Patents

Literature

90results about How to "Reduce air bubbles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

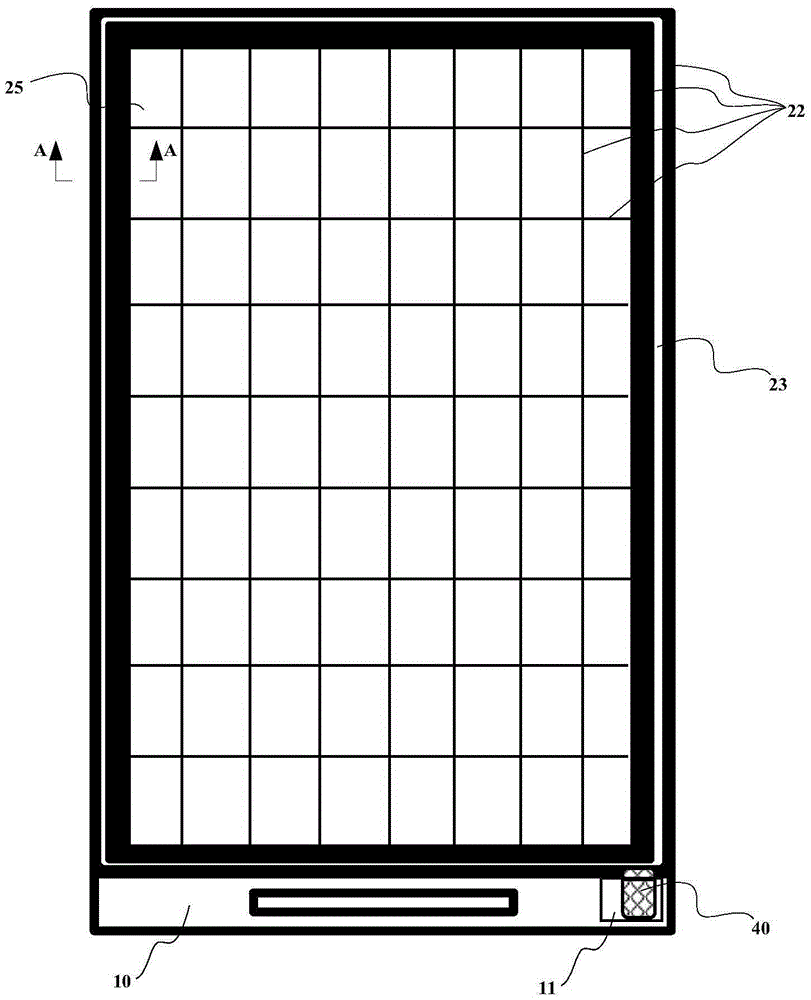

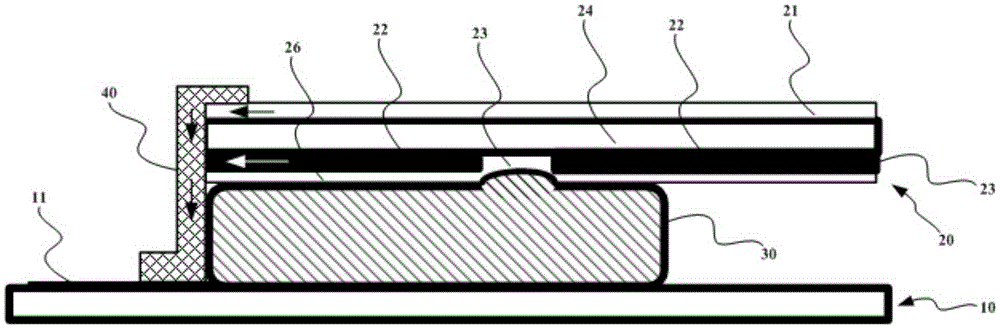

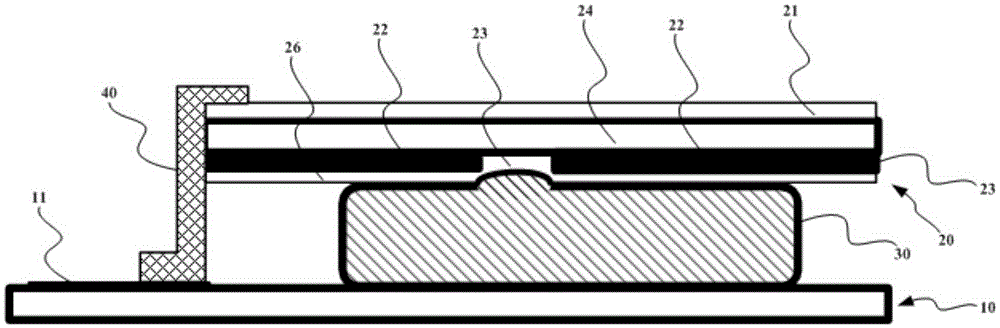

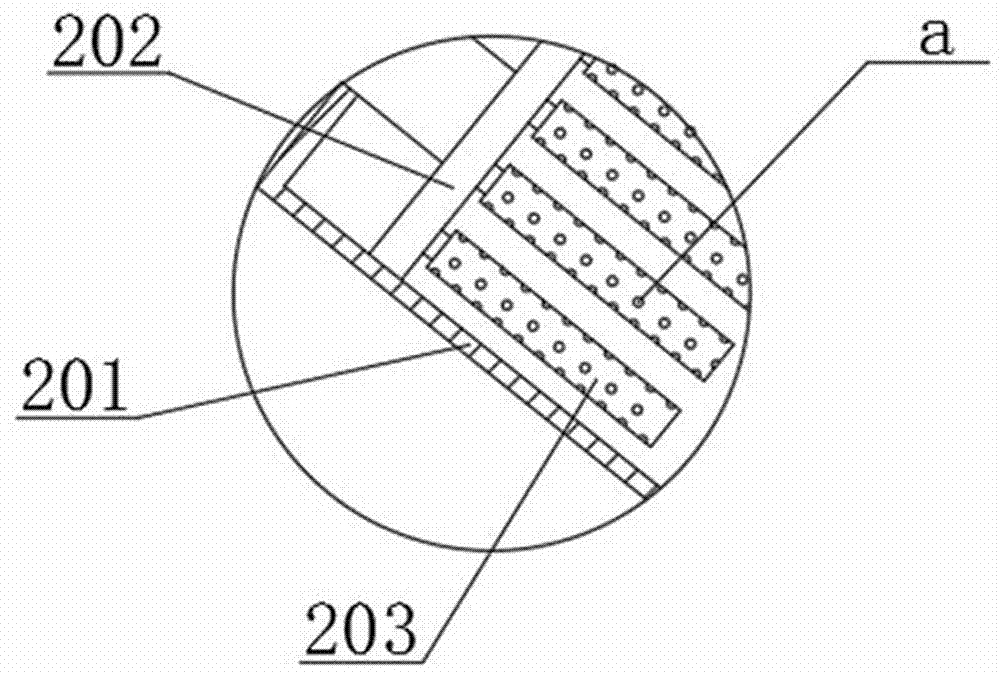

Liquid crystal panel and display device

InactiveCN105425457AReduce air bubblesImprove ESD phenomenonNon-linear opticsLiquid-crystal displayLiquid crystal

The invention discloses a liquid crystal panel and a display device, used to improve ESD phenomenon of a display device and improve quality of the product. The liquid crystal panel comprises an array substrate and a color film substrate which are aligned through frame sealing glue. The color film substrate comprises an electrostatic shielding layer and a black matrix which is in the electrostatic shielding layer and is close to a side of the array substrate. The surrounding region of the black matrix is provided with an annular channel whose position is opposite to the frame sealing glue. In the technical scheme of the embodiment, since the surrounding region of the black matrix is provided with the annular channel whose position is opposite to the frame sealing glue, when external static electricity enters, the static electricity can just reach the portion of the black matrix, on the outer side portion of the annular channel, and cannot reach an internal display region. Compared with the prior art, the liquid crystal panel and the display device can reduce defects of bubbles, broken lines, or green display, etc., and improve ESD phenomenon of the display device, and improve quality of products.

Owner:BOE TECH GRP CO LTD +1

Method for preparing polished crystal tile

The invention discloses a method for preparing a polished crystal tile, comprising the following steps of: accumulating a mixture of low-temperature clinkers and high-temperature clinkers on a printed tile surface baked at high temperature; baking; and polishing. The polished crystal tile prepared with the preparation process has high high-temperature viscosity and stable glass network structure, the baked clinker has certain height and has stereoscopic impression and artistic feeling. The action of the skeleton of the high-temperature clinker is favorable to the discharge of bubbles, and the obtained enamel layer has few bubbles, high transparency and high enamel quality. By regulating the proportion of the low-temperature clinkers and the high-temperature clinkers, the preparation method is suitable for different baking temperatures, is convenient and flexible and is suitable for different products.

Owner:广东道氏陶瓷材料有限公司

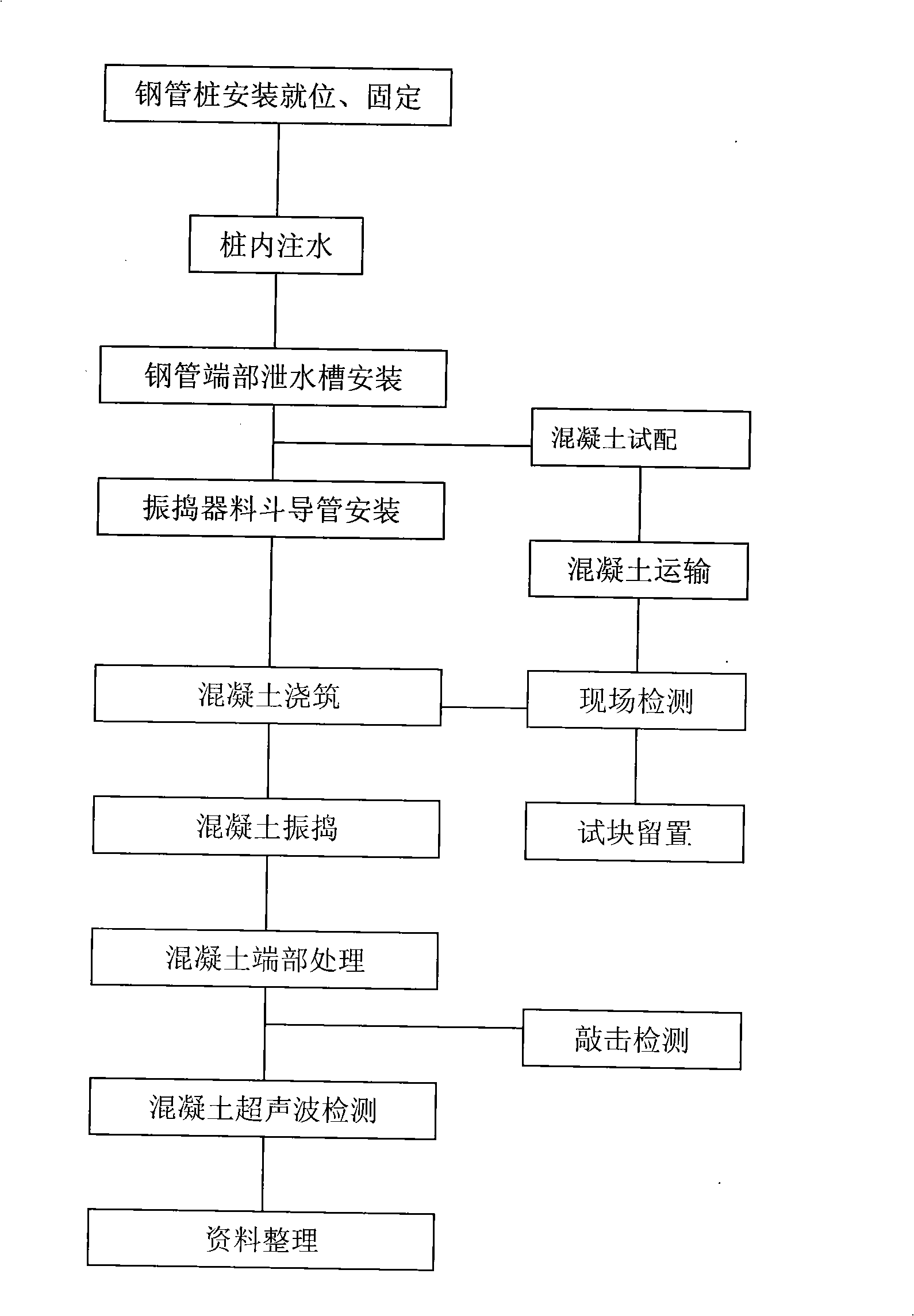

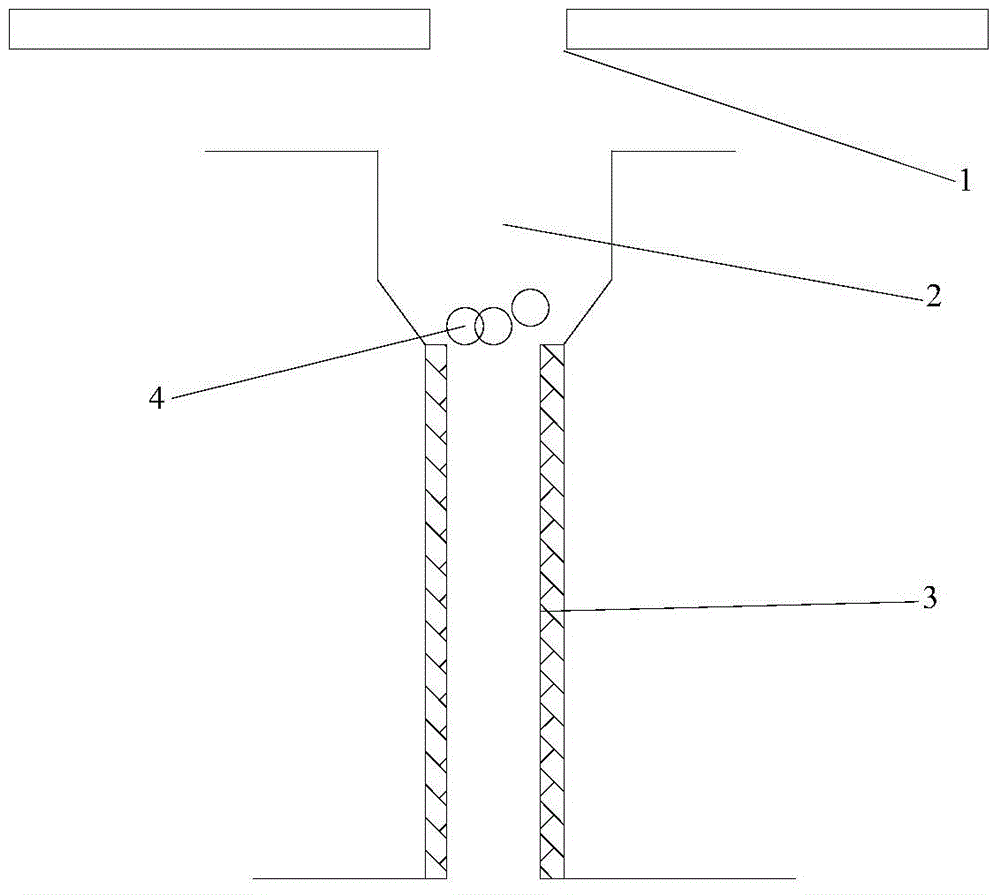

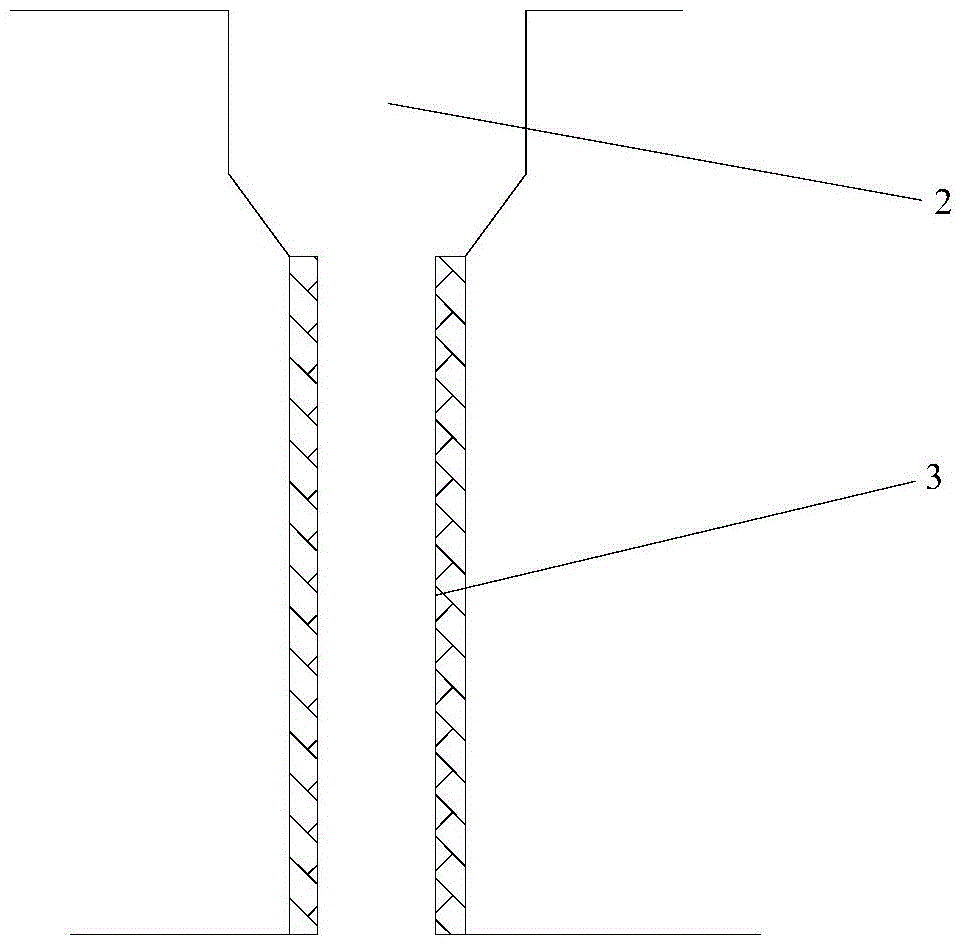

Construction method of steel pipe concrete column

InactiveCN101319550AImprove compactnessReduce air bubblesStrutsCeramic shaping apparatusSteel tubeAir bubble

The invention relates to the building field. The invention relates to a construction method for a concrete filled steel tubular column, comprising the following steps that: a tube is filled with water at first, and then a tremie is put down to the bottom of a pile; concrete is poured into the steel tube by a hopper through the tremie, and a vibrating tamper which is attached to the outerwall of the tube performs concrete vibrating when placing is performed simultaneously; primary concrete placing is performed until the height is 3 to 5 meters on the upper side of a nozzle of the tremie, and the tremie is lifted and guaranteed that the embedding depth of the tremie in concrete is not less than 2 meters; secondary concrete placing is performed, and the vibrating tamper which is attached to the outside of the tube on the bottom layer is started; lifting and placing are repeated, and the concrete is placed to the top of the column; and laitance is removed. The construction method solves the problem of the separation phenomenon caused by overhigh concrete placing height, increases the compactness of the concrete, reduces the number of air bubbles, has small shrinkage clearance between the concrete and the steel tube, can well give play to the function of stress, is convenient in construction, is mechanized, and is simple and convenient in operation. Moreover, the quality can be guaranteed; the equipment is saved by 30 percent; the stability is strong; and 50 percent of raw steel materials and 35 percent of the concrete are saved when the steel tube and the concrete are under same stress, thereby the production cost is effectively reduced.

Owner:DALIAN SANCHUAN CONSTR GROUP

Colored glaze with favorable clarification effect and high product quality

The invention relates to a colored glaze with favorable clarification effect and high product quality, which is prepared from the following raw materials in parts by weight: 95-110 parts of quartz sand, 42-46 parts of soda ash, 10-12 parts of aluminum oxide, 45-50 parts of lead peroxide, 1-1.5 parts of cerium oxide, 3-4 parts of antimony trioxide, 0.1-0.5 part of sodium nitrate and 1-1.5 parts of pigment. The cerium oxide and antimony trioxide are combined to be used as a clarifier, and thus, the clarification effect is obviously better than that of the independently used cerium oxide or antimony trioxide; by controlling the cerium oxide:antimony trioxide ratio at 1:(2-4), the prepared colored glaze has the advantages of high gloss, few bubbles, high transparency, few stripes in the finished product, obviously improved quality and short clarification time (6-8 hours); and the colored glaze formula materials have long acting property and low softening point, and thus, are suitable for forming the colored glaze.

Owner:太仓市科教新城琉璃艺术策划中心

Preparation process of double-surface flat glass steel plate for laboratory test

The invention relates to a preparation process of a double-surface flat glass steel plate for laboratory test. The preparation process is characterized in that glass-fiber cloth is laid on the upper surface of a glass working platform surface; a holed pressing plate is placed on the glass-fiber cloth; a flow guiding net is put on the area with small holes; a glue filling base is put on the flow guiding net, a breathable felt is laid and covers on the glass-fiber cloth; a winding pipe is put on the glass working platform surface and is covered by the breathable felt; one end of the winding pipe is connected with an exhaust pipe, and a vacuum film is laid and covers the winding pipe, the breathable felt, the glass-fiber cloth, the holed pressing plate, the flow guiding net and the glue filling base; the edge of the vacuum film is sealed by using a sealing rubber strip and is fixed on the glass working platform surface; one end of the exhaust pipe is connected with the winding pipe, the other end of the exhaust pipe is connected with a resin collector which is connected with a vacuum pump by the exhaust pipe. Compared with the prior art, the preparation process has the advantages that the flatness of a reinforced plastic plate product is improved and the influence of the demolding cloth on the reinforced plastic plate is avoided.

Owner:CHANGZHOU HONGFA ZONGHENG ADVANCED MATERIAL TECH

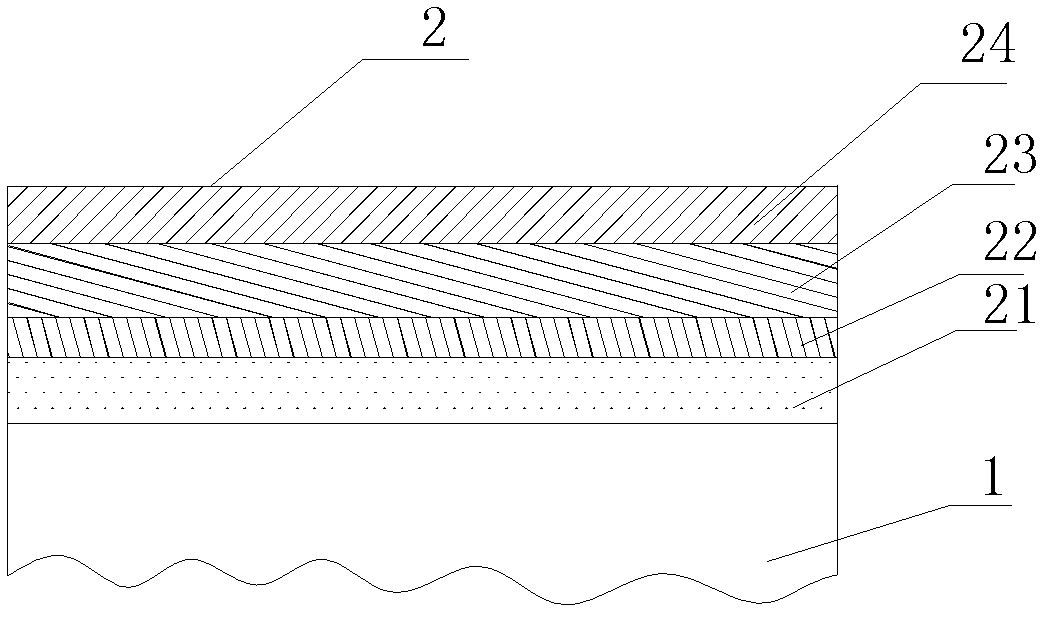

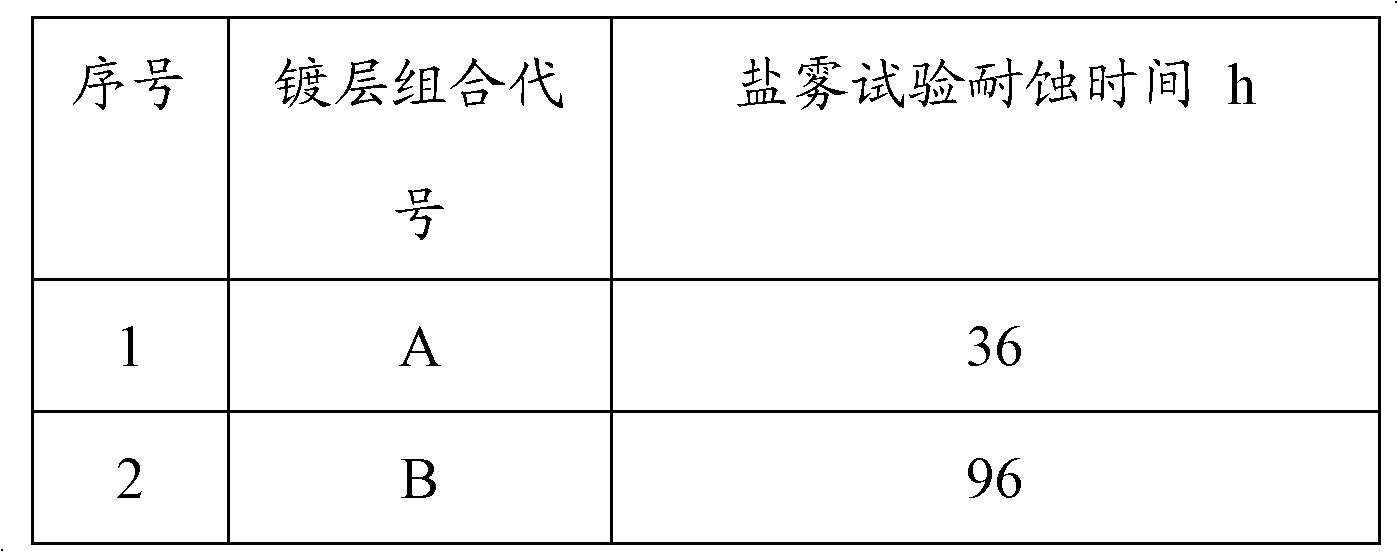

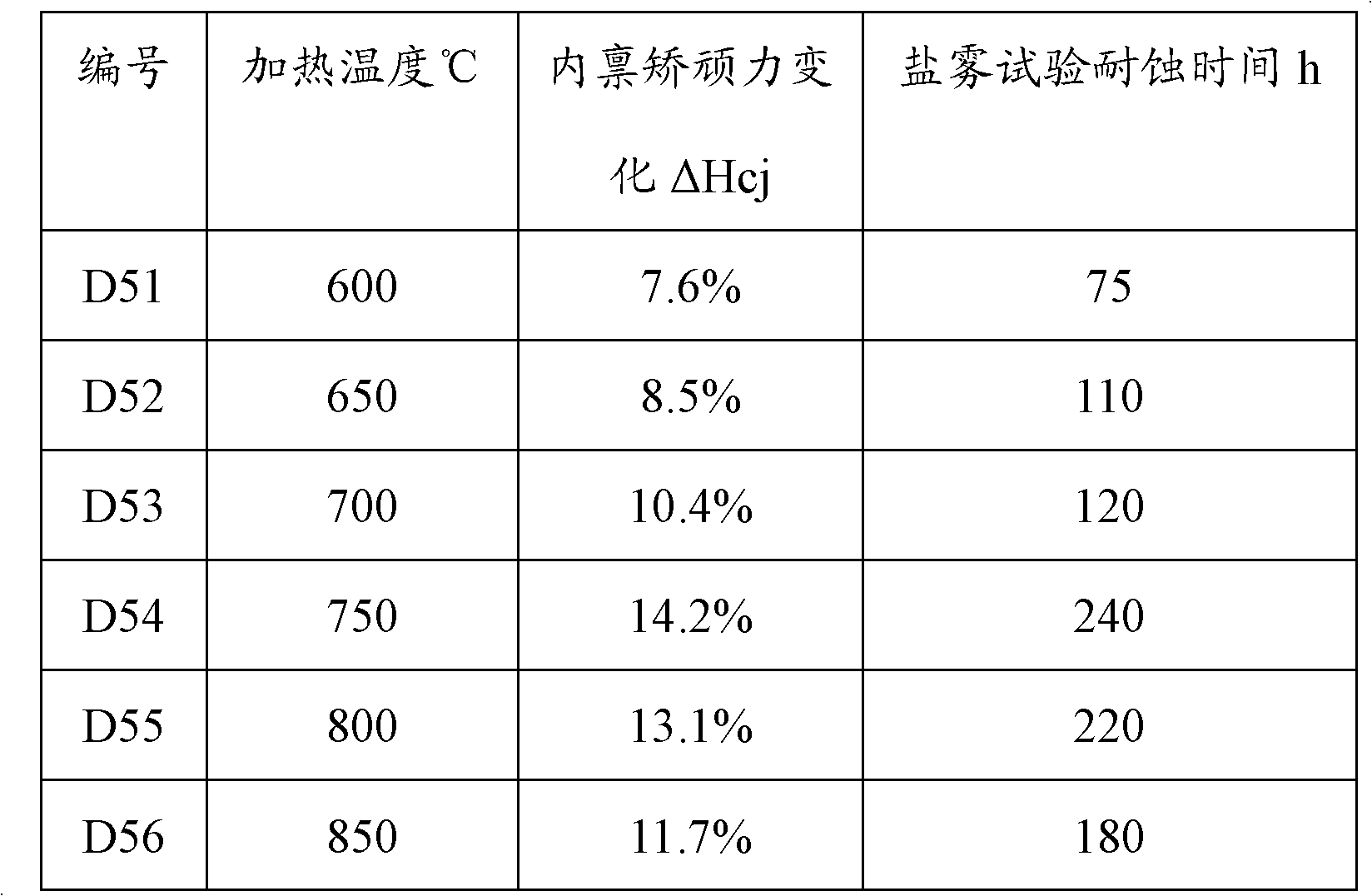

Surface coating process for neodymium iron boron permanent magnetic material and neodymium iron boron permanent magnetic material

ActiveCN102586776AReduce air bubblesImprove adhesionLiquid/solution decomposition chemical coatingMagnetic materialsVacuum furnaceTotal thickness

The present invention relates to a surface coating process for neodymium iron boron permanent magnetic material and a neodymium iron boron permanent magnetic material with coating layers. In the process, an electroplated bottom surface nickel layer, a chemically-coated nickel layer, an electroplated copper layer and an electroplated external nickel layer are sequentially coated on the substrate surface of the neodymium iron boron permanent magnetic material from inside to outside, and after coating, the neodymium iron boron permanent magnetic material is subjected to heat treatment in a vacuum furnace. The total thickness of the coating layers on the neodymium iron boron permanent magnetic material prepared with the process is 15-30mum, the thickness of electroplated bottom surface nickel layer is 5-10mum, the thickness of the electroplated copper layer is 5-10mum, the thickness of the electroplated external nickel layer is 5-10mum and the thickness of the chemically-coated nickel layer is 3-10mum. The coating process provided by the invention reduces the bubble formation, looseness and rust stains, enhances the adhesion of the coating layers, reduces the porosity and obtains compact coating layers, thus significantly improving the quality of the electroplated coating layers on the magnet surface, improving the indicates of a salt spray test and increasing the qualification rate of products.

Owner:SHENYANG GENERAL MAGNETIC

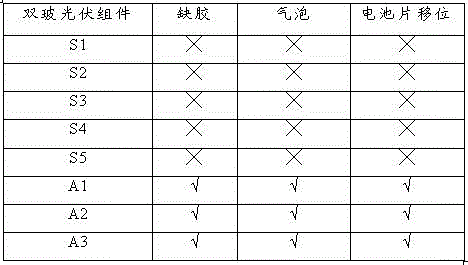

White packaging film for double-glazed photovoltaic module and preparation method thereof

ActiveCN105802548AIncrease profitImprove photoelectric conversion efficiencyNon-macromolecular adhesive additivesFilm/foil adhesivesMooney viscosityCarvacryl acetate

The invention discloses a white packaging film for a double-glazed photovoltaic module. The white packaging film comprises, by weight, 45-65 parts of ethylene-vinyl acetate, 25-50 parts of ethylene propylene rubber, 1-7 parts of white pigment and 0.5-10 parts of aids, wherein the ethylene-vinyl acetate comprises, by weight, 14-33% of vinyl acetate and 15-55% of ethylene propylene rubber; and the ethylene propylene rubber has a density of 0.80-0.91g / cm<3> and Mooney viscosity of 20-40. The dedicated white EVA film for the double-glazed photovoltaic module has high reflection rate, tenacity, volume resistivity and impact resistance, and the double-glazed photovoltaic module made of the film does not cause starved joints, bubbles or the like.

Owner:SUZHOU DUCHAMPS ADVANCED MATERIALS CO LTD

Basalt fiber reinforced cement based material and preparation method therefor

InactiveCN105541209AReduce air bubblesReduce porositySolid waste managementInterfacial bondingBasalt

The invention relates to cement-based materials and particularly discloses a basalt fiber reinforced cement based material and a preparation method therefor. The basalt fiber reinforced cement based material contains the following ingredients: 400-800kg / m<3> of cement, 150-330kg / m<3> of active mineral admixture, 800-1,500kg / m<3> of fine aggregate, 10-40kg / m<3> of water reducing agent, 0.01-0.05kg / m<3> of setting retarder, 0.5-3.0% (volume percent) of basalt fibers and 0.2-1.0% (mass percent) of fiber surface modifier. According to the basalt fiber reinforced cement based material and the preparation method therefor, through optimizing a formula, the compactness of the material is improved, meanwhile, the property of an interface layer between the basalt fibers and a cement bonding material is improved, and the interfacial bonding strength is improved. The structure and mechanical properties of the basalt fiber reinforced cement based material disclosed by the invention are improved relatively greatly, and the compression strength, folding strength and toughness are improved greatly.

Owner:CHINA MINSHENG ZHUYOU

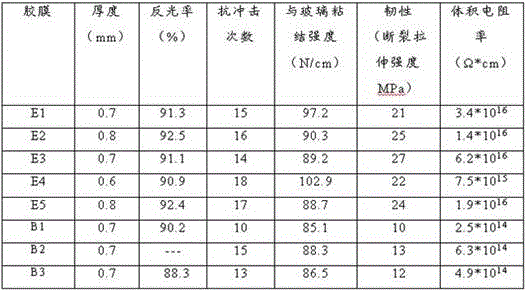

Water-based acrylic anti-corrosion coating and preparing method thereof

InactiveCN109627880AReduce air bubblesReduce the use of defoamersAnti-corrosive paintsEmulsionCorrosion inhibitor

The invention relates to a water-based acrylic anti-corrosion coating and a preparing method thereof, and belongs to the technical field of anti-corrosion coatings. The water-based acrylic anti-corrosion coating is prepared from, by mass, 50-70% of a water-based acrylic emulsion, 0.2-0.4% of a pH modifier, 0.1-0.2% of a defoaming agent, 0.3-0.6% of a wetting agent, 0.5-1.5% of a dispersing agent,1-2% of graphene powder, 12-18% of inorganic toner, 2-4% of a corrosion inhibitor, 2-4% of a cosolvent, 2-5% of a rust converting agent, 1-3% of a flash-rust resistor, 0.3-0.6% of a thickening agent and the balance deionized water. The water-based acrylic anti-corrosion coating is good in stability, high in drying speed, solid content, hardness and adhesive force, good in salt fog resistance and water resistance, and environmentally friendly.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

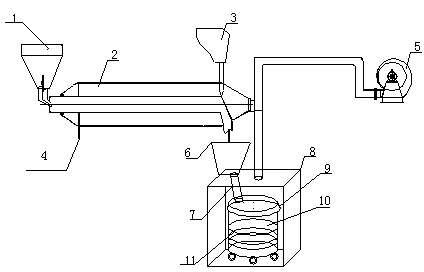

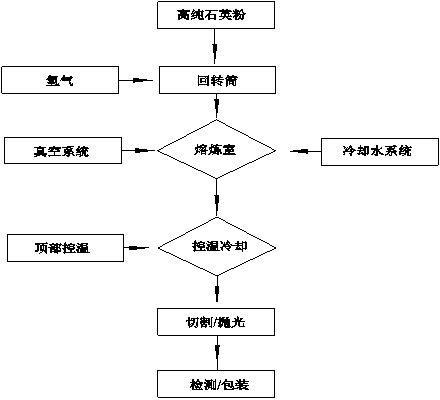

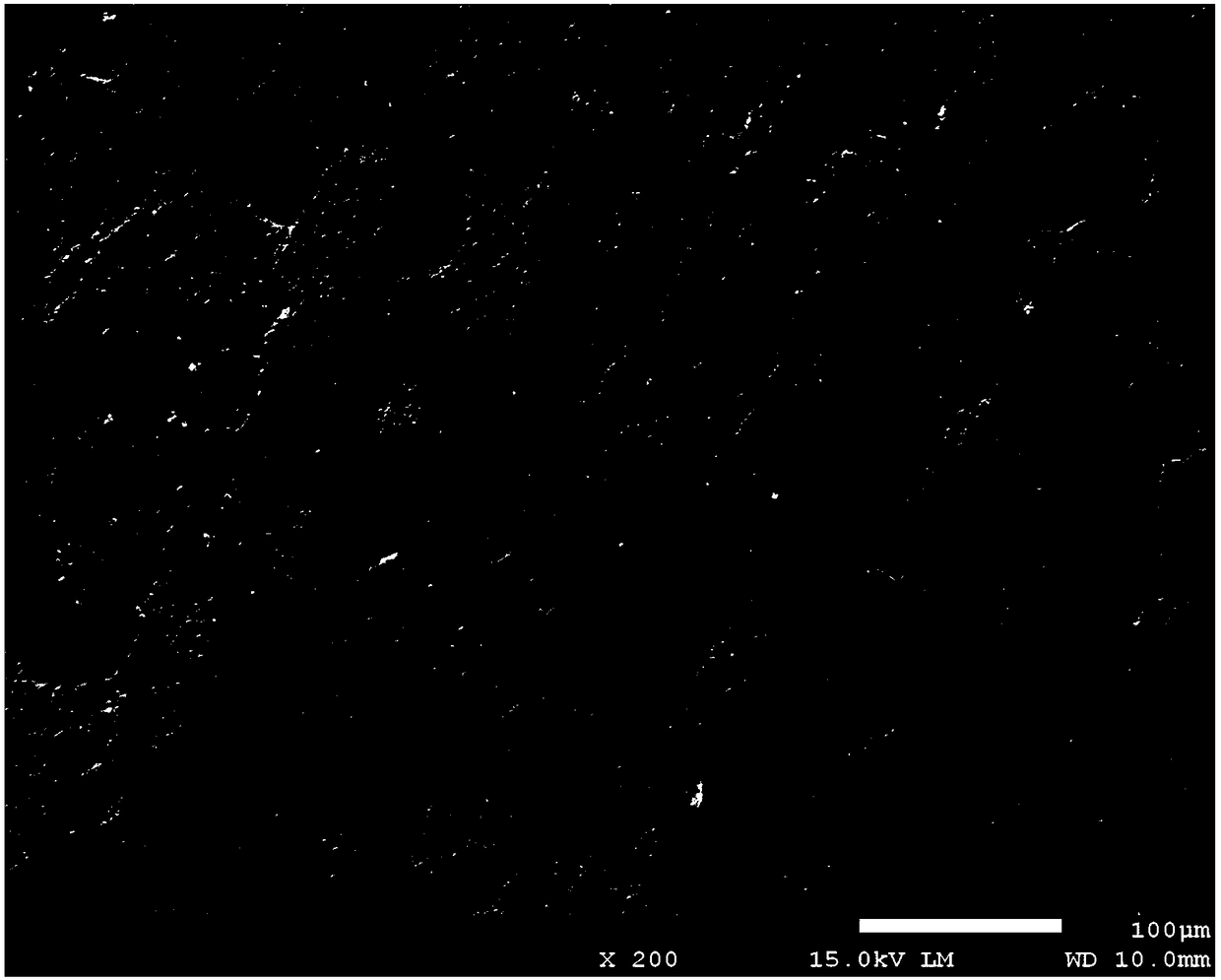

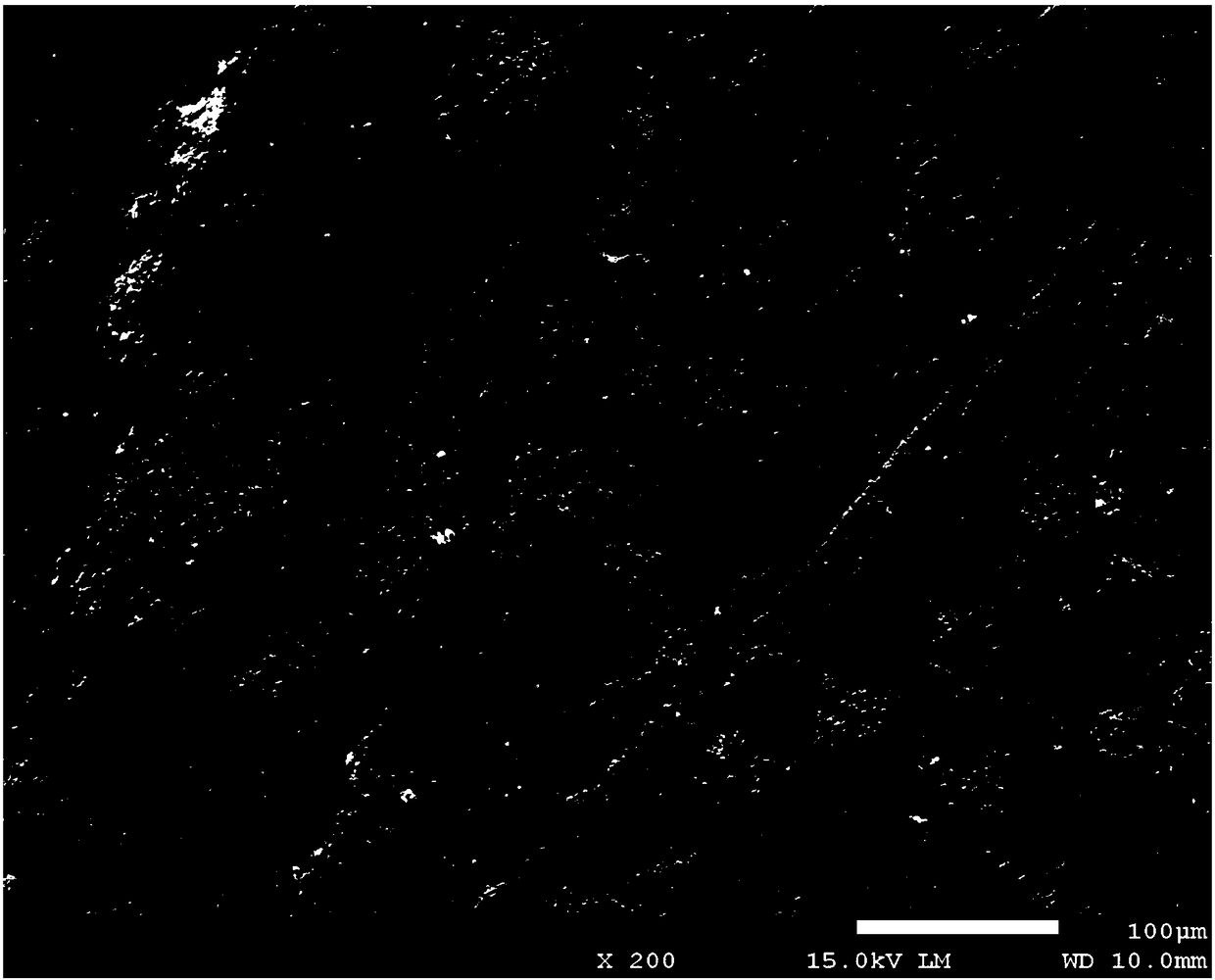

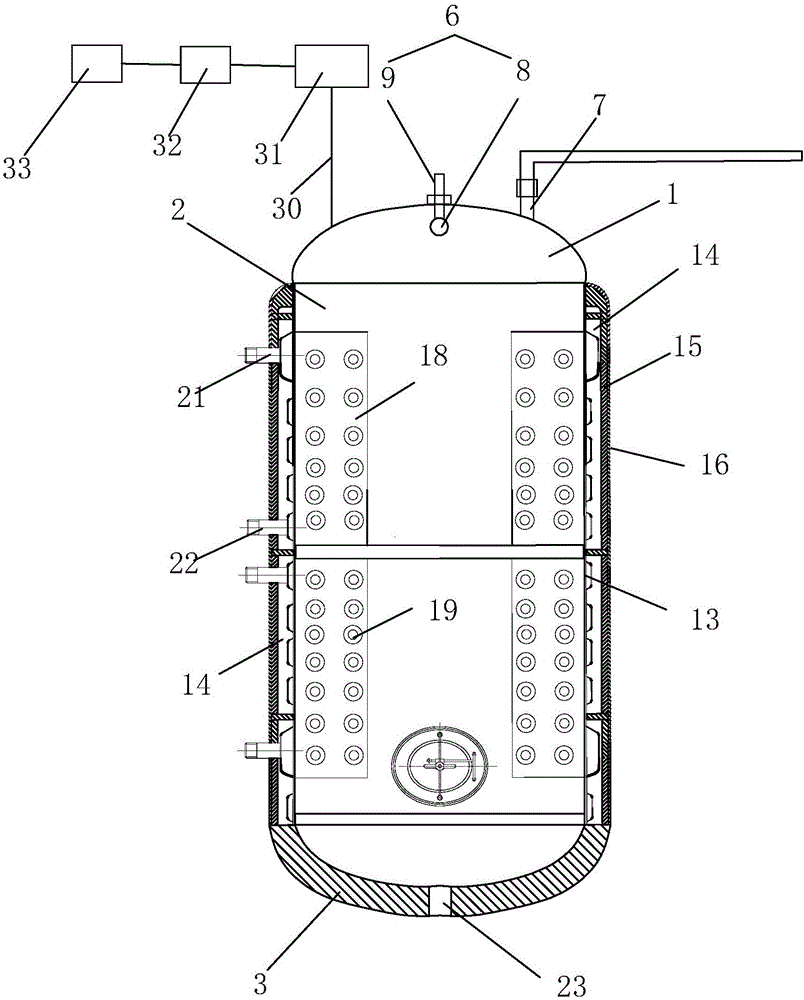

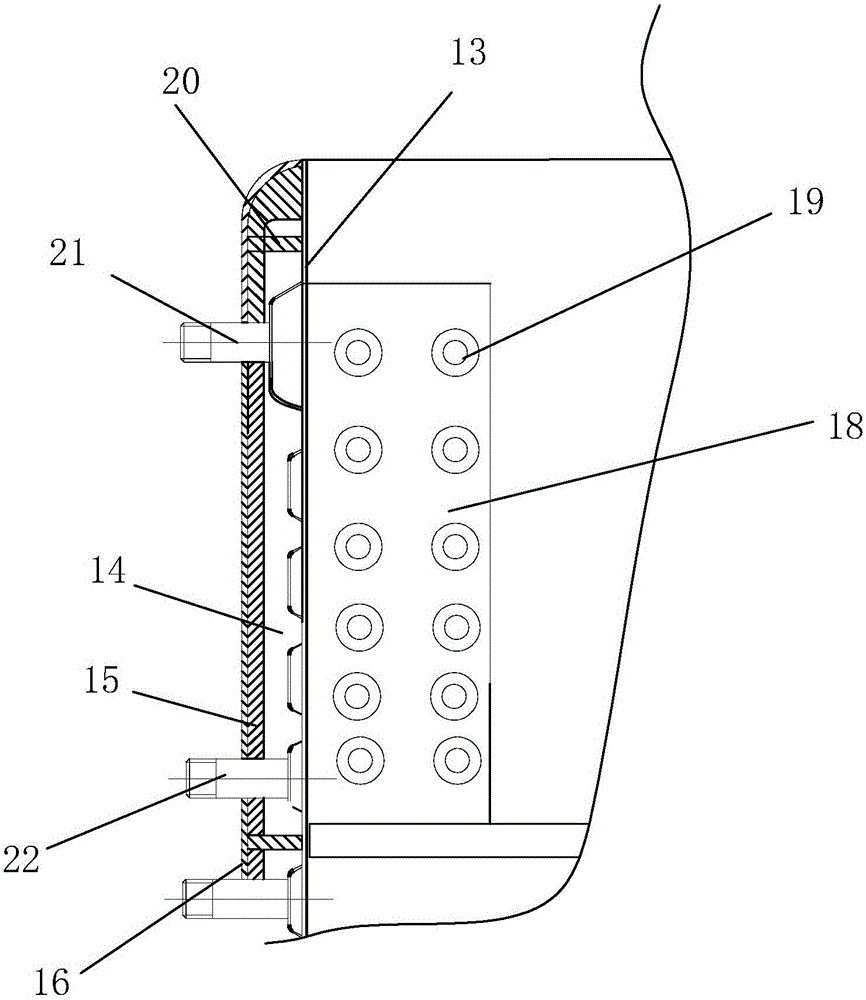

Device and method for producing large-size quartz glass by using composite induction-resistance melting induction smelting method

InactiveCN103102061AReduce air bubblesReduce internal stressGlass shaping apparatusGlass productionMineralogyElectromagnetic stirring

The invention provides a device and a method for producing large-size quartz glass by using a composite induction-resistance melting induction smelting method. The device comprises a raw material chamber, a hydrogen storage kettle, a rotary cylinder, a vacuum pump, a smelting chamber, a smelting furnace body, a smelting furnace cover and a material distributor of a material distribution chamber, which are connected with each other to form the device. The large-size quartz glass is prepared by processing highly pure quartz materials of 300 meshes with the purity higher than 99.9% by the device; a resistance-induction composite heating way is adopted; and the quartz flux is electromagnetically stirred by the induction heating, so that air bubbles are decreased and the yield is higher than 90%. The shape and size of glass ingots are determined according to the size of an induction crucible; the glass ingots are quartz glass ingots with the maximum diameter of 2000mm, which breaks through a limit that a method of producing the glass ingots by using a continuous smelting method has difficulty in producing the quartz glass ingots with the diameter larger than 500mm; the investment cost is less than 10% of that of the continuous smelting method; and the method has market flexibility of quantitative production.

Owner:齐国超

Copper clad ceramic and preparation method thereof

ActiveCN108147832AReduce small air bubbles and bulgesReduce air bubblesSurface modificationThermal treatment

In order to overcome the problems such as combination of a ceramic layer and a copper layer is not compact, small bubbles exist in an interface, bulge easily occurs, and bonding strength is relativelylow in the existing aluminium nitride ceramic copper cladding technology, the invention provides a copper clad ceramic and a method for preparing the copper clad ceramic. The method comprises following operation steps: forming an aluminium oxide film on an aluminium nitride ceramic surface; forming a modification layer on the aluminium oxide film surface. The modification layer includes modifiedparticles, and the modified particles include glass powder; a copper layer is formed on the modified layer surface; and the copper layer, the modification layer and the aluminium nitride ceramic are combined integrally through thermal treatment. The invention also provides the copper clad ceramic prepared by the method. The surface modification layer containing the glass powder is formed on the aluminium nitride ceramic surface, the phenomena such as the generation of small bubbles and bulges are inhibited in a DBS technical process, and interface bonding force between the copper layer and thealuminium nitride ceramic is added.

Owner:BYD CO LTD

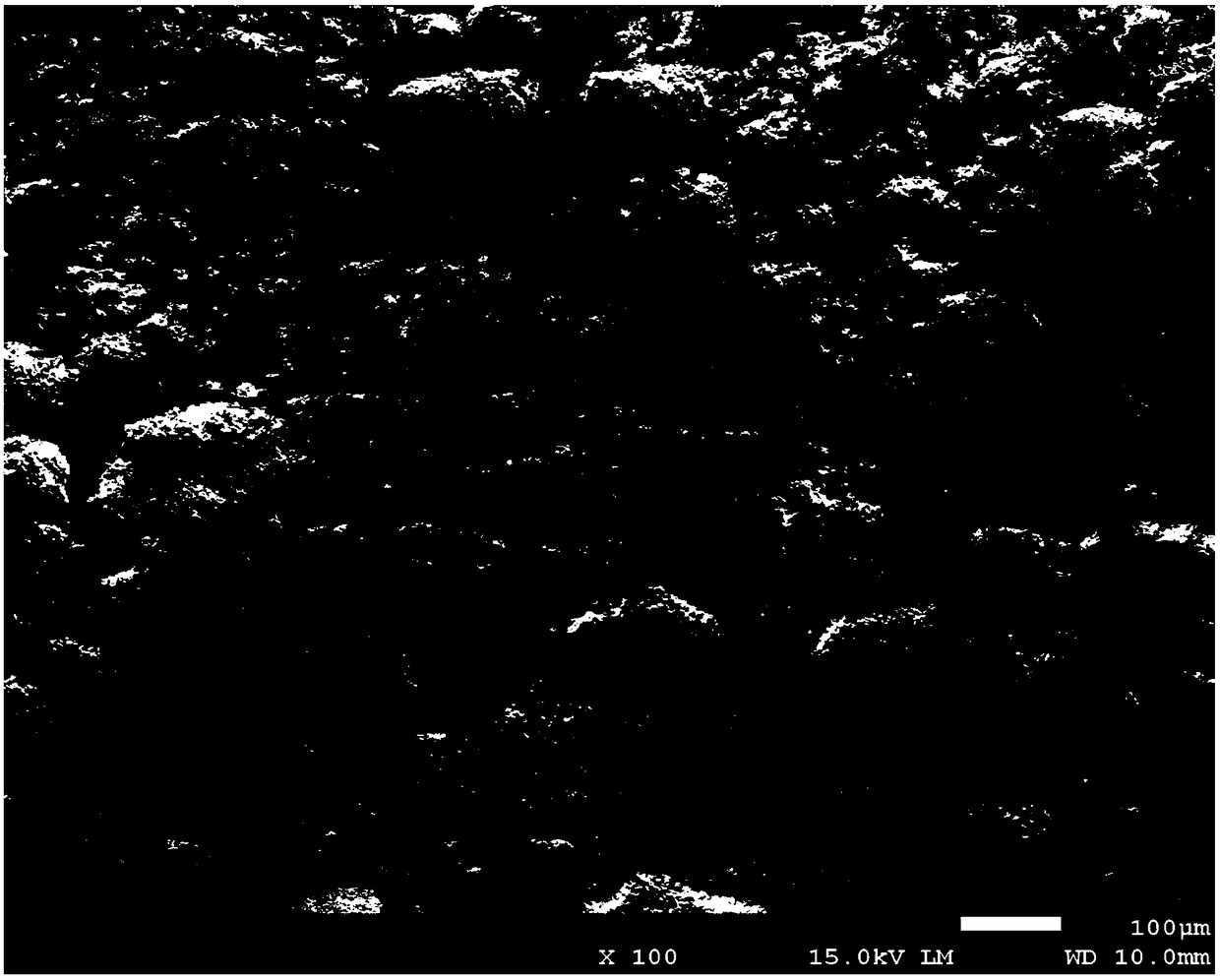

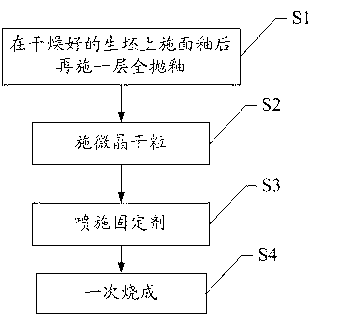

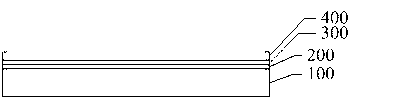

Microcrystal glass ceramic tile and production method for reducing air bubbles

The invention discloses a microcrystal glass ceramic tile and a production method for reducing air bubbles. The production method comprises the following steps of: applying an overglaze and a full-polishing glaze on a raw billet; applying microcrystal dry granules, wherein the microcrystal dry granules have the sieving meshes of 10 to 80, the microcrystal dry granules with the sieving meshes of 10 to 30 account for 40-50wt%, the microcrystal dry granules with sieving meshes of 30 to 60 account for 30-40wt%, the microcrystal dry granules with sieving meshes of 60-80 account for 15-25wt%; applying a fixing agent, and firing once at the temperature of 1,490-1,510 DEG C for 60-80 minutes. Due to the matching of the components and the sieving meshes of the microcrystal dry granules and the set of the firing temperature, the purpose of reducing the air bubbles of the microcrystal glass ceramic tile is achieved, the number of the air bubbles of the microcrystal glass ceramic tile is reduced greatly, the volume is minimized, the microcrystal layer of the microcrystal glass ceramic tile is more transparent, the glaze is clearer, and the quality is improved further.

Owner:GUANGDONG WEIBANG MICROCRYSTAL TECH

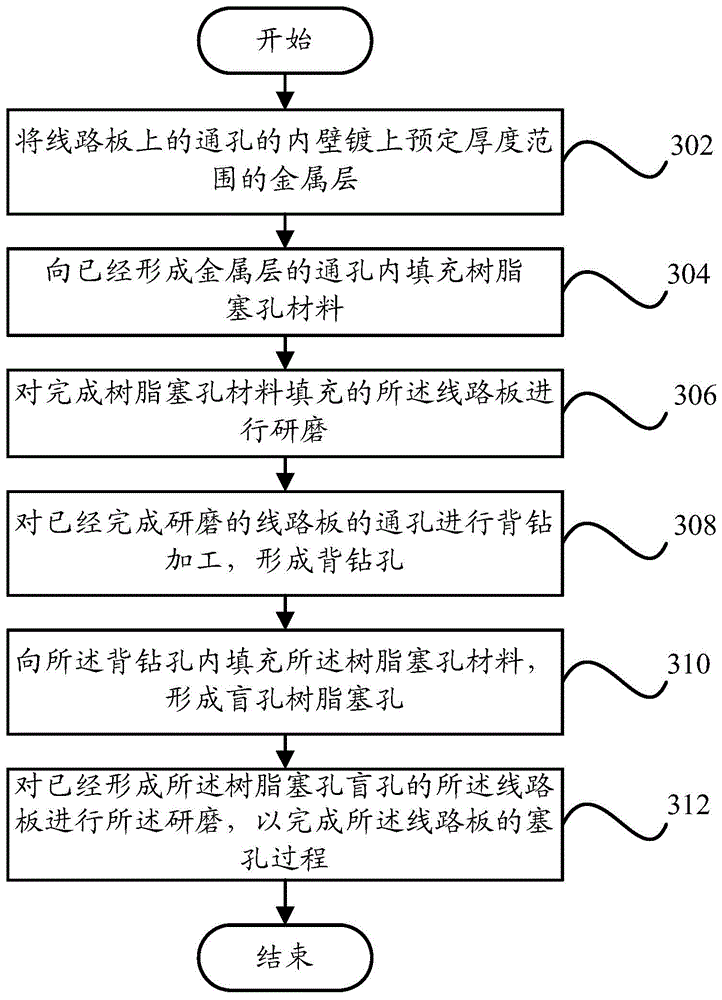

Circuit board hole filling method and circuit board

ActiveCN105722315AReduce air bubblesImprove plug hole qualityElectrical connection printed elementsPrinted element electric connection formationFilling materialsDrill hole

The invention provides a circuit board hole filling method and a circuit board, and the method comprises the steps: plating an inner wall of a through hole on a circuit board with a metal layer with the preset thickness; placing a resin hole-filling material in the through hole with the formed metal layer; carrying out the grinding of the circuit board after the filling of the resin hole-filling material; carrying out the back drilling of the through hole of the circuit board after grinding, and forming a back drill hole; placing the resin hole-filling material in the back drill hole, and forming a blind resin jack; carrying out the grinding of the circuit board provided with the blind resin jack, so as to complete the hole-filling process of the circuit board. According to the technical scheme of the invention, the method can effectively reduce the residual bubbles after hole filling, improves the hole filling material, and reduces the production cost of a circuit board jack because a vacuum jack is avoided.

Owner:新方正控股发展有限责任公司 +1

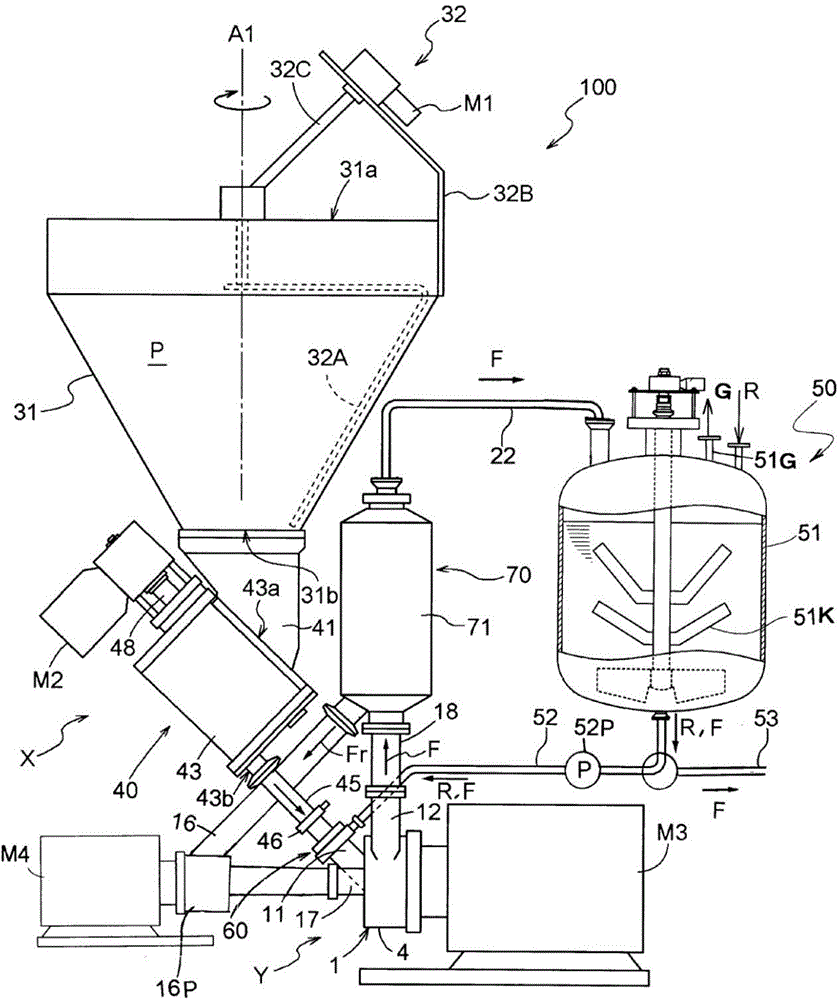

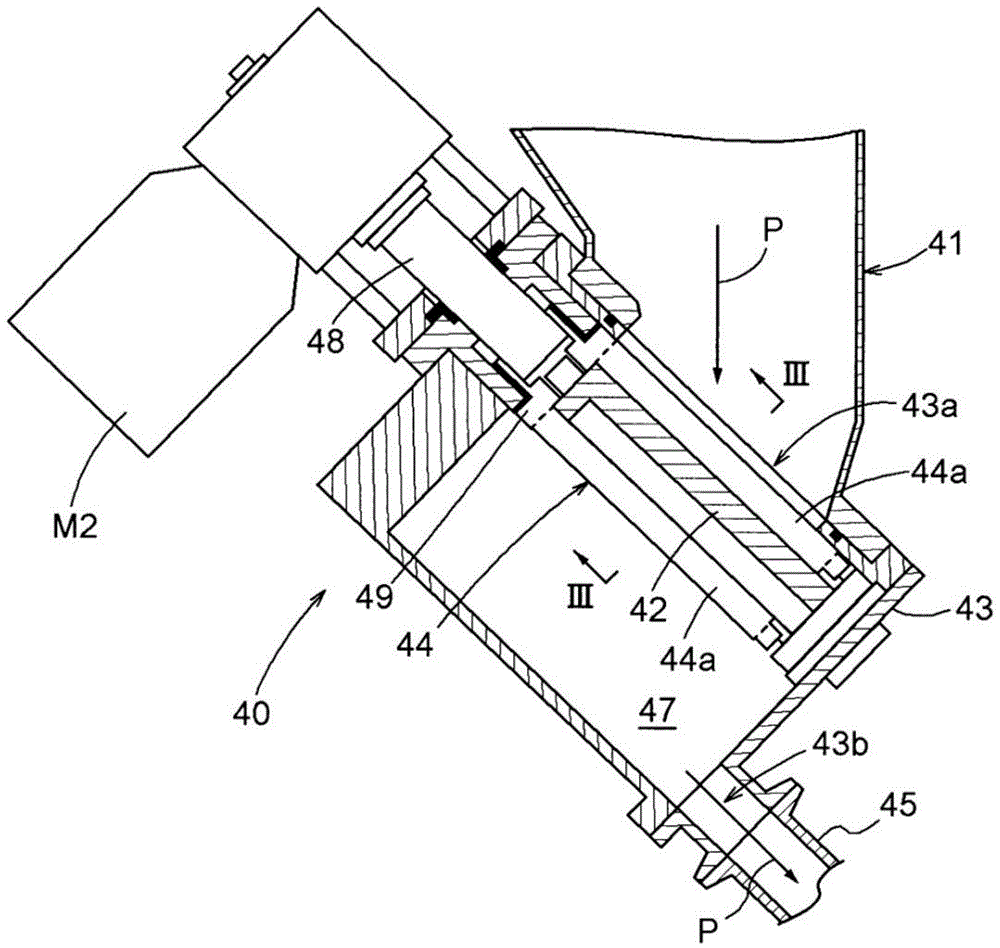

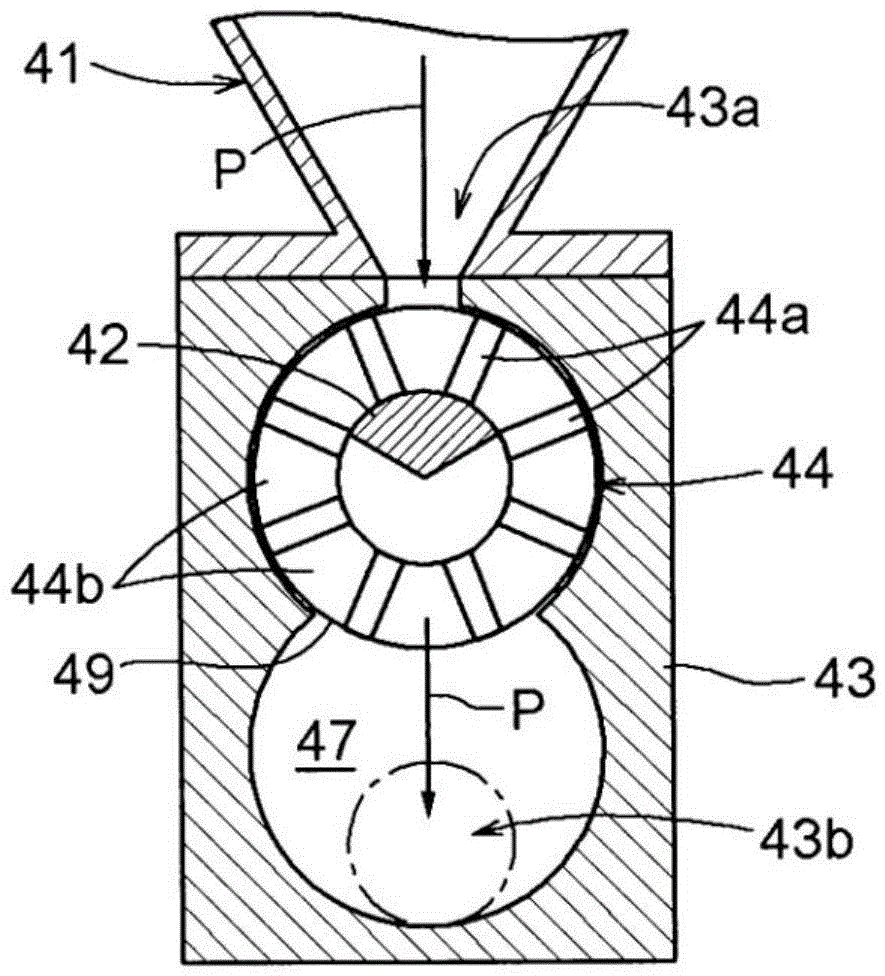

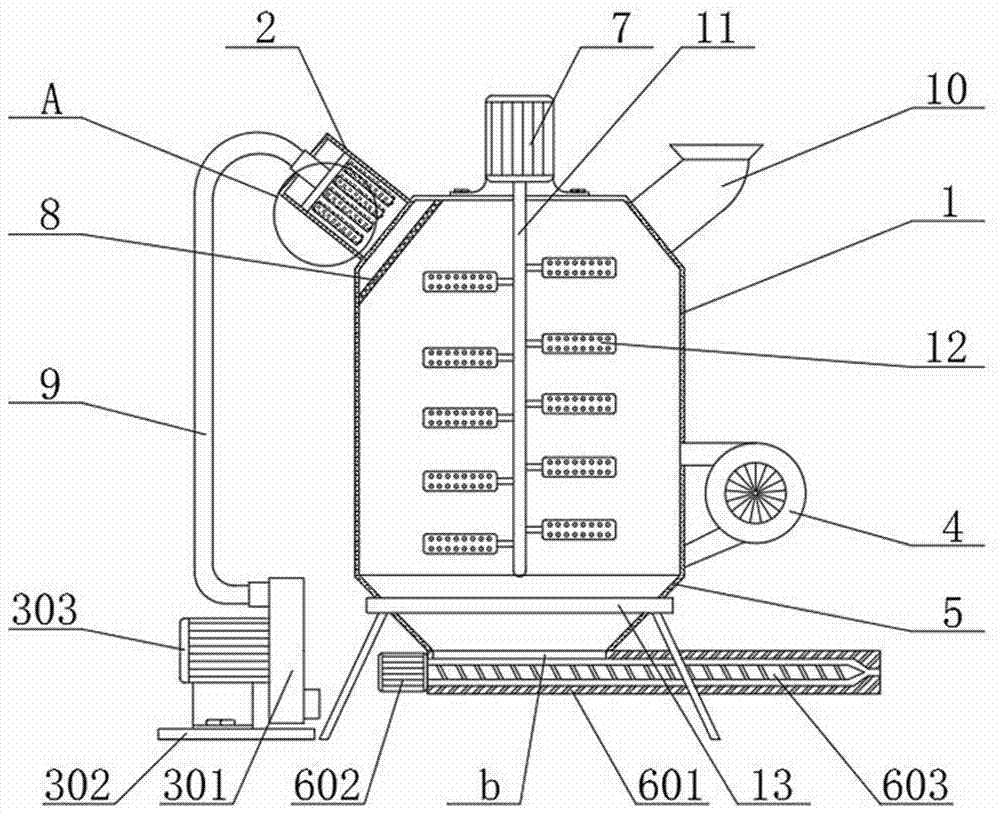

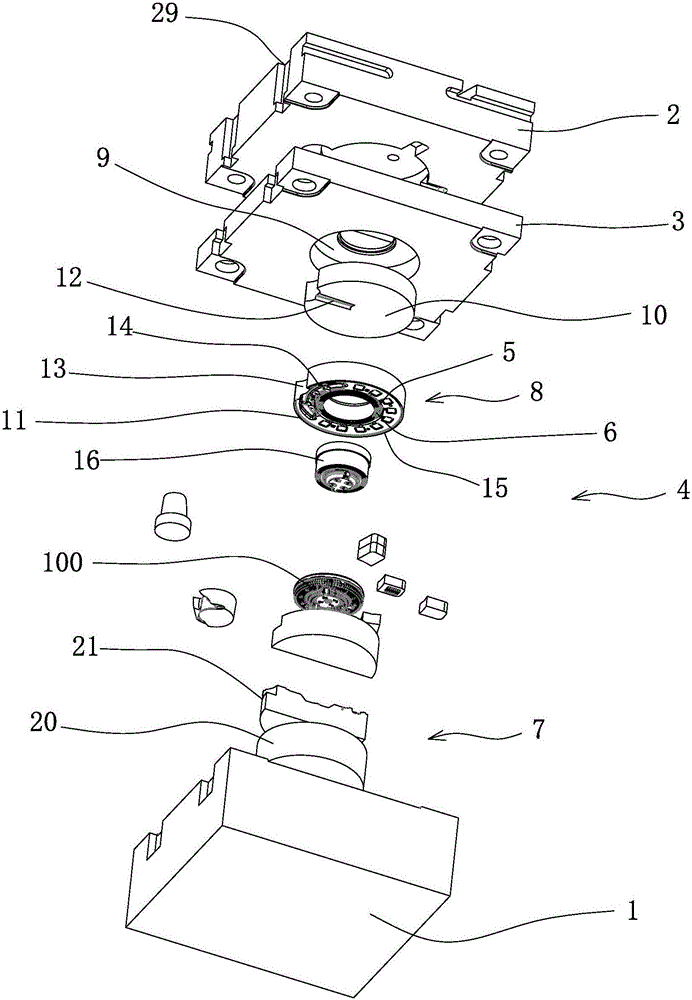

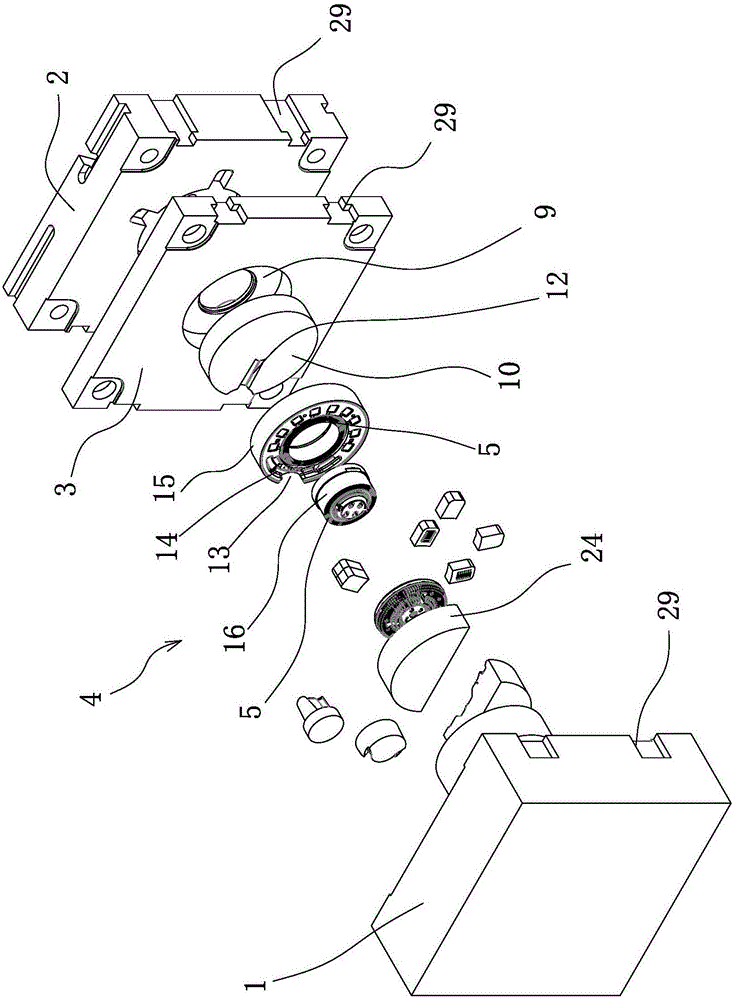

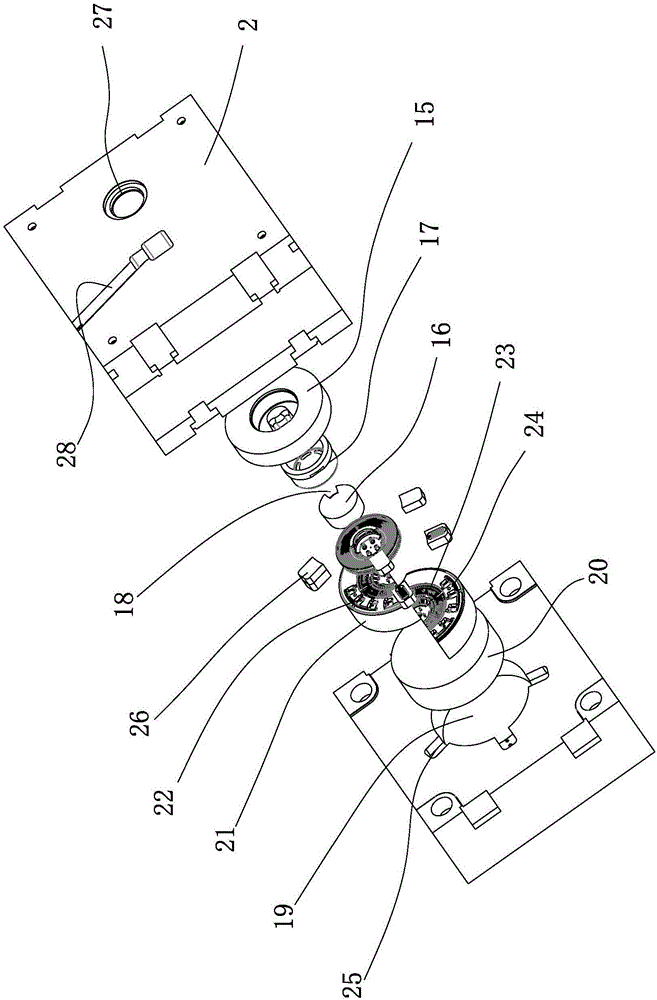

Dispersing mixer system used in producing slurry containing carbon and producing method of slurry containing carbon

InactiveCN104368266AReduce air bubblesSimplify the defoaming processFlow mixersNon-aqueous electrolyte accumulatorsSolventStator

The invention provides a dispersing mixer system equipped with a dispersing mixer pump used in producing slurry containing carbon and producing method of slurry containing carbon. The dispersing mixer system is provided with the following dispersing mixer pump that: a rotator of a rotation wing is eccentrically arranged in a cylindrical housing body, and by rotating and driving the rotator, solid ingredient and solvent are absorbed to a first guide-in chamber formed in the cylindrical housing body via a first supplying part; by using the rotation wing to stir, the solid ingredient and the solvent are spitted out from a spitting chamber via a discharging chamber; liquid spitted from the spitting part is circulated to a second supplying part via a circulation flow path; the liquid is absorbed to a second guide-in chamber formed by being separated from the first guide-in chamber via a separator plate from the second supplying part towards the interior of the cylindrical housing body; the liquid is allowed to pass a throttle flow path formed on a stator, after being stirred by the rotation wing, and is spitted out from the spitting part from the discharging chamber; and then the liquid spitted out from the spitting part is circulated to the a second supplying part via the circulation flow path.

Owner:NIHON SPINDLE MFG CO LTD +1

Anti-cracking, wear-resistant and seepage-proof compound mortar and preparation method thereof

The invention discloses anti-cracking, wear-resistant and seepage-proof compound mortar. The anti-cracking, wear-resistant and seepage-proof compound mortar is prepared from raw materials in parts by weight as follows: 20-30 parts of long and short reinforcing fiber, 15-20 parts of a waterproof additive, 10-20 parts of gelatine powder, 10-16 parts of a composite aid, 10-14 parts of glass beads, 65-75 parts of Portland cement, 55-65 parts of fine sand, 35-45 parts of composite filling sand, 1-2 parts of triethanolamine and 1-3 parts of sodium tripolyphosphate. The compound mortar has excellent anti-cracking, wear-resistant and efflorescence preventing properties and has better water resistance, seepage-proof property and adhesion force, relatively excellent impact resistance and thermal insulation and sound insulation effects and a certain pollutant air absorption function; besides, according to the provided preparation method, the material cost is lower, raw materials are easy to obtain, the process is simple, and the compound mortar has higher practical value and excellent application prospects.

Owner:HEFEI GUANGMIN BUILDING MATERIAL CO LTD

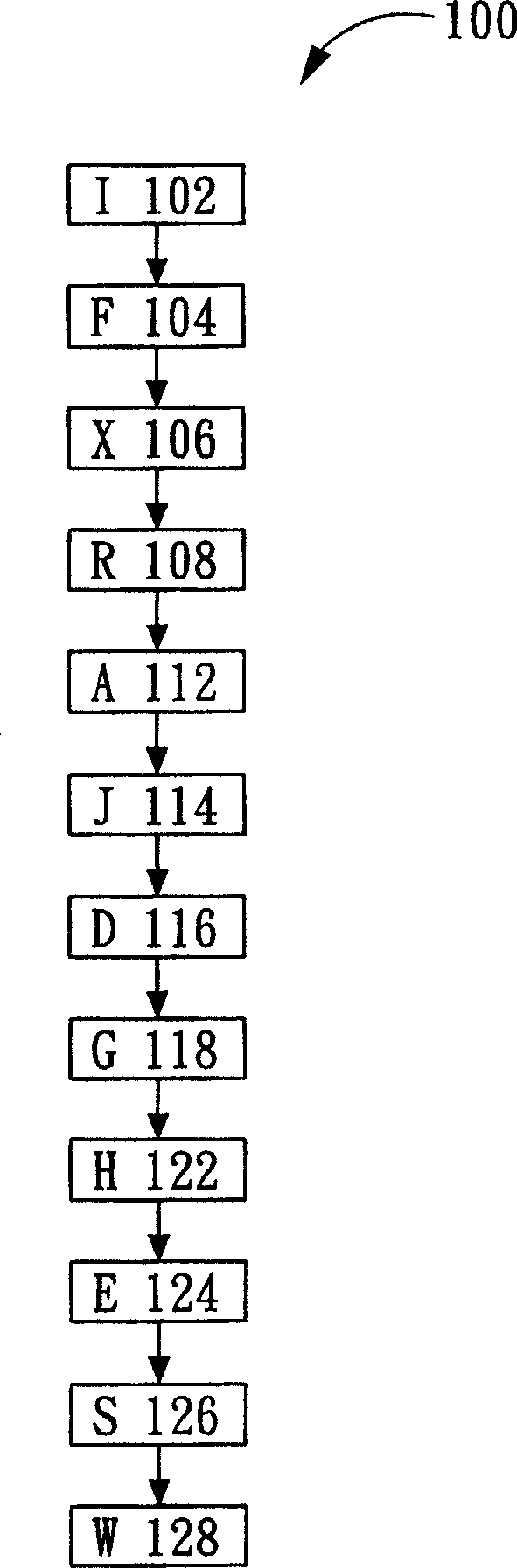

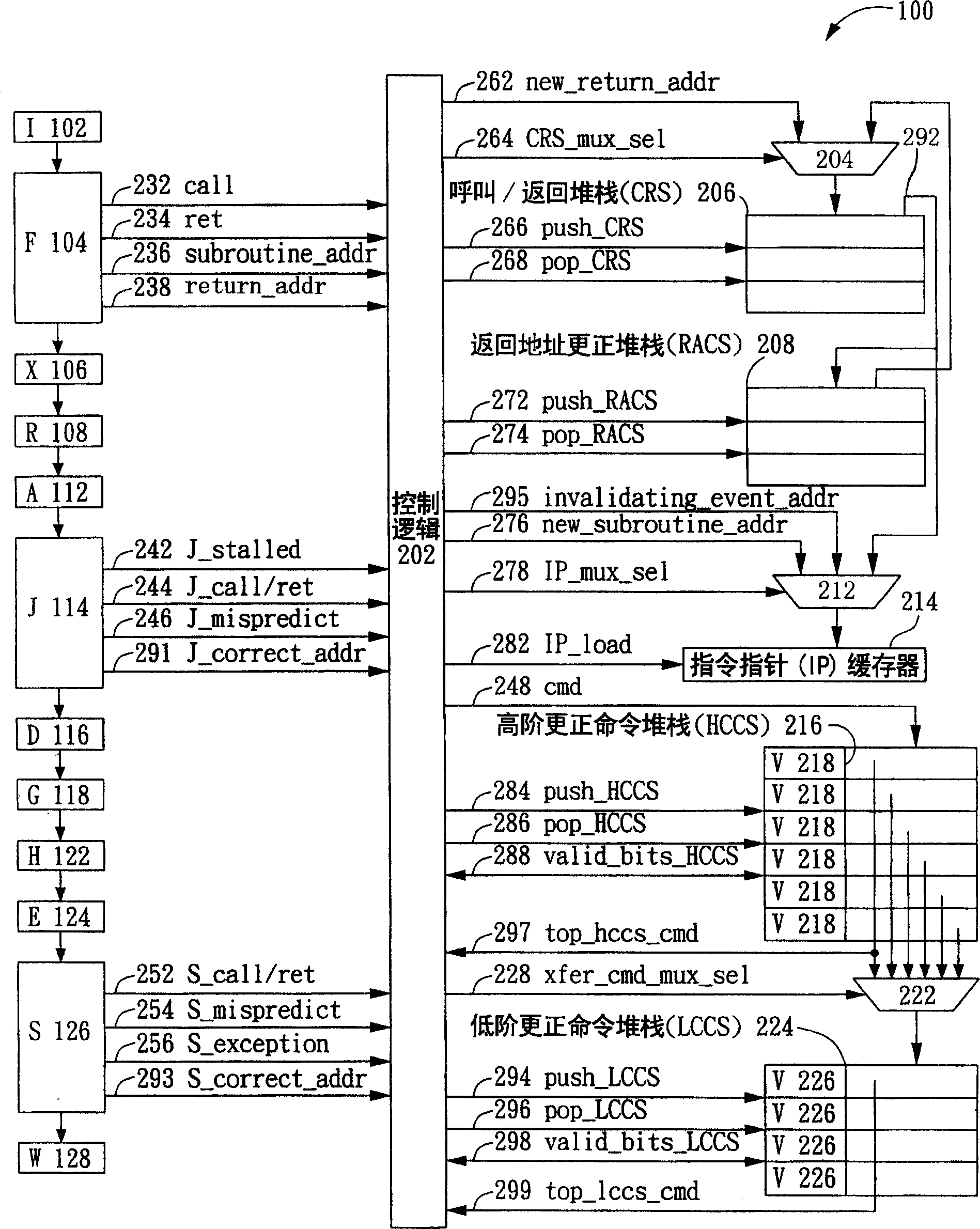

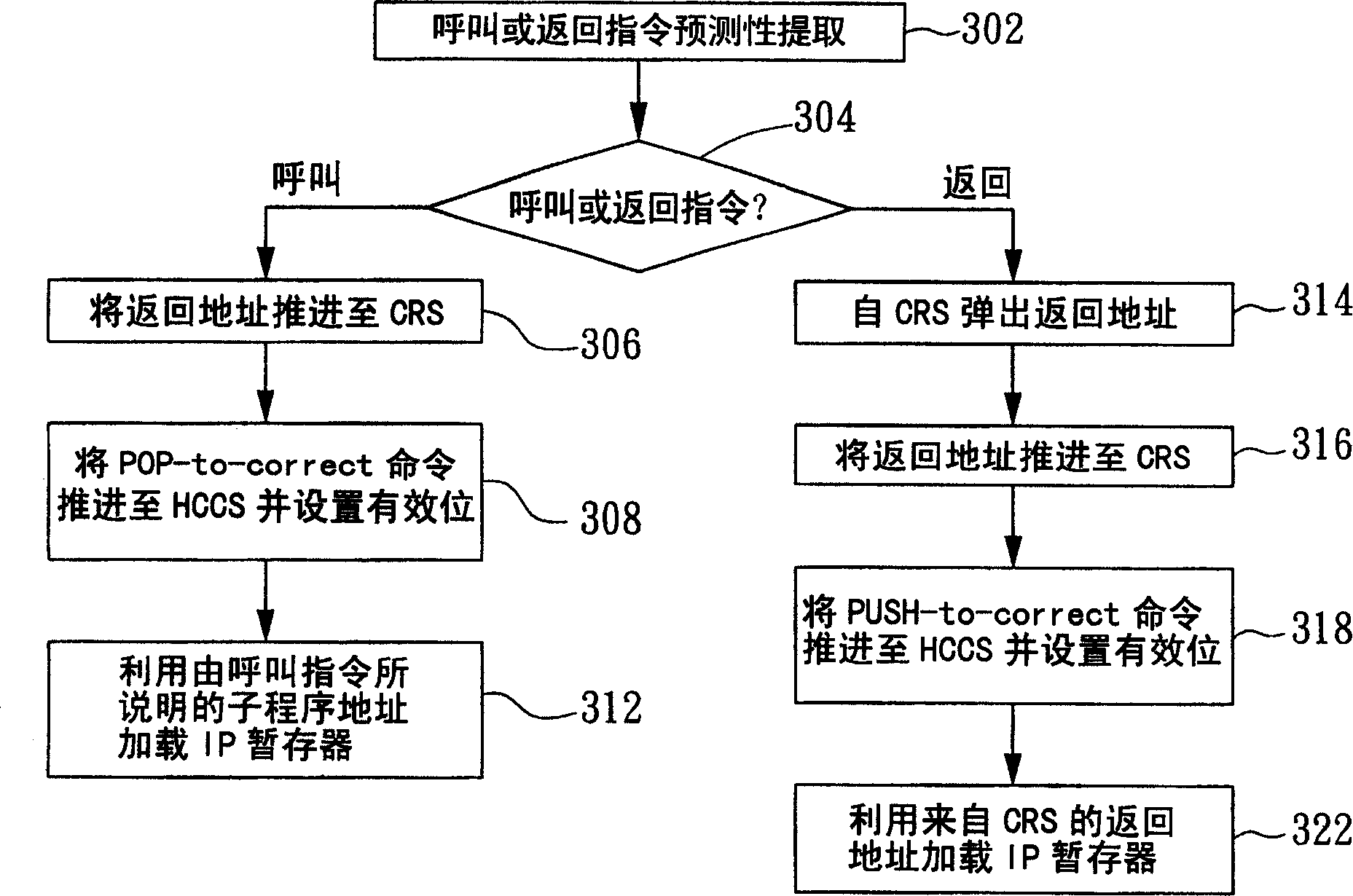

Method and device for correcting internal call or return stack in microprocessor

ActiveCN1558326AReduce air bubblesReduce the presence of air bubblesConcurrent instruction executionMemory systemsOperating systemLine tubing

The present invention discloses one call / return stack (CRS) updating device in pipeline microprocessor. Whenever the microprocessor updates CRS based on one call / return command, it also stores the updating information in the first updating stack. The microprocessor includes two different stages for detecting null event. Once the call / return command passes through the first detection stage, the relevant information will move from the first updating stack to the second updating stack. When some null event is detected in the upper detection stage, only the updating information in the first stack may be used in updating CRS. However, if some null event is detected in the lower detection stage, the updating information in both the first and the second stack may be used in updating CRS.

Owner:IP FIRST

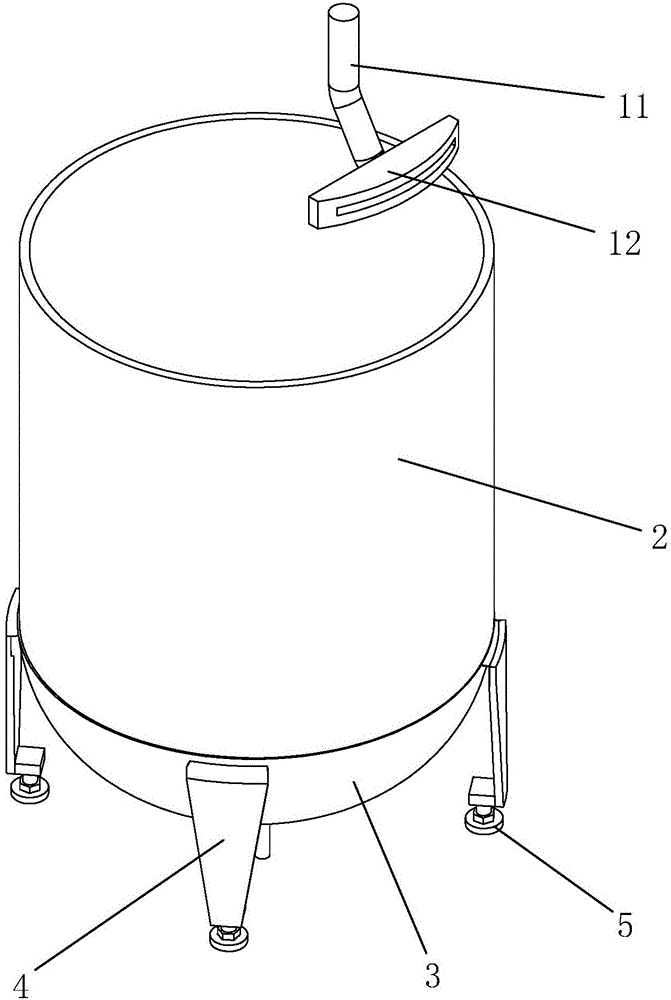

Liquor-stored tank

ActiveCN106742866AReduce air bubblesAvoid mass churnLarge containersTank wagonsCarbon dioxideProduct gas

The invention discloses a liquor-stored tank. The liquor-stored tank comprises a tank top, a tank body and a tank bottom. The tank top is provided with a cleaning device, a safety valve and a pouring inlet. The tank body sequentially comprises an inner container, a cooling jacket, an insulating layer and an outer coating body from inside to outside. An outlet is formed in the tank bottom. The pouring inlet is connected with a fluid director capable of guiding beer to be poured in along the inner wall of the tank body. By the adoption of the liquor-stored tank, the problem that carbon dioxide gas in beer fluid is lost when beer is poured into the tank body is solved, and poor zest of the beer is avoided; and meanwhile, the liquor-stored tank achieves a high-performance fluid separation effect and a preservation effect.

Owner:杭州旷博机械设备有限公司

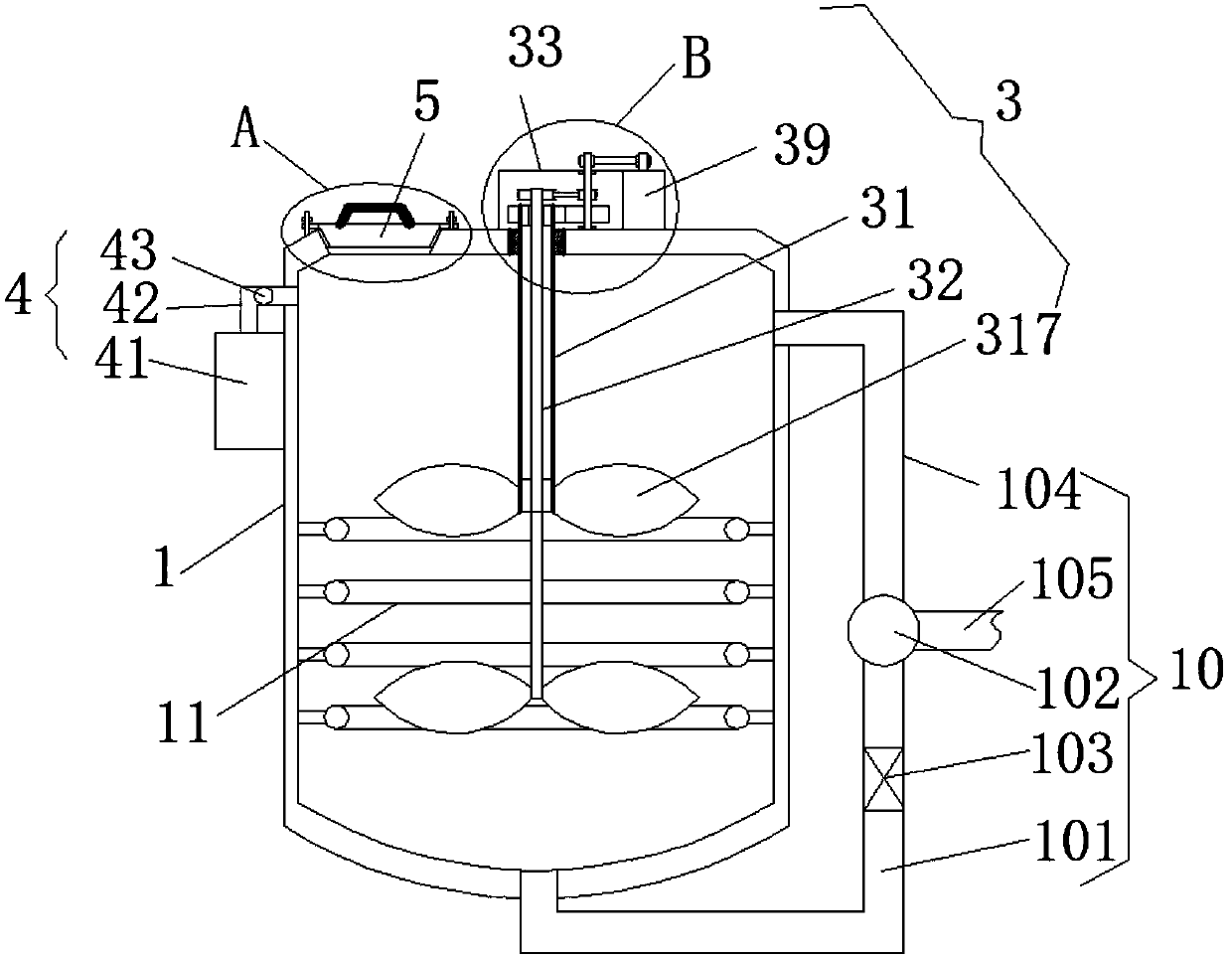

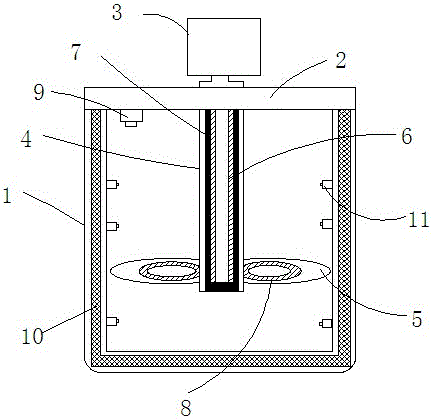

Size mixing device and using method

InactiveCN107790056ATurn up slurry qualityReduce air bubblesFlow mixersRotary stirring mixersEngineeringAir bubble

The invention discloses a size mixing device. The size mixing device comprises a size mixing tank, wherein one side of the top of the size mixing tank is provided with a charging hole; a stirring device is arranged on the size mixing tank; a bubble removing device and an anti-sediment device are arranged on the size mixing tank; a sealing gland is arranged on the charging hole; the edge of the charging hole of the size mixing tank is fixedly connected with a plurality of thread rods; the edge of the sealing gland is fixedly connected with a ring of baffle; the baffle is provided with a plurality of through holes; each thread rod passes through one through hole; a plurality of nuts which are matched with the thread rods are arranged above the baffle; sealing rubber is laid at an inner sidewall of the charging hole. The size mixing device has contribution to improvement of the prepared size quality and reduction of bubble quantity in the size, and has a function of preventing sediment in a process of mixing the size; the size can be uniformly stirred with the stirring device, so that the improvement of the prepared size is facilitated.

Owner:郑佳

Sponge foaming machine provided with hot stirring device

InactiveCN106584746AReduce air bubblesImprove the quality of sponge moldingHollow cylinderEngineering

The invention discloses a sponge foaming machine provided with a hot stirring device. The sponge foaming machine comprises a stirring bucket, a stirring bucket cap, the hot stirring device and a stirring motor. The hot stirring device is held in the stirring bucket and comprises a stirring shaft and stirring paddles. The upper end of the stirring shaft is in transmission connection with the stirring motor, and the lower end of the stirring shaft is fixedly connected with the stirring paddles. The stirring shaft is arranged to be of a hollow cylindrical structure with the lower end closed. A hollow cylinder of the stirring shaft is internally provided with a cylindrical heating pipe. A heat conduction layer is arranged between the pipe wall of the heating pipe and the inner wall of the stirring shaft and makes contact with the inner wall of the stirring shaft in an abutting mode to achieve the heat conduction process. The upper end of the heating pipe is connected with an outer circuit control system. By adoption of the sponge foaming machine provided with the hot stirring device, sponge foaming raw materials can be effectively heated in the stirring process of the raw materials, and therefore bubbles generated in the stirring process of the sponge foaming raw materials can be effectively reduced to improve the sponge forming quality, and the practicality is high.

Owner:苏州恒昇海绵机械制造有限公司

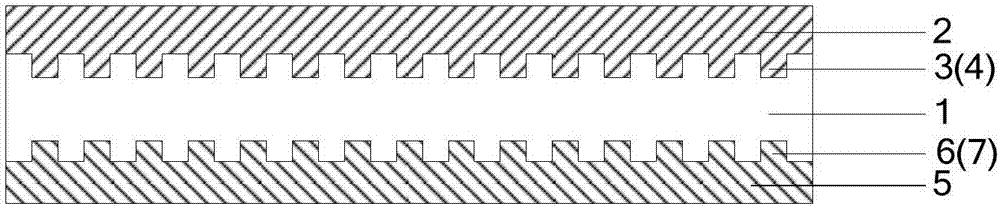

Optical transparent adhesive tape and preparation method for optical transparent adhesive tape

The invention provides an optical transparent adhesive tape and a preparation method for the optical transparent adhesive tape. The optical transparent adhesive tape comprises an optical transparent adhesive tape layer and a first release film, wherein the first release film is pressed on one side of the optical transparent adhesive tape layer; a first bulge is arranged on one side of the first release film adjacent to the optical transparent adhesive tape layer; a first groove, the shape of which is as same as the shape of the first bulge, is formed on one side of the optical transparent adhesive tape layer; when the side of the optical transparent adhesive tape layer with the first groove is adhered to a display panel, air between the optical transparent adhesive tape layer and the display panel can flow along the first groove, so that air can be conveniently exhausted, the air bubbles between the optical transparent adhesive tape layer and the display panel can be correspondingly reduced and the optical performance of the display module can be promoted. After the optical transparent adhesive tape layer is bonded with the display panel, the optical transparent adhesive tape layer has certain liquidity and the optical transparent adhesive tape layer can be conformed to the surface of the display panel, so that the optical performance of the display module can be further promoted.

Owner:BOE TECH GRP CO LTD

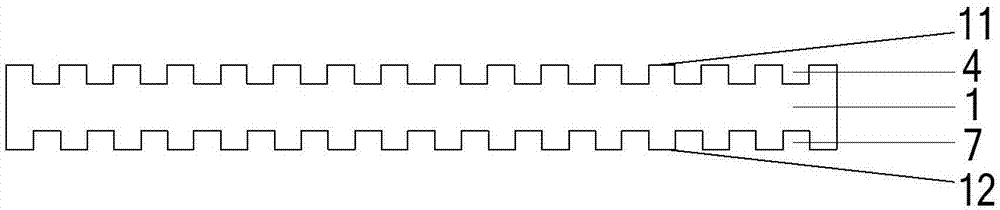

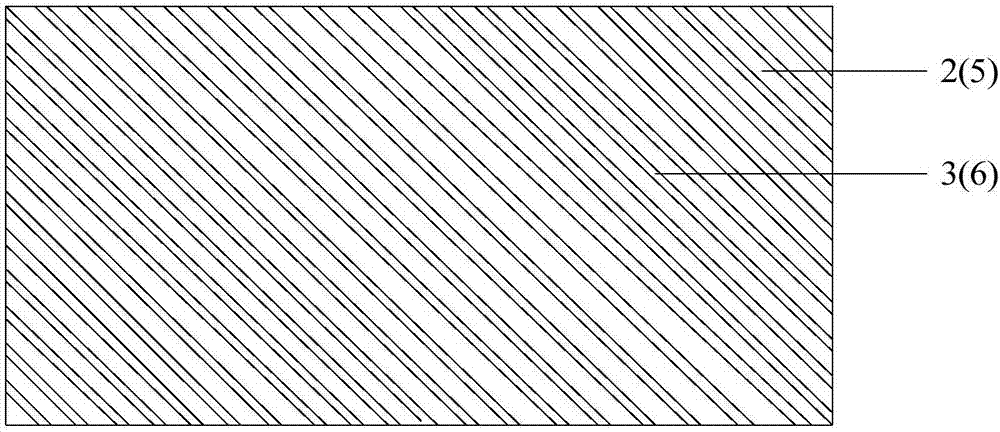

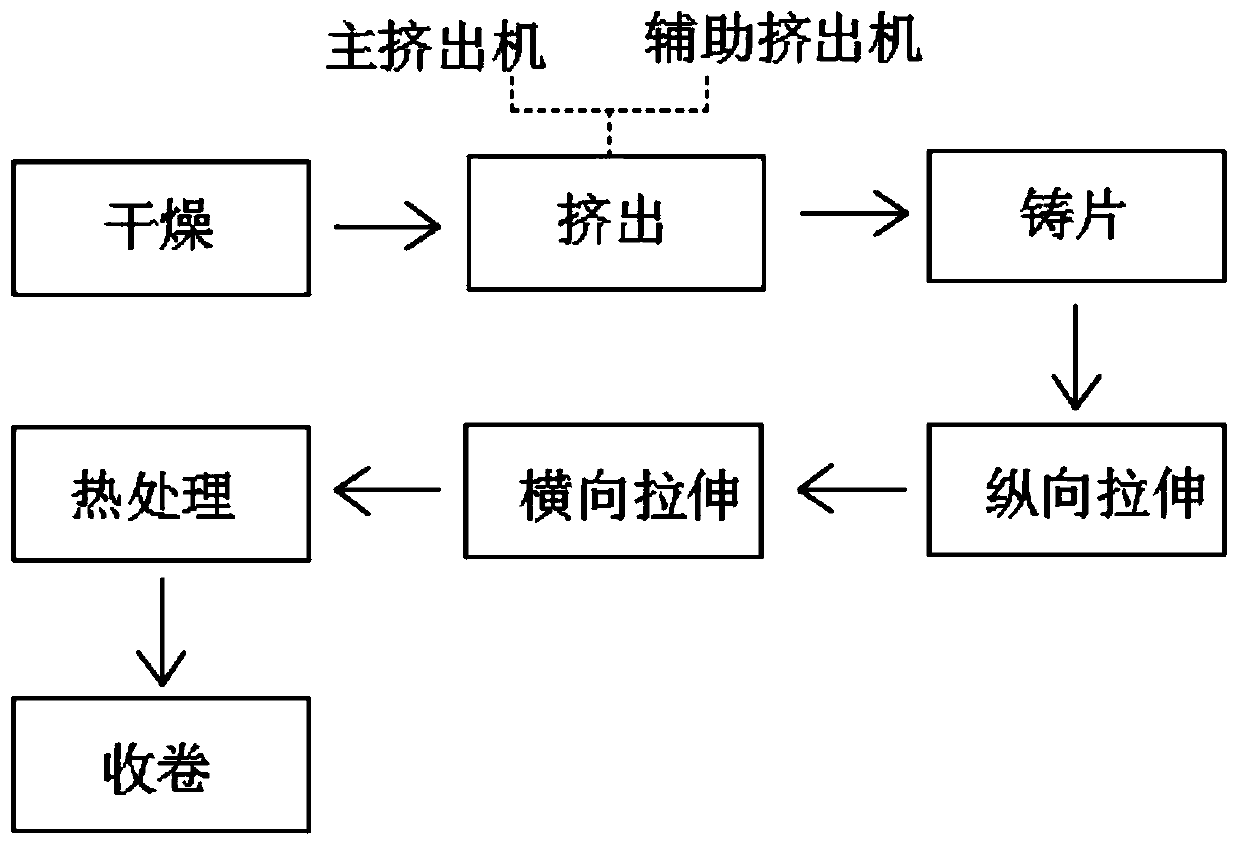

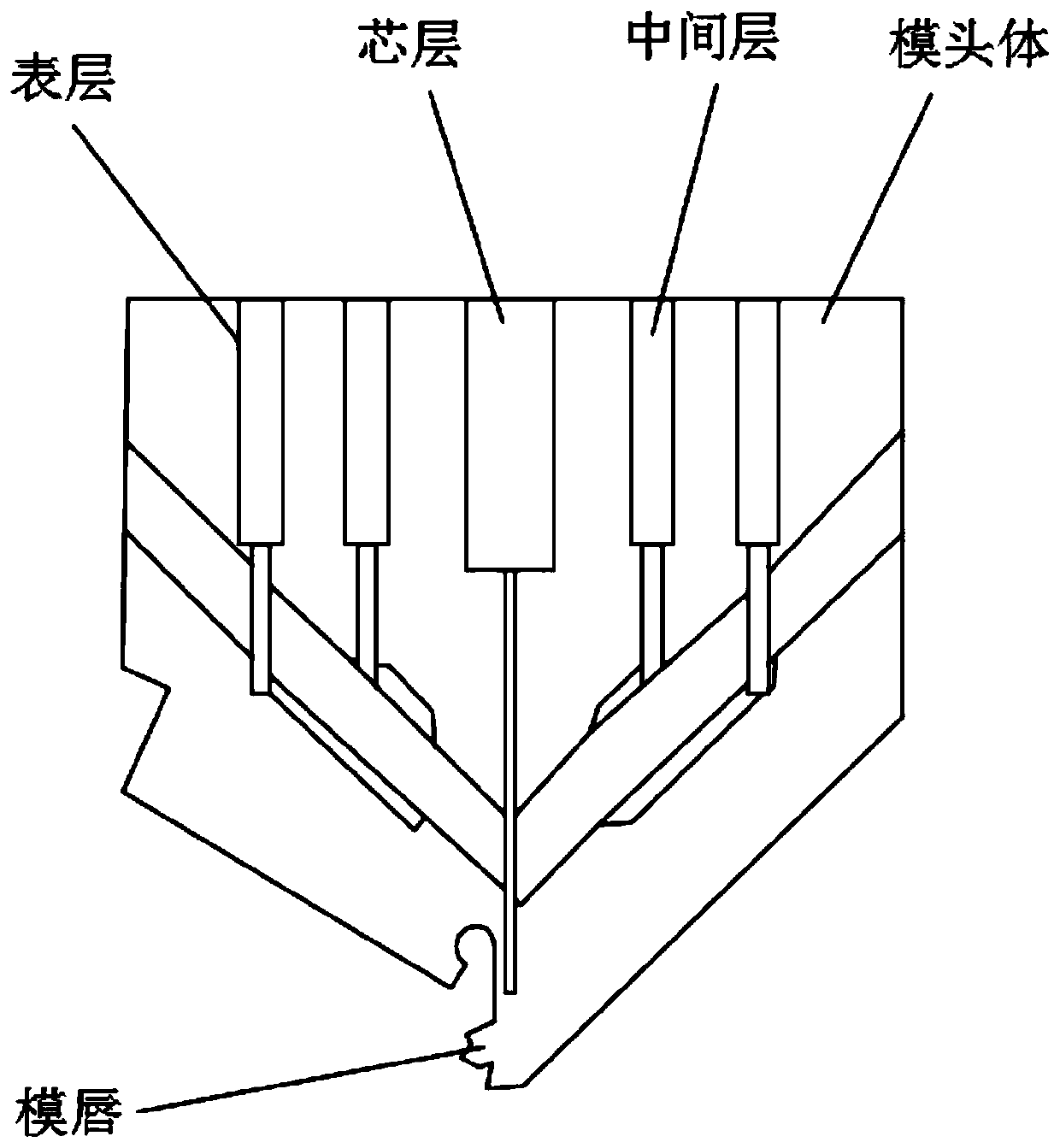

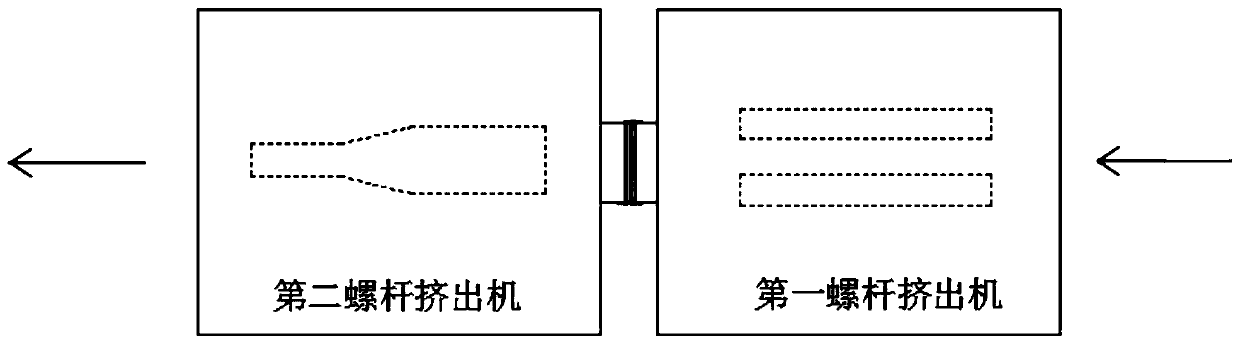

Manufacturing process of biaxially stretched color base film for manufacture process protection of electronic products

The invention discloses a manufacturing process of a biaxially stretched color base film for manufacture process protection of electronic products, and belongs to the field of manufacturing color basefilm. The manufacturing process comprises the steps of manufacture of a color masterbatch and manufacture and production of a color film by using a five-layer biaxial stretching device, specificallythe color masterbatch is produced by using a tandem type screw extruder; and the production of the color film by using the five-layer biaxial stretching device includes the following steps: drying, extruding, casting, longitudinal stretching, transverse stretching, heat treatment and winding, specifically the step of extruding includes extruding by a main extruder and extruding by using four auxiliary extruders. the four auxiliary extruders used in the step of extruding by using the four auxiliary extruders are able to make the film surface color be uniformly distributed, less in crystal point, less in bubbles, and high in gloss; the corona surface has a uniform corona value and no corona on the back surface, and the non-corona surface has no glue; the pollutant to a main batching system of a production line is less; and products are converted quickly after production is completed.

Owner:SUQIAN GETTEL PLASTIC IND

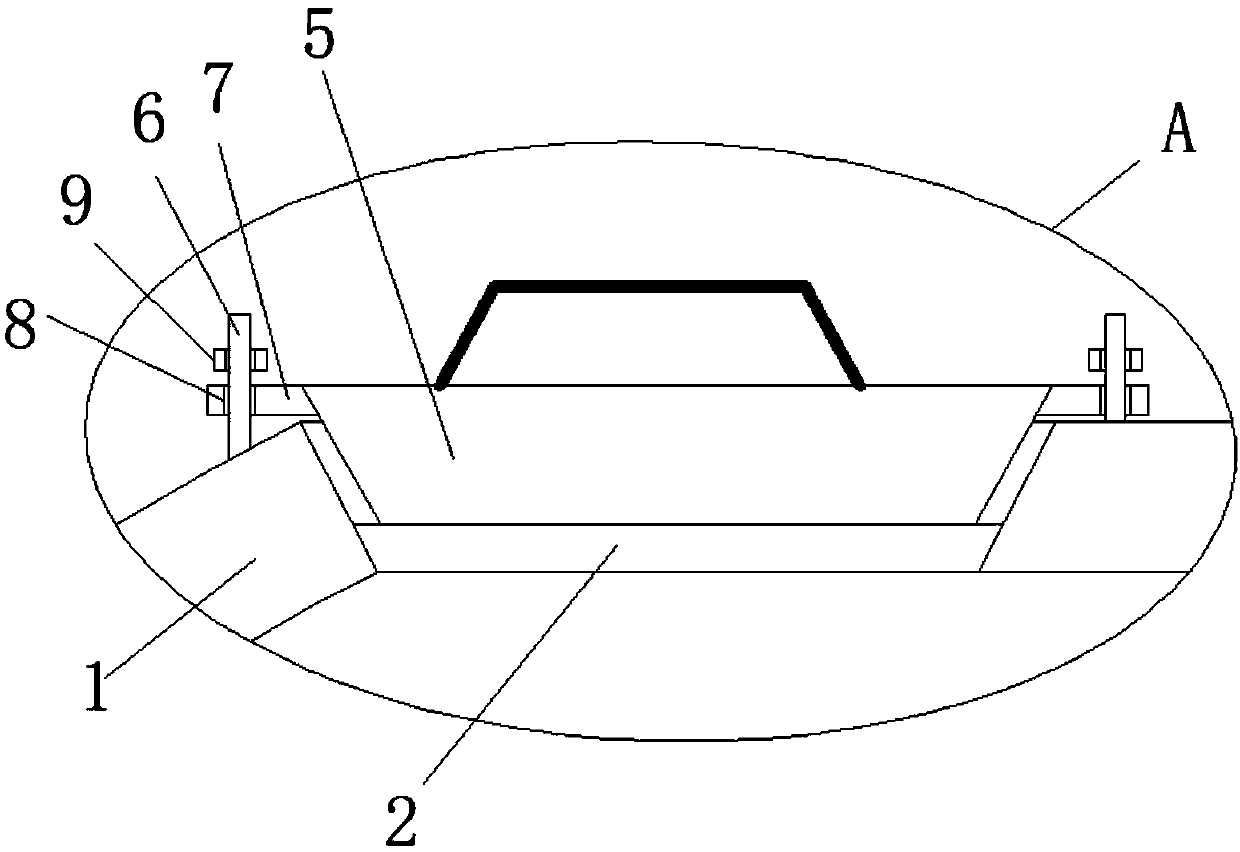

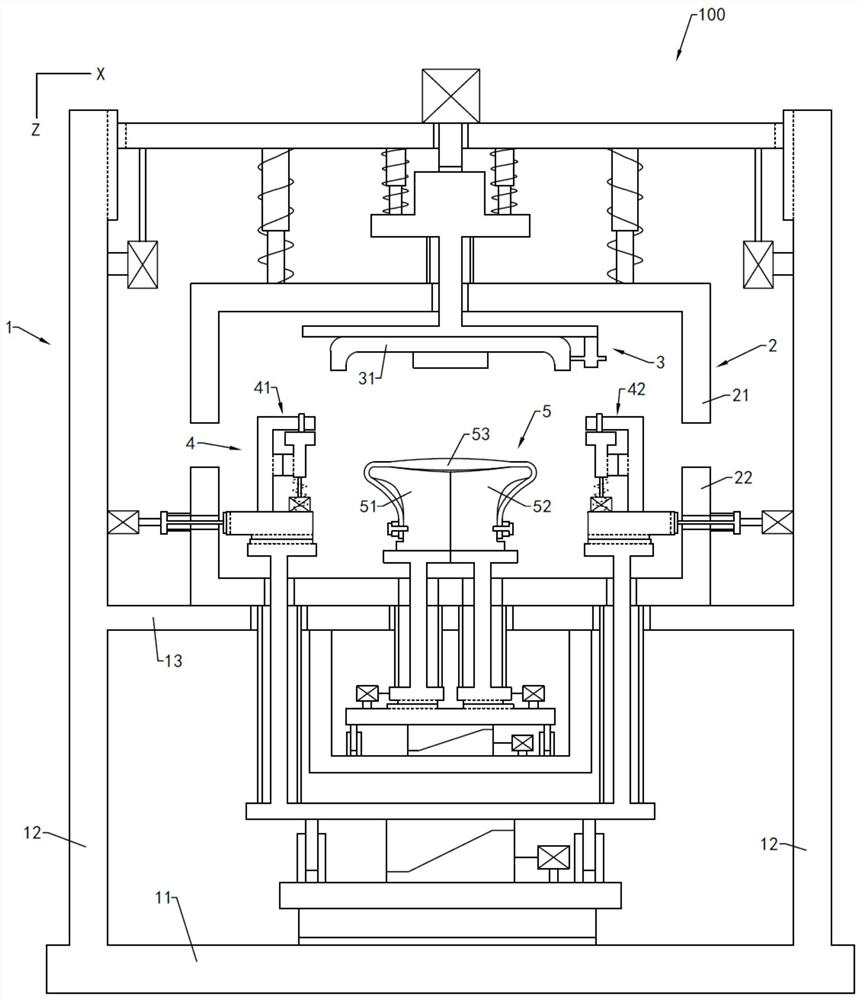

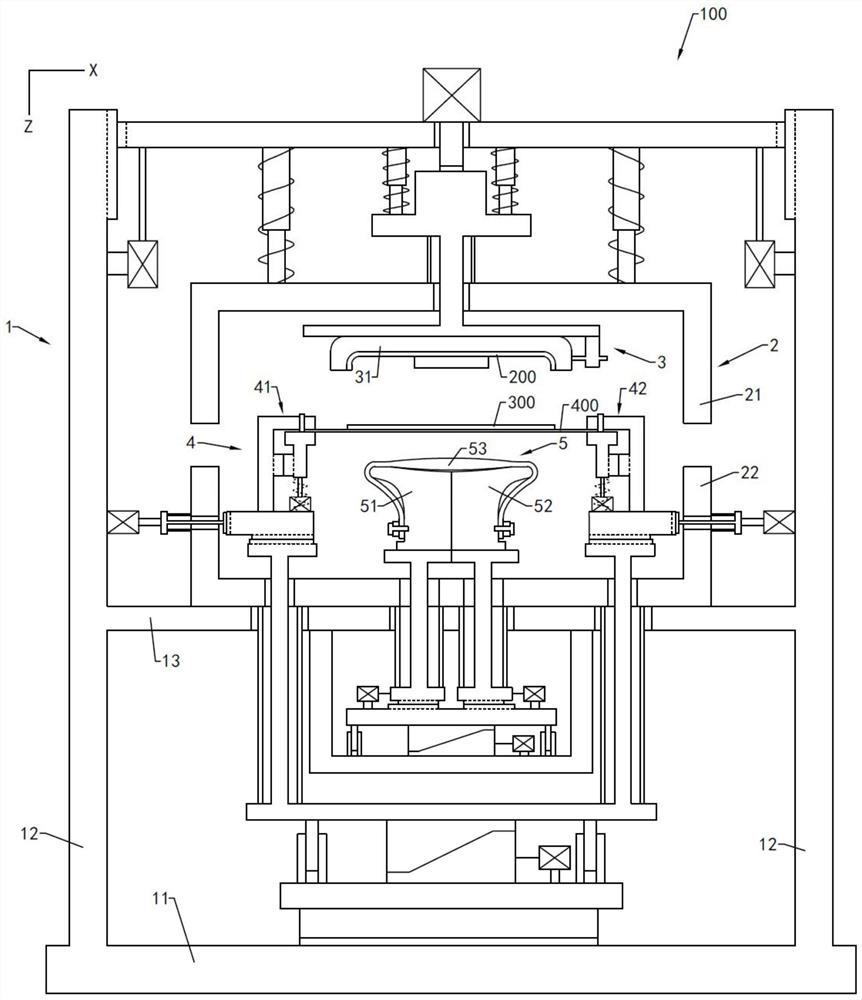

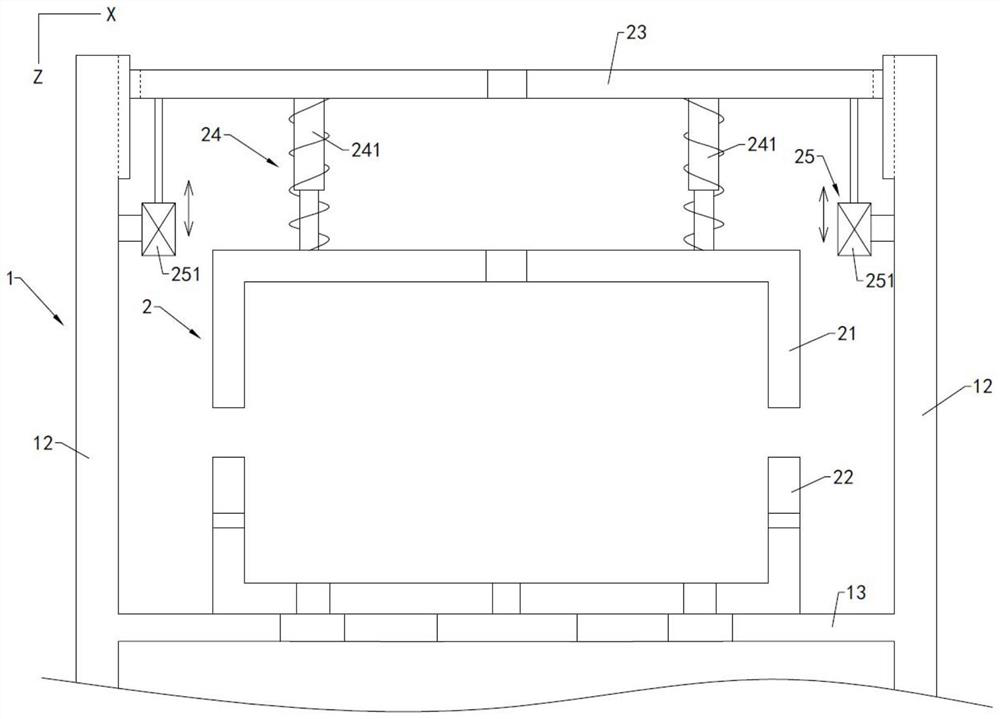

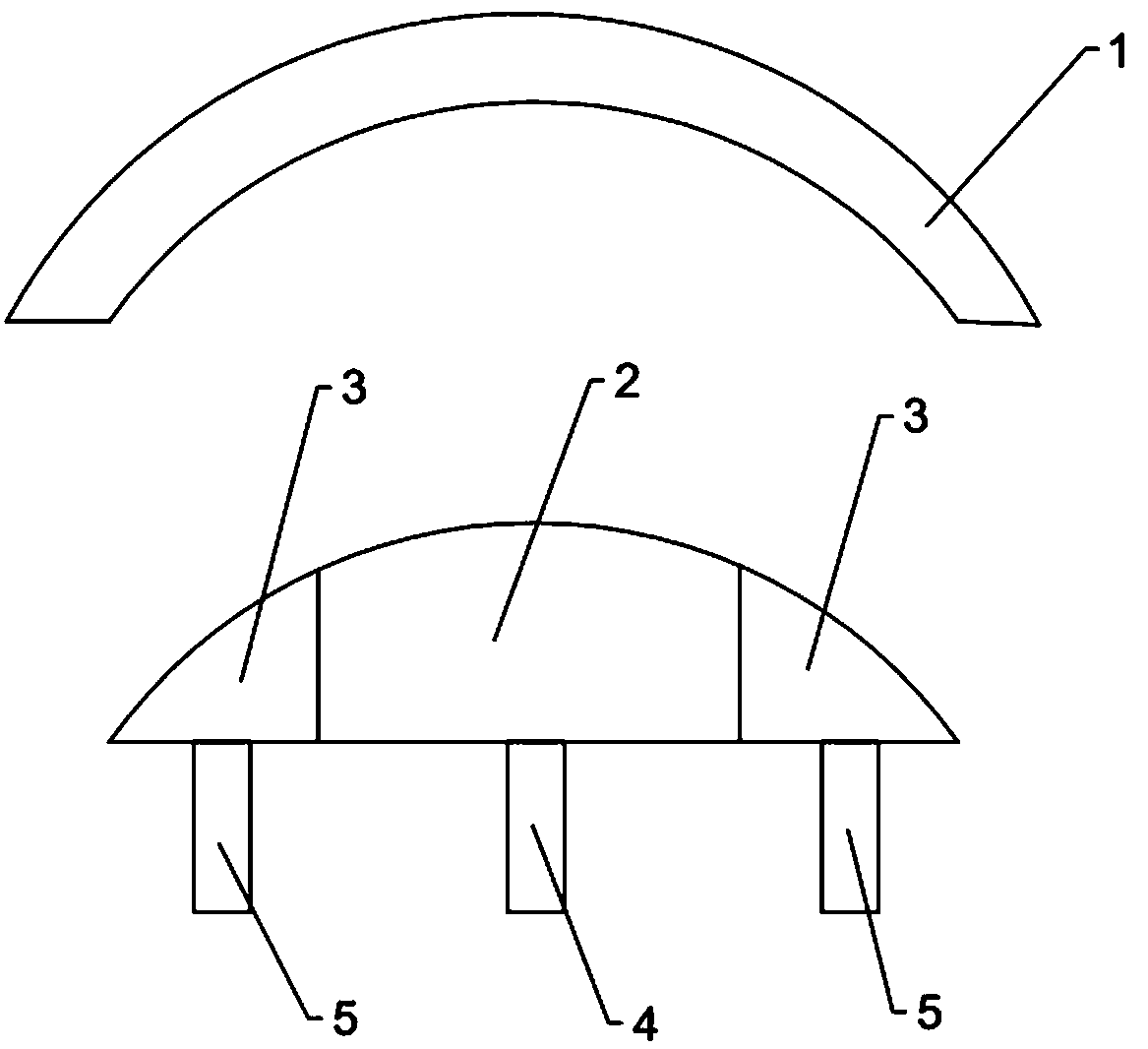

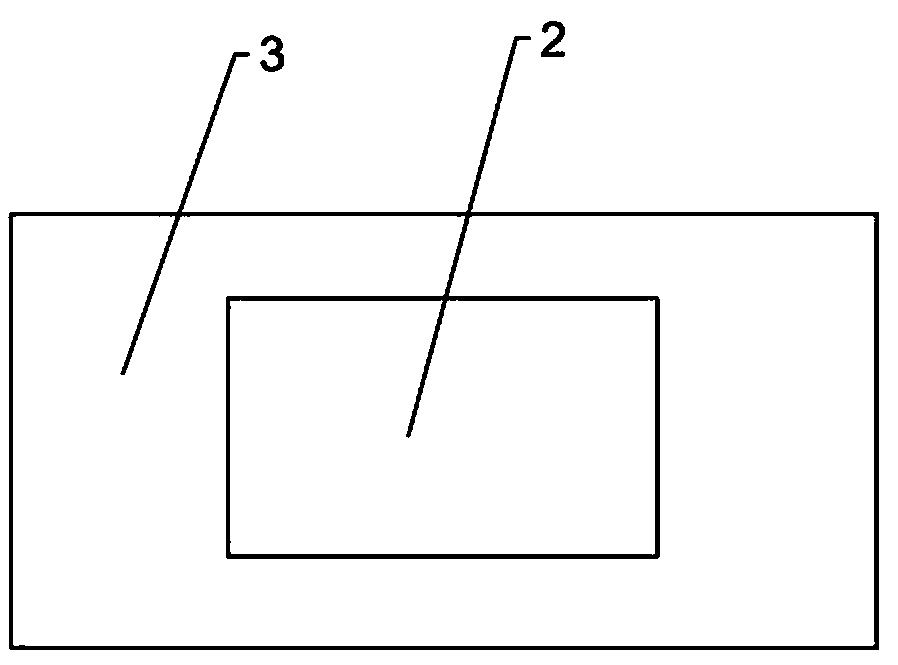

Laminating assembly, laminating pad and laminating equipment

ActiveCN111862796AGood fitReduce air bubblesIdentification meansStructural engineeringMechanical engineering

The embodiment of the invention discloses a laminating assembly. The laminating assembly comprises a first sliding block, a second sliding block and a laminating pad. The first sliding block and the second sliding block are arranged in the second direction and can be closed to each other and separated from each other. The laminating pad is made of elastic materials, the laminating pad extends fromthe side, away from the second sliding block, of the first sliding block to the side, away from the first sliding block, of the second sliding block, the laminating pad is used for supporting the flexible screen to be stacked and attached to the curved surface cover plate in the first direction, and the first direction is perpendicular to the second direction. According to the laminating assembly, the attaching quality of the curved surface cover plate and the flexible screen can be improved. The embodiment of the invention further discloses a laminating pad and laminating equipment.

Owner:HUAWEI TECH CO LTD

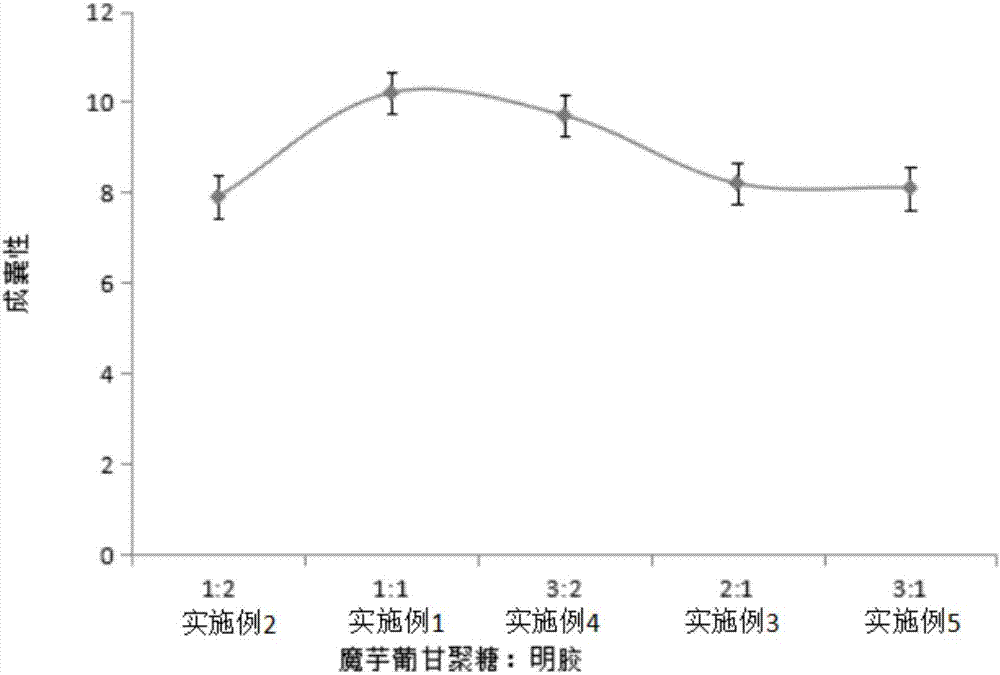

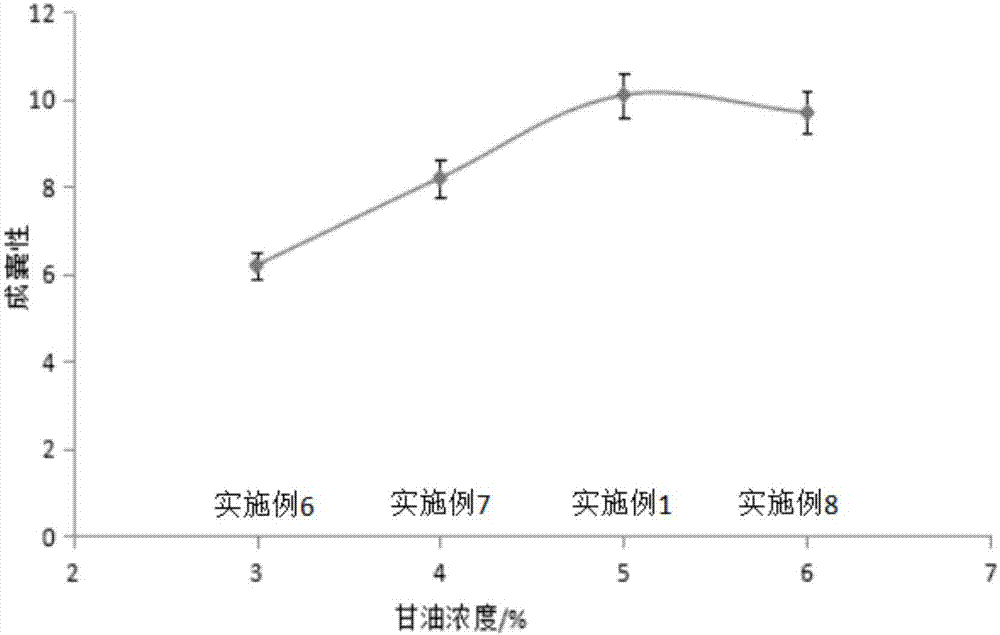

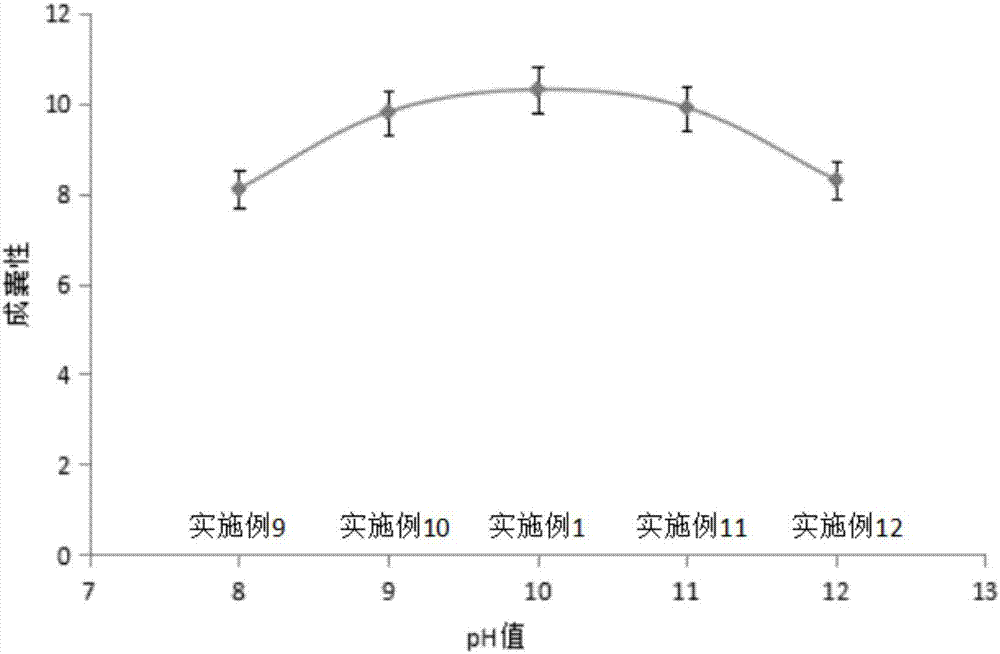

Preparation method of konjac glucomannan-gelatin based capsule

ActiveCN107260702AUniform thicknessReduce air bubblesCapsule deliveryMacromolecular non-active ingredientsMannoseFriability

The invention discloses a preparation method of a konjac glucomannan-gelatin based capsule. The method includes: using mannose to degrade konjac refined powder to obtain a konjac glucomannan degradation solution; adding glycerin into the konjac glucomannan degradation solution, stirring the substances evenly, then adding gelatin, performing stirring till complete dissolution of the gelatin in the degradation solution so as to obtain mixed sol; subjecting the mixed sol to degassing, then carrying out standing glue dipping, freezing, shell pulling, cutting and drying, thus obtaining the konjac glucomannan-gelatin based capsule. The konjac glucomannan-gelatin based capsule has the characteristics of uniform capsule shell thickness, easy shell pulling and no rupture, no insert split, few bubble, no collapse, and no thin head. Strength and elastic detection of the capsule shell shows that the friability is lower than that of single gelatin capsule shell, and the elasticity is stronger. Dissolution rate detection determines the drug release effect of the konjac glucomannan-gelatin capsule, and the test finds that drug release occurs at about 4-5min, and the dissolution rate at about 60min is 95.5%.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Feeding device for injection mold

The invention relates to the technical field of chemical equipment, in particular to a feeding device for an injection mold. The feeding device for the injection mold comprises a stirring box, a dustsucking device, a high pressure fan assembly, a propelling device and a supporting frame. The center of the top end of the stirring box is fixedly connected with a second motor. The tail end of a mainshaft of the second motor is fixedly connected with a vertically arranged stirring rod. The right side of the stirring box is fixedly connected with an air heater which can dry and dehumidify plasticraw materials. The dust sucking device is arranged at the left upper end of the stirring box, comprises a dust removal box, an air guide pipe and a dust removal filter core, and can conduct dust removal on the plastic raw materials. The propelling device comprises a propelling pipe, a first motor and a propelling screw rod. A feeding inlet is formed in the top end of the left side of the propelling pipe. The bottom end of the stirring box is fixedly connected with a collection hopper. The bottom end of the collection hopper is fixedly connected with the propelling pipe. The feeding device forthe injection mold is scientific and reasonable in structure, has great economic benefits and wide market demand, and is worth popularizing.

Owner:DONGGUAN ZHIPEI ELECTROMECHANICAL TECH CO LTD

Die-cast molding mould of aluminum alloy front cover of automobile silicone oil fan clutch

The invention belongs to the technical field of die-cast molding, and relates to a die-cast molding mould of an aluminum alloy front cover of an automobile silicone oil fan clutch. The die-cast molding mould comprises a fixed mold, a movable mold and a middle mold located between the fixed mold and the movable mold, wherein the middle mold is movably connected with a core component; the core component is provided with a plurality of silicone oil feeding surface molding rings arranged concentrically; and an annular silicone oil feeding surface molding cavity is formed between every two adjacent silicone oil feeding surface molding rings. The wall thicknesses of oil guide rings are reduced, few bubbles are generated in a casting process, the overall quality of a product is uniform, and a rejection rate is low.

Owner:TAIZHOU SHUNYI AUTOMOBILE PARTS

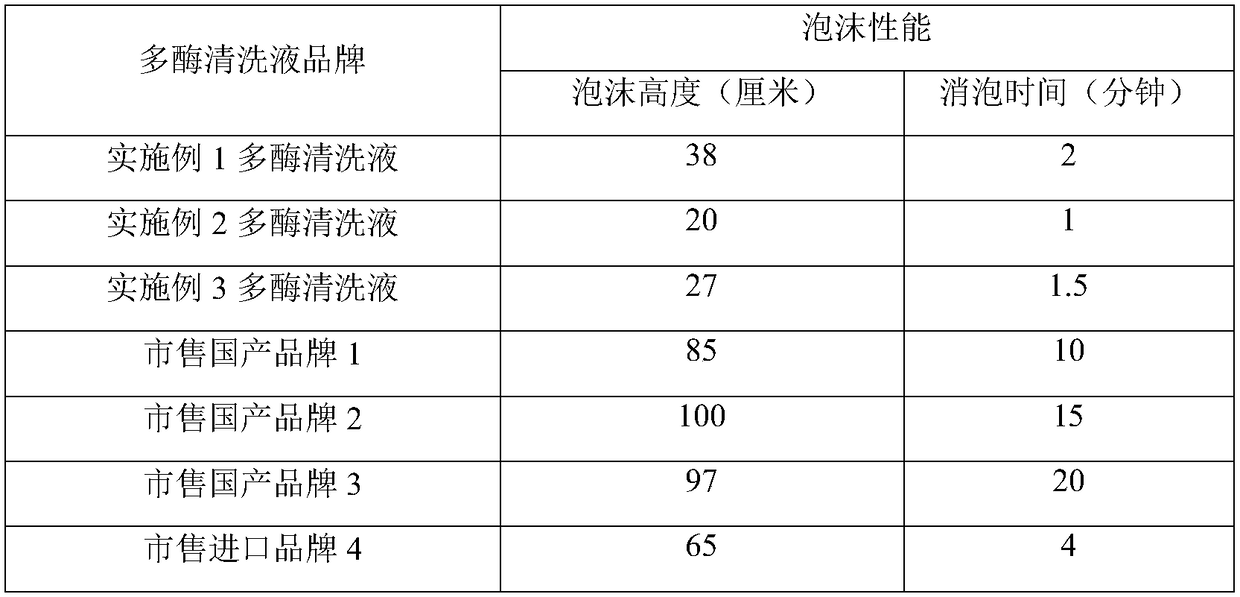

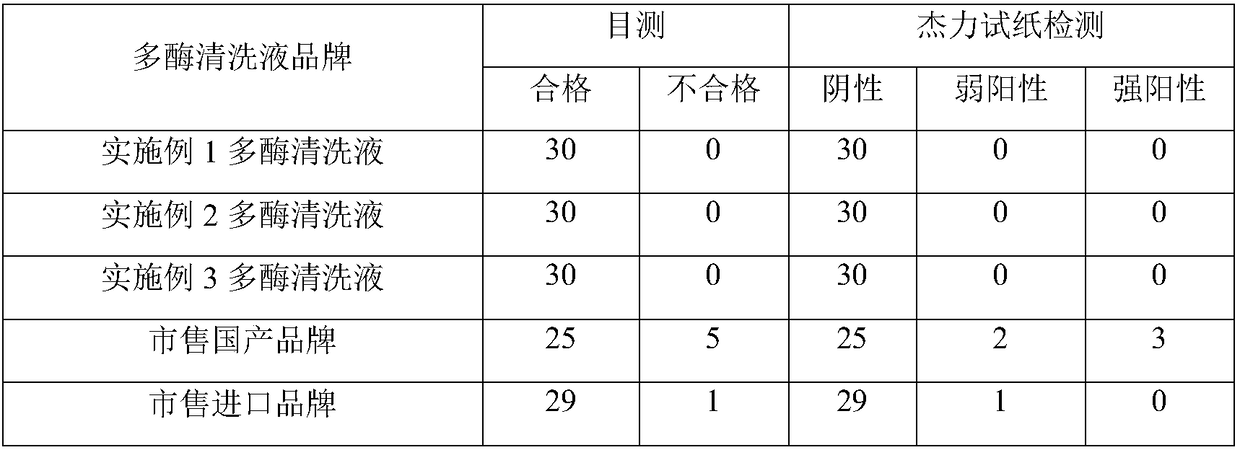

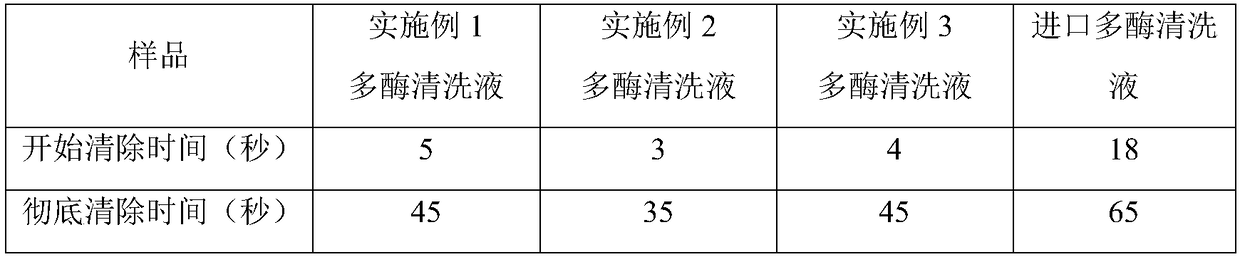

Medical multienzyme cleaning liquid and preparation method thereof

InactiveCN109234045AReduce usageReduce air bubblesOrganic detergent compounding agentsPolymeric surface-active compoundsChemistryProtease

The invention discloses a medical multienzyme cleaning liquid and a preparation method thereof and belongs to the technical field of medical detergents. According to the medical multienzyme cleaning liquid, protease and other enzymes such as lipase, catalase, ligninase and glucose oxidase coexist by matching the components, and meanwhile, the use level of total enzymes is reduced, so that the costis lowered. The cleaning liquid still has a relatively good cleaning efficiency and cleaning effect. Meanwhile, a safer and easily degraded antibacterial preservative theta-polylysine is added, so that the more stable, environment-friendly and efficient cleaning liquid can be formed.

Owner:重庆奥舍生物化工有限公司

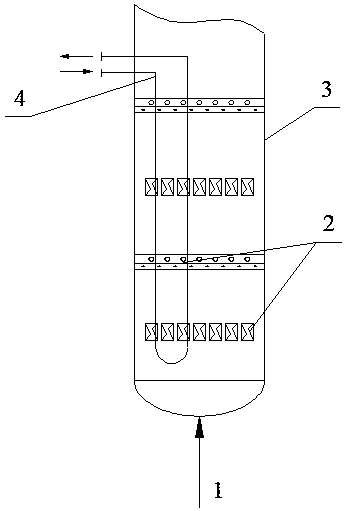

Fluidized-bed reaction device and fluidization reaction method for hydrogenation of nitrobenzene

ActiveCN111298727AImprove fluidization qualityReduce air bubblesOrganic compound preparationAmino compound preparationNitrobenzeneCatalytic hydrogenation

The invention relates to a fluidized-bed reaction device and a fluidization reaction method for hydrogenation of nitrobenzene. The invention mainly aims to solve the problems of low gas-solid contactefficiency, large bubble size, low fluidization quality and the like in a fluidized bed. According to a technical scheme in the invention, at least one group of composite components are arranged in afluidized-bed reactor, so when gas and catalyst particles pass through the components, bubbles and particle clusters are broken, fluidization quality is effectively improved, and the above technical problems are well solved; and the device and the method can be applied to industrial production of gas-phase catalytic hydrogenation of nitrobenzene.

Owner:CHINA PETROLEUM & CHEM CORP +1

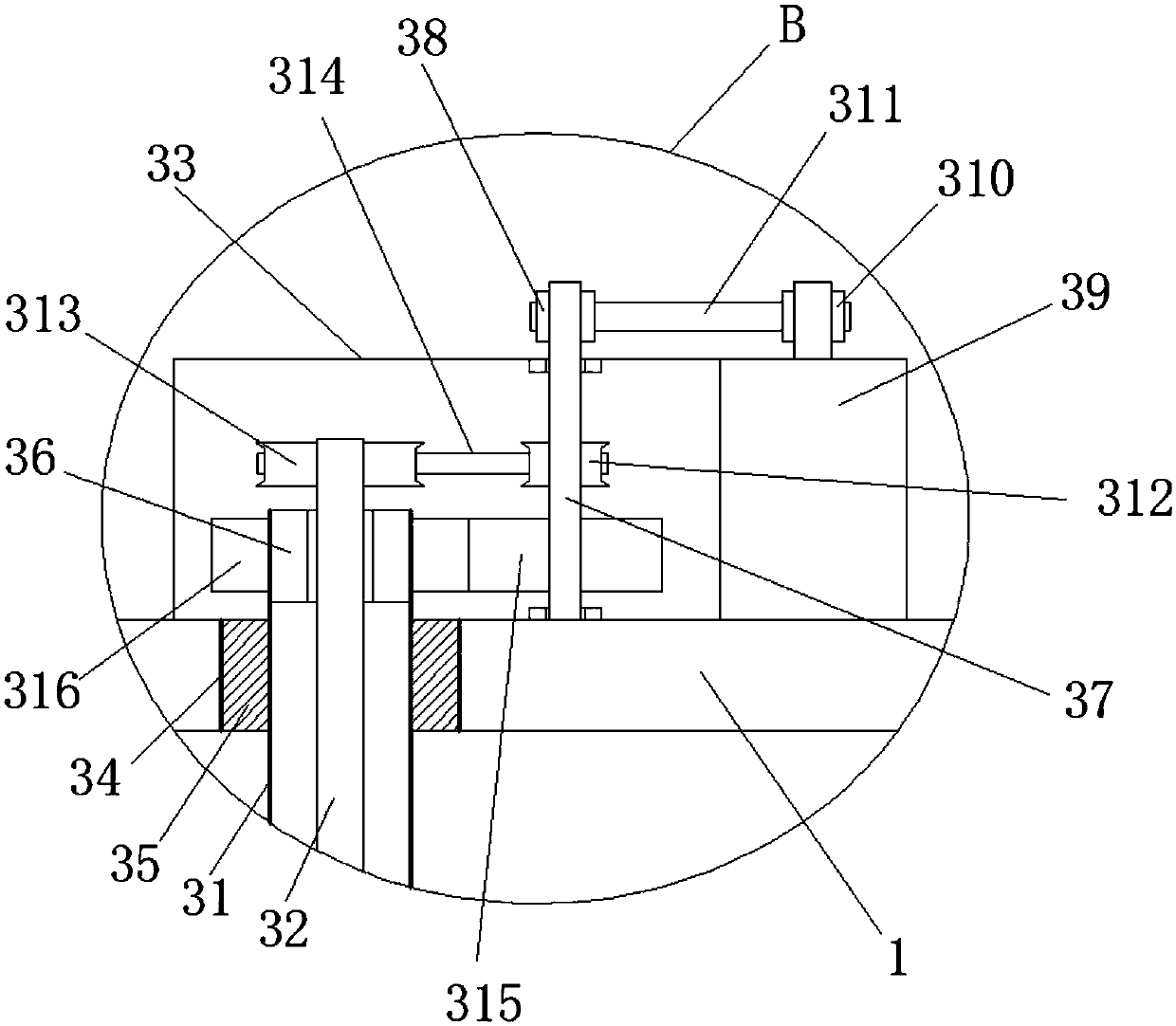

Curve surface attaching clamp and attaching method

The invention discloses a curve surface attaching clamp and an attaching method, wherein the attaching clamp comprises an upper clamp and a lower clamp, wherein the upper clamp is used for fixing a curve surface touch screen; the lower clamp is used for fixing a curve surface display screen; the lower clamp comprises a first clamp and a second clamp arranged around the first clamp; a first jackingmechanism is arranged under the first clamp and is used for driving the first clamp to do ascending and descending movement; a second jacking mechanism is arranged under the second clamp and is usedfor driving the second clamp to do ascending and descending movement. The existing lower clamp is divided into two independent clamps including the first clamp and the second clamp; the ascending height of the first clamp and the second clamp can be singly controlled; during the attaching, the middle region of the curve surface display screen on the first clamp is firstly attached to the curve surface touch screen; then, the edge part of the curve surface display screen is attached to the curve surface touch screen; bubbles are sufficiently discharged from the middle region of the curve surface display screen to the edge during the attachment; the bubble generation is reduced; the attaching effect is good.

Owner:TRULY OPTO ELECTRONICS

Method for reducing bubbles of continuous casting primary blank

The invention discloses a method for reducing bubbles of a continuous casting primary blank. Before casting of the continuous casting primary blank, 1.2-1.6 kg of silicon-calcium powder for each ton of steel is added into a tundish nozzle. According to the method, the silicon-calcium powder is added into the tundish nozzle before casting of the first furnace of continuous casting. The silicon-calcium powder reacts with oxygen in molten steel, the oxygen is fixed and discharged, thus appearing of the bubbles of the continuous casting primary blank is reduced, the quality of a casting blank is improved effectively, and production cost is lowered.

Owner:HEBEI IRON AND STEEL

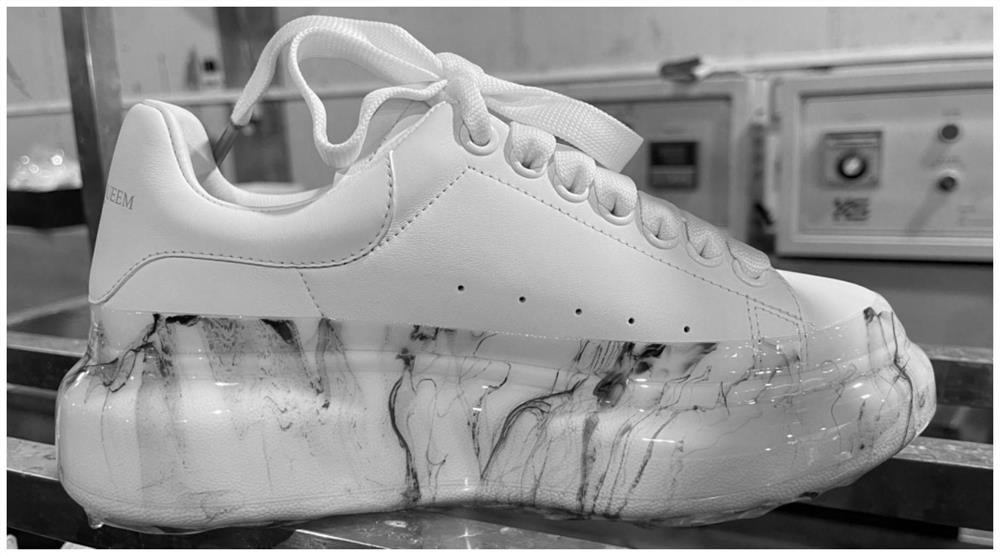

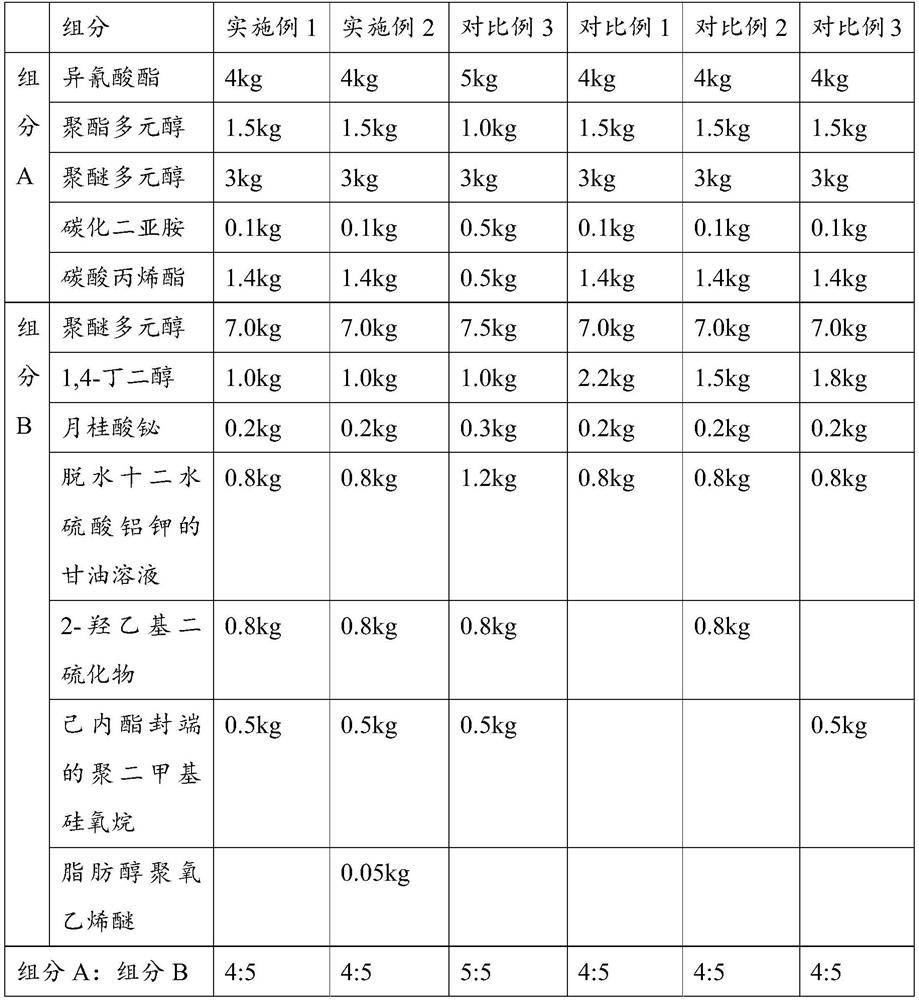

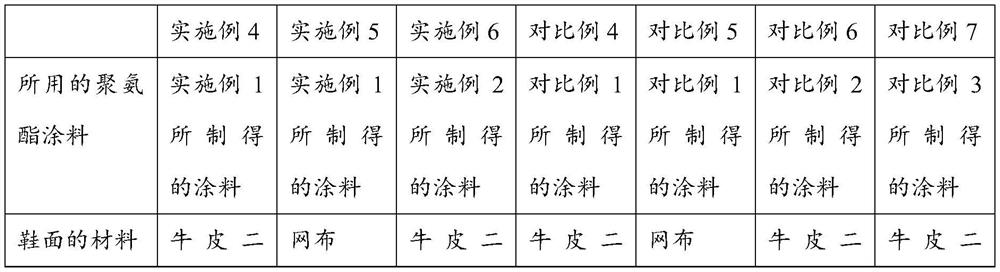

Polyurethane coating for shoes and manufacturing method of coating of polyurethane coating

ActiveCN114479628AImprove hydrophobicityHigh peel strengthPolyurea/polyurethane coatingsPolyesterPolymer science

The invention belongs to the technical field of polyurethane coatings, and particularly relates to a polyurethane coating for shoes and a manufacturing method of a coating of the polyurethane coating. The polyurethane coating is prepared from a component A and a component B, the component A is prepared from the following raw materials: isocyanate, polyester polyol, polyether polyol, a water removal agent and a diluent, and the component B is prepared from polyether polyol, 1, 4-butanediol, a catalyst, a glycerin solution of dehydrated aluminum potassium sulfate dodecahydrate, 2-hydroxyethyl disulfide and caprolactone-terminated polydimethylsiloxane. 2-hydroxyethyl disulfide and caprolactone-terminated polydimethylsiloxane are added, and the dosage and proportion of the 2-hydroxyethyl disulfide and caprolactone-terminated polydimethylsiloxane and a chain extender 1, 4-butanediol are regulated, so that the peel strength between the coating and the vamp is higher, the hydrophobicity is higher, and the coating is more durable. And bubbles in tiny holes at the edge of the vamp or the sole are prevented from expanding due to overheat chain extension.

Owner:FOSHAN NANHAI QIHONG SHOES MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com