Patents

Literature

5790 results about "Machine parts" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wearable compound layer material for machine parts and manufacturing method and equipment thereof

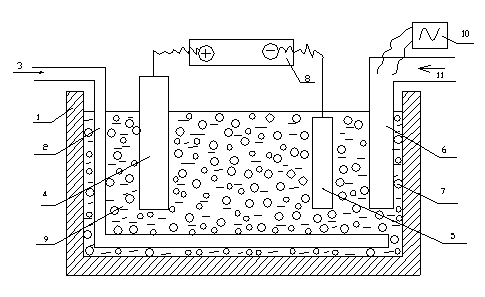

The invention relates to a wearable compound layer material for machine parts and a manufacturing method and equipment thereof. The wearable compound layer material is a metal-based wearable compound layer material which is composed of a matrix metal and lots of particles or fibers dispersed and distributed in the matrix metal, thereby having a multi-phase structure. The wearable compound layer material is manufactured by a direct-current electroplating or pulse electroplating method. The direct-current electroplating or pulse electroplating equipment is composed of parts such as an electroplating power source, an electroplating tank, a metal anode or a metal alloy anode, a machine part substrate cathode, a stirring device, a solution circulating device, a heating and temperature control device, an additive supplementing device and the like. The wearable compound layer material for machine parts provided by the invention is obviously superior in performance to good-quality cast iron wearable parts, good-quality cast steel wearable parts and wearable parts for surface heat treatment of common steel and good-quality steel commonly employed in the present product. The wearable compound layer also has high-temperature abrasive resistance and excellent corrosion resistance while having excellent abrasive performance; and the internal stress of the coating is very low.

Owner:肖云捷

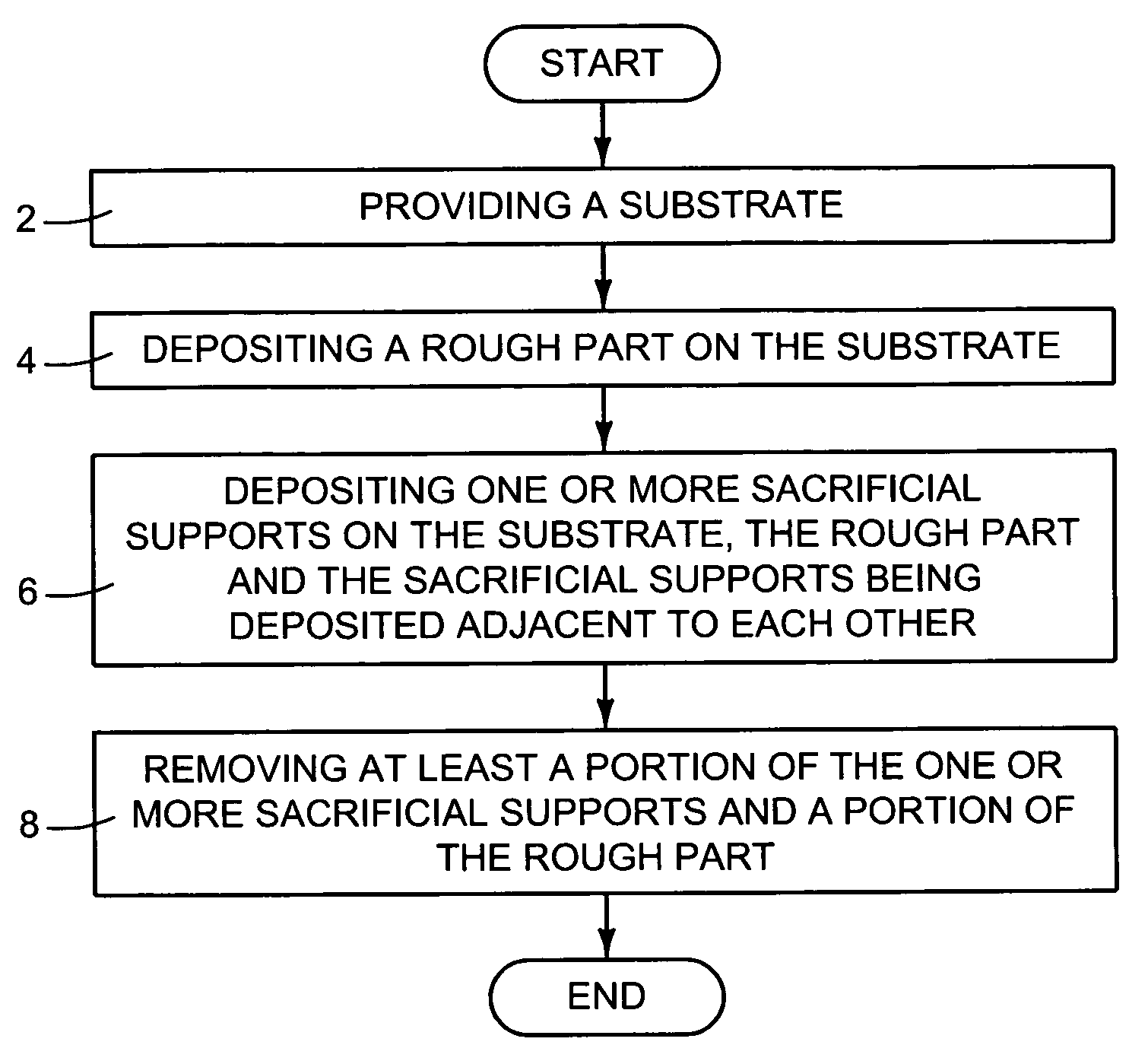

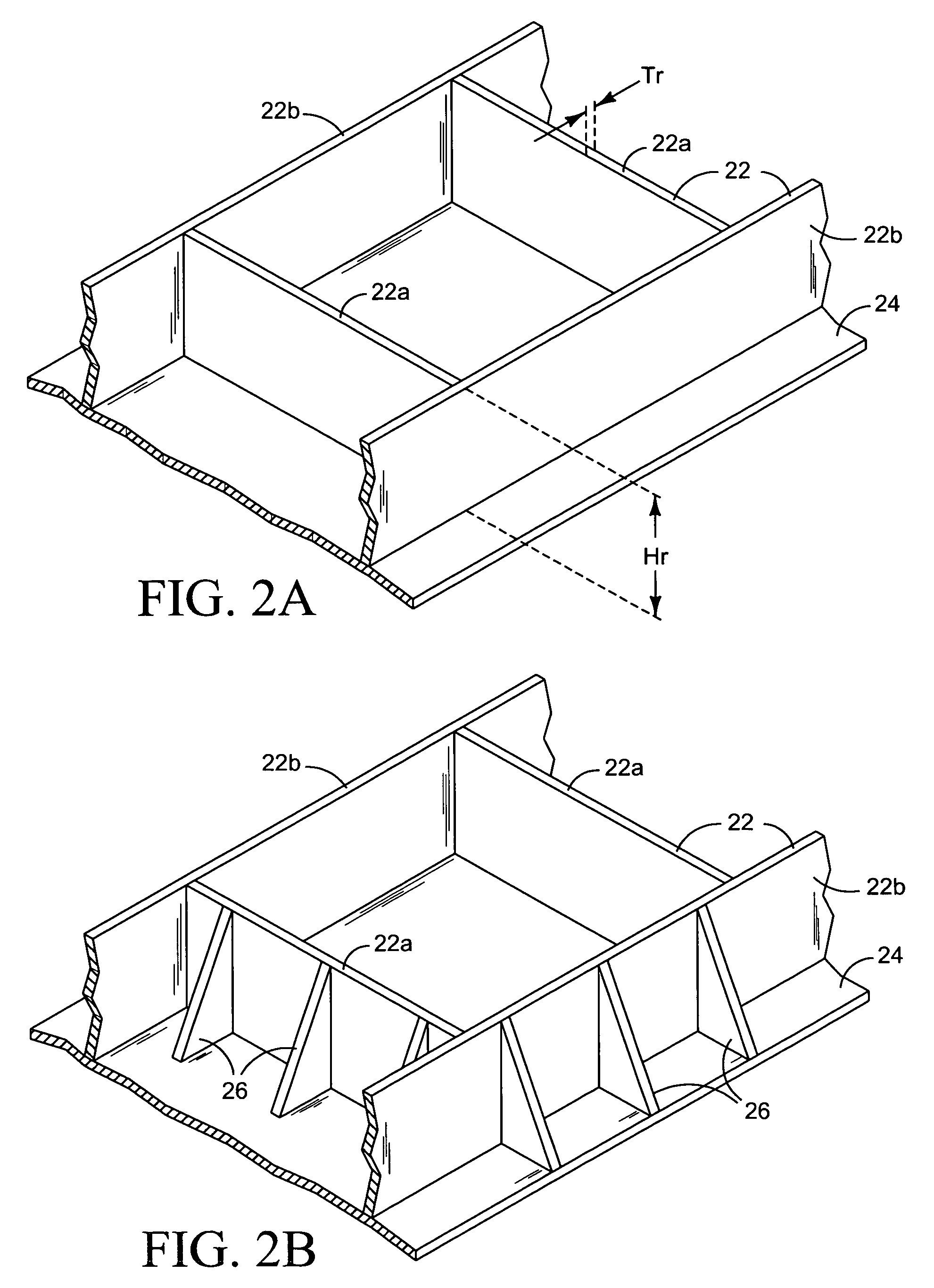

Method for machining using sacrificial supports

ActiveUS7716802B2Additive manufacturing apparatusElectron beam welding apparatusMachine partsFlight vehicle

Owner:THE BOEING CO

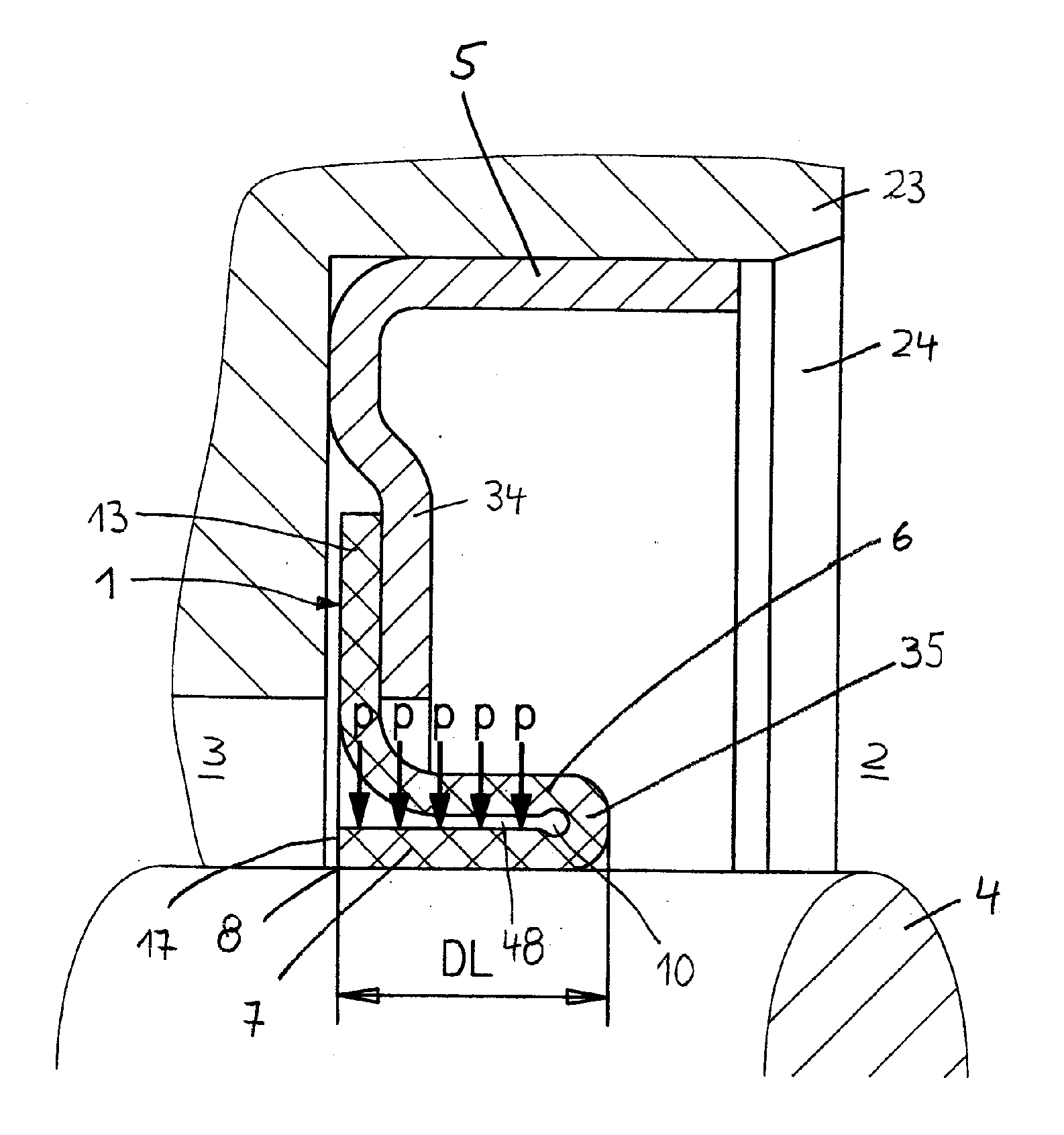

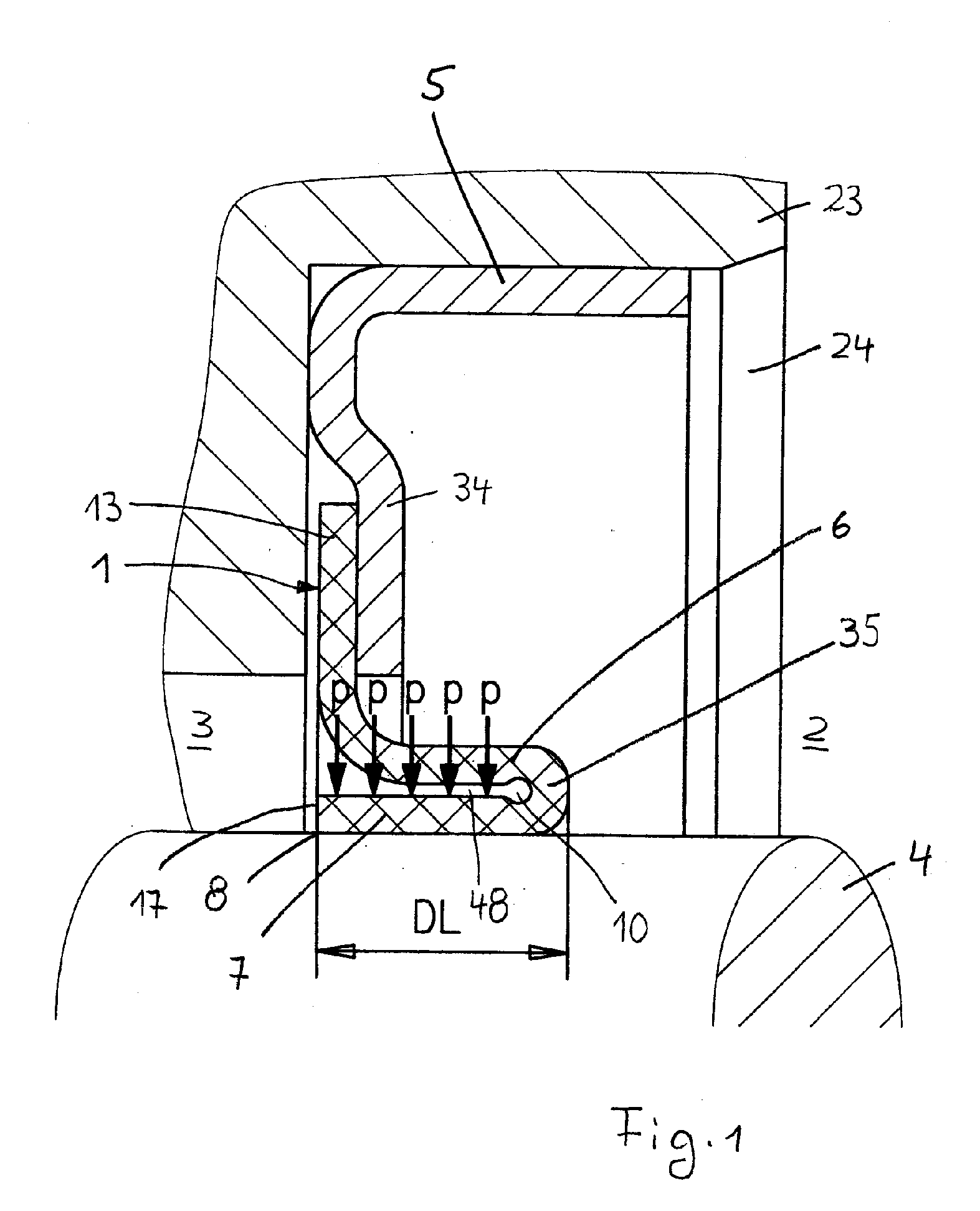

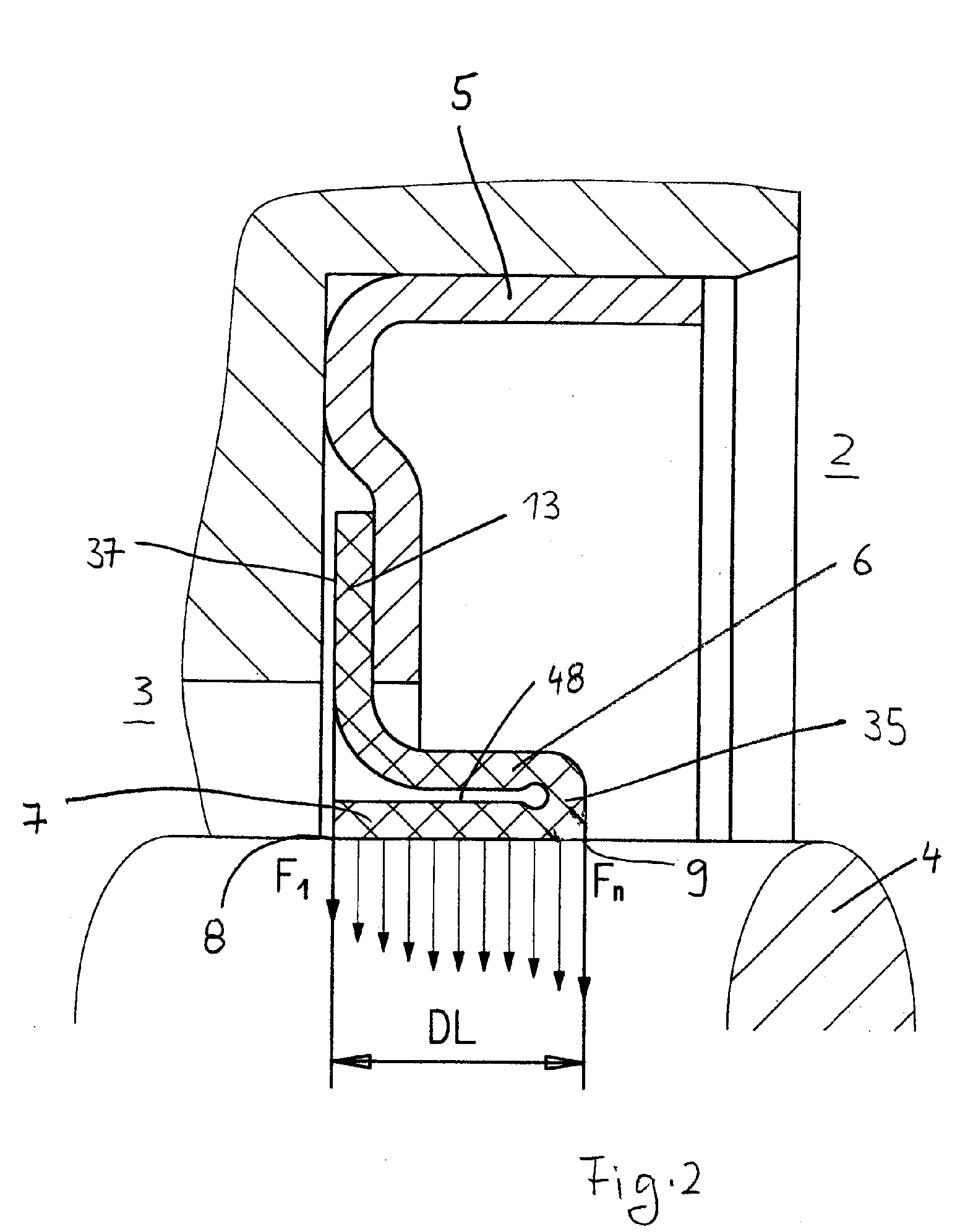

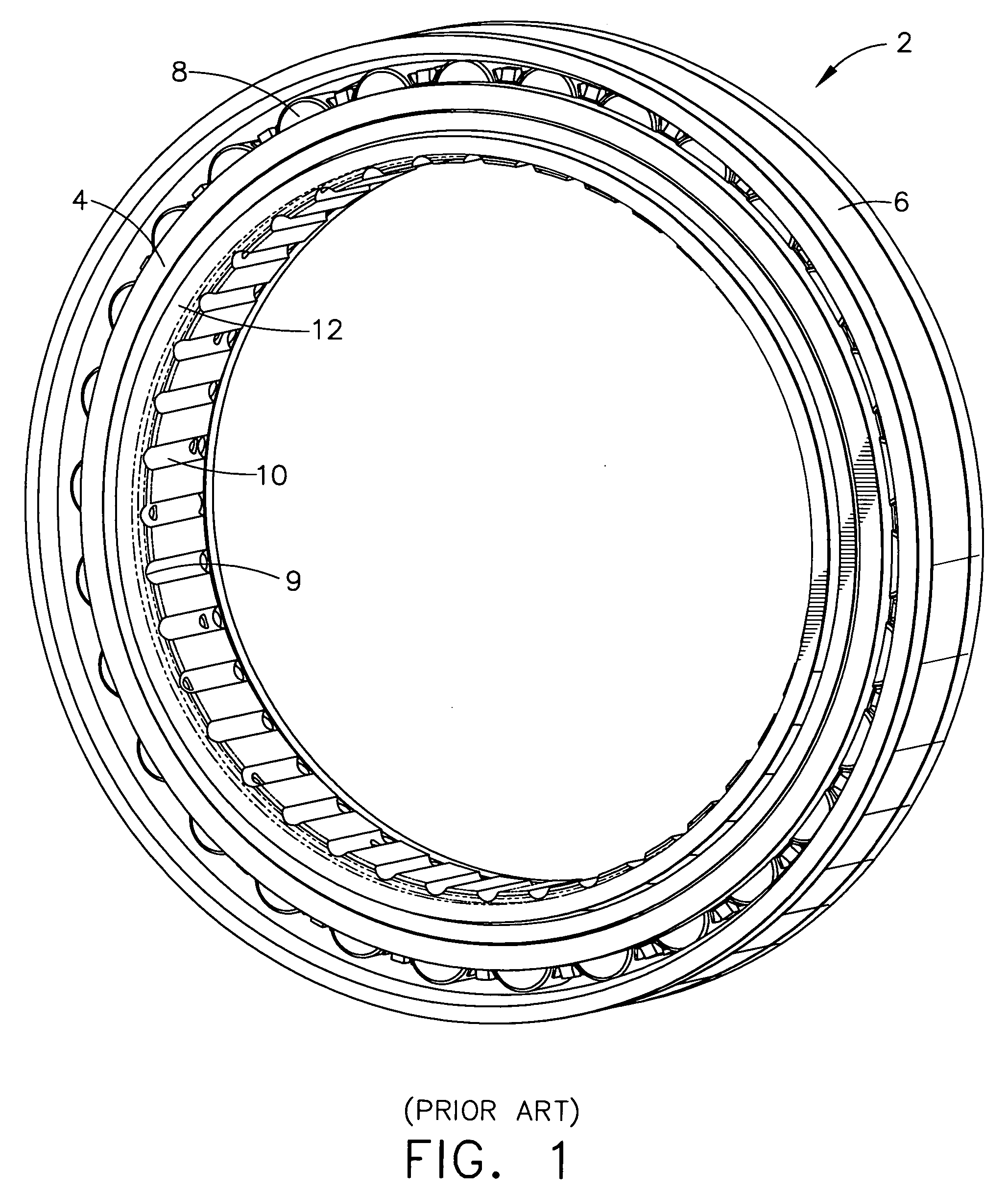

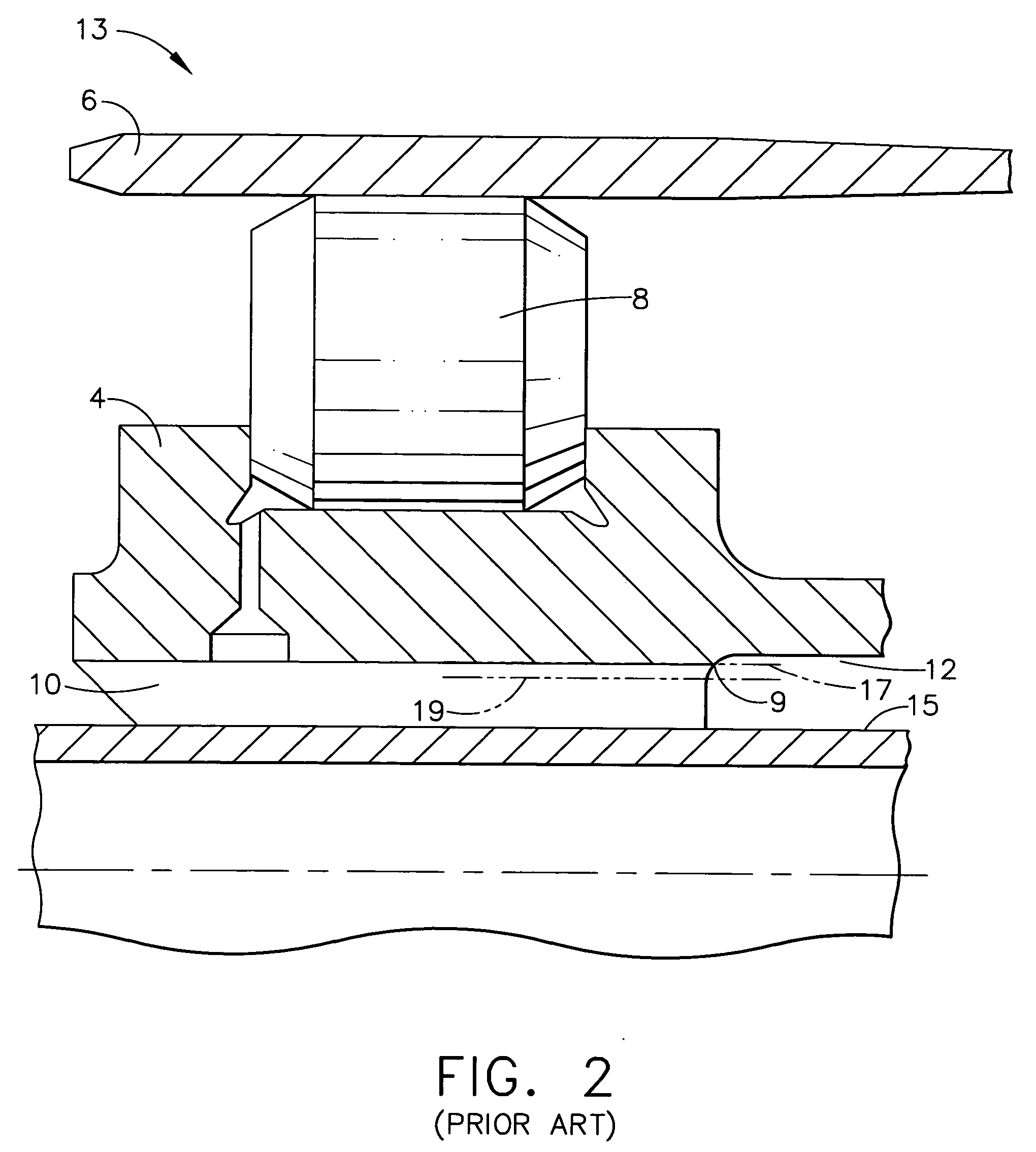

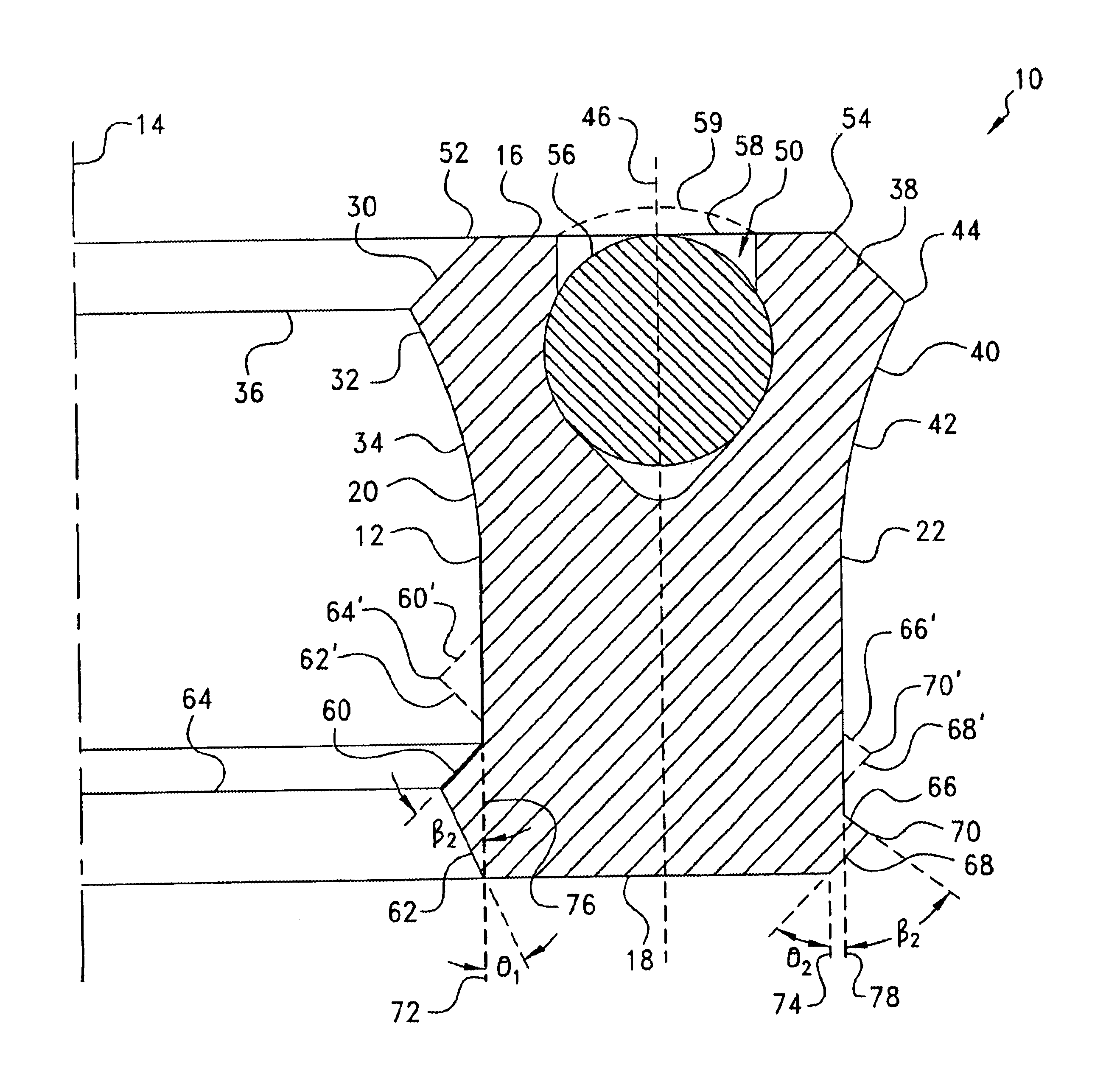

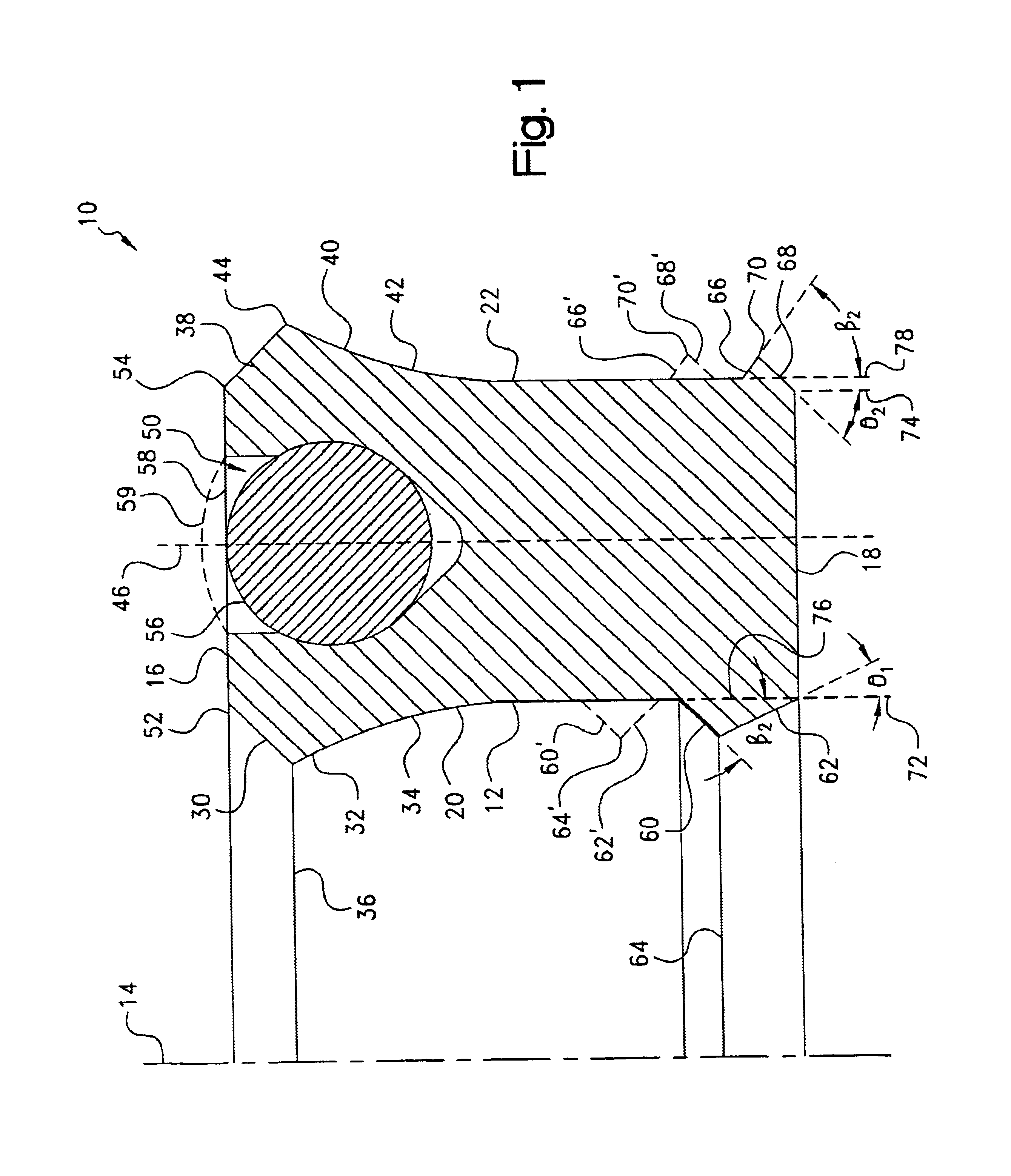

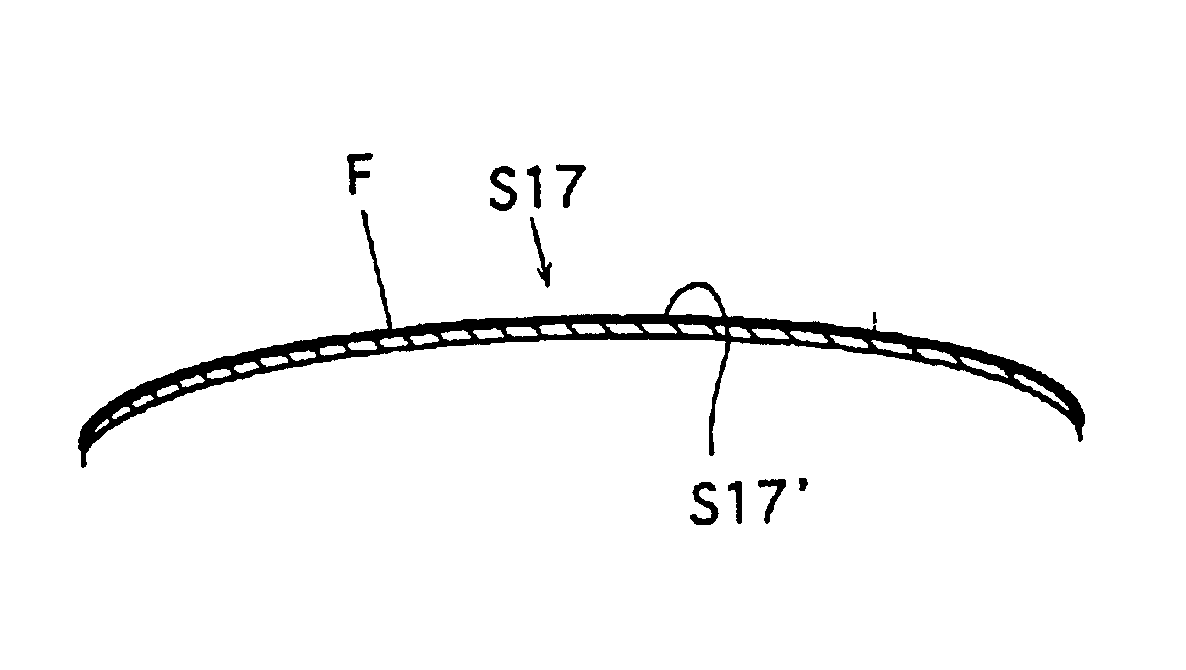

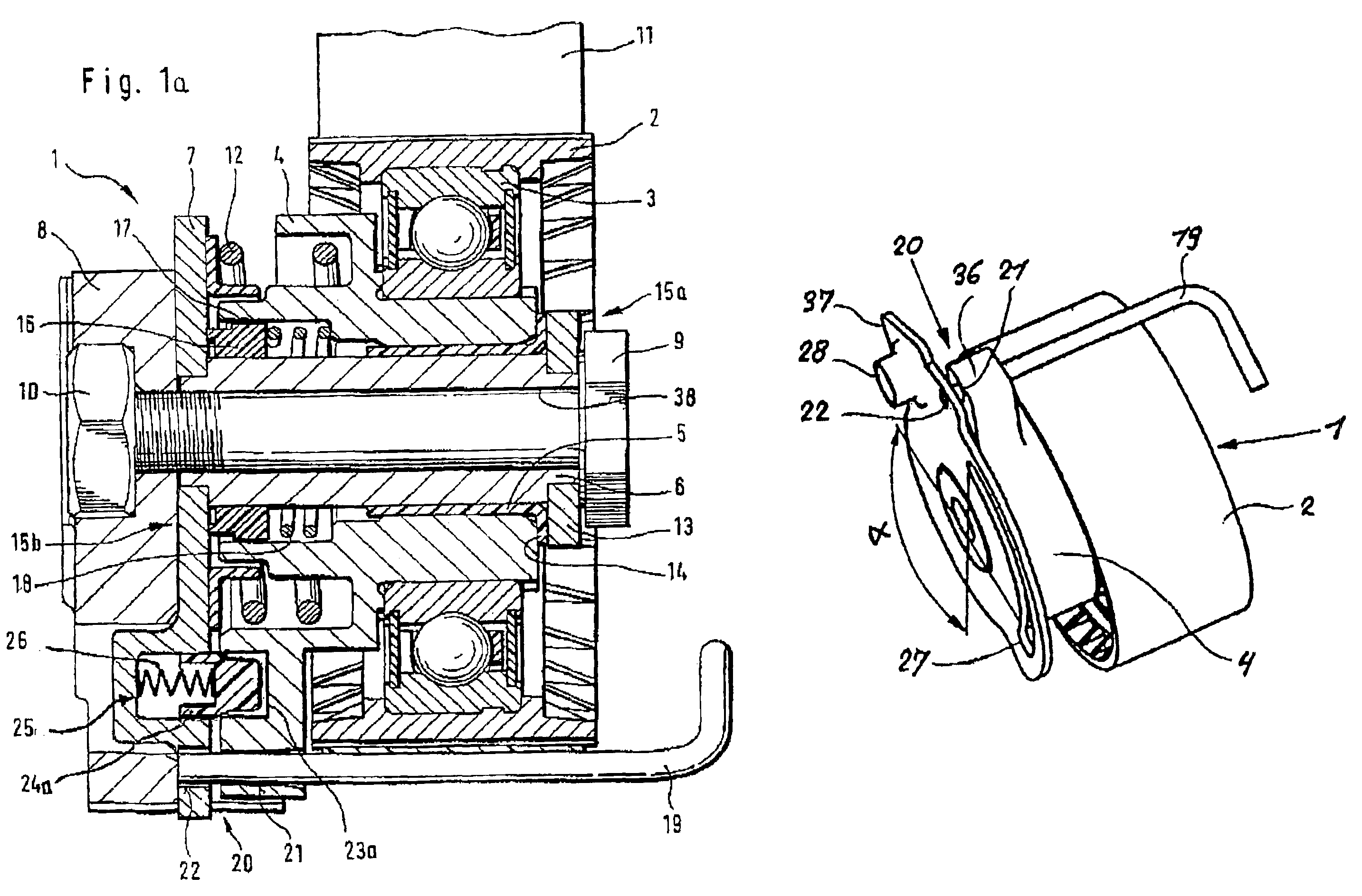

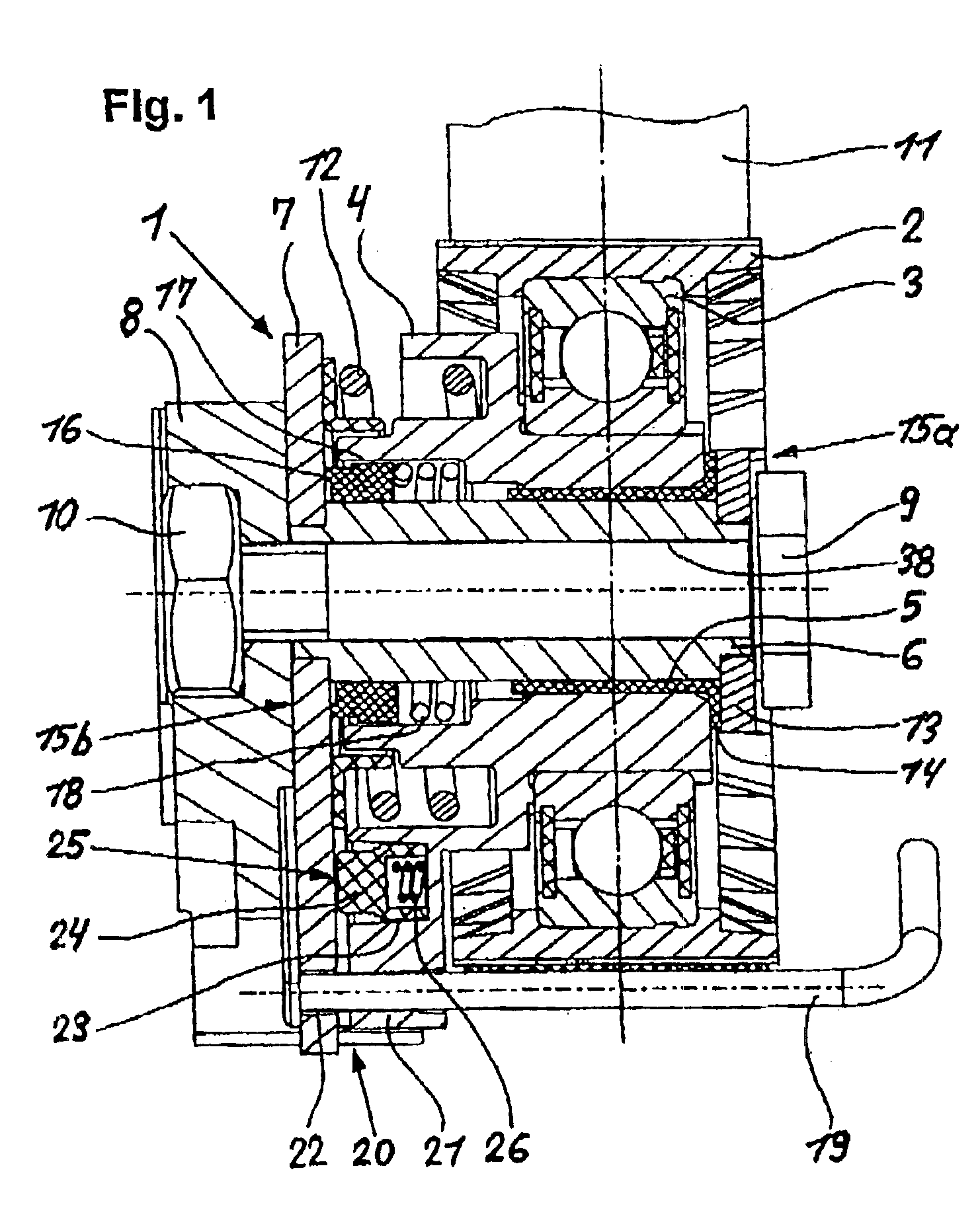

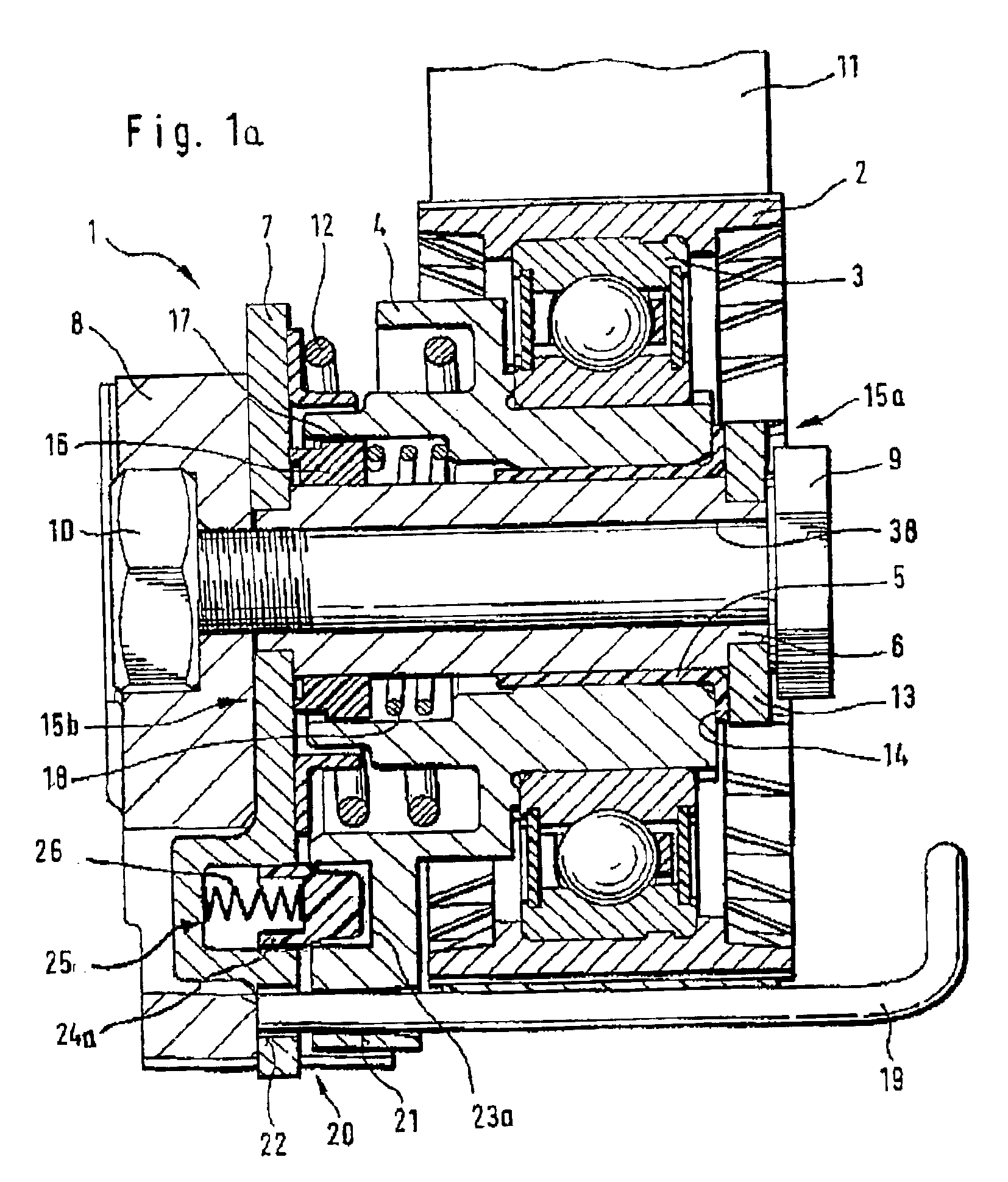

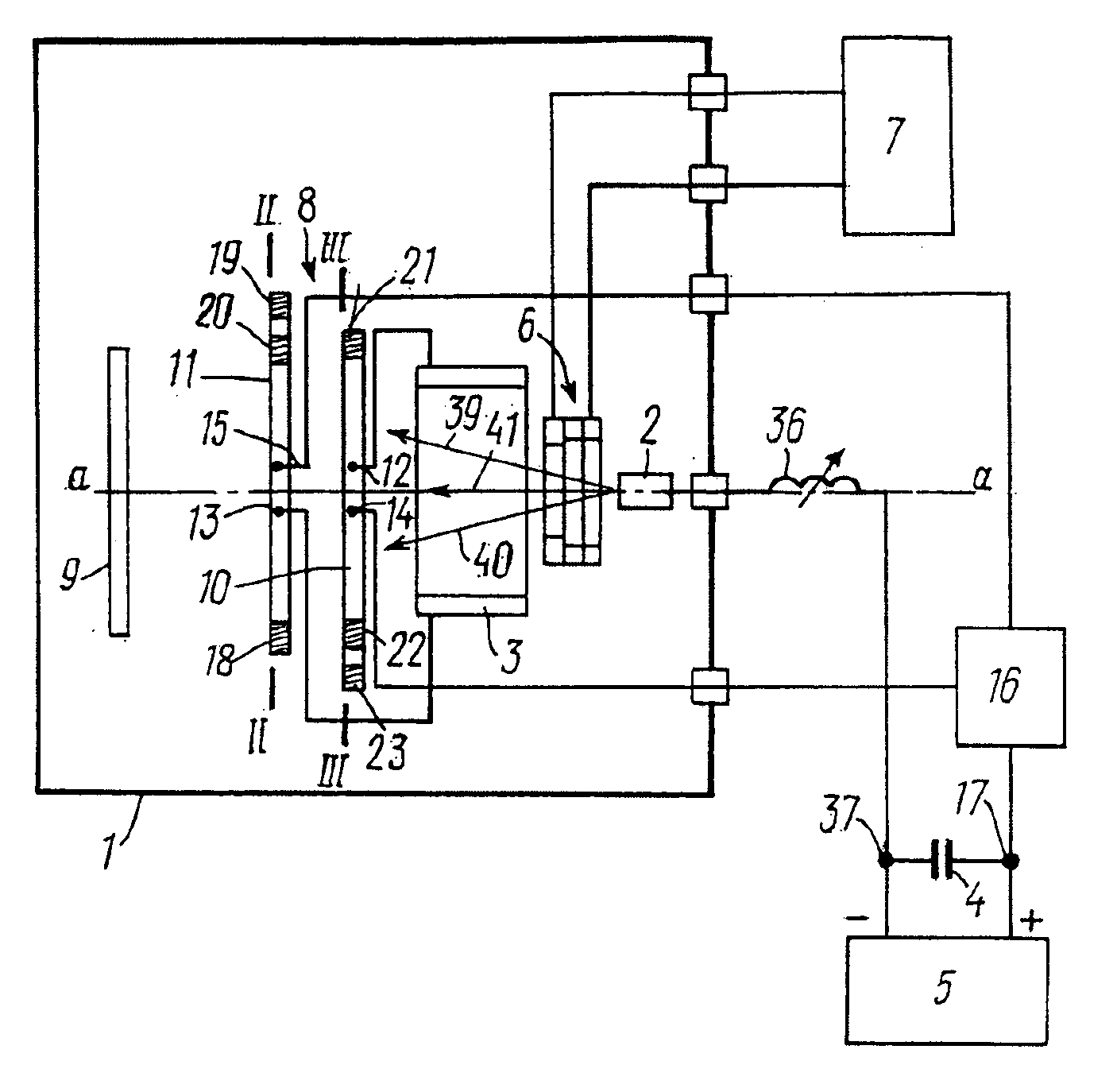

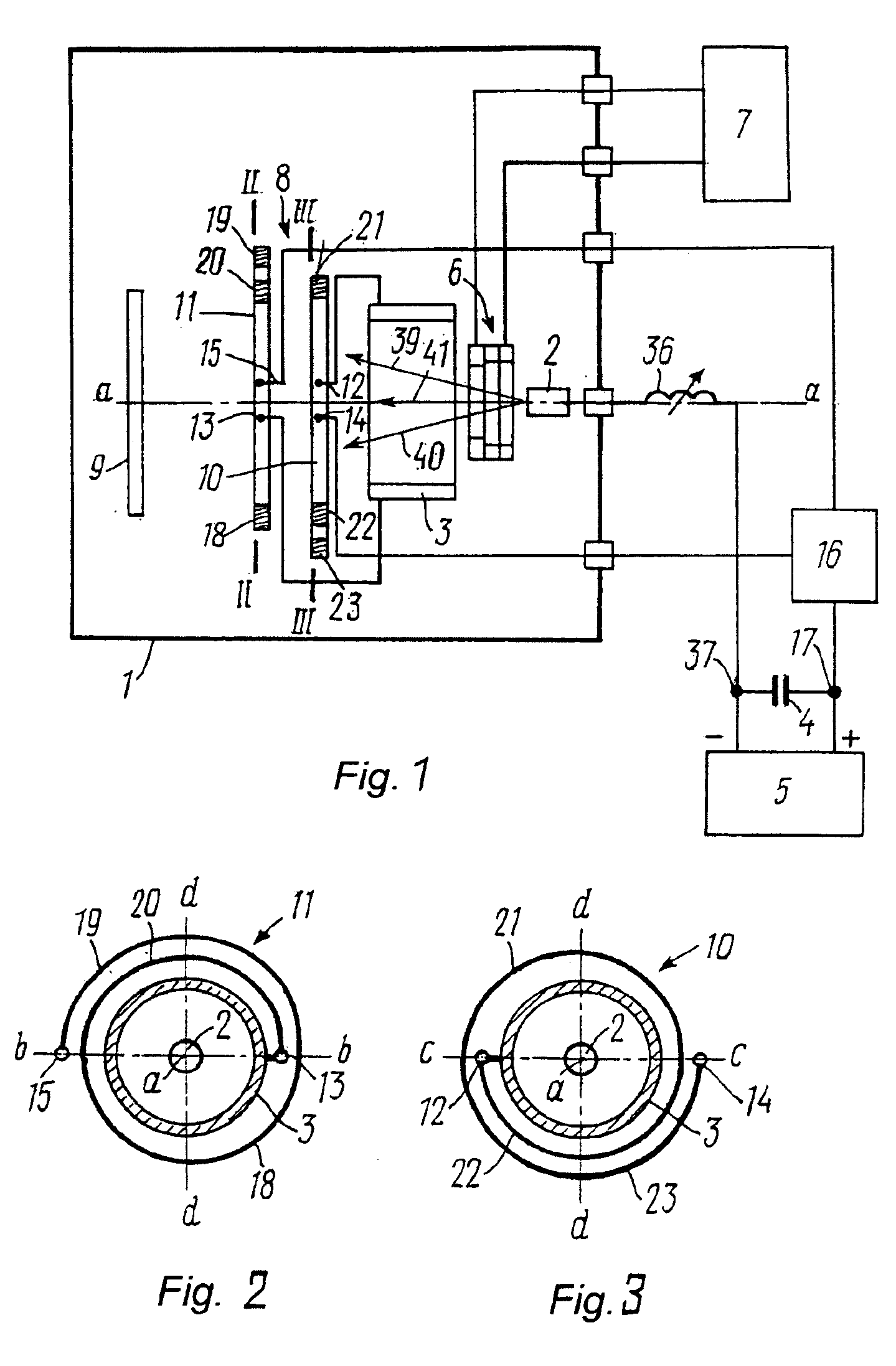

Sealing Ring, Especially Radial Shaft Seal

A sealing ring has a sealing disk having a fastening part and a seal part. The fastening part is connected to a first stationary machine part and the seal part seals a movable machine part and is oriented in an axial direction toward an atmosphere side or a medium side of the sealing ring. The seal part has a first sealing element and a second sealing element adjoining the first sealing element and oriented in a direction opposite to the first sealing element in a mounted position of the sealing ring. The second sealing part rests against the rotary machine part under a radial force.

Owner:KACO

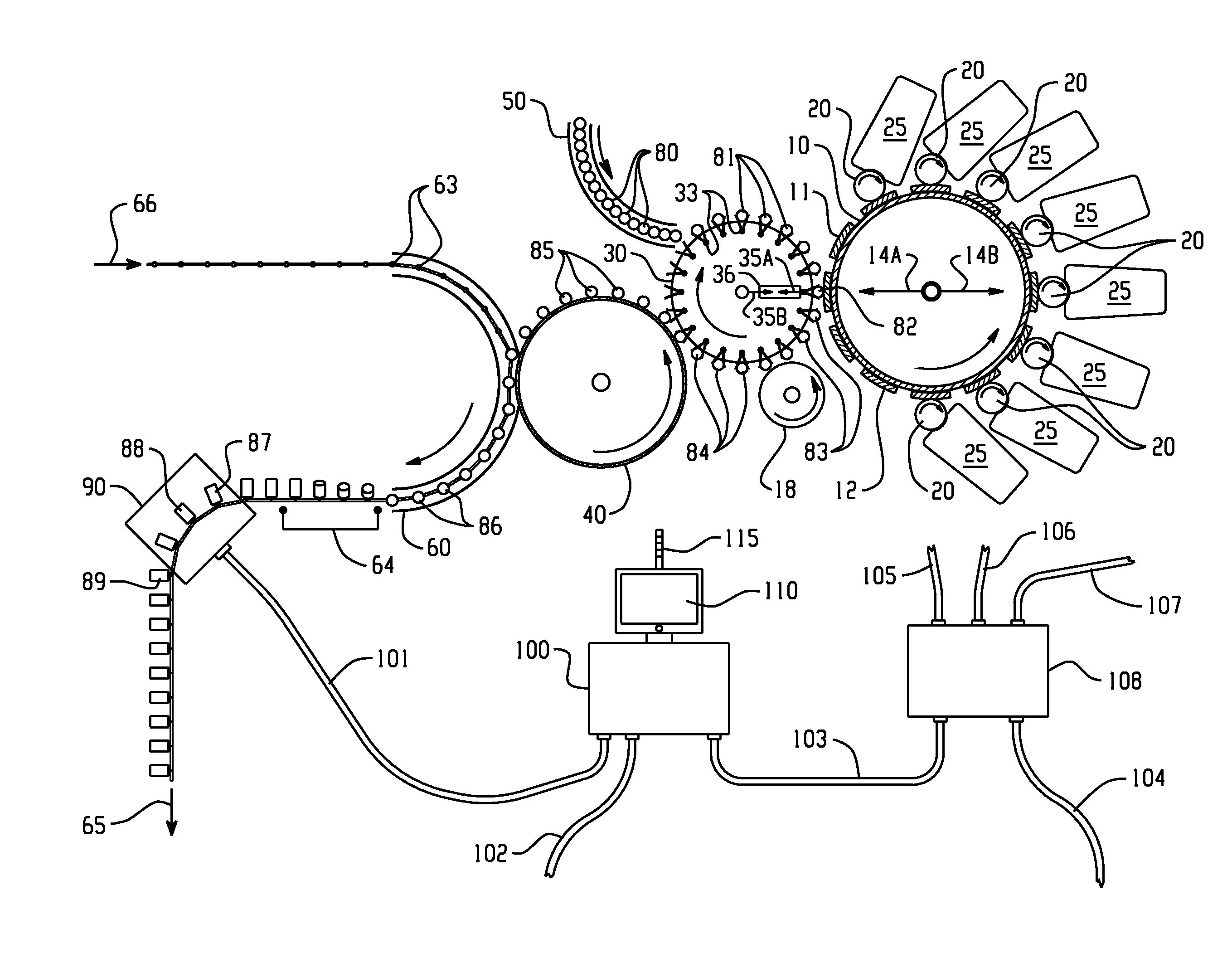

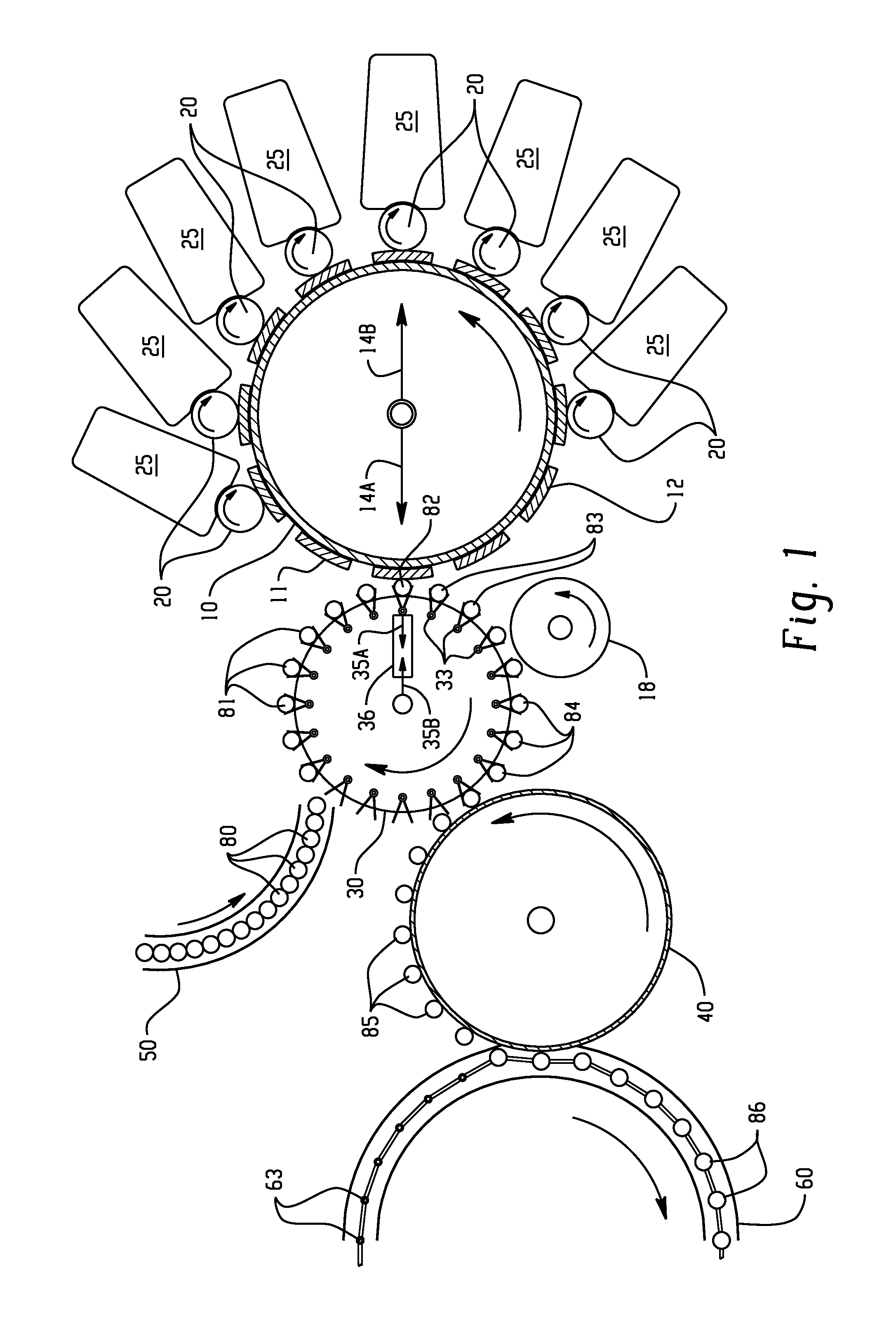

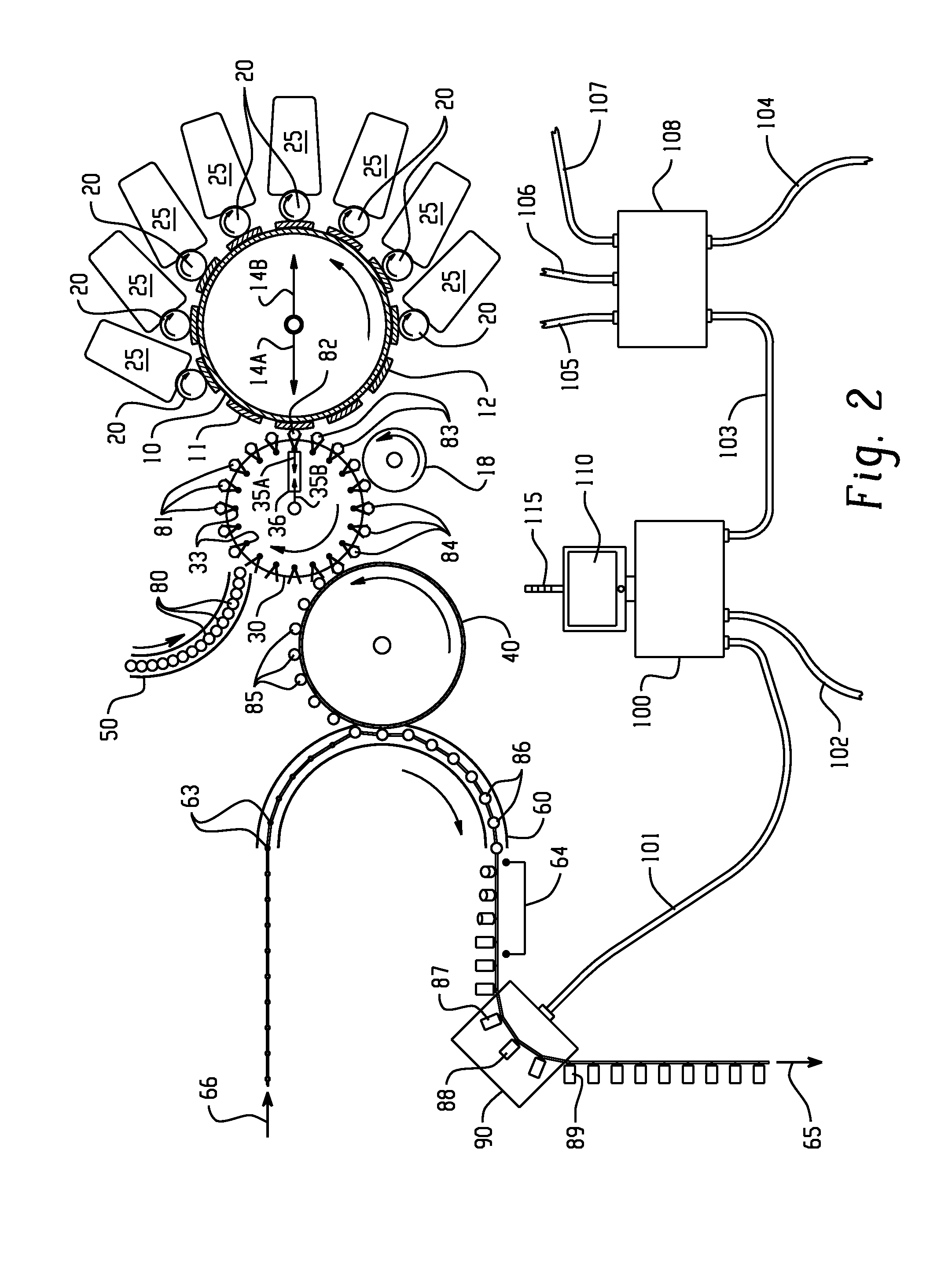

Method and system for decorator component identification and selected adjustment thereof

Automated inspection technology is integrated with a cylindrical container print decorator machine to optimize the decoration process by making critical process and machine information properly and immediately available for corrective adjustments to the process. With this information, a high speed decoration machine operator will be made directly aware of the portions or subsystems of the decorator machine not functioning properly. The information directly facilitates, and can even recommend, corrective adjustments that are necessary to the decorator to better optimize printing functions. It is possible to use this information to optimize the operation of the decorator. It is possible to use this information by way of a properly configured control system, after specific augmentation capabilities are added to the decorator machine, to automatically close the loops with specific decorator printing machine parts or subsystems to dramatically improve the decorating process even while the machine is printing.

Owner:PRESSCO TECH INC

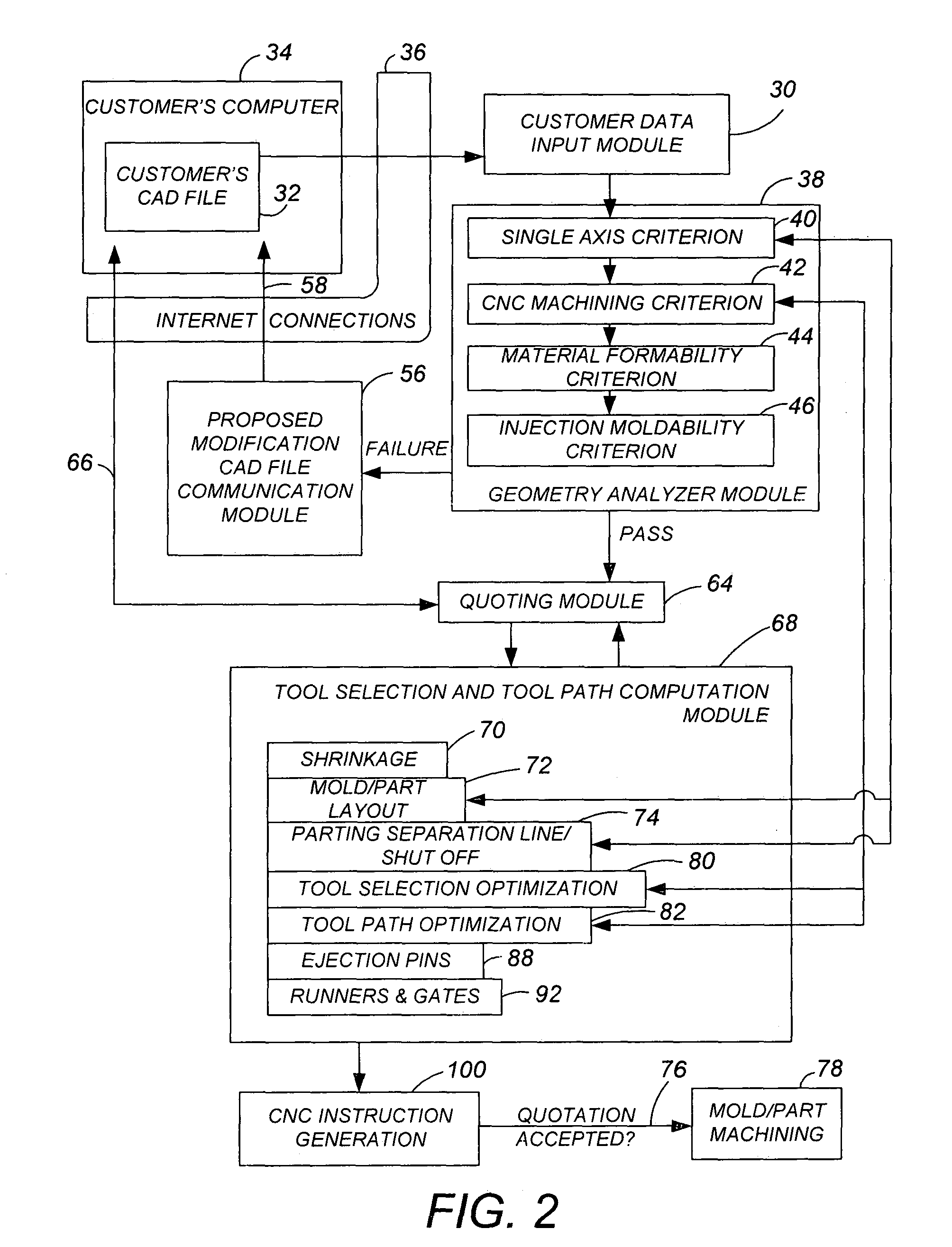

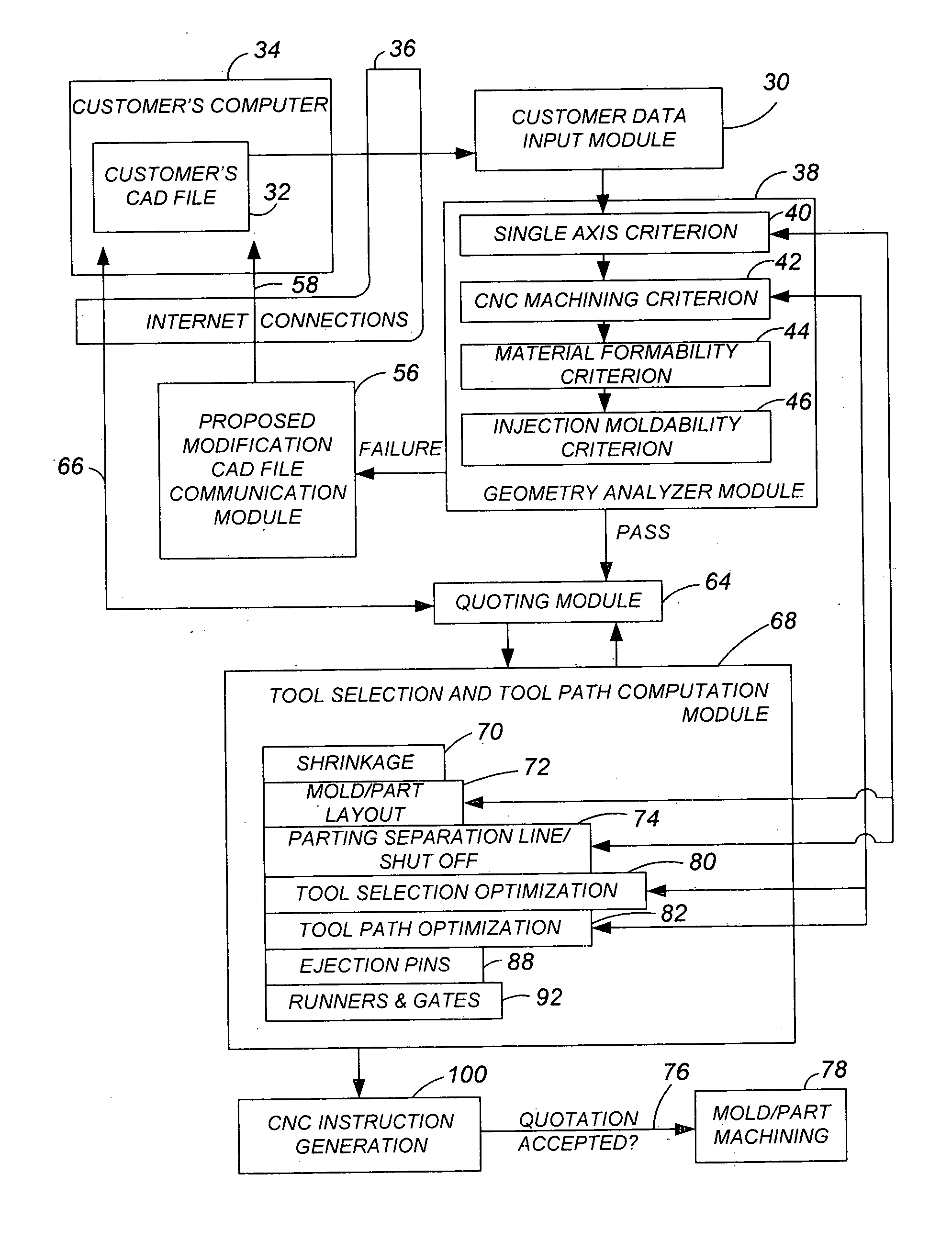

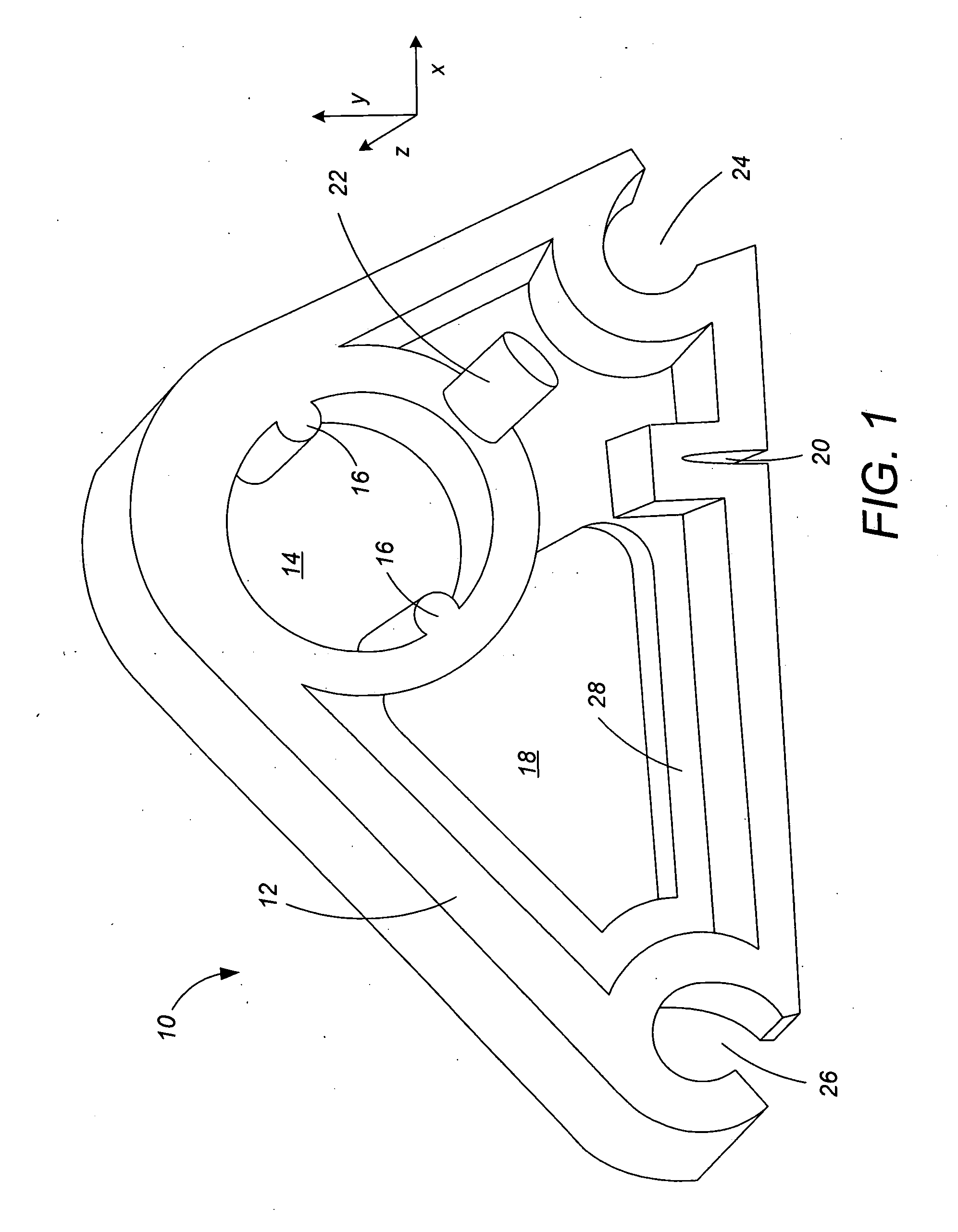

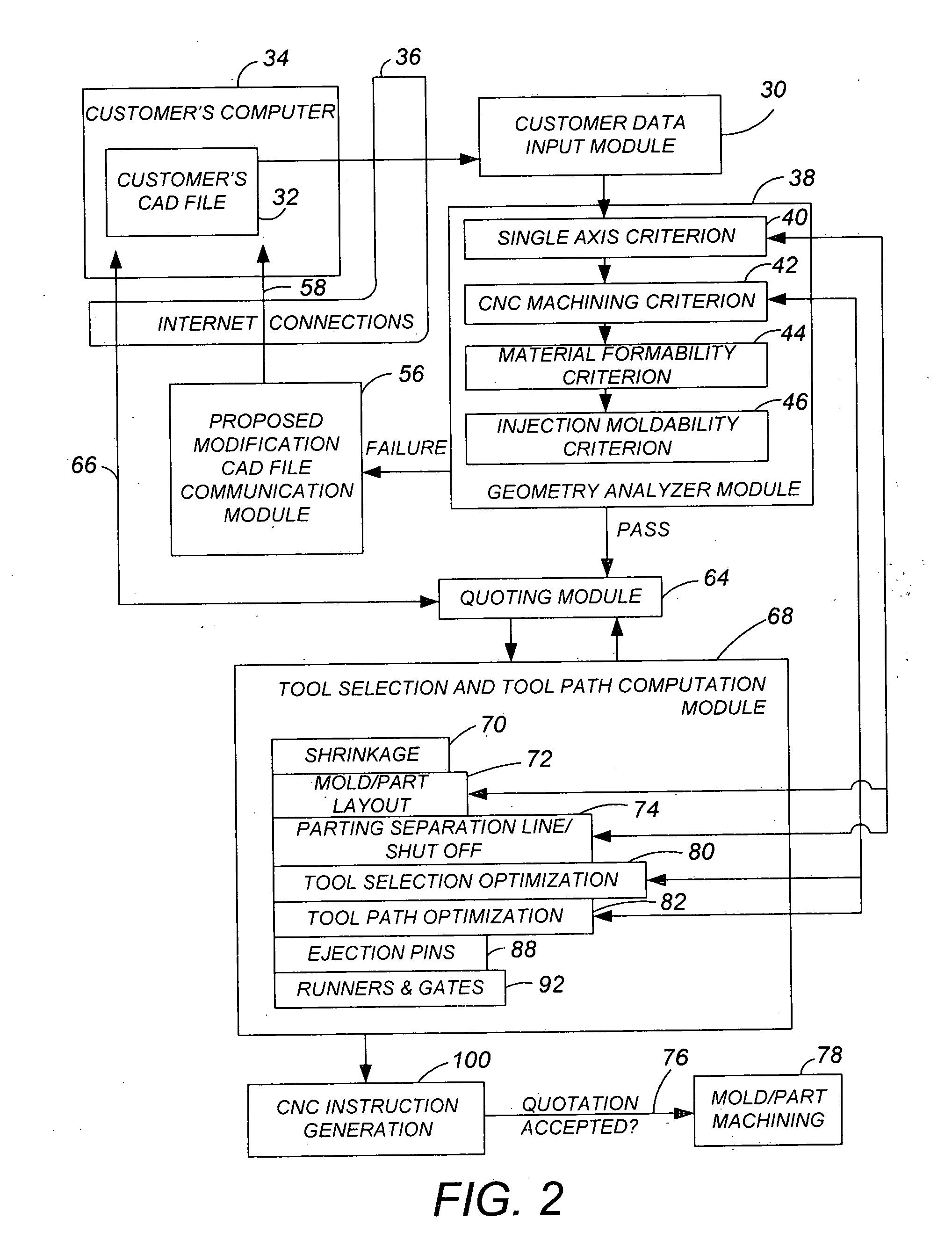

Automated quoting of CNC machined custom molds and/or custom parts

InactiveUS7840443B2Increase flexibilityImprove interactivityGeometric CADForecastingSurface finishGraphics

A customer sends a CAD file for the part to be manufactured to the system. The system assesses the CAD file to determine various pieces of manufacturing information. One or more acceptability criteria are applied to the part, such as whether the part can be machined in two opposing orientations in a 3 axis CNC machine. If not, the system sends a file to the customer graphically indicating which portions of the part need modification to be manufacturable. The system provides the customer with a quotation form, that allows the customer to select several parameters, such as number of cavities or parts per workpiece block, surface finish and material, which are independent of the shape of the part. The quotation module then provides the customer with the cost to manufacture the mold or a number of parts, which may include both molded parts and total profiled machined parts. Budget-driven quotation is possible, wherein proposed modifications in the molding process are controlled by the budget of the customer. Interactivity is also achieved, with the customer being able to modify the quotation interactively by modifying one or more of the initially selected parameters, including selecting a different budgeted amount.

Owner:PROTOLABS INC

Automated quoting of CNC machined custom molds and/or custom parts

InactiveUS20070038531A1Increase flexibilityImprove interactivityGeometric CADForecastingGraphicsSurface finish

Owner:PROTOLABS INC

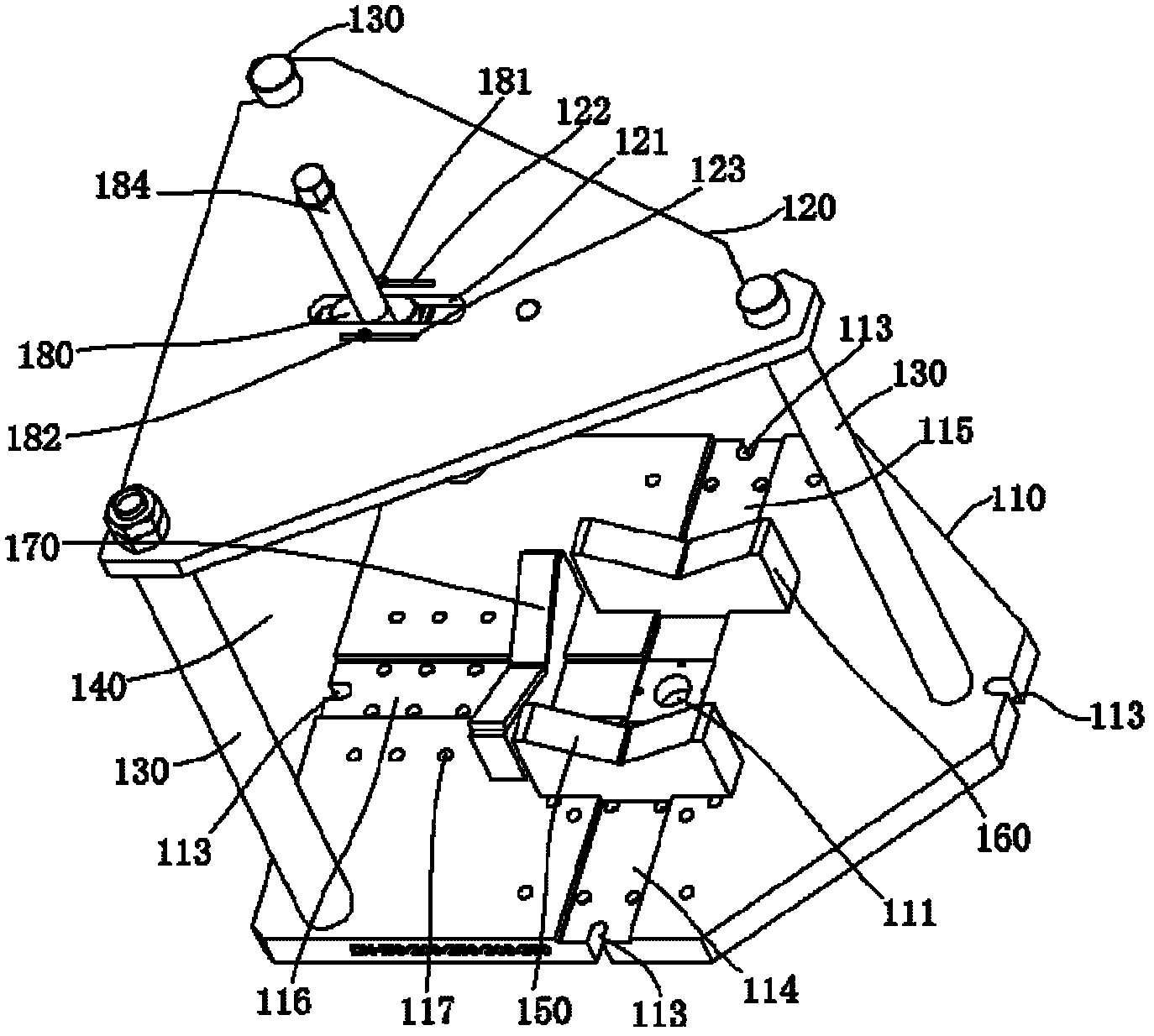

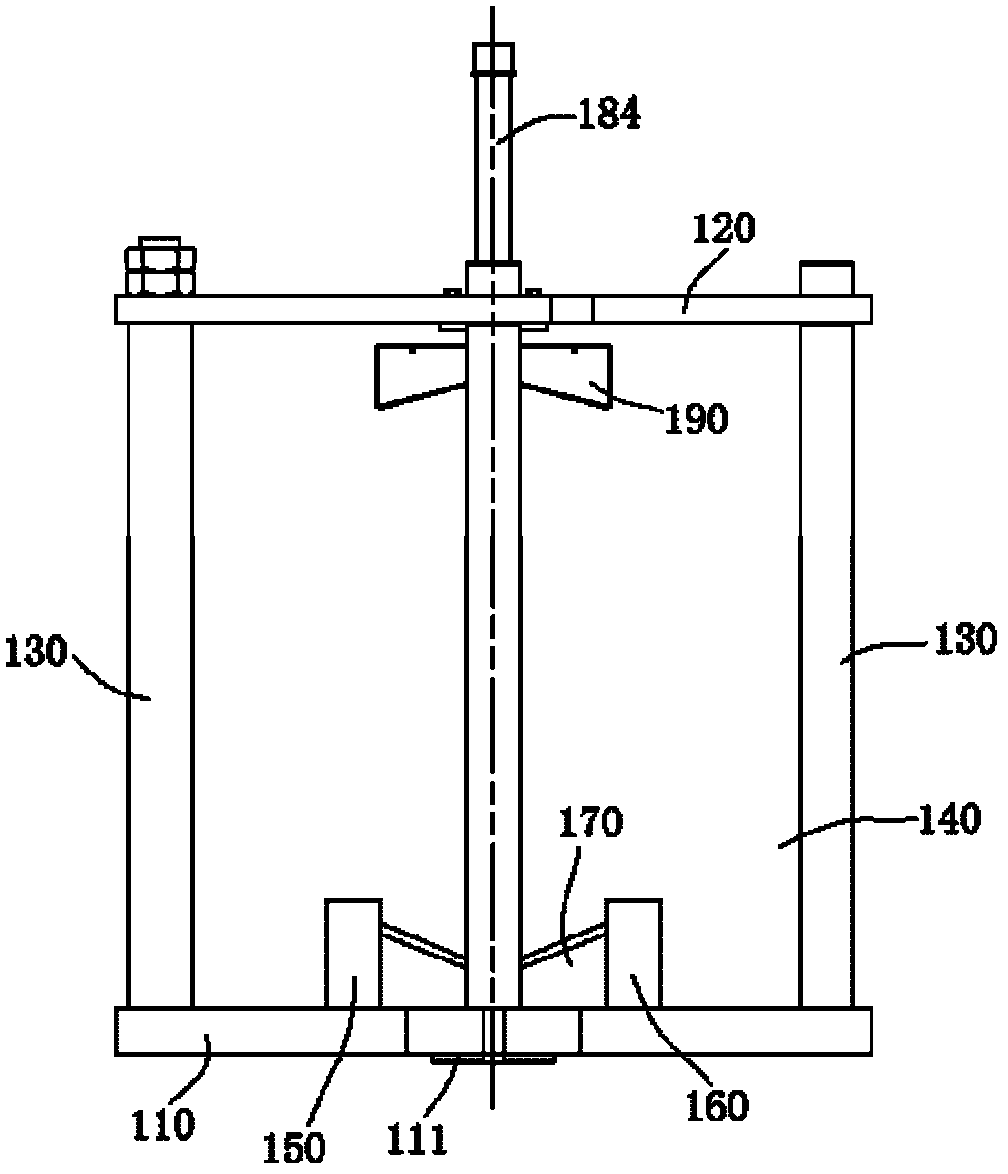

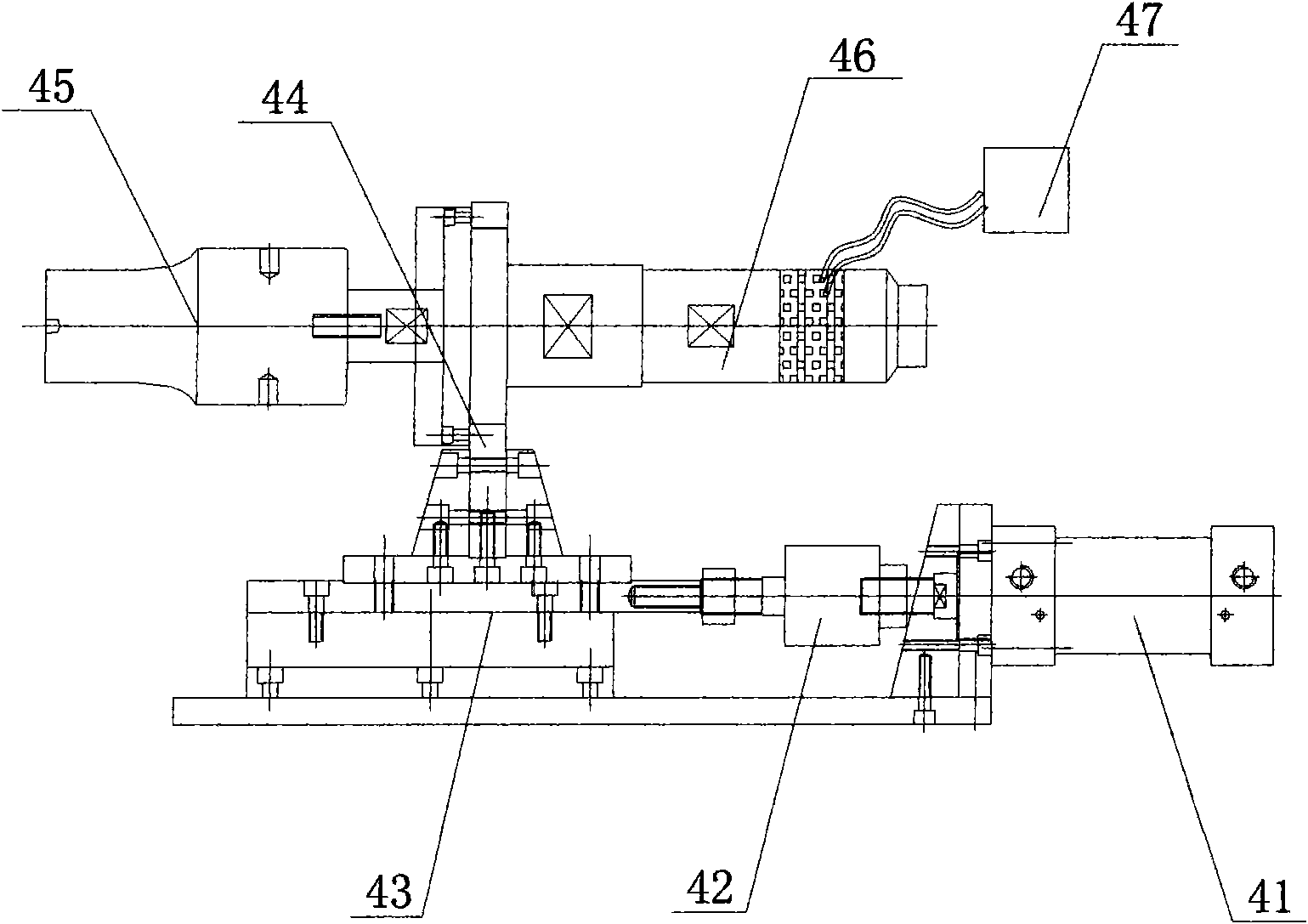

Machining method for valve body, clamping clamp and machining equipment

ActiveCN102528538AReduce the number of clampingReduce human resource investmentMetal working apparatusPositioning apparatusMachine partsEngineering

The invention discloses a machining method for a valve body. The valve body to be machined is horizontally clamped on a workpiece revolving platform of machining equipment by using a clamping clamp, and a plane to be machined of the valve body is adjusted to be perpendicular to the workpiece revolving platform of the machining equipment, so that an intersection point of a central axis of the plane to be machined of the valve body is overlapped with a revolving center of the workpiece revolving platform, and the machining method requires that an extension line of a central axis of a cutter revolving body of the machining equipment is intersected with that of the revolving central axis of the workpiece revolving platform; and after a machining part is machined, a next machining part can be machined every time when the workpiece revolving platform is turned for an angle. The invention also discloses the clamping clamp and the machining equipment for realizing the machining method. According to the machining method, the clamping clamp and the machining equipment, all machining can be finished with one person and one machine, so that the aims of reducing the clamping frequency, increasing the machining efficiency, reducing investment in human resources and reducing manufacturing cost of a product are fulfilled. The machining method can also be used for machining a part with a plurality of machining surface perpendicular to the same reference planes, and has broad universality.

Owner:SHANGHAI HONGGONG MASCH TECH CO LTD

Method for observation of a person in an industrial environment

Manufacturing processes profit greatly from a close collaboration between human and machine. Whereas a human behaves flexibly and adaptively but is inclined to make mistakes during repetitive work operations, machines operate quickly and exactly but are static and not very flexible. In order to enable an improved hazard protection in the context of a safe human-machine interaction, a spatial- and time-dependent variable degree of hazard is allocated to monitored spatial areas as a function of the current position and the current movement state of a machine or a machine element, as well as of the observed person. For this purpose, a multicamera system is used to acquire image data of the person in order to obtain the most detailed information possible about the position and alignment of a person, in particular also with reference to the body parts thereof, in an industrial environment. These image data are then examined with regard to the imaging of a person so that whenever a person has been detected in the image data, an articulated virtual 3D model of the human body is matched to this person hypothesis. Subsequently, this virtual body model is continuously matched to the movement behavior of the person detected in the image data. A hazard potential is determined using knowledge of the position and the movement behavior of the virtual body model in space. The hazard potential thus determined is subjected to a threshold value comparison in order to act upon the movement control of the machine or the machine part in the event of this threshold value being exceeded.

Owner:PILZ (COMPANY)

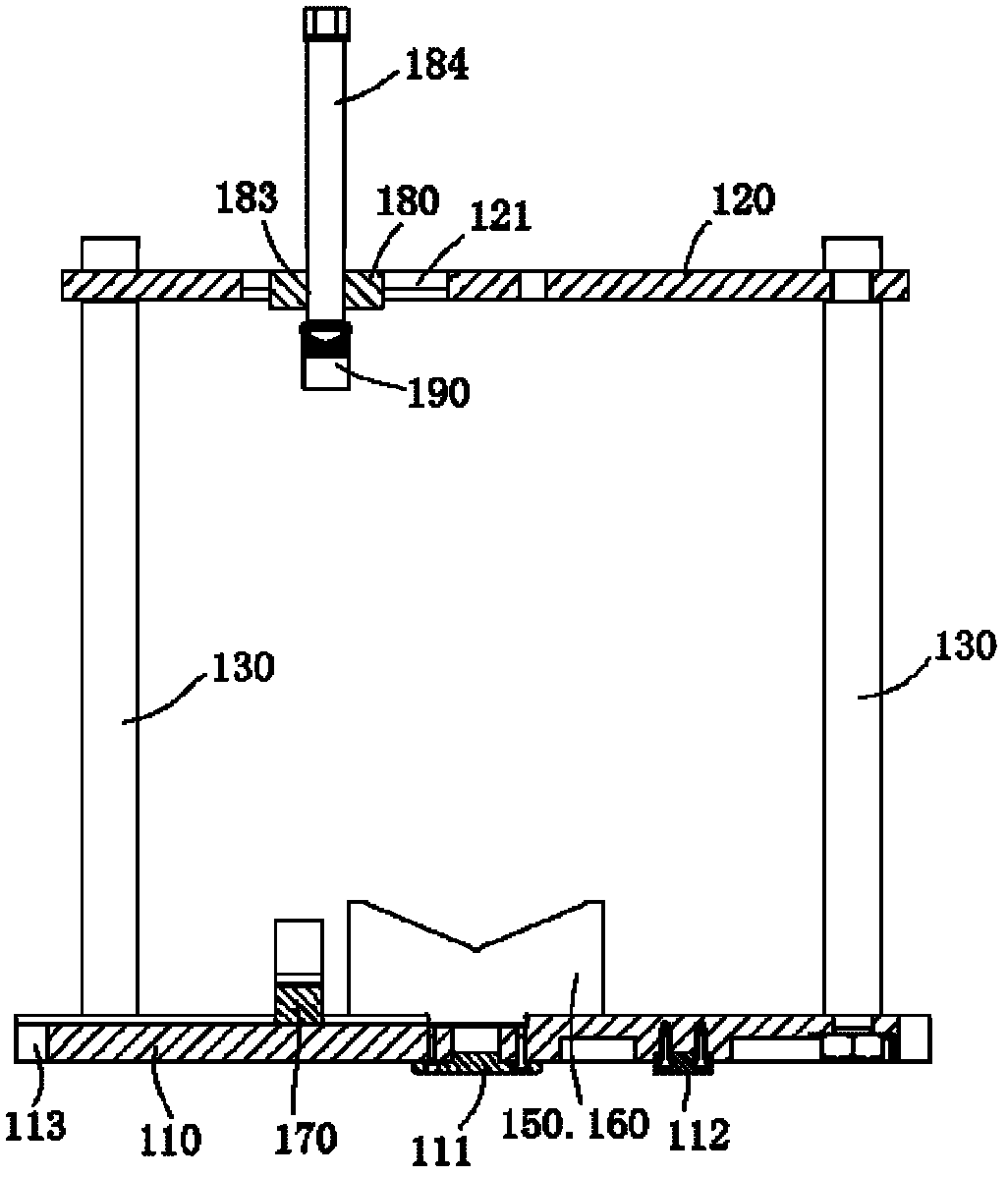

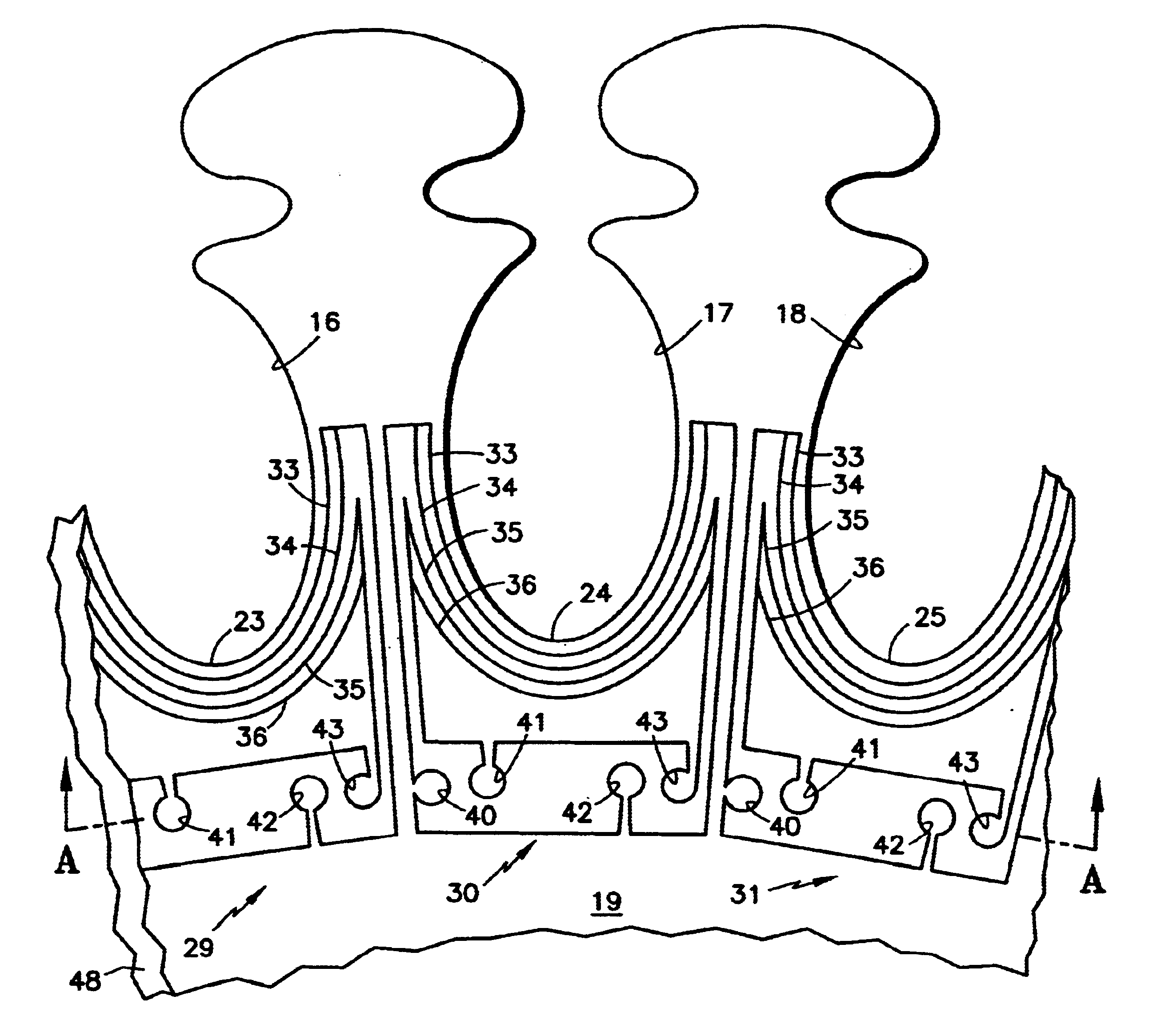

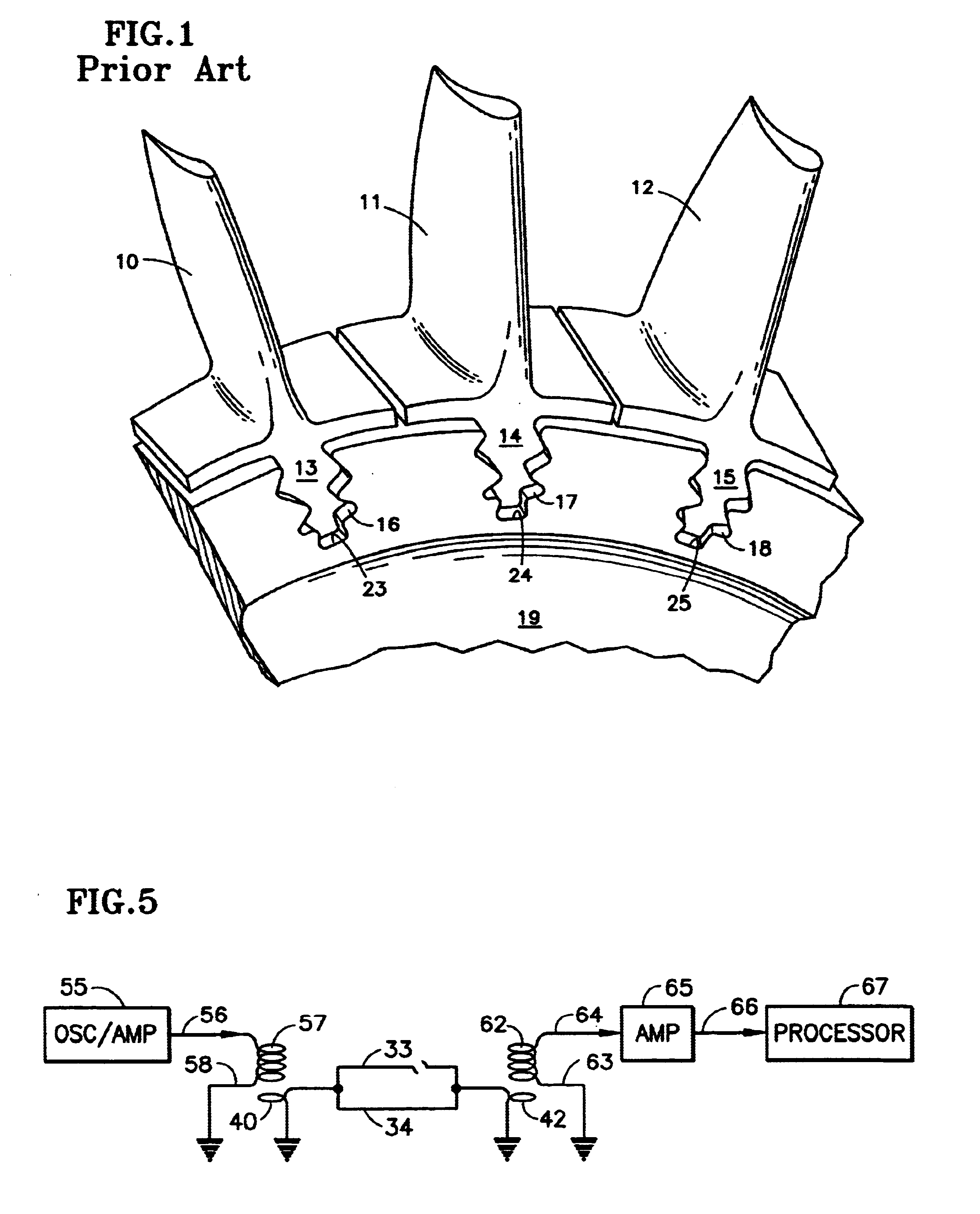

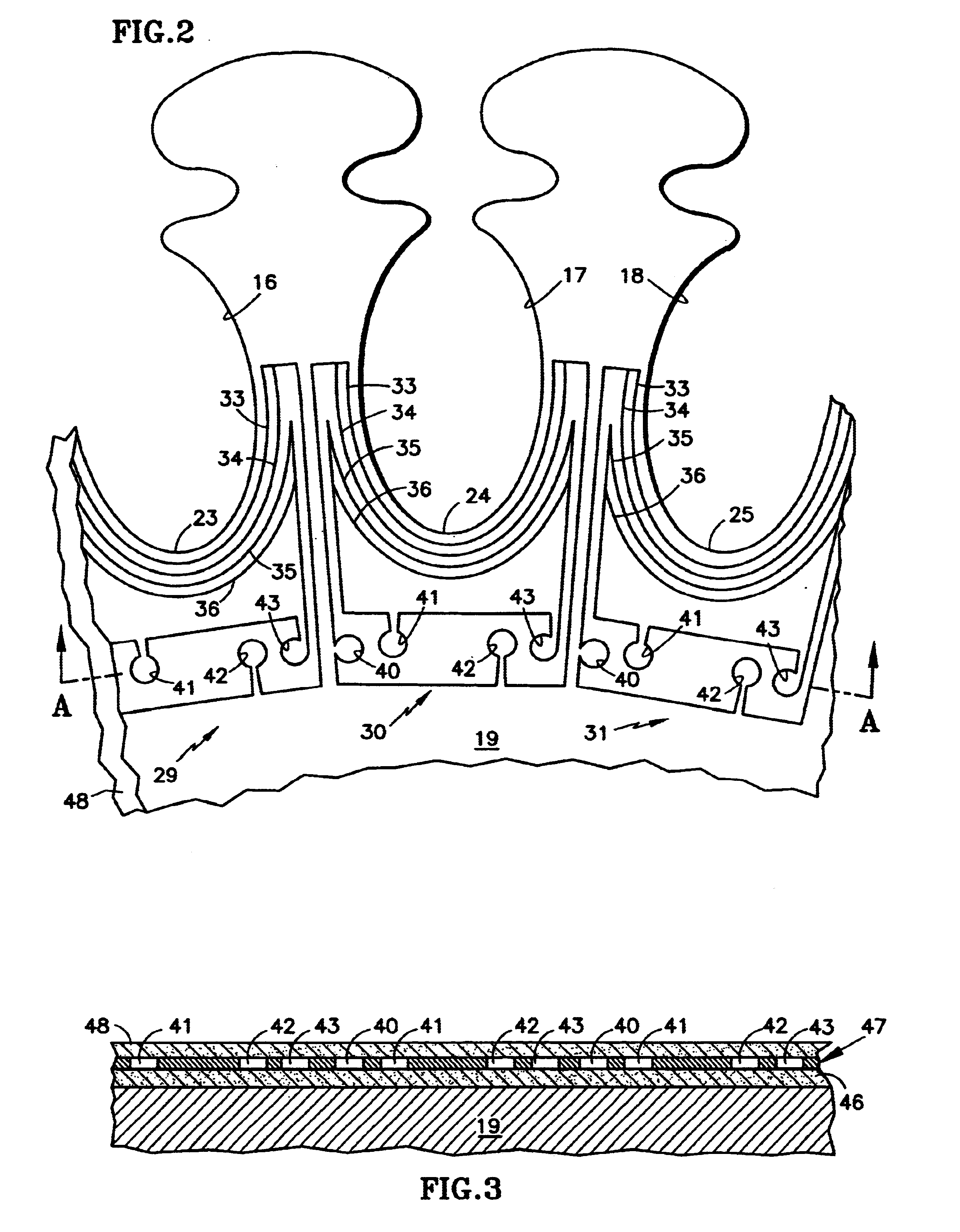

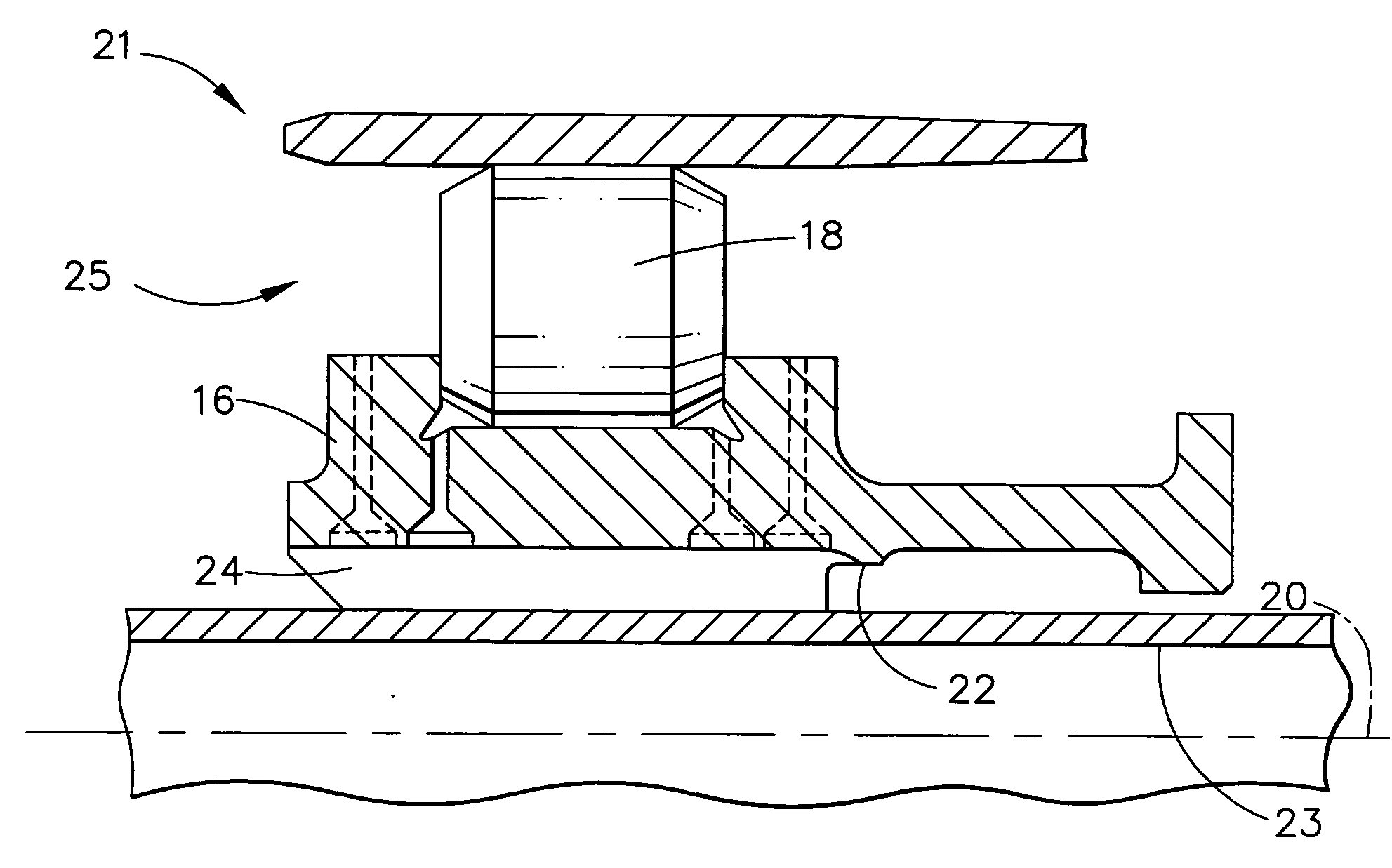

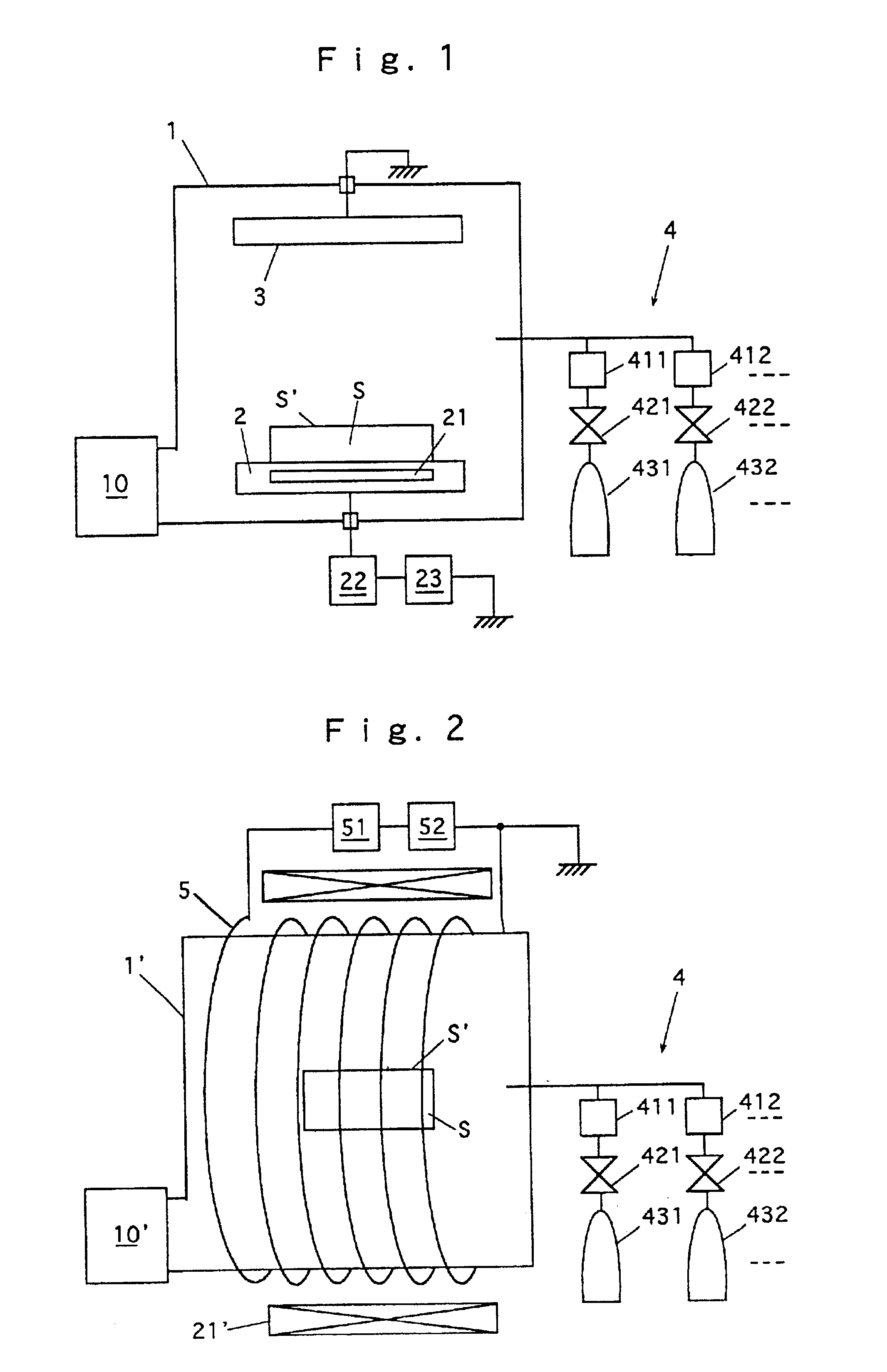

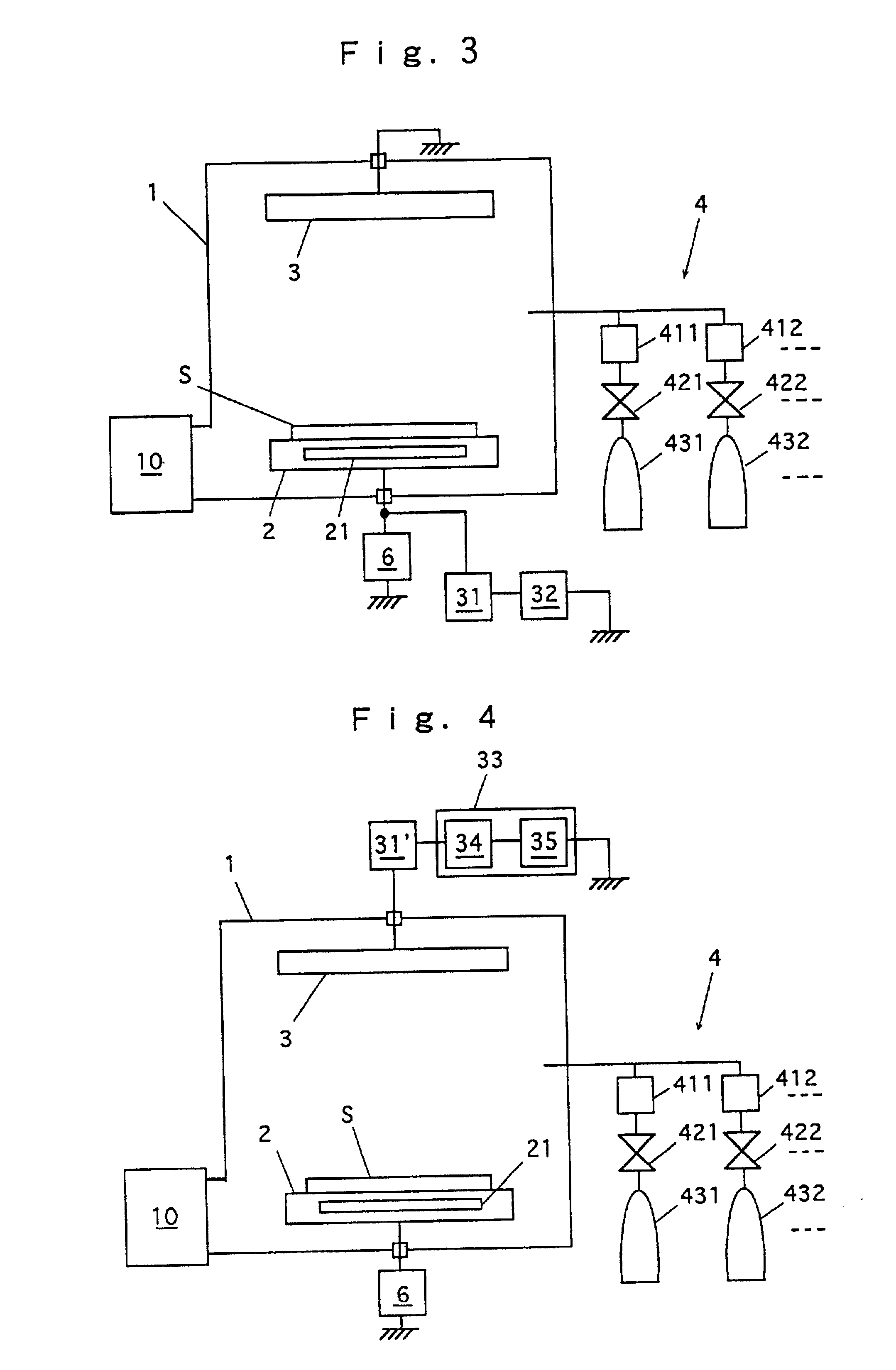

Crack detection in fracture-critical machine parts

InactiveUS6756908B2Environment highIncrease temperatureAnalysing fluids using sonic/ultrasonic/infrasonic wavesMolten spray coatingAudio power amplifierEtching

A plurality of wires (33, 34; 35, 36) are disposed near the bottom (23-25) of blade root sockets (16-18) of a rotating disk 39 of a gas turbine engine by vapor deposition and etching, the wires including connections to excitation nodes (40, 42) and detection nodes (41, 43). A nearby stationary member of the engine mounts an oscillator amplifier (55) which drives a coil (57) that excites the circuitry, and a coil (62) drives an amplifier (65) and a processor (67) which provides an indication of whether or not one or more of the wires are broken by a crack.

Owner:RAYTHEON TECH CORP

Lubricant distribution weir for lubricating moving machine elements

A device and method for uniformly providing lubricant to rotating machine parts is provided. The device comprises an axially mounted rotating circumferential lubricant reservoir with a weir comprising one side of the lubricant reservoir. The reservoir and weir are disposed at uniform radius and circumferentially about an axis of rotation causing lubricant added to the reservoir to flow uniformly over the weir about the circumference of the weir when the device is in high speed rotational motion. Because of the uniform flow of lubricant over the top of the weir around the circumference of the weir, lubricant can be directed to machine parts requiring lubrication in a uniform manner around the circumference of the moving device.

Owner:GENERAL ELECTRIC CO

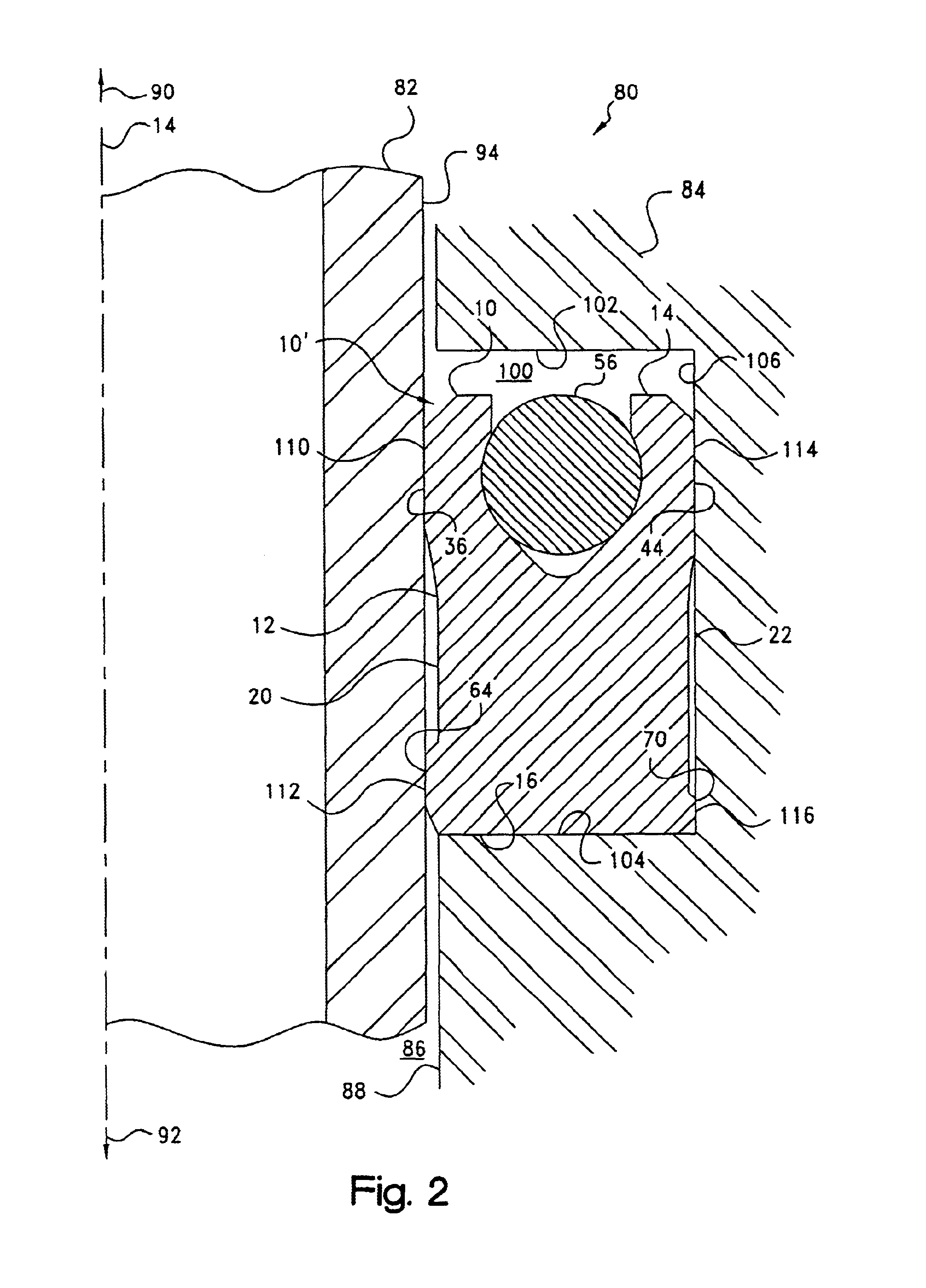

Seal ring having secondary sealing lips

InactiveUS6883804B2Economical and reliableFunctional integrationSleeve/socket jointsEngine sealsMachine partsActuator

Seal for the static or dynamic sealing of joints, machine parts or other components or structures such as may be found in choke, kill, or other auxiliary line strings for marine oil or gas well risers, hydraulic or pneumatic cylinders or other actuators. The seal may have a U-cup or solid geometry profile including a secondary sealing lip on both the inner and outer diameter thereof which functions as a wiper for the exclusion of outside contaminants, such as seawater, from joint sealed.

Owner:PARKER INTANGIBLES LLC

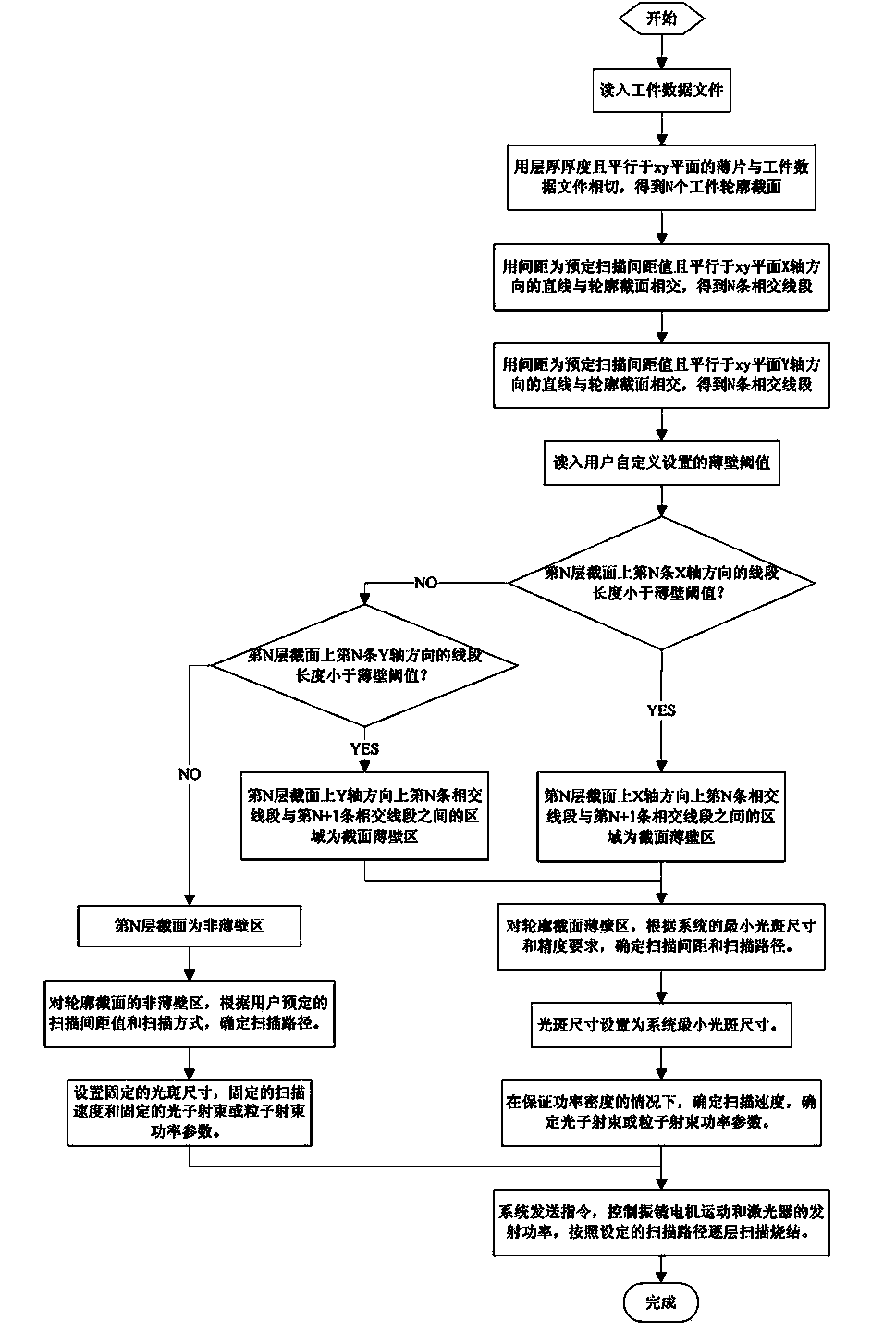

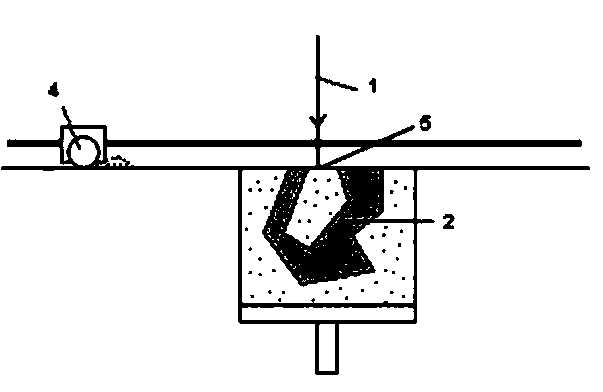

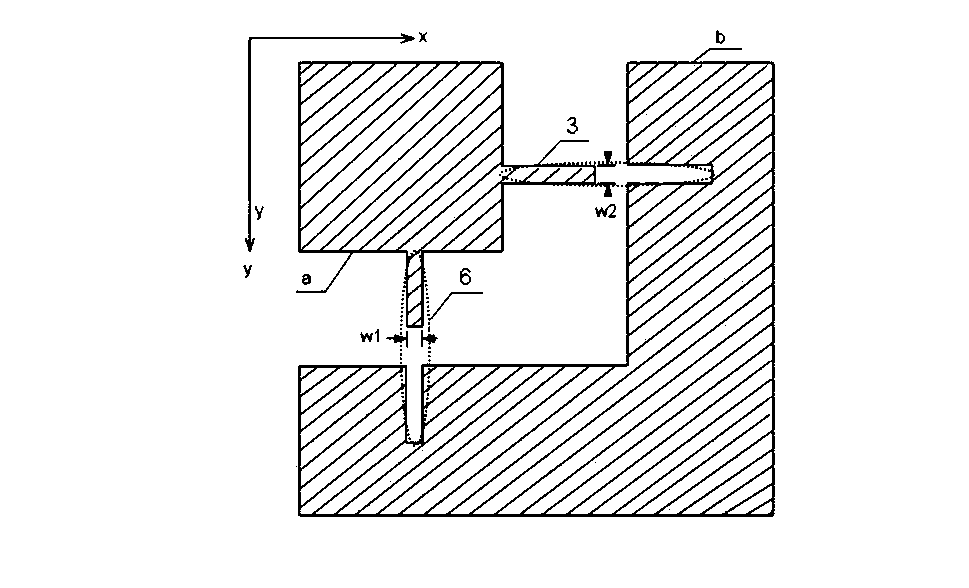

Scanning method for manufacturing three-dimensional object layer by layer

ActiveCN103639411AUniform efficiencyEqualization accuracyAdditive manufacturing apparatusCeramic shaping apparatusMachine partsParticle beam

A scanning method for manufacturing a three-dimensional object layer by layer comprises the following steps: (1), dividing each section layer of a three-dimensional object to be manufactured into a thin-wall area and a non-thin-wall area: setting a threshold of the gap width of the section profile of the three-dimensional object, and according to the gap width of the section profile in x / y direction, dividing a coating area required to be scanned into a thin-wall area and a non-thin-wall area, wherein the thin-wall area is an area of which the gap width of the section profile is smaller than the threshold and the non-thin-wall area is an area of which the gap width of the section profile is greater than or equal to the threshold; (2), according to the thin-wall area and the non-thin-wall area, scanning area by area, wherein the non-thin-wall area is scanned, relatively high photon beam or particle beam power and relatively large light spot diameter are selected, and when the thin-wall area is scanned, relatively low photon beam or particle beam power and relatively large light spot diameter are selected. By the scanning method, constraints of efficiency and precision in the process of manufacturing the three-dimensional object layer by layer are balanced to the maximum extent, so that the efficiency is ensured and the accuracy and the surface quality of a machined part are ensured.

Owner:HUNAN FARSOON HIGH TECH CO LTD

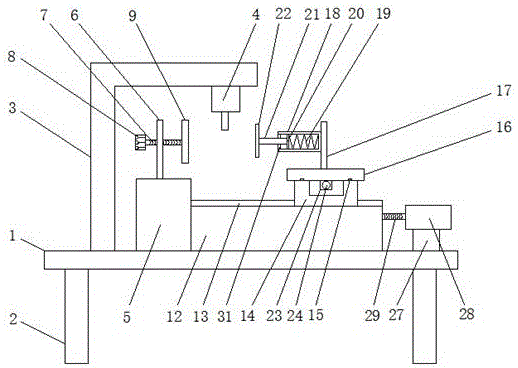

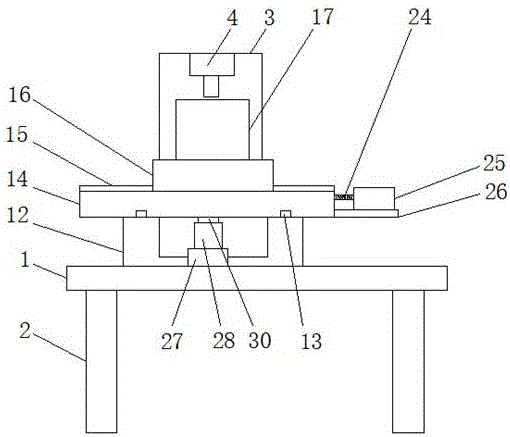

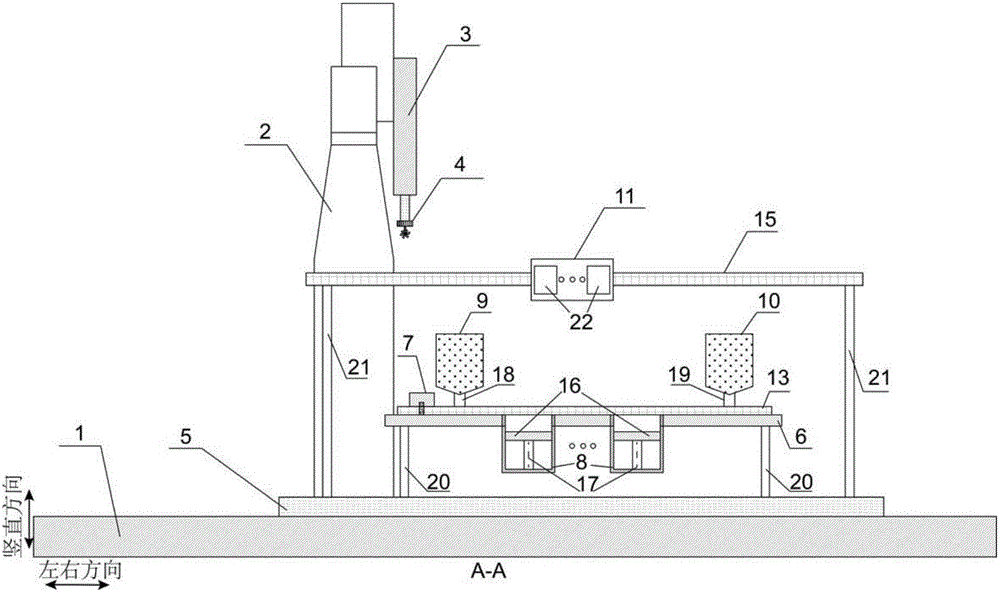

Convenient-to-use machine part machining device

ActiveCN106670857AEasy to useEasy to adjust the clamping positionPositioning apparatusMetal-working holdersMotor driveMachine parts

The invention provides a convenient-to-use machine part machining device, and relates to the field of machining. The convenient-to-use machine part machining device comprises a device table; supporting legs are fixedly arranged at the four corners of the bottom of the device table; a cutter head support is arranged on the left side of the top of the device table; a first fixed seat is arranged in the position, on the right side of the cutter head support, of the top of the device table; a cutter head is arranged at the bottom of the cutter head support; and a first fixed plate is arranged at the top of the first fixed seat. According to the convenient-to-use machine part machining device, a first motor drives a first rotary shaft to rotate to allow a second movable seat to move forwardly and reversely, a second motor drives a second rotary shaft to rotate to allow a first movable seat to move leftwards and rightwards, and a shock absorber moves along with the first movable seat to allow a third clamping plate to be matched with a first clamping plate and a second clamping plate for clamping a part, so that the clamped position of the part by a clamping device can be adjusted conveniently, and the precision of the part is improved.

Owner:芜湖鼎伟自动化工程有限公司

Object coated with carbon film and method of manufacturing the same

InactiveUS6893720B1Improve wear resistanceEasy to slideFlexible wall reciprocating enginesLayered productsCarbon filmMachine parts

An object such as an automobile part, an image forming apparatus part, a bicycle part, other machine parts, a sport article or its part, a toy or its part, or a rain article or its part has a portion to be in contact with a contact object. The contact portion is made of at least one kind of material selected from a group including polymer material such as resin or rubber as well as glass, and the contact portion has a surface entirely or partially coated with a carbon film (typically, a DLC film) having a wear resistance as well as at least one of a lubricity, a water repellency and a gas barrier property. The carbon film is formed on the object with a good adhesion.

Owner:NISSIN ELECTRIC CO LTD

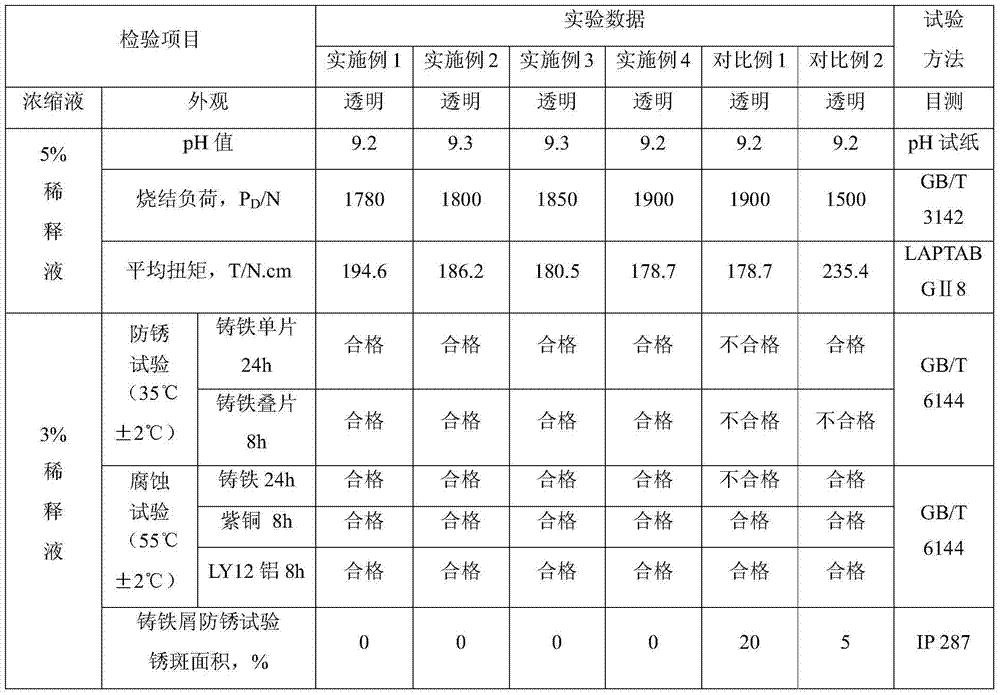

Heavy-load metal machining total synthesis cutting fluid as well as preparation method and application thereof

ActiveCN104277902AImprove the lubrication effectImprove extreme pressure performanceAdditivesMachine partsSuperalloy

The invention belongs to the field of metal machining fluids, and discloses a heavy-load metal machining total synthesis cutting fluid as well as a preparation method and an application thereof. The total synthesis cutting fluid comprises the following components in percentage by weight: 20%-30% of mixed alcohol amine, 6%-9% of anti-rust agents, 4%-6% of special amine, 6%-10% of lubricating agents, 15%-25% of extreme pressure agents, 6%-10% of cosolvents, 1%-2% of water-softening agents, 1%-3% of corrosion inhibitors and the balance of water. The total synthesis cutting fluid disclosed by the invention has excellent lubricating extreme pressure property, can meet the requirement for heavy-load machining, namely reaming, drilling, tapping, threading, broaching, thread machining and the like, of difficult-to-machine materials, namely high-temperature alloy steel, a titanium alloy and the like; a product is green and environment-friendly without containing boron, sodium nitrite, secondary amine, chlorine, phenol, formaldehyde, heavy metals and the like; in addition, the total synthesis cutting fluid disclosed by the invention has excellent anti-rust property, biological stability and machining property, and can enhance the surface quality of a machined part, prolong the service life of a cutter and reduce the rejection rate, thus improving the production efficiency.

Owner:广州国机润滑科技有限公司

Method for observation of a person in an industrial environment

A method for observing a person in an industrial environment using a multicamera system to acquire image data about the position and alignment of a person, including a person's body parts. These image data are then examined with regard to the imaging of a person so that whenever a person has been detected in the image data, an articulated virtual 3D model of the human body is matched to this person hypothesis. Subsequently, this virtual body model is continuously matched to the movement behavior of the person detected in the image data. A hazard potential is determined using knowledge of the position and the movement behavior of the virtual body model in space. The hazard potential thus determined is subjected to a threshold value comparison in order to act upon the movement control of the machine or the machine part in the event of this threshold value being exceeded.

Owner:PILZ (COMPANY)

Tensioner

A tensioner for a traction member includes a faceplate that is stationarily secured to a machine part, with a working eccentric member rotatably supported on the faceplate for limited rotation against a spring force. After pre-installation of the tensioner, a locking device fixes the position of the working eccentric member relative to the faceplate. In one installation position, a catch limits the pivot range of the working eccentric member.

Owner:INA SCHAEFFLER KG

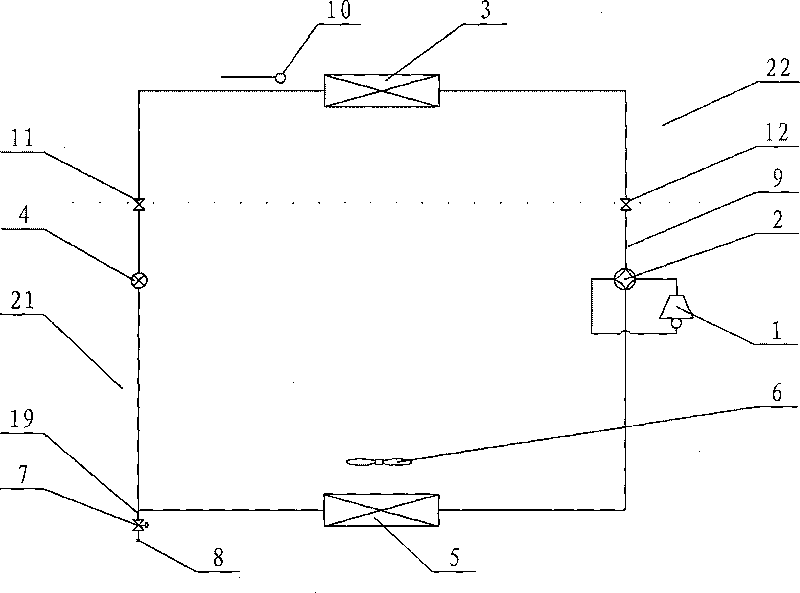

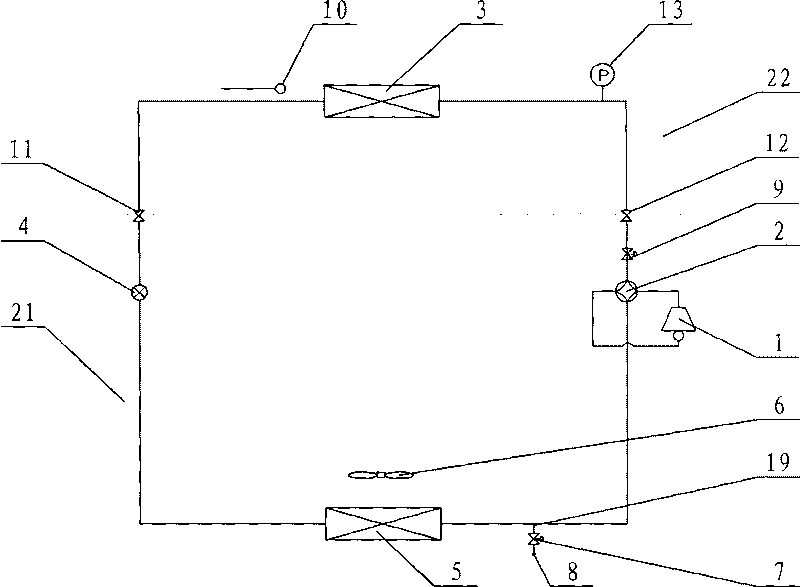

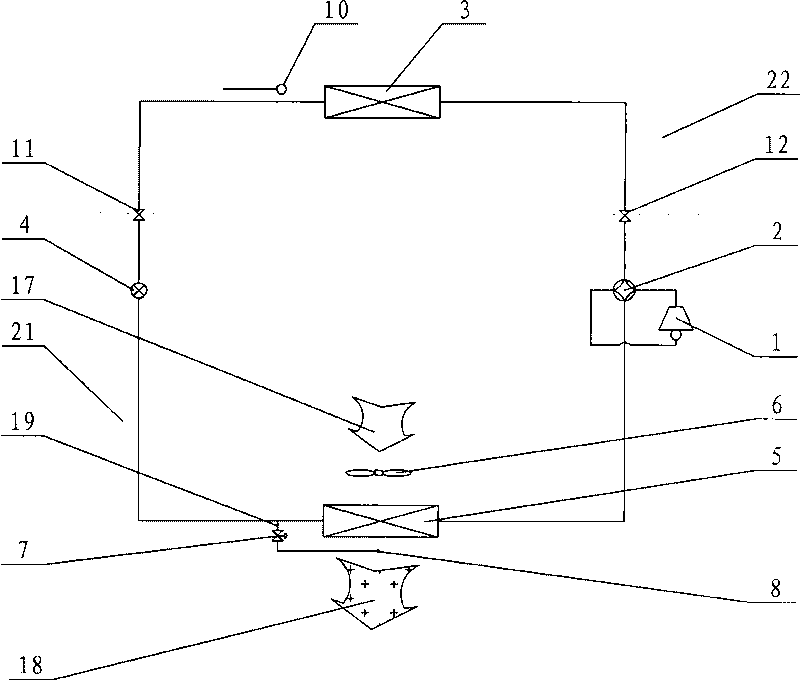

Air conditioner using combustible refrigerant and control method thereof

ActiveCN101737878AReduce leakageAvoid personal injurySpace heating and ventilation safety systemsLighting and heating apparatusAutomatic balancing valvesMachine parts

The invention relates to an air conditioner using a combustible refrigerant and a control method thereof. The air conditioner comprises a refrigeration / heat pump air conditioner system which consists of a compressor, a four-way valve, an indoor heat exchanger, a throttle mechanism, and an outdoor heat exchanger, wherein two ends of the indoor heat exchanger are provided with an air conditioner connecting pipe pneumatic valve and an air conditioner connecting pipe hydraulic valve respectively; a refrigerant working medium concentration sensor is arranged indoors; a drain pipe branch and an automatic drain valve of the drain pipe branch are arranged on the connecting pipes of the outdoor heat exchanger; the refrigerant working medium concentration sensor is arranged beside the indoor heat exchanger; and the drain pipe branch and the automatic drain valve of the drain pipe branch are arranged on the pipes between the throttle mechanism and the outdoor heat exchanger. The air conditioner using the combustible refrigerant is provided with the refrigerant working medium concentration sensor, the drain pipe branch, and the automatic drain valve of the drain pipe branch, and when the combustible refrigerant working medium is detected to be leaked, an outdoor machine part exhausts the refrigerant to the large outdoor space to reduce the indoor leakage quantity, so personal injury and property loss generated when the indoor combustible working medium concentration reaches the combustion limit are avoided.

Owner:MIDEA GRP CO LTD

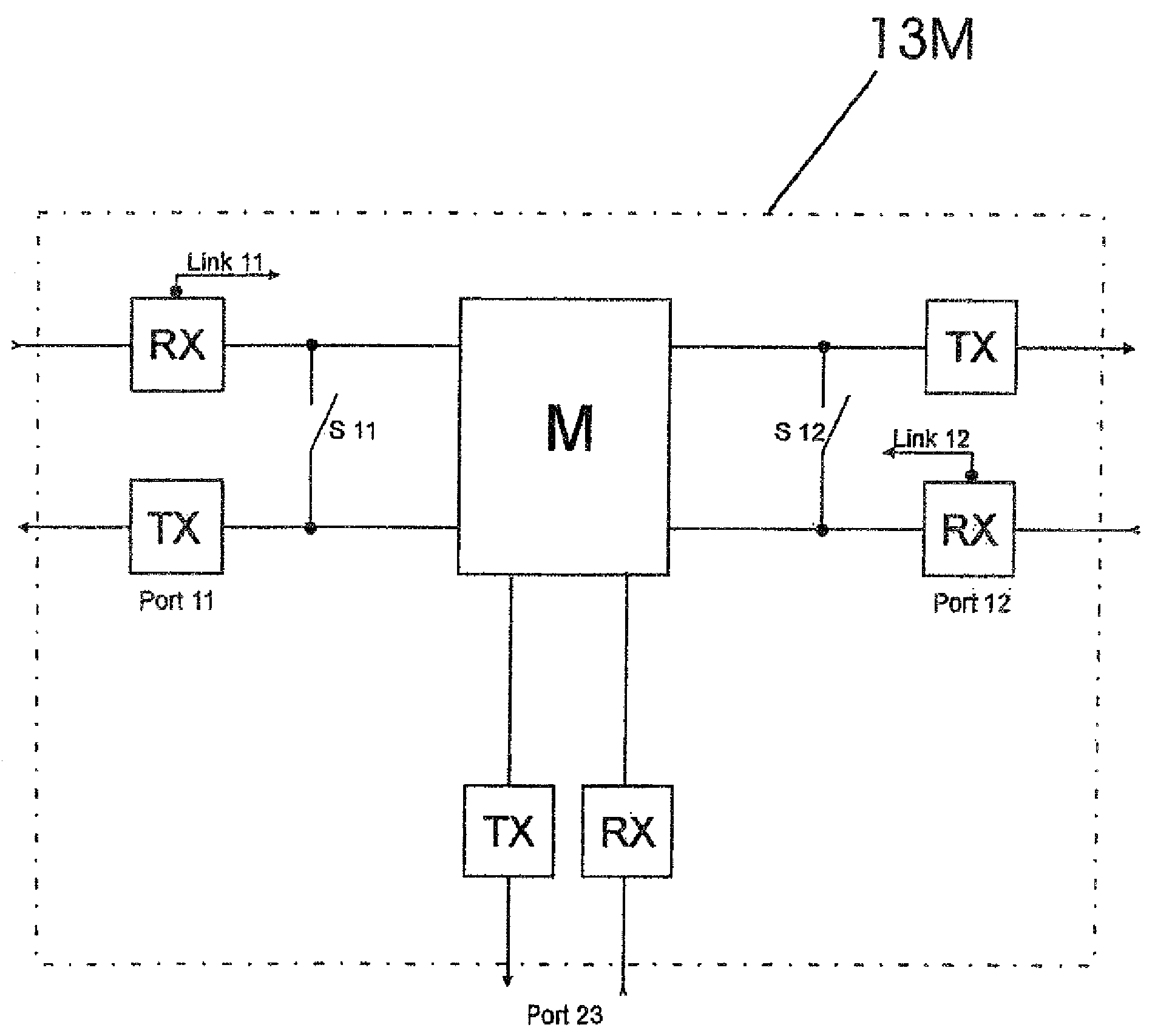

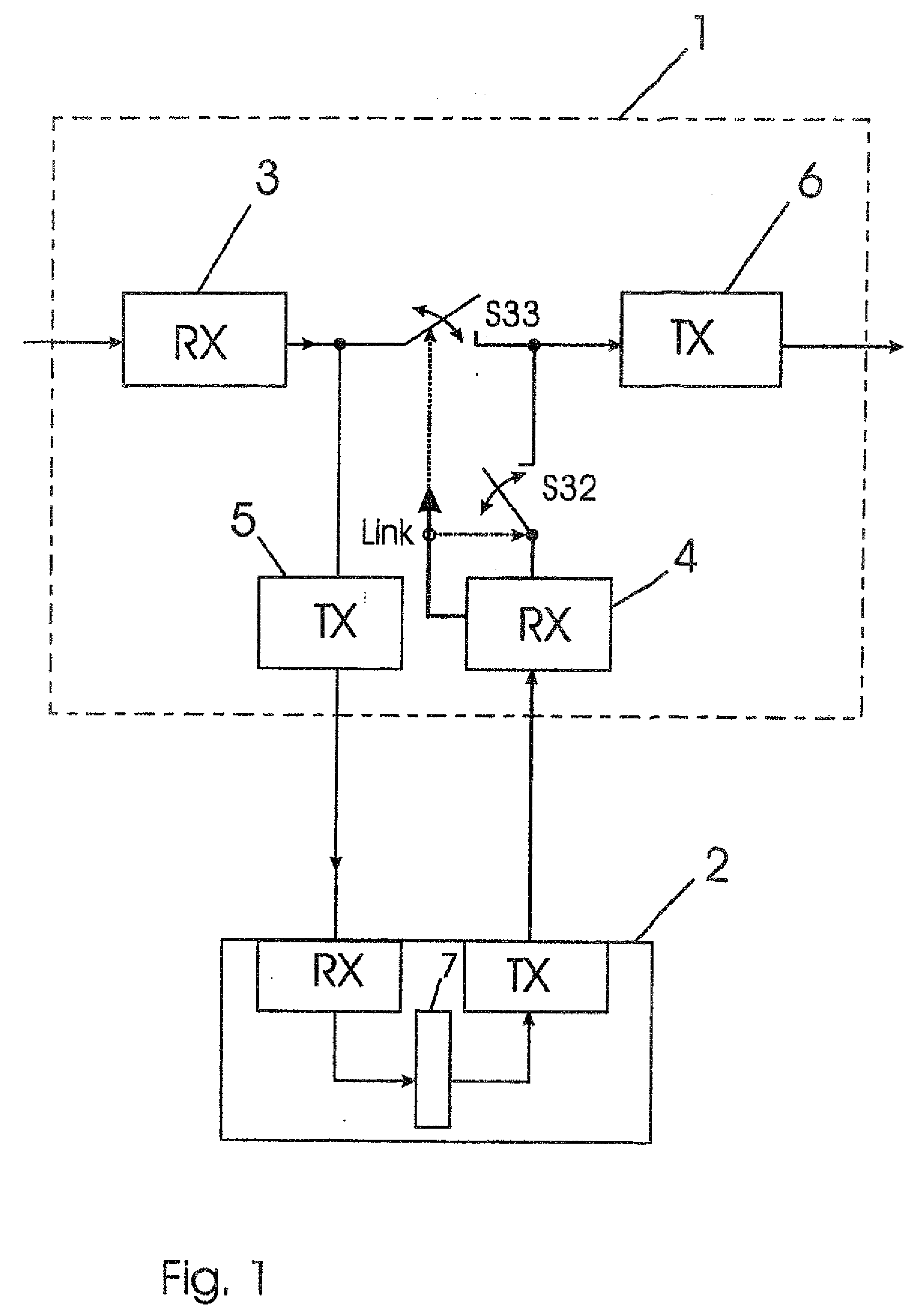

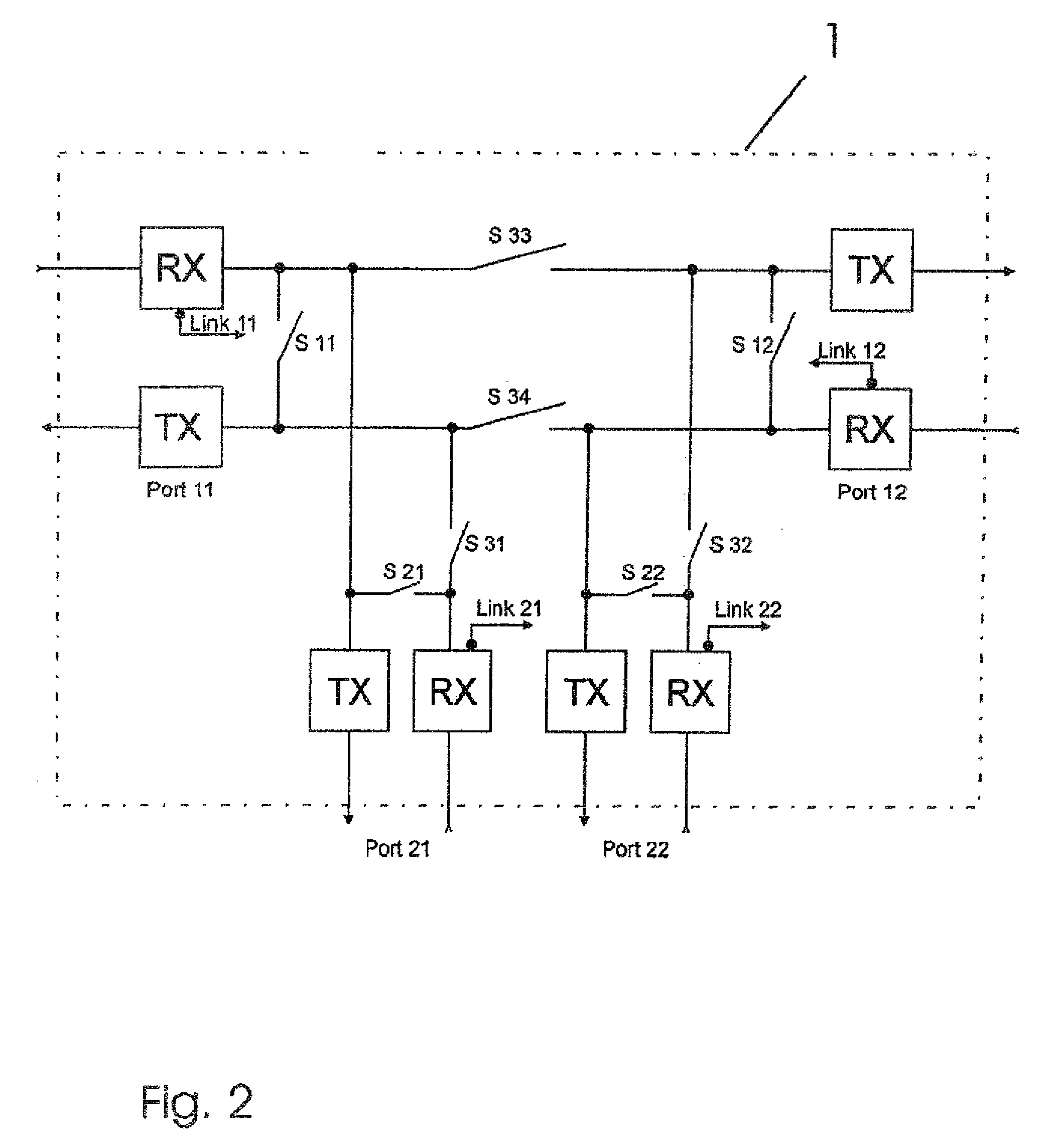

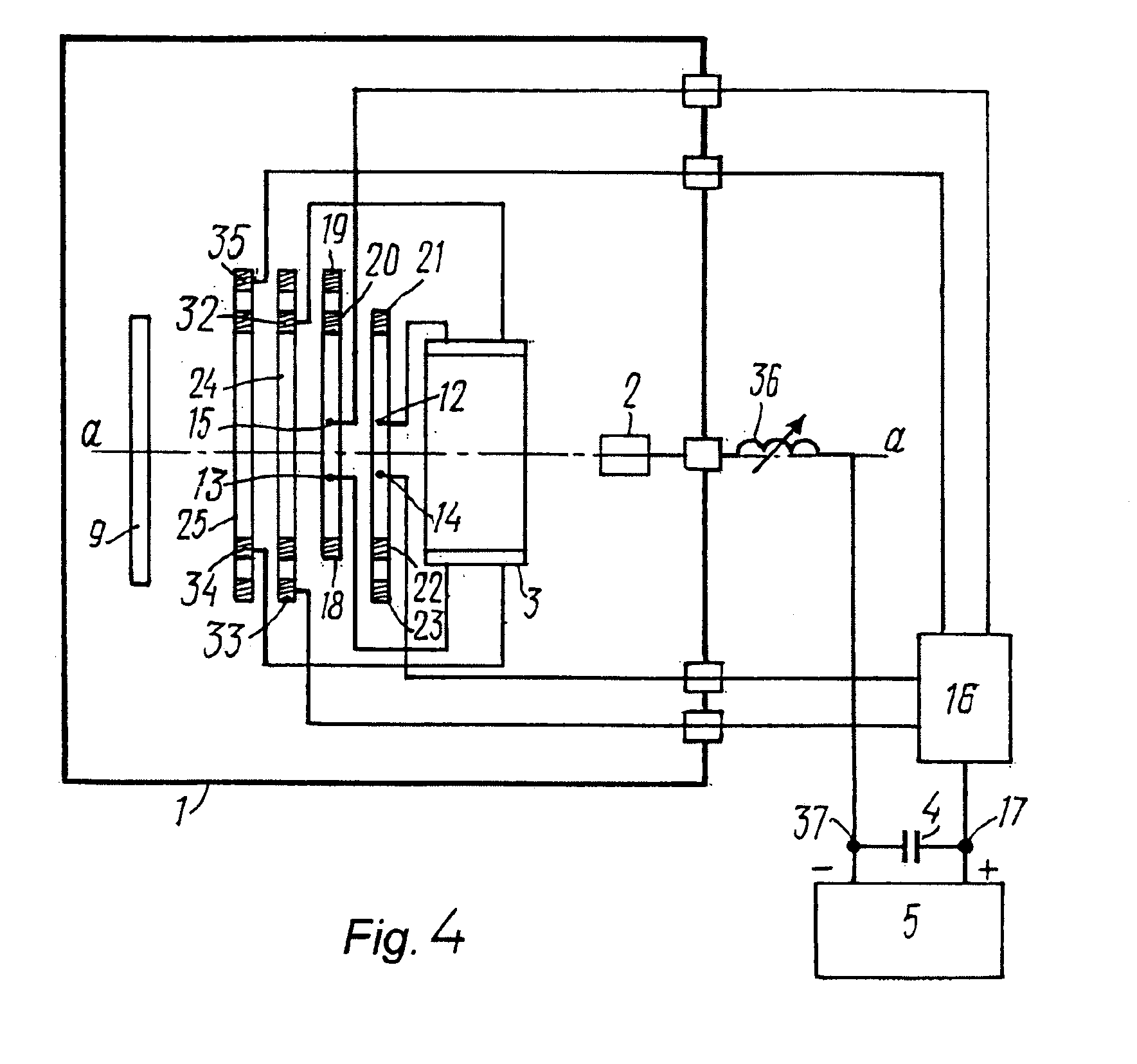

Breakdown and Decoupling Tolerant Communications Network, a Data Path Switching Device and a Corresponding Method

The invention relates to a method for tolerating the breakdown and / or decoupling of at least one network node in a communication network used for controlling and / or adjusting the movement of a plurality of machine parts, for example the rotation bodies in a printing machines, machine tools and other production machines, wherein the network is operated according to a closed single or multiple ring structure, in which each node communicates with the transmitter or the port of a first adjacent node by means of a receiver or a first port and with the receiver or the port of a second adjacent network node by means of a transmitter or a second port, the closed ring structure is preserved in the case of the breakdown or decoupling of at least one node, at least one network node is coupled to the network by means of a data path switching device which is actuated, in the case of the breakdown or decoupling of said node, in such a way that the communicating nodes, which exist in the network and are arranged next to each other in the ring structure, interact in communication by means of the port or respective transmitter thereof after the breakdown or decoupling.

Owner:BAUMULLER ANLAGEN SYSTTECHN

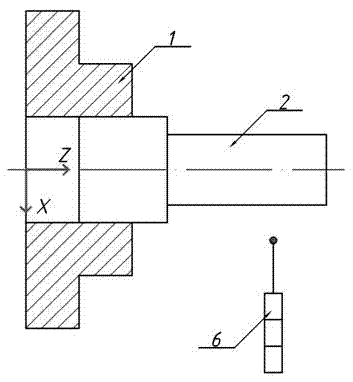

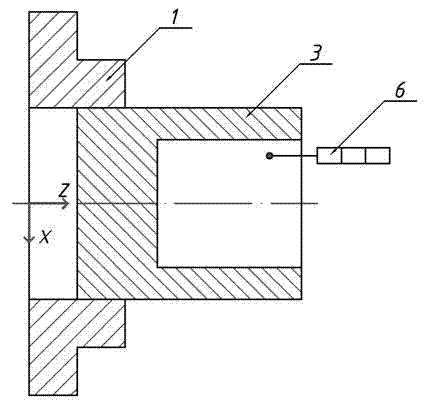

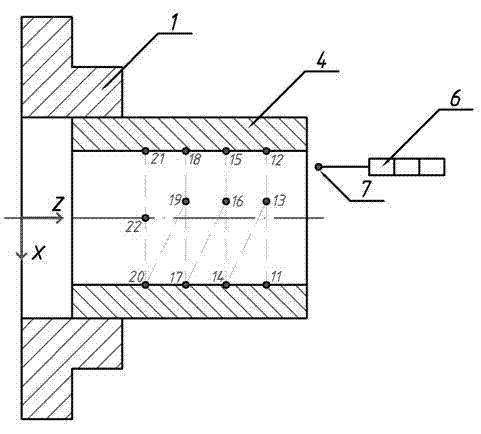

On-line detection system and detection method of machining accuracy of parts for numerically controlled lathe

ActiveCN102785128AImprove the efficiency of machining accuracy detectionSimple and fast operationProgramme controlComputer controlCommunication interfaceMachine parts

The invention relates to an on-line detection system and detection method of machining accuracy of parts for a numerically controlled lathe. The detection system comprises a chuck, a workpiece and a lathe probe, wherein the workpiece is arranged on the chuck, and the lathe probe is arranged at the side of the workpiece; and a signal output terminal of the lathe probe is connected with a controller of the detection system. The detection method comprises the following steps that 1) the lathe probe is arranged at the side of the workpiece; 2) the lathe probe is calibrated; 3) the measuring path and code generation of geometrical parts and curved-surface parts are planned; and 4) the heat distortion temperature error compensation and machining error analysis of parts are carried out by the controller of the detection system. The parts do not need to leave the lathe after being machined, a touch probe is used for replacing a turning tool, and the detection path of the probe is automatically planned and the detection code is generated according to the geometric outline and detection items of the machined workpiece; and through a communication interface of the numerically controlled lathe, the detection code is driven, so that the automatic measurement of the size and precision of size and form of the machined part is realized, and the detection accuracy and efficiency of the workpiece are improved.

Owner:GUANGDONG UNIV OF TECH

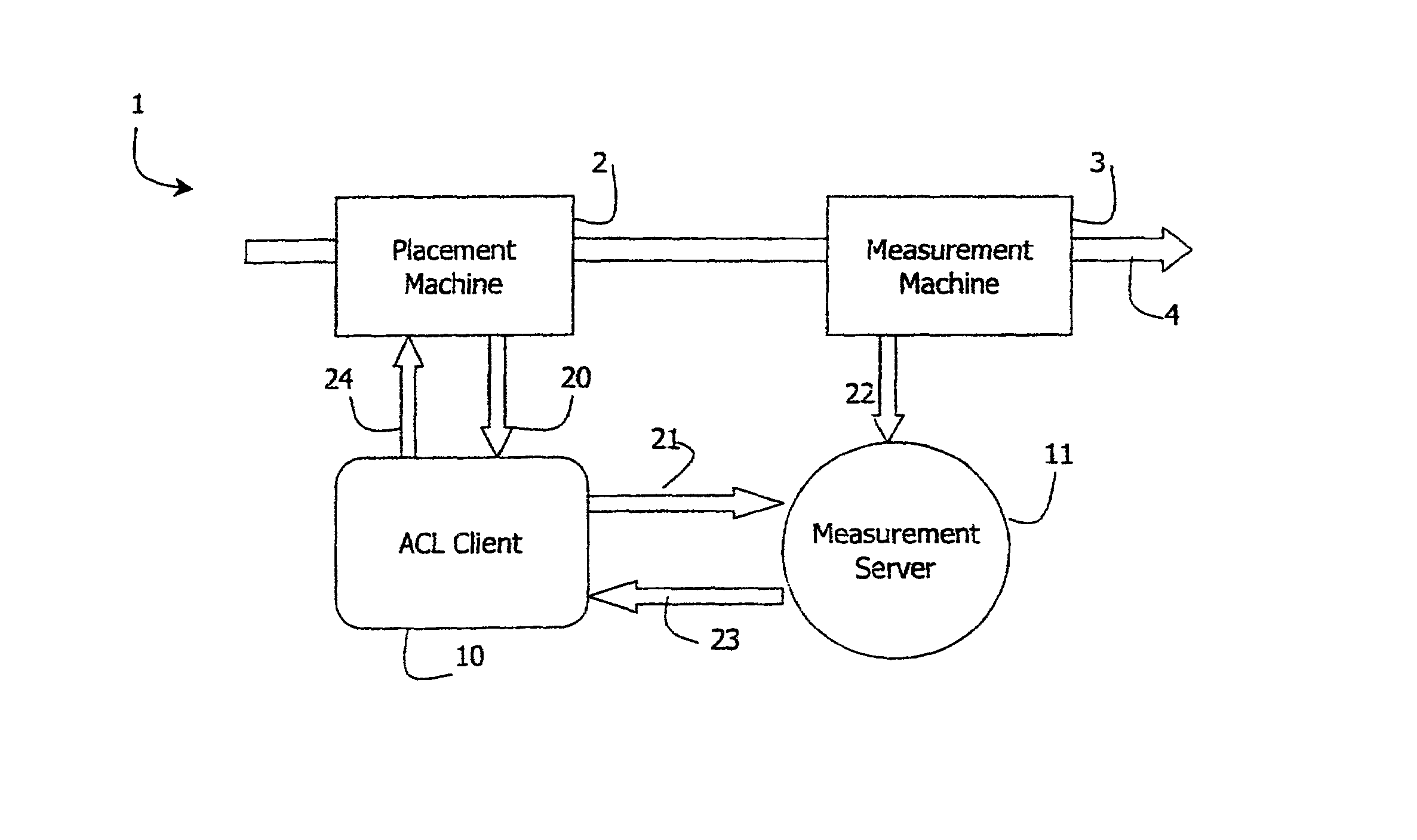

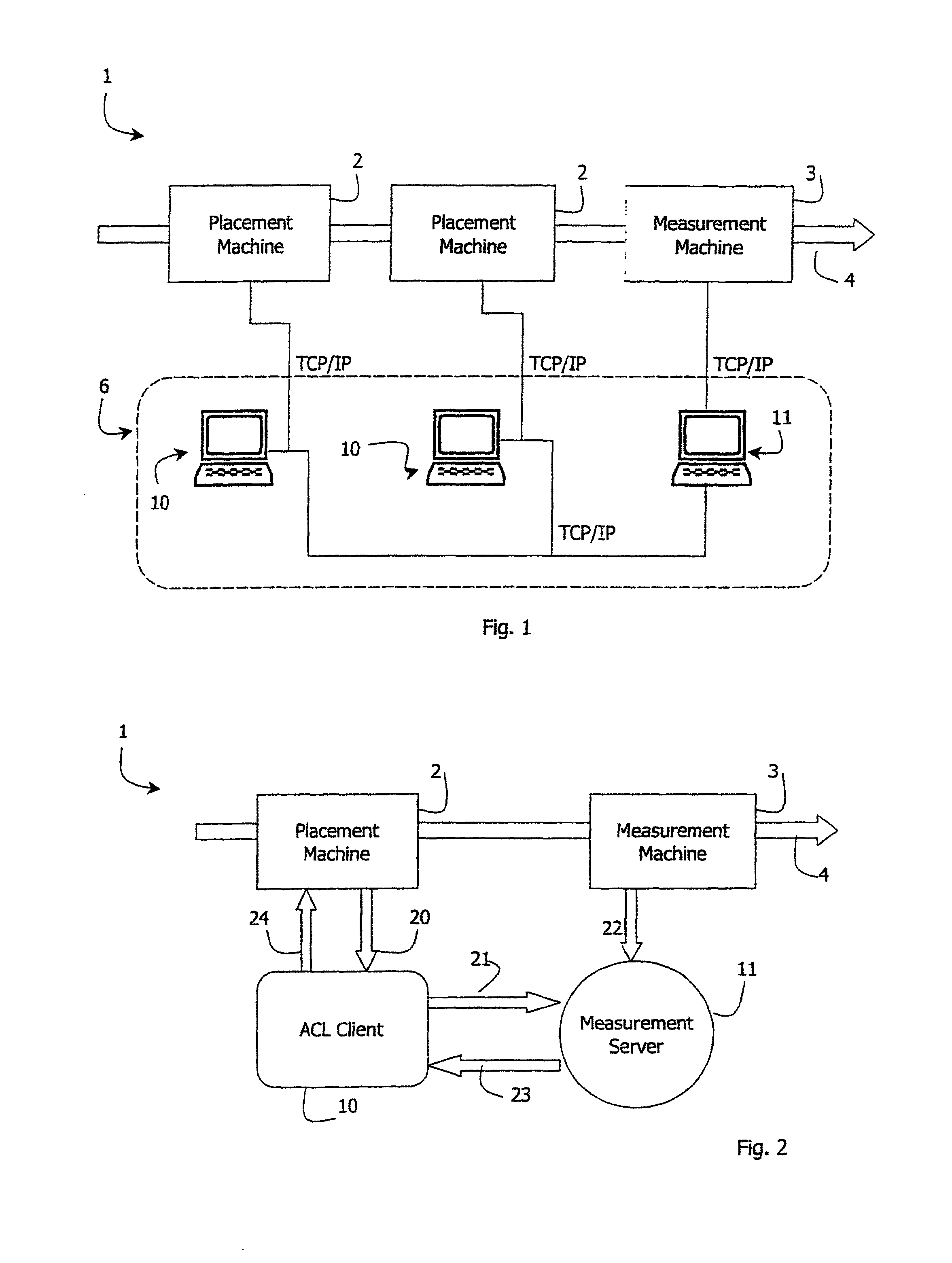

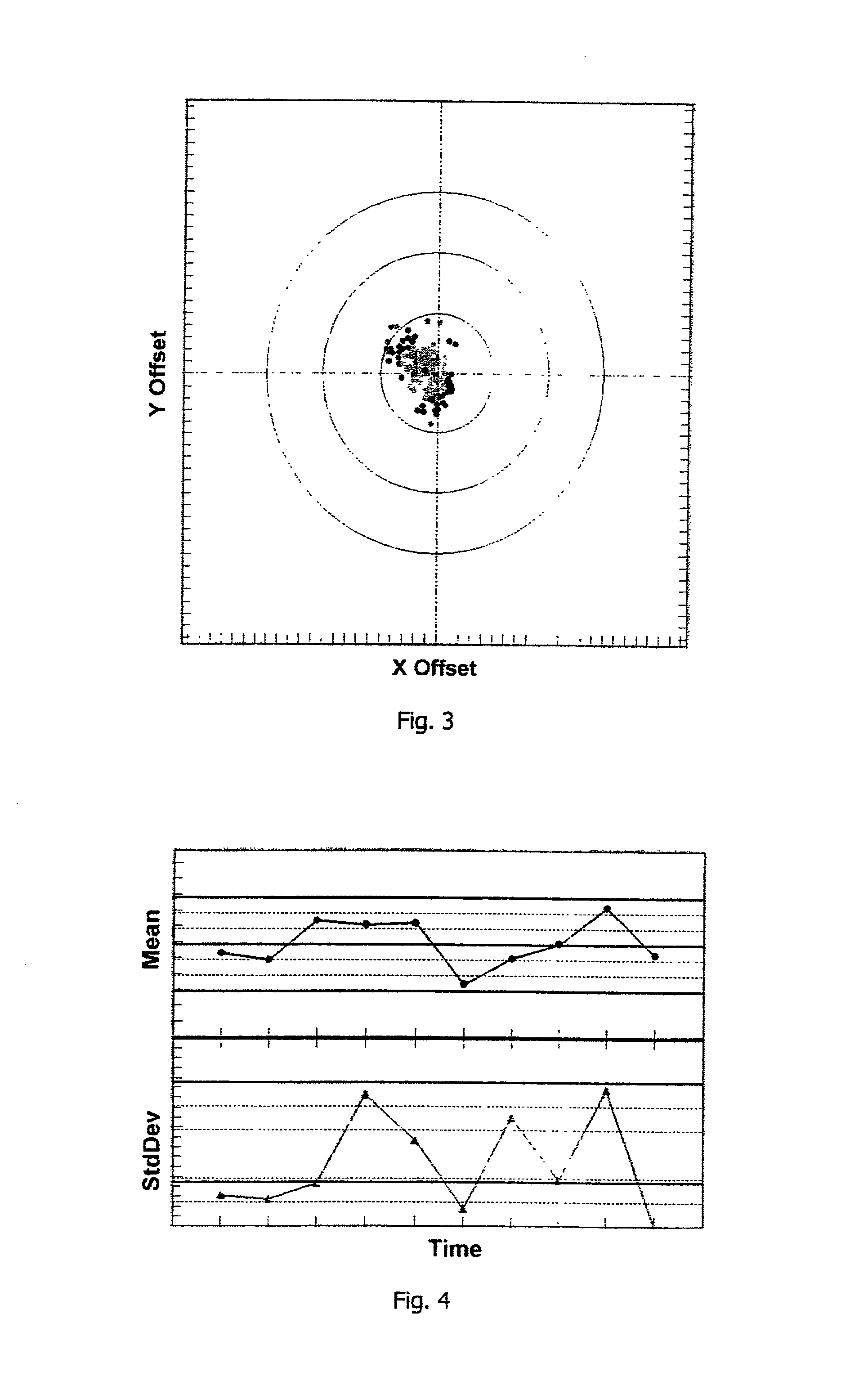

Circuit Production method

InactiveUS20020099466A1Easy to controlSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingMachine partsControl signal

A closed loop controller (6) has a measurement server (11) which captures measurement data from a measurement machine (3) via a link (22). It also receives production data indicating which placement machine parts were involved in depositing inspected items, via links (20, 21). The server (11) correlates this data and transmits it via a link (23) to a closed loop client (10), which generates process engineer displays of the correlated data and generates a control signal for the placement machine (2). These are fed back via a link (24) for automatic closed loop control.

Owner:MV RES

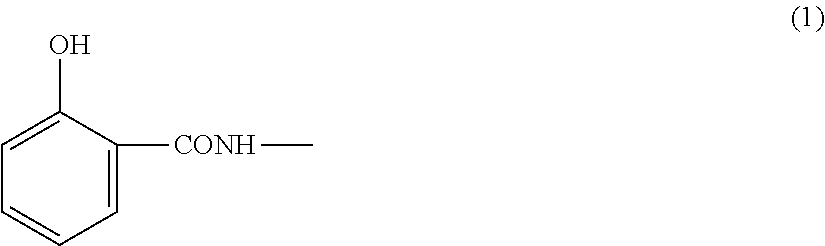

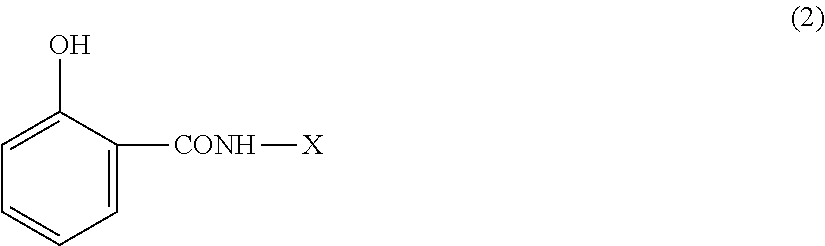

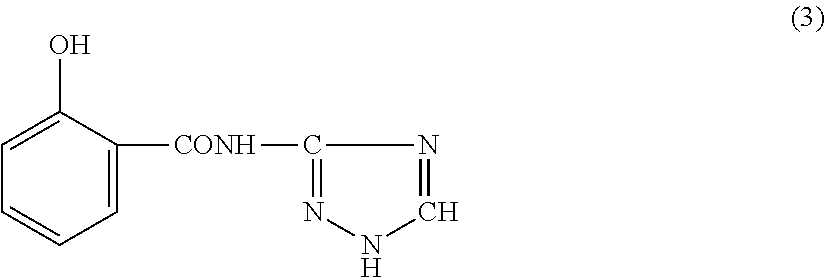

Flame-retardant thermoplastic resin composition and molded article

A flame-retardant thermoplastic resin composition that has a largely decreased corrosiveness to metals while maintaining a high degree of flame retardancy is provided, which is produced by adding a phosphinic acid salt and a compound having a specific structure to a thermoplastic resin, and molded articles with largely decreased corrosiveness to metals are also provided, so that useful molded articles can be provided as materials for mechanical machine parts, electric / electronic components, and automotive parts. The flame-retardant thermoplastic resin composition includes 65 to 99 wt % of (A) a thermoplastic resin, 1 to 35 wt % of (B) at least one phosphinic acid salt selected from the group of phosphinic acid salt, diphosphinic acid salt, polymer of phosphinic acid salts, and polymer of diphosphinic acid salts, and 0.001 to 0.70 wt % of (C) a compound having a specific, and molded articles produced therefrom.

Owner:TORAY IND INC

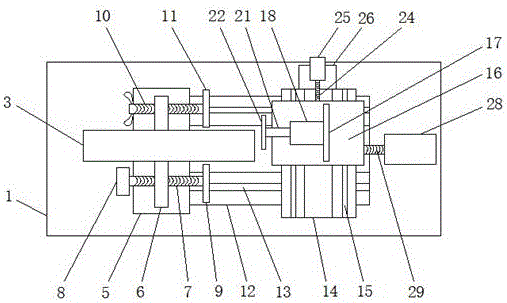

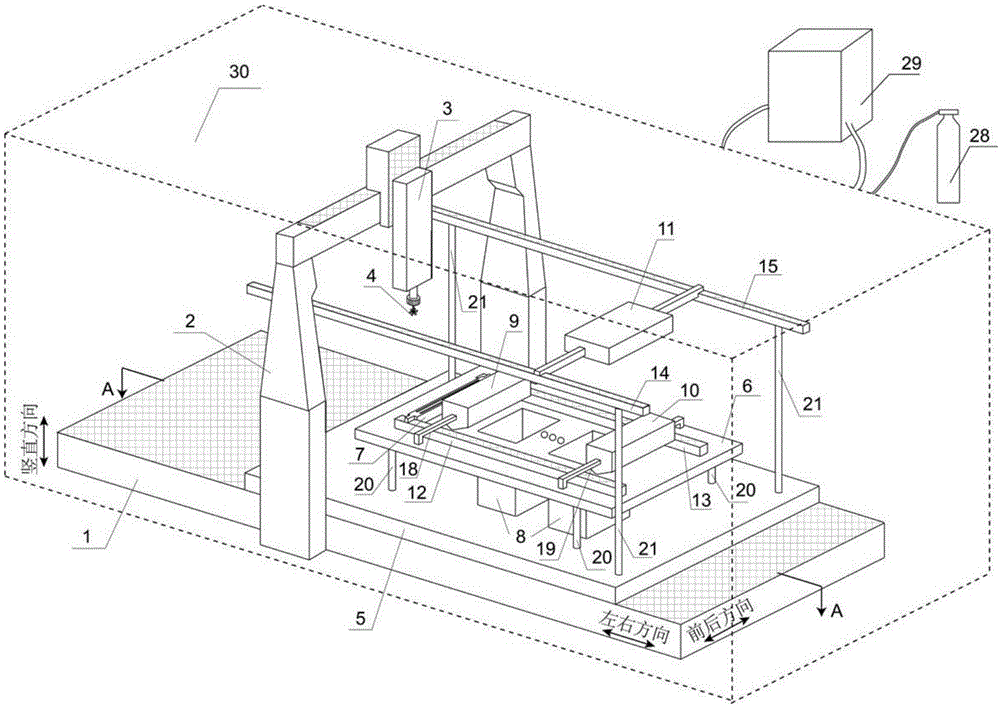

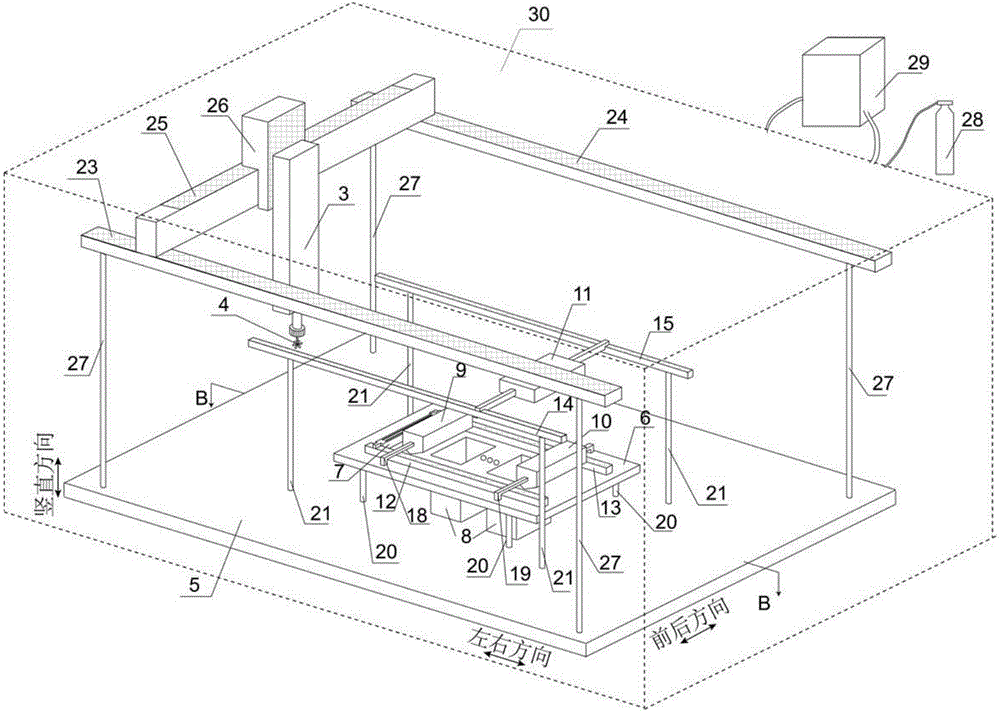

Material increasing and decreasing composite manufacturing equipment and method for metal parts

ActiveCN106735216AEfficient preparationManufacturing disposableAdditive manufacturing apparatusIncreasing energy efficiencyMachine partsMetallurgy

The invention discloses material increasing and decreasing composite manufacturing equipment and method for metal part. The material increasing and decreasing composite manufacturing equipment comprises a material increasing manufacturing assembly, a material decreasing manufacturing assembly, an atmosphere regulating and controlling assembly and a control system. The material increasing manufacturing assembly is used for conducting laser selective melting on the to-be-machined part. The material decreasing manufacturing assembly is used for conducting machining on a molten-formed metal part slice layer. The atmosphere regulating and controlling assembly is used for providing protective gas for a laser irradiation area during part manufacturing and for clear away metal smoke dust generated by the laser irradiation area. The control system is used for treating a to-be-formed metal part CAD model, for generating the machining tracks of the material increasing manufacturing assembly and the material decreasing manufacturing assembly, and for driving all parts of the equipment to operate. Through application of the material increasing and decreasing composite manufacturing equipment and method for the metal part, metal parts which have various size precision, good surface quality and complex structures can be manufactured once efficiently.

Owner:HUAZHONG UNIV OF SCI & TECH

Pulsed carbon plasma apparatus

InactiveUS6855237B2High degreeImprove life performanceCellsElectric discharge tubesDiamond-like carbonMachine parts

The present invention provides a pulsed carbon plasma apparatus to produce a diamond-like carbon coating over an extended object, the coating having a high degree of thickness uniformity achieved by scanning the plasma flow over the surface of the object. The pulsed carbon plasma apparatus of the invention comprises a carbon plasma flow scanning device having at least one pair of deflecting coils, where the deflecting coils have, in the scanning plane, a different number of turns on opposite sides. The object may be made of metal, ceramic, glass or plastic. The coatings may be used to improve life and operating performance of tools and machine parts, and as decorative coatings.

Owner:INT TECH EXCHANGE

Nanomer vibration-reducing noise-reducing self-repairing material and its prepn process

InactiveCN1740290AAutomatically adjust thicknessOptimizing friction pair clearanceBase-materialsMachine partsRepair material

The nanometer vibration-reducing and noise-reducing self repairing material is prepared with nanometer level metal powder and natural ore powder as main material and through adding several kinds of supplementary material and certain technological process, and is added into lubricating oil or ultrasonic medium as high performance repair material. The present invention features that the high performance repair material can create high hardness self-repairing lubricating film fast on the surface of metal friction pairs to regulate the interval of the friction pair, reduce friction coefficient, raise bearing capacity, leveling the friction surface, reduce vibration and noise caused by the unbalance, friction and damage of the moving machine parts, and prolong the service life of the machine parts. The present invention may be used widely in improving performance of mechanical friction parts.

Owner:JIANGSU MOLEDN PETROCHEM

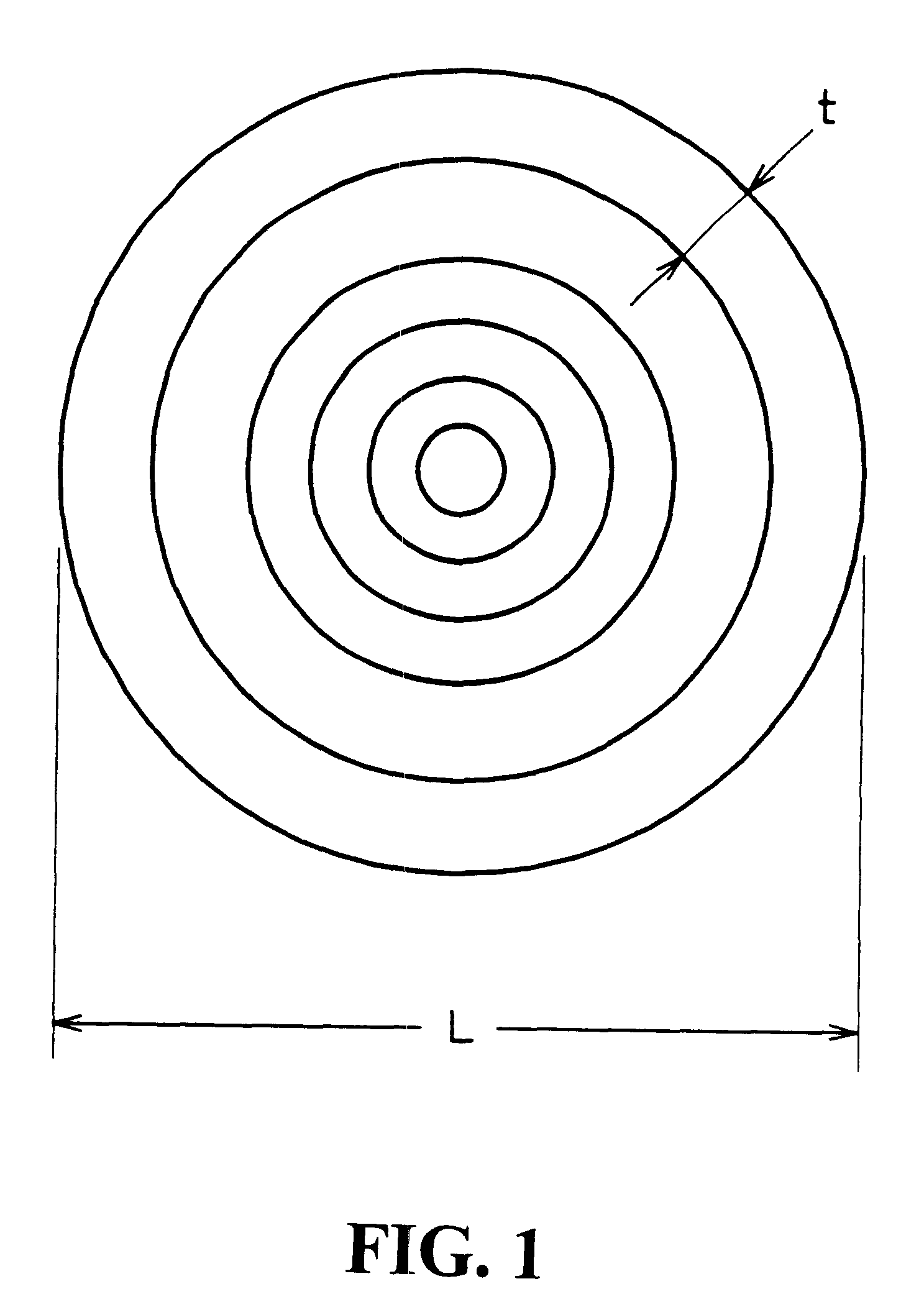

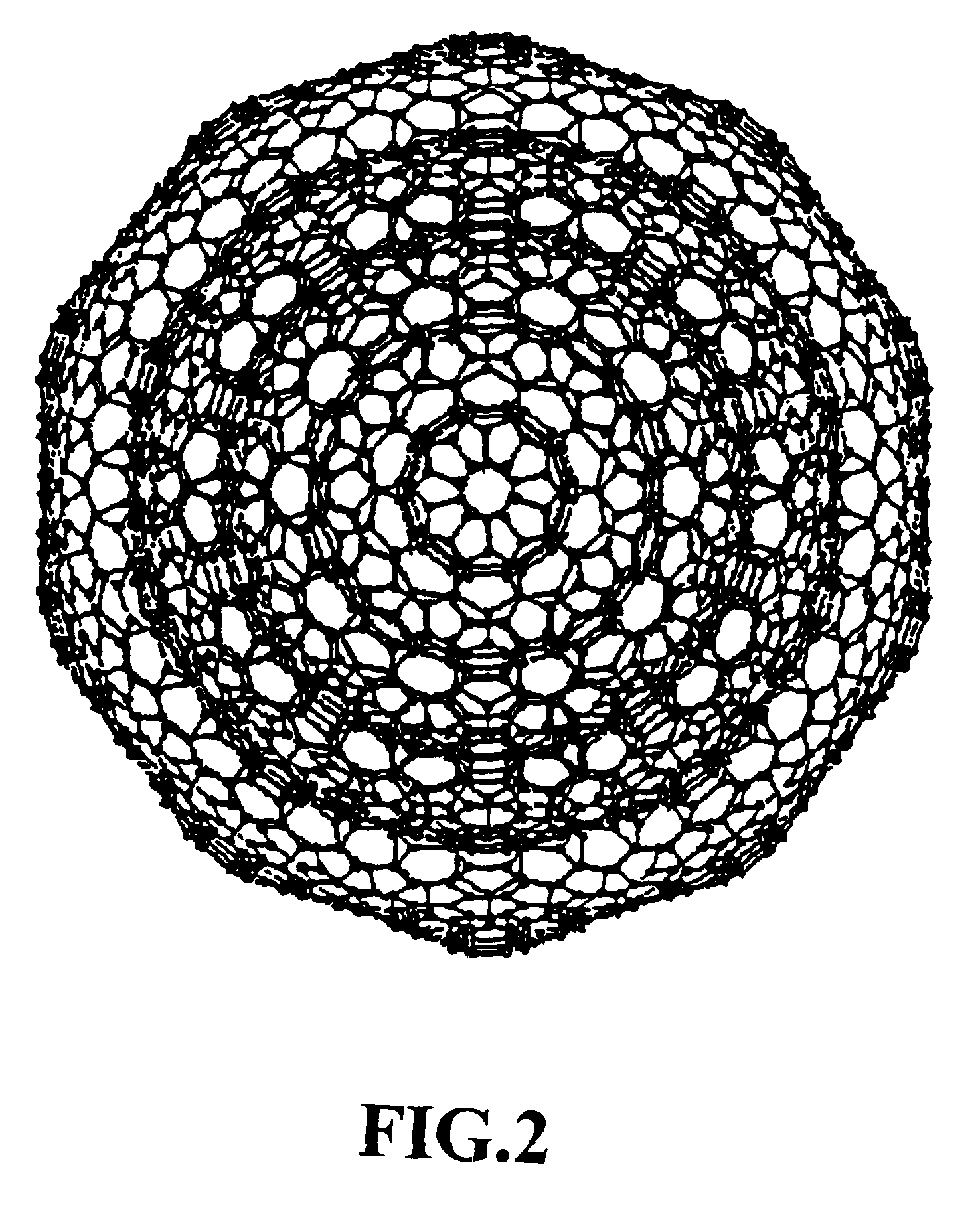

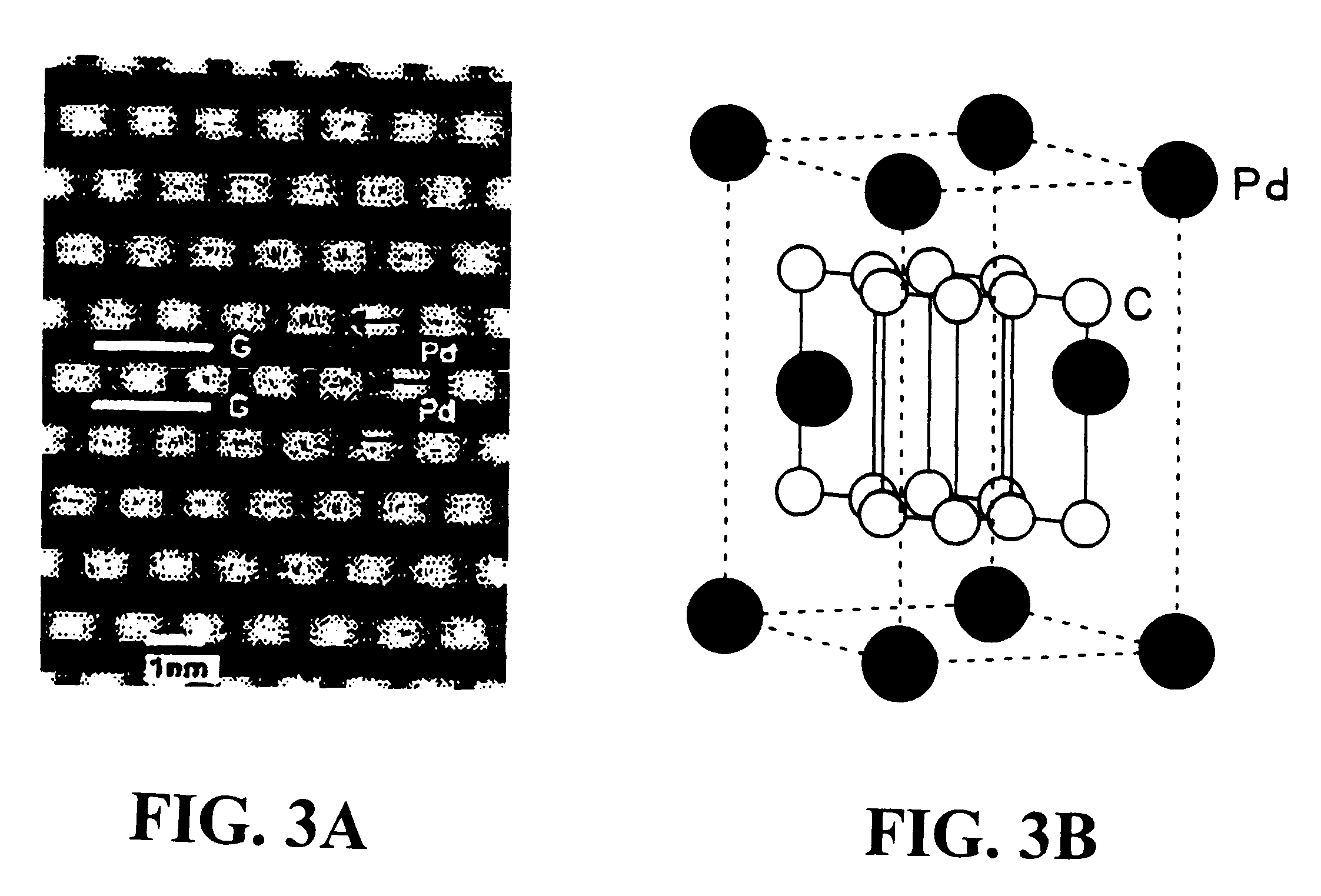

Onion-like carbon film and its production

An onion-like carbon thin film is provided which contains carbon as a main component, has a film thickness of at least 20 nm or more, and has clusters of an onion-like structure. Specifically, there is provided the onion-like carbon thin film satisfying the foregoing requirements, and in which (1) at least 20 or more clusters each having a diameter of 4 nm or more, and having an onion-like structure are contained per 0.001 mum2; or (2) the proportion of clusters each having an onion-like structure in a matrix is at least 50% by volume or more. The onion-like carbon thin film of the present invention is very useful in terms of availability in various industrial fields as a hard protective film or a solid lubricating film of the surface in various machine parts, electronic parts, and the like, or as a field electron emission material, or the like, an electronic part of a field emission display, or the like.

Owner:KOBE STEEL LTD

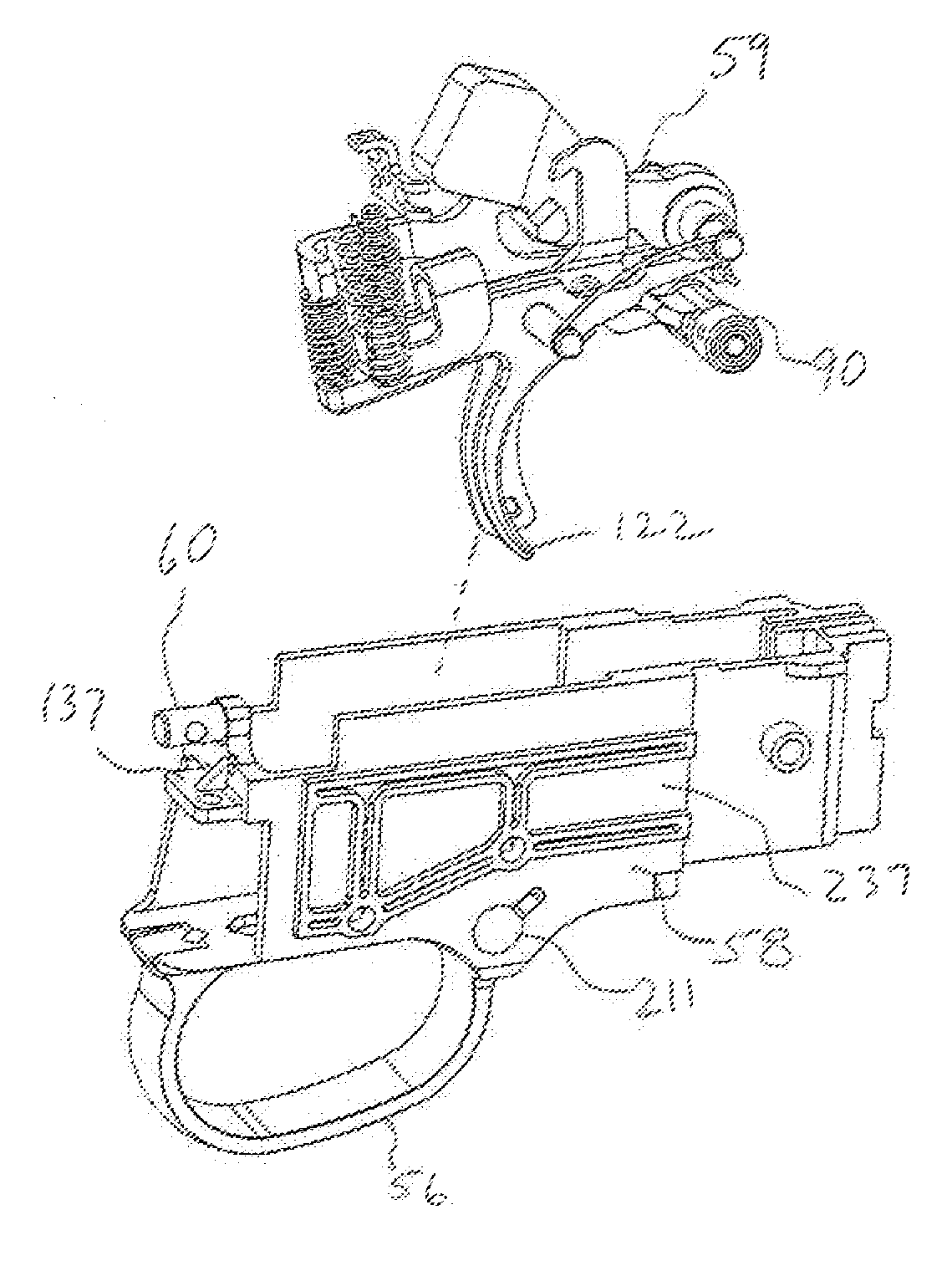

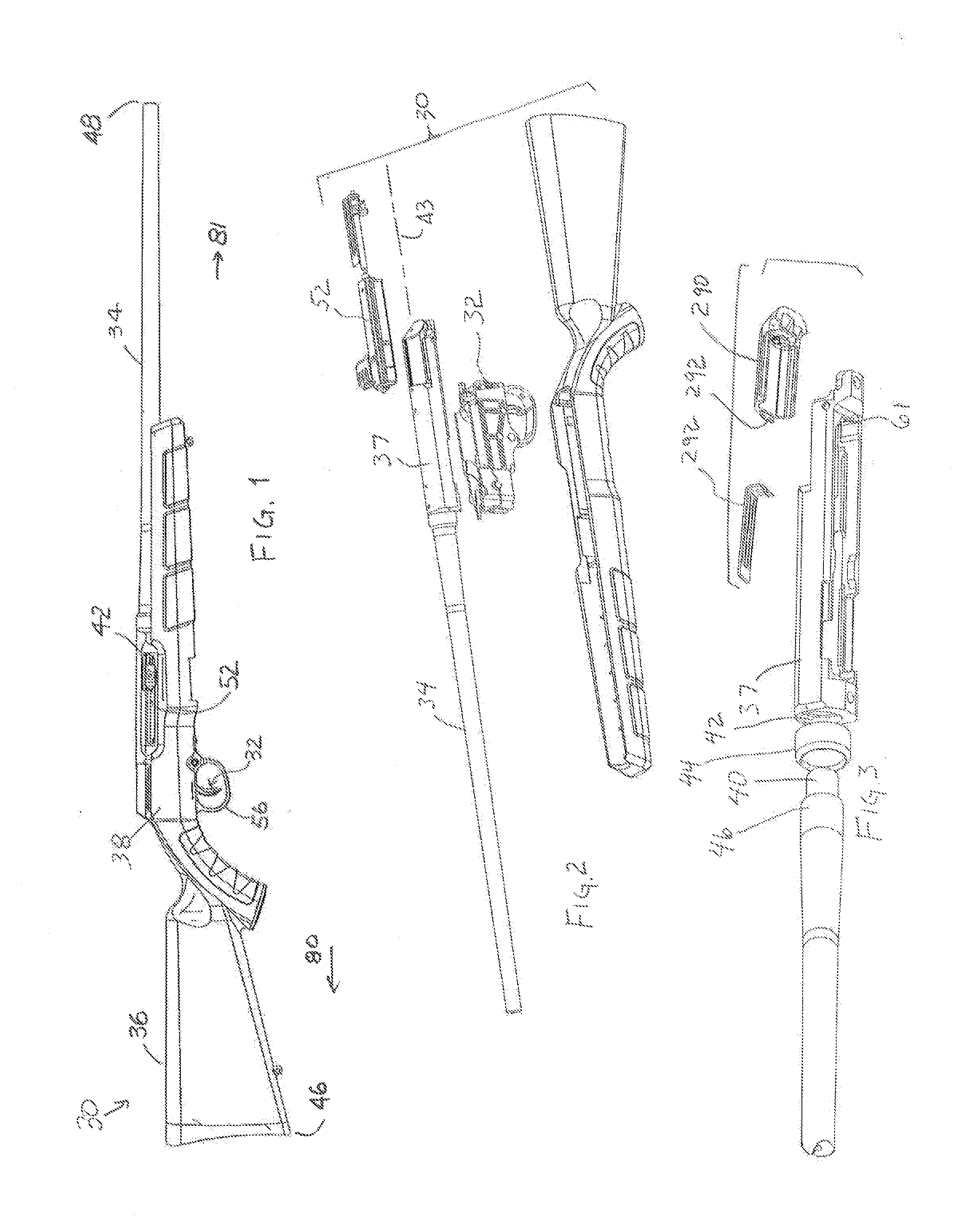

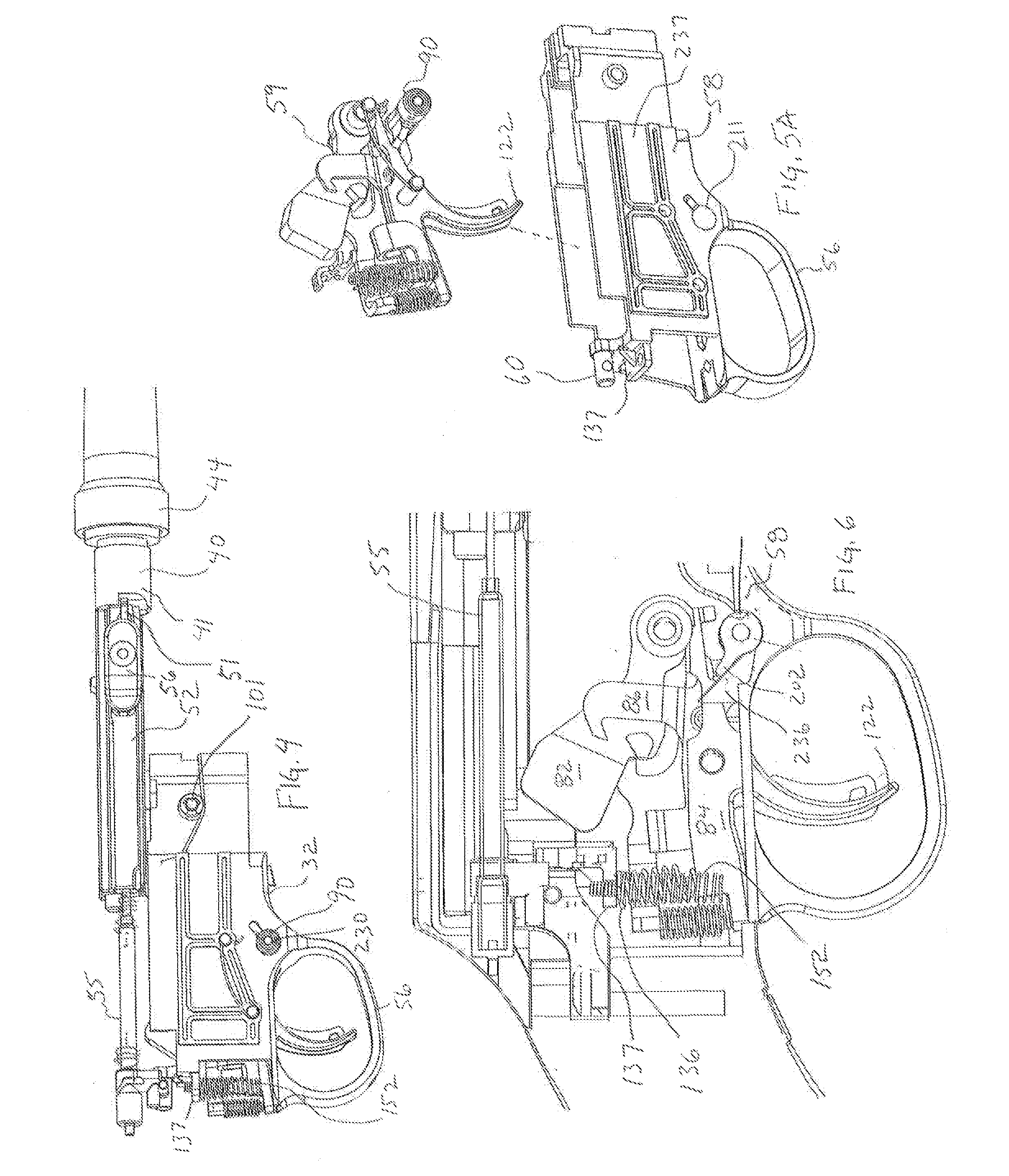

Semiautomatic firearm

ActiveUS20150330734A1Reduce failureWithout compromising safetySafety arrangementCartridge extractorsMachine partsSemi-automatic firearm

Owner:SAVAGE ARMS

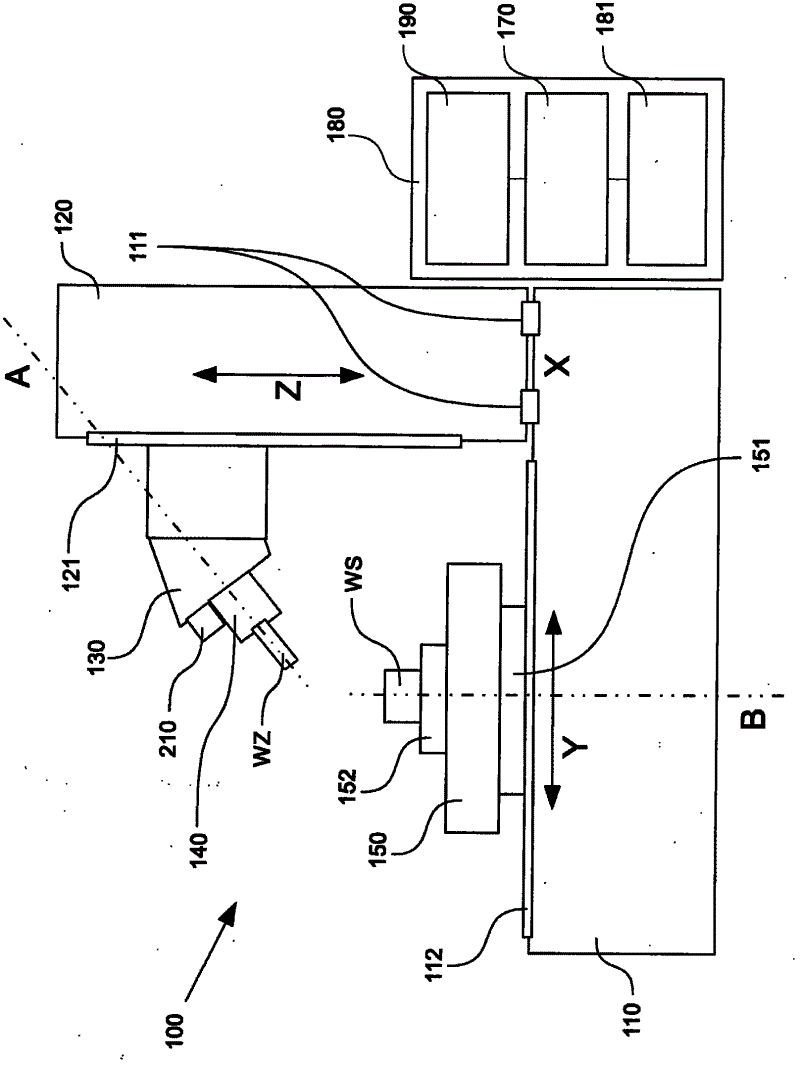

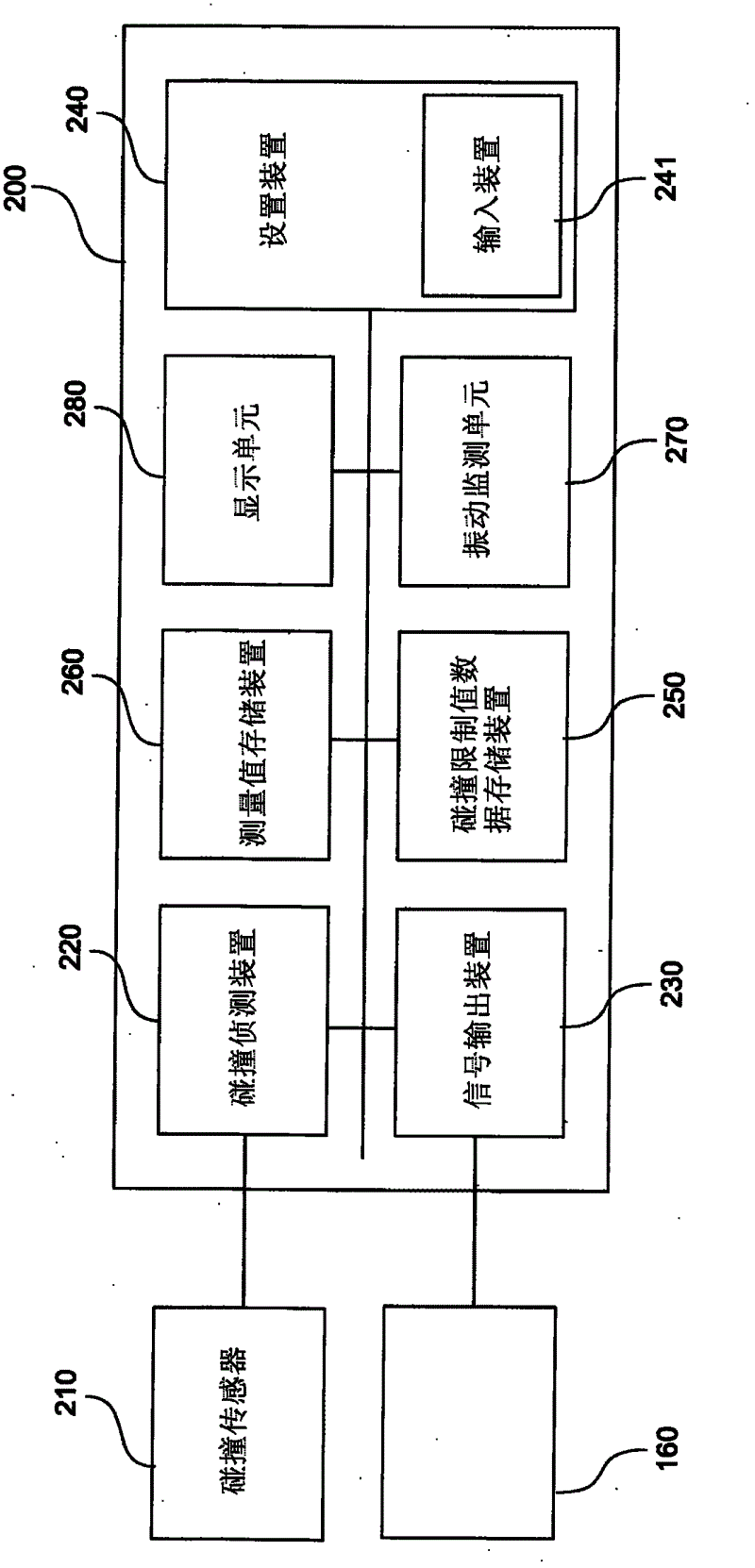

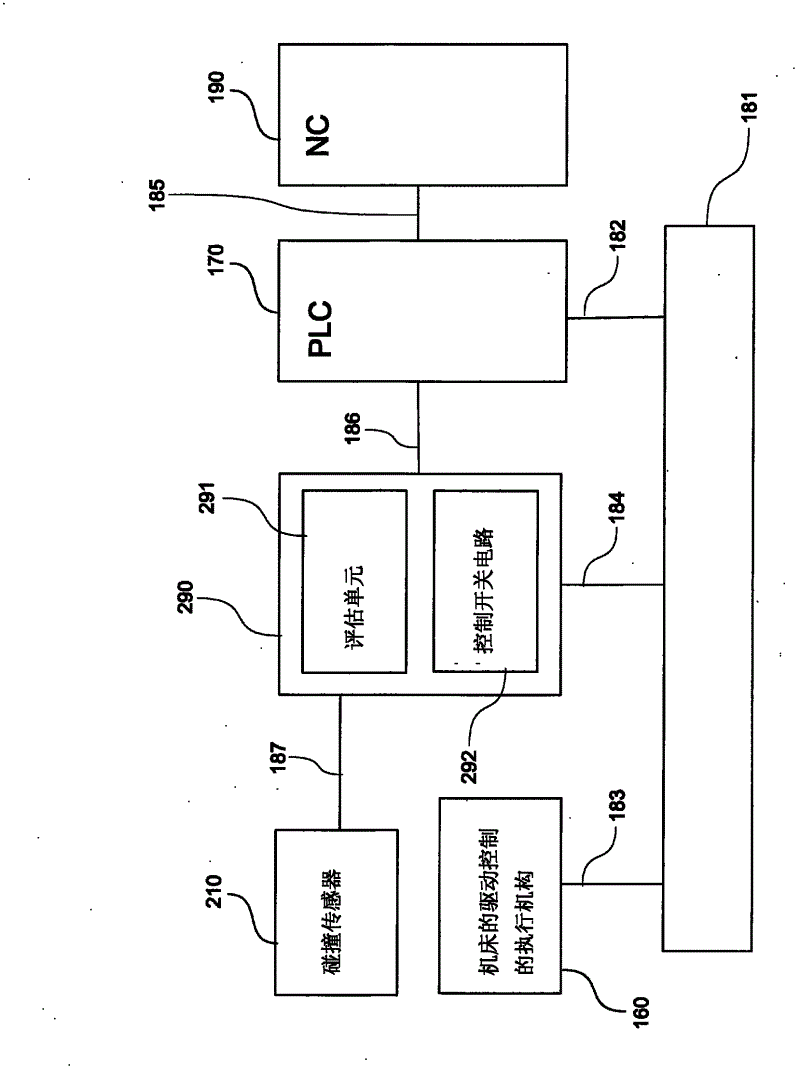

Machine tool comprising a device for collision monitoring

ActiveCN102615551ACollision limit optimizationFast and reliable collision detectionProgramme controlMeasurement/indication equipmentsNumerical controlMachine parts

A numerically controlled machine tool for machining a workpiece is provided. The machine tool includes a work spindle(140), at least one feed axis(X,111;Y112;Z,121), and a device for collision monitoring(200) on said machine tool(100), wherein the device for collision monitoring(200) includes a collision sensor(210) mounted on a machine part of the machine tool, collision detection means(220,290) for detecting a collision of machine parts(130,140,152,150) of the machine tool(100) when a measuring value detected by the collision sensor exceeds a collision limit value, and signal output means for outputting a stop signal for stopping the at least one work spindle and the at least one feed axis(X,111;Y112;Z,121), of the machine tool when the collision detection means detects a collision. The machine tool (100)includes a unit for determining the collision limit value on the machine tool(100).

Owner:DECKEL MAHO PFRONTEN GMBH

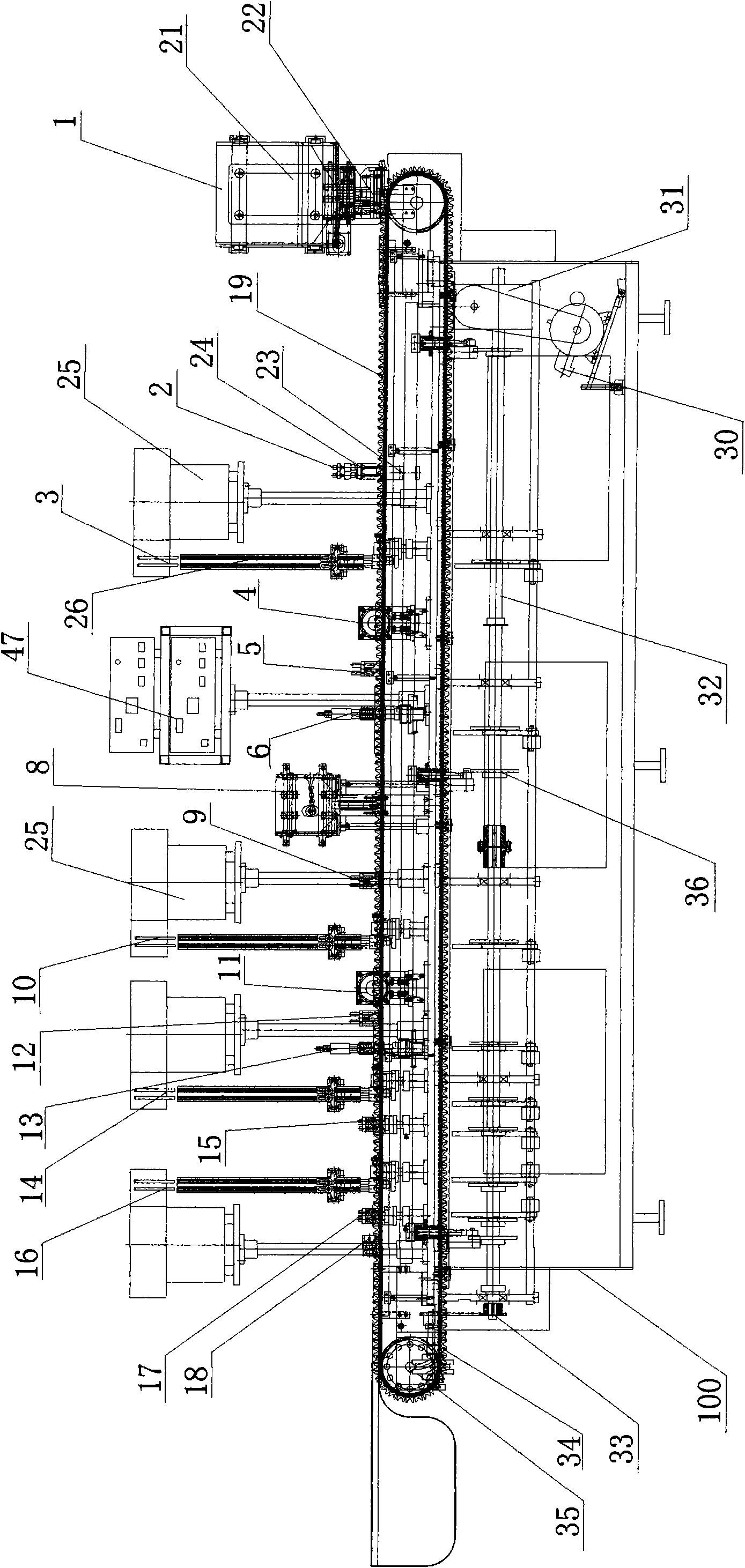

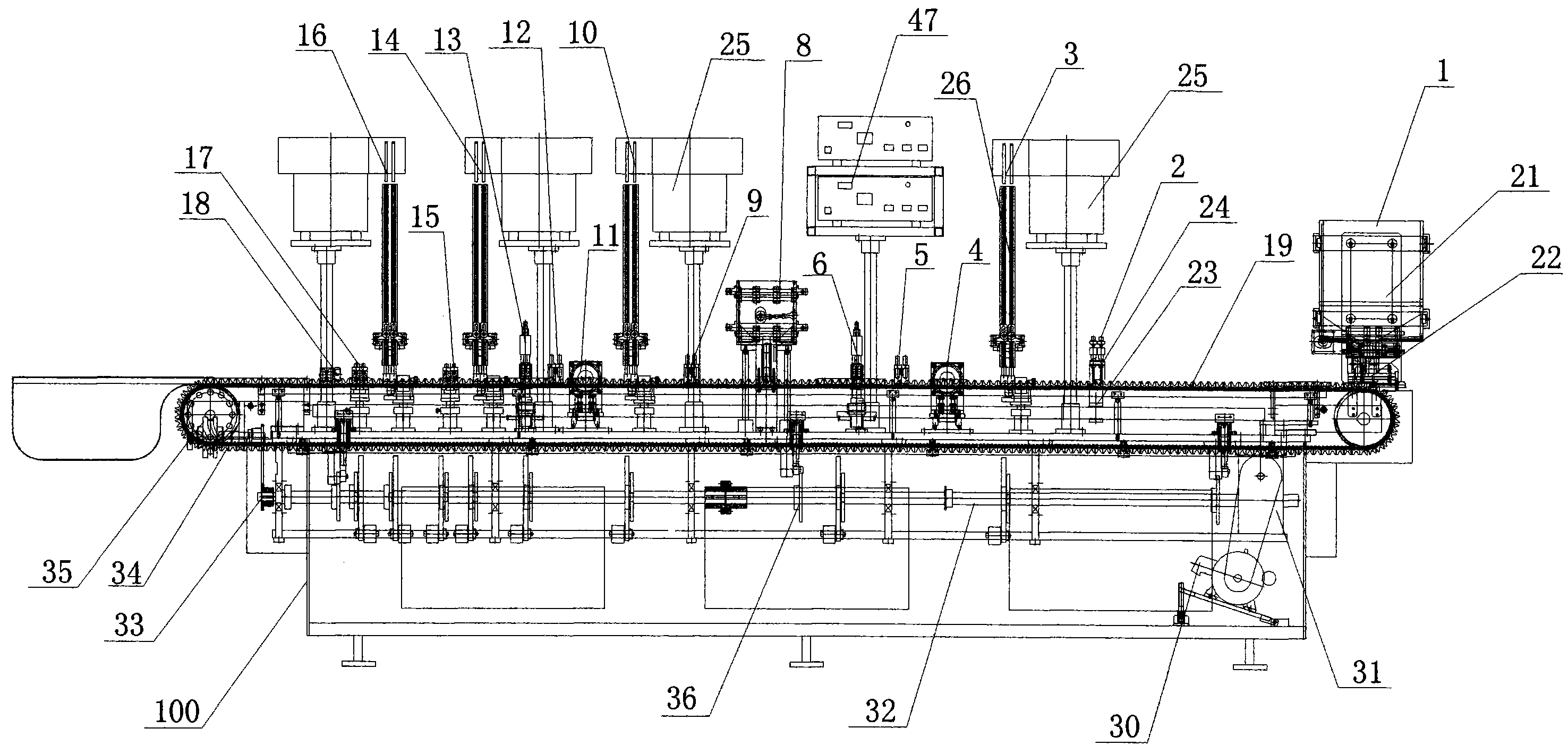

System and method for automatically assembling fountain pen

InactiveCN101830137AIncrease productivityImprove product qualityPen repairingMachine partsSoftware system

The invention relates equipment and method for assembling a fountain pen. The equipment comprises a plurality of operation units consisting of an electric machine part, a pneumatic machine part, a sensing element, a measuring element, an ultrasonic plastic welding electrical appliance and the like. The method comprises: simulating the manual operation methods of each working procedure in a manufacturing process flow; compiling an operational program software system; sending operation instructions to each operation unit; assembling all required fountain pen parts in sequence by adopting barrel cam control and a conveying chain stepping mode; automatically detect and screening the results of all operation units; and automatically segregating quality field products and non-qualified products. Thus, the method improves production efficiency, saves labor and cost, reduces labor intensity and improves product quality.

Owner:张汉平

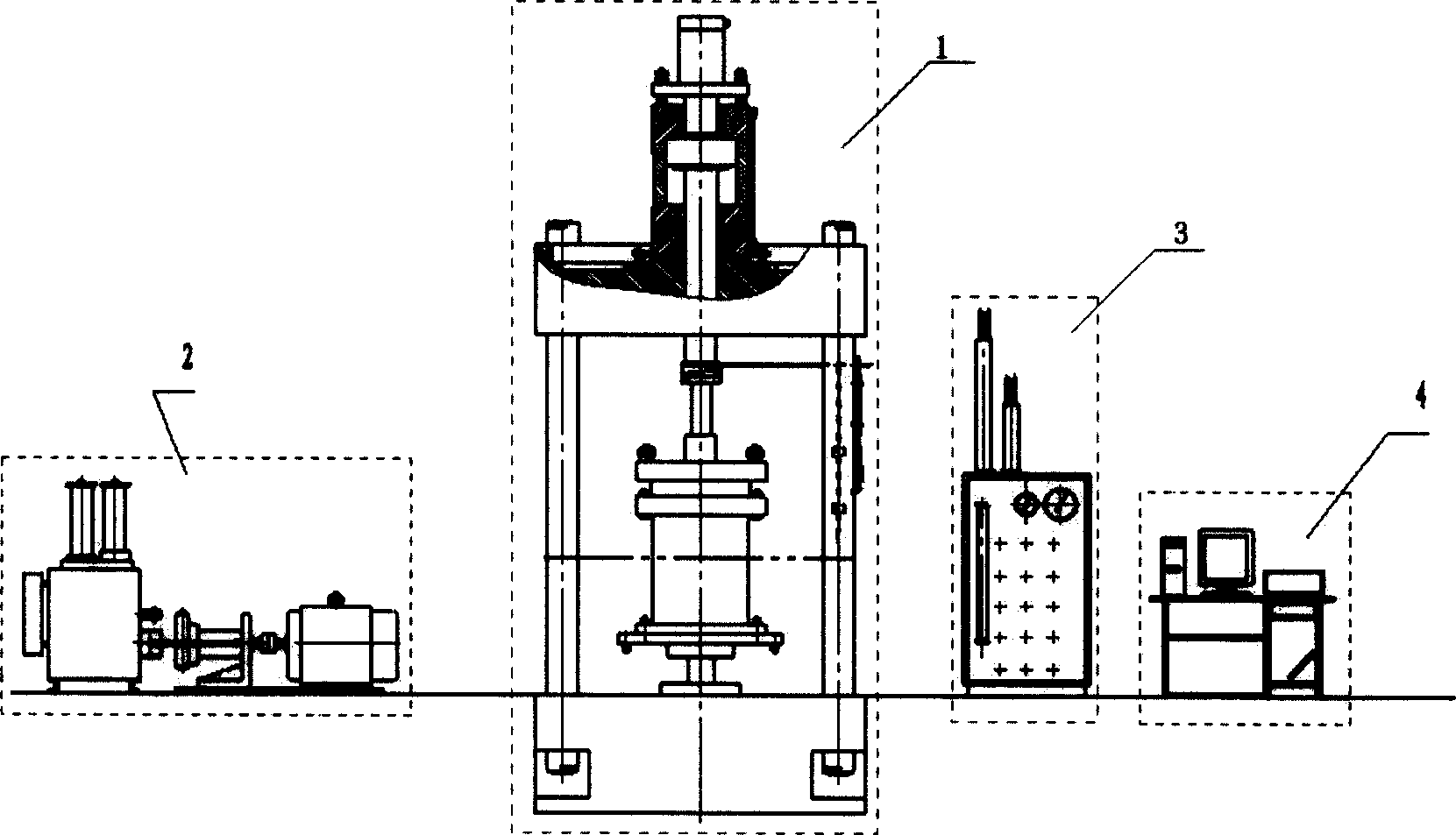

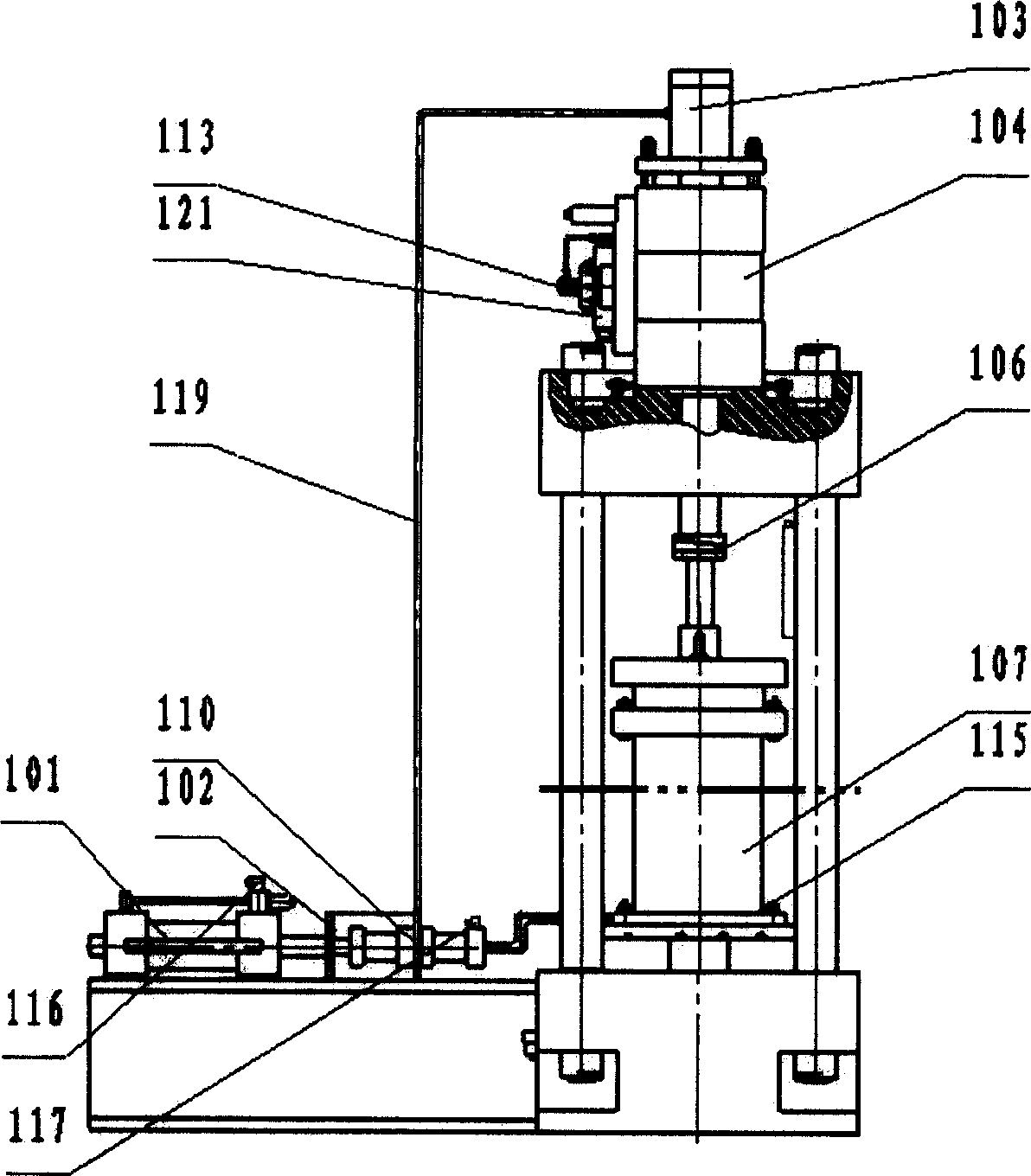

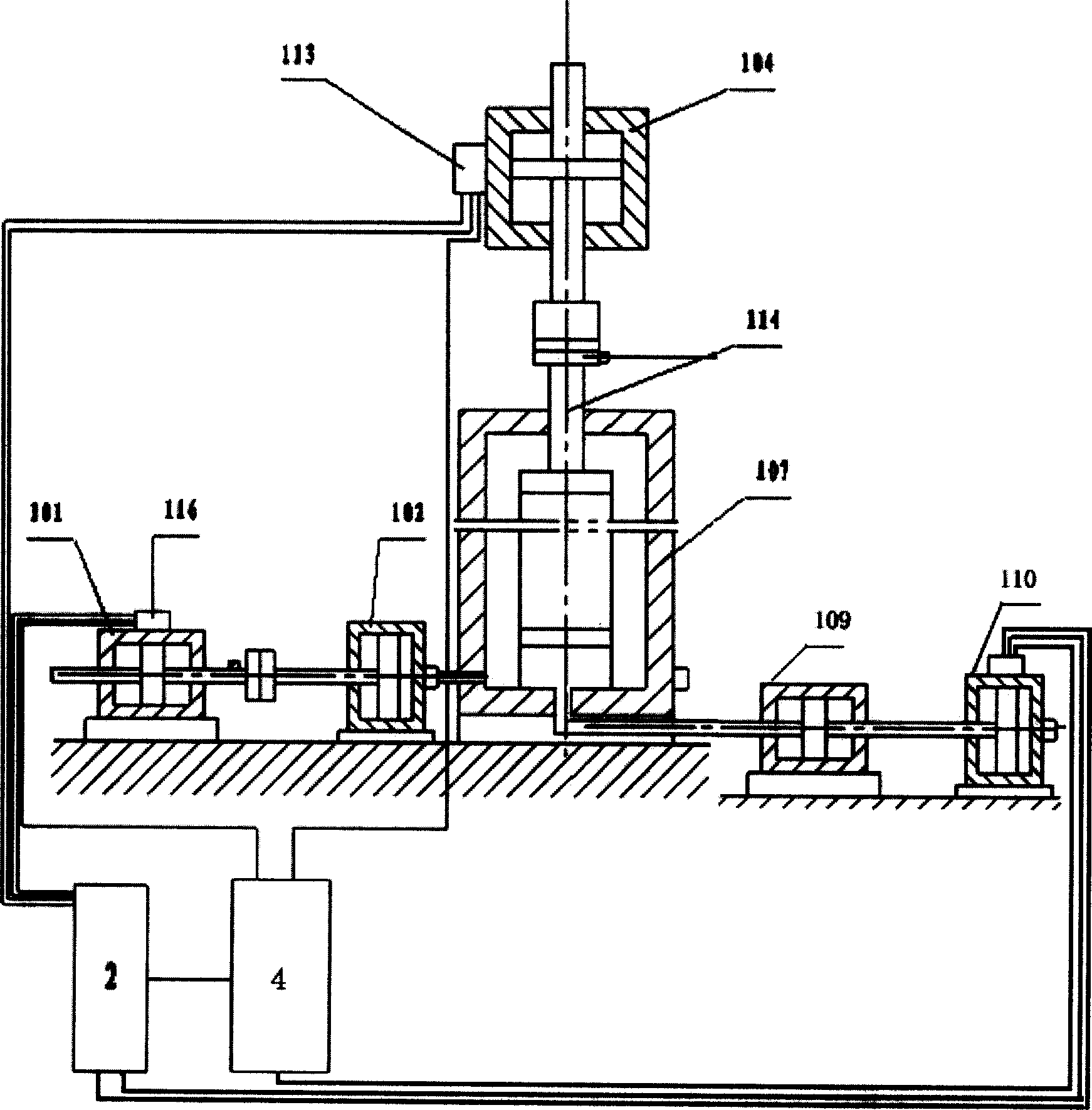

Large-sized multifunction material three-shaft static-dynamic test machine

InactiveCN1641350AIncrease profitHigh degree of automationEarth material testingStrength propertiesHydraulic cylinderMachine parts

The invention is a large-scale multifunctional material three-shaft static and dynamic tester, for providing a three-shaft static and dynamic tester for testing various materials, able to be adaptive to measure the mechanical performance of earth and stone and concrete materials, and also able to make separate seepage as well as seepage and stress coupling, and its characteristic: its main machine part includes side oil water exchange vat and serial water cylinder, side hydraulic cylinder driving the side oil water exchange cylinder,, seepage water cylinder, arranged at the bottom of the main machine and connected with the sample held in a three-shaft pressure room, and seepage hydraulic cylinder driving the seepage water cylinder, the serial water cylinder, is connected with the water path of the three-shaft pressure room through the side oil water exchange cylinder, the upper part of a piston rod driven by an axial vibration exciter is connected with the serial water cylinder and the lower part of the piston rod is connected with the sample held in the three-shaft pressure room. The tester of the invention has high rigidity, high measuring and control accuracy, multiple functions, and is extremely adaptive to material scientific research and engineering detection.

Owner:TSINGHUA UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com