High-viscosity continuous casting protective slag for solving slag inclusion on surface of low-carbon steel

A technology of continuous casting mold slag and high viscosity, which is applied in the field of metallurgical auxiliary materials for steelmaking to ensure the effect of heat preservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

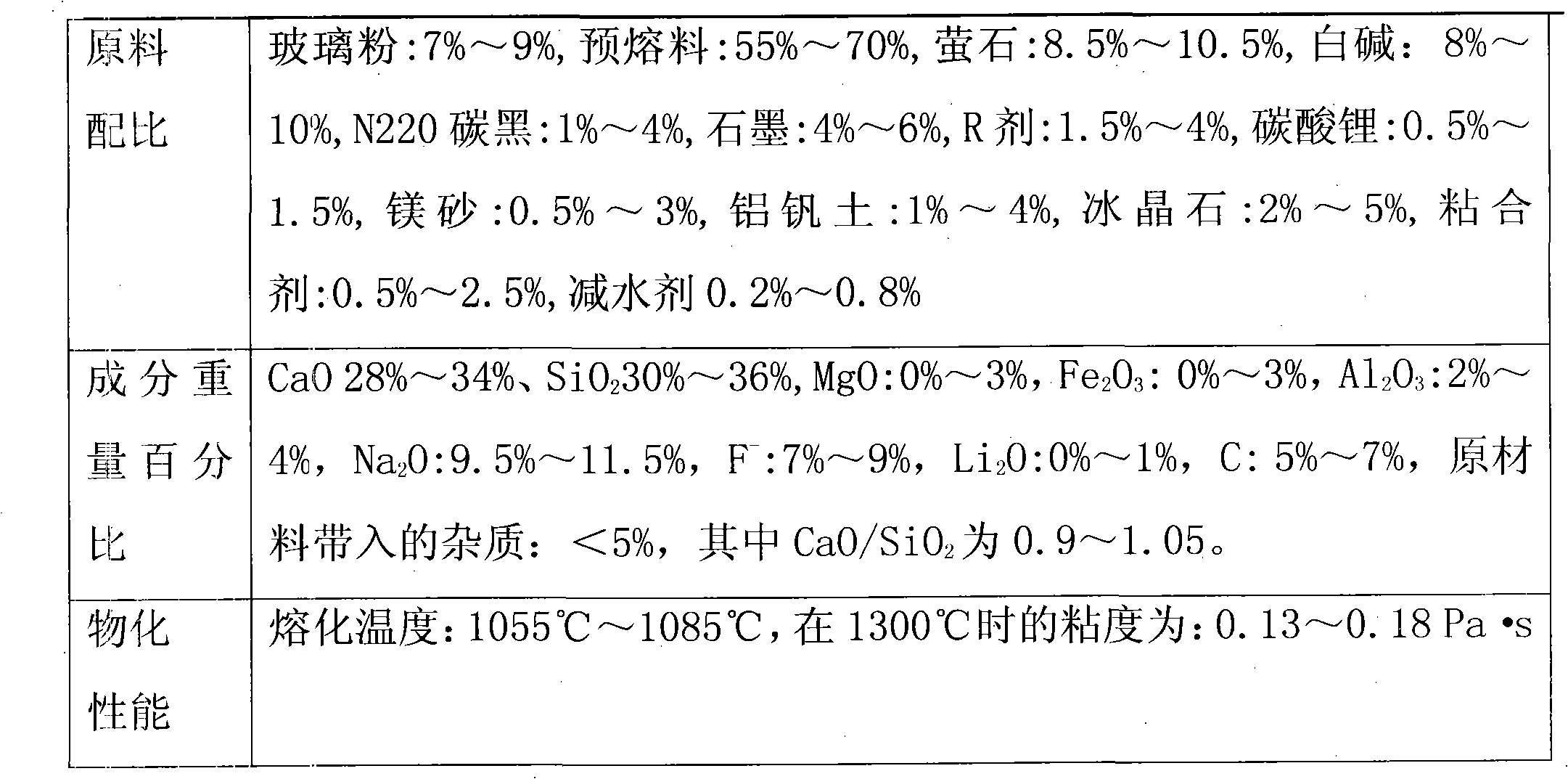

Method used

Image

Examples

Embodiment 1

[0020] A high-viscosity continuous casting mold flux for solving slag inclusion on the surface of low-carbon steel, the raw material ratio and weight percentage are as follows: glass powder: 6.5%, premelt: 57.8%, fluorite: 7.5%, white alkali: 6 %, N330 carbon black: 3%, graphite: 3.5%, R agent: 2%, lithium carbonate: 1%, magnesia 3%, manganese carbonate: 2%, bauxite: 4%, cryolite: 2%, Binder: 1.4%, superplasticizer 0.3%

[0021] The components in the low-carbon steel high-viscosity continuous casting mold flux are calculated by weight percentage: MgO: 3.8%, Fe 2 o 3 : 0.98%, Al 2 o 3 : 7.1%, Na 2 O: 8.9%, F - : 7.2%, MnO: 1.5%, Li 2 O: 0.4%, C: 5.6%, impurities brought in by raw materials: 0.42%, CaO: 29.2, SiO 2 : 34.9, CaO / SiO 2 is 0.84.

[0022] The physical properties of the mold flux are: melting temperature: 1080°C, viscosity at 1300°C: 0.28Pa·s

[0023] The low-carbon steel high-viscosity continuous casting mold slag with this ratio and performance requirement...

Embodiment 2

[0026] A high-viscosity continuous casting mold flux for solving slag inclusion on the surface of low-carbon steel, the raw material ratio and weight percentage are as follows: glass powder: 2%, premelt: 61.1%, fluorite: 6%, white alkali: 4.5 %, N330 carbon black: 3%, graphite: 3.5%, R agent: 1%, lithium carbonate: 1.5%, manganese carbonate: 3%, magnesia 4%, bauxite: 6.5%, cryolite: 1.5%, Binder: 2%, water reducer: 0.4%.

[0027] The components in the low-carbon steel high-viscosity continuous casting mold flux are calculated by weight percentage: MgO: 4.6%, Fe 2 o 3 : 1.15%, Al 2 o 3 : 9.0%, Na 2 O: 6.8%, F -: 5.9%, MnO: 2.2%, Li 2 O: 0.6%, C: 5.6%, impurities brought in by raw materials: 1.05%, CaO: 28.8, SiO 2 : 34.3, CaO / SiO 2 is 0.84.

[0028] The physical properties of the mold slag are: melting temperature: 1090°C, viscosity at 1300°C: 0.37Pa·s. The low-carbon steel high-viscosity continuous casting mold slag with this ratio and performance requirements is used...

Embodiment 3

[0031] A high-viscosity continuous casting mold flux for solving slag inclusion on the surface of low-carbon steel, the raw material ratio and weight percentage are as follows: glass powder: 3.5%, premelt: 58.7%, fluorite: 6%, white alkali: 6% %, N330 carbon black: 3%, graphite: 3.5%, R agent: 1.5%, lithium carbonate: 1.2%, manganese carbonate: 3.5%, magnesia 3.5%, bauxite: 5%, cryolite: 2%, Binder: 2%, water reducer 0.6%.

[0032] The components in the low-carbon steel high-viscosity continuous casting mold flux are calculated by weight percentage: MgO: 4%, Fe 2 o 3 : 1.5%, Al 2 o 3 : 8%, Na 2 O: 8%, F - : 6.5%, MnO: 2%, Li 2 O: 0.5%, C: 5.5%, impurities brought by raw materials: 1.5%, CaO: 28.5%, SiO 2 34%, of which CaO / SiO 2 is 0.84.

[0033] The premelt material of the present invention (its composition and weight percentage are composed of: SiO 2 42~45%, CaO36~39%, MgO 1.5~3.5%, Fe 2 o 3 Not more than 1%, Al 2 o 3 4~6%,Na 2 O 5~7%, F 2~4%) 58~66%, cement ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com