Patents

Literature

141 results about "Linear process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A linear process or development is one in which something changes or progresses straight from one stage to another, and has a starting point and an ending point. ...decisions that lead the story in various directions, rather than follow traditional linear storytelling.

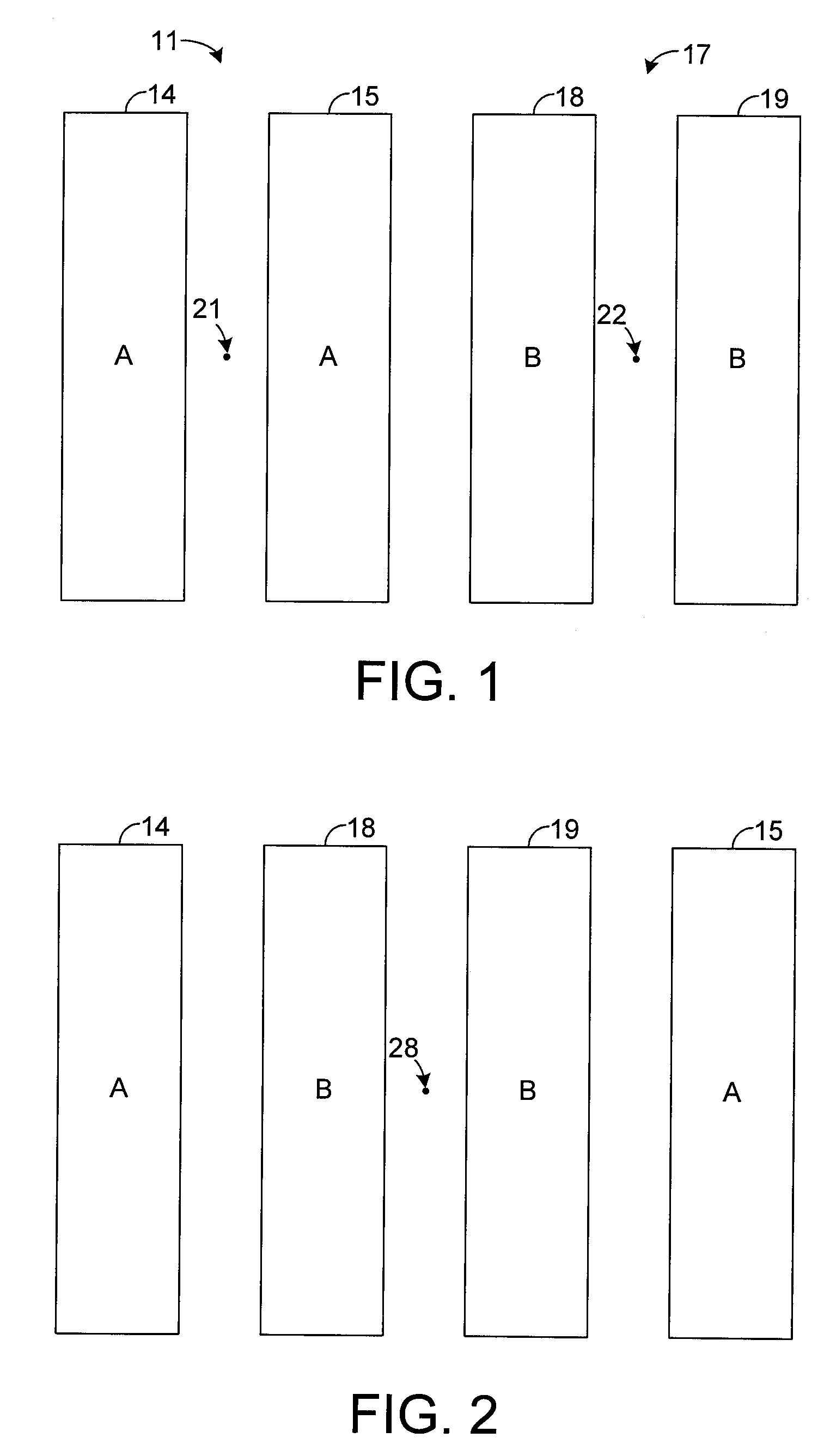

System and method for designing a common centroid layout for an integrated circuit

ActiveUS20070294652A1Computer programmed simultaneously with data introductionCAD circuit designEngineeringLinearity

An exemplary common centroid layout design system receives various inputs about an integrated circuit (IC) design. Based on such inputs, the system calculates a common centroid unit, which represents an array of segments of each device in the IC design. The number of segments for each device within the common centroid unit is selected based on the respective sizes of the devices. The common centroid unit is then tiled to automatically define the complete layout for the IC object. The system selects an algorithm for tiling the common centroid unit based on the size of such unit such that, upon completion of the tiling process, all of the devices have a common centroid. In other words, the system selects an algorithm for tiling such that a common centroid layout design is generated. Using the common centroid layout design, the IC object can be manufactured so that it is immune to linear process gradients and more resistant to non-linear gradients relative to ICs that do not have a common centroid layout design.

Owner:ADTRAN

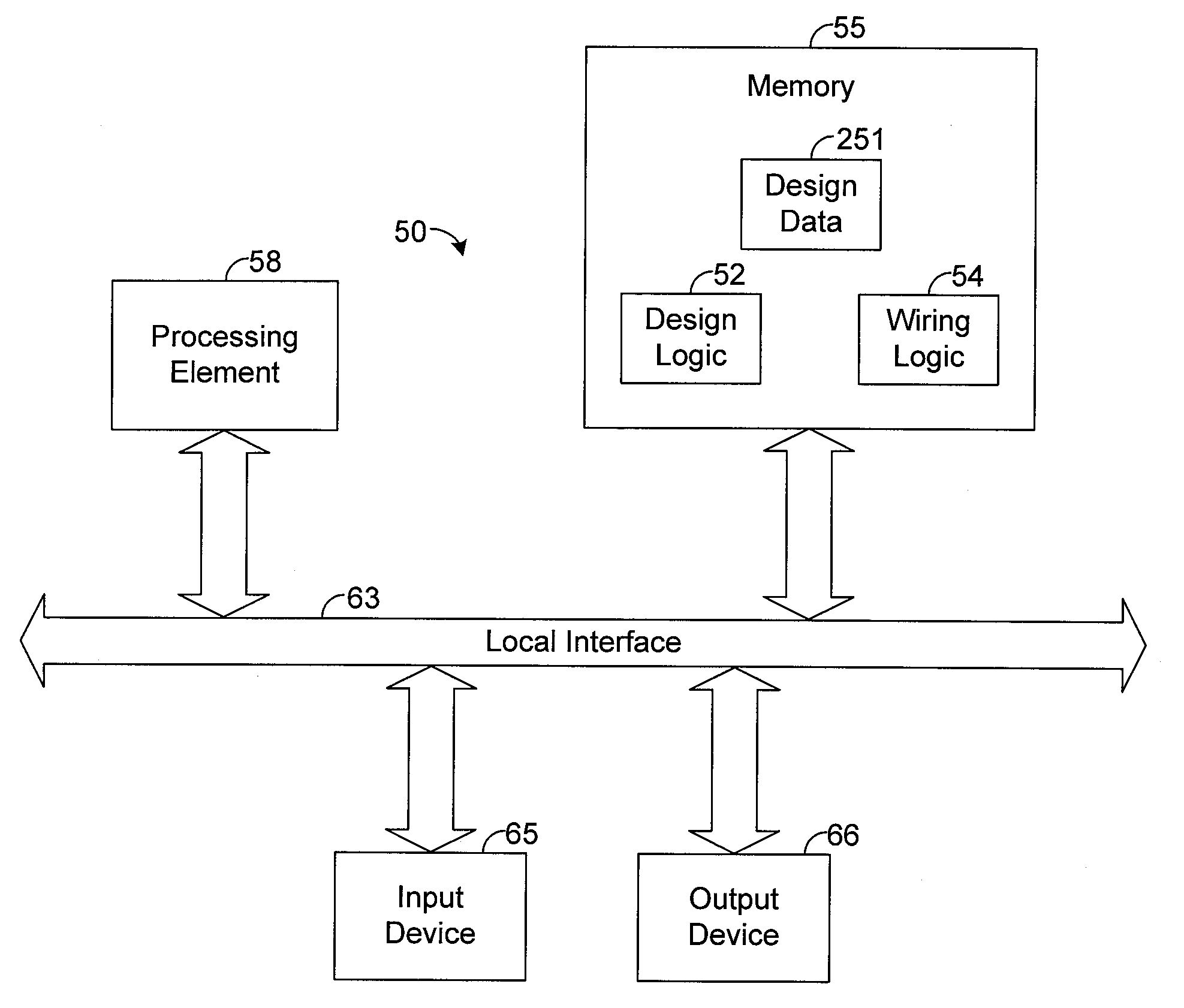

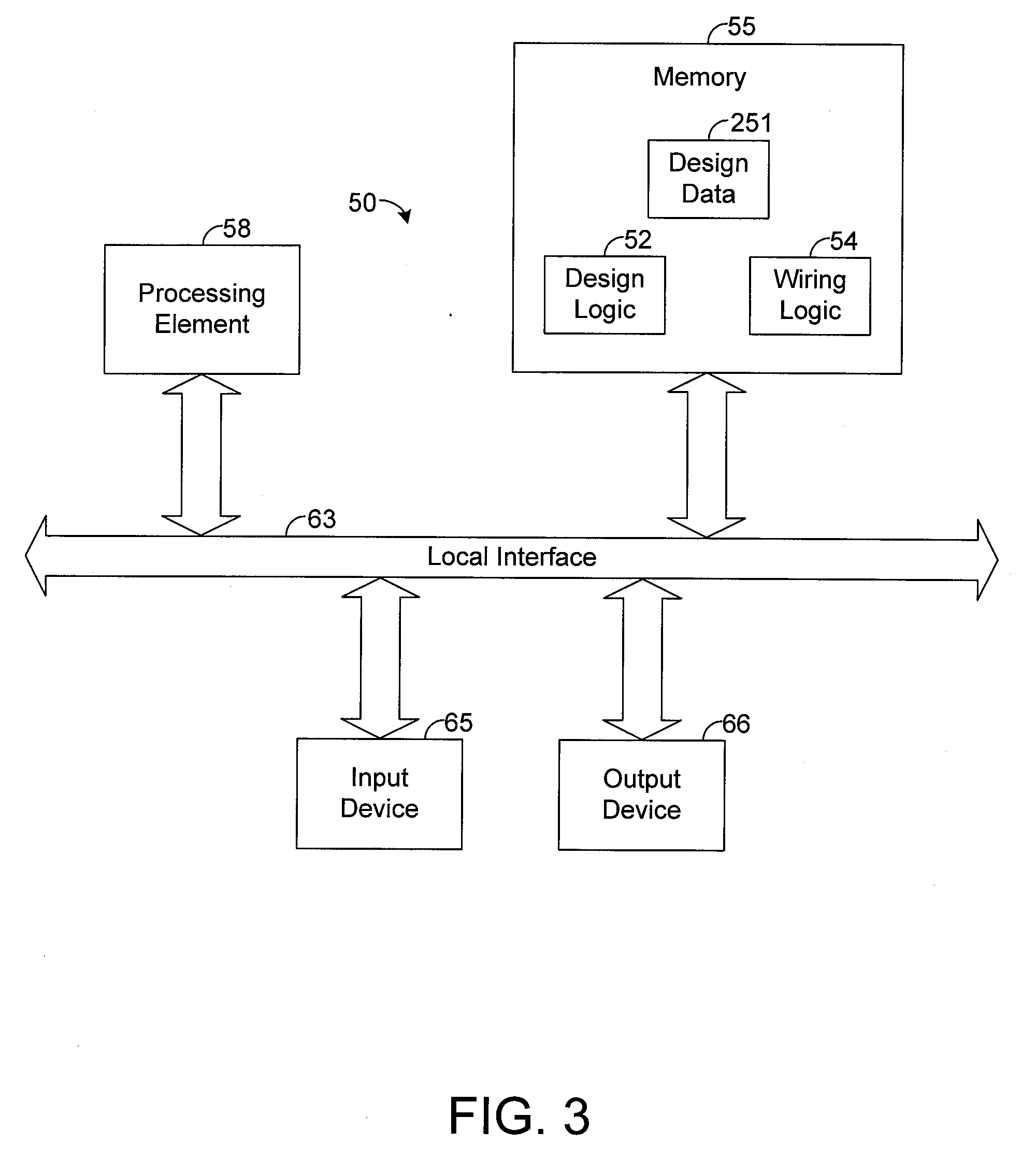

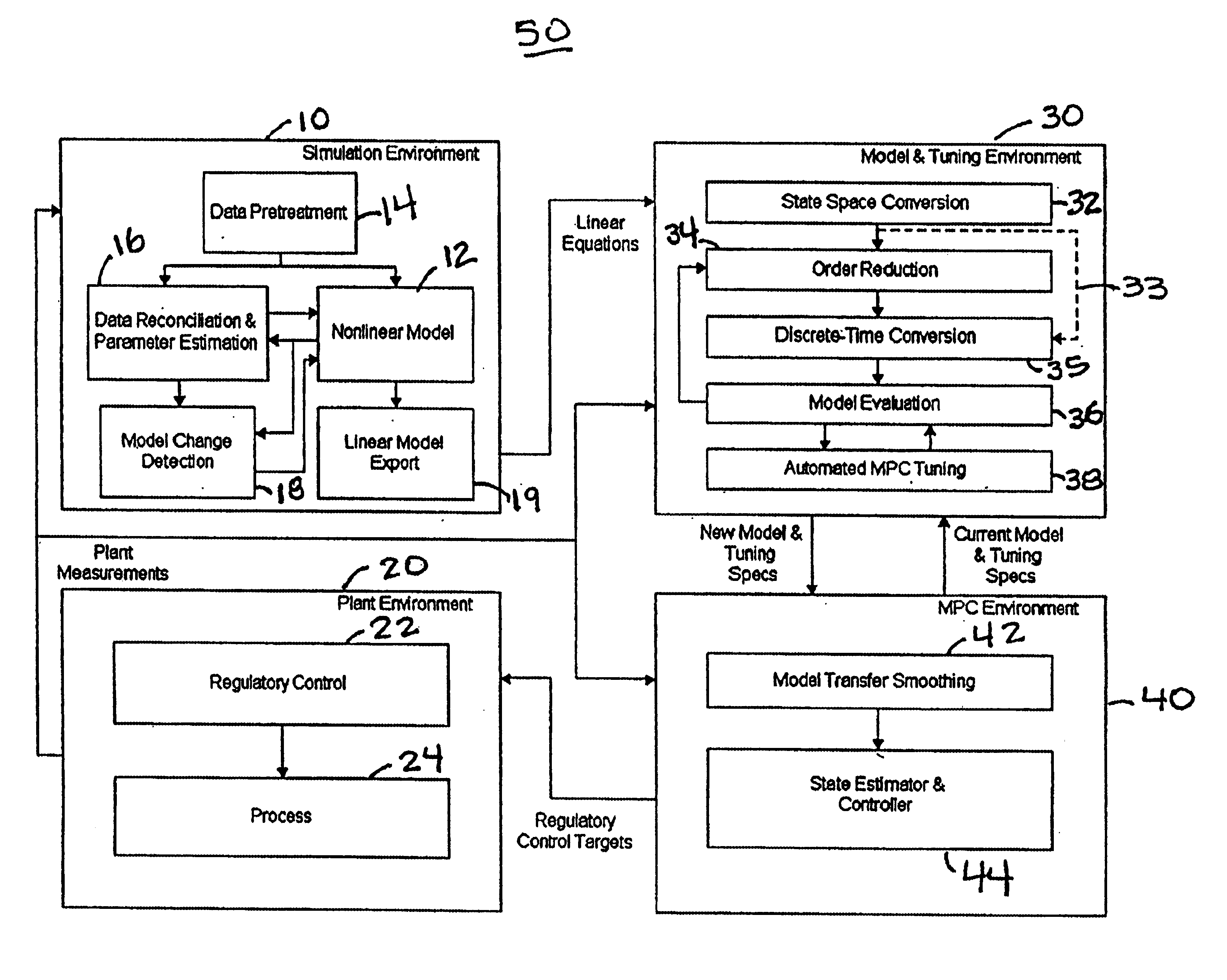

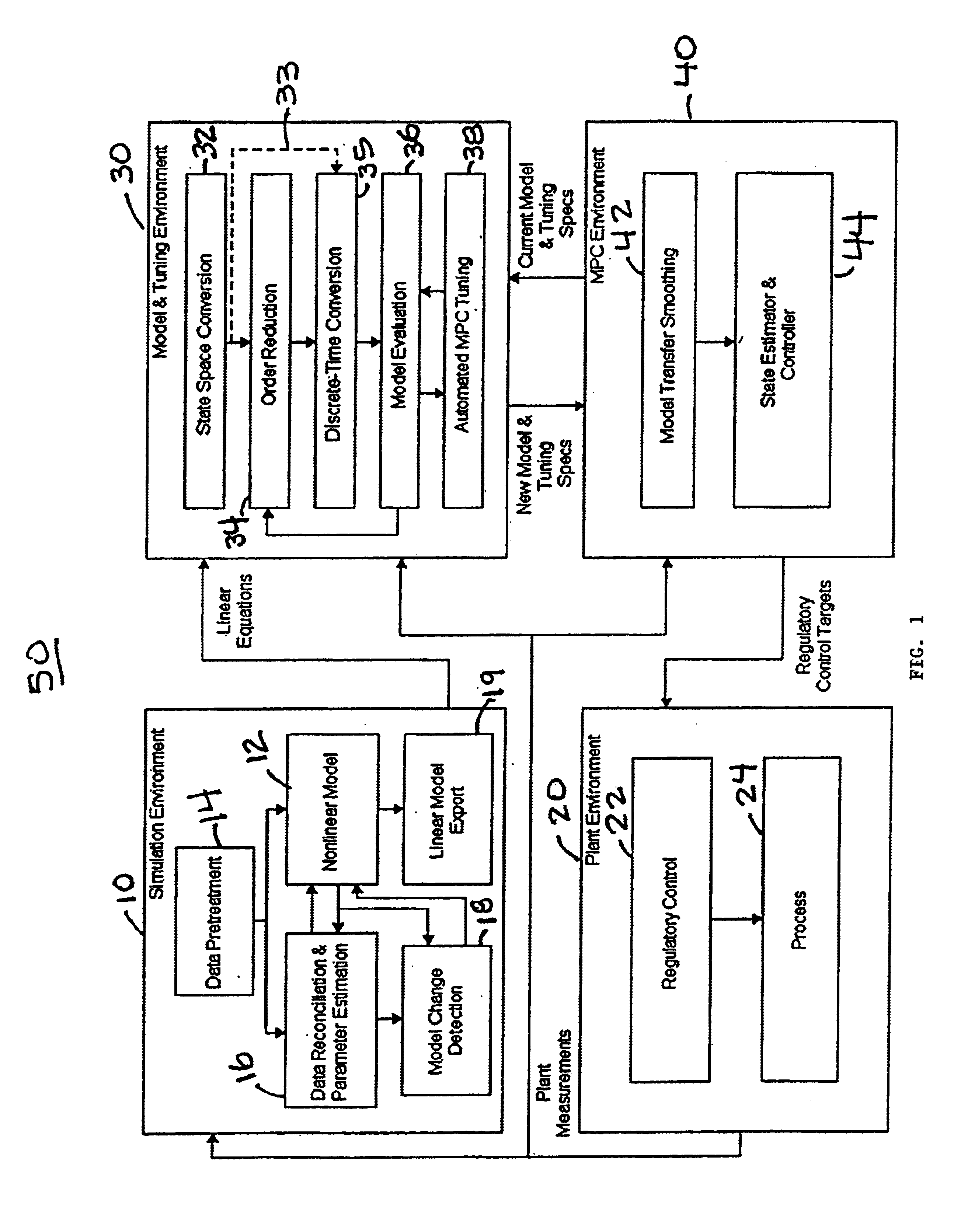

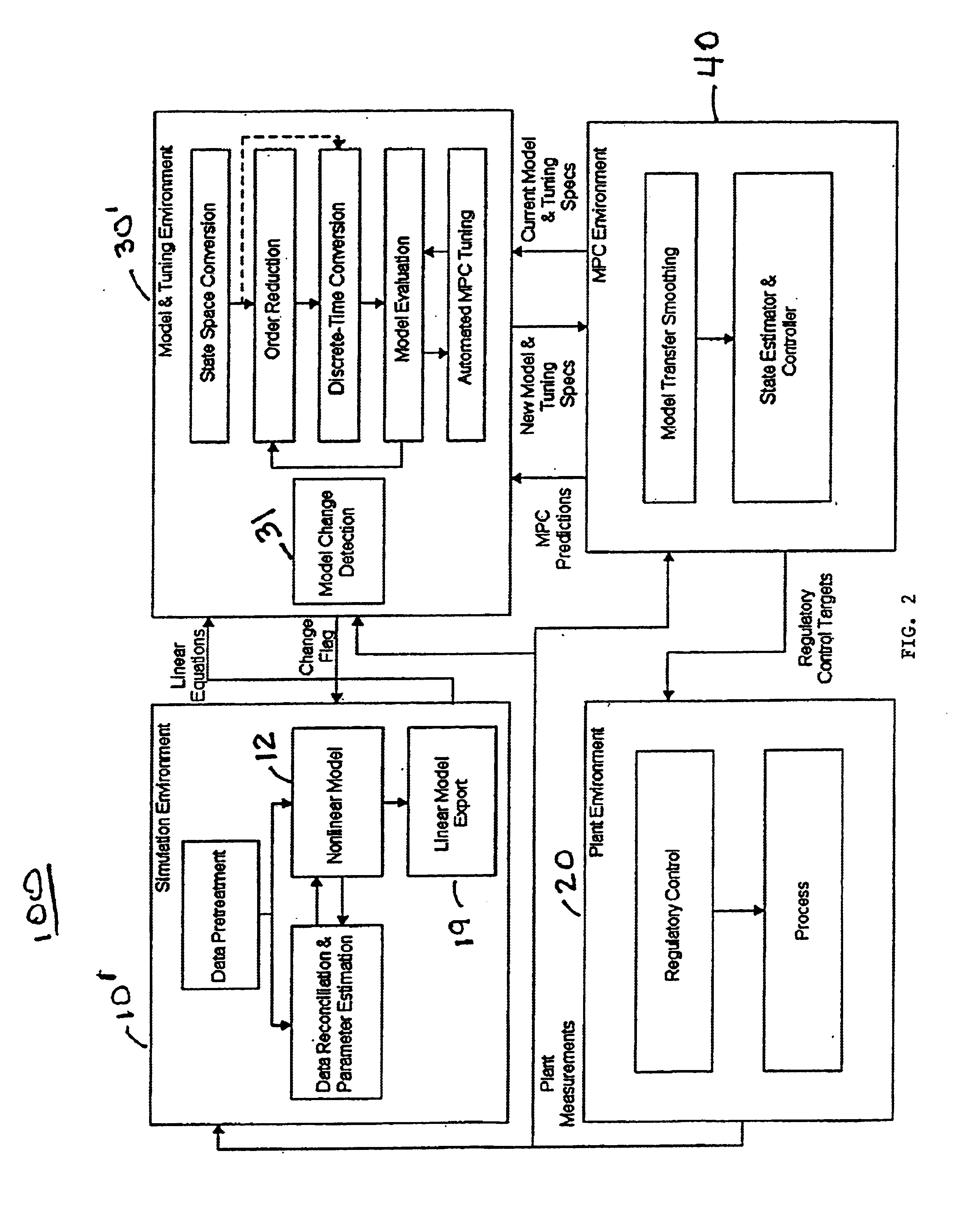

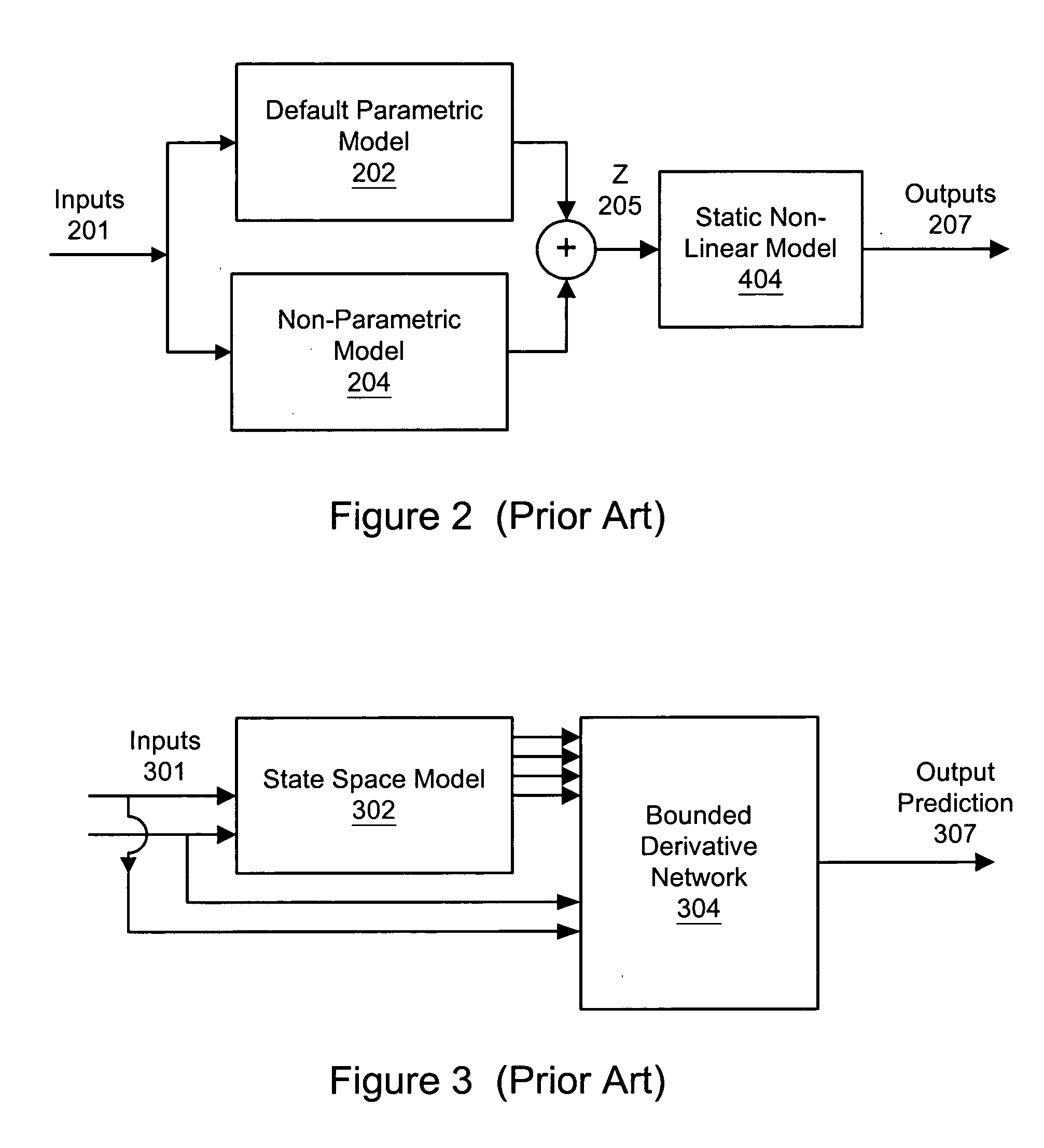

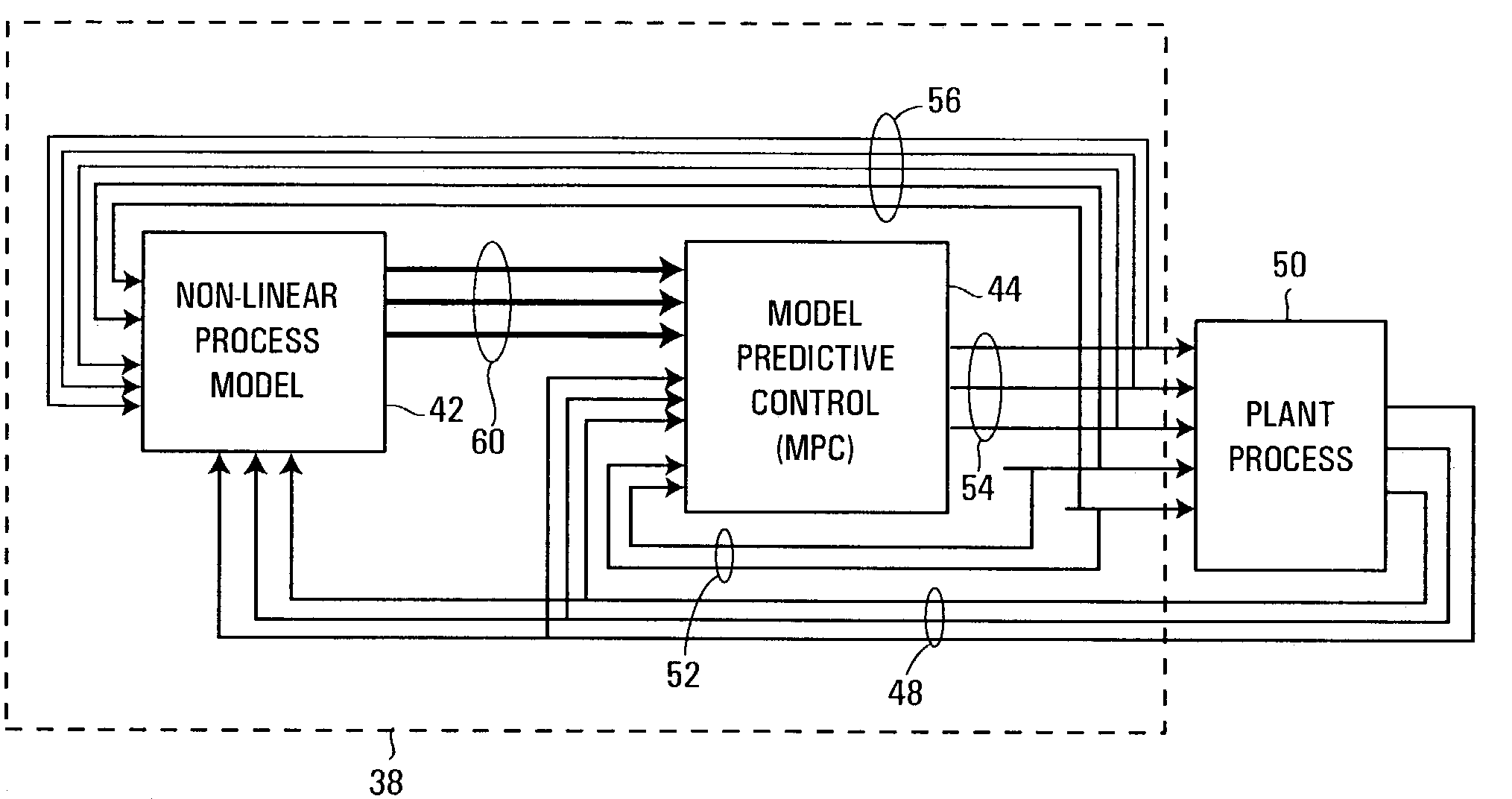

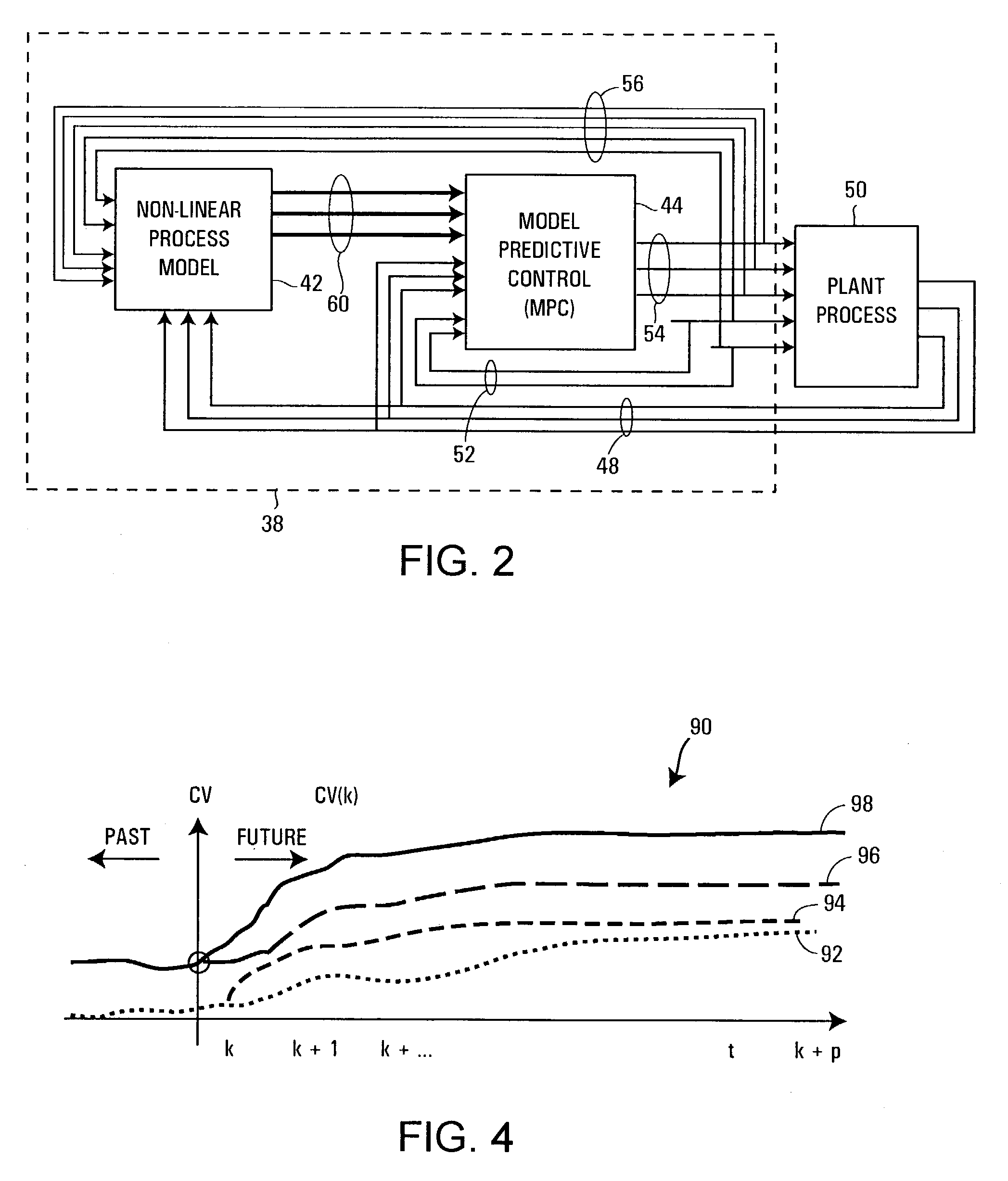

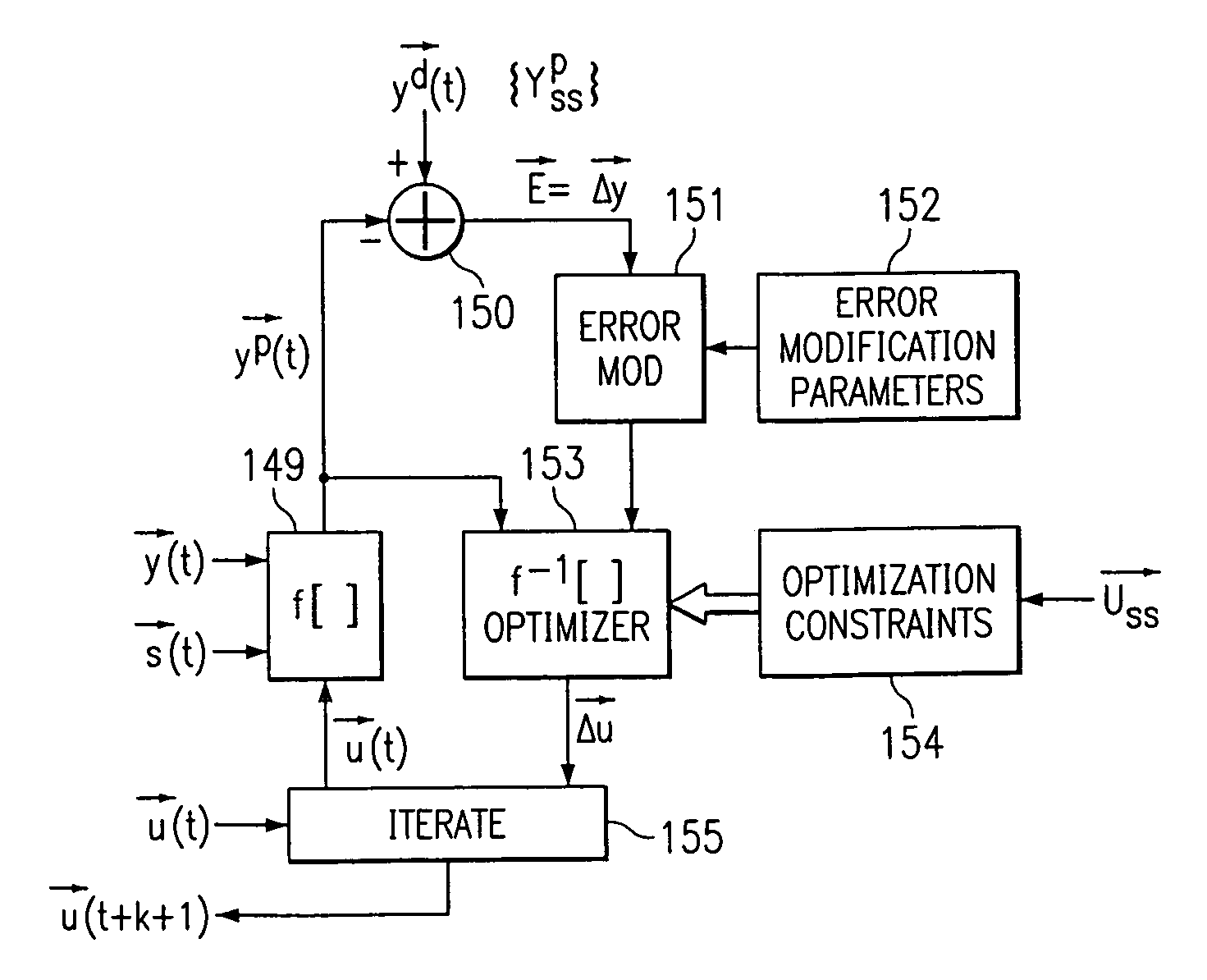

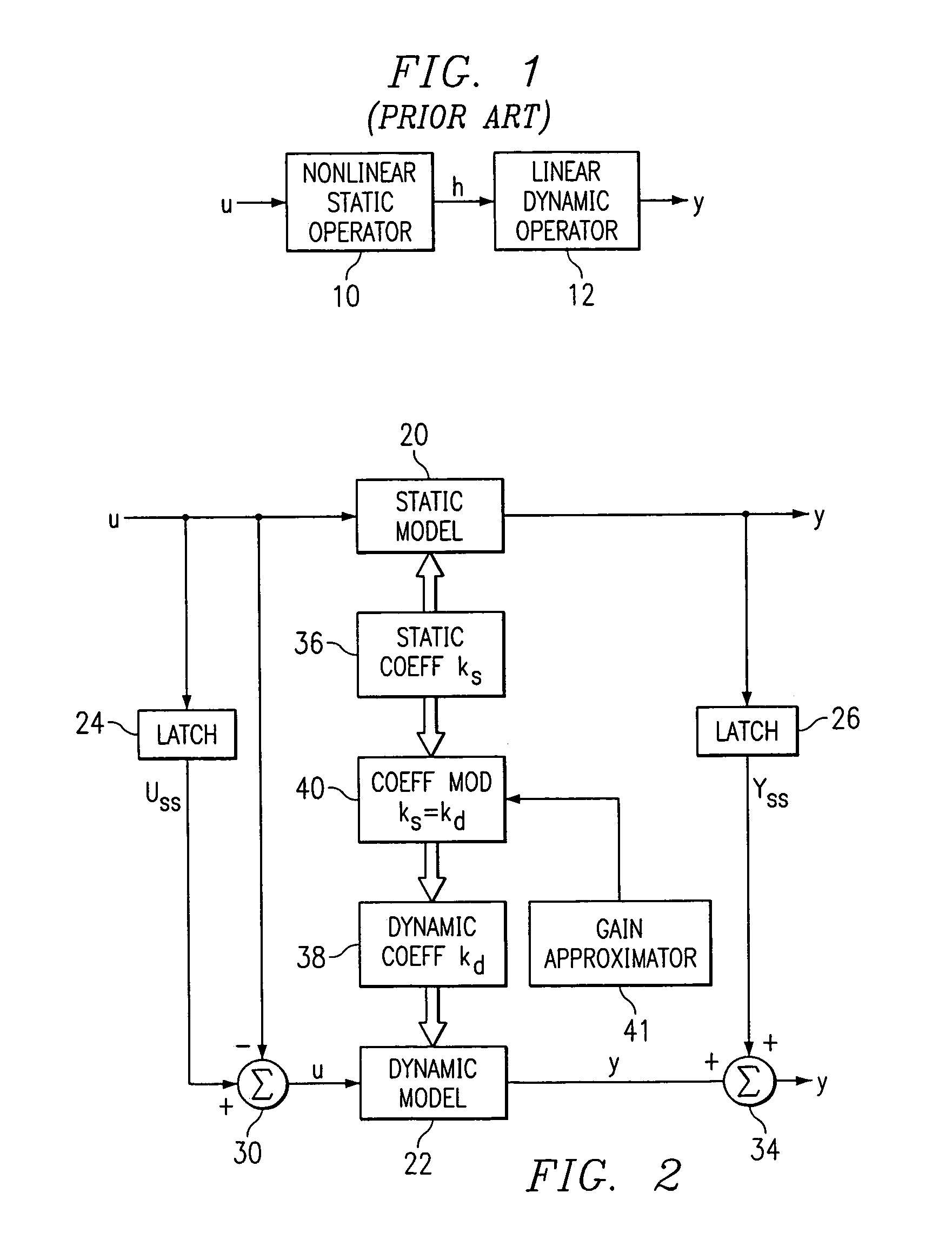

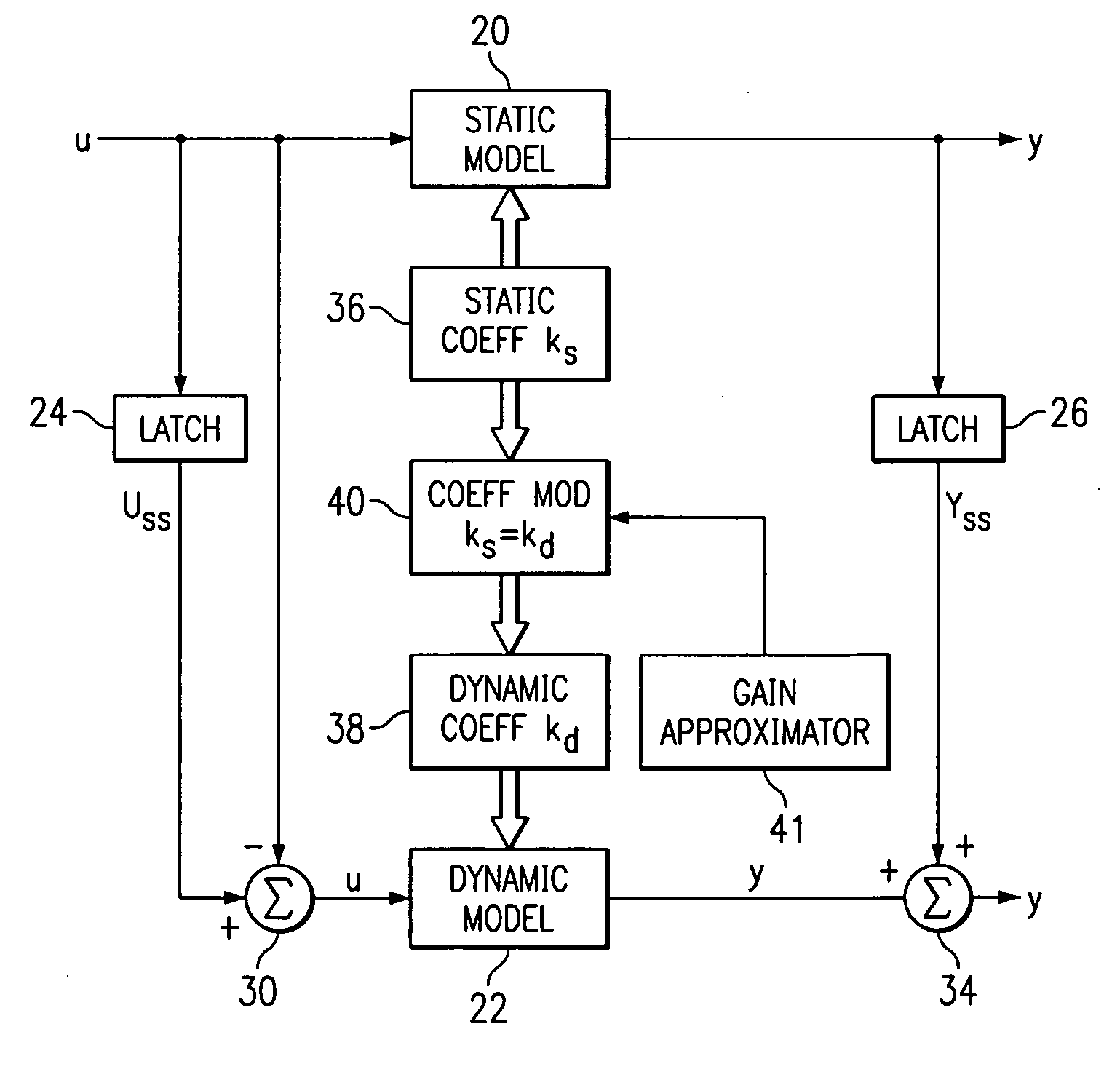

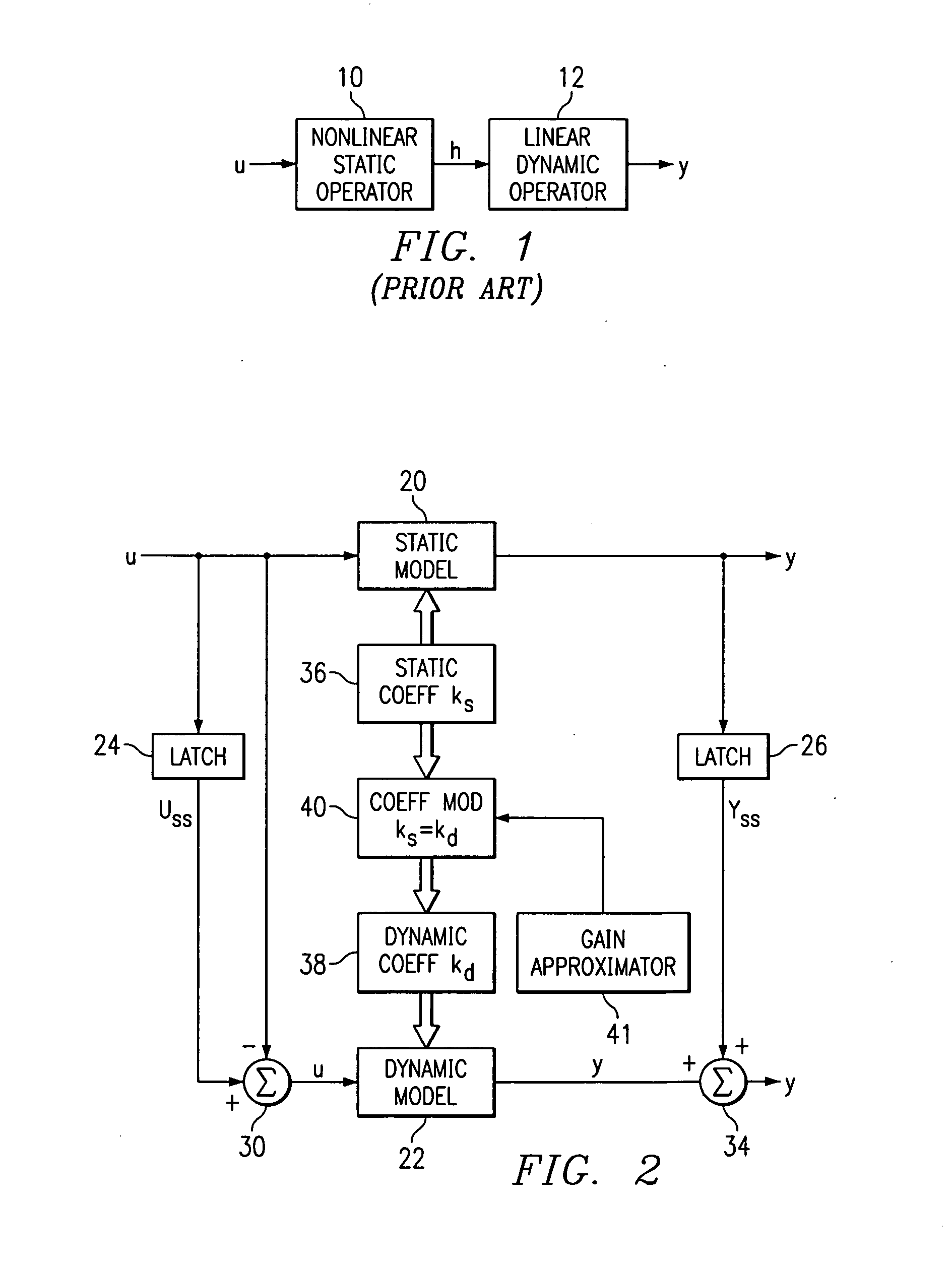

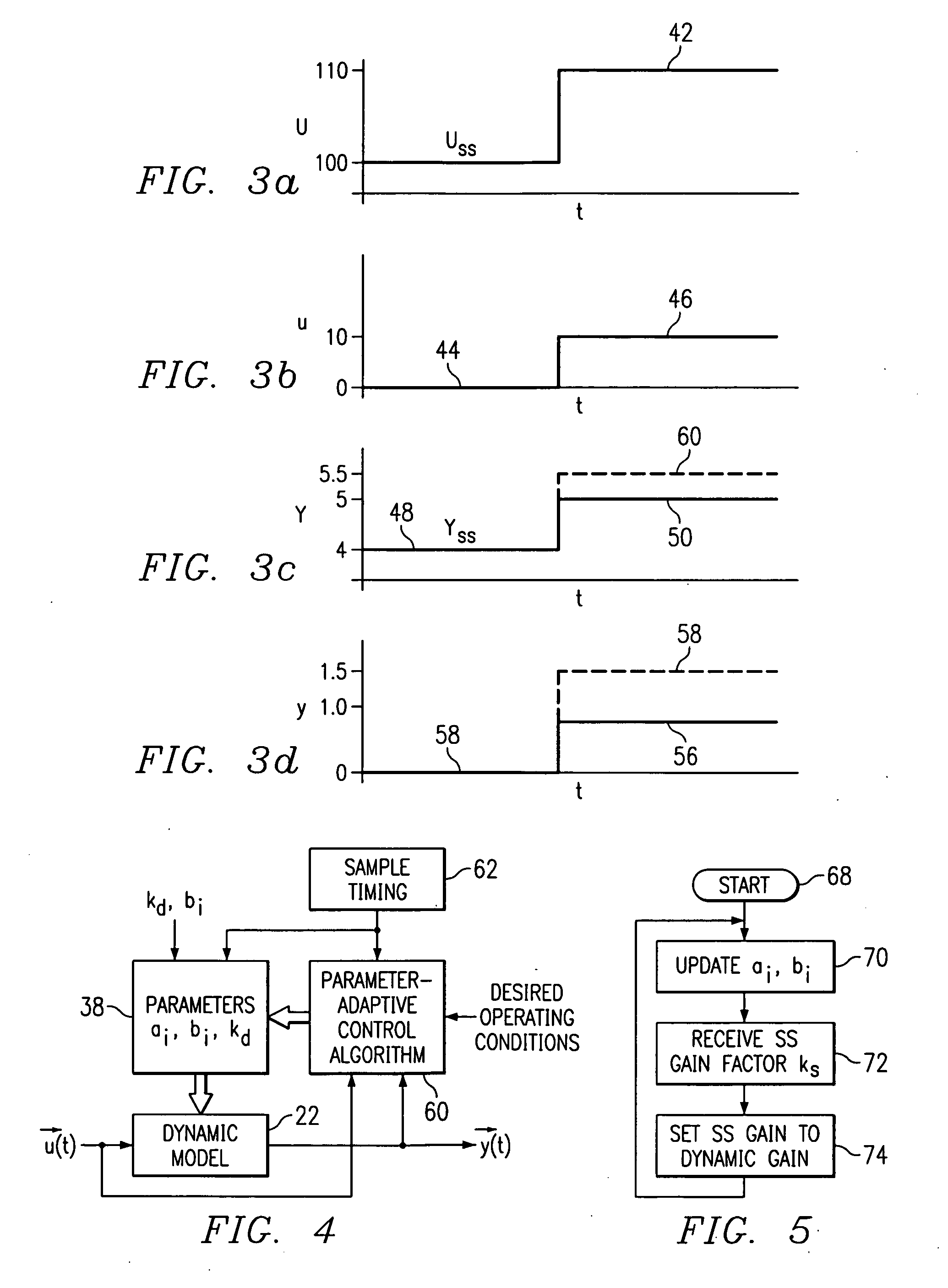

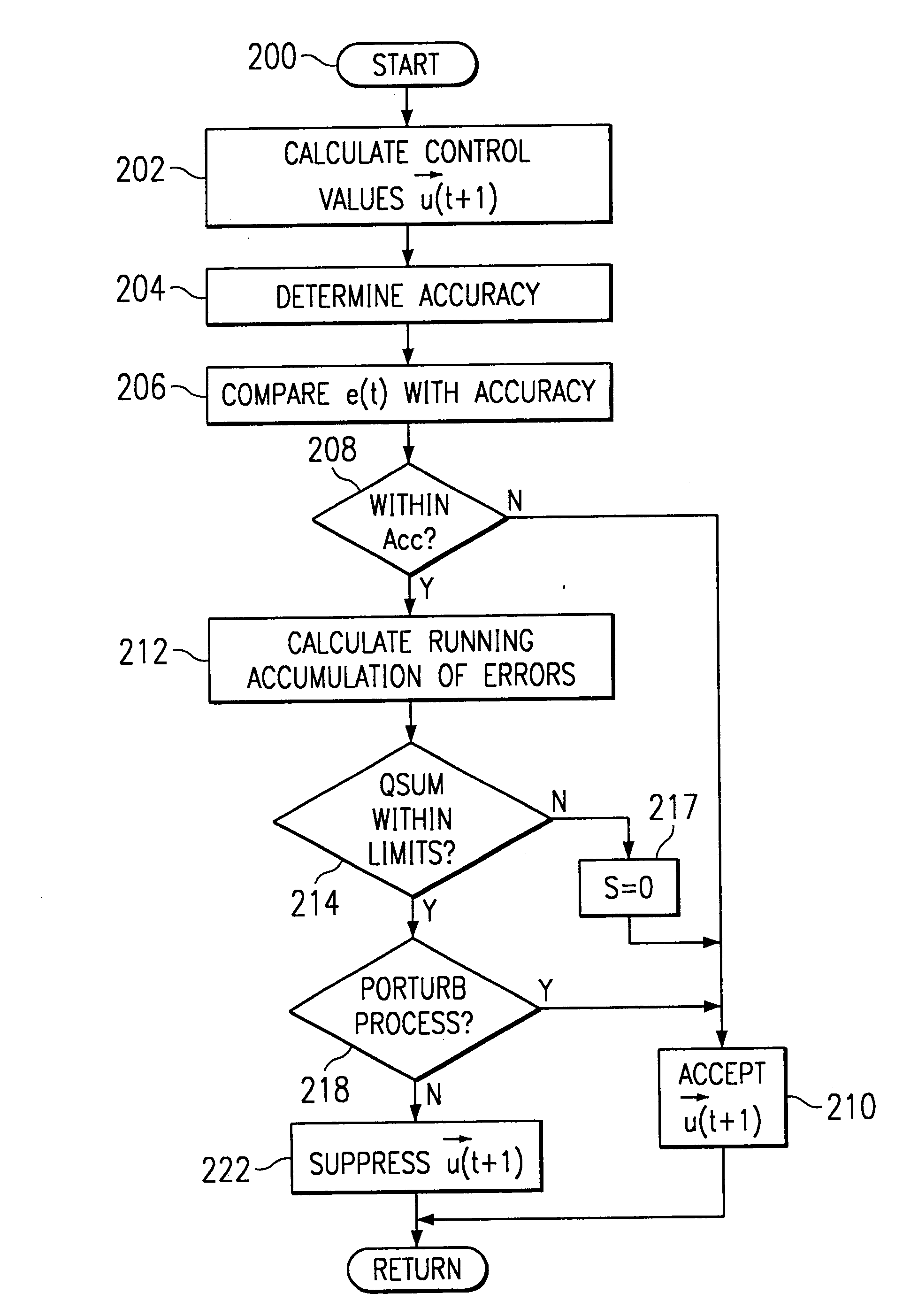

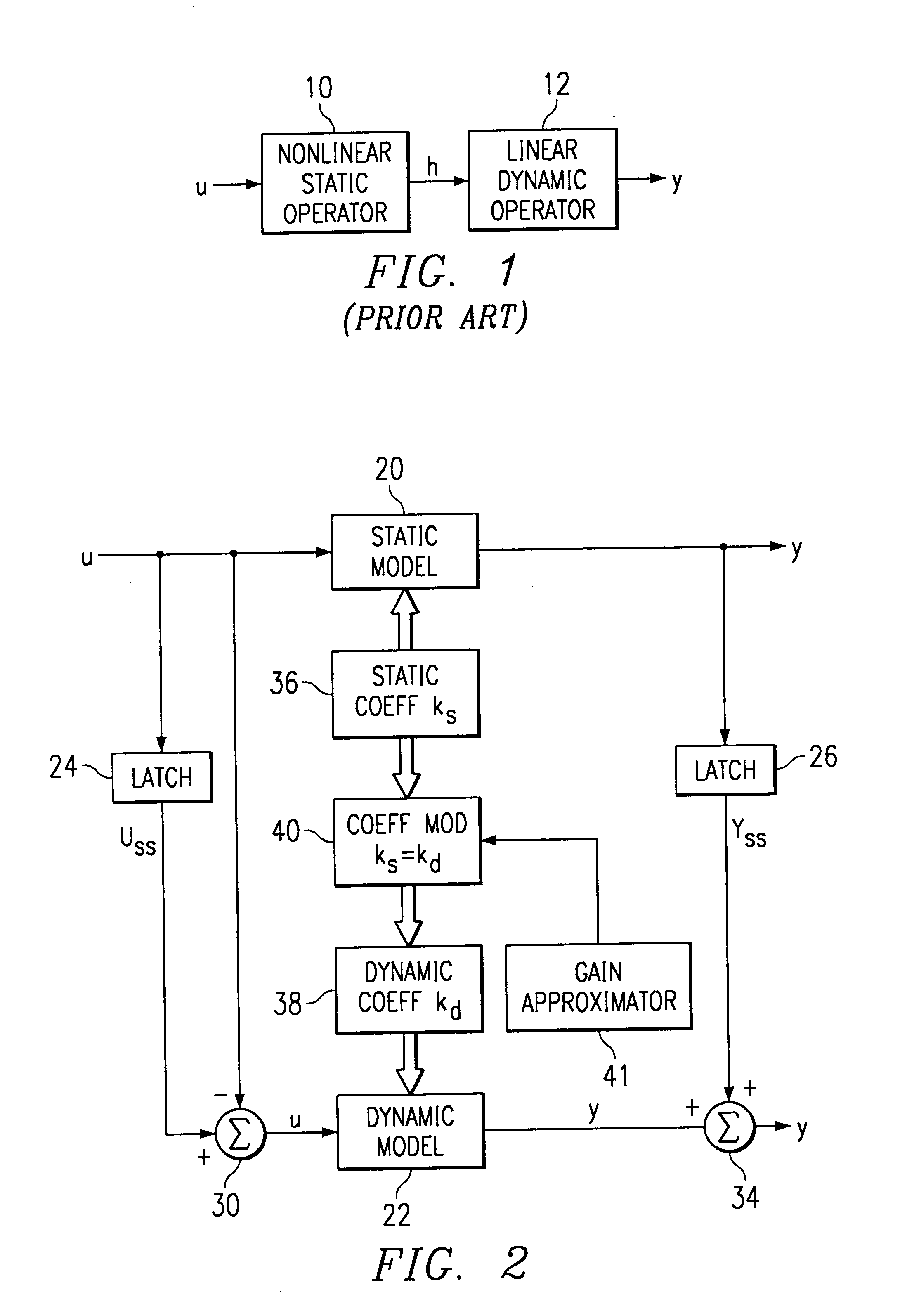

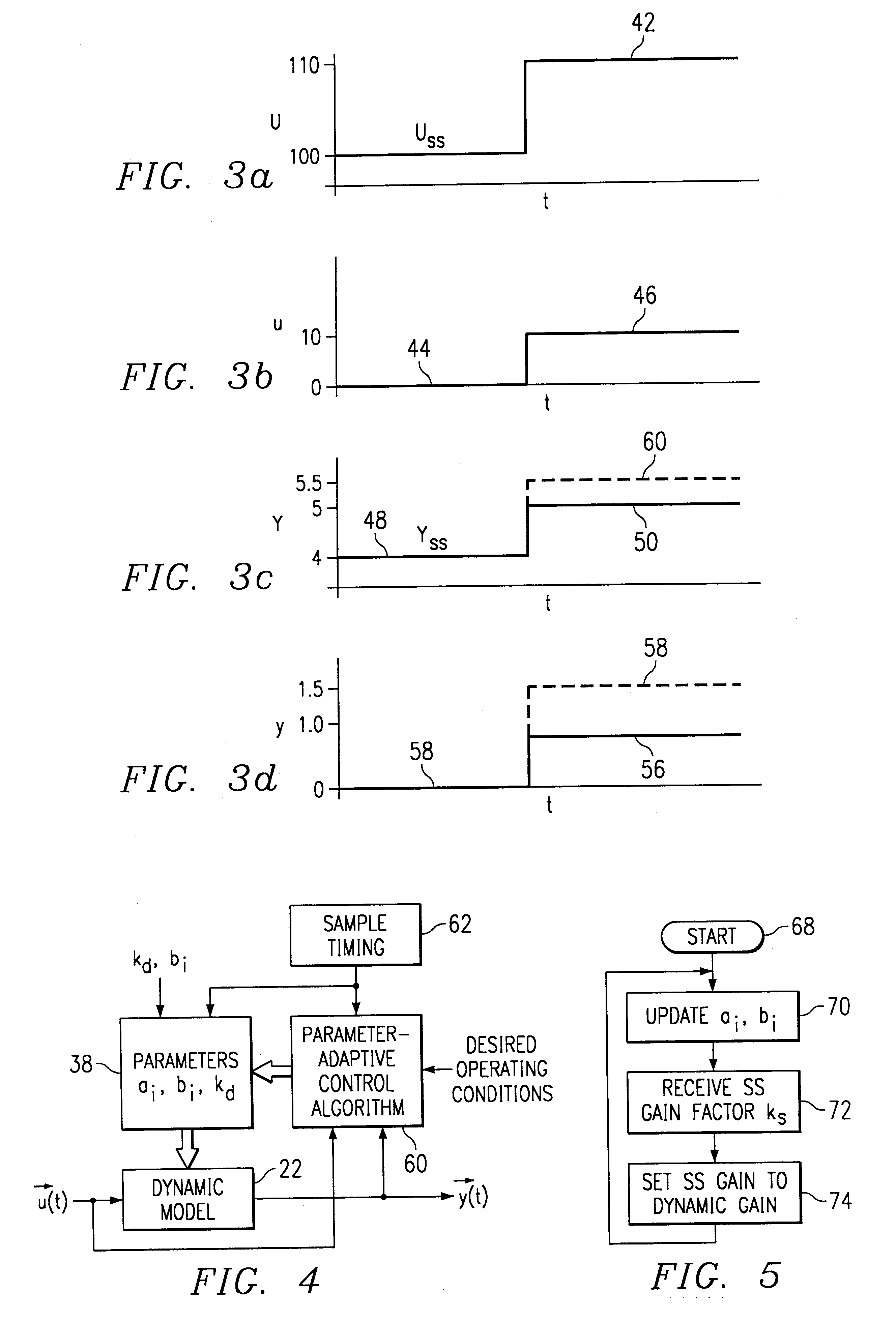

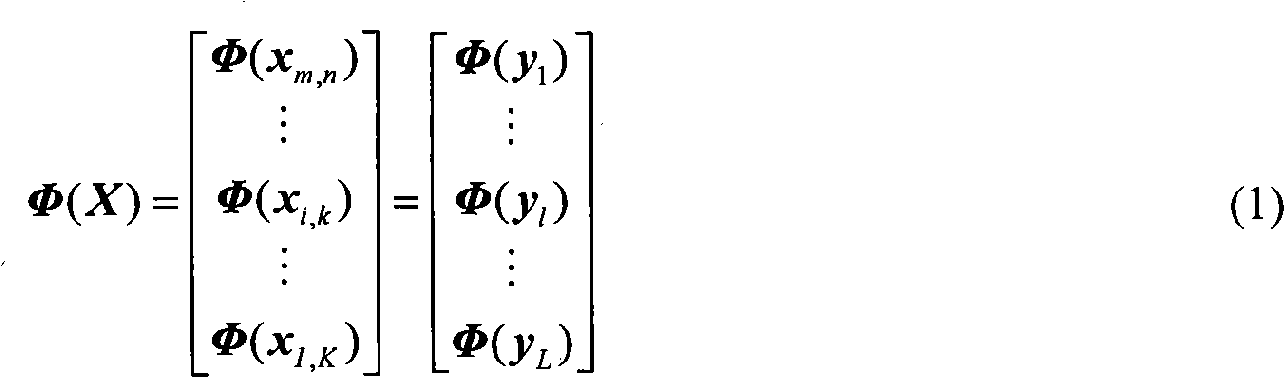

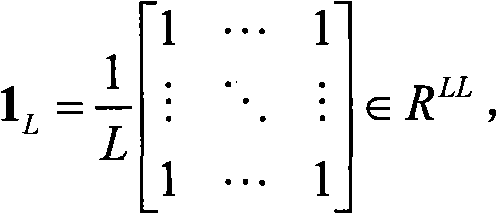

System and methodology and adaptive, linear model predictive control based on rigorous, nonlinear process model

InactiveUS6826521B1Analogue computers for chemical processesAdaptive controlSoftware systemPredictive controller

A methodology for process modeling and control and the software system implementation of this methodology, which includes a rigorous, nonlinear process simulation model, the generation of appropriate linear models derived from the rigorous model, and an adaptive, linear model predictive controller (MPC) that utilizes the derived linear models. A state space, multivariable, model predictive controller (MPC) is the preferred choice for the MPC since the nonlinear simulation model is analytically translated into a set of linear state equations and thus simplifies the translation of the linearized simulation equations to the modeling format required by the controller. Various other MPC modeling forms such as transfer functions, impulse response coefficients, and step response coefficients may also be used. The methodology is very general in that any model predictive controller using one of the above modeling forms can be used as the controller. The methodology also includes various modules that improve reliability and performance. For example, there is a data pretreatment module used to pre-process the plant measurements for gross error detection. A data reconciliation and parameter estimation module is then used to correct for instrumentation errors and to adjust model parameters based on current operating conditions. The full-order state space model can be reduced by the order reduction module to obtain fewer states for the controller model. Automated MPC tuning is also provided to improve control performance.

Owner:ABB AUTOMATION INC

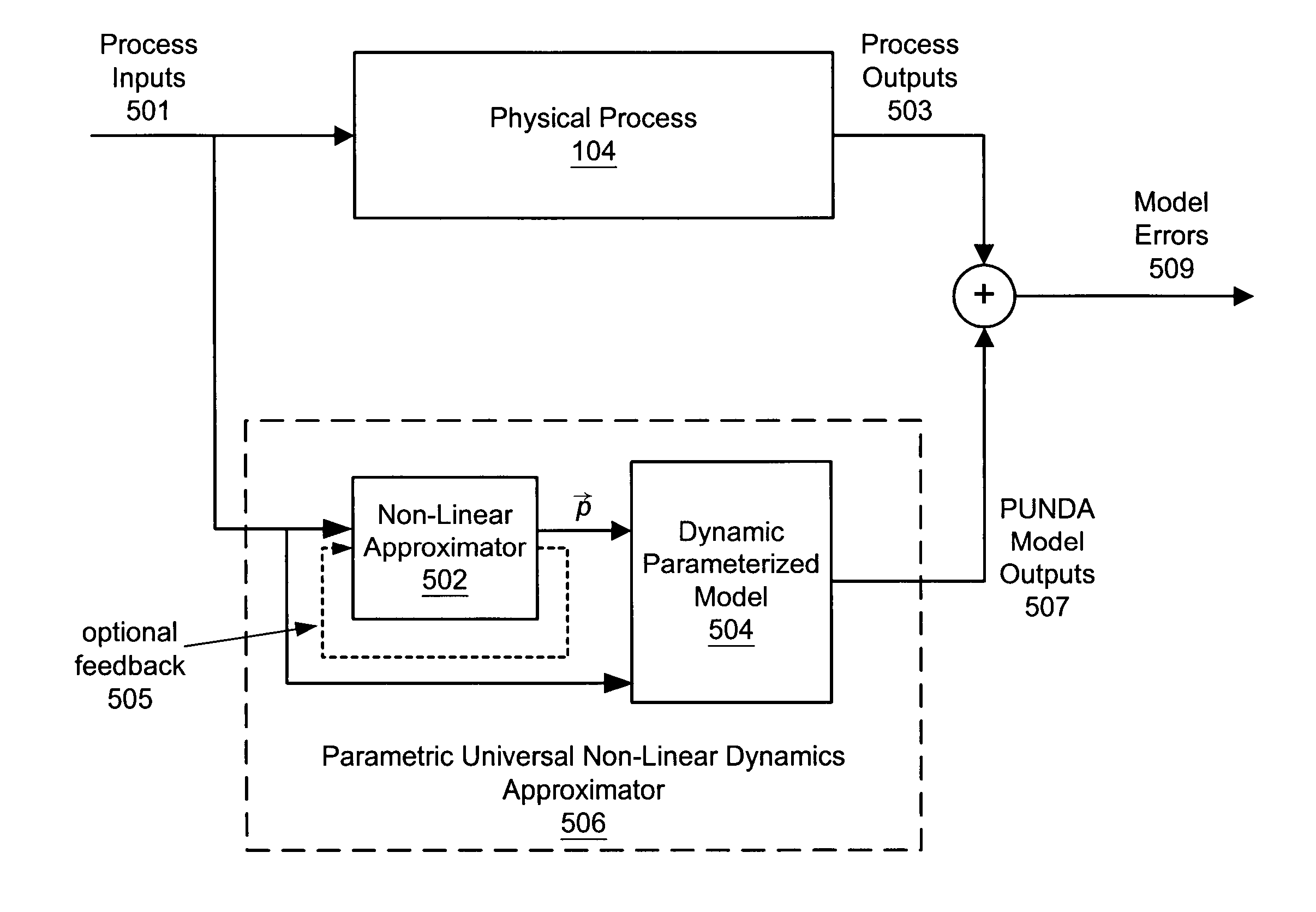

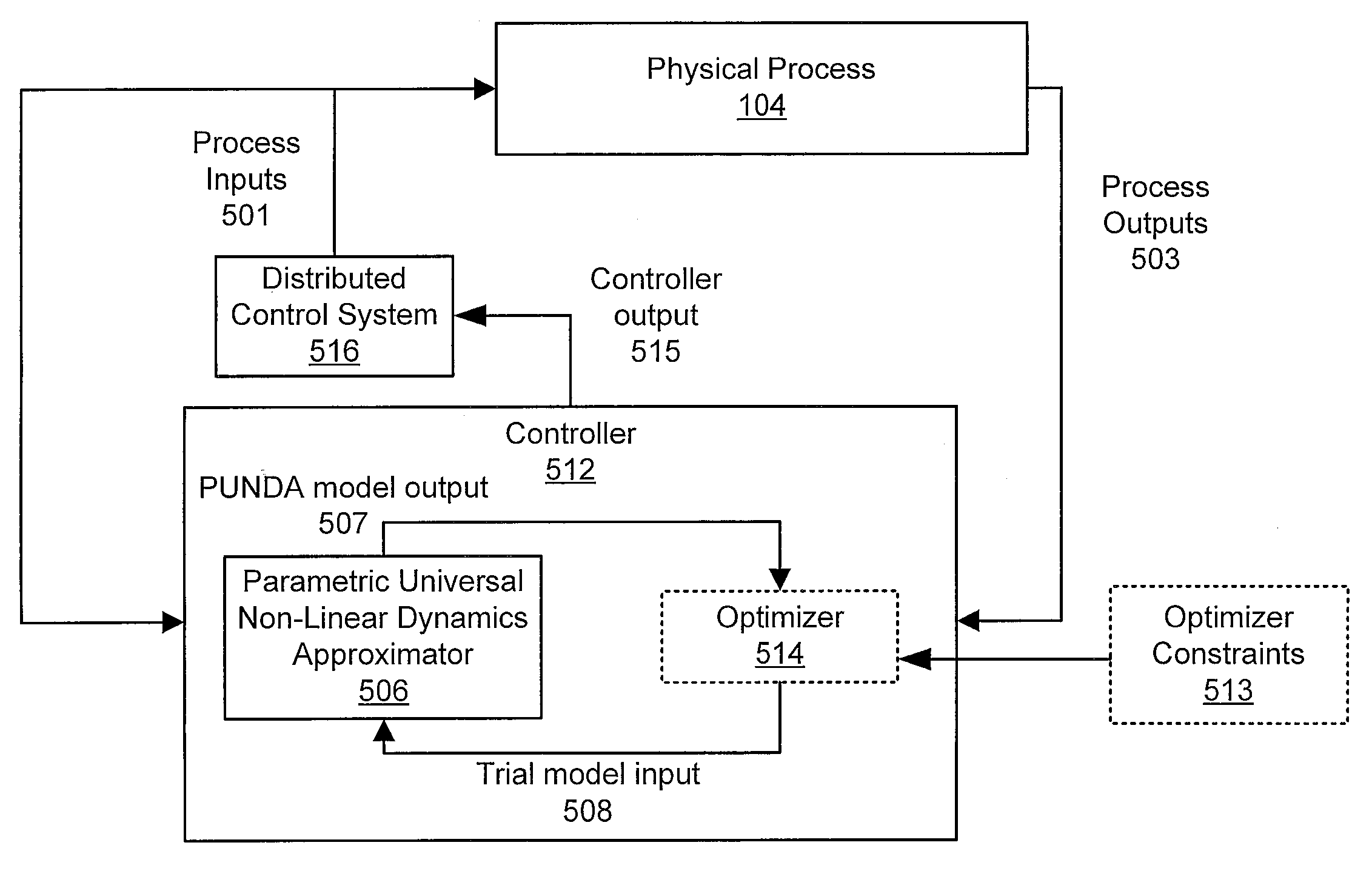

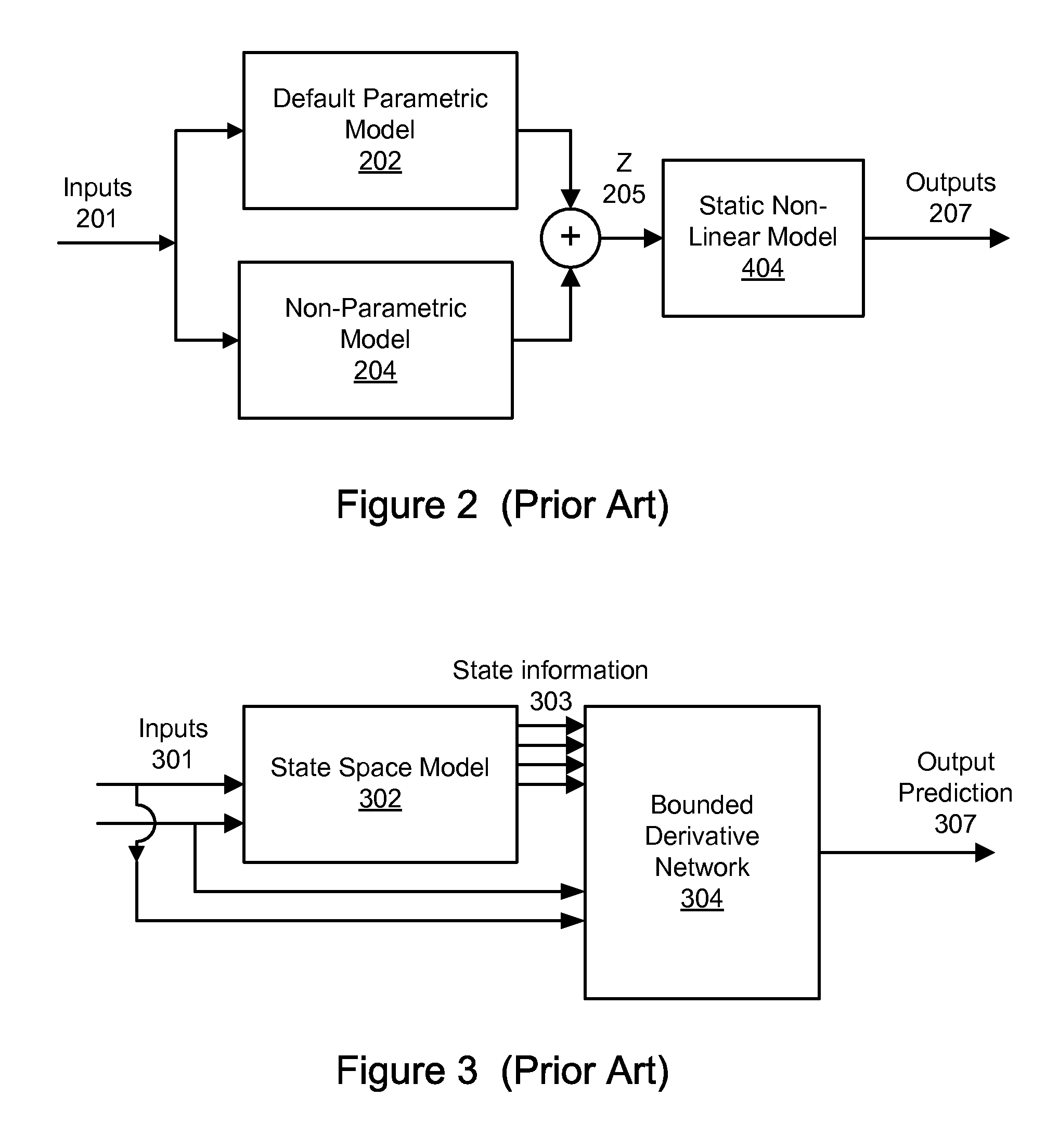

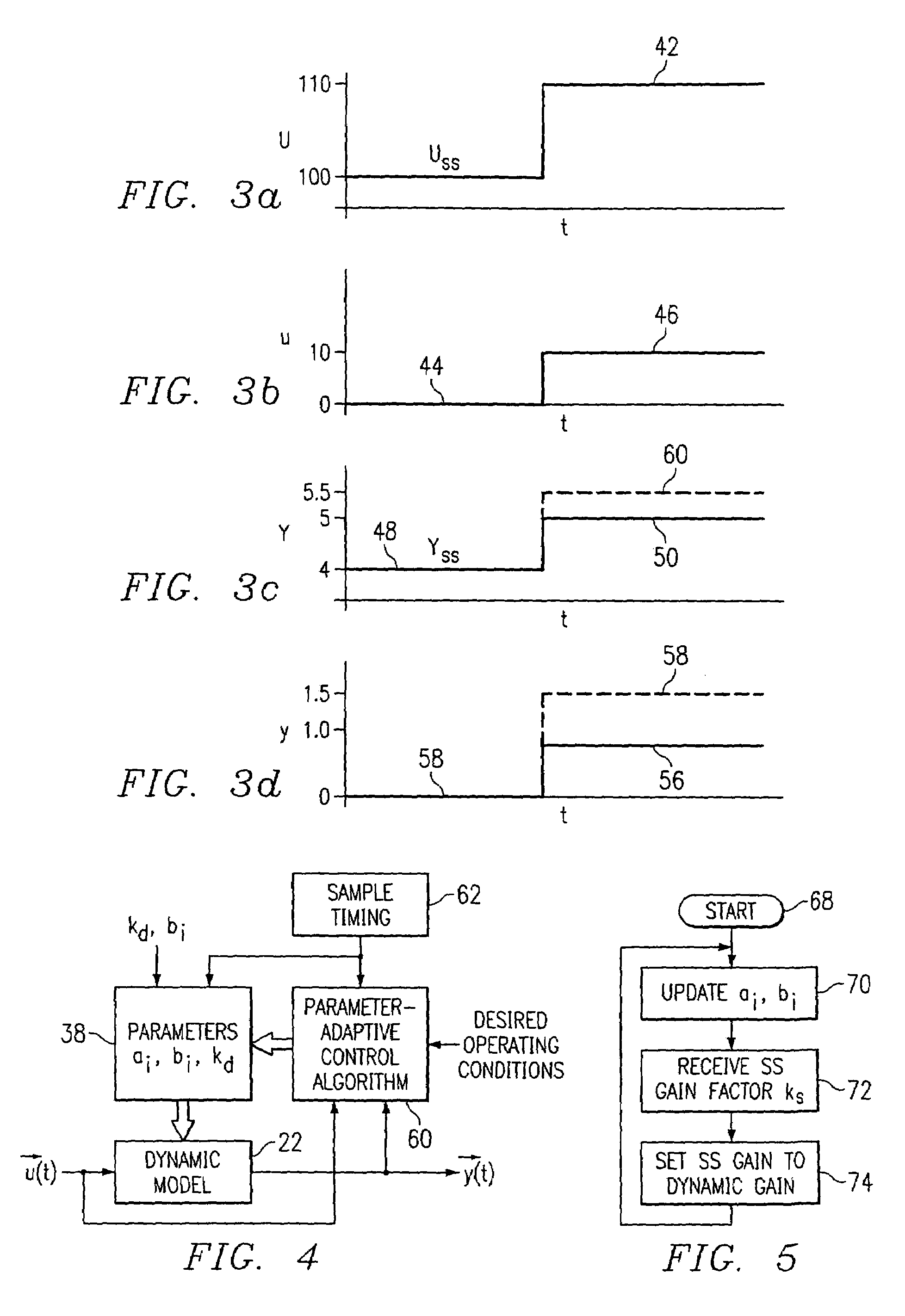

Parametric universal nonlinear dynamics approximator and use

InactiveUS20050187643A1Simulator controlDigital computer detailsNonlinear approximationDynamic models

Owner:ROCKWELL AUTOMATION TECH

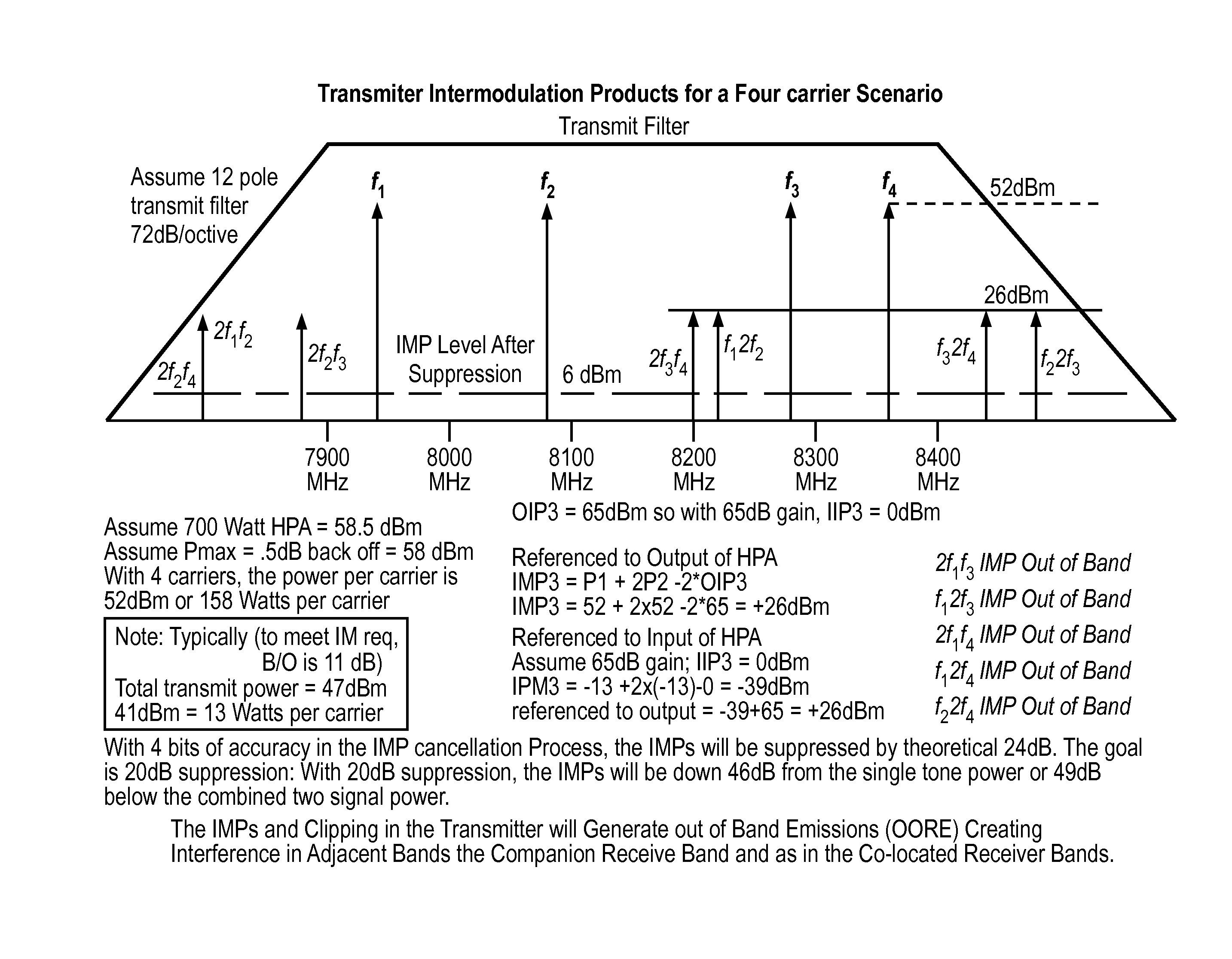

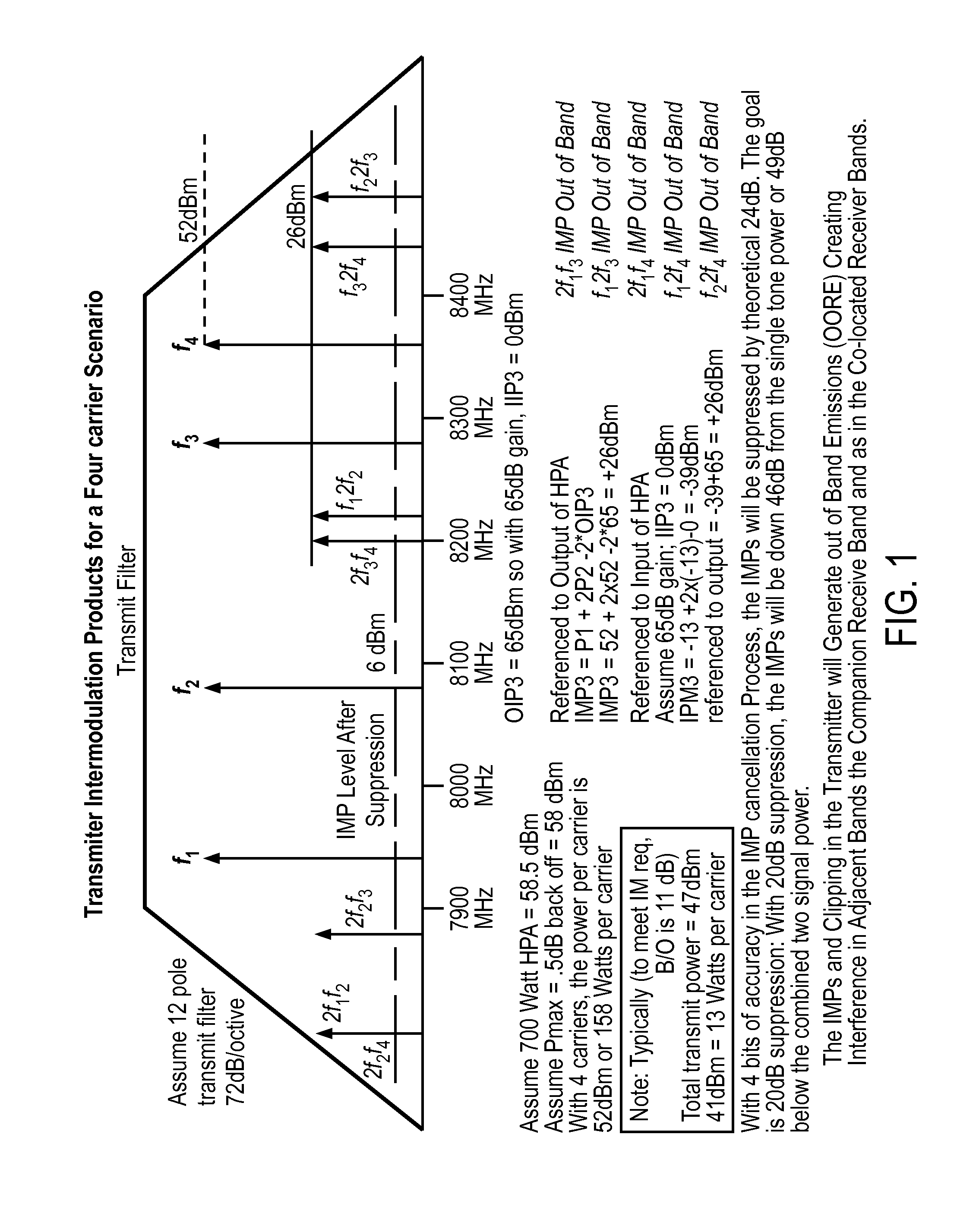

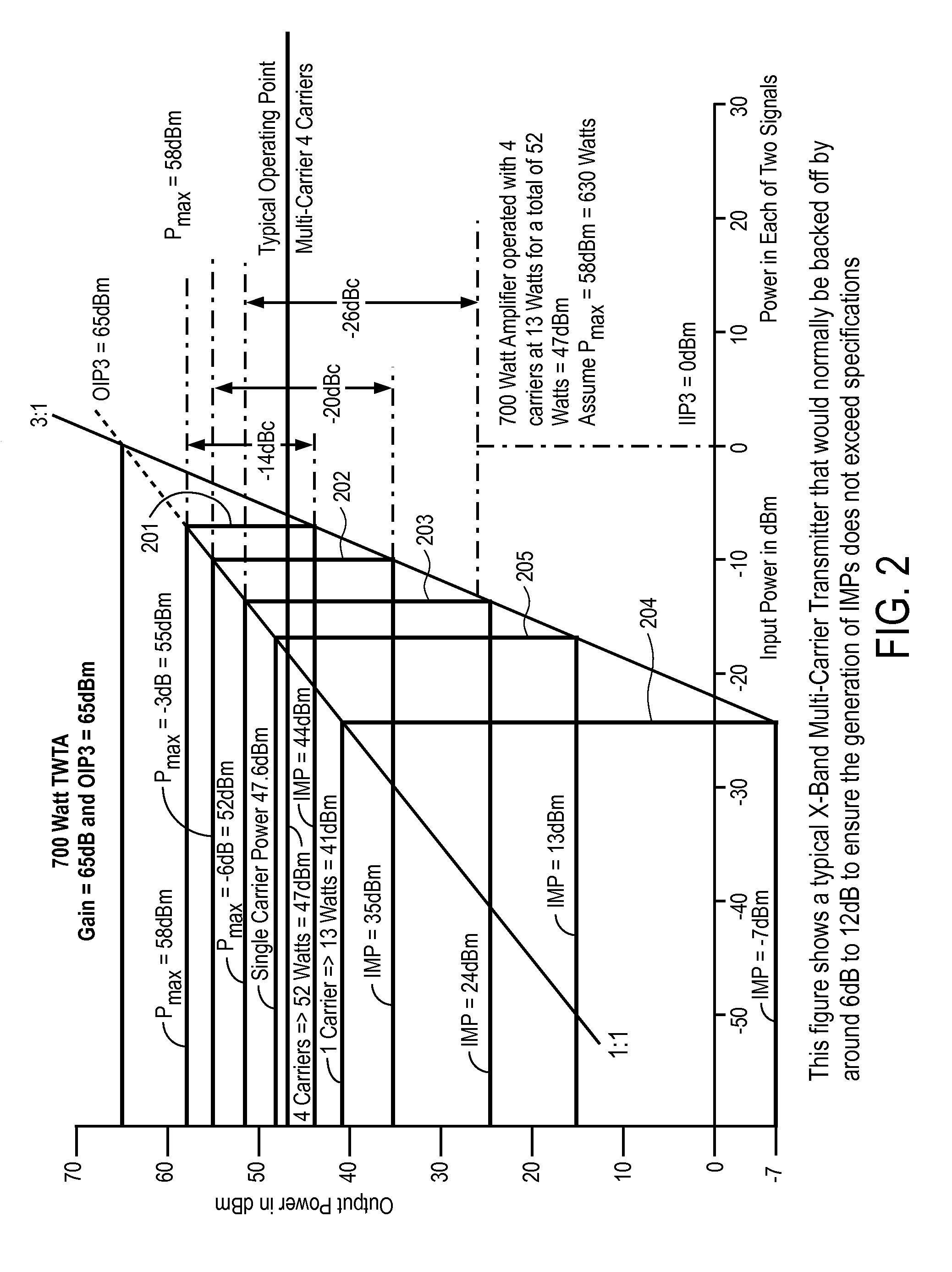

Mitigation of transmitter passive and active intermodulation products in real and continuous time in the transmitter and co-located receiver

ActiveUS20110075754A1Secret communicationTransmitter/receiver shaping networksLinear componentEngineering

A transmitter channel interference mitigation processing method for cancellation of intermodulation products are described. In one embodiment, a method comprising generating continuous and real time IMP cancellation signals (ICS) in the baseband digital signal set of the transmitter based on a transmitter signal set, combining digital IMP cancellation signals with a digital baseband transmitter signal set such that the digital cancellation signals, when converted to analog signals and transmitted as part of an analog transmitter signal set, are cancelled by and so cancel the IMPs generated by the non-linear components in the analog transmitter hardware, including digitally generating the IMP cancellation signals using a process based on a power series description of a non-linear process generating the IMPs, generating 3rd order IMP cancellation signals by digitally multiplying two or three signals of the transmitter signal set to create 3rd order IMP cancellation signals, generating 5th order IMP cancellation signals by digitally multiplying two or three or five signals of the transmitter signal set to create 5th order IMP cancellation signals, generating 7th order IMP cancellation signals by digitally multiplying two or three or five or seven signals of the transmitter signal set to create 7th order IMP cancellation signal, generating odd order IMP cancellation signals (ICS) by digitally multiplying an odd number of digital signals and combining multiplied digital signals with the transmitter baseband digital signals, creating IMP cancellation signals in the receiver, and cancelling one or both of active and passive IMPs generated in a transmitter path that fall within a receiver passband.

Owner:FINESSE WIRELESS LLC

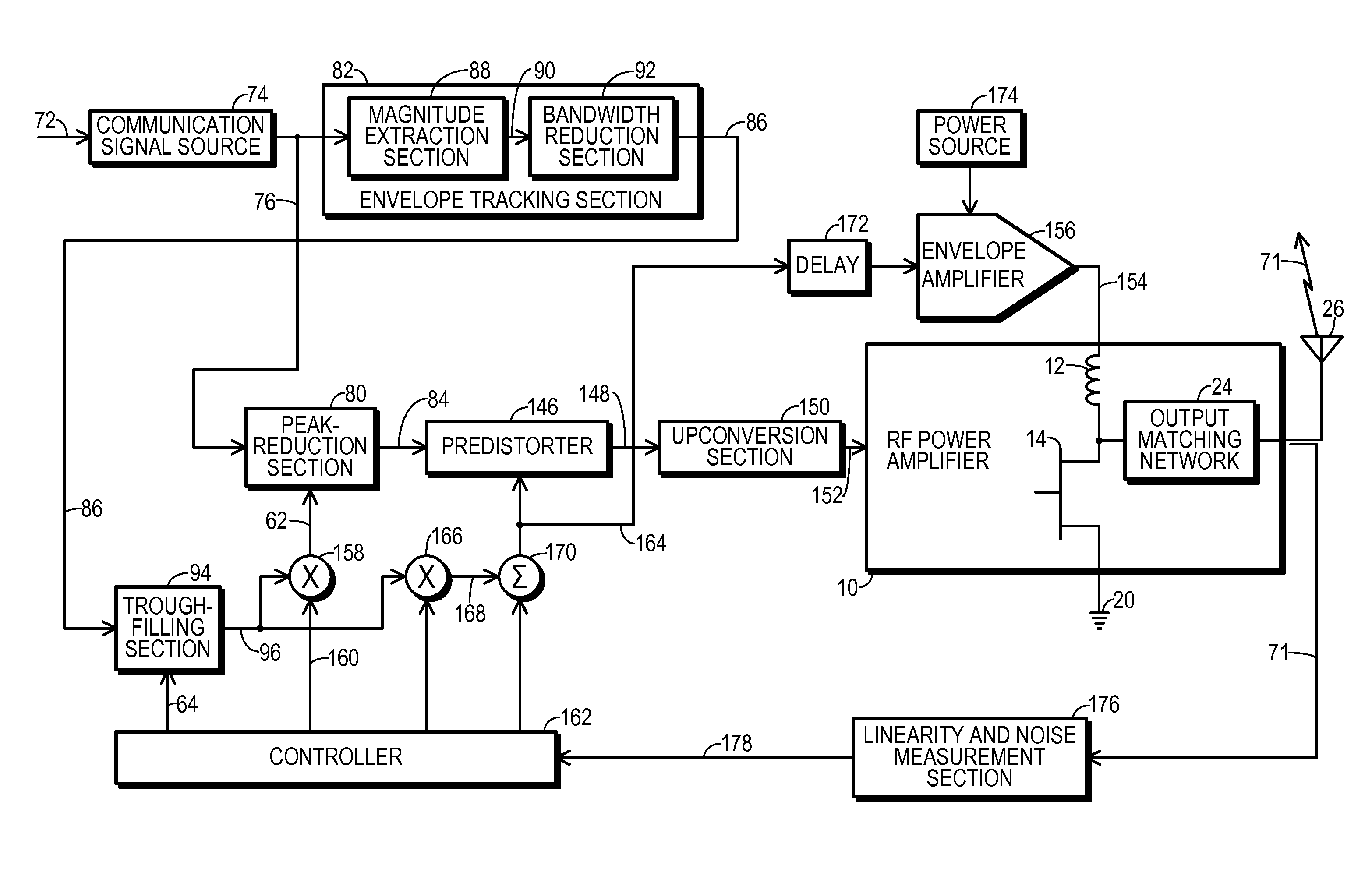

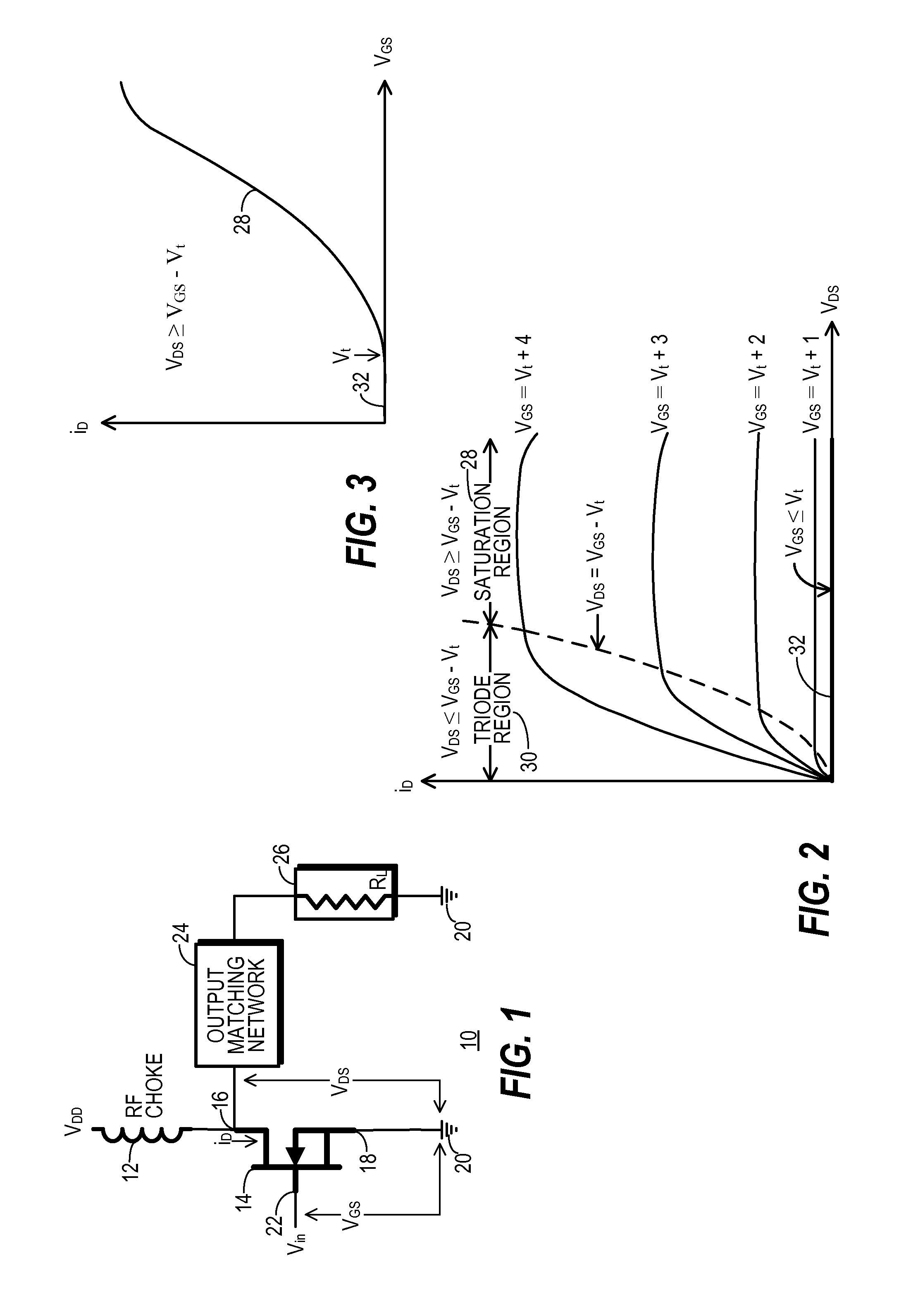

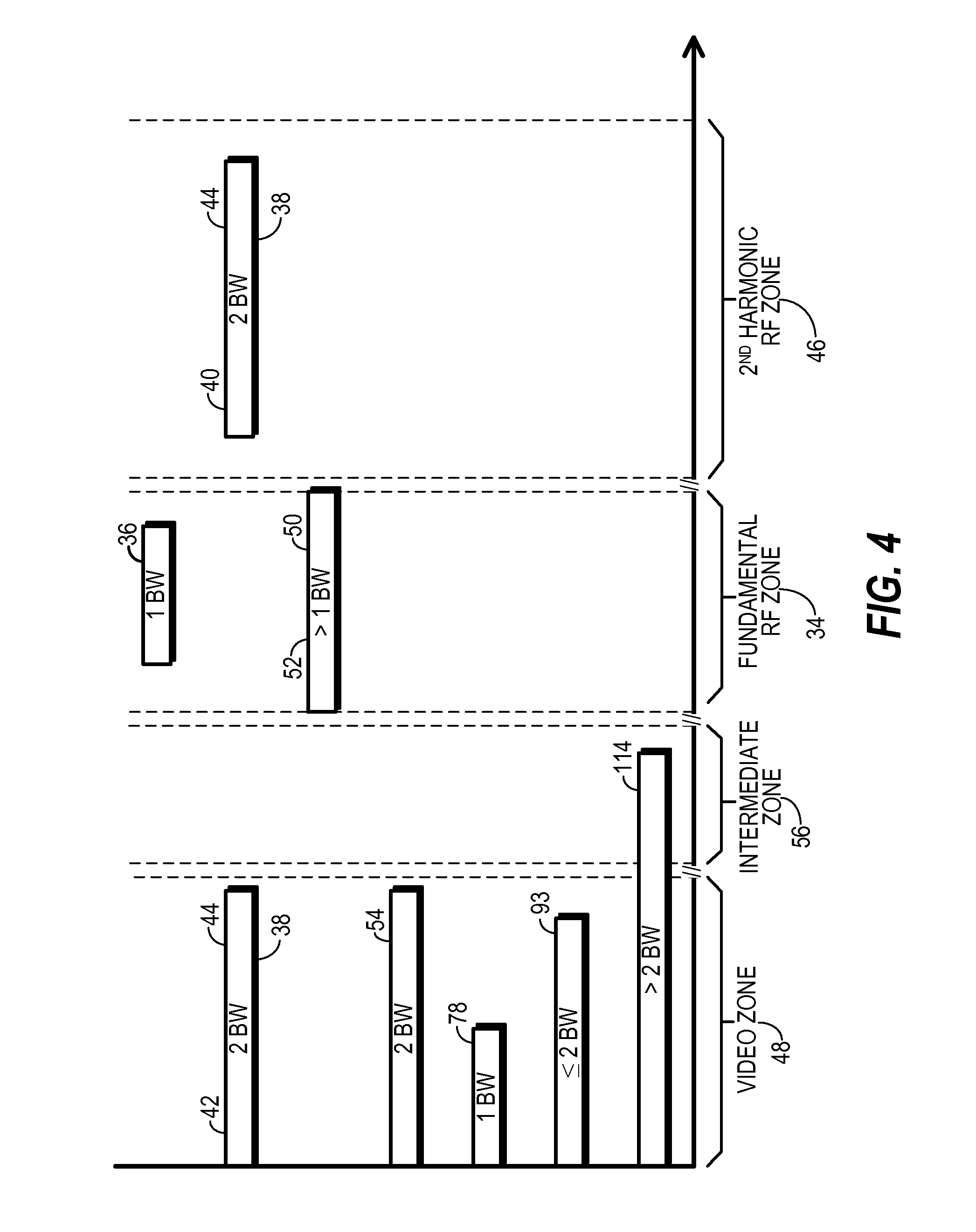

Transmitter and method for RF power amplifier having a bandwidth controlled, detroughed envelope tracking signal

A transmitter (70) generates a time-varying, detroughed, biasing signal (154) for an RF power amplifier (10) so that the RF power amplifier (10) is biased in accordance with an envelope tracking scheme. A trough-filling section (94) is responsive to an envelope tracking signal (86), which in turn is responsive to a magnitude signal (90) extracted from a complex baseband communication signal (76). The trough-filing section (94) includes a limiting stage (108) that forms a raw troughing signal (110) which expands the bandwidth of the envelope tracking signal (86). A filtering stage (116) reduces the bandwidth of the raw troughing signal (110) to form a trough-filling signal (122) that is combined back into the envelope tracking signal (86) using a linear process that maintains the bandwidth of the envelope tracking signal (86).

Owner:CRESTCOM INC

Controlling a non-linear process

InactiveUS20080208778A1Simulator controlDigital computer detailsNonlinear approximationDynamic models

Owner:ROCKWELL AUTOMATION TECH

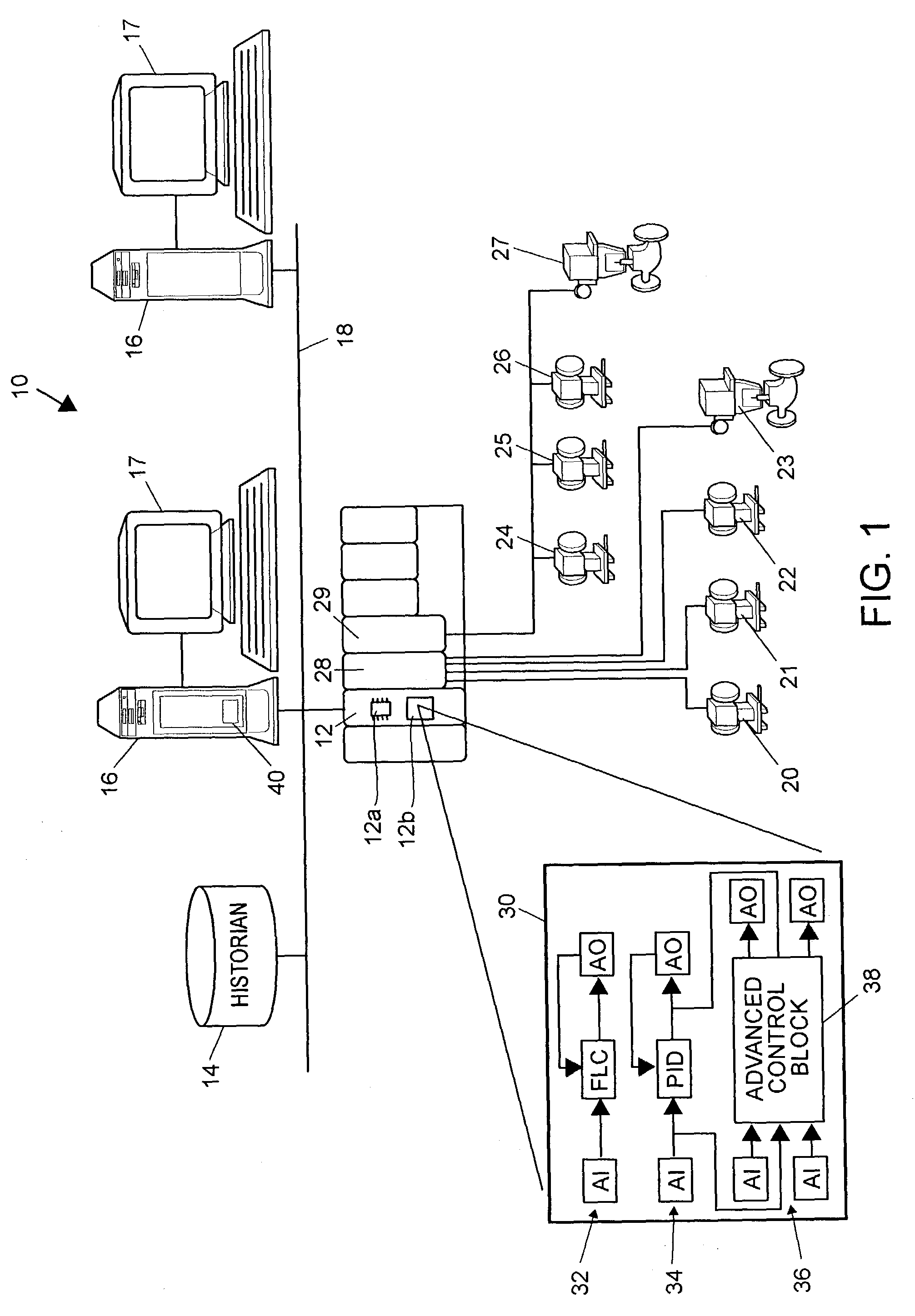

Multiple-input/multiple-output control blocks with non-linear predictive capabilities

ActiveUS7272454B2Easy to implementEasy to useComputer controlElectric testing/monitoringProcess engineeringMultiple input

A process controller that may be used to control a process having a set of process outputs effected by a set of process control input signals includes a multiple-input / multiple output controller that uses the process outputs to develop the set of process control input signals and a process model, which may be a non-linear process model, that receives the set of process control input signals to produce a prediction signal for one or more of the process outputs. The multiple-input / multiple-output control element includes another process model, which may be a standard linear process model, to develop a prediction vector for each of the process outputs and includes a correction unit that modifies the prediction vector for the one or more of the process outputs using the prediction signal for the one or more of the process outputs to thereby compensate for the non-linearities of the process.

Owner:FISHER-ROSEMOUNT SYST INC

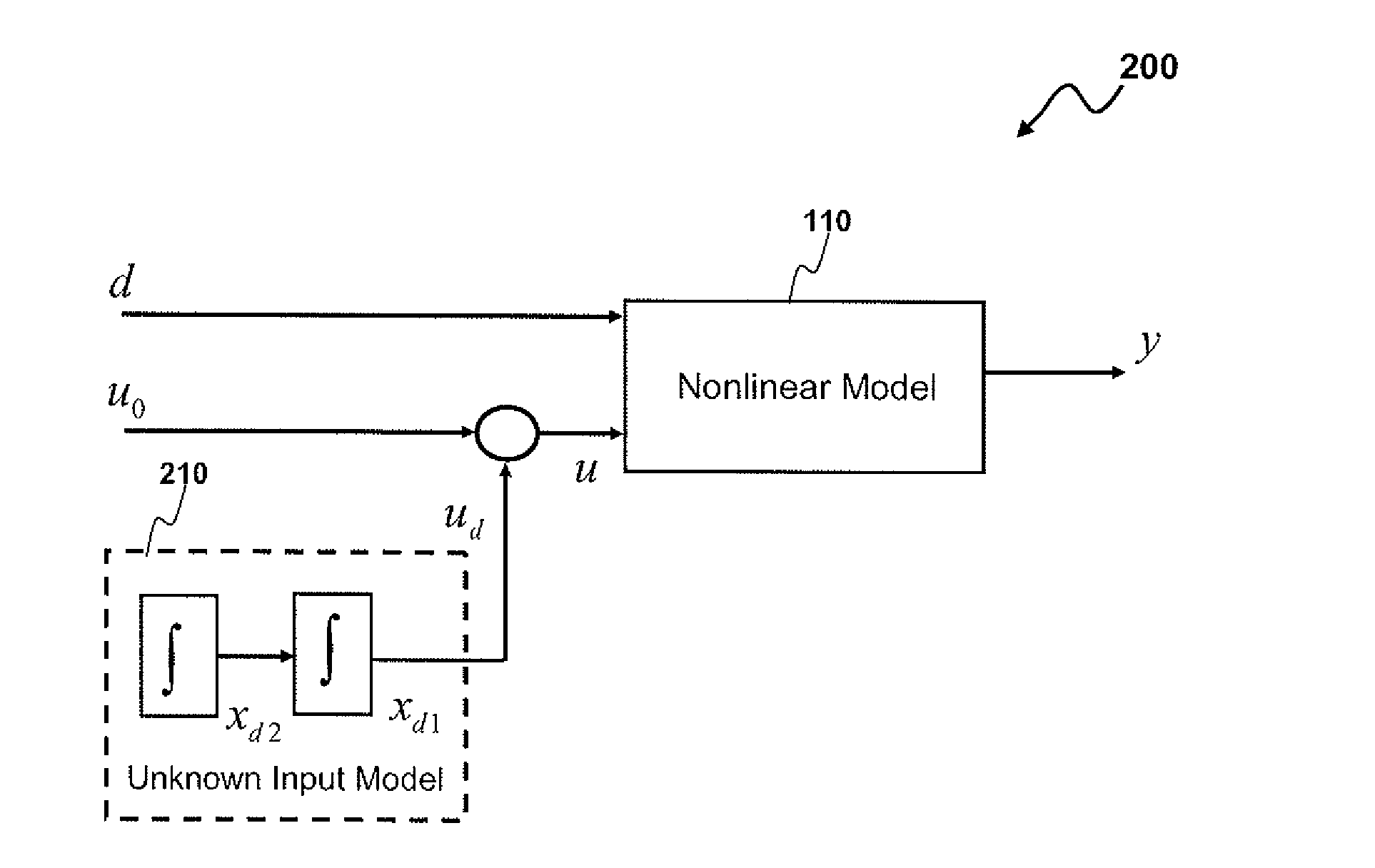

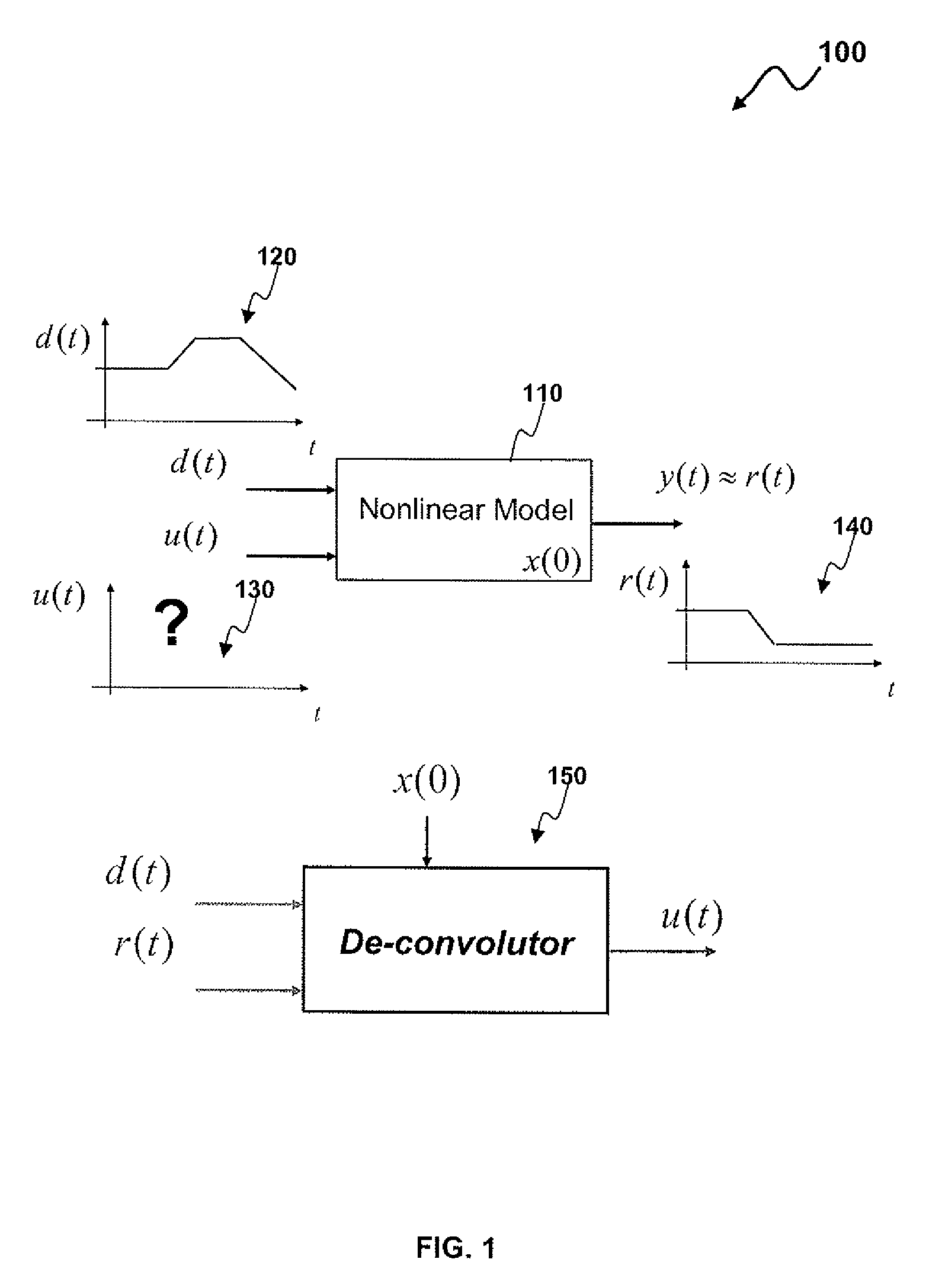

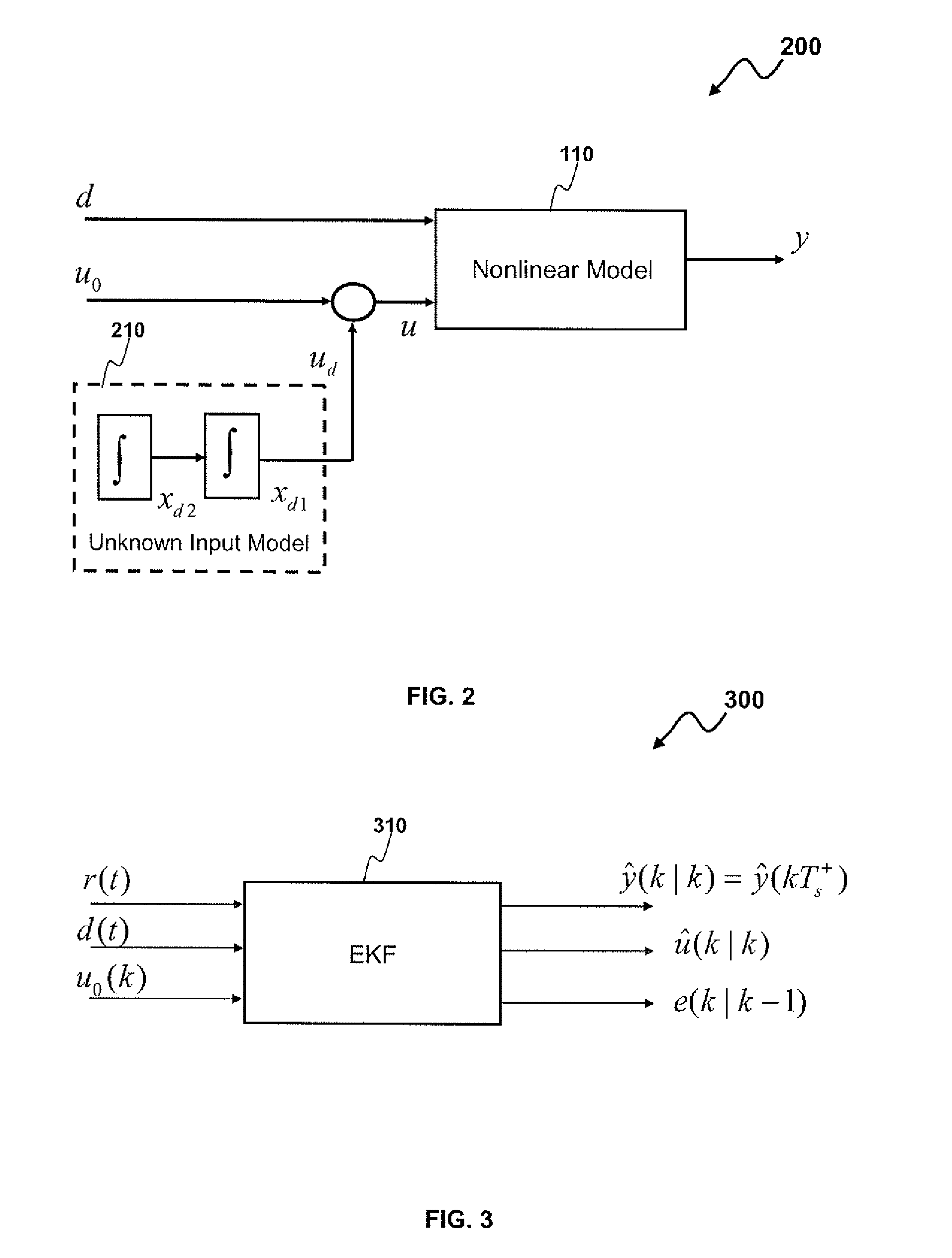

Target trajectory generator for predictive control of nonlinear systems using extended Kalman filter

A model predictive controller (MPC) for predictive control of nonlinear processes utilizing an EKF (Extended Kalman Filter) and a nominal trajectory generator. The nominal trajectory generator includes another instance of EKF, a linear corrector, and a time-varying deviation model. A nominal control trajectory can be predicted and an optimal solution for the time-varying deviation model can be computed based on an approximation of a system inverse known as signal de-convolution. The EKF can be utilized to estimate a current process state by supplying a measured output and to predict a future nominal trajectory by supplying a reference output. A Kalman smoother can also be utilized for the signal de-convolution in order to obtain enhanced trajectory estimates.

Owner:HONEYWELL INT INC

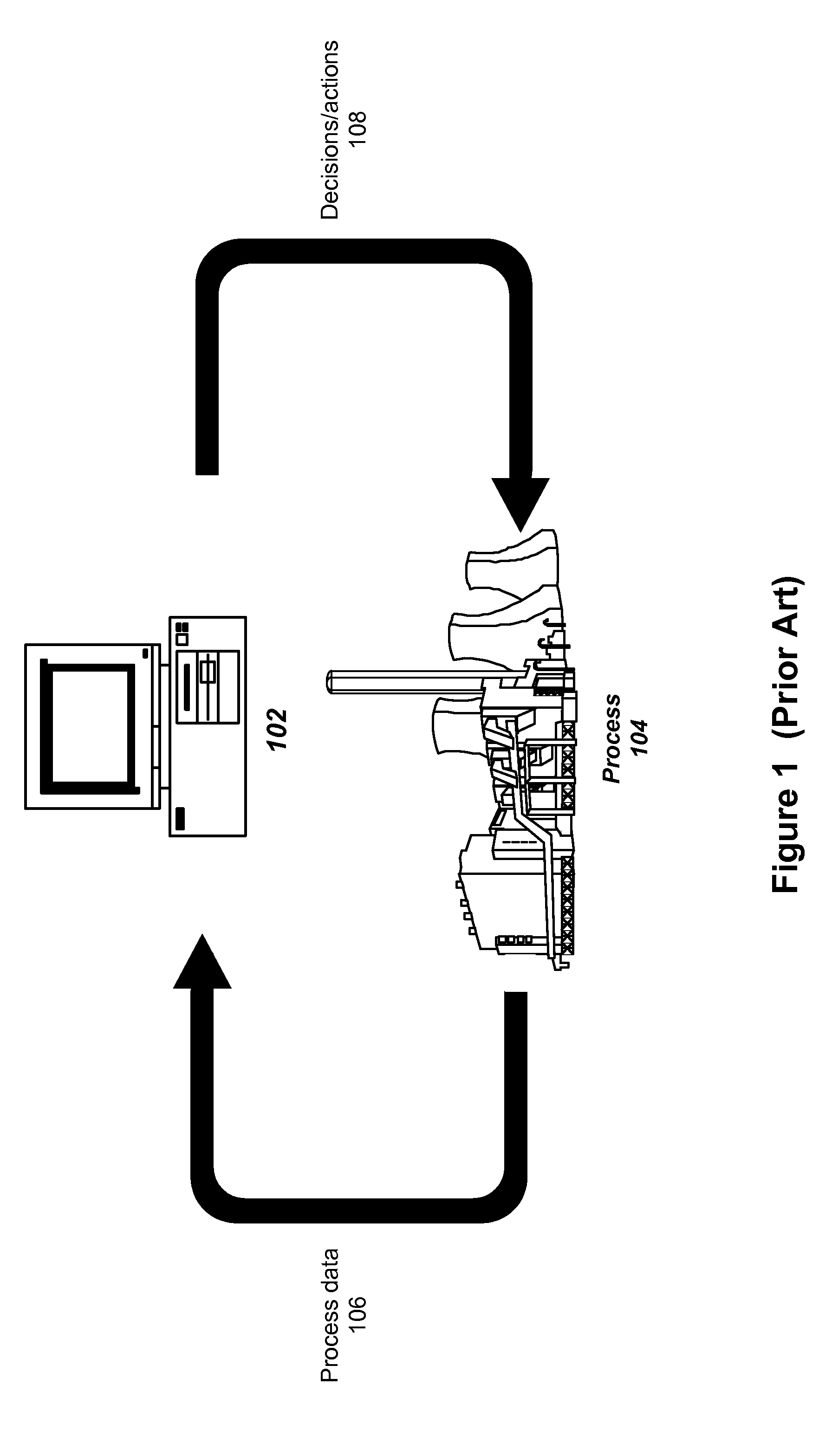

Kiln control and upset recovery using a model predictive control in series with forward chaining

InactiveUS7149590B2Simulator controlComputation using non-denominational number representationPredictive controllerControl theory

A method for controlling a non-linear process includes the steps of first providing a controller that is operable to receive inputs representing measured variables of the process and predicting on an output of the controller predicted control values for manipulatible variables that control the process. An expert system is provided that models the actions of an operator of the process over an operating region of the process that represents a set of rules for actions to be taken by an operator upon the occurrence of predetermined conditions in the operation of the process. The operation of the controller is modified with the expert system when one of the predetermined conditions exists.

Owner:ROCKWELL AUTOMATION TECH

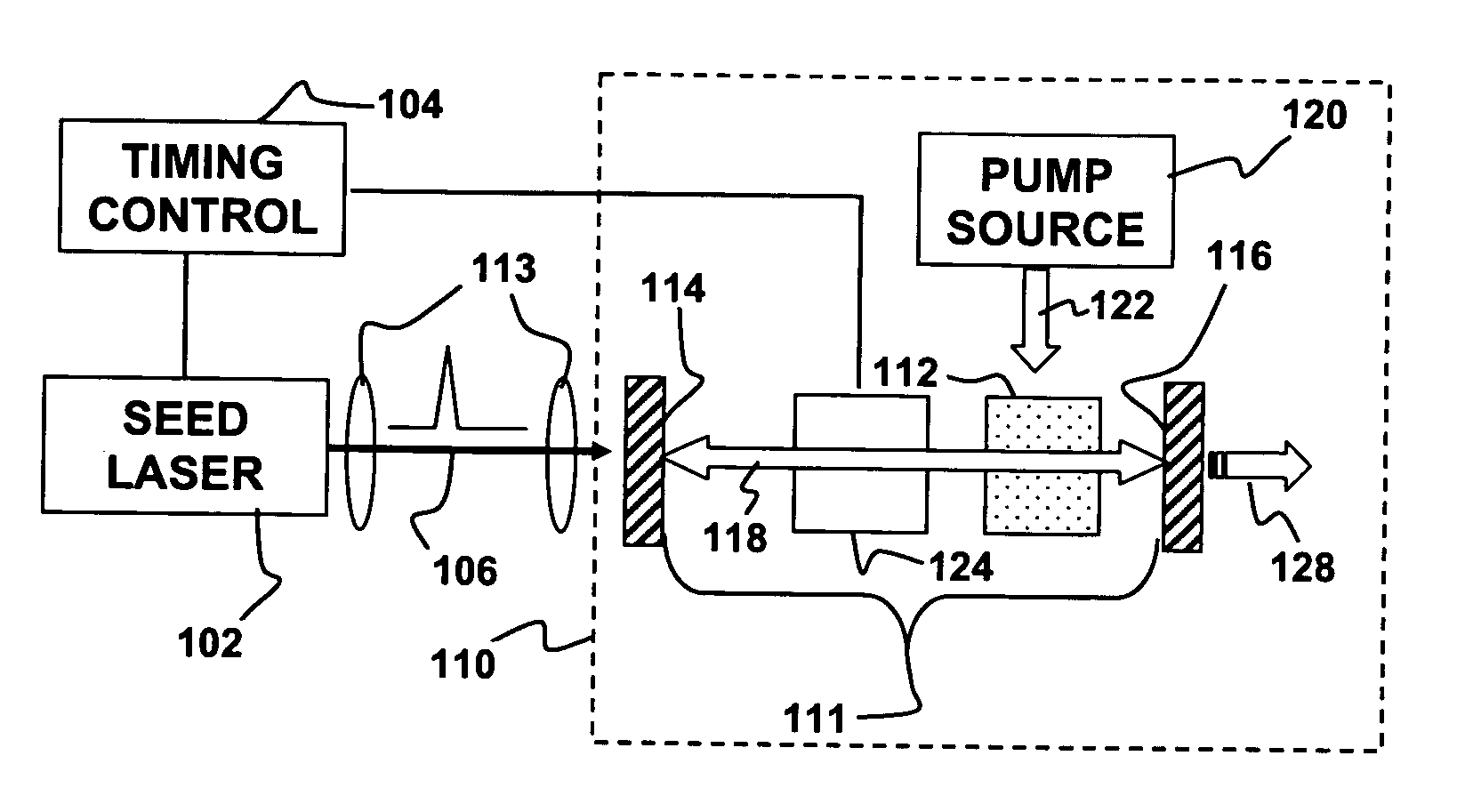

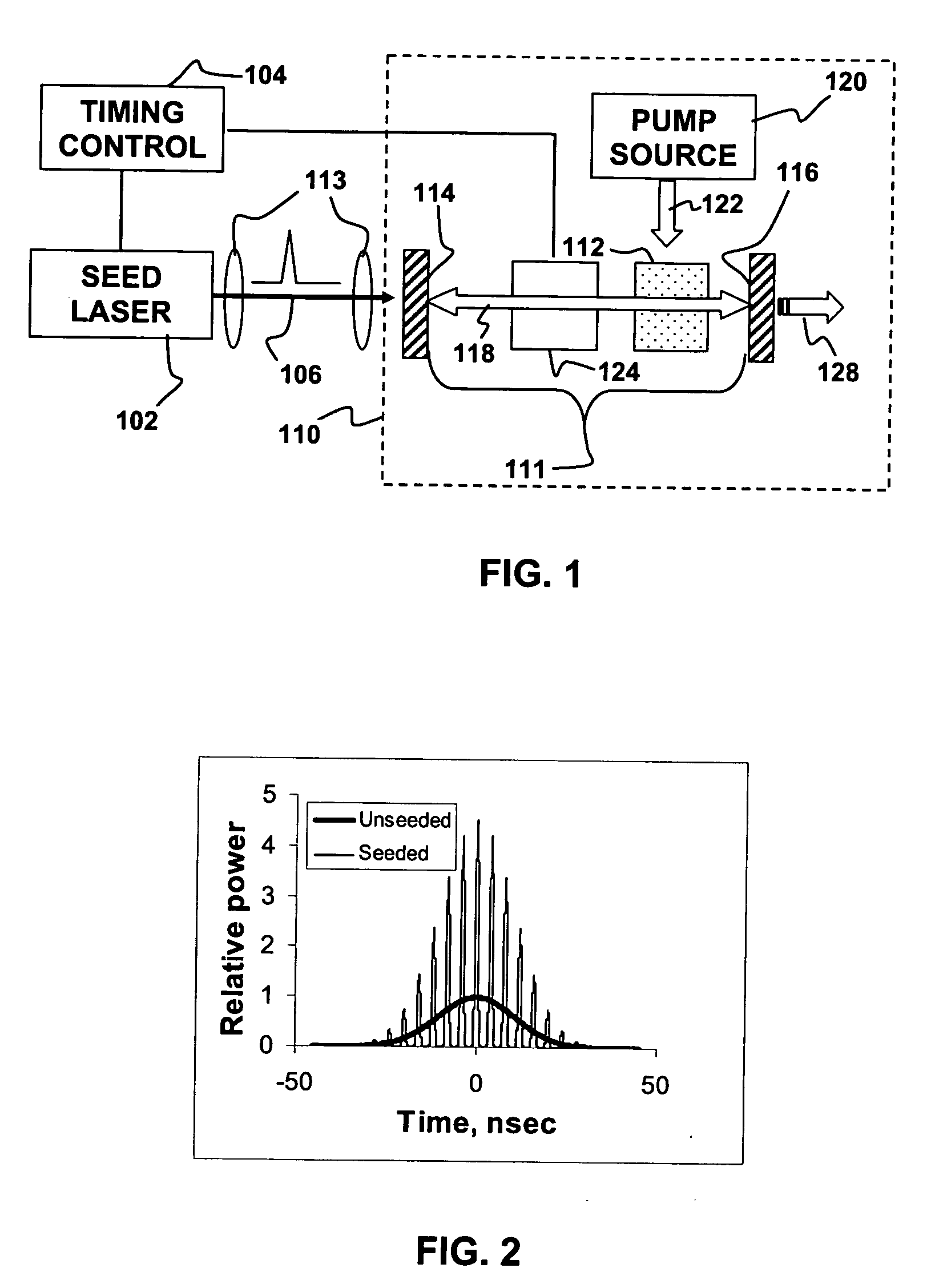

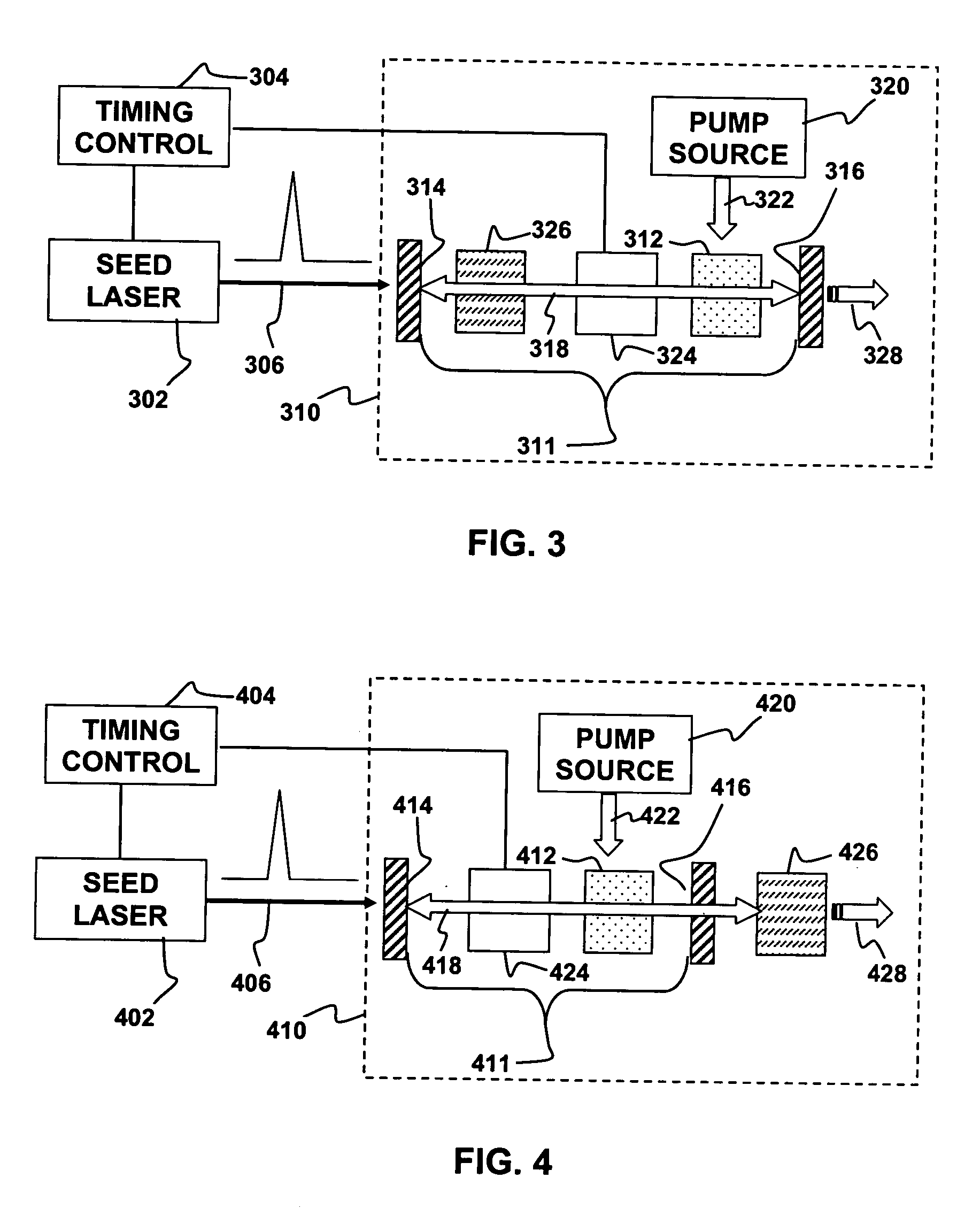

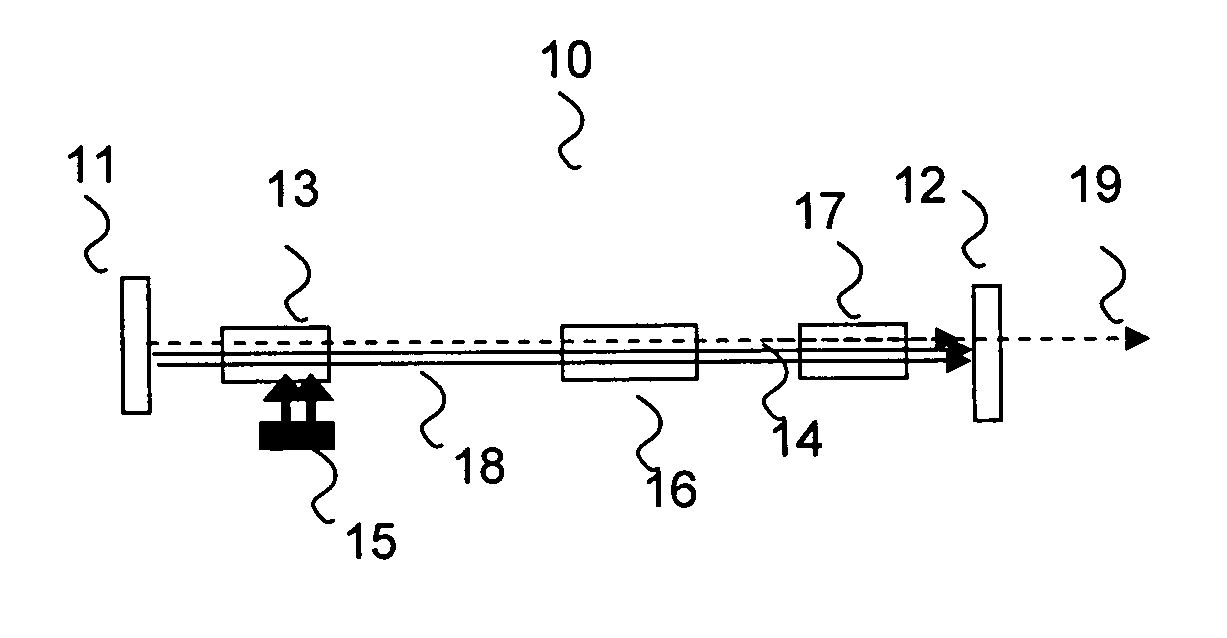

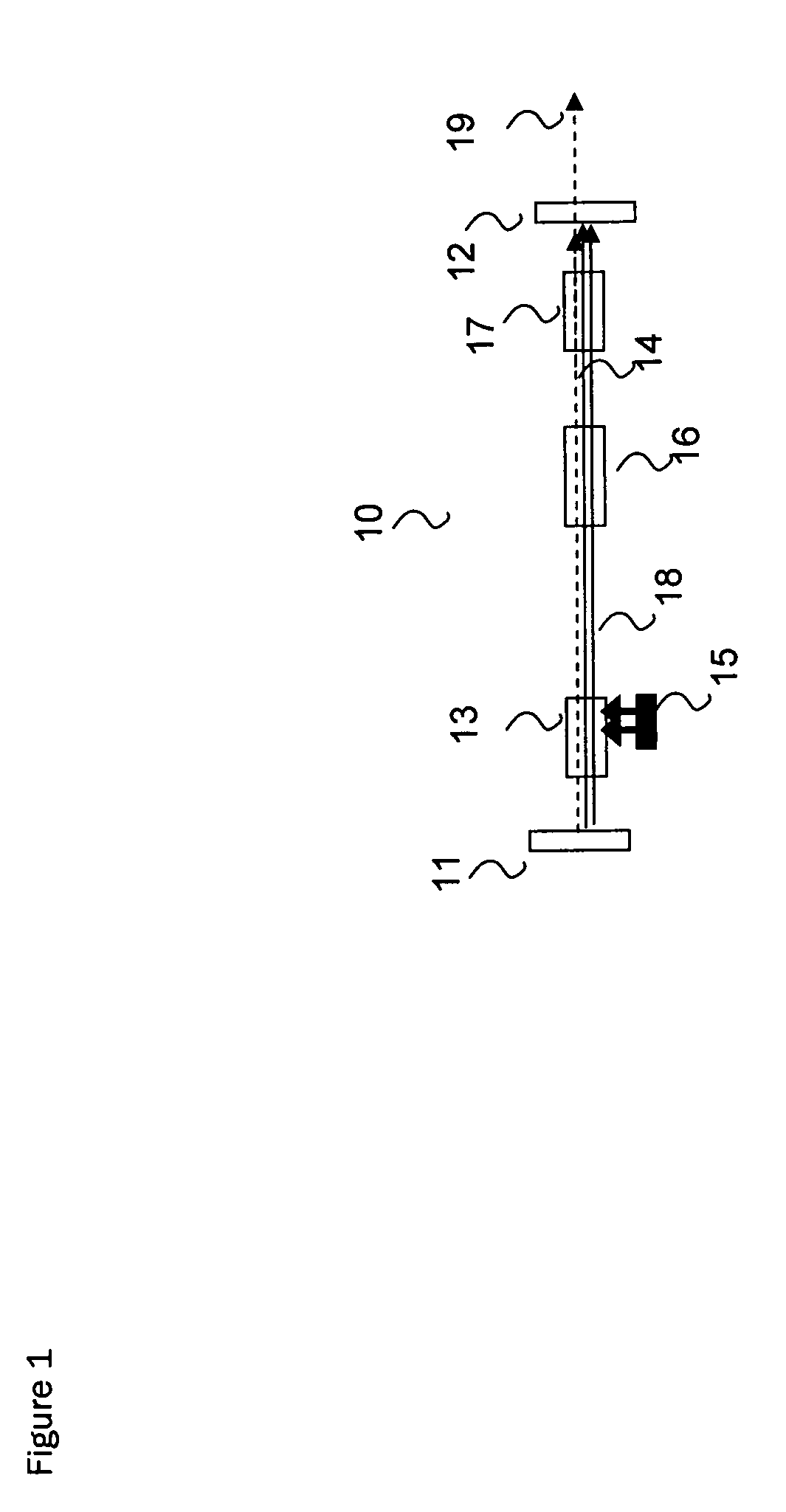

Injection seeding of frequency-converted Q-switched laser

ActiveUS20060268950A1Efficient non-linear frequency conversionHigh peak powerLaser detailsPhysicsLinear process

A non-linearly frequency-converted Q-switched laser is “injection seeded” with short pulses from another laser, called a seed laser. Radiation produced by the Q-switched laser is frequency converted in a non-linear process. The injection seeding can enhance peak power and frequency conversion efficiency while reducing damage to a non-linear medium used to frequency convert radiation generated by the Q-switched laser.

Owner:LUMENTUM OPERATIONS LLC

Kiln control and upset recovery using a model predictive control in series with forward chaining

InactiveUS20050154477A1Simulator controlComputation using non-denominational number representationLinear processPredictive controller

A method for controlling a non-linear process includes the steps of first providing a controller that is operable to receive inputs representing measured variables of the process and predicting on an output of the controller predicted control values for manipulatible variables that control the process. An expert system is provided that models the actions of an operator of the process over an operating region of the process that represents a set of rules for actions to be taken by an operator upon the occurrence of predetermined conditions in the operation of the process. The operation of the controller is modified with the expert system when one of the predetermined conditions exists.

Owner:ROCKWELL AUTOMATION TECH

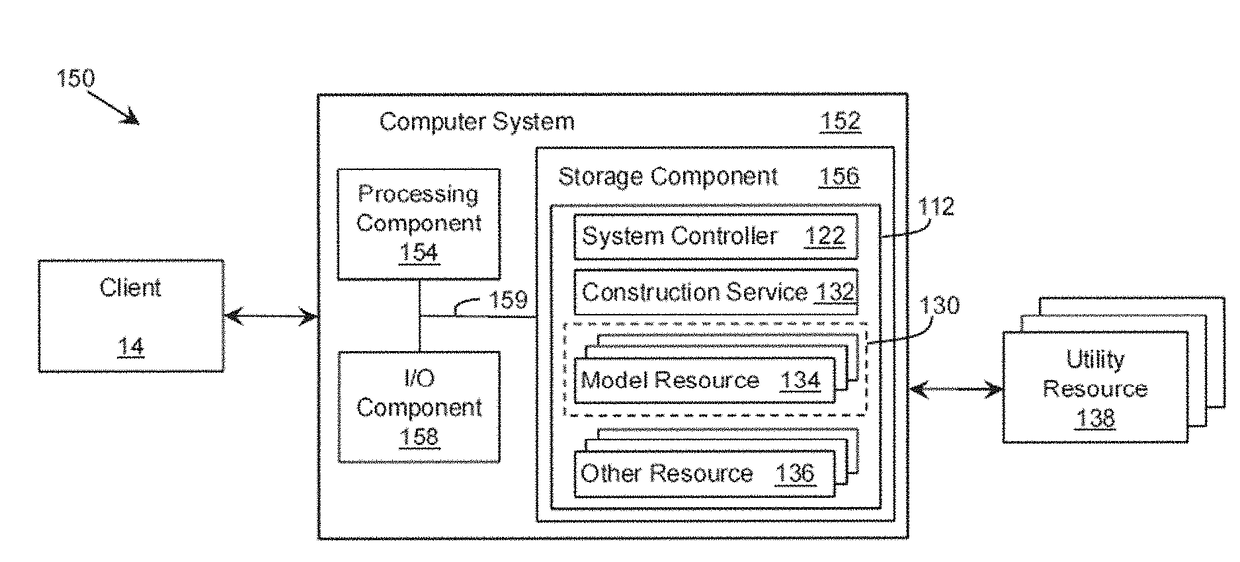

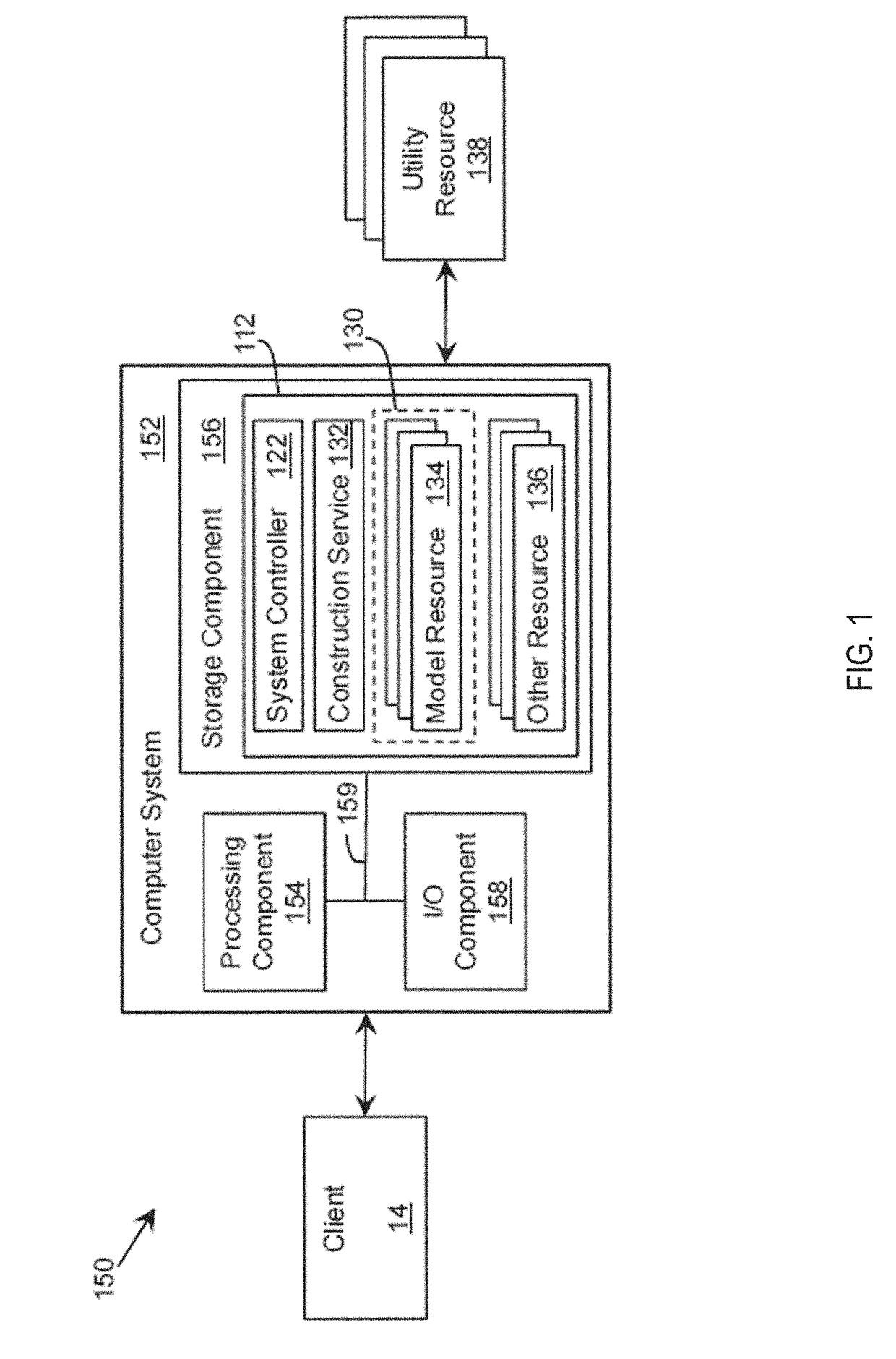

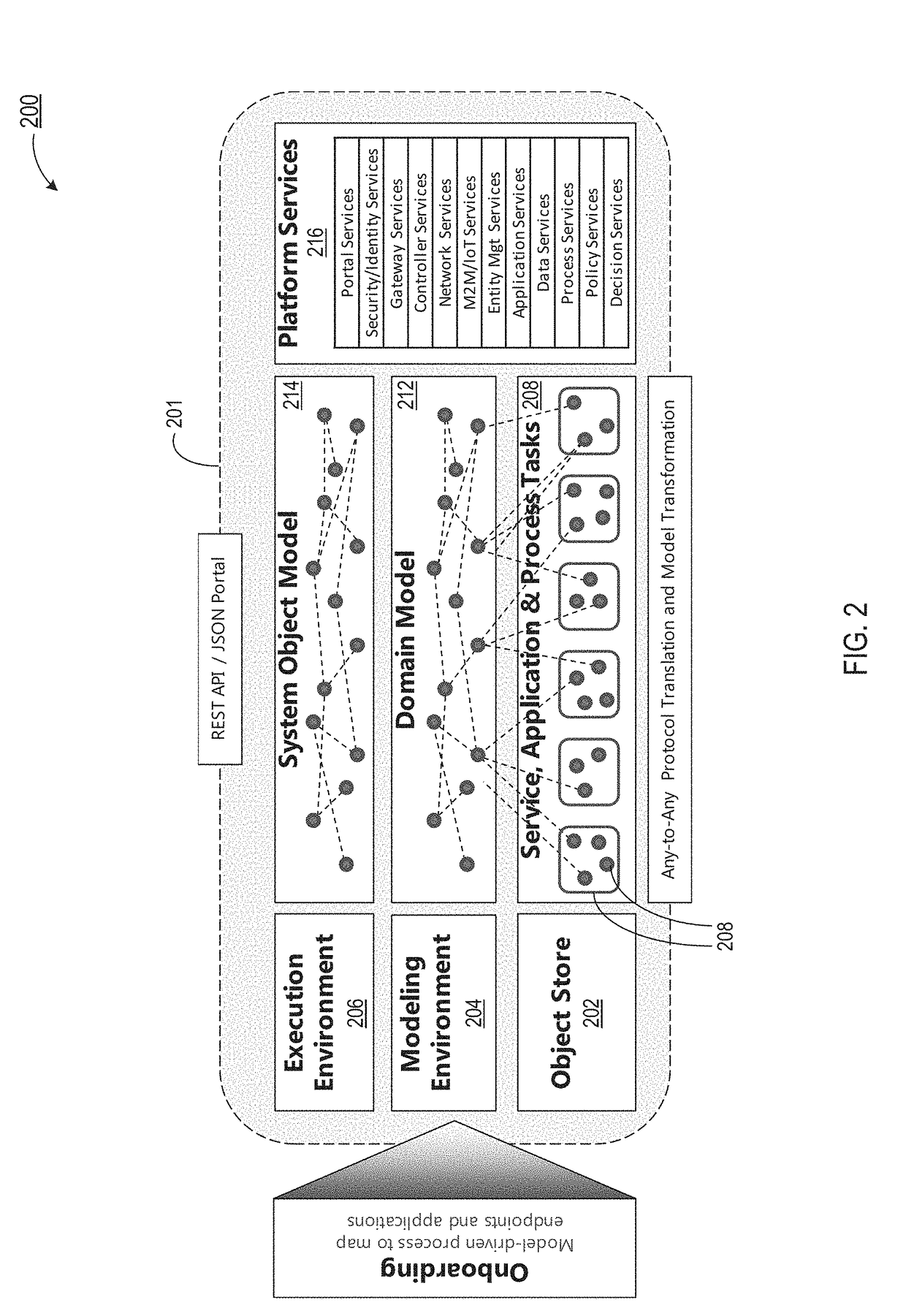

Systems and methods for domain-driven design and execution of modular and dynamic services, applications and processes

ActiveUS20170323089A1Object oriented databasesSoftware maintainance/managementObject basedModularity

A context of one or more interactions is determined. Base objects are transformed into interpreted objects by interpreting the base objects based on evaluation of the context, and by resolving references of the base objects relative to domain model types and concepts, each of the base objects modeled using a same declarative modeling language, the same declarative modeling language enabling transitions between the interpreted objects, at least one of the interpreted objects including at least one post-condition providing hooks for transition policies which allow the at least one of the interpreted objects to be logically chained in a non-linear process. Transitioning between at least two of the interpreted objects by chaining the at least two interpreted objects based on a particular post-condition of a particular interpreted object to create at least a portion of a particular non-linear process. At least a portion of the particular non-linear process is executed.

Owner:ENTERPRISEWEB

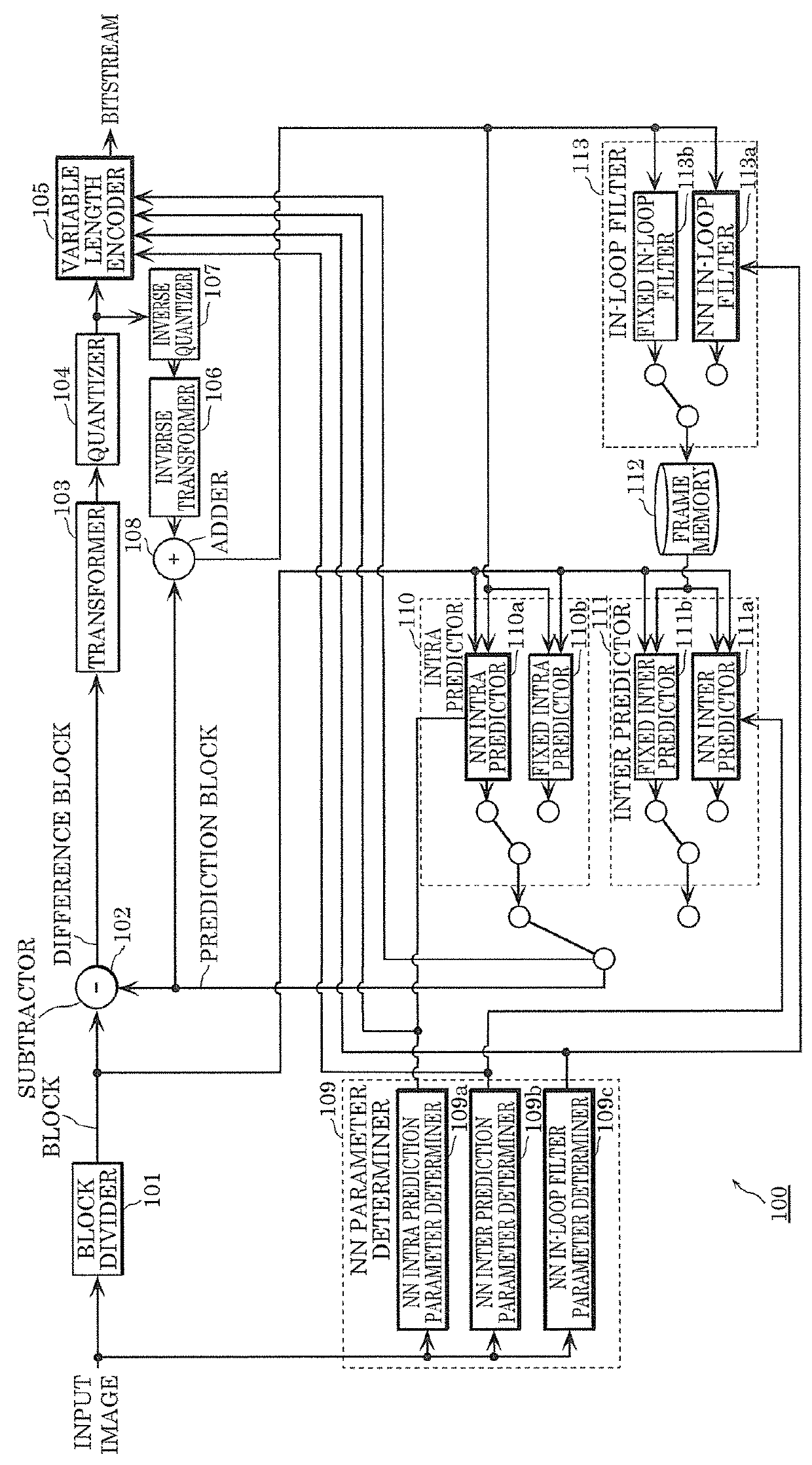

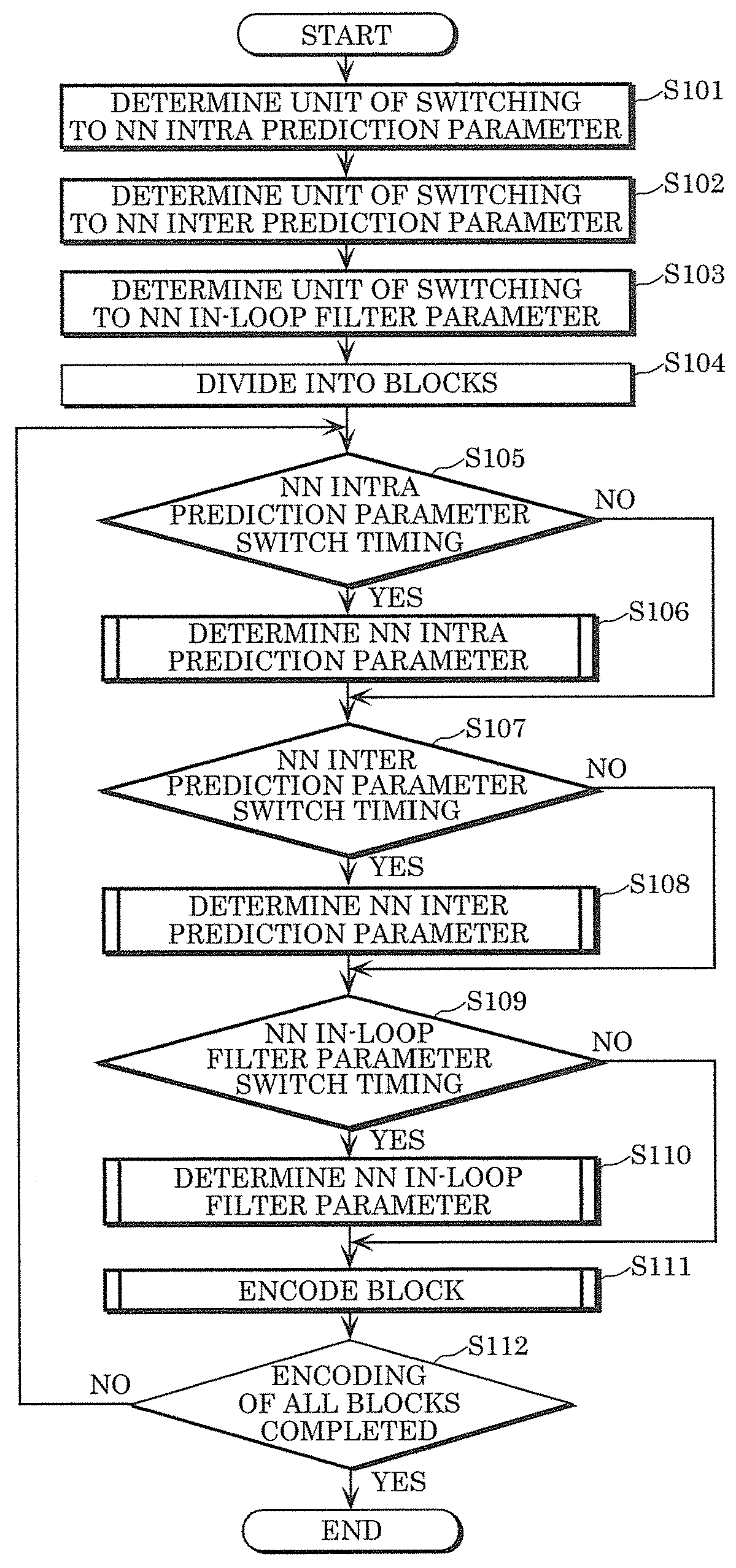

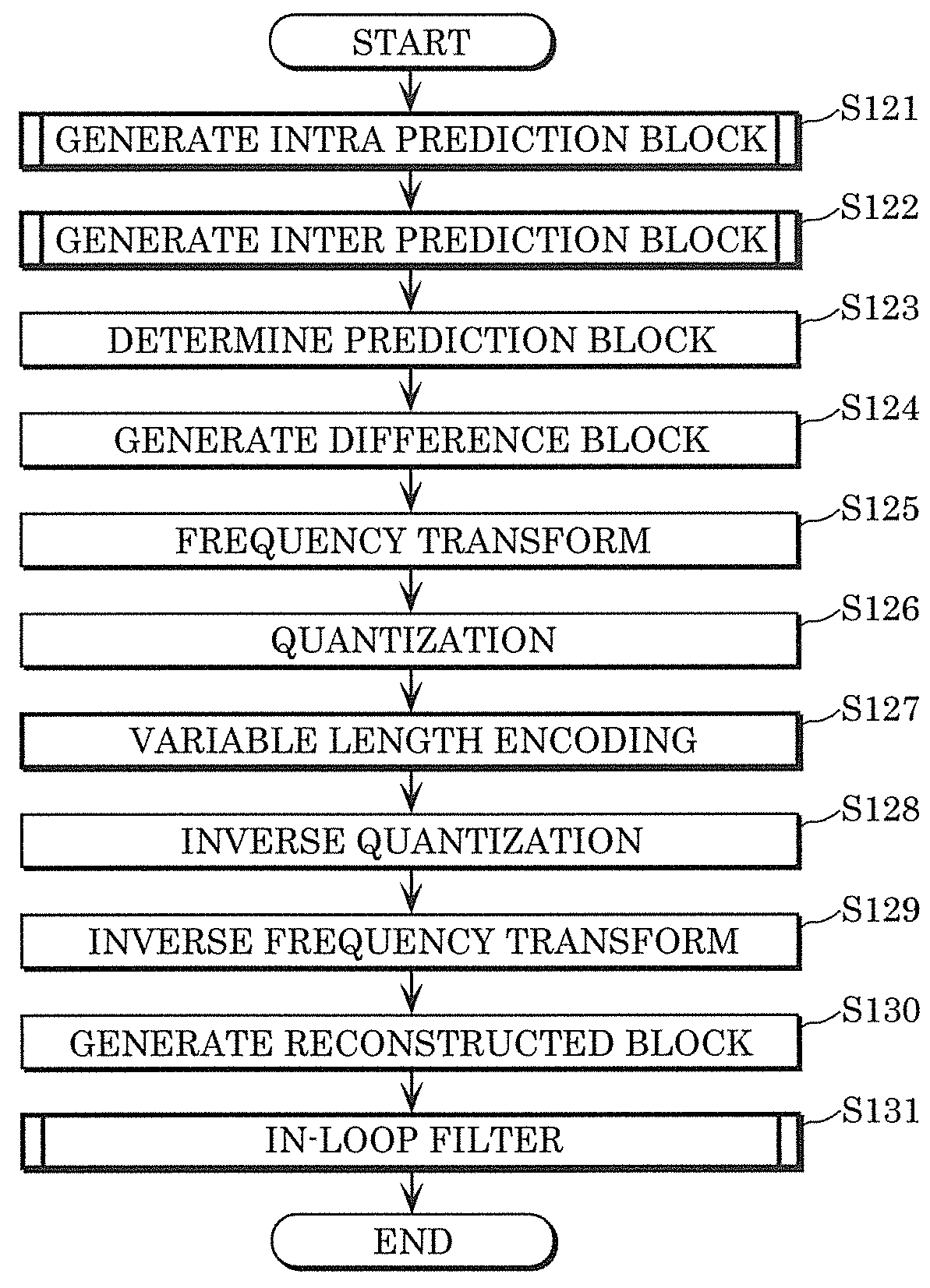

Image encoding method, image decoding method, image encoding apparatus, and image decoding apparatus

ActiveUS20180184123A1Efficient codingEffective imagingImage codingDigital video signal modificationDecoding methodsPattern recognition

The image encoding method includes: encoding an image including a block by performing, in at least one of intra prediction, inter prediction, and an in-loop filter, a non-linear process by which the input-output relationship becomes non-linear; and encoding an operation parameter of a non-linear filter to be used in the non-linear process.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

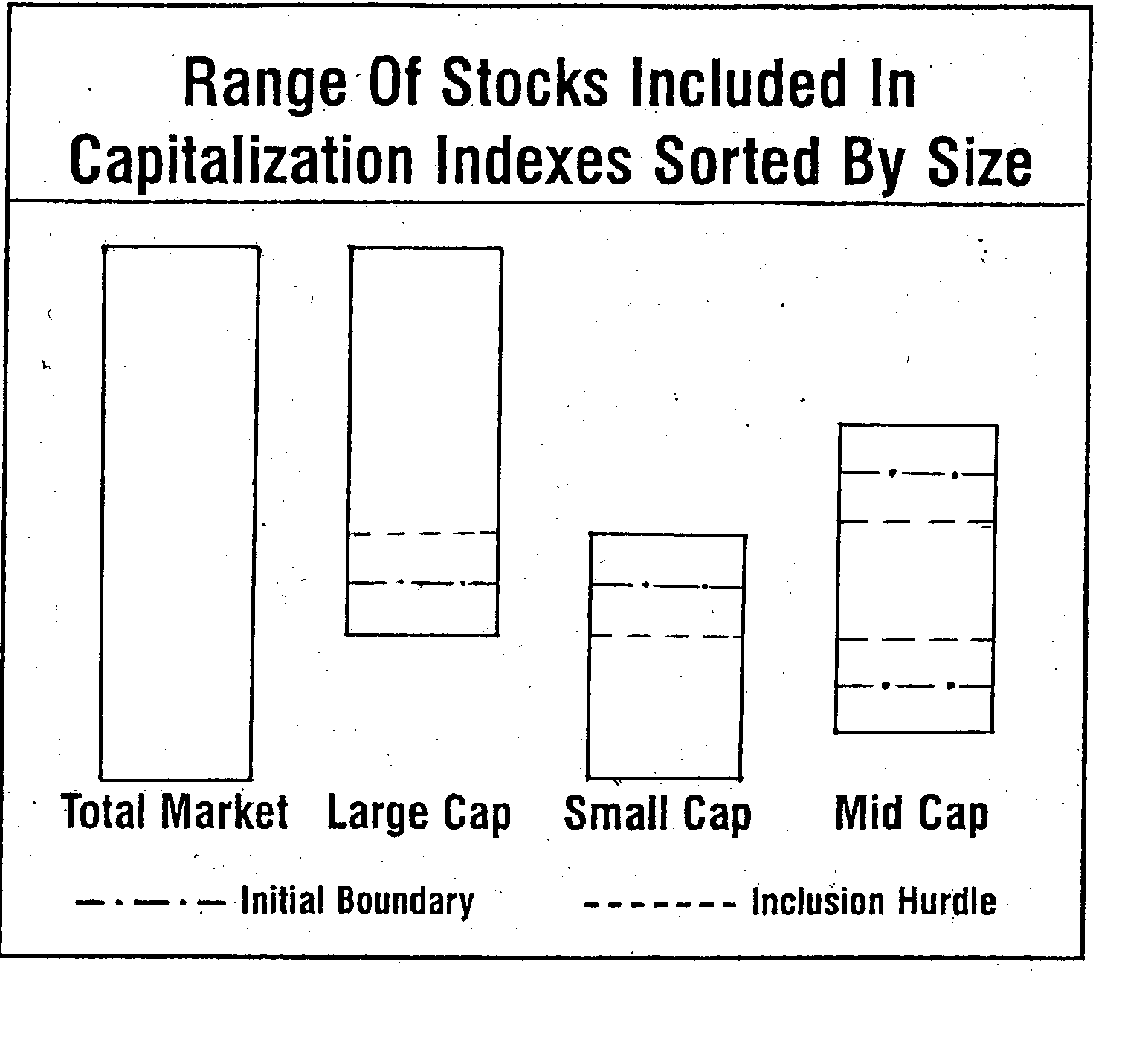

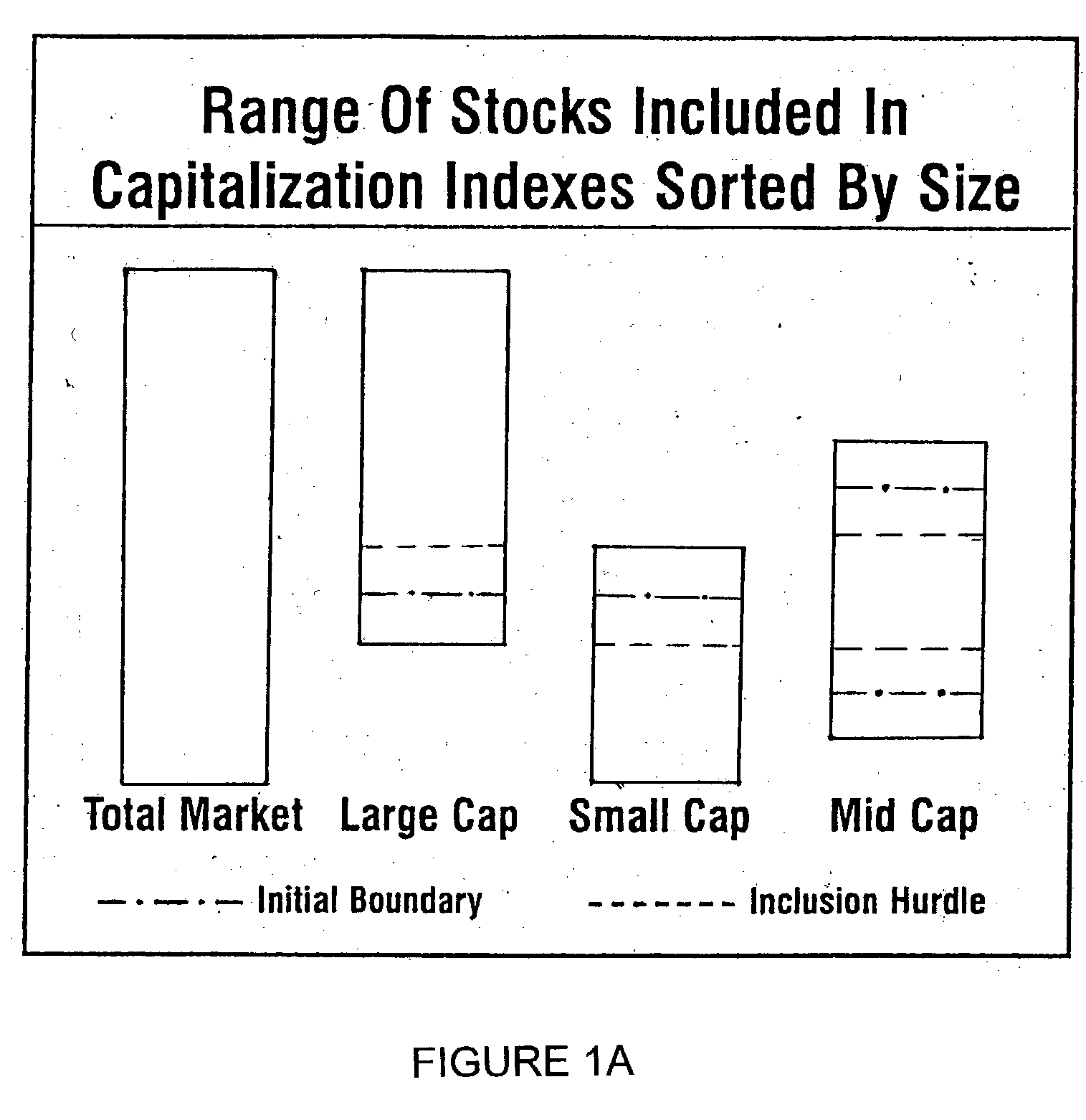

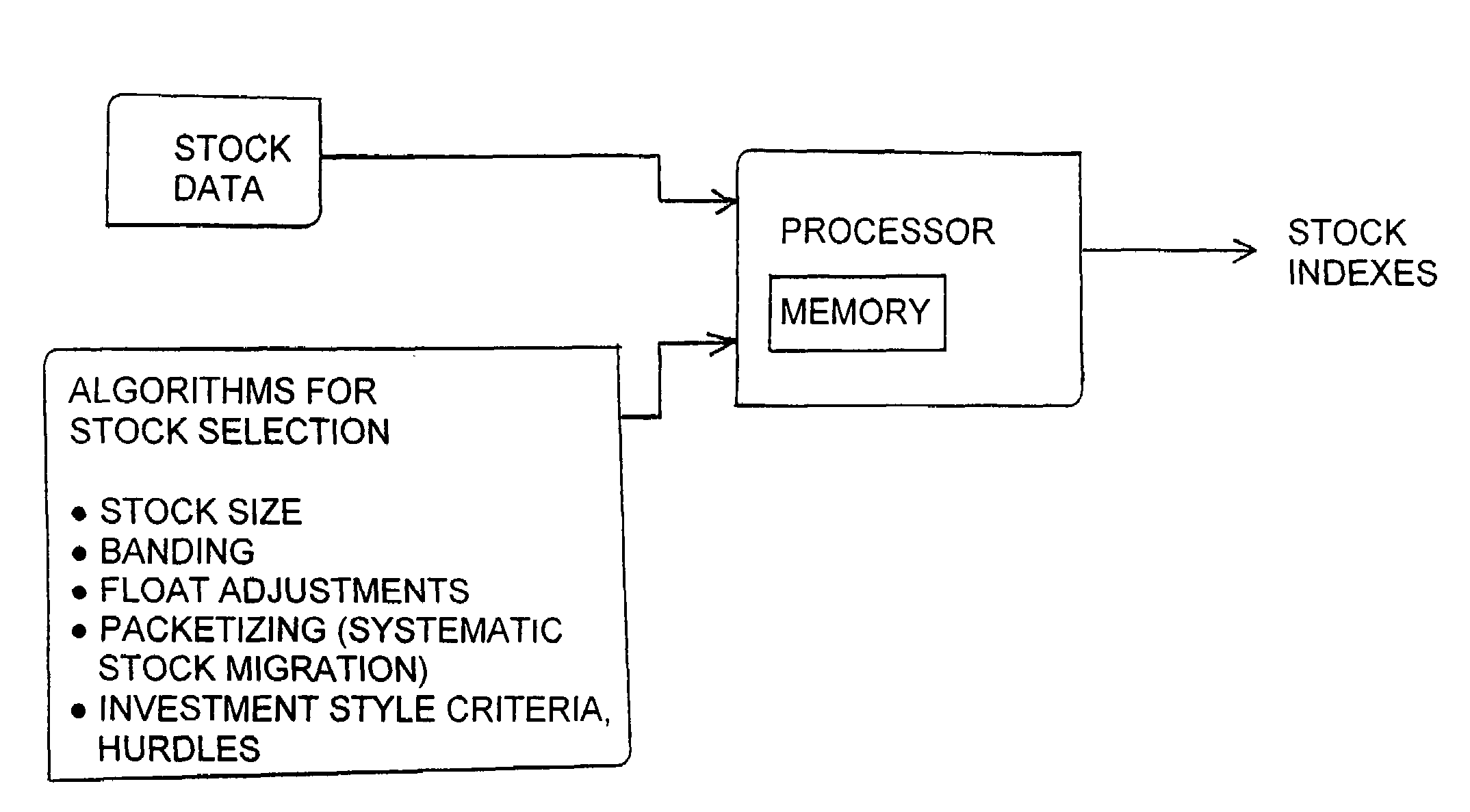

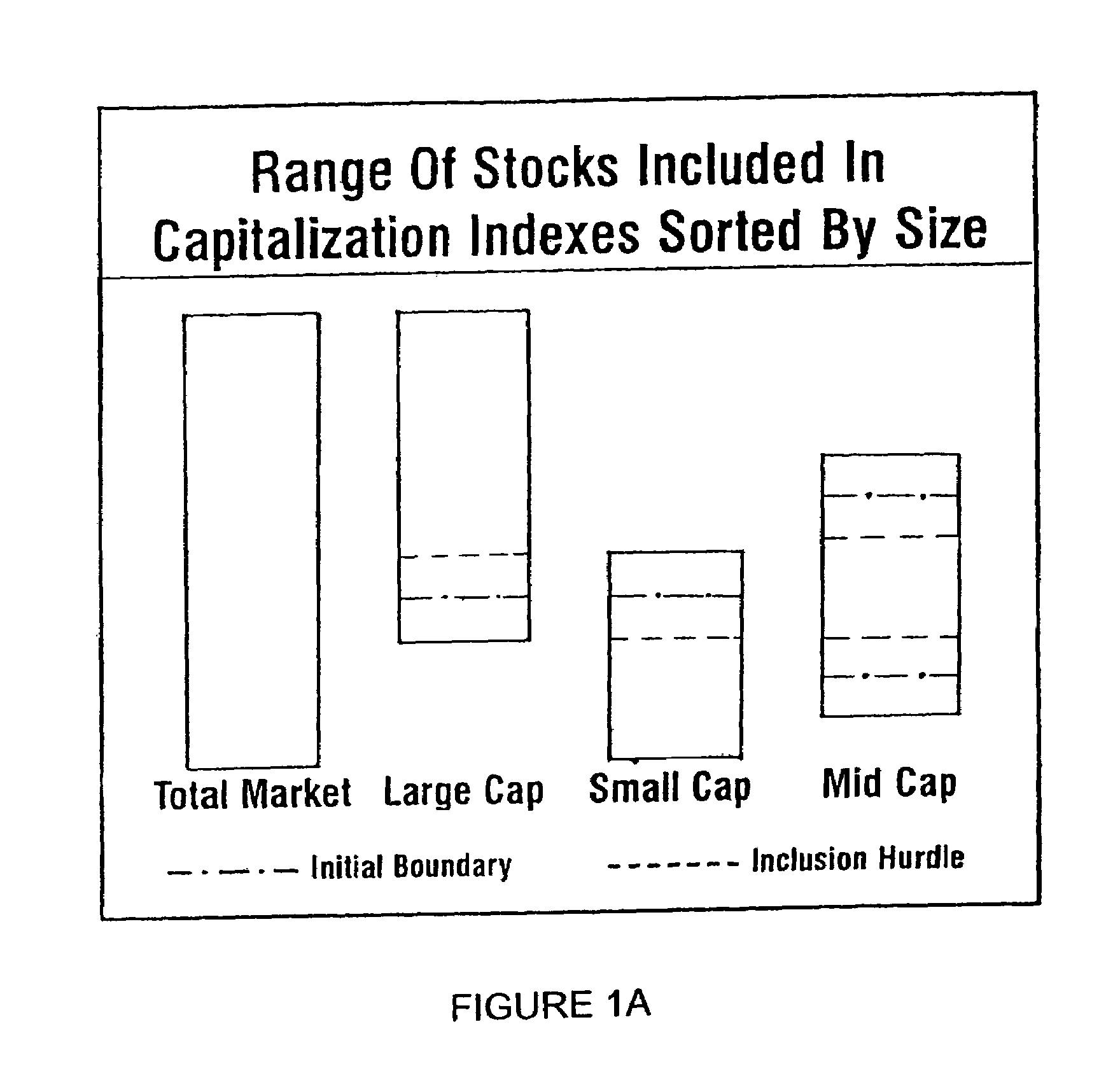

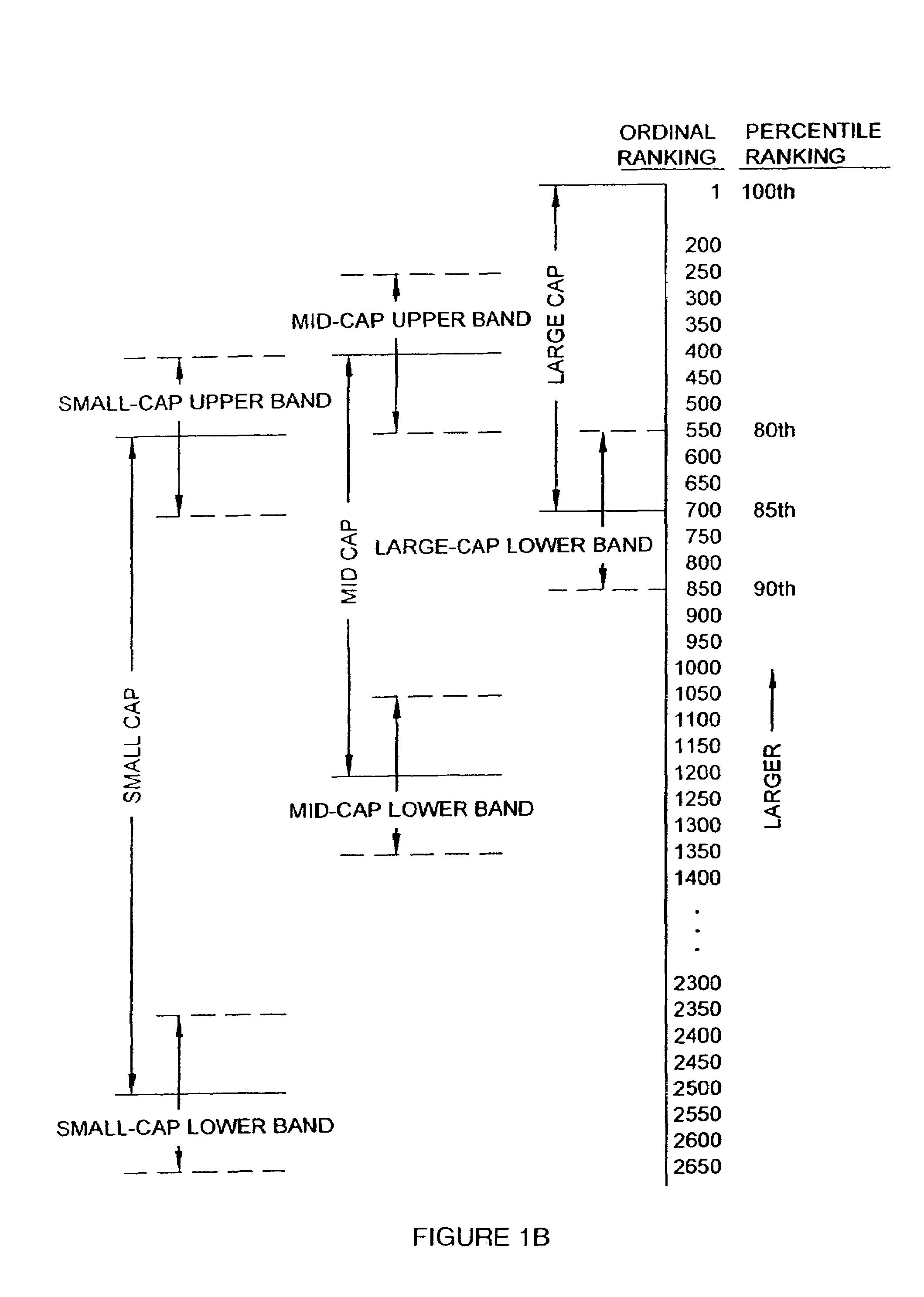

Method of constructing a stock index

Computer-implemented methods of creating and maintaining stock indexes are provided. For a stock index of a particular size, a band is defined around the upper and / or lower limits of the stock index. To be added to, or dropped from, a particular stock index, the stocks must fall outside of the bands for that particular stock index size. Stock migration is controlled using a systematic stock migration process so that stocks are gradually added and deleted from an index. Stock investment style is determined in a multi-dimensional process, instead of a linear process. Furthermore, the number of stocks in the stock index need not be a fixed value, but may depend upon how many stocks meet predefined criteria at any given point in time.

Owner:SIEMENS AG +1

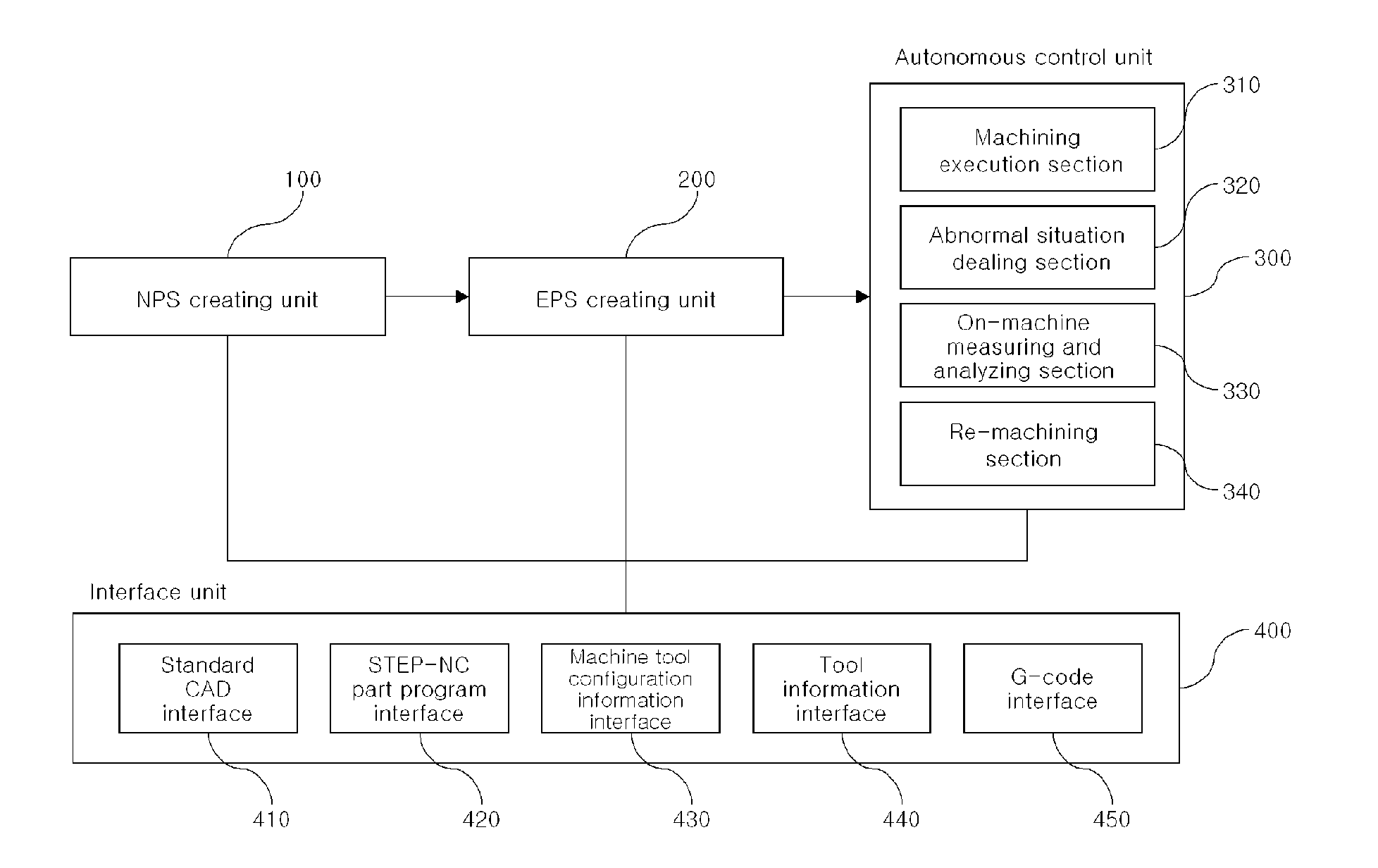

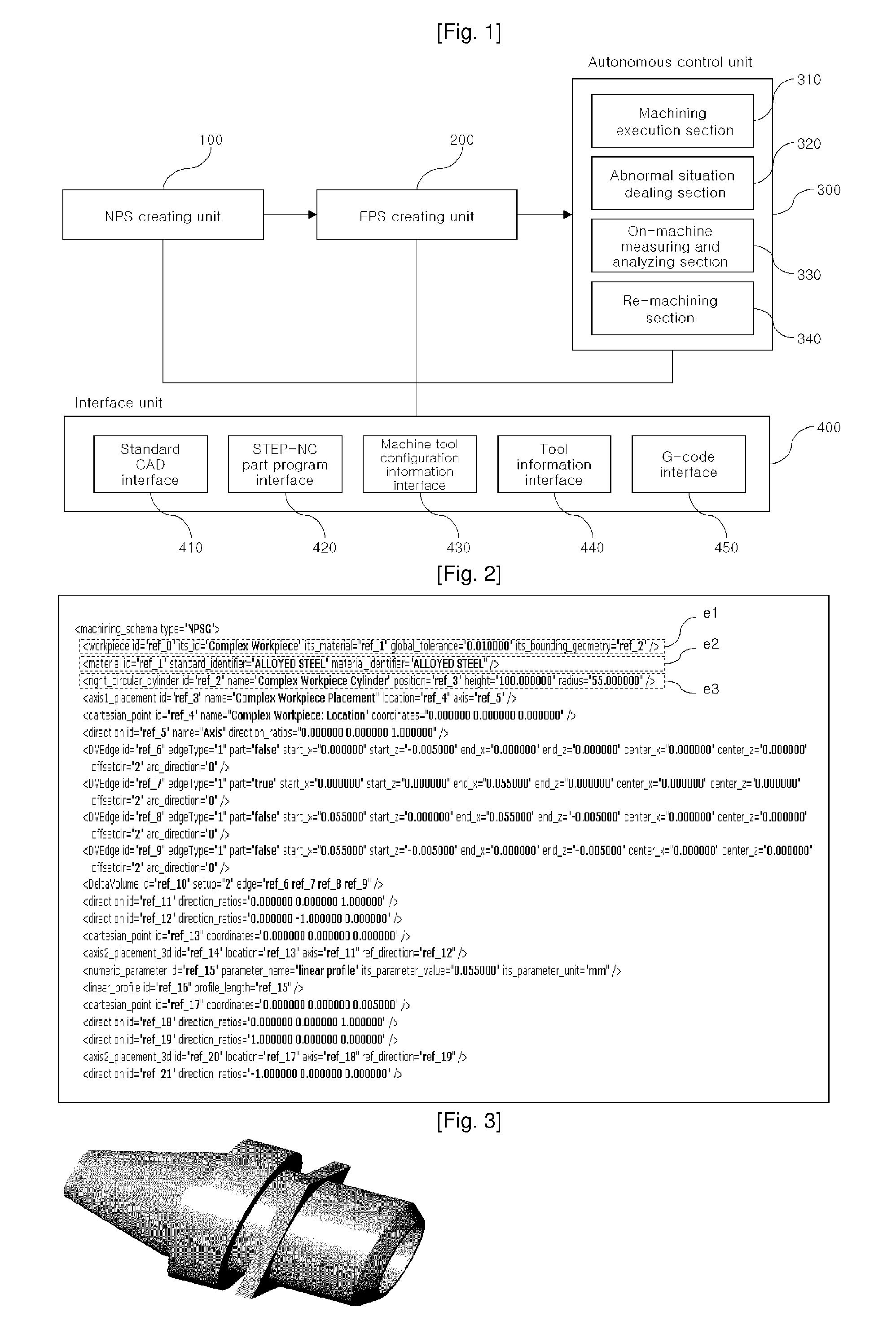

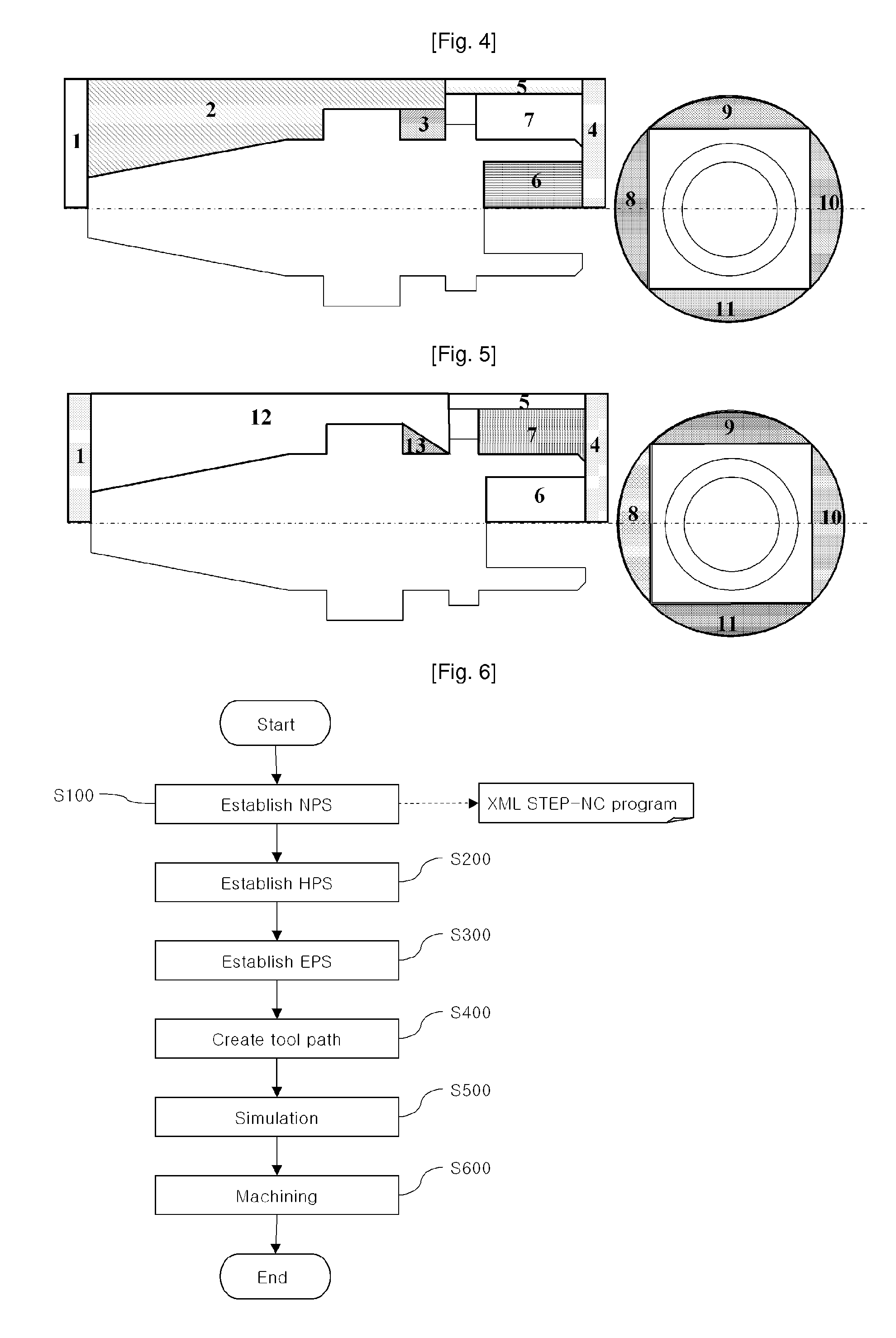

Method of Non-Linear Process Planning and Internet-Based Step-Nc System Using the Same

InactiveUS20080281463A1Decrease productivityEasy constructionProgramme controlSpecial data processing applicationsSTEP-NCAlternative process

The present invention relates to a method of creating a non-linear process plan and an Internet-based STEP-NC system using the same, and more particularly, to a method of creating a non-linear process plan, wherein the non-linear process plan including information on a variety of alternative processes and machining sequences is established in consideration of situations in the field, thereby autonomously dealing with abnormal situations while executing optimal machining, and to an Internet-based STEP-NC system, wherein a STEP-NC part program in an XML format is created based on the established process plan so that process information can be easily exchanged with other systems via the Internet. Since the present invention provide a plurality of machining alternatives to the field, and thus, allow a STEP-NC machine tool to execute machining optimized depending on field situations and to autonomously deal with abnormal situations that may occur during machining.

Owner:POSTECH ACAD IND FOUND

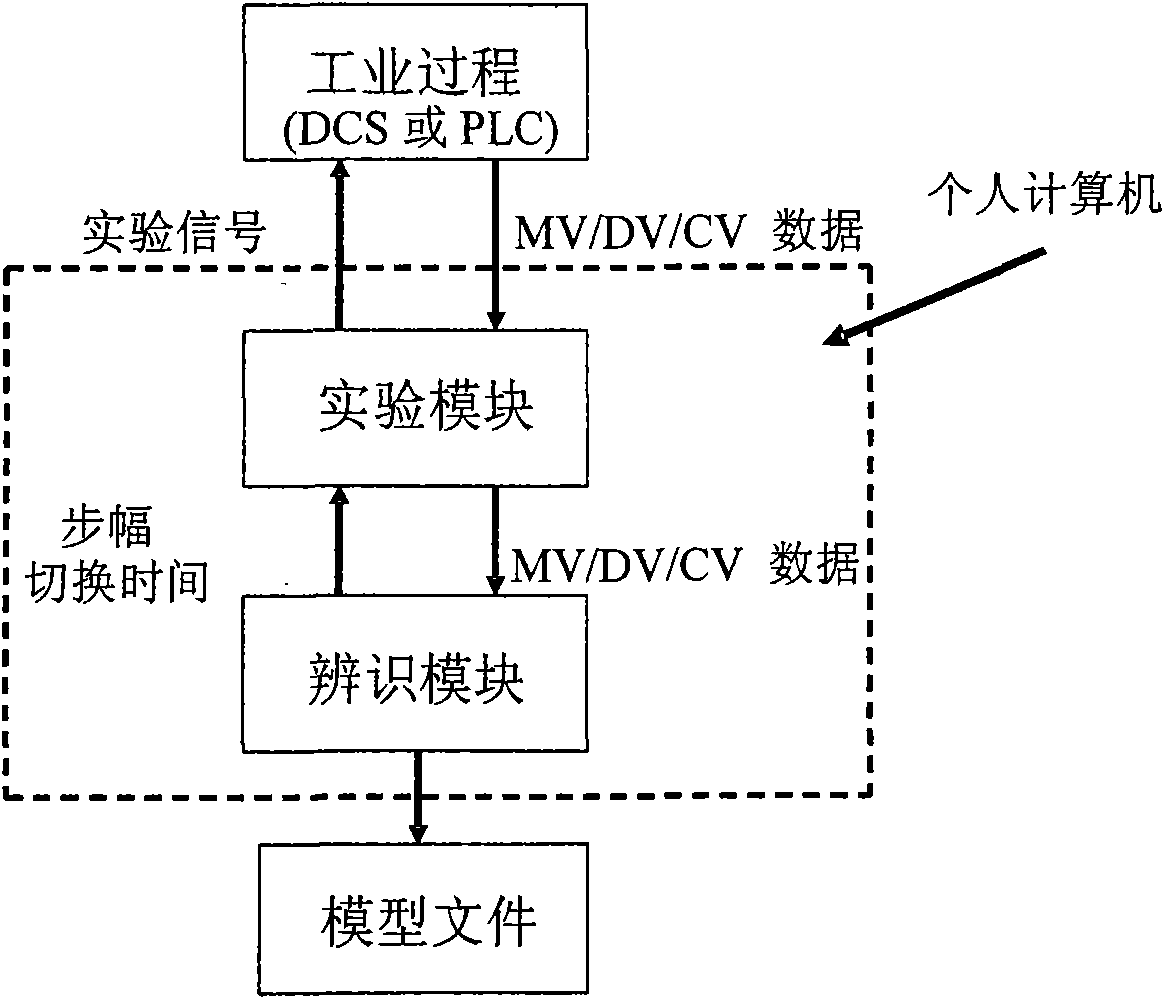

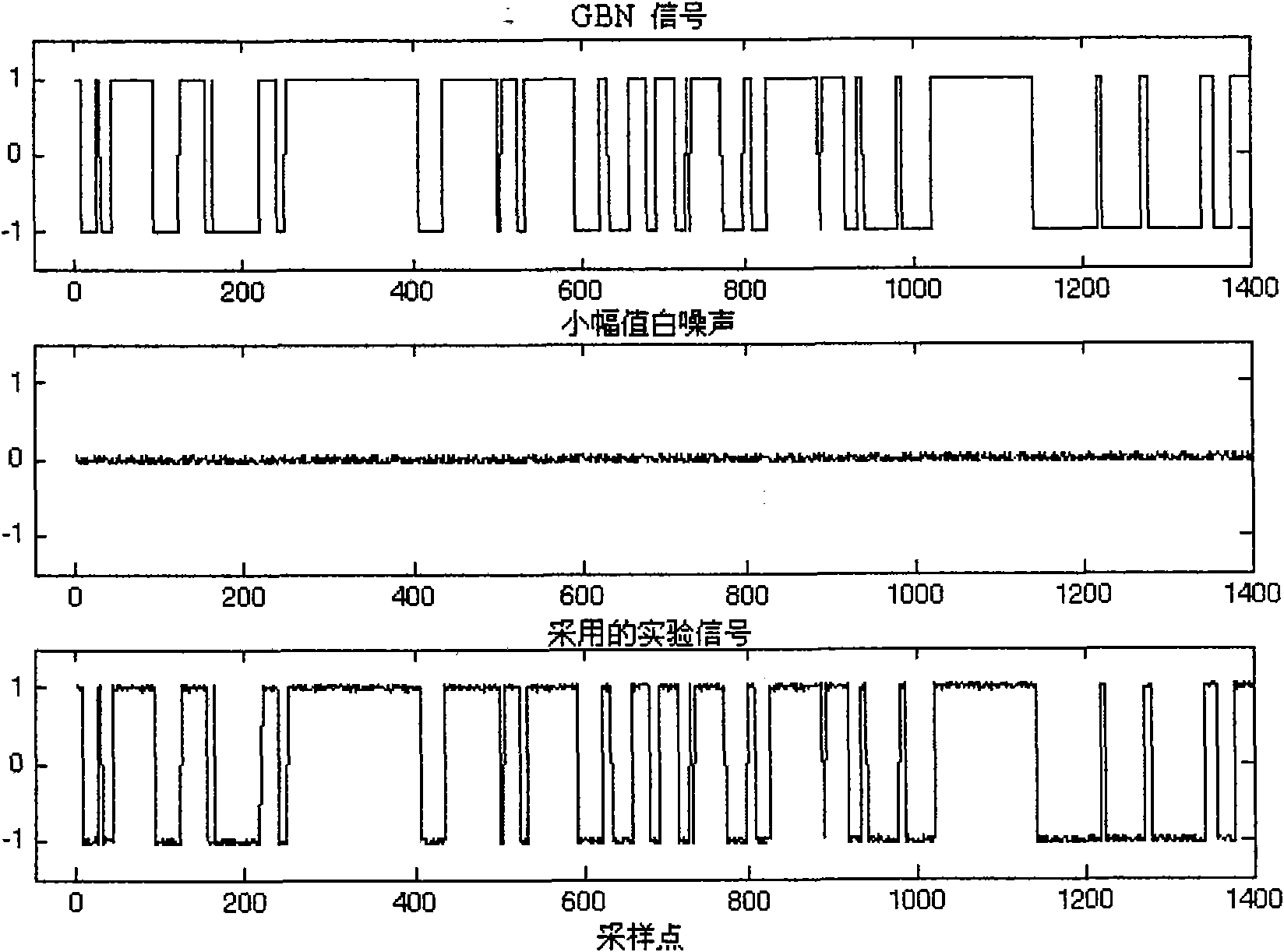

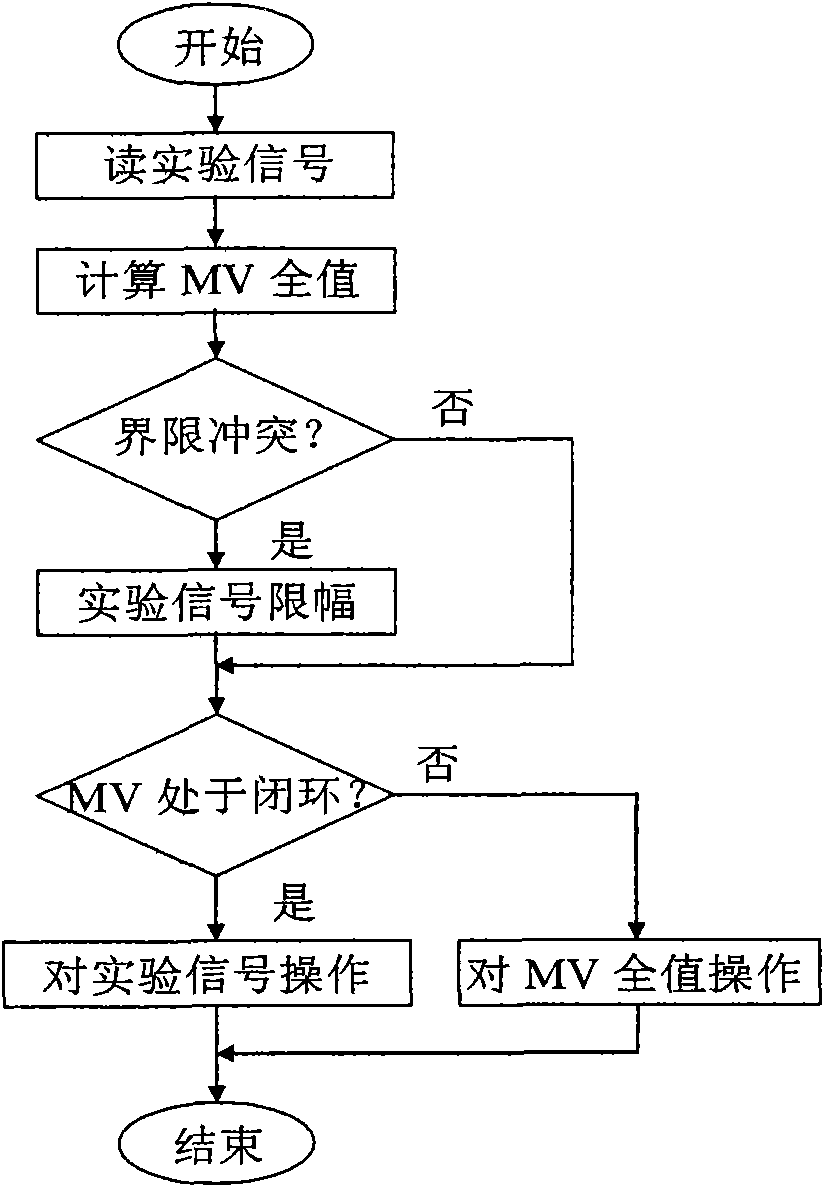

Device for identifying non-linear process dynamic model

ActiveCN101587328AOvercome limitationsSatisfied with the control effectAdaptive controlDynamic modelsPredictive controller

The invention relates to a device for identifying a non-linear process dynamic model, which comprises an experimental module and an identifying module. The experimental module is connected with a non-linear industrial process through DCS or PLC or other control machines and is connected with the identifying module. The experimental module generates an experimental signal and automatically carries out an experiment; and the identifying module uses the current process experimental data input by the experimental module to automatically identify the non-linear process dynamic model to check the quality of the model and send an adjusting signal according to the quality of the model, and the adjusting signal is input into the experimental module to adjust the current experimental parameter. The device for identifying the non-linear process dynamic model can be used for carrying out an identifying experiment and model identification for the non-linear industrial process, wherein the non-linear industrial process can be continuous, intermittent or feeding intermittent. An obtained non-linear process dynamic model can be used for model predictive controllers, conventional PID (proportion, integral and differential) controllers and other advanced process controllers, and can be also used for inference models for predicting product quality and soft measuring equipment.

Owner:朱豫才

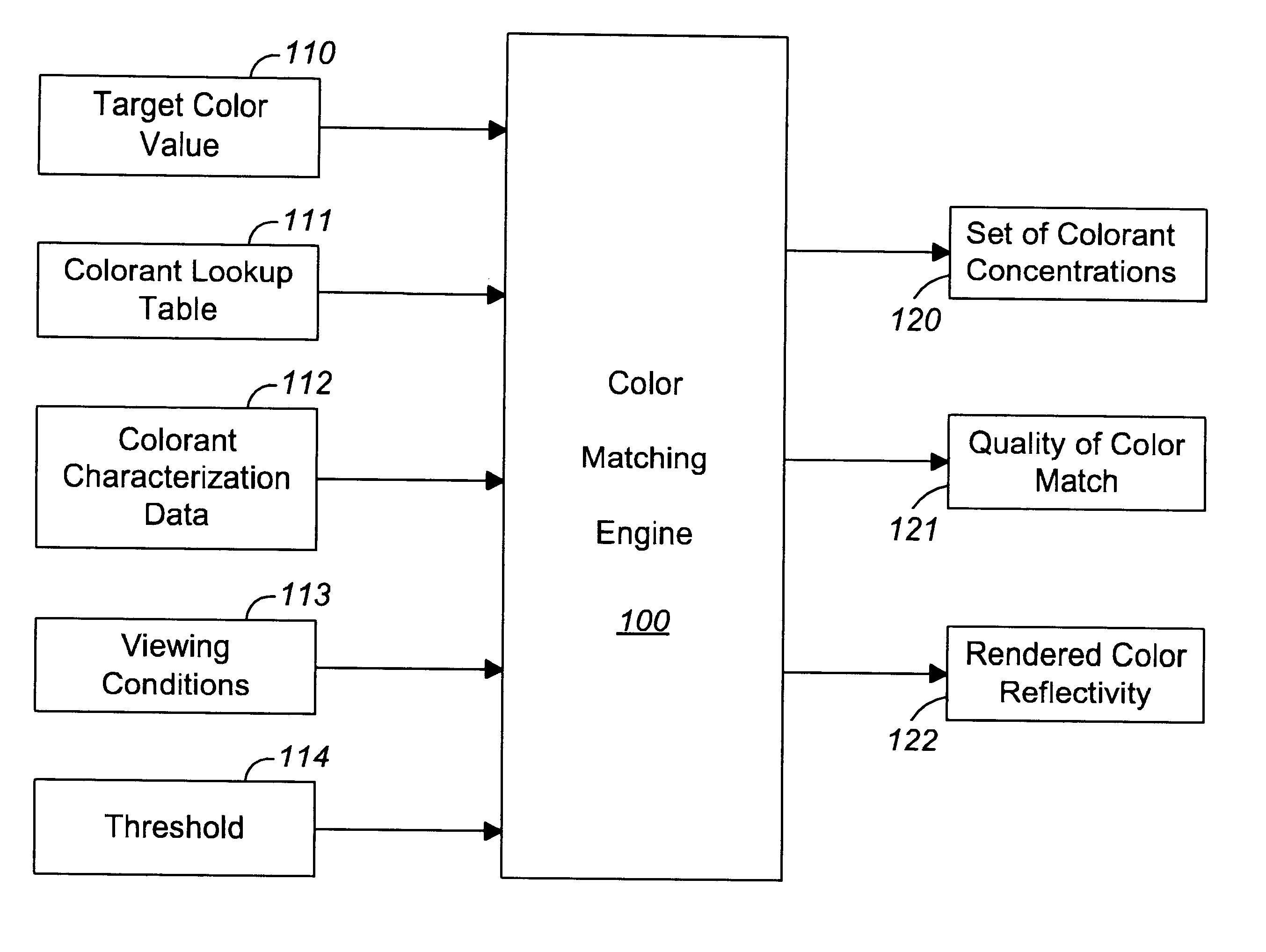

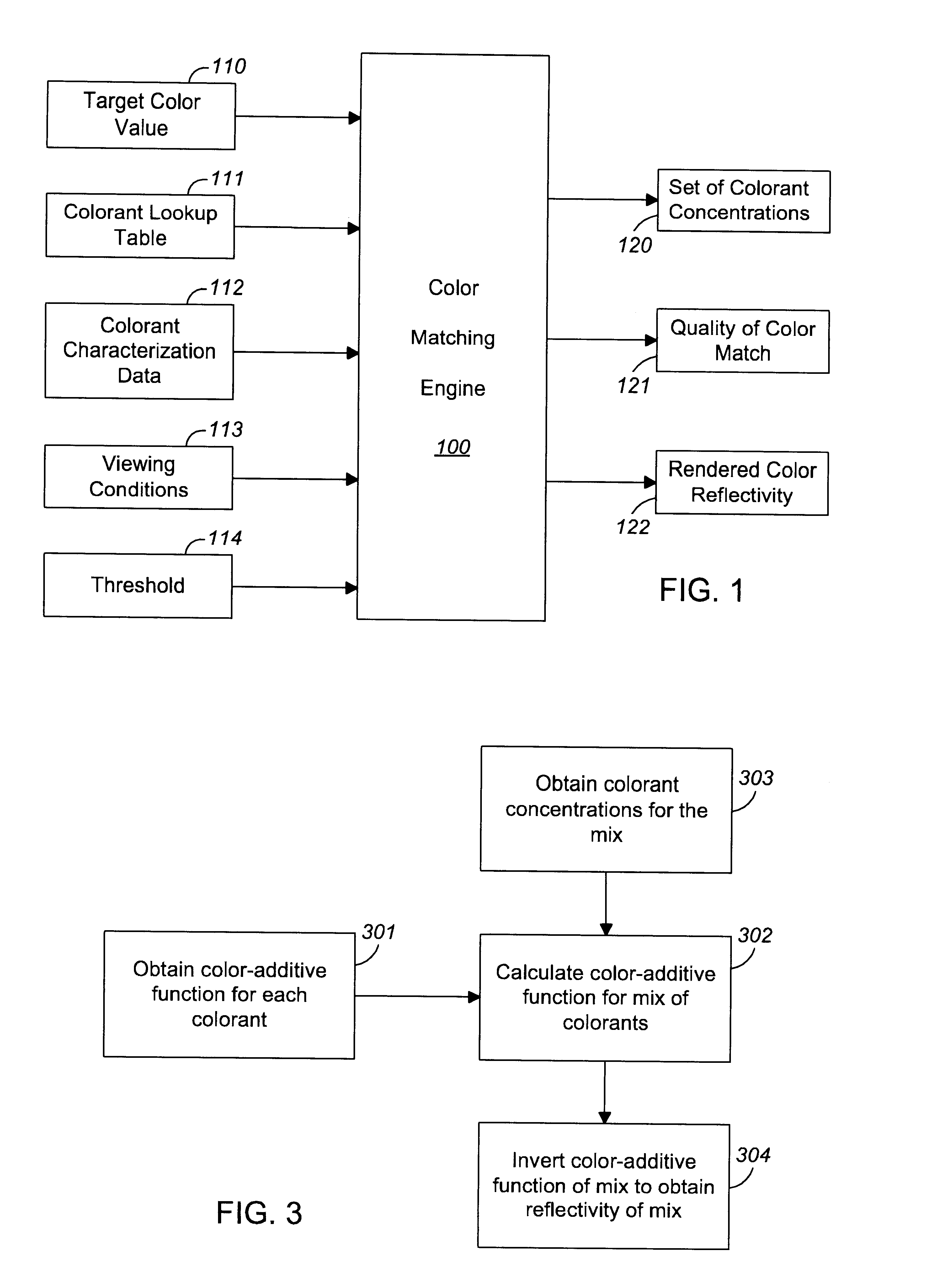

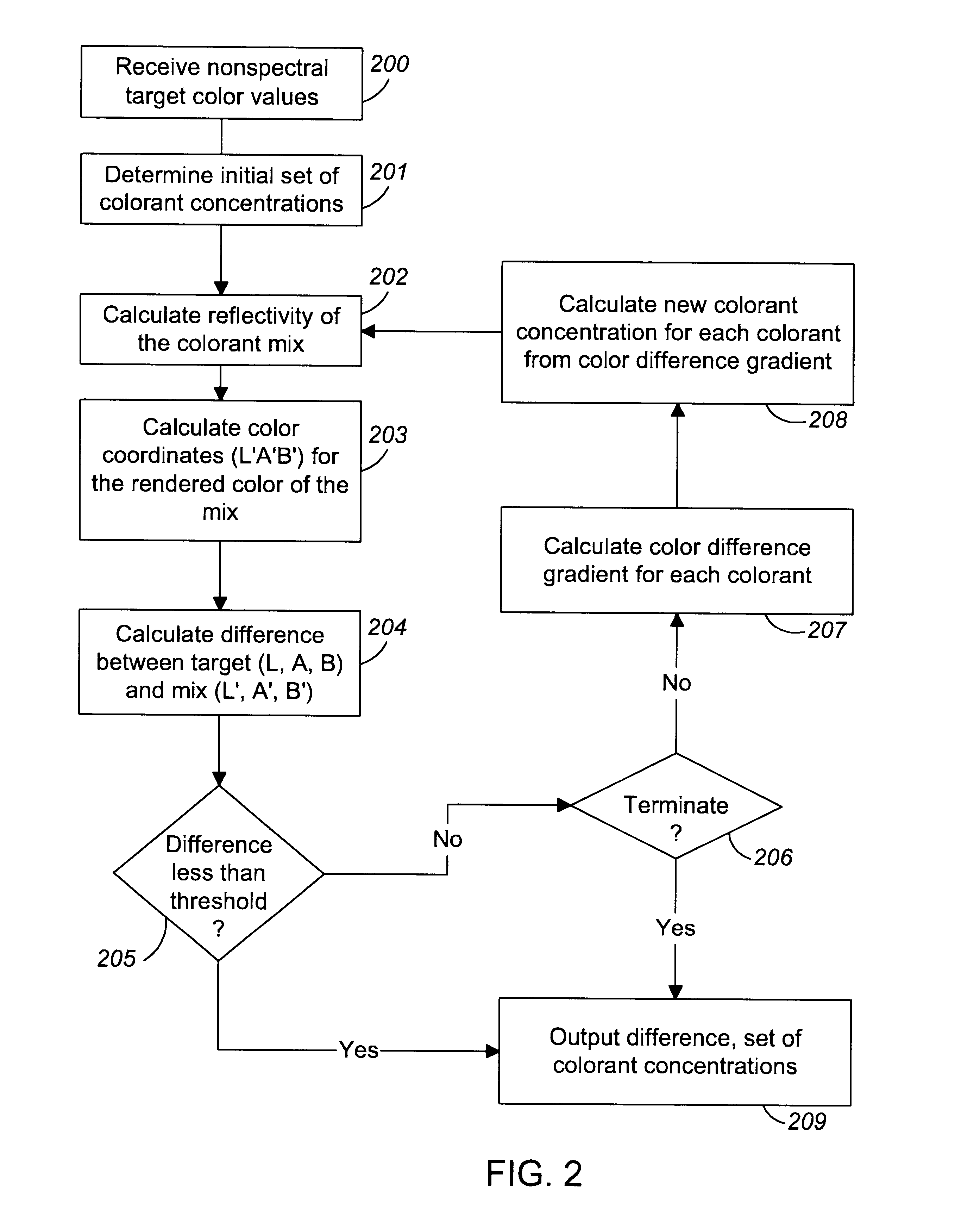

Spectral color matching to a device-independent color value

InactiveUS6646763B1Digitally marking record carriersVisual presentation using printersPattern recognitionTwo grid

Methods, systems, and apparatus for mapping a nonspectral representation of a target color, such as an input color tuple, to a set of concentration values for a set of device-specific colorants. The invention includes using the input color tuple to derive a first set of colorant concentration values from a color lookup table; and refining the first set of colorant concentration values by an iterative non-linear process to generate a final set of colorant concentration values. The first set of colorant concentration values can derived by using an input color tuple as an index to obtain grid-point concentration values at two grid points of the color lookup table and calculating the first set of colorant concentration values as a linear interpolation of the grid-point concentration values. In an implementation that provides a color function table of color-additive function values, the iterative non-linear process can include iteratively (a) calculating an interim color tuple from an interim set of colorant concentration values and the color function table, the initial interim set of colorant concentration values being the first set of colorant concentration values, and (b) deriving an interim set of colorant concentration values from a difference between the input color tuple and the interim color tuple. The calculations can include calculating a partial derivative of an error function from the difference between the input color tuple and the interim color tuple; and using the partial derivative to derive a successor interim set of colorant concentration values from a current interim set of colorant concentration values.

Owner:ADOBE SYST INC

Kiln/cooler control and upset recovery using a combination of model predictive control and expert systems

Kiln / cooler control and upset recovery using a combination of model predictive control and expert systems. A method for controlling a non-linear process includes the steps of first providing a controller that is operable to receive inputs representing measured variables of the process and predicting on an output of the controller predicted control values for manipulatible variables that control the process. An expert system is provided that models the actions of an operator of the process over an operating region of the process that represents a set of rules for actions to be taken by an operator upon the occurrence of predetermined conditions in the operation of the process. The operation of the controller is overridden with the expert system when one of the predetermined conditions exists and taking the associated action by the expert system to control the operation of the process by changing one or more of the manipulatible variables.

Owner:ROCKWELL AUTOMATION TECH

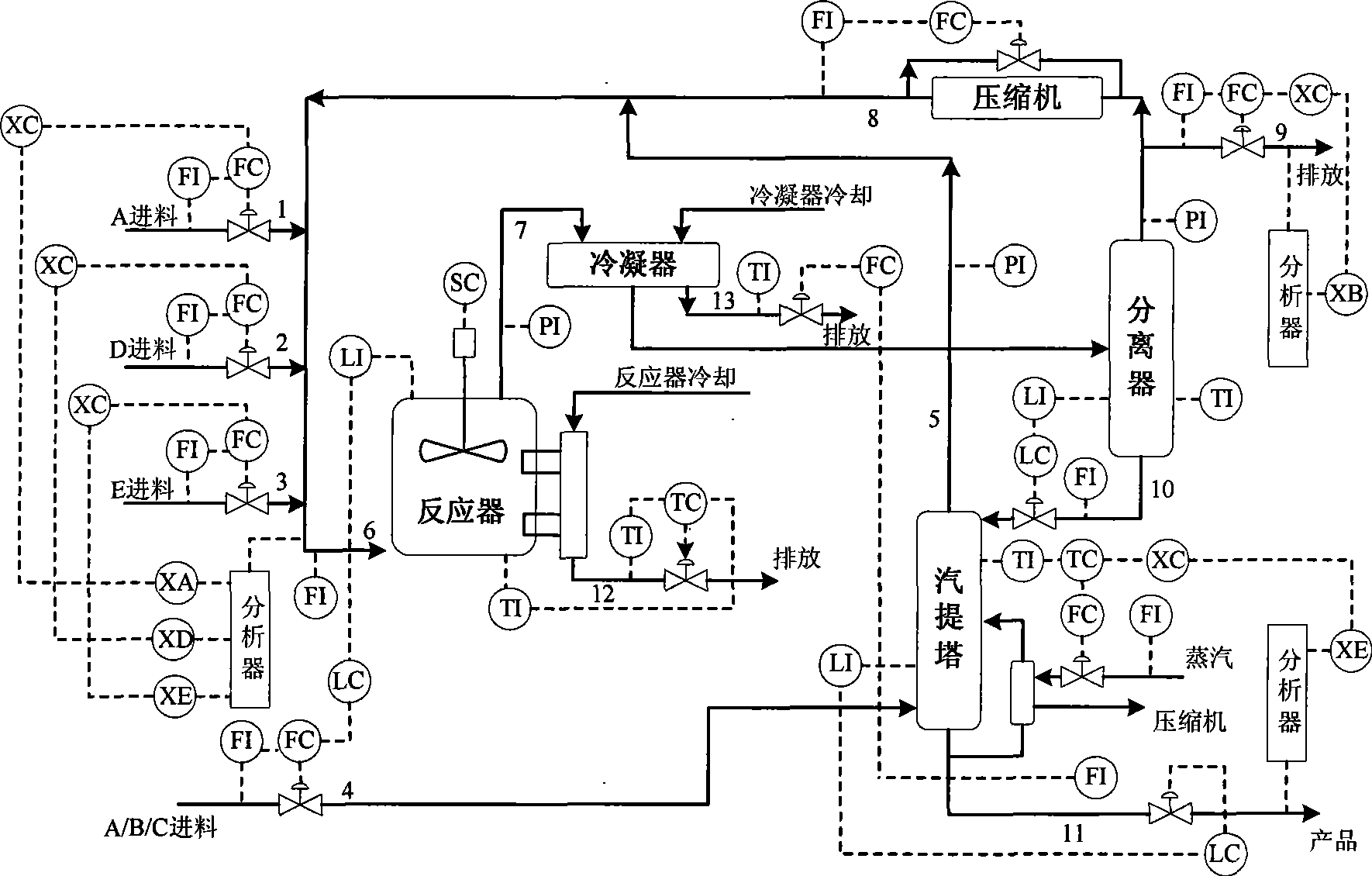

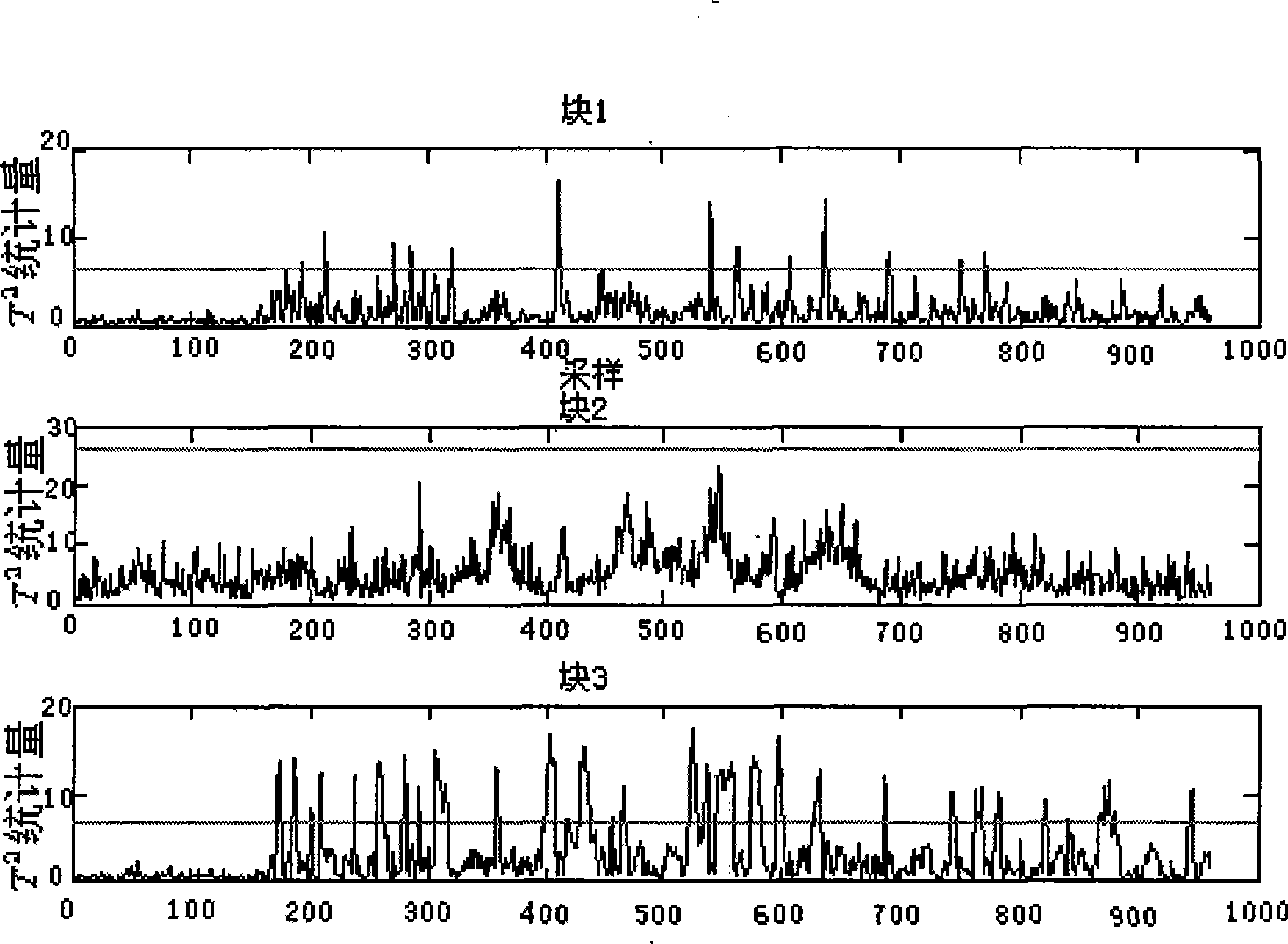

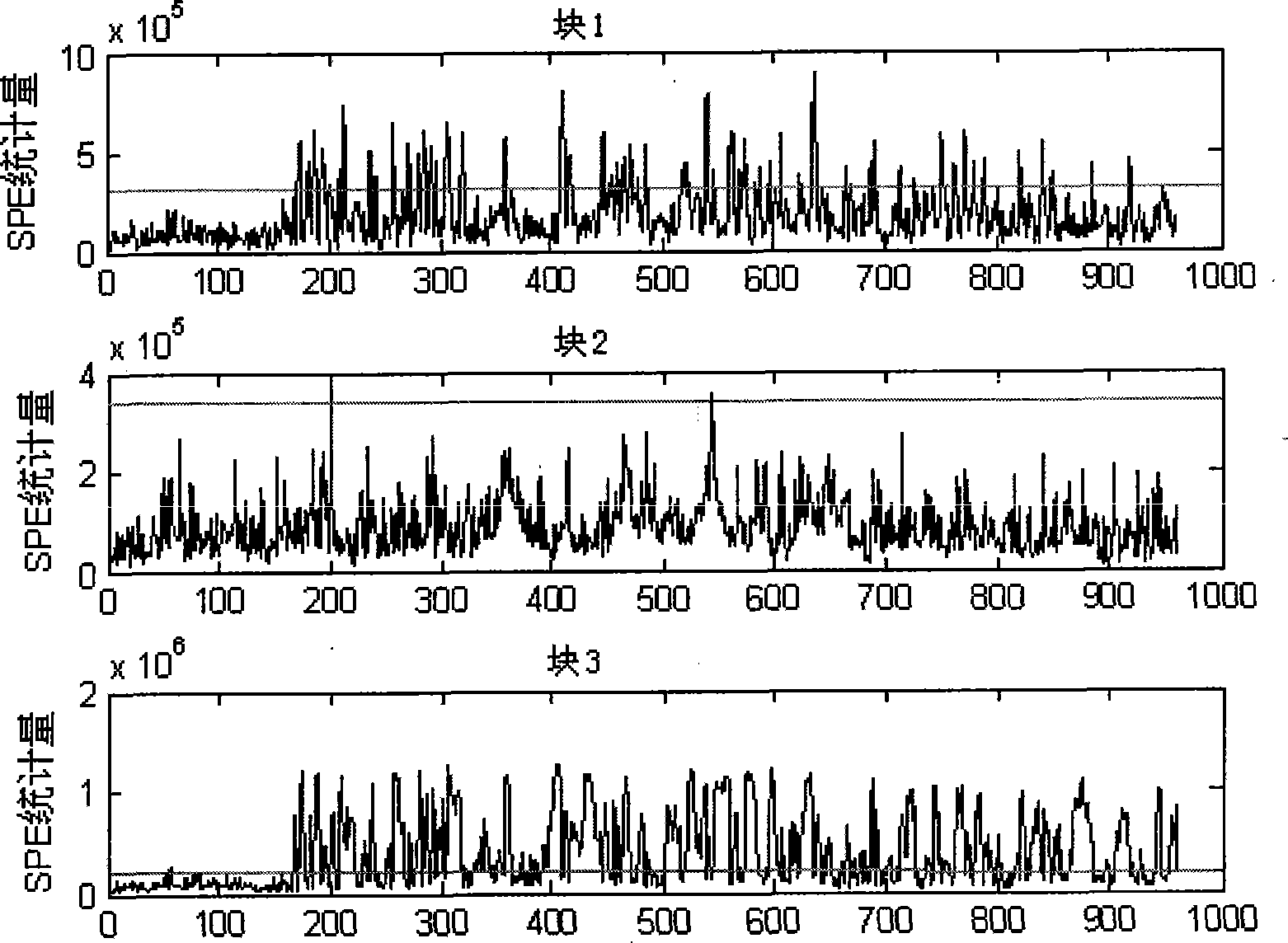

Non-linear procedure failure testing method based on two-dimensional dynamic kernel principal component analysis

InactiveCN101308385ACapture comprehensiveMonitor the production processElectric testing/monitoringCharacter and pattern recognitionKernel principal component analysisObservation data

Disclosed is a non-linear process fault detection method based on two-dimensional dynamic kernel principal component analysis, belonging to the fault detection technical field; the method comprises the following steps: the first step is to determine the sampling parameters, namely, to judge the execution process, determine the sampling parameters, select the data parameters which affect the fault, and then judge whether to carry through training or testing; the second step is training, that is, to collect the data of normal work, pick up the non-linear principal component of the training data through two-dimensional dynamic kernel principal component analysis, calculate the square prediction error of the training data and determine the control limit; the third step is testing, that is, to collect the online observation data, pick up the non-linear principal component of the online observation data through two-dimensional dynamic kernel principal component analysis, calculate the square prediction error of the real-time online observation data, compare the control limit of the square prediction error of the real-time online observation data with the control limit of the square prediction error of the training data, display and gives an alarm if the control limit of the former exceeds that of the latter. The invention can timely detect the fault in the production process and reduce losses in the industrial production process.

Owner:NORTHEASTERN UNIV

Decentralized process monitoring method

InactiveCN101446831AReduce complexityEasy to identifyElectric testing/monitoringCharacteristic spaceLeast squares

The invention relates to a decentralized process monitoring method, which comprises the steps as follows: in step one, data is acquired; in step two, acquired data is processed through blocking partition; in step three, partitioned data is mapped to feature space; in step four, a systematic process is processed through modeling; and in step five, failure detection and identification are performed by utilizing principal component statistic T<2> of observed data and residual error statistic SPE of observed data. The decentralized process monitoring method has the advantages as follows: the method is suitable for a complex large-scale systematic process; the advantages of kernel partial least square method and blocking partial least square method can be achieved; the complexity of nonlinear process analysis is reduced at the same time; and the identification capability is enhanced.

Owner:NORTHEASTERN UNIV

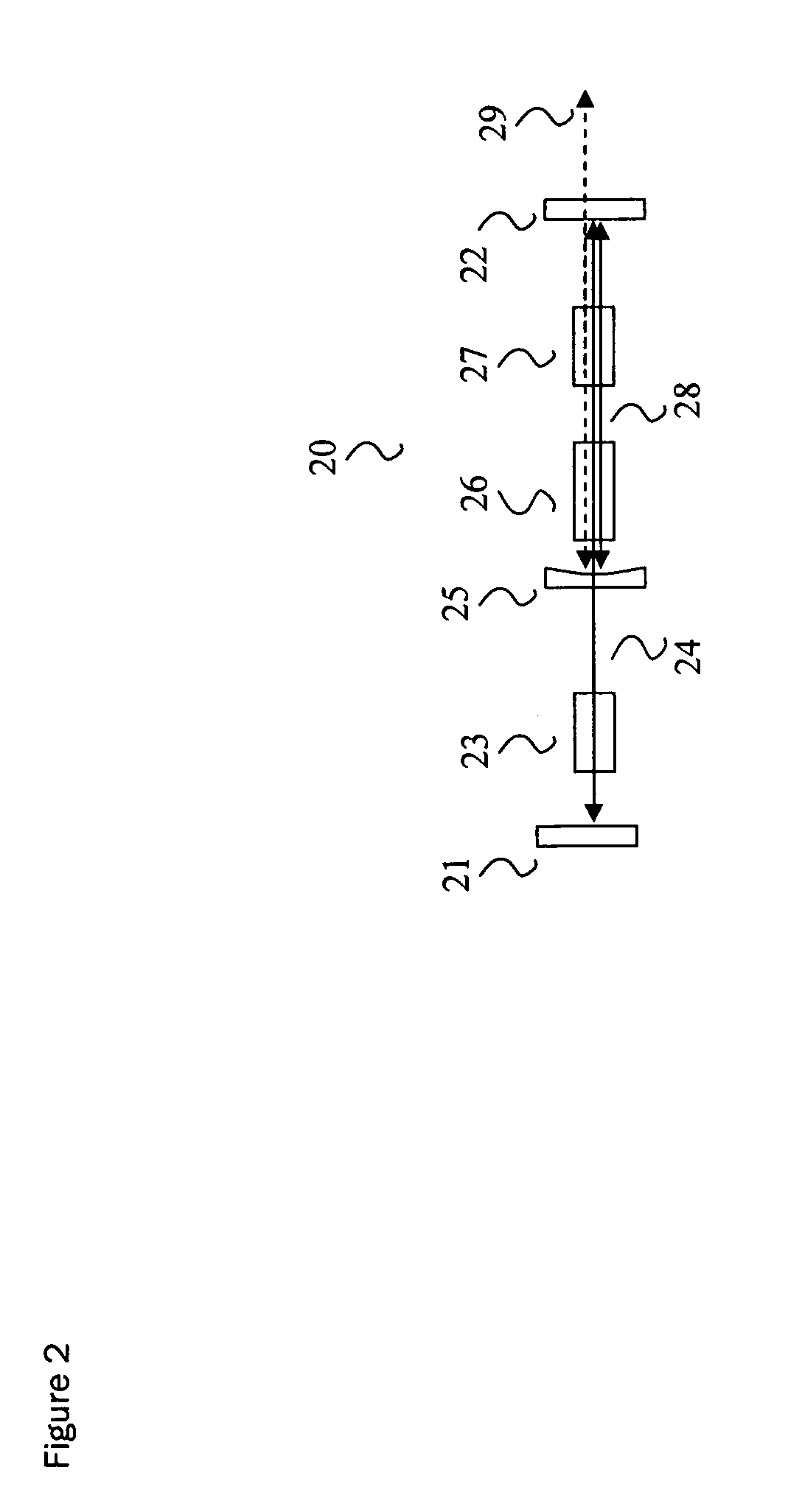

Generation of frequency-pre-selectable radiation by using more than one cascaded frequency conversion processes of resonantly enhanced beams

InactiveUS20110150015A1Improve frequency efficiencyCheap can be madeLaser detailsResonant cavityFrequency conversion

The invention describes methods and apparatus for the generation of laser radiation with pre-selectable frequency, which could be bigger or smaller than its fundamental beam frequency, through a combination of two or more intracavity frequency conversion processes of two or more resonantly enhanced beams. These techniques are particularly useful for generating continuous wave tunable frequency radiation in uv, visible and infrared wavelength ranges. These processes can be a combination of an intracavity fundamental beam pumped optical parametric oscillation (OPO) and an intracavity sum- or difference-frequency-mixing of the fundamental laser beam with an OPO generated beam and an intracavity frequency doubling the optical parametrical generated signal or idler beam to desirable frequencies for continuous wave. These plural intracavity nonlinear processes can be a combination of an intracavity or resonantly cavity-build-up fundamental beam pumped OPO and another frequency conversion within this OPO and the fundamental cavity. These intracavity enhanced frequency conversion processes allow for minimizing the parent frequency beams' losses and increasing the final conversion and, particularly, highly efficient conversion for continuous waves.

Owner:ZHOU DR JIANPING

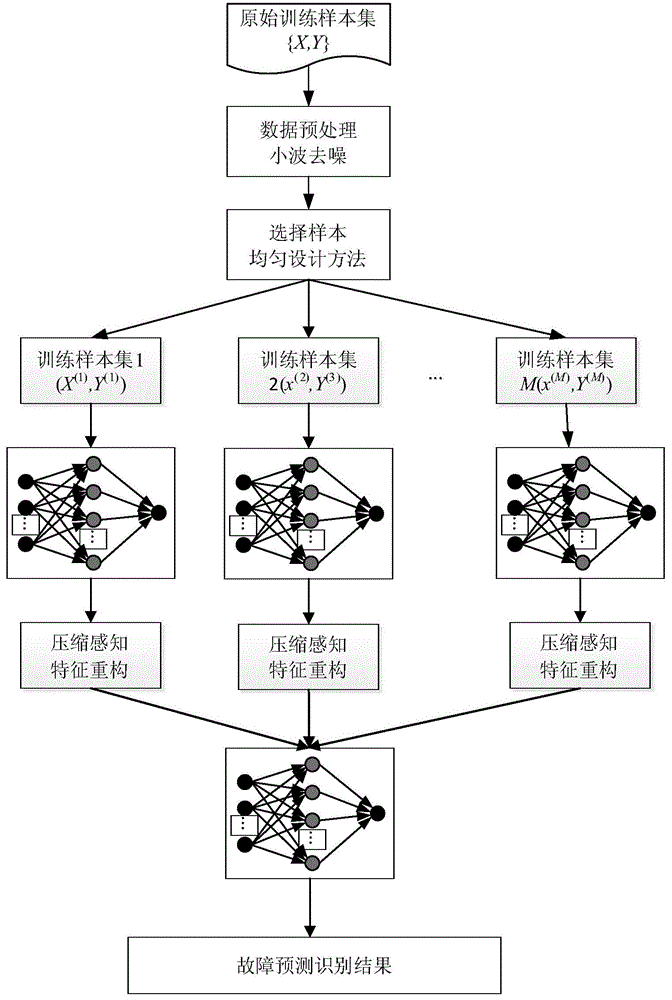

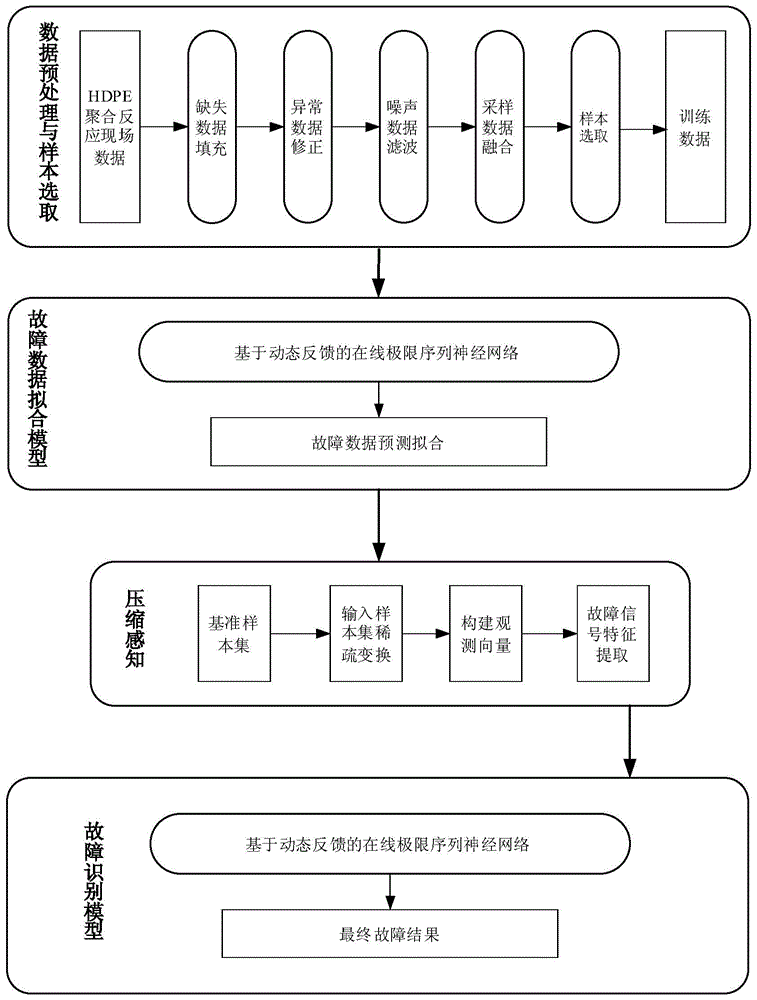

Non-linear process industrial fault prediction and identification method based on compressed sensing and DROS-ELM

ActiveCN104537415AFast learningFew adjustable parametersNeural learning methodsSpecial data processing applicationsFeature extractionIndustrial systems

The invention relates to a non-linear process industrial fault prediction and identification method based on compressed sensing and dynamic recurrent online sequential-extreme learning machine (DROS-ELM). According to the high-performance non-linear process industrial fault prediction and identification method, a problem of shortage of the on-line fault prediction and identification during the non-linear production process of the complicated industrial system can be solved. The compressed sensing and the artificial neutral network are applied to the industrial field and thus fault prediction and identification models based on the compressed sensing feature extraction and dynamic feedback OS-ELM neutral network technology is respectively constructed, thereby realizing fault prediction. Therefore, a technical support can be provided for guaranteed safety production, improved production efficiency, and saved production cost of the enterprise.

Owner:BEIJING UNIV OF CHEM TECH

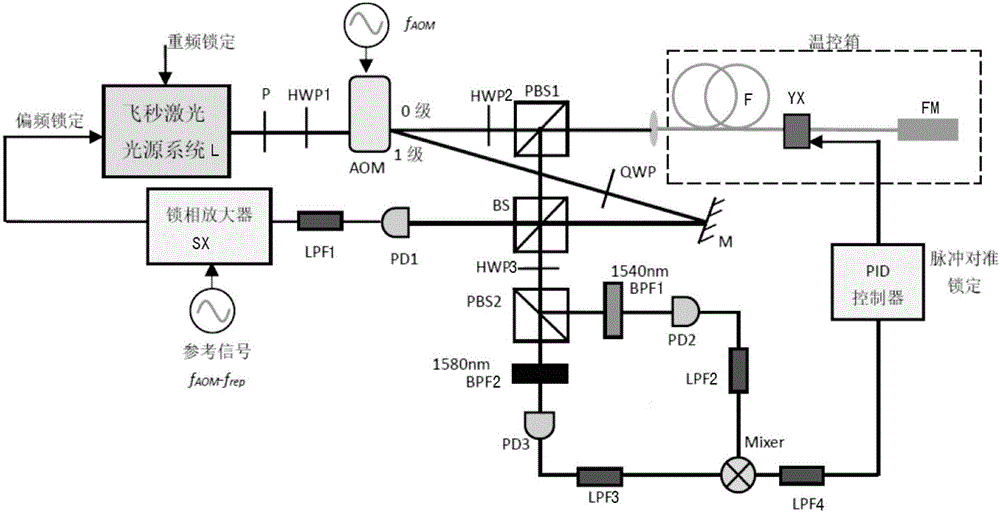

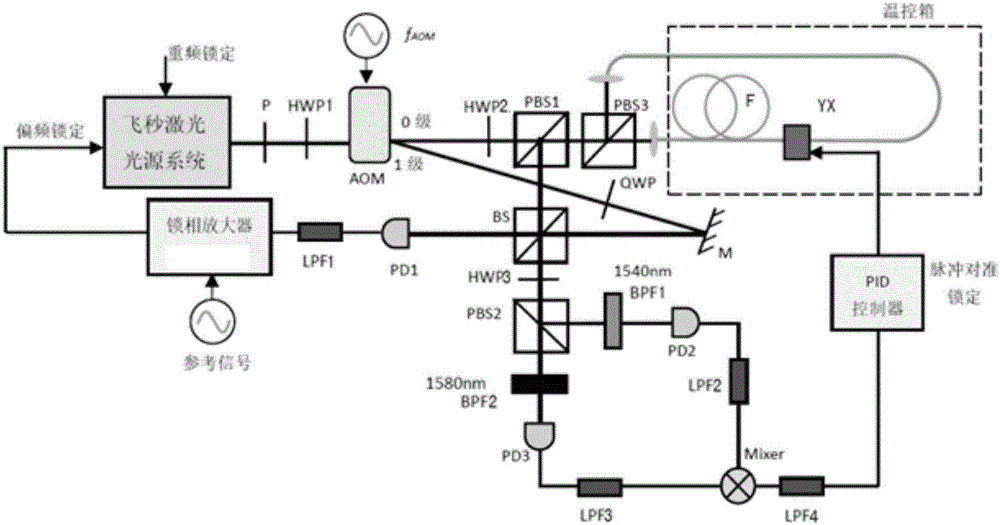

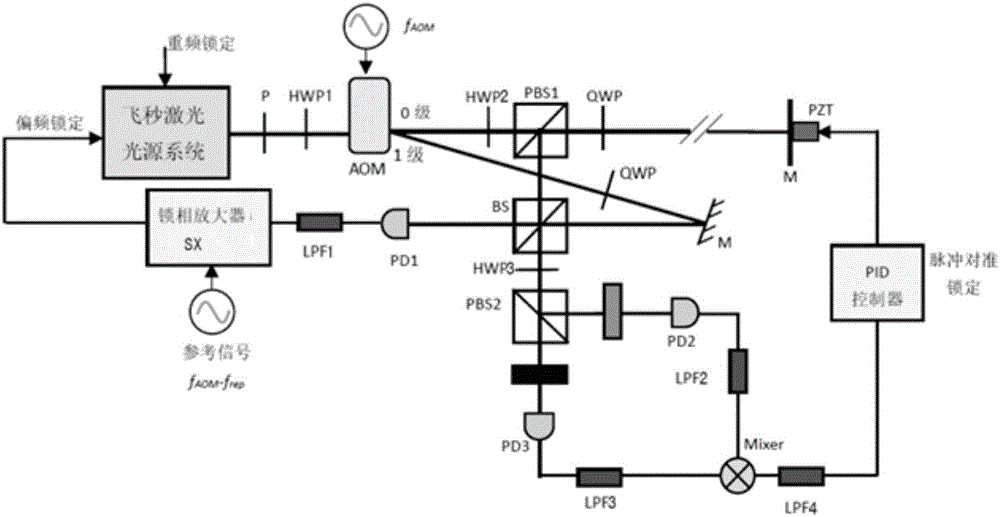

Femtosecond laser carrier envelope offset frequency lock system based on heterodyne interferometric method

The invention relates to a femtosecond laser carrier envelope offset frequency lock system based on a heterodyne interferometric method. The system is characterized by comprising a femtosecond laser light source system, an acousto-optic modulator, a controllable optical path retardation device, a light splitting prism, a first photoelectric detector, a phase lock amplifier, a phase difference voltage conversion device and a PID controller. Heterodyne interferometry can be conducted on first-level phase-shift diffraction light modulated by the acousto-optic modulator and zero-level diffraction light which is not modulated, and after mixing of interference signals with different wavelengths, direct-current level lock pulse envelope alignment is achieved; optical frequency comb envelope offset frequency is locked by means of interference signal phase, the linear process does not exist, high non-linear optical fibers, frequency doubling crystals and the like are not needed, and the system is simple in structure and low in requirement for laser energy.

Owner:TSINGHUA UNIV

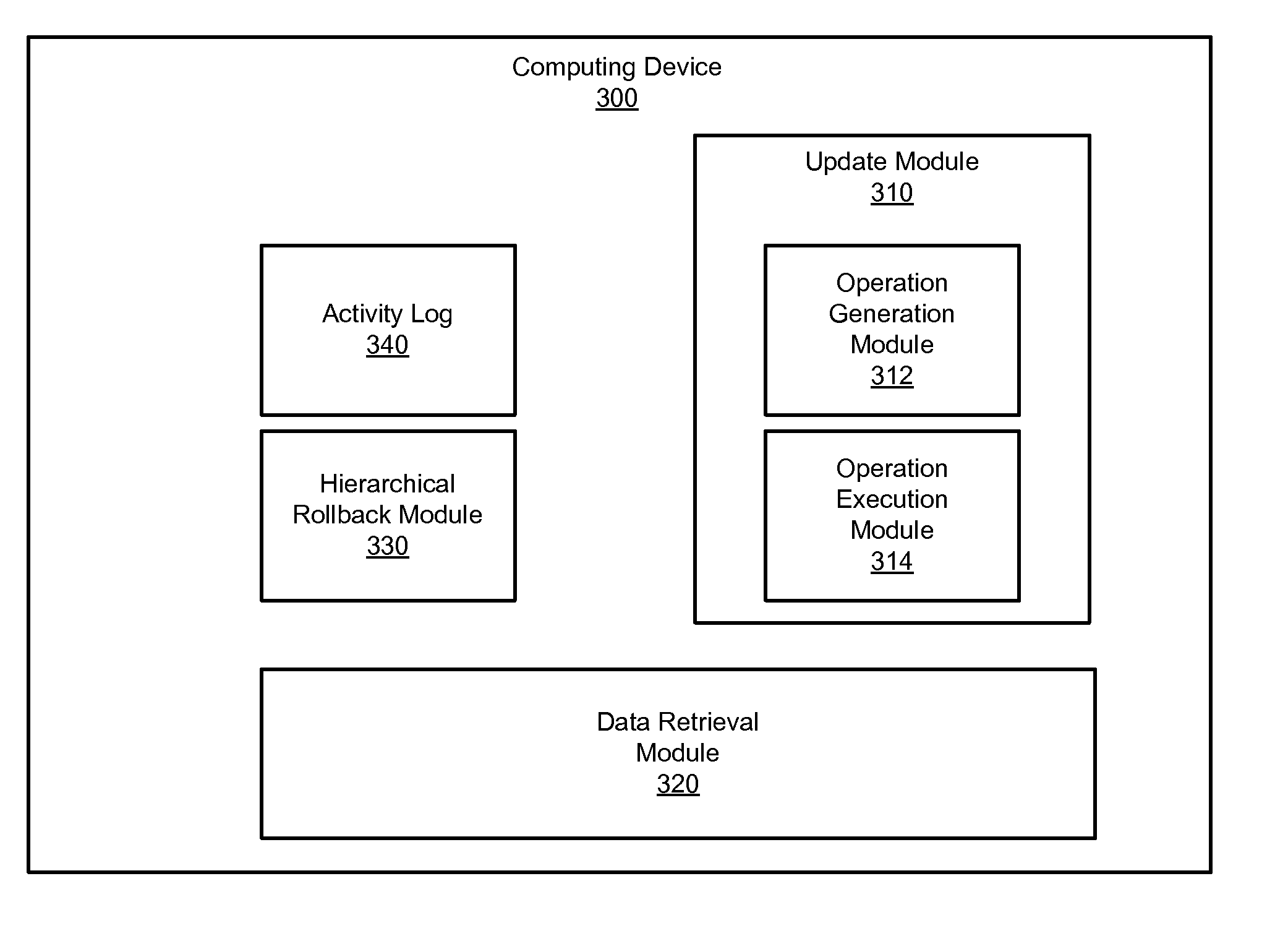

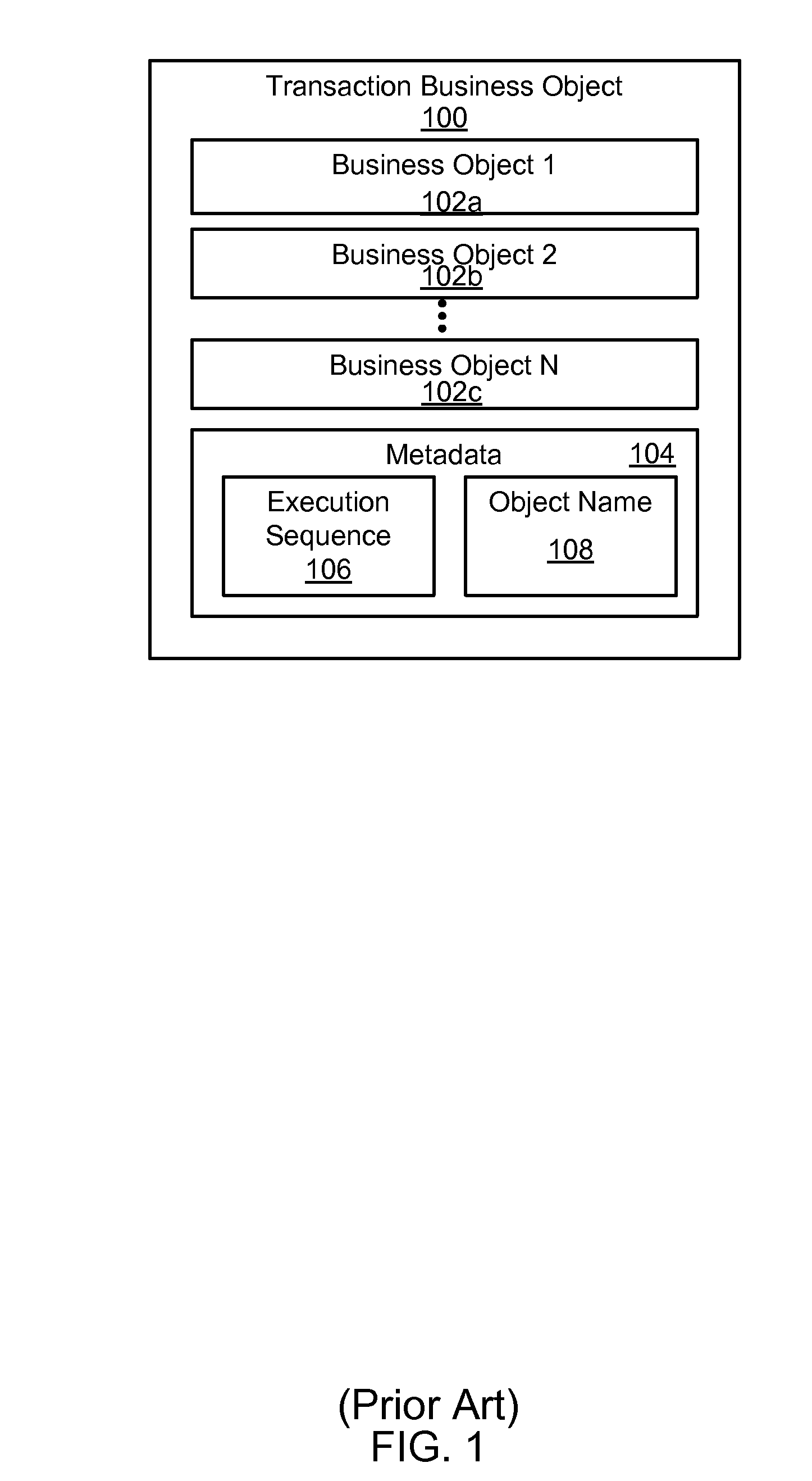

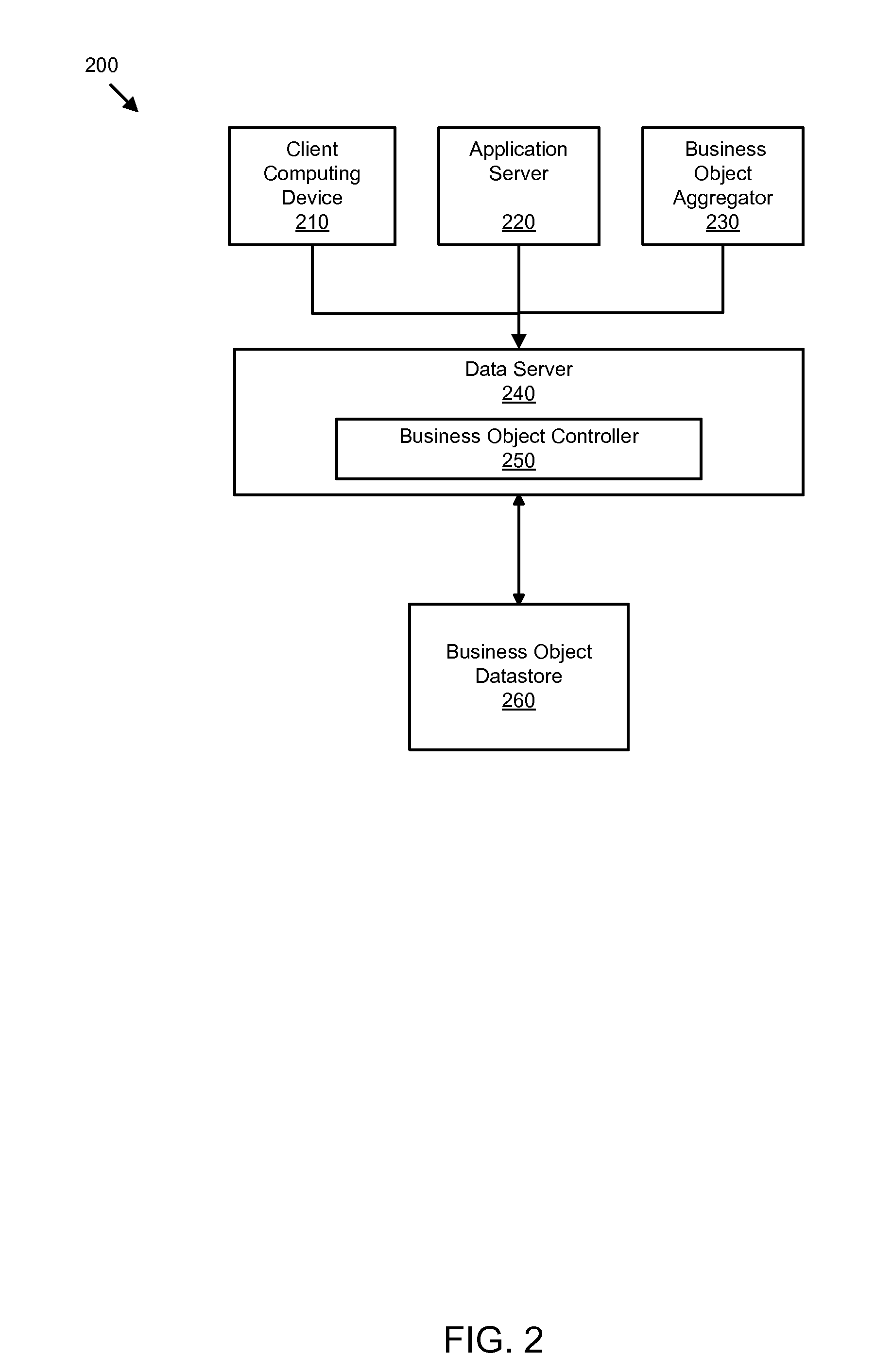

Apparatus, system, and method for hierarchical rollback of business operations

An apparatus, system, computer program product and method are disclosed for the hierarchical rollback of business objects on a datastore. The hierarchical rollback method utilizes a non-linear process designed to restore data to a previous point in the case of a data modification failure in order to prevent incorrect linking and data corruption. The hierarchical rollback methods are generated by retrieving existing data and creating commands in an order that will prevent orphan data in a datastore.

Owner:DOMO

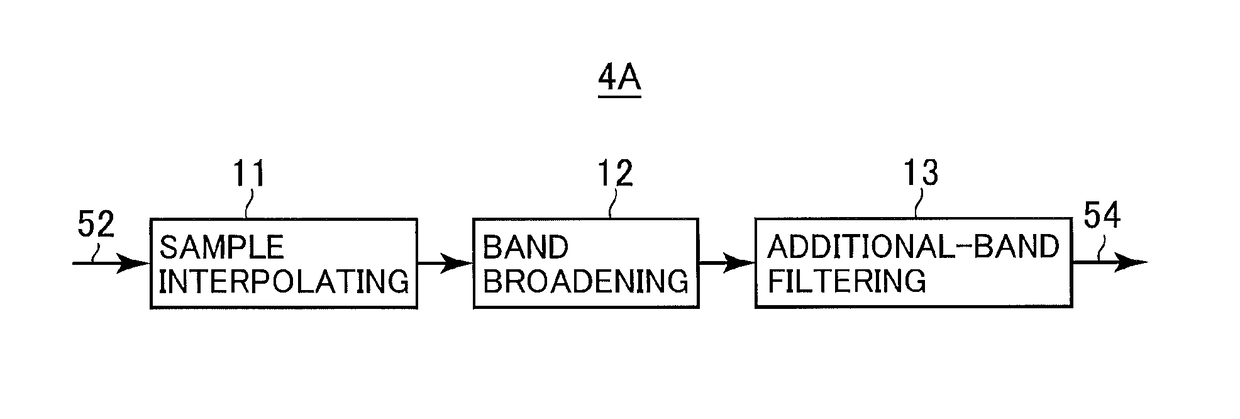

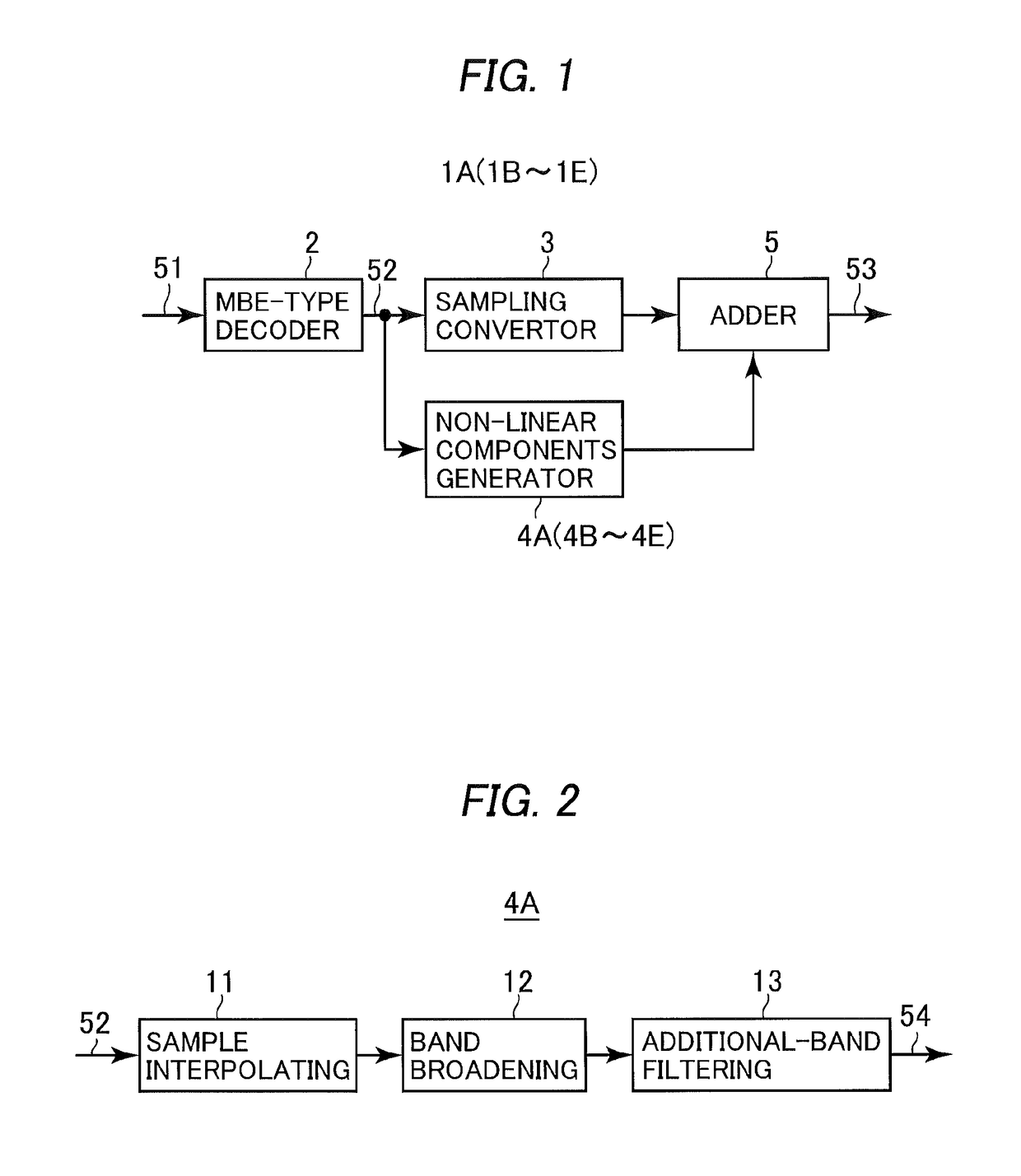

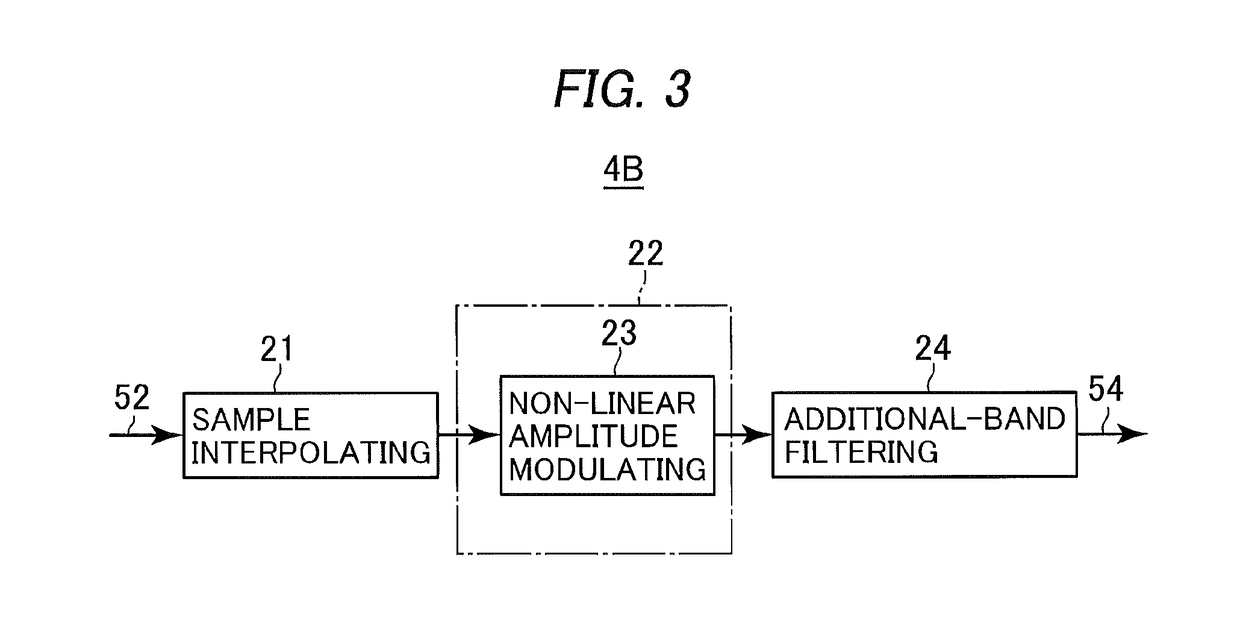

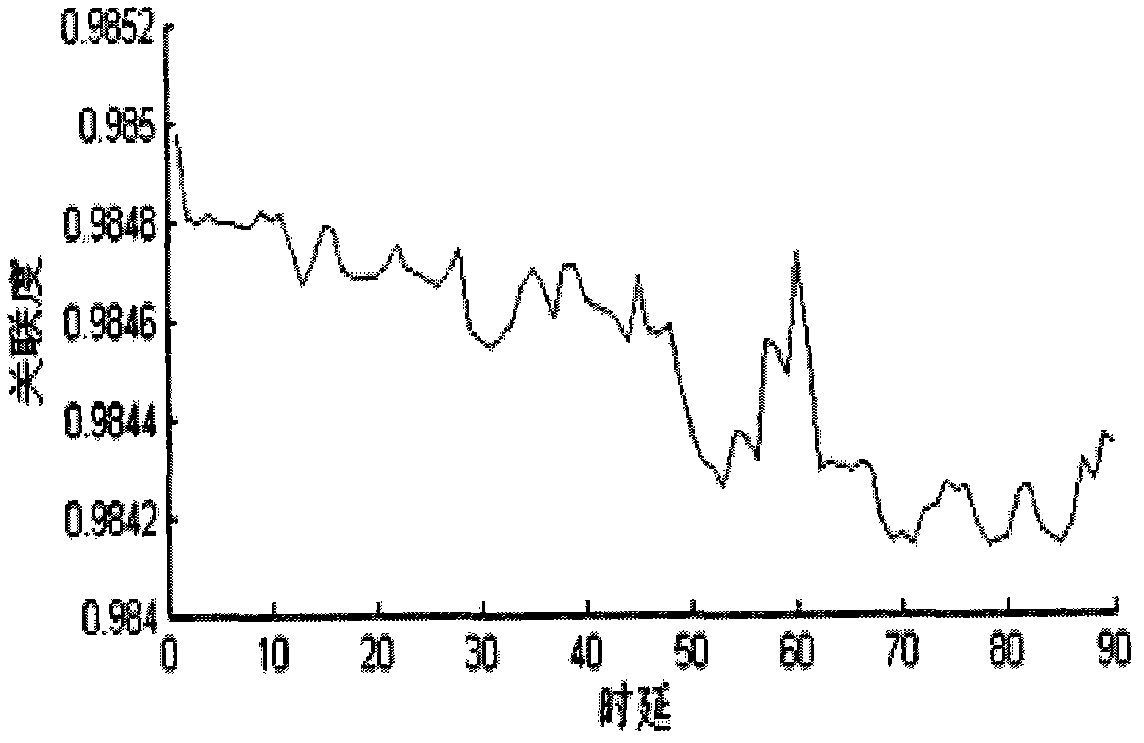

Voice decoding apparatus of adding component having complicated relationship with or component unrelated with encoding information to decoded voice signal

ActiveUS9734835B2Reduce cloggingImproved in nose clogging feelingSpeech analysisLinear componentSpeech sound

A voice decoding apparatus includes an MBE-type decoder, a sampling convertor, a non-linear components generator and an adder. The decoder decodes digital voice-encoded information to generate a first decoded voice signal. The convertor converts the first decoded voice signal to a second decoded voice signal with a higher sampling frequency. The generator performs a non-linear process to the first or second decoded voice signal to generate an additional voice signal with the same sampling frequency as the second decoded voice signal. The additional voice signal has components in a frequency band in which the first decoded voice signal has no component and continuing to another frequency band of the first decoded voice signal. The adder adds the second decoded voice signal to the additional voice signal.

Owner:OKI ELECTRIC IND CO LTD

Soft measurement method for sewage pumping station flow of urban drainage converged network

ActiveCN102032935ASolve the problem of drainage delay differenceSave resourcesVolume/mass flow measurementNeural learning methodsGrey correlation analysisNetwork model

The invention discloses a soft measurement method for sewage pumping station flow of an urban drainage converged network. The conventional drainage pipe network system has lots of uncertain factors and high measurement hardware cost. The method comprises the following steps of: analyzing main influencing factors of converged node pumping station flow by using mechanism analysis and priori information, and primarily determining influencing factors of a back-propagation (BP) neural network, namely determining input / output variables; determining lag time of different upstream pumping station flows by using a grey correlation analysis method; and establishing a grey neural network model on the basis of pumping station historical operating data, and predicting the converging node pumping station flow. By combining two methods of grey correlation analysis and grey neural network, the method solves the problem of difference of drainage time delay of different upstream pumping stations, well simulates the nonlinear pipe network drainage process, realizes soft measurement of converged node sewage pumping station flow, saves the hardware resources, and is low in cost and high in accuracy.

Owner:ZHEJIANG SUPCON INFORMATION TECH CO LTD

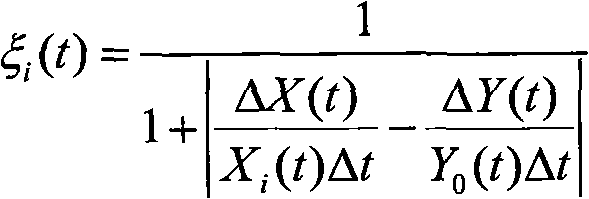

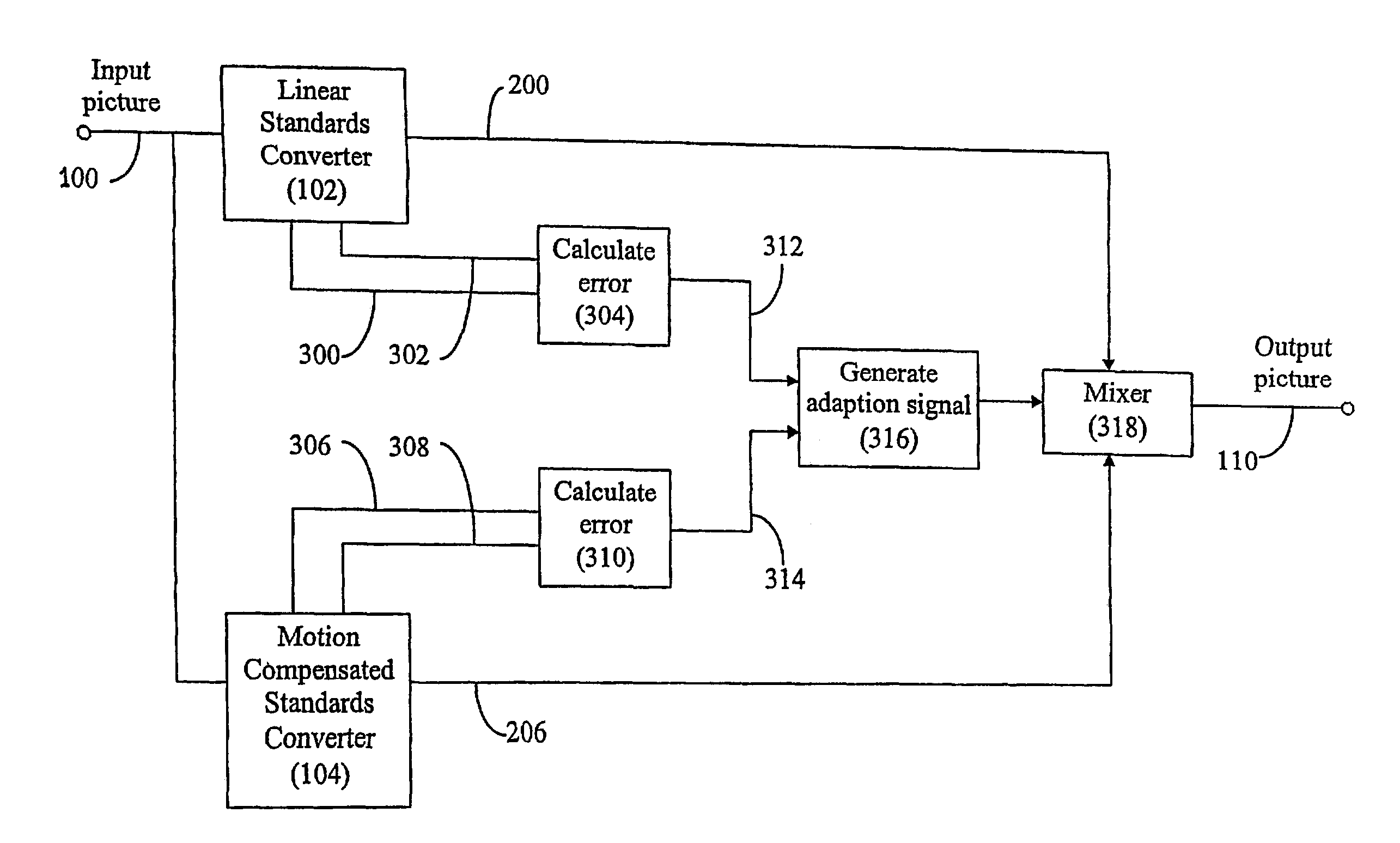

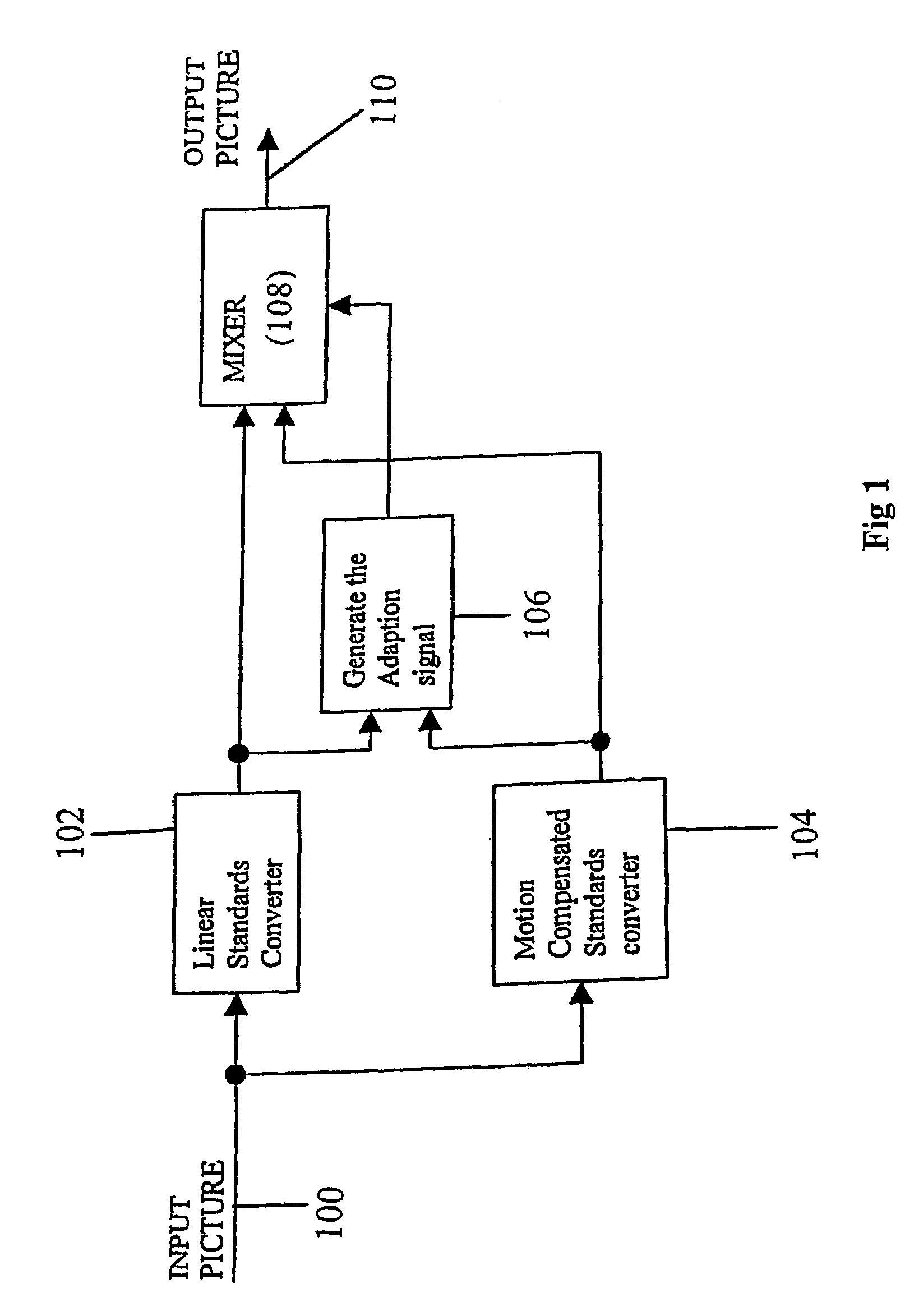

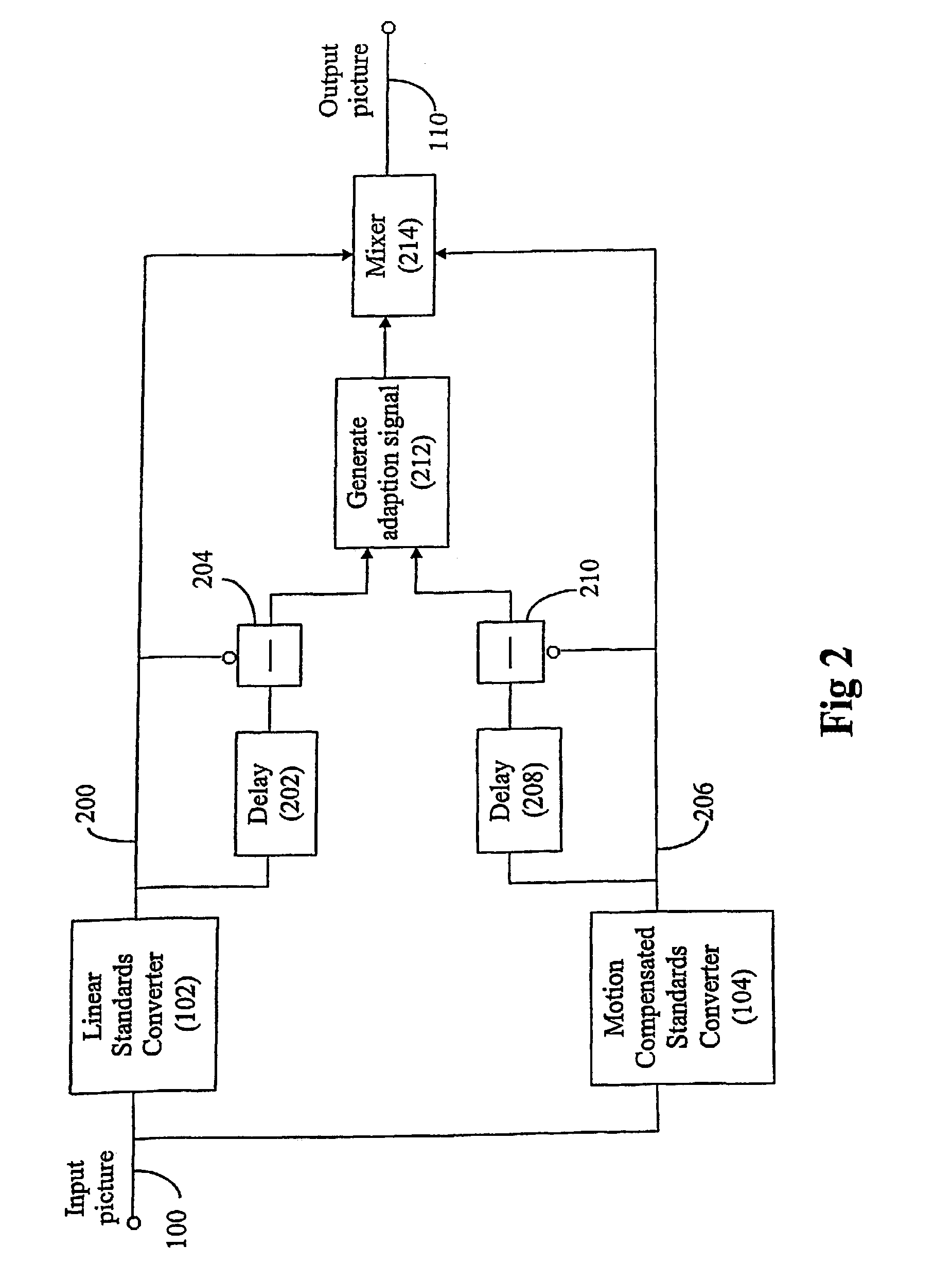

Video signal processing

InactiveUS7009656B2Television system detailsPicture reproducers using cathode ray tubesAlgorithmVideo processing

In video processing, a motion compensated process and an equivalent linear process are performed on an input signal, the processing errors of which are computed and compared. The comparison is then used to control a mix between the outputs of the two processes to produce an output signal.

Owner:GRASS VALLEY LTD

Method of constructing a stock index

Computer-implemented methods of creating and maintaining stock indexes are provided. For a stock index of a particular size, a band is defined around the upper and / or lower limits of the stock index. To be added to, or dropped from, a particular stock index, the stocks must fall outside of the bands for that particular stock index size. Stock migration is controlled using a systematic stock migration process so that stocks are gradually added and deleted from an index. Stock investment style is determined in a multi-dimensional process, instead of a linear process. Furthermore, the number of stocks in the stock index need not be a fixed value, but may depend upon how many stocks meet predefined criteria at any given point in time.

Owner:SIEMENS AG +1

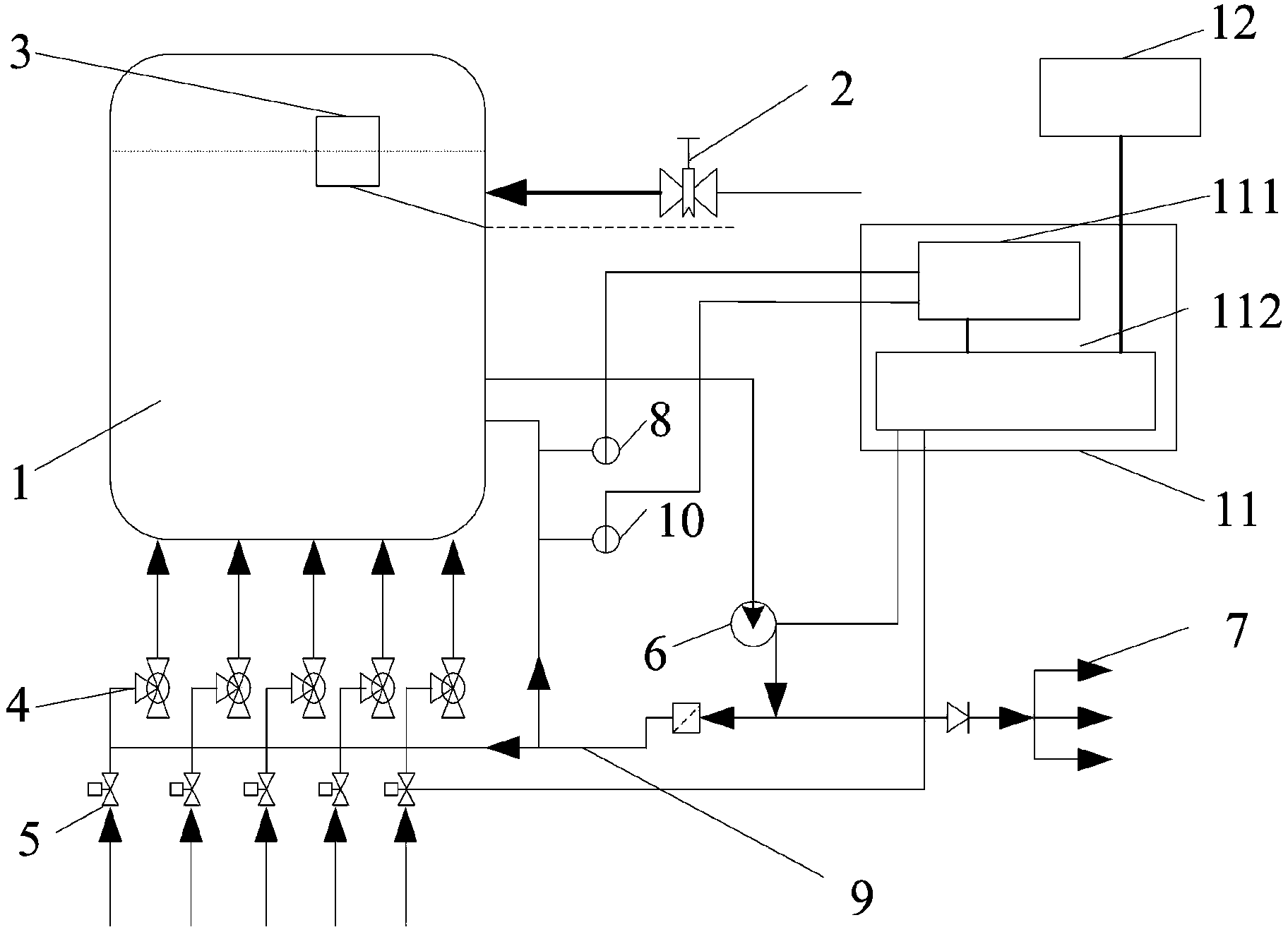

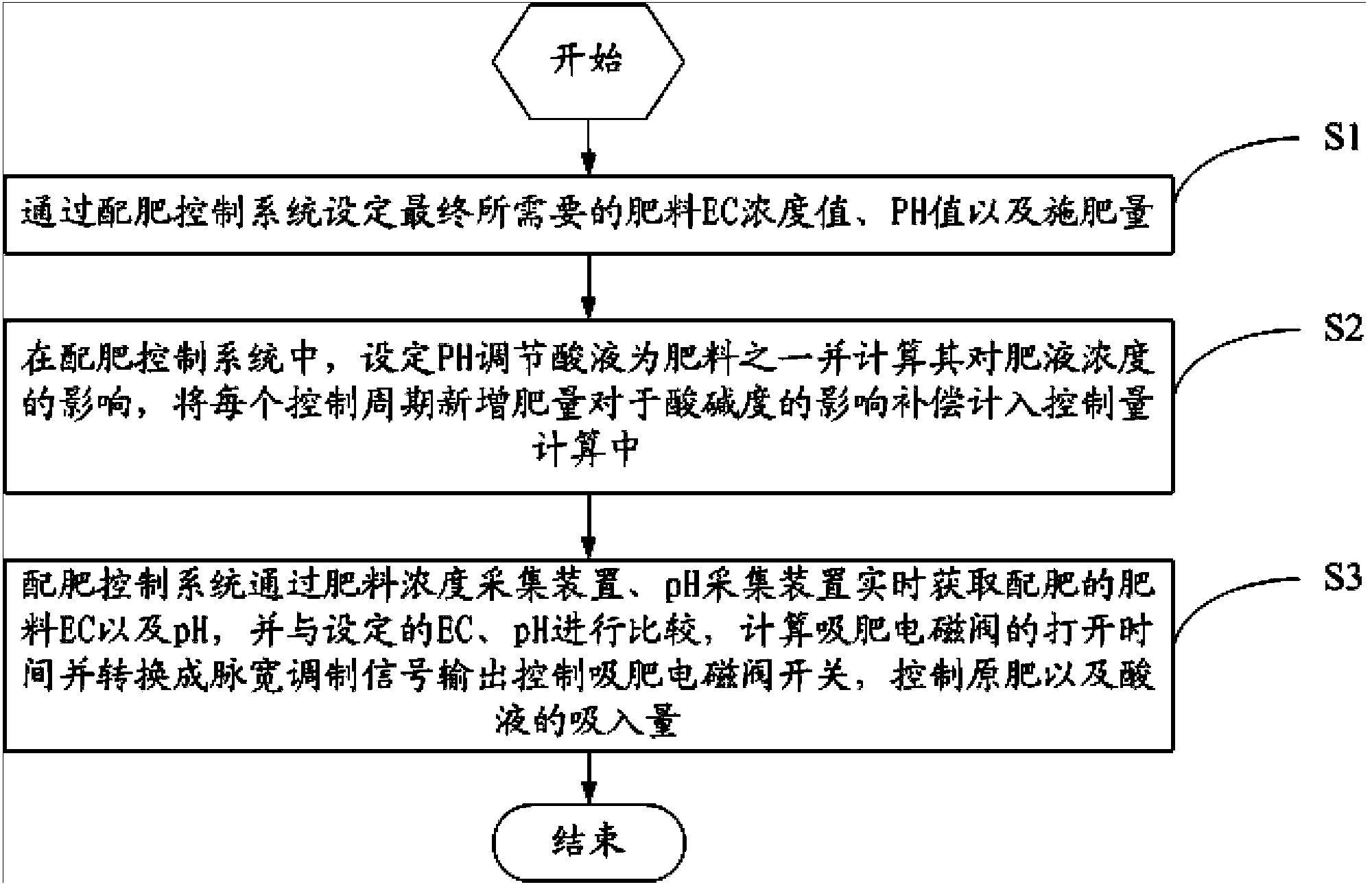

Dual-purpose fertilizing device capable of accurately preparing fertilizer and irrigating clear water and EC+PH adjusting method thereof

InactiveCN103931325APrecise and stable controlWatering devicesPressurised distribution of liquid fertiliserControl mannerAgricultural engineering

The invention provides a dual-purpose fertilizing device capable of accurately preparing a fertilizer and irrigating clear water and an EC+PH adjusting method thereof. According to the device, a water feeding system and a fertilizer feeding system are arranged in a fertilizer mixing tank; a backflow pipeline is arranged on the fertilizer mixing tank and a fertilizer feeding pipeline; a fertilizer concentration acquisition device and a pH acquisition device are arranged on the backflow pipeline, and are connected with a fertilizer preparation control system respectively through data lines; and the fertilizer preparation control system is electrically connected with a fertilizer suction electromagnetic valve and a fertilizing pump. Key parameters of an algorithm and a control way are adjusted in real time according to a parameter change situation on the basis of a closed-loop control principle and PID (Proportion Integration Differentiation) adjustment and in combination with the object features of a fertilizer liquid reaction process, in particular the non-linear process features of PH parameter change, and accurate and stable control of EC and PH of a fertilizer liquid is realized by using a most proper control strategy and corresponding regulation and control parameters under different working conditions of a fertilizer preparation reaction process.

Owner:SHANGHAI BANGBO MODERN AGRISCI

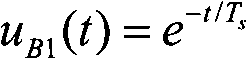

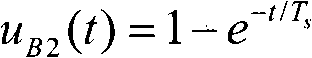

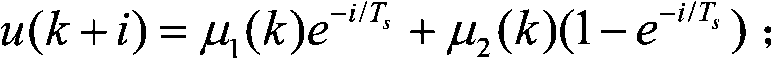

Self-adaptive prediction function control method for nonlinear production process

InactiveCN101813916AOnline Adaptive OptimizationStability impactAdaptive controlAviationChemical industry

The invention relates to a self-adaptive prediction function control method for a nonlinear production process, which mainly solves the problems that the non-linear process is difficult to control and model and is complicate to calculate on line in the prior art. In the invention, an on-line self-adaptive algorithm is set by using on-lined acquired production data, constructing control input with two degrees of freedom and using an aggregation concept in economics without pre-building a predication model of an object to be controlled and comprises the following steps of: (1) building control input with two degrees of freedom: selecting control input of a future system, formed by weighting two primary functions; (2) building an expected performance index of the future system; (3) deducting future prediction output; (4) self-adaptively optimizing system parameters on line; and (5) stably analyzing a control system and then stably analyzing a novel control method according to the aggregation concept, a zooming theory and a prediction control theory, thereby obtaining a technical scheme for a parameter adjusting method of the control system and better solving the problems. The invention can be used for nonlinear industrial devices for oil refining, chemical industry, pharmacy, machinery, aviation and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com