Patents

Literature

405 results about "Fuzzy pid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

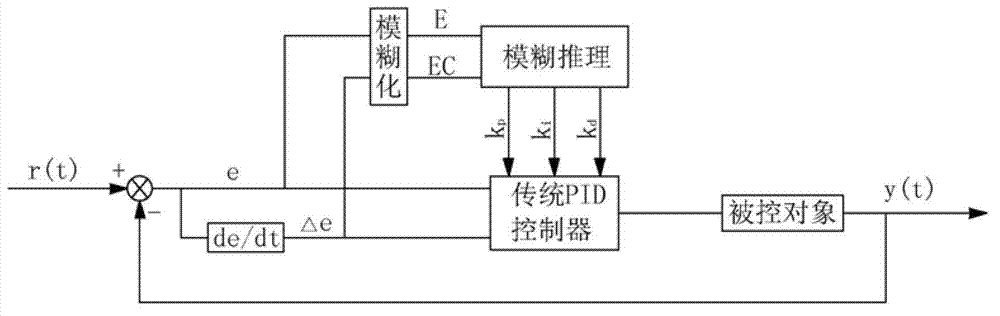

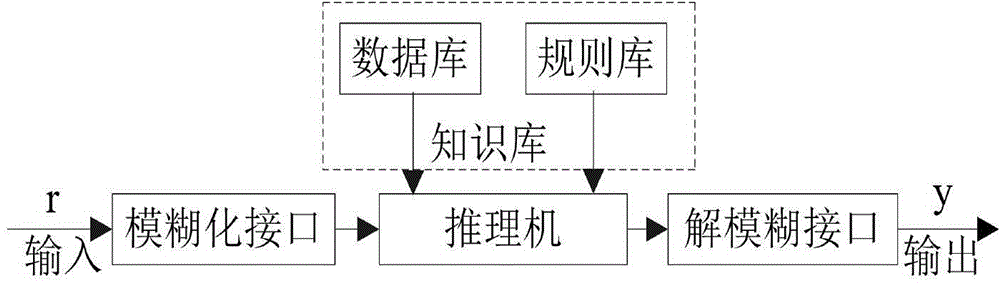

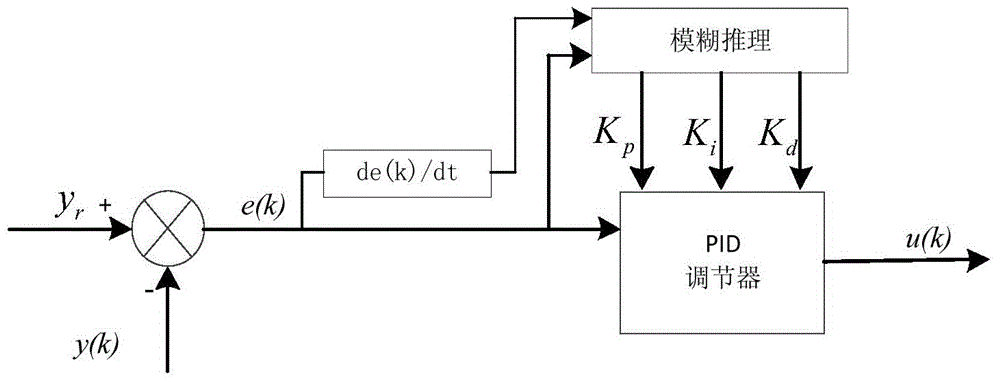

A fuzzy PID controller is a proportional-integral-derivative controller that uses fuzzy logic software principles as a form of error control in industrial systems. PID controllers are widely used in automation to adjust valves and other process controls based on the accumulation of errors over time.

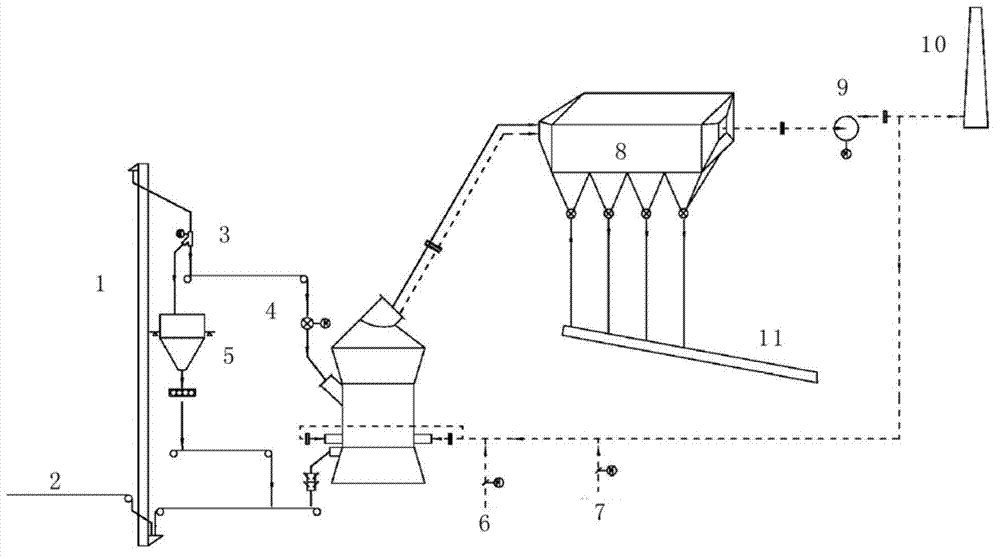

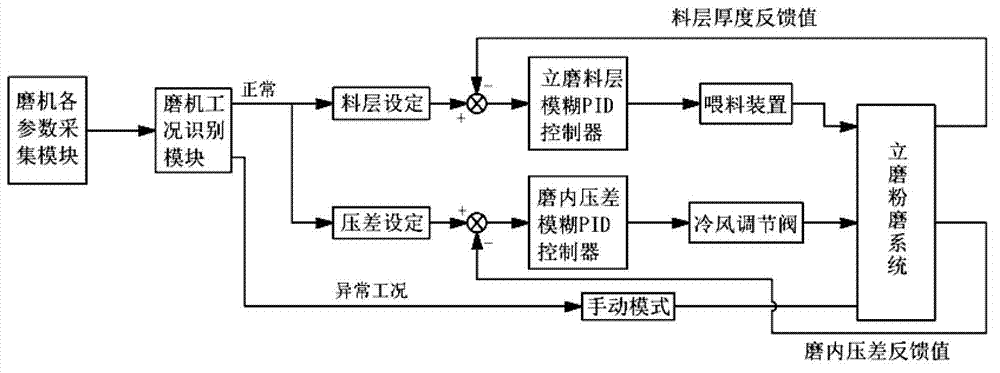

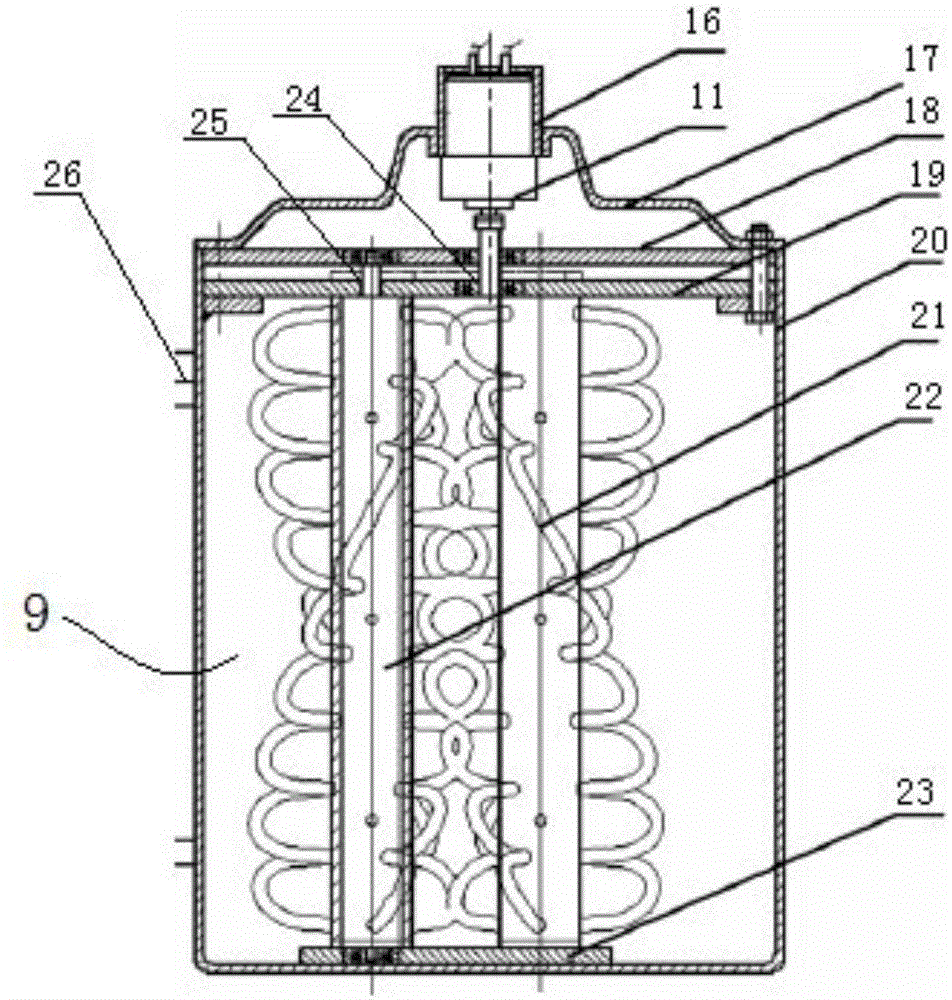

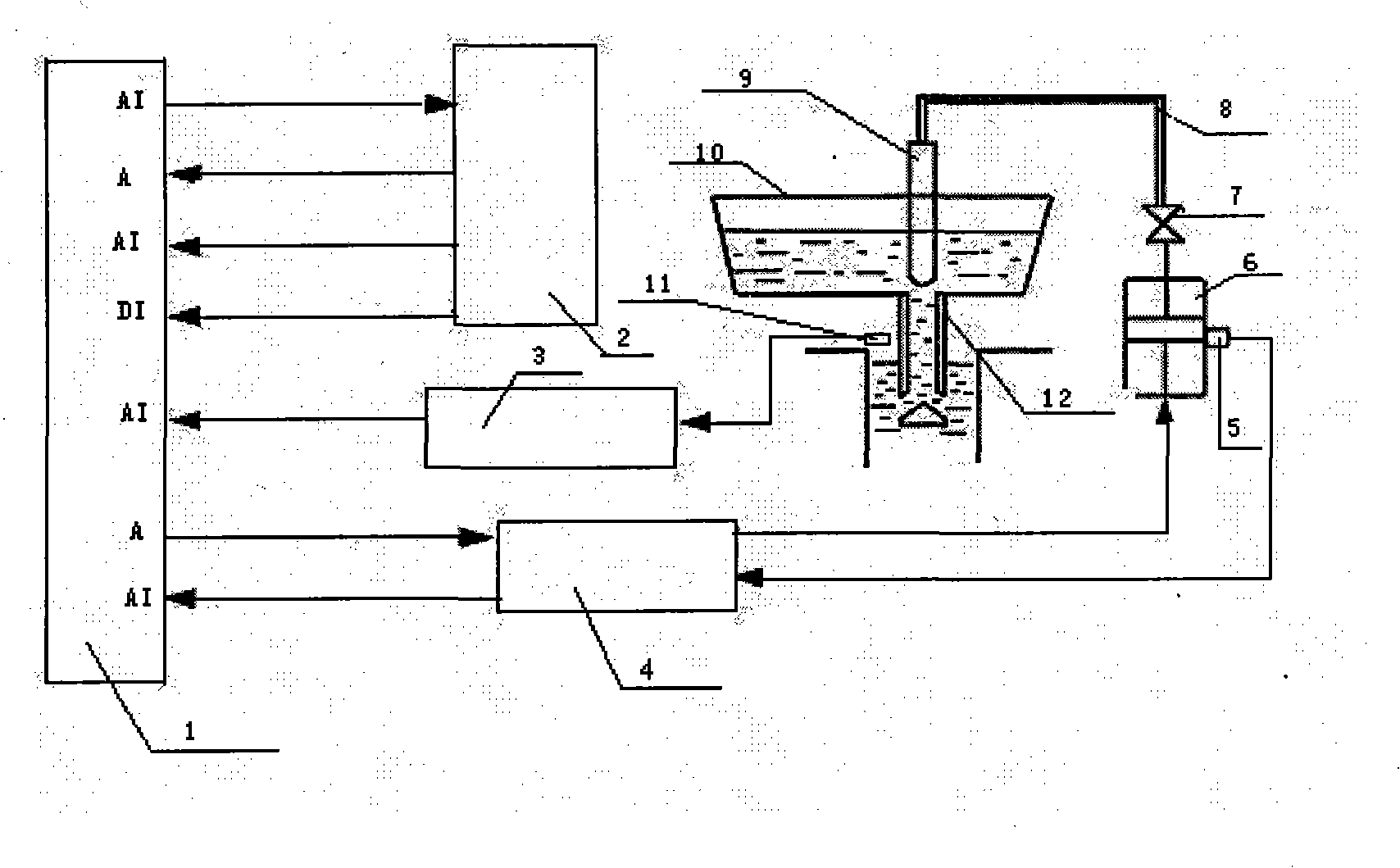

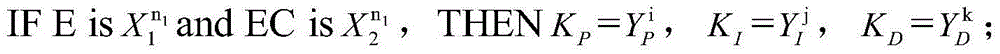

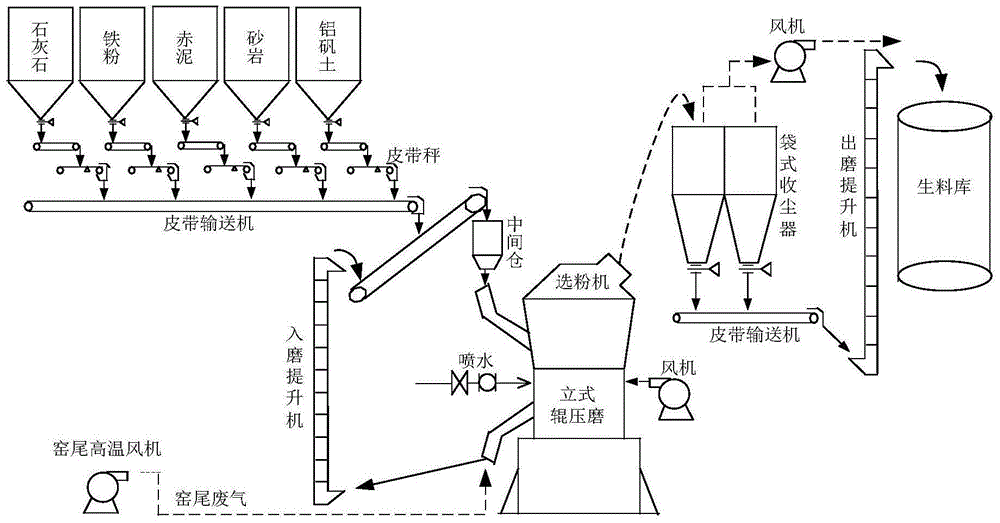

Intelligent control system for vertical mill based on fuzzy PID (proportion integration differentiation) algorithm

ActiveCN103028480AStable thicknessStable mill internal pressure differenceGrain treatmentsAdaptive controlCold airProportion integration differentiation

The invention relates to the technical field of control on production equipment, and particularly relates to an intelligent control system for a vertical mill based on a fuzzy PID (proportion integration differentiation) algorithm. The intelligent control system comprises the vertical mill, a dust remover and a feeding device, wherein the feeding device comprises an unloader, a bucket elevator and a storage bin; and the intelligent control system is characterized in that an air inlet in the bottom of the vertical mill is connected with a fan via a pipeline, a cold-air device and a hot-air stove are arranged on the pipeline between the air inlet and the fan, a cold-air adjusting valve and a hot-air adjusting valve are respectively arranged on the cold-air device and the hot-air stove, a vertical mill material layer PID controller is arranged on the feeding device, and an in-mill pressure difference fuzzy PID controller is arranged on the cold-air adjusting valve. According to the intelligent control system disclosed by the invention, mathematical models of the change of the vertical mill material layer thickness and an in-mill pressure difference along with parameters of a feeding amount, a mill inlet hot-air temperature and the like can be established only by inputting and outputting data without analyzing the complex grinding process of the vertical mill; and the intelligent control system is simple in process, high in adaptability, fast in the dynamic response time of a controller algorithm, high in robustness, high in control accuracy, and good in market prospect.

Owner:SHANGHAI TRIUMPH ENERGY CONSERVATION ENG TECH CO LTD

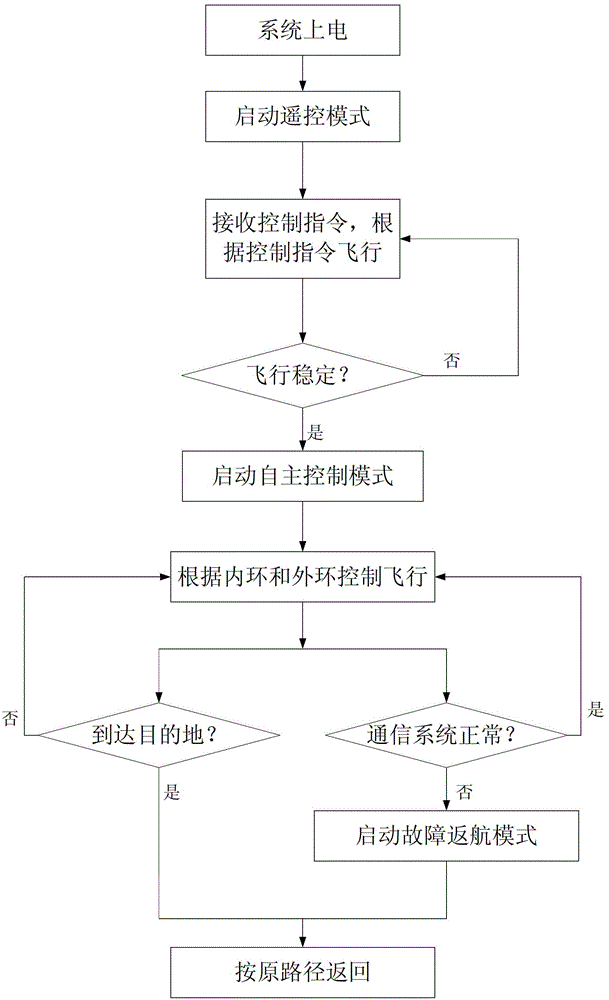

Control method of unmanned aircraft

InactiveCN102945046AImprove anti-interference abilityImprove fault toleranceAttitude controlFault toleranceCommunications system

The invention discloses a control method of an unmanned aircraft, which comprises the following steps that a system of the unmanned aircraft is electrified to start a remote control mode, so that the unmanned aircraft flies in accordance with a received control instruction; after flight stabilization, the control mode of the unmanned aircraft is switched into an independent control mode, and adaptive robust control and fuzzy PID (Proportion-Integral-Derivative) control are respectively adopted to control an inner loop and an outer loop of the unmanned aircraft; in the independent control mode, a communication system of the unmanned aircraft is continuously detected, and if problems of the communication system occur, the unmanned aircraft is controlled to return in accordance with an original route; and in the independent control mode, own position information of the unmanned aircraft is continuously detected, and if the unmanned aircraft flies to a destination, the unmanned aircraft is controlled to return in accordance with the original route. The control method of the unmanned aircraft can be applied to fixed-wing unmanned aircraft and unmanned helicopters, and the control method has good versatility. In addition, the control method has good noninterference, fault tolerance and control precision.

Owner:COMP APPL TECH INST OF CHINA NORTH IND GRP

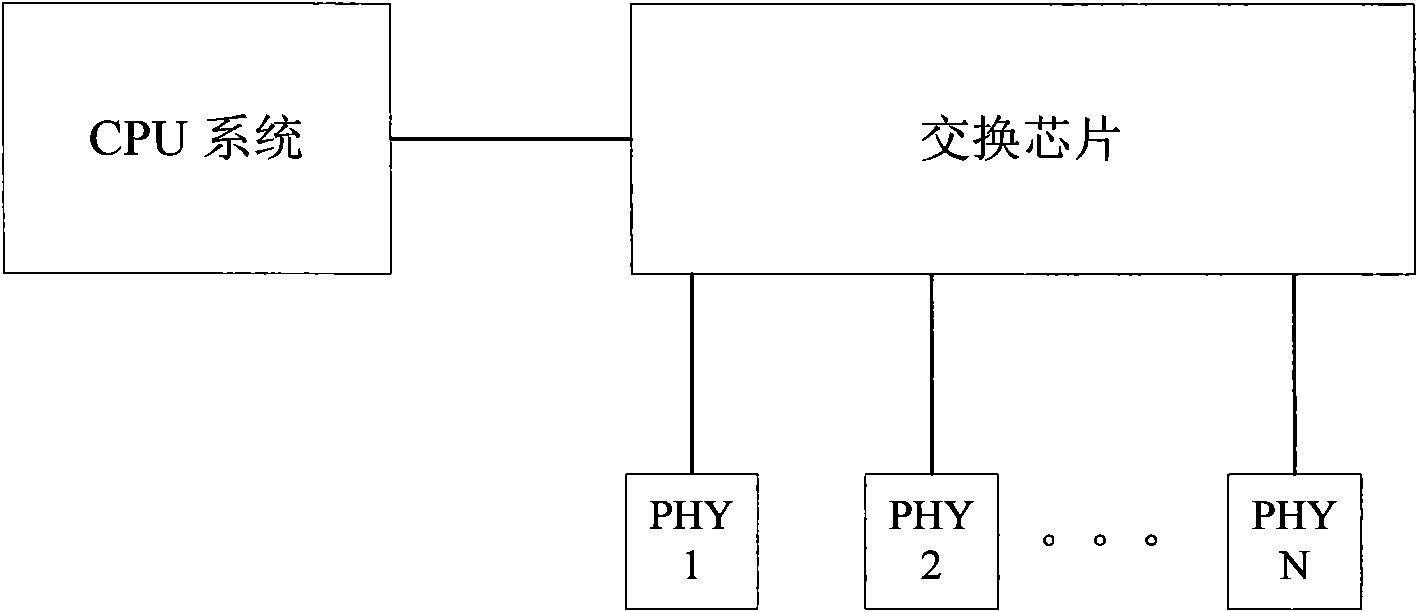

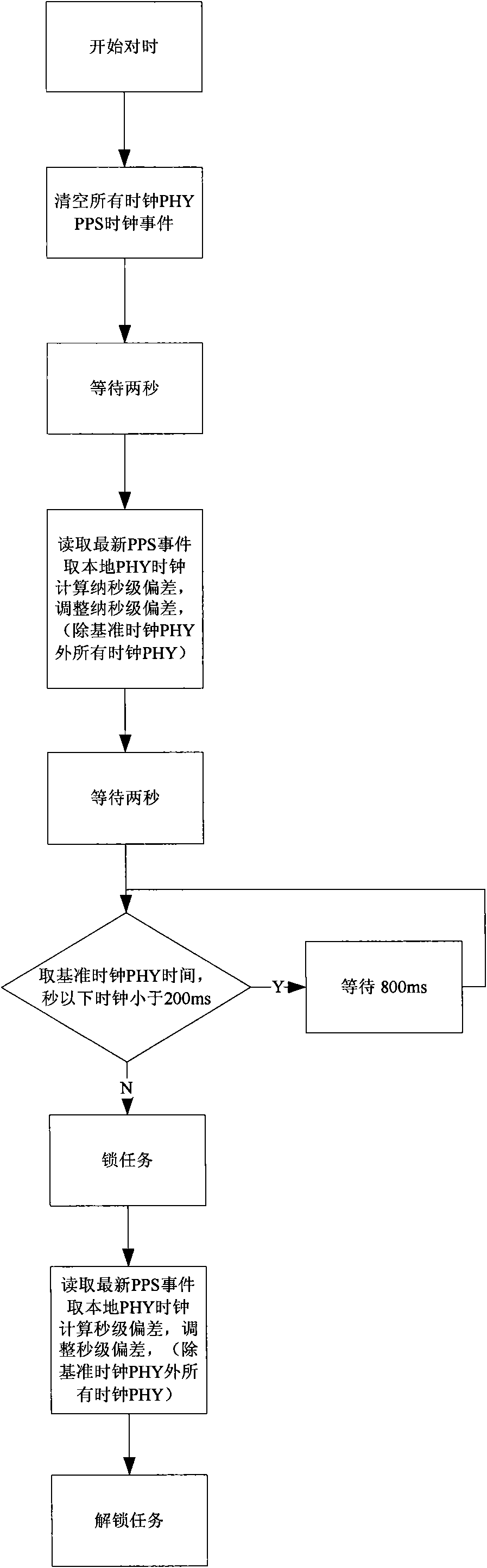

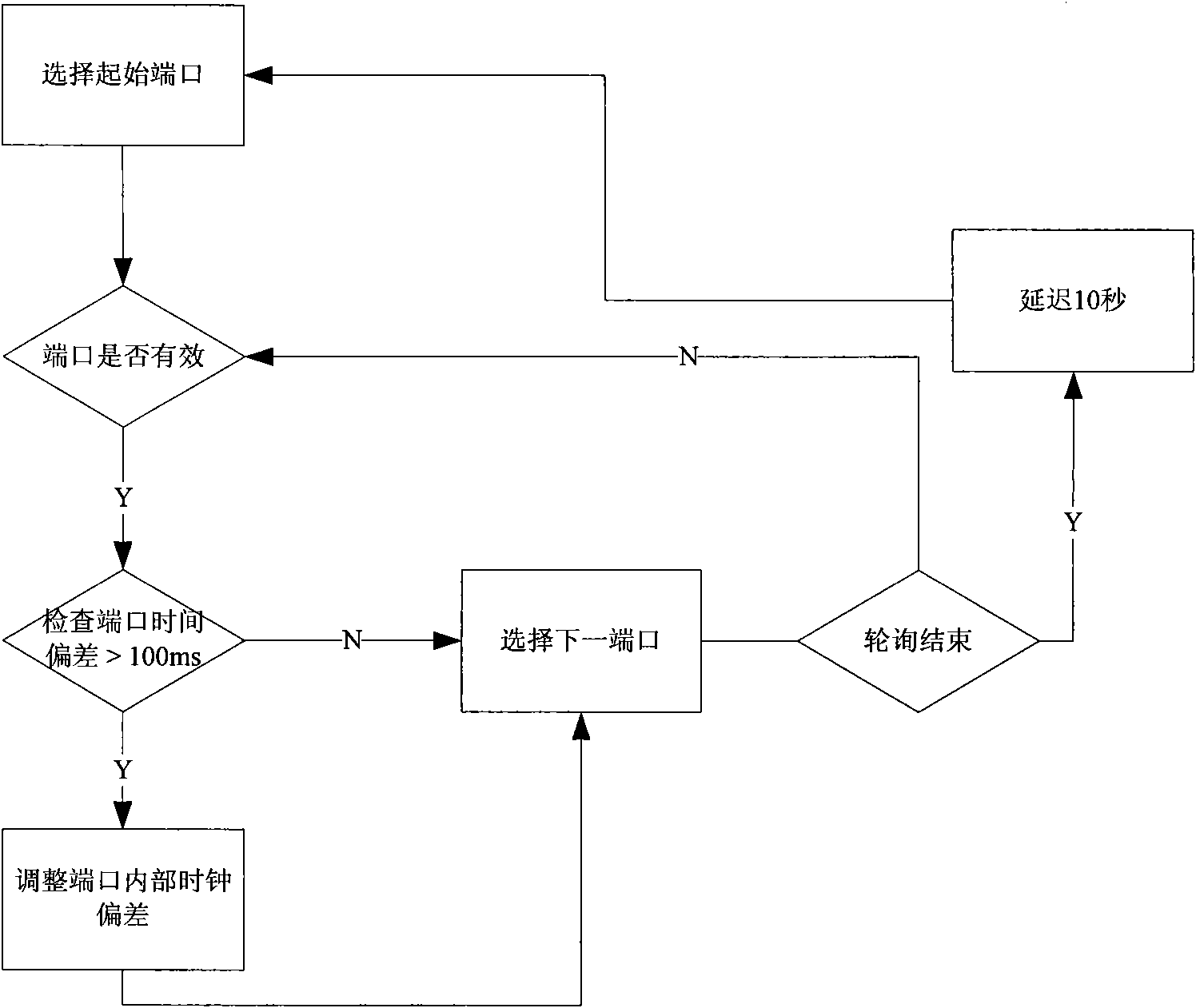

Realization method of precision synchronous clock

ActiveCN101867469AQuick switchDegraded Clock HOLDOVER FunctionTime-division multiplexSynchronising arrangementSoftwareFast switching

The invention discloses a realization method of a precision synchronous clock and aims at providing a transmission method of a precision synchronous clock in a measuring and automatic system based on an industrial Ethernet. The essential points of the technical scheme of the invention are that the realizing method comprises a frequency and deviation adjusting algorithm based on a fuzzy PID (Proportion Integration Differentiation), a quick internal clock synchronous algorithm, a real-time synchronous check method and a real-time clock frequency and time deviation adjusting algorithm. The invention has the following applications that the method can be used for realizing quick switch of the clock, can be applied to a high-reliability redundant clock source system and can finish the switch of the clock in ten seconds; the transmission precision of a single-stage clock can reach 50ns level; and since the algorithm can be used for realizing the quick switch of the clock, the algorithm is also applied to a high-reliability clock synchronous system under a redundant loop net and the clock HOLDOVER function on terminal equipment is degraded. The invention achieves the functions of software for receiving and transmitting a precision synchronous clock protocol message and adjusting and calibrating a system clock.

Owner:KYLAND TECH CO LTD

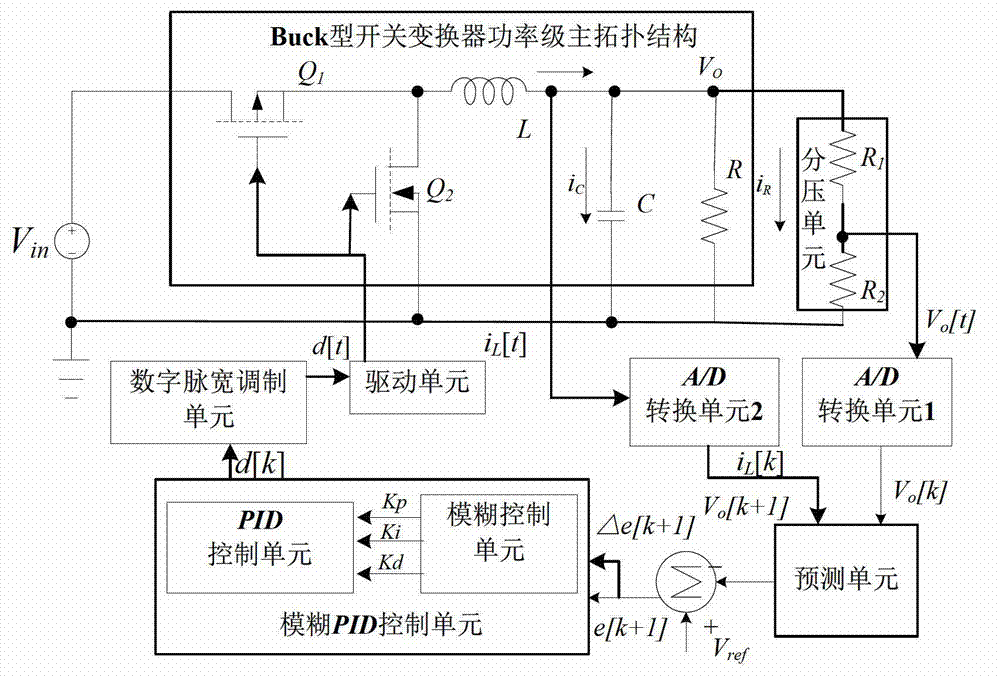

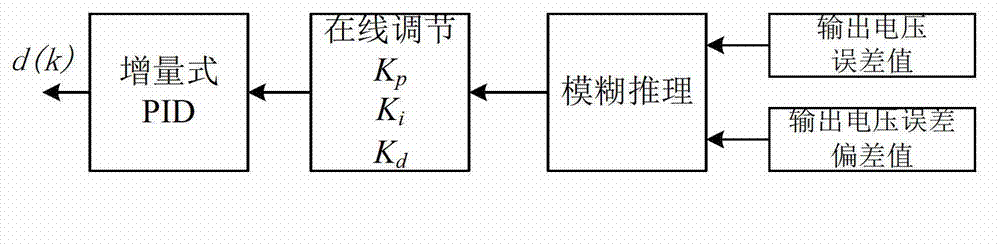

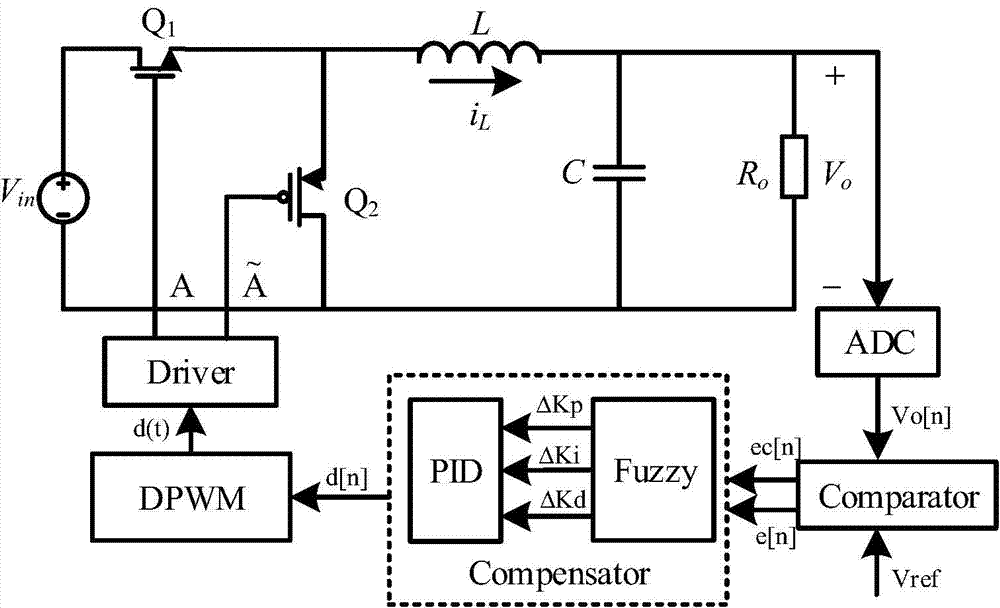

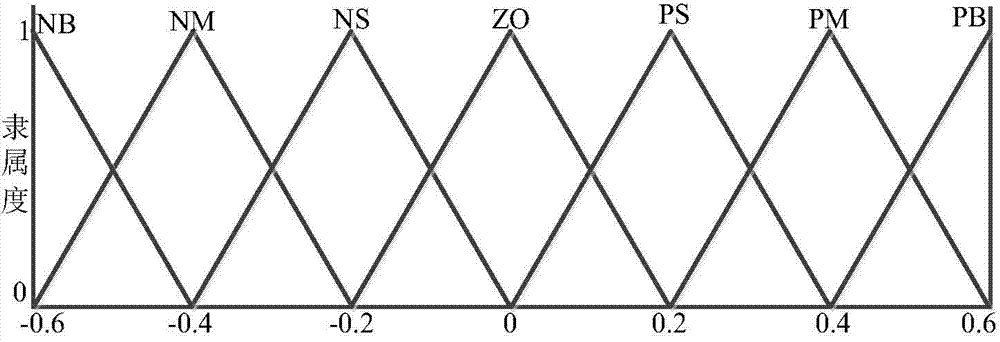

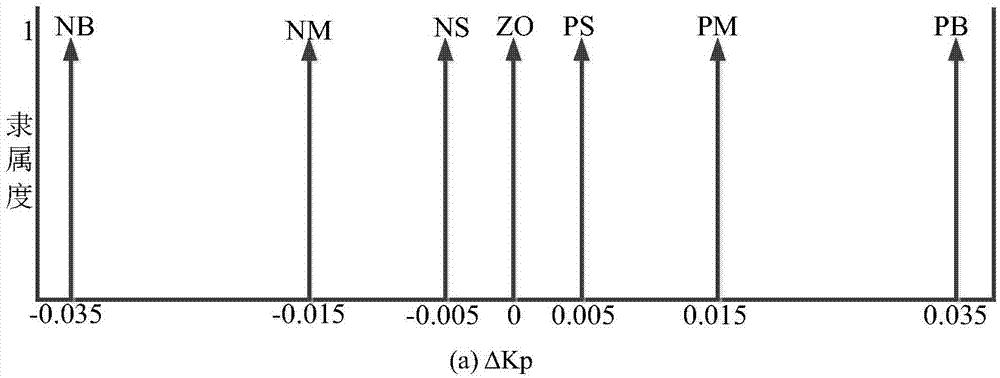

Fast transient response digital switch converter and control method of fast transient response digital switch converter

InactiveCN103051186AImproving the ability to respond to transient changesReduce Control LagDc-dc conversionElectric variable regulationProportion integration differentiationFuzzy pid control

The invention provides a digital switch converter with fast transient response capability. The digital switch converter comprises a Buck type switch converter power level main topology structure, an A / D (analog-to-digital) sampling conversion unit, a prediction control unit, a fuzzy PID (proportion integration differentiation) control unit, a DPWM (digital pulse width modulation) unit and a driving unit, wherein the A / D sampling conversion unit respectively samples the analog output voltage value and the analog inductor current value of the sampling switch converter and converts analog signals into digital signals, the prediction control unit predicts the next switch period output voltage value according to the A / D sampling digital signal value combined with the Buck type switch converter main topology structure, the fuzzy PID control unit determines the switch period duty ratio according to the output voltage error value and the output voltage error deviation value, and the DPWM unit and the driving unit output the corresponding on-off state of a power tube of the PWM driving switch converter according to the duty ratio for regulating the output voltage value.

Owner:SOUTHEAST UNIV

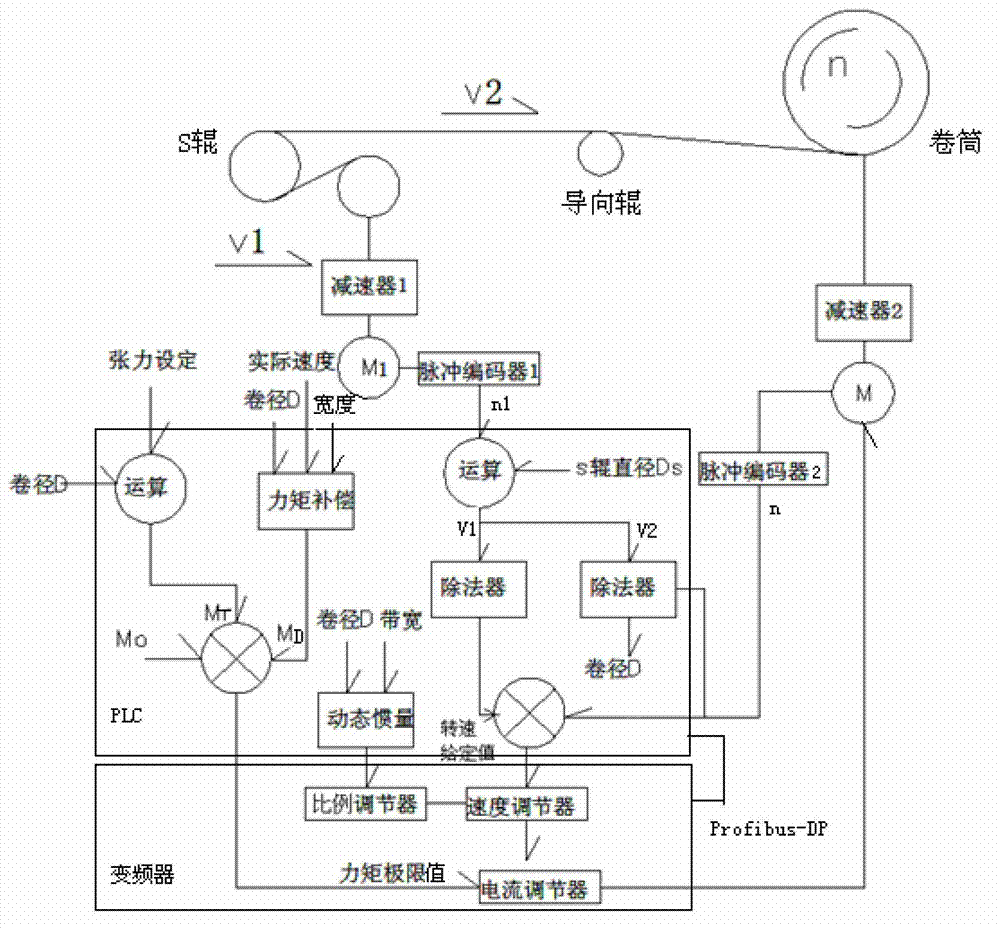

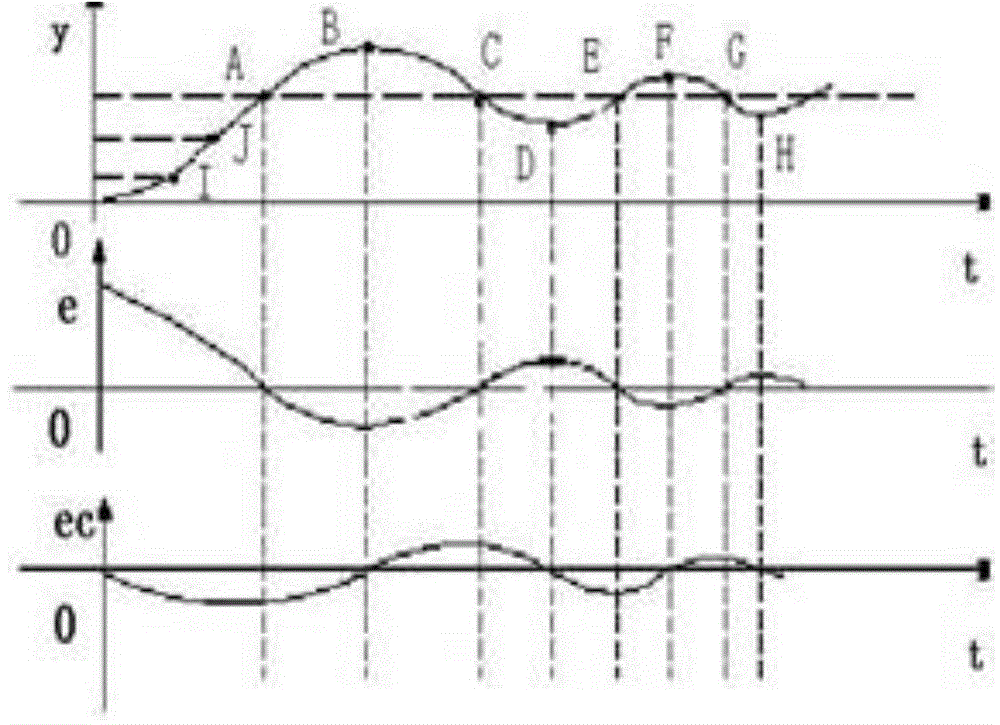

Tension fuzzy PID (Proportion Integration Differentiation) control method for recoiling machine

InactiveCN103076743AEasy to implementEasy to operateAdaptive controlAuto regulationAutomatic control

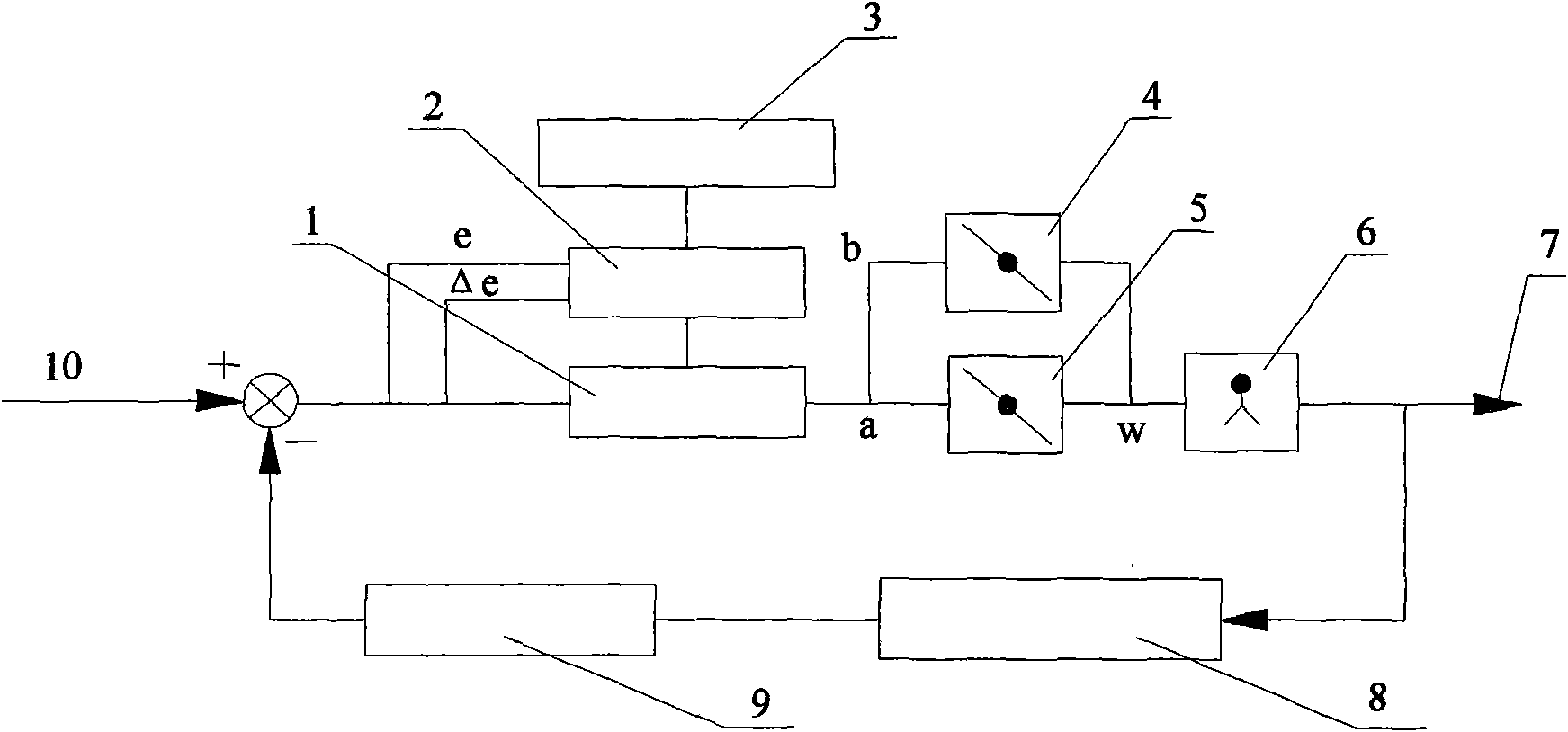

The invention discloses a tension fuzzy PID (Proportion Integration Differentiation) control method for a recoiling machine. In the method, current ring-speed ring double closed-loop control is adopted, a speed regulator and a current regulator are arranged respectively in the feedback elements of a current ring and a speed ring, six fuzzy controllers are adopted for controlling the PID parameters of the current ring and the speed ring, two inputs and one output are adopted for each fuzzy controller, input quantities are deviation values E and deviation change rates Ec of set tension, and output quantities are P, I and D parameters of a current controller and a speed controller respectively; three corresponding fuzzy controllers are connected in series respectively in front of the current regulator and the speed regulator, a subordinating degree function is regulated continuously in the running process of the recoiling machine, automatic control over the tension of the recoiling machine is realized by controlling the rotating speed of a motor and armature current, and the tension of the recoiling machine is regulated automatically and is always kept constant; and as proved by simulink simulation, the method has the advantages of quick response, high regulating capability, high robustness and effective improvement on the control effect.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

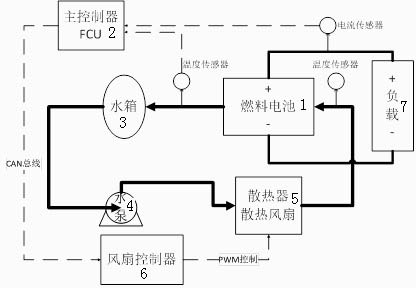

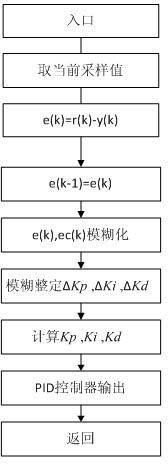

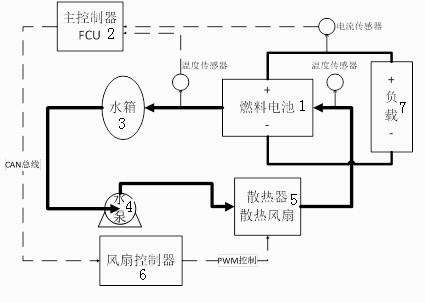

Application of fuzzy proportion integration differentiation (PID) algorithm in fuel cell radiating system

InactiveCN102569857AAdaptableHigh control precisionFuel cell auxillariesFuel cellsProportion integration differentiation

The invention discloses application of a fuzzy proportion integration differentiation (PID) algorithm in a fuel cell radiating system. The fuel cell radiating system comprises a water tank connected with a fuel cell, wherein the water tank is connected with a radiator and a radiator fan through a circulating water pump and a corresponding pipeline; a main controller acquires a data signal of the fuel cell through a sensor and transmits the data signal to a fan controller; and the fan controller controls the rotating speed of the radiator fan, and obtains a corresponding rotating speed of the radiator fan through the fuzzy PID algorithm to realize corresponding radiating capacity. The application of the fuzzy PID algorithm combines fuzzy control and PID control and has the advantages of flexible fuzzy control, strong adaptability and high control accuracy.

Owner:KUSN FUERSAI ENERGY

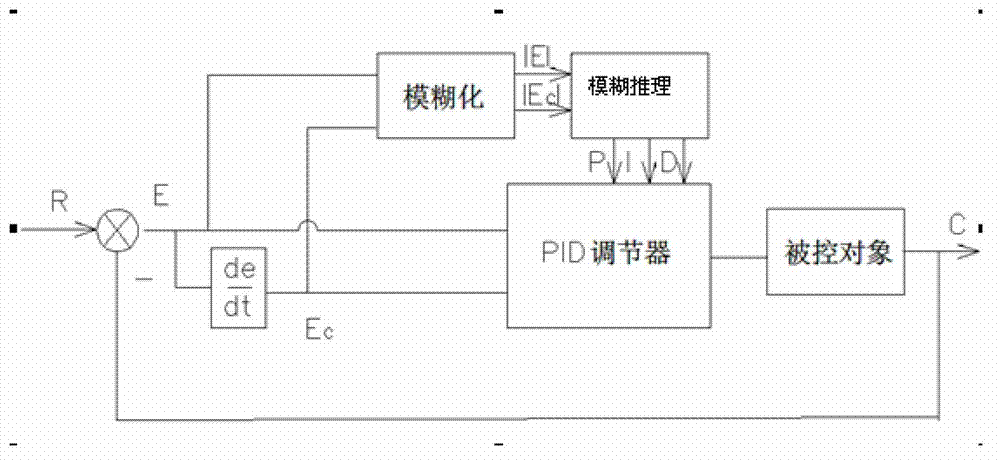

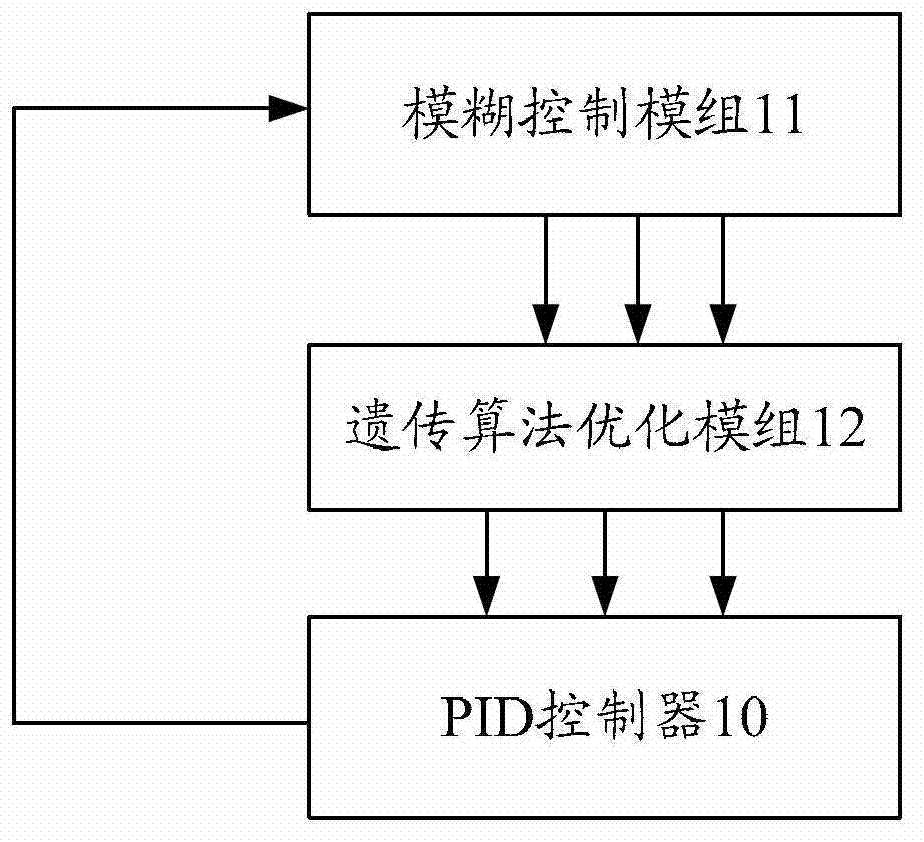

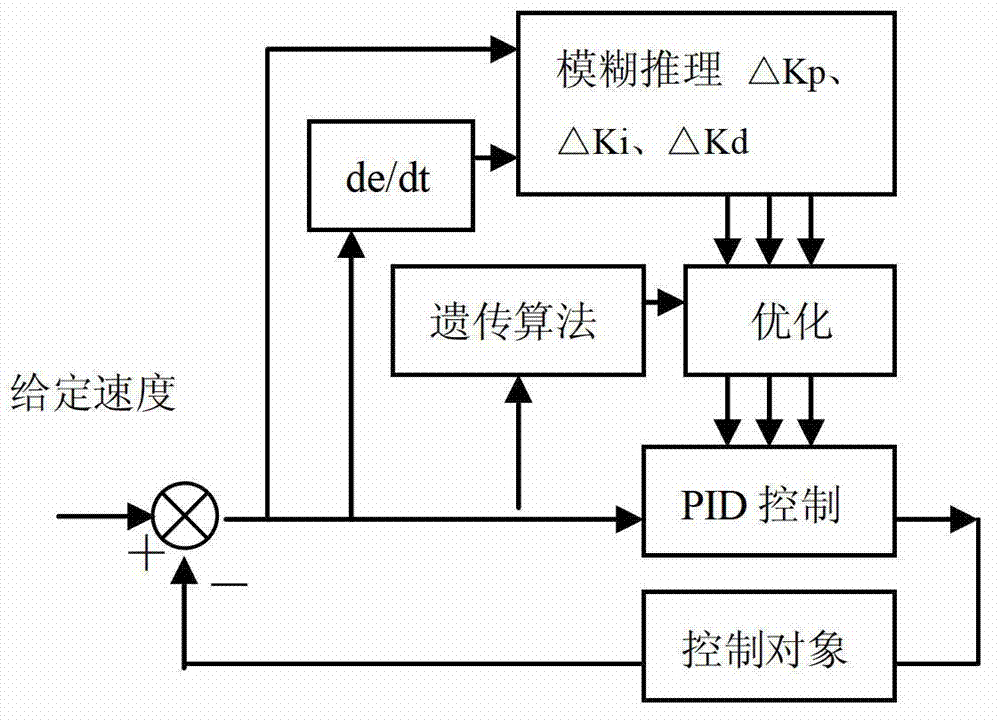

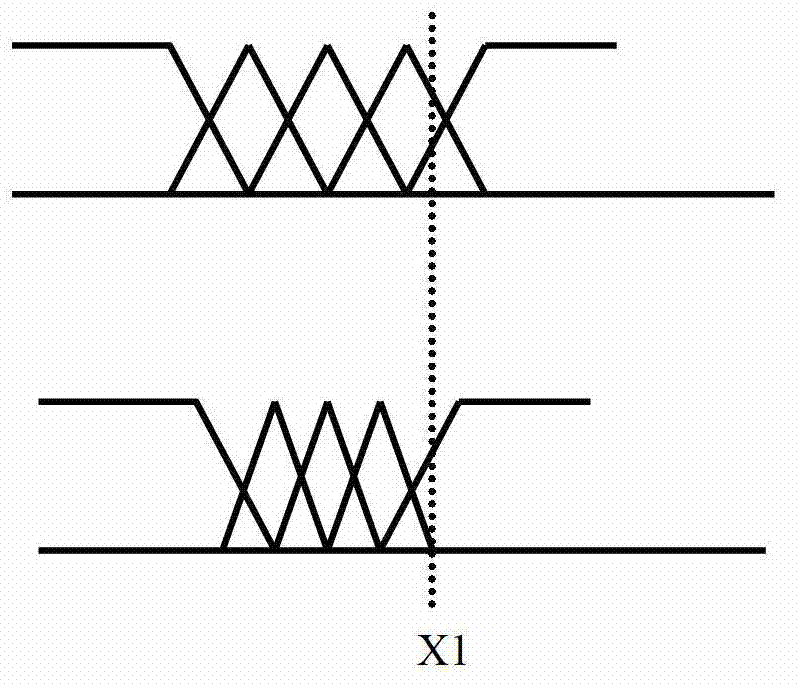

Fuzzy PID (Proportion Integration Differentiation) controller based on genetic algorithm and control method thereof

InactiveCN102968055AIncrease dynamicsImprove static performanceControllers with particular characteristicsProportion integration differentiationFuzzy pid control

The invention discloses a fuzzy PID (Proportion Integration Differentiation) controller based on genetic algorithm and a control method thereof. The control method comprises the following steps in sequence: controlling a controlled object by a fuzzy control algorithm; dynamically generating three parameters of the PID controller in an online manner; selecting a proper fitness function by virtue of the genetic algorithm; searching based on the fitness function of each individual in the population; increasing the speed of convergence of the genetic algorithm; calculating to obtain the optimal solution; and further optimizing three basic parameters output in the fuzzy control. By adopting the control method, dynamic and static performances of a control system can be improved while the accuracy in control detection is ensured.

Owner:SHANGHAI DIANJI UNIV

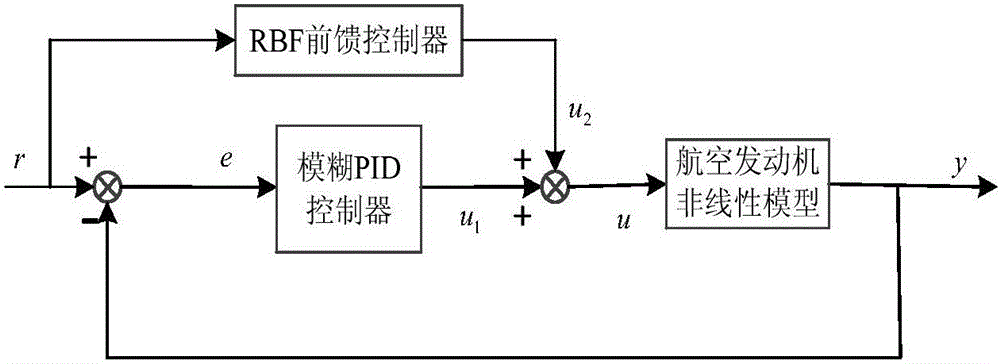

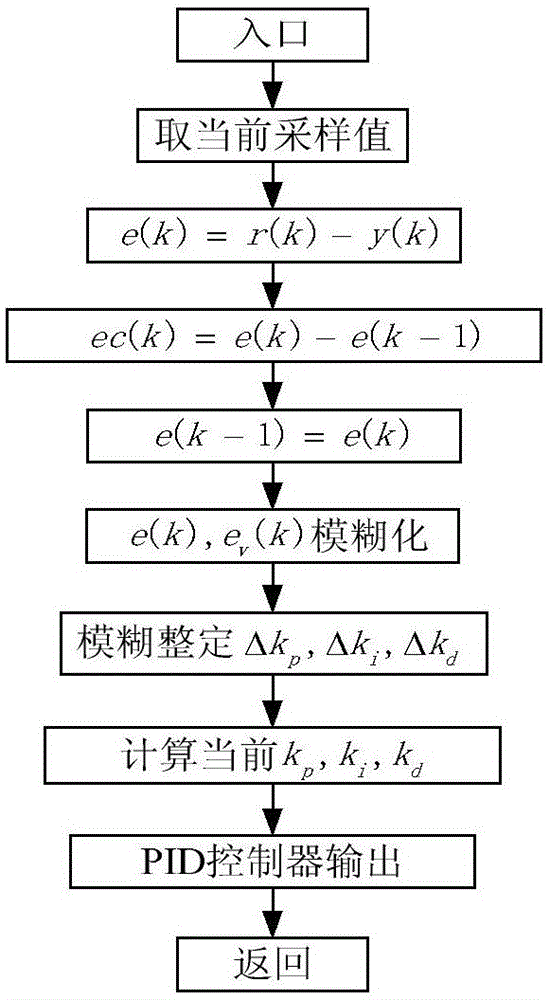

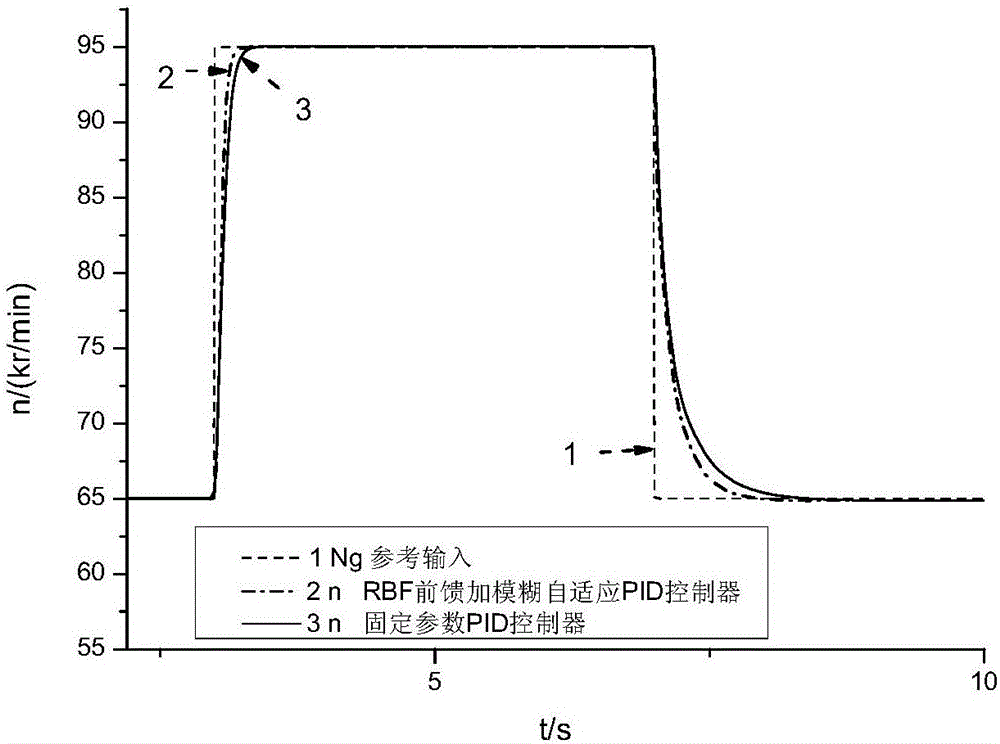

Fuzzy adaptive PID controller design method of aero-engine based on RBF neural network feedforward

The invention discloses a fuzzy PID adaptive controller design method of an aero-engine based on RBF neural network feedforward and belongs to the aero-engine numerical control system field. The method is used for improving acceleration and deceleration work states of the aero-engine and components under effects of an extraneous condition and internal control so that the engine possesses a good acceleration and deceleration characteristic. The technical scheme is characterized by based on an aero-engine steady state test data sample, using an RBF neural network to carry out off-line training so as to form a feedforward controller; and based on that, adding a fuzzy adaptive PID controller. In the invention, through carrying out acceleration and deceleration control on each state of the aero-engine, the controller possesses a good tracking effect and a good controller parameter online setting capability, control quality of the system in a large range can be further increased and a control difficulty brought by a non-linear characteristic of the engine can be effectively solved.

Owner:SHENYANG AEROSPACE XINGUANG GRP

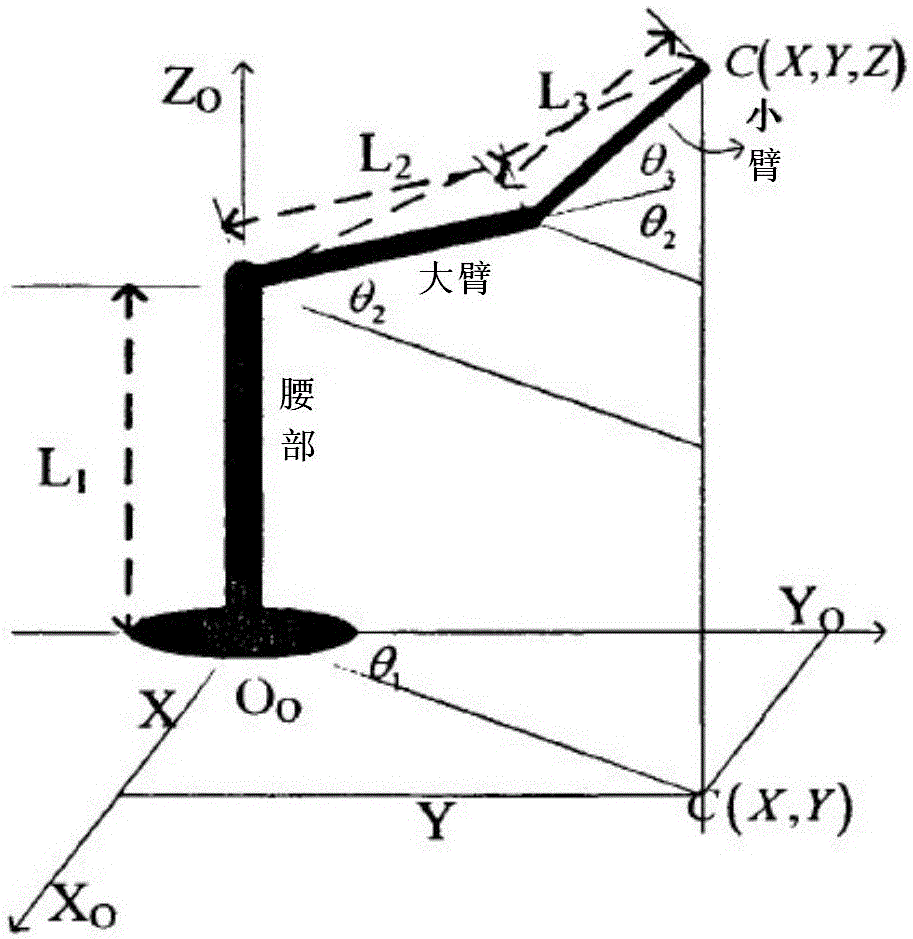

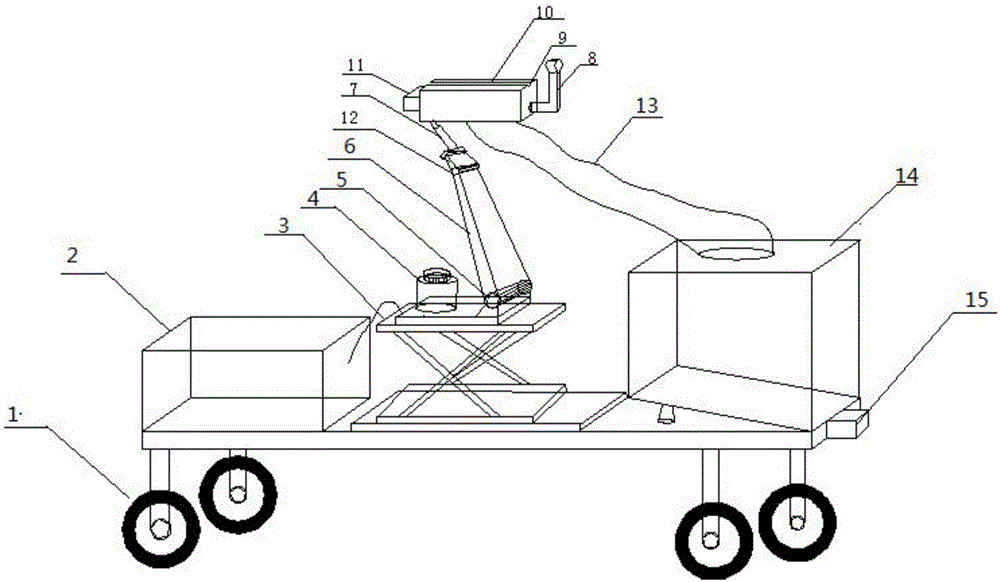

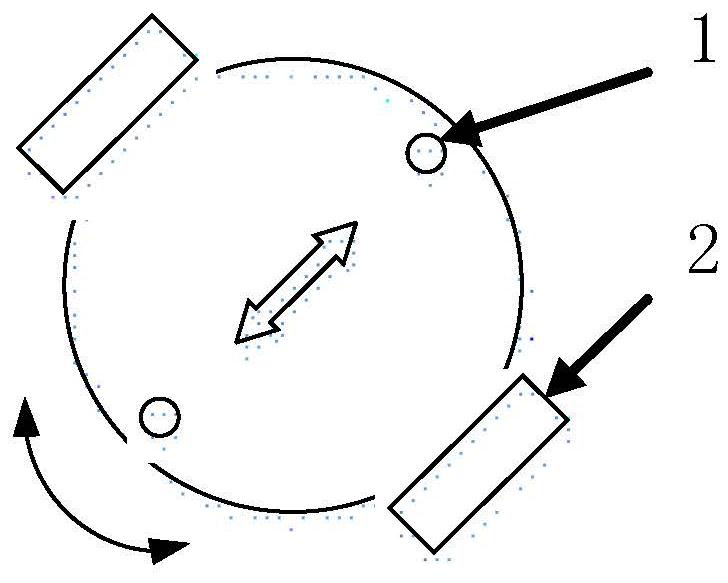

Wolfberry picking robot and control method thereof

InactiveCN105123127ARealize self-pickingRealize normal pickingPicking devicesControl mannerData acquisition

The invention discloses a wolfberry picking robot. A wolfberry picking robot system adopts a pinhole imaging technology and mainly comprises a data acquisition card and an analog-digital conversion module. A control method mainly adopts a fuzzy PID self-adaptive control way and is mainly used for controlling the vision. Hardware of the wolfberry picking robot mainly consists of a mechanical arm, a rotor structure, a picking head and various motors. By adopting the wolfberry picking robot, the automatic picking of wolfberry can be implemented, the manpower can be completely substituted, and the problem that the manual picking is subjected to the influence of the environment can be solved. The wolfberry picking robot is high in automation degree and high in picking efficiency.

Owner:BEIFANG UNIV OF NATITIES

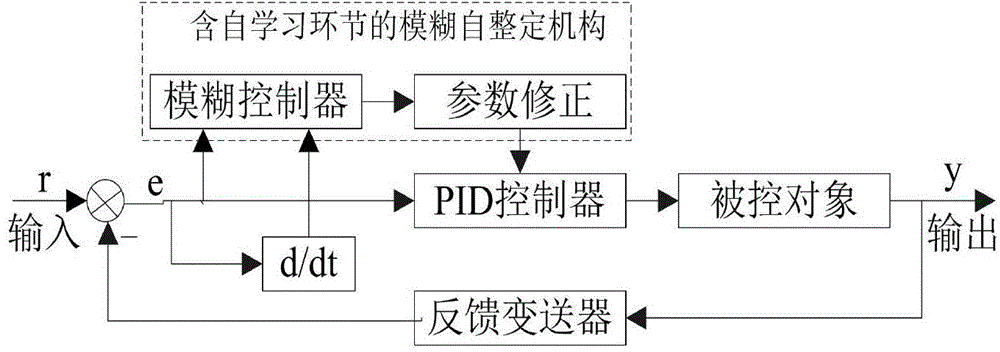

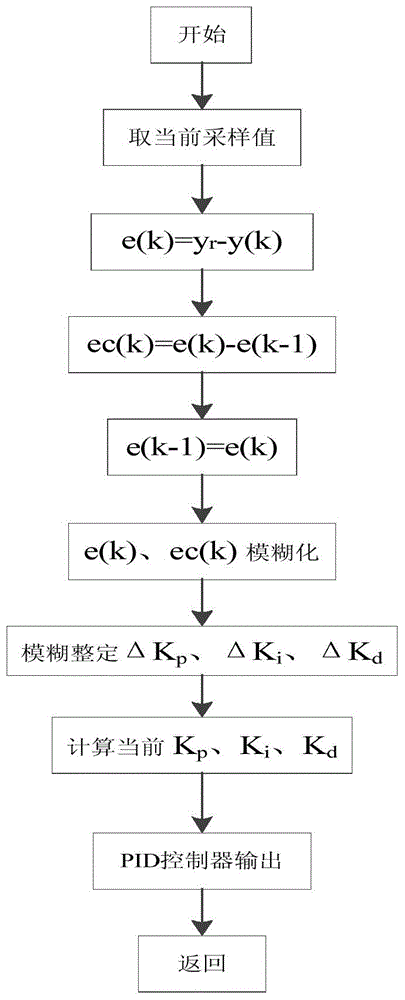

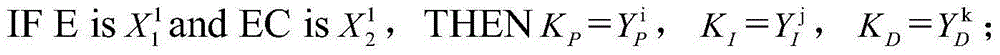

Method and system for self-adjusting fuzzy PID (Proportion Integration Differentiation) parameters in furnace temperature control system

InactiveCN104808708AImprove qualityTemperatue controlAdaptive controlFurnace temperatureDifferential coefficient

The invention provides a method and a system for self-adjusting fuzzy PID (Proportion Integration Differentiation) parameters in a furnace temperature control system. The method comprises the following steps: selecting and quantifying variables in a PID controller and finding out a fuzzy relation of three PID control parameters including a proportionality coefficient KP, an integral coefficient KI and a differential coefficient KD , and system deviation e and a deviation varying rate ec; establishing a fuzzy relation table; and carrying out online modification on the three parameters by a fuzzy control method. The system corresponds to the method. After PID parameter online fuzzy self-adjustment is carried out, a normal working state is automatically switched, and a PID parameter adjusting process is automatically started when system performances are changed and the readjusted PID parameters so that the system has the better control quality.

Owner:CHONGQING TECH & BUSINESS INST

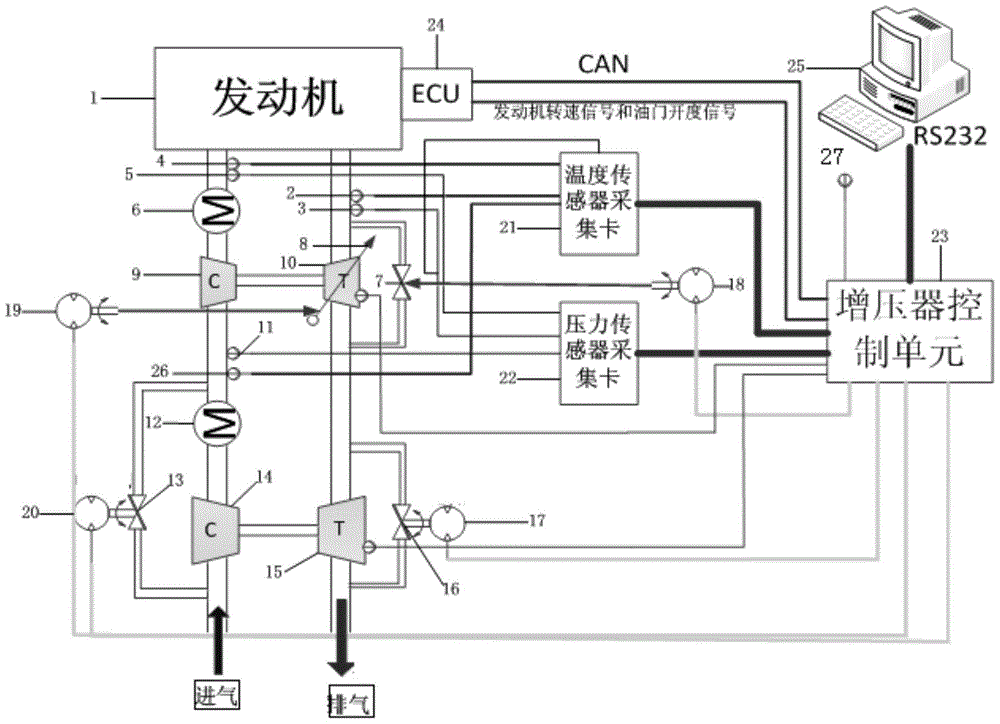

Diesel engine variable-altitude boost pressure control method

ActiveCN105673191APrevent surgeAvoid turbo overspeedInternal combustion piston enginesGas compressorOptimal control

Disclosed is a diesel engine variable-altitude boost pressure control method. Through a two-level adjustable booster controller ECU, according to change of altitude, diesel engine rotation speed and loads, opening of a high-pressure stage VGT vane of a two-level adjustable booster and opening of a high-pressure stage turbine regulating valve and a low-pressure stage turbine regulating valve are controlled in real time, optimal control is conducted on boost pressure in a variable-altitude and variable-working-condition mode, and the purpose that in the 0 m-5500 m altitude range, all performance indicators of a diesel engine are always kept the same as the performance under the plain conditions is achieved. The mode that feedforward control and fuzzy PID control are combined is adopted for the diesel engine variable-altitude boost pressure control method, and the boost pressure can be adjusted in real time according to change of altitude and working conditions of the diesel engine, so that the requirements for best power performance and fuel economy in the steady state working condition and the transient state working condition are met, the objective that power of the diesel engine at the altitude 5500 m fixed point is recovered to 95% or above that on plains is achieved, turbo lag is relieved, and pumping loss work is reduced. Meanwhile, the problems of gas compressor surges, turbine overspeed, excessively high turbine-front discharge temperature and the like are avoided.

Owner:MILITARY TRANSPORTATION UNIV PLA

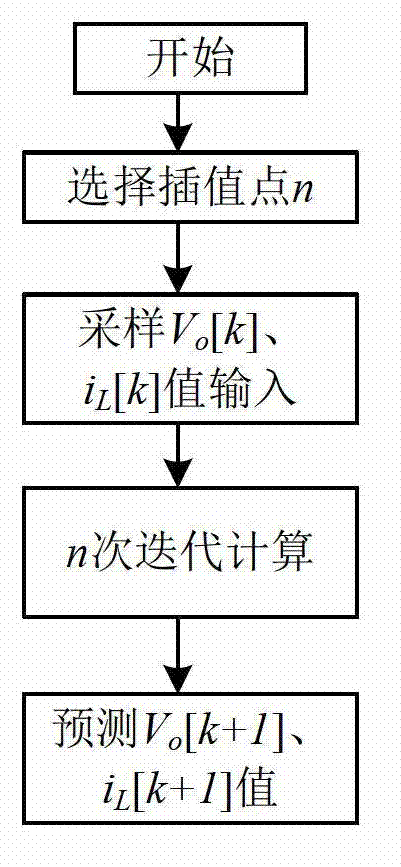

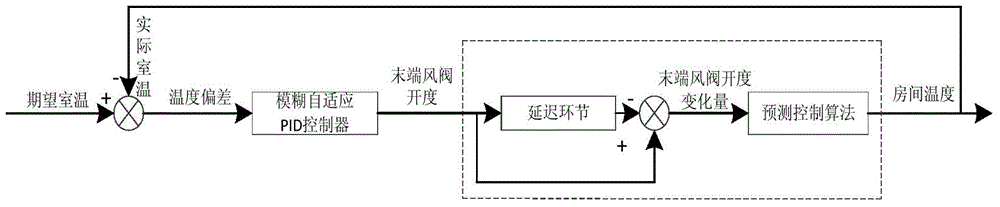

Variable air volume room temperature control method based on fuzzy PID and prediction control algorithm

InactiveCN104154635ASolve technical problems that require high precisionGood precisionMechanical apparatusSpace heating and ventilation safety systemsVariable air volumePoor adaptive skills

The invention discloses a variable air volume room temperature control method based on fuzzy PID and a prediction control algorithm. The method comprises the steps that the temperature deviation between an expected room temperature and an actual room temperature is input to a fuzzy adaptive PID controller, PID parameter incremental quantity of the opening degree of a tail end air valve is obtained through calculation, and calibrated opening degree of the tail end air valve is output; the opening degree of the tail end air valve of the fuzzy adaptive PID controller is subtracted from the opening degree of the tail end air valve of a previous moment by utilizing a time delay link to obtain the variable quantity of the opening degree of the tail end air valve; the prediction control algorithm is adopted to obtain the actual opening degree of the tail end air valve through the variable quantity of the opening degree of the tail end air valve, and the room temperature is maintained at a set value and is kept unchanged. The control method combining the fuzzy PID with the prediction control algorithm is adopted to solve the technical problems that parameter setting difficulty is large, working condition adaptive capacity is poor, and adaptive ability is weak in an air conditioning system in the prior art.

Owner:HOHAI UNIV CHANGZHOU

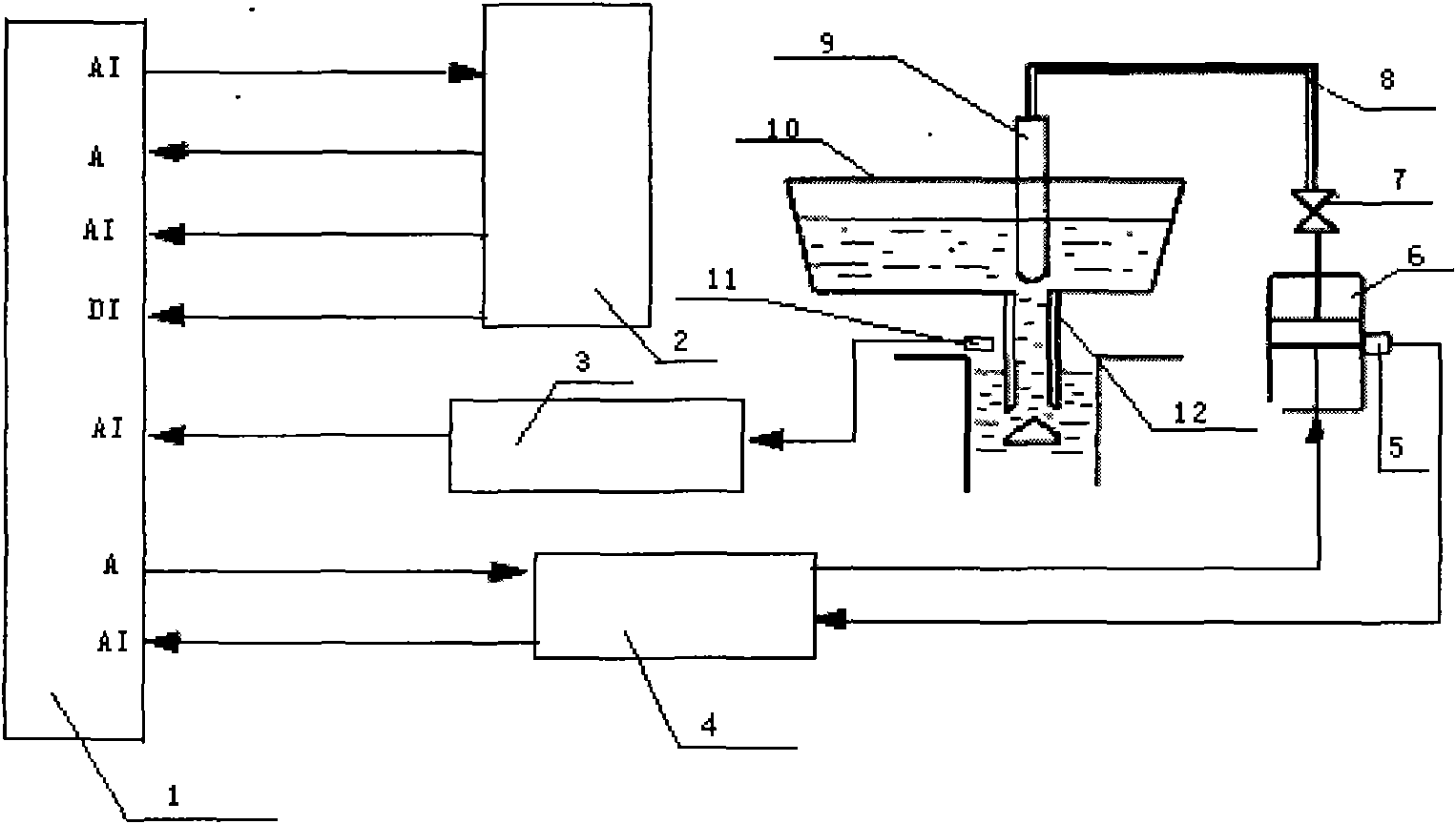

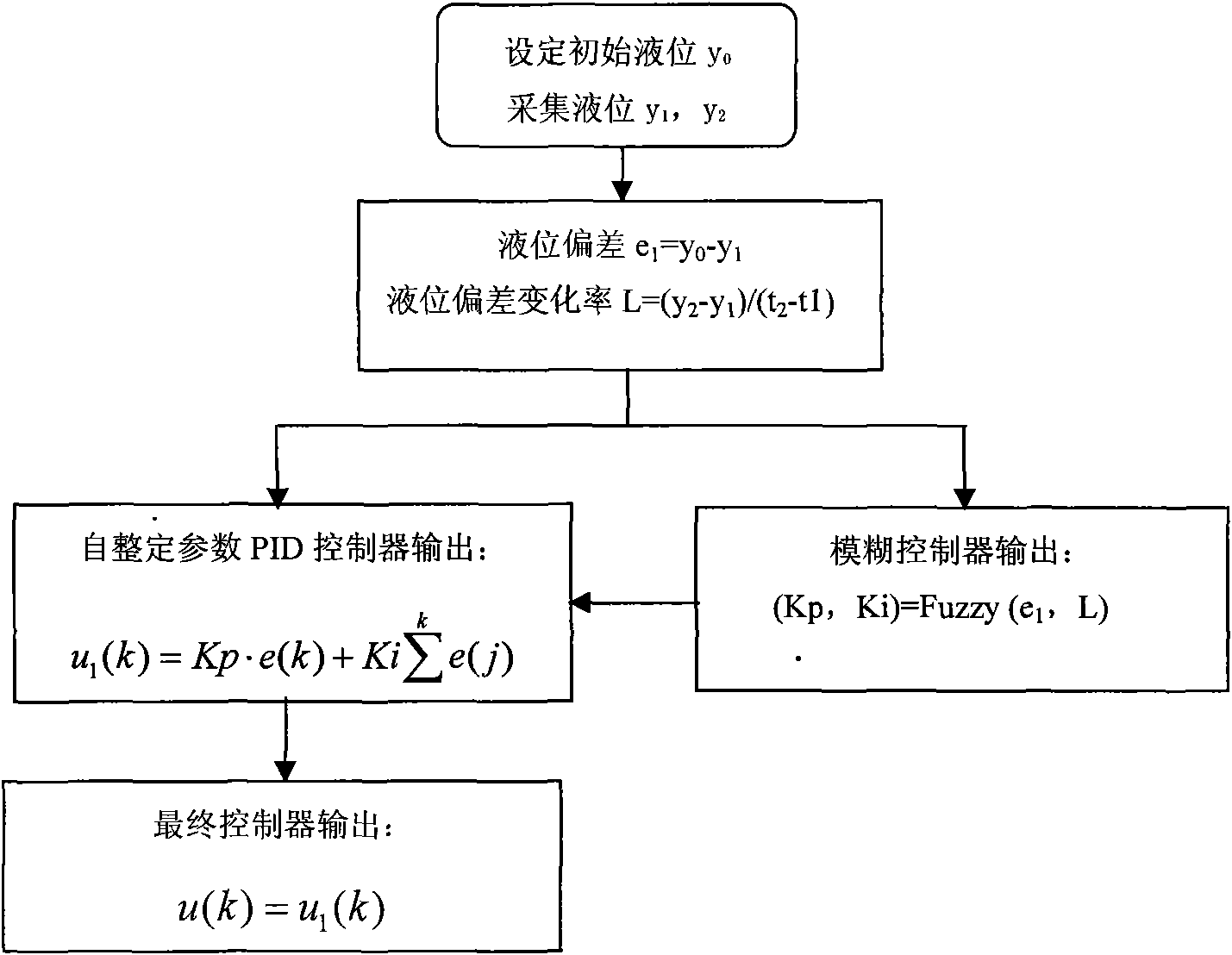

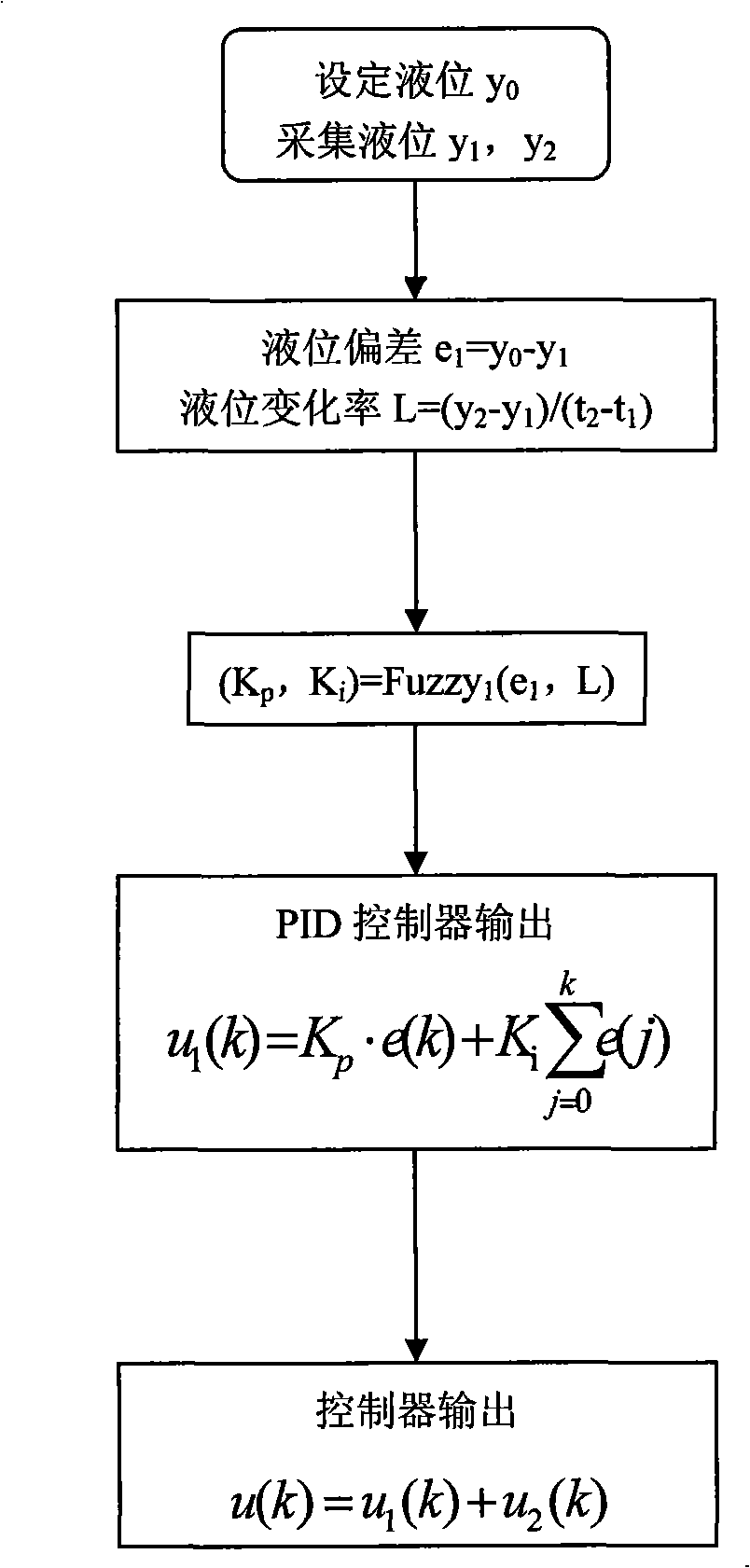

Liquid level control method of continuous casting crystallizer based on Fuzzy-PID

The invention relates to a liquid level control method of a continuous casting crystallizer based on Fuzzy-PID and belongs to the technical field of continuous casting production. The liquid level control method makes use of fuzzy control to carry out online correction of parameters in self-adjusting parameter PID control. Under the control of a computer and a PLC, the control method makes use of self-setting parameter PID control and fuzzy control to realize mixed control of the liquid level of the crystallizer, and also adopts a flow rate deviation compensating module, and the like. The control process of the control method comprises the following steps: setting an initial liquid level y0 and acquiring liquid levels y1 and y2 through a liquid level sensor and a liquid level measuring device; inputting the acquired data y1 and y2 in a PLC; adopting the self-setting parameter PID control and the fuzzy control to realize mixed control of a processing signal; and carrying out compensation through the compensating module; moreover, the output of the PLC, u(k) is equal to u1(k), and the PLC controls the position of a stopper through a stopper controller so as to control the liquid level of the crystallizer.

Owner:NORTHEASTERN UNIV LIAONING

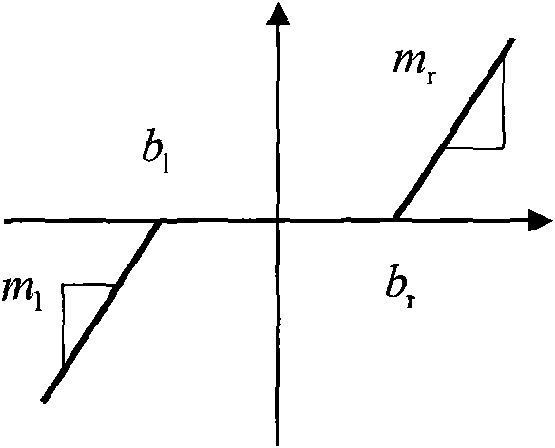

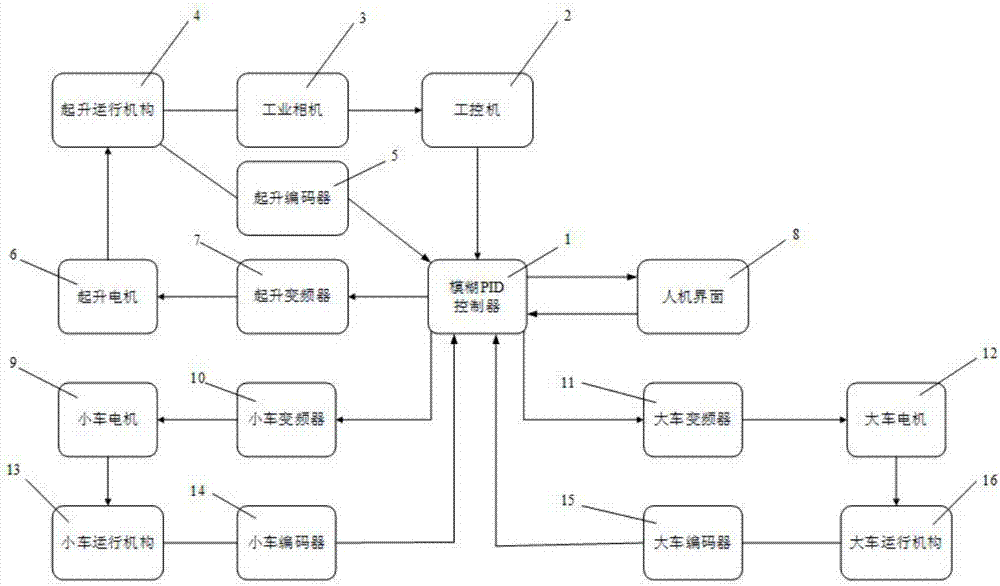

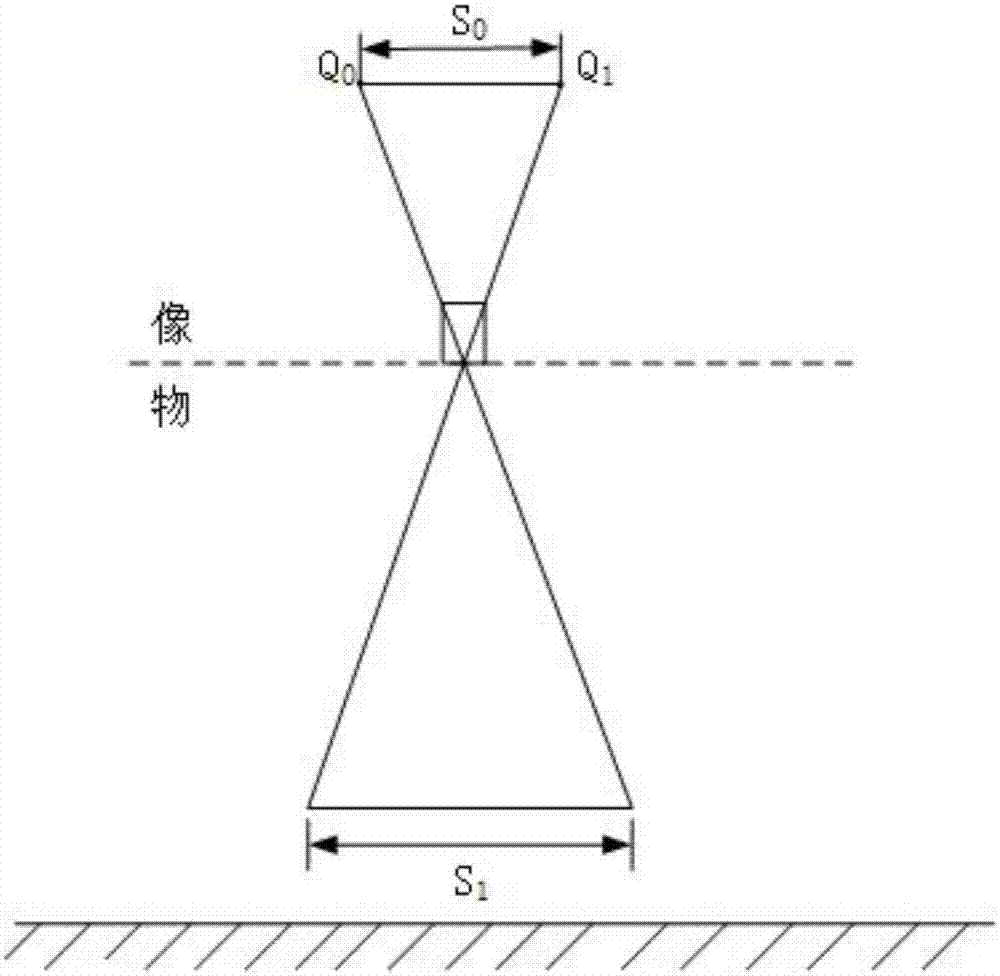

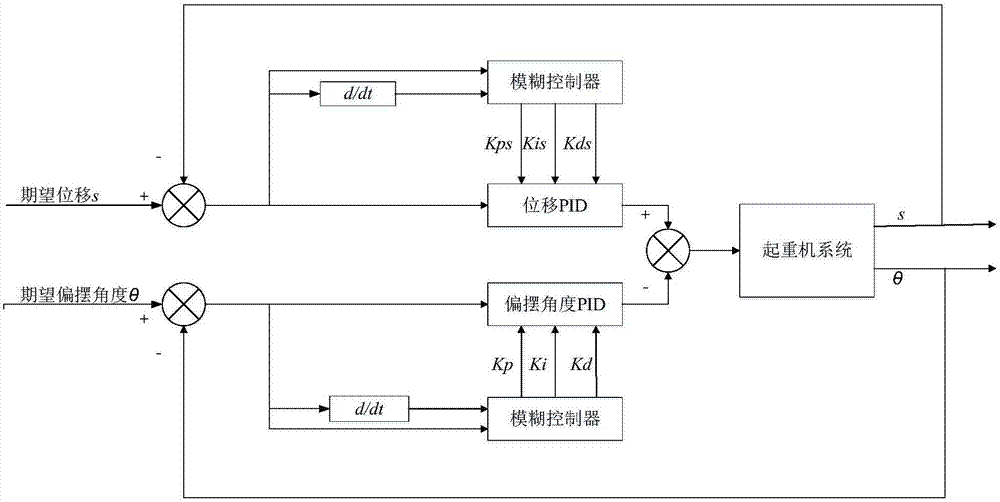

Intelligent anti-swinging crane control system and method based on fuzzy PID control

ActiveCN107487717ARealize real-time monitoringImprove the ability to resist external interferenceLoad-engaging elementsAdaptive controlHuman–machine interfaceControl system

The invention discloses an intelligent anti-swinging crane control system based on fuzzy PID control. The intelligent anti-swinging crane control system based on fuzzy PID control comprises a fuzzy PID controller, an industrial personal computer, an industrial camera, a lifting encoder, a human-computer interface, a trolley encoder and a gantry encoder. The human-computer interface is connected with the fuzzy PID controller. The industrial camera is installed on the lower side of a lifting operation mechanism. The lifting encoder is installed at one end of a lifting winding drum. The trolley encoder and the gantry encoder are installed on a trolley and a gantry correspondingly. The crane comprises the lifting operation mechanism, a trolley operation mechanism and a gantry operation mechanism. The lifting operation mechanism is connected with a lifting motor and a lifting frequency converter. The trolley operation mechanism is connected with a trolley motor and a trolley frequency converter. The gantry operation mechanism is connected with a gantry motor and a gantry frequency converter. The lifting frequency converter, the trolley frequency converter and the gantry frequency converter are connected with the fuzzy PID controller. The invention further discloses an intelligent anti-swinging crane control method based on fuzzy PID control. By the adoption of the intelligent anti-swinging crane control system and method based on fuzzy PID control, accurate control over the movement displacements of the gantry and the trolley of the crane and effective control over the swinging angle of a load can be achieved.

Owner:WUHAN UNIV OF TECH

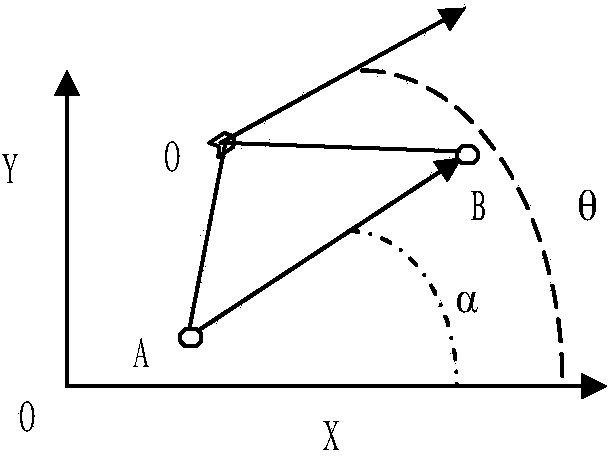

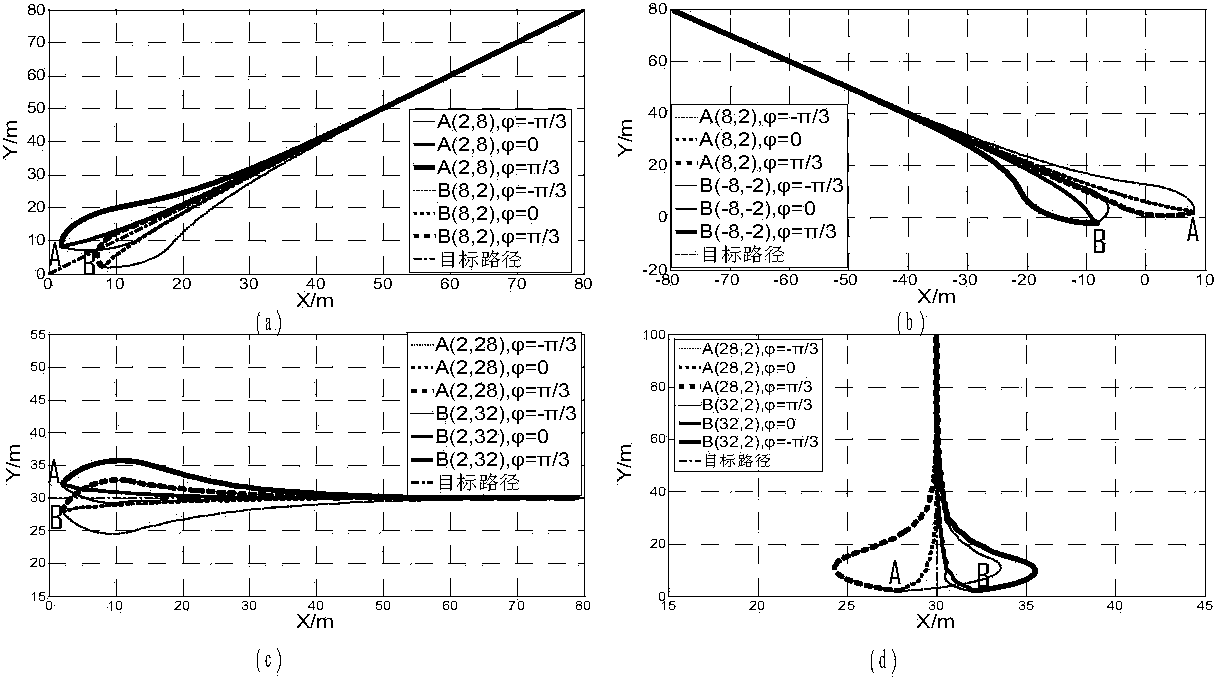

Unmanned surface vessel linear tracking method based on fuzzy PID

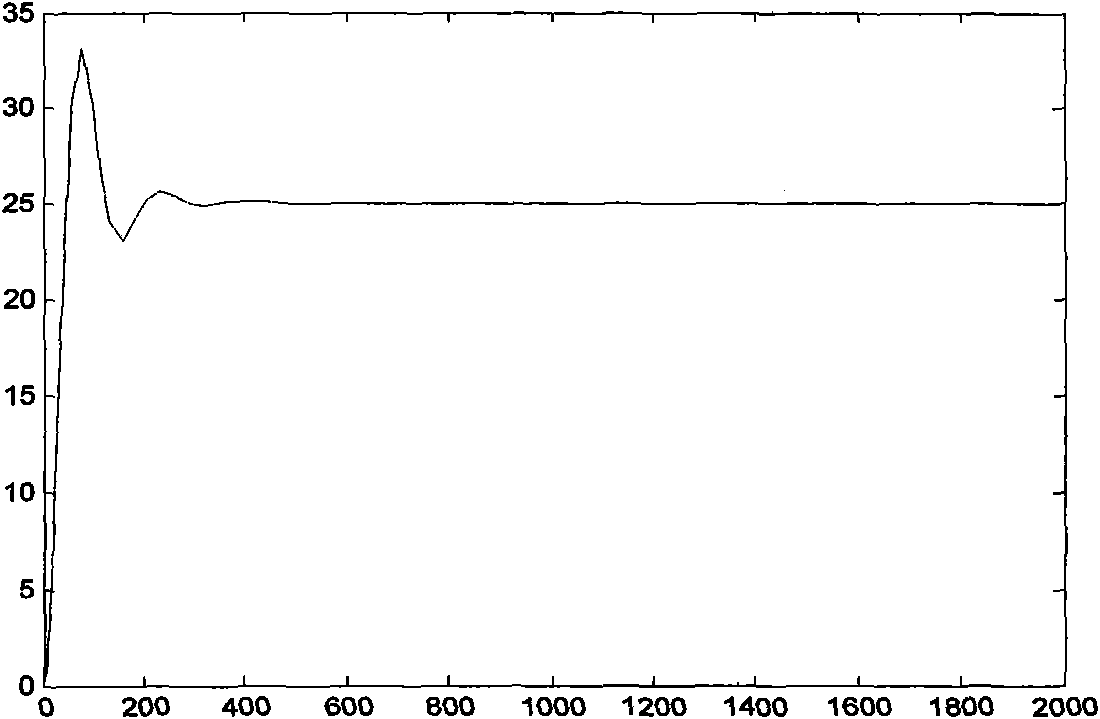

InactiveCN103777522AGood tracking effectImprove adaptabilityTarget-seeking controlAdaptive controlSimulationLongitude

The invention discloses an unmanned surface vessel linear tracking method based on a fuzzy PID. The method includes the following steps of dynamically obtaining a course angle of an unmanned surface vessel and real-time longitude and latitude coordinate values by means of a GPS device, calculating a distance deviation and an angle deviation by means of a vector cross product method, dynamically adjusting a parameter value of the PID by means of the fuzzy relationship between the distance deviation and the PID parameter and the angle deviation and the PID parameter, calculating control voltages U of a left electric propeller and a right electric propeller, and pushing the surface vessel to advance after control voltages are applied to a motor. As is shown by simulation and experiment results, the method has good tracking effects on the condition that a straight slope, a USV starting point and a starting angle are different, has good adaptability, can effectively avoid U-turn phenomena, and is superior to a PID controller in linear tacking performance.

Owner:SHANGHAI MARITIME UNIVERSITY

Continuous casting crystallizer fluid level control method based on Fuzzy-PID

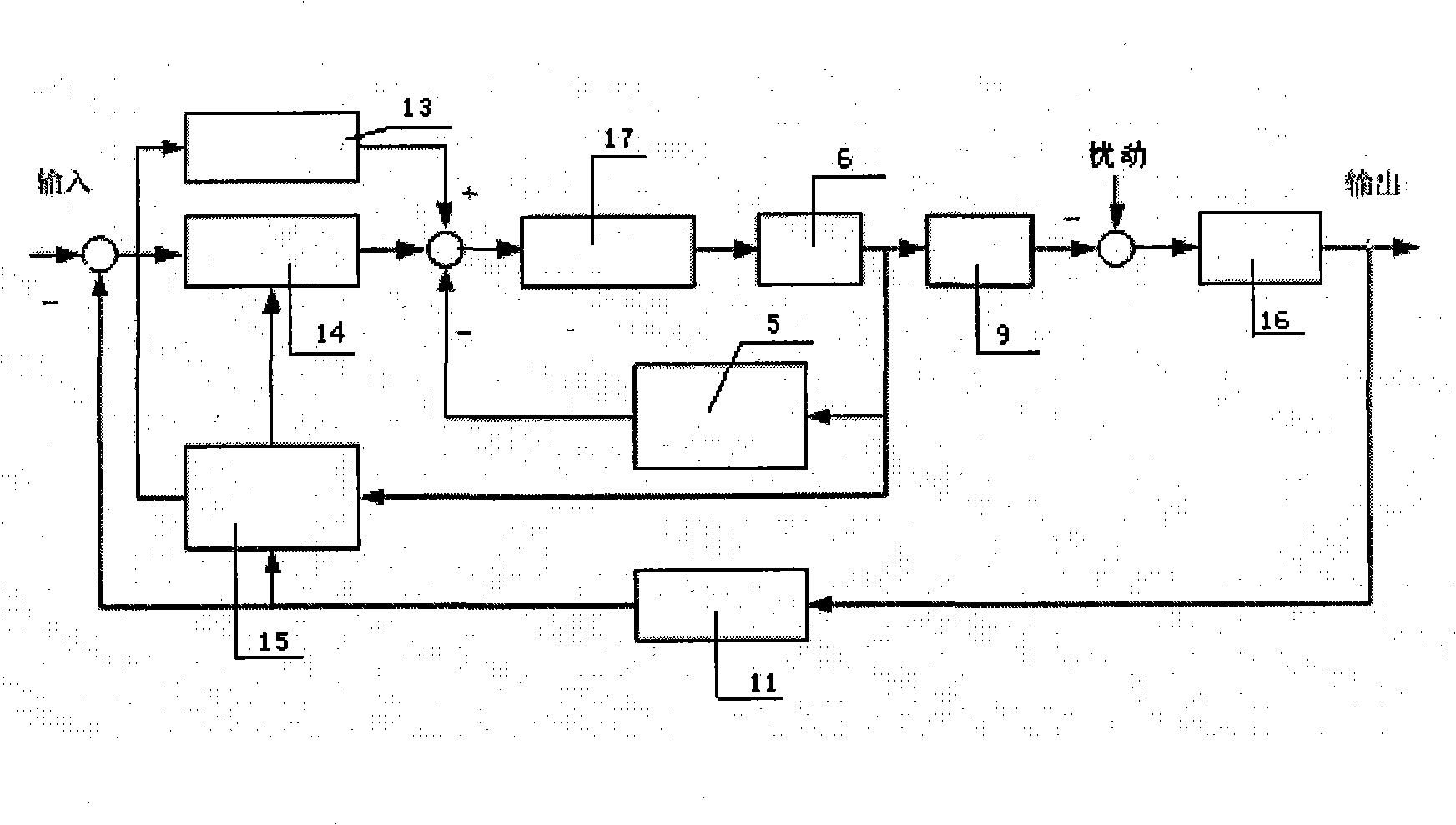

InactiveCN101403930AInhibition of overshootSmall overshootLevel controlAdaptive controlTransient stateFuzzy pid

The invention relates to a method for controlling the liquid level of a continuous casting crystallizer based on Fuzzy-PID. In the method, the liquid level is controlled by auto turning parameter PID control and fuzzy control under the control of a computer and a PLC, and the mechanical dead area is compensated. The method comprises the following steps: step 1, the original liquid level y0 is set, and the liquid level y1 and y2 are collected by a liquid level controller and a liquid level sensor; step 2, the collected data y1 and y2 are input PLC by a signal processor, the data is processed by the mixed control of the auto turning parameter PID control and the fuzzy control, and the mechanical dead area caused by insensitivity of the machine transmission is compensated by adjusting the PID parameter; step 3, the PLC outputs u(k)=u1(k)+u2(k), so that the liquid level is controlled by controlling the position of a stopper by a stopper controller. The method of the invention ensures that the system not only has good steady characteristic, but also has excellent transient characteristic under time-variation condition by reasonably designing fuzzy control rule and parameter setting rule.

Owner:NORTHEASTERN UNIV

Temperature control device for full-automatic injecting blowing plastic hollow molding machine and temperature control method thereof

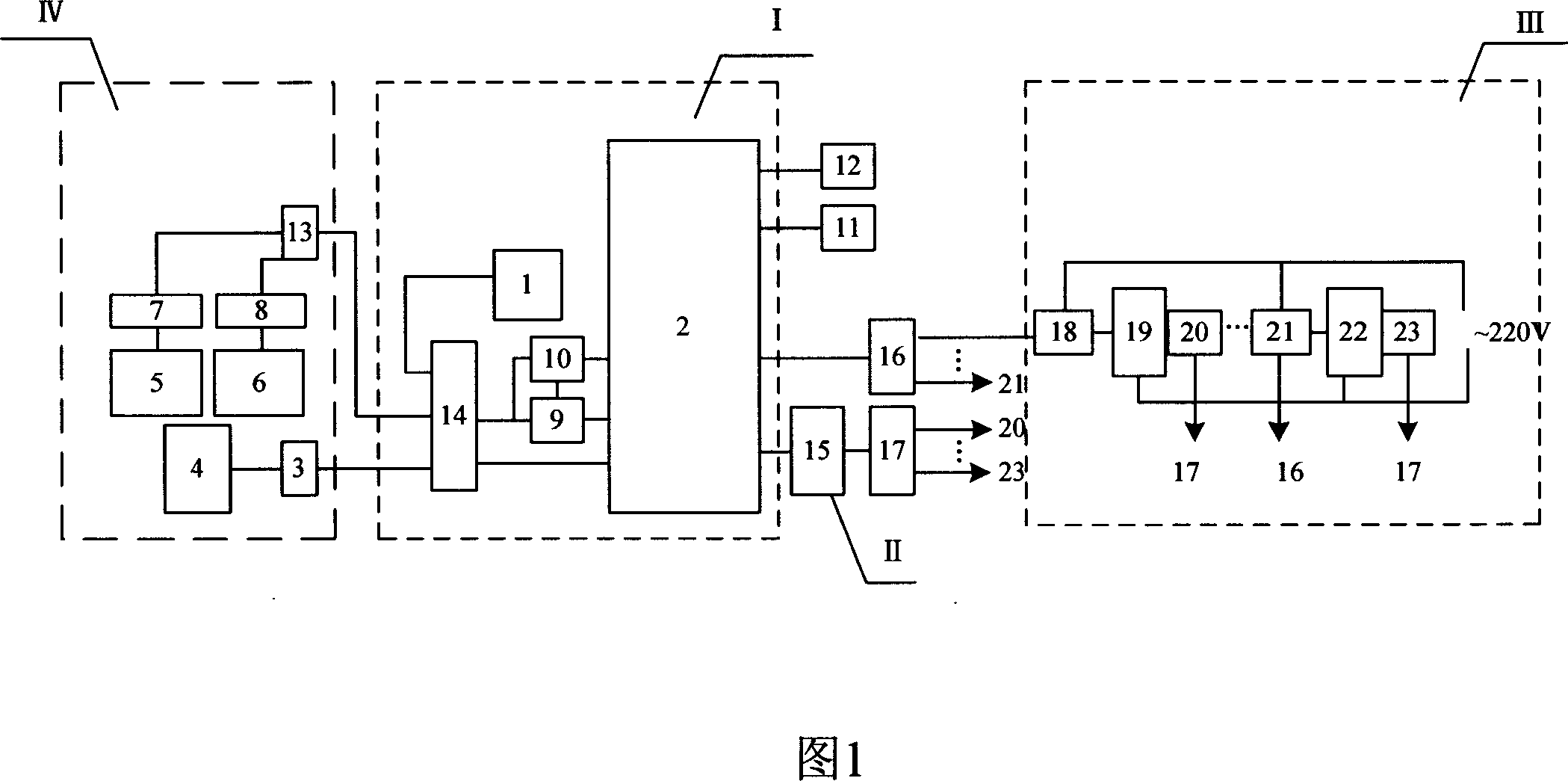

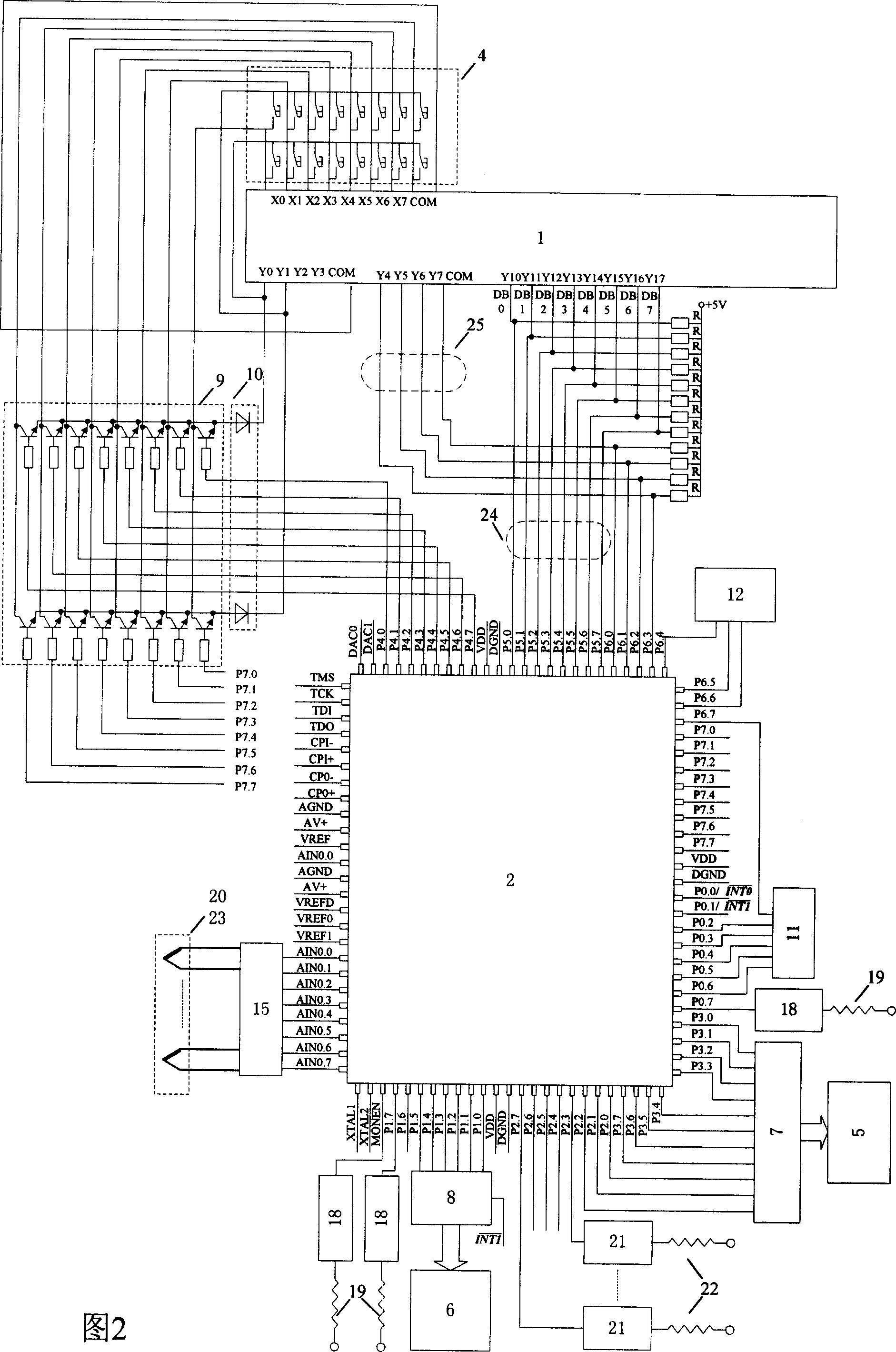

InactiveCN101117019AAchieve the effect of high precision temperature controlRealize monitoringTemperature control using electric meansControllers with particular characteristicsMicrocontrollerDot matrix

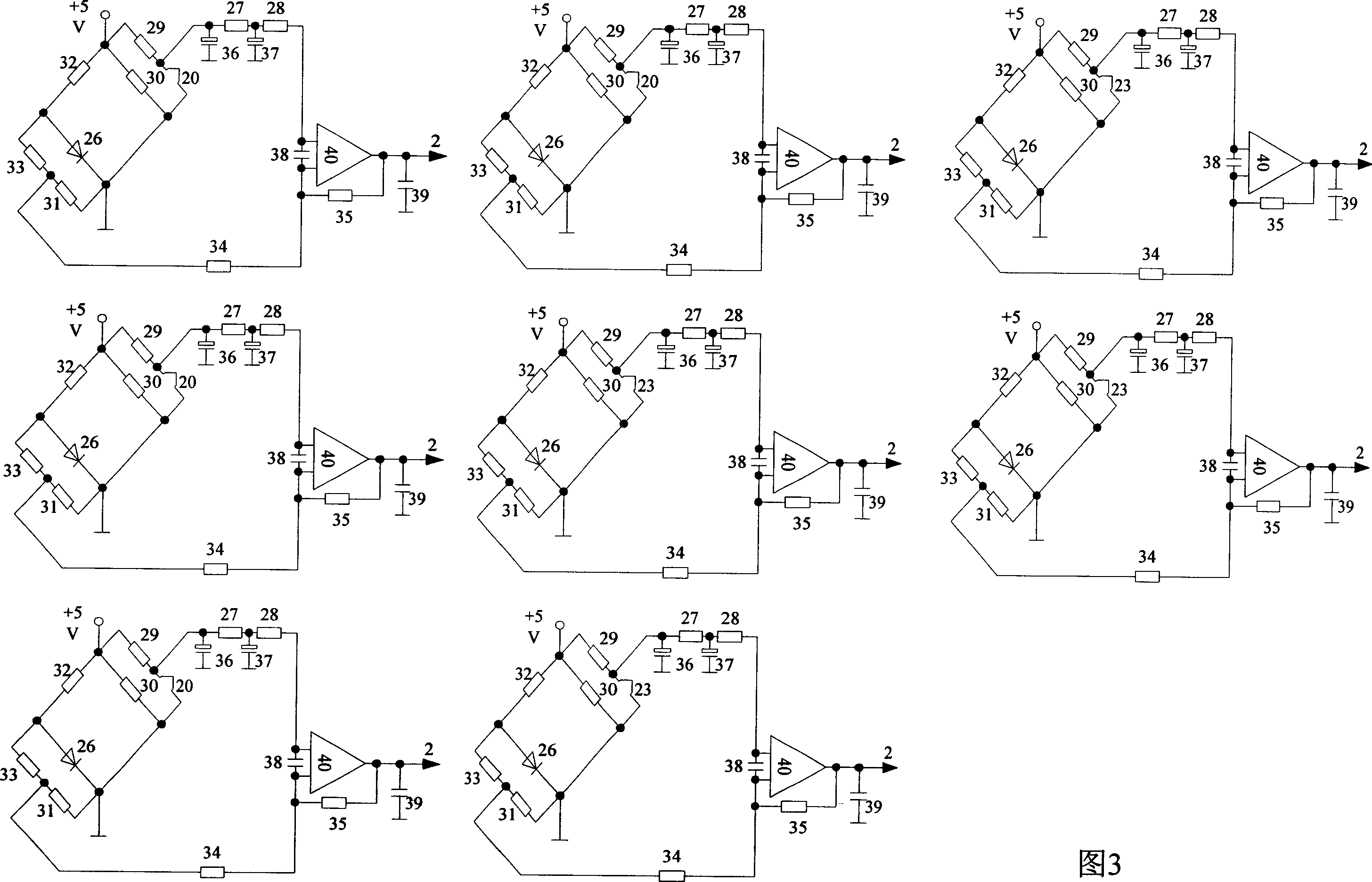

The present invention relates to a temperature control device of an automatic injection plastic hollow molding machine. The device consists of a PLC-high-speed singlechip system, a temperature sensor signal amplification circuit, a heating device drive circuit and an operation panel; the method is that temperature information is converted into electricity information through temperature sensor; temperature signal is exerted into an operational amplifier through a bridge detecting circuit of the temperature sensor signal amplification circuit and a lowpass; after amplification, the temperature signals are converted into digital signals through a A / D converter of the high-speed singlechip, and then difference value is achieved after comparison with a temperature setting control value, and then a control value is achieved through fuzzy PID calculation; the control value is converted into square waves with certain dutyfactor; heating power of a solid-state relay for driving heated circle is output and controlled by an I / O port of the high-speed singlechip; a dynamic value and a setting control value of eight-way temperature are displayed in a dot matrix LCD module of the operational panel in real-time. The device and the method are exact in temperature control effect, high in performance-price ratio, simple in operation.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

Air-conditioning control technique with variable air quantity based on enthalpy value control

InactiveCN101672509ARealize intelligenceSpace heating and ventilation safety systemsLighting and heating apparatusAir volumeControl signal

The invention relates to a novel air-conditioning control technique with variable air quantity based on enthalpy value control, which comprises a pressure relevant type end device control part and a fuzzy PID control part. The technique concretely comprises a PID controller, a parameter self-calibration module, a fuzzy database, an air return valve, an air delivery valve, an air-conditioning end with variable air quantity, a humiture sensor and an air enthalpy value operation module. The humiture sensor collects indoor humiture signals Tr and phi r, the indoor humiture signals are transformedinto an executable standard electric signal by a variable delivery link, the electric signal is delivered into the air enthalpy value operation module, an enthalpy value representing indoor humiture properties is obtained by calculation, and the enthalpy value is compared with a set enthalpy value. After comparison, a bias and a bias change rate are regulated and calibrated by the fuzzy control module, and a timely and accurate control signal is sent to the air delivery valve or the air return valve positioned at the end, thereby changing the air quantity so as to achieve the purpose of regulating the humiture in a room. The invention has intellectualized control and shorter response regulation time and realizes the purpose of energy saving of an air-conditioning host machine.

Owner:DONGGUAN GUANGDA REFRIGERATION

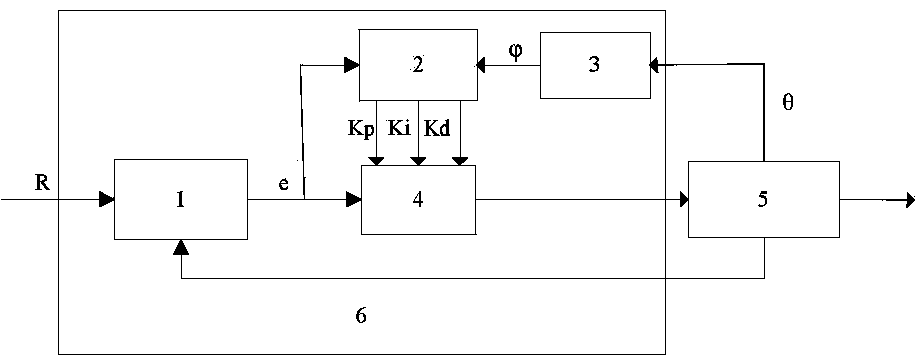

Method for controlling PID controller route based on fuzzy control

InactiveCN103995535AReduce power consumptionImprove efficiencyPosition/course control in two dimensionsDefuzzificationFuzzy pid control

The invention discloses a method for controlling a PID controller route based on fuzzy control. The method comprises the steps that on the basis of a motor PID controller, a route correcting strategy based on the fuzzy control idea is integrated, fuzzy PID controlled quantities of delta Kp, delta Ki and delta Kd are obtained by detecting deviation and the deviation regulating rate, after the fuzzy PID controlled quantities are received by the PID controller, the fuzzy PID controlled quantities are subjected to defuzzification to be adjusted to be three precise controlled quantities of Kp, Ki and Kd. Accordingly, a motor of self-tracking equipment is controlled, and the purpose of correcting the route is achieved.

Owner:SUZHOU INST OF INDAL TECH

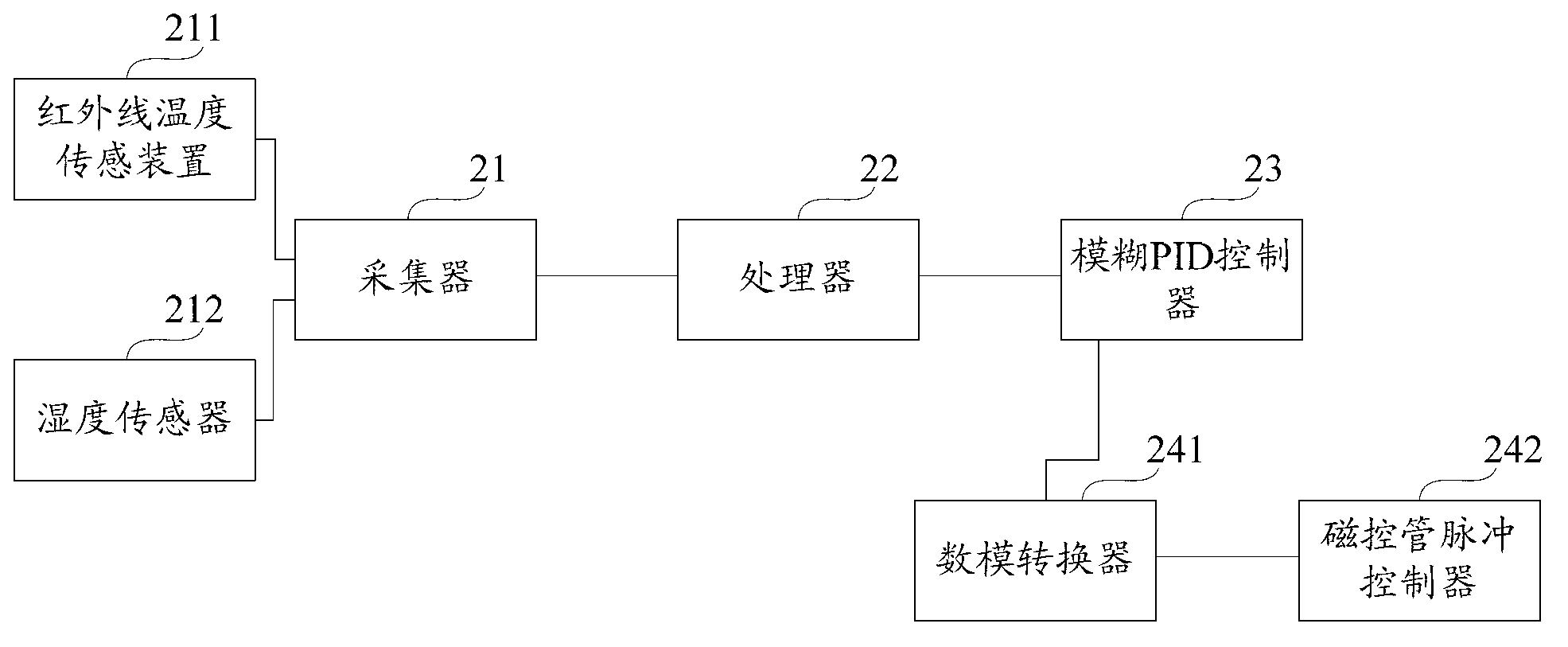

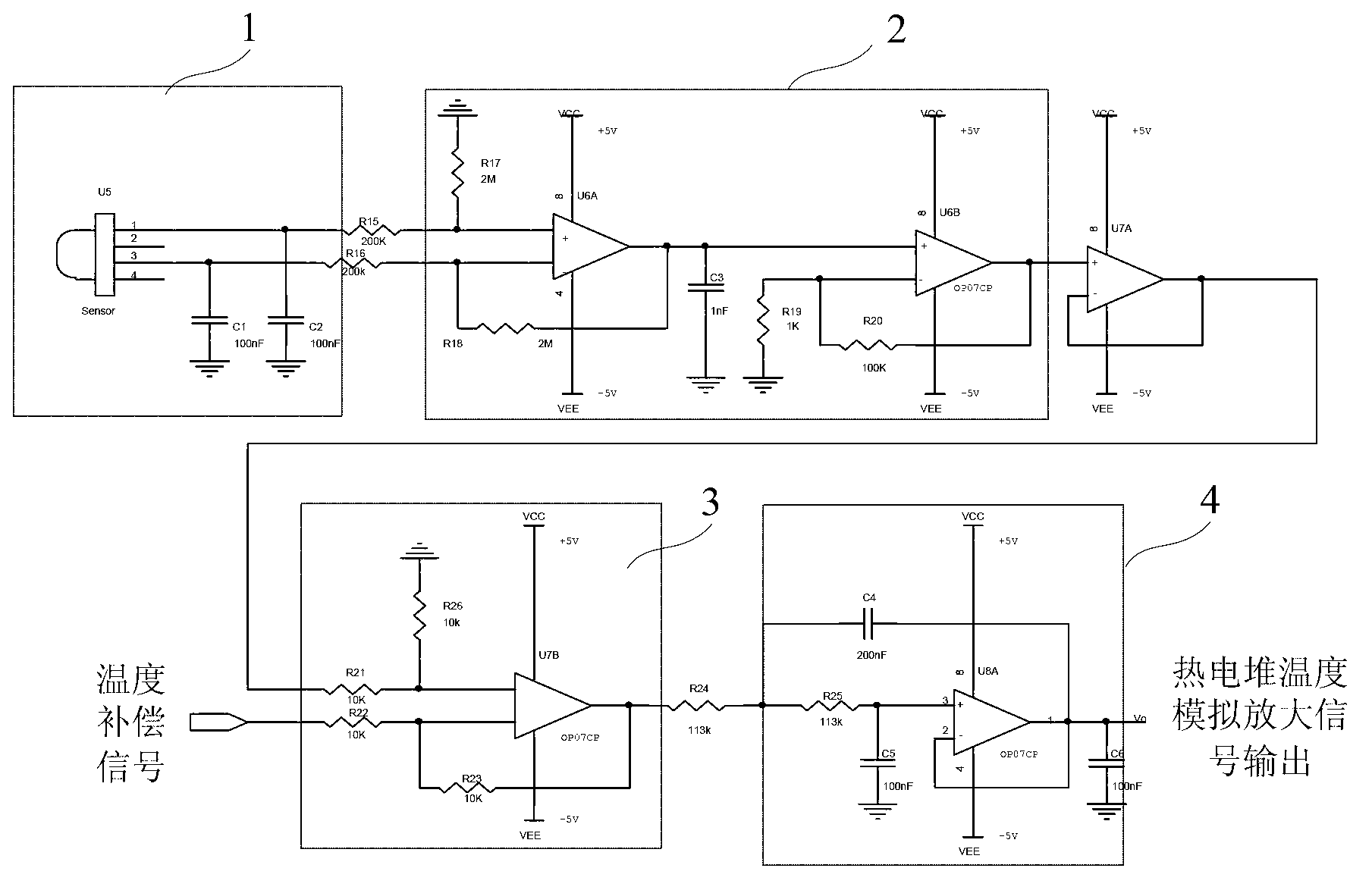

Micro-wave oven control method, control equipment and micro-wave oven

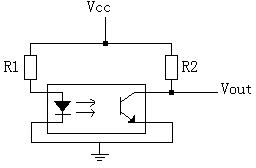

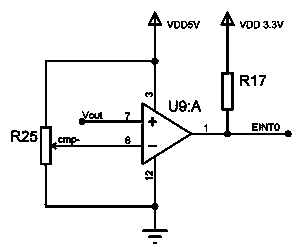

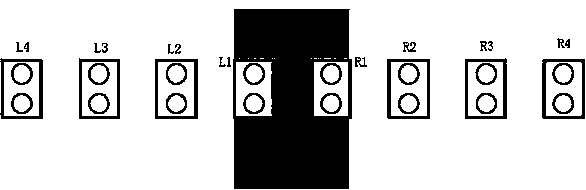

InactiveCN103017217AHigh precisionImprove convenienceDomestic stoves or rangesLighting and heating apparatusControl signalClosed loop

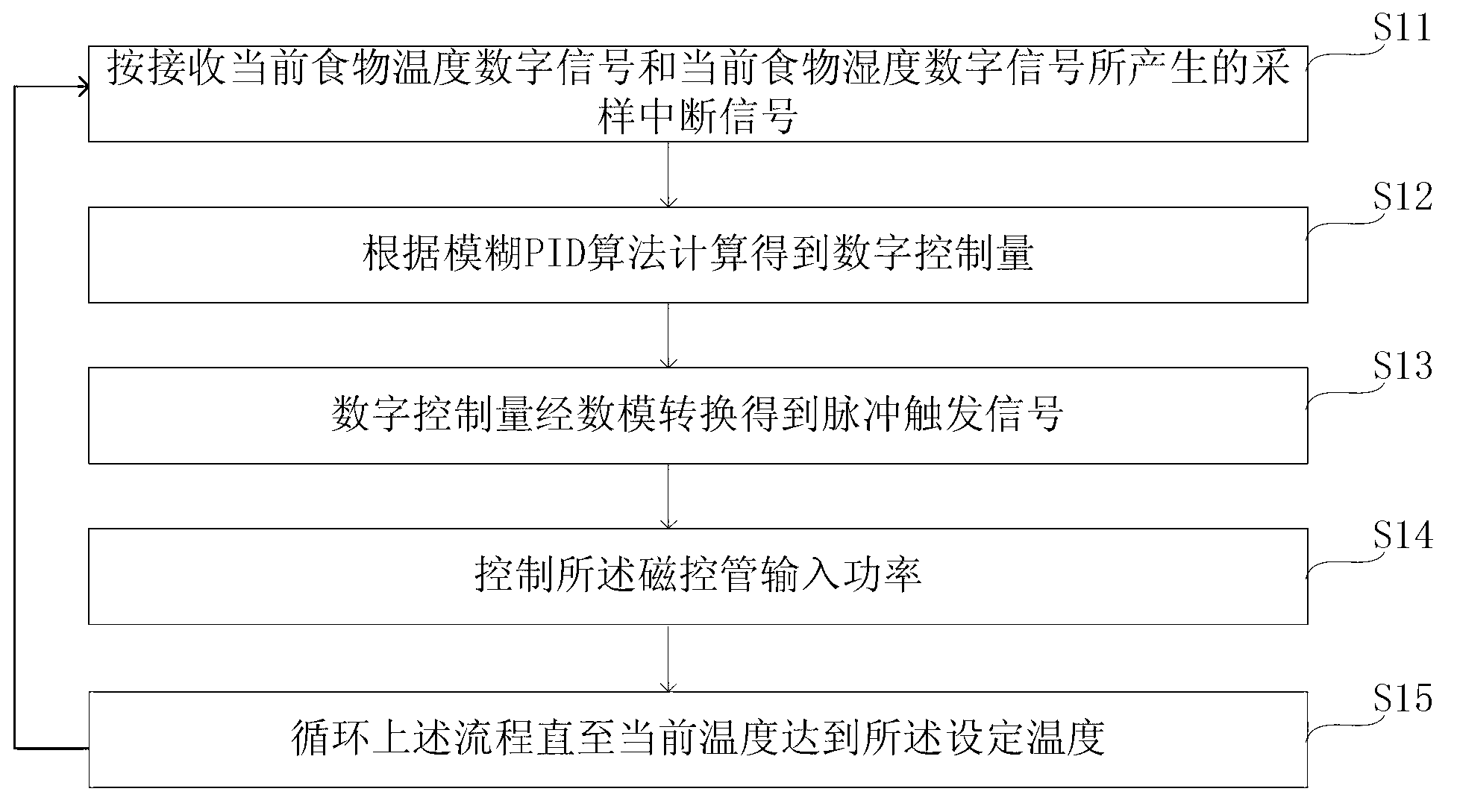

The embodiment of the invention discloses a micro-wave oven control method, micro-wave oven control equipment and a micro-wave oven. The method comprises the following steps: receiving a sampling interruption signal generated by a digital signal of the current food temperature and a digital signal of the current food humidity according to a pre-set period; responding to the sampling interruption signal, calculating the current food temperature , the current food humidity and the received setting temperature to obtain the amount of digital control according to a fuzzy PID (proportion integration differentiation) algorithm, and performing digital to analog conversion and PWM (pulse-width modulation) on the amount of digital control to obtain an analog pulse control signal; utilizing the analog pulse control signal to control the input power of a magnetron; and circulating the process until the current temperature reaches the setting temperature. According to the invention, through the closed-loop control method for continuously acquisition, calculation and output, the precision for temperature control is increased; and meanwhile, a user can obtain a pre-set heating effect without setting the heating time and heating manner of food according to experience, so that the convenience for use is further improved.

Owner:ORISE TECHNOLOGY CO LTD

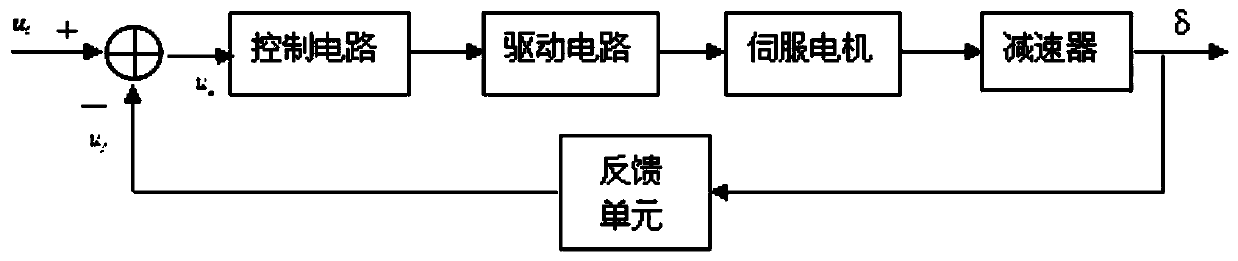

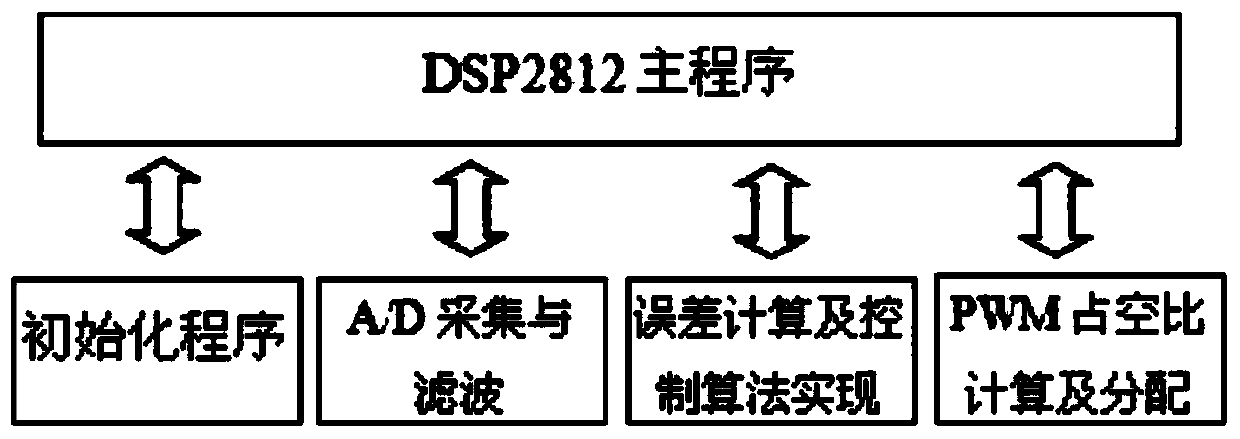

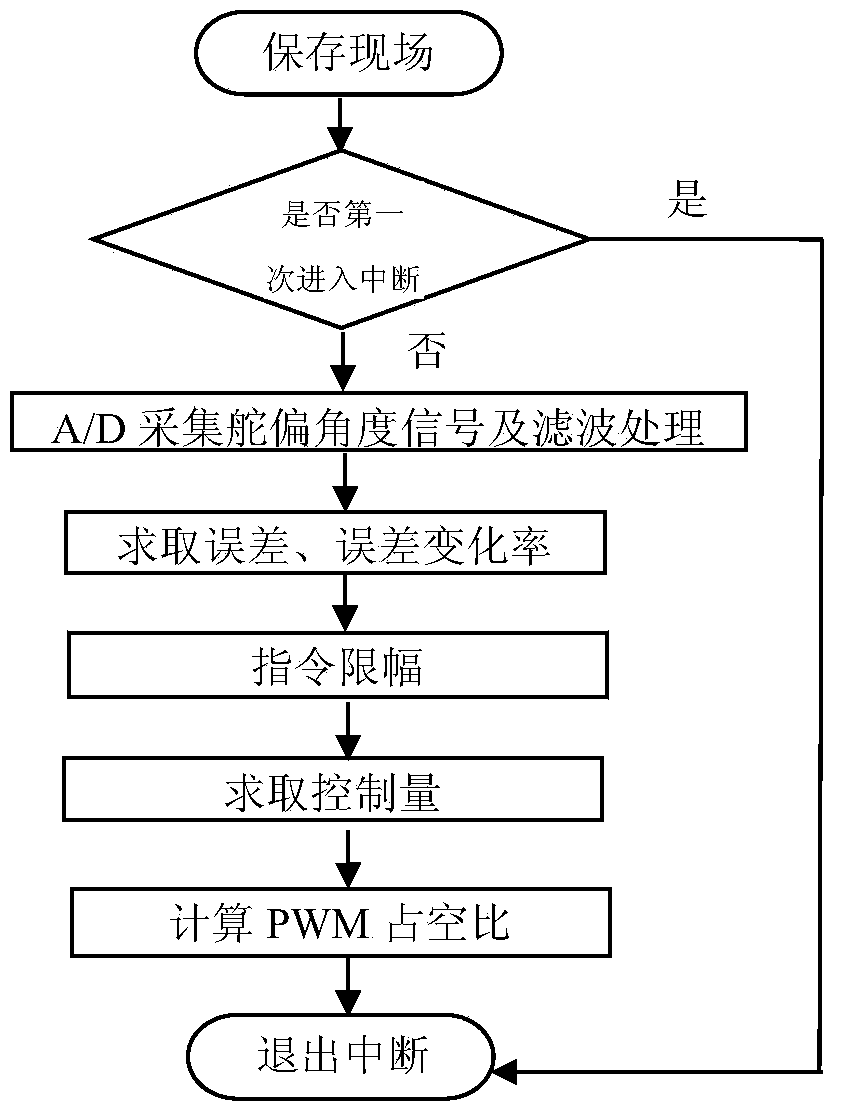

Position loop control-based electric steering engine system

InactiveCN103699134AOvercoming dispersionOvercome temperaturePosition/course control in three dimensionsLoop controlControl signal

The invention relates to an electric steering engine system, and particularly discloses a position loop control-based electric steering engine system, which is implemented in a way of combining hardware and software. A DC / DC (direct current / direct current) power supply with isolated output is adopted for a power circuit in a hardware design, and missile power is transformed to be supplied to each unit circuit; TMS320F2812 is adopted as a master control unit of a control circuit, and is used for acquiring a rudder control signal and a rudder deflection angle feedback signal, integrating and amplifying errors of the rudder control signal and the rudder deflection angle feedback signal, calculating an actually output PWM (pulse width modulation) signal by using a fuzzy PID (proportion integration differentiation) algorithm, and providing the PWM signal for a driving circuit; the driving circuit is used for performing power amplification on the signal, and driving a steering engine execution mechanism to rotate, thereby realizing closed-position loop control on the electric steering engine system.

Owner:陕西航天导航设备有限公司

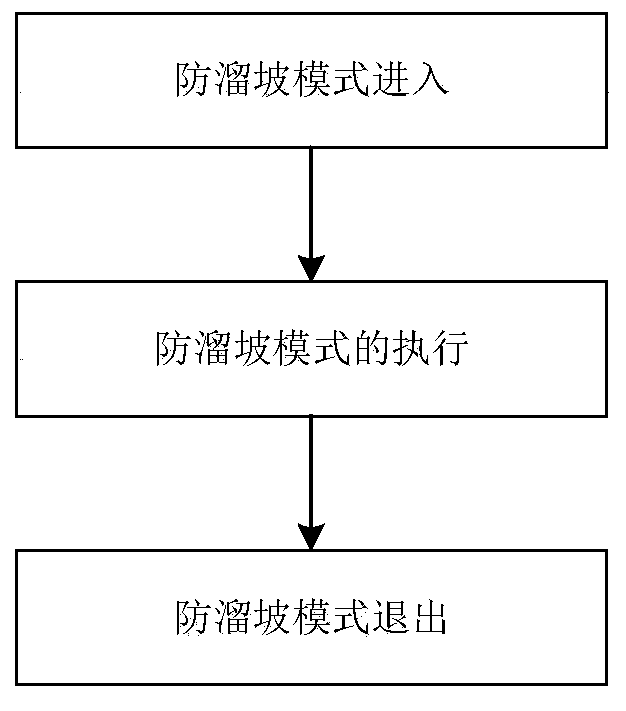

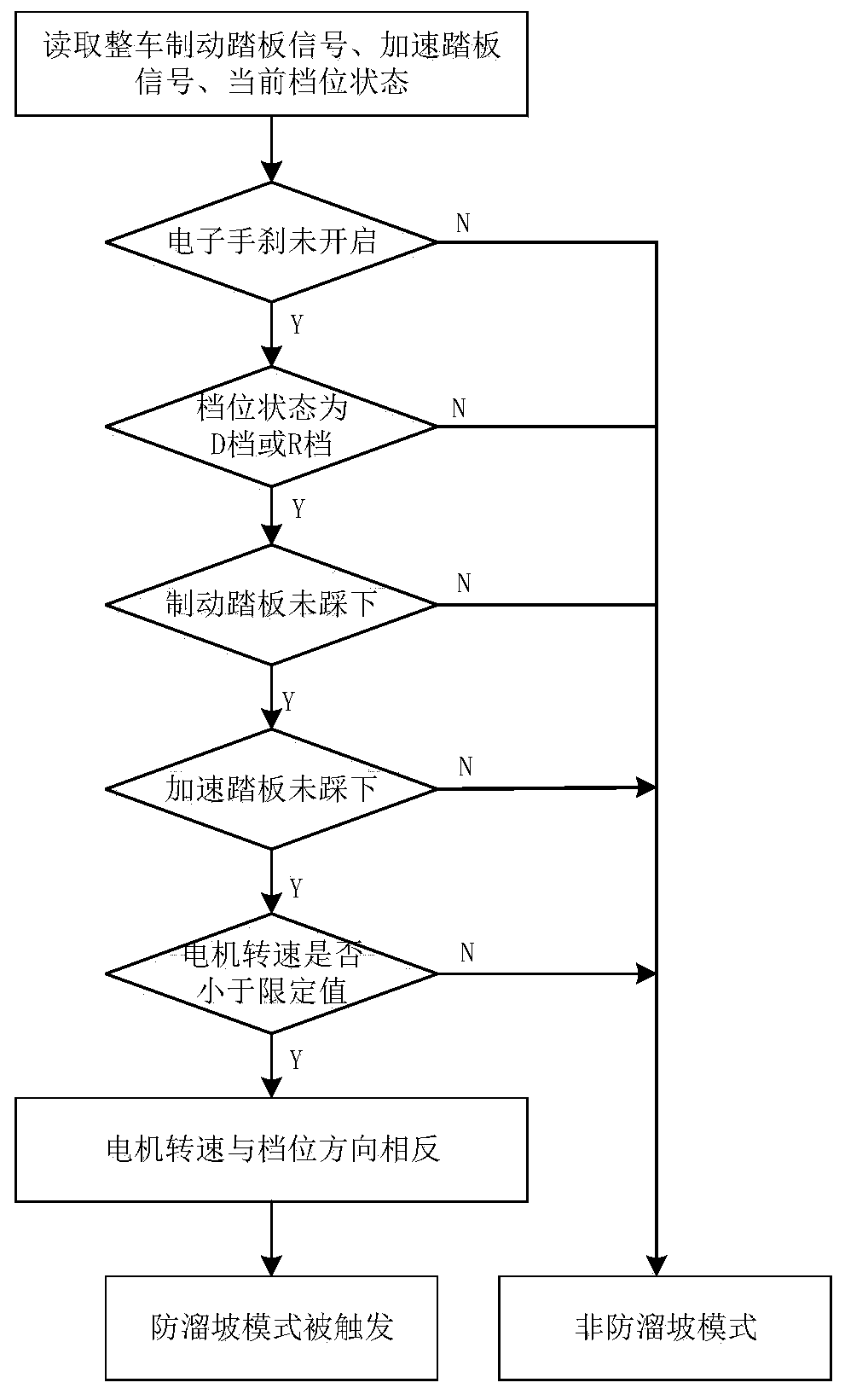

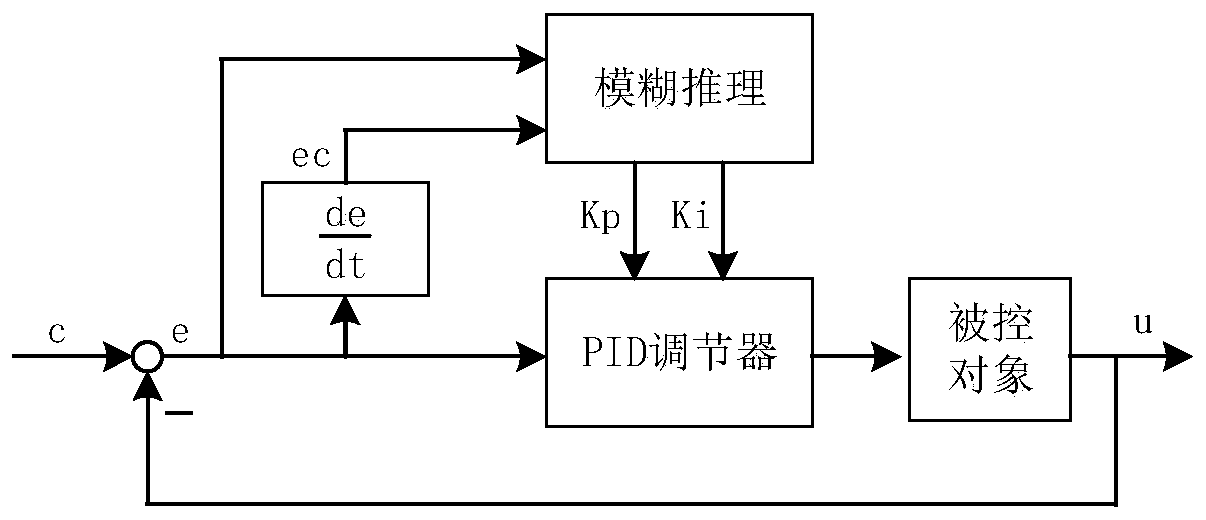

Fuzzy self-adaption PID control based slope sliding preventing method and system and electric vehicle

InactiveCN109808506AImprove stabilityImprove robustnessSpeed controllerElectric energy managementElectric machineDrive motor

The invention provides a fuzzy self-adaption PID control based slope sliding preventing method and system and an electric vehicle, and relates to the field of electric vehicles. The method comprises the following steps: 1) determining whether a slope sliding preventing mode performing condition based on the electric vehicle running information; 2) performing a slope sliding preventing mode on thevehicle; treating motor rotating speed system error and system error change as fuzzy controller input variable; and outputting fine parameter adjusting values delta Kp and delta Ki of a rectifying PIDcontroller by a fuzzy algorithm; 3) calculating Kp and Ki in parameters of a rectifying PI adjuster based on the foundation PI parameters Kp0 and Ki0 and the fine adjusting values delta Kp and deltaKi; 4) calculating actual torque for a driving motor by the self-adaptive fuzzy PID algorithm; and 5) driving the motor based on the actual torque required by the motor, and controlling the rotating speed of a motor of the electric vehicle by obtained fuzzy self-adaption PID. According to the method, the motor torque is dynamically adjusted, so that the electric vehicle achieves the slope slidingpreventing function under different slope conditions.

Owner:JIANGSU MINAN AUTOMOTIVE CO LTD

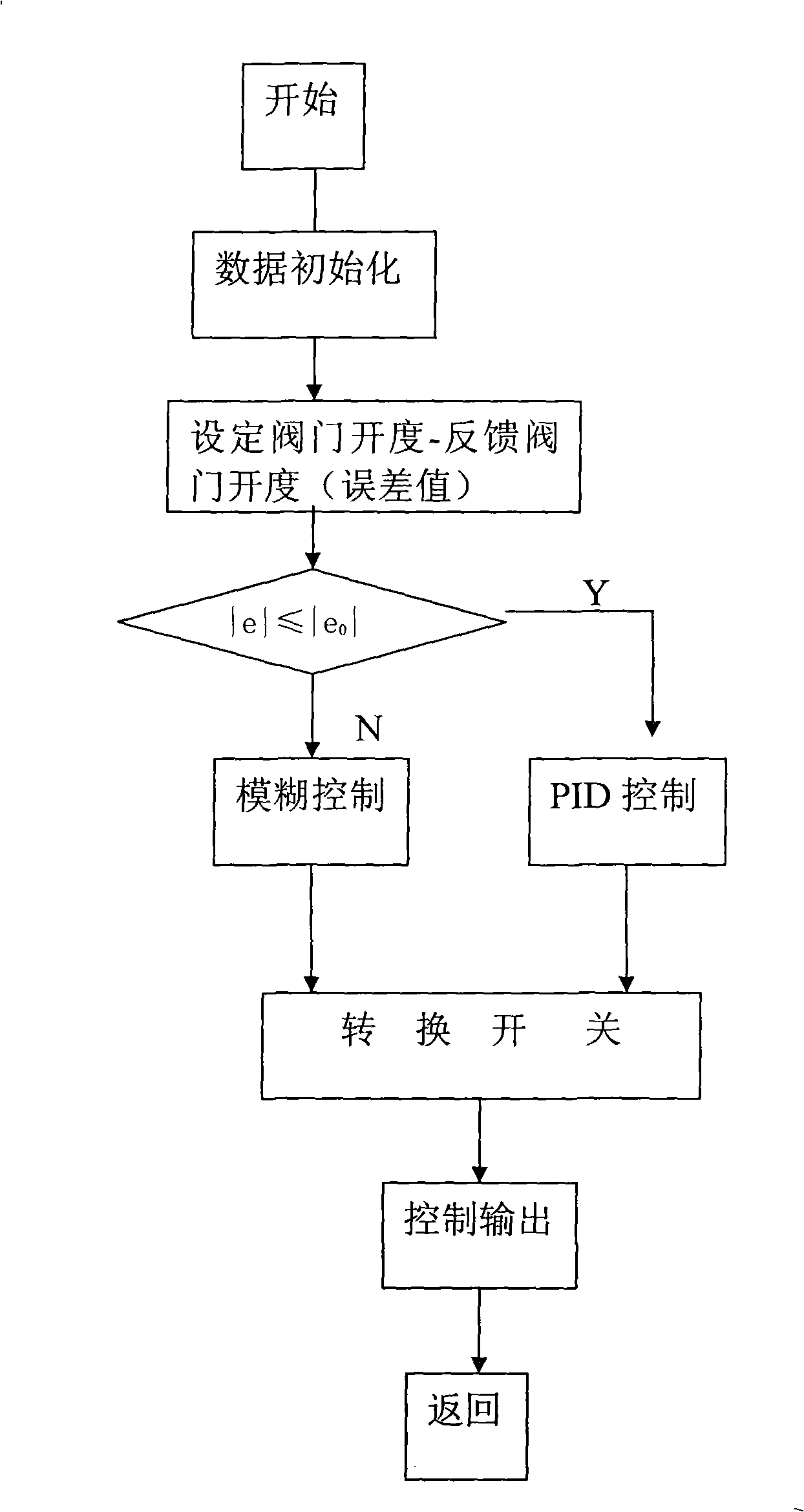

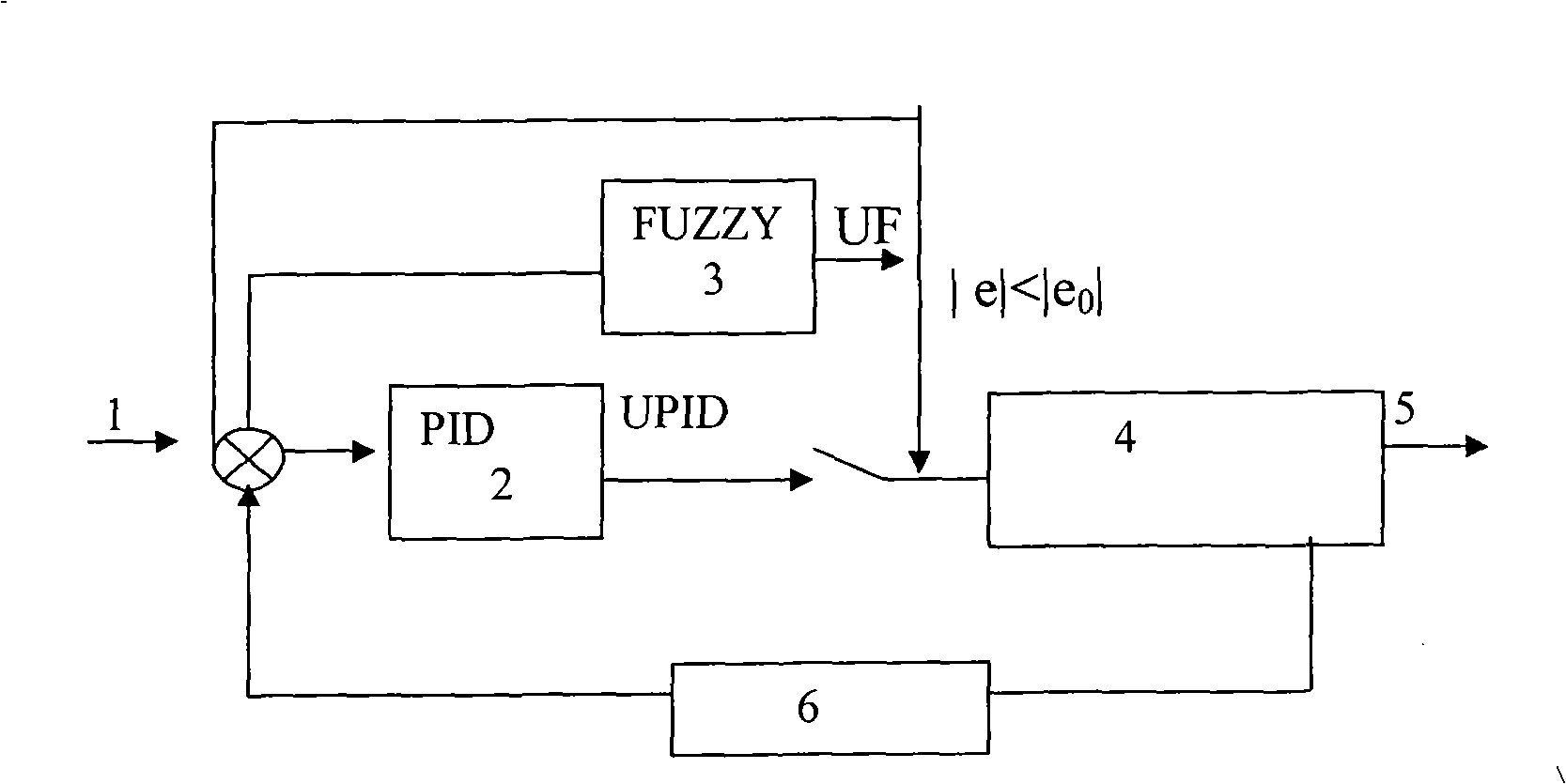

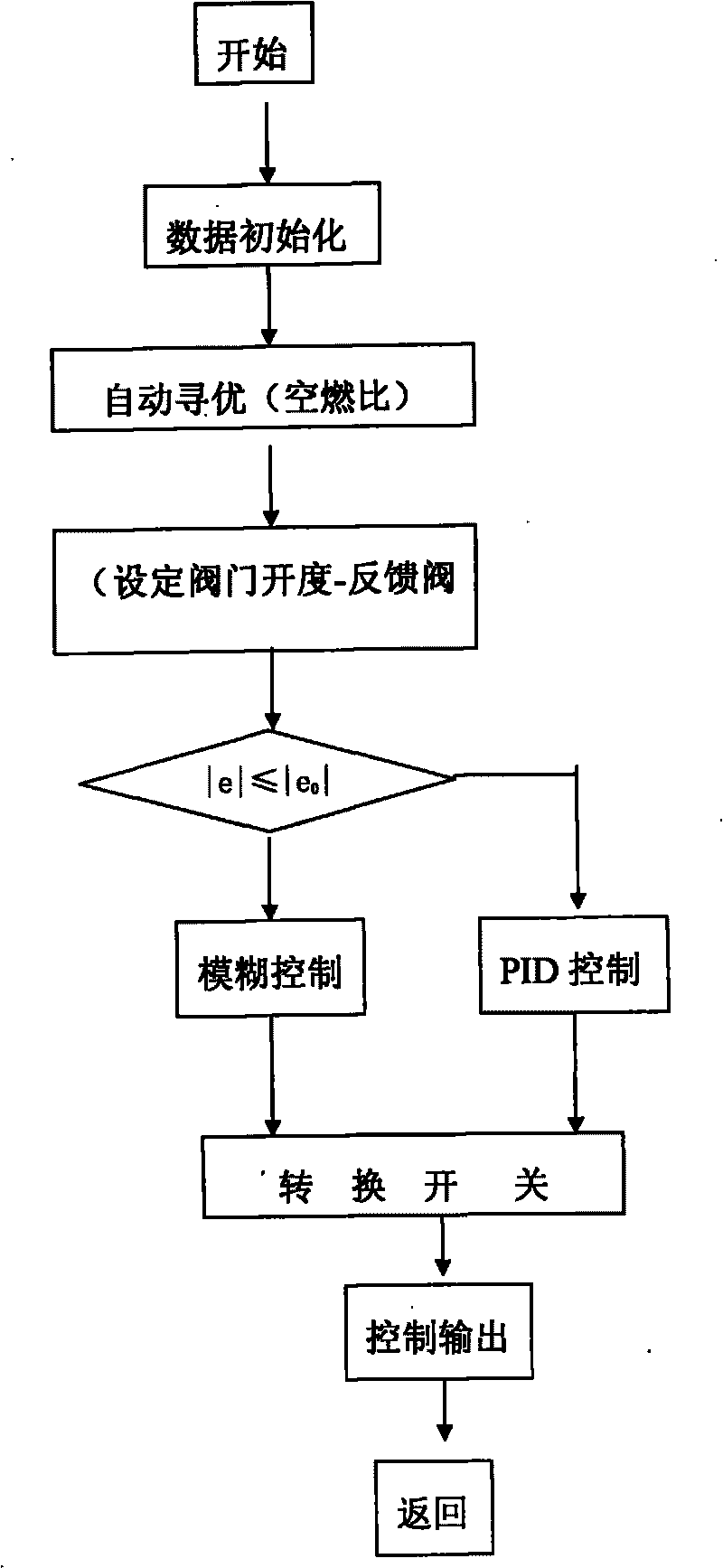

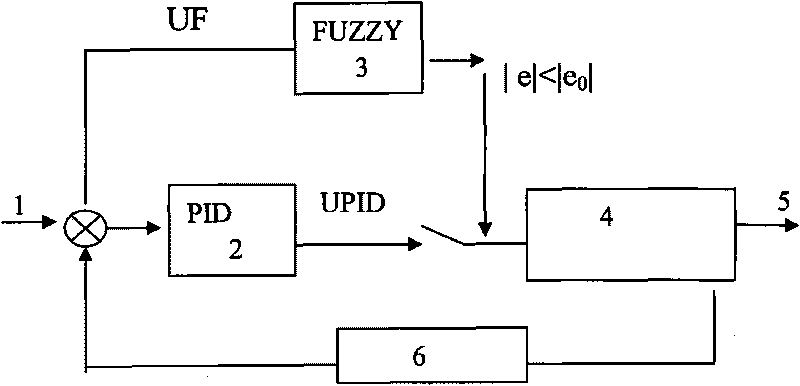

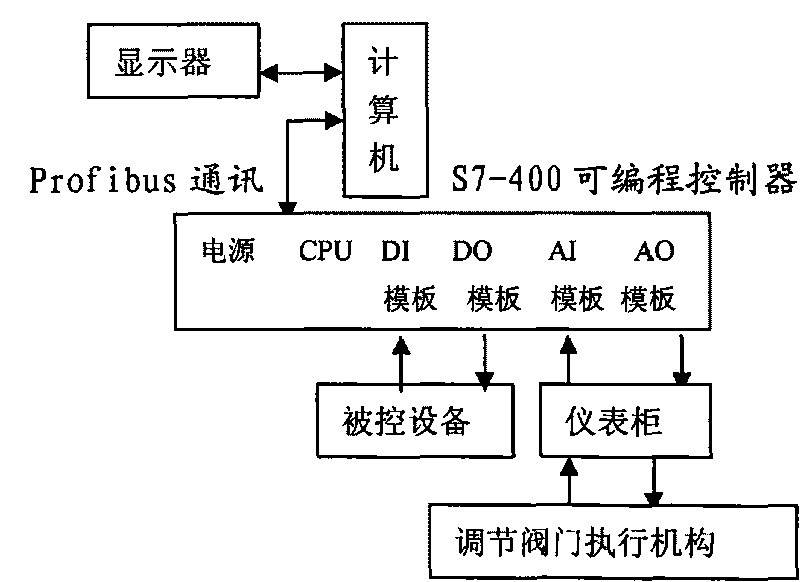

Fuzzy-PID compound control system in sintered mixing water supply

The invention relates to a sintering mixing water-feeding checking and controlling system, in particular to a Fuzzy-PID compound control system for sintering mixing water-feeding, which comprise a PID control strategy, a check instrument and a controller, wherein the control process of the Fuzzy-PID compound control system comprises: initializing the system data, setting a valve opening degree and a feedback valve opening degree error |e|, judging if |e|=|e0|, when |e|<=|e0|, using the PID control strategy, when |e|>=|e0|, using Fuzzy control strategy, when the PID control is switched to the Fuzzy control, the output of the adjuster holds the output value UPID under the PID control strategy until the Fuzzy controller output |UF|>=|UPID|, when the Fuzzy control is switched to the PID control, the output of the adjuster holds the output value UF under the Fuzzy control strategy until the PID controller output |UPID|<=|UF|. The invention improves the permeability of sintered mixture, improves the thickness of sintered layer, the speed of sintering machines and reduces sintering negative pressure.

Owner:NORTHERN ENG & TECH CORP MCC

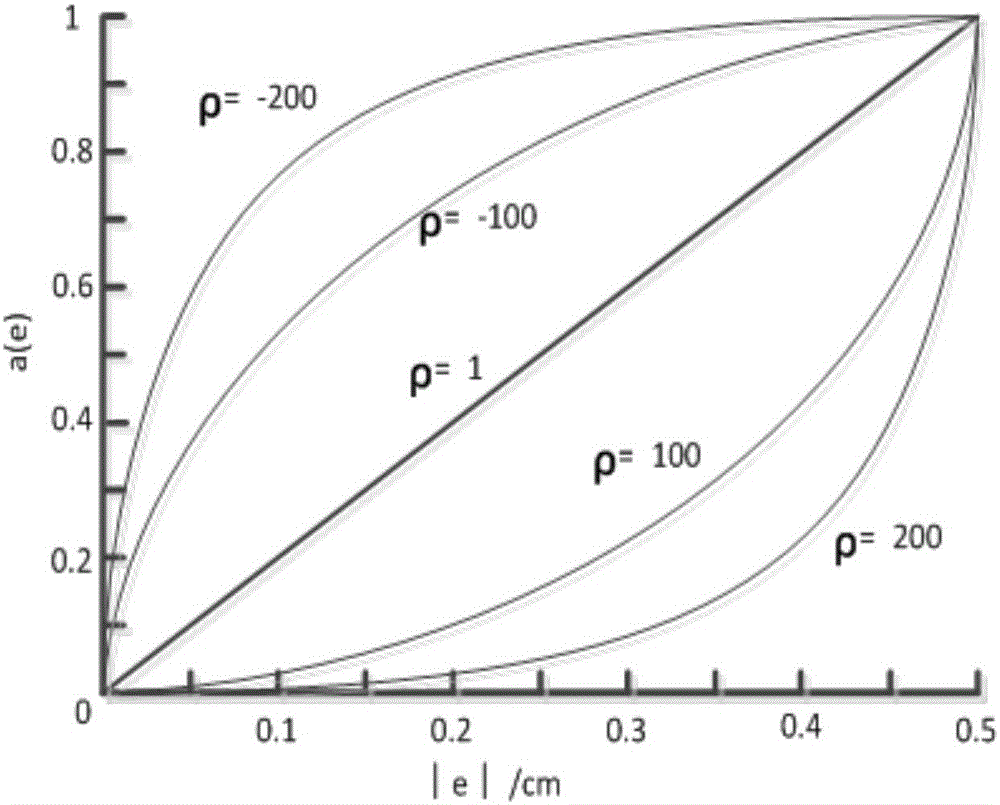

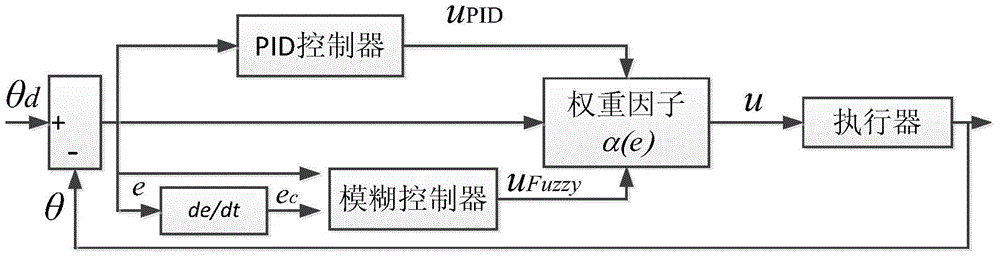

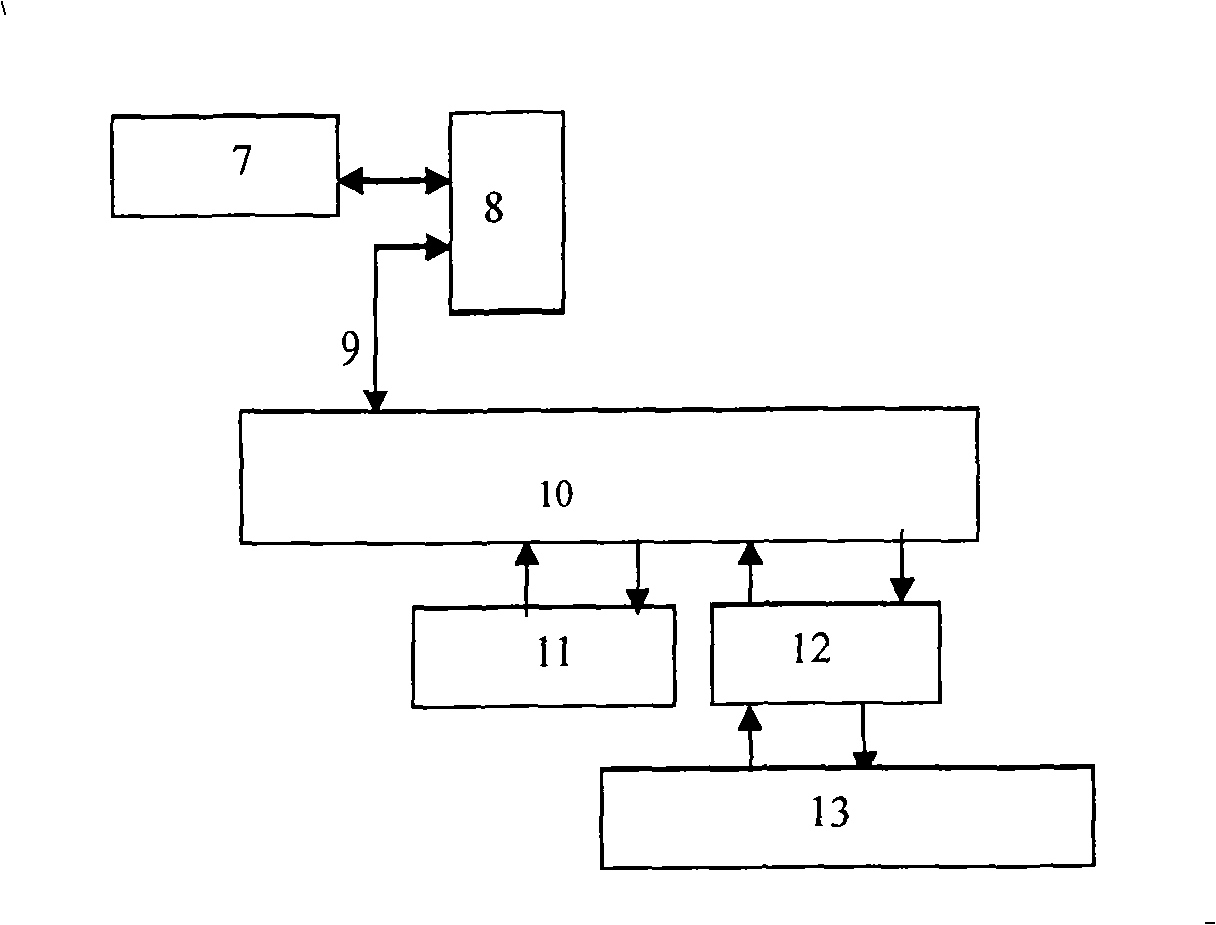

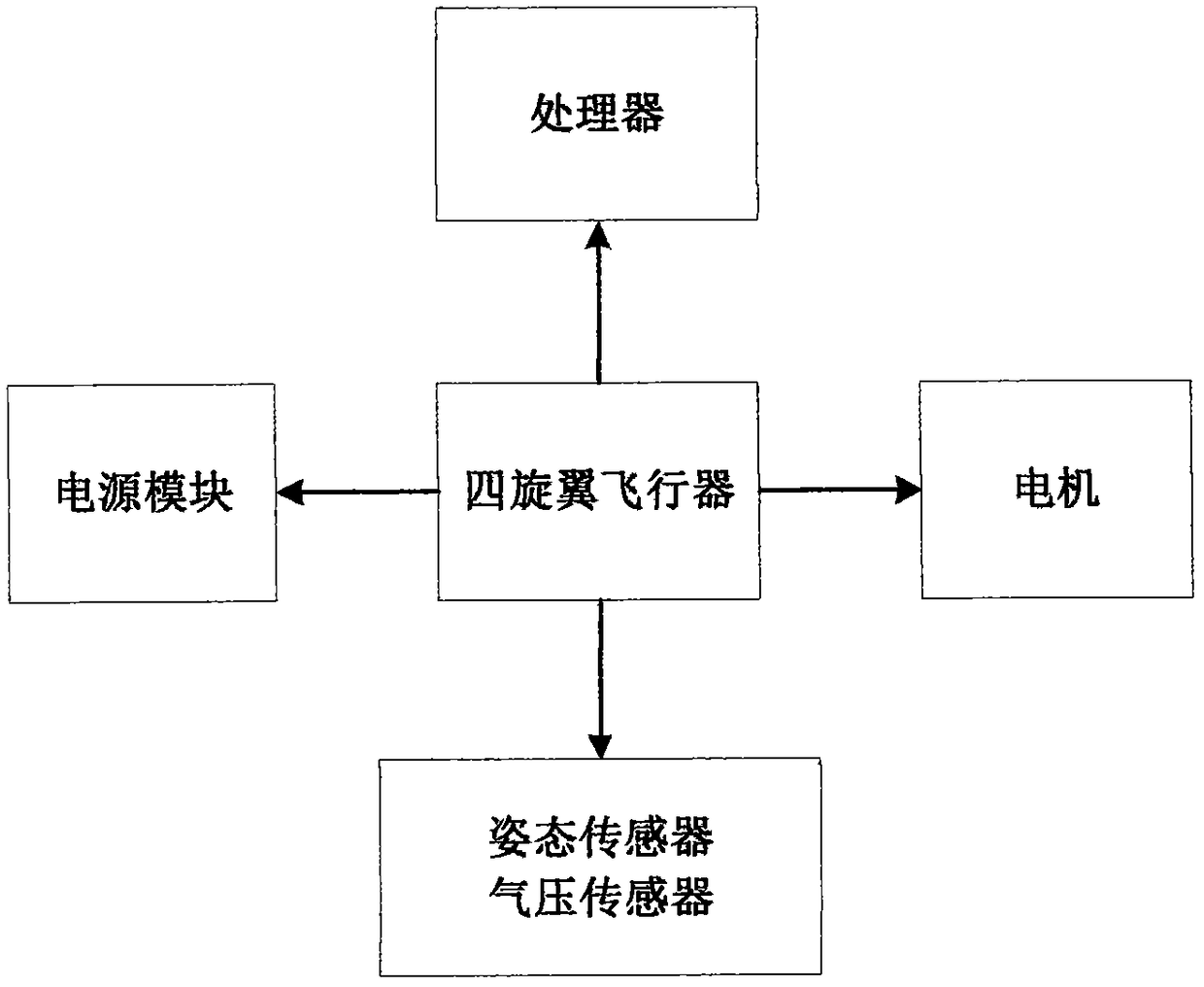

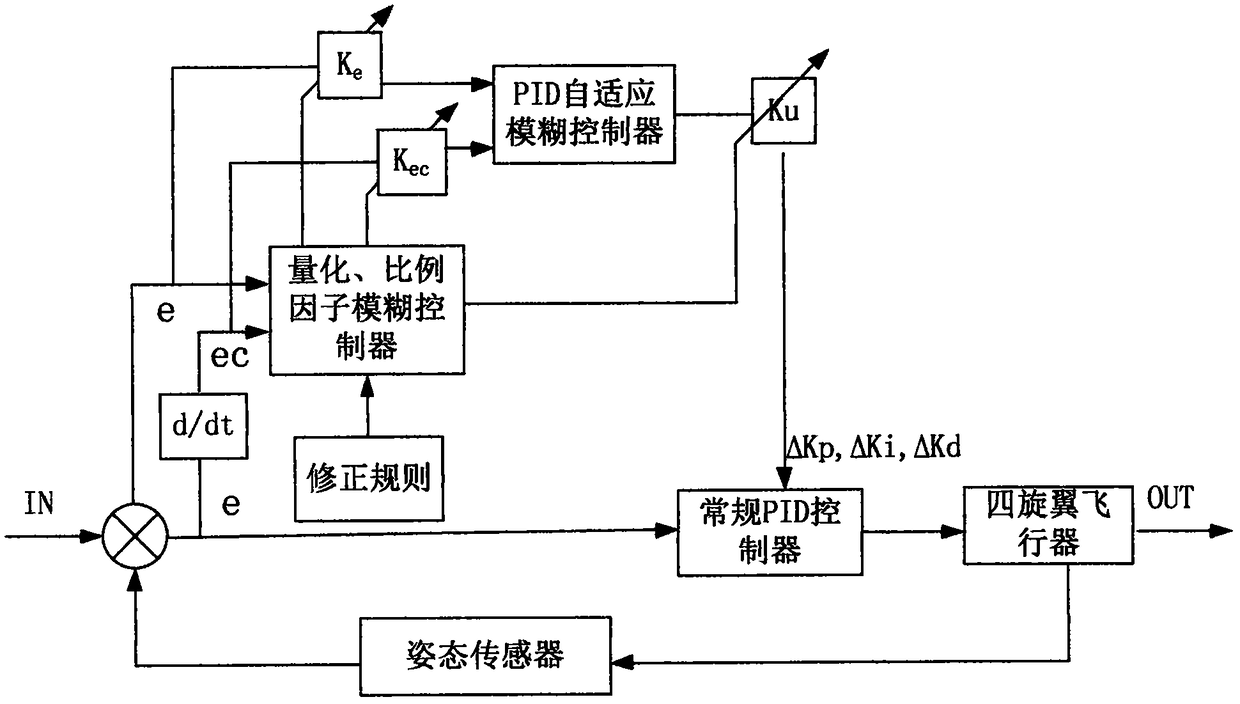

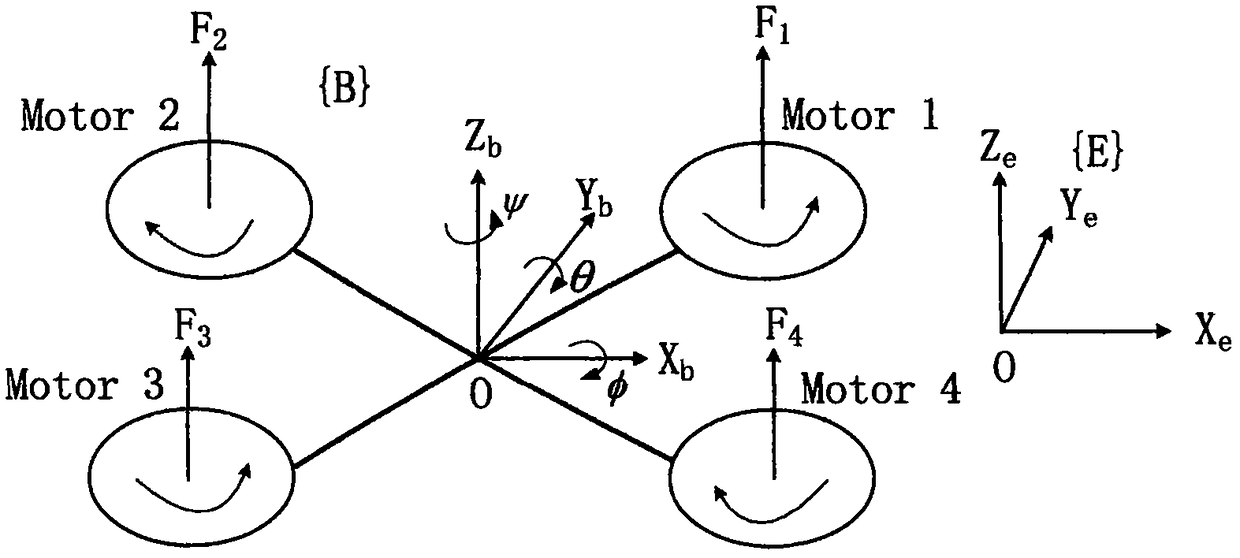

Four-rotor aircraft attitude control method based on factor self-adaptive fuzzy PID

ActiveCN108549208ASolving real-time optimization problemsRealize online self-tuningControllers with particular characteristicsAttitude controlFlight vehicle

The invention discloses a four-rotor aircraft attitude control method, which comprises the steps of: firstly, acquiring current attitude angle information of a four-rotor aircraft, wherein attitude angles include a pitch angle, a roll angle and a yaw angle; calculating an error amount between a given desired attitude angle and the current attitude angle; then determining a fuzzy logic relationshipamong a quantization factor, a scaling factor and errors and an error change rate, and developing a fuzzy rule table; and finally, regarding the errors and the error change rate as input, and regarding the quantization factor and the scaling factor as output to establish a fuzzy PID controller based on factor self-adaption, thereby realizing online real-time adjustment of the quantization factorand the scaling factor. The four-rotor aircraft attitude control method has better dynamic tracking effect and system robustness, and provides a reliable guarantee for the four-rotor aircraft to complete a flight mission more flexibly.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

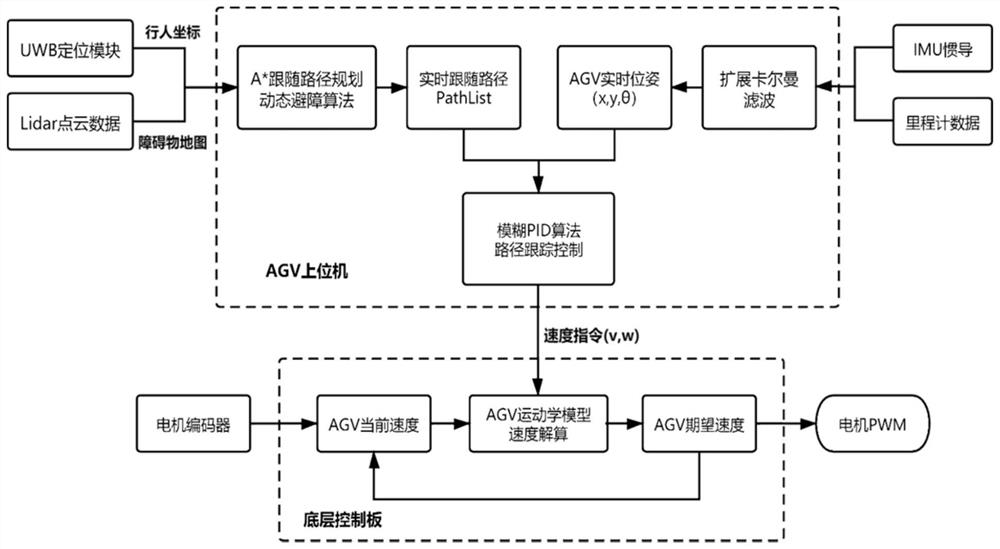

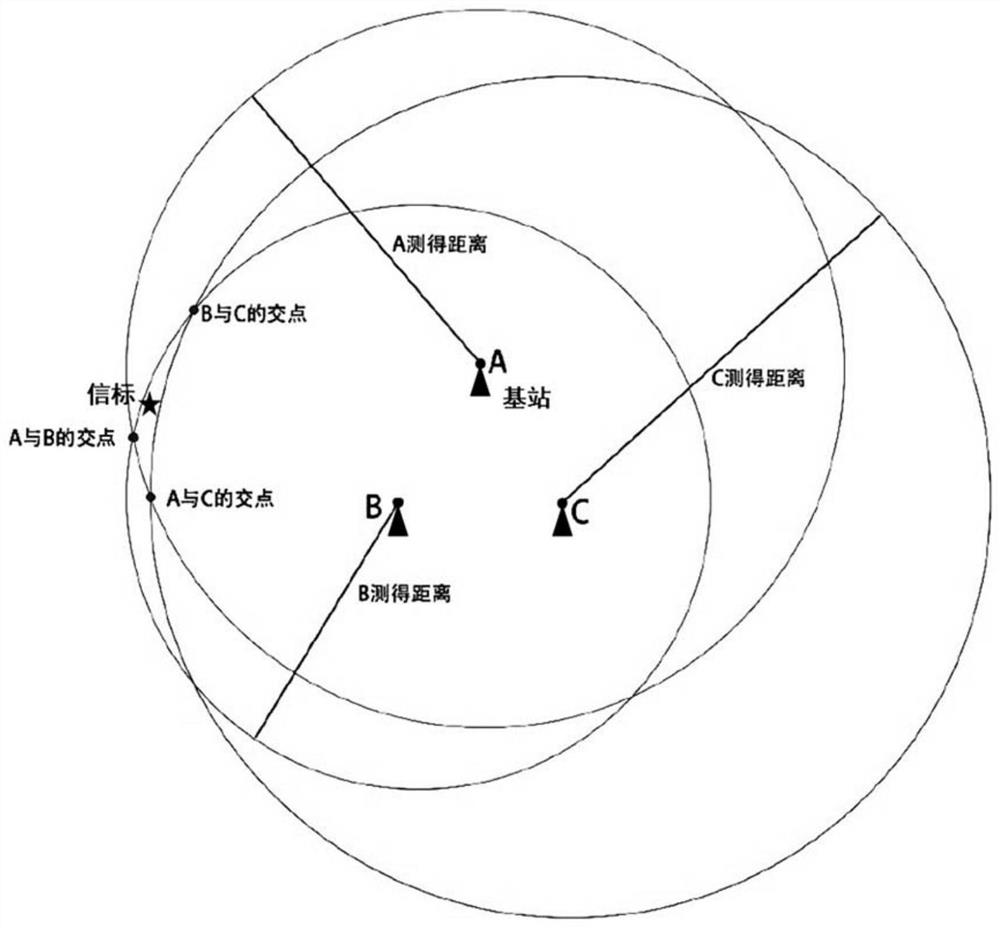

Indoor pedestrian following and obstacle avoidance method based on UWB and laser radar

InactiveCN112130559AWith stable following functionWith autonomous avoidance functionPosition/course control in two dimensionsIn vehicleEngineering

The invention relates to an indoor pedestrian following and obstacle avoidance method based on UWB and laser radar. The method comprises the following steps of: 1) acquiring pedestrian coordinate information by using an AGV vehicle-mounted UWB module, acquiring obstacle information by using the laser radar, and sending the obstacle information to an upper computer in real time; 2) searching a pedestrian following path according to the pedestrian coordinate information, planning an obstacle avoidance path according to the obstacle information, acquiring current pose information (x, y, theta) ofthe AGV, and sending the current pose information to a path tracking control module; 3) calculating a relation between the current pose of the AGV and the pedestrian following path by the path tracking control module, and outputting a linear velocity v and an angular velocity w through a fuzzy PID algorithm; and 4) sending the linear velocity v and the angular velocity w to the control module torealize stable tracking of the AGV on the pedestrian. Compared with the prior art, the indoor pedestrian following and obstacle avoidance method provided by the invention has the advantages of improving the accuracy and stability and the like.

Owner:TONGJI UNIV

Fuzzy-PID compound control system for sintering-machine ignition furnaces

InactiveCN101739004AReduce labor intensityPromote a virtuous circleTotal factory controlAdaptive controlControl flowAutomatic control

The invention relates to an automatic control system for sintering ignition furnaces, in particular to a Fuzzy-PID compound control system for sintering-machine ignition furnaces. The system comprises PID control strategy, instrumentation and a control device. A control process comprises: controlling ignition temperature by regulating the amount of fuel and air flow; automatically finding a suitable air-fuel ratio on the premise of fixing the air flow in order to realize the highest combustion temperature and the fullest combustion; setting a valve opening degree and a feedback valve opening deviation absolute value e; judging whether the absolute value of e is equal to the absolute value of e0; adopting the PID control strategy when the absolute value of e is less than the absolute value of e0; adopting Fuzzy control strategy when the absolute value of e is greater than the absolute value of e0; allowing the output of a regulator to keep an output value under the original control strategy till next controller output value exceeds the output value when control strategy is switched; and continuously adjusting the air flow while tracking an expected combustion temperature value in order to realize that combustion temperature and the expected combustion temperature are the same or close.

Owner:NORTHERN ENG & TECH CORP MCC

Method for controlling fuzzy PID digital control DC-DC converter

InactiveCN104779798AReduce the impact of transient performanceImprove transient performanceDc-dc conversionAdaptive controlDc dc converterControl system

The invention discloses a method for controlling a fuzzy PID digital control DC-DC converter. Based on a control system which comprises an ADC unit, a comparator, a fuzzy PID compensator with a fuzzy control unit and a PID control unit, a digital pulse width modulator and a driver unit, the control system and the main topology of a Buck type DC-DC converter are connected in series to form a closed loop, the analog output voltage of the converter is subjected to A / D conversion and then is input to the comparator to be compared with a digital reference voltage signal, the output voltage error value and the error deviation value are calculated, the fuzzy control unit determines the duty ratio value of the switching period according to the output voltage error value and the error deviation value, and the digital pulse width modulator and the driver unit output corresponding PWM according to the duty ratio value to control a power tube to be connected or disconnected so that the output voltage value can be regulated. The defect of the nonlinear effect of the converter is overcome, the system response is accelerated, overshooting is reduced, and good input disturbance resistance and load disturbance resistance are achieved.

Owner:SOUTHEAST UNIV

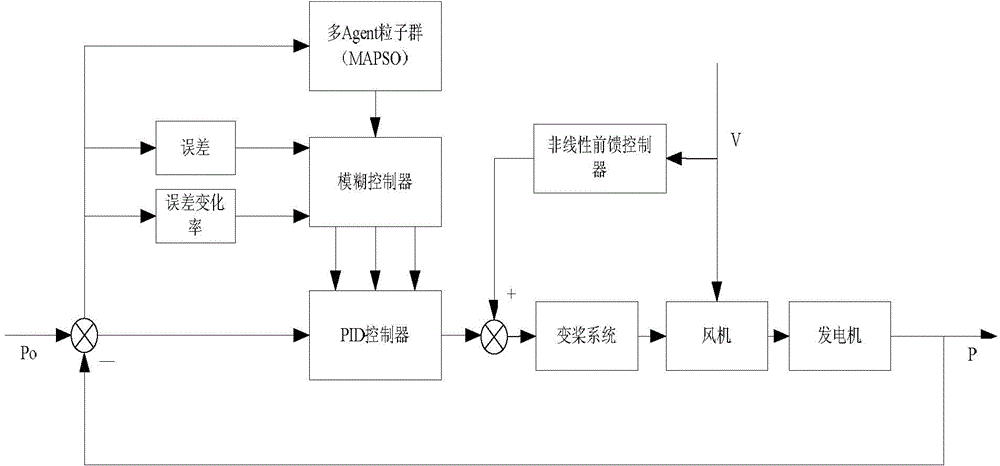

Nonlinear feed-forward and fuzzy PID combined variable pitch control method for wind generating set

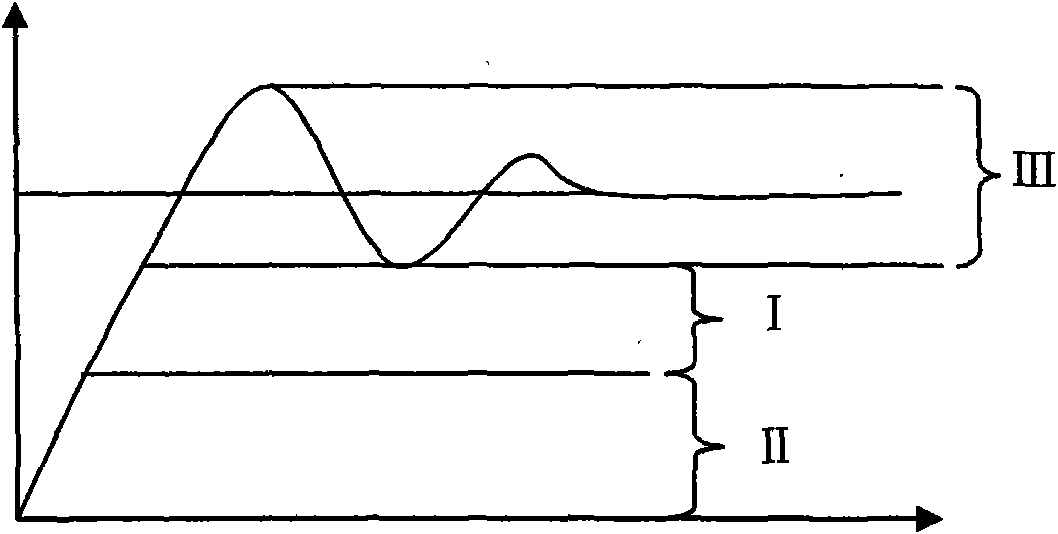

ActiveCN104005909AImprove robustnessHigh control precisionWind motor controlMachines/enginesFuzzy pidControl theory

The invention discloses a nonlinear feed-forward and fuzzy PID combined variable pitch control method for a wind generating set. The method comprises based on an active power deviation feed-forward control strategy, using active power P and rated power P0 of a generator to obtain the power deviation delta P when a generator unit operates above the rated wind speed; giving variable pitch control expected output pitch angle beta1 through an MAPSO fuzzy PID controller; obtaining a variable pitch control expected feed-forward pitch angle beta2 through a nonlinear feed-forward controller; adding the pitch angle beta1 obtained by the MAPSO fuzzy PID controller to the feed-forward pitch angle beta2 to obtain a pitch angle set value beta. By means of the method, the system adjusting time is reduced, the stability and the reliability of the system are increased, and compared with traditional controllers, apparent advantages are provided.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

Raw material grinding automatic control method

InactiveCN105182740ASpeed up tracking error convergenceImprove dynamic performanceNumerical controlAdaptive controlMachining vibrationsAutomatic control

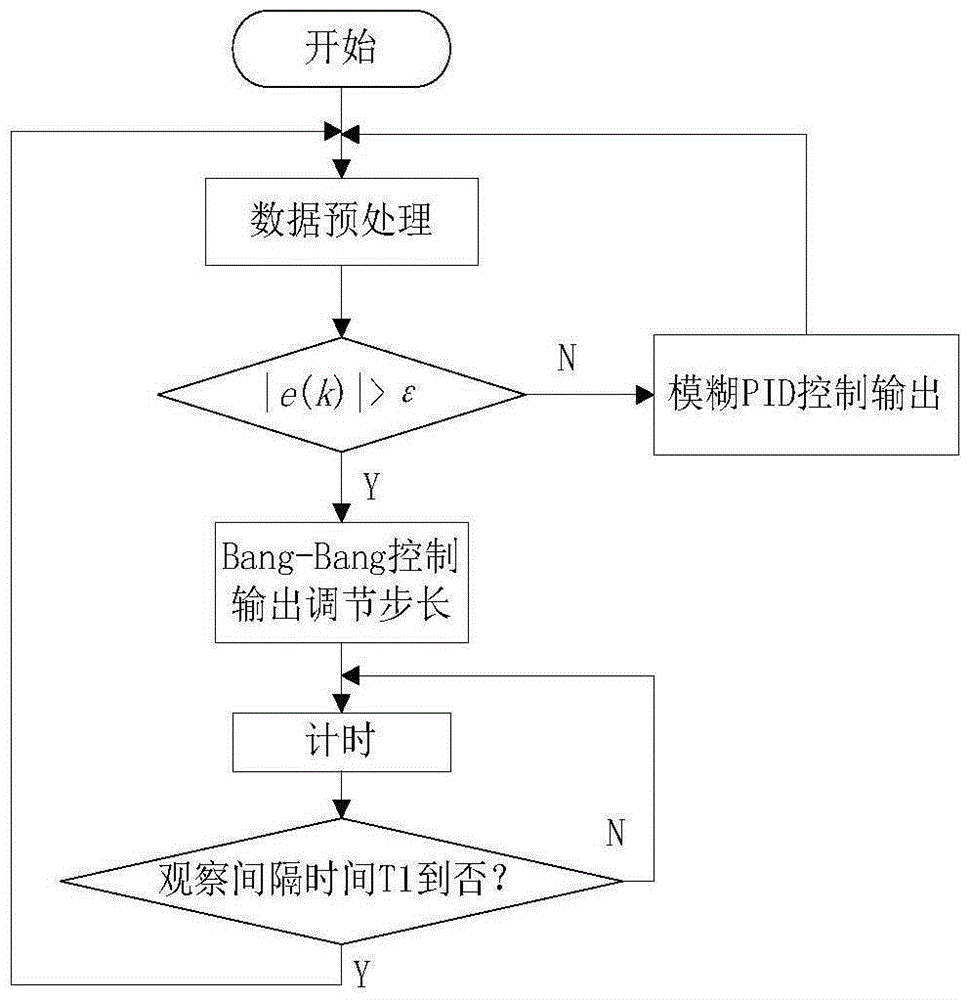

The invention discloses a raw material grinding automatic control method. In an automatic state, During amplitude control of a lifting and falling roller, an amplitude scope is tested mainly through observation and lifting and falling operation of a grinding roller is carried out. During control of water pump opening, operation conditions of a material layer thickness and a mill output temperature are integrated, a pid fuzzy control operation method is employed, and the water pump opening value is adjusted to achieve stabilization control effects. During the feed control link, feed quantity is controlled according to a current of a milling machine and a current of a powder selection machine and furthermore the current and the amplitude of the milling machine are stabilized. The problem that parameter adjustment cannot be tracked rapidly in a routine PID is avoided, according to characteristics that fuzzy control is independent from an accurate mathematic model and suitable for non-linear and large time delay production processes, by utilization of fuzzy PID and Bang-Bang control methods, a tracking error convergence speed is quickened, thus the vertical milling control process has a stable dynamic performance, milling machine vibration is reduced, the yield is raised and accurate and rapid control effects are achieved.

Owner:UNIV OF JINAN +1

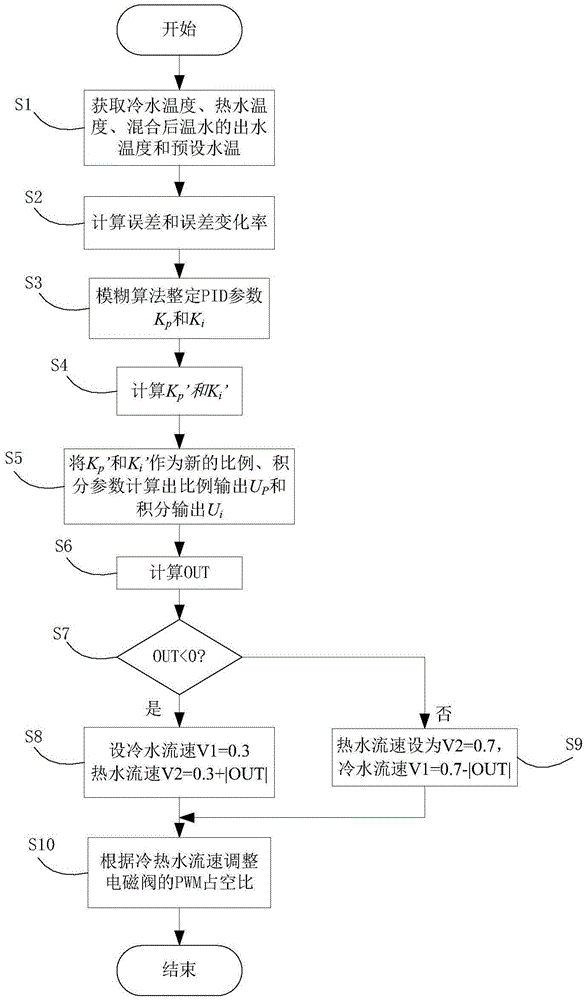

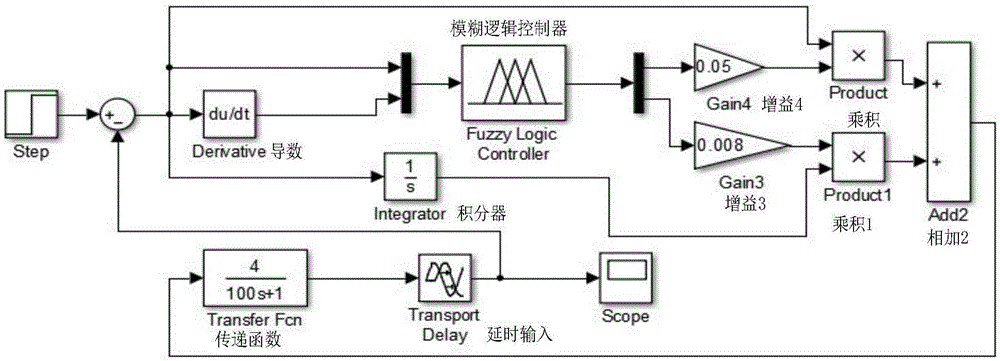

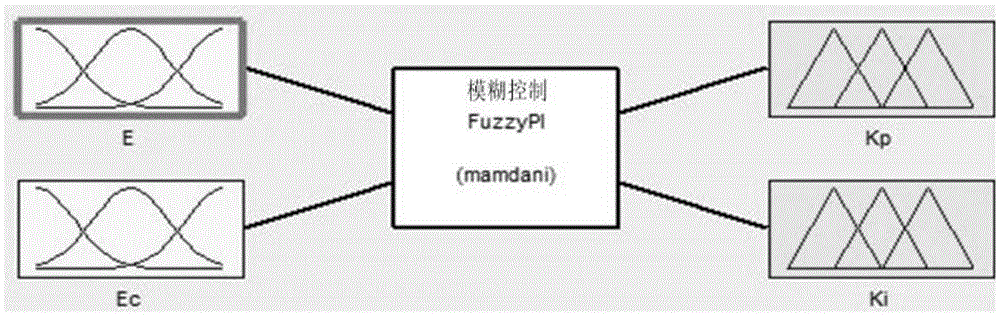

Water temperature control method and control system thereof based on adaptable fuzzy PID

InactiveCN105630033AFast temperature responseHigh precisionTemperatue controlAdaptive controlControl flowWarm water

The invention provides a water temperature control method and a control system thereof based on adaptable fuzzy PID. Fuzzy control and a PI algorithm in the PID algorithm are combined to form a fuzzy PID controller to carry out real-time monitoring and adjusting on the water temperature, that is, a microprocessor acquires cold water temperature, hot water temperature and mixed warm water outlet temperature in real time, the mixed warm water outlet temperature is compared with the preset temperature, the fuzzy PID algorithm is used for controlling flow speeds of the cold water and the hot water, and thus the mixed warm water outlet temperature is constant. The temperature adjustment reaction is quick, and the accuracy is high.

Owner:SOUTHWEST UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com