Patents

Literature

490results about How to "Improve billet quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-manganese high-nitrogen low-nickel stainless steel plate blank continuous casting crystallizer covering slag and preparation method thereof

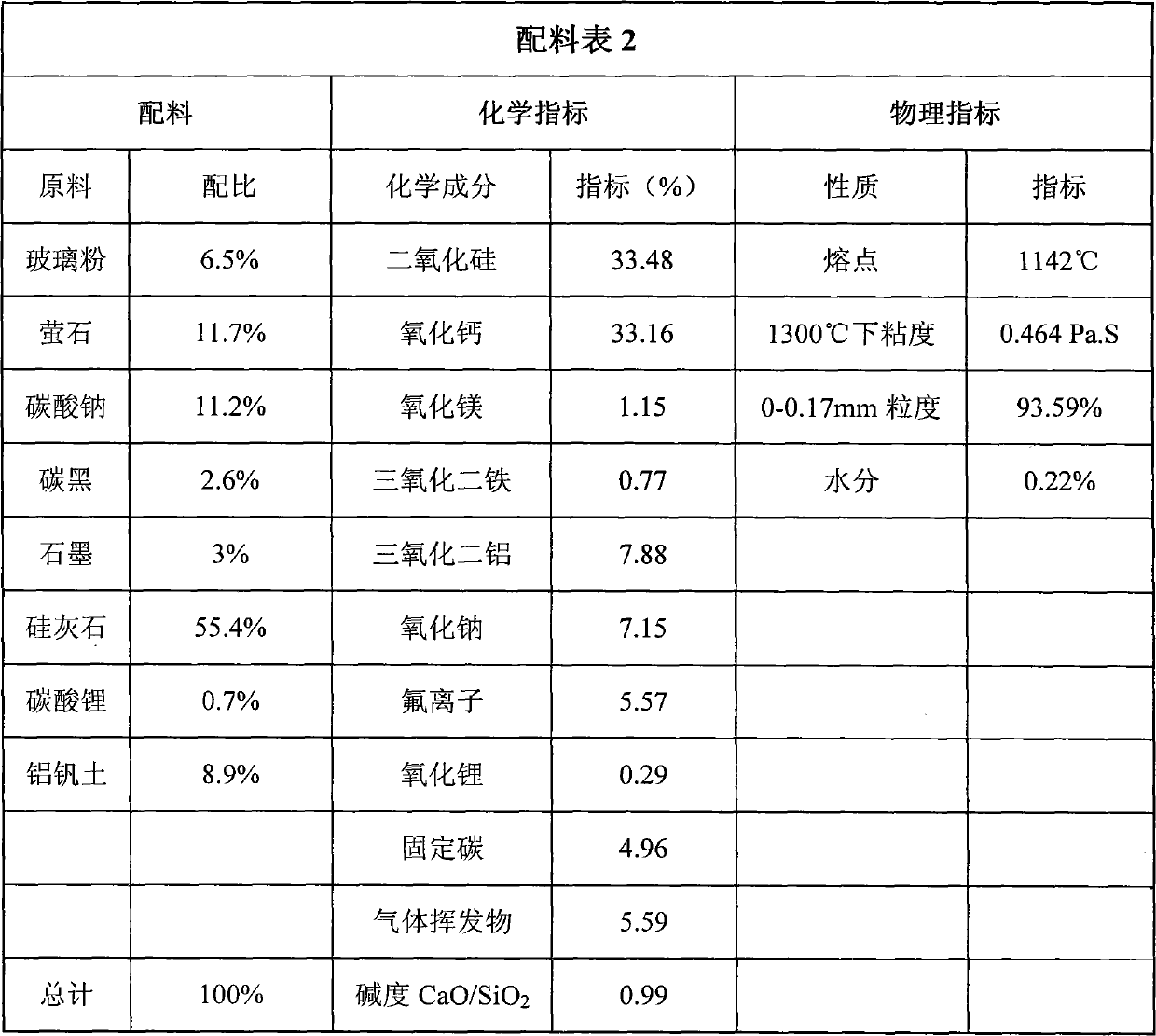

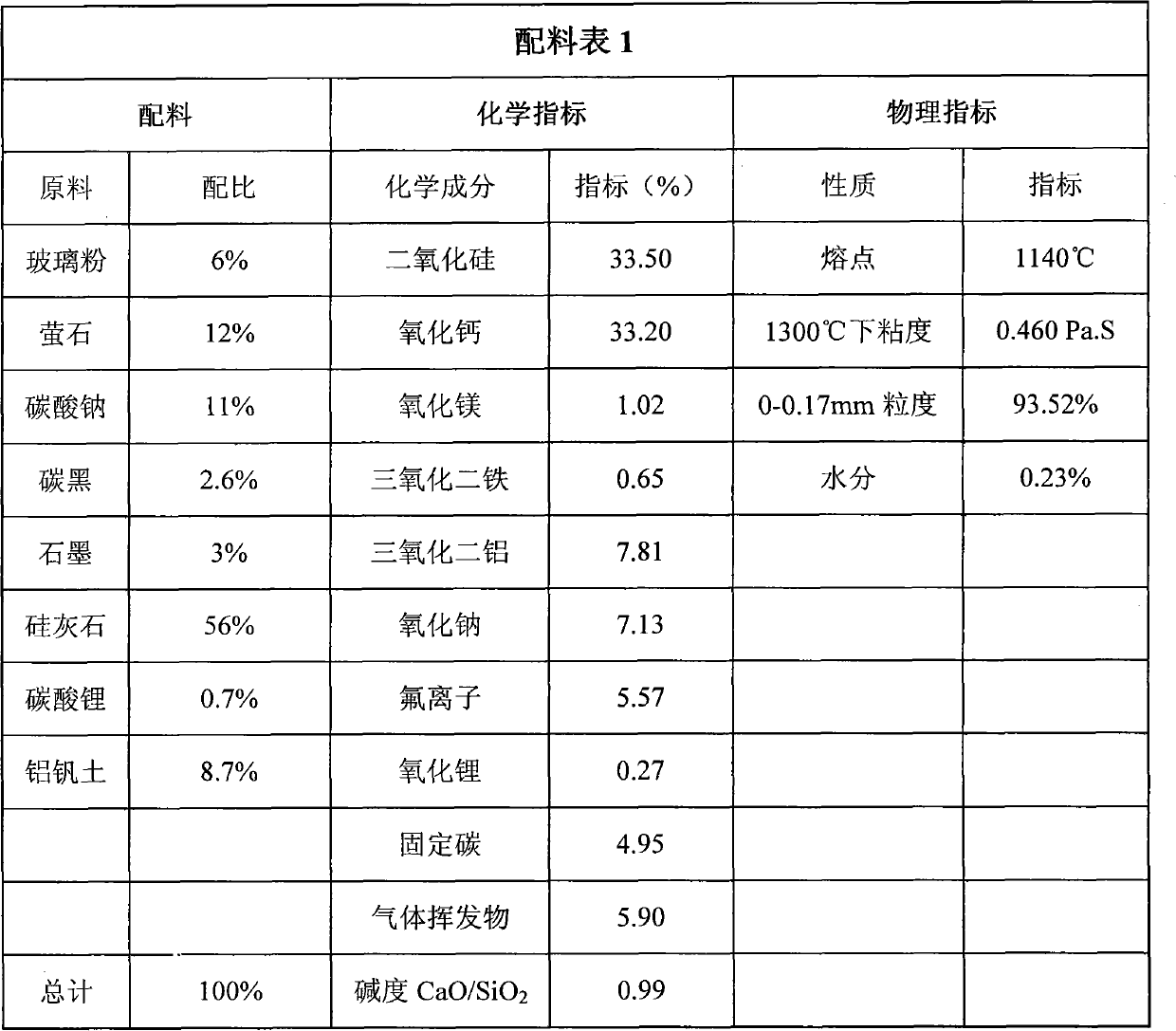

The invention discloses high-manganese high-nitrogen low-nickel stainless steel plate blank continuous casting crystallizer covering slag which comprises the following components in percentage by weight: 54-57% of wollastonite, 9-13% of fluorite, 9-13% of sodium carbonate, 0-1% of lithium carbonate, 5-7% of glass dust, 8-12% of vanadine soil, 2.5-2.7% of soot carbon and 3-3.5% of graphite, and comprises the chemical components in percentage by weight: 31.9-34.9% of calcium oxide, 32.1-35.1% of silicon dioxide, 7.3-8.3% of aluminium oxide, 0.5-1.5% of magnesium oxide, 0.5-1.4% of iron sesquioxide, 4.4-6.4% of fluorion, 6.5-7.5% of sodium oxide, 0-0.39% of lithium oxide, 4.5-6.0% of fixed carbon and 4-7% of gas volatile matters. The alkalinity of the covering slag, namely the ratio of CaO to SiO2, is 0.91 to 1.00, the melting point of the covering slag is 1100 DEG C to 1160 DEG C, and the viscosity of the covering slag is 0.3 to 0.6 Pa.s at 1300 DEG C. The invention can solve the problems of easy crusting, slag entrainment, slag inclusion, slag sticking on casting blank surfaces, bubbles under skins, cracks, deep chatter mark, felting, bleed-out, and the like of the covering slag in the crystallizer during high-manganese high-nitrogen low-nickel stainless steel plate blank continuous casting, and has the advantages of uniform and stable slagging in the crystallizer, good casting blank quality, difficult felting and bleed-out, and the like.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

Method for increasing flaw detection yield of continuous casting sheet head billet and tail billet

ActiveCN103586433AImprove internal qualityImprove the qualified rate of flaw detectionMetallurgyContinuous casting

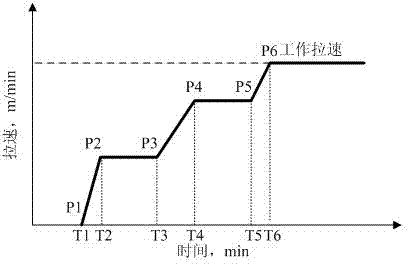

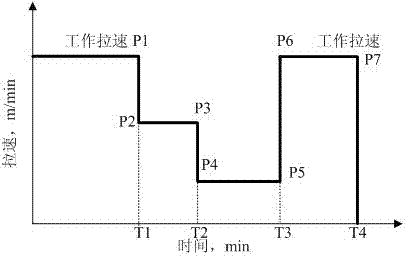

The invention discloses a method for increasing the flaw detection yield of a continuous casting sheet head billet and a tail billet. The flaw detection yield of the head billet and the tail billet is increased by improving internal quality of casting billets in the casting process and after the casting stopping process and optimizing technological operation. According to the method, through technological optimization and control under the unstable state condition, the internal quality of the head billet and the internal quality of the tail billet are improved, and then the flaw detection yield of steel sheets is increased. The method is suitable for the field of sheet billet continuous casting, and has significant economical value and practical significance in improving the quality of the casting billets under the continuous casting billet unstable state condition, and especially in improving the quality of variety steel and the material yield.

Owner:NANJING IRON & STEEL CO LTD

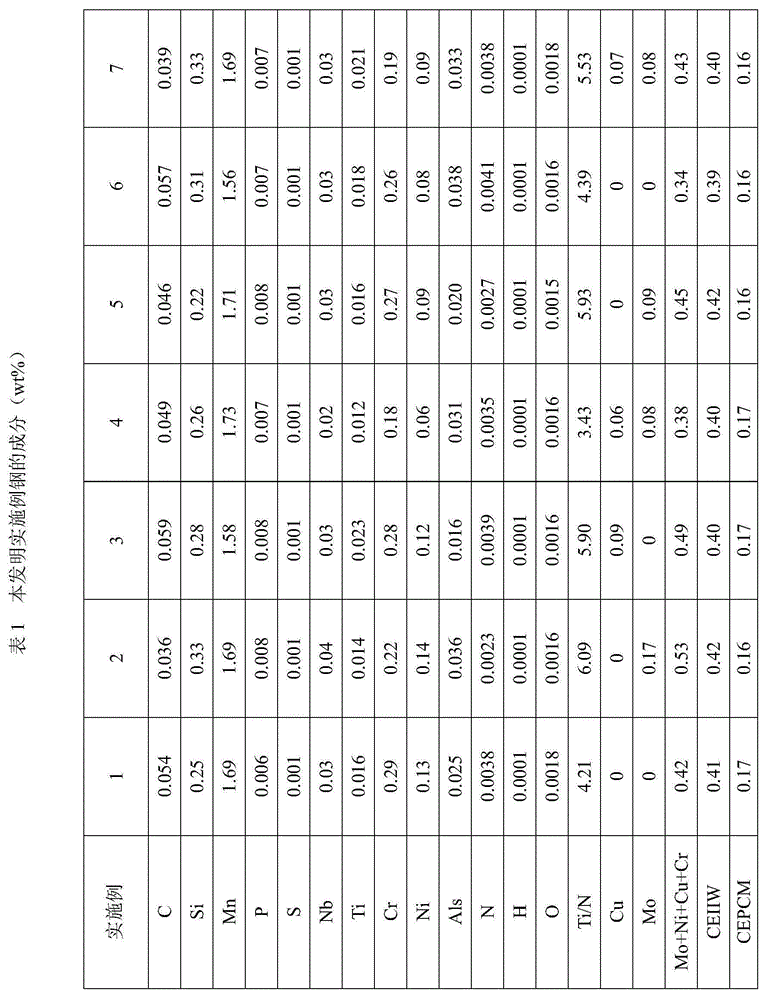

High-toughness and low-yield-ratio hot-rolled thick plate for cold-resistant pipeline and production method of high-toughness and low-yield-ratio hot-rolled thick plate

The invention provides a high-toughness and low-yield-ratio hot-rolled thick plate for a cold-resistant pipeline and a production method of the high-toughness and low-yield-ratio hot-rolled thick plate. The steel plate comprises the following components in percentage by weight: 0.045%-0.070% of C, 0.26%-0.39% of Si, 1.35%-1.55% of Mn, 0.01%-0.03% of Nb, 0.011%-0.019% of Ti, 0.18%-0.28% of Cr, 0-0.10% of Ni, 0-0.14% of Cu, 0.25%-0.44% of (Cr+Ni+Cu), 0.020%-0.045% of Als, 0.0020%-0.0045% of N, less than or equal to 0.010% of P, less than or equal to 0.001% of S, less than or equal to 0.00015% of H, less than or equal to 0.0020% of O, 3.42-5.71 of Ti / N and the balance of Fe and unavoidable impurities; and W is controlled at 0.355%-0.385%, and CEPcm is controlled at 0.155%-0.175%. The production method comprises molten iron pretreatment, converter smelting, external refining, casting blank reheating, continuous casting, rolling, relaxation and cooling. The invention provides a raw material suitable for manufacturing a large-thickness-wall steel pipe of a cold-resistant pipeline in a low-temperature area, and the raw material is excellent in comprehensive performance.

Owner:ANGANG STEEL CO LTD

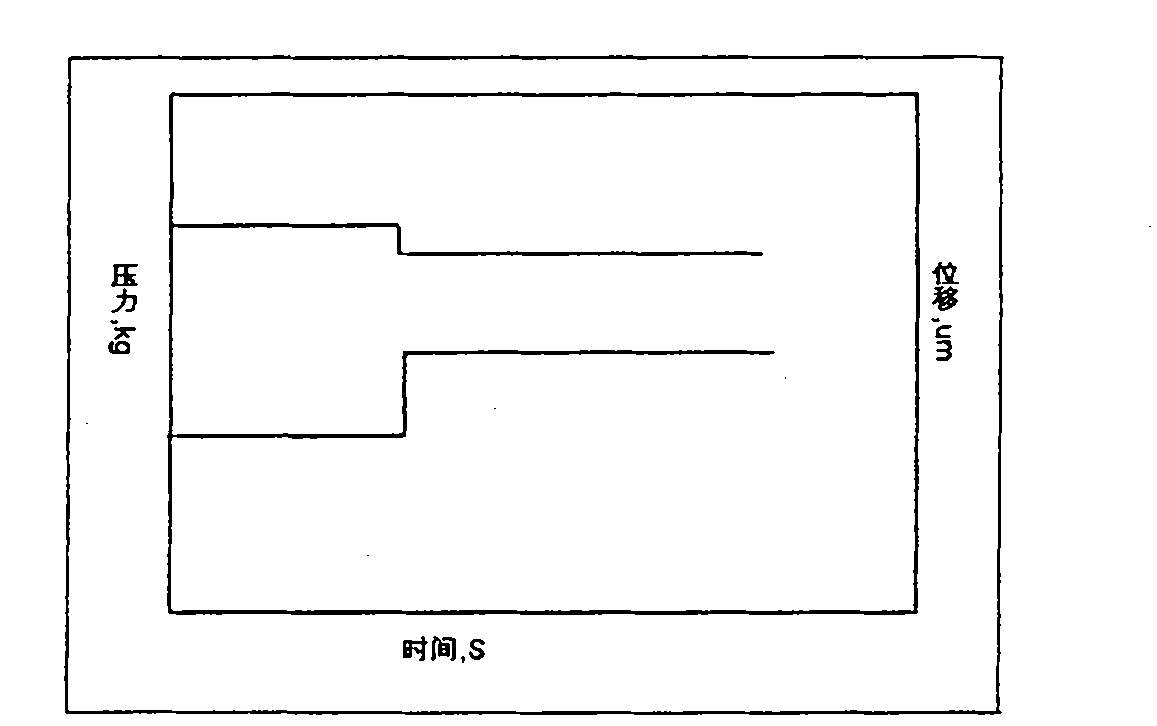

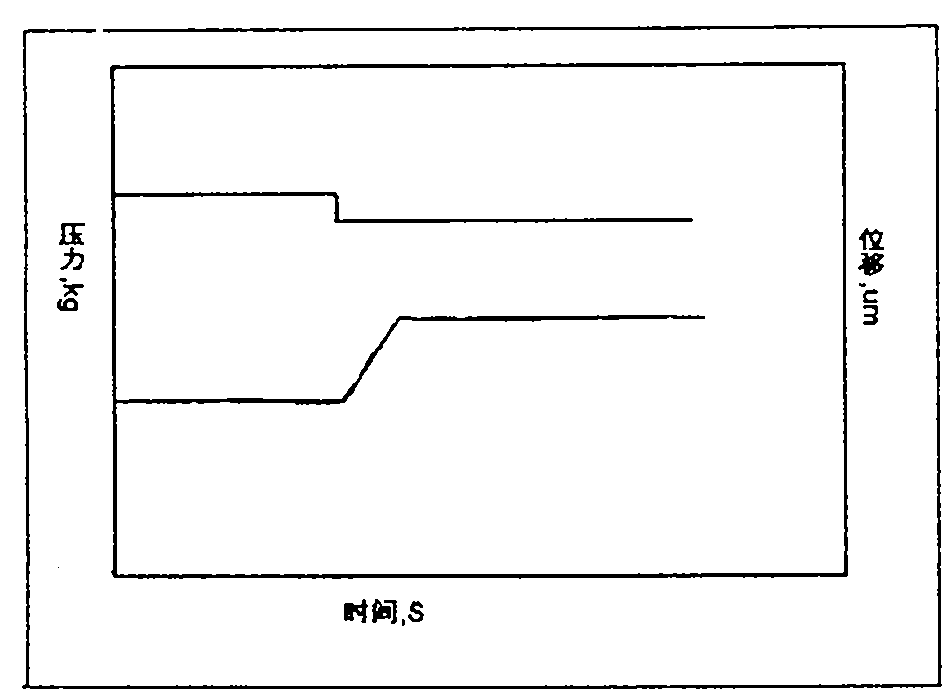

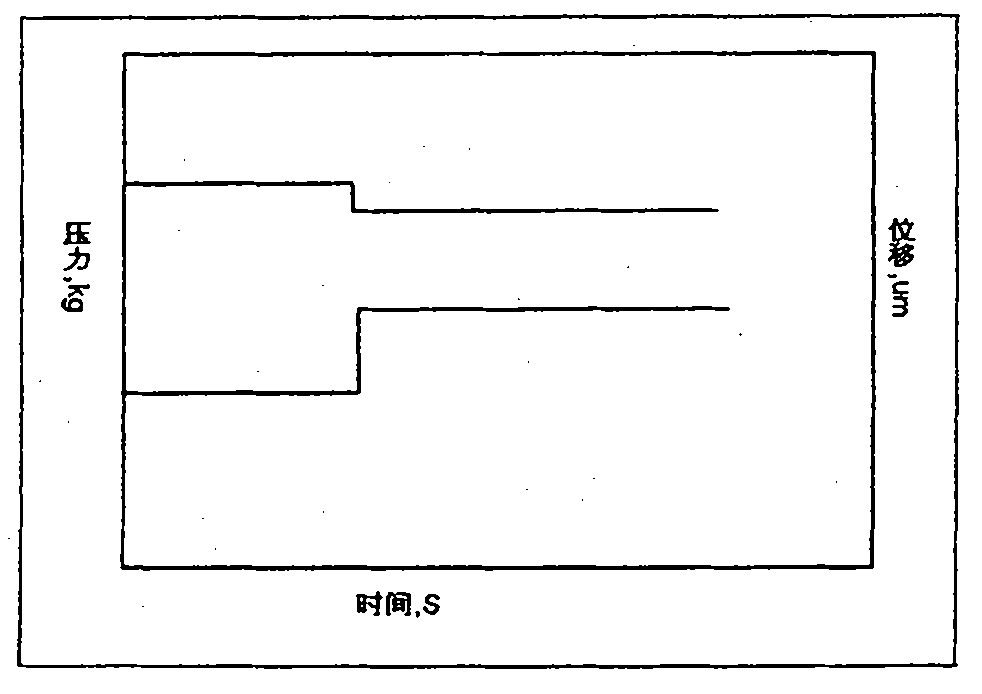

Dynamic soft reduction method for detecting tail end of solidified liquid core of casting blank based on pressure feedback

The invention relates to a dynamic soft reduction method for detecting the tail end of a solidified liquid core of a casting blank based on pressure feedback, belonging to the technical field of metallurgy continuous casting control. The method comprises the following steps of: firstly, establishing a control platform for remotely and automatically adjusting roll gaps of all sector sections on a continuous casting machine, and calculating the stress of the casting blank in different sector sections by utilizing the detection result of pressure sensors installed on all the sector sections; detecting the stress difference of the casting blank in each sector section during roll gap variation by changing the roll gap contraction size of each sector section; judging the position of the tail end of the solidified liquid core of the casting blank according to the stress difference between the casting blank with the liquid core and the casting blank without the liquid core; and finally, dynamically adopting different reduction quantities in all sector sections of a casting machine by using a soft reduction control system according to the position of the tail end of the liquid core judged by the method. The method for judging the tail end of the solidified liquid core of the casting blank is directly obtained by calculating the real-time stress of the casting blank. Because the calculation of casting blank surface temperature and blank shell thickness does not need a large quantity of mathematical models, the calculation method is simple and effective and ensures the stability and the execution efficiency of a casting machine control system.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

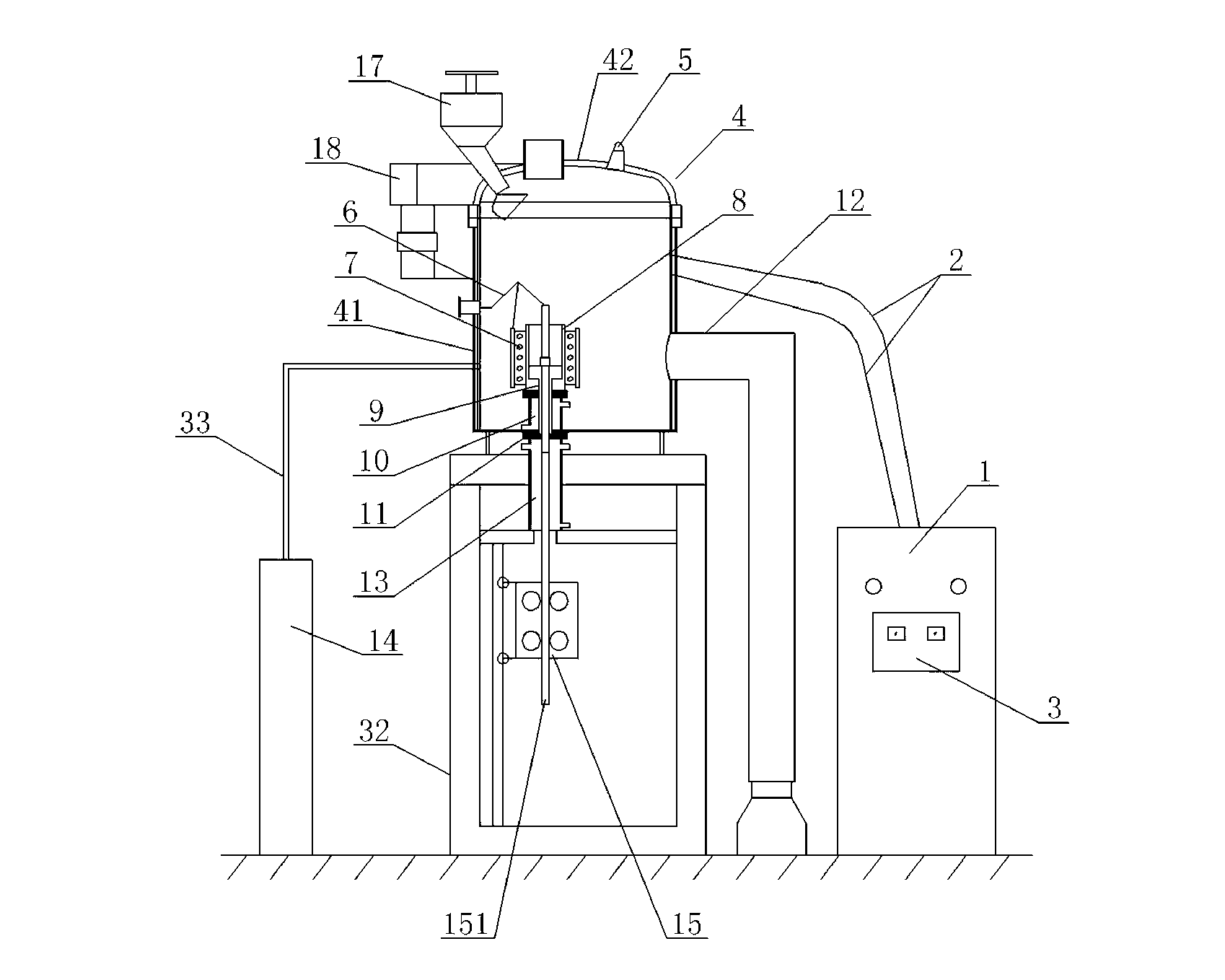

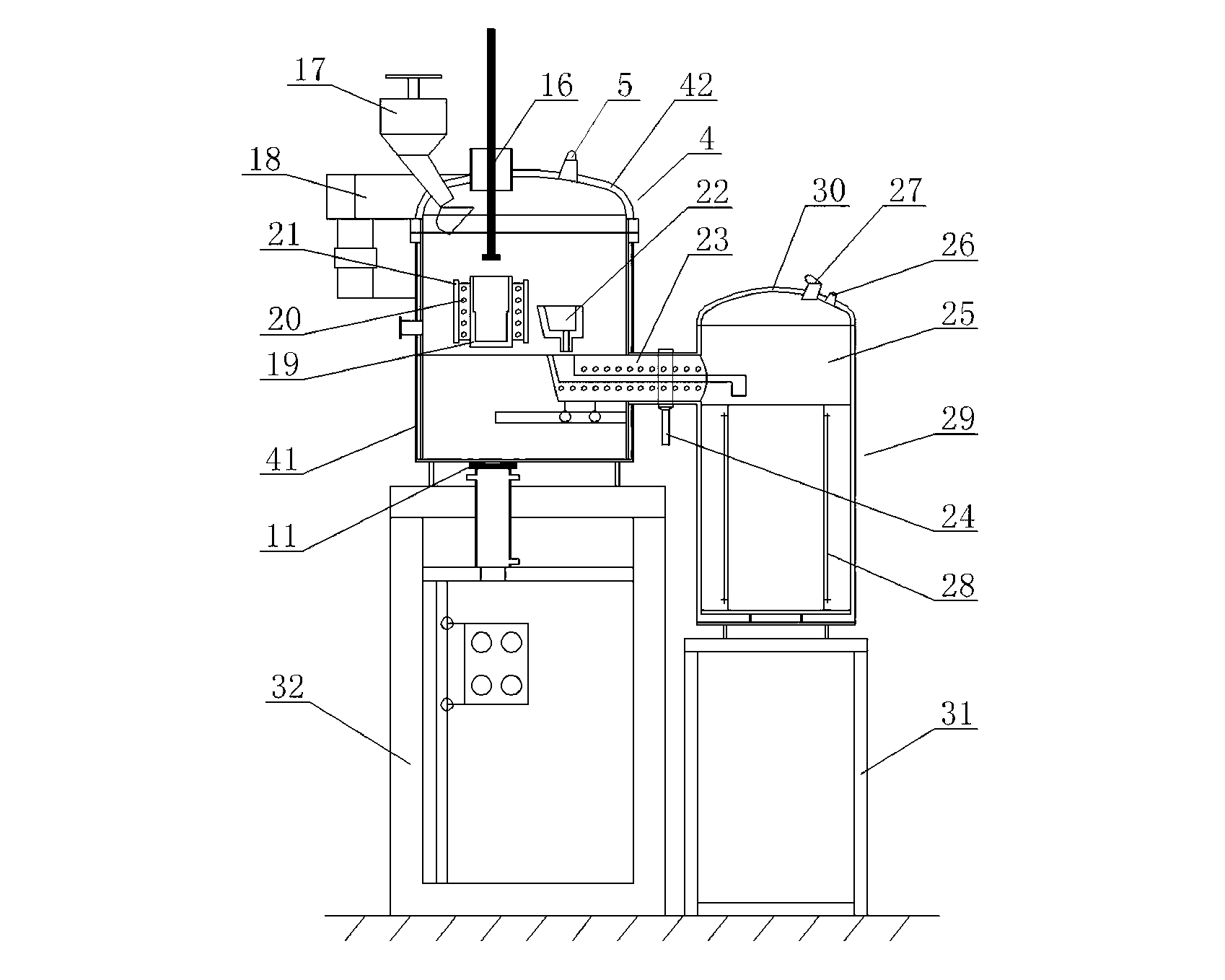

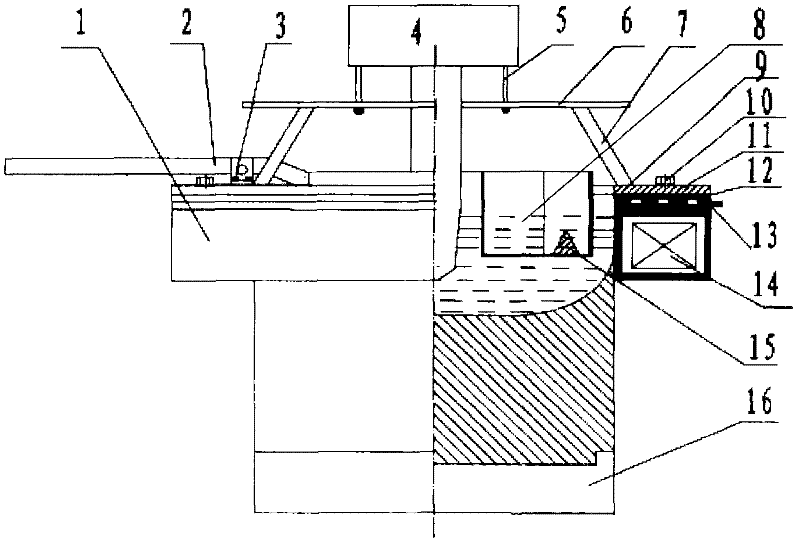

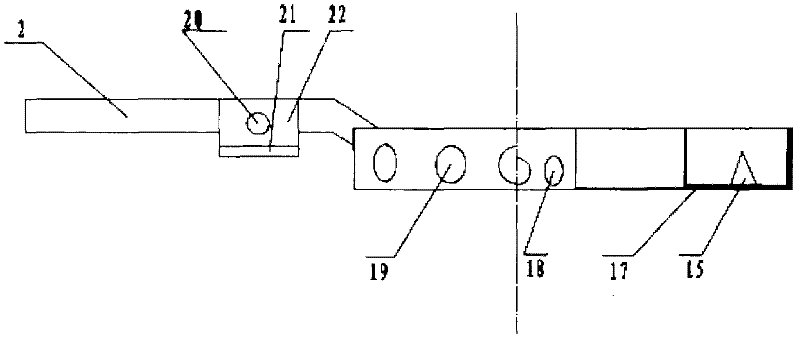

Multipurpose vacuum casting device

ActiveCN103170596AImprove liquidityAchieve oxidation inclusionsIncreasing energy efficiencyFailure rateVacuum pumping

A multipurpose vacuum casting device comprises a smelting furnace and a set of vacuum pumping system communicated with an inner cavity of the smelting furnace. The smelting furnace is provided with a casting pull-down continuous casting molding system which is formed together with the smelting furnace, a vacuum smelting system used for melting metal and a vacuum casting system used for ingot casting molding. Due to adoption of only one set of vacuum pumping system and one smelting furnace, a plurality of purposes such as vacuum induction heating smelting, vacuum casting, vacuum smelting and continuous casting under protection of inert gas can be achieved, the number of device components is greatly reduced, structure of a device is simplified, manufacture cost of the device is decreased to a large extent, production efficiency and casted blank quality are improved, operation is convenient and failure rate of the device is reduced.

Owner:GUANGDONG INST OF NEW MATERIALS

High-viscosity continuous casting protective slag for solving slag inclusion on surface of low-carbon steel

The invention discloses high-viscosity continuous casting protective slag for solving slag inclusion on the surface of low-carbon steel. The protective slag comprises the following raw materials by weight percent: 0%-7% of glass powder, 50%-70% of premelting material, 5.5%-8.5% of fluorite, 4%-8% of dietary alkali, 3% of N330 carbon black, 3.5% of graphite, 0%-3% of R agent, 0.5-2% of lithium carbonate, 2%-5% of manganese carbonate, 2%-5% of magnesite, 3%-7% of bauxite, 1%-3% of cryolite, 1%-3% of adhesive, and 0.3%-1% of water-reducing agent. By utilizing the high-viscosity continuous casting protective slag, mainly on the basis of CaO and SiO2, a certain amount of fluxing agents such as the lithium carbonate, the fluorite, the dietary alkali and the like and a certain amount of carbon materials such as carbon black and graphite are externally added, thus the viscosity is improved and the surface tension is increased; and under the same technique condition, slag inclusion on the surface of a steel billet can be effectively prevented.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

Novel corrosion-resistant alloy steel continuous casting powder and application thereof

The invention relates to novel corrosion-resistant alloy steel continuous casting powder and application thereof, and belongs to the technical field of continuous casting of iron and steel. The casting powder comprises the following components in mass percentage: 17 to 25% of CaO, 23 to 31% of SiO2, 10 to 15% of Al2O3, 1 to 4% of MgO, 10 to 14% of (Na2O+Li2O), 1 to 8% of B2O3, 1 to 6% of TiO, 4 to 8% of BaO, and 10 to 13% of F<->. The casting powder has the characteristics that the melting point is small (865-988 DEG C), the viscosity is small (0.11-0.23Pa.s under 1,300 DEG C), the crystallizing rate is moderate (40-70%), etc. The casting powder can be applied well to the continuous casting of corrosion-resistant alloy steel (Fe-Cr-Ni system) containing 0 to 0.3% of Al and 0.8 to 1.1% of Ti in mass percentage.

Owner:CENT SOUTH UNIV

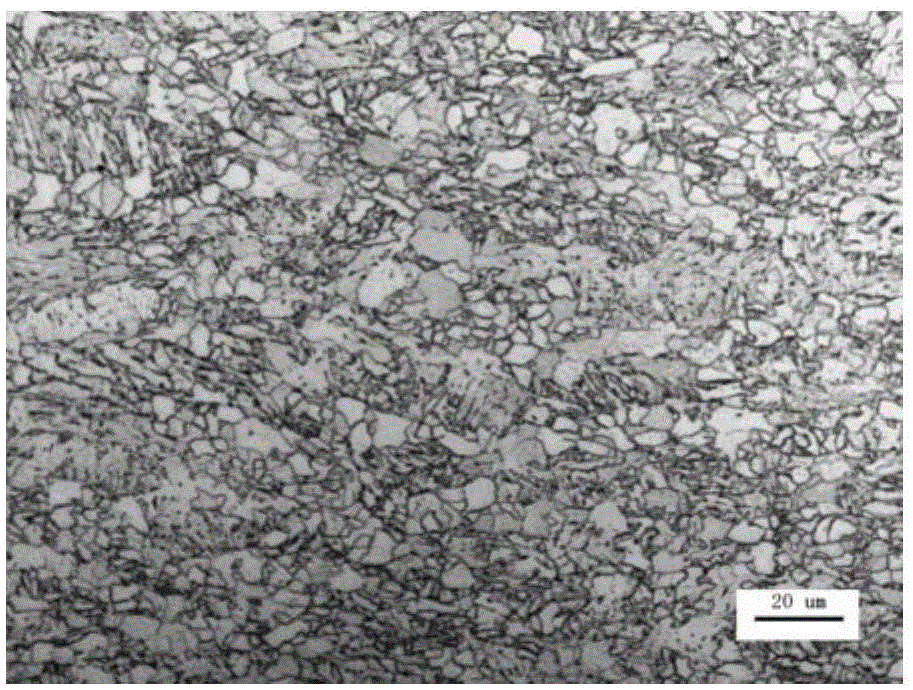

Hot-rolled wide and thick plate with good ductility and toughness for low temperature pipelines and manufacturing method thereof

The invention provides a hot-rolled wide and thick plate with good ductility and toughness for low temperature pipelines and a manufacturing method thereof. The steel plate comprises the following components in percentage by weight: 0.035 to 0.060% of C, 0.20 to 0.35% of Si, 1.56 to 1.74% of Mn, 0.01 to 0.04% of Nb, 0.011 to 0.025% of Ti, 0.18 to 0.30% of Cr, 0.06 to 0.15% of Ni, 0.015 to 0.040% of Als, 0 to 0.10% of Cu, 0 to 0.19% of Mo, 0.0020 to 0.0045% of N, not more than 0.009% of P, not more than 0.001% of S, not more than 0.0015% of H, not more than 0.0020% of O, and the balance being iron and inevitable impurities; wherein the total percentage of Mo, Ni, Cu, and Cr is in a range of 0.32 to 0.55%, and the ratio of Ti and N is in a range of 3.42 to 6.10. At the same time, CEIIW is controlled in a range of 0.385 to 0.430%, and CEPcm is controlled in a range of 0.159 to 0.175%. The manufacturing method comprises steps of molten iron pretreatment, converter smelting, external refining, continuous casting, casting blank reheating, rolling, and cooling. The provided wide and thick plate can be used as a raw material to prepare large diameter (not less than 1420 mm) thick wall low temperature steel pipelines, and the ductility and toughness are good.

Owner:ANGANG STEEL CO LTD

Continuous casting method of sulfur-containing easy-cutting pinion steel

The invention discloses a continuous casting method of a sulfur-containing easy-cutting pinion steel, belonging to the technical field of ferrous metallurgy and solving the problems of low pulling rate and output influence when qualified sulfur-containing easy-cutting pinion steel is produced in the prior art. The continuous casting method of the sulfur-containing easy-cutting pinion steel comprises the following steps of: a, injecting molten steel with the superheat degree of 15-30 DEG C into a crystallizer of a continuous casting machine charged with covering slag for cooling so as to obtain a continuous casting billet, and controlling the using amount of cooling water and the intensity of electromagnetic stirring; and b, pulling the continuous casting billet out of the crystallizer obtained from the step a, sequentially cooling through a secondary cooling zone and an air cooling zone, wherein the pulling rate is 1.3-1.8 m / minute, and the surface temperature of the continuous casting billet is controlled at 1000-1150 DEG C in the secondary cooling zone and controlled at 900-1050 DEG C when entering the air cooling zone. The continuous casting method disclosed by the invention ismainly used for the continuous casting of pinion steel with the section of 200*200 mm.

Owner:PANZHIHUA IRON AND STEEL +2

Device and process for internal and external cooling continuous casting of magnesium alloy and aluminum alloy ingot blanks

InactiveCN102430732AQuality improvementIncreased cooling rate in the middleIngot castingContinuous casting

The invention discloses continuous casting equipment and a continuous casting method for magnesium alloy and aluminum alloy ingot blanks. The continuous casting equipment comprises a mold and a dummy ingot block, a liquid level control lever, an internal cooling device, an oil way lubricating system and a split plate are further arranged in the continuous casting equipment, the internal cooling device comprises an internal cooling core pipe, an internal cooling head, a water inlet pipe, a sealing ring, a vibration head, an eccentric wheel, a variable-speed motor, a shell, a water outlet pipe,a spring and the like, the eccentric wheel is driven by the variable-speed motor, the upper end of the vibration head is connected with the eccentric wheel, the lower end of the vibration head and the upper end of the internal cooling head are fixedly connected into a whole and placed in a slide way defined by an upper plate and a lower plate, and the water inlet pipe is communicated with the internal cooling core pipe, an inner cavity of the internal cooling head and the water outlet pipe. When the continuous casting equipment for the magnesium alloy and aluminum alloy ingot blanks is operated, the internal cooling head of the internal cooling device is placed in the middle of a cast ingot to cool the center of the cast ingot, and accordingly, the quality of the center of the cast ingot is improved remarkably.

Owner:NORTHEASTERN UNIV

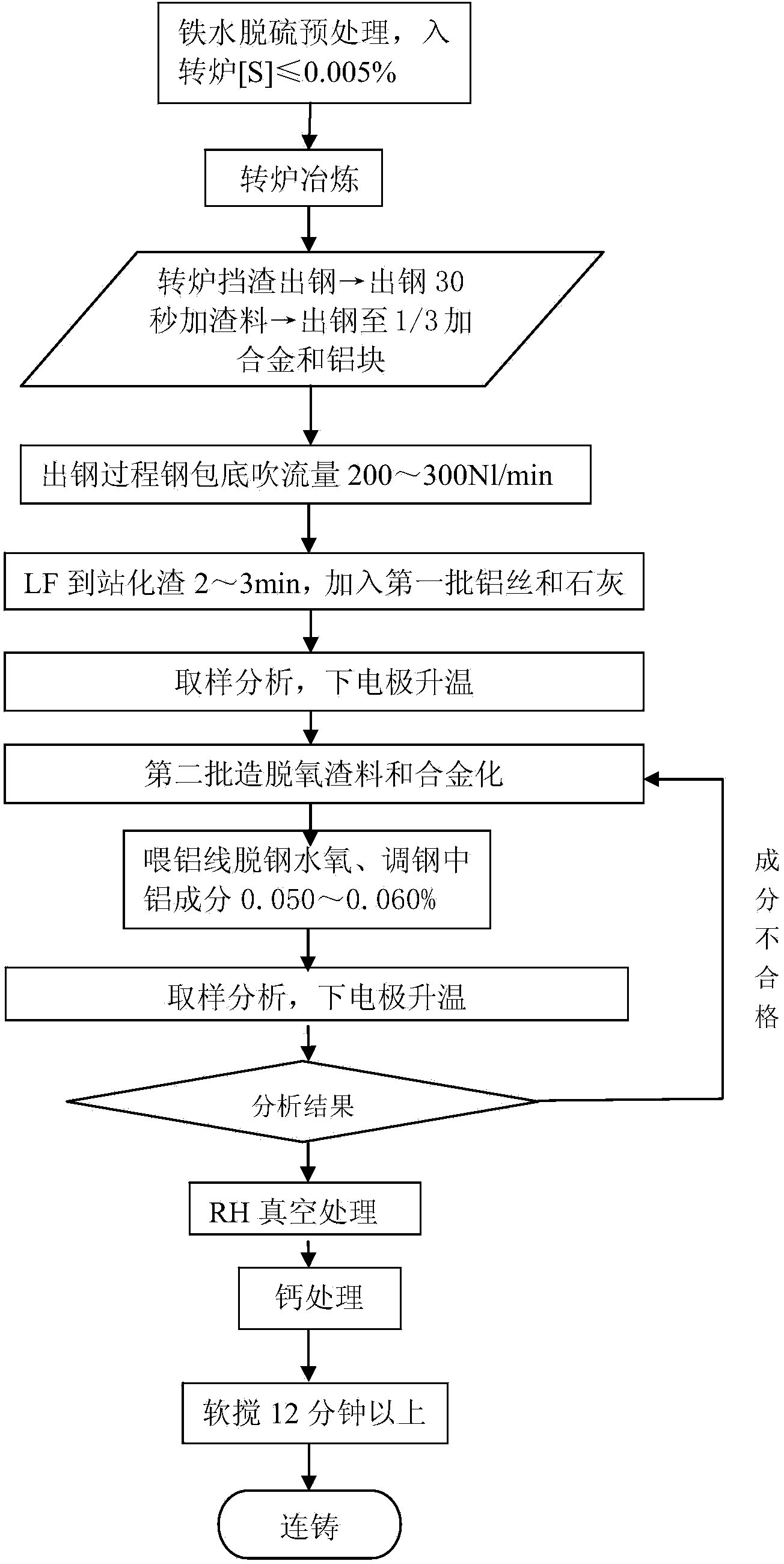

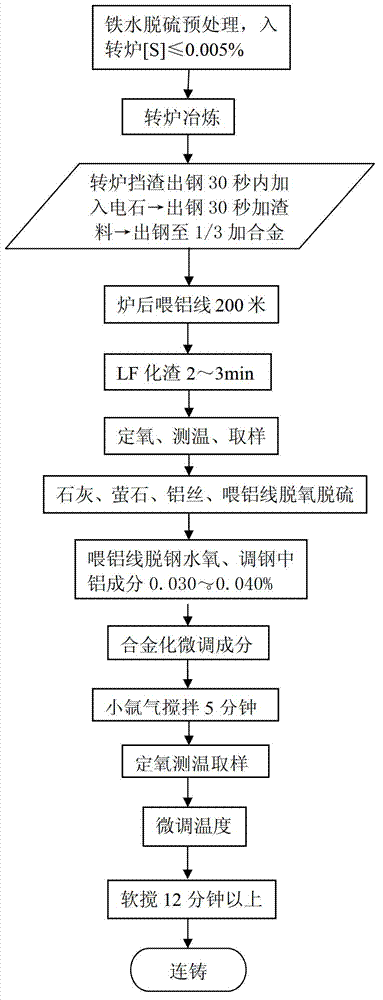

Ultralow sulfur steel quick smelting method

ActiveCN103898269AObvious slag desulfurization effectStable controlManufacturing convertersSmelting processMolten steel

The invention discloses an ultralow sulfur steel quick smelting method. The difficult points of slagging, deoxidizing and desulfurating in the smelting process of the ultralow sulfur steel ([S] is not more than 0.0010%) are successfully solved. The method comprises the following steps: pretreating molten steel to desulfurate and remove slag, deeply deoxidizing tapping aluminum block through a converter, modifying composite refined top slag, deoxidizing aluminum wire through a LF refining furnace, slagging through lime and feeding aluminum wire to trimming aluminum molten steel, combining the whole reasonable argon bottom blowing control in the smelting process of the LF furnace, fully playing the metallurgical thermodynamics and thermodynamics and kinetics of desulfuration, organically combining the diffusion deoxidization and sediment deoxidization, sufficiently evacuating deoxidization and desulfuration potential of the slag so that the sulfur content in the molten steel within 40min can be reduced to within 0.0010% through the LF refining furnace and the full oxygen content of casting blank is controlled within 0.0010%. The sulfur content control of the molten steel is stable, the casting blank is good in quality, the steel plate flaw detection yield can achieve above 99%, the ultralow sulfur steel production requirement is completely satisfied, and the smelting production rhythm and the continuous casting pouring furnace are guaranteed.

Owner:NANJING IRON & STEEL CO LTD

Continuous casting crystallizer casting powder for large circular blank abrasion resisting high manganese steel

The invention discloses continuous casting crystallizer casting powder for large circular blank abrasion resisting high manganese steel. According to the continuous casting crystallizer casting powder for the large circular blank abrasion resisting high manganese steel, cracks are reduced by adopting low carbon amount and high viscosity, reducing thermal stress inside blank shells and increasing powder consumption amount. The alkalinity of the casting powder is 0.8-1.1, the cracks caused by uneven heat transmission are avoided; through the adoption of 8-12% of Na2O, 6-8% of F- and 3-4.5% of Li2O, weak coldness and even heat transmission of the upper portion in a crystallizer are achieved, inclusion absorbing effects are improved, and the cracks are reduced; through the adoption of 2-8% of MnO, lattice vibration and conduction heat transmission are weakened, and the crystallization properties of the casting powder and the casting blank quality are improved. Raw materials of the continuous casting crystallizer casting powder for the large circular blank abrasion resisting high manganese steel are easy to obtain, and production cost is low. Through field testing, the casting power is good in spreadability and good in air permeability and can be smelted stably and be free of caking, the consumption amount of the casting powder is around 0.3-0.42kg per ton of steel, the consumption cost is relatively low, and the qualified rate of the first grate casting blanks is improved significantly.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

Method for producing 65Mn hot rolled steel plate

InactiveCN101773930AImprove product qualityUniform tissue performanceMetal rolling arrangementsContinuous rollingSmelting

The invention discloses a method for producing a 65Mn hot rolled steel plate, which comprises the steps of smelting, refining, thin slab casting, soaking, high pressure water descaling, hot continuous rolling, cooling and reeling based on the process of thin slab casting and rolling. The molten steel superheat temperature is T superheat (30 DEG C <T superheat < / = 45 DEG C), the charging temperature of casting blanks is T charging (900 DEG C < / = T charging < / = 1050 DEG C), the final rolling temperature is T final (850 DEG C < / = T final < / = 950 DEG C), the reeling temperature is T reeling ( 550 DEG C < / = T reeling < / = 650 DEG C), the liquid core pressure of casting blanks is L pressure (2 < / = L pressure < / = 20mm), and the depth of a single-surface decarburized layer is 0.3 to 0.9 percent of the depth of the steel plate. The chemical constitutes of molten steel after being alloyed in a refining process comprise 0.62-0.70 wt.% of C, 0.17-0.37 wt.% of Si, 0.90-1.20 wt.% of Mn, less than or equal to 0.035 wt.% of P, less than or equal to 0.035 wt.% of S, less than or equal to 0.25 wt.% of Cr, less than or equal to 0.25 wt.% of Ni and the balance of Fe and inevitable impurities. The 65Mn hot rolled steel plate produced in the method has the characteristics of uniform structure property, high thermal stability and high strength, and the quality of the 65Mn hot-rolled steel plate is obviously improved.

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

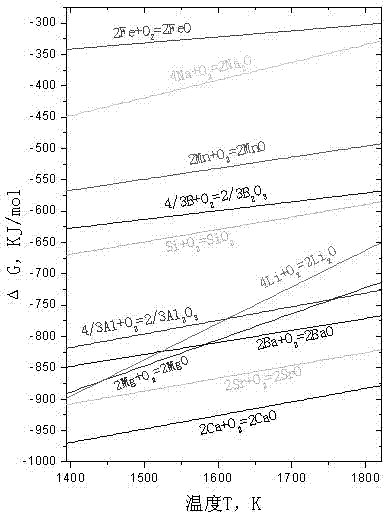

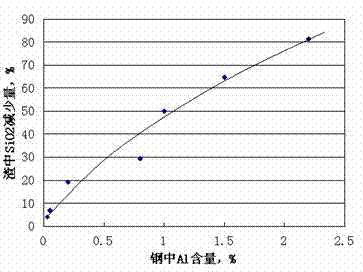

Process for smelting aluminum containing steel through calcium carbide deoxidation

ActiveCN102952923ASolve outstanding problems with high consumptionDoes not affect billet qualityManufacturing convertersSteelmakingSmelting process

The invention belongs to a steelmaking process in the metallurgy field and relates to a process for smelting aluminum containing steel through calcium carbide deoxidation without the aluminum deoxidation in the whole process. The process belongs to a production process that the converter steel tapping deoxidation system and the slagging system are optimized, aluminum wires are fed behind a converter, the aluminum in molten steel is regulated, the LF (ladle furnace) calcium carbide and aluminum wire deoxidation slagging is carried out, and in addition, the LF aluminum wire feeding is matched for finely regulating the aluminum in molten steel. The characteristics of calcium carbide and aluminum wires are utilized, and the diffusive deoxidation and the bulk deoxidation in the smelting process are fully and reasonably combined. The process has the advantages that the converter steel tapping deoxidation is stable, the LF slagging desulfurization effect is obvious, the casting blank quality is good, the flaw detection qualified rate of steel plates is high, the aluminum consumption of each ton of steel in the aluminum containing steel production is reduced by about 0.80kg, and the economic benefit of the aluminum containing steel production is greatly improved.

Owner:NANJING IRON & STEEL CO LTD

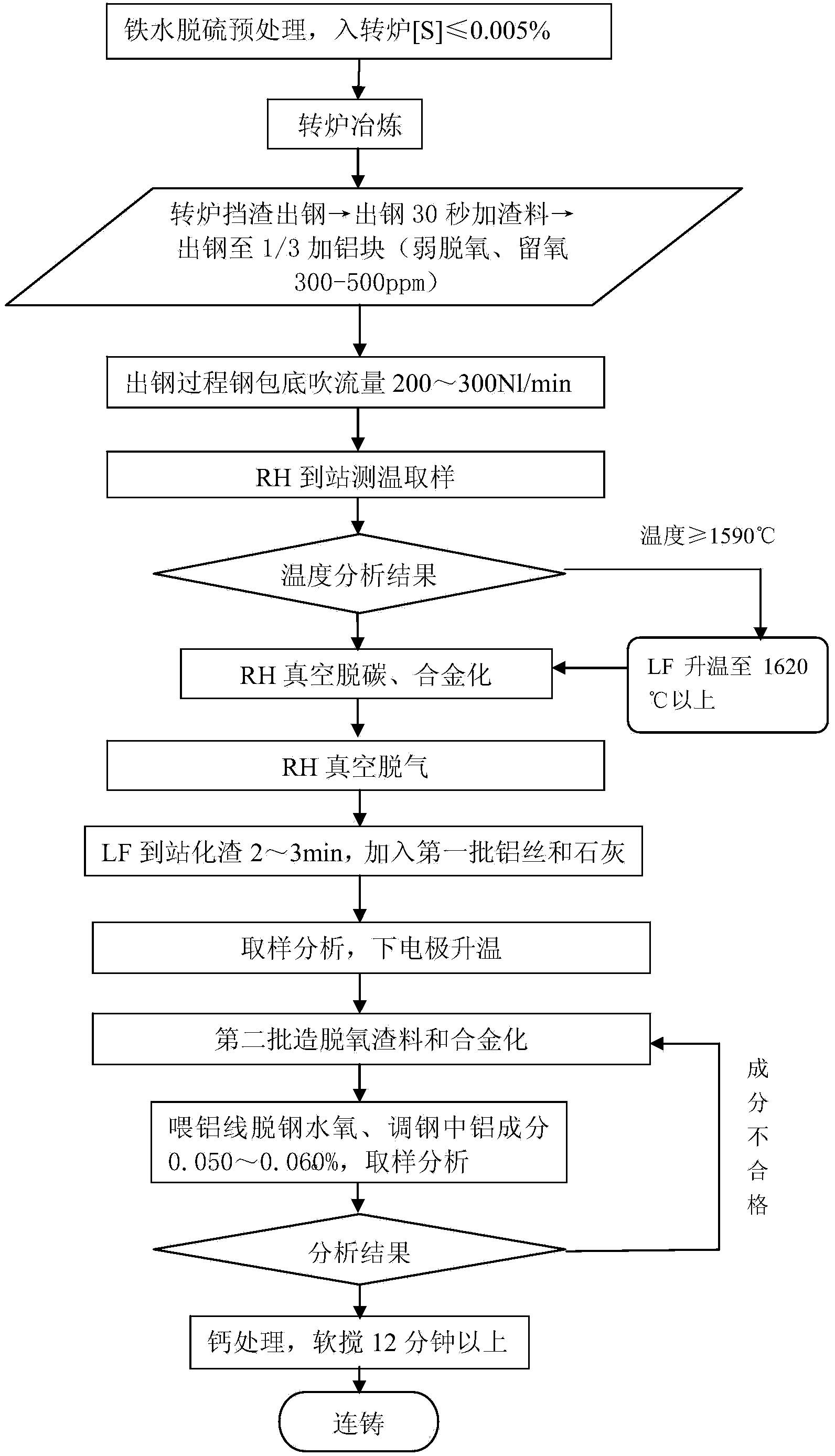

Low-carbon ultra-low sulfur steel smelting method

InactiveCN104232831AThe amount added is accurateStable flaw detection pass rateSteel manufacturing process aspectsManufacturing convertersSmelting processOxygen

The invention discloses a low-carbon ultra-low sulfur steel smelting method. The method comprises the following technological processes: pouring molten iron into a tank, pretreatment of molten iron, oxygen remaining operation of a converter, RH furnace vacuum decarburization, alloying and vacuum degassing in an RH furnace, deoxidization of aluminium yarn / aluminium wire in an LF refining furnace, slagging by using lime and CCM. Through combination of molten iron desulphurization and drossing, optimization of a converter steel tapping and oxygen remaining system and a slagging system, the vacuum decarburization, alloying and degassing control in the RH furnace, and the aluminium wire diffusing deoxidation slagging and aluminium wire sediment deoxidation in the LF furnace, deep decarburization and desulphurization are carried out. With an emphasis on combination of convertor steel tapping and oxygen remaining operations, RH deep decarburization and LF furnace deep desulphurization, technical optimization is carried out; due to reasonable ladle argon bottom blowing control in the smelting process, carbon content control and metallurgical thermodynamics and dynamics conditions of desulphurization are given a full play; the RH furnace decarburization is stable; LF furnace slagging and desulphurization and recarburization control effects are obvious; and low-carbon ultra-low sulfur steel smelting is achieved.

Owner:NANJING IRON & STEEL CO LTD

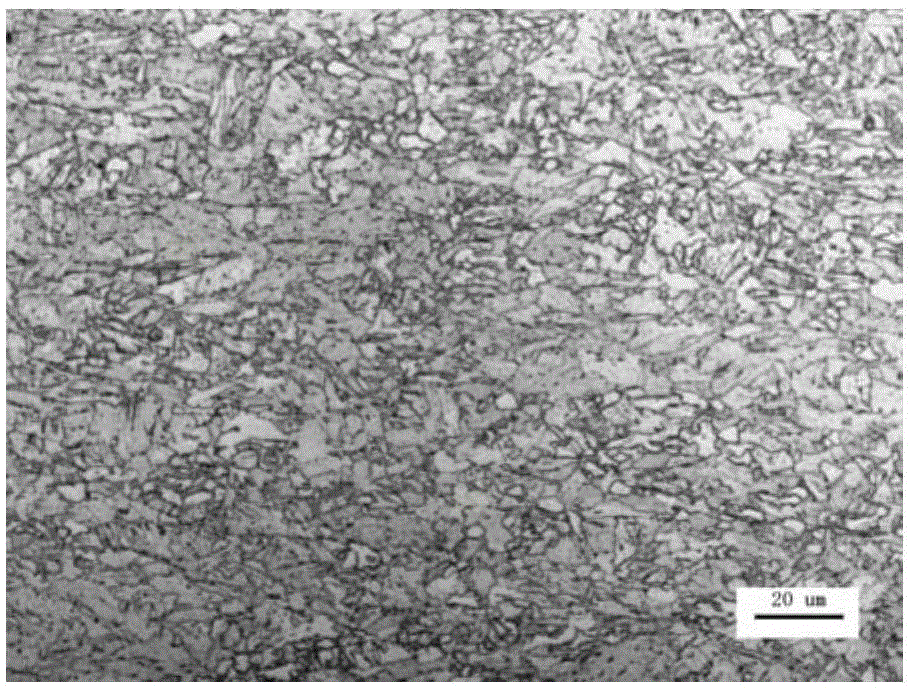

Ultra-wide high-toughness hot-rolled thick plate for low-temperature pipeline, and production method thereof

The invention discloses an ultra-wide high-toughness hot-rolled thick plate for a low-temperature pipeline, and a production method thereof. The steel is prepared from 0.030 percent to 0.055 percent of C, 0.16 percent to 0.30 percent of Si, 1.45 percent to 1.70 percent of Mn, 0.04 percent to 0.07 percent of Nb, 0.012 percent to 0.025 percent of Ti, 0.20 percent to 0.40 percent of Cr, less than orequal to 0.14 percent of Mo, less than or equal to 0.20 percent of Ni, less than or equal to 0.15 percent of Cu, less than or equal to 0.030 percent of Al, less than or equal to 0.010 percent of P, less than or equal to 0.0015 percent of S, 0.0005 percent to 0.0020 percent of O, 0.001 percent to 0.004 percent of N, 0.0010 percent to 0.0045 percent of Ca, larger than or equal to 1.8 percent of Ca / S, 0.30 percent to 0.60 percent of (Mo+Ni+Cr+Cu), and the balance Fe and inevitable impurities. The rough rolling starting temperature is 1080 to 1130 DEG C, the finish rolling temperature is 980 to 1030 DEG C, the precision rolling starting temperature is 820 to 860 DEG C, the precision rolling finish rolling temperature is 740 to 760 DEG C, the cooling speed is 8 to 15 DEG C / s, and the hot straightening speed is 0.7 to 1.2m / s. The finished product steel plate has the thickness being larger than or equal to 21mm and the width being larger than 4300mm, and has excellent low-temperature toughness.

Owner:ANGANG STEEL CO LTD

Wire rod of high-speed railroad no-slag sleeper slab steel wire and production method thereof

InactiveCN101705429AImprove mechanical propertiesImprove cooling effectManufacturing convertersWire rodTemperature control

The invention belongs to the technical field of steel and iron smelting technology, and particularly provides a high wire rod of a high-speed railroad no-slag sleeper slab steel wire and a production method thereof. The traditional single sleeper does not meet the requirements of high-speed railroad, and is upgraded into a sleeper slab. Aiming at the requirements for the wire rod of the high-speed train sleeper slab wire, the invention designs a special wire rod of a high-speed railroad no-slag sleeper slab steel wire and a manufacture method thereof. The wire rod comprises the following control components in percent by weight: 0.34-0.39% of C, 1.55-1.85% of Si, 0.75-1.00 % of Mn, 0.35-0.60 % of Cr, no more than 0.025% of P, no more than 0.025%of S, no less than 0.0008% of B and the balance of Fe. The production process of the wire rod comprises the following steps of: top-bottom blowing smelting by adopting high-quality concentrate and synthesizing of slag charge and wash during tapping; LF refining which adopts calcium carbide, carborundum and the like to form white slag; continuous casting protection pouring under the conditions that the degree of superheat is controlled in the range of 20-40 DEG C and the pulling rate is 1.9-2.8m / min; steel rolling under the conditions of controlling the tapping temperature of steel billet in the range of 950-1010 DEG C, cooling by the control of a water tank and the control of large amount wind during rolling and controlling the spinning temperature in the range of 840-860 DEG C.

Owner:TIANJIN IRON & STEEL GRP

Crystallizer protective slag for effectively controlling carbon steel cracks in compact strip production (CSP)

The invention discloses crystallizer protective slag for effectively controlling carbon steel cracks in a compact strip production (CSP). The crystallizer protective slag comprises the following chemical components in percentage by mass: 35 to 38 percent of CaO, 28 to 31 percent of SiO2, 1 to 3 percent of Al2O3, 1 to 2 percent of MgO, 0.5 to 1.5 percent of Fe2O3, 10 to 11.5 percent of F, 9 to 11.5 percent of Na2O, 1.5 to 3.5 percent of MnO, 5 to 8 percent of fixed carbon, and the balance of inevitable trace elements. Through the crystallizer protective slag for controlling the carbon steel cracks in the CSP, the alkalinity is improved by 0.04 to 0.09, the alkalinity is controlled to be 1.20 to 1.25, the constraint that the alkalinity cannot be more than 1.16 in the field is broken, the viscosity is controlled to be 0.08 to 0.09Pa.S, and the melting point is from 1,155 to 1,185 DEG C; capabilities of dissolving and absorbing inclusions are improved, and heat transfer is retarded by reducing a vitreous body, so that an aim of reducing longitudinal cracks is fulfilled; and by adjusting the proportioned carbon and controlling the thickness of a liquid slag layer, bonding steel leakage caused by high crystallization temperature and deteriorated lubricating performance due to over high alkalinity of the protective slag is relieved.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

Wide and heavy steel plate for high-strength high-toughness and low-yield-ratio hot-bending bend and production method of wide and heavy steel plate

The invention provides a wide and heavy steel plate for a high-strength high-toughness and low-yield-ratio hot-bending bend and a production method of the wide and heavy steel plate. The steel plate comprises, by weight percentage, 0.055%-0.080% of C, 0.16%-0.30% of Si, 1.76%-1.95% of Mn, 0.051%-0.080% of Nb, 0.010%-0.025% of Ti, 0.09%-0.13% of V, 0.25%-0.45% of Cr, 0.20%-0.35% of Mo, less than 0.25% of Ni, less than 0.25% of Cu, 0.010%-0.035% of Al, not larger than 0.010% of P, not larger than 0.002% of S, 0.001%-0.004% of N and the balance iron and inevitable impurities, wherein (Mo+Ni+Cr+Cu) is controlled within the range of 0.6%-1.0%, CEIIW is controlled within the range of 0.50%-0.55%, and CEPcm is controlled within the range of 0.19%-0.23%. The production method includes the steps ofmolten iron pretreatment, converter smelting, external refining, continuous casting, heating, rolling, cooling and heat treatment. The microstructure of the wide and heavy steel plate is a compositestructure of bainite and ferrite, and the performance meets the requirement of manufacturing X90-grade hot-bending bends with ultra-wide and thick walls in a low-temperature environment.

Owner:ANGANG STEEL CO LTD

Metal ceramic coating on surface of copper plate of continuous casting mold and manufacturing process for metal ceramic coating

The invention discloses a metal ceramic coating on surface of a copper plate of a continuous casting mold. The metal ceramic coating is a coating obtained by performing hypersonic flame spraying on cobalt coated tungsten carbide WC-12Co powder and has the thickness of 0.2 to 0.6mm. Correspondingly, the invention also provides a process for manufacturing the metal ceramic coating on the surface of the copper plate of the continuous casting mold. The process comprises the following steps of: cleaning the surface of the copper plate of the continuous casting mold; performing shot blasting treatment on the surface of the copper plate of the continuous casting mold; spraying the cobalt coated tungsten carbide WC-12Co powder on the surface of the copper plate of the continuous casting mold by employing a hypersonic flame spraying process, wherein the hypersonic flame spraying process has the parameters of the oxygen flow of 700 to 1,000L per minute, the kerosene flow of 5.0 to 6.0 gph, the spraying distance of 300 to 400mm and the coating thickness of 0.2 to 0.6mm. The metal ceramic coating is low in porosity and high in microhardness, the adhesive strength between the coating and a matrix is high, and the wear resistance and corrosion resistance of the mold are obviously improved.

Owner:BAOSHAN IRON & STEEL CO LTD

Tinning substrate for deep-punching food can and production method thereof

The invention relates to a steel metallurgical material, in particular to a tinning substrate for deep-punching food cans and a production method thereof. The tinning substrate comprises the following chemical element compositions in percentage by weight: less than or equal to 0.04% of C; less than or equal to 0.02% of Si, 0.20-0.25% of Mn, less than or equal to 0.02% of P, less than or equal to 0.018% of S, 0.005-0.040% of Als, and the balance iron and unavoidable inclusion. The production method comprises the following processes: smelting, continuous casting, heating, hot rolling, cooling and reeling, pickling and cold rolling, and annealing and leveling, wherein the heating temperature is 1210 DEG C, the primary rolling temperature is 1100-1150 DEG C, the final rolling temperature is 890+ / -10 DEG C, the reeling temperature is 560+ / -15 DEG C, the annealing temperature is 670-690 DEG C, and others are performed as conventional processes. The invention has small production control difficulty, low cost, stable performance and high can manufacturing percent of pass, and is suitable for manufacturing deep-punching food cans and can covers with more complex transformation.

Owner:TANGSHAN GUOFENG IRON & STEEL

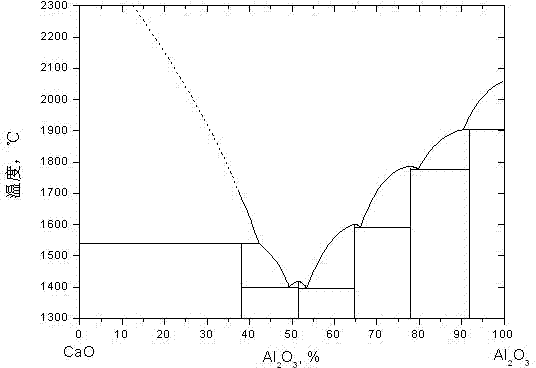

Silica-free glassy state covering slag

The invention relates to an auxiliary material for continuous casting during steelmaking, in particular to plate blank continuous casting covering slag for high aluminum steel (steel containing 2% of Al, i.e., silica-free glassy state covering slag which comprises the components in percentage by mass: 4-10% of Na2O, 3-8% of F, 2-5% of Li2O, 1-4% of MgO, 5-8% of SrO, 5-8% of BaO, 1-5% of C, impurities with the total mass not being more than 5% and the balance CaO and Al2O3, wherein CaO / Al2O3=0.82-1.33, and the sum of all the components is 100%. The melting point of the covering slag is 1000-1200 DEG C, the viscosity of the covering slag at the temperature of 1300 DEG C is 0.1-0.5Pa.s and the vitrification rate of the covering slag is not lower than 70%. By using the covering slag provided by the invention, the extent of reaction of slag steel can be greatly reduced, and the glassy state covering slag ensures the lubricating effect of a casting blank.

Owner:BAOSHAN IRON & STEEL CO LTD

Mold powder capable of effectively controlling peritectic steel thick slab narrow face depression defect

The invention relates to a mold powder capable of effectively controlling peritectic steel thick slab narrow face depression defect. The mold powder comprises the following elements by weight percent: 38.02 to 40.1 percent of Cao, 28.8 to 30.02 percent of SiO2, 9.9 to 10.5 percent of CaF2, 9.06 to 9.5 percent of Na2O, 1.55 to 1.93 percent of MgO, 1.5 to 1.93 percent of AL203, 0.01 to 0.037 percent of Li2O and 0.035 to 0.053 percent of MnO. The mold powder has good lubricating property and spreadability. Because of the high melting speed, the invention can complement the quick consumption of liquid slag in time; because of the high alkalinity, the invention has strong absorbing and mixing capability; and because of the proper viscosity and the reasonable crystallization temperature, the invention plays an important role in uniformity. When the mold powder is applied to the casting of peritectic steel thick slab, the slag entrapment defect caused by crystallizer liquid level fluctuation is reduced greatly, the heat transmission uniformity is improved greatly and the surface quality of casting blank is good.

Owner:SHOUGANG CORPORATION

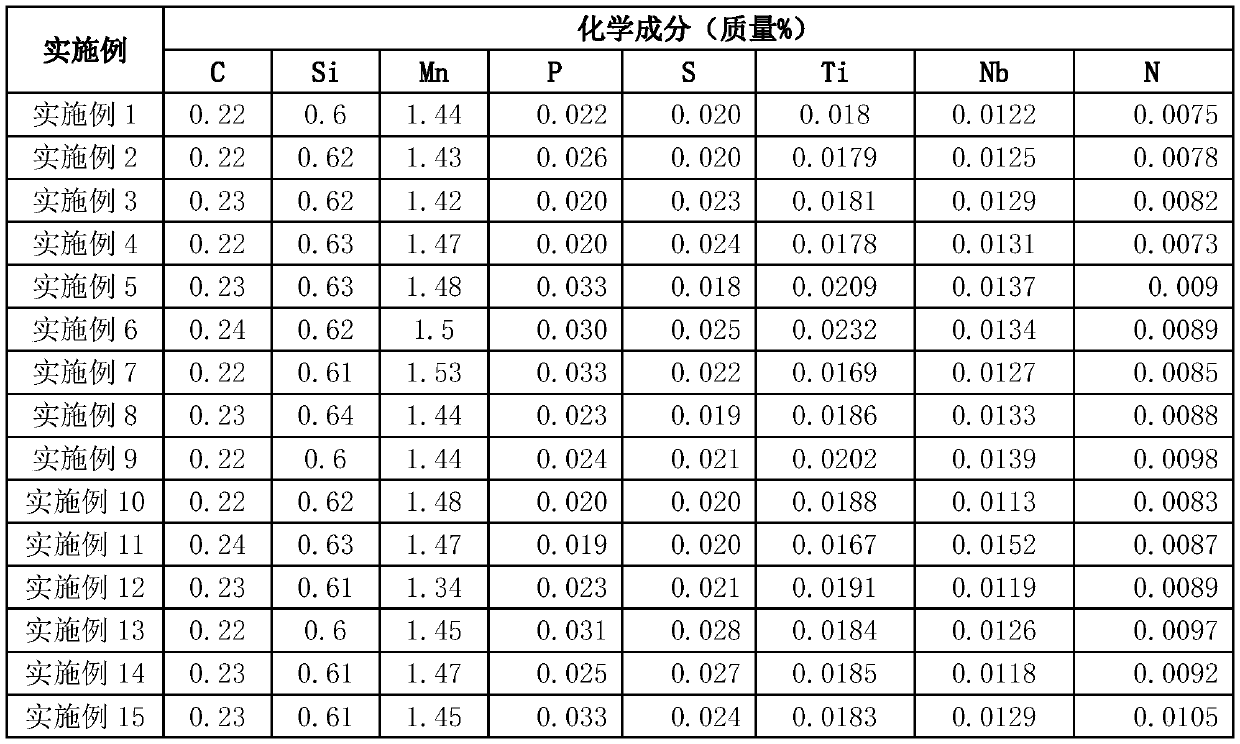

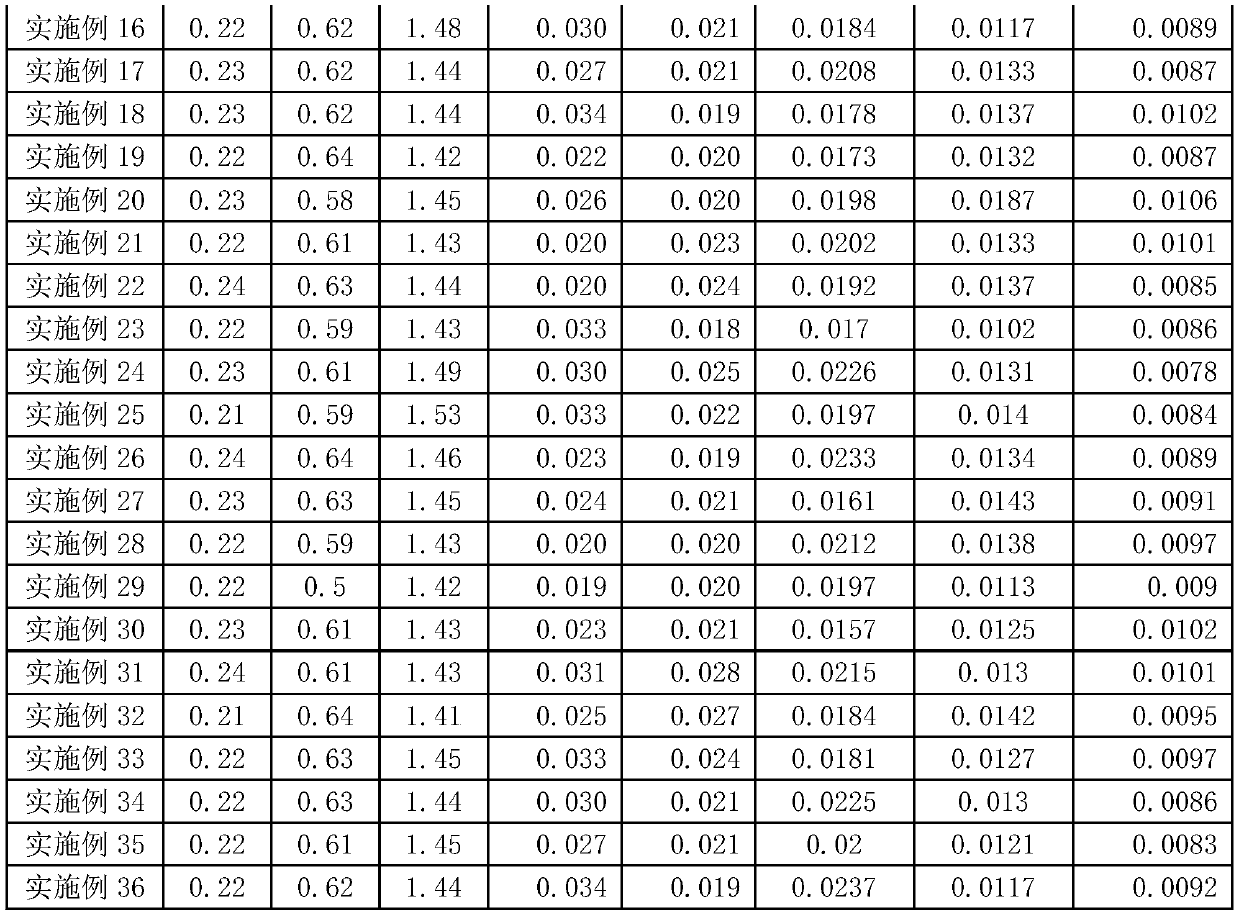

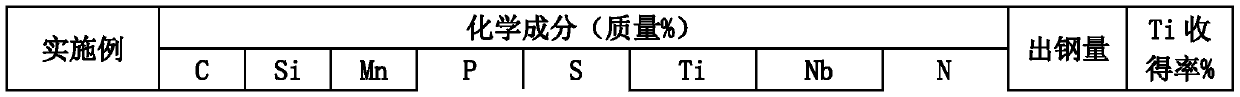

Niobium-titanium-nitrogen and titanium-nitrogen composite micro-alloyed HRB400E steel bar and production method thereof

The invention provides a niobium-titanium-nitrogen and titanium-nitrogen composite micro-alloyed HRB400E steel bar and a production method thereof, and belongs to the technical field of iron and steelsmelting. The niobium-titanium-nitrogen and titanium-nitrogen composite micro-alloyed HRB400E steel bar comprises, by mass, 0.21-0.25% of C, 0.50-0.65% of Si, 1.40-1.55% of Mn, not greater than 0.045% of P, not greater than 0.045% of S, 0.015-0.025% of Ti, 0.010-0.020% of Nb, 0.0070-0.0110% of N, and the balance Fe and other impurities. In the production method, ferrosilicon, silicomanganese anda carburant are added at the time of 1 / 4 tapping, and all alloys are added at the time of 3 / 4 tapping; the titanium-nitrogen alloy is added at an argon blowing station, and the argon blowing time is greater than or equal to 6 minutes; and high-casting-speed casting powder is adopted for continuous casting, a billet is heated, rolled and fed onto a cooling bed, and finally, the finished product isobtained. According to the niobium-titanium-nitrogen and titanium-nitrogen composite micro-alloyed HRB400E steel bar and the production method thereof, by adding the titanium-nitrogen alloy at the molten steel exposure positon of the argon blowing station, the titanium yield is increased; by reducing the influence of the niobium and titanium content on the quality of the high-casting-speed continuous casting billet, the titanium inclusion in steel is reduced, and the castability of molten steel meets requirements; and by adopting the high-casting-speed continuous casting powder, the cast billet quality is improved.

Owner:YANGCHUN NEW STEEL CO LTD

Method for producing 30CrMo hot rolled steel plate

InactiveCN101773929AImprove product qualityImprove qualityMetal rolling arrangementsHigh pressure waterHigh pressure

The invention discloses a method for producing a 30CrMo hot rolled steel plate, which mainly comprises the steps of smelting, refining, thin slab casting, soaking, high pressure water descaling, hot continuous rolling, cooling and reeling based on the process of thin slab casting and rolling. The withdrawing speed of continuous casting is S withdrawing (3.5m / min < / = S withdrawing < / = 5.5m / min), the charging temperature of casting blanks is T charging (900 DEG C < / = T charging < / = 1050 DEG C), the final rolling temperature is T final (830 DEG C < / = T final < / = 930 DEG C), the reeling temperature is T reeling ( 520 DEG C < / = T reeling < / = 620 DEG C), and the depth of a single-surface decarburized layer is 0.2 to 1.2 percent of the thickness of the steel plate. The chemical constitutes of molten steel after being alloyed in a refining process comprise 0.26-0.34 wt.% of C, 0.17-0.37 wt.% of Si, 0.40-0.70 wt.% of Mn, less than or equal to 0.035 wt.% of P, less than or equal to 0.035 wt.% of S, 0.80-1.10 wt.% of Cr, 0.15-0.25 wt.% of Mo and the balance of Fe and inevitable impurities. The 30CrMo hot rolled steel plate produced in the method has the characteristics of uniform structure property, high thermal stability and high strength, and the quality of the 30CrMo hot-rolled steel plate is obviously improved.

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

High-drawing-speed sheet billet peritectic steel continuous casting crystallizer casting powder and preparation method thereof

The invention discloses high-drawing-speed sheet billet peritectic steel continuous casting crystallizer casting powder and a preparation method thereof. According to the raw material formula, the casting powder comprises, by weight, 57%-60% of aedelforsite, 7%-9% of fluorite, 8%-10% of sodium carbonate, 0%-2% of lithium carbonate, 7%-9% of glass powder, 3%-5% of bauxite, 4.5%-4.7% of carbon black and 5%-5.5% of graphite. According to the chemical composition, the casting powder comprises, by weight, 36.8%-38.3% of calcium oxide, 23.5%-25% of silicon dioxide, 2.9%-3.4% of magnesium oxide, 3.1%-3.7% of aluminum oxide, 4%-4.2% of sodium oxide, 0-1.3% of lithium oxide and 7.8%-8.5% of fixed carbon, casting powder basicity, namely CaO / SiO2, is 1.50-1.54, the melting point is 1,050 DEG C-1,100 DEG C, and the viscosity is 0.2-0.25 Pa.s at 1,300 DEG C. The casting powder can effectively solve the problems that during continuous casting, crusting and slag inclusion of casting powder of peritectic steel happen, and the surface of a casting blank cracks and is prone to breakout by sticking. Besides, the casting powder has the advantages that slag melting in a crystallizer is uniform and stable, and the surface quality of the casting blank is good and not prone to breakout by sticking.

Owner:TANGSHAN IRON & STEEL GROUP

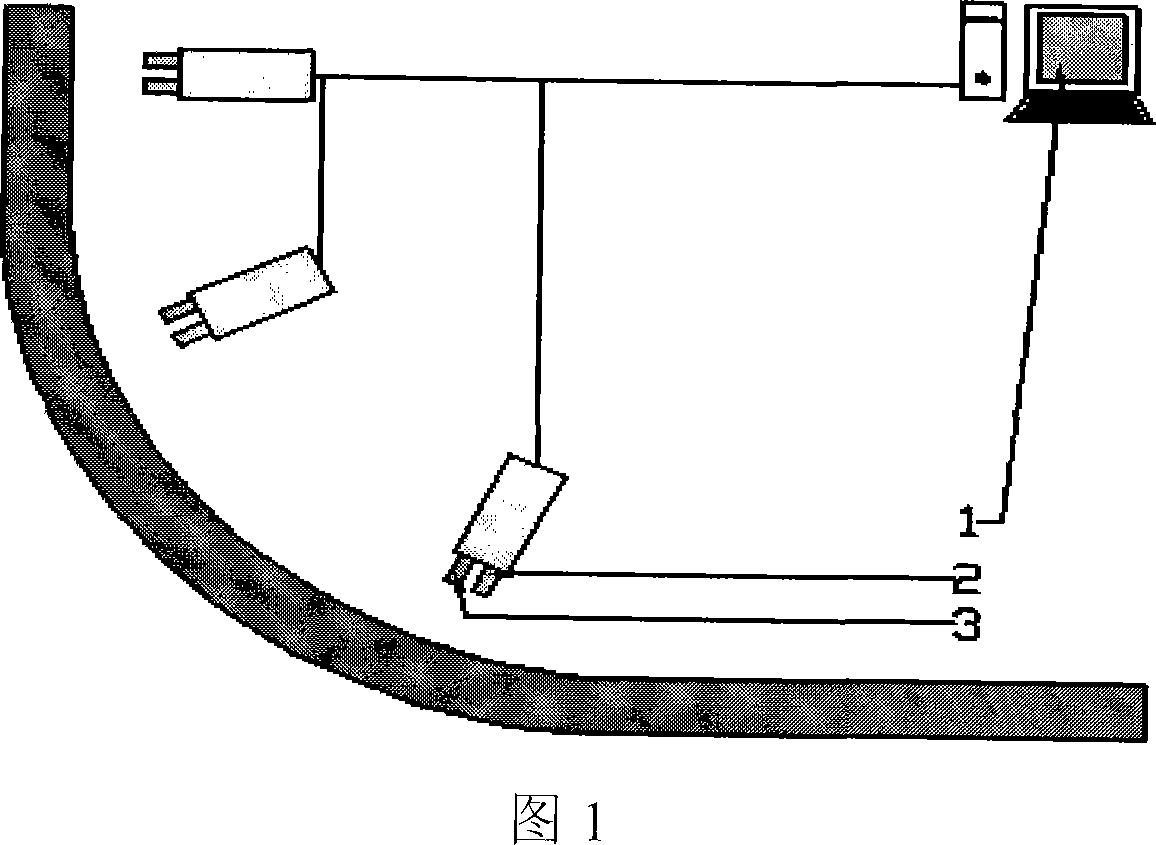

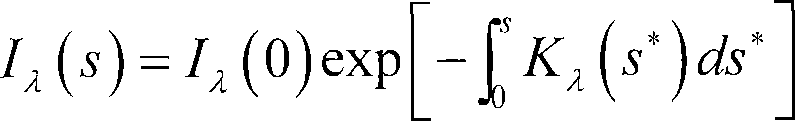

Method for measuring surface temperature of high-temperature casting billet within water fog medium

InactiveCN101162171AAccurate temperatureTemperature correctionRadiation pyrometryParticle suspension analysisFront edgeMaterials science

The present invention discloses a method for measuring the surface temperature of a high-temperature casting blank in water-fog medium; the water-fog concentration of the surface of the high-temperature casting blank is measured and transmitted to a remote computer through an air water-fog concentration sensor; the attenuation coefficient K lambda of water-fog medium to radiant energy in the water-fog concentration is gained by the remote computer through the relation curve between the attenuation coefficients of the water-fog medium and the radiant energy; temperature data tested by a thermodetector are modified by the attenuation coefficient K lambda and the emissivity of filam on the surface of the casting blank and the real temperature of the surface of the casting blank in the water-fog medium can be measured in real-time; the gain of accurate temperature has an important support on the application of continuous casting front-edge technology such as electromagnetic mixing, secondary cooling dynamic control and so on in dynamic slight press and has very important significance on improving the quality of casting blank and the whole level of continuous casting.

Owner:CHONGQING UNIV

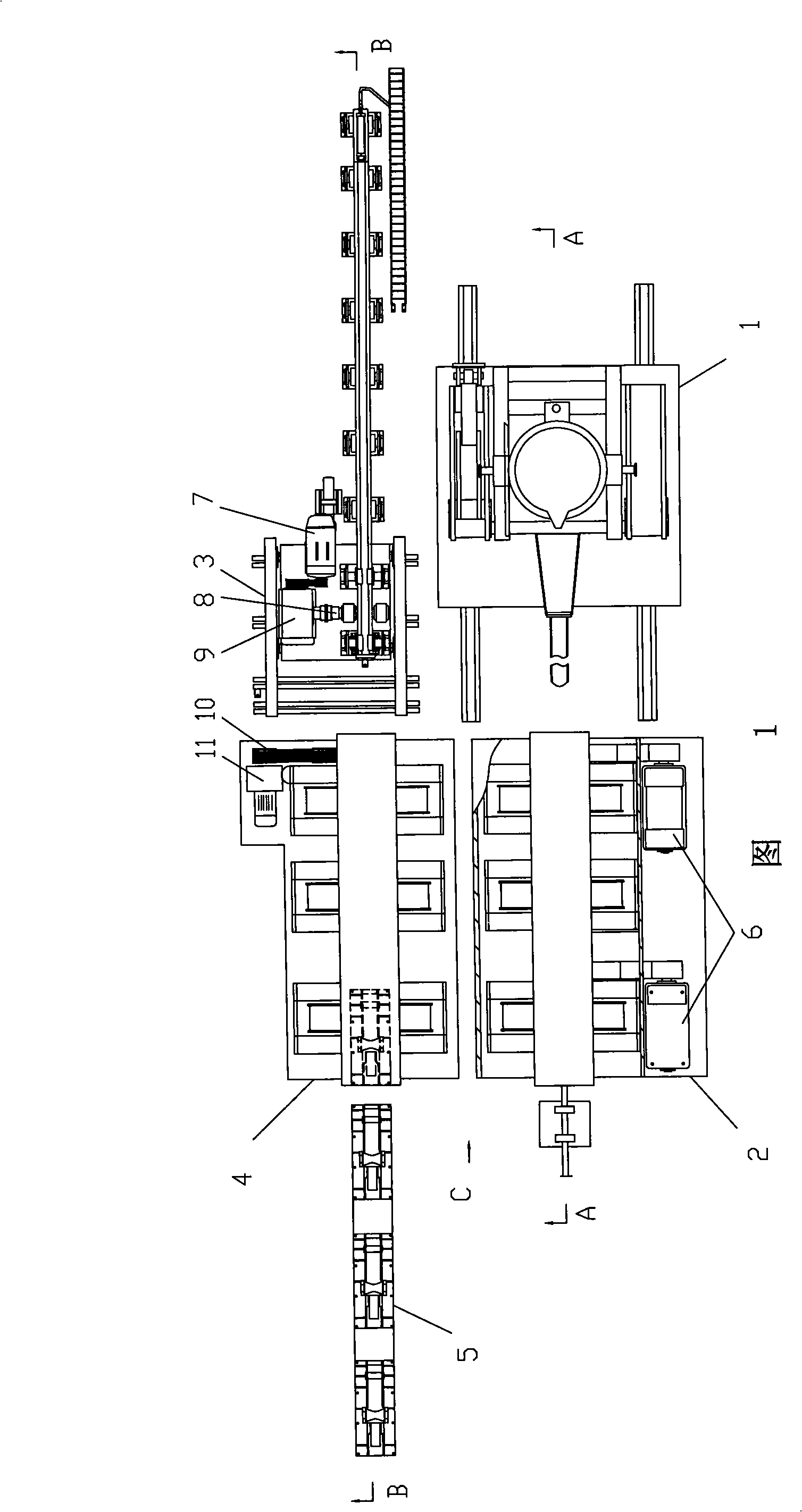

Centrifuge for casting steel tube by heated mould method

ActiveCN101298100AImprove organizationSmall sizeCasting plantsMolten metal conveying equipmentsVehicle frameEngineering

The invention relates to a pipe casting centrifuge machine by a thermodyn process, which comprises an equivalently casting device, a centrifugal host, a pushing pipe device, a pipe supporting device and a pipe connecting device. The frame of the equivalently casting device is fixed with a ladle fixing frame and a pouring ladle with a long pouring channel, and the ladle fixing frame is fixed with a same-speed board; the support wheel groups of centrifugal host are driven by a motor and support pipe die; the supporting frame of the pushing pipe device fixes a pushing rod through a guide rail, and the pushing rod is driven by a motor through pin teeth transmission for the pipe rough breaking away from the pipe die and cleaning inner wall of the pipe die and coating the inner wall of the pipe die; the pipe supporting device ensures the separation of the steel pipe from the pipe die; the pipe connecting device is used for connecting the pipe rough separated from the pipe pushing device. The pipe casting centrifuge machine of the invention can obtain the hollow steel pipe with good structure, precise size and high output rate of material and realizes whole machine automatic production.

Owner:XINXING DUCTILE IRON PIPES CO LTD

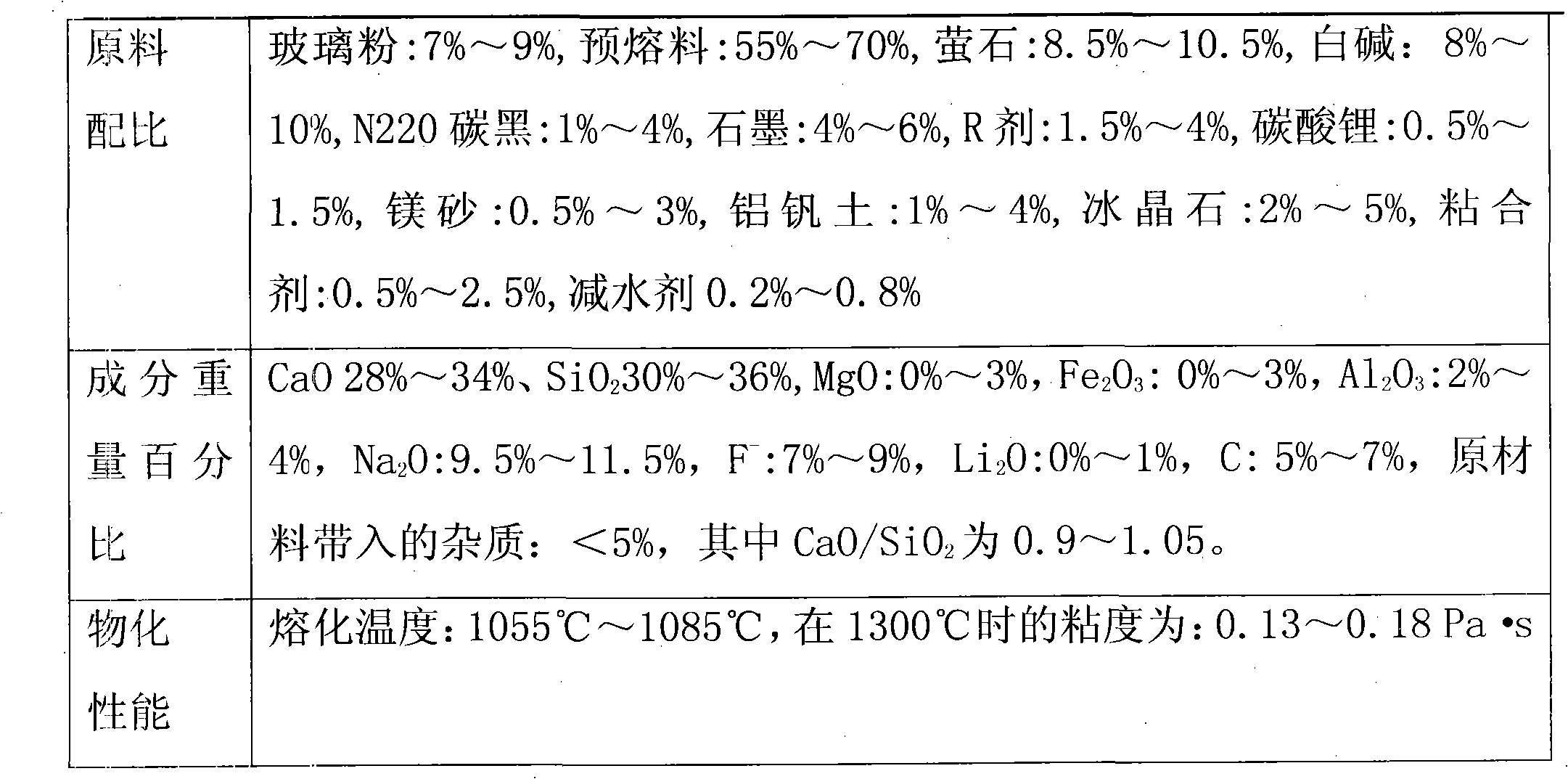

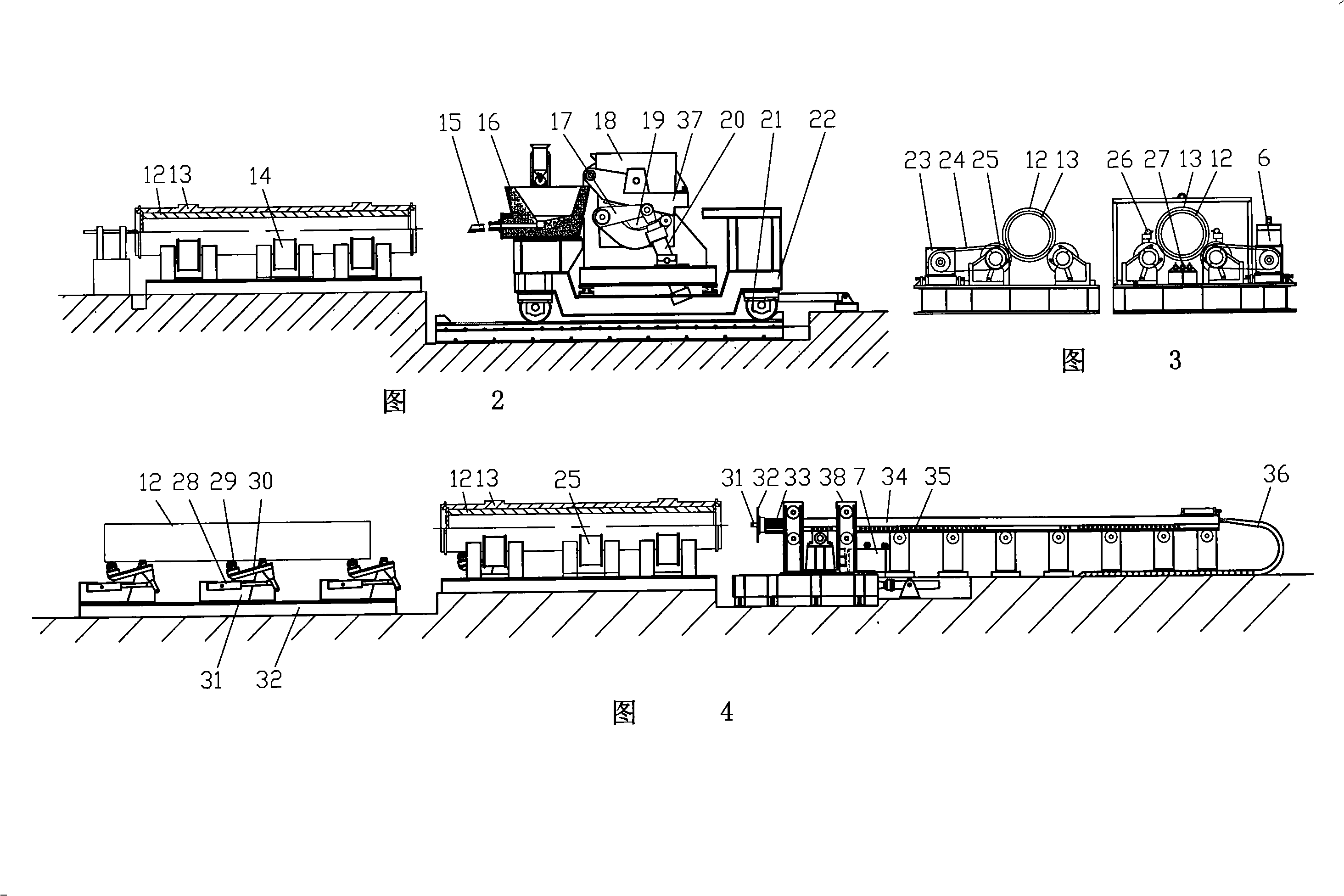

Crystallizer casting powder for austenite antibacterial stainless steel

ActiveCN103785808AMeet the needs of shrinkage characteristicsGood control of heat transferHeat resistanceField tests

The invention discloses continuous casting crystallizer casting powder for austenite antibacterial stainless steel. The alkalinity of the continuous casting crystallizer casting powder ranges from 1.0 to 1.1, and the continuous casting crystallizer casting powder can achieve a very good heat transfer control effect and meet the requirement for shrinkage characters of the austenite antibacterial stainless steel. The viscosity is set as 0.10 Pa*s-0.18 Pa*s at the temperature of 1300 DEG C, so that the casting powder flows in gaps between blank shells and a crystallizer copper plate more evenly, casting blanks are lubricated, the requirement for the consumption of the crystallizer casting powder is met, and the viscosity is mainly controlled Al2O3, MgO and F-. The melting point ranges from 1130 DEGC to 1190 DEG C, heat resistance of the casting powder is increased, the heat transfer uniformity index of the crystallizer casting powder is increased, and cracks are difficult to produce. Raw materials of the continuous casting crystallizer casting powder are easy to obtain, and cost is relatively low. By means of field tests, the casting powder is melt uniformly and stably, the indentation rate of the edges of the casting blanks is decreased by about 9.5%-19%, quality of the casting blanks is improved, and smooth operation of processes of a steel mill is guaranteed.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

Continuous casting tundish hollow particle carbon-free covering agent and preparation method thereof

The invention relates to a continuous casting tundish hollow particle carbon-free covering agent, belonging to the iron and steel smelting field. The carbon-free covering agent comprises the followingcomponents by weight percent: 25-35% of SiO2, 8-20% of Al2O3, less than 1.5% of Fe2O3, 25-35% of CaO, 8-16% of MgO and less than 0.5% of H2O, wherein 0.15-1.0mm of particles account for 90-100% and the bulk specific weight is 0.6-0.9g / cm<3>. The continuous casting tundish hollow particle carbon-free covering agent has good spreadability, when added the covering agent can be molten fast and can cover the whole surface of molten steel, thus avoiding the secondary oxidation of molten steel; the covering agent has function of absorbing inclusion, can purify molten steel and increase the casting blank quality; the covering agent has good thermal insulation property, thus significantly reducing the temperature loss of molten steel; the slag of the covering agent can not incrust and stick to thestopper rod; and the content of carbon in molten steel is not increased.

Owner:SHANDONG IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com