Continuous casting crystallizer fluid level control method based on Fuzzy-PID

A continuous casting crystallizer and liquid level control technology, applied in the direction of liquid level control, adaptive control, general control system, etc., can solve the problem of increased system disturbance due to disturbance impact, difficult adaptation of PID controller, frequent occurrence of overshoot, etc. problem, to achieve the effect of reducing liquid level overshoot and accurately adjusting the position of stopper rod

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

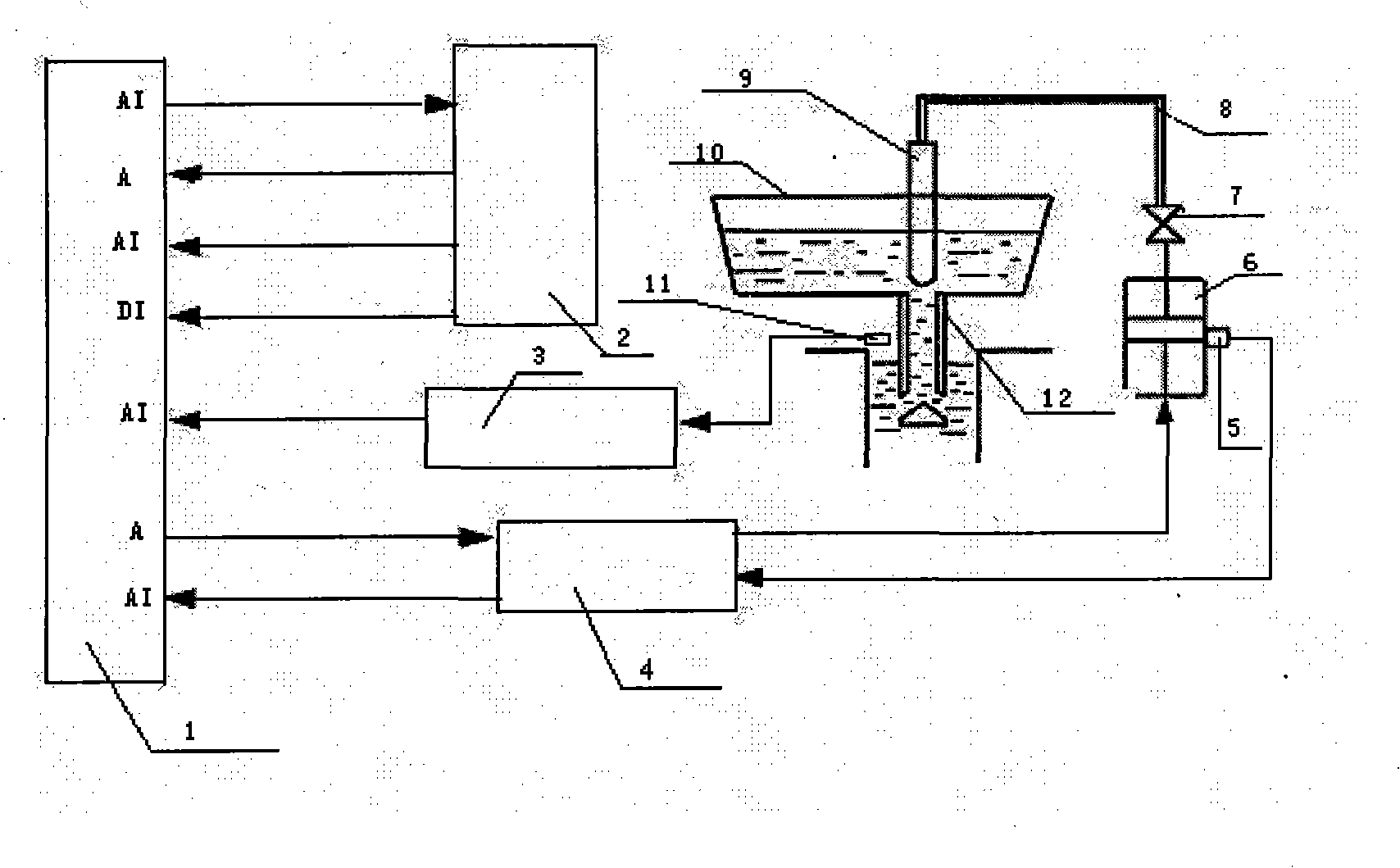

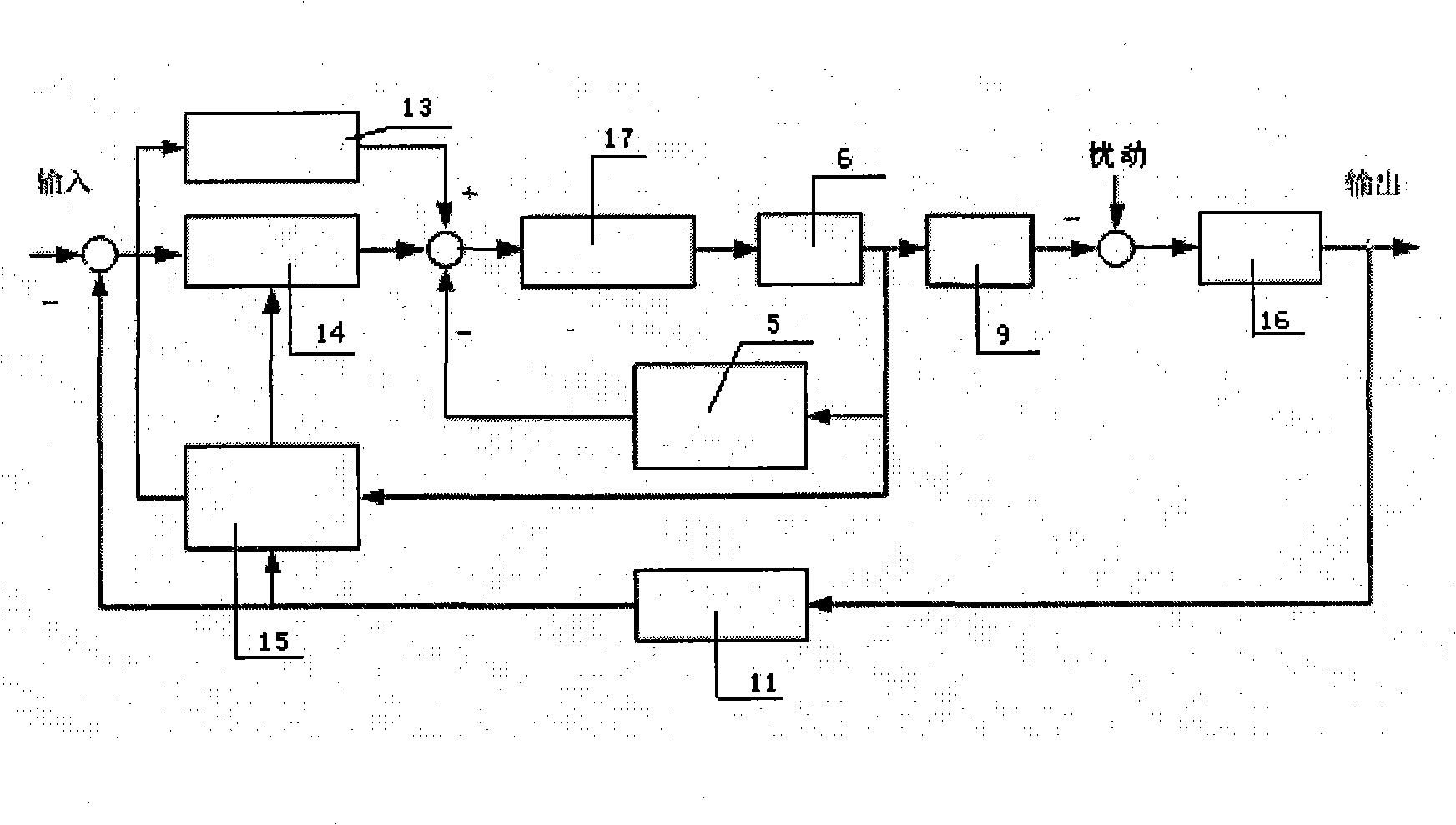

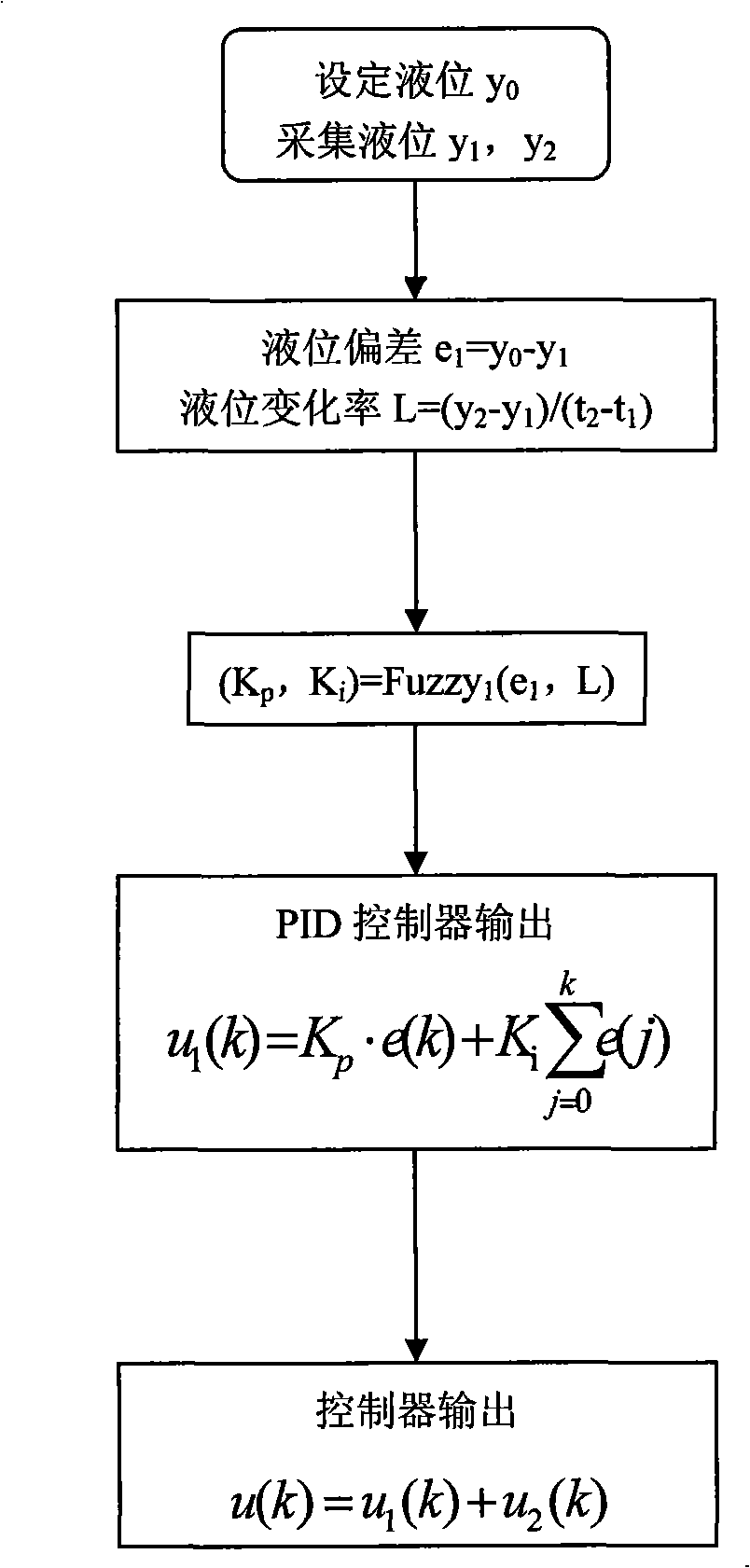

[0058] The Fuzzy-PID-based method for controlling the molten steel level of the continuous casting mold of the present invention will be further described in conjunction with the accompanying drawings. figure 1 The PLC1 is connected to the liquid level sensor 11 through the liquid level measuring device 3, and the PLC1 is connected to the motor transmission position sensor 5 through the stopper controller 4 to collect real-time liquid level signals and motor transmission position signals; the stopper 9 passes through the connecting mechanism 7 is connected with the servo motor 6, and the servo motor 6 controls the position of the stopper rod 9; the opening of the (submerged) nozzle is controlled by the stopper rod 9 to adjust the flow of molten steel to stabilize the liquid level. figure 2 The middle control system is a cascade control as a whole, and is divided into two parts, the inner ring and the outer ring. The inner ring controls the position of the motor, and the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com