Makrolon/modified polyester blending rolling base material and preparation method thereof

A technology of polycarbonate and calendered substrates, applied in the field of calendered substrates, can solve the problems of low heat-resistant softening point, environmental pollution, poor processing performance, etc., and achieve high Vicat softening point, high surface quality and good printing performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Recipe: (weight)

[0035] Polycarbonate 61.32%

[0036] Modified copolyester 18.33%

[0037] Modified copolyester additive 7.97%

[0038] Compatibilizer 4051 3.07%

[0039] Titanium dioxide 6.13%

[0040] Calcium Carbonate 3.12%

[0041] Everlasting Violet 0.06%

[0042] The raw materials are respectively metered into the kneader, kneaded at a temperature of 115°C, the kneader speed is 600 rpm, then cooled and stirred at a temperature of 85°C, and then calendered by a five-roller calender. The processing temperatures are: 1 Roll No. 190°C, Roll No. 2 200°C, Roll No. 3 210°C, Roll No. 4 205°C, Roll No. 5 200°C.

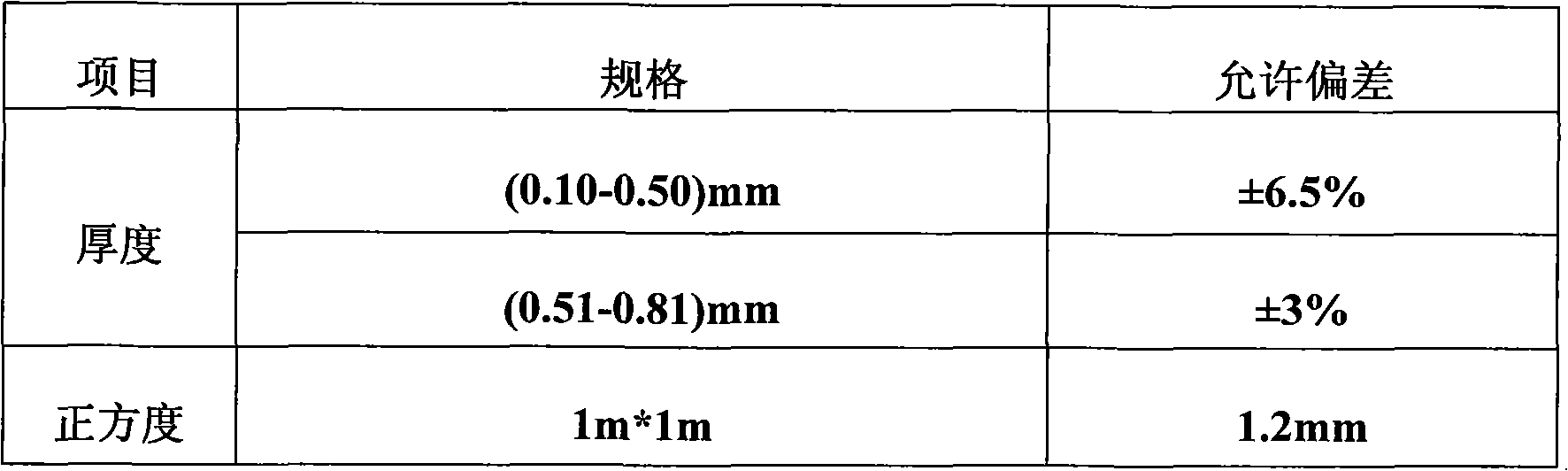

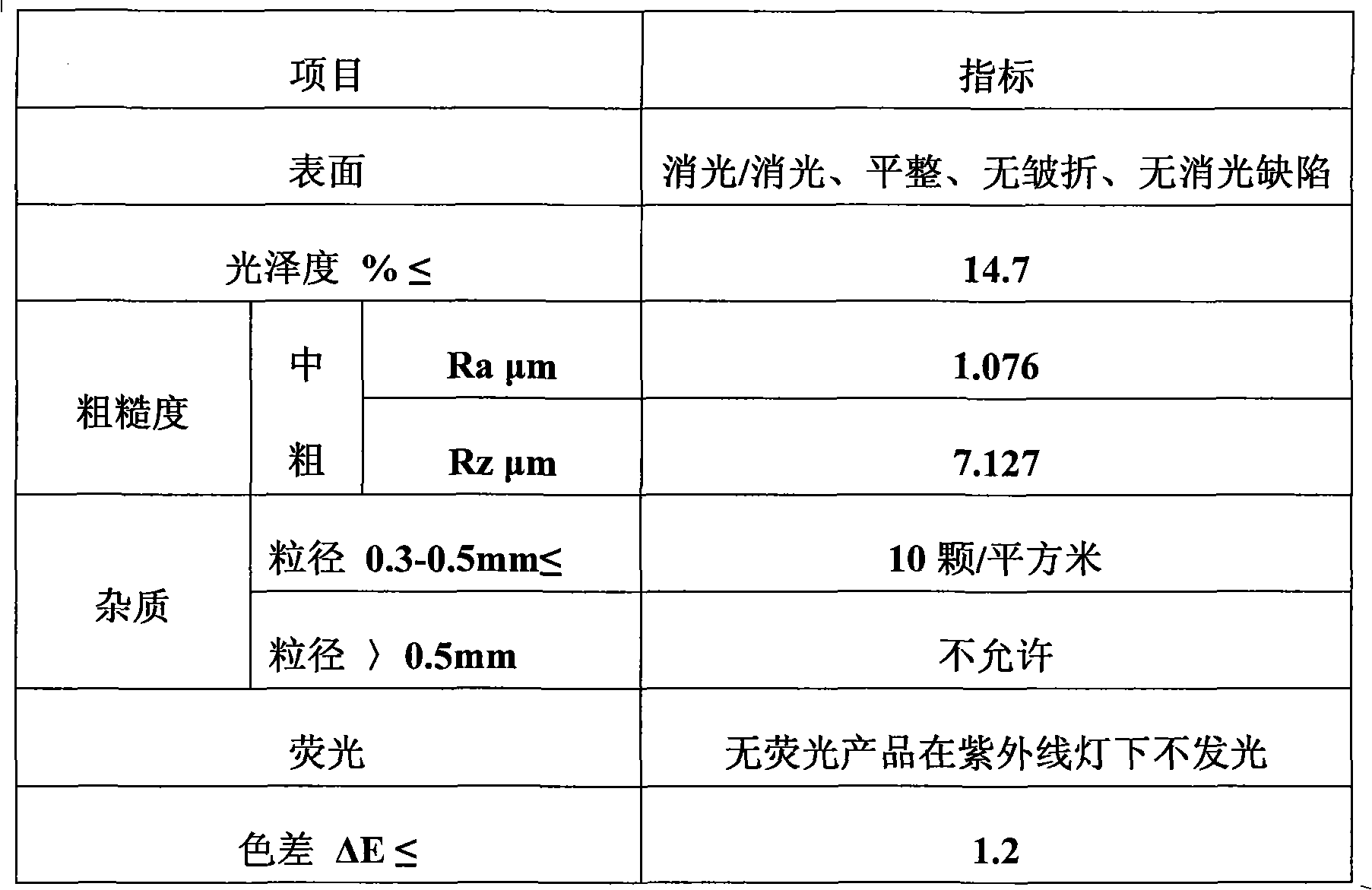

[0043] Prepare the calendered base material for smart cards with the thickness and squareness shown in Table 1, and use the Q / GHJN1-2004 standard for detection, and the technical parameters of the front and back sides are shown in Table 2; use the Q / GHJN 1-2004 standard for detection , and the mechanical properties are shown in Table 3.

[0044] Table 1 ...

Embodiment 2

[0051] Recipe: (weight)

[0052] Polycarbonate 64.37%

[0053] Modified copolyester 15.25%

[0054] Modified copolyester additive 5.64%

[0055] Compatibilizer 4051 4.00%

[0056] Titanium dioxide 5.34%

[0057] Calcium Carbonate 5.35%

[0058] Ultramarine 504 0.05%

[0059] The raw materials are respectively metered into the kneader, kneaded at a temperature of 120 ° C, the kneader speed is 650 rpm, and then cooled and stirred at a temperature of 95 ° C, and then calendered by a five-roller calender. The processing temperatures are: 1 Roll No. 200°C, Roll No. 2 210°C, Roll No. 3 220°C, Roll No. 4 215°C, Roll No. 5 210°C

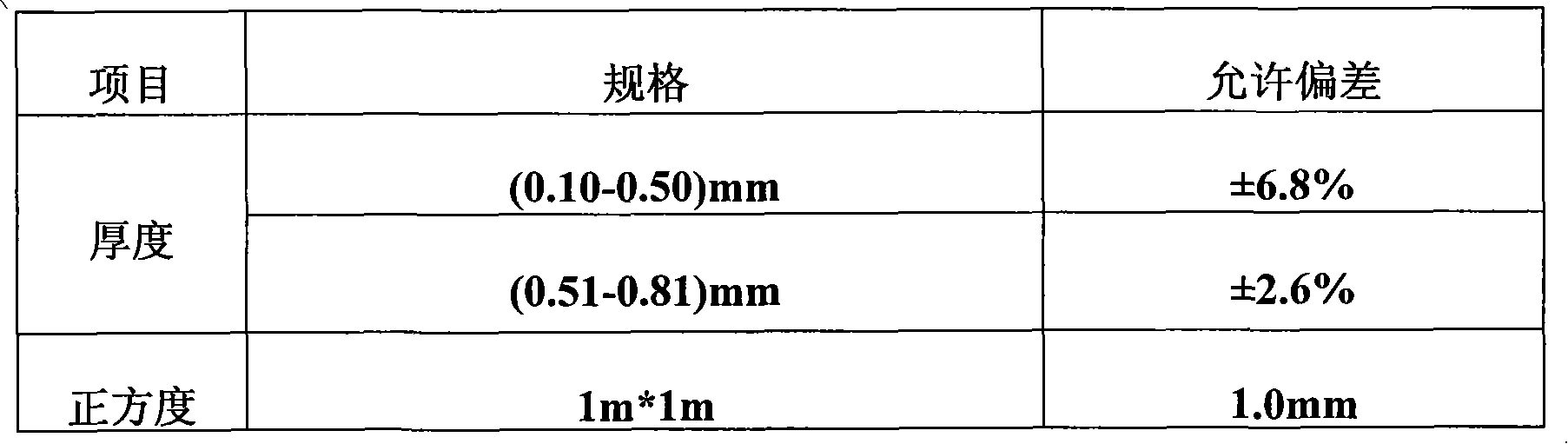

[0060] Prepare the calendered base material for the smart card into the thickness and squareness shown in Table 4, and use the Q / GHJN1-2004 standard for testing, and the technical parameters of the front and back sides are shown in Table 5; use the Q / GHJN 1-2004 standard for testing , the mechanical properties are shown in Table 6.

[0061] Table 4 T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile impact strength | aaaaa | aaaaa |

| Vicat softening temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com