PDLC composition with high bonding force

A technology of composition and photocuring prepolymer, which is applied in the direction of liquid crystal materials, chemical instruments and methods, etc., can solve the problems of low surface energy of PET substrates and cannot meet the use of PDLC materials on PET substrates, and solve the problem of bonding Poor power, excellent photoelectric performance, strong shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

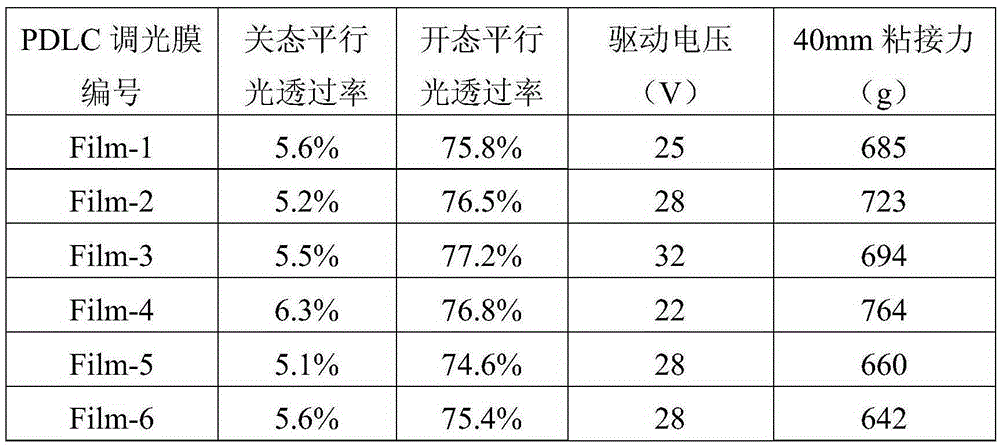

Embodiment 1

[0048] The liquid crystal PDLC dimming material 1 includes the following components, 12 parts of acrylic polyurethane CN704 (Sartomer Guangzhou Chemical Co., Ltd.), 23 parts by mass of hydroxypropyl acrylate, liquid crystal material SL-79 (Chengzhi Yonghua Display Materials Co., Ltd.) ) 64.9 parts by mass, photoinitiator UV1840.1 parts by mass, 1 part by mass of spacer rigid microbeads (10um), 1 part by mass of phosphorus element providing agent glyceric acid dimethacrylate.

Embodiment 2

[0050] The liquid crystal PDLC dimming material 1 includes the following components, 14 parts by mass of acrylic polyurethane CN966J75NS (Sartomer Guangzhou Chemical Co., Ltd.), 24 parts by mass of lauryl acrylate, and 61.5 parts by mass of liquid crystal material SLC1717 (Chengzhi Yonghua Display Materials Co., Ltd.). Parts by mass, 0.5 parts by mass of photoinitiator UV184, 2 parts by mass of spacer rigid microbeads (particle size 15um), 2 parts by mass of phosphorus element providing agent acryloyloxyethylphenyl phosphate.

Embodiment 3

[0052] The liquid crystal PDLC dimming material 1 includes the following components, 17 parts by mass of acrylic polyurethane UV65 (Shanghai Kuer Industrial Co., Ltd.), 12 parts by mass of lauryl acrylate, 3 parts by mass of isobornyl acrylate, 1,6-hexanediol 3 parts by mass of diacrylate, 6 parts by mass of hydroxypropyl acrylate, 58 parts by mass of liquid crystal material SL-16 (Chengzhi Yonghua Display Material Co., Ltd.), 1 part by mass of photoinitiator TPO, spacer rigid microbeads (particle diameter 15um ) 2 mass parts, phosphorus element providing agent 4-methacryloyloxyethyl trimellitic anhydride 3 mass parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com