Patents

Literature

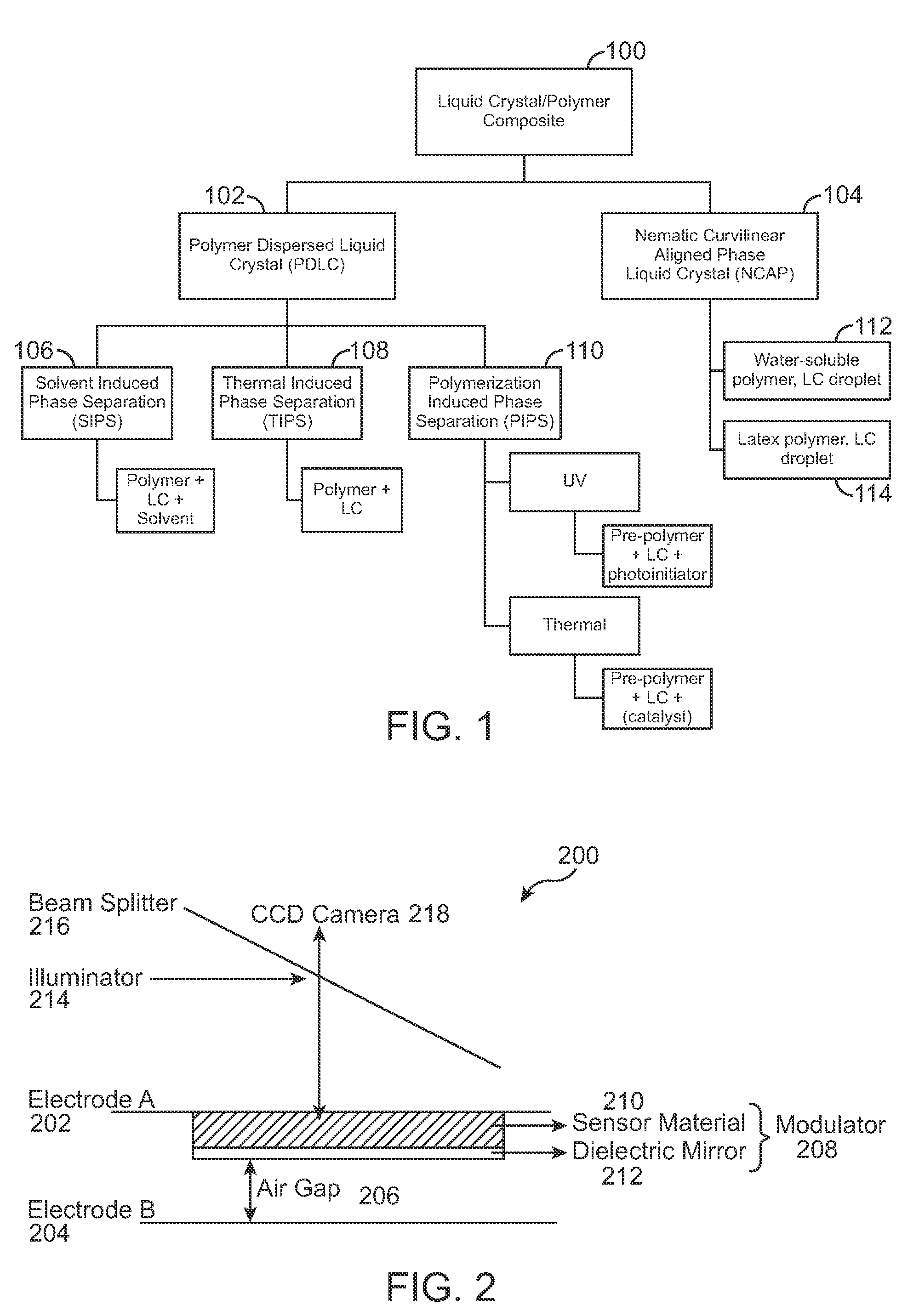

169 results about "Liquid crystal droplet" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

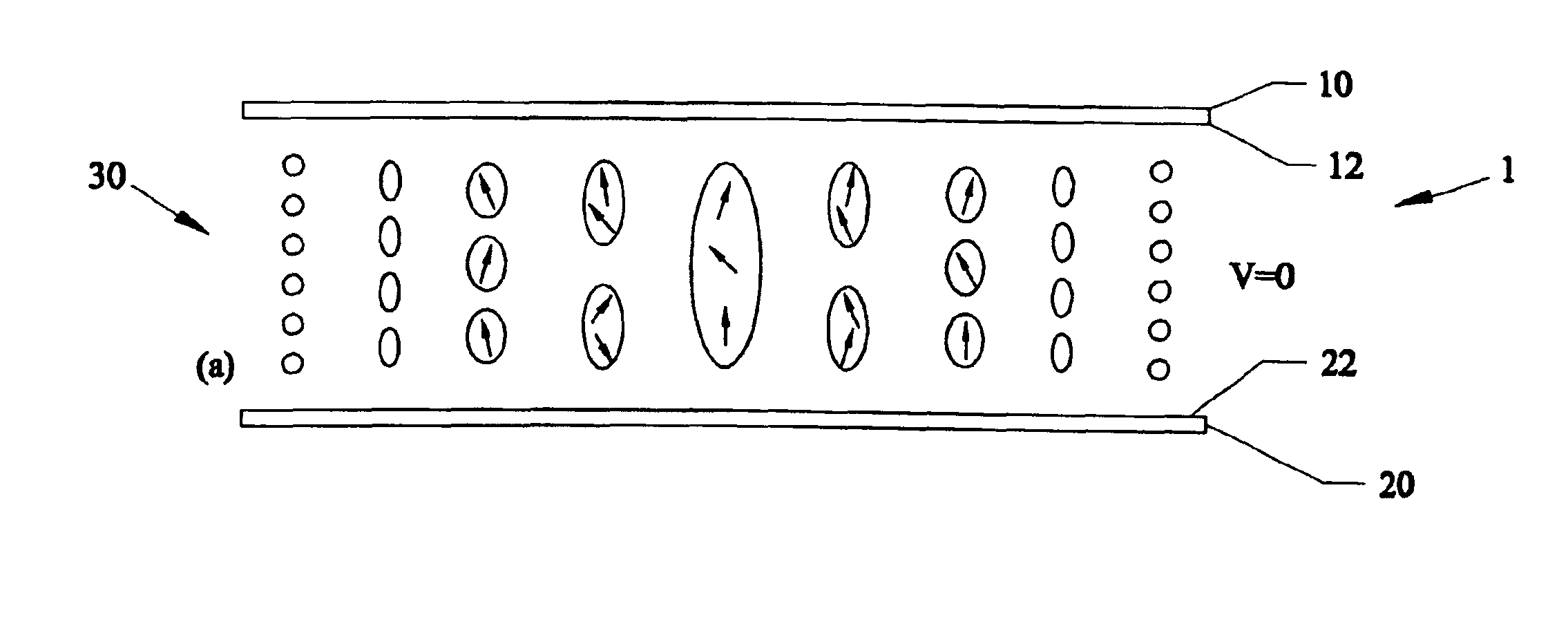

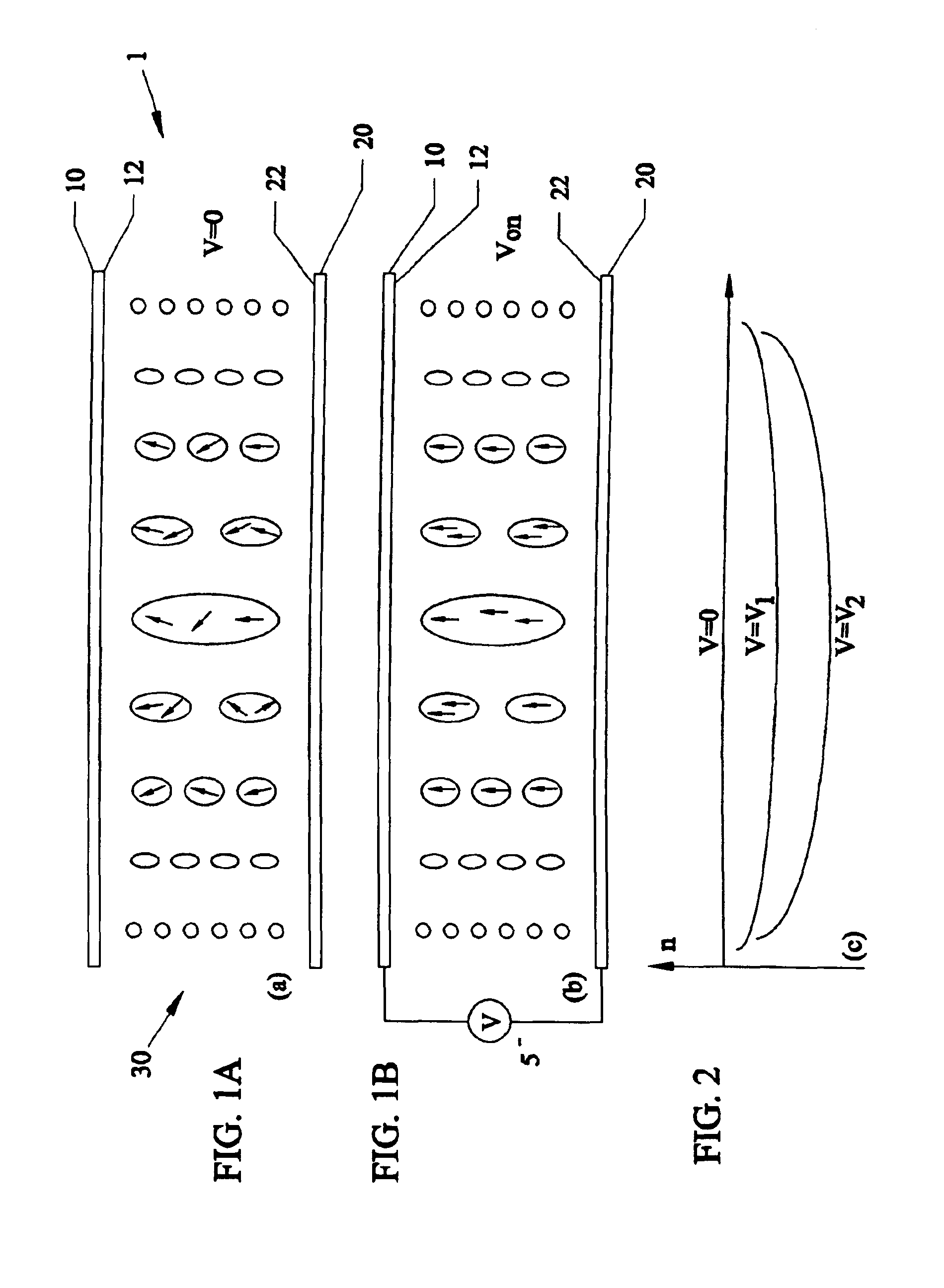

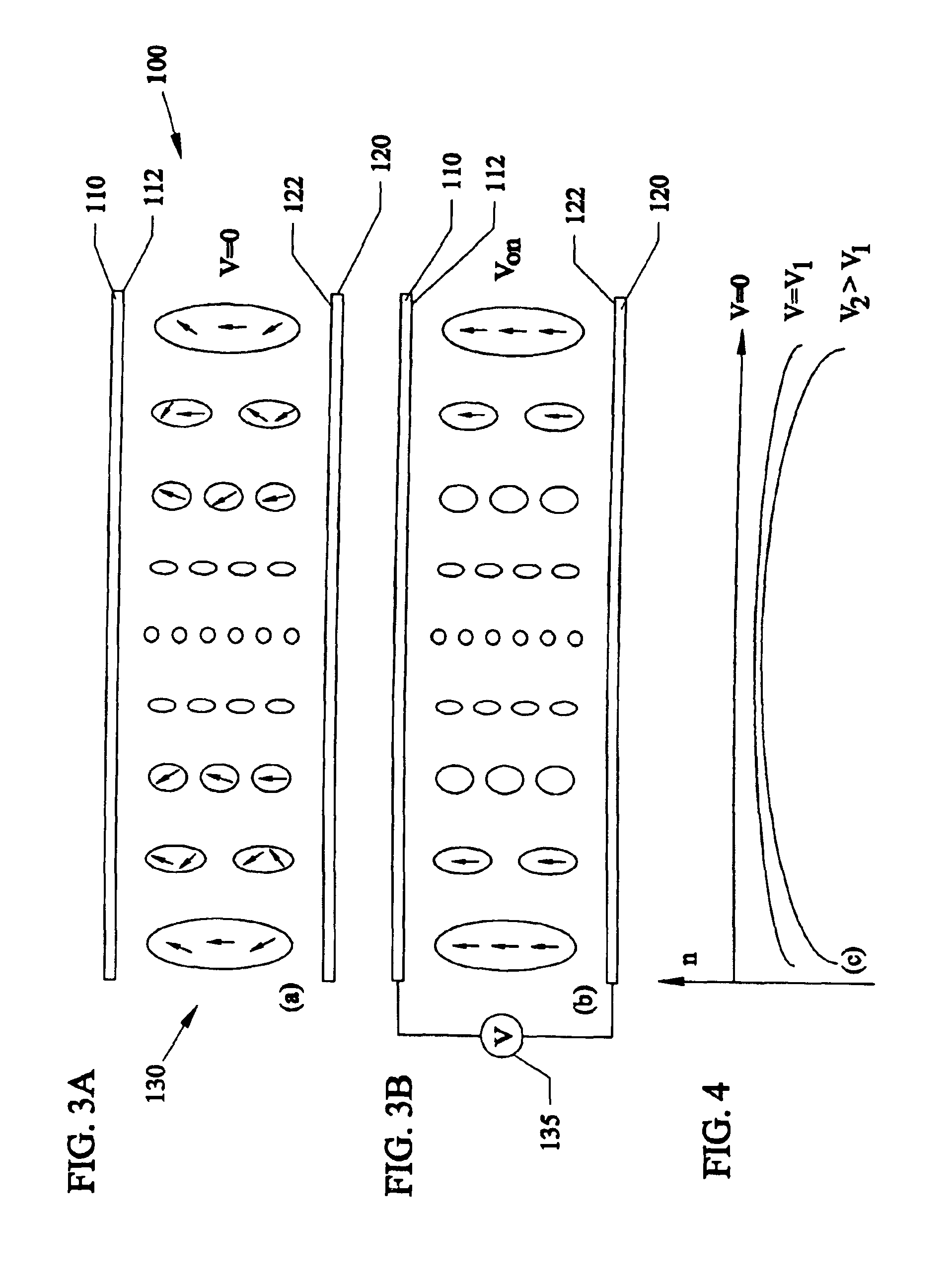

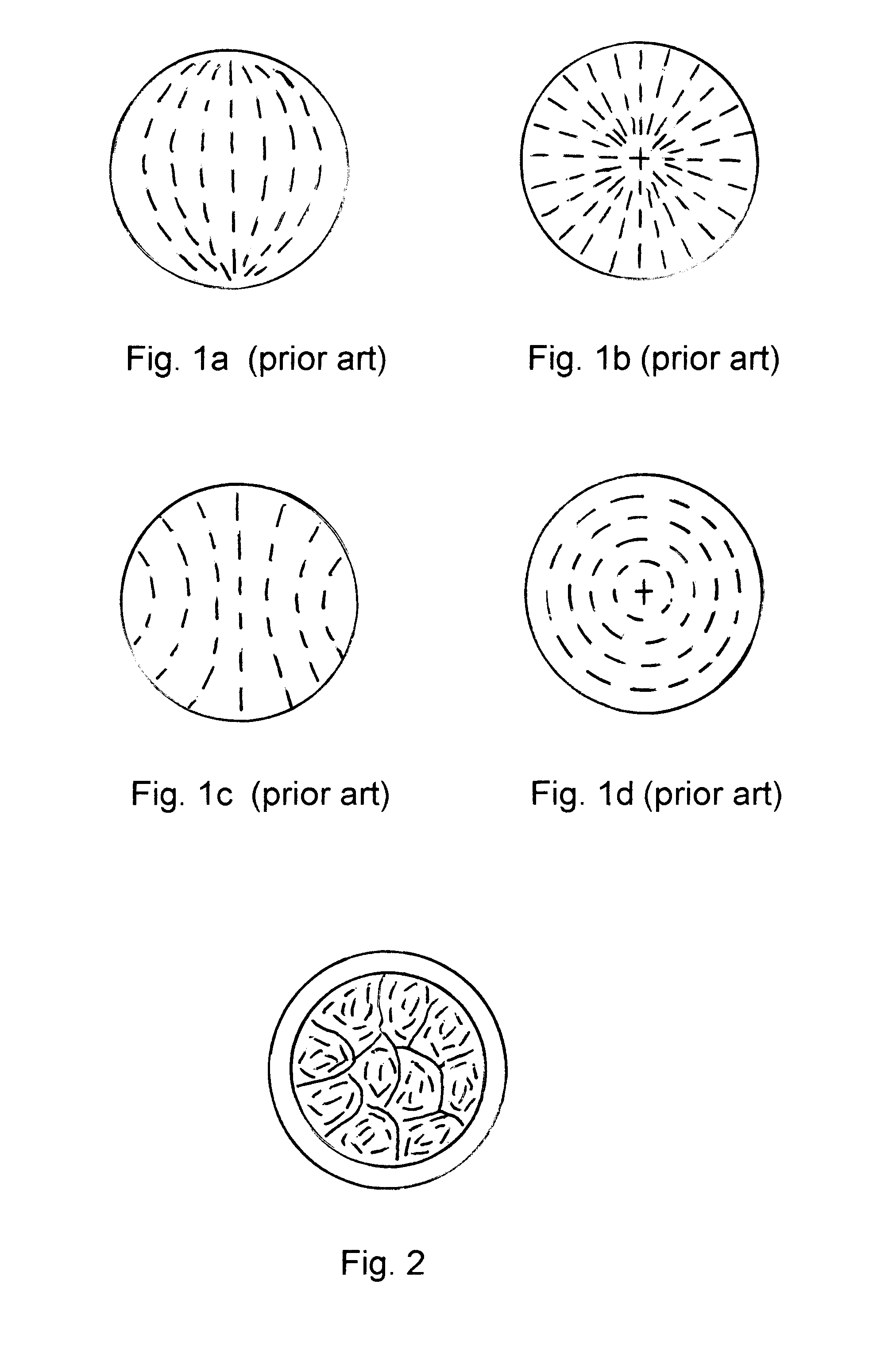

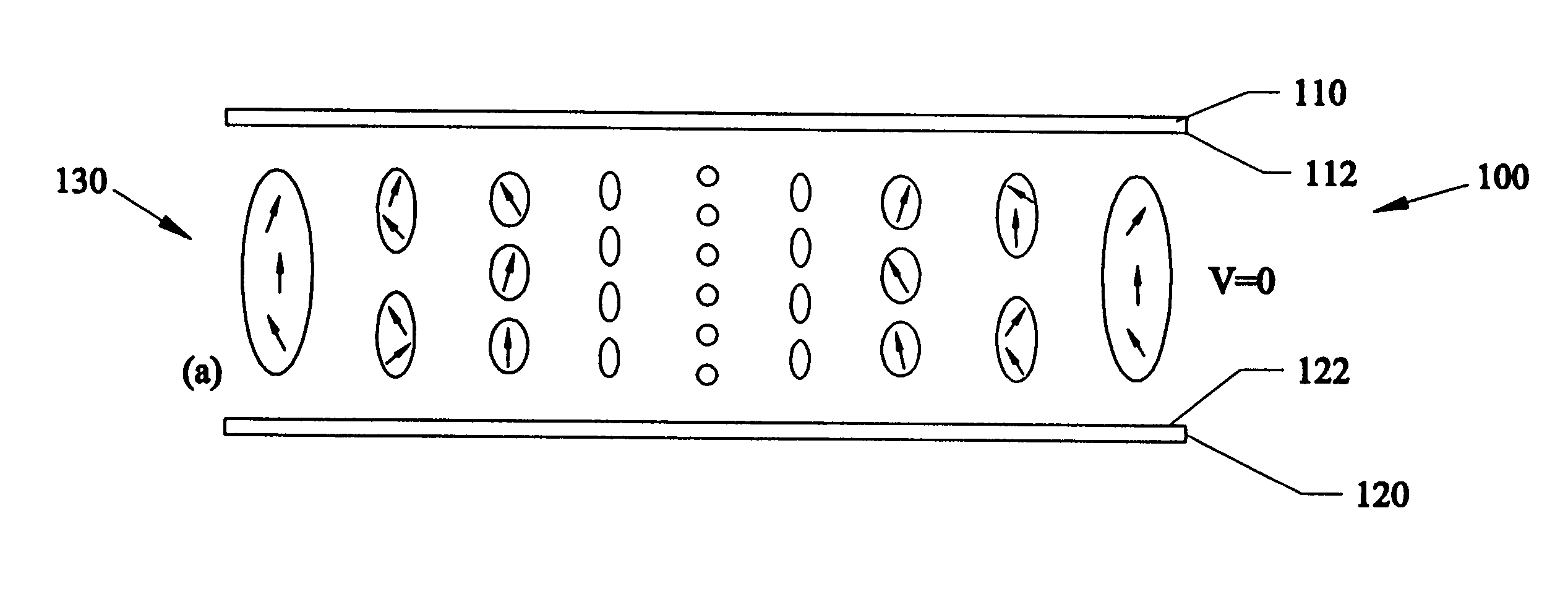

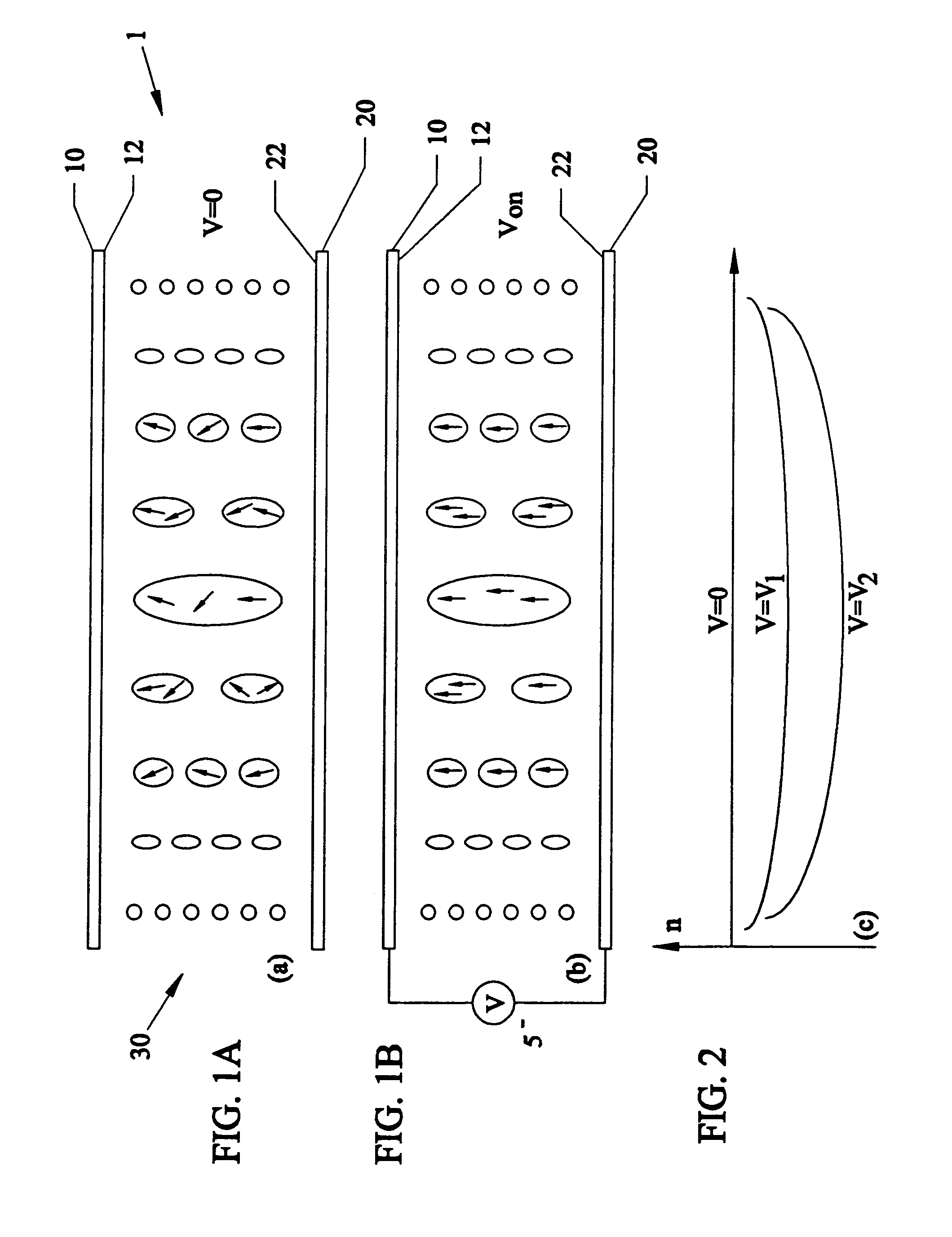

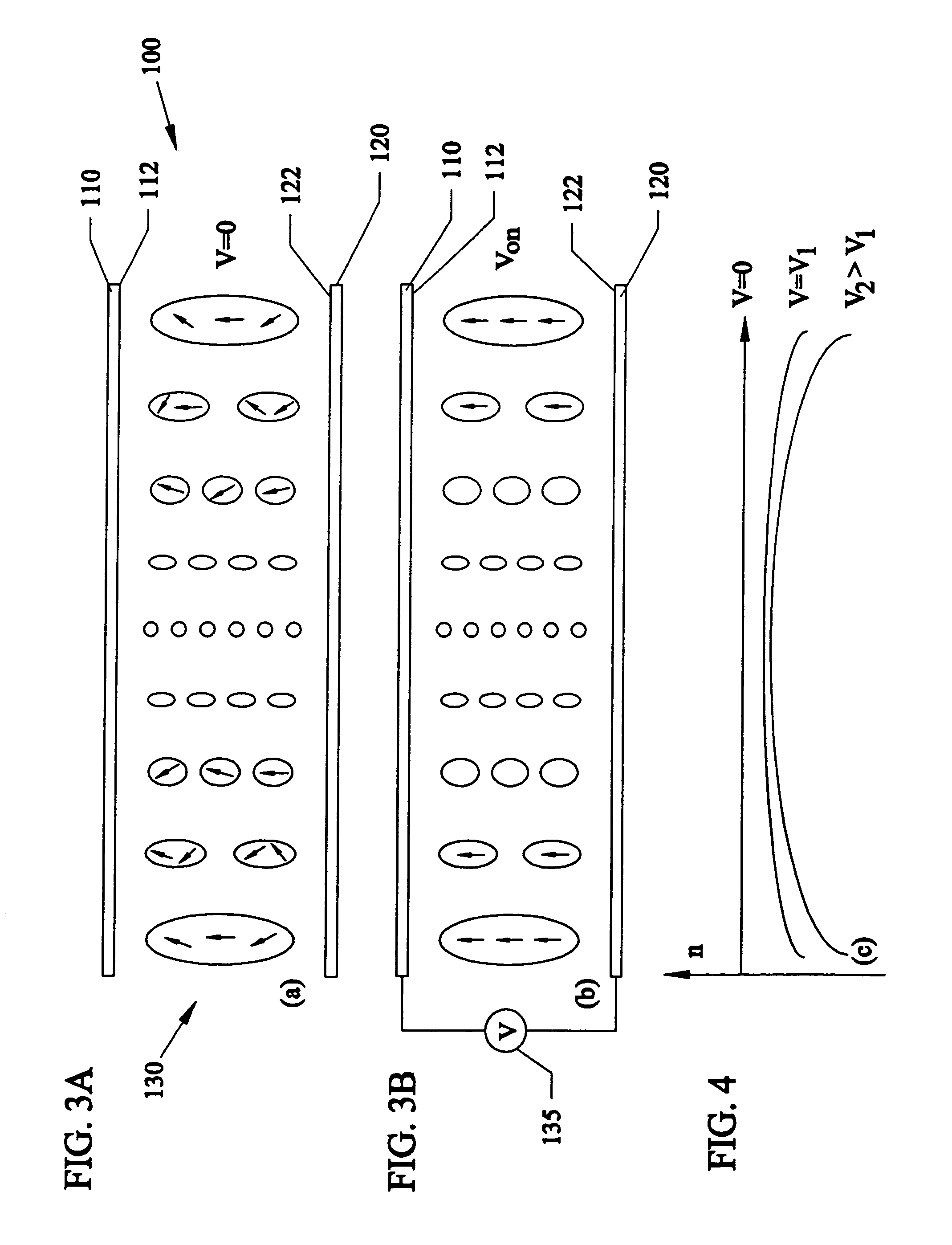

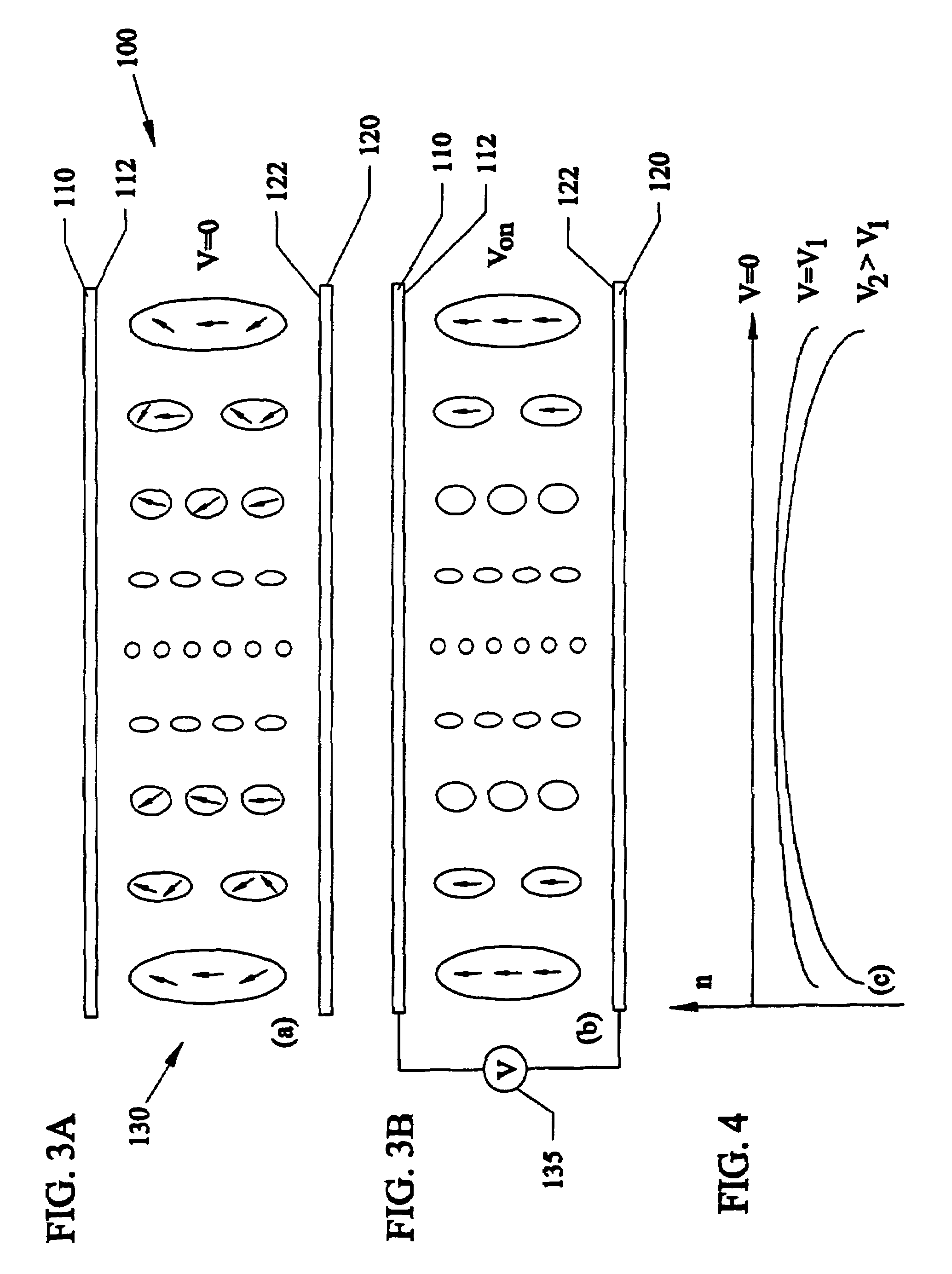

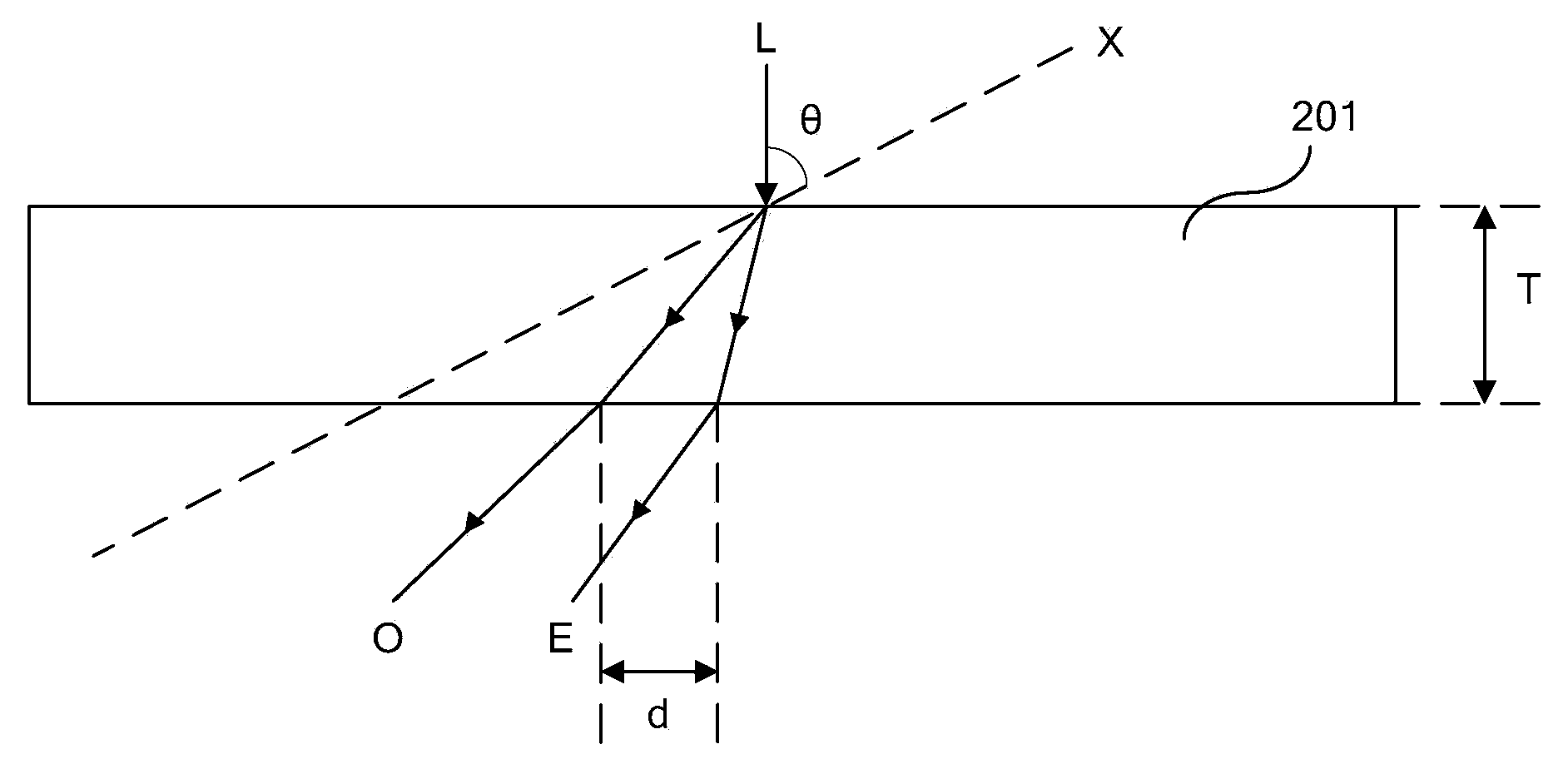

Tunable electronic lens and prisms using inhomogeneous nano scale liquid crystal droplets

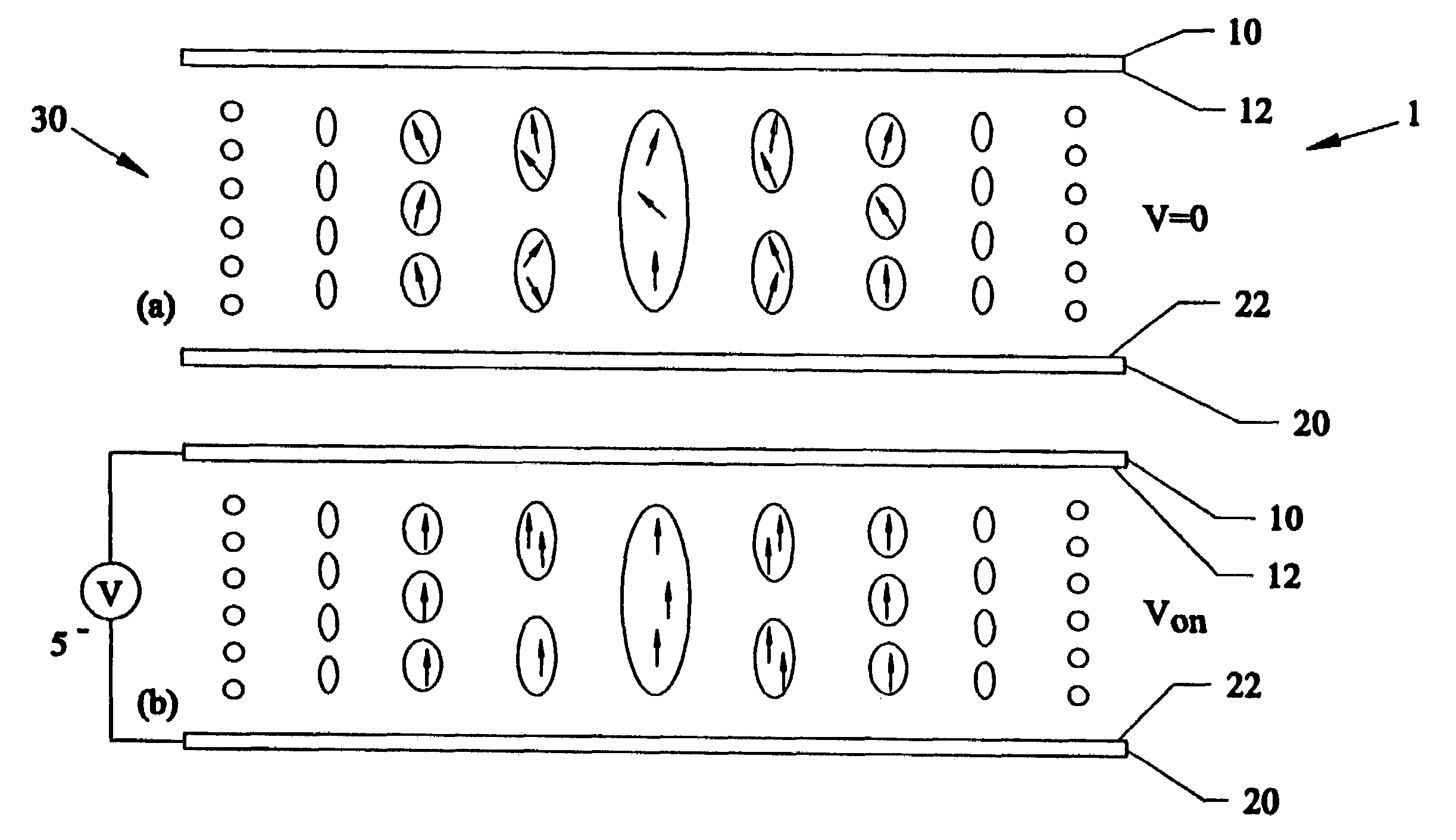

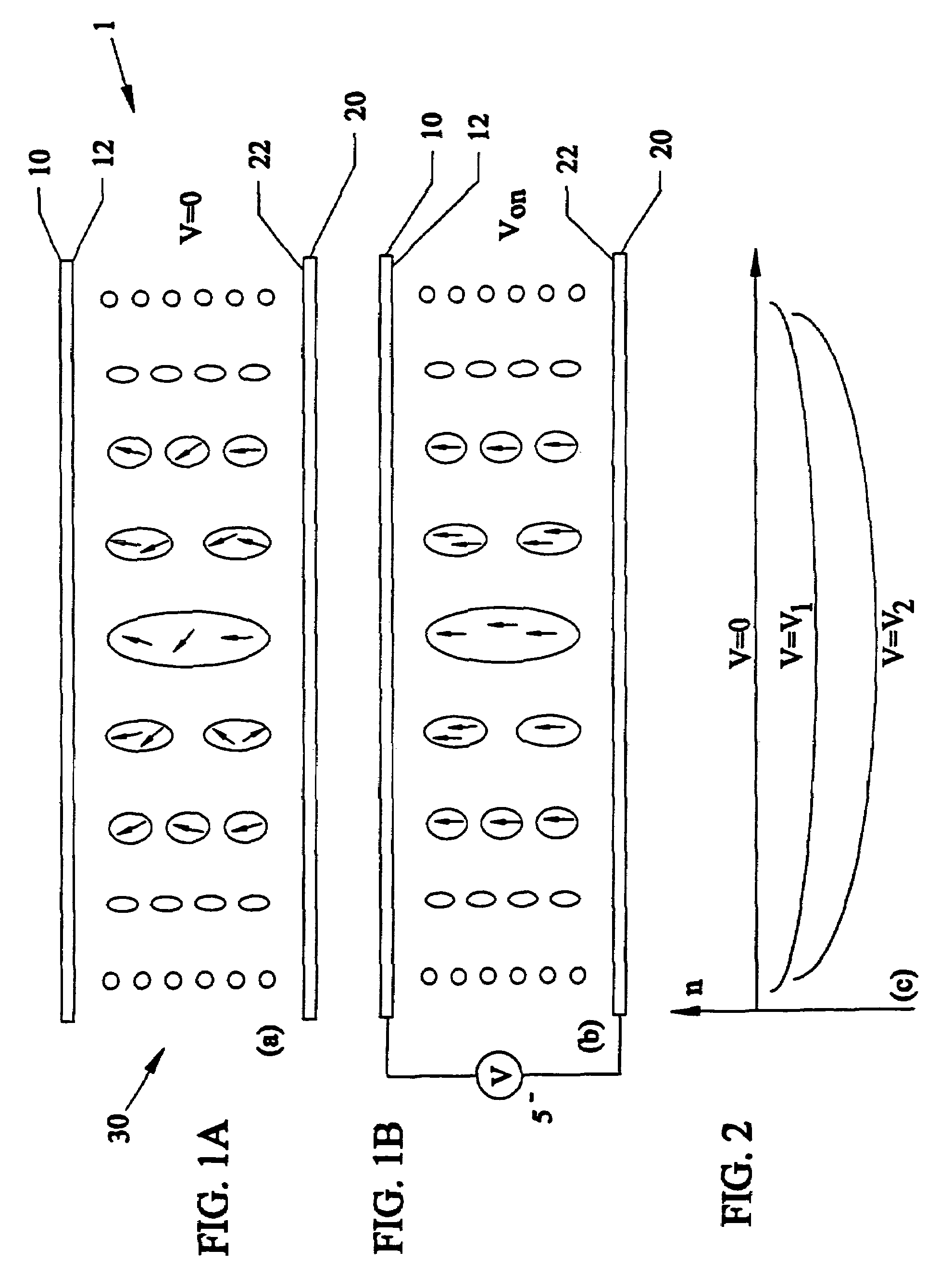

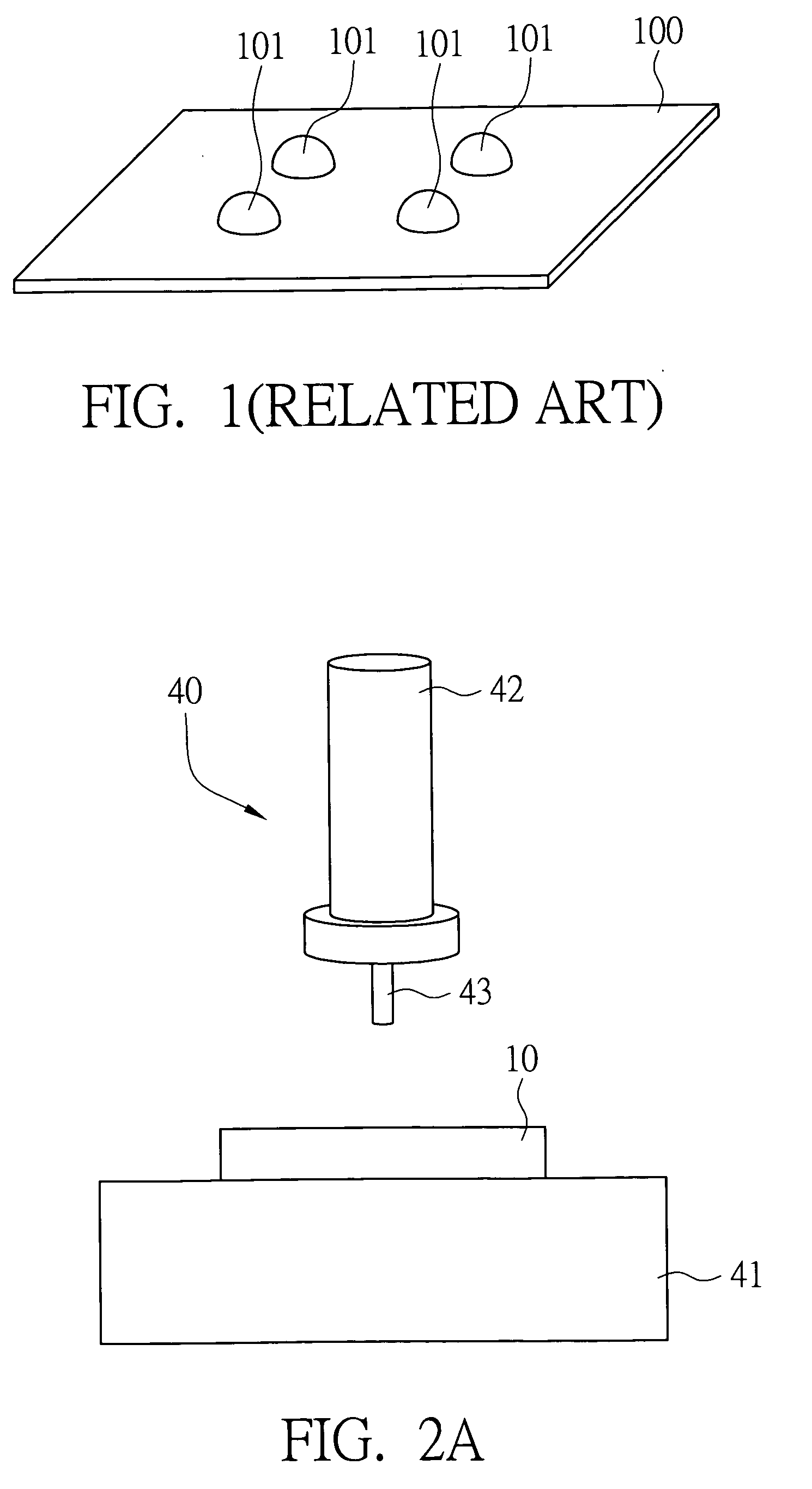

InactiveUS6864951B1Simple manufacturing processLiquid crystal compositionsNon-linear opticsCamera lensFresnel lens

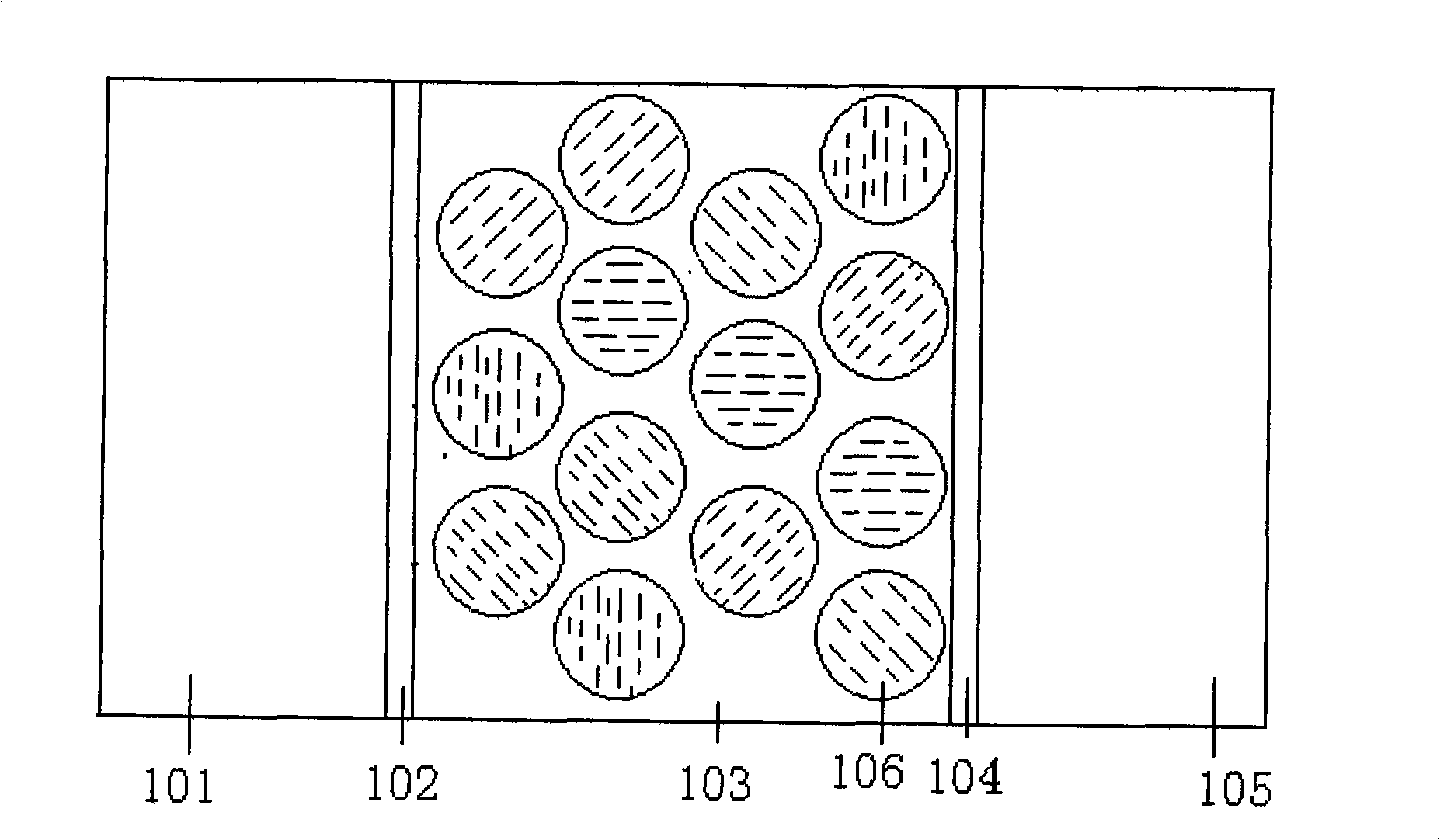

Using inhomogeneous sized liquid crystal (LC) droplets for lens and prisms. For forming a positive lens, the LC droplet size can gradually increase from the center to the side edges. For forming a negative lens, the LC droplet size can gradually decrease from the center to the side edges. The lens can be created by Ultra Violet light exposure to patterns. The lens can be tuned by applying voltage to the droplets. The inhomogeneous droplets can also be used in Fresnel lens and prisms. Applications of the invention can be used for eyeglasses, arrays, camera type zoom lenses and beam steering applications.

Owner:UNIV OF CENT FLORIDA RES FOUND INC +1

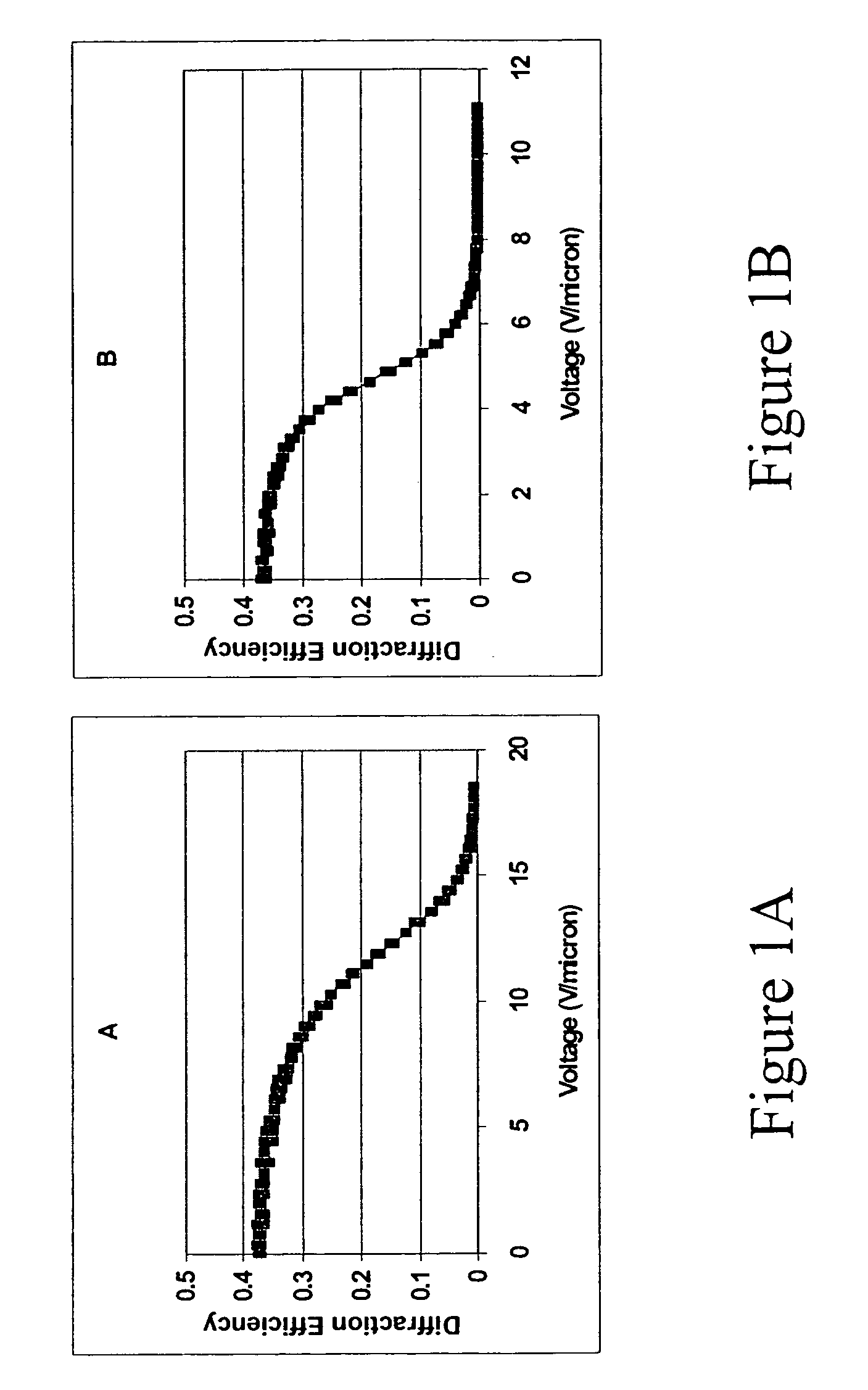

Tailoring material composition for optimization of application-specific switchable holograms

InactiveUS7175780B1Improve efficiencyOptical qualityLiquid crystal compositionsThin material handlingCrystallographyChemical composition

The process described herein offers the optimizing of performance parameters of holograms, such as reducing scattering effects in a polymer-dispersed liquid crystal optical element. In the process, an interfacial tension agent is added to a polymer-dispersed liquid crystal material. The polymer-dispersed liquid crystal material has at least one acrylic acid monomer, at least one type of liquid crystal material, a photoinitiator dye, and a co-initiator. The polymer-dispersed liquid crystal material is subjected to a polymerization. The interfacial tension agent reduces the size of liquid crystal droplets formed within the polymer-dispersed liquid crystal optical element during polymerization.

Owner:LEIDOS

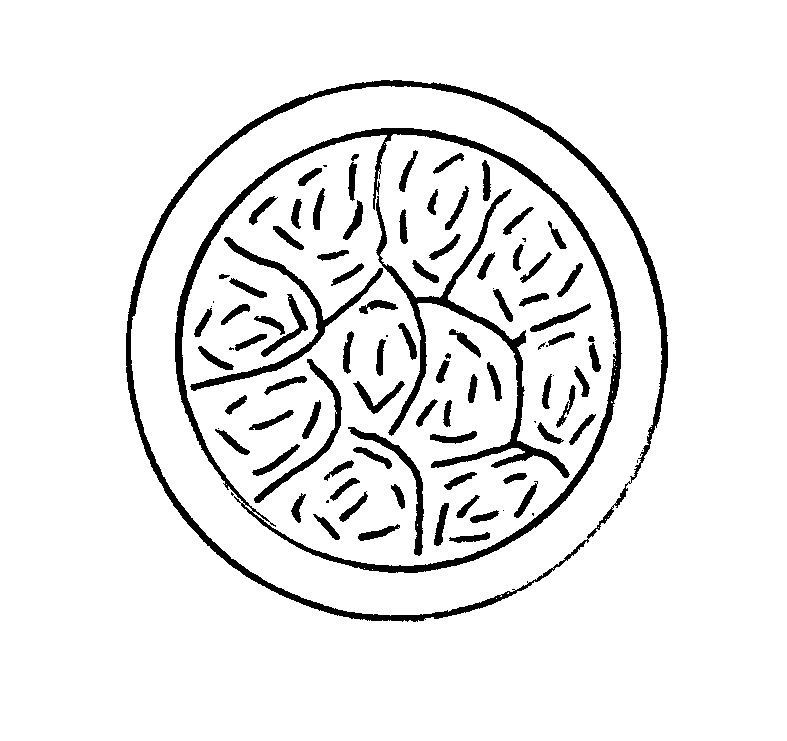

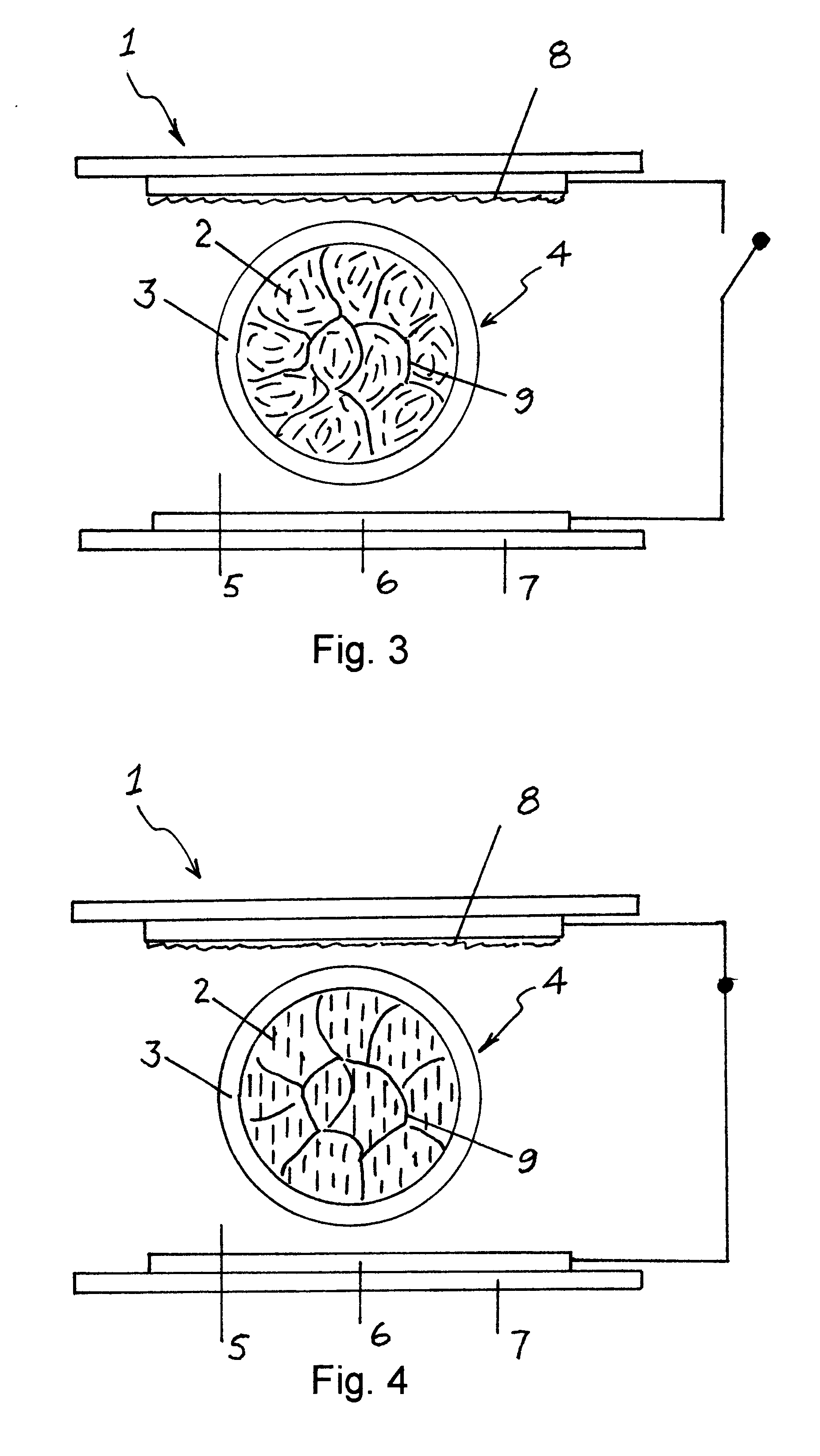

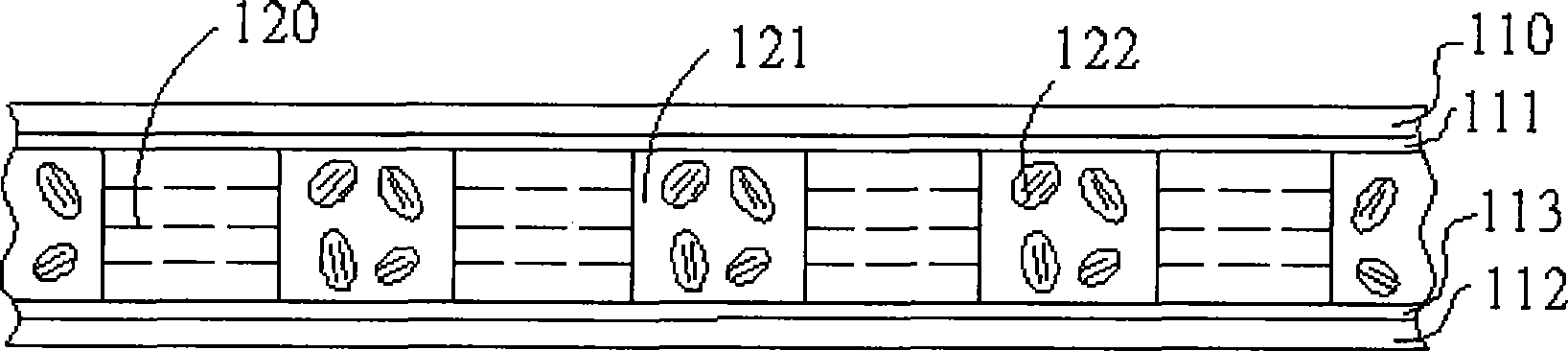

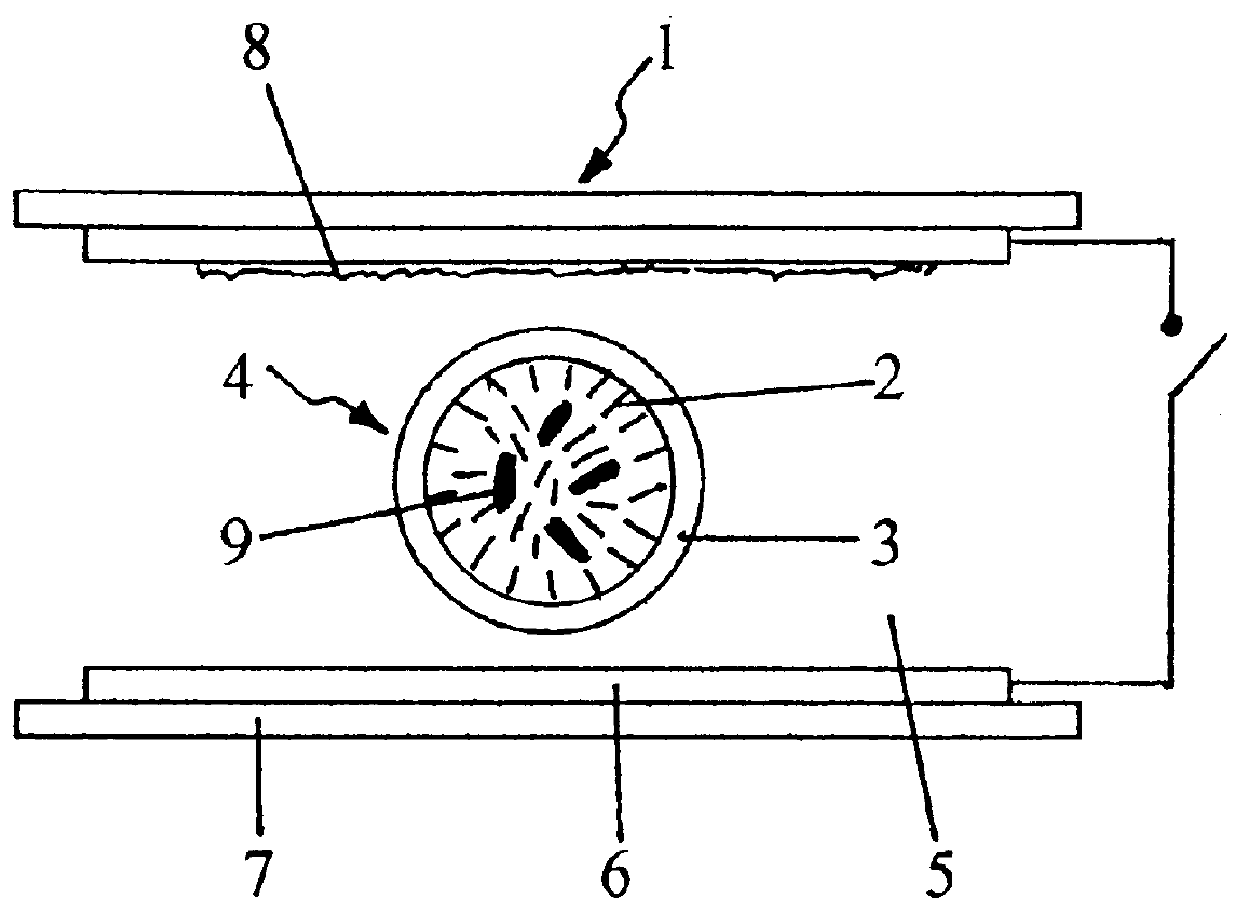

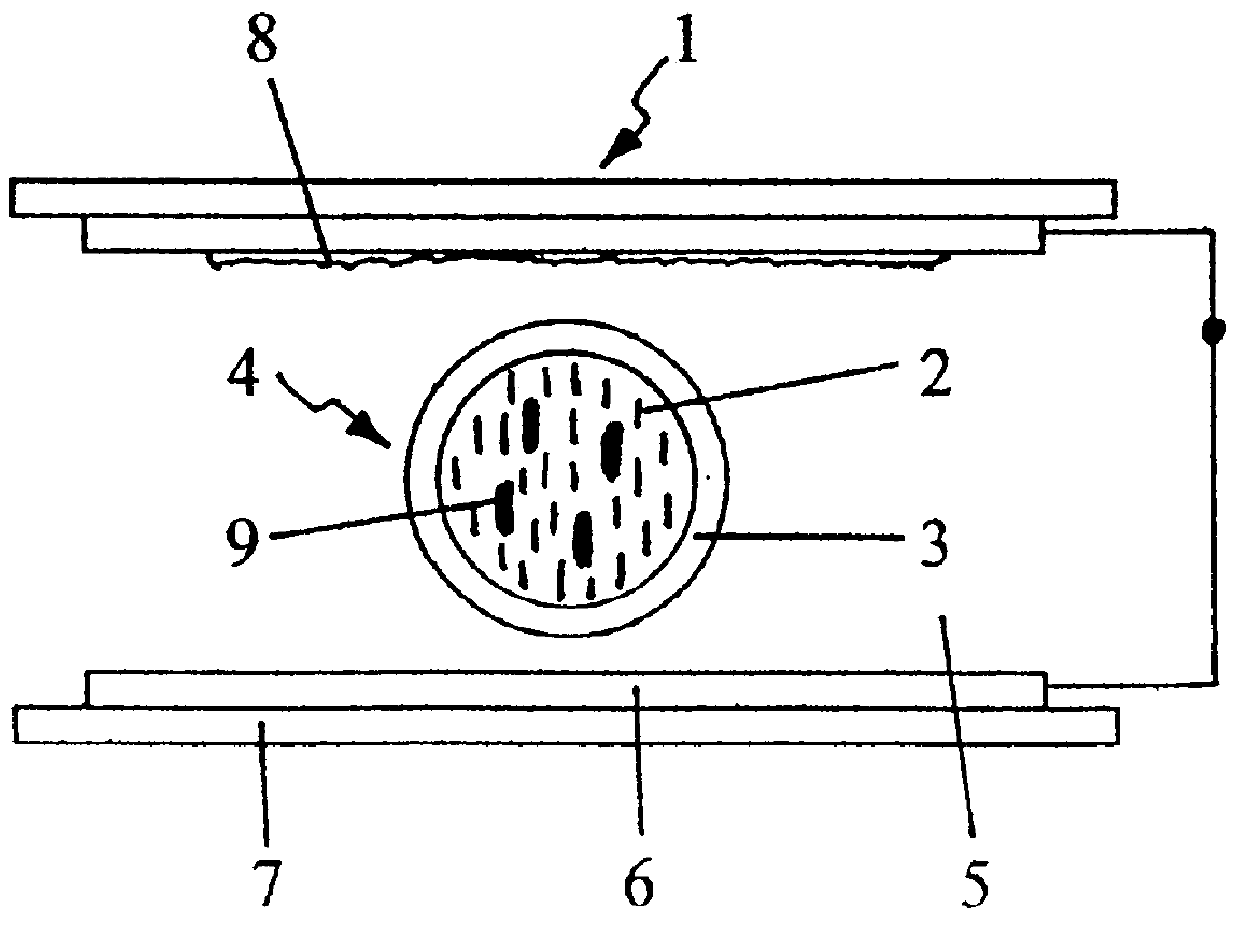

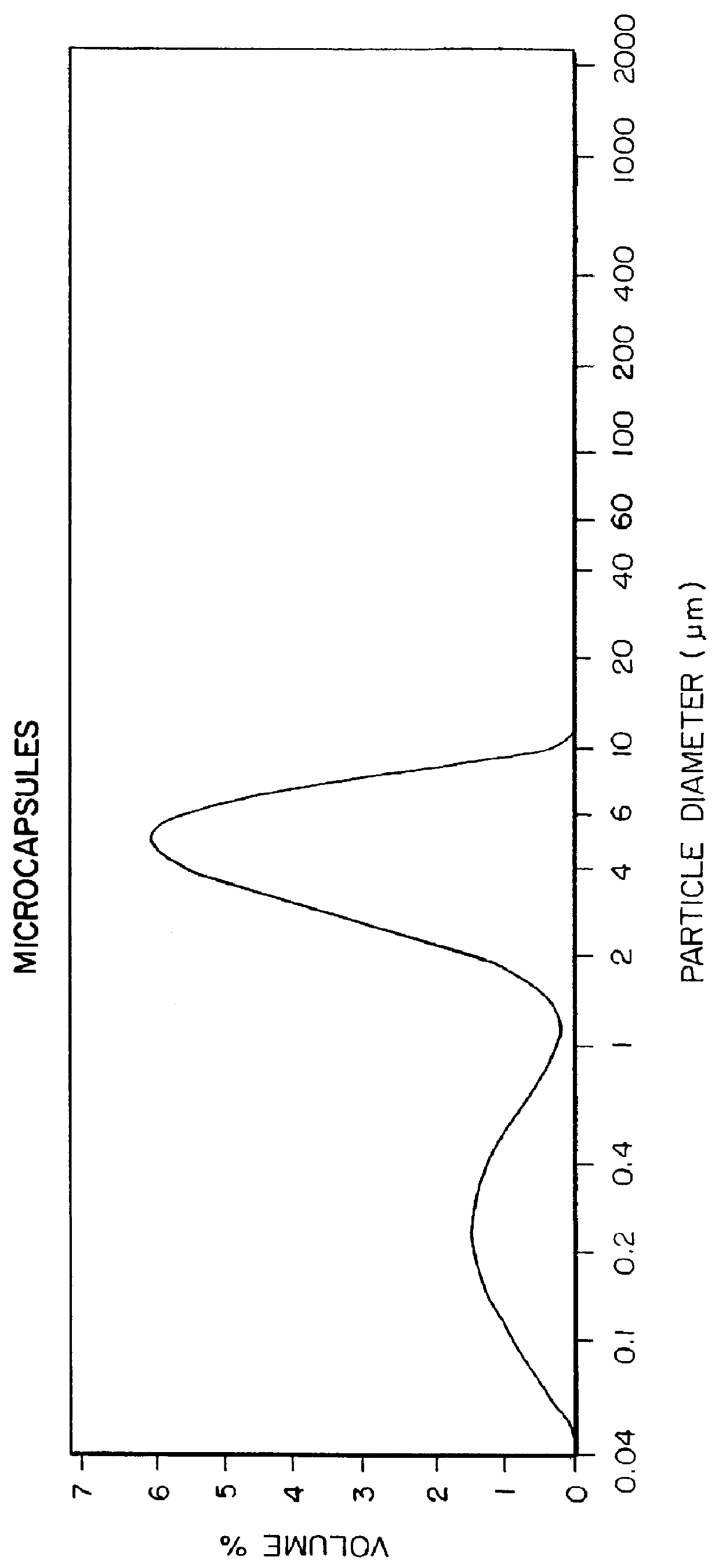

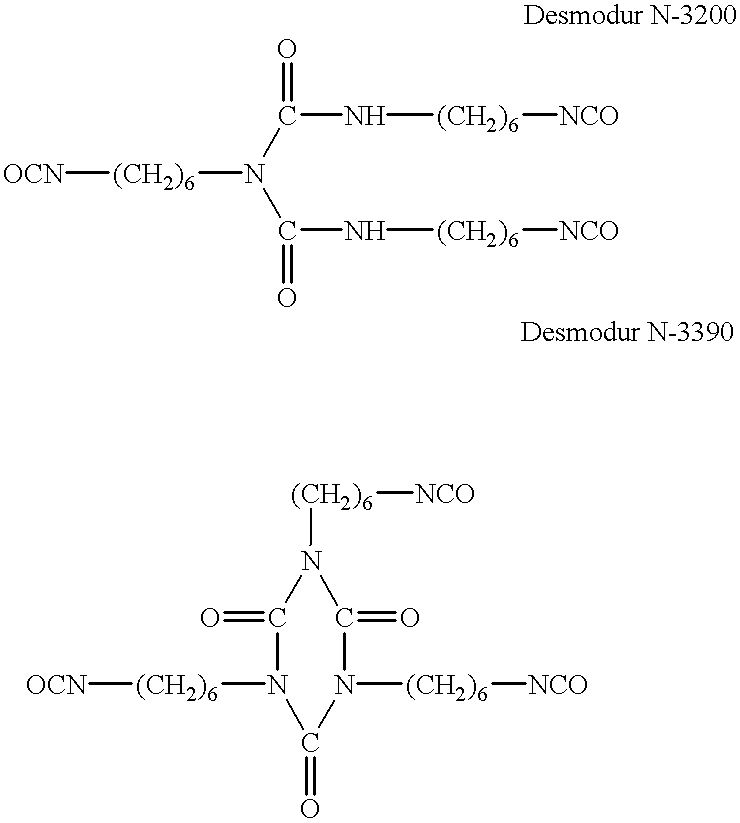

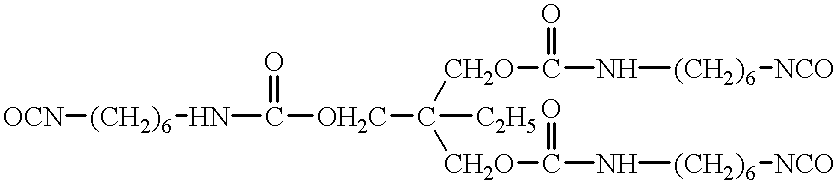

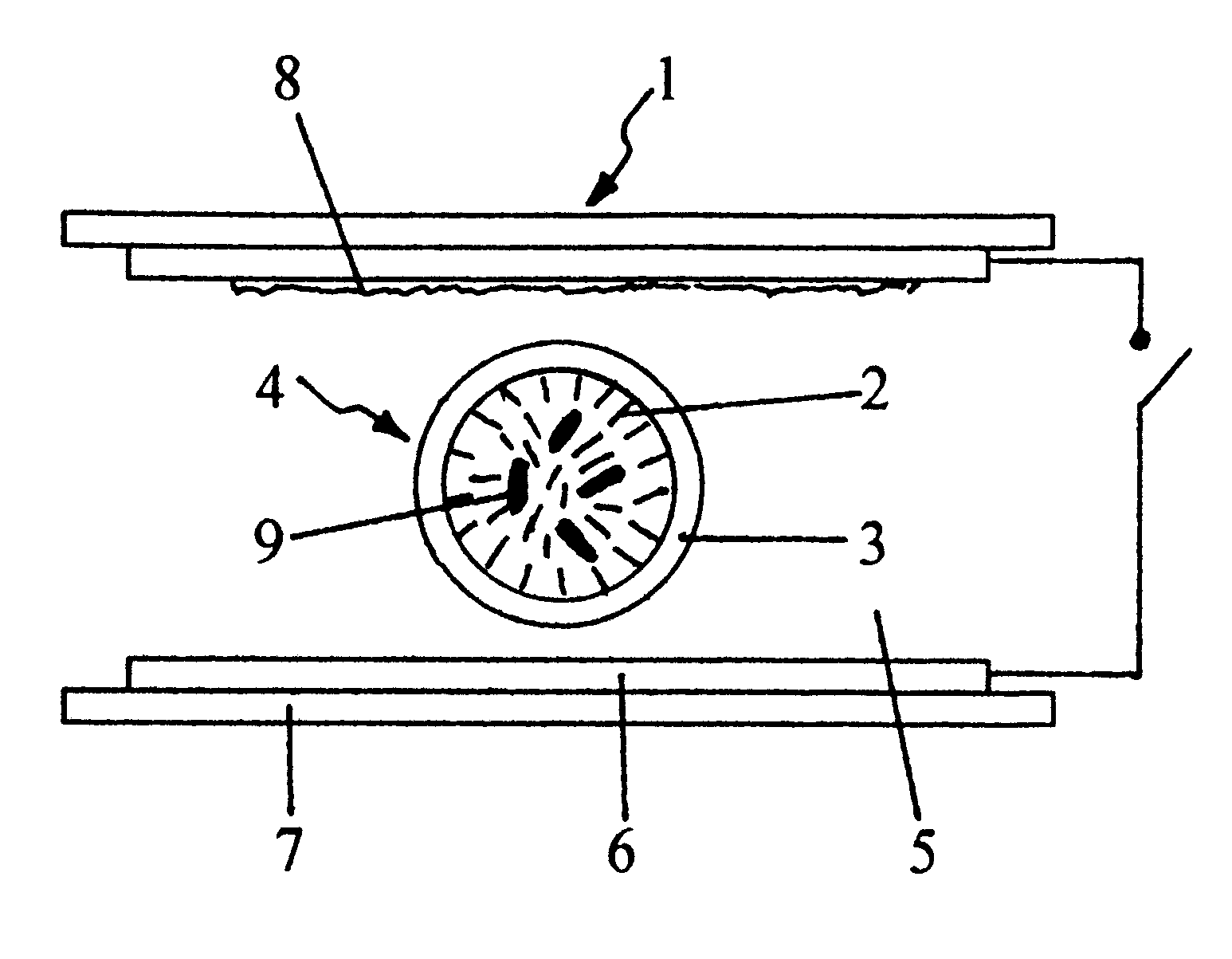

Microencapsulated liquid crystal having multidomains induced by the polymer network and method

A liquid crystal material containing polymer network forming material is microencapsulated by a method utilizing an interfacial polymerization which creates a combination of polyurethane and polyurea polymers or melamine fromaldehyde or urea formaldehyde polymer which form the capsule walls surrounding the discrete liquid crystal droplets. The prepolymer of urethane acrylate and acrylate within the liquid crystal capsules is cured under UV light irradiation to form a web-like structure and induce the formation of polydomain configuration of nematic director. This allows to produce the display having faster switching property and showing significant lower threshold voltage.

Owner:HSU YING YEN

Tunable electronic lens and prisms using inhomogeneous nano scale liquid crystal droplets

Using inhomogeneous sized liquid crystal (LC) droplets for lens and prisms. For forming a positive lens, the LC droplet size can gradually increase from the center to the side edges. For forming a negative lens, the LC droplet size can gradually decrease from the center to the side edges. The lens can be created by Ultra Violet light exposure to patterns. The lens can be tuned by applying voltage to the droplets. The inhomogeneous droplets can also be used in Fresnel lens and prisms. Applications of the invention can be used for eyeglasses, arrays, camera type zoom lenses and beam steering applications.

Owner:UNIV OF CENT FLORIDA RES FOUND INC

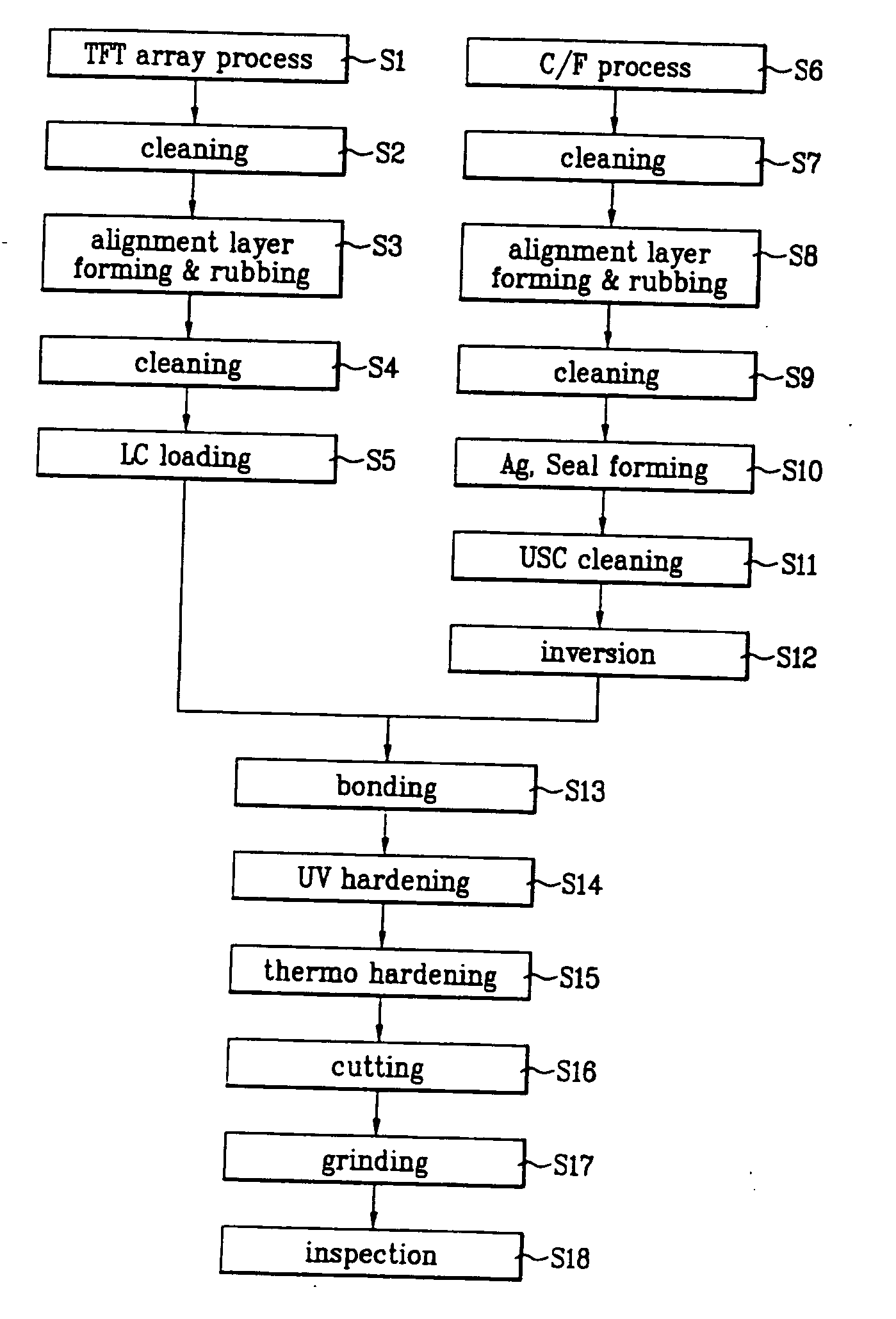

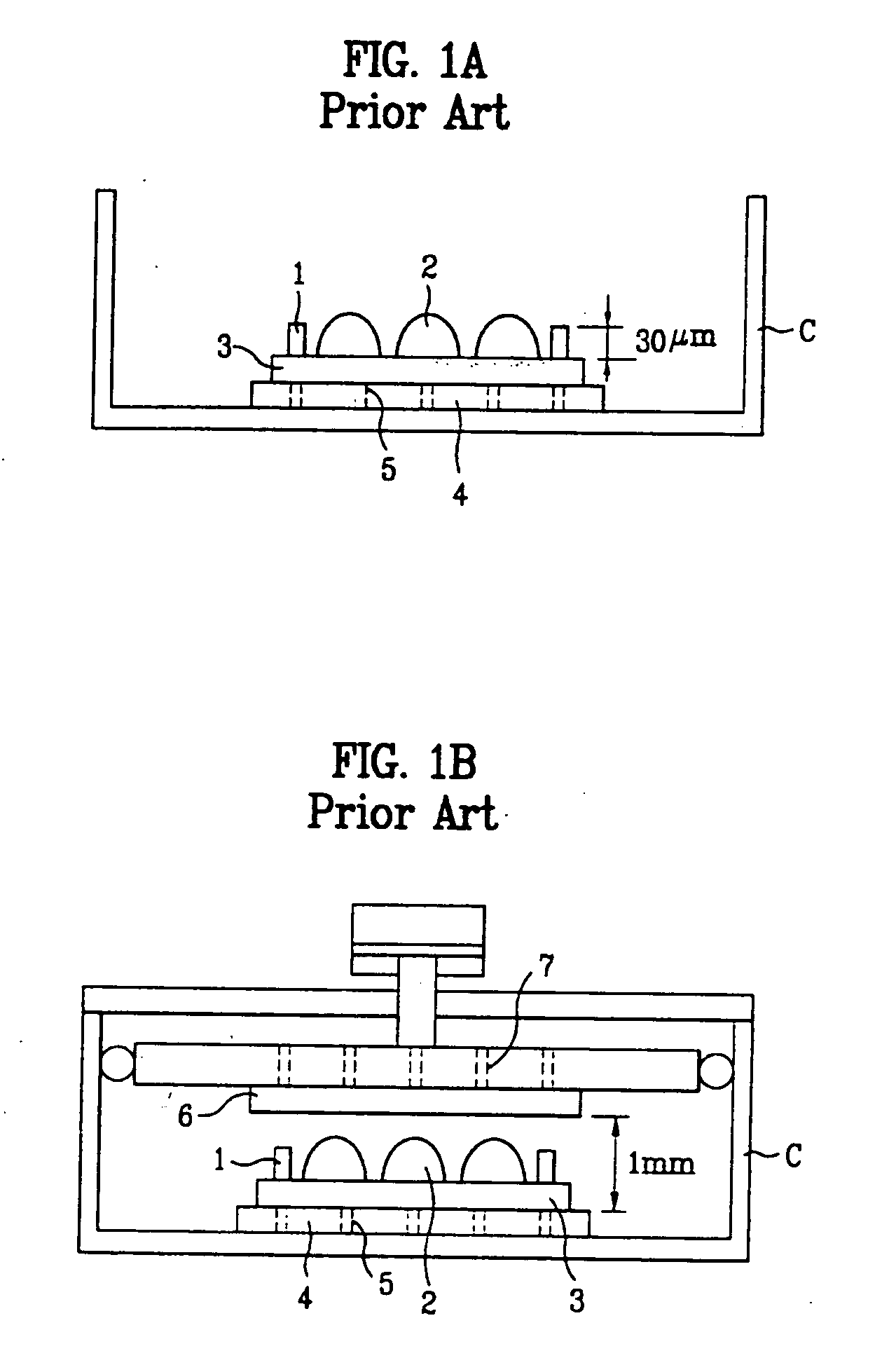

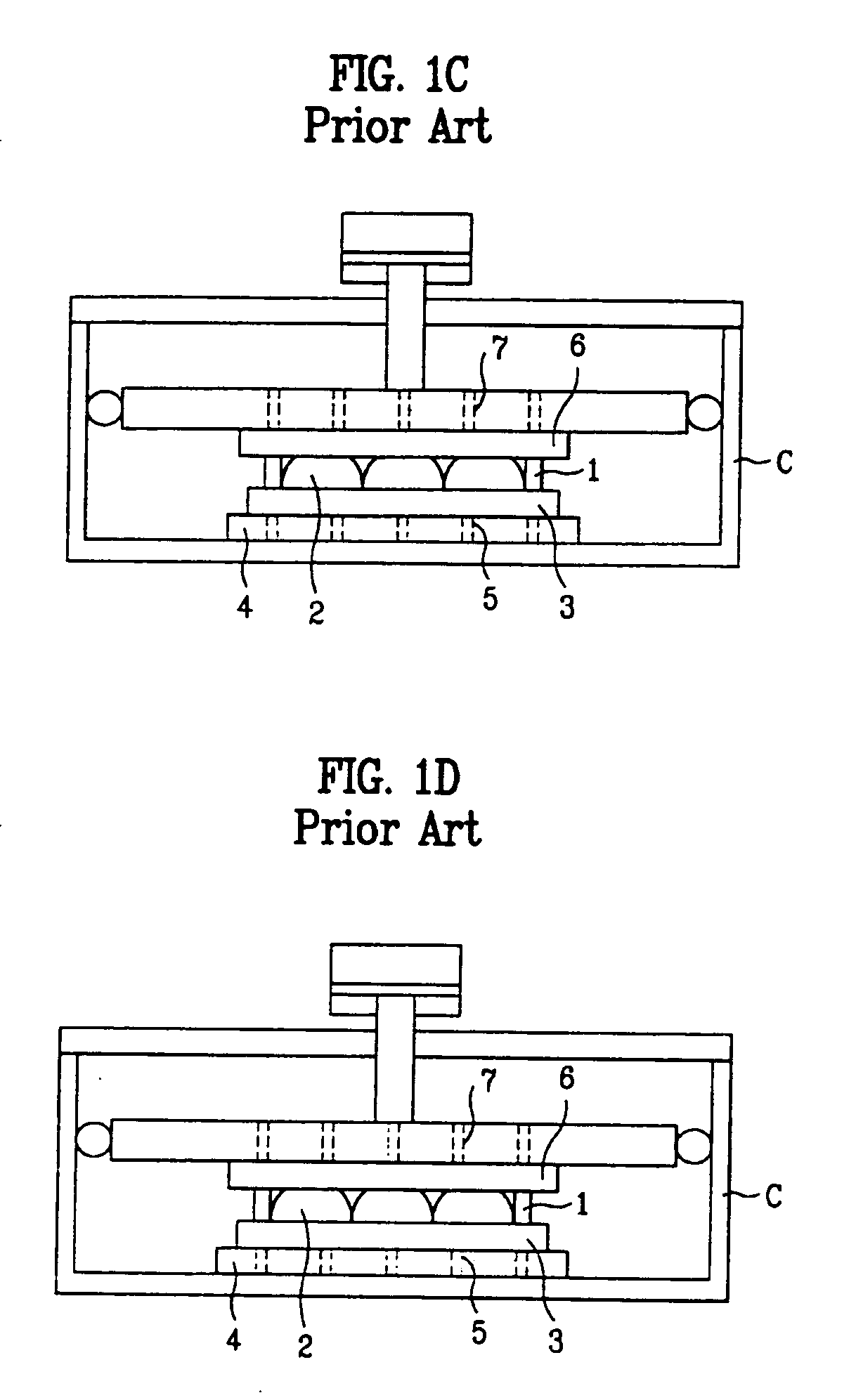

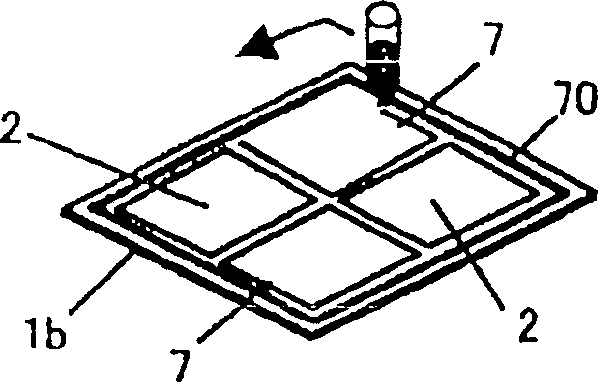

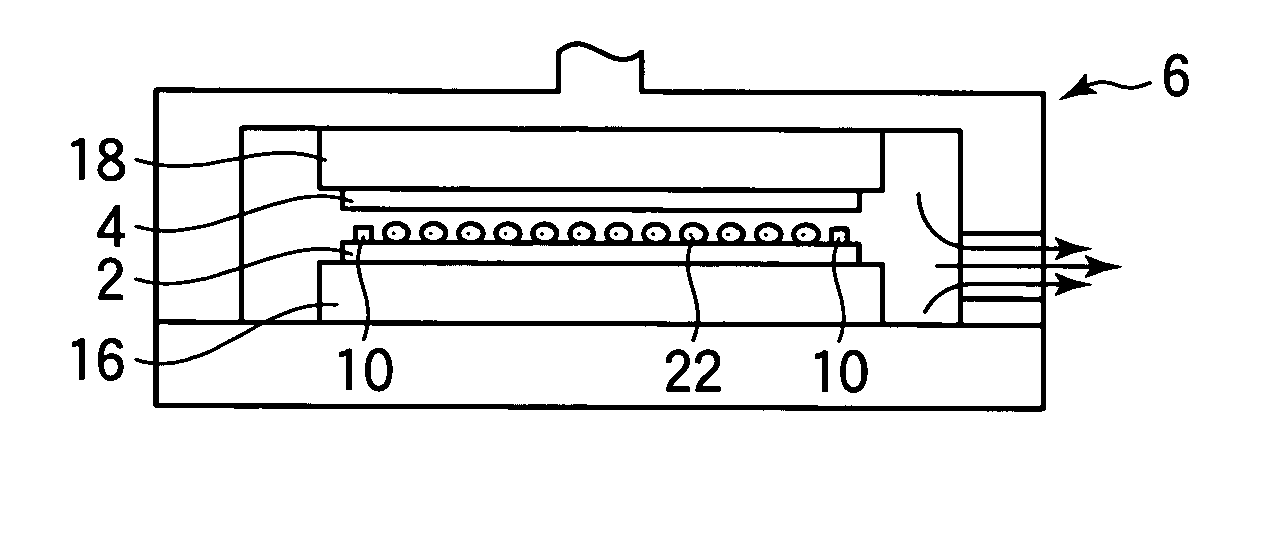

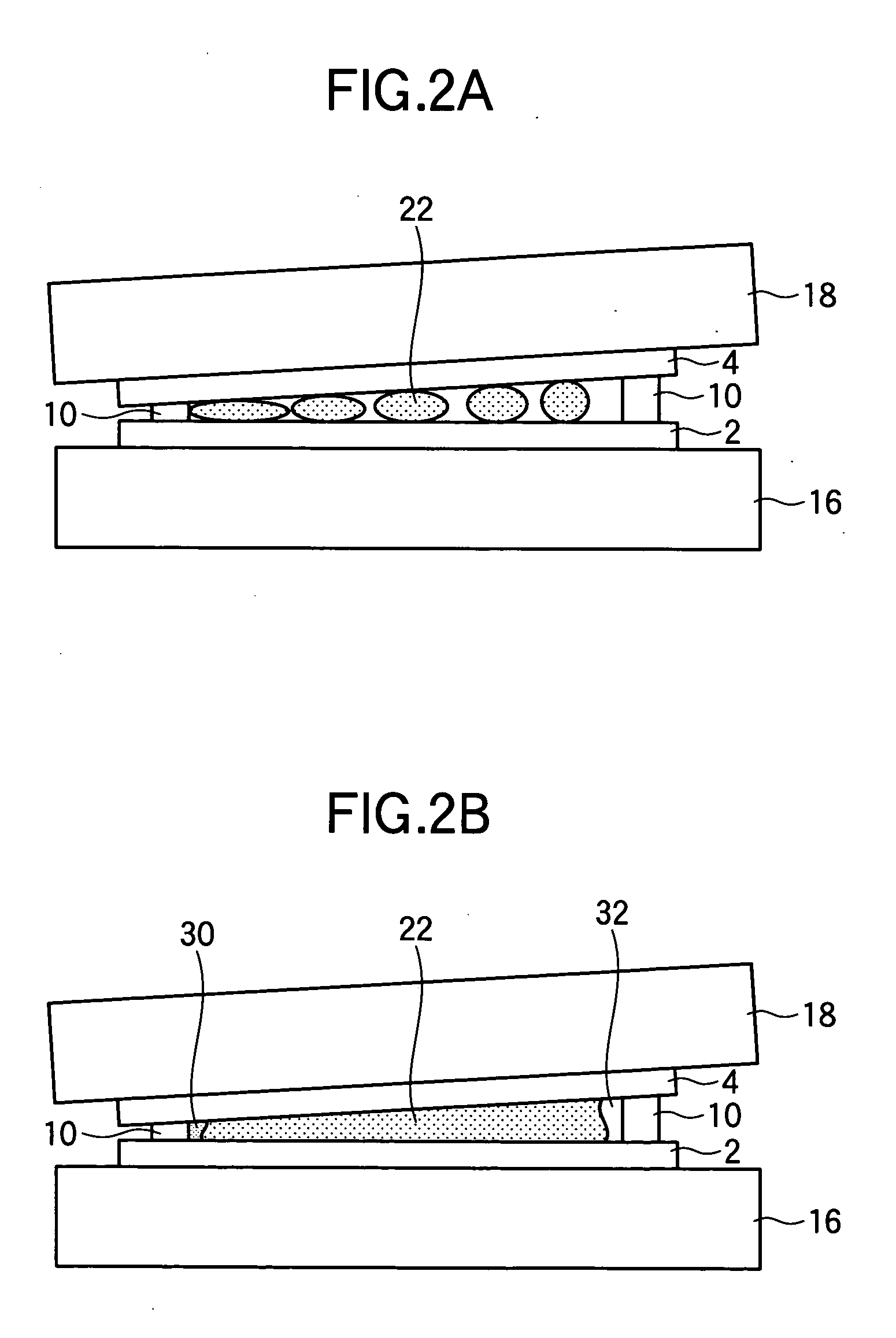

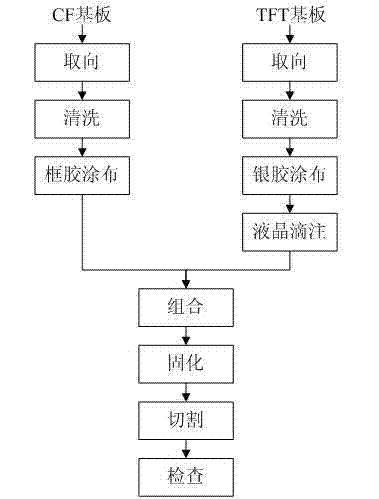

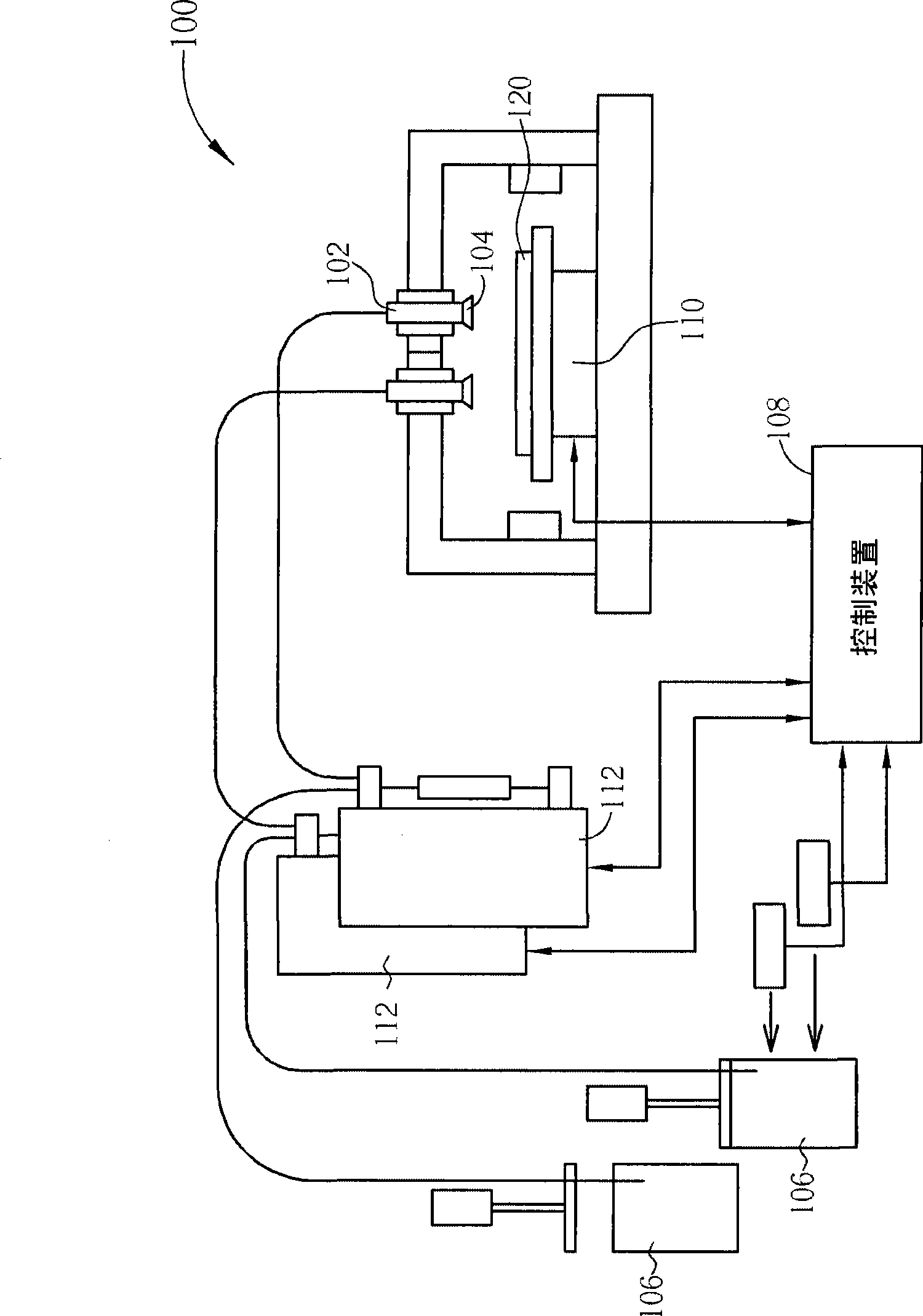

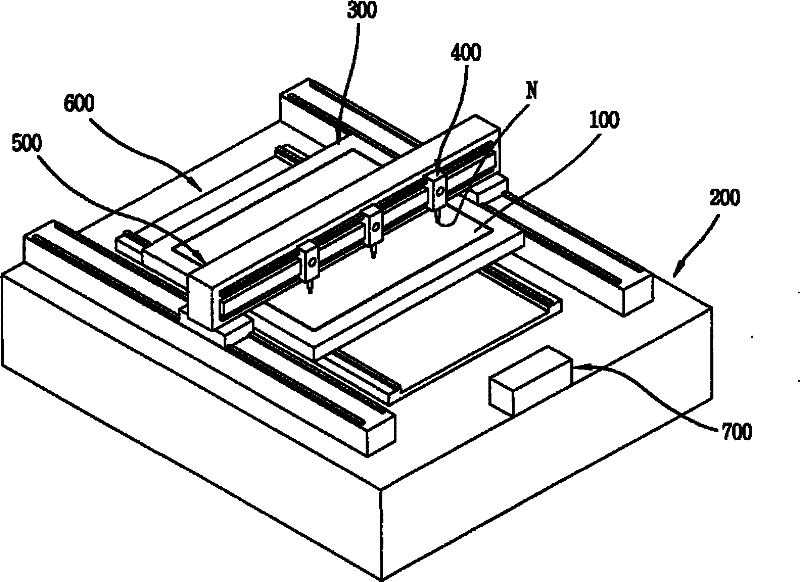

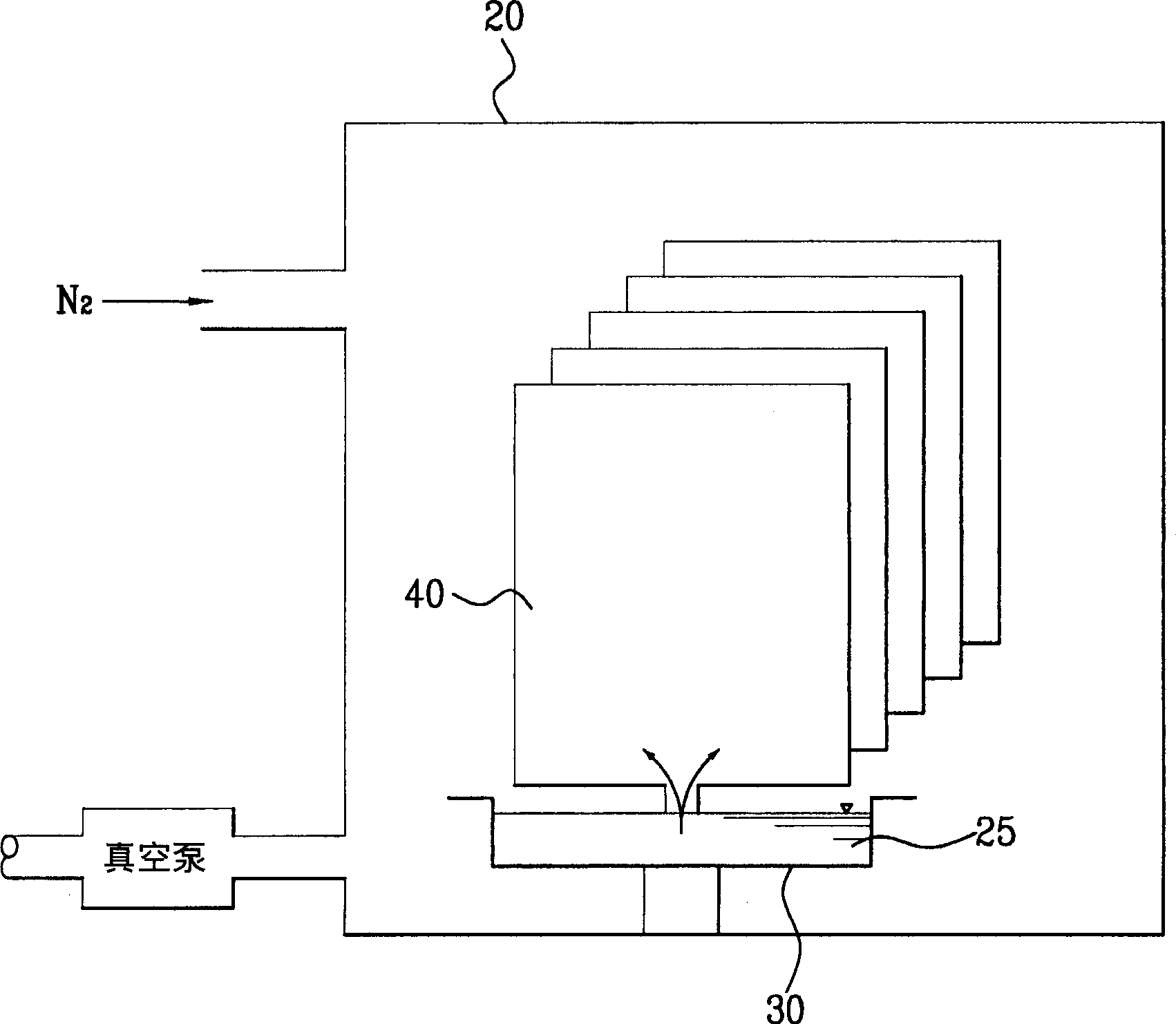

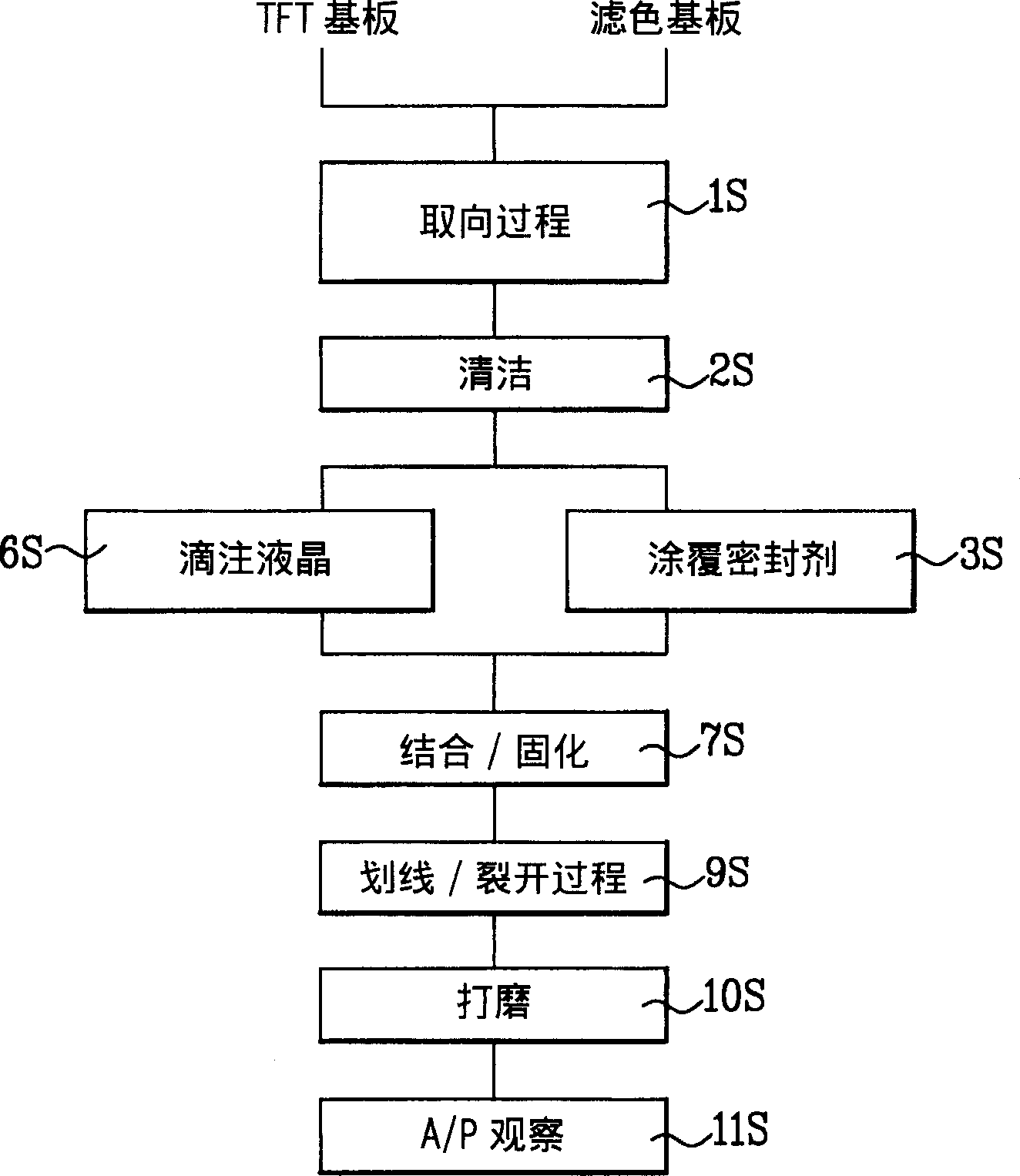

System for fabricating liquid crystal display and method of fabricating liquid crystal display using the same

InactiveUS20050248715A1Reduce processing timeImprove productivityNon-linear opticsLiquid-crystal displaySealant

Disclosed is a system for fabricating a liquid crystal display using liquid crystal dropping and a method of fabricating a liquid crystal display using the same. The present invention includes a liquid crystal forming line dropping liquid crystals on the first substrate, a sealant forming line forming the sealant on the second substrate, and a bonding and hardening line bonding the two substrates to each other and hardening the sealant, printing a sealant, bonding the substrates each other, and hardening the sealant and an inspection process line of cutting the bonded substrates into panel units and grinding and inspecting the unit panels. And, the GAP process line includes And, the present invention includes the processes of dropping LC on a first substrate using a dispenser, forming a main UV hardening sealant on a second substrate, bonding the first and second substrates to each other in a vacuum state, UV-hardening the main UV hardening sealant, cutting the bonded substrates into cell units, grinding the cut substrates, and inspecting the grinded substrates finally.

Owner:LG DISPLAY CO LTD

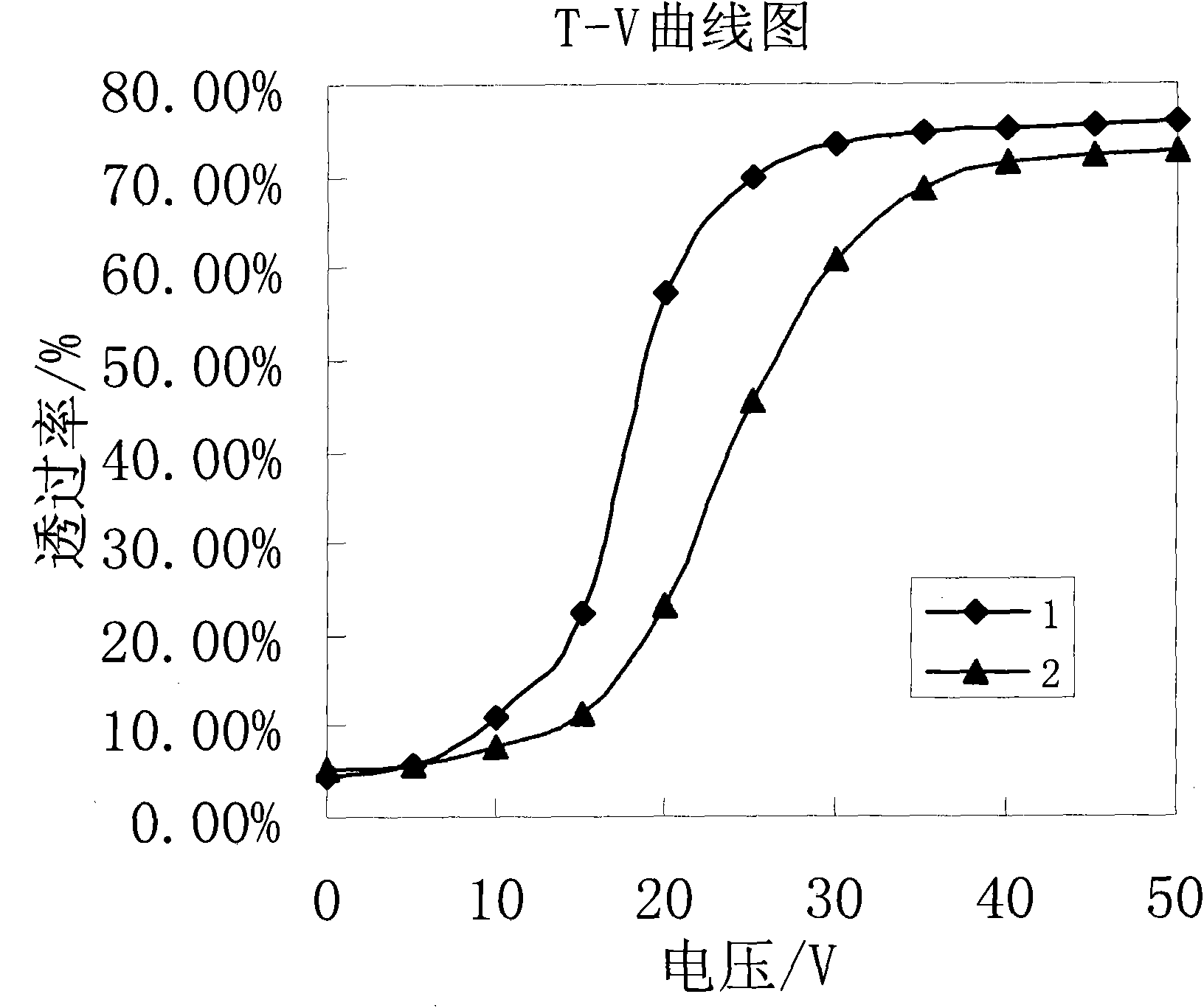

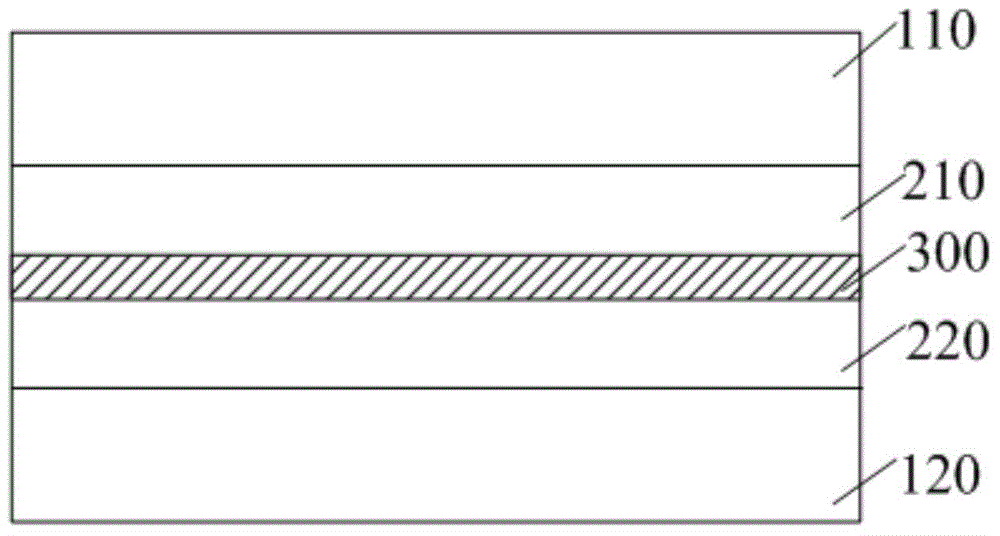

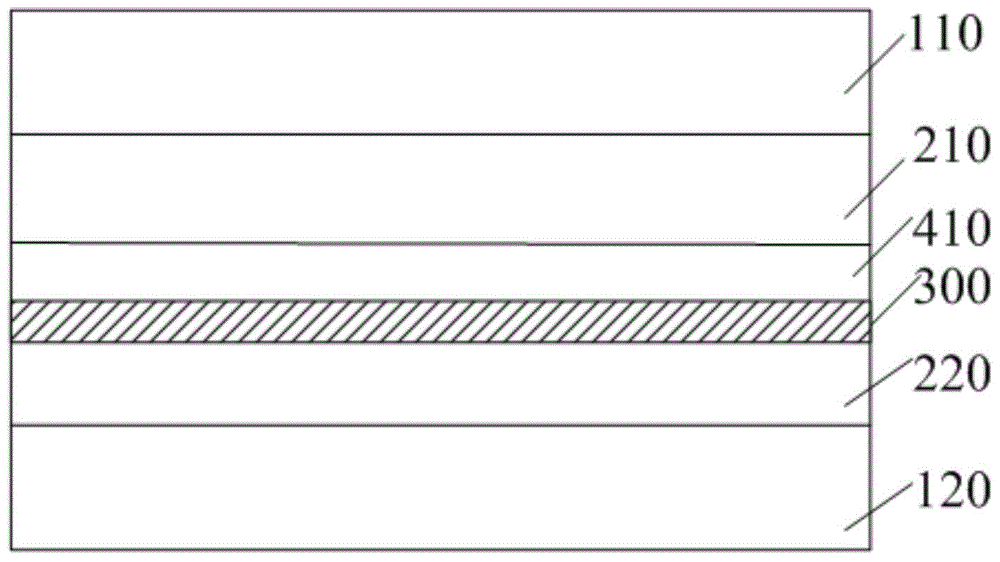

Polymer dispersed liquid crystal composition, polymer dispersed liquid crystal layer and preparation method, polymer dispersed liquid crystal film and preparation method

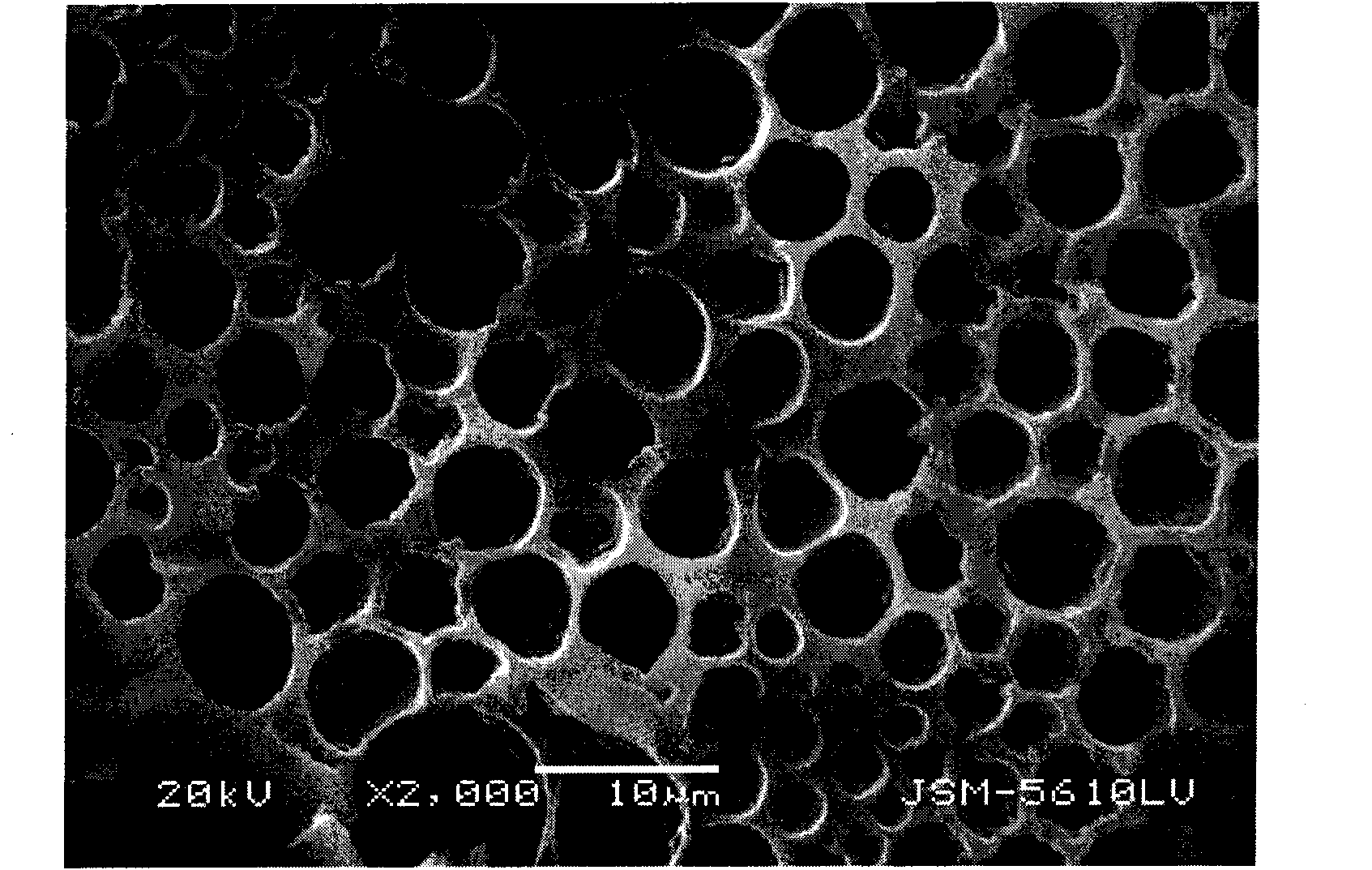

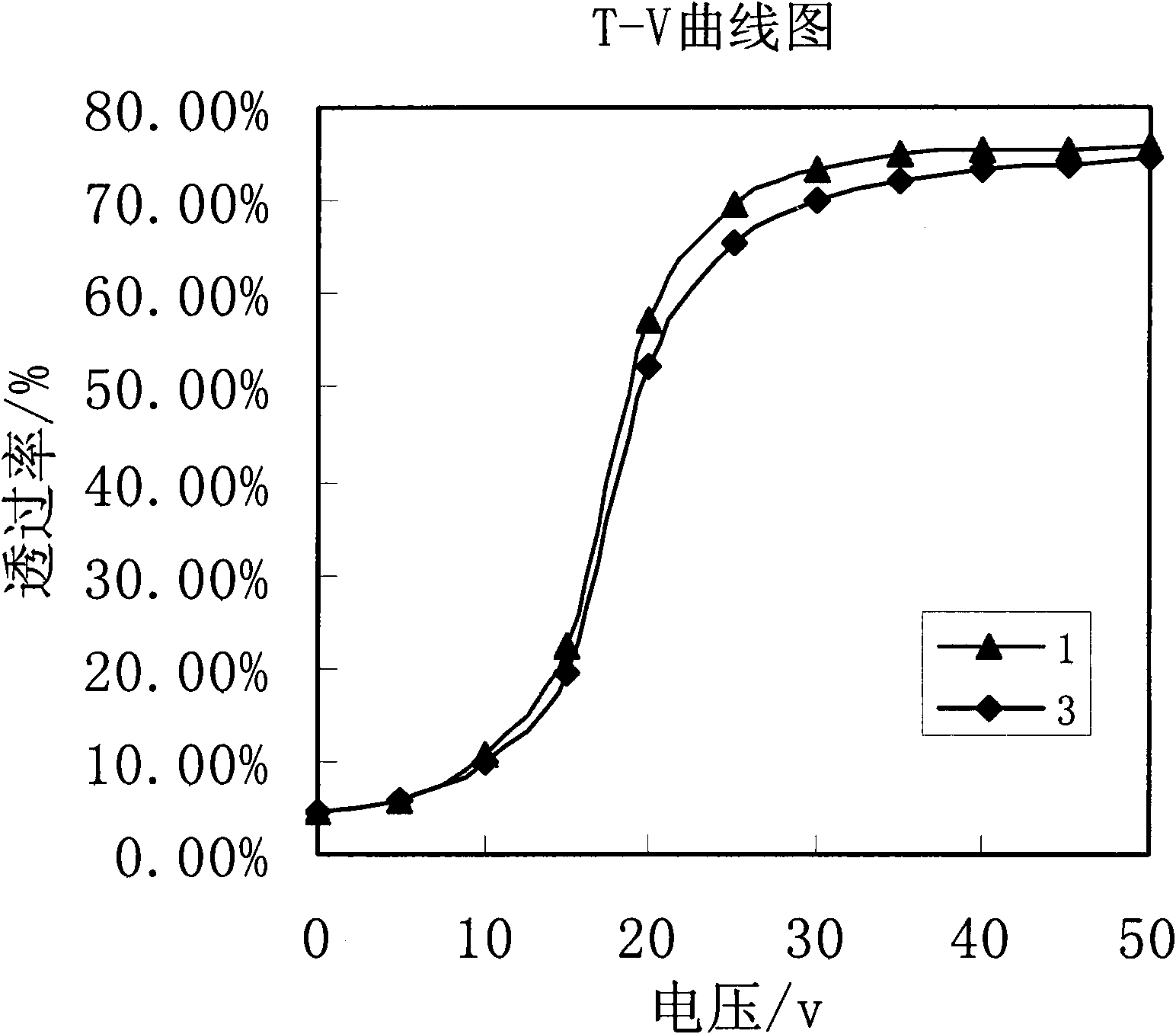

ActiveCN101768449AOpen state transmittance decreasesLiquid crystal compositionsNon-linear opticsPolymer scienceLiquid-crystal display

The invention provides a polymer dispersed liquid crystal layer and a polymer dispersed liquid crystal film containing the polymer dispersed liquid crystal layer. The polymer dispersed liquid crystal layer is non-white. A polymer dispersed liquid crystal composition comprises a polymer monomer, a liquid crystal and a dye. The polymer dispersed liquid crystal layer comprises a three-dimensional porous structure formed by polymers. The pores are filled with liquid crystal droplets and have an average pore size of 2-5mu m. The invention also provides the polymer dispersed liquid crystal composition and methods for preparing the polymer dispersed liquid crystal layer and the polymer dispersed liquid crystal film. By adopting the non-white polymer dispersed liquid crystal layer or the polymer dispersed liquid crystal film containing the polymer dispersed liquid crystal layer, the driving voltage can be simultaneously less than or equal to 40V and the on-state transmittance under 40V can bemore than 75%.

Owner:BYD CO LTD

Tunable electronic lens and prisms using inhomogeneous nano scale liquid crystal droplets

Using inhomogeneous sized liquid crystal (LC) droplets for lens and prisms. For forming a positive lens, the LC droplet size can gradually increase from the center to the side edges. For forming a negative lens, the LC droplet size can gradually decrease from the center to the side edges. The lens can be created by Ultra Violet light exposure to patterns. The lens can be tuned by applying voltage to the droplets. The inhomogeneous droplets can also be used in Fresnel lens and prisms. Applications of the invention can be used for eyeglasses, arrays, camera type zoom lenses and beam steering applications.

Owner:UNIV OF CENT FLORIDA RES FOUND INC

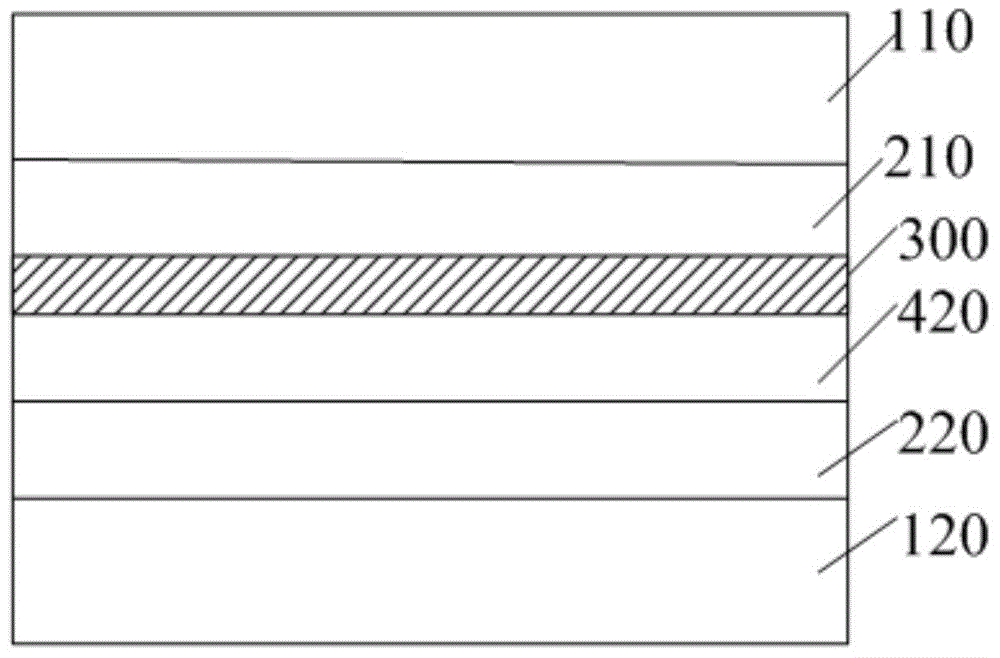

PDLC grating of lcd equipment and making method

ActiveCN101424814AControl work characteristicsImprove transmittancePhotomechanical apparatusLaminationElectricityGrating

The invention discloses a PDLC raster and a manufacture method of an LCD device, wherein the raster structurally comprises a first base plate, a second base plate, a first electrode layer and a second electrode layer, the first electrode layer is arranged on the upper surface of the first base plate, the second electrode layer is arranged on the lower surface of the second base plate, and PDLC material is infused in a palisade groove formed by a palisade light resistance insulating object to be disposed to a polymer and liquid crystal droplets which are arranged between the first electrode layer and the second electrode layer. When an electric field is applied, the PDLC raster presents a full transparent state; when the electric field is not applied, the PDLC raster forms a light shield slit and a light transmission slit and presents the raster characteristic, thus, two display functions of the transparent display state and the raster characteristic can be realized in the way that the electricity is applied or not applied, the consuming quantity of the polymer and liquid crystal can be saved, the manufacture process is simplified, and the LCD quality can be improved simultaneously.

Owner:BYD CO LTD

Microencapsulated liquid crystal and a method and system for using same

InactiveUS6120701AIncrease display contrastExtended service lifeLiquid crystal compositionsThin material handlingCrystallographyLiquid-crystal display

Briefly, according to one aspect of the invention, liquid crystal material is microencapsulated by a method utilizing an interfacial polymerization reaction which creates a combination of polyurethane and polyurea polymers which form the capsule walls surrounding the discrete liquid crystal droplets. The formed capsule walls are designed to have an adjustable refractive index so as to allow for the matching of the refractive index to that of the liquid crystal and polymeric binder materials. This allows for the production of a liquid crystal droplet surrounded by polymer film, which is optically clear when the liquid crystal director is aligned with the electric field. The microencapsulated liquid crystal droplets improves the dye stability of a dichroic dye and enhances the contrast of a liquid crystal display.

Owner:HSU YING YEN

Liquid crystal display panel with fluid control wall

InactiveCN1523401AInsufficient bonding strength suppressedPoor shape qualityNon-linear opticsFluid controlLiquid-crystal display

A substrate includes fluid control walls for controlling the liquid crystal fluid closer to the liquid crystal dropped spot of a display area or frame-like fluid control walls between a sealing material and the display area. After the liquid crystal is dropped on the display area, a pair of substrates are pasted and then picked out in the atmosphere for applying pressure onto the pair of substrates and diffusing the liquid crystal. The liquid crystal fluid control walls serve to control the liquid crystal fluid, thereby suppressing the liquid crystal contamination caused by the contact of the unhardened sealing material with the liquid crystal and the relevant display failure.

Owner:HITACHI DISPLAYS

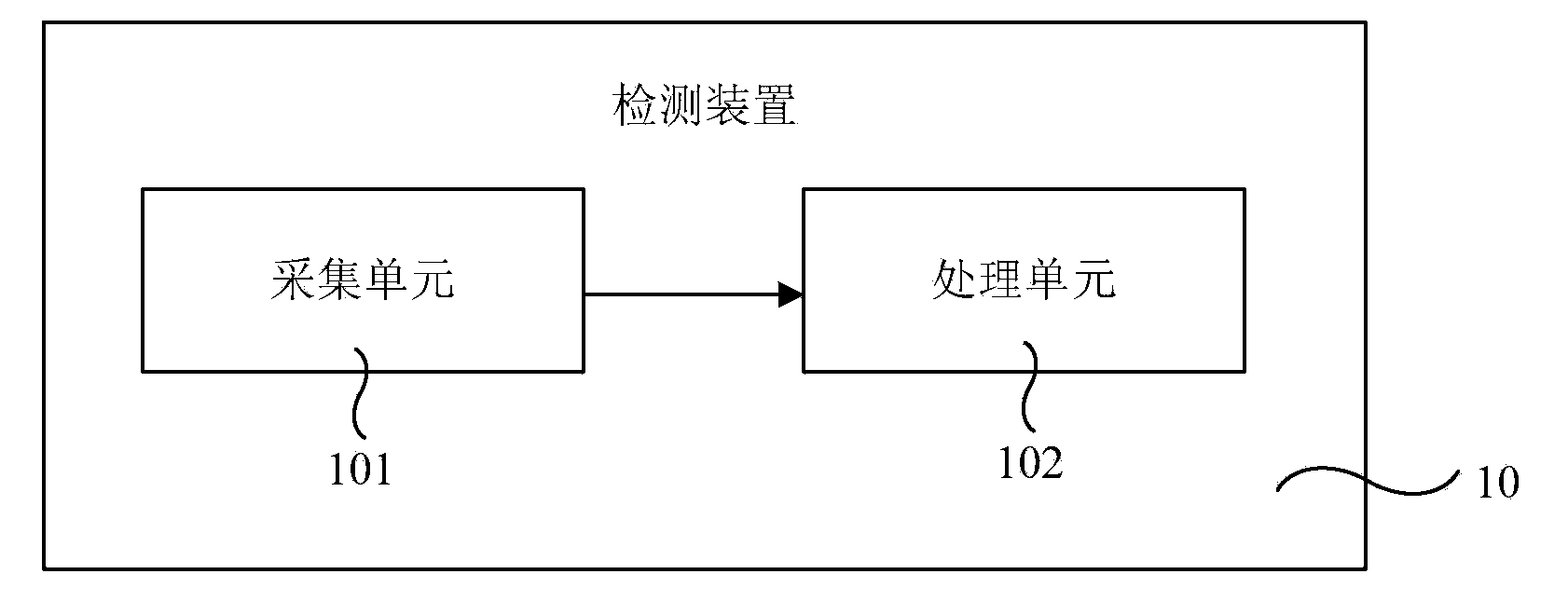

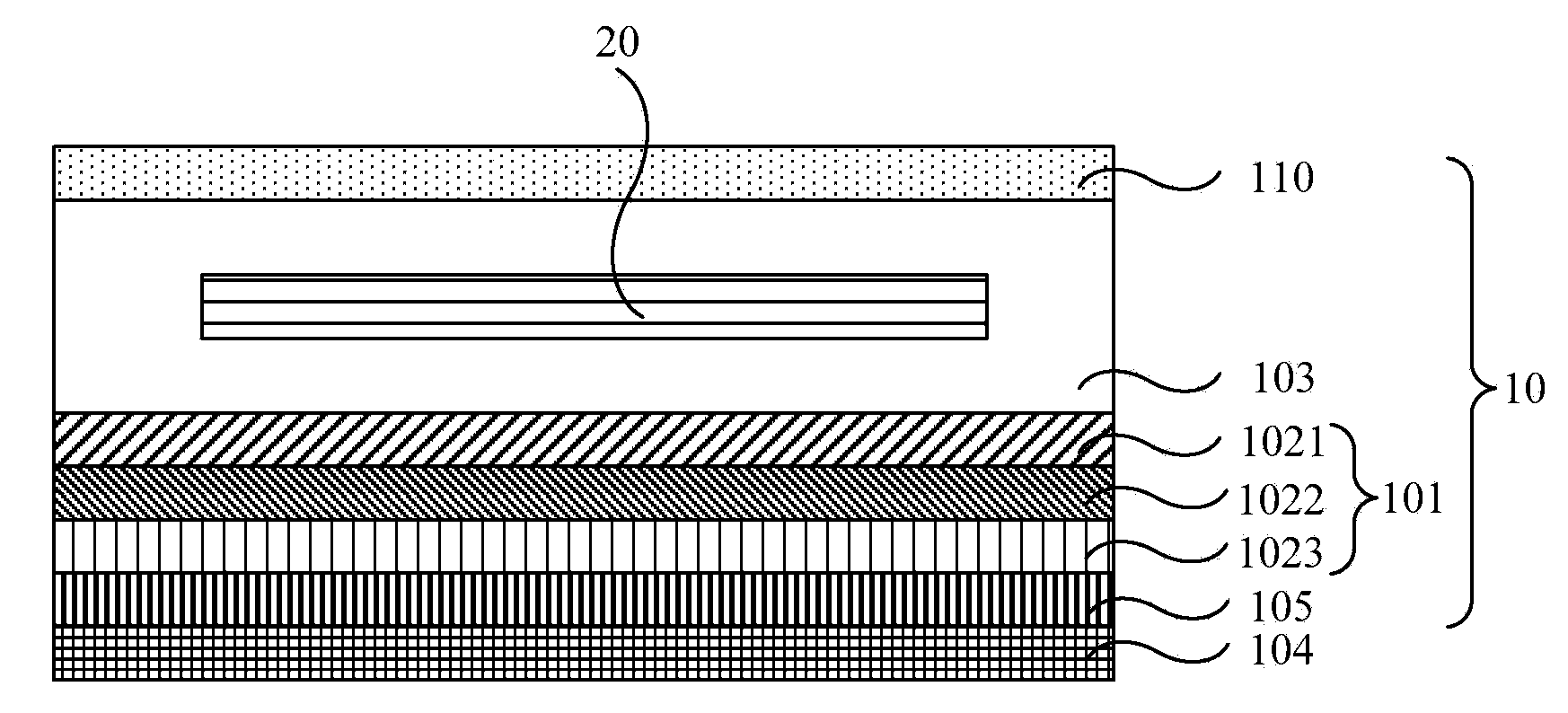

Detector, liquid crystal drop filling system and liquid crystal drop filling control method

InactiveCN103454790AEasy to detectImprove quality and efficiencyLiquid surface applicatorsCoatingsLiquid-crystal displayColor film

The embodiment of the invention provides a detector, a liquid crystal drop filling system and a liquid crystal drop filling control method and relates to the technical field of displaying. Real-time detection and drop filling control of liquid crystal amount can be realized, and therefore, the product quality and the production efficiency are improved, and the production cost is reduced. The liquid crystal drop filling system comprises a drop filling machine and drop filling detection equipment. The drop filling machine is used for dropwise filling liquid crystal between an array substrate and a color film substrate of box forming; the drop filling detection equipment is used for detecting the amount of the injected liquid crystal between the array substrate and the color film substrate, so that liquid crystal drop filling between the next batch of array substrate and color film substrate of the box forming is adjusted according to the amount of the injected liquid crystal.

Owner:HEFEI BOE OPTOELECTRONICS TECH +1

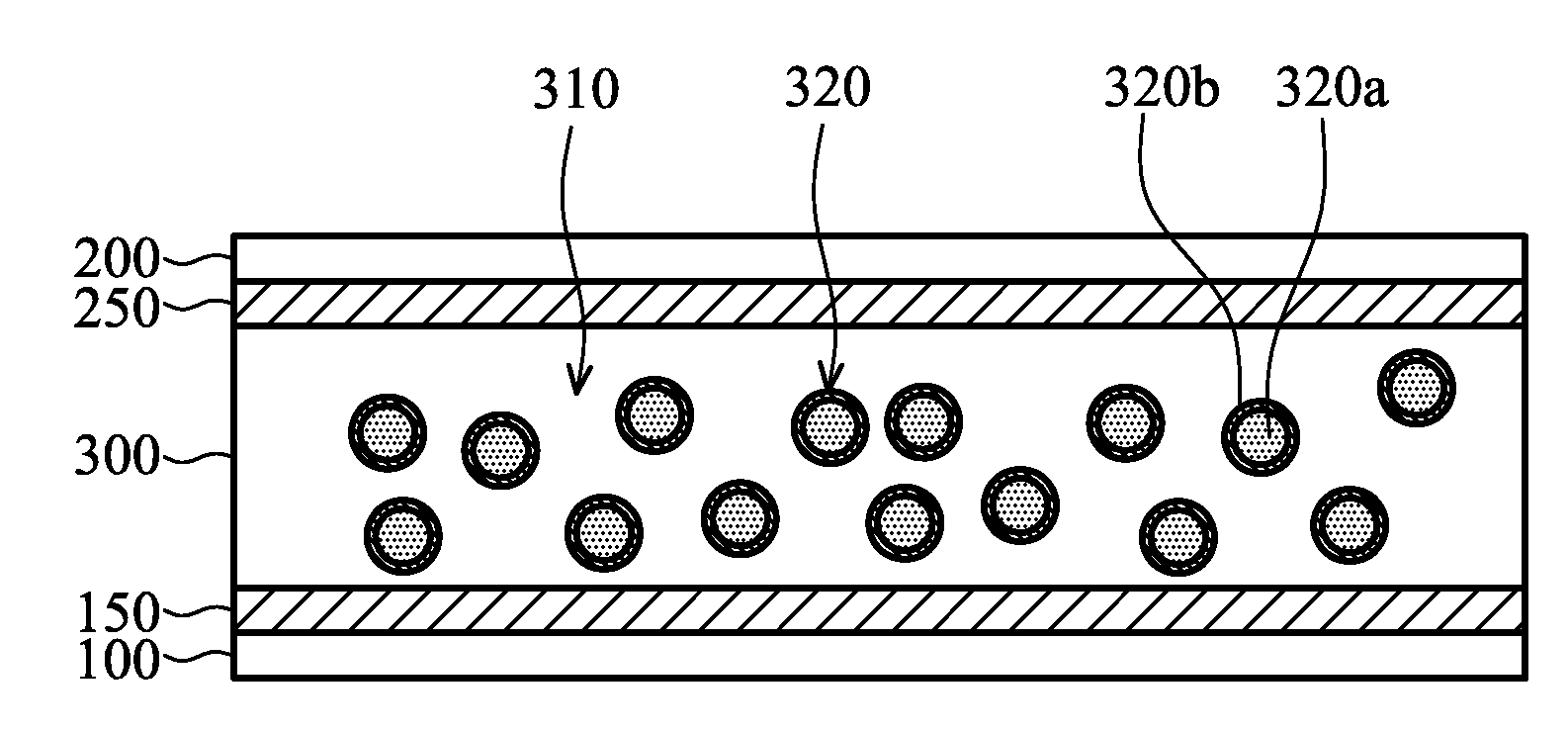

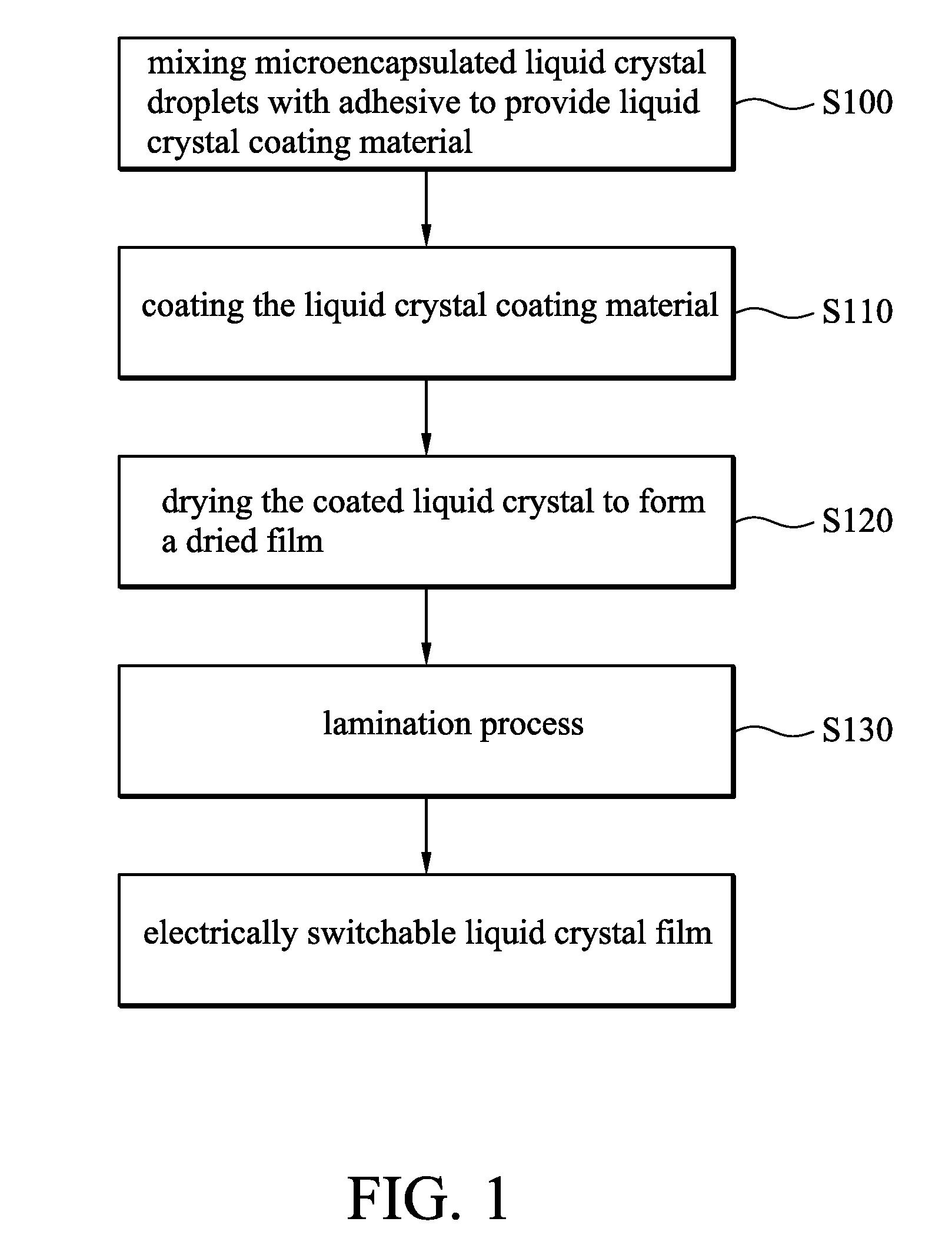

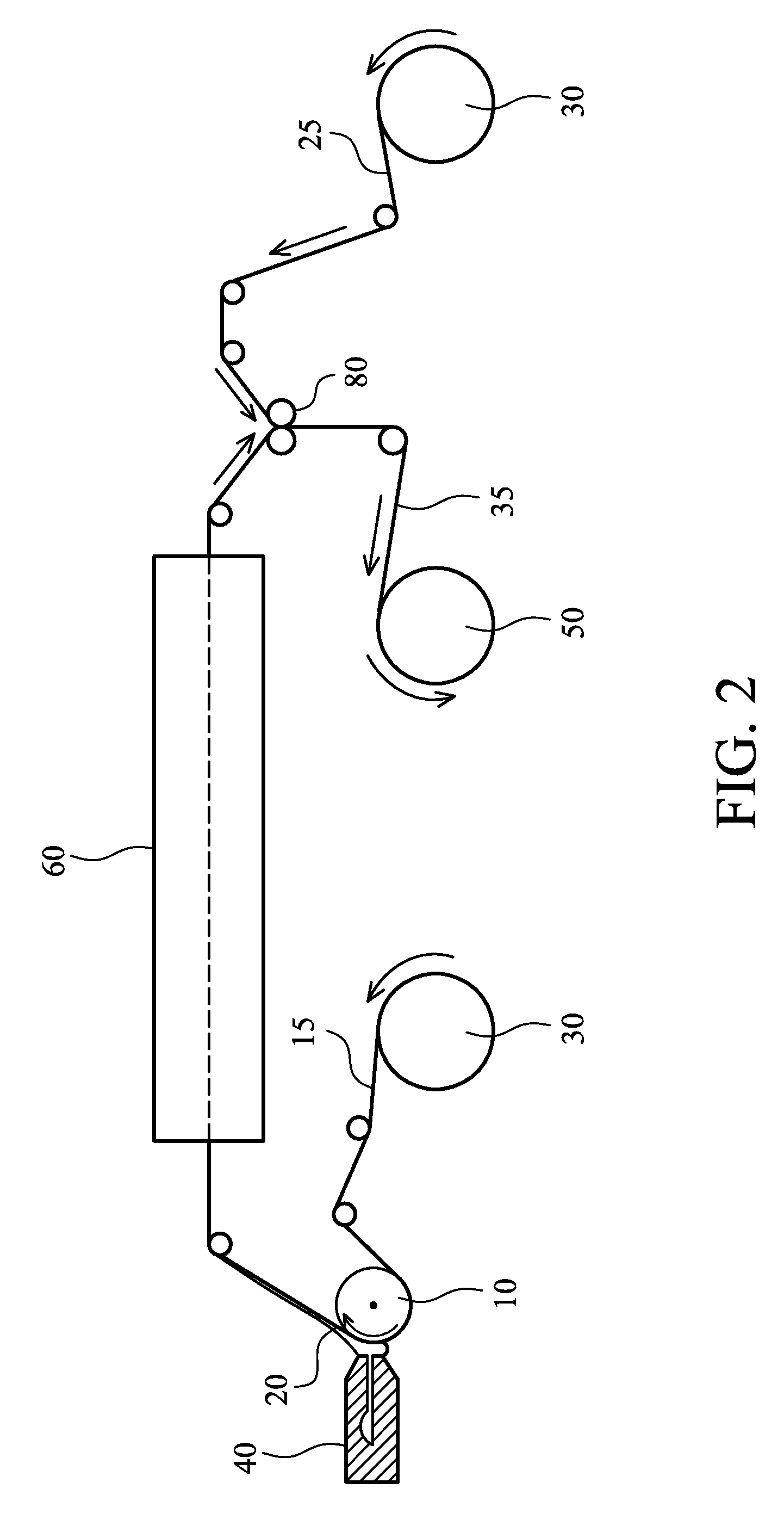

Reworkable liquid crystal film and manufacturing method thereof

InactiveUS20100151228A1Pretreated surfacesRecord information storageThermoplastic polymerLiquid crystal droplet

The invention provides a reworkable liquid crystal film, including a first substrate, a first conductive layer disposed on the first substrate, and a liquid crystal layer disposed on the first conductive layer. The liquid crystal layer contains microencapsulated liquid crystal droplets dispersed in a thermoplastic polymer matrix. The invention also provides a method for forming the reworkable liquid crystal film.

Owner:IND TECH RES INST

Polymer dispersed liquid crystal electronic paper and manufacturing method thereof

InactiveCN101329462AAchieve decentralizationEasy to prepareStatic indicating devicesNon-linear opticsComposite filmPolymer science

The invention relates to a polymer dispersed liquid crystal electronic paper and a manufacturing method thereof. A composite film is constituted by two transparent flexible conductive films and a polymer dispersed liquid crystal layer, wherein, electrodes are etched on the two flexible transparent conductive films. A polymer is modified polyurethane acrylate which is added by a surfactant and lecithin, and liquid crystal is dielectric switching liquid crystal material which is the mixture of 20 percent biphenyl ester and 80 percent difluoro diphenylacetylene or the product with the same series. When a low-frequency electric field is imposed on the polymer dispersed liquid crystal electronic paper, the polymer dispersed liquid crystal electronic paper is in the transparent open state, and the transparent open station is still maintained after removing the electric field; when a high-frequency electric field is imposed, the polymer dispersed liquid crystal electronic paper is in the scattering closed state, and the scattering closed state is still maintained after removing the electric field. The manufacturing method of the polymer dispersed liquid crystal electronic paper is to form the weak anchoring polymer which is packaged by a dielectric switching liquid crystal droplet structure by separating after mixing the weak anchoring polymer with the dielectric switching liquid crystal. The manufacturing method combines the natures of the weak anchoring polymer and the dielectric switching liquid crystal with the dual-frequency drive of low-frequency writing and high-frequency erasing so as to realize the stable zero-field of the polymer dispersed liquid crystal, thereby obtaining the new electronic paper technology or being applied as a new product of dimming glass.

Owner:HEBEI UNIV OF TECH

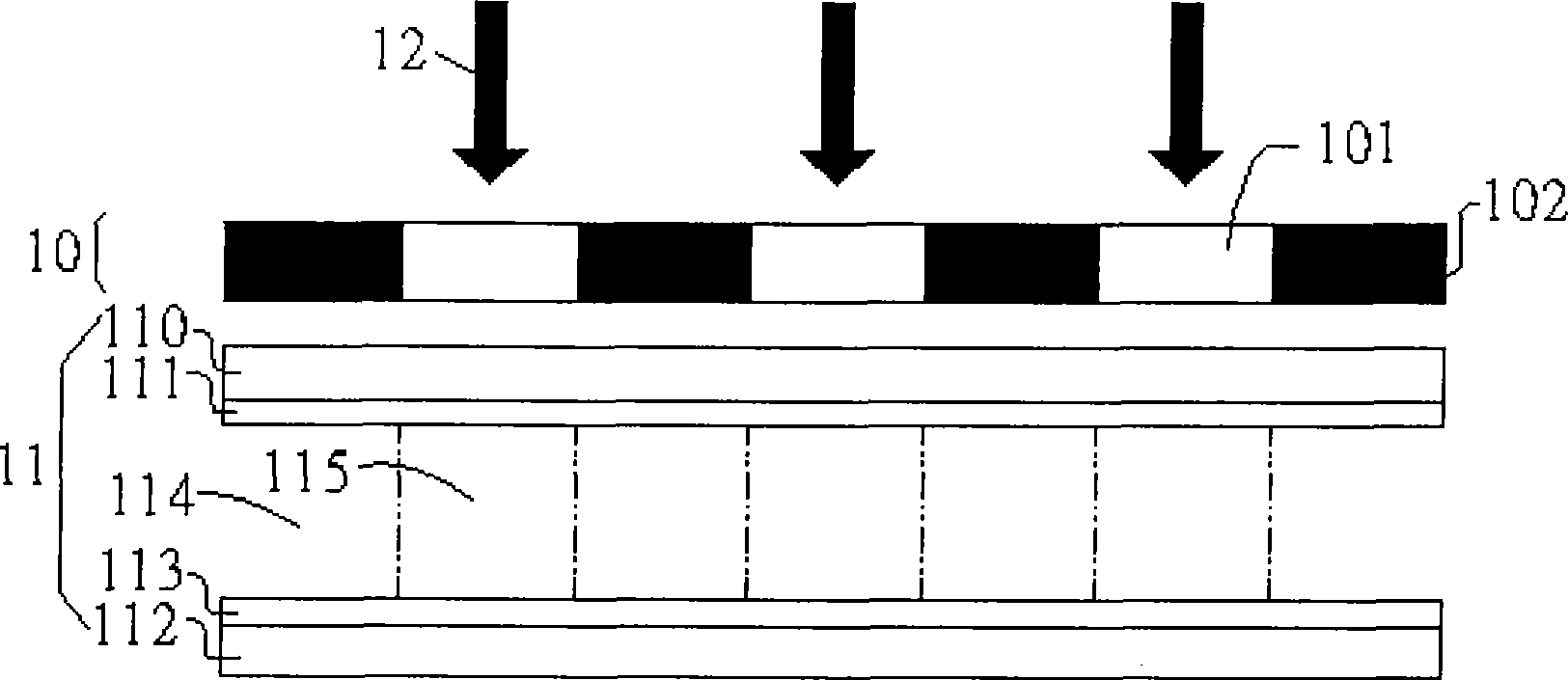

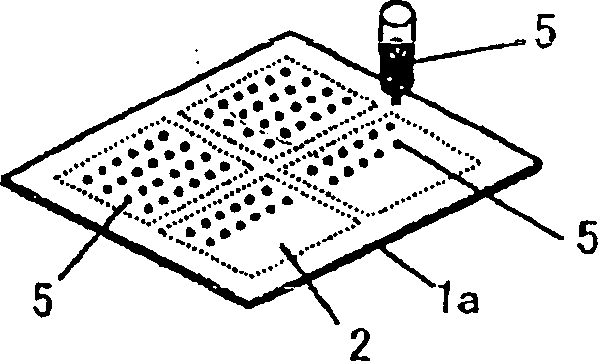

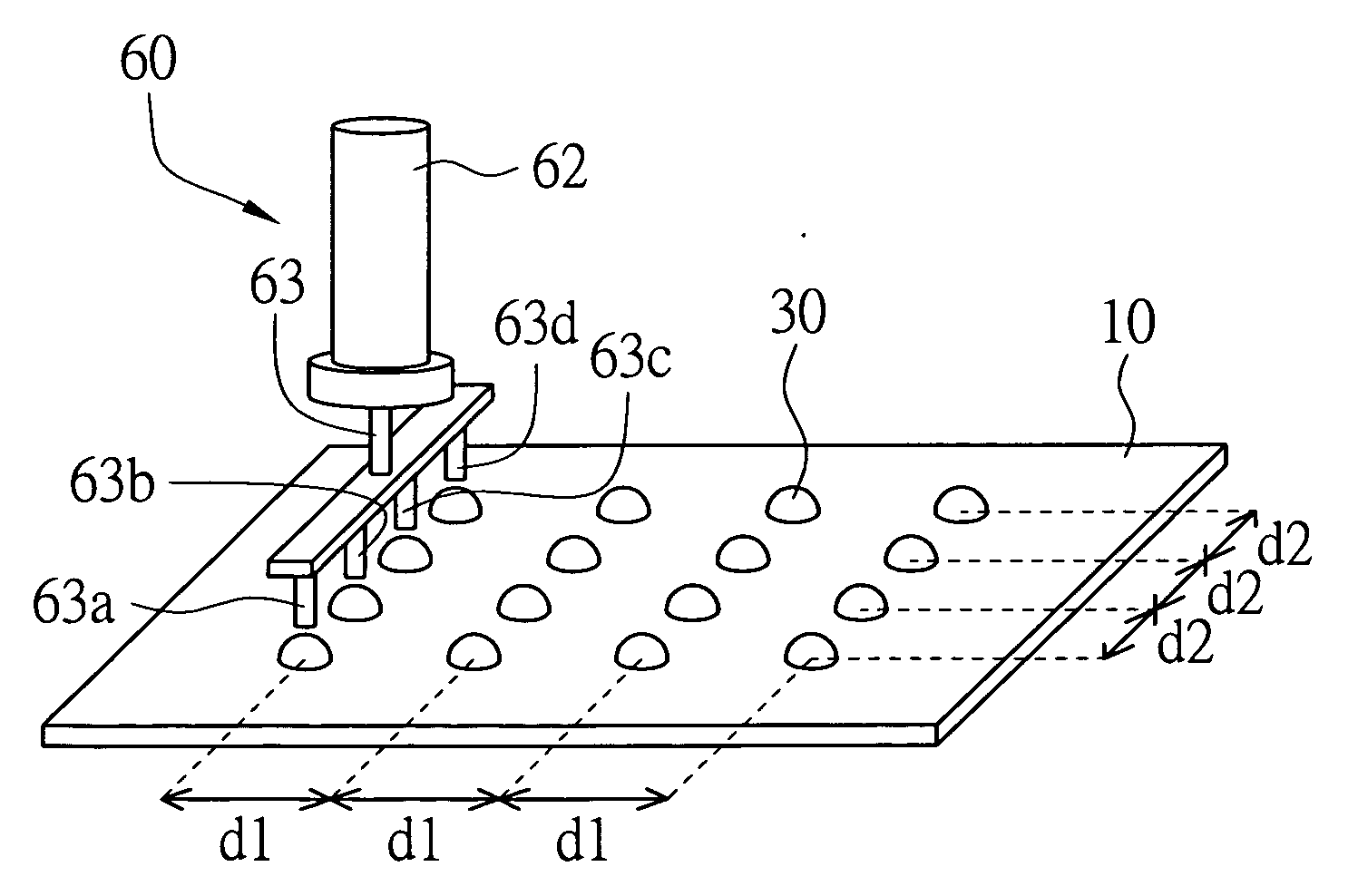

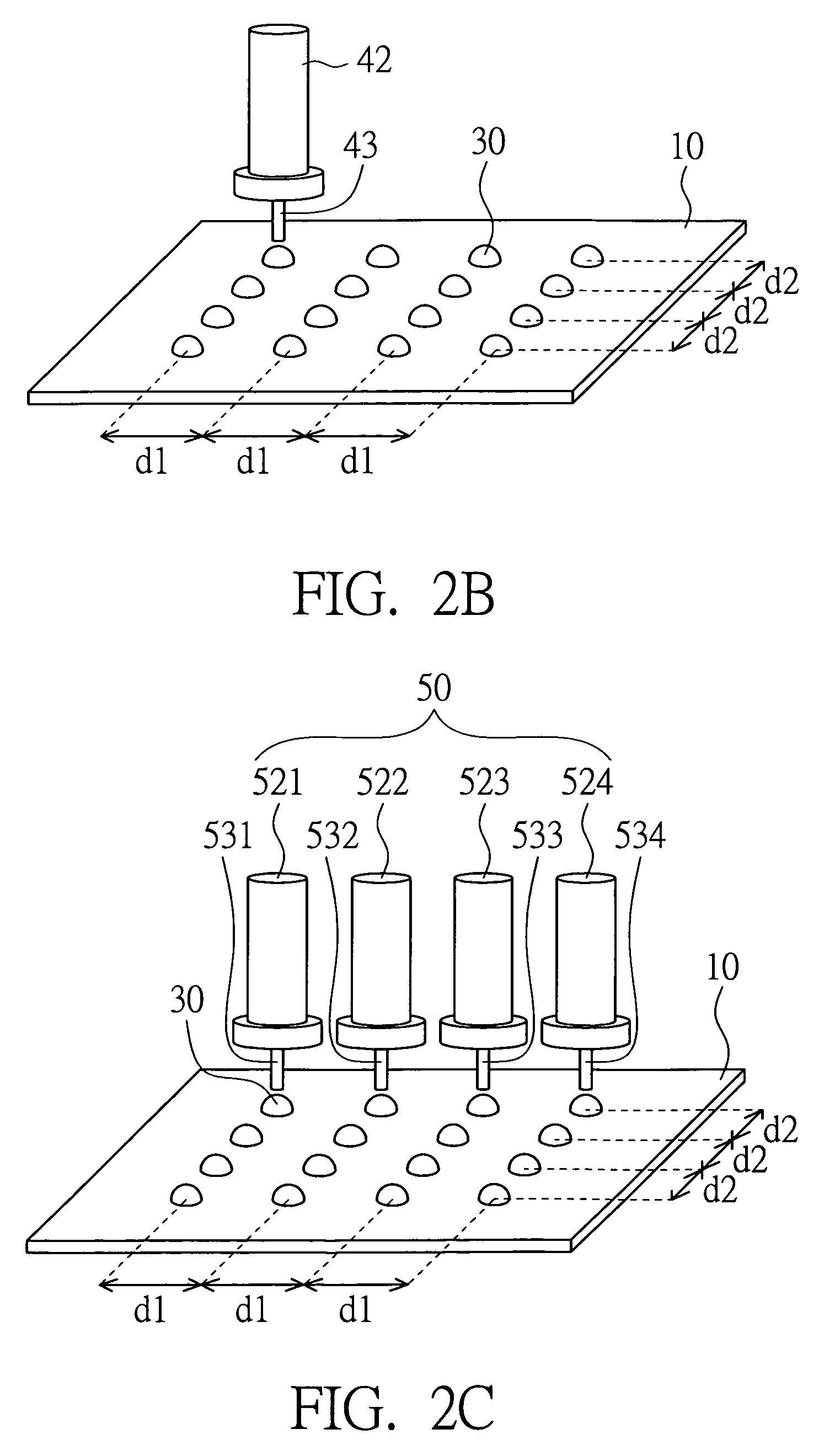

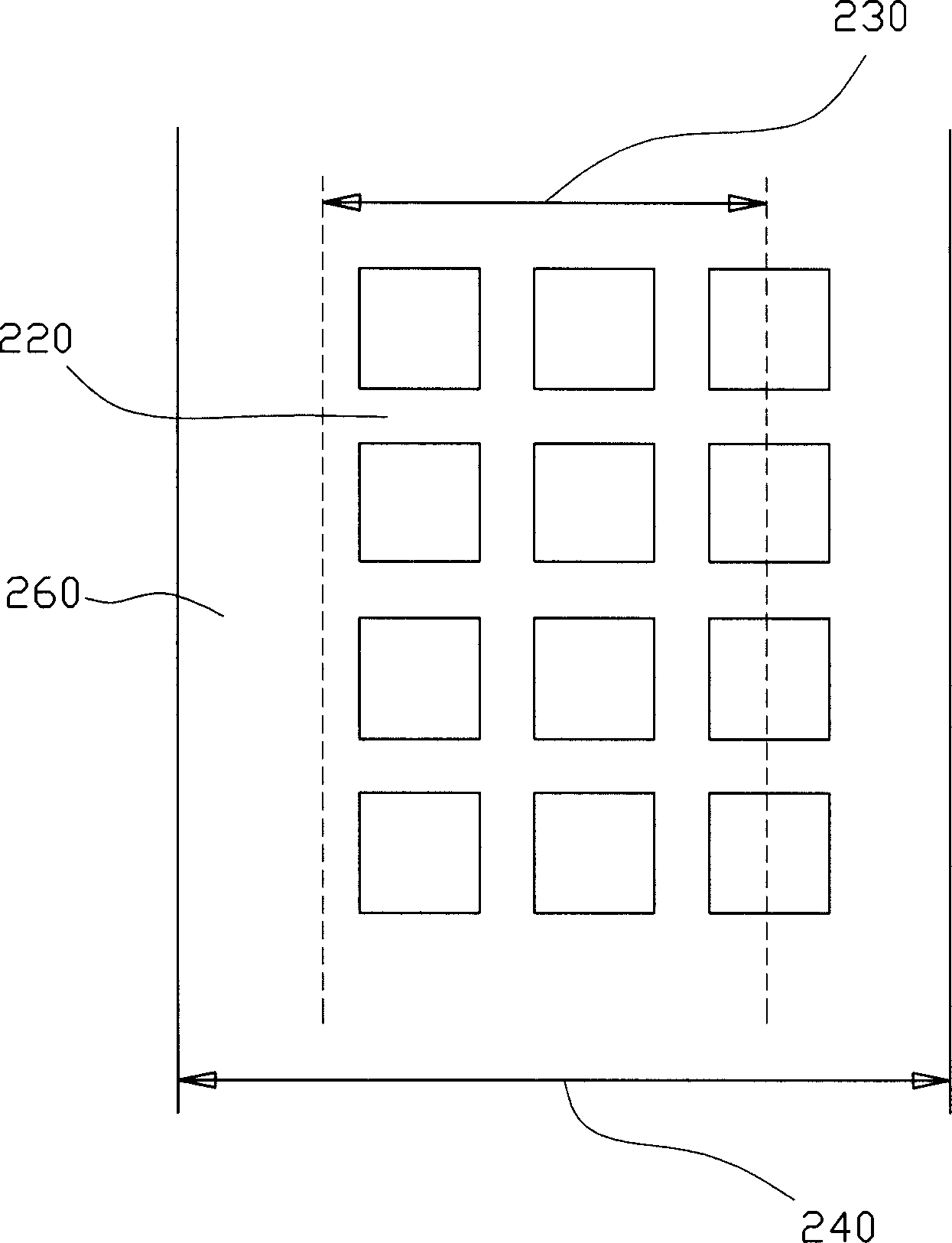

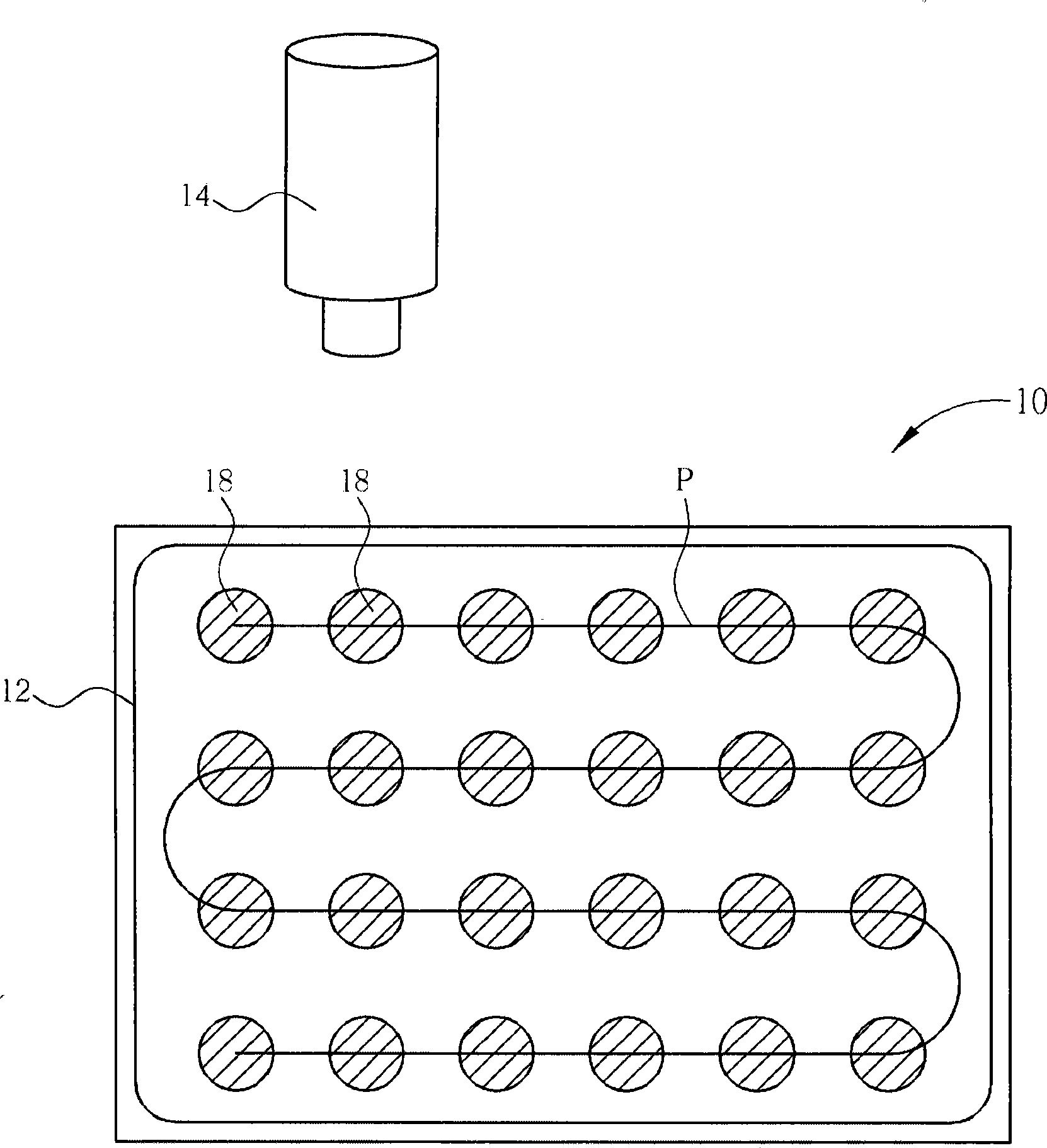

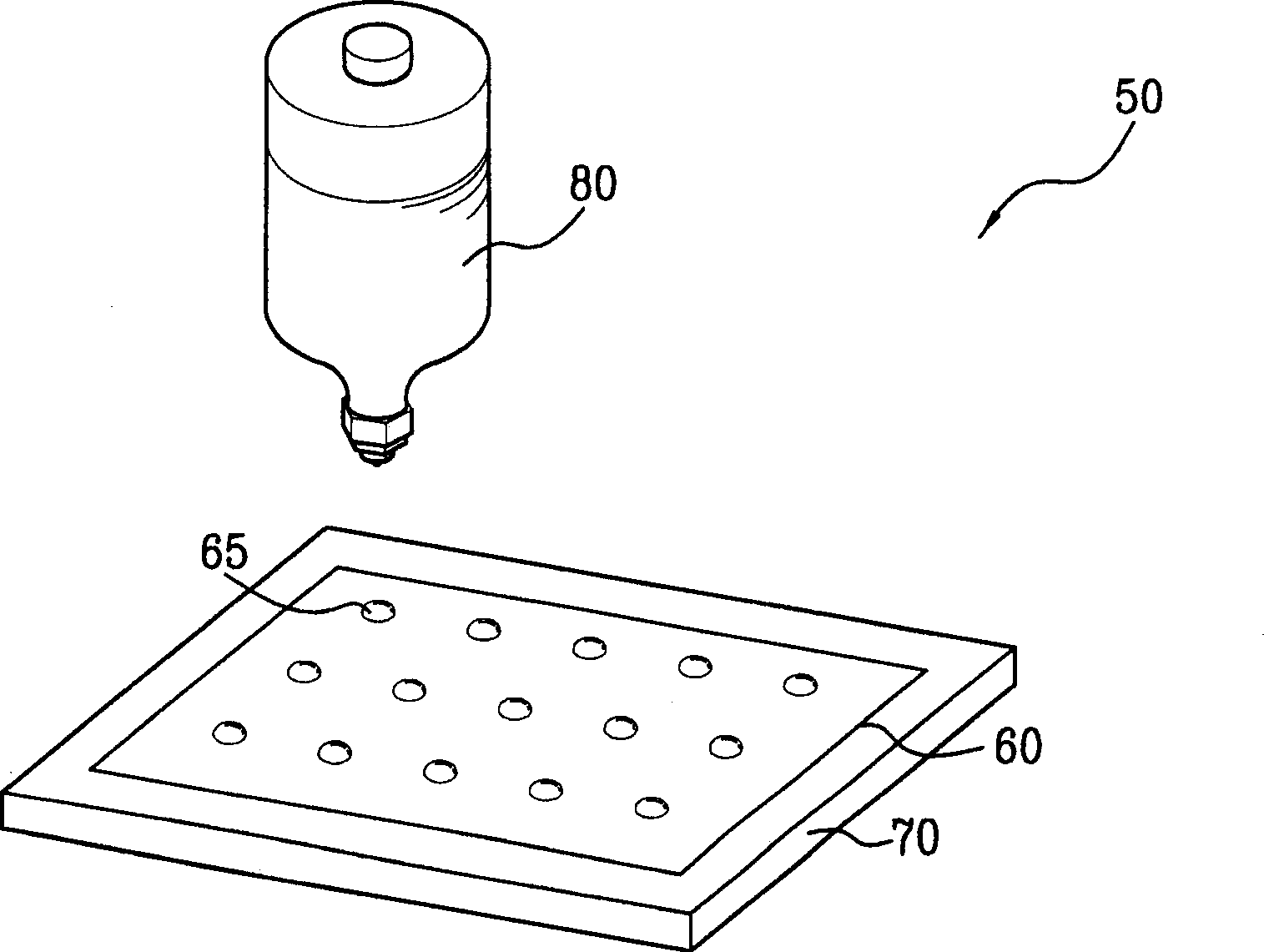

Liquid crystal display panel and method for manufacturing the same

InactiveUS20090213317A1Increase brightnessImprove MuraLiquid crystal compositionsNon-linear opticsLiquid-crystal displayEngineering

A method for manufacturing a liquid crystal display panel is provided. The method includes: providing a first substrate and a second substrate; providing a plurality of liquid crystal drops on the first substrate, wherein two adjacent liquid crystal drops in X direction is kept by a distance d1 mm, and two adjacent liquid crystal drops in Y direction is kept by a distance d2 mm, each liquid crystal drop is G mg, d1≦16.7, d2≦15.4, and G≦1; and connecting the first substrate and the second substrate so that the liquid crystal drops are sealed between the first substrate and the second substrate.

Owner:AU OPTRONICS CORP

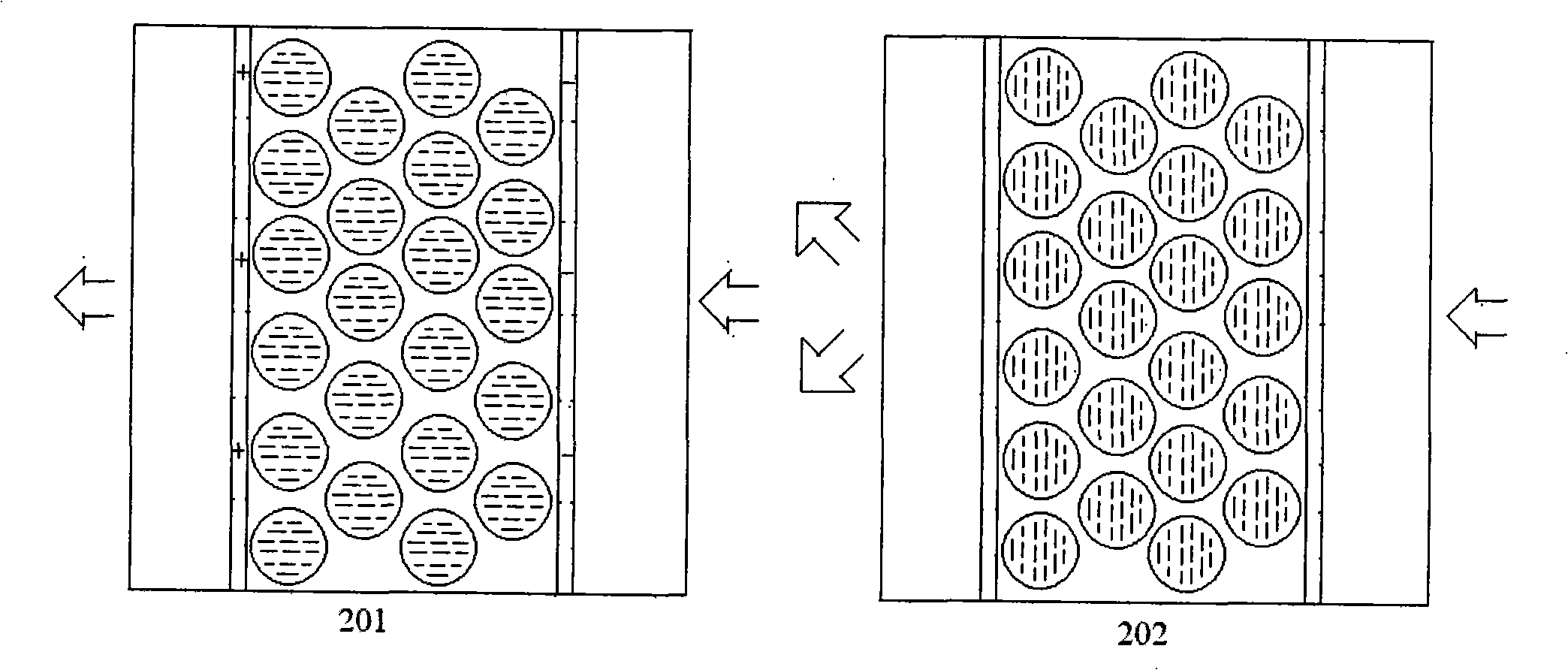

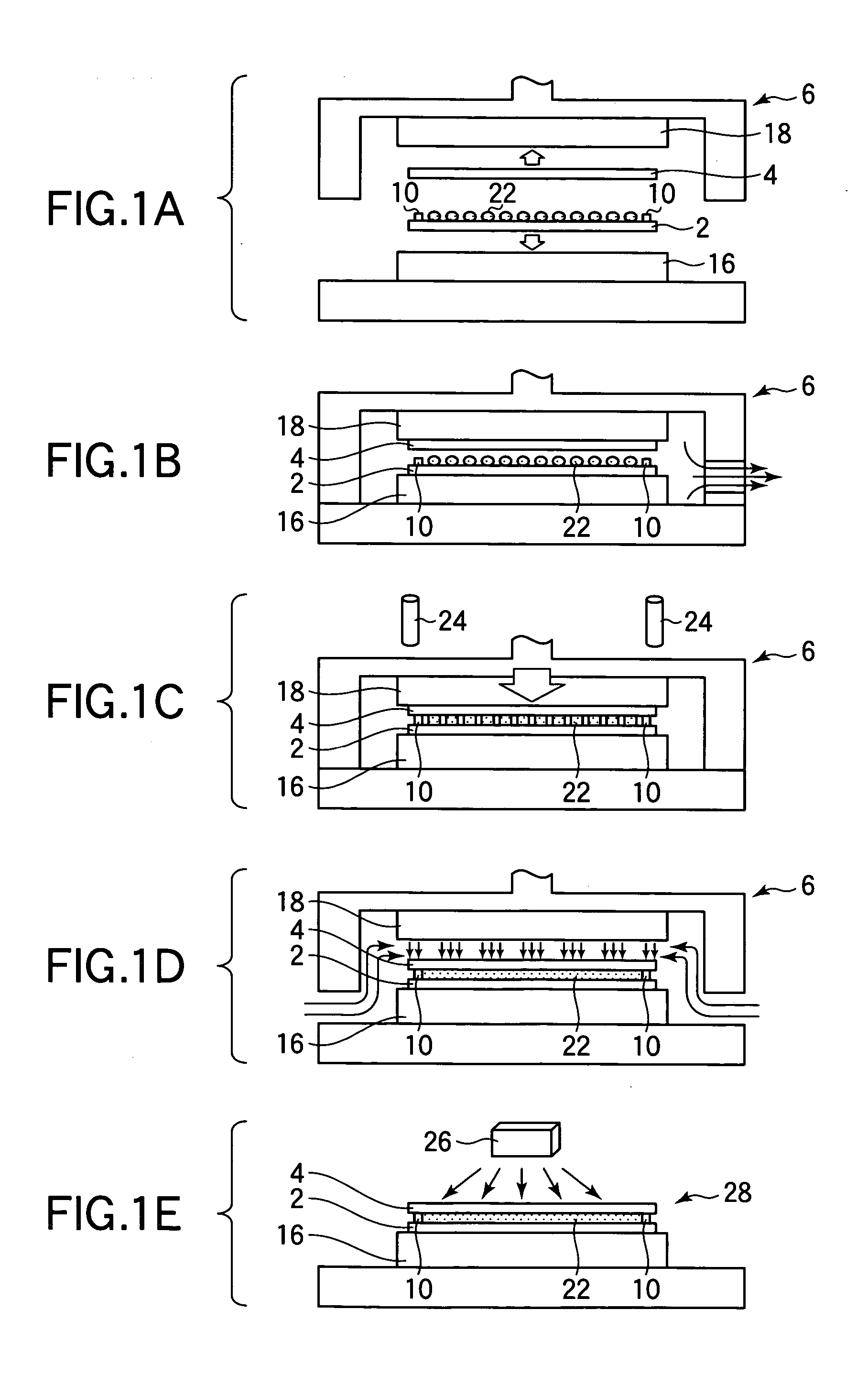

Method of manufacturing liquid crystal display device and one drop fill apparatus used for the same

InactiveUS20050126700A1Stable manufacturingDownsize display deviceLayered product treatmentLaminationLiquid-crystal displayEngineering

A method of manufacturing a liquid crystal display device in which liquid crystal is sealed between substrates using a one drop fill method, and a one drop fill apparatus used for the method, and particularly a method of manufacturing a liquid crystal display device using a one drop fill method that enables reduction of product defects of the liquid crystal display device and realization of a stable production process, and a one drop fill apparatus used for the method are provided. Dropping of liquid crystal is controlled so that the dropping quantity of the liquid crystal is reduced in an area including the vicinity of a seal material on the left side with a relatively narrow cell gap width while the dropping quantity of the liquid crystal is increased in an area including the vicinity of the seal material on the right side with a relatively broad cell gap width. Alternatively, dropping of the liquid crystal is controlled so that the number of times the liquid crystal is dropped is reduced in the area including the vicinity of the seal material on the left side while the number of times the liquid crystal is dropped is increased in the area including the vicinity of the seal material on the right side without changing the dropping quantity of one drop.

Owner:SHARP KK

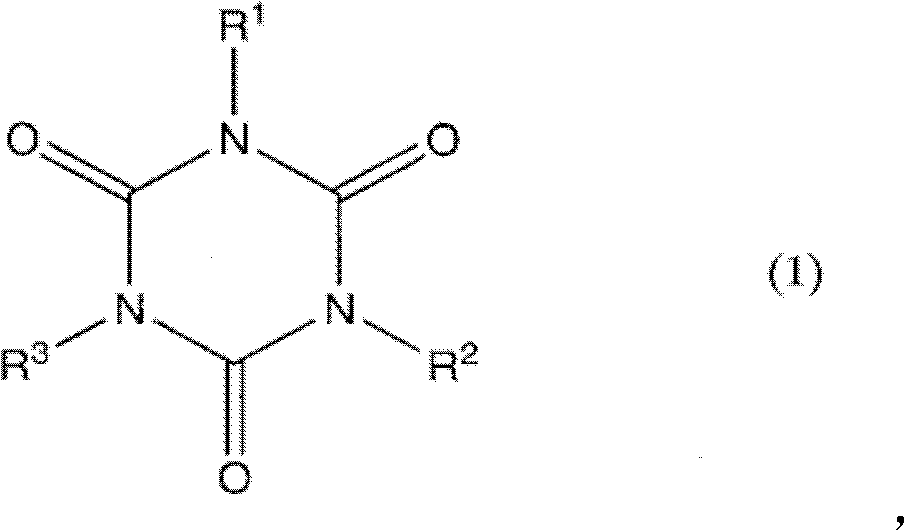

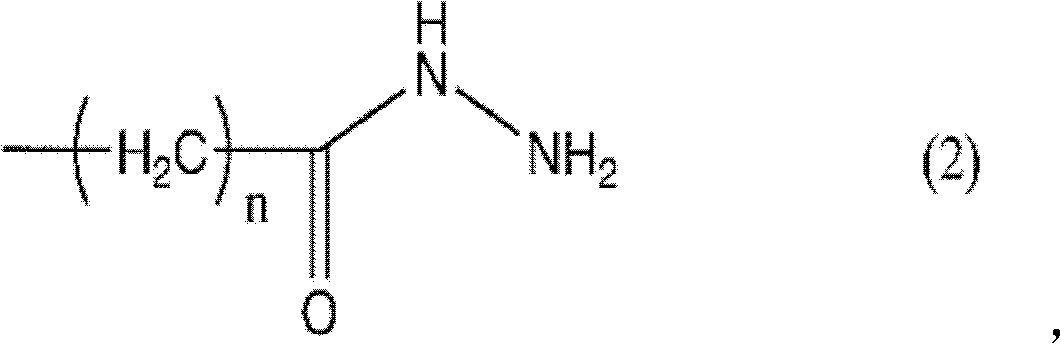

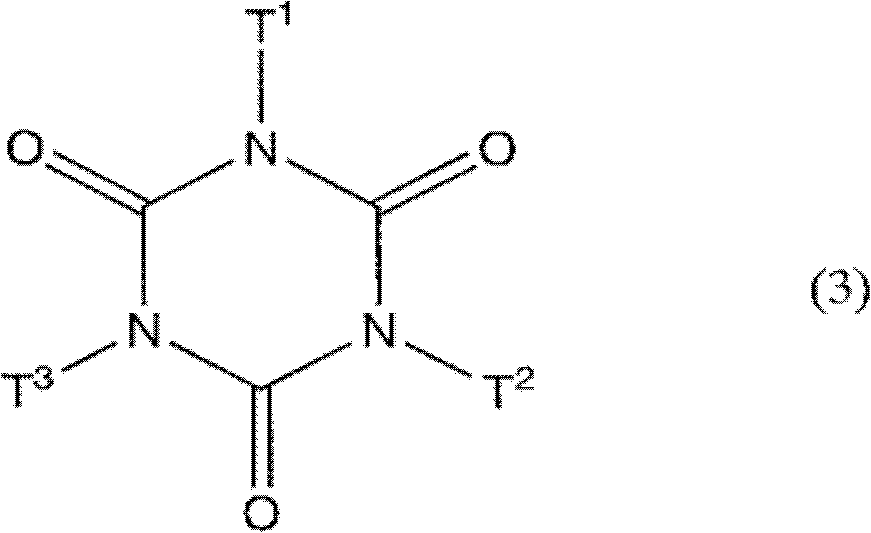

Liquid crystal sealing agent for liquid crystal dropping method and liquid crystal display cell using same

ActiveCN102472928AReduce pollutionImprove adhesion strengthOther chemical processesNon-linear opticsEpoxyPolymer science

Disclosed is a thermosetting liquid crystal sealing agent for a liquid crystal dropping method, which contains, as essential components, (a) a curable resin that is composed of an epoxy resin and a (meth)acrylated epoxy resin, (b) a polyfunctional hydrazide compound, (c) a curing accelerator, (d) an inorganic filler and (e) a silicone rubber powder that has a true specific gravity of 0.95-1.0 and an average particle diameter of 10-18 [[mu] m]m. The thermosetting liquid crystal sealing agent for a liquid crystal dropping method contains the silicone rubber powder (e) in an amount of 5-40% by mass relative to the liquid crystal sealing agent.

Owner:NIPPON KAYAKU CO LTD

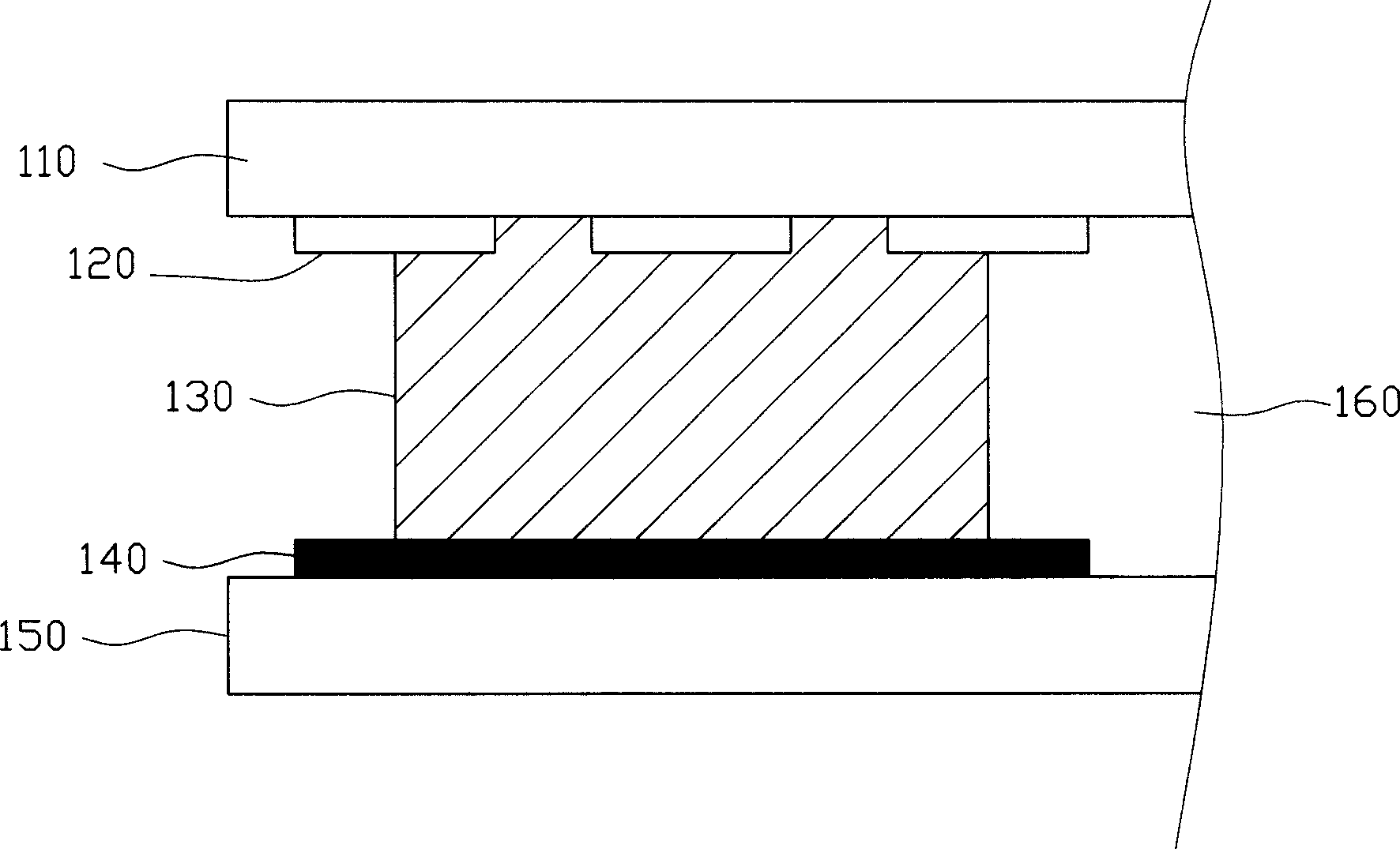

Structure of liquid-crystal displaying device from liquid-crystal dripping process and production thereof

ActiveCN1713056AImprove pre-hardeningImprove pollutionNon-linear opticsThin-film-transistor liquid-crystal displayIndium

A liquid crystal display prepared by liquid crystal dropping process consists of the first and the second base plates, conductive pattern layer, shading layer, liquid crystal layer and glue line cured by ultraviolet ray. It is featured as using conductive pattern layer formed from indium - tin oxide material on the first base plate as peripheral circuit to let it have ability of ultraviolet ray penetration, forming liquid crystal layer by dropping liquid crystal and gardening glue line by ultraviolet ray lamp.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

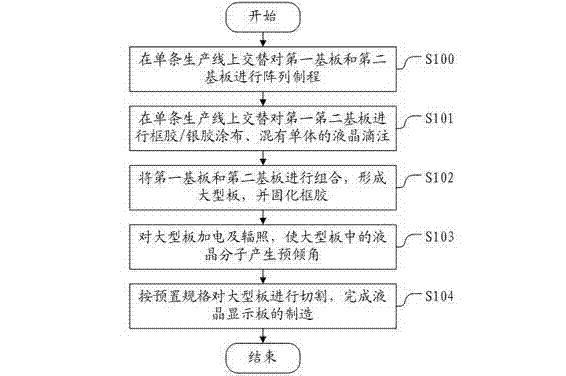

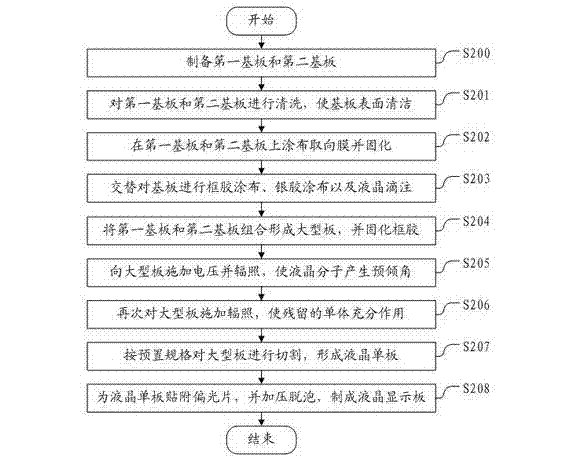

Method and device for manufacturing liquid crystal display panel

InactiveCN102236200AReduce manufacturing costAvoid idle stateNon-linear opticsProduction lineEngineering

The embodiment of the invention discloses a method and device for manufacturing a liquid crystal display panel. The manufacturing method comprises the following steps of: alternately processing a first substrate and a second substrate on a single production line, completing array processing, frame glue coating, silver glue coating and monomer-mixed liquid crystal instilling on the first substrate and the second substrate, wherein the first substrate is a thin film field effect transistor (TFT) substrate, and the second substrate is a colour filter (CF) substrate; combining the first substrate with the second substrate to form a large panel, and curing the frame glue; carrying out power on and radiation on the large panel to cause liquid crystal molecules in the large panel to produce a pretilt angle; and cutting the large panel according to a preset specification so as to complete manufacturing of the liquid crystal display panel. By adopting the method and device for manufacturing the liquid crystal display panel, provided by the embodiment of the invention, production of the liquid crystal display panel can be completed on the single production line, an idle state of the production line of the liquid crystal display panel is avoided, production efficiency is improved, occupying area of equipment of the production line is reduced, and production cost of the liquid crystal display panel is reduced.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Microencapsulated liquid crystal and method

InactiveUS6174467B1Extended service lifeIncrease display contrastLiquid crystal compositionsGlass/slag layered productsPolymer scienceLiquid-crystal display

Briefly, according to one aspect of the invention, liquid crystal material is microencapsulated by a method utilizing an interfacial polymerization reaction which creates a combination of polyurethane and polyurea polymers which form the capsule walls surrounding the discrete liquid crystal droplets. The formed capsule walls are designed to have an adjustable refractive index so as to allow for the matching of the refractive index to that of the liquid crystal and polymeric binder materials. This allows for the production of a liquid crystal droplet surrounded by polymer film, which is optically clear when the liquid crystal director is aligned with the electric field. The microencapsulated liquid crystal droplets improves the dye stability of a dichroic dye and enhances the contrast of a liquid crystal display.

Owner:HSU YING YEN

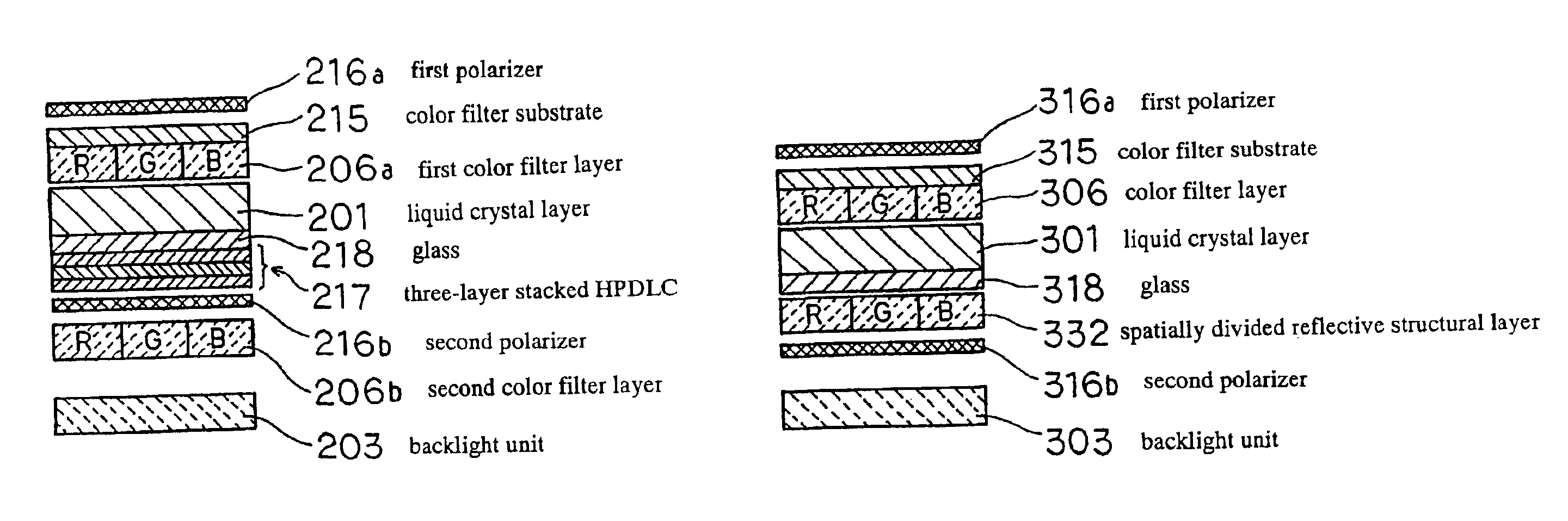

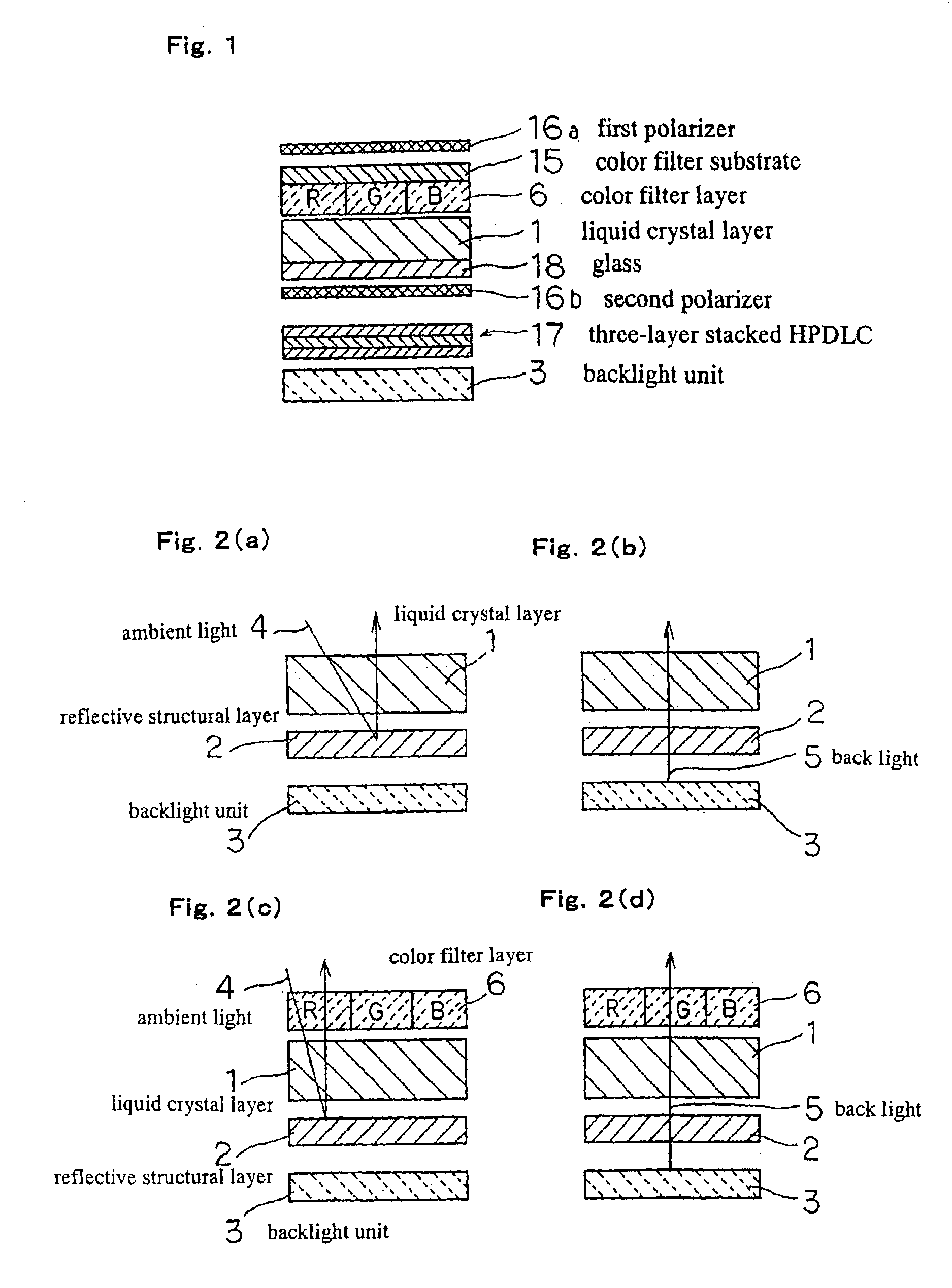

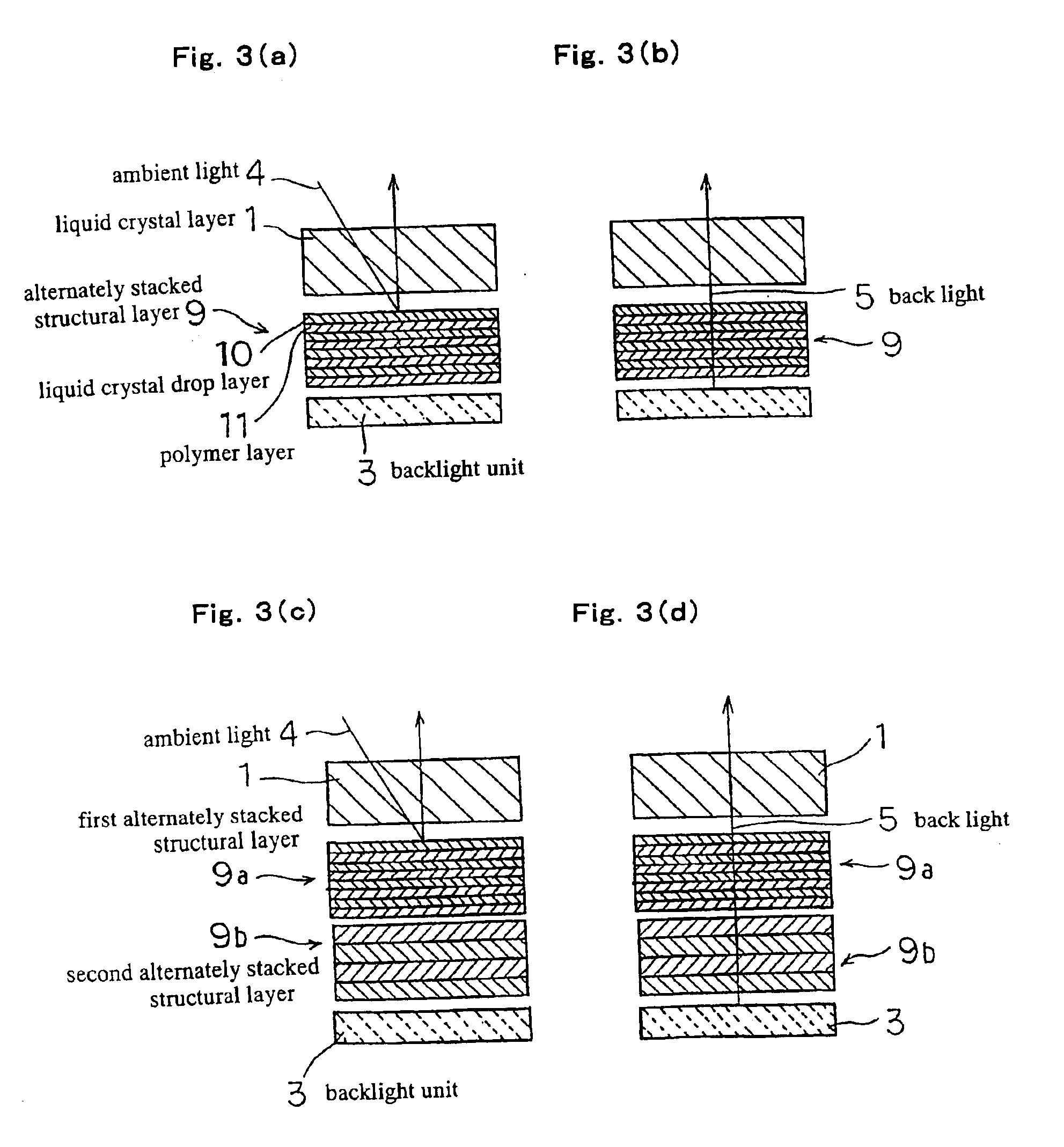

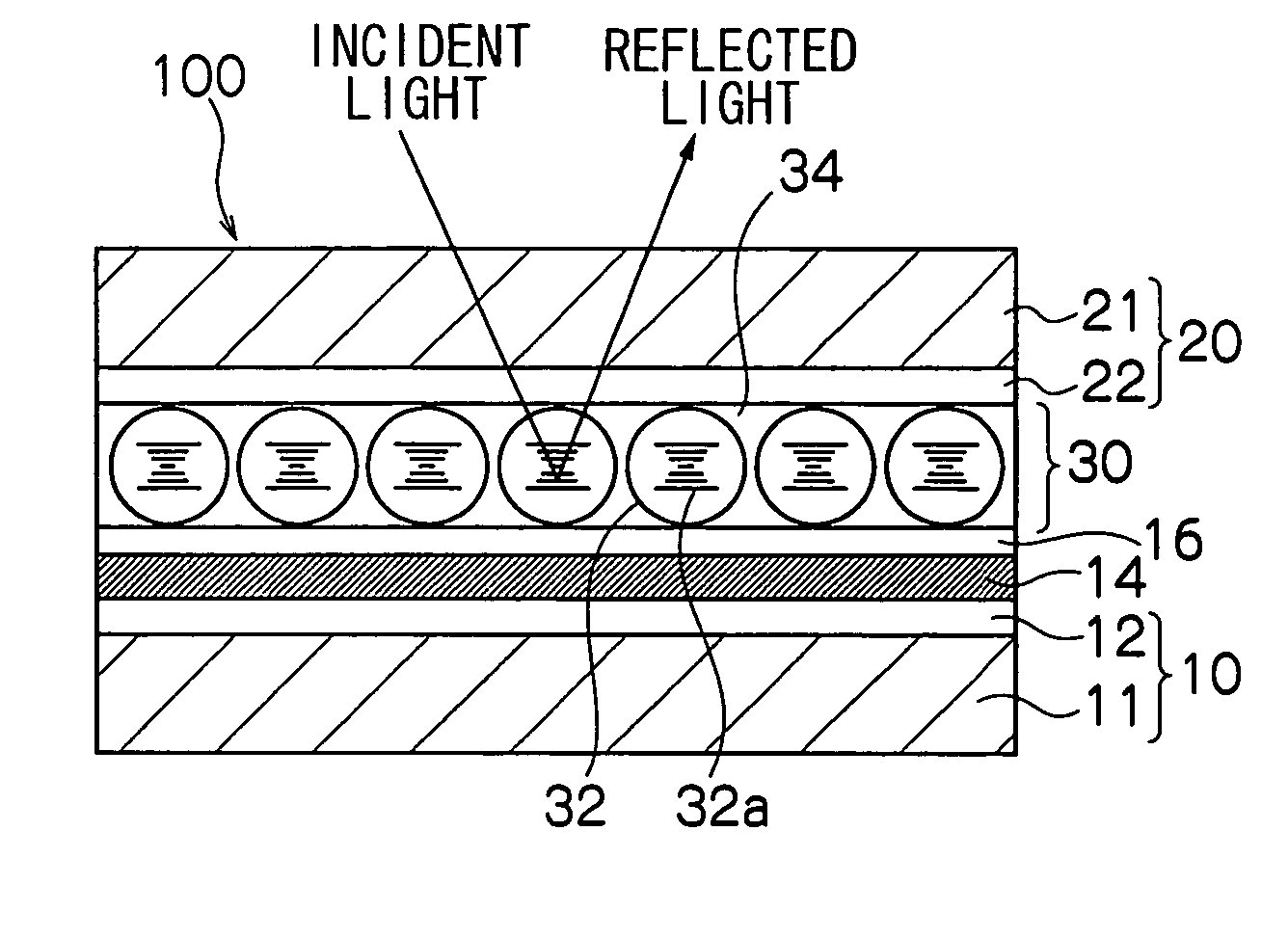

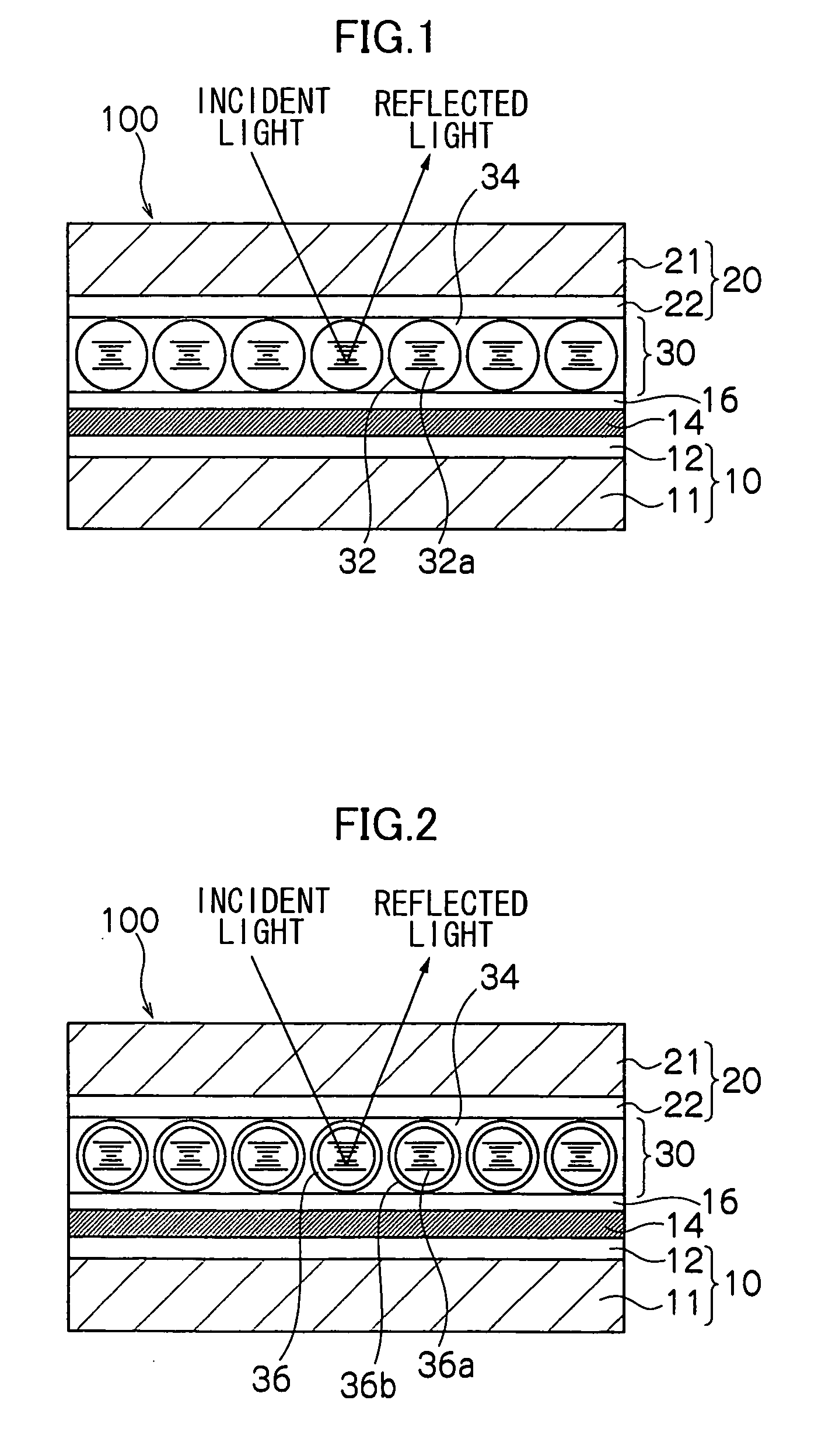

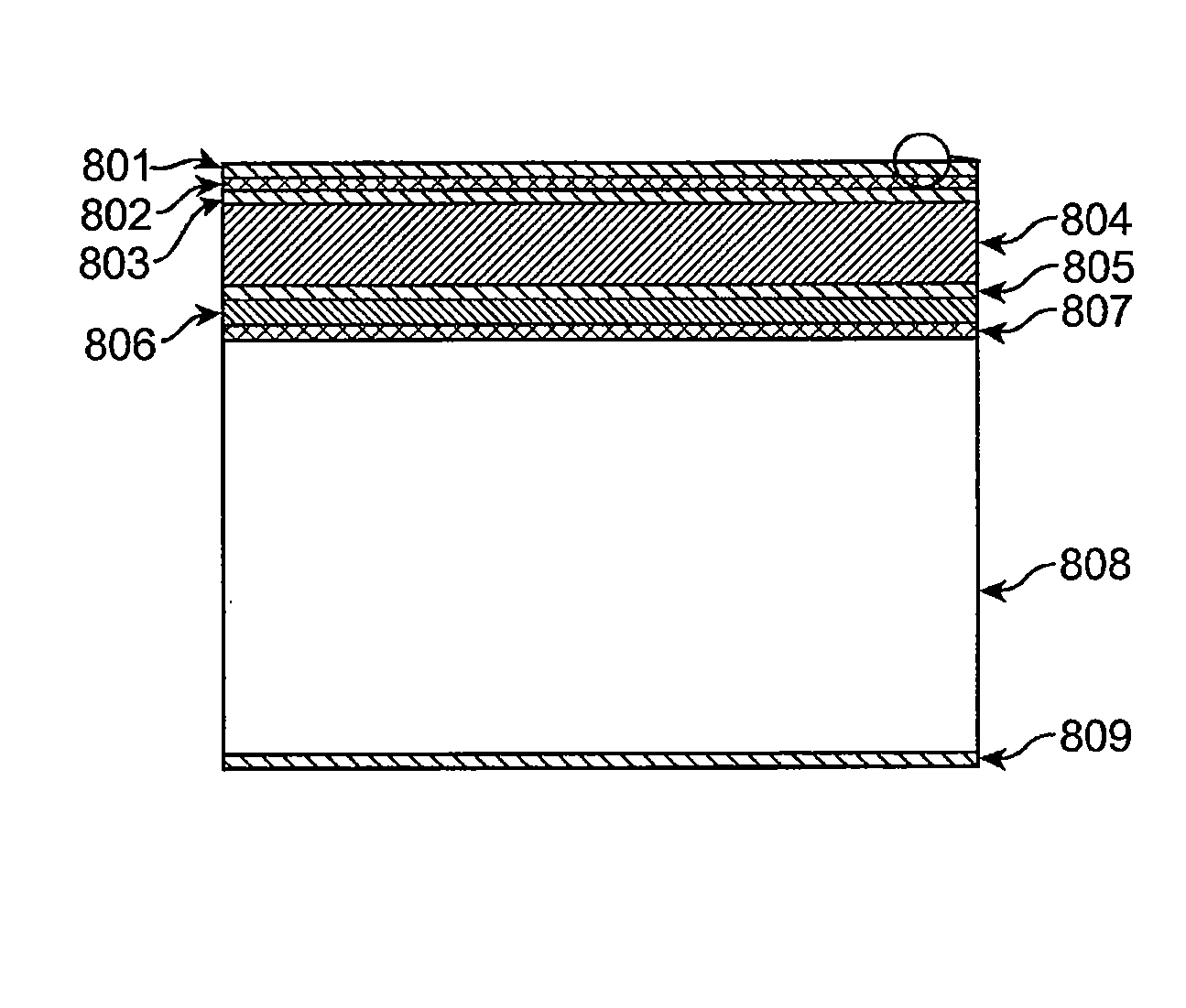

Liquid crystal display device having switchable reflective layer

InactiveUS6842209B2High light transmittanceLow purityStatic indicating devicesNon-linear opticsLiquid-crystal displayReflective layer

A liquid crystal display device comprising a first polarizing sheet (16a), a color filter layer (6) formed on glass sheet (18), a second polarizing sheet (16b), three-layered HPDLC (17) formed below the liquid crystal layer (1) and acting as a reflective structural layer having a reflectivity changed electrically, and a backlight unit as the lowermost layer. Each layer of the three-layered HPDLC (17) is composed of a liquid crystal droplet layer polymer layer and reflects blue, green, red by Bragg reflection. When voltage is applied to the three-layered HPDLC (17), the reflectivity of liquid crystal droplet layer of each layer change, so that the HPDLC can be made transparent by equalizing the reflectivities of the liquid crystal liquid droplet layer to those of polymer layers.

Owner:NEC CORP

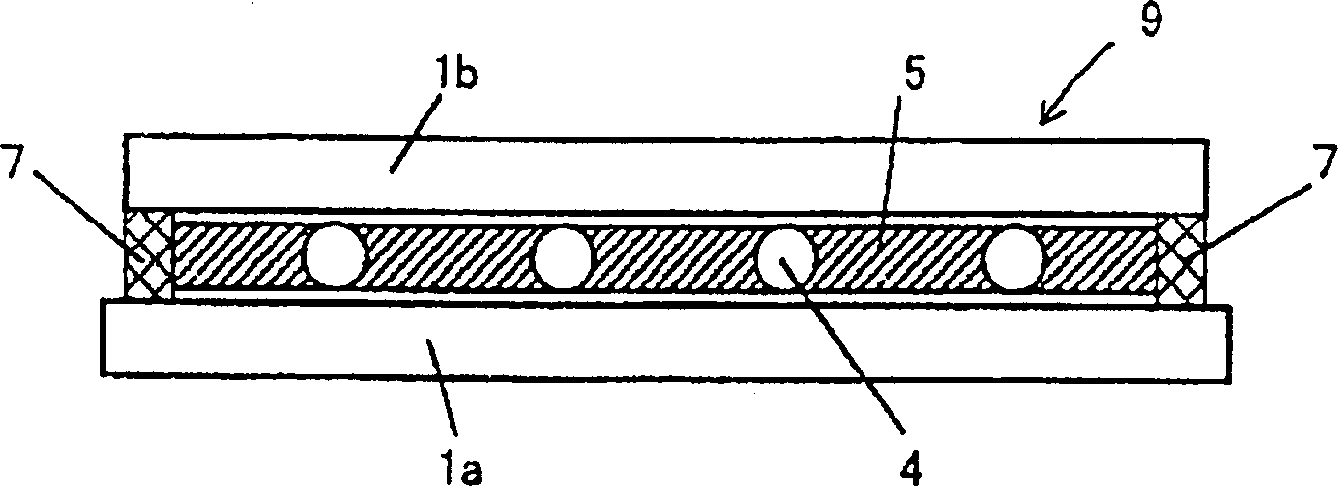

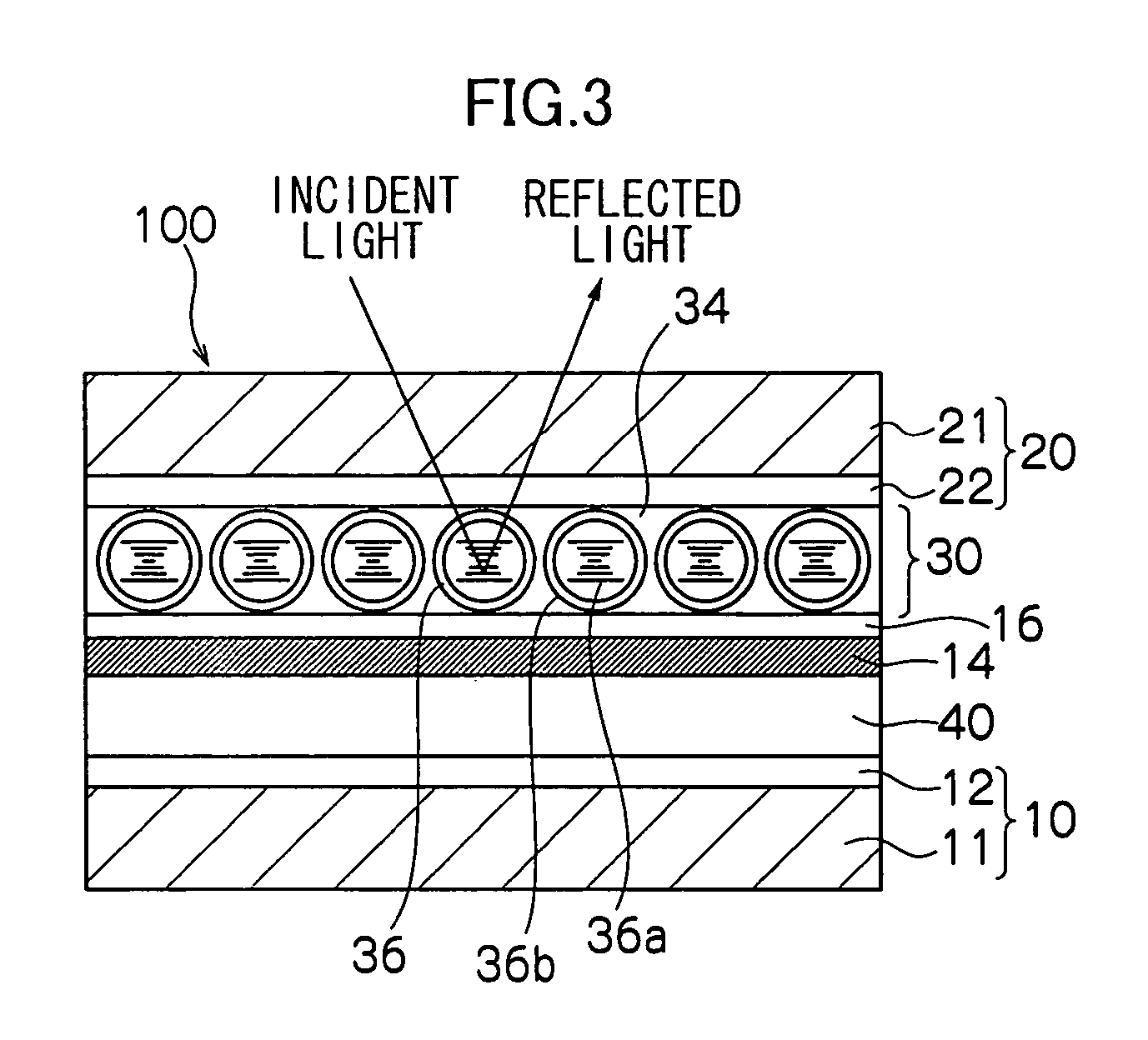

Liquid crystal display element and manufacturing method thereof

InactiveUS20050200775A1Increase steepnessAvoid problemsNon-linear opticsLiquid-crystal displayEngineering

The invention discloses a liquid crystal display element including: a pair of display substrates each having a support and an electrode provided on one surface of the support; and a display layer provided between the electrodes of the pair of display substrates, wherein the display layer contains gelatin and liquid crystal drops or microcapsules; and the liquid crystal drops or microcapsules are densely arrayed in a monolayer, and a method of manufacturing the liquid crystal display element, including: applying to a surface of one of the display substrates which surface has the electrode, a coating solution in which liquid crystal drops or microcapsules are dispersed in a solution containing gelatin and a solvent, thereby forming a coating layer; and evaporating the solvent in the coating layer at a temperature not less than the freezing point of the gelatin to provide a display layer between the electrodes of the display substrates.

Owner:FUJIFILM BUSINESS INNOVATION CORP

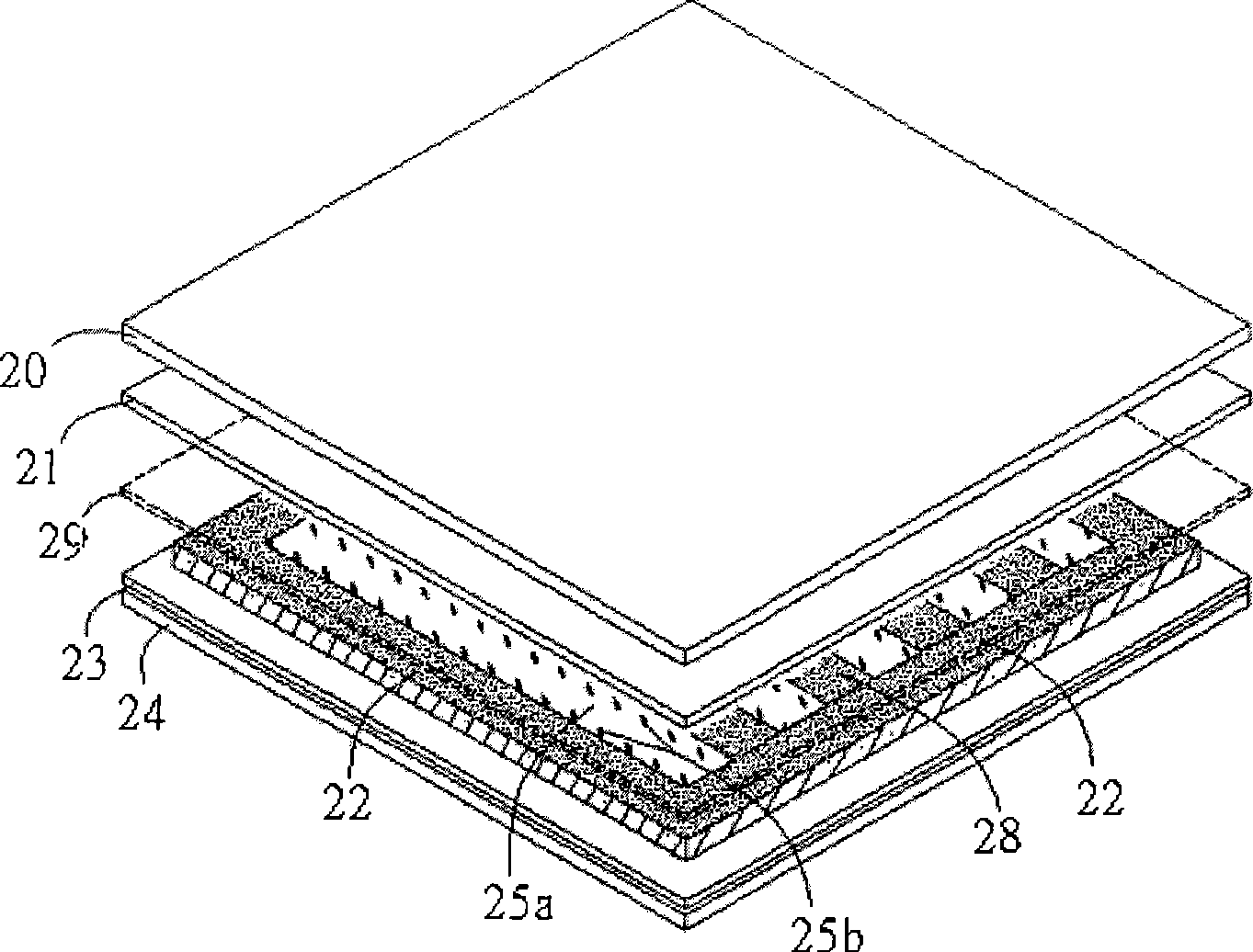

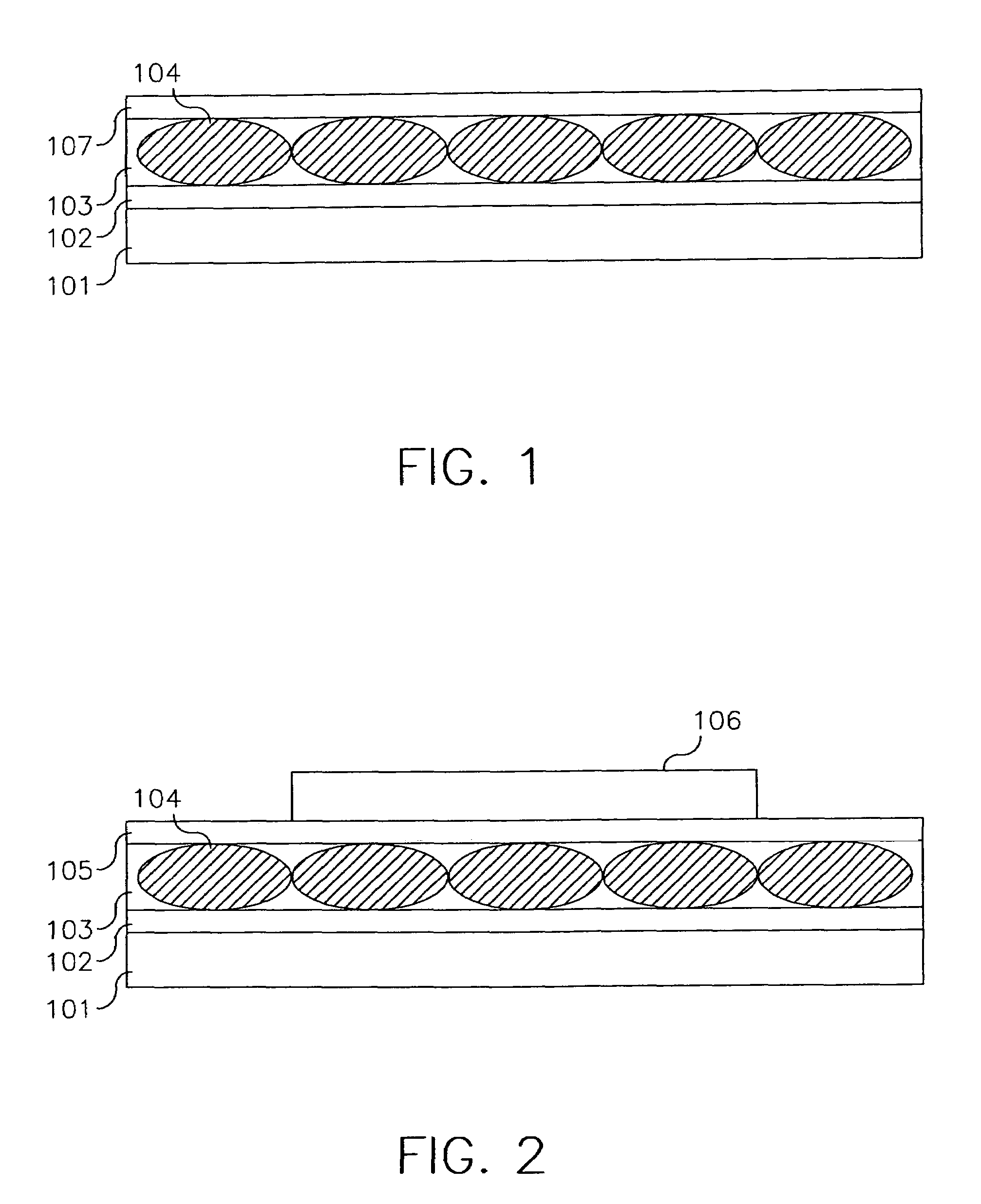

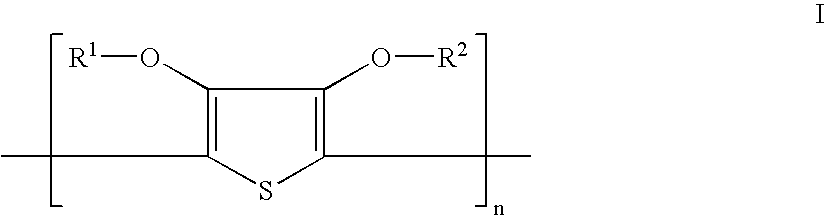

Display comprising liquid crystal droplets in a hydrophobic binder

ActiveUS7387856B2Low costLow switching voltageLiquid crystal compositionsMaterial nanotechnologyLiquid-crystal displayWater insoluble

The present invention relates to a display comprising at least one substrate and at least one electronically modulated imaging layer and at least one electrically conductive layer, wherein the electronically modulated imaging layer comprises a self-assembled, close-packed, ordered monolayer of domains of electrically modulated material in a water insoluble, hydrophobic polymer matrix and the at least one electrically conductive layer comprises electronically conductive polymer and a conductivity enhancing agent.

Owner:IRIS OPTRONICS CO LTD

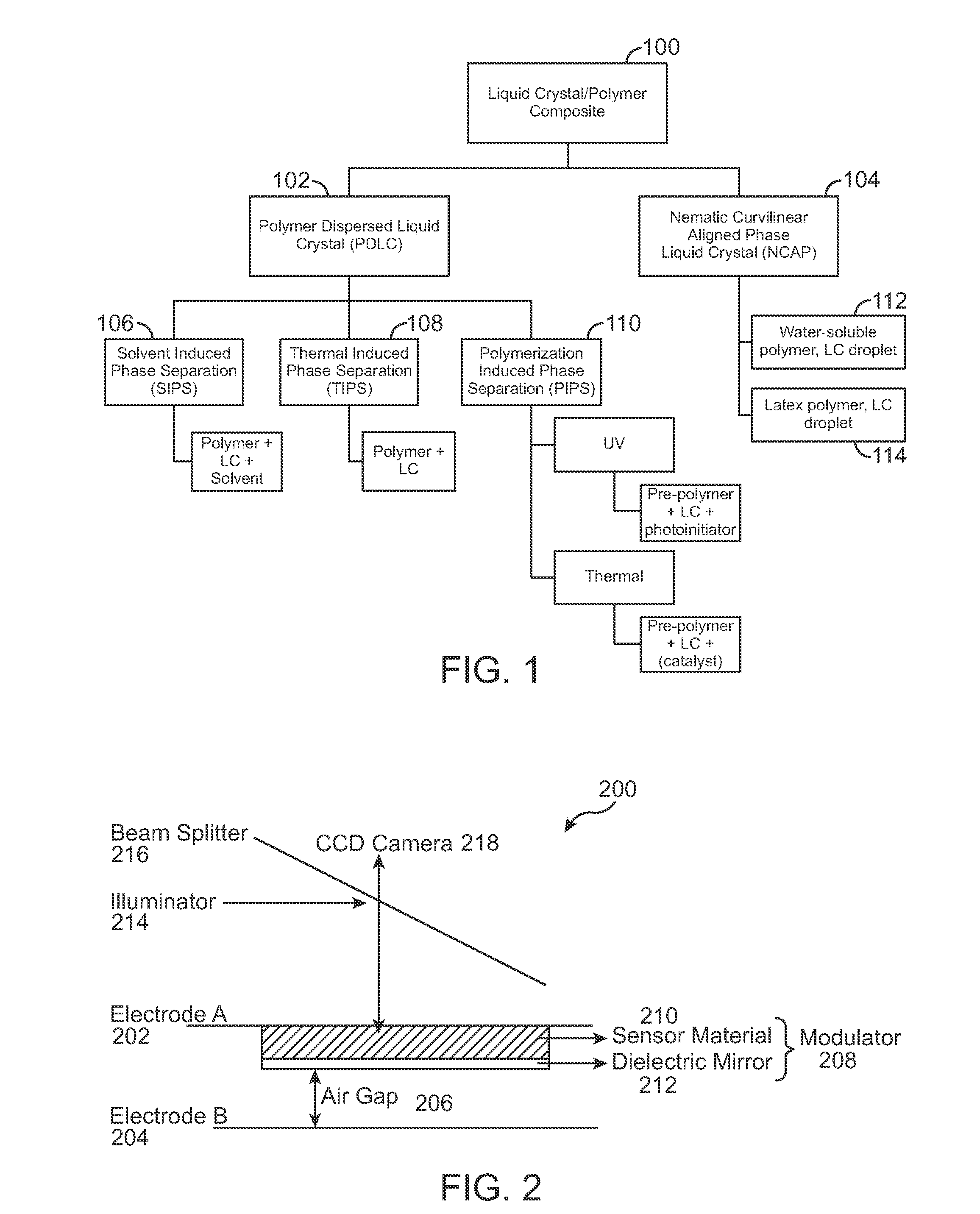

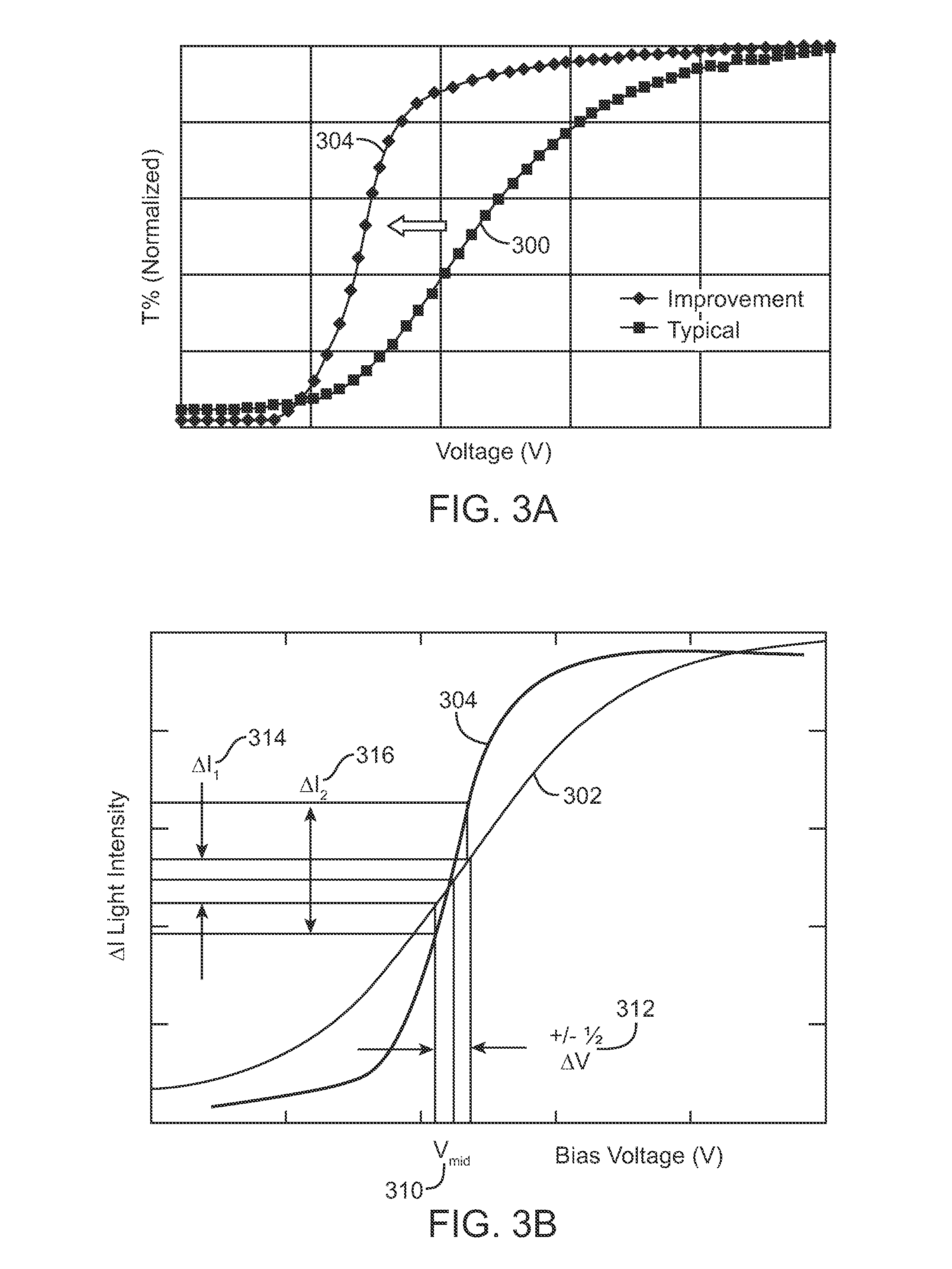

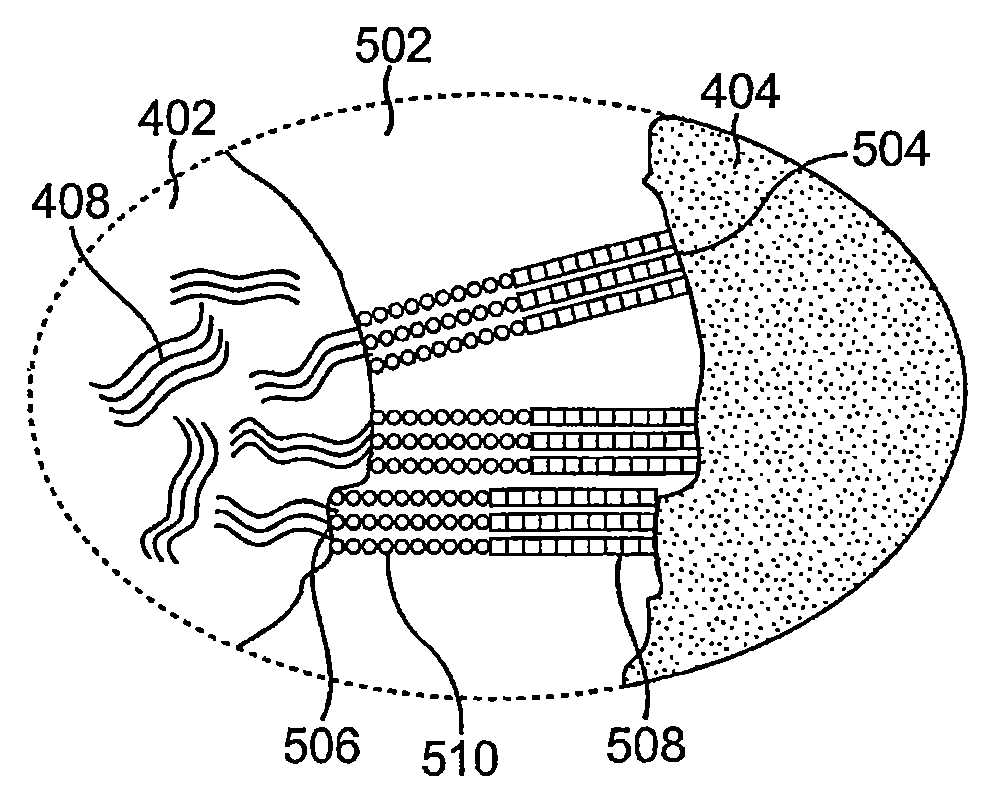

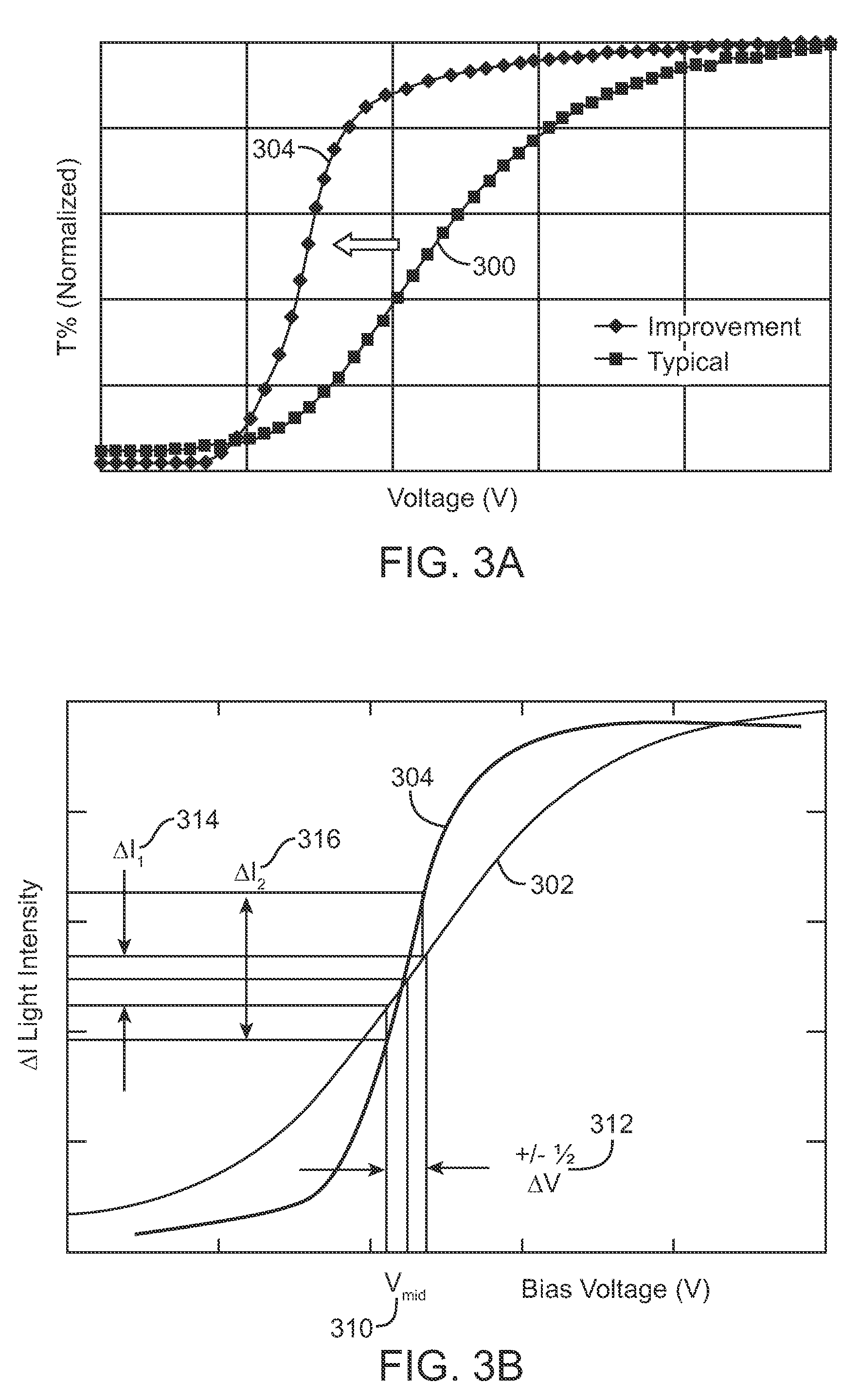

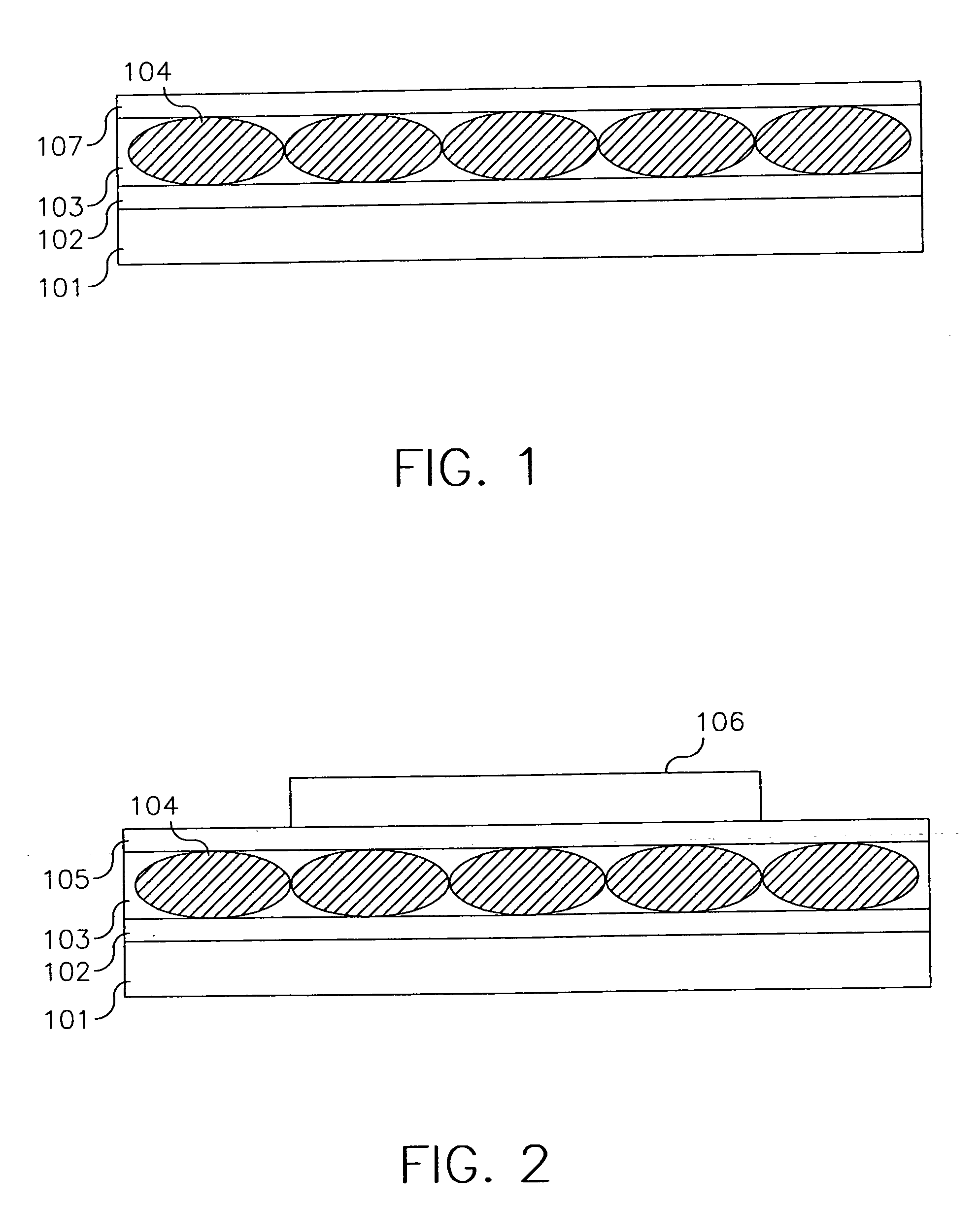

Modulator with Improved Sensitivity and Life Time

ActiveUS20080186563A1Low working voltageLiquid crystal compositionsVacuum evaporation coatingEnd-groupEngineering

An electro-optic modulator assembly includes a sensor layer made from an electro-optic modulator material that comprises liquid crystal droplets encapsulated within a polymer matrix. The sensor layer material comprises an interfacial agent, for example a defoaming agent, in an amount sufficient to lower an intrinsic operating voltage at which the sensor layer transmits light. The defoaming agent can comprise from about 1 to about 10 percent by weight of the electro-optic modulator material, and the defoaming agent may comprise a reactive component to react with the polymer matrix, for example at least one of a siloxane with a reactive end group, a reactive fluorinated polymer or a non-ionic block copolymer to react with the polymer matrix. The assembly can also include a hard coating layer to protect the sensor layer.

Owner:ORBOTECH LTD

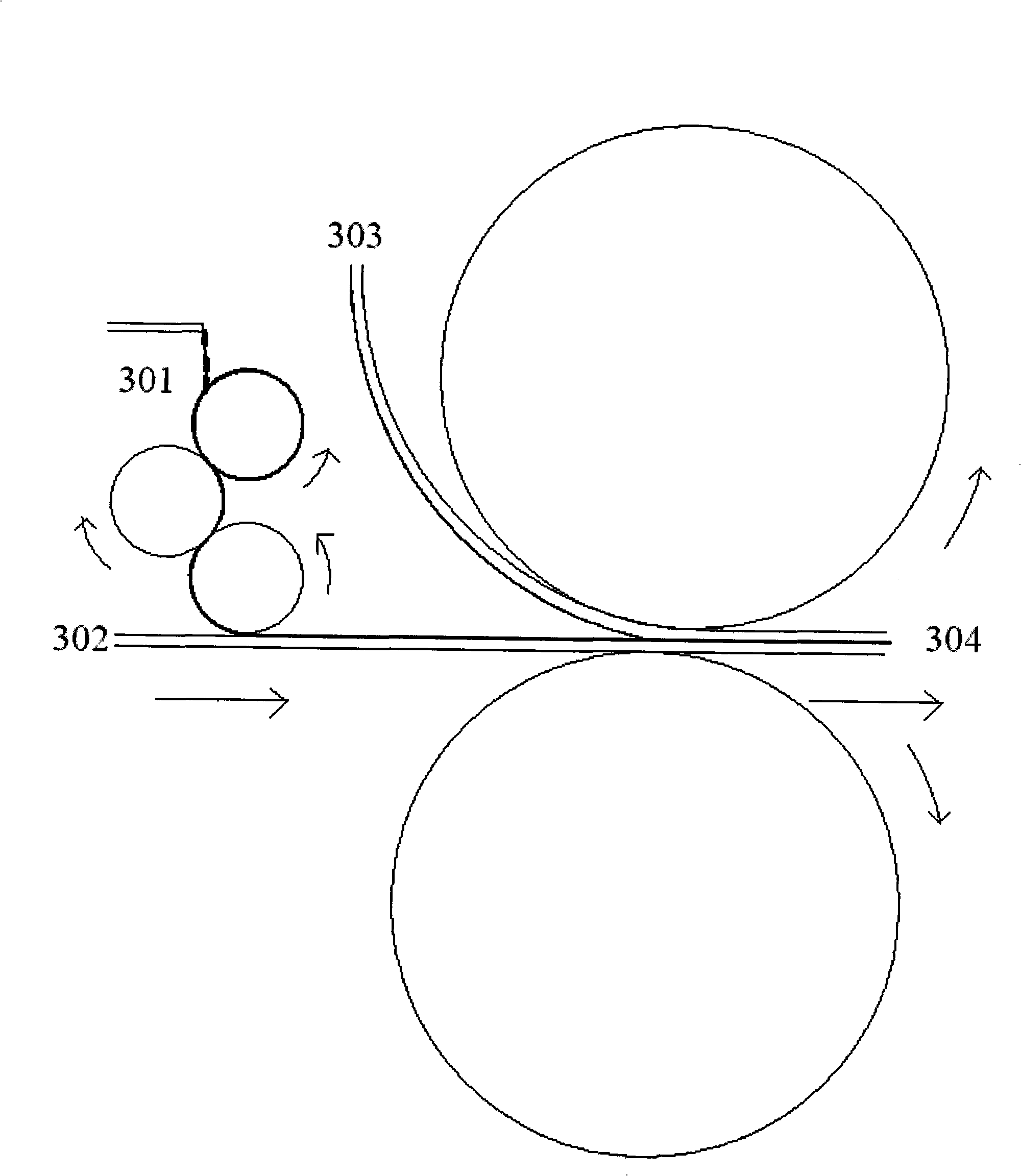

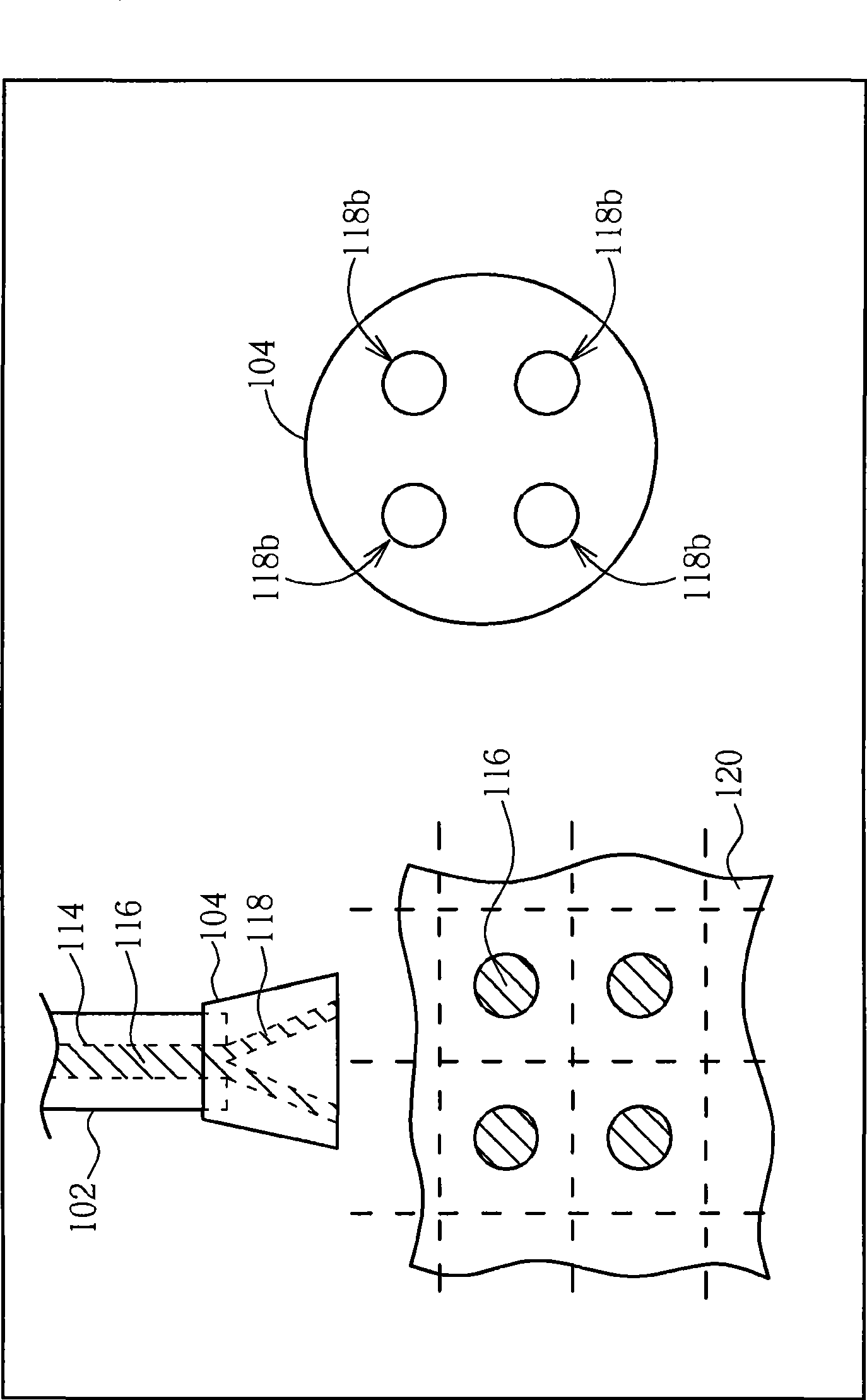

Liquid crystal spraying apparatus

ActiveCN101510028AImprove processing efficiencyGood and badNon-linear opticsEngineeringLiquid crystal droplet

The invention relates to a liquid crystal spraying device used for improving the efficiency of liquid crystal dripping. The liquid crystal spraying device contains a dripping device and a spray head. The dripping device is provided with a distribution pipe which is used for conveying liquid crystal materials. The spray head is installed on the bottom of the dripping device and connected the distribution pipe, and is provided with a plurality of spraying flow channels, wherein, each spraying flow channel is respectively and directly communicated to the distribution pipe. By the invention, the technical efficiency of the liquid crystal dripping technique can be greatly improved. Besides, as the invention utilizes non-bending straight spraying flow channels for spraying liquid crystal drops, the liquid crystal materials are not easy to be blocked at the bending point and can be evenly distributed to each spraying flow channel, and the phenomenon that the sizes of the sprayed liquid crystal drops are different, which is caused by the excess difference.of the shape and the length of the all the spraying flow channels, is not easy to occur.

Owner:AU OPTRONICS CORP

Composition for forming polymer-dispersed liquid crystal, polymer dispersed liquid crystal coating, and self-luminescent light-adjusting film

ActiveCN104962120AStable color changeReversible color changeLiquid crystal compositionsCoatingsUltraviolet lightsTransmittance

The present invention provides a composition for forming a polymer dispersed liquid crystal, a polymer dispersed liquid crystal coating and a self-luminescent light-adjusting film. According to the present invention, the composition comprises a binder, an inorganic electroluminescence material, a liquid crystal material and a photo-initiator; the polymer dispersed liquid crystal coating formed from the composition can occur stable and reversible color change and the reversible change of the lights with different colors and the transparency are presented in appearance, such that the polymer dispersed liquid crystal coating formed from the composition achieves the color change in the true sense; and compared with the dye, the influence of the inorganic electroluminescence material on the curing rate and the curing degree on the binder polymer is low, and under the ultraviolet light irradiation, the formed liquid crystal droplet separated from the binder polymer and liquid crystal mixture has the good separation moldability and can form the droplet having the large pore size, such that the polymer dispersed liquid crystal coating formed from the composition has characteristics of low driving voltage and high on-state transmittance.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

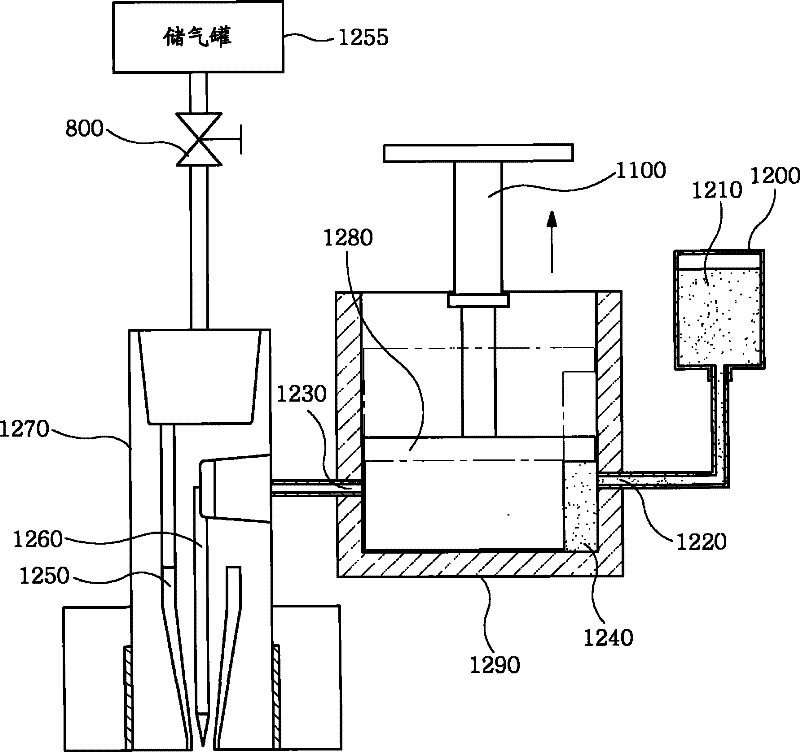

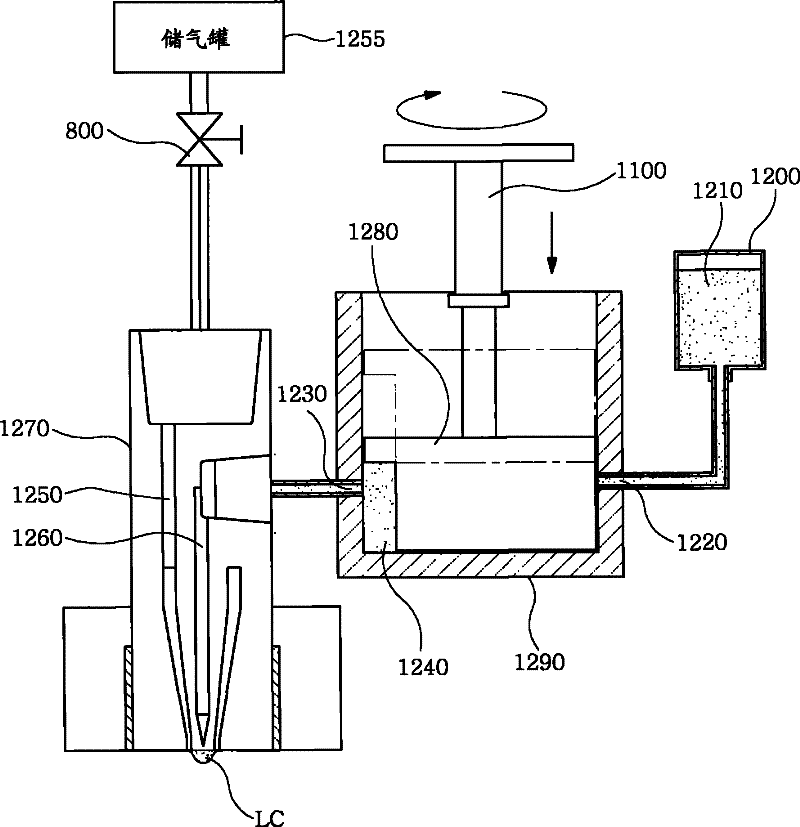

Device used for controlling liquid crystal dripping

The invention discloses a device used for controlling liquid crystal dripping, which controls dripping of liquid crystal on a substrate. The device comprises a head part unit, a temporary storage unit and a dual-fluid control unit. The head part unit is provided with a gas supply path and a liquid crystal supply path, liquid crystal supplied via the liquid crystal supply path drip via a nozzle, and liquid crystal drops formed at the end part of the nozzle drip on a substrate via the gas supplied by the gas supply path. The temporary liquid storage unit pumps liquid crystal from a liquid crystal storage vessel and temporarily stores liquid crystal. The dual-fluid control unit controls amount of liquid crystal supplied from the temporary liquid crystal storage unit to the nozzle end part, and adjusts gas used for making the liquid crystal drip from the nozzle end part.

Owner:TOP ENG CO LTD

Device for controlling liquid crystal distribution and method for making liquid crystal display

A device for controlling liquid crystal distribution, comprising: a platform and an adjustable temperature control device for controlling liquid crystal distribution in the platform, wherein the adjustable temperature control device is composed of a heating wire, which can control the temperature in the range of about 30°C to 120°C In this way, the gap between liquid crystal droplets can be narrowed.

Owner:LG DISPLAY CO LTD

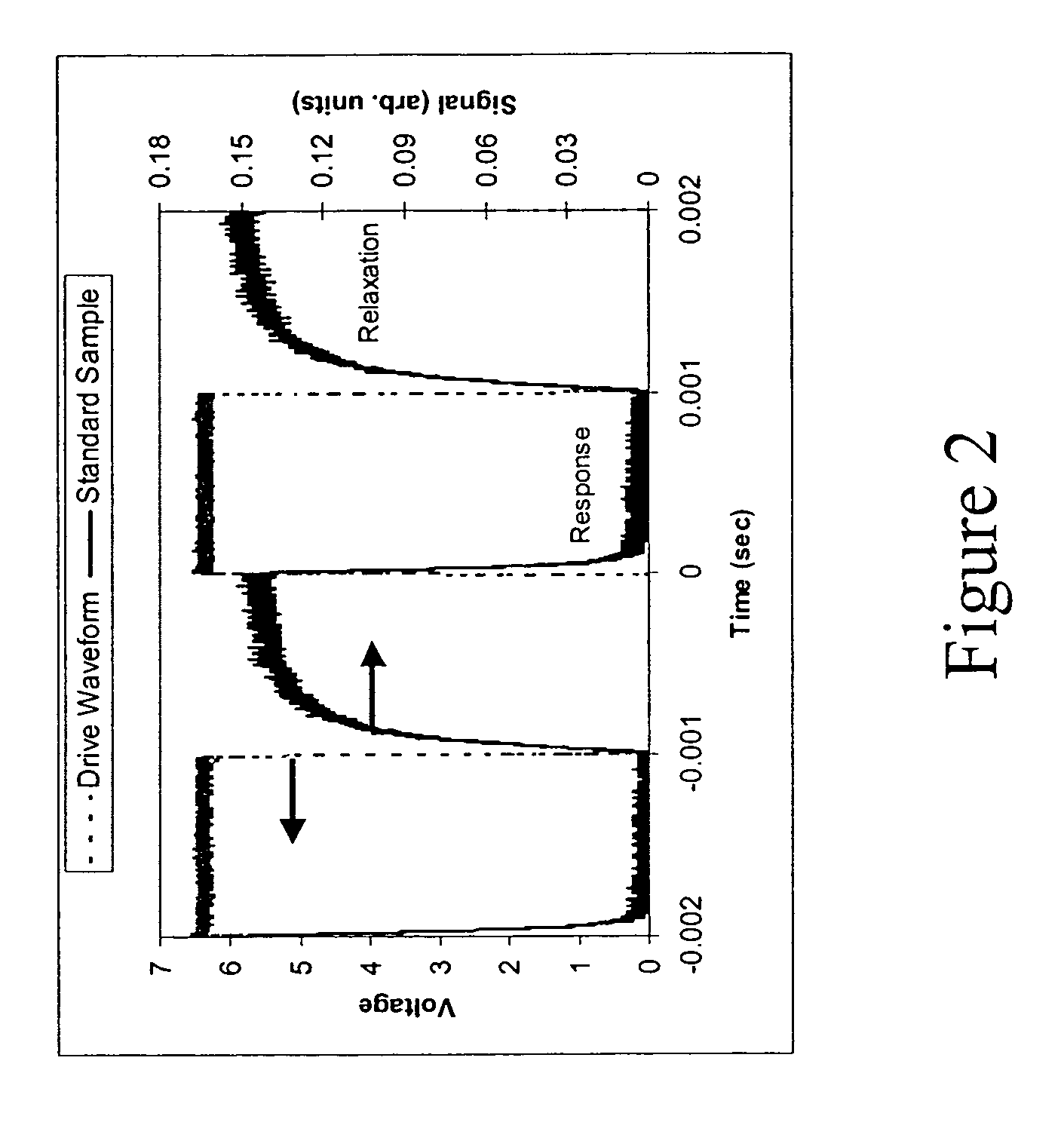

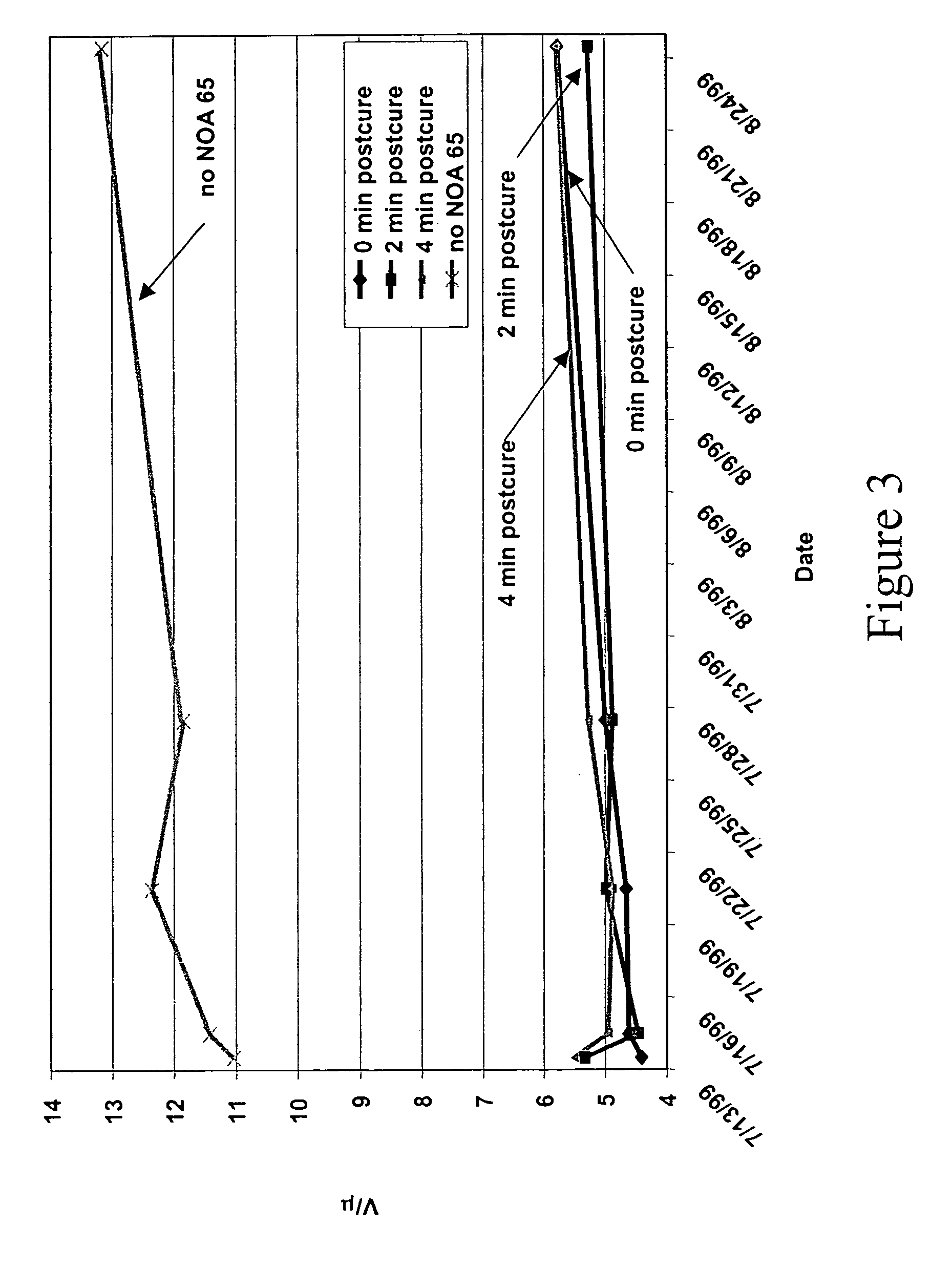

Modulator with improved sensitivity and life time

ActiveUS7817333B2Low working voltageLiquid crystal compositionsVacuum evaporation coatingEnd-groupEngineering

An electro-optic modulator assembly includes a sensor layer made from an electro-optic modulator material that comprises liquid crystal droplets encapsulated within a polymer matrix. The sensor layer material comprises an interfacial agent, for example a defoaming agent, in an amount sufficient to lower an intrinsic operating voltage at which the sensor layer transmits light. The defoaming agent can comprise from about 1 to about 10 percent by weight of the electro-optic modulator material, and the defoaming agent may comprise a reactive component to react with the polymer matrix, for example at least one of a siloxane with a reactive end group, a reactive fluorinated polymer or a non-ionic block copolymer to react with the polymer matrix. The assembly can also include a hard coating layer to protect the sensor layer.

Owner:ORBOTECH LTD

Display comprising liquid crystal droplets in a hydrophobic binder

ActiveUS20060286309A1Low costImprove conductivityLiquid crystal compositionsMaterial nanotechnologyConductive polymerWater insoluble

The present invention relates to a display comprising at least one substrate and at least one electronically modulated imaging layer and at least one electrically conductive layer, wherein the electronically modulated imaging layer comprises a self-assembled, close-packed, ordered monolayer of domains of electrically modulated material in a water insoluble, hydrophobic polymer matrix and the at least one electrically conductive layer comprises electronically conductive polymer and a conductivity enhancing agent.

Owner:IRIS OPTRONICS CO LTD

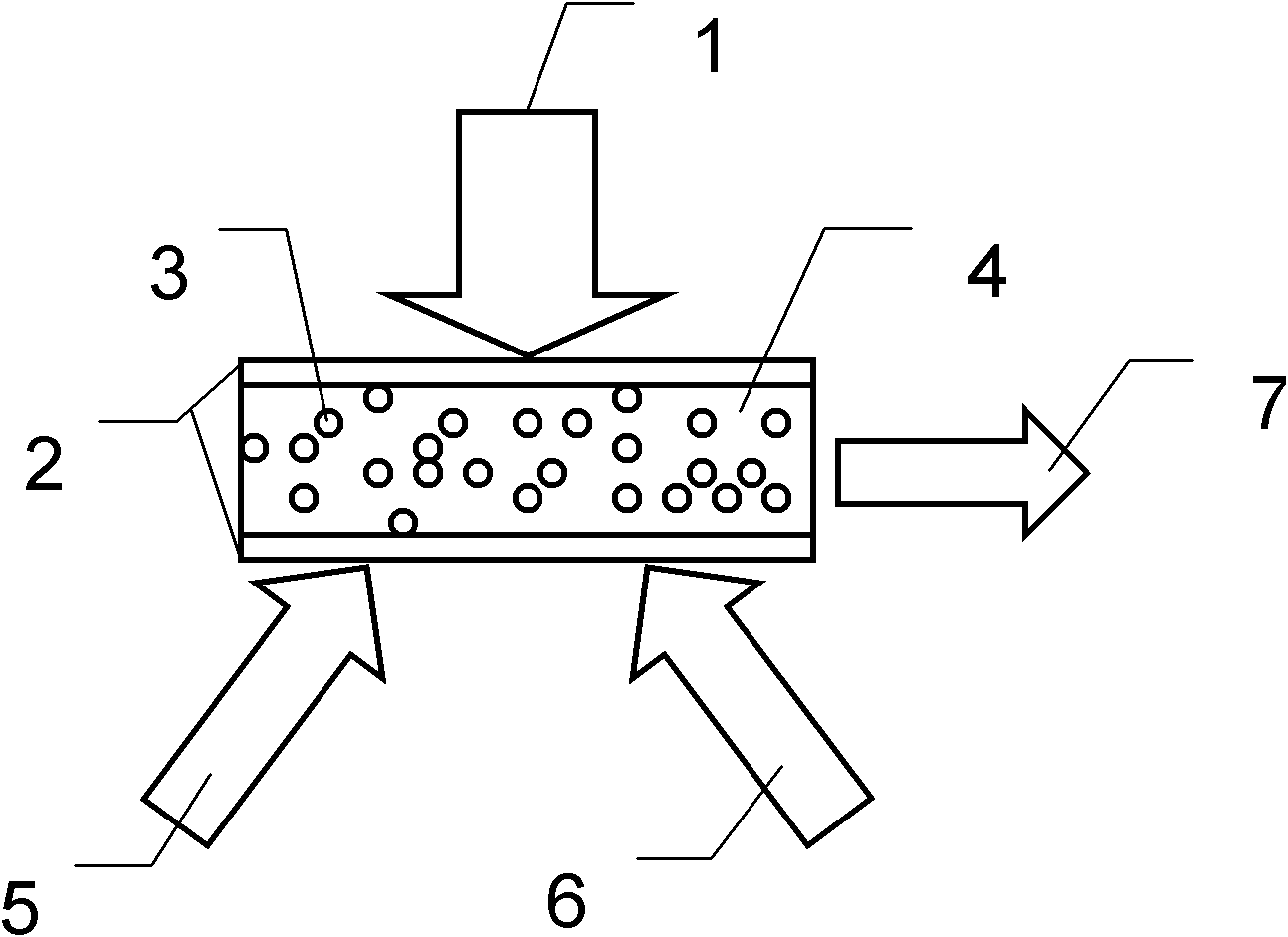

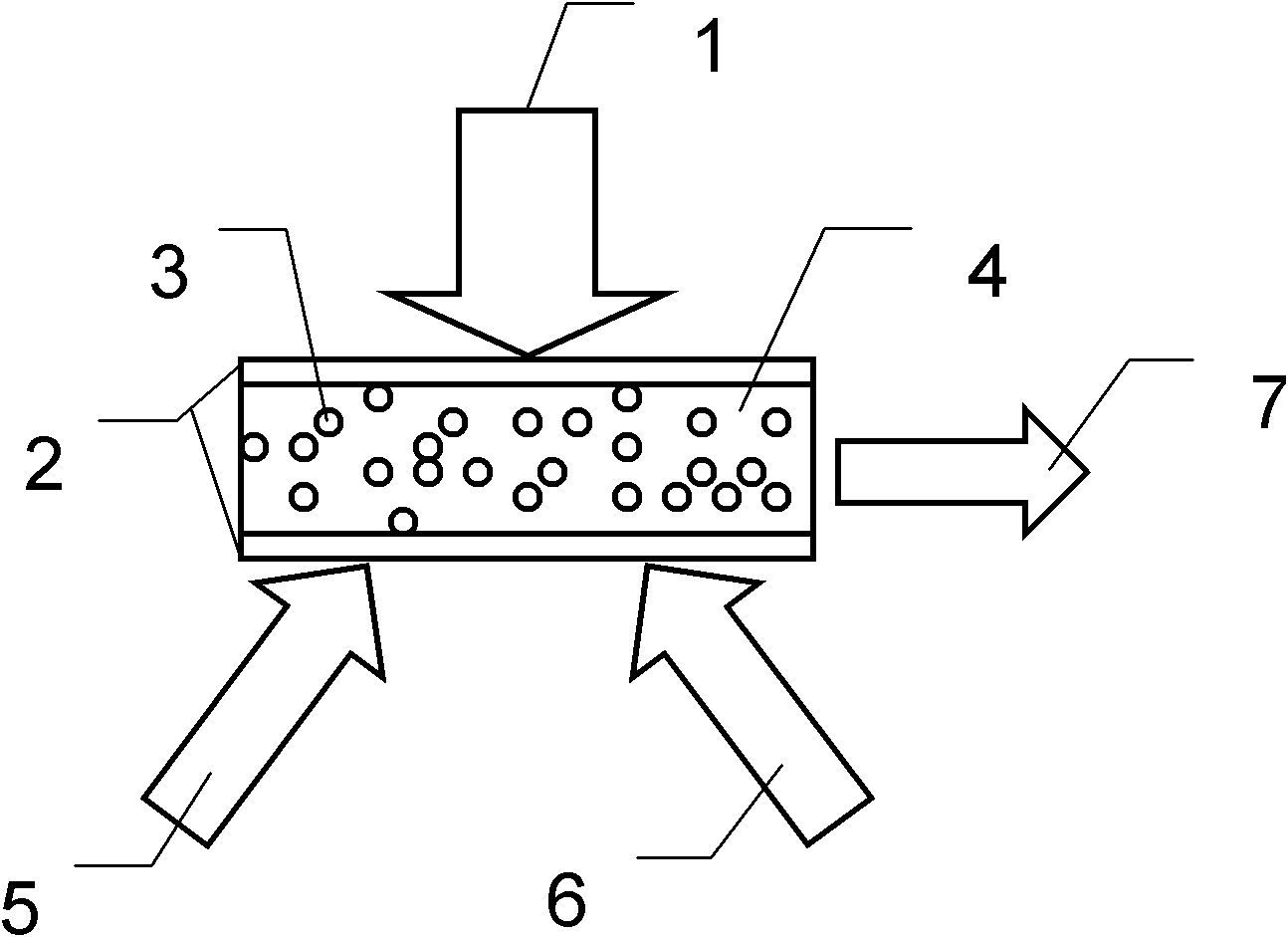

Method for regulating laser emission of gain medium under all-optical control

InactiveCN102097740ADynamic adjustment of stimulated emission intensitySimple structureLaser detailsLaser dyeRandom laser

The invention discloses a method for regulating the laser emission of a gain medium under all-optical control, which comprises the following steps of: first irradiating a carrier with random mediums by using infrared light beams with the wavelength of lambda2 or green light beams with the wavelength of lambda3; then emitting pump light (1) with the wavelength of lambda1 from a laser, converging the pump light to form stripes by using a cylindrical lens, making the stripes incident onto the carrier, arranging a detector on the bottom edge of the carrier to receive laser emitted from the carrier, and arranging a device for adjusting the energy of the pump light at the front end of the cylindrical lens; and finally prolonging the irradiation time of the red light beams (5) or improving the irradiation intensity of the red light beams (5) to improve the intensity of stimulated emitted light (7), or prolonging the irradiation time of the green light beams (6) or improving the irradiation intensity of the green light beams (6) to improve the intensity of the stimulated emitted light (7), wherein the random mediums are liquid crystal droplets which are dispersed in the azo dye-containing laser dye gain medium. The method provided by the invention ensures fixed environmental temperature, fixed electric field, simple structure and convenience of manufacturing at the same time of ensuring that a random laser can dynamically regulate stimulated emission intensity.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com