Patents

Literature

1147 results about "Continuous casting mold" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

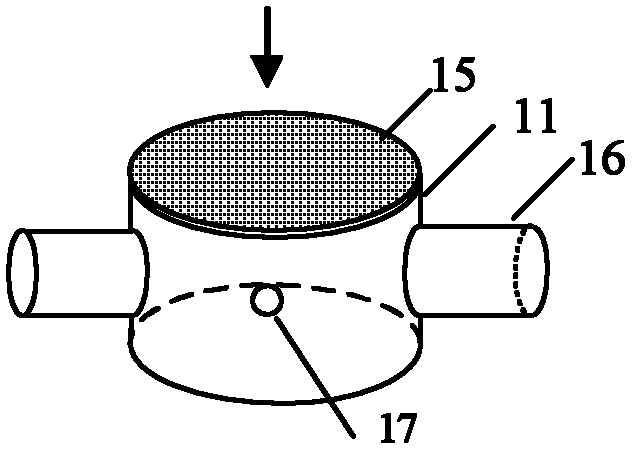

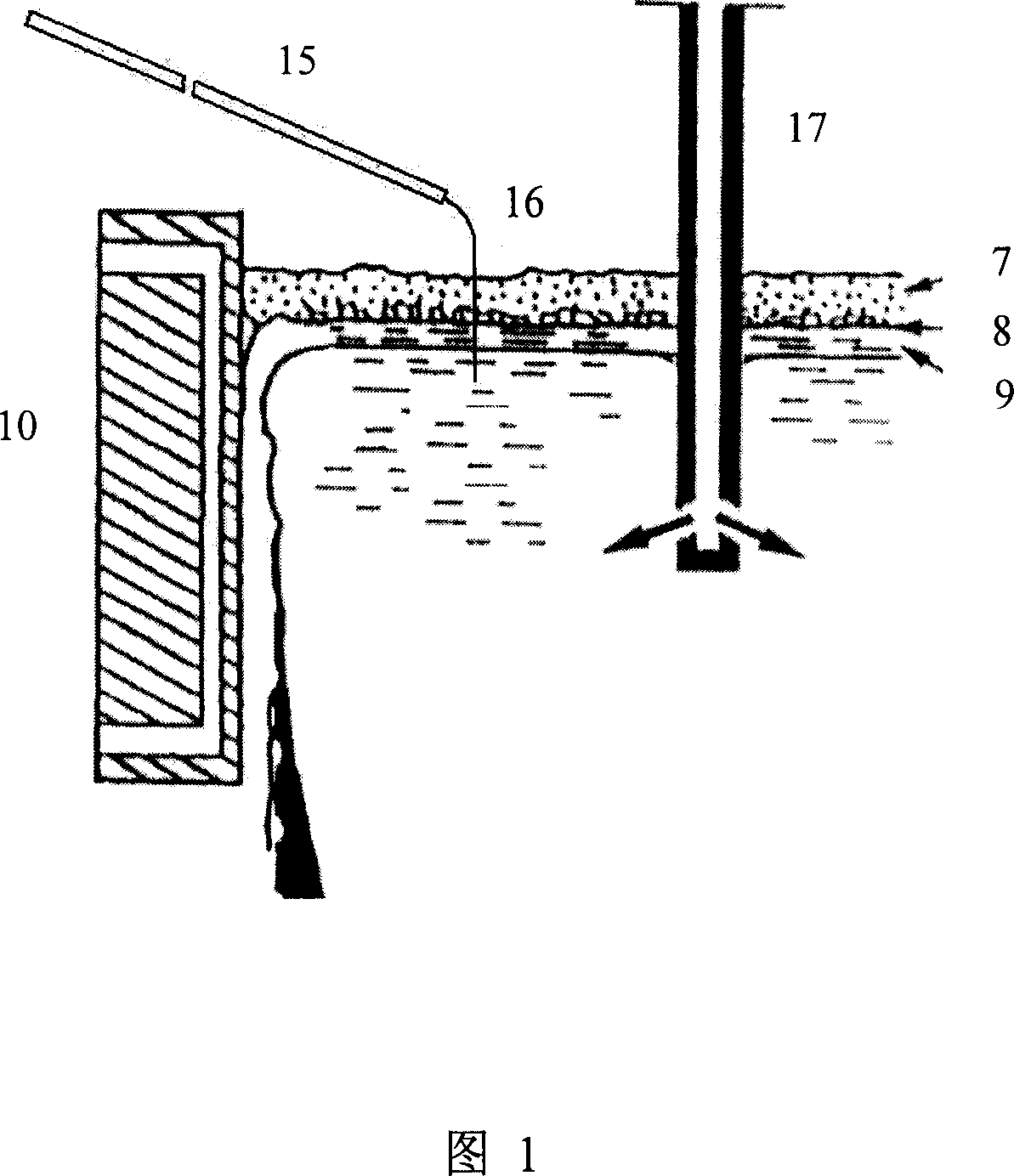

Stirring chamber for stirring molten metal and using method thereof

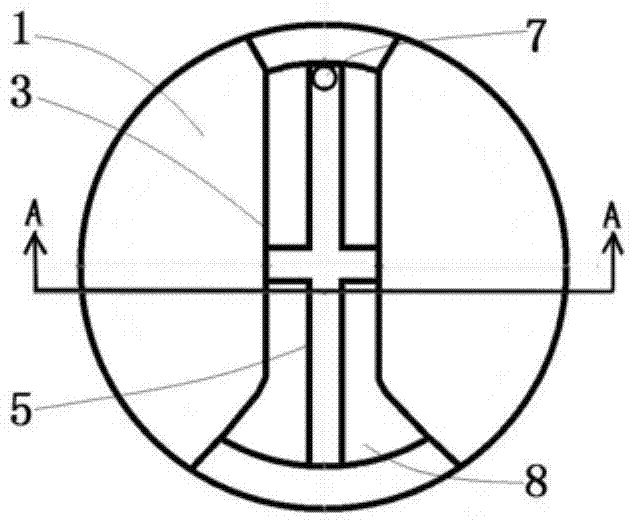

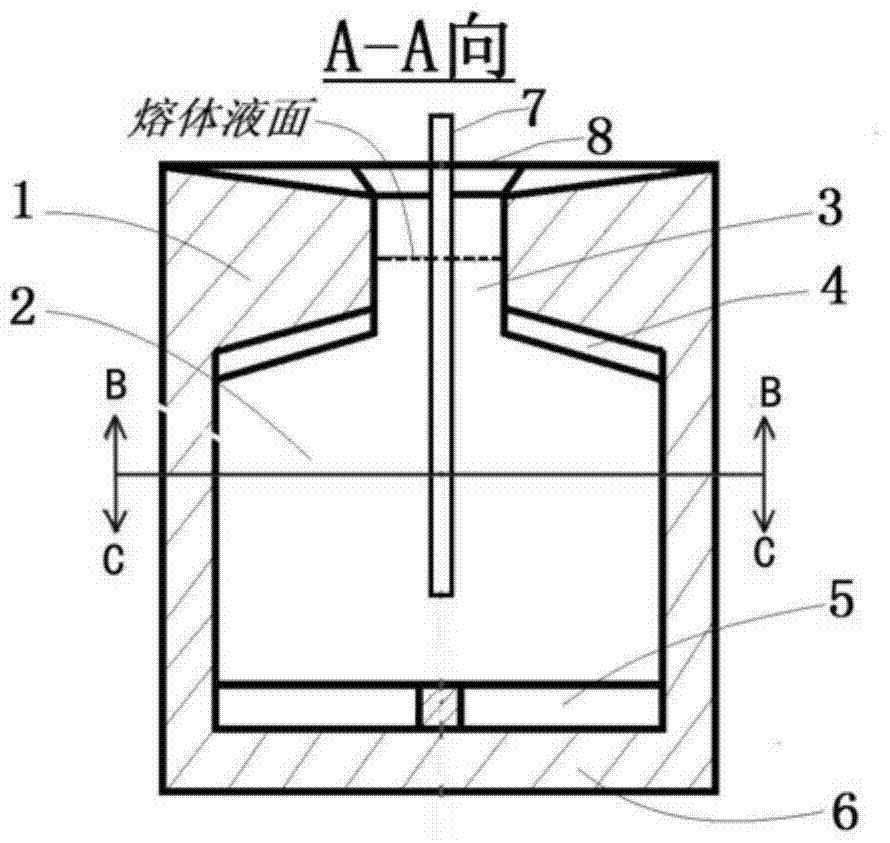

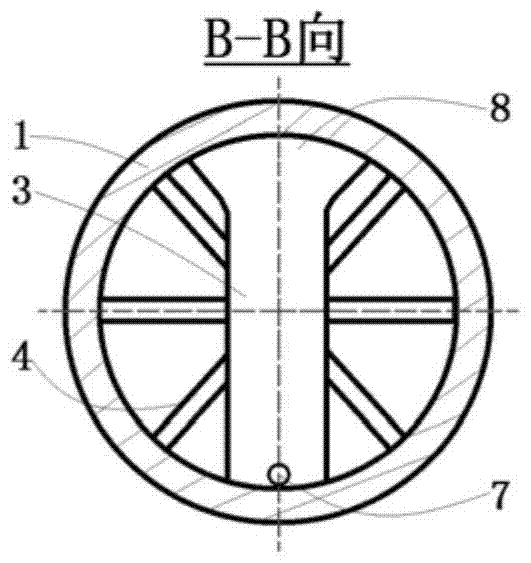

The invention discloses a stirring cavity used for stirring metal melt and a use method thereof, which belong to the field of material processing apparatuses for metallurgy, casting, chemical engineering and the like. The stirring cavity structurally consists of a melt container, a stirring cavity body, an upper stop opening, an upper blocking flange, a lower blocking flange, a lower bottom, a temperature sensor and a liquid taking / pouring port. According to the stirring cavity, the melt liquid level inside the stirring cavity is narrowed, so the stirring effect is effectively stopped from transferring to the liquid level, and the problems of melt oxidation and entrapped air risk are solved. The stirring cavity can be applied to various metal melt stirring and casting occasions; when the stirring cavity is used for batch-type casting such as pressure casting, the stirring cavity is adopted as the internal cavity structure of a pouring ladle; when the stirring cavity is used for continuous casting, the stirring cavity is adopted as the internal cavity structure of a melt hot top and can be directly connected with a continuous casting crystallizer; and full automation is realized in the whole process of melt stirring, chemical refining and casting in a pressure casting site.

Owner:GRIMAT ENG INST CO LTD

High-strength weathering steel and method for producing same

InactiveCN101792888AImprove economyGood weather resistanceTemperature control deviceMetal rolling arrangementsChemical compositionImpurity

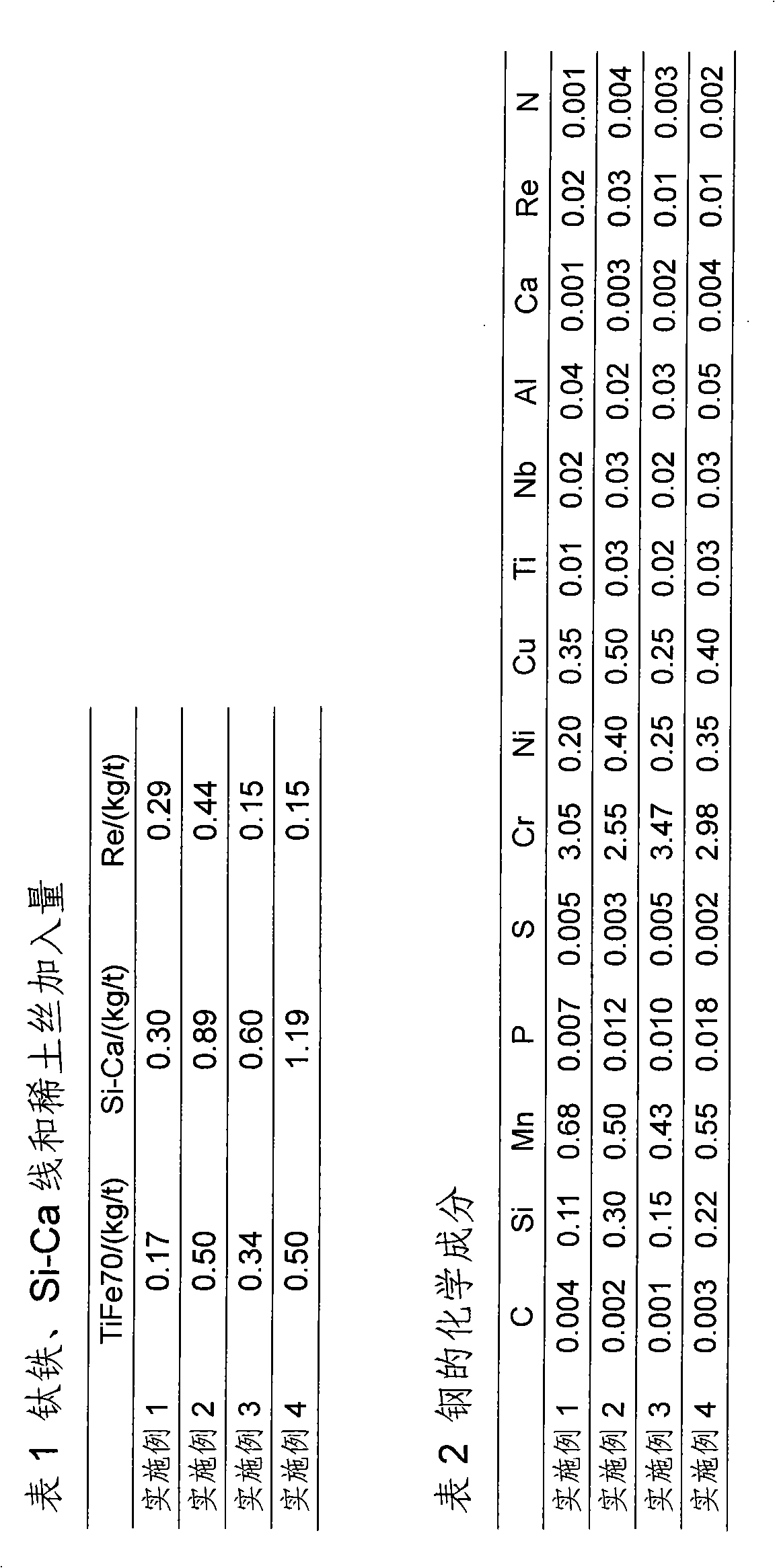

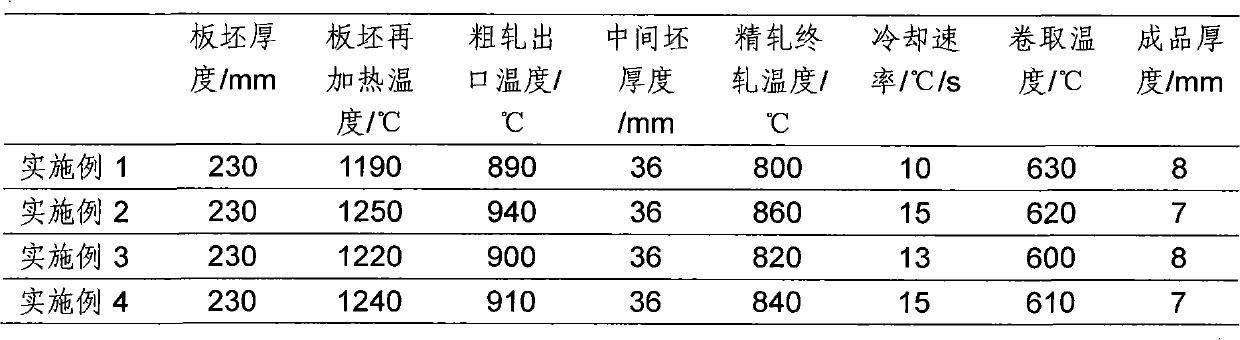

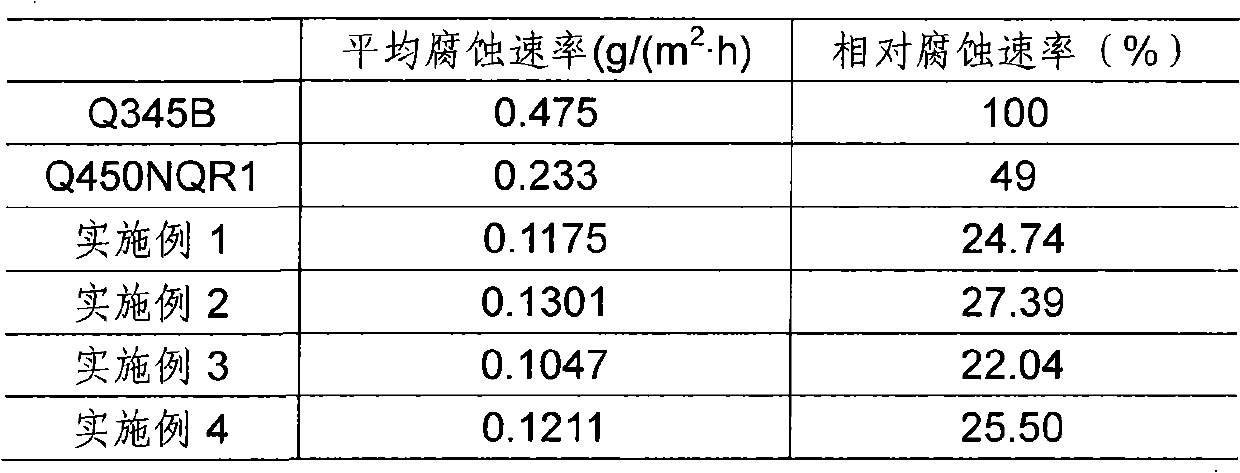

The invention relates to high-strength weathering steel and a method for producing same. The high-strength weathering steel comprises the following components by weight percent (wt%): 0.001-0.004 percent of C, 0.10-0.30 percent of Si, 0.40-0.70 percent of Mn, 0.020 percent of P or less, 0.008 percent of S or less, 2.50-3.50 percent of Cr, 0.20-0.40 percent of Ni, 0.25-0.50 percent of Cu, 0.01-0.03 percent of Re, 0.02-0.06 percent of Al, 0.001-0.004 percent of Ca, 0.001-0.005 percent of N, 0.01-0.03 percent of Ti, 0.01-0.03 percent of Nb and the balance of Fe and other inevitable impurities. After the molten iron is fully deoxidized and before the refining of the molten iron is finished, ferrotitanium is added to steel ladle, a Ca wire is fed to the steel ladle, a Re wire is fed into a continuous casting crystallizer, and a slab is reheated at 1180-1300 DEG C; the two-stage controlled rolling is adopted; the ratio of the thickness of the intermediate slab to the thickness of the finished product is controlled at 3.0; the refining outlet temperature is controlled at 890-1050 DEG C; the finishing rolling temperature is controlled at 800-860 DEG C; the rate of cooling after finishing rolling is controlled at 10-15 DEG C per second; and the winding temperature is controlled at 580-640 DEG C. The invention has the advantages that the relative corrosion rate of the weathering steel subjected to the 72h periodic infiltration is less than 30 percent compared with that of the steel Q345B, the weathering performance of the weathering steel is obviously better than the traditional high-strength weathering steel, and the weathering steel of the invention has the yielding strength of more than 550 Mpa and the elongation rate of more than 24 percent. The high-strength weathering steel of the invention can be applied to the fields of the railway truck, the container, the bridge, the communication, the power tower and the like.

Owner:SHOUGANG CORPORATION +1

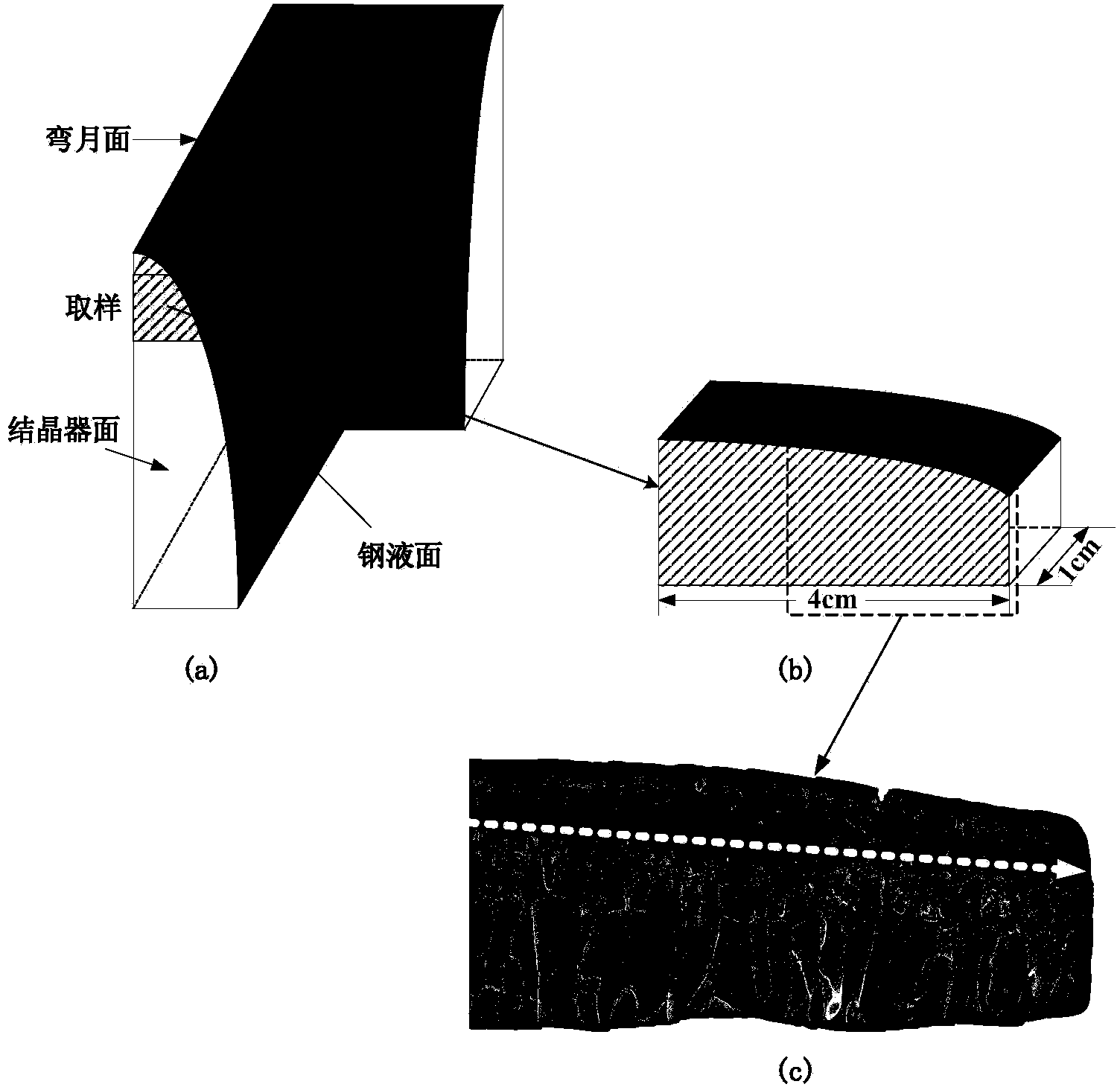

Prediction system and method for thickness of initially solidified shell in continuous steel casting crystallizer

ActiveCN104384469APredict growth behaviorPredicting Microscopic Solidification BehaviorMetallurgyPrediction system

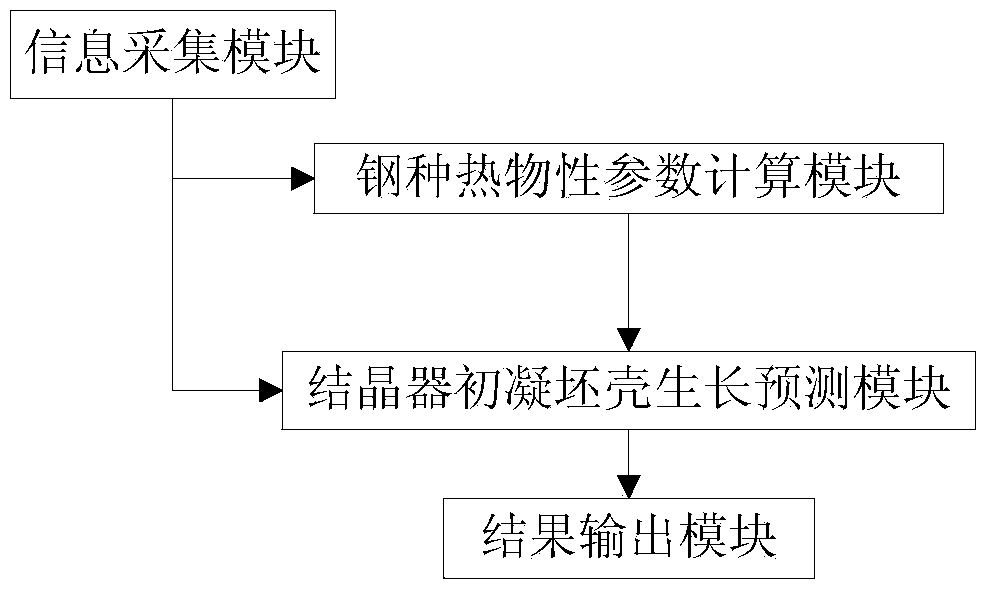

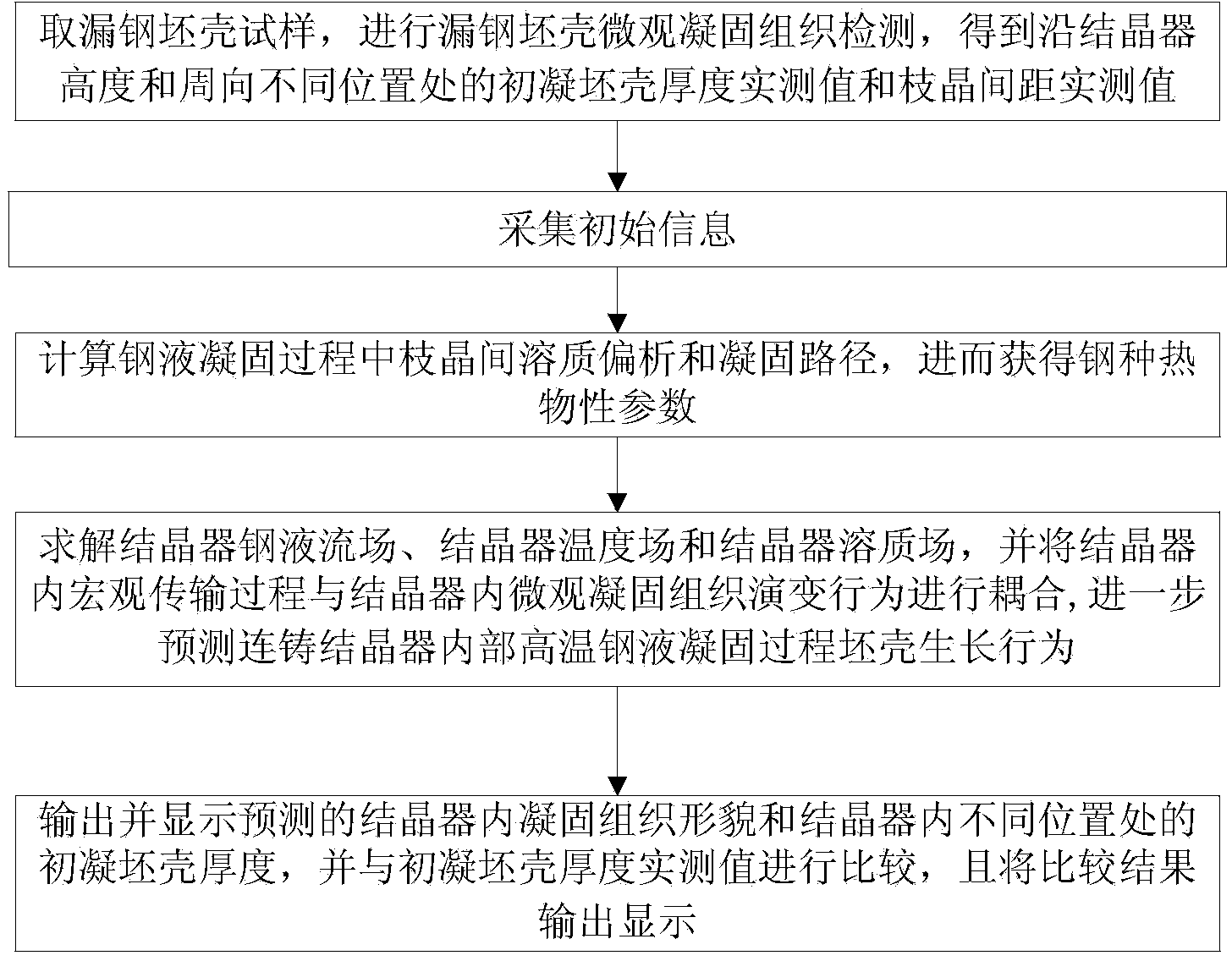

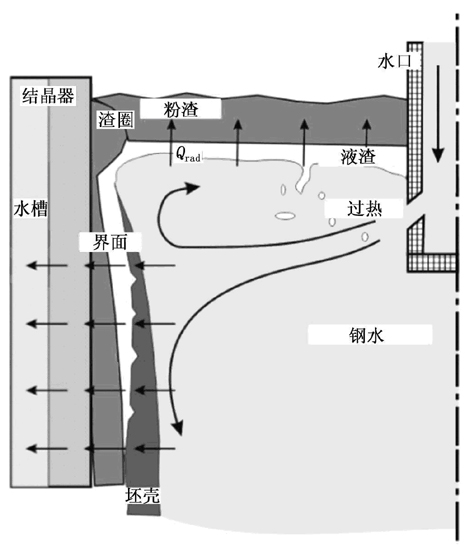

The invention provides a prediction system and method for the thickness of an initially solidified shell in a continuous steel casting crystallizer. The system comprises an information collection module, a steel grade thermophysical parameter calculation module, a crystallizer initially solidified shell growth prediction module and a result output module. The method comprises the following steps: detecting a bleed-out shell microcosmic solidification structure; collecting initial information; computing the interdendritic solute segregation and solidification path in a molten steel solidification process to obtain a steel grade thermophysical parameter; solving a crystallizer molten steel flow field, a crystallizer temperature field and a crystallizer solute field, coupling a macroscopic transport process in the crystallizer and the evolution behavior of the microcosmic solidification structure in the crystallizer, and further predicting the shell growth behavior in the solidification process of high-temperature molten steel in the continuous steel casting crystallizer; outputting and displaying the comparative results of the predicted morphology of the solidification structure in the crystallizer, the predicted initially solidified shell thicknesses in different positions in the crystallizer and the actual thickness of the initially solidified shell. The system and the method can accurately predict the microcosmic solidification behavior of the initially solidified shell in the crystallizer.

Owner:NORTHEASTERN UNIV LIAONING

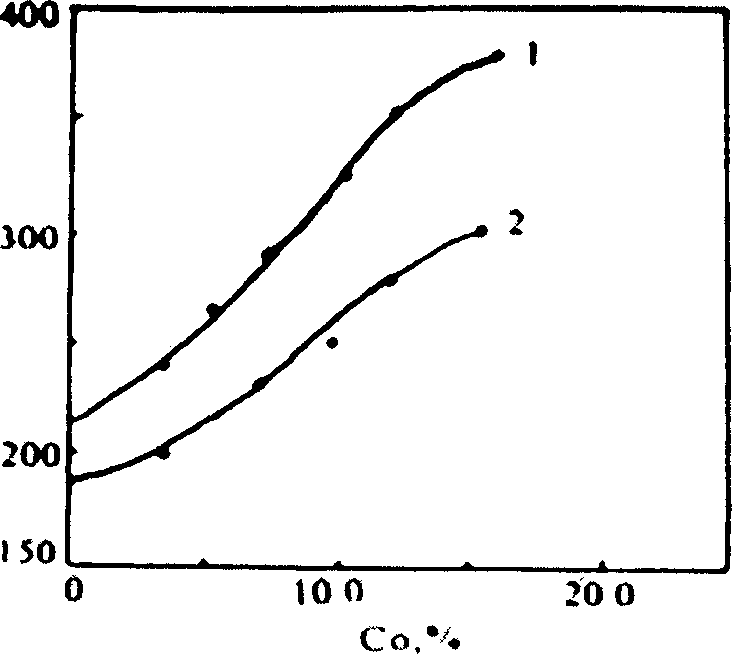

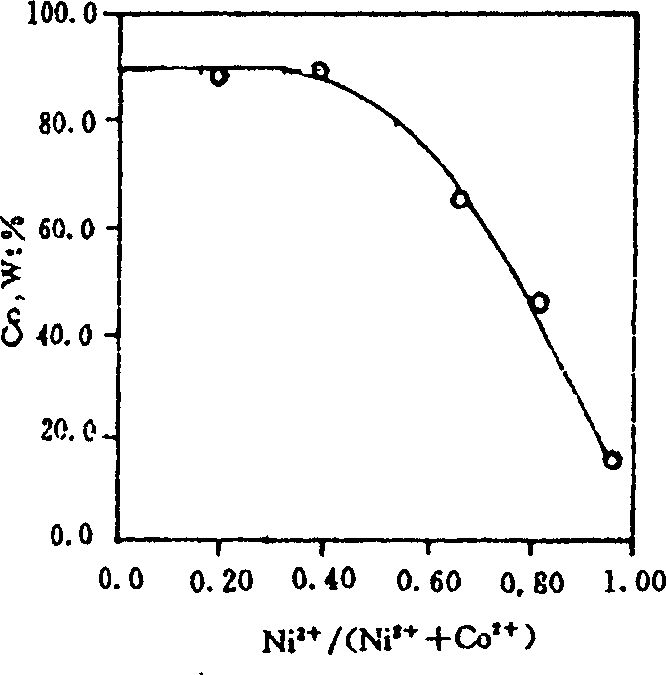

Gradient composite deposite for continuous casting crystallizer copper plate and production method thereof

InactiveCN1500916AImprove the state of the structureImprove acceleration performanceElectrolytic coatingsSulfonatePre treatment

The gradient composite coating layer for continuous casting crystallizer copper plate contains Co in 50-79.9 vol%, Ni in 20-49.9 vol% and Al2O3 grains of size below 0.5 micron in 0.1-10 vol%. The coating is in gradient structure with outwards gradually increased Co and Al2O3 content and decreased Ni content. During production of the composite coating layer, inside amino sulfonate system with Al2O3 grains in 10-80 g / L and size below 0.5 micron added, gradient Co-Ni-Al2O3 coating is deposited onto copper or copper alloy via specific Al2O3 grain activating pre-treatment and electric deposition process. In the activating pre-treatment, FC-4 cation surfactant is used as ion dispersant. The composite Co-Ni-Al2O3 coating may be used in various high temperature wear resisting fields widely.

Owner:BAOSHAN IRON & STEEL CO LTD +1

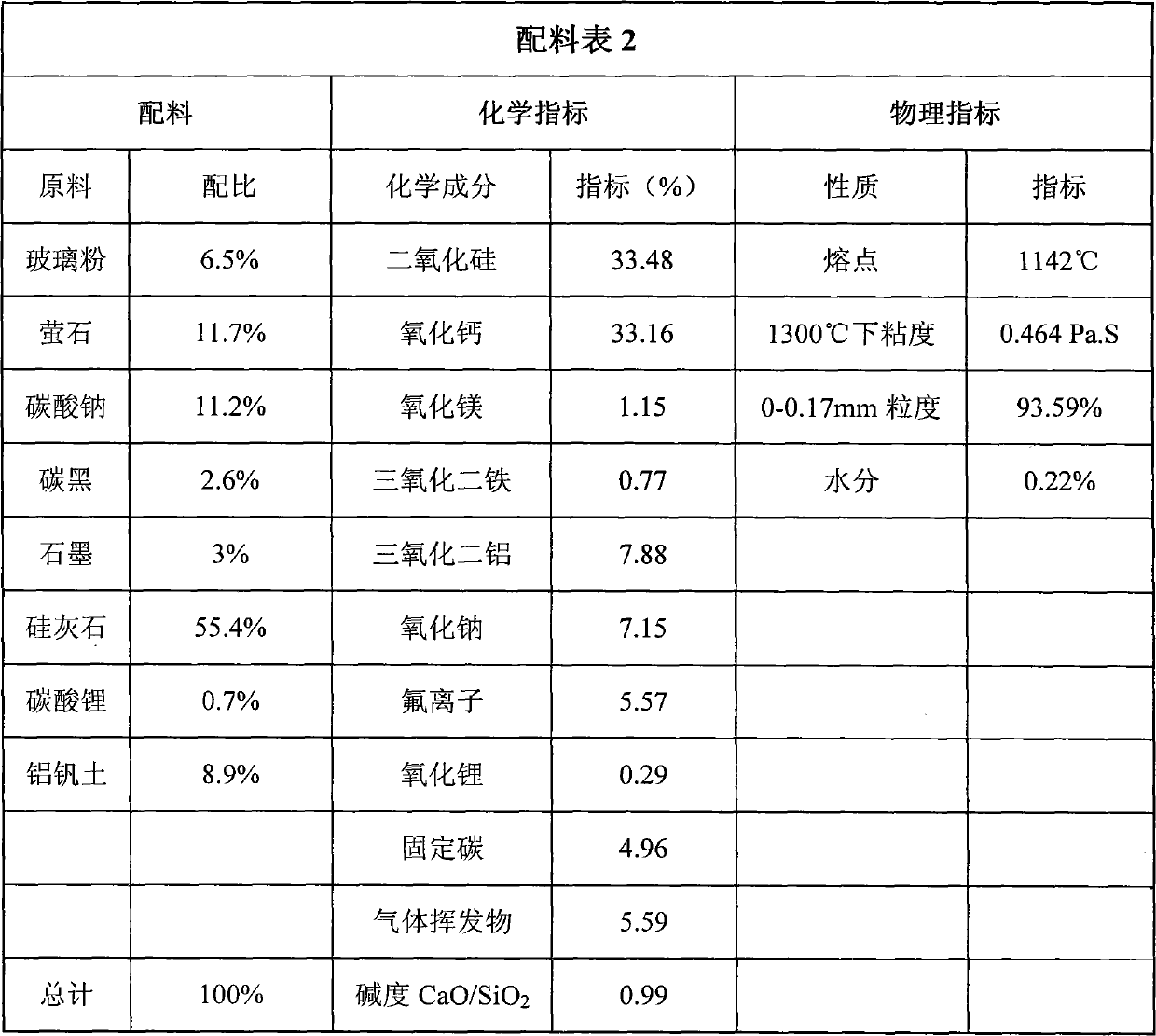

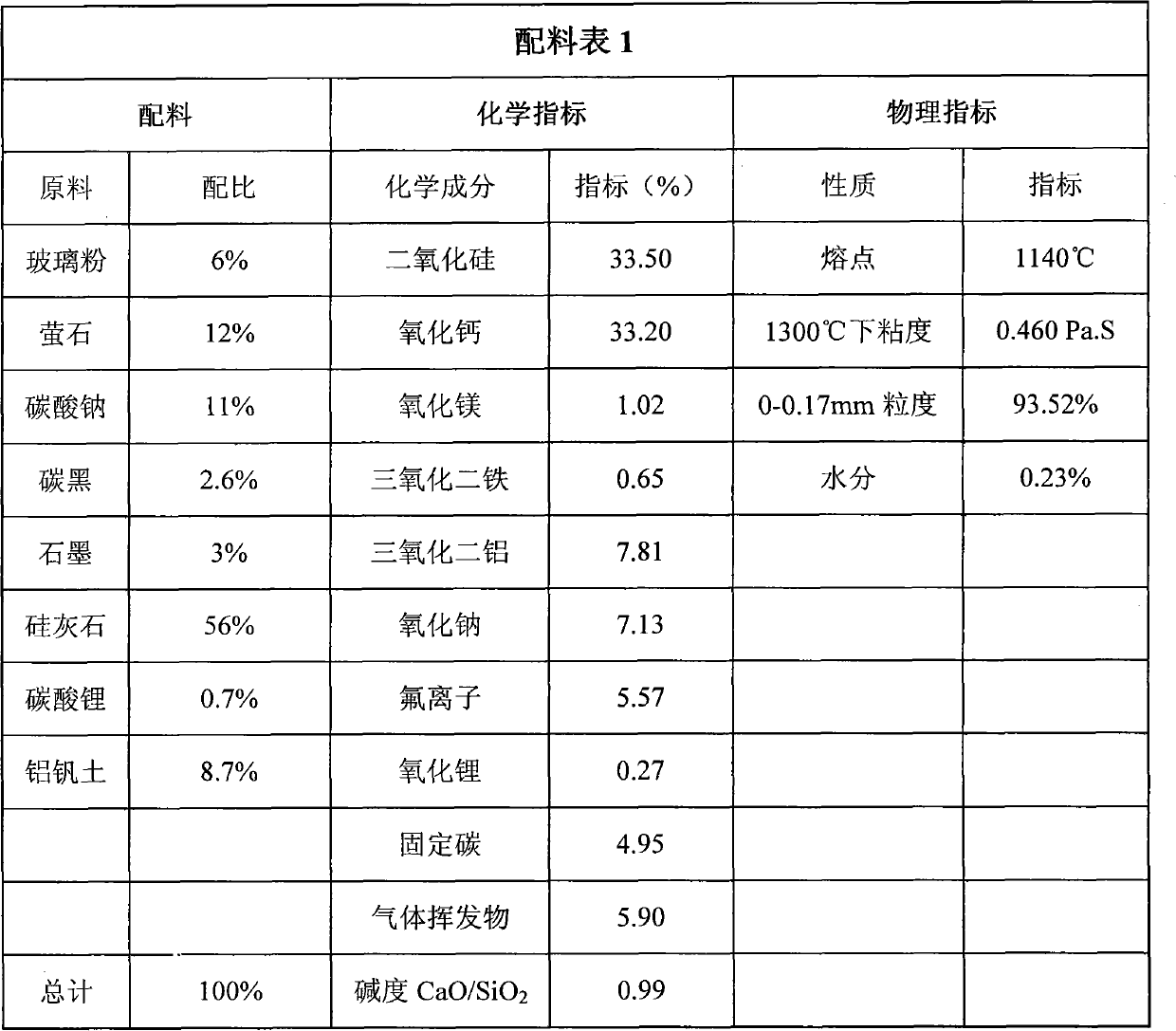

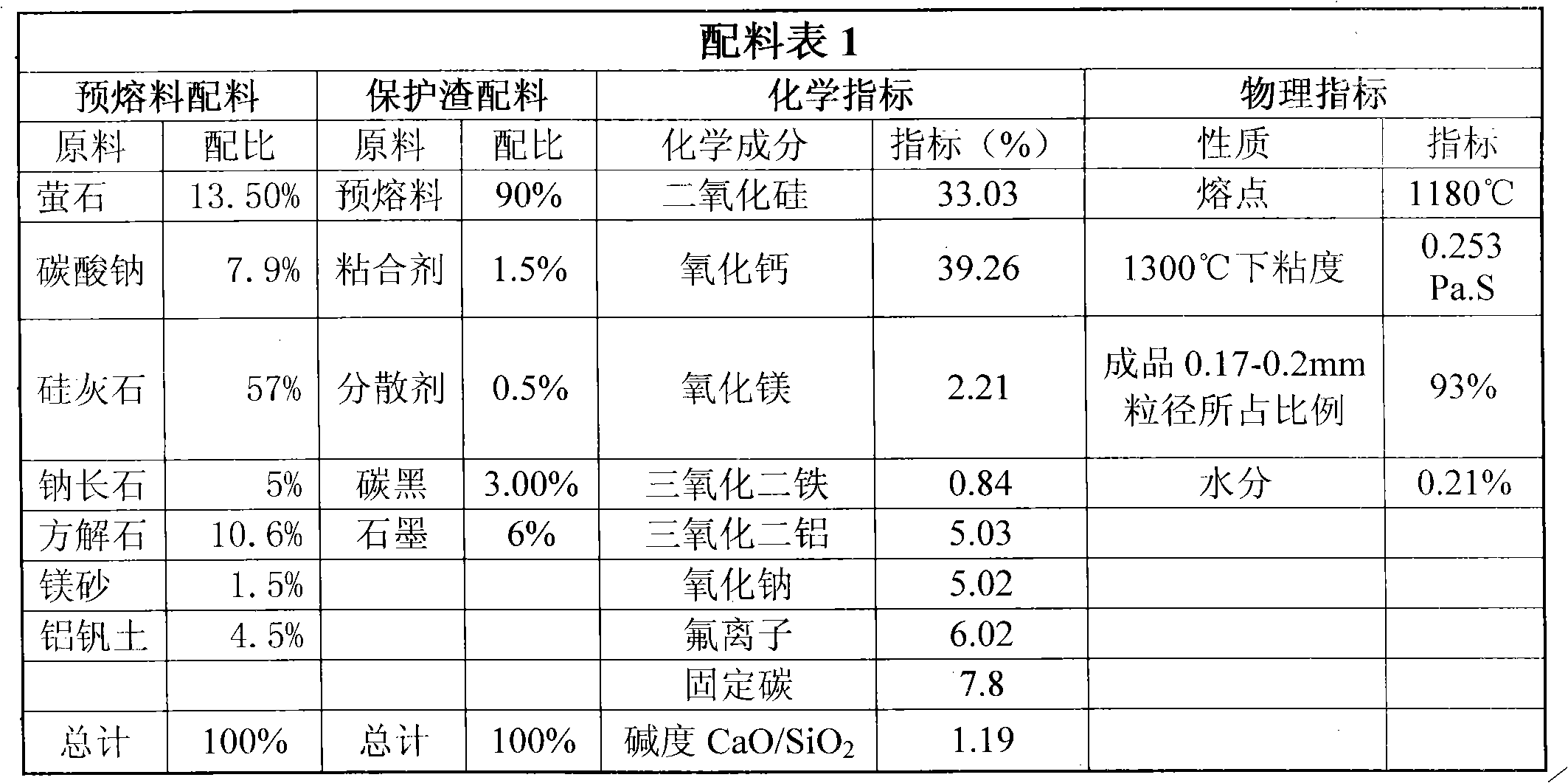

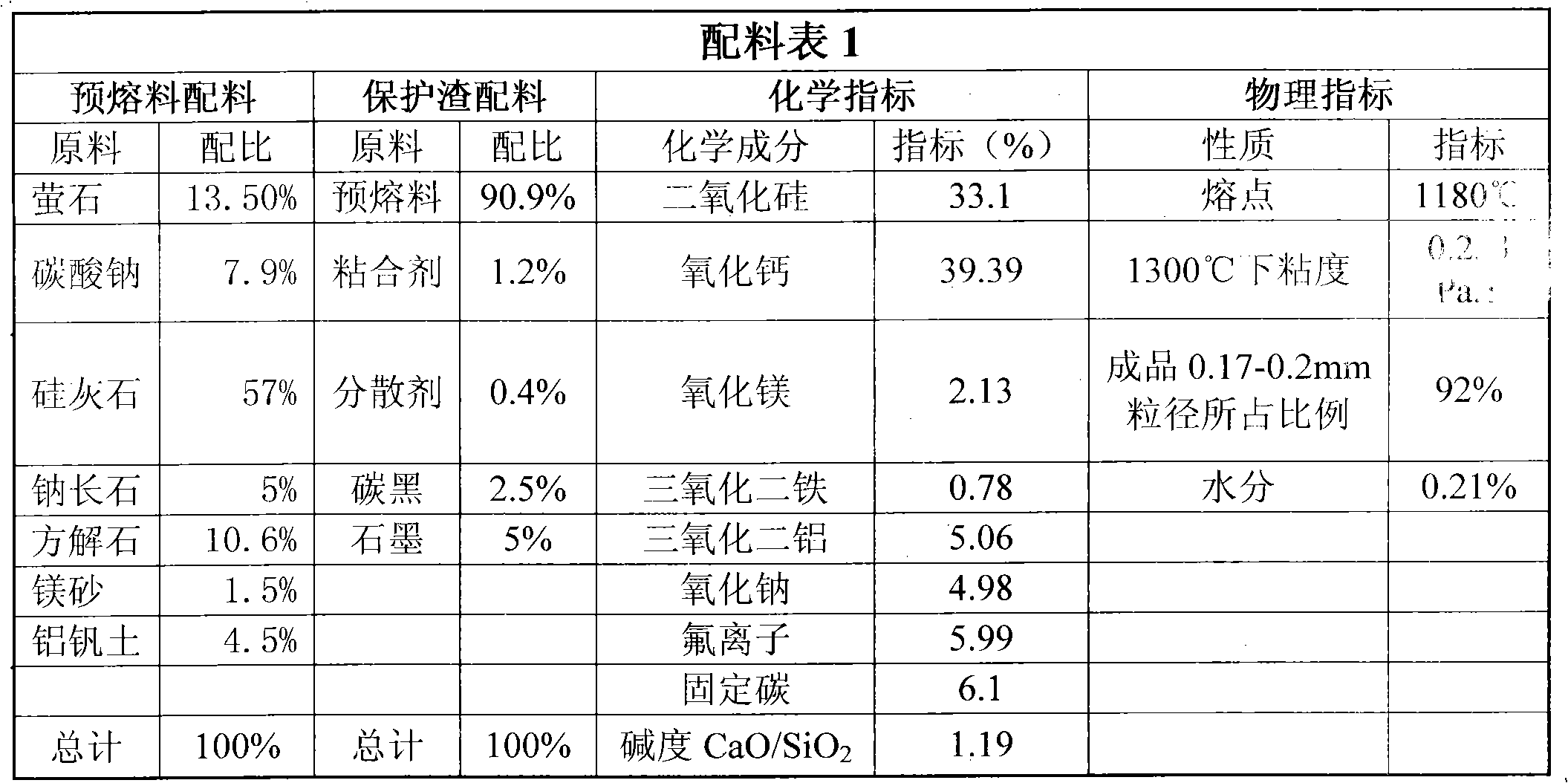

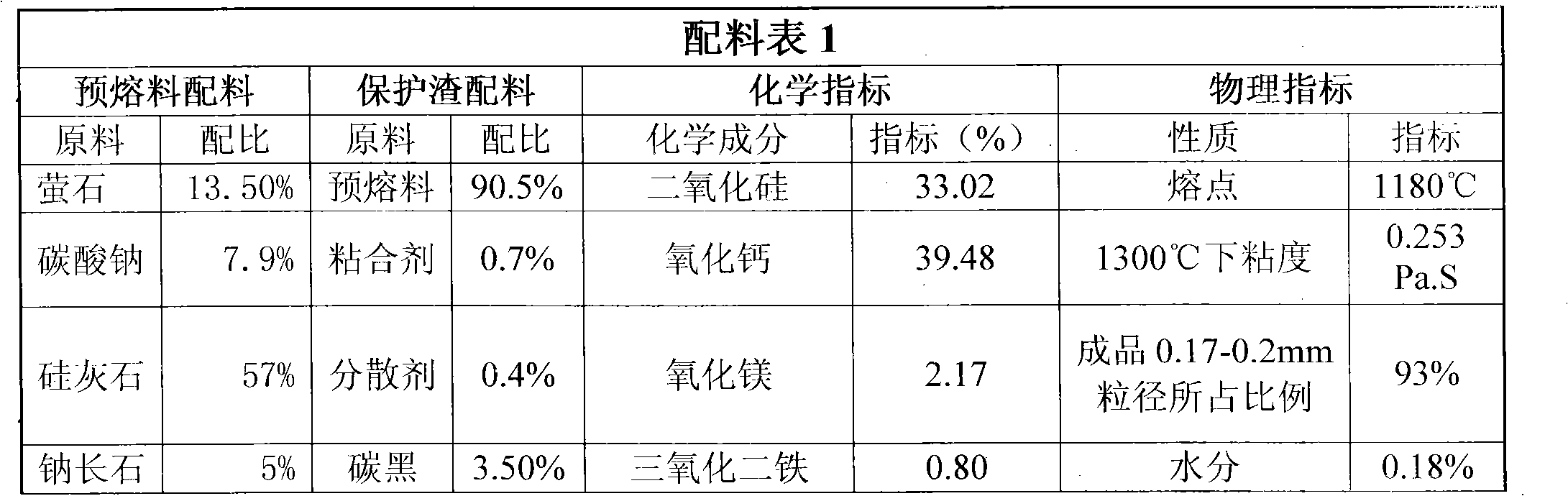

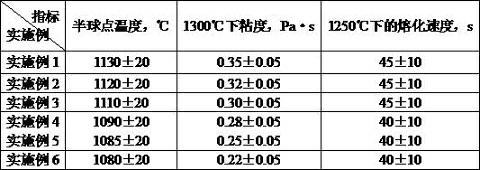

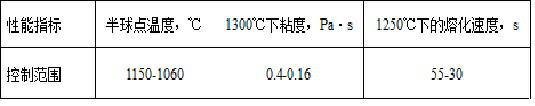

High-manganese high-nitrogen low-nickel stainless steel plate blank continuous casting crystallizer covering slag and preparation method thereof

The invention discloses high-manganese high-nitrogen low-nickel stainless steel plate blank continuous casting crystallizer covering slag which comprises the following components in percentage by weight: 54-57% of wollastonite, 9-13% of fluorite, 9-13% of sodium carbonate, 0-1% of lithium carbonate, 5-7% of glass dust, 8-12% of vanadine soil, 2.5-2.7% of soot carbon and 3-3.5% of graphite, and comprises the chemical components in percentage by weight: 31.9-34.9% of calcium oxide, 32.1-35.1% of silicon dioxide, 7.3-8.3% of aluminium oxide, 0.5-1.5% of magnesium oxide, 0.5-1.4% of iron sesquioxide, 4.4-6.4% of fluorion, 6.5-7.5% of sodium oxide, 0-0.39% of lithium oxide, 4.5-6.0% of fixed carbon and 4-7% of gas volatile matters. The alkalinity of the covering slag, namely the ratio of CaO to SiO2, is 0.91 to 1.00, the melting point of the covering slag is 1100 DEG C to 1160 DEG C, and the viscosity of the covering slag is 0.3 to 0.6 Pa.s at 1300 DEG C. The invention can solve the problems of easy crusting, slag entrainment, slag inclusion, slag sticking on casting blank surfaces, bubbles under skins, cracks, deep chatter mark, felting, bleed-out, and the like of the covering slag in the crystallizer during high-manganese high-nitrogen low-nickel stainless steel plate blank continuous casting, and has the advantages of uniform and stable slagging in the crystallizer, good casting blank quality, difficult felting and bleed-out, and the like.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

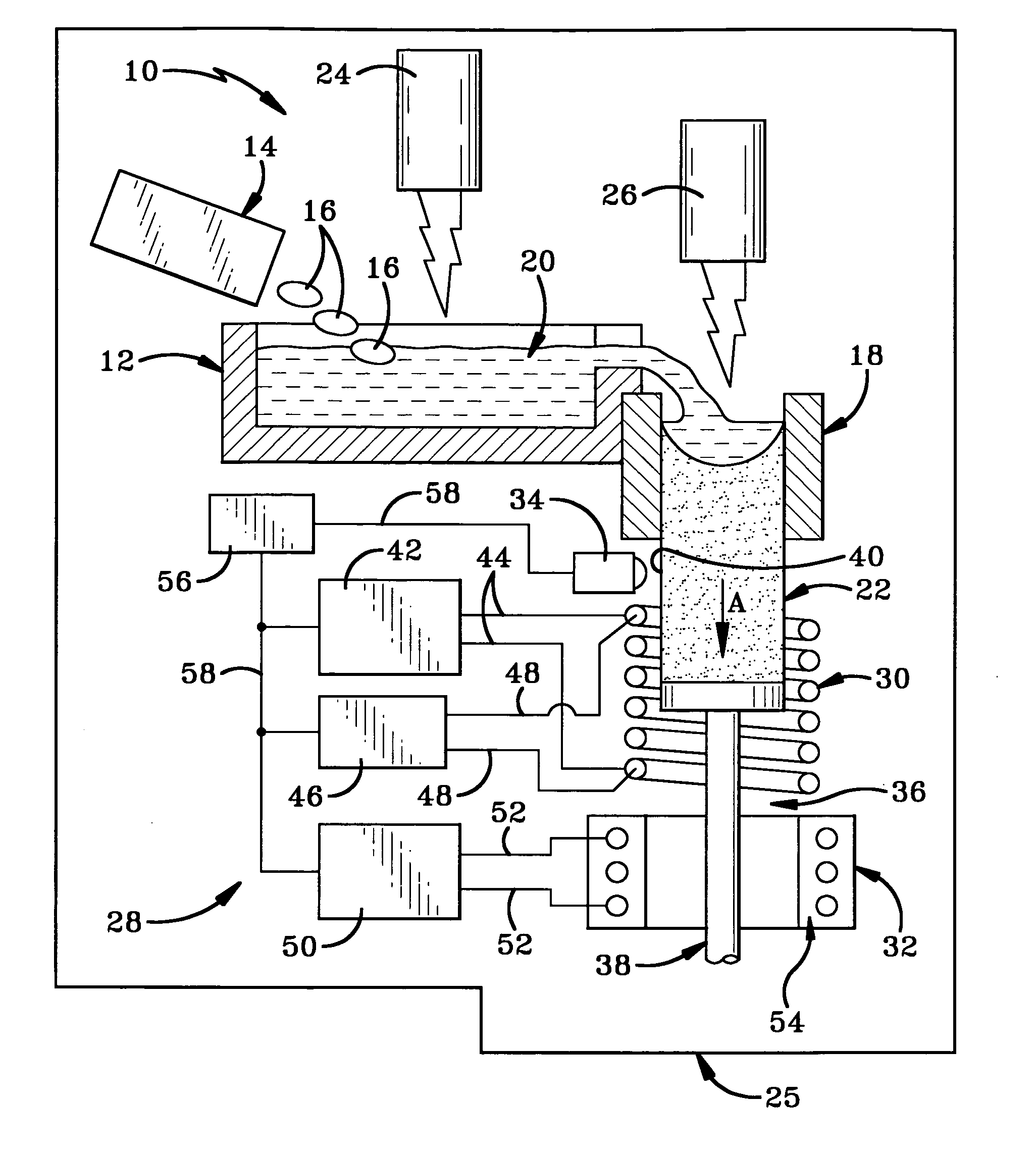

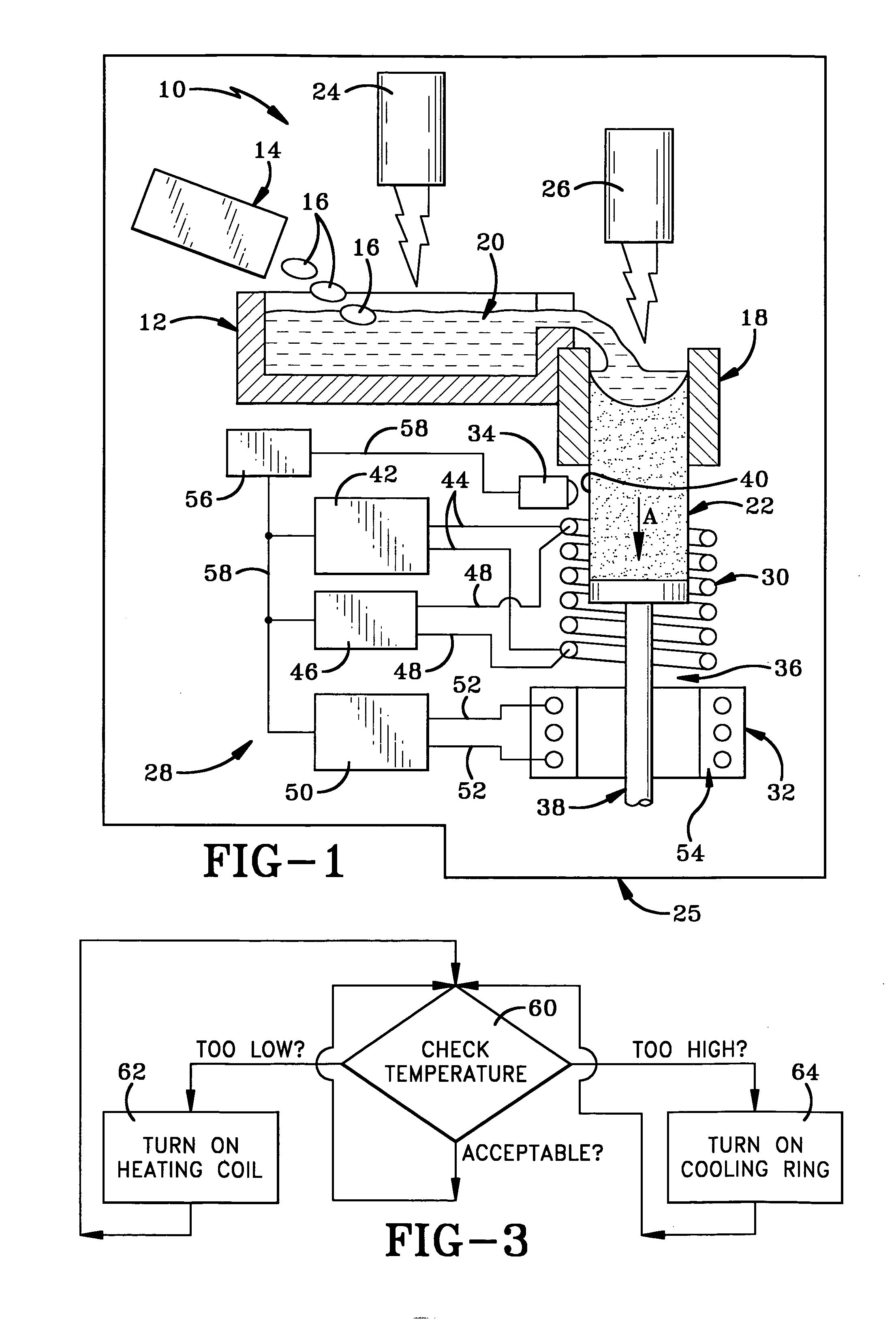

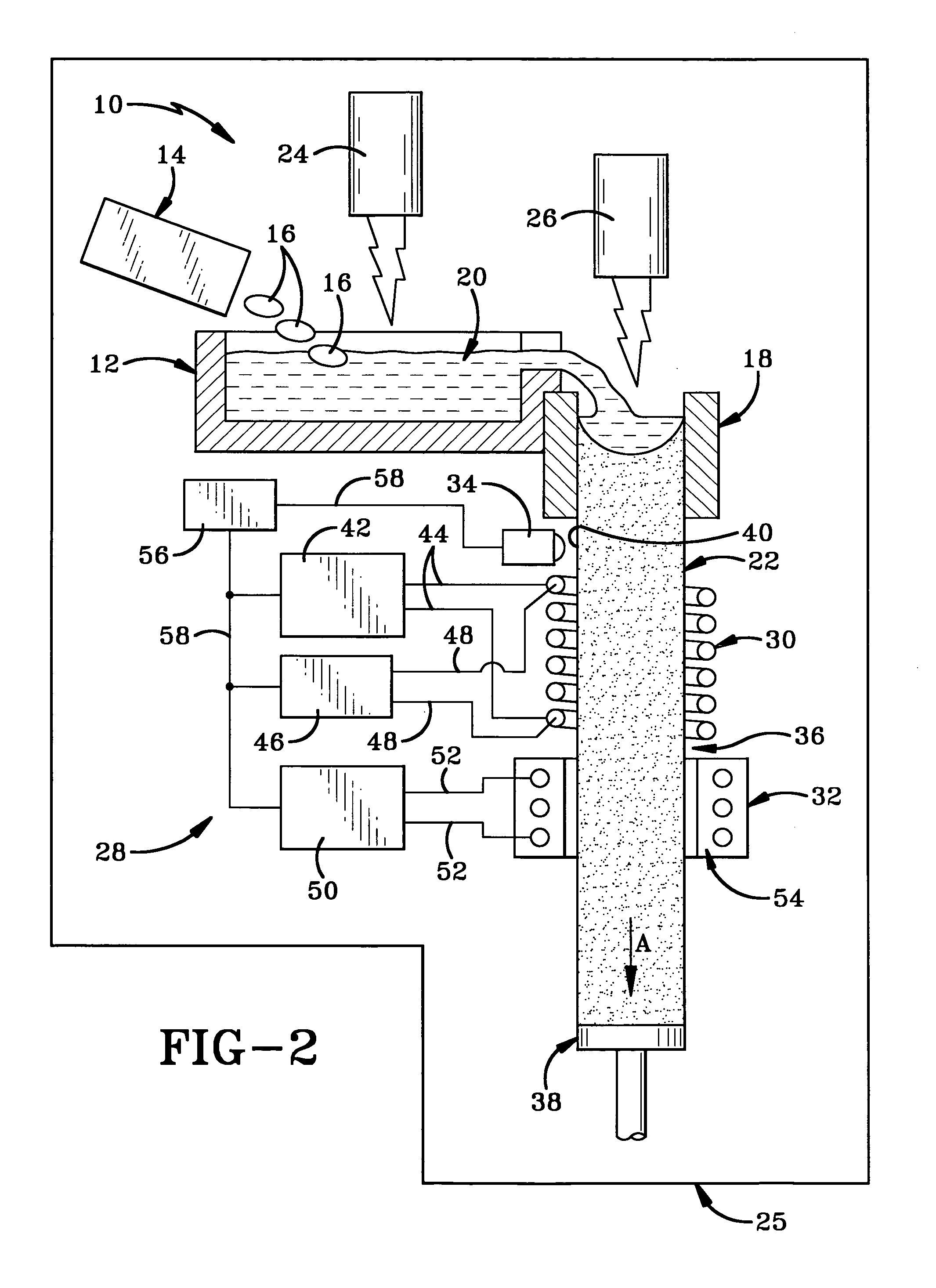

Method and apparatus for temperature control in a continuous casting furnace

ActiveUS20080035298A1Lighting and heating apparatusCasting safety devicesTemperature controlCasting mold

A continuous casting furnace includes a temperature control mechanism for controlling the temperature of a metal cast as it exits a continuous casting mold in order to provide improved characteristics of the metal cast. The temperature control mechanism includes a temperature sensor for sensing the temperature of the metal cast, and a heat source and cooling device for respectively heating and cooling the metal cast in light of the temperature of the metal cast. A control unit determines if the temperature of the metal cast is within a predetermined range and controls the heat source and cooling device accordingly. The heat source may double as a cooling device or the cooling device may be separate from the heat source.

Owner:HOWMET AEROSPACE INC

Laser cladding cobalt-base alloy coating material of continuous casting crystallizer copperplate and process

InactiveCN101775525AEnough widthDense tissueMetallic material coating processesSocial benefitsAutomatic control

The invention relates to a laser cladding cobalt-base alloy coating material of a continuous casting crystallizer copperplate and a process, which is characterized in that the cobalt-base alloy coating is a cobalt-base alloy and contains the components by weight percent: 0.6-1.2 percent of C, 20-30 percent of Cr, 13-20 percent of W, 3-5 percent of Mo, 0.8-1.2 percent of Si, 0.4-1.0 percent of Fe, 7-9 percent of Ni, 5 percent of Nb and the balance of Co. The cladding coating has compact tissue and does not have cracks or air holes and forms good metallurgical bonding with the surface of a crystallizer copperplate, and a cladding layer which is 2mm thick or above can be formed. The process can accurately control the thickness of the coating and realize automatic control on the whole process and has the advantages of low energy consumption, no pollution, high efficiency and low cost. Consequently, the invention can improve the disadvantages of the original crystallizer coating technology and has obvious economic benefits and social benefits.

Owner:QINHUANGDAO SHOUGANG CHANGBAI MOLD +1

Surface repairing method for thin-strip continuous casting crystallizing roller or casting blank continuous casting crystallizer

The invention discloses a surface repairing method for a thin-strip continuous casting crystallizing roller or a casting blank continuous casting crystallizer, comprising the following steps of: firstly, pre-processing the surface of the crystallizing roller or the crystallizer properly, then plating monolayer nickel base alloy on the surface of the crystallizing roller or the crystallizer, ending plating when the clad layer meets the requirement on size of the product and machining the crystallizing roller or the crystallizer. The nickel base alloy can be replaced by a nickel base composite clad layer which is formed by diffusing more than one micron-scale or nano-scale solid particles or fiber evenly in a substrate metal by taking pure nickel or the nickel base alloy as the substrate metal; the clad layer is even or of gradient; the clad layer further can be a multi-layer clad layer covered with the nickel base alloy or the nickel base composite clad layer again thereon by using pure nickel as a bottom clad layer. The method has the advantages that the clad layer of the crystallizing roller or the crystallizer is even and compact, has low inner stress, and high bonding strength with the matrix, thereby prolonging service life, reducing the manufacturing cost of continuous casting of the thin strip and casting blank and improving production efficiency and quality of product.

Owner:SHANGHAI BAOSTEEL EQUIP MAINTENANCE CO LTD

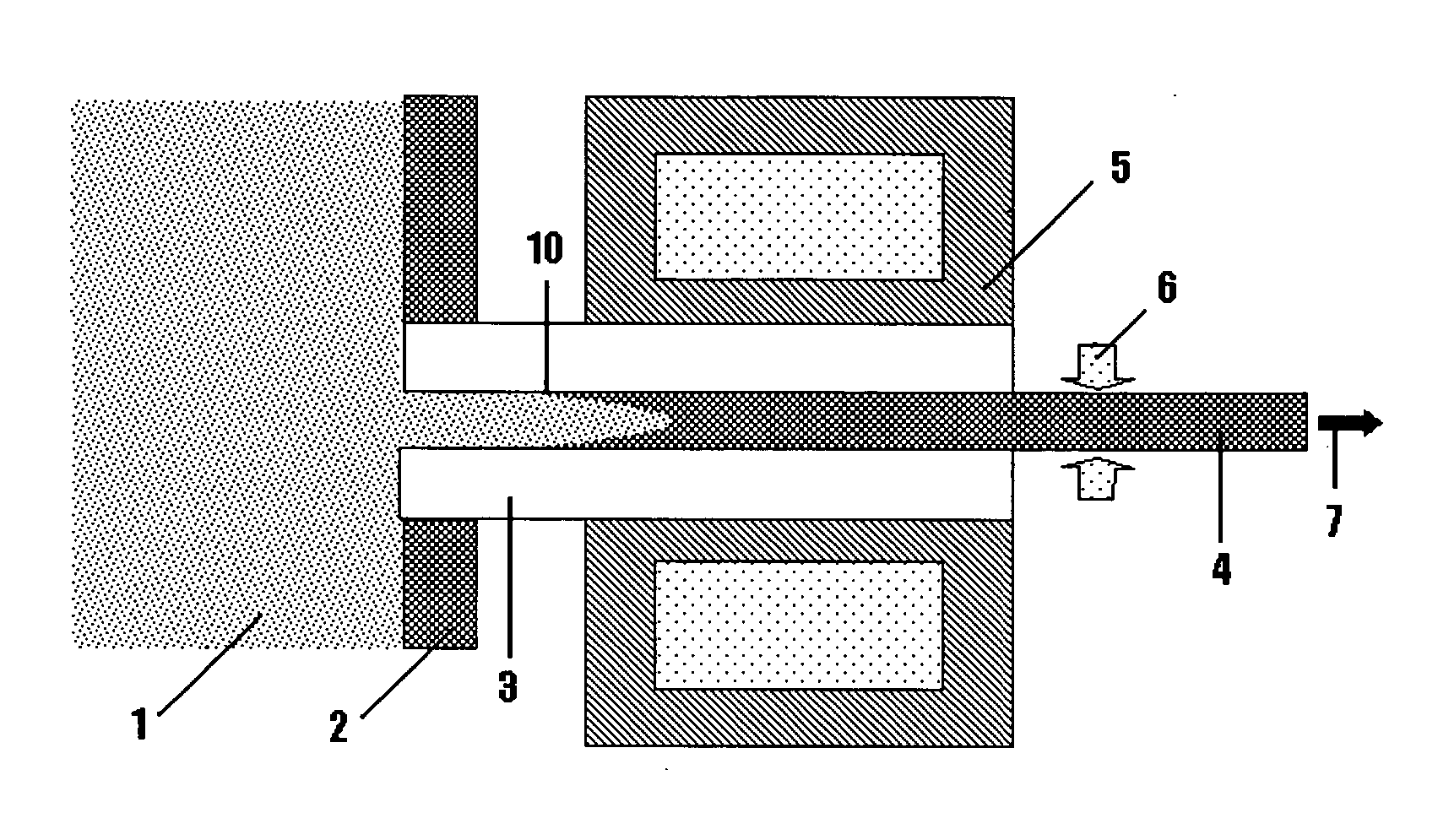

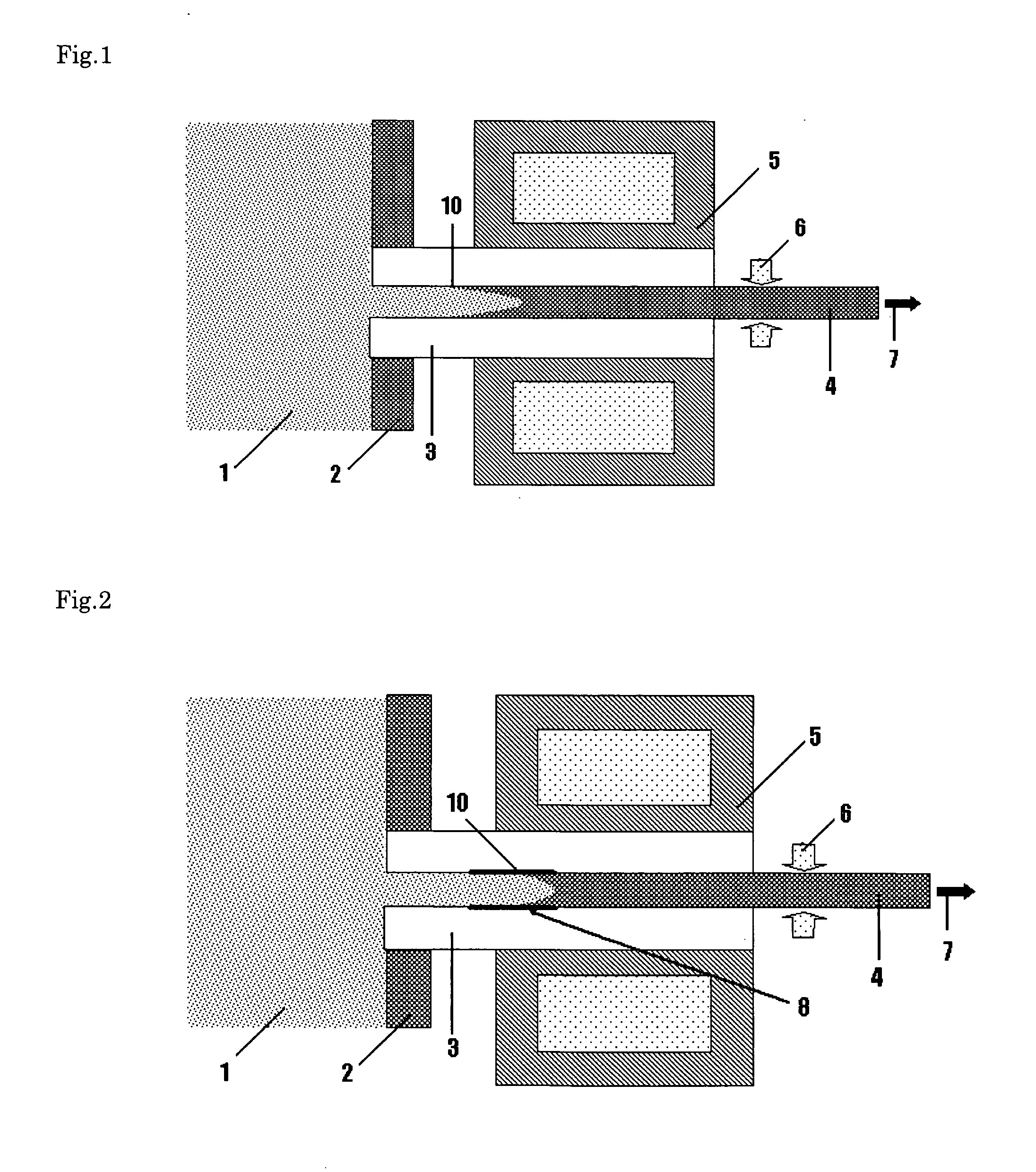

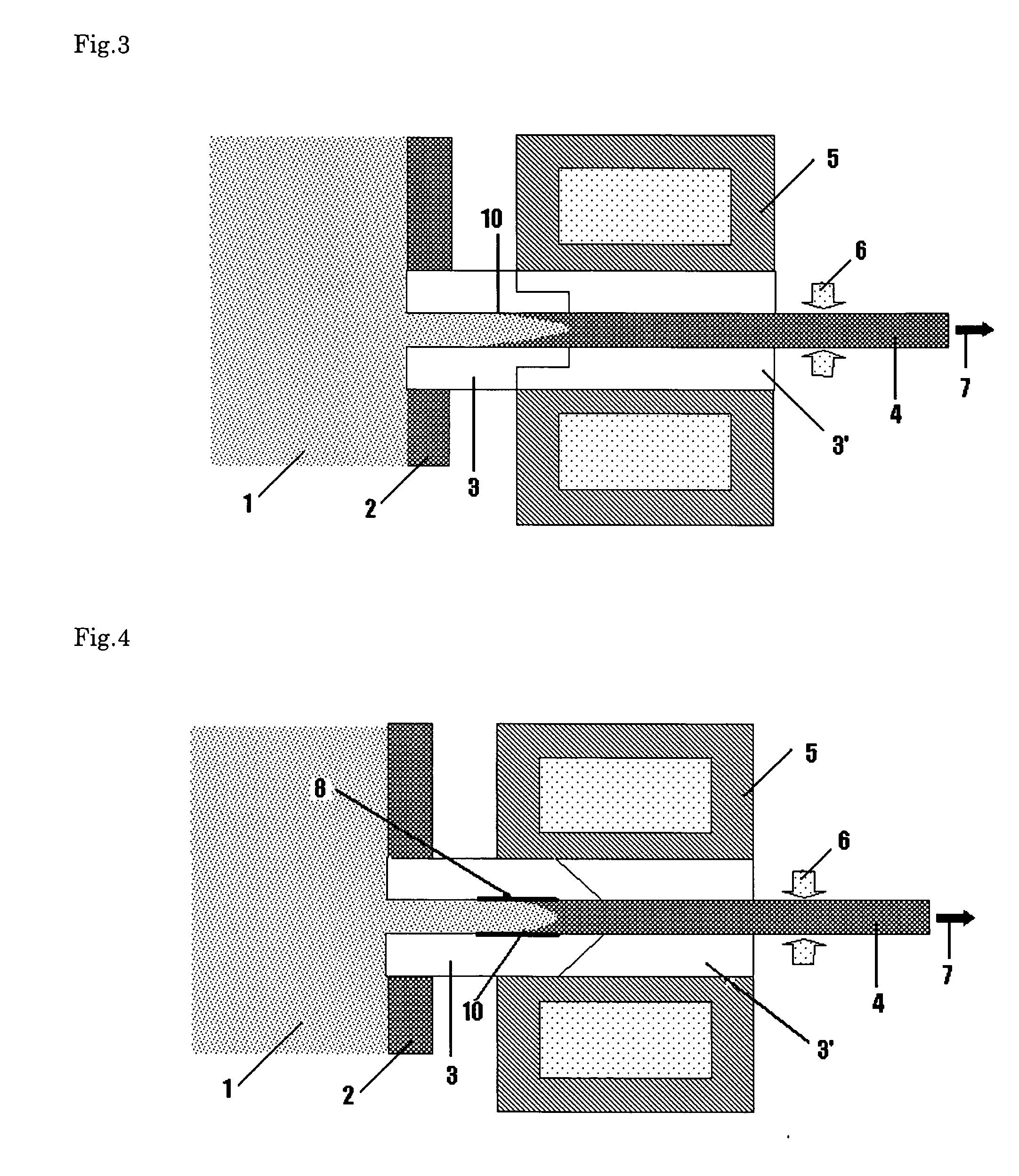

Continuous casting mold and a continuous casting method of copper alloy

A continuous casting mold for a Cu alloy, using any one member selected from a glassy carbon, a metal-based self-lubricating composite or a graphite with a bulk density exceeding 1.92, at least for the mold member including the solidification starting position of the Cu alloy melt. A continuous casting mold for a Cu alloy, composed of any one member selected from a graphite, a ceramic and a metal member or of a combination of two or more parts of members thereof, in which at least the inner wall in the solidification starting position of the Cu alloy melt is coated with a self-lubricant or a metal-based self-lubricating composite material. A continuous casting method of a Cu alloy, comprised of giving, at the time of continuously casting the Cu alloy by an intermittent pulling out method, a vibration that has a frequency larger than the slab intermittent pulling out frequency by two orders or more and that has a component vertical to the pulling out direction of the slab, or continuously supplying a lubricant or an anti-sticking material between the inner wall of the mold and the slab.

Owner:SUMITOMO METAL IND LTD

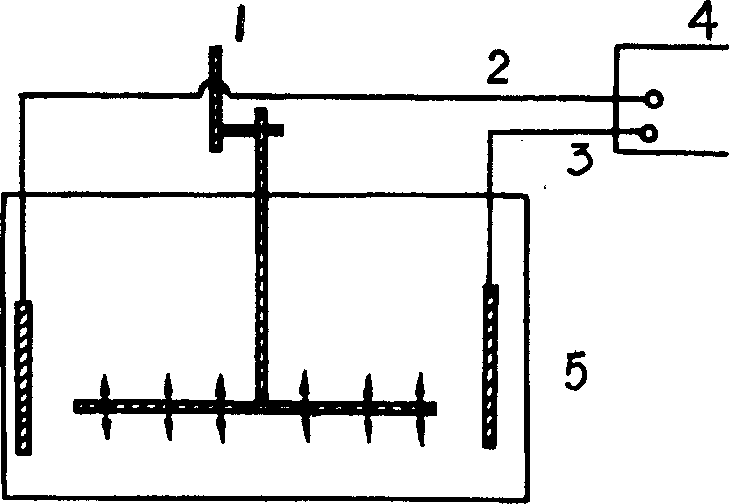

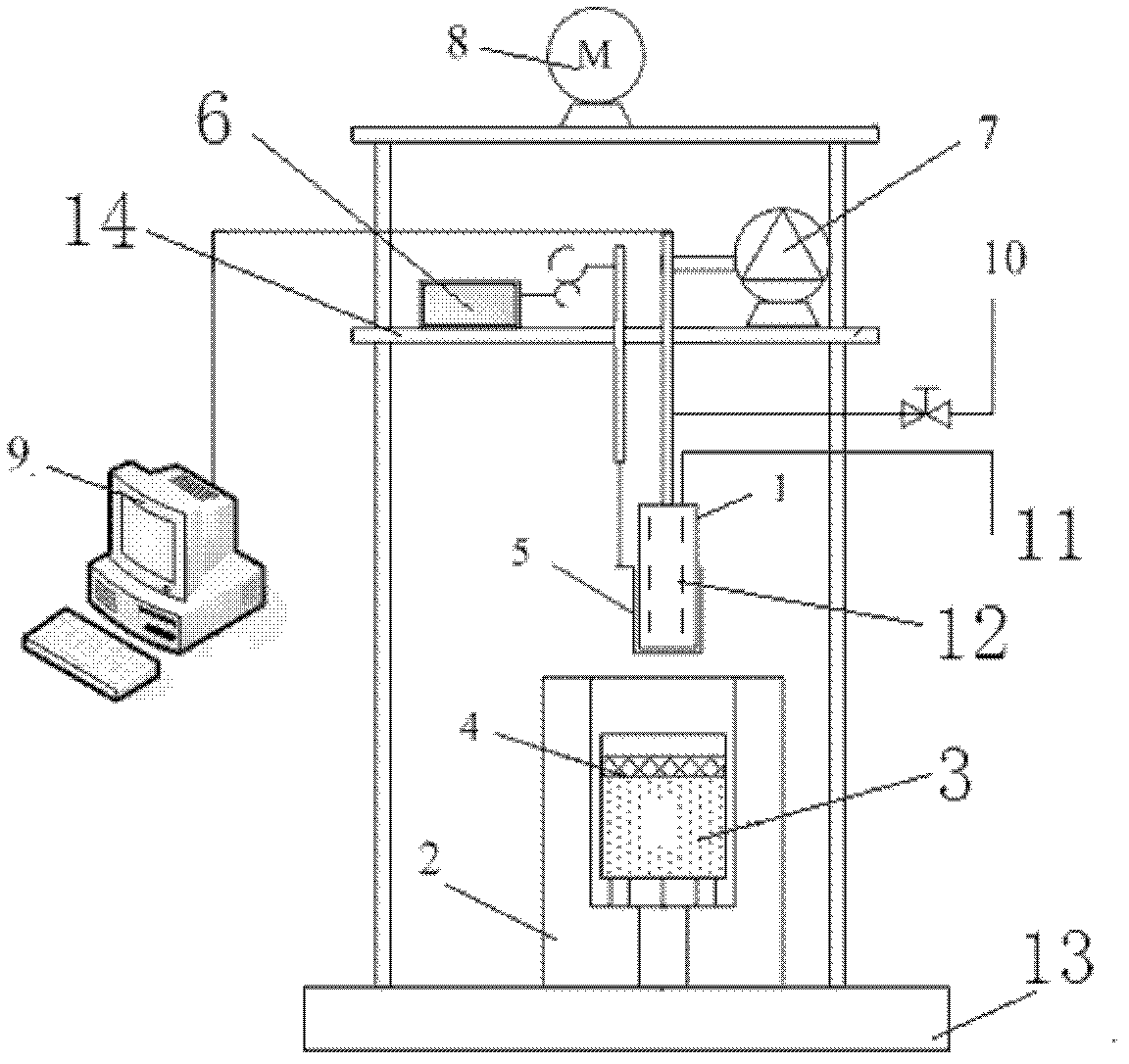

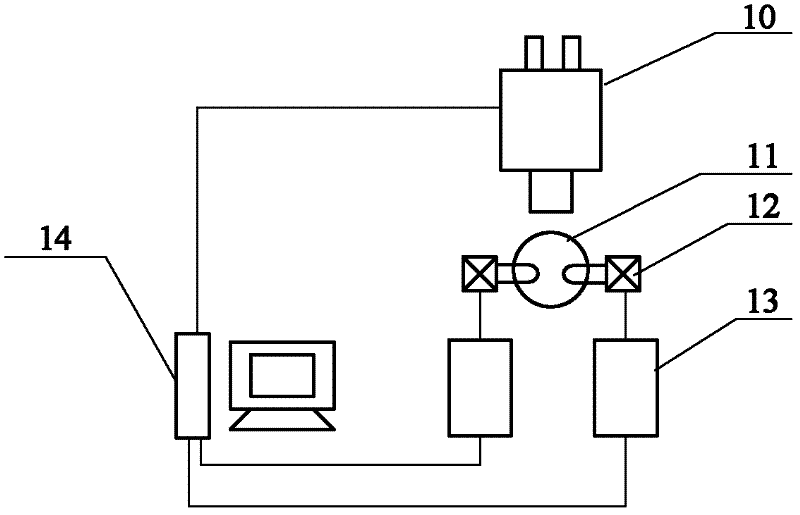

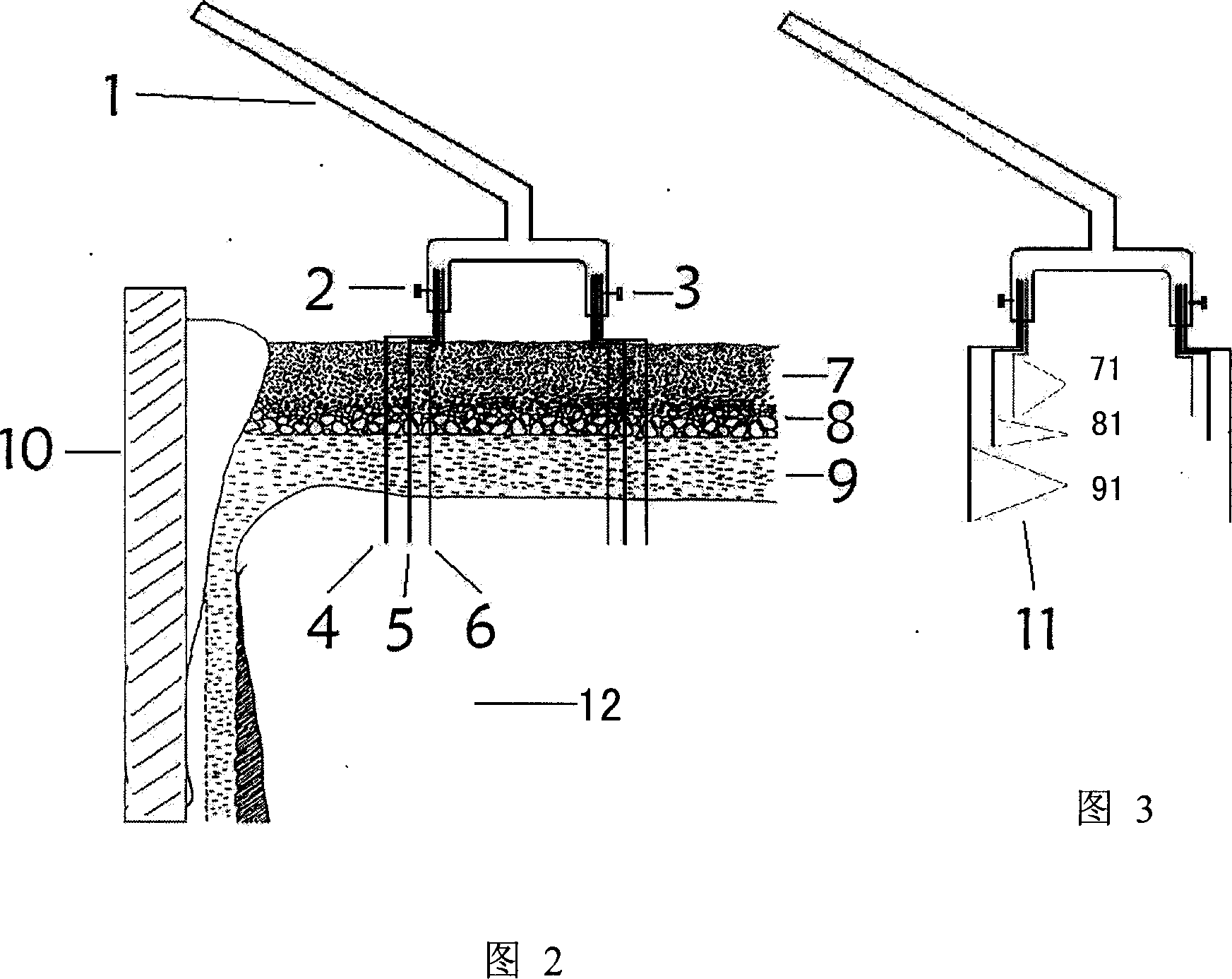

Steel liquid solidification simulator in continuous casting crystallizer

InactiveCN102357650AAchieve mechanical propertiesResearch on Vibration Waveform OptimizationHeat fluxMotor drive

A steel liquid solidification simulator in a continuous casting crystallizer comprises a machine seat, a steel furnace, a crystallizer, a throwing motor, a vibration motor, a cooling water channel and a data acquisition system. Two lead screws are arranged on the machine seat, one ends of the lead screws are perpendicular to the plane of the machine seat, and the other ends of the lead screws areconnected with a motor driving device. A lifting bracket is arranged on the lead screws. The steel furnace is arranged on the machine seat. Both the throwing motor and the vibration motor are arranged on the lifting bracket, the crystallizer is driven by the vibration motor to vertically vibrate, the throwing motor drives a throwing board, and the throwing board is located below the crystallizer.By simulating practical production process of continuous casting, the steel liquid solidification simulator in the continuous casting crystallizer measures heat flux change curves at meniscus positions in the crystallizer under different continuous casting process parameters, obtains a steel liquid solidification shell with characteristics of practical casting blank, and achieves research on initial solidification performance of steel liquid in the crystallizer and influence of the continuous casting process parameters on steel liquid initial solidification performance, and is convenient to operate, low in test cost and suitable for serving as a device for laboratory to research various process conditions of the continuous casting crystallizer.

Owner:CENT SOUTH UNIV

Cogged ingot continuous casting crystallizer protecting slag and preparation method thereof

The invention relates to a cogged ingot continuous casting mold powder, belonging to the iron and steel smelting technical field. The mold powder comprises the following chemical components with the weight percent of 30-35 percent of SiO2, 25-30 percent of CaO, 2.5-3.5 percent of MgO, 1.5-2.5 percent of Fe2O3, 3.5-4.5 percent of Al2O3, 4.5-5.5 percent of NaF2+CaF2, 5.5-6.5 percent of Na2O+K2O, 11-14.5 percent of solid carbon, and the rest is binder used for pelleting and water. A preparation method of the mold powder is also provided by the invention. The mold powder is exclusively applied to the cogged ingot continuous casting mold powder, in particular to cogged ingot 27SiMn continuous casting mold. The zero defect production of continuous casting can be realized, the hot delivery and hot charging of the continuous casting can be guaranteed, the systematic energy consumption from the continuous casting to rolled products can be lowered, the production cycle from the continuous casting slab to the rolled products can be shortened, and the quality of steels can be ensured.

Owner:SHANDONG IRON & STEEL CO LTD

Continuous casting crystallizer covering slag special for extra-thick slab peritectic steel and preparation method thereof

ActiveCN102029366ALarge thermal resistanceReduce the speed of heat transfer to the outsideAlkalinityHeat resistance

The invention discloses continuous casting crystallizer covering slag special for extra-thick slab peritectic steel and a preparation method thereof. In the covering slag, a peritectic reaction is performed in the process of solidifying the peritectic steel, and the overquick or overlarge volume contraction of the peritectic steel leads to the surface quality problems such as casting blank cracks, and causes dangers in a continuous casting process. In consideration of the characteristics of the peritectic steel, the covering slag for the extra-thick slab peritectic steel shall be cooled slowly and has higher alkalinity and melting points so as to increase the heat resistance of a slag membrane of the covering slag, reduce the speed of transferring heat outwards by casting blanks, and increase the uniformity of heat transfer.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

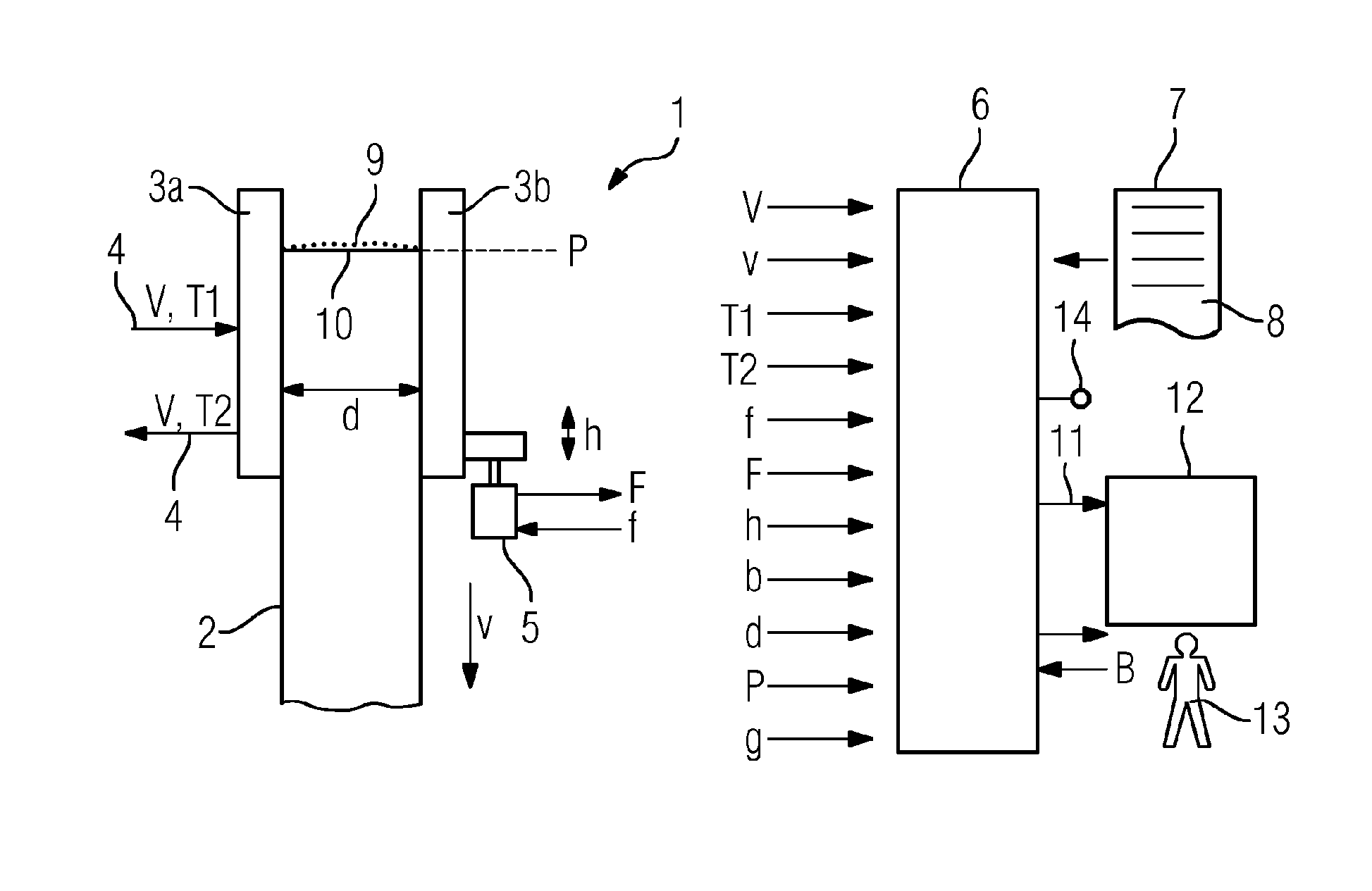

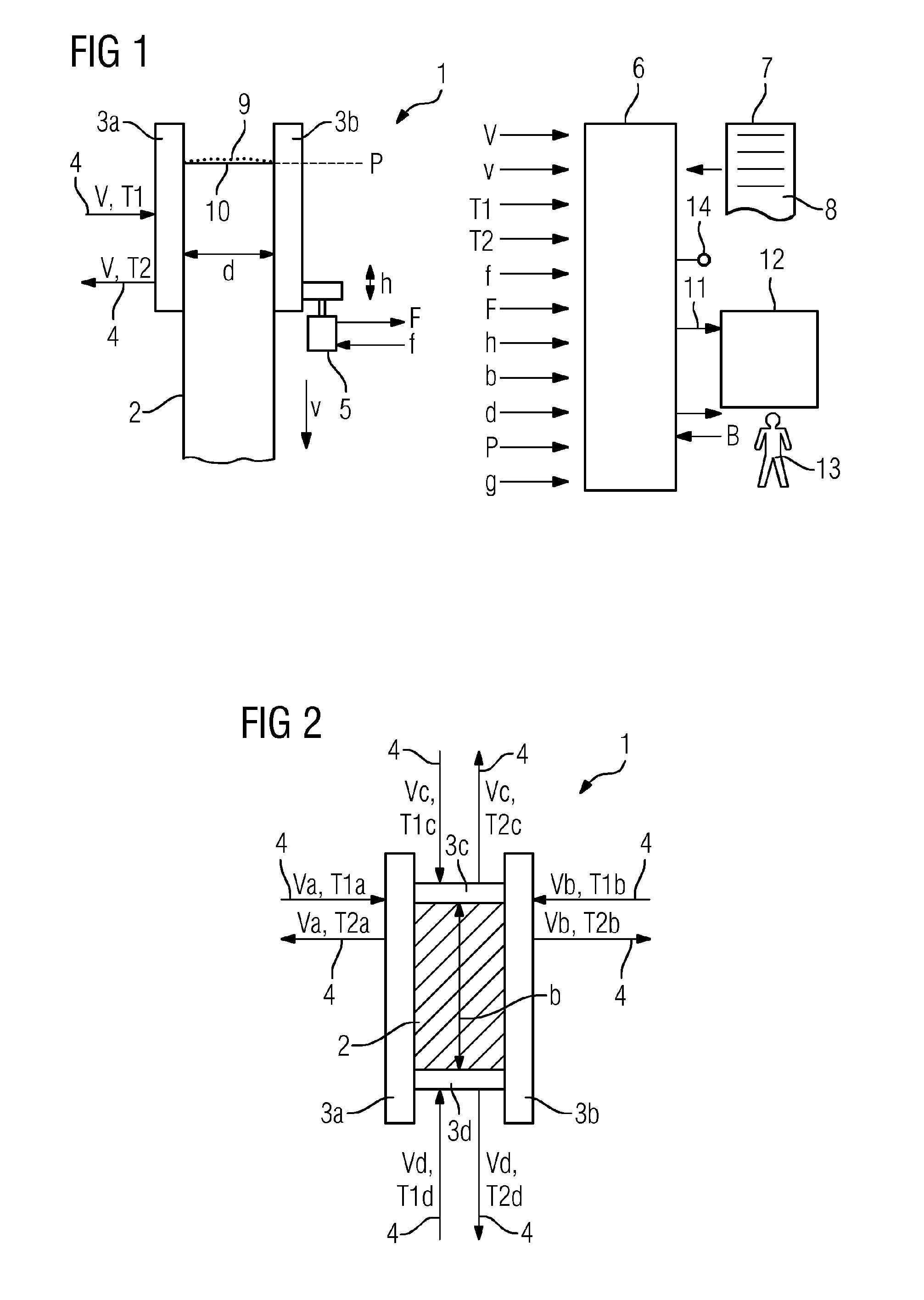

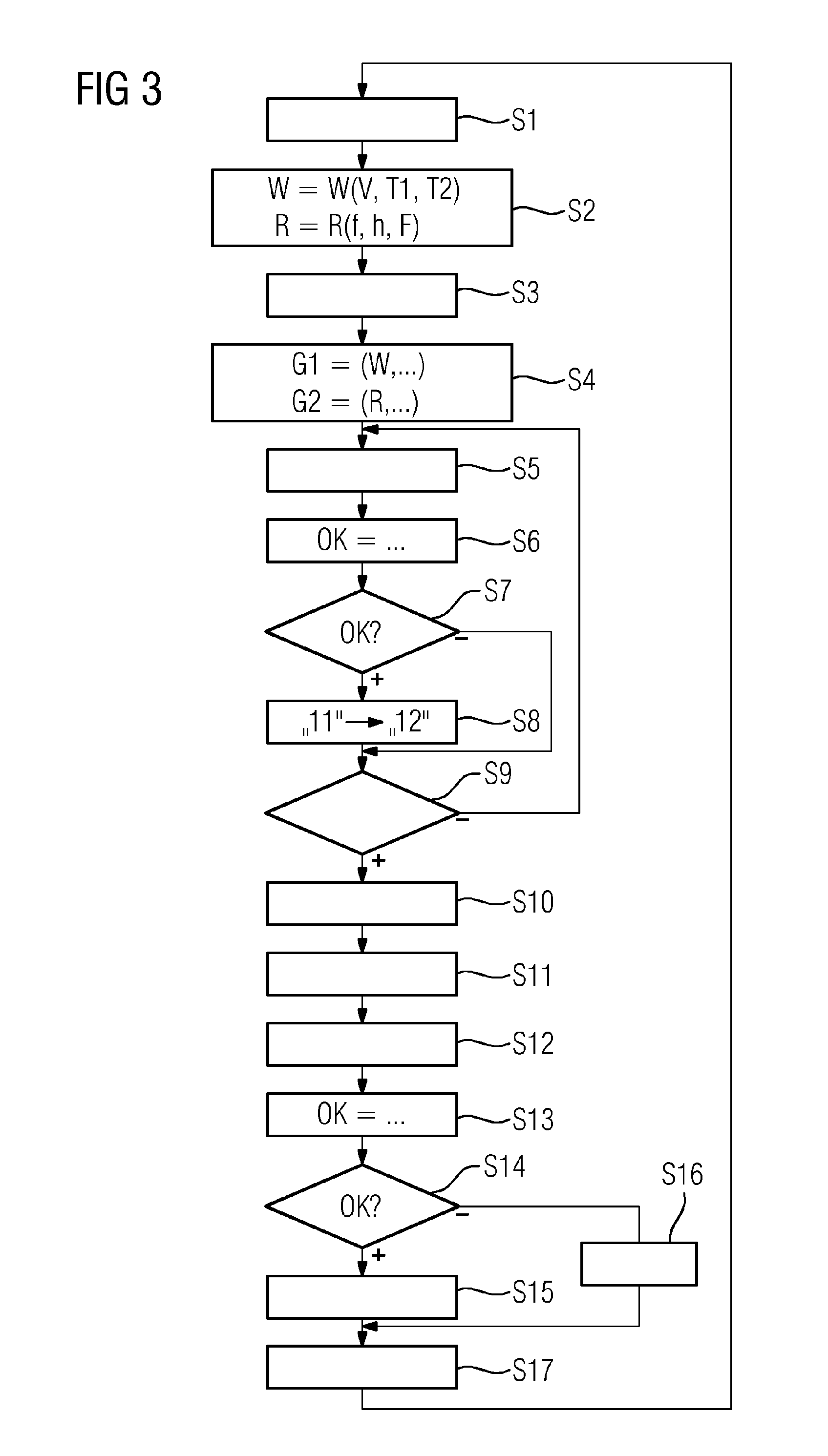

Monitoring method for a continuous casting mould including building up a database

InactiveUS20150314368A1Casting safety devicesMould controlling devicesStability criterionMaterials science

A monitoring device (6) records variables that are characteristic of operating parameters of a continuous casting mold (1) for casting a metal strand (2). The monitoring device (6) records at least some of the characteristic variables by independently performing measurements during the casting of the metal strand (2). The monitoring device (6) forms groups (G1, G2) of operating parameters and independently tests whether the operating parameters of the respective group (G1, G2) satisfy a respective predetermined stability criterion. The monitoring device (6) accepts the operating parameters into a database (12). The monitoring device (6) determines those data records (11) contained in the database (12) that coincide in their input variables with the basic operating parameters and determines admissible operating parameter ranges for supplementary operating parameters. The monitoring device (6) independently tests whether the supplementary operating parameters lie within the admissible operating parameter ranges.

Owner:PRIMETALS TECH AUSTRIA GMBH

Protective slag of large-profile round billet continuous-casting crystallizer and method for preparing same

The invention discloses a protective slag of a large-profile round billet continuous-casting crystallizer and a method for preparing same. The protective slag comprises the following components by weight percentage: 27-33% of SiO2, 24-30% of CaO, 1-3% of MgO, not more than 2% of Fe2O3, 5-10% of Al2O3, 4-9% of Na2O, 1-4% of F, 0.5-2.5% of MnO and 15-20% of C (solid). The components of the protective slag of the continuous casting crystallizer are selected according to the regions of fake siliceous lime in a three-element system CaO-SiO2-Al2O3; out of the components for composing the protectiveslag, the CaO is taken as a main alkaline material, the SiO2 is taken as a main acid material, the Na2O, the CaF2 and the Li2O are taken as main flux agents, and the carbon component is taken as a framework material and a fusing speed controlling agent. By organic combination of the basic materials and the flux agents, the chemical components of the protective slag are adjusted, so as to adjust the physico-chemical indexes of the protective slag, such as fusing temperature, viscosity, crystallization performance, absorbing and including capability, heat conducting capability and the like and meet the requirements of keeping normal slag consumption, thickness of liquid slag layer and reasonable heat conducting amount under a special profile condition, thus ensuring the thickness of the billet shell at the outlet end of the crystallizer and realizing non-gluing continuous casting production.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

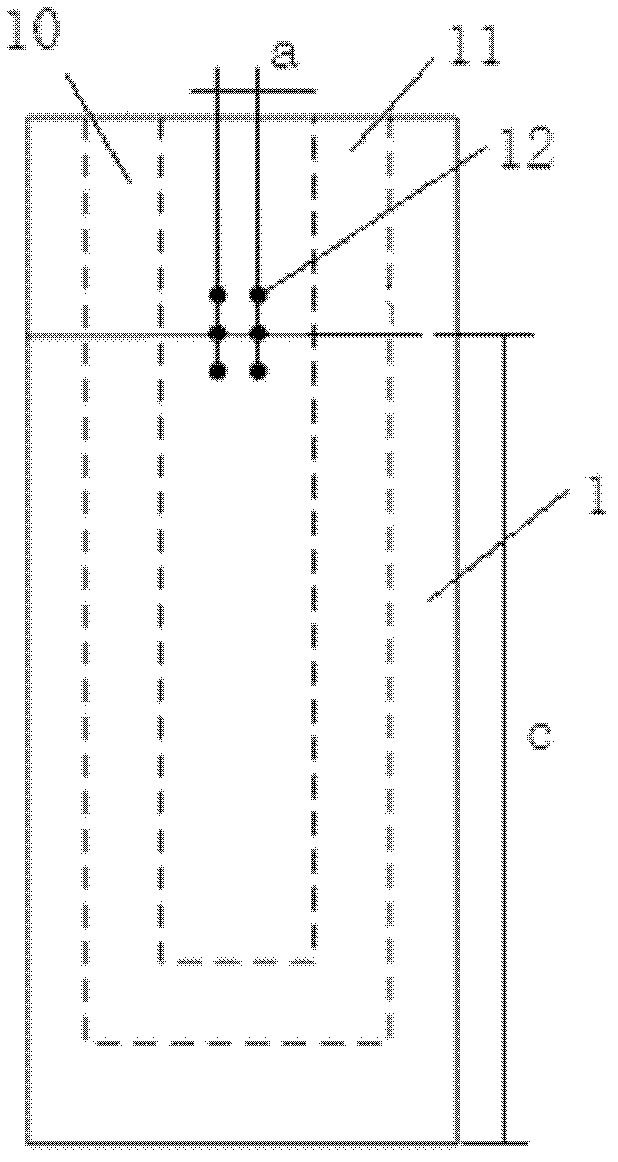

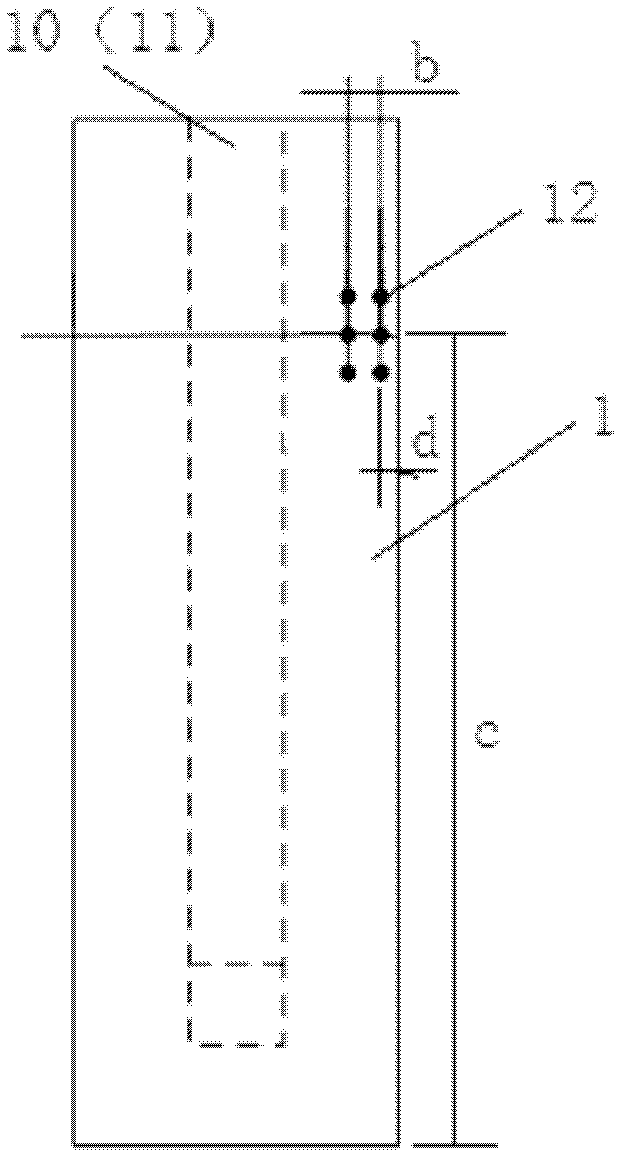

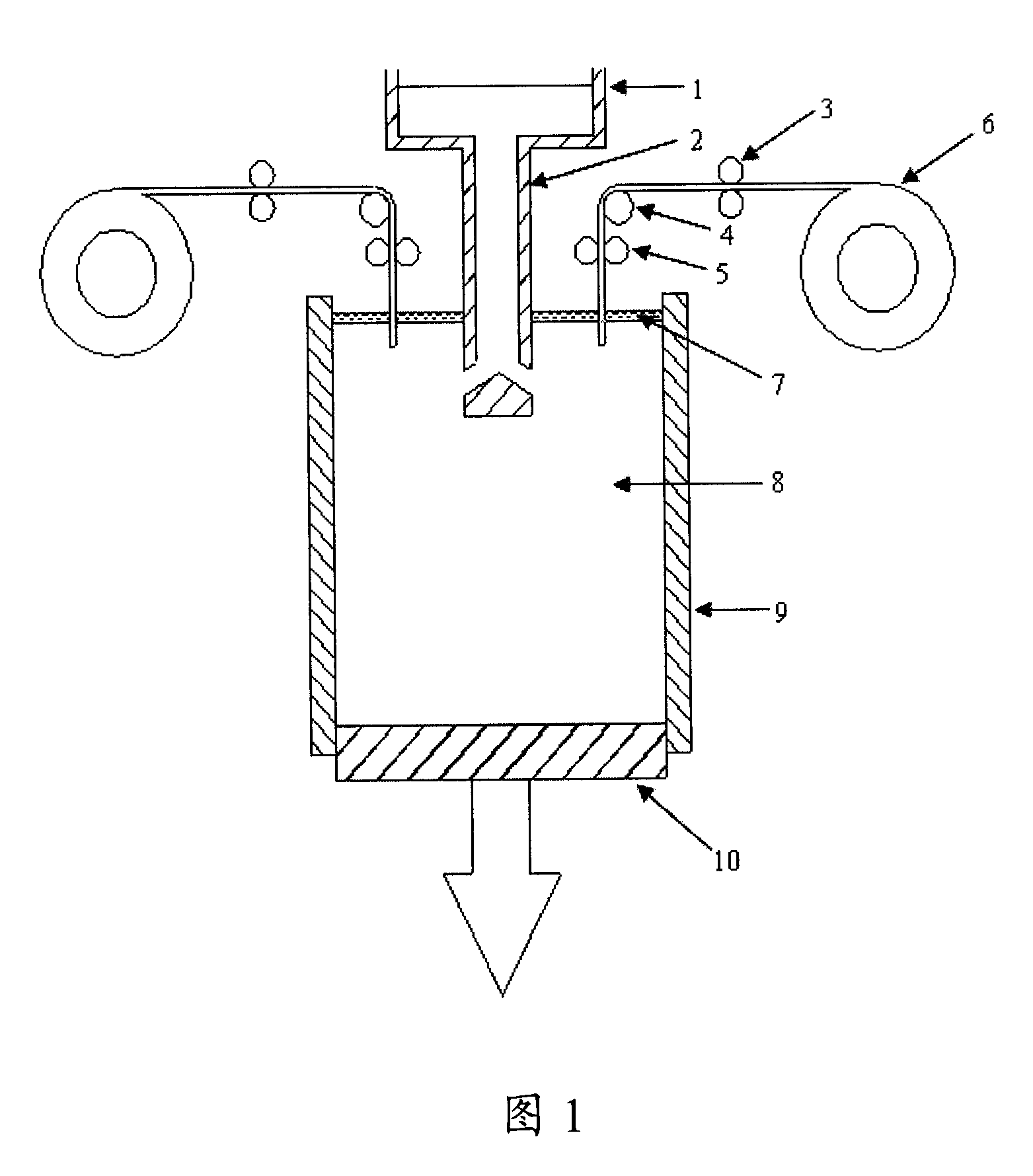

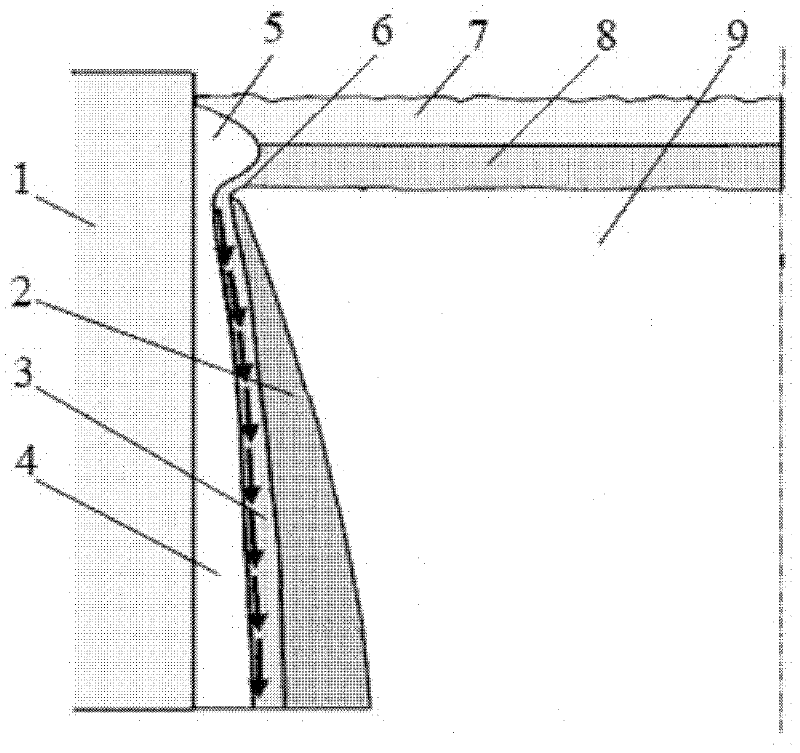

Continuous casting crystallizer capable of controlling liquid level flow field and wave motion

The invention relates to a device of continuous casting crystallization mould with a controllable liquid level and fluctuation, pertaining to the metal continuous casting process technology field. The invention can reduce slag entrapment on liquid surface of crystallization mould according to the mechanism of slag entrapment production in crystallization mould to inhibit metallic liquid flow horizontally. The main part of the invention is basically the same as the traditional crystallization mould, while the difference lies in that the two sides of the crystallization mould upper part are provided with self consumption metal plates and feeding mechanisms; the self consumption metal plate is inserted into the metallic liquid of the crystallization mould through a straightening roller, a guide roller and a transport roller; continuously casting billets are finally drawn off by a dummy bar. The structure of the invention comprises: a metallic pouring basket (1), a submerged nozzle (2), a straightening roller(3), a guide roller(4), a conveying roller (5), a self-consumption metal plate (6), mould power (7), casting billets (8), a water cooled crystallization mould (9) and a dummy bar (10). The invention can reduce and inhibit the slag entrapment production in the crystallization mould, thereby improving quality of continuous casting billet.

Owner:SHANGHAI UNIV

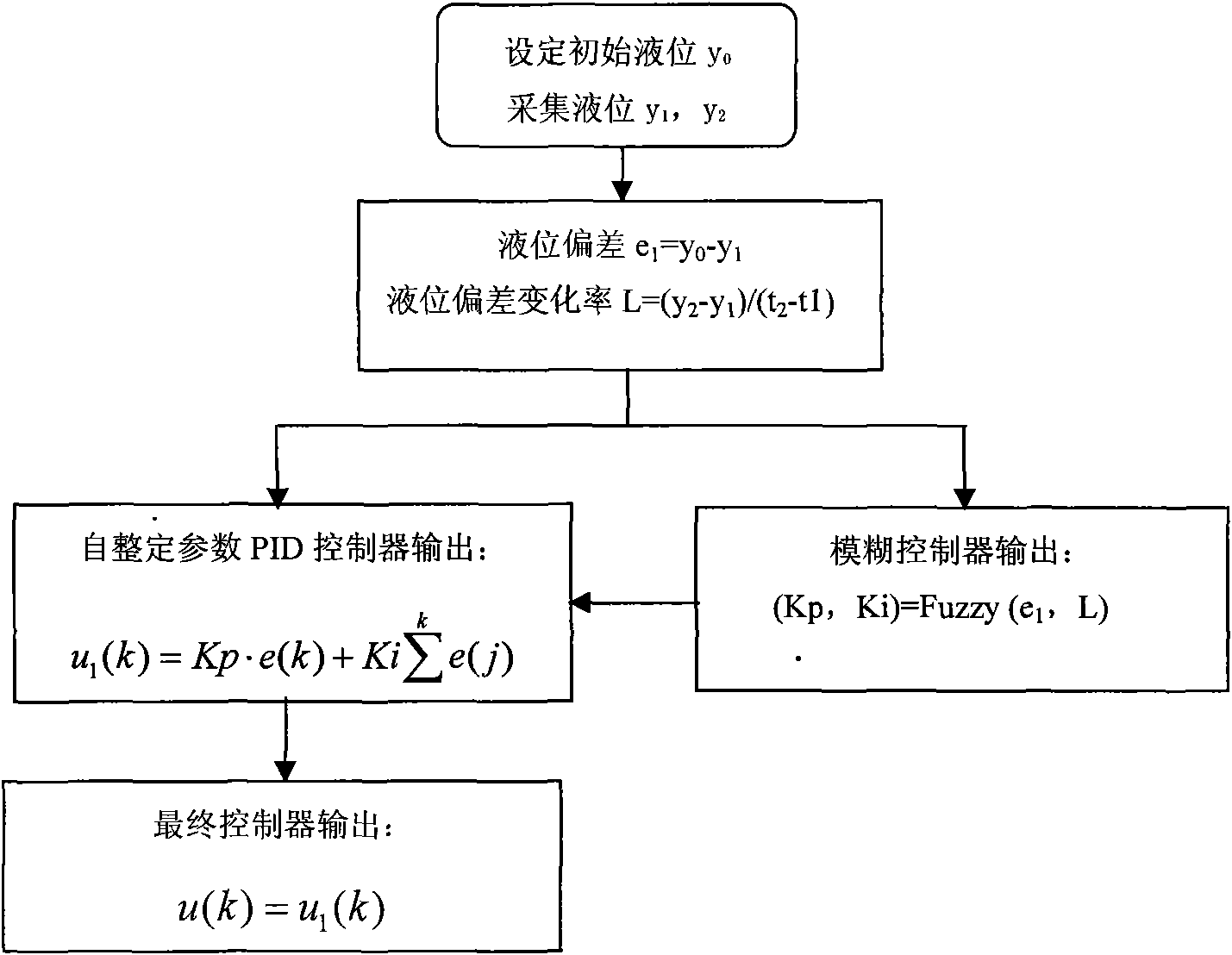

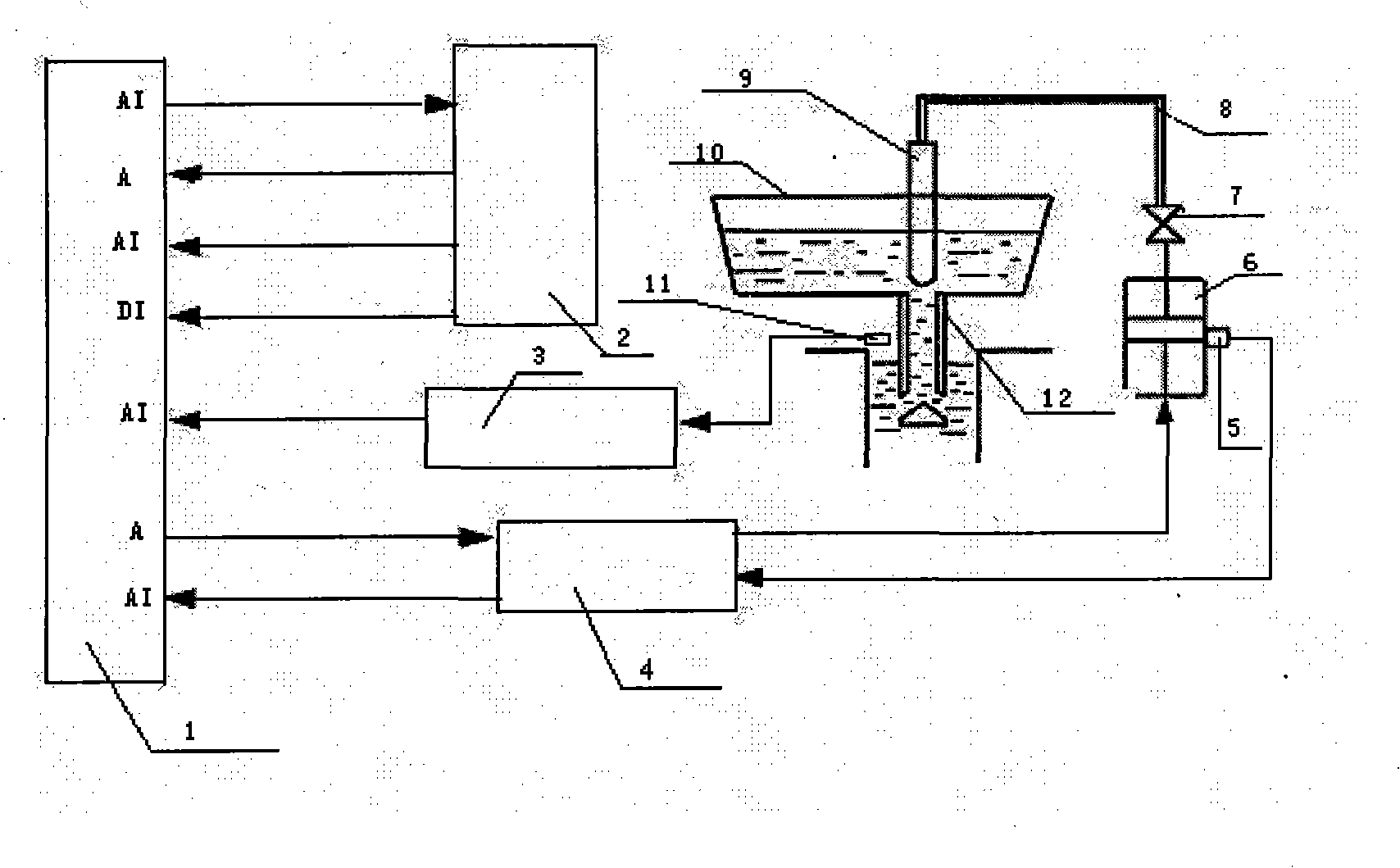

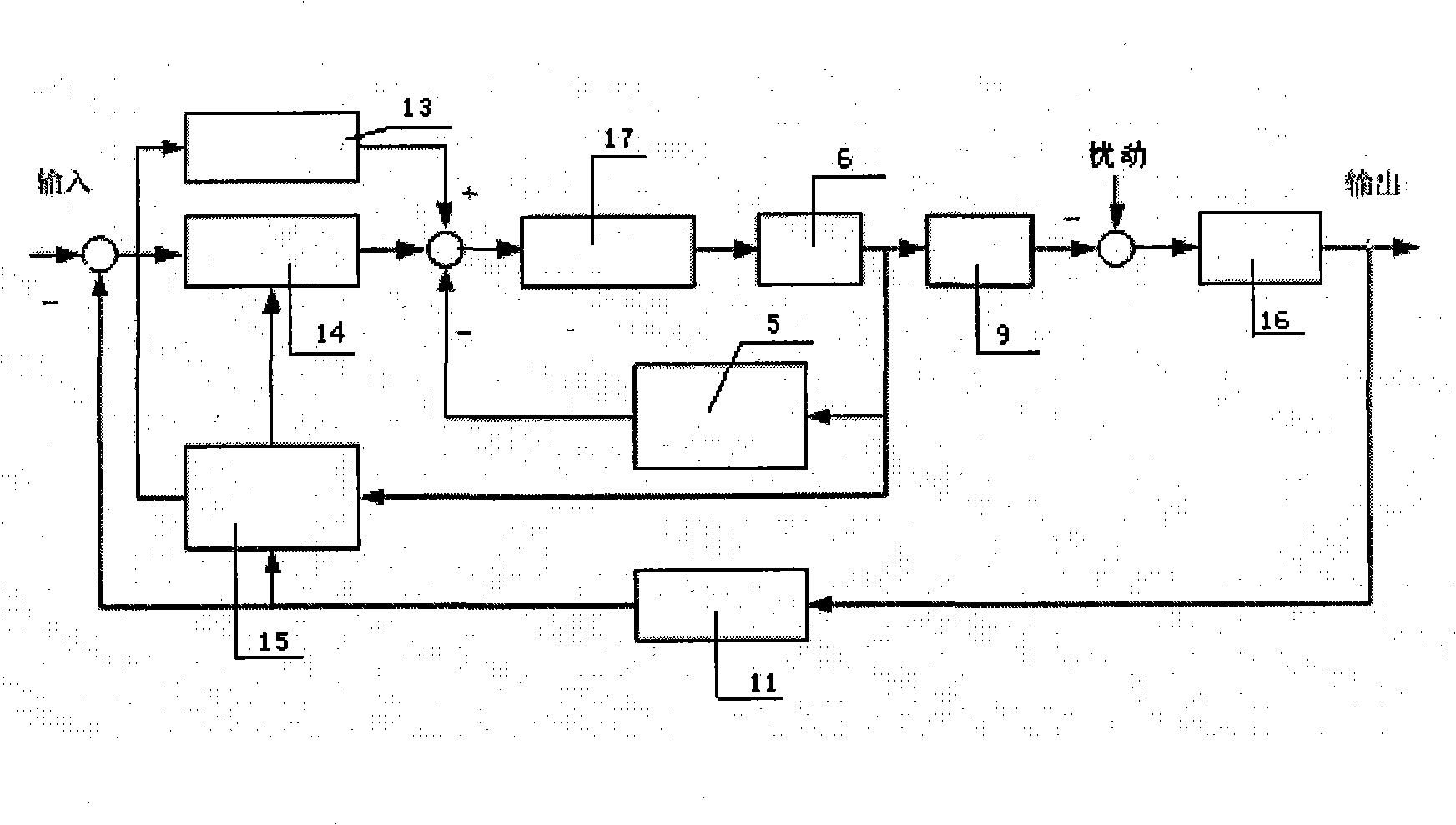

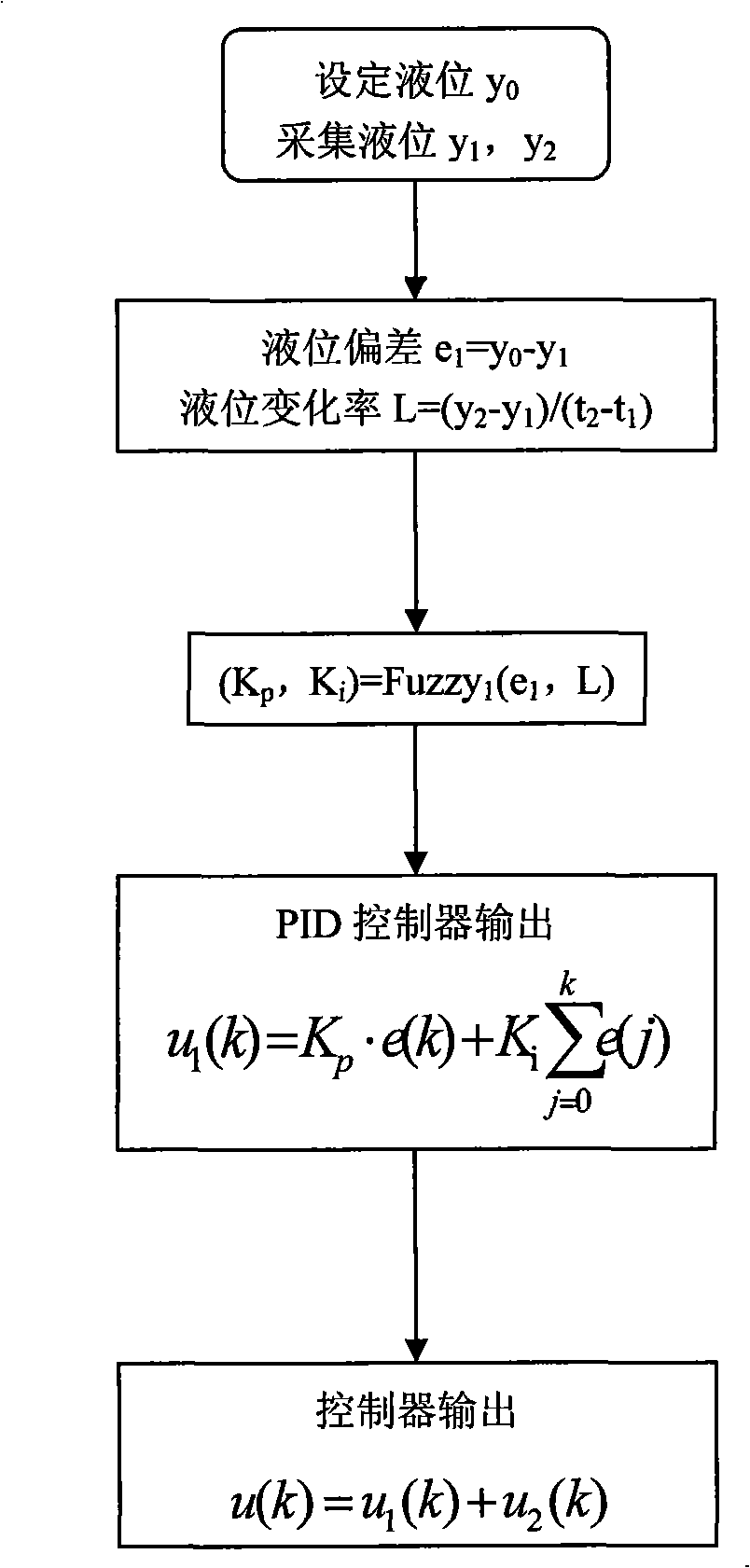

Liquid level control method of continuous casting crystallizer based on Fuzzy-PID

The invention relates to a liquid level control method of a continuous casting crystallizer based on Fuzzy-PID and belongs to the technical field of continuous casting production. The liquid level control method makes use of fuzzy control to carry out online correction of parameters in self-adjusting parameter PID control. Under the control of a computer and a PLC, the control method makes use of self-setting parameter PID control and fuzzy control to realize mixed control of the liquid level of the crystallizer, and also adopts a flow rate deviation compensating module, and the like. The control process of the control method comprises the following steps: setting an initial liquid level y0 and acquiring liquid levels y1 and y2 through a liquid level sensor and a liquid level measuring device; inputting the acquired data y1 and y2 in a PLC; adopting the self-setting parameter PID control and the fuzzy control to realize mixed control of a processing signal; and carrying out compensation through the compensating module; moreover, the output of the PLC, u(k) is equal to u1(k), and the PLC controls the position of a stopper through a stopper controller so as to control the liquid level of the crystallizer.

Owner:NORTHEASTERN UNIV LIAONING

Method for thermally spraying protective coating on surface of copper plate of continuous casting crystallizer

The invention discloses a method for thermally spraying a protective coating on the surface of a copper plate of a continuous casting crystallizer. The method comprises the following steps: pretreating the surface of the copper plate of the crystallizer; using an alloy powder material which consists of the following thermal spraying powder components in percentage by weight: 0.4 to 1.0 percent of C, 12 to 20 percent of Cr, 2.5 to 4.0 percent of B, 2.0 to 5.0 percent of Si, less than or equal to 10 percent of W, less than or equal to 5 percent of Fe, less than or equal to 4 percent of Mo, less than or equal to 4 percent of Cu and the balance of Ni and has a grain size of between 10 and 70 mu m; spraying the alloy powder material on the surface of the copper plate for the crystallizer by using an ultrasonic flame spraying device or a powder flame spraying device, wherein the thickness of the coat is between 0.1 and 1.2 millimeters; and performing thermal treatment with the following thermal treatment technical parameters that: a thermal treatment temperature is between 950 and 1,100 DEG C; and heat preservation time is between 10 and 50 minutes. The method has simple operation process, and the prepared coating has high bonding strength with a substrate body of the copper plate of the crystallizer and high consistency and stability.

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE

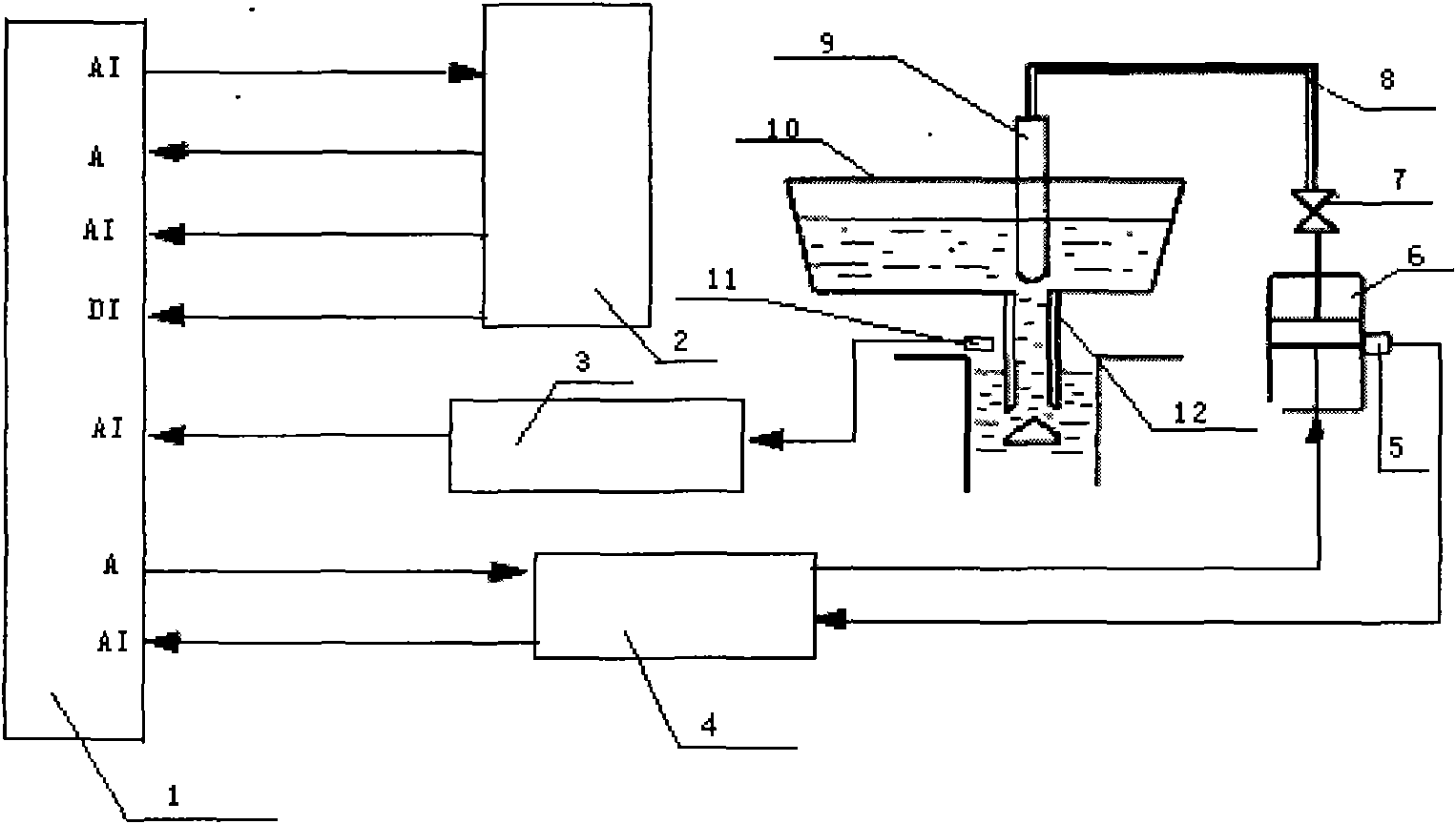

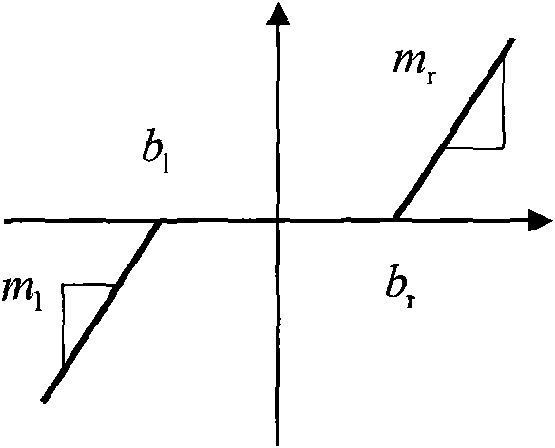

Continuous casting crystallizer fluid level control method based on Fuzzy-PID

InactiveCN101403930AInhibition of overshootSmall overshootLevel controlAdaptive controlTransient stateFuzzy pid

The invention relates to a method for controlling the liquid level of a continuous casting crystallizer based on Fuzzy-PID. In the method, the liquid level is controlled by auto turning parameter PID control and fuzzy control under the control of a computer and a PLC, and the mechanical dead area is compensated. The method comprises the following steps: step 1, the original liquid level y0 is set, and the liquid level y1 and y2 are collected by a liquid level controller and a liquid level sensor; step 2, the collected data y1 and y2 are input PLC by a signal processor, the data is processed by the mixed control of the auto turning parameter PID control and the fuzzy control, and the mechanical dead area caused by insensitivity of the machine transmission is compensated by adjusting the PID parameter; step 3, the PLC outputs u(k)=u1(k)+u2(k), so that the liquid level is controlled by controlling the position of a stopper by a stopper controller. The method of the invention ensures that the system not only has good steady characteristic, but also has excellent transient characteristic under time-variation condition by reasonably designing fuzzy control rule and parameter setting rule.

Owner:NORTHEASTERN UNIV

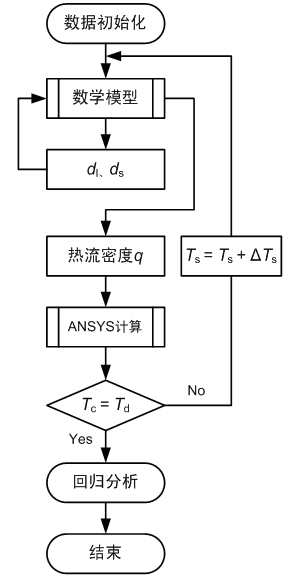

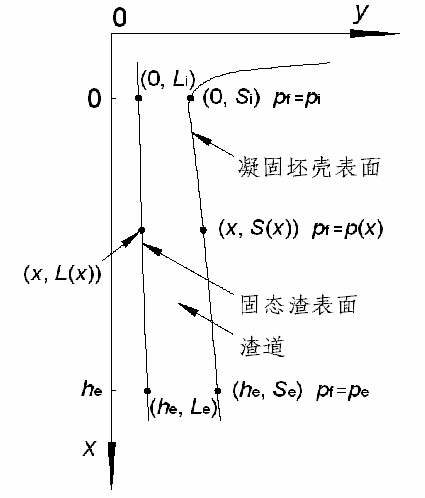

Determination method of copperplate heat flux based on mass balance and heat balance continuous casting mould

The invention discloses a determination method of copperplate heat flux based on mass balance and heat balance continuous casting mould, which belongs to the field of numerical calculation and application in ferrous metallurgical continuous casting process. The method comprises the steps of (1) acquiring raw data, (2) acquiring the consumption rate of mould powders,(3) acquiring molten slag layer thickness (d1) and solid slag layer thickness (ds) by utilizing the equation models of mass balance and heat balance,(4) acquiring heat-flow density q, (5) constructing the physical model of crystallizers, calculating thermocouple temperature Tc and comparing the calculated value Tc with the measured value Td. The above method has the advantages of coupling the mass balance of mould powder consumption and the energy balance of molten steel heat transfer. According to the method of the invention, specific boundary condition equations are obtained by regression method after the temperature and heat flow value of specific locations being determined, without being heavily dependent on specific equations of heat transfer boundary.

Owner:NORTHEASTERN UNIV

Boron-containing fluoride-free covering slag for steel continuous-casting crystallizer and preparation method thereof

The invention belongs to the technical field of steel smelting continuous casting production and in particular relates to boron-containing fluoride-free covering slag for a steel continuous-casting crystallizer and a preparation method thereof. The boron-containing fluoride-free covering slag is characterized by being prepared form the following raw materials in percentage by weight: 50-60 percent of boric sludge powder, 20-30 percent of wollastonite powder, 10-20 percent of lime powder and 1-2 percent of coke powder. The preparation method comprises the steps of: fully drying and dewatering the raw materials, weighing and burdening the raw materials according to weight fractions, levigating, uniformly mixing, and preparing the levigated materials into granular finished products of slag by adopting a traditional covering slag preparing and forming process. The covering slag has better melting property and absorption and entrapment capability, and particularly, boron is used to replacefluoride to realize the fluoride-free property of the covering slag and the recycling of the waste boric sludge, therefore, the advantages of cost reduction, environment friendliness and obvious economic and social benefits are achieved.

Owner:JIANGSU UNIV

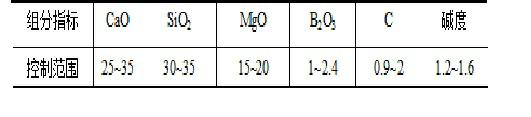

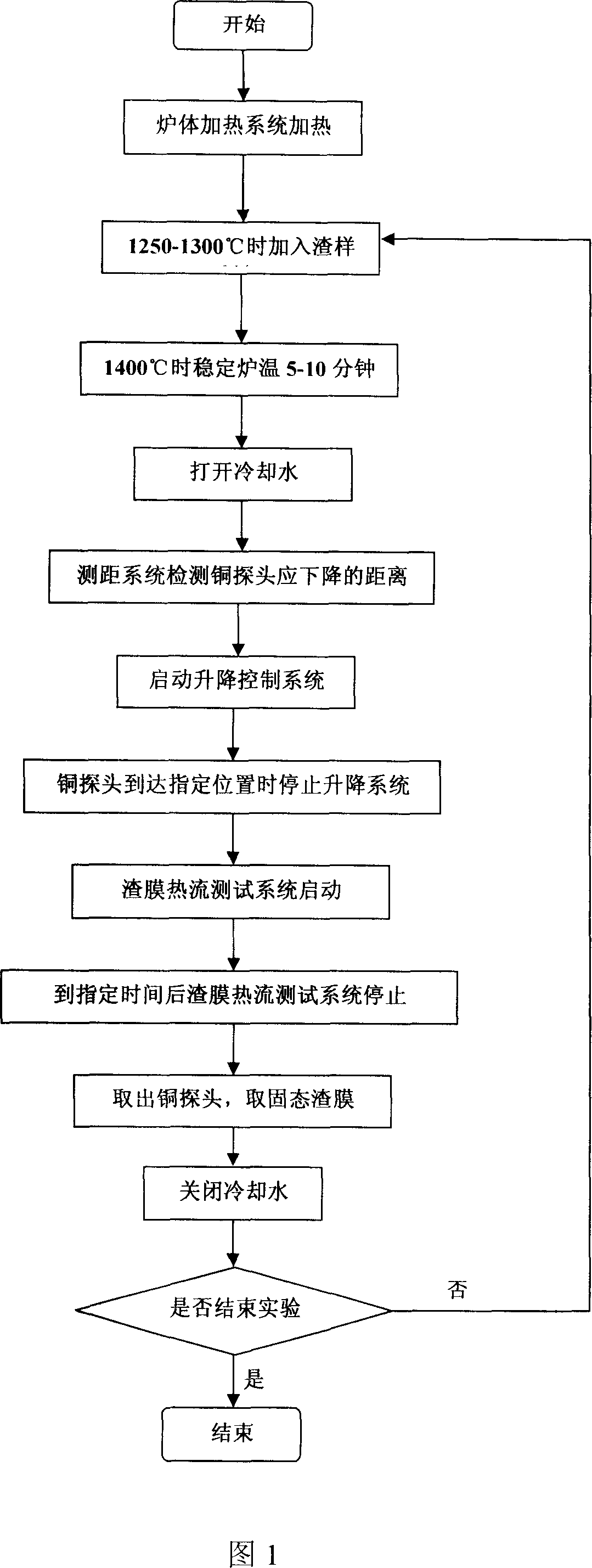

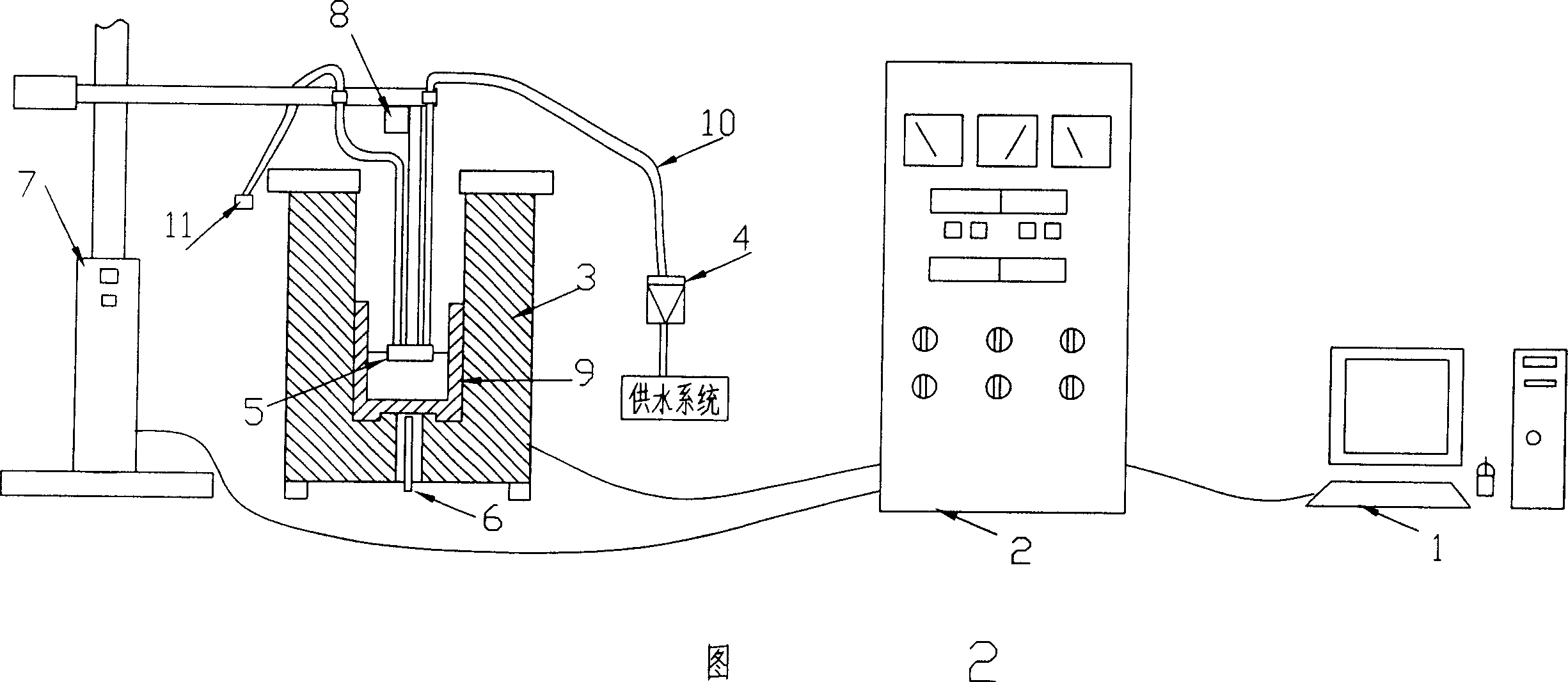

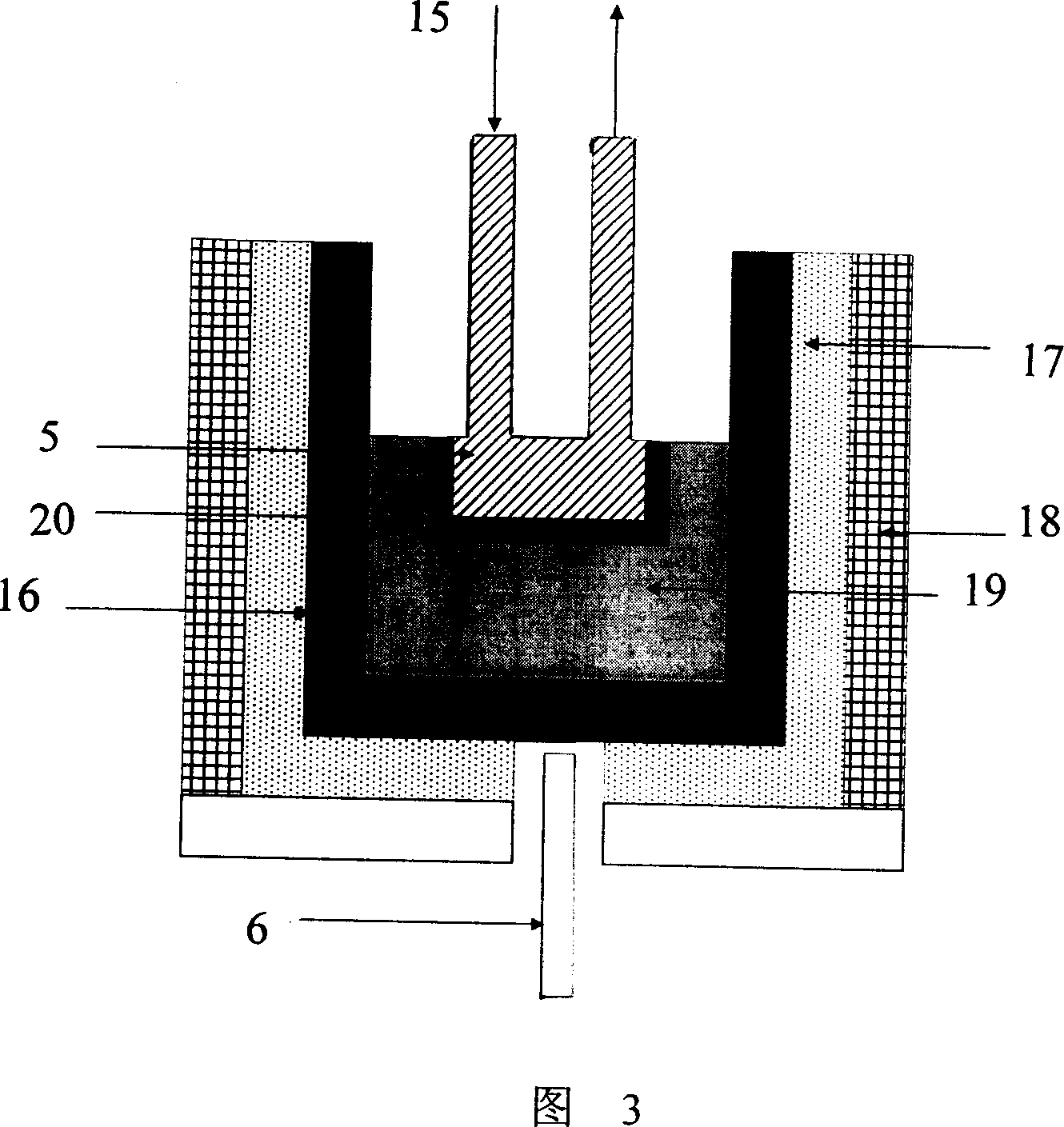

Internal slag heat current inspector and inspection for continuously-casting crystallizer

InactiveCN1940547AAccurately reflect heat transferGood test reproducibilityMaterial thermal conductivityMaterial heat developmentFurnace temperatureHeat current

A method for detecting heat flow of slag diaphragm in continuous casting crystallizer includes adding 250g-500g slag sample when furnace temperature is at 1250-1350deg.c and holding temperature for 5-10min when furnace temperature is on 1400deg.c, obtaining temperature-time relation curve by measuring temperature variation of cooling water passing through metal probe to know density variation state of heat flow passing through slag diaphragm at different time. The device used for realizing said method is also disclosed.

Owner:CHONGQING UNIV

Continuous casting crystallizer casting powder for large circular blank abrasion resisting high manganese steel

The invention discloses continuous casting crystallizer casting powder for large circular blank abrasion resisting high manganese steel. According to the continuous casting crystallizer casting powder for the large circular blank abrasion resisting high manganese steel, cracks are reduced by adopting low carbon amount and high viscosity, reducing thermal stress inside blank shells and increasing powder consumption amount. The alkalinity of the casting powder is 0.8-1.1, the cracks caused by uneven heat transmission are avoided; through the adoption of 8-12% of Na2O, 6-8% of F- and 3-4.5% of Li2O, weak coldness and even heat transmission of the upper portion in a crystallizer are achieved, inclusion absorbing effects are improved, and the cracks are reduced; through the adoption of 2-8% of MnO, lattice vibration and conduction heat transmission are weakened, and the crystallization properties of the casting powder and the casting blank quality are improved. Raw materials of the continuous casting crystallizer casting powder for the large circular blank abrasion resisting high manganese steel are easy to obtain, and production cost is low. Through field testing, the casting power is good in spreadability and good in air permeability and can be smelted stably and be free of caking, the consumption amount of the casting powder is around 0.3-0.42kg per ton of steel, the consumption cost is relatively low, and the qualified rate of the first grate casting blanks is improved significantly.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

Dual-thermocouple test apparatus for crystallization property of continuous casting mould casting powder

InactiveCN102445464ASimple methodImprove methodThermometers using electric/magnetic elementsUsing electrical meansMetallurgyElectrical connection

The invention relates to a dual-thermocouple test apparatus for crystallization property of continuous casting mould casting powder. The apparatus comprises an imaging device, a reaction chamber, a heating and temperature measurement device, and a central processing unit. The central processing unit comprises a data acquisition device and an image recording device. Both sides of the reaction chamber are symmetrically provided with two ducts. The imaging device is arranged above the reaction chamber, and forms an electrical connection with the central processing unit. The heating and temperature measurement device comprises two thermocouples, and forms an electrical connection with the central processing unit. According to the present invention, the apparatus is simple; the operation is convenient; the two thermocouples are adopted to carry out heating and temperature measurement for the casting powder, such that the real operating conditions among the casting billet inside the continuous casting mould, the casting powder and the continuous casting mould wall are simulated, in situ observation, record, measurement of the thermophysical properties of the fusion process and the phase change process of the casting powder are achieved; the tested result by the apparatus of the present invention is close to the actual production, and provides high reliability when the result is used to guide the production process; the apparatus is applicable for rapid detection of the thermophysical properties of the fusion process and the phase change process of the casting powder in the continuous casting production line.

Owner:CENT SOUTH UNIV

Method and apparatus for measuring protection slag thickness in continuous casting crystallizer in

The invention relates to measuring method and device of protecting cinder in continuous metal cast crystallizer. A measuring method is following: step 1, several groups of wire is set on a rack; every suit of wire is three sticks, the melting points of three wires are 600-700 deg.C, 1000-1100deg.C, 1500-1530deg.C; Step 2, several suits of wires whose length is bigger than thickness of protecting cinder and length is similar are inserted into the protecting cinder, level part of the wire is the same as protecting cinder, keep for several seconds and pick out; step 3, measuring the length of wires, the difference of length is the thickness of protecting cinder. The data measured in the invention is precise, reliable, intuitionistic, the invention not only can be used in common crystallizer, but also in crystallizer with electromagnetism mixing.

Owner:BAOSHAN IRON & STEEL CO LTD

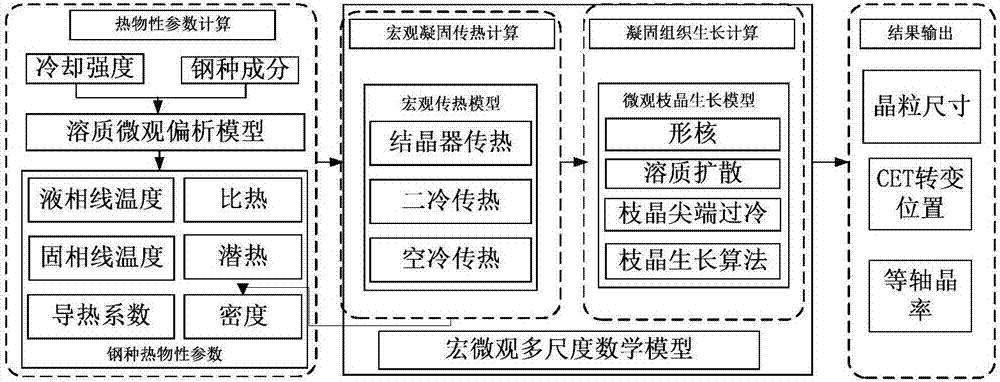

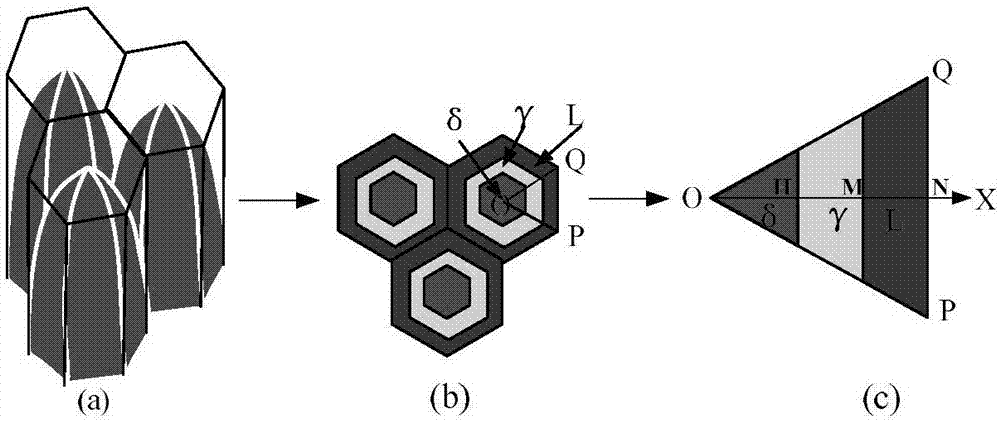

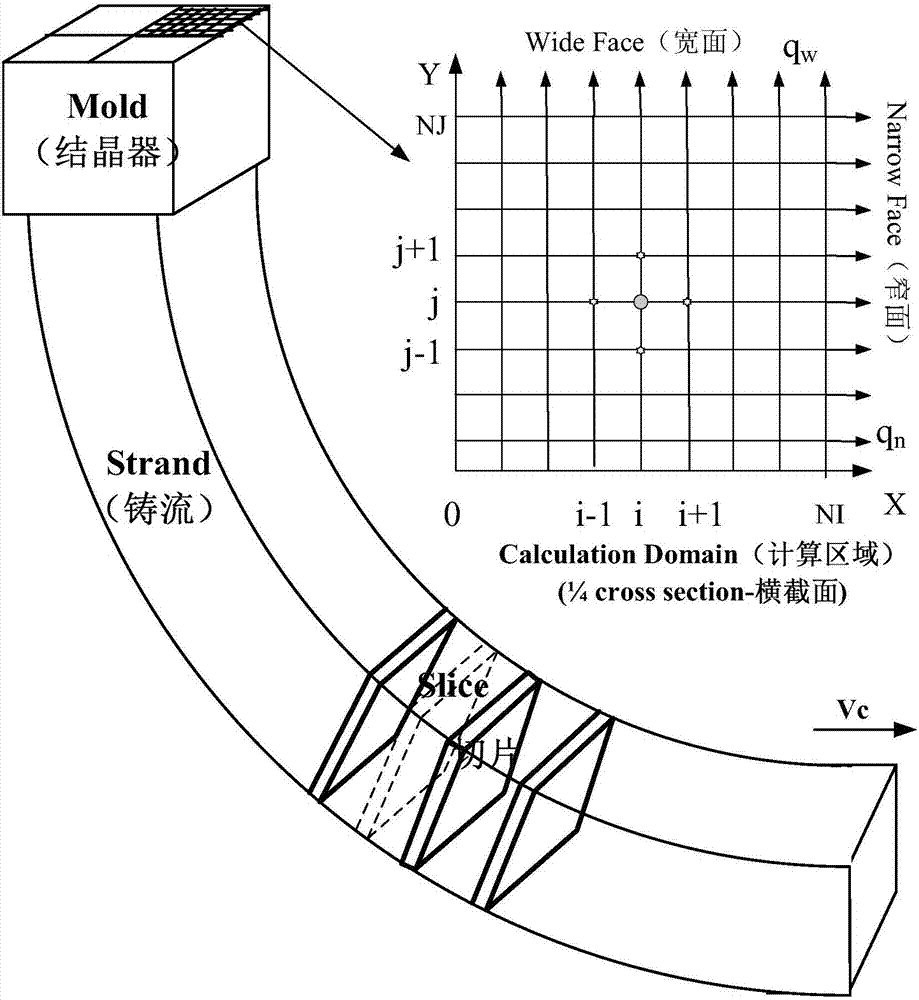

Method for forecasting continuous-casting-production casting blank microstructure

InactiveCN107229803AContinuous Casting Process OptimizationImprove calculation accuracyDesign optimisation/simulationSpecial data processing applicationsMathematical modelProcess conditions

The invention provides a method for forecasting a continuous-casting-production casting blank microstructure. The method includes the steps that device parameters and technology parameters of a continuous casting device producing casting blanks with to-be-analyzed steel grades are collected; according to parameters of the to-be-analyzed steel grades, thermal physical parameters of the steel grades are determined; a pre-established macro-and-micro multi-scale mathematical model is used in cooperation with the device parameters, the technology parameters and the thermal physical parameters, and structure information of the casting blanks corresponding to the current continuous casting device is forecasted. By means of the method, a continuous-casting-blank solidification structure can be well forecasted, and direct and reliable information is provided for optimizing the continuous-casting-crystallizer technology condition.

Owner:NORTHEASTERN UNIV

A short-process and high-efficiency production method for brass pipes

ActiveCN102260840AReduce processHigh yieldRoll force/gap control deviceMetallic materialsCasting types

The invention belongs to the field of metal materials and relates to a short-flow efficient production method for brass tubes. The method is characterized in that: brass tube billets which have axial orientated tissue and high internal and external surface quality are produced efficiently by using the low-consumption hot and cold combination cast type continuous casting technology; the tube billets are subjected to subsequent forming directly under the condition that surfaces are not peeled, wherein intermediate annealing is not needed to be performed or only a little bit of low-temperature annealing is needed to produce the brass tubes efficiently. The hot and cold combination cast type continuous casting is characterized in that: a continuous casting crystallizer is formed by combining a hot section which is heated and a cold section which is subjected to forced cooling by circulating water, and the tube billets which are high in the quality of the surfaces and have the axial orientated tissue are prepared efficiently by controlling solidification interfaces of the tubes to be positioned nearby the junction of the hot section and the cold section. The method has the advantages of short production flow, low consumption, high yield and high production efficiency.

Owner:UNIV OF SCI & TECH BEIJING

Graphite material for continuous casting mold and preparation method thereof

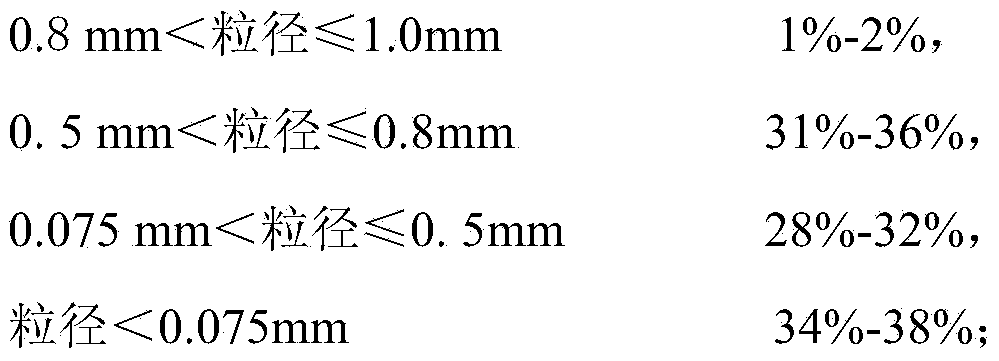

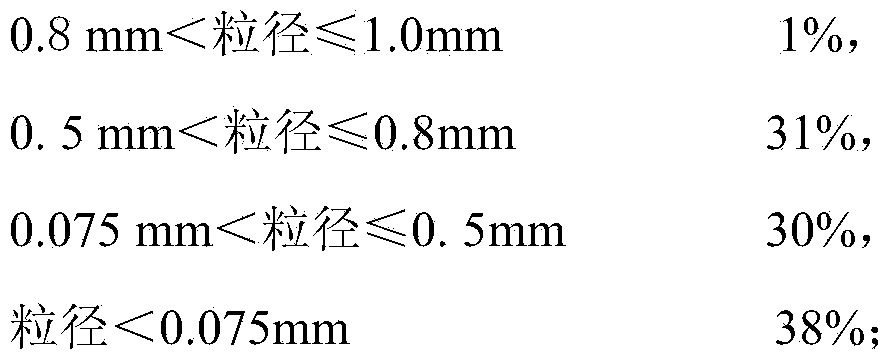

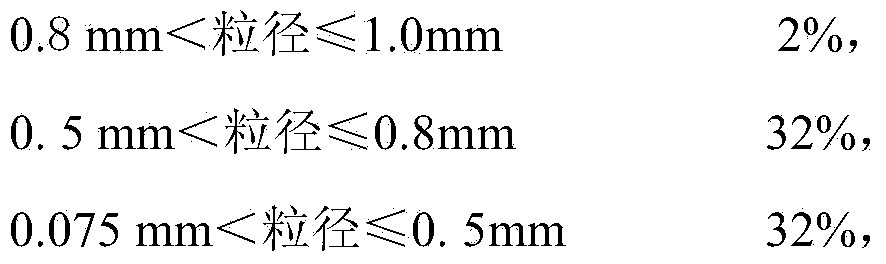

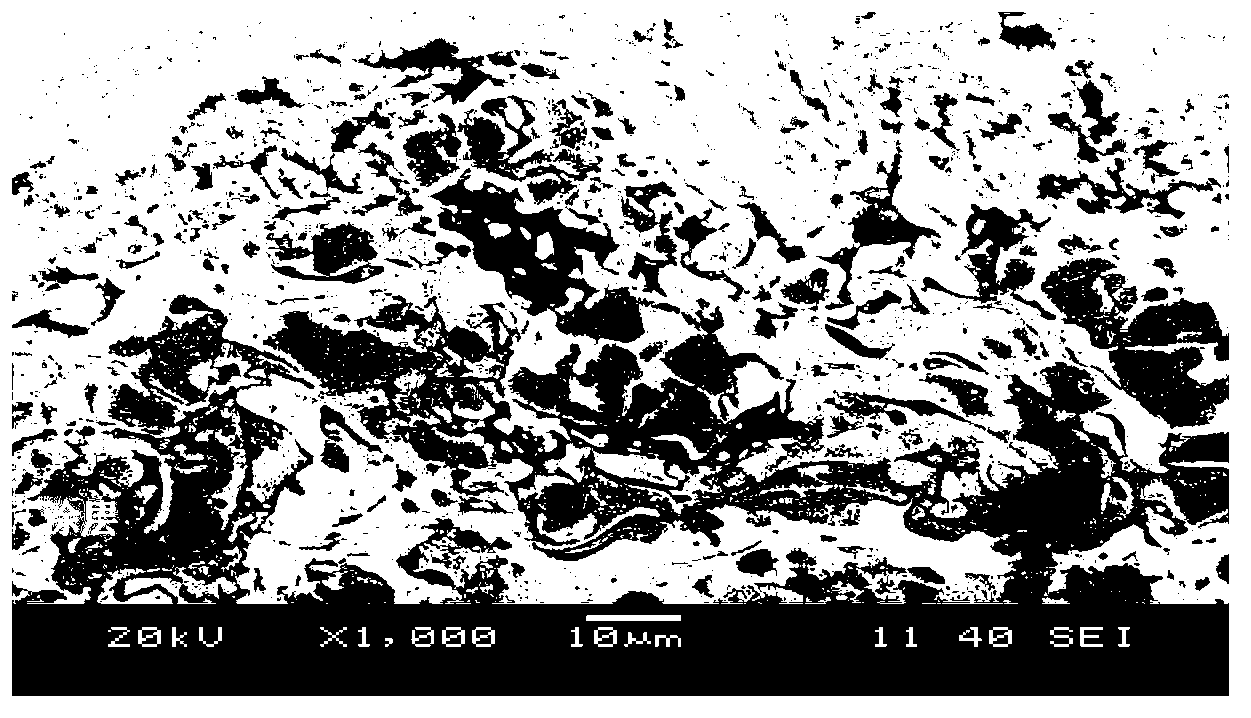

The invention relates to a preparation method of a graphite material for a continuous casting mold. The preparation method comprises the following steps: crushing, screening and burdening calcined coke, adding mid-temperature pitch, and carrying out mixing, molding, primary roasting, primary dipping, secondary roasting, secondary dipping, third roasting and graphitizing to obtain the product, wherein the particle size range and the content of the calcined coke are that the calcined coke with the particle size which is smaller than or equal to 1.0mm and greater than 0.8mm accounts for 1-2%; the calcined coke with the particle size which is smaller than or equal to 0.8mm and greater than 0.5mm accounts for 31-36%; the calcined coke with the particle size which is greater than 0.075mm and smaller than or equal to 0.5mm accounts for 28-32%; the calcined coke with the particle size which is smaller than 0.075mm accounts for 34-38%; the mixing is divided into dry blending and wet blending; the wet blending comprises the following processes: firstly heating the mid-temperature pitch to 180-230 DEG C, carrying out heat preservation and stirring for 30-60 minutes, and then adding the mid-temperature pitch to aggregate twice to knead, wherein the kneading temperature is 140-150 DEG C.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

Method for preparing high-temperature wear-resistant coating on continuous casting crystallizer copper alloy plate surface

InactiveCN102851632AHigh bonding strengthImprove deposition efficiencyMolten spray coatingWear resistantThermal shock

The invention discloses a method for preparing a high-temperature wear-resistant coating on a continuous casting crystallizer copper alloy plate surface, which comprises the following step: spraying metal ceramic powder on a pretreated copper alloy plate surface by a plasma spraying process to form a metal ceramic coating of which the thickness is 0.5mm, wherein the metal ceramic powder is Cr3C2-NiCr powder of which the particle size is 325-500 meshes; the Cr3C2-NiCr powder comprises 70-80 wt% of Cr3C2 and the balance of NiCr alloy powder; and the Ni / Cr mass ratio in the NiCr alloy powder is 80:20. The coating prepared by the method disclosed by the invention has the advantages of high bonding strength, favorable thermal shock resistance and long thermal-fatigue life, can satisfy the working requirements for crystallizer copper alloy plates, and obviously prolongs the service life of the crystallizer copper alloy plate.

Owner:JIANGSU UNIV OF SCI & TECH

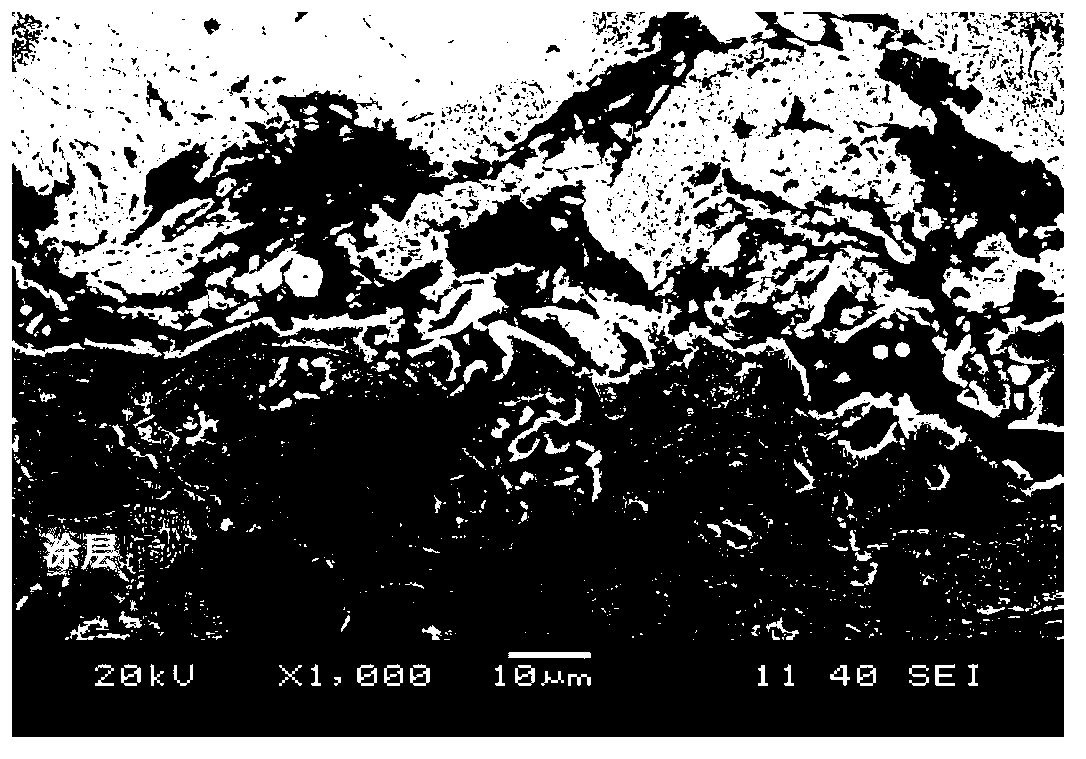

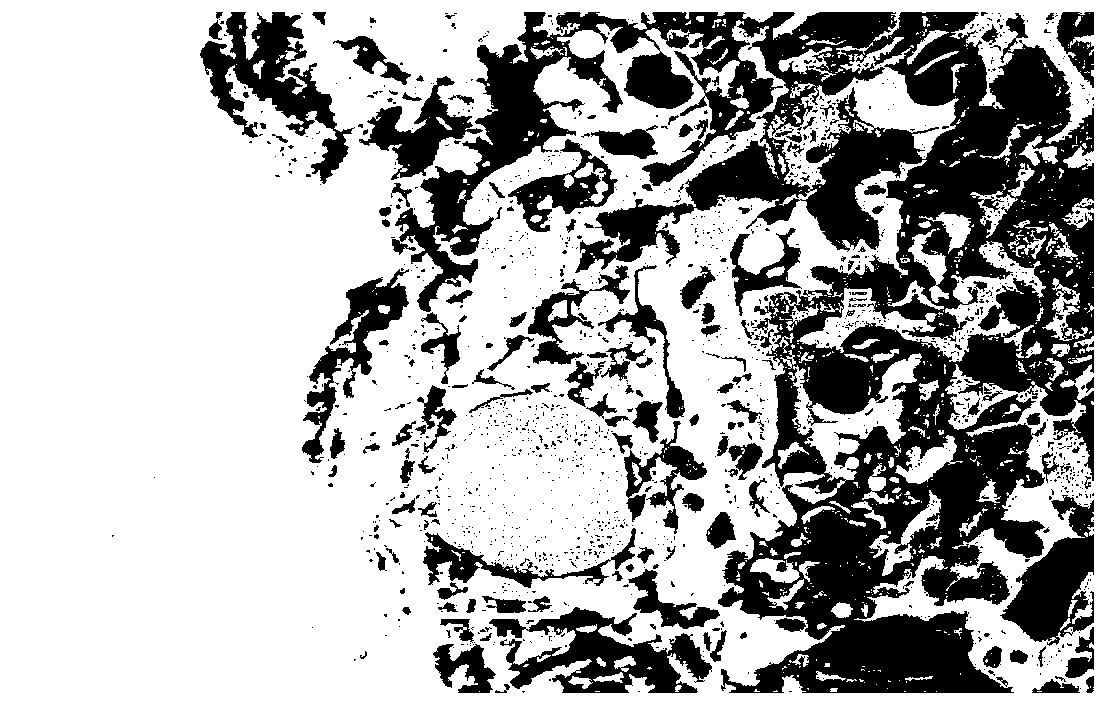

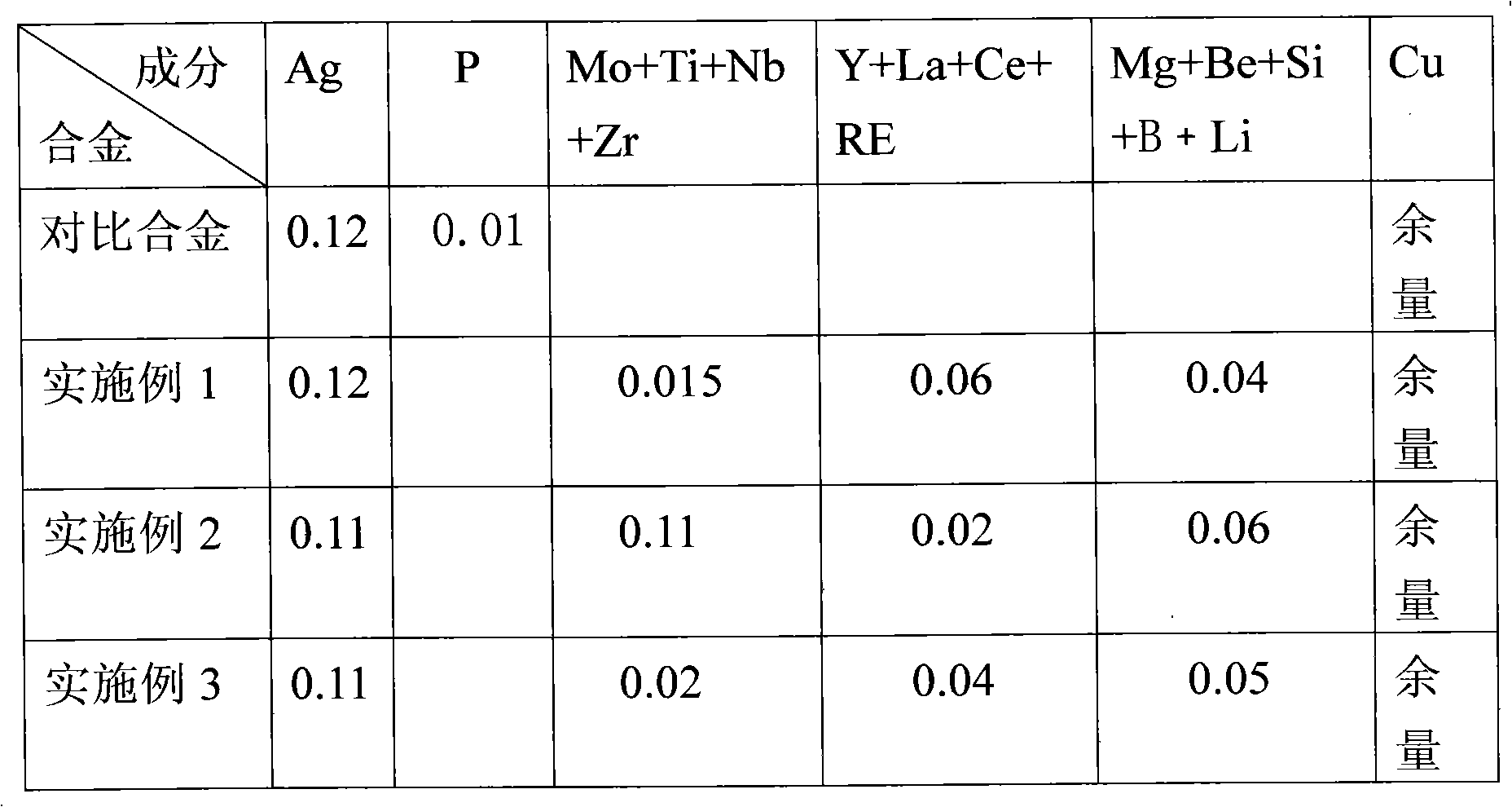

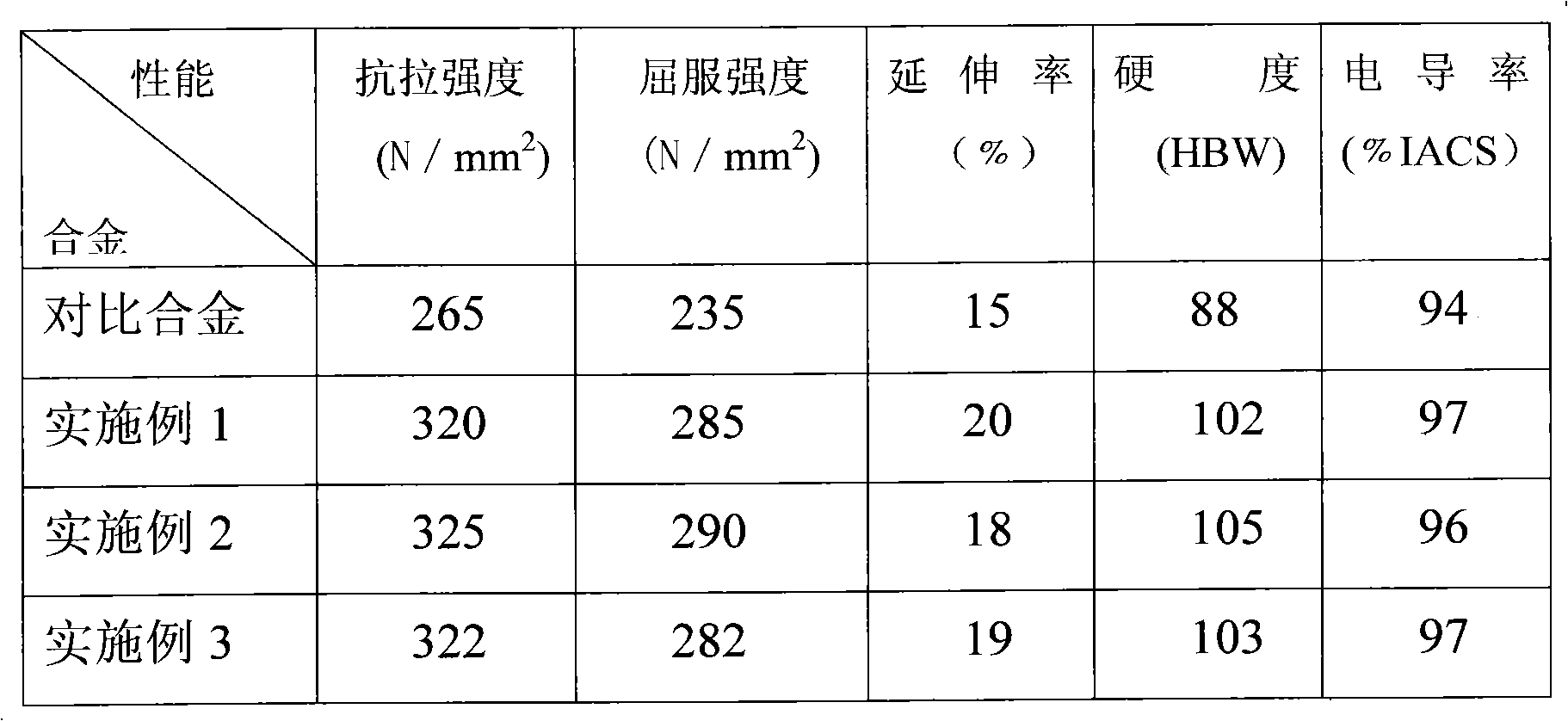

Low silver-copper alloy board for thin slab continuous casting crystallizer and manufacturing method thereof

The invention concretely provides a low silver-copper alloy board for a thin slab continuous casting crystallizer and a manufacturing method thereof. The low silver-copper alloy board comprises the following chemical components in percentage by weight: 0.08-0.12% of Ag, 0.008-0.11% of one or more of Mo, Ti, Nb and Zr, 0.01-0.08% of one or more of Y, La, Ce and RE (mixed rare earth), 0.005-0.09% of one or more of Mg, Be, Si, B and Li and the balance of Cu. After a trace amount of silver is added into copper and a trace amount of one or more of Mo, Ti, Nb and Zr is added into the copper simultaneously, very small influence is generated on electrical conductivity and thermal conductivity of the alloy, the oxidation resistance and the corrosion resistance of the alloy are improved, the strength of the alloy is increased, and the alloy becomes more tough, heat-resistant and wear-resistant.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

Metal ceramic coating on surface of copper plate of continuous casting mold and manufacturing process for metal ceramic coating

The invention discloses a metal ceramic coating on surface of a copper plate of a continuous casting mold. The metal ceramic coating is a coating obtained by performing hypersonic flame spraying on cobalt coated tungsten carbide WC-12Co powder and has the thickness of 0.2 to 0.6mm. Correspondingly, the invention also provides a process for manufacturing the metal ceramic coating on the surface of the copper plate of the continuous casting mold. The process comprises the following steps of: cleaning the surface of the copper plate of the continuous casting mold; performing shot blasting treatment on the surface of the copper plate of the continuous casting mold; spraying the cobalt coated tungsten carbide WC-12Co powder on the surface of the copper plate of the continuous casting mold by employing a hypersonic flame spraying process, wherein the hypersonic flame spraying process has the parameters of the oxygen flow of 700 to 1,000L per minute, the kerosene flow of 5.0 to 6.0 gph, the spraying distance of 300 to 400mm and the coating thickness of 0.2 to 0.6mm. The metal ceramic coating is low in porosity and high in microhardness, the adhesive strength between the coating and a matrix is high, and the wear resistance and corrosion resistance of the mold are obviously improved.

Owner:BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com