Patents

Literature

135results about How to "Improve life performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

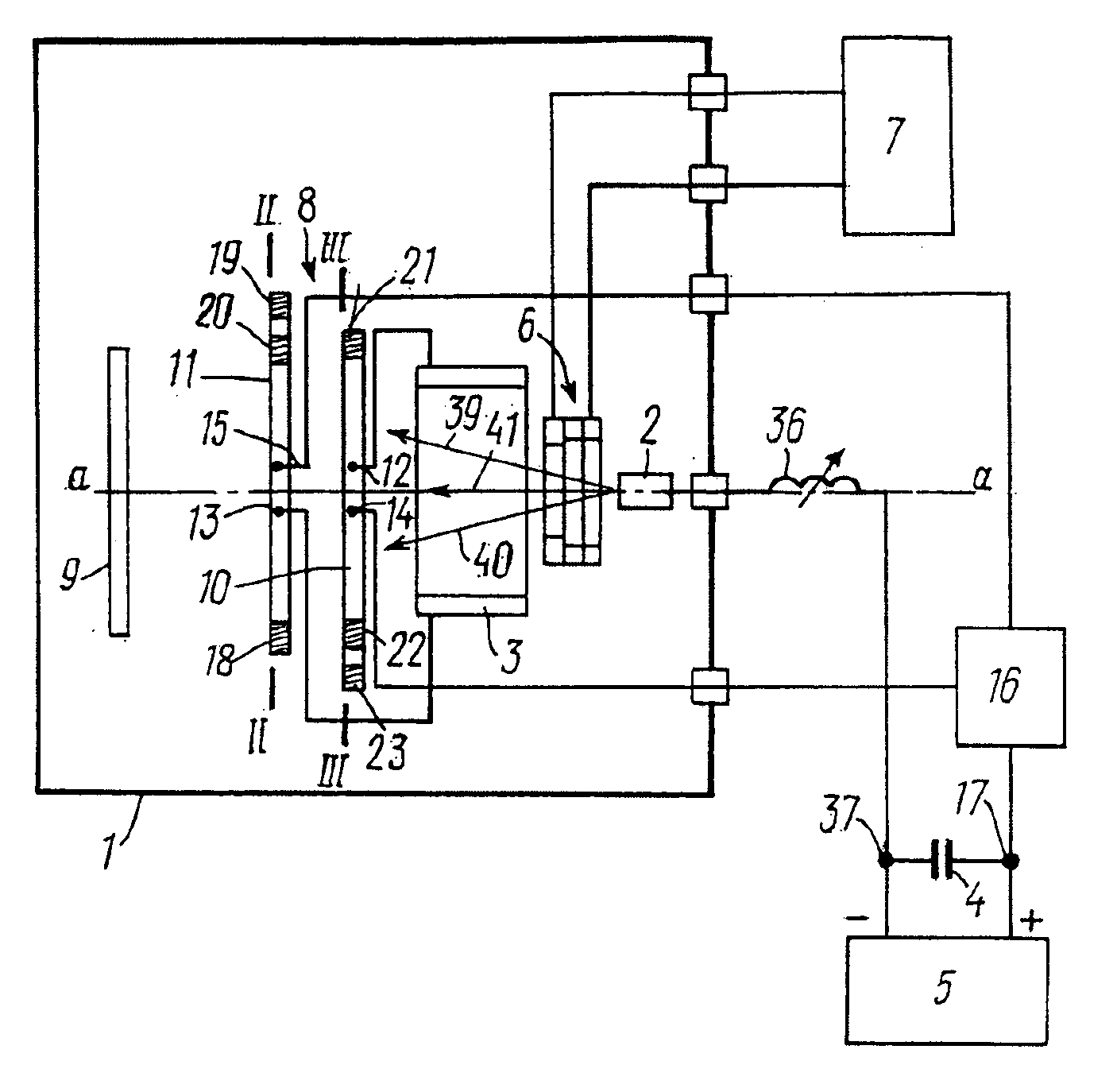

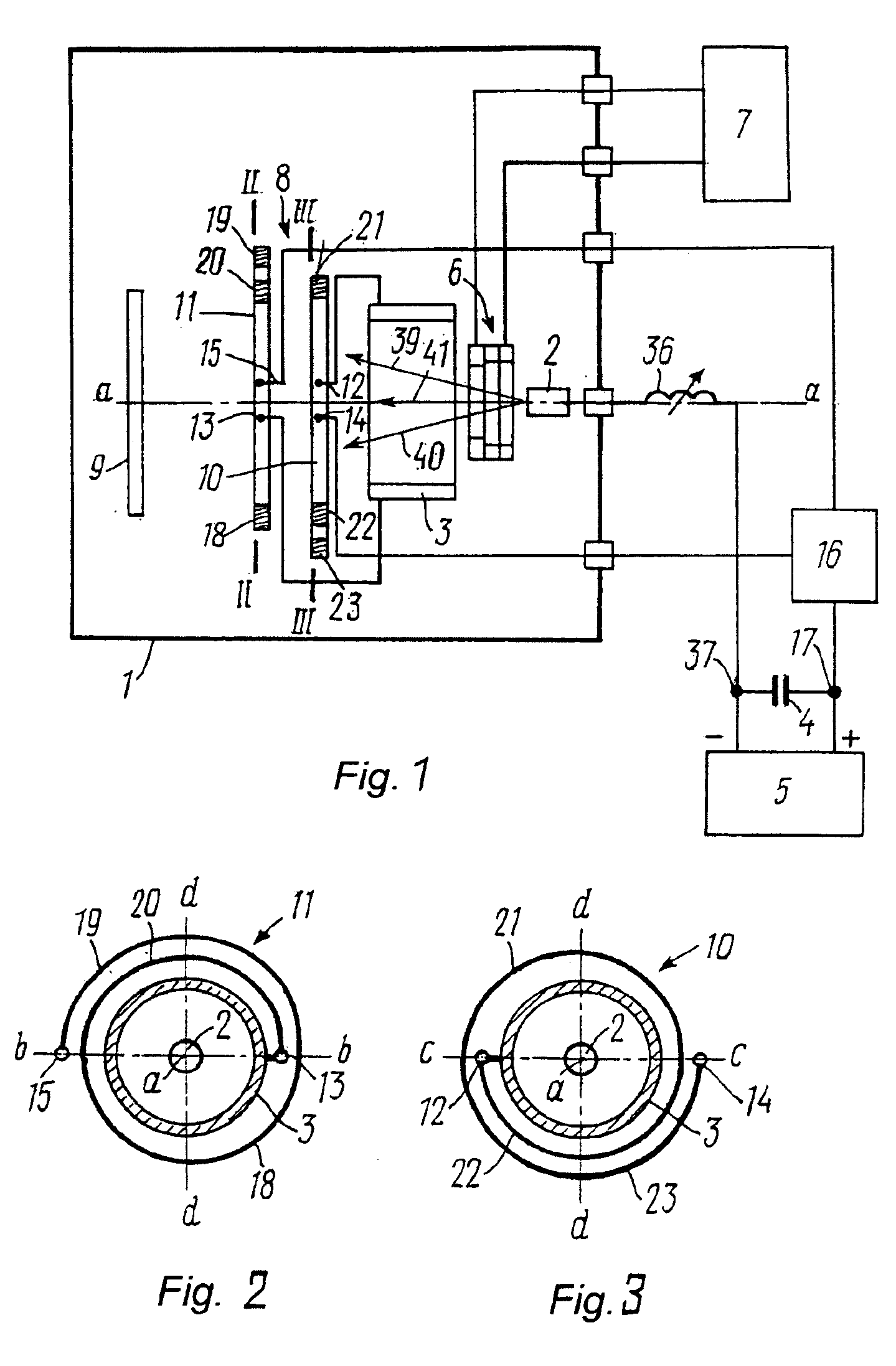

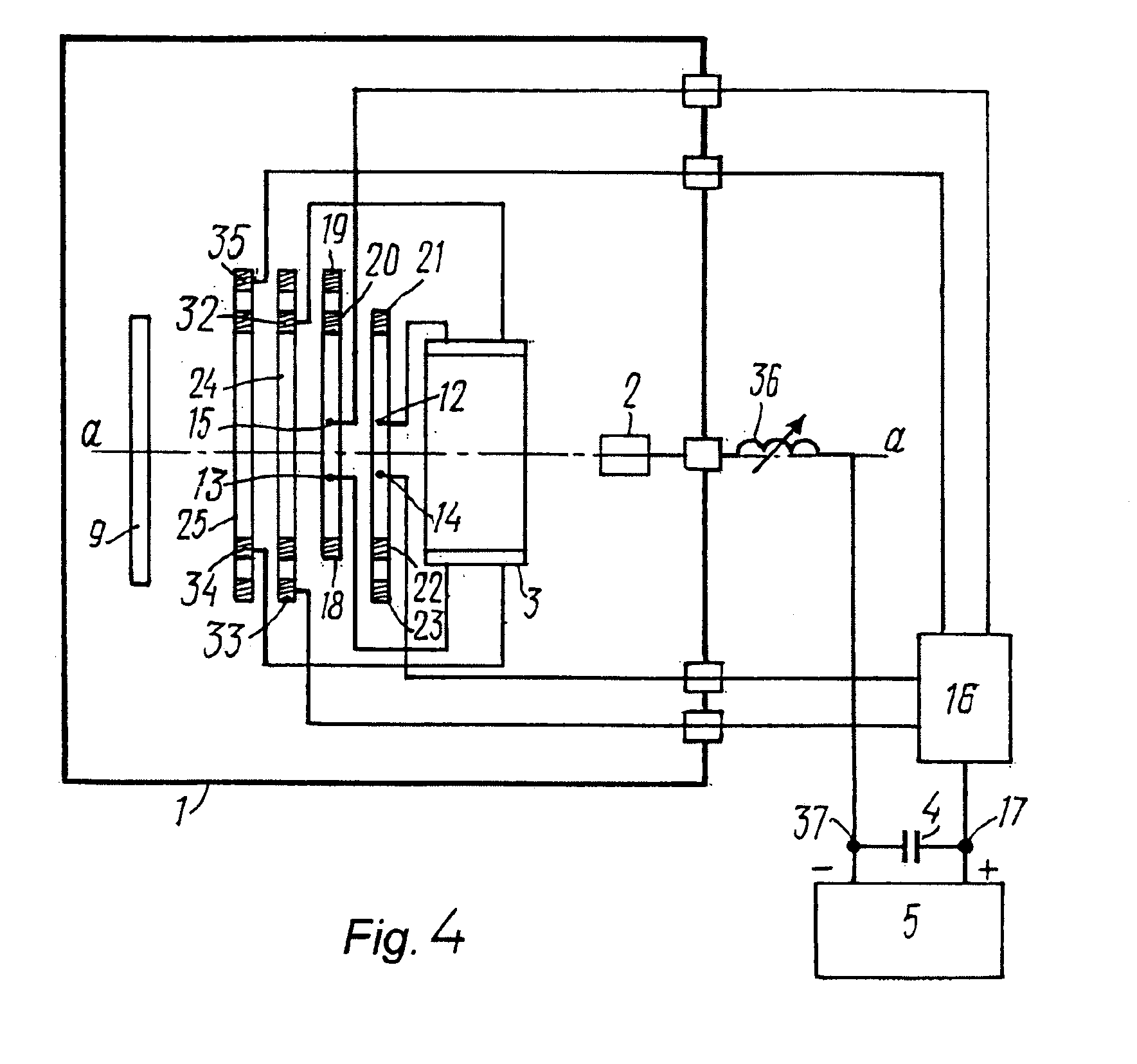

Pulsed carbon plasma apparatus

InactiveUS6855237B2High degreeImprove life performanceCellsElectric discharge tubesDiamond-like carbonMachine parts

The present invention provides a pulsed carbon plasma apparatus to produce a diamond-like carbon coating over an extended object, the coating having a high degree of thickness uniformity achieved by scanning the plasma flow over the surface of the object. The pulsed carbon plasma apparatus of the invention comprises a carbon plasma flow scanning device having at least one pair of deflecting coils, where the deflecting coils have, in the scanning plane, a different number of turns on opposite sides. The object may be made of metal, ceramic, glass or plastic. The coatings may be used to improve life and operating performance of tools and machine parts, and as decorative coatings.

Owner:INT TECH EXCHANGE

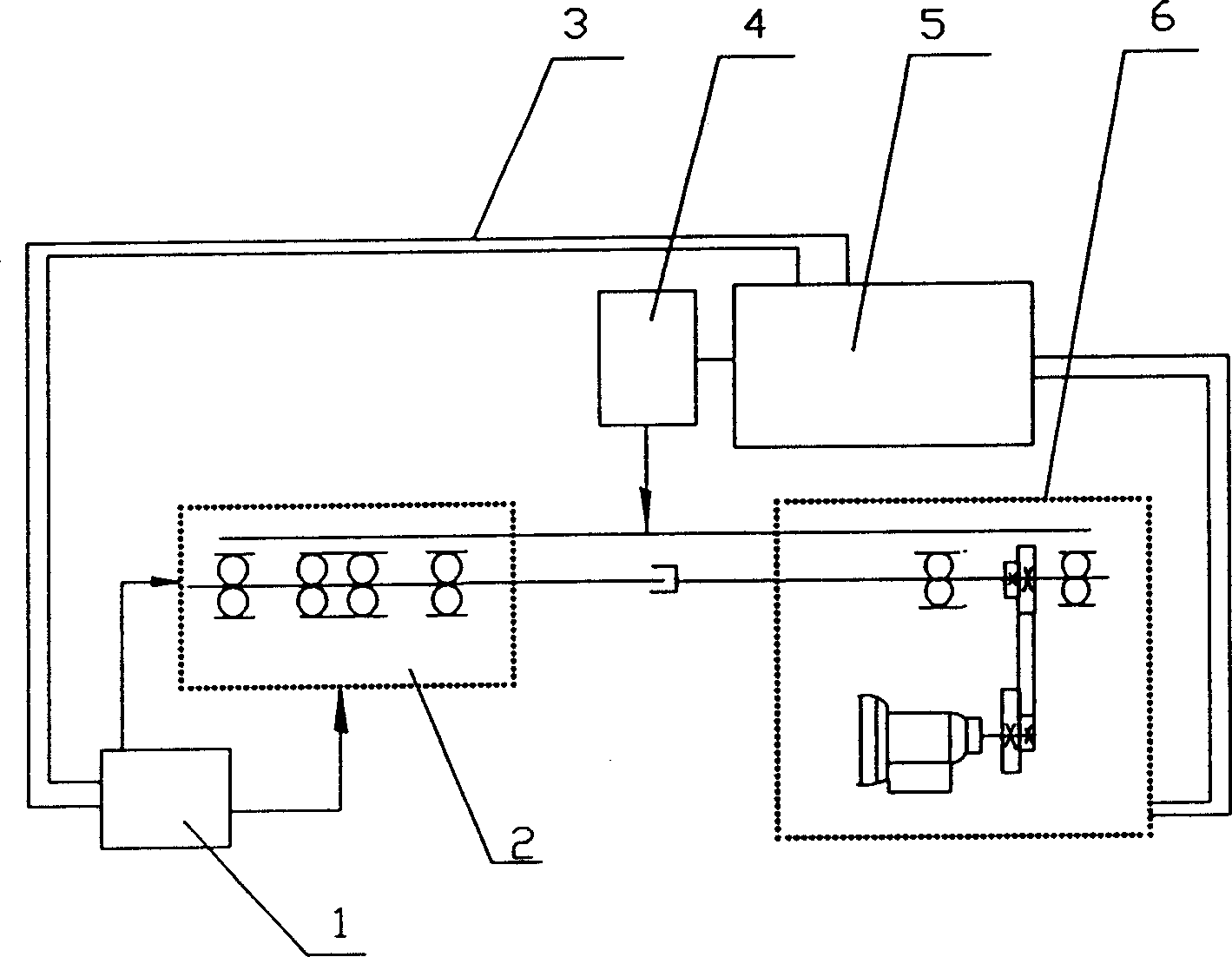

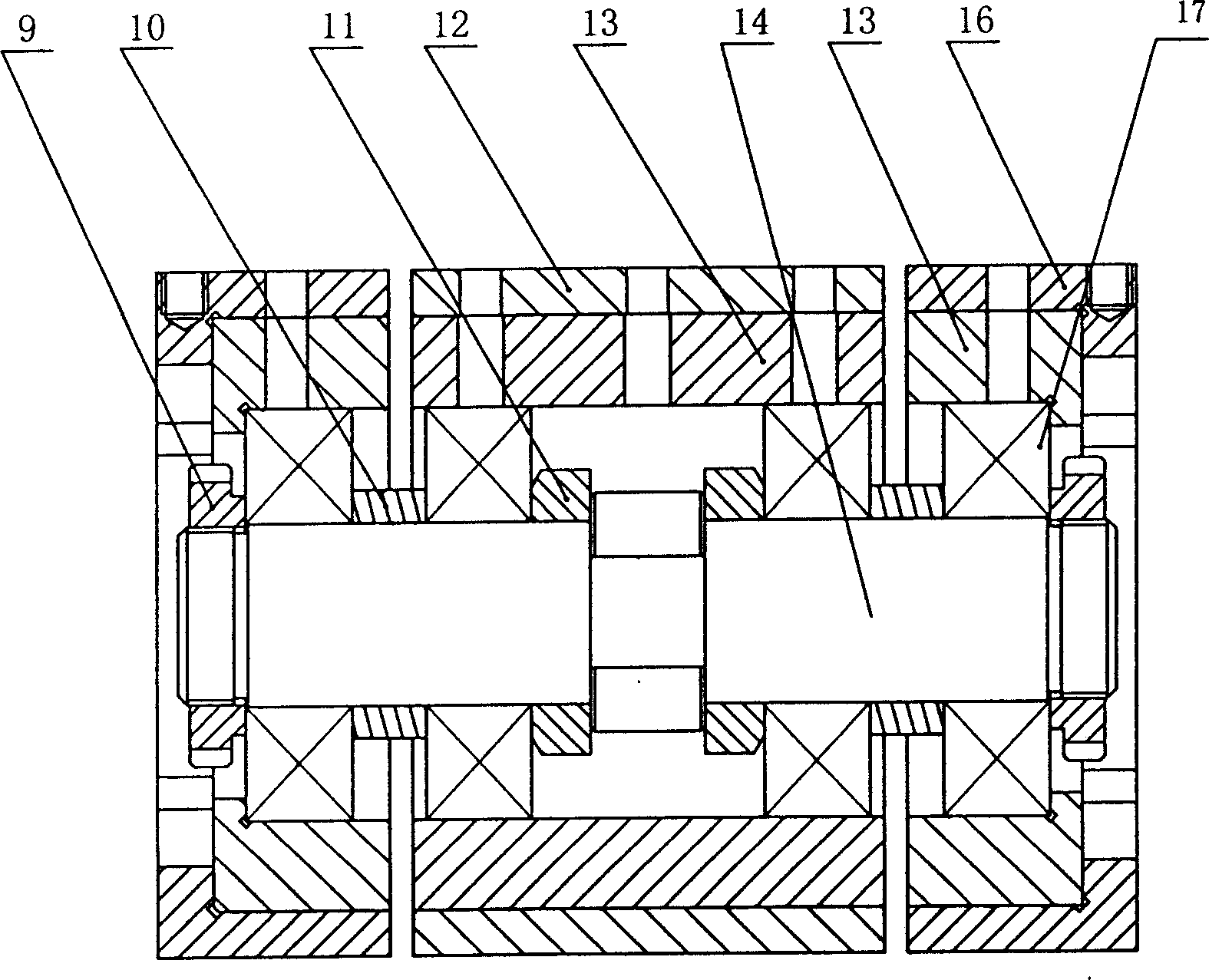

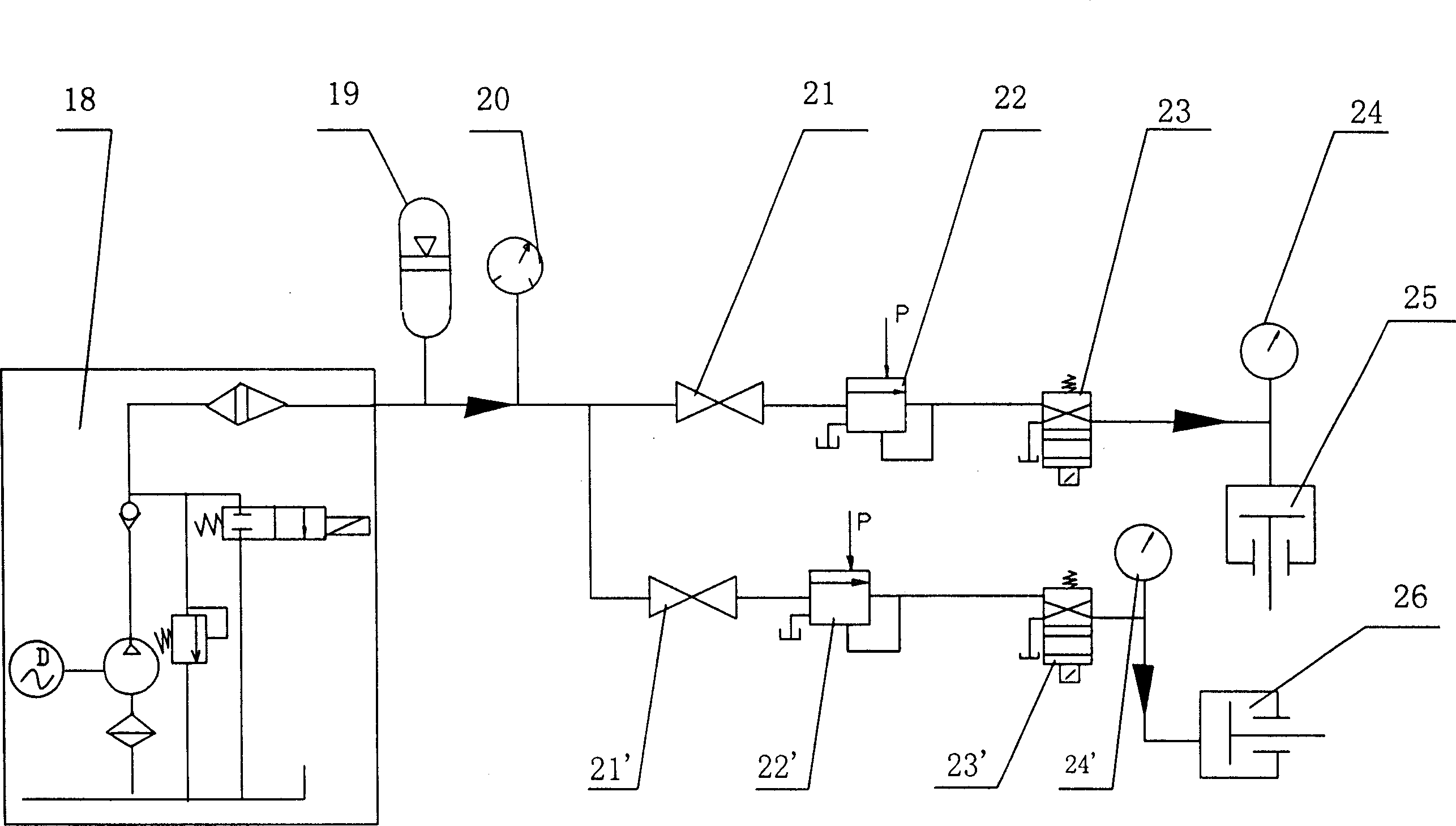

Reinforced test machine for rolling bearing life and reliability and its test method

ActiveCN1900674AGuaranteed accuracyImprove life performanceMachine bearings testingRolling-element bearingControl system

The intensified tester includes load maintainer, test head parts, lubricating mechanism, control system and drive gear. The test head parts include test head and seat of test head. The test head is connected to the drive gear, and load maintainer. The control system is connected to the drive gear, the load maintainer, and the lubricating mechanism. The drive gear supplies power needed for test. The load maintainer supplies load needed for test. The lubricating mechanism makes tested bearing lubricating and cooling down adequately under normal condition. The control system is in use for controlling electric operations, protecting and recording test parameters, monitoring operational aspect of test, analyzing test procedure, test result, and carrying control feedback properly. Features are: reasonable design, compact structure, capable of presetting, measuring, controlling and auto recording test parameters. The tester can make alarming and stopping operation, and printing out cause.

Owner:HANGZHOU BEARING EXPERIMENT & RES CENT

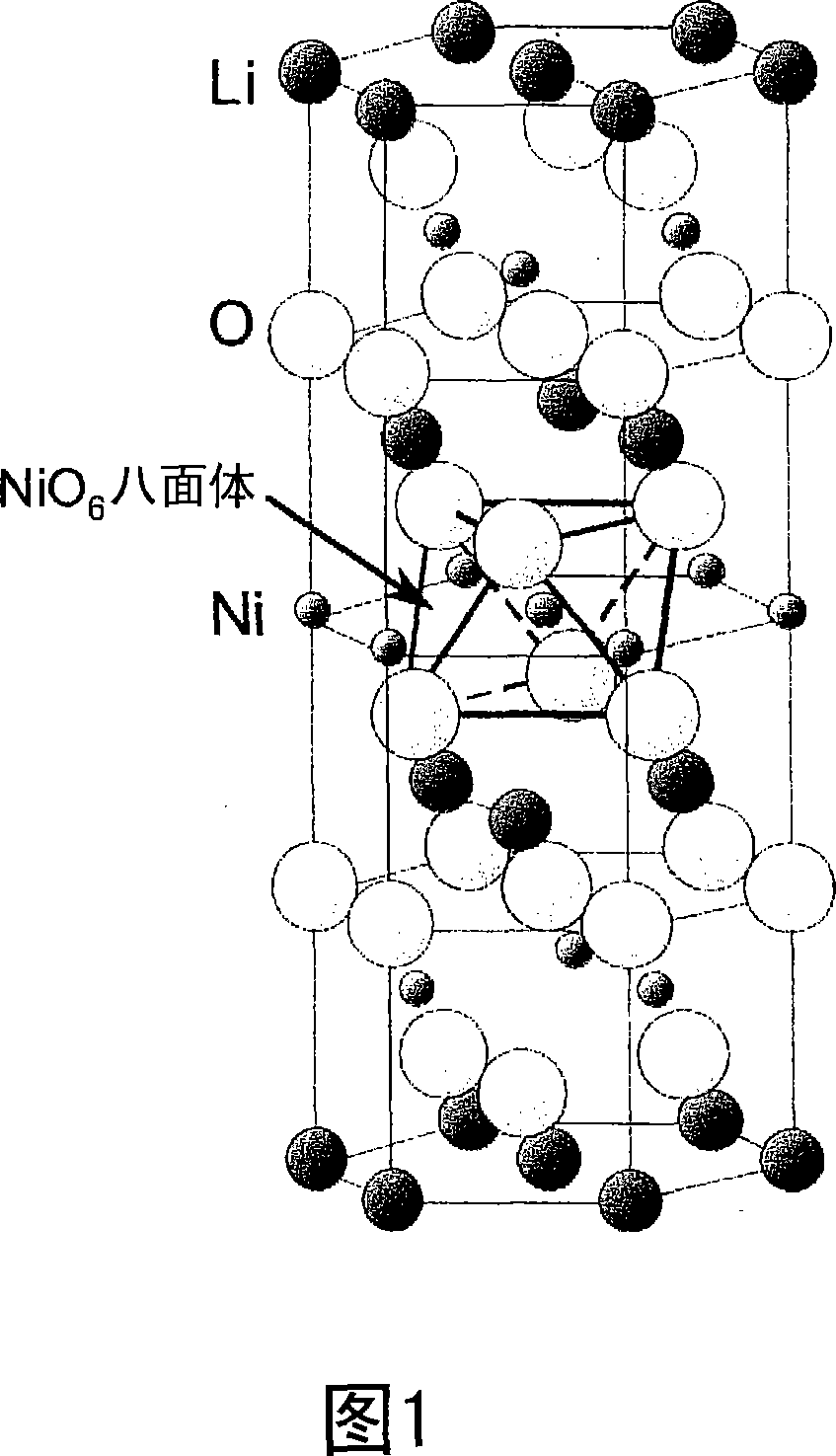

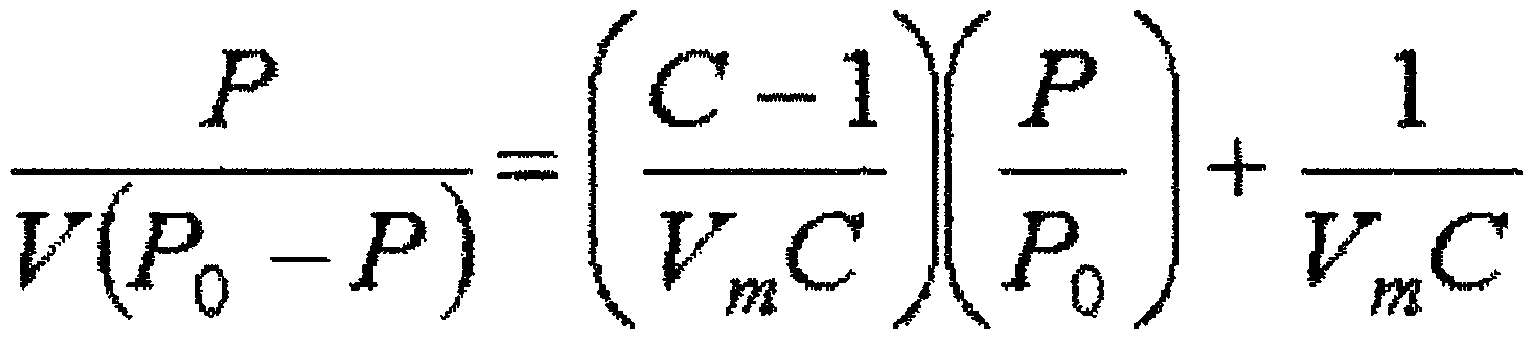

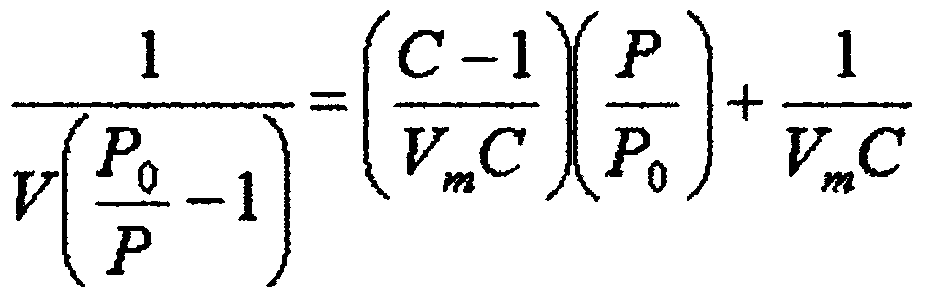

Positive electrode active material for non-aqueous electrolyte secondary battery and manufacturing method thereof, and non-aqueous electrolyte secondary battery using same

ActiveCN101047237ALower internal resistanceIncrease output powerElectrode manufacturing processesNon-aqueous electrolyte accumulatorsLithium metalInternal resistance

To provide a positive electrode active material for a non-aqueous electrolyte secondary battery, which if used as a positive electrode for a lithium ion secondary battery, the battery internal resistance can be reduced, giving a secondary battery superior in output characteristics and life property. After mixing raw material powders in specified quantities of each so as to become a lithium-metal complex oxide represented by Li z Ni 1-w M w O 2 (wherein M is at least one kind or more of metal elements selected from the group consisting of Co, Al, Mg, Mn, Ti, Fe, Cu, Zn, and Ga; and w and z respectively satisfy 0 H01M 4 / 02 H01M 4 / 36 H01M 4 / 04 1 29 3 2007 / 3 / 23 101047237 2007 / 10 / 3 000000000 Sumitomo Metal Mining Co. Japan Oda Syuuhei Kuzuo Ryuichi Ueki Tomoyoshi Suzuki Satoru Yamada Manabu gaolong xin 72003 Japan 2006 / 3 / 23 2006-080375

Owner:SUMITOMO METAL MINING CO LTD +1

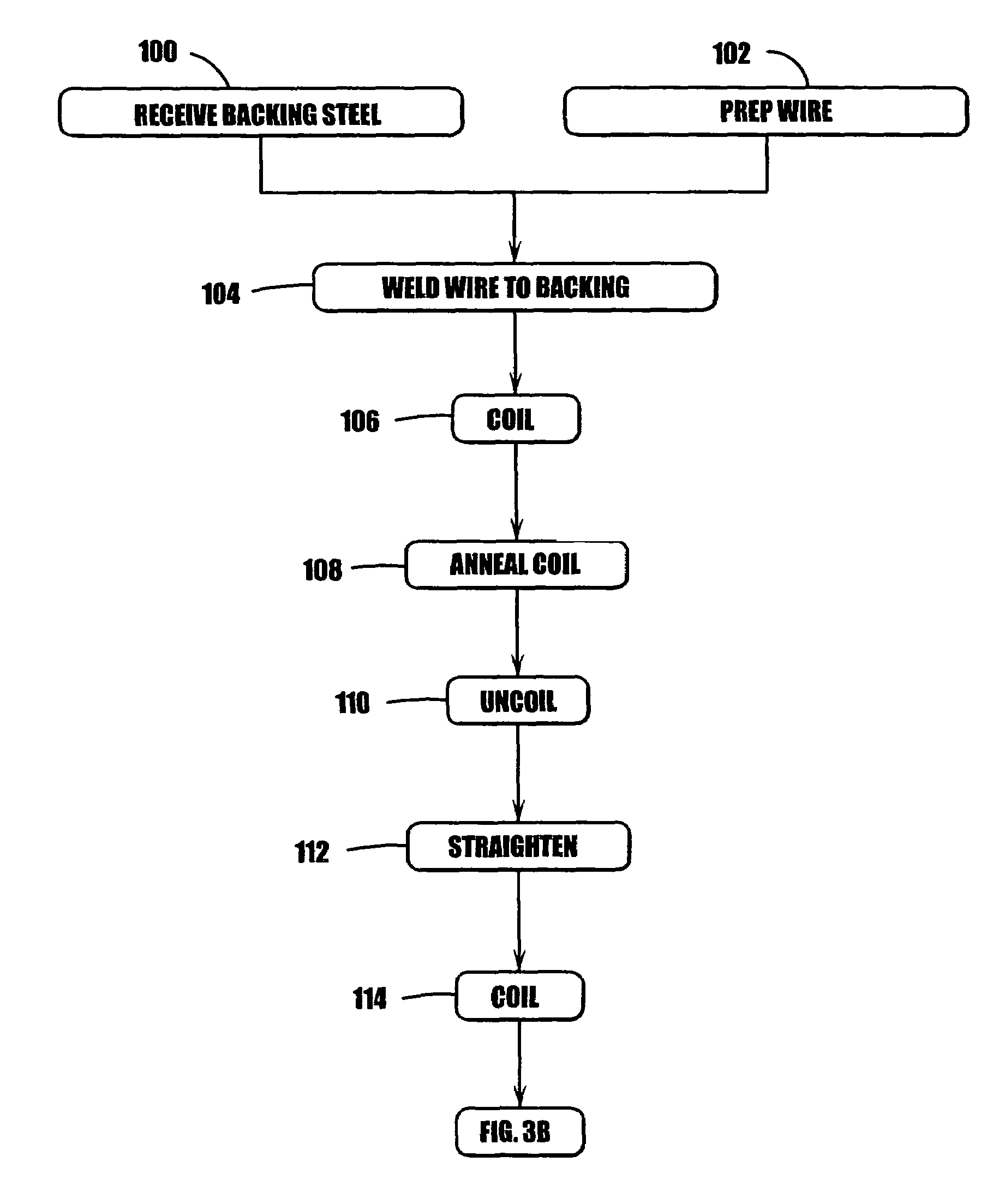

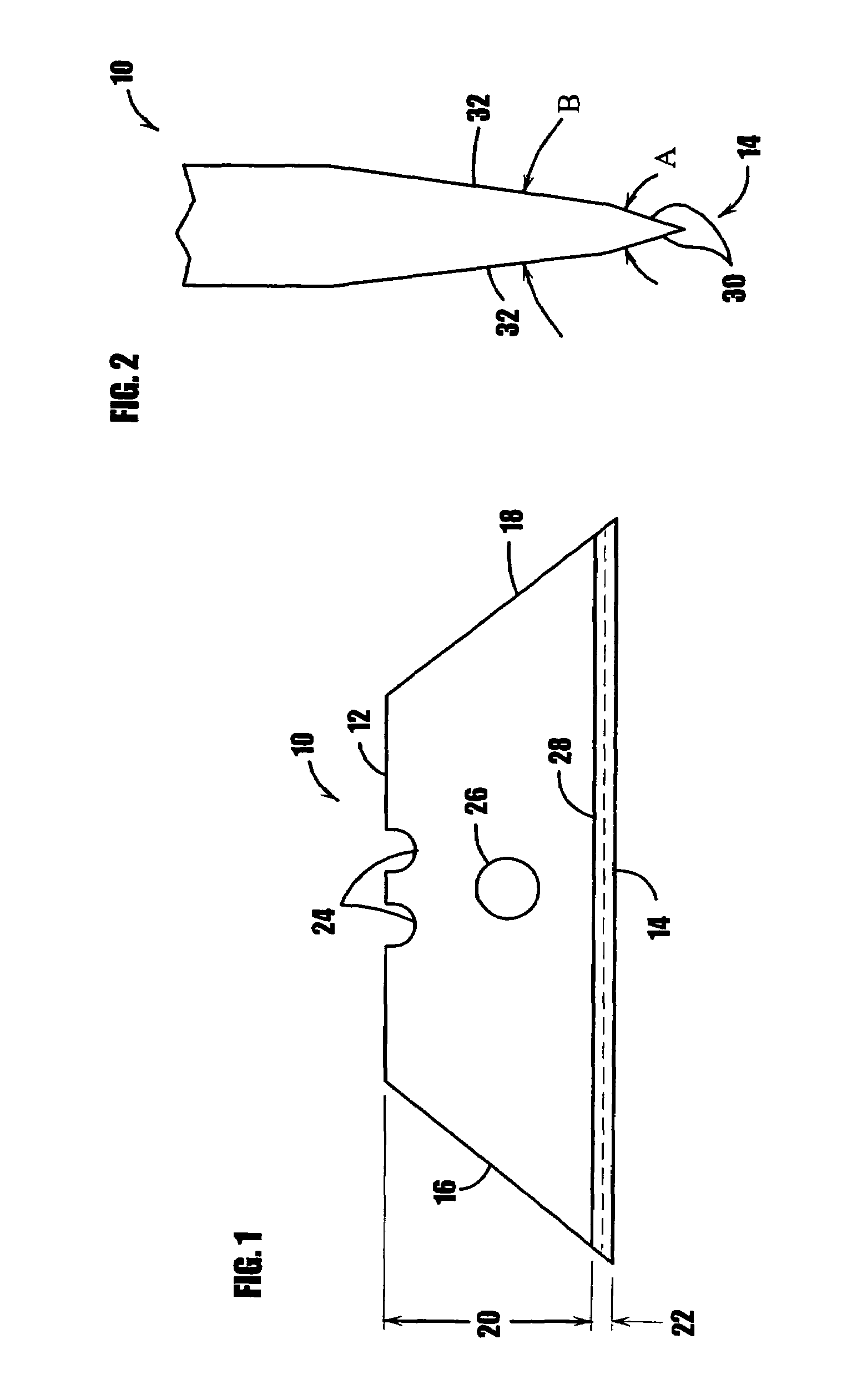

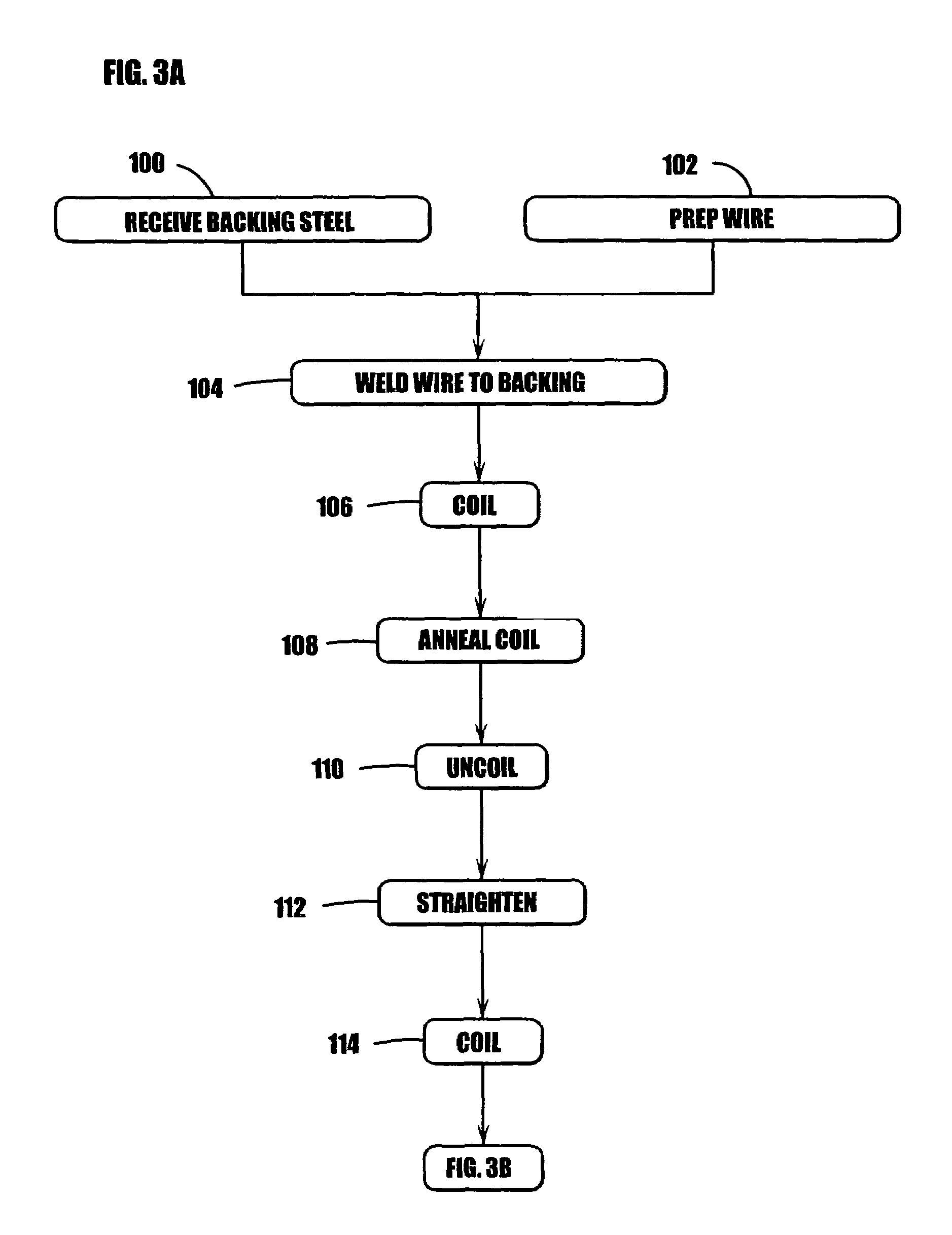

Composite utility blade, and method of making such a blade

InactiveUS7712222B2Hard and wear-resistantExtend blade lifeThin material handlingMetal working apparatusHardnessFront edge

A composite utility blade and method of making such a blade involves butt joining a high speed or tool steel wire to a front edge of an alloy steel backing strip. The wire defines a predetermined cross-sectional shape that substantially corresponds to the cross-sectional shape of the cutting edge of the blade. The wire is electron beam welded to the backing strip to form a composite strip defining a first metal portion formed by the alloy steel backing strip, a second metal portion formed by the high speed or tool steel wire, and a weld region joining the first and second metal portions. The composite strip is then annealed, and the annealed strip is straightened to eliminate any camber therein. The annealed composite strip is then hardened such that the first metal portion defines a first surface hardness and the second metal portion defines a second surface hardness greater than the first surface hardness. The hardened strip is then subjected to tempering and quenching cycles, and facets are formed on the edge of the second metal portion to form a straight, tool steel cutting edge. The composite strip is then scored at axially spaced locations to form a plurality of score lines, and the plurality of score lines define a plurality of blade sections there between. The cutting edge may be coated with AlTiN, TiN, or an inner coating of AlTiN and an outer coating of TiN.

Owner:BLACK & DECKER INC

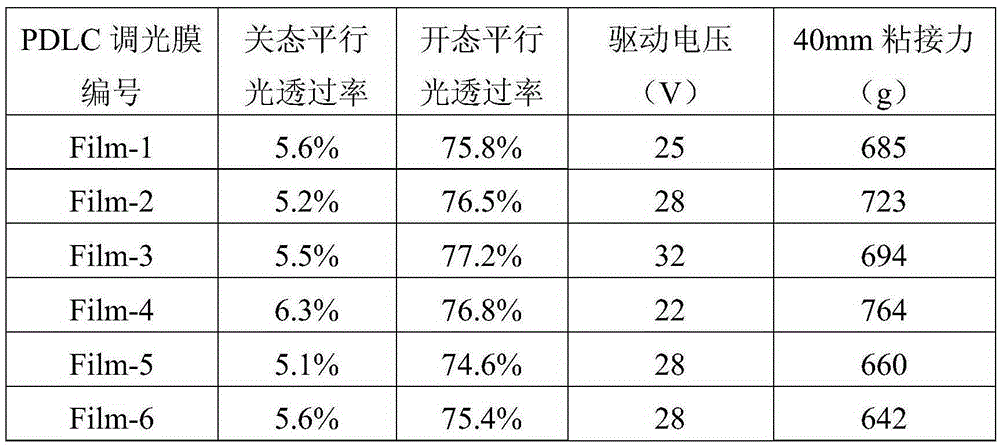

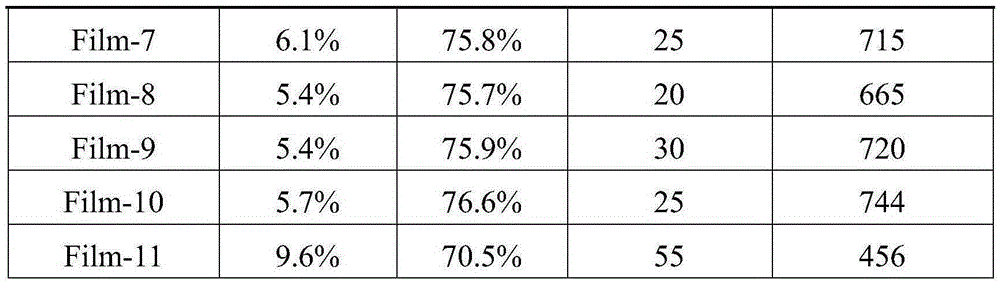

PDLC composition with high bonding force

InactiveCN105418854AHigh bonding strengthReduce the driving voltageLiquid crystal compositionsNon-linear opticsTransmittancePhotoinitiator

The invention discloses a PDLC composition with a high bonding force. The PDLC composition is prepared from the following raw materials: light-cured prepolymer monomers, a liquid crystal material, a photoinitiator, spacers and a phosphor element providing agent through a light curing reaction. The light adjusting material is applied in a light adjusting membrane or light adjusting glass, has excellent bonding intensity, excellent photoelectric performances and a good service life performance, the problem can be solved that the bonding force is not good when a light adjusting material is used on a PET base material, and different demands of users are met. Compared with the present conventional PDLC light adjusting membranes at market, the PDLC light adjusting membrane has a high membrane transmittance and an obviously low driving voltage, the bonding force performance is excellent, and the provided PDLC light adjusting membrane has obvious visual effects and applicability.

Owner:SHIJIAZHUANG CHENGZHI YONGHUA DISPLAY MATERIALS CO LTD

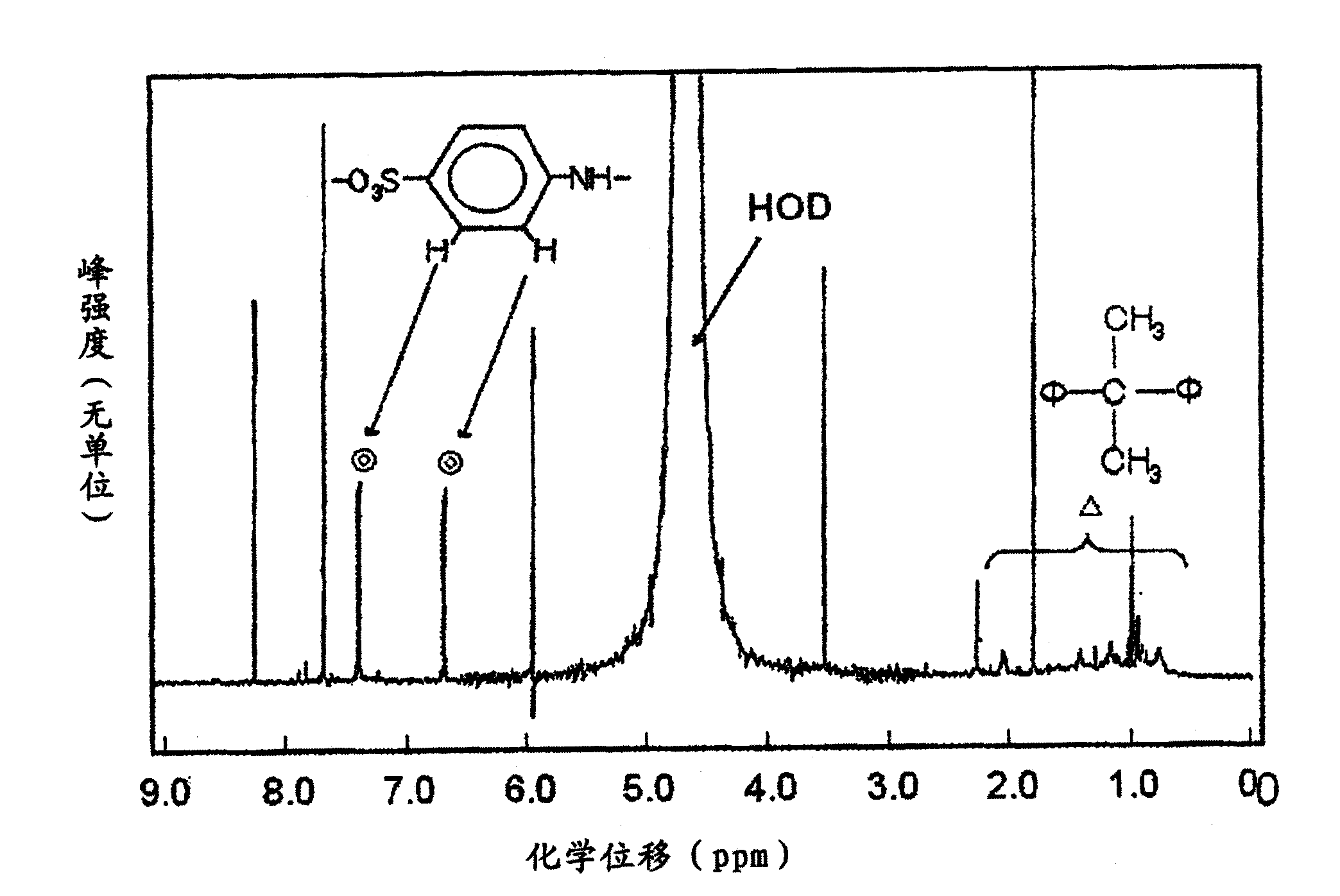

Lead storage battery

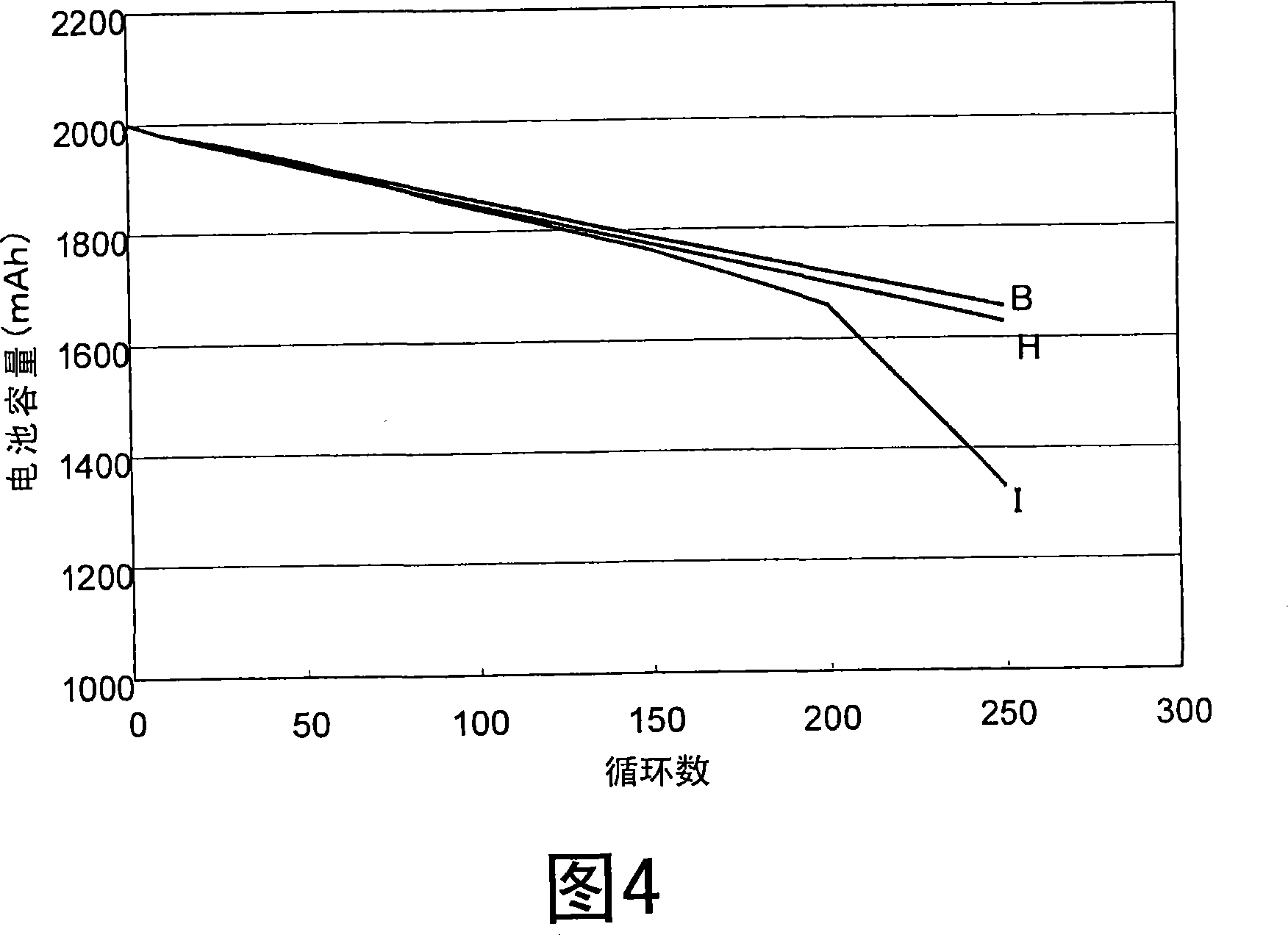

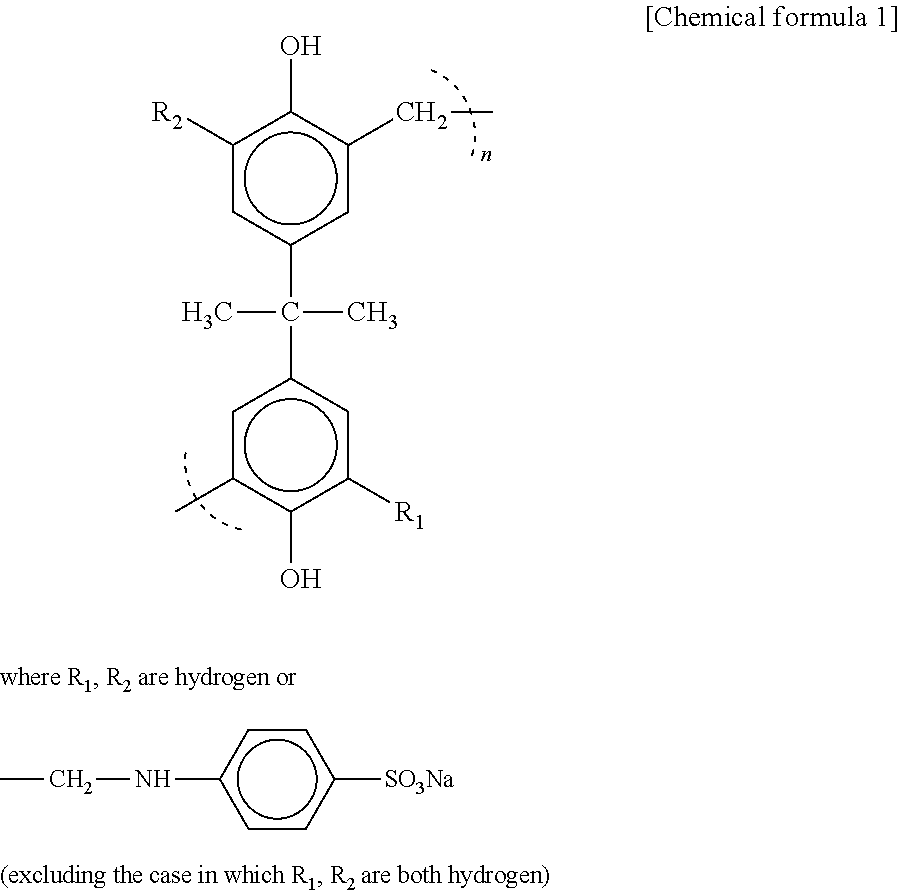

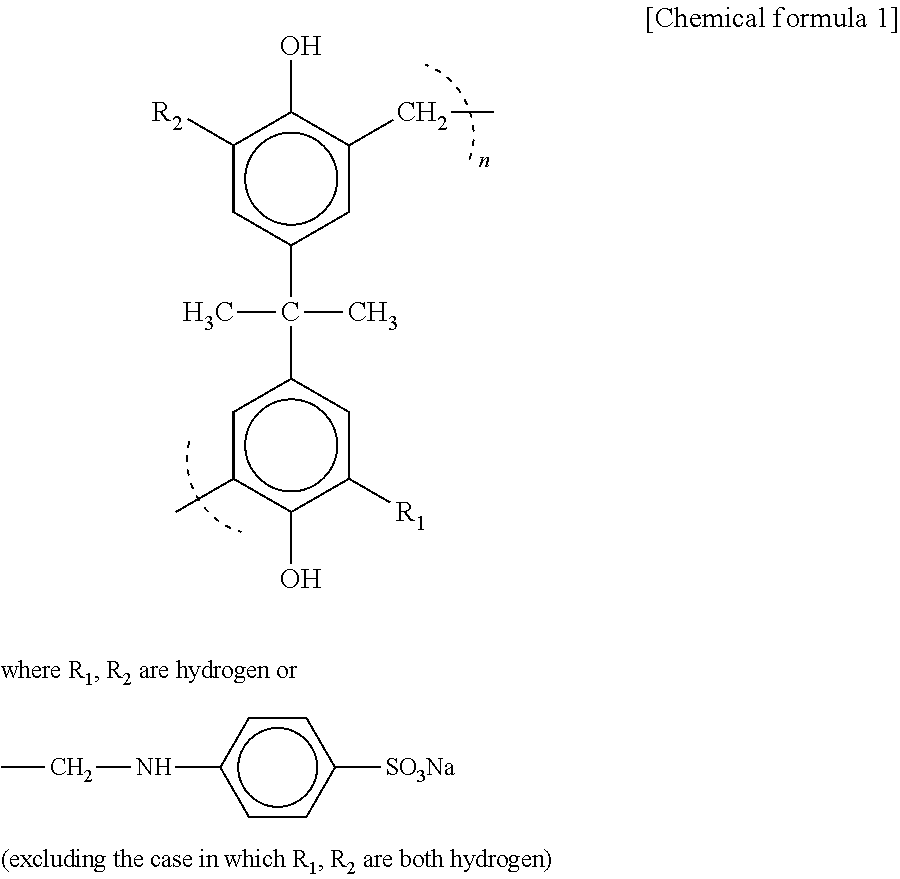

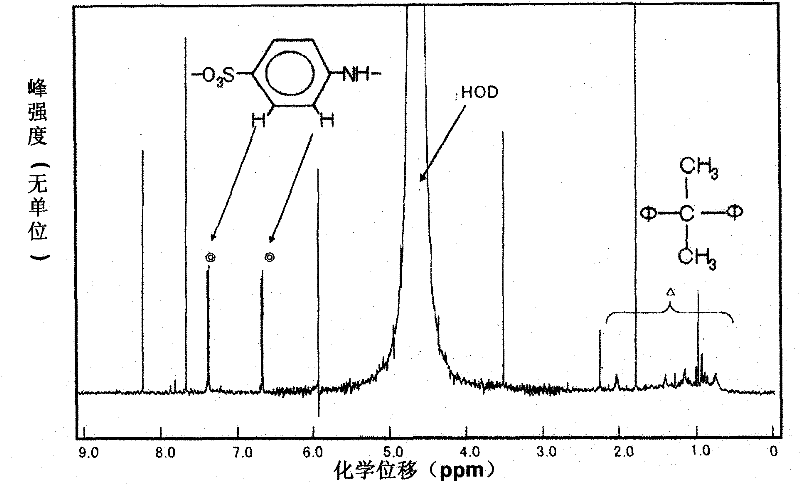

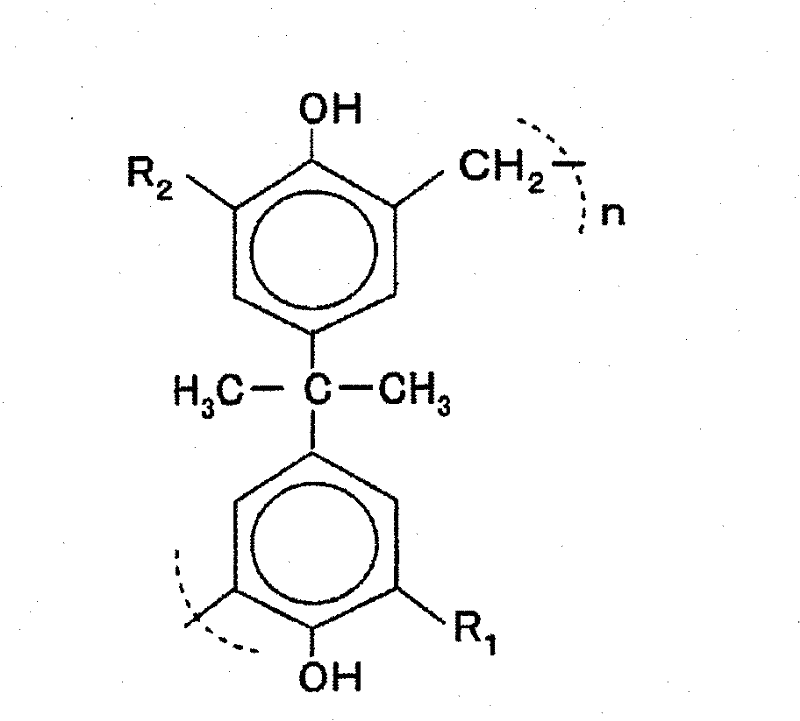

InactiveCN102246343AImprove charge acceptanceSuppress coarseningLead-acid accumulatorsCell seperators/membranes/diaphragms/spacersPolyolefinHigh rate

The disclosed liquid lead storage battery, which is charged intermittently for short periods at a time and which performs high-rate discharge to a load while in a partially charged state, has increased operating-life characteristics and charge acceptance by means of using: a cathode plate wherein the specific surface area of active material is at least 6 m2 / g; an anode plate wherein a carbonaceous conductive material and a bisphenol / aminobenzenesulfonic acid / formaldehyde condensate are added to an anode active material, increasing charge acceptance and operating-life performance; and a separator of which the surface that faces the anode plate is formed from a nonwoven fabric of a material selected from glass, pulp, and a polyolefin.

Owner:SHIN KOBE ELECTRIC MASCH CO LTD

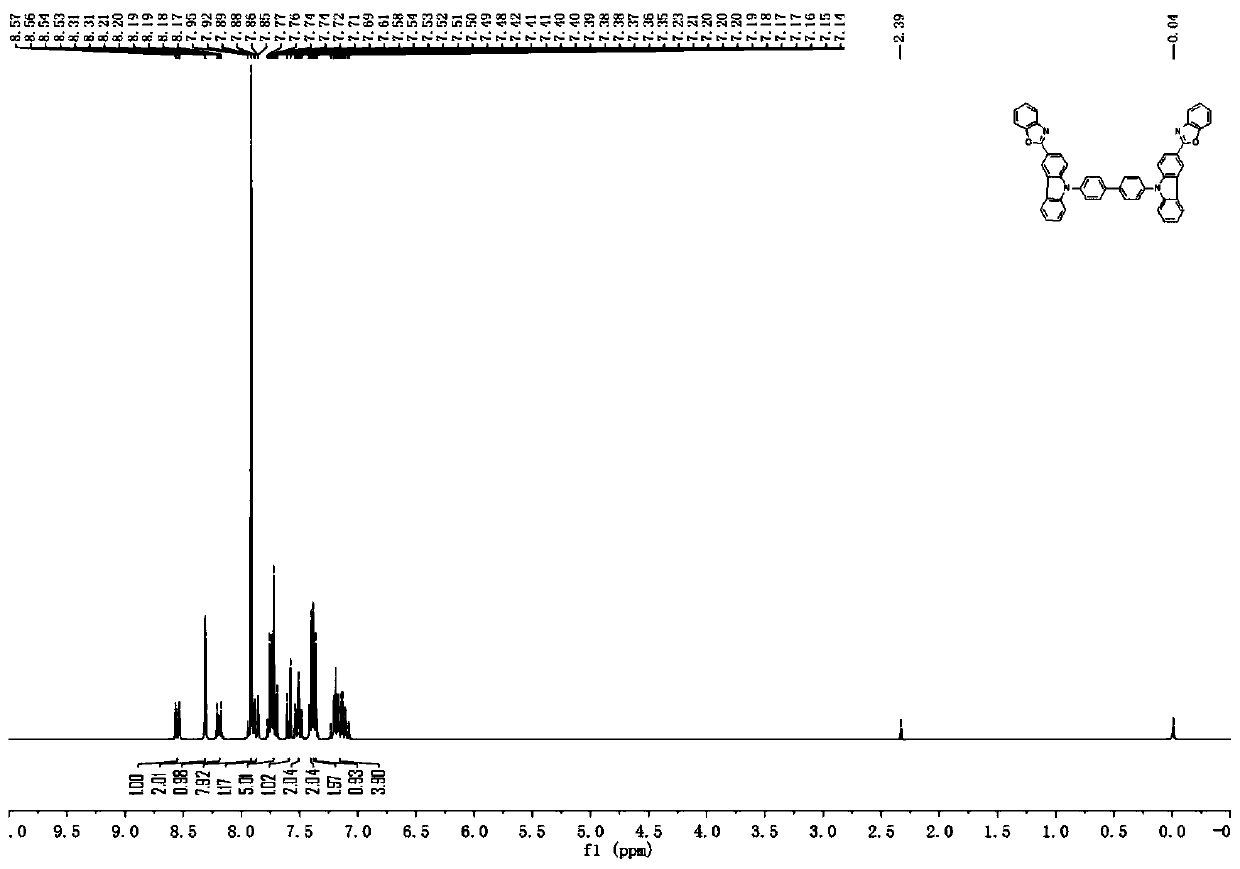

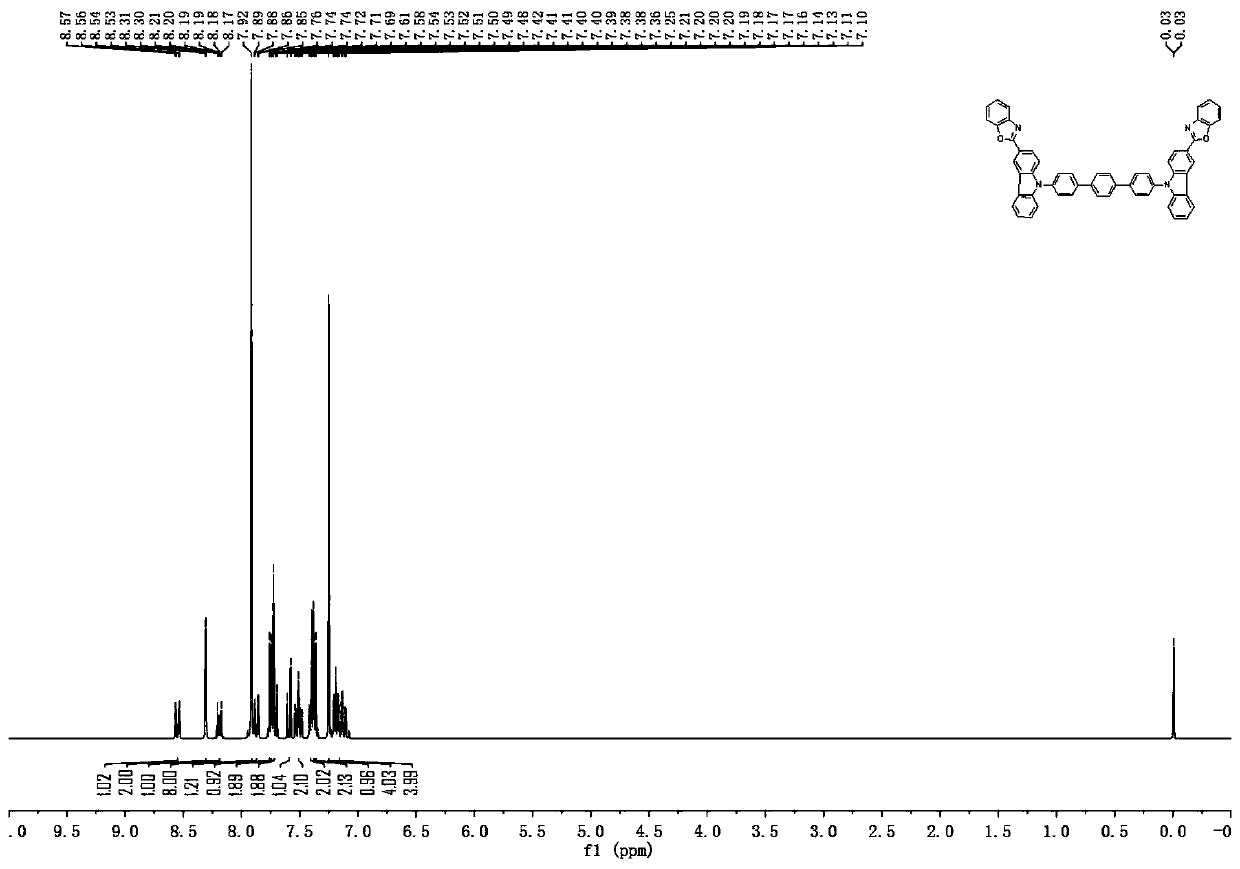

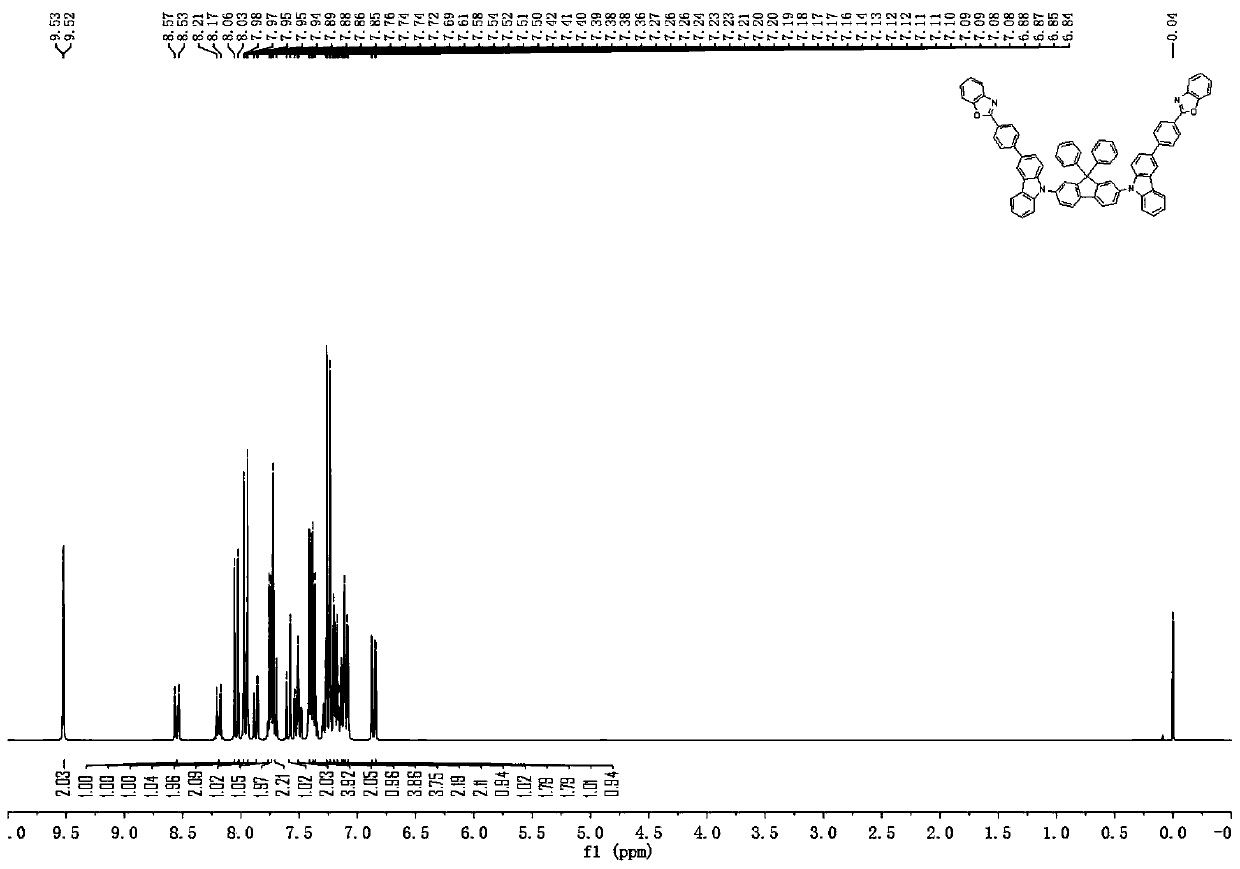

Heterocyclic compound and organic electroluminescent device thereof

ActiveCN110483495AHigh refractive indexImprove transmittanceOrganic chemistrySolid-state devicesBenzoxazoleOrganic light emitting device

The invention provides a heterocyclic compound and an organic light-emitting device thereof, and relates to the technical field of organic photoelectric materials. The heterocyclic compound provided by the invention has a high refractive index, the refractive index can reach 1.95-2.10, and when the heterocyclic compound is used as a covering layer material, the transmittance of a semi-transmissiveelectrode can be improved, the light emitting direction can be adjusted, and the light emitting efficiency can be improved. Secondly, according to the heterocyclic compound provided by the invention,by optimizing the structure and introducing nitrogen-containing five-membered heterocycle or six-membered heterocycle, benzoxazole or benzothiazole groups, the glass-transition temperature is increased, the film-forming property and stability are better, and the service lifetime of the device can be effectively prolonged when the heterocyclic compound is used as a covering layer material of the organic light-emitting device.

Owner:CHANGCHUN HYPERIONS TECH CO LTD

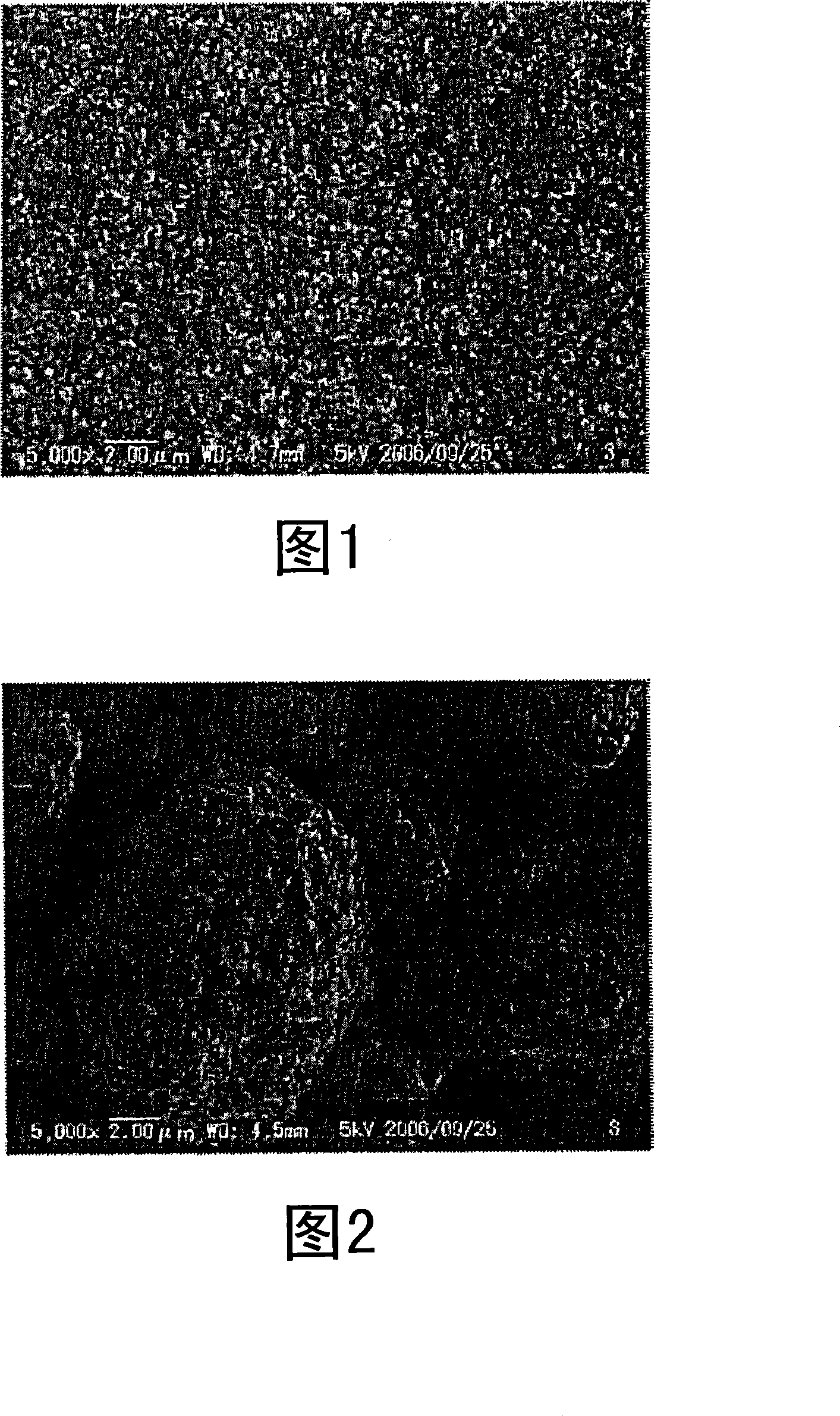

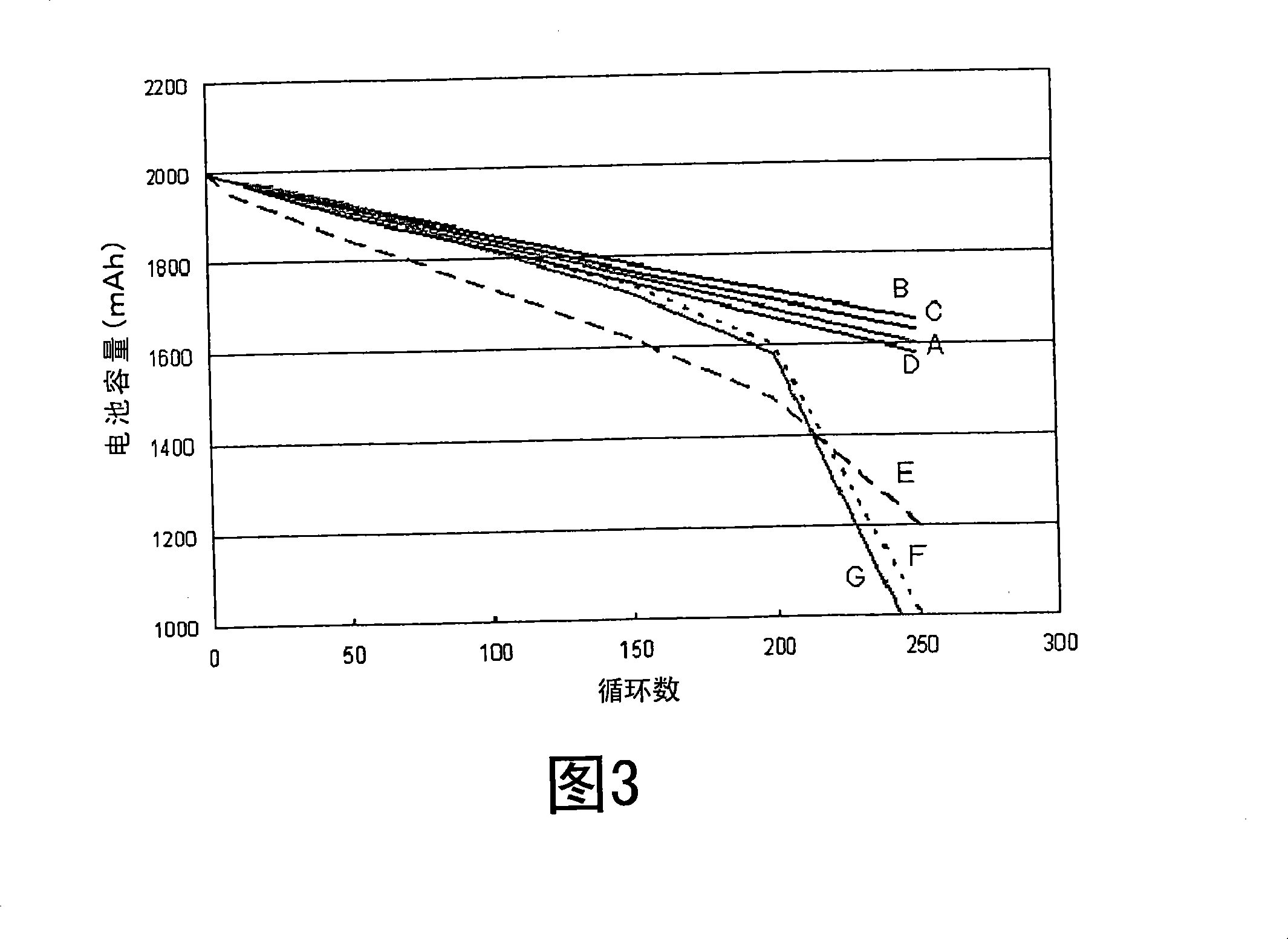

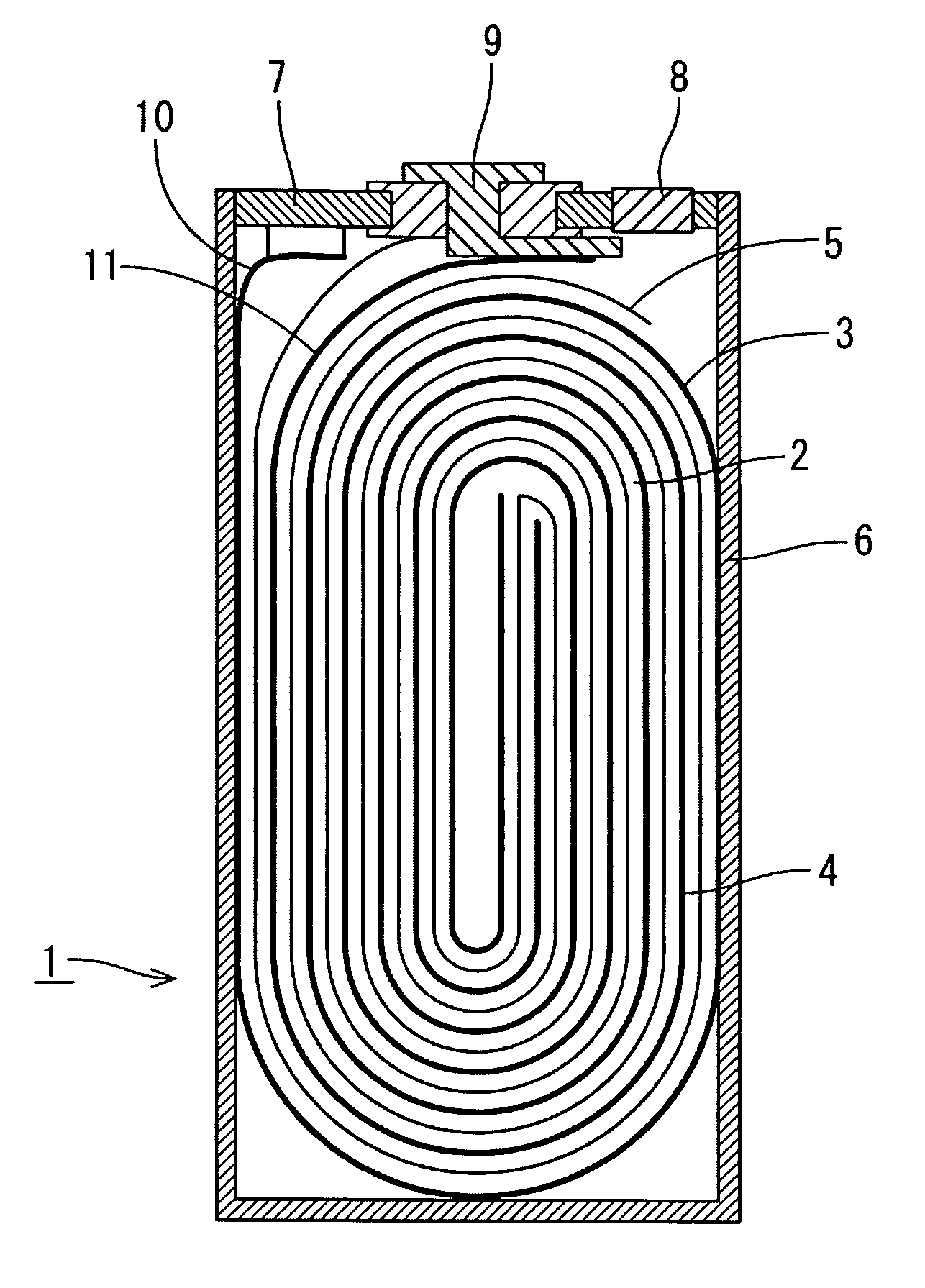

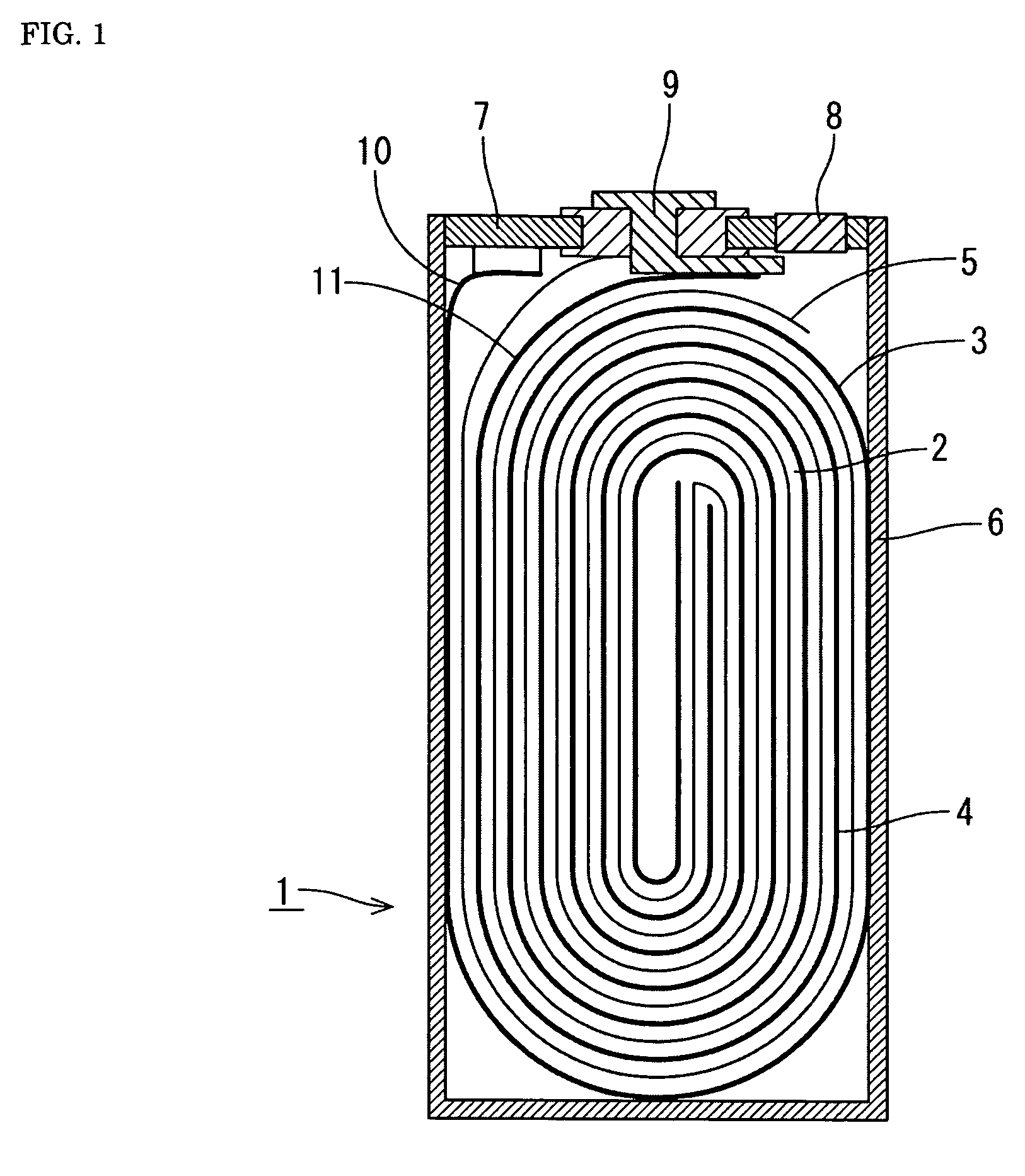

Non-aqueous electrolyte secondary battery

InactiveCN101237069AReduce capacityInhibition of adhesion (precipitationSecondary cellsActive material electrodesEngineeringBattery capacity

In a non-aqueous electrolyte secondary battery including an electrode assembly including a positive electrode containing a positive electrode active material, a negative electrode containing a negative electrode active material, and a separator interposed therebetween; and a non-aqueous electrolyte, 80 wt % or more of the positive electrode active material is primary particles, and the separator is formed by a porous film, or the porous film is formed at at least one position from the following: between the positive electrode and the separator main body, between the negative electrode and the separator main body, and inside the separator main body, to capture the metal ions leached from the positive electrode active material. Such an arrangement enables a non-aqueous electrolyte secondary battery with significantly less decline in battery capacity, excellent charge and discharge cycle life performance, and capable of stable output for a longer period of time.

Owner:PANASONIC CORP

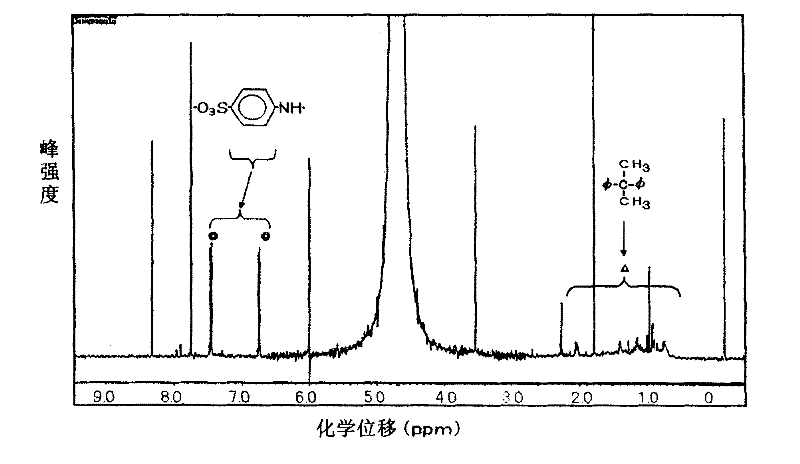

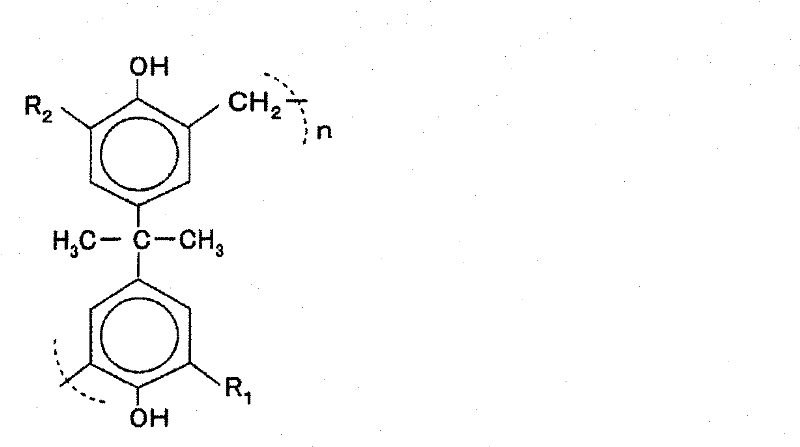

Lead acid storage battery

InactiveUS20130022860A1Improve service life effectHigh acceptanceLead-acid accumulatorsCell seperators/membranes/diaphragms/spacersPolyolefinState of charge

A flooded-type lead acid storage battery in which charging is intermittently carried out in a short period of time and high-efficiency discharge to a load is carried out in a partial state of charge, wherein the charge acceptance and service life characteristics are improved by using a positive plate in which the specific surface area of the active material is set to 6 m2 / g or more; a negative plate with improved charge acceptance and service life performance obtained by adding a carbonaceous electrically conductive material, and a bisphenol aminobenzenesulfonic acid formaldehyde condensate to the negative active material; and a separator formed from a nonwoven in which the surface facing the negative plate is composed of material selected from glass, pulp, and polyolefin.

Owner:SHIN KOBE ELECTRIC MASCH CO LTD

Lead storage battery

ActiveCN102576911AImprove charge acceptanceExtend your lifeFinal product manufactureNegative electrodesHigh rateState of charge

Provided is a valve-regulated lead storage battery which is intermittently charged, each charge being conducted for a short period, and which in a partial state of charge (PSOC) is discharged at a high rate to apply a voltage to a load. The battery shows higher charge acceptance and has better life characteristics under PSOC than conventional valve-regulated lead storage batteries. Use is made of a positive electrode plate in which the active material has a specific surface area of 5.5 m2 / g or more. Use is made of a negative electrode plate in which the charge acceptance and life performance have been improved by adding a carbonaceous conductive material and a product of condensation of a bisphenol compound, aminobenzenesulfonic acid, and formaldehyde to a negative active material. The specific gravity of an electrolytic solution is set at 1.30-1.35. Thus, the valve-regulated lead storage battery is produced.

Owner:RESONAC CORPORATION

Lead-acid battery

InactiveUS20130099749A1Improve charge acceptanceImproved life performanceBatteries circuit arrangementsFinal product manufactureState of chargeHigh rate

A flooded-type lead-acid battery in which charging is intermittently carried out in a short period of time and high-rate discharge to a load is carried out in a partial state of charge, wherein the charge acceptance and service life characteristics under PSOC are improved by using a positive plate in which the total surface area of the positive active material per unit of the plate pack volume is set in a range of 3.5 to 15.6 m2 / cm3; a negative plate with improved charge acceptance and service life performance obtained by adding a carbonaceous electrically conductive material, and a formaldehyde condensate of bisphenol and aminobenzene sulfonic acid to the negative active material; and a separator formed from a nonwoven in which a surface facing the negative plate is composed of material selected from glass, pulp, and polyolefin.

Owner:SHIN KOBE ELECTRIC MASCH

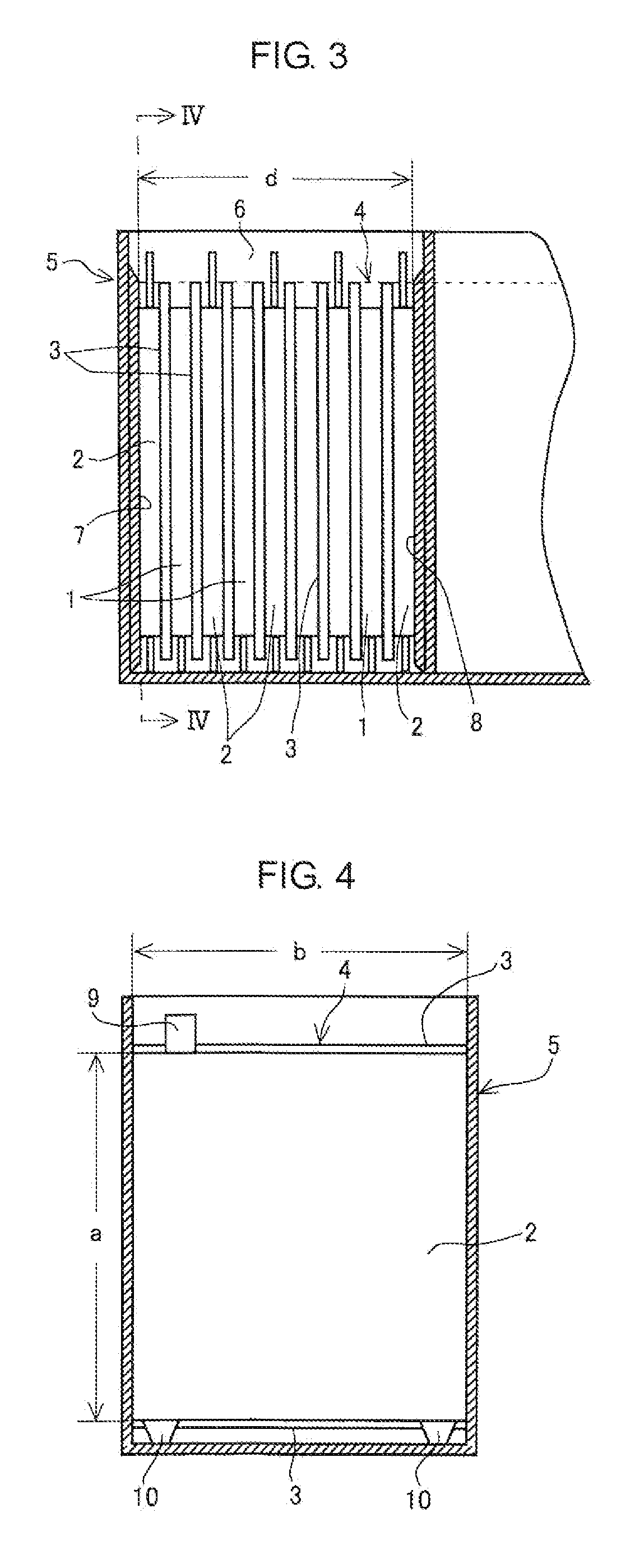

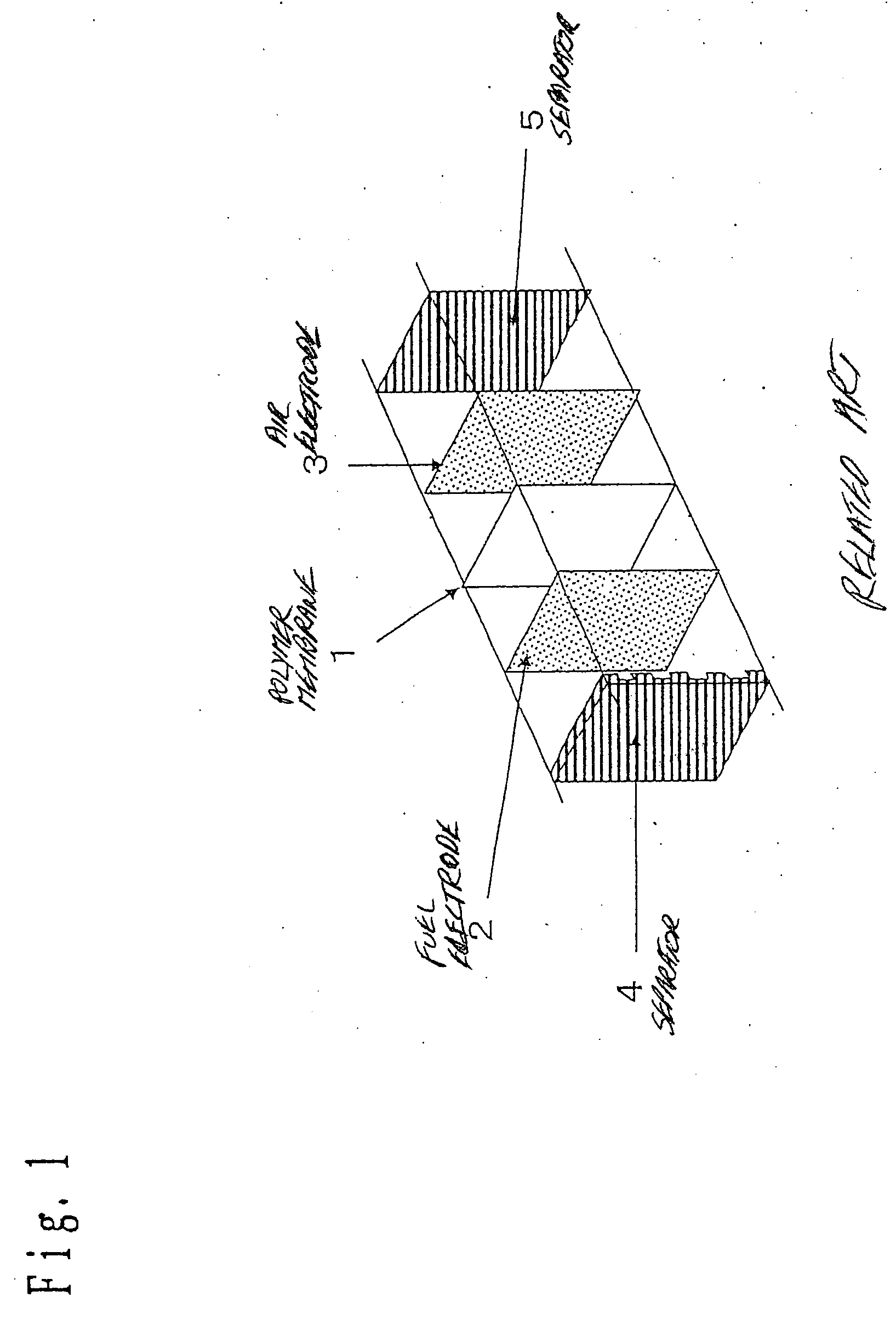

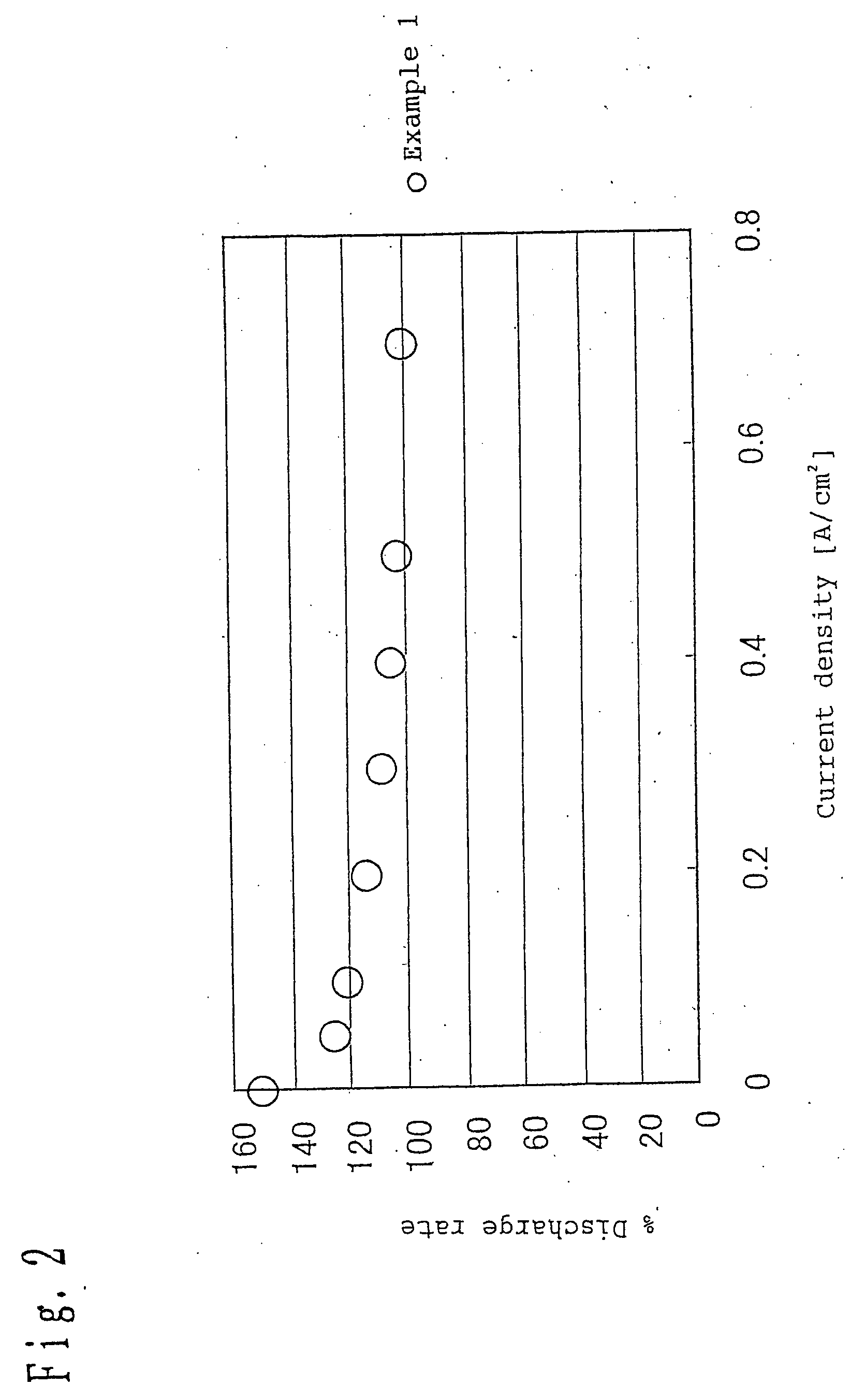

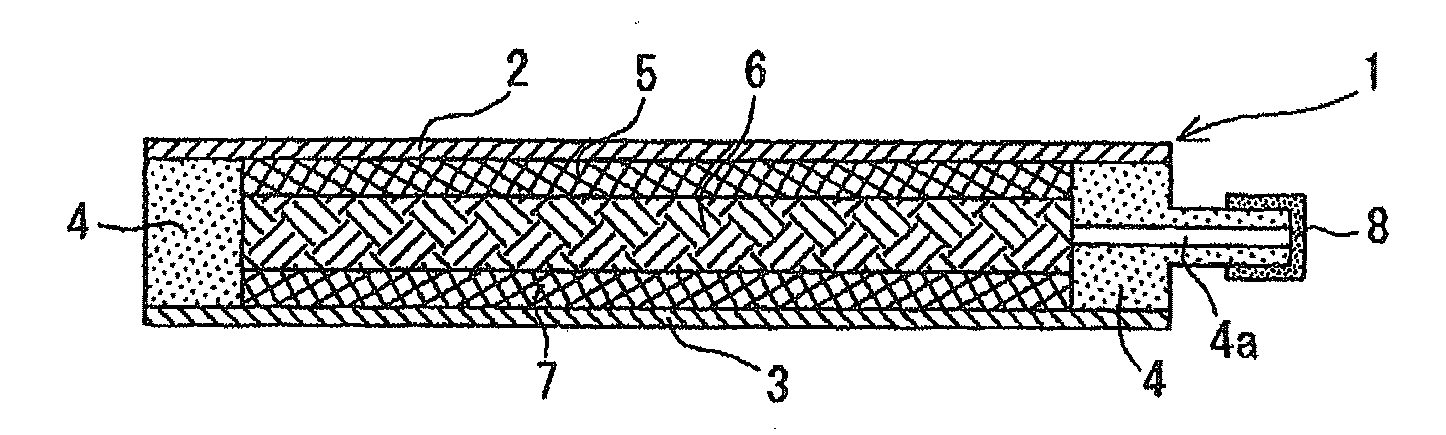

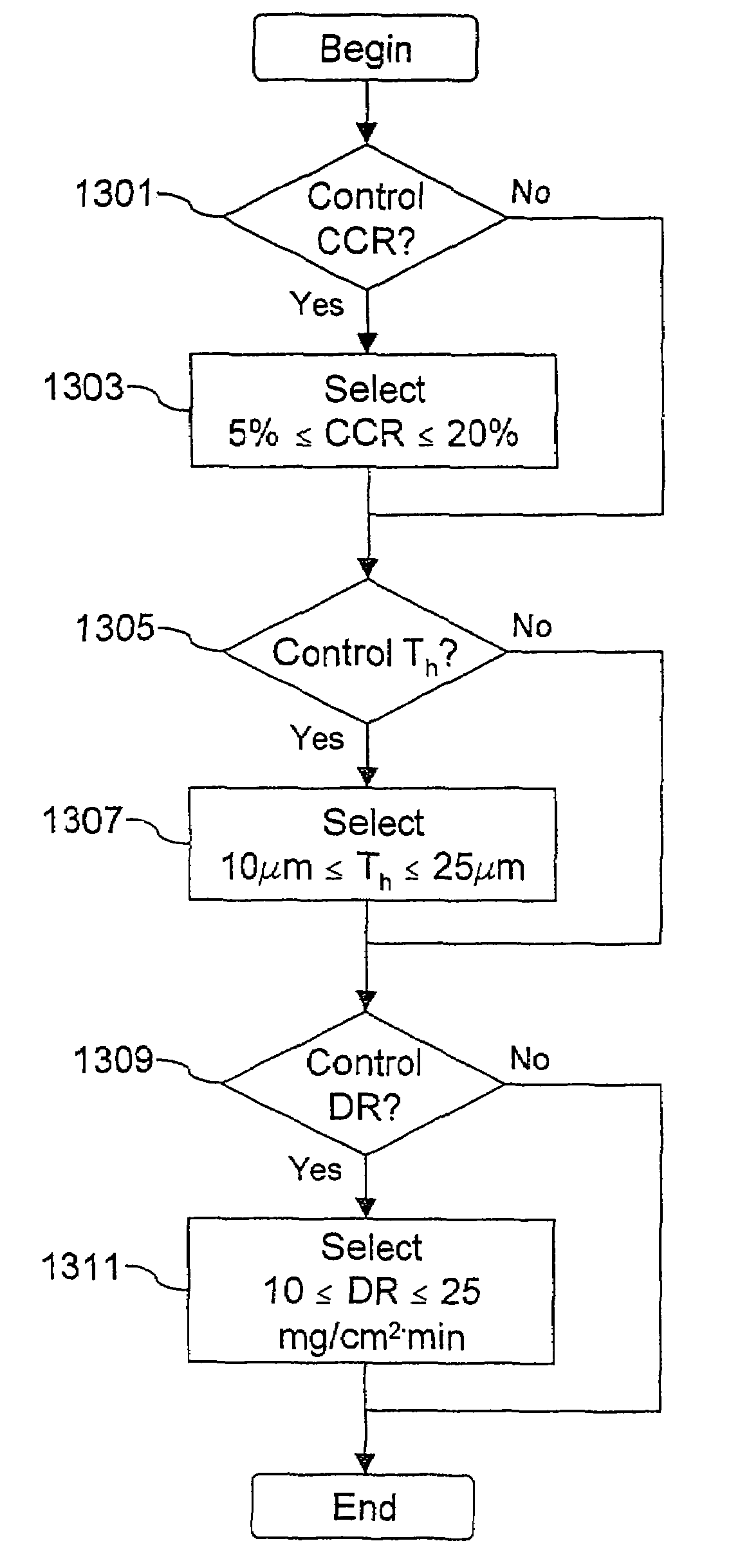

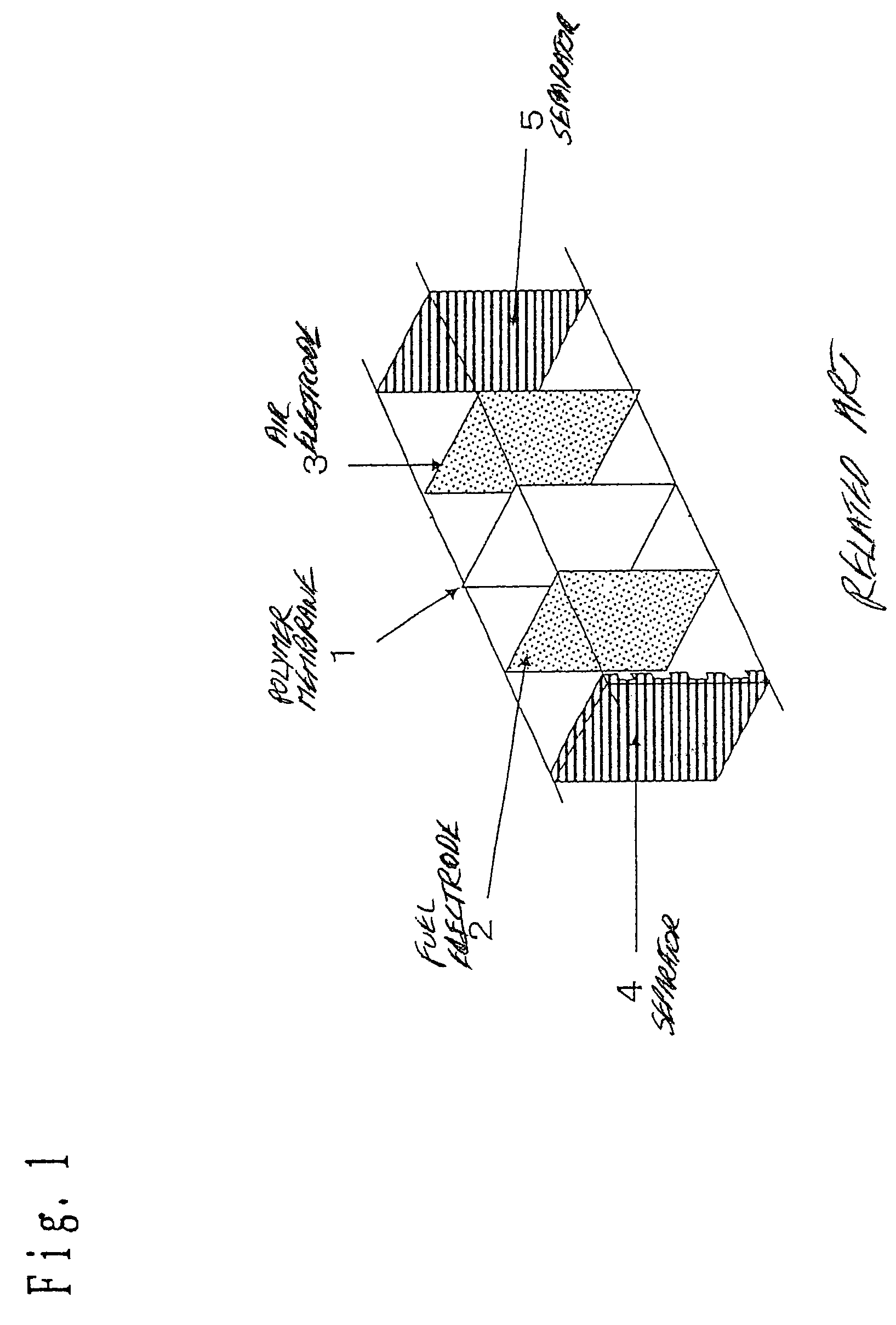

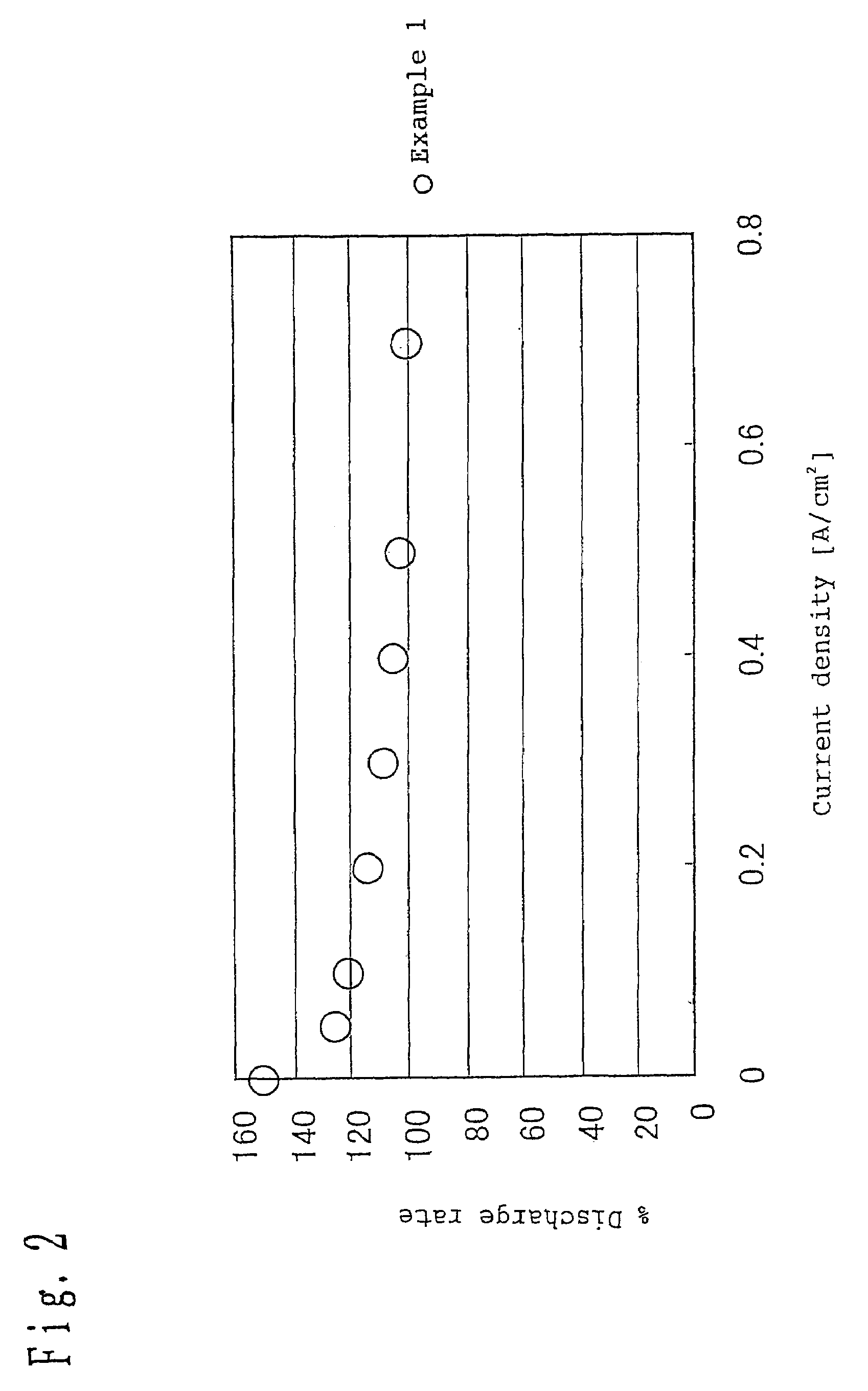

Polymer electrolyte fuel cell, fuel cell electrode, method for producing electrode catalyst layer, and method for producing polymer electrolyte fuel cell

InactiveUS20040209138A1Little and no crackingHigh volume resistivityFinal product manufactureActive material electrodesPolymer electrolytesFuel cells

A method for producing a polymer electrolyte membrane type fuel cell including a polymer electrolyte membrane, fuel and air electrodes that sandwich therebetween the polymer electrolyte membrane and that each include a gas diffusion layer and a catalyst layer provided in contact with the polymer electrolyte membrane, and separators provided in contact with the gas diffusion layers. A paste containing at least a carbon powder having a catalyst supported thereon is spread over a predetermined support, and the coated support is dried to form the catalyst layer. A cracking occupation area on the electrodes is controlled to a predetermined tolerance by controlling at least one of (1) a thickness of the catalyst layer, (2) a kind of carbon having the catalyst supported thereon, and (3) a drying rate of a solvent of the paste.

Owner:PANASONIC CORP

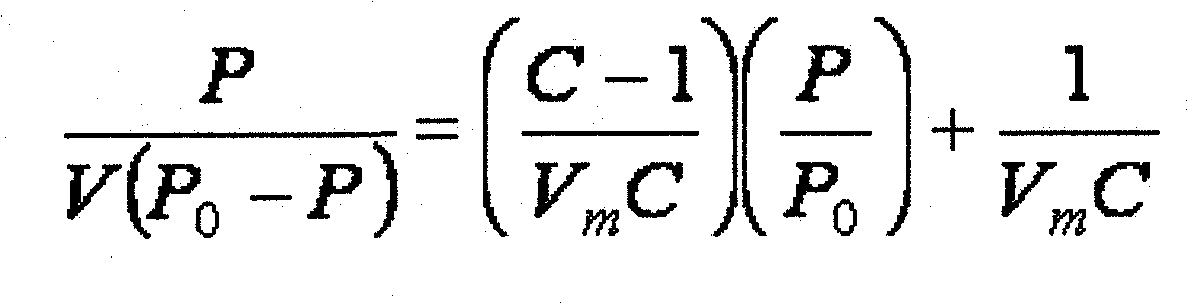

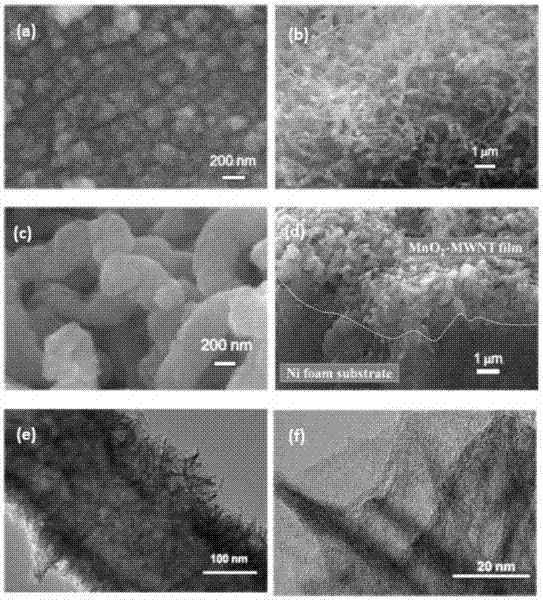

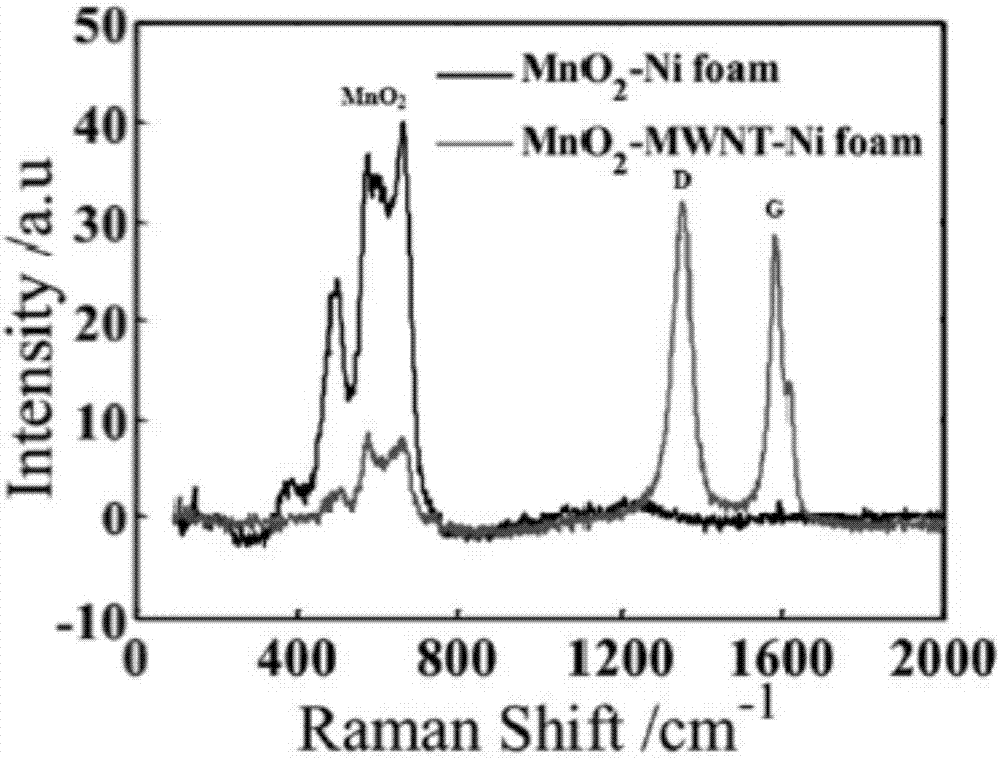

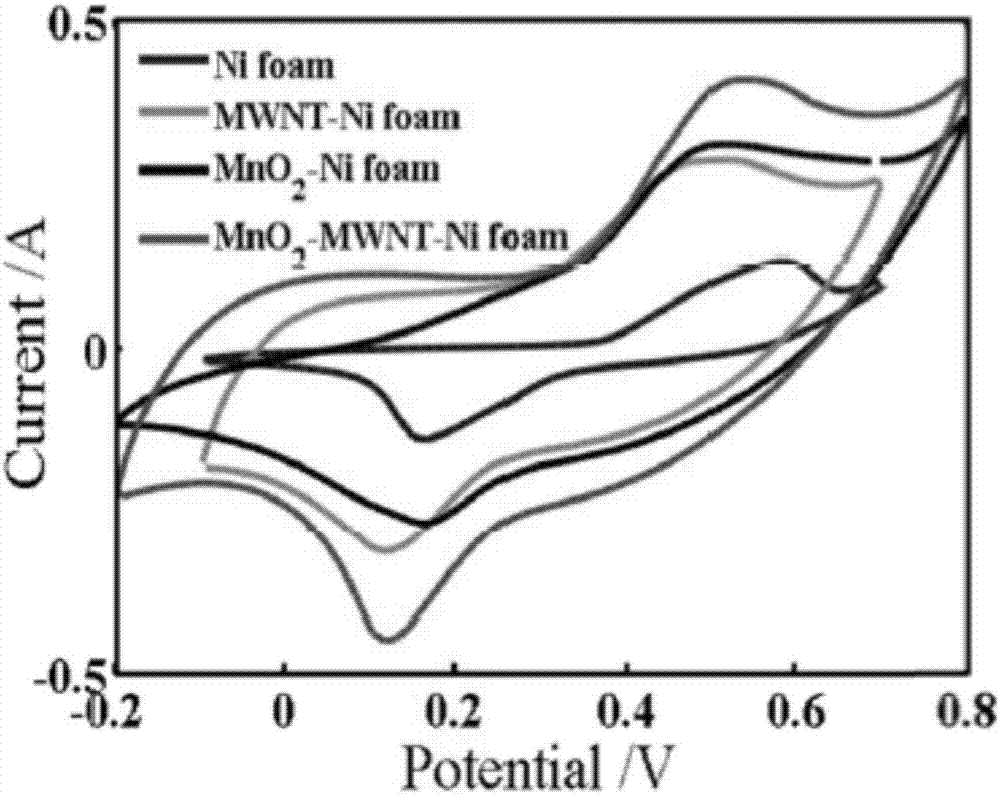

Preparation method for manganese dioxide-carbon nanotube-foamed nickel composite material capacitor electrode

InactiveCN107887177AReduce sheddingImprove mechanical propertiesMaterial nanotechnologyHybrid capacitor electrodesSupercapacitorCarbon nanotube

The invention discloses a preparation method for a manganese dioxide-carbon nanotube-foamed nickel composite material capacitor electrode, and the method comprises the following steps: (1), preparinga carbon nanotube-foamed nickel composite: selecting foamed nickel as a catalysis and substrate material, directly carrying out the growth of a carbon nanotube through a chemical vapor deposition method, and obtaining the carbon nanotube-foamed nickel composite; (2), synthesizing a manganese dioxide-carbon nanotube-foamed nickel composite material through a hydrothermal method: preparing lauryl sodium sulfate: KMnO4 solution with the concentration ratio being in the section of 0.5-5: 5-15, carrying out the dripping of the mixture into a reaction still after the full mixing, putting an MWNT-foamed nickel material in the reaction still for reaction under the temperature of 100-200 DEG C for 1-15h, and obtaining the manganese dioxide-carbon nanotube-foamed nickel composite material; (3), obtaining a manganese dioxide-carbon nanotube-foamed nickel composite material capacitor electrode after the preforming of the manganese dioxide-carbon nanotube-foamed nickel composite material. The method is advantageous in that an MnO2-MWNT-foamed nickel composite material capacitor displays the excellent structure and electrochemical and supercapacitor characteristics, and has the remarkable technological advantages.

Owner:WENZHOU UNIVERSITY

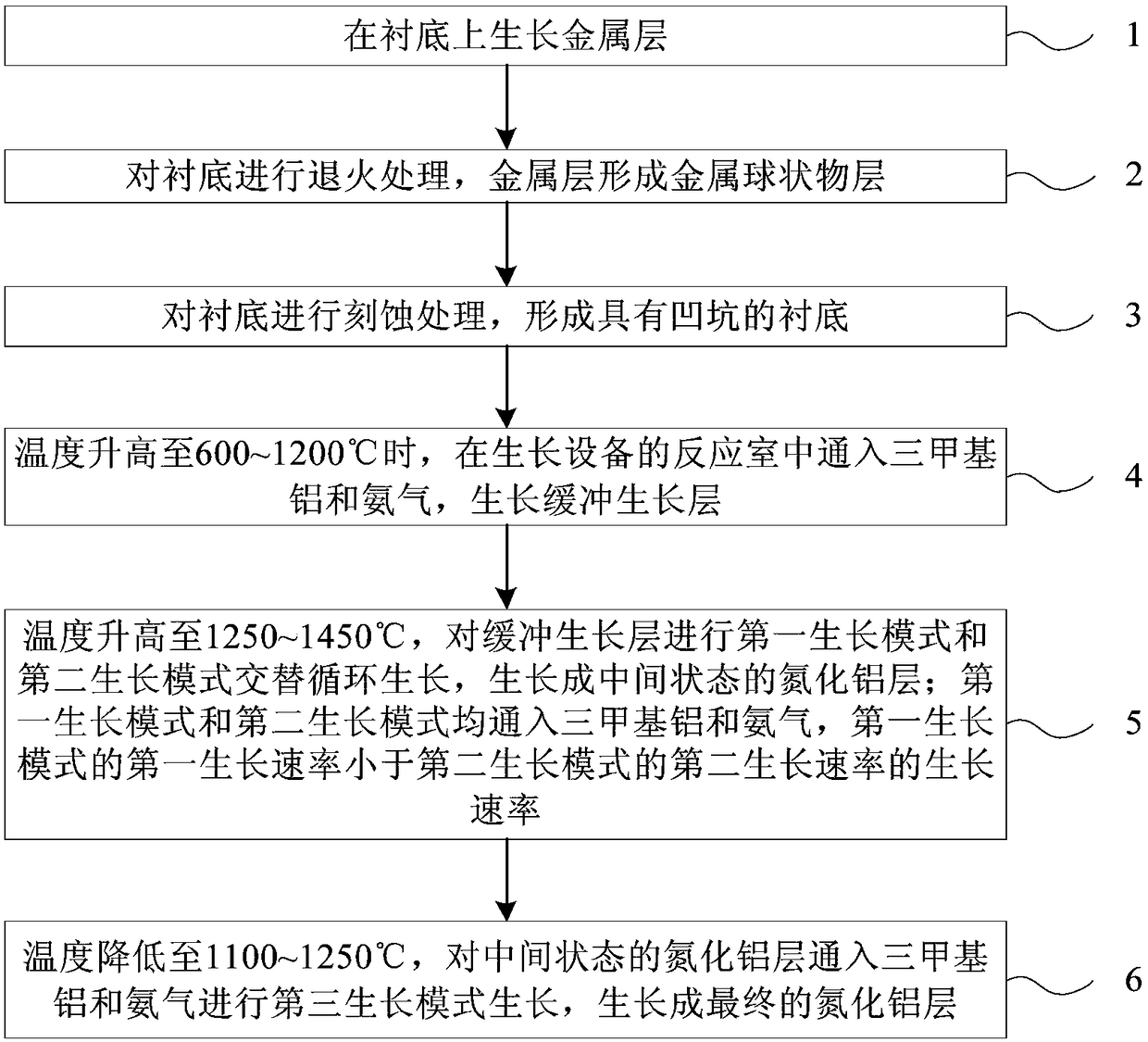

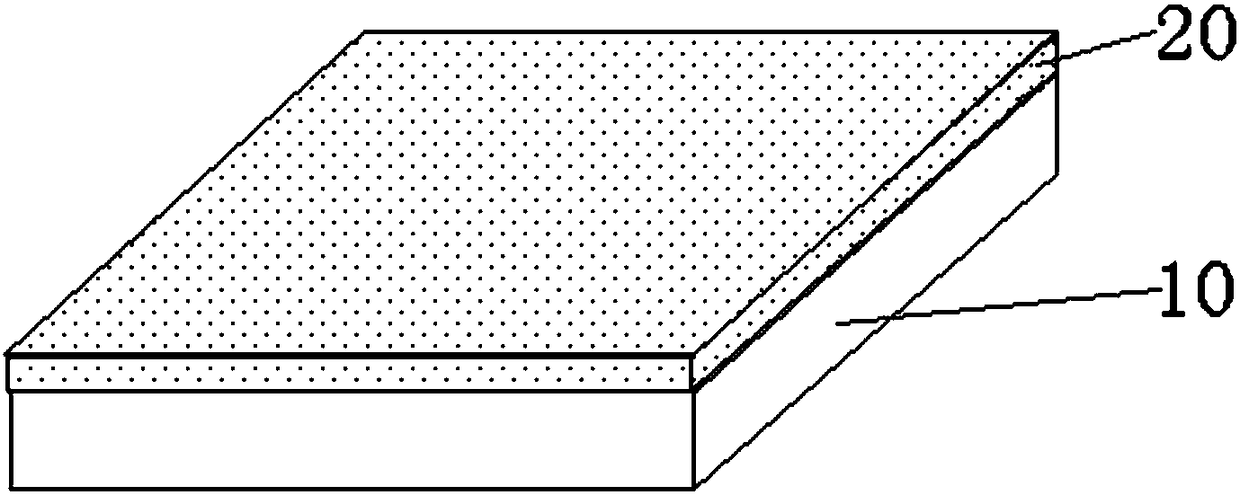

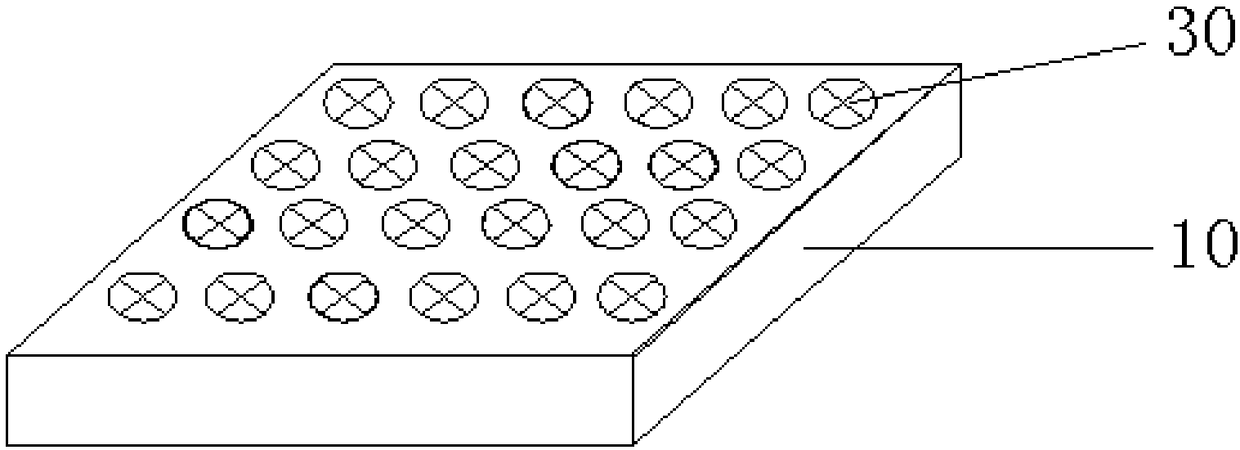

Epitaxial structure of ultraviolet LED with aluminum nitride film and growth method of aluminum nitride film

ActiveCN108257853APromote growthEasy to implementSemiconductor/solid-state device manufacturingChemical vapor deposition coatingUltravioletAmmonia gas

The present invention provides an epitaxial structure of an ultraviolet LED with an aluminum nitride film and a growth method of the aluminum nitride film. The growth method of the aluminum nitride film includes the following steps that: 1) a metal layer is grown on a substrate; 2) annealing treatment is performed on the substrate, so that the metal layer can form a metal ball-shaped object layer;3) etching treatment is performed on the substrate, so that a pitted substrate can be formed; 4) when temperature rises to 600 to 1200 DEG C, trimethylaluminum and ammonia gas are introduced into a reaction chamber, so that a buffer growth layer can be to grown; 5) when temperature rises to 1250 to 1450 DEG C, first growth mode / second growth mode alternate cyclic growth is carried out, so that anintermediate-state aluminum nitride layer can be formed; and 6) when temperature drops to 1100 to 1250 DEG C, the trimethylaluminum and ammonia are introduced into the aluminum nitride layer, so thatthird growth mode growth can be performed. The aluminum nitride film obtained by using the method has good crystal quality; and the surface cracks of the aluminum nitride film can be reduced.

Owner:MAANSHAN JASON SEMICON CO LTD

Positive electrode current collector for lead accumulator

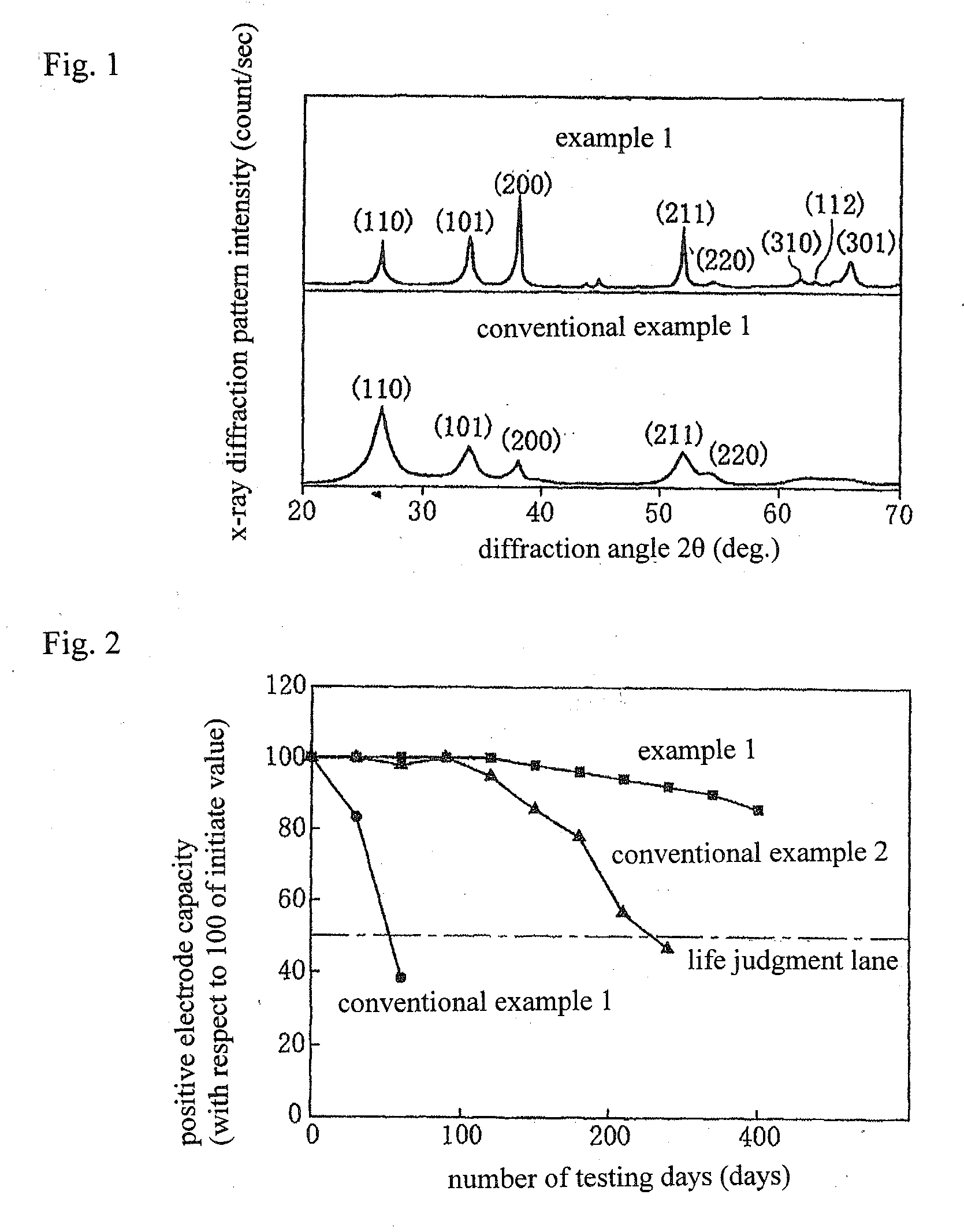

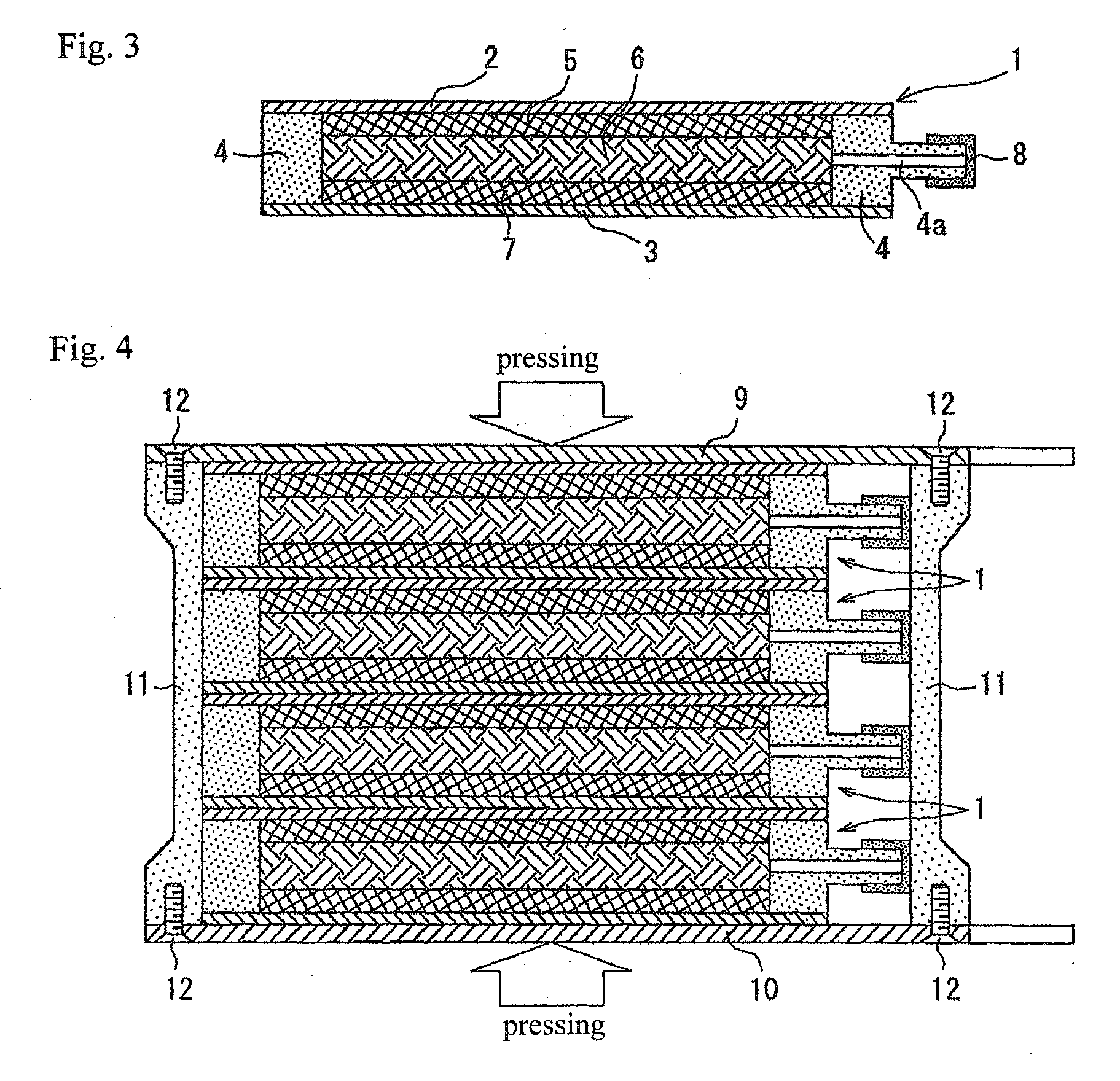

InactiveUS20090181306A1Improve conductivityImprove life performanceElectrode carriers/collectorsNon-aqueous electrolyte accumulator electrodesTin dioxideX-ray

In a positive electrode current collector for a lead-acid battery including a coating of tin dioxide formed on the surface of a current collector substrate of titanium or a titanium alloy, the half width of a peak with the maximum intensity among peaks of tin dioxide in the x-ray diffraction pattern of the positive electrode current collector for a lead-acid battery is 1° or lower.

Owner:GS YUASA INT LTD

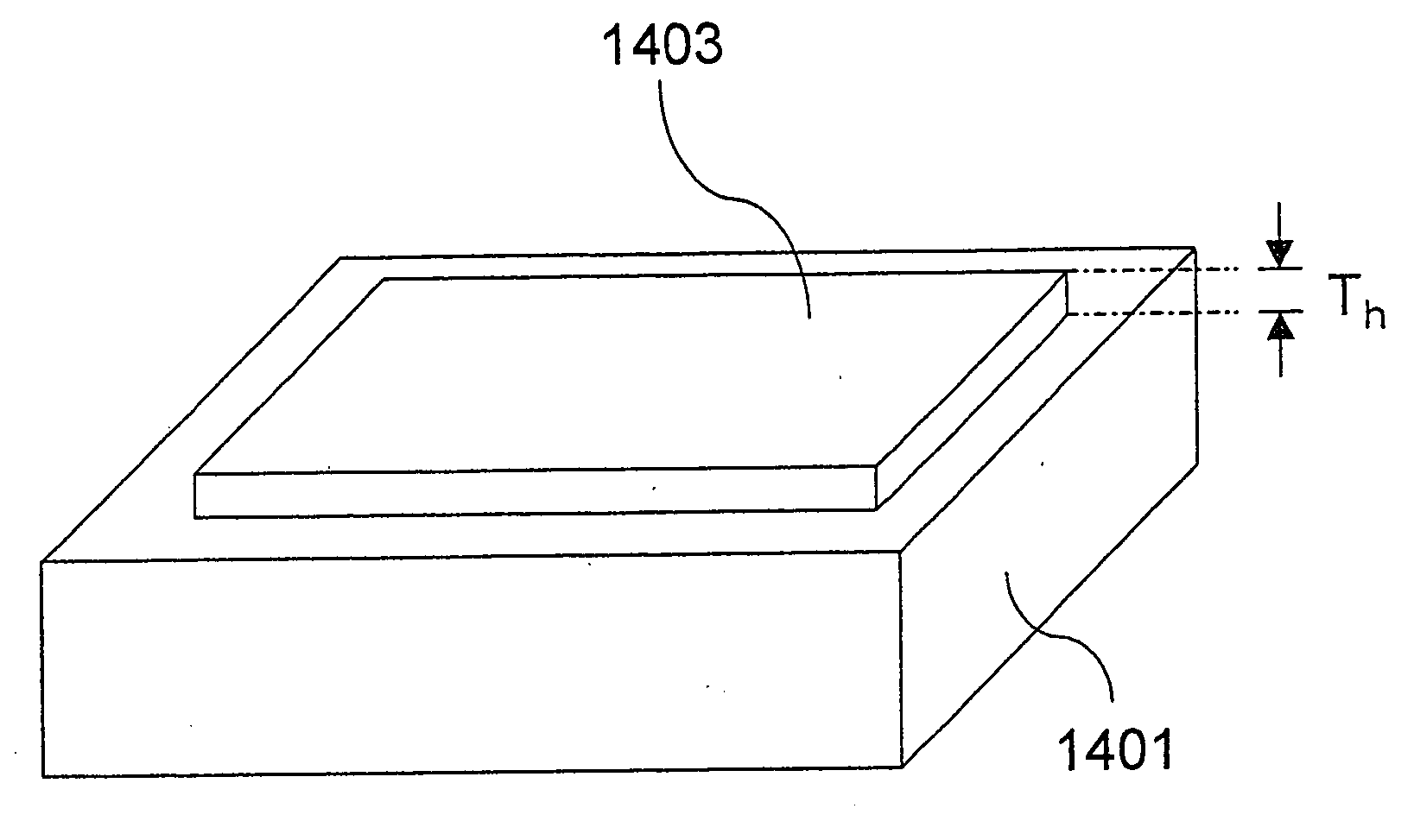

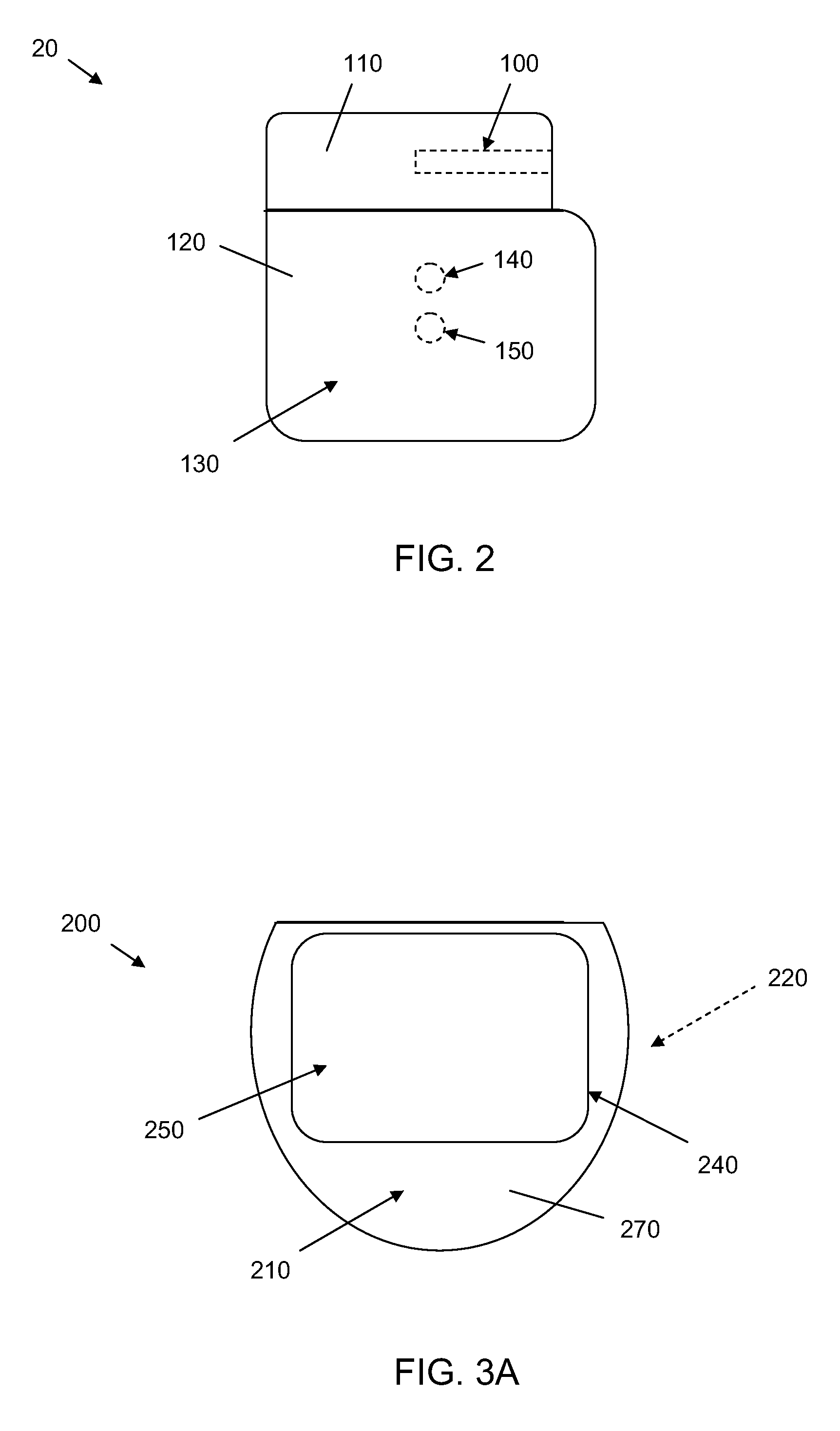

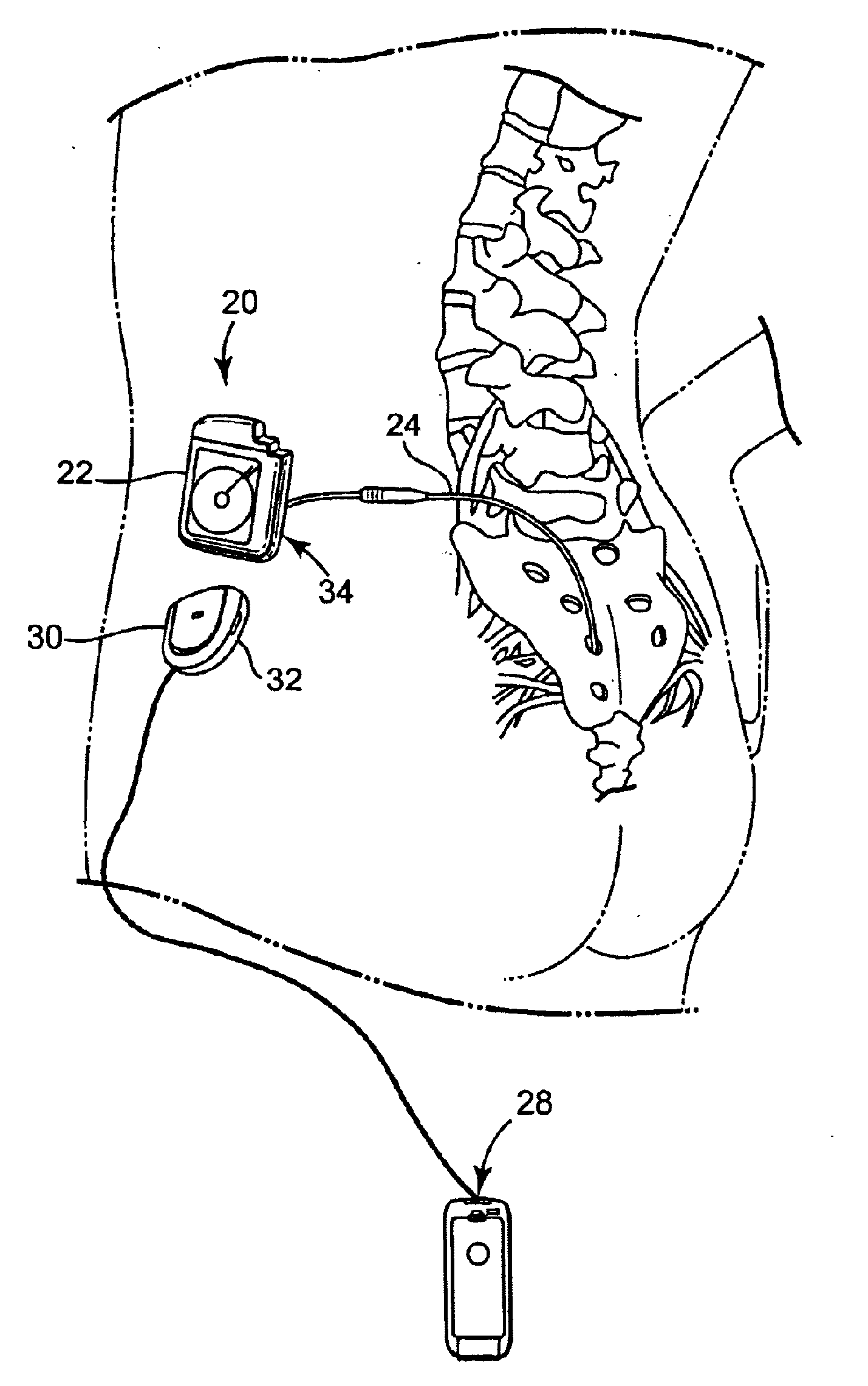

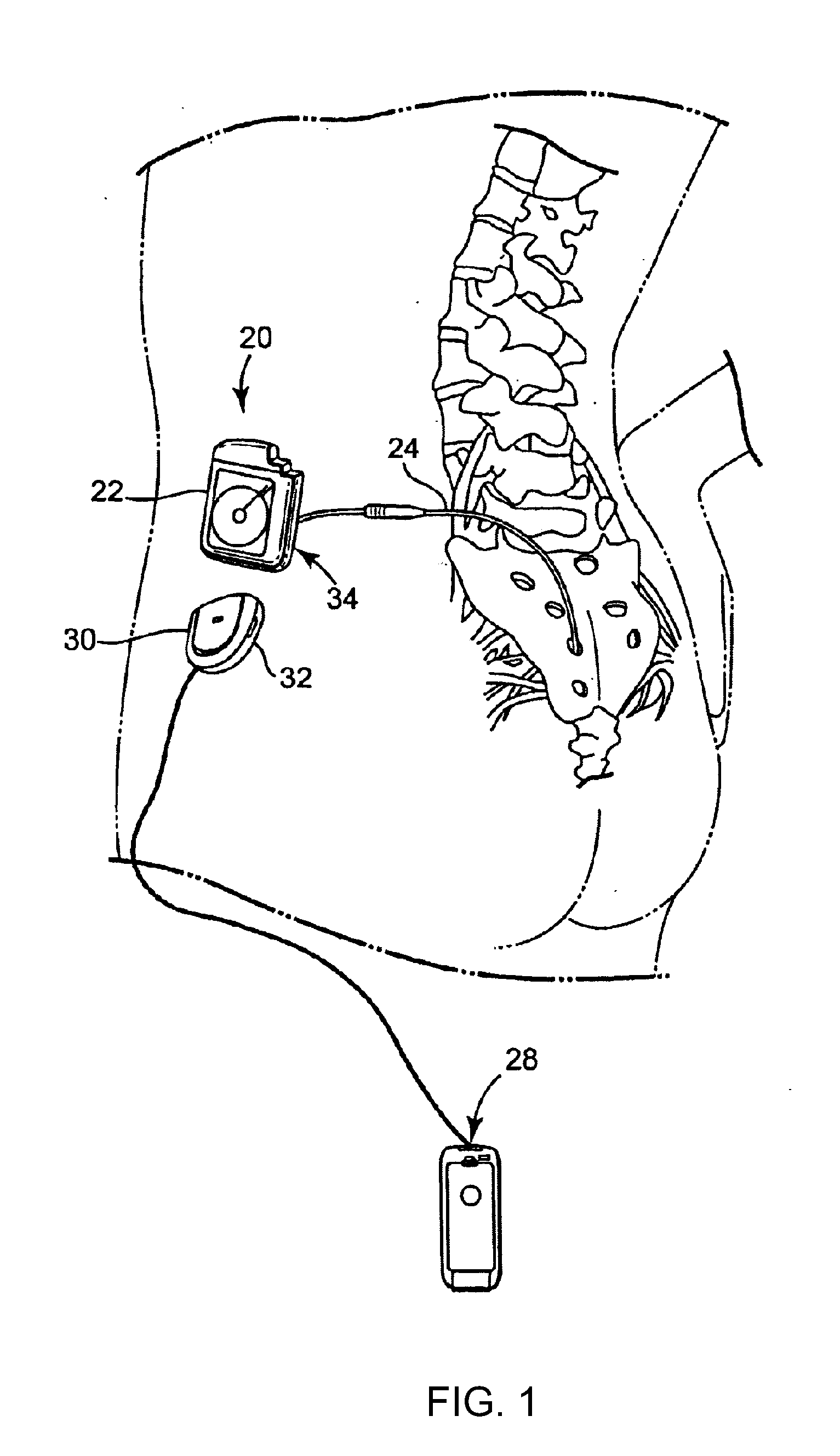

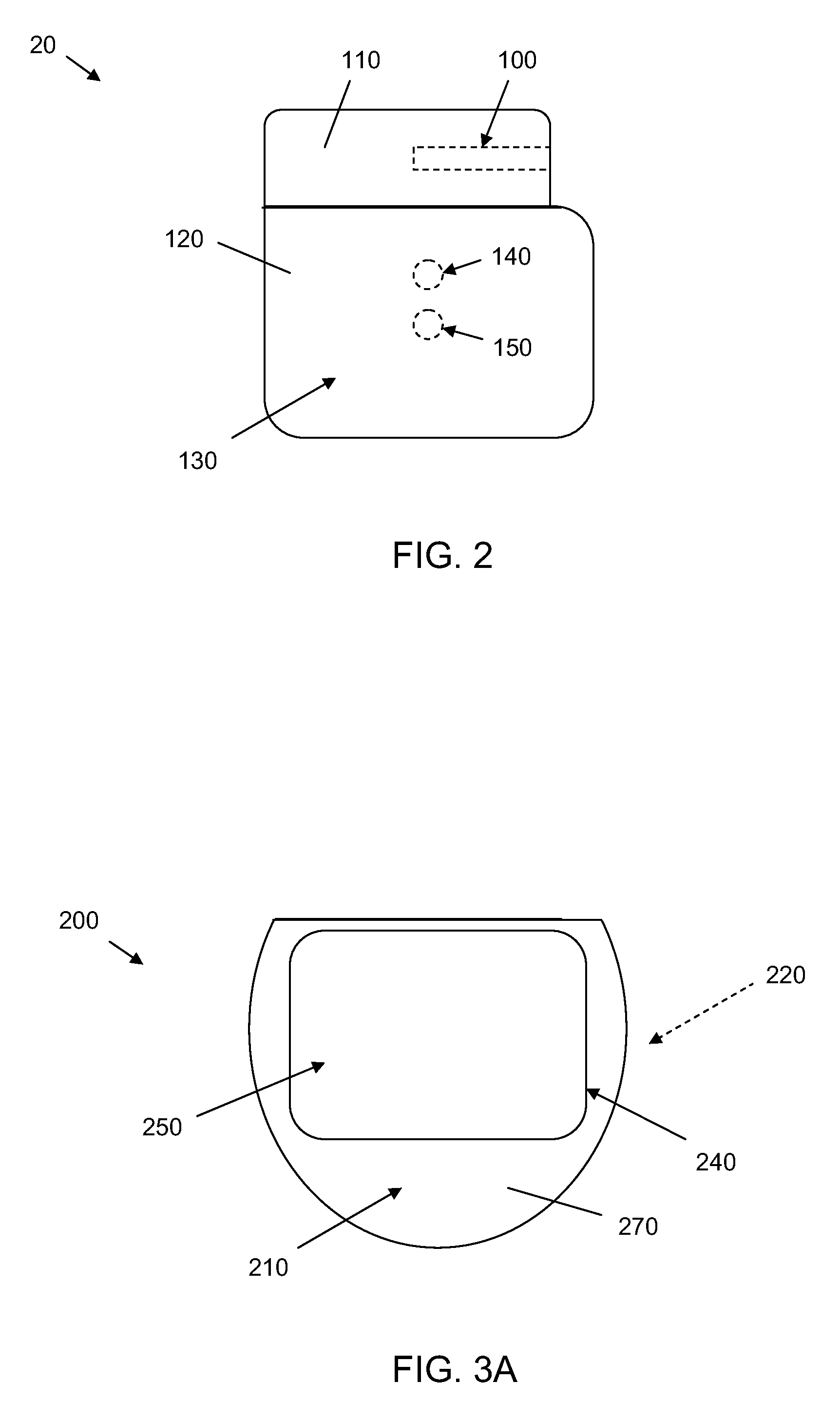

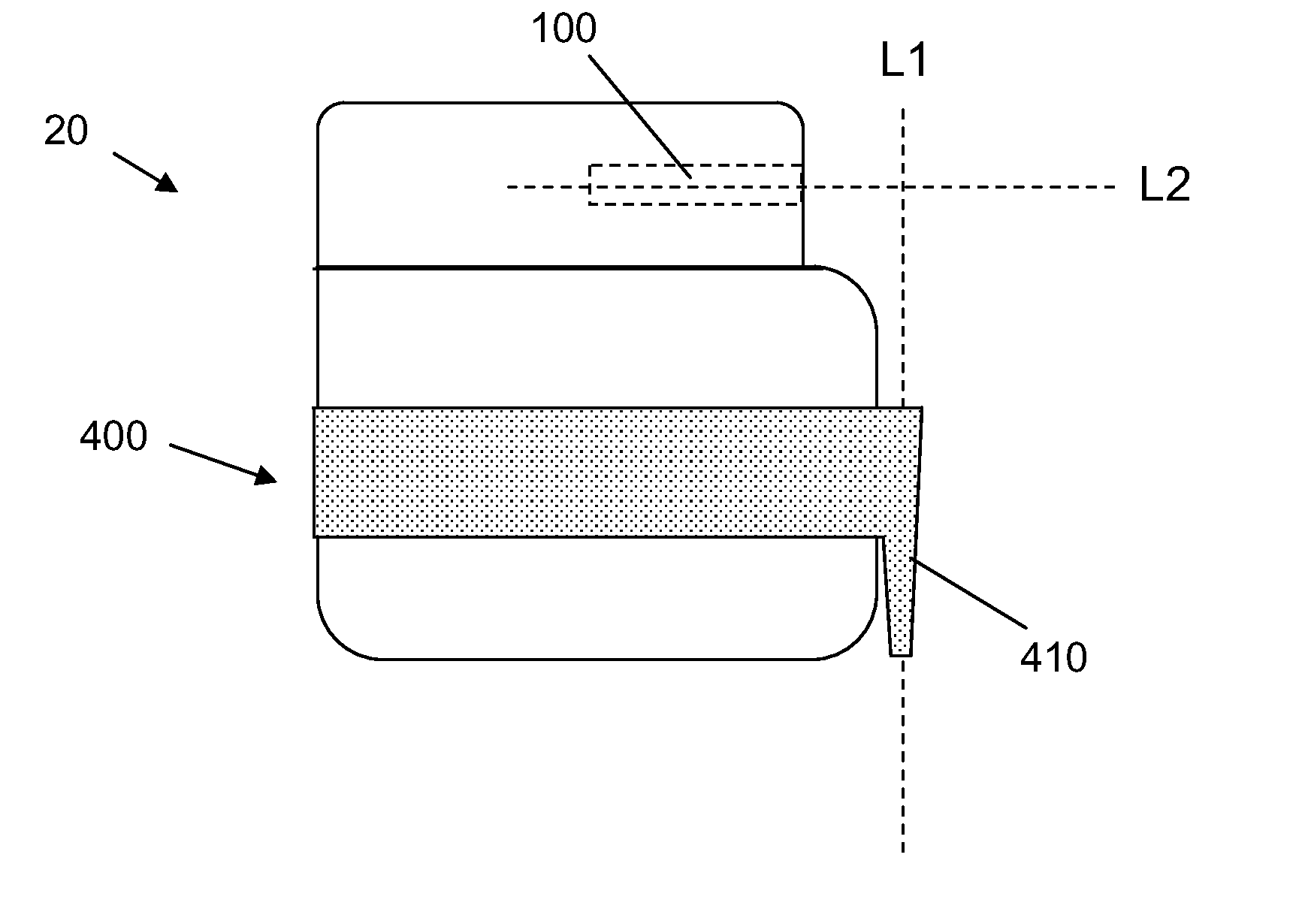

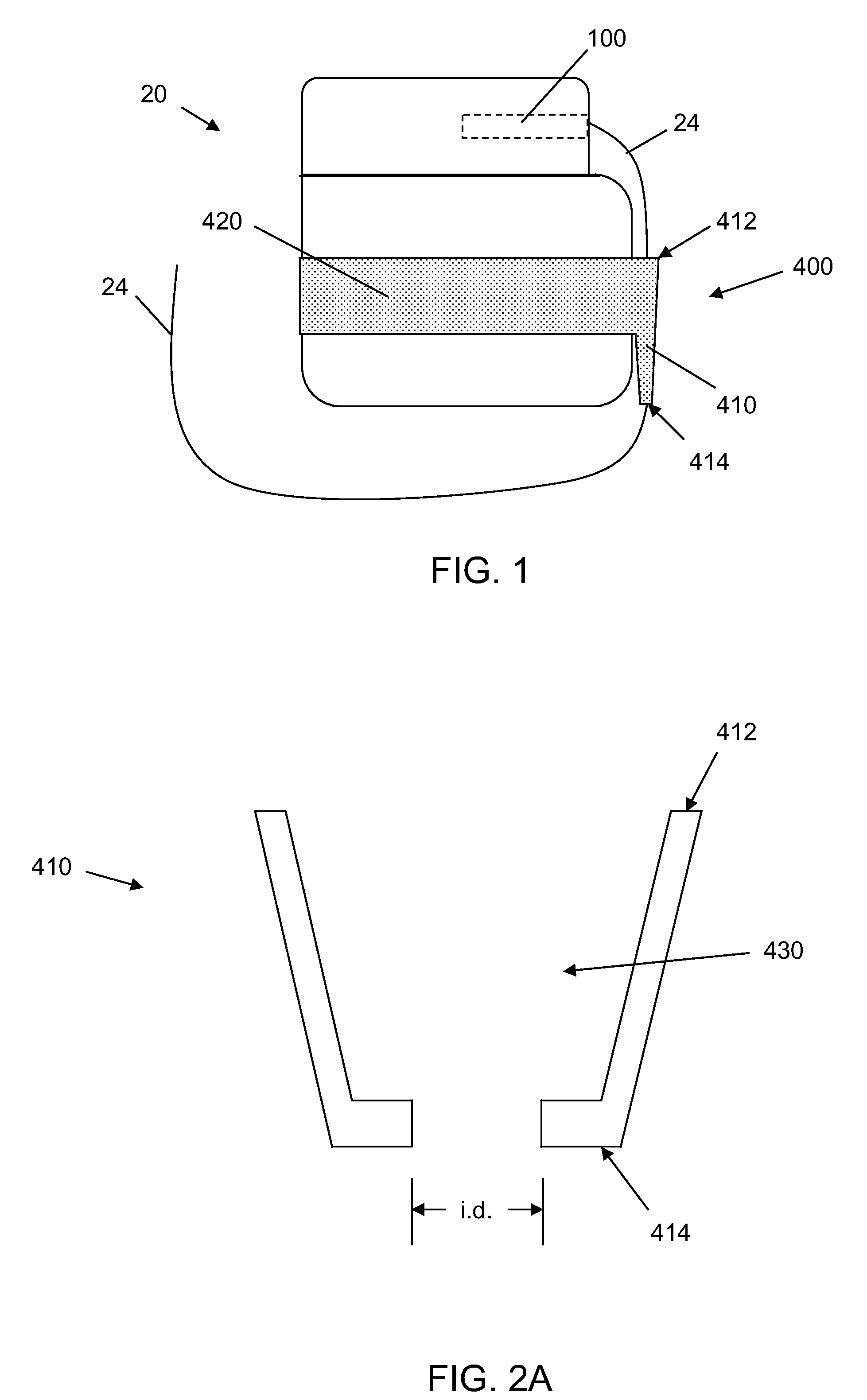

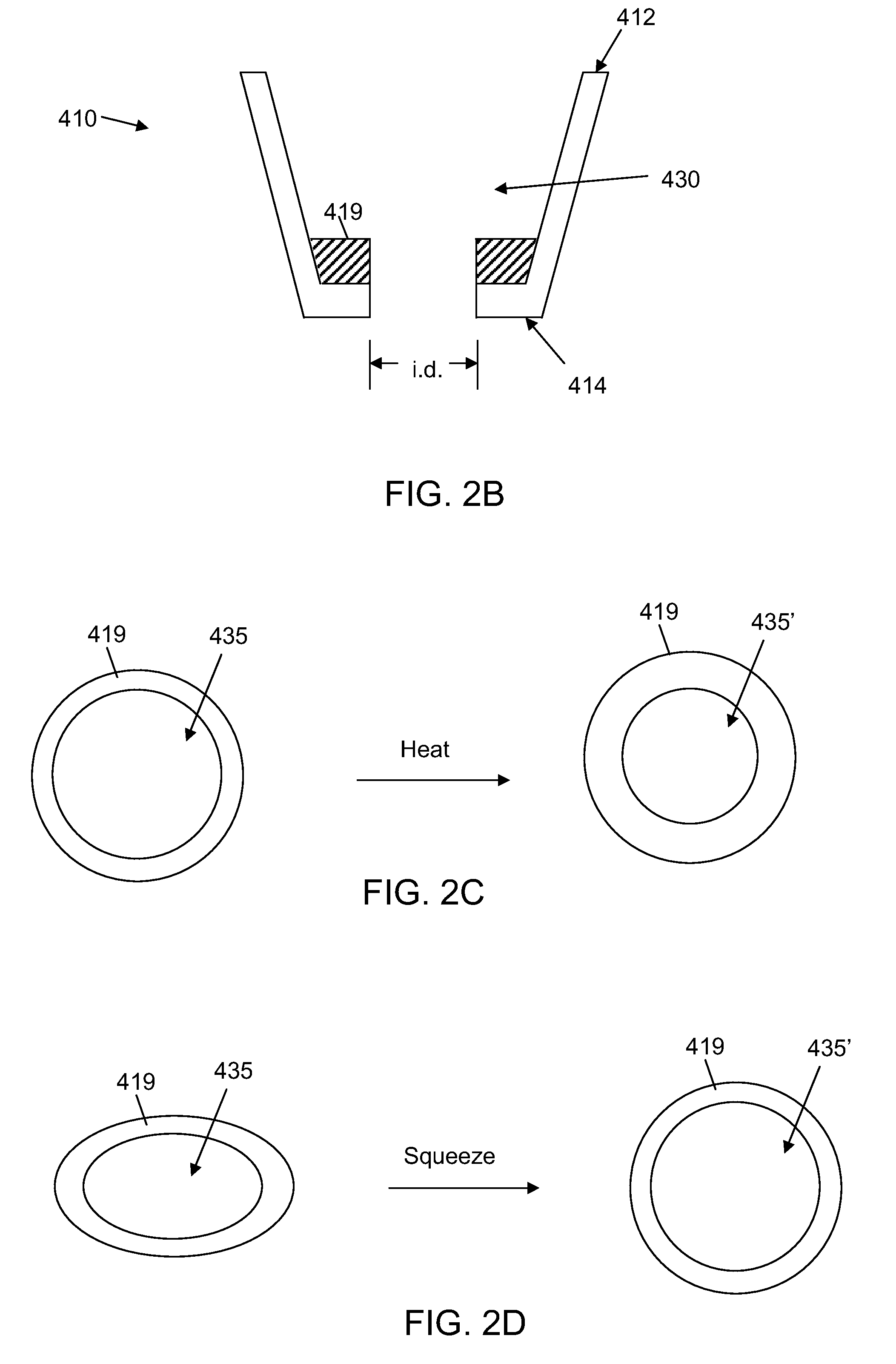

Accessory apparatus for improved recharging of implantable medical device

ActiveUS9517352B2Improve recharge efficiencySmall sizeElectrotherapyMedical deviceBiomedical engineering

An apparatus configured to be placed about an implantable medical device having a face with a geometric center offset from a center of a recharge coil of the device includes first and second opposing major exterior surfaces, and a continuous exterior side surface joining the first and second opposing major exterior surfaces. A cavity is defined between, and an opening is formed by, the first and second major surfaces and the continuous side surface. The opening is in communication with the cavity and is configured to allow the device to access the cavity. An asymmetric region, adjacent to the cavity, is formed between a portion of the first and second major surfaces and the continuous side surface. The asymmetric region is configured to shift the geometric center of the combined apparatus and device, when the device is received in the cavity, towards the center of the recharge coil.

Owner:MEDTRONIC INC

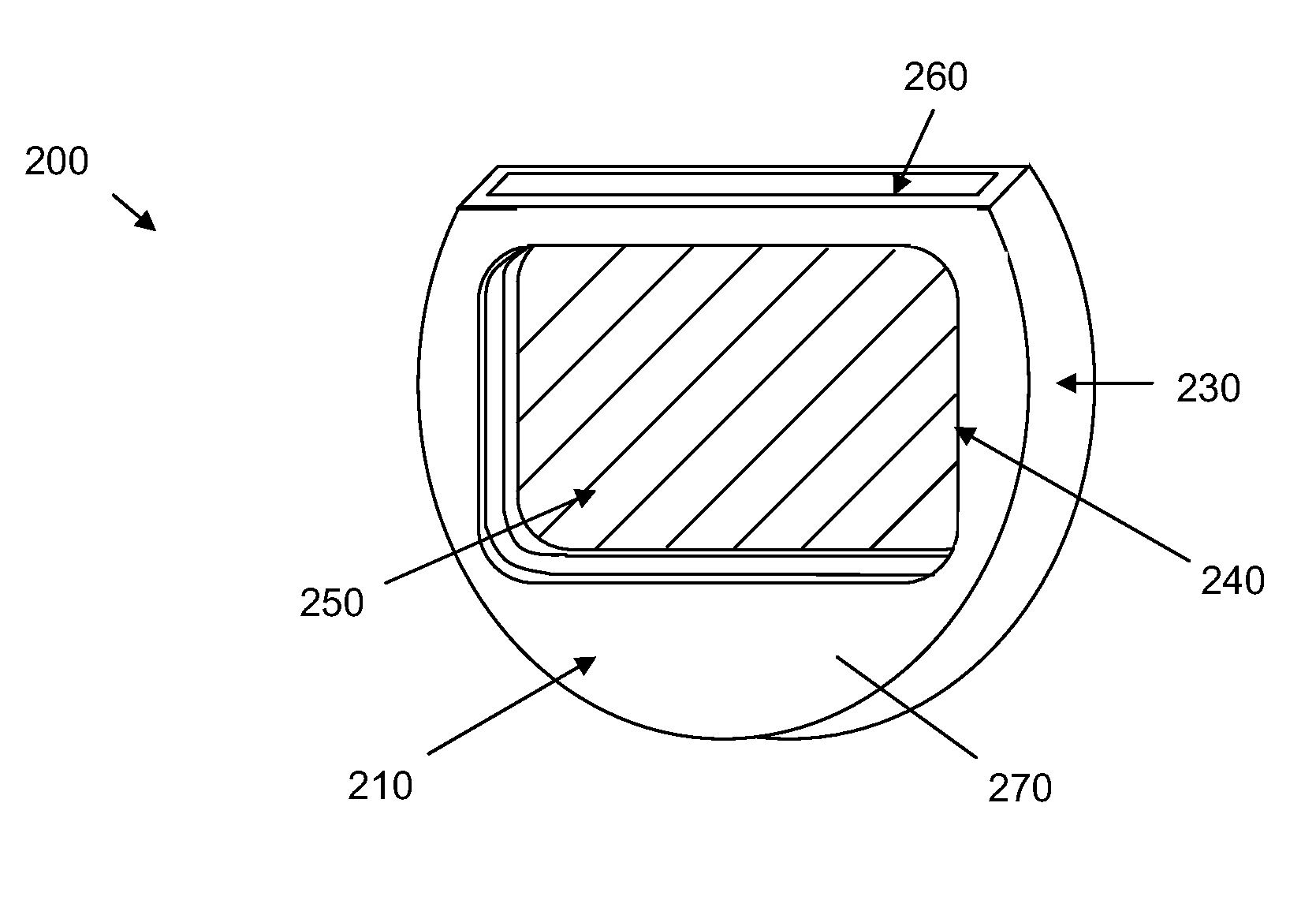

Polymer electrolyte fuel cell, fuel cell electrode, method for producing electrode catalyst layer, and method for producing polymer electrolyte fuel cell

InactiveUS7285354B2Quality improvementImprove life performanceFinal product manufactureActive material electrodesPolymer electrolytesFuel cells

A method for producing a polymer electrolyte membrane type fuel cell including a polymer electrolyte membrane, fuel and air electrodes that sandwich therebetween the polymer electrolyte membrane and that each include a gas diffusion layer and a catalyst layer provided in contact with the polymer electrolyte membrane, and separators provided in contact with the gas diffusion layers. A paste containing at least a carbon powder having a catalyst supported thereon is spread over a predetermined support, and the coated support is dried to form the catalyst layer. A cracking occupation area on the electrodes is controlled to a predetermined tolerance by controlling at least one of (1) a thickness of the catalyst layer, (2) a kind of carbon having the catalyst supported thereon, and (3) a drying rate of a solvent of the paste.

Owner:PANASONIC CORP

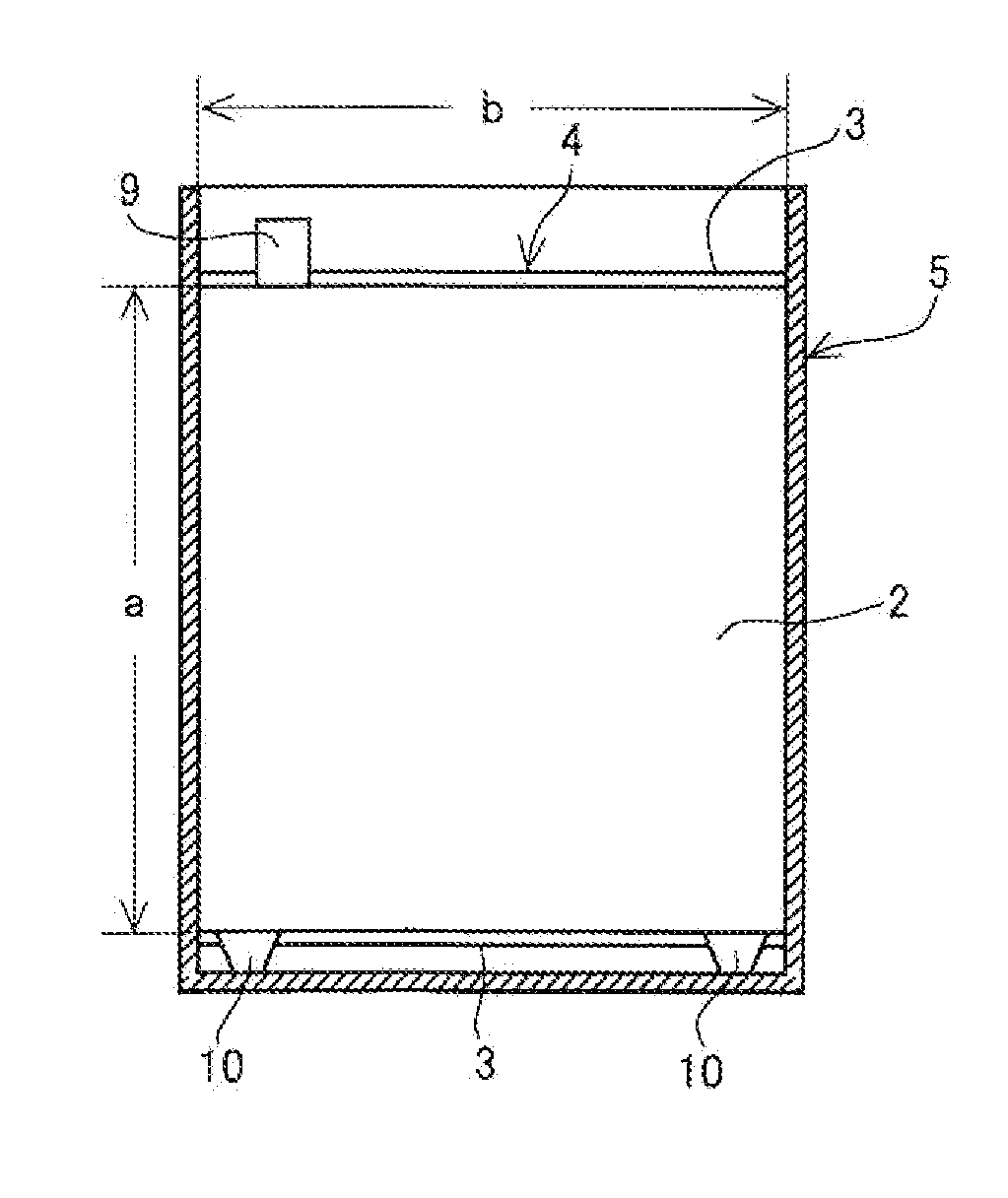

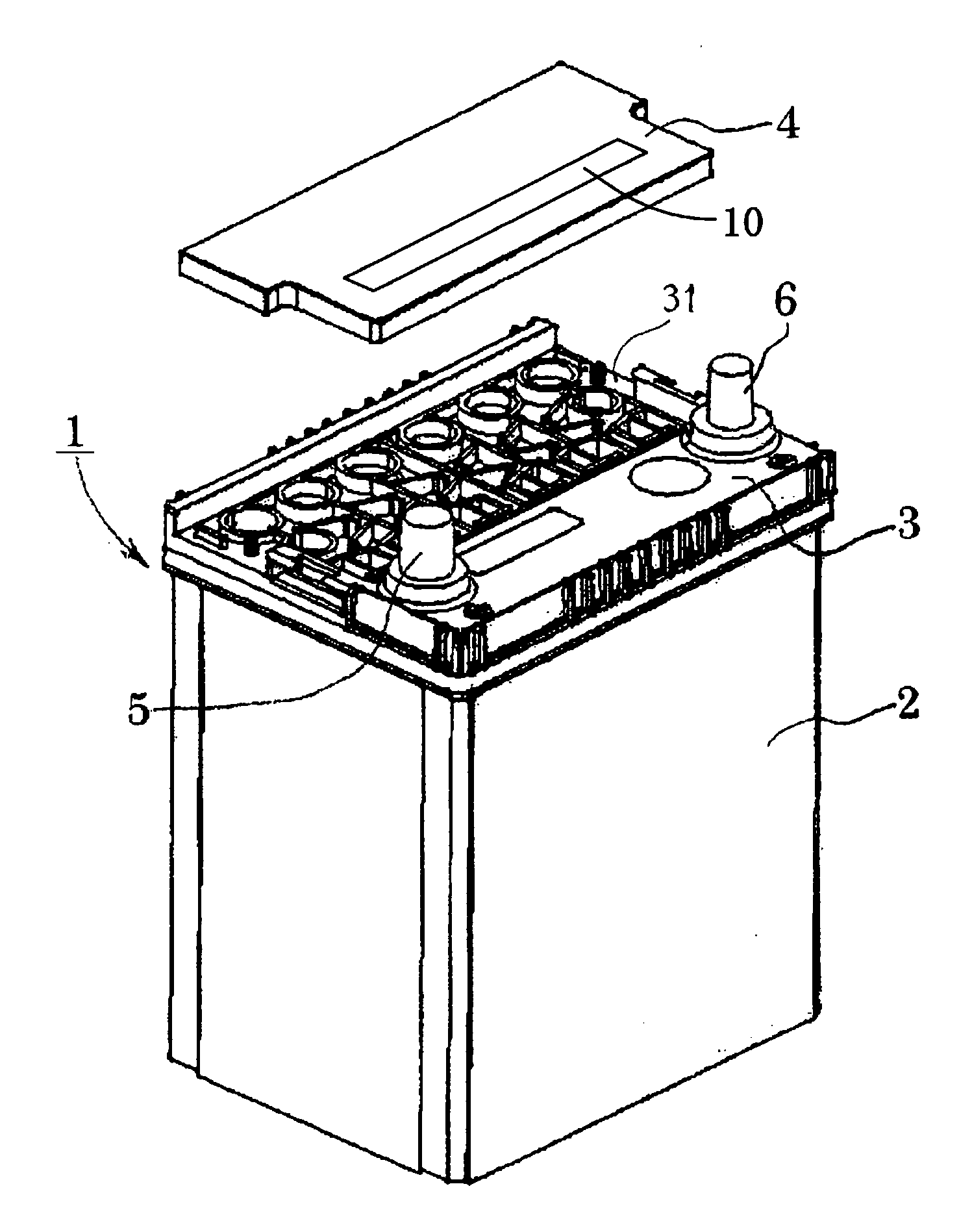

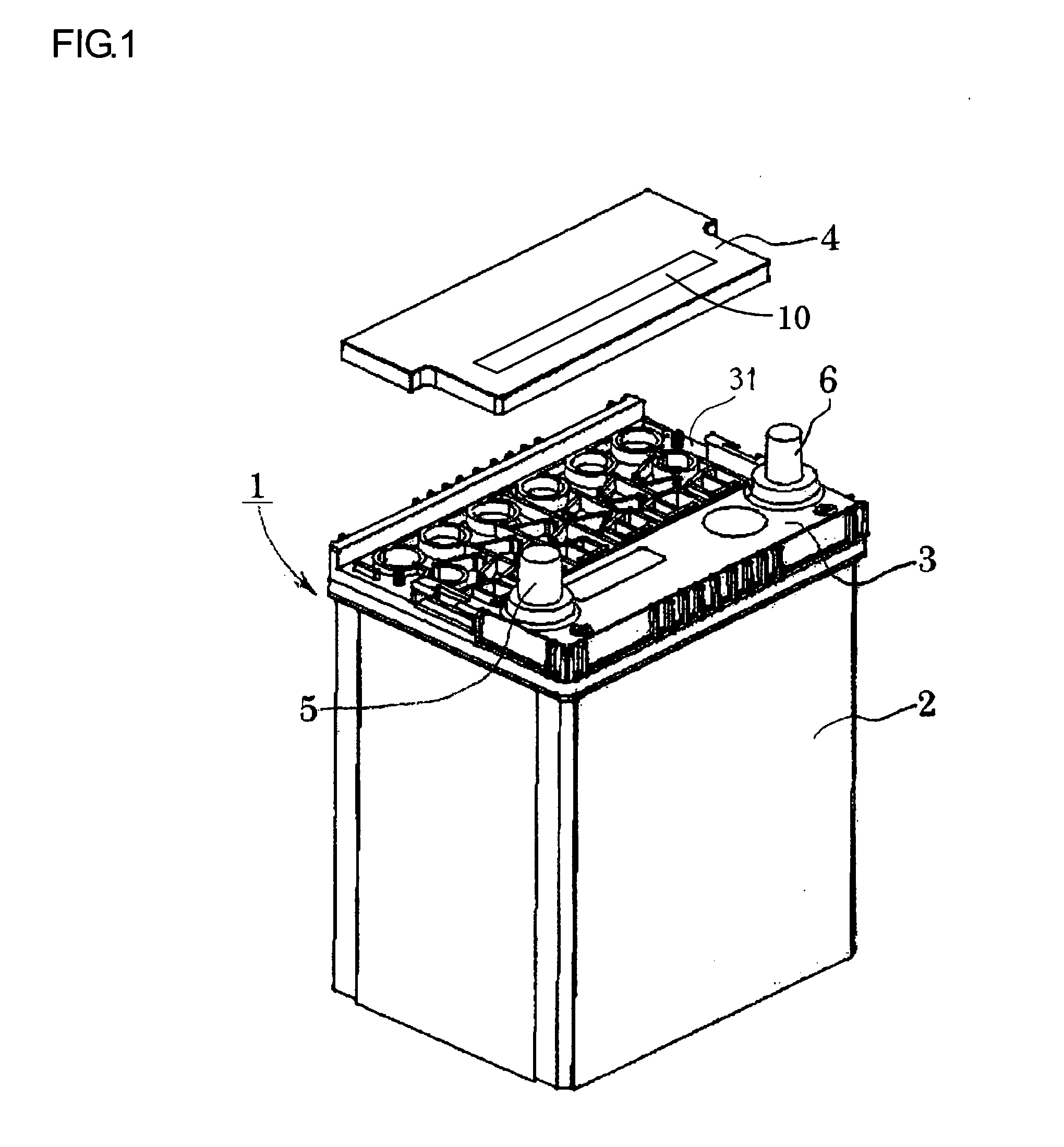

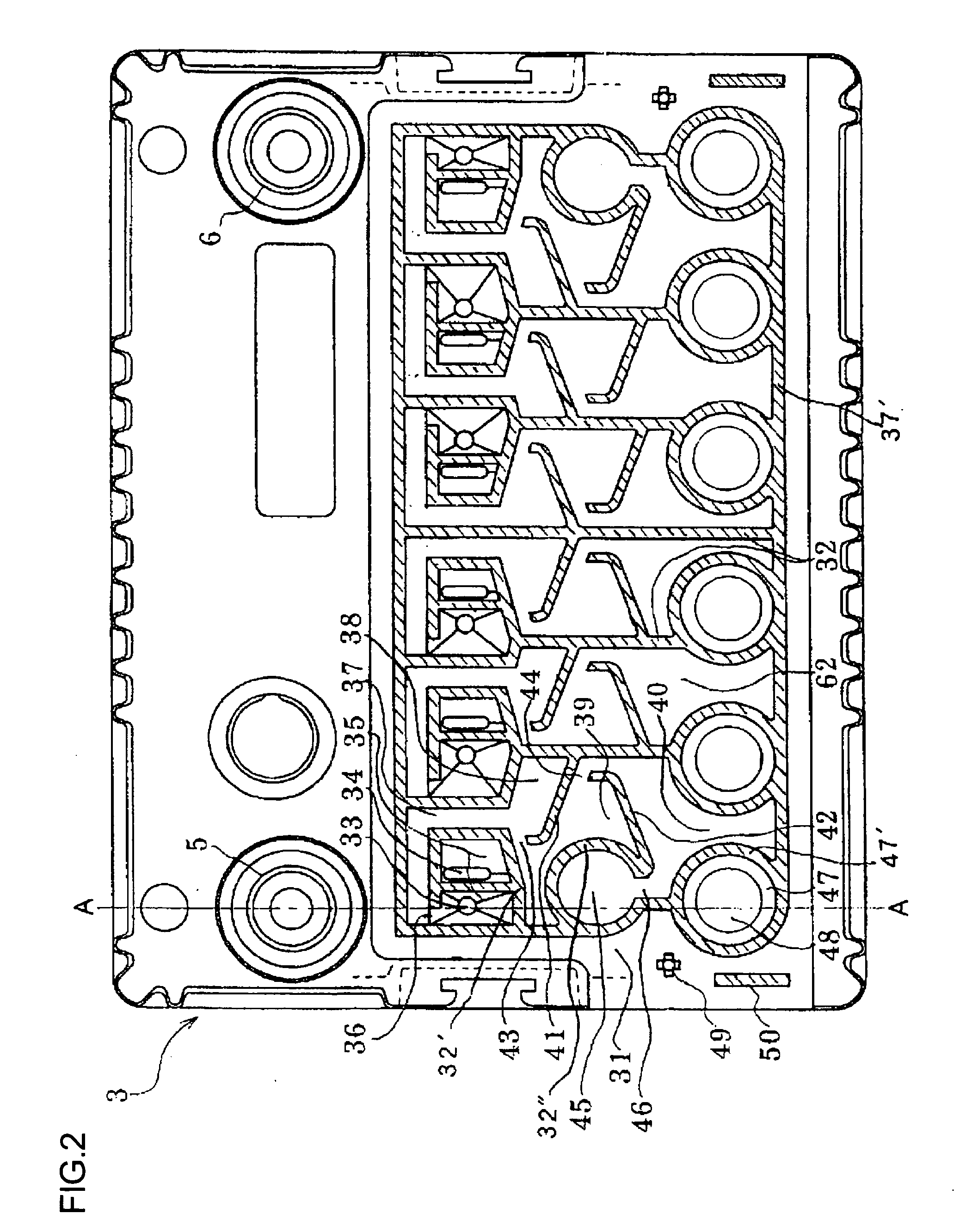

Lead acid storage battery

ActiveUS20090325040A1Improve life performanceUniform heightSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsEngineeringMoisture

A lead acid storage battery according to the present invention comprises a battery container for housing a plurality of cells, a middle lid for covering the battery container, and an upper lid for covering the middle lid, wherein, on the upper surface of the middle lid, a gas discharging port for discharging the gas generated inside of the cell and an electrolyte recirculating port for recirculating the moisture to be discharged along with the gas within the cell are formed as corresponding to each cell. A plurality of exhaust chambers separated by an exhaust chamber partition are formed in a space surrounded by the middle lid and the upper lid, and a mechanism for collectively exhausting the gas discharged from the gas discharging port to the outside of the battery by interconnecting the plurality of exhaust chambers is comprised.

Owner:GS YUASA INT LTD

lead battery

InactiveCN102265448AImprove charge acceptanceSuppress coarseningCell seperators/membranes/diaphragms/spacersFinal product manufacturePartial chargeElectrical battery

In a liquid lead-acid storage battery that performs short-term intermittent charging and high-efficiency discharge to the load in a partially charged state, a positive electrode plate with a utilization rate of the positive electrode active material set in the range of 50 to 65% and carbon added to the negative electrode active material are used. A negative electrode plate that improves charge acceptance performance and life performance by using a high-quality conductive material and bisphenol-aminobenzenesulfonic acid-formaldehyde condensate, and uses a non-woven fabric formed of a material selected from glass, pulp, and polyolefin as a separator. The separator on the surface facing the negative electrode plate can further improve the charge acceptance performance and life characteristics at PSOC than conventional batteries.

Owner:SHIN KOBE ELECTRIC MASCH CO LTD

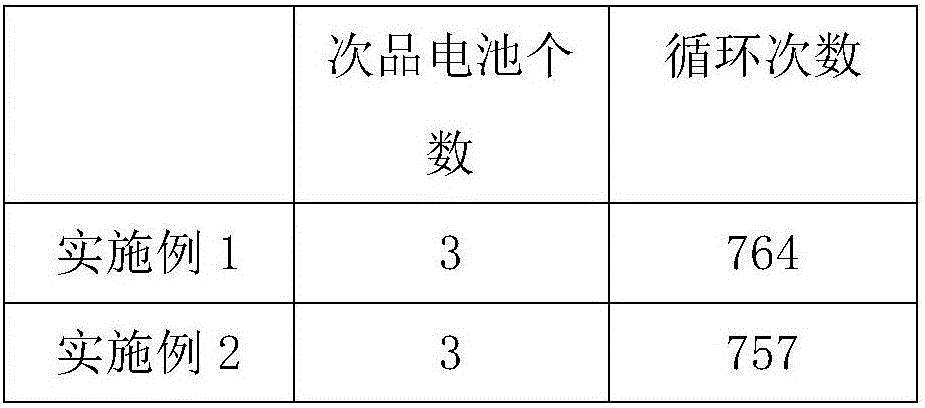

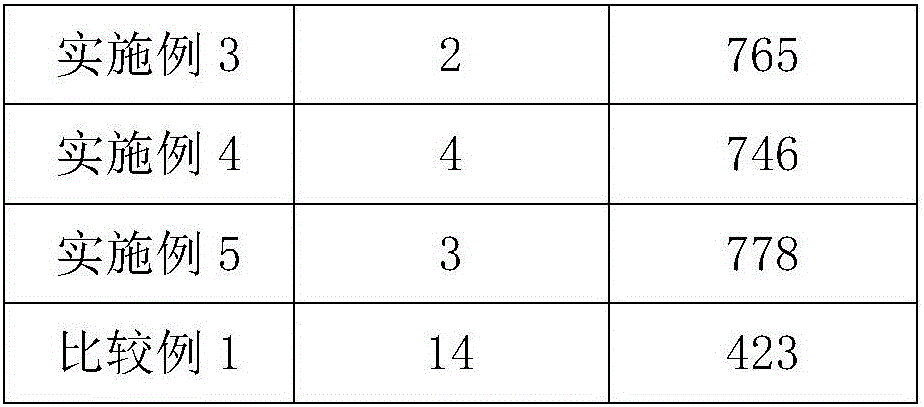

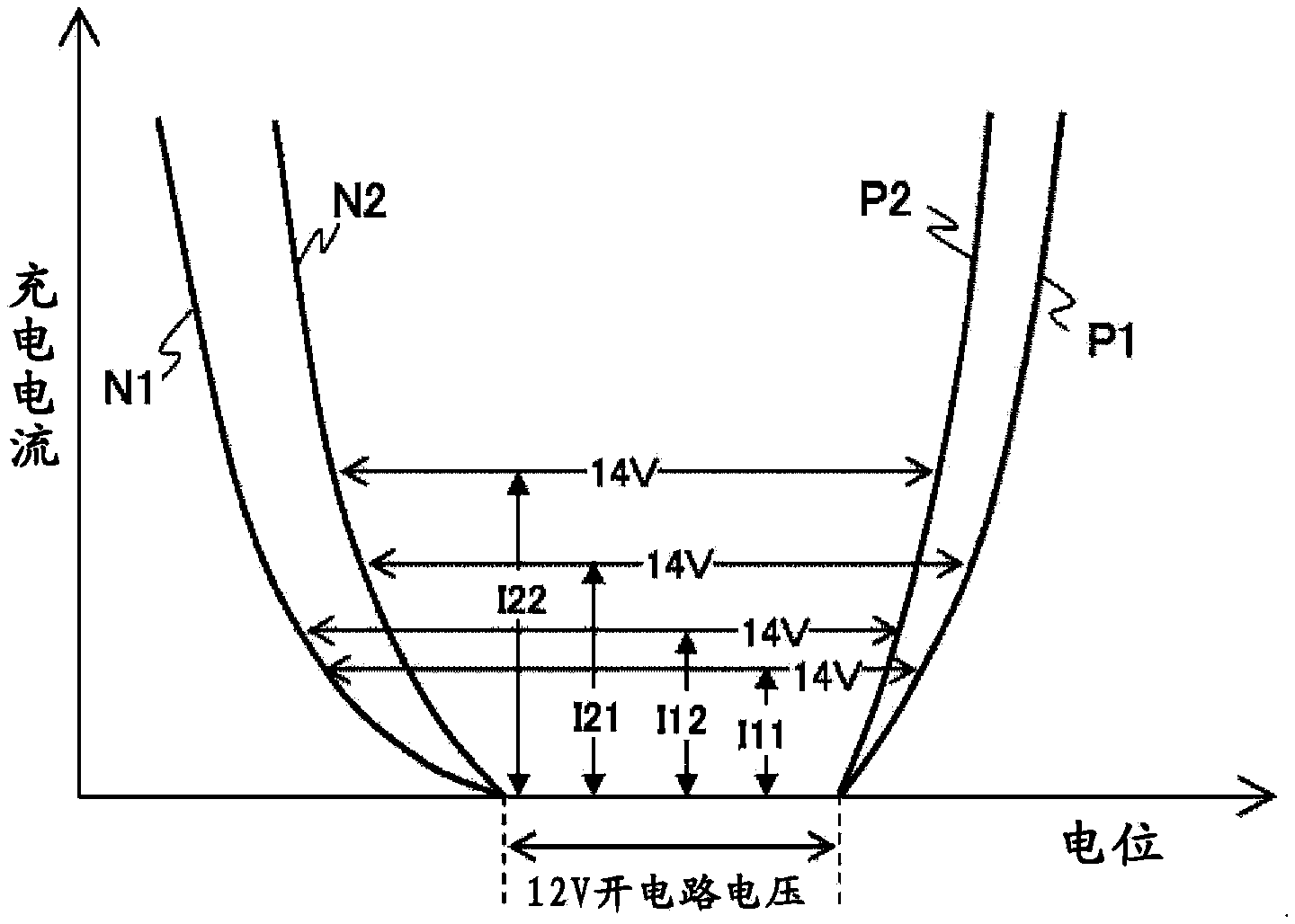

Intelligent formation method of lithium ion battery

InactiveCN107528091AImprove performanceImprove life performanceFinal product manufactureElectrolyte accumulators manufactureGeneration ratePower flow

The invention provides an intelligent formation method of a lithium ion battery. The parameters of the battery are detected in a formation process, relevant parameters of current and voltage in the formation process are formulated according to the condition of the battery, and a formation procedure is formulated according to internal conditions of each battery, so that the generation rate of poor products in the formation process is reduced, and the performance of the lithium ion battery is improved. According to the method provided by the invention, the rate of qualified lithium ion batteries is increased, the life performance of the lithium ion batteries is improved, and the production cost is lowered.

Owner:青岛恒金源电子科技有限公司

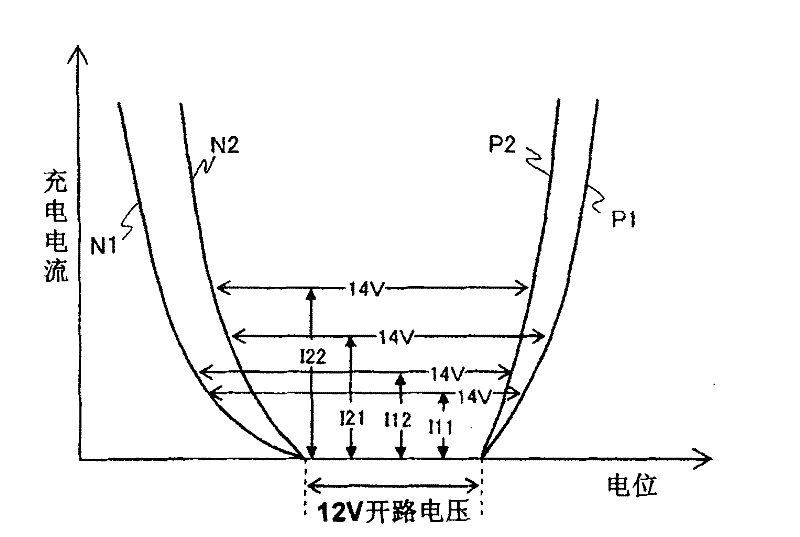

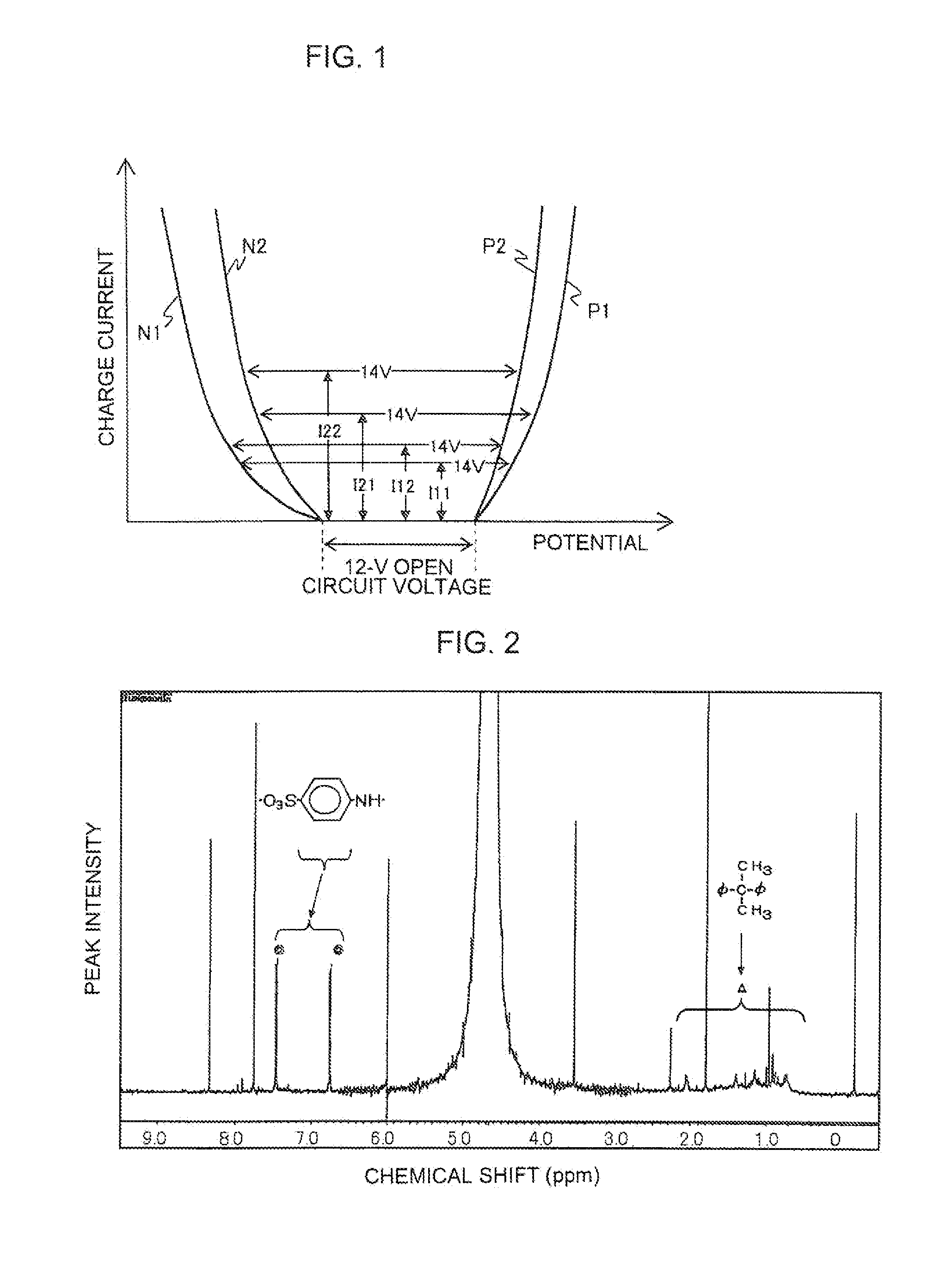

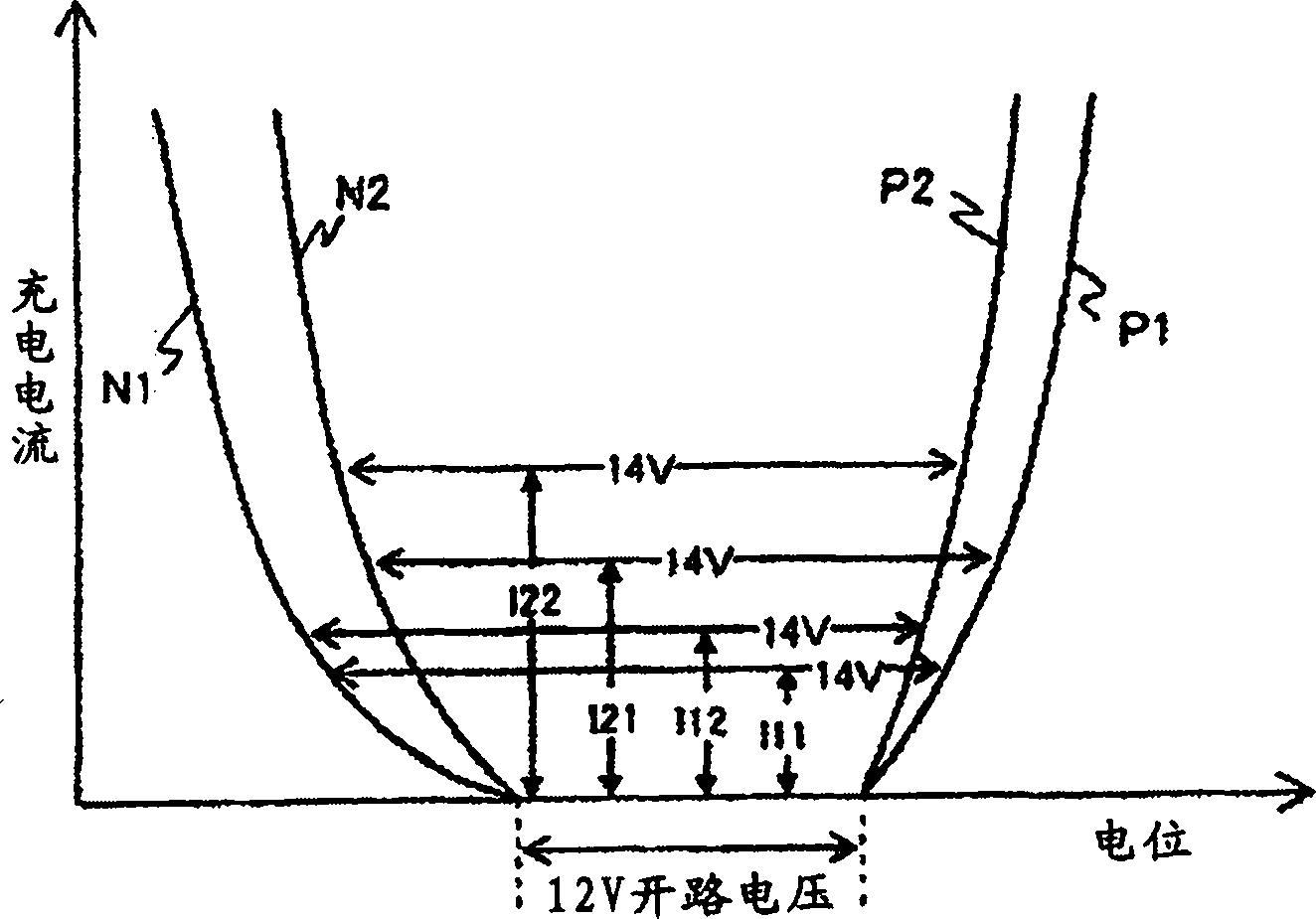

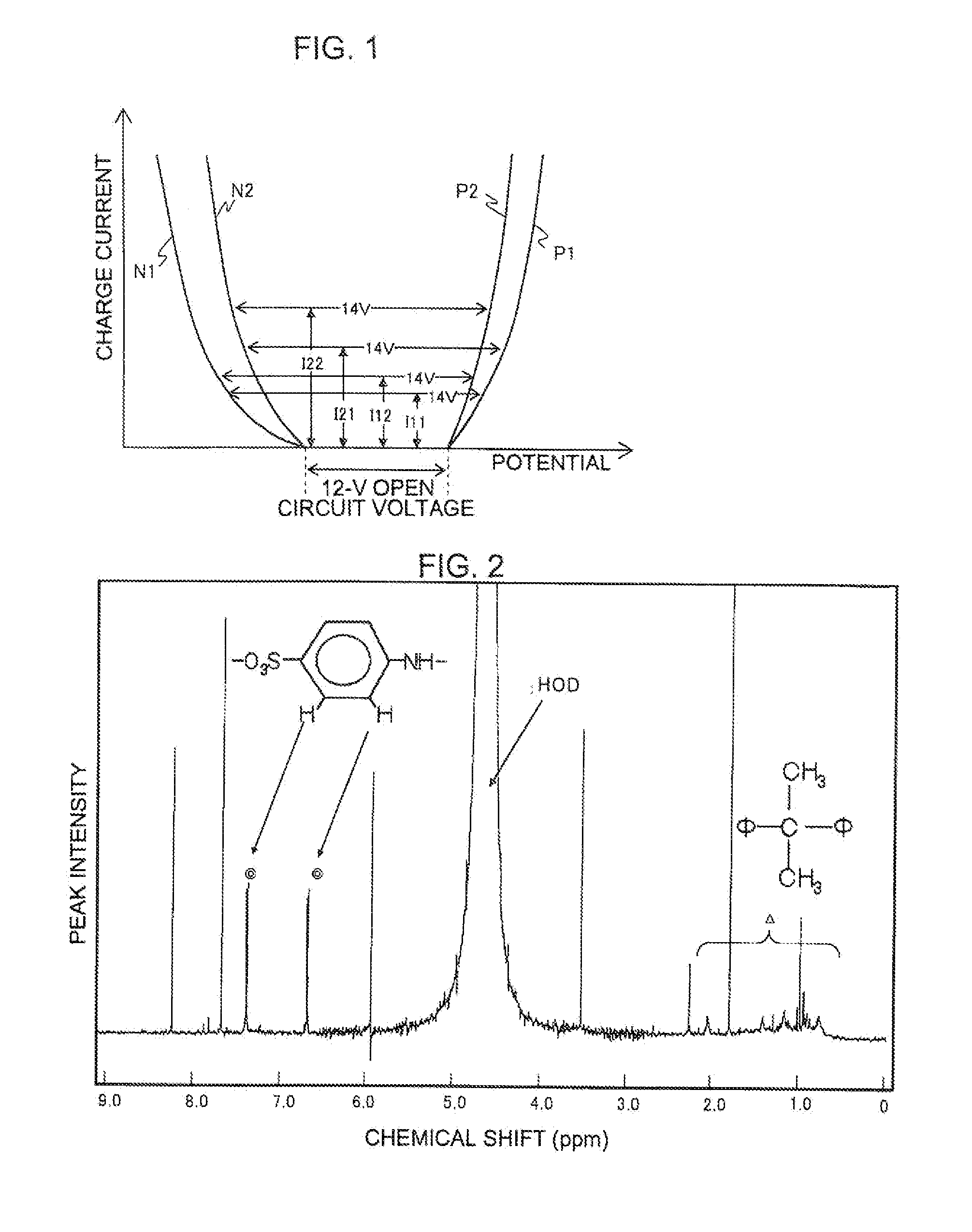

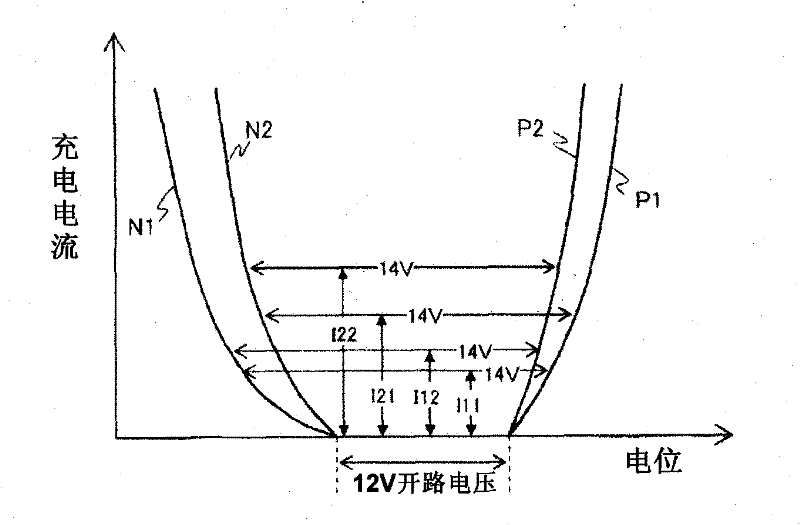

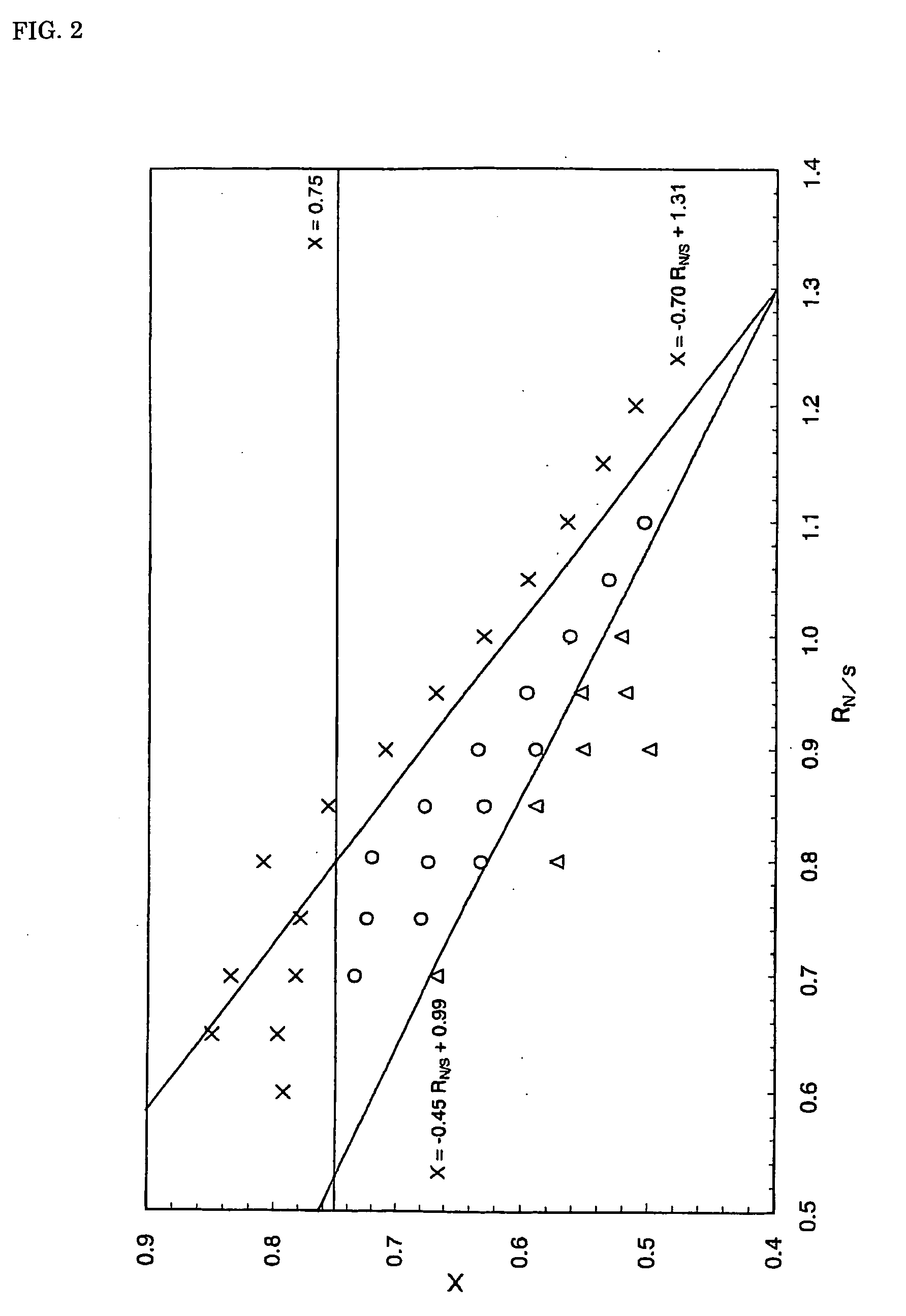

Method for Charging Nonaqueous Electrolytic Secondary Cell and Nonaqueous Electrolytic Secondary Cell

InactiveUS20060121335A1Improve life performanceExclude influenceSecondary cells charging/dischargingLi-accumulatorsElectrolysisElectrical battery

A charging method of a nonaqueous electrolyte secondary battery which comprises a positive electrode plate including a lithium-manganese composite oxide with spinel structure; a negative electrode plate including graphite capable of storing and discharging lithium; and nonaqueous electrolyte. When the ratio of a theoretical capacity of the negative electrode plate to a theoretical capacity of the positive electrode plate is set as RN / s and the graphite which has stored lithium by charging is represented by LixC6, the nonaqueous electrolyte secondary battery is characteristically charged so that the maximum value Xmax X can have satisfies the following Conditions (1) and (2): Xmax≦0.75 Condition (1) Xmax≦−0.70RN / S+1.31 Condition (2) The life performance is remarkably improved by charging the nonaqueous electrolyte secondary battery while satisfying the Conditions.

Owner:GS YUASA CORP

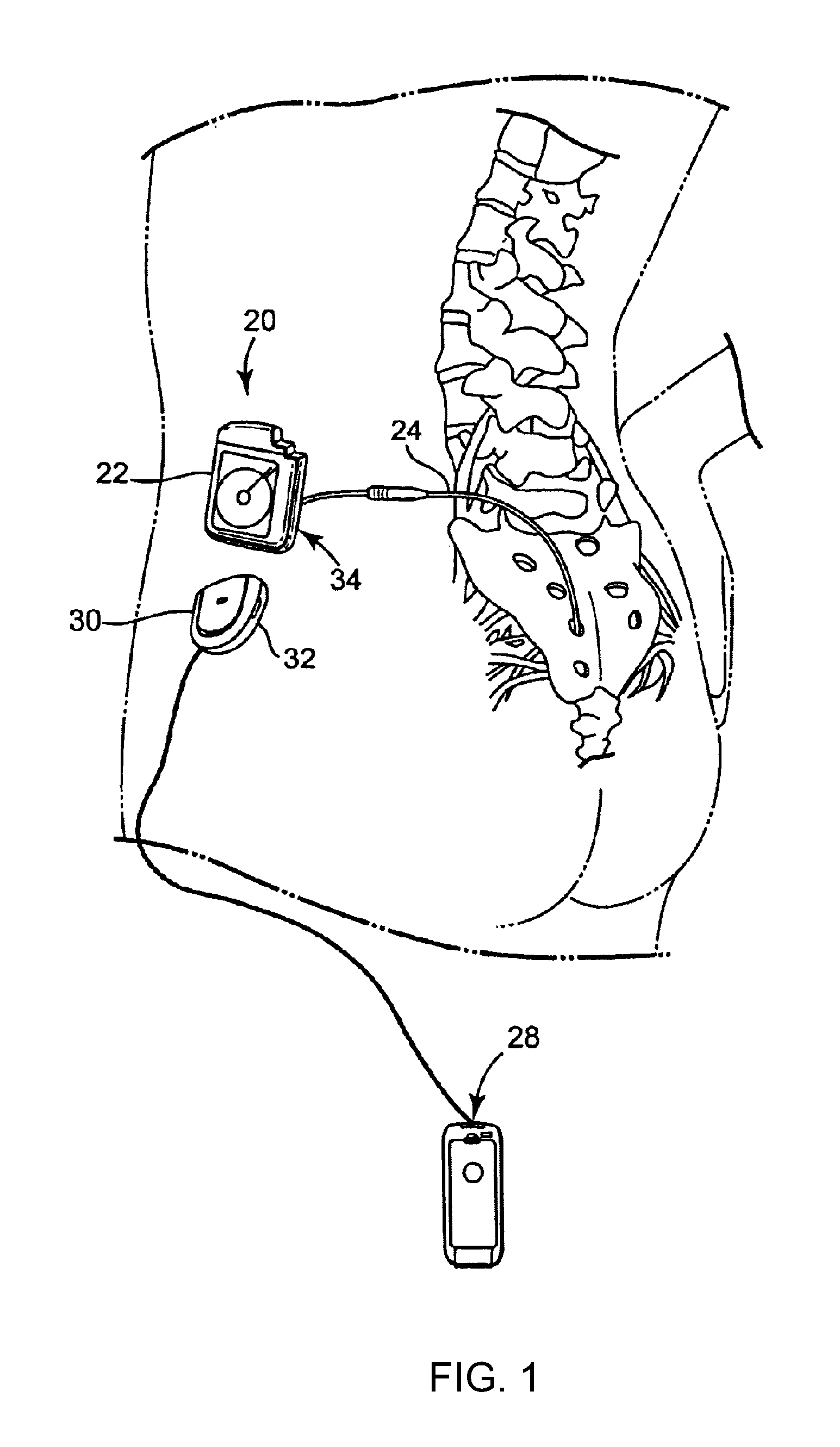

Accessory apparatus for improved recharging of implantable medical device

ActiveUS20100241194A1Improve recharge efficiencyReduce wearElectrotherapyMedical deviceBiomedical engineering

An apparatus configured to be placed about an implantable medical device having a face with a geometric center offset from a center of a recharge coil of the device includes first and second opposing major exterior surfaces, and a continuous exterior side surface joining the first and second opposing major exterior surfaces. A cavity is defined between, and an opening is formed by, the first and second major surfaces and the continuous side surface. The opening is in communication with the cavity and is configured to allow the device to access the cavity. An asymmetric region, adjacent to the cavity, is formed between a portion of the first and second major surfaces and the continuous side surface. The asymmetric region is configured to shift the geometric center of the combined apparatus and device, when the device is received in the cavity, towards the center of the recharge coil.

Owner:MEDTRONIC INC

Lead storage battery

ActiveCN103891037ALess quantitySuppress coarseningFinal product manufactureLead-acid accumulator electrodesSimple Organic CompoundsElectricity

Provided is a fluid-type lead storage battery wherein charging is performed intermittently for a short duration each time, and high-rate discharging to a load is performed in a partial state of charge, said lead storage battery improving the charge acceptance and the PSOC life characteristic relative to the prior art. A positive electrode plate is used that has a positive-electrode active substance total surface area per unit electrode plate group volume set in a range of between 3.5 and 15.6 m2 / cm3. A negative electrode plate is used in which a carbonaceous conductive material and an organic compound that inhibits coarsening of a negative-electrode active substance accompanied by charging / discharging are added to the negative-electrode active substance. Moreover, compounds chosen from among cationic coagulant, cationic surfactant and phosphoric acid are added to an electrolyte, improving the charge acceptance and the life performance.

Owner:HITACHI CHEM CO LTD

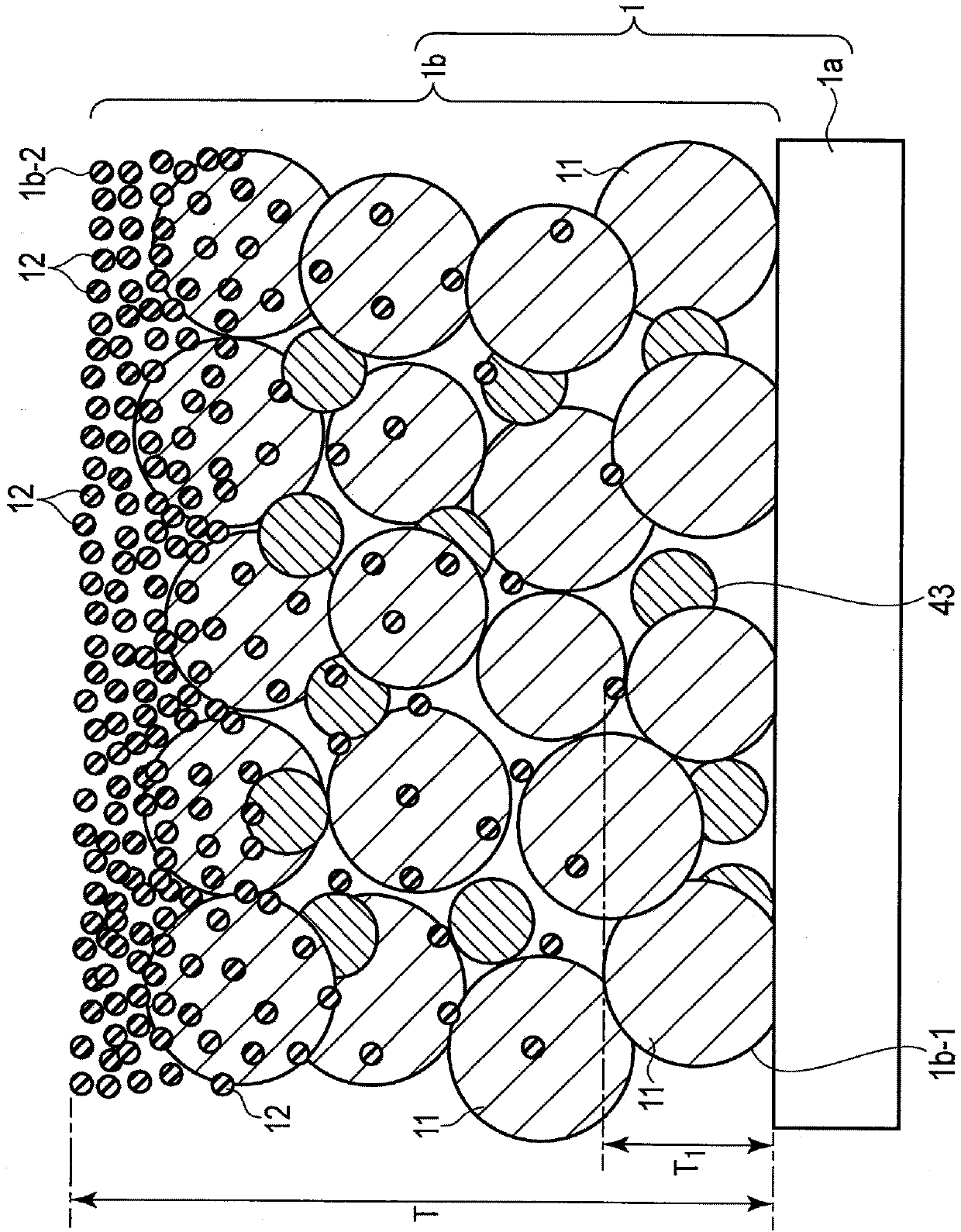

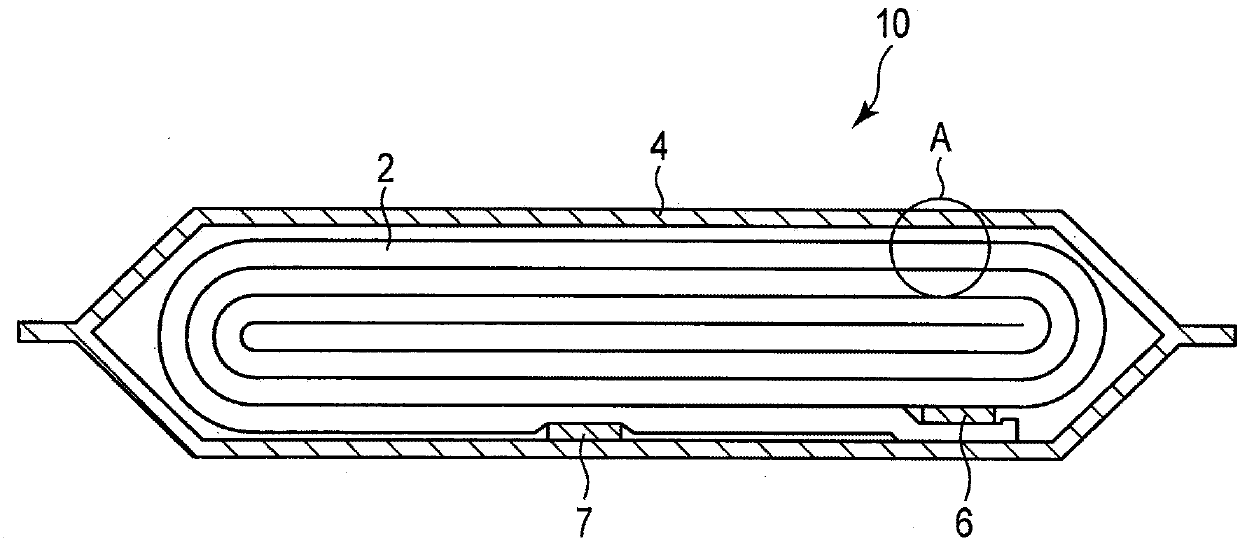

Electrode, nonaqueous electrolyte battery, battery pack and vehicle

ActiveCN107845768AImprove life performanceBatteries circuit arrangementsSmall-sized cells cases/jacketsEngineeringBattery pack

Embodiments of the invention relate to an electrode, a nonaqueous electrolyte battery, a battery pack, and a vehicle. The technical problem to be solved by the invention is to provide an electrode that can realize a nonaqueous electrolyte battery capable of exhibiting excellent lifetime performance. According to one embodiment, an electrode (1) is provided. The electrode (1) includes a current collector (1a) and an active material-containing layer (1b) formed on the current collector (1a). The active material-containing layer (1b) includes active material particles (11) and insulator particles(12). The active material-containing layer (1b) has a first face (1b-1) facing the current collector (1a) and a second face (1b-2) as a surface of the active material-containing layer (1b). At leasta part of the second face (1b-2) is composed of the insulator particles (12). A volume ratio of the insulator particles (12) decreases from the second face (1b-2) toward the first face (1b-1) in the active material-containing layer (1b).

Owner:KK TOSHIBA

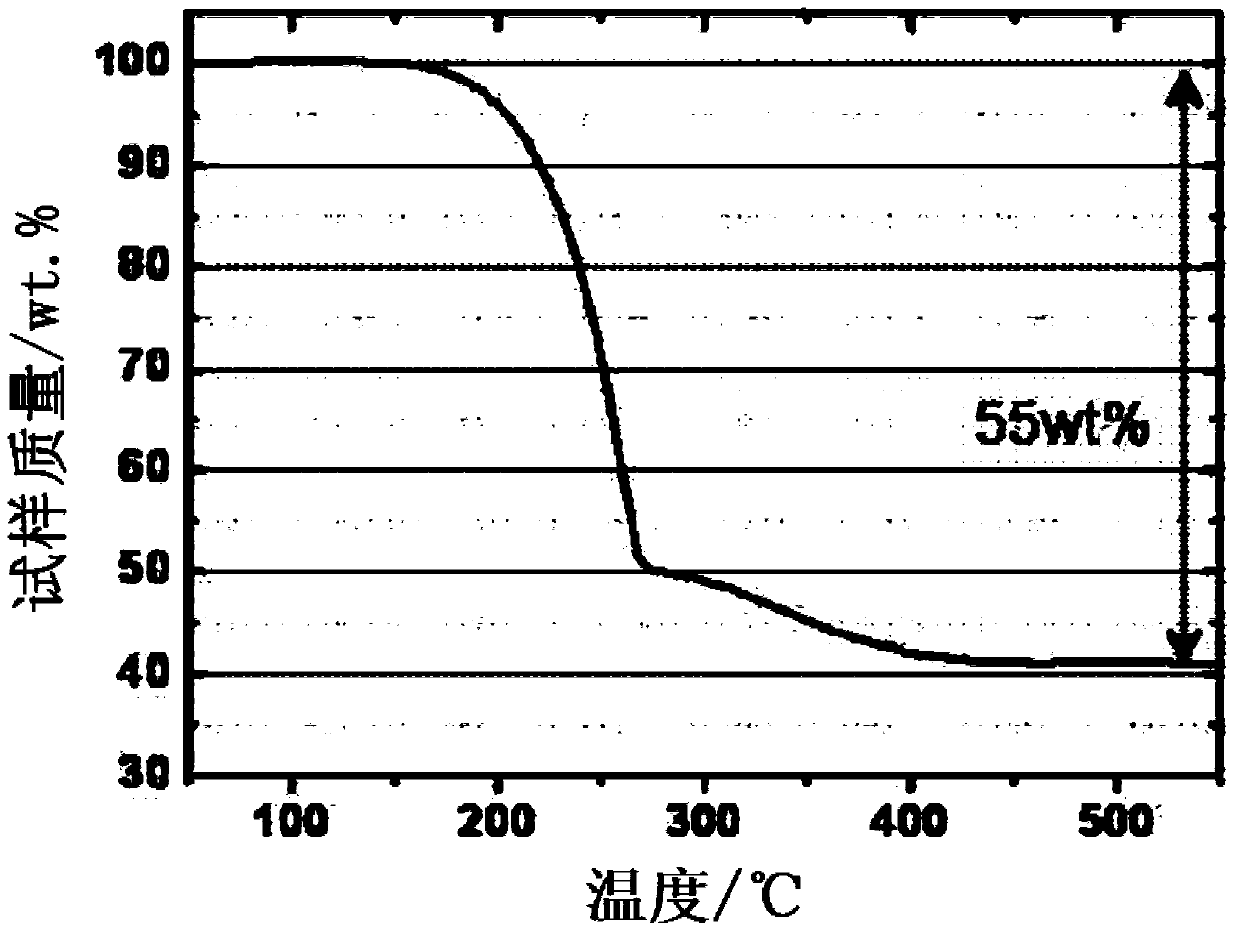

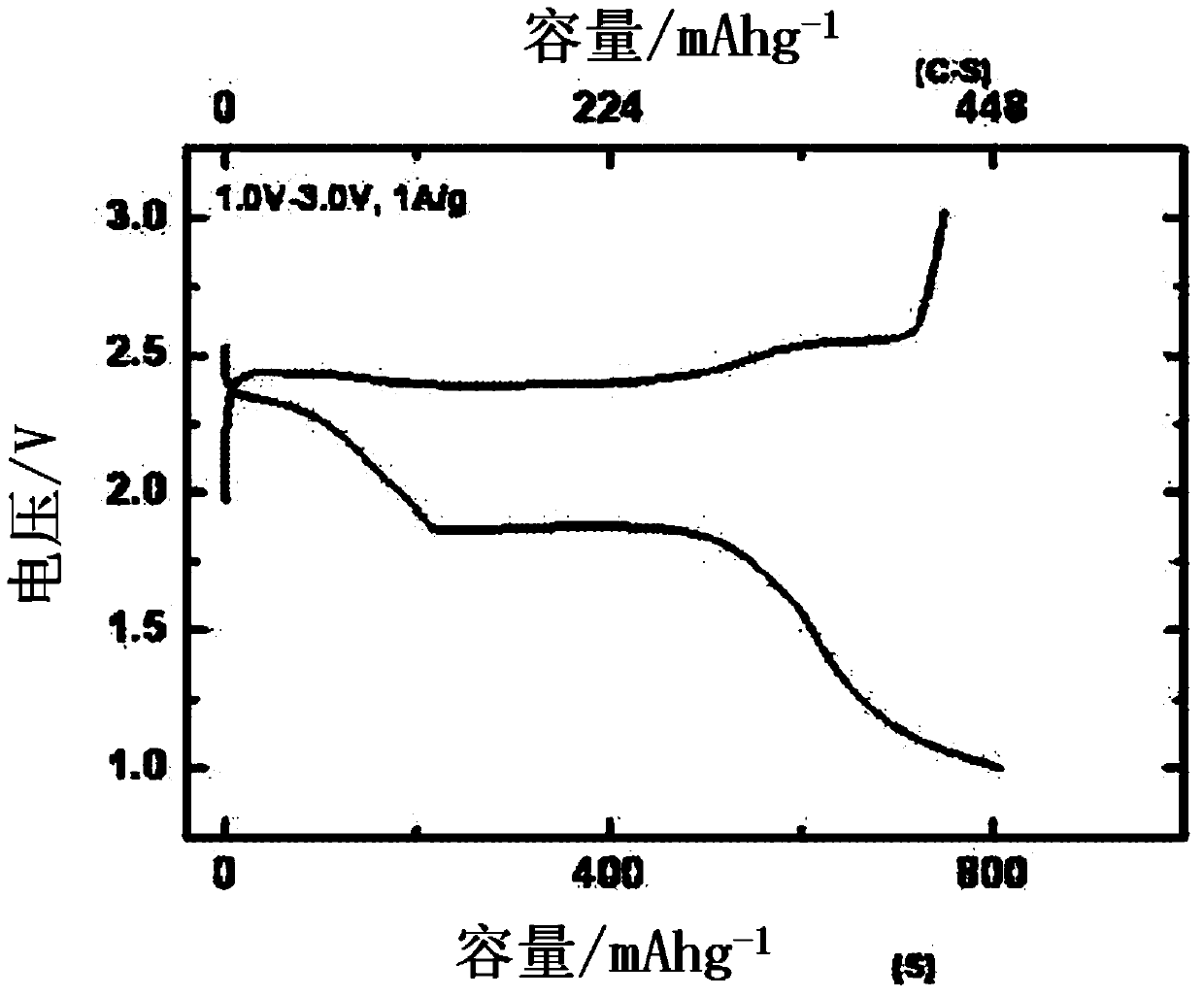

Method for manufacturing carbon-sulfur composite, carbon sulfur composite manufactured thereby, and electrochemical device including same

InactiveCN104272504AHigh sulfur contentImprove Capacitive PerformanceElectrode manufacturing processesCarbon preparation/purificationLiquid stateElectrochemistry

The present invention relates to a method for manufacturing a carbon-sulfur composite, a carbon-sulfur composite manufactured by the method, and an electrochemical device including the same. Since the carbon-sulfur composite manufactured by the carbon-sulfur composite manufacturing method of the present invention is evenly distributed by filling up sulfur inside a hollow carbon ball, the sulfur content increases, and thus the capacity increases. The composite also has stable life cycles since the electrode structure is not destroyed even if the sulfur becomes a liquid state during a charge / discharge process.

Owner:IUCF HYU (IND UNIV COOP FOUND HANYANG UNIV)

Formation method of power lithium ion battery

ActiveCN111129604AAvoid polarizationSpeed up the formation timeFinal product manufactureCell electrodesElectrolytic agentChemical physics

The invention provides a formation method of a power lithium ion battery. The power lithium ion battery comprises a positive electrode, a separator between the positive electrode and the negative electrode; the positive electrode is a composite positive electrode formed by mixing a plurality of active substances; wherein the plurality of active substances comprise LiNi0.15Mn0.65Co0.15Mg0.03Al0.02O2, Li0.95Na0.05Mn2 and LiMn0.75Co0.2Mg0.03Al0.02O2; wherein the mass ratio of the LiNi0.15Mn0.65Co0.15Mg0.03Al0.02O2 to the Li0.95Na0.05Mn2 to the LiMn0.75Co0.2Mg0.03Al0.02O2 is 33: 42: 35-26: 60: 14.The formation method comprises the following steps: injecting a first electrolyte into an assembled battery, and carrying out pre-formation under a first predetermined voltage; injecting a second electrolyte of which the additive is FEC, and formally forming at a voltage higher than a first preset voltage. According to the formation method, the rate capability of the battery can be improved and the cycle life of the battery can be prolonged by a formation mode set for a specific active substance.

Owner:萧县鑫辉源电池有限公司

Implantable lead management

ActiveUS8209016B2Small sizeImprove life performanceCoupling device detailsInternal electrodesIcd leadMedical device

An apparatus for managing a lead of an implantable medical device includes a lead retention element and a fixation element. The lead retention element has a proximal end, a distal end, and a lumen extending from the proximal end to the distal end. The lumen is configured to slidably receive the lead. The fixation element is configured to fix the lead retention element relative to the implantable medical device in an orientation orthogonal to a lead receptacle of the device such that the proximal end of the lead retention element is closer to an opening of the lead receptacle than the distal end of the retention element. The distal end of the lead retention element is configured to firmly engage the lead to resist proximal sliding of the lead in the lumen of the retention element once the lead has been moved distally through the lumen.

Owner:MEDTRONIC INC

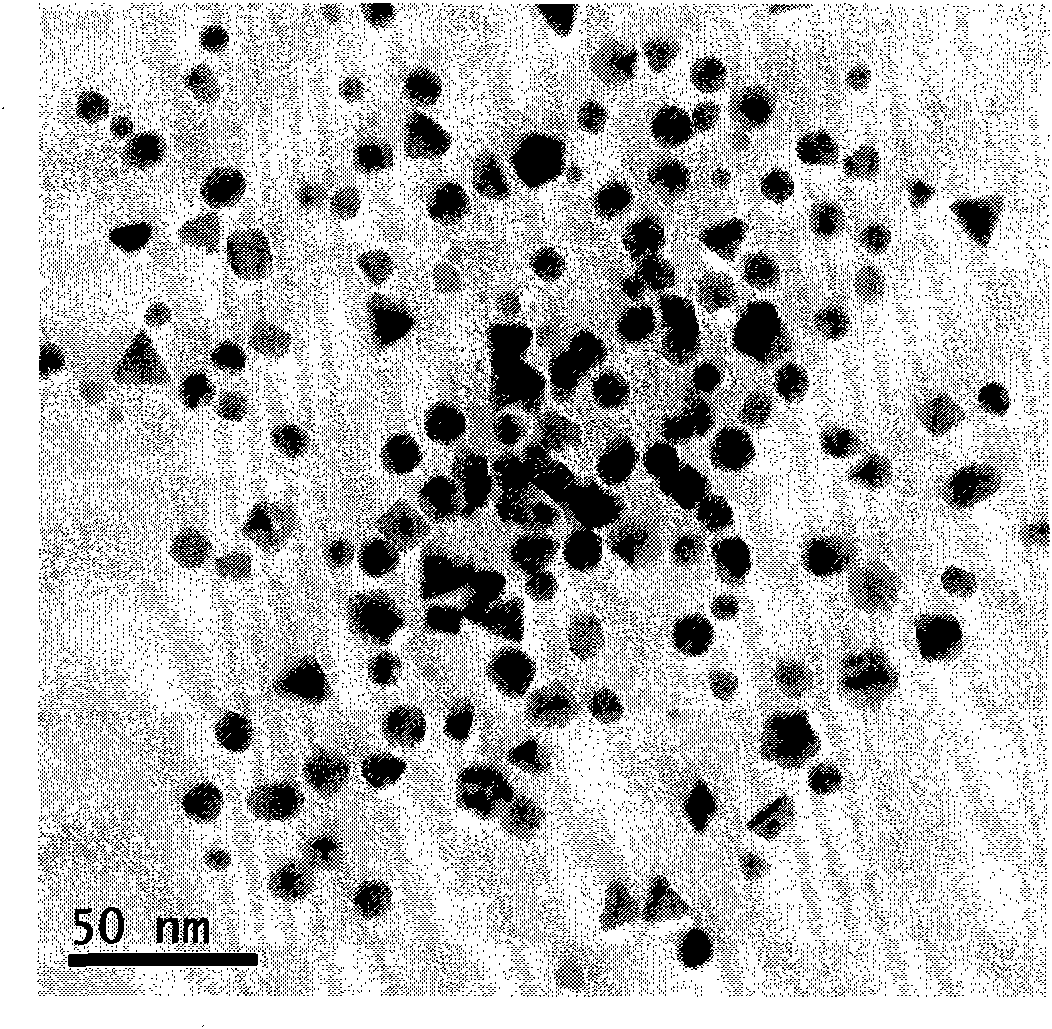

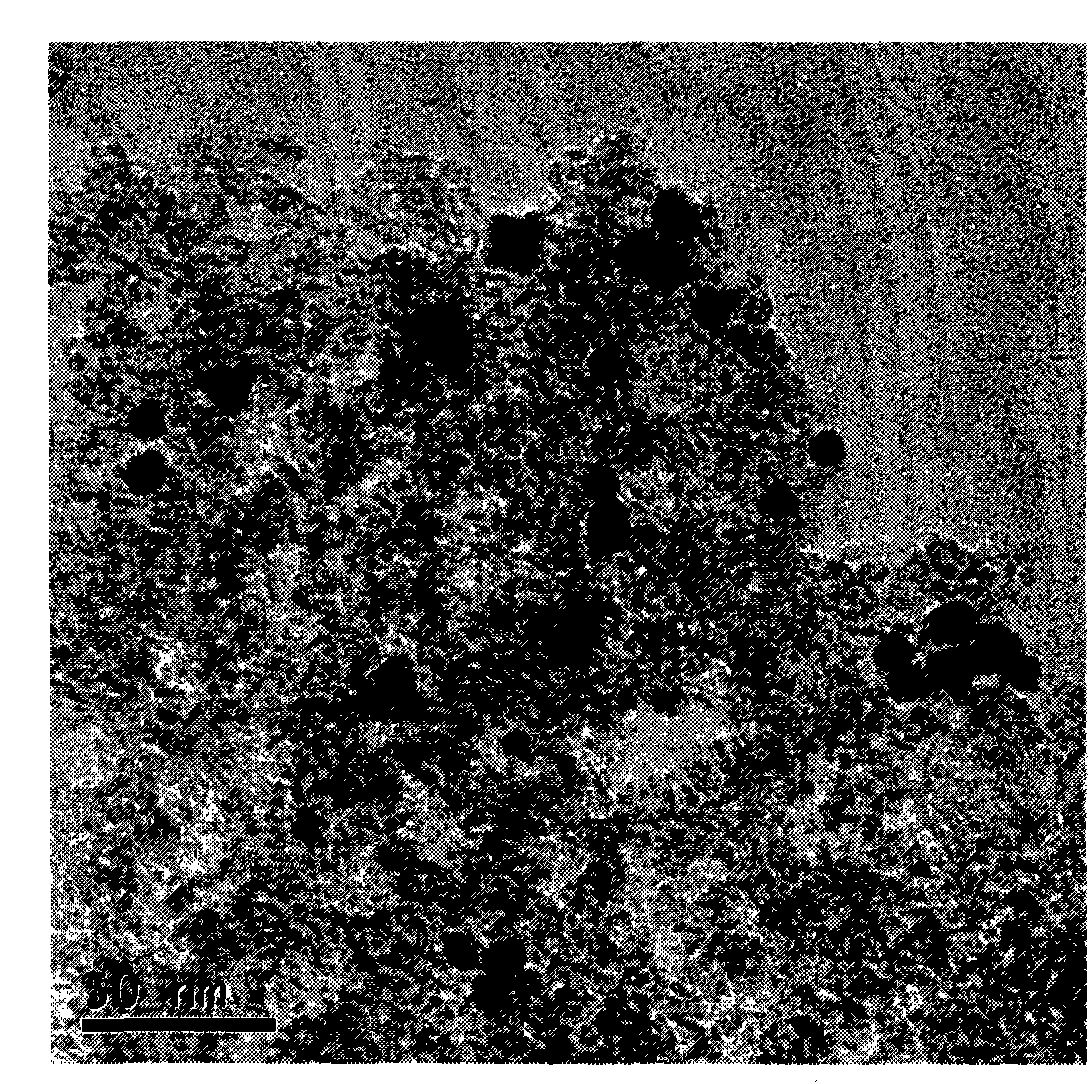

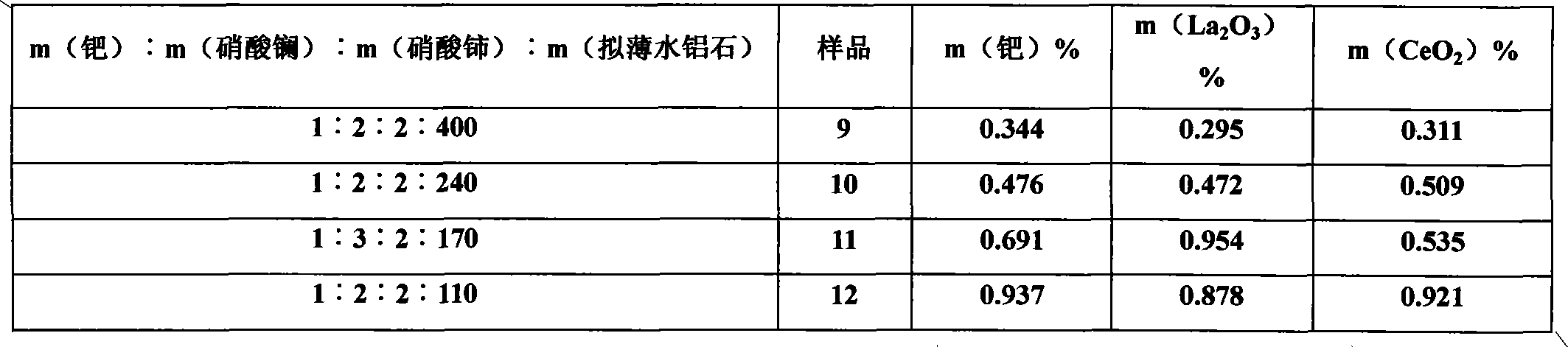

Catalyst for use in preparation of hydrogen peroxide by anthraquinone method and preparation method thereof

ActiveCN101966454ASmall particle sizeControl shapePeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesCatalyst activation/preparationPorous carbonSlurry

The invention belongs to the field of load catalysts, in particular relates to a palladium load catalyst for use in preparation of hydrogen peroxide by an anthraquinone method and a preparation method thereof. The method comprises the following steps of: (1) preparing metal palladium sol from palladium acetate serving as a raw material and mixed solution of ethanol and water serving as solvent in the presence of a stabilizing agent; and (2) preparing serous fluid of pseudo-boehmite, dripping solution containing the metal palladium sol obtained by the step (1) and rare-earth metal nitrate into the serous fluid of the pseudo-boehmite, stirring, reacting at the temperature of between 60 and 100 DEG C for 2 to 6 hours, removing the solvent through rotary evaporation, drying, grinding and roasting to obtain a load palladium catalyst serving aluminum oxide as a carrier. The catalyst has the advantages of low load capacity of noble metals, uniform size distribution of active ingredients, high catalytic activity and the like. In addition, polymer is decomposed into porous carbon and distributed on interfaces of the catalyst carrier and metal active particles, so the catalyst has excellent stability and long service period.

Owner:浙江泰德新材料有限公司

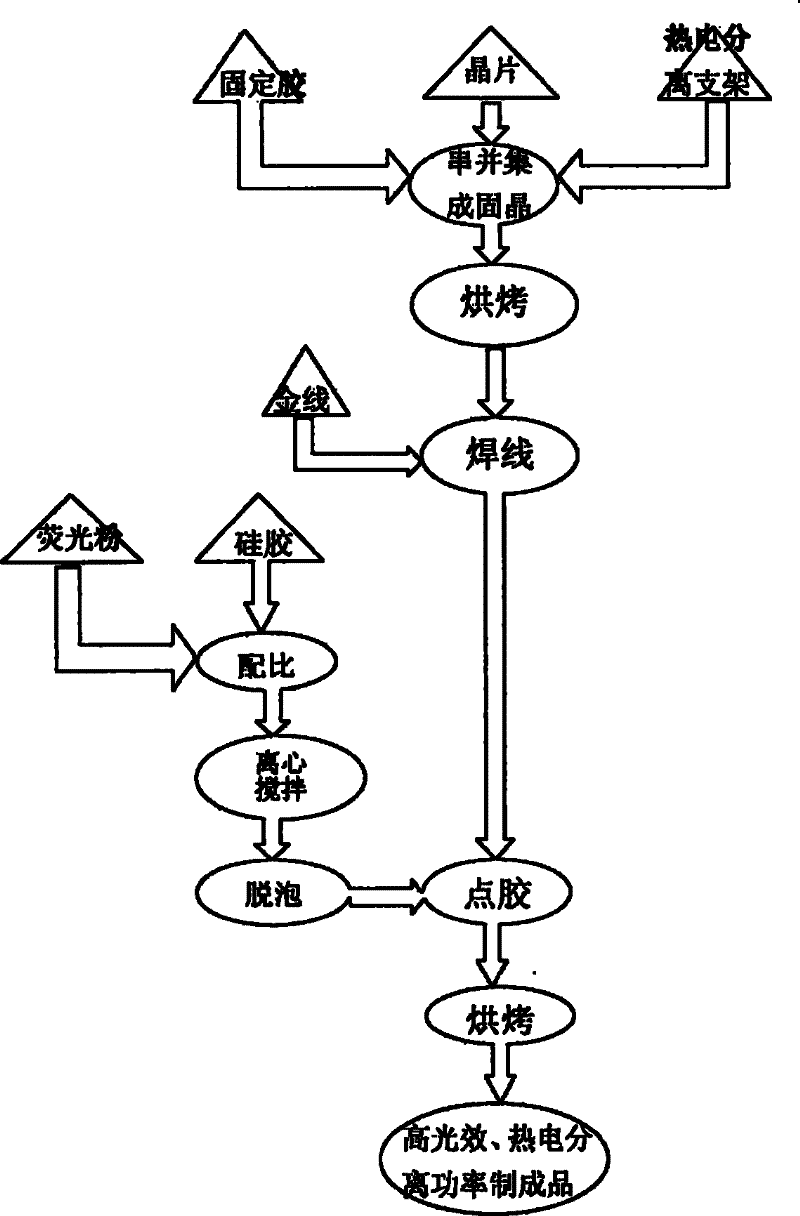

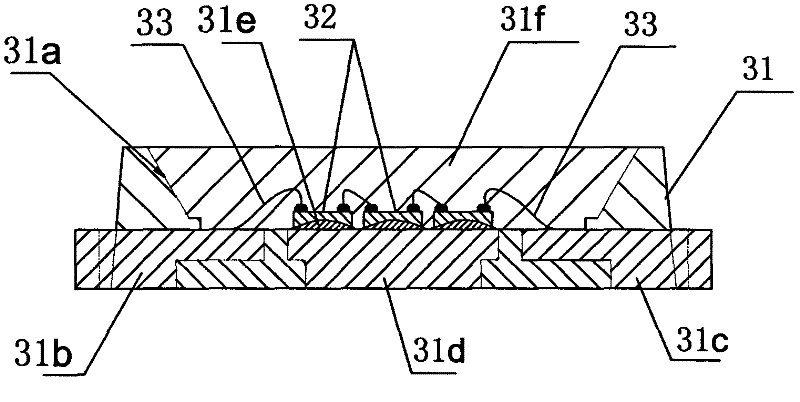

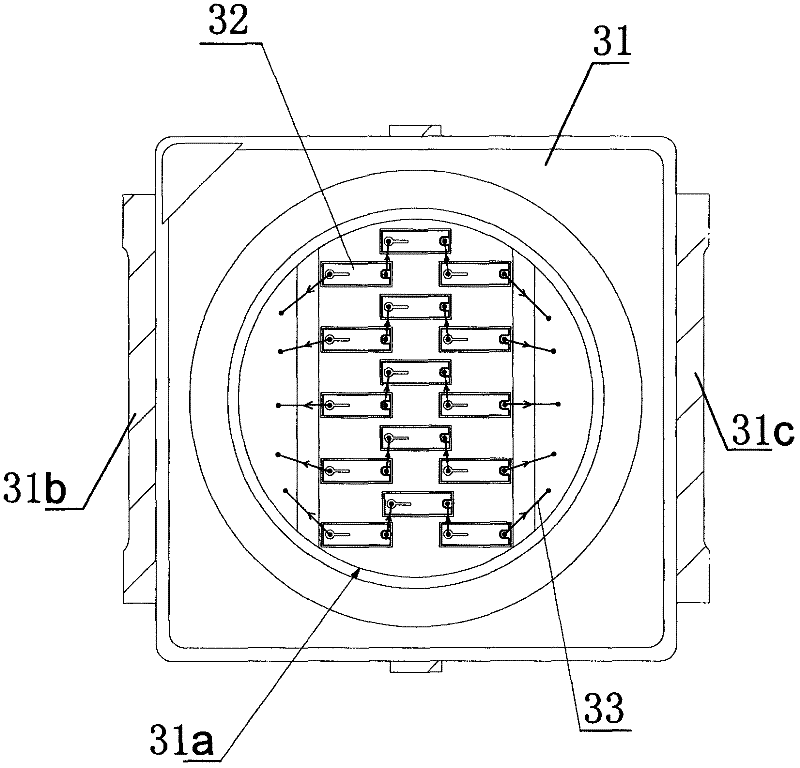

Highly integrated high light efficiency thermoelectric separation power type light emitting diode (LED) and encapsulating method thereof

InactiveCN102646673ASolve the problem of generally low light efficiencyHigh light efficiencySolid-state devicesSemiconductor devicesElectricityHeat conducting

The invention discloses a highly integrated high light efficiency thermoelectric separation power type light emitting diode (LED). The LED comprises a paster type bracket, an LED chip and gold threads, wherein a concave cup is formed on the upper surface of the bracket, electric conducting channels which are independently communicated into two sides of the concave cup are arranged at left and right sides of the bracket, the bottom surface of the bracket is provided with a heat conducting channel of which the middle part is communicated to the middle part of the concave cup, the LED chip is stuck with the heat conducting channel through heat conducting insulation paste, two poles of the LED chip are respectively electrically connected with the electric conducting channel through the gold threads, and a fluorescent colloid which is formed by mixing silica gel and fluorescent powder is filled and sealed in the concave cup. Because of the design of thermoelectric separation, heat dissipated when the LED chip works can be independently conducted to a heat dissipating pillar in time, and the impacts of heat on the reliability of second spot welding and the service life of the chip are reduced. With the design of polycrystal serial and parallel integration and thermoelectric separation, the LED disclosed by the invention has the technical effects of high light efficiency, independent heat and electric channels, simple structure, good heat dissipation effect and the like.

Owner:OUTRACE TECH

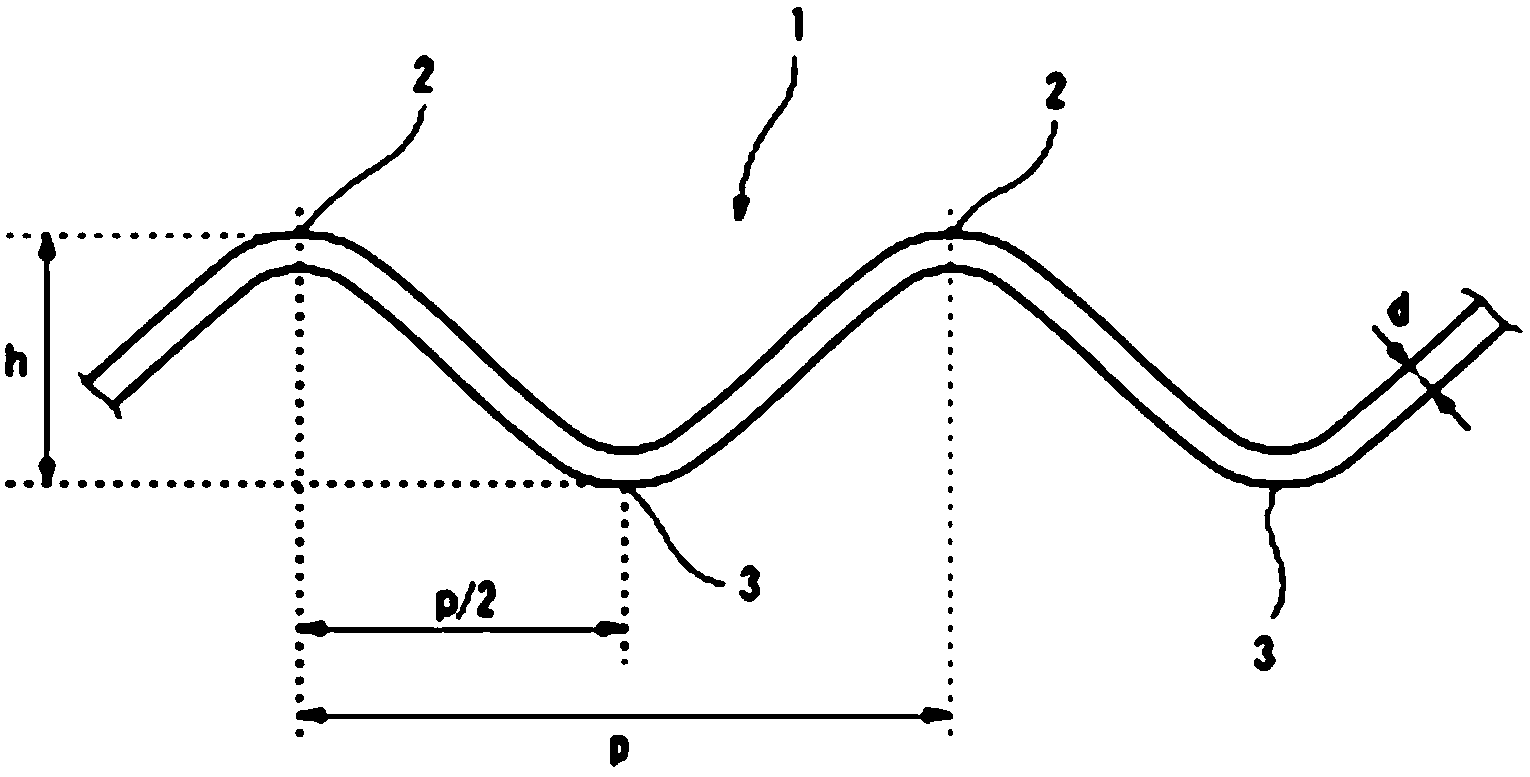

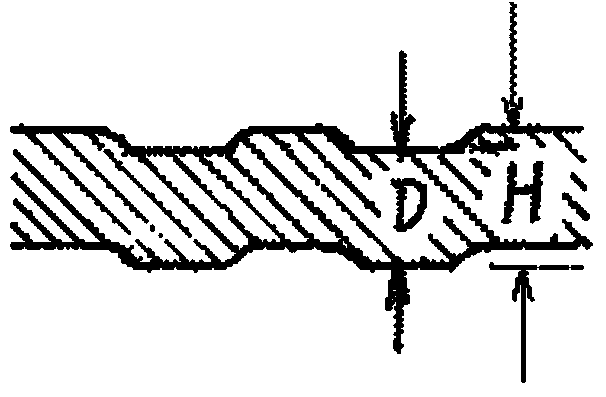

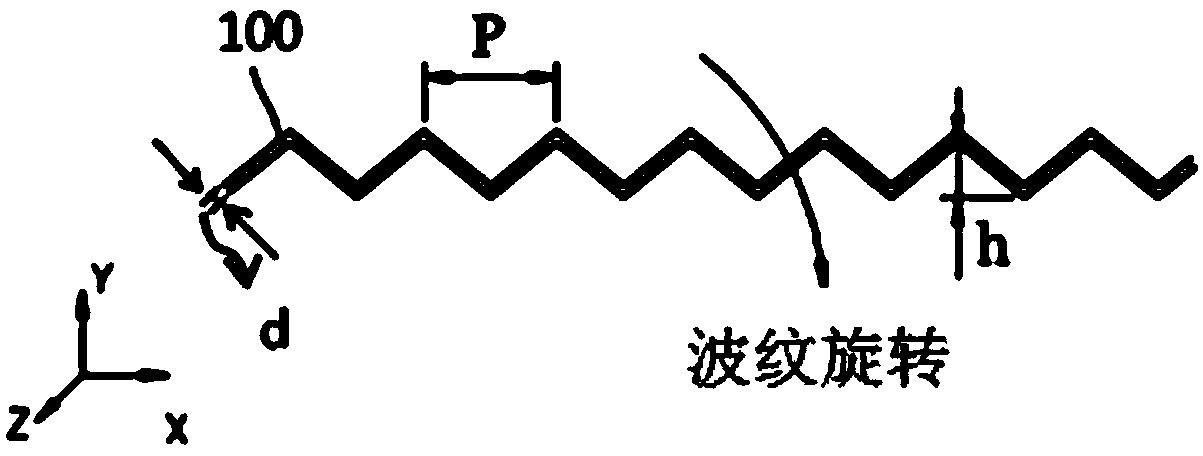

Wavy-patterned monowire for cutting

InactiveCN104108141AEnough containmentImprove performanceSemiconductor/solid-state device manufacturingFine working devicesAlloySemiconductor

Owner:HYOSUNG ADVANCED MATERIALS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com