Raw material grinding automatic control method

A raw material powder and grinding technology, which is applied in the field of automatic control and automatic control of raw material grinding, can solve the problems of the vertical mill control method, such as the lack of control force, the inability to quickly track parameter adjustment, and speed up the convergence speed of tracking errors, so as to speed up the convergence speed , fast control, small overshoot effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

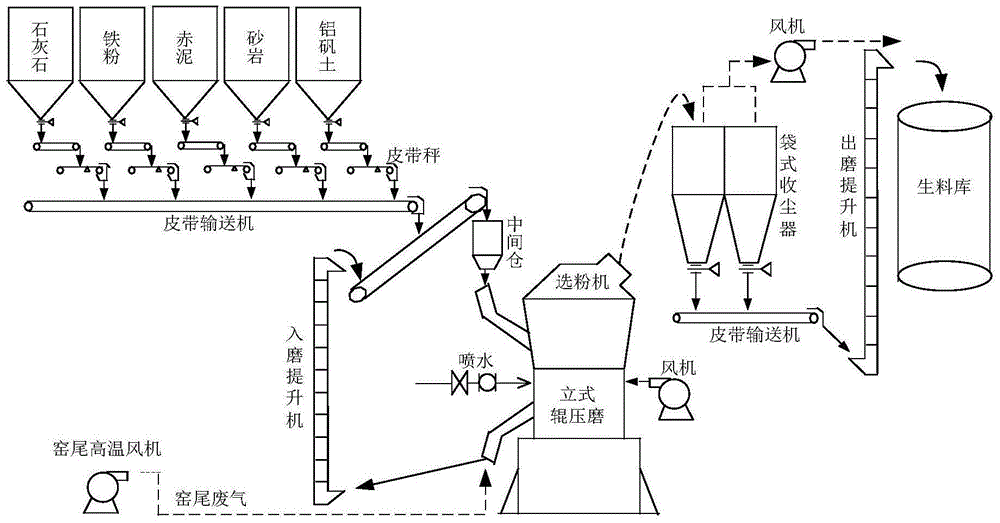

[0036] The technological process of raw material grinding by vertical mill is as follows: figure 1 shown.

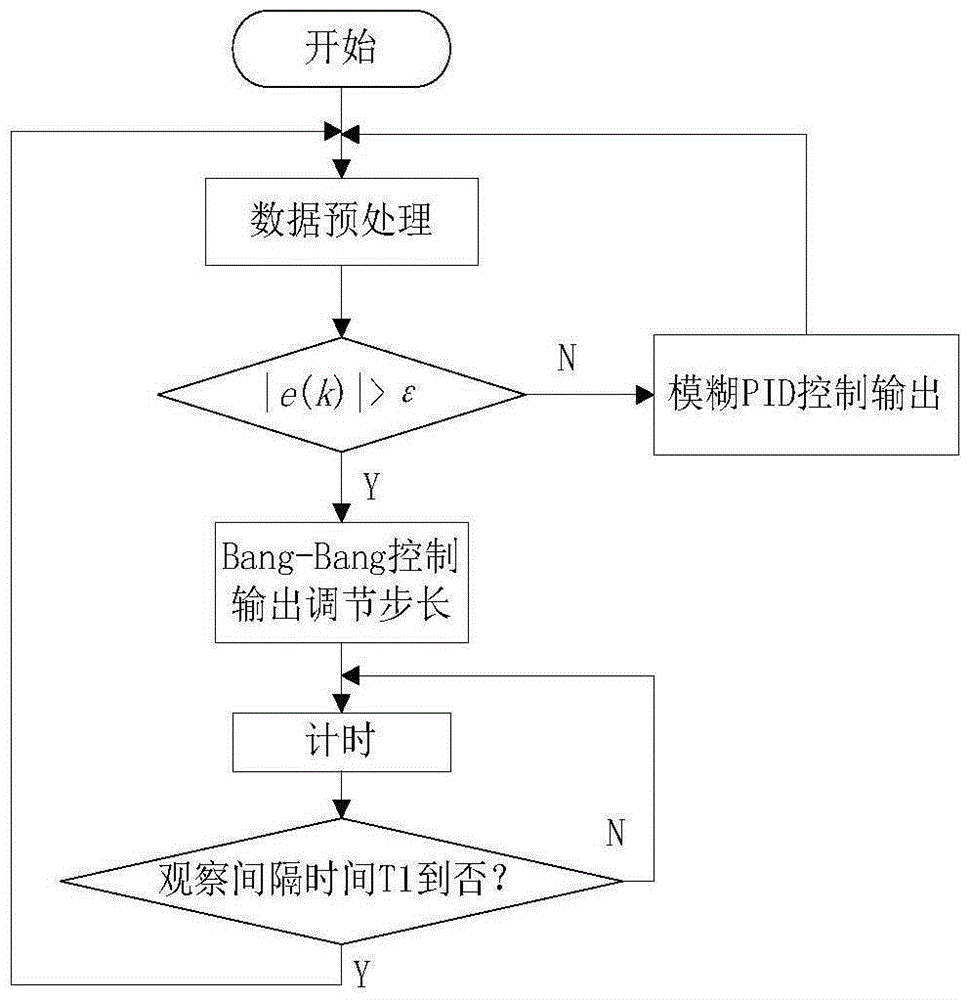

[0037] Aiming at the control problem of the vertical mill, the present invention proposes a controller design method based on Bang-Bang and fuzzy PID. In order to take advantage of the small overshoot of fuzzy PID, the fuzzy control and PID control are combined into fuzzy PID. At the same time, the Bang-Bang control method is used to speed up the convergence speed of the tracking error, so that the vertical mill control process has stable dynamic performance. , to achieve precise and rapid control purposes.

[0038] According to the actual operation experience in the cement industry on site, the stable operation of the mill is mainly guaranteed by adjusting the total amount given (feeding volume): whether the material bed is stable or not can lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com