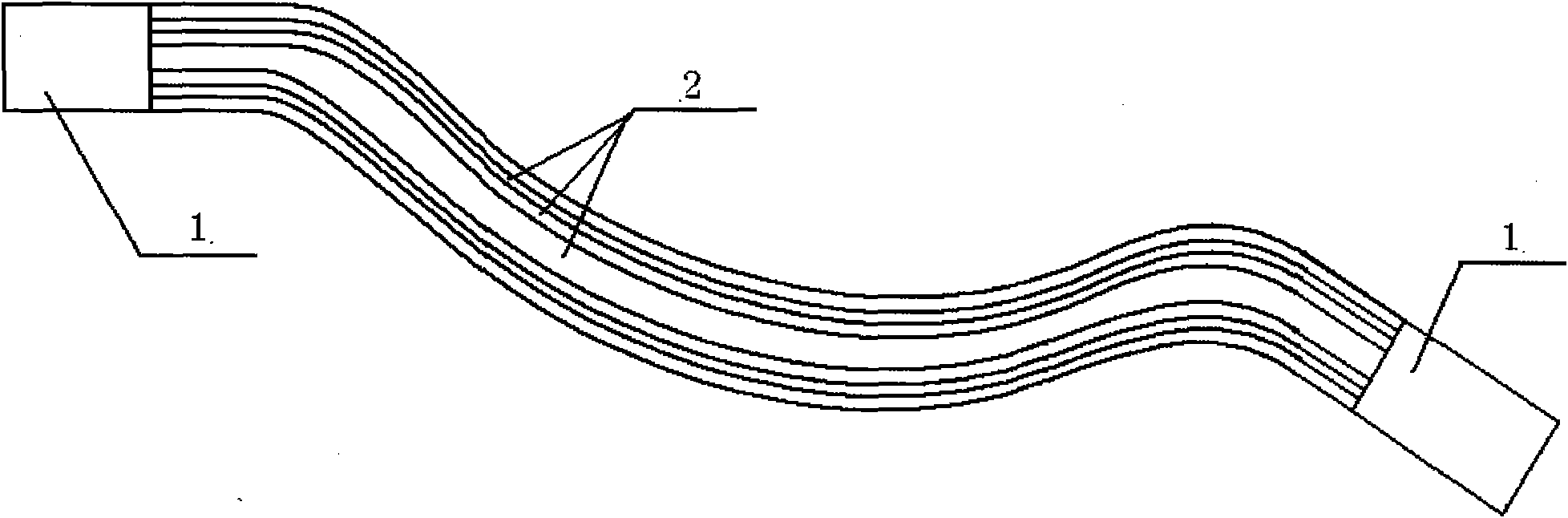

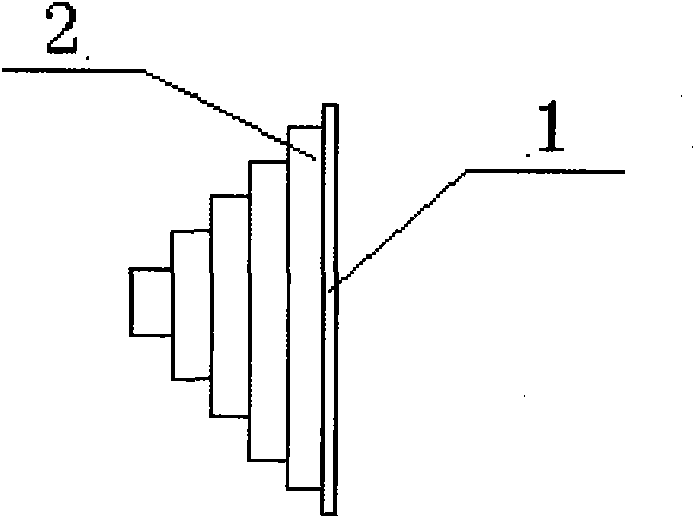

Method and device for light, powder and gas coaxial transmission laser cladding forming manufacturing

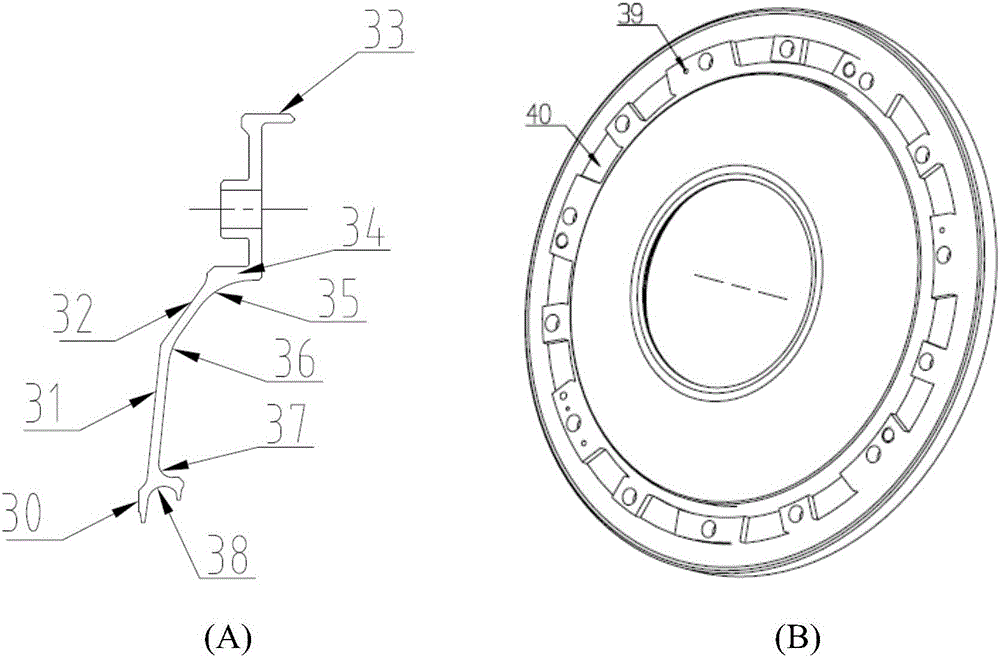

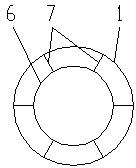

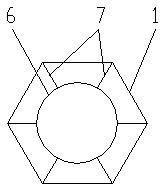

InactiveCN101774084AGood rigidityReduce divergenceMetallic material coating processesLaser beam welding apparatusOptical pathCircular section

The invention discloses a method for light, powder and gas co-axial transmission laser cladding forming manufacturing, which is characterized in that: a circular section solid laser beam emitted by a laser is subjected to transformation and beam expansion by the optical path transformation to become a circular laser beam; the circular laser beam is focused to become a hollow circular cone focused laser beam; a powder spraying nozzle is arranged on the hollow part of the circular cone focused laser beam; the powder spraying nozzle and the circular cone focused laser beam are coaxial; the periphery of a single powder beam sprayed by the powder spraying nozzle is provided with a circle of collimation shielding gas curtain; and the collimation shielding gas curtain, the circular cone focused laser beam and the single powder beam sprayed by the powder spraying nozzle are coaxial. By arranging the collimation shielding gas curtain on the periphery of the powder beam, the method realizes the coaxial transmission of light, powders and gas and solves the defects in the prior art.

Owner:SUZHOU UNIV

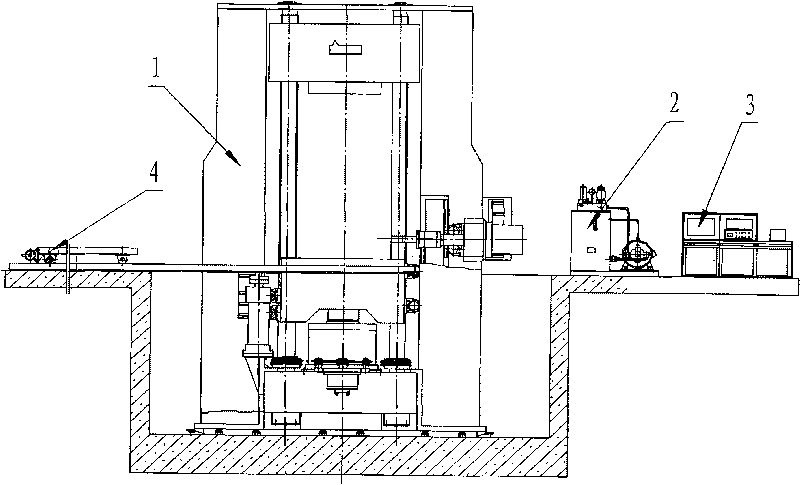

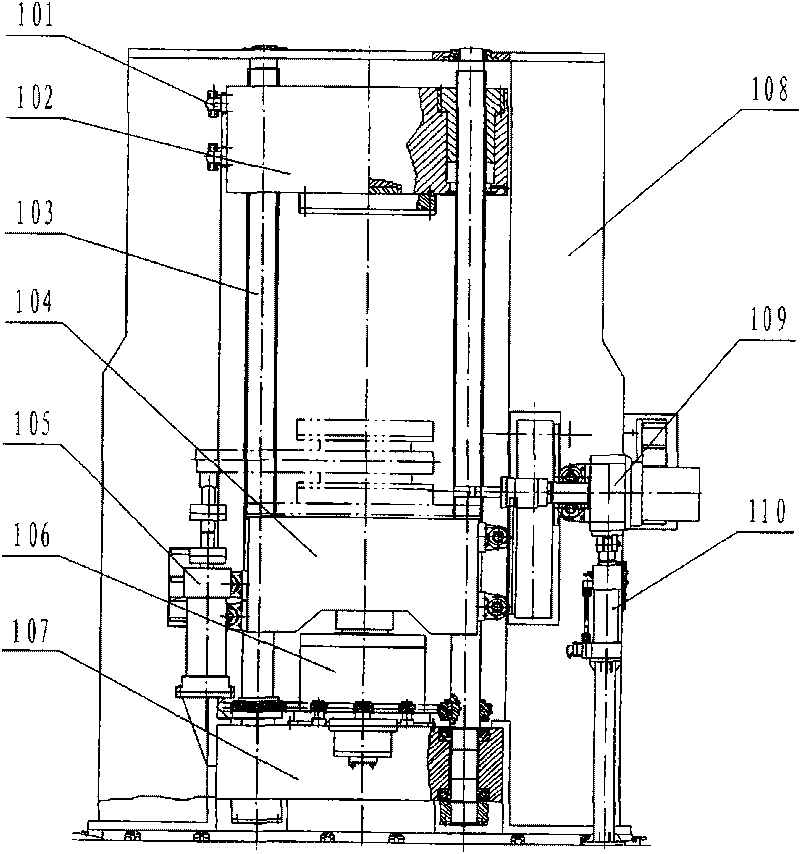

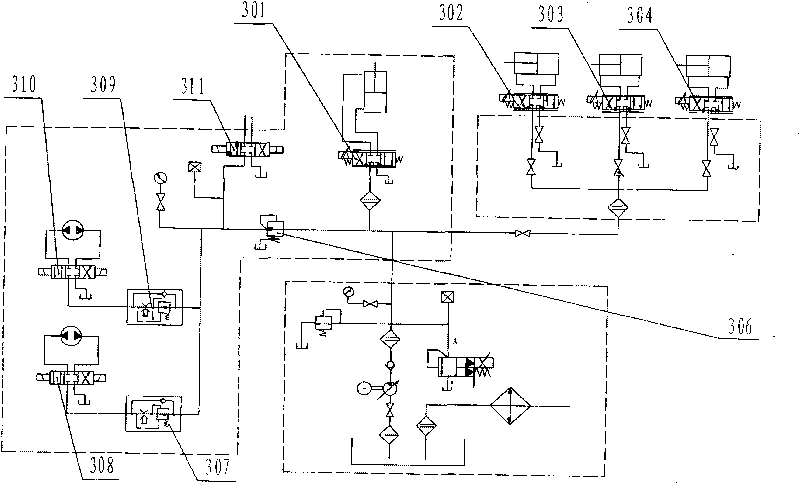

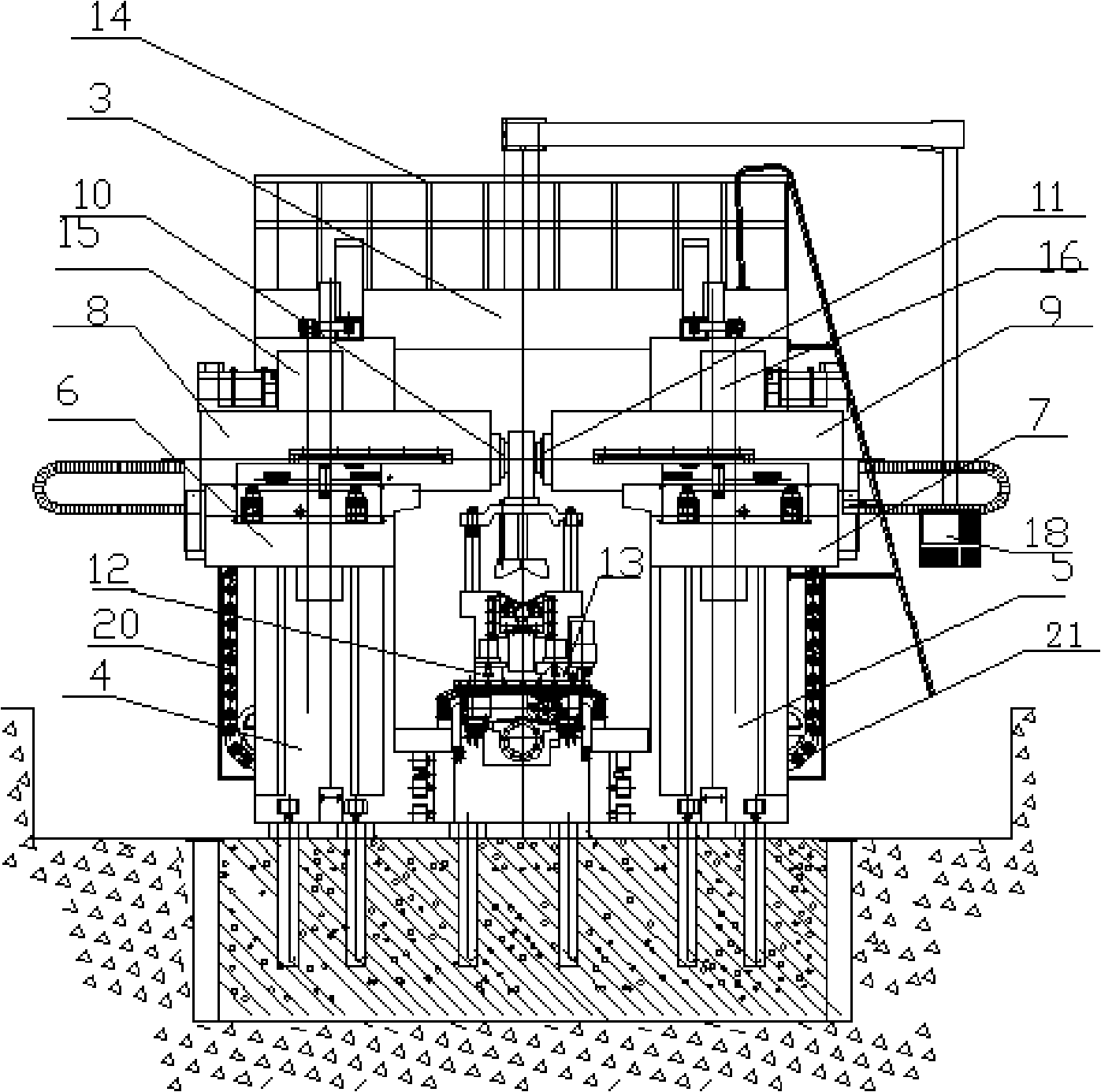

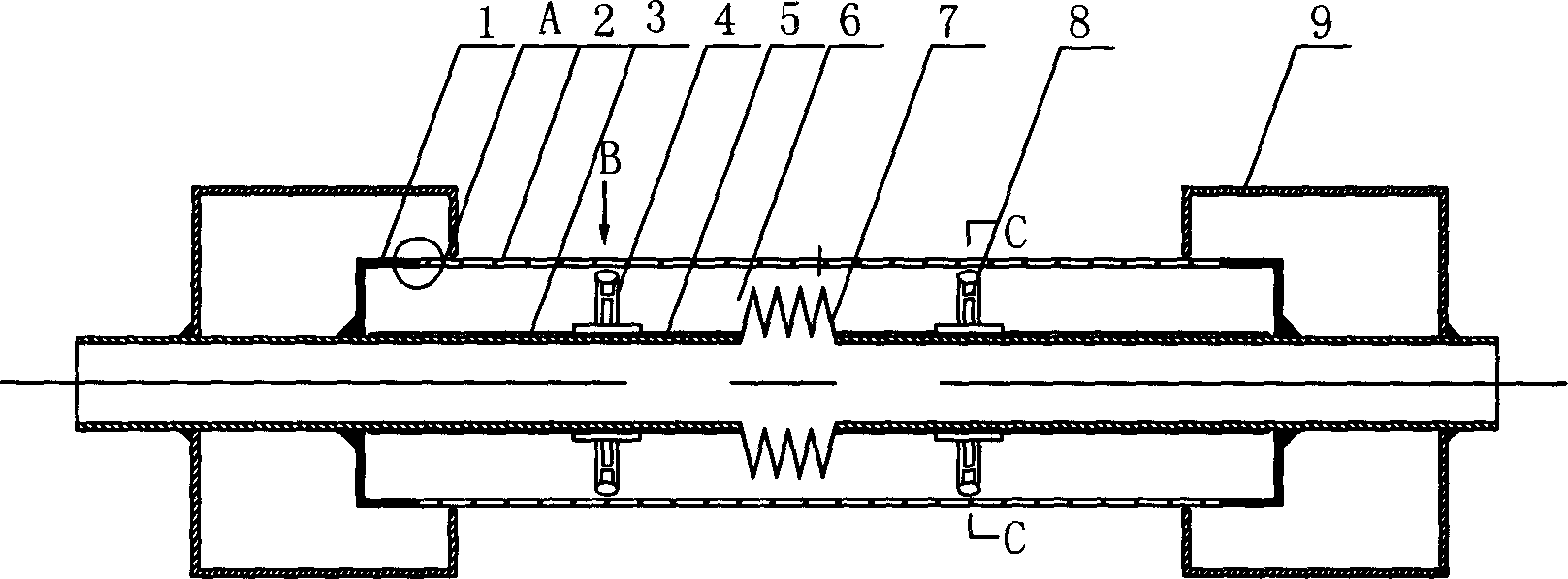

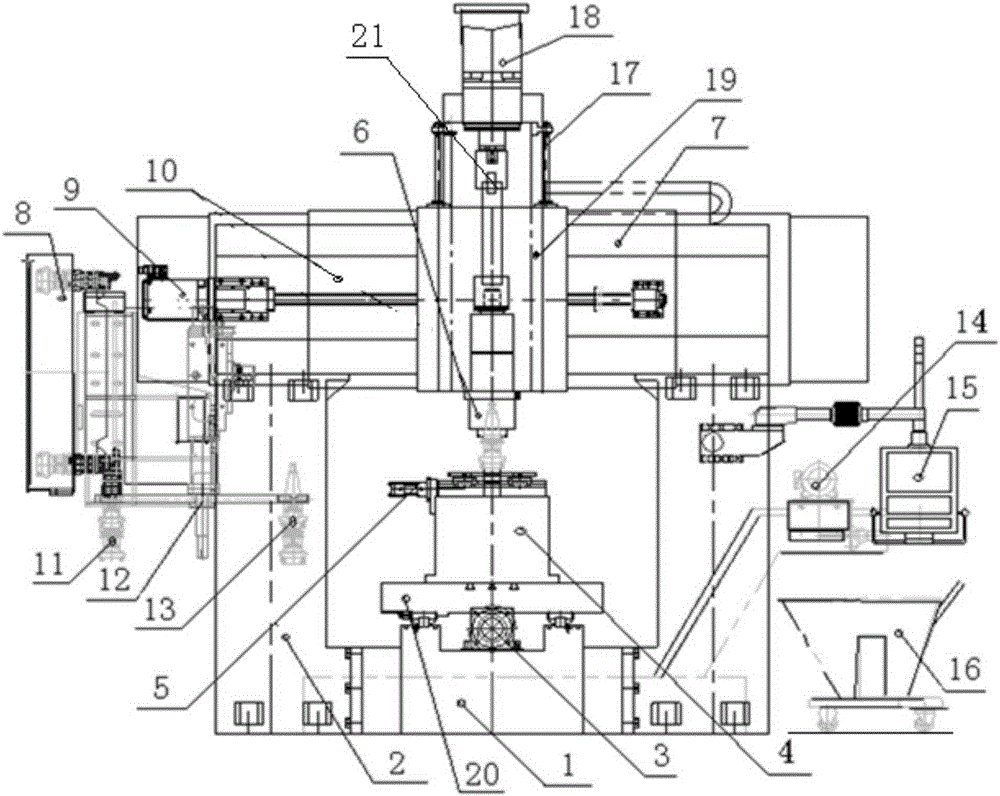

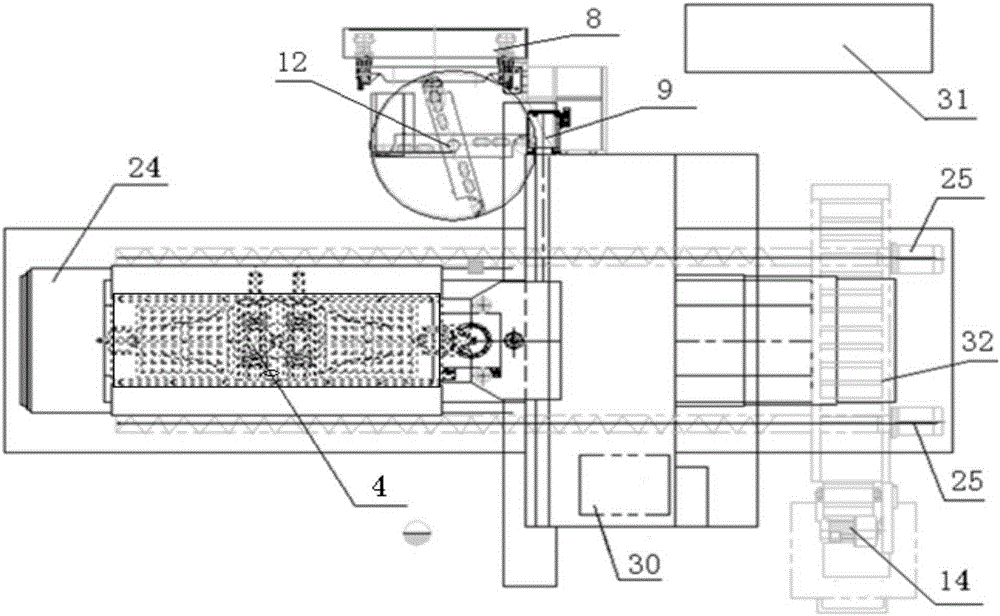

Microcomputer controlled electro-hydraulic servo multi-functional pressure-shear test machine

InactiveCN101750250AOutstanding structural featuresGood rigidityMaterial strength using tensile/compressive forcesStructural/machines measurementMultiple functionMachine parts

The invention discloses a microcomputer controlled electro-hydraulic servo multi-functional pressure-shear test machine which belongs to the field of material test machines, and mainly solves the precision, speed and stress value problems of basic material performance test in the bridge construction. The machine comprises a main machine part, a hydraulic system, a control system and a specimen transportation car. The frame of the main machine comprises a stand, a screw rod, a movable cross beam, the frame and the like; the main machine is provided with a box-shaped pressure plate, a vertical servo loading oil cylinder, a horizontal shear servo loading oil cylinder, an angle servo loading oil cylinder, a synchronous floating servo oil cylinder, a cross beam lifting mechanism and a test device. The hydraulic system comprises a servo oil source, a hydraulic oil distributor and a remote pressure control system; the control system comprises an industrial personal computer, a conversion board, an electro-hydraulic servo control cabinet and a measuring instrument. The microcomputer controlled electro-hydraulic servo multi-functional pressure-shear test machine is used for the mechanical performance test to the middle plate-type and pot-type rubber brackets and spherical brackets in the bridge construction, such as single-pressure, pressure-shear and angle tests, and can take single-pressure test to metal and other non-metal and concrete components.

Owner:TIANSHUI HONGSHAN TESTING MACHINE

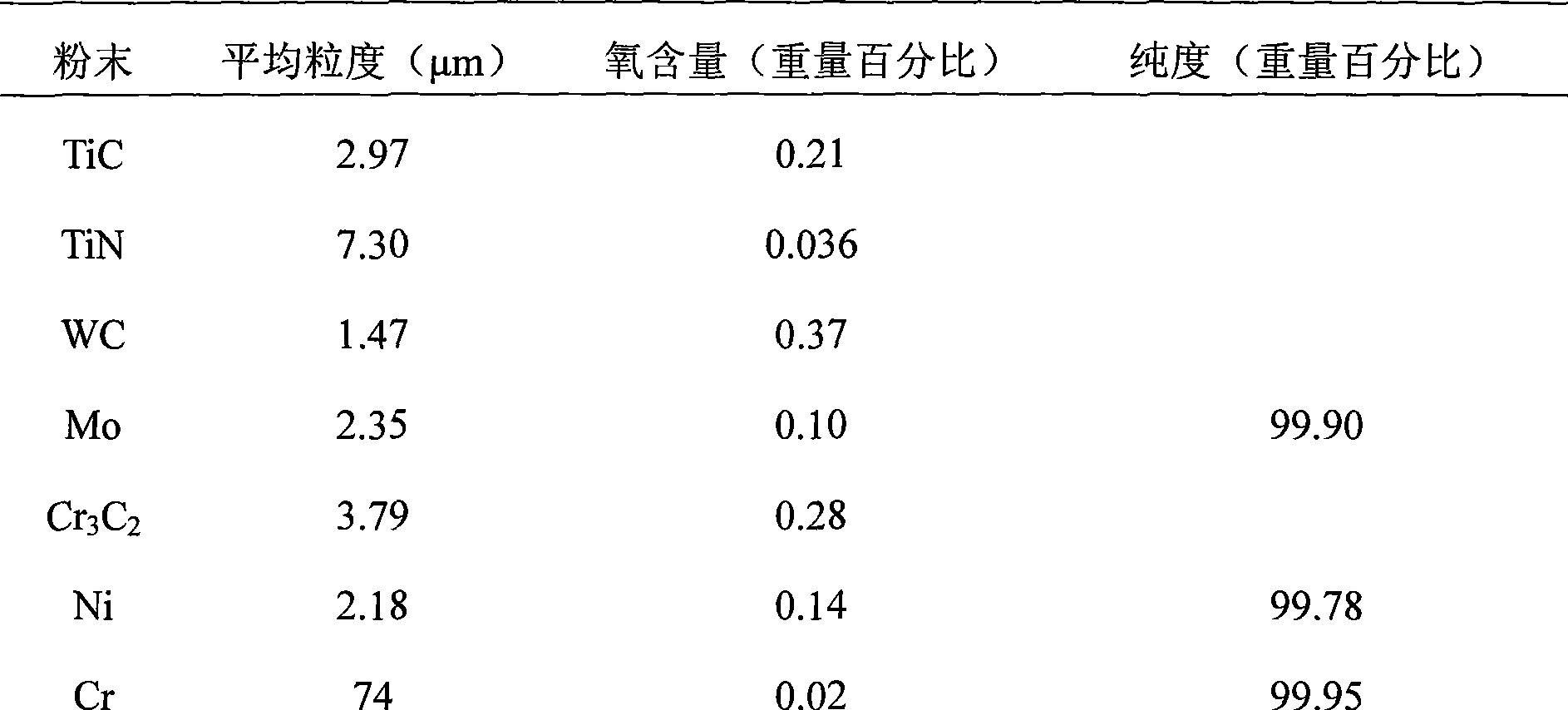

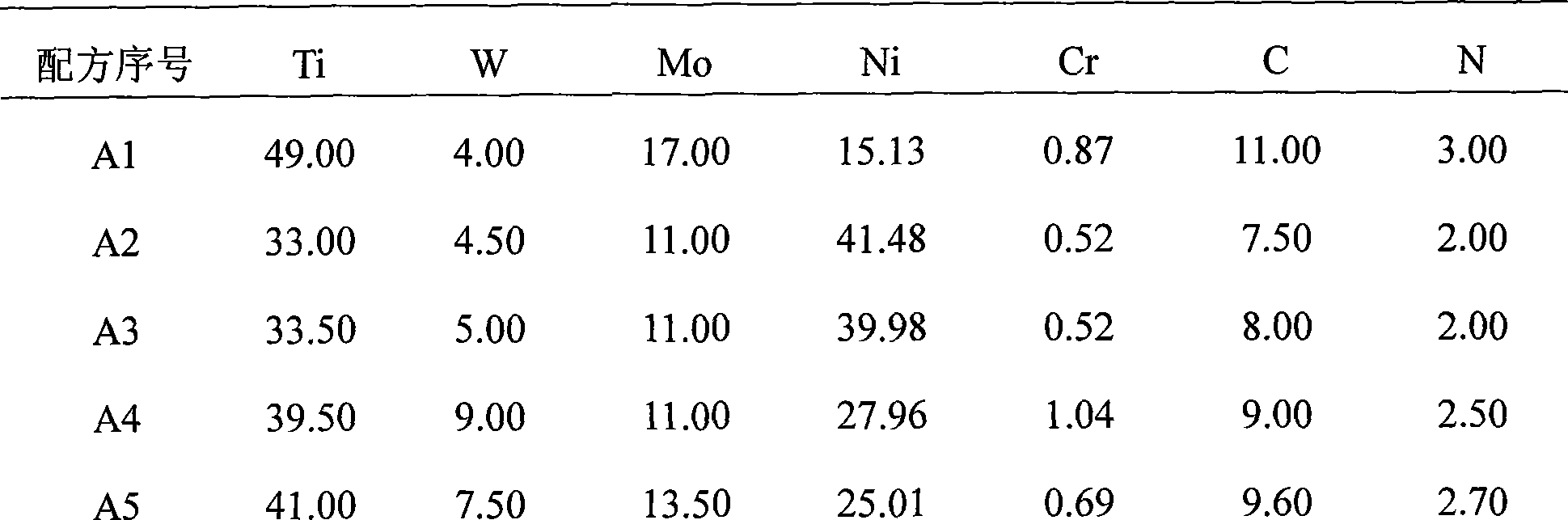

Ceramet containing Ni-Cr binder and preparation thereof

Owner:HUAZHONG UNIV OF SCI & TECH

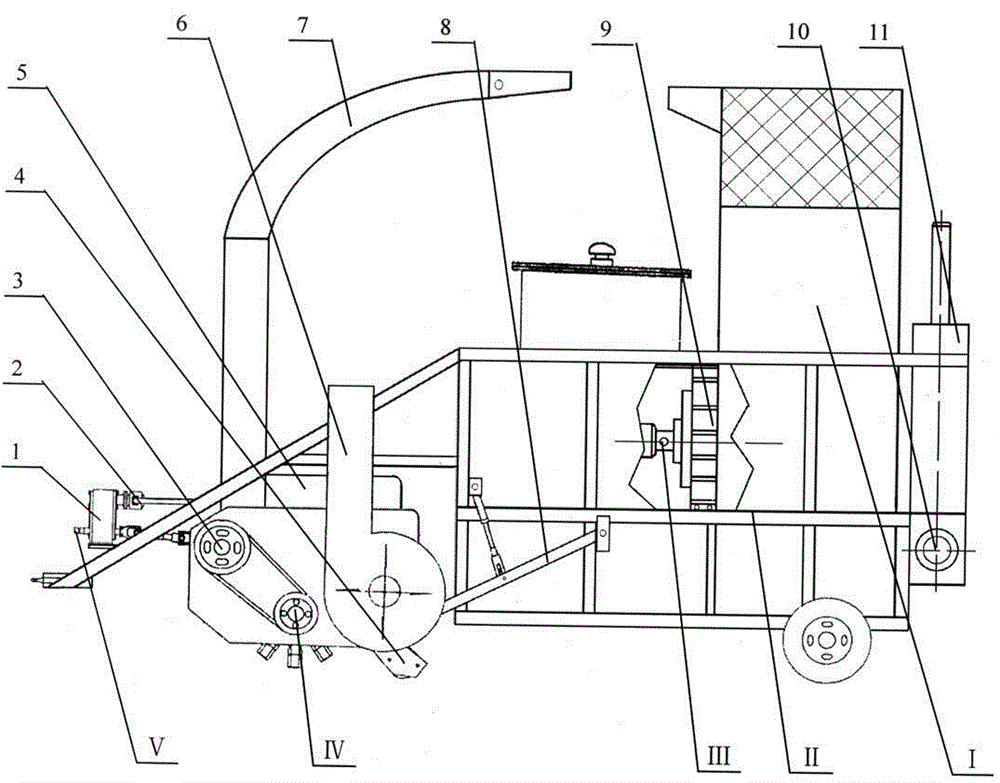

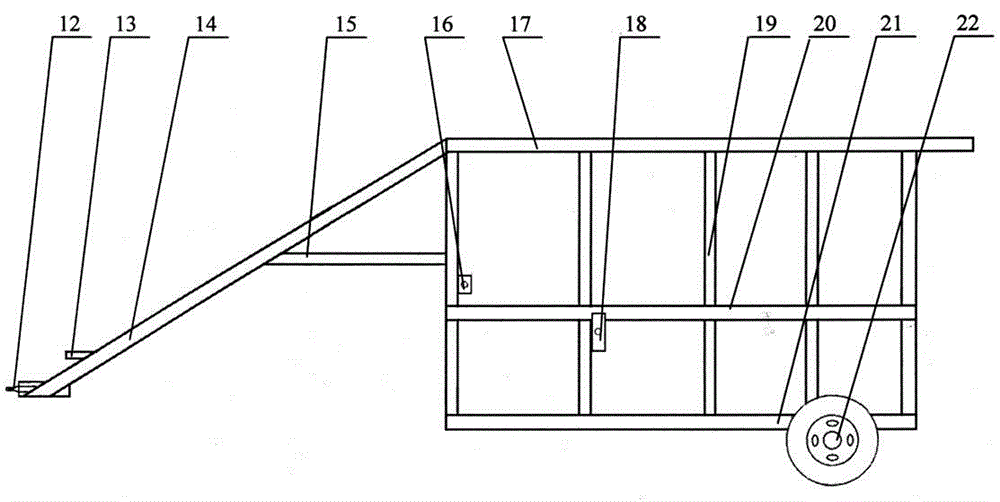

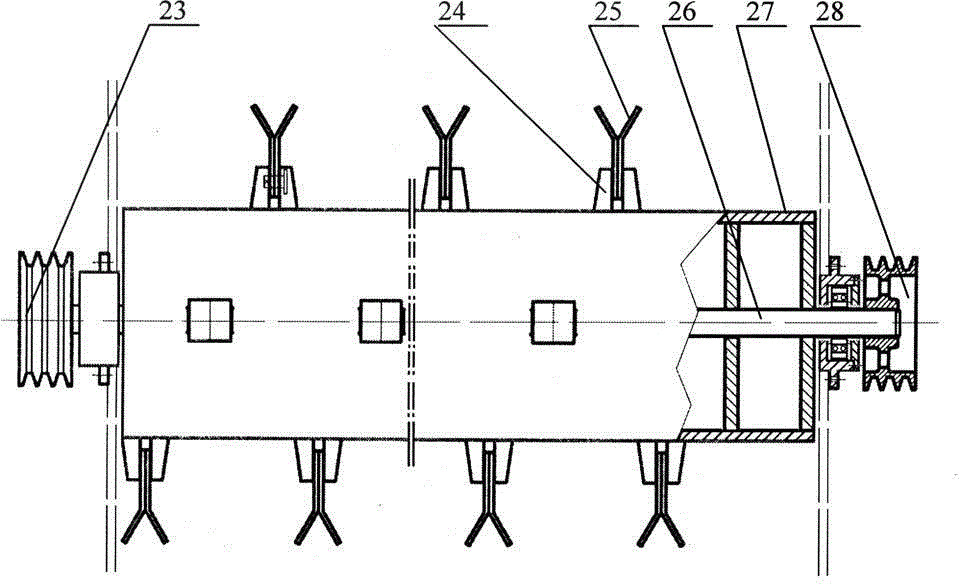

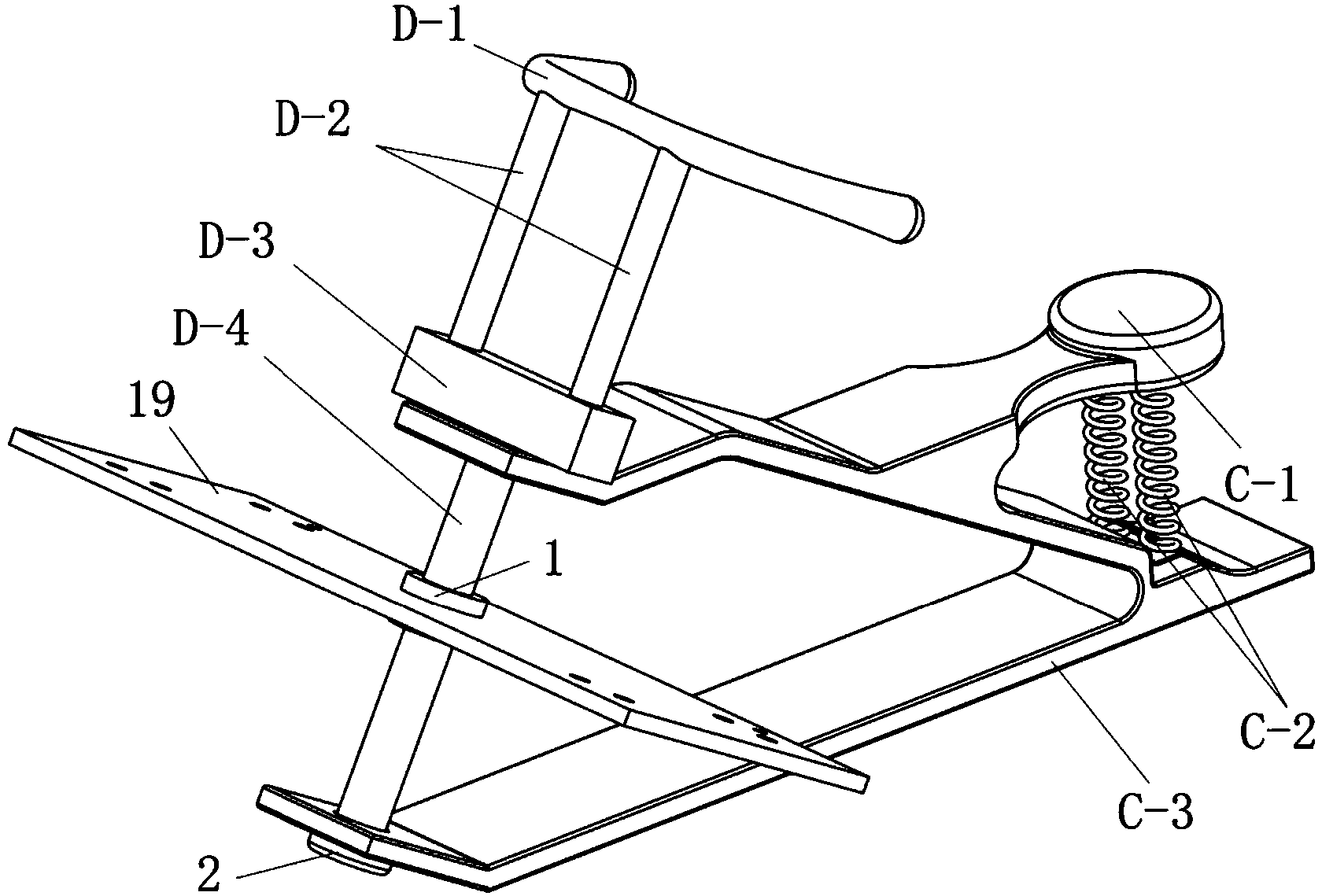

Pull-type picking, kneading, bundling and bagging machine for straw feed

ActiveCN104904437AGood rigidityGood precise shape and position benchmarkLoadersBalingGrazingEngineering

The invention discloses a pull-type picking, kneading, bundling and bagging machine for straw feed. The pull-type picking, kneading, bundling and bagging machine comprises an integral rack, a picking, kneading and transporting device, a straw smashing filling bin, a straw compacting, bundling and bagging device and a powder transmission system. The innovative technologies such as the picking kneading and transporting device being front-arranged to suspend and hydraulically lift, deep tearing, kneading and smashing processing conducted on coarse hard section head and dense surface of corn straw, straw smashing three-direction hydraulic strong compaction and bundling to transport, straw compaction bundling, automatic packing after manual bagging are adopted, and combination processes of picking and smashing, compacting and bundling, bagging and packing are conducted on corn straw in the field. And the pull-type picking, kneading, bundling and bagging machine for the straw feed has the advantages that the technology is advanced, the structure is reasonable, the production efficiency is high, and the working quality is good. Straw feed compaction bales made by the machine has good sealing environment, microbial fermentation action can also occur in a natural condition, the slaking degree is improved, the nutrition ingredient is increased, and the palatability, the grazing rate and the digestion and absorption rate are improved when cattle and sheep are fed.

Owner:四平市顺邦农机制造有限公司

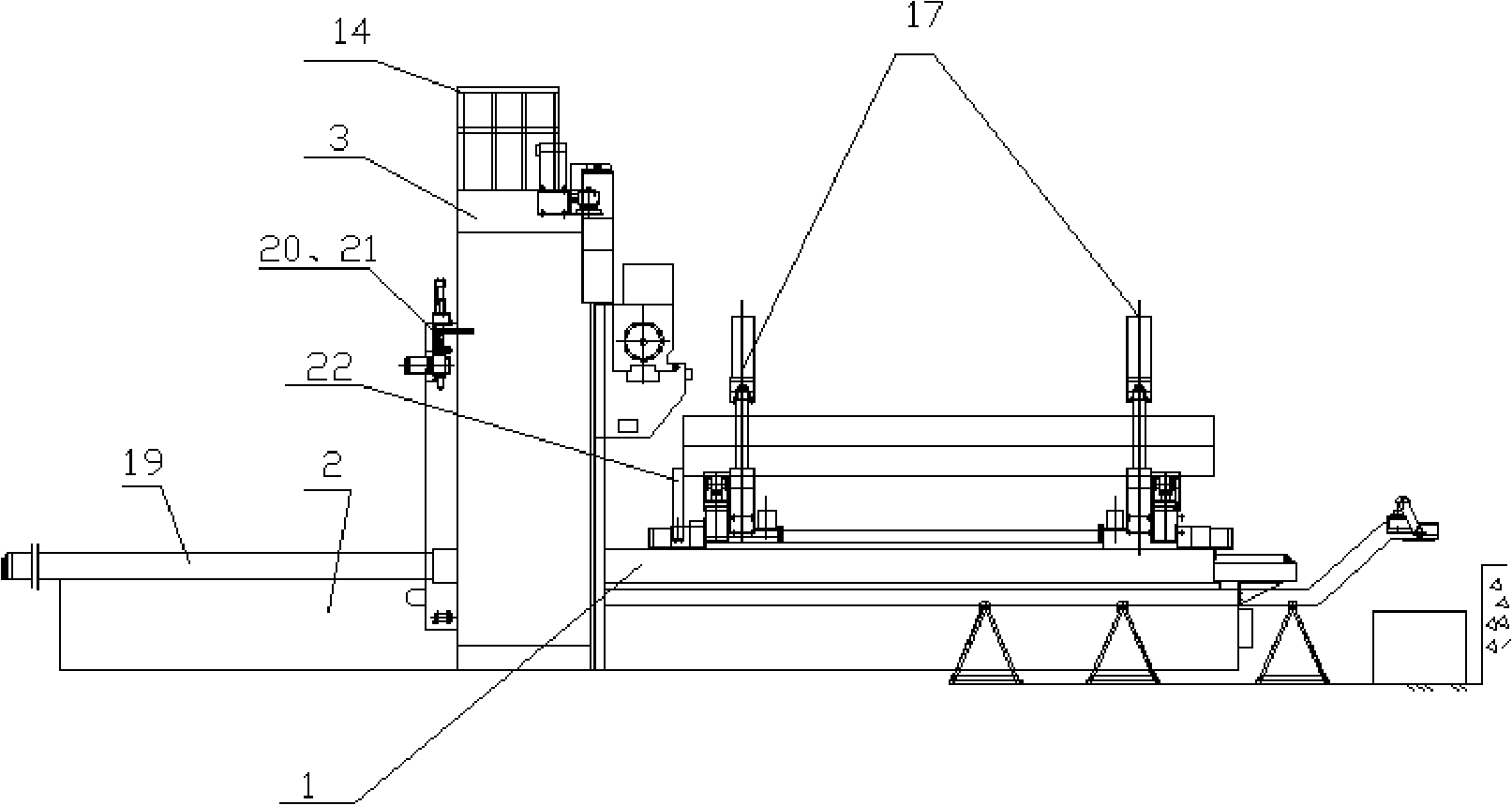

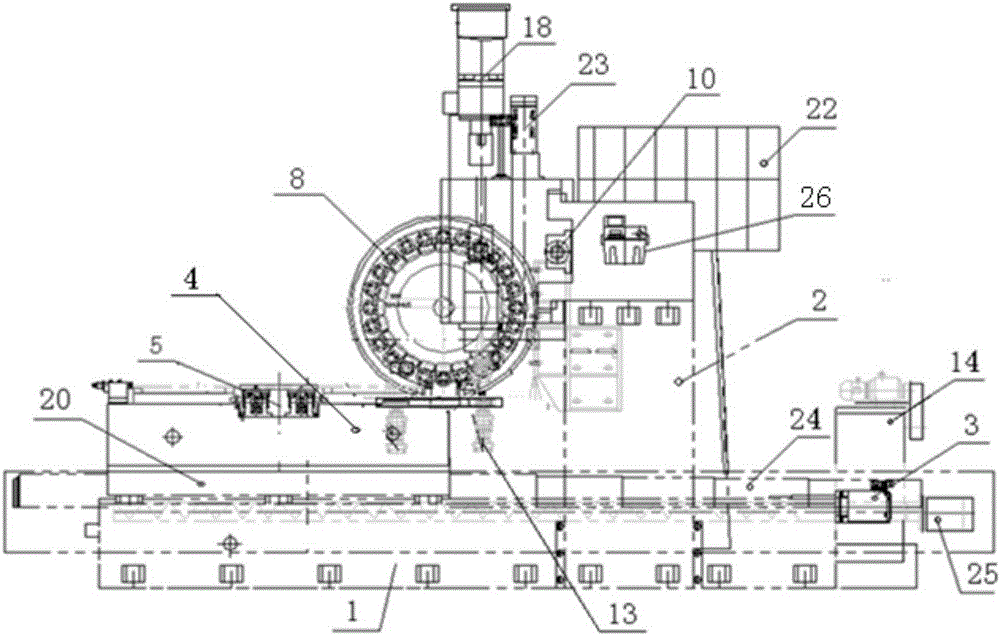

Two-sided lathe bed miller

InactiveCN101314188AGood rigidityLarge three-way travelMilling machinesLarge fixed membersNumerical control systemMachining process

The invention relates to a double-sided bed-type milling machine. Two sides of a machine bed are symmetrically provided with a set of milling units; each milling unit consists of an upright post, a slide carriage, a slide ram and a horizontal type mainshaft; the upright post is vertically close to the machine bed; a worktable which moves along an X direction is arranged on the machine bed; the slide carriage is arranged on the upright post and moves along a Y direction; the slide ram is arranged on the top of the slide carriage and moves along a Z direction; the horizontal type mainshaft is arranged inside the slide ram along the Z direction; a cross beam is connected between the tops of two side upright posts; the two side upright posts and the cross beam form a high-rigidity gantry frame; the movement and rotation of the worktable, the slide carriage, the slide ram and the horizontal type mainshaft are driven by a servo motor controlled by a numerical control system; two sets of the milling units are respectively provided with a tool magazine; an automatic reblading system of the tool magazine is controlled by the numerical control system; in order to fit the use of a full automatic hydraulic clamp in the double-sided bed milling machine, an X-direction rectangular guide rail and an X-direction hill-type guide rail are also arranged on the worktable. The double-sided bed-type milling machine has good rigidity and large three-way stroke and can once carry out the machining processes of milling, boring and drilling to a horizontal type workpiece.

Owner:GUILIN MACHINE TOOL

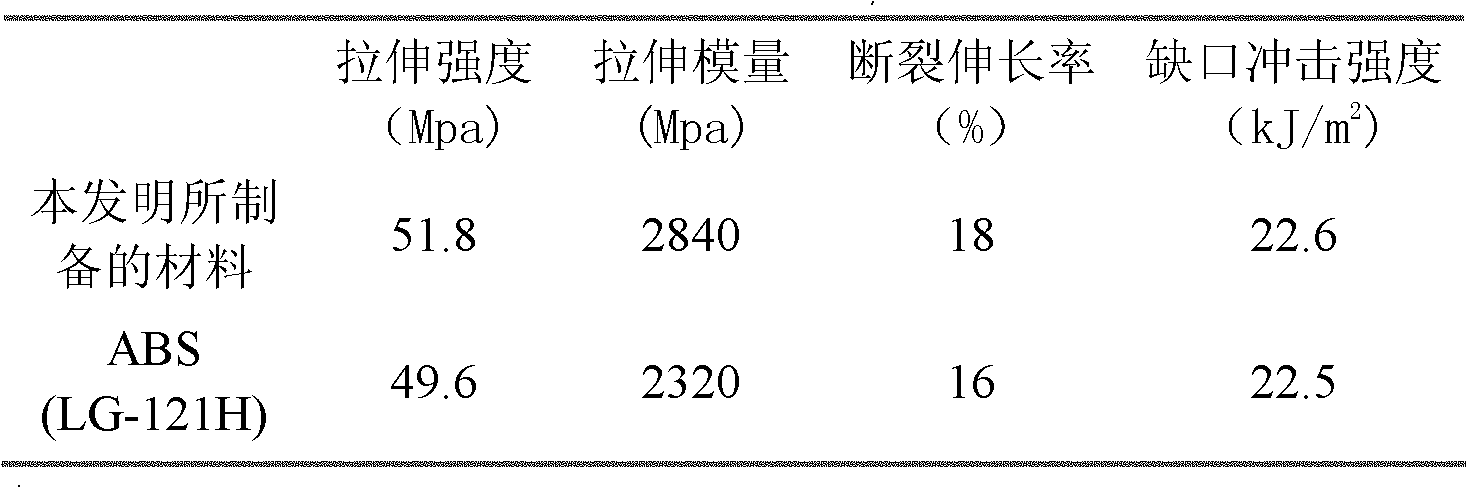

Glass fiber reinforced co-polypropylene composite material and preparation method of the Glass fiber reinforced co-polypropylene composite material

InactiveCN102181100AHigh tensile yield strength and impact resistanceGood rigidityMaleic anhydrideThin walled

The invention discloses a glass fiber reinforced co-polypropylene composite material and a preparation method of the glass fiber reinforced co-polypropylene composite material. The preparation method includes the steps as follows: uniformly mixing co-polypropylene, polypropylene grafted with maleic anhydride, homopolymerized polypropylene organic peroxide initiator, and antioxidant in proportion;adding the mixture in a double-screw extruder and simultaneously adding glass fiber strand roving; and conducting melt extrusion for granulation at the temperature of 170-220 DEG C, thus obtaining the glass fiber reinforced co-polypropylene composite material, wherein the melt index of the obtained composite material is 18-35g / 10min, the tensile strength is 49-89 Mpa, the breaking elongation is 9-35%, the Young modulus is 2.3-5.3GPa and the notch impact strength is 10-33kJ / m2. The glass fiber reinforced co-polypropylene composite material provided by the invention has not only outstanding strength, modulus, and impact resisting and heat resisting properties, but also excellent processing flow property, and can injection-mold and form thin-wall products with attractive appearance and complex shape; and the glass fiber reinforced co-polypropylene composite material has the characteristics of being light in weight and cheap in cost can substitute for engineering plastics such as expensive ABS (Acrylonitrile Butadiene Styrene) and nylon.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD +1

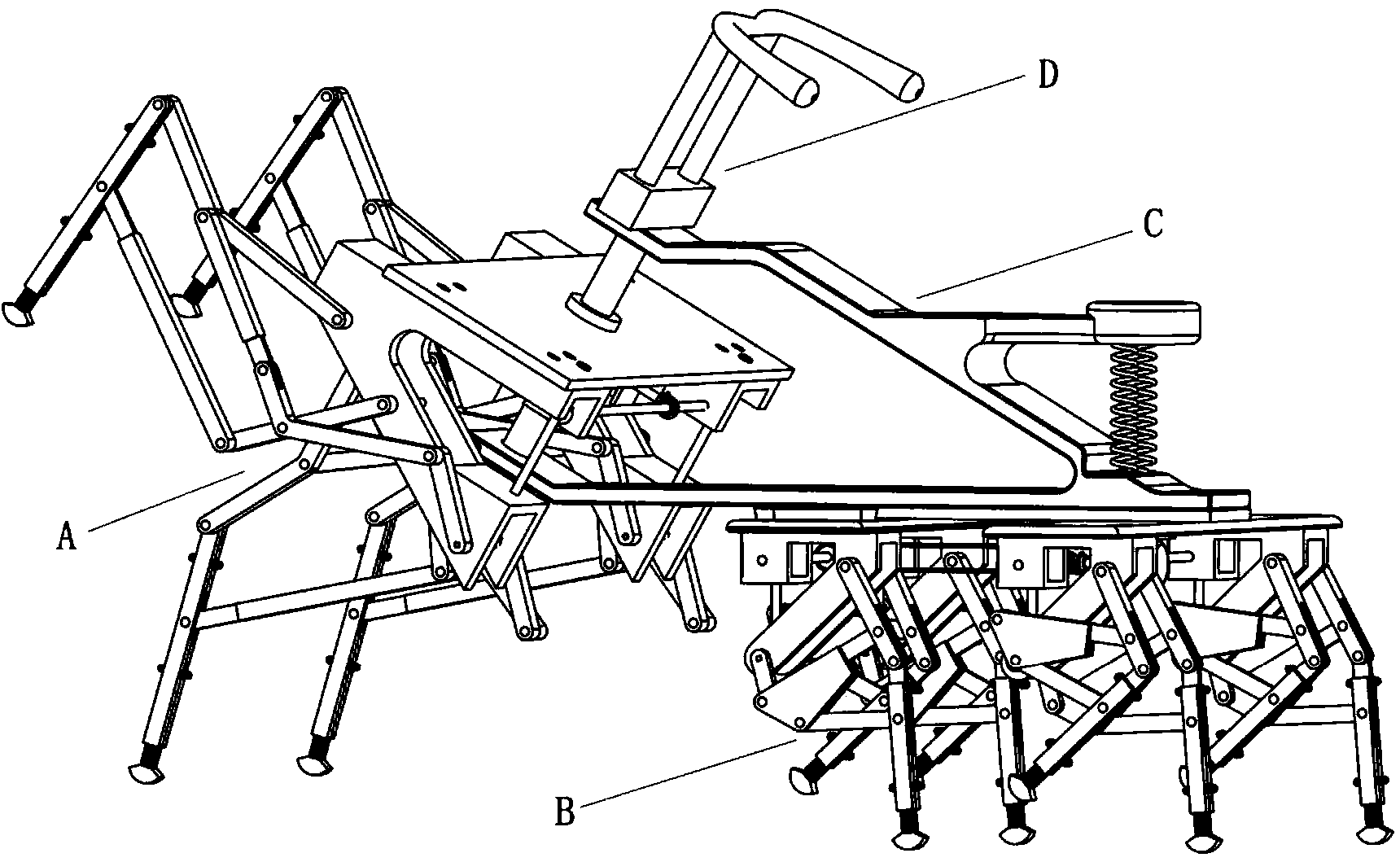

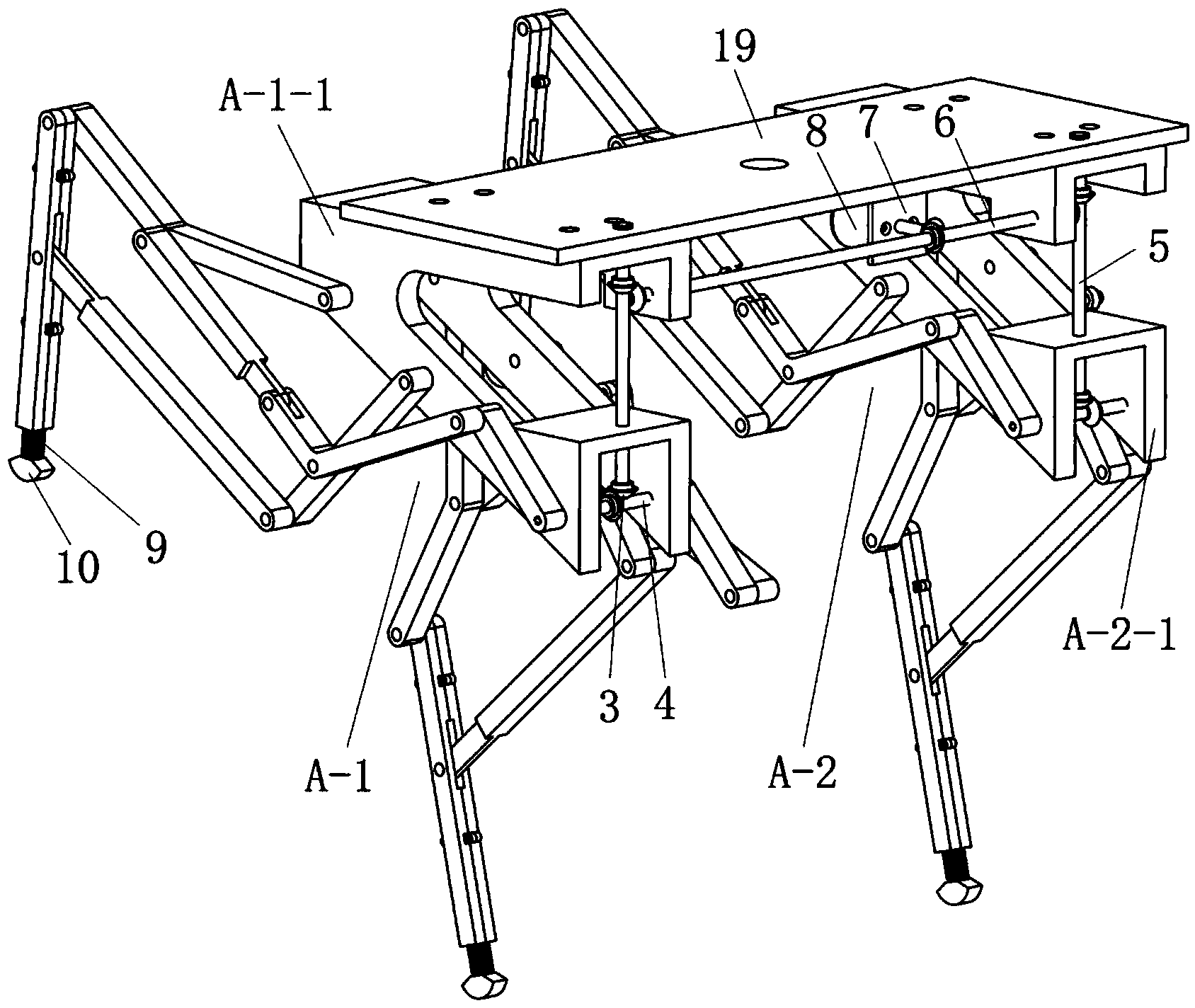

Manpower-operated leg type walking vehicle

ActiveCN103832505AGood rigidityStrong load carrying capacity and ground passing performanceVehiclesVehicle frameEngineering

Disclosed is a manpower-operated leg type walking vehicle comprising an obstacle crossing mechanism (A), a bearing mechanism (B), a frame (C) and an operation mechanism (D). A left leg and a right leg of the obstacle crossing mechanism (A) match with two sides of a connection plate 1 respectively, the obstacle crossing mechanism (A) is fixedly connected with the operation mechanism (D), in the bearing mechanism (B), legs of the first group and the second group match with two sides of a connection plate 3 respectively, legs of the third group and the fourth group match with two sides of a connection plate 4 respectively, the connection plate 3 and the connection plate 4 are fixedly connected via the connection plate 2, and the bearing mechanism (B) and the frame (C) are fixedly connected. Via an intelligent bionic control program and motors on the obstacle crossing mechanism (A) and the bearing mechanism (B), a walking state of the manpower-operated leg type walking vehicle is achieved, and turning of the manpower-operated leg type walking vehicle is realized by operating the operation mechanism (D) by manpower. Obstacle crossing performance of a machine is improved effectively, and the manpower-operated leg type walking vehicle can serve as a transportation means instead of walking and an auxiliary tool in an urban environment.

Owner:BEIJING JIAOTONG UNIV

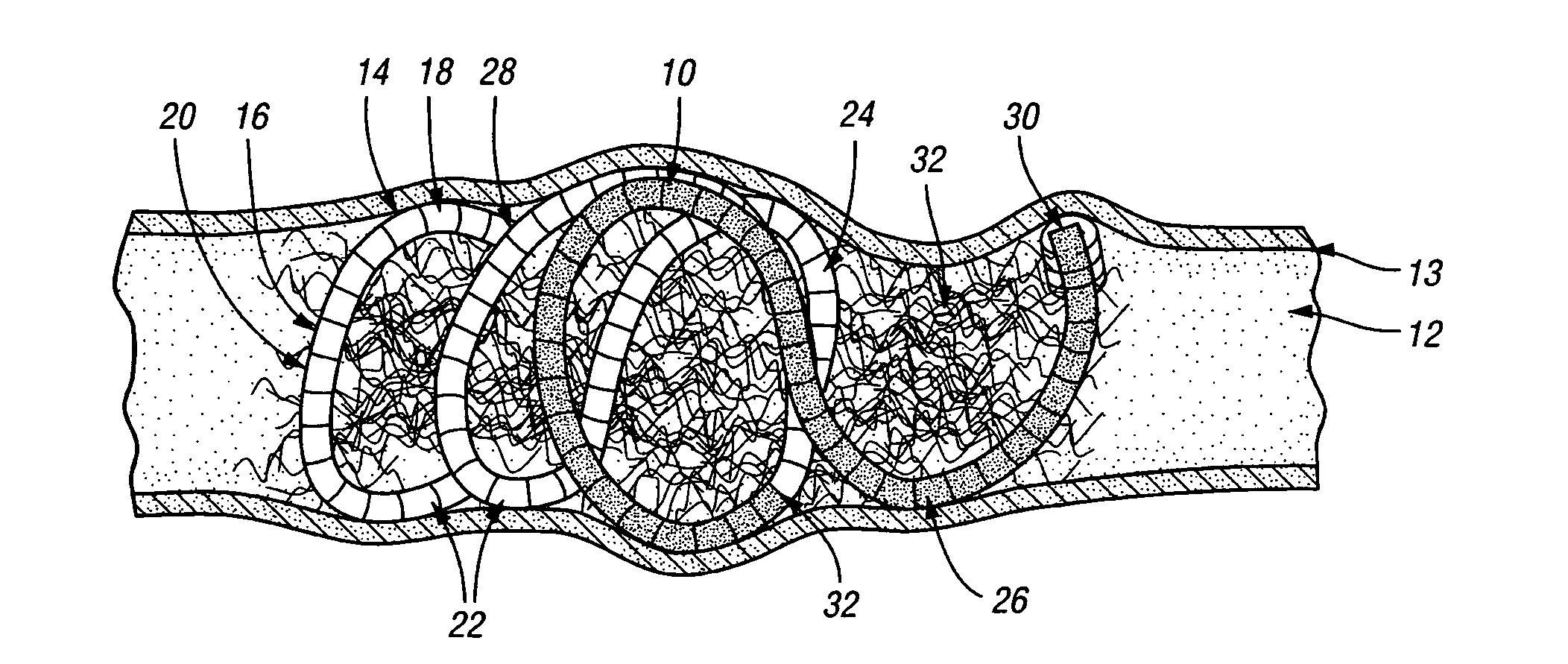

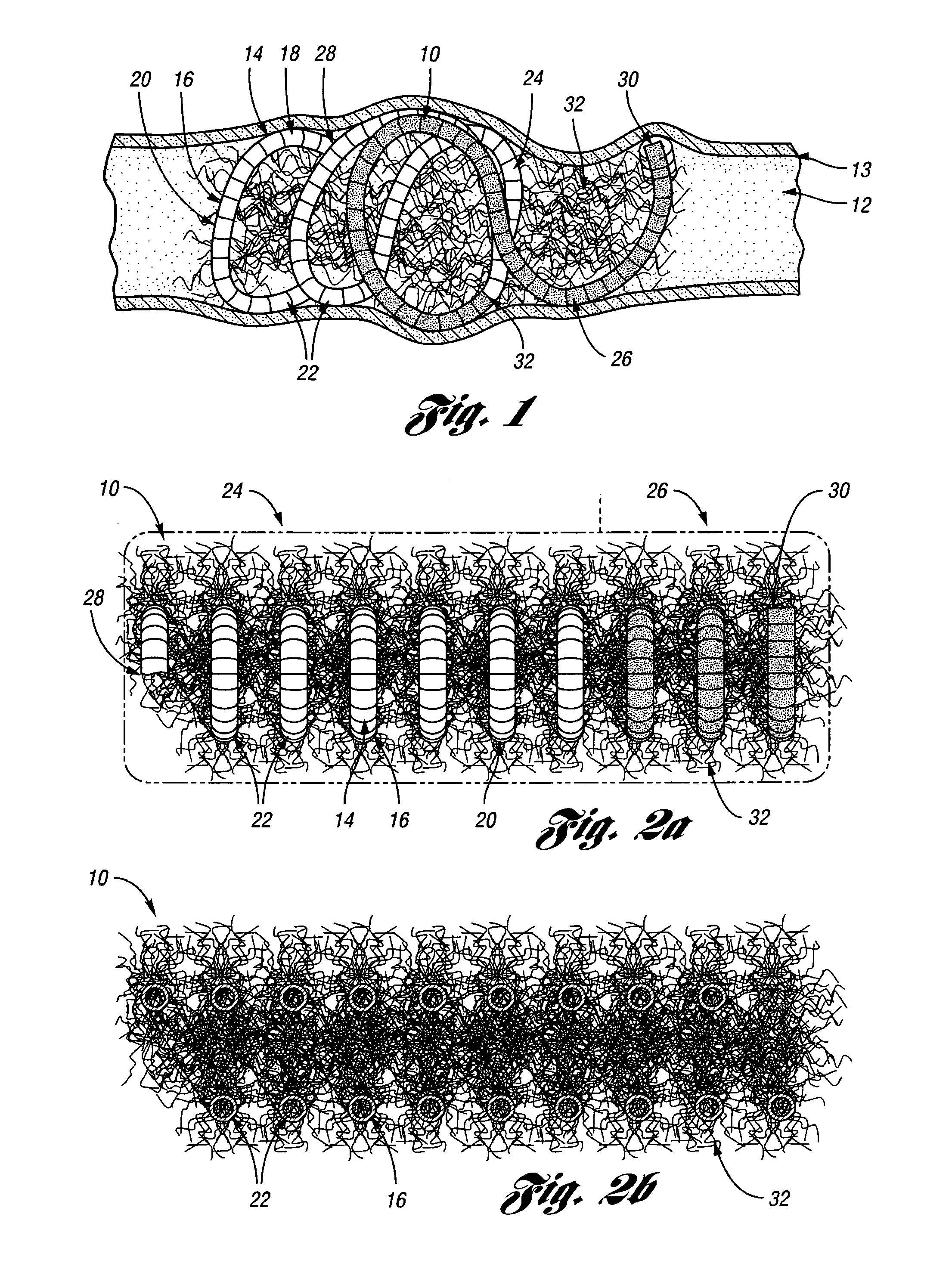

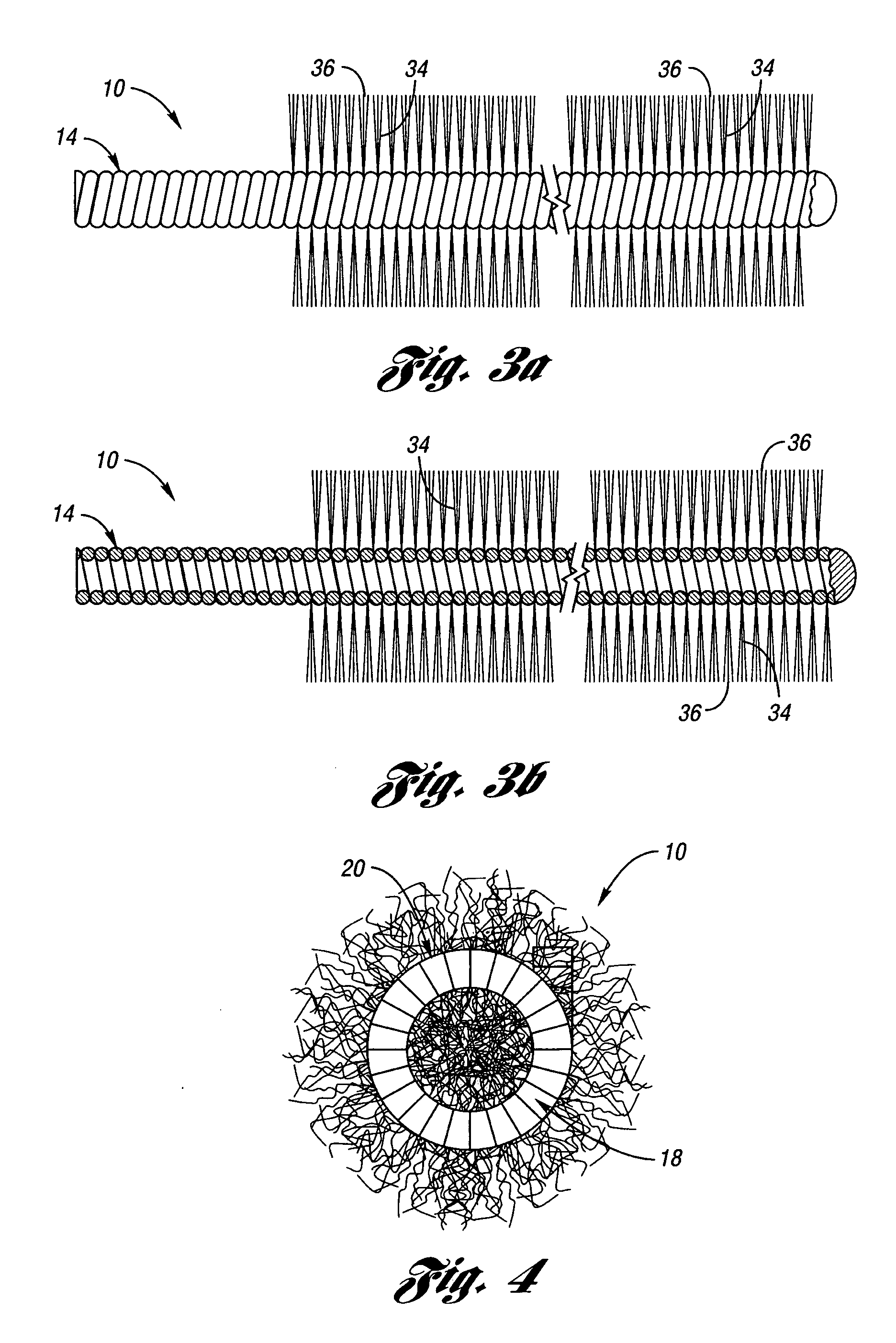

Variable stiffness occluding device

An occluding device designed for occlusion of fluid flow through a body cavity. The device comprises a coil and fibers attached to the coil. The coil has a proximal and distal portion, with variable rigidity along the length of the coil. The distal portion has greater rigidity than the proximal portion. The fibers extend from the coil at a length.

Owner:COOK INC

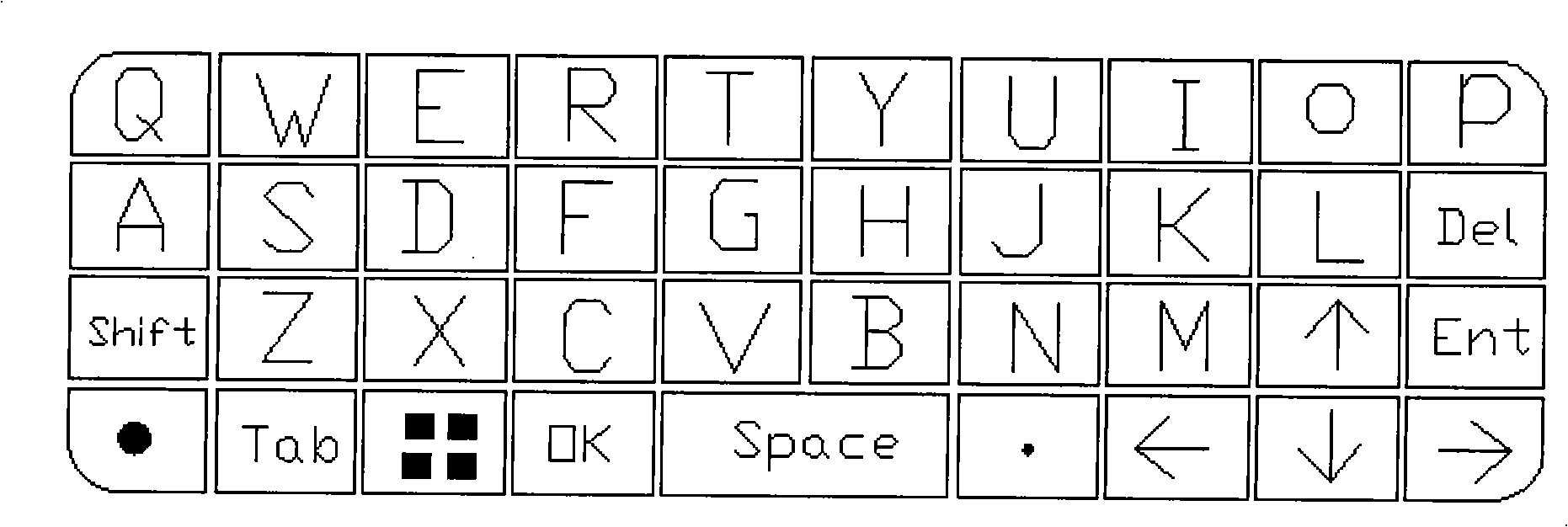

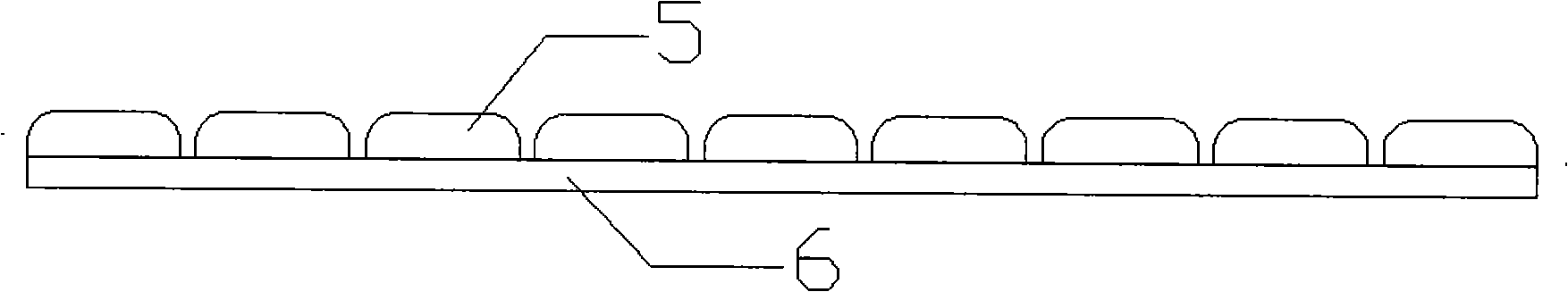

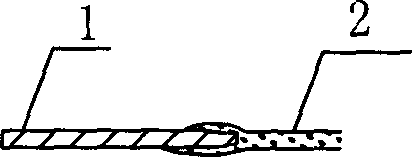

Ultra-thin QWERTY full keyboard and manufacturing method thereof

The invention discloses a method for manufacturing an ultrathin QWERTY whole keyboard, which includes the following steps: step one, under the condition of ultraviolet illumination, a UV hardening adhesive is used for solidifying and shaping a UV keycap layer on a first plastic panel by the heat pressing technique; step two, a Rubber layer can be directly formed by a piece of steel strap, a second plastic panel and silica gel by the oil pressing technique; step three, the UV keycap layer and the Rubber layer are stuck and fixed with each other. The method for manufacturing the ultrathin QWERTY whole keyboard of the invention has the advantages of simple technique for assembling the keyboard and high production efficiency. The ultrathin QWERTY whole keyboard of the invention has ultrathin thickness, and the color of the characters and the background are not easy to be worn. No keystroke linkage occurs in the keycap layer, and appearance effect is good. The Rubber layer is good in rigidity, thereby having high evenness of the surface of the keyboard as well as good and uniform hand feeling.

Owner:ZTE CORP

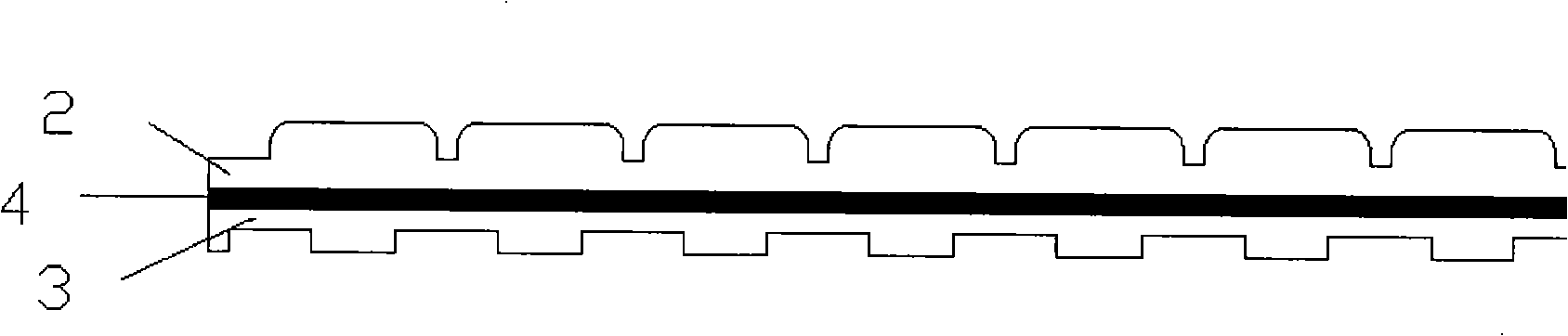

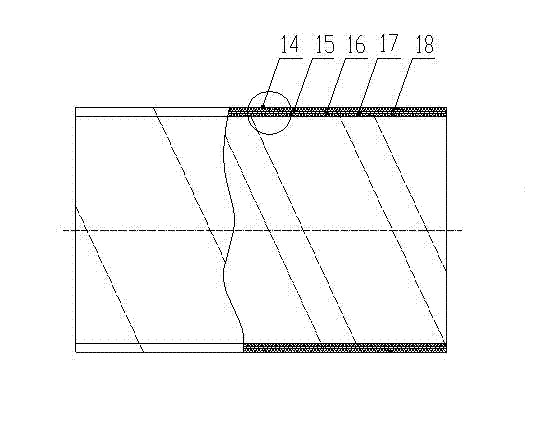

Large-caliber spiral welding steel plastic composite pressure pipe and manufacturing method thereof

The invention relates to the technical field of steel plastic composite steel pipe manufacturing, in particular to a large-caliber spiral welding steel plastic composite pressure pipe and a manufacturing method thereof, and the problems that the manufacturing method of the existing steel plastic composite steel pipe is single, the structural strength of the pipe body is not ideal, and the adhesion strength of a plastic composite layer is poor are solved. The large-caliber spiral welding steel plastic composite pressure pipe is formed by compounding five or more than five layers of materials with different characteristics, wherein the middle layer is a spirally formed welded steel pipe, the inner surface and the outer surface of the spirally formed welded steel pipe are respectively provided with an inner hot melt adhesive layer and an outer hot melt adhesive layer, the outer hot melt adhesive layer of the spirally formed welded steel pipe is provided with an outer wound plastic layer, and the inner hot melt adhesive layer of the spirally formed welded steel pipe is provided with an inner wound plastic layer. The large-caliber spiral welding steel plastic composite pressure pipe has large integral structure strength and ring stiffness, good rigidity, high bearing pressure, and smooth inner and outer wall surfaces, and the manufacturing method is suitable for manufacturing large-caliber steel plastic composite pressure pipes.

Owner:ZHEJIANG SHUANGLIN PLASTIC MACHINERY

Turbine disc cavity structure with closely-sealing and cooling guide plate

ActiveCN106089312AGood rigidityEliminate flow dead endsBlade accessoriesLeakage preventionTurbine bladeThrottle

The invention discloses a turbine disc cavity structure with a closely-sealing and cooling guide plate. The turbine disc cavity structure comprises a large bent pipe, a turbine guider, the guide plate, a turbine disc, a turbine blade and a bearing seat installing edge; the large bent pipe, the turbine guider and the guide plate are fixed to the bearing seat installing edge through screws to form a first cold air cavity, a second cold air cavity, a third cold air cavity, a fourth cold air cavity, a fifth cold air cavity, a sixth cold air cavity and a seven cold air cavity. According to the turbine disc cavity structure, by designing the step blade type closely-sealing structure and circular throttle holes on the portions, with the different radiuses, of the guide plate and optimizing the profile surface of the guide plate, the amount of cooling and closely-sealing gas entering the different portions of a turbine disc cavity can be reasonably allocated, the circulating area of the cooling gas in the turbine disc cavity is greatly decreased, the cooling gas approximately flows along the surface of a turbine disc, therefore, the utilization efficiency and the cooling effect of the cooling gas are greatly improved, and backward fuel gas flowing can be effectively prevented.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

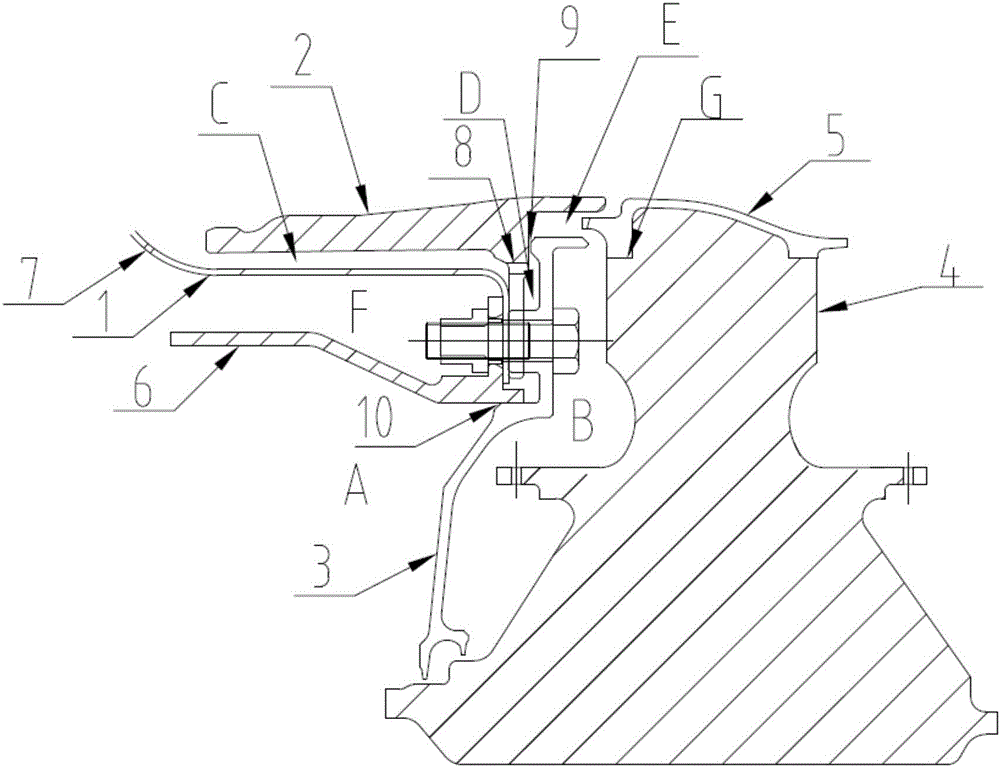

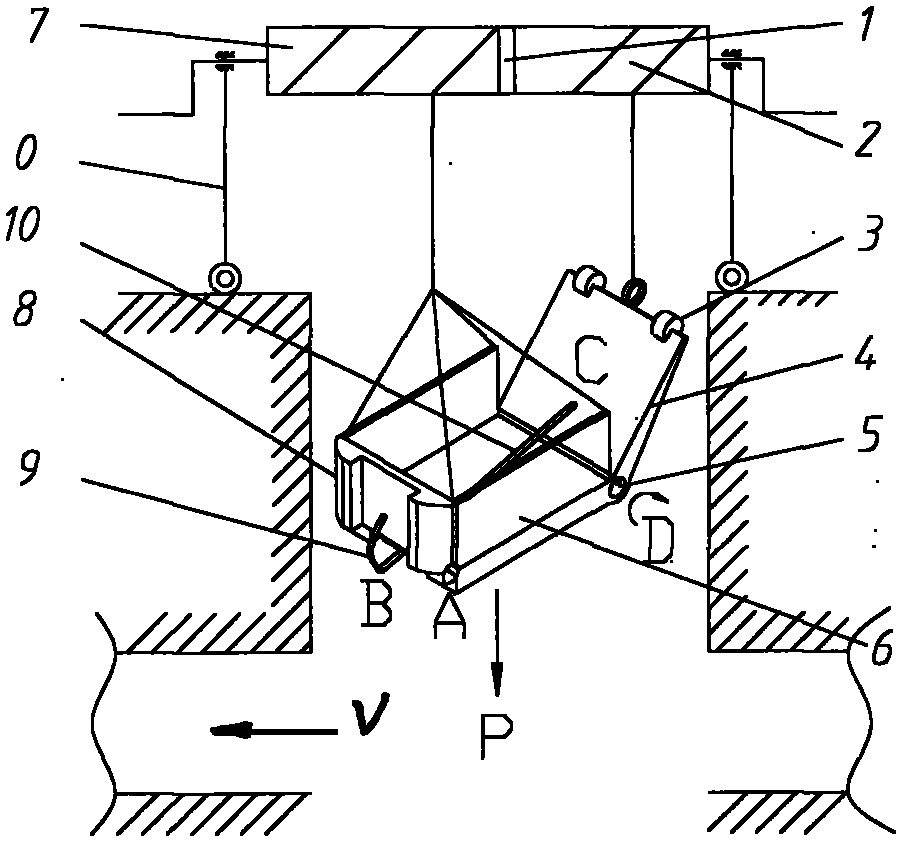

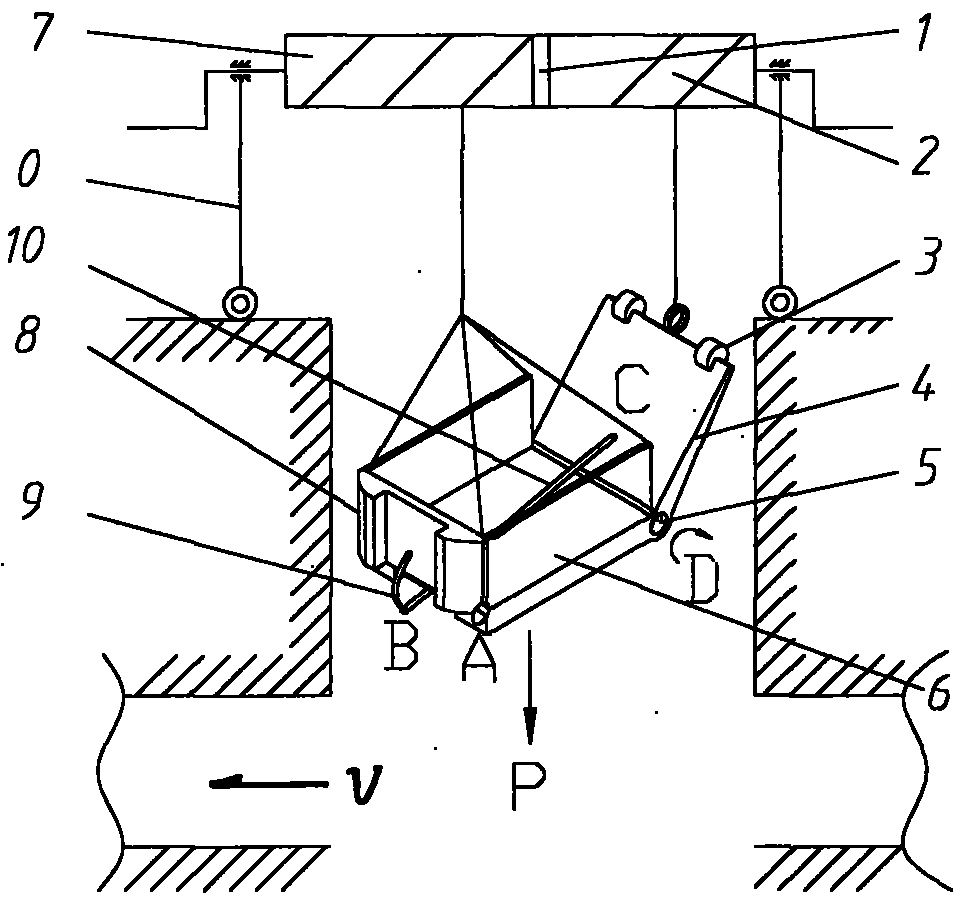

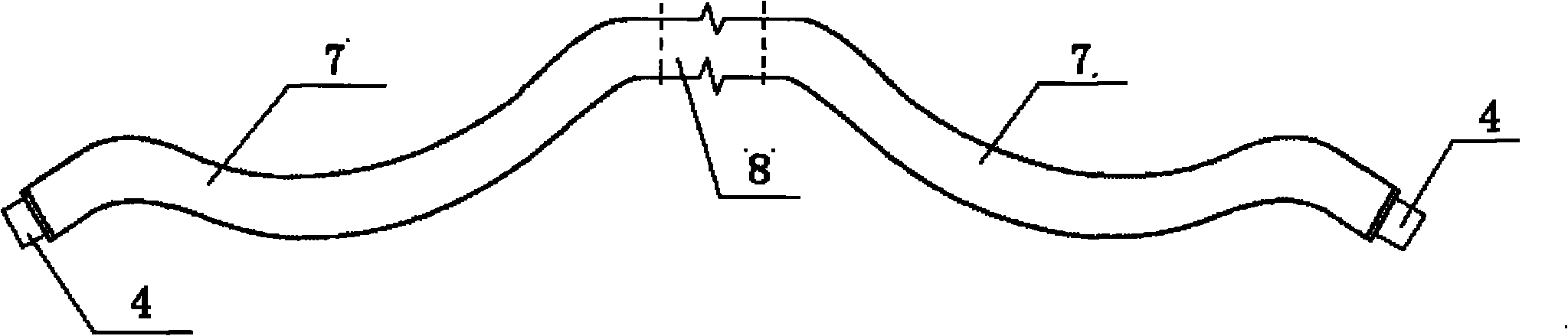

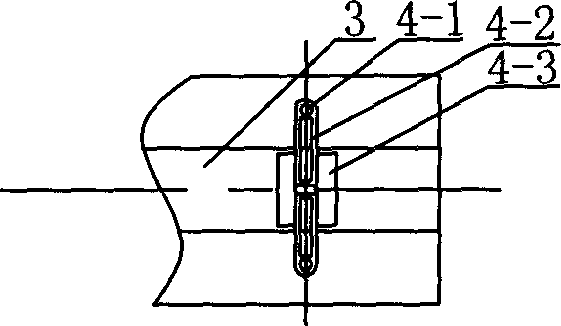

Double-drum type releasing and recovering device of pipeline robot

The invention relates to a double-drum releasing and recovering device of a pipeline robot, which comprises a frame (0), a coupler (1), a drum I (2), a drum II (7), a guide wheel (3), a side plate (4), a torsional spring (5), a carrying platform (6), a baffle plate (8) and a double-rocker mechanism. The drum I (2) and the drum II (7) installed on the frame (0) of a trolley are connected through the coupler (1). The carrying platform (6) is connected on a rope of the drum I (2) and the drum II (7). The side plate (4) is connected on the carrying platform (6) by a revolute pair IV (D) and the torsional spring (5) is installed at the connection part. The baffle plate (8) is connected on the carrying platform (6) by a revolute pair I (A) at one side opposite to the side plate (4). One end of the rocker (9) is fixed with the baffle plate (8) while the other end is connected with one end of a connecting rod (10) through a revolute pair II (B). The other end of the connecting rod (10) is connected on the side plate (4) through a revolute pair III (C). Thus, the side plate (4), the connecting rod 910), the rocker (9) and the carrying platform (6) form the double-rocker mechanism. The device is convenient to operate, has a simple structure, low cost and strong adaptability, and can meet demand of releasing and recovering operational robots with different pipe diameters.

Owner:CHANGZHOU UNIV

Method for forming end insulation of stator coil by vacuum pressure impregnation

ActiveCN101882846AUniform pressureGood rigidityApplying solid insulationVacuum pressurePolytetrafluoroethylene

The invention provides a method for forming end insulation of a stator coil by vacuum pressure impregnation, which is characterized by comprising the following steps: making a fiber-woven heat shrinkable wraparound sleeve; making unvulcanized hot-pressing packing strips and vulcanizing the hot-pressing packing strips; and clamping the vulcanized hot-pressing packing strips on an end surface of the stator coil which is wounded with a polytetrafluoroethylene film insulation demoulding material, winding the fiber-woven heat shrinkable wraparound sleeve on the vulcanized hot-pressing packing strips in a half-lap manner and heating the hot-pressing packing strips for solidification. In the invention, the hot-pressing packing strips adapting to the shape of the coil are manufactured and can be used repeatedly; and four hot-pressing packing strips shrink naturally to form a circular arc shape in the vulcanization process, the pressure applied by the heat shrinkable wraparound sleeve during shrinkage is uniform, the mold rigidity is high, and the coil is insusceptible to deformation under heat. The heat shrinkable wraparound sleeve with a proper shrinkage force is woven and replaces a mold in processing, the lap winding mode is changed, the pressure applied can be controlled, and the shrinkage force is uniform with the uniform lap winding.

Owner:SHANGHAI ELECTRIC POWER GENERATION EQUIPMENT CO LTD

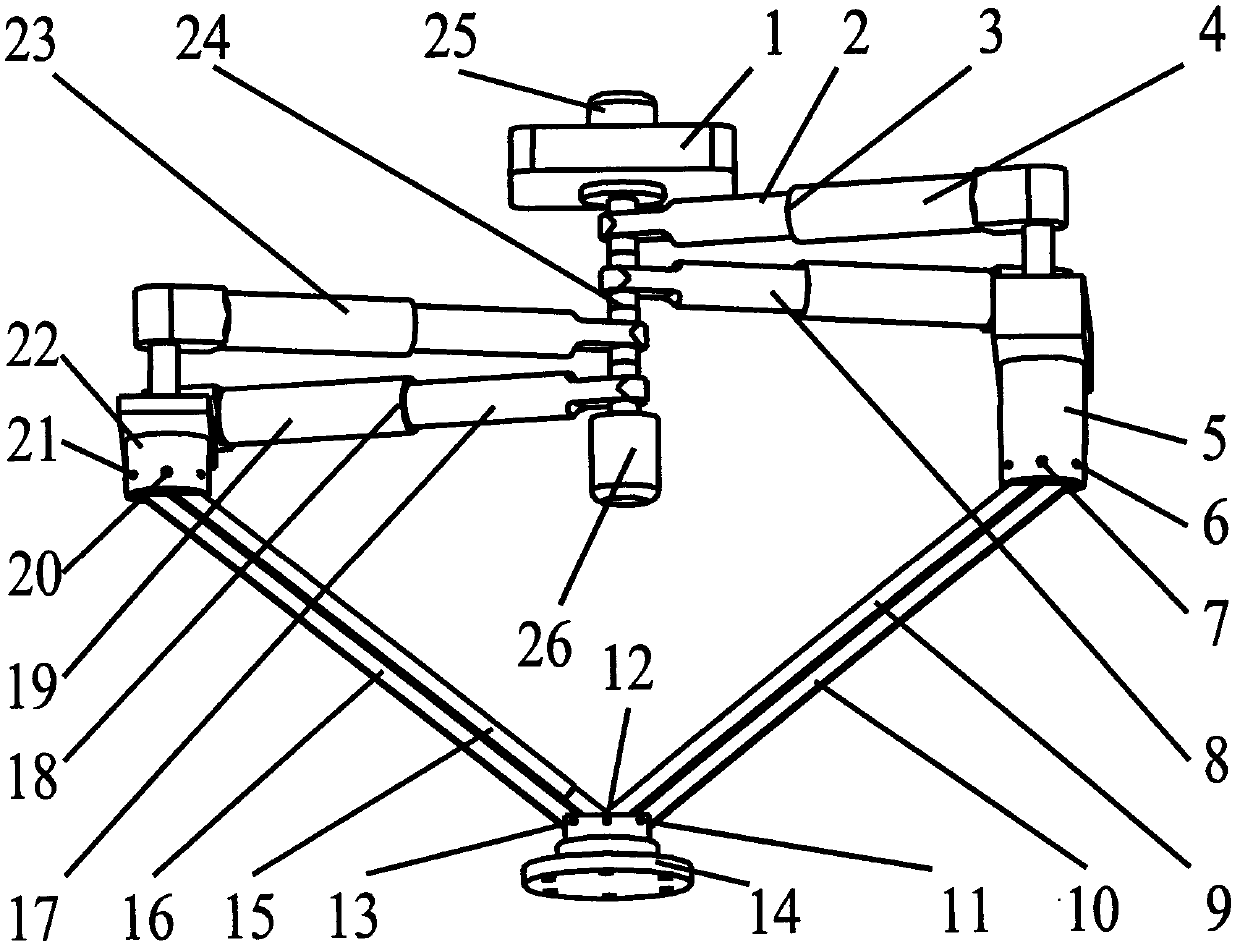

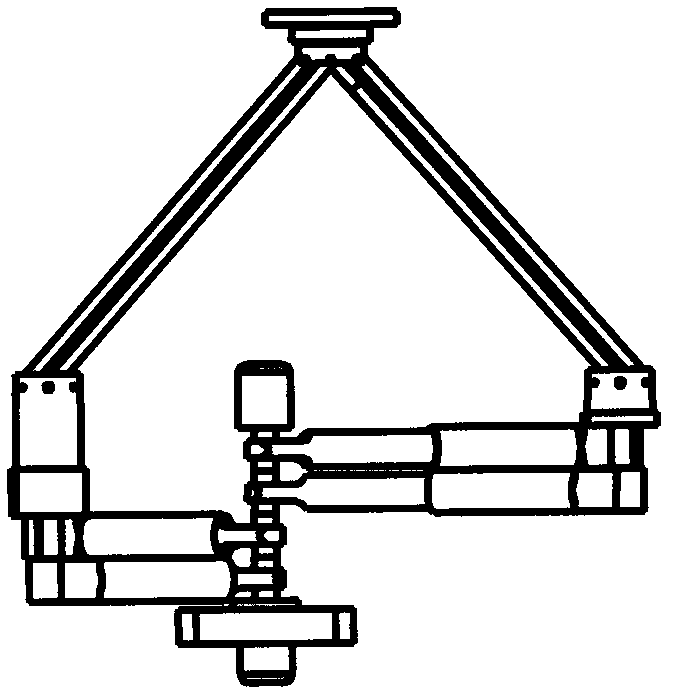

Three-dimensional translation and one-dimensional circumferential rotation type parallel welding robot

InactiveCN102601791AReduce the weight of the mechanismGood rigidityProgramme-controlled manipulatorWelding/cutting auxillary devicesTwo degrees of freedomEngineering

The invention relates to a three-dimensional translation and one-dimensional circumferential rotation type parallel welding robot, which comprises a first RPRR closed-loop subchain, a second RPRR closed-loop subchain and an executive mechanism subchain. Rotation shafts of control rods of the first RPRR closed-loop subchain and the second RPRR closed-loop subchain are coaxial, the first RPRR closed-loop subchain can control planar two-degree-of-freedom movement of a first rotary table which is capable of rotating circumferentially, the second RPRR closed-loop subchain can control planar two-degree-of-freedom movement of a second rotary table which is capable of rotating circumferentially, and spatial four-degree-of-freedom movement of a flange can be realized by mean of movement of the first rotary table and the second rotary table. The two closed-loop subchains are used for controlling planar movement of the two rotary tables so as to realize spatial four-degree-of-freedom movement of the flange, and the parallel welding robot has the advantages of compact structure and simplicity in control. All active rods are connected to a frame and can be made into light rods, and the robot is low in the mechanism motion inertia and high in dynamic performance.

Owner:GUANGXI UNIV

Inner-expanded-type solar vacuum heat-collecting pipe

InactiveCN1908548AHigh strengthGood rigiditySolar heating energySolar heat devicesIntegrated systemsEngineering

The invention relates to an internal expansion groove type solar vacuum heat collection tube, which belongs to the technical field of solar heat collection facilities. The vacuum heat collecting tube includes an outer glass tube, the glass tube is set on the metal tube in the middle, and the metal tube is coated with a heat-absorbing coating. The middle of the metal tube is broken and connected by a wave expansion joint. The alloy transition pieces are respectively sealed with the extended ends of the two sections of metal tubes, the glass tube, the metal tube and the corrugated expansion joint are vacuumed to form a vacuum layer, and the middle part of the metal tube and the glass tube are respectively equipped with self-centering supports . The invention internally digests the expansion of the metal tube larger than the glass tube, simplifies the installation and connection structure; at the same time, it has sufficient strength and rigidity, and is convenient for system installation and integration, and is especially suitable for high-temperature and high-power solar thermal power generation and other occasions.

Owner:HOHAI UNIV

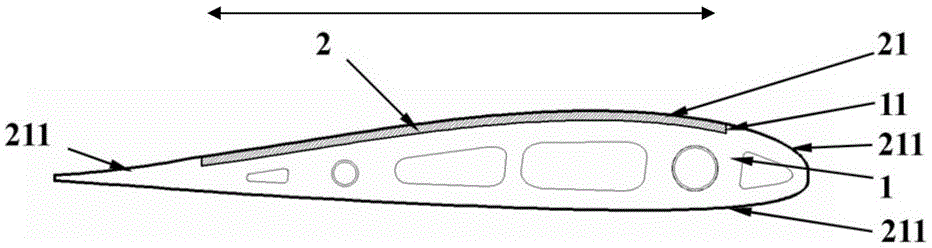

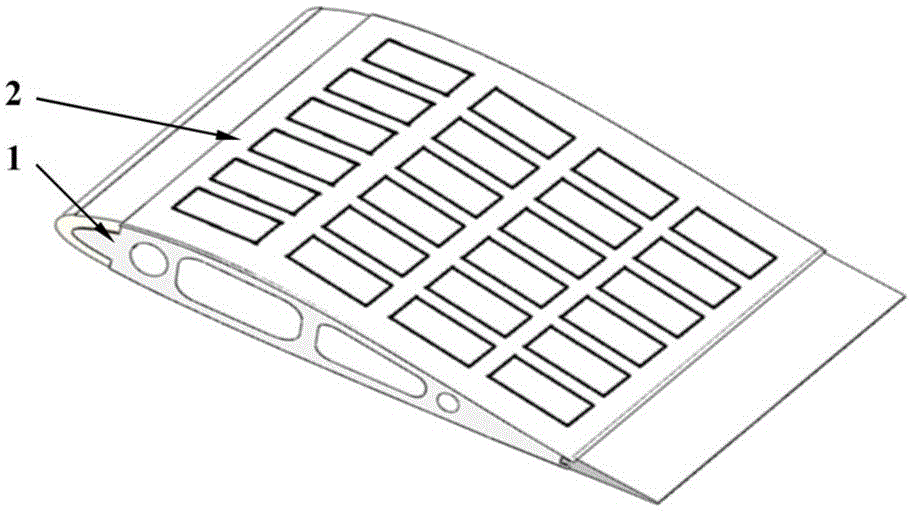

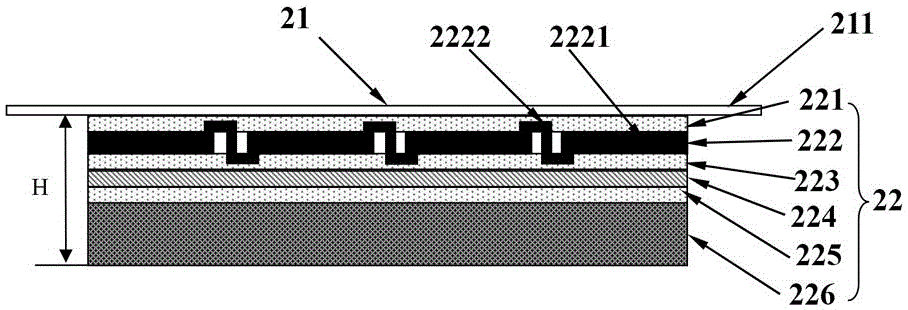

Solar-powered airplane wing and manufacturing method thereof

ActiveCN106379516AGood conformabilityImprove surface smoothnessFinal product manufactureWingsHigh surfaceSolar cell

The invention discloses a solar-powered airplane wing and a manufacturing method thereof. The solar-powered airplane wing comprises a wing framework and a flexible solar cell module, wherein the middle part of the upper surface of the wing framework is provided with a groove; the flexible solar cell module comprises a packaging skin and an assembly framework arranged on the lower surface of the packaging skin; the assembly framework is arranged in the groove; the packaging skin extends outwards along the two sides of the wing framework in the spanwise direction to form a coating side; and the coating side is coated on the wing framework. The manufacturing method comprises the following steps: S1: preparing the wing framework; S2: preparing the flexible solar cell module; and S3: assembling. The solar-powered airplane wing has the advantages of favorable conformal effects between the solar cell module and wing framework, high surface smoothness, excellent aerodynamic performance, light weight and the like. The preparation method has the advantages of convenient assembly, weight reduction and favorable reliability.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

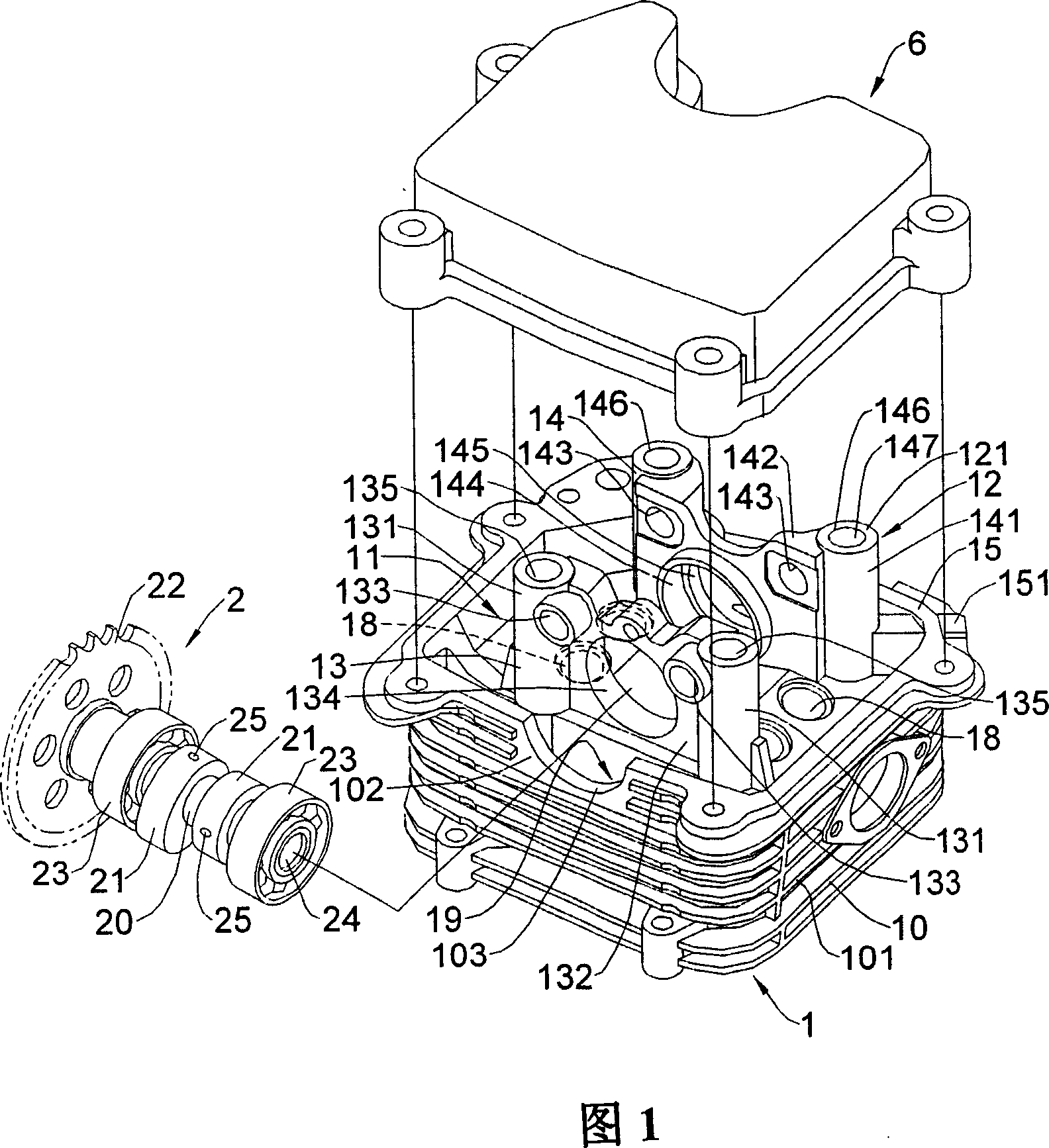

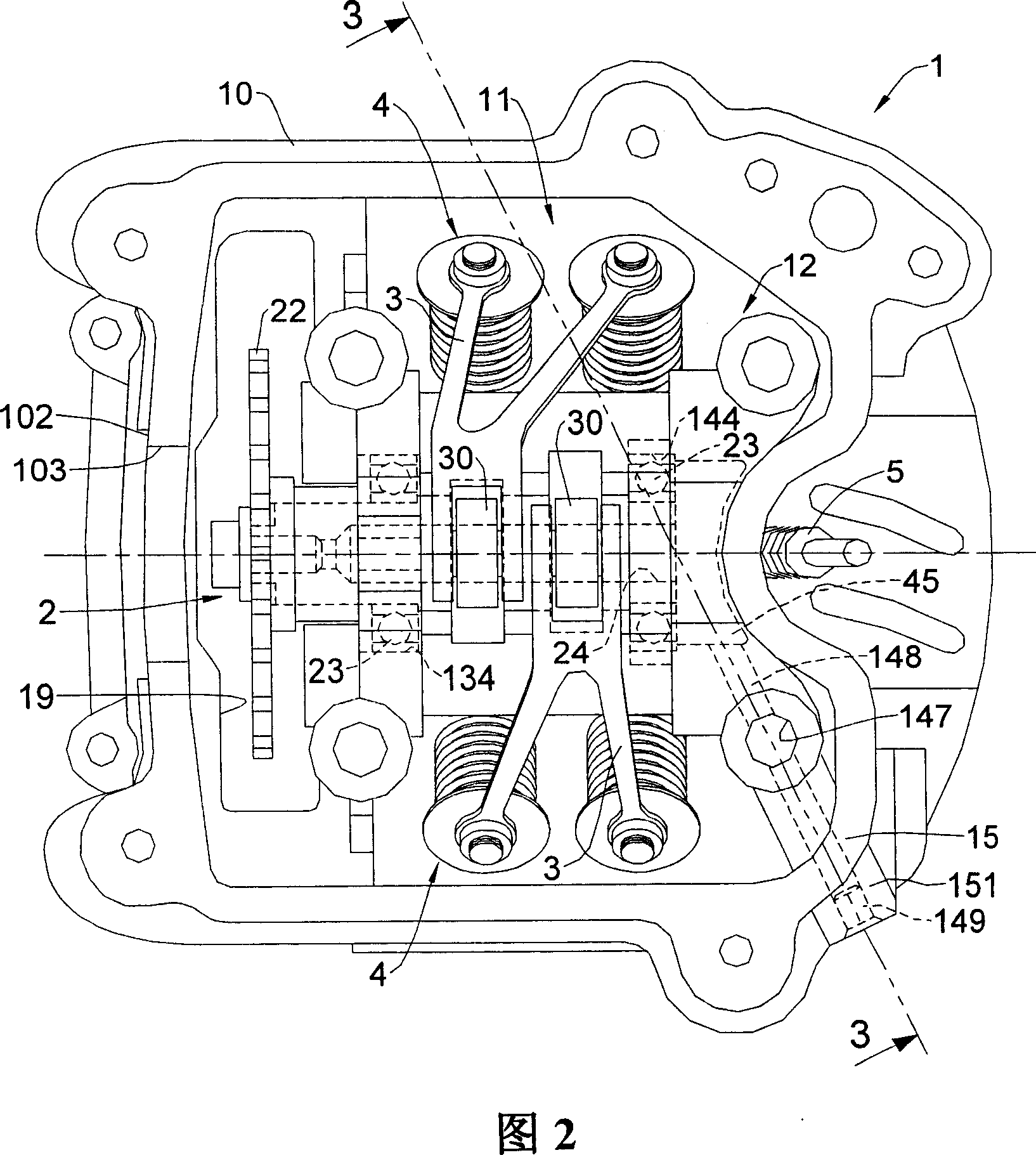

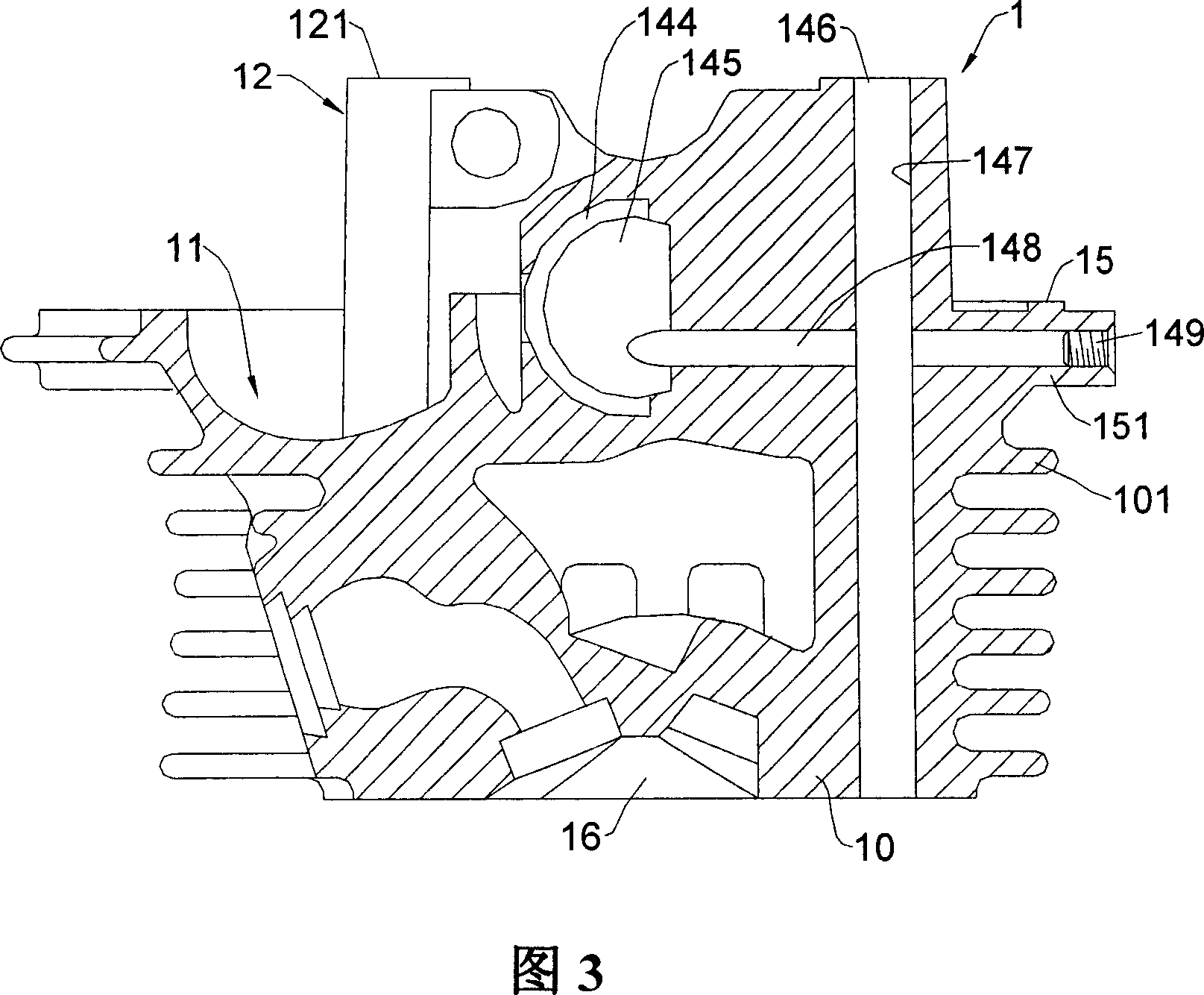

Cylinder head having integral supporting seat

InactiveCN1948738AGood rigidityGood strengthLubrication of auxillariesCylinder headsExhaust valveCylinder head

This invention is a kind of cylinder head with the integrated supporting bed. There is a pole hole in the supporting bed of the cylinder head body. The camshaft and the rocker are set on the pivot of the supporting bed which is connected to the intake and exhaust valve block in the cylinder head body by the rocker. The cylinder head is installed with the spark plug, and in the combination surface of the cylinder head is set with a cylinder head cover. The supporting bed is the integrated one in the cylinder head which is set with the shaft contacting groove and form the oil room in it. The top of the bed is the combination surface which is higher than the cylinder head which the wall is set with the oil access connected the pole hole and the oil room. The cylinder head has the good rigidity, the strength, so it can decrease the noise when using it and improve the lubricating effect between the camshaft and the rocker.

Owner:KYMCO

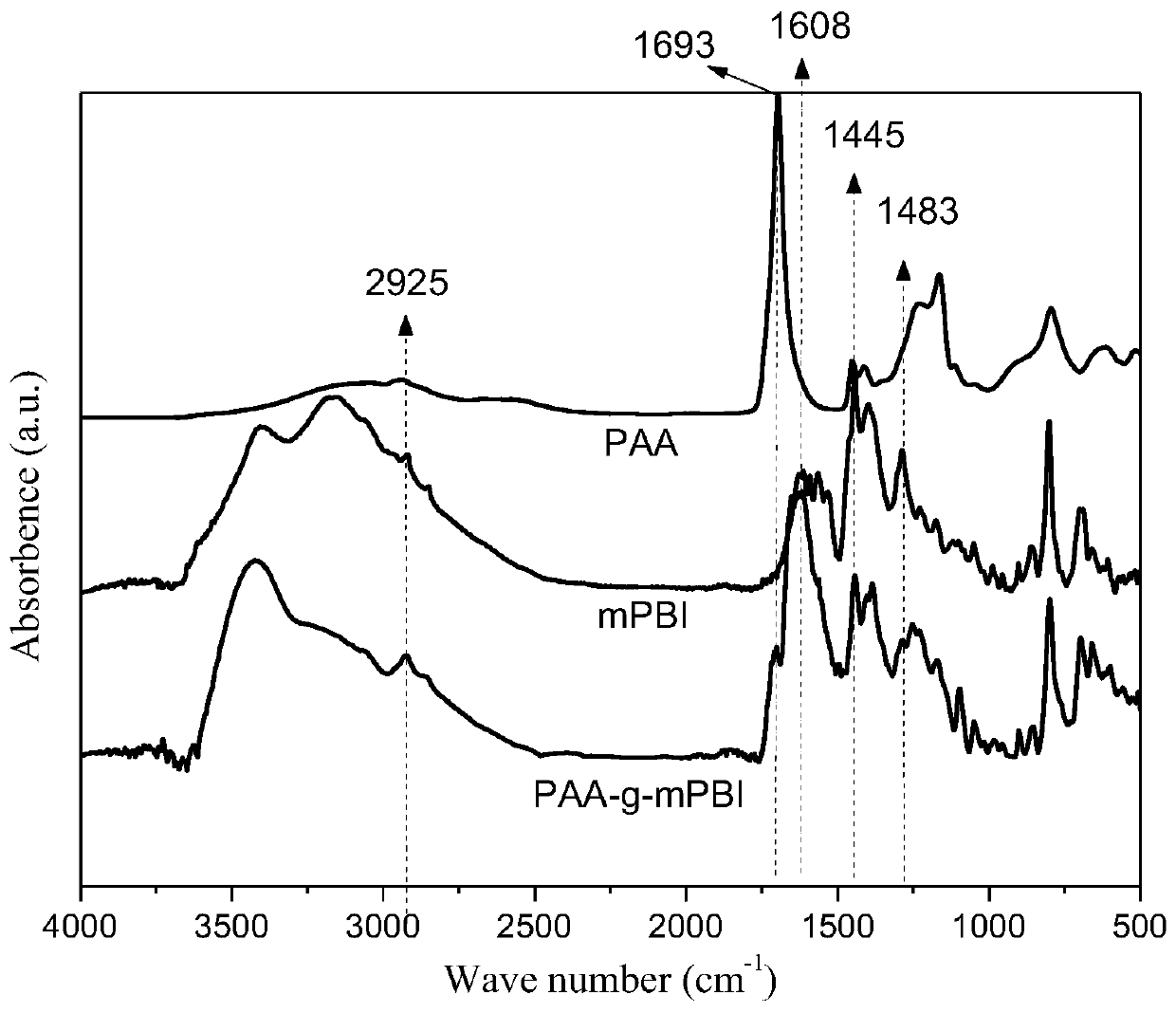

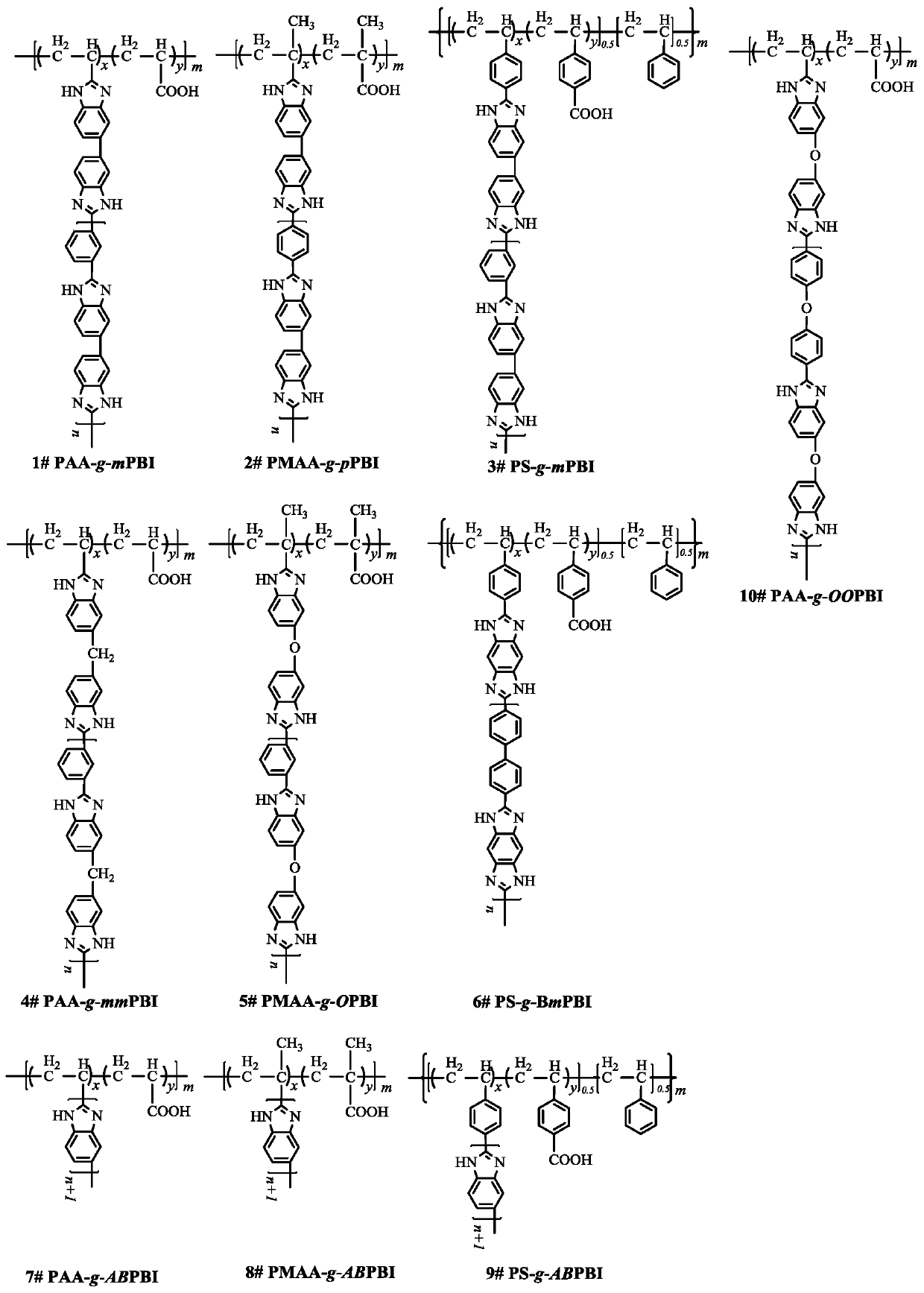

Polyolefin-g-polybenzimidazole grafted copolymer as well as preparation method and application thereof

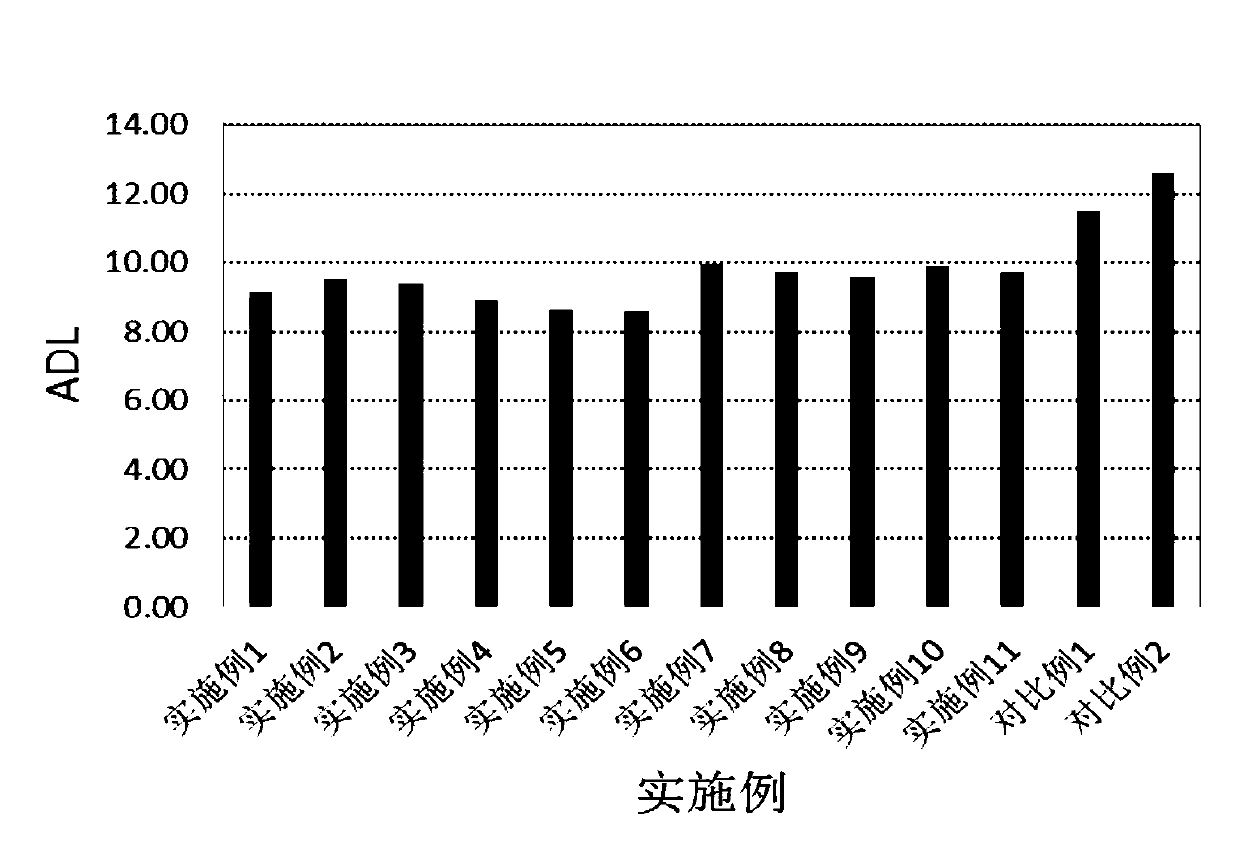

The invention relates to a polyolefin-g-polybenzimidazole grafted copolymer as well as a preparation method and an application thereof. The grafted copolymer is the grafted copolymer of a polyolefin grafted benzimidazole polymer, which is obtained by carrying out a condensation reaction on a terminal amino group in the benzimidazole polymer and a carboxyl group in an olefin polymer with the side chain containing the carboxyl group. According to the present invention, a proton transmission channel is constructed through a phase separation structure of the two chain segments so as to improve theproton conductivity, such that the high temperature proton exchange membrane with the high proton conductivity can be obtained under the low phosphoric acid doping level (ADL is less than 10) condition, and the preparation method is simple, is simple to operate, and can be used for fuel cells, flow cells and the like.

Owner:ZHUHAI COSMX BATTERY CO LTD

Amorphous silicon solar receiving device

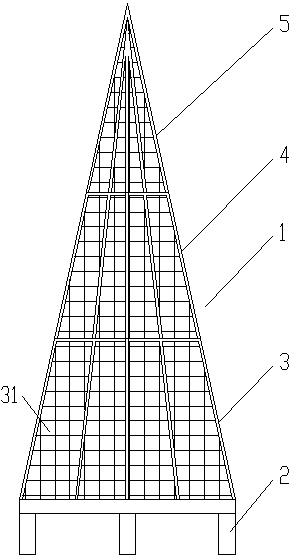

InactiveCN102201467ALower center of gravityGood rigidityPhotovoltaic supportsPhotovoltaic energy generationSmall footprintEngineering

The invention discloses an amorphous silicon solar receiving device, which comprises an amorphous silicon solar panel module, wherein an amorphous silicon solar panel is connected to a frame; the amorphous silicon solar panel module has a shape of a conical tower with a smaller top and a larger bottom and is fixedly connected to the frame through a lower frame; the conical tower is a circular conical tower or one of regular polygon conical towers, preferably the conical tower is 3 to 5 storied tower; the periphery of each layer of the tower has a split structure; the back of the amorphous silicon solar panel module is connected with a reinforced framework through a reinforcing plate; furthermore, an amorphous silicon solar cell film for forming the amorphous silicon solar panel module has a laminated structure with 2 to 4 layers. The invention has the advantages that: the device has small occupied area, small wind area, high wind damage resistance, high earthquake disaster resistance, long illumination time, large photic area, high photoelectric conversion efficiency and high photoelectric conversion quantity.

Owner:肖华荣

Drawing method of edge sealing frame type part hydraulically formed based on rubber bladder

The invention belongs to the feild of a machinery manufacturing technology and relates to a drawing method of an edge sealing frame type part hydraulically formed based on a rubber bladder. The drawing method comprises the following steps of: step 1, analyzing according to the part forming technology and the material forming features, confirming the drawing direction and the part position easily wrinkled, and further confirming the amount, position and shape of drawing thresholds or drawing ribs on a drawing and shaping die, and designing and manufacturing the drawing and shaping die; step 2, selecting the forming material status, the wool size, the material fiber direction and the forming pressure of the hydraulic forming machine of the rubber bladder, and manufacturing the part. According to the drawing method, the part can be formed by one time, the part cannot be affected due to sizing after being quenched and the drawing and forming effect is ensured, so that the part surface is higher in quality and better in rigidity, and the adhesion quality of the edge sealing frame type part is also improved.

Owner:HARBIN

Acoustic structures

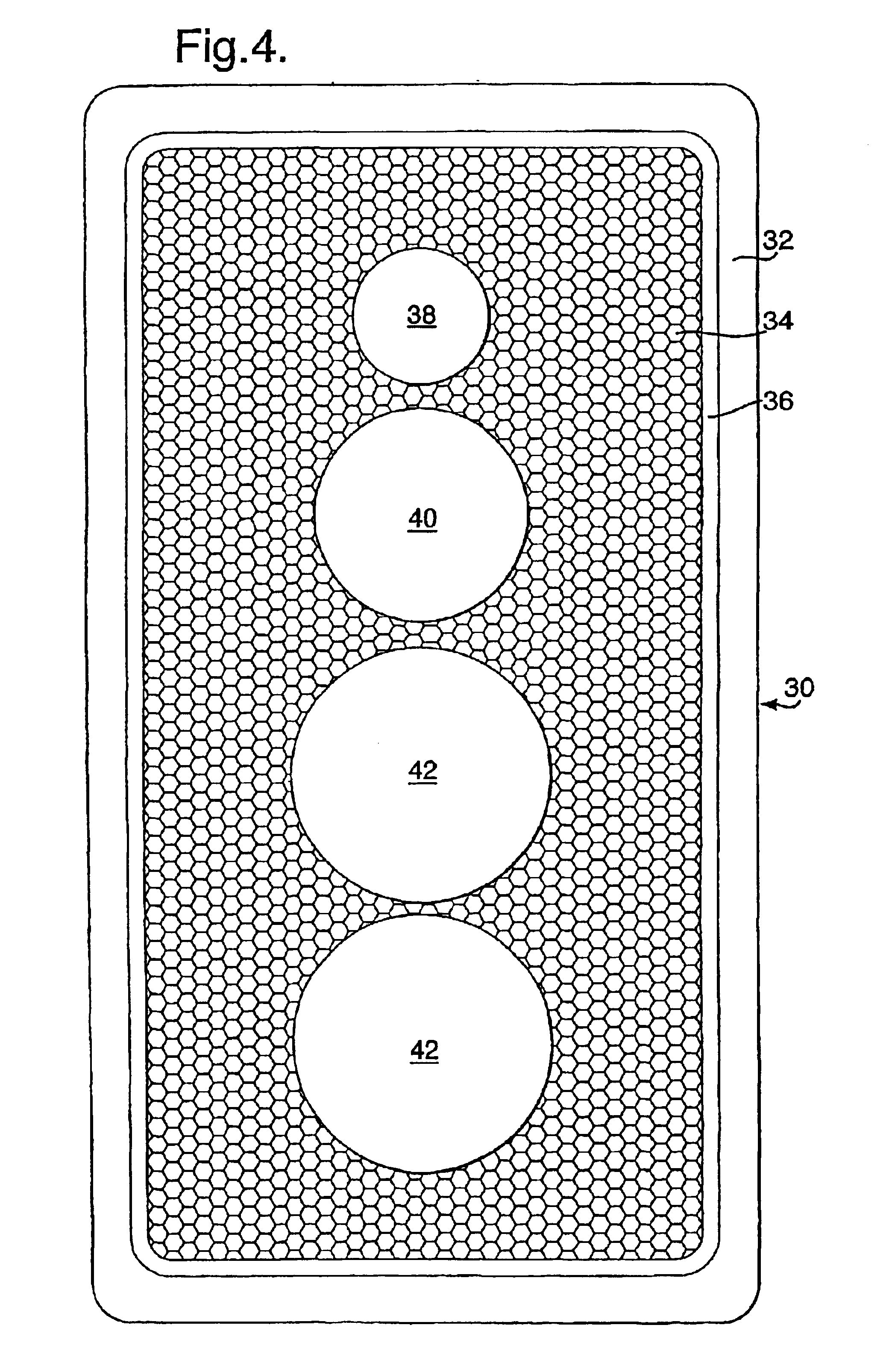

InactiveUS6896096B2Avoid lossGood rigidityCasings/cabinets/drawers detailsCabinetsInterior spaceEngineering

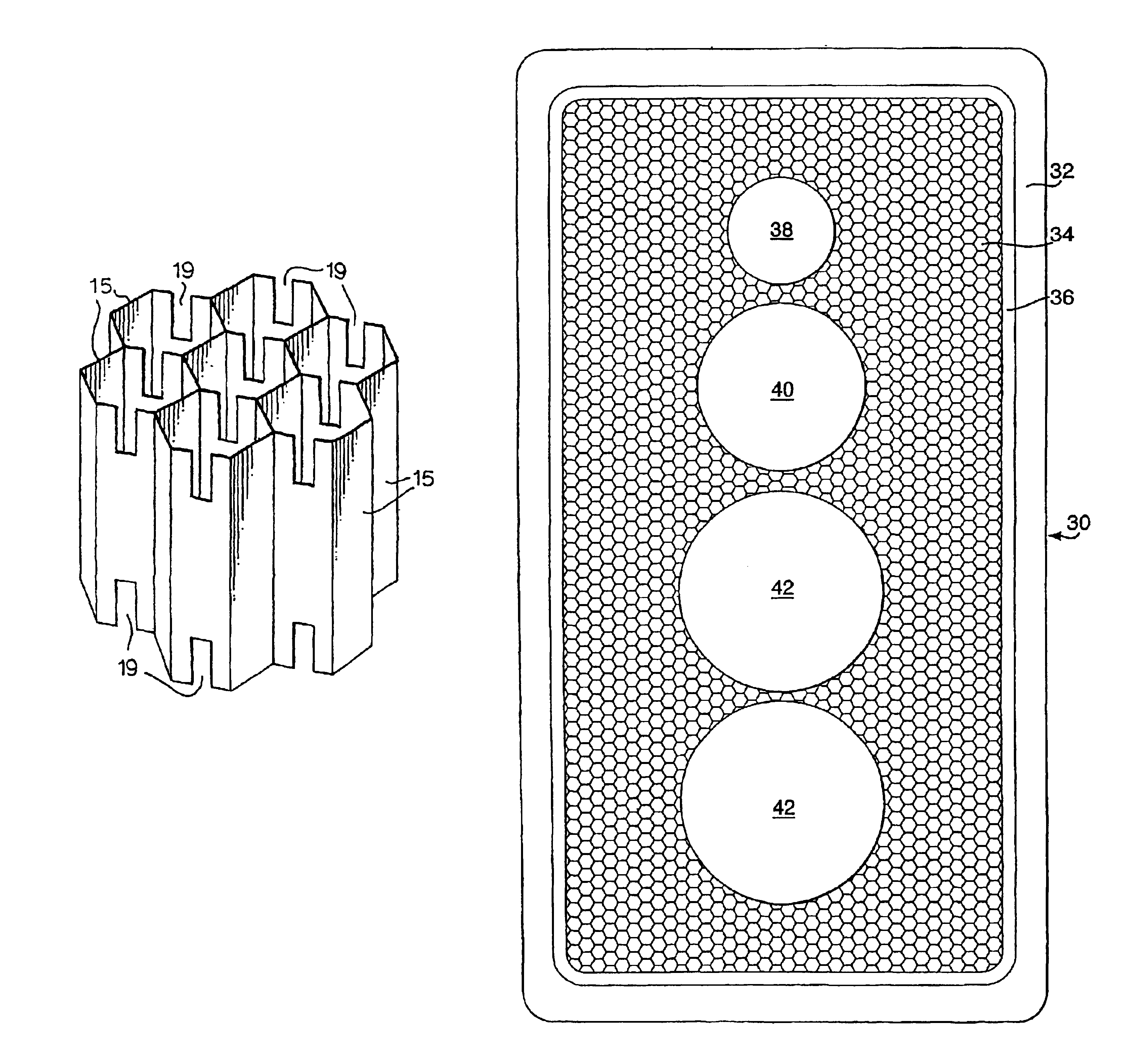

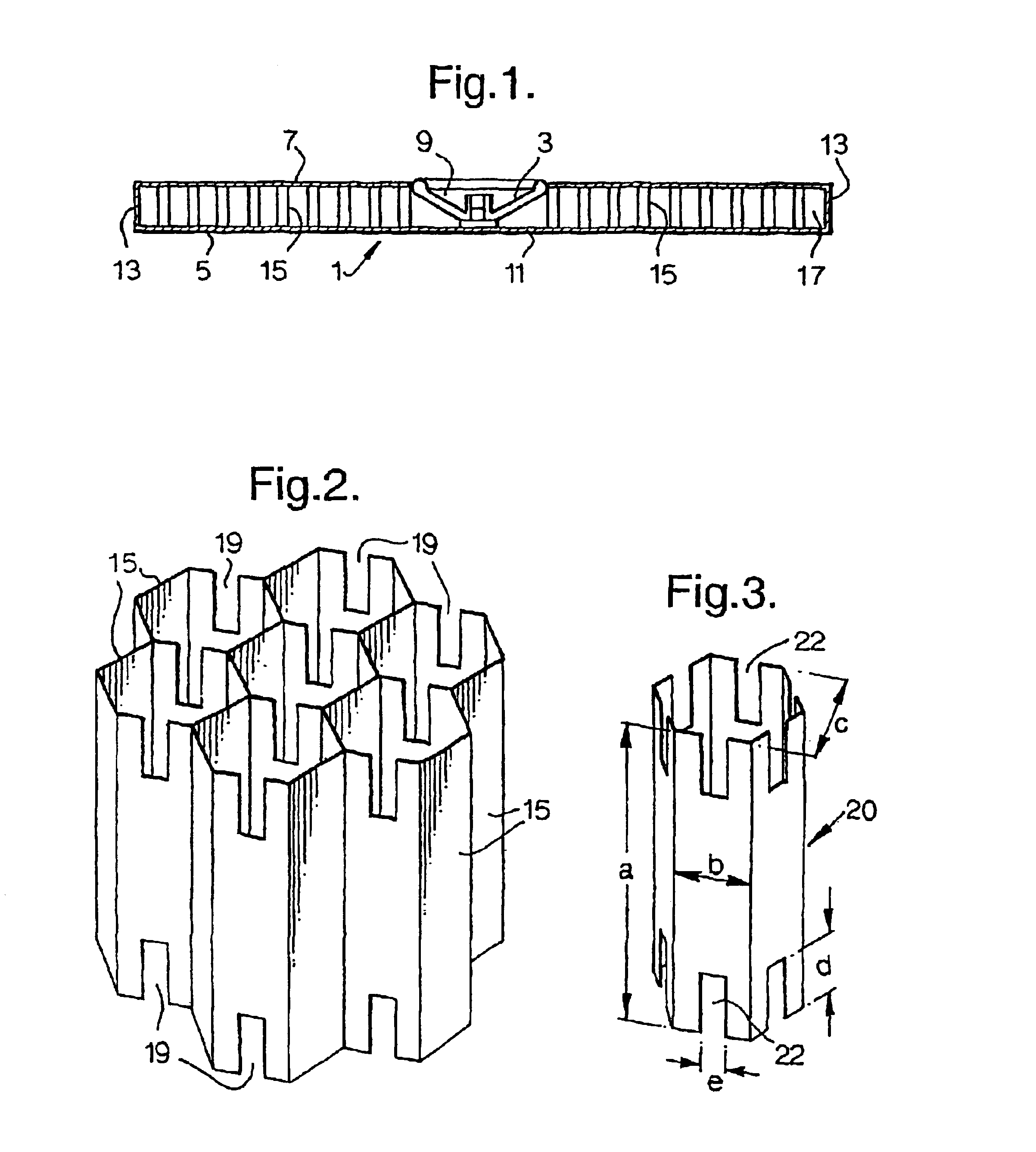

An acoustic structure includes a first, rigid panel (7), a second, rigid panel (11) aligned in spaced, substantially parallel, relationship with the first panel (7), a multiplicity of partition walls (15) running transverse to the panels of the panels (7, 11) and dividing the interior space of the enclosures into a single layer of cells (17) bounded at one face by the inside of the first panel (7) and bounded at the opposite face by the inside of the second panel (11), the partition walls (15) being bonded at the one face to the inside of the first panel (7) and at the opposite face to the inside of the second panel (11), and a multiplicity of apertures (19) in the partition walls (15) providing communication between adjacent cells of the single layer of cells (17).

Owner:B & W GRP LTD

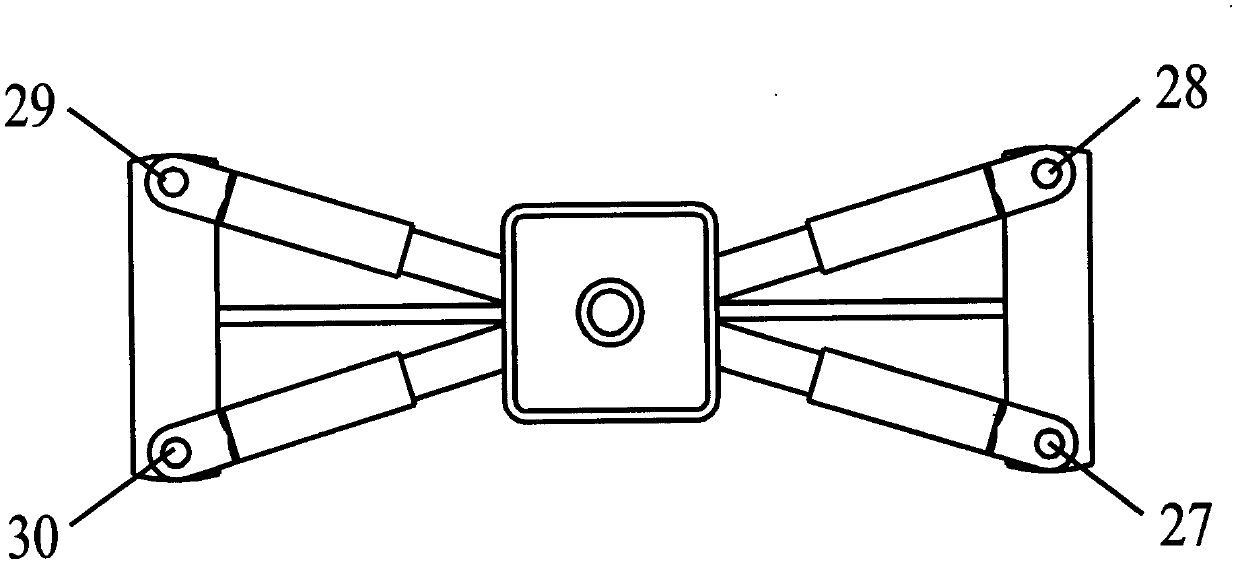

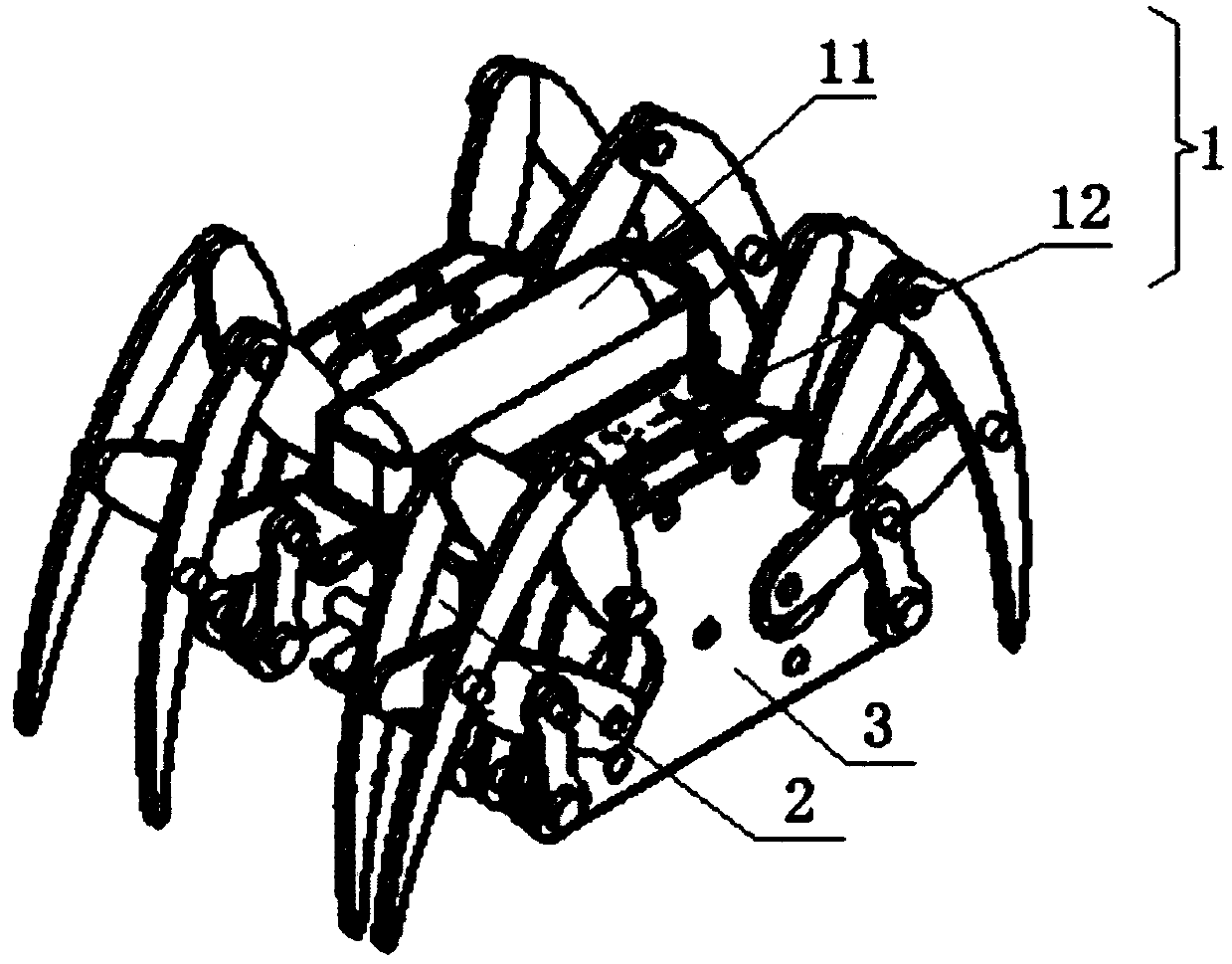

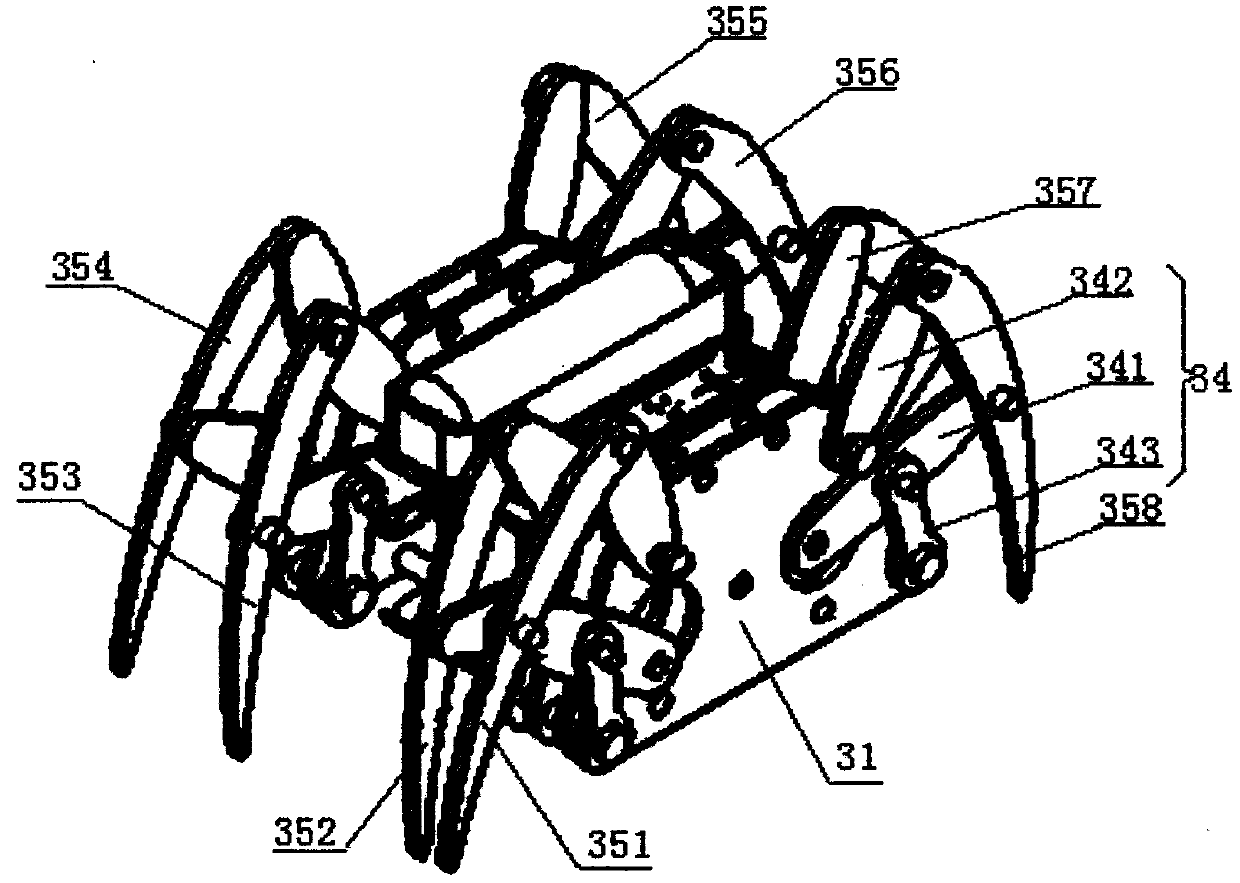

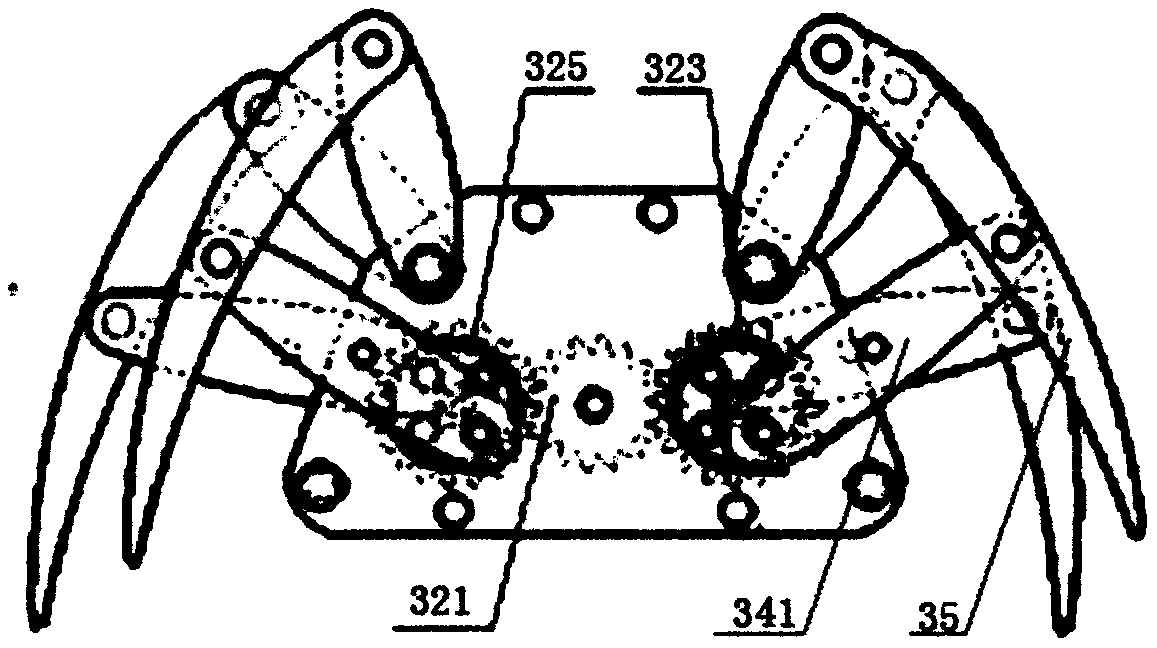

Six-bar mechanism multi-foot robot and modeling method thereof

PendingCN110562348AExcellent force transmission performanceGood rigiditySpecial data processing applicationsVehiclesGear transmissionBevel gear

The invention discloses a six-bar mechanism multi-foot robot and a modeling method thereof. The six-bar mechanism multi-foot robot comprises a control device, bevel gear speed reducers and left-rightsymmetrical leg mechanisms, wherein the control device is composed of a power supply, a controller internally provided with a direct-current motor control board, a direct-current motor A and a direct-current motor B, and the output shafts of the direct-current motor A and the direct-current motor B are correspondingly connected to the bevel gear speed reducers; and each leg mechanism consists of shell plates, a gear transmission assembly A, a gear transmission assembly B, a six-bar mechanism and a foot claw assembly, and in the case of each leg mechanism, the gear transmission assembly A is mounted between the two shell plates, and the gear transmission assembly B is mounted between the other two shell plates, and both the gear transmission assembly A and the gear transmission assembly B drive the foot claw assembly through the six-bar mechanism. According to the six-bar mechanism multi-foot robot and the modeling method thereof, the two leg mechanisms are driven by the two direct-current motors, the six-bar mechanisms push eight foot claws of front and rear groups to move in a staggered mode, so that walking of the robot is achieved through the staggered movement of the adjacent six-bar mechanisms; and assembling of the robot is compact, thus meeting the requirements of narrow-space operation.

Owner:LULIANG UNIV

Gantry vertical type numerical control single-head milling machine machining center

InactiveCN105171495AGood rigidityIncrease speedPositioning apparatusMetal working apparatusNumerical control systemEngineering

The invention relates to a gantry vertical type numerical control single-head milling machine machining center. The gantry vertical type numerical control single-head milling machine machining center comprises a base, gantry stand columns, a fixed type transverse beam, a cross-shaped numerical control sliding table, an X-axis main sliding table, a workpiece platform, a clamp, a main shaft milling head, a disc tool changer and a numerical control system; the clamp is installed on the workpiece platform of the X-axis main sliding table; and the cross-shaped numerical control sliding table composed of a Y-axis sliding table and a Z-axis sliding table is arranged above the fixed type transverse beam, the special vertical type main shaft milling head is installed in the center of the cross-shaped numerical control sliding table, the disc tool changer is installed on the outer side of the stand column on the left side, and the continuous cutting and machining requirement of complex workpieces can be met through a machine tool under control of the numerical control system. A main shaft is provided with a broach mechanism, and rapid and automatic tool changing can be achieved under matching of a tool hitting cylinder and the tool changer; the main shaft milling head is transmitted through an alternating current servo motor and a ZF reducer casing, operation is stable, and the transmitting torque is large; and after first-time clamping of the workpieces, rough and finish machining of multiple work procedures including boring, milling, drilling and stranding on the workpieces can be automatically completed.

Owner:西安宝钢钢材加工配送有限公司

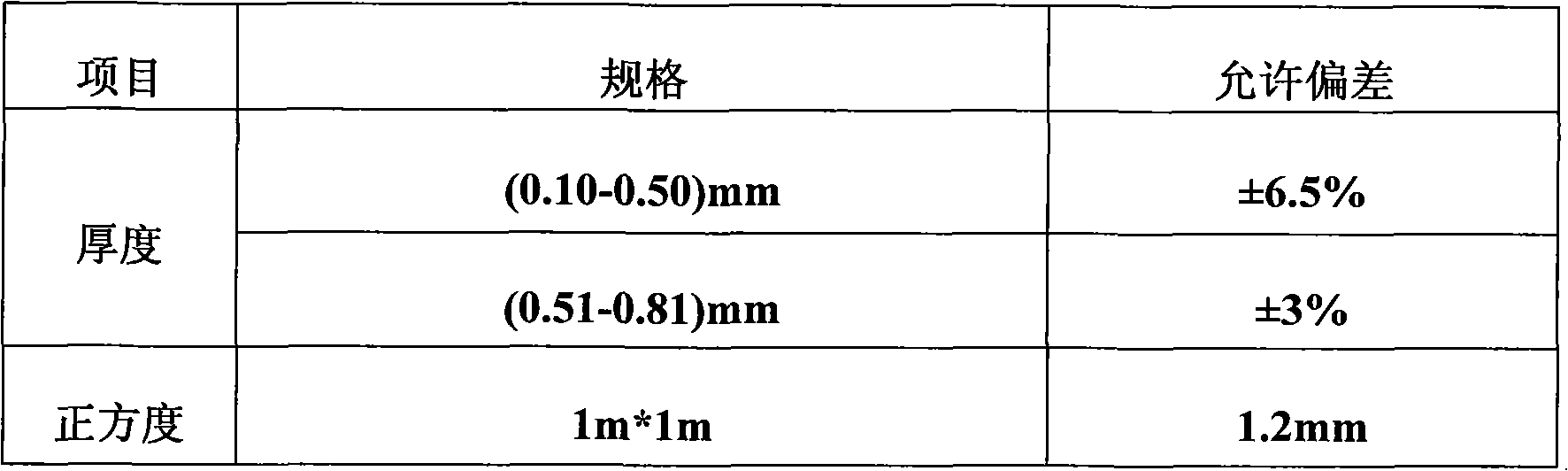

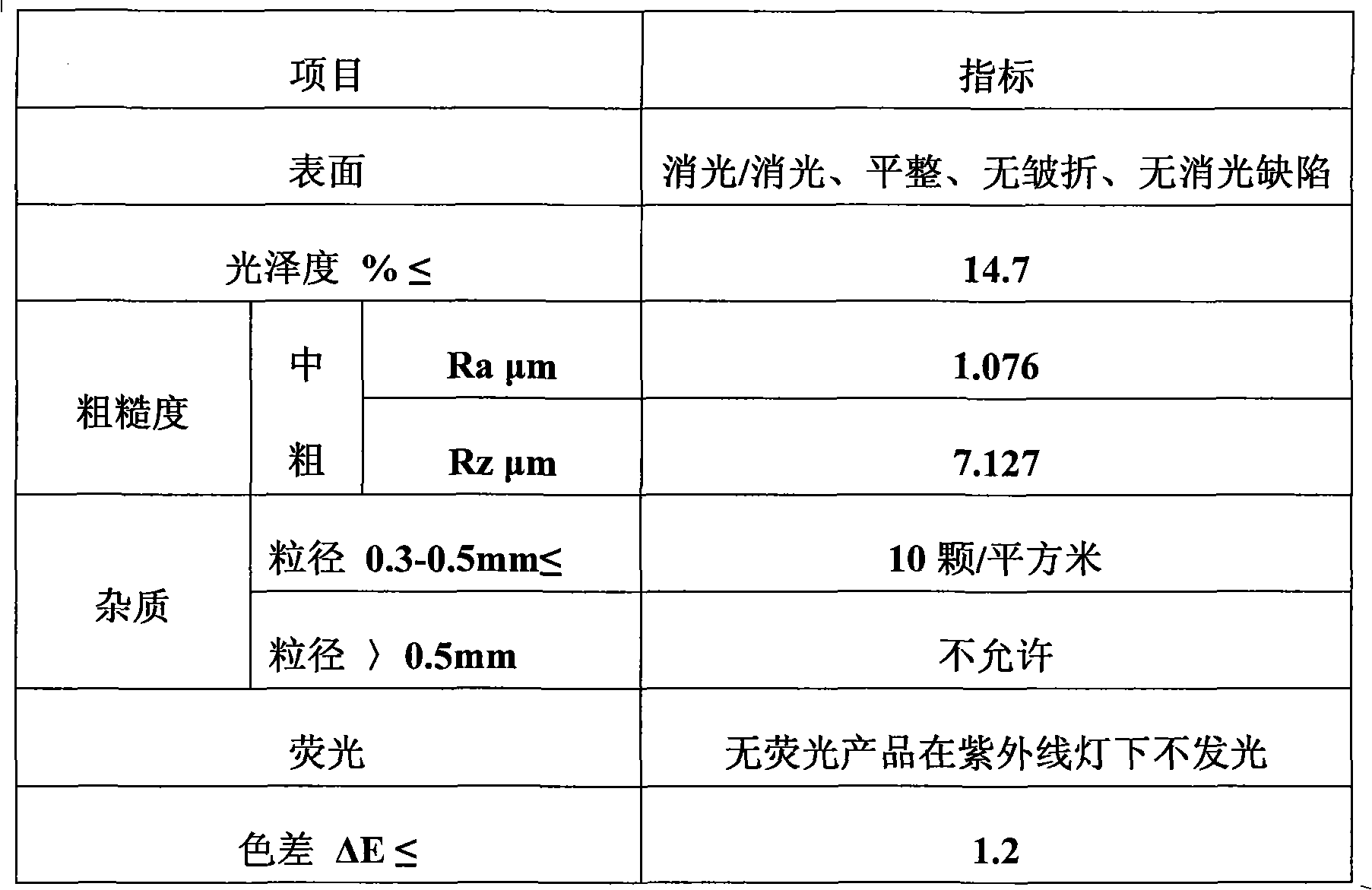

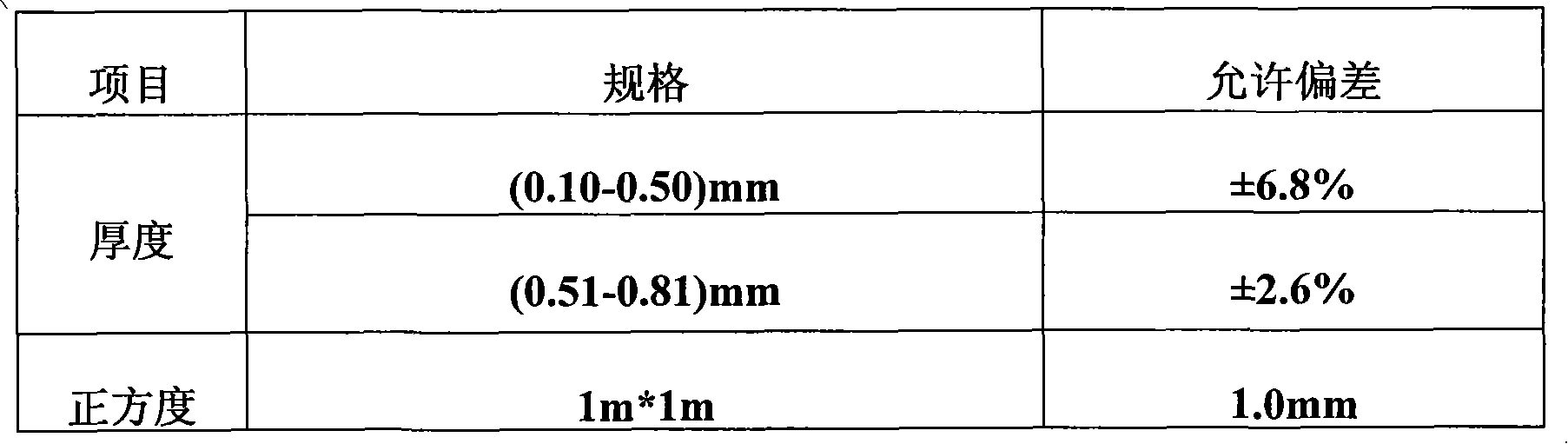

Makrolon/modified polyester blending rolling base material and preparation method thereof

The invention provides a markrolon / modified polyester blending rolling base material and a preparation method thereof. The markrolon / modified polyester blending rolling base material comprises the following components by weight percent: 55-65% of makrolon, 15-20% of modified polyester, 4-8% of modified copolyesters additive, 3-5% of compatilizer 4051, 4-7% of titanium white, 2-6% of calcium carbonate and 0.01-0.1% of pigment. The vicat softening point of the invention can be 115 DEG C+ / -2 (50-5kg of vicat A), the tensile strength is larger than 45Mpa, the tensile yield strength is larger than 750KJ / m<2>; and the invention meets the rolling technology requirement by improving the formula lubrication systems, can meet the requirement of the processes such as material application, card making technology of smart card base materials and the like.

Owner:上海达凯塑胶有限公司

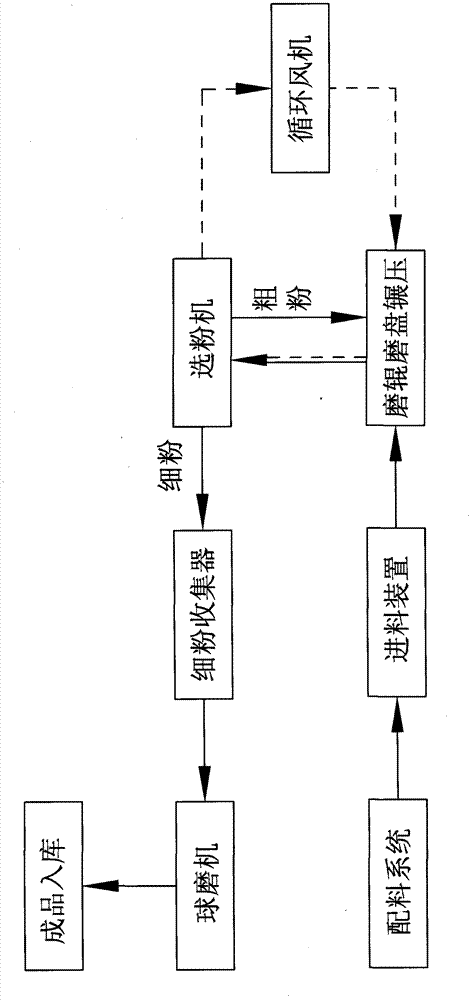

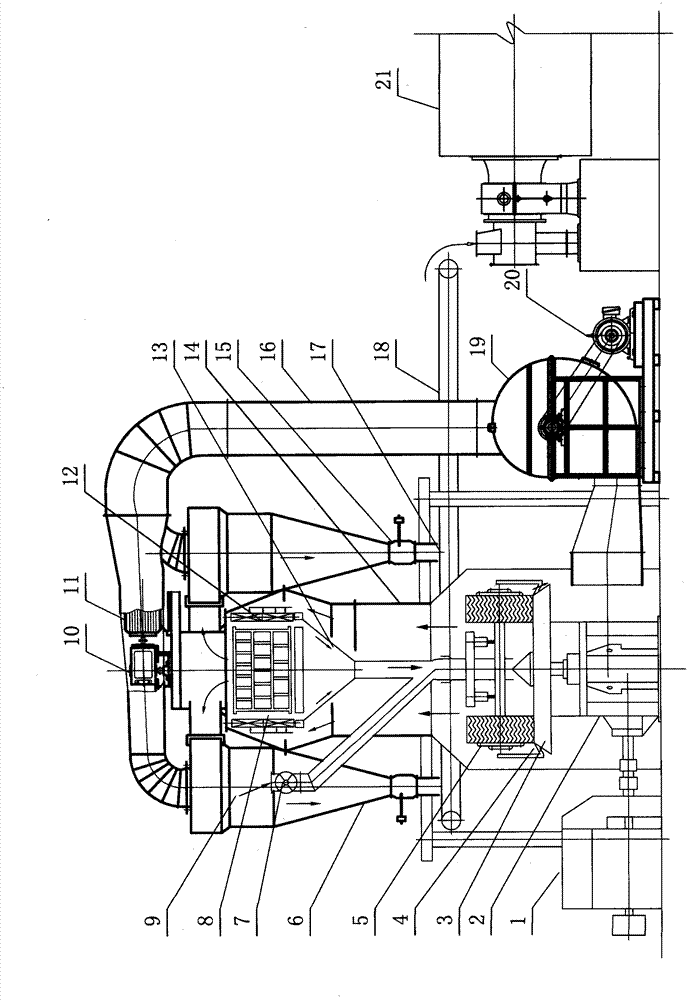

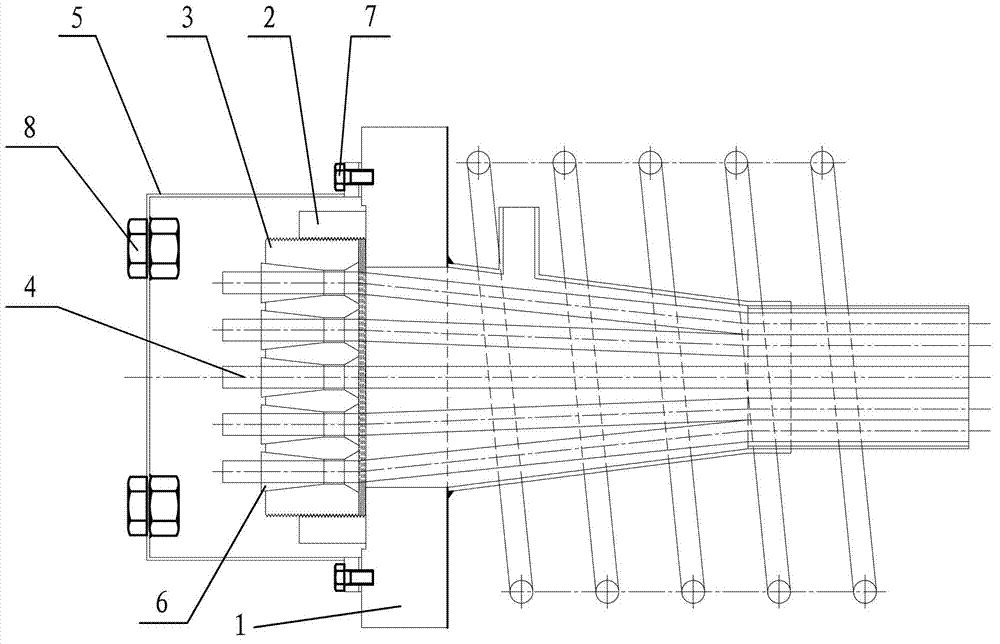

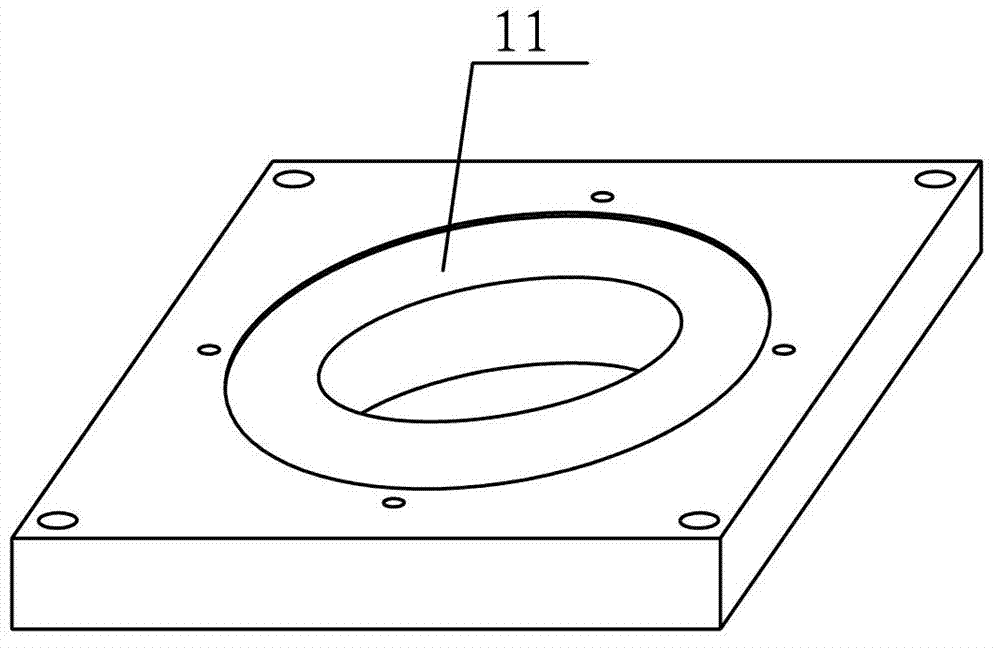

Serially-connected grinding technology and equipment thereof

Serially-connected grinding technology and equipment thereof belong to grinding technology and equipment thereof; the equipment comprises a vertical mill, a powder separator, a blower fan, and a ball mill; the powder separator is connected with the upper part of the vertical mill; fine powder collectors are disposed at the periphery of the powder separator; a powder outlet of the powder separator is connected with the ball mil through a powder conveying device; an air outlet of the blower fan is connected with the bottom of the vertical mill; a backwind pipe is connected with the top of the powder separator. The invention adopts the grinding technology combining the vertical mill with the ball mill and the material bed-rolling grinding technology; powder grading is realized inside the equipment; qualified materials are collected in advance, which reduces material underlay and over-grinding phenomena of the ball mill; a traditional mode in which the millstone rotates and the grinding roller is driven for a vertical mill is changed into a mode in which the millstone is fixed and the grinding roller rolls; powder grading is realized inside the equipment; the working efficiency is high; the fine grinding performance is good; the abrasion is less; the energy consumption is low; the investment is saved; and the maintenance is safe and simple.

Owner:YANCHENG JIDA ENVIRONMENTAL PROTECTION EQUIP

Large-tonnage low-retraction pres-stress anchor and tightening device thereof

InactiveCN102776830AEnsure structural safetyAvoid local weakeningBridge structural detailsBridge erection/assemblyStress concentrationReinforced concrete

The invention discloses a large-tonnage low-retraction pre-stress anchor. The large-tonnage low-retraction pre-stress anchor comprises a bearing plate, an anchor block and a bearing nut, wherein the anchor block is matched with the bearing nut in a threaded manner; the bearing nut is firmly adhered on the bearing plate; a protective cover is arranged on the bearing plate; the anchor block and the bearing nut are covered inside the protective cover; and the bearing plate is a steel plate. According to the large-tonnage low-retraction pre-stress anchor, the bearing plate adopts the steel plate after corrosion prevention and thermal treatment, and can improve rigidity characteristic of the bearing plate, thereby avoiding an occasion that the bearing plate is crushed by the supporting foot in a second large-tonnage tension process; simultaneously, the anchor is externally arranged on a reinforced concrete anchorage region, so that local weakening to the concrete section can be avoided by the anchor structure and the structural safety of the concrete anchorage region is ensured. The invention further discloses a tightening device for the anchor, and the supporting foot of the tightening device is of a sleeve structure, so that the contact area of the supporting foot and the bearing plate can be increased, the stress concentration is reduced, and the occasion that the bearing plate is crushed in the second large-tonnage tension process can be avoided.

Owner:ZHEJIANG PROVINCIAL INST OF COMM PLANNING DESIGN & RES CO LTD

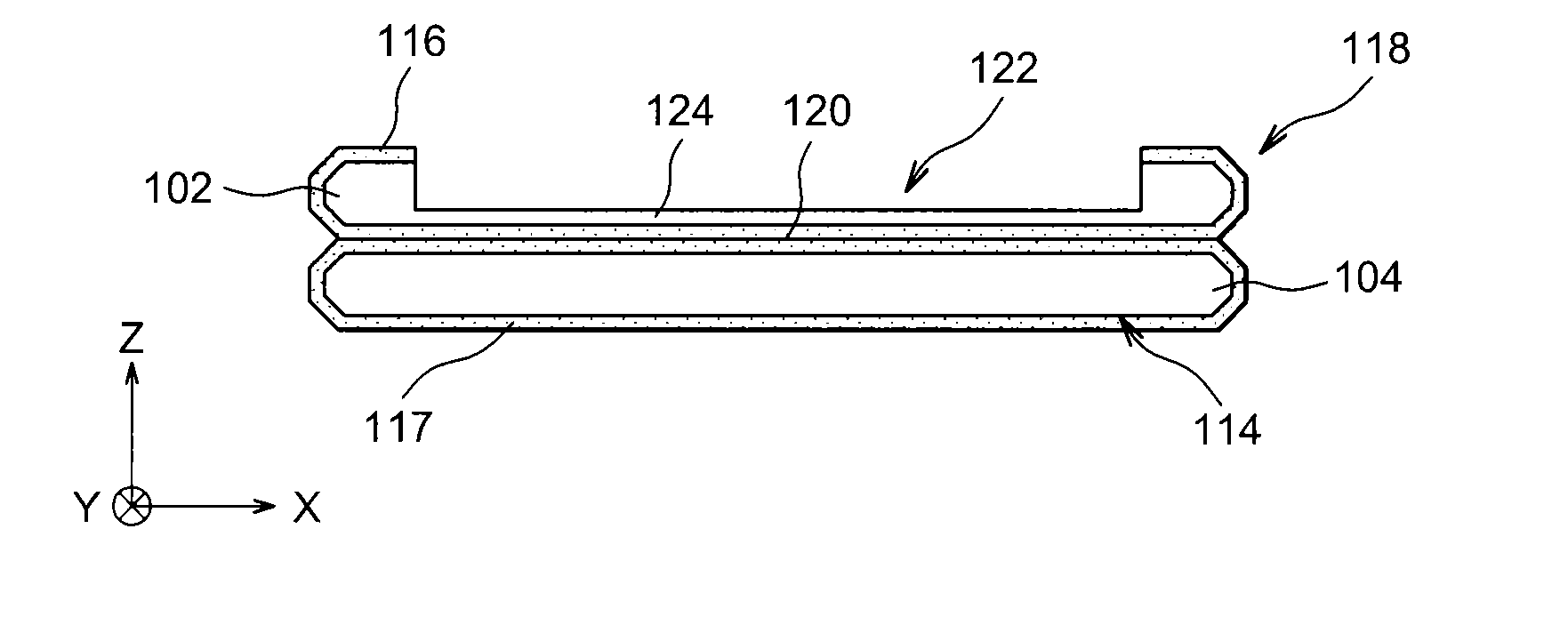

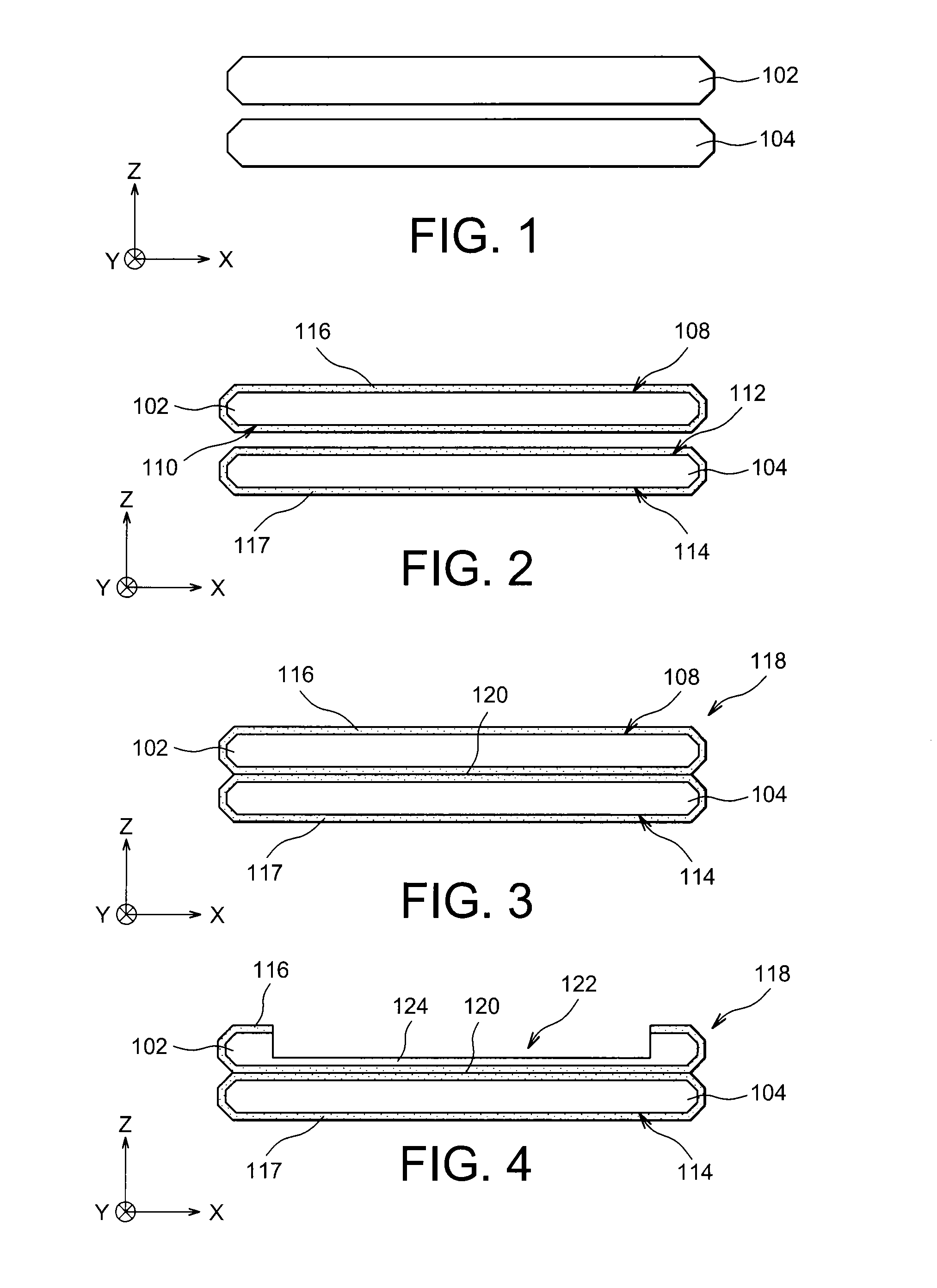

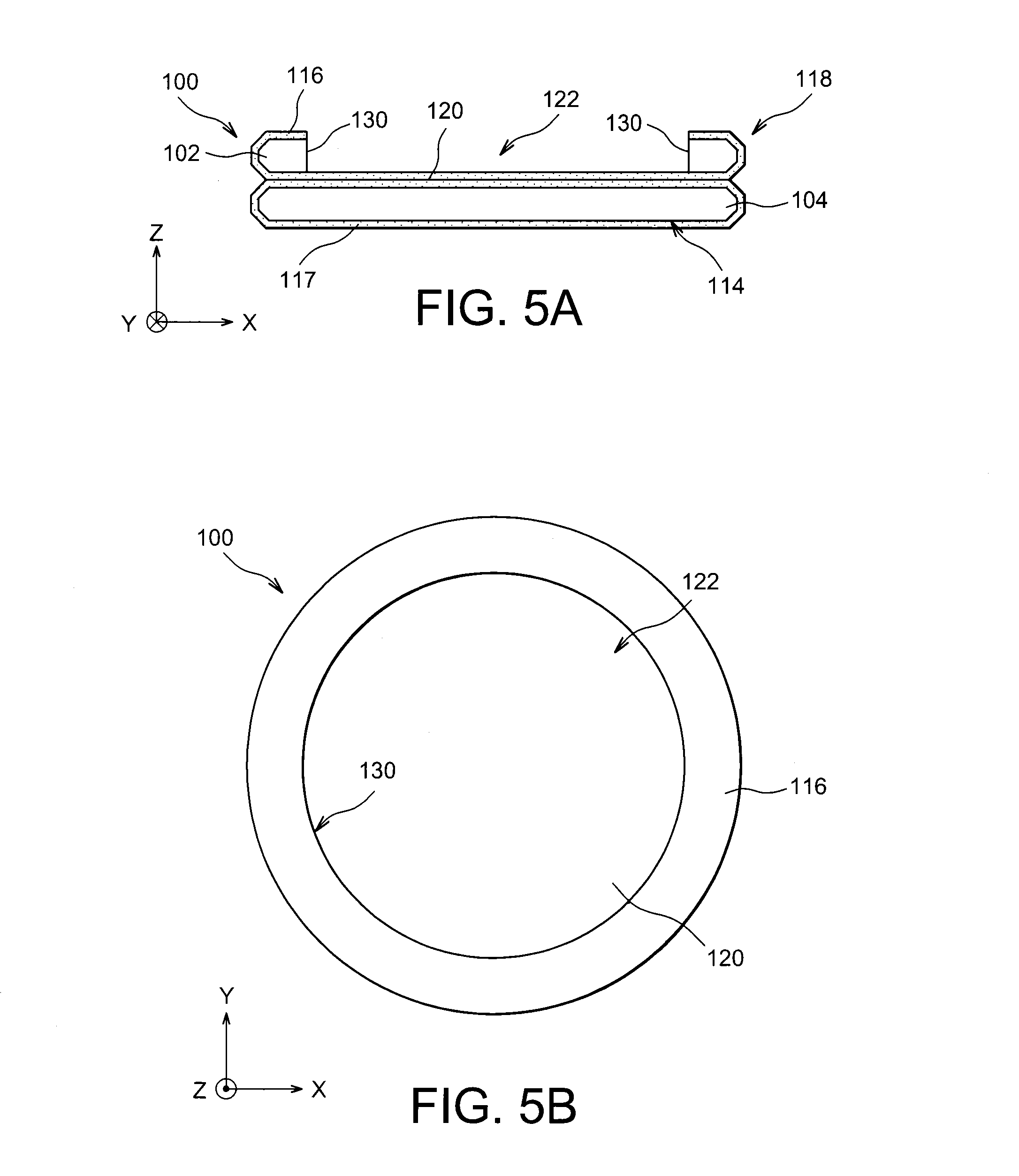

Method for building a substrate holder

InactiveUS20130075365A1Good rigidityGood resistance to temperatureDecorative surface effectsSemiconductor/solid-state device manufacturingEngineering

A method for making a support of at least one substrate, including: making a stack including at least two substrates, each of the two substrates including two opposite main faces, both substrates being secured to each other such that one of the main faces of a first of the two substrates is positioned facing one of the main faces of the second of the two substrates and against an etch-stop material; etching, through the first of the two substrates and with stop on the etch-stop material, at least one location that can receive a substrate that can be supported by the support.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Solar building material and building integrated solar utilization device

InactiveCN102071779AHigh strengthGood rigidityRoof covering using slabs/sheetsRoof covering using tiles/slatesEnvironmental resistanceThin sheet

The invention discloses a solar building material and building integrated solar utilization device which has good environmental protection and energy conservation effects. The device is characterized in that: a vanadium, titanium and black porcelain composite ceramic solar panel, a metal thin sheet with high heat conductivity and a heat pipe or an inorganic heat-conducting pipe are machined into a whole; the metal thin sheet which is integrally machined with the heat pipe or the inorganic heat-conducting pipe has a building decoration function, and is also used as a solar heat collection sheet of the heat pipe or the inorganic heat-conducting pipe, namely a novel building material with a solar utilization function; a building is constructed by composite heat-preservation building blocks; a modified polyurethane rigid foam water-proof heat-preservation material is sprayed to a building roofing and an exterior wall; and the vanadium, titanium and black porcelain composite ceramic solar panel is formed in the way that: a hollow ceramic plate-shaped biscuit is formed by a normal ceramic raw material without whiteness requirements by continuous extrusion molding; vanadium, titanium and black porcelain slurry is applied to the surface of the biscuit; and the biscuit is dried and fired into a sunlight absorbing layer with a vanadium, titanium and black porcelain surface. The building is constructed by the composite heat-preservation building blocks; and the modified polyurethane rigid foam water-proof heat-preservation material is sprayed to the building roofing and the exterior wall.

Owner:李代虹

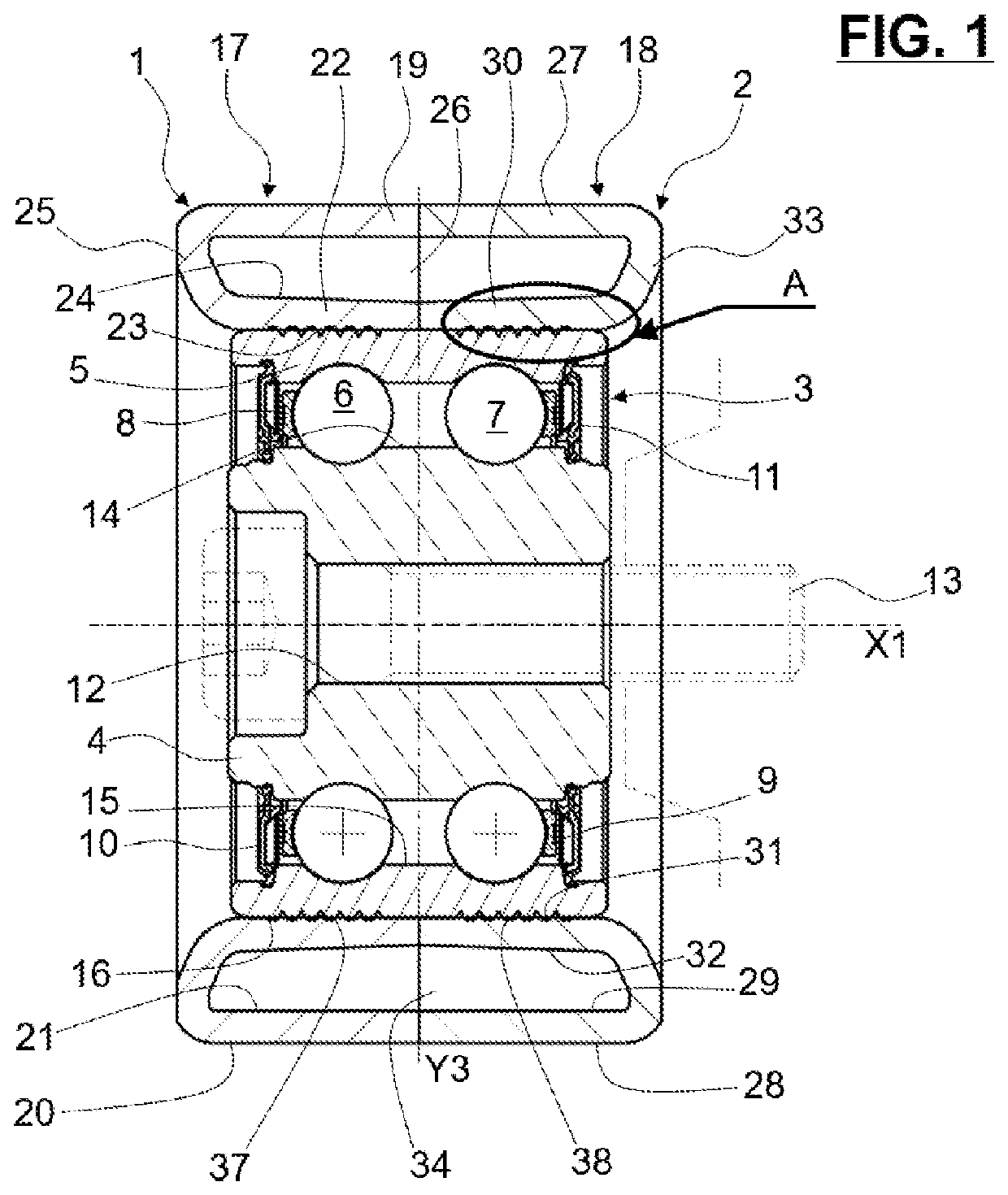

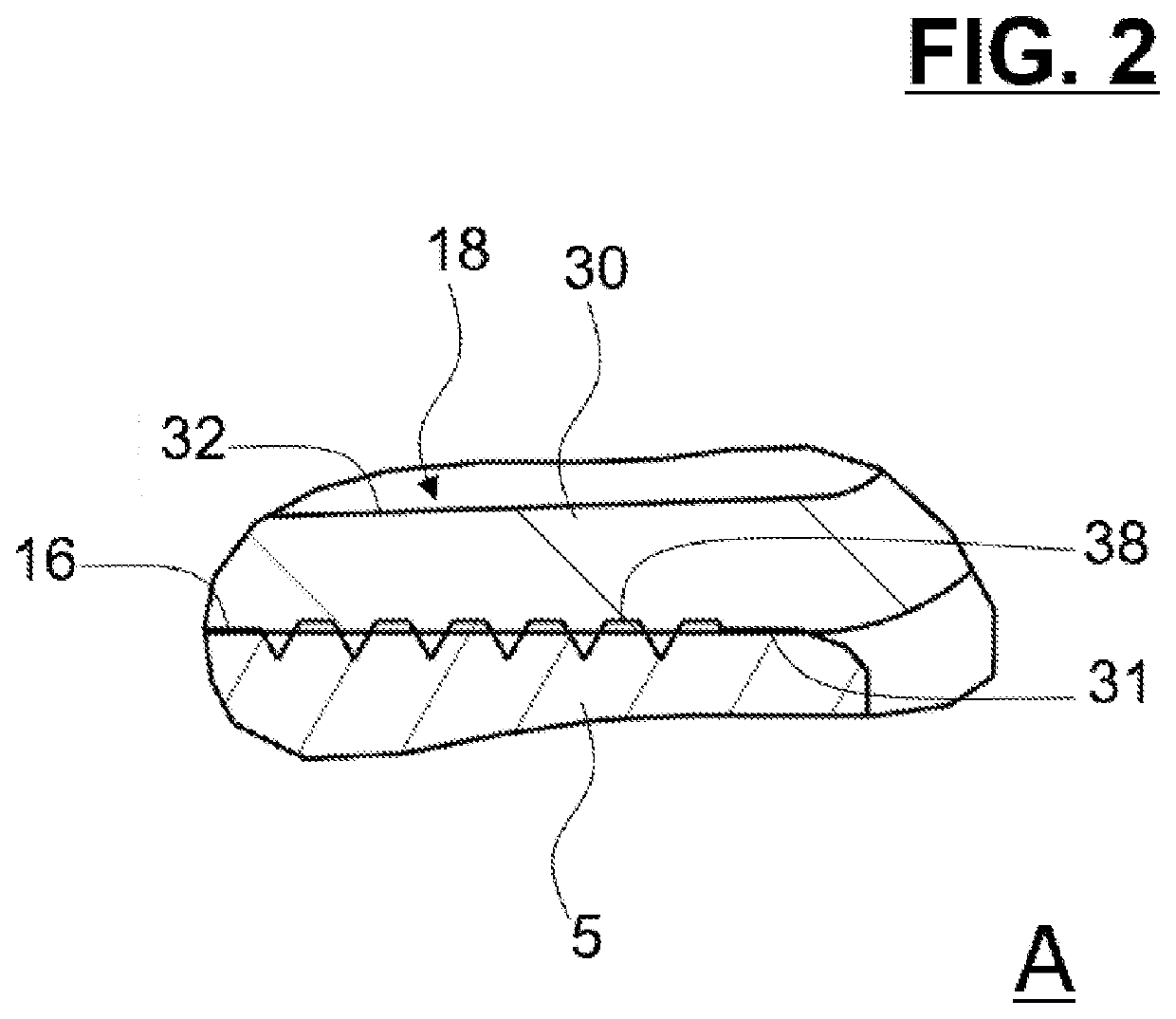

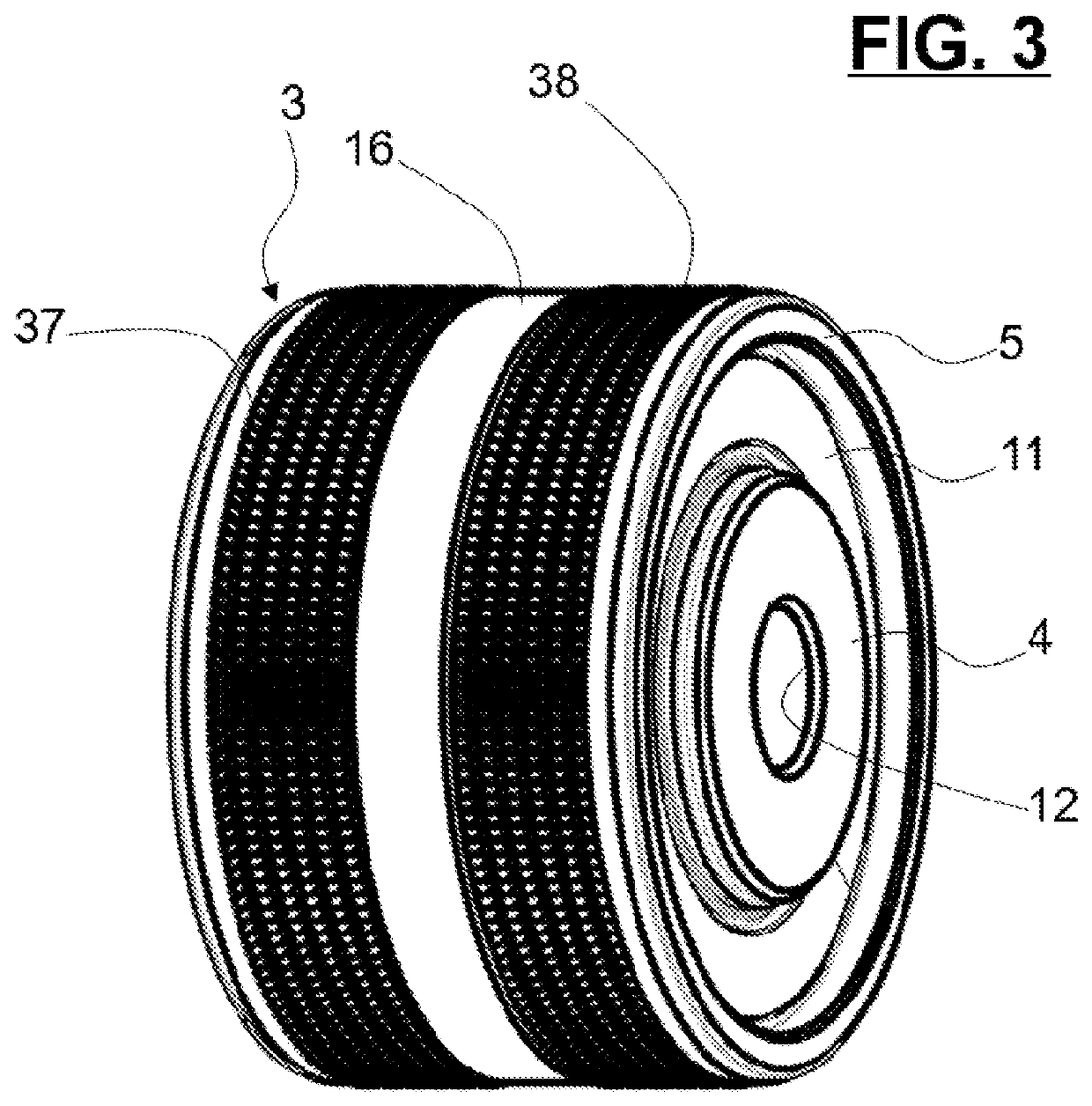

Pulley device, in particular for tensioning idler or runner roller

ActiveUS20200256378A1Easy to installGood rigidityGearingBall bearingsLeather beltClassical mechanics

A pulley device provides a pulley, and a bearing. The pulley has at least one C-shaped pulley part having an inner portion mounted on the bearing, an outer portion having an outer cylindrical surface dedicated to interact with a belt or a chain, and an intermediate portion extending substantially radially between axial ends of inner and outer portions on one axial side of pulley device. A grip surface portion is provided to one surface among the outer cylindrical surface of the outer ring and the inner cylindrical surface of the inner cylindrical portion of the pulley part, the grip surface portion including a plurality of indentations and recesses.

Owner:AB SKF

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com