Copper clad ceramic and preparation method thereof

A technology of copper-clad ceramics and aluminum nitride ceramics, which is applied in the field of ceramic copper cladding, can solve the problems of non-dense bonding between ceramic layers and copper layers, small bubbles, and low bonding strength, so as to reduce small bubbles and bulges, reduce bubbles, The effect of increasing the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] In another embodiment of the present invention, a method for preparing copper-clad ceramics is disclosed, comprising the following steps:

[0059] Form an aluminum oxide film on the surface of aluminum nitride ceramics;

[0060] A modified layer is formed on the surface of the aluminum oxide film; wherein, the modified layer includes modified particles, and the modified particles include glass powder;

[0061] A copper layer is formed on the surface of the modified layer, and the copper layer, the modified layer and the aluminum nitride ceramic are combined into one body through heat treatment.

[0062] It should be noted that this embodiment does not limit the specific shape of the aluminum nitride ceramic. The aluminum nitride ceramic can be a flat sheet material, or a regular three-dimensional shape, or an irregular curved surface. Materials can be selected by those skilled in the art according to needs.

[0063] In this embodiment, an aluminum oxide film is formed...

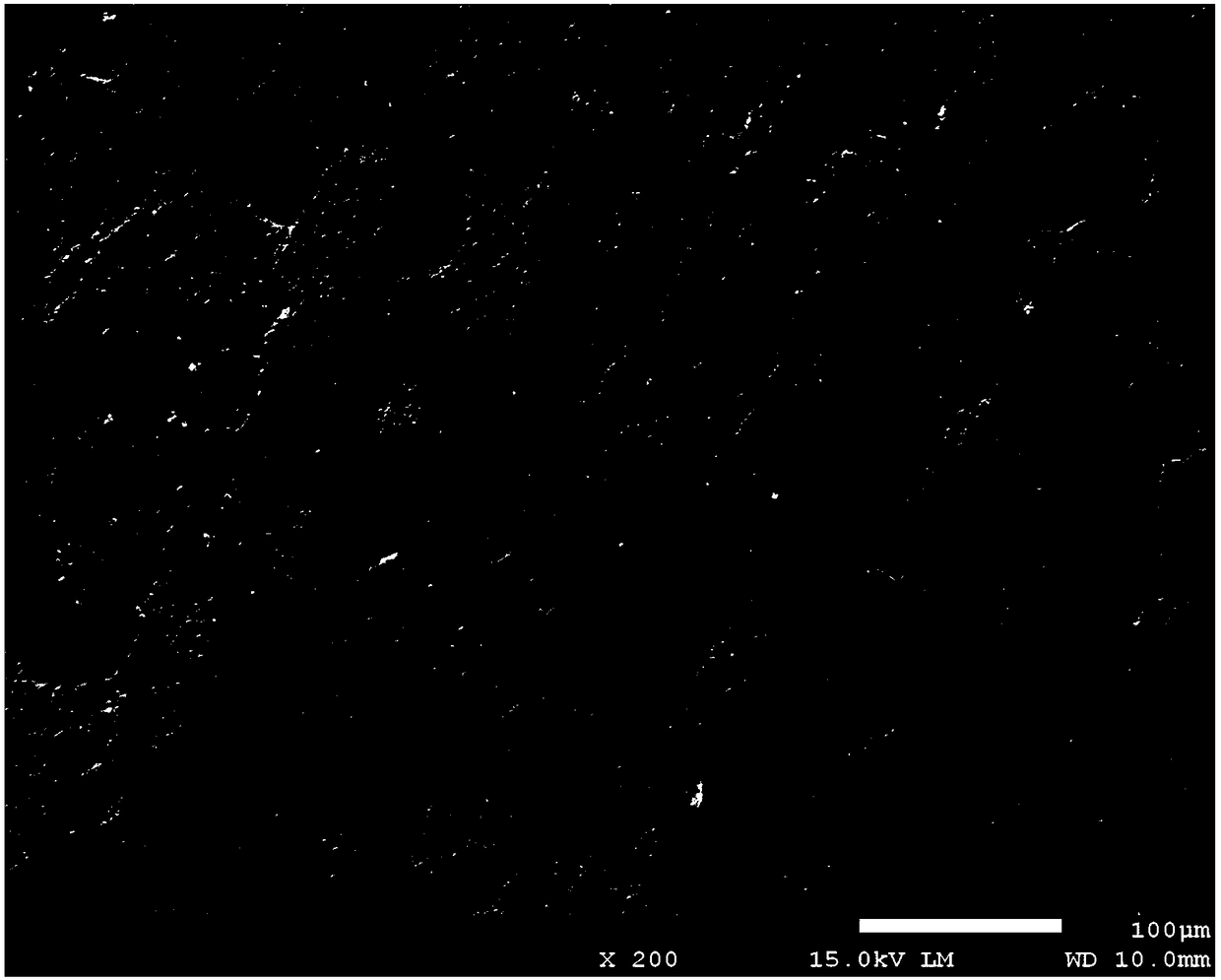

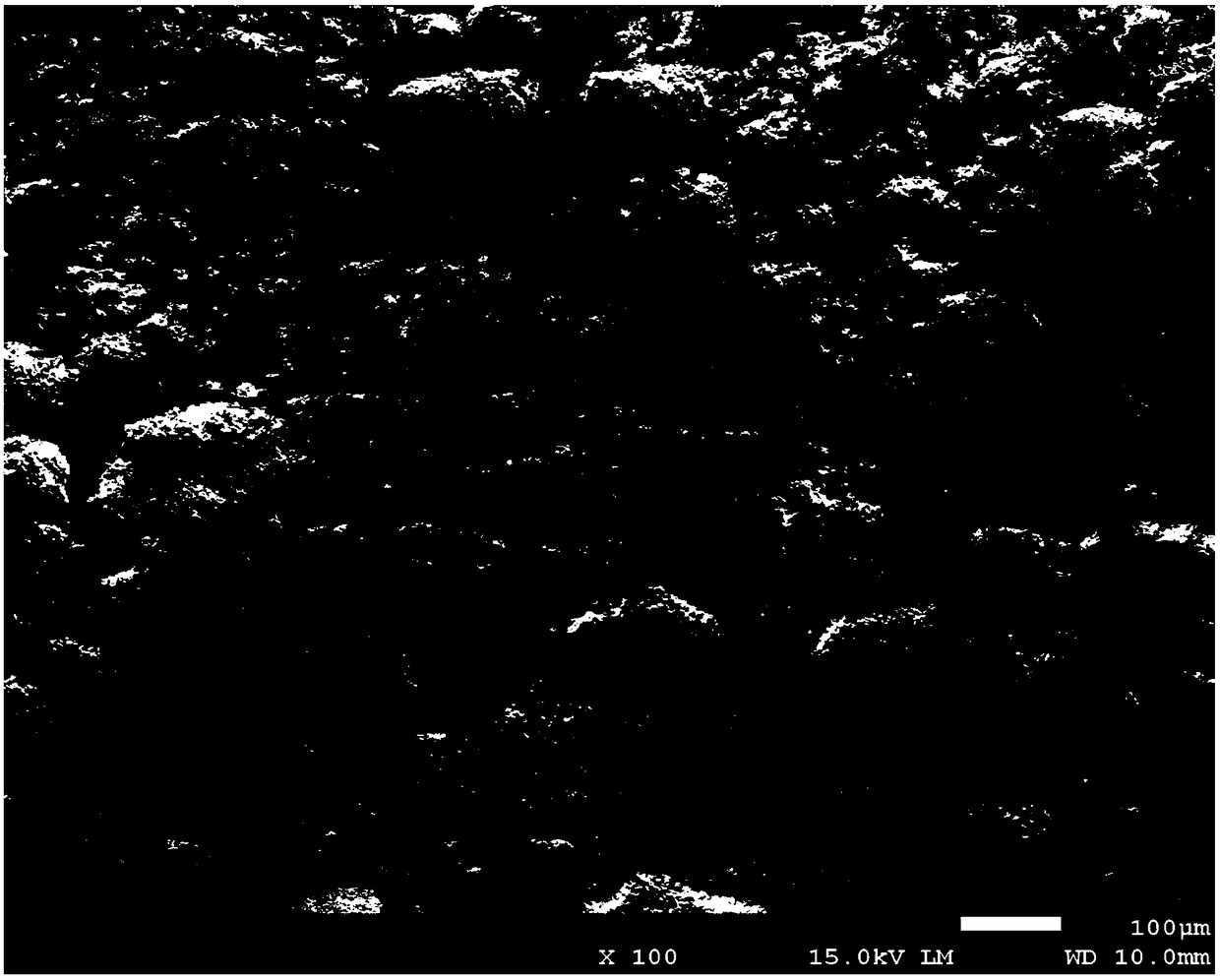

Embodiment 1

[0084] This embodiment is used to illustrate the copper-clad ceramic disclosed in the present invention and its preparation method, including the following process steps:

[0085] ① Place the aluminum nitride ceramic substrate in a flowing atmosphere, raise the temperature to 1200°C at a heating rate of 10°C / min and keep it for 90 minutes. The oxygen partial pressure in the flowing atmosphere is 0.21atm, forming oxide aluminum film, and then naturally cooled to room temperature;

[0086] ② Disperse the modified particles in a dispersant and an organic binder to prepare a modified slurry, the modified particles include the following weight components: glass powder (main components silicate, silicon dioxide): 50%; Alumina powder (molecular formula Al 2 o 3 ): 45%; copper powder: 5%;

[0087] ③ Print the prepared modified slurry on the surface of the aluminum oxide film of the aluminum nitride ceramic substrate by screen printing, and bake in an oven at 90°C for 120 minutes to...

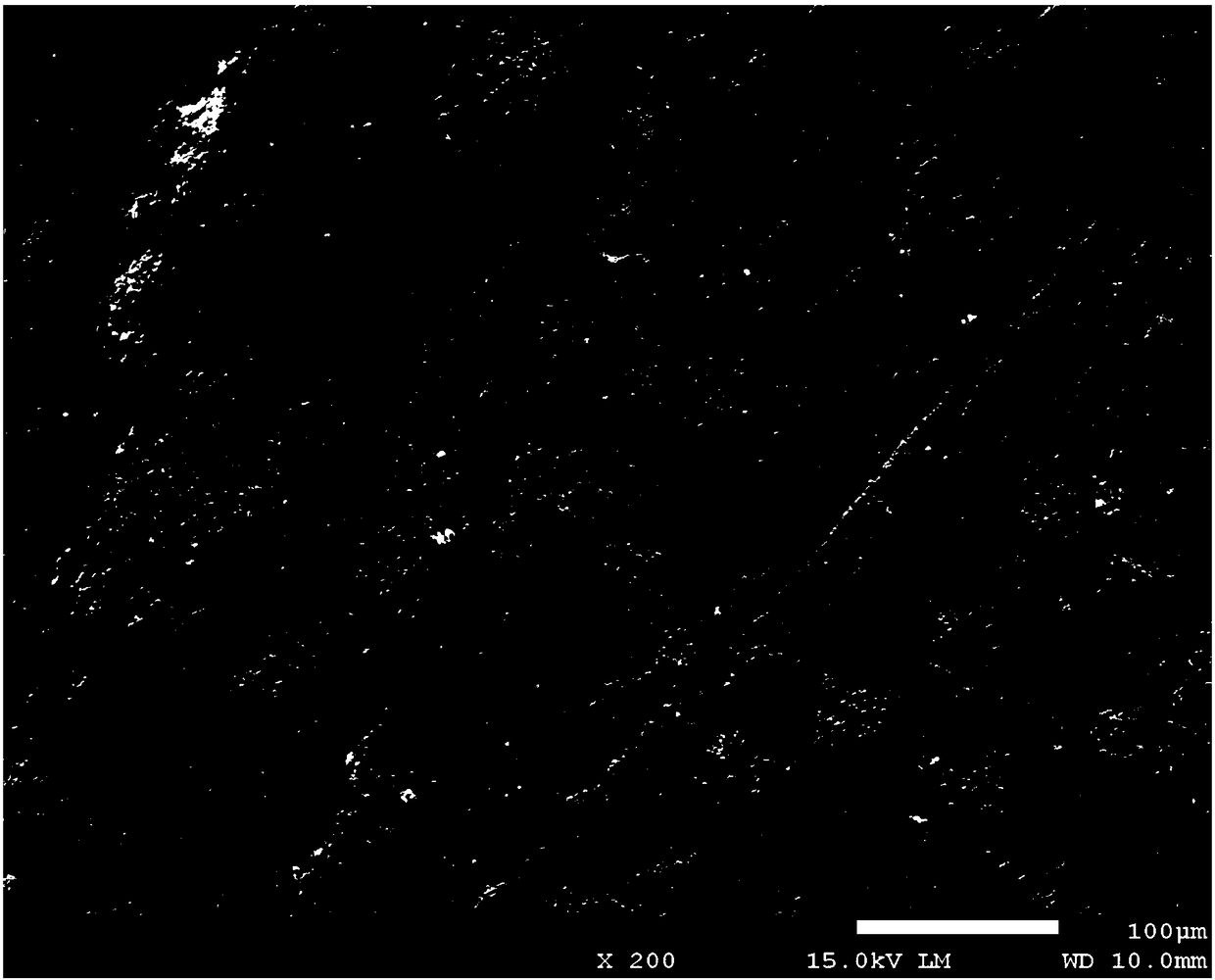

Embodiment 2

[0093] This embodiment is used to illustrate the copper-clad ceramic disclosed in the present invention and its preparation method, including the following process steps:

[0094] ① Place the aluminum nitride ceramic substrate in a flowing atmosphere, raise the temperature to 1200°C at a heating rate of 10°C / min and keep it for 90 minutes. The oxygen partial pressure in the flowing atmosphere is 0.21atm, forming oxide aluminum film, and then naturally cooled to room temperature;

[0095] ② Disperse the modified particles in a dispersant and an organic binder to prepare a modified slurry, the modified particles include the following weight components: glass powder (main components silicate, silicon dioxide): 50%; Alumina powder (molecular formula Al 2 o 3 ): 40%; cuprous oxide: 5%; copper powder: 5%;

[0096] ③ Print the prepared modified slurry on the surface of the aluminum oxide film of the aluminum nitride ceramic substrate by screen printing, and bake in an oven at 90°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Printing thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com