Patents

Literature

211 results about "STEP-NC" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

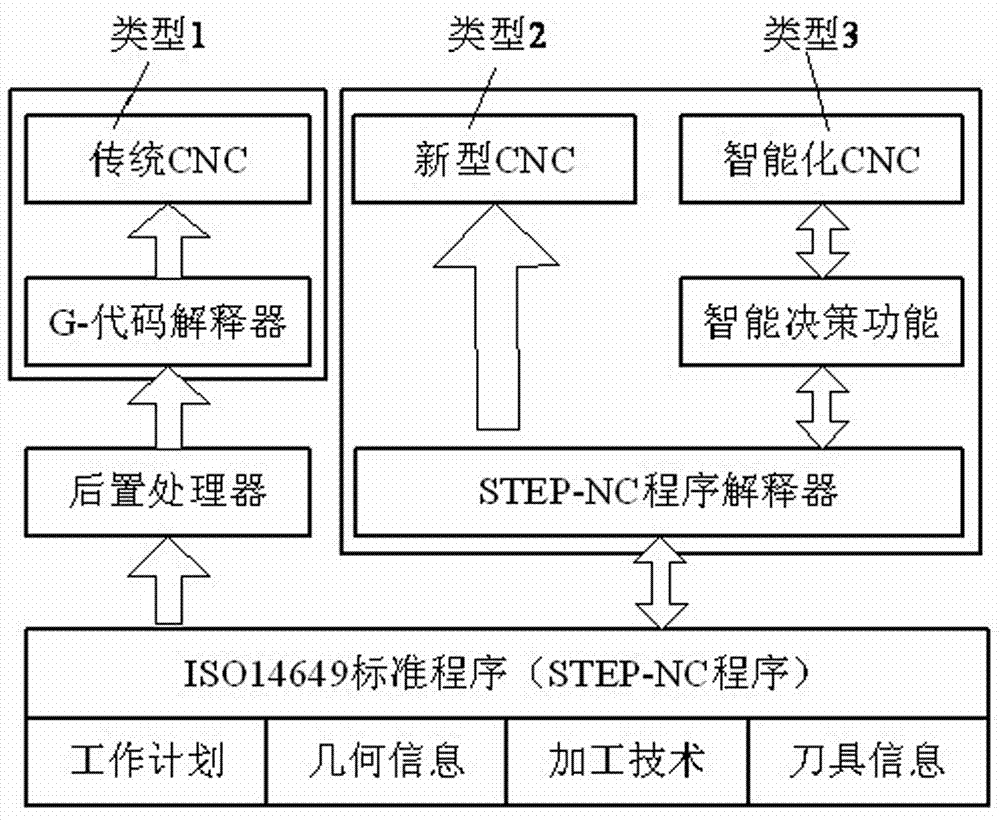

STEP-NC is a machine tool control language that extends the ISO 10303 STEP standards with the machining model in ISO 14649, adding geometric dimension and tolerance data for inspection, and the STEP PDM model for integration into the wider enterprise. The combined result has been standardized as ISO 10303-238 (also known as AP238).

Method for preparing trimeric high-strength and high-toughness energy-saving fishing net

ActiveCN102251303AMonocomponent polyolefin artificial filamentArtifical filament manufacturePolymer sciencePolyamide

The invention discloses a method for preparing a trimeric high-strength and high-toughness energy-saving fishing net, which is implemented by carrying out synthesis on polyethylene (1), polypropylene (2), polyamides (3), Nano silicon dioxide (4), polyethylene wax (5), a coupling / bulking agent (6), a UV (ultraviolet) resistant agent 173 (7), a coloring agent (8) and white mineral oil (9) accordingto five steps (namely, a step A, a step B, a step C, a step D and a step E).

Owner:HUNAN XINHAI CO LTD

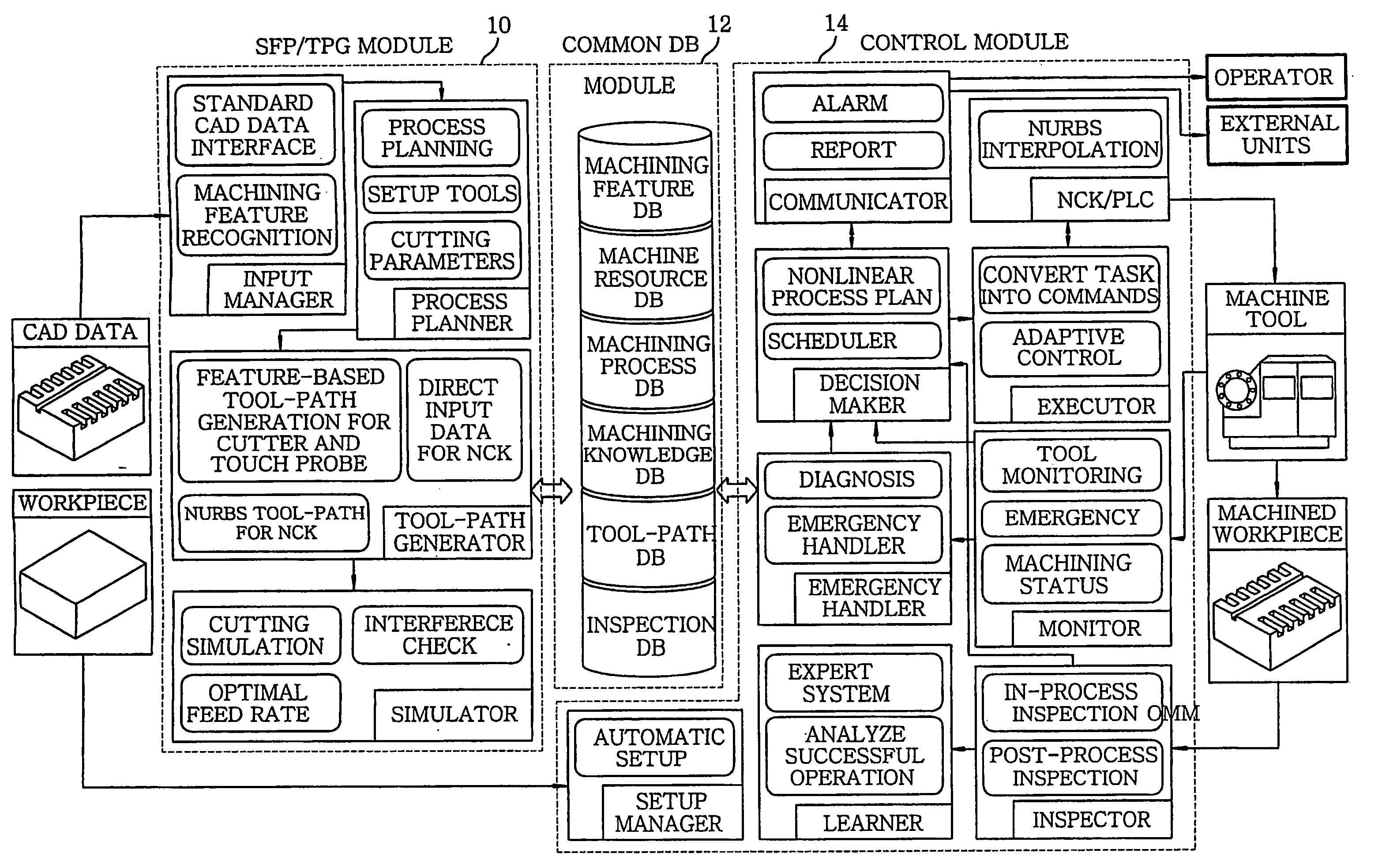

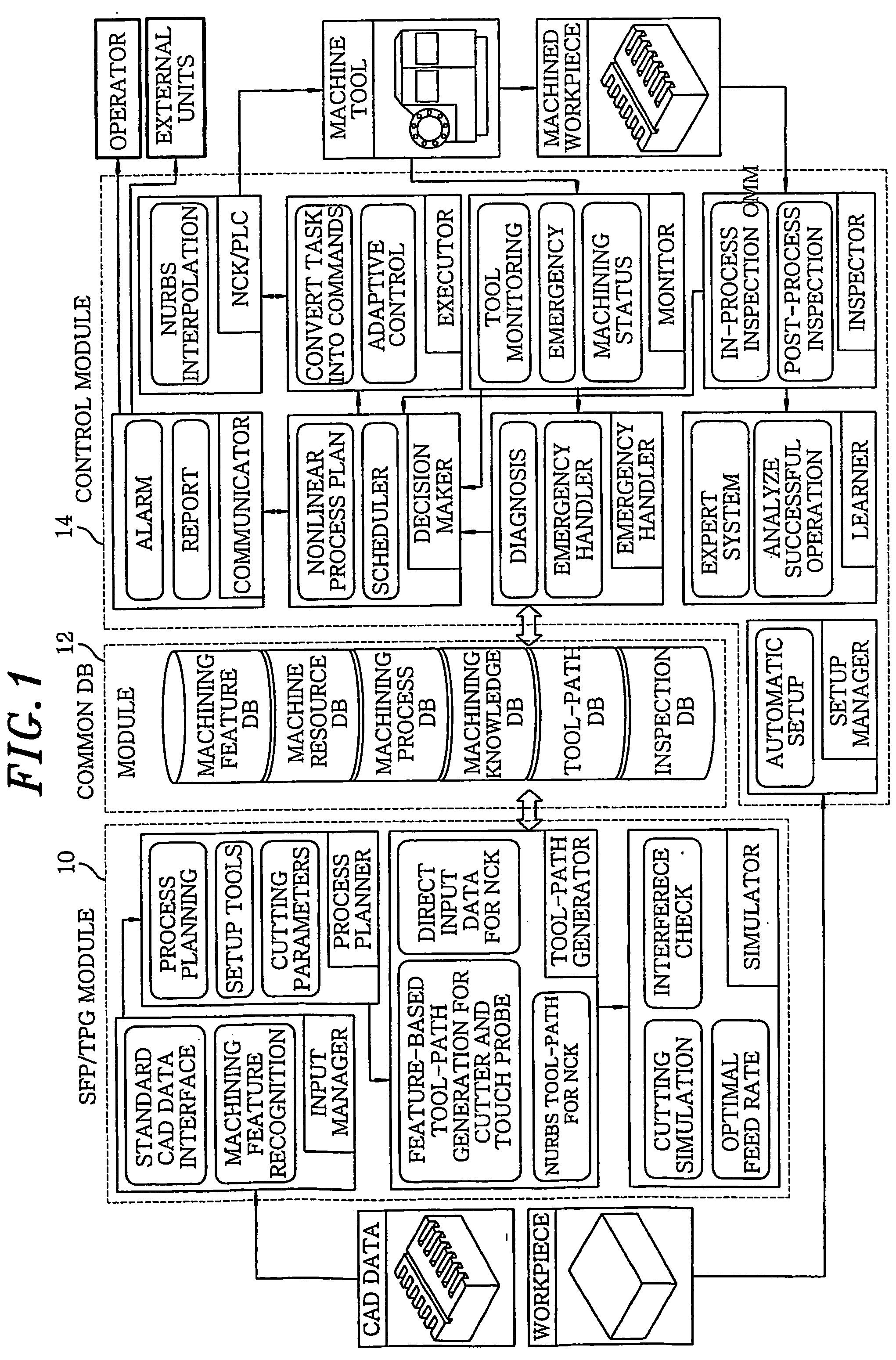

Method of Non-Linear Process Planning and Internet-Based Step-Nc System Using the Same

InactiveUS20080281463A1Decrease productivityEasy constructionProgramme controlSpecial data processing applicationsSTEP-NCAlternative process

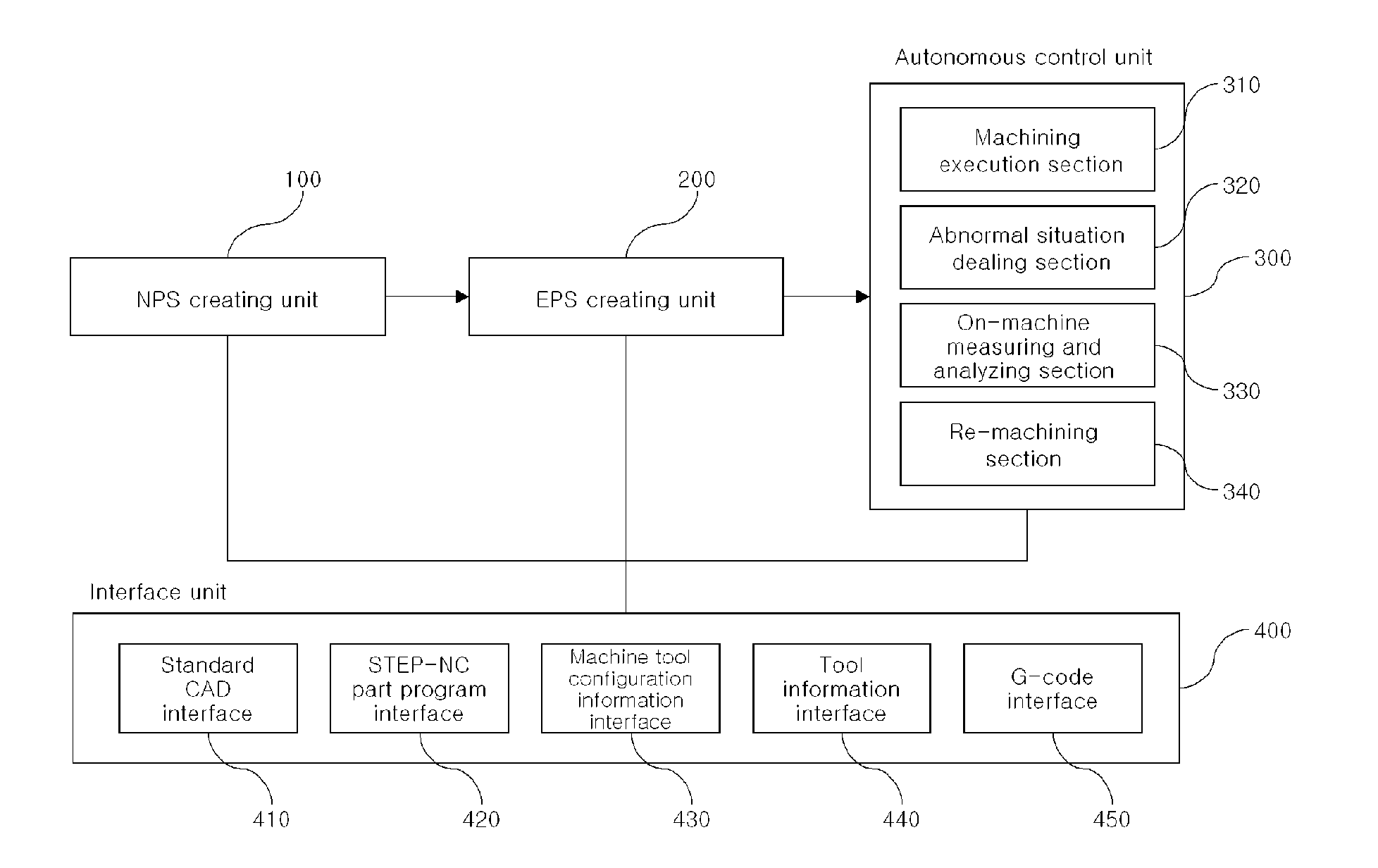

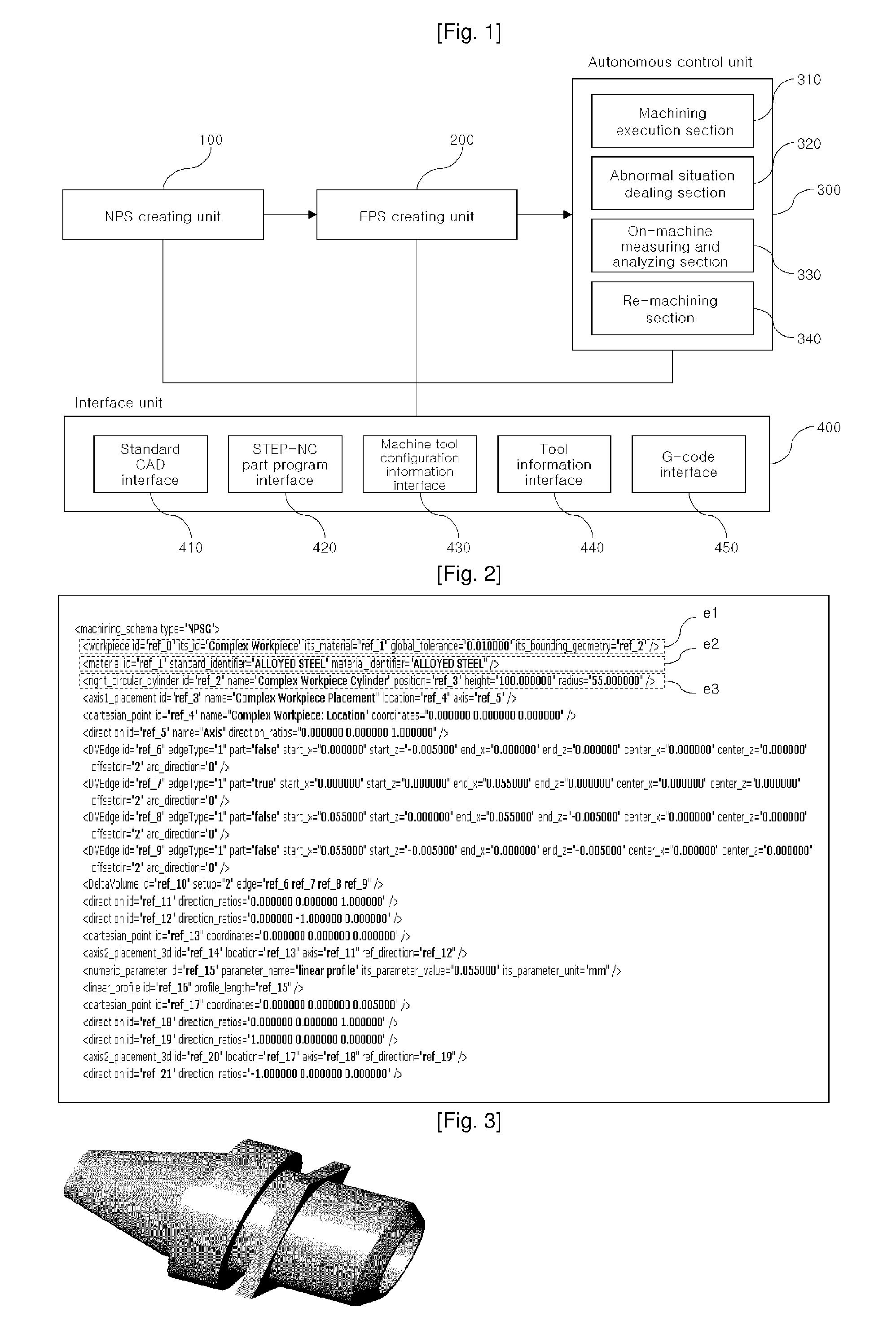

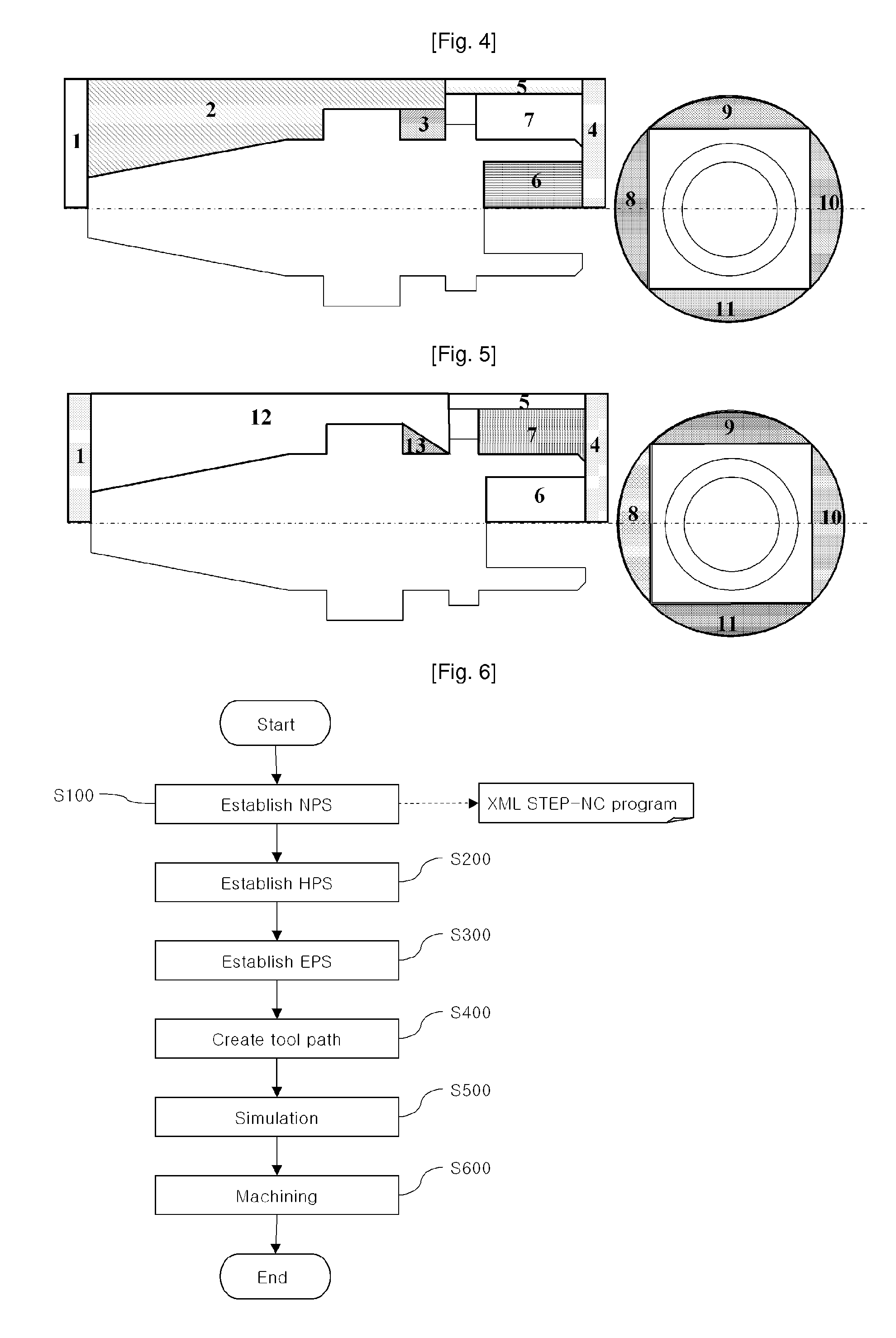

The present invention relates to a method of creating a non-linear process plan and an Internet-based STEP-NC system using the same, and more particularly, to a method of creating a non-linear process plan, wherein the non-linear process plan including information on a variety of alternative processes and machining sequences is established in consideration of situations in the field, thereby autonomously dealing with abnormal situations while executing optimal machining, and to an Internet-based STEP-NC system, wherein a STEP-NC part program in an XML format is created based on the established process plan so that process information can be easily exchanged with other systems via the Internet. Since the present invention provide a plurality of machining alternatives to the field, and thus, allow a STEP-NC machine tool to execute machining optimized depending on field situations and to autonomously deal with abnormal situations that may occur during machining.

Owner:POSTECH ACAD IND FOUND

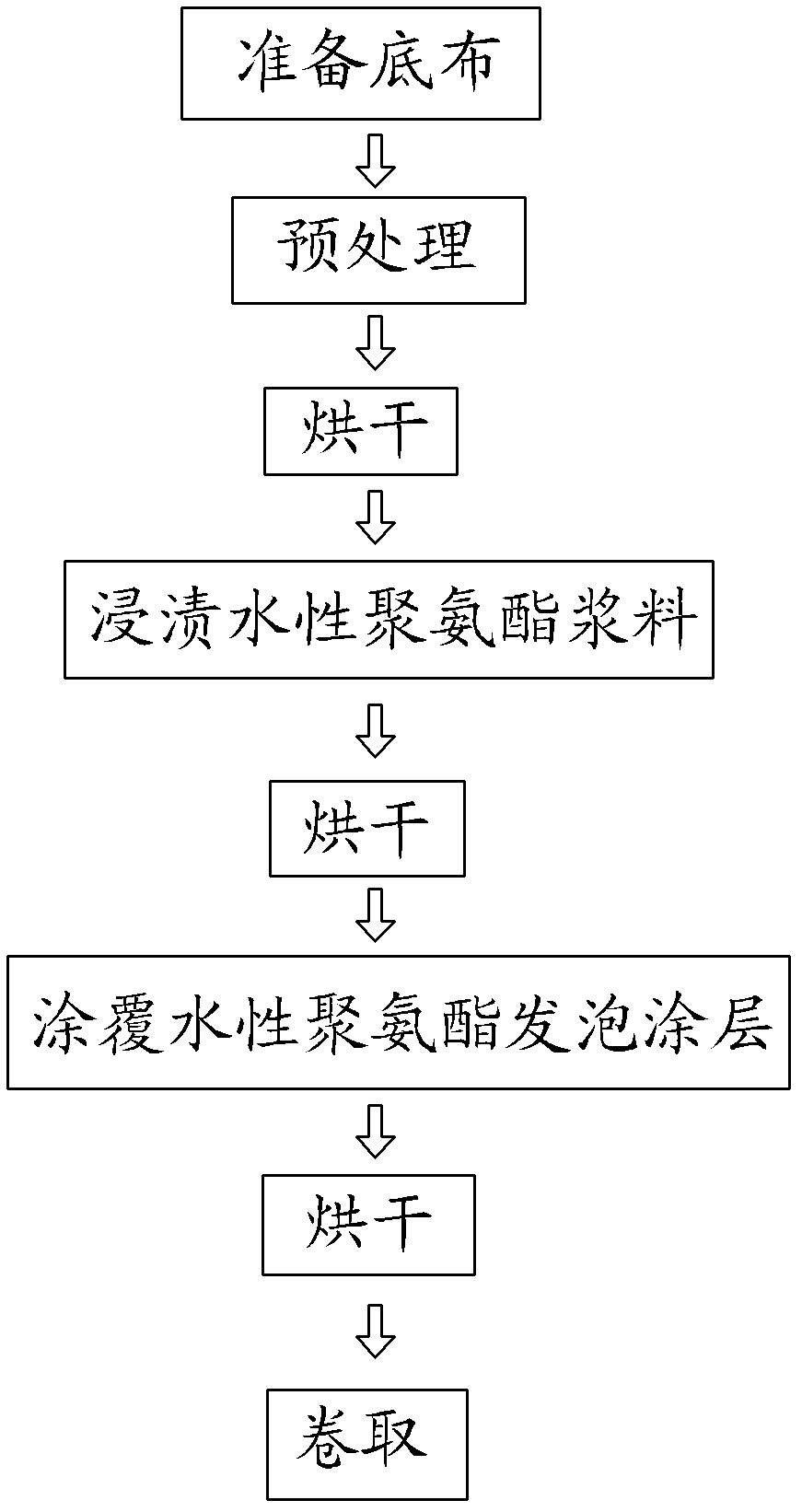

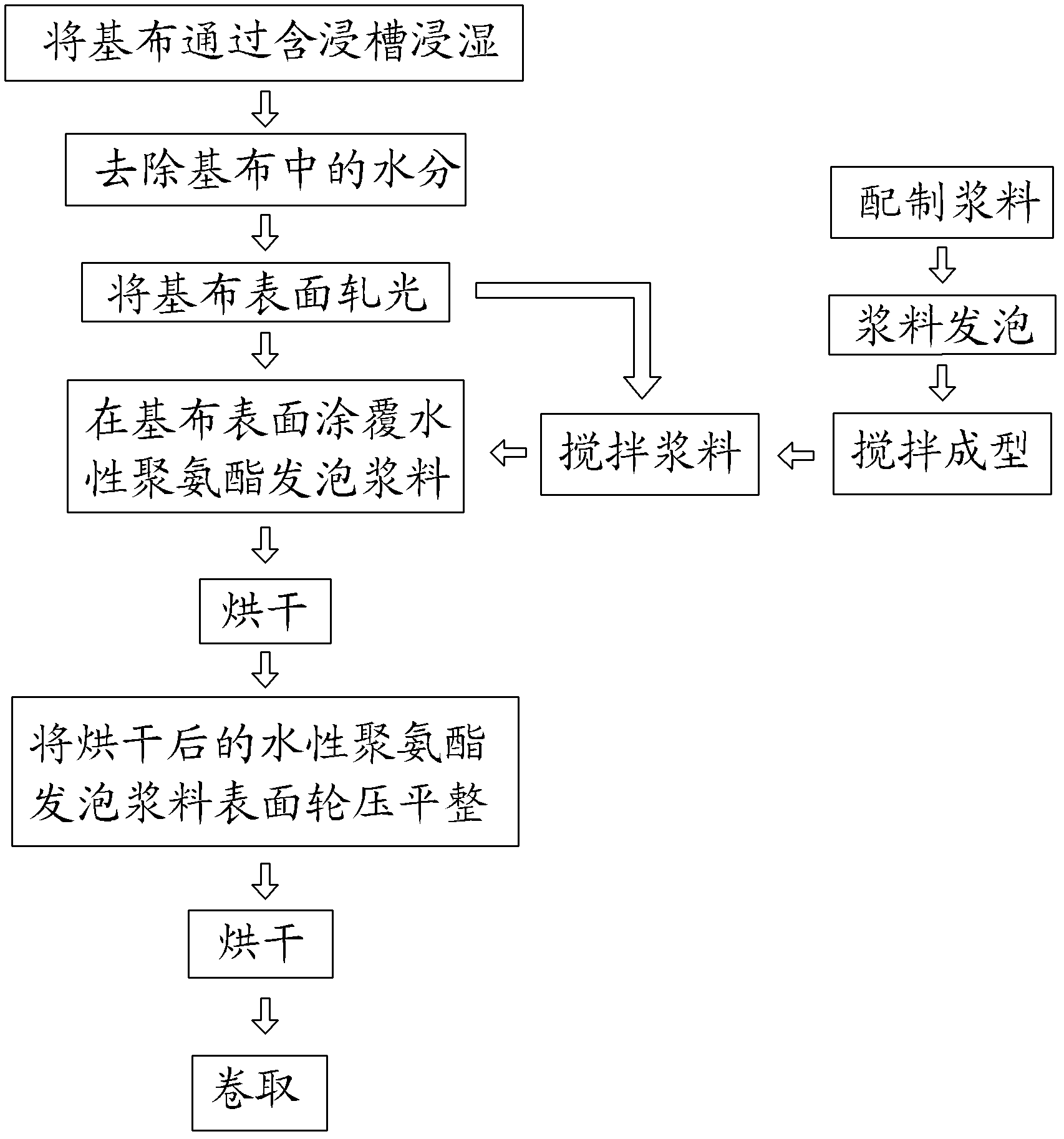

Preparation method of water-soluble polyurethane leather beth

ActiveCN102418284AReduce dosageHigh surface flatnessLiquid/gas/vapor textile treatmentPolymer scienceSolvent based

The invention relates to a preparation method of water-soluble polyurethane leather beth. The preparation method sequentially comprises the following steps of: a step A, soaking a base fabric; a step B, removing moisture in the base fabric; a step C, calendaring the surface of the base fabric; a step D, coating a water-soluble polyurethane foaming paste on the surface of the base fabric and then drying; and a step E, carrying out wheel loading and flattening on the surface of the dried water-soluble polyurethane foaming paste. By adopting the preparation method of the water-soluble polyurethane leather beth provided by the invention, the surface evenness of the product can be improved, the production cost can be reduced, the handfeel of the product is softer, and simultaneously the product is closer to a solvent-based synthetic leather beth product in appearance performance and physical properties.

Owner:FUJIAN POLYTECH TECH CO LTD

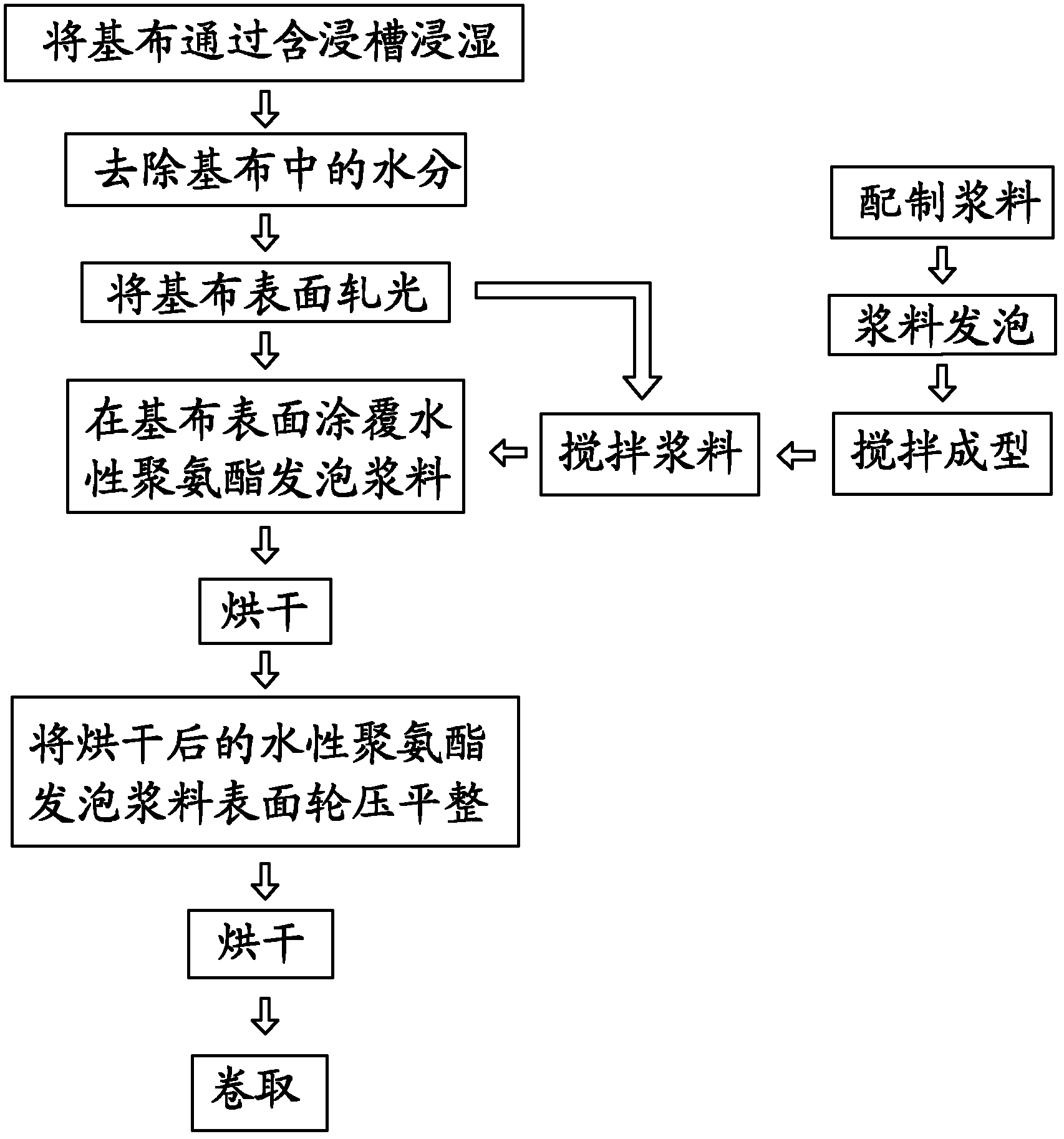

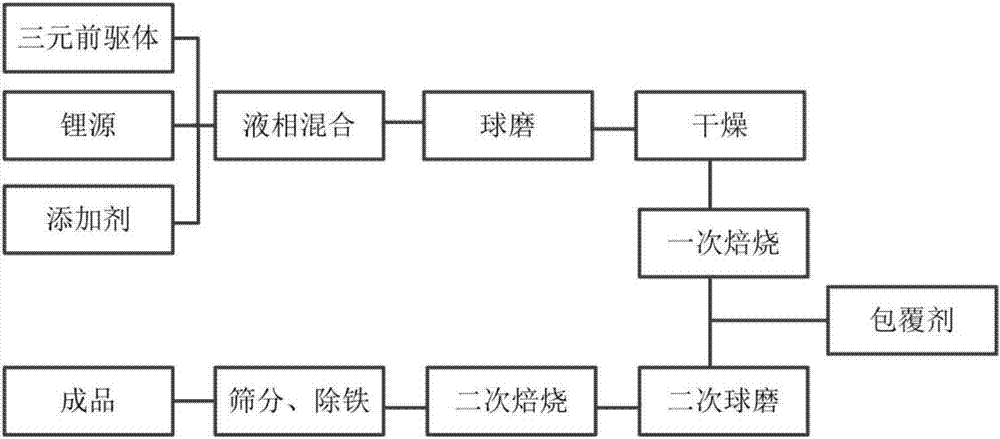

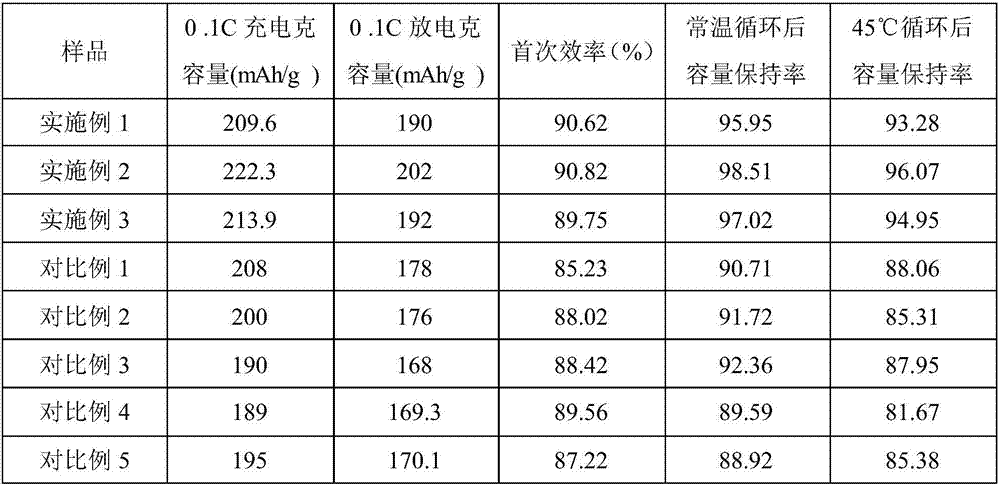

Preparation method of nickel-cobalt-manganese ternary anode material

The invention discloses a preparation method of a nickel-cobalt-manganese ternary anode material. The method comprises the following preparation steps: step A, screening a lithium source to obtain granules, and controlling the granularity D50 to be 3-8 mum for later use; step B, sequentially performing liquid phase mixing, wet ball milling and drying treatment on the lithium source granules obtained in step A, a ternary precursor LiNi0.6Co0.2Mn0.2(OH)3 and an additive to obtain mixed powder; step C, roasting the mixed powder obtained in step B for 5-15 h at the temperature of 500-850 DEG C; step D, mixing the primary roasted material obtained in step C with a coating agent, and performing ball milling to obtain a mixed material; and step E, performing secondary roasting on the mixed material obtained in step D for 10-20 h at the temperature of 750-950 DEG C to obtain the nickel-cobalt-manganese ternary anode material. The nickel-cobalt-manganese ternary anode material prepared by improving the raw material selection of the additive and the coating agent, introducing appropriate oxygen and adopting a two-roasting process has relatively high capacitance and first charge rate and long service life cycle.

Owner:四川新锂想能源科技有限责任公司

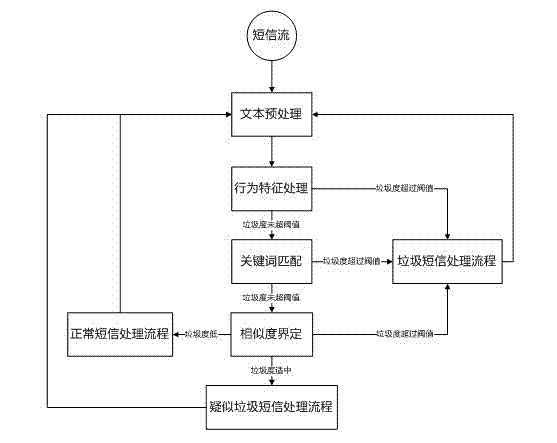

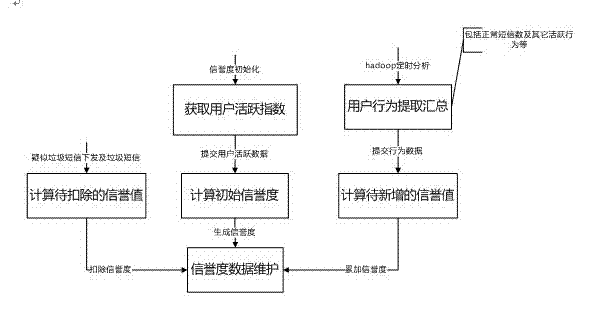

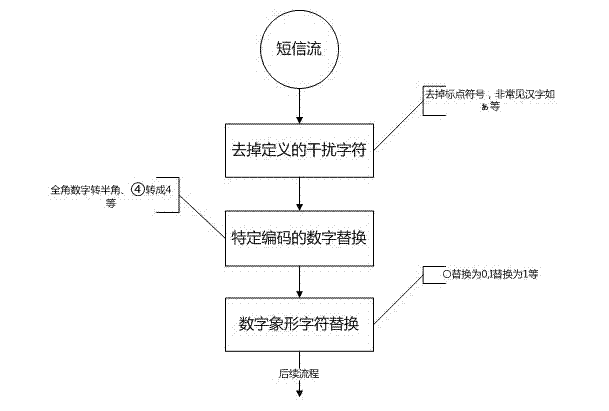

Short message filtering method based on user creditworthiness and short message spam degree

ActiveCN103037339AReal-time maintenance of reputationImplement filteringMessaging/mailboxes/announcementsSecurity arrangementUniform resource locatorSTEP-NC

The invention discloses a short message filtering method based on user creditworthiness and short message spam degree. The short message filtering method includes the following steps: a step A is that initial creditworthiness is given to each short message service user according to active conditions of the short message service user; a step B is text preprocessing, wherein normal punctuations are eliminated first, disturbing characters set by a system are identified, the number of the disturbing characters is recorded, the disturbing characters are eliminated, and digits with specific codes and pictographic codes are used for replacing the disturbing characters; a step C is that a cell phone number and a uniform resource locator (URL) address are extracted, and correlation behavior features of a short message are extracted; a step D is that the essential attribute of the spam degree is newly added to a keyword, the keyword is matched based on contents which are obtained after the text preprocessing in the step B, and all matched keywords are recorded; a step E is that similar contents are defined, and the short message spam degree is calculated based on the similarity; and a step F is that whether interception is conducted is judged by combination of the user creditworthiness and the short message spam degree. Due to the fact that the short message filtering method is based on the user creditworthiness and the short message spam degree, filtering of spam short messages can be realized more accurately, and misjudgments of the spam short messages can be reduced.

Owner:彩讯科技股份有限公司

Processing technology of camshaft

InactiveCN103433709ASimple processing technologyFlexible processing technologyMachine partsMechanical components

The invention belongs to the field of machine part machining, and particularly relates to a processing technology of a camshaft. The processing technology of the camshaft comprises the step A of blanking according to the standard that two finished products are blanked from each work-blank; the step B of carrying out rough machining, rough turning and end face flattening on the work-blank and machining eccentric circles through a numerically controlled lathe; the step C of thermal refining and enabling the rigid to be 26-31 HRC; the step D of carrying out half finish turning on the work-blank through the numerically controlled lathe; the step E of carrying out accurate grinding on the work-blank through a cylindrical grinding machine; the step F of carrying out linear cutting on the work-blank for forming two same products; the step G of carrying out flat facing through the numerically controlled lathe; the step H of carrying out punching through a machining center and carrying out punching and chamfering on the two products; and the step I of thermal treating. The processing technology of the camshaft is simple, the two products can be machined at the same time, and therefore the producing and machining cost is saved greatly, the production efficiency is improved, the processing technology is flexible, and the universality is good.

Owner:宁波富莱茵汽车部件有限公司

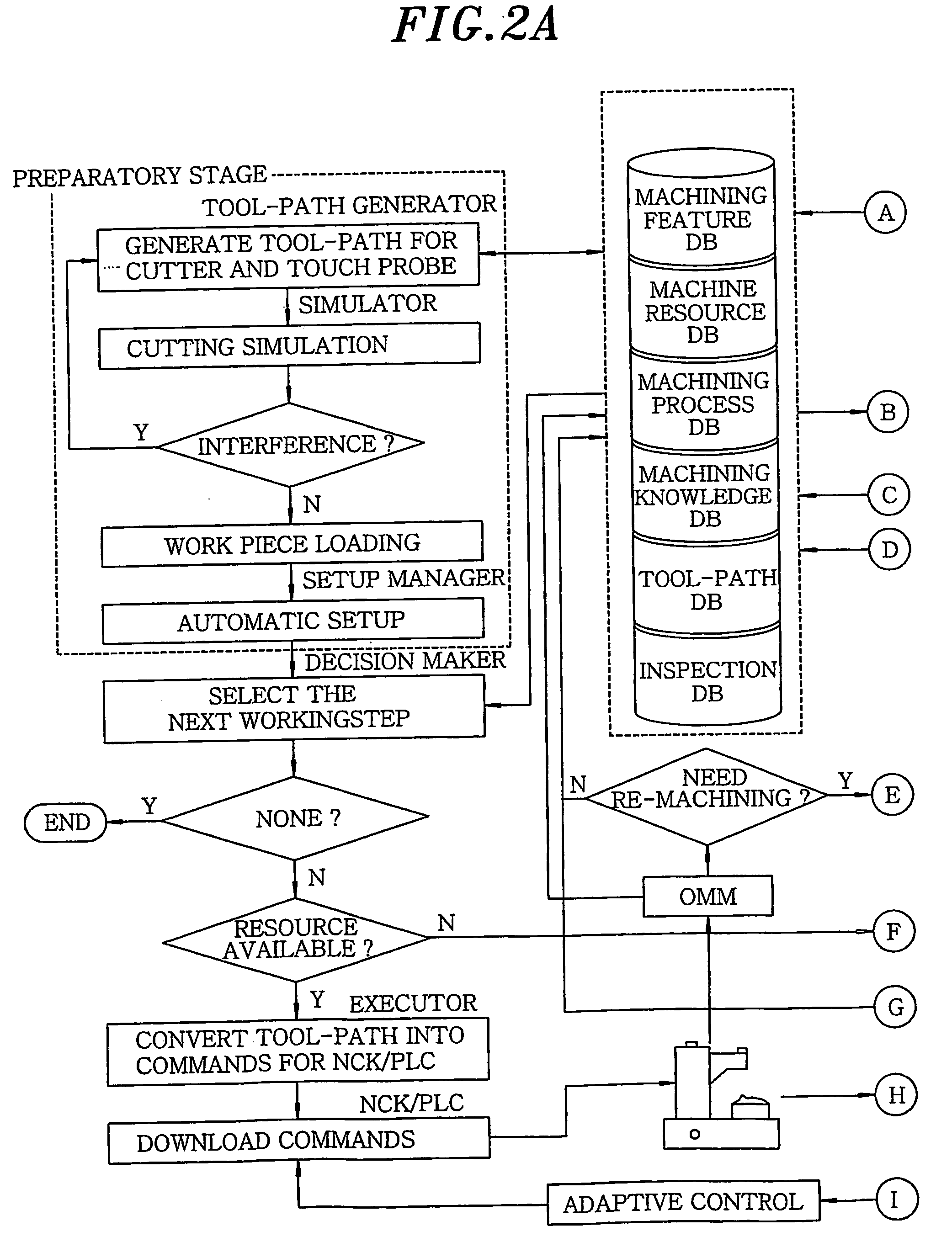

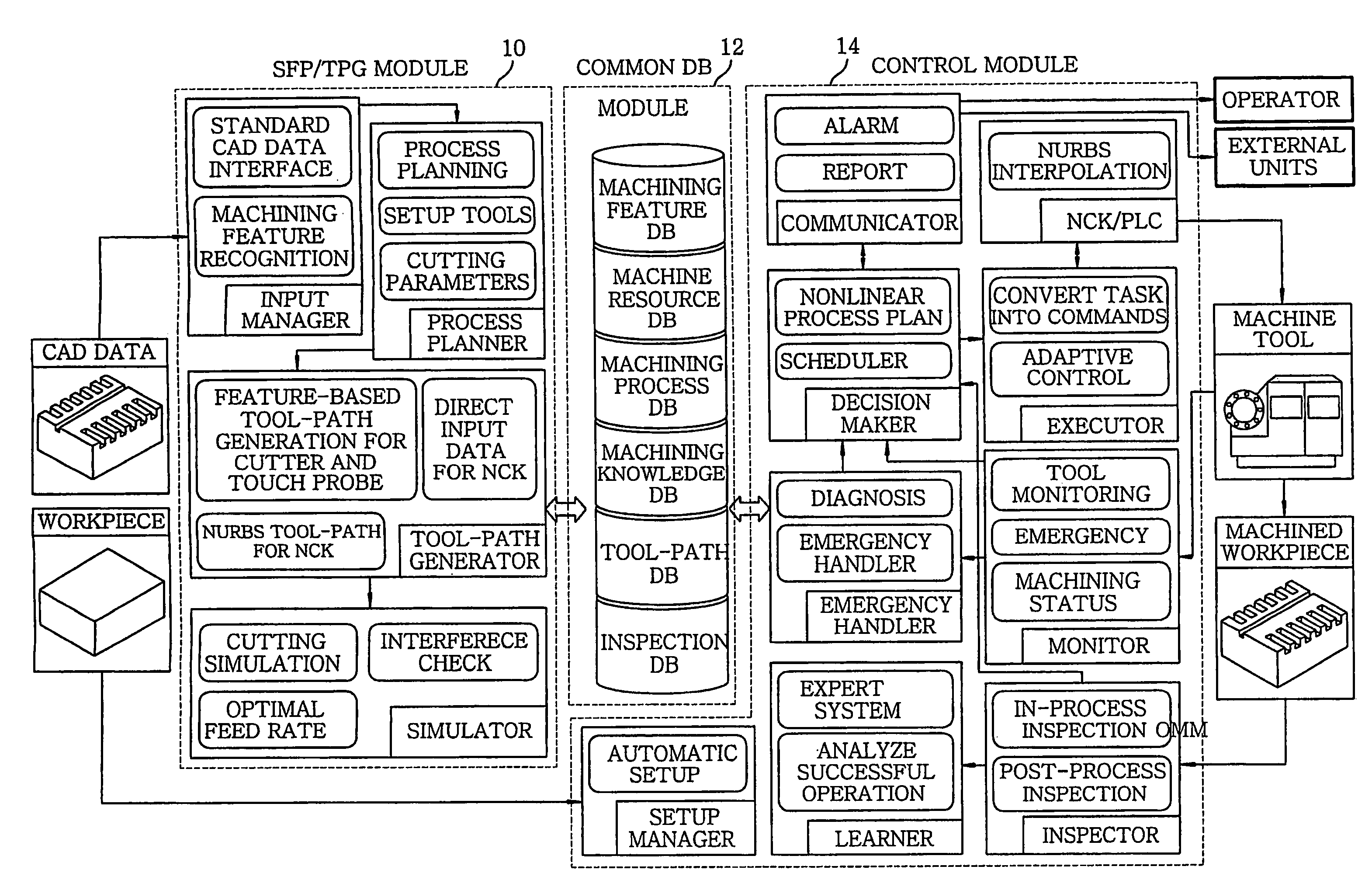

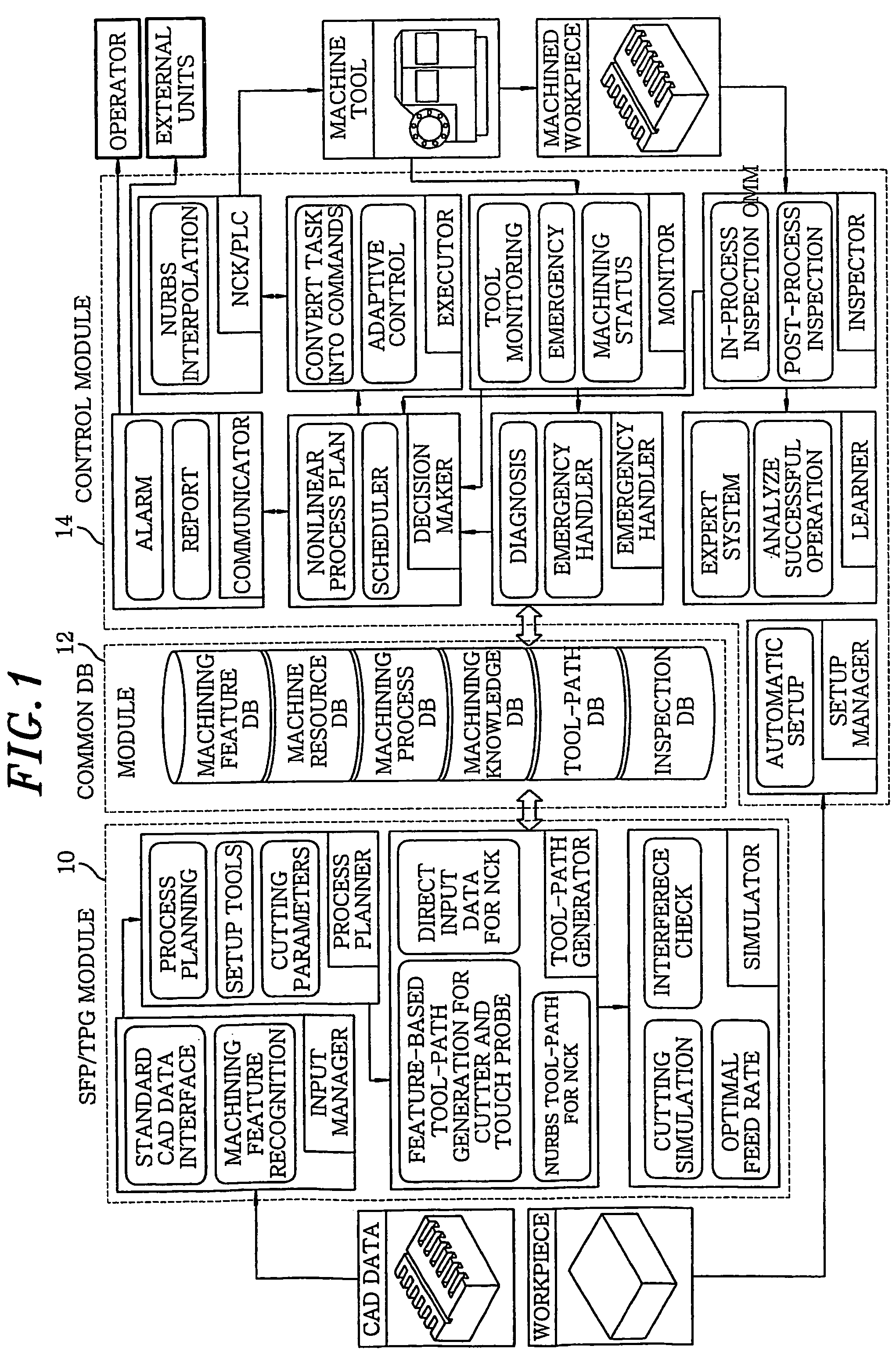

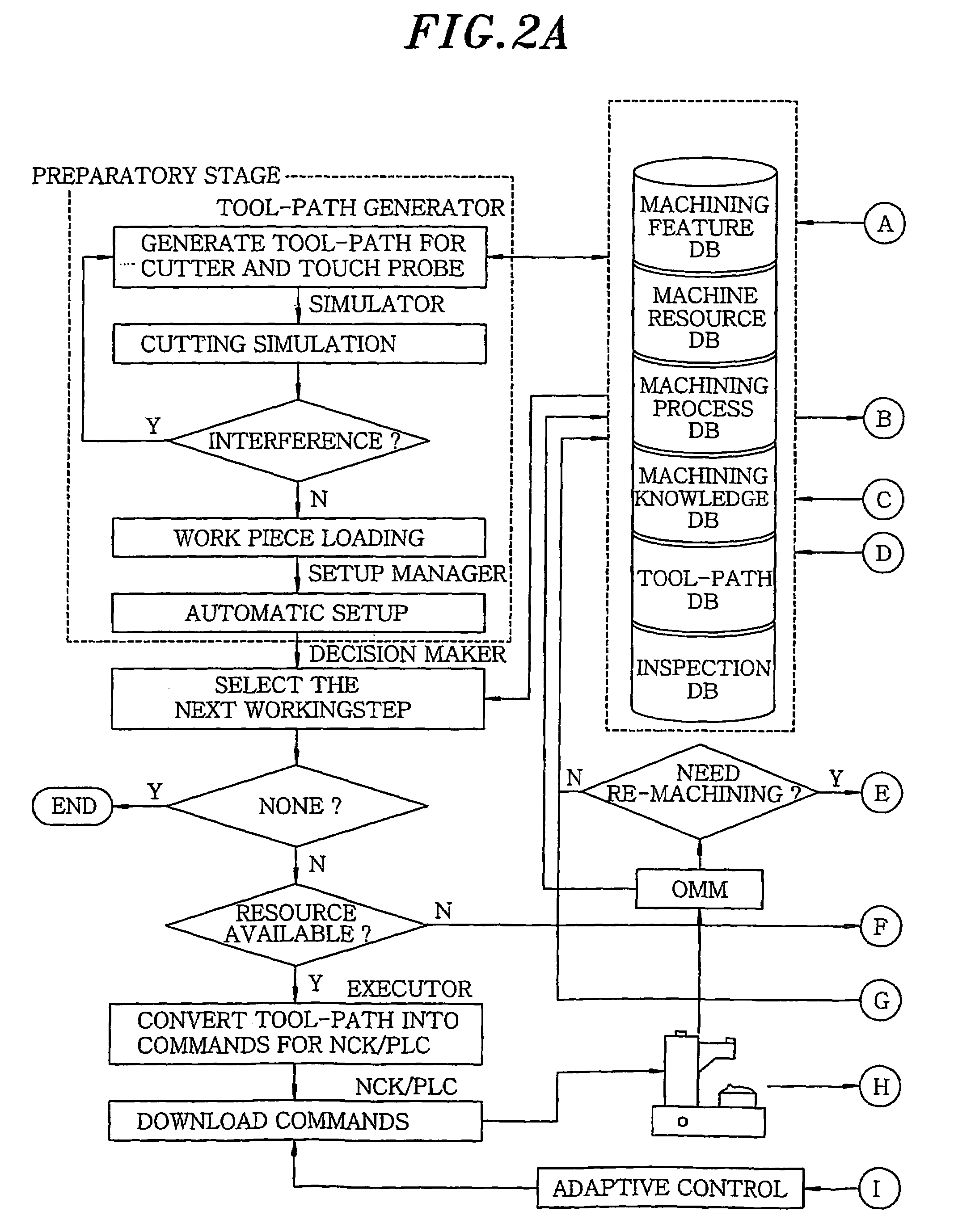

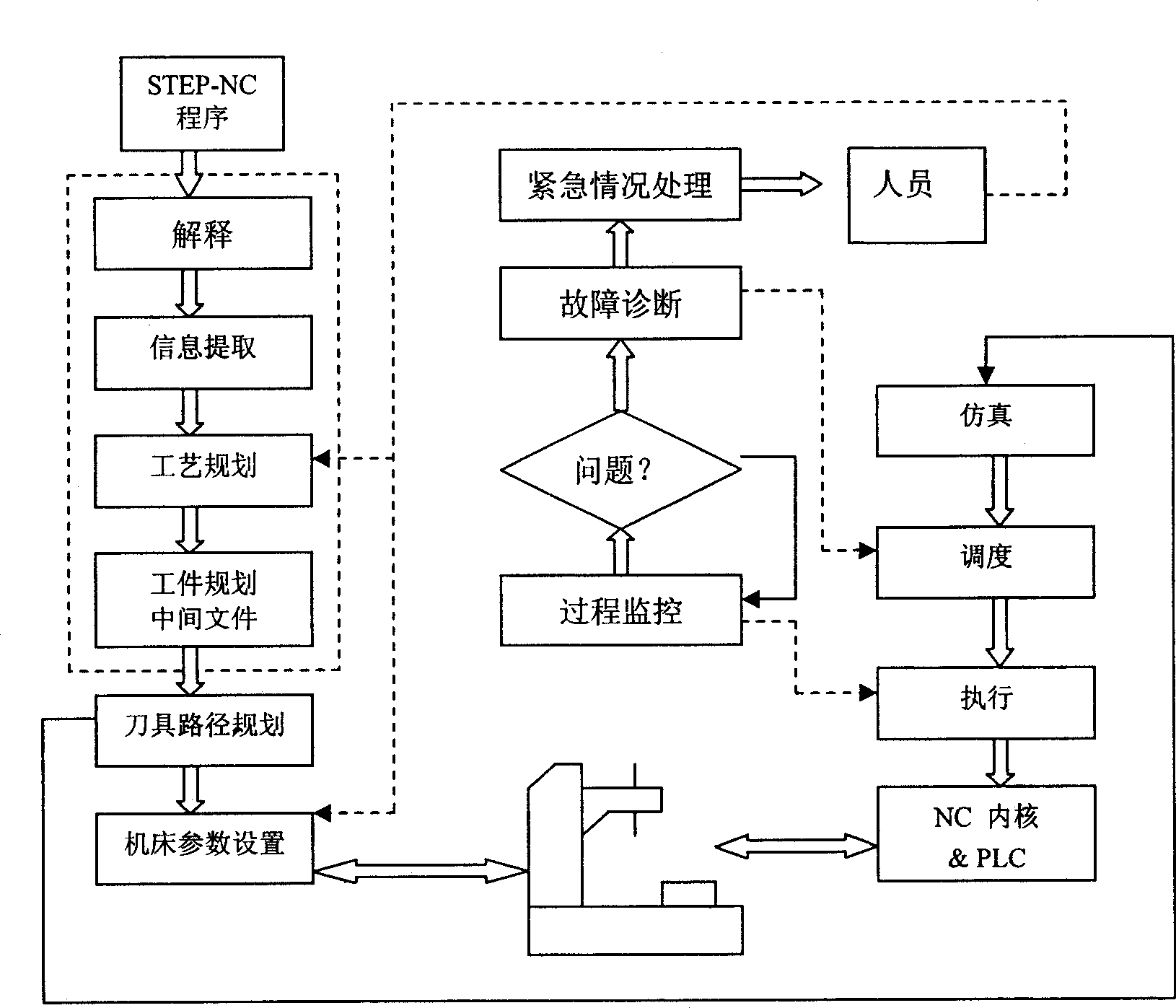

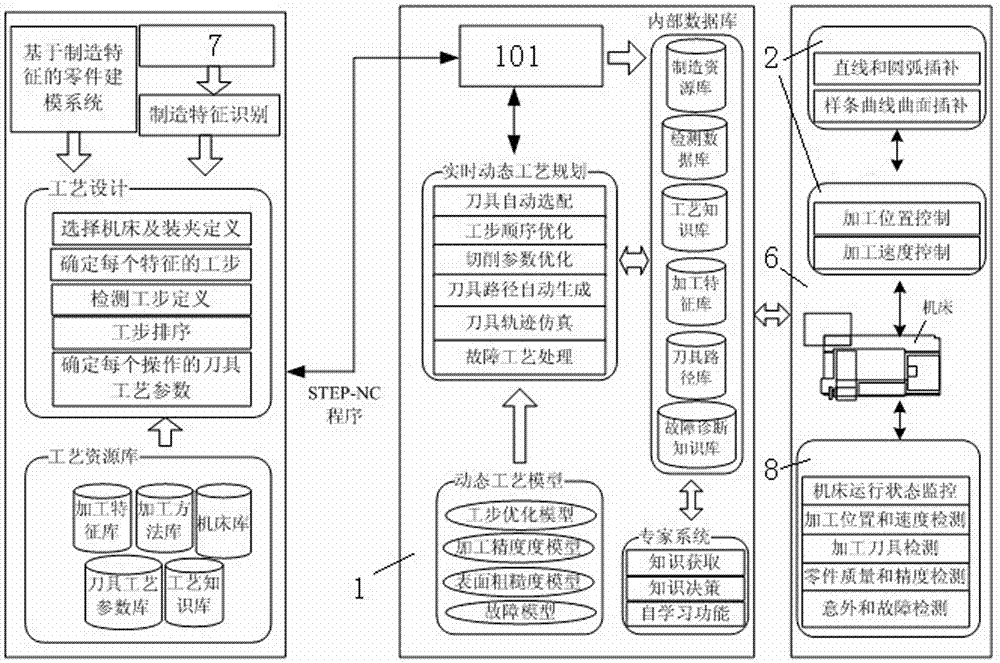

Intelligent step-nc controller

InactiveUS20050171629A1Improve efficiencyMinimize directionProgramme controlAutomatic control devicesEngineeringCam

An intelligent STEP-NC (Standard for the Exchange of Produce model-Numerical Controller) overcomes short-comings of conventional NCs with a closed structure The intelligent STEP-NC intelligently performs a machining process based on ISO 14649 data while autonomously coping with an emergency at a shop-floor. Thus, the discontinuity of information in a CAD-CAM-CNC chain where the current NCs are operated can be overcome and the concept of “design-to-manufacture” can be realized.

Owner:POSTECH ACAD IND FOUND

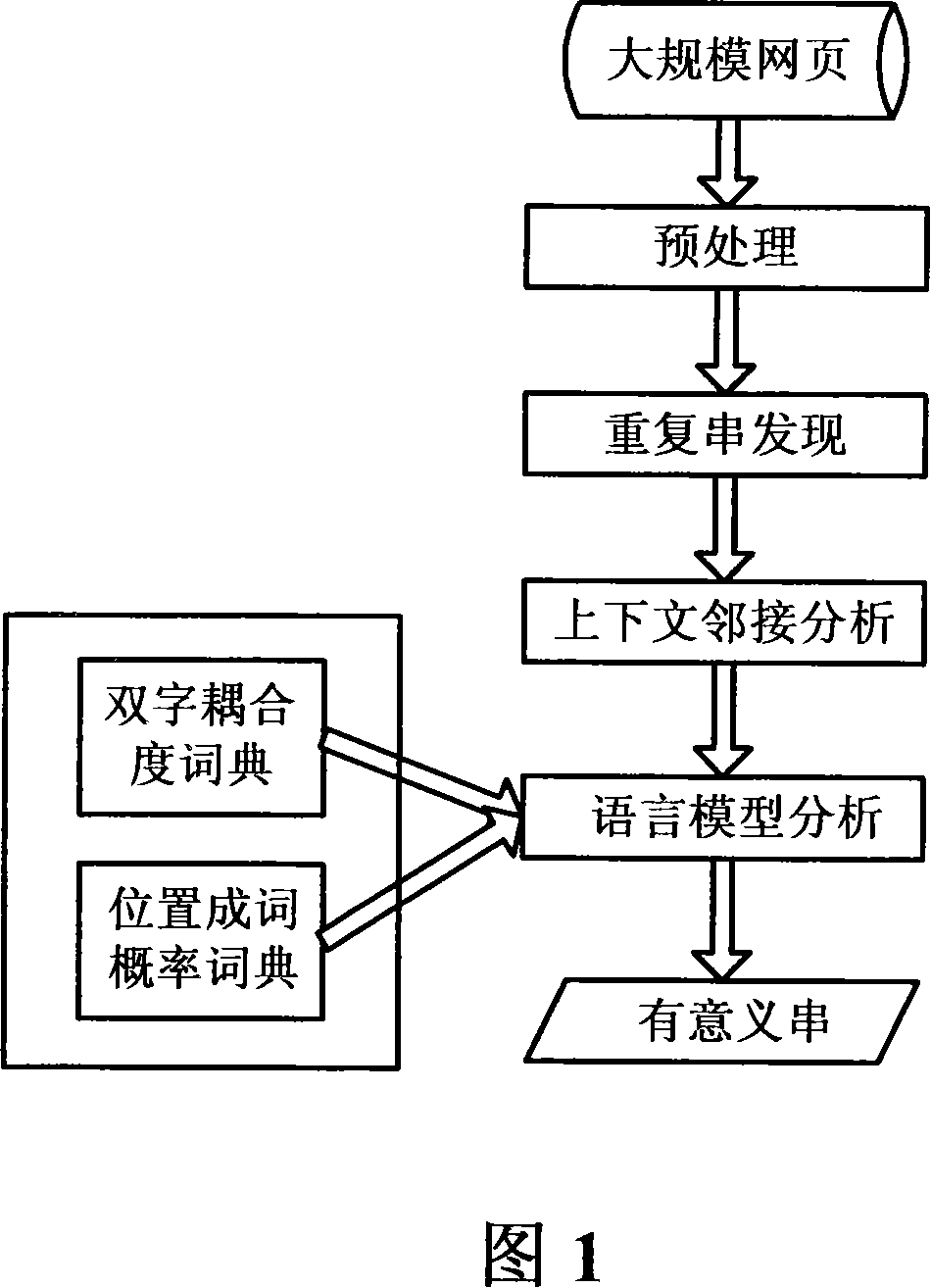

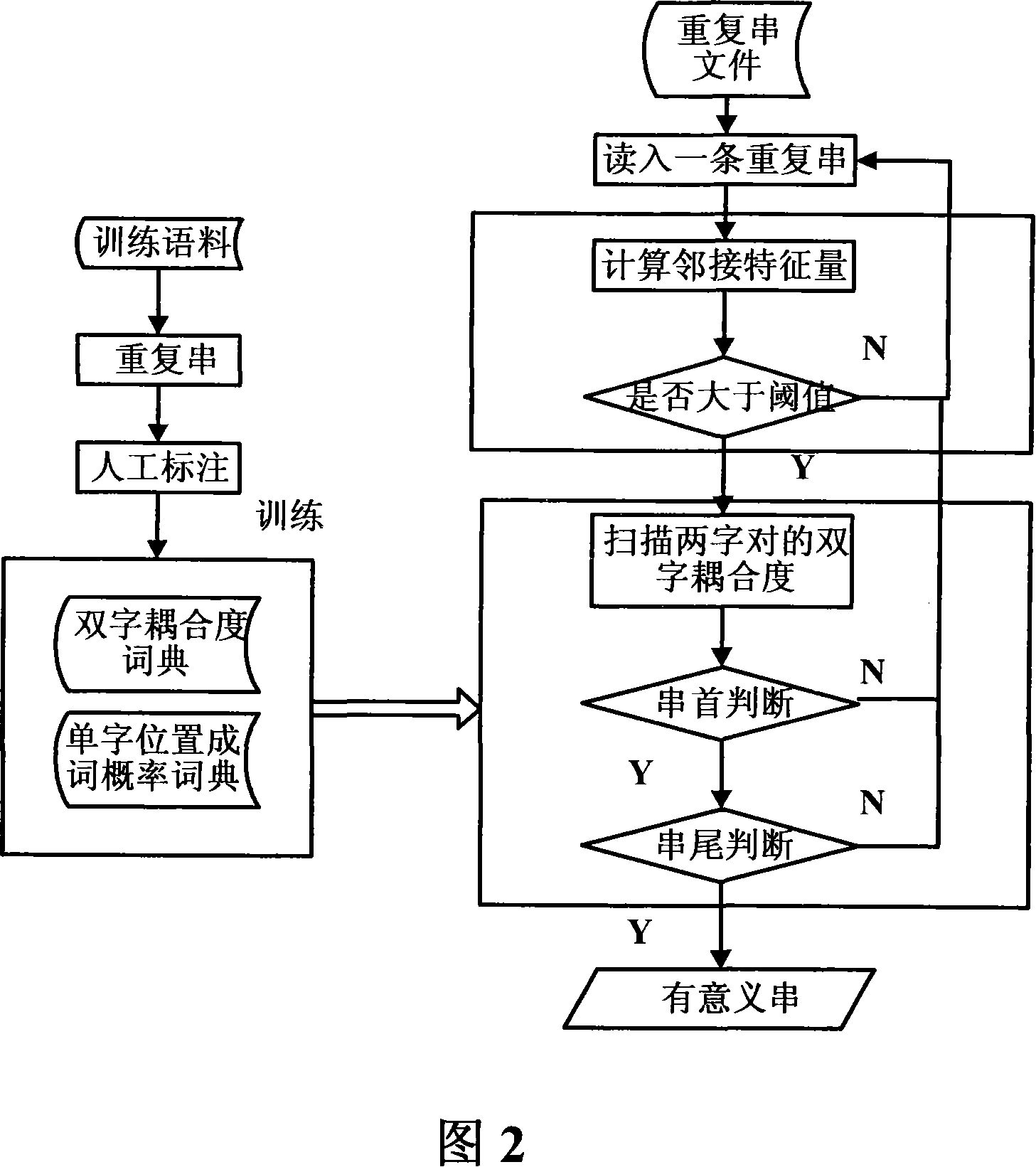

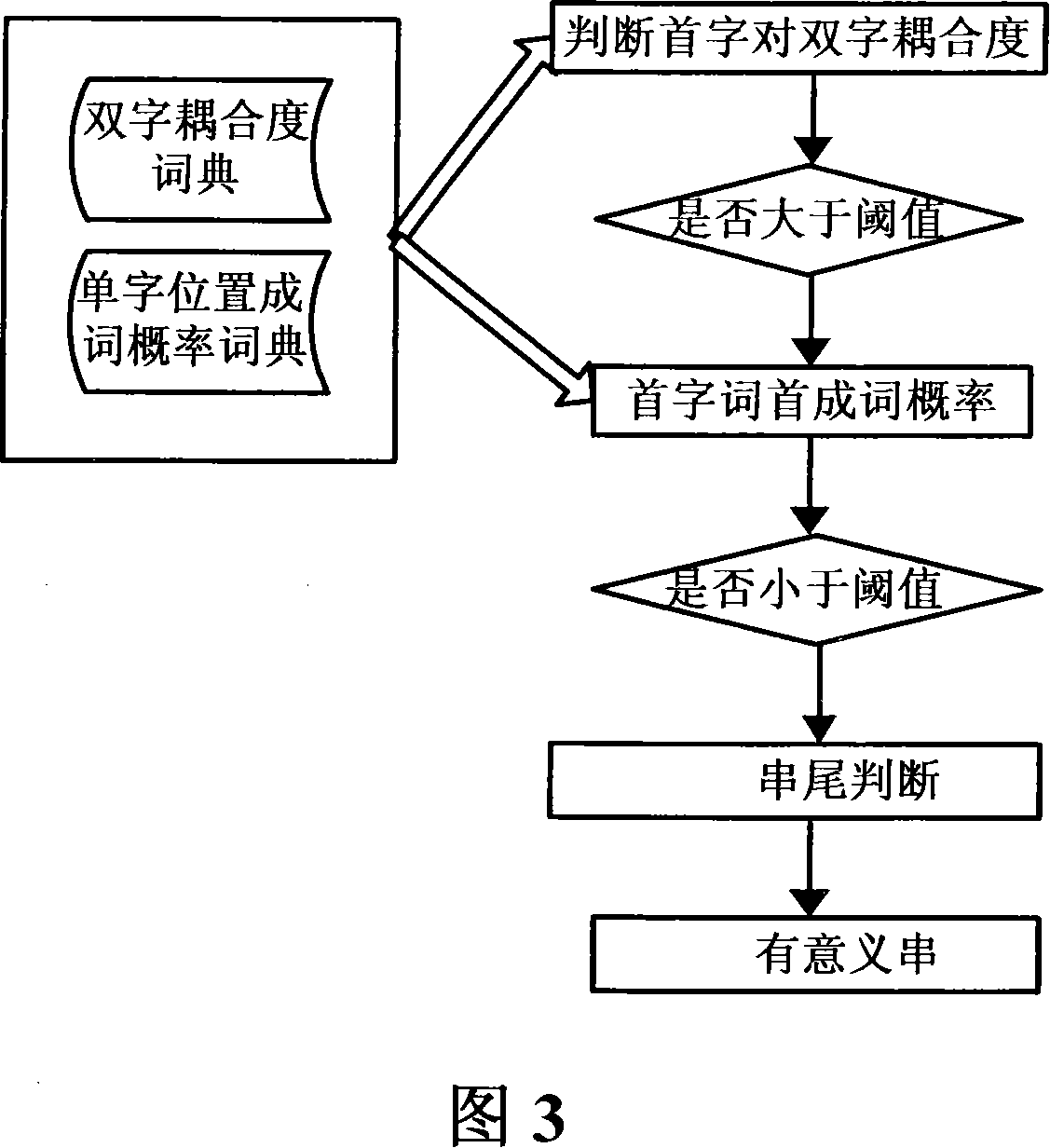

Internet faced sensing string digging method and system

InactiveCN101149739AReduce time complexityEvenly distributedSpecial data processing applicationsThe InternetSTEP-NC

The invention discloses an Internet-oriented meaningful excavating method and system. The method includes the following steps: step A, repeat character string discovery; steps B, filter the character string through analysis the context; steps C, analysis and filter character string through language model. It can effectively extract net page or meaningful string in large scale of text data.

Owner:INST OF COMPUTING TECH CHINESE ACAD OF SCI

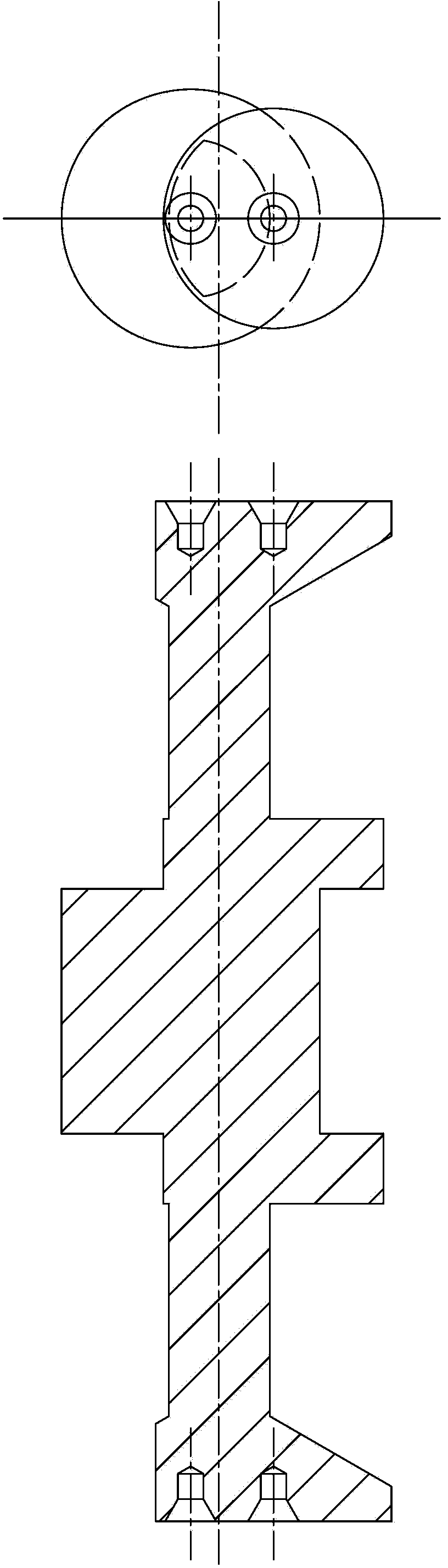

Intelligent STEP-NC controller

InactiveUS7099737B2Improve efficiencyMinimize directionProgramme controlAutomatic control devicesProduction modelEngineering

An intelligent STEP-NC (Standard for the Exchange of Produce model-Numerical Controller) overcomes short-comings of conventional NCs with a closed structure The intelligent STEP-NC intelligently performs a machining process based on ISO 14649 data while autonomously coping with an emergency at a shop-floor. Thus, the discontinuity of information in a CAD-CAM-CNC chain where the current NCs are operated can be overcome and the concept of “design-to-manufacture” can be realized.

Owner:POSTECH ACAD IND FOUND

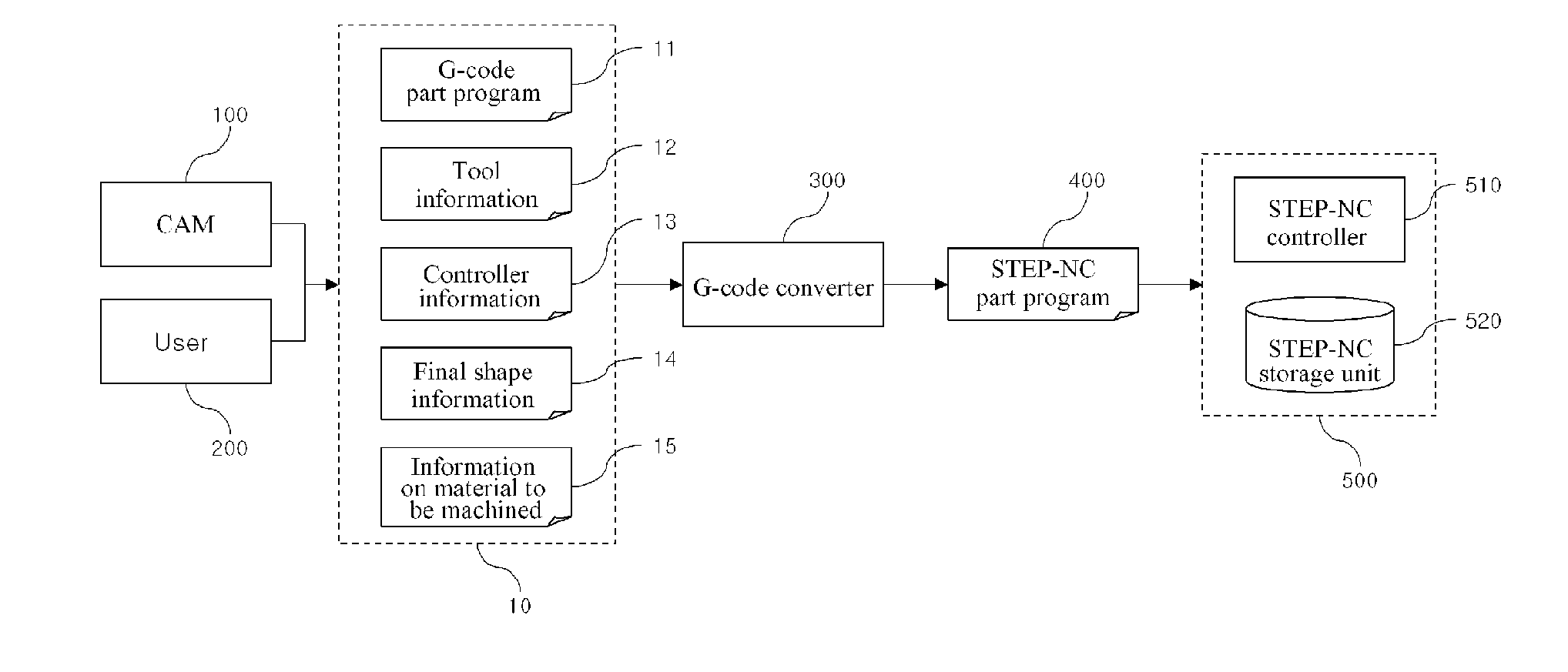

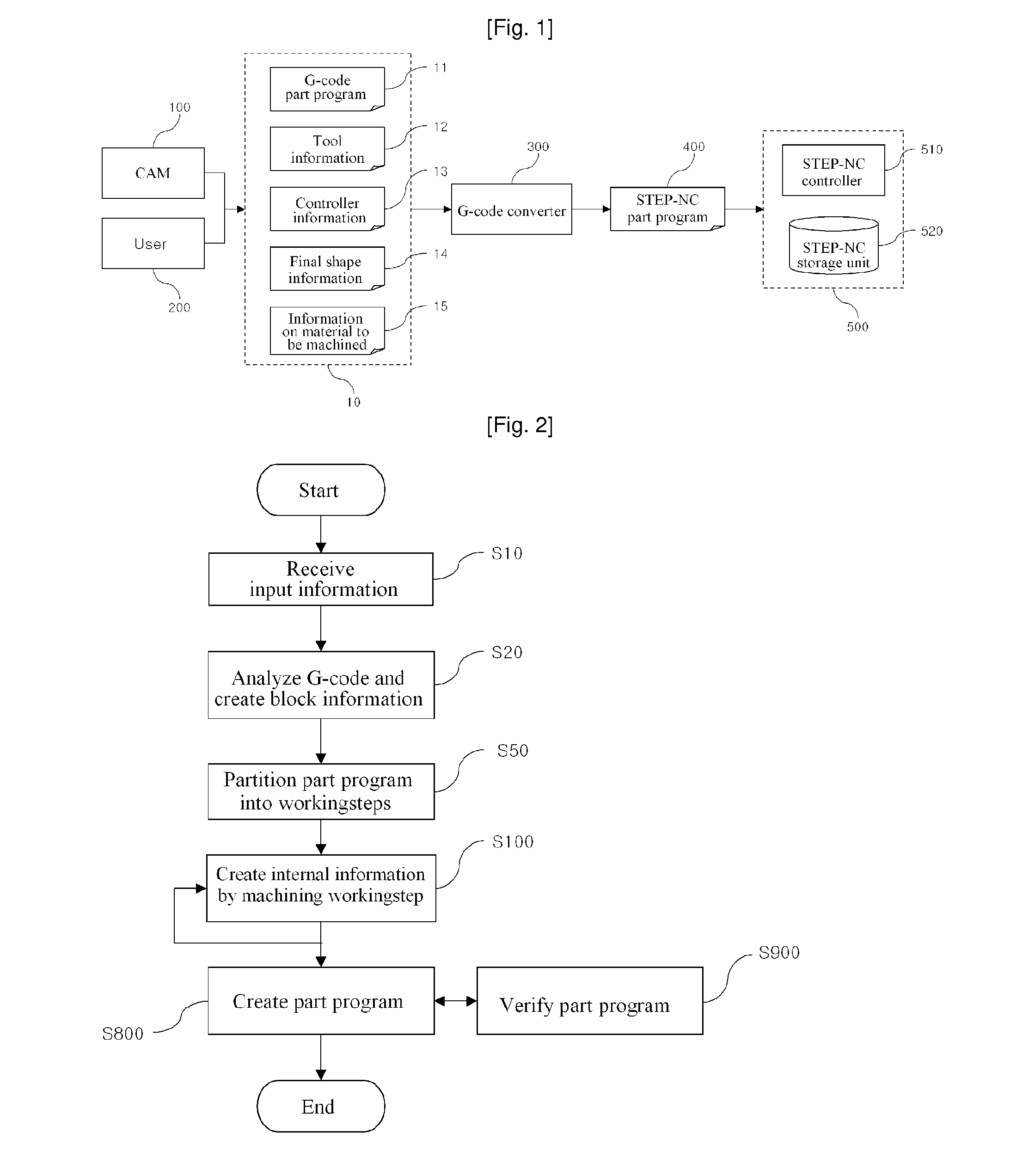

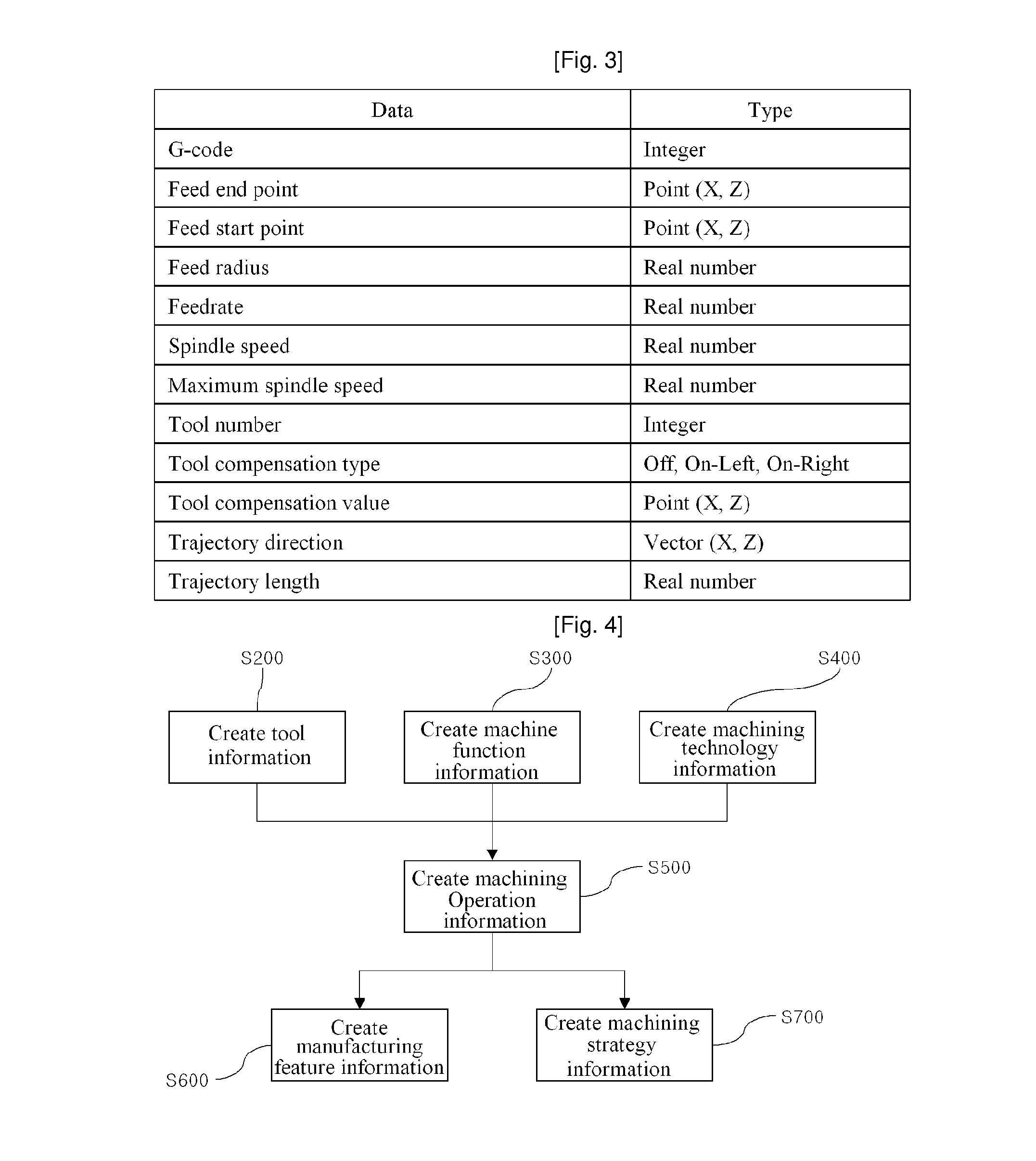

Transformation Method Of G-Code Into Step-Nc Part Program

A method of transforming a G-code type part program into a STEP-NC language type part program is provided and more particularly, a method is provided for enabling a G-code type part program mainly used in the field to be easily applied to a STEP-NC controller without a troublesome correction. A STEP-NC language type part program is automatically created, which is composed of machining operation information, manufacturing feature information, machining strategy information and the like, through a process of analyzing G-codes from the G-code type part program and tool information. A method of transforming a G-code into a STEP-NC part program includes receiving a G-code part program, tools and a numerical controller; creating G-code block information, and partitioning the entire part program on a workingstep basis. The method further includes creating machining strategy information and creating the STEP-NC part program by arranging the machining workingsteps.

Owner:POSTECH ACAD IND FOUND

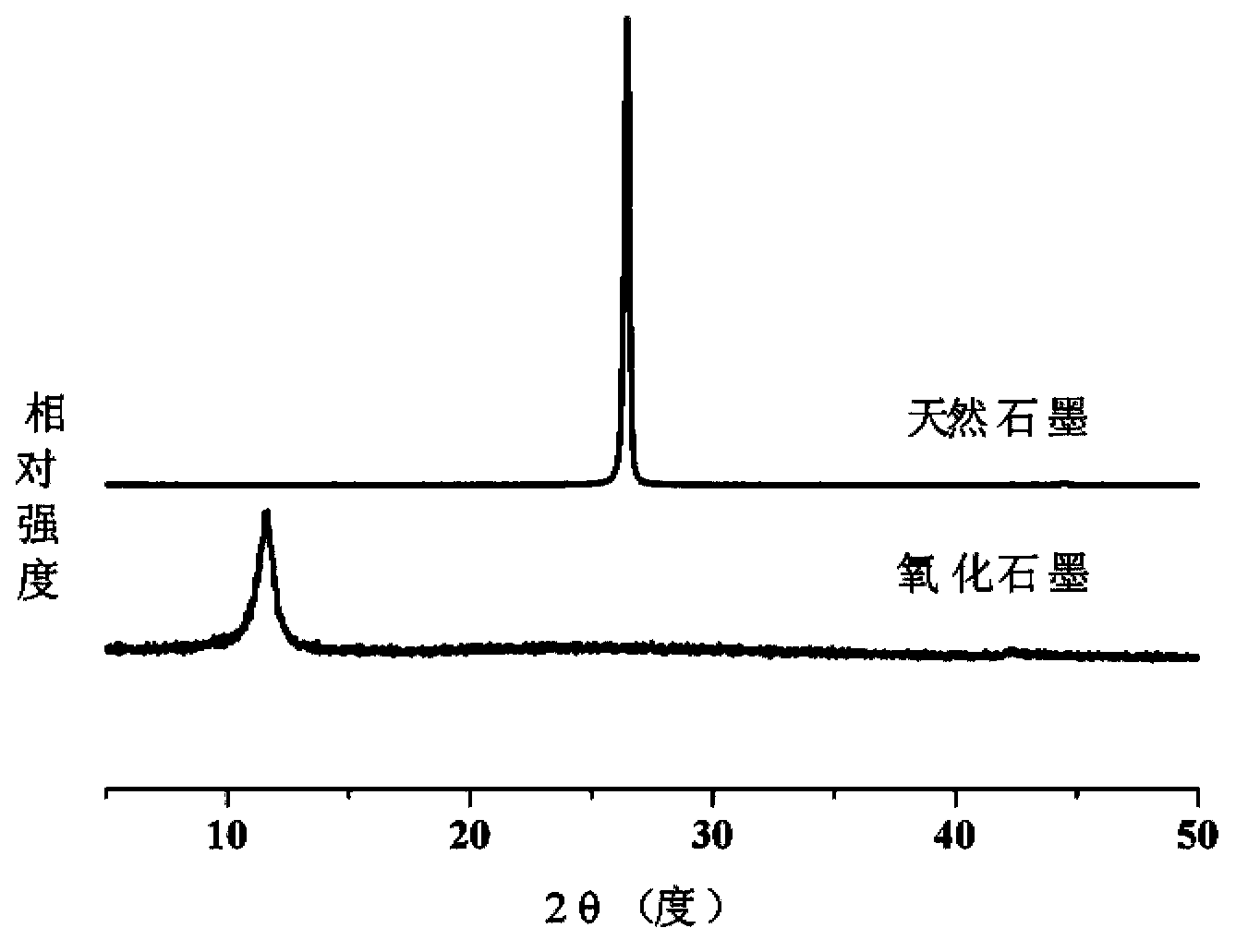

Preparation method of graphite oxide

The invention provides a process method for preparing graphite oxide. The process method comprises the following steps: a. mixing graphite, a nitric acid compound, permanganate and concentrated sulfuric acid; b. heating to 50 to 90 DEG C, and reacting for 10 minutes and 10 hours; c. pouring the solution obtained in the step b into a vessel B containing water or an ice water mixture under 0 to 60 DEG C; d. adding hydrogen peroxide to the product obtained in the step c to obtain a graphite oxide dispersion liquid; and e. filtering, washing and drying the dispersion liquid obtained in the step d to obtain graphite oxide powder. By adopting the method, the risk in the preparation of graphite can be reduced; the requirements on production equipment can be reduced; and the stripping effect of graphite oxide can be remained. The graphite oxide prepared by the method can be used for preparing graphene as well as be applicable to the cell materials, composite materials, electronic devices, energy storage material and other fields.

Owner:TORAY ADVANCED MATERIALS RES LAB CHINA

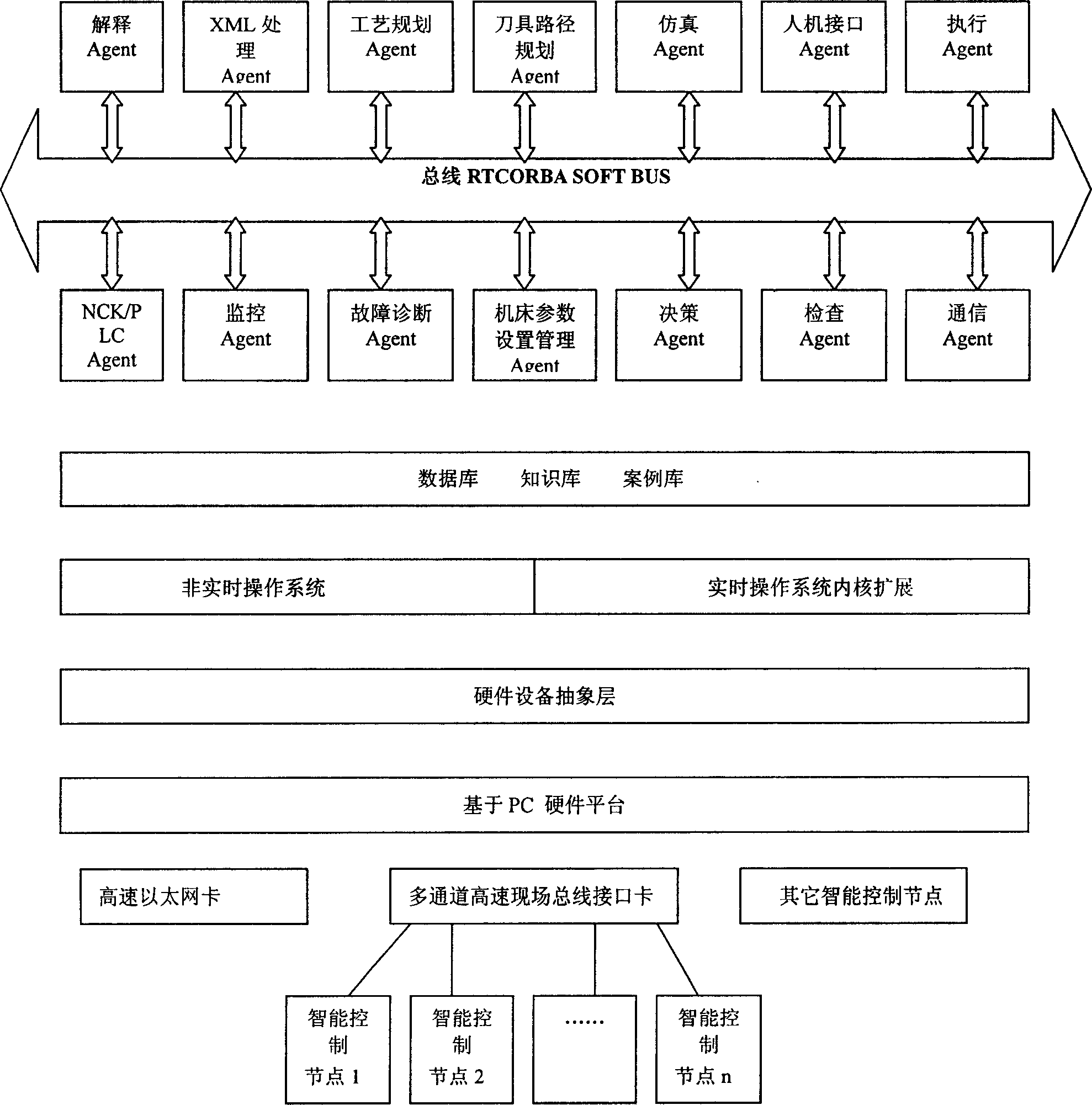

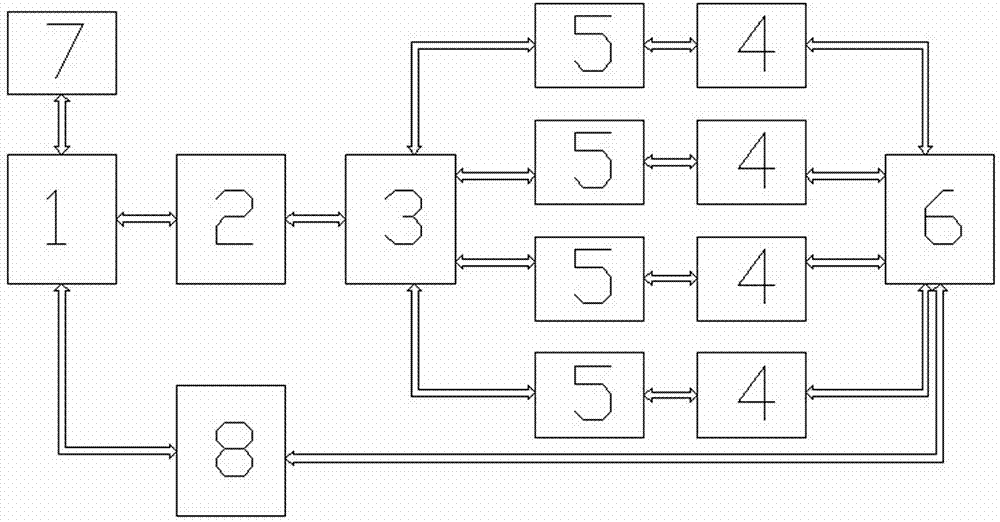

Intelligent STEP-NC controller system and its complementing method

InactiveCN1912783AStrong real-time processing functionWell reconfigurableNumerical controlBus interfaceSTEP-NC

An intelligent STEP-NC controller system us prepared as applying real time soft bus RTCORBA to carry out communication between various function agent modules at application layer, using high speed real time serial bus and core expansion of real time operation system to control high real time module in digital control system, providing information and data to application layer by data layer, operating application layer and data layer as well as operation system layer based on PC hardware platform being used to connect with various peripheral devices through bus interface card.

Owner:SHANDONG UNIV

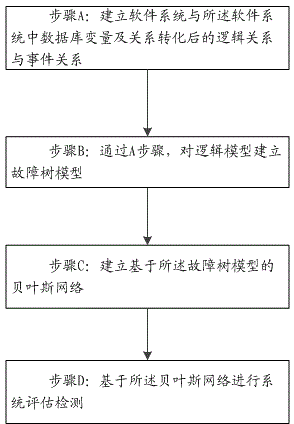

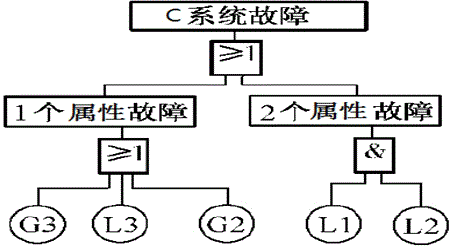

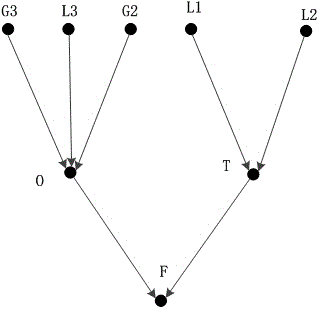

System evaluation and detection method by Bayesian model

InactiveCN104573386ASmall amount of calculationReduce computational difficultySpecial data processing applicationsSoftware systemComputational complexity theory

The invention discloses a system evaluation and detection method by a Bayesian model. The method includes: step A, establishing a logic relationship and an event relationship between a software system and a database therein after variable and relationship conversion; step B, establishing a fault tree model for a logic model according to the step A; step C, establishing a Bayesian network based on the fault tree model; step D, conducting system evaluation and detection based on the Bayesian network. The system evaluation and detection method by the Bayesian model has the advantages of low computational complexity, low computational difficulty, simplicity and practicality when used for system evaluation and detection by the Bayesian model.

Owner:STATE GRID SICHUAN ELECTRIC POWER CORP ELECTRIC POWER RES INST +2

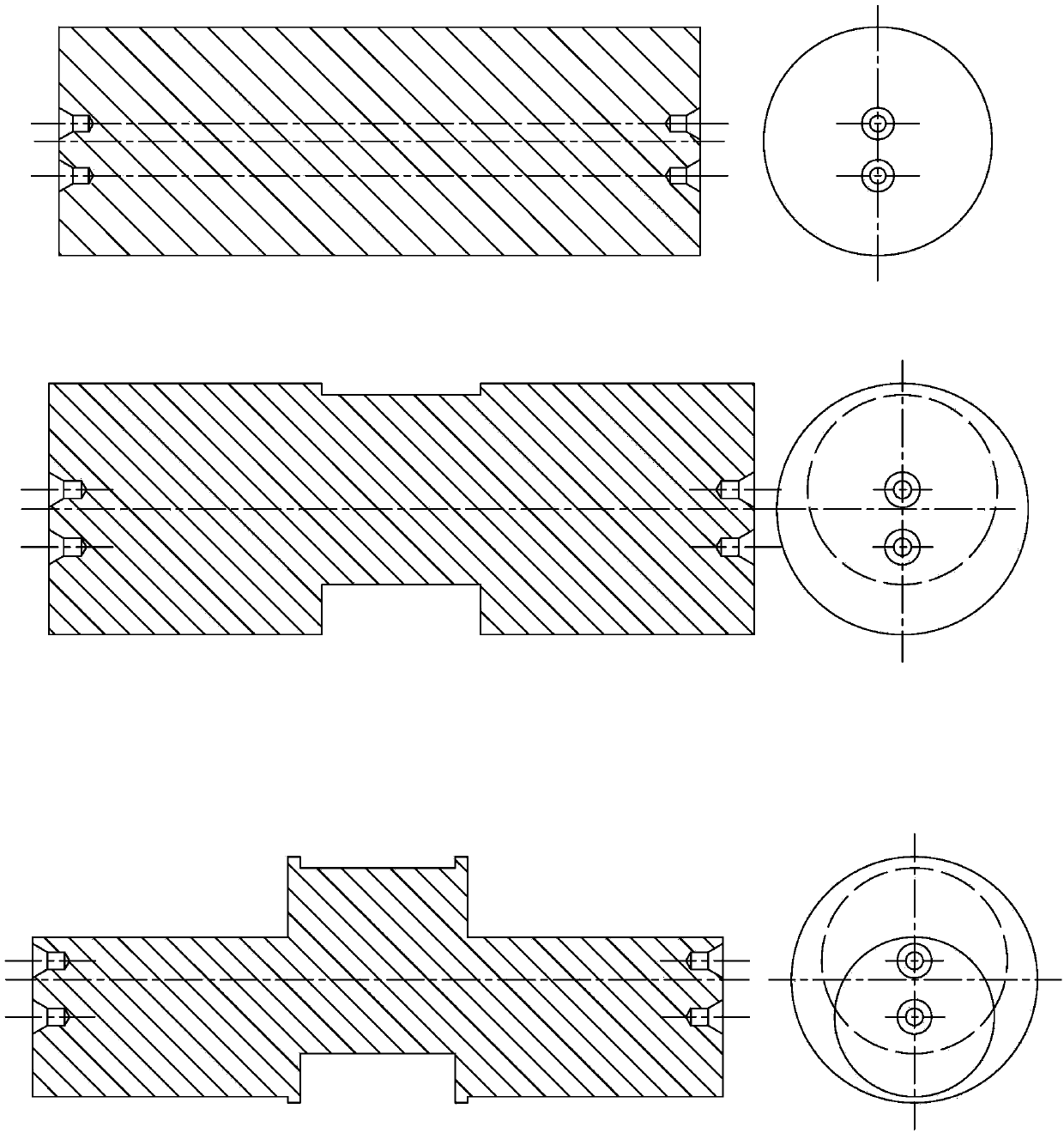

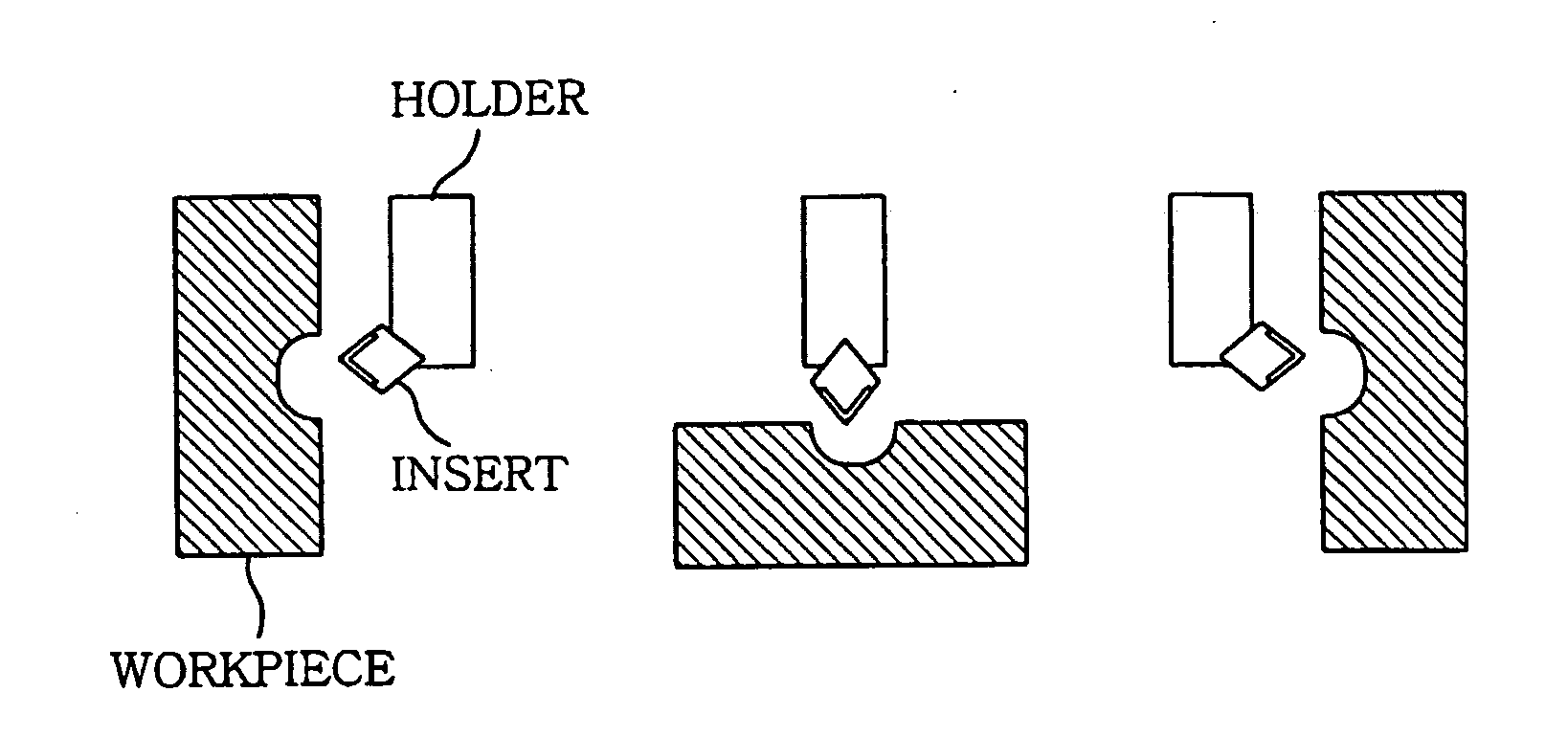

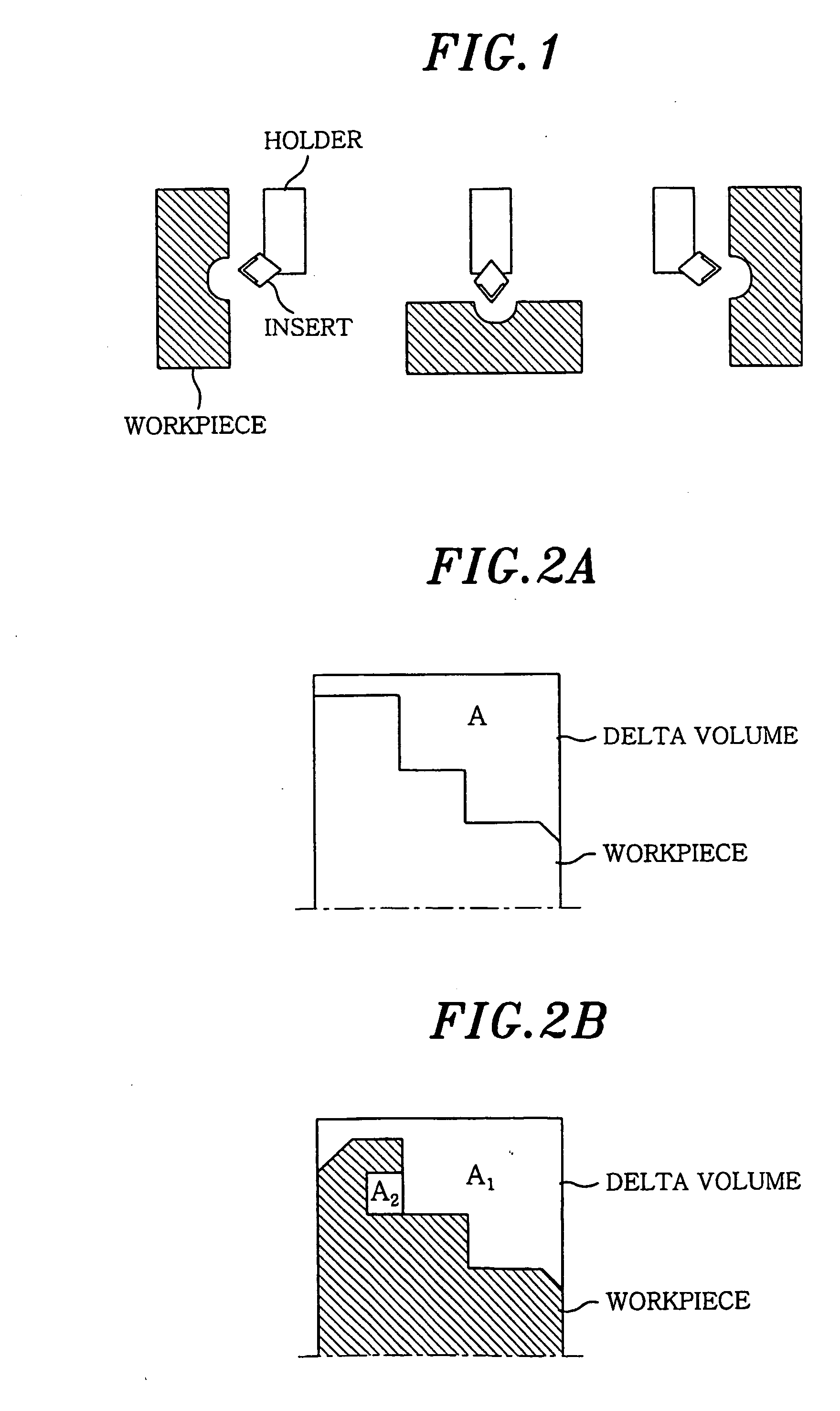

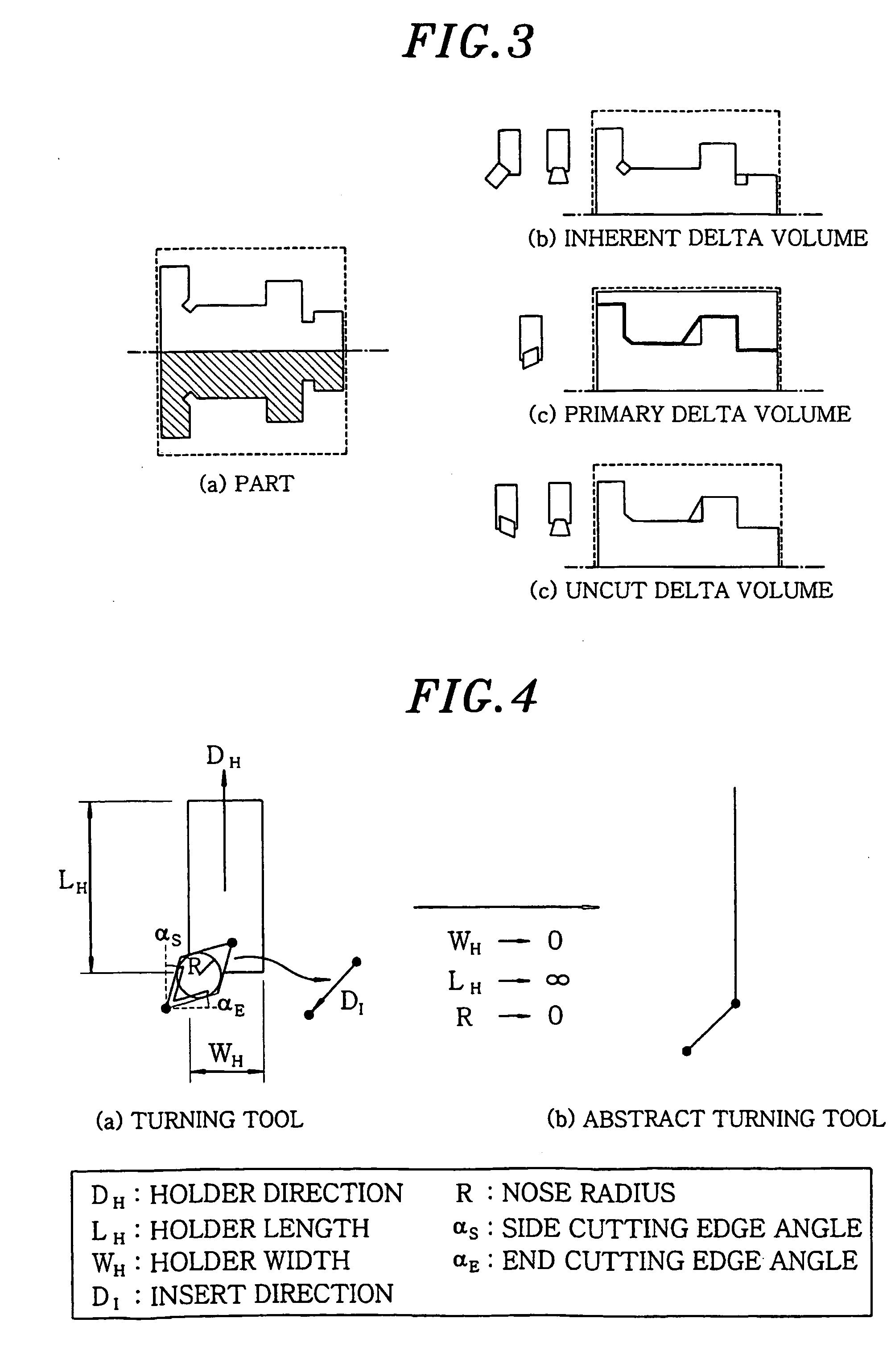

Method for performing delta volume decomposition and process planning in a turning step-nc system

A profile of a finished part is recognized based on an inputted CAD data. A delta volume for the finished part is decomposed based on information on cutting tools and the profile. Thereafter, a dependency graph representing precedence relation between the decomposed delta volumes is generated. And then, a process sequence graph representing process plans is generated based on the dependency graph. The delta volume decomposition is performed based on information on cutting tools and a machine configuration as well as part geometry, such that the decomposed delta volumes are suitable to be cut away from a raw stock by the cutting tools.

Owner:POSTECH ACAD IND FOUND

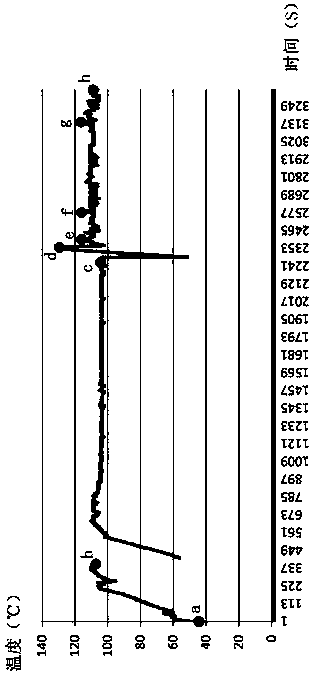

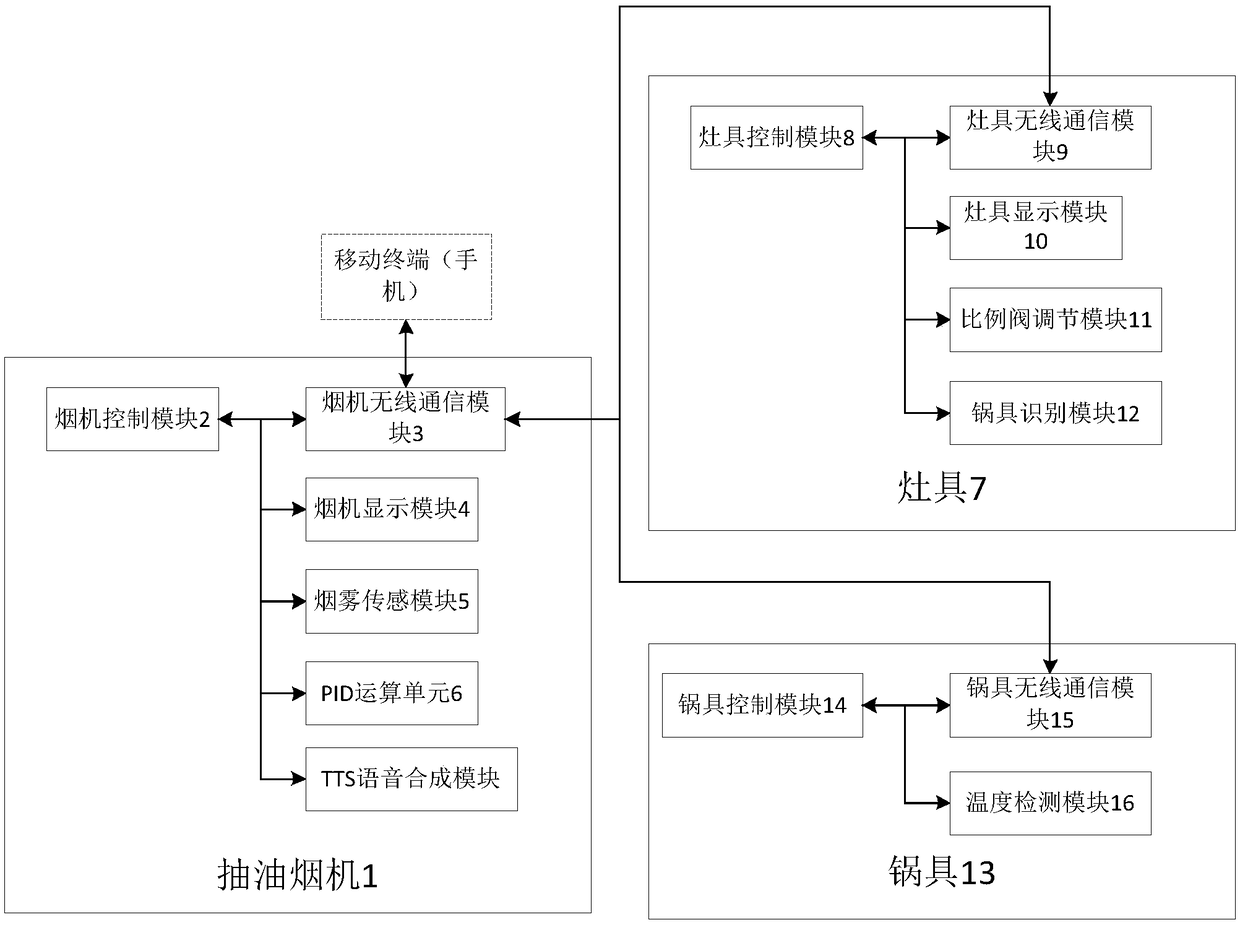

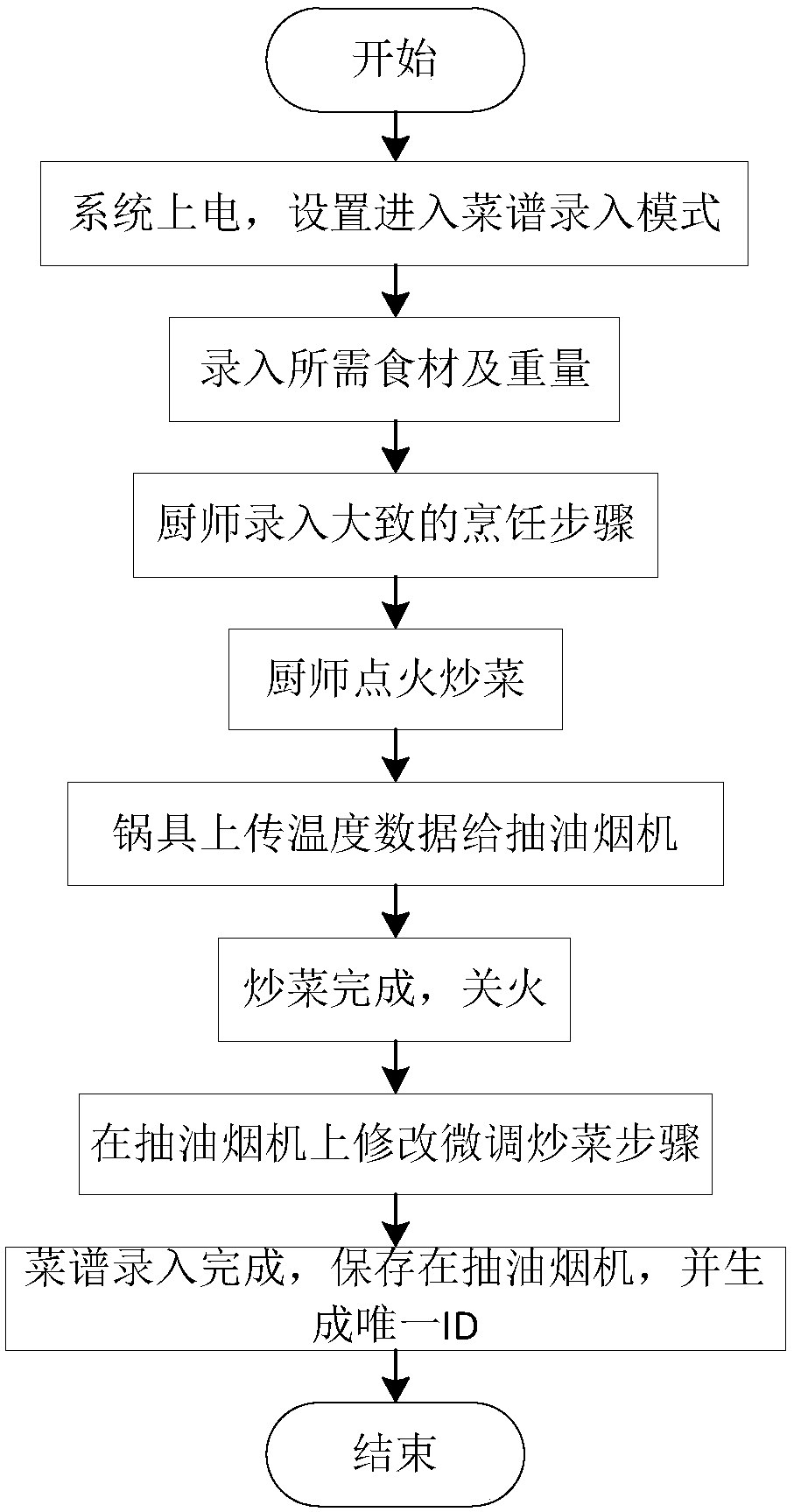

Recipe generation method and kitchen appliance

InactiveCN108594673AEasy to learnIntuitively informedProgramme control in sequence/logic controllersAdditive ingredientProcess engineering

The invention relates to a recipe generation method and a kitchen appliance. The kitchen appliance comprises a heater and a controller, a recipe is generated by the controller according to the following method, and the heating power of the heater is controlled according to the recipe. The method comprises steps that step A, desired ingredients, the weight of the ingredients and cooking steps are inputted; step B, artificial cooking is carried out, the heater starts to heat, and cooking parameters in the artificial cooking process are recorded; step C, cooking is completed, and the heater stopsheating; and step D, the cooking steps inputted in the step A are matched with the cooking parameters recorded in the step B, nodes of the cooking steps and nodes of the cooking parameters are made to correspond to each other, and the generated recipe is saved. The method is advantaged in that as the recipe is generated through artificial input and artificial cooking links, increase of the artificial links not only effectively meets taste needs of different people, learners are convenient to learn cooking methods of specific objects in a targeted manner, individual needs of the learners are satisfied, and the learners are convenient to visually learn more about the cooking steps of the recipe.

Owner:GUANGDONG WANHE THERMAL ENERGY TECH CO LTD

Automatic identification method based on standard for the exchange of product model data-compliant numerical control data interface (STEP-NC) intersection features

InactiveCN102629287AReduce independent featuresSpecial data processing applicationsDatabase queryCam

An automatic identification method based on STEP-NC intersection machining features comprises construction of machining feature adjacency graphs, determination of intersection features, segmentation of the intersection features, matching of machining features and STEP-NC expression of the machining features. The method firstly identifies the intersection features by utilizing a mode based on combination of graphs and traces, the traces refer to convex edges produced by intersection of features, and in order to guarantee that no public volume is included among the features and to reduce independent features of production, based on the principle of priority processing of feature base-face, constructs an ordered intersection features split factor queue; Secondly, the method encodes the machining features during feature matching, and identifies the machining features by the aid of the existing relatively mature database query technology, so that a time-consuming subgraph matching algorithm is avoided; and finally, according to the ISO10303-238 protocol, the method stores the identified machining features in a STEP file in a hidden mode in order to provide consistent interface for the follow-up computer aided process planning (CAPP) and the computer-aided manufacturing (CAM).

Owner:SHENYANG LIGONG UNIV

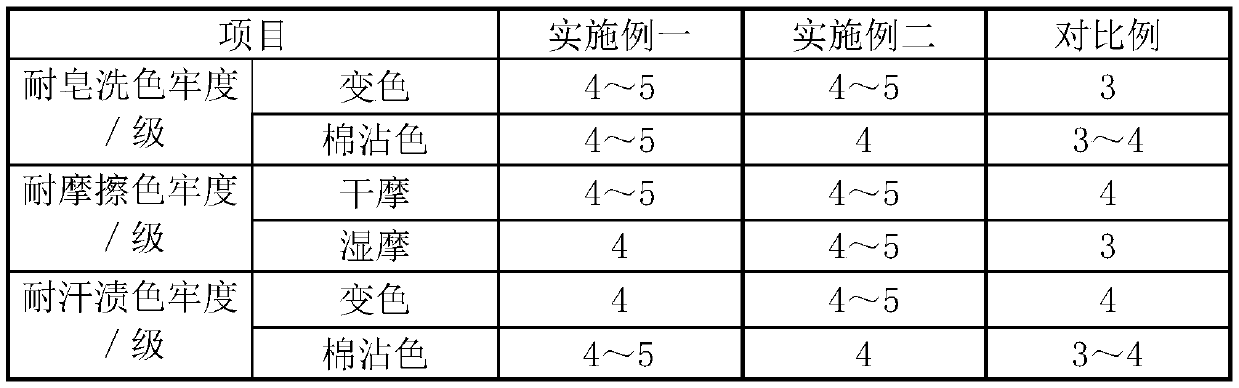

Method for producing antibacterial fabric finished by bamboo vinegar liquor

The invention relates to a method for producing antibacterial fabric finished by bamboo vinegar liquor, which is characterized by comprising the following production steps: a, firstly cleaning dirt onthe fabric and then drying the fabric; b, preparing finishing liquor at the temperature of between 30 and 50 DEG C by using clear water, adding the bamboo vinegar liquor and assistant into the finishing liquor, and stirring the finishing liquor evenly; c, placing the finishing liquor prepared in the step b into a bath of drying equipment, and slowly passing the fabric in the step a through the bath; d, controlling the mangle expression of the fabric in the step c at 70 to 80 percent through the action of a roller; e, pre-drying the fabric in the step d in a dryer at the temperature of between70 and 90 DEG C and at the speed of 8 to 18 meters per minute; and f, drying the fabric in the step e in the dryer at the temperature of between 130 and 180 DEG C and at the speed of 15 to 25 metersper minute. The method which adopts the bamboo vinegar liquor to carry out antibacterial finishing for the fabric for producing various textiles has the following advantages: (1) rich resources, (2) nature and environmental protection, (3) simple and convenient production, (4) convenient use, and (5) remarkable antibacterial effect.

Owner:ZHEJIANG TEXTILE GARMENT TECH

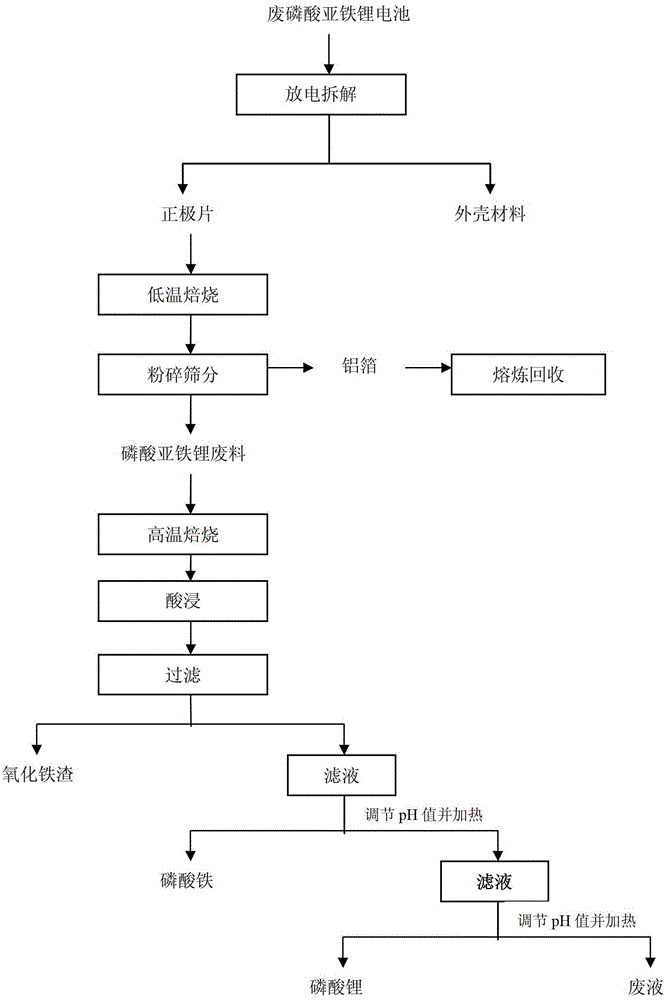

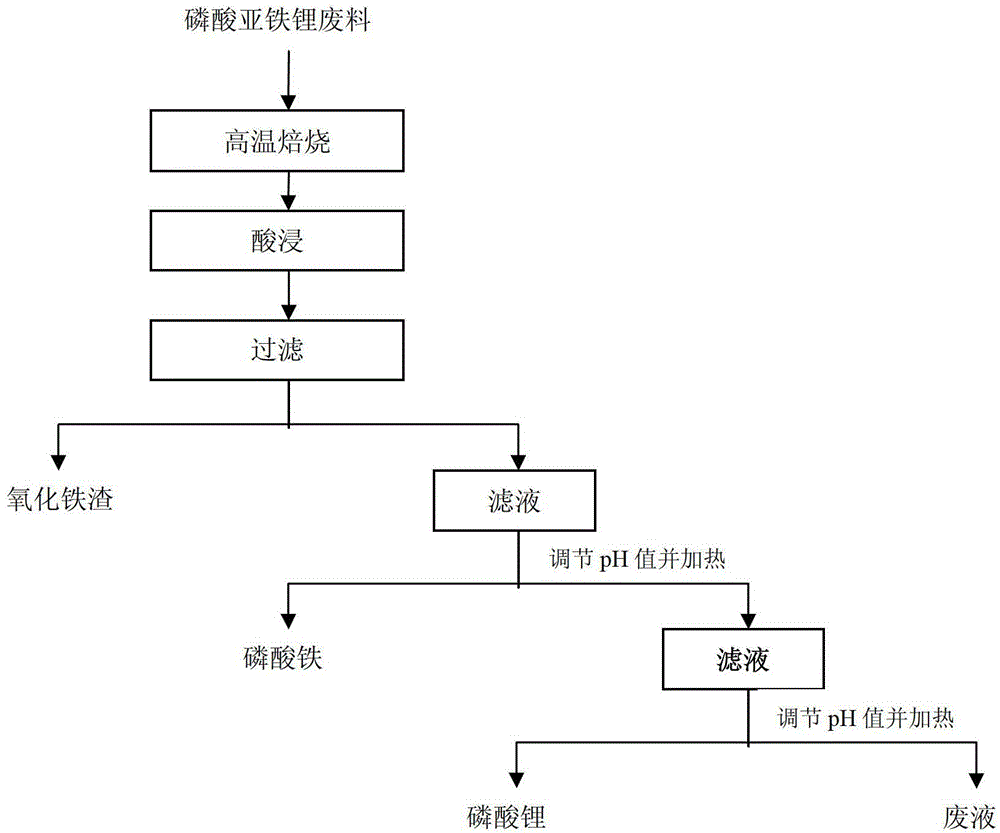

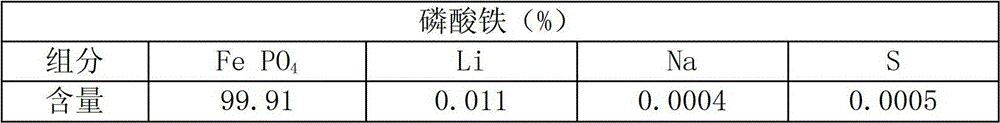

Comprehensive recycling method for lithium iron phosphate cathode material

ActiveCN102910607ASolve the problem of resource recyclingWaste accumulators reclaimingPhosphorus compoundsLithium iron phosphatePhosphate

The invention relates to a comprehensive recycling method for a lithium iron phosphate cathode material, belonging to the technical field of recycle of waste lithium ion batteries. The invention aims to provide the comprehensive recycling method for the lithium iron phosphate cathode material, comprising the following steps of: a, roasting the lithium iron phosphate cathode material at the temperature of 500-800 DEG C for 1-4h; b, adding sulfuric acid into a roasted material to leach, controlling the pH value between 0.5 and 1 during leaching, and filtering to obtain a mixed solution of lithium phosphate, ferric phosphate and ferric sulfate; c, heating the mixed solution obtained in the step b to 80-100 DEG C, adjusting the pH value of the mixed solution to 2-2.5, reacting for 1-4h, filtering, cleaning and drying to obtain the ferric phosphate; and d, adjusting the pH value of a filtrate obtained through filtering in the step c to 10-12, reacting for 0.5-2h, filtering, cleaning and drying to obtain the lithium phosphate.

Owner:天齐锂业(江苏)有限公司 +2

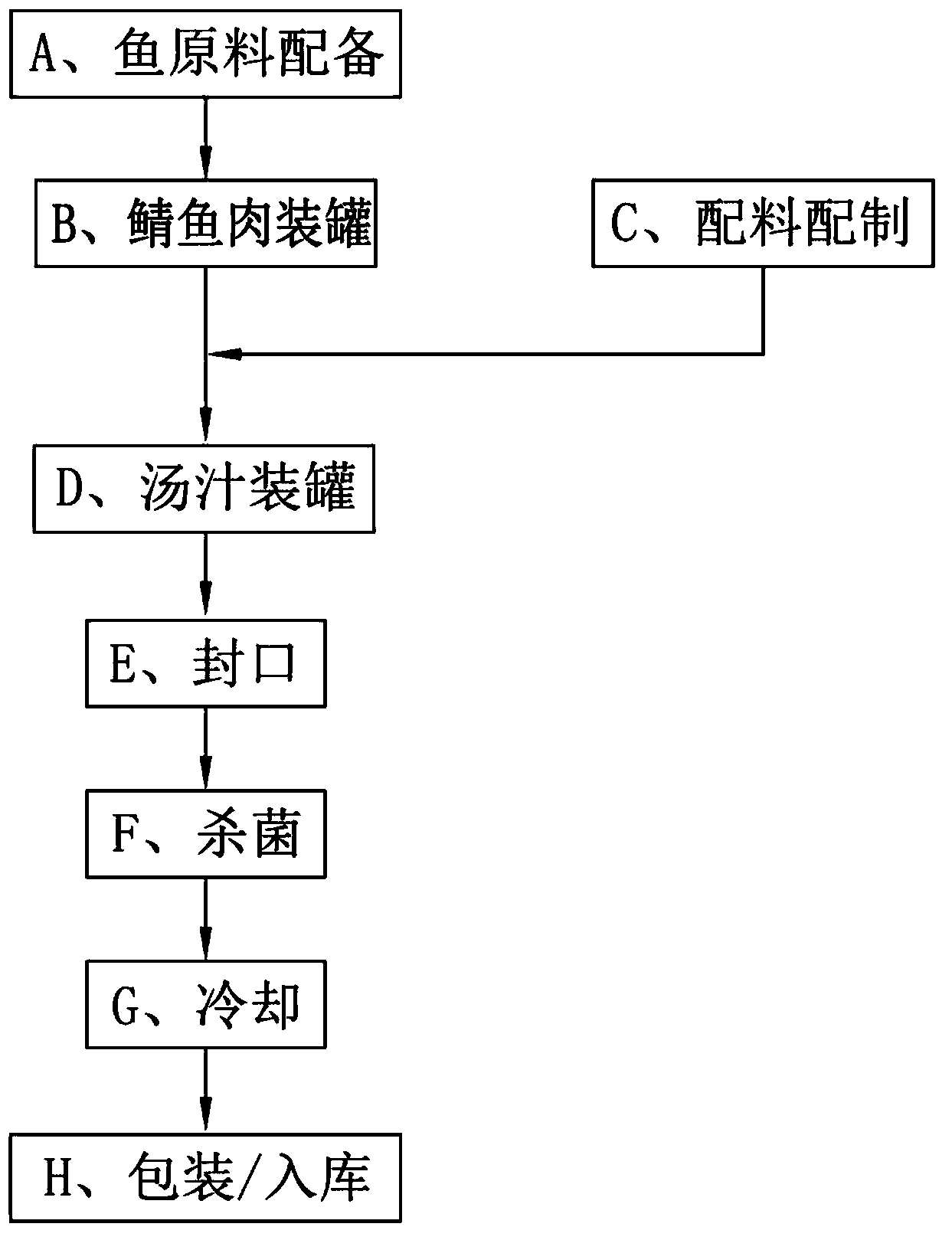

Processing method for tomato juice mackerel can

The invention discloses a processing method for a tomato juice mackerel can. The processing method comprises step A, raw mackerel material preparation; step B, canning of mackerel meat; step C, ingredient preparation; step D, canning of juice; step E, sealing; step F, sterilization; step G, cooling; step H, packing / storage, wherein the step C and the step A or the step B can be performed simultaneously. The raw mackerel material preparation in the step A comprises step A1, raw mackerel material check; step A2, unfreezing; step A3, cutting; step A4, washing; step A5, salting; step A6, draining; step A7, impurity removing. The sterilization in the step F comprises step F1, filled can washing; step F2, can stacking; step F3, thermal treatment or sterilization. The tomato juice mackerel can produced through the processing method is delicious and good in taste and safe and sanitary, and nutritional ingredients can be well reserved.

Owner:陈义方

Intelligent and numerical control system based on STEP-NC

InactiveCN103197606AImprove machining accuracyAchieve intelligenceProgramme controlComputer controlFree accessSocial benefits

An intelligent and numerical control system based on STEP-NC is arranged on a machine tool body in a connected mode, and is composed of a computer control device, a machine tool controller, a driver, a servo device, an interface and a machine tool monitoring device, wherein a machine tool processing and controlling unit is respectively connected with the computer control device and the driver, and the driver is further connected with the servo device through the interface; the servo device is arranged on the machine tool body in a connected mode; and the machine tool monitoring device is respectively connected with the computer control device and the machine tool body. The intelligent and numerical control system based on the STEP-NC is favorable for free access and data sharing of processed data flow, bottleneck effect between CAD / CAM and CNC also does not exist, and production cycles of products are greatly shortened. The intelligent and numerical control system based on the STEP-NC is of important economic significances and significant social benefits.

Owner:SHENYANG LIGONG UNIV

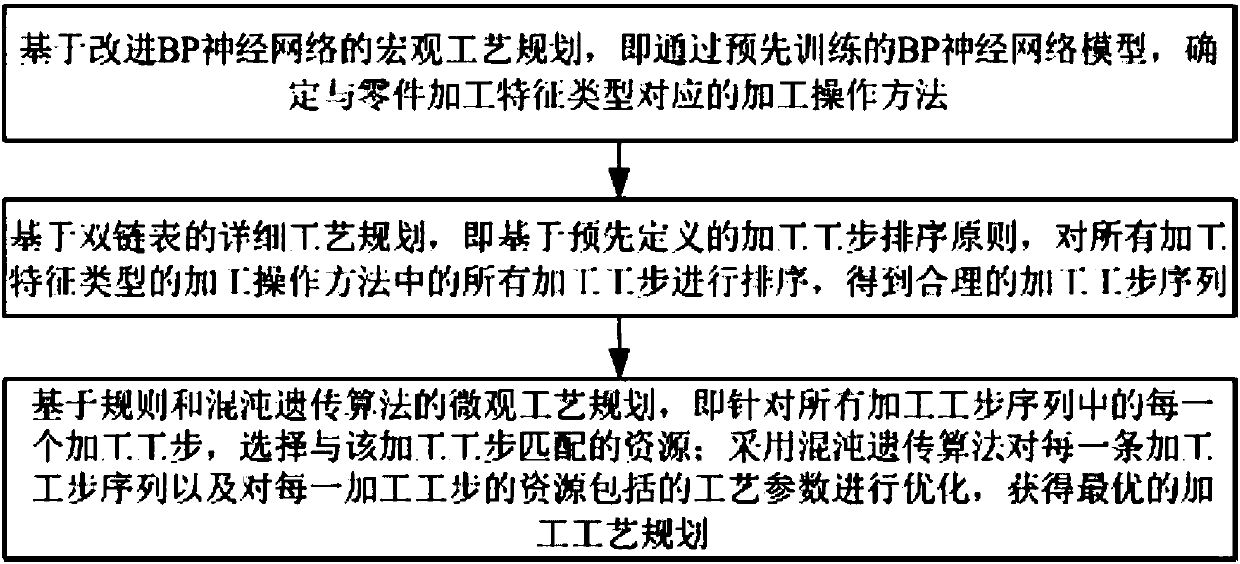

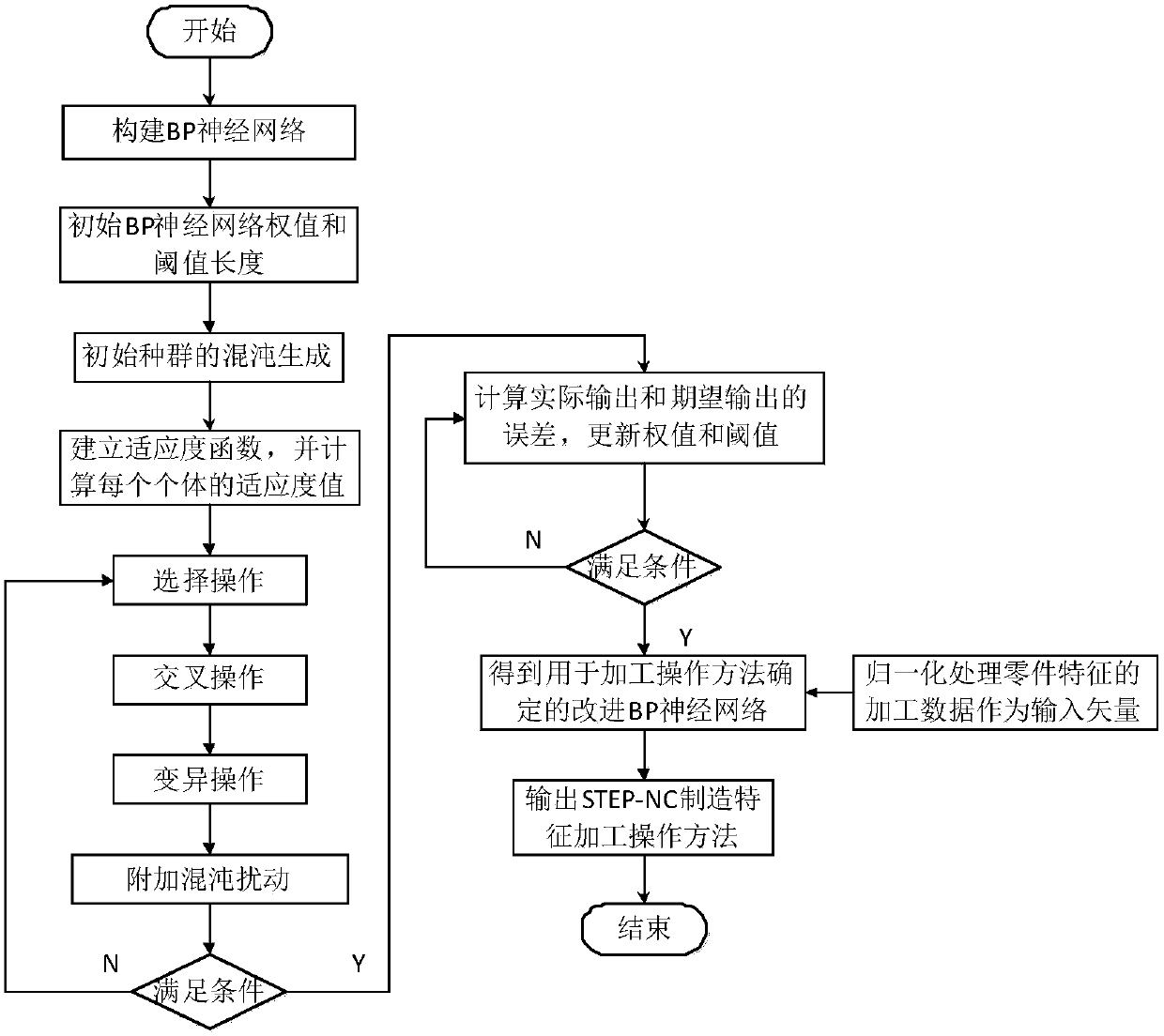

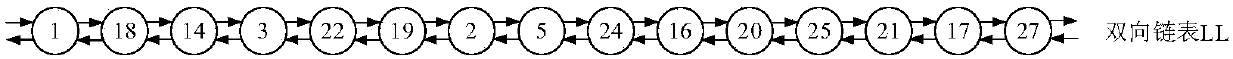

STEP-NC based intelligent nonlinear process planning method

ActiveCN108389001AMeet needsShort processing timeChaos modelsNon-linear system modelsProcess optimizationCharacteristic type

The invention relates to an STEP-NC based intelligent nonlinear process planning method. The method comprises the steps of determining a machining operation method corresponding to a component machining feature type through a pre-trained BP neural network model; sequencing all machining steps in the machining operation method based on pre-defined machining step sequencing principles to obtain a reasonable machining step sequence; and in allusion to each machining step in the machining step sequence, selecting resources matched with the machining step, and optimizing each machining step and process parameters of each machining step by adopting a chaotic genetic algorithm to obtain an optimal machining process plan. According to the method, the chaotic algorithm, the genetic algorithm and the BP neural network are organically combined and applied to process optimization for the STEP-NC, thereby being capable of performing efficient, accurate and intelligent logical reasoning, effectivelysolving a complex process planning problem, and having important significance for the further study of the STEP-NC theory.

Owner:NORTHEASTERN UNIV LIAONING

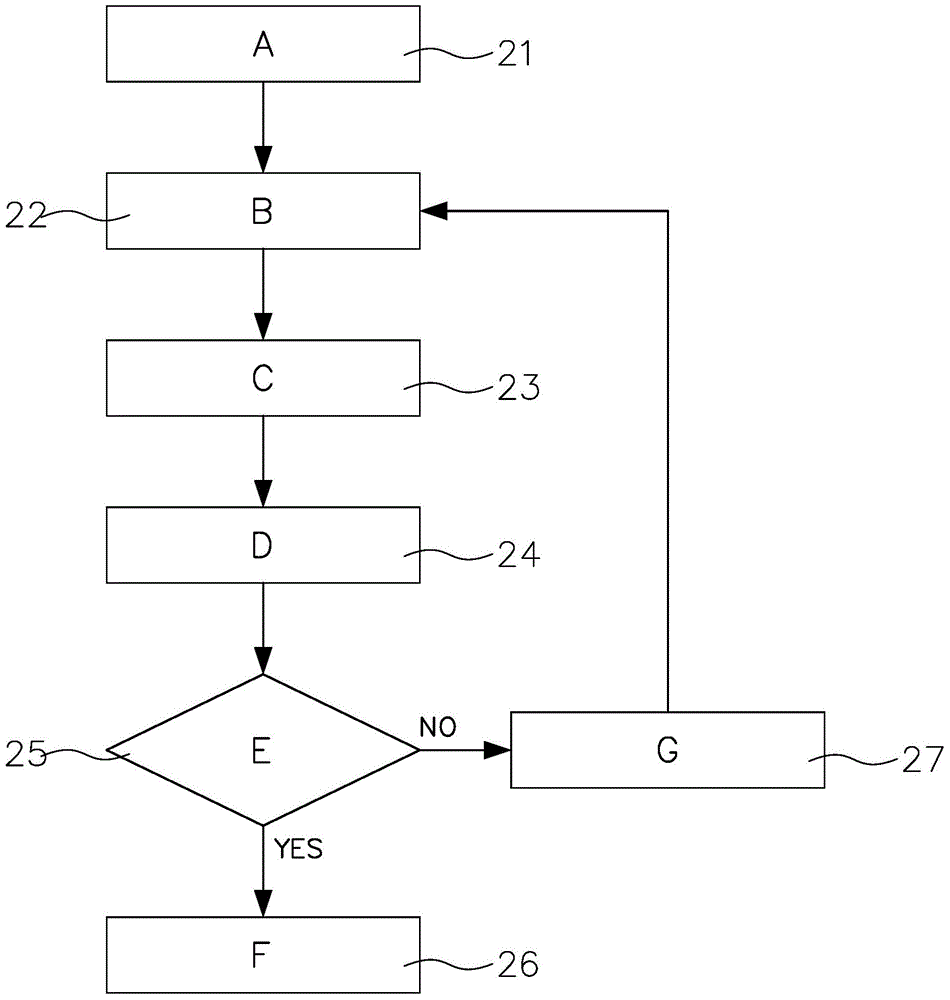

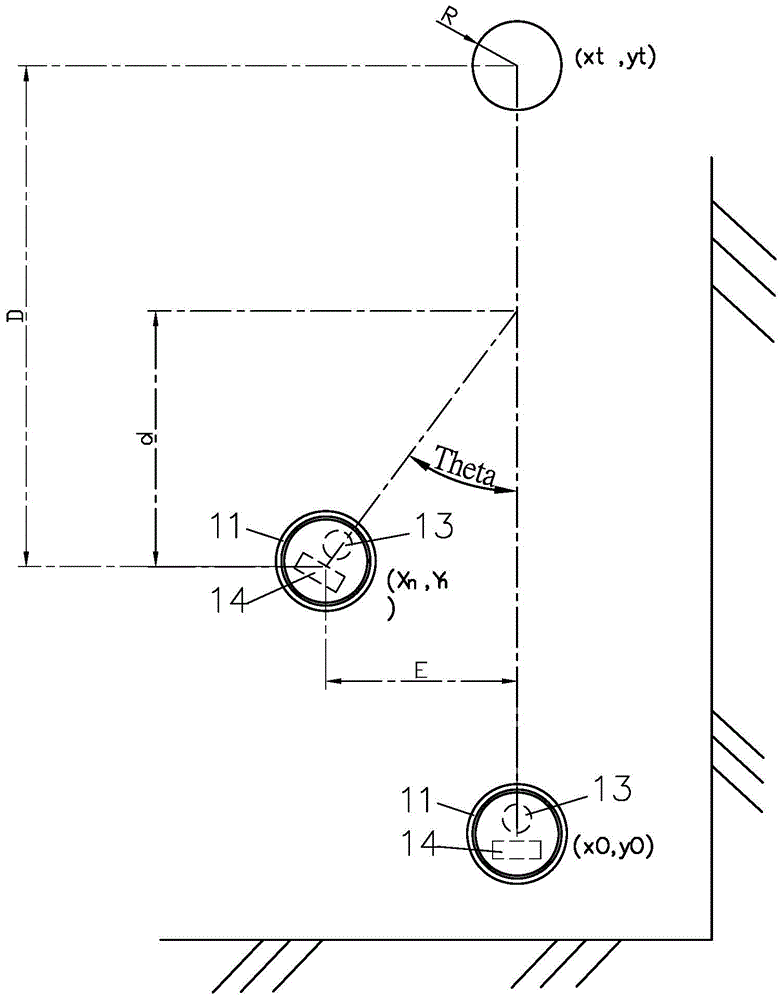

Mobile Device Having Route Correction Function And Working Steps Thereof

InactiveCN104656650AArrived correctlyCorrect walking errorPosition/course control in two dimensionsVehiclesLaser rangingWorking set

A mobile device having a route correction function comprises a body, at least two wheel bodies assembled on the body, a laser ranging scanner arranged in the body and a microprocessor arranged in the body and electrically connected with the laser ranging scanner, and possesses a working step A of using the laser ranging scanner to obtain the coordinates of a starting point and a terminal point; a step B of executing the 360-degree omnibearing rotation scanning work during the walking process; a step C of obtaining the coordinate of each point during the walking process; a step D of obtaining the vertical distance, the horizontal error distance and the deviation angle of the position and the terminal point by the two dimensional operation of the microprocessor; a step E of determining whether the vertical distance is in the radius of the terminal point coordinate; a step F of arriving at the terminal pint if yes; a step G of if no, using the microprocessor to calculate the position by the displacement distance of the at least two wheel bodies as the starting point, and repeating the steps B, C,D,E and F or G.

Owner:WEISTECH TECH CO LTD

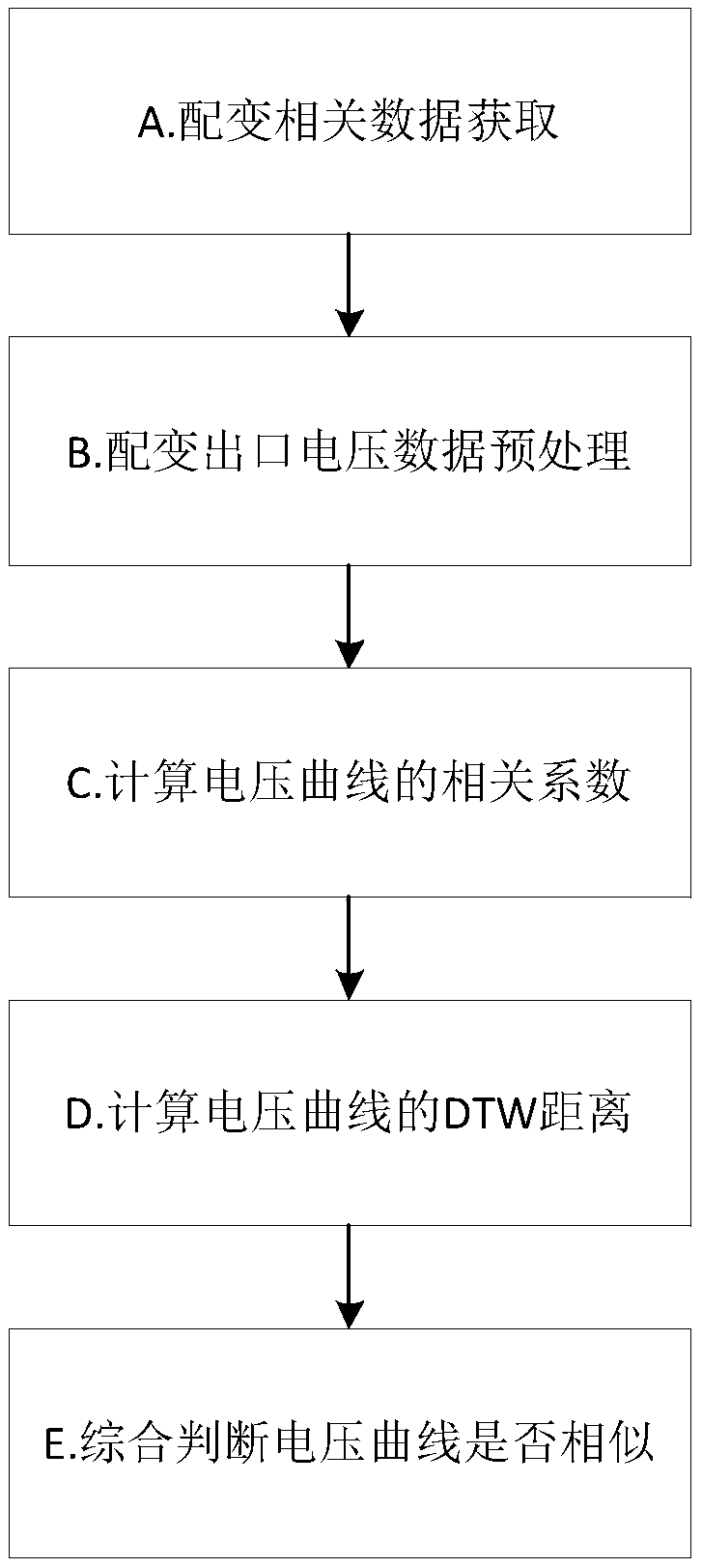

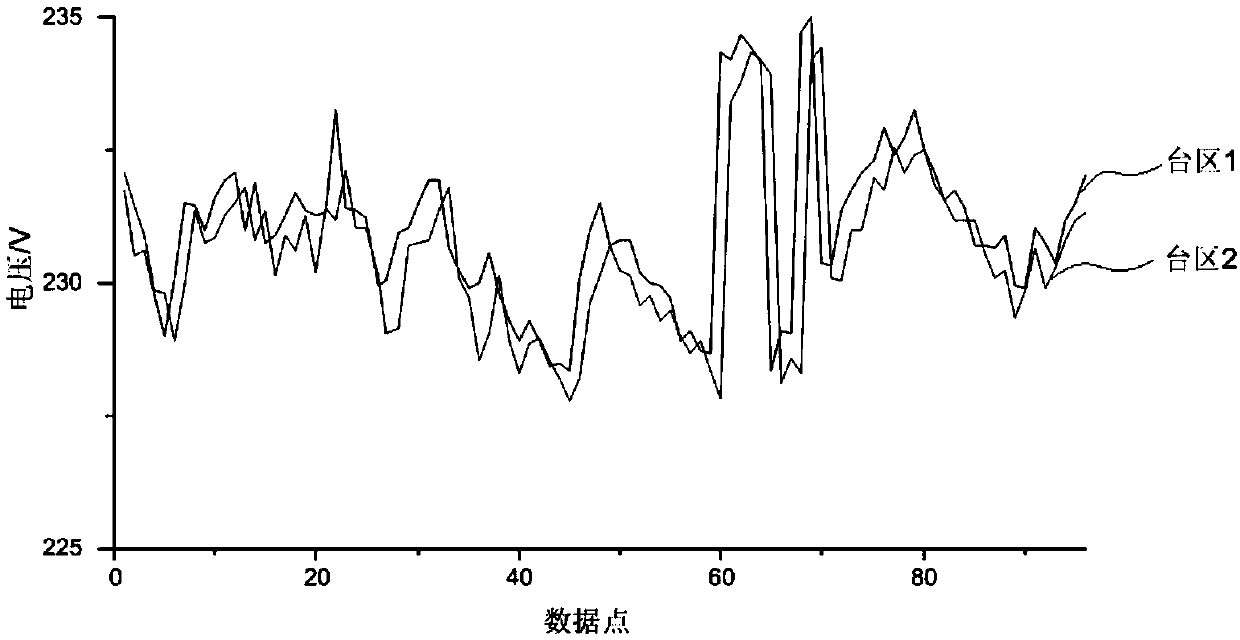

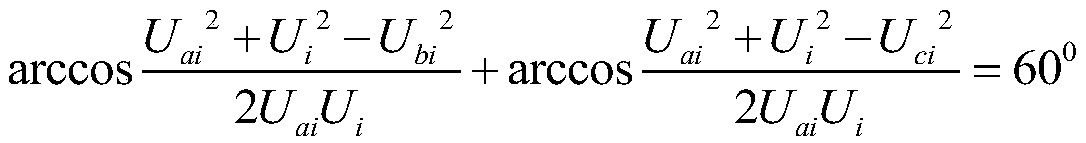

Voltage curve similarity judging method for considering asynchronous influence of clock

ActiveCN109596929AGuaranteed correctnessElectrical testingVoltage measurements onlyCorrelation coefficientDistribution transformer

The invention provides a voltage curve similarity judging method for considering asynchronous influence of a clock. The method comprises the steps of: A, acquiring related data of a distribution transformer, which includes a corresponding relationship between a 10kV line and the distribution transformer, a name of the distribution transformer, an address code of the distribution transformer, and output voltage data of the distribution transformer; B, pre-processing the output voltage data of the distribution transformer acquired in the step A; C, computing a correlation coefficient of the voltage curve according to the output voltage data of the distribution transformer pre-processed in the step B; D, computing DTW (Dynamic Time Warping) distance of the voltage curve according to the output voltage data of the distribution transformer pre-processed in the step B; and E, comprehensively judging whether the voltage curves of two areas are similar or not according to the computing resultsin the step C and the step D. The method provided by the invention can correctly judge whether the voltage curves of two areas are similar or not when the asynchronous influence of the clock exists.

Owner:STATE GRID CORP OF CHINA +2

Preparing method of homogeneity fused quartz ceramic

The invention discloses a preparing method of homogeneity fused quartz ceramic. The preparing method comprises the step A, mixing high purity fused quartz powder; adding quartz powder material into deionized water as well as polyvinyl alcohol, lactic acid and sodium sesquicarbonate to make slurry; B, conducting mixing of 40wt% acrylamide aqueous solution with N,N'-Methylenebisacrylamide N,N'-Methylenebis (2-propenamide) to obtain premixed liquid; C, conducting mixing of the slurry in the step A, sintering aid and the premixed liquid in the step B, and adding initiator to obtain formed slurry after dispersion; D, pouring the formed slurry in the step C into a mold of a dynamic gel casting device, conducting solidification after vibration, and opening the mold after cooling, so that the green ceramic required is obtained; E, firing the green ware body in the step D in a high temperature wave until being molded, so that the fused quartz ceramic required is prepared.

Owner:FOSHAN GAOMING DISTRICT MINGCHENG TOWN NEW ENERGYNEW MATERIAL IND TECH INNOVATION CENT

Production process of spandex jacquard four-faced elastic fabric

The invention discloses a production process of a spandex jacquard four-faced elastic fabric. The method comprises the following steps of step A, preparation of a polyester air coated yarn; step B, preparation of a warp yarn; step C, beaming; step D, sizing; step E, weaving; step F, desizing and vinylon dissolution; step G, dyeing and step H, shaping. The production process of the spandex jacquardfour-faced elastic fabric has the advantages that warp and weft yarns adopt a twisted yarn of a polyester ammonia covering yarn and water soluble vinylon, the method of adopting the polyester ammoniacovering yarn for active yarn feeding makes the twisted yarn have no elasticity, a conventional loom can be used for weaving, and vinylon dissolution is performed after weaving, so that the elasticity of warp and weft yarns is restored. And gaps reserved by the vinylon dissolution make the fabric have better air permeability.

Owner:JIAXING MINGYE TEXTILES CO LTD

Preparation method of natural silk functional textile

ActiveCN103710965AImprove antibacterial propertiesEasy to prepareAnimal fibresDiethyl etherNonwoven fabric

The invention relates to a preparation method of a natural silk functional textile. The preparation method comprises the following steps: A) adding a cocoon stripping nonwoven fabric, ethylene glycol diglycidyl diethyl ether and alanine into alanine, and stirring for reacting; B) putting sodium cyanoborohydride and beta-cyclodextrin monoaldehyde into a solution obtained in the step A) to react, after the reaction is completed, adjusting the pH value to be neutral, and cleaning the obtained product; C) putting the product obtained by reaction into a beta-cinnamic acid solution, carrying out heat preservation at a temperature of 45-55 DEG C, and taking out the product; D) preparing a solution from tea polyphenols, chitosan and water, putting the cocoon stripping nonwoven fabric treated in the step C) into the solution to soak, taking out the cocoon stripping nonwoven fabric and then drying the cocoon stripping nonwoven fabric so as to obtain the natural silk functional textile. The method disclosed by the invention has the beneficial effects that 1) the preparation method is simple; 2) the elapsed time is drastically reduced; 3) tea polyphenols have an inhibition effect and antimicrobial and bactericidal effects on cancer cells, and chitosan has a good antibacterial effect; 4) a molecule network-like structure is formed on the surface of the functional textile, and achieves a protective effect on the textile.

Owner:XINYUAN COCOON SILK GROUP

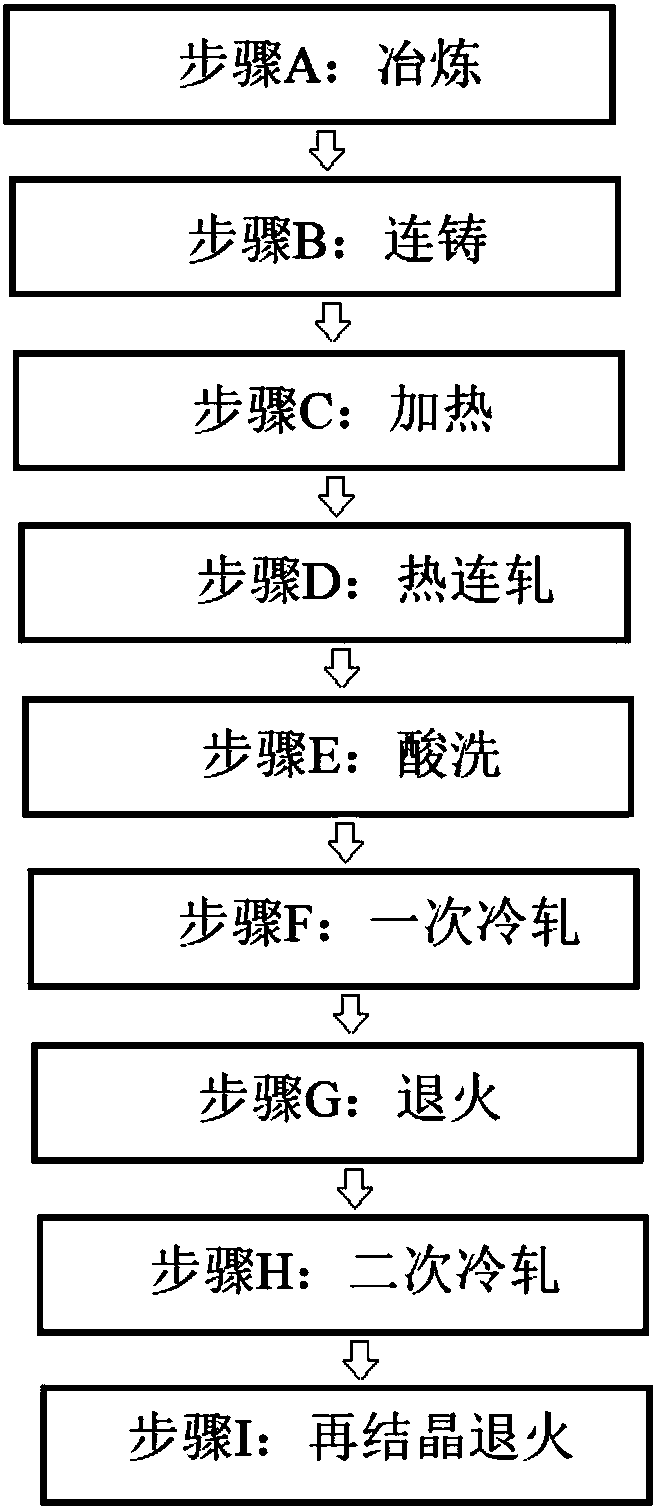

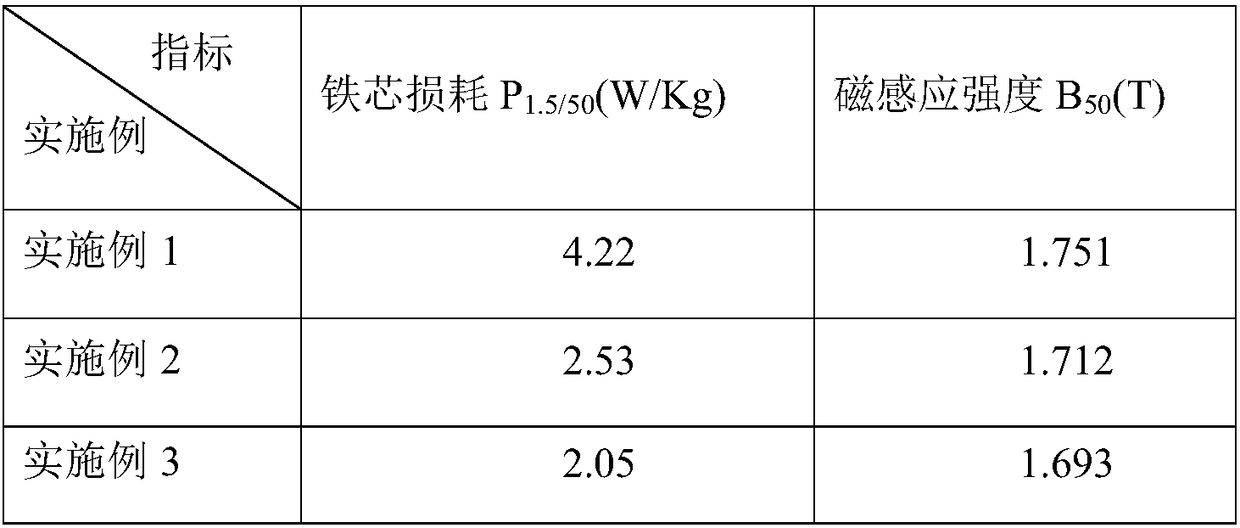

Method for producing non-oriented electrical steel with high magnetic induction and low iron loss by CSP process

The invention discloses a method for producing non-oriented electrical steel with high magnetic induction and low iron loss by a CSP process, and relates to a production method of non-oriented electrical steel. The method comprises the following steps that step A, smelting is carried out; step B, continuous casting is carried out; step C, heating is carried out; step D, hot continuous rolling is carried out; step E, pickling is carried out; step F, one-time cold rolling is carried out; step G, annealing is carried out; step H, secondary cold rolling is carried out; and step I, recrystallization and annealing are carried out. The purpose of the method is to overcome the defect of unqualified magnetic properties caused by too large cold rolling reduction rate in the process of producing non-oriented electrical steel by an existing CSP process, and the produced non-oriented electrical steel has excellent magnetic properties of high magnetic induction and low iron loss under the premise that the total pressure reduction rate of cold rolling is far greater than 85%.

Owner:INNER MONGOLIA UNIV OF TECH

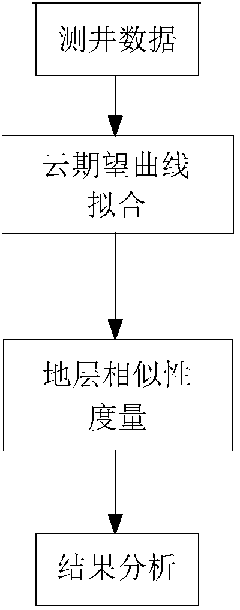

Stratigraphic correlation method

InactiveCN103995972AEmbody local characteristicsEasy to analyze and make decisionsSeismic signal processingSeismology for water-loggingWell loggingTrust level

The invention discloses a stratigraphic correlation method. The stratigraphic correlation method includes the steps that a, hierarchical processing is performed on two wells to be compared according to the form and the degree of a well logging curve, and each well is divided into a plurality of well layers; b, each hierarchically processed well layer is fitted through a cloud expectation curve, a plurality of cloud models are obtained through fitting, numerical characteristics of all the cloud models are calculated, and an appropriate cloud model to be used for comparison is selected; c, the appropriate cloud model is selected from the step b, similarity measurement based on Euclidean distance and similarity measurement based on trust level cloud are performed, and a similarity measurement value is obtained through calculation; d, stratigraphic correlation is completed according to the similarity measurement value obtained in the step c. According to the method, the characteristics of well logging data are fully utilized, the recognition accuracy is improved to a great extent, and stratigraphic correlation work can be carried out in production practice.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

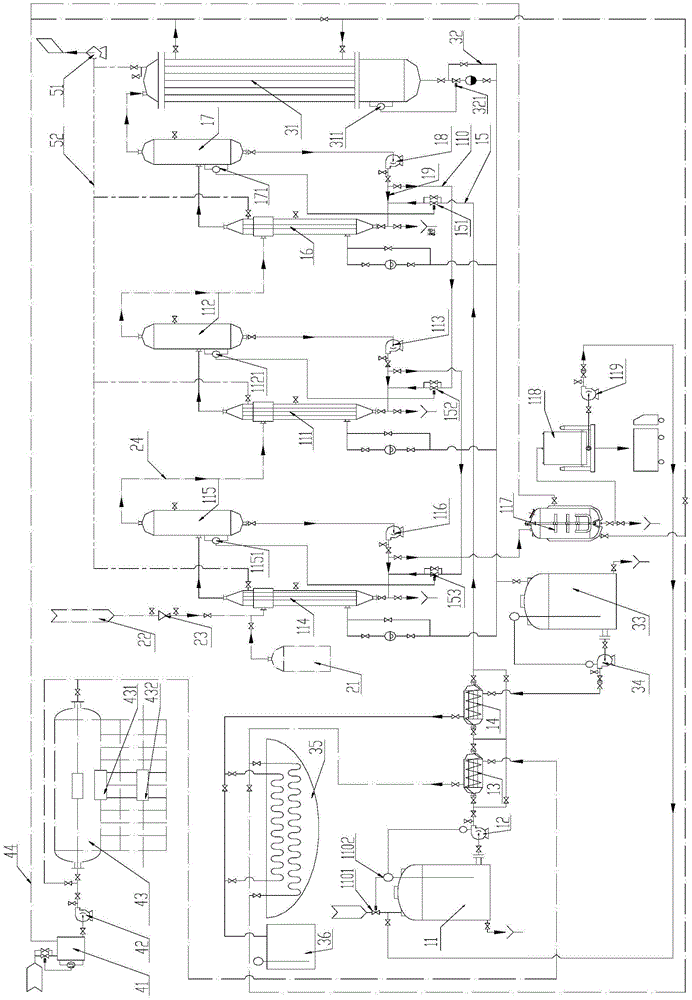

Multifunctional energy-saving type continuous wastewater evaporative crystallization process and device

ActiveCN105461141AHigh evaporation strengthPerfect energy saving measuresWater/sewage treatment by centrifugal separationEnergy based wastewater treatmentBoiling pointWastewater

The invention discloses a multifunctional energy-saving type continuous wastewater evaporative crystallization process. The process includes the step A of first-stage preheating of wastewater, the step B of second-stage preheating of wastewater, the step C of triple-effect heating of wastewater, the step D of triple-effect separation of wastewater, the step E of vapor condensation, the step F of forced circulation and two-effect heating of wastewater, the step G of two-effect separation of wastewater, the step H of cyclic utilization of two-effect vapor, the step I of forced circulation and one-effect heating of wastewater, the step J of one-effect separation of wastewater, the step K of cyclic utilization of one-effect vapor, the step L of recovery of vapor condensate, the step M of discharged of non-condensable gas, the step N of forced circulation and crystallization of wastewater, the step O of centrifugal separation and the step P of sewage discharge and secondary circulation of wastewater. Corresponding adjustment can be conduced according to the properties and boiling points of wastewater, conditions required by users, concentration changes of material crystallization and the like, and therefore optimization of the effective number and the minimization of the heat exchange area are achieved, and the evaporation intensity is improved to the maximum.

Owner:ZHEJIANG HAIYAN POWER SYST RESOURCES ENVIRONMENTAL TECH

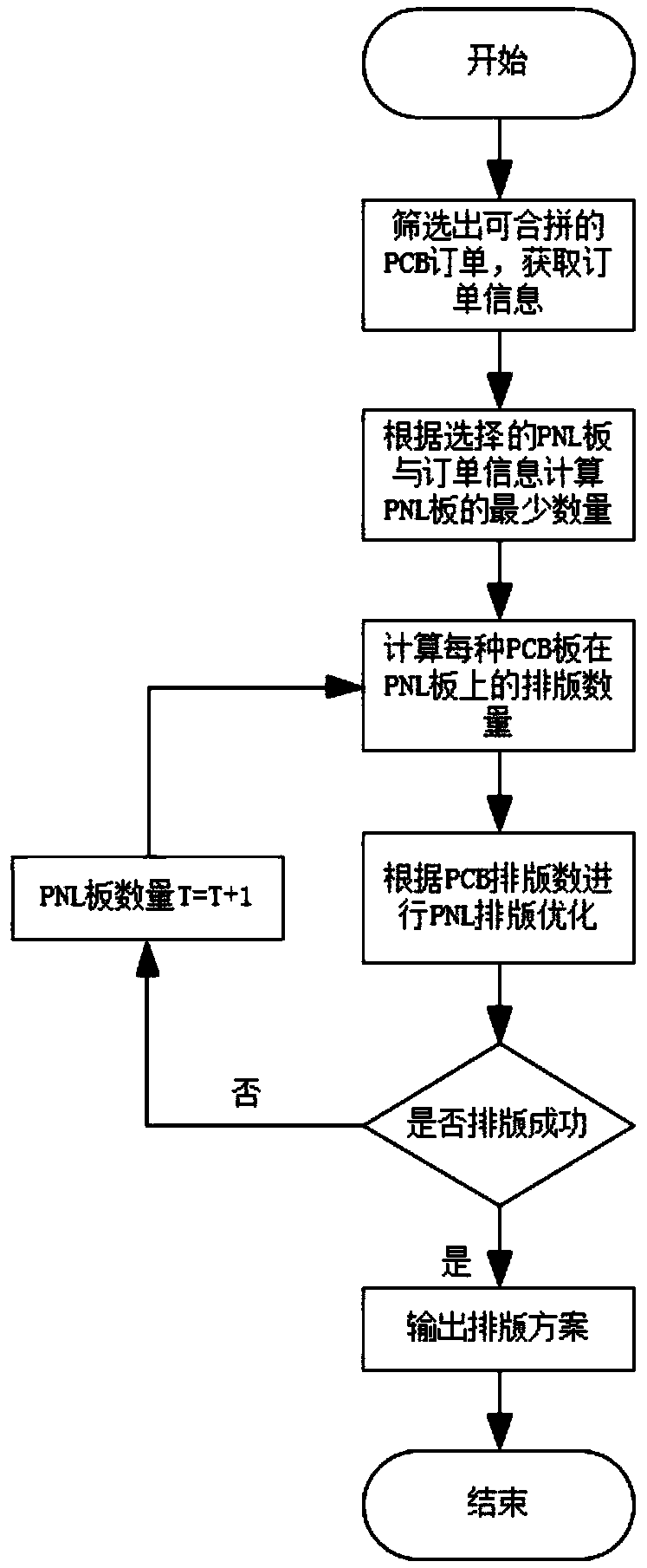

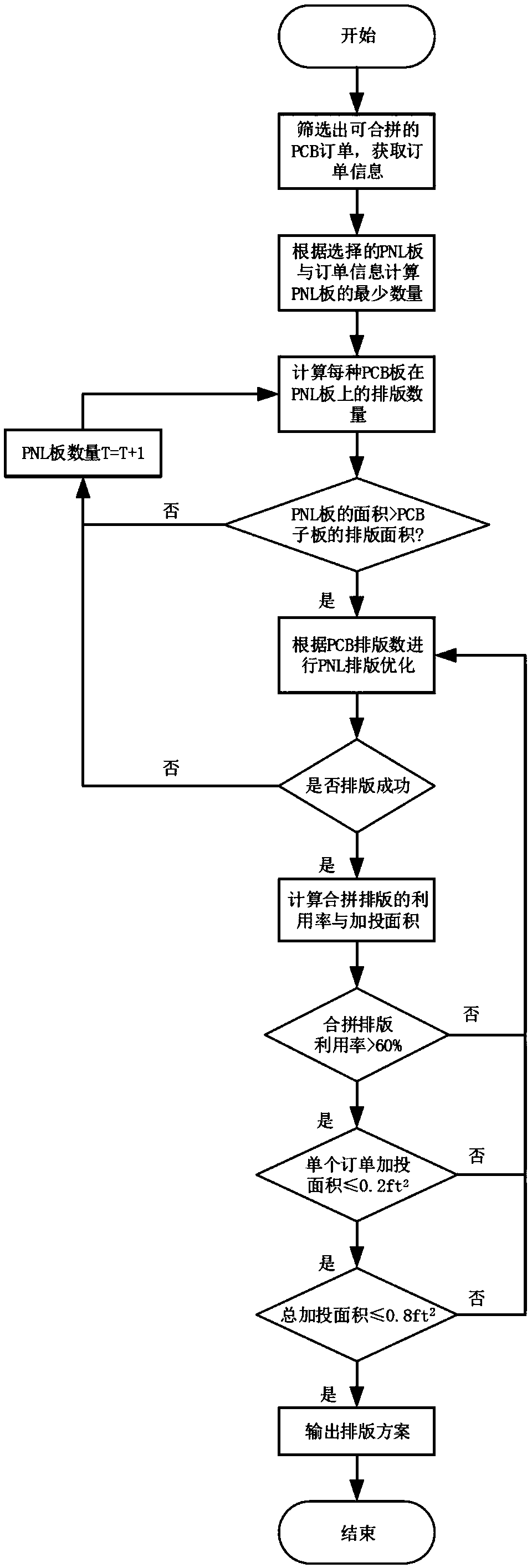

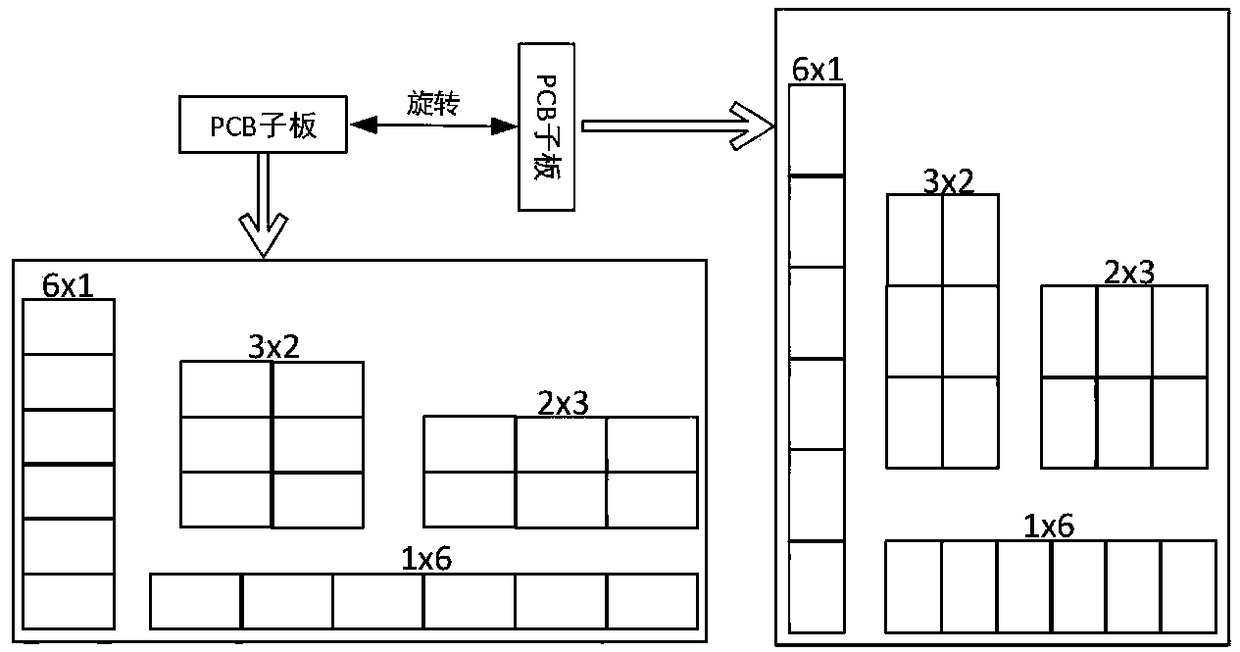

PCB stock layout optimization method considering multiple process constraints

The invention discloses a PCB stock layout optimization method considering multiple process constraints. The method comprises the following steps of step A, screening according to the constraint process of PCB daughter boards, and acquiring the order information of the PCB daughter boards which can be integrated; step B, calculating the minimum number of required PNL boards based on the PNL boardand the order information; step C, calculating the number of each type of PCB daughter boards which need layout on each PNL board; step D, carrying out single PNL layout optimization based on the layout number of each type of PCB daughter boards; step E, acquring the layout result of the step D: If the layout is successful, entering into step F; and if the layout is failed, adding 1 to the numberof the PNL boards, and then executing the step C; and step F, acquiring the best layout solution, and calculating a layout usage rate and the number of the required PNL boards. In the invention, whenthe PCB daughter boards satisfy respective constraint conditions, the number of the PNL boards is reduced, production efficiency is increased and cost is reduced.

Owner:GUANGDONG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com