Processing technology of camshaft

A processing technology and camshaft technology, applied in the field of mechanical parts processing, can solve the problems of low processing efficiency, high production cost, cumbersome process, etc., and achieve the effects of improving production efficiency, good versatility and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

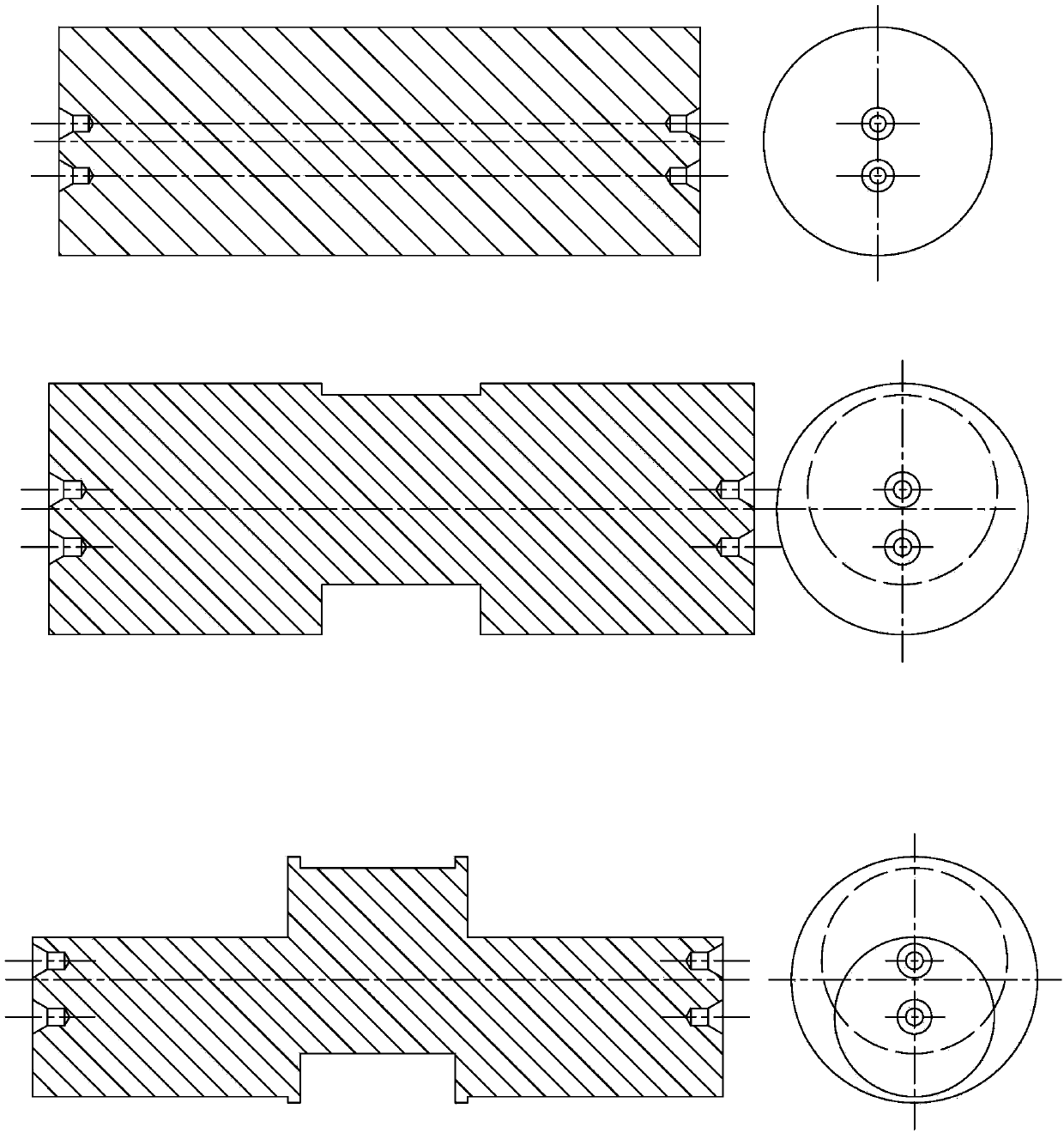

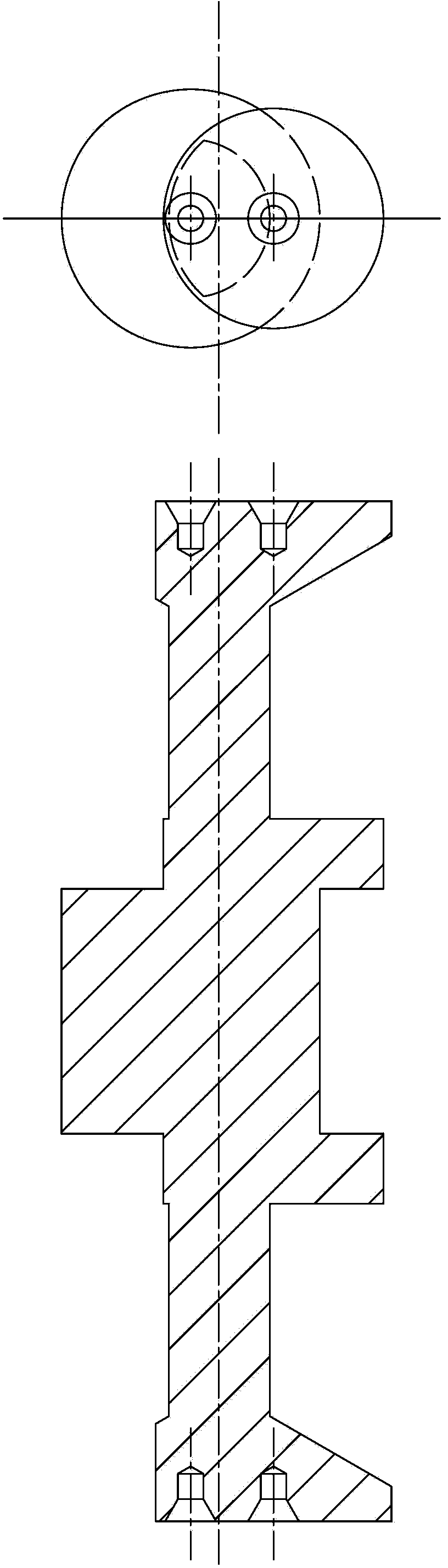

[0025] Example: such as Figure 1 to 8 As shown, the machining process of the camshaft of the present invention includes the following steps:

[0026] A. Blanking, according to two finished products for each blank, the length of the selected blank is 82mm, the diameter is 30mm, and the material is 42CrMo;

[0027] B. CNC lathe rough machining of the blank, the outer circle of the rough turning, the diameter of the outer circle is 28.5mm, the end face of the blank is flat, and the eccentric circle is processed; according to the eccentric center distance of the cam, the two ends of the blank are drilled with center holes, which are divided into upper, The lower center hole, the center distance is 6.5mm; CNC lathe roughing, the upper center hole is positioned, the eccentric circle in the middle of the car, its diameter reaches 21.5mm; the CNC lathe roughing, the lower center hole is positioned, the eccentric circle at both ends of the car, its The diameter reaches 18.5mm; the thickne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com